Page 1

Auto Racing Display

Model CH-1318V

Installation & Service Manual

ED-6041

ED-6041

Project#1081

Rev. 5 - 31 July 1998

Copyright © 1991 Daktronics, Inc.

All rights reserved. While every precaution

has been taken in the preparation of this

manual, the publisher assumes no

responsibility for errors or omissions. No part

of this book covered by the copyrights

hereon may be reproduced or copied in any

form or by any means - graphic, electronic,

or mechanical, including photocopying,

taping, or information storage and retrieval

systems - without written permission of the

publisher.

DAKTRONICS, INC.

Setting New Standards Worldwide

P.O. Box 5128 331 32nd Ave. Brookings, SD 57006

Phone (605)697-4400 or (800) 843-9879 Fax 697-4444

Page 2

Page 3

Table of Contents

1. Introduction .............................................................................................................1-1

1.1 How to Use this Manual.............................................................................................1-1

1.2 Display Overview.......................................................................................................1-1

2. Installation ...............................................................................................................2-1

2.1 General System...........................................................................................................2-1

2.2 Beam and Footing Selection.......................................................................................2-1

2.3 Display Mounting.......................................................................................................2-2

2.4 Electrical Installation..................................................................................................2-2

2.4.1 Control Signal Cable.....................................................................................2-2

2.4.2 Power Wiring ................................................................................................2-3

3. Maintenance & Troubleshooting............................................................................3-1

3.1 Lamp Replacement.....................................................................................................3-1

3.2 Lamp Driver...............................................................................................................3-1

3.3 Digit Segmentation.....................................................................................................3-2

3.4 Schematic ...................................................................................................................3-2

3.5 Troubleshooting .........................................................................................................3-2

3.6 Replacement Parts......................................................................................................3-3

3.7 Unit Exchange/Replacement Procedure.....................................................................3-3

Table of Contents i

Page 4

Page 5

Section 1 : Introduction

1.1 How to Use this Manual

This manual explains the installation and the maintenance of the display system. For

questions regarding the safety, installation, operation or service of this system, please refer to

the telephone numbers listed on the cover page of this manual.

Important Safeguards:

1. Read and understand these instructions before installing.

2. Do not drop the control console or allow it to get wet.

3. Be sure the display is properly grounded with a ground rod at the display location.

4. Disconnect power to the display when it is not in use.

5. Disconnect power when servicing the display.

6. Do not modify the display structure or attach any panels or coverings to the

display without the written consent of Daktronics, Inc.

The box below illustrates Daktronics drawing numbering system. The drawing number

“7087-P08A-69945” is how Daktronics identifies individual drawings. This number is

located in the lower-right corner of the drawing. This manual refers to drawings by listing the

last set of digits and the letter preceding them. In the example below, the drawing would be

referred to as Drawing A-69945. Referenced drawings are inserted at the end of the first

section which references them.

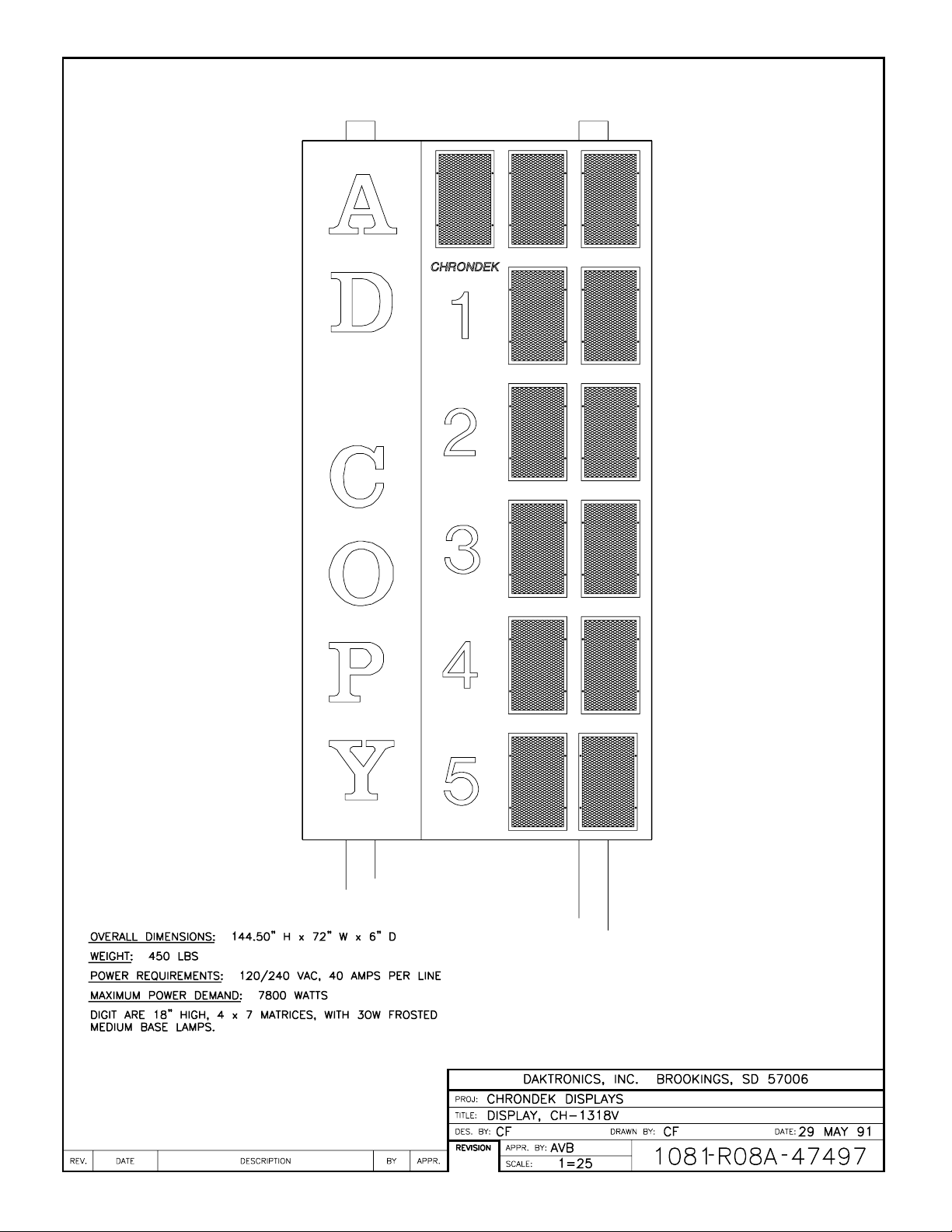

1.2 Display Overview

Reference Drawing: Display, CH-1318V........................................Drawing A-47497

Drawing A-47497 shows a Daktronics CH-1318V display. The CH-1318V display along

with the use of the Daktronics CHTS-300 timing console will display the lap number and the

first five car positions on the display.

Introduction 1-1

Page 6

Page 7

Section 2 : Installation

2.1 General System

Reference Drawings: Pwr/Sig Entrance, 1 Driver Display .............Drawing A-46755

Color Code, 25-Pin J-Box ...........................Drawing A-47207

System Layout, CH-1318V..........................Drawing A-47498

Footing & Beam, CH-1318V........................Drawing A-47512

Display Mounting, CH-1318V......................Drawing A-47517

Electrical Installation, CH-1318V ................Drawing A-47519

Component Locations, CH-1318V ..............Draw ing A-47520

Refer to Drawing A-47498 for the general system layout.

The general procedure for installing the CH-1318V display is as follows:

1. Select beam and footing recommendations from the table located below.

2. Dig the footing holes and install beams and footings.

3. Route power and signal cables to the display and control locations.

4. Mount the displays to the beams as described in Section 2.3 and Drawings A-47512 and

A-47517.

5. Route power and signal wires into the displays as described in Section 2.4 and Drawings

A-47519, A-47520, A-46755 and A-47207.

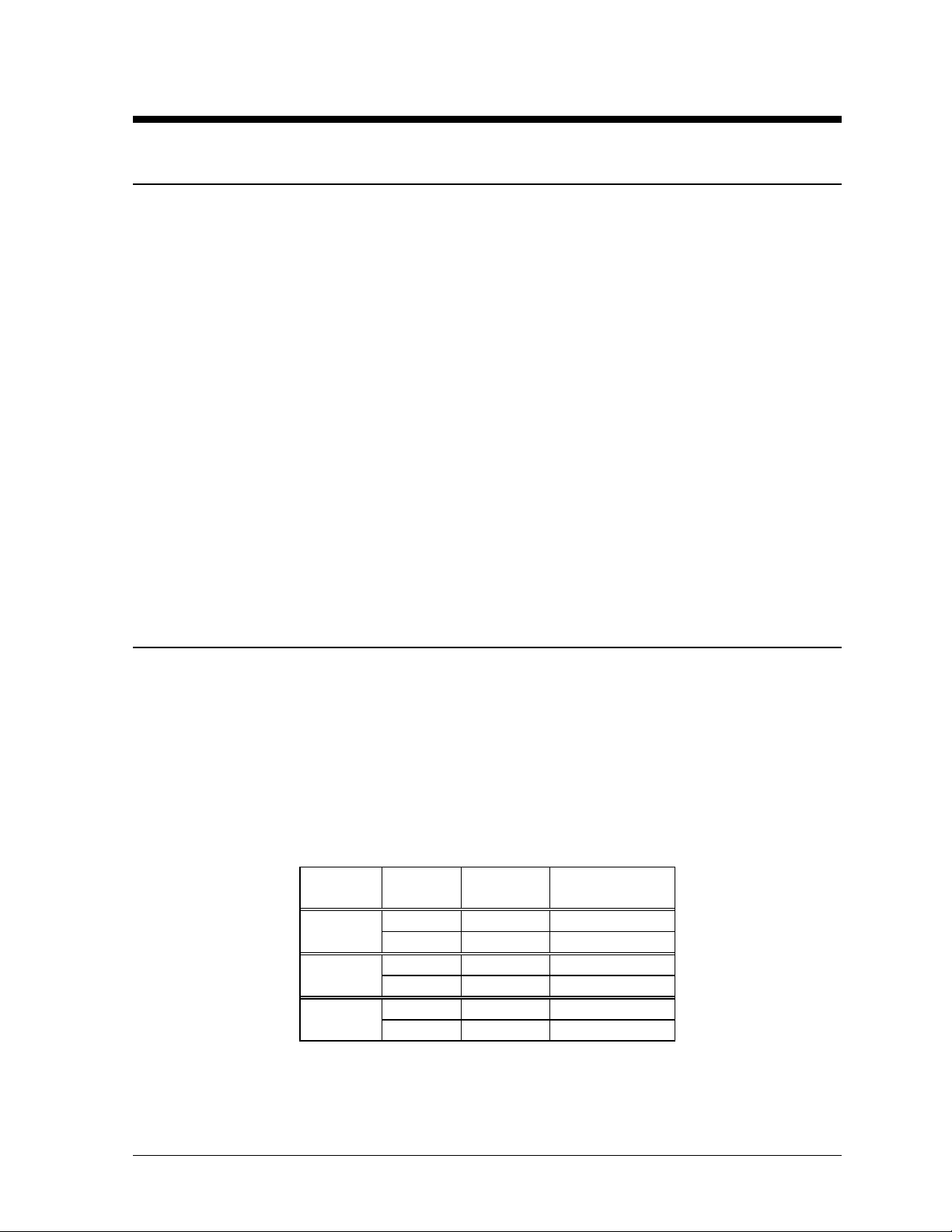

2.2 Beam and Footing Selection

Reference Drawing: Footing & Beam, CH-1318V..........................Drawing A-47512

The table below contains recommendations for W-shape beams and footings to support the

display as shown on Drawing A-47512. The first column is wind velocity in miles per hour.

The distance in the second column is from the ground to the bottom of the display. The

choice from these columns depends upon the display location.

The beams listed below are beams which provide maximum wind load strength for the weight

and cost of the beams.

Wind

Speed

70 mph 10 W8 x 15 4 ¾ ft x 3 ft

15 W6 x 20 5 ½ ft x 3 ft

80 mph 10 W8 x 15 5 ½ ft x 3 ft

15 W8 x 20 6 ¾ ft x 3 ft

90 mph 10 W8 x 17 6 ¼ ft x 3 ft

15 W8 x 24 7 ft x 3 ft

The calculations for footing diameters and depths are based on the assumption that footings

are in undisturbed soils, not fill soils. Lateral bearing capacity of 300 psf per foot of depth in

natural grade was used to derive these figures.

Height

(ft)

Beam

Section

Footing

Depth x Dia.

Installation 2-1

Page 8

The footings recommendations are based on the allowable soil bearing pressure of 3000 psf

vertically and 300 psf/ft of depth horizontally. However, these recommendations are

suggestions only and soil bearing pressure at the site must be determined by a sample test

prior to specifying the actual footings. Be sure that the installation complies with local codes

and is suitable for particular soil and wind conditions. Daktronics assumes no responsibility

for displays installed by others. Daktronics

used for beams, and that 28-day (strength 3000 psi) concrete be used for footings.

A note about beam nomenclature: For a typical beam, W8x24 for example, “W” stands for

“Wide-Flange Beam”. The first number (8) is the approximate front to rear dimension of the

beam in inches. The second number (24) is the weight per foot in pounds. This numbering is

a standard in the steel industry. Widths are from 6.00 to 8.125 inches in the chart above.

Note: Recommendations for a single rectangular structural steel tube and footing to support

the display as shown in Drawing A-47512 must be determined by a qualified structural

engineer using data from a soil sample test at the site.

2.3 Display Mounting

Reference Drawings: Footing & Beam, CH-1318V........................Drawing A-47512

Display Mounting, CH-1318V......................Drawing A-47517

Drawings A-47512 and A-47517 show the typical mounting for the display.

Note: The bolts that secure the display to the beam(s) do not go through the beam(s), but run

along both sides of the beam, clamping the display to the beam(s).

A mounting kit consisting of mounting angles and ½” hardware are provided to mount the

display.

1. Position the display against the mounting beam(s) as shown.

2. Secure the bottom of the display to the beam(s).

3. Secure the top of the display and then the middle of the display. Once mounting angles

are attached, the display may be slid up or down to the desired height.

4. Tighten all bolts once the display is positioned as desired.

2.4 Electrical Installation

2.4.1 Control Signal Cable

Reference Drawings: Pwr/Sig Entrance, 1 Driver Display...Drawing A-46755

Color Code, 25-Pin J-Box.................Drawing A-47207

Component Locations, CH-1318V....Drawing A-47520

For the display, two conductors of 24 AWG are needed. For distances up to 600 ft. or

22 AWG, up to 1000 ft. are required. Daktronics has 24 AWG direct burial cable,

Daktronics part no. W-1105 with 6 conductors, and 22 AWG cable that must be

pulled through the conduit before burial, Daktronics part no. W-1077 with 2

conductors.

recommends that W-sections of grade 36 steel be

2-2 Installation

Page 9

At the control location, mount the signal J-box to a convenient location. Route the

cables and connect to the wires leading from the connector in the cover according to

the table below and the Drawing A-47207.

At the display, open the bottom hinged panel covering the entrance enclosure as

shown on Drawing A-47520. Remove the cover from the entrance enclosure. Refer

to Drawing A-46755 for an illustration of the components inside the entrance

enclosure. Connect the signal wires to TB31 as indicated in the table below.

Control End Display End

J-box Terminal No. Wire Color Output No. TB31 Terminal No.

14 Red/Wht 1* 1 (+)

15 Grn/Wht 2 (-)

*Auxiliary display(s) require(s) a different output no.(s). Consult your CHTS-300 console

manual.

2.4.2 Power Wiring

Reference Drawing: Pwr/Sig Entrance, 1 Driver Display....Drawing A-46755

The CH-1318V display requires a 120/240 VAC, 40 amp circuit per line. When

equipped with 30W lamps, the maximum current draw is 65 amps.

Route power wires into the display and connect to TB41 in the entrance enclosure, as

shown on Drawing A-46755.

Connect the ground wire to E41 and to a ground rod near the display, according to the

local codes.

Installation 2-3

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Section 3 : Maintenance & Troubleshooting

IMPORTANT NOTES:

1. Disconnect power before any repair or maintenance work is done on the

display!

2. Any access to internal display electronics must be made by qualified

service personnel.

3. Disconnect power when the display is not in use.

3.1 Lamp Replacement

Reference Drawing: Digit Service ..................................................Drawing A-27674

The primary service required by the CH-1318V display is to replace burned-out lamps. Refer

to Drawing A-27674 for an illustration of lamp changing. Replacement lamps are 130V,

30W frosted, medium base, available at your local store or directly from Daktronics, part

number DS-1182.

Do not use lamps larger than those originally installed in the display. Using higher powered

lamps will likely cause fuse failures in the display and could exceed the current levels that the

display’s circuits can safely handle.

3.2 Lamp Driver

Reference Drawings: Lamp Driver, 16 Col., w/ Fan.......................Drawing A-37070

Component Locations, CH-1318V ..............Draw ing A-47520

In the display, the task of switching lamps on and off is performed by the lamp driver.

Drawing A-47520 in Section 2 shows the location of the lamp driver in the display.

Drawing A-37070 is an illustration of the lamp driver and the fuses located in it.

The lamp driver has 21 connectors, providing power and signal inputs and outputs to digits.

The functions of these connectors are as follows:

Connector Number Function

1-16 Outputs to digits

17 Signal Input

18 Power input for outputs 1-8 (120 V)

19 Power input for driver logic and fan (120V)

20 Power input for outputs 9-16 (120V)

24 Dim option selector

In Drawing A-47520, the numbers on the digits refer to the lamp driver output connector

wired to each digit.

Maintenance & Troubleshooting 3-1

Page 20

3.3 Digit Segmentation

Reference Drawing: Segments, 4x7 Lamp Matrix Digit..................Drawing A-37685

In a digit certain lamps always go on and off together. These groupings of lamps are known

as “segments”. Each digit has eight segments, referred to by letters A through H. Drawing

A-37685 illustrates these segments and shows which connector pin and wire color is wired to

each segment.

3.4 Schematic

Reference Drawings: Schematic, 1 Driver Display ........................Drawing A-46754

Pwr/Sig Entrance, 1 Driver Display.............Drawing A-46755

Component Locations, CH-1318V..............Drawing A-47520

The schematic diagram on Drawing A-46754 shows the power and signal inputs into the

display and to the lamp driver. The component numbers correspond to those shown on

Drawings A-47520 and A-46755.

3.5 Troubleshooting

This section lists some symptoms that may be encountered with the CH-1318V display. For

these symptoms, possible causes and corrective actions are indicated. This list does not

include every possible problem, but does represent some of the more common situations that

may occur.

Observed Problem Possible Cause

One lamp won’t light

Digit segment won’t light

Entire digit won’t light

Half the display won’t light

Entire display won’t light

Segment stays lit

Garbled display

If a problem is observed in one digit, the cause may be isolated by swapping plugs on the

3-2 Maintenance & Troubleshooting

• Burned-out lamp

• Broken wire behind digit

• Broken wire

• Poor contact at driver connector

• Internal driver malfunction

• Broken wire (black)

• Poor contact at connector, pin 7

• Fuse blown in driver

• Service breaker tripped

• Main fuse blown

• Poor contact at main power connection

• P18 disconnected

• Power disruptions

• Poor signal connection

• Driver logic fuse blown

• Control not connected to display

• P20 disconnected

• Broken wire behind digit

• Internal driver malfunction

• Control malfunction

• Internal driver malfunction

Page 21

driver (connect the plug from the digit into a different jack). If the same digit shows the same

problem, the cause may be in the digit or the wiring. If the problem moves to another digit,

then the cause is probably an internal driver problem.

Use a volt meter at driver inputs to determine if power is being supplied to the driver. An

ohmmeter can be helpful in finding broken wires and bad connections. Internal electronic

problems must be correct by Daktronics or an authorized service center.

3.6 Replacement Parts

Part Name or Description Type Part Number

Lamp Driver 0A-1033-0122

J-Box, CHTS-300 Timer 0A-1067-0056

Fuse, Main Power, 20A FNW-20 F-1016

Fuse, Lamp Driver, 10A AGC-10 F-1006

Fuse, Driver Logic, 1/2A AGC-1/2 F-1000

Digit Lampbank, 18” 4x7 0A-1027-0071

Digit Screen, 18” 4x7 0S-1064-0002

Socket, Med. Base X-1046

Lamp, 30W Frosted DS-1182

3.7 Unit Exchange/Replacement Procedure

Daktronics unique exchange program offers our clients the quickest, most economical way of

receiving product repairs. If a component fails, Daktronics will send the customer a

replacement. The customer, in turn, sends the failed component to Daktronics. This not only

saves money but decreases the time the display is inoperable. Daktronics offers repair and

return on a timely basis; in urgent situations, every attempt is made to ship by the fastest

transit method available.

1. Packaging for Return: Package and pad the item well to prevent damage during

shipment. Electronic components, such as printed circuit boards, should either be

installed in an enclosure or placed in an anti-static bag before boxing.

Please enclose your name and address along with a list of all the symptoms. Please be

as specific as possible.

2. Driver Packaging Instructions: Drivers should be placed in a static-free enclosure

for return shipping. An anti-static convoluted foam packing is available from

Daktronics (part number PK-1135). The shipping box (Daktronics part number PK-

1006) should be used along with the foam.

3. Where to Send: Contact your local representative prior to shipment to acquire a

Return Material Authorization Number (RMA#). This will speed up the repair of

your unit.

When returning defective items under the exchange program, please use the UPS Blue

Return Tags found in the package containing the exchange unit sent from Daktronics.

This will speed up the transaction and help avoid confusion when the part is returned

to Daktronics. The defective item must be returned within 15 days of receiving a

replacement part. Using the UPS Blue Return Tag immediately will eliminate the

Maintenance & Troubleshooting 3-3

Page 22

possibility of late charges being assessed against your account.

Mail: Daktronics, Inc., Customer Service

PO Box 5128

331 32

nd

Avenue

Brookings, SD 57006

Phone: Toll Free: 1-800-843-9879

or 1-605-697-4400

Customer Service Fax: 1-605-697-4444

E-Mail: helpdesk@daktronics.com

3-4 Maintenance & Troubleshooting

Page 23

Page 24

Page 25

Page 26

Loading...

Loading...