Page 1

Installation Guide

AME 410, AME 413

VFG 2 VFU 2 VFGS 2 AFQM AFQM 6

VFG 21

VFG 25

ENGLISH

DEUTSCH

FRANCAIS

POLSKI

РУССКИЙ

中文

Electrical Actuator AME 410, 413 www.danfoss.com Page 5

Elektrischer Stellantrieb AME 410, 413 www.iwk.danfoss.de Page 7

Servomoteur électrique AME 410, 413 www.danfoss.fr Page 9

Siłownik elektryczny AME 410, 413 www.danfoss.pl Page 11

Электропривод AME 410, 413 www.danfoss.ru Page 13

电动调节阀驱动器 www.danfoss.com.cn

第15页

Danfoss Heating VI.AA.R4.6Z DEN-SMT/SI

1

Page 2

Installation Guide AME 410, AME 413

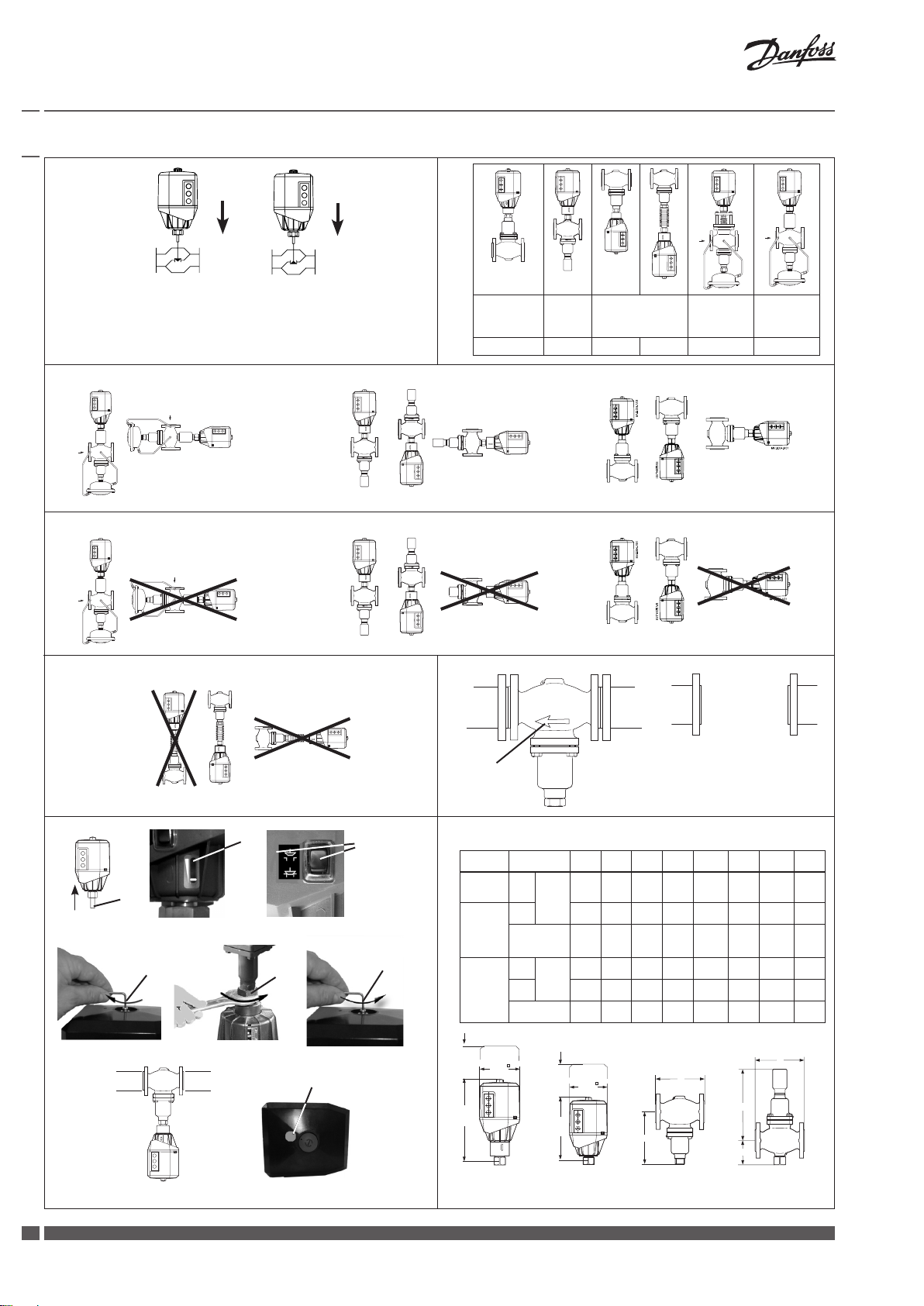

❶

❸

DN 15 - 80 < 120 °C

DN 15 - 80 > 120 °C

❹

VFG (DN 15-80)

VFGS 2 (DN 15-80)

AFQM )DN 65, 80

AFQM 6 (DN 40, 50)

AFQM , AFQM 6

AFQM , AFQM 6

VFU 2 (DN 15-80)

❷

VFG 2

VFG 21

VFG 25

15-80 15-65 15-80 15-80 15, 80 40, 50

VFU 2

VFU 2

VFU 2 VFGS 2 AFQM AFQM 6

VFG 2 (21), (25)

VFG 2 (21), (25)

❺

❼

VFGS 2

①

⑦

④

②

⑤

⑧

③

⑥

❻

❾

①

VFG..

VFU 2

VFG 2

VFG 21

VFG 25

VFGS 2

VFU 2

②

DN 15 20 25 32 40 50 65 80

L

B 212 212

B

C 311 311

130

mm

kg 7 9 10 13 17 22 33 41

mm

kg 7 9 10 13 17 22 33 41

250 260 280

95 95

238 238

106 106

337 337

200

230

290 310

240

240

275

123

123

135 135

339

339

374 374

275

AME 413 AME 410

2

DEN-SMT/SI VI.AA.R4.6Z Danfoss Heating

VFG(S) VFU

Page 3

Installation Guide AME 410, AME 413

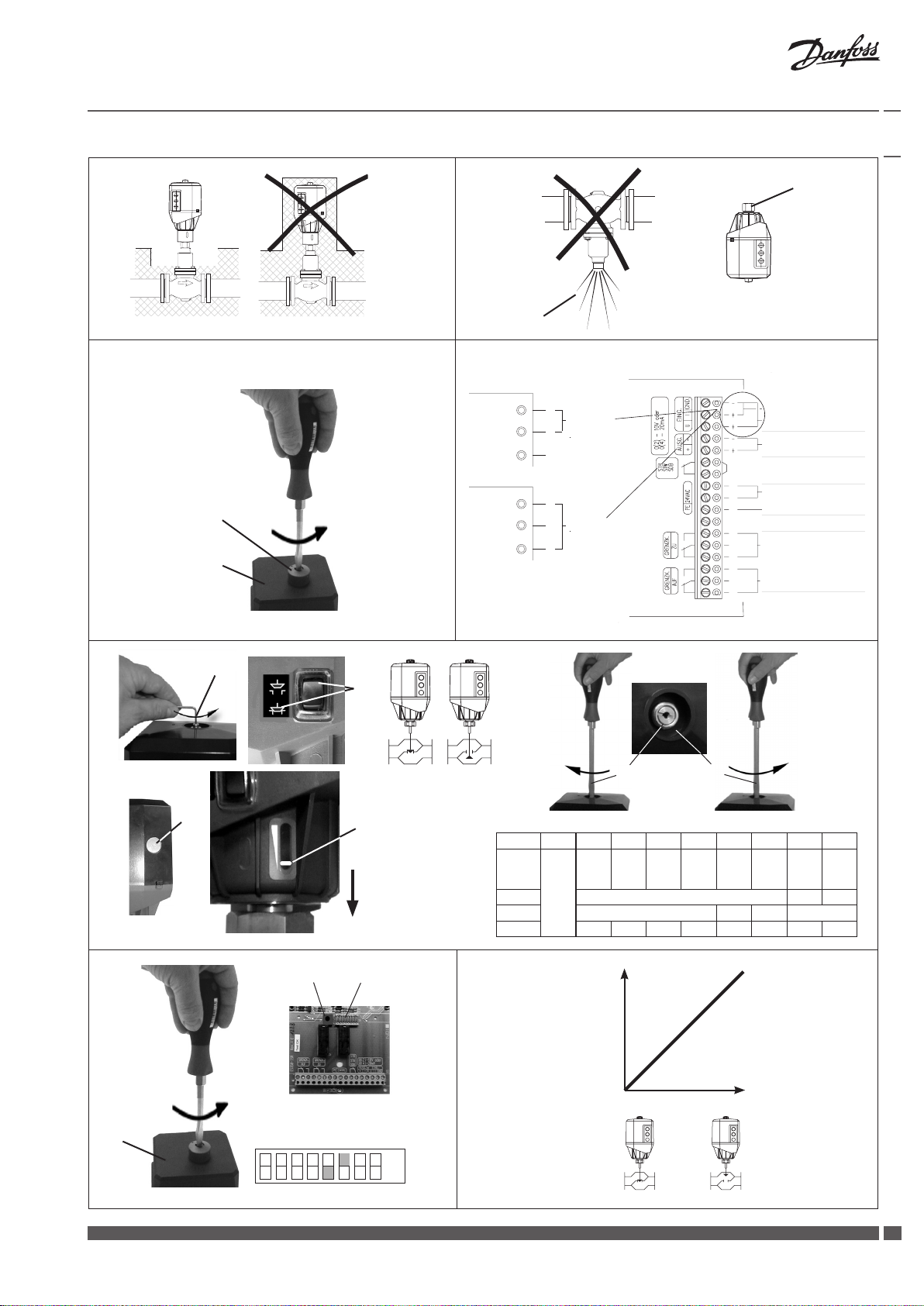

➑

❿

①

①

②

②

•

21

⓫

①

–

++

+

–

++

+

0(4)-20 mA

0(2)-10 V

①

0(4)-20 mA

0(2)-10 V

0(4)-20 mA

0(2)-10 V

24 VAC

PE

End

switches

②

Input

stroke

Output

controller

Power

supply

Valve closed

(VFU Open)

Valve Open

VFU2 closed

⓬

⓭

①

3 mm

⑤

①

④

②

⑥

② ③

6

5

③ ④

ON

OFF

⑦ ⑧

⑨

VFG 2

VFG 21

VFG 25

AFQM – 12 18

AFQM 6 – 8 12 –

VFU 2 8 8 8 10 10 14 14 2 0

⓯

15 2 0 25 32 4 0 50 65 80

6 6 6 8 8 12 12 18

mm

20 mA

10 V

0 (2,4)

Stroke

0 100 %

Hub

Course

Skok

Danfoss Heating VI.AA.R4.6Z DEN-SMT/SI

33

Page 4

Installation Guide AME 410, AME 413

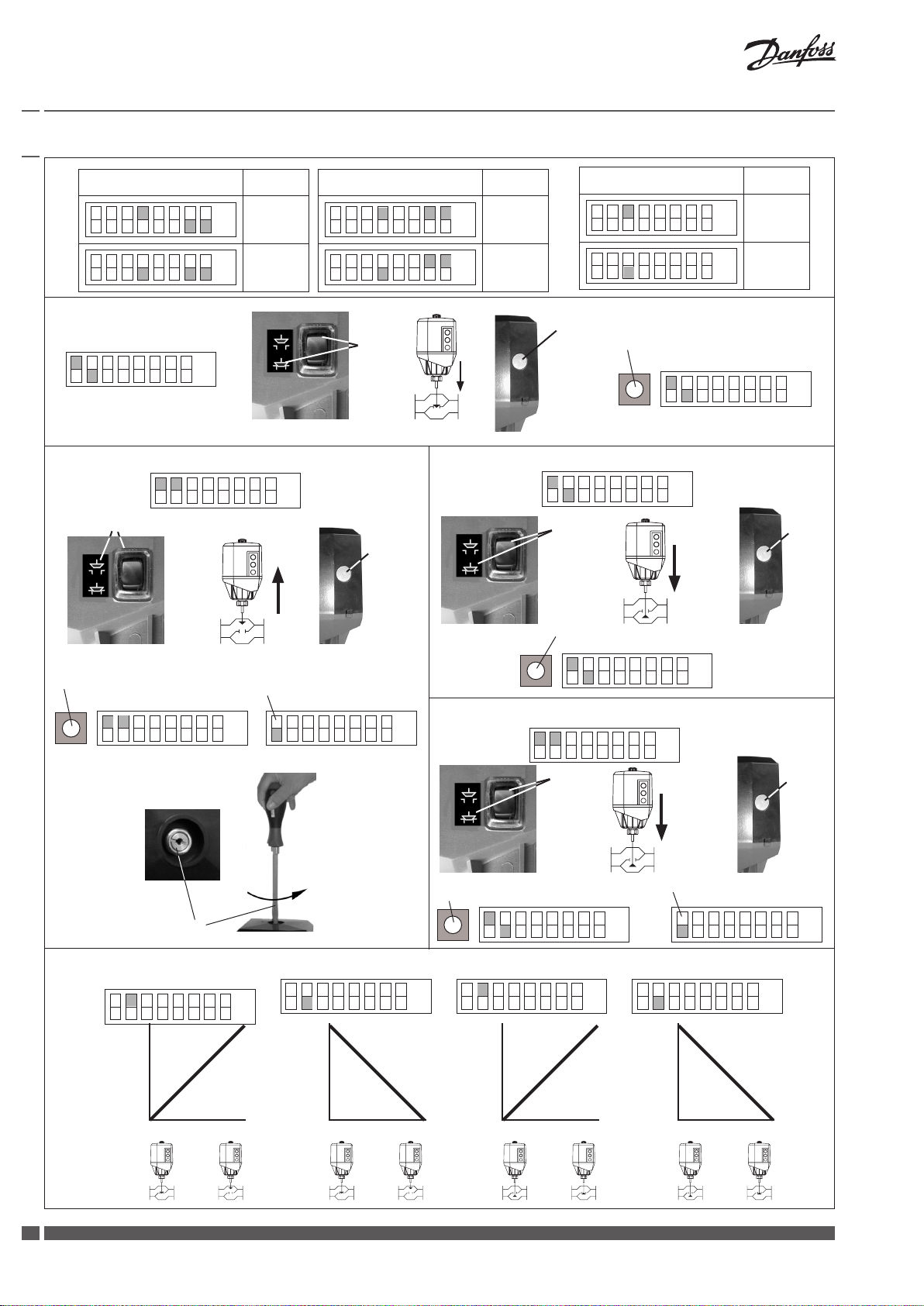

⓮

⓰

⓱

①

⑤

S2

3

3

ON

OFF

ON

OFF

1

2

ON

OFF

②

0-20 mA

0-10 V

4-20 mA

2-10 V

ON

OFF

④

S2

4

4

ON

7

8

OFF

ON

7

8

OFF

①

0-20 mA

4-20 mA

S2

ON

7

4

4

8

OFF

ON

7

8

OFF

③

①

0-10 V

2-10 V

④

②

①

ON

OFF

⓲

2

1

③

ON

OFF

④

①

1

②

2

③

1

2

②

⑤

⓴

⑤

1

21

②

2

ON

OFF

③

⑥

21

ON

OFF

1

ON

OFF

⓳

①

⑤

ON

OFF

ON

OFF

2

20 mA

10 V

⑦

1

2

VFG .., AFQM 6 VFG .., AFQM 6 VFU 2 VFU 2

2

20 mA

10 V

ON

OFF

2

20 mA

10 V

ON

OFF

2

20 mA

10 V

⑥

ON

OFF

④

1

ON

OFF

ON

OFF

0 (2,4)

4

DEN-SMT/SI VI.AA.R4.6Z Danfoss Heating

Stroke

0 100 %

Hub

Course

Skok

Ход

行程

0 (2,4)

0 100 %

Stroke

Hub

Course

Skok

Ход

行程

0 (2,4)

0 100 %

Stroke

Hub

Course

Skok

Ход

行程

0 (2,4)

0 100 %

Stroke

Hub

Course

Skok

Ход

行程

Page 5

Installation Guide AME 410, AME 413

LANGUAGEENGLISH

Safety Notes

Mounting

Dimensions, Weights ❾

Prior to assembly and commissioning

to avoid injury of persons and damages

of the devices, it is absolutely necessary

to carefully read and observe these

instructions.

Necessary assembly, start-up, and

maintenance work must be performed

only by qualified, trained and authorized

personnel.

Prior to assembly and maintenance work

on the controller, the system must be:

- depressurized,

- cooled down,

- emptied and

- cleaned.

Please comply with the instructions of the

system manufacturer or system operator.

Do not remove the cover before the power

supply is fully switched off.

Disposal instruction

This product should be

dismantled and its

components sorted, if

possible, in various groups

before recycling or disposal.

Always follow the local disposal

regulations.

Definition of Application

The electrical actuator is used in

connection with the following valves:

VFG 2(21), VFG 25, VFU 2, VFGS 2, AFQM,

AFQM 6.

Fields of application are the temperature

control of water, water-glycol mixtures

and steam for heating, district heating and

cooling systems.

Safety ReturnFunction and

Effective Direction ❶

Safety function and effective direction of

stem:

AME 410

AME 413 valid only for AMV 413.

Permissible Installation Positions

DN 15 - 80 ❸

medium temperatures up to 120 °C.

DN 15 - 80 ❹

medium temperatures > 120 °C.

For valves VFGS 2 ❺ steam.

Valve Installation ❻

• Install strainer in front of valve.

• Rinse system before installing valve.

• Observe flow direction ① on the valve

body.

Flanges ② in the pipeline system must be

in parallel direction, the sealing surfaces

must be clean and undamaged.

• Install valve.

• Tighten screws crosswise in 3 steps up

to the maximum torque.

Actuator and Valve Installation ❼

The actuator must only be mounted with

the stem retracted

Stroke indicator

On delivery the stem is retracted with a

screwed-in mounting screw ④.

If this is not the case, then:

• carry out the electrical connection, see

next section,

• press pushbutton ③ and completely

retract the stem ①.

• Screw in mounting screw ④ up to its

stop.

• Place actuator on the valve and align.

• Tighten union nut ⑤ torque 100 Nm0

•

It is absolutely necessary to unscrew

the mounting screw

actuator is out of function.

• If the actuator is installed in a

downward hanging position ⑦,

remove label ⑧.

①.

② must be in position ②.

⑥, otherwise, the

Electrical Connection ❿

HIGH VOLTAGE !

Danger of injury and life in case of

improper handling.

Switch off power supply prior to

connecting lines.

The electrical connection must only be

performed by an expert electrician.

Procedure

• Unscrew cap nut ① and remove

cover ②.

• Connect lines in accordance with

connection diagram ⓫.

• Prior to remounting the cover, carry

out settings at the actuator, see next

section.

Electrical Connection Diagram ⓫

① Connection for:

STB - Safety Temperature Limiter

STW - Safety Temperature Monitor

SDB - Safety Pressure Limiter

Prior to connection, it is absolutely

necessary to remove the jumper

only types AME 413 with safety return

function.

Mechanical Stroke Setting ⓬

The stroke of the electrical actuator must

be adjusted to the valve stroke.

• If not yet done, unscrew the mounting

screw ①.

• Press pushbutton ② until the valve ③

is completely closed (compl. open

VFU 2 ④) and the direction indicator ⑤

stops.

Observe stroke indicator, it must move

to position ⑥.

• Screw in stroke setting screw ⑦ up to

its stop.

• Take valve stroke from table ⑨.

• Unscrew stroke setting screw ⑧ by one

turn per mm valve stroke.

The stroke setting is completed.

Valve Types for AME 410, 413

The electrical actuator AME 41. can be

mounted on the following valves, see

table ❷.

Danfoss Heating VI.AA.R4.6Z DEN-SMT/SI

Insulation ❽

• acceptable ①

• intolerable ②

55

Page 6

Installation Guide AME 410, AME 413

Actuator Electrical Settings ⓭

Prior to commissioning, the settings for the

input und output signals and for the final

positions must be carried out.

Prior to any settings, dismount the

cover ①.

Switch Designations

② Pushbutton S1

③ Switch S2

Switches 5, 6 ④

Switch 5 must be on “OFF”.

Switch 6 has no function.

Setting the Output Signal

The output signal is proportional to the

actuating stroke.

Setting of the switch S2, see ⓮①.

Setting the Input Signal

Connecting the lines to the terminal strip

determines the “current” or “voltage”

input signal, see “Electrical Connection

Diagram”, ⓫.

Setting of 0 or 4 mA, 0 or 2 V, see ⓮②.

Setting the Final Positions

When the stroke is set (see ⓯), the

final positions “Valve OPEN” and “Valve

CLOSED” must be equalized with current

and voltage values 0(4) - 20 mA, 0(2) - 10 V.

Valves VFG.., AFQM 6

Setting the final position “Valve

CLOSED” ⓰

• Set switches 1 and 2 ①.

• Press pushbutton ② until the valve ③

is completely closed and the direction

indicator ④ stops.

• Press pushbutton ⑤.

The final position “Valve CLOSED” is set.

• Set the assignment of the effective

direction for the input and output

signals, see ⓴

Setting the Final Positions for

valves VFU 2

In contrary to the valves VFG .., AFQM6, the

valve VFU 2 ⓲③ has a reversed closing

direction.

The valve VFU 2 is opened by the safety

return function.

Setting the final position “Valve

OPEN” (VFU 2) ⓲

• Set switches 1 and 2 ①.

• Press pushbutton ② until the valve ③

is completely open and the direction

indicator ④ stops.

• Press pushbutton ⑤.

The final position “Valve OPEN” (VFU 2)

is set.

Setting the final position “Valve

CLOSED” (VFU 2) ⓳

• Set switches 1 and 2 ①

• Press pushbutton ② until the valve ③

is completely closed and the direction

indicator ④ stops.

• Press pushbutton ⑤.

The final position “Valve OPEN” is set.

• Set switch 1 ⑥

The setting of the final positions for the

valves VFU 2 is completed.

• Set the assignment of the effective

direction for the input and output

signals, see ⓴

Assignment of the effective

direction for the input and output

signals

Setting of switch 2 ⓴

Then, remount cap nut and cover.

Setting the final position “Valve

OPEN” ⓱

• Set switches 1 and 2 ①.

• Press pushbutton ② until the valve ③

is completely open and the direction

indicator ④ stops.

• Press pushbutton ⑤.

The final position “Valve OPEN” is set.

• Set switch 1 to standard mode ⑥.

• Unscrew the stroke limiting screw ⑦ by

one turn.

The setting of the final positions for the

valves VFG.., AFQM 6 is completed.

6

DEN-SMT/SI VI.AA.R4.6Z Danfoss Heating

Dismounting of Valve and

Actuator •

Danger

Danger of injury by steam or hot water!

Valve without actuator is open ①, sealing

② is in the actuator.

It is absolutely necessary to depressurize

system prior to dismounting.

Carry out dismounting in reverse order as

mounting.

21

Page 7

Installation Guide AME 410, AME 413

LANGUAGEDEUTSCH

Sicherheitshinweise

Vor dem Einbau und der Inbetriebnahme

ist zur Vermeidung von Personenschäden

und Schäden an den Geräten die

vorliegende Betriebsanleitung sorgfältig

durchzulesen und unbedingt zu beachten.

Einbau-, Inbetriebnahme- und

Wartungsarbeiten dürfen nur durch

geschultes und autorisiertes Fachpersonal

durchgeführt werden.

Vor dem Einbau des Ventils und der

anschließenden Montage des Stellantriebs

und vor Wartungsarbeiten an der

Ventileinheit muss die Anlage:

- drucklos gemacht werden

- abkühlen

- entleert werden

- gereinigt werden.

Die Vorgaben des Anlagenherstellers oder

des Anlagenbetreibers sind zu beachten.

Entfernen Sie die Abdeckung nicht,

bevor die Stromversorgung komplett

ausgeschaltet ist.

Entsorgungshinweise

Vor der Entsorgung ist der

Stellantrieb zu zerlegen. Die

einzelnen Komponenten

sind dann, nach Werkstoffen

getrennt, zu entsorgen.

Entsorgungsbestimmungen sind zu

beachten.

Bestimmungsgemäße

Verwendung

Der elektrische Stellantrieb wird in

Verbindung mit folgenden Ventilen

eingesetzt: VFG 2(21), VFG 25, VFU 2, VFGS

2, AFQM, AFQM 6

Einsatzgebiete sind Temperaturregelung

von Wasser, Wasser-Glykolgemischen und

Dampf für Heizungs-, Fernheizungs- und

Kühlungsanlagen.

Sicherheitsfunktion und

Wirkrichtung ❶

Sicherheitsfunktion und Wirkrichtung der

Antriebsstange.

Ventiltypen für AME 410, 413

Der elektrische Stellantrieb AME 41. kann

auf folgende Ventile montiert werden,

siehe Tabelle ❷.

Montage

Zulässige Einbau-lagen

DN 15 - 80 ❸

Mediumstemperaturen bis 120 °C

DN 15 - 80 ➍

Mediumstemperaturen größer 120 °C

Für Ventile VFGS 2 ❺

Dampf

Einbau Ventil ❻

• Schmutzfänger vor dem Ventil

einbauen

• Anlage vor dem Einbau des Ventils

spülen

• Durchflussrichtung ① auf dem

Ventilgehäuse beachten

Flansche ② in der Rohr-leitung müssen

parallel, Dichtflächen sauber und ohne

Beschädigung sein..

• Ventil einbauen

• Schrauben über Kreuz in 3 Stufen bis

zum max. Drehmoment anziehen.

Montage Stellantrieb und Ventil ❼

Der Stellantrieb darf nur mit eingefahrener

Schubstange ① montiert werden.

Hubanzeige ② muss in Position ② stehen.

Bei Auslieferung ist die Schubstange

mittels eingeschraubter Montagechraube

④ eingefahren.

Ist das nicht der Fall, dann :

• elektrischen Anschluss durchführen,

siehe nächsten Abschnitt

• Taster ③ drücken und Schubstange ①

vollständig einfahren

• Montageschraube ④ bis zum Anschlag

einschrauben.

• Stellantrieb am Ventil ansetzen und

ausrichten

• Überwurfmutter ⑤ anziehen

Anzugsmoment 100 Nm

•

Montageschraube ⑥ unbedingt

herausschrauben, sonst ist der

Stellantrieb außer Funktion.

• Bei hängendem Einbau des

Stellantriebs ⑦ Aufkleber ⑧ entfernen.

Isolierung ➑

• zulässig ①

• unzulässig ②

Abmessungen, Gewichte ❾

Elektrischer Anschluss ❿

Gefahr durch stromschlag!

Bei unsachgemäßer Handhabung besteht

Lebens- oder Verletzungsgefahr.

Vor dem Anschluss der Leitungen

unbedingt Spannungsversorgung

abschalten.

Durchführung des elektrischen

Anschlusses nur durch Elektrofachkraft.

Vorgehensweise

• Hutmutter ① abschrauben und Haube

② abnehmen

• Leitungen nach dem Anschlussplan

anschließen ⓫

• Vor Montage der Haube, Einstellungen

am Stellantrieb durchführen, siehe

nächsten Abschnitt

Elektrischer Anschlussplan ⓫

① Anschluss für:

STB - Sicherheits-temperaturbegrenzer

STW - Sicherheits-temperaturwächter

SDB- Sicherheits-druckbegrenzer

Bei Anschluss unbedingt Brücke

entfernen nur Typen AME 413 mit

Sicherheitsfunktion.

Input cont roller Eingang re gler

Output s troke Ausgang Hu b

Power supp ly Spannun gs versorgung

Valve close d (VFU2 Open) Ventil zu (VFU2 Auf )

End swit sches Endschal ter

Valve Open ( VFU2 closed) Ventil Auf (VFU2 zu)

Danfoss Heating VI.AA.R4.6Z DEN-SMT/SI

77

Page 8

Installation Guide AME 410, AME 413

Mechanische Hubeinstellung ⓬

Der Hub des elektrischen Stellantriebs

muss dem Ventilhub angepasst werden.

• Falls noch nicht durchgeführt, die

Montageschraube ① herausschrauben.

• Taster ② drücken bis das Ventil ③ ganz

geschlossen (VFU 2 ④ ganz geöffnet)

ist und die Lauf-richtungsanzeige ⑤

zum Stillstand kommt.

Hubanzeige beachten, sie muss bis

Position ⑥ fahren.

• Hubeinstellschraube ⑦ bis zum

Anschlag eindrehen.

• Ventilhub aus Tabelle ⑨ entnehmen

• Hubeinstellschraube ⑧ pro mm

Ventilhub um eine Umdrehung

herausdrehen

Die Hubeinstellung ist abgeschlossen

Elektrische Einstellungen am

Stellantrieb ⓭

Vor der Inbetriebnahme müssen die

Einstellungen für die Ein-, Ausgangssignale

und für die Endlagen durchgeführt

werden.

Vor den Einstellungen die Haube ①

demontieren.

Ventile VFG.., AFQM 6

Endlage “ Ventil ZU” einstellen

• Schalter 1 und 2 einstellen ①.

• Taster ② drücken bis das Ventil ③

ganz geschlossen ist und die Laufrichtungsanzeige ④ zum Stillstand

kommt

• Taster ⑤ drücken

Endlage “Ventil

Endlage “Ventil AUF” einstellen ⓱

• Schalter 1 und 2 einstellen Á

• Taster  drücken bis das Ventil

Ă ganz geöffnet ist und die.

Laufrichtungsanzeige Ä zum Stillstand

kommt

• Taster Ĺ drücken

Endlage “Ventil AUF” ist eingestellt

• Schalter 1 auf Standardeinstellung

stellen Ć

• Hubbegrenzungs-schraube Ŕ um eine

Umdrehung herausdrehen

Einstellung der Endlagen für Ventile

VFG.., AFQM 6 ist abgeschlossen

• Zuordnung der Wirkrichtung zum Ein-,

Ausgangssignal einstellen, siehe ⓴

Einstellung der Endlagen für Ventile

VFU 2 ist abgeschlossen

• Zuordnung der Wirkrichtung zum

Ein-, Ausgangssignal einstellen, siehe ⓴

Zuordnung der Wirkrichtung zum

Ein-, Ausgangssignal

Einstellung Schalter 2 ⓴

Anschließend Hutmutter und Haube

montieren

Demontage •

Gefahr

Verletzungsgefahr durch Dampf oder

Heißwasser

Ventil ist ohne Antrieb offen ①,

Abdichtung ② befindet sich im Antrieb.

Vor Demontage Anlage unbedingt

drucklos machen.

Demontage in umgekehr-ter Reihenfolge

wie die Montage durchführen.

21

Schalterbezeichnungen

② Taster S1

③ Schalter S2

Schalter 5, 6 ④

Schalter 5 muss auf “OFF” stehen.

Schalter 6 hat keine Funktion.

Einstellung Ausgangssignal

Das Ausgangsignal ist proportional zum

Stellhub.

Einstellung des Schalters S2 siehe ⓮①.

Einstellung Eingangssignal

Durch den Anschluss an der Klemmleiste

wird das Eingangssignal “Strom” oder

“Spannung” festgelegt, siehe “Elektrischer

Anschlussplan” ⓫

Einstellung von 0 oder 4 mA, 0 oder 2 V

siehe ⓮②.

Einstellung der Endlagen

Nach Durchführung der Hubeinstellung

(siehe ⓯) müssen die Endlagen “Ventil

AUF” und “Ventil ZU” noch mit den Strom-,

Spannungswerten 0(4) - 20 mA, 0(2) - 10 V

abgeglichen werden.

Einstellung der Endlagen Ventile

VFU 2

Das Ventil VFU 2 ⓲③ hat gegenüber den

Ventilen VFG.., AFQM 6 eine umgekehrte

Schließrichtung.

Das Ventil VFU 2 wird durch die

Sicherheitsfunktion geöffnet.

Endlage “ Ventil AUF” (VFU 2)

einstellen ⓲

• Schalter 1 und 2 einstellen ①

• Taster ② drücken bis das Ventil

③ ganz geöffnet ist und die Laufrichtungsanzeige ④ zum Stillstand

kommt

• Taster ⑤ drücken

Endlage “Ventil AUF” (VFU 2) ist

eingestellt

Endlage “ Ventil ZU” (VFU 2)

einstellen ⓳

• Schalter 1 und 2 einstellen ①

• Taster ② drücken bis das Ventil ③

ganz geschlossen ist und die Laufrichtungsanzeige ④ zum Stillstand

kommt

• Taster ⑤ drücken

Endlage “Ventil AUF” ist eingestellt

• Schalter 1 einstellen ⑥

8

DEN-SMT/SI VI.AA.R4.6Z Danfoss Heating

Page 9

Installation Guide AME 410, AME 413

LANGUAGEFRANCAIS

Sécurité

Pour éviter des dommages physiques et

matériels, il est absolument nécessaire

de lire attentivement et de respecter ces

instructions avant le montage et la mise en

service.

Le travail d’assemblage, de démarrage

et de maintenance nécessaire doit être

effectué uniquement par un personnel

qualifié, formé et autorisé.

Avant le travail d'assemblage et de

maintenance du contrôleur, le système

doit être:

- dépressurisé

- refroidi

- vidé

- nettoyé

Suivre les instructions du fabricant du

système ou de son service.

Indications de mise au rebus

Ce produit peut être

démonté et tous ses

composants classés si

possible en différentes

catégories en vue de leur

recyclage ou destruction

Dans tous les cas , suivre la législation

locale de mise au rebus.

Conditions d’utilisation

Le servomoteur électrique est utilisé en

combinaison avec les vannes suivantes:

VFG 2(21), VFG 25, VFU 2, VFGS2, AFQM (6)

Domaines d’application : régulation de la

température de l’eau, de l’eau glycolée et

de la vapeur pour chauffage, chauffage

urbain et installations de réfrigération.

Fonction de secours et sens de

fonctionnement ❶

Fonction de secours et sens de

fonctionnement de la tige

Types de vannes pour

AME 410, 413

Le moteur électrique AME 41. peut être

monté sur les vannes suivantes, voir

tableau ❷

Montage

Orientations de montage autorisées

DN 15 - 80 ❸

Température du fluide jusqu’à 120°C :

DN 15 - 80 ➍

Température du fluide supérieure à

120°C :

Pour vannes VFGS2 ❺

Vapeur

Montage vanne

• Monter le filtre devant la vanne

• Rincer l’installation avant le montage de

la vanne

• Respecter le sens d’écoulement ①

indiqué sur le corps de la vanne

Les brides ② dans la tuyauterie doivent

être parallèles, les surfaces d’étanchéité

propres et sans dommages.

• Monter la vanne

• Serrer les vis en 3 étapes en croix,

jusqu’au couple de rotation max.

Montage moteur et vanne ❼

Uniquement monter le moteur avec la

tige ① rétractée.

L’indication de course ② doit être en

position ②

Lors de la livraison, la tige est rétractée

à l’aide de la vis de montage ④ qui est

vissée.

Si cela n’est pas les cas, alors :

• Procéder au branchement électrique,

voir prochain paragraphe

• Presser la touche ③ et rétracter

totalement la tige ①

• Visser la vis de montage ④ jusqu’en

butée.

• Positionner le moteur sur la vanne et

procéder ŕ l’alignement

• Serrer l’écrou prisonnier ⑤ , facteur de

serrage 100 Nm

•

Dévisser impérativement la vis de

montage ⑥ , sinon le moteur est hors

fonction.

• Lors d’un montage du moteur ⑦ vers le

bas, retirer l’autocollant ⑧.

Isolation

① Autorisé

② Non autorisé

Dimensions, poids ❾

Branchement électrique ❿

Danger d’électrocution

Lors d’une manipulation non appropriée,

danger de mort ou risques de blessures.

Avant le branchement des câbles,

impérativement couper l’alimentation.

Le branchement doit être effectué

uniquement par du personnel qualifié.

Procédure:

• Dévisser l’écrou du capot ① et retirer le

capot ②

• Raccorder les câbles selon le schéma de

branchement, voir ⓫

• Avant de remettre le capot, effectuer les

réglages sur le moteur, voir paragraphe

suivant

Schéma de branchement

électrique ⓫

① Branchement pour:

STB – Limiteur de température de sécurité

STW – Contrôleur de température de

sécurité

SDB – Limiteur de pression de sécurité

Lors du branchement, impérativement

retirer le pont Uniquement types

AME 413 avec fonction de secours.

Input cont roller Entrée régulateu r

Output s troke Sorti e Course

Power supp ly Aliment ation

Valve close d (VFU2 Open) Vanne ferm ée (VFU2 ouvert e)

End swit sches Contact s fin de course

Valve Open ( VFU2 closed) Vanne ouver te (VFU2 fermé e)

Réglage mécanique de la

course ⓬

La course du moteur doit être adaptée à la

course de la vanne.

• Si cela n’est pas fait, dévisser la vis de

montage ①.

Danfoss Heating VI.AA.R4.6Z DEN-SMT/SI

99

Page 10

Installation Guide AME 410, AME 413

• Presser la touche ② jusqu’à ce

que la vanne ③ soit totalement

fermée (VFU 2 ④ totalement

ouverte), et l’indicateur de sens de

fonctionnement ⑤ soit arrêté.

Observer l’indication de course, elle

doit aller jusqu’en position ⑥.

• Serrer la vis de réglage de course ⑦

jusqu’en butée

• Relever la course de la vanne dans le

tableau ⑨

• Dévisser la vis de limitation de

course ⑧ d’un tour par mm de course

de vanne

Le réglage de la course est terminé

Réglages électriques sur le

moteur ⓭

Avant la mise en route, procéder aux

réglages pour les signaux d’entrée et de

sortie, et les positions fins course.

Avant les réglages, démonter le capot ①.

Désignation des commutateurs

② Touche S1

③ Interrupteur S2

Interrupteurs 5,6

L’interrupteur 5 doit être sur «OFF».

L’interrupteur 6 n’a pas de fonction.

Vannes VFG..., AFQM6

Régler la position fin de course

«vanne fermée» ⓰

• Régler les interrupteurs 1 et 2 ①.

• Presser la touche ② jusqu’ŕ ce

que la vanne ③ soit totalement

fermée et l’indicateur de sens de

fonctionnement ④ soit arręté

• Presser la touche ⑤

La position fin de course «vanne

fermée» est réglée

Régler la position fin de course

«vanne ouverte» ⓱

• Régler les interrupteurs 1 et 2 ①

• Presser la touche ② jusqu’à ce

que la vanne ③ soit totalement

ouverte et l’indicateur de sens de

fonctionnement ④ soit arrêté

• Presser la touche ⑤

La position fin de course «vanne

ouverte» est réglée

• Positionner l’interrupteur 1 sur réglage

standard ⑥

• Hubbegrenzungs-schraube ⑦ d’un tour

Le réglage des positions fins de course

pour vanne VFG..., AFQM 6 est terminé

• Régler l’affectation du sens de

fonctionnement au signal d’entrée/

sortie, voir page, ⓴

Régler la position fin de course

«vanne fermée» (VFU2) ⓳

• Régler les interrupteurs 1 et 2 ①

• Presser la touche ② jusqu’à ce

que la vanne ③ soit totalement

fermée et l’indicateur de sens de

fonctionnement ④ soit arrêté

• Presser la touche ⑤

La position fin de course «vanne

fermée» est réglée

• Régler l’interrupteur 1 ⑥

Le réglage des positions fins de course

pour vannes VFU2 est terminé

• Régler l’affectation du sens de

fonctionnement au signal d’entrée/

sortie, voir ⓴

Affectation du sens de

fonctionnement au signal

d’entrée/sortie

Réglage de l’interrupteur 2 voir cidessous ⓴

Ensuite monter le capot et l’écrou du capot

Démontage •

Danger

Danger of injury by steam or hot water!

21

Réglage du signal de sortie

Le signal de sortie est proportionnel au

réglage de la course.

Réglage de l’interrupteur S2 ⓮①.

Réglage du signal d’entrée

Le choix de l’entrée «courant» ou

«tension» se fait par le branchement sur

le bornier, voir «schéma de branchement

électrique» ⓫

Réglage de 0 ou 4 mA, 0 ou 2 V, voir ⓮②.

Réglage des positions fins de

course

Après le réglage de la course ⓯, les

positions fins de course «vanne ouverte» et

«vanne fermée» doivent être alignées avec

les valeurs courant et tension 0(4)-20 mA

et 0(2)-10V.

Régler les positions fins de

course pour vannes VFU2

La vanne VFU 2 ⓲③ a un sens de

fermeture contraire par rapport aux

vannes VFG..., AFQM 6

La vanne VFU 2 est ouverte par la fonction

de secours.

Régler la position fin de course

“vanne ouverte” (VFU2) ⓲

• Régler les interrupteurs 1 et 2 ①

• Presser la touche ② jusqu’à ce

que la vanne ③ soit totalement

ouverte et l’indicateur de sens de

fonctionnement ④ soit arrêté

• Presser la touche ⑤

La position fin de course «vanne

ouverte» (VFU2) est réglée

La vanne n’est pas étanche sans moteur ①,

le cône d’étanchéité ② se trouve dans

l’écrou de fixation du moteur.

Impérativement mettre l’installation hors

pression avant tout démontage.

Pour le démontage suivre la procédure de

montage dans le sens inverse.

10

DEN-SMT/SI VI.AA.R4.6Z Danfoss Heating

Page 11

Installation Guide AME 410, AME 413

LANGUAGEPOLSKI

Warunki bezpieczeństwa

W celu uniknięcia zranienia osób

i uszkodzenia urządzeń należy

bezwzględnie przed montażem i

uruchomieniem zaworu zapoznać się

dokładnie z niniejszą instrukcją.

Czynności związane z montażem,

uruchomieniem i obsługą mogą

być dokonywane wyłącznie przez

osoby uprawnione i odpowiednio

wykwalifikowane.

Przed montażem i obsługą konserwacyjną

regulatora należy:

- zrzucić ciśnienie,

- ostudzić urządzenie

- opróżnić układ,

- oczyścić

Prosimy stosować się do instrukcji

producenta lub operatora układu.

Instructiuni de dispensare

Ten produkt powinien być

rozebrany a jego

komponenty

posegregowane, jeśli to

możliwe, na różne grupy

przed poddaniem recyklingowi lub

utylizacji.

Zawsze stosuj siê do miejscowych

przepisów w zakresie usuwania

odpadów.

Zakres zastosowań

Siłownik elektryczny stosowany jest w

połączeniu z następującymi zaworami:

VFG 2(21), VFG 25, VFU 2, VFGS 2, AFQM,

AFQM 6.

Znajdują zastosowanie w regulacji

temperatury wody, roztworu woda-glikol

i pary wodnej w układach grzewczych,

instalacjach sieci cieplnych i chłodzenia.

Safety Function and Effective

Direction ❶

Funkcja bezpieczeństwa i kierunek

działania trzpienia.

Typy zaworów do AME 410, 413

Siłownik elektryczny typu AME 41. może

współpracować z zaworami regulacyjnymi,

zgodnie z Tabelą ❷

Montaż

Dopuszczalne pozycje montażu

DN 15 –80 ❸

temperatura czynnika do 120 °C

DN 15 – 80 ❹

temperatura czynnika powyżej 120 °C;

Dla zaworów VFGS 2 ❺

Czynnik para wodna

Montaż zaworu ❻

• Zamontować filtr przed zaworem.

• Przed zamontowaniem zaworu

przepłukać instalację.

• Zwrócić uwagę na wskaźnik kierunku

przepływu na korpusie zaworu ①.

Kołnierze ②‚ na rurociągu muszą być

wzajemnie równoległe, a powierzchnie

pod uszczelki czyste i bez uszkodzeń.

• Zamontować zawór.

• Dokręcać przeciwległe nakrętki w 3

krokach do osiągnięcia maksymalnego

momentu.

Montaż siłownika i zaworu ❼

Aby siłownik mógł być zamontowany musi

mieć cofniêty trzpień ①.

Wskaźnik położenia ② musi być w pozycji

③.

W przypadku dostawy trzpień jest cofnięty

i zaplombowany śrubą montażową ④.

W przeciwnym wypadku:

• wykonać połączenie elektryczne, patrz

następny rozdział

• naciśnij przycisk ③ do całkowitego

cofnięcia trzpienia ①

• wkręcić śrubę montażową aż do

zatrzymania ④.

• Umieścić siłownik na zaworze

• Dokręcić nakrętkę łączącą ⑤. Moment

35 Nm, klucz 36 mm

•

Należy koniecznie wykrêcić śrubê

montażową ⑥ w innym przypadku

siłownik nie bêdzie działał.

• Kiedy napęd jest skierowany do dołu ⑦

usunąć nalepkę ⑧.

Izolacja ❽

① do przyjęcia

② nie do przyjęcia

Rozmiar, Waga ❾

Podłączenie elektryczne ❿

WYSOKIE NAPIÊCIE !

Ryzyko obrażeń i zagrożenie życia w

przypadku nieprawidłowej obsługi.

Przed wykonaniem podłączeń

elektrycznych należy bezwzględnie

wyłączyć zasilanie.

Podłączenia elektryczne mogą być

wykonane wyłącznie przez uprawnionego

elektryka.

Tryb postępowania

• Odkręcić śrubę ① i usunąć obudowę ②.

• Podłączyć przewody zgodnie ze

schematem podłączeń elektrycznych patrz ⓫.

• Przed założeniem obudowy wykonać

wszystkie nastawy siłownika - patrz

następny rozdział.

Schemat podłączeń

elektrycznych ⓫

① Zaciski do:

STB – Ogranicznik temperatury

bezpieczeństwa

STW – Strażnik temperatury

bezpieczeństwa

SDB – Ogranicznik ciśnienia

bezpieczeństwa

Przed połączeniem należy koniecznie

usunąć mostek.

dot. wyłącznie typów AME 413 z funkcją

sprêżyny powrotnej.

Input cont roller Wejscie sterujace

Output s troke Wyjscie s ygnalu polozen ia

Power supp ly Napięci e zasilania

Valve close d (VFU2 Open) Zawór za mknięty (VFU 2

otwar ty)

End swit sches Przełą czniki krań cowe

Valve Open ( VFU2 closed) Zawór ot warty (VFU2

zamkni ęty)

Danfoss Heating VI.AA.R4.6Z DEN-SMT/SI

1111

Page 12

Installation Guide AME 410, AME 413

Nastawy skoku

mechanicznego ⓬

Skok siłownika elektrycznego musi być

przystosowany do skoku zaworu.

• Jeżeli nie jest to jeszcze zrobione,

odkręcić śrubę montażową ①.

• Wcisnąć przycisk ‚ aż do całkowitego

zamknięcia zaworu ② (VFU 2 ④

całkowitego otwarcia) i do zatrzymania

wskaźnika poziomu ⑤.

Obserwować wskaźnik poziomu, musi

osiągnąć pozycję ⑥.

• Dokręcić śrubę nastawy skoku ⑦, aż do

jej zatrzymania.

• Odczytać skok zaworu z poniższej

tabeli ⑨

• Odkręcić śrubę nastawy skoku ⑧ jeden

obrót na 1 mm skoku zaworu.

Nastawa skoku została zakończona.

Nastawy elektryczne

siłownika ⓭

Przed oddaniem do eksploatacji muszą

być przeprowadzone nastawy sygnałów

wyjściowych i wejściowych jak również

pozycji krańcowych.

Przed dokonaniem nastaw zdjąć

pokrywę ①.

Oznaczenie wyłączników

① przycisk S1

② przełącznik S2

Przełączniki 5, 6 ④

Przełącznik 5 musi być w pozycji „OFF”.

Przełącznik 6 jest niewykorzystany.

Nastawa sygnału wyjściowego

Sygnał wyjściowy jest proporcjonalny do

ruchu trzpienia.

Nastawy przełączników S2 ⓮①

Nastawa sygnału wejściowego

Podłączyć przewody do listwy zaciskowej

określając „prąd” lub „napięcie”

sygnału wejściowego patrz „Schemat

elektryczny” ⓫.

Ustawienie 0 lub 4mA, 0 lub 2V, patrz ⓮②.

Nastawa pozycji krańcowych

Kiedy skok jest ustawiony (patrz ⓯),

należy zrównać pozycje krańcowe „Zawór

otwarty” i „Zawór zamknięty” z wartością

prądu i napięcia 0 (4) – 20 mA, 0(2) – 10V.

Zawory VFG..,, AFQM

Ustawienie pozycji krańcowej

“Zawór zamknięty” ⓰

• Ustaw przełącznik 1i 2 ①

• Naciskać przycisk ② do całkowitego

zamknięcia zaworu ③ i zatrzymania

wskaźnika poziomu ④

• Nacisnąć przycisk ⑤

Pozycja krańcowa „Zawór zamknięty”

została nastawiona.

Ustawienie pozycji krańcowej

“Zawór otwarty” ⓱

• Ustaw przełącznik 1i 2 ①

• Naciskać przycisk ② do całkowitego

otwarcia zaworu ③ i zatrzymania

wskaźnika poziomu ④

• Nacisnąć przycisk ⑤

Pozycja krańcowa „Zawór otwarty”

została nastawiona.

• Nastawić przełącznik 1 na tryb

standardowy ⑥.

• Odkręcić śrubę nastawy skoku ⑦ jeden

obrót.

Nastawa pozycji krańcowych dla

zaworów VIM2, VIS2, AIQM została

zakończona.

• Ustawić przypisanie kierunku sygnałom

wejściowemu i wyjściowemu patrz ⓴

Nastawa pozycji krańcowych dla

zaworów VFU 2

W przeciwieństwie do zaworów VFG..,

AFQM 6 zawór VFU 2 ⓲③ ma odwrotny

kierunek zamykania.

Zawór VFU2 jest otwierany przez funkcję

bezpieczeństwa sprężyny powrotnej.

Ustawienie pozycji krańcowej

“Zawór otwarty” (VIU 2) ⓲

• Ustaw przełącznik 1 i 2 ①

• Naciskać przycisk ② do całkowitego

otwarcia zaworu ③ i zatrzymania

wskaźnika poziomu ④

• Nacisnąć przycisk ⑤

Pozycja krańcowa „Zawór otwarty”

(VFU2) została nastawiona.

Ustawienie pozycji krańcowej

“Zawór zamknięty” (VFU 2) ⓳

• Ustaw przełącznik 1 i 2 ①

• Naciskać przycisk ② do całkowitego

zamknięcia zaworu ③ i zatrzymania

wskaźnika poziomu ④

• Nacisnąć przycisk Ă

Pozycja krańcowa „Zawór zamknięty”

została nastawiona.

• Ustaw przełącznik 1 ⑤

Nastawa pozycji krańcowych dla

zaworów VFU2 została zakończona.

• Ustawić przypisanie kierunku sygnałom

wejściowemu i wyjściowemu patrz ⓴

Przypisanie kierunku sygnałom

wejściowemu i wyjściowemu

Nastawa dla przełącznika 2 ⓴

Następnie zamontować nakrętkę

kołpakową i pokrywę.

Demontaż zaworu, napędu •

Uwaga

Ryzyko poparzenia parą lub gorącą wodą!

Zawór bez napędu jest otwarty ①,

uszczelnienie ② znajduje się w napędzie.

Przed demontażem należy bezwzględnie

zrzucić ciśnienie z układu.

Kolejność wykonywanych czynności przy

demontażu odwrotna w stosunku do

kolejności podczas montażu.

21

12

DEN-SMT/SI VI.AA.R4.6Z Danfoss Heating

Page 13

Installation Guide AME 410, AME 413

LANGUAGEРУССКИЙ

Правила по технике

безопасности

Для предупреждения травматизма

и повреждения оборудования перед

началом производства работ по его

монтажу и вводу в эксплуатацию

следует изучить и соблюдать настоящую

инструкцию.

Монтаж, наладку и техническое

обслуживание оборудования может

выполнять только квалифицированный

персонал, имеющий допуск к таким

работам.

В целях соблюдения правил техники

безопасности перед началом работ по

монтажу или обслуживанию регулятора

необходимо произвести следующие

действия с трубопроводной системой:

- сбросить давление;

- охладить;

- опорожнить;

- прочистить.

При этом также должна соблюдаться

инструкция по эксплуатации системы.

Инструкция по утилизации

Данная продукция

подлежит демонтажу на

части, для раздельной

утилизации составных

компонентов.

Всегда следуйте требованиям

местного законодательства в сфере

по обращению с отходами.

Область применения

Электропривод используется совместно

со следующими клапанами: VFG 2(21),

VFG 25, VFU 2, VFGS 2, AFQM, AFQM 6.

Области применения: регулирование

температуры воды, водного

раствора гликоля и пара в системах

централизованного теплоснабжения

или охлаждения.

Функция безопасности и

эффективное направление ❶

Функция безопасности и эффективное

направление пара

Типы клапанов для

Установка

Разрешённые положения для

установки

Ду = 15–80 мм ❸

температуры среды до 120 °C

Ду = 15–80 мм ❹

температуры среды > 120 °C:

Для клапанов VFGS 2 ❺: пар

Монтаж клапана ❻

• Установите сетчатый фильтр перед

клапаном.

• Промойте систему перед установкой

клапана.

• Проверьте направление потока ① на

корпусе клапана.

Фланцы ② в трубопроводной системе

должны располагаться параллельно,

поверхности уплотнения должны

быть чистыми и неповреждёнными.

• Установите клапан.

• Затяните винты крестообразно в 3

этапа до достижения максимального

крутящего момента.

Монтаж исполнительного

механизма и клапана ❼

Электропривод должен

монтироваться только с поднятым

штоком ①.

Индикатор хода ② должен быть в

положении ②.

При поставке шток поднят и закреплён

ввинченным монтажным винтом ④.

Если это не так, то выполните

следующее:

• Выполните электрическое

соединение, см. следующий раздел.

• Нажмите на кнопку ③ и полностью

поднимите шток ①.

• Ввинтите монтажный винт ④ до

стопора.

• Поместите исполнительный

механизм на клапан и выровняйте.

• Затяните соединительную гайку ⑤ до

момента 100 Нм.

•

AME 410, 413.

Электропривод AME 41 можно

смонтировать на следующих клапанах,

см. таблицу ❷.

Danfoss Heating VI.AA.R4.6Z DEN-SMT/SI

Абсолютно необходимо отвинтить

монтажный винт ⑥, а иначе

исполнительный механизм не

будет работать.

• Если исполнительный механизм

установлен в положение ⑦ (опущен

вниз), то снимите ярлык ⑧.

Теплоизоляция ❽

① приемлемо

② недопустимо

Габаритные и

присоединительные

размеры ❾

Электрическое соединение

ВЫСОКОЕ НАПРЯЖЕНИЕ!

Опасность травмы или гибели в

случае неправильного обращения.

Отключите электропитание перед

подключением линий. Электрическое

соединение должно выполняться только

квалифицированным электриком.

Последовательность настройки

• Отвинтите гайку колпачка ① и

снимите крышку ②.

• Подключайте линии в соответствии

со схемой соединений ⓫

• Прежде чем ставить крышку на

место, выполните настройки на

исполнительном механизме, см.

следующий раздел.

Электрическая схема

соединений ⓫

① Соединение для следующего:

STB — Термостатический ограничитель

безопасности

STW — Термостатический элемент

безопасности

SDB — Ограничитель безопасного

давления

Перед подключением абсолютно

необходимо удалить перемычку

только типа AME 413 с функцией

безопасного возврата.

Input cont roller Контроллер вход а

Output s troke Ход выхода

Power supp ly Питающе е напряжение

Valve close d (VFU2 Open) Клапан з акрыт (VFU2 отк рыт)

End swit sches Концевые в ыключатели

Valve Open ( VFU2 closed) Клапан о ткрыт (VFU2 зак рыт)

1313

Page 14

Installation Guide AME 410, AME 413

Механическая регулировка

длины хода ⓬

Ход исполнительного механизма должен

быть отрегулирован по ходу клапана.

• Если это ещё не было сделано,

отвинтите монтажный винт ①.

• Нажимайте на кнопку ② до тех

пор, пока клапан ③ полностью не

закроется (полн. открыт VFU 2 ④)

и индикатор направления ⑤

не остановится. Посмотрите

на индикатор хода: он должен

переместиться в положение ⑦.

• Ввинтите регулировочный винт хода

7 до стопора.

• Возьмите ход клапана из таблицы ⑨.

• Отвинчивайте регулировочный

винт хода ⑧ по одному обороту на

каждый миллиметр хода клапана.

Регулировка хода выполнена.

Электрические параметры

исполнительного

механизма ⓭

Перед вводом в эксплуатацию

необходимо выполнить регулировки

входного и выходного сигналов и

окончательных положений. Перед

любыми регулировками снимайте

крышку ①.

Назначения переключателей

② Кнопка S1

③ Переключатель S2

Переключатели 5, 6 ④

Переключатель 5 должен быть в

положении «ВЫКЛ.».

Переключатель 6 не имеет функций.

Регулирование выходного

сигнала

Выходной сигнал пропорционален ходу

исполнительного механизма.

Регулирование переключателя S2,

см. ⓮①.

Регулирование входного сигнала

Подключение линий к колодке

зажимов определяет входной сигнал

(«ток» или «напряжение»), см. раздел

«Электрическая схема соединений»,

страница ⓫.

Регулирование от 0 до 4 мА, от 0 до 2 В,

см. ⓮②.

Регулирование окончательных

положений

Когда ход отрегулирован (см. ⓯),

окончательные положения «Клапан

ОТКРЫТ» и «Клапан ЗАКРЫТ» должны

быть выровнены с величинами тока и

напряжения 0(4) – 20 мА, 0(2) – 10 В.

Клапаны VFG.., AFQM 6

Регулирование окончательного

положения «Клапан ЗАКРЫТ» ⓰

• Настроить переключатели 1 и 2 ①.

• Нажимайте на кнопку ② до

тех пор, пока клапан ③ не

закроется полностью и индикатор

направления ④ не остановится.

• Нажмите на кнопку ⑤.

Окончательное положение «Клапан

ЗАКРЫТ» установлено.

Регулирование окончательного

положения «Клапан ОТКРЫТ» ⓱

• Настройте переключатели 1 и 2 ①.

• Нажимайте на кнопку ② до

тех пор, пока клапан ③ не

откроется полностью и индикатор

направления ④ не остановится.

• Нажмите на кнопку ⑤.

Окончательное положение «Клапан

ОТКРЫТ» установлено.

• Установите переключатель 1 в

стандартный режим ⑥.

• Отвинчивайте винт ограничения

хода ⑦ по одному обороту.

Регулирование окончательных

положений для клапанов VFG..,

AFQM 6 выполнено.

• Установите назначение эффективного

направления для входного и

выходного сигналов, см. ⓴.

Регулирование окончательных

положений для клапанов VFU 2

в отличие от клапанов VFG .., AFQM6,

клапан VFU 2 ⓲③ имеет обратное

направление закрытия. Клапан VFU 2

открывается функцией безопасного

возврата.

Регулирование окончательного

положения «Клапан ОТКРЫТ»

(VFU 2) ⓲

• Настройте переключатели 1 и 2 ①.

• Нажимайте на кнопку ② до

тех пор, пока клапан ③ не

откроется полностью и индикатор

направления ④ не остановится.

• Нажмите на кнопку ⑤.

Окончательное положение «Клапан

ОТКРЫТ» (VFU 2) установлено.

Регулирование окончательного

положения «Клапан ЗАКРЫТ»

(VFU 2) ⓳

• Настройте переключатели 1 и 2 ①

• Нажимайте на кнопку ② до тех

пор, пока клапан ③ не закроется

полностью и индикатор направления

④ не остановится.

• Нажмите на кнопку ⑤.

Окончательное положение «Клапан

ОТКРЫТ» установлено.

• Настройте переключатель 1 ⑥

Регулирование окончательных

положений для клапанов VFU 2

выполнено.

• Установите назначение эффективного

направления для входного и

выходного сигналов, см. ⓴.

Назначение эффективного

направления для входных и

выходных сигналов

Регулирование переключателя 2 см. ⓴

Затем установите на место гайку

колпачка и крышку.

Демонтаж клапана и

исполнительного

механизма •

Опасно

Опасность травмы из-за пара или

горячей воды!

Клапан без исполнительного механизма

открыт ①, уплотнение ② находится в

исполнительном механизме. Абсолютно

необходимо сбросить давление в

системе перед демонтажом.

Выполните демонтаж в обратном

порядке по сравнению с монтажом.

21

14

DEN-SMT/SI VI.AA.R4.6Z Danfoss Heating

Page 15

Installation Guide AME 410, AME 413

中文

LANGUAGE

安全注意事项

为避免可能发生的人身和设备事故,安装和

使用前请先仔细阅读本手册

安装,调试,维修必须由专业人员进行.

进行安装和拆除工作时,请卸去系统压力.

安装,使用时应与系统设计者或系统操作

者配合.

本产品的使用场合

本驱动器和下列阀门配合使用:

VFG2(21),VFG25, VFU2, VFGS2, AFQM,

AFQM6

本产品用于供热,区域供热,制冷等系统中

的温度控制, 介质可以为水,水─乙二醇

混合物,蒸汽等。

安全功能及其实现时驱动杆的运动

方向 ⓫

安全功能及动作方向

与AME410, 413 驱动器相配的阀

的类型

AME41. 系列驱动器可用于下列各种阀门,

详见表❷

Valve type

Medium

Hot water

Steam

|介质

热水

热水

蒸汽

安装

驱动器和阀体的连接 ❼

安装时驱动器内驱动杆必须处于完全收

缩的位置. ①

阀位指示器 2 必须处于 ② 的位置.

出厂时驱动器的驱动杆处于收缩的位置,

并由锁定螺丝锁定. ④

若未处于收缩位置,可以:

• 按下节中的接线图接好线.

• 按按钮 ③ ,直到驱动杆达到完全收缩

的位置 ①

• 拧紧锁定螺丝 ④

• 将驱动器置于阀体上并对正

• 用100Nm的力矩拧紧螺帽 ⑤

•

安装完毕后需注意 ⑥ 将锁定螺丝

松开, 否则, 驱动器将不能正常

工作.

• 如果驱动器安装位置为朝下安装 ⑦ 则

应揭去标签 ⑧.

保温 ❽

① 可接受的

② 不允许的

尺寸,重量 ❾

电气连接 ❿

连接此功能前,应取下跳线.

仅AME 413有弹簧复位功能.

Input cont roller

Output s troke

Power supp ly

Valve close d (VFU2 Open)

End swit sches

Valve Open ( VFU2 closed)

阀位反馈

阀门给定

电源

阀门关闭(VFU2开)

限位开关

阀门打开(VFU2关)

行程的机械设定 ⓬

驱动器的行程必须调整到与阀体的行程一

致.

• 若未调整,则按下列方法将他们调整为

一致, 松开驱动杆锁定螺丝. ①

• 用按钮 ② 将阀门关到关闭位置 ③

(VFU 2 为全开位置). ④ 直到阀位运

动指示器完全停止转动. ⑤

此时观察阀位行程指示器, 应位于 ⑥

的位置.

• 将行程设定螺丝 ⑦ 顺时针方向拧进,

直到停止.

• 从表⑨中查出阀门行程.

• 逆时针拧行程设定螺丝 ⑦ 每毫米的行

程为一圈.

―行程的机械设定完毕.

Valve stroke=阀体行程

驱动器的电气设定 ⓭

在调试阀门之前,应设定好输入,输出信号

以及阀门的全开 / 全关位置。

进行任何设定前,应先打开护罩. ①

允许的安装位置

DN 15 – 80

介质温度不超过120 °C ❸

DN 15 – 80

介质温度大于120 °C ❹

对于VFGS 2

介质为蒸汽 ❺

阀体的安装 ❻

• 在阀前应安装过滤器.

• 在安装阀门前应清洗管道.

• 注意阀门上标示的 ① 介质流动方向

注意高电压!

不正确的操作将引发危险.

连接前需切断电源.

必须由电气专业人员进行连接.

步骤

• 松开护罩固定螺丝 ① 并取下护罩. ②

• 接下页所示的接图连接 ⓫.

• 盖回护罩前,应先设定好驱动器.详见下

一章.

开关及按钮的排列

② 按钮S1

③ 拨动开关S2

拨动开关5,6两位

开关5必须在 “OFF” 位置.

开关6没有功能

设定输出信号

输出信号与驱动器的行程成比例.

根据右边表格设定S2 ⓮①.

输入信号的设定

法兰 ② 必须平行,其密封表面应清洁

且无损伤.

• 安装阀门

• 按对角方向拧紧螺栓

Danfoss Heating VI.AA.R4.6Z DEN-SMT/SI

接线图 ⓫

① 用作连接:

STB - 温度限制安全功能

STW - 温度监测安全功能

SDB - 压力限制安全功能

输入信号是电压还是电流由接于哪个断子

来决定,详见电气接线图 ⓫.

对于0或4 mA,以及0或2 V的选择,见 ⓮②

1515

Page 16

Installation Guide AME 410, AME 413

全开 / 全闭位置设定 ⓯

当驱动器的行程按照所配的阀体设定完毕

之后,必须使阀门的开和关的位置与相应电

流或电压值相对应.0(4)-20mA,0(2)-10V.

对于阀门VFG.., AFQM 6

设定阀门全关位置 ⓰

1. 将开关1和2按右图所示设定. ①

2 按按钮 ② 直到阀门完全关闭. ③ 此

时阀门动作指示器 ④ 应停止转动.

3. 按一下按钮 1 一次 ⑤

阀门全闭位置设定完毕.

阀门全开位置设定 ⓱

1. 将拨动开关1和2设定为如图所示位

置.①

2. 按下按钮 ②将阀完全打开. ③ 此时阀

门动作指示器 ④ 应停止转动.

3. 按一下按钮⑤

阀门全开位置设定完毕.

4. 将拨动开关1设定为标准运行模式. ⑥

5. 将行程限定螺丝往回旋转一圈. ⑦

至此, VFG..,AFQM阀门的开 / 关位置

设定完毕.

6. 设定输入/输出信号相对应的阀门运行

方向,见第⓴页

输入输出信号相对应的阀门运行方向

此功能由拨动开关2设定

见下图. ⓴

设定完毕后盖好护罩.

Stroke=行程

从阀体上取下驱动器 •

危险

小心蒸汽或热水!

阀门在未安装驱动器时是敞开的①,密封

② 在驱动器上.

因此在取下驱动器前,必须先卸去系统内

的压力.

拆卸的步骤与安装相反.

21

VFU 2 阀的全开 / 全关位置设定

与VFG .., AFQM6 相比,2 VFU2 ⓲③阀

门运行方向与阀门开和关的对应关系与之

相反.

在安全功能实现时,VFU 2 阀门处于打开

状态.

VFU2阀门全开位置设定 ⓲

1. 将拨动开关1和2设定为如下位置.①

2. 按按钮 ② 直到阀门完全打开. ③ 此时

阀门运行指示器应完全停止. ④

3. 按一下按钮 ⑤.

阀门全开位置设定完毕. (VFU2)

设定阀门全关位置(VFU 2) ⓳

1. 按如下位置设定拨动开关1和2 ①

2. 操作按钮 ② 直到阀门完全关闭. ③

此时阀门运行指示器应完全停止转动.

④

3. 按一下按钮 ⑤,

阀门全开状态设定完毕.

4. 如图设定拨动开关1 ⑥

至此VFU2阀门的开/关位置设定完毕

5. 设定输入输出信号相对应的阀门运行方

向,见第⓴页.

16

DEN-SMT/SI VI.AA.R4.6Z Danfoss Heating

Page 17

Installation Guide AME 410, AME 413

Danfoss Heating VI.AA.R4.6Z DEN-SMT/SI

1717

Page 18

Installation Guide AME 410, AME 413

18

DEN-SMT/SI VI.AA.R4.6Z Danfoss Heating

Page 19

Installation Guide AME 410, AME 413

Danfoss Heating VI.AA.R4.6Z DEN-SMT/SI

1919

Page 20

Installation Guide AME 410, AME 413

73696010 / VI.AA.R4.6Z

Produced by Danfoss A/S © 05/2011

Loading...

Loading...