Page 1

Data Sheet

Flow director 013G1526 for tube segment

radiators - apply with integrated valve 013G1382

Application

Code Nos. and Technical

Data

Flow director 013G1526

Flow director

Flow director type

For tube segment

radiators

The Danfoss flow director 013G1526 is designed

to be used with Danfoss integrated valve type

013G1382 for incorporation into tube segment

radiators.

Tube segment radiators are constructed by a

series of elements, which are welded together.

The first segment is used as inlet pipe, while

return is through the bottom of the second

segment.

When integrated valves are used in tube

segment radiators, the water flow needs to be

directed correctly through the valve to avoid

noise problems. This is made with the Danfoss

flow director.

Connection

radiator

1¼” ½” 120 °C 013G1526

Connection integr.

valve

Max. water

temperature

Code no.

Accessories and spare parts for flow director

Product Code no.

Flow director plug 013G1508

Open rubber plug 013G1533

Closed rubber plug 013G1534

Spring 013G1569

Integrated valve for flow director

Valve type

For Danfoss RA

type sensors

Accessories and spare parts for integrated valve 013G1382

Product Code no.

Gland seal 013G0290

Protection cap (red) 013G0951

Differential pressure

Recom. Technical

0.05-0.2 bar 0.6 bar 16 bar 10 bar 120 °C 013G1382

1)

Test pressure Work. pressure

Max. water

temp.

Code no.

Danfoss Heating Solutions VDCNG202 © Danfoss 02/2011 1

Page 2

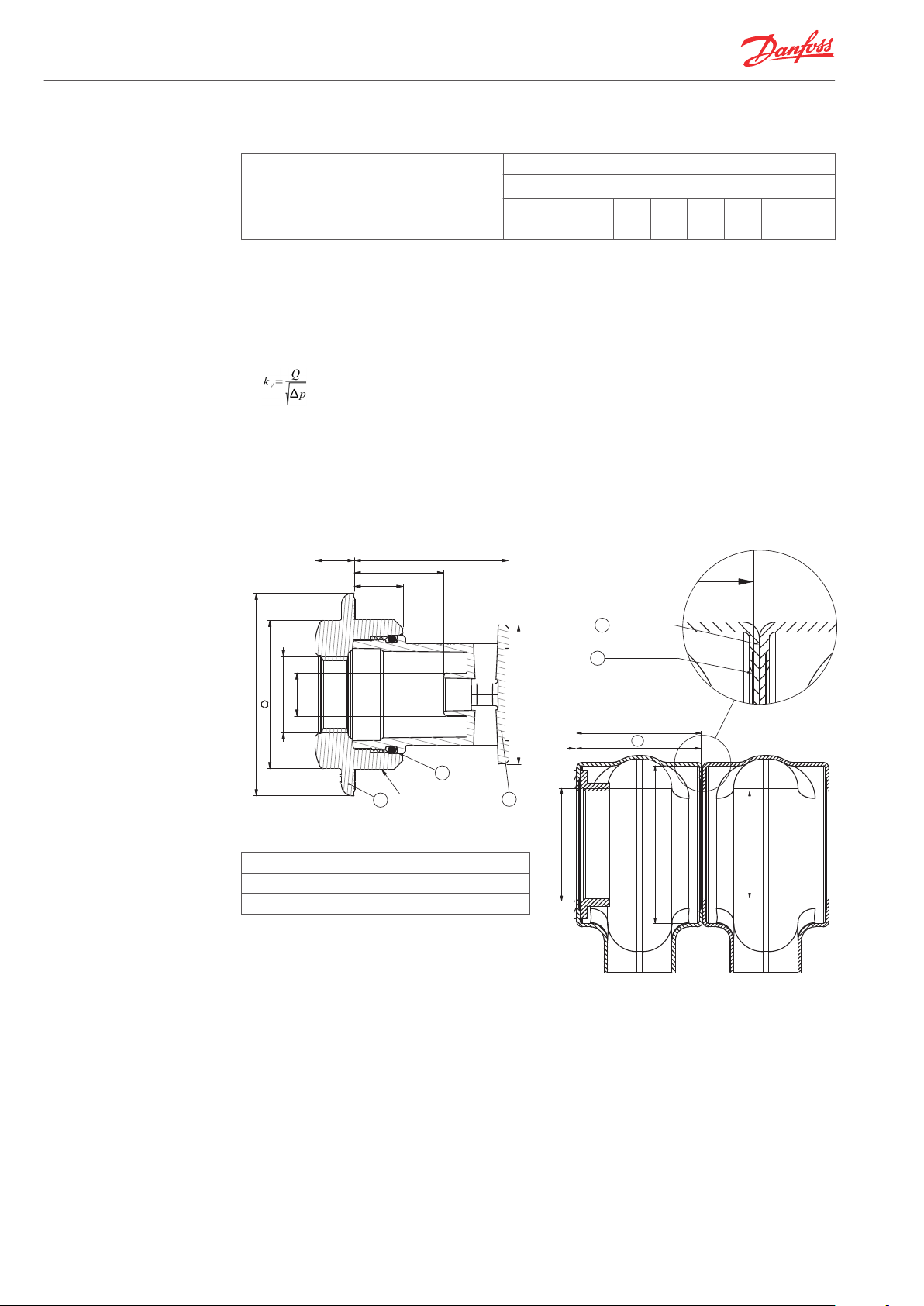

G1 1/4” ISO 228/1

10.8 42.7 ± 0.3

25

13.5

Ø56

41

G1/2” ISO 228/1

11.95

Ø38.5 ± 0.2

3

2

1

44.5 ± 1 mm

G1 1/4” ISO 228/1

min. Ø52 mm

Ø38-42 mm

REF.

2

1

3

Data Sheet Flow director 013G1526 for tube segment radiators - apply with integrated valve 013G1382

Pre-setting values, flow director + integrated valve

Flow director + integrated valve Presetting

kv-value

2)

1 2 3 4 5 6 7 N N

Flow director 013G1526 + RA 013G1382 0.14 0.18 0.26 0.32 0.45 0.55 0.69 0.84 1.18

1)

The technical differential pressure indicates the upper limit for a proper valve function. In most twopipe systems the recommended differential pressure is sufficient. In order to achieve a noiseless

function we recommend in smaller systems to apply automatic bypass valves or automatic balancing

valves. If pump differential pressure exceeds the recommended max. valve differential pressure it is

recommended that an automatic balancing valve type ASV-P/PV is added to the system.

2)

kv-values indicate the flow volume (Q) in m³/h at a pressure loss (Δp) across the valve of 1 bar ;

. At setting N, the kv-value in accordance with EN 215 can be stated as Xp = 2 K. At lower preset

values, Xp will be reduced until approximately Xp 0.5 at presetting 1. The table shows the average

measured values for integrated valves with radiator. The kvs-values indicate the valve capacity, when

the valve is fully open. If a remote temperature adjuster is used, the P-band is increased by a factor of

1.1. If a liquid filled radiator thermostat is used, the P-band is increased by a factor of 1.6.

k

vs

Design and Dimensions

Flow director 013G1522

Materials

Plug Nickel plated steel

1.

2. Flow director body PPS

3. O-ring EPDM

Radiator dimensions

1. Resistance seam welding

2. Burr at welding max. 0.5 mm

3. Gasket max. 1 mm after assembly

2 VDCNG202 © Danfoss 02/2011 Danfoss Heating Solutions

Page 3

[bar]

[mwg]

Q [l/h]

kW

kW

kW

10

8

6

5

4

3

2

∆p

1

0.8

0.6

0.5

0.4

0.3

0.2

0.1

1

0.8

0.6

0.5

0.4

0.3

0.2

∆p

0.1

0.08

0.06

0.05

0.04

0.03

0.02

0.01

1 2 3 4 5 6 7 N

100

80

60

50

40

30

20

∆p

10

8

6

5

4

3

0.2

1

[kPa]

5 7 10 20 30 40 50 70 100 200 300 400 500 700 1000 2000

∆ t = 10 ˚C

∆ t = 15 ˚C

∆ t = 20 ˚C

0.07 0.1 0.2 0.3 0.4 0.5 0.7 1 2 3 4 5 7 10 20

0.1 0.2 0.3 0.4 0.5 0.7 1 2 3 4 5 7 10 20 30

0.2 0.3 0.4 0.5 0.7 1 2 3 4 5 7 10 20 30 40

Data Sheet Flow director 013G1526 for tube segment radiators - apply with integrated valve 013G1382

Capacities

Flow director 013G1525/013G1557 + integrated valve 013G1382

Danfoss Heating Solutions VDCNG202 © Danfoss 02/2011 3

Page 4

Data Sheet Flow director 013G1526 for tube segment radiators - apply with integrated valve 013G1382

Danfoss A/S

Heating Solutions

Haarupvaenget 11

8600 Silkeborg

Denmark

Phone:+45 7488 8000

Fax: +45 7488 8100

Email: heating.solutions@danfoss.com

www.heating.danfoss.com

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequential changes being necessary in specifications already agreed. All trademarks in this material are property of the respective

companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

4 VDCNG202 © Danfoss 02/2011 Danfoss Heating Solutions

Loading...

Loading...