Page 1

Data sheet

Data sheet

APP pumps

APM motor

APM 0.8 / APM 1.0 / APM 1.2 /

APP 0.6-1.0 / APP 1.5-3.5 / APP (W) 5.1-10.2 /

APM 1.8 / APM 2.0 / APM 2.5 / APM 2.9

for energy recovery

APP 11-13 / APP 16-22 / APP 21-43

hpp.danfoss.com.

ro-solutions.com

Page 2

Data sheet | APM 0.8 – 2.9 motors

Table of Contents

1. Introduction ............................................................................3

2. Benets.................................................................................3

3. Technical data ..........................................................................4

3.1 APM 0.8 – 1.2............................................................................4

3.2 APM 1.8 – 2.9............................................................................5

4. Direction of rotation ...................................................................6

5. Shaft load...............................................................................6

6. Temperature and corrosion..............................................................7

7. Noise level ..............................................................................7

8. Filtration................................................................................7

9. Orientation .............................................................................8

10. Installation..............................................................................8

11. Preferred system design.................................................................9

11.1 Membrane system with energy recovery ...............................................10

11.2 Membrane system with energy recovery and VFD.......................................11

12. Combinations..........................................................................12

12.1 Examples of motor / pump combinations...............................................12

12.2 Flow ...................................................................................12

12.3 Energy consumption vs. pressure.......................................................13

12.4 Power consumption....................................................................13

13. Dimensions ............................................................................14

13.1 APM 0.8 – 1.2...........................................................................14

13.2 APM 1.8 – 2.9...........................................................................15

14. Service.................................................................................16

2 | Danfoss | DCS im) |2020.09

AI354846545311en-000101

Page 3

Data sheet | APM 0.8 – 2.9 motors

1. Introduction

APM motors are designed for energy recovery

systems together with an APP hydraulic pump

and a double shaft motor. APM motors convert

hydraulic energy (pressure, ow) to mechanical

energy (torque, speed).

This data sheet is valid for APM hydraulic motors.

APM hydraulic motors are build to operate on

salt water and are based on the axial piston

principle with xed displacement, enabling a

very light and compact design. Lubrication of the

moving parts is provided by the salt water itself.

Shaft speed is proportional to the input ow.

The APM motor is not self-starting but needs a

rotational force to start turning.

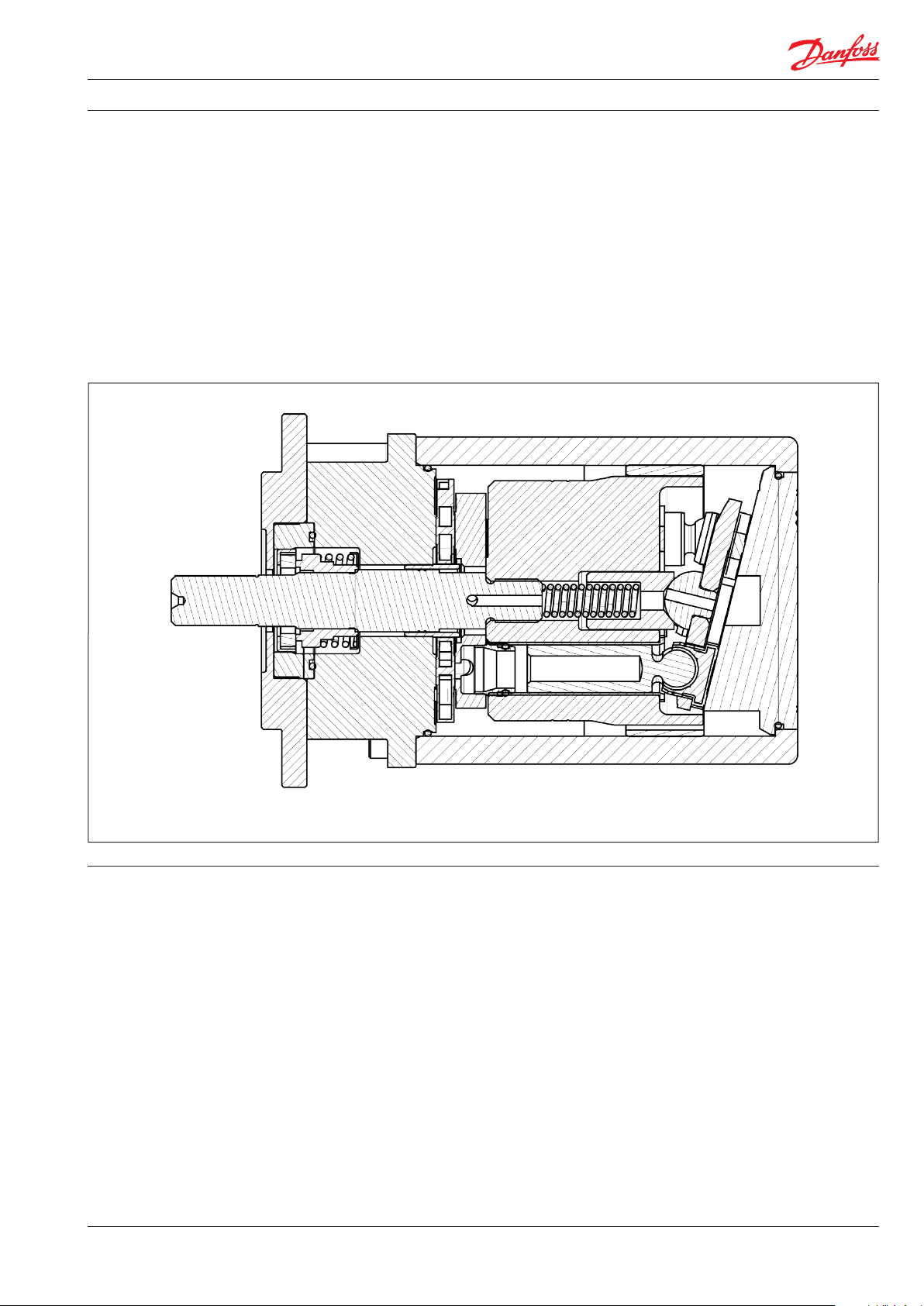

Below a sectional drawing as an example of an

APM motor

2. Benets

• Constant torque over a wide speed range

• Compact design

• Easy to install

• Long life under severe operating conditions

• Few wear parts and low maintenance costs

• No oil lubrication

• Non-corroding materials

• Made for RO applications

AI354846545311en-000101 | 3Danfoss | DCS (im | 2020.09

Page 4

Data sheet | APM 0.8 – 2.9 motors

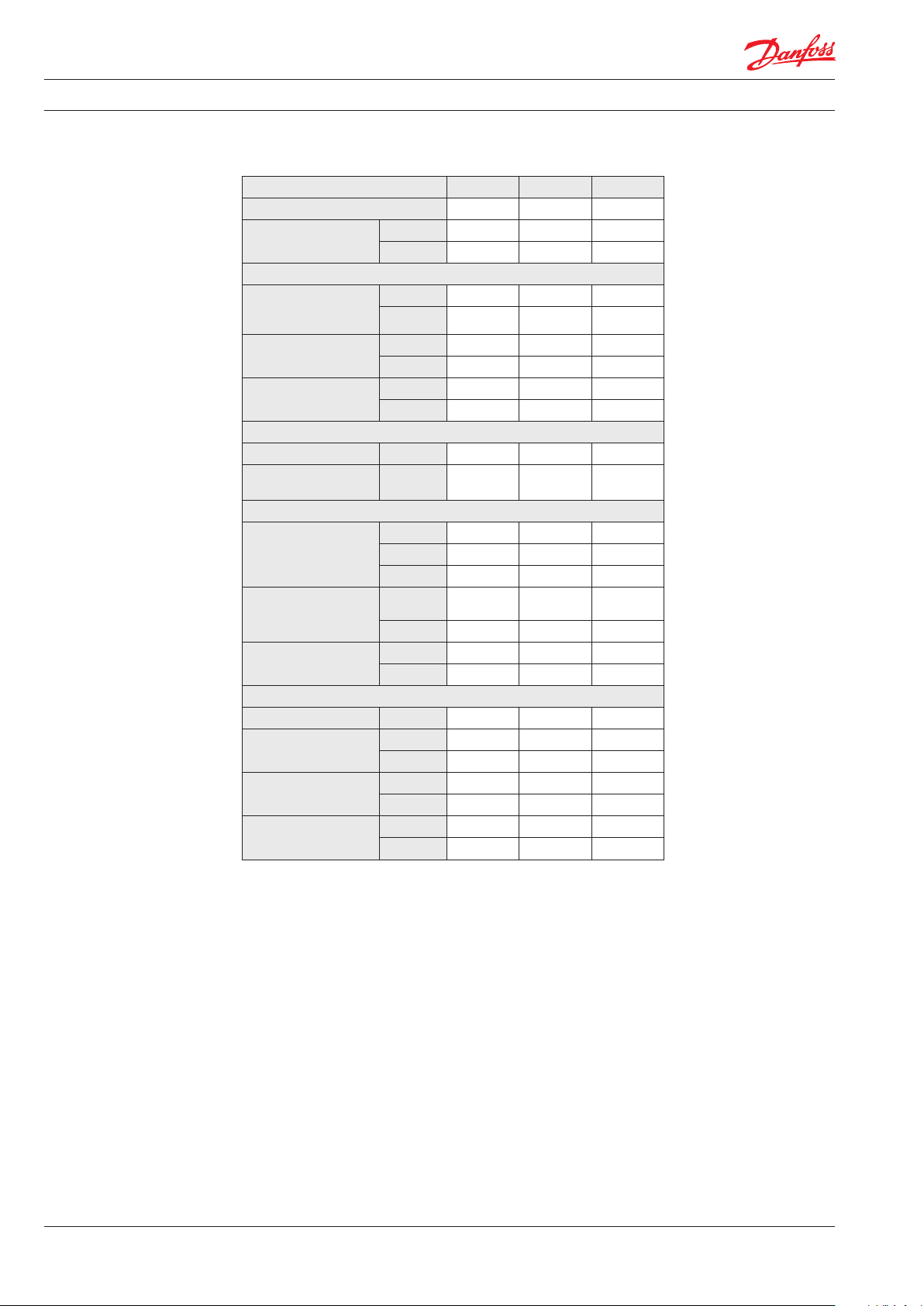

3. Technical data

3.1 APM 0.8 – 1.2

Motor size APM 0.8 APM 1.0 APM 1. 2

Code number APM CCW 180F1000 180F1001 180F1002

Geometric displacement

Pressure

Max. inlet

pressure

continuous

Min. inlet pressure

continuous

Outlet

pressure

Speed

Min. speed rpm 700 700 700

Max. speed

continuous

Typical performance

Max. waterow

Max. power at

max. speed cont. and

max. pressure

Max. torque at max.

pressure

Technical specications

Sound pressurre level dB(A) 74 74 74

Media temperature

Ambient temperature

Weight (dry)

cm³/rev. 4.07 5.08 6.30

in³/re v. 0.25 0.31 0.38

barg 80 80 80

psig 116 0 116 0 1160

barg 10 10 10

psig 145 145 145

barg 0.5 – 5 0.5 – 5 0.5 – 5

psig 7.3 – 72.5 7.3 – 72.5 7.3 – 72.5

rpm 3450 3450 3450

m³/h 0.92 1.12 1.37

l/min 15.3 18.6 22.9

gpm 4.0 4.9 6.1

kW 1.7 2.1 2.6

HP 2.3 2.8 3.5

Nm 4.7 5.8 7. 2

lbf-ft 3.4 4.3 5.3

°C 2 – 50 2 – 50 2 – 50

°F 35.6 – 122 35.6 – 122 35.6 – 122

°C 0 – 50 0– 50 0 – 50

°F 32 – 122 32 – 122 32 – 122

kg 5.2 5.2 5.2

lb 11.5 11. 5 11.5

4 | Danfoss | DCS im) |2020.09

AI354846545311en-000101

Page 5

Data sheet | APM 0.8 – 2.9 motors

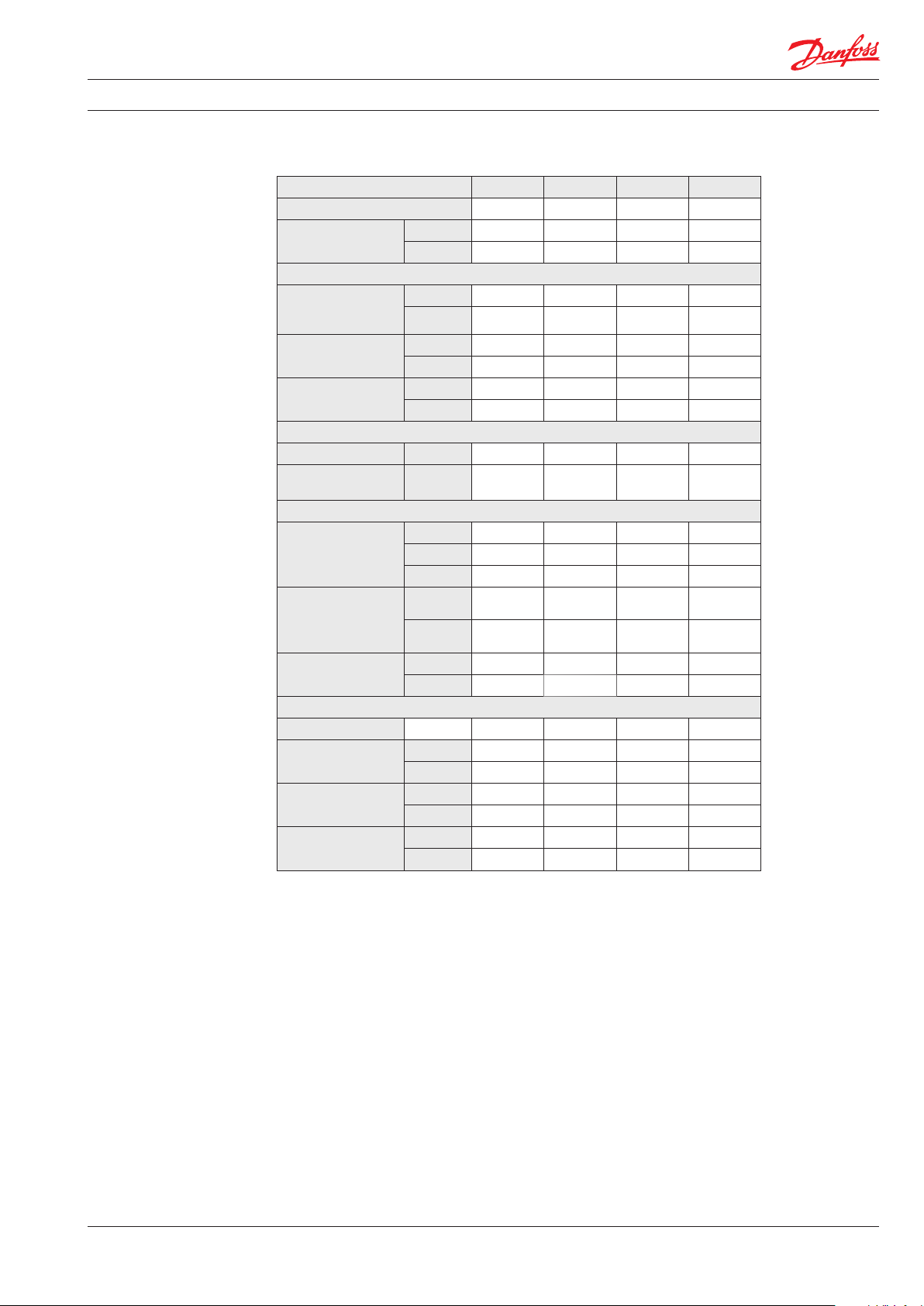

3.2 APM 1.8 – 2.9

Motor size APM 1.8 APM 2.0 APM 2.5 AMP 2.9

Code number APM CCW 18 0F1100 18 0F1101 18 0F1102 180F110 3

Geometric displacement

Pressure

Max. inlet

pressure

continuous

Min. inlet pressure

continuous

Outlet pressure

Speed

Min. speed rpm 700 700 700 700

Max. speed

continuous

Typical performance

Max. waterow

cm³/rev. 9. 31 10.0 12 .5 15. 3

in³/re v. 0.57 0 .61 0.76 0.93

barg 80 80 80 80

psig 116 0 116 0 1160 1160

barg 10 10 10 10

psig 145 145 145 145

barg 0.5 – 5 0.5 – 5 0.5 – 5 0.5 – 5

psig 7.3 – 72.5 7.3 – 72.5 7.3 – 72.5 7.3 – 72.5

rpm 3450 3450 3450 3000

m³/ h 2.03 2.18 2.69 2.83

l/min 33.9 36.4 44.8 47.2

gpm 9.0 9.6 11.8 12 .5

Max. power at

max. speed cont. and

max. pressure

Max. torque at max.

pressure

Technical specications

Sound pressure level dB(A) 77 77 77 81

Media temperature

Ambient temperature

Weight (dry)

kW 3.9 4.2 5.3 5.6

HP 5.2 5.7 7.1 7.6

Nm 10.8 11 .7 14.7 18.0

lbf-ft 8.0 8.6 10.8 13.2

°C 2 – 50 2 – 50 2 – 50 2 – 50

°F 35.6 – 122 35.6 – 122 35.6 – 122 35.6 – 122

°C 0 – 50 0 – 50 0 – 50 0– 50

°F 32 – 122 32 – 122 32 – 122 32 – 122

kg 8.6 8.6 8.6 8.6

lb 19 19 19 19

AI354846545311en-000101 | 5Danfoss | DCS (im | 2020.09

Page 6

Data sheet | APM 0.8 – 2.9 motors

4. Direction of rotation

Connections and direction of rotation appear

from the product label on the motors (see also

the below drawing).

I Inlet

O Outlet

Motor variants

APM motors are optimezed for operation in one

direction: CCW

5. Shaft load

Any axial and/or radial loads on the shaft must

be avoided.

6 | Danfoss | DCS im) |2020.09

AI354846545311en-000101

Page 7

Data sheet | APM 0.8 – 2.9 motors

80

70

60

50

40

30

20

6. Temperature and

corrosion

Fluid temperature:

Min. +2 °C to max. +50 °C

(Min. +35.6 °F to max. +122 °F)

Ambient temperature:

Min. 0 °C to max. +50 °C

(Min. +32 °F to max. +122 °F)

Storage temperature:

Min. -40 °C to + 70 °C - provided that the APM

is drained of uid and stored “plugged”.

Antifreeze protection is required at temperatures

below 0 °C.

º

C

316L

Duplex

Danfoss recommends using Dowcal N from Dow

Chemical Company or Chillsafe mono propylene

glycol from Arco Chemical Company.

The chart below illustrates the corrosive

resistance of dierent types of stainless steel

related to NaCl concentration and temperature.

All critical parts of the APM motors are made of

Duplex and Super Duplex. If the APM motor is

operated above the Duplex line, always ush the

APM with fresh water at operation stop to

minimize the risk of crevice corrosion.

NaCI vs. temperature

Super Duplex

7. Noise level

8. Filtration

100

1000

160 1600

Generally, noise will be reduced if speed is reduced and vice versa. Use exible hoses in order

to minimize vibrations and noise.

Since the APM motor typically is mounted on a

bell housing or frame, the noise level can only be

determined for complete unit (system).

Proper ltration is crucial for the performance

maintenance and warranty.

The water supplied must be ltered: 10 µm absolute, ß10-value > 5000 lter is recommended.

-

10 000

16000

It is therefore very important that the energy

recovery unit is mounted correctly on a frame

with vibration absorber to minimize vibrations

and noise.

The noise level is inuenced by:

• The speed of the pump/motor. High rpm

creates more noise than low rpm

• Rigid mounting of the pump/motor generates more noise than exible mount

• Pipe mounting direct to the pump/motor

increases the noise level compared to a

exible hose

For further information on lters, please contact

Danfoss High Pressure Pumps sales department.

100 000

160000

CI

ppm

NaCI

ppm

AI354846545311en-000101 | 7Danfoss | DCS (im | 2020.09

Page 8

Data sheet | APM 0.8 – 2.9 motors

9. Orientation

The drawing shows preferred acceptable, and

not acceptable orientations of the motor.

Preferred

Not acceptable

10. Installation

8 | Danfoss | DCS im) |2020.09

It is recommended to use exible coupling and

ensure that the gab between the two metal parts

of the coupling is min. 3 mm.

A: Elastic coupling

B: Bell housing

C: Motor shaft

AI354846545311en-000101

Page 9

Data sheet | APM 0.8 – 2.9 motors

11. Preferred system

design

APM is used for energy recovery unit which consists of an APP pump and an APM motor, both

connected to a double shafted electric motor.

Energy recovery is obtained when high-pressure

brine from the membranes is fed to the APM that

converts the energy in the pressurized brine to

mechanical energy to be reused by the electric

motor. As the APM has a xed volumetric displacement, the recovery rate will be xed.

System example

Permeate

Outlet

Pump

Feed

Motor

AI354846545311en-000101 | 9Danfoss | DCS (im | 2020.09

Page 10

Data sheet | APM 0.8 – 2.9 motors

The design of the system must ensure that self

emptying of the water motor during standstill

is avoided. Always place the outlet line

higher than the water motor.

Air in the water will cause cavitation and

damage the water pump and the water motor.

11.1 Membrane system with energy recovery

1

4

APP

5

M

APM

8

Feed

Outlet

10 micron

2

absolut

Filter

6

PS

In order to eleminate the risk of damage and

cavitation, observe the following guidelines:

1.

For easy system bleeding without starting up the system, the APP pump has an

integrated ushing valve (1).

2.

Place an inlet lter (2) in front of the APP

pump (3). Please consult section 8, “Filtration” guidance on how to select the right

lter.

Important:

Thoroughly clean pipes and ush system

prior to start-up — the APP pump and the

APM must be bypassed

3.

Place a monitoring pressure switch (6) set

at min. 1 bar between lter and pump inlet.

The monitoring switch must stop the pump

at pressures lower than 1 bar (14.5 psi). At

3000 rpm — use 2 bar (29 psi) as set point.

4.

Dimension the inlet and outlet lines to

obtain minimum pressure loss (large ow,

minimum pipe length, minimum number of

bends/connections, and ttings with small

pressure losses).

7

9

PI

3

5

9

PI

Brine

55

5.

Always maintain a positive pressure at the

17

Permeate

pump inlet (4) of min. 0.5 bar (7.3 psi) and

max. 5 bar (72.5 psi). At speeds above 3000

rpm the pressure at the inlet of the water

pump must be min. 2 bar (29 psi).

6.

Use exible hoses (5) to minimize vibrations

and noise.

7.

Install a safety valve (7) in order to avoid

system damage as the Danfoss APP pump

creates pressure and ow immediately after

start-up, despite any counter pressure.

8.

Always maintain a pressure at the motor inlet

(8) of min. 10 bar (145 psi) and max. 80 bar

(1160 p si).

9.

As the pressure on the outlet line must not

exceed 5 bar (72.5 psi), do not throttle the

water motor outlet.

10 | Danfoss | DCS im) |2020.09

AI354846545311en-000101

Page 11

Data sheet | APM 0.8 – 2.9 motors

11.2 Membrane system with energy recovery and VFD

1

4

APP

5

M

APM

8

Feed

Outlet

10 micron

2

absolut

Filter

6

PS

In order to eleminate the risk of damage and

cavitation, observe the following guidelines:

1.

For easy system bleeding without starting up the system, athe APP pump has an

integrated ushing valve (1).

2.

Place an inlet lter (2) in front of the APP

pump (3). Please consult section 8, “Filtration” guidance on how to select the right

lter.

Important:

Thoroughly clean pipes and ush system

prior to start-up — the APP pump and the

APM must be bypassed

3.

Place a monitoring pressure switch (6) set

at min. 1 bar between lter and pump inlet.

The monitoring switch must stop the pump

at pressures lower than 1 bar (14.5 psi). At

3000 rpm — use 2 bar (29 psi) as set point.

4.

Dimension the inlet and outlet lines to

obtain minimum pressure loss (large ow,

minimum pipe length, minimum number of

bends/connections, and ttings with small

pressure losses).

7

9

P-18

PT

3

5

9

10

55

Brine

In order to eliminate the risk of damage and

5.

PI

17

Permeate

cavitation, a positive pressure at the pump

inlet (4) is always to be maintained at min.

0.5 bar (7.3 psi) and max. 5 bar (72.5 psi). At

speeds above 3000 rpm the pressure at the

inlet of the water pump must be min. 2 bar

(29 psi)

Use exible hoses (5) to minimize vibrations

6.

and noise.

Always maintain a pressure at the motor inlet

7.

(8) of min. 10 bar (145 psi) and max. 80 bar

(1160 p si).

As the pressure on the outlet line must not

8.

exceed 5 bar (72.5 psi), do not throttle the

water motor outlet.

Using a VFD (10) makes it possible to control

9.

the rotation speed, ramp up and ramp down

of the electric motor. By altering the rotation speed, the permeate production can be

changed to obtain optimum energy recovery.

Install a pressure transmitter (9) to measure

10.

the pressure at the membran inlet. Use the

signal from the pressure transmitter to obtain

an automatic pressure-controlled adjustment

of the VFD and optimum utilization and load

of the membrane.

AI354846545311en-000101 | 11Danfoss | DCS (im | 2020.09

Page 12

Data sheet | APM 0.8 – 2.9 motors

12. Combinations 12.1 Examples of motor / pump combinations

APP pump/AMP motor APP 1.0/APM 0.8 APP 1.5/APM 1.2 APP 1.8/APM 1.2 APP 2.5/APM 2.0 APP 2.5/APM 1.8

1450 rpm

Feed ow m³/h (g pm) 0.50 (2.2) 0.80 (3.5) 0.85 (3.7) 1.25 (5.5) 1.25 (5.5)

Recovery rate % 29 28 32 29 32

Permeate (± 10%) m³/ h (gpm) 0.14 (0.6) 0. 22 (1.0) 0.27 (1.2) 0. 36 (1.6) 0.40 (1.8)

Electric motor (4 pole) 1.1 kW, IEC 90 1.5 kW, IEC 90 1.5 kW, IEC 90 2.2 kW, IEC 100 2.2 kW, IEC 100

2900 rpm

Feed ow m³/h (g pm) 1.05 (4.6) 1.55 (6.8) 1.65 (7.3) 2.55 (11.2) 2.55 (11.2)

Recovery rate % 29 28 32 29 32

Permeate (± 10%) m³/ h (gpm) 0.30 (1.3) 0.43 (1.9) 0.52 (2. 3) 0.74 (3.3) 0.82 (3.6)

Electric motor (2 poles) 2.2 kW, IEC 90 3 kW, IEC 100 3 kW, IEC 100 5.5 kW IEC 132 5.5 kW IEC 132

1 gpm = 3.79 l/min

12. 2 Flow

1 l/min = 0.26 gpm

1 m³/h = 4.40 gpm

1 gpm = 0.23 m³/h

APP 2.5/APM 1.8

APP 1.8/APM 1.2

APP 1.0/APM 0.8

APP 2.5/APM 2.0

APP 1.5/APM 1.2

12 | Danfoss | DCS im) |2020.09

Due to tolerances of both the pumps and the motors, permeate production will vary according to the

gures above.

AI354846545311en-000101

Page 13

Data sheet | APM 0.8 – 2.9 motors

3

3,5

4

4,5

5

50 60 70

kWh/m

3

bar

Energy cons umption vs. Pre ssure

APP1.5/APM1.2

APP1.0/APM0.8

APP2.5/APM2.0

APP1.8/APM1.2

APP2.5/APM1.8

12.3 Energy consumption vs. pressure

A variation of up to 20% may occur depending

on the rpm and the eciencies of the pump and

the motor.

The curves below are calculated using an eciency of the electric motor of 86% and provided

that the pressure at the inlet of the APM motor is

1 bar less than the pressure from the APP pump.

12.4 Power consumption

Motor / pump combination

APP 1.0/

APM 0.8

kWh

APP 1.5/

APM 1.2

kWh

APP 1.8/

APM 1.2

kWh

1 hp hr = 0.75 kWh

1 kWh = 1.34 hp hr

APP 2.5/

APM 2.0

kWh

APP 2.5/

APM 1.8

kWh

Recovery rate (%) 29 28 32 29 32

50 bar (725psi) 1450 rpm 0.6 0.9 0.9 1.4 1.5

50 bar (725 psi) 2900 rpm 1.2 1.7 1.9 2.8 3.0

60 bar (870 psi) 1450 rpm 0.7 1.0 1.2 1.7 1.5

60 bar (870 psi) 2900 rpm 1.5 2.1 2.3 3.4 3.5

70 bar (1015 psi) 1450 rpm 0.8 1.2 1.3 2.0 2.1

70 bat (1015 psi) 2900 rpm 1.7 2.4 2.7 3.8 4.0

The gures in the table above are calculated

using an eciency of the electric motor of 86%

and provided that the pressure at the inlet of the

APM motor is 1 bar less than the pressure from

the APP pump.

AI354846545311en-000101 | 13Danfoss | DCS (im | 2020.09

Page 14

Data sheet | APM 0.8 – 2.9 motors

13. Dimensions

13.1 APM 0.8 – 1.2

14 | Danfoss | DCS im) |2020.09

AI354846545311en-000101

Page 15

Data sheet | APM 0.8 – 2.9 motors

13.2 APM 1.8 – 2.9

Outlet

Outlet

Inlet

AI354846545311en-000101 | 15Danfoss | DCS (im | 2020.09

Page 16

14. Service Warranty

Danfoss APM motors are designed for long

operation, low maintenance and reduced

lifecycle costs.

Provided that the motorp has been running

according to the Danfoss specications, Danfoss

guarantees 8,000 hours service-free operation,

however, max. 18 months from date of

production.

If Danfoss recommendations concerning

system-design are not followed, it will strongly

inuence the life of the APM motors.

Other factors that aect motor performance and

lifetime include:

- Running the motor at speed outside

specications.

- Supplying the motor with water at

temperature higher than recommended.

- Running the motor at inlet pressure outside

specications.

- Running the motor at outlet pressure

outside the specications.

Maintenance

Periodic inspections are required to ensure worn

parts (if any), are replaced in due time. Operational conditions such as water quality should be

taken into consideration when determining the

frequency of the inspections. Danfoss recommends yearly inspections.

It is recommended to order the purposedesigned tool kit.

Motor shutdown:

The APM motors are made of Duplex/Super

Duplex materials with excellent corrosion

properties. It is, however, always recommended

to ush the motor with freshwater when the

system is shut down.

When stopping the motor for more than 1 day

ush the motor with permeate by rotating the

motor for 10 sec. The motor can be ushed with

biocide like the membranes. The biocide must be

compatible with the materials used in our

motors.

Repair assistance

In case of irregular function of the APM motor,

please contact Danfoss High Pressure Pumps.

Danfoss A/S

High Pressure Pumps

DK-6430 Nordborg

Denmark

Danfoss ca n accept no respons ibility for pos sible errors in ca talogues, bro chures and other pr inted material. Da nfoss reserves t he right to alter its p roducts with out notice.

This also a pplies to produc ts already on ord er provided that su ch alterations ca n be made without su bsequential cha nges being nece ssary in speci cations alread y agreed.

All trade marks in this mate rial are proper ty of the respec tive companies . Danfoss and the Dan foss logotyp e are trademark s of Danfoss A/S. Al l rights reserv ed.

© Danfoss | DCS (im) | 2020.09

AI354846545311en-000101 | 16

Loading...

Loading...