Page 1

DataTrac

p

CE-1010

1.2”, 2.1”, 3.2”, 4.2”

Display Manual

ED11477 Rev 4 1 September 2004

331 32nd Ave PO Box 5128 Brookings SD 57006

Tel 605-697-4034 or 877-605-1113 Fax 605-697-4444

www.daktronics.com e-mail: hel

desk@daktronics.com

Page 2

ED11477

Product 1120

Rev 4- 1 September 2004

DAKTRONICS, INC.

Copyright © 2004

All rights reserved. While every precaution has been taken in the preparation of this manual,

the publisher assumes no responsibility for errors or omissions. No part of this book covered by

the copyrights hereon may be reproduced or copied in any form or by any means – graphic,

electronic, or mechanical, including photocopying, taping, or information storage and retrieval

systems – without written permission of the publisher.

DataTrac is a registered trademarks of Daktronics, Inc. All others are trademarks of their respective companies.

Page 3

Table of Contents

Section 1: Introduction....................................................................................1-1

1.1 Safety Precautions..................................................................................... 1-2

1.2 Display Overview...................................................................................... 1-2

1.3 Network Concepts.....................................................................................1-3

1.4 Part Definitions.......................................................................................... 1-4

1.5 Daktronics Nomenclature.......................................................................... 1-5

Section 2: Mechanical Installation.................................................................2-1

2.1 Support Structure Design ..........................................................................2-1

2.2 Z-Bracket Installation for Sectional Display Mounting ............................ 2-2

2.3 Electrical Junction Box Installation........................................................... 2-2

2.4 Hanging Display Sections ......................................................................... 2-2

2.5 Display Ventilation Requirements............................................................. 2-3

Section 3: Electrical Installation ....................................................................3-1

3.1 Signal......................................................................................................... 3-1

Cables .....................................................................................................3-1

Installing an RJ11 Connector .................................................................... 3-1

3.2 Power......................................................................................................... 3-2

Power Requirements.................................................................................. 3-2

Grounding.................................................................................................. 3-2

Power Connection – Pluggable Cord Connected Displays........................3-2

3.3 RS422 System ........................................................................................... 3-3

3.4 Sign to Sign/Section to Section Connections ............................................ 3-3

Section 4: Maintenance and Troubleshooting..............................................4-1

4.1 Accessing the Interior of the Display........................................................ 4-2

4.2 Display Interior.......................................................................................... 4-3

LED Module Replacement........................................................................ 4-3

Power Supply Replacement....................................................................... 4-4

Display Controller..................................................................................... 4-5

4.3 Controller Address and Test Mode............................................................ 4-6

4.4 Troubleshooting......................................................................................... 4-6

4.5 Replacement Parts ..................................................................................... 4-7

4.6 Daktronics Exchange and Repair and Return Programs............................4-8

Appendix A: Reference Drawings ........................................................................ A-1

Appendix B: Signal Converter .............................................................................. B-1

Table of Contents

i

Page 4

List of Figures

Figure 1: Drawing Label........................................................................................................1-1

Figure 2: Positions-1648 Display...........................................................................................1-5

Figure 3: Typical Label..............................................................................................................1-6

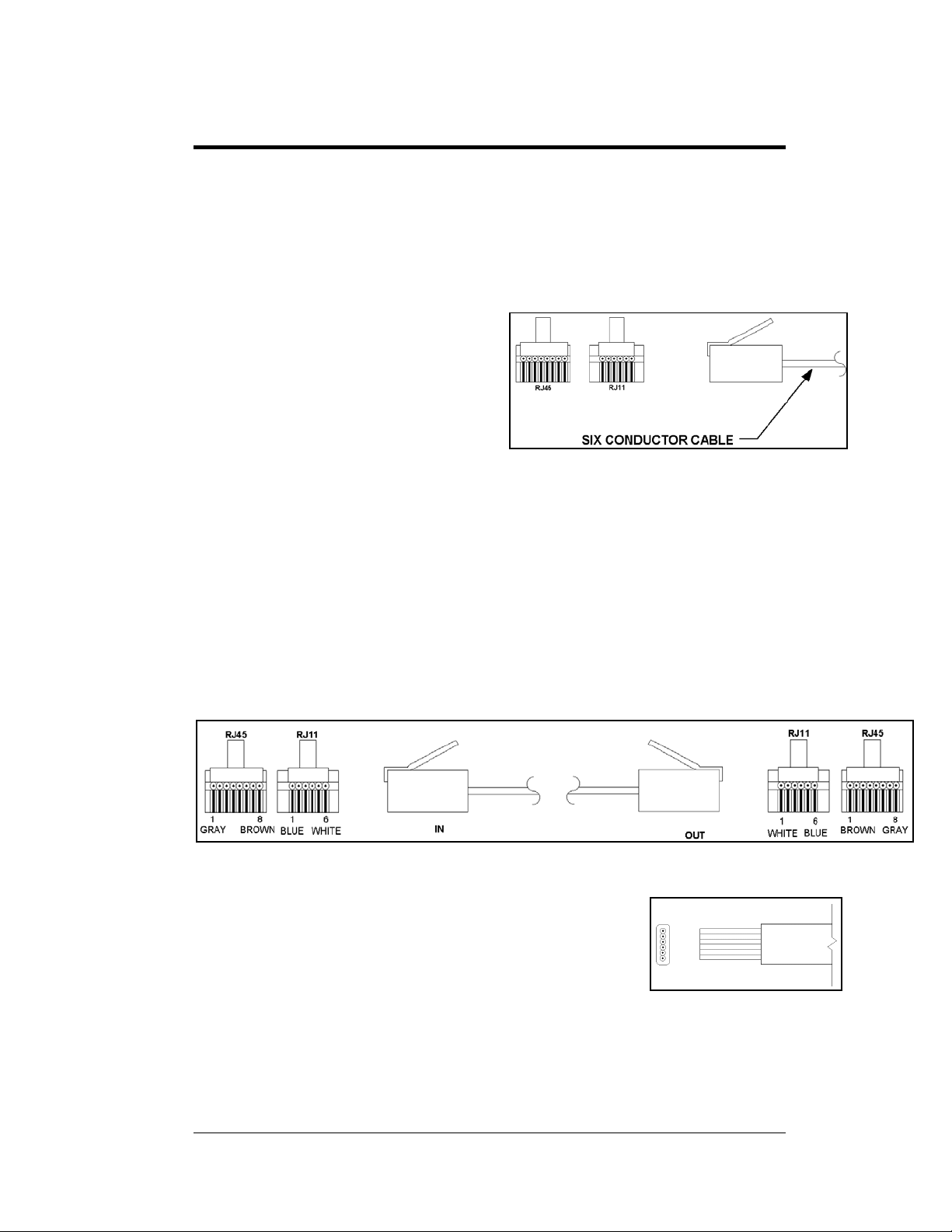

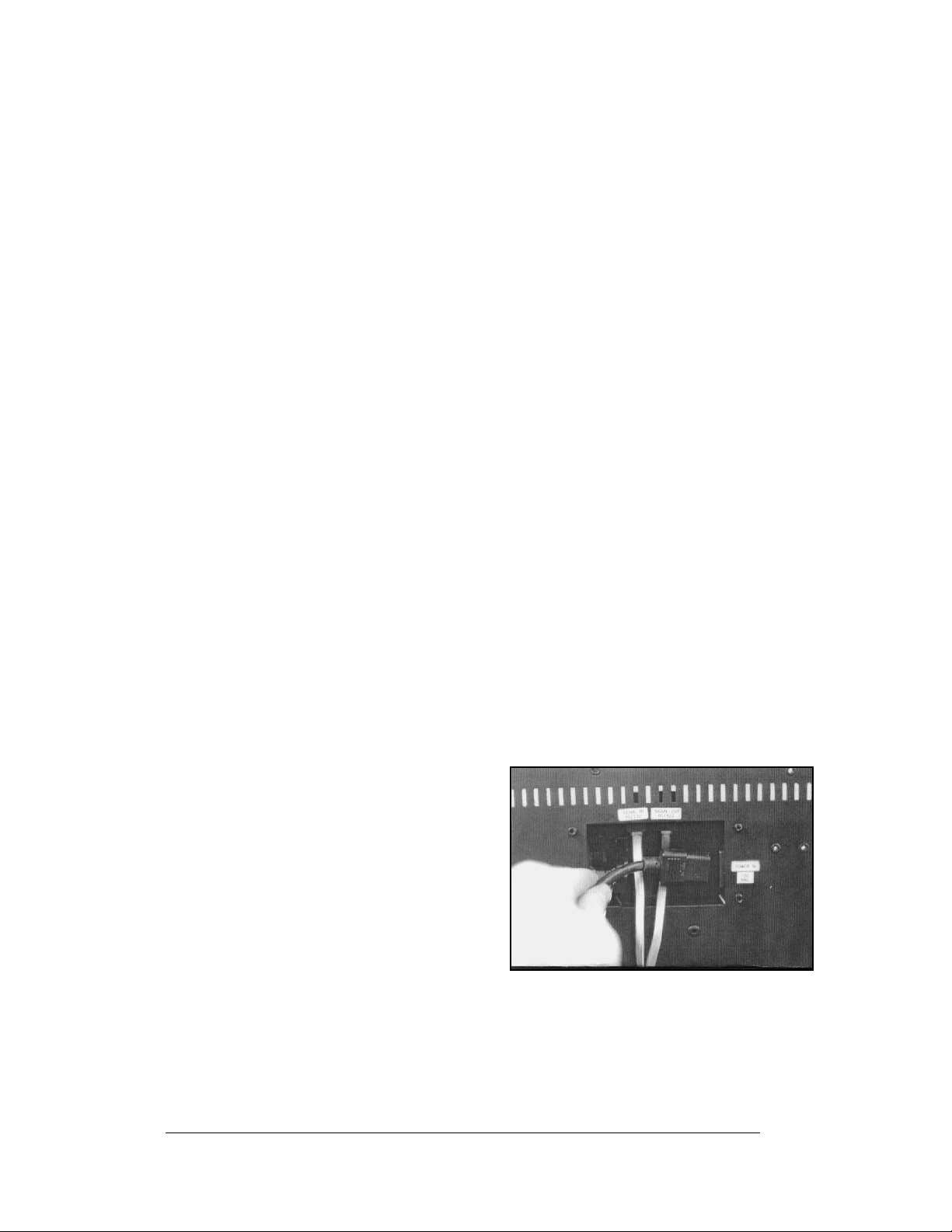

Figure 4: Six conductor RJ11 Connector and Cable.............................................................. 3-1

Figure 5: Flipped Cable with RJ Connectors .........................................................................3-1

Figure 6: Wire with Outer Jacket Stripped.............................................................................3-1

Figure 7: Power Cord Connection..........................................................................................3-2

Figure 8: Output Signal Cable Connection ............................................................................3-3

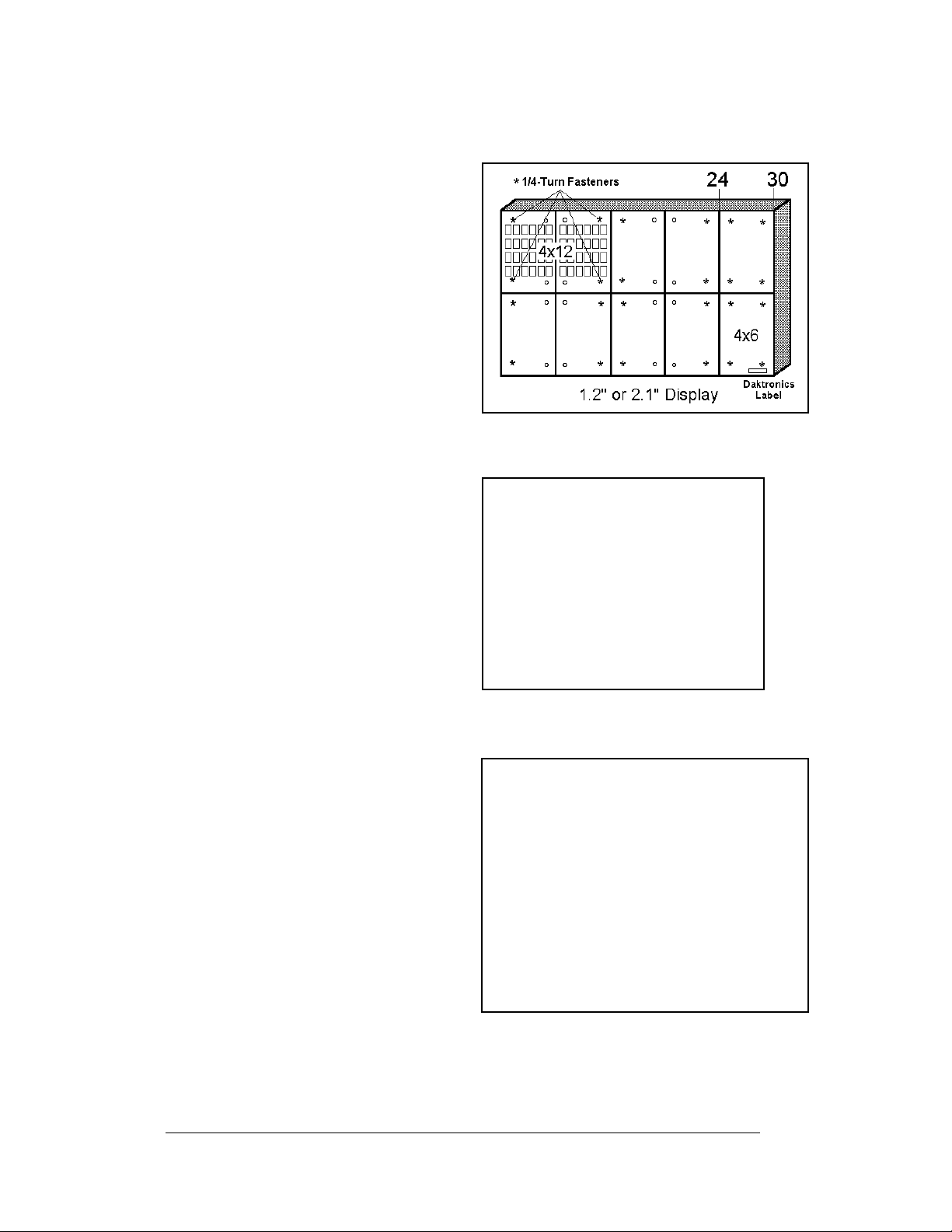

Figure 9: Screw Locations......................................................................................................4-2

Figure 10: Locating module panel ¼-turn fasteners...............................................................4-2

Figure 11: Module Panel Removal.........................................................................................4-2

Figure 12: LED Module Ribbon Cable Removal...................................................................4-3

Figure 13: Removing the wire cloth retainer frame nuts........................................................4-3

Figure 14: Removing Top and Bottom Module Screws.........................................................4-4

Figure 15: Power Supply........................................................................................................4-4

Figure 16: Power Supply Cable Connections.........................................................................4-4

Figure 17: MDC Controller.................................................................................................... 4-5

Figure 18: End View; Display Controller DIP Switches........................................................4-6

ii

List of Figures

Page 5

Section 1: Introduction

This manual explains the installation and maintenance of Daktronics Panelized DataTrac™

CE-1010 displays. For questions regarding the safety, installation, operation or service of this

system, please refer to the telephone numbers listed on the cover page of this manual.

The manual is divided into six sections: Introduction, Mechanical Installation, Electrical

Installation, Maintenance and Troubleshooting, Appendix A and Appendix B.

• Introduction covers the basic information needed to make the most of the rest of this

manual. Take time to read the entire introduction as it defines terms and explains

concepts used throughout the manual.

• Mechanical Installation offers general guidance on sign mounting.

• Electrical Installation provides general guidance on terminating power and signal cable

of the sign.

• Maintenance and Troubleshooting addresses such things as removing basic sign

components, troubleshooting the sign, performing general maintenance, and exchanging

sign components.

• Appendix A includes most of the drawings referenced in this manual.

• Appendix B includes information on the signal converter.

Daktronics identifies manuals by an ED number located on the cover page of each manual.

For example, this manual would be referred to as ED11477.

Listed below are a number of drawing types commonly used by Daktronics, along with the

information that each is likely to provide. This manual might not contain all these drawings

• System Riser Diagrams: overall system layout from control computer to sign, power

and phase requirements.

• Shop Drawings: fan locations, mounting information, power and signal entrance points

and access method (front and rear).

• Schematics: power and signal wiring for various components.

• Component Placement Diagrams: locations of critical internal sign components such as

power supply assemblies, controller boards, thermostats and light detectors.

Figure 1 illustrates Daktronics drawing label. The drawing number is located in the lowerright corner of the drawing. Listing the last set of digits and the letter preceding them

identifies drawings in the manual. In the example below, the drawing would be referred to as

Drawing B-206146. Reference drawings are inserted in Appendix A.

.

Introduction

Figure 1: Drawing Label

1-1

Page 6

All references to drawing numbers, appendices, figures, or other manuals are

presented in bold typeface, as shown below.

“Refer to Drawing B-206146 for the power supply connections.”

Additionally, drawings referenced in a particular section are listed at the beginning

of that section as seen in the following example:

Reference Drawing:

Schem; Primary Signal, Internal W/.QC ............................ Drawing B-206146

Daktronics signs are built for long life and require little maintenance. However, from

time to time, certain sign components will need replacing. The Replacement Parts

List in Section 7 provides the names and numbers of components that may need to

be ordered during the life of the sign. Most sign components have a white label that

lists the part number. The component part number is in the following format: 0P-_ _

_ _-_ _ _ _ (circuit board) or 0A-_ _ _ _-_ _ _ _ (multi-component assembly).

Following the Replacement Parts List is the Daktronics Exchange and Repair

and Return Programs. Refer to these instructions if any sign component needs

replacement or repair.

1.1 Safety Precautions

1. Read and understand these instructions before installing.

2.

Be sure that the display is properly grounded.

3.

Disconnect power before working on the display.

4.

Do not modify the displays or attach any panels or coverings to the display

without the express written consent of Daktronics, Inc.

5.

Most products are equipped with a 3-wire grounding-type plug, a plug

having a third (grounding) pin. This plug will only fit into a grounding-type

power outlet. This is a safety feature. If you are unable to insert the plug

into the outlet, contact a qualified electrician to replace your obsolete outlet.

Do not defeat the purpose of the grounding-type plug.

1.2 Display Overview

The Daktronics DataTrac CE-1010 Indoor LED displays have been designed and

manufactured for performance, reliability, easy maintenance, and long life. The

displays consist of an array of LED pixels. The configuration of the LED pixels is

dependent on the family of LED displays. The standard character is seven pixels

high by five pixels wide.

The DataTrac CE-1010 system is available with DataView or Venus 1500 protocol

for message control. The PC controls one or more DataTrac sectional displays. The

displays are offered as single-face sectional displays, which are single-sided standalone units. They can be mounted side-by-side and stacked on top of each other to

create a larger display.

1-2

Introduction

Page 7

DataTrac displays are character-based indoor LED displays, which are available in

ri-color (red, green and amber) characters. This display family is for 5x7 single-

t

stroke fonts. Daktronics offers the DataTrac displays with a 1.2", 2.1", 3.2", or 4.2"

character height in various lengths. The DataTrac model numbers are described as

follows: CE-1010-RRR-CCC-HH-XX

= Panelized DataTrac Display

CE

1010

RRR

CCC

= 1010-Panelized with screen

= Number of rows of characters—1.2 available in 8 and 12 high sections; 2.1 available in

4, 8 and 12 high sections; 3.2 and 4.2 available in 4 or 6 high sections

= Number of columns of characters—1.2 and 2.1 available in 24 and 30 character

sections; 3.2 available in 18 and 24 character sections; 4.2 available in 12 and18

character sections

= Character height—1.2, 2.1, 3.2 or 4.2

HH

= RG=Tri-color (red, green and amber)

XX

1.3 Network Concepts

The concept of using LED displays as a cost effective, high impact method of

communication is rapidly growing throughout many industries and businesses. The

reasons for this growth are many, but the need for additional features and complexity

of multiple sign installations has emerged, and the Daktronics display systems have

been designed to meet those needs. The common thread to most clients’ requests is a

means of programming and controlling a group of signs from a central control point.

Daktronics responded by developing a powerful system of interconnecting and

controlling signs. Great care has been taken to design products that will satisfy a

wide variety of installations. Some of the design goals of these systems include the

following:

• Easy transfer of messages

• The ability to tell a sign in the network which message it should run

• The ability to determine the status of any sign on the network

• The ability to control multiple sign technologies on the same network

All of the programming features would seem insignificant if the installation of the

system

s could not be accomplished with basic tools and without technical difficulty.

Daktronics decided to use the very popular and readily available RJ11 connector.

This connector is also used on modern home and office telephone equipment.

All that is required for signal installation is standard six (6) conductor modular

t

elephone wire. For some installations, it may be possible to buy pre-terminated

telephone cables for use with the displays.

The DataTrac CE-1010 display uses a RS422 networking system. RS422 (EIA/TIA422-B) is a standard com

transmission scheme, which uses a typical maximum cable length of 1.2 km

(approximately 4000 feet). The main advantage of RS422 over RS232 is the longer

cable length that is possible. A signal converter is needed to convert the computer’s

RS232 to RS422.

munication interface that utilizes a differential balanced

Introduction

1-3

Page 8

1.4 Part Definitions

Com Port: connector on the back of the controller PC. The Com Port is used to

control the sign network through either a 9- or 25-pin serial connector.

Display Configuration: refers t

information will be automatically displayed when the display is powered up.

Flipped Cable: si

6 of connector B.

LAN: abbreviation for Local Area Network

Loop Back Test: troubleshooting test that connects the transm

more information on this test refer to Appendix B.

Module: one uni

lines by 6 characters. The 3.2" and 4.2" displays' modules consist of 2 lines by 6

characters.

Network: consists of multiple signs connected to each other.

RS232: standard PC communication type with a maximum cable length of 25 feet

(7.62 m

RS422: standard differential communication type with a maximum cable length of

4000 feet

RX LED: LED on t

back to the signal converter.

Sign Address: identification num

software uses the address to locate and communicate with each display.

Signal Cable Tester: used to test the cable connections and data communication.

Signal Converter: Dakt

RS422. The signal converter is used in RS422 systems.

TX LED: LED on t

to the display.

X,Y Coordinates: u

sectionalized DataTrac display.

eters).

(1.2 kilometers).

x (6) conductor phone cable. Pin 1 of connector A connects to pin

t of the display. The 1.2" and 2.1" displays’ modules consist of 4

he signal converter that indicates if the display is sending data

ronics supplied unit that converts the data from RS232 to

he serial converter that indicates the control PC is sending data

sed to reference the location of LED blocks within the entire

o a display’s model number, address, etc. This

it to receive lines. For

ber assigned to each sign of a network. The control

1-4

Introduction

Page 9

1.5 Daktronics Nomenclature

The X-coordinate refers to the LED block placement within a row of characters. To

count the placement of the X-coordinate, begin with the left-most LED block as X=1

and continue counting across through the entire display to the right-most LED block.

The Y-coordinate refers to the LED block placement within a column of characters.

To count the placement of the Y-coordinate, begin with the upper-most LED block

as Y=1 and continue counting down through the entire display to the bottom-most

LED block. The software on the control PC uses these coordinates to determine the

placement of data within the larger display.

The X,Y coordinates at the upper left character of each section need to be configured

for proper display orientation.

In addition, various Daktronics drawings may contain the following labeling

formats:

Finally, drawings commonly have Daktronics part numbers. You can use those part

numbers when requesting replacement parts from Daktronics Customer Service.

Take note of the following part number formats:

Introduction

Figure 2: Positions-1648 Display

• “TB_ _” shows a termination block for power or signal cable.

• “F_ _” denotes a fuse.

• “E_ _” signifies a grounding point.

• “J_ _” stands for a power or signal jack.

• “P_ _” represents a power or signal plug for the opposite jack.

• “0P-_ _ _ _-_ _ _ _” gives the form of an individual circuit board, such as a

module driver.

1-5

Page 10

• “0A-_ _ _ _-_ _ _ _” represents an assembly, such as a circuit board and the

plate or bracket to which it mounts. A collection of circuit boards working

as a single unit may also carry an assembly label.

• “W-_ _ _ _” indicates a wire or cable. Cables may also carry the assembly

numbering format in certain circumstances. This is especially true of ribbon

cables.

• “F-_ _ _ _” signifies a fuse.

Most circuit boards and components within this sign

carry a label that lists the part number of the unit. If

the Replacement Parts List in Section 4.13 does not

list a circuit board or assembly, use the label to order a

replacement.

Figure 3 illustrates a typical label. The

Figure 3: Typical Label

part number is in bold.

1-6

Introduction

Page 11

Section 2: Mechanical Installation

Reference Drawings:

Shop Dwg; CE-1010-***-1.2-RG-Thin Mount

Shop Dwg; CE-1010-4**-2.1-RG-Thin Mount

Shop Dwg; CE-1010-***-2.1-RG-Thin Mount

Shop Dwg; CE-1010-***-3.2-RG-Thin Mount

Shop Dwg; CE-1010-***-4.2-RG-Thin Mount

Spacing Plate; XX.XX" Tall-Thin Mount

Shop Dwg; Install Notes-Thin Mount

Mtg Brkt Assy; CE-10**-824-2.1-Thin

Shop Dwg; Install Details CE-1010-1672-2.1-Thin

Generic; System Riser Diagram

The sectional display models shown in Draw

151293 and A-154044 are available in various standard sizes and can be arranged to create

larger display sizes. The arrangement of these sections requires Daktronics contract

engineering.

Daktronics contract engineering and the Daktronics project manager will provide installation,

l

ayout, and riser diagrams once the overall display size has been determined. Drawings A-

152630, A-152599, A-155773, and B-155789 are typical illustrative drawings of those that

are contract specific, and are made available by the Daktronics project manager. Installation

drawings are also included in the installation kits that co me with the d isp lay section(s).

It is important to have received and reviewed the installation drawings and riser

dia

grams before installation begins. Installation personnel should be familiar with these

drawings and have copies of them on site.

........................................Drawing A-152599

.......................................Drawing A-155773

...............................................Drawing A-113523

ings A-154011, A-151214, A-152954, A-

Note: Daktronics engineering staff must approve any changes made to the display. If any

modifications are made, detailed drawings of the changes must be submitted to Daktronics

for evaluation and approval, or the warranty may be void.

Refer to the shop draw

manager.

ings referenced above, and the other drawings provided by the project

...........................Drawing A-154011

...........................Drawing A-151214

...........................Drawing A-152954

...........................Drawing A-151283

...........................Drawing A-154044

....................................Drawing A-152630

...................Drawing B-155789

2.1 Support Structure Design

The wall, framing members, or structure that will support the Daktronics supplied Zbrackets and display sections are to be designed to support the weight of the

completed system. Review all drawings to determine special requirements and the

total system weight. It is the customer’s responsibility to ensure that the installation

will meet local codes and or standards. Daktronics is not responsible for the

installations or the structural integrity of support structures done by others.

Mechanical Installation

2-1

Page 12

2.2 Z-Bracket Installation for Sectional Display Mounting

Review all drawings to determine special requirements. Display sections are to be

mounted to a wall or structural frame using Z-shaped aluminum brackets provided

by Daktronics in an installation kit. The Z-brackets allow for one (1) inch of air

space behind the displays for power and signal terminations, and for the

corresponding customer supplied junction boxes. Installation drawings will provide

the necessary dimensions for the mounting of the display, Z-brackets, and power

termination junction boxes.

It is the customer’s responsibility to attach the Z-brackets with the correct am

and type of hardware to support the weight of all display sections mounted to those

Z-brackets as well as the support structure mentioned in Section 2.1. It is the

customer’s responsibility to ensure that the installation will meet local codes and or

standards. Daktronics is not responsible for the installations or the structural

integrity of support structures done by others.

When mounting a display system containing one or multiple rows of display

sectio

ns, the bottom row of displays will require two rows of Z-brackets attached to

the support structure. Upper rows of displays will require only one row of Z-brackets

per row of displays. This is due to the fact that each display section has alignment

pins located on the top of the section that interlo c k into the bottom of the display

section stacked on top of it. It is important to check these pins for tightness before

hanging a display section.

ount

2.3 Electrical Junction Box Installation

Review all drawings to determine special requirements. Installation drawings will

provide the necessary dimensions for the power termination junction boxes. The

contract specific riser diagram will identify power specifications for the display

system. Also read Section 3 for any other pertinent information that may be needed

during the mechanical installation process.

2.4 Hanging Display Sections

Each DataTrac CE-1010 section has threaded insert nut holes on the rear side for the

attachment of mounting brackets. These are required for the hanging of the

individual sections. The mounting brackets come in the installation kit along with

the required ¼-20x3/4 hex head bolts. A drawing or drawings showing the correct

mounting bracket attachment will be included in the installation kit. Drawing A-

155773 illustrates the attachment of mounting brackets.

Hang the section that receives the incoming signal to the bottom

mounted Z-brackets. Subsequent sections are to be mounted to the Z-brackets, as

they are daisy-chained together with signal interconnects per the contract specific

riser diagram and Section 3 for electrical and signal information.

2-2

left side of the

Mechanical Installation

Page 13

Each section is labeled with an address and X

proper section is mounted to the Z-bracket in the proper place.

Make sure that the mounted Z-brackets have screws attached vertically to each

end to prevent the display sections from sliding off. This is discussed and

illustra

ted in the included install kit drawings.

-Y coordinate. Make sure that the

2.5 Display Ventilation Requirements

Fresh air inlets and exhaust vents should not be obstructed in any way. Using the

Daktronics suggested mounting methods will ensure proper ventilation. If using a

different mounting method, consult a Daktronics sales representative for clearance

requirements regarding the particular display. If ventilation requirements are not

met, the display warranty will be void.

Mechanical Installation

2-3

Page 14

Page 15

Section 3: Electrical Installation

3.1 Signal

Cables

The conductor connector used in the

network is an industry standard 6-pin

RJ11 or an 8-pin RJ45. This

connector can be found on many

telephones and LANs.

The cable used in the network is a

standard flat six-conductor telephone

cable (standard flipped cable). Refer

to Figure 4. This cable has one end

that is the mirror image of the other end (i.e. the cable is flipped). Refer to Figure 5

for a standard flipped cable.

Notice in Figure 5 that the color code on one connector must be made the opposite

on the other connector. When installing a network, it is not easy to remember in

which direction the previous end was oriented. One simple way to avoid confusion

is to standardize the color code, having one color for the connector going into the

output of a sign, and the opposite color for a connector going into the input of a

sign. This will help ensure correct cabling since cables are always installed from the

output jack of one sign to the input jack of the next sign.

Figure 4: Six conductor RJ11 Connector and

Cable

Figure 5: Flipped Cable with RJ Connectors

Installing an RJ11 Connector

Installing an RJ11 connector on the end of the sixconductor cable is a simple task when the correct tools are

used. The RJ11 crimping tool (Daktronics part number TH-

1033) performs two separate steps.

First, use the crimping tool to strip the outer insulation from the inner wires. This

does not result in bare wires since only the gray outer jacket is removed. After

correct stripping, the wire will appear as shown in Figure 6.

Electrical Installation

Figure 6: Wire with Outer

Jacket Stripped

3-1

Page 16

The crimping tool is then used to crimp the RJ11 connector onto the cable. The RJ11

connector is locked into a special socket in the tool. The stripped wire is inserted

into the RJ11 connector. Finally, the tool is squeezed like a pliers to crimp the

connector onto the wire. This completes the installation of an RJ11 connector onto

the wire.

3.2 Power

Reference Drawing:

Generic; System Riser Diagram..................................Drawing A-113523

Power Requirements

Each display system comes with a contract specific riser diagram similar to the

drawing referenced above.

Refer to the specifications sheet for voltage and current requirements. The displays

accept a universal input voltage of 85-265 VAC at 50 or 60 Hz.

Do not connect the display to any voltage other than that listed on the Daktronics

product label attached to the back of the display.

Grounding

Proper grounding is necessary for reliable equipment operation, and provides some

protection to the equipment from damaging electrical disturbances. All of the

displays are supplied with a power cord that contains an earth ground conductor.

Make sure to plug this cord into a grounded outlet. If the proper grounding methods

are not followed, the warranty will be void.

Note: Displays must be earth grounded according to national and local electrical

codes.

3-2

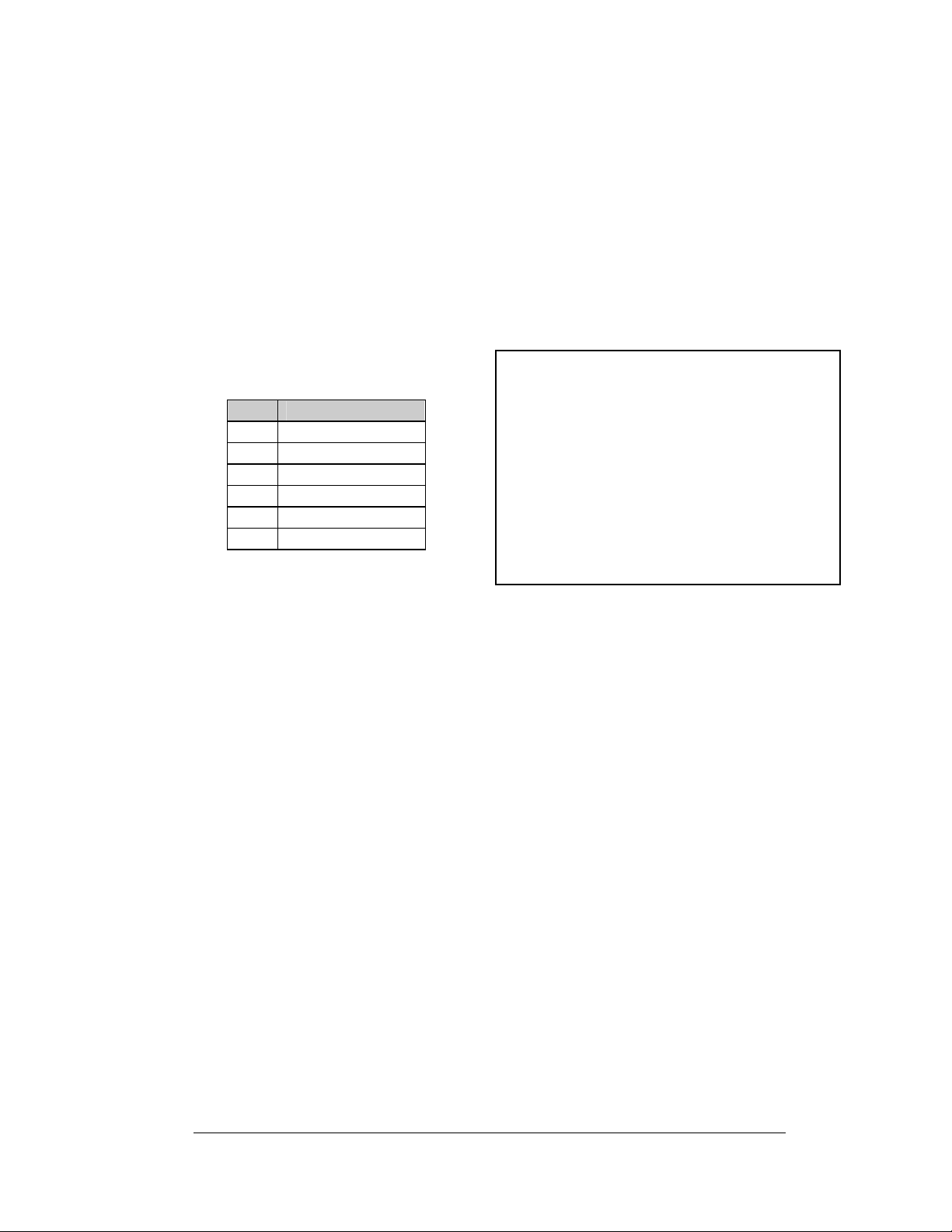

Power Connection – Pluggable Cord Connected Displays

The DataTrac CE-1010 displays are

supplied with an eight (8) foot power cord.

The socket-outlet should be installed near

the equipment and be easily accessible.

Plug the power cord into the socket as

shown in Figure 7.

It is important to check this connector to

make sure it is fully secured before

hanging a display section.

Figure 7: Power Cord Connection

Electrical Installation

Page 17

3.3 RS422 System

A RS422 system requires a signal converter to connect the first sign to the computer.

1. Plug the serial cable’s 25-pin connector into the signal converter.

2. Plug either the 9-pin or the 25-pin connector (depending on your PC) into

the RS232 COM port to be used.

3. Plug the signal converter’s power cord into a 120 VAC grounded outlet.

4. Plug a flipped phone cable into the “RS422 OUT” of the signal converter

and the opposite end into the “RS422 IN” of the first display.

The “RS422 IN” jack’s pin out is as

follows:

Pin Function

1 N.C.

2 D1OUT-P

3 D1OUT-N

4 D1IN-P

5 D1IN-N

6 N.C.

Figure 8: Output Signal Cable Connection

3.4 Sign to Sign/Section to Section Connections

When wiring the sign to sign network, the cable and connectors discussed earlier in

this section are used. Pay special attention to the information regarding flipped

cables to help ensure a successful installation. The best method of wiring the signs

together is to start at the first sign, as it is designated to begin the n etwork.

1. Plug the cable into the “SIGNAL OUT” output jack of the first sign (refer

to Figure 8) and the other end of the cable into the input jack of the next

sign.

2. Continue this procedure throughout the network. When the wiring is

complete, the last sign will have nothing in the output jack.

3. Before hanging the displays, review Section 2.4.

Electrical Installation

3-3

Page 18

Page 19

Section 4: Maintenance and

Troubleshooting

Important Notes:

1. Disconnect power before any repair or maintenance work is

done on the display.

2. Qualified service personnel must make any access to internal

display electronics.

3. Disconnect power when the display is not in use.

Reference Drawings:

Label Detail Drawing, CE-10**-****-*.*, RS422.........................Drawing A-110324

1.2" Displays

Final Assy; CE-1010-****-1.2-RG .............................................Drawing B-110268

Schematic; CE-10**-824/30-1.2-**............................................Drawing B-113015

Schematic; CE-10**-1224/30-1.2-**..........................................Drawing B-113344

2.1" Displays

Final Assy; CE-1010-4**-2.1-SBRG .........................................Drawing B-140722

Final Assy; CE-1010-****-2.1-RG .............................................Drawing B-121808

Schematic; CE-10**-424/30-2.1-**............................................Drawing B-140608

Schematic; CE-10**-824/30-2.1-**............................................Drawing B-121853

Schematic; CE-10**-1224/30-2.1-**..........................................Drawing B-121854

3.2" Displays

Final Assy; CE-1010-****-3.2-RG .............................................Drawing B-146115

Schematic; CE-10**-418/24-3.2-**............................................Drawing B-145059

Schematic; CE-10**-618/24-3.2-**............................................Drawing B-144982

4.2" Displays

Final Assy; CE-1010-****-4.2-RG .............................................Drawing B-110430

Schematic; CE-10**-412/18-4.2-**............................................Drawing B-107790

Schematic; CE-10**-612/18-4.2-**............................................Drawing B-109996

The DataTrac CE-1010 displays are front access. The components within the displays are not

field repairable. In most cases, it is easiest to completely replace the failed part or return it to

Daktronics for repair.

Refer to the project specific shop drawings provided by the project manager.

Maintenance and Troubleshooting

4-1

Page 20

4.1 Accessing the Interior of the Display

Depending on the overall size of a

display system, sectional displays may

have two sizes of front access

removable panels. Finding the

Daktronics labels on the front of the

display will help in locating the lower

right corner of a display section.

For 1.2" and 2.1" display types, the

module in this corner may either be a

4x6 or 4x12 panel. For 3.2" and 4.2"

displays, the modules are all 2x6

panels. Panels are removed by

accessing ¼-turn fasteners in the

corners of a module panel.

Note: Not every hole has a ¼-turn

fastener. Only the four corner holes of

the module panel do. Refer to Figure

9.

The screwdriver must pass through the

face panel. The ¼-turn screws are

located behind the face panel.

Using a #1 Philips screwdriver, turn

the 4 ¼-turn screws securing the LED

module panel to the cabinet of the

display one-quarter turn counterclockwise. Refer to Figure 9 and

Figure 10. The screws are designed to

remain in the LED module flanges,

but release from the cabinet.

Gently pull the LED module panel

from the body of the display. It will

come forward as a complete unit.

Refer to Figure 9 and Figure 10.

Note: Use caution when removing the

LED module panel. The power wires

and ribbon cable connecting the LEDs

to the inside of the display will still be

connected. Take care not to scratch the

modules wire cloth filter.

Figure 9: Screw Locations

Figure 10: Locating module panel ¼-turn fasteners

Figure 11: Module Panel Removal

4-2

Maintenance and Troubleshooting

Page 21

To completely remove the LED module panel from the cabinet of the display:

1. Spread the clasps of the 40-

pin connectors on the rear

side of the panel.

2. Gently pull the cable to

disconnect the pin connector

(refer to Figure 12).

3. Disconnect the four-pin

power connectors. The power

cable is released by squeezing

the tabs on each side of the

connector.

Figure 12: LED Module Ribbon Cable Removal

4.2 Display Interior

Once the LED module panel is removed, the display interior is visible. Various

internal components, including the display controller and the power supplies, are

now accessible for repair or replacement.

LED Module Replacement

If any LED modules fail, the recommended

procedure is to replace the failed module,

send it to Daktronics, or send it to a certified

dealer for repair. Refer to Section 4.6 for

information on packaging components for

shipment.

To remove an LED module:

1. Remove the appropriate LED

module panel as described in

Section 4.1.

2. Disconnect the remaining 40-

pin ribbon cable from the failed

module.

3. Removing the wire cloth retainer frame requires the following: For 1.2"

displays, remove the four nuts located along the rear edge of the LED

circuit board. For the 2.1" displays, remove the four perimeter nuts and

one in the center of the circuit board. For the 3.2" and 4.2" displays,

remove the six perimeter nuts and two in the center. Refer to Figure

13.

4. Flip the module panel over and remove the wire cloth filter from the

front of the failed module.

Figure 13: Removing the wire cloth

retainer frame nuts

Maintenance and Troubleshooting

4-3

Page 22

5. Remove the screws located along

the top and bottom edge of the

module, and lift the PC board off of

the rails. Refer to Figure 14.

6. Reverse the previous procedure to

attach a new module.

Figure 14: Removing Top and Bottom Module

Screws

Power Supply Replacement

1.2" and 2.1" Power to the LED modules is

provided by small 5V power supplies. Each

power supply can support two 4x6 modules.

The controller board also requires a 5V power

supply. The power supplies are mounted to the

back sheet within the display cabinet.

3.2" and 4.2" Power to the LED modules is

provided by 6.5V power supplies. Each power

supply can support two 2x6 modules. The

controller board also requires a 5V power

supply.

Figure 15: Power Supply

To remove a power supply that has failed, first

remove the LED module in front of the failed

power supply as described in Section 4.1.

Each power supply is attached to a power

supply plate by two metric screws. The plate is

secured to the back sheet by two (2) #6 hex

head screws. Refer to Figure 15. Use a

3

/16-nut

driver to remove the #6 hex head screws.

Lift the power supply and plate back. The

metric screws securing the power supply to the

Figure 16: Power Supply Cable Connections

plate are now accessible. Use a #1 Philips head screwdriver to remove the screws and

free the power supply.

Disconnect the power cables as shown in Figure 16. The power supply is now fully

released and ready for replacement. Follow the previous steps in reverse order to reattach

the new power supply. Refer to the display’s schematic for the proper wiring

configuration.

4-4

Maintenance and Troubleshooting

Page 23

Display Controller

The display controller is mounted to the inside rear of the display cabinet. Refer to

Figure 17 for an illustration of the controller and the appropriate schematic for its

location in the display. The controller receives information from the computer, interprets

it, and activates the appropriate LEDs on the display. The display controller also has a set

of eight switches by which an address can be set using standard binary code (refer to

Section 4.3).

Figure 17: MDC Controller

Under normal operation, the normal state of the controller’s status indicator LEDs is as

follows:

Status Indicator Normal State

MDC Power LED On Constant

Product Board Power

LED

Run LED Flashes once per

To replace a failed controller:

1. Remove the module panels as described in Section 4.1. Each display section has

one controller mounted inside it. Refer to the appropriate schematic for the

controller location.

2. Disconnect the power cable and signal ribbon cables. Release the power cable

by squeezing the tabs on each side of the connector. Release the signal ribbon

cables by spreading the clasps on the jack and gently pulling up on the ribbon

cable. Take note of the signal cables and their appropriate jacks.

3. Remove all #6 connecting screws and the controller will be free. If the address

switches are used, take note of the switch configuration and set the same address

on the new controller.

4. To install a new controller, reverse the previous procedure.

On Constant

second

Maintenance and Troubleshooting

4-5

Page 24

4.3 Controller Address and Test Mode

The controller has a set of “DIP” switches on

the side of the controller as shown in Figure

18. These DIP switches set the hardware

address. When replacing a controller board,

be sure to set the DIP switches in the same

address configuration as the defective

controller. Turn power off and then back on to

recognize the new address.

Note: Setting the DIP switches to address 0

(turn all the switches to OFF by flipping them

toward the printed switch numbers) can

activate a test mode. The display’s power

must be downed and then reconnected to run

the test mode.

Switch 8 Switch 7 Switch 6 Switch 5 Switch 4 Switch 3 Switch 2 Switch 1 Address

Off Off Off Off Off Off Off On 1

Off Off Off Off Off Off On Off 2

Off Off Off Off Off Off On On 3

Off Off Off Off Off On Off Off 4

Off Off Off Off Off On Off On 5

Off Off Off Off Off On On Off 6

Off Off Off Off Off On On On 7

Off Off Off Off On Off Off Off 8

Off Off Off Off On Off Off On 9

Off Off Off Off On Off On Off 10

Off Off Off Off On Off On On 11

. . . . . . . . . . . . . . . . . . . . . . . . . . .

On On On On Off Off Off Off 240

Figure 18: End View; Display

Controller DIP Switches

4.4 Troubleshooting

This section contains some symptoms that may be encountered with the LED

displays. Possible remedies are provided. This list does not include every possible

problem, but does represent some of the more common situations that may occur.

Symptoms/Conditions Possible Cause/Remedy

Cannot communicate with the

display.

Display will not run. • Check power cord.

4-6

• Check flipped phone cable connections.

• Check display configuration.

• Check signal converter TX and RX LEDs.

• Power down, then power up the display.

• Check the controller status indicators.

Maintenance and Troubleshooting

Page 25

Entire display is garbled or a

• Power down, then power up the display.

section of the display is bad.

Section of the display network is

not working.

• Bad input on the first bad display.

• Bad output on the last good display.

• Switch the suspect display with a known good display.

Note: The display configuration is shown on operation and contains the following

inform

ation:

1. Posi

2. Firm

3. Si

4. C

5. C

6. Di

7. M

tions (x=1, y=1)

ware Version

ze 4x8

OM1 Configuration (DataView

OM2 Configuration (DataView

™

19200)

™

9600)

splay Address—displayed in binary code (i.e. 001)

odem (if present)

4.5 Replacement Parts

Common Parts

Part Description Part Number

DataTrac CE-1010 Display Manual ED11477

Signal Converter- 120 VAC 0A-1127-0255

Signal Converter- 240 VAC 0A-1127-0250

Serial Cable W-1249

Adapter DB9M to DB25F A-1603

Patch Cable, 10ft, RJ45, 4 Pair Twisted W-1383

Network Tester 0A-1146-0005

Display Interconnect Cable 0A-1120-0176

Power Cord, 120VAC W-1181

Cable, 18” RJ11 6-cond straight 0A-1137-0160

Cable; 25” RJ11 6-cond straight W-1265

Cable, 36” RJ11 6-cond straight 0A-1120-0134

Cable, 100” RJ11 6-cond straight 0A-1146-0002

Cable; 500” RJ11 6-cond straight 0A-1146-0003

Cable Assy; 40 Pos 8” W-1341

Cable Assy; 40 Pos 18” W-1362

Cable Assy; 40 Pos 36” 0A-1000-0006

Power Supply; 5V @10A A-1568

Power Supply; 6.5V @15A A-1591

1.2” Display

Controller- 422 DVIEW 0A-1120-0135

Controller- 422 V1500 0A-1120-0016

Module; CE-10**-4x6-1.2-RG 0P-1120-0030

Panel; CE-1010-4x6-1.2-RG-Flush 0A-1120-0514

Panel; CE-1010-4x6-1.2-RG-Flush 0A-1120-0515

2.1” Display

Controller- 422 DVIEW 0A-1120-0135

Maintenance and Troubleshooting

4-7

Page 26

Controller- 422 V1500 0A-1120-0016

Module; CE-10**-4x6-2.1-SBRG 0P-1120-0034

Panel; CE-1010-4x6-2.1-RG 0A-1120-0132

Panel; CE-1010-4x12-2.1-RG 0A-1120-0131

Panel; CE-1010-4x6-231-RG 0A-1120-0448

Panel; CE-1010-4x12-2.1-RG 0A-1120-0496

3.2” Display

Controller- 422 DVIEW 0A-1120-0136

Controller- 422 V1500 0A-1120-0530

Module; CE-10**-26-3.2-RG 0P-1120-0035

Panel; CE-1010-2x6-3.2-RG-Flush 0A-1120-0533

4.1” Display

Controller- 422 DVIEW 0A-1120-0136

Controller- 422 V1500 0A-1120-0530

Module; CE-10**-2x6-4.2-RG 0P-1120-0031

Panel; CE-1010-2x6-4.2-RG 0A-1120-0529

Previously Used Parts

Part Description Part Number Dates Used In Displays

Panel: CE-1010-4x6-1.2-RG 0A-1120-0152 Before 10/31/00

Panel : CE-1010-4x12-1.2-RG 0A-1120-0153 Before 10/31/00

Module; CE-10**-4x6-2.1-RG 0A-1120-0130 7/16/98-9/15/99

Module; CE-10**-4x6-2.1-SBRG 0P-1120-0032 9/15/99-10/31/00

Panel; CE-1010-4x6-2.1-RG 0A-1120-0132 7/16/98-9/15/99

Panel; CE-1010-4x12-2.1-RG 0A-1120-0131 7/16/97-9/15/99

Panel; CE-1010-4x6-2.1-RG 0A-1120-0448 9/15/99-10/31/00

Panel; CE-1010-4x12-2.1-RG 0A-1120-0449 9/15/99-10/31/00

Panel; CE-1010-2x6-4.2-RG 0A-1120-0137 11/19/98-3/8/01

4.6 Daktronics Exchange and Repair and Return

Programs

To serve customers' repair and maintenance needs, Daktronics offers both an

Exchange Program and a Repair and Return Program.

Daktronics' unique Exchange Program is a quick, economical service for replacing

key

components in need of repair. If a component fails, Daktronics sends the

customer a replacement, and the customer, in turn, sends the failed component to

Daktronics. This not only saves money but also decreases scoreboard downtime.

Daktronics provides these plans to ensure users get the most from their Daktronics

product

guidelines explained below. Please call the Help Desk 877-605-1115 if you have

questions regarding the Exchange Program or any other Daktronics service.

4-8

s, and it offers the service to qualified customers who follow the program

Maintenance and Troubleshooting

Page 27

When you call the Help Desk, a trained service technician will work with you to

solve the equipm

determine which replacement part to ship. If, after you make the exchange, the

equipment still causes problems, please contact our Help Desk immediately.

If the replacement part fixes the problem, package the defective part in the same box

and wrapping in which the replacem

UPS shipping document, and return the part to Daktronics. In most

circumstances, you will be invoiced for the replacement part at the time it is shipped.

This bill, which represents the exchange price, is due when you receive it.

Daktronics expects immediate return of an exchange part if it does not solve the

problem

damaged due to acts of nature or causes other than normal wear and tear.

If you do not ship the defective equipment Daktronics within 30 working days from

the invoice date, Daktronics assum

outright (with no exchange), and you will be invoiced for it. This second invoice

represents the difference between the exchange price and the full purchase price of

the equipment. The balance is due when you receive the second invoice.

If you return the exchange equipment after 30 working days from the invoice date,

you will be credited for the am

To avoid a restocking charge, you must return the defective equipment within

30 days from the invoice date.

Daktronics also offers a Repair and Return Program for items not subject to

exchange.

Return Materials Authorization: To return parts for serv

representative prior to shipment to acquire a Return Material Authorization (RMA)

number. If you have no local representative, call the Daktronics Help Desk for the

RMA. This expedites repair of your component when it arrives at Daktronics.

Packaging for Return: Pack

damaged in shipment. Electronic components such as printed circuit boards should

be installed in an enclosure or placed in an antistatic bag before boxing. Please

enclose your name, address, phone number and a clear description of symptoms.

This is how to reach us:

Ma

PO Box 5128

Phone:

Fax: 605-697-4444

E-ma

. The company also reserves the right to refuse equipment that has been

il: Customer Service, Daktronics Inc.

331 32nd Ave

Brookings SD 57006

Daktronics Help Desk: 877-605-1115 (toll free)

or 605-697-4036

il: helpdesk@daktronics.com

ent problem. You will work together to diagnose the problem and

ent part arrived, fill out and attach the enclosed

es you are purchasing the replacement part

ount on the second invoice, minus a restocking fee.

ice, contact your local

age and pad the item well so that it will not be

Maintenance and Troubleshooting

4-9

Page 28

Page 29

Appendix A: Reference Drawings

General Drawings:

Generic; System Riser Diagram

Label Detail Drawing, CE-10**-****-*.*, RS422

Spacing Plate; XX.XX" Tall-Thin Mount

Shop Dwg; Install Notes-Thin Mount

Mtg Brkt Assy; CE-10**-824-2.1-Thin

Shop Dwg; Install Details CE-1010-1672-2.1-Thin

1.2" Displays

Shop Dwg; CE-1010-***-1.2-RG

Final Assy; CE-1010-****-1.2-RG

Schematic; CE-10**-824/30-1.2-**

Schematic; CE-10**-1224/30-1.2-**

2.1" Displays

Shop Dwg; CE-1010-4**-2.1-RG

Shop Dwg; CE-1010-***-2.1-RG

Final Assy; CE-1010-4**-2.1-SBRG

Final Assy; CE-1010-****-2.1-RG

Schematic; CE-10**-424/30-2.1-**

Schematic; CE-10**-824/30-2.1-**

Schematic; CE-10**-1224/30-2.1-**

3.2" Displays

Shop Dwg; CE-1010-***-3.2-RG

Final Assy; CE-1010-****-3.2-RG

Schematic; CE-10**-418/24-3.2-**

Schematic; CE-10**-618/24-3.2-**

4.2" Displays

Shop Dwg; CE-1010-***-4.2-RG

Final Assy; CE-1010-****-4.2-RG

Schematic; CE-10**-412/18-4.2-**

Schematic; CE-10**-612/18-4.2-**

......................................................Drawing A-113523

...............................Drawing A-110324

..........................................Drawing A-152630

...............................................Drawing A-152599

..............................................Drawing A-155773

.........................Drawing B-155789

.....................................................Drawing A-154011

....................................................Drawing B-110268

..................................................Drawing B-113015

................................................Drawing B-113344

.....................................................Drawing A-151214

.....................................................Drawing A-152954

................................................Drawing B-140722

....................................................Drawing B-121808

..................................................Drawing B-140608

..................................................Drawing B-121853

................................................Drawing B-121854

.....................................................Drawing A-151283

....................................................Drawing B-146115

..................................................Drawing B-145059

..................................................Drawing B-144982

.....................................................Drawing A-154044

....................................................Drawing B-110430

..................................................Drawing B-107790

..................................................Drawing B-109996

Appendix A: Reference Drawings

A-1

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

Page 48

Page 49

Page 50

Page 51

Page 52

Page 53

Page 54

Page 55

Page 56

Page 57

Page 58

Page 59

Page 60

Appendix B: Signal Converter

Appendix B: Signal Converter

B-1

Page 61

Page 62

Signal Converters and Loop-back Testing

for Direct Connections

The following table gives the typical state of the signal converter when the LEDs are either on

or off. Refer to

converters and the locations of the various components.

LED

Indicators

Power

TX

RX

TX/RX

Figure 1 and Figure 2 on next the page for an illustration of the signal

Typical States Troubleshooting

ON

OFF

On Steady

OFF Steady

Brief Flicker SC is transmitting data

ON Steady

OFF Steady Normal state, SC is not receiving data

Brief Flicker SC is receiving data

ON Steady (If serial cable is connected) Bad SC Replace SC

Signal Converter (SC) is receiving

power

SC is not receiving power Check power/Replace fuse

Internal 1 AMP fuse is bad Replace fuse

SC is not connected to a serial port Connect to open computer

1. Serial port or serial cable is bad

2. Computer COM port is in sleep

mode

Normal state, SC is not transmitting

data

1. Field cabling between SC and display

is bad

2. Is connected to display output jack or

terminated inc

3. Bad COM port is on display controller

orrectly

COM port (COM port could be

sleep mode.)

1. Try another port or replace

seri

2. Communicate with display

1. Eliminate cabling by

discon

from SC to display controller

2. Check connections and

terminatio

3. Eliminate by disconnecting

wire/

controller

al cable

necting wire/cable

ns

cable to display

6/30/2004

ED-14413

Page 1

Page 63

RS422 Wire Signal Converter

following tables list the jack pin-outs for a wire signal converter:

The

Figure 1: RS232/RS422 Signal Converter

Fiber Signal Converter

The following tables give the jack pinouts for a fiber signal converter.

JACK OPERATION

J2 TX1 (out)

J3 RX1 (in)

J4 TX2 (out)

J5 RX2 (in)

J1 - 25 Pin DB-F

PIN OPERATION

2 TX-P (out)

3 RX-P (in)

7 GND

J4 and J5 –

Phoenix

PIN OPERATION

1 GND

2 RX-P (in)

3 RX-N (in)

4 TX-P (out)

5 TX-N (out)

6 GND

J2 and J3 –

RJ/11

PIN OPERATION

1 GND

2 TX-N (out)

3 TX-P (out)

4 RX-N (in)

5 RX-P (in)

6 GND

J1 – 25 Pin DB-F

PIN OPERATION

2 TX-P (out)

3 RX-P (in)

7 GND

Figure 2: RS232/Fiber Signal Converter

6/30/2004

ED-14413

Page 2

Page 64

RS422 Loop-Back Test (Outdoor Displays)

Note: This test should be performed with only one jack at a time. Do not connect a loop-back

to more than one jack at a time.

Serial Cable (W-1249)

To complete the test, the serial cable must be plugged into the signal converter. The table

below lists the pin connections when using a serial cable (Daktronics part# -1249).

DB9-F DB25-F

Pin 3 – TX Pin 2 – TX

Pin 2 – RX Pin 3 – RX

Pin 5 – GND Pin 7 - GND

Loop-Back Test: To perform a loop-back for

testing purposes only, use the spare plug in the

signal converter and connect the copper conductor

jumpers using the following table. Refer to

Figure 3. (To eliminate the display, pull out the

phoenix plug with the signal wires connected into

it.)

J2 and J3 J4 and J5

(Pin 5) TX-N to

(Pin 3) RX-N

(Pin 4) TX-P to

(Pin 2) RX-P

When the wires are connected, perform the loop-back test using the

Venus 1500 software as described in Conducting the Venus 1500

Software Test

This test can also be done at the signal termination enclosure on the

surge board assembly, as shown in

controller board input. In that case, the wires coming from the signal

converter must remain connected, and the jumpers will be inserted

along with them. Leave the plug disconnected from the surge board

while conducting the test.

TB1 - RS422 In

(Pin 4) RX-P to

(Pin 2) TX-P

(Pin 5) RX-N to

(Pin 3) TX-N

When the wires are connected, perform the loop-back test using the

Venus 1500 software as described in Conducting the Venus 1500

Software Test

(Pin 2) RX-P to

OR

(Pin 3) RX-N to

(Pin 4) TX-P

(Pin 5) TX-N

Figure 4, or, on some displays, at the

Figure 3: Jumpers at RS232/RS422 Signal Converter

Figure 4: Jumpers at Surge

Board

6/30/2004

ED-14413

Page 3

Page 65

RS422 Loop-Back Test (Indoor/Outdoor Displays)

All indoor displays and some outdoor displays (AE-3010, AF-3010, AF-3020, and X-1000)

use RJ11 plugs or connectors. In those cases, a “Network Cable Tester” (

to conduct the test.

The Network cable tester is used to test for two things:

1. A flipped RJ11 cable used instead of a straight through cable.

2. A good connection from a computer or signal converter to a through the connecting

cable.

The use of a flipped (reversed) or straight cable can be determined visually. Use the figures

below as a guide, or use the Network Cable Tester box for assistance.

Figure 7) is provided

Figure 5: Flipped Cable (Reversed)

Figure 6: Straight Cable

1. Plug one end of the flipped cable into the output from the computer or signal

converter.

2. Plug one end of the flipped

cable into J2 (Loopback

Connector) on the Network

cable tester box.

3. When both ends are connected,

perform the loop-back test

using the Venus 1500 software

as described in Conducting

the Venus 1500 Software

Test.

Figure 7: Network Cable Tester

6/30/2004

ED-14413

Page 4

Page 66

4. For AE-3010, AF-3010, AF-3020, and X-1000 displays

only, disconnect the cable going into the COM module

input (J3) on the controller and connect to J2 on the

loop-back box. See

connector.

Figure 8 for location of the RJ11

Loop-Back test with Fiber

1. Locate the signal termination enclosure or open the bottom left

corner of the display

2. Locate the fiberboard, as shown in Figure 9, and label the fiber

ends connected to the board.

3. Remove the ends from the board that are in jacks J5 and J4.

4. Connect the ends into the fiber splice (Daktronics part# P-1197),

as shown in

Figure 10.

Figure 8: AF-3010/X-1000 COM

Module

Figure 10: Connecting TX and RX Fibers with Fiber Splice

5. When the fibers are connected, perform the loop-back test using

the Venus 1500 software as described in Conducting the Venus

1500 Software Test

6. For AF-3010 and X-1000 displays only, the cable that connects

the fiberboard to the controller board input uses a RJ11 jack at

the controller and can be connected to a loop-back box at J2 to

run the test as usual.

Figure 9: Fiber Optic Board

6/30/2004

ED-14413

Page 5

Page 67

Conducting the Venus 1500 Software Test

1. Open Venus 1500 Administrator.

2. Click Network Configuration and open the direct network by clicking on the [+] in

front of Direct Network.

3. Right click the network you want to test.

6/30/2004

ED-14413

Page 6

Page 68

4. Click [TEST].

5. If the Transmit LED on the signal converter flickers, the signal is getting to the

signal converter. That means that the right Com port is being used. However, if it

does not flicker, the computer has either a software or hardware problem.

6. If you get the same message in the “Received” box as in the “Sent” box, the loop-

back test was successful, implying that the cable has continuity to the point of the

connection.

Note: Flipped and straight cables will provide the same results. Check for correct

order of the wires.

7. If “No Response” appears in the “Received” box, the test failed due to one of the

following problems:

a. The correct computer COM port is not being used, or USB port is not

configured as a “serial” port. (If the Transmit LED flickered, this was not

the problem.)

b. A communication problem exists:

• The fiber or the ends on the fiber are bad.

• (or) The wire or the terminations are bad.

c. There was a problem conducting the test:

• The serial cable to the signal converter is bad or not plugged in.

• The signal converter is not plugged in.

8. If the words “It appears as if this port has a modem attached” appear, the modem will

need to be moved, or you need to use a different COM port.

After the test is complete:

1. Remove the wire jumpers and make sure terminations are correct.

2. (or) Remove the fiber splice, and reconnect fiber to fiberboard.

3. Run the test again without the jumpers, splice, or loop-back box. The test should

fail.

4. Use Venus 1500 Display Manager to receive the status to ensure communication

now works correctly.

6/30/2004

ED-14413

Page 7

Loading...

Loading...