Page 1

Data sheet

Automatic balancing valves

ASV-PV DN 50 -100 (3rd gen.)

Description / Application

ASV-PV

DN 50

ASV balancing valves are used for dynamic

hydronic balance in heating and cooling systems.

One of the major challenges in heating and

cooling systems is a lack of good hydronic

balancing, caused by differential pressure, which

is changing constantly and unpredictably in the

system. This often results in complaints about

poor indoor comfort, noise and high energy bills.

ASV automatic balancing valves ensure an

optimal pressure differential for control valves

as well as the correct flow within the individual

risers at all times. The ASV automatically

creates an optimal hydronic balance within the

installation, whether under full or partial load.

This balance is never disrupted.

F low limitation

By using combination of pressure controller ASV

and settable terminal’s unit valve, f low limitation

is established.

F low limitation for each terminal unit prevents

underf lows on distant units and overf lows on

others thus allows efficient pumping.

Lower noise emission

Differential pressure limitation provides the

pressure over the control valve not to increase at

partial loads thus noise emission will be lower.

(This is the reason why DIN 18380 requires

control of differential pressure by partial load.)

No balancing method needed

F low limitation is achieved by adjusting each

hydronic loop separately without inf luencing

others, which consequently results in one time

adjusting process. No special balancing method

is needed so commisioning cost can be saved.

ASV-PV

DN 65-10 0

Partner valve

MSV-F2

DN 50-10 0

Control valve authority

Controlling differential pressure over the control

valve means that authority is high – which allows

an accurate and stable control as well as energy

saving.

Zone balancing

By installing the ASV sets you can divide

the piping system in pressure independent

zones. This allows a gradual connection of

zones to the main in new constructions or

at renovation without using an additional

balancing method. There is no need to perform

a new commissioning every time the system is

changed because the hydronic balance is done

automatically.

ASV-PV valves are settable in different ranges:

• 5-25 kPa setting is mostly used for radiator

application,

• 20-40 kPa setting is used for fan coil, chilled

beam and f lat station applications,

• 35-75 kPa setting is used for f lat station and

fan coil, chilled beam application,

• 60-100 kPa setting is used for large terminal

unit application (air handling units, fan coils,

etc.).

Using ASV valves it is possible to optimize pump

head while independent pressure zones allow to

keep authority of terminal unit’s valve high.

ASV balancing valves are designed to guarantee

high quality of the automatic balancing by:

- a pressure released cone,

- an adapted membrane for every valve

dimension which provide constant quality

performance for all sizes,

- spring with linear characteristic that makes

setting required ∆p easy.

© Danfoss | 2019.04

VD.A6.E7.02 | 1

Page 2

Data sheet Automatic balancing valves ASV

Description / Application

(continuous)

ASV valves DN 50 is supplied with external

thread only. Threaded or weld tail pieces can be

supplied as an accessory. Dimensions

DN 65-100 are supplied as f langed valves.

ASV balancing valves have integrated service

functions such as shut-off.

ASV-PV can be equipped with plug for f low

measuring. In that case measuring

plugs need to be ordered separately and

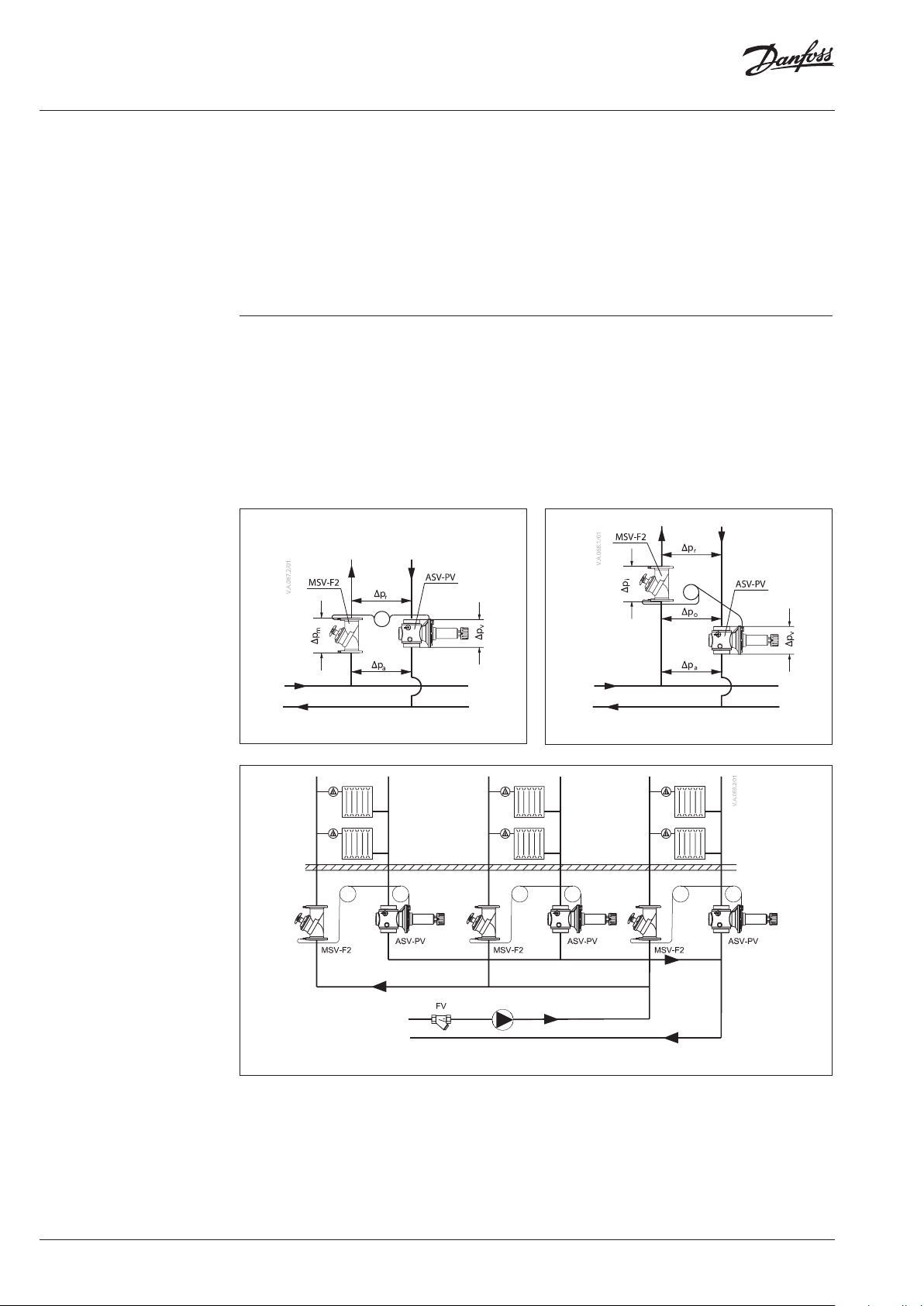

There are two basic configurations when using ASV

partner valves (MSV-F2):

• partner valve outside the control loop (Fig. 1).

Recommended configuration: it results in best

performance since whole controlled pressure

range is available to the riser. Flow limitation

is done on each terminal unit in the riser.

MSV-F2, by connecting impulse tube to downflow test plug.

mounted on the valve as follows:

• on top of drain connection (DN 50),

• on the f lange connection before the valve is

filled with water (DN 65-100).

ASV-PV valves are to be mounted in return pipe,

in combination with partner valves mounted

in f low pipe. As a partner valve MSV-F2 is

recommended.

• partner valve inside control loop (Fig. 2).

Offers flow limitation on the riser however

part of the controlled pressure range is used

by pressure drop on partner valve (pi). It is

recommended when flow limitation on each

terminal units is not possible.

MSV-F2, by connecting impulse tube to up-flow

test plug.

Fig. 2 Setting of ASV-PV = priser + piFig. 1 Setting of ASV-PV = ∆priser

Fig. 3 ASV in riser / typical heating application (general e xample)

ASV valves are to be used in heating systems

to control the differential pressure in risers. To

limit the f low for every radiator, the thermostatic

radiator valve with pre-setting facilities (feature)

is used together with a constant pressure

provided by the ASV, thus providing balanced

heat distribution.

Controlling differential pressure over the riser

means also that the valve authority over the

thermostatic radiator valves is high – which

allows an accurate and stable temperature

control and saves energy.

2 | VD.A6.E7.02

© Danfoss | 2019.04

Page 3

Data sheet Automatic balancing valves ASV

Description / Application

(continuous)

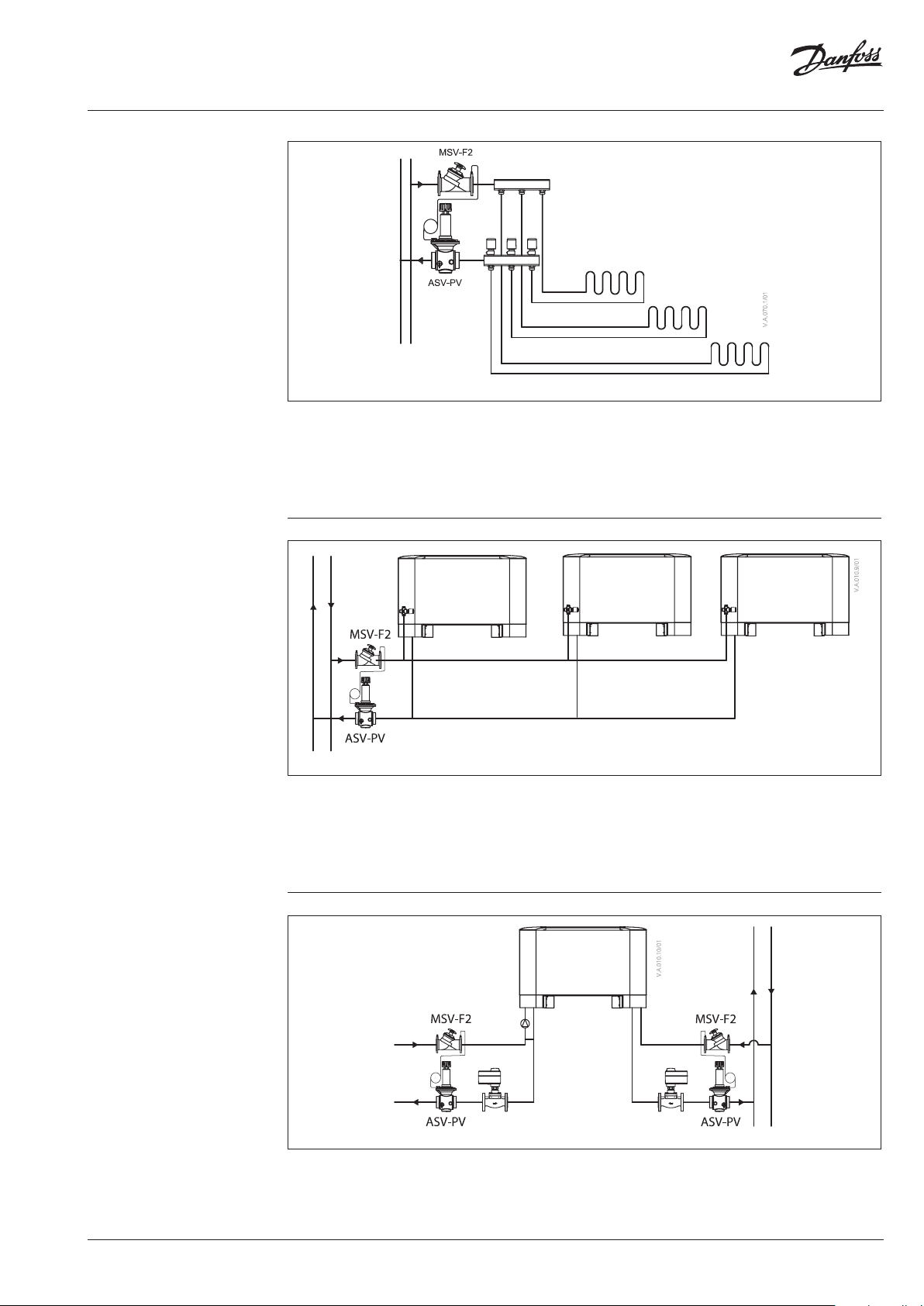

Fig. 4 ASV in manifold for f loor heating system

ASV valves are to be used in f loor heating

systems. To limit the f low for every loop valves

with an integrated f low limiting or presetting

function should be used together with a

constant pressure provided by an ASV-PV valve.

Fig. 5 ASV with fan coil

The ASV valves are to be used in systems with fan

coils, induction devices and air-heaters to secure

an automatic hydronic balance by the means of

differential pressure control in branches or at

every coil.

ASV-PV valves can control the differential

pressure in several ranges if different pressure is

needed.

© Danfoss | 2019.04

Fig. 6 ASV with air handling unit

The ASV valves are to be used in air handling

units to secure an automatic hydronic balance

by the means of differential pressure control at

every unit.

VD.A6.E7.02 | 3

Page 4

Data sheet Automatic balancing valves ASV

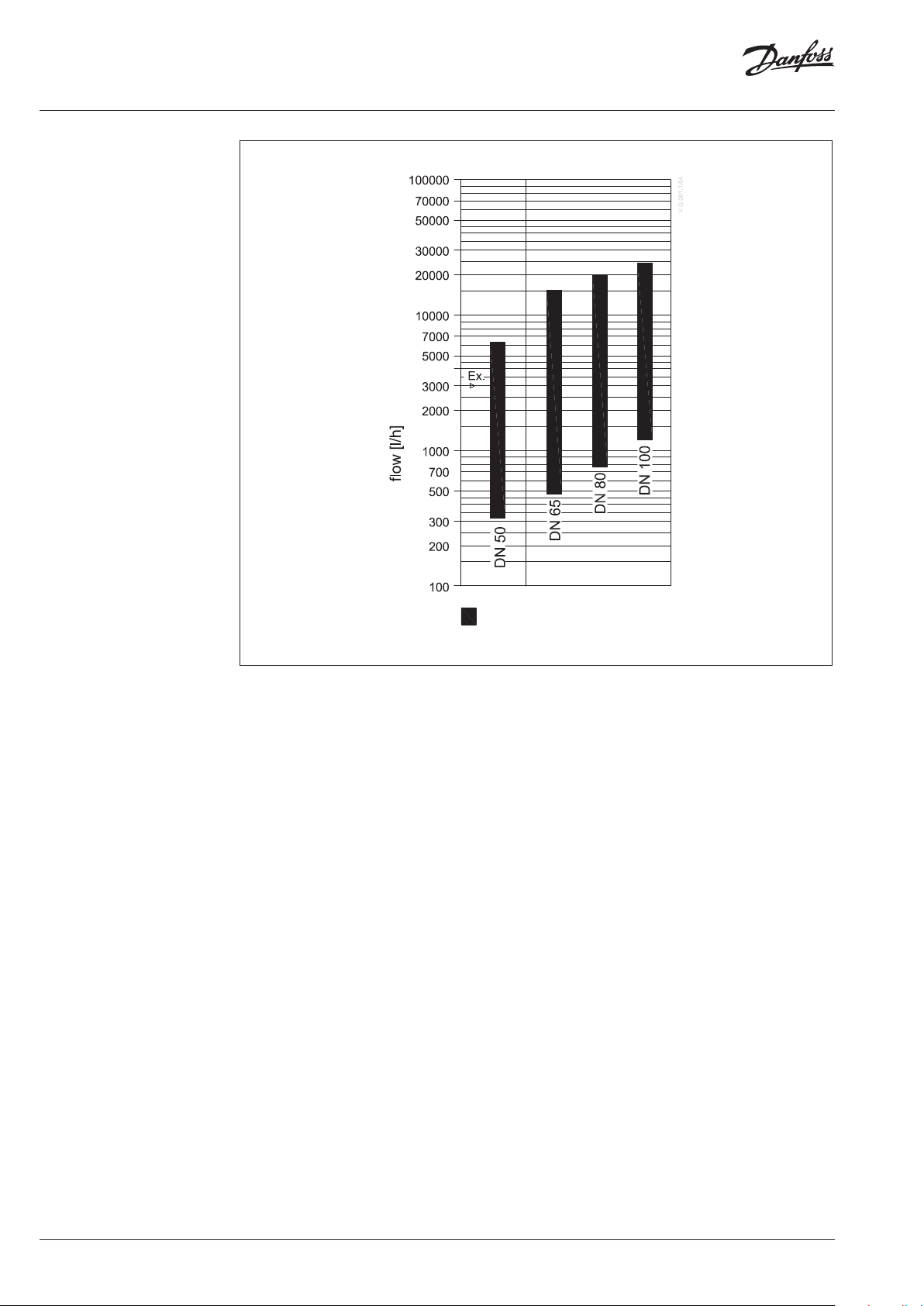

Sizing

Thread

F lange

Q

≤ Q ≤ Q

min

Fig. 7

Column diagram for sizing ASV valves at ∆ pv = 10 kPa. For different ∆pv values use diagram A in Appendix.

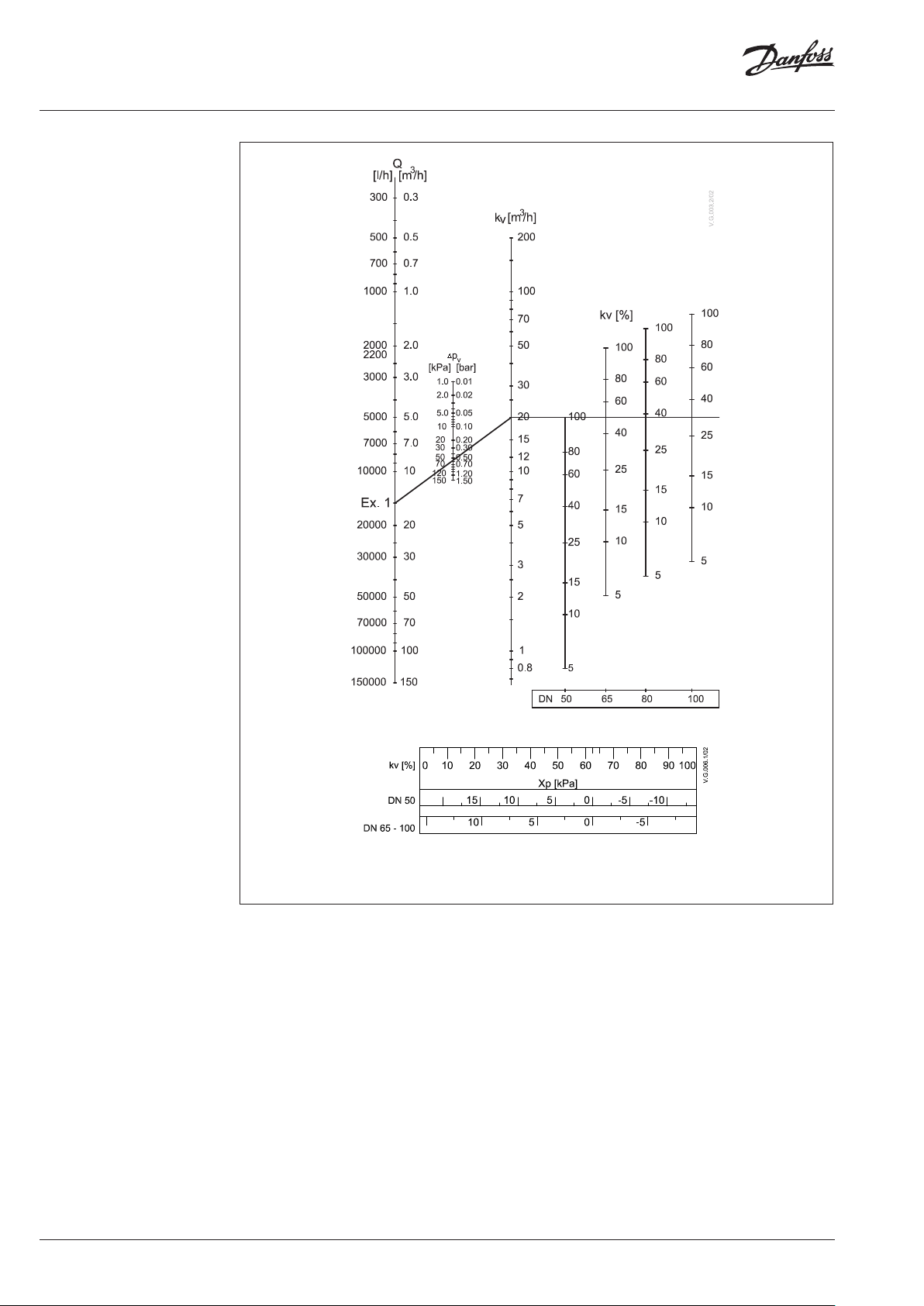

We recommend to size the diameter of

ASV-PV valves by using Fig 7. Maximum f low rates

are based on 10 kPa differential pressure over the

valve which allows effcient pumping and saves

energy.

10 kPa

Connection between valves size and pipe size

Kv values per particular dimension were designed

to cover f low range according to VDI 2073 with

water velocity of up 0.8 m/s, at differential

pressure of 10 kPa over the valve. As long as the

water velocity in the pipe is between 0.3 and 0.8

After ASV-PV valves have been sized the same

dimension of partner valve MSV-F2 valve should

m/s dimension of the valve should be equal to

pipe dimension.

be selected.

This rule is derived out of the fact that Kv values

Example:

per particular dimension were designed to cover

f low range according to VDI 2073 at differential

Given:

pressure of 10 kPa over the valve.

Pipe f low 3000 l/h, pipes DN 50

Solution:

Horizontal line intersects the column for the

valve DN 50 which can therefore be selected as

required size.

For detailed sizing see examples on pages 9. For

different pv (differential pressure over the valve)

see diagrams in Appendix A.

4 | VD.A6.E7.02

© Danfoss | 2019.04

Page 5

Data sheet Automatic balancing valves ASV

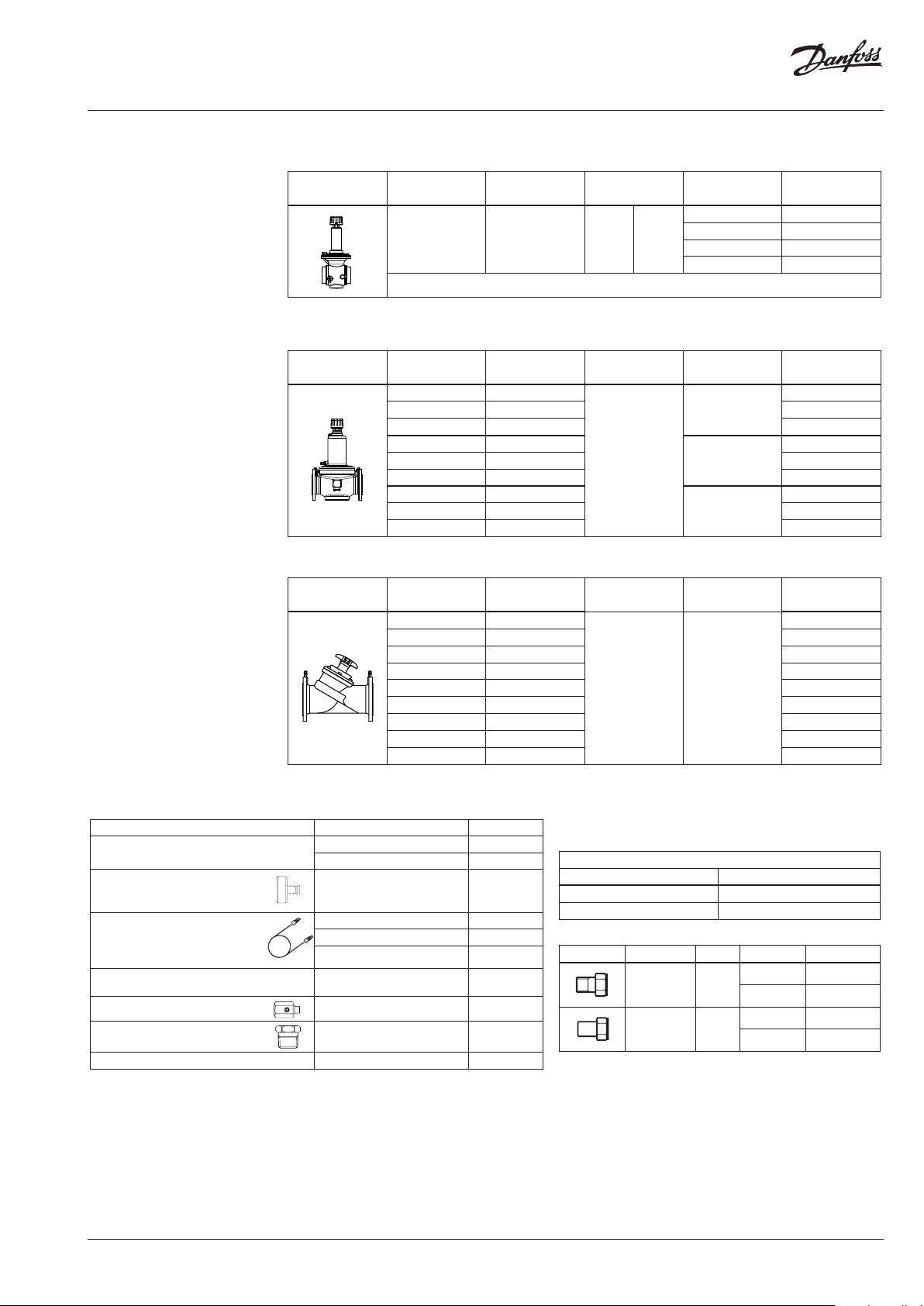

Ordering ASV-PV balancing valve, inclusive in the box:

2.5 m impulse tube (G ⁄ A) drain connection (G ⁄ A) and adapter 0 03L8151

k

Typ e DN

VS

(m⁄h) (kPa)

50 20

ASV-PV balancing valve, inclusive in the box:

2.5 m impulse tube (G ⁄ A), adapter ASV large 003Z0691 and 003L8151

k

Typ e DN

VS

(m⁄h) (kPa)

65 48

80 63 003Z0624

100 76.0 003Z0625

65 48

80 63 003Z0634

100 76.0 003Z0635

65 48

80 63 003Z0644

100 76.0 003Z0645

MSV-F2 Partner valve with shut-off, flowlimitation and test plugs.

k

Typ e DN

15 3.1

20 6.3 003Z1086

25 9.0 00 3Z1087

32 15. 5 003Z1088

40 32.3 00 3Z1089

50 53.8 0 03Z10 61

65 93.4 003Z106 2

80 122 .3 003Z1063

100 200.0 003Z1064

1)

For more inform ation see MSV-F2 datasheeet

VS

(m⁄h)

G 2 ⁄

∆p setting range

5-25 003Z0 611

20-40 003Z0621

35-75 003 Z0631

60 -100 003Z0641

∆p setting range

20-40

35-75

60 -100

1)

DN20

Code No.

Code No.

003Z0623

003Z0633

003Z0643

Code No.

003Z1085

Connection

External

thread

ISO 228/1

Connection

F lange

EN 10 92-2

T

MAX.

(°C) (bar)

130 16

Accessories and spare parts

Description Comments/connection Code No.

Shut off knob for MSV-F2

Differential pressure measuring

connector

DN 50 00 3Z0179

DN 65 -100 0 03Z0180

For drain connection 003L8143

1.5 m 00 3L8152

Impulse tube, with O-rings

2.5 m 003Z0690

5 m 00 3L8153

Plastic impulse tube with connectors and

adapters

Adapter large ASV

Plug for connecting impulse tube

O-ring for impulse tube

1)

Recommende d for use with MSV-F2, connected to me asuring hole, it allows conne ction of impulse

tube from ASV w hile retaining measurement f unctionality.

2)

Recommended for use wit h MSV-F2, connected to measuring h ole. Can also be used for connec ting

impulse tube d irectly on the pipe.

3)

Set of 10 pieces.

4)

Total 15 meter of impulse tu be

1)

2)

3)

For making set of 10 pieces 4)003Z0689

G ¼-R ¼; G ⁄ 003Z0691

G ⁄-R ¼ 003L8151

2.90 × 1.7 8 00 3L8175

© Danfoss | 2019.04

Fitting

For valves with external thread Danfoss offers

threaded or welded tailpieces as accessory.

Materials

Nut brass

Tailpiece welding steel

Tailpiece threaded brass

Typ e Comment to pipe to valve Code No.

Tailpiece

threaded

(1 pcs.)

Tailpiece

welding

(1 pcs.)

DN 50 (2 ¼˝) 00 3Z0274

R2

DN 50 (2 ½˝) 003Z0278

DN 50 (2 ¼˝) 003Z0272

DN 50

DN 50 (2 ½˝) 003Z 0276

VD.A6.E7.02 | 5

Page 6

Data sheet Automatic balancing valves ASV

Technical data

Design

1. Shut-off knob

2. Differential pressure

setting spindle

3. O-ring

4. Reference spring

5. Impulse tube connection

6. Diaphragm element

7. Control diaphragm

8. Pressure-relieved valve cone

9. Valve body

10. Seat

Typ e ASV-P V MSV-F2

Nominal diameter DN 50 -100 50 -100

Max. pressure

Test pressure 25 25

Differential pressure over the valve kPa 10-250

Temperature °C –10 … 120 -10 … 130

Material of parts in contact with water

Valve body Grey cast iron EN-

Cone Stainless steel CW602N

Membrane / O-rings EPDM

Spring Stainless steel -

1)

For more info rmation see MSV-F2 datasheet.

2)

Please note that the m aximum admissible dif ferential pressure across the val ve 250 kPa should also not be exceeded a t partial load.

5-25 20-40 35-75 60 -100

n

(turns)

(kPa) (kPa) (kPa) (kPa)

0 25 40 75 100

1 24 39 73 98

2 23 38 71 96

3 22 37 69 94

4 21 36 67 92

5 20 35 65 90

6 19 34 63 88

7 18 33 61 86

8 17 32 59 84

9 16 31 57 82

10 15 30 55 80

11 14 29 53 78

12 13 28 51 76

13 12 27 49 74

14 11 26 47 72

15 10 25 45 70

16 9 24 43 68

17 8 23 41 66

18 7 22 39 64

19 6 21 37 62

20 5 20 35 60

bar

16 (PN 16) 16 (PN 16)

2)

GJL-250 (GG 25)

Cast iron EN-GJL 250 (GG 25)

1)

10-150

6 | VD.A6.E7.02

Factory presetting

∆p setting range

(kPa)

5-25 10

20-40 30

35-75 60

60 -100 80

Fig. 8 ASV-PV (DN 50)

kPa

DN 50 5

ASV-PV is designed to maintain a constant set

differential pressure. Via an internal connection

and together with the reference spring (4),

pressure in the return pipe acts on the underside

of the control diaphragm (7) while via an impulse

tube (5), pressure in the f low pipe acts on the top

of the diaphragm. In this way the balancing valve

maintains adjusted differential pressure.

The ASV-PV valves are sold in four different p

setting ranges. The valves are factory–set to a

defined value as described on Factory presseting

table on Fig. 8 and 9.

Use the following procedure to set the desired

differential presure:

the setting on ASV-PV can be changed by

turning the setting spindle (2).

Turning the spindle clockwise increases the

setting; turning it counter clockwise reduces the

setting.

If the setting is not known, turn the spindle fully

clockwise. With this the setting on ASV-PV is at

maximum value within setting range. Now turn

the spindle a number of times (n) as described

in Fig. 6, 7 or 8 until the required differential

pressure setting is obtained.

© Danfoss | 2019.04

Page 7

Data sheet Automatic balancing valves ASV

Design (continuous)

1. Shut-off knob

2. Differential pressure

setting spindle

3. O-ring

4. F l at gasket

5. Reference spring

6. Impulse tube connection

7. Diaphragm element

8. Control diaphragm

9. Pressure-relieved valve cone

10. Valve body

11. Seat

12. Measuring holes-plugged

13. Air-vent

DN

65 13

80 13

100 13

Factory presetting

∆p setting range (kPa) kPa

20-40 30

35-75 60

60 -100 80

20-40 35-75 60-100

n

(turn s)

10 30 65 90

11 29 64 89

12 28 63 88

13 27 62 87

14 26 61 86

15 25 60 85

16 24 59 84

17 23 58 83

18 22 57 82

19 21 56 81

20 20 55 80

(kPa) (kPa) (kPa)

0 40 75 100

1 39 74 99

2 38 73 98

3 37 72 97

4 36 71 96

5 35 70 95

6 34 69 94

7 33 68 93

8 32 67 92

9 31 66 91

(turn s)

21 54 79

22 53 78

23 52 77

24 51 76

25 50 75

26 49 74

27 48 73

28 47 72

29 46 71

30 45 70

31 44 69

32 43 68

33 42 67

34 41 66

35 40 65

36 39 64

37 38 63

38 37 62

39 36 61

40 35 60

(kPa) (kPa) (kPa)

20-40 35-75 60-100

n

© Danfoss | 2019.04

Fig. 9 ASV-PV (DN 65-100)

VD.A6.E7.02 | 7

Page 8

Data sheet Automatic balancing valves ASV

Design (continuous)

1. Body EN-GJL250

2. Plug

3. Valve cone

3.1 . Seat soft sealing

4. Rod

5. Stroke limiter/Allen screw

6. Gasket

7. Handwheel with display - DN

50 -100 p lastic

8. Fixed screw

9. Spindle

10. Stuffing box

11. Bonn et

12 . Allen screw /Hexagon screw

13. Flat gasket

MSV-F2 DN 50-80

Fig. 10 MSV-F2 DN 50-100

Partner valves MSV-F2 1) are to be used

together with the automatic balancing valves

ASV-PV to control differential pressure in the

risers.

Impulse tube connection

The impulse line must be connected to impulse

tube connection piece (2) (adaptor sold as

accessory). In working position,

one of test plugs needs to be open while other

closed. There are two possible configurations,

with partner valve inside or outside control loop.

It can be chosen by impulse tube connection side:

- Partner valve outside controlled loop:

opened outlet test plug

- Partner valve inside controlled loop: opened

inlet test plug

MSV-F2 DN 100

MSV-F2 is manual presetting and shut-off valves.

The valves have position indicator and stroke

limiter as standard. Hood of spindle is integrated

with stroke limiter. Setting can be locked.

Valves have built in flow limitation

1)

For more inform ation see MSV-F2 datasheet

8 | VD.A6.E7.02

© Danfoss | 2019.04

Page 9

Data sheet Automatic balancing valves ASV

k

v=

Q

�

∆p

v

=

15

√

0.6

=19.36 m3h⁄

2

Sizing-design examples

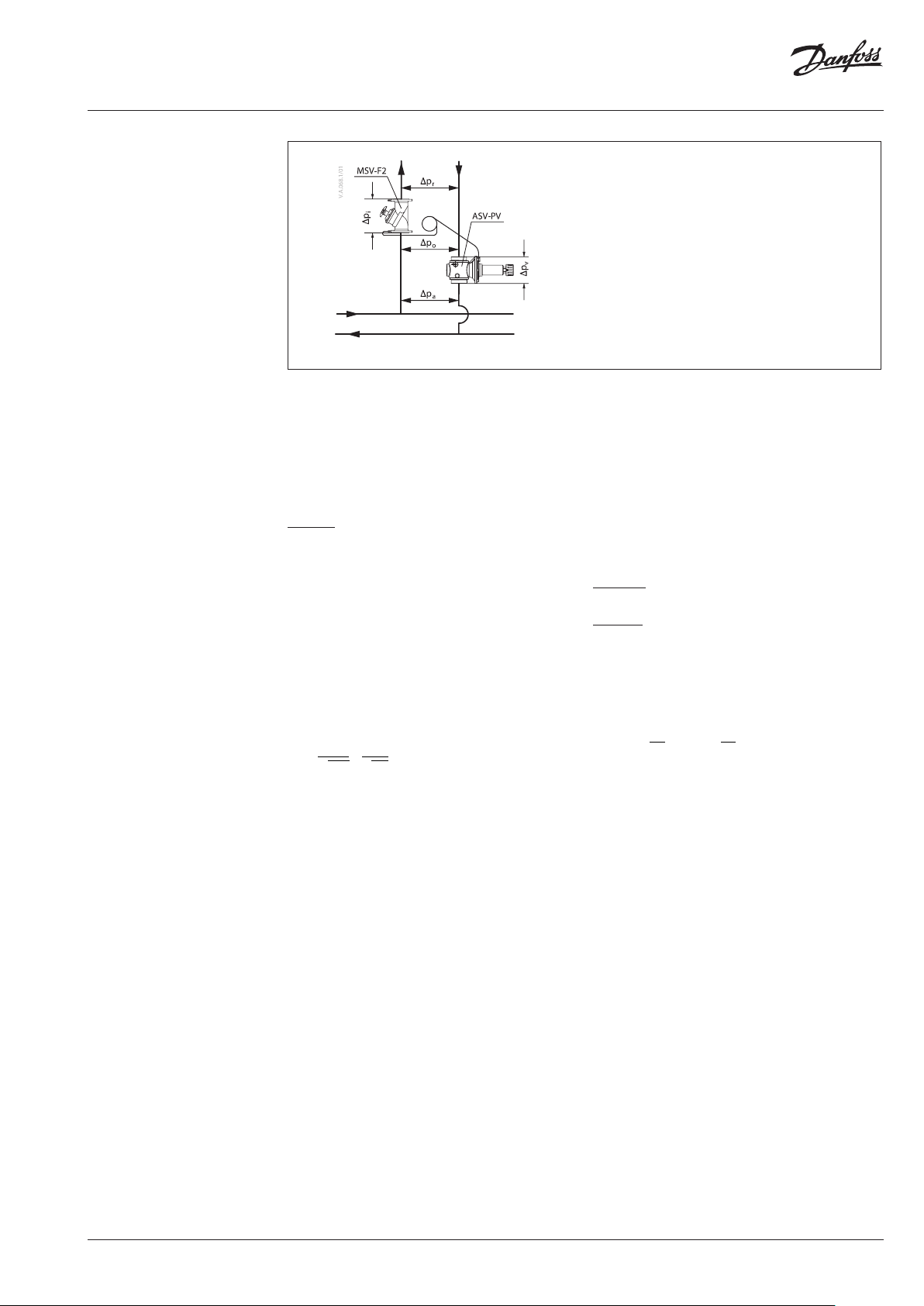

Fig . 11

∆pa = ∆pm + ∆pr + ∆pv

Δpv Pressure drop across ASV-PV valve

Δpi Pressure drop across MSV-F2

Δpo Pressure drop across the riser including MSV-F2

Δpa Pressure drop across the riser

Δpr Pressure drop in the riser excluding MSV-F2

1. Example (AHU - air handling unit)

Given:

Desired f low for the riser (Q): .........................15 m3/h

Minimal available pressure

for that riser (∆pa) ...............................................10 0 kPa

Estimated pressure drop over the riser

at the desired f low (∆p0) .................................... 40 kPa

Wanted:

- Valve type

- Valve size

Selection and sizing of automatic balancing

valves for air handling unit. The customer have

choosen ASV-PV with partner valve MSV-F2

inside the control loop is choosen. Since the

calculated pressure drop over the riser is 40 kPa

ASV-PV with setting range between 35-75 kPa is

selected. The minimal available pressure for the

riser is 100 kPa and pressure drop across ASV-PV

(∆pv) will following be 60 Kpa

∆pv = ∆pa−∆p0 = 100−40 = 60 kPa

Based on this calculation ASV-PV DN 65 is

selected with partner valve MSV-F2 also DN65.

Set the valve to 40 kPa, see figure 11 (40kPa = 35

turns). Selection can also be made by reading

from diagram Appendix A. fig A

2. Example (continued AHU - air handling

unit)

Given:

Correcting the flow with the differential pressure

setting.

Desired flow for the riser (Q2): .......................15 m3/h

Measured flow for the riser (Q1) ....................18 m3/h

Estimated pressure drop over the

riser at desired flow (∆pr) ................................. 40 kPa

Required:

Correct flow to 15 m3/h for the riser.

Solution:

Measuring the flow show that it is higher then

what is desired for the riser, this could be caused

by the real pressure drop over the riser is higher

than the estimated 40 kPa, following setting on

the ASV-PV valve can be adjusted to limit the

flow.

P2=P1×

Q

2

=40×

Q

1

15

18

2

=28 kPa

If we decrease the setting from 40 to 28 kPa flow

will be decreased to 15 m3/h.

Alternatively, flow limitation inside the loop

can also be done with MSV-F2 by adjusting the

setting of the valve.

© Danfoss | 2019.04

VD.A6.E7.02 | 9

Page 10

Data sheet Automatic balancing valves ASV

Measurement of f low and

differential pressure

MSV-F2 is equipped with two test plugs so that

the differential pressure across the valve can be

measured using Danfoss measuring equipment

or any other measuring device. Valve can be

converted to actual f low.

Note: When measuring sized f low, all radiator

valves must be fully open (nominal f low).

Installation ASV-PV must be installed in the return pipe with

f low in the direction of the arrow on thevalve

body. Partner valves (MSV-F2) must be installed

in the f low pipe, with f low in the direction of the

arrow on the valve body. The impulse tube must

be installed between partner valve and ASV-PV.

003L8151

Measurement of differential pressure (Δpr)

across riser.

Fit a measuring connector (Danfoss code no.

003L 8143) on the ASV-PV balancing valve drain

connection (DN 50) or threaded connection

closer to the terminal unit (TU). Measurements

must be taken between the test plug at MSV-F2

valve port B and the measuring connector on the

ASV- PV.

The impulse tube must be f lushed through

before installation. ASV-PV and MSV-F2 must

in addition be installed as determined by

installation conditions.

003Z0691

Fi g. 13

Pressure testing Max. test pressure ............................................... 25 bar

When pressure testing the system you must

secure that both sides of the membrane have the

same static pressure to prevent damage of the

pressure controller. That means the impulse tube

must be connected and any needle valves must

be open.

Starting

During system start – opening the shut-off on

ASV-PV and partner valve-please secure that

there is the same static pressure on both sides or

higher pressure on upper side of the membrane.

If filling is done by opening ASV-PV and partner

valve, please make sure there is a pressure on the

upper side of the membrane by opening partner

valve first before ASV-PV is opened.

10 | VD.A6.E7.02

© Danfoss | 2019.04

Page 11

Data sheet Automatic balancing valves ASV

Dimensions

ASV-PV

∆p setting range L1 L2 L3 H1 H2 D1 D2 b c

DN

50

kPa mm ISO 228/1

5-25

20-40

35-75

60 -100

130 244 234

232

61 55 133 G 2⁄ G ⁄ A

273

© Danfoss | 2019.04

Fi g. 14

ASV-PV

DN

65

80

100

L1 H1 H2 D1 D2 D3

mm

290 385 93 68 205 145

310 390 100 68 218 160

347 446 112 68 248 180

VD.A6.E7.02 | 11

Page 12

Data sheet Automatic balancing valves ASV

Appendix A-Sizing diagram

12 | VD.A6.E7.02

Fig. A

Sizing diagram ASV-PV DN 50-100

-

© Danfoss | 2019.04

Page 13

Data sheet Automatic balancing valves ASV

Appendix A-Sizing diagram

Appendix B

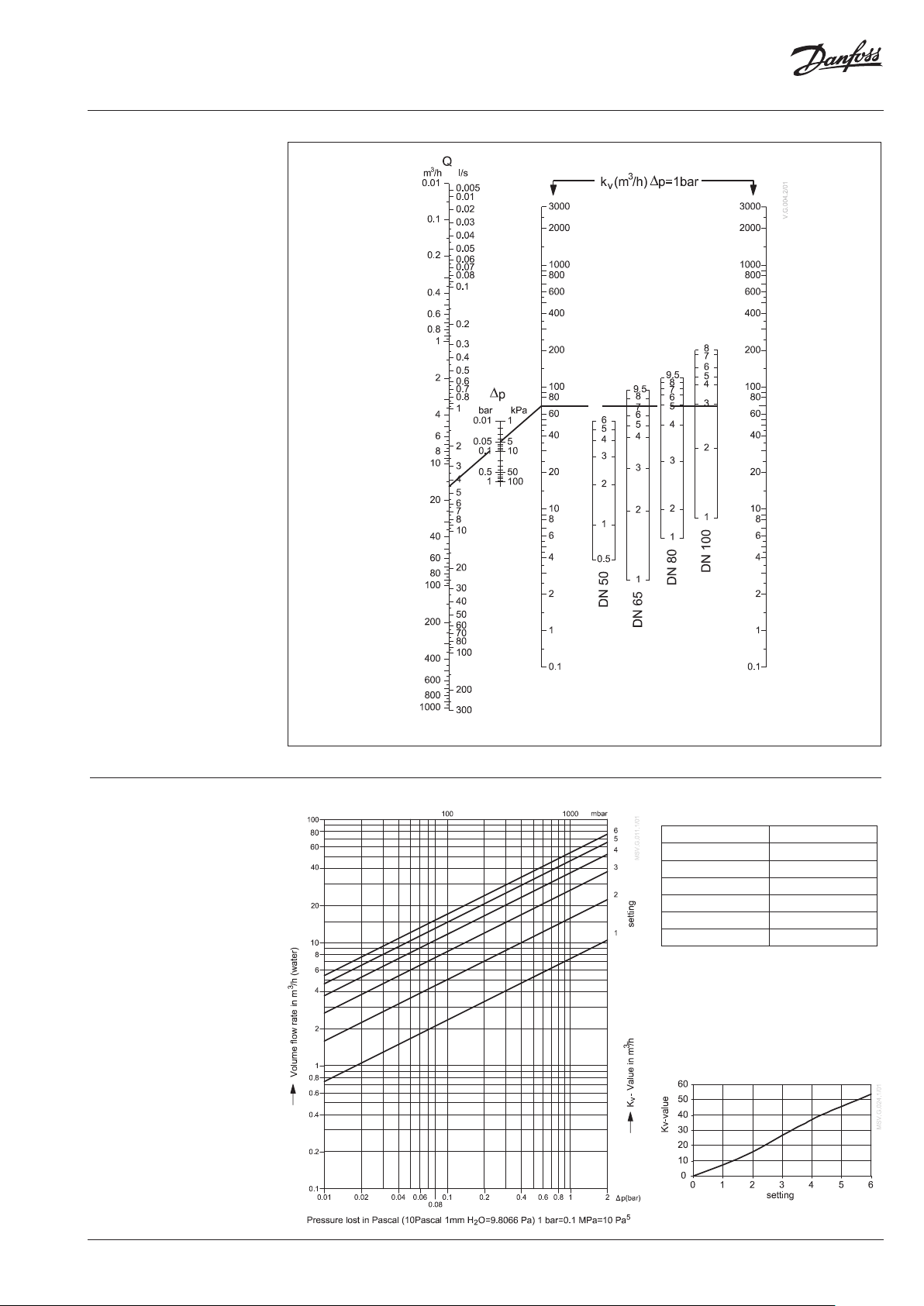

MSV-F Flow diagrams

Fig.B -Sizing diagram MSV-F2 DN 50-100

DN 50 / PN 16 / PN 25

Setting kv-value

1 7.4

2 15. 8

3 26.7

4 36.9

5 46.2

6 53.8

Max. permissible differential pressure

in throttling function 1.5 /2.0 bar.

Max. permissible flow speed: ≤ 4 m/s

Condition:

• The flow must be free of

cavitation.

Flow characteristic

© Danfoss | 2019.04

VD.A6.E7.02 | 13

Page 14

Data sheet Automatic balancing valves ASV

Appendix B (continued)

MSV-F Flow diagrams

DN 65 / PN 16 / PN 25

Setting kv-value

1 2.6

2 8.8

3 21.6

4 39.0

5 49.8

6 58.5

7 69.3

8 79.0

9 8 7.8

9.5 93.4

Max. permissible differential pressure

in throttling function 1.5 /2.0 bar.

Max. permissible flow speed: ≤ 4 m/s

Condition:

• The flow must be free of

cavitation.

Flow characteristic

DN 80 / PN 16 / PN 25

Setting kv-value

1 5.8

2 9.9

3 24.5

4 48.5

5 71.3

6 8 7.0

7 96.4

8 109. 3

9.5 122. 3

Max. permissible differential pressure

in throttling function 1.5 /2.0 bar.

Max. permissible flow speed: ≤ 4 m/s

Condition:

• The flow must be free of

cavitation.

Flow characteristic

14 | VD.A6.E7.02

© Danfoss | 2019.04

Page 15

Data sheet Automatic balancing valves ASV

Appendix B (continued)

MSV-F Flow diagrams

DN 100 / PN 16 / PN 25

Setting kv-value

1 8.3

2 32.4

3 72.9

4 107. 2

5 128 .2

6 152.8

7 180.0

8 200.0

Max. permissible differential pressure

in throttling function 1.5 /2.0 bar.

Max. permissible flow speed: ≤ 4 m/s

Condition:

• The flow must be free of

cavitation.

Flow characteristic

© Danfoss | 2019.04

VD.A6.E7.02 | 15

Page 16

Danf

already on order pro

All trademarks in this material are property of the respec

Data sheet Automatic balancing valves ASV

ASV-PV tender text

1. Tender text

a.

Product is differential pressure controller for automatic hydronic balance of heating and cooling systems.

b. The differential pressure controller should be based on integrated membrane element.

c. Valves should have shut-off function separated from the setting mechanism. Shut-off service

function should be possible with a hand knob.

d. The setting of differential pressure should be hidden to prevent unauthorized change of setting.

e. The differential pressure setting should be linear throughout the setting range (1 turn 1 kPa or 1

turn 2 kPa depending on dimension).

f.

Packaging of differential pressure controller should contain impulse tube (1.5 m)

g. Valve should be delivered in reliable packaging for safe transport and handling.

2. Product characteristics:

a. Pressure class: PN 16

b. Temperature range: −10 … +120 °C.

c. Connection size: DN 50-100

d. Connection type (depending on dp setting range): External thread ISO 228/1 (DN15-50) and

Flange EN 1092-2 (DN 65-100)

e. p setting range: 5-25 kPa (DN 50), 20-40 kPa (DN 50-100), 35-75 kPa (DN 50-100) and 60-100 kPa

(DN 65-100).

f. Installation: differential pressure controller should mounted on return pipe with connection via

impulse tube to supply pipe.

Nominal diameter: _ _ _ _ _ _

Connection: _ _ _ _ _ _

Adjustment range from-to: _ _ _ _ _ _ kPa

Produced by: Danfoss Type: ASV-PV

Ordering no.: 003L_ _ _

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

16 | VD.A6.E7.02

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | DHS-SRMT/SI | 2019.04

Loading...

Loading...