Page 1

Data sheet

Actuator for modulating control

AME 435 QM

Description

AME

435 QM actuator for modulating control is

used with pressure independent balancing and

control valve type AB-QM from DN 40 to DN 100.

The actuator has some special features:

•

it automatically adapts its stroke to the valve end

positions which reduces commissioning time

• valve ow adjustment feature; ow can be

variably-adjusted from linear to logarithmic or

opposite.

• the advanced design incorporates load

related ‘switch-o’ to ensure that actuators

and valves are not exposed to overload

Main data:

• Nominal voltage (AC or DC):

- 24 V, 50 Hz/60 Hz

• Control input signal:

- 0(4)-20 mA

- 0(2)-10 V

• Force: 400 N

• Stroke: 20 mm

• Speed (selectable):

- 7.5 s/mm

- 15 s/mm

• Max. medium temperature: 120 °C

• Self calibrating

• LED signalling

• External RESET button

• Output signal

• Manual operation

Ordering

Technical data

Actuator

Typ e Supply voltage Code No.

AME 435 QM

Power supply V 24 AC/DC; ±10%

Power consumption

Frequency Hz 50/60

Control input Y

Output signal X V 0-10 (2-10); RL = 650 Ω (maximal load)

Closing force N 400

Max. stroke mm 20

Speed s/mm 7,5 or 15

Max. medium temperature

Ambient temperature 0 … 55

Storage and transport temperature –40 … 70

Protection class II

Grade of enclosure IP 54

Weight kg 0,45

- marking in accordance with standards

24 VAC /DC

running

standby 1,2

08 2H017 1

VA

V 0-10 (2-10); Ri = 95 kΩ

mA 0-20 (4-20); Ri = 500 Ω

°C

Accessories-Adapter

Typ e for valve ’s DN for Actuator Code No.

AB-QM adapter

st

(2

generation)

AB-QM adapter

st

(1

generation)

4,5

120

Low Voltage Directive (LVD) 2006/95/EC: EN 60730-1, EN 60730-2-14

EMC Directive 2004/108/EC: EN 61000-6-2, EN 61000-6-3

40 -100

AME 15 QM 003Z0694

AME 435 QM 065 Z0313

SMT/ SI

VD. CV.S 2.02 © Danfoss 09/2014

1

Page 2

Data sheet Actuator for modulating control AME 435 QM

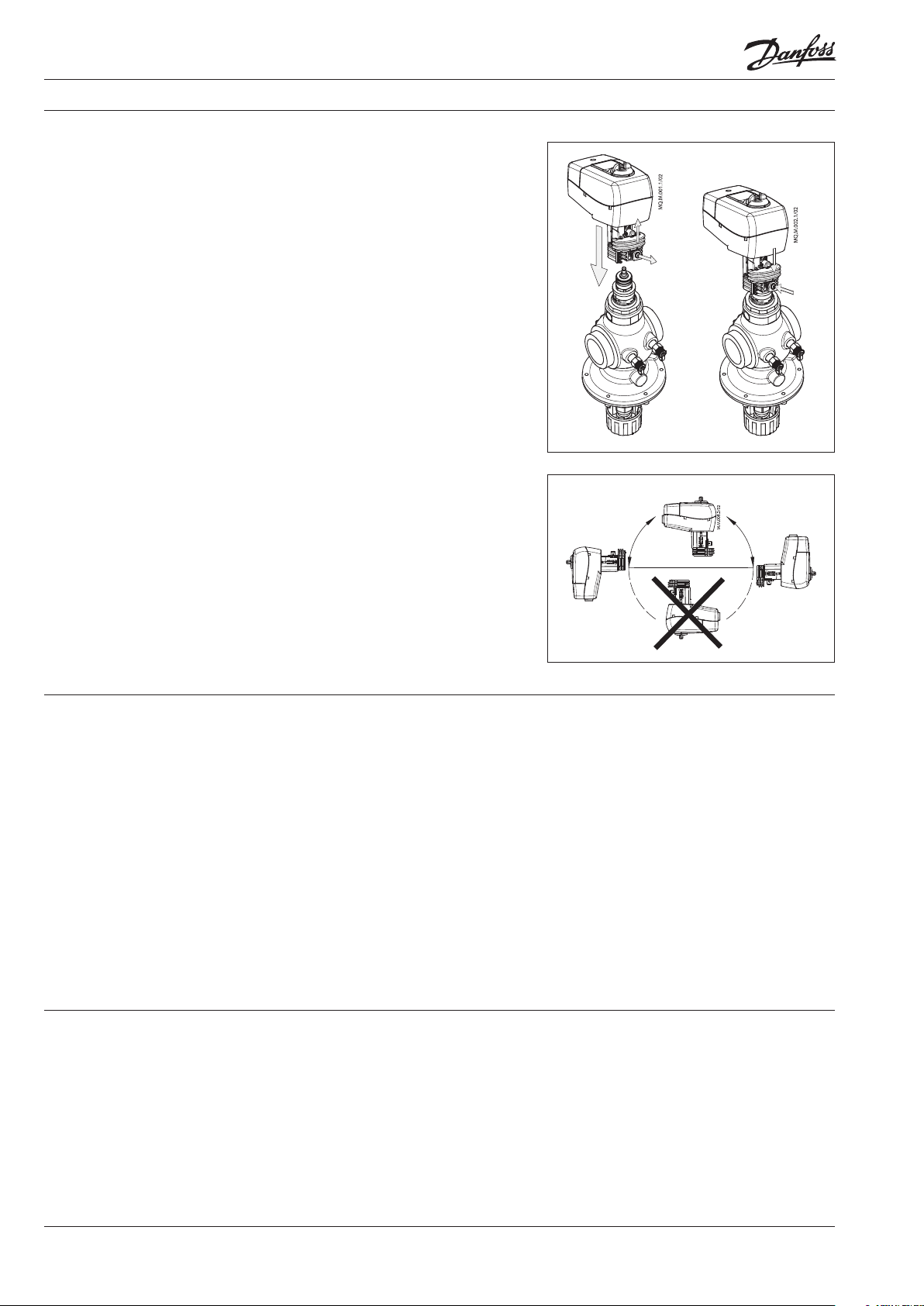

Installation Mechanical

No tool is required to mount actuator on the

valve. Installation of the valve with the actuator

is allowed in horizontal position or upwards.

Installation downwards is not allowed.

The actuator must not be installed in an

explosive atmosphere, at ambient temperature

lower than 0 °C or at ambient temperature

higher than 55 °C. It must not be subject to

steam jets, water jets or dripping liquid as well.

Note:

The actuator may be rotated up to 360° with

respect to the valve stem by loosening the retaining

xture. Once the actuator is placed, retighten the

xture.

Electrical

Electrical connections can be accessed by

removing the actuator cover. Two cable gland

entries without thread (Ø16 and combined Ø16/

Ø20) are prepared for cable glands. From factory

one entry is provided by rubber cable gland and

the other entry is prepared for opening.

③

①

②

⑤

④

Note:

Cable and cable gland used must not compromise

the actuator’s IP rating, and must ensure the

connectors are fully strain relieved.

Rubber cable gland delivered from factory does not

compromise IP rating but it does not provide fully

strain relieve according to LVD directive.

Please observe local rules and regulations as well.

Commissioning Automatic Calibrating feature

Complete the mechanical and electrical

installation, set jumper and DIP-switches, then

perform the necessary checks and tests:

The actuator automatically adapts its stroke to

the valve end positions :

- when power is applied for the rst time or

• Apply power

Note that the actuator will now perform

- afterwards by pressing the STAND BY/RESET

button for 5 seconds

automatic Calibrating function

Testing entire valve stroke length

• Apply the appropriate control signal and

check:

- SW7 setting

The actuator can be driven to the fully-open or

closed positions by connecting SN to terminals

1 or 3.

- the actuator drives the valve over the entire

stroke length

The unit is now fully commissioned.

Disposal

2

The actuator must be dismantled and the

elements sorted into various material groups

before disposal.

VD. CV.S 2. 02 © Danfoss 09/2014

SMT/ SI

Page 3

Data sheet Actuator for modulating control AME 435 QM

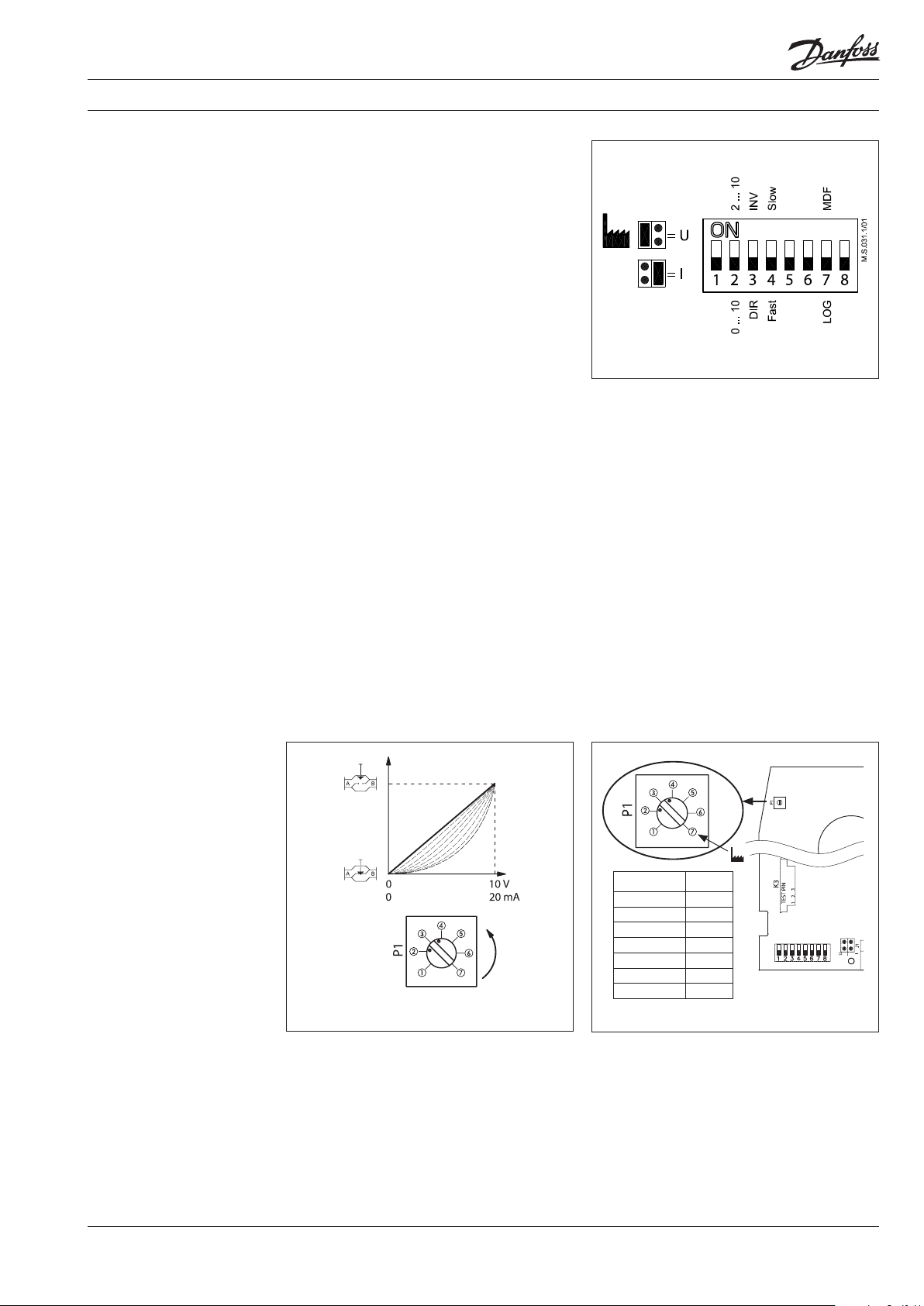

Jumper/DIP switch setting

Jumper

• U/I - Input signal type selector

- U position; voltage input is selected

- I position; current input is selected

Factory setting: jumper is in U position.

DIP switches

Factory setting: all switches are in OFF position.

• SW 1: Not used

• SW 2: Input signal range selector

- OFF position; the input signal is in the range

from 0-10 V (voltage input) or from 0-20 mA

(current input)

- ON position; the input signal is in the range

from 2-10 V (voltage input) or from 4-20 mA

(current input)

• SW 3: Direct or Inverse acting selector

- OFF position; the actuator is in direct acting

mode (stem extracts as voltage increases)

- ON position; the actuator is in inverse acting

mode (stem retracts as voltage increases)

If used with AB-QM valves, SW 3 is recommended

to be in OFF position (factory setting).

• SW 4: Fast/Slow - Speed selector

- OFF position; the actuating speed is 7.5 s/mm

- ON position; the actuating speed is 15 s/mm

• SW 5: Not used

• SW 6: Not used

• SW 7: LOG/MDF - Logarithmic or modied

ow through valve selector

- OFF position; ......... LOG (α=0.2, factory setting)

- ON position; ........... MDF (initial setting:

α=1, linear)

Explanation:

If SW 7 is in OFF position, alpha knob is

not activated. Turning alpha knob will not

inuence α value (α=0.2).

If SW 7 is in ON position, α value can be

manipulated using alpha knob. MDF initial

setting of alpha knob is 1, which means

linear setting. Regarding alpha knob setting

see explanation below.

• SW 8: Not used

SMT/ SI

Alpha knob f ound on PCB in MDF initial se tting (linear, α=1)

Equal-percentage valve-ow adjustment

(SW 7 in position ON)

The actuator has a special valve-ow

adjustment feature called alpha value. Actuator

characteristics can be, by turning the alpha knob

counter clockwise (CCW), variably-adjusted

from α=1 (linear) to α=0.1.

VD. CV.S 2. 02 © Danfoss 09/2014

α-knob position α- value

①

②

③

④

⑤

⑥

⑦

0,084

0,088

0, 111

0,18 0

0,308

1,000

1,000

In order to have optimal control, linear

characteristics of system (valve, actuator, HEX)

is required. This can be assured using the

right α value. Appropriate α value depends on

temperatures of heating/cooling medium and

controlled temperature of heated/cooled medium.

Calculate α value according to the Tech Note

number VNHUA102 (Setting the right α value).

3

Page 4

Data sheet Actuator for modulating control AME 435 QM

Led signalling/

Actuator operating modes

RESET/STAND BY

LED function indicator

The bi-colour (green/red) LED function indicator

is located on the actuator cover. It indicates the

operating modes.

External button

Actuator has external STAND BY/RESET button

which is located next to LED indicator. By

pressing on this button dierent operating

modes are initiated:

• Calibrating mode

Pressing the STAND BY/RESET button for

5sec. causes the actuator to start Calibrating

procedure:

The bi-colour LED ashes green at 1 sec.

intervals during calibration procedure, which

begins by extracting the stem. When the

maximum force is detected (at the end valve

position), the actuator then retracts the

stem, until the maximum force is once again

detected (on the other valve end position).

The actuator will then enter to normal mode

and respond to the control signal.

Flashing green LED:

Calibrating mode

(period is every

second)

Constant green LED:

Positioning mode

Flashing green LED:

Normal mode (period

is every 6 seconds)

Flashing red LED:

STAND BY mode

(period is every two

seconds)

≈

• Positioning mode

The bi-colour LED is green and stays on

during positioning of the actuator according

to the control signal

• Normal mode

When the positioning of the actuator is

nished the LED ashes green every 6

seconds.

• STAND BY mode

Pressing the STAND BY/RESET button switches

the actuator to STAND BY mode. The actuator

keeps its last position in this mode and does

not react to any control signal. This mode

can be used for manual operation during the

commissioning of other equipment, or for

service purposes.

The bi-colour LED ashes red at 2 sec.

intervals.

After pressing the STAND BY/RESET button

again actuator switches to normal mode.

4

VD. CV.S 2. 02 © Danfoss 09/2014

SMT/ SI

Page 5

Data sheet Actuator for modulating control AME 435 QM

Manual override Manual override is done by means of control

knob on actuator housing:

• Disconnect power supply or press STAND BY/

RESET button

• Adjust valve position using the control knob

(observe the rotation direction)

When manual override is not needed:

• Restore power supply or press STAND BY/

RESET button again

Remark:

When the manual override has been used, the

output signal (X) is not correct until the actuator

reaches its end position.

Wiring

24 VAC/DC only

power

supply

down

SP 24 VAC/DC .............. Power supply

SN 0 V ............................. Common

Y 0-10 V ........................ Input signal

(2-10 V)

0-20 mA

(4-20 mA)

X 0-10 V ........................ Output signal

(2-10 V)

1, 3 Override input signal

The actuator can be driven to the fully-open

position by connecting SN to terminal 1 or fullyclosed by connecting SN to terminal 3.

Signal 1 can be connected to thermostat to

prevent freezing and signal 3 can be connected

to thermostat to prevent overheating.

Wiring length

0-50 m 0.75 mm

up

> 50 m 1. 5 mm

Recommended cross-sectional

area of the wiring

2

2

Important: AME 435QM can be used only for

modulating control. For 3-point control use

AMV 435 (082H0162/163). It is recommend to use

modulating control with AB-QM.

SMT/ SI

VD. CV.S 2. 02 © Danfoss 09/2014

5

Page 6

Data sheet Actuator for modulating control AME 435 QM

Actuator - valve

combinations

AME 435 QM + AME 435 QM + AME 435 QM +

AB-QM (DN 40/50) AB-QM (DN 50) AB-QM (DN 65-100)

Dimensions

147

82,5

159, 5

min . 180

6

VD. CV.S 2. 02 © Danfoss 09/2014

SMT/ SI

Page 7

Data sheet Actuator for modulating control AME 435 QM

SMT/ SI

VD. CV.S 2. 02 © Danfoss 09/2014

7

Page 8

Data sheet Actuator for modulating control AME 435 QM

8

VD. CV.S 2. 02

Produce d by Danfoss A/S © 09/2014

Loading...

Loading...