Page 1

Data sheet

Automatic balancing valves

ASV DN 15-50 (4th gen.)

ASV-PV ASV-BD ASV-M

DN 15-50 DN 15-50 DN 15-50

Description

ASV whiteboa rd animation

ASV valves are automatic balancing valves.

Together with Danfoss presetting radiator

thermostatic valves they are part of the Danfoss

two-pipe solution and are perfect for creating

optimal hydronic balance in residential two-pipe

heating systems.

One of the major challenges in heating systems

is a lack of good hydronic balancing, caused

by differential pressure, which is changing

constantly and unpredictably in the heating

system. This results in complaints from residents

about poor indoor comfort, noise and high

energy bills.

Trying to solve these complaints, larger pumps

are often installed to improve - especially under

heated - circulation of the water. Unfortunately,

this affects pressure differentials and energy

consumption within the system even more.

Besides, the higher pressure differential, the

greater the noise from the system, particularly

from radiator valves.

ASV automatic balancing valves ensure an

optimal pressure differential for control valves

as well as the correct flow within the individual

risers at all times. This is the reason why DIN

18380 requires control of differential pressure at

partial loads. The ASV automatically creates an

optimal hydronic balance within the installation,

whether under full or partial load. This balance is

never disrupted.

The ASV valves can also be used in cooling

applications (fan coil, chilled beam, etc) with

variable flow, to secure an automatic hydronic

balance (see general ASV datasheet for details).

Benefits

Installing an ASV combination ensures:

• Fewer complaints:

ASV makes the system more reliable, with less

disturbances such as noisy radiators, under

heating of rooms far away from the heat

source, or over-heating of rooms close to the

heat source. Fewer complaints means less

call-backs to installer to solve the complaints.

• Improved indoor comfort:

ASV provides stable pressure conditions

to radiator or floor heating control valves

resulting in more accurate room temperature

control.

• Lower energy bills:

Higher energy efficiency is contributed by

solving overheating problem and ensuring

more accurate temperature control. Proper

balance prevents overflows thus resulting

in low return water temperature, which

improves energy efficiency of condensing

boilers and district heating systems.

• Simplicity:

ASV divides the piping system in pressure

independent zones, typically individual

risers or apartments so complex and time

consuming calculation and commissioning

methods are not needed anymore. It also

allows a gradual connection of zones to

the main constructions without additional

balancing.

• Ease of use:

The new generation of ASV automatic

balancing valves is even simpler to use than

before. The improved setting scale can now

be set without using an allen key, saves time

for the installer during commissioning and

maintenance of the system while new flushing

function saves time during flushing of pipe

network.

© Danfoss | 2016.11

VD.A9.J2.02 | 1

Page 2

Data sheet Automatic balancing valves ASV

Applications ASV balancing valves are designed to guarantee

high quality of automatic balancing by:

• a pressure released cone,

• an adapted membrane for valve dimension

which provides constant quality performance

for all sizes,

• linear and accurate setting scale that makes

setting required ∆p easy.

• low required 10 kPa pressure drop on ASV-PV

valve contributes to smaller pump head.

The Danfoss ASV solution comprises an

automatic balancing valve ASV-PV and an

associated partner valve (Fig. 1 and 2). The ASVPV is a differential pressure controller, fitted into

the return pipe.

The partner valve is fitted into the supply pipe.

Both valves are connected to each other using a

mpulse tube.

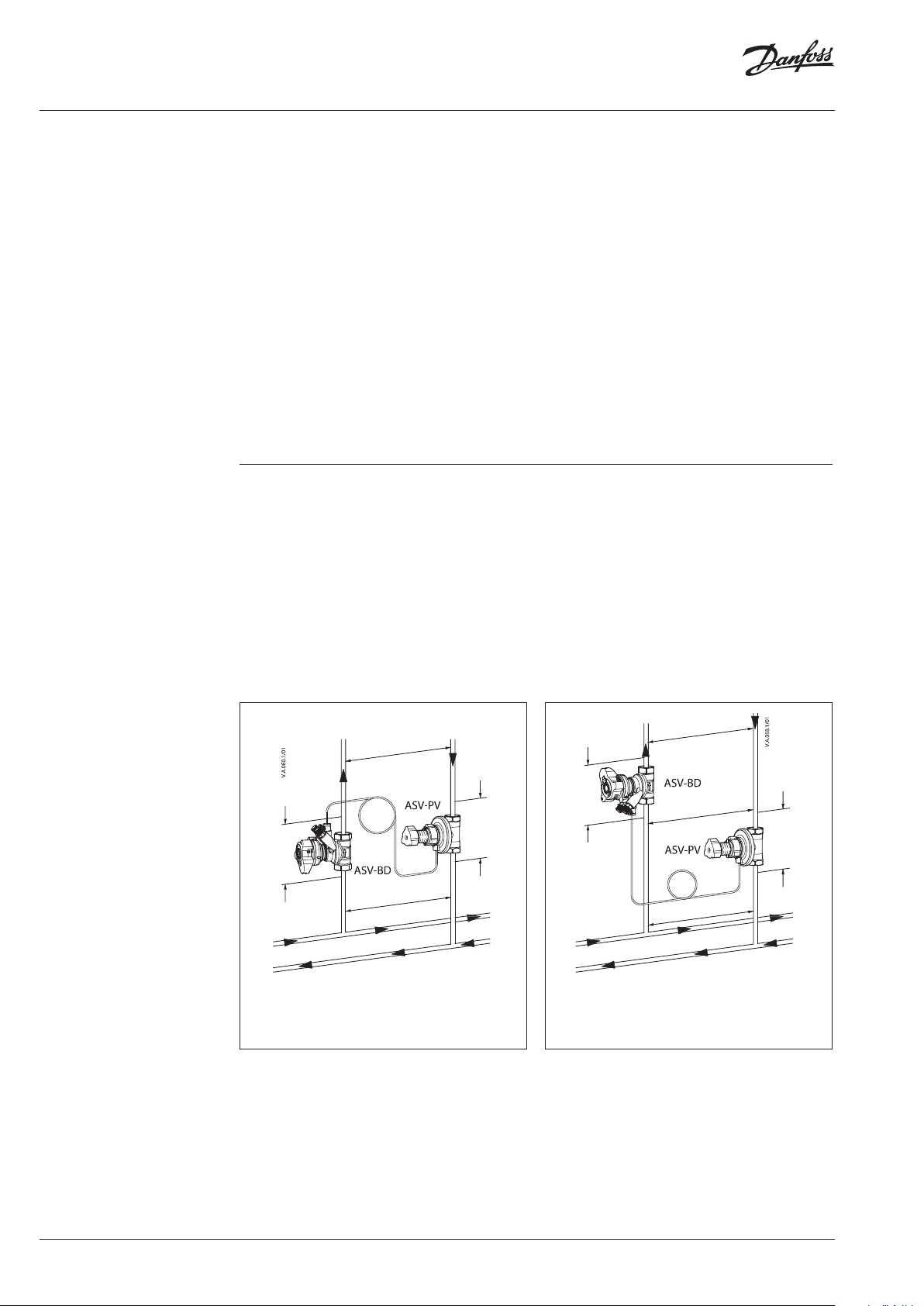

There are two basic configurations when using

ASV partner valves:

Partner valve outside the control loop (Fi g .1).

Recommended valve ASV-BD (default

configuration: blue test plug needs to be open,

red is in closed position) or ASV-M:

It results in best performance since whole

controlled pressure range is available to the riser.

Flow limitation is done on each terminal unit in

the riser (for example, RA-N with presetting on

radiator, etc).

The pressure controller has a factory setting

of 10 kPa or 30 kPa, perfect for typical radiator

based heating systems. Of course it can easily

be adjusted to another setting using the setting

scale. If the pressure differential tends to become

greater than this setting, then the ASV automatic

balancing valve immediately reacts and keeps

the pressure differential constant. By this the

pressure in the controlled riser or loop does not

increase due to any system load changes.

ASV balancing valves have integrated service

functions such as: *Flushing

*shutt-off

*draining

Shut-off function is separated from the setting

mechanism.

Partner valve inside the control loop (Fig.2).

Recommended valve ASV-BD (red test plug

needs to be open, blue is in closed position):

Offers flow limitation on the riser however part of

the controlled pressure range is used by pressure

drop on partner valve (∆pp). It is recommended

when flow limitation on each terminal is not

possible.

p

r

p

r

v

p

p

1)

Please note tha t blue test plug on ASV-BD ne eds to be open

(default co nfiguration)

Fig. 1 Setting of ASV-PV = ∆p

outside the control loop)

1)

p

a

(partner valve

riser

p

p

p

1)

Please note tha t the red test plug on ASV-BD ne eds to be

open and blu e test plug closed

Fig. 2 Setting of ASV-PV = p

p

p

1)

o

v

p

a

+ p

riser

p

ASV-BD can be used outside or inside the control loop by choice of which measuring nipple is open.

Change of configuration can be done under pressure - simply by closing/opening test plugs.

Configuration inside the control loop (default position) allows flow verification, while configuration

outside the control loop allows flow limitation.

2 | © Danfoss | 2016.11

VD.A9.J2.02

Page 3

Data sheet Automatic balancing valves ASV

Applications (continuous)

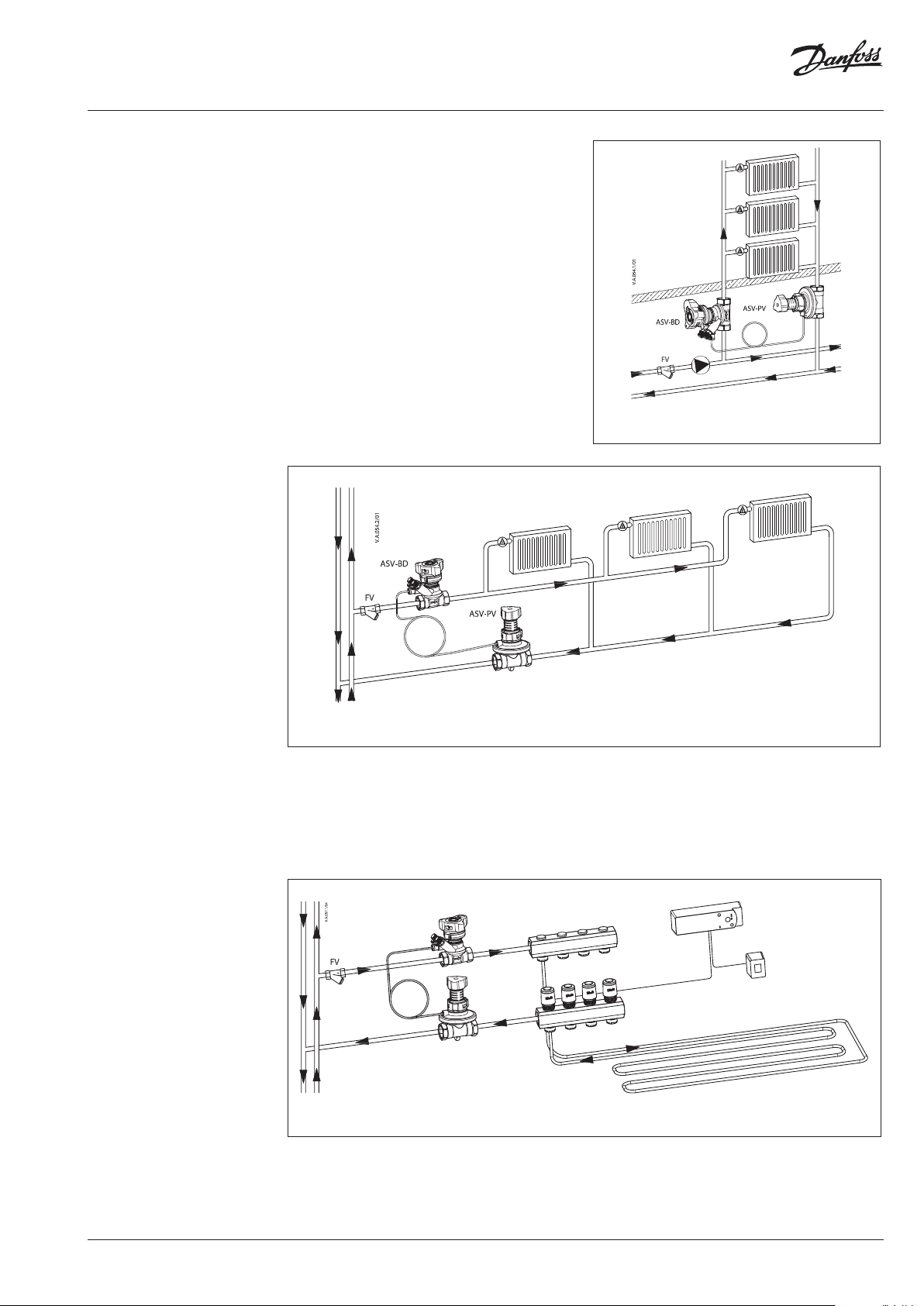

ASV valves are to be used in radiator heating

systems to control the differential pressure in

risers (Fig. 3) or horizontal loops - mostly used in

new installation (Fig. 4). To limit the flow for every

radiator, the thermostatic radiator valve with presetting function is used together with a constant

pressure provided by the ASV, thus providing

balanced heat distribution.

Fig. 3 ASV in vertical riser / t ypical radiator heating

application (general example)

Fig. 4 ASV in horizontal loop / t ypical radiator heating application (general example)

ASV valves are also a perfect solution in floor

heating systems (Fig. 5). To limit the flow, every

manifold with integrated presetting should be

used together with a constant pressure provided

by an ASV-PV valve.

ASV-BD

ASV-PV

Fig. 5 ASV in manifold for floor heating system

Alternatively the flow for the whole manifold

can be limited by using the setting function of

the ASV-BD. Due to its small dimensions the ASV

automatic balancing valves are easy to install in a

wall mounted box for floor heating manifolds.

VD.A9.J2.02

© Danfoss | 2016.11 | 3

Page 4

Data sheet Automatic balancing valves ASV

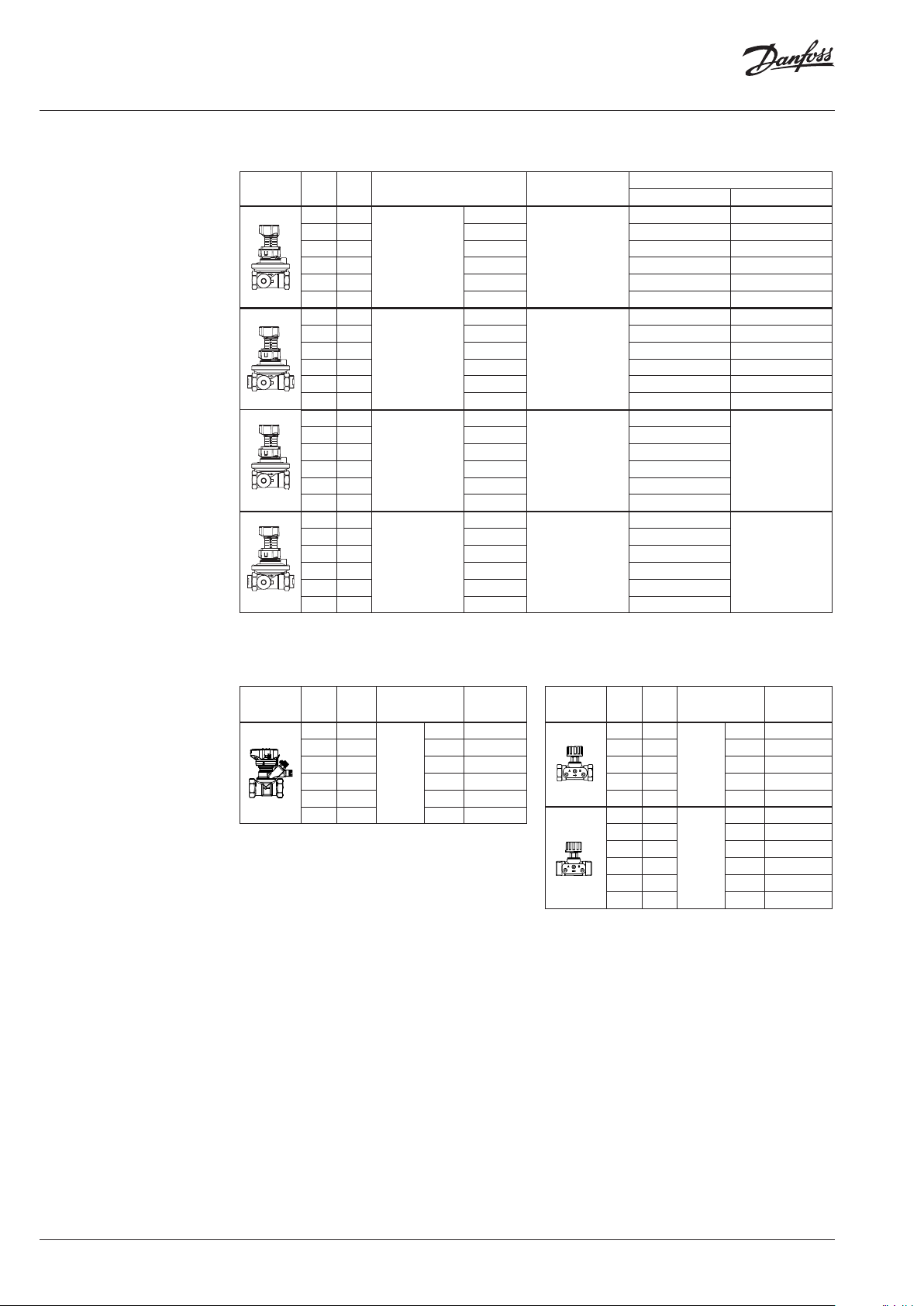

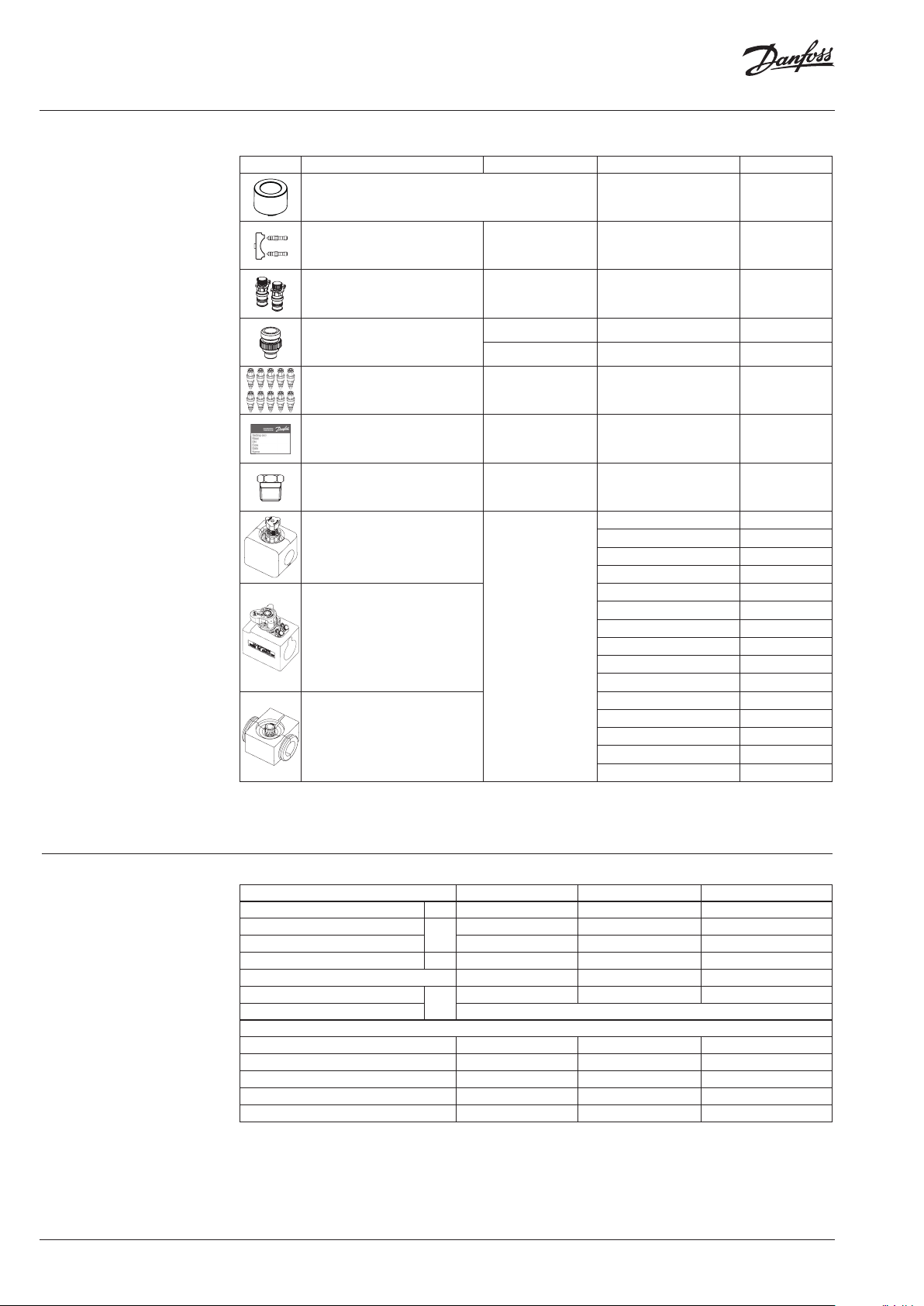

Ordering

ASV-PV balancing valve, included in the box:

1,5 m impulse tube (G ⁄ A)

k

Typ e DN

VS

(m3/h) (kPa)

15 1, 6

20 2,5 Rp ¾ 003Z5502 003Z5602

25 4,0 Rp 1 003Z5503 003Z5603

32 6,3 Rp 1¼ 003Z5504 003Z5604

40 10,0 Rp 1½ 003Z5505 003Z5605

50 16, 0 Rp 2 003Z5506 003Z56 06

15 1, 6

20 2,5 G 1 A 003Z5512 00 3Z5612

25 4,0 G 1¼ A 00 3Z5513 0 03Z5 613

32 6,3 G 1½ A 00 3Z5514 -

40 10,0 G 1¾ A 0 03Z5515 -

50 16, 0 G 2¼ A 003Z5516 -

15 1, 6

20 2,5 Rp ¾ 003Z5542

25 4,0 Rp 1 003Z5543

32 6,3 Rp 1¼ 003Z5544

40 10,0 Rp 1½ 003Z5545

50 16, 0 Rp 2 003Z5546

15 1, 6

20 2,5 G 1 A 003Z5552

25 4,0 G 1¼ A 003Z5553

32 6,3 G 1½ A 003Z5554

40 10,0 G 1¾ A 003Z5555

50 16, 0 G 2¼ A 003Z5556

Connection

Rp ½

Internal thread

IS O 7/1

G ¾ A

External thread

ISO 228/1

Rp ½

Internal thread

IS O 7/1

G ¾ A

External thread

ISO 228/1

∆p setting range Code No.

without insulation with EPP insulation

003Z 5501 003Z 5601

5-25

003 Z55 11 0 03 Z56 11

5-25

003Z5 541

20-60

003Z5551

20-60

-

-

ASV-BD shut-off valve, multifunctional partner

valve (shut-off, rotating measuring station) and

EPP insulation

k

Typ e DN

VS

(m3/h)

15 3,0

20 6,0 Rp ¾ 003Z4042

25 9,5 Rp 1 003Z4043

32 18 Rp 1¼ 003Z404 4

40 26 Rp 1½ 003Z4045

50 40 Rp 2 003Z4046

Connection Code No.

Rp ½ 003Z4 041

Internal

thread

IS O 7/1

ASV-M shut-off valve, without test plugs and

with EPS insulation

k

Typ e DN

VS

(m3/h)

15 1, 6

20 2,5 Rp ¾ 0 03L7692

25 4,0 Rp 1 0 03L7693

32 6,3 Rp 1¼ 0 03L7694

40 10 Rp 1½ 0 03L7695

15 1, 6

20 2,5 G 1 A 003L7697

25 4,0 G 1¼ A 0 03L7698

32 6,3 G 1½ A 003L7699

40 10 G 1¾ A 003L7700

50 16 G 2¼ A 003L7702

Connection Code No.

Rp ½ 003L7691

Internal

thread

IS O 7/1

G ¾ A 003L7696

External

thread

ISO 228/1

4 | © Danfoss | 2016.11

VD.A9.J2.02

Page 5

Data sheet Automatic balancing valves ASV

Ordering (continuous)

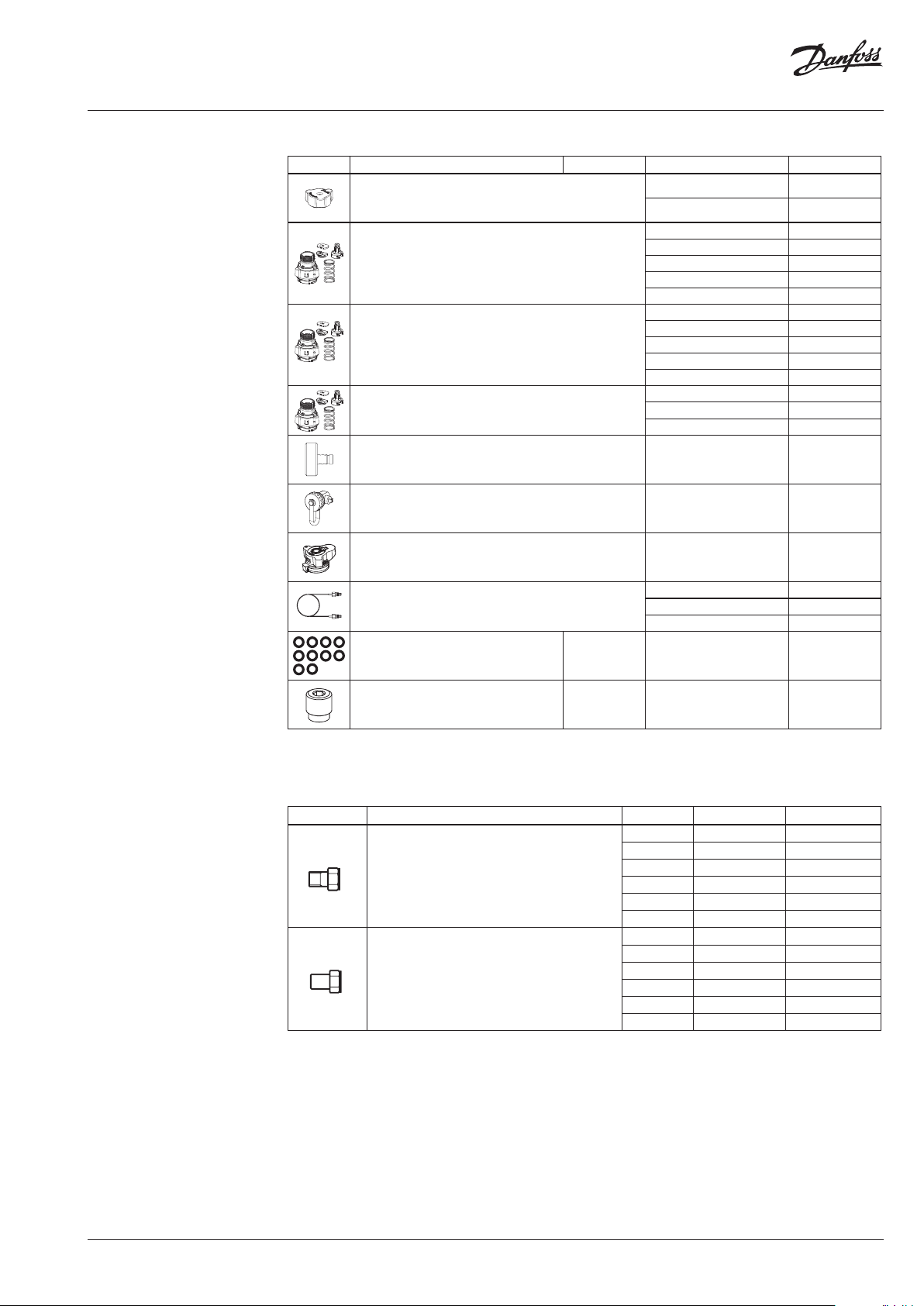

Spare parts

Typ e Description Comments Connection/Dimension Code No.

ASV-PV handle

ASV-PV Service kit 20- 60 kPa

ASV-PV Service kit 5-25 kPa

ASV-PV Service kit 20-80 kPa

Differential pressure measuring connector For ASV-PV drain connection 003L8143

ASV-PV drain connection DN 15-50 00 3L8141

ASV-BD handle

Impulse tube, with O-rings

2)

DN 15-25 003Z7855

DN 32-50 003Z7857

DN15 -20 003 Z7831

DN 25 003Z7832

DN 32 003Z7833

DN 40 003Z7834

DN 50 003Z7835

DN15 -20 0 03Z7841

DN 25 003Z7842

DN 32 003Z7843

DN 40 003Z7844

DN 50 003Z7845

DN 32 003Z7836

DN 40 003Z7837

DN 50 003Z7838

1,5 m 003L 8152

2,5 m 003Z0690

5 m 0 03L8153

003Z4652

O-ring for impulse tube Set of 10 pieces 2,90 × 1,7 8 003L8175

Plug for impulse tube connection ASV-BD/M Set of 10 pieces G ⁄ A 0 03L 8174

1)

With handle

2)

For com plete range of ASV-BD accessori es please refer to LENO™ MSV-BD datashe et.

Accessories - Fittings

Typ e Comments to pipe to valve Code No.

R / DN 15 003Z0232

R / DN 20 0 03Z0233

Tailpiece threaded (1 pcs.)

Tailpiece welding (1 pcs.)

R 1 DN 25 003Z0234

R 1 / DN 32 003Z0235

R 1/ DN 4 0 003Z0273

R 2 DN 50 (2 /”)

DN 15

DN 20

DN 25

DN 32

DN 40

DN 50 DN 50 (2 /”)

DN 15 003Z0226

DN 20 003Z0227

DN 25 003Z0228

DN 32 003Z0229

DN 40 003Z0271

00 3Z0274

003Z0272

VD.A9.J2.02

© Danfoss | 2016.11 | 5

Page 6

Data sheet Automatic balancing valves ASV

Accessories

Typ e Description Comments Connection/Dimension Code No.

ASV-PV flushing accessory 003Z7850

Two test plugs and one locking plate For ASV-M, rectus t ype 00 3L8145

3 mm test plugs, 2 pcs For ASV- BD

ASV-BD drain connection

Plastic impulse tube with connec tors

and adapters

Commissioning label

2)

½” hose connection 003Z4096

¾” hose connection 003Z4097

For making set of 10

pieces

Set of 10 pieces DN15 -50 003Z7860

1)

3)

Plug for connecting impulse tube G ⁄-R ¼ connection 00 3L8151

EPP insulation cap for ASV-PV

EPP insulation cap for ASV-BD

max. 120 °C

EPP insulation cap for ASV-M

1)

For com plete range of ASV-BD accessori es please refer to LENO™ MSV-BD datashe et.

2)

To be fitte d on insulation

3)

10m of impulse tube

003Z4662

003Z0689

DN 15-20 003Z7800

DN 25 0 03Z7802

DN 32 003Z7803

DN 40-50 003Z7804

DN 15 003Z4781

DN 20 0 03Z4782

DN 25 0 03Z4783

DN 32 003Z4784

DN 40 003Z4785

DN 50 0 03Z4786

DN 15 00 3L8170

DN 20 0 03L 8171

DN 25 0 03L8172

DN 32 00 3L817 3

DN 40 0 03L8139

Technical data

6 | © Danfoss | 2016.11

Typ e ASV-P V ASV-M ASV-B D

Nominal diameter DN 15- 50 15- 50 15-50

Max. pressure (PN)

Test pressure 25 25 30

bar

Differential pressure over the valve kPa 10-250 10-150

Shut Off leakage No visible leakage

Working temperature

Storage and transport temperature –40 … 70

°C

16 16 20

1)

2)

2)

D

10-2 50

2)

A

0 … 120 –20 … 120 –20 … 120

Material of parts in contact with water

Valve body Brass Brass DZR brass

Cone DZR brass Brass

Membrane / O-rings EPDM EPDM EPDM

Spring Patent wire - -

Ball - - Brass / chromium plated

1)

Pl ease note that the maximum adm issible differential p ressure across the valve 150 kPa should also not be excee ded at partial load.

2)

ISO 5208

VD.A9.J2.02

Page 7

Data sheet Automatic balancing valves ASV

Design

1. Spring guide

2. Shut-off handle

3. Spring

4. Differential pressure setting

spindle

5. Setting scale

6. O-ring

7. Locking ring

8. Impulse tube connection

9. Diaphragm element

10. Control diaphragm

11. Internal connection

12. Valve body

13. Pressure-relieved valve cone

14. Seat

ASV handling video

ASV-PV is a compact differential pressure

controller designed to guarantee

high quality of automatic balancing. Innovative

construction and ease of use are incorporated

into the valve with the following features:

• integrated membrane part into valve body ⑫,

• easy setting with locking function ⑦,

• flushing function,

• shutt-off function, separated from presetting

• membrane adapted to valve size.

Via an internal connection and together with the

reference spring ③, pressure in the return pipe

acts on the lower side of the control diaphragm

⑩ while via an impulse tube ⑧, pressure in the

flow pipe acts on the top of the diaphragm. In

this way the balancing valve maintains adjusted

differential pressure.

Partner valves ASV-BD/M are to be used together

with the automatic balancing valves ASV-PV to

control differential pressure in the risers.

The valves factory set to 10 kPa or 30 kPa.

They can be easily adjusted to another setting

using setting scale ⑤. Turning the setting ring

clockwise increases the setting; turning it counter

clockwise reduces the setting.

Fig. 6 ASV-PV

1. Handle with setting scale

2. Spindle head

3. Rotation lock

4. Te st plug

5. Valve top

6. Spindle

7. Impulse tube connection

8. Closing bush

9. Hose connection

10. Rotating measuring station

11. Throttle bush

12. Supporting screw

13. Ball seat

14. Ball

15. Valve body

1. Shut-off handle

2. Shut-off spindle

3. O-rings

4. Valve cone

5. Seat

6. Valve body

ASV-BD is a combined presetting and shut-off

valve with a range of unique features:

• high kv values for small pressure losses,

• partner valve position inside or outside the

control loop (see page 2 for details), can even

be changed after the valve is already installed

and under pressure,

• numeric presetting scale, visible from multiple

angles ①,

• easy locking of presetting,

• rotating measuring station ⑩ with built-in

test plugs for 3 mm needles,

• drain function via drain connection accessory

(Code No. 003Z4096 or 003Z4097) ⑦ ,

• removable handle for easy mounting,

• shut-off function separated from presetting,

• open-closed colour indicator.

ASV-BD can be used outside or inside the control

loop (see page 2 for details) dependent on which

test plug is open. Configuration is changeable

under pressure.

The shut-off function features a ball valve, which

only requires a 90 degree turn to shut the valve

completely.

ASV-M is designed to shut-off the pipe flow.

ASV-M has a connection for an impulse tube to

ASV-PV. It can be equipped with test plugs for

flow measuring (which are sold separately as

accessories).

ASV-BD valve is supplied with two test plugs for

3 mm needles. A twin bracket enables the user to

connect both needles simultaneously.

Fig. 7 ASV-BD DN 15-50

VD.A9.J2.02

Fig. 8 ASV-M

© Danfoss | 2016.11 | 7

Page 8

Data sheet Automatic balancing valves ASV

Sizing

Q

≤ Q ≤ Q (at 10 kPa)

min

Fig. 9

diagram A and B in Appendix.

Column diagram for sizing Q =required design flow ASV valves at ∆pv = 10 kPa. For different ∆pv values use

We recommend to size the diameter of ASV-PV

valves by using Fig 9. Maximum flow rates are

based on 10 kPa differential pressure over ASV-PV

valve which allows perfect control performance of

ASV-PV and saves energy, while minimal nominal

flow allow controllability close to zero.

After ASV-PV valves have been sized the same

dimension of partner valve ASV-BD / ASV-M valve

should be selected.

Example:

Given:

Pipe flow 200 l/h, pipes DN 15

Solution:

Horizontal line intersects the column for the

valve DN 15 which can therefore be selected

as required size (in case more columns

are intersected the smaller valve size is

recommended.)

For detailed sizing see examples on pages 14 and

15. For different ∆pV (differential pressure over

the valve) see diagrams in Appendix A.

Connection between valves size and pipe size

Kv values per particular dimension were

designed to cover flow range according to

VDI 2073 with water velocity of up 0,8 m/s, at

differential pressure of 10 kPa over the valve. As

long as the water velocity in the pipe is between

0,3 and 0,8 m/s dimension of the valve should be

equal to pipe dimension.

This rule is derived out of the fact that Kv values

per particular dimension were designed to cover

flow range according to VDI 2073 at differential

pressure of 10 kPa over the ASV-PV valve.

8 | © Danfoss | 2016.11

VD.A9.J2.02

Page 9

Data sheet Automatic balancing valves ASV

kPa 5bar 0,05

0,4

9,0

Kv

Q

p

2

2

p

1

Sizing-design examples

p

r

v

p

p

p

p

a

Fig . 10

1. Example

Given:

Radiator system with thermostatic radiator valves

with pre-setting function.

Desired flow for the riser (Q): ...........................900 l/h

Minimal available pressure

for that riser (∆pa) ..................................................60 kPa

Estimated pressure drop over the riser

at the desired flow (∆pr) .....................................10 kPa

Wanted:

• Valve type

• Valve size

Since radiator valves have pre-setting function

ASV-M is selected.

ASV-PV should control 10 kPa pressure over the

riser that means that 50 kPa out of 60 will be

disposed over two valves.

∆pv + ∆pp = ∆pa−∆pr = 60−10 = 50 kPa

We presume that dimension DN 25 is the right

dimension for this example (please mind that

both valves should be of the same dimension). As

ASV-M DN 25 is to be fully open pressure drop is

calculated by following equation:

∆pa ≥ ∆pp + ∆pr + ∆pv

Δpv Pressure drop across ASV-PV

Δpp Pressure drop across ASV-M valve

Δpr Necessary pressure for the riser

Δpa Available pressure for the riser

2. Example

Correcting the flow with the differential pressure

setting.

Given:

Measured flow for the riser Q1 ........................ 900 l/h

ASV-PV valve’s setting ∆pr ................................ 10 kPa

Wanted:

New valves’ setting to increase the flow for 10 %,

Q2 = 990 l/h.

Setting on the ASV-PV valve:

When needed setting of the control pressure can

be adjusted to particular value or 20-60 kPa.

With increasing/decreasing the setting it is

possible to adjust flow trough the riser, terminal

or similar. (100 % increase of control pressure will

increase the flow for approx. 41 %)

2

Q

2

pp

12

Q

10,0

990

900

2

kPa 21

If we increase the setting to 12 kPa flow will be

increased to 10 % to 990 l/h.

or by reading from diagram in

Appendix A, fig. C

as follows:

Draw horizontal line from 0,9 m3/h (~900 l/h)

trough the line that depicts dimension DN 25.

From the intersection draw vertical line to read

that pressure drop is 5 kPa.

Pressure drop over ASV-PV valve is therefore:

∆pv= (∆pa-∆pr)−∆pp = 50 kPa−5 kPa = 45 kPa

as can be read from diagram in Appendix A,

Fig. A.

VD.A9.J2.02

© Danfoss | 2016.11 | 9

Page 10

Data sheet Automatic balancing valves ASV

hm1,5

03,0

880,0

p

Q

k

3

v

v

Sizing-design examples

(continuous)

p

r

p

p

p

o

v

p

p

a

Fig . 11

3. Example

Limiting the flow with ASV-BD valve

Given:

Desired flow for the branch (Q): .....................880 l/h

ASV-PV and ASV-BD (DN 25)

Setting on the ASV-PV valve (∆po) ..................10 kPa

Estimated pressure drop over

the riser at desired flow (∆pr) ............................. 7 kPa

∆pa ≥ ∆pp + ∆pr + ∆p

Δpv Pressure drop across ASV-PV valve

Δpp Pressure drop across ASV-BD valve

Δpo Pressure drop in the riser including ASV-BD

Δpa Available pressure for the riser

Δpr Pressure drop in the riser excluding ASV-BD

v

4. Example

Floor heating application with ASV-PV on return

manifold

Given:

Pressure drop (largest loop): ............................. 16 kPa

Pressure drop manifold: ........................................2 kPa

Flow demand of manifold: ............................... 900 l/h

Connection pipe: .....................................................DN25

Required:

Setting of the ASV-BD valve to achieve desired

flow

Solution:

When needed setting of the ASV-BD can be

adjusted to perform flow limitation function.

ASV-BD namely is inside the control loop of the

pressure controller therefore adjusting ASV-BD

would result in adjusting flow limitation. Red test

plug on ASV-BD valve needs to be open (blue

one in closed position). (General rule is that 100

% increase of kv value will increase the flow for

100 %).

The result can be read as well from diagram in

Appendix A, Fig.B.

At desired flow pressure drop over the entire

branch is 7 kPa. Without using ASV-BD flow

trough the branch at fully open control valve

will be 19 % higher thus causing overflow (7 kPa

allow 880 l/h, while 10 kPa allow 1.050 l/h). With

adjusting the ASV-BD DN 25 pre-setting to 4,3 kv

value (5,1 m3/h) we will limit the flow to 880 l/h as

desired.

Wanted:

• Valve size (DN)

• Valve setting (∆po)

ASV-PV DN25 / 5-25 kPa is selected (same size as

connection pipe).

Since the valve setting is given by sum. of total

pressure loss:

manifoldloopo

kPa 18 = Pa2k + kPa 16 =Δp + Δp =Δp

Setting 18 kPa on ASV-PV setting scale is needed.

10 | © Danfoss | 2016.11

This value is obtained by following calculation:

∆pp = ∆po − ∆pr = 10 − 7 = 3 kPa.

Alternative, flow limitation can also be done by

bigger ∆p setting on ASV-PV valve.

VD.A9.J2.02

Page 11

Data sheet Automatic balancing valves ASV

Installation

ASV-PV should be installed in the return pipe

with flow in the direction of the arrow on the

valve body. Partner valves (ASV-M/BD) should

be installed in the flow pipe, with flow in the

direction of the arrow on the valve body. The

impulse tube should be installed between

partner valve and ASV-PV.

The impulse tube should be flushed through

from flow pipe direction before connection to

ASV-PV.

Small installation dimensions enable easy

installation of ASV valves even in very limited

space. A 90° angle between all service features

(shut-off, draining, setting, measuring) allows an

easy access under any installing condition.

Setting Δp setting

The setting of differential pressure can be easily

changed using the setting scale, which saves

time for the installer during maintenance of the

system.

① ② ③

Draining

The drain connection on ASV-PV or ASV-BD can

be used for water tapping and filling.

Use the following procedure to drain via ASV-BD

valve:

1. Close opened test plug.

2. Remove the impulse tube.

3. Dismount the hose connection.

4. Fit drain connection accessory

(Code No. 003Z4096 or 003Z4097).

5. Blue test plug opens the outlet while red test

plug opens the inlet. Make sure not to use

more than max. 3 turns. Drain connection and

test plugs can rotate to any position.

Use the following procedure to set the desired

differential presure:

1. Unblock the setting ①.

2. Make the setting by rotating of scale to desire

value ②.

3. Block the setting back to final position ③.

Factory presetting

Δp setting range (kPa) kPa

5 - 25 10

20 - 60 30

Pressure testing

Click

Max. test pressure ............................................... 25 bar

When pressure testing the system the impulse

tube should be connected and all partner valves

should be open.

Click

−

p

+

VD.A9.J2.02

© Danfoss | 2016.11 | 11

Page 12

Data sheet Automatic balancing valves ASV

Flushing

Measurement of flow and

differential pressure

ASV-PV valves provides ability to flush the system

from flow pipe. Use the following procedure for

flushing the system:

1. Ensure system is filled with water

2. Dismount shut off handle ① and fit flushing

accessory ② (Code No. 003Z7850) on the

ASV-PV valve spring guide.

3. Rotate by hand flushing accessory clockwise

➊

003Z7850

Click

DN32-50 DN15 -25

to end position before flushing the system ③.

4. Flushing of the system should be done with

flow in direction of the arrow on the valve

body.

5. After flushing the system rotate counter

clockwise to starting position.

Note:

Make sure system is f illed with water before mo unting flushing

accessory to ensu re differential pressure d oes not exceed 5 bar.

❸➋

Differential pressure across the ASV-BD valve can be taken by:

• Measuring: by using Danfoss PFM or any other measuring device. ASV-BD is equipped with two test

plugs so that the differential pressure across the valve can be measured.

• Using the pressure drop graph for ASV-BD (Appendix A, fig B), where the actual differential

pressure across a valve can be converted to actual flow.

Note: When measurin g sized flow, all radiator thermos tat sensors should be fully o pen (nominal flow).

Measurement of differential pressure (Δpr)

across riser.

Fit a measuring connector (Code No. 003L8143)

on the ASV-PV balancing valve drain connection

(DN 15-50). Measurements should be taken

between :

• the test plug at ASV-BD valve (blue test plug

needs to be open-factory position) and the

measuring connector on the ASV-PV.

• the test plug at ASV-M valve (port B) and the

measuring connector on the ASV-PV.

Flow verification (in case ASV-BD is used

outside the controlled loop)

Use the following procedure:

1. Blue test plug on ASV-BD needs to be open

(factory position).

2. ASV-BD setting is at maximum value.

3. Flow can be measured using Danfoss PFM or

other brand of measuring instrument.

4. If pressure drop across the valve is too low for

reliable flow measurement, ASV-BD needs

to be set to lower setting to achieve high

enough pressure drop across the valve.

12 | © Danfoss | 2016.11

VD.A9.J2.02

Page 13

Data sheet Automatic balancing valves ASV

Pump optimization ∆p measurement can also be used to optimize

the pump head – it is important to measure on

the last (index) riser of the system and at full

system load (all TRV’s fully open).

The pump head can be decreased until no more

than the minimal required pressure is available

on the last riser.

Troubleshooting

Check the following if the riser valve does not

function correctly:

1. Is the flow direction through the valve correct?

2. Is the impulse tube fitted correctly and are any

test plugs open?

3. Is the valve shut-off open?

Installation heights To ease installation of ASV-PV where space is

limited, installation heights can be reduced.

Valve is turned to max setting and blue knob can

be removed.

For advanced users: see installation guide for

ASV-PV upgrade kit for further information on

installation heights.

With observation of the ∆p while reducing the

pump speed, the goal is to optimize the pump

at the lowest possible setting while making sure

that enough pressure and flow is available.

H min.

DN H min.

15 80

20 80

25 100

32 150

40 150

50 15 0

Insulation

Fittings

ASV-PV (versions with insulation) and ASV-BD

valve are supplied together with EPP insulation cap.

Insulation cap offers click on feature for fast and

easy mounting on the valve. Insulation cap in EPP is

offered for use at higher temperatures, up to 120 °C.

ASV-M valve is supplied with EPS insulation

packaging, which can be used as insulation in

systems where the temperature does not exceed

80 °C under continuous operation.

For ordering see Accessories and spare parts

table.

Both materials (EPS and EPP) are approved in

accordance with fire class standard B2, DIN 4102.

For valves with external thread Danfoss offers

threaded or welded tailpieces as accessory.

Materials:

Nut ................................................................................brass

Tailpiece welding .....................................................steel

Tailpiece threaded ..................................................brass

For ordering see Accessories and spare parts

table.

ASV-M

ASV-BD / ASV-PV

VD.A9.J2.02

© Danfoss | 2016.11 | 13

Page 14

Data sheet Automatic balancing valves ASV

Dimensions

H

b b

S

c

a

L

1

Internal thread (ISO 7/1)

L

2

L

3

L

4

External thread (ISO 228/1)

ASV-PV

L1L2L3L4H 1)H

DN

mm I SO 7/1 ISO 228/1

15 65 85 14 0 159 111 96 116 27 Rp ½ G ¾ A

20 75 100 161 184 111 96 116 32 Rp ¾ G 1 A

25 85 110 180 194 13 6 113 14 3 41 Rp 1 G 1¼ A

32 95 121 206 184 191 18 3 213 50 Rp 1¼ G 1½ A

40 10 0 136 242 220 200 192 222 55 Rp 1½ G 1¾ A

50 130 166 280 250 203 195 225 67 Rp 2 G 2¼ A

1)

at 10 kPa or 30 kPa factory se tting

2)

at 25 kPa or 60 kPa settin g

3)

at 5 kPa or 20 kPa settin g

min

2)H

3)S a b c

max

ASV-BD

L H S a

mm ISO 228/1

65 92 27 G ½

15

75 95 32 G ¾

85 98 41 G 1

95 121 50 G 1¼

32

100 125 55 G 1½

130 12 9 67 G 2

G⁄

DN

H

20

25

S

a

a

L

40

50

G ¾ A

14 | © Danfoss | 2016.11

ASV-M

DN

15

20

25

32

40

50

D

1

1

a

H

2

H

L

a

S

S

L

1

L

1

L

H

2

3

H

1

2

b

D

1

b

L

1

L

2

L

3

S a b

mm IS O 7/1 ISO 228/1

65 120 139 48 15 28 27 Rp ½ G ¾ A

75 136 159 60 18 35 32 Rp ¾ G 1 A

85 155 169 75 23 45 41 Rp 1 G 1¼ A

95 172 179 95 29 55 50 Rp 1¼ G 1½ A

100 206 18 4 100 31 55 55 Rp 1½ G 1¾ A

130 246 214 106 38 55 67 - G 2¼ A

VD.A9.J2.02

Page 15

Data sheet Automatic balancing valves ASV

Dimensions - insulation

A

C

A

C

ASV-P V

A B C H

H

B

H

B

DN

15

95 120 110 36

20

25 110 130 130 42

32 135 145 14 0 50

40

155 165 17 0 59

50

ASV-B D

A B C H

DN

15 79 85 12 2 31

20 84 85 12 2 33

25 99 85 122 45

32 132 85 18 5 55

40 138 130 185 57

50 138 126 18 5 53

mm

mm

ASV-M

A B C

H

A

B

C

DN

15 61 110 111 30

20 76 12 0 136 38

25 100 135 155 50

32 118 148 160 60

40 118 148 180 60

mm

H

VD.A9.J2.02

© Danfoss | 2016.11 | 15

Page 16

Data sheet Automatic balancing valves ASV

Appendix A-Sizing diagram

Ex. 1

Fig. A - Sizing diagram ASV-PV DN 15-50

16 | © Danfoss | 2016.11

VD.A9.J2.02

Page 17

Data sheet Automatic balancing valves ASV

Appendix A-Sizing diagram

(continuous)

Ex. 3

Fig.B - Sizing diagram ASV-BD DN 15-50

VD.A9.J2.02

© Danfoss | 2016.11 | 17

Page 18

Data sheet Automatic balancing valves ASV

Appendix A-Sizing diagram

(continuous)

Fig.C - Pressure drop over ASV-M valves, DN 15-50

18 | © Danfoss | 2016.11

VD.A9.J2.02

Page 19

Data sheet Automatic balancing valves ASV

ASV-PV tender text

Tender Text ASV-PV DN 15-50 (4th gen.)

Branch should be balanced with a differential pressure controller for dynamic hydronic balance, with

following characteristics:

- Valve should keep stable differential pressure across the branch by membrane driven controller

- Valve should have variable Differential pressure setting.

- Minimum needed differential pressure over the valve should not be higher than 10 kPa,

independently from Dp setting

- Valve should have metal to metal (valve cone and seat) sealing to ensure optimal performance of

differential pressure control at low flows

- Differential pressure setting should be linear via visual scale and without tool, locking function

should be integrated to prevent unauthorized change of setting

- The setting range should be adaptable via spring replacement. Spring should be exchangeable

under pressure

- Setting range on spring should not be more than 40 kPa to achieve best accuracy

- Valve should provide differential pressure setting range fit to application to ensure optimal system

performance (such as 5-25 kPa setting range for radiator based systems)

- Valve capacity per valve size should cover flow range according to VDI 2073 Standards (with water

velocity of up 0.8 m/s)

- Valve should have shut-off function separated from the setting mechanism. Shut-off service

function should be possible to do by hand / without tool

- Drain function should be integrated in valve

- Valves should have integrated flushing service function. Flushing can be done with flushing

accessory

- Valve should be delivered with impulse tube. Inner diameter of impulse tube should not be bigger

than 1.2 mm to ensure optimal performance within the system

- Valve should be delivered with thermal insulation caps, up to 120°C

- Valve should be delivered in reliable packaging for safe transport and handling

Product characteristics:

a. Pressure class: PN 16

b. Temperature range: 0 … +120 °C

c. Connection size: DN 15-50

d. Connection type: Internal thread ISO 7/1 (DN 15-50), External thread ISO 228/1 (DN 15-50)

e. ∆p setting range: 5-25 kPa, 20-60 kPa and 20-80 kPa

f. Max differential pressure across valve: 2.5 bar

g. Installation: differential pressure controller should mounted on return pipe with connection via

impulse tube to supply pipe.

VD.A9.J2.02

© Danfoss | 2016.11 | 19

Page 20

Danf

already on order pro

All trademarks in this material are property of the respec

Data sheet Automatic balancing valves ASV

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

20 | © Danfoss | DHS-SRMT/SI | 2016.11

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

VD.A9.J2.02

Loading...

Loading...