Page 1

COMPACT GAS RANGE

Owner’s Manual.............................1 - 26

OWNER’S MANUAL

MANUEL DU PROPRIÉTAIRE

MODEL * MODÈLE

ESTUFAS DE GAS COMPACTAS

Manuel du propriétaire.................27 - 52

DR202WGLP

DR202BGLP

www.Danby.com

DANBY PRODUCTS LIMITED, ONTARIO, CANADA N1H 6Z9

DANBY PRODUCTS INC., FINDLAY, OHIO, USA 45840

2018.08.13

Page 2

Welcome

Welcome to the Danby family. We are proud of our quality products and we believe in

dependable service. We suggest that you read this owner’s manual before plugging in your new

appliance as it contains important operation information, safety information, troubleshooting and

maintenance tips to ensure the reliability and longevity of your appliance.

Visit www.Danby.com to access self service tools, FAQs and much more. For additional assistance

call 1-800-263-2629.

Note the information below; you will need this information to obtain service under warranty.

You must provide the original purchase receipt to validate your warranty and receive service.

Model Number: _________________________________________________

Serial Number: _________________________________________________

Date of Purchase: _______________________________________________

Need Help?

Before you call for service, here are a few things you can do to help us serve you better.

Read this owner’s manual:

It contains instructions to help you use and maintain your appliance properly.

If you receive a damaged appliance:

Immediately contact the retailer or builder that sold you the appliance.

Save time and money:

Check the troubleshooting section at the end of this manual before calling. This section

will help you solve common problems that may occur.

1-800-26- Danby

(1-800-263-2629)

1

Page 3

Important Safety Information

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

WARNING - If the information in this

manual is not followed exactly, a fi re or

explosion may result, causing property

damage, personal injury or death.

• Do not store or use gasoline or other

fl ammable vapors and liquids in the

vicinity of this or any other appliance.

• Installation and service must be

performed by a qualifi ed installer,

service agency or the gas supplier.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in the building.

• Immediately call your gas supplier from

a neighbor’s phone. Follow the gas

supplier’s instructions.

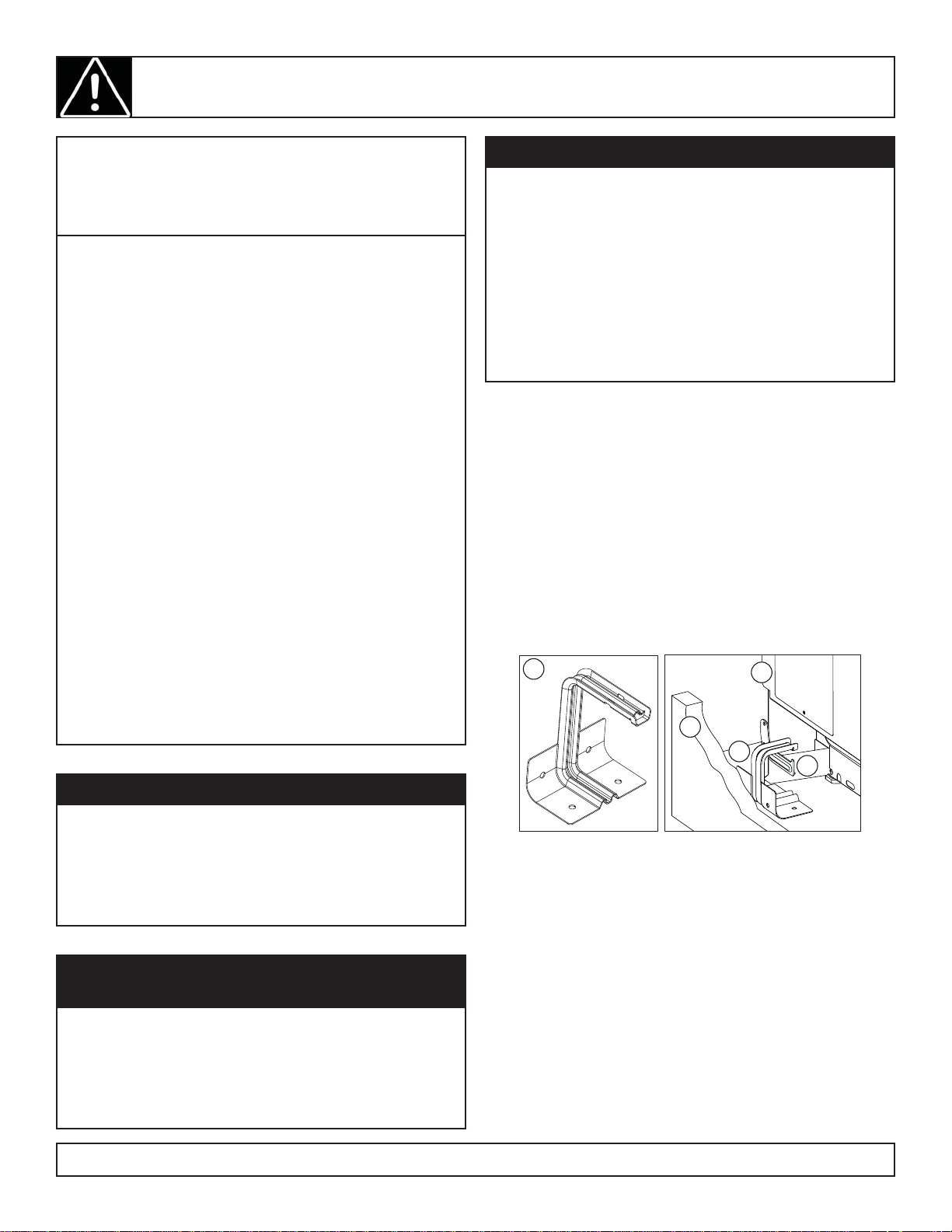

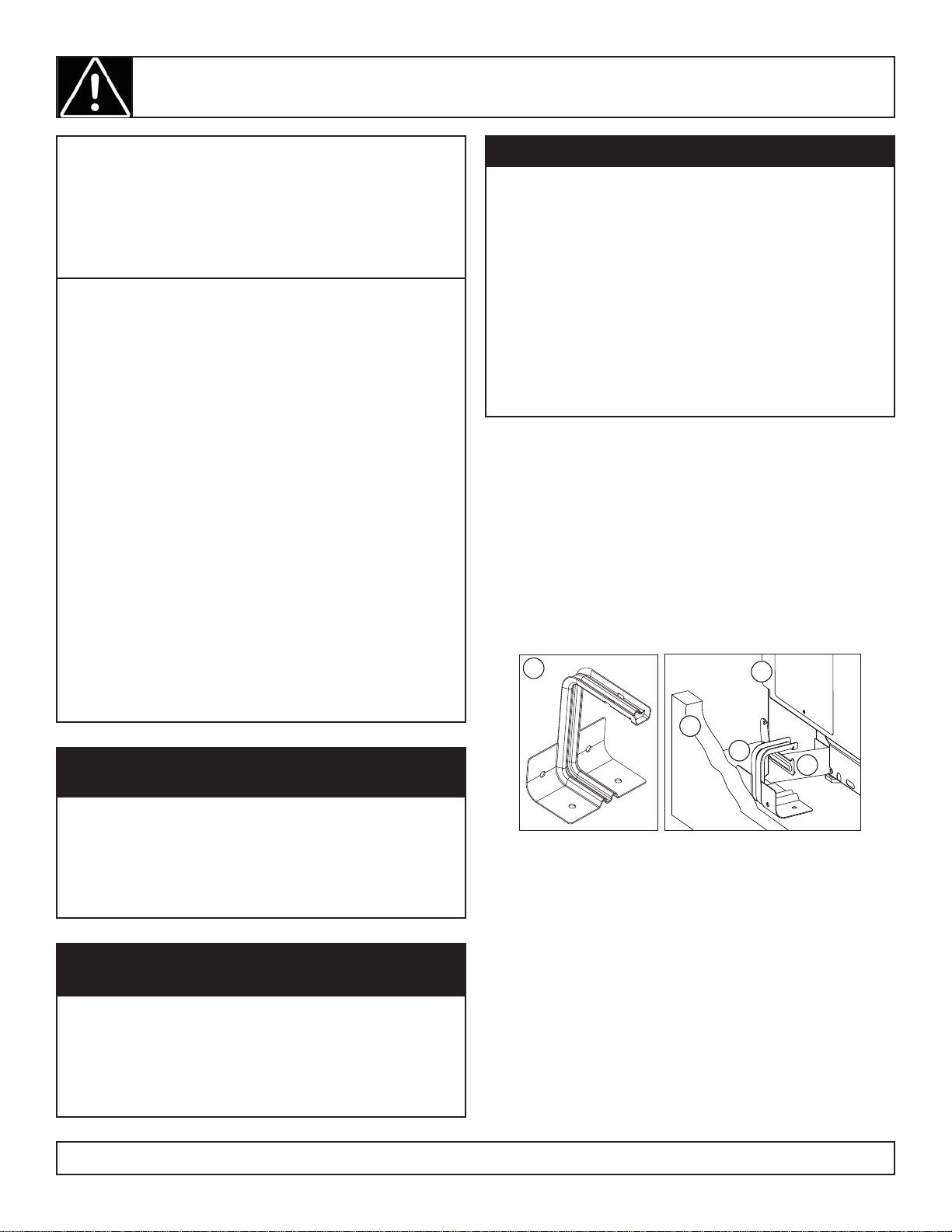

WARNING - TIP OVER HAZARD

• A child or adult can tip the appliance and be

killed.

• Verify the anti-tip bracket has been properly

installed and engaged to the fl oor or wall.

• Ensure the anti-tip bracket is re-engaged when

the range is moved by sliding the anti-tip arm

under the bracket.

• Do not operate the range without the anti-tip

bracket in place and engaged.

• Failure to follow these instructions can result in

death or serious burns to children or adults.

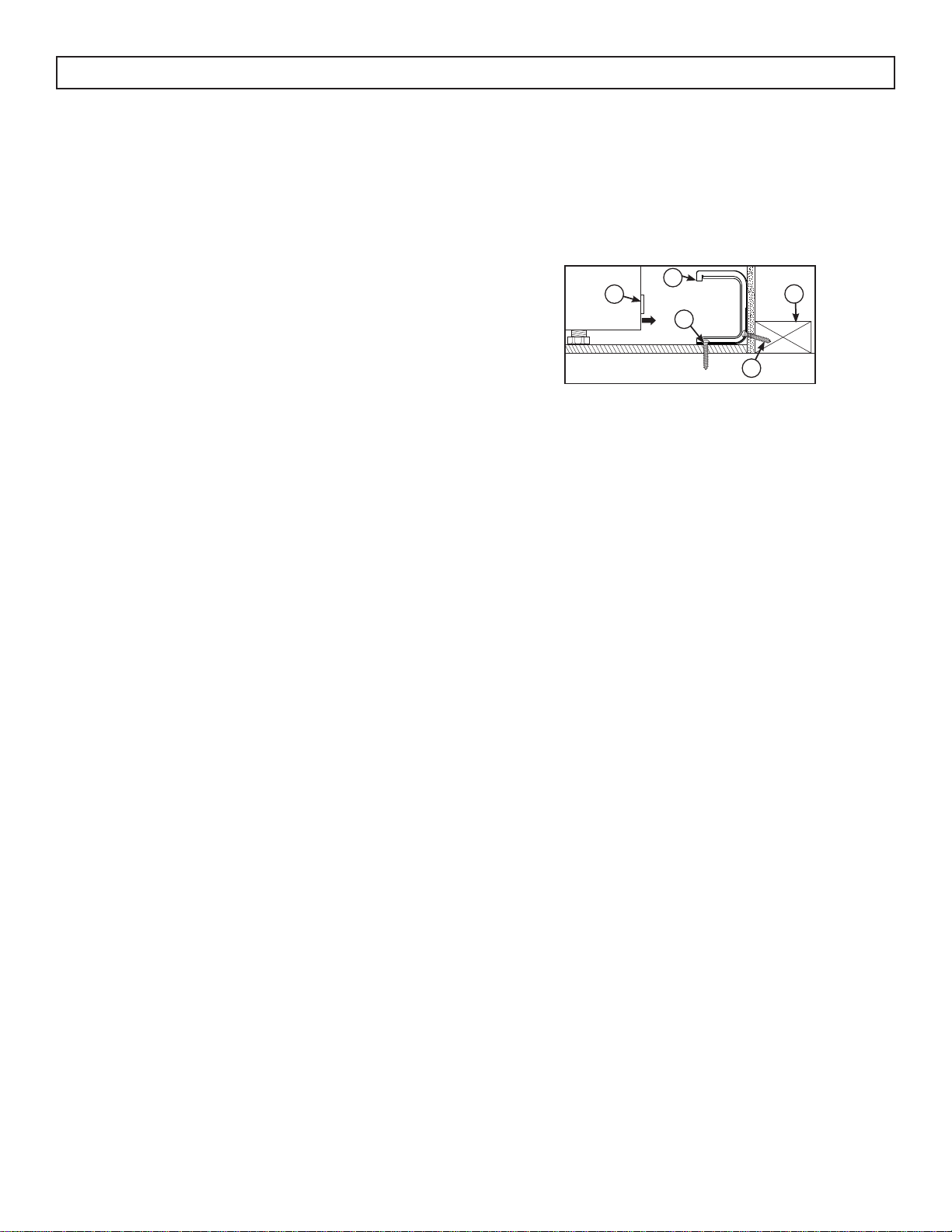

ANTI-TIP BRACKET

To reduce the risk of the appliance tipping over, an

anti-tip bracket is provided that must be installed

before operating the appliance. See installation

instructions shipped with the bracket for complete

details.

1. Anti-tip bracket

2. Right side panel

3. Rear wall

4. Anti-tip bracket

5. Anti-tip arm

1

2

• If you cannot reach your gas supplier,

call the fi re department.

WARNING - CARBON MONOXIDE

It is highly recommended to install a carbon

monoxide detector in your home.

Check local and national regulations concerning

installing and maintaining carbon monoxide

detectors.

IN THE COMMONWEALTH OF

MASSACHUSETTS

• This product must be installed by a licensed

plumber or gas fi tter.

• When using ball-type gas shut-off valves, they

shall be the T-handle type.

• A fl exible gas connector, when used, must not

exceed 3 feet in length.

3

4

5

To check if the bracket is installed and engaged

properly, look underneath the range to see that

the anti-tip arm attached to the right side panel

is engaged on the bracket. On some models, the

storage drawer or kick panel can be removed for

easier inspection.

If visual inspection is not possible, slide the range

forward, confi rm the anti-tip bracket is securely

attached to the fl oor or wall and slide the range

back so the anti-tip arm slides under the anti-tip

bracket. If the range is pulled from the wall for

any reason, always repeat this procedure to verify

that the range is properly secured by the anti-tip

bracket.

SAVE THESE INSTRUCTIONS!

2

Page 4

Important Safety Information

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

WARNING

NEVER use this appliance as a space heater to

heat or warm the room. Doing so may result in

carbon monoxide poisoning and overheating of

the oven.

GENERAL SAFETY REQUIREMENTS

Use this appliance for its intended purpose as

described in this Owner’s Manual.

Have your range installed and properly grounded

by a qualifi ed installer in accordance with the

provided installation instructions. Any adjustment

and service should be performed only by a qualifi ed

gas range installer or service technicians. Do not

attempt to repair or replace any part of your range

unless it is specifi cally recommended in this guide.

Your range is shipped from the factory set for use

with natural gas. It can be converted for use with LP

gas. If required, these adjustments must be made

by a qualifi ed technician in accordance with the

installation instructions and local codes. The agency

performing this work assumes responsibility for the

conversion.

Avoid scratching or impacting glass doors, the

cooktop or control panel. Doing so may lead to

glass breakage. Do not cook on a product with

broken glass. Shock, fi re or cuts may occur.

Do not leave children alone or unattended in an

area where an appliance is in use. They should

never be allowed to climb, sit or stand on any part

of the appliance.

Do not store items of interest to children above a

range or on the backguard of a range - children

climbing on the range to reach items could be

seriously injured.

Do not allow anyone to climb, stand or hang on the

oven door, drawer or cooktop. They could damage

the range or tip it over causing severe injury or

death.

Never block the vents (air openings) of the range.

They provide the air inlets and outlets that are

necessary for the range to operate properly with

correct combustion. Air openings are located at the

rear of the cooktop, at the top and bottom of the

oven door, and at the bottom of the range under the

warming drawer, lower oven drawer or kick panel.

Have the installer show you the location of the

range gas shut-off valve and how to turn it off if

necessary.

Plug your range into a 120-volt grounded outlet

only. Do not remove the round grounding prong

from the plug. If in doubt about the grounding of the

home electrical system, it is your responsibility and

obligation to have an ungrounded outlet replaced

with a properly grounded, three prong outlet in

accordance with the National Electrical Code. Do

not use an extension cord with this appliance.

Before performing any service, unplug the range

or disconnect the power supply at the household

distribution panel by removing the fuse or switching

off the circuit breaker.

Be sure all packing materials are removed from the

range before operating to prevent ignition of these

materials.

Use only dry pot holders—moist or damp pot

holders on hot surfaces may result in burns from

steam. Do not let pot holders touch surface burners,

burner grates, or oven heating elements. Do not use

a towel or other bulky cloth in place of pot holders.

Be careful not to touch hot surfaces of the range.

Potentially hot surfaces include burners, grates,

cooktop, backguard, oven and door interior and

crevices around the oven door.

Do not heat unopened food containers. Pressure

could build up and the container could burst,

causing an injury.

Cook meat and poultry thoroughly - meat to at least

an internal temperature of 160°F and poultry to

at least an internal temperature of 180°F. Cooking

to these temperatures usually protects against

foodborne illness.

SAVE THESE INSTRUCTIONS!

3

Page 5

Important Safety Information

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

WARNING - FLAMMABLE MATERIALS

Do not store or use fl ammable materials in an oven

or near the cooktop, including paper, plastic, pot

holders, linens, wall coverings, curtains, drapes and

gasoline or other fl ammable vapors and liquids.

Never wear loose-fi tting or hanging garments while

using the appliance. Avoid storing commonly used

items in cabinets above the range and be careful

when reaching over the range. Clothing in close

proximity to burners or hot surfaces may ignite

causing severe burns.

Do not let cooking grease or other fl ammable

materials accumulate in or near the range. Grease

in the oven or on the cooktop may ignite.

Clean ventilating hoods frequently. Grease should

not be allowed to accumulate on the hood or fi lter.

WARNING - IN CASE OF FIRE

In the event of a fi re, never pick up a fl aming pot

or pan. Turn the burner off if it is safe to do so.

Extinguish the fi re with a dry chemical or foam-type

extinguisher.

Do not use water on grease fi res. Water will spread

the grease and will not extinguish the fi re. Smother

the fi re with a tight fi tting pot lid, cookie sheet or fl at

tray or use dry chemical or foam-type extinguisher.

If there is a fi re in the oven during baking, smother

the fi re by closing the oven door and turning

the oven off or use dry chemical or foam-type

extinguisher.

COOKTOP SAFETY INSTRUCTIONS

Never leave the range unattended while a surface

burner is ON. Foods, especially oily foods,

may ignite resulting in fi re that could spread to

surrounding cabinets.

Never leave oil unattended while frying. If allowed

to heat beyond its smoking point, oil may ignite

resulting in fi re that may spread to surrounding

cabinets. Use a deep fat thermometer whenever

possible to monitor oil temperature.

To avoid oil spillover and fi re, use a minimum

amount of oil when shallow pan-frying and avoid

cooking frozen foods with excessive amounts of ice.

Use proper pan size and avoid pans that are

unstable or easily tipped. Select cookware that is

matched to the size of the burner. Burner fl ames

should be adjusted so that they do not extend

beyond the bottom of the pan. Excessive fl ames may

be hazardous.

Always use the LITE position when igniting the top

burners and make sure the burners have ignited.

When using glass or ceramic cookware, make sure

it is suitable for cooktop service; others may break

because of sudden changes in temperature.

To minimize the possibility of burns, ignition of

fl ammable materials and spillage, the handle of a

container should be turned toward the center of the

range without extending over nearby burners.

When preparing fl aming foods under a hood, turn

the fan on.

Do not use a wok with a round metal support ring.

The ring may trap heat and block air to the burner

resulting in a carbon monoxide hazard.

Do not attempt to lift the cooktop if your range has

sealed surface burners. Doing so may damage the

gas tubing to the surface burners resulting in a gas

leak and risk of fi re.

Do not use aluminum foil to cover the grates or

line any part of the cooktop. Doing so may result

in carbon monoxide poisoning, overheating of the

cooktop surfaces, or a potential fi re hazard.

SAVE THESE INSTRUCTIONS!

4

Page 6

Important Safety Information

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

WARNING

NEVER cover any slots, holes or passages in

the oven bottom or cover and entire rack with

materials such as aluminum foil. Doing so blocks

air fl ow through the oven and may cause carbon

monoxide poisoning. Aluminum foil linings may

also trap heat, causing a fi re hazard.

OVEN SAFETY INSTRUCTIONS

Stand away from the range when opening the oven

door. Hot air or steam which escapes can cause

burns to hands, face and/or eyes.

Keep the oven free from grease build-up. Grease in

the oven may ignite.

Place oven racks in desired location while oven is

cool. If rack must be moved while oven is hot, do

not let potholder contact the hot heating element in

the oven.

Place oven racks in desired location while oven is

cool. If rack must be moved while oven is hot, be

careful to avoid touching hot surfaces.

Pull the oven rack to the stop-lock position when

loading and unloading food from the oven. This

helps prevent burns from touching hot surfaces of

the door and oven walls.

LOWER OVEN DRAWER SAFETY

INSTRUCTIONS

The purpose of the warming drawer is to hold hot

cooked foods at serving temperature. Bacteria will

grow very rapidly in food that is between 40 and

140°F. Do not put cold food in the warming drawer.

Do not keep food in the warming drawer for more

than 2 hours. Failure to follow these instructions

may result in foodborne illness.

Do not leave paper products, plastics, canned food

or combustible materials in the drawer. They may

ignite.

Do not touch the heating element or the interior

surface of the drawer. These surfaces may be hot

enough to cause burns.

Use care when opening the drawer. Open the

drawer a crack and let hot air or steam escape

before removing or replacing food. Hot air or steam

that escapes can cause burns to hands, face and/

or eyes.

Do not use aluminum foil to line the warming

drawer. Foil is an excellent heat insulator and will

trap heat beneath it. This will upset the performance

of the drawer and potentially cause a fi re hazard.

Do not leave items such as paper, cooking utensils

or food in the oven when not in use. Items stored in

an oven can ignite.

Do not leave items on the cooktop near the oven

vent which is in the center of the backguard. Items

may overheat resulting in a risk of fi re or burns.

When using cooking or roasting bags in the oven,

follow the manufacturer’s directions.

Never broil with door open. Open-door broiling is

not permitted due to overheating of control knobs.

SAVE THESE INSTRUCTIONS!

WARNING

Read all safety instructions before using the

product. Failure to follow these instructions may

result in fi re, electric shock, serious injury or

death.

5

Page 7

INSTALLATION INSTRUCTIONS

FOR YOU SAFETY

Do not store or use combustible materials, gasoline

or other fl ammable vapors and liquids in the vicinity

of this or any other appliance.

If you smell gas:

1. Open windows.

2. Do not touch electrical switches.

3. Extinguish any open fl ame.

4. Immediately call your gas supplier.

REQUIRED TOOLS

1. Phillips screwdriver

2. Flat blade screwdriver

3. Pencil and ruler

4. Pipe wrench

5. Open end or adjustable wrench

6. Level

7. Drill, awl or nail

MATERIALS YOU WILL NEED

1. Gas-line shut-off valve.

2. Pipe joint sealant or UL-approved pipe thread

tape with Tefl on* that resists action of natural

and LP gases.

3. Flexible metal appliance connector (1/2” I.D.)

A 5 foot length is recommended for ease of

installation but other lengths are acceptable.

Never use an old connector when installing a

new range.

4. Flare union adapter for connection to gas supply

line (3/4” or 1/2” NPT x 1/2” I.D.)

5. Liquid leak detector or soapy water.

6. Lag bolt or 1/2” O.D. sleeve anchor (for

concrete fl oors only).

*Tefl on is a registered trademark of DuPont.

1

2

3

4

5

6

7

6

Page 8

INSTALLATION INSTRUCTIONS

INSTALLATION SAFETY INSTRUCTIONS

Read these instructions completely and carefully.

Failure to follow these instructions can result in

electrical shock, fi re, serious injury, or death.

Improper installation, adjustment, alteration, service

or maintenance can cause injury or property

damage. Refer to this manual. For assistance or

additional information, consult a qualifi ed installer,

service agency, manufacturer (dealer) or the gas

supplier.

Never reuse old fl exible connectors. The use of

old fl exible connectors can cause gas leaks and

personal injury. Always use new fl exible connectors

when installing a gas appliance.

Leak testing of the appliance shall be conducted

according to the manufacturer instructions.

Remove all packing material and literature from

oven before connecting gas and electrical supply to

range.

Do not attempt to operate the oven of this range

during a power failure.

Have your range installed by a qualifi ed installer.

Your range must be electrically grounded in

accordance with local codes or, in the absence

of local codes, in accordance with the National

Electrical Code, ANSI/NFPA 70, latest edition.

Your range must conform with local gas codes or, in

the absence of local codes, in accordance with the

National Fuel Gas Code, ANSI Z223.1/NFPA 54.

Appliances designed for manufactured mobile home

installtion must conform with the Manufactured

Home Construction and Safety Standard, Title 24

CFR, Part 3280, [formerly the Federal Standard

for Mobile Home Construction and Safety, Title

24, HUD (part 280)] or with local codes where

applicable.

Appliances designed for Recreational Park Trailers

must conform with the state or other codes or, in

the absence of such codes, with the Standard for

Recreational Park Trailers, ANSI A1 19.5.

Before installing your range on linoleum or any

other synthetic fl oor covering, make sure the fl oor

covering can withstand 180° F without shrinking,

warping or discoloring. Do not install the range

over carpeting unless a sheet of 1/4” thick plywood

or similar insulator is placed between the range and

carpeting.

Make sure the cabinets, fl oor, and wall coverings

around the range can withstand heat generated by

the range up to 200° F.

Avoid placing cabinets above the range. To reduce

the hazard caused by reaching over the open

fl ames of operating burners, install a ventilation

hood over the range that projects forward at least

5” beyond the front of the cabinets.

The ventilating hood must be constructed of sheet

metal not less than 0.0122” thick. Install above

the cooktop with a clearance of not less than

1/4” between the hood and the underside of the

combustible material or metal cabinet. The hood

must be at least as wide as the appliance and

centered over the appliance. Clearance between the

cooking surface and the ventilation hood surface

must never be less than 24”. Exception: Installation

of a listed microwave oven or cooking appliance

over the cooktop shall conform to the installation

instructions packed with that appliance.

If cabinets are placed above the range, allow a

minimum clearance of 30 “ between the cooking

surface and the bottom of unprotected cabinets.

If a 30” clearance between cooking surface and

overhead combustible material or metal cabinets

cannot be maintained, protect the underside of

the cabinets above the cooktop with not less than

1/4” insulating miliboard covered with sheet metal

not less than 0.0122” thick. Clearance between

the cooking surface and protected cabinets MUST

NEVER BE LESS THAN 24”.

The vertical distance from the plane of the cooking

surface to the bottom of adjacent overhead cabinets

extending closer than 1” to the plane of the range

sides must not be less than 18”. (See the Dimensions

and Clearances Illustration in this section).

7

Page 9

INSTALLATION INSTRUCTIONS

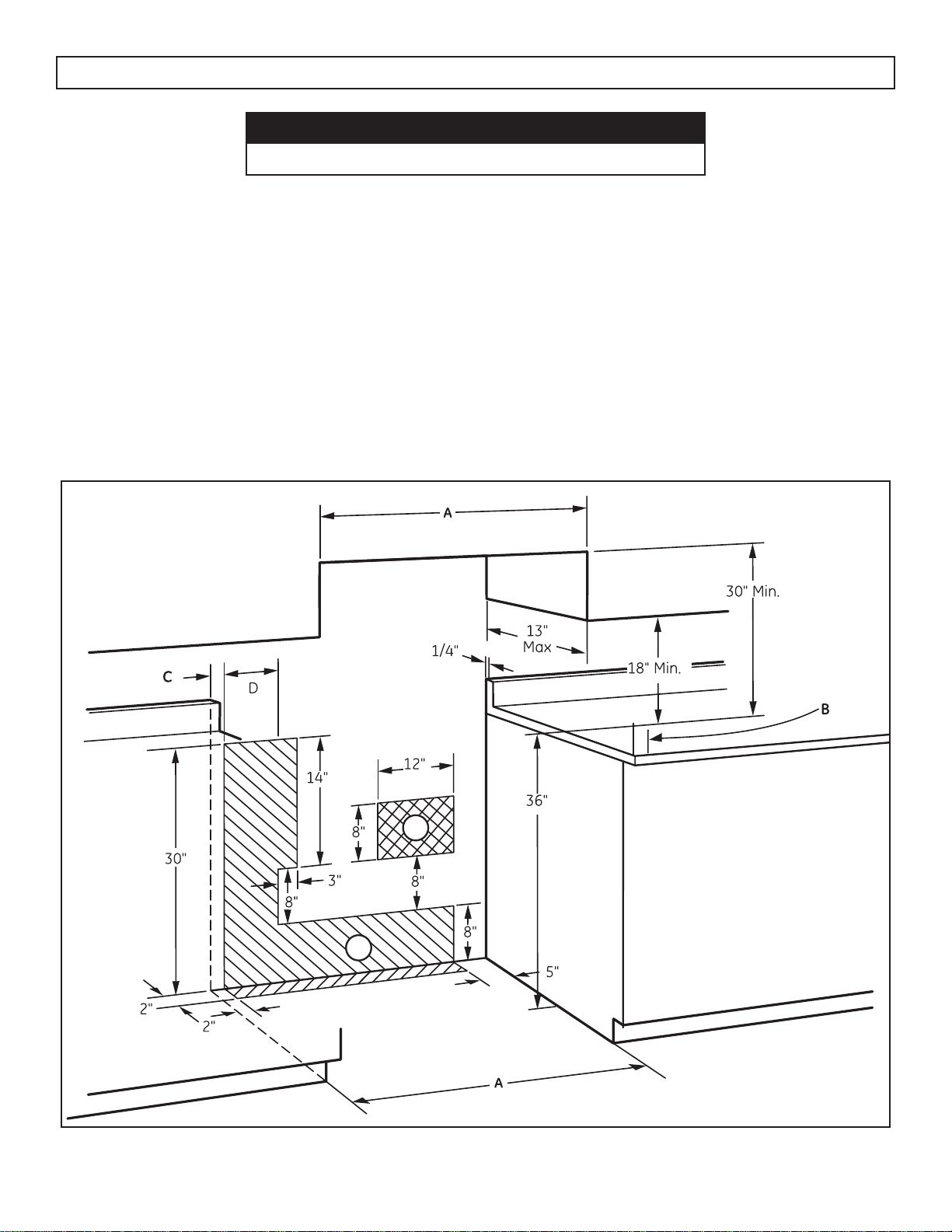

DIMENSIONS AND CLEARANCES

Provide adequate clearances between the

range and adjacent combustible surfaces. These

dimensions must be met for safe use of the range.

The placement of the power outlet and the opening

of the piping can be adjusted to comply with the

specifi c requirements.

The range may be placed with 0” clearance below

the cooktop and at the back wall.

Minimum

LOCATION

Do not locate the range where it may be subject

to strong drafts. Any openings in the fl oor or wall

behind the range should be sealed. Make sure the

openings around the base of the range that supply

fresh air for combustion and ventilation are not

obstructed by carpeting or woodwork.

Your range, like many other household items,

is heavy and can settle into soft fl oor coverings

such as cushioned vinyl or carpeting. Use care

when moving the range on this type of fl ooring.

It is recommended that the following simple and

inexpensive instructions be followed to protect your

fl oor.

The range should be installed on a sheet of plywood

or similar material. When the fl oor covering ends at

the front of the range, the area that the range will

rest on should be built up with plywood to the same

level or higher than the fl oor covering.

This will allow the range to be moved for cleaning

or servicing. Also,make sure your fl oor covering will

withstand 180° F.

Make sure the cabinets and wall coverings around

your range can withstand the heat generated (up to

200° F) by the range.

IMPORTANT

Remove all tape and packaging.

A: 19 3/4”

B: 19 3/4”

C: 2”

D: 44 3/8”

E: 41 3/4”

E

36”

¾ ± ¼”

Make sure the burners are properly seated and

level.

Take the accessory pack out of the oven or drawer.

Check to be sure that no range parts have come

loose during shipping.

8

Page 10

INSTALLATION INSTRUCTIONS

POWER CORD AND STRAIN RELIEF INSTALLATION

Remove the wire cover on the lower back of the

range by removing its top center screw. Do not

discard this screw.

Remove the knockout ring located on the bracket

directly below the terminal block. To remove the

knockout, use a pair of pliers to bend the knockout

ring away from the bracket and twist until the ring is

removed.

For power cord installations

Assemble the strain relief in the hole of the bracket.

If tabs are present at the end of the winged strain

relief they can be removed for a better fi t.

Insert the power cord through the strain relief and

tighten. Allow enough slack to easily attach the cord

terminals to the terminal block.

Do not install the power cord without a strain relief.

The strain relief bracket should be installed before

reinstalling the rear range wiring cover.

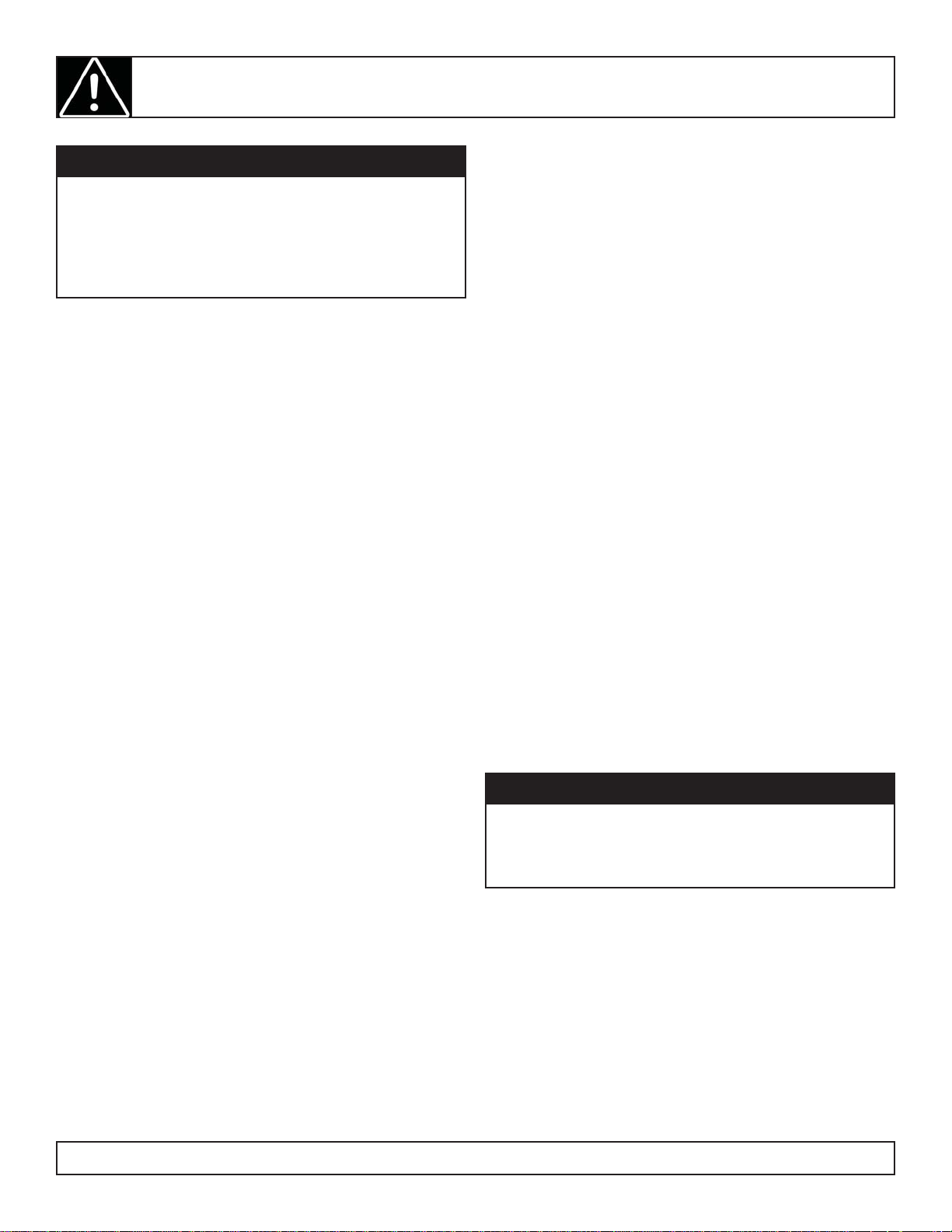

1. Terminal block

2. Strain relief

3. Bracket

4. Power cord

1. Terminal block

2. Knockout ring in bracket

3. Knockout ring removed

1

3

2

For conduit installations

Purchase a squeeze connector matching the

diameter of your conduit and assemble it in the

hole of the bracket. Insert the conduit through the

squeeze connector and tighten. Allow enough slack

to easily attach the wires to the terminal block.

Do not install the conduit without a squeeze

connector. The squeeze connector should be

installed before reinstalling the rear range wiring

cover.

1. Terminal block

2. Squeeze connector

3. Bracket

4. Conduit

2

4

1

3

1

2

3

4

9

Page 11

INSTALLATION INSTRUCTIONS

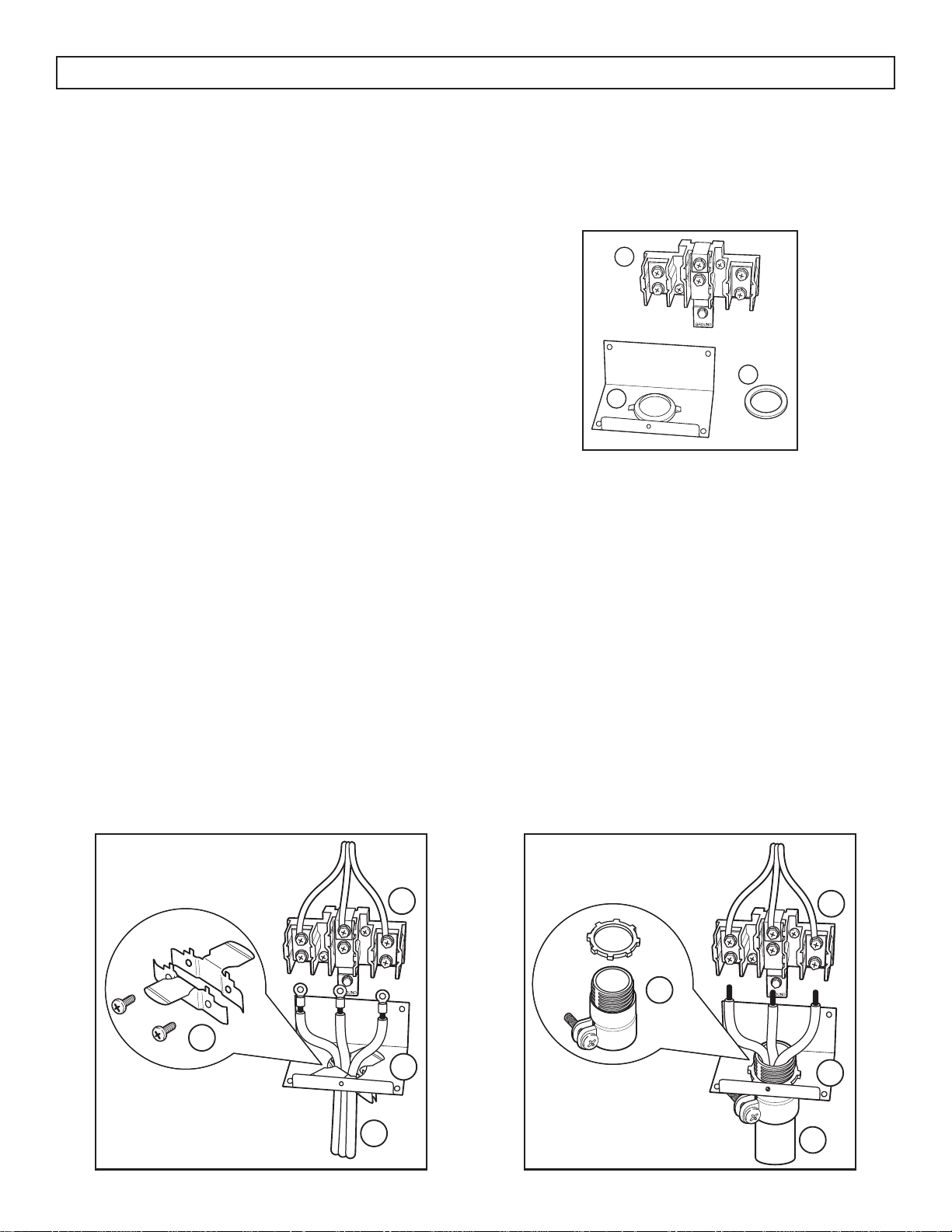

3 WIRE POWER CORD INSTALLATION

The neutral or ground wire of the power cord must

be connected to the neutral terminal located in the

center of the terminal block. The power leads must

be connected to the lower left and the lower right

terminals of the terminal block.

1. Remove the three lower terminal screws from the

terminal block.

2. Insert the three terminal screws through each

power cord terminal ring and into the lower

terminals of the terminal block.

3. Be certain that the center wire is connected to

the center lower position of the terminal block.

4. Tighten screws securely into the terminal block.

5. Do not remove the ground strap connection.

1. Terminal block

2. Neutral terminal

3. Ground strap

4. Power cord

5. Ground plate

1

2

5

3

4

10

Page 12

INSTALLATION INSTRUCTIONS

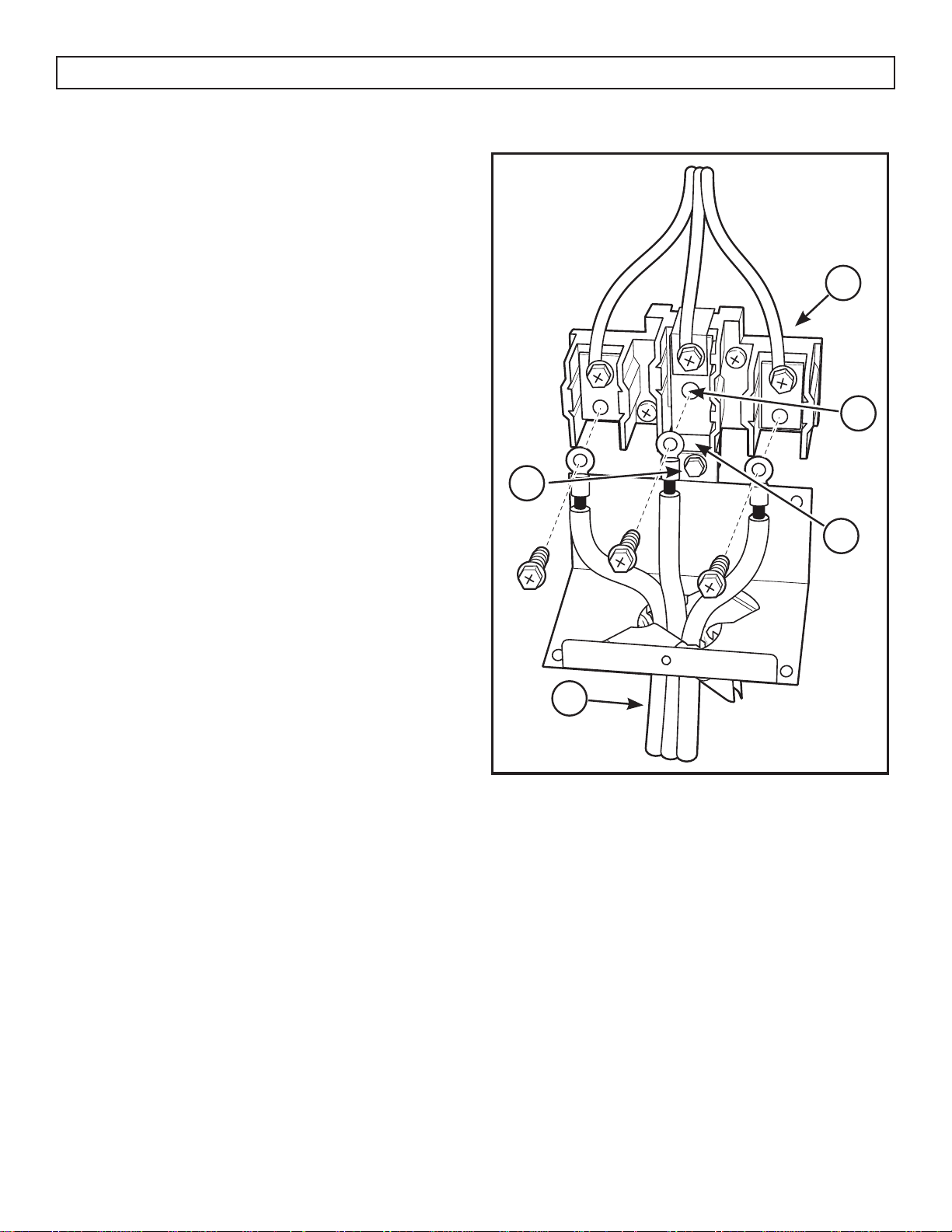

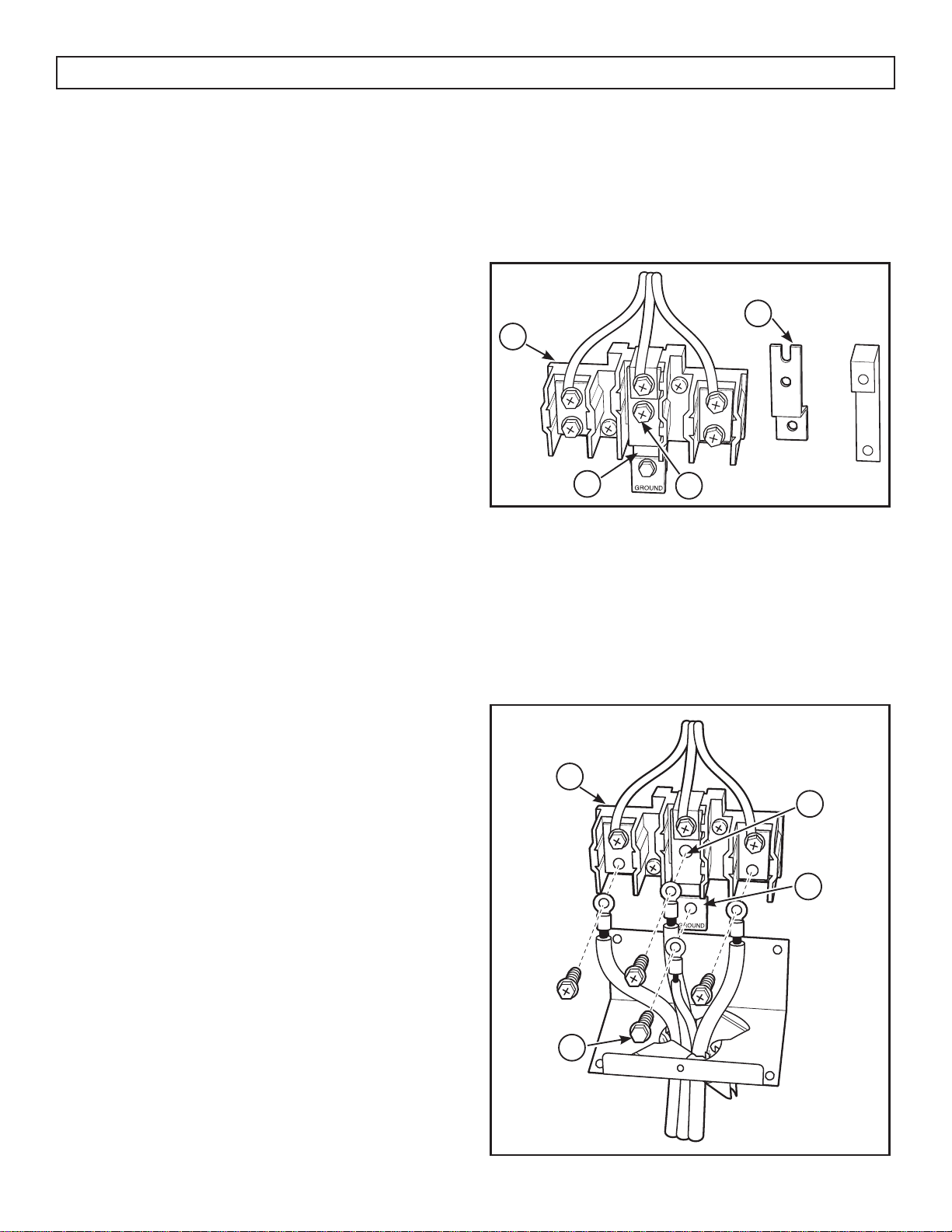

4 WIRE POWER CORD INSTALLATION

The neutral wire of the supply circuit must be

connected to the neutral terminal located in the

lower center of the terminal block. The power

leads must be connected to the lower left and the

lower right terminals of the terminal block. The 4th

grounding lead must be connected to the frame of

the range with the ground plate and the ground

screw.

1. Remove the three lower terminal screws from the

terminal block.

2. Remove the ground screw and ground plate and

retain them.

3. Cut and discard the ground strap. Do not

discard any screws.

4. Insert the one ground screw into the power cord

ground wire terminal ring, through the ground

plate and into the frame of the range.

5. Insert the three terminal screws that were

removed earlier through each power cord

terminal right and into the lower terminals of the

terminal block.

6. Be certain that the center wire is connected to

the center lower position of the terminal block.

Before

1. Terminal block

2. Ground strap

3. Neutral terminal

4. Cut and discard the ground strap

2

1

4

After

1. Terminal block

2. Neutral terminal

3. Ground plate (grounding to range)

4. Ground screw

3

or

7. Tighten the screws securely into the terminal

block.

1

2

3

4

11

Page 13

INSTALLATION INSTRUCTIONS

ELECTRICAL CONNECTIONS

Electrical requirements:

120 volt, 60 hertz, properly grounded dedicated

circuit protected by a 15 amp or 20 amp circuit

breaker or time delay fuse.

NOTE: Use of automatic, wireless, or wired external

switches that shut off power to the appliance are not

recommended for this product.

WARNING SHOCK HAZARD: This appliance must

be properly grounded. Failure to do so can result in

electric shock.

The power cord of this appliance is equipped with

a three prong (grounding) plug which mates with

a standard three-prong grounding wall receptacle

to minimize the possibility of electric shock hazard

from this appliance.

The customer should have the wall receptacle and

circuit checked by a qualifi ed electrician to make

sure the receptacle is properly grounded.

Where a standard two-prong wall receptacle is

encountered, it is the personal responsibility and

obligation of the customer to have it replaced with a

properly grounded three-prong wall receptacle.

DO NOT, UNDER ANY CIRCUMSTANCES, CUT OR

REMOVE THE THIRD (GROUND) PRONG FROM

THE POWER CORD.

DO NOT USE AN ADAPTER.

DO NOT USE AN EXTENSION CORD.

A word about GFCIs - GFCIs are not required or

recommended for gas range receptacles.

Ground Fault Circuit Interrupters (GFCIs) are

devices that sense leakage of current in a circuit and

automatically switch off power when a threshold

leakage level is detected. These devices must be

manually reset by the consumer. The National

Electrical Code requires the use of GFCIs in kitchen

receptacles installed to serve countertop surfaces.

Performance of the range will not be affected if

operated on a GFCI-protected circuit but occasional

nuisance tripping of the GFCI breaker is possible.

ANTI-TIP BRACKET INSTALLATION

1. Anti-tip arm on the back of the appliance

2. Anti-tip bracket

3. Screw must enter wood or concrete

4. Wall sill plate

5. Screw must enter wood

2

1

3

To reduce the risk of the appliance tipping, the antitip bracket must be installed before operation.

Note: The installation of the anti-tip bracket must

meet all local codes for securing the appliance.

The anti-tip bracket must be secured to either the

rear wall or the fl oor and must be positioned in such

a way that it will overhang the anti-tip arm on the

rear of the appliance.

4

5

Rear wall installation

Use the two screws provided to secure the bracket

to the rear wall. The screws must enter a wood sill

plate. If the wall contains any metal studs or similar

materials, or if the back of the appliance cannot

reach the rear wall, the fl oor installation should be

used.

Floor installation

Wood fl oor: Use the two screws provided to secure

the bracket to the fl oor.

Concrete fl oor:

1. Mark the location where the screws need to be

installed.

2. Use a power drill and a concrete bit to drill a

5/32” pilot hole 2” deep into the concrete at the

center of each of the marked locations.

3. Use the two screws provided to secure the

bracket to the fl oor.

Double check the installation

After installing the bracket, slide the appliance into

its fi nal location. Look underneath the appliance

and ensure that the anti-tip arm attached to the side

panel of the appliance is engaging the bracket.

12

Page 14

INSTALLATION INSTRUCTIONS

INSTALL THE RANGE

1. Provide adequate gas supply

Your range is designed to operate at a pressure of

5” of water column on natural gas or, if desired for

LP gas (propane or butane), 10” of water column.

Make sure you are supplying your range with the

type of gas for which it is designed.

This range is convertible for use on natural or

propane gas. If you decide to use this range on LP

gas, conversion must be made by a qualifi ed LP

installer before attempting to operate the range on

that gas.

For proper operation, the pressure of natural gas

supplied to the regulator must be between 6” and

13” of water column.

For LP gas, the pressure supplied must be between

11” and 13” of water column.

INSTALL THE RANGE

2. Connect the range to gas

Shut off the main gas supply valve before

disconnecting the old range and leave it off until the

new hook-up has been completed. Don’t forget to

relight the pilot on other gas appliances when you

turn the gas back on.

Because hard piping restricts movement of the

range, the use of a CSA International-certifi ed

fl exible metal appliance connector is recommended

unless local codes require a hard-piped connection.

Never use an old connector when installing a new

range. If the hard piping method is used, you must

carefully align the pipe, the range cannot be moved

after the connection is made.

To prevent gas leaks, put pipe joint compound on,

or wrap pipe thread tape with Tefl on around all

male (external) pipe threads.

When checking for proper operation of the

regulator, the inlet pressure must be at least 1”

greater than the operating (manifold) pressure as

given above.

The pressure regulator located at the inlet of the

range must remain in the supply line regardless of

whether natural or LP gas is being used.

A fl exible metal appliance connector used to

connect the range to the gas supply line should have

an I.D. of 1/2” and be 5 feet in length for ease of

installation. In Canada, fl exible connectors must be

single wall metal connectors no longer than 6 feet in

length.

Installation steps:

1. Install a manual gas line shut-off valve in the gas

line in an easily accessed location outside of the

range. Make sure everyone operating the range

knows where and how to shut off the gas supply

to the range.

2. Install male 1/2” fl are union adapter to the

1/2” NPT internal thread at inlet of regulator.

Use a backup wrench on the regulator fi tting

to avoid damage. When installing the range

from the front, remove the 90° elbow for easier

installation.

3. Install male 1/2” or 3/4” fl are union adapter

to the NPT internal thread of the manual shut-off

valve to keep it from turning.

4. Connect fl exible metal appliance connector to

the adapter on the range. Position range to

permit connection at the shut-off valve.

5. When all connections have been made, make

sure all range controls are in the off position and

turn on the main gas supply valve. Use a liquid

leak detector at all joints and connections to

check for leaks in the system.

13

Page 15

INSTALLATION INSTRUCTIONS

WARNING

Fire hazard: Do not use a fl ame to check for gas leaks.

Recommended gas and electric supply location

When using test pressures greater than 1/2 psig to pressure test the gas supply system of the residence,

disconnect the range and individual shut-off valve from the gas supply piping. When using test pressures

of 1/2 psig or less to test the gas supply system, simply isolate the range from the gas supply system by

closing the individual shut-off valve.

Note: Recommended gas hook-up locations behind the range. Gas and shut-off valve should not protrude

more than 2” from the wall to allow the range to rest against the wall.

Check local codes before making connections.

2

1

1. Electrical connection area

2. Gas hook-up area

A. 20 3/8”

B. (minimum distance to

walls above the cooktop

on each side): 2”

C. 2”

D. 2 1/2”

14

Page 16

INSTALLATION INSTRUCTIONS

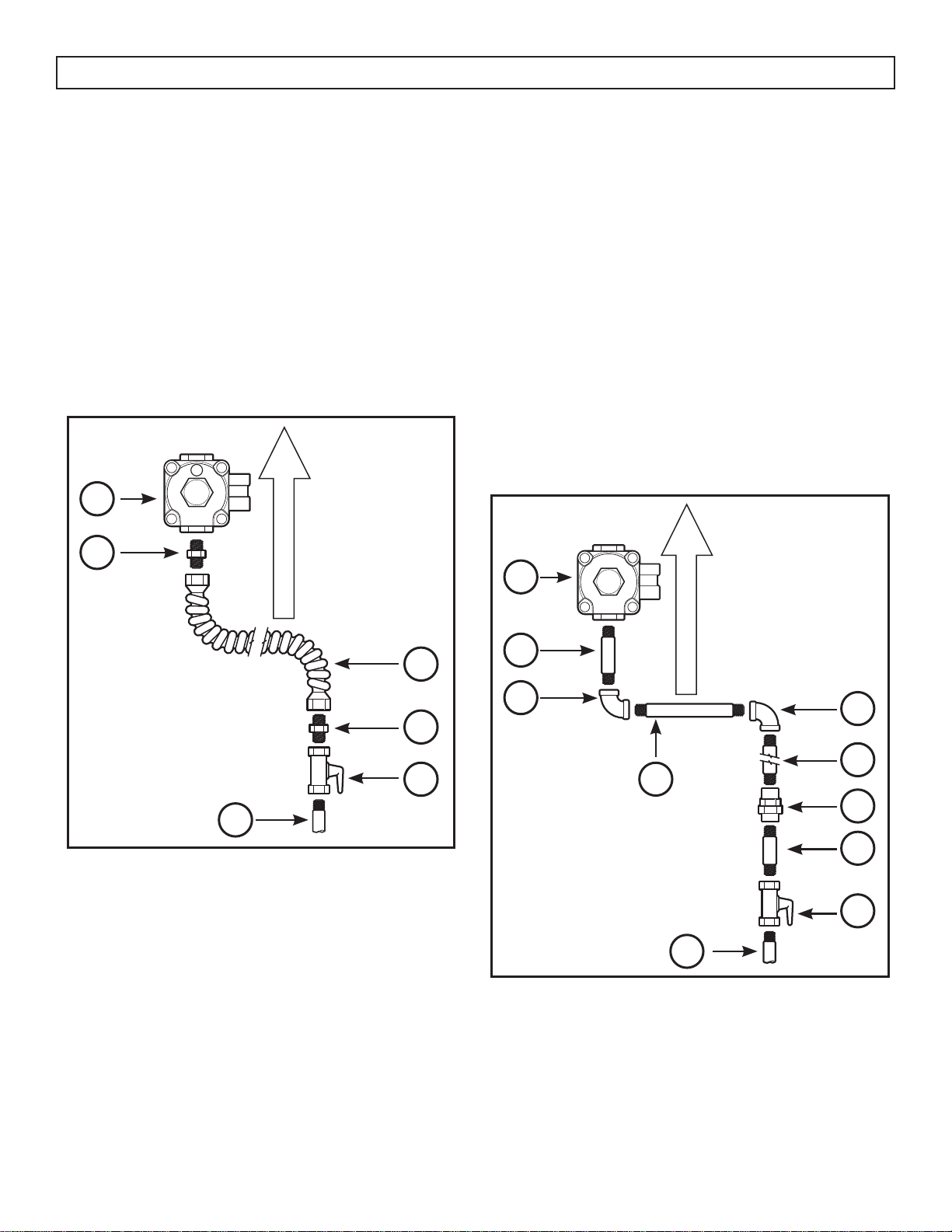

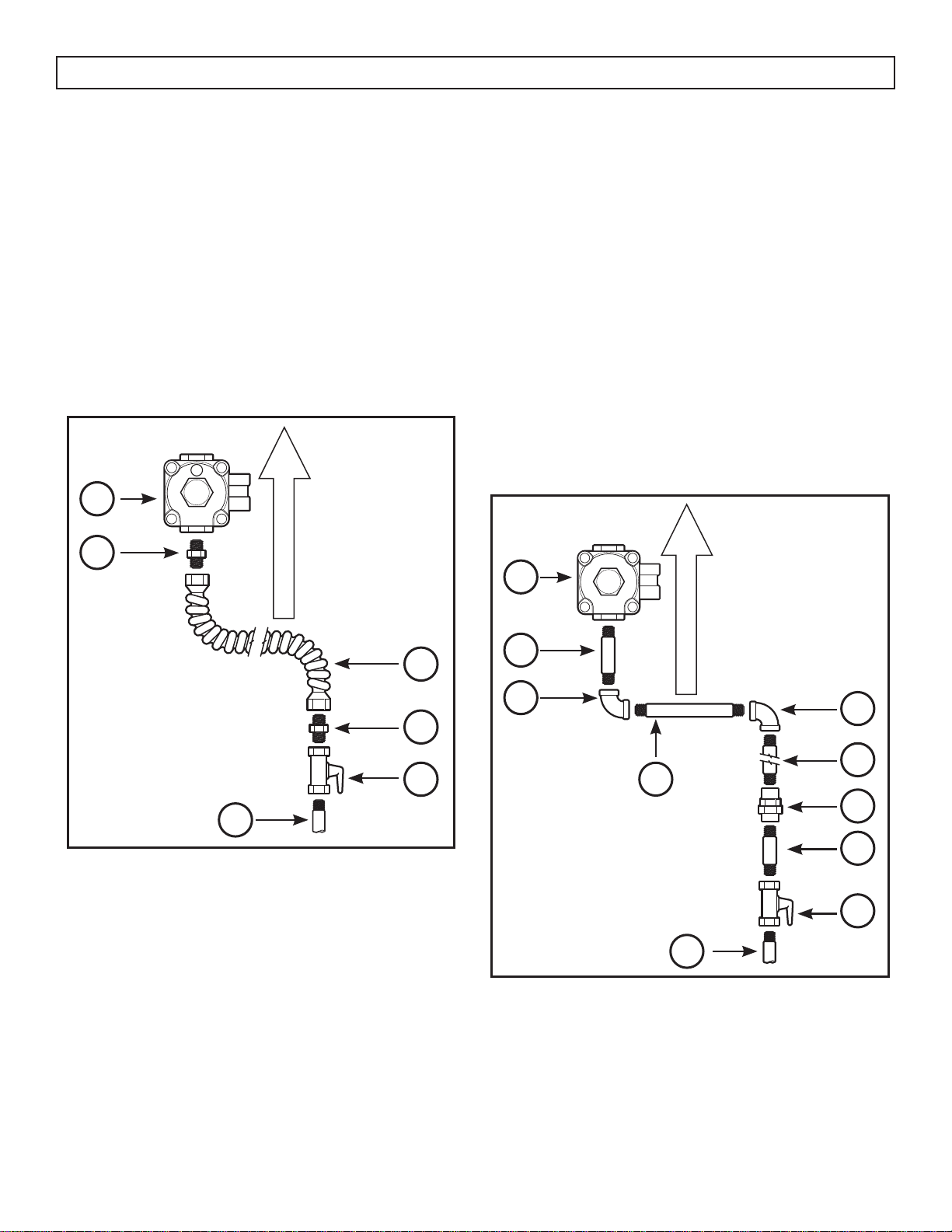

FLEXIBLE CONNECTOR HOOKUP EXAMPLE

To the installer: Inform the consumer of the location

of the gas shut-off valve and leave these instructions

with the consumer for future use.

Note: The arrow indicates the direction of gas fl ow

into the range.

1. Pressure regulator

2. Adapter

3. Flex connector (4 1/2 feet maximum)

4. Adapter

5. Gas shut off valve

6. 1/2” or 3/4” gas pipe

1

2

RIGID CONNECTOR HOOKUP EXAMPLE

To the installer: Inform the consumer of the location

of the gas shut-off valve and leave these instructions

with the consumer for future use.

Note: The arrow indicates the direction of gas fl ow

into the range.

1. Pressure regulator

2. Black iron pipe 4 1/2”

3. 90° elbow

4. Nipple (may not be required)

5. 90° elbow

6. Black iron pipe

7. Union

8. Nipple

9. Gas shut off valve

10. 1/2” or 3/4” gas pipe

1

6

3

4

5

2

3

4

INSTALL THE RANGE

3. Seal the openings

5

6

7

8

9

10

Seal any openings in the wall behind the range

and in the fl oor under the range when hookups are

completed.

15

Page 17

INSTALLATION INSTRUCTIONS

INSTALL THE RANGE

4. Electric ignition

There are separate ignition devices for the left and

right hand surface burners. Both of these ignition

devices are ON when any knob is turned to the LITE

setting. The ignition devices will spark as long as

any of the top burner knobs are at the LITE setting.

In the event of an electrical power failure, the top

knobs can still be used. To light a burner, hold a lit

kitchen match adjacent to the top burner to be used

and turn the valve knob to LITE.

USE EXTREME CAUTION WHEN LIGHTING A

BURNER THIS WAY.

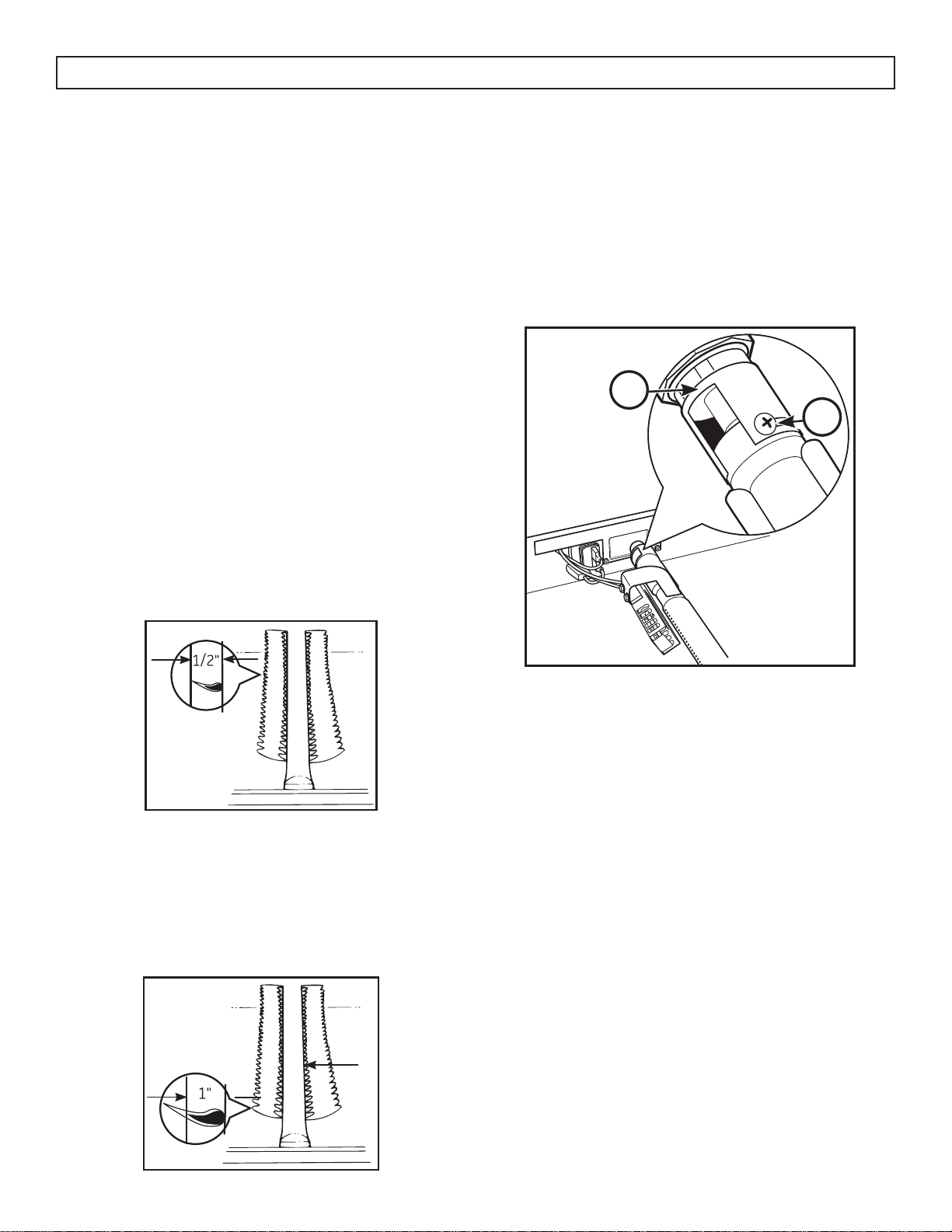

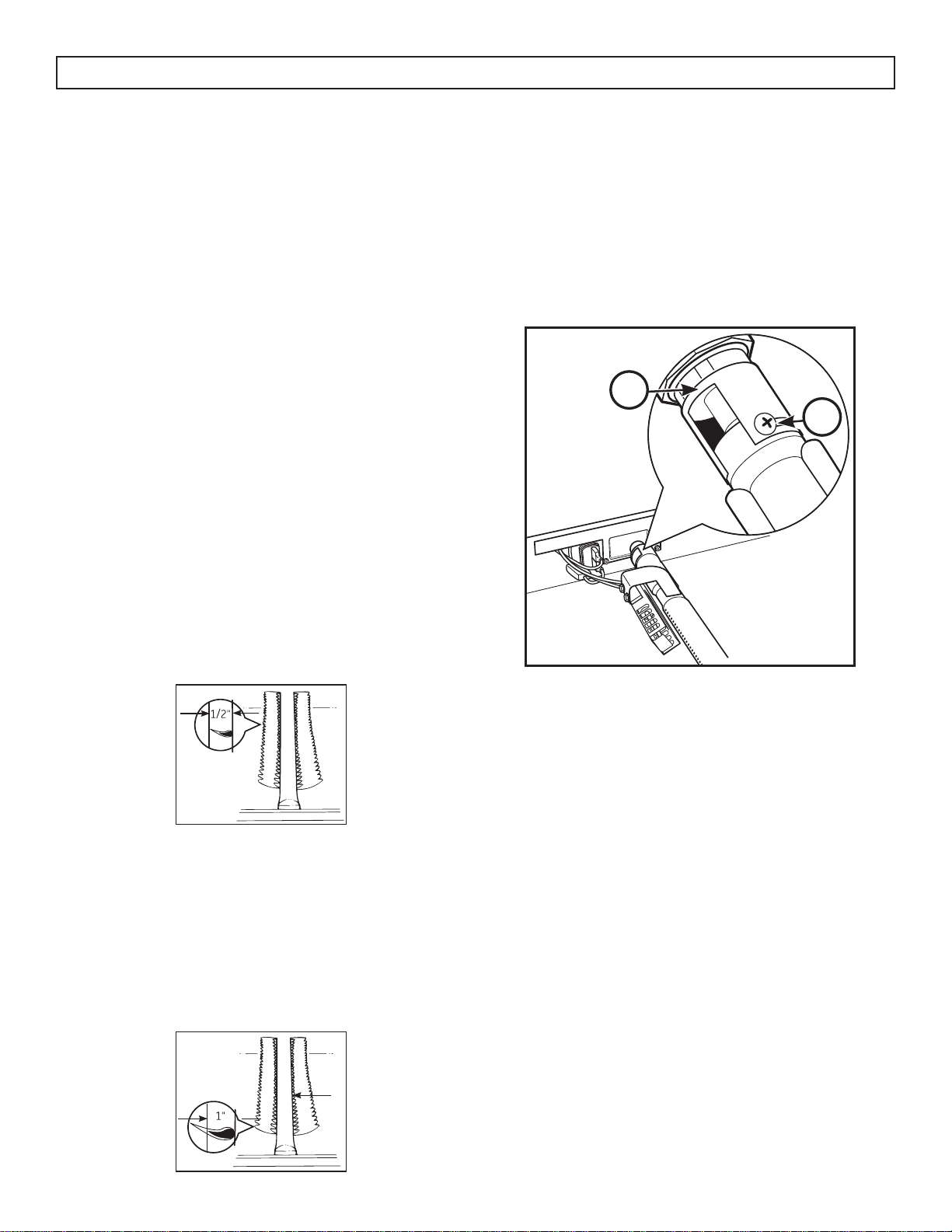

5. Adjust the oven burner air shutter

For Natural Gas: The oven burner fl ame should

be a clean, blue fl ame with distinct inner cones

approximately 1/2” long. A soft, lazy fl ame with

indistinct cones means too much gas or not enough

air. A noisy lifting fl ame means too much air.

INSTALL THE RANGE

If burner adjustment is necessary:

Loosen the lock screw located at the top of the air

shutter, then rotate the air shutter to the correct

position and retighten the screw.

1. Air shutter

2. Lock screw

1

2

For LP gas: The fl ame should have approximately

1-inch blue cones. After 30 seconds of burner

operation, check for fl ames lifting off the burner

ports. If lifting is observed, gradually reduce the air

shutter opening until fl ames are stabilized. Some

yellow tipping may be normal for LP gas.

The oven burner fl ame can be checked as follows

(without burner baffl e in place):

• To correct a yellow fl ame, increase size of air

shutter opening.

• To correct a lifting, but distinct, blue fl ame,

decrease size of air shutter opening.

The air shutter should be set approximately 2/3

open for natural gas, and approximately full open

for LP gas.

16

Page 18

INSTALLATION INSTRUCTIONS

INSTALL THE RANGE

6. Quality of fl ames

The combustion quality of burner fl ames needs to be

determined visually.

A: Yellow fl ames; call for service

B: Yellow tips on outer cones; normal for LP gas

C: Soft blue fl ames; normal for natural gas

A

B

INSTALL THE RANGE

8. Level the range

Check that the appliance is level using a spirit level

or a clear measuring cup partially fi lled with water.

Ensuring that the oven is level will ensure even

cooking.

Use an open end or adjustable wrench to adjust

the leveling legs. Turn the leg clockwise to raise the

range. Turn the leveling leg counterclockwise to

lower the range.

C

7. Replace the oven parts

Once all adjustments are completed, ensure all

oven parts are installed correctly such as the bottom

drawer, the oven shelves and the oven door.

INSTALLATION CHECK LIST

• Make sure all controls are in the OFF position.

• Make sure the fl ow of combustion and

ventilation air to the range is unobstructed.

• Make sure all oven parts are installed correctly.

• Double check that the anti-tip bracket is installed

and working correctly.

CONVERT TO LP GAS

This range leaves the factory set for use with natural

gas. The conversion to LP gas must be performed by

a qualifi ed LP gas installer.

The conversion instructions and LP orifi ces can be

found attached to the back of the range.

17

Page 19

OPERATING INSTRUCTIONS

USING GAS SURFACE BURNERS

Before lighting a gas burner:

• Make sure all burners are in place.

• Make sure all grates on the range are properly

places before using any burner.

After lighting a gas burner:

• Do not operate the burner for an extended

period of time without cookware on the grate.

The fi nish on the grate may discolor or chip

without cookware to absorb the heat.

• Be sure the burners and grates are cool before

you place your hand, a pot holder, cleaning

cloths or other materials on them.

How to light a gas surface burner:

• Make sure all the surface burners are placed in

their respective positions.

• Push the control knob in and turn it to the LITE

position.

• You will hear a clicking noise, this is the sound

of the electric spark igniting the burner.

• Turn the knob to adjust the fl ame size. If the

knob stays at LITE, it will continue to click.

• When one burner is turned to LITE, all the

burners spark. Do not attempt to disassemble or

clean around any burner while another burner

is on. An electric shock may result, which could

cause you to knock over hot cookware.

• Watch the fl ame, not the knob, as you adjust

heat. When fast heating is desired, the fl ame

size on a gas burner should match the cookware

you are using.

WARNING

Flames that are not covered by cookware

may present a risk of burns or clothing

ignition. Never let fl ames extend beyond the

sides of the cookware.

ACCEPTABLE COOKWARE

Aluminum: Medium-weight cookware is

recommended because it heats quickly and evenly.

Most foods brown evenly in an aluminum skillet.

Use saucepans with tight-fi tting lids when cooking

with minimum amounts of water.

Cast-Iron: If heated slowly, most skillets will give

satisfactory results.

Enamelware: Under some conditions, the enamel

of some cookware may melt. Follow cookware

manufacturer’s recommendations for cooking

methods.

Glass: There are two types of glass cookware—

those for oven use only and those for top-of-range

cooking (saucepans, coffee and teapots). Glass

conducts heat very slowly.

Heatproof Glass Ceramic: Can be used for either

surface or oven cooking. It conducts heat very

slowly and cools very slowly. Check cookware

manufacturer’s directions to be sure it can be used

on gas ranges.

Stainless Steel: This metal alone has poor heating

properties and is usually combined with copper,

aluminum or other metals for improved heat

distribution. Combination metal skillets usually work

satisfactorily if they are used with medium heat as

the manufacturer recommends.

IN CASE OF POWER FAILURE

• Flames larger than the bottom of the cookware

will not result in faster heating and may be

hazardous.

In case of a power failure, you can light the surface

burners on your range with a match. Hold a lit

match to the burner ports, then slowly turn the

control knob to the LITE position. Use extreme

caution when lighting burners this way.

Surface burners in use when an electrical power

failure occurs will continue to operate normally.

18

Page 20

OPERATING INSTRUCTIONS

USING THE OVEN

Oven controls

The oven is controlled by the oven temp knob. It can

take up to 90 seconds before the fl ame comes on.

After the oven reaches the selected temperature, the

oven burner maintains the selected temperature.

IN CASE OF POWER FAILURE

OVEN SHELVES

The oven shelves are designed with stop-locks so

that when they are placed correctly on the shelf

supports, they will stop before coming completely

out of the oven and will not tilt when food is being

removed or added.

To remove the shelves from the oven, pull the shelf

outward, tilt the front end upward and pull it out.

To replace the shelves, place the shelf on the support

with the stop locks facing up and toward the back of

the oven. Tilt up the front and push the shelf toward

the back of the oven until it goes past the bump on

the shelf support, then lower the front of the shelf

and push it all the way into the oven.

The oven has four different shelf support positions to

accommodate different cooking requirements.

The oven or broiler cannot be lit during a power

failure.

If the oven is in use when a power failure occurs,

the oven burner shuts off. This is because the fl ow

of gas is automatically stopped and will not resume

until power is restored.

UPPER OVEN VENT

Your oven is vented through ducts at the rear of the

range. Do not block these ducts when cooking in

the oven - it is important that the fl ow of hot air

from the oven and fresh air to the oven burner be

uninterrupted. Avoid touching the vent openings or

nearby surfaces during oven or broiler operations they may become hot.

Handles of pots and pans on the cooktop may

become hot if left too close to the vent.

Do not leave plastic or fl ammable items on the

cooktop - they may melt or ignite if left too close to

the vent.

SHELF POSITIONS

• Most baking is done on the second or third shelf

position from the bottom of the oven.

• When baking multiple items, use two shelves

positioned on the second and fourth shelf

supports from the bottom of the oven.

• Roasting is usually done on the bottom shelf

position.

• As a general rule, place most foods in the

middle of the oven on the second or third shelf.

Do not leave closed containers of the cooktop. The

pressure in closed containers may increase, which

may cause them to burst.

Metal items will become very hot if they are left on

the cooktop, and could cause burns.

• Pans should not touch each other or the walls

of the oven. Allow 1 to 1 1/2 inches of space

between pans as well as from the back of the

oven, the door and the sides. If you need to

use two shelves stagger the pans so one is not

directly above the other.

19

Page 21

OPERATING INSTRUCTIONS

OVEN BAKING AND ROASTING

1. Position the shelves in the oven. If cooking on

two shelves at the same time, stagger the pans

for the best heat circulation.

2. Place the food on the center of the oven shelf.

Allow at least 2 inches between the end of the

pan and the oven wall or any adjacent pans.

3. Turn oven temperature knob to the desired

temperature.

4. Check the food regularly. Remove once done

and ensure the oven is turned off.

BAKING AND ROASTING TIPS

• Follow a tested recipe and measure the

ingredients carefully. If you are using a package

mix, follow label directions.

• Do not open the oven door while baking or

roasting. Heat will be lost and the cook time

might need to be extended. If you must open the

door, open it partially and close it as quickly as

possible.

• Roasting is cooking by dry heat. Tender meat

or poultry can be roasted uncovered. Roasting

temperatures, which should be low and steady,

keep spattering to a minimum. When roasting,

it is not necessary to sear, baste, cover, or add

water to the meat.

• Frozen roasts of meat can be cooked without

thawing, but allow 10 to 25 minutes of

additional time per pound of meat (10 minutes

per pound for roasts under 5 pounds, more time

for larger roasts).

• Thaw frozen poultry before roasting to ensure

even cooking. Some commercial frozen poultry

can be cooked successfully without thawing.

Follow directions given on package label.

SAFE COOKING

The USDA recommends the following minimum safe

internal temperatures:

• Raw beef, pork, lamb and veal steaks or chops:

145°F as measured with a food thermometer

before removing meat from the heat source. For

safety and quality, allow meat to rest for at least

three minutes before carving or consuming.

• Raw ground beef, pork, lamb or veal: 160°F as

measured with a food thermometer.

• Poultry: 165°F as measured with a food

thermometer.

• For more information, visit: www.isitdoneyet.gov

or call toll free to the USDA meat and poultry

hotline at 1-888-674-6854.

OVEN BROILING

Broiling is cooking food by direct heat from above

the food. Most fi sh and tender cuts of meat can be

broiled. The range has a compartment below the

oven for broiling. A specially designed broiler pan

allows dripping fat to drain away from the food.

Both the oven door and broiler compartment drawer

should be closed during broiling.

1. Preheating the boiler drawer is not necessary

and can produce poor results.

2. If the meat has fat or gristle around the edge,

cut vertical slashes through both about 2” apart.

If desired, fat may be trimmed, leaving a layer

about 1/8” thick.

3. Place the meat on a broiler grid in a broiler pan

designed for broiling. Always use the grid so

the fat drips into the broiler pan; otherwise the

juices may become hot enough to catch fi re.

4. Place the food in the broiler and close the door.

5. Turn the oven temperature knob to BROIL.

6. Food can be turned during broiling if necessary.

Be cautious of hot air or steam when opening

the oven door.

7. Make sure to turn the oven temperature knob to

OFF once broiling is complete.

BROILING TIPS

• Always use the broiler pan and grid that comes

with your range. It is designed to minimize

smoking and spattering by trapping juices in the

shielded lower part of the pan.

• For steaks and chops, slash fat evenly around

the outside edges of the meat. Use tongs to turn

the meat over to prevent piercing the meat and

losing juices.

• If desired, marinate meats before broiling, or

brush with barbecue sauce in the last 5-10

minutes only.

• When arranging the food on the pan, do not

let fatty edges hang over the sides because

dripping fat could soil the oven.

• Frozen steaks can be broiled by positioning

the rack at the next lowest rack position and

increasing the cooking time 1 1/2 times per

side.

• Aluminum foil can be used to line the broiler

pan and grid, however, it must be molded tightly

to the grid and slits must be cut in the foil so that

fat and juices can leak through into the lower

part of the pan.

20

Page 22

OPERATING INSTRUCTIONS

ADJUST THE OVEN THERMOSTAT

You may fi nd that the new oven cooks differently

than the one it replaced. Use the new oven for a

few weeks to become familiar with it. If you still fi nd

the oven is too hot or too cold, you can adjust the

thermostat.

Do not use thermometers, such as those found in

grocery stores to check the temperature of the oven.

They are not calibrated for high temperatures and

can vary from 20 - 40 degrees.

This adjustment will not affect the broiling

temperatures. The adjustment will be retained after

a power failure.

1. Pull the oven temperature knob off the

range and look at the back of it. To make an

adjustment, loosen by one turn the two screws

on the back of the knob. Do not completely

remove the screws.

2. With the back of the knob facing you, hold the

outer edge of the knob with one hand and turn

the front of the knob with the other hand.

3. To increase the oven temperature, move the top

screw toward the right.

4. To decrease the oven temperature, move the top

screw toward the left.

5. You will hear a click for each notch you move

the knob. Each click will change the oven

temperature approximately 10°F. The range is

plus or minus 60°F from the arrow. We suggest

that you adjust the temperature by one click and

then test the oven performance before adjusting

further.

6. After the adjustment is made, retighten the

screws so they are snug. Be careful not to overtighten.

7. Replace the knob, matching the fl at area of the

knob to the shaft.

ALUMINUM FOIL

Do not use aluminum foil to line the bottom of

the oven. The foil will trap heat below and upset

the performance of the oven. Foil can melt and

permanently damage the bottom of the oven.

Damage from improper use of aluminum foil is not

covered by the product warranty.

Foil may be used to catch spills by placing a sheet

on a lower rack, several inches below the food. Do

not use more foil than necessary and never entirely

cover an oven rack with aluminum foil. Keep foil at

least 1 to 1 1/2 inches from oven walls to prevent

poor heat circulation.

OVEN MOISTURE

As the oven heats up, the temperature change of the

air in the oven may cause water droplets to form on

the door glass. These droplets are harmless and will

evaporate as the oven continues to heat up.

OVEN AIR VENTS

Never block the air vents. They provide the air

inlet and outlet that are necessary for the range to

operate properly with correct combustion.

Air openings are located at the rear of the cooktop,

at the top and bottom of the oven door, and at the

bottom of the range.

Vent appearance and location may vary.

L

O

O

S

E

N

S

C

R

E

W

S

T

O

R

O

T

A

T

E

R

E

T

T

E

O

K

H

A

M

C

O

O

M

L

A

E

K

R

E

21

Page 23

CARE & MAINTENANCE

BURNER GRATES

The range has two or three professional-style

double grates. These grates are position specifi c.

For maximum stability, these grates should only

be used in their proper position; they cannot be

interchanged left to right or front to back.

For convenience, the undersides of the left and

right grates are marked “LEFT FRONT” and “RIGHT

FRONT”. Make sure the front portion of both grates

is in front. The middle grate has a bow in front.

Make sure the bowed portion is toward the front of

the range. In addition, the middle grate is supported

by the left and right grates and must be installed last

for stability.

Cleaning burner grates

Lift out when cool. Grates should be washed

regularly and, of course, after spillovers. Wash

them in hot, soapy water and rinse with clean

water. When replacing the grates, be sure they are

positioned securely over the burners.

Replace the grates so that continuous arcs are

formed with the center ribs of all three grates.

Do not operate a burner for an extended period of

time without cookware on the grate. The fi nish on

the grate may chip without cookware to absorb the

heat.

To get rid of burned-on food, place the grates in a

covered container. Add 1/4 cup ammonia and let

soak several hours or overnight. Wash, rinse well

and dry.

Although they are durable, the grates will gradually

lose their shine, regardless of the best care you can

give them. This is due to their continual exposure to

high temperatures. You will notice this sooner with

lighter color grates.

CLEANING

Cooktop surface

To avoid damaging the porcelain-enamel surface of

the cooktop and to prevent it from becoming dull,

clean up spills right away. Foods with a lot of acid

or foods with high sugar content could cause a dull

spot if allowed to set.

When the surface has cooled, wash and rinse. For

other spills such as fat spattering, wash with soap

and water once the surface has cooled. Then rinse

and polish with a dry cloth.

Control panel and knobs

It is a good idea to wipe the control panel after

each use of the oven. Use a damp cloth to clean or

rinse. For cleaning, use mild soap and water or a

50/50 solution of vinegar and water. For rinsing,

use clean water. Polish dry with a soft cloth.

Do not use abrasive cleansers, strong liquid

cleaners, plastic scouring pads or oven cleaners on

the control panel as they will damage the fi nish.

Do not try to bend knobs by pulling them up or

down or by hanging a towel or other such loads.

This can damage the gas valve shaft.

The control knobs may be removed for easier

cleaning. Make sure the knobs are in the OFF

positions and pull them straight off the stems for

cleaning. The knobs can be cleaned in a dishwasher

or they may also be washed with soap and water.

Make sure the insides of the knobs are dry before

replacing.

Replace the knobs in the OFF position to ensure

proper placement. Note that knobs are not

interchangeable. Be sure to reinstall the knobs to the

original location.

Metal parts can be cleaned with soap and water.

Do not use steel wool, abrasives, ammonia, acids or

commercial oven cleaners. Dry with a soft cloth.

22

Page 24

CARE & MAINTENANCE

Oven shelves and broiler rack

The shelves and broiler rack can be cleaned by

hand using soap and water or with an abrasive

cleaner or steel wool. After cleaning, rinse the

shelves and broiler rack with clean water and dry

with a clean cloth.

After cleaning, grease all oven rack edges with a

light coating of vegetable oil. This will help maintain

the ease of sliding the racks in and out of the oven.

Porcelain oven interior

With proper care, the porcelain enamel interior will

retain its fi nish for many years.

Soap and water can be used to clean the interior.

Heavy splattering or spills may require cleaning

with a mild abrasive cleaner.

Do not allow spills with high acid content such as

milk, tomatoes, fruit juices or pie fi lling, to remain

on the surface. They may cause dull spots even after

cleaning.

Household ammonia may make cleaning easier.

Place 1/2 cup of ammonia in a shallow glass pan

and leave in a cold oven over night. The ammonia

fumes will help loosen burned on grease and food.

Removable oven bottom

On some models the bottom panel of the oven is

removable and can be washed separately.

To remove the oven bottom:

1. Remove the knurled screw in the front of the

oven bottom.

2. Grasp each side of the oven bottom and push

back.

3. Lift the front up and pull it out of the oven.

To replace the oven bottom:

1. Grasp each side of the oven bottom and guide

its rear tabs into the slots in the back of the oven.

2. Lower the oven bottom and pull it forward until it

is secure under the front oven fl oor edge.

3. On models so equipped, replace the knurled

screw in the front of the oven bottom.

NOTE: If the oven bottom is replaced incorrectly, it

may warp and cause undesirable baking results.

Broiler compartment

The broiler pan is held in place in the broiler rack.

To remove the broiler pan:

Cautions about using spray-on oven cleaners

Do not spray oven cleaner on the electrical controls

and switches as it could cause a short circuit and

result in sparking or fi re.

Do not allow a fi lm from the oven cleaner to remain

on the temperature sensor as it could cause the oven

to heat improperly. The sensor is located on the top

of the oven. Carefully wipe the bulb clean after each

oven cleaning, being careful not to move the sensor

since a change in its position could affect how the

oven bakes.

Do not spray oven cleaner on the outside of the

oven door, handles or any exterior surface of the

oven, cabinet or painted surfaces. The cleaner can

damage these surfaces.

1. Gently pull forward on the drop down broiler

door.

2. Pull the broiler rack with pan forward until the

rack stops.

3. Grasp the broiler pan and remove it from the

broiler rack.

To replace the broiler pan:

1. Slide the broiler pan onto the rack and push

both the broiler pan and the rack all the way

into the broiler compartment.

2. Close the broiler door.

If a spillover occurs in the broiler compartment,

allow the compartment to cool fi rst. You can clean

the compartment with soap and water, a mild

abrasive cleanser, soap-fi lled scouring pads or an

oven cleaner following package directions.

23

Page 25

CARE & MAINTENANCE

Broiler pan and guard

After broiling, remove the broiler pan from the

oven. Remove the grid from the pan. Carefully pour

out grease from the pan into a proper container.

Wash and rinse the broiler pan and grid in hot

water with a soap-fi lled or plastic scouring pad.

If food has burned on, sprinkle the grid with

detergent while hot and cover with wet paper towels

or a dishcloth. Soaking the pan will remove burned

on foods.

Do not store a soiled broiler pan and grid anywhere

in the range.

Removable oven door

The oven door is removable but it is heavy. It

is recommended that at least two people work

together to remove it.

To remove the door:

1. Open the door to the full open position.

2. Pull the hinge locks up over the hinge hooks on

both sides.

3. Grasp the door fi rmly on both sides, lift slightly

and pull it straight out and away from the oven.

OVEN LIGHT REPLACEMENT

Important: Before replacing the oven light bulb,

make sure the electrical power is disconnected from

the appliance. Failure to do so may result in electric

shock or burn.

Be sure to let the light cover and bulb cool

completely before replacing.

Removing the oven door can make this process

easier.

To remove the light cover:

1. Twist the lens counterclockwise roughly 1/4 turn

to remove. Do not remove any screws to remove

the light cover.

2. Do not touch the light bulb with a wet cloth.

Replace the light bulb with a 40 watt appliance

light bulb.

To replace the light cover:

1. Line up the tabs of the lens with the tabs on the

light housing and rotate clockwise by roughly

1/4 turn to install.

To replace the door:

1. Firmly grasp both sides of the door at the top.

2. Insert and seat the upper and lower hinge arms

into the oven slots.

3. Push the hinge locks down from the hinge hooks.

4. Close the oven door and make sure it is working

properly. If it seems uneven or does not close

completely, remove it again and repeat the steps

to replace it.

Note: Do not attempt to close the door until it is

properly installed. The hinges could be damaged.

Glass door window

To clean the outside of the glass door window, use a

glass cleaner. Rinse and polish with a dry cloth.

Avoid scratching or impacting the glass window.

Doing so may cause the glass to break.

24

Page 26

TROUBLESHOOTING

Danby Consumer Care: 1-800-263-2629

Hours of operation:

Monday to Thursday 8:30 am - 6:00 pm Eastern Standard Time

Friday 8:30 am - 4:00 pm Eastern Standard Time

Information in this manual is subject to change without notice.

PROBLEM POSSIBLE CAUSE

No power • A fuse may be blown or the circuit breaker tripped

• Plug not fully inserted into the wall outlet

Surface elements not working properly • Burner holes on the side or around the top of the burner

may be clogged.

• Burners may not be fi tted correctly onto the mounting

brackets.

Burners have yellow or yellow-tipped

fl ames

Burner fl ames very large or yellow • LP gas is improperly connected.

Strong odor • Improper air to gas ratio in the oven.

Surface burners light but oven does not • The oven gas shut off valve may have been accidentally

• The combustion quality of burner fl ames needs to be

determined visually. See the “Quality of fl ames” section of

the installation instructions for more information.

• The thermostat capillary bulb must be clean and

unobstructed.

• The oven vent is blocked.

• Oven control improperly set.

• Improper size of cookware is being used.

• An odor from the insulation around the oven liner is

normal the fi rst few times the oven is used.

moved during cleaning or moving. Raise the cook top

and look for the gas shut off lever in the left rear corner.

Ensure the lever is in the open position.

Oven light does not work • Light bulb is loose

• Light switch is not operating correctly

25

Page 27

LIMITED “IN HOME” WARRANTY

LIMITED IN-HOME APPLIANCE WARRANTY

This quality product is warranted to be free from manufacturer’s defects in material and workmanship, provided that the unit is used under the normal operating

This quality product is warranted to be free from manufacturer’s defects in material and workmanship, provided that the unit is used

conditions intended by the manufacturer.

under the normal operating conditions intended by the manufacturer.

This warranty is available only to the person to whom the unit was originally sold by Danby Products Limited (Canada) or Danby Products Inc. (U.S.A.) (hereafter

This warranty is available only to the person to whom the unit was originally sold by Danby Products Limited (Canada) or Danby

“Danby”) or by an authorized distributor of Danby, and is non-transferable.

Products Inc. (U.S.A.) (hereafter “Danby”) or by an authorized distributor of Danby, and is non-transferable.

TERMS OF WARRANTY

Plastic parts are warranted for thirty (30) days from the date of purchase, with no extensions provided.

Plastic parts, are warranted for thirty (30) days only from purchase date, with no extensions provided.

First 12 months

First Year

To obtain service

To obtain

Service

Boundaries of

in-home service

During the first twelve (12) months, any functional parts of this product found to be defective, will be repaired or

replaced, at warrantor’s option, at no charge to the original purchaser.

During the rst twelve (12) months, any functional parts of this product found to be defective, will be repaired or replaced, at warrantor’s

option, at no charge to the ORIGINAL purchaser.

Contact the dealer where the unit was purchased, or contact the nearest authorized Danby service depot, where

service must be performed by a qualified service technician. If service is performed on the unit by anyone other

Danby reserves the right to limit the boundaries of “In Home Service” to the proximity of an Authorized Service Depot. Any app liance

than an authorized service depot, all obligations of Danby under this warranty shall be void.

requiring service outside the limited boundaries of “In Home Service” , it will be the consumer’s responsibility to transport the appliance (at

their own expense) to the original retailer (point of purchase) or a service depot for repair. See “Boundaries of In Home Serv ice” below.

Danby reserves the right to limit the boundaries of “In Home Service” to the proximity of an authorized service

Contact your dealer from whom your unit was purchased, or contact your nearest authorized Danby service depot, where service

depot. Any appliance requiring service outside the limited boundaries of “In Home Service”, will be the consumer’s

must be performed by a qualied service technician.

responsibility to transport at their own expense to the original point of purchase or a service depot for repair. If the

If service is performed on the units by anyone other than an authorized service depot, or the unit is used for commercial appli cation, all

appliance is installed in a location that is 100 kilometers (62 miles) or more from the nearest service center, it must

obligations of Danby under this warranty shall be void.

be delivered to the nearest authorized Danby Service Depot by the purchaser.

TERMS OF WARRANTY

Boundaries of

In Home Service

If the appliance is installed in a location that is 100 kilometers (62 miles) or more from the nearest service center your unit must be

Transportation charges to and from the service location are not protected by this warranty and are the

delivered to the nearest authorized Danby Service Depot, as service must only be performed by a technician qualied and certif ied for

responsibility of the purchaser.

warranty service by Danby. Transportation charges to and from the service location are not protected by this warranty and are t he

Nothing within this warranty shall imply that Danby will be responsible or liable for any spoilage or damage to food or other

contents of this appliance, whether due to any defect of the appliance, or its use, whether proper or improper.

responsibility of the purchaser.

Nothing within this warranty shall imply that Danby will be responsible or liable for any spoilage or damage to food or other c ontents of this appliance, whether due

to any defect of the appliance, or its use, whether proper or improper.

Save as herein provided, by Danby, there are no other warranties, conditions, representations or guarantees, express or implied, made

or intended by Danby or its authorized distributors and all other warranties, conditions, representations or guarantees, including any

warranties, conditions, representations or guarantees under any Sale of Goods Act or like legislation or statute is hereby expressly

Save as herein provided, Danby, there are no other warranties, conditions, representations or guarantees, express or implied, m ade or intended by Danby or its

excluded. Save as herein provided, Danby shall not be responsible for any damages to persons or property, including the unit itself,

authorized distributors and all other warranties, conditions, representations or guarantees, including any warranties, conditio ns, representations or guarantees

howsoever caused or any consequential damages arising from the malfunction of the unit and by the purchase of the unit, the

under any Sale of Goods Act or like legislation or statue is hereby expressly excluded. Save as herein provided, Danby shall no t be responsible for any damages

purchaser does hereby agree to indemnify and hold harmless Danby from any claim for damages to persons or property caused by

to persons or property, including the unit itself, howsoever caused or any consequential damages arising from the malfunction o f the unit and by the purchase of

the unit.

the unit, the purchaser does hereby agree to indemnify and hold harmless Danby from any claim for damages to persons or propert y caused by the unit.

No warranty or insurance herein contained or set out shall apply when damage or repair is caused by any of the following:

No warranty or insurance herein contained or set out shall apply when damage or repair is caused by any of the following:

1) Power failure.

2) Damage in transit or when moving the appliance.

1) Power failure.

3) Improper power supply such as low voltage, defective house wiring or inadequate fuses.

2) Damage in transit or when moving the appliance.

4) Accident, alteration, abuse or misuse of the appliance such as inadequate air circulation in the room or abnormal operating

3) Improper power supply such as low voltage, defective house wiring or inadequate fuses.

conditions (ie. extremely high or low room temperature).

4) Accident, alteration, abuse or misuse of the appliance such as inadequate air circulation in the room or abnormal operating con ditions

5) Use for commercial or industrial purposes (ie. If the appliance is not installed in a domestic residence).

6) Fire, water damage, theft, war, riot, hostility, acts of God such as hurricanes, floods etc.

7) Service calls resulting in customer education.

8) Improper Installation (ie. Building-in of a free standing appliance or using an appliance outdoors that is not approved for outdoor

application, including but not limited to: garages, patios, porches or anywhere that is not properly insulated or climate controlled).

Proof of purchase date will be required for warranty claims; retain bills of sale. In the event that warranty service is required, present

Proof of purchase date will be required for warranty claims; so, please retain bills of sale. In the event warranty service is required, present this document to our

the proof of purchase to our authorized service depot.

AUTHORIZED SERVICE DEPOT.

(extremely high or low room temperature).

5) Use for commercial or industrial purposes (ie. If the appliance is not installed in a domestic residence).

6) Fire, water damage, theft, war, riot, hostility, acts of God such as hurricanes, oods etc.

7) Service calls resulting in customer education.

8) Improper Installation (ie. Building-in of a free standing appliance or using an appliance outdoors that is not approved for out door application).

EXCLUSIONS

EXCLUSIONS

GENERAL PROVISIONS

GENERAL PROVISIONS

Danby Products Limited

Danby Products Limited

PO Box 1778, Guelph, Ontario, Canada N1H 6Z9

PO Box 1778, Guelph, Ontario, Canada N1H 6Z9

Telephone: (519) 837-0920 FAX: (519) 837-0449

Telephone: (519) 837-0920 FAX: (519) 837-0449

Warranty Service

Warranty Service

In-home

In Home

1-800-263-2629

1-800-263-2629

04/17

04/09

Danby Products Inc.

PO Box 669, Findlay, Ohio, U.S.A. 45840

Telephone: (419) 425-8627 FAX: (419) 425-8629

PO Box 669, Findlay, Ohio, U.S.A. 45840

Telephone: (419) 425-8627 FAX: (419) 425-8629

Danby Products Inc.

Page 28

Bienvenido

Bienvenido a la familia Danby. Estamos orgullosos de nuestros productos de calidad y creemos en

un servicio confi able. Sugerimos que lea este manual del propietario antes de conectar el nuevo

aparato ya que contiene información importante sobre la operación, información de seguridad,

solución de problemas y consejos de mantenimiento para garantizar la fi abilidad y longevidad de

su electrodoméstico.

Visite www.Danby.com para acceder a herramientas de autoservicio, preguntas frecuentes y

mucho más. Para asistencia adicional, llame al 1-800-263-2629.

Tenga en cuenta la información siguiente; Necesitará esta información para obtener un servicio

bajo garantía.

Debe proporcionar el recibo de compra original para validar su garantía y recibir servicio.

Número de modelo: _____________________________________________

Número de serie: _______________________________________________

Fecha de compra: _______________________________________________

Necesitas ayuda?

Antes de llamar al servicio, aquí hay algunas cosas que puede hacer para ayudarnos a

servirle mejor.

Lea este manual del propietario:

Contiene instrucciones para ayudarle a usar y mantener su aparato correctamente.

Si recibe un aparato dañado:

Inmediatamente póngase en contacto con el minorista o el constructor que le vendió el

aparato.

Ahorre tiempo y dinero:

Consulte la sección de solución de problemas al fi nal de este manual antes de llamar. Esta

sección le ayudará a resolver problemas comunes que pueden ocurrir.

1-800-26- Danby

(1-800-263-2629)

27

Page 29

Importantes Instrucciones de Seguridad

LEA Y SIGA TODAS LAS INSTRUCCIONES DE SEGURIDAD

ADVERTENCIA - Si no se sigue

exactamente la información de este

manual, se puede producir un incendio o

una explosión que puede causar daños

a la propiedad, lesiones personales o la

muerte.

• No almacene ni use gasolina u otros

vapores y líquidos infl amables cerca de

este o cualquier otro electrodoméstico.

• La instalación y el servicio deben ser

realizados por un instalador califi cado,

una agencia de servicio o el proveedor

de gas.