Page 1

Data Sheet

Safety relief valves

Type BSV-8

Used as pressure limiting devices to protect

hydraulic systems and components

BSV is a standard, back pressure independent

safety relief valve, especially designed for

protection of small components against

excessive pressure and as a pilot valve for the

pilot operated internal safety valve, type POV.

BSV is an angle-way safety relief valve which

can operate with a very high back pressure. The

valve is designed to meet the strict quality

demands and safety requirements for

refrigeration installations, specied by the

international classication societies.

As the valve is not dependent on the back

pressure, it is recommended for use as an

internal safety relief valve. However, the valve

can also be used as an external safety relief

valve. The spring housing is tightly sealed to

avoid refrigerant leakage.

The inlet ow diameter of the BSV 8 is 8.0 mm

5

(

⁄16 in.).

The valves can be delivered with set pressures

between 10 and 25 bar (145 and 363 psig).

Standard pressure setting valves having "TÜV

Pressure Setting Certicate" with each valve are

also available.

Features:

• Classication: DNV, BV, EAC etc. To get an

updated list of certication on the products

please contact your local Danfoss Sales

Company.

AI183186419214en-000702

Page 2

Safety relief valves, Type BSV-8

Media

Refrigerants

Applicable for the refrigerants HCFC, HFC, R717 (Ammonia), R744 (CO2). Flammable hydrocarbons are not

recommended. For further information please contact your local Danfoss Sales Company.

New refrigerants

Danfoss products are continually evaluated for use with new refrigerants depending on market requirements.

When a refrigerant is approved for use by Danfoss, it is added to the relevant portfolio, and the R number of the

refrigerant (e.g. R513A) will be added to the technical data of the code number. Therefore, products for specic

refrigerants are best checked at store.danfoss.com/en/, or by contacting your local Danfoss representative.

© Danfoss | Climate Solutions | 2021.10 AI183186419214en-000702 | 2

Page 3

Working pressure

Reseating pressure

Set pressure p

Opening pressure

p + 10%

p – 10%

0 100%

Safety relief valves, Type BSV-8

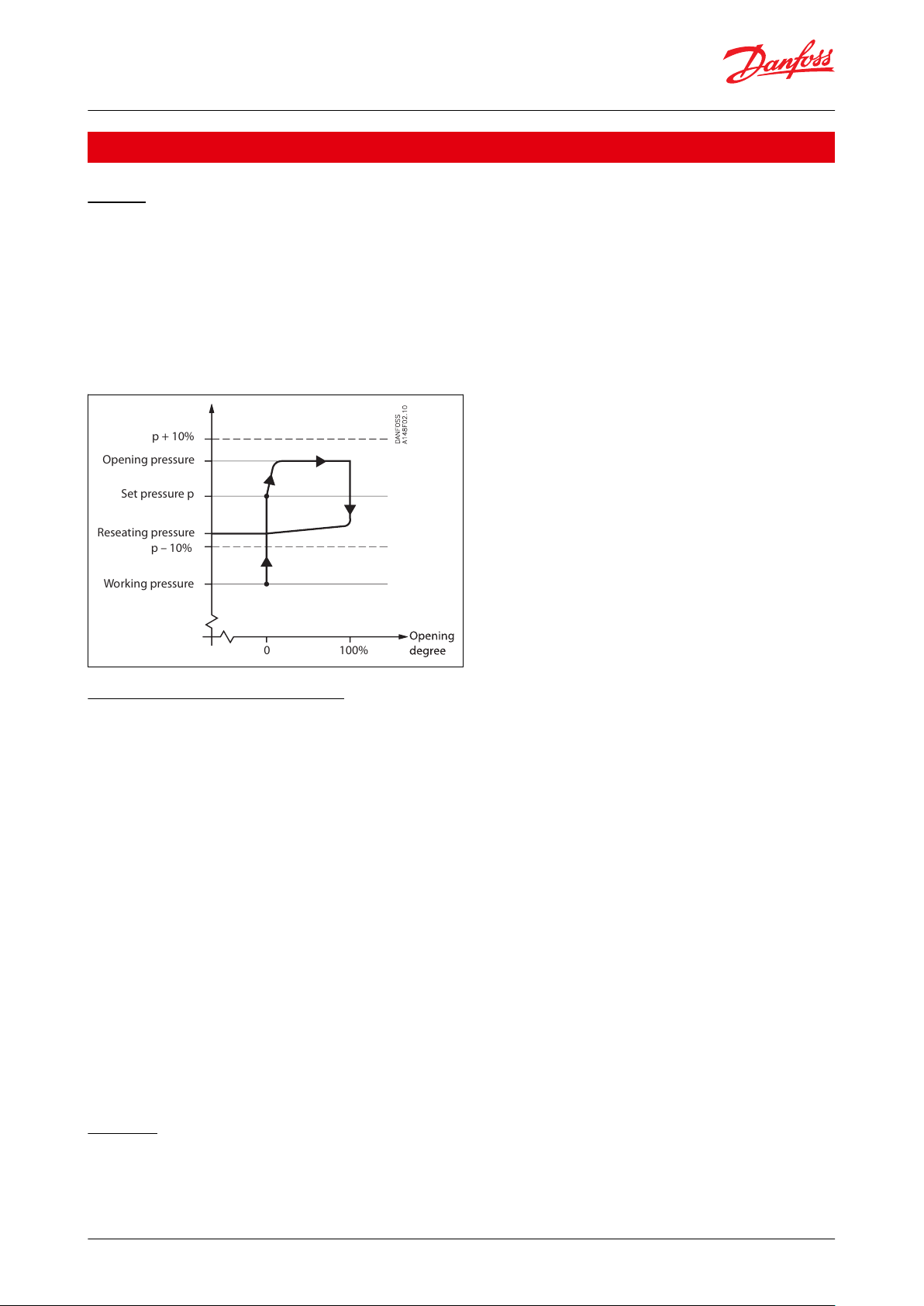

Product specication

Design

BSV is designed as a standard safety relief valve (DIN 3320) which are recommended for refrigeration plants. On a

rise in pressure above the set pressure, the safety relief valve will initially start opening slightly, to minimise the

outlet of refrigerant. If the pressure continues to increase, the valve will open fully. The safety relief valve will be fully

open before the pressure is 10% higher than set pressure, and fully closed before the pressure is 10% below set

pressure.

The valve is recommended as an internal safety relief valve because its function is independent of the back pressure.

The valve can also be used as an external safety relief valve.

Figure 1: Design

Pressure and temperature data

Pressure

Pressure setting range: 10 – 25 bar (145 – 363 psig), For further information please contact your local Danfoss Sales

Company.

The valves are designed for:

Strength test: 43 bar (624 psig)

Leakage safety: 25 bar (363 psig)

Special circumstances such as vibrations (which should be avoided) and oscillating pressure may require an

increased dierence between the operational pressure and the closing pressure.

Pressure setting

The operating pressure of the plant should be at least 15% below the set pressure. This allows a perfect re-seating of

the safety relief valve after having been activated.

Temperature range for BSV used as an external safety relief valve:

-30 °C /+ 100 °C (-22 °F /+ 212 °F)

Temperature range for BSV used as a pilot valve for POV:

-50 °C /+ 100 °C (-58 °F /+ 212 °F)

NOTE:

For temperatures below -30 °C (-22 °F), the valve may not re-seat to a 100% gas tightness when activated.

Housing

Made of special steel approved for low temperature application. Spindle and seat are made of stainless steel, to

ensure precise operation even during extraordinary conditions. The gasket of the valve cone is made of a special

neoprene compound.

© Danfoss | Climate Solutions | 2021.10 AI183186419214en-000702 | 3

Page 4

21

2

3

17

6

12

13

11

10

8

7

1

Danfoss

M148F0001_1

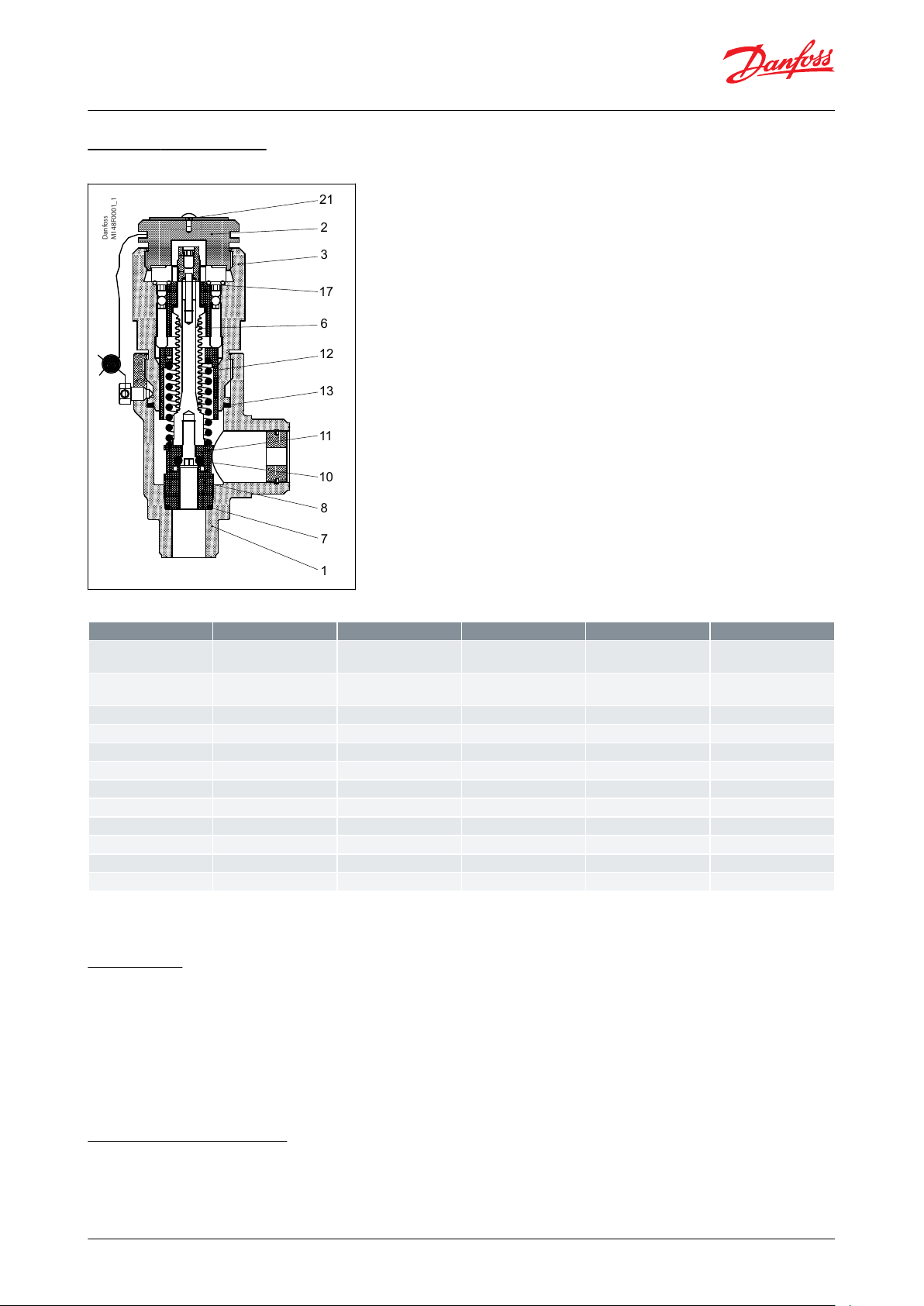

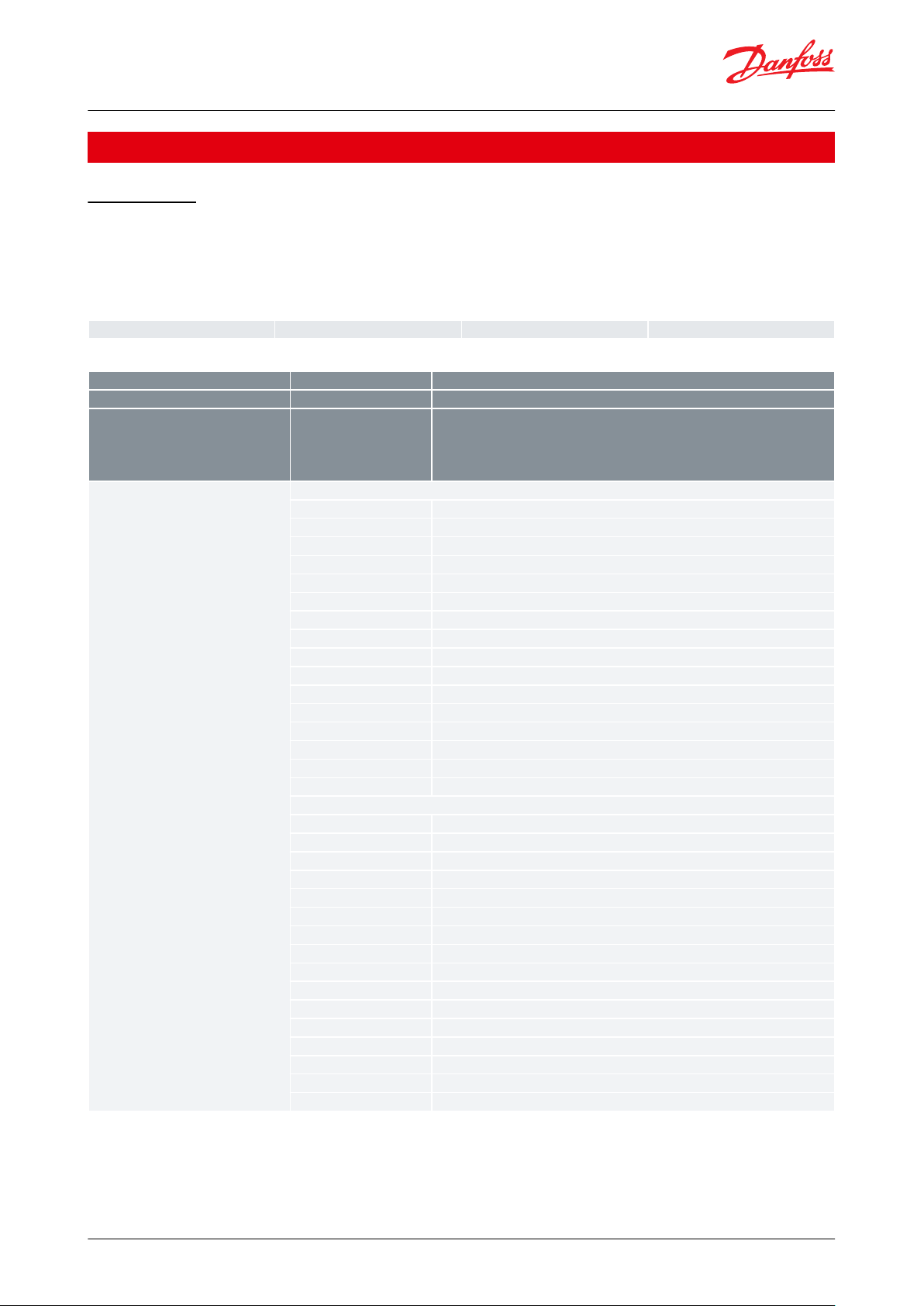

No.

Part

Material

DIN

ISO

ASTM

1

Housing

Steel

TT St 35 N/V, 17173

TW 6, 2604/3‑75

Grade 1, A333, A334

A350 LF2

(1)

2

Threaded plug

Steel

9S Mn28

1651 - 88

11S Mn28

630/9 - 88

1213

SAE J 403

3

Valve top

Steel

St. 37.2, 1652 - 2 - 90

Fe 360 B, 660 - 80

Grade C, A 283

6

Bellow

Stainless steel

7

Gasket

Aluminium

8

Valve seat

Stainless steel

10

O-ring

Cloroprene (Neoprene)

11

Valve cone

Steel12Spring

Steel

Class C, 17223-1-84

A 679SAE J 403

13

O-ring

Cloroprene (Neoprene)

17

Gasket

Aluminium

21

Marking label

Aluminium

Safety relief valves, Type BSV-8

Material specication

Figure 2: BSV-8

Table 1: Material specication

(1)

(1)

Alternative material

Alternative material

Installation

To ensure exact operation of the safety relief valve it should be installed with the spring housing upwards. If the

valve is mounted as an internal safety relief valve without any demand for exact opening pressure, the valve may be

tted with the spring housing in other positions. When the valve is mounted, it is important to avoid the inuence

of static, dynamic and thermal stress.

A very precise technique has been applied for the production of the seal. However, this seal can still be damaged, if

dirt is blown from the pipe system into the valve.

Re-calibration/servicing

In certain countries the authorities demand that the valves are checked at least once a year (see local rules).

© Danfoss | Climate Solutions | 2021.10 AI183186419214en-000702 | 4

Page 5

Size mm

Size in.

Inlet

Outlet

L [mm]

L [in.]

8

5

⁄16

G

3

⁄4

G 1170.67

Valve

Nominal size

Flow diameter

Flow area

De-rated,

certied coef‐

ficient of discharge

Inlet

Outlet

d0A0K

dr

BSV 8

15 mm

20 mm

8 mm

50 mm2

0.43

1

⁄2

in.

3

⁄4

in.

0.315 in.

0.078 in2

q

m

= 0.2883 x C × A0 × Kdr × Kb × √

p

⁄v

q

m

Discharge capacity (kg/h)

C

Discharge function depending of the actual refrigerant (κ) see table 2.

A

0

Flow area of the safety relief valve (mm

2

).

Safety relief valves, Type BSV-8

Control/Identication

After adjustment of the set pressure at Danfoss, the valves are sealed. For that reason Danfoss can only guarantee

correct operation, as long as the seal remains unbroken.

All valves are provided with a metal plate with the following information:

• Flow diameter

• Set pressure

• Date of production

• Production number

• Type approved code

Transport/Handling

The valves are tted with special protection covers and packed in purpose made transportation cartons. It is

important that the cover remains tted around the valve until it is installed.

NOTE:

To ensure the exact and precise operation of the valve it must be handled with care.

Connections

Available with the following connections:

Outside pipe thread T (ISO 228/1)

Figure 3: Connections T

Table 2: T outside pipe thread, (ISO 228/1)

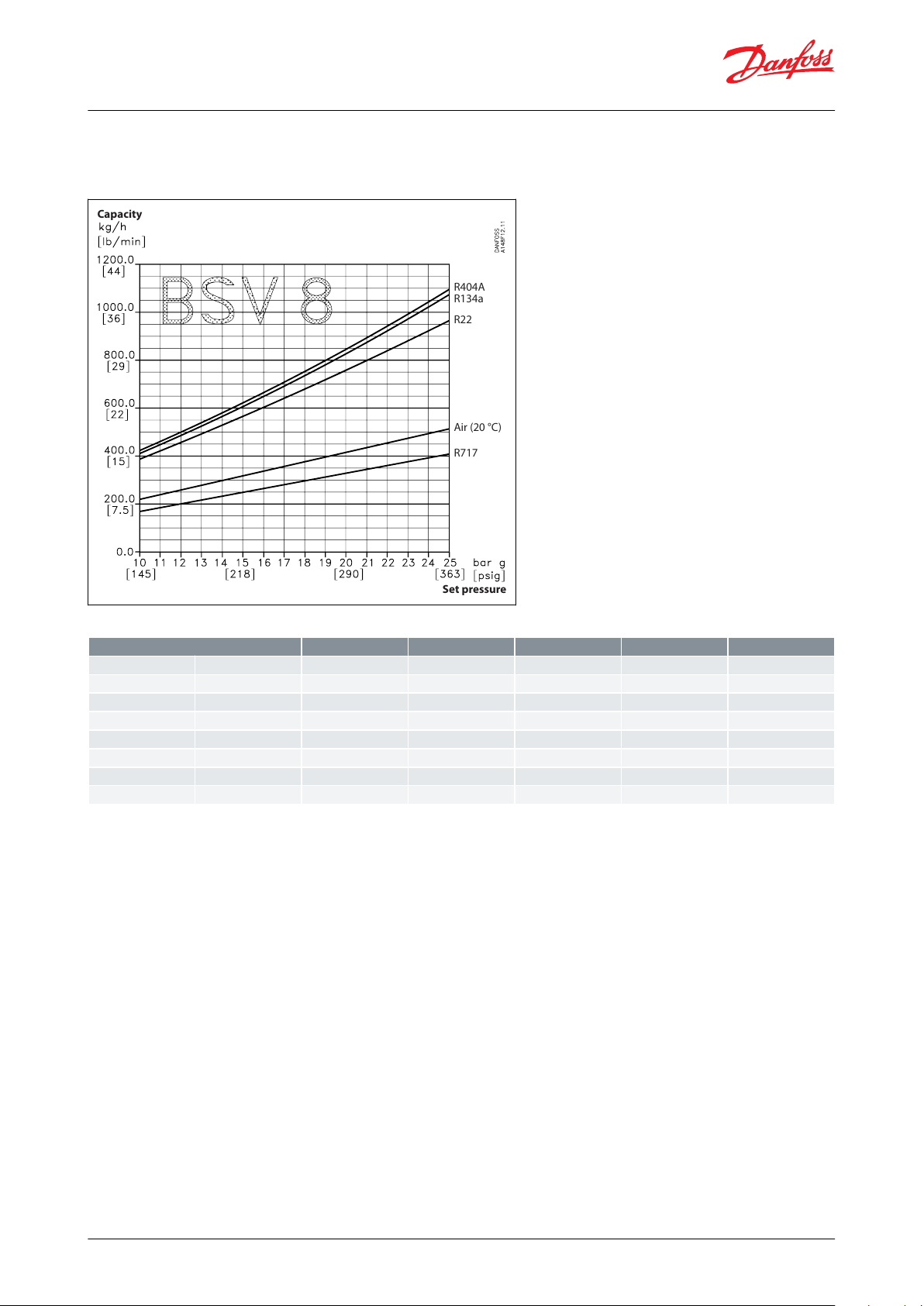

Capacity

The design and construction of the safety relief valve has been tested and approved by TÜV. This test comprises

control of the function of the valve as well as measuring of the capacity, which is the basis of the curves and tables

on the following pages. The values in the table are based on saturated gas.

If e.g. back pressure or superheated gas have to be taken into consideration, the formulas or the Danfoss

computation program Coolselector can be used.

Table 3: Capacity

NOTE:

The discharge capacity of the safety relief valves are based on (IS0 4126‑1/EN 1268‑1 / prEN 1313 6 (1998)).

Table 4: Discharge capacity

© Danfoss | Climate Solutions | 2021.10 AI183186419214en-000702 | 5

Page 6

qm = 0.2883 x C × A0 × Kdr × Kb × √

p

⁄v

K

dr

De-rated coecient of discharge (Kdr = Kd × 0.9), (the

Kdr

is certied by TÜV) see table 1.

K

b

Correction factor for sub-critical ow. (-)

Kb = 1.0 when the back pressure is lower than approx. 0.5 × relieving pressure (Pb < 0.5 × p).

v

Specic volume of the vapour. (m3/kg)

p

set

Set pressure, the predetermined pressure at which a pressure relief valve under operation starts to open (p

set

is indicated on the metal plate on

the safety relief valve). (bar g)

p

atm

Atmospheric pressure. (1 bar)

p

Relieving pressure, p = p

set

× 1.1 + P

atm

(bar a)

Refrigerant

Isentropic exponent [κ]

Discharge function [C]

R22

1.17

2.54

R134a

1.12

2.5

R404A

1.12

2.49

R410A

1.17

2.54

R717 (Ammonia)

1.31

2.64

R744 (CO2)

1.3

2.63

Air

1.4

2.7

R404A

R134a

R22

Air (20 °C)

R717

Set pressure

Capacity

Set pressure

R22

R134a

R404A

R717

Air (20 °C)

13 barg

kg/h

540

575

590

240

300

189 psig

lb/min

19.9

21.2

21.6

8.7

11.1

18 barg

kg/h

745

810

825

325

410

261 psig

lb/min

27.5

29.7

30.3

11.9

15

21 barg

kg/h

875

955

970

375

475

305 psig

lb/min

32.2

35.1

35.7

13.8

17.4

25 barg

kg/h

1060

1175

1200

445

560

363 psig

lb/min

38.9

43.24416.4

20.6

Safety relief valves, Type BSV-8

NOTE:

For back pressure higher than 0.5 × p, the Danfoss computer program Coolselector or the above mentioned

standard must be used when calculating the capacity.

Table 5: Properties of Refrigerants

Figure 4: BSV 8, back pressure = atmosphere pressure

Table 6: BSV 8, back pressure = atmosphere pressure

© Danfoss | Climate Solutions | 2021.10 AI183186419214en-000702 | 6

Page 7

R404A

R134a

R22

Air (20 °C)

R717

Set pressure

Capacity

Set pressure

R22

R134a

R404A

R717

Air (20 °C)

13 barg

kg/h

495

525

535

215

275

189 psig

lb/min

18.2

19.4

19.7810.1

18 barg

kg/h

680

740

755

295

375

261 psig

lb/min

25.1

27.1

27.7

10.9

13.7

21 barg

kg/h

800

875

885

345

435

305 psig

lb/min

29.4

32.1

32.6

12.6

15.9

25 barg

kg/h

965

1075

1095

410

510

363 psig

lb/min

35.5

39.4

40.21518.8

Safety relief valves, Type BSV-8

NOTE:

The capacity calculation is based on ISO 4126 - 1 / EN 1268 - 1 /prEN 13136 (1998).

Figure 5: BSV 8, back pressure = 0.6 × set pressure (barg/psig)

Table 7: BSV 8, back pressure = 0.6 × set pressure (barg/psig)

NOTE:

The capacity calculation is based on ISO 4126 - 1 / EN 1268 - 1 /prEN 13136 (1998).

© Danfoss | Climate Solutions | 2021.10 AI183186419214en-000702 | 7

Page 8

Valve size

ABC∅DAF

Weight

BSV 8 (

5

⁄16 in.)

mm

45

1503250461.5 kg

in.

1.77

5.91

1.26

1.97

1.81

3.3 lb

Safety relief valves, Type BSV-8

Dimensions and weight

Figure 6: BSV 8

Table 8: BSV 8, with threaded connections ISO 228/1 pipe threads

NOTE:

Specied weights are approximate values only.

© Danfoss | Climate Solutions | 2021.10 AI183186419214en-000702 | 8

Page 9

BSV8T

211

Valve type

BSV

Back pressure independent safety valve

Nominal size in mm

8

DN 8

Connections

T

Outside threaded connections: ISO 228/1 Pipe thread

Fittings for connections must be ordered seperately

Fittings for pilot operation

The welding ttings for single mounted safety relief valve must be ordered seper‐

ately

Pressure setting

Standard pressure setting: 2××

210

10 barg (145 psig)

211

11 barg (160 psig)

212

12 barg (174 psig)

213

13 barg (189 psig)

214

14 barg (203 psig)

215

15 barg (218 psig)

216

16 barg (232 psig)

217

17 barg (247 psig)

218

18 barg (261 psig)

219

19 barg (276 psig)

220

20 barg (290 psig)

221

21 barg (305 psig)

222

22 barg (319 psig)

223

23 barg (334 psig)

224

24 barg (348 psig)

225

25 barg (363 psig)

Standard pressure setting with TÜV certicate: 3××

310

10 barg (145 psig)

311

11 barg (160 psig)

312

12 barg (174 psig)

313

13 barg (188 psig)

314

14 barg (203 psig)

315

15 barg (218 psig)

316

16 barg (232 psig)

317

17 barg (247 psig)

318

18 barg (261 psig)

319

19 barg (276 psig)

320

20 barg (290 psig)

321

21 barg (304 psig)

322

22 barg (319 psig)

323

23 barg (334 psig)

324

24 barg (348 psig)

325

25 barg (362 psig)

Safety relief valves, Type BSV-8

Ordering

How to order

The table below is used to identify the valve required.

Please note that the type codes only serve to identify the valves, some of which may not form part of the standard

product range. For further information please contact your local Danfoss Sales Company.

Table 9: Example for type codes

Table 10: Type codes

NOTE:

Where products need to be certied according to specic certication societies, the relevant information should be

included at the time of order.

© Danfoss | Climate Solutions | 2021.10 AI183186419214en-000702 | 9

Page 10

Size

Construction and test facilities are approved by TÜV

mm

in.

Type

barg (psig)

Part No.

8

5

⁄16

BSV8 T 210

10 (145)

2416+200

8

5

⁄16

BSV8 T 211

11 (160)

2416+309

8

5

⁄16

BSV8 T 212

12 (174)

2416+310

8

5

⁄16

BSV8 T 213

13 (189)

2416+201

8

5

⁄16

BSV8 T 214

14 (203)

2416+311

8

5

⁄16

BSV8 T 215

15 (218)

2416+312

8

5

⁄16

BSV8 T 216

16 (232)

2416+221

8

5

⁄16

BSV8 T 217

17 (247)

2416+313

8

5

⁄16

BSV8 T 218

18 (261)

2416+202

8

5

⁄16

BSV8 T 219

19 (276)

2416+225

8

5

⁄16

BSV8 T 220

20 (290)

2416+203

8

5

⁄16

BSV8 T 221

21 (305)

2416+204

8

5

⁄16

BSV8 T 222

22 (319)

2416+224

8

5

⁄16

BSV8 T 223

23 (334)

2416+314

8

5

⁄16

BSV8 T 224

24 (348)

2416+315

8

5

⁄16

BSV8 T 225

25 (363)

2416+205

Size

Each valve is

certied by a representative from TÜV

mm

in.

Type

barg (psig)

Part No.

8

5

⁄16

BSV8 T 310

10 (145)

2416+316

8

5

⁄16

BSV8 T 311

11 (160)

2416+317

8

5

⁄16

BSV8 T 312

12 (174)

2416+318

8

5

⁄16

BSV8 T 313

13 (189)

2416+206

8

5

⁄16

BSV8 T 314

14 (203)

2416+319

8

5

⁄16

BSV8 T 315

15 (218)

2416+320

8

5

⁄16

BSV8 T 316

16 (232)

2416+222

8

5

⁄16

BSV8 T 317

17 (247)

2416+321

8

5

⁄16

BSV8 T 318

18 (261)

2416+207

8

5

⁄16

BSV8 T 319

19 (276)

2416+322

8

5

⁄16

BSV8 T 320

20 (290)

2416+208

8

5

⁄16

BSV8 T 321

21 (305)

2416+209

8

5

⁄16

BSV8 T 322

22 (319)

2416+210

8

5

⁄16

BSV8 T 323

23 (334)

2416+323

8

5

⁄16

BSV8 T 324

24 (348)

2416+324

8

5

⁄16

BSV8 T 325

25 (363)

2416+211

Type

Code number

For stand-alone SFV 15/ SFA 15/ BSV-8: Nipples + gaskets set

148F3019

For system POV + BSV: Nipples + gaskets set

148H3453

Safety relief valves, Type BSV-8

Certied BSV valves with standard set pressure

Table 11: Certied BSV valves with standard set pressure

Certied BSV valves with standard set pressure and TÜV pressure setting certicate with

each valve

Table 12: Certied BSV valves with standard set pressure and TÜV pressure setting certicate with each valve

Nipples and gaskets

Table 13: Attention: Fittings for connections must be ordered separately

© Danfoss | Climate Solutions | 2021.10 AI183186419214en-000702 | 10

Page 11

Type

File name

Document type

Document topic

Approval authority

BSV

EAC RU Д-DK.БЛ08.B.03706

EAC Declaration

Machinery & Equipment

TÜV 0045 202 1204 Z 00354 19 D 001(00)

Pressure - Safety Certicate

EAC RU C-DK.БЛ08.B.01096_20

Pressure - Safety Certicate

PED

033F0473.AD

Manufacturers Declaration

ATEX

Danfoss

EU 033F0685.AK

EU Declaration

EMCD/PED

Danfoss

BSV 8

BV 39409-B0 BV

Marine - Safety Certicate

DNV GL TAP000000M

Marine - Safety Certicate

TUV SV 17-1013

Pressure - Safety Certicate

RMRS 19.10327.266

Marine - Safety Certicate

The BSV-valves are approved in accordance with the European standard specied in the Pressure Equipment Directive and are CE marked. For further details / restrictions - see Installation guide.

Type

BSV 8

Nominal bore

8 mm (0.315 in.)

Classied for

Fluid group I

Category

IV

Safety relief valves, Type BSV-8

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Table 14: Valid approvals

Table 15: Pressure Equipment Directive (PED)

Table 16: Compliance

© Danfoss | Climate Solutions | 2021.10 AI183186419214en-000702 | 11

Page 12

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Spare Parts

Get access to the Danfoss spare parts and service kit catalog right from your smartphone. The app

contains a wide range of components for air conditioning and refrigeration applications, such as

valves, strainers, pressure switches, and sensors.

Download the Spare Parts app for free at www.danfoss.com/en/service-and-support/downloads.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Any information, including, but not limited to information on selection of product, its application or use, product design, weight, dimensions, capacity or any other

technical data in product manuals, catalogues descriptions, advertisements, etc. and whether made available in writing, orally, electronically, online or via download,

shall be considered informative, and is only binding if and to the extent, explicit reference is made in a quotation or order conrmation. Danfoss cannot accept any

responsibility for possible errors in catalogues, brochures, videos and other material. Danfoss reserves the right to alter its products without notice. This also applies to

products ordered but not delivered provided that such alterations can be made without changes to form, t or function of the product. All trademarks in this material

are property of Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.10 AI183186419214en-000702 | 12

Loading...

Loading...