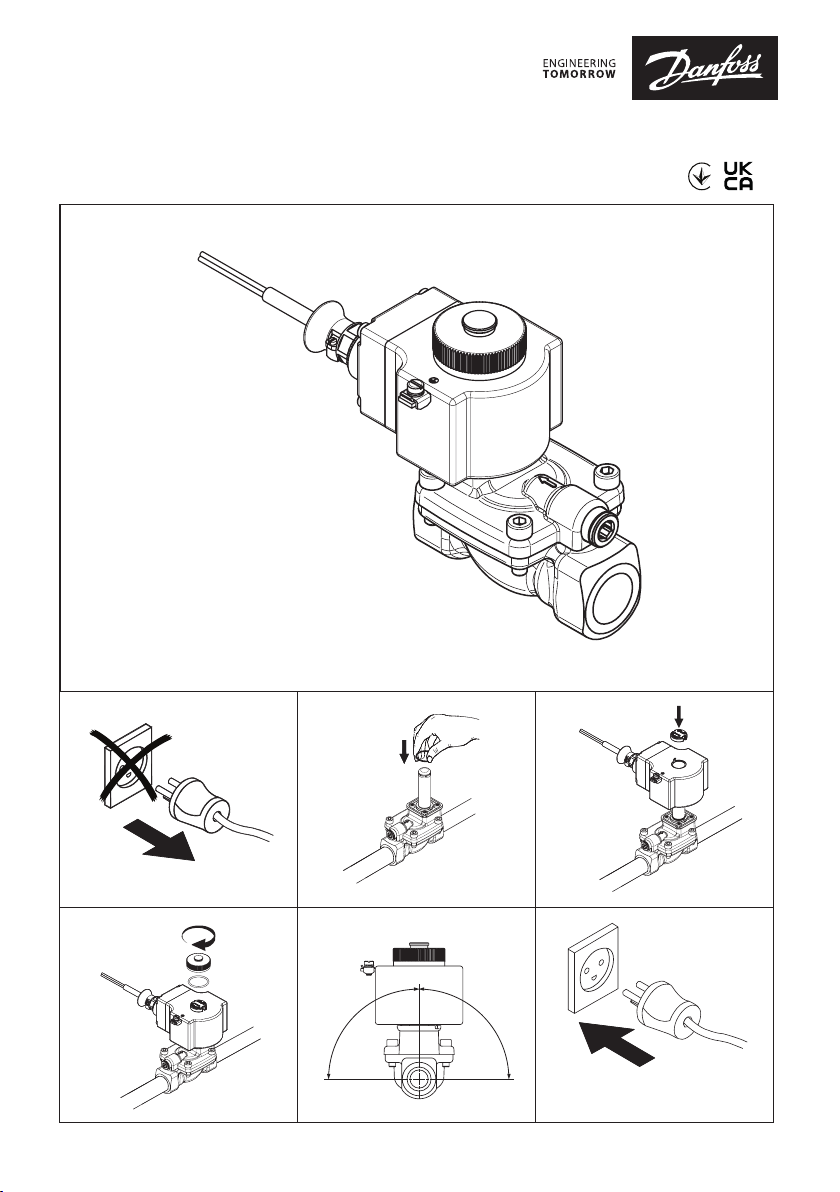

Installation guide

M

a

1

5

°

089

Solenoid coil for control in potentially explosive areas

Type BO

042R 0151

1 2 3

042R 0151

4 5 6

1. 5 Nm+ /-0 .15

Імпортер:ТОВ з іі “Данфосс ТОВ” 04080, Київ 80, п/с 168, Україна

© Danfoss | Climate Solutions | 2021.12

°

5

1

d

e

d

n

e

m

m

o

c

e

R

,

°

0

9

x

M

a

x

9

0

°

,

R

e

c

o

m

m

e

n

d

e

d

Info for UK customers only: Danfoss Ltd., 22 Wycombe End, HP9 1NB, GB

AN196386442447en-000601 | 1

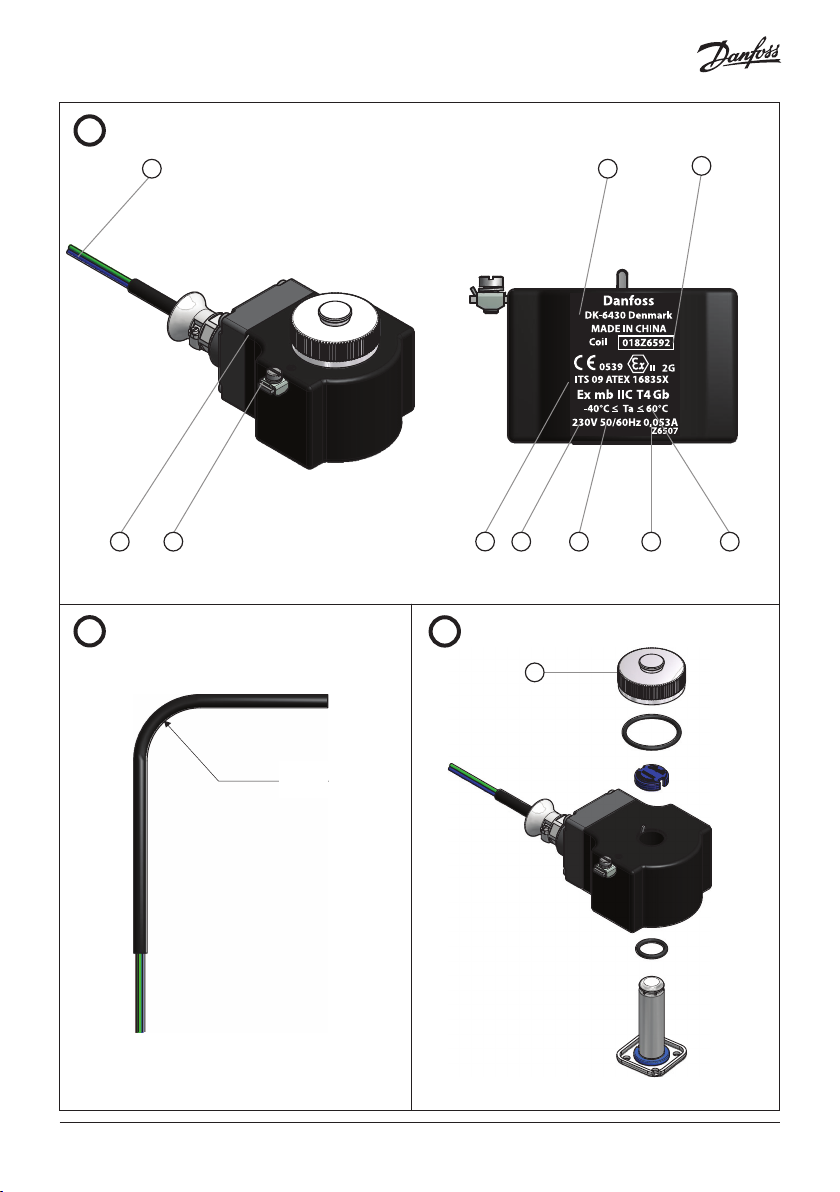

A

1

2 3 5 6 7 8

B

10

C

1

9

4

r > 35 mm

2 | AN196386442447en-000601

© Danfoss | Climate Solutions | 2021.12

A

Identification

1

Green/Yellow cord for earthing

2

Week and date of manufacturing

3

External earth terminal

4

Code number

5

Voltage

6

Frequency

7

Current

8

Ambient temperature range

9

Country of manufacturing

10

Approval/Certificate number

Description and approval

Solenoid valve for control in potentially

explosive area.

Approval

EMC 2014/30/EU

ROHs 2011/6 5/EU

ATEX 2014/34/EU

Ex mb IIC T4 Gb

ITS 09 ATEX 16835X

The coil may only be installed with following valve combinations

• EVR NC 2 - 40

• EVR NO 3 - 40

• EVRH NO and NC 10 - 20

• EVRA(T) 3 - 40

• EVRS(T) 3 - 20

• EVM-EVRF-EVRP-EVRB

• GPLX

• EVM NO and NC

• EV210B 1.5 - 25

• EV310B 1.5 - 3.5

• EV220B 6 - 100

• EV250B 6 - 22

• EV251B 10 - 22

• EV222B 15 - 50

• EV224B 15-32

• EV227B 6 - 22

• VDH

• VDHT

• VPH

Application and specification:

Ambient media -40 °C ≤ T

Media -40 °C < T

≤ +60 °C Protection degree IP67

ambient

< +90 °C Polution degree 3 (EN60730-1)

media

Humidity 0% ≤ RH ≤ 100% Over voltage category 2.5 kV (EN60730 -1)

Voltage variation ± 10% Mode of operation Type 1 action (EN60730-1)

Connection 3-core cable 3 x 0.75 mm² External earth core Minimum A > 4 mm²

Weight 1.0 kg Incorporated control –

Class I control –

© Danfoss | Climate Solutions | 2021.12

AN196386442447en-000601 | 3

Safety instruction:

All national safety regulations must be

complied with in connec tion with installation,

start-up and operation of Danfoss solenoid valve.

Furthermore the requirements of the declaration of

conformity and national regulations for installation

in explosion area. Disregarding such regulations involves a risk of serious personal injury or extensive

material damage. Work in connection with the

solenoid valve mentioned must be performed only

by suitable qualified persons.

Basic safety and health requirements are

fulfilled through complains with:

• EN60079-0: 2012 + A11: 2013

EN60079 -0: 2 018

EN60079-18: 2015 + A1: 2017

Installation, operation and maintenance:

• The coil must be protected against external

impact.

• If the coil is installed in wet environment

(pollution degree 3) the coil shall be

mounted with wet kit accession 018Z0090.

• Always install a fuse in front of the coil.

DI N 41571-2

High breaking capacity 1500 A

Medium Time lag

Minimum voltage 250 V

• Ensure that the o -ring is proper mounted.

This is done by position the O-ring in the

middle of the armature tub e, and let the

coil push the O -ring into position at the

bottom of the armature tube ( ).

C

• The cable supplied with the solenoids must

not be handled or flexed and protected

against impact if the ambient temperature

is below 0 °C or similar. Minimum bending

diameter for fixed installation:

r ≥ 35 mm ( ).

B

• Mount the aluminum cap with 1.5 Nm+/-0.15

C

( ) and ensure that the O -ring is placed

correct.

• The end user must ensure the earthing of

the coil is maintained.

• Non-detachable cords method Z repairing not

allowed. If the coil failed, it must be replaced by a

new coil.

Special Conditions of Certification/Use:

• For Solenoid in use under -30 °C the cable must be

protected from impact

• The Solenoid is manufactured with a permanently

connected cable. The connection of this cable supplying the solenoid must be done in accordance

with the appropriate electrical code and good

engineering practice

• The product is provided with a Y/G coloured earth

wire for internal earthing. This internal earth

connection shall not be used if the external earth

connection is connected to the earth or bounding

system and must be cut off, isolated and not

connected.

• The solenoid must not b e removed from the valve

when energized. This would other wise impair the

surface temperature specifications.

• Enclosures or parts of enclosure are non-conduct-

ing and may generate an ignition capable level

of discharge under certain extreme conditions.

The user shall ensure that the equipment is

not installed or used in a location where it may

be subjec ted to external conditions (such as

high-pressure steam) which might cause a build-up

of electrostatic charge or non-conducting surfaces.

Additionally, cleaning of the equipment shall only

be done with a damp cloth.

• The solenoid must be protected against direct

sunlight and ultraviolet sources.

• The power supplying the solenoid must be limited

to a prospec tive short circuit current of 1500 A

according to EN 60079-18:2015 clause 7.9.2.1

• Each product shall be subjected to a visual inspec-

tion according to EN 60079-18:2015 clause 9.1

• Each product shall be subjected to a Dielec tric

strength test according to EN 60079-18:2015 clause

9.2

Warning:

Potential Electrostatic Charging Hazard.

The solenoid valve must only be installed in

surroundings with low wind speed, and where rubbing the coil is unlikely.

Cleaning with damp cloth is recommended. To avoid

buildup of electrostatic discharge it must be ensured

the coil is having a reliable connection to earth with

an impedance no exceeding 1 GΩ.

In case of p roblems, cont act:

Danfoss A/S

DK-6430 Nordborg

Denmark

4 | AN196386442447en-000601 |

© Danfoss | Climate Solutions | 2021.12

Loading...

Loading...