Page 1

MAKING MODERN LIVING POSSIBLE

Technical Information

Electronic Control Modules

EH Modules

powersolutions.danfoss.com

Page 2

Technical Information EH Modules

Revision history Table of revisions

Date Changed Rev

January 2016 Converted to Danfoss layout 0103

September 2010 New Back cover AC

May 2010 Japan location AB

October 2004 First edition A

2 520L0804 • Rev 0103 • January 2016

Page 3

Technical Information

EH Modules

Contents

Electronic control modules - EH modules

General.................................................................................................................................................................................................5

Mounting base and accessories - EHB

General.................................................................................................................................................................................................6

Dimensions, code numbers, and weight................................................................................................................................. 7

Electronic flow regulation - EHF

General ................................................................................................................................................................................................8

Function...............................................................................................................................................................................................8

Signal monitoring.............................................................................................................................................................................9

Characteristic..................................................................................................................................................................................... 9

Electrical system ............................................................................................................................................................................10

Technical data................................................................................................................................................................................. 10

Code number and weight...........................................................................................................................................................11

Electronic alarm logic - EHA

General ..............................................................................................................................................................................................12

Function............................................................................................................................................................................................ 13

Electrical system.............................................................................................................................................................................14

Monitoring more than eight functions.................................................................................................................................. 15

Electric remote to mechanical operation..............................................................................................................................16

Technical data................................................................................................................................................................................. 17

Code number and weight...........................................................................................................................................................17

Electronic ramp generator - EHR

General ..............................................................................................................................................................................................18

Function............................................................................................................................................................................................ 18

Signal monitoring..........................................................................................................................................................................19

Electrical system - Principle 1.....................................................................................................................................................20

Electrical system - Principle 2.....................................................................................................................................................21

Ramp times.......................................................................................................................................................................................22

External break contacts................................................................................................................................................................23

KA, KB signals...................................................................................................................................................................................23

Technical data................................................................................................................................................................................. 24

Code number and weight...........................................................................................................................................................24

Electronic speed control - EHS

General ..............................................................................................................................................................................................25

Function............................................................................................................................................................................................ 25

Potentiometer 1..............................................................................................................................................................................26

Potentiometer 2..............................................................................................................................................................................26

Potentiometer (P)...........................................................................................................................................................................27

Recommendation.......................................................................................................................................................................... 27

Input reference............................................................................................................................................................................... 27

Electrical connection.................................................................................................................................................................... 29

Technical data................................................................................................................................................................................. 29

Code number and weight...........................................................................................................................................................30

Electronic, frequency controlled loop speed control - EHSC

General ..............................................................................................................................................................................................31

Adjustment possibilities..............................................................................................................................................................31

Function monitoring.....................................................................................................................................................................32

Adjustments.....................................................................................................................................................................................32

Potentiometer 1 .......................................................................................................................................................................32

Potentiometer 2 .......................................................................................................................................................................33

Potentiometer 3 .......................................................................................................................................................................34

Potentiometer 4 .......................................................................................................................................................................35

Potentiometer (P)...........................................................................................................................................................................35

Resistance (R)...................................................................................................................................................................................36

Electrical system.............................................................................................................................................................................37

Technical data................................................................................................................................................................................. 37

520L0804 • Rev 0103 • January 2016 3

Page 4

Technical Information

EH Modules

Contents

Required control and feedback frequency signal..............................................................................................................38

Main spools and electrical actuation modules....................................................................................................................38

Code number and weight...........................................................................................................................................................38

Electronic, voltage controlled closed loop speed control - EHSC

General ..............................................................................................................................................................................................39

Adjustment possibilities..............................................................................................................................................................39

Function monitoring.....................................................................................................................................................................40

Adjustments.....................................................................................................................................................................................41

Potentiometer 1 and 2............................................................................................................................................................41

Potentiometer 3 .......................................................................................................................................................................41

Potentiometer 4 .......................................................................................................................................................................42

Potentiometer (P)...........................................................................................................................................................................43

Resistance (R)...................................................................................................................................................................................43

Electrical system.............................................................................................................................................................................45

Technical data................................................................................................................................................................................. 45

Required feedback frequency signal...................................................................................................................................... 46

Main spools and electrical actuation modules....................................................................................................................46

Code number and weight...........................................................................................................................................................47

Electronic closed loop position control - EHC

General ..............................................................................................................................................................................................48

Adjustment possibilities..............................................................................................................................................................48

Inverse function..............................................................................................................................................................................49

Interruption of the signal output............................................................................................................................................. 49

ON/OFF signal t1/t6...................................................................................................................................................................... 50

Redundant position transducer................................................................................................................................................50

Function monitoring.....................................................................................................................................................................51

Adjustment.......................................................................................................................................................................................52

Potentiometer 1 .......................................................................................................................................................................52

Potentiometer 2........................................................................................................................................................................52

Potentiometer 3........................................................................................................................................................................52

Potentiometer 4........................................................................................................................................................................52

Electrical system.............................................................................................................................................................................53

Resistance values........................................................................................................................................................................... 53

Technical data................................................................................................................................................................................. 54

Code numbers and weight.........................................................................................................................................................54

EH modules dimensions

Dimensions.......................................................................................................................................................................................55

4 520L0804 • Rev 0103 • January 2016

Page 5

Technical Information

EH Modules

Electronic control modules - EH modules

General

Electronic control modules - EH modules

Danfoss electronic control modules are a series of module boxes used for signal matching, for the control

of the electric activating modules of a proportional valve, and for function monitoring inhydraulic

systems. EH modules are built into a plastic box with an 11-pole plug and are designed in compliance

with IEC publication 67, second edition part 1, drawing 67-1-18a.

520L0804 • Rev 0103 • January 2016 5

Page 6

Technical Information

EH Modules

Mounting base and accessories - EHB

General

Mounting base, 11-pole, for EH modules - EHB

EHB can be mounted using two screws. It can also be clipped onto DIN rails (DIN 46277).

EHB is designed to be wired and contains self-lifting terminals and cross/slotted screws.

On all electrical diagrams with EH modules the terminal connections are located in relation to EHB. If

another mounting base is used, the terminal connections can be re-allocated, but the terminal numbers

will remain the same.

Retaining clip on EH module

Retaining clip in spring steel for additionally securing EH modules on EHB where strong vibrations occur.

The code number covers 10 off retaining clips.

6 520L0804 • Rev 0103 • January 2016

Page 7

Technical Information EH Modules

Mounting base and accessories - EHB

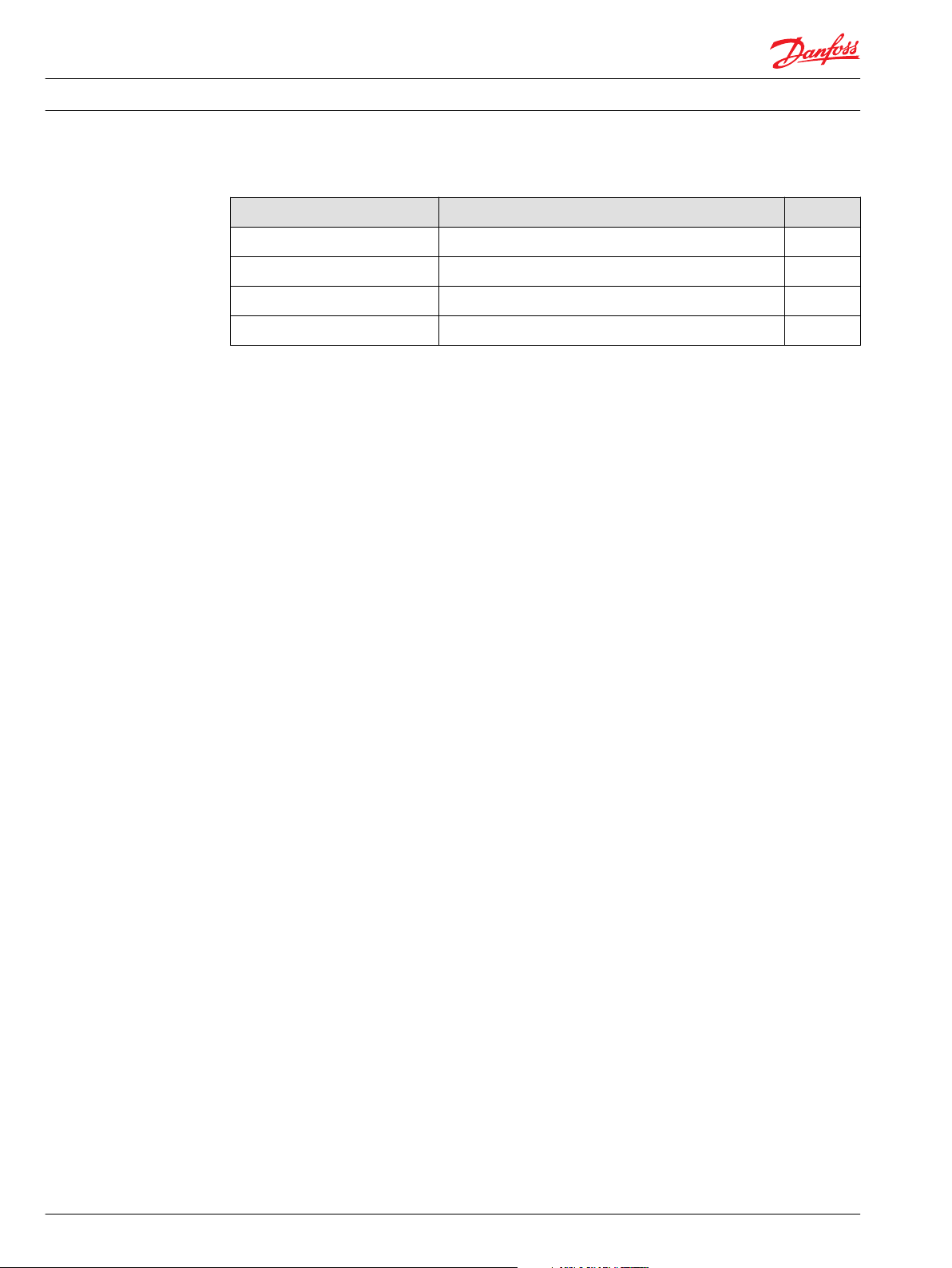

Dimensions, code numbers, and weight

EHB dimensions in millimeters [inches]

EHB mounting base code number EHB base weight

155U0933 0.065 kg (0.143 lb)

EH module retaining clip

EH module retaining clip code number Quantity

155U0932 10

520L0804 • Rev 0103 • January 2016 7

Page 8

Technical Information

EH Modules

Electronic flow regulation - EHF

General

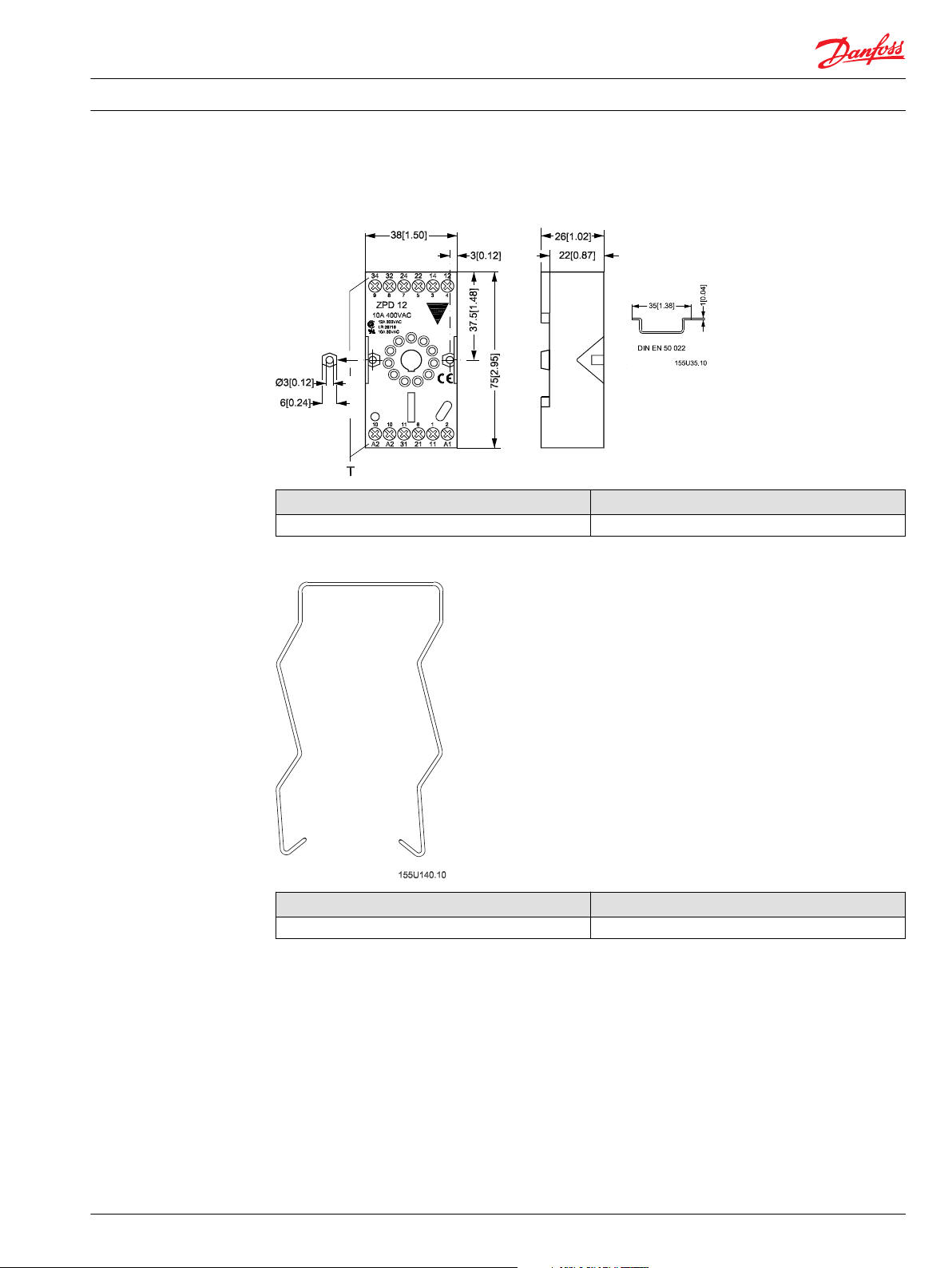

Electronic flow regulation - EHF

Function

Danfoss electronic flow regulation EHF is for use where the requirement is individual reduction of the

flow from the two ports of the proportional valve.

The flow can be reduced individually for ports A and B, infinitely down to 25% of maximum flow.

An EHF built into an electrohydraulic system gives very precise control of the working functions.

EHF is supplied for the regulation of two working functions.

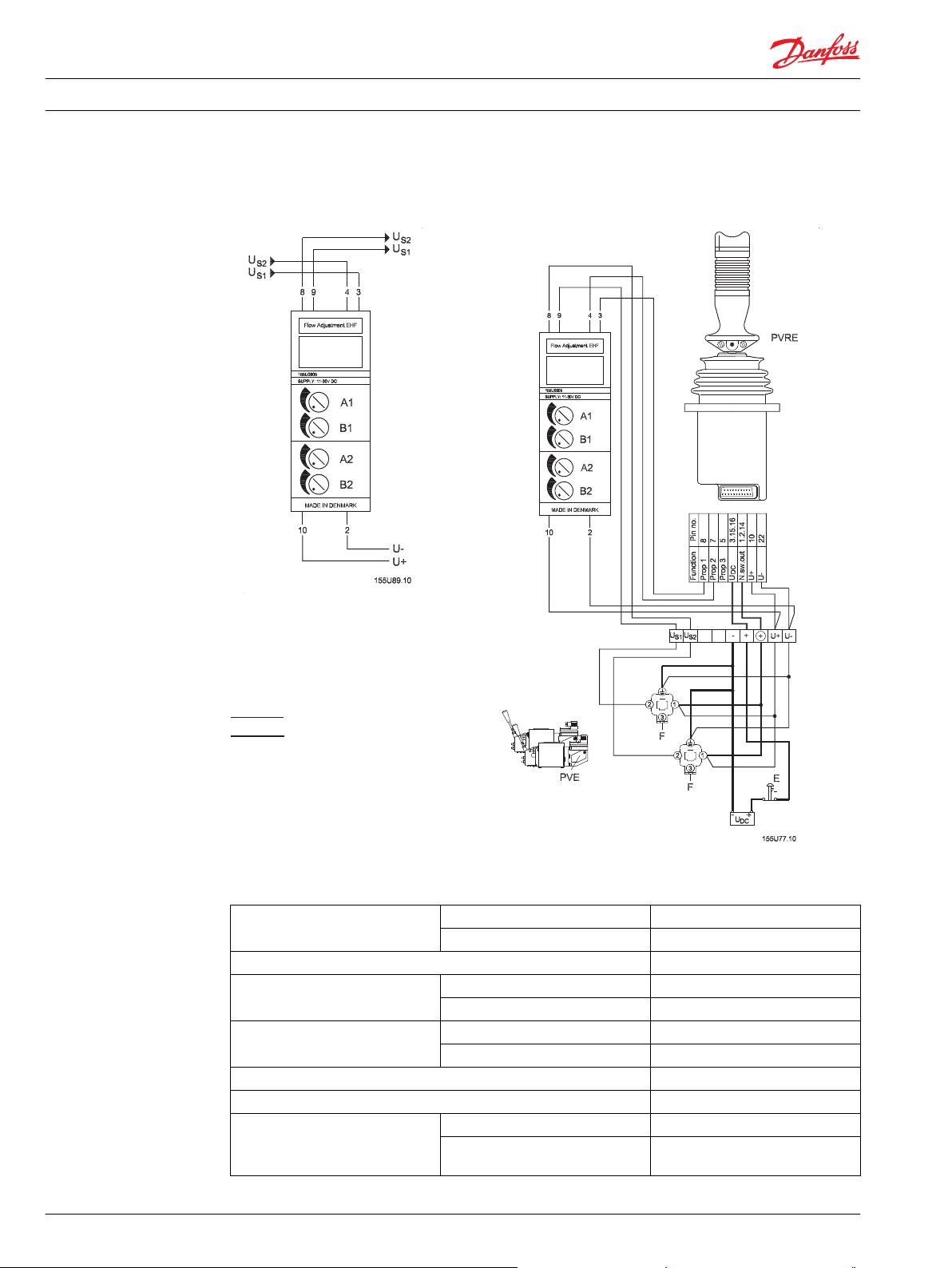

Flow adjustment - EHF

EHF must be inserted in the signal connection between the electric remote control lever and PVG

proportional valve.

There are two built-in potentiometers per function. Independently of each other, these will limit the

signal voltage and thereby the flow from ports A and B.

The remote control unit retains its full regulation range because EHF incorporates dead-band

compensation and reduced signal voltage instead of mechanical reduction of the regulation range of the

remote control unit.

8 520L0804 • Rev 0103 • January 2016

Page 9

Technical Information EH Modules

Electronic flow regulation - EHF

Signal monitoring

EHF has signal monitoring on the signal inputs (terminals 3 and 4). This means that input signals must lie

within the range 0.15 • UDC to 0.85 • UDC.

If the signal is outside the stated range, such as a consequence of short-circuiting to plus or minus supply,

the signal monitoring cuts off the output signal to the proportional valve which then immediately sets

the main spool into neutral position.

If monitoring has cut off the output signal, EHF can only begin functioning again when the supply

voltage has been cut off.

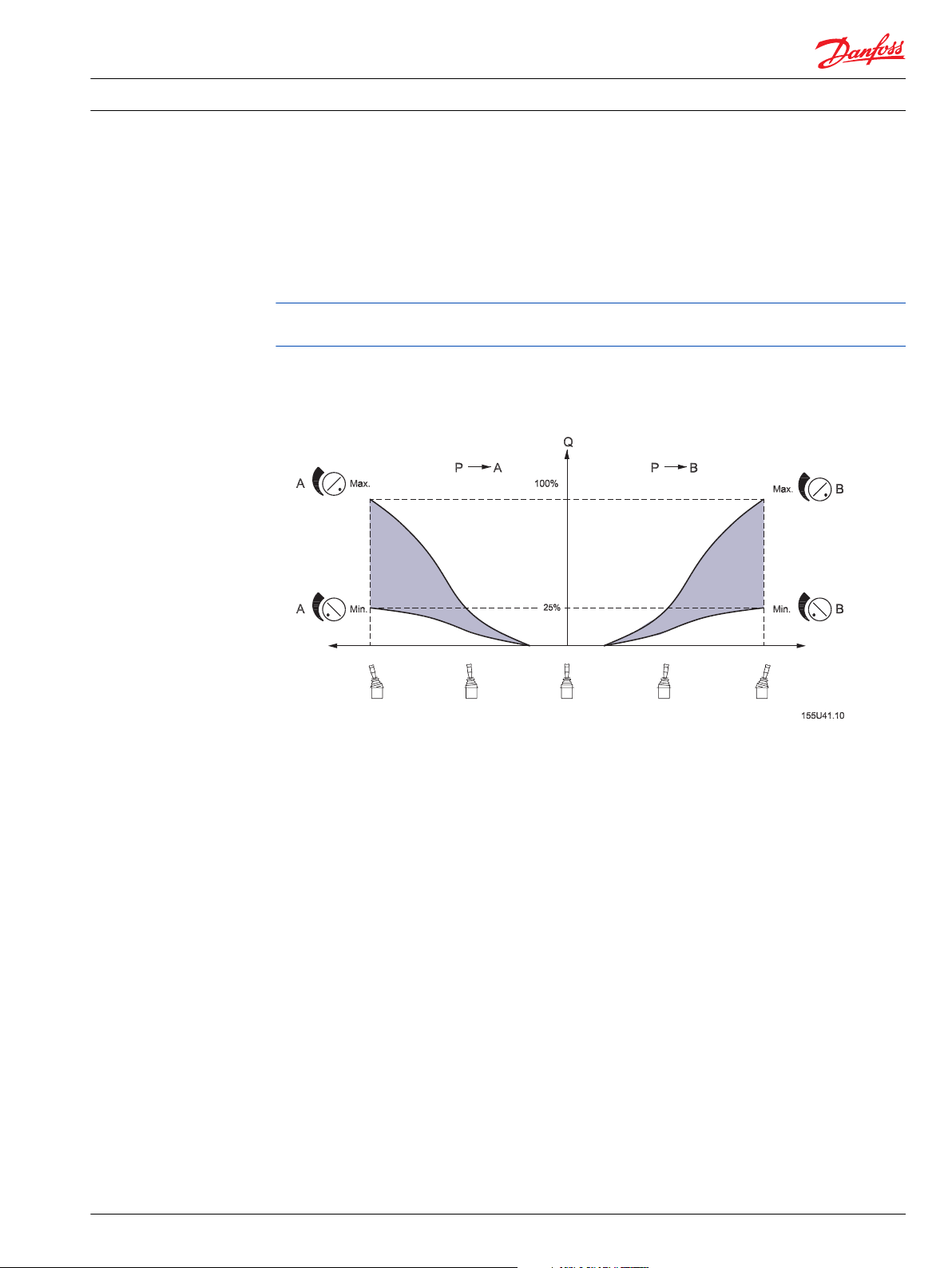

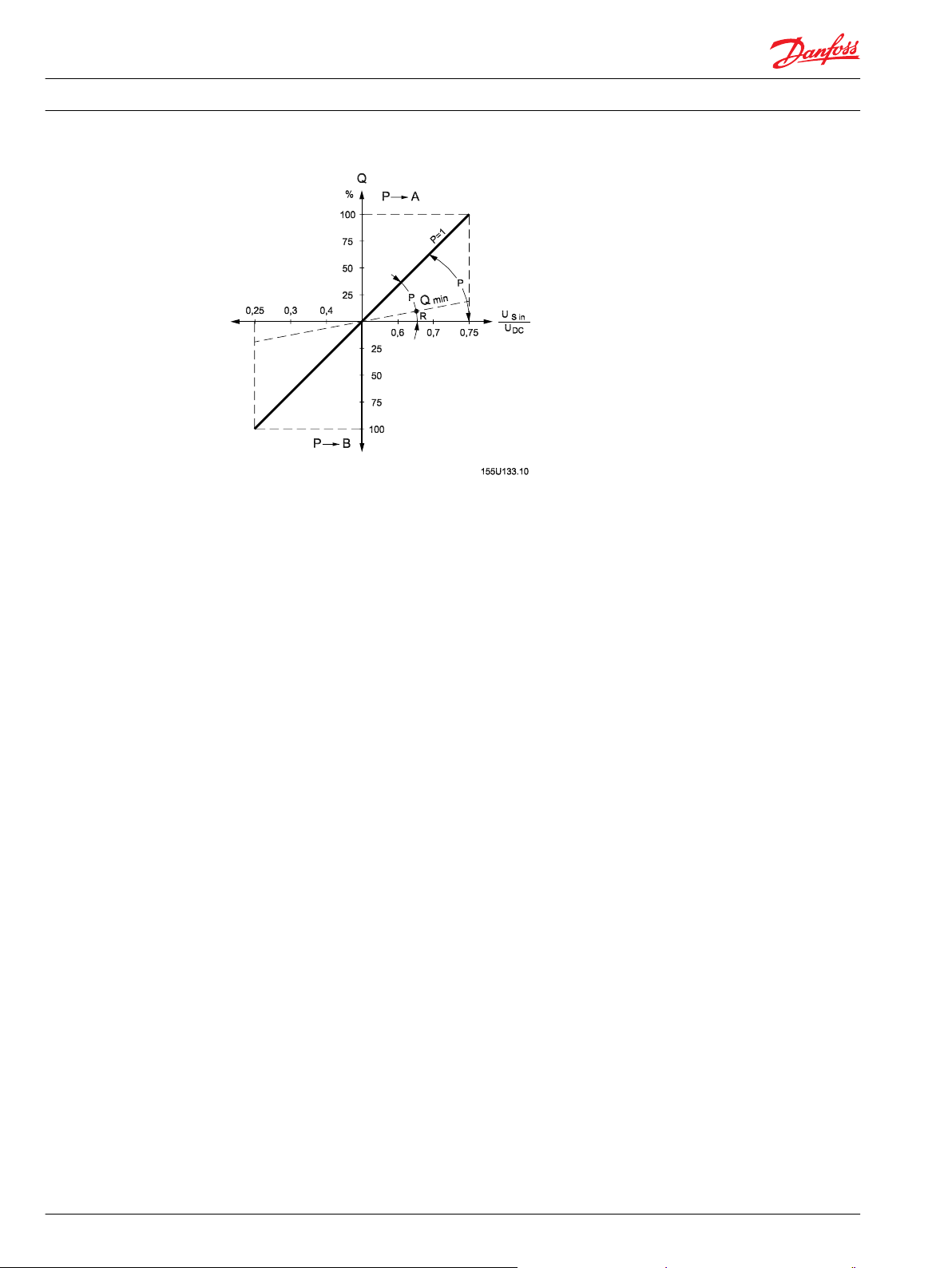

Characteristic

Flow as a function of the input signal and the two potentiometers for the flow limitation at ports A and B

520L0804 • Rev 0103 • January 2016 9

Page 10

Signal leads

Supply leads

Technical Information EH Modules

Electronic flow regulation - EHF

Electrical system

EHF - electrical system

Technical data

Supply voltage U

Current consumption < 50 mA

Output voltage (US) U

Neutral voltage (US) U

Input signal Remote control lever, potentiometer

Input impedance 12 kΩ at 0.5 • UDC

Output signal Maximum load Two parallelconnected PVEs

10 520L0804 • Rev 0103 • January 2016

DC

11 to 30 V

Maximum ripple 5%

S

U

DC

S

U

DC

Minimum load impedance to 0.5 •

U

DC

0.25 → 0.75

0.5

6 kΩ

Page 11

Technical Information EH Modules

Electronic flow regulation - EHF

Signal current maximum UDC = 12 V ±0.5 mA

Ambient temperature -30 to +60°C [-22 to 140 °F]

Enclosure to IEC 529 IP 42

EHF must be connected to the supply voltage at the same point as the remote control lever.

Code number and weight

EHF mounting base code number EHF base weight

905 0.10 kg (0.22 lb)

UDC = 24 V ±1.0 mA

520L0804 • Rev 0103 • January 2016 11

Page 12

Technical Information

Electronic alarm logic - EHA

General

EH Modules

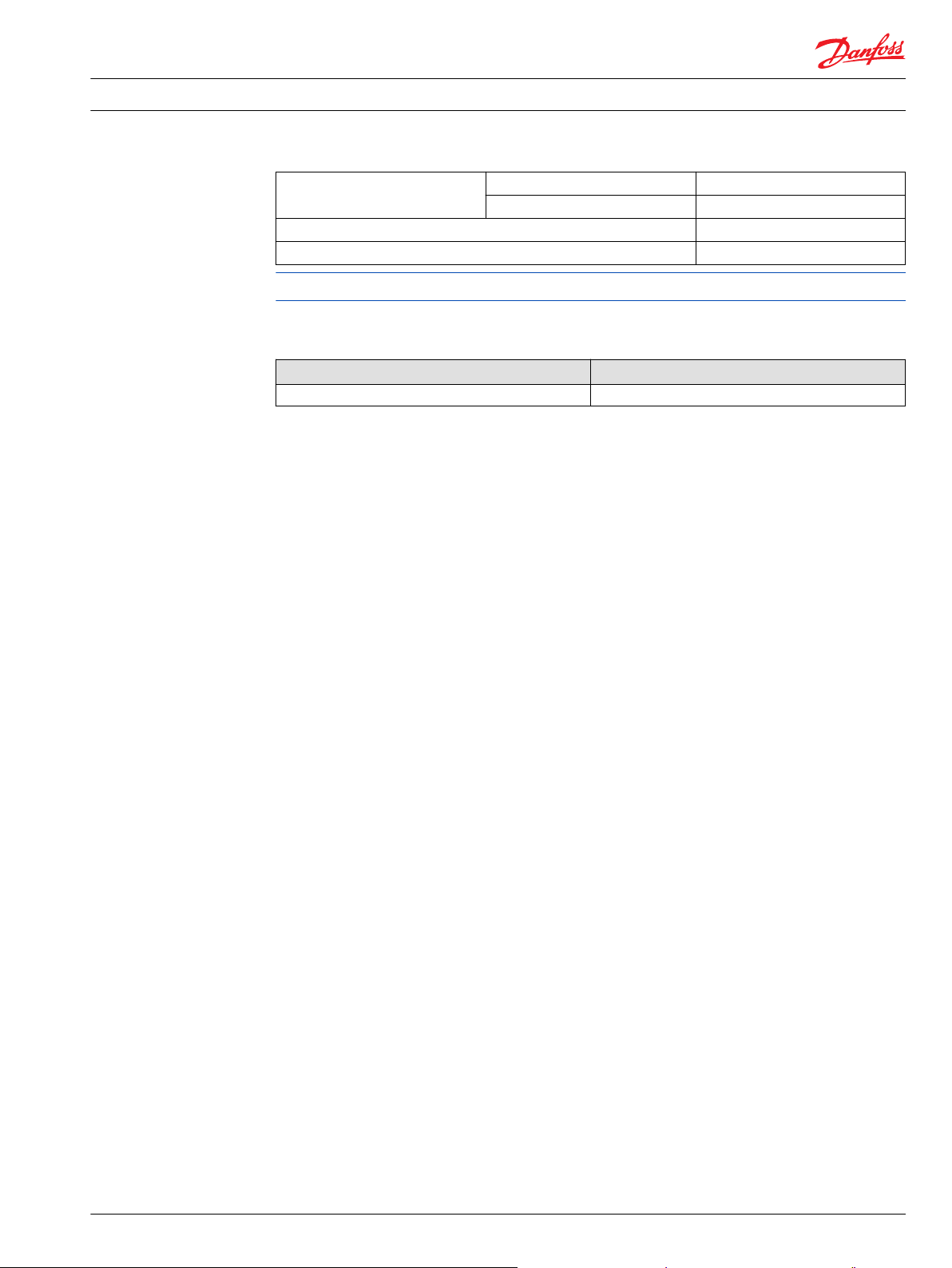

Electronic alarm logic - EHA

Danfoss EHA electronic alarm logic modules are used primarily where together with PVEH electric

activation modules they must meet requirements for optimum system safety.

In principle, EHA can be compared with eight series-connected relays that collect alarm signals from up

to eight PVEH activation modules and via the series connection combine them into a single active output

signal.

The output signal is able to control electric PVPX and PVPE relief valves, normally open (NO) version

which will relieve the LS signal/pump pressure to tank on fault signal from PVEH. These relief functions

make the PVG valves hydraulically inactive.

Alternatively, EHA can be used to control sirens, warning lamps and other alarm sources to indicate

function fault.

12 520L0804 • Rev 0103 • January 2016

Page 13

Fault-free function Fault function

Technical Information

Electronic alarm logic - EHA

Function

EH Modules

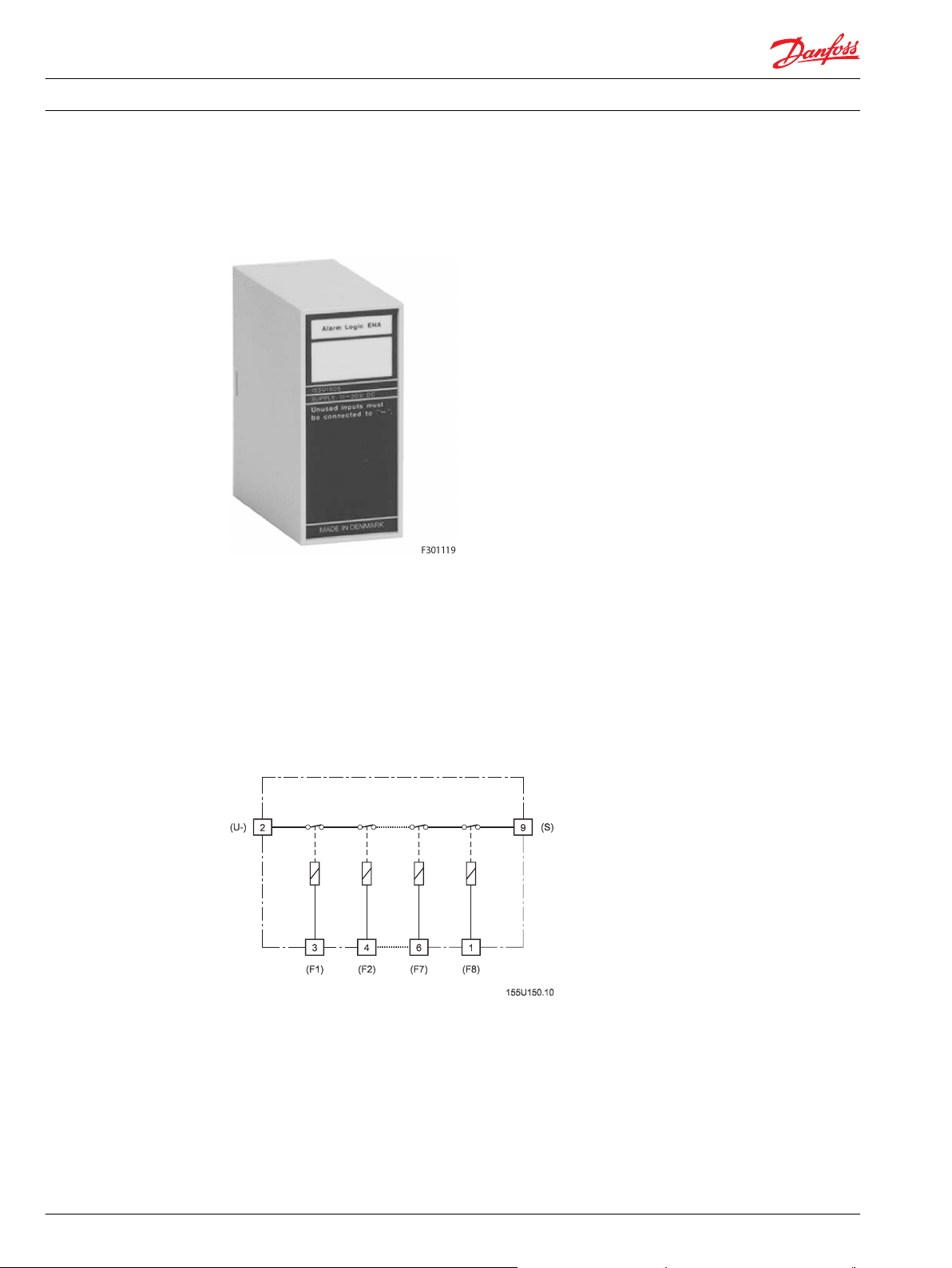

The alarm outputs from the electrically activated PVEHs in a valve group must be connected to EHA.

EHA is built up so that it is able to monitor up to eight PVEH alarm outputs.

With fault-free function, the EHA output signal is internally connected to minus

If one or more of the PVEH alarms indicate a fault, the EHA output signal is cut off immediately.

To ensure correct function, all unused inputs must be connected to minus, i.e. EHA regards all inputs

without connection as a fault. In addition, all input signals exceeding 8 V are also regarded as faults while

signals of less than 3 V are regarded as fault-free.

In the range 3-8 V the condition remains undefined.

EHA automatically resets when the fault condition no longer exists.

520L0804 • Rev 0103 • January 2016 13

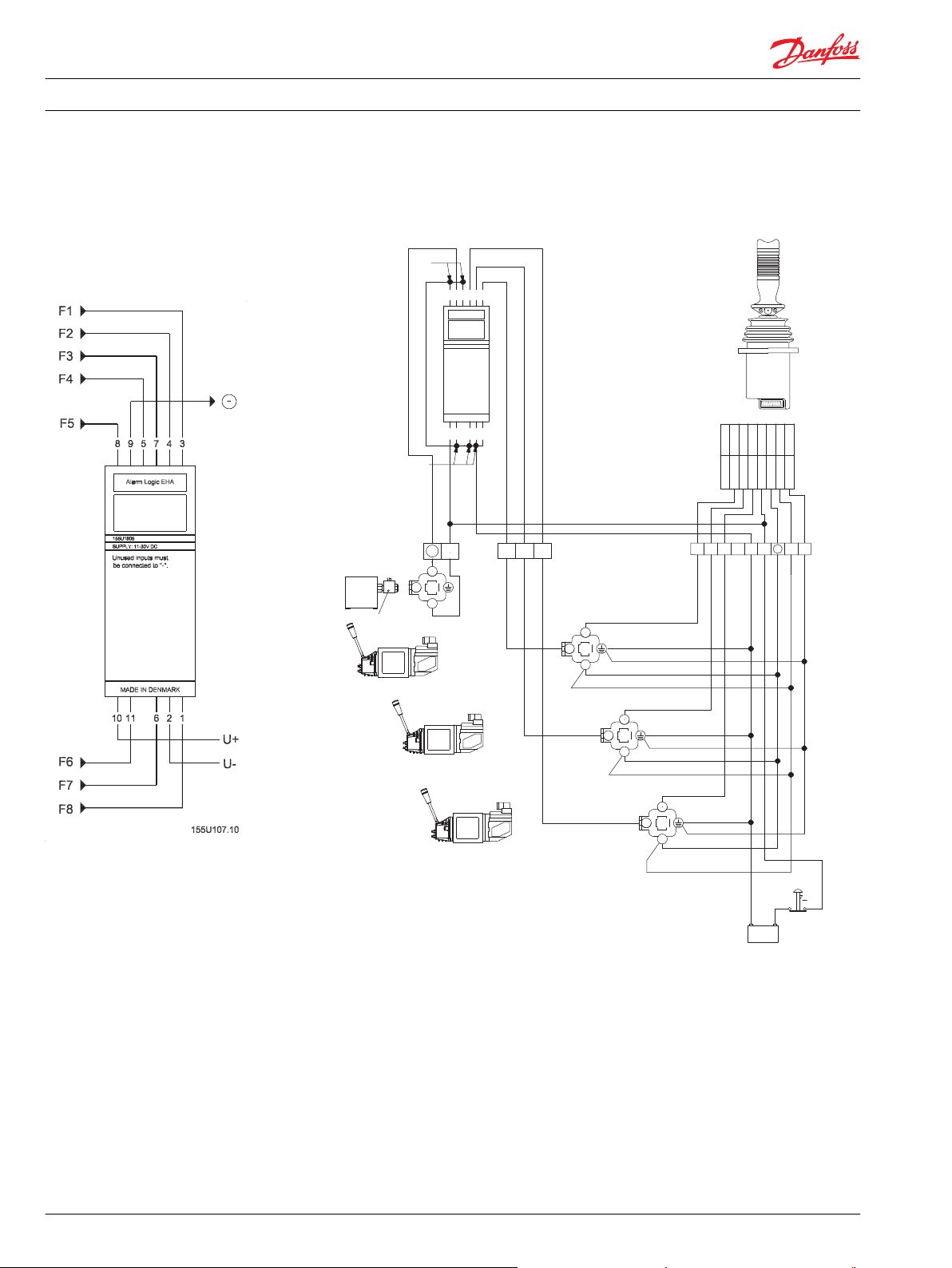

Page 14

DC

U+

Prop 2

Function

Prop 1

Prop 3

N.sw.out

U-

16211

10

PVPX

2

-

3

1

+

1

2

3

U

-

DC

+

E

F3

F2F1

US1UU

S2 S3

- +

U

U-U++

Alarm Logic EHA

be connected to "-".

Unused inputs must

SUPPLY: 11-30V DC

MADE IN DENMARK

155U1805

8 95743

Pin no.

873,15,1651,2,141022

V310176.A

1

2

3

3

1

2

*1

*1

*2

PVEH

PVEH

PVEH

Technical Information EH Modules

Electronic alarm logic - EHA

Electrical system

Electronic alarm logic EHA electrical system

1 To avoid being regarded as a fault, unused inputs must be connected to minus.

E Emergency stop

14 520L0804 • Rev 0103 • January 2016

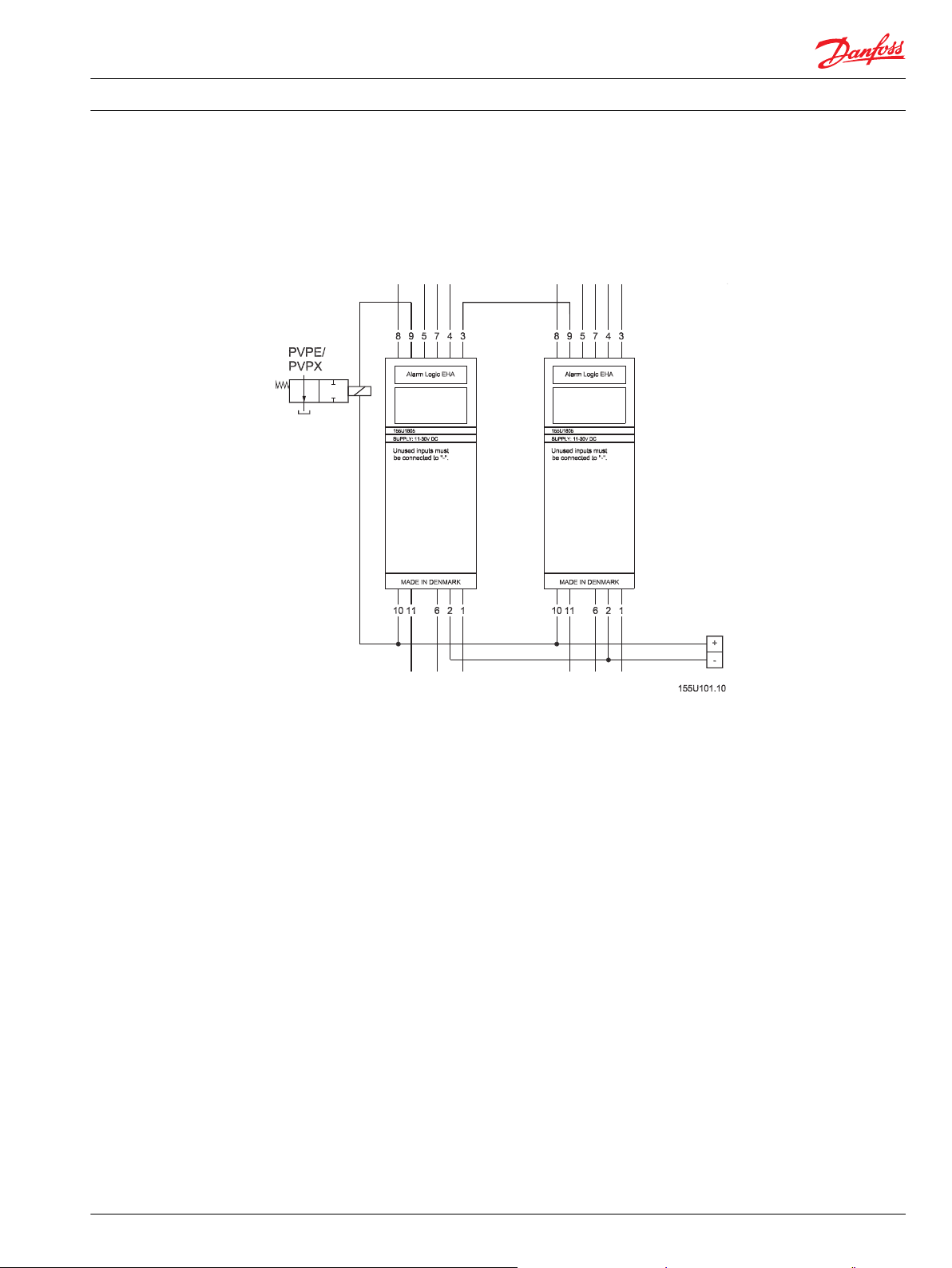

Page 15

Technical Information EH Modules

Electronic alarm logic - EHA

Monitoring more than eight functions

With standard connections, EHA will monitor up to eight alarm outputs.

If more outputs are to be monitored, two or more EHAs can be connected in series by allowing the

output from one EHA to control an input on the following EHA. This extends the capacity by seven inputs

for every extra EHA.

520L0804 • Rev 0103 • January 2016 15

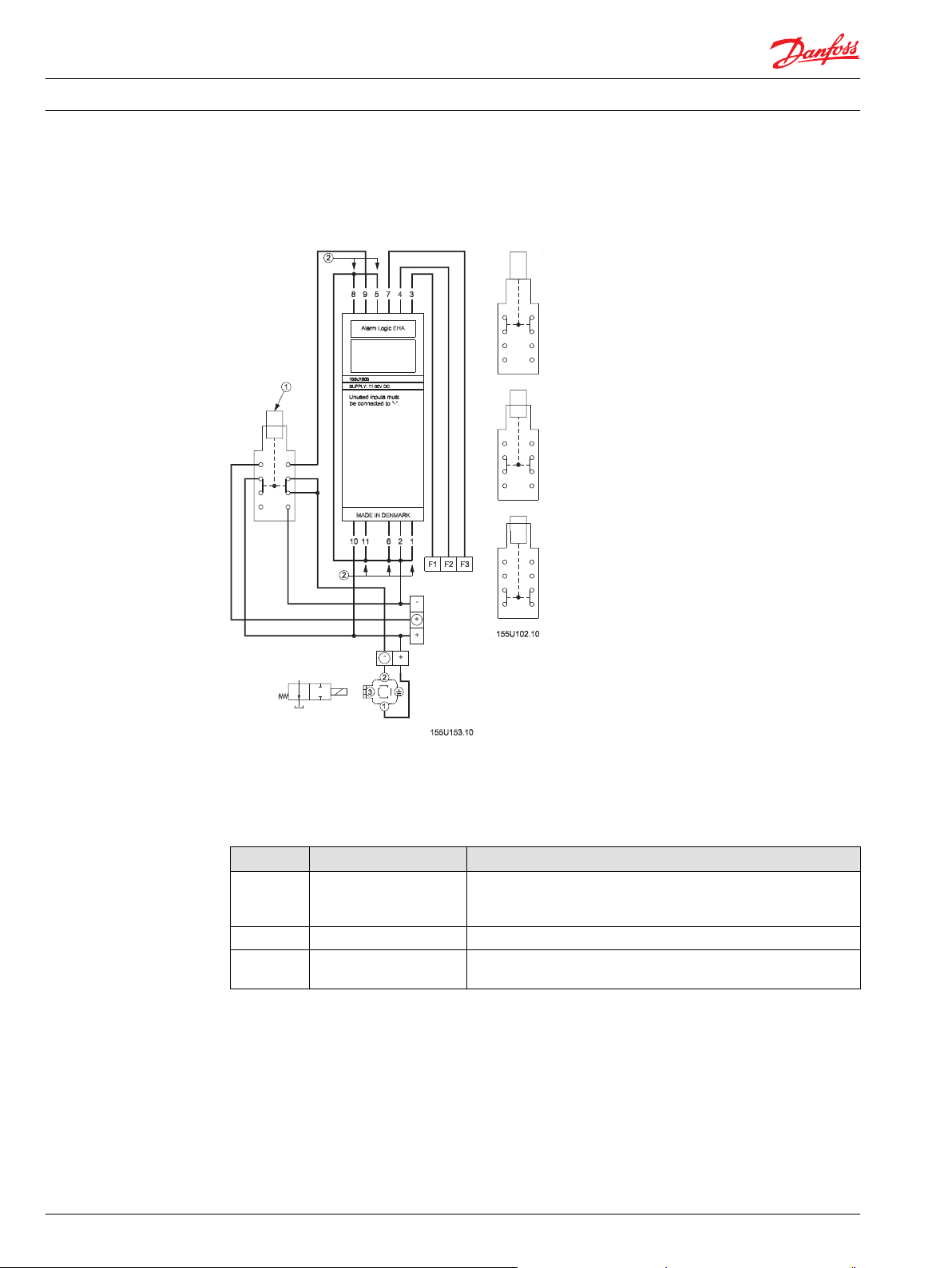

Page 16

Technical Information EH Modules

Electronic alarm logic - EHA

Electric remote to mechanical operation

Changeover between electric remote operation and mechanical operation

1 Switch

2 Unused inputs must be connected to minus

Positions

Position Description Comment

1 Electrical system operation

2 Off

3 Mechanical system

operation

The hydraulics can only be operated by electrical remote control.

The PVEs lock main spools hydraulically and prevent mechanical

operation.

The hydraulics cannot be operated either mechanically or electrically.

The hydraulics can only be operated mechanically.

The relief valve is activated only via the switch.

16 520L0804 • Rev 0103 • January 2016

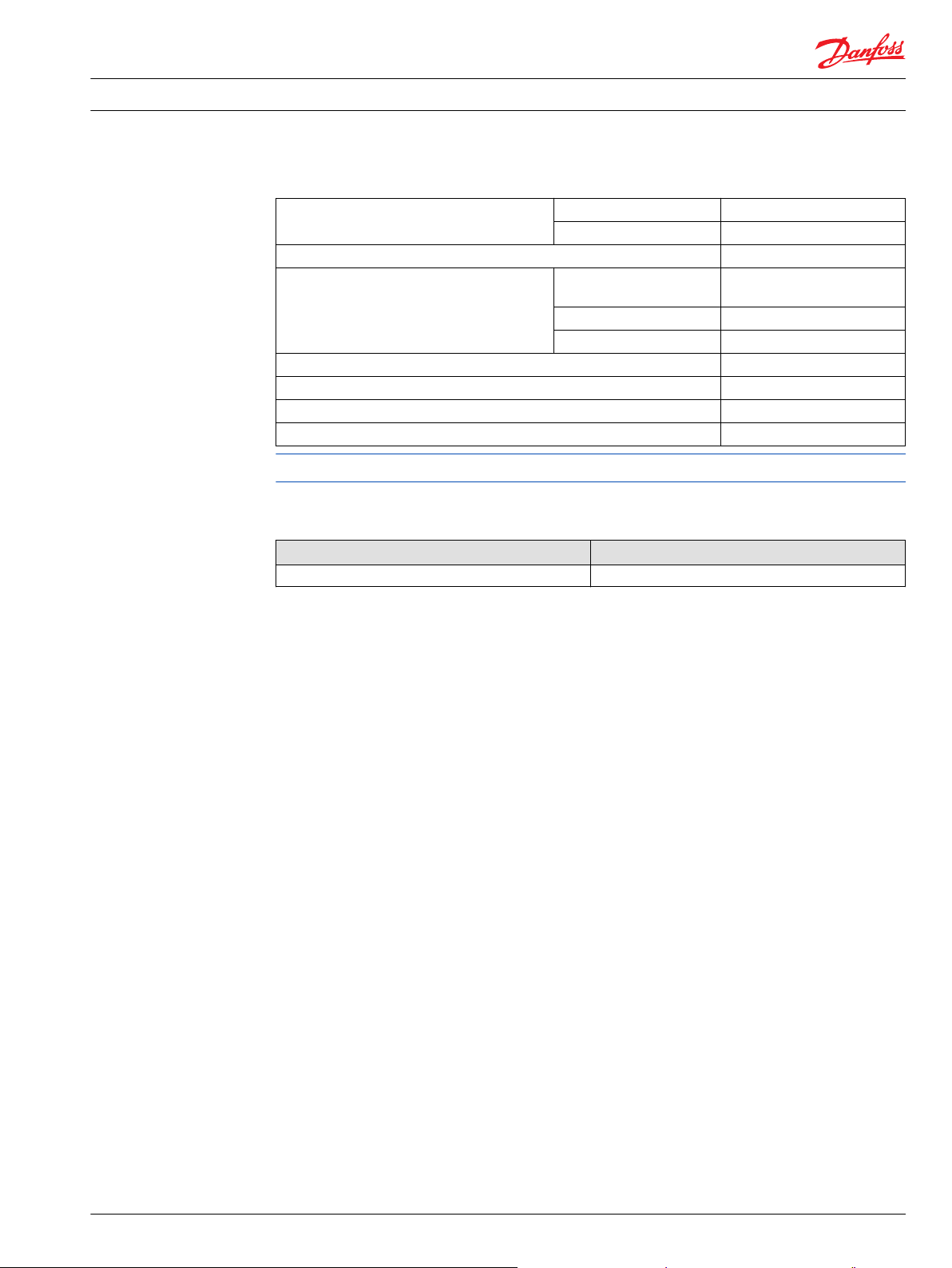

Page 17

Technical Information EH Modules

Electronic alarm logic - EHA

Technical data

Code number and weight

Supply voltage U

Current consumtion without output load < 40 mA

Input signal Tapping from PVEH fault

Input impedance >3 kΩ

Output load 30 V / 1.5 A

Ambient temperature -30 to + 60°C [-22 to 140 °F]

Enclosure to IEC 529 IP 42

DC

Maximum ripple 5%

Fault-free signal 0 to 3 V

Fault signal 8 V - UDC/Off

11 to 30 V

monitoring

EHA must be connected to supply voltage at the same point as PVEH.

EHA mounting base code number EHA base weight

155U1805 0.09 kg (0.20 lb)

520L0804 • Rev 0103 • January 2016 17

Page 18

Technical Information

EH Modules

Electronic ramp generator - EHR

General

Electronic ramp generator - EHR

Danfoss electronic ramp generator EHR controls the acceleration and deceleration times for flow from

proportional valve ports A and B.

The acceleration and deceleration control is individual for Ports A and B. This form of control is called

ramping of, positive and negative respectively. As standard, ramp times can be controlled from 0-2.5 s,

but can be extended up to 20 s.

When used in an electrohydraulic system, EHR gives "soft" start and stop of the working function.

Function

Setting ramp times - EHR

EHR is inserted in the signal connection between the electric remote control lever and the activation

module in the proportional valve.

EHR damps rapid signal changes while signals that are changed more slowly than the set ramp times are

not changed.

EHR contains four potentiometers for the setting of ramp times. The setting of positive ramps, are made

with A+ and B+ potentiometers for A and B ports respectively, while negative ramps, are set with A− and

B− potentiometers.

There are two different ways of building in EHR:

18 520L0804 • Rev 0103 • January 2016

Page 19

Technical Information EH Modules

Electronic ramp generator - EHR

Principle 1 : Positive and negative ramps

•

Principle 2 : Primarily positive ramps.

•

These two principles are described in more detail in Electrical system - Principle 1 on page 20 and

Electrical system - Principle 2 on page 21.

Signal monitoring

EHR incorporates signal input monitoring, terminal 3. This means that the input signal must lie within the

limits 0.15 • UDC to 0.85 • U

If these limits are exceeded, such as a consequence of short-circuiting to plus or minus supply voltage,

the signal monitoring cuts off the output signal to the proportional valve which as a result immediately

neutral positions the main spool.

If the signal monitoring has cut off the output signal, EHR will only function again after the voltage supply

to it has been cut off.

DC

520L0804 • Rev 0103 • January 2016 19

Page 20

Signal leads

Supply leads

Technical Information

EH Modules

Electronic ramp generator - EHR

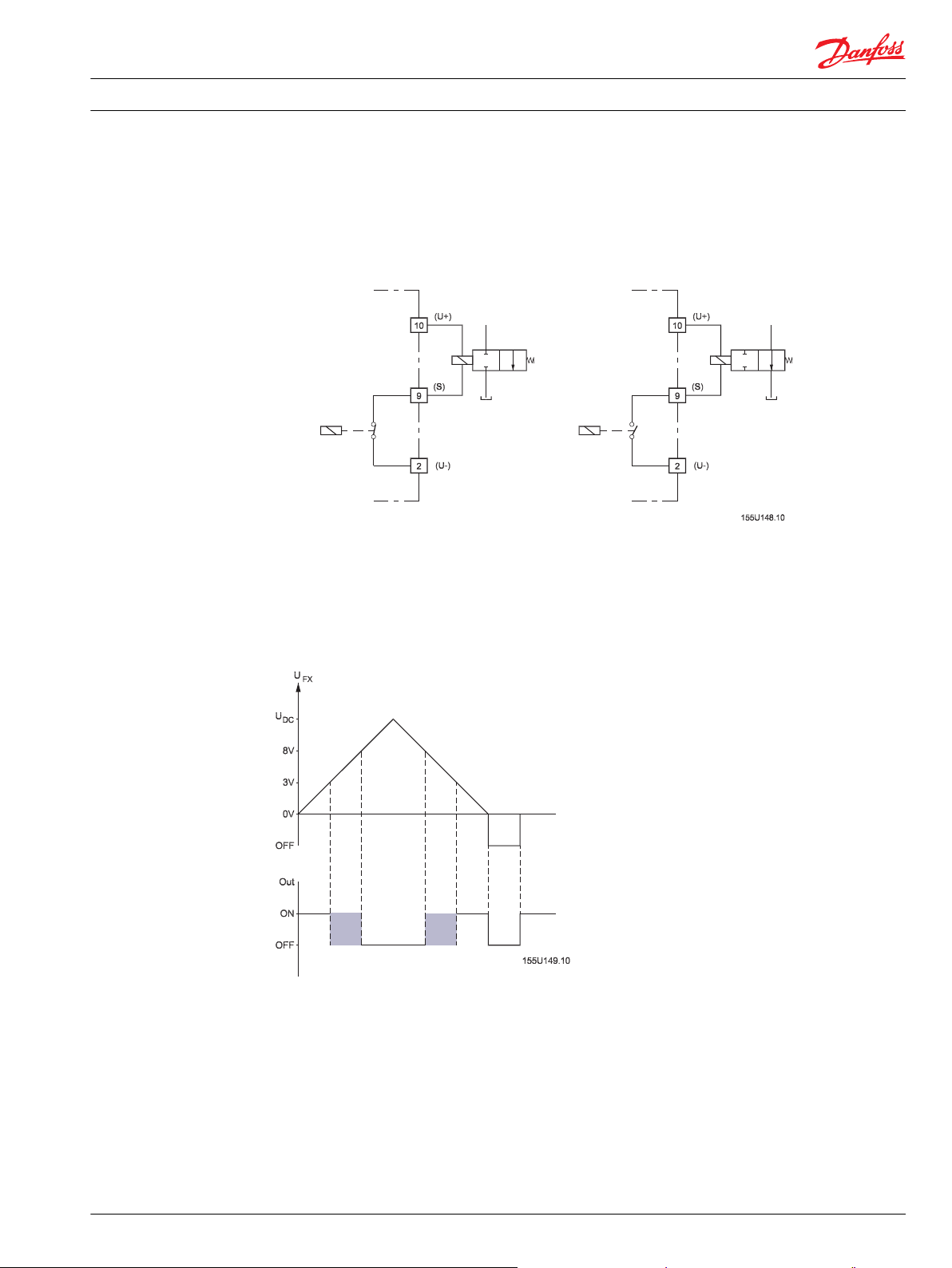

Electrical system - Principle 1

EHR electrical system - Principle 1

With the electrical system - Principle 1, it is possible to obtain positive/negative ramps for all input signal

changes.

A signal change over neutral means that the negative ramp is complete before the positive ramp begins.

Terminals 1 and 10 are short-circuited. The neutral position switch (N) is not used. If the external break

contacts (see External break contacts on page 23) are not used, terminals 6 and 11 must be shortcircuited to terminal 10.

20 520L0804 • Rev 0103 • January 2016

Page 21

Signal leads

Supply leads

Technical Information

EH Modules

Electronic ramp generator - EHR

Electrical system - Principle 2

The following system will give mainly positive ramps.

EHR electrical system - Principle 2

An input signal that goes to or passes neutral will prevent a negative ramp. Negative ramps can be

obtained in two ways:

•

On signal changes that do not go completely to neutral.

•

With use of external break contacts (see External break contacts on page 23).

To fulfill principle 2, terminal 1 and 10 must not be short-circuited. If the external break contacts are not

used, terminals 6 and 11 must be short-circuited to terminal 10.

520L0804 • Rev 0103 • January 2016 21

Page 22

C = t-2.5

0.7

[µF]

Technical Information

EH Modules

Electronic ramp generator - EHR

Ramp times

As standard, ramp times can be set between 0 and 2.5 s for 0 to max. flow.

Ramp times can be increased by inserting a bipolar capacitor externally between terminals 8 and 5.

Ramp times are dependent on the size of the capacitor, which can be calculated using the following

formula for t > 2.5 s:

t is the required ramp time in seconds. The ramp time must not exceed 20 seconds.

To ensure that the capacitor (C) functions as intended, it must have very low leakage current (see

specification in Technical data on page 10).

22 520L0804 • Rev 0103 • January 2016

Page 23

Technical Information

EH Modules

Electronic ramp generator - EHR

External break contacts

KA, KB signals

Negative ramps can be obtained with break contacts KA/KB, both in principle 1 and 2.

When KA or KB breaks, a negative ramp is generated for ports A and B respectively. A contact in break

position prevents further signals in the same direction. KA and KB are therefore suitable as limit switches,

such as for slewing movement on a crane.

When the voltage on KA/KB is less than 3 V or OFF, the KA/KB function is regarded as OFF and a negative

ramp is generated.

When the voltage on KA/KB is greater than 8 V, the KA/KB function is regarded as ON.

In the range between 3 and 8 V, the KA/KB function remains undefined.

520L0804 • Rev 0103 • January 2016 23

Page 24

Technical Information EH Modules

Electronic ramp generator - EHR

Technical data

Supply voltage U

DC

11 to 30 V

Max. ripple 5%

Current consumption < 50 mA

Output voltage (US) U

Neutral voltage (US) U

S

U

DC

S

U

DC

0.25 → 0.75

0.5

Input signal Remote control lever, potentiometer

Input impedance t3 12 kΩ to 0.5 • U

DC

t1/6/11 > 5Ω

Output signal Maximum load Two parallel connected PVEs

Minimum load impedance to 0.5 •

M6 kΩ

UDC

Signal current UDC = 12 V ± 0.5 mA

UDC = 24 V ± 1.0 mA

Settings Positive ramp port A A+

Negative ramp port A A-

Positive ramp port B B+

Negative ramp port B BExternal cutoff switches KA breaks ramp A -

KB breaks ramp B -

KA/KB OFF < 3 V/OFF

KA/KB ON 8 V → UDC

Ramp times (0 to max. flow) Standard 0 → 2.5 s.

With external capacitor (C) 0 → 20 s.

Ambient temperature -30 to + 60 °C [-22 to 140 °F]

Enclosure to IEC 529 IP 42

External capacitor (C) Operating voltage Minimum 10V

Insulation resistance Minimum 5 GΩ

Time constant, RC Minimum 5000 s.

EHR ramp generator must be connected to supply voltage at the same point as the remote control lever.

Code number and weight

EHR mounting base code number EHR base weight

155U2905 0.12 kg (0.26 lb)

24 520L0804 • Rev 0103 • January 2016

Page 25

Technical Information

EH Modules

Electronic speed control - EHS

General

Electronic speed control - EHS

The Danfoss electronic speed control EHS takes up an electric pulse signal related to rotational

movement. e.g. the speed of a shaft, the speed of a vehicle.

The pulse signal is converted into a proportional signal that is applied, via port A on the proportional

valve, to control the speed of a hydraulic motor.

EHS also gives the possibility of infinite flow regulation.

In other words, EHS and PVG together create a variable electrohydraulic gear.

Function

EHS controls the flow from the proportional valve, in relation to the frequency of the electric signal from a

tachometer pulse source.

EHS contains two potentiometers, used to set the frequency necessary to give maximum movement of

the proportional valve and compensate for leakage in the hydraulic system itself.

An externally connected potentiometer allows the infinite regulation of the ratio between frequency and

flow.

When a frequency is applied to EHS, the proportional valve immediately functions to give the

corresponding flow.

520L0804 • Rev 0103 • January 2016 25

Page 26

Technical Information

EH Modules

Electronic speed control - EHS

To ensure linearity between frequency and flow, EHS compensates for the progressive flow characteristic

of the proportional valve.

Potentiometer 1

Potentiometer 1 - Adjustment of f

max

Potentiometer 2

Potentiometer 1 determines the frequency, f

the proportional valve 50 Hz < f

< 200 Hz

max

, i.e. the frequency that must give maximum flow from

max

Q0 is the least flow supplied from the proportional valve. The adjustment of potentiometer 2

compensates both for the dead band of the proportional valve and leakage in the hydraulic system.

Q0 becomes effective at not more than 3% of f

max

.

If 100 % (maximum flow) is exceeded, potentiometer Px (see Potentiometer (P) on page 27) is inserted to

eliminate the excess in order to obtain optimum utilization of the regulation range. If Px is not used,

either Q0 (potentiometer 2) or f

(potentiometer 1) must be adjusted down.

max

26 520L0804 • Rev 0103 • January 2016

Page 27

P

R =

__________________

[Ω]

Q

max

__________

− 1

Q

min

Technical Information

EH Modules

Electronic speed control - EHS

Potentiometer (P)

Recommendation

Potentiometer (P) regulates the amplification in EHS and thereby the ratio between frequency and flow.

The resistor (R) increases Q

R can be calculated with f

over Q0. R must always be inserted as at least 5% of P.

min

as:

max

5Ω < (R + P ( + Px)) < 22 kΩ

R + P : Recommendation 10 kΩ

To ensure reliable regulation of the hydraulic system, the ratio between amplitude and pulse pause (X:Y)

for the pulse signal must be maintained (see Technical data on page 29).

It is recommended that EHS be used with electric activation module PVEH in every case.

Input reference

In some cases the pulse source is unable to fulfill the requirement that amplitude must be ± 1 V in

relation to the reference 0,5 • UDC.

520L0804 • Rev 0103 • January 2016 27

Page 28

Technical Information EH Modules

Electronic speed control - EHS

In these cases it is possible to reduce the reference level by using an external potentiometer between

terminals (10) and (2) with input to terminal (1). The reference will then be the same as the voltage level

on terminal (1).

28 520L0804 • Rev 0103 • January 2016

Page 29

Signal leads

Supply leads

Technical Information EH Modules

Electronic speed control - EHS

Electrical connection

Technical data

Supply voltage U

DC

11 to 30 V

Maximum ripple 5%

Current consumption < 35 mA

Output voltage (US) U

Neutral voltage (US) U

S

U

DC

S

U

DC

0.5 → 0.25

0.5

Input signal Pulse source

Minimum amplitude 0.5 • UDC ± 1 V

Pulse - pause ratio (x : y) 1 : 1 ± 10%

Maximum flow frequency 50 - 200 Hz

Input impedance to 0.5 • UDC 56 Ω

520L0804 • Rev 0103 • January 2016 29

Page 30

Technical Information EH Modules

Electronic speed control - EHS

Output signal Maximum load Two parallel connected PVEs

Signal current maximum UDC = 12 V 0 → - 0.5 mA

Resistance (terminals (4) to (8)) R + P (+Px) 5 → 22 kΩ

Terminal (5) Impedance to 0.5 • U

Terminal (1) Impedance to 0.5 • U

Ambient temperature -30 to + 60 °C [-22 to 140 °F]

Enclosure to IEC 529 IP 42

EHS must be connected to supply voltage at the same point as PVE.

Code number and weight

Minimum load impedance to 0.5 •

UDC

Flow P → A

Error in % of US maximum < 5

UDC = 24 V 0 → - 1.0 mA

Recommended 10 kΩ

DC

DC

6 kΩ

1 MΩ

> 56 kΩ

EHS mounting base code number EHS base weight

155U3905 0.10 kg (0.22 lb)

30 520L0804 • Rev 0103 • January 2016

Page 31

Technical Information

EH Modules

Electronic, frequency controlled loop speed control - EHSC

General

Electronic, Frequency Controlled Loop Speed Control - EHSC

Danfoss electronic, frequency controlled speed control EHSC is used in closed loop control systems. It

controls the oil flow from the proportional valve A port and thus the speed of a hydraulic motor.

The speed is adjusted to correspond to a control frequency (speed signal) from, for example, a speed

encoder on the wheelaxle of a vehicle. A second speed encoder fitted on the hydraulic motor shaft

provides a feedback frequency.

EHSC compares the control and the feedback frequency, and the oil flow is adjusted so the ratio between

the two signals is correct. In this way the speed of the hydraulic motor corresponds to the speed of the

vehicle.

When the vehicle changes speed, the speed of the hydraulic motor will be changed accordingly. This

means, for example, that a gritter will distribute a constant quantity of sand over every m2 road surface regardless of the speed of the vehicle and the load on the hydraulic motor.

Adjustment possibilities

In EHSC there are four built-in potentiometers which are adjusted in order to achieve optimum speed

control.

520L0804 • Rev 0103 • January 2016 31

Page 32

Technical Information

EH Modules

Electronic, frequency controlled loop speed control - EHSC

By adjusting potentiometer 1, proportional valve dead band and internal leakage of the hydraulic

•

system are compensated.

With potentiometer 2 the working range of the EHSC is set and thereby the control frequency that

•

gives maximum oil flow from the proportional valve.

With potentiometer 3 the feedback frequency is set corresponding to maximum motor speed at

•

maximum oil flow from the proportional valve.

With potentiometer 4 possible tendencies to system hunting are eliminated.

•

With an external potentiometer the relationship between control frequency and oil flow can be adjusted

in the range from 0 to 2. This means that maximum oil flow from the proportional valve is possible even

at 50% of the set maximum control frequency, just as it is possible to shut off oil flow irrespective of

control frequency.

Function monitoring

EHSC has an INFO output controlled by a function monitor. A warning lamp can be connected to the

INFO output.

Constantly lit lamp means that EHSC is functioning correctly.

•

Flashing lamp means that the difference between the control and the feedback frequencies is too big

•

for the EHSC to correct.

Unlit lamp means that either the control or the feedback frequency has been interrupted.

•

If the feedback frequency has been interrupted, EHSC switches automatically to open loop speed control.

This means it will still control the oil flow from the proportional valve, but only in relation to the control

frequency.

Adjustments

Potentiometer 1

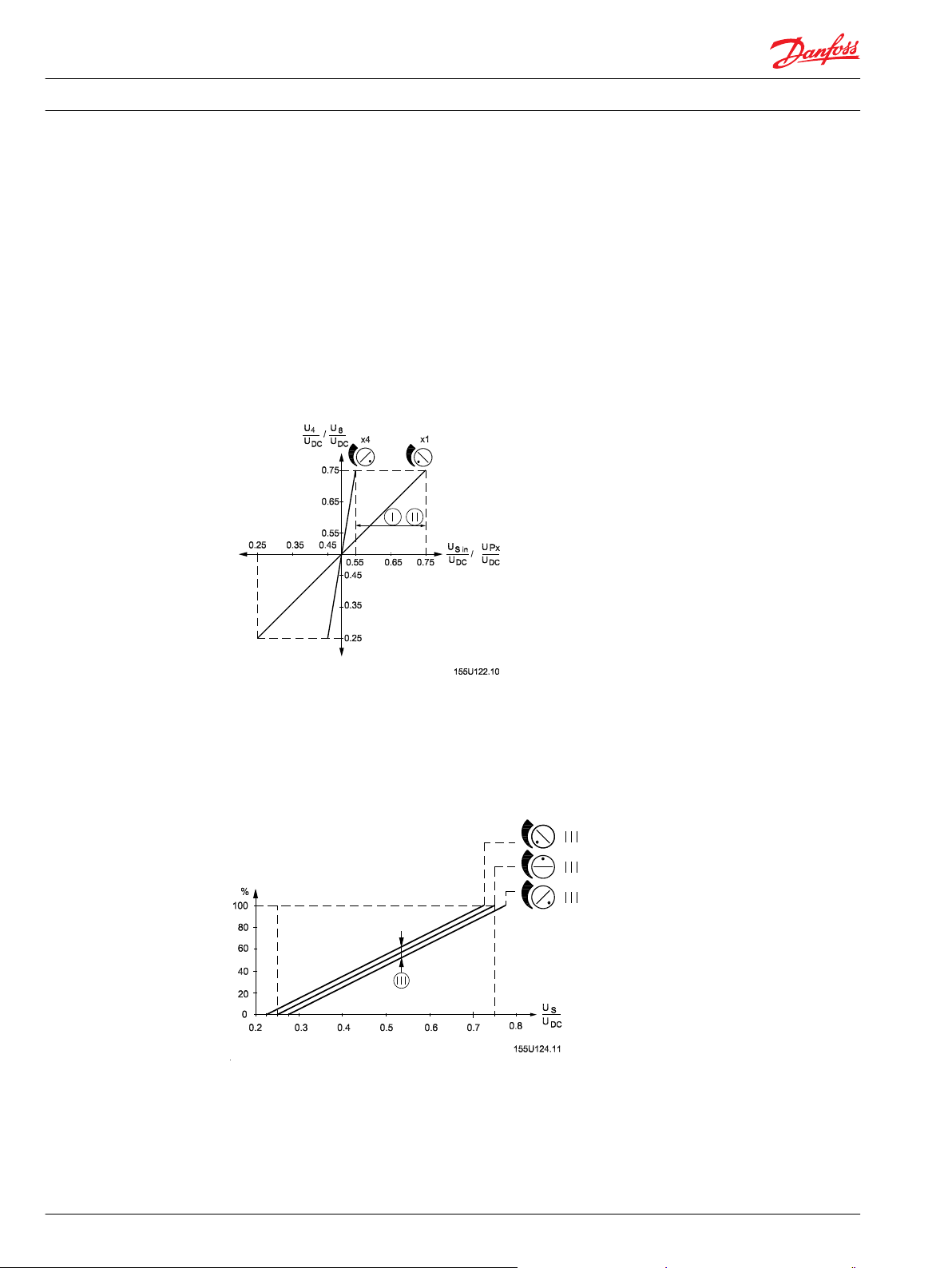

Q0 is the least oil flow supplied from the proportional valve at a stable control frequency (3% of f

32 520L0804 • Rev 0103 • January 2016

fmax

).

Page 33

Technical Information

EH Modules

Electronic, frequency controlled loop speed control - EHSC

Adjustment of minimum oil flow (Q0)

Potentiometer 2

Adjustment of maximum feed back frequency (f

): 50 Hz < f

fmax

fmax

< 300 Hz

The setting of potentiometer 2 determines the control frequency giving maximum oil flow (Q

the proportional valve. If f

If Q

is exceeded, potentiometer Px can be inserted to obtain optimal use of the control range. If Px is

100

not used, either Q0 or f

is set correctly, the test signal terminal 4 (U4) will be 5.25 V.

fmax

should be reduced. (See Potentiometer 1 on page 32 and Potentiometer 2 on

fmax

100

) from

page 33).

520L0804 • Rev 0103 • January 2016 33

Page 34

fb [Hz]

U6

[V] = • 1,75 [V] + 3,5 [V]

f

b max

[Hz]

Q l/min [US gal/min]

• ppr • 1000

motor displacement [cm3]

fb [Hz] =

60

Technical Information EH Modules

Electronic, frequency controlled loop speed control - EHSC

Potentiometer 3

Adjustment of maximum feed back frequency (f

The setting of potentiometer 3 determines the maximum feedback frequency corresponding to

maximum speed for the hydraulic motor at maximum oil flow.

When ordering EHSC there is a choice of two ranges for feedback frequency:

800 Hz < f

•

b max

< 8000 Hz

b max

)

or

30 Hz < f

•

If f

is set correctly, the test signal terminal 6 (U6), will be 5.25 V.

b max

b max

< 300 Hz

If the system utilizes the maximum flow capacity of the main spool, the test signal on terminal 6 (U6) must

be 5.25 V at f

b max

.

If the system does not utilize the maximum flow capacity of the main spool, the setting of U6 must be

calculated as follows:

fb is the actual maximum system feedback frequency. fb maximum is the feedback frequency on

maximum movement of the main spool.

Both fb and f

can be calculated thus:

b max

In calculating fb, Q is inserted as the actual maximum system flow. At fb maximum, Q is inserted as the

maximum flow capacity of the main spool.

Example:

Main spool Motor

PVG 32 OMS 80 EM

157B9764 151F3000

34 520L0804 • Rev 0103 • January 2016

Page 35

65 l/min [17.17 US gal/min]

• 15 • 1000

80 cm

3

fb [Hz] =

60

= 203 Hz

100 l/min [26.42 US gal/min]

• 15 • 1000

80 [cm3]

f

b max

[Hz] =

60

= 313 Hz

[V] = 203 Hz

• 1.75 [V] + 3.5 [V]

313 Hz

U

6

Technical Information

EH Modules

Electronic, frequency controlled loop speed control - EHSC

Example: (continued)

Main spool Motor

100 l/min

[26.42 US gal/min]

(4/3-open) (ppr = 15)

80 cm

3

Potentiometer (P)

Potentiometer 4

Potentiometer 4 is used to set the integration time in the EHSC integrator stage. The integrator stage

equalises the difference between forward and feedback frequencies. The integration time can be set

between 50 and 300 ms.

A short integration time means fast correction of speed deviations.

The permissible integration time is systemdependent. Too short an integration time can produce hunting

in the system.

520L0804 • Rev 0103 • January 2016 35

Page 36

Technical Information

EH Modules

Electronic, frequency controlled loop speed control - EHSC

The external potentiometer (P) determines the relationship between the control frequency and the oil

flow.

The ratio is infinitely variable in the range from 0 to 2.

Max. oil flow is achieved from 0.5 ↔ ff max at P = 2.

The oil flow may be cut off in the entire control range at P = 0.

Recommended value for potentiometer resistance P: 10 kΩ

Range for potentiometer resistance

P: 5 kΩ < P < 20 kΩ

Resistance (R)

The resistance (R) is only inserted if the oil flow must not be cut off completely. R forms a lower limit for

the control frequencey and oil flow (Qmin) ratio.

Recommended value for the total resistance P + R = 10 kΩ

Range for the total resistance P + R: 5 kΩ < P + R < 20 kΩ

36 520L0804 • Rev 0103 • January 2016

Page 37

Signal leads

Supply leads

Technical Information EH Modules

Electronic, frequency controlled loop speed control - EHSC

Electrical system

Technical data

E Emergency stop

F Signal output, fault monitoring

Supply voltage

Current consumption < 100 mA

Control frequency

Control frequency test, value at maximum control frequency (terminal 4) 5.25 V

Signal voltage (US) 0.50 → 0.25 • U

Neutral position voltage (ff = 0 Hz) 0.50 • U

520L0804 • Rev 0103 • January 2016 37

*

U

DC

11 to 30 V

Maximum ripple 5%

†

Minimum amplitude 3.5 V ± 1 V

Pulse-pause-ratio 1 : 1 ± 10%

Frequency at maximum flow 50 - 300 HZ

Input impedance >30 kΩ

DC

DC

Page 38

Technical Information EH Modules

Electronic, frequency controlled loop speed control - EHSC

Feedback frequency

†

Minimum amplitude 3.5 V ± 1 V

Pulse-pause-ratio 1 : 1 ± 10%

Frequency at maximum flow 800 → 8000 Hz

30 → 300 Hz

Input impedance > 30 kΩ

Feedback frequency test, value at maximum frequency (terminal 6) 5.25 V

Output signal Maximum load Two parallel connected PVE

Minimum load impedance to 0.5 •

U

DC

6 kΩ

Error in relation to maximum flow < 1%

Oil flow direction US = 0.50 → 0.75 • U

US = 0.50 → 0.25 • U

DC

DC

P → A

P → B

Signal current UDC = 12 V 0 → -0.5 mA

UDC = 24 V 0 → -1.0 mA

Load between terminals 4 and 8 P or (P + R) 5 → 20 kΩ

Recommended 10 kΩ

Input impedance (terminal 5) > 1 MΩ

Info output (terminal 11) Maximum load -100 mA

Ambient temperature - 30 → + 60°C [-22 to 140 °F]

Enclosure to IEC 529 IP 42

*

EHSC must be connected to the voltage supply in the same place as PVE.

†

See Required control and feedback frequency signal on page 38.

Required control and feedback frequency signal

To ensure reliable control of the hydraulic system, it is necessary to comply with the amplitude and pulse/

pause ratio (X : Y) stated for the control and feedback frequencies (see Technical data on page 37).

Main spools and electrical actuation modules

Danfoss recommends the use of a PVBS main spool with linear characteristic and a PVES electrical

actuation module.

Code number and weight

EHSC mounting base code number EHSC base weight EHSC feedback frequency

155U3815 0.14 kg (0.31 lb) 30 → 300 Hz

38 520L0804 • Rev 0103 • January 2016

Page 39

Technical Information

EH Modules

Electronic, voltage controlled closed loop speed control - EHSC

General

Electronic, Voltage Controlled Closed Loop Speed Control - EHSC

Danfoss electronic, voltage controlled speed control EHSC is used in closed loop control systems. It

controls the oil flow from the A and B ports of the proportional valve and consequently the speed of a

hydraulic motor.

The speed is controlled so that it corresponds to an analogue voltage signal from e.g. a remote control

lever. A speed encoder connected to the hydraulic motor shaft provides a feedback frequency.

EHSC compares the control signal with the feedback frequency and controls, via a PVG proportional

valve, the oil flow so that the feedback frequency corresponds to the control signal. The speed of the

hydraulic motor will then correspond to the move-ment of the remote control lever regard-less of the

load on the hydraulic motor.

Adjustment possibilities

In the EHSC four built-in potentiometers are used for the adjustment, to achieve optimum speed control:

Adjusting potentiometers 1 and 2 compensates for proportional valve dead band in directions A and

•

B plus the internal leakage of the hydraulic system.

Potentiometer 3 sets the max. feedback frequency corresponding to the max. speed of the motor at

•

max. oil flow from the proportional valve.

With potentiometer 4 possible tendencies of system hunting are eliminated.

•

520L0804 • Rev 0103 • January 2016 39

Page 40

Technical Information

EH Modules

Electronic, voltage controlled closed loop speed control - EHSC

With an external potentiometer the relationship between control signal and oil flow can be infinitely

varied in the 0 to 1 range. A reduction of the control signal and oil flow ratio applies to both the A and the

B port.

Function monitoring

EHSC has an INFO-output controlled by a function monitor. A warning lamp can be connected to the

INFO output.

Constantly lit lamp means that EHSC is functioning correctly

•

Flashing lamp means that the deviation between the control signal and feedback frequency is too big

•

for EHSC to correct.

No light means that the control signal or the feedback frequency has been cut off.

•

The INFO-output cannot be damaged by a short circuit.

If the feedback frequency is cut off, EHSC switches automatically to open loop

speed control. This means that EHSC is still controlling the oil flow from the proportional valve, but now

only in relation to the control signal.

The control signal is constantly monitored. If the signal is outside the range 0.15 → 0.85 • UDC, the signal

output to PVE is cut off. This results in the main spool returning to neutral position, and at the same time

the INFO-output light will switch off.

If the function monitor has cut off the signal output, EHSC can only be re-activated after a disconnection

of the supply voltage.

40 520L0804 • Rev 0103 • January 2016

Page 41

Technical Information

EH Modules

Electronic, voltage controlled closed loop speed control - EHSC

Adjustments

Potentiometer 1 and 2

Adjustment of min. oil flow (Q0A), A-port; Adjustment of min. oil flow (Q0B), B-port

DA : Dead band P

→ A

DB : Dead band P → B

Q0 is the smallest oil flow supplied by the proportional valve at a stable control signal.

Potentiometer 3

Adjustment of maximum feed back frequency (f

b max

)

The setting of potentiometer 3 determines the maximum feedback frequency corresponding to

maximum speed for the hydraulic motor at maximum oil flow.

520L0804 • Rev 0103 • January 2016 41

Page 42

fb [Hz]

U6

[V] = • 1,75 [V] + 3,5 [V]

f

b max

[Hz]

Q l/min [US gal/min]

• ppr • 1000

motor displacement [cm3]

fb [Hz] =

60

65 l/min [17.17 US gal/min]

• 15 • 1000

80 cm

3

fb [Hz] =

60

= 203 Hz

100 l/min [26.42 US gal/min]

• 15 • 1000

80 [cm3]

f

b max

[Hz] =

60

= 313 Hz

[V] = 203 Hz

• 1.75 [V] + 3.5 [V]

313 Hz

U

6

Technical Information

EH Modules

Electronic, voltage controlled closed loop speed control - EHSC

When ordering EHSC there is a choice of two ranges for feedback frequency:

800 Hz < f

•

or

30 Hz < f

•

If f

is set correctly, the test signal terminal 6 (U6), will be 5.25 V.

b max

If the system utilizes the maximum flow capacity of the main spool, the test signal on terminal 6 (U6) must

be 5.25 V at f

If the system does not utilize the maximum flow capacity of the main spool, the setting of U6 must be

calculated as follows:

fb is the actual maximum system feedback frequency. fb maximum is the feedback frequency on

maximum movement of the main spool.

Both fb and f

< 8000 Hz

b max

< 300 Hz

b max

.

b max

can be calculated thus:

b max

In calculating fb, Q is inserted as the actual maximum system flow. At fb maximum, Q is inserted as the

maximum flow capacity of the main spool.

Example:

Main spool Motor

PVG 32 OMS 80 EM

157B9764 151F3000

100 l/min

[26.42 US gal/min]

(4/3-open) (ppr = 15)

42 520L0804 • Rev 0103 • January 2016

Potentiometer 4

Potentiometer 4 - Error signal amplification is used to set the amplification of the deviation between the

control signal and the feedback frequency. This amplification means that even small deviations can be

corrected.

80 cm

3

Page 43

Technical Information

EH Modules

Electronic, voltage controlled closed loop speed control - EHSC

The permissible amplification factor depends on the system. An excessively high factor may lead to

system hunting.

Potentiometer (P)

Resistance (R)

The external potentiometer (P) determines the relationship between the control signal and the oil flow.

The ratio is infinitely variable from 0 to 1. The oil flow can be cut off completely within the control range

(at P = 0).

Recommended value for potentiometer resistance P: 10 kΩ

Range for potentiometer resistance: P: 5 kΩ < P < 20 kΩ

The resistance (R) is only inserted if the oil flow must not be cut off.

R marks a lower limit for the control signal and oil flow (Qmin) ratio.

Recommended value for the total resistance P + R = 10 kΩ

Range for the total resistance

P + R: 5 kΩ < P + R < 20 kΩ

520L0804 • Rev 0103 • January 2016 43

Page 44

Technical Information EH Modules

Electronic, voltage controlled closed loop speed control - EHSC

44 520L0804 • Rev 0103 • January 2016

Page 45

Signal leads

Supply leads

Technical Information EH Modules

Electronic, voltage controlled closed loop speed control - EHSC

Electrical system

E Emergency stop

F Signal output, fault monitoring

Technical data

Supply voltage

Current consumption < 100 mA

Signal voltage (US) 0.50 → 0.75 • U

Neutral position signal 0.5 • U

Control signal Remote control lever or

520L0804 • Rev 0103 • January 2016 45

*

U

DC

11 - 30 V

Maximum ripple 5%

DC

DC

potentiometer

Input impedance >30 kΩ

Page 46

Technical Information

EH Modules

Electronic, voltage controlled closed loop speed control - EHSC

Feedback frequency

Feedback frequency test, value at max. frequency (terminal 6) 5.25 V

Output signal Maximum load Two parallel connected PVEs

Oil flow direction US = 0.50 → 0.75 • U

Signal current UDC = 12 V ± 0.5 mA

Load between terminals 4 and 8 P or (P + R) 5 → 20 kΩ

Input impedance (terminal 5) > 1 MΩ

Info output (terminal 11) Maximum load -100 mA

Ambient temperature - 30 → + 60°C [-22 to 140 °F]

Enclosure to IEC 529 IP 42

*

EHSC must be connected to the voltage supply in the same place as PVE.

†

See Required control and feedback frequency signal on page 38.

†

Minimum amplitude 3.5 V ± 1 V

Pulse-pause-ratio 1 : 1 ± 10%

Freqency at maximum flow 800 → 8000 Hz

30 → 300 Hz

Input impedance > 30 kΩ

Minimum load impedance to 0.5 •

U

DC

Error in relation to max. flow < 1%

DC

US = 0.50 → 0.25 • U

UDC = 24 V ± 1.0 mA

Recommended 10 kΩ

DC

6 kΩ

P → A

P → B

Required feedback frequency signal

To ensure reliable control of the hydraulic system it is necessary to comply with the amplitude and pulse/

pause ratio for the feedback frequency (see technical data).

Main spools and electrical actuation modules

Danfoss recommends the use of a PVBS main spool with linear characteristic and a PVES electrical

actuation module.

46 520L0804 • Rev 0103 • January 2016

Page 47

Technical Information EH Modules

Electronic, voltage controlled closed loop speed control - EHSC

Code number and weight

Electronic, voltage controlled closed loop speed control EHSC

Code number

Weight

Feedback

frequency

155U3815

0.14 kg (0.31 lb)

30 → 300 Hz

520L0804 • Rev 0103 • January 2016 47

Page 48

Technical Information

EH Modules

Electronic closed loop position control - EHC

General

Electronic Closed Loop Position Control - EHC

Adjustment possibilities

Danfoss electronic position control EHC is used for the positioning of an actuator in a closed loop control

system. The set-point signal is an analogue voltage signal from e.g. a remote control lever. A position

transducer on the actuator provides the feedback signal (position signal).

EHC compares the set-point signal with the feedback signal and adjusts the oil flow, via the PVG

proportional valve, so that the actuator position corresponds to the set-point signal.

This means that the actuator shaft or piston rod is moved into and kept in the position corresponding to

the controlling movement of the remote control lever.

In EHC there are four built-in potentiometers for the adjustment of EHC, in order to achieve optimum

position control.

Potentiometer 1 - Setting of scale for set point signal.

•

Potentiometer 2 - Setting of scale for feedback signal.

•

The scale settings for the set-point and feedback signals are used for the adjustment of standard

transducers, so their signal range can be fully utilized. The scaling is used when, e.g. a 270° angle

transducer is utilized only in 60° of its turning range.

48 520L0804 • Rev 0103 • January 2016

Page 49

Technical Information

EH Modules

Electronic closed loop position control - EHC

Potentiometers 1 and 2 can be set for between 1 and 4 times amplification of the set-point and feedback

signals respectively. The amplification is made in proportion to half supply voltage (0,5 • UDC ).

Potentiometer 3 - Position adjustment. The position adjustment adds a fixed signal to the set-point

•

signal. The adjustment is used to make sure that the set-point signal and feedback signal correspond

to each other at a certain, critical actuator position. This may be the neutral position, an extreme

position, etc.

Potentiometer 4 - Error signal amplification control. Potentiometer 4 is used to set the amplification

•

of the deviations between the set-point signal and the feedback signal. The amplification means that

even small deviations can be corrected. The amplification factor can be set at between 1 and 100.

Inverse function

With the built-in inverse function the EHC set-point signal can be reversed in relation to 0,5 UDC so that

set-point signals in the 0,5 → 0,75 UDC range are converted to set-point signals in the 0,5 → 0,25

•

UDC range and

set-point signals in the 0,5 → 0,25 UDC range are converted to set-point signals in the 0,5 → 0,75

•

UDC range.

The inverse function is activated by connecting terminals 1 and 10. If terminals 1 and 10 are connected

via a switch, it will be possible to alternate between normal and inverse function.

Interruption of the signal output

The signal output to the proportional valve (US ) can be controlled by placing a make contact between

terminals 6 and 10. If this connection between terminals 6 and 10 is made, the signal to the proportional

valve and the INFO-output are interrupted.

When there is no connection between terminals 6 and 10, the signal output is controlled by the function

monitoring alone.

520L0804 • Rev 0103 • January 2016 49

Page 50

Technical Information

EH Modules

Electronic closed loop position control - EHC

ON/OFF signal t1/t6

The external contact function cannot be used on EHC with no relay in the signal output.

When voltage on t1/t6 is less than 3 V or OFF, the t1/t6 function is regarded as OFF.

When t1/t6 voltage is greater than 8 V, the t1/t6 function is regarded as ON.

In the range 3 to 8 V, t1/t6 remains undefined.

Redundant position transducer

EHC can receive and compare two parallel feedback signals. This gives higher system security.

In case just one of the signals fails, the INFO-output is switched off (and the signal output, terminal 9, if

any). See the section on function monitoring. If only one position transducer is used, it must be

connected to both terminals 5 and 7.

50 520L0804 • Rev 0103 • January 2016

Page 51

Technical Information

EH Modules

Electronic closed loop position control - EHC

Function monitoring

EHC has function monitoring on the set-point and feedback signals. The function monitoring has two

purposes:

1. Via a relay in the signal output terminal 9 to cut off the signal to the proportional valve in case of a

functional error.

2. Via the INFO-output (terminal 11) to indicate an error, for example via a connected lamp.

The two feedback signals must be the same.

If the limits are exceeded, the relay in the signal output will be cut off, and the INFO-output will be

switched off.

If the function monitoring has cut off the relay and the INFO-output, EHC can only be reactivated after a

disconnection of the supply voltage.

EHC is available in a version without a relay in the signal output.

520L0804 • Rev 0103 • January 2016 51

Page 52

Technical Information

EH Modules

Electronic closed loop position control - EHC

Adjustment

Potentiometer 1

Setting of set-point signal scale (factor 1 to 4)

•

Potentiometer 2

Setting of feedback signal scale (factor 1 to 4)

•

The set scale for the set-point signal can be checked by measuring the resulting voltage on terminal 4.

The set scale for the feedback signal can be checked by measuring the resulting voltage on terminal 8.

The scale for the feedback signal applies to both feedback signals (terminals 5 and 7).

Potentiometer 3

Potentiometer III - position adjustment makes a controlled offset of the actuator possible.

The offset is obtained by adding a voltage of up to ± 0,05 ↔ UDC to the set-point signal.

Relative actuator movement

Potentiometer 4

Potentiometer 4 - error signal amplification is used to set the amplification of the error signal. The

amplification factor can be set at between 1 and 100. The amplification factor determines the response

time of the system.

52 520L0804 • Rev 0103 • January 2016

Page 53

Signal leads

Supply leads

Technical Information

EH Modules

Electronic closed loop position control - EHC

A high amplification factor gives quick response. The permissible amplification factor is depending on

the system. A too high amplification factor leads to hunting.

Electrical system

Resistance values

E Emergency stop

F Signal output, fault monitoring

P The effective working range of the position transducer

R The effective working range of the position transducer

Control signal

25 ↔ (R+P+R) < P < 0,5 ↔ (R+P+R)

•

Ω < (R+P+R) < 10 kΩ

•

(R+P+R) recommended 3 kΩ

•

Position signal

Ω < (R+P+R) < 100 kΩ

•

(R+P+R) recommended 10 kΩ

•

These resistance demands also apply to the set-point signal source.

520L0804 • Rev 0103 • January 2016 53

Page 54

Technical Information EH Modules

Electronic closed loop position control - EHC

When Danfoss remote control levers are used as set-point signal source, these demands are always

complied with.

Technical data

Supply voltage

Current consumption < 100 mA

Signal voltage (US) 0.50 → 0.75 • UDC

Neutral position signal (US) 0.5 • UDC

Control signal Signal transmitter Remote control lever or potentiometer

Feedback Signal transmitter Potentiometer ohmic transducer or the like

Amplification factor for control signal in relation to

0.5 • UDC

Amplification factor for control signal in relation to

0.5 • UDC

Position adjustment Pot. III ± 0.05 UDC

Amplification factor Pot. IV 1 → 100

Control signal test at max. control signal (terminal 4) 0.25/0.75 • UDC

Feedback signal test at max. control signal (terminal 8) 0.25/0.75 • UDC

Output signal Max. load Two parallel connected PVEs

Signal current UDC = 12 V ± 0.5 mA

Info output (terminal 11) Max. load - 100 mA

Input impedance t1/t6 > 1 MΩ

Ambient temperature - 30 → + 60°C [-22 to 140°F]

Enclosure to IEC 529 IP 42

*

EHC must be connected to the voltage supply in the same place as PVE.

*

UDC 11 - 30 V

Max. ripple 5%

Input impedance >30 kΩ

Input impedance >1 MΩ

Pot. I 1 → 4

Pot. II 1 → 4

Min. load impedance to 0.5 • UDC 6 kΩ

UDC = 24 V ± 1.0 mA

Code numbers and weight

EHC

Code number

Weight

54 520L0804 • Rev 0103 • January 2016

With a relay in signal output: 155U7905

Without a relay signal output: 155U7915

0.14 kg (0.31 lb)

Page 55

Technical Information EH Modules

EH modules dimensions

Dimensions

EH modules dimensions in millimeters [inches]

520L0804 • Rev 0103 • January 2016 55

Page 56

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions Trading

(Shanghai) Co., Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Products we offer:

Comatrol

www.comatrol.com

Schwarzmüller-Inverter

www.schwarzmuellerinverter.com

Turolla

www.turollaocg.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Bent Axis Motors

•

Closed Circuit Axial Piston

•

Pumps and Motors

Displays

•

Electrohydraulic Power

•

Steering

Electrohydraulics

•

Hydraulic Power Steering

•

Integrated Systems

•

Joysticks and Control

•

Handles

Microcontrollers and

•

Software

Open Circuit Axial Piston

•

Pumps

Orbital Motors

•

PLUS+1® GUIDE

•

Proportional Valves

•

Sensors

•

Steering

•

Transit Mixer Drives

•

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electronic components. We specialize in providing state-of-the-art technology and solutions

that excel in the harsh operating conditions of the mobile off-highway market. Building on

our extensive applications expertise, we work closely with our customers to ensure

exceptional performance for a broad range of off-highway vehicles.

We help OEMs around the world speed up system development, reduce costs and bring

vehicles to market faster.

Danfoss – Your Strongest Partner in Mobile Hydraulics.

Go to www.powersolutions.danfoss.com for further product information.

Wherever off-highway vehicles are at work, so is Danfoss. We offer expert worldwide support

for our customers, ensuring the best possible solutions for outstanding performance. And

with an extensive network of Global Service Partners, we also provide comprehensive global

service for all of our components.

Please contact the Danfoss Power Solution representative nearest you.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to

products already on order provided that such alterations can be made without changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

520L0804 • Rev 0103 • January 2016 www.danfoss.com

Local address:

©

Danfoss A/S, 2016

Loading...

Loading...