Operation guide

APP pumps

APP 53 / APP 65 / APP 78 / APP 86 / APP 92

Installation, Operation and

Maintenance Manual

hpp.danfoss.com

Operation guide | Installation, Operation and Maintenance APP 53-92 pumps

Table of Contents Contents

Table of Contents ..................................................................................2

Validity .........................................................................................4

1. Introduction ............................................................................5

1.1 General.................................................................................5

1.2 Symbols ................................................................................5

1.3 Manufacturer and customer service address .............................................6

1.4 Country specific information ............................................................6

1.4.1 United Kingdom ........................................................................6

2. Safety ..................................................................................6

2.1 General information.....................................................................6

2.2 Preferred system design.................................................................6

2.3 Commissioning and servicing the unit ...................................................7

2.4 Adhere to the following important points ...............................................7

2.5 In case of doubt .........................................................................7

3. Technical data ..........................................................................7

3.1 Approved applications and operational limits for the pumps .............................7

3.2 Application range .......................................................................7

3.3 Electric motor data......................................................................7

3.4 VFD and Direct on line ..................................................................7

3.5 Noise and vibration .....................................................................7

3.6 Dimension drawings ....................................................................7

3.7 Space requirement......................................................................8

3.8 Filtration................................................................................8

3.9 Properties of water ......................................................................8

3.10 Air bubbles .............................................................................8

3.11 Chemicals...............................................................................8

4. Arrival inspection, transportation, handling, lifting and storage ..........................8

4.1 Arrival inspection .......................................................................8

4.2 Warning ................................................................................8

4.3 General safety information ..............................................................8

4.4 Transport and handling .................................................................8

4.5 Return to supplier .......................................................................9

4.6 Storage .................................................................................9

5. Installation and commissioning.........................................................10

5.1 Important dimensions .................................................................10

5.2 Cleanliness.............................................................................10

5.3 Fluid temperature......................................................................10

5.4 Electrical data..........................................................................10

5.5 Local regulations.......................................................................10

5.6 Pre mounting checklist, based on Danfoss preferred system design .....................11

5.7 Lifting and positioning.................................................................11

5.8 Mount the different equipment ........................................................11

5.9 Electrics ...............................................................................11

5.10 Instrumentation .......................................................................11

5.11 Connections ...........................................................................12

5.12 Ensure free flow .......................................................................12

5.13 Verify setting of safety/relief valves .....................................................12

5.14 Flush the pump ........................................................................12

5.15 Bleed and remove air from the pump...................................................12

5.16 Verify direction of rotation .............................................................12

5.17 Commissioning ........................................................................12

5.18 Check the filter condition...............................................................12

5.19 Instruct operator and maintenance personnel ..........................................12

2 | © Danfoss | DCS (im) | 2021.12 180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701

Operation guide | Installation, Operation and Maintenance APP 53-92 pumps

6. Operation of pump unit ...............................................................13

6.1 General safety information.............................................................13

6.2 What to listen and look for .............................................................13

7. Maintenance and service of the pump unit .............................................13

7.1 General safety information .............................................................13

7.2 Service and inspection interval for the pump ...........................................13

7.3 Shut down of the system ...............................................................13

7.4 Disassembling and assembling the pump unit ..........................................14

7.5 Assembling the pump unit .............................................................14

7.6 Procedure for mounting the pump onto the electric motor..............................14

7.7 Getting the pump unit back into operation .............................................14

7.8 Storage of the pump ...................................................................14

8. Troubleshooting and scrapping criteria .................................................15

8.1 General safety information .............................................................15

8.2 Operational conditions which can cause pump failures..................................15

8.3 Mechanical failure......................................................................15

8.4 Electrical failure........................................................................15

8.5 Responsibility..........................................................................15

8.6 Scrapping criteria ......................................................................15

Appendices .......................................................................................17

1. Data sheet for APP pumps 53-92 AI167386503010en-001301) ...................

2. Instruction for APP pumps 53-92 (180R9368) ............................................43

3. Electric motors (180R9230) ..............................................................55

4. Bowex coupling manual .................................................................61

5. Recommended service intervals (AX281930801330en-000401) ..........................85

6. Parts list (AX191786502906en-001101) ...................................................89

7. Trouble shooting (521B1447) ...........................................................101

8. Right and wrong (180R9042) ..........................................................113

........19

© Danfoss | DCS (im) | 2021.12

180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701 | 3

Operation guide | Installation, Operation and Maintenance APP 53-92 pumps

Validity

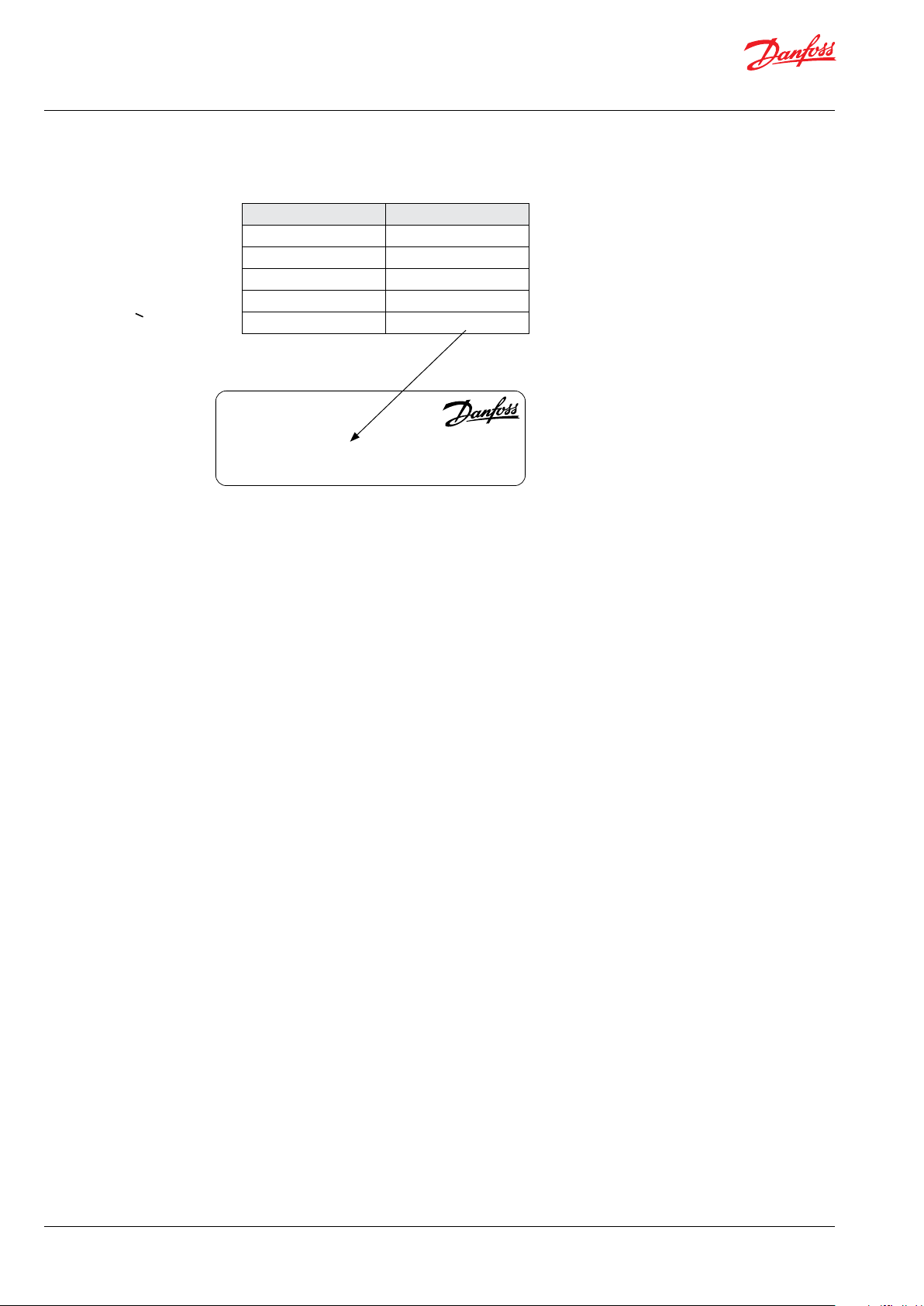

This manual is valid for APP pumps with the

following type an serial number or higher:

Typ e Serial no.

APP 53 XXXXXX08-XXX

APP 65 XXXXXX08-XXX

APP 78 XXXXXX08-XXX

APP 86 XXXXXX08-XXX

APP 92 XXXXXX08-XXX

PUMP

Type APP 78

Code no. 180BXXXX

Serial no. XXXXXX08-XXX

MADE IN DENMARK

Danfoss A/S, 6430 Nordborg, Denmark

The serial number is referring to the Serial no. on

the product label. The digits shown (08) indicate

the version number of the pump.

4 | © Danfoss | DCS (im) | 2021.12 180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701

Operation guide | Installation, Operation and Maintenance APP 53-92 pumps

© Danfoss | DCS (im) | 2021.12

1. Introduction

1.1 General

The APP pumps and pump units are manufactured by Danfoss A/S, and are sold and marketed

by a net of authorized distributors world wide.

• If any changes are made without written

approval the warranty will automatically

become void.

This manual contains the necessary instructions

for the installation, operation and service of the

pumps used in a Sea Water Reverse Osmosis

(SWRO) system or Brackish Water Reverse

Osmosis (BWRO) system.

In case the pump delivered is ATEX certified, the

additional ATEX instruction must also be read.

The APP pumps must not be used for other

purposes than those recommended and

specified without first consulting your local

pump distributor.

Use of the pump in other applications that are

not suitable for the pump unit can cause

damages to the pump unit, with risk of personal

injury.

All personnel being responsible for operation

and maintenance of the pump unit must read

and fully understand these instructions,

especially the section “Safety”, before:

It is important that these instructions are

always available to the personnel concerned.

1.2 Symbols

Indicates something to be noted by the

reader

Indicates a situation which will or could

result in damage to the pump and its

function

Indicates a situation which will or could

result in personal injury and/or damage

to the pump

Electrical hazard - Indicates a highvoltage warning

Safety glasses required

• Transportation of the pump unit

• Lifting the unit

• Installing the pump unit

• Connecting the pump unit to the water

system

• Connecting the electric motor and instrumentation

• Commissioning the unit

• Servicing the pump unit, mechanical and

electrical parts

• Decommissioning the pump unit

The pump must always be installed and used in

accordance with existing national/local

sanitary, safety regulations and laws.

It is the responsibility of the safety officer or

the chief operator to assure compliance with all

local regulations that are not taken into

account in this manual.

Changing the pumps’ or pump units’ operational limits and hardware:

• Changes to the delivered pump or motor

pump unit may only be done with a written

approval from Danfoss High Pressure Pumps.

• Operation outside the Danfoss specifications

requires a written approval from Danfoss

High Pressure Pumps.

!

Hearing protection required

Safety shoes required

Safety helmet required

Protective

garments

must be wor n

Protective garments

must be worn

Danger HOT.

Do not touch

180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701 | 5

Operation guide | Installation, Operation and Maintenance APP 53-92 pumps

2. Safety

1.3 Manufacturer and customer service

address

Danfoss A/S

Danfoss High Pressure Pumps

RO Solutions

Nordborgvej 81,

DK-6430 Nordborg

Denmark

Telephone: +45 7488 4024

Fax: +45 7445 3831

Email: highpressurepumpss@danfoss.com

Homepage: hpp.danfoss.com

2.1 General information

Dangers that can arise from not following the

instructions:

When the pump or pump unit is managed by

untrained personnel, there is a danger of:

• Death or fatal injuries

• Costly damages and claims

Your local Danfoss pump distributor can be

found on our homepage.

Data sheets and instructions on all accessories

are available on hpp.danfoss.com

1.4 Country specific information

1.4.1 United Kingdom

UK importer:

Danfoss Ltd.

22 Wycombe End

HP9 1NB Beaconsfield

United Kingdom

When using an electric motor, the motor must

always be supplied with adequate cooling

ventilation.

When using an electric motor together with a

VFD, the motor must be designed for operation

with a VFD.

VFD operation may increase the temperature

inside the electric motor if the motor is not

designed for VFD operation. This can damage

the motor and cause unintended breakdown.

All electrical installation work must only be

carried out by authorized personnel in

accordance with EN60204-1 and/or local

regulations.

It is recommended to install a lockable circuit

breaker to avoid inadvertent starting and/or

electrical hazard. The lockable circuit breaker

must be used during installation, operation and

maintenance.

It is recommended to place a local safety switch

nearby the pump, enabling service personnel to

cut power for the electric motor.

Protect the motor and other electrical equipment from overloads with suitable equipment.

In case the pump delivered is ATEX certified, the

additional ATEX instruction must also be read.

Protective

garments

!

must be wor n

Always wear suitable safety clothing when

handling the pump.

When working near the pump system, safety

shoes, safety glasses, hearing protection and

safety helmet must always be worn.

Danger

Installation and maintenance must always

take place during complete shutdown in an

unpressurised condition.

The drive unit must be secured against

switching-on (with signs, switching off electricity

power supply) in order to avoid serious injuries

due to rotating parts. Do not reach inside the

working area during the operation of the coupling.

For protection against accidental contact

appropriate security must be installed.

Before start-up, the settings for all protective

devices, such as sensors/switches and safety

valves must be verified and free flow from safety

valves must be ensured.

All pipe and hose connections must be stressfree mounted, securely fastened to the pump

and well supported. Improper installation will or

can result in personal injury and/or damage to

the pump.

Use of this manual does not relieve operation

and maintenance personnel of the responsibility of applying good judgment when operating

and maintaining the pump and its components.

inadvertent

Under certain operational conditions the surface

of the pump can be above 60°C / 140°F. Under

these conditions the pump must be labelled with

a “Danger Hot” sign.

6 | © Danfoss | DCS (im) | 2021.12 180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701

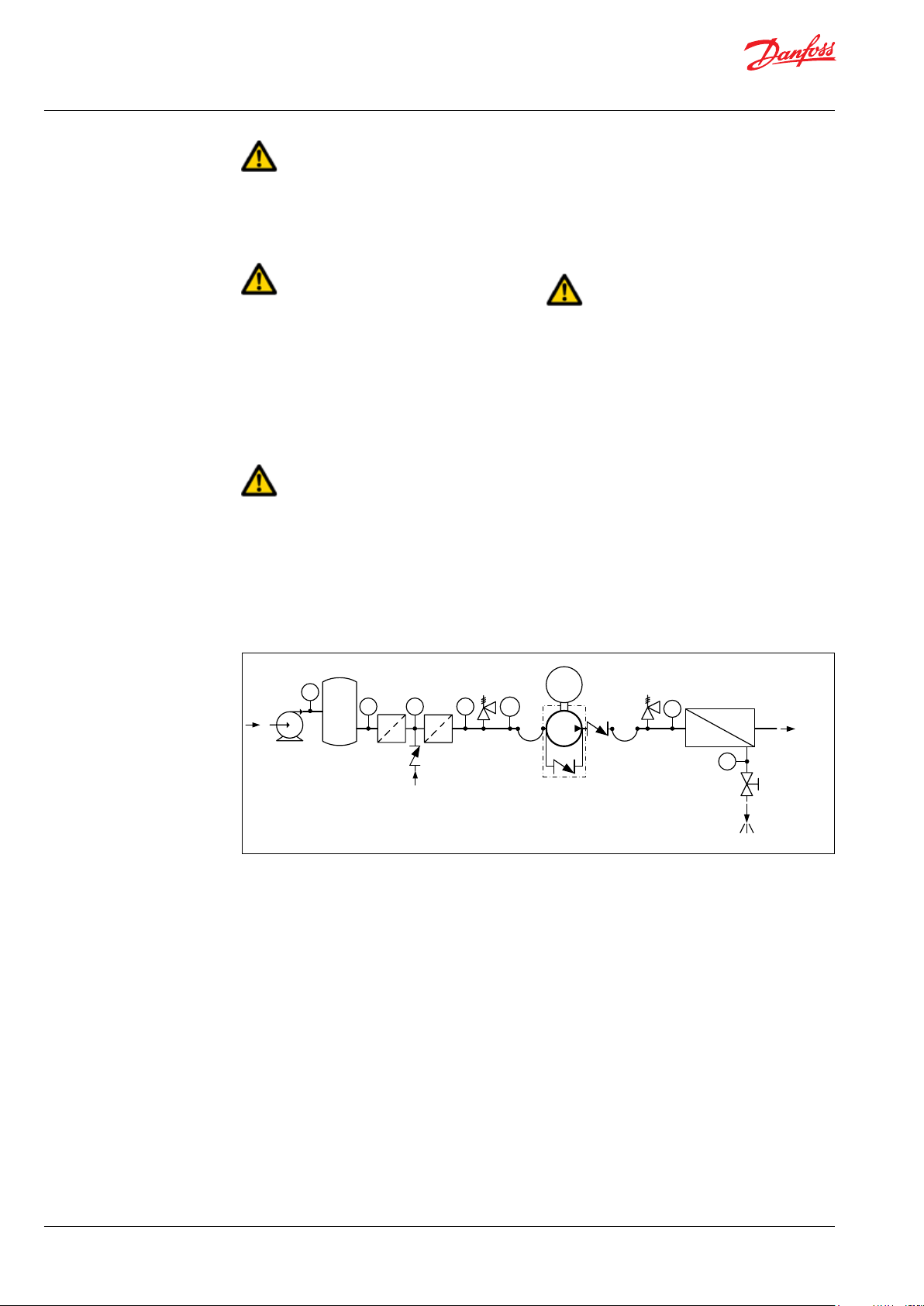

2.2 Preferred system design

Danfoss recommends to build systems with a

high degree of safety. Danfoss preferred system

design and P&ID are found in appendix 1, Data

sheet, and appendix 2, Instruction.

Operation guide | Installation, Operation and Maintenance APP 53-92 pumps

© Danfoss | DCS (im) | 2021.12

It is always the system builder´s responsibility

that the system design does not cause any kind

of hazard and is adapted to local regulations and

standards.

Proper installation, proper start up and shutdown devices as well as high-pressure protection

equipment is essential.

2.3 Commissioning and servicing the unit

It is recommended that commissioning and

servicing are carried out by a minimum of two

people, where one is acting as a supervisor.

• Do not try to lift the pump unit manually;

most of the pumps weigh more than

20 kilos, see specific weight for the pump

in the appendix 1, Data sheet.

• Always bleed the pump prior to initial

start-up.

• Do not mount the pump without the bell

housing and a flexible coupling.

• Do not try to start the unit before the

system components are mounted, bleeded

and adjusted.

• Flush the system throughly before

connecting the pump or pump unit.

• Check rotation direction of the motor

before mounting the pump.

3. Technical data

2.4 Adhere to the following important

points

• Before using the pump/pump unit it is very

important to read and understand this user

manual.

3.1 Approved applications and operational

limits for the pumps

The pump and the pump units are designed for

the use in a Sea Water Reverse Osmosis (SWRO)

or Brackish Water Reverse Osmosis (BWRO)

systems.

The APP pumps must not be used for other

purposes than those recommended and

specified without first consulting your local

pump distributor.

Use of the pump in other applications not

suitable for the pump unit can cause damages

to the pump unit, with risk of personal injury.

2.5 In case of doubt

Please contact Danfoss A/S in case of doubt.

Contact information is listed in section 1.3,

Manufacturer and customer service address.

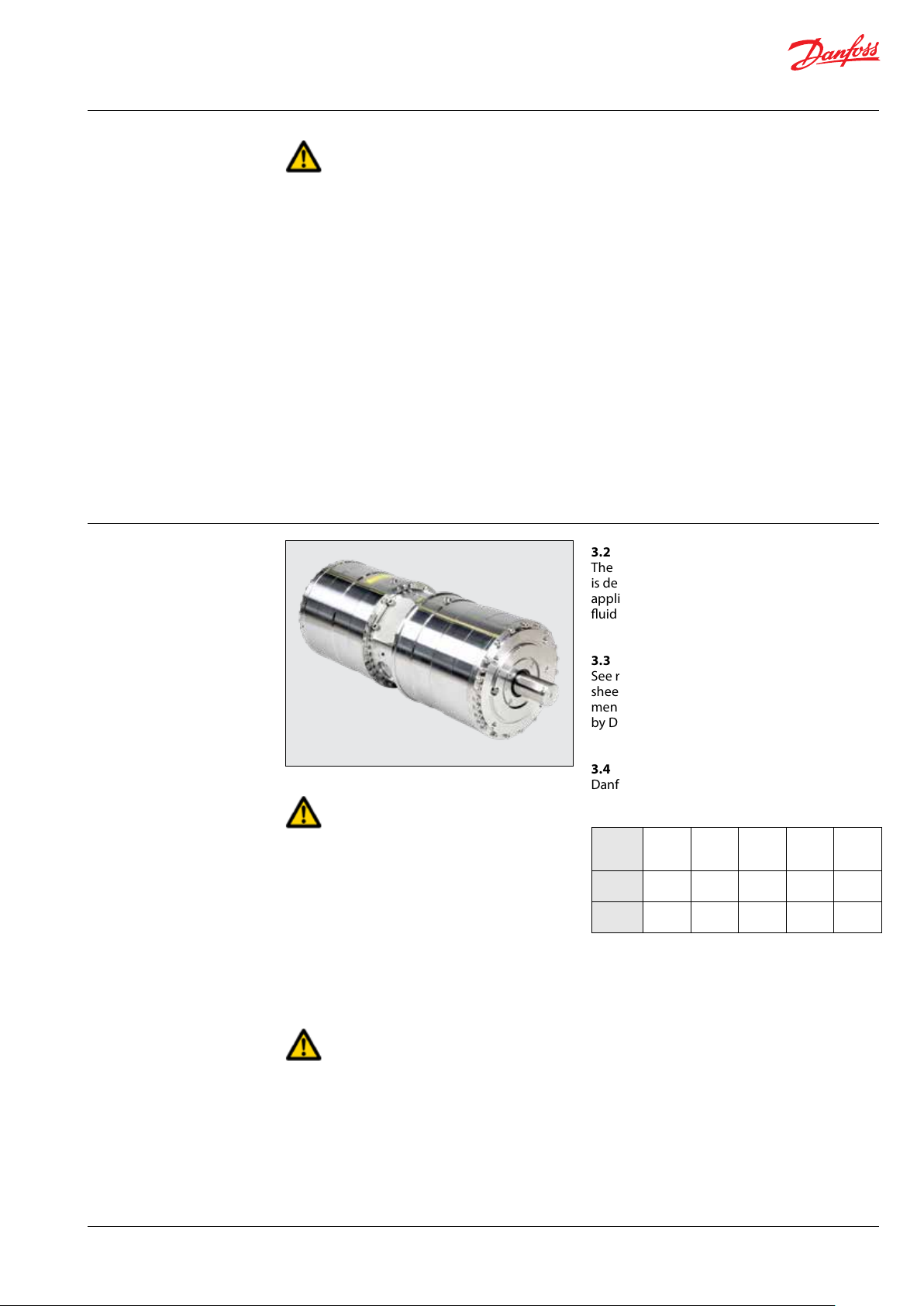

3.2 Application range

The Danfoss range of APP high-pressure pumps

is designed according to EN 809 for use in RO

applications with low viscosity and corrosive

fluids such as sea water.

3.3 Electric motor data

See recommended motor in appendix 1, Data

sheet or appendix 3, IOM for motors. The motors

mentioned are the most common used motors

by Danfoss High Pressure Pumps.

3.4 VFD and Direct on line

Danfoss APP pumps can be used with VFD and

direct on line.

Torque limits can be found in the table below:

Nm APP 53APP 65APP 78APP 86APP

92

MAWT 878 1,118 1,257 1,112 1,112

MAST 1,700 1,70 0 1,70 0 1,70 0 1,70 0

MAWT: Maximum allowable working torque

MAST: Maximum allowable starting torque

3.5 Noise and vibration

Noise level for a pump unit with a ”standard”

motor measured according to EN ISO 3744: 2010,

see appendix 1, Data sheet. Possibilities to

reduce noise and vibration are described in the

same Data sheet.

For system integration of the pump, please see

appendix 1, Data sheet and appendix 2,

Instruction.

180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701 | 7

3.6 Dimension drawings

Dimensions of the different pumps can be found

in appendix 1, Data sheet.

Operation guide | Installation, Operation and Maintenance APP 53-92 pumps

3.7 Space requirement

When doing service or replacing the complete

pump unit, it is recommended to have sufficient

space available around the pump in order to

ensure easy access. Sufficient space means at

least 1 meter/40 inches around the pump. When

working with high pressures, it is important to

have the right space available around the pump

as stated in the safety requirements.

3.8 Filtration

(10µm absolute [ß

Requirements are specified in appendix 1, Data

≥ 5000])

10

sheet and in appendix 2, Instruction.

Danfoss recommends not to build a filter bypass

function or to use filters with an integrated

bypass. If the above recommendation is not

followed the warranty for the pump will

automatically become void.

It should be possible to monitor the condition of

the filter via the differential/delta pressure across

the filter.

Using insufficient filtration or a filter bypass

can cause a failure or decreased service life of

the pump.

3.9 Properties of water

It is recommended NOT to use the pumps in feed

water concentrations higher than 50,000 ppm

TDS without consulting your local Danfoss pump

distributor.

3.10 Air bubbles

Large bubbles in a pressurised RO system can

result in damage to piping, equipment and the

pump.

All air must be bleeded from both the lowpressure and high-pressure side before the RO

system is pressurised. Special consideration

should be given in order to minimize air bubbles

in the feed flow. Air bubbles can cause cavitation.

3.11 Chemicals

The pump should not be exposed to any

chemicals as it can result in damage to piping,

equipment and internal parts in the pump.

4. Arrival inspection,

transportation,

handling, lifting and

storage

4.1 Arrival inspection

The pump is packed in a cardboard or wood box

with plugs in the port connections to protect the

pumps from damage during transportation.

When the shipment has arrived it is important to

check the pump for any damages. The name

plate/type designation must be in accordance

with the delivery note and your order.

In case of damage and/or missing parts, a report

should be documented and presented to the

carrier at once.

4.2 Warning

Before any lifting operation is performed,

environmental conditions must be taken into

consideration (Ex-rated areas, wind speed, wet/

dry conditions, lifting height, etc.).

4.3 General safety information

Personnel involved in lifting and transporting the

equipment (see Safety, chapter 2) must be

trained in handling and in safety procedures for

lifting heavy loads. Many of the pumps and

pump units weigh more than 20 kilos, which

requires lifting slings and suitable lifting devices;

e.g. an overhead crane or industrial truck to be

used as minimum.

4.4 Transport and handling

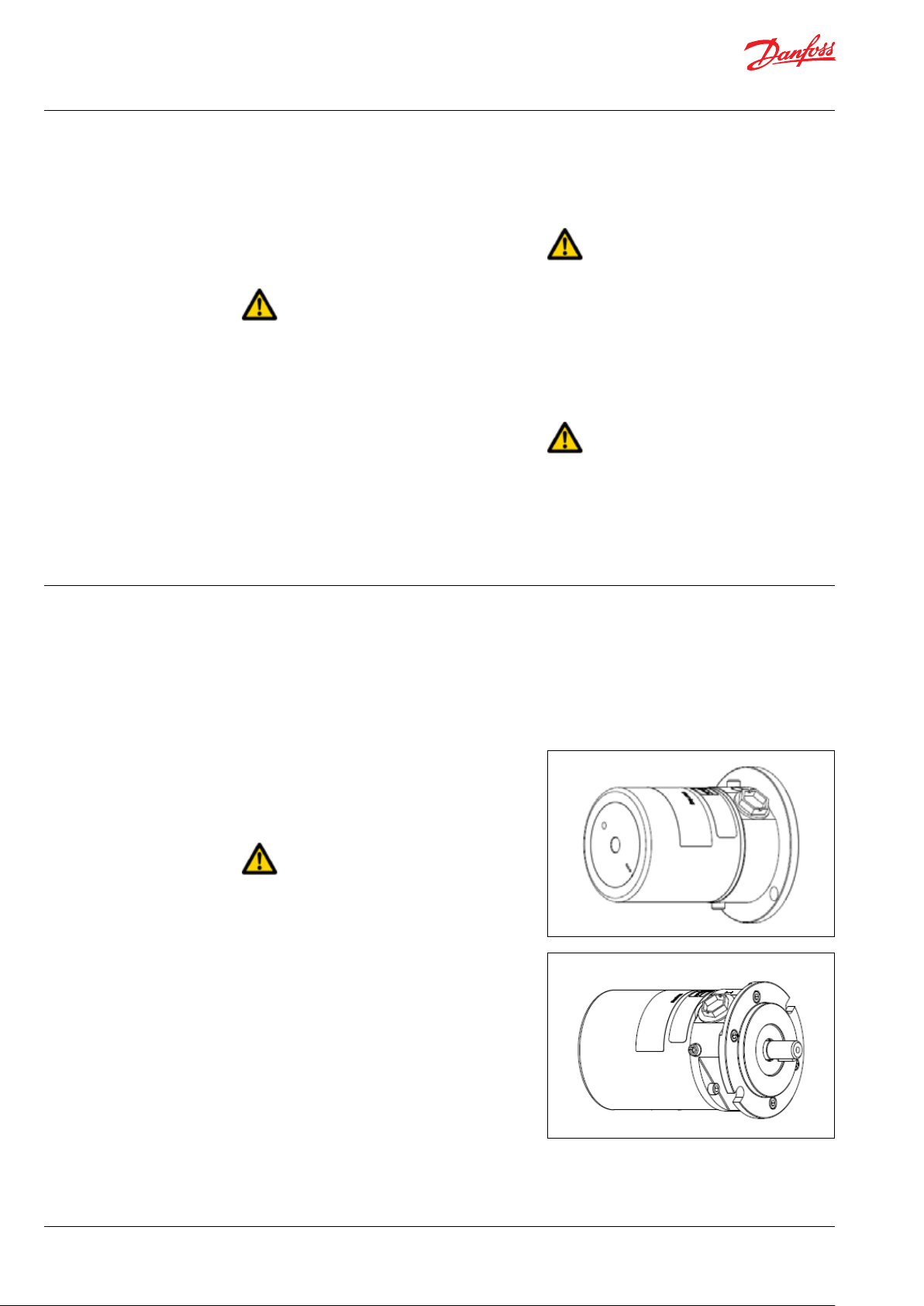

Small pumps which have a weight below 20 kilos

can be handled by hand if they are not mounted

together with an electric motor. The weight of a

small pump with a motor will be above 20 kilos.

Do not use connections/nozzles for lifting!

Do not use only one sling!

8 | © Danfoss | DCS (im) | 2021.12 180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701

Operation guide | Installation, Operation and Maintenance APP 53-92 pumps

© Danfoss | DCS (im) | 2021.12

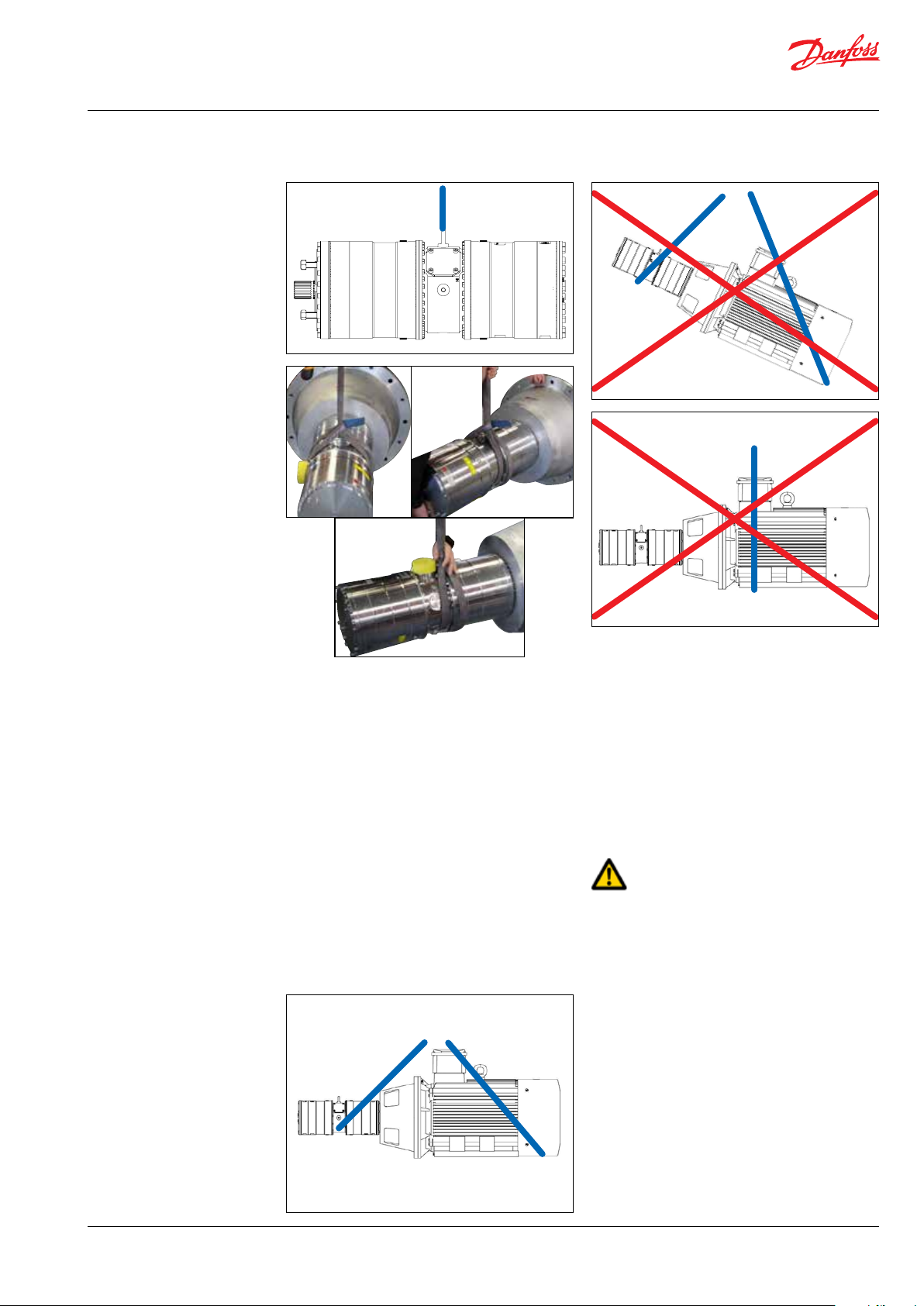

Pumps which have a weight above 20 kilos must

be handled by using lifting eyes and slings.

Wrong lifting:

When the pump is mounted together with a bell

housing, the pump can be rotated and in that

case the lifting eye cannot be used in all

positions. When lifting a pump with bell housing,

a sling can be used to lift the pump by positioning it on the drive end of the pump outlet.

When the pump is mounted together with an

electric motor, it must not be lifted in the lifting

eye. A pump unit with motor must be handled by

using two slings around the pump unit. One sling

must be attached to the electric motor and one

sling around the pump.

Make sure that the unit/load is balanced before

lifting. The centre of the mass varies from pump/

pump unit size to pump(pump unit).

See below examples of where to/not to attach

the lifting slings on the pump unit with motor:

Correct lifting with 2 separate slings:

Some motors and pumps have specific lifting

eyes.

Do not use connections/nozzles for lifting!

Do not use only one sling!

Make sure that the unit/load is balanced before

lifting. The centre of the mass varies from pump/

pump unit size to pump/pump unit.

How to mount the pump and the electric motor

correctly, see appendix 1, Data sheet or appendix

2, Instruction.

Incorrect lifting can result in personal injury

and/or damage to the pump unit, see appendix

2, Instruction.

Once the lifting is done the lifting eye must

be removed from the pump.

4.5 Return to supplier

Please see maintenance chapter 7.

4.6 Storage

Each pump is tested before shipment, and will

therefore contain water. For storage temperature

and frost protection see appendix 2, Instruction.

The pumps are NOT delivered frost protected

from the factory.

180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701 | 9

Operation guide | Installation, Operation and Maintenance APP 53-92 pumps

5. Installation and

commissioning

5.1 Important dimensions

Physical dimensions and connections of the

pump unit are described in appendix 1, Data

sheet.

5.4 Electrical data

Check voltage, current frequency and rated

power on the electric motor and VFD settings on

the name plate placed on both the motor and

the VFD.

5.2 Cleanliness

It is very important that the tubes and pipes are

completely clean: no dirt, chips or burrs are

allowed. Flush all piping before connecting the

high-pressure pump to ensure the system is

clean. Internal surfaces of the piping must not be

corroded. If dirt or rust is not removed, the pump

and the valves can be damaged. In worst case

the pump can be damaged beyond repair!

5.3 Fluid temperature

Before start-up, the fluid and pump housing

temperature must be within the specified

temperature range listed see appendix 1, Data

sheet.

Schematic 1: Recommended system design

Media filter

Feed

PI

PI

PI PI

PT

5.5 Local regulations

Commissioning must always be done in

accordance with valid regulations and local

standards.

M

PI

Permeate

Fresh water

permeat flush

PI

Brine

10 | © Danfoss | DCS (im) | 2021.12 180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701

Operation guide | Installation, Operation and Maintenance APP 53-92 pumps

© Danfoss | DCS (im) | 2021.12

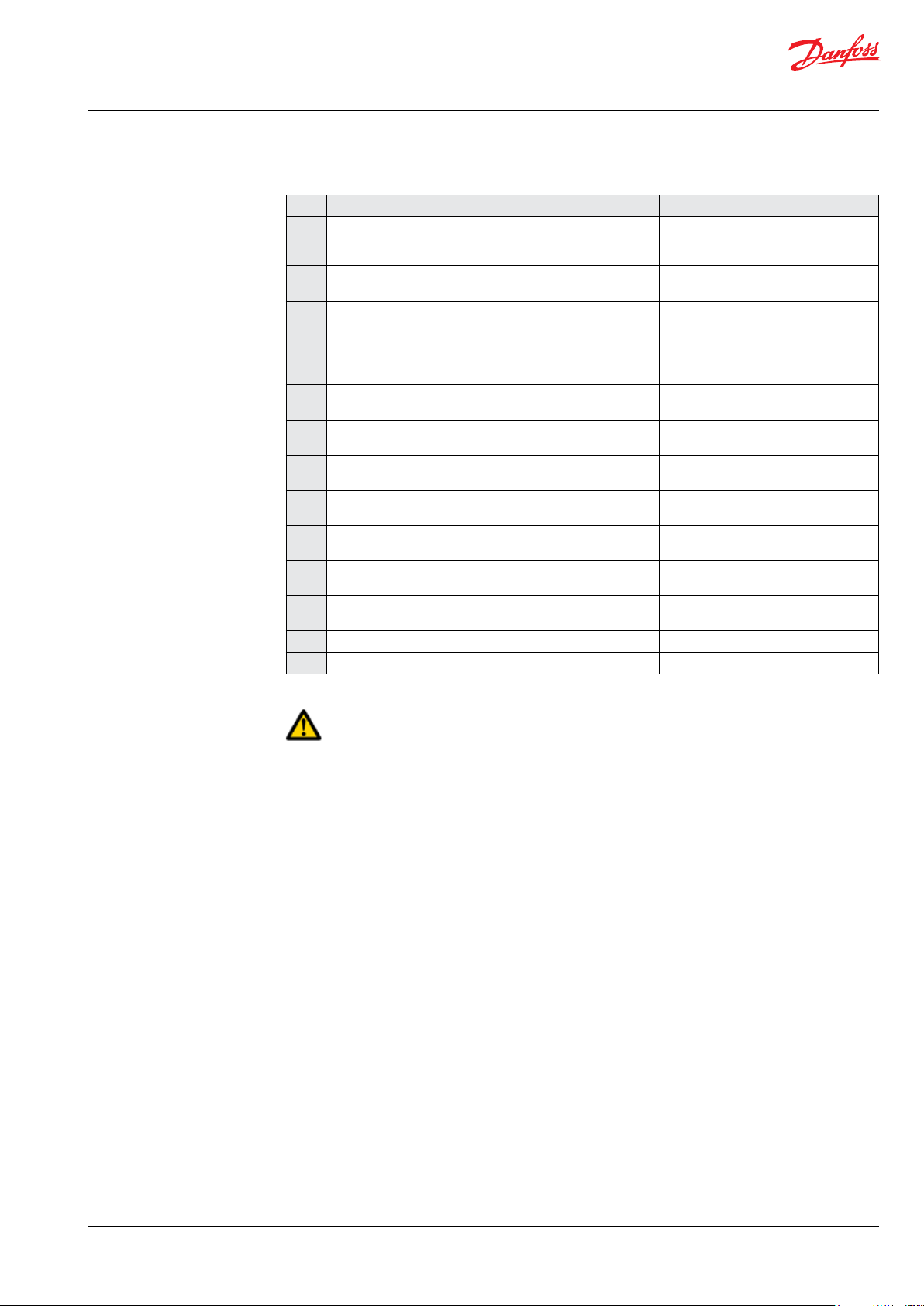

5.6 Pre mounting checklist, based on Danfoss preferred system design

Table 1: Check points when assembling and commissioning system

Check points Comment OK ?

Ensure that the environmental conditions are safe. See Arrival inspection,

CP1

Minimum and maximum start-up temperature for fluid and

CP2

pump.

Filtration condition (10 µm absolute (ß

CP3

Power supply for electric motor and VFD. See Data sheet for the used

CP4

Safety circuit / breaker must be sized for the motor and

CP5

environment (corrosion and humidity)

Bolts and screws must conform to environmental conditions

CP6

as well as fluid and torque requirements.

Instrumentation, pressure switch should be designed to

CP7

conform to the environment (corrosion and humidity).

Check the factory settings of the safety/relief valves or

CP8

pressure relief valves (page 11).

Check the settings of the pressure transmitter/switch (3) set

CP9

at min. inlet pressure (page 11).

Check that all pressure indicators (PI) are selected to be able

CP10

to measure the system pressure range (page 11).

Check that the coupling is installed according to manufac-

CP 11

turers instruction

Ensure all pipings have been flushed and are correct installed

CP12

Check piping for possible air gaps.

CP13

transportation, handling,

lifting and storage, chapter 4.

See Data sheet or Instruction,

appendices 1 and 2.

≥ 5000) See Danfoss requirements in

10

Data sheet and Instruction,

appendices 1 and 2

motor and VFD.

See Data sheet for the used

safety circuit.

See Data sheet for the used

equipment.

See Data sheets for the used

valves.

See Data sheet or Instruction,

appendices 1 and 2.

Scaling should at least be 1 bar

or more precise.

5.7 Lifting and positioning

Lift the pump unit onto base (Remember

vibration dampeners, if needed). Fasten the

motor to the base.

See also chapter 4, Arrival inspection, transportation, handling, lifting and storage.

5.8 Mount the different equipment

(connections, pipes, tubes, check and safety/relief

valves, etc.)

• The hard piping and flexible hoses used,

must be of proper design and must be

installed in accordance with the manufacturer’s recommendations. (see also Design

guides 180R9084 and 180R9367 - both

available on hpp.danfoss.com).

• Misalignment of the hard pipes may give

unintended stress on the pump port

connections and may damage the pump.

• Prevent excessive external pipe load.

• Do not connect piping by applying external

force (use of wrenches, crane, etc.) Piping

must be aligned without residual stress.

• Do not mount expansion joints so that their

force applies internal pressure on the pump

connections.

5.9 Electrics

All electrical installation work must be carried

out by authorized personnel in accordance with

EN60204-1 and/or local regulations. (see also

Safety, chapter 2)

Turn off the safety circuit breaker and lock it.

Mount the power cable on the electric motor.

If a VFD is used, adjust the protective motor

switch/VFD to the current limits found on the

name plate of the electric motor.

5.10 Instrumentation

The pressure switch/sensor should be mounted

as close to the pump as possible. It is recommended to test the pressure/sensor switch via an

instrumentation manifold.

Mount the pressure switch/sensors according to

the manufacturer’s instructions.

180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701 | 11

Operation guide | Installation, Operation and Maintenance APP 53-92 pumps

5.11 Connections

Mount and tighten connections and check

valve(s) as specified.

Danfoss check valve VCM 92 comes with a flange

connection that is easily mounted directly on the

outlet port (outlet connection is not required).

Note: Bolts (ref. 11) must be tightened with

torque 95Nm ± 9.5 Nm.

Use only Style 77DX coupling or equivalent for

the 3” victaulic OSG outlet on the VCM 92.

95 Nm ± 9.5 Nm

5.12 Ensure free flow

Ensure free flow from the safety/relief valves 8

and 9 (schematic1, page 10). A blocked safety/

relief valve can cause excessive build-up of

pressure and thereby cause dangerous situations

and damage to the whole system.

5.13 Verify setting of safety/relief valves

Make sure, the safety/relief valves 8 and 9 are

placed correctly.

Check the pressure settings on the name plates

of the safety/relief valves. If they are within

specifications, you can continue.

Unlock the safety circuit breaker. Start the motor

for 1 second and observe the direction of

rotation either looking at the fan of the motor or

the coupling through the inspection hole in the

bell housings (not available on all bell housings).

If the motor is turning the wrong direction,

switch two phases in the connection box of the

motor or reprogram the direction in VFD.

When the motor is turning in the right direction,

the pump can be mounted.

5.17 Commissioning

• Close all the bleeding and draining plugs.

• Open the pressure valve at the brine site.

• Switch the safety circuit breaker on for both

motor(s) and VFD(s).

• Start the feed pump.

• Start the high-pressure pump.

• If a VFD or a soft starter is used, a ramp up

time of minimum 10 seconds is required to

avoid damage of the pump.

• Monitor the inlet and outlet pressure of the

high-pressure pump and look for leakages.

• Check the function of the pressure

indicators by slowly closing the valves. The

pump unit should stop when the minimum

inlet pressure and maximum outlet

pressure has been reached.

• Adjust the pressures to the specified inlet

and outlet pressure for the system and let

the pump unit run until the electric motor

and pump temperature is stable.

• If the system is running within the system

design limits, the system is released for

operation.

5.14 Flush the pump

Fully open the pressure valve at the brine outlet.

Close all the bleeding and draining plugs on the

high-pressure pump.

Start the feed pump and ensure free flow to the

high-pressure pump.

5.15 Bleed and remove air from the pump

Open the bleeding plugs. Keep the plugs open

until the high-pressure pump is bleeded.

5.16 Verify direction of rotation

The direction of rotation must always follow the

arrow. The arrow is placed on the pump or pump

unit.

Check the direction of rotation before mounting

the pump.

5.18 Check the filter condition

Evaluate contamination found in filter, replace

filter elements, if necessary.

5.19 Instruct operator and maintenance

personnel

Before using the pump/pump unit, the personnel

must be instructed in using the pump/pump

unit, its function, components, documentation

and safety.

Danfoss offers commissioning and service at

system manufacturer’s location. Rate quotes are

offered upon request.

12 | © Danfoss | DCS (im) | 2021.12 180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701

Operation guide | Installation, Operation and Maintenance APP 53-92 pumps

© Danfoss | DCS (im) | 2021.12

6. Operation of pump

unit

6.1 General safety information

Before inspecting the pump unit, read the Safety

chapter 2 in this user manual.

6.2 What to listen and look for

If one or more of the following examples are

observed, please act as indicated:

A) Loose bolts – check all bolts and, if

necessary, contact the maintenance

department in order to have all bolts

tightened to the specified torque(s).

B) Leakage – if a small leakage from the bell

housing is observed. Contact the maintenance department.

C) Leakage – if there is a large leak, the unit

should be stopped immediately. Contact

the maintenance department.

D) High frequency tones – safety/relief valves

are either damaged or running very close

to their design pressure, stop the unit

immediately. Contact the maintenance

department.

E) Increased noise or vibration – requires the

unit to be stopped immediately. Contact

the maintenance department.

F) Very high temperatures – may indicate that

one or more parts are damaged inside the

pump. The pump must be stopped

immediately and inspected before it is

restarted. Contact the maintenance

department.

G) Drop in flow and/or pressure – may indicate

wear on one or more parts inside the

pump. The pump must be stopped

immediately and inspected before it is

restarted. Contact the maintenance

department.

H) Other observations or troubles, please see

appendix 7, Right and Wrong or appendix

6, the Trouble shooting guide.

Both appendices give good advises

regarding design, installation, wiring and

troubleshooting.

See also service and warranty section in

appendix 1, Data sheet and appendix 2,

Instruction.

If the pump is not stopped for inspection as

recommended, it can lead to damage of the

pump or break-down. See also service and

warranty section in the appendix 1, Data sheet,

in appendix 2, Instruction or appendix 4,

Instruction for recommended service intervals.

Danfoss offers service of the pump at the system

manufacturer’s location as well as we offer

training in how to service the pump. Quotes are

offered upon request.

Danfoss recommends simultaneously to check

the filter and membrane condition and to

evaluate contamination; filter and membrane

elements must be replaced if necessary.

7. Maintenance and

service of the pump

unit

7.1 General safety information

Before servicing the pump unit, it is necessary to

read and understand this user manual, especially

the Safety, chapter 2. Remember to wear suitable

safety equipment according to Safety, chapter 2.

7.2 Service and inspection interval for the

pump

Maintenance and service intervals are depending

on the cleanliness level of the water, hydraulic

load and temperature of the pump unit. The

most important parameter is the filtration of the

water.

See the section Service and warranty in the

appendix 1, Data sheet, in appendix 2, Instruction and appendix 4, Instruction for recommended service intervals.

For spare parts and service tools, please see

appendix 5, Parts list.

180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701 | 13

Danfoss offers service of the pump at the system

manufacturer’s location and training in how to

service the pump. Quotes are offered upon

request.

7.3 Shut down of the system

A) Stop the high-pressure pump.

B) Open the pressure valves at the brine site

to release the pressure.

C) Stop the feed pump.

D) Switch off the safety circuit breaker for

both the high-pressure pump, feed pump

and VFD and lock them. Only personnel

servicing the pump unit should be able to

unlock/activate the switch again.

E) Open bleeding and drain plugs. Wait until

the pump and system are emptied for

water.

Operation guide | Installation, Operation and Maintenance APP 53-92 pumps

F) Make sure the system is not pressuized!

Slowly unscrew and remove the bolts and

gaskets from the inlet/outlet hoses or

pipes, be careful about jets of water.

Beware that the system can be pressurized!

G) Attach the lifting equipment to the pump

unit. For instructions on lifting the

complete pump unit, see chapter 4, Arrival

inspection, transportation, handling, lifting

and storage.

H) For the small pumps, unscrew the bolts

holding the pump to the bell housing. For

the bigger pumps, unscrew the bolts/nuts

from the pump and bell housing to the

motor. Afterwards unscrew the bolts/nuts

holding the pump and bell housing.

I) Carefully pull the pump out of the bell

housing by using lifting equipment, if

necessar y.

J) Hold the pump in different positions above

a drip tray; this should allow most of the

water trapped in the pump to drain. Clean

and dry the pump surface and plug the

bleeding and draining plugs.

K) Move the pump to a clean and safe location

where the pump can be inspected/

serviced.

7.4 Disassembling and assembling the

pump unit

A) Remove all connections from the pump.

Returns without a return number will be

rejected !!!

7.5 Assembling the pump unit

Assemble the pump according to the Disassembling and Assembling Instruction

(available at hpp.danfoss.com).

7.6 Procedure for mounting the pump onto

the electric motor

Mount the flexible coupling and bell housing

according to appendix 2, Instruction.

7.7 Getting the pump unit back into

operation

Find instructions of how to put the pump unit

back into operation in chapter 4, Arrival inspection, transportation, handling, lifting and storage

and Installation and commissioning, chapter 5.

B) Disassemble the pump according to the

Disassembling and Assembling Instruction

(available at hpp.danfoss.com)

Clean all parts and surfaces with a fluid

compatible with the materials found in the

pump. Wipe the parts clean and dry with a

lint-free clothing.

C) Inspect all parts including shaft seal and if

necessary, replace them; see appendix 5,

Parts list.

D) If the pump is going to be returned to

Danfoss for repair or a warranty claim, it is

important to contact Danfoss in order to

receive a return number and a form to fill

out with product information. A copy of the

form together with contact information

and reason for returning should be sent to

the email address on the form. The same

documents should be attached to the

shipment.

14 | © Danfoss | DCS (im) | 2021.12 180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701

7.8 Storage of the pump

If the pump has to be shut down for a longer

period, instructions can be found in appendix 2,

Instruction.

Operation guide | Installation, Operation and Maintenance APP 53-92 pumps

© Danfoss | DCS (im) | 2021.12

8. Troubleshooting and

scrapping criteria

8.1 General safety information

Before inspecting the pump unit, it is necessary

to read and understand this user manual,

especially the Safety chapter 2.

Remember to wear suitable safety equipment

according to Safety chapter 2.

If water is leaking into the electric motor; it can

cause electric shock, fire, short circuit or even

death. When mounting the pump vertically

always mount the motor above the pump to

avoid water leaking into the electric motor.

8.2 Operational conditions which can cause

pump failures

The following conditions can cause a pump

failure :

• The pump is running dry.

• The inlet pressure is too high.

• The inlet pressure is too low.

• The temperature of the fluid is too high.

• The ambient temperature is too high.

• The pump is running against a blocked

port/closed manual valve.

• The pump is operating at a pressure out of

specification.

• The pump is running with a non-specified/

approved fluid.

• The pump is running in the wrong

direction.

• The filtration is insufficient.

• The pump is not being serviced according

to Danfoss specifications (end of life).

• There is excessive mechanical load on the

shaft coupling and piping.

8.3 Mechanical failure

If the pump is running dry, the temperature will

quickly increase which can cause burns.

If there is any leakage at start-up or during

operation, a high-pressure jet can cause eye or

skin damage.

Leakage can result in flooding, which can cause

slipping, tripping or falling.

8.4 Electrical failure

If the wiring of the electric motor is incorrect or

the ground connection is missing, it can cause

electric shock, burn damages, fire or even death.

If a VFD is used and wrongly programmed, it can

damage the pump and lead to high temperatures or other dangers.

All electrical installation must be carried out by

authorized personnel in accordance with

EN60204-1 and/or local regulations.

8.5 Responsibility

Danfoss takes no responsibility for any abnormal

injuries, risks or damages that could arise caused

by abnormal conditions, vibrations, corrosion,

abrasives, foreign objects or excessive temperatures and shall not be liable for any consequential or incidental damages.

8.6 Scrapping criteria

Whether the pump can be repaired or need to be

scrapped, depends on in which conditions the

internal parts are, or how damaged the whole

unit is. Please use appendix 6, Trouble shooting

guide as guideline or send the pump to Danfoss

headquarter in Denmark for evaluation.

For other observations or troubles, please see

appendix 7, Right and Wrong which gives good

advises regarding design, installation, wiring and

troubleshooting.

In case the pump needs to be scrapped, please

follow your local environmental rules.

180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701 | 15

Operation guide | Installation, Operation and Maintenance APP 53-92 pumps

16 | © Danfoss | DCS (im) | 2021.12 180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701

Operation guide

APP pumps

APP 53 / APP 65 / APP 78 / APP 86 / APP 92

Appendices for Installation, Operation

and Maintenance Manual

hpp.danfoss.com

Operation guide | Installation, Operation and Maintenance APP 53-92 pumps

Table of Contents

Appendices .......................................................................................17

1. Data sheet for APP pumps 53-92 AI167386503010en-0013

2. Instruction for APP pumps 53-92 (180R9368) ............................................43

3. Electric motors (180R9230) ..............................................................55

4. Bowex coupling manual .................................................................61

5. Recommended service intervals (AX281930801330en-000401) ..........................85

6. Parts list (AX191786502906en-001101) ...................................................89

7. Trouble shooting (521B1447) ...........................................................101

8. Right and wrong (180R9042) ..........................................................113

01) ...........................19

18 | © Danfoss | DCS (im) | 2021.12 180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701

Data sheet

Data sheet

APP Pumps

APP pumps

APP 53 / APP 65 / APP 78 / APP 86 / APP 92

APP 53-86

hpp.danfoss.com

ro-solutions.com

Data sheet | APP 53-92 Pumps

Table of Contents

1. Introduction ...........................................................................21

2. Benefits................................................................................21

3. Application examples ..................................................................21

4 Technical data .........................................................................22

4.1 APP 53-92..............................................................................22

5. Performance curves....................................................................24

5.1 APP 53 flow at different rpm............................................................24

5.2 APP 65 flow at different rpm............................................................25

5.3 APP 78 flow at different rpm............................................................26

5.3 APP 86 flow at different rpm............................................................27

5.4 APP 92 flow at different rpm............................................................28

6. Flushing valve curves ..................................................................29

6.1 APP 53-92 integrated flushing valve ....................................................29

7. Motor requirements....................................................................29

7.1 Calculation factor at 60 barg / 870 psig for APP 53-92 ...................................29

8. Temperature and corrosion.............................................................30

8.1 Operation..............................................................................30

9. Installation.............................................................................30

9.1 Filtration...............................................................................31

9.2 RO system with direct supply: ..........................................................31

10. Dimensions and connections...........................................................33

10.1 APP 53.................................................................................33

10.2 APP 65 - 92.............................................................................34

10.3 APP 53-92 with IE3 motor, IEC 315S - 4 ..................................................36

10.4 APP 53-92 with IE3 motor, IEC 315M - 4..................................................36

10.5 APP 53-92 with IE3 motor, IEC 315L 1-4 .................................................37

10.6 APP 53-92 with IE3 motor, IEC 315L 2 - 4 ................................................37

11. Pump connections .....................................................................38

11.1 APP 53 - 92.............................................................................38

12. VCM 3” Victaulic........................................................................39

12.1 Technical data .........................................................................39

12.2 Flow versus pressure ...................................................................40

13. Accessories ............................................................................41

14. Service and warranty...................................................................41

20 | © Danfoss | DCS (im) | 2021.12

180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701

Data sheet | APP 53-92 Pumps

1. Introduction

The Danfoss range of APP high-pressure pumps

is designed according to EN 809 for use in RO

applications with low viscosity and corrosive

fluids such as sea water.

Danfoss APP pumps are positive displacement

pumps with axial pistons that move a fixed

amount of water in each cycle. Flow is proportional to the number of input shaft revolutions

(rpm).

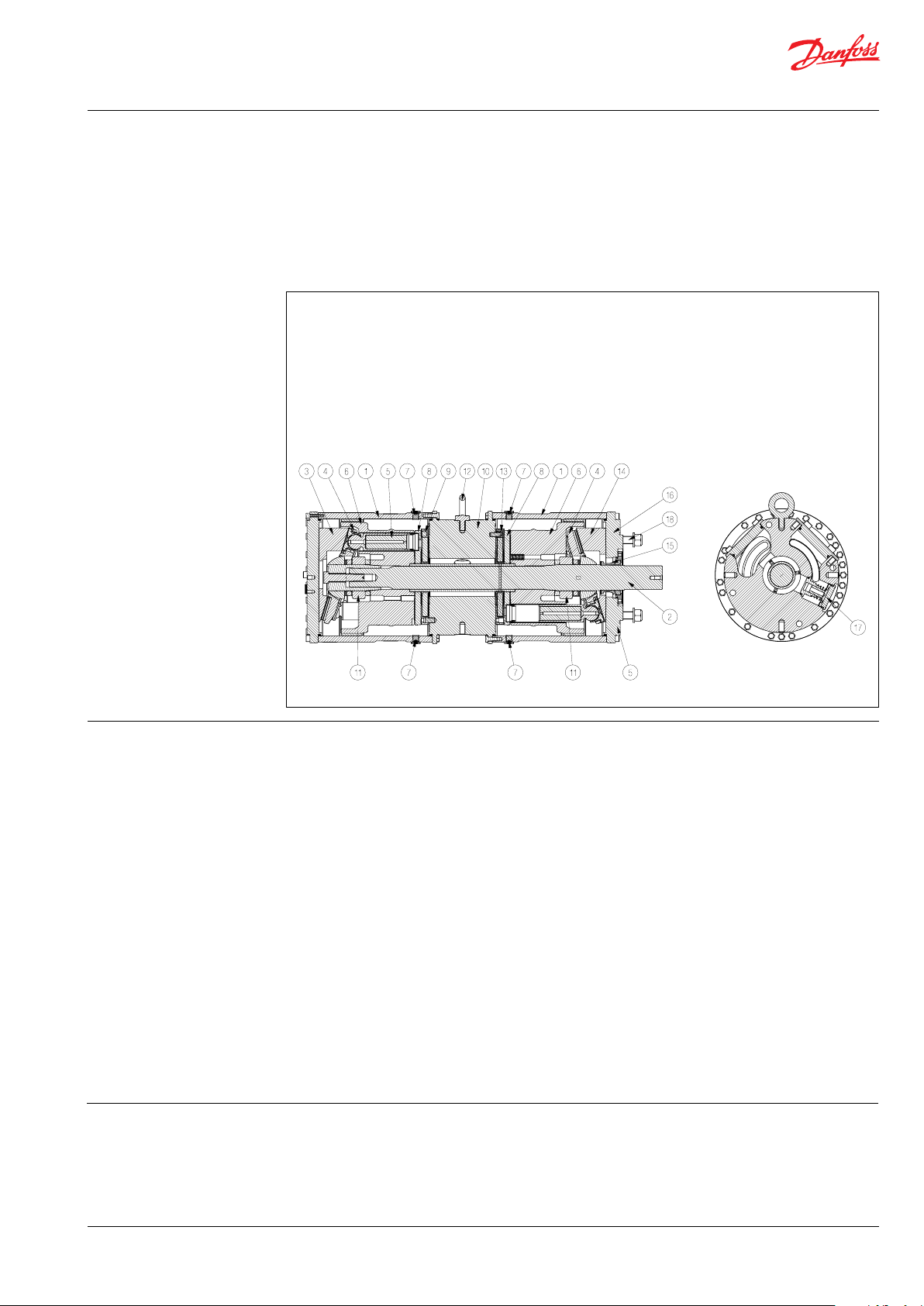

1 Housing

2 Shaft

3 Swash plate (non drive end)

4 Retainer plate

5 Piston

6 Cylinder barrel

7 Bleeding / drain plug

8 Valve plate

9 Port plate (non drive end)

Unlike centrifugal pumps, they produce the same

flow at a given speed no matter what the

discharge pressure.

The sectional drawing below illustrates the main

components of the APP 53-92 pump range.

10 Center flange

11 Spring cartridge

12 Eye bolt

13 Port plate (drive end)

14 Swash plate (drive end)

15 Shaft seal

16 Motor flange

17 Flushing valve

18 Tail stock screws

2. Benefits

3. Application examples Danfoss APP pumps are built into a broad range

• Zero risk of lubricant contamination:

- Oil lubricants are replaced with the

pumped medium, water, so there is no

contamination risk from the pump.

• Low maintenance costs:

- Efficient design and all-stainless steel

construction ensure exceptionally long

life. When Danfoss specifications are

met, service intervals of 8,000 hours can

be expected. Service is easy, and can be

carried out on-site due to the simple

design and few parts.

• Low energy costs:

- The highly efficient axial piston design

provides the lowest energy

consumption of any comparable pump

on the market.

• Easy installation:

- The most compact and lightest design

available.

- The pump can be installed horizon-

tally in different positions rotating it

around the shaft (see section 10 for

example).

of RO desalination plants around the world:

• Containerized solutions for hotels, resorts

and residences on islands and in coastal

regions

No pulsation dampeners necessary due

to extremely low pressure pulsation.

- Powered directly by electric motors or

combustion engines (with special

coupling).

- All pumps are supplied with an

integrated flushing valve that allows the

fluid to flow from inlet to the outlet,

when the pump is not running.

• High reliability:

- All parts are made of high corrosion

resistant materials e.g. Duplex

(EN1.4462/ UNS S31803) and

Super Duplex (EN1.4410/UNS S32750)

stainless steel and carbon reinforced

PEEK.

• Certified quality:

- Available with positive material

idenfication (PMI) certification on

request.

- ISO 9001, ISO 14001, IAFT 16949

- ATEX certification available for APP S (all

Super Duplex) and APP S 674 (API).

Please see relevant data sheets.

• Mobile systems for humanitarian and

military organizations

• Onboard systems for ships and yachts

• Offshore platforms for the oil and gas

industry

• Municipal and regional waterworks

© Danfoss | DCS (im) | 2021.12

180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701 | 21

Data sheet | APP 53-92 Pumps

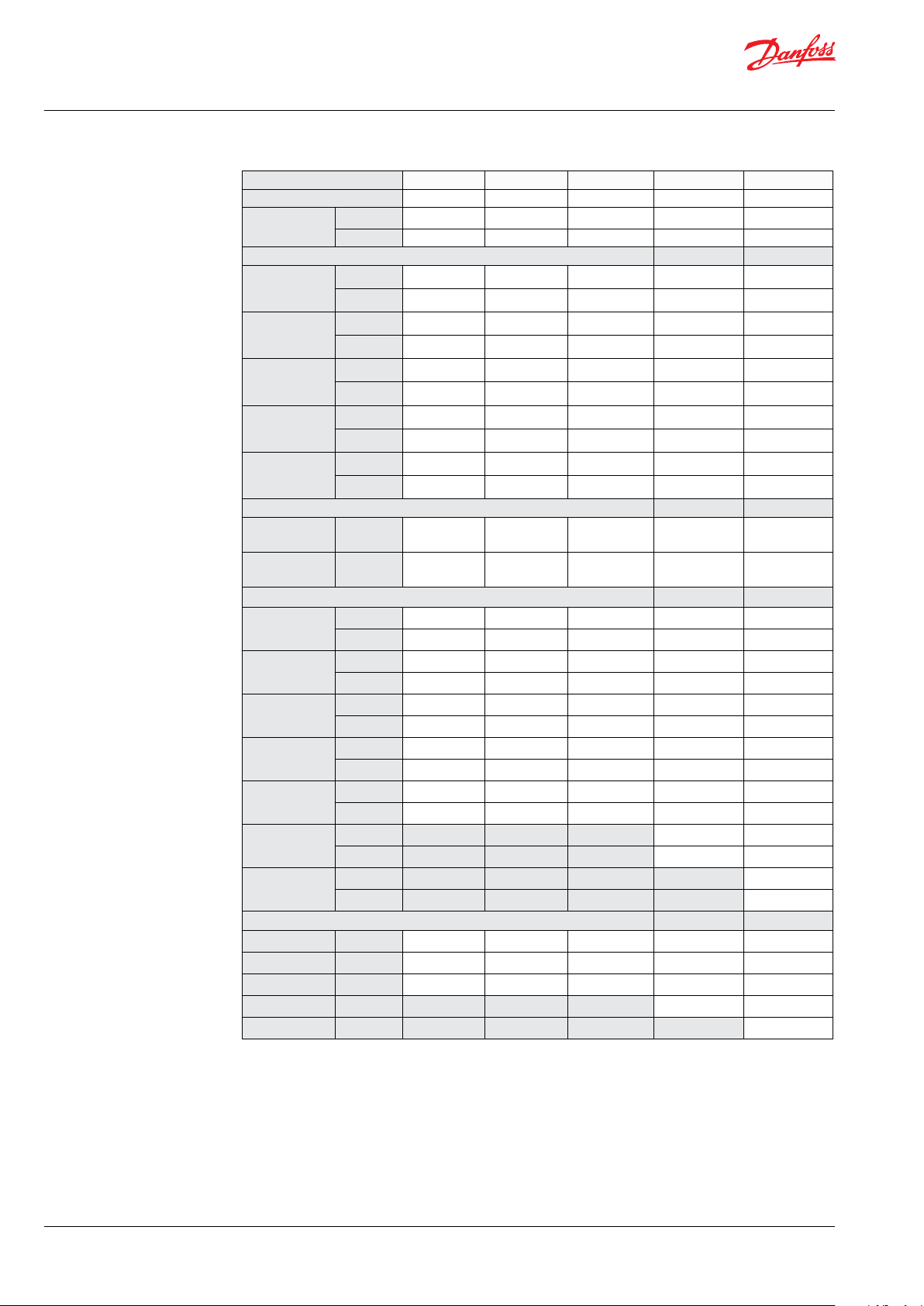

4.1 APP 53-924 Technical data

Pump size APP 53/1500 APP 65/1500 APP78 /1500 A PP 8 6/1700 APP 92 /178 0

Code number 180B7806 180B7807 180B7808 180B7809 180B7810

Geometric

displacement

Pressure

Max. outlet

pressure

(MAWP)

Min. inlet

operating

pressure

Max. inlet

operating

pressure

Max. inlet

pressure peak

Min. outlet

pressure

Speed

Min. speed

continuous

Max. speed

continuous

Flow

Min. flow

700 rpm at

max. pressure

1000 rpm at

max. pressure

1200 rpm at

max. pressure

1500 rpm at

max. pressure

1700 rpm at

max. pressure

1780 rpm at

max. pressure

Efficiency

1000 rpm

1200 rpm

1500 rpm

170 0 rp m

178 0 rp m

cm³/rev. 617 778 888 888 888

in³/rev. 37. 7 47. 3 54.2 54.2 54.2

1)

barg 83 83 83 70 70

psig 1,200 1,200 1,200 1,015 1,015

barg 2 2 2 2.5 3.5

psig 29 29 29 36 50

barg 5 5 5 5 5

psig 73 73 73 73 73

barg 10 10 10 10 10

psig 145 145 145 145 145

barg 30 30 30 30 30

psig 435 435 435 435 435

rpm 700 700 700 700 700

rpm 1,500 1,500 1, 500 1,700 1,780

m³/h 24 32 36 36 36

gpm 106 141 158 158 15 8

m³/h 24 32 36 36 36

gpm 106 141 158 158 15 8

m³/h 35 45 52 52 52

gpm 15 4 198 228 228 228

m³/h 42 54 62 62 62

gpm 187 238 275 275 275

m³/h 53 68 78 78 78

gpm 235 299 345 345 345

m³/h 88 88

gpm 387 387

m³/h 92

gpm 405

3)

% 88 88 89 89 89

3)

% 89 89 90 89 89

3)

% 88 89 89 88 88

3)

% 88 88

3)

% 87

22 | © Danfoss | DCS (im) | 2021.12

180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701

Data sheet | APP 53-92 Pumps

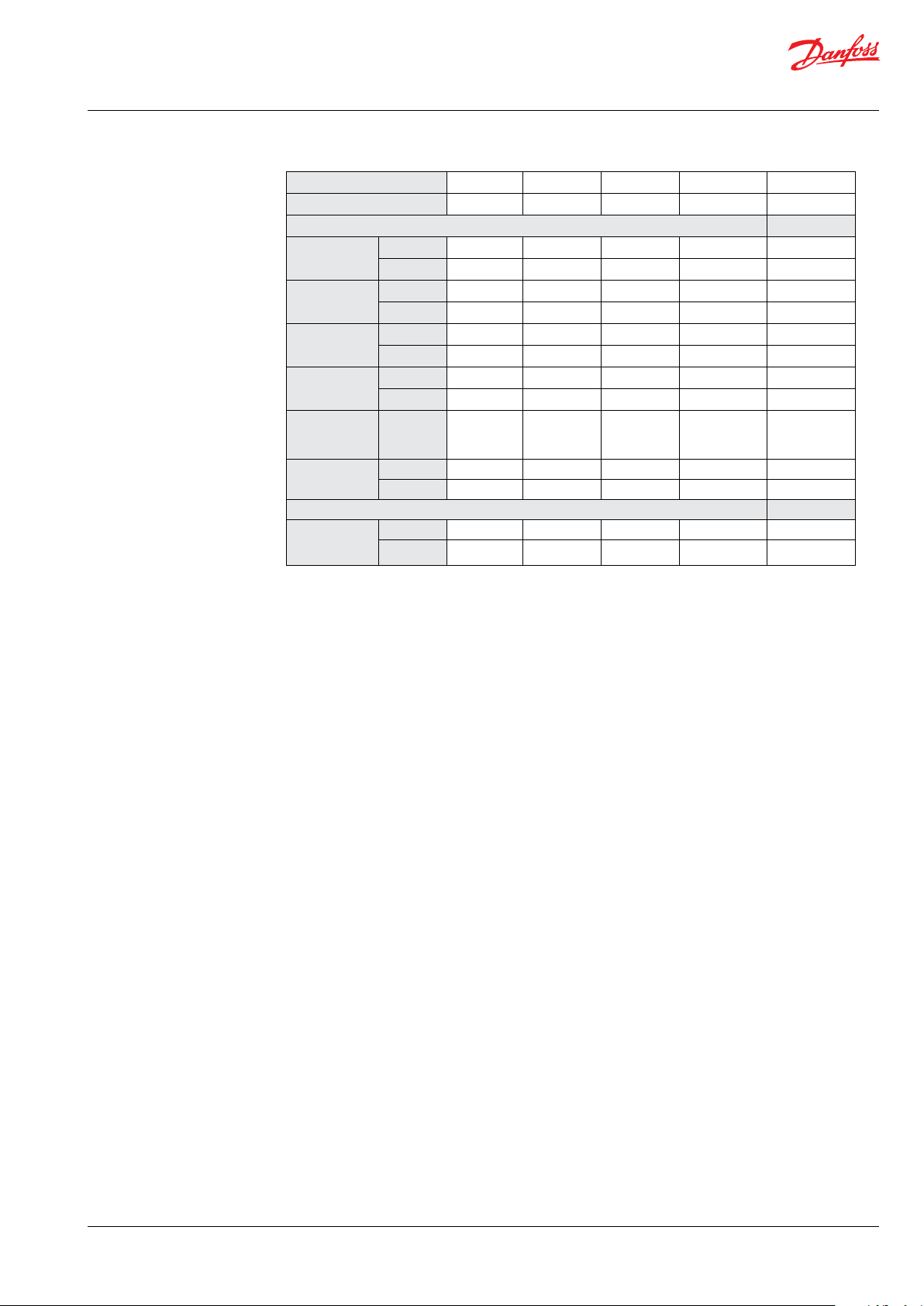

Pump size APP 53/150 0 APP 65/15 00 APP 78/1500 APP 86/1700 APP 92 /1780

Code number 180B7806 180B7807 180B7808 180B7809 18 0B7810

Technical specifications

2)

Media

temperature

Ambient

temperature

Weight (dry)

Weight

(operation)

°C 2–50 2-50 2–50 2-50 2-50

°F 36–122 36-122 3 6–122 36-122 36-12 2

°C 0–50 0-50 0–50 0-50 0-50

°F 32–122 32-12 2 32–122 32-12 2 32-122

kg 196 196 196 19 6 196

lb 432 432 432 432 432

kg 204 204 204 204 204

6)

lb 450 450 450 450 450

Sound

pressure level

Footprint with

IE3 motor

db(A) 84-95 84-95 84-93 84-96 84-96

m² 1.49 1.49 1. 50 1.50 1.50

4)

Foot² 16.0 17. 0 16.1 16.1 16.1

Typical motor size

Max.speed at

max. pres-

5)

sure

1)

Max. allowable working pressure at continuous operation. The pump is designed according to EN809, i.e. to

withstand hydrostatic test pressure (HTP) of 1.3 x MAWP. For lower and higher pressure, please contact Danfoss.

2)

Dependent on the NaCI concentration.

3)

Typical efficiency at max. pressure after a system has been commissioned and run in.

4)

Maximum area covered with recommended IE3 motor configurations (excl. of space to service pump)

5)

IE3 and NEMA motors, 4-pole, current insulated ND non drive end bearing

6)

Operating with water

kW 132 16 0 160 200 200

HP 200 250 250 300 300

© Danfoss | DCS (im) | 2021.12

180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701 | 23

Data sheet | APP 53-92 Pumps

100,00

120,00

140,00

160,00

180,00

200,00

220,00

240,00

260,00

280,00

300,00

320,00

340,00

360,00

380,00

400,00

Flow [gpm]

Speed [RPM]

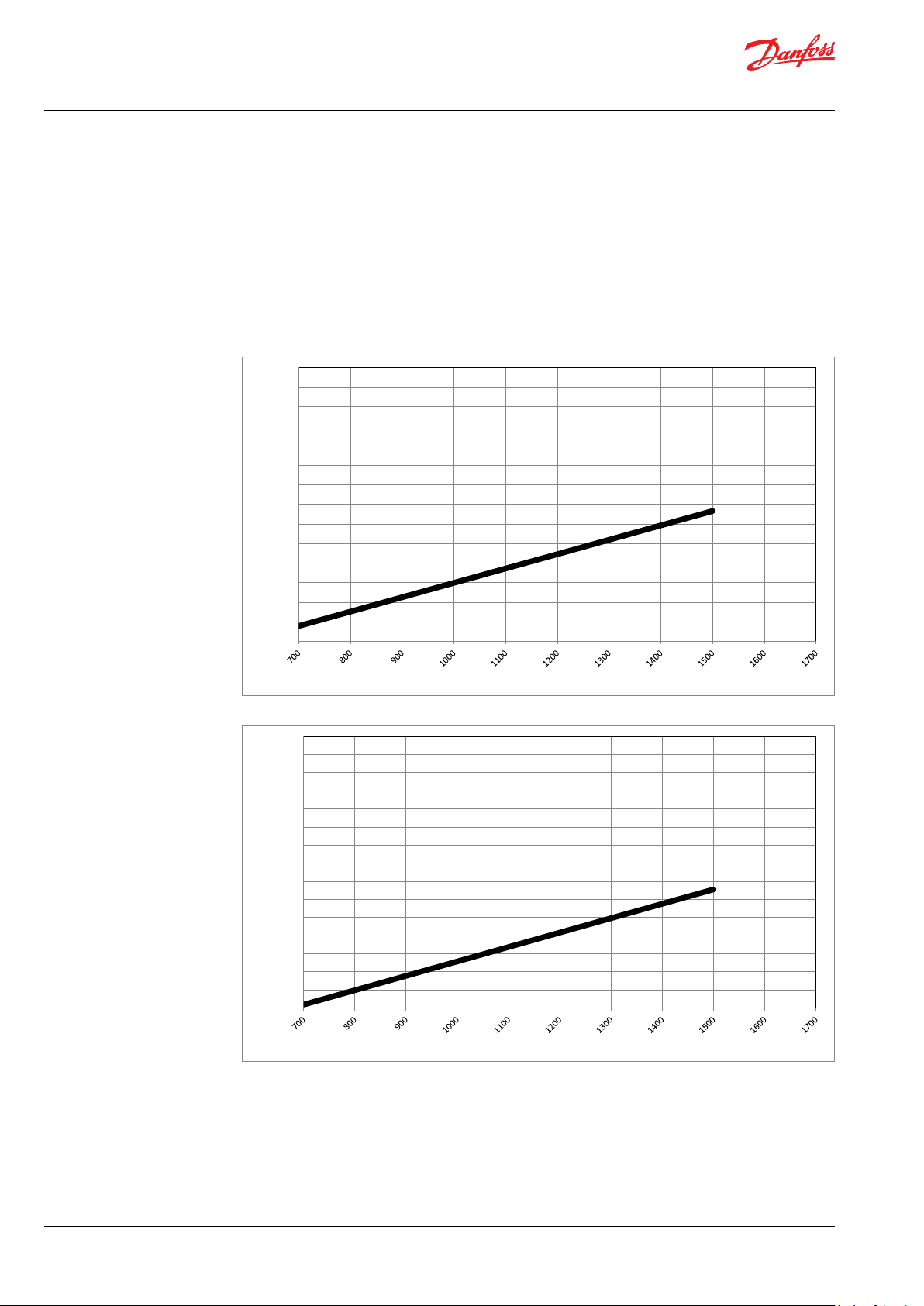

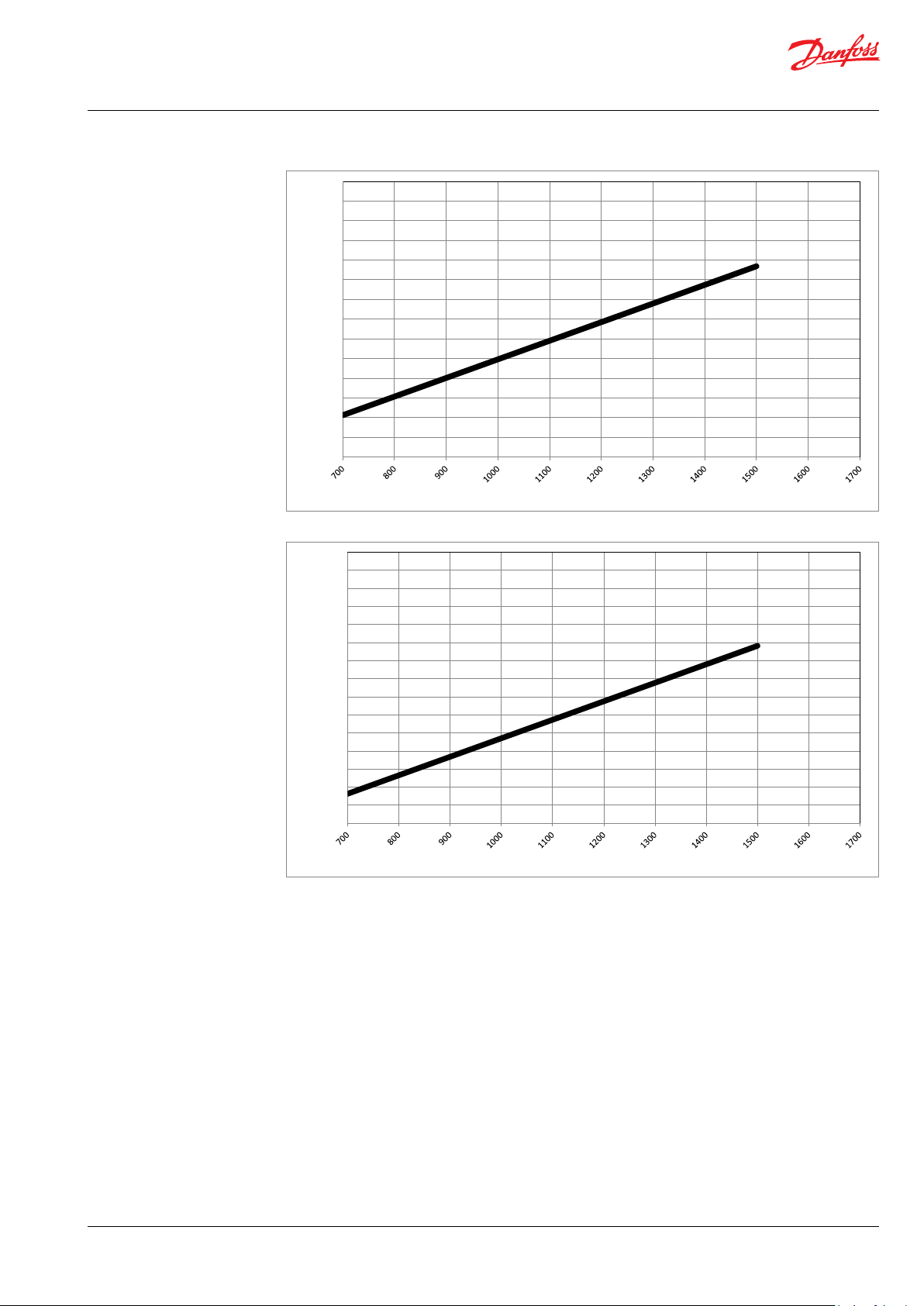

5. Performance curves

If the flow required and the rotation speed (rpm)

of the pump is known, it is easy to select the

pump, fitting the application best, by using the

diagram below.

5.1 APP 53 flow at different rpm

90,00

85,00

80,00

75,00

70,00

65,00

60,00

55,00

50,00

Flow [m3/h]

45,00

40,00

35,00

30,00

25,00

20,00

Furthermore, this diagram shows that the

flow can be changed by changing the rotation

speed of the pump. The flow/rpm ratio is

constant, and the “required” flow can be

obtained by changing the rotation speed to a

corresponding value. Thus, the required rpm

can be determined as:

Required flow x Rated rpm

Required rpm =

Rated flow

24 | © Danfoss | DCS (im) | 2021.12

Speed [RPM]

180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701

Data sheet | APP 53-92 Pumps

20,00

25,00

30,00

35,00

40,00

45,00

50,00

55,00

60,00

65,00

70,00

75,00

80,00

85,00

90,00

Flow [m3/h]

Speed [RPM]

100,00

120,00

140,00

160,00

180,00

200,00

220,00

240,00

260,00

280,00

300,00

320,00

340,00

360,00

380,00

400,00

Flow [gpm]

Speed [RPM]

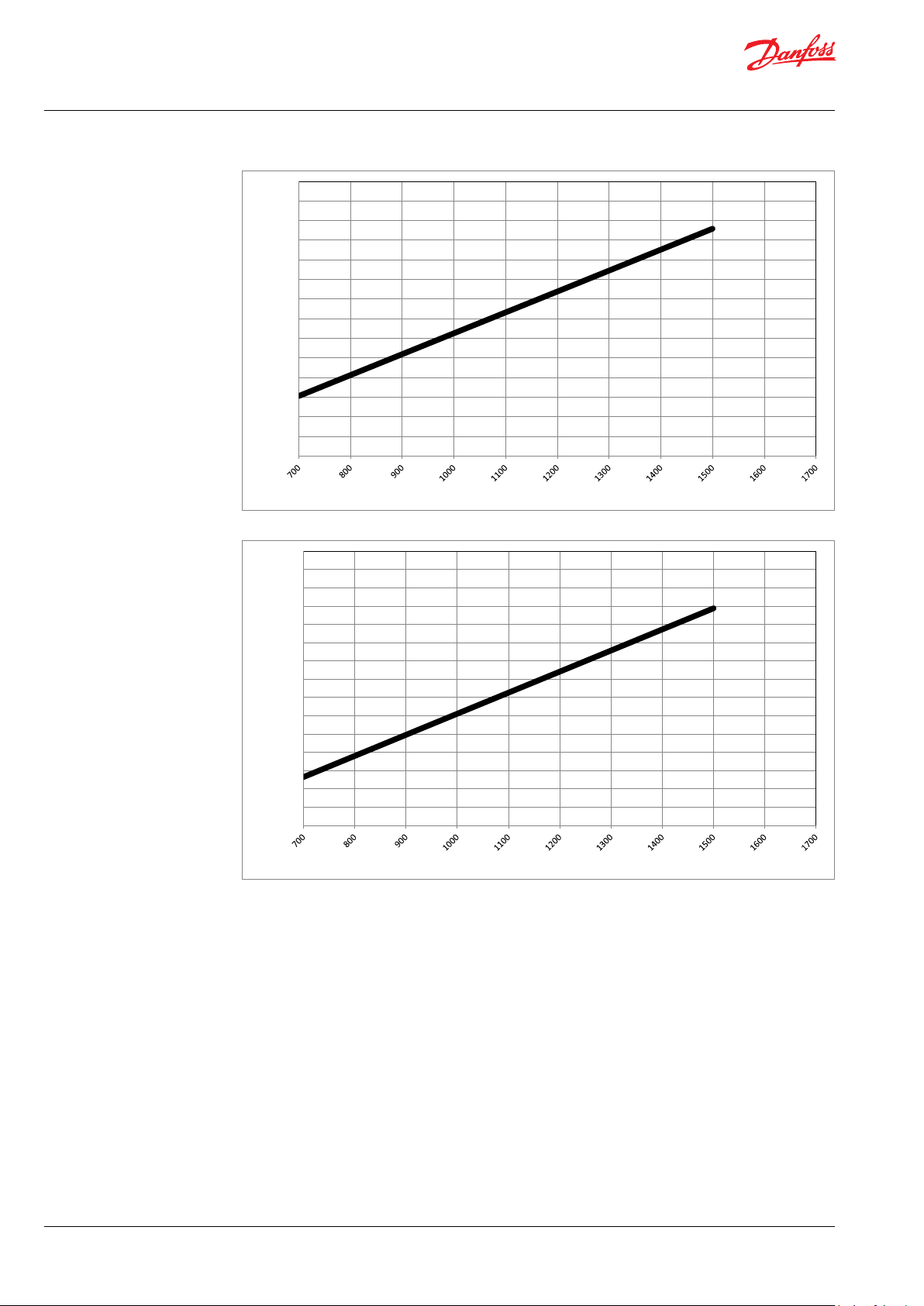

5.2 APP 65 flow at different rpm

© Danfoss | DCS (im) | 2021.12

180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701 | 25

Data sheet | APP 53-92 Pumps

20,00

25,00

30,00

35,00

40,00

45,00

50,00

55,00

60,00

65,00

70,00

75,00

80,00

85,00

90,00

Flow [m3/h]

Speed [RPM]

5.3 APP 78 flow at different rpm

26 | © Danfoss | DCS (im) | 2021.12

400,00

380,00

360,00

340,00

320,00

300,00

280,00

260,00

240,00

Flow [gpm]

220,00

200,00

180,00

160,00

140,00

120,00

100,00

Speed [RPM]

180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701

Data sheet | APP 53-92 Pumps

100,00

120,00

140,00

160,00

180,00

200,00

220,00

240,00

260,00

280,00

300,00

320,00

340,00

360,00

380,00

400,00

Flow [gpm]

Speed [RPM]

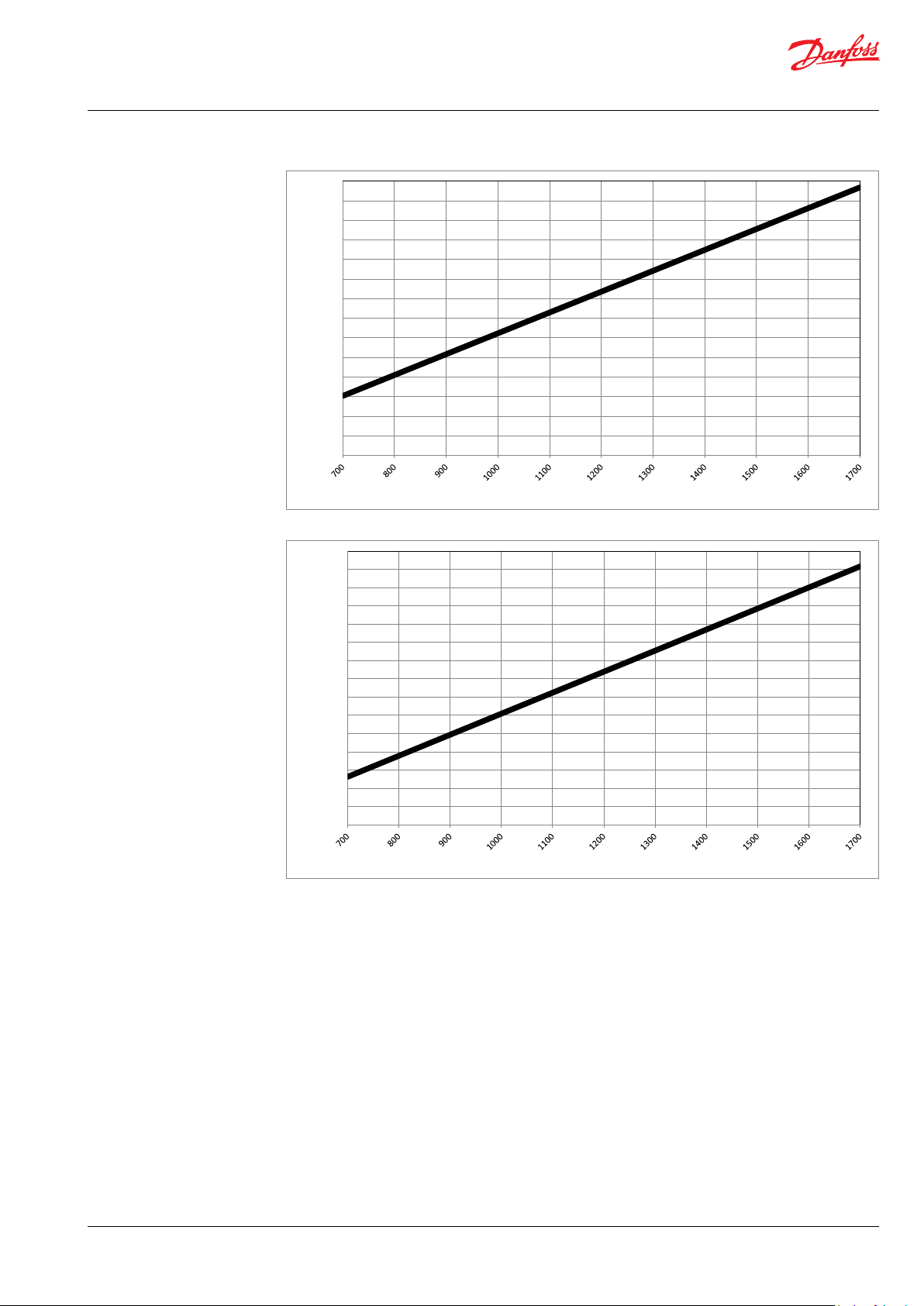

5.3 APP 86 flow at different rpm

90,00

85,00

80,00

75,00

70,00

65,00

60,00

55,00

50,00

Flow [m3/h]

45,00

40,00

35,00

30,00

25,00

20,00

Speed [RPM]

© Danfoss | DCS (im) | 2021.12

180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701 | 27

Data sheet | APP 53-92 Pumps

20,00

25,00

30,00

35,00

40,00

45,00

50,00

55,00

60,00

65,00

70,00

75,00

80,00

85,00

90,00

95,00

100,00

Fl ow [m3/h]

Speed [RP M]

100,00

120,00

140,00

160,00

180,00

200,00

220,00

240,00

260,00

280,00

300,00

320,00

340,00

360,00

380,00

400,00

420,00

Fl ow [gpm]

Speed [RPM]

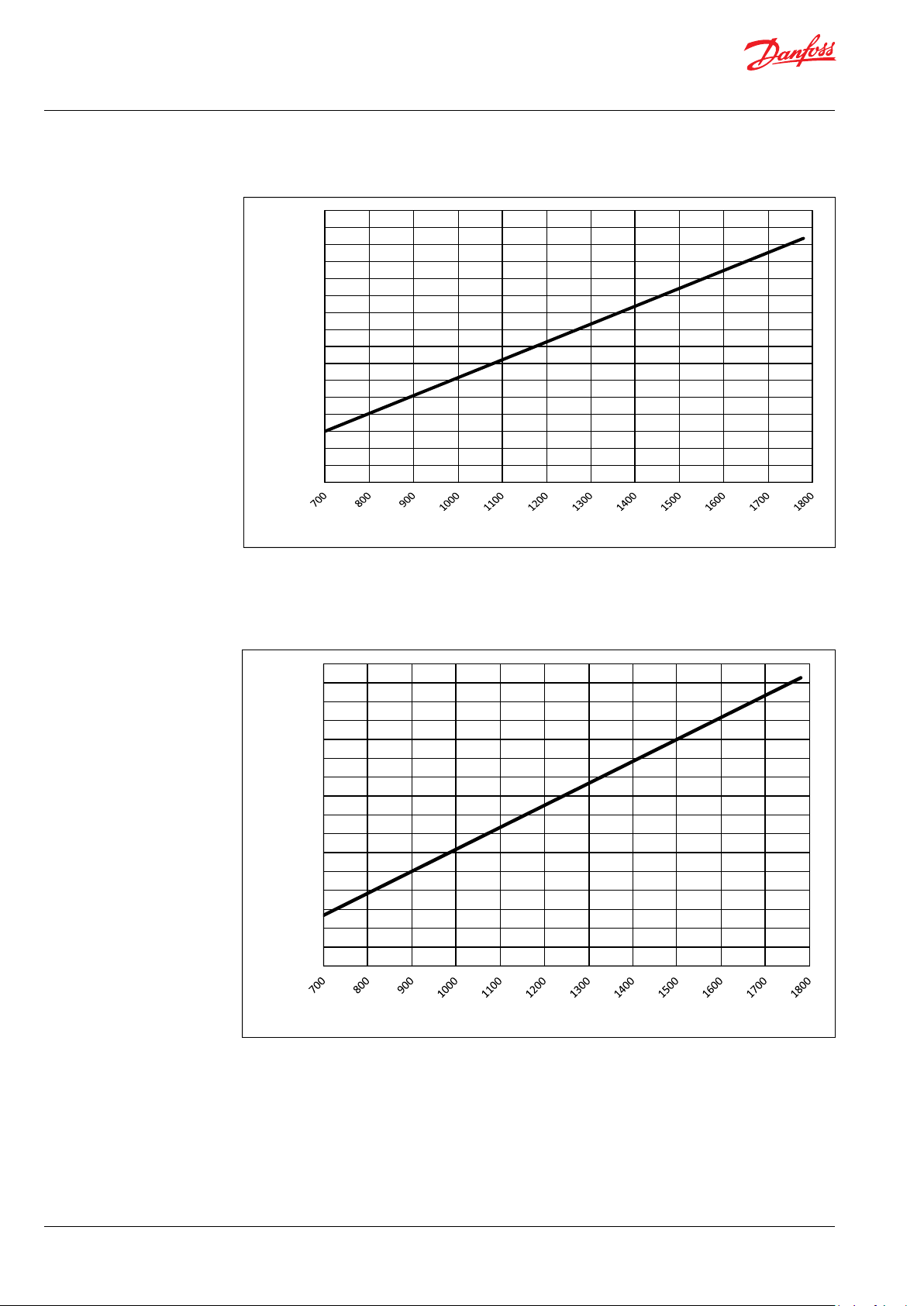

5.4 APP 92 flow at different rpm

28 | © Danfoss | DCS (im) | 2021.12

180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701

Data sheet | APP 53-92 Pumps

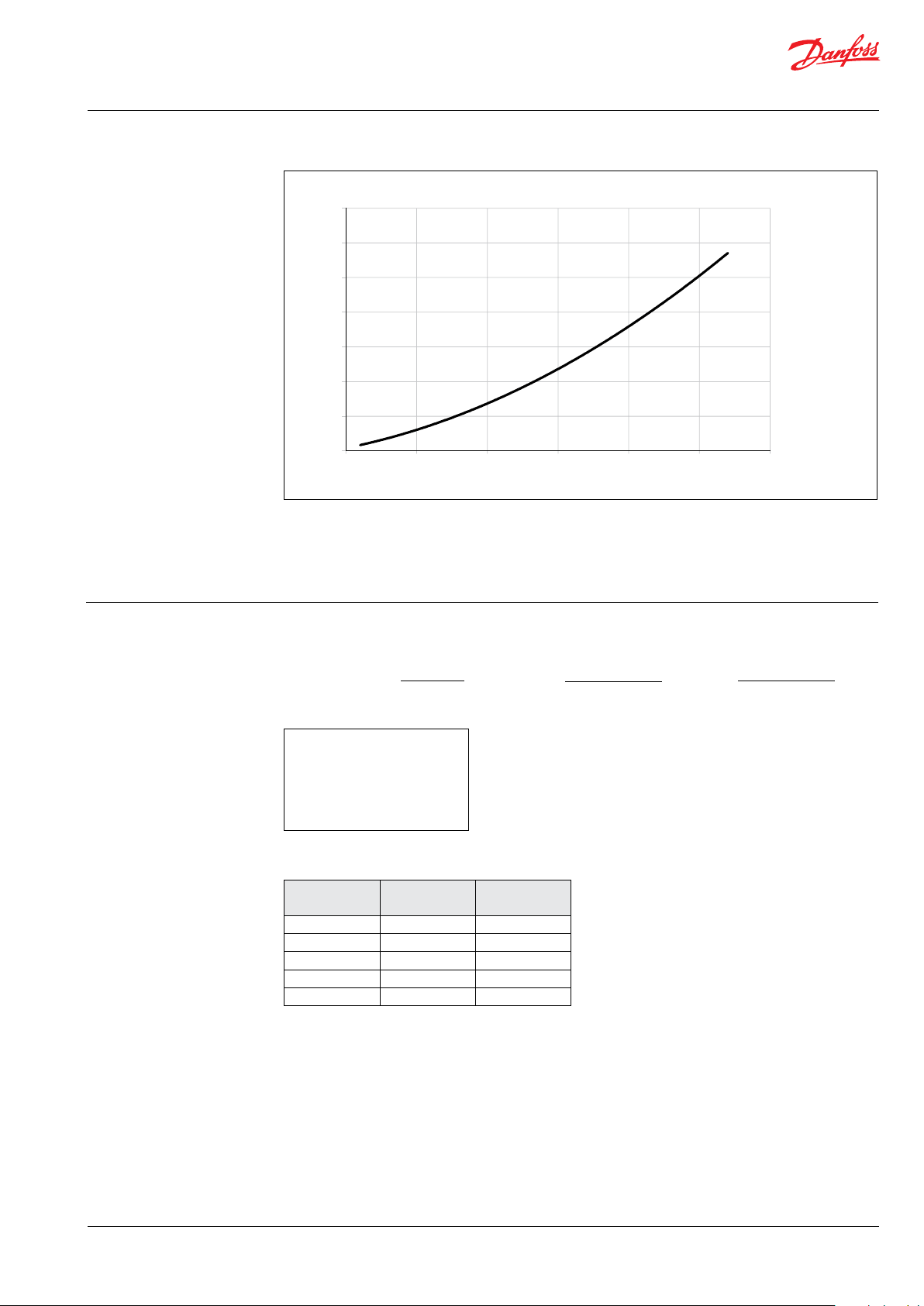

6. Flushing valve curves

6.1 APP 53-92 integrated flushing valve

Pressure [barg]

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0

0

100

200

300

400

500

Flow [l/min]

600

The power requirements can be determined using one of the following guiding equations:7. Motor requirements

3

l/min x barg 16.7 x m

/h x barg 0.35x gpm x psig

Required power = [kW] or [kW] or

Calc. factor Calc. factor Calc. factor

1 hp = 0.75 kW

1 gpm = 3.79 l/min

3

1 m

/h = 4.40 gpm

1 kW = 1.34 hp

1 l/min = 0.26 gpm

1 gpm = 0.23 m

3

/h

7.1 Calculation factor at 60 barg / 870 psig for APP 53-92

Name rpm

APP 53 1500 528

APP 65 150 0 534

APP 78 150 0 534

APP 86 170 0 528

APP 92 178 0 522

Calculation

factor

[Hp]

© Danfoss | DCS (im) | 2021.12

180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701 | 29

Data sheet | APP 53-92 Pumps

8. Temperature and

corrosion

8.1 Operation

The chart below illustrates the corrosive

resistance of different types of stainless steel

related to NaCl concentration and temperature.

All wetted parts of the APP pump are made of

Duplex or Super Duplex.

º

80

C

Duplex

70

60

50

316L

40

30

20

100

160 1600

1000

10 000

16000

If the water pump is operated at high salinity

always flush the water pump with fresh water at

operation stop in order to minimize the risk of

crevice corrosion.

NaCI vs. temperature

Super Duplex

-

100 000

160000

CI

ppm

NaCI

ppm

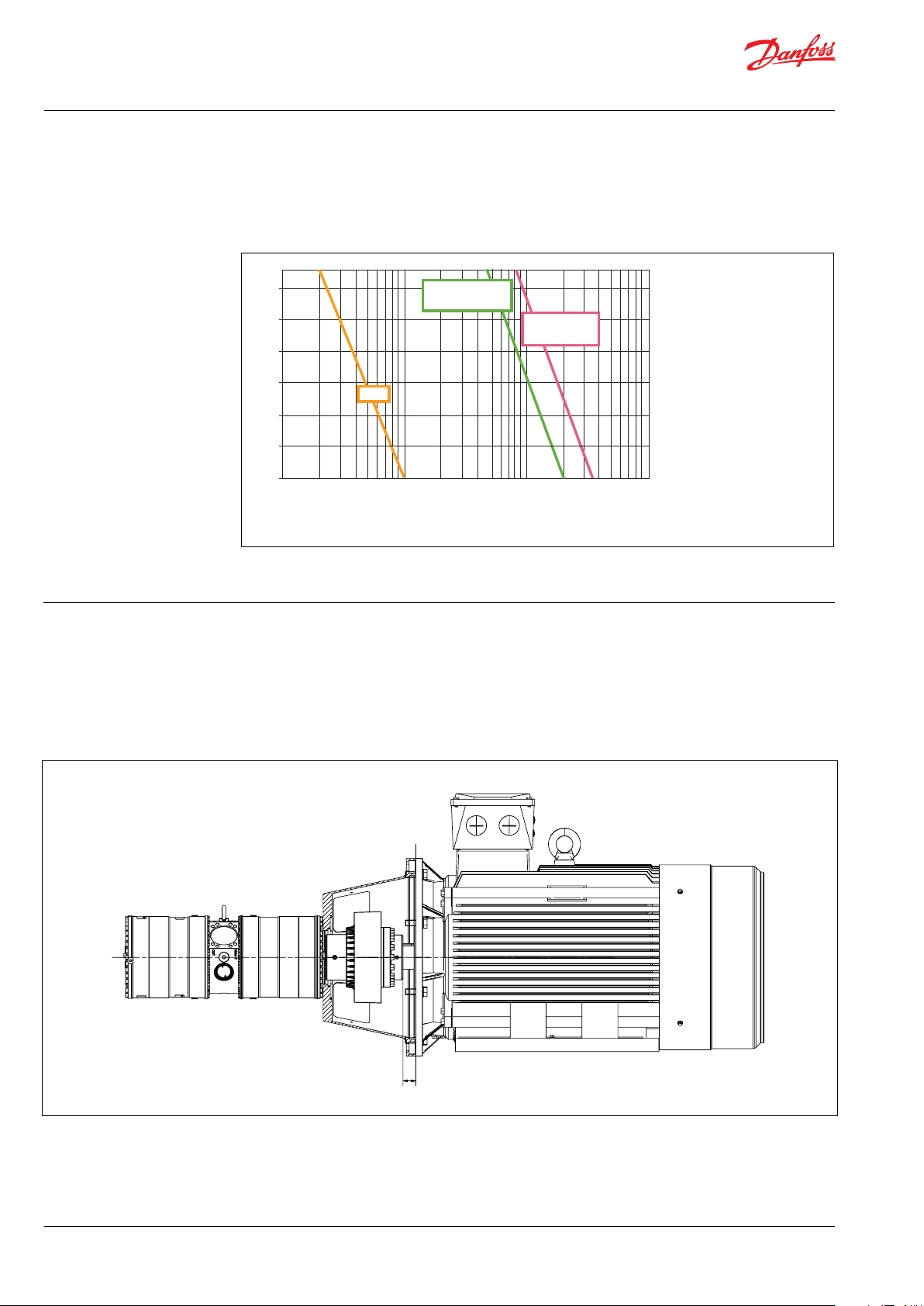

9. Installation See example below on how to mount the pump

and connect it to an electric motor or combustion engine (special coupling).

For further instruction on installation of coupling

see APP Pump Instruction 180R9368.

If alternative mounting is required. please

contact your Danfoss sales representative for

further information.

Note: Do not add any axial or radial loads to the

pump shaft.

30 | © Danfoss | DCS (im) | 2021.12

180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701

Data sheet | APP 53-92 Pumps

9.1 Filtration

Proper filtration is crucial for the performance,

maintenance and warranty of your pump.

Protect your pump, and the application in which

it is installed, by always ensuring that all filtration

specifications are met, and by always changing

filter cartridges according to schedule.

Since water has very low vicosity, Danfoss APP

pumps have been designed with very narrow

clearances in order to control internal leakage

rates and improve component performance.

To minimize wear on the pump, it is therefore

essential to filter inlet water properly.

The main filter must have a filtration efficiency of

99.98% at 10 μm. We strongly recommend that

you always use precision depth filter cartridges

rated 10μm abs. ß

≥5000.

10

Please note that we do not recommend bag

filters or string-wound filter cartridges, which

typically have only 50% filtration efficiency. This

means that out of the 100,000 particles that

enter such filters, 50,000 particles pass right

through; compare this to precision depth filters

that are 99.98% efficient, and only allow 20 of the

same 100,000 particles to pass through.

For more information on the importance of

proper filtration, including explanation of

filtration principles, definitions and guidance on

how to select the right filter for your pump,

please consult our Filtration information and

specifications (Danfoss document number

521B1009).

Noise

Since the pump unit is typical mounted on a

frame or bell housing the overall noise level can

only be determined for a complete system. To

minimize vibrations and noise throughout the

system, it is therefore very important to mount

the pump unit correctly on a frame with

anti-vibration-dampeners, and to use flexible

hoses rather than metal pipes where possible.

The noise level is influenced by:

• Pump speed:

High rpm generates more fluid/structure

borne pulsations/vibrations than low rpm,

because of higher frequency.

• Discharge pressure:

High pressure generates more noise than

low pressure.

• Pump mounting:

Rigid mounting generates more noise than

flexible mounting, because of structureborne vibrations. Be sure to use dampeners

when mounting.

• Connections to pump:

Pipes connected directly to the pump make

more noise than flexible hoses, because of

structure-borne vibrations.

• Variable frequency drives (VFD):

Motors regulated by VFDs can produce

more noise if the VFD does not have the

right settings.

•

9.2 RO system with direct supply:

Inlet line:

a) Dimension the inlet line to obtain mini

mum pressure loss (large flow, minimum

pipe length, minimum number of bends/

connections, and fittings with low or no

pressure losses) .

Inlet filter:

b) Install an inlet filter (1) in front of the APP

pump (2). Please consult section 9.1,

“Filtration” for guidance on how to select

the right filter. Thoroughly clean pipes and

flush system prior to start-up.

Inlet pressure:

c In order to eliminate the risk of cavitation

and other pump damage, pump inlet

pressure must always be maintained

according to specifications described in

item 4 about technical data.

Low pressure relief valve:

d) Install a low pressure relief valve (9) in order

to avoid system or pump damage in case

the pump stops momentarily or is spinning

backwards.

Monitoring pressure switch:

e Install a monitoring pressure switch (3)

between the filter (1) and the pump inlet.

Set the minimum inlet pressure according

to specifications described in item 4 about

technical data. If the inlet pressure is lower

than the minimum pressure set, the

monitoring pressure switch must prevent

the pump from starting or from running.

Hoses:

f) Always use flexible hoses (4) to minimize

vibrations and noise. Please consult the

Danfoss Hoses and hose fittings data

sheet (521B0909) for guidance.

Flushing valve:

g) For easy system filling and flushing, the

APP pump has an integrated valve (6).

Non-return valve:

h) A non-return valve (7) in outlet can be

installed in order to avoid backspin of the

pump. The volume of water in the

membrane vessel works as an accumulator

and will send flow backwards in case the

pump stops momentarily.

© Danfoss | DCS (im) | 2021.12

180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701 | 31

Data sheet | APP 53-92 Pumps

High pressure safety or relief valve:

i) As the Danfoss APP pump begins to create

pressure and flow immediately after

start-up and regardless of any counter

pressure, a safety or pressure relief valve (8)

should be installed after the non-return

valve to prevent system damage and to

avoid high pressure peaks.

Note: If a non-return valve is mounted in the inlet

line, a low-pressure relief valve is also required

between the non-return valve and

pump as protection against high-pressure peaks.

Feed

Media filter

PI

PI

PI PI

Fresh water

permeat flush

M

PT

PI

Brine

Permeate

PI

32 | © Danfoss | DCS (im) | 2021.12

180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701

Data sheet | APP 53-92 Pumps

connections

10.1 APP 5310. Dimensions and

© Danfoss | DCS (im) | 2021.12

180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701 | 33

Data sheet | APP 53-92 Pumps

10.2 APP 65 - 92

34 | © Danfoss | DCS (im) | 2021.12

APP 65 - 92

180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701

Data sheet | APP 53-92 Pumps

The APP 53-92 connections (inlet and outlet) can be adjusted in intervals of 45 degrees.

Please see typical installations with check valve VCM 92 mounted in the outlet port in the drawing

below. Non-standard configurations are available on request. For adjustment on site, please see

Installation, Operation and Maintenance Manual or contact Danfoss.

Non-standard configuration, turned 90 degrees left.

Non-standard configuration, turned 45 degrees left.Standard configuration

Non-standard configuration, turned 180 degrees .

© Danfoss | DCS (im) | 2021.12

180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701 | 35

Data sheet | APP 53-92 Pumps

10.3 APP 53-92 with IE3 motor, IEC 315S - 4

10.4 APP 53-92 with IE3 motor, IEC 315M - 4

36 | © Danfoss | DCS (im) | 2021.12

180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701

Data sheet | APP 53-92 Pumps

10.5 APP 53-92 with IE3 motor, IEC 315L 1-4

10.6 APP 53-92 with IE3 motor, IEC 315L 2 - 4

© Danfoss | DCS (im) | 2021.12

180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701 | 37

Data sheet | APP 53-92 Pumps

11. Pump connections

11.1 APP 53 - 92

Use only Style 77DX coupling or equivalent.

3” Victaulic OSG LP Inlet

3” Victaulic OSG HP Outlet

38 | © Danfoss | DCS (im) | 2021.12

Connection

3” Inlet

connector

3” outlet

connector

1

) The installation instuction for Style 77DX is located in the Victaulic document I-100 Field Installation

Diameter

(A)

87. 8 m m

(3.46 inch)

87. 8 m m

(3.46 inch)

Victaulic

3” Vic. OSG

3” Vic. OSG

(B)

1)

Length

(C)

61.0 mm

(2.40”)

65.0 mm

(2.56”)

Material Max. Pressure Code number

Super

Duplex

Super

Duplex

10 barg

(145 psi g)

80 barg

(1160 ps ig)

180Z1991

180Z1992

Handbook (htpp://static.victaulic.com)

180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701

Data sheet | APP 53-92 Pumps

12. VCM 3” Victaulic

The non-return valve is designed for use in

Seawater Reverse Osmosis (SWRO) membrane

systems. In case the high-pressure pump stops

momentarily, the volume of water in the

membrane vessel may work as an accumulator

and will send flow backwards.

When using multiple pumps in parallel, the

non-return valve

12.1 Techni cal data

prevents the water from one pump to run into

the parallel-coupled pumps at start-up.

The VCM 92 is prepared for easy installation on

the high pressure outlet of APP 53-92, series 08

or higher..

Use only Style 77DX coupling or equivalent.

Diameter

valve

)

1)

mm (inch)

87. 7

(3.45)

Typ e Connection

VCM 92

1)

The check valve is mounted directly in the outlet port with a flange with 8 screws M12 x 25.

2)

Wetted parts materials: Super Duplex, PEEK, PP, Hasteloy; FKM, NBR

3)

The installation instuction for Style 77DX is located in the Victaulic document I-100 Field Installation

3” outlet check

Victaulic

(outlet

connection)

3)

3” Vic. OSG

Length

mm (inch)

180.5

(7.10)

Material2

Super

Duplex

Max.

2)

pressure

barg (psig)

83 (1.200) 180H0058

Code

number

Handbook (htpp://static.victaulic.com)

VCM VCM 92

Min. flow continously

Max. flow continously

Max pressure MAWP

Opening pressure barg 0.05- 0.08

Pressure loss at max. flow barg < 0.45

m³/h 20

gpm 88

m³/h 92

gpm 405

barg 83

psig 1200

psig 0.73-1.16

psig < 6.5

© Danfoss | DCS (im) | 2021.12

180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701 | 39

Data sheet | APP 53-92 Pumps

0

0,05

0,1

0,15

0,2

0,25

0,3

0,35

0,4

0,45

0,5

20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

dP [ bar ]

Flow [ m3/h ]

Flow versus pre ssure f or VCM 92

1

2

3

4

5

6

7

80 100 120 140 160 180 200 220 240 260 280 300 320 340 360 380 400 420 440

dP [ PSI ]

Flow [ GPM]

Flow versus pre ssure f or VCM 92

1. Valve housing (Super Duplex)

2. Valve guide and valve stop (Super Duplex,

PEEK and PP)

3. Valve Cone (Super Duplex)

5. Spring (Hasteloy)

6. O-ring (NBR)

7. O-ring (FKM 75)

8. O-ring (NBR)

12.2 Flow versus pressure

Pressure drop curves for check valve VCM 92

40 | © Danfoss | DCS (im) | 2021.12

180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701

Data sheet | APP 53-92 Pumps

13. Accessories

14. Service and warranty

Accessories Typ e Code num-

Coupling APP 53 - APP 92 IEC 315 Diameter: motor Ø80 mm, pump Ø50 180Z4066

Coupling APP 53 - APP 92 IEC 280 Diameter: motor Ø75 mm, pump Ø50 180Z4081

Coupling kit APP 53 - APP 92 incl. bell housing IEC 315 Ø80/Ø50. IEC 315 Ø660/310 180Z4083

Coupling kit APP 53 - APP 92 incl. bell housing IEC 280 Ø75/Ø50. IEC280 Ø550/265 18 0Z4082

Base frame incl. vibration dampeners IEC 315 180Z06 61

Warranty

Danfoss APP pumps are designed for long

operation, low maintenance and reduced

lifecycle costs.

Pump shutdown:

The APP pumps are made of Duplex/Super

Duplex materials with excellent corrosion

properties. It is, however, always recommended

to flush the pump with freshwater when the

Provided that the pump has been running

according to the Danfoss specifications, Danfoss

guarantees 8,000 hours service-free operation,

however, max. 18 months from date of

production.

system is shut down.

When stopping the pump for more than 1 day

flush the pump for 10 sec. Flushing through the

flushing valve of the pump without rotating the

pump is not enough for cleaning the inside of

the pump.

If Danfoss recommendations concerning

system-design are not followed, it will strongly

influence the life of the APP pumps.

Other factors that affect pump performance and

lifetime include:

The pump can be flushed with biocide like the

membranes. The biocide must be compatible

with the materials used in our pump (materials

can be found in the parts list in the instruction

and operational manual).

- Insufficient filtration

- Insufficient bleeding and venting

- Running the pump at speed outside

specifications.

Repair

In case of irregular function of the APP pump,

please contact Danfoss High Pressure Pumps.

- Supplying the pump with water at

temperature higher than recommended.

- Running the pump at inlet pressure outside

specifications.

- Running the pump at outlet pressure

outside the specifications.

- Wrong direction of rotation.

Maintenance

After 8,000 hours of operation it is strongly

recommended to inspect the pump and change

any worn parts, e.g. pistons and shaft

seal. This is done in order to prevent a potential

breakdown of the pump. If the parts are not

replaced, more frequent inspection is

recommended according to our guidelines.

ber

© Danfoss | DCS (im) | 2021.12

180R9346 | IOM APP 53-92 pumps | AQ240486503020en-001701 | 41

© Danfoss | DCS (im) | 2021.12

AI167386503010en-001301 | 42

Instruction

APP Pump Instruction

APP 53 / APP 65 / APP 78 / APP 86 / APP 92

hpp.danfoss.com

Instruction | APP Pump Instruction APP 53-92

Table of Contents

Table of Contents