Page 1

KEG COOLER

GLACIÈRE DE BIÈRE PRESSION

BARRIL REFRIGERADOR

OWNER’S USE AND CARE GUIDE

GUIDE D’UTILISATION ET D'ENTRETIEN

GUÍA DE UTILIZACIÓN Y CUIDADO PARA EL PROPIETARIO

MODEL • MODÈLE • MODELO

DKC054A1BSL2DB

DANBY PRODUCTS LIMITED, ONTARIO, CANADA N1H 6Z9

DANBY PRODUCTS INC., FINDLAY, OHIO, USA 45840

2017.03.03

Page 2

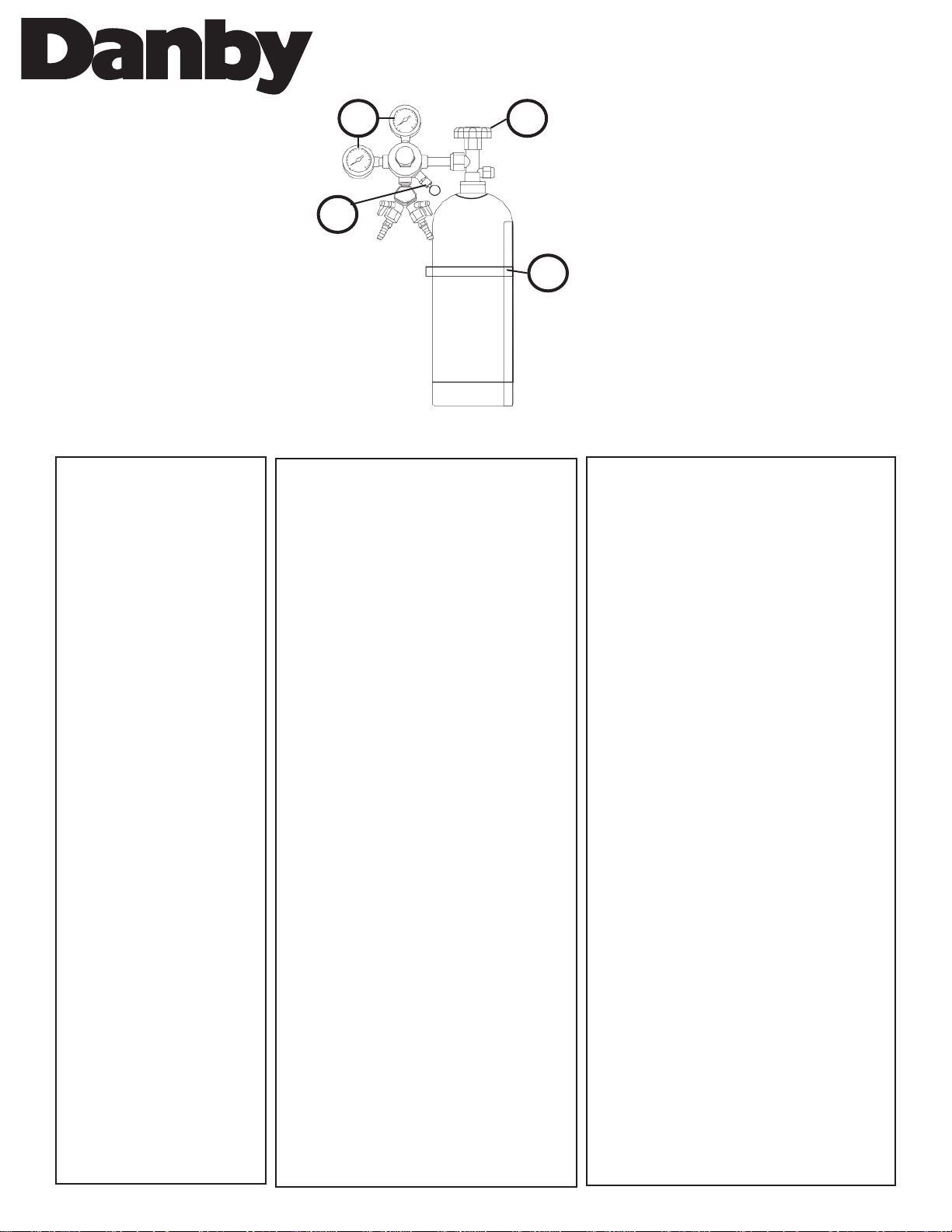

1

3

2

4

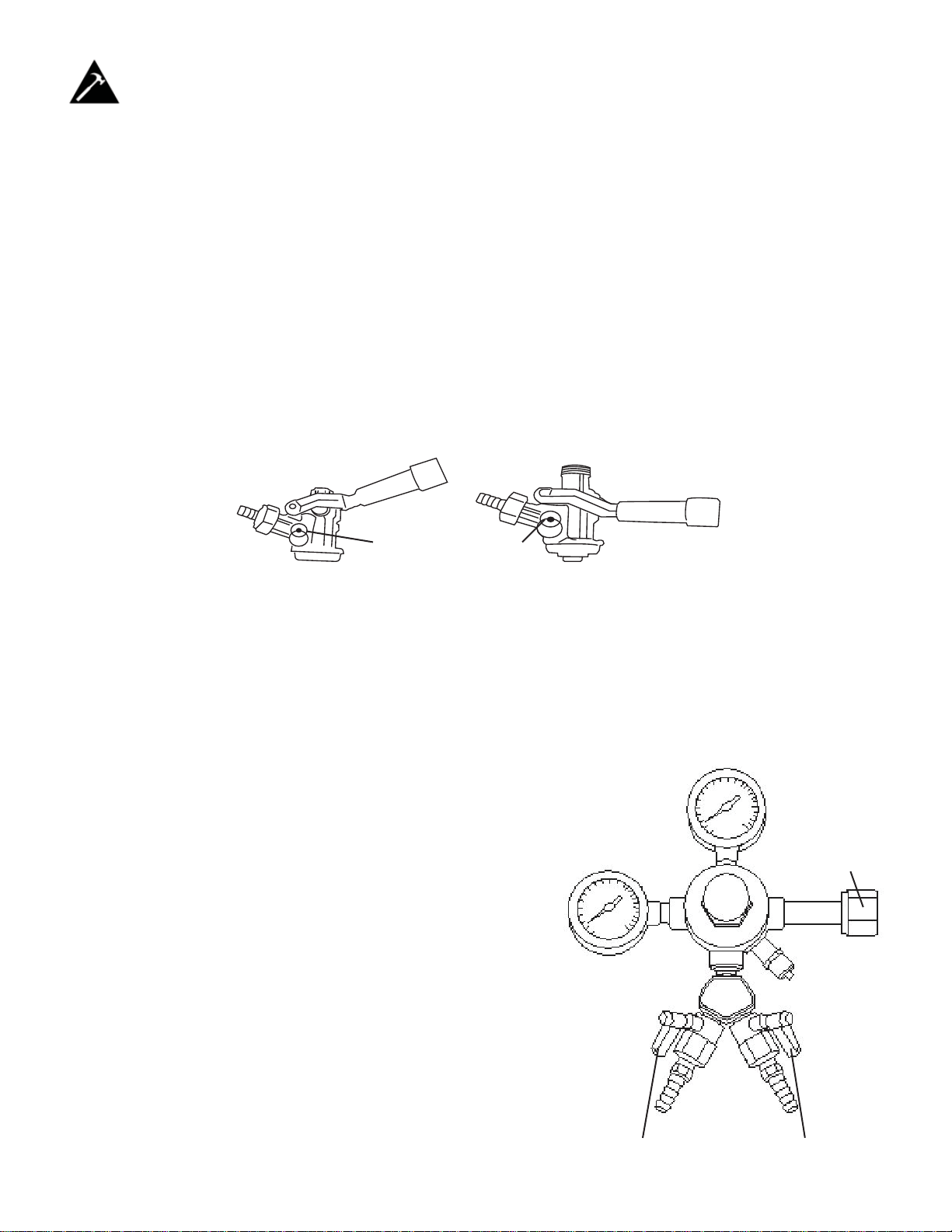

1. Pressure gauge dial

2. Pressure relief ring

3. Open / Close valve

4. Tank strap

Ensure the CO2 tank is

empty before courier

or 3rd party transport.

DANGER - A full or

partially full CO2 tank

is under extreme

pressure. Uncontrolled

release of pressure is

extremely dangerous. The

instructions below use the

regulator to control the

release of this pressure

in a safe manner. Do not

bypass the regulator.

1. Ensure tank is secure

2. Fully open valve

by turning counterclockwise. Pressure

gauge dial will show a

value if tank contains

pressure.

3. Gently pull pressure

relief ring. Released

gas should be heard.

4. The pressure dial

will read zero when

the tank is empty.

Continue to hold

pressure relief open

until tank is empty.

5. Release the pressure

relief ring.

6. Fully close valve by

turning clock-wise.

1. Cadran de manomètre

2. Anneau de limitation de pression

3. Soupape de l’ouverture /

fermeture

4. Sangle du réservoir

Vérifi ez que le réservoir de CO2

est vide avant de messagerie ou

transport 3e parti.

DANGER - Un réservoir plein ou

partiellement plein de CO2 est

sous une pression extrême. La

libération incontrôlée de la pression

est extrêmement dangereuse. Les

instructions ci-dessous utilisent le

régulateur pour contrôler la libération

de cette pression de manière sûre. Ne

contournez pas le régulateur.

1. Assurez-vous que le réservoir est

bien fi xé

2. Ouvrir complètement la soupape

en tournant dans le sens antihoraire. Le cadran du manomètre

indiquera une valeur si le réservoir

contient de la pression.

3. Tirez doucement la bague de

décharge de pression. Le gaz

rejeté doit être entendu.

4. Le cadran de pression indique

zéro lorsque le réservoir est

vide. Continuez à maintenir le

soulagement de pression ouvert

jusqu’à ce que le réservoir soit

vide.

5. Relâcher l’anneau de décharge de

pression.

6. Fermez complètement la soupape

en tournant dans le sens horaire.

1. Indicador del manómetro

2. Anillo de alivio de presión

3. Abrir / cerrar la válvula

4. Correa del tanque

Asegúrese de que el tanque

de CO2 esté vacío antes del

transporte por mensajería o por

terceros.

PELIGRO - Un tanque lleno o

parcialmente lleno de CO2 está

bajo presión extrema. La liberación

incontrolada de presión es

extremadamente peligrosa. Las

instrucciones a continuación utilizan el

regulador para controlar la liberación de

esta presión de una manera segura. No

elimine el regulador.

1. Asegúrese de que el tanque esté

seguro

2. Abra completamente la válvula

girando en sentido antihorario. El

indicador del manómetro mostrará

un valor si el tanque contiene

presión.

3. Tire suavemente el anillo de alivio

de presión. Se debe oir el gas

liberado.

4. El dial de presión mostrará cero

cuando el depósito esté vacío.

Continúe manteniendo el alivio de

presión abierto hasta que el tanque

esté vacío.

5. Suelte el anillo de alivio de presión.

6. Cierre completamente la válvula

girándola en el sentido de las

agujas del reloj.

Page 3

CONTENTS * TABLE DES MATIÈRES * ÍNDICE

KEG COOLER

Owner’s Use and Care Guide ...........................................1-16

• Welcome

• Important Safety Information

• Features

• Installation Instructions

• Operation Instructions

• Care and Maintenance

• Troubleshooting

• Warranty

GLACIÈRE DE BIÈRE PRESSION

Guide d’utilisation et d’entretien du propriétaire..........17-32

• Bienvenue

• Consignes de sécurité importantes

• Caractéristiques

• Consignes d’installation

• Consignes d’utilisation

• Soins et entretien

• Dépannage

• Garantie

BARRIL REFRIGERADOR

Guía de utilización y cuidado para el propietario........33-48

• Bienvenido

• Información importante sobre seguridad

• Características

• Instrucciones de instalación

• Instrucciones de funcionamiento

• Cuidado y mantenimiento

• Solución sugerida

• Garantía

Includes American Sankey tap coupler only.

Inclut robinet de prise Américain Sankey seulement.

Incluye grifo Americano solamente.

TO OBTAIN WARRANTY SERVICE YOU MUST PROVIDE A VALID PROOF OF PURCHASE.

PLEASE STAPLE YOUR RECEIPT TO THIS PAGE FOR FUTURE REFERENCE.

POUR OBTENIR LE SERVICE SUR GARANTIE VOUS DEVEZ FOURNIR UNE PREUVE D’ACHAT

VALIDE. VEUILLEZ AGRAFER VOTRE REÇU À CETTE PAGE POUR RÉFÉRENCE FUTURE.

PARA OBTENER SERVICIO DE GARANTÍA, DEBE PROVEER UN RECIBO ORIGINAL. POR

FAVOR ENGRAPE SU RECIBO A ÉSTA PÁGINA EN CASO QUE NECESITE HACER UN

RECLAMO.

Model • Modèle • Modelo

DKC054A1BSL2DB

Page 4

Welcome

Welcome to the Danby family. We are proud of our quality products, and we believe in dependable service. We suggest

that you read this Owner’s Manual before plugging in your new appliance as it contains important operational information,

safety information, troubleshooting and maintenance tips to ensure the reliability and longevity of your appliance.

Visit www.Danby.com to access self-service tools, FAQs and much more. For additional assistance call 1-800-263-2629.

Note the information below; you will need this information to obtain service under warranty.

To receive service, you must provide the original receipt.

Model Number:

Serial Number:

Date of Purchase:

NEED HELP?

Before you call for service, here are a few things you can do to help

us serve you better:

Read this Owner’s Use and Care Guide:

It contains instructions to help you use and maintain your

appliance properly.

If you received a damaged appliance:

Immediately contact the retailer (or builder) that sold you the

appliance.

Save time and money:

Check the Troubleshooting section at the end of the guide before calling. This section helps you solve common problems that may occur.

If you do need service, you can relax, knowing help is only a phone

call away.

1-800-26-

(1-800-263-2629)

1

Page 5

Important Safety Information

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

IMPORTANT WARNING

DANGER: Risk of child entrapment. Before you throw away your old appliance:

• Take off doors or remove the gasket.

• Leave the shelves in place so that children may not easily climb in.

DON’T WAIT! DO IT NOW!

OPERATION REQUIREMENTS

To avoid installation or operation diffi culties, read these instructions thoroughly.

• This appliance must be grounded. Connect only to a properly grounded outlet. See Grounding

Instructions section.

• Do not operate this appliance if it has a damaged power cord or plug, if it is not working properly,

or if the appliance has been damaged or dropped. If the power cord is damaged it must be

replaced by the manufacturer, its service agent or similarly qualifi ed person to avoid hazard.

• Never allow children to operate, play with, or crawl inside the appliance.

• Never clean appliance parts with fl ammable fl uids. The fumes can create a fi re hazard or

explosion.

• Do not store or use gasoline or any other fl ammable vapors or liquids in the vicinity of this or any

other appliance. The fumes can create a fi re hazard or explosion.

• Do not splice the power cord that is equipped with this appliance.

• Keep power cord away from heated surfaces.

• Do not immerse power cord, plug or the appliance itself in water.

• Do not use this product near water for example, in a wet basement, laundry room or near a sink.

• Do not use corrosive chemicals or vapors in this appliance.

• Use this appliance only for its intended use, as described in this manual.

• Do not store open containers in this appliance.

• Do not cover or block any openings on the appliance.

• Do not store perishable food items such as (but not limited to) meats and dairy products in your

wine cooler. This appliance does not get cold enough to be food safe.

• This appliance is intended for household use only. Do not operate or store this appliance

outdoors.

• This appliance should be serviced only by qualifi ed service personnel. Contact the nearest

authorized service facility for examination, repair or adjustment.

• Before connecting the appliance to a power source, let it stand upright for approximately 6

hours; this will reduce the possibility of a malfunction in the cooling system from handling during

transportation.

SAVE THESE INSTRUCTIONS!

2

Page 6

Important Safety Information

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

GROUNDING INSTRUCTIONS

This appliance must be grounded. In the event of an electrical short circuit, grounding reduces the

risk of electric shock by providing an escape wire for the electric current. This appliance is equipped

with a cord having a grounding wire with a grounding plug. The plug must be plugged into an outlet

that is properly installed and grounded

WARNING - Improper use of the grounding plug can result in a risk of electric shock. Consult a

qualifi ed electrician or service agent if the grounding instructions are not completely understood, or if

doubt exists as to whether the appliance is properly grounded.

If the outlet is a standard 2-prong wall outlet, it is your personal responsibility and obligation to have it

replaced with a properly grounded 3-prong wall outlet.

For best operation, plug this appliance into its own electrical outlet to prevent fl ickering of lights,

blowing of fuse or tripping of circuit breaker

DO NOT USE AN EXTENSION CORD

Use an exclusive 115V wall outlet. Do not connect your appliance to extension cords or together with

another appliance in the same wall outlet. Do not splice the cord. Do not under any circumstances

cut or remove the third ground prong from the power cord. Do not use an adapter plug with this

appliance.

SAFETY REQUIREMENTS

Ensure that component parts shall be replaced with like components and that servicing shall be done

by factory authorized service personnel, so as to minimize the risk of possible ignition due to incorrect

parts or improper service.

This appliance must be grounded. In the event of an electrical short circuit, grounding reduces the

risk of electrical shock by providing an escape wire for the electrical current. The serial rating plate

indicates the voltage and frequency the appliance is designed for.

WARNING! EXPLOSION HAZARD! Risk of fi re or explosion due to puncturing of refrigerant tubing.

Do not use sharp objects to aid in defrost. Please handle with care. Keep fl ammable materials and

vapors such as gasoline away from the refrigerator. Use nonfl ammable cleaner.

Disposal of this unit should be in accordance with federal and local regulations.

This appliance is not intended for use by persons (including children) whose physical, sensory or

mental capabilities may be different or reduced, or who lack experience or knowledge, unless such

persons receive supervision or training to operate the appliance by a person responsible for their

safety.

WARNING: Keep ventilation openings, in the appliance enclosure or in the built-in structure, clear of

obstruction.

WARNING: Do not use mechanical devices or other means to accelerate the defrosting process,

other than those recommended by the manufacturer.

WARNING: Do not damage the refrigerant circuit.

WARNING: Do not use electrical appliances inside the food storage compartments of the appliance,

unless they are of the type recommended by the manufacturer.

SAVE THESE INSTRUCTIONS!

3

Page 7

Important Safety Information

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

WARNING: CO

CAN BE DANGEROUS!

2

CO2 Cylinders, when charged, contain high pressure compressed gas which can be hazardous if not

handled properly. Read and understand the following procedures for CO

cylinders before installation:

2

1. Always check the D.O.T. (Department of Transportation) as well as the T.C. (Transport Canada)

test date located on the neck of the cylinder before installation. If the date is older than fi ve (5)

years, do not use! Return the gas cylinder to a gas supplier for re-certifi cation (service charges

may be applicable).

2. Always connect a CO

gas cylinder to a regulator. Failure to do so could result in an explosion

2

which can possibly result in death or injury when the cylinder valve is opened.

3. Always follow correct procedures when cylinders are changed as per local codes.

4. Always secure a CO

5. Always keep a CO

gas cylinder in an “upright” position.

2

gas cylinder away from heat. Store extra cylinders in a cool place (preferably

2

70°F/21°C). Securely fasten with a chain in an upright position when storing.

6. Always ventilate and leave the area immediately after any leakage of CO

.

2

7. Never connect a CO

8. Never drop or throw a CO

gas cylinder directly to a beer keg.

2

cylinder.

2

9. Never connect a keg without at least one safety pressure release. There are two safety

mechanisms in the pressure system;

• One at or on the CO

regulator.

2

• One at or on the product container coupler in the pressure gas line.

Note: The regulator and keg coupler supplied with this unit are inclusive of such safety

mechanisms.

CO

WARNING

2

If it becomes diffi cult to breathe and/or your head starts to ache, abnormal concentrations of

carbon dioxide (CO

CLOSE THE MAIN VALVE ON THE CO

) may be present in the area.

2

CYLINDER, VENTILATE AND LEAVE THE ROOM

2

IMMEDIATELY!

IMPORTANT WARNING

Beer is easily available with Danby’s Keg Cooler, however, it is not intended to be available to

people under the legal age to consume beer. Danby does not assume liability for the unlawful

use or consumption of the beer.

PLEASE DRINK RESPONSIBLY AND PLEASE DON’T DRINK AND DRIVE!

SAVE THESE INSTRUCTIONS!

4

Page 8

Installation Instructions

INCLUDED ACCESSORIES

Remove and inspect all accessories supplied with this unit and ensure they are all present and in

good condition. In the event any of the accessories are missing and/or not in good condition, please

call Danby toll free at 1-800-263-2629 and speak with one of our Consumer Service Representatives.

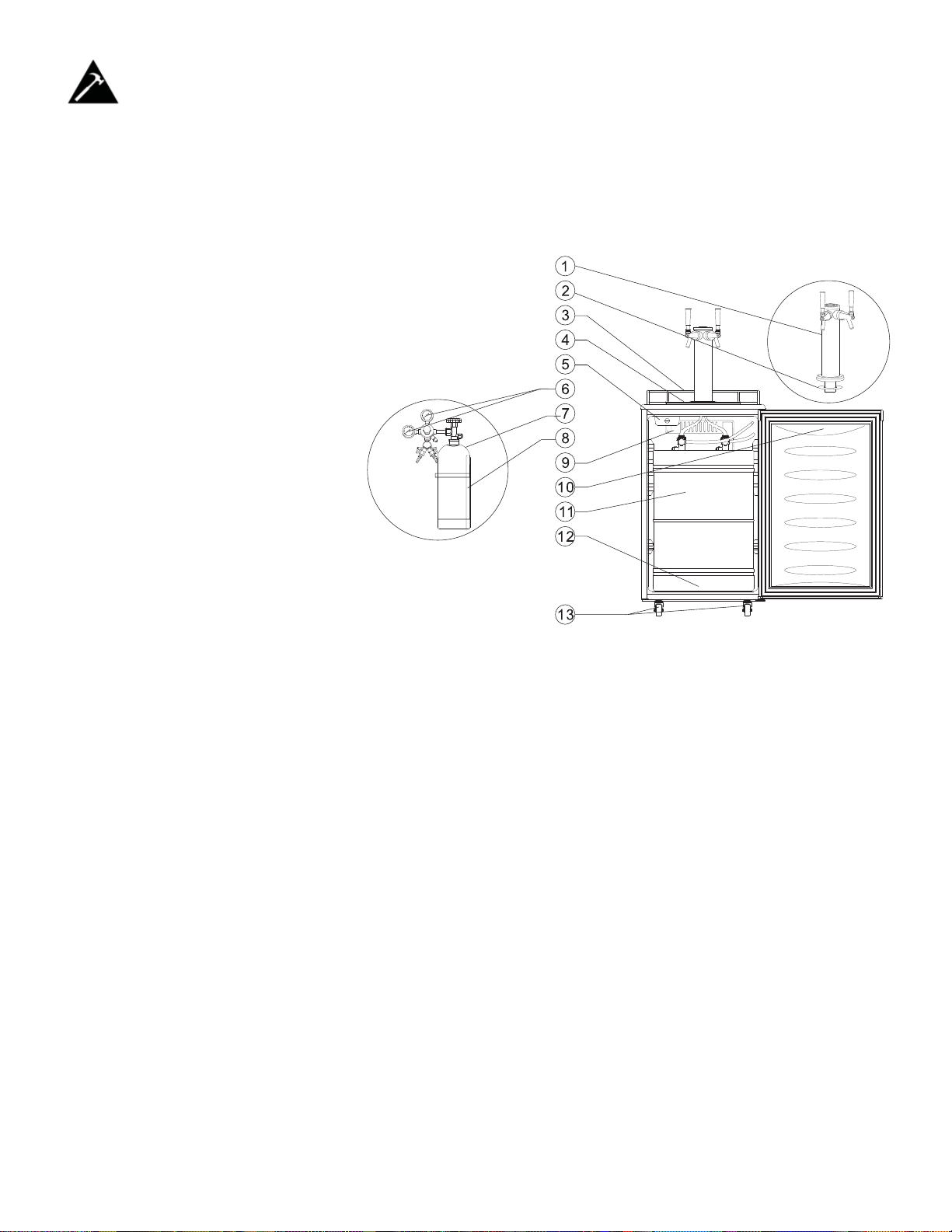

1. Beer Tower

2. Rubber Gasket (may not be

required in all unit confi gurations)

3. Safety Guard Rail

4. Drip Tray

5. Adjustable Thermostat

6. CO

7. CO2 Gas Cylinder

8. CO2 Gas Cylinder Support

9. Evaporator

10. Door

11. Beer Keg (not included)

12. Metal Plate

13. Castors (4)

Regulator

2

BEFORE USING YOUR KEG COOLER

• Remove the exterior and interior packaging.

• Check to be sure you have all the following parts:

• 2 Safety Guard Rail

• 1 drip tray (2 pieces)

• 1 CO2 Cylinder support

• 1 CO2 Regulator

• 1 CO2 Empty Cylinder

• 2 CO2 Gas line hose (coloured)

• 2 Beer Hose

• 2 Beer keg couplers

• 1 Beer tower

• 2 Pull handle (Beer tower faucet)

• 4 Plugs: For guard rail holes

• 1 metal plate for cabinet bottom

• 3 Wire shelf

• 2 steel clamp for coloured hose

• 2 plastic washers for front casters

• 4 Casters (2 front with locks)

• Before plugging in the keg cooler, let it stand upright for approximately 6 hours. This will reduce

the possibility of a malfunction in the cooling system from handling during transportation.

• Clean the interior surface with lukewarm water using a soft cloth.

5

Page 9

Installation Instructions

INSTALLATION OF KEG COOLER

• This appliance is designed to be free standing only and should not be recessed or built-in.

• Place your keg cooler on a fl oor that is strong enough to support the unit when it is fully loaded.

• Allow 8-12 cm (3-5 inches) of space between the back and sides of the keg cooler and any

adjacent wall to allow proper air circulation to cool the compressor.

• Locate the keg cooler away from direct sunlight and sources of heat (stove, heater, radiator,

etc.). Direct sunlight may affect the acrylic coating and heat sources may increase electrical

consumption. Extreme cold ambient temperatures may also cause the keg cooler not to perform

properly.

• This unit is not designed for outside installation (i.e. garages, porches, patio, etc.).

• Avoid locating the keg cooler in excessive humidity.

• Plug the keg cooler into a dedicated, properly installed-grounded wall outlet. Do not under any

circumstance cut or remove the third ground prong from the power cord. Any questions concerning

power and or grounding should be directed toward a certifi ed electrician or an authorized service

centre.

• After plugging the appliance into a wall outlet, allow the unit to cool down for 2-3 hours before

placing any contents in the keg cooler compartment.

WARNING

CO2 GAS CAN BE DANGEROUS

CO

cylinders contain high-pressure compressed gas which can be

2

hazardous if not handled properly. Make sure you read and understand all

safety procedures for CO

cylinders before installation.

2

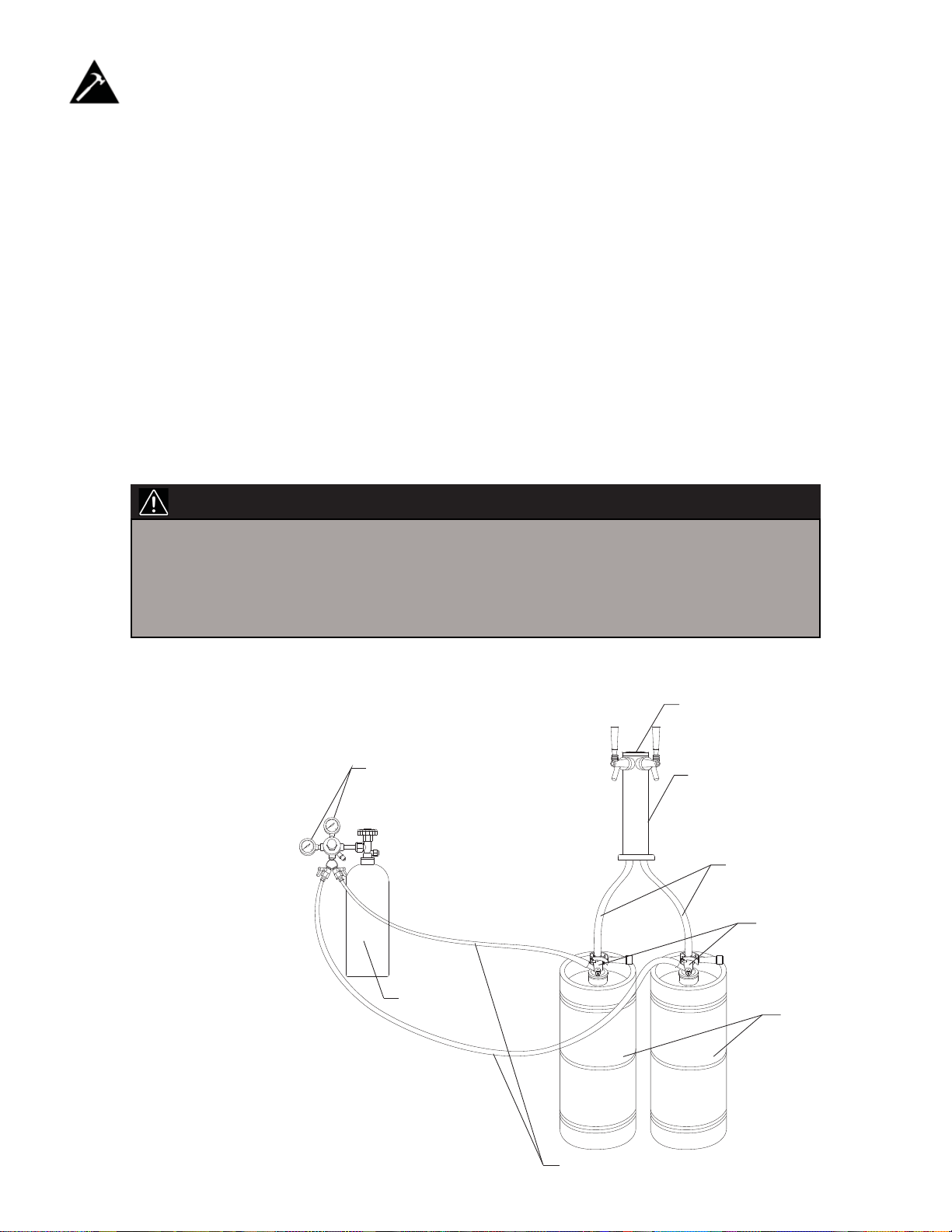

BEER KEG INSTALLATION INSTRUCTIONS

Keg Installation Sketch

Pressure

Regulator

CO

Tank

2

Faucet Assembly

Tower

Clear Hose with

Wing Nut

American Sankey

Tap (Coupler)

Keg

Coloured Pressure Hose

6

Page 10

Installation Instructions

BEER KEG INSTALLATION INSTRUCTIONS

Install the four castors. The two locking castors should be placed at the front. Four screw holes have

been pre-drilled into the unit’s bottom at each corner for each castor. Put the plastic washers provided

on the front castors before installing them.

METAL

Castors

WASHERS

Put washers on the

front casters.

Fig. 1

Fig. 2

Castor Brake Guide

The two front castors are supplied with brakes to ensure the unit does not move excessively while

being used. It is recommended to engage the brakes while the unit is in use to avoid damage to the

unit, the contents or your personal property.

Step on to

Step on to brake

release brake

Installation of CO2 Cylinder Support

Install the metal support provided onto the four studs

located on the exterior back wall of the chassis.

Align the holes in the support with the studs and push

down fi rmly.

7

Page 11

Installation Instructions

Installation of CO2 Cylinder and CO2 Regulator

The CO2 cylinder does not come fi lled. The cylinder

must be fi lled with CO

Place the charged cylinder into the support stand.

Attach the CO2 regulator to the cylinder by turning

the regulator nut onto the cylinder valve, making sure

the washer is securely inserted into the connecting

nut. Tighten snug using an adjustable wrench (not

supplied) and ensure there are no leaks, i.e. no hissing

sounds when the CO2 is turned on.

Installation of CO2 Air Line Outside Cabinet and CO2 Air Line Hose to Regulator

Remove the plug located at the exterior back of the

cabinet, in the top left hand corner. Save the plug

for later use if you decide to convert the unit to a

refrigerator.

before use.

2

Feed the gas line through the cabinet and out through

the uncovered hole.

Attach the open end of the hose to the hose barb

connection on the regulator. Secure the hose by using

one clamp provided. Use pliers or a screwdriver to

tighten the clamp to prevent leaks.

Installation of the Beer Tower

• Remove the plug from the top of the fridge cabinet

by twisting and pulling out. Save the plug for

later use if you decide to convert the unit to a

refrigerator.

• Unravel the beer line (clear hose) from the tower

and insert the beer line and wing nut through the

uncovered hole on top of the unit.

• Lock the beer tower assembly to the top of the unit

and make sure to position the beer faucet so it is

aligned with the front of the cabinet.

• The rubber gasket can be used to make the

connection between the tower and the cooler

tighter if needed. If the beer tower will not turn

to lock in place, try removing the rubber gasket.

(The rubber gasket may not be required in all unit

confi gurations).

• If the tower faucet is leaking or if the beer is very

foamy, ensure that the washers inside the faucet

are intact. Replace the washers with spare parts

from the accessory bag, if necessary.

8

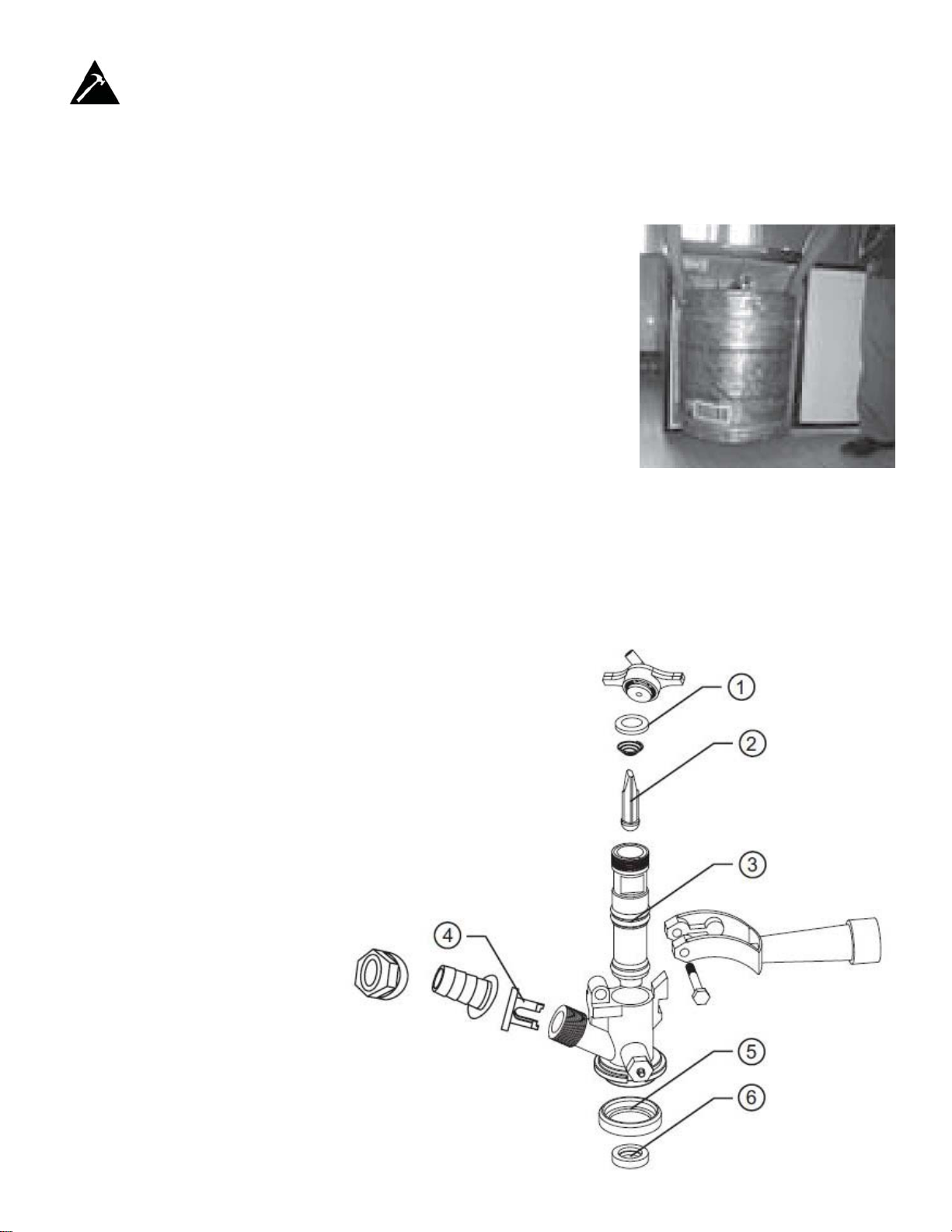

1. Tap rocker washer

2. Tap valve washer

3. Tap valve spool washer

Page 12

Installation Instructions

Installation of the Protective Metal Plate

The protective metal plate should be installed on the bottom of the inside of the cabinet. This plate

should always be installed when a keg is in place to protect the fl oor of the cabinet against damage.

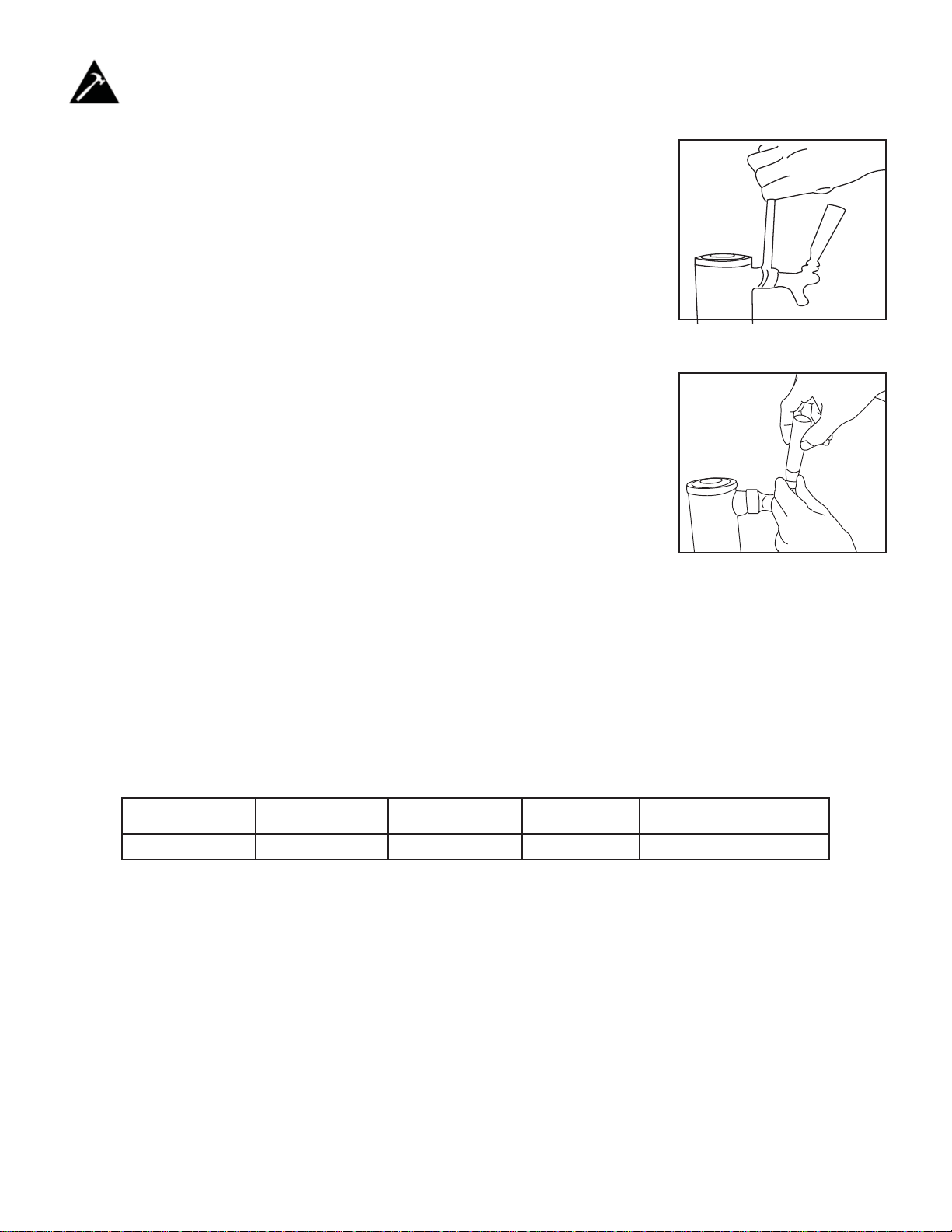

Installation of the Beer Keg

• Position the beer keg directly in front of the open door. Using keg

handles only, carefully lift the beer keg.

• To place the beer keg inside the cabinet, brace your knees behind

the beer keg. Lift the front of the keg just enough so the front end

of the keg is resting on the front edge of the keg cooler bottom

cabinet.

• Grasp the keg handles and slide it all the way into the cabinet.

Note: Two people should lift the keg to avoid back injury.

Installation of the CO2 Air Line Hose

Attach the end of the air line (coloured) hose provided to the hose connection on the side of the

coupler. Ensure that the check valve is inserted into the connection, number 4 on the image below.

If, after assembly, beer will not fl ow, ensure that the check valve has a small hole in it. If there is no

hole in the check valve then CO2 cannot enter the line and the beer will not fl ow .

Connecting the Beer Tower to the Coupler

• Ensure all washers are properly inserted into the

coupler, as per below image.

• Ensure the valve spool plastic rod is in place inside the

coupler, number 2 on the below image.

• Place the wing nut attached to the end of the beer line

into the top of the coupler, turning until tight.

If, after assembly, the beer is very foamy, it most likely

means that a connection in the coupler is leaking and air

is entering the lines. Double check all connections in the

coupler and replace the washers from the accessory bag

as necessary.

1. Valve washer

2. Valve spool plastic rod

3. Valve spool O-type washer

4. Check valve

5. Valve washer

6. Valve washer

9

Page 13

Installation Instructions

Installation of the Keg Coupler

Insert the keg coupler into the locking neck of the beer keg and turn it clockwise to lock into position,

making sure the keg coupler handle is in the closed position, with the handle up.

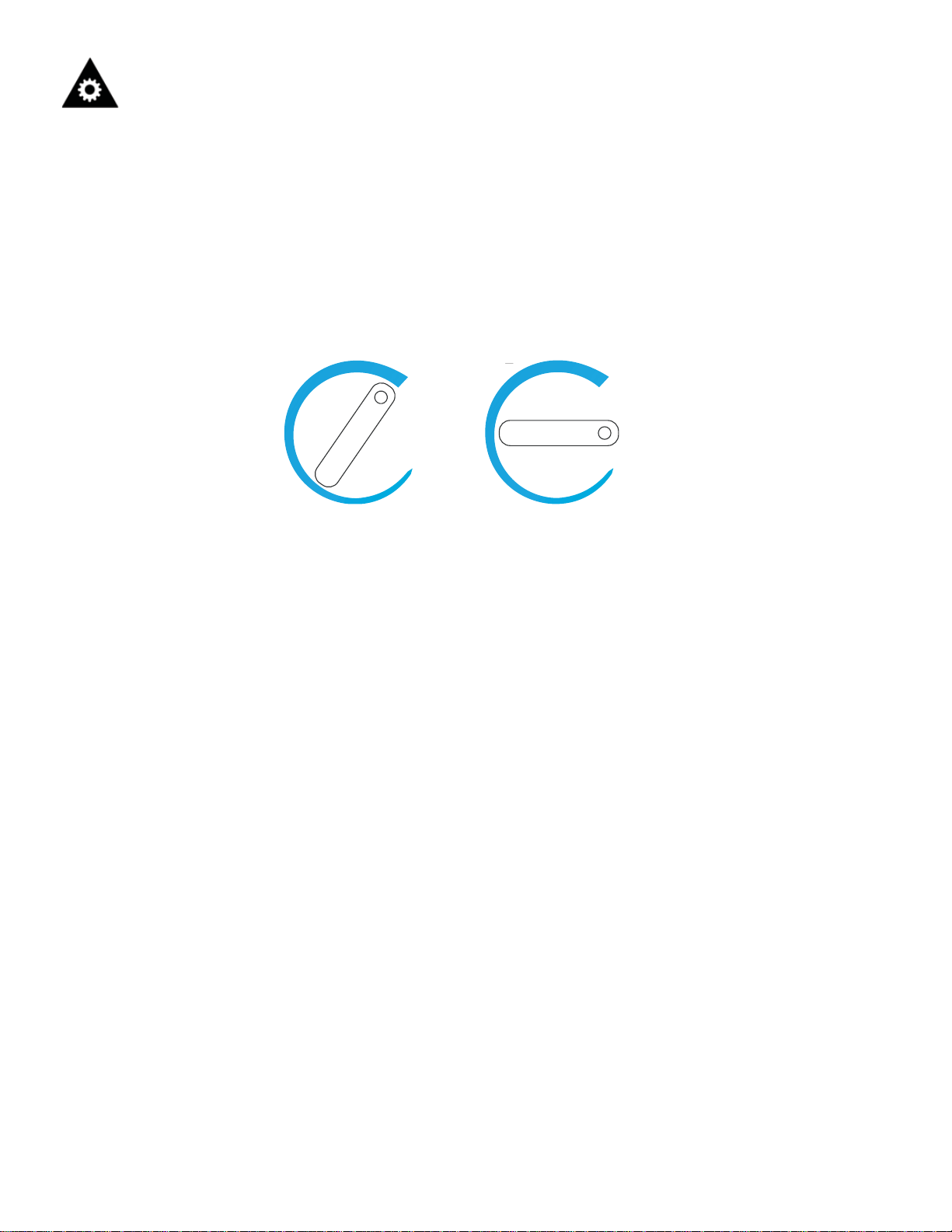

How to Tap a Keg of Beer

• Make sure the CO2 is turned off and the valve on the regulator is in the closed position.

• Pull out and release the pressure release valve on the coupler to purge any air pressure.

• Make sure the beer tower faucet handle is in the closed position.

• Pull coupler handle out and downward until it locks into its open position. The teeth on the

underside of the coupler will bite into the locking neck of the beer keg.

Note: If a keg is very tall, it may be necessary to connect the coupler to the keg before inserting the

keg into the keg cooler.

Coupler closed position Coupler open position

Coupler pressure

release valve

Opening the CO2 Cylinder Main Valve

• Make sure the secondary shut-off valve (shown below in “open” position) is closed. To open the

main CO2 cylinder valve, slowly turn the main valve counter-clockwise until fully open.

• Notice the needle on the regulator gauge start to climb.

Adjusting the CO2 Regulator

The gauge monitors low internal keg pressure and should

be adjusted to read between 8-12 PSI. The pressure can be

adjusted as needed. If the beer is very foamy, try turning the

PSI down. If the fl ow of beer is very weak, try turning the PSI

up.

Note: After making any adjustment to the PSI, wait 5 - 10

minutes before attempting to pour another beer to allow the

pressure to equalize.

• Release adjustment lock nut marked 2.

• Using a fl at screwdriver, turn regulator screw marked 3.

- To increase pressure, turn screw clockwise.

- To decrease pressure, turn screw counter-clockwise.

• Retighten lock nut marked 2.

• Open secondary shut off valve to let CO2 fl ow into the

keg.

• Allow several minutes for the keg to properly pressurize.

Regulator gauge may drop while this happens.

Main shut

off valve

Note: Listen for hissing along all connections to identify if

there are any leaks.

10

Secondary shut off valve

Page 14

Installation Instructions

Spanner Faucet Wrench

Spanner faucet wrench (provided) is for either removing or tightening the

faucet connection.

Note: To prevent leakage, use the provided wrench to further tighten the

faucet connection.

Plastic Faucet Lever

Attach the black plastic lever (pull handle) to the top of the faucet by

tightening it by hand going clockwise until the end, holding in the silver nut

underneath so it does not turn. If there is still a small drip from the faucet,

you may have overtightend the silver nut and may need to unscrew silver

snug going counter-clockwise (as shown one turn).

DISPENSING OF BEER

• Keep beer keg refrigerated at all times.

• Never allow beer lines to dry out.

• Use clean glassware before pouring.

• Hold glass at a 45° angle, when it is 2/3 full, start to straighten glass as the glass fi lls.

• Always make sure the faucet handle is pushed all the way back.

This keg cooler has been designed to chill and dispense beer from two of the following size kegs

simultaneously:

1/6 barrel 20 Liters 5.2 gals. 661 oz. 55 x 12-oz. Glasses

1/8 barrel 15 Liters 4.0 gals. 496 oz. 41 x 12-oz. Glasses

Note: The refrigerator compartment cannot accommodate the “Coors” style beveled barrel keg.

Note: Our keg cooler accepts domestic kegs up to 16-1/8” in diameter and up to 23-3/8” in height.

Check with your distributor to make sure keg is correct size.

Note: It is important to allow the keg to sit upright and undisturbed, for 2 hours before tapping.

11

Page 15

Operating Instructions

SETTING THE TEMPERATURE

The temperature is controlled by adjusting the thermostat control knob. To start the unit and achieve

maximum cooling quickly:

• Turn the temperature control knob clockwise to the maximum setting on the wide, blue section of

the control dial (Fig. A).

• Allow the unit to run at this setting for 3-4 hours.

• When maximum cooling is achieved, turn back the temperature control knob to a medium

temperature.

• To turn off the cooling, rotate the control knob to the “0” (OFF) position (Fig. B).

Fig A.

Max Max

Fig B.

MinMin

Fig. BFig. A

AUTOMATIC DEFROSTING

There is no need to defrost the keg cooler. Defrost water collects and passes through the drain outlet

in the rear wall into a tray located above the compressor, where it evaporates.

Note: If the unit is unplugged, power lost or turned off, you must wait 3 to 5 minutes before restarting

the unit. If you attempt to restart before this time delay, the compressor may not start.

CONVERTING TO AN ALL REFRIGERAT OR

1. Turn the control knob to the “OFF” position.

2. Close the main valve on the CO2 cylinder.

3. Close the secondary shut-off valve on the regulator pipe.

4. Close the connection between the beer keg and the keg coupler.

5. Drain any remaining beer from the lines. (We recommend cleaning at this point, please see Care

and Maintenance section).

6. Disconnect the beer line and CO

7. Remove the beer keg.

8. Remove the keg coupler.

9. Disconnect the gas line from the CO2 cylinder.

10. Remove the CO2 gas line from cabinet plug.

11. Replace the gas line rear cabinet plug.

12. Remove the beer tower. Also pull the beer line through the top of the cabinet.

13. Replace the top cabinet plug.

14. Adjust the temperature as desired.

gas line from the keg coupler.

2

Note: In order to convert the unit, you must disconnect the gas line from the regulator in order to

remove it from the cabinet.

Note: If you desire a shelf in the converted “All Refrigerator” install the shelf by sliding it into the

desired spot in the unit.

12

Page 16

Operating Instructions

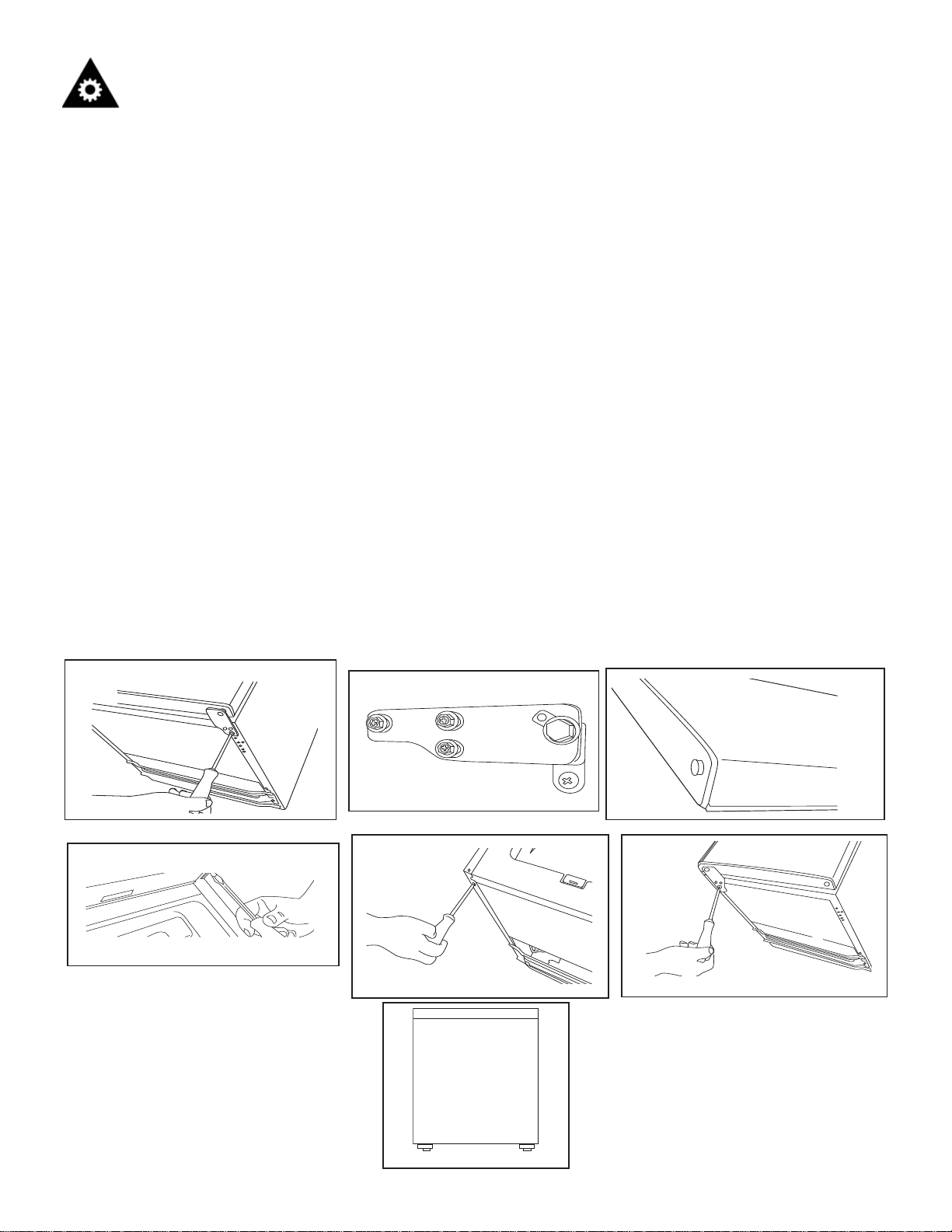

DOOR REVERSAL INSTRUCTIONS

To avoid personal injury to yourself or property, we recommend that someone assist you during the

door reversal process.

This keg cooler has a door that can be set to open from the left or right side. This unit is delivered

to you with the door opening from the left side. To reverse the opening direction, please follow the

instructions below.

1. Undo the three (3) screws in each bracket using a Phillips screwdriver.

2. Remove the screws and bracket. Place to one side.

3. Slide the door down about 15 cm (6”) and off the top hinge pin and lift away.

4. Use a fl at head screwdriver to remove te pin from the top bracket. Replace it in the hinge bracket

on the opposite side.

5. Remove the screw from the side of the fridge where the bracket is to be re-fi tted.

6. Slide the fridge door back onto the top hinge, making sure it’s the right way up. Screw the bottom

hinge into place on the new side.

7. Check that the door is aligned horizontally and vertically and that the seals are closed on all sides

before fi nally tightening the bottom hinge.

1

4

2

3

5

7

6

13

Page 17

Care and Maintenance

CLEANING YOUR KEG COOLER

• Turn the temperature control to “OFF”, unplug the keg cooler, and remove the contents.

• Wash the inside surfaces with a warm water and baking soda solution. The solution should be 2

tablespoons of baking soda to a quart of water.

• Wash the shelves and stand with a mild detergent solution.

• Wipe down any electrical controls with a dry cloth.

• Wash the outside cabinet with warm water and mild liquid detergent. Rinse well and wipe dry with

a clean soft cloth.

CLEANING YOUR BEER LINES

Beer lines have to periodically be cleaned because of a crystallized sugar build up which forms on

the fi ttings, lines and taps commonly referred to as “beerstore”. If the “beerstore” is not completely

removed in a cleaning process it will leave an unsanitary surface that can harbor microorganisms

which will cause an undesirable fl avour and/or cause the beer to go fl at. Suffi cient “beerstore” will

also lead to dispense problems ranging from ‘wild’ beer (too much foam) to fl at beer, regardless of the

carbonation levels or quality (age) of the beer in the keg.

Scheduled line and faucet cleaning, with the proper equipment and chemical, eliminates the build-up

of “beerstore” protecting the integrity of the product and condition of the dispense system and seals.

The dispenser (beer) line should be cleaned approximately once every three (3) weeks or every other

keg - which ever comes fi rst. The dispenser faucet should be cleaned on a weekly basis or prior to

every use if not used on a regular basis.

Note: If you have trouble manipulating the faucet lever, this is usually indicative that it may require

cleaning. DO NOT apply force to move the handle in this situation, as this will likely lead to damaging

the handle or faucet, and will not be covered by your warranty.

A standard cleaning kit will perform approximately eight (8) scheduled line cleanings. Line cleaning

kits are readily available and can be purchased through our after sales service department.

For more information please call 1-800-26-DANBY (1-800-263-2629).

VACATION

Short Vacations - Leave the keg cooler operating during vacations of less than three (3) weeks.

Long Vacations - If the appliance will not be used for several months, remove all contents and

unplug the power cord. Clean and dry the interior thoroughly. To prevent odor and mold growth, leave

the door open slightly.

MOVING YOUR KEG COOLER

• Remove all the contents.

• Securely tape down all loose items inside your keg cooler.

• Tape the door shut.

• Be sure the keg cooler stays secure in the upright position during transportation. Also protect the

outside of the keg cooler with a blanket or similar item.

14

Page 18

Troubleshooting

Danby Consumer Care: 1-800-263-2629

Hours of operation:

Monday to Thursday 8:30 am - 6:00 pm Eastern Standard Time

Friday 8:30 am - 4:00 pm Eastern Standard Time

PROBLEM POSSIBLE CAUSE

The unit does not operate • Not plugged in

• The circuit breaker tripped or blown fuse

Turns on and off

frequently

Vibrations • Check that the keg cooler is level

The keg cooler seems to

make too much noise

The door will not close

properly

Excessive beer foam • Ensure the beer line hose from the tower and the CO

Weak beer fl ow • Ensure the beer line hose from the tower and the CO

• The room temperature is hotter than normal

• The door is open too often

• The door is not closed completely

• The temperature control is not set correctly

• The door gasket does not seal properly

• The unit does not have proper clearance

• The rattling noise may come from the fl ow of refrigerant, which is

normal

• Gurgling, caused by liquid refrigerant cycling is normal

• Contraction and expansion of the inside walls may cause popping

and crackling noises

• The keg cooler is not level

• The keg cooler is not level

• The door was reversed and not properly reinstalled

• The gasket is dirty

• The shelves or stand are out of position

• The keg is not properly centered in the unit

• The casters are not attached

from the CO2 regulator are attached to the correct connections on

the coupler; beer line to the top of the coupler, CO2 air line to the

side of the coupler

• Check that there are no leaks in any connections

• Ensure that the reed valve in the CO2 connection at the coupler

has a hole in it

• The CO2 pressure may be set too high; try turning the pressure

down

• Ensure that the valve spool plastic rod is inserted into the coupler

from the CO2 regulator are attached to the correct connections on

the coupler; beer line to the top of the coupler, CO2 air line to the

side of the coupler

• Check that there are no leaks in any connections

• Ensure that the reed valve in the CO2 connection at the coupler

has a hole in it

• The CO2 pressure may be set too low; try turning the pressure up

• Ensure there are no bends or kinks in any of the hoses that could

impede fl ow

air line hose

2

air line hose

2

15

Page 19

LIMITED IN-HOME APPLIANCE WARRANTY

LIMITED IN-HOME APPLIANCE WARRANTY

This quality product is warranted to be free from manufacturer’s defects in material and workmanship, provided that the unit is used under the normal operating

This quality product is warranted to be free from manufacturer’s defects in material and workmanship, provided that the unit is

conditions intended by the manufacturer.

used under the normal operating conditions intended by the manufacturer.

This warranty is available only to the person to whom the unit was originally sold by Danby Products Limited (Canada) or Danby Products Inc. (U.S.A.) (hereafter

This warranty is available only to the person to whom the unit was originally sold by Danby Products Limited (Canada) or

“Danby”) or by an authorized distributor of Danby, and is non-transferable.

Danby Products Inc. (U.S.A.) (hereafter “Danby”) or by an authorized distributor of Danby, and is non-transferable.

TERMS OF WARRANTY

Plastic parts, are warranted for thirty (30) days only from purchase date, with no extensions provided.

Plastic parts, are warranted for thirty (30) days only from purchase date, with no extensions provided.

First year

First Year

To obtain

service

To obtain

Service

Boundaries of

Boundaries of

in-home service

In Home Service

During the first twelve (12) months, any functional parts of this product found to be defective, will be

repaired or replaced, at warrantor’s option, at no charge to the ORIGINAL purchaser.

During the rst twelve (12) months, any functional parts of this product found to be defective, will be repaired or replaced, at warrantor’s

option, at no charge to the ORIGINAL purchaser.

Danby reserves the right to limit the boundaries of “In Home Service” to the proximity of an Authorized

Service Depot. Any appliance requiring service outside the limited boundaries of “In Home Service” ,it

Danby reserves the right to limit the boundaries of “In Home Service” to the proximity of an Authorized Service Depot. Any app liance

will be the consumer’s responsibility to transport the appliance (at their own expense) to the original

requiring service outside the limited boundaries of “In Home Service” , it will be the consumer’s responsibility to transport the appliance (at

retailer (point of purchase) or a service depot for repair. See “Boundaries of In Home Service” below.

their own expense) to the original retailer (point of purchase) or a service depot for repair. See “Boundaries of In Home Serv ice” below.

Contact your dealer from whom your unit was purchased, or contact your nearest authorized Danby

Contact your dealer from whom your unit was purchased, or contact your nearest authorized Danby service depot, where service

service depot, where service must be performed by a qualified service technician. If service is performed

must be performed by a qualied service technician.

on the units by anyone other than an authorized service depot, or the unit is used for commercial

If service is performed on the units by anyone other than an authorized service depot, or the unit is used for commercial appli cation, all

application, all obligations of Danby under this warranty shall be void.

obligations of Danby under this warranty shall be void.

If the appliance is installed in a location that is 100 kilometres (62 miles) or more from the nearest

If the appliance is installed in a location that is 100 kilometers (62 miles) or more from the nearest service center your unit must be

service centre your unit must be delivered to the nearest authorized Danby Service Depot, as service

delivered to the nearest authorized Danby Service Depot, as service must only be performed by a technician qualied and certif ied for

must only be performed by a technician qualified and certified for warranty service by Danby. Transpor-

warranty service by Danby. Transportation charges to and from the service location are not protected by this warranty and are t he

tation charges to and from the service location are not protected by this warranty and are the responsi-

responsibility of the purchaser.

bility of the purchaser.

TERMS OF WARRANTY

Nothing within this warranty shall imply that Danby will be responsible or liable for any spoilage or damage to food or other c ontents of this appliance, whether due

Nothing within this warranty shall imply that Danby will be responsible or liable for any spoilage or damage to food or other

to any defect of the appliance, or its use, whether proper or improper.

contents of this appliance, whether due to any defect of the appliance, or its use, whether proper or improper.

EXCLUSIONS

EXCLUSIONS

Save as herein provided, by Danby, there are no other warranties, conditions, representations or guarantees, express or

Save as herein provided, Danby, there are no other warranties, conditions, representations or guarantees, express or implied, m ade or intended by Danby or its

implied, made or intended by Danby or its authorized distributors and all other warranties, conditions, representations or

authorized distributors and all other warranties, conditions, representations or guarantees, including any warranties, conditio ns, representations or guarantees

guarantees, including any warranties, conditions, representations or guarantees under any Sale of Goods Act or like legislation

under any Sale of Goods Act or like legislation or statue is hereby expressly excluded. Save as herein provided, Danby shall no t be responsible for any damages

or statute is hereby expressly excluded. Save as herein provided, Danby shall not be responsible for any damages to persons

to persons or property, including the unit itself, howsoever caused or any consequential damages arising from the malfunction o f the unit and by the purchase of

or property, including the unit itself, howsoever caused or any consequential damages arising from the malfunction of the unit

the unit, the purchaser does hereby agree to indemnify and hold harmless Danby from any claim for damages to persons or propert y caused by the unit.

and by the purchase of the unit, the purchaser does hereby agree to indemnify and hold harmless Danby from any claim for

damages to persons or property caused by the unit.

No warranty or insurance herein contained or set out shall apply when damage or repair is caused by any of the following:

1) Power failure.

No warranty or insurance herein contained or set out shall apply when damage or repair is caused by any of the following:

1) Power failure.

2) Damage in transit or when moving the appliance.

2) Damage in transit or when moving the appliance.

3) Improper power supply such as low voltage, defective house wiring or inadequate fuses.

3) Improper power supply such as low voltage, defective house wiring or inadequate fuses.

4) Accident, alteration, abuse or misuse of the appliance such as inadequate air circulation in the room or abnormal operating con ditions

4) Accident, alteration, abuse or misuse of the appliance such as inadequate air circulation in the room or abnormal operating

conditions (extremely high or low room temperature).

5) Use for commercial or industrial purposes (i.e., If the appliance is not installed in a domestic residence).

6) Fire, water damage, theft, war, riot, hostility, acts of God such as hurricanes, floods etc.

7) Service calls resulting in customer education.

8) Improper Installation (i.e., building-in of a free standing appliance or using an appliance outdoors that is not approved for

outdoor application). Proof of purchase date will be required for warranty claims; so, please retain bills of sale. In the event

Proof of purchase date will be required for warranty claims; so, please retain bills of sale. In the event warranty service is required, present this document to our

warranty service is required, present this document to our AUTHORIZED SERVICE DEPOT.

AUTHORIZED SERVICE DEPOT.

(extremely high or low room temperature).

5) Use for commercial or industrial purposes (ie. If the appliance is not installed in a domestic residence).

6) Fire, water damage, theft, war, riot, hostility, acts of God such as hurricanes, oods etc.

7) Service calls resulting in customer education.

8) Improper Installation (ie. Building-in of a free standing appliance or using an appliance outdoors that is not approved for out door application).

GENERAL PROVISIONS

GENERAL PROVISIONS

Danby Products Limited

Danby Products Limited

PO Box 1778, Guelph, Ontario, Canada N1H 6Z9

PO Box 1778, Guelph, Ontario, Canada N1H 6Z9

Telephone: (519) 837-0920 FAX: (519) 837-0449

Telephone: (519) 837-0920 FAX: (519) 837-0449

Warranty Service

Warranty Service

In-home

In-home

1-800-263-2629

1-800-263-2629

07/14

04/09

Danby Products Inc.

PO Box 669, Findlay, Ohio, U.S.A. 45840

Telephone: (419) 425-8627 FAX: (419) 425-8629

PO Box 669, Findlay, Ohio, U.S.A. 45840

Telephone: (419) 425-8627 FAX: (419) 425-8629

Danby Products Inc.

Page 20

Merci d’avoir choisi Danby

Nous savons que vous êtes excité. Nous sommes aussi! Cependant, le plus que vous vous familiarisez avec votre

nouvel appareil, le mieux va être votre expérience. Nous suggérons donc de lire ces instructions avant connecter votre

nouvel appareil. Ce manuel contient des informations opérationnel important qui vous aidera à faire un usage pleine de les

caractéristiques techniques disponibles dans votre appareil Danby. Le manuel contient également des informations conçu

pour améliorer la fiabilité et la sécurité de votre appareil ainsi que des conseils pour le maintien, pour vous assurez des annees

de bonheur.

Se il vous plaît visitez www.danby.com pour accéder les outils libre-service, FAQ et plus encore. Si jamais vous avez besoin

d'aide supplémentaire, s’il vous plaît appelez 1-800-26-Danby (1-800-263-2629). S’il vous plaît ayez votre facture d’achat, le

numéro de modèle, et le numéro de série près durant l'appel.

Remarque : Ces renseignements seront nécessaires si votre appareil a besoin d’entretien ou pour les demandes de

renseignements généraux. Pour bénéficier d’une opération de maintenance ou de dépannage, le reçu

original sera exigé.

Numéro de modèle :

Numéro de serie :

Date d’achat :

BESOIN D’ASSISTANCE ?

Veuillez trouver quelques conseils avant de faire appel à nos services, cela

nous aidera à mieux vous servir :

Lisez ce guide :

Il comprend des instructions pour l’utilisation et l’entretien adapté de votre

appareil.

Si votre nouvel appareil est endommagé :

Contactez immédiatement le revendeur (ou le fabricant).

Gagnez du temps et de l’argent :

Avant de faire appel à nos services, consultez à nouveau la section

« Dépannage ». Cette section vous aidera à résoudre des problèmes courants.

Si une réparation est nécessaire, ne vous inquiétez pas, la solution est au

bout du fil.

Tel: 1-800-26-

(1-800-263-2629)

17

Page 21

Consignes de sécurité importantes

LIRE ET SUIVRE TOUTES LES INSTRUCTIONS DE SÉCURITÉ

AVERTISSEMENT IMPORTANT

DANGER: Risque de piégeage d’enfant. Avant de jeter votre appareil:

• Enlever les portes.

• Laissez les étagères en place afi n que les enfants ne grimpent pas facilement.

N’ATTENDEZ PAS! FAIS LE MAINTENANT!

EXIGENCES DE FONCTIONNEMENT

Pour éviter toute diffi culté d’installation ou de fonctionnement, lisez attentivement ces instructions.

• Cet appareil doit être mis à la terre. Branchez le seulement dans une prise correctement mise à la

terre.

• Ne faites pas fonctionner cet appareil s’il a un cordon ou fi che électrique endommagé ou si

l’appareil a été endommagé ou échappé. Si le cordon d’alimentation est endommagé, il doit être

remplacé par le fabricant, son agent de service ou une personne qualifi ée pour éviter tout risque.

• Ne permettez jamais à un enfant de faire fonctionner l’appareil, de jouer avec ou de ramper à

l’intérieur.

• Ne nettoyez jamais de pièces de l’appareil avec un liquide infl ammable. Les vapeurs peuvent

constituer un risque d’incendie ou provoquer une explosion.

• N’entreposez et n’utilisez pas d’essence ou d’autres liquides ou vapeurs infl ammables à proximité

de cet appareil ou de tout autre appareil. Les vapeurs peuvent constituer un risque d’incendie ou

provoquer une explosion.

• N’épilez pas le cordon d’alimentation qui est équipé de cet appareil.

• Gardez le cordon électrique éloigné des sources de chaleur.

• Ne plongez pas le cordon d’alimentation, la fi che ou l’appareil lui-même dans l’eau.

• N’utilisez pas cet appareil près de bassins d’eau, par exemple dans un sous-sol détrempé, près

d’une piscine ou d’un évier.

• N’utilisez pas de produits chimiques ou vapeurs corrosives dans/près de cet appareil.

• N’utilisez cet appareil que pour les fi ns aux quelles il est conçu comme indiqué dans ce guide.

• Ne pas entreposer les contenants ouverts dans cet appareil.

• Ne recouvrez pas ou n’obstruez aucune ouverture de l’appareil.

• Ne placez pas les articles périssables de nourriture dans votre appareil. (Par exemple, les viandes

et les produits laitiers). Cet appareil n’est pas assez froid pour être sécuritaire pour les aliments.

• Cet appareil est conçu pour un usage domestique à l’intérieur seulement. N’entreposez ni

n’utilisez pas cet appareil à l’extérieur.

• Cet appareil ne devrait être réparé que par du personnel qualifi é. Pour tout examen, réparation ou

réglage, contactez votre centre de service le plus rapproché.

• Avant de brancher l ‘appareil à une source d’ alimentation, laissez - le debout pendant environ 6

heures; Ceci réduira la possibilité d’un dysfonctionnement dans le système de refroidissement de

la manipulation pendant le transport.

SAUVE CES INSTRUCTIONS!

18

Page 22

Consignes de sécurité importantes

LIRE ET SUIVRE TOUTES LES INSTRUCTIONS DE SÉCURITÉ

MISE À LA TERRE

Cet appareil doit être mis à la terre. Dans l’éventualité d’un court-circuit, la mise à la terre procure un

chemin direct contournement du courant pour prévenir l’électrocution des manipulateurs de l’appareil.

L’appareil est muni d’un cordon électrique comprenant un fi l de mise à la terre et une fi che de terre.

Branchez la fi che dans une prise de courant correctement installée et mise à la terre.

AVERTISSEMENT - Une fi che de mise à la terre mal branchée peut entraîner un risque d’incendie,

de choc électrique ou de blessures aux personnes qui utilisent l’appareil. Si vous n’êtes pas certain

que l’appareil est correctement mis à la terre, consultez un préposé du service qualifi é.

Si la prise murale est un prise à 2 branches, c’est votre obligation, et la responsabilité vous en

incombe, de la faire remplacer par une prise à trois branches adéquatement mise à la terre.

Pour un meilleur rendement et pour éviter que les ampoules d’éclairage de la résidence soient

affectées d’un affaissement de tension, ou que le fusible ou disjoncteur du circuit ne grille ou ne se

déclenche, dédiez un circuit individuel d’alimentation à la machine à glaçons.

N’UTILISEZ JAMAIS DE FIL DE RALLONGE

Brancher l’appareil à son propre curcuit de 115V. N’utilisez pas de rallonge électrique pour brancher

votre appareil. Ne branchez pas l’appareil à une prise femelle multiple qui sera également utilisée

pour d’autres appareils électriques. N’épissez pas le cordon électrique. N’utilisez pas d’adaptateur de

fi che avec cet appareil. N’utilisez pas de cordon de rallonge avec cet appareil.

EXIGENCES DE SÉCURITÉ

Assurez-vous que les composants doivent être remplacés par des composants similaires et que

l’entretien doit être effectué par le personnel de maintenance agréé en usine, afi n de minimiser le

risque d’allumage dû à des pièces incorrectes ou à un mauvais entretien.

Cet appareil doit être mis à la terre. En cas de court-circuit électrique, la mise à la terre réduit le

risque de choc électrique en fournissant un fi l d’échappement pour le courant électrique. La plaque

signalétique en série indique la tension et la fréquence pour lesquelles l’appareil est conçu.

ATTENTION! DANGER D’EXPLOSION! Risque d’incendie ou d’explosion dû à la perforation des

tuyaux de réfrigérant. N’utilisez pas d’objets tranchants pour faciliter le dégivrage. Veuillez manipuler

avec précaution. Garder les matériaux et les vapeurs infl ammables tels que l’essence à l’écart du

réfrigérateur. Utiliser un nettoyant non infl ammable.

L’élimination de cet appareil doit être conforme aux règlements fédéraux et locaux.

Cet appareil n’est pas destiné à être utilisé par des personnes (y compris des enfants) dont les

capacités physiques, sensorielles ou mentales peuvent être différentes ou réduites, ou qui manquent

d’expérience ou de connaissances, sauf si ces personnes reçoivent une supervision ou une formation

pour faire fonctionner l’appareil par une personne responsable de leur sécurité.

AVERTISSEMENT: Veillez à ce que les ouvertures de ventilation, dans l’enceinte de l’appareil ou

dans la structure intégrée, ne soient pas obstruées.

AVERTISSEMENT: N’utilisez pas de dispositifs mécaniques ou d’autres moyens pour accélérer le

processus de dégivrage, autres que ceux recommandés par le fabricant.

AVERTISSEMENT: Ne pas endommager le circuit frigorigène.

AVERTISSEMENT: N’utilisez pas d’appareils électriques à l’intérieur des compartiments de l’appareil,

sauf s’ils sont du type recommandé par le fabricant.

SAUVE CES INSTRUCTIONS!

19

Page 23

Consignes de sécurité importantes

LIRE ET SUIVRE TOUTES LES INSTRUCTIONS DE SÉCURITÉ

AVERTISSEMENT: LE GAZ CARBONIQUE PEUT ÊTRE DANGEREUX!

Les bouteilles de gaz carbonique chargées contiennent du gaz hautement pressurisé, qui peut

présenter un danger s’il n’est pas manipulé correctement. Avant l’installation, lisez et assurez-vous de

bien comprendre les procédures suivantes concernant les bouteilles de gaz carbonique:

1. Avant de l’installer, vérifi ez toujours la date d’essai du D.O.T. (Ministère des transports), située sur

le col de la bouteille. Si l’essai a eu lieu il y a plus de cinq (5) ans, retournez la bouteille de gaz à

votre fournisseur.

2. Branchez toujours la bouteille de gaz carbonique à un régulateur. Sans quoi, l’ouverture de la

valve de la bouteille pourrait causer une explosion qui risque d’entraîner la mort ou des blessures.

3. Toujours suivre les procédures correctes lorsque les bouteilles sont changées selon les codes

locaux.

4. Fixez toujours la bouteille de gaz carbonique en position verticale.

5. Gardez toujours la bouteille de gaz carbonique à l’abri de la chaleur. Les bouteilles de

gaz carbonique doivent être rangées préférablement dans les pièces les plus froides de

l’établissement, à 70°F (21°C). Elles doivent toujours être fi xées en position verticale..

6. Toujours ventiler et quitter la zone immédiatement après toute fuite de gaz carbonique.

7. Ne brancher jamais la bouteille de gaz carbonique directement sur le fût de bière.

8. Ne jamais laisser tomber ni jeter un cylindre de gaz carbonique.

9. Ne branchez jamais une bouteille sans au moins une pression de sécurité. Il existe deux

mécanismes de sécurité dans le système de pression;

• Un au niveau du régulateur de gaz carbonique.

• Un au niveau du coupleur de la bouteille, sur la conduite de pression du gaz.

Remarque : Le régulateur et le coupleur de fût compris avec cet appareil constituent de tels

mécanismes de sécurité.

AVERTISSEMENT DE LE GAZ CARBONIQUE

Si la respiration devient diffi cile et / ou la tête commence à souffrir, des concentrations

anormales de dioxyde de carbone (CO

FERMER LA VALVE MAIN SUR LA BOUTEILLE DE GAZ CARBONIQUE, VENTILER ET

LAISSER LA CHAMBRE IMMEDIATEMENT!

) peuvent être présentes dans la région.

2

AVERTISSEMENT IMPORTANT

La bière est facile d’accès avec la glacière de bière pression de Danby. La glacière n’est

cependant pas conçue pour offrir de la bière aux personnes n’ayant pas l’âge légal pour

consommer. Danby n’est pas responsable de la consommation ou utilisation illégales de la bière.

RAPPELEZ-VOUS : LA MODÉRATION A BIEN MEILLEUR GOÛT! LE

VOLANT ET L’ALCOOL NE FONT PAS BON MÉNAGE!

SAUVE CES INSTRUCTIONS!

20

Page 24

Instructions d’installation

ACCESSOIRES FOURNIS

Enlevez et inspectez tous les accessoires fournis avec cet appareil pour vous assurer qu’ils sont

présents et en bon état. Si certains accessoires manquent ou ne sont pas en bon état, veuillez

appeler Danby au numéro sans frais indiqué ci-dessous pour parler à l’un de nos représentants du

service à la clientèle. (1-800-263-2629)

1. Colonne de bière

2. Joint d’étanchéité en

caoutchouc (sera peut-

être pas nécessaire en tout

confi gurations)

3. Barre de retenue

4. Plateau perforé

5. Thermostat réglable

6. Régulateur de CO

7. Bouteille de CO2 gazeux

8. Support de la bouteille de CO2

gazeux

9. Évaporateur

10. Porte

11. Baril à bière (non fourni)

12. Plaque métallique

13. Roulettes à blocage (4)

2

AVANT D’UTILISER VOTRE GLACIÈRE DE BIÈRE PRESSION

• Enlevez l’emballage extérieur et intérieur.

• Assurez-vous que vous avez en main toutes les pièces suivantes:

• 2 barre de retenue

• 1 plateau perforé (2 pièces)

• 1 support pour bouteille de CO

• 1 régulateur de CO

• 1 bouteille vide de CO

• 2 tuyau (coloré) de CO

2

2

2

• 2 tuyau de bière

• 2 tirant pour le baril à bière

• 1 colonne de bière

• 2 poignée de tirage (robinet de la colonne de bière)

• 4 bouchons pour les orifi ces de la barre de retenue

• 1 plaque métallique pour le fond du boîtier

• 3 tablettes en fi l d’acier

• 2 brides de serrage en acier pour le tuyau (coloré)

• 2 rondelles plastique (pour les roulettes à l’avant)

• 4 roulettes (2 à l’avant avec des serrures)

• Avant de brancher la glacière de bière pression, laissez-la en position verticale pendant environ 6

heures. Cela réduira le risque que le système de refroidissement subisse une défaillance causée

par la manutention lors du transport.

2

• Nettoyez la surface intérieure avec de l’eau tiède, au moyen d’un chiffon doux.

21

Page 25

Instructions d’installation

INSTALLATION DU GLACIÈRE DE BIÈRE PRESSION

• Cet appareil est conçu pour être autonome; il ne doit pas être encastré.

• Placez votre glacière de bière pression sur un sol suffi samment solide pour le supporter lorsqu’il

est plein.

• Laissez un espace libre de 8-12 cm (3-5 pouces) autour du glacière de bière pression (à l’arrière

et sur les côtés), ce qui permet à l’air de circuler suffi samment pour refroidir le compresseur.

• Installez le glacière de bière pression loin des rayons directs du soleil et de toute source de

chaleur (four, appareil de chauffage, radiateur, etc.). Les rayons directs du soleil affectent le

revêtement acrylique et les sources de chaleur peuvent augmenter la consommation électrique.

Les températures extrêmement basses peuvent également causer un mauvais fonctionnement du

glacière de bière pression.

• Cet appareil n’est pas conçu pour être utilisé à l’extérieur (p. ex., garage, porche, patio, etc.).

• Évitez d’installer le glacière de bière pression à un endroit où l’humidité est excessive.

• Branchez le glacière de bière pression sur une prise murale exclusive, installée correctement et

avec mise à la terre. Sous aucun prétexte, vous ne devez couper ou enlever la troisième broche

(mise à la terre) de la fi che du cordon électrique. Pour toute question relative à l’alimentation ou à

la mise à la terre, faites appel à un électricien qualifi é ou à un centre de service autorisé.

• Après avoir branché l’appareil sur une prise murale, laissez l’appareil refroidir pendant 2 à 3

heures avant de placer quoi que ce soit dans le compartiment du glacière de bière pression.

AVERTISSEMENT

LE CO2 GAZEUX PEUT ÊTRE DANGEREUX

Les bouteilles de CO2 contiennent du gaz comprimé à haute pression qui peut être dangereux

s’il n’est pas manipulé correctement. Assurez-vous de lire et de comprendre les procédures

suivantes relatives aux bouteilles de CO2 avant l’installation.

INSTRUCTIONS D’INSTALLATION DU BARIL À BIÈRE

Croquis d’installation du baril

Régulateur

de pression

Bouteille

de CO

2

Assemblage du robinet

Colonne

tuyau transparent

avec écrou à oreilles

Robinet de prise

american sankey

Baril

22

Tuyau coloré sous pression

Page 26

Instructions d’installation

INSTRUCTIONS D’INSTALLATION DU BARIL À BIÈRE

Installez les quatre roulettes. Les deux roulettes de verrouillage doivent être placées à l’avant. Quatre

trous de vis ont été pré-percés dans le fond de l’unité à chaque angle pour chaque roulette. Placez

les rondelles en plastique fournies sur les roulettes avant avant de les installer.

METAL

Roulettes

WASHERS

Placez les rondelles sur

les roulettes avant.

Fig. 1

Fig. 2

Guide de freinage des roulettes

Les deux roulettes avant sont fournies avec des freins pour s’assurer que l’unité ne se déplace pas

excessivement pendant l’utilisation. Il est recommandé d’engager les freins pendant que l’appareil est

utilisé pour éviter d’endommager l’appareil, son contenu ou vos biens personnels.

Appuyez avec le

Appuyez avec le

pied pour freiner

Installation du support de la bouteille de CO

Installez le support métallique fourni sur les 4 goujons

qui se trouvent sur la paroi arrière extérieure.

2

pied pour relâcher

le frein

Alignez les orifi ces du support avec les goujons et

appuyez fermement vers le bas.

23

Page 27

Instructions d’installation

Installation de la bouteille de CO2 et du régulateur de CO

La bouteille de CO2 fournie n’est pas remplie. La

bouteille doit être remplie de CO2 avant l’utilisation.

Installez votre bouteille complètement remplie dans

son support.

Fixez le régulateur de CO2 à la bouteille en vissant

l’écrou du régulateur sur le robinet de la bouteille, en

vous assurant que la rondelle est bien insérée dans

l’écrou de raccordement. Serrez complètement au

moyen d’une clé ajustable (non fournie) et assurezvous qu’il n’y a aucune fuite - pas aucun bruit de

siffl ement.

2

Installation du conduit d’air extérieur CO2 et du tuyau d’air CO2 au régulateur

Retirez la fi che située à l’arrière de l’armoire, dans le

coin supérieur gauche. Conservez-le pour utilisation

future, au cas où vous décideriez de convertir l’appareil

en réfrigérateur.

Alimenter la conduite de gaz à travers le coffret et

sortir par le trou découvert.

Attachez l’extrémité ouverte du tuyau à la connexion

du barbillon de tuyau sur le régulateur. Fixer le tuyau

en utilisant une pince fournie. Utilisez une pince ou un

tournevis pour serrer la pince pour éviter les fuites.

Installation de la colonne de bière

• Enlevez le bouchon supérieur en le tournant et en

tirant dessus et conservez-le pour utilisation future,

au cas où vous décideriez de convertir l’appareil en

réfrigérateur.

• Déroulez la conduite de bière (tuyau transparent)

qui se trouve autour de la colonne et insérez la

conduite de bière et l’écrou à oreilles en passant

par l’orifi ce découvert sur le dessus.

• Verrouillez l’assemblage de la colonne de bière sur

le dessus et assurezvous de positionner le robinet

de bière de façon à ce qu’il soit aligné avec le

devant du boîtier.

• Le joint en plastique peut être utilisé pour resserrer

le raccord entre la colonne et la glacière, au

besoin. Si la colonne de bière ne peut être tournée

pour le verrouillage, essayez d’enlever le joint

en caoutchouc. (Le joint en caoutchouc peut ne

pas être requis dans toutes les confi gurations de

l’unité).

• Si le robinet de la tour coule ou si la bière est très

mousseuse, assurez-vous que les rondelles à

l’intérieur du robinet sont intactes. Remplacer les

rondelles avec des pièces de rechange de la poche

d’accessoires, si nécessaire.

24

1. Rondelle de culbuteur

2. Rondelle de soupape

3. Rondelle porte-soupape

Page 28

Instructions d’installation

Installation de la plaque métallique protectrice

La plaque métallique de protection doit être installée au bas de l’intérieur de l’armoire. La plaque

doit toujours être installée lorsque le bail est en place afi n de ne pas endommager le fond du boîtier

inutilement.

Installation du baril à bière

• Positionnez le baril à bière directement devant la porte ouverte.

Soulevez doucement le baril à bière par les poignées uniquement.

• Pour placer le baril à bière dans le boîtier, appuyez les genoux

derrière le baril à bière. Soulevez le devant du baril juste assez

pour que le bord avant du baril repose sur le bord avant du boîtier

inférieur du glacière de bière pression.

• Prenez les poignées du baril et faites-le glisser jusqu’au fond du

boîtier.

Remarque: Deux personnes doivent soulever le fût pour éviter les

blessures au dos.

Installation du tuyau de CO

Fixez l ‘extrémité du tuyau d’ air (coloré) fourni au raccord du tuyau sur le côté du coupleur. Assurezvous que le clapet de retenue est insérée dans la connexion, le numéro 4 sur l’image ci-dessous.

Si, après assemblage, la bière ne coulera pas, en sorte que le clapet anti-retour a un petit trou. S’il

n’y a pas de trou dans le clapet anti-retour, le CO2 ne peut pas pénétrer dans la canalisation et la

bière ne s’écoule pas.

2

Raccordement de la tour de bière au coupleur

• Assurez-vous que toutes les rondelles sont correctement

insérées dans le coupleur, comme indiqué ci-dessous.

• Assurez-vous le tige en plastique est en place à l’intérieur

du coupleur, numéro 2 sur l’image ci-dessous.

• Placez l’écrou à oreilles fi xé à l’extrémité de la ligne

de bière dans le haut du coupleur, en tournant jusqu’à

serrage.

Si, après assemblage, la bière est très mousseuse, cela

signifi e très probablement qu’une connexion dans le coupleur

est une fuite et que de l’air pénètre dans les lignes. Vérifi ez

toutes les connexions dans le coupleur et remplacez les

rondelles du sac d’accessoires si nécessaire.

1. Rondelle de soupape

2. Tige en plastique

3. Rondelle de type O

4. Clapet anti-retour

5. Rondelle de soupape

6. Rondelle de soupape

25

Page 29

Instructions d’installation

Installation du tirant du baril

Insérez le tirant du baril fourni dans le col à verrouillage du baril à bière et tournez-le dans le sens des

aiguilles d’une montre pour le verrouiller en place, en vous assurant qu’il est sur la position fermée,

avec la poignée vers le haut.

Comment percer un baril de bière

• Assurez-vous que le robinet de CO2 est fermé et que le robinet secondaire du régulateur est sur la

position fermée.

• Tirez sur la soupape de surpression qui se trouve sur le tirant et relâchez-la pour purger toute

pression d’air.

• Assurez-vous que le robinet de la colonne de bière est sur la position fermée.

• Tirez sur la poignée de perçage vers l’extérieur et appuyez vers le bas jusqu’à ce qu’elle se

verrouille en place. Le baril est maintenant percé.

Remarque: Si un fût est très grand, il peut être nécessaire de raccorder le coupleur au fût avant

d’insérer le fût dans le frigidaire de fût.

Position fermée du coupleur Position ouverte du coupleur

Vanne de libération de

pression du coupleur

Ouverture du robinet principal de la bouteille de CO

• Assurez-vous que le robinet d’arrêt secondaire (illustré en position ouverte ci-dessous) est fermé.

2

Pour ouvrir le robinet principal de la bouteille de CO2, tournez-le lentement dans le sens contraire

des aiguilles d’une montre jusqu’à ce qu’il soit complètement ouvert.

• Vous verrez que l’aiguille de la jauge du régulateur commencera à grimper.

Réglage du régulateur de CO

La jauge surveille la basse pression interne du baril et doit

2

être réglée afi n de produire une lecture entre 8 et 12 lb/po².

La pression peut être réglée au besoin. Si la bière est très

mousseuse, essayez de tourner la pression vers le bas. Si

le débit de la bière est très faible, essayez de transformer la

pression.

Remarque: Après avoir réglé la pression, attendre 5 à 10

Robinet

d’arrêt

principal

minutes avant de tenter de verser une autre bière afi n de

permettre une égalisation de la pression.

• Desserrez le contre-écrou de réglage portant la marque 2.

• Tournez l’écrou du régulateur portant la marque 3.

- Pour augmenter la pression, tournez l’écrou dans le

sens des aiguilles d’une montre.

- Pour réduire la pression, tournez l’écrou dans le sens

contraire des aiguilles d’une montre.

• Resserrez le contre-écrou 2.

• Ouvrez le robinet d’arrêt secondaire pour que le CO

puisse pénétrer dans le baril.

2

• Attendez plusieurs minutes, jusqu’à ce que le baril atteigne la bonne pression. Il est possible que la jauge du

régulateur baisse pendant ce processus.

Remarque: Écoutez le siffl ement le long de toutes les

connexions pour identifi er s’il ya des fuites.

26

Robinet d’arrêt secondaire

Page 30

Instructions d’installation

Clé pour raccords de tuyaux

Une clé pour raccords de tuyaux (fournie) pour enlever ou serrer les

raccords.

Remarque : Pour éviter les fuites, utilisez le clé fournie pour resserrer

davantage le robinet.

Levier en plastique

Fixez le levier en plastique noir (poignée de tirage) sur la partie supérieure

du robinet en le serrant à la main jusqu’au bout dans le sens des aiguilles

d’une montre, en tenant l’écrou argenté situé en-dessous afi n qu’il ne

tourne pas. Si le robinet dégoutte encore, vous avez peut-être trop serré

l’écrou argenté; vous devrez peut-être desserrer l’écrou argenté d’un tour

dans le sens contraire des aiguilles d’une montre (tel qu’illustré).

COMMENT SERVIR LA BIÈRE

• Gardez le baril à bière toujours froid.

• Ne laissez jamais sécher les conduites de bière.

• Prenez un verre à bière propre avant de verser.

• Tenez le verre à un angle de 45° jusqu’à ce qu’il soit plein aux deux-tiers; commencez alors à

redresser le verre tout en continuant à le remplir.

• Assurez-vous de toujours pousser la poignée du robinet complètement vers l’arrière.

Ce refroidisseur de fût a été conçu pour refroidir et distribuer la bière de deux des fûts suivants de

taille simultanément:

1/6 barril 20 litres 5.2 gallons 661 onces 55 verres de 12 onces

1/8 barril 15 litres 4.0 gallons 496 onces 41 verres de 12 onces

Remarque: Le compartiment réfrigérateur ne peut pas accueillir le style “Coors” tonneau biseauté

baril.

Remarque: Notre glacière de bière pression accepte des barils de format domestique ayant un

diamètre maximal de 16-1/8 po et une hauteur maximale de 23-3/8 po. Confi rmez avec votre

distributeur que le baril a le bon format.

Remarque: Il est important de permettre du baril de se asseoir debout, tranquille, pendant 2 heures

avant de taper.

27

Page 31

Consignes d’utilisation

RÉGLAGE DE LA TEMPÉRATURE

La température est contrôlée en ajustant de la commande du thermostat. Pour démarrer l’appareil et

assurer un maximum de refroidissement rapide :

• Tournez la commande du thermostat dans la direction des aiguilles d’une montre à la posìtion

la plus éloignée (maximum) qui se trouve dans la section (épaisse) blue foncê ure le cadran à

êchelle (Fig A.).

• Laisser l’unité de fonctionner à ce paramètre pour 3-4 heures.

• Lorsque le refroidissement maximum est atteint, tournez le bouton de contrôle de la température à

une température modérée à moyen terme.

• Pour désactiver (pas de refroidissement), tournez le bouton de commande sur le “0” (arrêt)

(Fig.B.).

Fig A.

Max Max

Fig B.

MinMin

Fig. BFig. A

DÉGIVRAGE AUTOMATIQUE

Il n’est pas nécessaire de dégivrer le glacière de bière pression. L’eau s’accumule et coule par la

sortie de drainage qui se trouve dans la paroi arrière jusque dans un plateau situé au-dessus du

compresseur, où elle s’évapore.

Remarque : Lorsque l’appareil est débranché, le courant coupé ou lorsqu’il est arrêté, vous devez

attendre de 3 à 5 minutes avant de le remettre en marche. En cas de tentative de remise en marche

avant l’expiration de ce délai, le compresseur ne se remettra pas en marche.

CONVERSION EN RÉFRIGÉRATEUR

1. Tournez le bouton de réglage sur la position ARRÊT (OFF).

2. Fermez le robinet principal de la bouteille de CO2.

3. Fermez le robinet d’arrêt secondaire situé sur le tuyau du régulateur.

4. Fermez le raccord entre le baril à bière et le tirant du baril à bière.

5. Drainez toute la bière qui reste dans les conduites, le cas échéant. (Nous recommandons de

nettoyer à ce point, s’il vous plaît voir la section Soins et entretien).

6. Débranchez la conduite de bière et le tuyau de CO

7. Retirez le baril à bière.

8. Retirez le tirant du baril.

9. Débranchez le tuyau de la bouteille de CO2.

10. Enlevez le tuyau de CO2 du bouchon qui se trouve dans le boîtier.

11. Remettez le bouchon du tuyau dans l’arrière du boîtier.

12. Retirez la colonne de bière. Tirez également sur la conduite de bière par le dessus du boîtier pour

la faire sortir.

13. Remettez le bouchon du dessus du boîtier.

14. Réglez la température à la valeur désirée.

du tirant du baril.

2

Remarque : Afi n de convertir l’appareil, vous devez débrancher la conduite de gaz du régulateur afi n

de le retirer de l’armoire.

Remarque : Si vous désirez une étagère dans le converti “Tout réfrigérateur” installer le plateau en le

glissant dans l’endroit désiré dans l’unité.

28

Page 32

Consignes d’utilisation

INVERSION DE LA PORTE

Afi n d’éviter de vous blesser ou de causer des dégâts matériels, nous vous recommandons de

solliciter l’aide d’autrui lors des manœuvres liées à l’inversion de la porte.

Le glacière de bière pression est équipé d’une porte qui peut être réglée pour s’ouvrir du côté droit

ou du côté gauche. Lors de la livraison, l’appareil est équipé d’une porte qui s’ouvre du côté gauche.

Pour inverser la direction de l’ouverture, suivez les consignes que voici.

1. Desserrez les trois (3) vis qui se trouvent dans chaque ferrure d’articulation au moyen du

tournevis cruciforme.

2. Enlevez les vis et les ferrures d’articulation. Mettez-les de côté.

3. Faites glisser la porte du réfrigérateur garde-manger vers le bas d’environ 15 cm (6 po) pour que

l’axe de charnière supérieure sorte; ensuite, soulevez-la pour l’écarter l’appareil.

4. Au moyen du tournevis à lame plate, enlevez l’axe de charnière de la ferrure d’articulation

supérieure. Remettez-la en place dans la ferrure d’articulation qui se trouve du côté opposé.