Data sheet

Automatic balancing valve

ASV-I (DN 15-50)

Description

Ordering

NOTE: for whole range o f ASV partner

valves, spare pa rts and

accessories ple ase refer to ASV

datasheet.

ASV-I is a partner valve to be used together with

the automatic balancing valves ASV-PV/P to

control differential pressure in the risers where

the radiator valves have no presetting facilities.

It is a combined adjustment and shut-off valve

designed for installation in the flow pipe. It

incorporates flow limitation so that it can be set

for required maximum flow in the riser.

ASV-I is supplied with rectus measuring nipples

so that flow in the pipe can be measured.

The valve (DN 15 -40) is packaged in styropore

(EPS) which can be used for insulation at

temperatures up to 80 °C. An insulation cap is

available as an accessory for insulation at higher

temperatures (up to 120 °C).

ASV-I adjustment valve, inclusive two measuring nipples

k

Internal thread

Typ e DN

VS

3

(m

/h)

15 1,6 Rp ½ 003L7641 G ¾ A 003L7646

20 2,5 R

25 4,0 R

32 6,3 R

40 10 R

50 16 G 2¼ A 003L7652

(I SO 7/1) (ISO 228/1)

¾ 003L 7642 G 1 A 003L7647

p

1 003L7643 G 1¼ A 003L764 8

p

1¼ 003L764 4 G 1½ A 0 03L7649

p

1½ 003 L7645 G 1¾ A 003L76 50

p

Code No. Ty pe

External thread

Code No.

Accessories and spare parts

Technical data

© Danfoss | 2017.07

Typ e Description Comments/connection Code No.

DN 15 003L 8155

Shut-off knob for ASV-I (black)

Two test plugs and one locking plate

Plug for impulse tube connection ASV-I/M Set of 10 pieces / G ⁄ A 00 3L8174

Nominal diameter DN 15- 50

Max. pressure

Test pressure 25

Differential pressure over the valve kPa 10-150

Temperature °C –20 … 120

Material of par ts in contact with water

Valve body Brass

Membrane / O-rings EPDM

Spring Stainless steel

1)

Please no te that the maximum admissibl e differential pressure a cross the valve 150 kPa should also not be exceeded at p artial load.

bar

DN 20 003L 8156

DN 25 003L 8157

DN 32 / DN 40 / D N 50 003L 8158

For ASV-I and ASV-M,

rectus t ype (DN 15-40)

16 (PN 16)

1)

00 3L8145

VD.A9.K1.02 | 1

Data sheet Automatic balancing valves ASV-I

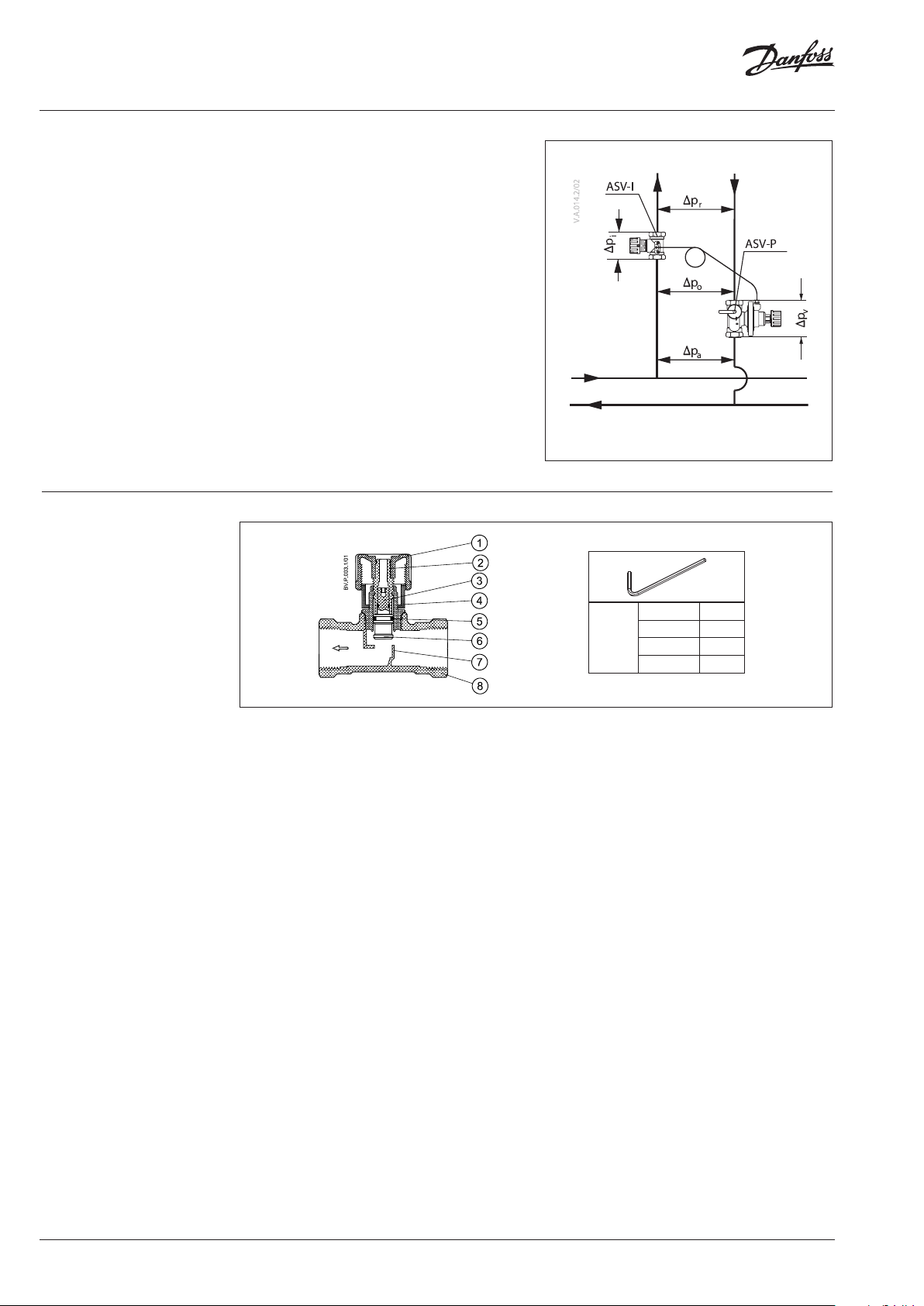

Application

Design

1. Shut-off knob

2. Shut-off spindle

3. Setting spindle

4. Scale disc

5. O-rings

6. Valve cone

7. Seat

8. Valve body

ASV-I has to be used as partner valve inside

control loop (Fig. 1). ASV-I and ASV-P(V) is

connected via an impulse tube, and there by

giving a constant differential pressure across the

riser and ASV-I.

This configuration offers flow limitation on the

riser however part of the controlled pressure

range is used by pressure drop on partner valve

(∆p

). It is recommended when flow limitation on

i

each terminal units is not possible.

This way it is possible to control the maximum

flow for each riser, and ensuring distribution

between them.

- partner valve inside control loop (Fig. 1).

Offers flow limitation on the riser however

part of the controlled pressure range is used

by pressure drop on partner valve (p

recommended when flow limitation on each

). It is

i

terminal units is not possible.

Fig. 1 Setting of ASV-I = ∆ p

15 2.5

DN

20 3

25 4

32/4 0/50 5

riser

+ ∆p

i

ASV-I incorporates a double cone able to give

maximum stroke limitation, thus achieving f low

limitation. It also incorporates shut off function.

ASV-I is equipped with the nipples for the f low

measurement and a connection for the ASV-I/

ASV-PV impulse tube.

Use the following procedure to limit the f low:

turn the valve knob fully counter clockwise to

open the valve. The mark on the knob will now

be opposite »0« on the scale. Turn the valve

knob clockwise to the required setting (e.g. for

setting 2.2 the knob must be rotated two full

turns and then forward to »2« on the scale. Hold

the knob to keep the setting (e.g. 2.2) and using a

hexagon socket key turn the spindle fully counter

clockwise (until a stop can be felt). Turn the valve

knob fully counter clockwise so that the mark on

the knob is opposite »0« on the scale.

The valve is now open as many turns from

the closed position (2.2) as indicated by the

conversion from required f low. To annul the

setting, turn the hexagon socket key fully

clockwise (until a stop can be felt).

Remember, at the same time the knob must be

held on its »0« setting.

To read presetting valve has to be closed.

2 | © Danfoss | 2017.07

VD.A9.K1.02

Data sheet Automatic balancing valves ASV-I

Sizing

Dimensions

D

1

DN

1

a

H

2

H

L

1

a

S

S

L

1

L

L

H

2

3

H

1

2

a

D

1

mm

a

L

1

L

2

L

3

S

a b

IS O 7/1 ISO 228/1

15 65 120 139 48 15 28 27 Rp ½ G ¾ A

20 75 136 159 60 18 35 32 Rp ¾ G 1 A

25 85 155 169 75 23 45 41 Rp 1 G 1¼ A

32 95 17 2 179 95 29 55 50 R p 1¼ G 1½ A

40 100 206 184 100 31 55 55 Rp 1½ G 1¾ A

50 130 246 214 10 6 38 55 67 - G 2¼ A

Insulation

H

A

DN

15 61 110 111 30

1)

A B C H

mm

20 76 120 136 38

25 100 135 155 50

B

C

32 118 14 8 160 60

40 11 8 14 8 180 60

1)

Insulation avail able for sizes DN 15-40

VD.A9.K1.02

© Danfoss | 2017.07 | 3

Danf

already on order pro

All trademarks in this material are property of the respec

Data sheet Automatic balancing valves ASV-I

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

4 | © Danfoss | DHS-SRMT/SI | 2017.07

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

VD.A9.K1.02

Loading...

Loading...