Page 1

LED Aquatics/Track Displays

SW-2000 Series

10" Numeric Digit

Display Manual

ED-12156 Rev 13 – 9 December 2014

331 32nd Ave PO Box 5128 Brookings SD 57006

Tel 605-697-4036 or 877-605-1115 Fax 605-697-4444

www.daktronics.com/support

Page 2

Page 3

ED-12156

Please fill in the information below for your display; use it for reference

when calling Daktronics for assistance.

Display Serial No. ______________________________________

Display Model No. ______________________________________

Date Installed __________________________________________

P1153

Rev 13 – 9 December 2014

DAKTRONICS, INC.

Copyright 2003-2014

All rights reserved. While every precaution has been taken in the preparation of this manual,

the publisher assumes no responsibility for errors or omissions. No part of this book covered

by the copyrights hereon may be reproduced or copied in any form or by any means –

graphic, electronic, or mechanical, including photocopying, taping, or information storage and

retrieval systems – without written permission of the publisher.

OmniSport® and All Sport® are registered trademarks of Daktronics, Inc. Omega®,

FinishLynx®, and Colorado Time System® are registered trademarks of their owners.

Page 4

Page 5

Table of Contents

Section 1: Introduction ........................................................................................ 1

1.1 How to Use This Manual ...............................................................................1

1.2 Product Overview ..........................................................................................2

1.3 Model Identification ......................................................................................3

1.4 System Layout ...............................................................................................4

Section 2: Mechanical Installation ....................................................................... 5

2.1 Installing Caption Modules ............................................................................5

2.2 Mounting Digit Modules ...............................................................................6

Vertical Wall Mounting, Indoors or Outdoors ........................................6

Horizontal Wall Mounting, Indoors Only ...............................................7

Corner-Mounting Modules, Indoors Only ..............................................7

Beam Mounting Digit Modules, Outdoors .............................................8

Section 3: Electrical Installation ........................................................................ 11

3.1 Grounding Indoor Displays .........................................................................11

3.2 Connecting Power and Signal, Indoor Displays ...........................................11

3.3 Internal Cable Routing .................................................................................12

3.4 Grounding Outdoor Displays .......................................................................13

3.5 Installing Load Centers, Outdoor Displays ..................................................13

3.6 Setting Driver Addresses and Protocols ......................................................14

Address settings, LED Fixed-Digit Aquatics/Track Displays ...............14

Section 4: Maintenance and Troubleshooting .................................................... 21

4.1 Cabinet Specifications .................................................................................21

4.2 LED Driver ..................................................................................................21

4.3 Segmentation ...............................................................................................22

4.4 Component Location and Access .................................................................22

4.5 Schematic .....................................................................................................22

4.6 Troubleshooting ...........................................................................................23

4.7 Replacement Parts List ................................................................................23

Appendix A: Reference Drawings .......................................................................... 25

Appendix B: Daktronics Warranty and Limitation of Liability .............................. 27

Table of Contents i

Page 6

Page 7

Figure 1: Daktronics Drawing Label

Section 1: Introduction

This manual explains the installation and maintenance of Daktronics SW-2000 Series

Aquatics/Track Displays. The SW-2000 Series includes models in the 2000, 2100, and the

2200 lines.

1.1 How to Use This Manual

The manual is divided into four main sections:

Introduction offers basic explanations and provides a brief overview.

Mechanical Installation details techniques for proper mounting of the

scoreboards.

Electrical Installation shows the method for completing power and control

signal connections to the scoreboards.

Maintenance and Troubleshooting highlights some common problems

encountered with scoreboard operation.

If you have questions regarding the safety, installation, operation, or service of these

systems, contact Daktronics. Customer Service Help Desk telephone numbers are

listed on the cover page of this manual.

Important Safeguards

1. Read and understand these instructions before installing the display.

2. Do not drop the controller or allow it to get wet.

3. Disconnect power to the display when the unit is not in use.

4. Disconnect power when servicing the display.

5. Do not modify the scoreboard structure or attach any panels or coverings to

the scoreboard without the express written consent of Daktronics, Inc.

Figure 1 illustrates Daktronics drawing numbering system. Daktronics identifies

individual engineering drawings by the drawing number (7087-P08A-69945 in the

example), located in the lower right corner of the drawing. This manual refers to

drawings by the last set of numbers and the letter preceding them. An example would

be Drawing A-69945.

Introduction 1

Reference drawings are grouped and inserted in alphanumeric order in Appendix A.

Page 8

The serial and model number of a Daktronics scoreboard can be found on the ID

Figure 2: Scoreboard ID Label

label, located on the display. This label will be similar to the one shown in Figure 2.

When calling Daktronics Customer Service, please have this information available to

ensure that your request is serviced as quickly as possible. For future reference, write

your scoreboard model number, serial number, and installation date on the front page

of this manual.

1.2 Product Overview

Daktronics SW-2000 aquatics and track scoreboards belong to a system of modular

scoring and timing displays designed to offer easy installation, readability, and

reliability. Microprocessor control assures consistent operation and accuracy.

Based on one- and two-line modules, the SW-2000 displays feature easy-to-read 10"

digits in red and amber. Light emitting diodes, or LEDs, illuminate the display.

(LEDs are tiny, solid-state components that use a semiconductor chip to transform

electrical current into light; they are high-intensity, low-energy lighting units.)

Outdoor displays use red LEDs. Indoor boards are available with all red digits or

with an amber and red digit combination.

Because the series is based on a modular design, several display combinations are

available. Some scoreboards utilize a single module, while others consist of multiple

modules arranged either vertically or horizontally. As noted previously, the

scoreboards are manufactured for both indoor and outdoor settings, with 120 V and

230 V versions to accommodate both American and European use.

Caption modules are units without power that attach to the top or bottom of a digit

module. They hold changeable captions for several events. The SW-2000 assemblies

may also contain optional ad panels, which can be attached to the board to display

team logos, sponsor names or other advertising messages.

The aluminum cabinets have a 1’2" display face and measure 6" deep by 9’0" long.

The front face of the two-line module cabinet is 2’4". The single-line and two-line

modular units have mounting weights of 45 and 80 pounds, respectively.

2 Introduction

Page 9

1.3 Model Identification

Reference Drawings:

Module Model Descriptions & LED

Aquatics/Track Displays ................................. Drawing A-129639

Model Configurations, Swim/Track Timing ............ Drawing A-130101

Model Configurations, Aquatics Multisport ............. Drawing A-130102

SW-2000 Series scoreboards are differentiated by their model numbers. The digit

modules are the building blocks for each new system:

SW-2001 and SW-2002 are timing building blocks, featuring one- and two-

line LED displays showing lane, place and time information.

SW-2003 is the multisport timing module, incorporating an extra digit into

its display for judged events such as diving.

SW-2004 – 2009 are auxiliary display modules.

SW-2004 and SW-2005 are one- and two-line scoring displays.

SW-2006 is a one-line event/heat display.

SW-2007 is a one-line record timer.

SW-2008 is a one-line lengths/record timer.

SW-2009 is an add-on module for additional scoring.

SW-21xx displays are the models created by using different combinations of

the SW-2001 and SW-2002 modules.

SW-22xx multisport displays are created by adding the SW-2003 and

additional caption panels to the SW-2001 and SW-2002 modules.

Daktronics scoreboards and timing displays are identified by model numbers: TN-

2007, for example, designates a specific tennis scoreboard. The two-letter prefix for

displays in this manual, SW-, identifies aquatics/track scoreboards.

Model numbers for both the SW-2100 and SW-2200 series typically reflect the

number of lanes – six, eight, or 10 – in swimming or track events served by that

display. For example, the SW-2106 refers to a six-lane aquatics display. Model SW-

2108 is a swimming/track timing display, used for events with up to eight lanes.

The last two numbers comprising SW-2100 and SW-2200 model names differentiate

between vertical and horizontal displays. Horizontal model numbers add 10 to the

number of lanes. For example, SW-2218 is a multisport, horizontal display used for

events with up to eight lanes. SW-2120 refers to a 10-lane horizontal aquatics display.

All displays also carry a two-number suffix, which refers to indoor/outdoor status and

power supply: -13 and -14 are indoor displays, 120 V and 230 V respectively; -11

and -12 are outdoor displays, 120 V and 230 V. To correctly identify your display,

refer to Drawings A-129639, A-130101 and A-130102.

Introduction 3

Page 10

1.4 System Layout

Reference Drawings:

Track Scbd. w/ Finish LynxTM,

in Press Box .................................................... Drawing A-104300

Scan'O'Vision LED Driver Address

Configuration on 12 Pin ................................... Drawing A-118398

Equipment Layout, 50 M Swim,

Course #1, indeck ........................................... Drawing A-121329

Riser Diagram with OmniSport® 6000 ................... Drawing A-130977

Riser Diagram with OmniSport 1000 ..................... Drawing A-130978

Riser Diagram with CTS® Timer ............................ Drawing B-130979

Riser Diagram with Ares or OSM6 ........................ Drawing A-131037

Riser Diagram with All Sport® 4000 ....................... Drawing A-131226

System Riser; Track Scbd w/

Omni 2000, in field .......................................... Drawing A-186548

The Daktronics SW-2000 Series LED displays can be interfaced with a variety of

timers. Identify your timer and refer to the appropriate layout diagram. The drawing

has information on how to connect your timer and any restrictions for your model

scoreboard and controller. Refer to the operator's controller manual for information

on setup, operation, and scoreboard output.

4 Introduction

Page 11

Section 2: Mechanical Installation

Mechanical installation involves the following procedures:

Erecting the mounting structure or preparing the wall surface for mounting

Mounting the caption modules to the digit modules

Mounting the digit modules to the wall or mounting structure

These steps are described in greater detail in the following sections.

Refer to the electrical installation drawing before beginning the mechanical installation

procedure. It is important to recognize where the electrical wires are located so knockouts can

be removed respectively before the display has been mounted. It will be easier to install

electrical hookup items, route conduits and attach hookup boxes before mechanical

installation.

2.1 Installing Caption Modules

Reference Drawings:

Caption Layout, 6-Lane Multisport Systems ........... Drawing A-130319

Caption Layout, 8-Lane Multisport Systems ........... Drawing A-130321

Caption Layout, 10-Lane Multisport Systems ......... Drawing A-130801

Caption Module Detail ............................................ Drawing A-130840

Attach the caption module to the digit module before attaching the digit module to

the wall.

The caption modules are attached to the top or bottom of a digit module with #10

machine screws (refer to Drawing A-130319). Before attaching the caption module,

note its orientation. The top and bottom guides for holding the caption panel are

different sizes. Be sure the module is oriented so that the deeper guide is toward the

top.

To insert a caption panel, fit the top edge of the caption panel into the module's upper

guide, and then slide the bottom edge under the lower guide (refer to Drawing A-

130840). The construction of the guides allows the caption panels to be lifted out for

changing, rather than having to slide them out one end.

The caption panels must be properly positioned in relation to the scoreboard digits

for different activities. Refer to Drawings A-130319, A-130321, and A-130801 for

caption layouts. The drawings indicate the location of the digits that will be used for

the various events and sports. The captions may be positioned accordingly.

Mechanical Installation 5

Page 12

2.2 Mounting Digit Modules

Figure 3: Strut nut with spring

Scoreboard digit modules may be mounted directly to a wall, to universal mounting

struts (channels), or to other support structures. Modular construction permits varied

configurations, and the unique requirements of each facility will determine the setup

and anchoring method best suited for the display.

Daktronics recommends using universal mounting struts (channels). Use 3/8" bolts

through the holes in both ends of the module frame. For displays with multiple digit

modules, mount the lowest module first and work upward.

There are two basic methods to mount the display to a wall: corner mounting and

flush wall mounting. Corner mounting requires an additional bracket, which can be

ordered from Daktronics. Flush wall mounting requires standard bolts and anchors,

found in most hardware stores.

Before installing any wall anchors or the mounting structure, determine where all of

the mounting holes will be located on the display modules. Holes provided on the

modules should be convenient for most installations.

Vertical Wall Mounting, Indoors or Outdoors

Reference Drawing:

Vertical Wall Mounting .................................... Drawing A-130545

Use this method when the overall display requires that the digit modules be mounted

on top of one another.

1. Attach the mounting struts to the wall. Refer to Drawing A-130545 to

determine the strut length and the distance between struts.

2. Attach the caption module to the digit module before attaching the digit

module to the wall. Note: Caption modules do not require extra strut length

when they are mounted at either top or bottom of the column.

3. Use 3/8" bolts to attach the modules to the struts (refer to Drawing A-

130545). Mount the lowest module first, and then add modules working

upward. Note: Strut nuts should be equipped with springs, to hold nuts in

place until ready to install to bolts. (Refer to Figure 3 below)

6 Mechanical Installation

Page 13

Horizontal Wall Mounting, Indoors Only

Reference Drawings:

Strut Spacing, Horizontal Wall Mounting ......... Drawing A-129905

End Bracket Attachment, Horizontal Wall

Mounting ................................................... Drawing A-129906

Horizontal Wall Mounting, Final Steps ............. Drawing A-129907

Use this method when the overall display requires that digit modules be mounted side

by side.

1. Attach the mounting struts to the wall. Refer to Drawing A-130545 to

determine the strut length and the distance between the struts.

2. Attach the caption module to the digit module before attaching the digit

module to the wall. Note: Caption modules do not require extra strut length

when they are mounted at either top or bottom of the column.

3. Start with the left column of modules. Attach the end brackets to the right

end of all the modules in the left column. Next, attach brackets to the left

end of all the modules in the right column. (Refer to Drawing A-129906).

4. Attach the modules in the left column first:

Use

3

/8" bolts to attach the struts (Refer to Drawing A-129907).

Mount the lowest module first, and then add modules working

upward until the left column is complete.

5. Starting at the bottom, attach the modules in the right column. Join the left

and right columns using the end brackets:

Insert the screw heads on the end brackets into the keyholes on the

mating bracket and press down on the right side (Refer to Drawing

A-129907).

As the modules are joined, use

3

/8" bolts to attach the right end of

each module to the struts (Refer to Drawing A-129907).

Complete the lowest module first. Add any remaining modules,

working upward until the right column is completed.

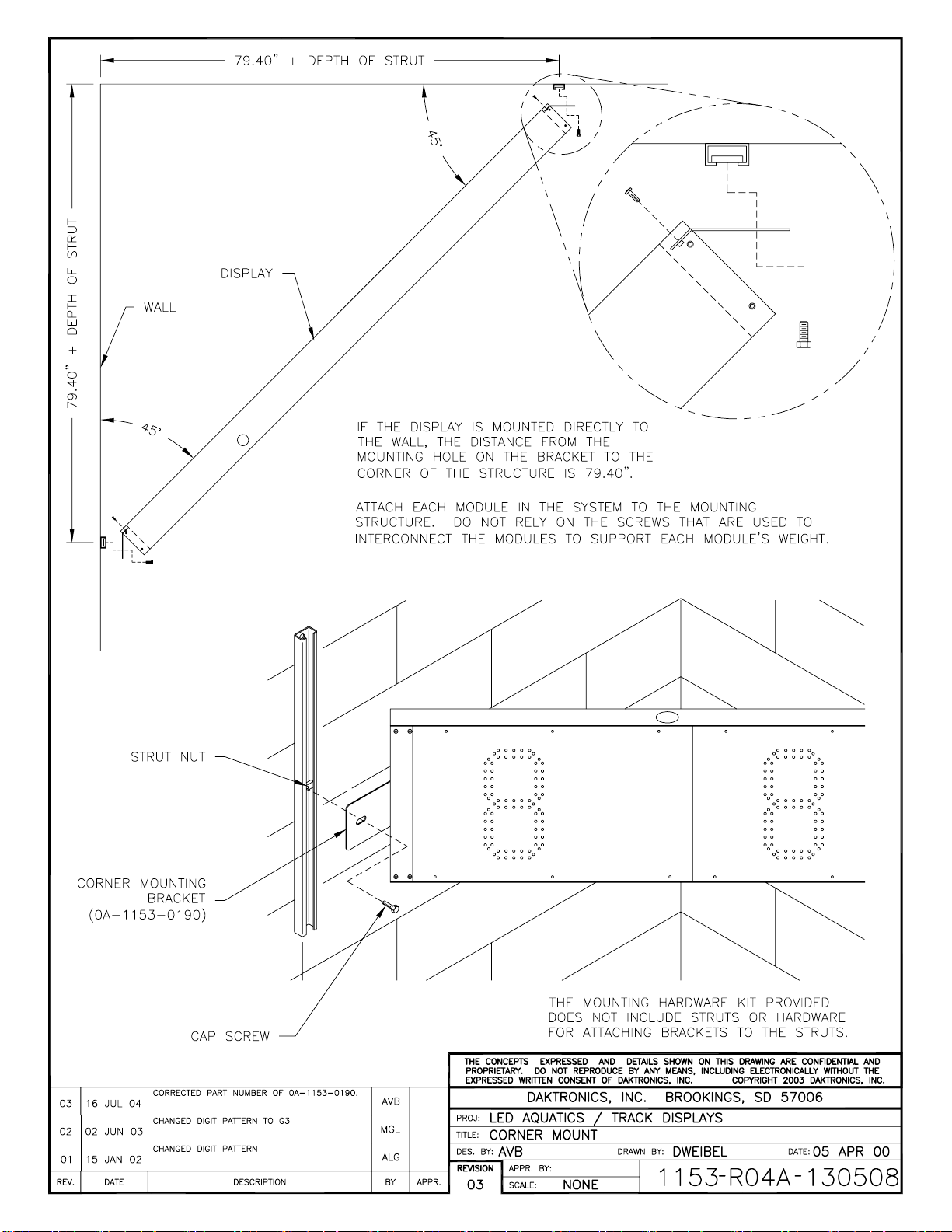

Corner-Mounting Modules, Indoors Only

Reference Drawing:

Corner Mount ................................................... Drawing A-130508

If the display is to be mounted across the corner of adjoining walls, you may order

special corner-mounting brackets as an option. Drawing A-130508 shows the

procedure for this type of mounting.

Mechanical Installation 7

Page 14

Multi-line display models that use a single vertical arrangement of modules may be

mounted with corner brackets. Horizontal display configurations, however, cannot be

mounted across a corner using the simple brackets. Such displays must be attached to

a structure or framework that spans across the corner and safely supports the entire

display. This type of mounting must be designed by a qualified engineer.

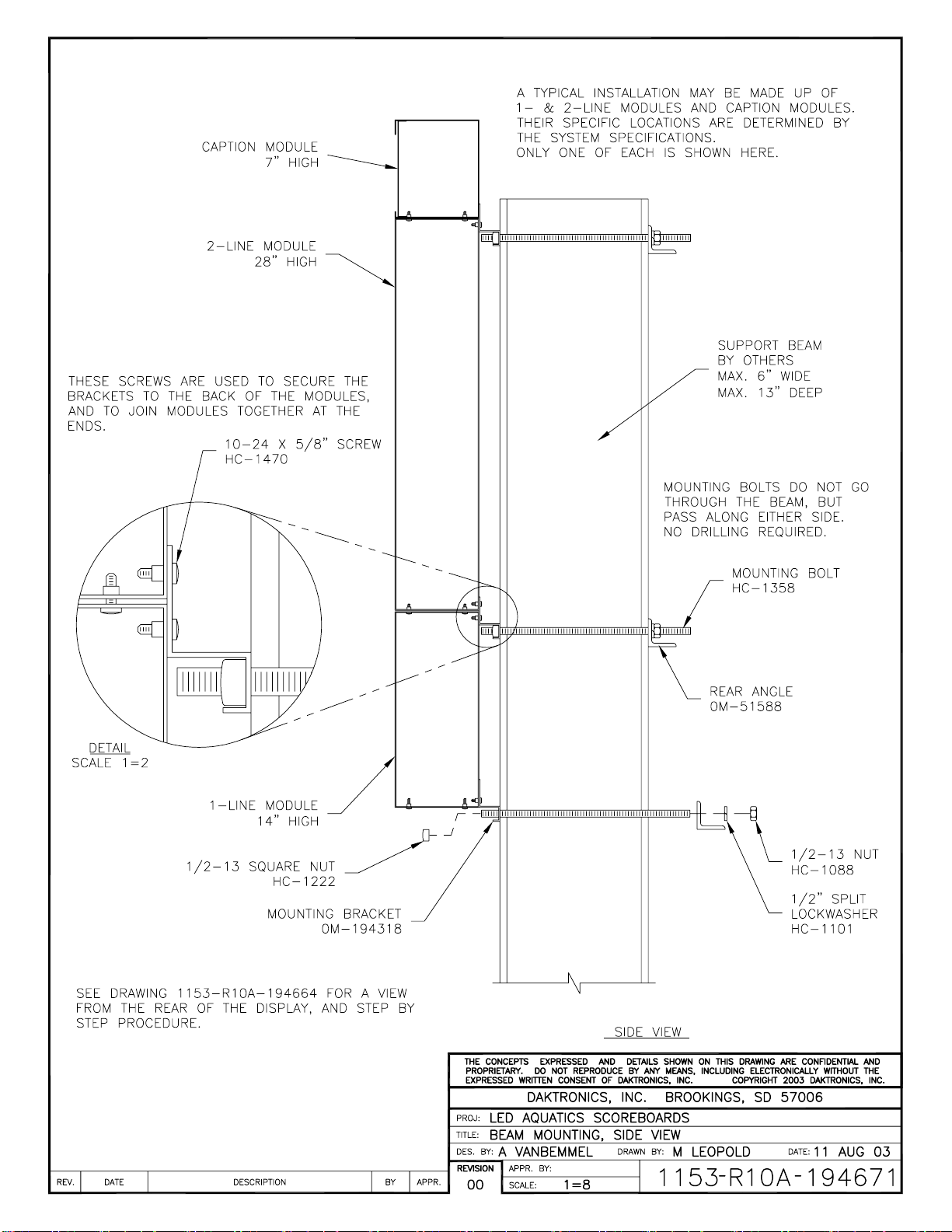

Beam Mounting Digit Modules, Outdoors

Reference Drawings:

Beam Mounting Procedure ............................. Drawing A-194664

Beam Mounting, Side View ............................. Drawing A-194671

Beam Mounting, Top View .............................. Drawing A-194674

Beam Mounting, Rear, Horizontal Display ...... Drawing A-194678

Beam Mounting, Rear, Vertical Display........... Drawing A-194677

SW-2000 Series scoreboards are frequently displayed as freestanding units, mounted

on steel beams. Because every display is different in terms of module configuration,

scoreboard options and environments, every installation will be unique.

Such beam-mounted installations require that a qualified engineer provide

specifications for both the reinforced concrete footings and the steel support beams.

Two beams are required for each column of display modules, and they must be set 4'6” apart, center-to-center. Installations of vertical and horizontal displays are shown

in Drawings A-194678 and A-194677, both of which specify the overall space

requirements for the scoreboards as well as their specific dimensions.

Each digit module has knockouts in both the rear and the end for power and signal

entrance. Power and signal are brought into one module through these external

knockouts, and connections to other modules are made internally.

Once the support beams have been installed, the scoreboard-mounting procedure is

typically a six-step process (Refer to Drawing A-194664):

1. Begin by attaching mounting brackets to the top and bottom of the lowest

digit module in the display. The brackets are fastened to the modules by

inserting 10-24 x 5/8" screws through the holes in each bracket and threading

them into the captivated nuts on the back of the module.

2. With the brackets attached, position the module against the beam and secure

it with the 15" long threaded rods with the washers and nuts provided. These

1

/2-13 x 15 threaded rods, or mounting bolts, do not go through the beam but

pass along either side; no drilling is required (Refer to Drawings A-194671

and A-194674). The square nuts go inside the bracket, and the hex nuts are

used inside the rear mounting angles that straddle the back of each support

beam. Tighten the assembly with a 3/4" socket, taking care not to over

tighten.

Note: Over tightening can deform the brackets and angles.

8 Mechanical Installation

Page 15

3. Attach the upper mounting bracket to the next module and set it on top of

the first module.

4. Insert screws through the upper bracket of the first module to secure the

bottom of the second module. This secures the bracket to the back of both

modules. (The modules will also be joined later at each end.)

5. Secure the upper bracket of the second module to the beams with bolts,

washers and nuts.

6. Join the modules together at the ends by inserting screws up through the

holes in the top of the lower module and into the captivated nuts in the

bottom of the upper module.

The building process continues in the same manner for any remaining modules.

Caption modules are attached directly to their adjoining digit modules and do not use

beam mounting brackets (Refer to Drawing A-194671).

Mechanical Installation 9

Page 16

Page 17

Section 3: Electrical Installation

Electrical installation involves the following procedures:

Providing power to the display and control locations.

Routing signal cable from the control location to the display location.

Connecting power and signal wiring between digit modules.

Installing the address and protocol plugs into each digit module.

Connecting the signal input to the first digit module.

Connecting power to the first digit module.

It may be helpful to open the front panels on the digit modules before mounting them and

installing the address and protocol plugs. This will determine the order in which the digit

module will be installed.

These steps are described in greater detail in the following sections.

3.1 Grounding Indoor Displays

Connect the scoreboard to earth ground. Proper grounding assures reliable equipment

operation and protects the equipment against damaging electrical disturbances and

lightning.

Note: It is the customer’s responsibility to properly ground the 120 V AC outlet.

Failure to ground the 120 V AC outlet connection voids the warranty for the timing

display.

3.2 Connecting Power and Signal, Indoor Displays

Reference Drawings:

Electrical Hookup, Indoor Display, 120 V ............... Drawing A-130661

Electrical Hookup, Indoor Display, 230 V ............... Drawing A-130676

The SW-2000 Series of aquatics/track scoreboards have been designed for easy

access to components, and the power and control signal hookup has been simplified.

Refer to Drawings A-130661 and A-130676 to determine where the power and

signal cable will be brought into the display. Daktronics recommends that

connections begin with the lowest module in the system, on the left side of the

cabinet. If the scoreboard is two or more modules wide, start connections with the

lowest module on the farthest left-hand side.

Front panels can be removed to allow access to the digits, cabling and other

electronic components.

Electrical Installation 11

Page 18

Electrical hookup for both 120 V and 230 V indoor scoreboards consist of a simple,

seven-step process. Begin by opening the left access panel of the module (Refer to

Drawing A-130661):

1. Mount the power/signal plate in the left side of the lowest digit module in

the display. Remove both the 2" knockout and the upper 7/8" knockout from

the left end of the module. Run the power cord out of the module through

the knockout and position the plate inside, on the end. Secure the plate with

two screws, inserting them externally through the pre-drilled holes.

2. Route the cable from the power/signal plate into the driver enclosure and

connect the 12-pin plug to the mating plug.

Note: All the connectors are “keyed”— they can only fit into the jacks one

way.

3. Insert 2'' bushings into the holes between modules.

4. Pull the power/signal cable from the lower module through the 2" hole in

the top of the cabinet up into the next module and connect the 12-pin plug to

the mating connector in the driver enclosure.

5. Repeat the connection process in Step 4 with any other modules in the

system.

6. Connect the power cord to a 120 V AC power outlet, and connect signal to

the 1/4" phone jack in the end of the bottom module.

7. Replace cover and panels. Insert a 2" hole plug in the bottom hole of the

lowest module.

The hookup procedure for a 230 V display is identical; the only difference

between the two electrical systems is the 230 V power cord (Refer to Drawing

A-130676).

3.3 Internal Cable Routing

Reference Drawing:

Internal Cable Routing ........................................... Drawing A-130679

Section 3.1 describes signal and power connections for scoreboard digit modules

arranged vertically. Horizontal, or side-by-side, modules additionally require

installation of a power/signal interconnect cable. Only one interconnect cable is

needed for each installation (Refer to Drawing A-130679).

Connect the modules by running the interconnect cable from the driver of the bottom

left module to the driver of the bottom right module. There are knockouts in the ends

of the modules through which the cable may be run. The cable is connected with

mating 12-pin plugs in each module.

12 Electrical Installation

Page 19

3.4 Grounding Outdoor Displays

Displays MUST be grounded according to the provisions outlined in Article 250 of

the National Electrical Code and according to the specifications in this manual

Daktronics recommends a resistance-to-ground of 10 ohms or less.

The electrical contractor who is performing the electrical installation can verify ground

resistance. Daktronics Sales and Service personnel can also perform this service.

The display system must be connected to an earth electrode installed at the display.

Proper grounding is necessary for reliable equipment operation. It also protects the

equipment from damaging electrical disturbances and lightning. The display must be

properly grounded or the warranty will be void.

The material for an earth-ground electrode differs from region to region and may

vary according to conditions present at the site. Consult the National Electrical Code

and any local electrical codes that may apply. The support structure of the display

cannot be used as an earth-ground electrode. The support is generally embedded in

concrete, and if it is in earth, the steel is usually primed or it corrodes, making it a

poor ground in either case.

3.5 Installing Load Centers, Outdoor Displays

Reference Drawing:

Electrical Hookup, Outdoor Display ....................... Drawing A-129998

Outdoor displays have a fully enclosed load center that brings power and signal to the

scoreboard. The harsher environment and outdoor electrical hookup requirements

mandate the use of this component. The load center is mounted in the cabinet during

display installation. The procedure is as follows:

1. Remove the lower left panels from the lowest digit module in the display,

and remove the nuts from the three screws already installed in the cabinet. If

the load center cover is on, remove it. Position the load center on the back

panel screws, and complete the mounting by tightening the nuts.

2. Route the cable from the load center into the driver enclosure and connect

the 12-pin plug to the mating plug.

3. Insert 2" bushings into the holes between modules.

4. Pull the power/signal cable from the lower module up into the module above

it and connect the cable to the 12-pin plug on its driver.

5. Follow the same procedure for the other modules.

6. Make main power and signal connections in the load center (See the detail

of the unit's interior in the lower right corner of Drawing A-129998).

7. Replace covers and panels.

Electrical Installation 13

Page 20

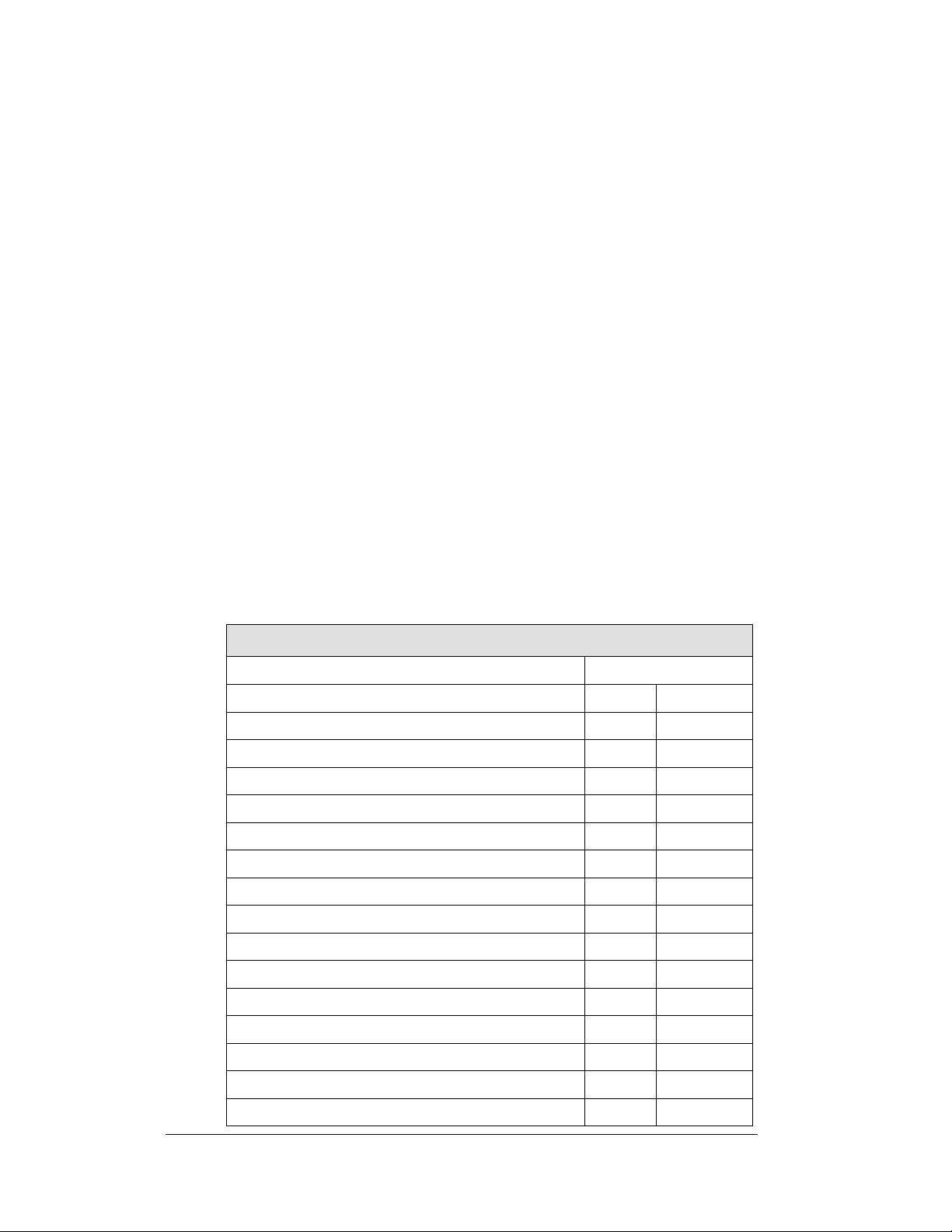

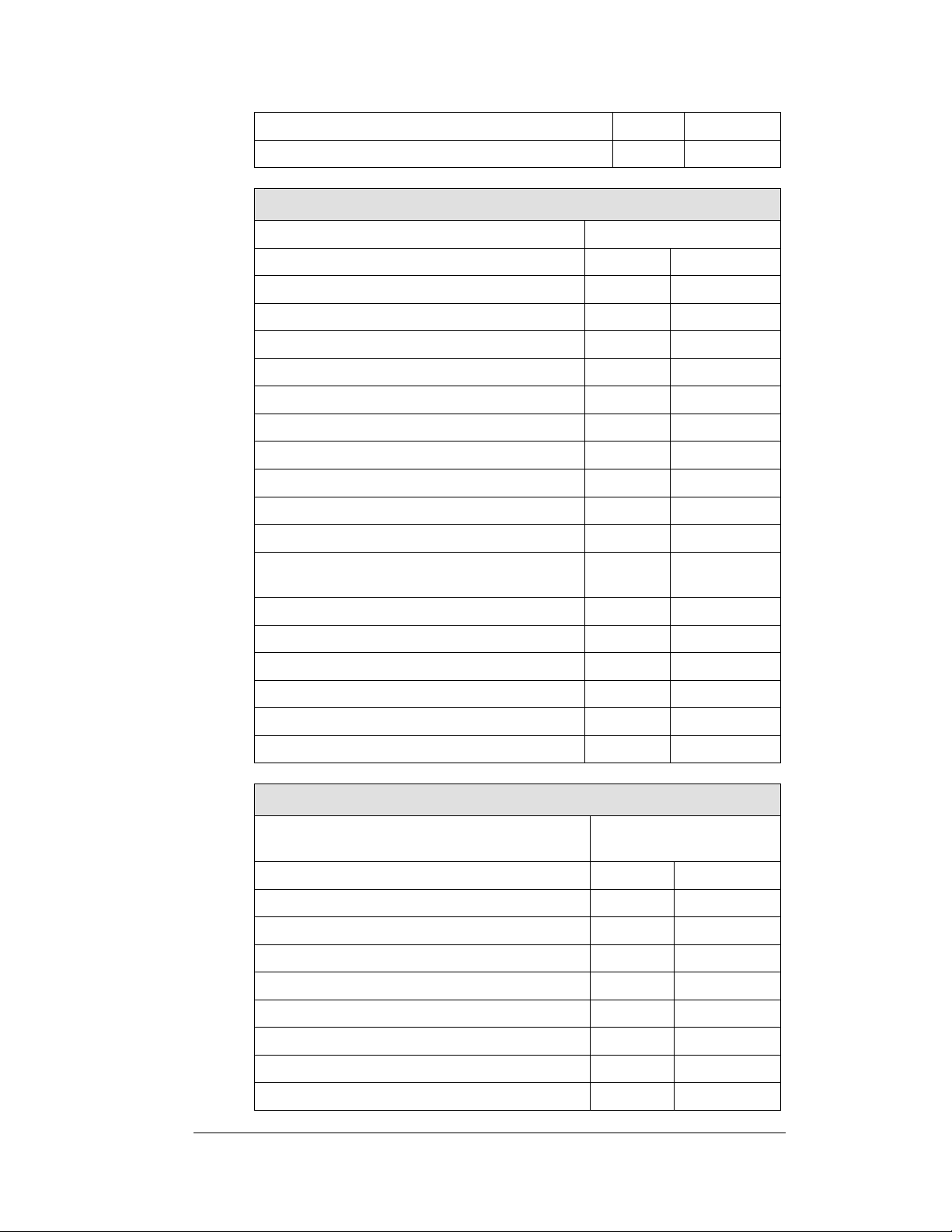

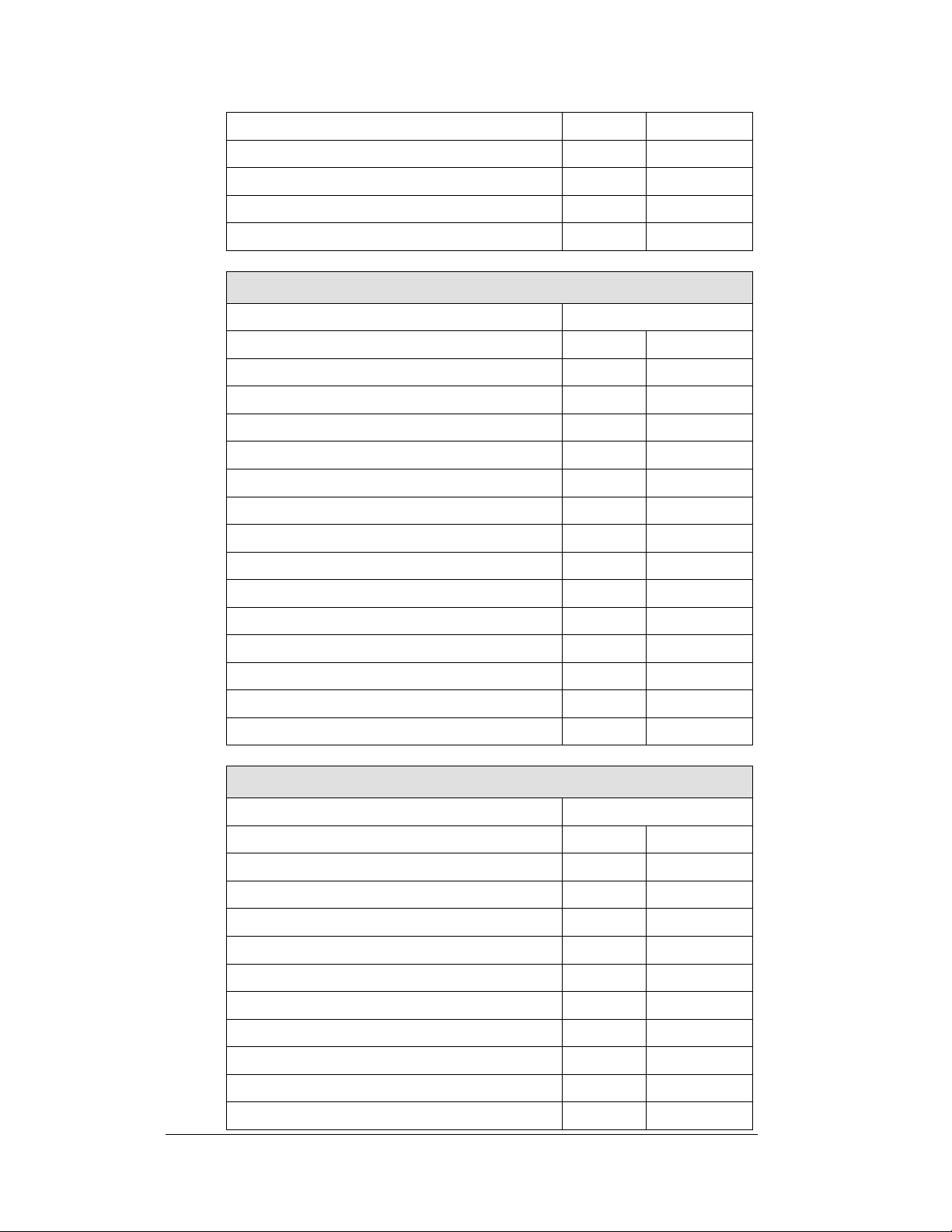

3.6 Setting Driver Addresses and Protocols

Daktronics Omni Sport 1000

Protocol=1

Address

Function

Dec.

Binary

Line 1 or 1 and 2

1

00000001

Line 2 or 2 and 3

2

00000010

Line 3 or 3 and 4

3

00000011

Line 4 or 4 and 5

4

00000100

Line 5 or 5 and 6

5

00000101

Line 6 or 6 and 7

6

00000110

Line 7 or 7 and 8

7

00000111

Line 8 or 8and 9

8

00001000

Line 9 or 9 and 10

9

00001001

Line 10

10

00001010

Event/Heat or Home/Guest, Record Time

11

00001011

N.A

12

00001100

Running Time

13

00001101

N.A

14

00001110

Line 4 MS w/ horn

15

00001111

Reference Drawings:

16 Column LED Driver II Specifications ................ Drawing A-126174

Address Configurations, Timing Displays .............. Drawing B-130318

For the scoreboard to receive signal and function properly, the driver must be set to

the correct address and protocol. This address is set with jumper wires in a 12-pin

plug which mates with jack J19 on the driver. Address and protocol plugs are

supplied in a separate kit for field installation. Plugs are marked with address or

protocol numbers. Select the appropriate plugs and connect them to the jacks on the

driver.

The LED scoreboard can be interfaced to a variety of timers. Identify your timer and

refer to the appropriate address configurations for various timing displays. This

information is also presented in the tables at the end of Section 3. (Note that Protocol

1 is used with all Daktronics Omega and Finish Lynx timing systems, Protocol 2 is

used with Colorado Time System units; one-line displays controlled by Daktronics

OmniSport 1000 or 6000 timers require no protocol or address plug; all displays

controlled by the Daktronics OmniSport 2000 require no protocol. OmniSport 2000

requires an address plug for single line displays.

Address settings, LED Fixed-Digit Aquatics/Track Displays

Multi-line Display Addresses

14 Electrical Installation

Page 21

Line 6 MS w/ horn

16

00010000

Line 8 MS w/ horn

17

00010001

Daktronics Omni Sport 6000

Protocol=1

Address

Function

Dec.

Binary

Line 1 or 1 and 2

1

00000001

Line 2 or 2 and 3

2

00000010

Line 3 or 3 and 4

3

00000011

Line 4 or 4 and 5

4

00000100

Line 5 or 5 and 6

5

00000101

Line 6 or 6 and 7

6

00000110

Line 7 or 7 and 8

7

00000111

Line 8 or 8and 9

8

00001000

Line 9 or 9 and 10

9

00001001

Line 10

10

00001010

Event/Heat or Home/Guest, Lengths, Record

Time

11

00001011

Home/Guest 1/Guest 2/Guest 3

12

00001100

Running Time

13

00001101

N.A

14

00001110

Line 4 MS w/ horn

15

00001111

Line 6 MS w/ horn

16

00010000

Line 8 MS w/ horn

17

00010001

Daktronics Omni Sport 2000

Protocol=Multidrop protocol does not require a

protocol plug

Address

Function

Dec.

Binary

Stand Alone Single Line

40

101000

Line 1 or 1 and 2

41

101001

Line 2 or 2 and 3

42

101010

Line 3 or 3 and 4

43

101011

Line 4 or 4 and 5

44

101100

Line 5 or 5 and 6

45

101101

Line 6 or 6 and 7

46

101110

Line 7 or 7 and 8

47

101111

Electrical Installation 15

Page 22

Line 8 or 8 and 9

48

110000

Line 9 or 9 and 10

49

110001

Line 10

50

110010

Home, Guest 1, Guest 2, Guest 3

31

11111

Event/Heat, Lengths, Record Time

32

100000

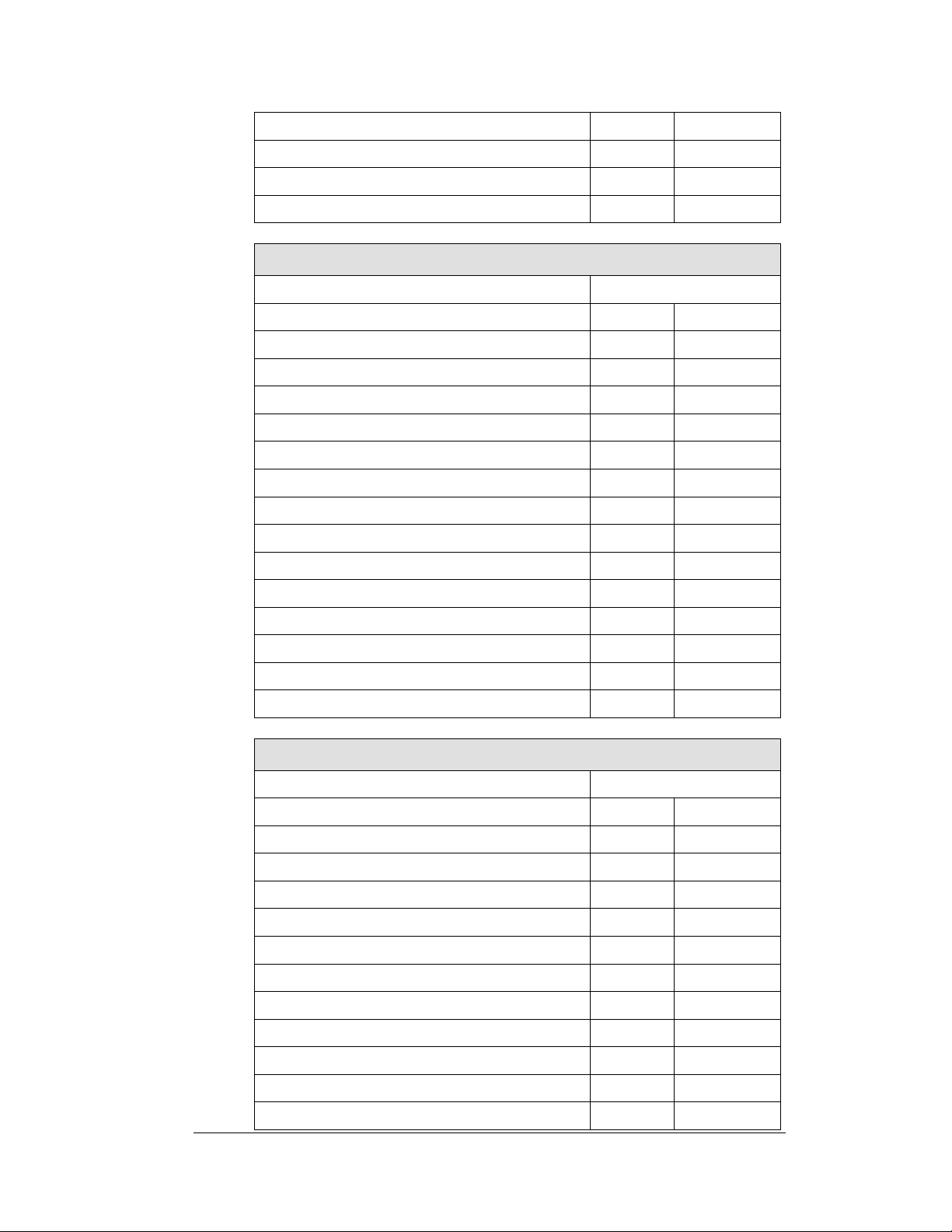

Omega Ares

Protocol=1

Address

Function

Dec.

Binary

1-line Timing Display

1

00000001

Line 1 or 1 and 2

1

00000001

Line 2 or 2 and 3

2

00000010

Line 3 or 3 and 4

3

00000011

Line 4 or 4 and 5

4

00000100

Line 5 or 5 and 6

5

00000101

Line 6 or 6 and 7

6

00000110

Line 7 or 7 and 8

7

00000111

Line 8 or 8and 9

8

00001000

Line 9 or 9 and 10

9

00001001

N.A.

10

00001010

Event/Heat, or Home/Guest, Rec. Time

11

00001011

Home, Guest, Guest, Guest

12

00001100

Running Time

13

00001101

Omega OSM6 or Scan’O’Vision

Protocol=1

Address

Function

Dec.

Binary

1-line Timing Display

1

00000001

Line 1 or 1 and 2

1

00000001

Line 2 or 2 and 3

2

00000010

Line 3 or 3 and 4

3

00000011

Line 4 or 4 and 5

4

00000100

Line 5 or 5 and 6

5

00000101

Line 6 or 6 and 7

6

00000110

Line 7 or 7 and 8

7

00000111

Line 8 or 8and 9

8

00001000

Line 9 or 9 and 10

9

00001001

16 Electrical Installation

Page 23

N.A.

10

00001010

N.A.

11

00001011

N.A.

12

00001100

N.A.

13

00001101

Omega Power Time

Protocol=1

Address

Function

Dec.

Binary

1-line Timing Display

1

00000001

Line 1 or 1 and 2

1

00000001

Line 2 or 2 and 3

2

00000010

Line 3 or 3 and 4

3

00000011

Line 4 or 4 and 5

4

00000100

Line 5 or 5 and 6

5

00000101

Line 6 or 6 and 7

6

00000110

Line 7 or 7 and 8

7

00000111

Line 8

8

00001000

N.A.

9

00001001

N.A.

10

00001010

Event/Heat

11

00001011

N.A.

12

00001100

Running Time

13

00001101

FinishLynx

Protocol=1

Address

Function

Dec.

Binary

1-line Timing Display

1

00000001

Line 1 or 1 and 2

1

00000001

Line 2 or 2 and 3

2

00000010

Line 3 or 3 and 4

3

00000011

Line 4 or 4 and 5

4

00000100

Line 5 or 5 and 6

5

00000101

Line 6 or 6 and 7

6

00000110

Line 7 or 7 and 8

7

00000111

Line 8 or 8 and 9

8

00001000

Line 9 or 9 and 10

9

00001001

N.A.

10

00001010

Electrical Installation 17

Page 24

Event/Heat

11

00001011

N.A.

12

00001100

Running Time

13

00001101

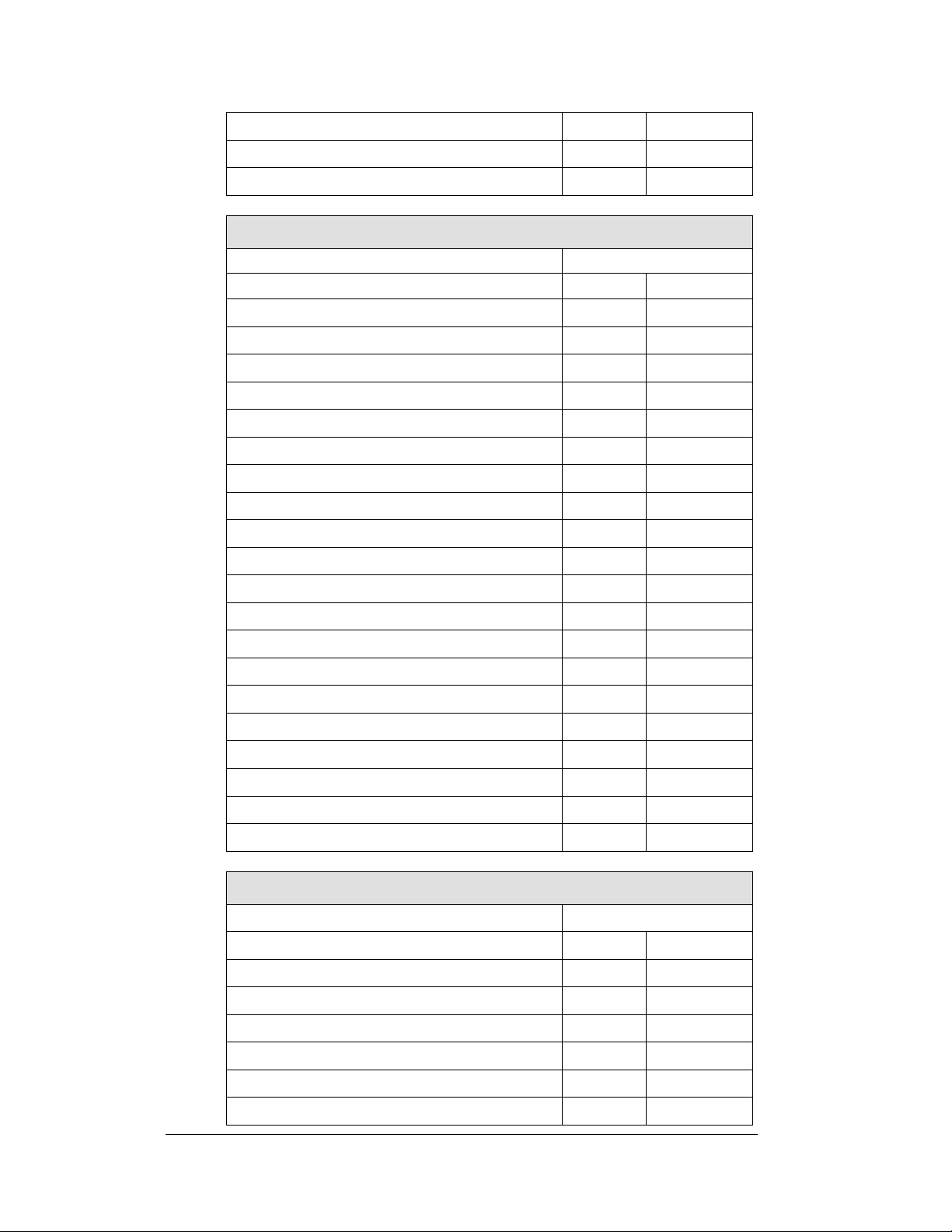

Colorado Timing, 9600 BAUD

Protocol=2

Address

Function

Dec.

Binary

Line 1 or 1 and 2

1

00000001

Line 2 or 2 and 3

2

00000010

Line 3 or 3 and 4

3

00000011

Line 4 or 4 and 5

4

00000100

Line 5 or 5 and 6

5

00000101

Line 6 or 6 and 7

6

00000110

Line 7 or 7 and 8

7

00000111

Line 8 or 8and 9

8

00001000

Line 9 or 9 and 10

9

00001001

Line 10

10

00001010

Lengths, Record Time

11

00001011

Event/Heat

11

00001011

Home, Guest

13

00001101

N.A

14

00001110

1-line timing

15

00001111

N.A.

16

00010000

N.A.

17

00010001

N.A.

18

00010010

N.A.

19

00010011

Home, Guest, Guest, Guest

20

00010100

Colorado Timing, 2400 BAUD

Protocol=2

Address

Function

Dec.

Binary

Line 1 or 1 and 2

33

01000001

Line 2 or 2 and 3

34

01000010

Line 3 or 3 and 4

34

01000011

Line 4 or 4 and 5

35

01000100

Line 5 or 5 and 6

36

01000101

Line 6 or 6 and 7

37

01000110

18 Electrical Installation

Page 25

Line 7 or 7 and 8

38

01000111

Line 8 or 8and 9

39

01001000

Line 9 or 9 and 10

40

01001001

Line 10

41

01001010

Lengths, Record Time

42

01001011

Event/Heat

42

01001011

Home, Guest

44

01001101

N.A

45

01001110

1-line timing

46

01001111

N.A.

47

01010000

N.A.

48

01010001

N.A.

49

01010010

N.A.

50

01010011

Home, Guest, Guest, Guest

51

01010100

One-Line Timing Display Controlled by Daktronics OmniSport 1000, or 6000 Timers

Protocol= 0 (No protocol plug required)

Address= 0 (No protocol plug required)

Auxiliary Scoring Display Modules Controlled By Daktronics All Sport 4000 Series Controller

Protocol= 1

Event/Heat, Lengths, Record Time Address= 11

Home/Guest 1/Guest 2/Guest 3 Address= 12

Electrical Installation 19

Page 26

Page 27

Connector No.

Function

1 through 16

Output to digits and indicators

17

Control signal and power input

18

Control for horn

19

Address

Section 4: Maintenance and

Troubleshooting

IMPORTANT NOTES:

1. Disconnect power before doing any repair or maintenance

work on the display!

2. Allow only qualified service personnel access to internal

display electronics.

3. Disconnect power when the display is not in use.

4.1 Cabinet Specifications

Reference Drawings:

Mechanical Specifications, 2-Line Digit Module ..... Drawing A-194679

Mechanical Specifications, 1-Line Digit Module ..... Drawing A-194673

Mechanical Specifications, Ad Panels ................... Drawing A-194676

Cabinets for the modules in the SW-2000 Series are of all-aluminum construction.

The drawings referenced above, A-194673, A-194679, and A-194676, give exact

dimensions, screw and knockout locations, and other mechanical specifications. The

illustrations include details for the one-line digit module, the two-line digit module,

and for ad panels that may be attached to the display as well.

4.2 LED Driver

Reference Drawing:

16 Column LED Driver II Specifications ................. Drawing A-126174

The task of switching LEDs on and off is performed by the LED driver (Refer to

Drawing A-126174). Each driver has 19 connectors providing power and signal

inputs/outputs to digits and indicators. The function of each of these connectors is as

follows.

Maintenance and Troubleshooting 21

Page 28

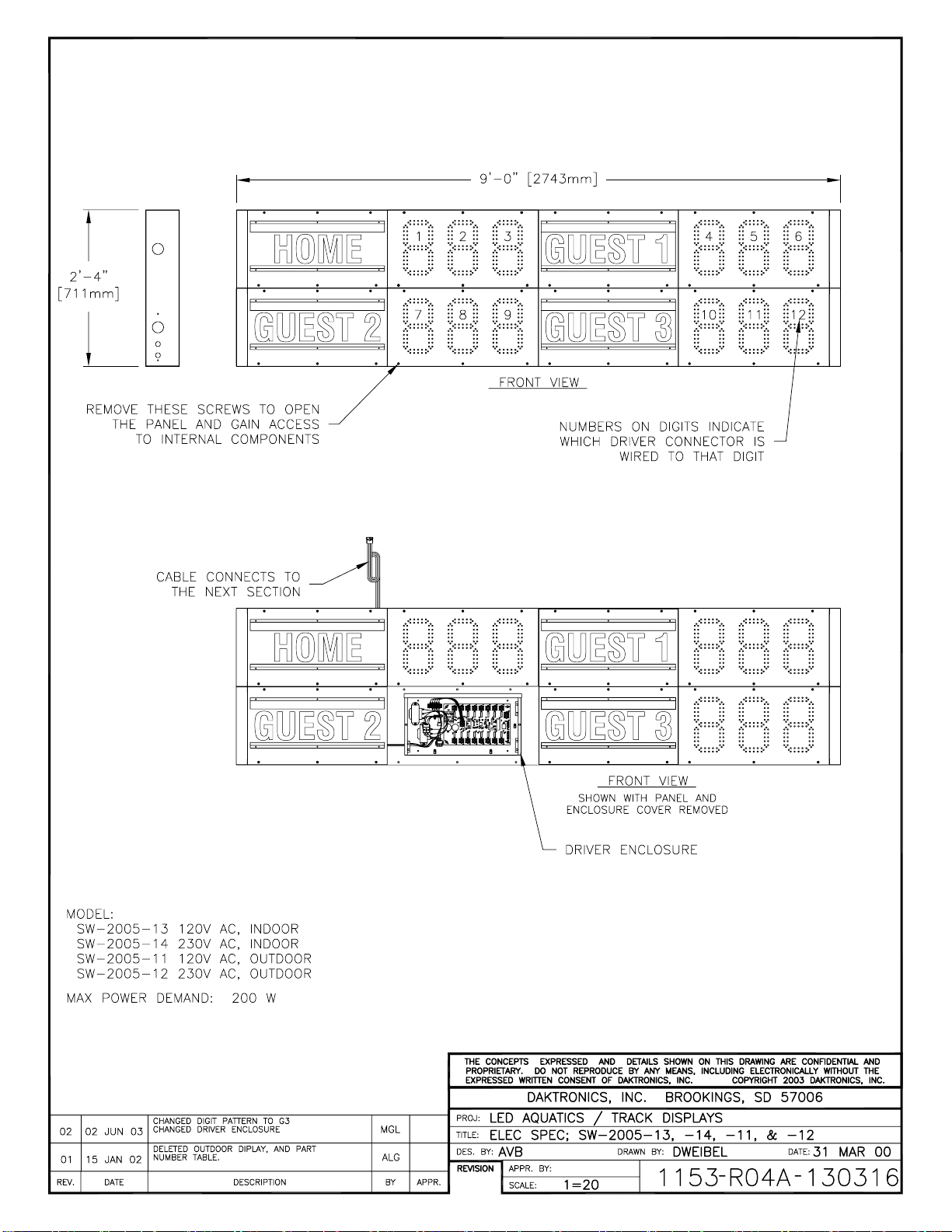

Output connectors 1 through 16 each have nine pins. Pin 7 provides power to the

digit or indicators wired to that connector. The other eight pins provide switching

connections. The electrical specification drawings for each of the models in the SW2000 Series, shown at the beginning of this section, specify the driver connectors

controlling the digits. Numbers on each digit indicate which connector is wired to

that digit. Scoreboard model numbers are shown on the lower left side of each

drawing.

4.3 Segmentation

Reference Drawing:

Digit Service ........................................................... Drawing A-130891

In each digit, certain LEDs always go on and off together. These groupings of LEDs

are referred to as segments. Drawing A-130891 shows which connector pin number

is wired to each digit segment and the wiring color code used throughout the display

(illustrated at the lower left corner of the drawing).

4.4 Component Location and Access

Reference Drawings:

Electrical Hookup, Indoor Display, 120 V .............. Drawing A-130661

Electrical Hookup, Indoor Display, 230 V .............. Drawing A-130676

Digit Service ........................................................... Drawing A-130891

Drawings A-130661, A-130676, and A-130891 show front views of display

modules. The digit circuit board, the platform for the LEDs, is mounted on the front

panel in each section. The panels are easily removed for front access.

The drivers are located on the left side of each module (typically behind the second

panel), and the load center, if present, is immediately to the left of the driver. The

power/signal plate used in indoor scoreboards is usually mounted on the left end of

the module cabinet.

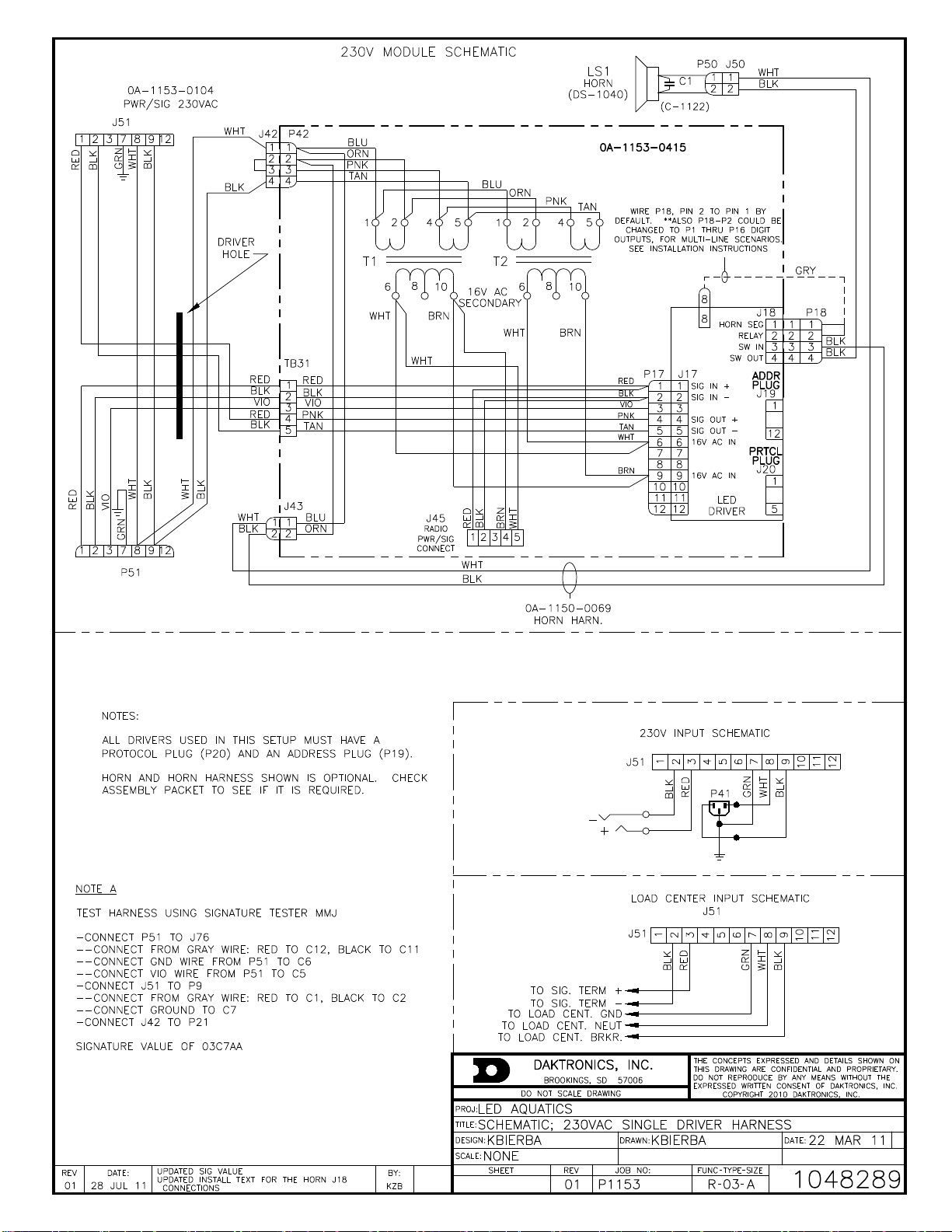

4.5 Schematic

Reference Drawing:

Schematic; 120VAC Single Driver, Harness ....... Drawing A-1048280

Schematic; 230VAC Single Driver, Harness ....... Drawing A-1048289

Drawing A-1048280 is the schematic diagram of the power and signal inputs and all

wiring in 120VAC SW-2000 Series displays. Drawing A-1048289 is the schematic

diagram of the power and signal inputs and all wiring in 230VAC SW-2000 Series

displays.

Disconnect power before servicing the display.

Disconnect power when the display is not in use. Prolonged power-on may shorten

the life of some electronic components.

22 Maintenance and Troubleshooting

Page 29

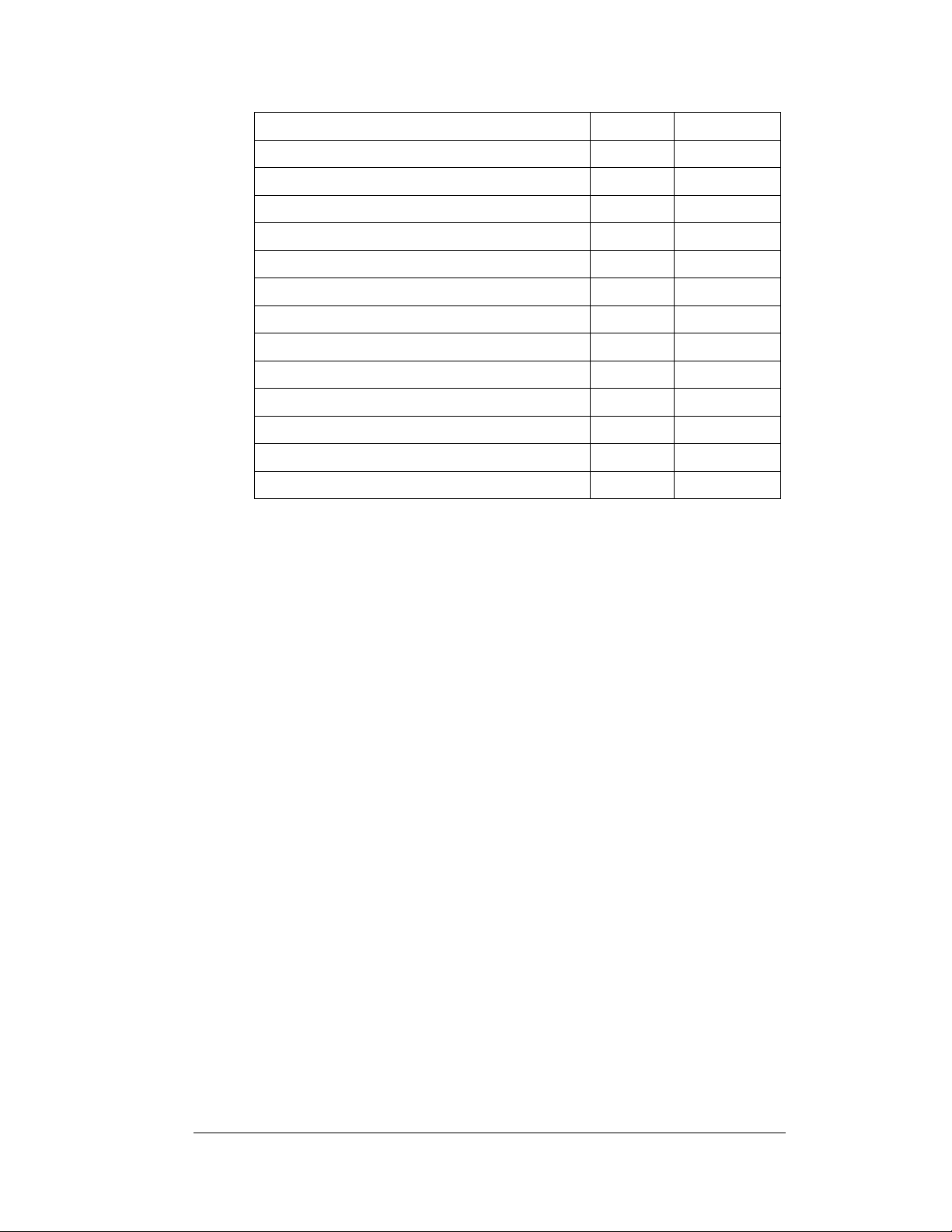

Symptom/Condition

Possible Cause

Scoreboard will not light

Console not connected or poor connection

No power to control console

No power to the scoreboard

Driver fuse blown

Main fuse blown

Garbled display

Internal driver logic malfunction

Control console malfunction

Digit will not light

Black wire to digit broken

Poor contact at driver connection

Driver malfunction

Segment will not light

Broken LED or connection

Driver shift register failure

Broken wire between lamp driver and digit

Poor contact at driver connector

Segment stays lit

Driver shift register failure

Short circuit on digit

Date appears in the wrong

place on the display

Incorrect address settings on drivers

(consult tables and set correct addresses)

Description

Part Number

Load center

0A-1153-0177

Power/signal plate, 120 V

0A-1153-0105

Power/signal plate, 230 V

0A-1153-0106

Address Protocol Plug Set

0A-1153-0187

Horn; 120 V AC 60Hz LS1

0A-1152-0332

4.6 Troubleshooting

This section lists some symptoms and problems that may be encountered with

scoreboard operation. For these symptoms, possible cause and corrective actions are

indicated. This list does not include every possible problem, but it does represent

some of the more common situations that may occur.

4.7 Replacement Parts List

To prevent loss due to theft, Daktronics recommends purchasing a lockable cabinet

to store manuals and replacement or spare parts. Refer to the appropriate

supplementary manual for a complete list of replacement parts.

Maintenance and Troubleshooting 23

Page 30

Cable, 22 AWG, one pair

W-1077

Junction box; phone jack

0A-1009-0038

LED driver

0P-1150-0127

Digit, 10” Red, Outdoor

0P-1192-0265 (prior to January 2013)

0A-1192-5121 (after January 2013)

Digit, 10” Amber, Outdoor

0P-1192-0266 (prior to January 2013)

0A-1192-5221 (after January 2013)

Digit 10”, Red, Indoor

0P-1150-0240 (prior to January 2013)

0A-1192-5122 (after January 2013)

Digit 10”, Amber, Indoor

0P-1150-0241 (prior to January 2013)

0A-1192-5222 (after January 2013)

Transformer, 16 V

T-1066

Signal cable, 10'

W-1340

Signal cable, 20'

W-1236

Signal cable, 30'

W-1238

Signal cable, 50'

W-1237

Signal cable, 100'

W-1381

24 Maintenance and Troubleshooting

Page 31

Appendix A: Reference Drawings

A Drawing Title Drawing Number

Track Scbd. w/ Finish Lynx, in Press Box....................................................... A-104300

Address Table, 1 through 128 ........................................................................ A-115078

Scan’O’Vision LED Driver Address Configuration on 12 Pin. ......................... A-118398

Equipment Layout, 50 M Swim, Course #1, indeck ........................................ B-121329

16 Column LED Driver II Specifications.......................................................... A-126174

Module Model Descriptions, LED Aquatics/Track .......................................... A-129639

Elec Spec: SW-2101-11, -12, -13 & -14 ......................................................... A-129652

Strut Spacing, Horizontal Wall Mount. ............................................................ A-129905

End Bracket Attach, Horizontal Wall ............................................................... A-129906

Horizontal Wall Mount, Final Steps. ................................................................ A-129907

Elec Spec: SW-2001-11, -12, -13 & -14 ......................................................... A-129984

Electrical Hookup, Display .............................................................................. A-129998

Elec Spec: SW-2003-11, -12, -13 & -14 ......................................................... A-130053

Elec Spec: SW-2004-11, -12, -13 & -14 ......................................................... A-130054

Model Configurations, Swim/Track Timing ..................................................... A-130101

Model Configurations, Aquatics Multi-sport .................................................... A-130102

Elec Spec: SW-2006-11, -12, -13 & -14 ......................................................... A-130284

Elec Spec: SW-2007-11, -12, -13 & -14 ......................................................... A-130286

Elec Spec: SW-2008-11, -12, -13 & -14 ......................................................... A-130309

Elec Spec: SW-2002-11, -12, -13 & -14 ......................................................... A-130312

Elec Spec: SW-2005-11, -12, -13 & -14 ......................................................... A-130316

Address Configurations, Timing Displays ....................................................... B-130318

Caption Layout, 6-Lane Multisport Systems. .................................................. A-130319

Caption Layout, 8-Lane Multisport Systems. .................................................. A-130321

Corner Mount .................................................................................................. A-130508

Vertical Wall Mounting .................................................................................... A-130545

Electrical Hookup, Indoor Display, 120 V ....................................................... A-130661

Electrical Hookup, Indoor Display, 230 V ....................................................... A-130676

Internal Cable Routing .................................................................................... A-130679

Caption Layout, 10-Lane Multisport Systems. ................................................ A-130801

Caption Module Detail..................................................................................... A-130840

Digit Service .................................................................................................... A-130891

Riser Diagram with OmniSport 6000 .............................................................. A-130977

Riser Diagram with OmniSport 1000 .............................................................. A-130978

Riser Diagram with CTS Timer ....................................................................... B-130979

Riser Diagram with Omega Timer .................................................................. A-131037

Elec Spec: SW-2009-11, -12, -13 & -14 ......................................................... A-131039

Riser Diagram with All Sport 4000 .................................................................. A-131226

System Riser; Track Scbd w/ Omni 2000, in field .......................................... A-186548

Beam Mounting Procedure. ............................................................................ A-194664

Beam Mounting, Side View ............................................................................. A-194671

Mechanical Specifications, 1-Line Digit Module ............................................. A-194673

Beam Mounting, Top View .............................................................................. A-194674

Mechanical Specifications, Ad Panels ............................................................ A-194676

Beam Mounting Rear, Vertical Display ........................................................... A-194677

Beam Mounting, Rear, Horizontal Display ...................................................... A-194678

Reference Drawings 25

Page 32

Mechanical Specifications, 2-Line Digit Module .............................................. A-194679

Electrical Hookup, Radio Hookup ................................................................... A-305509

Schematic; 120VAC Single Driver, Harness ................................................. A-1048280

Schematic; 230VAC Single Driver, Harness ................................................. A-1048289

26 Reference Drawings

Page 33

Page 34

Page 35

Page 36

%+

83'$7('3$57180%(563(55('/,1(6

'$7(5(9 %<

)(% --/

'$.7521,&6,1&

(48,30(17/$<28706:,0&2856(,1'(&.

-:$51(

121(

6+((7 -2%125(9

83'$7('%2$5'(5$1'7,7/(%/2&.

'5$:1 '$7(

+%21(5 6(3

3 5

7+(&21&(376(;35(66('$1''(7$,/66+2:1217+,6

'5$:,1*$5(&21),'(17,$/$1'35235,(7$5<'2127

5(352'8&(%<$1<0($16:,7+2877+((;35(66('

:5,77(1&216(172)'$.7521,&6,1&

&23<5,*+7'$.7521,&6,1&

%

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

Page 48

Page 49

Page 50

Page 51

Page 52

Page 53

Page 54

Page 55

Page 56

Page 57

Page 58

Page 59

Page 60

Page 61

Page 62

Page 63

Page 64

Page 65

Page 66

Page 67

%+

&767,0(5:,5(':,7+'$.7521,&66,*1$/&$%/(&767,0(5:,5('86,1*&2/25$'26,*1$/&$%/(

$

$

(;,67,1*

&2/25$'2-%2;

(;,67,1*&2/25$'2

0212-$&.

-%2;

:'$.7521,&6

67(527267(52&$%/(

'$.7521,&6

,1'225',63/$<

9$&259$&9$&259$&

'$.7521,&6

,1'225',63/$<

$

:'$.7521,&6

67(527267(52&$%/(

$

'$.7521,&6

287'225',63/$<

6,*1$/685*(&$5'

6,*1$/,1

'$.7521,&6

287'225',63/$<

6,*1$/685*(&$5'

6,*1$/,1

25

$

(;,67,1*

&2/25$'2-%2;

(;,67,1*&2/25$'2

0212720212&$%/(

5(3/$&((;,67,1*&2/25$'2

0212-$&.:,7+'$.7521,&6

-%2;

$67(5(2-%2;

:,5('723/8*,172'$.7521,&6

-%2;)25),;('',*,76&%'

$

$'$.7521,&6

67(527267(5(2

&$%/(

',63/$<66:,00,1*,1)221/<

121

&767,0(5:,//12723(5$7(''',*,76

2108/7,63257/,1(,1',9,1*02'(

$''5(66('&255(&7/<,7:,//6281'

7+(+251)25:$7(532/25()(572

7+(',63/$<0$18$/)25$''5(66,1*

:,5('723/8*,172&767,0(5

83'$7('6,*1$/&211(&7,21)5207,0(5726&%'

'$7(5(9 %<

129 &0(

/('$48$7,&66&25(%2$5'

5,6(5',$*5$0:,7+&767,0(5

121(

$''('7:2',))(5(170(7+2'62)&211(&7,21

'$.7521,&6,1&

$9%

6+((7 -2%125(9

7+(&21&(376(;35(66('$1''(7$,/66+2:1217+,6

'5$:,1*$5(&21),'(17,$/$1'35235,(7$5<'2127

5(352'8&(%<$1<0($16:,7+2877+((;35(66('

:5,77(1&216(172)'$.7521,&6,1&

&23<5,*+7'$.7521,&6,1&

'5$:1 '$7(

':(,%(/ $35

3 5

$

Page 68

Page 69

Page 70

Page 71

STANDS

W-1238 (30')

0A-1056-0156 BUTTON W/

12' TYPICAL @ 8

0A-1240-0010 BUTTON INTERFACE

W/ 20' CORD

OMNISPORT

J13 POWER

J15 FAR

J14 NEAR

J12 START

J11 FAR

J10 NEAR

J9-S-SWITCH

J8-M-SWITCH

J7-S-INPUT

J6-RESULTS

J4-E-PORT

J3-SCBD

J2-SCBD

2000E

LL-2573 TRACK

J5-RTD

0A-1091-0227,

SCBD J-BOX

TRACK SYSTEM RISER DIAGRAM

TRACK SCBD WITH

OMNISPORT 2000E, TRACK SIDE

A

A

TRACK EQUIPMENT BOM:

0A-1240-0082 OMNISPORT 2000E (TRACK TIMER) @ 1

W-1238 30' SIGNAL CABLE @ 1

0A-1091-0227 TRACK SIDE J-BOX @ 1

0A-1240-0010 BUTTON INTERFACE @ 1

0A-1056-0156 12' PUSH BUTTON @ 9

-IF MORE THAN 8 LANES ARE REQUIRED, OR MORE

THAN 1 BUTTON PER LANE, REPLACE 0A-1240-0010

WITH 0A-1240-0016 AND ORDER THE NUMBER OF

BUTTONS NEEDED.

SCOREBOARD SIGNAL CABLE OPTIONS:

- W-1234, 2 PAIR SIGNAL CABLE.

CONDUIT REQUIRED.

LAPTOP COMPUTER

BY

COMPUTER

HYTEK

PRINTER

NETWORKUSB

COMM1*

OTHERS

PRESS BOX

AH

OMNI SPORT 2000E TIMER

SYSTEM RISER: TRACK SCBD /W OMNI 2K- TRACK SIDE

MMILLER 08 APR 03

P1240 R

01 A

1=1

MMILLER

186548

06

01 13 MAY 03 SAL

ADDED TYPICAL FOR ALL CABLE

REQUIREMENTS IN NOTE

02 10 FEB 04 MWM

UPDATED TITLE BLOCK AND DRAWING TEXT.

03 28 DEC 05 SAL

DELETED START CABLE AND START

EQUIPMENT OPTIONS

04 15 SEPT 09 CME

ADDED RADIO TO HYTEK OPTION

05 18 APR 12 KZB

UPDATED CABLES FROM RADIOS

0A-1240-0065

CONNEXLINK PRO

900MHZ

W-1267

**RADIO TO HYTEK OPTION**

W-2060

**RADIO TO HYTEK OPTION**

*A-2221

USB/SERIAL

ADAPTER

W-1267 - 9 PIN DB MALE TO FEMALE

STRAIGHT THROUGH SERIAL CABLE

FEM

W-2060 - 9 PIN DB MALE TO MALE

NULL MODEM SERIAL CABLE

0A-1240-0065

CONNEXLINK PRO

900MHZ

FEM

06 14 FEB 14 SMB

UPDATED HYTEK RADIO EQUIPMENT.

0A-1240-0082

OMNISPORT 2000 WITH E-NET

Page 72

Page 73

Page 74

Page 75

Page 76

Page 77

Page 78

Page 79

Page 80

4424

LL-2567

POWER

RADIO IN RANGE

DATA OUT

DAKTRONICS

WIRELESS RECEIVER

HORN

2

3

4

1

Page 81

Page 82

Page 83

Appendix B: Daktronics Warranty and

Limitation of Liability

Daktronics Warranty and Limitation of Liability 27

Page 84

Page 85

DAKTRONICS WARRANTY & LIMITATION OF LIABILITY

This Warranty and Limitation of Liability (the “Warranty”) sets forth the warranty provided by Daktronics with respect to the Equipment. By accepting delivery of the

Equipment, Purchaser agrees to be bound by and accept these terms and conditions. Unless otherwise defined herein, all terms within the Warranty shall have the

same meaning and definition as provided elsewhere in the Agreement.

DAKTRONICS WILL ONLY BE OBLIGATED TO HONOR THE WARRANTY SET FORTH IN THESE TERMS AND CONDITIONS UPON RECEIPT OF FULL PAYMENT FOR THE

EQUIPMENT.

1. Warranty Coverage

2. Exclusion from Warranty Coverage

A. Daktronics warrants to the original end-user that the Equipment will be free from Defects (as defined below) in materials and

workmanship for a period of one (1) year (the “Warranty Period”). The Warranty Period shall commence on the earlier of: (i) four weeks from the date

that the Equipment leaves Daktronics’ facility; or (ii) Substantial Completion as defined herein. The Warranty Period shall expire on the first anniversary

of the commencement date.

“Substantial Completion” means the operational availability of the Equipment to the Purchaser in accordance with the Equipment’s specifications,

without regard to punch-list items, or other non-substantial items which do not affect the operation of the Equipment.

B. Daktronics’ obligation under this Warranty is limited to, at Daktronics’ option, replacing or repairing, any Equipment or part thereof that is found by

Daktronics not to conform to the Equipment’s specifications. Unless otherwise directed by Daktronics, any defective part or component shall be

returned to Daktronics for repair or replacement. This Warranty does not include on-site labor charges to remove or install these components.

Daktronics may, at its option, provide on-site warranty service. Daktronics shall have a reasonable period of time to make such replacements or repairs

and all labor associated therewith shall be performed during regular working hours. Regular working hours are Monday through Friday between 8:00

a.m. and 5:00 p.m. at the location where labor is performed, excluding any holidays observed by either Purchaser or Daktronics.

C. Daktronics shall pay ground transportation charges for the return of any defective component of the Equipment. All such items shall be shipped by

Purchaser DDP Daktronics; designated facility. If returned Equipment is repaired or replaced under the terms of this warranty, Daktronics will prepay

ground transportation charges back to Purchaser and shall ship such items DDP Purchaser’s designated facility; otherwise, Purchaser shall pay

transportation charges to return the Equipment back to the Purchaser and such Equipment shall be shipped Ex Works Daktronics designated facility. All

returns must be pre-approved by Daktronics before shipment. Daktronics shall not be obligated to pay freight for any unapproved return. Purchaser

shall pay any upgraded or expedited transportation charges.

D. Any replacement parts or Equipment will be new or serviceably used, comparable in function and performance to the original part or Equipment, and

warranted for the remainder of the Warranty Period. Purchasing additional parts or Equipment from the Seller does not extend the Warranty Period.

E. Defects shall be defined as follows. With regard to the Equipment (excepting LEDs), a “Defect” shall refer to a material variance from the design

specifications that prohibit the Equipment from operating for its intended use. With respect to LEDs, “Defects” are defined as LED pixels that cease to

emit light. The limited warranty provided by Daktronics does not impose any duty or liability upon Daktronics for partial LED pixel degradation nor does

the limited warranty provide for the replacement or installation of communication methods including but not limited to, wire, fiber optic cable, conduit,

trenching, or for the purpose of overcoming local site interference radio equipment substitutions.

EXCEPT AS OTHERWISE EXPRESSLY SET FORTH IN THIS WARRANTY, TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, DAKTRONICS DISCLAIMS

ANY AND ALL OTHER PROMISES, REPRESENTATIONS AND WARRANTIES APPLICABLE TO THE EQUIPMENT AND REPLACES ALL OTHER WARRANTIES OR

CONDITIONS, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO ANY IMPLIED WARRANTIES OR CONDITIONS OF MERCHANTABILITY, FITNESS FOR A

PARTICULAR PURPOSE, ACCURACTY OR QUALITY OF DATA. NO ORAL OR WRITTEN INFORMATION, OR ADVICE GIVEN BY THE COMPANY, ITS AGENTS OR

EMPLOYEES, SHALL CREATE A WARRANTY OR IN ANY WAY INCREASE THE SCOPE OF THIS LIMITED WARRANTY.

THIS LIMITED WARRANTY IS NOT TRANSFERABLE.

The limited warranty provided by Daktronics does not impose any duty or liability upon Daktronics for:

A. Any damage occurring, at any time, during shipment of Equipment unless otherwise provided for in the Agreement. When returning Equipment to

Daktronics for repair or replacement, Purchaser assumes all risk of loss or damage, and agrees to use any shipping containers that might be provided by

Daktronics and to ship the Equipment in the manner prescribed by Daktronics;

B. Any damage caused by the improper installation, adjustment, repair or service of the Equipment by anyone other than personnel of Daktronics or its

authorized repair agents;

C. Damage caused by the failure to provide a continuously suitable environment, including, but not limited to: (i) neglect or misuse, (ii) a failure or

sudden surge of electrical power, (iii) improper air conditioning, humidity control, or other environmental conditions outside of the Equipment’s

technical specifications such as extreme temperatures, corrosives and metallic pollutants, or (iv) any other cause other than ordinary use;

D. Damage caused by fire, flood, earthquake, water, wind, lightning or other natural disaster, strike, inability to obtain materials or utilities, war,

terrorism, civil disturbance or any other cause beyond Daktronics’ reasonable control;

Copyright © Daktronics, Inc. SL-02374 Rev 12 27Jun14 Page 1 of 2

Page 86

DAKTRONICS WARRANTY & LIMITATION OF LIABILITY

E. Failure to adjust, repair or replace any item of Equipment if it would be impractical for Daktronics personnel to do so because of connection of the

Equipment by mechanical or electrical means to another device not supplied by Daktronics, or the existence of general environmental conditions at the

site that pose a danger to Daktronics personnel;

3. Limitation of Liability

4. Assignment of Rights

5. Governing Law

6. Availability of Extended Service Agreement

F. Any statements made about the product by any salesperson, dealer, distributor or agent, unless such statements are in a written document signed by

an officer of Daktronics. Such statements as are not included in a signed writing do not constitute warranties, shall not be relied upon by Purchaser and

are not part of the contract of sale;

G. Any damage arising from the use of Daktronics products in any application other than the commercial and industrial applications for which they are

intended, unless, upon request, such use is specifically approved in writing by Daktronics;

H. Any performance of preventive maintenance;

J. Third-party systems and other ancillary equipment including without limitation front-end video control systems, audio systems, video processors and

players, HVAC equipment, batteries and LCD screens;

K. Incorporation of accessories, attachments, software or other devices not furnished by Daktronics; or

L. Paint or refinishing the Equipment or furnishing material for this purpose.

Daktronics shall be under no obligation to furnish continued service under this Warranty if alterations are made to the Equipment without the prior

written approval of Daktronics.

It is specifically agreed that the price of the Equipment is based upon the following limitation of liability. In no event shall Daktronics (including its

subsidiaries, affiliates, officers, directors, employees, or agents) be liable for any special, consequential, incidental or exemplary damages arising out of or

in any way connected with the Equipment or otherwise, including but not limited to damages for lost profits, cost of substitute or replacement

equipment, down time, lost data, injury to property or any damages or sums paid by Purchaser to third parties, even if Daktronics has been advised of

the possibility of such damages. The foregoing limitation of liability shall apply whether any claim is based upon principles of contract, tort or statutory

duty, principles of indemnity or contribution, or otherwise.

In no event shall Daktronics be liable to Purchaser or any other party for loss, damage, or injury of any kind or nature arising out of or in connection with

this Warranty in excess of the purchase price of the Equipment actually delivered to and paid for by the Purchaser. The Purchaser’s remedy in any

dispute under this Warranty shall be ultimately limited to the Purchase Price of the Equipment to the extent the Purchase Price has been paid.

The Warranty contained herein extends only to the original end-user (which may be the Purchaser) of the Equipment and no attempt to extend the

Warranty to any subsequent user-transferee of the Equipment shall be valid or enforceable without the express written consent of Daktronics.

The rights and obligations of the parties under this warranty shall not be governed by the provisions of the United Nations Convention on Contracts for

the International Sales of Goods of 1980. Both parties consent to the application of the laws of the State of South Dakota to govern, interpret, and

enforce all of Purchaser and Daktronics rights, duties, and obligations arising from, or relating in any manner to, the subject matter of this Warranty,

without regard to conflict of law principles.

For Purchaser’s protection, in addition to that afforded by the warranties set forth herein, Purchaser may purchase extended warranty services to cover

the Equipment. The Extended Service Agreement, available from Daktronics, provides for electronic parts repair and/or on-site labor for an extended

period from the date of expiration of this warranty. Alternatively, an Extended Service Agreement may be purchased in conjunction with this warranty

for extended additional services. For further information, contact Daktronics Customer Service at 1-800-DAKTRONics (1-800-325-8766).

Copyright © Daktronics, Inc. SL-02374 Rev 12 27Jun14 Page 2 of 2

Loading...

Loading...