MAKING MODERN LIVING POSSIBLE

Service Manual

Steering Unit

EH Electro Proportional

Hydraulic Valve In-line Version

powersolutions.danfoss.com

Service Manual EH Electro Proportional Hydraulic Valve In-line Version

Revision History Table of Revisions

Date Changed Rev

Mar 2014 Converted to Danfoss layout - DITA CMS BA

Sep 2010 New back cover AB

Jun 2010 First edition AA

2 L1026660 • Rev BA • Mar 2014

Service Manual EH Electro Proportional Hydraulic Valve In-line Version

Contents

Exploded view

Exploded view EH valve with dynamic orifice (no PVFC Spool)...................................................................................... 4

Exploded viev EH Valve with PVFC Spool................................................................................................................................5

Tools

Tools......................................................................................................................................................................................................6

Dismantling

Dismantling the EH valve.............................................................................................................................................................. 7

Preassembly

Inspection, cleaning and replacement...................................................................................................................................13

Cleaning.......................................................................................................................................................................................13

Inspection and replacement.................................................................................................................................................13

Lubrication..................................................................................................................................................................................13

Reassembly

Reassembly of the EH valve........................................................................................................................................................14

L1026660 • Rev BA • Mar 2014 3

17

3

5

6

7

8

6

13

1

16

2

15

14

11

10

9

12

4

5

16

18

P301 292

Service Manual EH Electro Proportional Hydraulic Valve In-line Version

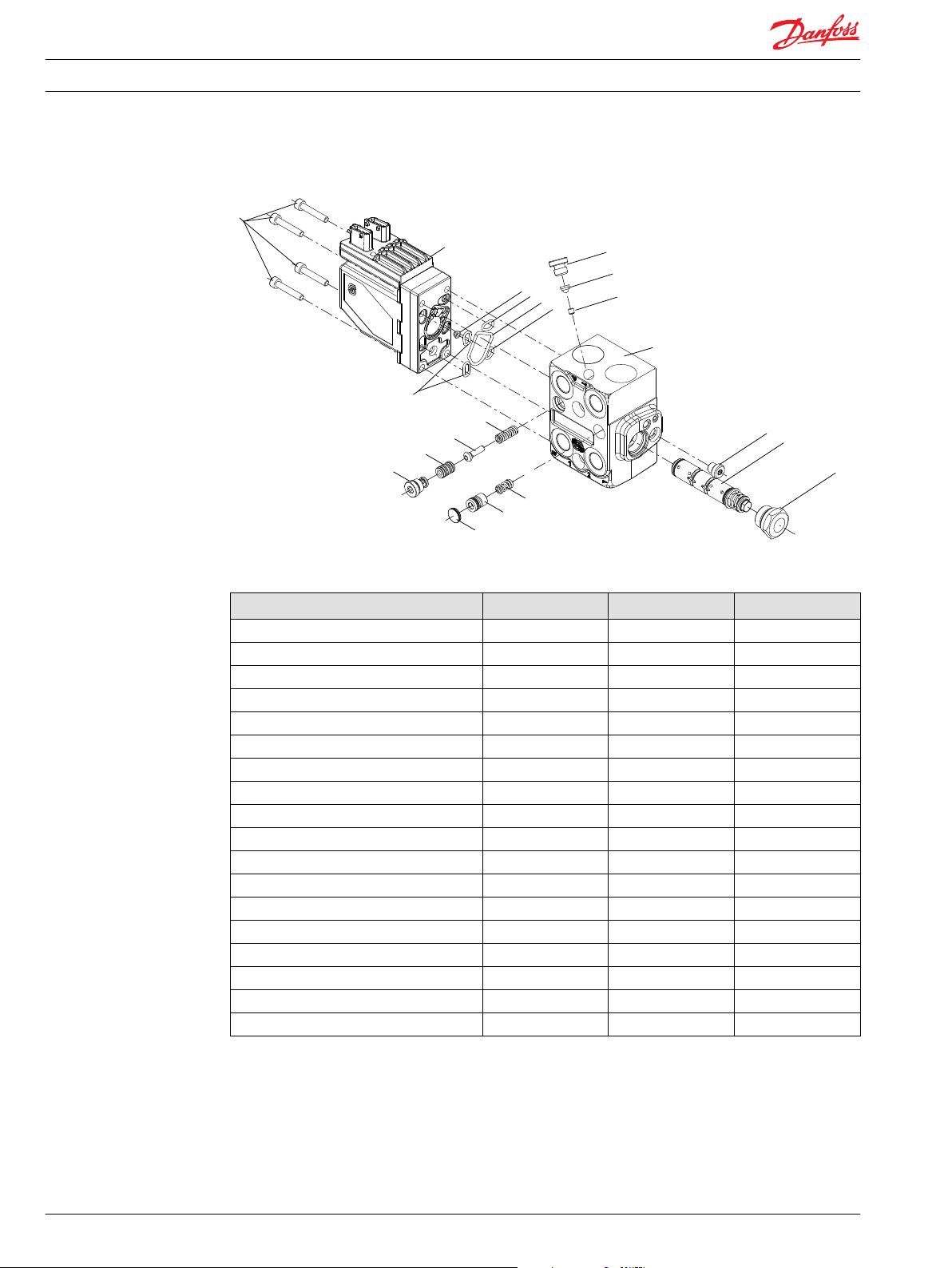

Exploded view

Exploded view EH valve with dynamic orifice (no PVFC Spool)

Spare parts list

Spare parts Item Number per unit Torque setting Nm

Valve housing 1 1 Main spool 2 1 PVE 3 1 Plug 4 1 50 ± 5

Filter 5 2 O-ring 6 3 O-ring 7 1 O-ring 8 1 Spring 9 1 PR cone 10 1 PR spool 11 1 Plug 12 1 15 ± 2

Pilot cone and spring 13 1 Adjusting screw 14 1 Protection plug 15 1 Plug 16 2 15 ± 2

Screw 17 4 8 ± 0.5

Throttle screw 18 1 1 ± 0.1

4 L1026660 • Rev BA • Mar 2014

18

15

14

13

17

12

11

10

8

9

3

7

8

5

6

16

2

4

1

P301 293

Service Manual EH Electro Proportional Hydraulic Valve In-line Version

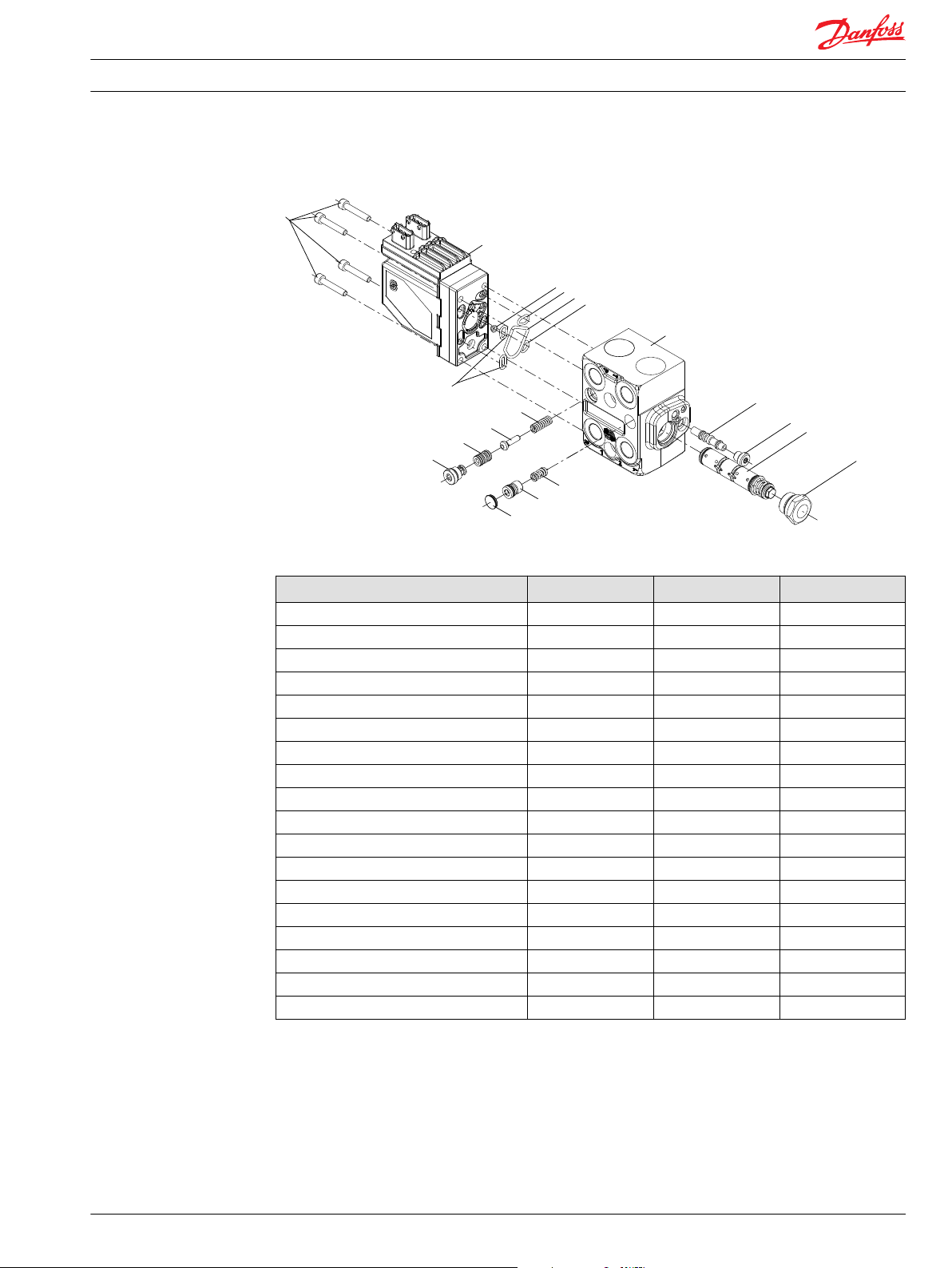

Exploded view

Exploded viev EH Valve with PVFC Spool

Spare parts list

Parts Item Number per unit Torque setting Nm

Valve housing 1 1 Main spool 2 1 PVE 3 1 Plug 4 1 50 ± 5

Filter 5 1 O-ring 6 3 O-ring 7 1 O-ring 8 1 Spring 9 1 PR cone 10 1 PR spool 11 1 Plug 12 1 Pilot cone and spring 13 1 Adjusting screw 14 1 Protection plug 15 1 Plug 16 1 15 ± 3

Screw 17 4 8 ± 0.5

PVFC spool 18 1 -

L1026660 • Rev BA • Mar 2014 5

Service Manual EH Electro Proportional Hydraulic Valve In-line Version

Tools

Tools

Open-ended spanner (or socket wrench) 27 mm

•

Hexagonal socket spanners 2.5 mm, 4 mm, 5 mm

•

Calibration Torque wrench

•

Small screw driver

•

Magnetized tool

•

O-ring pick or similar

•

3 mm threaded screw

•

Bench vise

•

Tools are not available from Danfoss

6 L1026660 • Rev BA • Mar 2014

Service Manual EH Electro Proportional Hydraulic Valve In-line Version

Dismantling

Dismantling the EH valve

Remove the 4 screws (17) and pull

PVE (3) from the housing.

(5 mm hexagon spanner).

Carefully pries lose the o-ring seals (6, 7, and 8) and

Screen Mesh Filter (5) from PVE.

Fasten housing in a vice and remove the spool

retainer plug (4) using a 27 mm spanner or socket

wrench.

L1026660 • Rev BA • Mar 2014 7

Service Manual EH Electro Proportional Hydraulic Valve In-line Version

Dismantling

Remove spool (2) by holding the centering spring

and pull out slowly.

Remove the PVFC spool retainer plug (16) using a 5

mm Allan key.

This only applies to units with PVFC spool.

Insert a 3 mm threaded screw into the end of the

PVFC spool (18) and use to remove the spool from

the housing.

8 L1026660 • Rev BA • Mar 2014

Service Manual EH Electro Proportional Hydraulic Valve In-line Version

Dismantling

Screw out the pressure reducing valve plug (12)

with a 5 mm Allan key.

Remove the Pressure Reducing spool (11) from the

cavity.

Remove the Pressure Reducing poppet (10) with a

magnetized tool.

L1026660 • Rev BA • Mar 2014 9

Service Manual EH Electro Proportional Hydraulic Valve In-line Version

Dismantling

Remove the Pressure Reducing spring (9) with Oring pick or similar.

Pries of the Pilot Relief Valve plastic protection

cover (15) with a small screw driver or O-ring pick.

Then remove the Pilot Pressure relief valve

adjusting screw (14) with a 5 mm Allan key.

10 L1026660 • Rev BA • Mar 2014

Service Manual EH Electro Proportional Hydraulic Valve In-line Version

Dismantling

Remove Pilot Relief Valve poppet/spring unit (13).

(Use O-ring pick or similar).

Screw out the Dynamic Orifice sealing plug (16)

with a 5 mm Allan key if it has been installed.

This only applies to units with dynamic orifice (i.e. units

without PVFC spools).

Pries out the “screen mesh” filter (20) with a small

pick or small screw driver.

This only applies to units with dynamic orifice (i.e. units

without PVFC spools).

L1026660 • Rev BA • Mar 2014 11

Service Manual EH Electro Proportional Hydraulic Valve In-line Version

Dismantling

Remove the Load Sense orifice plug (21) with a 2.5

mm Allan key.

This only applies to units with dynamic orifice (i.e. units

without PVFC spools).

12 L1026660 • Rev BA • Mar 2014

Service Manual EH Electro Proportional Hydraulic Valve In-line Version

Preassembly

Inspection, cleaning and replacement

Cleaning

Clean all parts carefully in low aromatic kerosene.

Inspection and replacement

Check all parts carefully and make any replacements as necessary.

All O-rings and screen filters must be replaced.

Lubrication

Before assembly, lubricate all parts with hydraulic oil.

L1026660 • Rev BA • Mar 2014 13

Service Manual EH Electro Proportional Hydraulic Valve In-line Version

Reassembly

Reassembly of the EH valve

If the EH valve has the PVFC spool (18) option,

make sure it is lubricated with a thin film of oil.

Carefully insert the spool (18) into the bore. Ensure

that only minimal force is applied by your fingers.

Screw the PVFC retainer hexagonal plug (16) into

the housing with a 5 mm Allan key and tighten.

Remember to lubricate the O-ring with light

weight grease.

Make sure that the main directional spool (2) is

lubricated with a thin film of oil. Carefully insert the

spool (2) into the bore held by the spring end and

ensure that only minimal force is applied by hand.

14 L1026660 • Rev BA • Mar 2014

Service Manual EH Electro Proportional Hydraulic Valve In-line Version

Reassembly

Mount the EH housing in a vice and screw the

spool retainer plug (4) into the housing and

tighten with 27 mm Torque wrench. Remember to

lubricate the O-ring with a small amount of grease.

Insert PV poppet/spring unit (13) into the housing.

Then screw in PV pressure adjustment setting

screw (14) with 5 mm hexagon socket spanner.

Make sure O-ring is lubricated.

L1026660 • Rev BA • Mar 2014 15

Service Manual EH Electro Proportional Hydraulic Valve In-line Version

Reassembly

Press fit the plastic protection plug protection plug

into the cavity. This will have to be done after the

PV adjustment screw (14) is set to the required

pressure on a test bench.

Insert the Pressure reducing spring (9) into the

housing.

Then the PV poppet (10) must be inserted into the

spring, stem end first.

16 L1026660 • Rev BA • Mar 2014

Service Manual EH Electro Proportional Hydraulic Valve In-line Version

Reassembly

Then insert the PR valve spool (11) ensuring that

the end with the larger opening fits against the

rounded head of the poppet (10). Remember to

lubricate the spool first with a thin film of oil.

Screw in RP retaining plug (12) with

5 mm Allan key.

Make sure O-ring is lubricated.

If your EH valve has a dynamic orifice function then

screw the plug (18) into housing with 2.5 mm

Allan key.

L1026660 • Rev BA • Mar 2014 17

Service Manual EH Electro Proportional Hydraulic Valve In-line Version

Reassembly

Then insert replacement filter screen (5), dome side

first.

Screw the dynamic orifice cover plug (16) into

housing with 4 mm Allan key.

Carefully place the “screen mesh” filter (5) dome

first into the PVE housing, followed by the O-rings

(6, 7 and 8).

Remember to use a light grade grease to keep the

O-rings in place.

18 L1026660 • Rev BA • Mar 2014

Service Manual EH Electro Proportional Hydraulic Valve In-line Version

Reassembly

Mount the PVE (3) to EH housing with the four cap

screws (17) and tighten with 5 mm Allan key.

L1026660 • Rev BA • Mar 2014 19

Danfoss Power Solutions is a global manufacturer and supplier of high-quality hydraulic and

electronic components. We specialize in providing state-of-the-art technology and solutions that

excel in the harsh operating conditions of the mobile off -highway market. Building on our extensive

applications expertise, we work closely with our customers to ensure exceptional performance for a

broad range of off -highway vehicles.

We help OEMs around the world speed up system development, reduce costs and bring vehicles to

market faster.

Danfoss – Your Strongest Partner in Mobile Hydraulics.

Go to www.powersolutions.danfoss.com for further product information.

Wherever off -highway vehicles are at work, so is Danfoss.

We off er expert worldwide support for our customers, ensuring the best possible solutions for

outstanding performance. And with an extensive network of Global Service Partners, we also provide

comprehensive global service for all of our components.

Please contact the Danfoss Power Solution representative nearest you.

Danfoss

Power Solutions GmbH & Co. OHG

Krokamp 35

D-24539 Neumünster, Germany

Phone: +49 4321 871 0

Danfoss

Power Solutions ApS

Nordborgvej 81

DK-6430 Nordborg, Denmark

Phone: +45 7488 2222

Danfoss

Power Solutions US Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239 6000

Danfoss

Power Solutions

(Shanghai) Co. Ltd.

Building #22, No. 1000 Jin Hai Rd

Jin Qiao, Pudong New District

Shanghai, China 201206

Phone: +86 21 3418 5200

Products we off er:

• Bent Axis Motors

• Closed Circuit Axial Piston

Pumps and Motors

• Displays

• Electrohydraulic Power

Steering

• Electrohydraulics

• Hydraulic Power Steering

• Integrated Systems

• Joysticks and Control

Handles

• Microcontrollers and

Software

• Open Circuit Axial Piston

Pumps

• Orbital Motors

• PLUS+1® GUIDE

• Proportional Valves

• Sensors

• Steering

• Transit Mixer Drives

Comatrol

www.comatrol.com

Schwarzmüller-Inverter

www.schwarzmuellerinverter.com

Turolla

www.turollaocg.com

Valmova

www.valmova.com

Hydro-Gear

www.hydro-gear.com

Daikin-Sauer-Danfoss

www.daikin-sauer-danfoss.com

Local address:

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to

products already on order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

L1026660 • Rev BA • Mar 2014 www.danfoss.com

©

Danfoss A/S, 2014

Loading...

Loading...