Page 1

Data sheet

Automatic balancing valve

ASV-P (DN 15-40)

Description

Ordering

ASV balancing valves are designed to guarantee

high quality of the automatic balancing by:

- a pressure released cone,

- an adapted membrane for every valve

dimension which provide constant quality

performance for all sizes.

A 90° angle between all service features (shut-off,

draining, measuring) allows an easy access under

any installing condition.

ASV valves (DN 15-40) are packaged in styropore

(EPS) which can be used for insulation at

ASV-P valves are automatic balancing valves

with fixed setting (10 kPa) for creating optimal

hydronic balance in residential heating systems.

The setting can be increased to 20 or 30 kPa

by spring replacement. Spring can be replaced

under pressure.

temperatures up to 80 °C. An insulation cap is

available as an accessory for insulation at higher

temperatures (up to 120 °C).

ASV-P valves are to be mounted in return pipe,

in combination with partner valves mounted

in f low pipe. As a partner valve ASV-M/I/BD are

recommended.

ASV-P balancing valve, inclusive in the box: 1.5 m impulse tube (G ⁄ A) and drain cock (G ⁄ A)

Constant differential pressure 10 kPa ; can be upgraded to 20 or 30 kPa setting respectively

Internal thread

k

Typ e DN

15 1.6 Rp ½ 003L7621 G ¾ A 003L7626

20 2.5 Rp ¾ 003L7622 G 1 A 0 03L7627

25 4.0 Rp 1 0 03L7623 G 1¼ A 003L7628

32 6.3 Rp 1¼ 003L7624 G 1½ A 003L762 9

40 10 Rp 1½ 003L7625 G 1¾ A 003L7630

Note: for whole rang e of ASV partner valves, spa re parts and accessories pl ease refer to ASV datasheet.

VS

3

(m

/h) (I SO 7/1) (ISO 228/1)

Code No. Ty pe

External thread

Code No.

Accessories and spare parts

© Danfoss | 2017.07

Typ e Description Comments/connection Co de No.

1.5 m 003L 8152

Impulse tube, with O-rings

ASV-P 20 kPa spring (yellow)

ASV-P 30 kPa spring (green)

2.5 m 003Z0690

5 m 003L 8153

DN 15 003 L8182

DN 20 003L8183

DN 25 003L8184

DN 32 / DN 40 003 L8185

DN 15 003L8192

DN 20 003L 8193

DN 25 003L 8194

DN 32 / DN 40 003 L8195

VD.A9.L1.02 | 1

Page 2

Data sheet Automatic balancing valves ASV-P

Technical data

Application

Nominal diameter DN 15- 40

Max. pressure

Test pressure 25

Differential pressure over the valve kPa 10 -150

Temperature °C –20 … 120

Materi al of parts in cont act with water

Valve body Brass

Cone ASV-P DZR brass

Membrane / O-rings EPDM

Spring Stainless steel

1)

Please note tha t the maximum admissible dif ferential pressure across t he valve 150 kPa should also not be e xceeded at partial lo ad.

bar

16 (PN 16)

1)

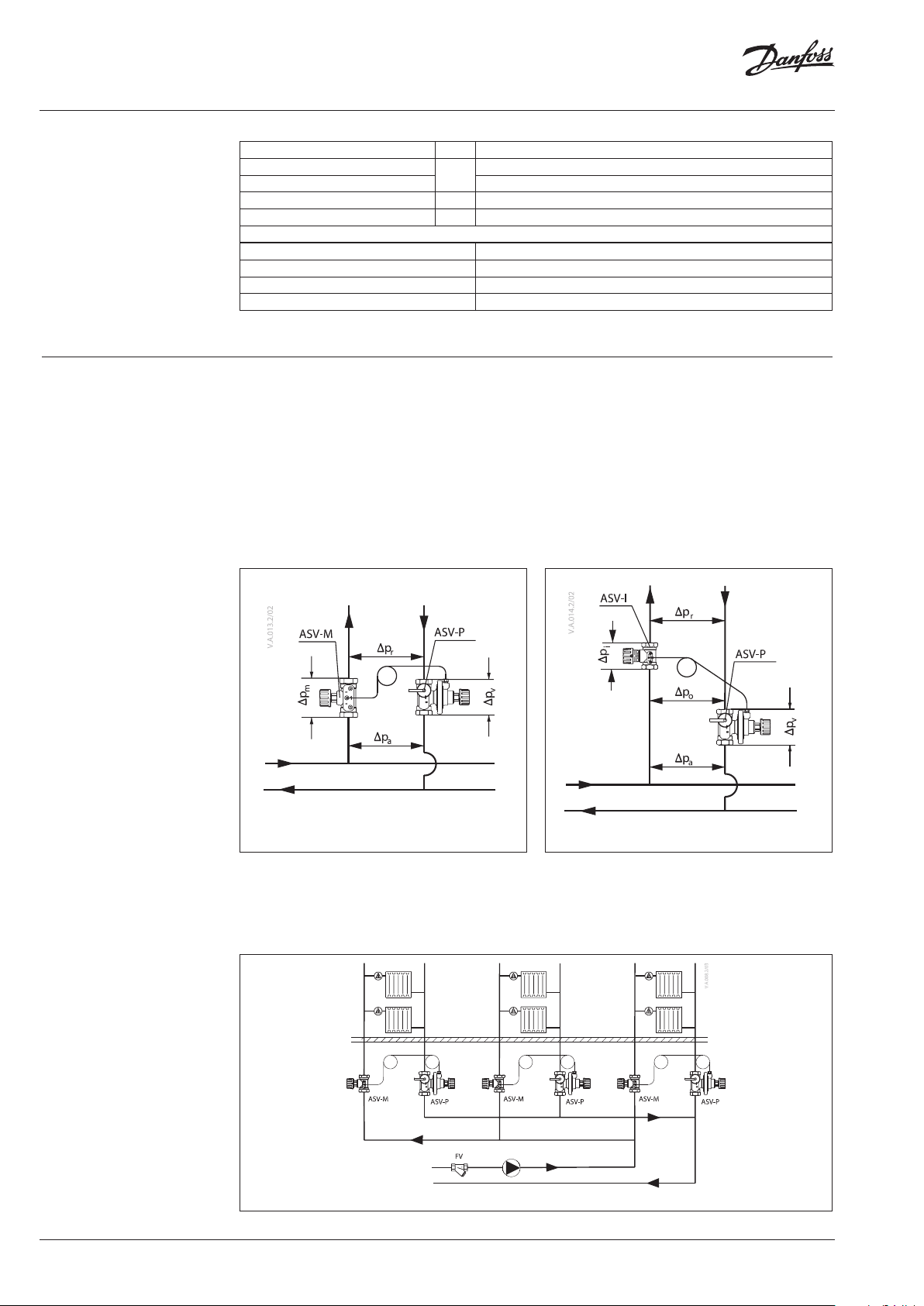

There are two basic configurations when using

ASV partner valves (ASV-BD, ASV-I, ASV-M,

MSV-F2):

- partner valve outside the control loop (Fig. 1).

Recommended configuration: it results in best

performance since whole controlled pressure

range is available to the riser. Flow limitation

is done on each terminal unit in the riser (for

example, RA-N with presetting on radiator,

- partner valve inside control loop (Fig. 2).

Offers flow limitation on the riser however

part of the controlled pressure range is used

by pressure drop on partner valve (p

recommended when flow limitation on each

). It is

i

terminal units is not possible.

etc).

2 | © Danfoss | 2017.07

Fig. 1 Setting of ASV-P = Δpriser Fig. 2 Setting of ASV-P = ∆priser + ∆p

i

ASV-BD can be used outside or inside control loop by choice of which measuring nipple is open.

To be used outside control loop, blue measuring nipple needs to be open. In this position, flow

verification can be done (default position). To be used inside control loop, red measuring nipple

needs to be open. In this position, flow verification & flow verification can be done.

Fig. 3 ASV in riser / typical heating application (general example)

VD.A9.L1.02

Page 3

Data sheet Automatic balancing valves ASV-P

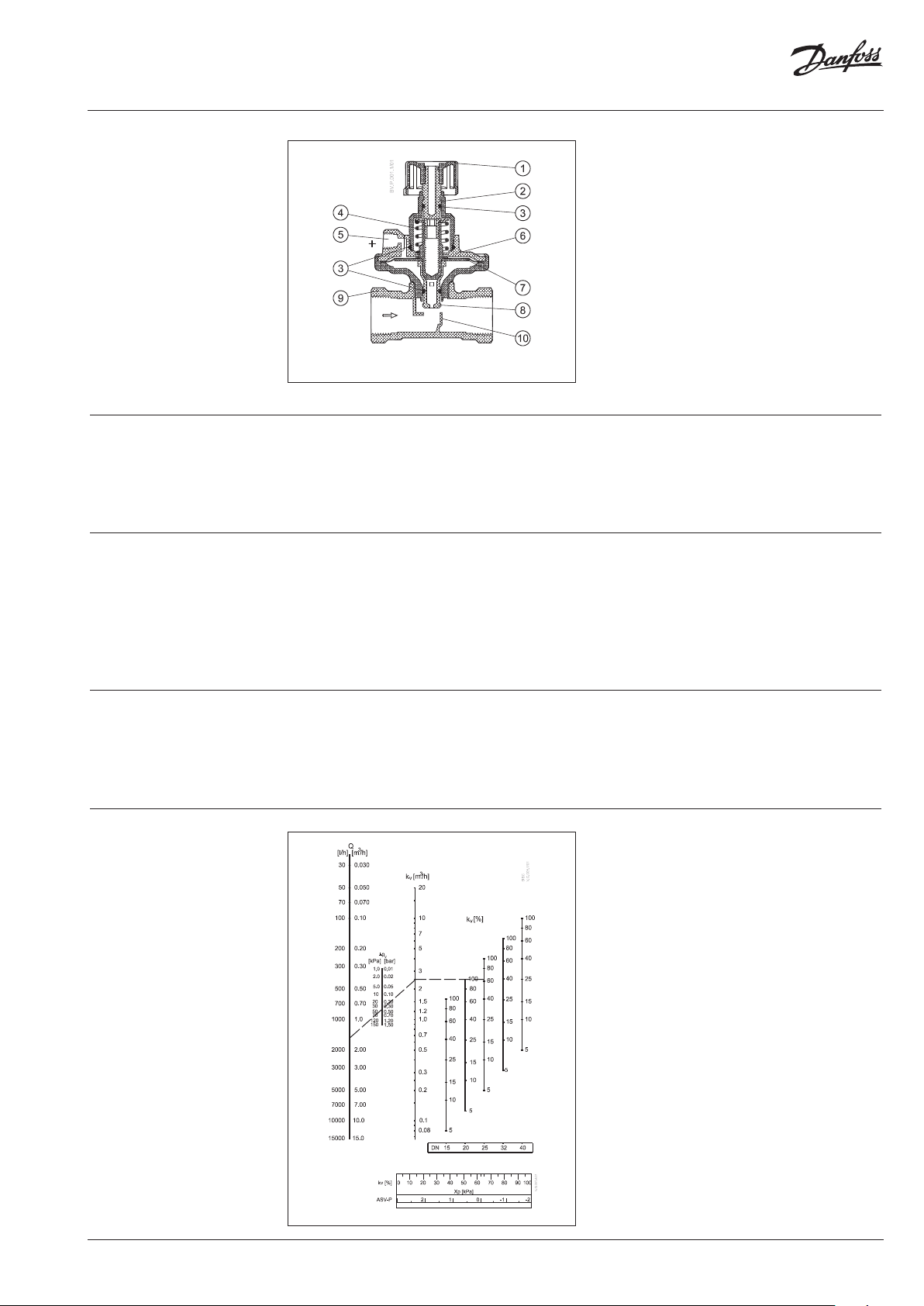

Design

1. Shut-off knob

2. Shut-off spindle

3. O-ring

4. Reference spring

5. Impulse tube connection

6. Diaphragm element

7. Control diaphragm

8. Pressure-relieved valve cone

9. Valve body

10. Seat

Dimensions - insulation

Pressure testing

ASV-P must be installed in the return pipe with

flow in the direction of the arrow on the valve

body. Partner valves (ASV-M/I/BD, MSV-F2 must

be installed in the flow pipe, with flow in the

Max. test pressure is 25 bar. When pressure

testing the system you must secure that both

sides of the membrane have the same static

pressure to prevent damage of the pressure

controller. That means the impulse tube must

be connected and any needle valves must be

open. If ASV-P is installed in combination with

The ASV-P is designed to maintain constant

differential pressure across a riser. Via an internal

connection and together with the reference

spring, pressure in the return pipe acts on the

underside of the control diaphragm ⑦ while via

an impulse tube ⑤, pressure in the f low pipe

acts on the top of the diaphragm. In this way the

balancing valve maintains a fixed differential

pressure of 10 kPa.

The setting can be increased to 20 or 30 kPa

by spring replacement. Spring can be replaced

under pressure. The ability to increase the

setting is especially useful in case of trouble

shooting. It gives insurance that design flow can

be achieved even if calculation doesn’t match

actual installation.

direction of the arrow on the valve body. The

impulse tube must be installed between partner

valve and ASV-P. The impulse tube must be

flushed through before installation.

ASV-M both valves must be open or closed (both

valves must be in the same position!). If ASV-P

is installed in combination with ASV-I /ASV-BD

both valves must be open. During this operation

(closing or opening the valves) please make sure

that there is never lower pressure on upper side

of the membrane to prevent damaging it.

Starting

Appendix A-Sizing diagram

During system start – opening the shut-off on

ASV and partner valve-please secure that there

is the same static pressure on both sides or

higher pressure on upper side of the membrane.

If filling is done by opening ASV-P and partner

valve, please make sure there is a pressure on the

upper side of the membrane by opening partner

valve first before ASV-P is opened.

VD.A9.L1.02

© Danfoss | 2017.07 | 3

Page 4

Danf

already on order pro

All trademarks in this material are property of the respec

Data sheet Automatic balancing valves ASV-P

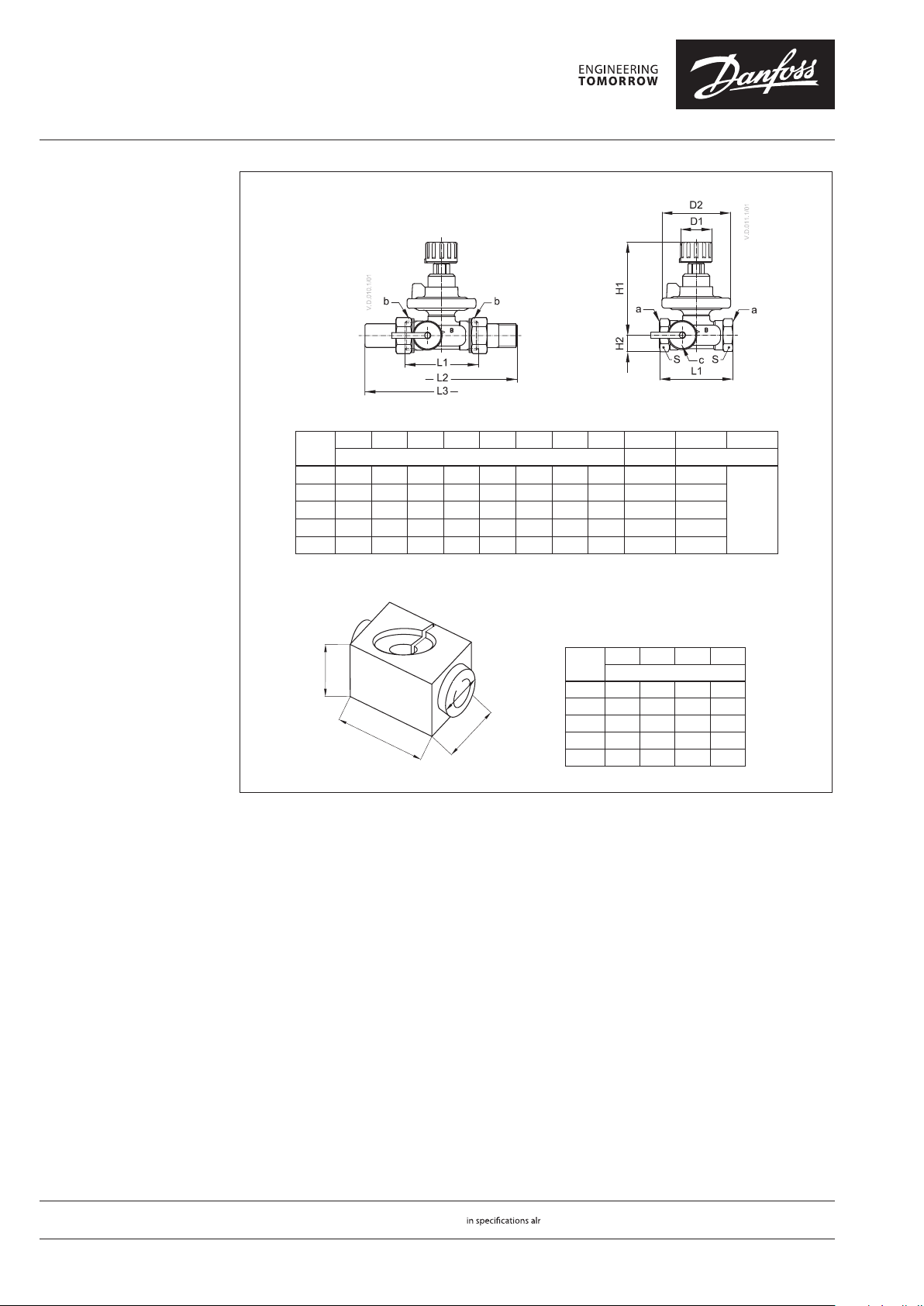

Dimensions

L1 L2 L3 H1 H2 D1 D2 S a b c

DN

65 120 139 82 15 28 61 27 Rp ½ G ¾ A

15

75 13 6 159 103 18 35 76 32 Rp ¾ G 1 A

20

85 155 169 132 23 45 98 41 Rp 1 G 1¼ A

25

95 17 2 179 165 29 55 122 50 R p 1¼ G 1½ A

32

100 206 184 170 31 55 12 2 55 R p 1½ G 1¾ A

40

mm IS O 7/1 ISO 228/1

G ¾ A

Insulation

A B C D

A

D

BC

DN

15 61 110 111 37

20 76 120 136 45

25 100 135 155 55

32 118 148 160 70

40 118 14 8 180 70

mm

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

4 | © Danfoss | DHS-SRMT/SI | 2017.07

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

VD.A9.L1.02

Loading...

Loading...