ENGINEERING

R

80G8127

Battery

Pressure

80 mm / 3.15 in

TOMORROW

Installation guide

Electronic superheat controller

Type EIM 316 / 336 / 365

Introduction

Superheat controller EIM series is for use where superheat must be accurately

controlled, typically in commercial air conditioning, heat pumps, commercial

080 R9347

refrigeration and food retailing applications.

Reference: For details please see EIM data sheet.

Technical specifications

Supply voltage 24 V AC / DC (+ 15%), 50 / 60 Hz, 15 VA / 8 W, Class II isolation

Idle

Power consumption

Input signals

For the EMC compliance, sensor cable length must be

< 3 m / 118 in. For longer sensor cable, a ferrite bead

should be used.

Valve support

operating

Po 0.5 - 4.5 Vdc ratiometric pressure sensor i.e AKS 32R

S2 PT1000 (measuring range -60 – 120 °C /

S4 PT1000 or digital input from external contact

EIM 365: ETS 6 / ETS / ETS Colibri, KVS / KVS Colibri, CCM, CCMT

EIM 316/336: ETS 6

Data communication RS 485 – MODBUS RTU (Not terminated internally)

Storage : -34 – 71 °C / -30 – 160 °F

Environment

Operating : -25 – 60 °C / -13 – 140 °F

Humidity : < 95% RH, non condensing

Battery backup (Only for EIM 365) 18 - 28 V DC, > 49 VmAh

Operation Standalone or via MODBUS data communication

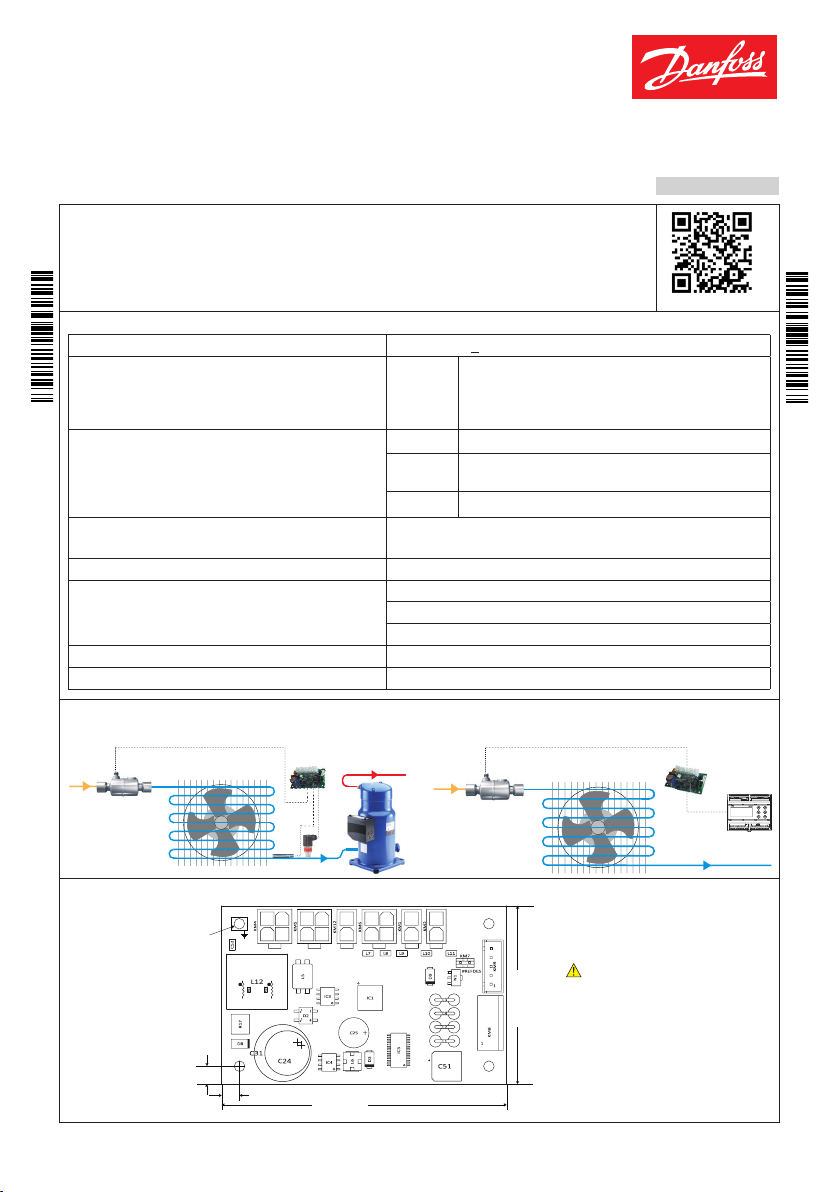

Applications

1. Superheat controller: standalone 2. Valve driver

Max. 10 mA @ 24 V DC (EIM 316 & 336)/ 25mA @

24V DC (EIM 365)

Max. 150 mA @ 24 V DC (EIM 316 & 336)/ 625mA @

24V DC (EIM 365)

-76 – 248 °F)

English

080 R9347

More info

EIM 316 / 335 / 336

© Danfoss | DCS (sb) | 2020.02

ETS Colibri®

ø 3 mm /

0.118 in

GND

5 mm / 0.2 in

S2 Pe

Power

1

2

4

3

5 mm / 0.2 in

BAckup

MODbus

11131

3

sensor

4

2

4

Danfoss

Danfoss

64-8040

R64-8040

ETS Colibri®

S2

S4

122

2

2

Danfoss

Reference signal

via MODBUS

Danfoss

R64-8041

Note:

S2 - Temperature sensor or DI

S4 - Temperature sensor

Weight : 40 gm

50 mm / 1.97 in

AN327425434124en -000201 | 1

Danfoss

80G165.10

PWR

COM

PWR

COM

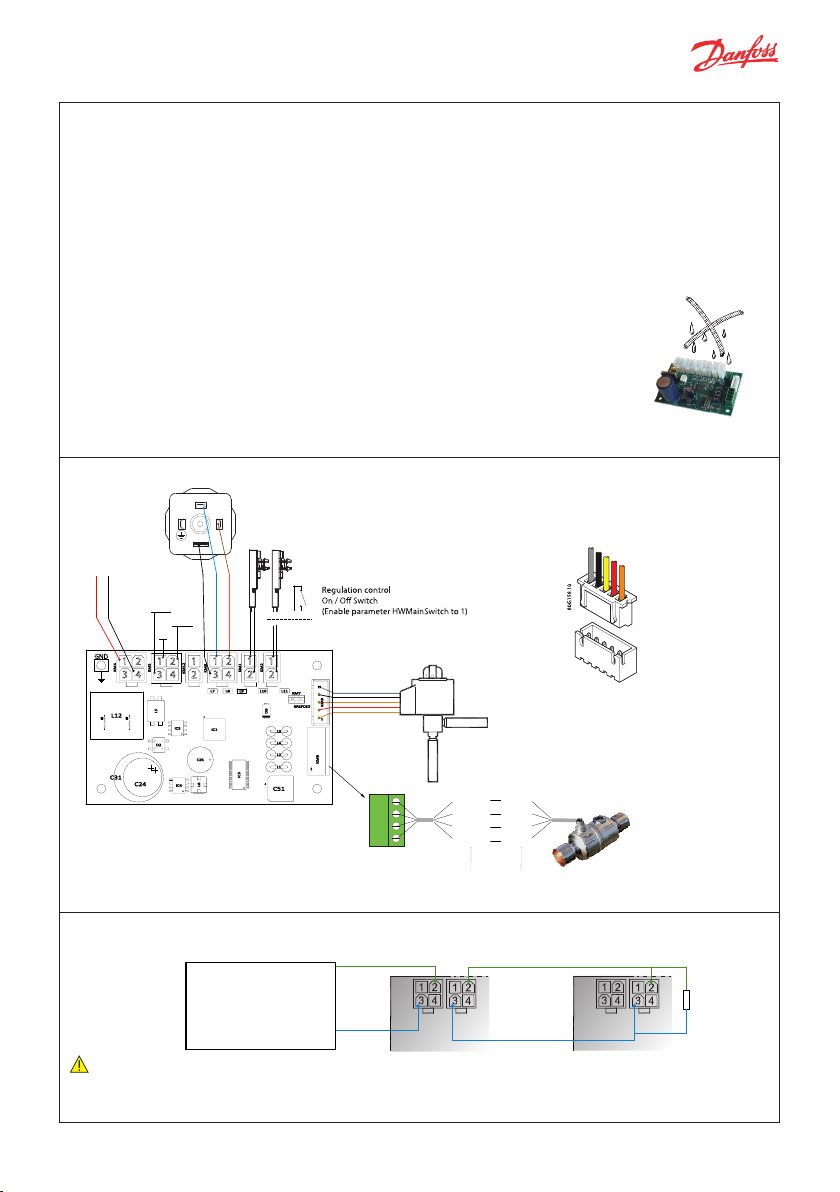

Installation warnings

Colibri®

- Recommended mounting position: vertical

- Installation must comply with local standards and legislation

- Before working on the electrical connections, disconnect the device from the main power supply

- Before carrying out any maintenance operations on the device, disconnect all electrical connections

- For safety reasons the appliance must be fitted inside an electrical panel with no live parts accessible

- Do not expose the device to continuous water sprays or to a relative humidity greater than 90%

- Avoid exposure to corrosive or pollutant gases, natural elements, environments where explosives or

mixes of flammable gases are present, dust, strong vibrations or shock, large and rapid fluctuations

in ambient temperature that might cause condensation in combination with high humidity, strong

magnetic and/or radio interference (e.g. transmitting antennae).

- When connecting loads be aware of the maximum current for each relay and connector

- Use cable ends suitable for the corresponding connectors. After tightening connector screws, tug the

cables gently to check their tightness.

- Use appropriate data communication cables. Refer to the EIM data sheet for the kind of cable to be

used and setup recommendations.

- Minimize the length of probe and digital input cables as much as possible, and avoid spiral

routes around power devices. Separate from inductive loads and power cables to avoid possible

electromagnetic noises.

- Avoid touching or nearly touching the electronic components fitted on the board to avoid

electrostatic discharges.

Connection overview

TxD -

3

2

Temperature sensors

3

PT 1000

i.e. AKS 11

1

TxD

+

D

11 1

1

12

2

3

2 2

44

2

ETS 6 with

JST-XHP 5 connector

JST XHP-5 CONNECTOR

Pressure transmitter

Ratiometric 0.5 – 4.5 V

i.e. AKS 32R

Power Supply

24 V AC or DC

+

-

MODBUS to master

controller

GND

1

3

2

4

Connector on

ETS 6 coil

Connector on

EIM 336 controller

MODBUS connection overview

MODBUS in Daisy Chain

Note:

• If two EIMs are connected remember to remove the addressing jumper on one of the EIMs

• MODBUS transmission lines usually require termination resistors, especially for longer cable lengths

© Danfoss | DCS (sb) | 2020.02

Black

B2

B1

A2

A1

EIM slave 1

RS485 (+)

Master controller

RS485 (-)

Red

Yellow

Orange

ETS 6 valve

Green

Red

Black

White

ETS / KVS

RS485 (+)

RS485 (-)

EIM slave 2

R = 120 Ohm

Min. 0.25 W

AN327425434124en -000201 | 2

80G159.10

11.6 mm

10.7 mm

8.5 mm

0.33 in

6.3 mm

0.25 in

80G161.10

10.6 mm

Mating connectors for EIM Controller

80G163.10

Type Molex Mini-Fit Jr.™

4 WAY MINI-FIT RECEPTACLE

Molex 39-01-2040 or similar

0.46 in

0.42 in

80G160.10

Connector kit for 5x EIM controller 080G1601

Quick guide for parameter selection

A. Setting controller in Superheat

control mode.

Make sure that r12 = 0 (OFF) and change the settings.

The setting will depends on the system requirement.

Enabling Regulation control ON / Off switch (optional)

HwMainSwitch = 1 (default is 0, i.e S4 sensor).

For standalone configuration it is recommended to

enable Regulation control ON / Off switch in order to

control start/stop regulation when needed, otherwise

the controller will start regulating when controller is

powered up.

Select Refrigerant

o30 = 1 – 49

Select valve setting

For EIM 365, first select Proper Danfoss valve t ype

(PNU 3002). For EIM 316/336, the default valve type is

ETS 6.

n37 = 384 x 10 micro step (3840 micro steps = 480 half

steps)

n38 = Max. steps / sec

Define pressure sensor range in bar absolute (x10)

o20 = Min. Transducer pressure

o21 = Max. Transducer pressure

Define min/max superheat

Define SH control type:

SH Mode : 1 = MSS , 2= LoadAP (PNU 3026 )

n10 = min. superheat reference

n09 = max. superheat reference

For fixed superheat define n09 = n10

Define MOP (optional)

n11 = maximum operating pressure

2 WAY MINI-FIT RECEPTACLE

Molex 39-01-2020 or similar

0.42 in

RECEPT CONTACT

24-18AWG Molex

39-00-0039 or similar

80G162.10

Set force opening of the valve (optional)

Start-up OD% (PNU 3015)

Start-up time (PNU 3017)

For EIM 365, Startup mode P-control has been enabled as

default. for detail check startup mode parameter

(PNU 64322).

To start the superheat control

Set r12= ON

B. Setting controller in valve driver mo de

using MODBUS signal

Make sure that r12 = 0 (OFF) and change the

settings so they fit to their application:

Select Application mode

o18 (PNU 2075 )= 1 i.e Manual control

Select valve setting (optional)

For EIM 365, first select Proper Danfoss valve t ype

(PNU 3002). For EIM 316/336, the default valve type is

ETS 6.

n37 = 384 x 10 micro step (3840 micro steps = 480 half

steps).

n38 = Max steps / sec

Select manual opening degree

o45 Manual OD % (PNU 2064)

0 = fully closed, 100 = fully open

By changing parameter o45 Manual OD, the valve will

move accordingly regardless of r12 parameter value.

© Danfoss | DCS (sb) | 2020.02

AN327425434124en -000201 | 3

EIM – Commonly used parameter identification

Group PNU Param-

Regulation

117 r12 Main switch 0 1 0

Control

2075 o18 Manl control 0 1 0

2064 o45 Ma nual OD 0 100 0 %

3026 n21 SH Mode 1 2 2

Super Hea t

3015 n09 Max. superheat 20 200 90 K

Control

3021 n10 Min. superheat 10 200 40 K

3032 n37 Max steps 10 0

3033 n38 Max steps / sec 10 400 16

Valve

(Valve

selec tion

valid

for EIM

365, FOR

EIM 316

3002

and 336

default i s

ETS 6 )

Refriger-

2551 o30 Refrigerant 1 49

ant

113 r09 Adjust S2 -100 100 0 K

2033 o21

Sensors

2034 o20

Note :

• “e2” is the value stored in EEPROM. “W” is writing to the register possible “*10” is scale of the parameter.

• For detail parameter list, refer to the EIM datasheet.

• Default Modbus setting 19200 8E1.

Symbol ic

eter

name

n03 Valv e Type

Max. transducer pressure

Min. transducer

pressure

Min. Max. Default Units e2 W *10 Description

With this setting the regulation can be started

and stopped. This can also be accomplished with

ü

the external hardware main switch.

0 = Superheat control, 1 = Manual control

ü

Manual opening degree for manual control.

Used when the o18 Manual Control is set

ü

to 1 (fully closed = 0% , fully open = 100%).

1: MSS, 2: Load AP

Maximum superheat reference setting

Minimum superheat reference setting

Maximum number of steps

(384 x 10 microsteps = 480 half steps)

(Values in bracket is for EIM 316,336)

Steps per second

0 : ETS 12.5, ETS 25, KVS 15

1 : ETS 50, CCM 10, CCM 20, CCM30

2 : ETS 100, CCM 40

3 : ETS 250, KVS 42

4 : ETS 400

5 : User defined

6 : UKV, SKV, VKV, PKV

7 : ETS 6

8 : CCMT 2, CCMT 4, CCMT 8

9 : CTM16

10 : CCMT 24

11 : CCMT 30

12 : CMT 42

13 : CTR

14 : CCMT 0

15 : CCMT 1

16 : No valve sele cted

17 : ETS 12C, 24C, 25C, 50 C, 100C, KVS 2C, 3 C, 5C

0: None

1: R12

2: R22

3: R134a

4: R502

5: R717

6: R13

7: R13B1

8: R23

9: R500

10: R503

11: R114

12: R142b

13: User

14: R32

15:R227ea

16: R401A

S2 Offset adjustment

Maximum transducer pressure

(in bar absolute * 10)

Minimum transducer pressure

(in bar absolute * 10)

8000

(1000)

0 17 EIM 365: 16

10 600 16 0

-10 0 0

240

(384)

EIM 365: 0

EIM 316,

336: 23

bar

(abs.)

bar

(abs.)

ü ü

ü ü ü

ü ü ü

ü ü

ü ü

ü ü

ü ü

ü ü ü

ü ü ü

ü ü ü

17: R507A

18: R402A

19: R404A

20: R407C

21: R407A

22: R407B

23: R410A

24: R170

25: R290

26: R600

27: R600a

28: R744

29: R1270

30: R417A

31: R422A

32: R413A

33: R422D

Related products

Pressure transducer

AKS 32R, NSK BExx

Temperature sensor

AKS 21, AKS 11, ACCPBT

Programming key / display

MYK - EIM interfacer

Electric Expansion valve

ETS series

Backup power module

EKE 2U

34: R427A

35: R438A

36: R513A

37: R407F

38: R1234zeE

39: R1234yf

40: R448A

41: R449A

42: R452A

43: R450A

44: R452B

45: R454B

46: R1233zdE

47: R1234zeZ

48: R449B

49: R407H

© Danfoss | DCS (sb) | 2020.02

AN327425434124en -000201 | 4

Loading...

Loading...