Page 1

Daktronics C-44 Drag Race

-

Timer & Accessories

Installation, Operation

Maintenance Manual

7175 Rev 11 -25 March 2004

ED

331 32nd Ave PO Box 5128 Brookings SD 57006

Tel 605-697-4036 or 877-605-1115 Fax 605-697-4444

www.daktronics.com e-mail: helpdesk@daktronics.com

Page 2

Page 3

ED-7175

P1067

Rev 11 — 25 March 2004

Please fill in the information below for your display; use it for reference

when calling Daktronics for assistance.

Display Serial No. ______________________________________

Display Model No._______________________________________

Date Installed __________________________________________

DAKTRONICS, INC.

Copyright © 2003

All rights reserved. While every precaution has been taken in the preparation of this manual, the

publisher assumes no responsibility for errors or omissions. No part of this book covered by the

copyrights hereon may be reproduced or copied in any form or by any means – graphic, electronic, or

mechanical, including photocopying, taping, or information storage and retrieval systems – without

written permission of the publisher.

CARS™ and C-44™ are trademarks of Daktronics, Inc.

Page 4

Page 5

Table of Contents

Table of Contents....................................................................................................................i

List of Figures .........................................................................................................................i

Section 1: Introduction..................................................................................................1-1

1.1 How to Use this Manual.............................................................................................1-1

1.2 C-44 Version Descriptions.........................................................................................1-2

C-44 Version 2.0 Enhancements..............................................................................................1-2

C-44 Version 2.1......................................................................................................................1-3

C-44 Version 2.2......................................................................................................................1-3

C-44 Version 2.3......................................................................................................................1-3

C-44 Version 2.4......................................................................................................................1-3

C-44 Version 2.5......................................................................................................................1-3

C-44 Version 2.6......................................................................................................................1-3

C-44 Version 2.7......................................................................................................................1-3

C-44 Version 2.8......................................................................................................................1-4

C-44 Version 2.9......................................................................................................................1-4

C-44 Version 3.0......................................................................................................................1-4

C-44 Version 3.1......................................................................................................................1-4

1.3 C-44 Computer Update ..............................................................................................1-5

Section 2: New Track Installation.................................................................................2-1

2.1 Unpacking/Damage Information................................................................................2-1

2.2 Daktronics Exchange/Repair & Return Programs......................................................2-1

2.3 Warranty.....................................................................................................................2-2

2.4 Parts Identification .....................................................................................................2-2

2.5 System Diagrams........................................................................................................2-2

2.6 Location Requirements...............................................................................................2-3

Signal Conduit and Cable.........................................................................................................2-3

Power .......................................................................................................................................2-3

Electrical..................................................................................................................................2-4

2.7 Mounting and Locating Equipment............................................................................2-4

Intermediate and Speed Trap Distances...................................................................................2-5

Photocells.................................................................................................................................2-5

Tree Mounting Considerations .................................................................................................2-5

Time Slip and Logging Printer Considerations........................................................................2-5

Starters’ Box Interface Mounting.............................................................................................2- 5

Isolation Interface Mounting....................................................................................................2-6

2.8 Field Wiring ...............................................................................................................2-6

Start Line/Isolation Interface Wiring .......................................................................................2-6

Start Line Photocells................................................................................................................2-8

Installation of the Three-Amber Tree.......................................................................................2-8

Intermediate Wiring (Optional) and Finish Line......................................................................2-8

Time Slip Printer/Printer Interface Wiring.............................................................................2-10

Optional: Wiring Between the Isolation Interface and Scoreboards ...................................... 2-10

2.9 Operational Check....................................................................................................2-11

Timer - Monitor - Keyboard - Isolation Interface ..................................................................2-11

Timer - Start Line - Emergency..............................................................................................2-12

Start Line Photocell Check.....................................................................................................2-13

Timer - Intermediate Photocell Check ...................................................................................2-13

Timer - Win Lights - Finish Line Photocell Check................................................................2-13

Page 6

Printers...................................................................................................................................2-13

Scoreboards (Optional) ..........................................................................................................2-13

Final Testing ..........................................................................................................................2-13

2.10 Sighting Infrared Photocells .................................................................................... 2-13

Section 3: C-44 Race Timer Operation ........................................................................3-1

3.1 General Operation...................................................................................................... 3-1

3.2 C-44 Race Controller Functions ................................................................................ 3-1

Power Button............................................................................................................................3-1

Entering Dial-ins......................................................................................................................3-1

Timers Reset ............................................................................................................................3-2

Tree Countdown Modes...........................................................................................................3-2

Sure Start..................................................................................................................................3-2

True Win/Breakout ..................................................................................................................3-2

Emergency ...............................................................................................................................3-3

Altitude Adjustment.................................................................................................................3-4

Reaction Timer.........................................................................................................................3-8

Printers.....................................................................................................................................3-8

Reset Win Light.......................................................................................................................3-8

Photocell Check .......................................................................................................................3-8

Margin of Victory (MOV)........................................................................................................3-8

3.3 Additional Functions.................................................................................................. 3-8

Help Screen..............................................................................................................................3-8

Setup Parameters Menu............................................................................................................3-9

System Configuration Settings...............................................................................................3-13

Category Settings.............................................................................................................. .....3-16

Race Operation.......................................................................................................................3-18

Infractions ..............................................................................................................................3-19

Guard Beam Option Use........................................................................................................3-19

Results System Option: Daktronics Automated Results System (CARS).............................. 3-19

Section 4: Maintenance & Troubleshooting................................................................4-1

4.1 Troubleshooting the System ...................................................................................... 4-1

Tree Problems..........................................................................................................................4-2

Printer Problems.......................................................................................................................4-2

Display Problems.....................................................................................................................4-2

Photocell Problems...................................................................................................................4-3

Monitor Problems.....................................................................................................................4-3

Isolation Interface Problems.....................................................................................................4-3

4.2 Maintenance............................................................................................................... 4-3

4.3 Replacement Parts...................................................................................................... 4-4

Appendix A: Infrared Photocells ......................................................................................... 1

A-1 Introduction to Infrared Photocells................................................................................1

A.2 Installation and Alignment; Opposed Beam Infrared Photocells...................................2

A.3 Installation and Alignment Retro-reflective Photocells.................................................3

A.4 Installation and Alignment: SM30 Series Barrel Sensors.............................................4

Appendix B: Glossary of Drag Racing Terms.....................................................................1

Appendix C: Miscellaneous Drawings................................................................................1

Page 7

List of Figures

Figure 1: ..............................................................................C-44 Main Screen 3-1

Figure 2: .................................................Altitude Adjustment Example Screen 3-5

Figure 3: ................................Time Slip Printout Showing Adjustment Factors 3-6

Figure 4: .........................................Log Printout Showing Adjustment Factors 3-6

Figure 5: ...............................................................Without Altitude Adjustment 3-7

Figure 6: .............................................................................. C-44 Help Screen 3-9

Figure 7: ..................................................................Setup Parameters Screen 3-9

Figure 8: ............................................................................Altitude Adjustment 3-10

Figure 9: .....................................................................................Combinations 3-10

Figure 10:..........................................................................Finish Line Distance 3-11

Figure 11:........................................................................Time Slip Information 3-11

Figure 12:.................................................................................Change Format 3-11

Figure 13:.....................................................................................Configuration 3-12

Figure 14:.................................................................................. Time and Date 3-12

Figure 15:.............................................................................................Timeout 3-12

Figure 16:....................................................................................... Diagnostics 3-13

Figure 17:....................................................................... Win Light Diagnostics 3-13

Figure 18:........................................................... System Configuration Screen 3-13

Figure 19:..................................................................................... Speed Traps 3-14

Figure 20:........................................................................................ Log Printer 3-14

Figure 21:............................................................................... Time Slip Printer 3-14

Figure 22:................................................................................... Speed Format 3-14

Figure 23:.............................................................................. Scoreboard Type 3-14

Figure 24:...............................................................................Dual Deep Stage 3-15

Figure 25:...................................................................................... Timer Reset 3-15

Figure 26:.............................................................................No Tree Handicap 3-15

Figure 27:......................................................................Reaction Time Display 3-16

Figure 28:..............................................................................Auto Start of Tree 3-16

Figure 29:...........................................................................Tie Break Selection 3-17

Figure 30:...................................................................Category Setting Screen 3-17

Figure 31:............................................................................Category Selection 3-19

Figure 32:................................................................Category Settings Printout 3-19

Page 8

Page 9

Section 1: Introduction

1.1 How to Use this Manual

The Daktronics C-44™ timer system utilizes the latest in microprocessor technology and is

designed and manufactured for reliability, easy service and long use.

This manual is designed to explain installation and operation of the Daktronics C-44 Drag

Race Timer. Details for display maintenance are also given. Follow all instructions as given

in the text. All instructions are given in a logical order for best installation and operation. For

questions regarding the safety, installation, operation or service of this system, please refer to

the telephone numbers listed on the cover page of this manual.

Important Safeguards:

1. Read and understand installation instructions before installing.

2. Do not drop the control console or allow it to get wet.

3. Opening or disassembly of equipment by non-qualified personnel can void the

warranty.

4. Do not disassemble the control console or the electronic controls of the display

unless you are qualified to do so and there is need for equipment to be installed or

serviced or the warranty will be void.

5. Disconnect power from the unit when not in use, or when servicing.

6. Disconnect cables from the back of the C-44 race controller at the end of the day or

when lightning is occurring in the area.

7. If field cabling is to remain connected to the isolation interface when not in use. The

isolation interface should be powered down via the front panel switch and must

remain plugged in to a three-conductor earth grounded outlet (to provide a discharge

path to ground for any voltage surges picked up by field cabling).

The box below is an illustration of Daktronics drawing numbering system. The drawing

number “7087-P08A-69945” is how Daktronics identifies individual drawings. This number

is located in the bottom right corner of the drawing. The manual will refer to drawings by the

last five digits and the letter preceding them. In the example, the drawing would be referred to

as Drawing A-69945. All drawings referred to as such will be inserted at the end of each

section unless otherwise specified.

Introduction 1-1

Page 10

1.2 C-44 Version Descriptions

C-44 Version 2.0 Enhancements

Split Tree Operation

Split tree operation allows each side to count down in its own mode. The split tree is

enabled by setting up a category with split tree set on and selecting two different tree

modes. Next, select the category. Both lanes will default to the 1st tree setting, but either

lane can be switched to a different mode. Press <ALT><F5> to select the mode for the

left lane and <SHIFT><F5> to select the mode for the right lane. The right lane tree

mode will be displayed below the right lane on the C-44 monitor.

When not in a split tree mode, only one line will show below the left lane on the monitor

and that will be the mode for both lanes. When in a split tree mode and if the handicap is

on or if True Win is on, the timer will account for the different tree times when counting

down. For example, if the dial-in times were the same or zero and there was a full tree on

the left lane and a pro tree on the right lane, the left tree will start 1st and then the right

tree would start after it so that both would go green at the same time. If handicap and

True Win were turned off, the tree would start the countdown on both sides at the same

time and the right lane would turn green before the left lane.

When using a split tree mode, the scoreboard will display an F or a P in front of the dialin to show which mode the tree for that lane is currently in. If the mode for the tree is

changed after the dial-in is displayed, then the ready key, <F5>, must be cycled to

redisplay the new mode.

Auto Start of Tree Countdown After Cars Stage

This mode of operation can be selected under the Configuration Settings Menu by

selecting the <G> item and then setting the option to On. A delay time of 2, 3, or 4

seconds can also be selected. With this option on, the tree will start to count down after

the ready has been set on and both cars have staged for the selected delay time. When this

option is on, the Go switch on the starter box will not be active so that the tree will not be

started ahead of time by the starter's box. If sure start is on, both the pre-stage and the

stage lights for both lanes must be on before the tree will start.

Auto Foul of Car for Not Staging in Time

This mode of operation can be selected under the Configuration Settings Menu by

selecting the <G> item and then setting the option to On. A delay time of 5, 10, or 15

seconds can also be selected. With this option on, when one car has been properly staged

for the selected delay time and the other car has not yet been staged, the tree will start to

count for the staged car and the unstaged car will get a red light. The staged car will get

an automatic win. The monitor and printouts will show a DNS for “Did Not Stage” for

the lane that did not stage. When Sure Start is on, the car must be properly staged with

both the pre-stage and stage lights for the delay time before the red light will occur.

Margin of Victory (MOV)

The Margin of Victory is the amount of time the winner crossed the finish line ahead of

the car in the other lane. This time is displayed on the C-44 monitor by the MOV label.

The MOV will also be printed on the time slip on the same line as the Over/Under time.

The MOV is calculated by adding the elapsed time and the reaction time for each lane. If

there is a handicap, that time is added to the lane that does not have the handicap and then

the times are subtracted from each other to get the MOV.

1-2 Introduction

Page 11

There will not be a MOV displayed or printed if there was a foul, break-out or if True

Win was not on.

Auto Retrieve for Next Driver

The data for the next driver can be set to retrieve automatically after the next vehicle

number is entered. Press <CTRL><F10> to set the C-44 in the auto-retrieve mode and

will display the word “Auto” to the right of the left lane next driver dial-in time. Press

<CTRL><F10> again to set auto-retrieve to Off and the word “Auto” will be removed.

When set to Auto, the next driver's name and dial-in will be retrieved when the vehicle

number is entered, if it is available.

C-44 Version 2.1

Version 2.1 corrected a problem in which reaction time being shown was wrong for the

right lane if a split tree was being used and the tree-based reaction times were being used.

C-44 Version 2.2

Version 2.2 corrected a problem with single-line five-digit displays. The right lane would

have both decimal points on when the reaction time was displayed. It also corrected a

problem where True Win, Sure Start, and Break Out would randomly be set to Off in a

category when that category was selected. Finally, it added a 0.5 second increment

setting to the delay for Auto Start of the tree.

C-44 Version 2.3

Corrected time slip problem when using split tree mode.

Corrected problem with Margin of Victory being miscalculated when using tree-based

reaction time and split tree.

Added information to log printer output. In dead heat races, an asterisk is printed if the

winner is calculated based on speed.

C-44 Version 2.4

Corrected scoreboard problem for fixed decimal points between third and fourth digits.

C-44 Version 2.5

Made auto tree delay selections to go from 1.0 to 3.9 seconds in .1 second increments. In

addition, the data timing of the tree was adjusted so it would not display out of sync

compared to the old tree.

C-44 Version 2.6

Corrected problem with -.001 reaction time not showing a red light or indicating a foul on

monitor.

Updated results system for CARS information.

C-44 Version 2.7

Corrected problem with erratic mph caused by turning off Isolation Interface or the 1/4

mile photocells being tripped while the timers are reset on the C-44.

Corrected auto tree so the delay timer can be reset before the tree drops as described in

<G> Auto Tree / No Stage Foul in Section 3.3.

Introduction 1-3

Page 12

C-44 Version 2.8

Added a configuration item to select if tied races will be selected by reaction time or by

speed.

Made Auto Tree No Stage Foul selectable from 5 to 20 seconds in 1 second increments.

Made log printout show T-S or T-R to indicate how winners of tied races are selected, by

speed or reaction time.

Added configuration item in Auto Tree to enable or disable the Reset/Go switch when

Auto Tree is on. If the switch is enabled and Auto Tree is on, the Reset switch will stop

the tree countdown and Go will start it.

Made the Auto Tree No Stage Foul on, only if auto tree is on. If Auto Tree is turned on, it

then automatically turns off DNS foul.

C-44 Version 2.9

Added a printer selection for an Epson 40 column time slip printer.

Corrected problem of Dial-ins blanking when the tree started counting.

Made the selection of tie break decision or speed or reaction time so it was saved and not

altered by the category selection.

C-44 Version 3.0

Added dial-in displays for next driver.

Added use of MPH as tie breaker after ET and reaction time.

Removed extra lines from 40 column printer printout.

Made auto tree have some random time in countdown of +.1 and +.2 sec.

Made minimum time in auto tree setting change to 0.5 sec instead of 1.0 second.

Added option for time trials in category menu.

Changed so it powers up to default of Pro .4 and Full .5 tree settings.

Moved the Reset/Next function to Shift-F7 (from control-F8), so timer is not accidentally

reset when trying to print with control-F8.

C-44 Version 3.1

Added a tree countdown mode for crosstalk referred to in the program as 3X mode. This

mode will turn on both top amber lights at the same time and then counts each side of the

tree based on its dial-in. This was also added to the category settings so it could be set for

a certain category.

Added a delay setting for LED trees so the tree will act more like an incandescent tree.

With LED trees the light comes on sooner and this causes the drivers to start sooner so

they end up red lighting.

1-4 Introduction

Page 13

1.3 C-44 Computer Update

To correspond to European standards, Daktronics has replaced the C-44 with the new C-44

CE computer. This computer works the same as the C-44, but now conforms to European

standards. The software on both machines is identical. Throughout this manual, references to

the C-44 also apply to the C-44 CE.

Introduction 1-5

Page 14

Page 15

Section 2: New Track Installation

2.1 Unpacking/Damage Information

Open all packages and inspect for shipping damage, such as rattles or dents. See that all

equipment is included as shown on the packing slip. Report any deficiencies immediately to

Daktronics, Inc. Save all packing for shipping if warranty repair or exchanging is needed.

Shipping packages also work well for off-season equipment storage.

2.2 Daktronics Exchange/Repair & Return Programs

To serve customers’ repair and maintenance needs, Daktronics offers both an exchange and a

repair and return program. The exchange program reduces down time by providing timely

replacement of key components. This service is provided to qualified customers who follow

the program guidelines explained below. It is our pleasure to provide this service to ensure

you get the most from your Daktronics products. Please call our Help Desk (1-877 / 605-

1115) if you have any questions regarding the exchange program or any other Daktronics

service.

When you call the Daktronics Help Desk, a trained service technician will work with you to

solve the equipment problem. You will work together to diagnose the problem and determine

which exchange replacement part to ship. If, after you make the exchange, the equipment still

causes problems, please contact our Help Desk immediately.

If the replacement part fixes the problem, package the defective part in the same packaging

the replacement part arrived in, fill out and attach the enclosed UPS shipping document and

RETURN THE PART TO DAKTRONICS. (You may use the same box and packing the

exchange part was sent in.) This will speed up the transaction and alleviate confusion when

the failed component arrives at Daktronics. (Daktronics expects immediate return of the

exchange part if it does not solve the problem.) For most equipment, you will be invoiced for

the replacement part at the time it is shipped. This invoice is due when you receive it.

Daktronics reserves the right to refuse equipment that has been damaged due to acts of nature

or causes other than normal wear and tear.

If the defective equipment is not shipped to Daktronics within 30 working days from the

invoice date, it is assumed you are purchasing the replacement part and you will be invoiced

for it. This second invoice represents the difference between the exchange price and the

purchase price of the equipment. This amount is due when you receive the second invoice. If

you return the exchange equipment after 30 working days from invoice date, you will be

credited for the amount on the second invoice minus a 20 percent restocking fee.

@ To avoid a 20 percent restocking charge, please return the defective equipment within

30 days from the invoice date.

Daktronics also offers a Repair and Return program for items not subject to exchange.

Where to Send: To return parts for service, contact your local representative prior to

shipment to acquire a Return Material Authorization Number (RMA#). If you have no local

representative, call the Daktronics Help Desk for the RMA#. This will expedite the receiving

process.

New Track 2-1

Installation

Page 16

Packaging for Return: Package and pad the item well so that it will not be damaged in

shipment. Electronic components such as printed circuit boards should either be installed in an

enclosure or should be put in an anti-static bag before boxing. Please enclose your name,

address, phone number and a clear description of symptoms.

Mail: Daktronics, Inc., Customer Service

PO Box 5128

331 32nd Avenue

Brookings, SD 57006

Phone: Daktronics Help Desk: 1-877/605-1115

or 1-605/697-4036

Customer Service Fax: 1-605-697-4444

e-mail: helpdesk@daktronics.com

2.3 Warranty

Daktronics has a one year warranty on all equipment. Daktronics reserves the option to

decide what damage will be covered by the warranty. All installations must use the cables (or

equivalent) specified by Daktronics. All installations must also be properly terminated and

earth grounded, per Daktronics specification. Failure to do so may void the warranty. The

owner has the responsibility of paying for shipping both to and from Daktronics. Upon

expiration of warranty Daktronics provides an optional maintenance agreement that provides

extended coverage of equipment. Questions concerning maintenance agreements may be

directed to Daktronics via the above listed address/phone number.

2.4 Parts Identification

Identify each component of the system by using the illustrations throughout this manual.

Once all parts have been identified, group the parts into logical groups for assembly. To avoid

unnecessary trips down the track, organize all the equipment into separate groups, for

instance: equipment used in the tower, all equipment for the start line, intermediate parts of

the track, and finish line. This will organize the installation procedure so that unnecessary

trips down the track are avoided.

2.5 System Diagrams

Reference Drawings:

Layout w/AC cells, start line J-box & C44 CE............................. Drawing B-91012

Field Cabling for dwg. B-91012 ................................................ Drawing B-114631

System diagrams show the complete setup for a new track. Refer to Drawings B-91012 and

B-114631 when installing the system. Your track may have some variations from this

diagram (i.e. more cable, no guard beam etc.), but basically all tracks will have this configuration. On these drawings you will find conduit sizes, cable lengths and type, as well as

equipment locations for installing the system.

In addition, these diagrams can aid in removal in the off-season, emergency replacement,

maintenance, safety, and security.

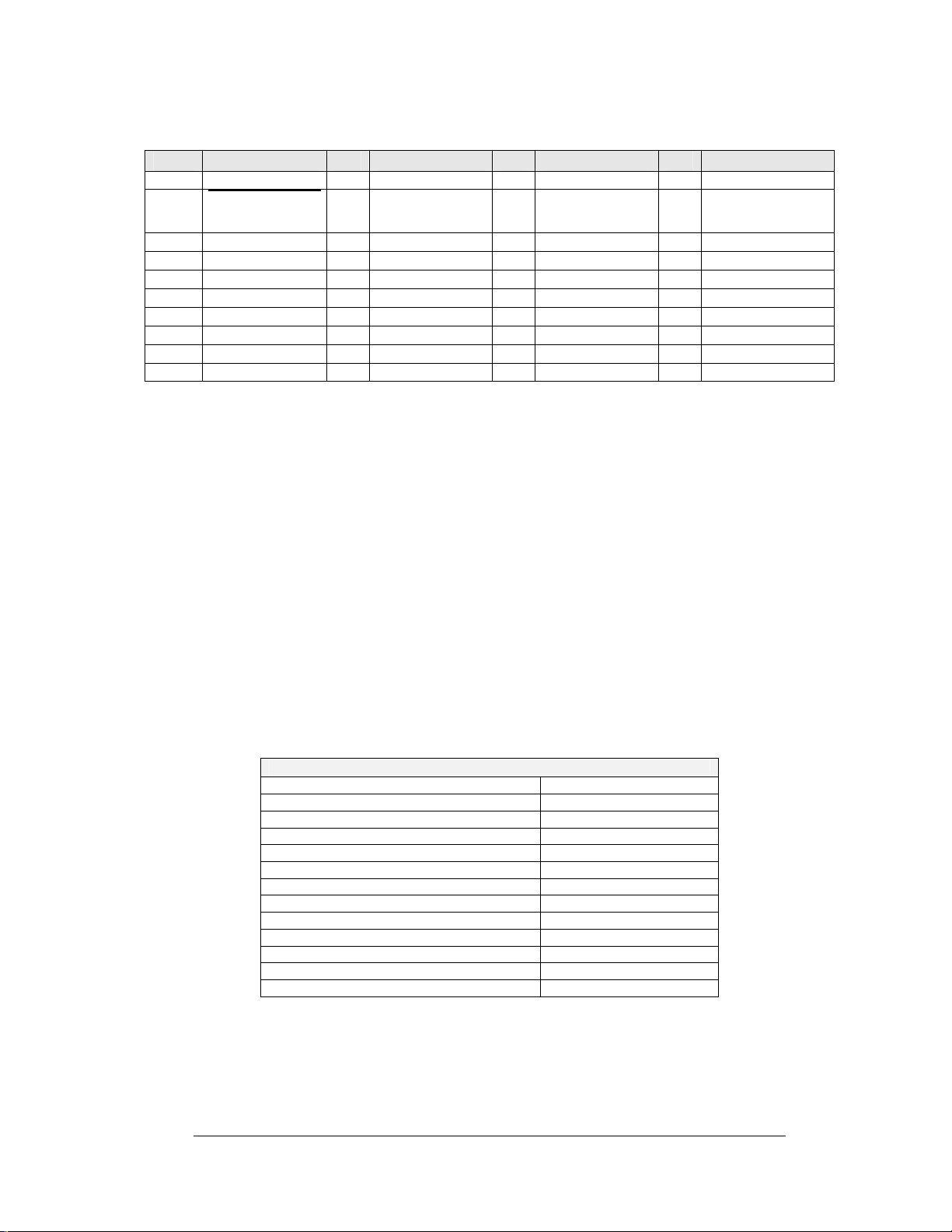

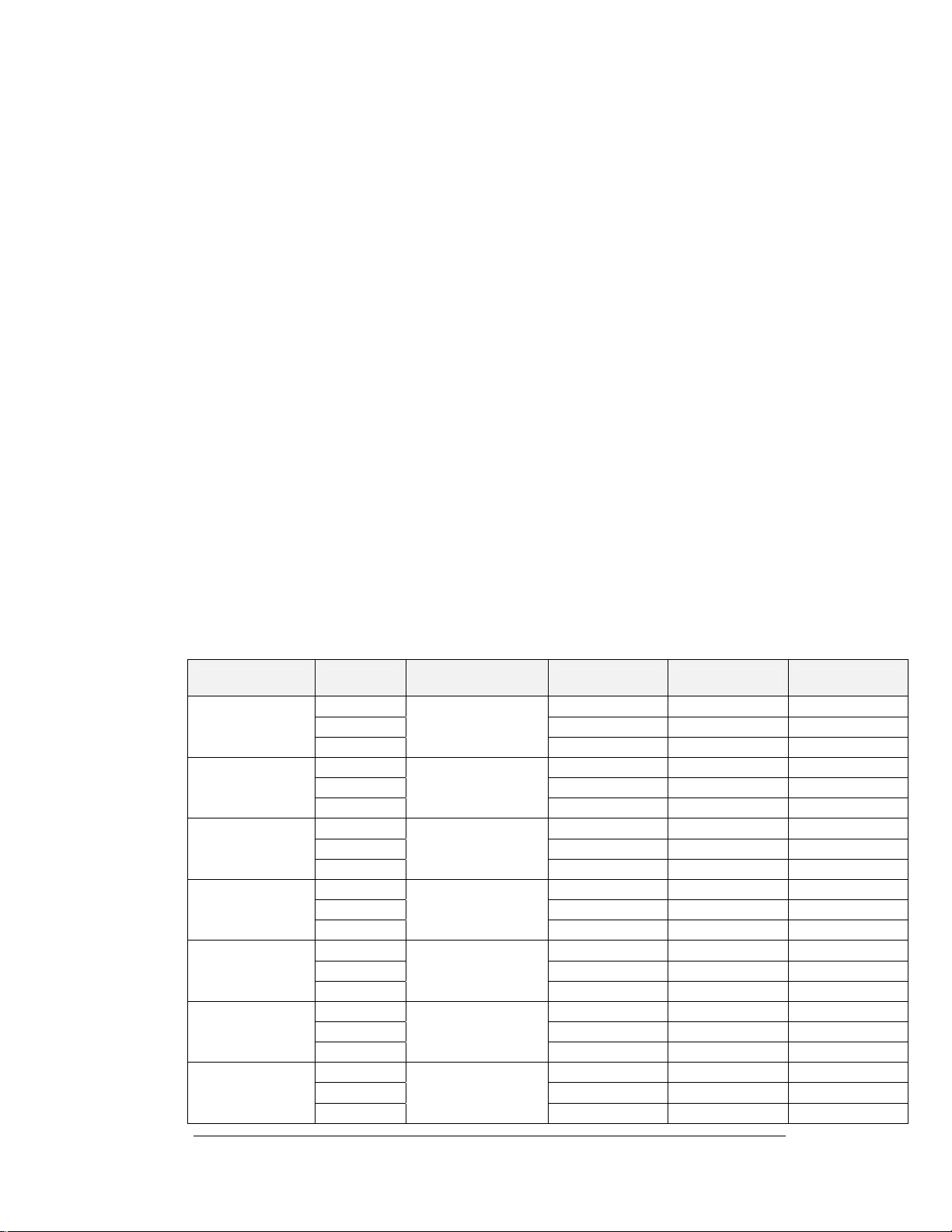

The following table refers to the information in Drawing B-91012

2-2 New Track

Installation

Page 17

Infrared Photocells

Item Part No. # Part No. # Part No. # Part No.

1 0A-1067-0128 11 W-1267 21 0A-1067-0108 31 Incl. w/item #28

2

Incl. w/item

12 W-1117 22 0A-1067-0111 32 A-1157

#1

3 A-1305 13 0A-1067-0099 23 0A-1067-0064 33 0A-1081-0016

4 A-1157 14 0A-1067-0100 24 0A-1067-0065 34 Custom

5 W-1239 15 W-1399 25 0A-1067-0063 35 Custom

6 0A-1067-0076 16 0A-1067-0010 26 W-1117 36 0A-1067-0143

7 W-1266 17 0A-1081-0146 27 0A-1067-0080 37 W-1117

8 W-1266 18 W-1237 28 0A-1067-0050 38 EC-1082

9 W-1264 19 0A-1067-0107 29 W-1350 39 A-1078

10 W-1267 20 0A-1067-0071 30 A-1305 40 Custom

2.6 Location Requirements

Reference Drawings:

Field Cabling; C-44 Timer...........................................................Drawing B-75554

This section explains the equipment locations on the track for best operation. Such topics as

conduit, power and electrical requirements, noise levels, and other location considerations are

discussed. Daktronics recommends that these guidelines be followed as closely as possible.

Signal Conduit and Cable

All cable should be 18 awg twisted shielded pair, Beldon 8760 (Dak W-1117) unless

noted. All cable should be in conduit. Refer to Drawing B-75554 for conduit sizes and

cable types.

Power

The following is a list of electrical items and their respective power requirements.

Unit Power Requirement (Watts)

Start line outlet 100

Tower outlets 1800

C-44 console 100

Color monitor (C-44) 114

Isolation interface 30

Printer (log or time slip) 30

Time slip printer booth outlet 84

60 ft. line outlet 200

1/8th mile line outlet 30

Starters box interface 100

Color monitor (results) 102

DAKTRONICS 486DX computer 100

Three-amber tree 2000 (min 20 amps)

New Track 2-3

Installation

Page 18

Electrical

All electrical equipment used in the timing system runs on standard 120 Volts AC/60 Hz.

Noise (Radio/PA)

Important: The C-44 data cables must never be run with AC (power) or PA (Public

Address) cables. The data cables may cross AC or PA cables when absolutely

necessary but only at 90-degree angles. If it is necessary to run AC or PA cables

parallel to a data able, the cables must not be closer than 24".

In addition, care must be taken to insure that radio transmitters or television high

voltage transmitters are far enough from the track to prevent noise interference. If

these transmitters are close to the track, all cable must be shielded to prevent

interference.

Care must be used to insure that the cable not be crimped or bent into too tight a

radius. If it is necessary to put bends in conduit, they should be sweeping nineties.

Grounding

All equipment used with the timing system must be properly earth grounded. Make

sure all outlets and cords are three-conductor (grounded). All extension cords or

extra wiring must be three-conductor as well.

Important: Check to be sure that the service entrance (for the power) is properly

earth grounded. If it is not grounded, have it properly grounded.

Isolated Power Circuits

Daktronics recommends that the control equipment (i.e. C-44 console) be on a

dedicated power circuit to prevent noise interference. Air conditioners, fans, or highpowered electrical equipment may cause noise interference or a brown-out which

would reset the system.

Electrical Code

The National Electrical Code and all local codes must be followed when installing

electrical equipment. It is the responsibility of the installer to see that this is done.

Equipment damage or personal injury can occur if these codes are not followed.

2.7 Mounting and Locating Equipment

Reference Drawing:

Isolation Inter. Encl. Detail.......................................................... Drawing A-56253

Photocell Mnt. Dist. Dia. ............................................................. Drawing A-56354

Starter’s Box Interface................................................................ Drawing A-72242

Layout w/AC cells, st. ln. J-bx &C44CE...................................... Drawing B-91012

Field Cabling for dwg. B-91012 ................................................ Drawing B-114631

This section will explain how and where the track equipment should be mounted for a 1/8th

and 1/4th mile track. The distances for track setup are national standards and should be

followed.

2-4 New Track

Installation

Page 19

Intermediate and Speed Trap Distances

Refer to Drawing A-56354. With guard beam, the start line is the guard beam line and

all points should be measured from there. Without guard beam, the start line is the stage

line and all points should be measured from there.

Four different speed trap lengths can be used with the C-44. Each one starts at a different

point. Find the length to be used in the list below and mount the start of speed trap

photocells that same distance before the finish line. General practice is to use the 66'

speed trap.

Possible speed trap lengths: 2' 7-11/16"

13' 2-3/8"

66' 0"

132' 0"

Burn-out Box = 90 ft. from designated box to start line.

Photocells

Roll Out- Height of the beams must be adjusted as necessary, to provide 12" of roll

using standard dragster wheel/tire (22" diameter). Beam height must be low enough to

accommodate clearance rulings.

Infrared Photocell Mounts

Mounting- The photocell stands can mount to either the protective guard rail or

directly to a concrete surface. Ensure that the mount is level both horizontally and

vertically to ensure proper photocell alignment. Photocell mounts are equipped with

slots for side to side and up and down alignment.

Photocell Mounting

Mounting- Photocells with pipe mounts must be attached so the photocells are

secure. The 60' photocell must be 10 1/2 inches above the crest of the track. All

other interval photocells (i.e. 1/8th mile, speed trap, etc.) must be six inches above

the crest of the track.

Tree Mounting Considerations

The distance from the start line to the tree must be 38 to 40 ft. The height of the tree

should be 80 inches from the ground to the center of the pre-stage bulb.

Time Slip and Logging Printer Considerations

The Time Slip and logging printers will be Epson LX-300's standard. Locate the printers

as shown in the system diagram (refer to Drawing B-91012). Care should be taken when

choosing a site that can keep the printer from getting wet. The Time Slip printer cable

can be routed with the finish line cable or scoreboard cables. Note: The E.T. printer

requires two 18 awg twisted shredded pairs, Beldon 8760 (Dak W-1117). The shield

should only be connected to earth in the control tower.

Starters’ Box Interface Mounting

Refer to Drawing A-72242 for an example of the starters box interface. The starters box

interface has transmit and receive lines hard-wired between the starters box and isolation

interfaces, and it is hardwired to the start line for the starters console. J2, located on the

starters box interface, is an optional place to plug in the starters console. The starters box

interface is located in the control tower as shown in Drawings B-114631 and B-91012.

New Track 2-5

Installation

Page 20

Isolation Interface Mounting

The isolation interface is designed with all field cabling connections made with clamping

screw plugs, and all tower cabling connections made with supplied, D-type connector

cables. Field equipment which must be connected to the isolation interface includes all

photocells, all start-line equipment via the start line junction box, time slip printer, and

ET/MPH displays.

Mounting considerations consist of access to all previously mentioned field cabling,

proximity to C-44 timer (all interconnects made with standard 10' cables), position C-44

timer operator unrestricted view of isolation interface LED indicators, and adequate

clearance for any high traffic areas. An ideal mounting location would allow the C-44

operator to view both the C-44 monitor and the isolation interface front panel, yet not

restrict maintenance access (as depicted in Drawing A-56253). Refer to Drawing B-

91012 for suggested tower equipment location.

2.8 Field Wiring

Reference Drawings:

Iso. Interface Term Blk. Detail .................................................... Drawing A-56252

Iso. Interface Encl. Detail............................................................ Drawing A-56253

Start Box Int. Wiring.................................................................... Drawing A-72242

C-44 Start Line J-Box ................................................................. Drawing A-75431

Field Cabling; C-44 Timer........................................................... Drawing B-75554

Lay. w/AC clls,stlnJ-bx&C44CE.................................................. Drawing B-91012

Field Cabling for dwg B-91012 ................................................. Drawing B-114631

This section pertains to the field wiring of the drag strip. The wiring will be done as followsstart line, intermediate, finish, and then tower. For all wiring, refer to the system diagram and

pay close attention to the field cabling diagram Drawing B-75554.

When making connections, make sure all equipment power is off!

Photocell Connection: Connect all photocells (except the start line photocells) in this

manner. Photocells are connected to the cables as per wiring instruction found in the power

board box.

Daktronics uses only 18 awg twisted shielded cable, Beldon part #8760 (Daktronics part #W-

1117) unless specified. The shield conductor provides protection from electrical noise and

interference. To provide proper protection, the shield conductor must be terminated at the

isolation interface end only. The field end of the shield should be cut back even with the outer

insulation of the cable and wrapped with an electrical insulation tape. When wiring

photocells to isolation, always jumper the unused photocells from positive to negative on

the isolation interface.

Start Line/Isolation Interface Wiring

The start line wiring consists of wiring the isolation interface, the start line junction box,

starter’s box interface, start line photocells, and the guard beam (optional).

Cables coming into the tower should come to the isolation interface. Refer to Drawings

A-56252, A-56253, A-72242, A-75431, B-91012, and B-114631 to aid in wiring.

2-6 New Track

Installation

Page 21

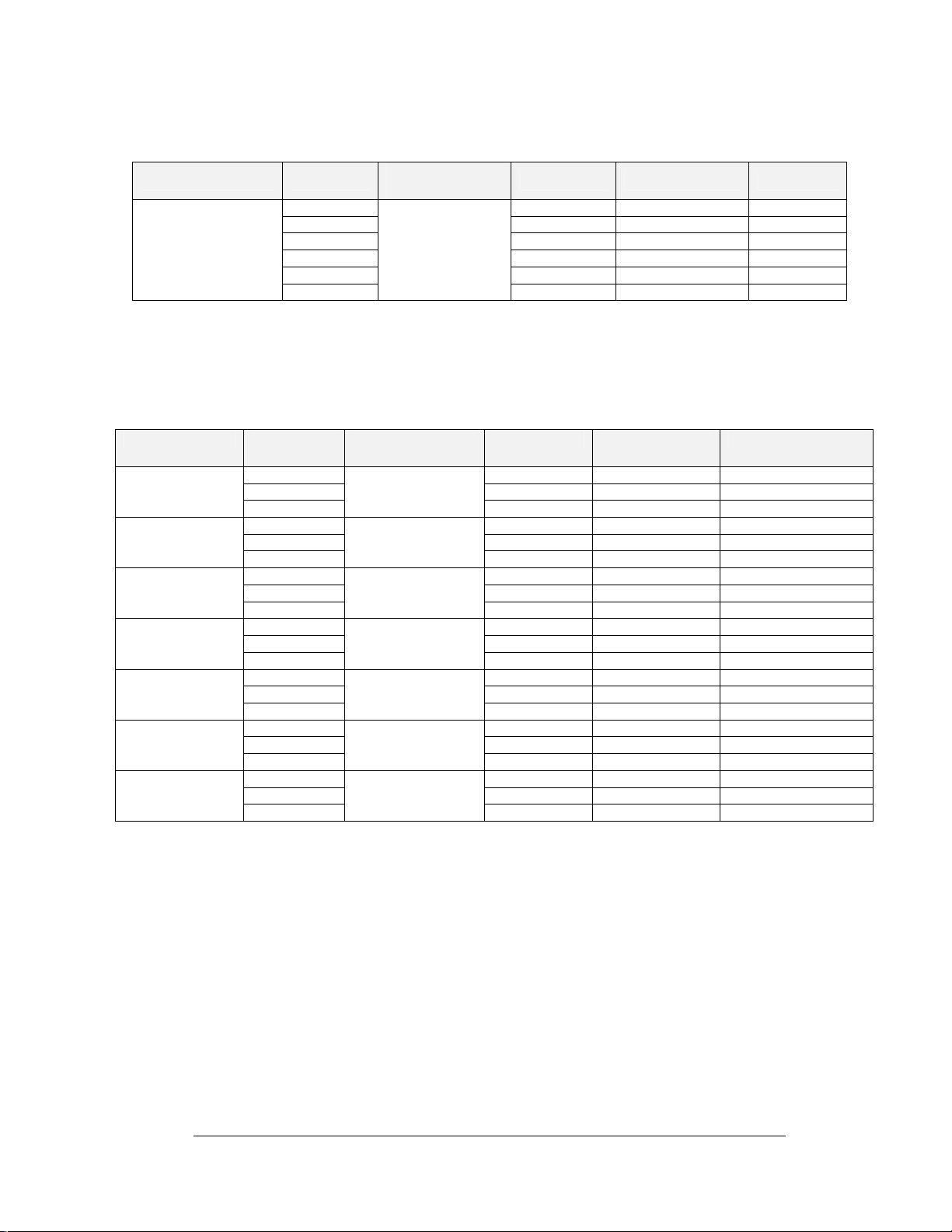

Isolation Interface to Starters Box Interface Wiring

Description Form (I/I)*

TB 13-1 Red Trans + Rec-P

Isolation Interface/

Start line Interface

Communications

TB 13-2 Black Trans - Rec-N

TB 13-3 Shield Not Connected Earth

TB 13-4 Green Rec + Trans-P

TB 13-5 White Rec - Trans-N

TB 13-6

Specifications

Manhattan u4473

(Dak W-1234)

*Isolation Interface Drawing A-56252

**Start Line Interface Drawing A-72242

Isolation Interface to Start Line J-Box

Description From (I/I)* Cable

Specification

Pre-Stage

Left Lane

Stage Left Lane

Guard Left Lane

Pre-Stage Right

Lane

Stage Right Lane

Guard Right Lane

Tree Signal

TB7-1 Red TB3-1 LPSTAGEPCL-P

TB7-2 Black TB3-7 LPSTAGEPCL-N

TB7-3

TB7-4 Red TB3-2 LSTAGEPCL-P

TB7-5 Black TB3-7 LSTAGEPCL-N

TB7-6

TB7-7 Red TB3-3 LGUARDPCL-P

TB7-8 Black TB3-7 LGUARDPCL-N

TB7-9

TB1-1 Red TB3-4 RPSTAGEPCL-P

TB1-2 Black TB3-8 RPSTAGEPCL-N

TB1-3

TB1-4 Red TB3-5 RSTAGEPCL-P

TB1-5 Black TB3-8 RSTAGEPCL-N

TB1-6

TB1-7 Red TB3-6 RGUARDPCL-P

TB1-8 Black TB3-8 RGUARDPCL-N

TB1-9

TB16-1 Red TB1-1 SIG3-P

TB16-2 Black TB1-2 SIG3-N

TB16-3

Beldon 8760

(Dak W-1117)

Beldon 8760

(Dak W-1117)

Beldon 8760

(Dak W-1117)

Beldon 8760

(Dak W-1117)

Beldon 8760

(Dak W-1117)

Beldon 8760

(Dak W-1117)

Beldon 8760

(Dak W-1117)

Refer to the Operational Check (Section 2.8) for connection and power up procedure.

*Isolation Interface

**Start Line Junction Box

Note: If field cabling for guard beam photocells is present, but guard beam

photocells are not used, do not connect unused guard beam cabling to the isolation

interface terminal blocks (TB7-7, TB7-8, TB7-9, LGUARDPCL, and TB1-7, TB1-8,

TB1-9, RGUARDPCL).

Cable

Wire Color To (SLI)** Function

N.C. Not Connected Earth

Wire Color To (SLJB)** Function

Shield No Connection Shield-N

Shield No Connection Shield-N

Shield No Connection Shield-N

Shield No Connection Shield-N

Shield No Connection Shield-N

Shield No Connection Shield-N

Shield No Connection Shield-N

New Track 2-7

Installation

Page 22

Start Line Interface from Start Line J- Box

Description To (SLI)* Cable

Specifications

Cable From

SBI to SLJB for

Hand-held

Starters

Console

+12V Yel Pair 5 TB2-1 +12V-P

L-Pro Tree Black Pair 1 TB2-2 PROTREE light

L-Ready Red Pair 1 TB2-3 Ready light –N

L-Times Reset Brn Pair 6 TB2-4 Timer Reset

S-STARTGO Blu Pair 4 TB2-5 GO/Reset

S-EMERG Grn Pair 3 TB2-6 Emergency

S-SINGLE Wht Pair 2 TB1-3 Singles/Drag

GND Black Pair 2 TB1-4 GND-N

SHIELD

Beldon 9774

(Dak W-1399)

*Start Line Interface Drawing A-72242

**Start Line J-Box Drawing A-75431

Start Line Photocells

The cable used for connecting the start line photocells to the start line junction box

(spreader cable) is pre-marked showing which photocell it connects to. Connect the cable

to the photocells as marked.

Installation of the Three-Amber Tree

The Daktronics three-amber tree is totally compatible with all Daktronics C-44 race

controllers. To install the three-amber tree, connect the tree cables into the connector on

the bottom side of the tree. Plug the AC power cord into an outlet capable of supplying a

minimum of 20 amps.

Regulations stipulate that the pre-stage bulb should be approximately 80 inches from the

ground; a longer mounting pipe will be necessary in some cases.

Eight, 60-watt yellow "bug" lights should be used for the stage and pre-stage lamps.

(There are two bulbs for each stage and pre-stage position to prevent confusion should

one bulb burn out.) The twelve amber, four green, and four red lamps should be standard

85-watt colored flood lamps (GE part #13472 red, #13474 green, #13463 amber). These

should be installed in the sockets using the supplied gasket to provide adequate bulb

support and moisture protection. The gaskets should be used with the lamp sockets to

seal and prevent vibration. The blue Sure Start lamp (if used) may be any blue-colored

reflector-type bulb rated at 100 watts or less.

Due to the increased power consumption of this starting tree, it is essential that the tree be

connected to a power supply sufficient to supply a minimum 20-amp current at the outlet.

If the power available is insufficient, some slight dimming of the staging lamps will be

noticed. This will not harm the tree, but the use of long extension cords should be

avoided. Refer to Section 4.2 for details on maintenance.

Intermediate Wiring (Optional) and Finish Line

This section consists of wiring the intermediate section of the track and the finish. This

includes the 60 foot (I 1), the 330 foot (I 2), the 1/8th mile speed trap (I 3), the 1/8 mile

finish, the 990 foot (I 4), and the 1/4 mile speed trap/finish.

Wire Color From (SLJB)** Function

–N

light-N

switch-N

switch-N

switch-N

SHIELDS Not Connected EARTH

2-8 New Track

Installation

Page 23

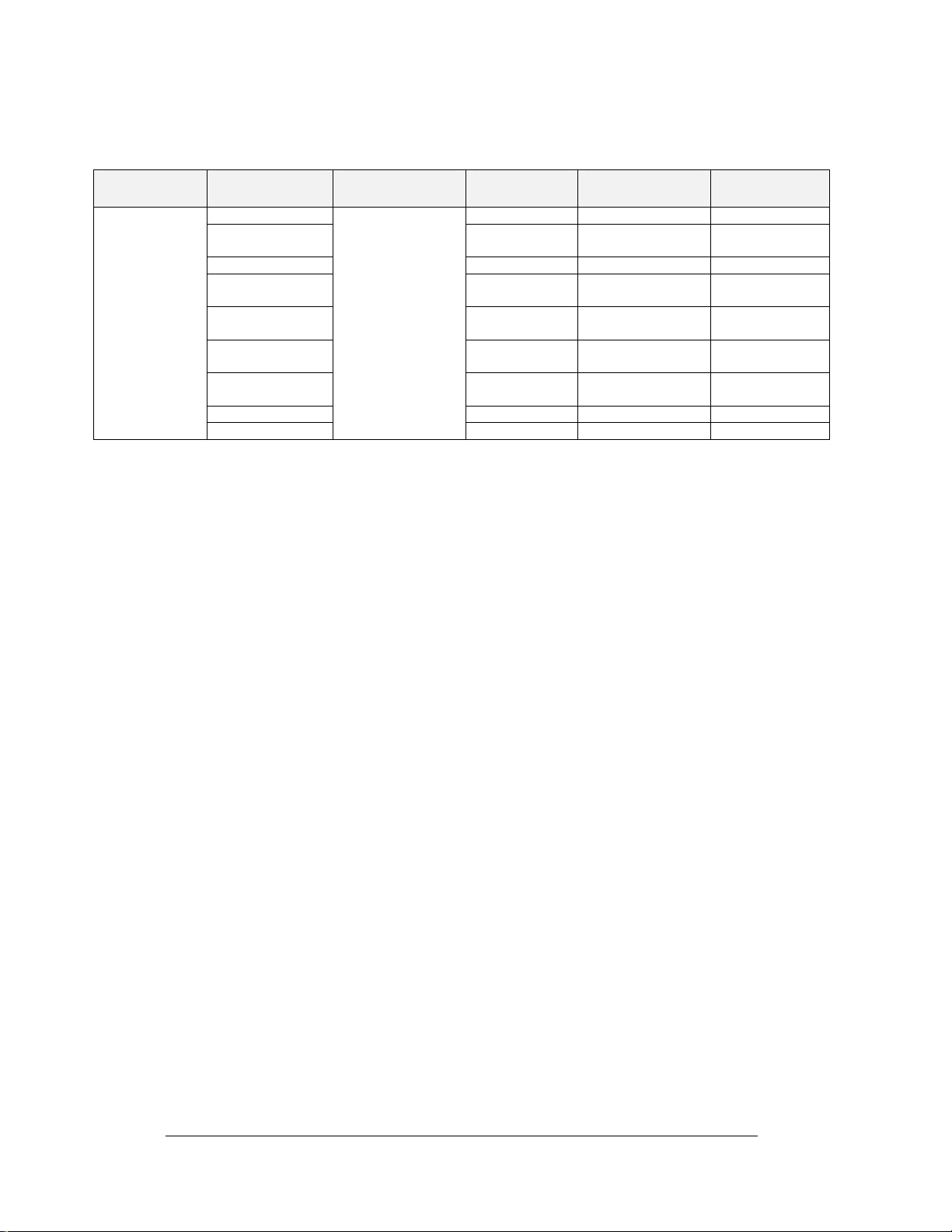

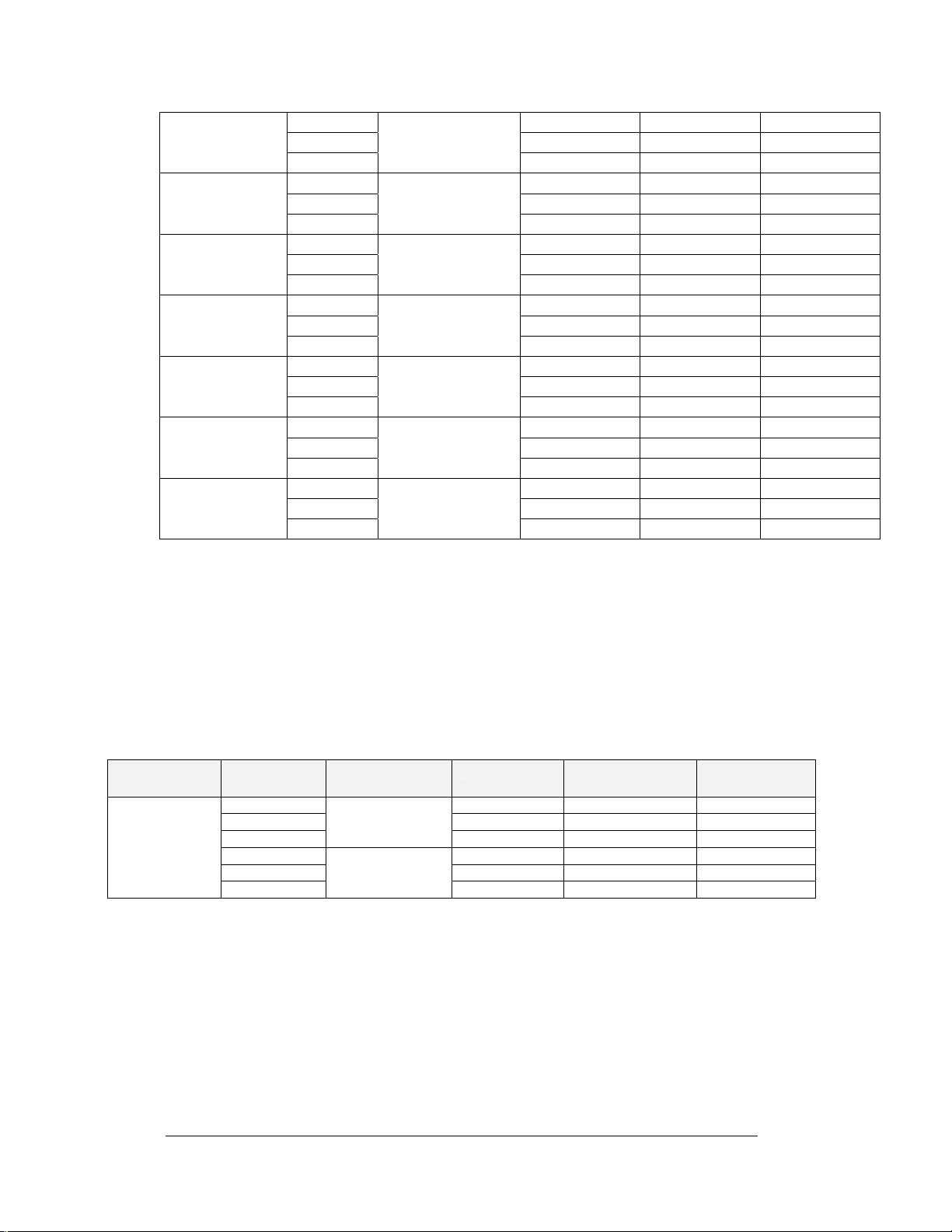

Intermediate One, 60'- Wiring between the isolation interface and the 60' photocell Jboxes use multiple one pair shielded 18 awg cable. Plugs with clamping screws are used

for connection to the isolation interface. Refer to the following connection table to assist

in the installation. You may also reference the field cabling diagrams (Drawing B-

91012 and B-114631).

Intermediate Two, 330'- Wiring between the isolation interface and the 330' photocell J-

boxes use multiple one pair shielded 18 awg cable. Plugs with clamping screws are used

for connection to the isolation interface. Refer to the following connection table to assist

in the installation. You may also reference the field cabling diagrams (Drawings B-

91012 and B-114631).

1/8 mile, 660' (Speed Trap)- Wiring between the isolation interface and the 660' speed

trap photocell J-boxes use multiple one pair shielded 18 awg cable. Plugs with clamping

screws are used for connection to the isolation interface. Refer to the following

connection table to assist in the installation. You may also reference the field cabling

diagrams (Drawings B-91012 and B-114631).

Intermediate 990'- Wiring between the isolation interface and the 990' photocell J-boxes

use multiple one pair shielded 18 awg cable. Plugs with clamping screws are used for

connection to the isolation interface. Refer to the following connection table to assist in

the installation. You may also reference the field cabling diagrams (Drawings B-91012

and B-114631 in Section 2.5).

1/4 mile, 1320' (Speed Trap)- Wiring between the isolation interface and the finish line

photocell J-boxes use multiple one pair shielded 18 awg cable. Plugs with clamping

screws are used for connection to the isolation interface. Refer to the following

connection table to assist you in the installation. You may also reference the field cabling

diagrams (Drawings B-56301 and B-114631).

Description To (I/I)*

TB8-1 Red J1-1 SIGNAL-P

60N Left Lane

60N Right Lane

330N Left Lane

330N Right Lane

Start of Speed

Trap #1 Left Lane

(594N)***

Start of Speed

Trap #1 Right

Lane (594N)***

1/8 Mile Left

Lane (660N)

TB8-2 Black J1-3 GND

TB8-3

TB2-1 Red J1-1 SIGNAL-P

TB2-2 Black J1-3 GND

TB2-3

TB8-4 Red J1-1 SIGNAL-P

TB8-5 Black J1-3 GND

TB8-6

TB2-4 Red J1-1 SIGNAL-P

TB2-5 Black J1-3 GND

TB2-6

TB9-1 Red J1-1 SIGNAL-P

TB9-2 Black J1-3 GND

TB9-3

TB3-1 Red J1-1 SIGNAL-P

TB3-2 Black J1-3 GND

TB3-3

TB9-4 Red J1-1 SIGNAL-P

TB9-5 Black J1-3 GND

TB9-6

Cable

Specifications

Beldon 8760

(Dak W-1117)

Beldon 8760

(Dak W-1117)

Beldon 8760

(Dak W-1117)

Beldon 8760

(Dak W-1117)

Beldon 8760

(Dak W-1117)

Beldon 8760

(Dak W-1117)

Beldon 8760

(Dak W-1117)

Wire Color From (Cell)** Function

Shield Not Connected EARTH

Shield Not Connected EARTH

Shield Not Connected EARTH

Shield Not Connected EARTH

Shield Not Connected EARTH

Shield Not Connected EARTH

Shield Not Connected EARTH

New Track 2-9

Installation

Page 24

1/8 Mile Right

Lane (660N)

990N Left Lane

990N Right Lane

Start of Speed

Trap #2 Left Lane

(1254N)***

Start of Speed

Trap #2 Right

Lane (1254N)***

1/4 Mile Left

Lane (1320N)

1/4 Mile Right

Lane (1320N)

TB3-4 Red J1-1 SIGNAL-P

TB3-5 Black J1-3 GND

TB3-6

TB9-7 Red J1-1 SIGNAL-P

TB9-8 Black J1-3 GND

TB9-9

TB3-7 Red J1-1 SIGNAL-P

TB3-8 Black J1-3 GND

TB3-9

TB10-1 Red J1-1 SIGNAL-P

TB10-2 Black J1-3 GND

TB10-3

TB4-1 Red J1-1 SIGNAL-P

TB4-2 Black J1-3 GND

TB4-3

TB10-4 Red J1-1 SIGNAL-P

TB10-5 Black J1-3 GND

TB10-6

TB4-4 Red J1-1 SIGNAL-P

TB4-5 Black J1-3 GND

TB4-6

*Isolation Interface

**Intermediate/ Finish Line Photocell J-Box

*** Based on a 66 Ft Speed Trap

Time Slip Printer/Printer Interface Wiring

The Time Slip Printer is a 40 column Epson TM-4200 or an Epson LX300 (contact

Daktronics for other choices or models). The Time Slip Printer is then plugged into a

Printer Interface. The printer interface has a terminal block (TB1) to connect to the cable

coming from the isolation interface. Refer to the following table for connecting the cable

to the isolation interface. Use two, shielded 18 awg pair cables. You may also reference

the field cabling diagrams (Drawings B-91012 and B-114631).

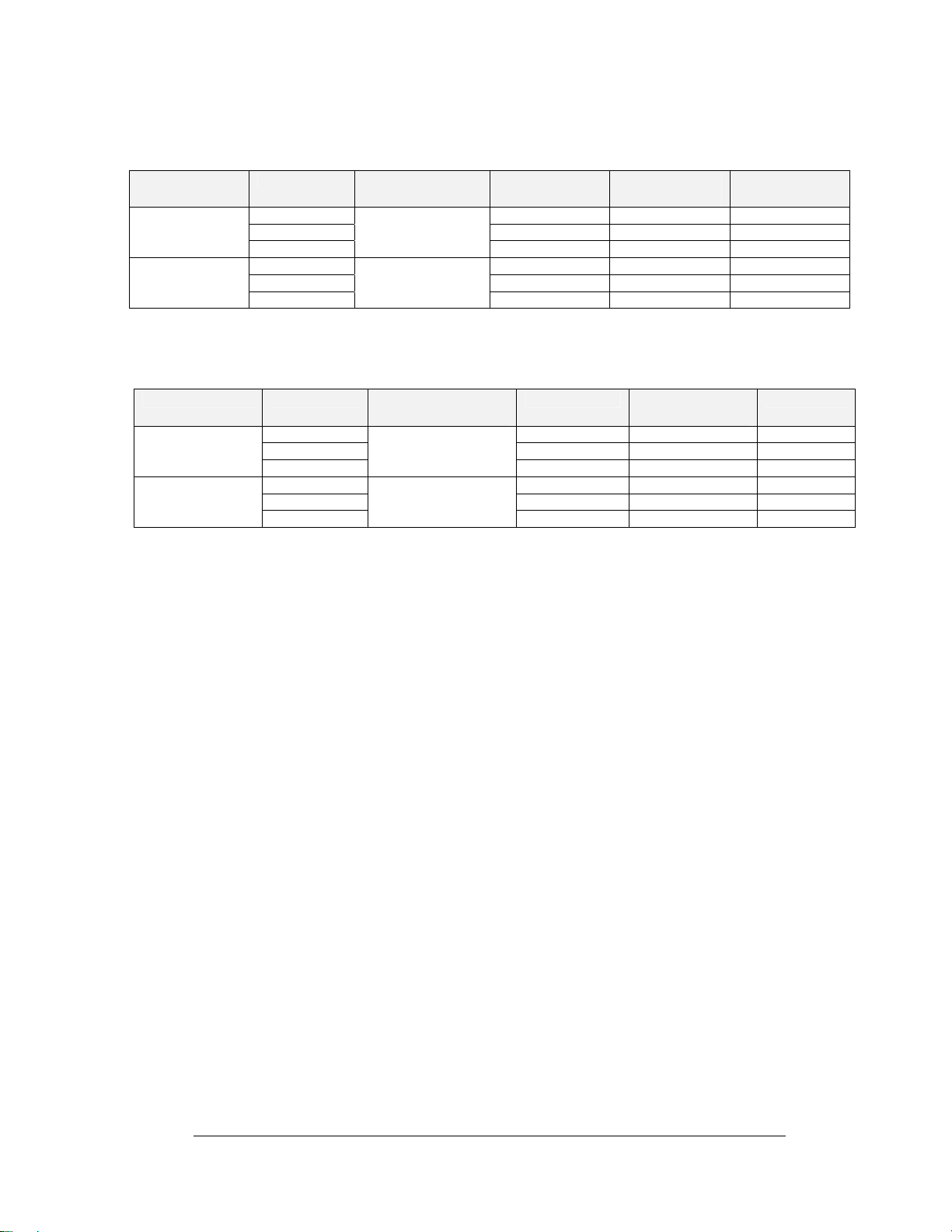

Description From (I/I)* Cable

Specification

Time Slip

Printer

TB14-1 Red TB1-4 ETFAULT-P

TB14-2 Black TB1-5 ETFAULT-N

TB14-3

TB14-4 Red TB1-1 ETDATA-P

TB14-5 Black TB1-2 ETDATA-N

TB14-6

Beldon 8760

(Dak W-1117)

Beldon 8760

(Dak W-1117)

*Isolation Interface

Optional: Wiring Between the Isolation Interface and Scoreboards

Wiring between the isolation interface and the scoreboards/dial-in displays use multiple

one pair 18 awg shielded cables. Refer to the following wire connection table to assist in

the installation. You may also reference the field cabling diagrams (Drawings B-91012

and B-114631).

Beldon 8760

(Dak W-1117)

Beldon 8760

(Dak W-1117)

Beldon 8760

(Dak W-1117)

Beldon 8760

(Dak W-1117)

Beldon 8760

(Dak W-1117)

Beldon 8760

(Dak W-1117)

Beldon 8760

(Dak W-1117)

Wire Color To (Printer

Shield Not Connected EARTH

Shield Not Connected EARTH

Shield Not Connected EARTH

Shield Not Connected EARTH

Shield Not Connected EARTH

Shield Not Connected EARTH

Shield Not Connected EARTH

Function

Interface)

Shield Not Connected Earth

Shield Not Connected Earth

2-10 New Track

Installation

Page 25

Isolation Interface to Left Scoreboard Wiring List

Description From (I/I)* Cable

Specifications

Left Lane SCBD

Left Lane Dial-in

Display

TB15-1 Red TB31-1 SIG1-P

TB15-2 Black TB31-2 SIG1-N

TB15-3

TB15-1 Red Tip SIG1-P

TB15-2 Black Ring SIG1-N

TB15-3

Beldon 8760

(Dak W-1117)

Beldon 8760

(Dak W-1117)

*Isolation Interface

Isolation Interface to Right Scoreboard Wiring List

Description From (I/I)* Cable

Specifications

Right Lane SCBD

Right Lane Dial-

In Display

TB15-4 Red TB31-1 SIG2-P

TB15-5 Black TB31-2 SIG2-N

TB15-6

TB15-4 Red Tip SIG2-P

TB15-5 Black Ring SIG2-N

TB15-6

*Isolation Interface

Beldon 8760

(Dak W-1117)

Beldon 8760

(Dak W-1117)

Wire Color To (Left

Function

Scbd)

Shield Not Connected Earth

Shield Not Connected Earth

Wire Color To (Right

Function

Scbd)

Shield Not Connected Earth

Shield Not Connected Earth

2.9 Operational Check

Reference Drawing:

Printer Interface Assy..................................................................Drawing A-65810

C-44Start Line J-Box...................................................................Drawing A-75431

Field Cabling; C-44 Timer.........................................................Drawing B-114631

During the operational check, the final connections are made on the system and preliminary

tests are done to determine if all the equipment is working properly. First, the equipment in

the tower is checked, then the start line, the intermediate equipment, and finally, the finish

line.

Timer - Monitor - Keyboard - Isolation Interface

This section will cover the connection of the equipment in the tower. Refer to the system

diagram and cabling diagram for information on the items that connect to the C-44. Refer

to Drawing A-65810 to view the back panel of the C-44.

Connect the cable that came with the video monitor to the "VIDEO BOARD

(VIDEO 1)" port on the back of the C-44. The power switch is on the lower

right side of the monitor.

Connect the cable that came with the keyboard to the "KEYBOARD" port.

Plug the C-44 and the monitor into a tower outlet. Other equipment will be

connected as the system is turned on.

Make sure the timer and monitor are plugged in. Turn on the power to the C-44

and monitor. Check to be sure the green power LED lights up when turned on

and the fan in the rear of the console is moving air. Make sure a clear picture of

New Track 2-11

Installation

Page 26

the C-44 main screen appears on the monitor (Refer to Figure 1 in Section 3).

Some adjusting of the monitor brightness or focus may be necessary.

Use the keyboard to type in sample drivers' names, etc. to test if the keyboard is

operating properly. Next, connect the equipment using the following

instructions.

Using one of the 9-pin "D" cables, connect the isolation interface port marked

“SLEB” to the C-44 port marked "COM1."

Using the other 9-pin "D" cable, connect the isolation interface port marked "ET

Printer" to the C-44 port marked "ET PRINTER (COM3)."

Using the 15-pin "D" cable, connect the isolation interface port marked

"DISPLAY" to the port marked "DISPLAY TRANSMITTER (DISPLAY1)."

Using the two 37-pin "D" cables, connect the isolation interface ports marked

"LEFT PHOTOCELLS" and "RIGHT PHOTOCELLS" to the C-44 ports

marked "PHOTOCELL BOARD #1 LEFT LANE (PHOTO1)" and

"PHOTOCELL BOARD #2 RIGHT LANE (PHOTO2)" respectively.

Connect the logging printer cable into the port marked "LOGGING PRINTER

(LPT1)" on the back of the C-44; connect the other end to the logging printer.

Refer to the printer user’s manual for instructions on how to insert the paper (8

1/2" by 11" white paper with tear-off edges should be used).

Optional: If a results system is being used, connect the results system cable to

the port marked "RESULTS (COM2)" on the back of the C-44 and the serial

port of the results computer.

For best results in protecting against glitches in the timing system, it is

recommended that a UPS power supply be attached to the timer and results

computer. For areas with irregular power supplies, a line voltage regulator is

recommended in conjunction with the UPS.

Timer - Start Line - Emergency

Connecting the starter’s box interface and start line junction box (Refer to Drawing A-

75431).

Plug in the power cord to starter’s box interface.

Connect the cable on the starter’s console into the connector on the start line

junction box.

The cable for connecting the start line junction box to the start line photocells is

a pre-marked spreader cable. Connect the start line photocell cable into the

military connector on the back of the start line junction box.

Emergency

To activate the emergency light, press the <F9> key while holding down the <CTRL>

key on the C-44 keyboard. Check to make sure that the red tree light comes on and that

the C-44 screen shows the emergency sign. Turn off Emergency by pressing

<CTRL><F9> a second time and reset the timer <SHIFT><F7>. Check the emergency

switch on the starter’s console. The emergency setting on the C-44 and the emergency

2-12 New Track

Installation

Page 27

switch on the starter’s console must be off to reset the timer. The switch on the starter’s

console marked emergency also turns the lights on and off.

Switch both to emergency mode. Test to be sure that the starter’s console cannot reset the

tree while the emergency light is on. Turn off the emergency switch on the starter’s

console. Now test the C-44 to make sure it cannot reset the timers. Now turn both

switches off and check to be sure the timer can be reset by the C-44.

Start Line Photocell Check

Use the photocell check function that is built into the isolation interface to check the

operation of the start line photocells. Refer to Photocell Check in 3.2 for instructions on

the use of the photocell check function.

Timer - Intermediate Photocell Check

Test the operation of the intermediate photocells and light sources. Use the photocells

check function as in Photocell Check in 3.2.

Timer - Win Lights - Finish Line Photocell Check

Use the Win Lights diagnostics function that is built into the C-44 to test the optional Win

Lights. Refer to <Ctrl-W> Win Light Diagnostics in Section 3.3 for instructions.

Use the photocell check function again to check the operation of the finish line

photocells. Now all photocells should be operational.

Printers

Before each race, ensure that the printers and timer are connected. Make sure both

printers are on and on-line. Check to be sure both printers are enabled. If “off” shows up

by either Log or Time Slip, refer to System Configuration Settings in Section 3.3 on

enabling them. If “not ready” shows up by Log or Time Slip, something is not working

right from the computer to the printer.

Scoreboards (Optional)

Use the scoreboard diagnostics function that is built into the C-44 to test the operation of

the scoreboards. Refer to <Ctrl-S> Scoreboard Diagnostics in Section 3.3 for

instructions on the use of the scoreboard diagnostics function.

Final Testing

Finally, drive a car down the track at constant speed and check the operation of the entire

system. Verify the accuracy of the times that are returned as well as the speeds.

2.10 Sighting Infrared Photocells

Follow the photocell alignment procedures that come with the photocells.

New Track 2-13

Installation

Page 28

Page 29

Section 3: C-44 Race Timer Operation

3.1 General Operation

Access to all of the race controller’s functions is through the function keys (<F1> through

<F12>) located along the top edge of the keyboard. Many of the function keys have more

than one purpose, which are accessed by using the function keys in conjunction with the

<SHIFT>, <CTRL>, or <ALT> keys. A table of all functions (Figure 7) is given in Help

Screen in Section 3.3 of this manual, or can be viewed from the race controller by pressing

the <F6> key (Help Screen).

Keystroke sequences associated with functions are given in parentheses throughout this

manual. If a function key is listed by itself, such as <F1>, that means that the <F1> key alone

is used to access that function. If a function key is listed with another key, such as

<SHIFT><F1>, the <SHIFT> key must be held down while the <F1> key is momentarily

depressed.

3.2 C-44 Race Controller Functions

Reference Drawing:

Starter’s Console.........................................................................Drawing A-57318

Power Button

The power button used to supply main power to the unit, is on the front of the C-44 race

controller. When the unit is connected to a proper power source and the switch is on, the

power LED will be illuminated.

When the system is powered up, the monitor should display the following screen (Refer

to Figure 1). Note: Some systems may be configured differently when powered up,

therefore each screen may show some subtle differences to the one shown here. It should,

however, be very close.

Figure 1: C-44 Main Screen

Entering Dial-ins

Entering dial-ins is just like entering numbers on a calculator. Just type in the number,

leading and trailing 0's are put in automatically. However, the decimal point must be

C-44 Race Timer 3-1

Operation

Page 30

entered by the user. There is also a maximum of two digits before and after the decimal

point. After entering the dial-in press the <ENTER> key.

Timers Reset

To reset the timers, use one of three possible keystroke combinations depending on the

desired reset options:

1. <CTRL><F6> is used to reset the timers for both lanes only.

2. <SHIFT><F7> is used to reset the timers for both lanes and move the next driver

information to current.

3. <CTRL><F8> is used to reset the timers for both lanes and move the next driver

information to current and cause the tower log printer and time slip printer to

output preceding race information. When both timers are reset, a timers reset light

on the starter's console will be illuminated, and a timer reset message will appear

for each lane on the monitor.

Tree Countdown Modes

<ALT><F5> is used to select the tree countdown mode. The selected countdown mode

will alternate between full tree and pro tree with each press of <ALT><F5>. The

countdown sequence and rate that are currently active are displayed below the left lane

portion of the main screen. This gives the operator constant verification of the

countdown mode. If the selected category has split tree on, the countdown mode of the

right lane will display below the right lane. The keystroke <SHIFT><F5> will alternate

the countdown mode for the right lane when in split tree and <ALT><F5> will change

the left lane. The exact countdown rate used is selected by pressing <CTRL><F1> to get

the Setup Parameters Menu, followed by <C> to access the Tree Countdown Mode

feature (Refer to Figure 9 in Section 3.3).

Sure Start

<ALT><F6> will put the timer in sure start mode. When in this mode, a foul will be

generated if a vehicle was not pre-staged at the instant the starter's switch was thrown to

GO. This feature allows a track operator to enforce the no deep staging rule.

When sure start is activated, the blue bulb on the starting tree between the stage lights

will be on, and “SS” is displayed in the lower left portion of the main screen. If

<ALT><F6> is pressed a second time, the sure start is turned off, the blue bulb is no

longer illuminated, and the SS indicator is off.

True Win/Breakout

The keystroke combination <ALT><F7> activates the True Win function and causes

“TW” to be displayed in the lower left portion of the main screen. The True Win

function allows the winner of a race to be determined based on the following factors.

A. General disqualifications (entered manually by the operator)

B. Crossing a lane boundary line (entered manually by the operator)

C. A foul (red light)

D. Crossing the finish line first

E. Not finishing the course (entered manually by the operator)

If True Win is activated, the Breakout function can be selected by pressing <ALT><F8>.

Breakout is activated and “BO” is displayed in the lower center portion of the main

screen, this allows the inclusion of E.T. breakouts into the determination of a winner.

When both True Win and Breakout are activated, the following factors are used to

determine the true winner:

3-2 C-44 Race Timer

Operation

Page 31

1. General Disqualifications (DSQ)- Disqualifications are infractions manually

entered by the operator <ALT><F1> (left lane) or <ALT><F9> (right lane).

These include unsportsmanlike conduct, intentional delay of run, and others as

determined by the officials. The C-44 handles DSQ's in the following way. If

one driver is disqualified, the other driver automatically receives the win. If

both drivers are disqualified, the driver with the least severe infraction wins the

race. To determine the severity of an infraction, see the race officials.

Infractions may be canceled manually by the operator: <ALT><F4> (left lane)

or <ALT><F12> (right lane).

2. Crossing Lane Boundary Lines (OB)- Leaving lane boundary lines is an

infraction of the rules. If the operator is notified that a driver has left the driving

lane, the operator enters an out-of-bounds (OB) <ALT><F2> (left lane) or

<ALT><F10> (right lane). The driver who leaves the driving lane is

disqualified, the other driver automatically wins even if his or her car leaves the

driving lane during the remainder of the race, unless a more severe infraction

occurs.

3. Fouls (red lights)- A foul (or red light) is caused when a driver crosses the

starting line before the green light is on (negative reaction time). The C-44

automatically senses a foul, if one has occurred. When a foul does occur, the

driver who fouled is disqualified and the other driver receives the win. If both

drivers foul, the driver who fouled first loses the race. Note: When Sure Start is

active and both drivers foul, both are disqualified in accordance with the no deep

staging rule mentioned earlier.

4. E.T. Breakouts- A breakout occurs when the driver beats his or her respective

dial-in. The C-44 automatically detects breakouts. When a breakout occurs, the

driver who “broke-out” is disqualified and the other driver receives the win. If

both drivers breakout, the driver who “broke out” by the least amount of time

receives the win. If both breakouts are equal the driver that crossed the finish

line first is the winner.

5. Which Vehicle Crossed the Finish Line First- The C-44 automatically

determines which driver finishes the race first. This determination is used to

decide the winner when two drivers have equal dial-ins and no other infractions

occur, or when a double breakout of equal time occurs.

6. Not Finishing the Course (DNF)- If a driver does not finish the course, the C44 operator manually enters a did-not-finish (DNF): <

<ALT><F11> (right lane). The driver who did not finish the race loses the race.

If both drivers do not finish, both drivers are given losses.

Both True Win and Breakout are deactivated by pressing their respective

keystroke combinations a second time.

ALT><F3> (left lane) or

Emergency

<CTRL><F9> will activate the flashing red lights on the tree and inhibit any countdown

of the tree. An emergency message on the monitor will also flash. Press <CTRL><F9>

a second time to deactivate the emergency mode.

There is also an emergency switch on the starter's console (Drawing A-57318), which

will also activate the emergency mode. The emergency mode will rema in active until

both the keyboard select on the C-44 and the switch on the control box are off.

C-44 Race Timer 3-3

Operation

Page 32

Altitude Adjustment

An Introduction to Altitude Adjustment

Many race car engines run better, and consequently the cars move faster, when the

air available to the engine is denser. In general, cars will run faster at sea-level

tracks than at high elevation tracks such as in “mile high” Denver. The drag racing

industry has developed lists of altitude correction factors that can be used to adjust

E.T. and MPH values for races that are run at various altitudes. The basic concept is

to adjust the E.T. and MPH values that are experienced at the higher elevation tracks

to sea-level values so that all results can be directly compared.

In the past, the E.T. and MPH values had to be manually adjusted using the altitude

correction factor when preparing a timer for a race or verifying the results. The

altitude adjustment feature of the C-44 timer allows this operation to be performed

automatically by the timer to prevent errors and allow quicker verification of race

results. The C-44 also allows the automatic altitude adjustment function to be

quickly switched off if manual calculations are desired or if the altitude correction

factors are not used for some races.

The C-44 system allows three sets of adjustment factors to be entered by the

operator. Each set contains one factor for adjusting the E.T. and one factor for

adjusting the MPH. This allows different categories of classes to have different

adjustment factors pre-entered and quickly available for each race. The

determination and accuracy of the actual factors used are the responsibility of the

track operator and the track’s sanctioning body.

Altitude Adjustment Example

Figure 2 shows the results of a race that was run using the altitude adjustment factors

of the C-44.

Figure 2: Altitude Adjustment Example

1. Notice at the bottom of the screen: Altitude adjustment feature is turned on

("ADJ"). Adjustment factor set #1 is selected. This factor set has an E.T. factor

= 1.0000 and speed factor = 1.0000.

2. Dial-ins were entered as sea-level dial-ins. Dial-ins of 10.25 for the left lane and

10.17 for the right lane were entered.

3. The C-44 automatically divides the sea-level dial-in by the E.T. adjustment

factor to produce an actual (at altitude) elapsed time value that will be used to

3-4 C-44 Race Timer

Operation

Page 33

determine the tree handicap. This at altitude elapsed time value is shown on the

screen after the word “Hdcp” for each lane.

4. As the race is run, the C-44 multiplies the actual measured at altitude times by

the E.T. adjustment factor to produce the sea-level times for:

- Reaction Time

- Interim 1 Time

- Interim 2 Time

- Interim 3 Time

- Interim 4 Time

- Final E.T.

5. The actual at altitude MPH which is calculated in the speed trap by the C-44 is

multiplied by the MPH adjustment factor to produce sea-level MPH.

6. Note that all the times and MPH shown on the monitor, scoreboard, and

printouts are sea-level values. Most drivers and spectators are familiar with the

sea-level values which are also listed in most racing publications.

7. Note that the values in the E.T. printout (Figure 3) are marked with A1 to show

that they are sea-level values that have been calculated from the actual at

altitude values using altitude adjustment factor #1. This is also true for the log

slip (Refer to Figure 4).

Figure 5 shows the results of an identical race that was run without using the altitude

adjustment feature.

C-44 Race Timer 3-5

Operation

Page 34

Note: The dial-ins were manually adjusted before being entered. The times and

MPH shown are the actual unadjusted at altitude values that were read by the C-44

timer.

WELCOME TO THUNDER VALLEY'S 1993 FINALE

"$1,000 BRACKET BONANZA BASH"

TASTE IT NOW? BUDWEISER AND PEPSI-COLA