Page 1

Transparent Shot Clocks

Display Manual

ED-15168 Rev 5 – 26 August 2011

Models

BB-2140

BB-2150 (NBA only)

BB-2141

BB-2151 (NBA only)

201 Daktronics Drive PO Box 5128 Brookings, SD 57006-5128

Tel: 1-800-DAKTRONICS (1-800-325-8766) Fax: 605-697-4700

Web: www.daktronics.com

Page 2

Page 3

Please fill in the information below for your display; use it for reference when

calling Daktronics for assistance.

Scoreboard Serial No. __________________________________________

Scoreboard Model No. __________________________________________

Date Installed _________________________________________________

ED-15168

Product 1322

Rev 5 – 26 August 2011

DAKTRONICS, INC.

Copyright 2004-2011

All rights reserved. While every precaution has been taken in the preparation of this manual, the publisher

assumes no responsibility for errors or omissions. No part of this book covered by the copyrights hereon may be

reproduced or copied in any form or by any means – graphic, electronic, or mechanical, including photocopying,

taping, or information storage and retrieval systems – without written permission of the publisher.

All Sport®, PanaView®, and Tuff Sport® are trademarks of Daktronics, Inc.

Page 4

Page 5

Table of Contents

Section 1: Introduction ............................................................................................................................ 1

1.1 Resources .................................................................................................................................. 1

1.2 Daktronics Nomenclature ...................................................................................................... 2

1.3 Model Number ........................................................................................................................ 3

1.4 Scoreboard Controllers ........................................................................................................... 3

1.5 Product Safety Approval........................................................................................................ 3

Section 2: Specifications .......................................................................................................................... 5

Section 3: Mechanical Installation ........................................................................................................ 7

3.1 Lifting the Display .................................................................................................................. 7

3.2 Shot Clock Mounting .............................................................................................................. 7

3.3 Control Enclosure Mounting ................................................................................................. 7

3.4 Remote Horn Enclosure Mounting ....................................................................................... 7

3.5 Camera Mounting ................................................................................................................... 7

Section 4: Electrical Installation ............................................................................................................ 9

4.1 Installation Overview ............................................................................................................. 9

4.2 Power ........................................................................................................................................ 9

Grounding ......................................................................................................................... 9

4.3 Power-On Self-Test (POST) ................................................................................................. 10

Radio Settings ................................................................................................................. 10

4.4 Signal Connection ................................................................................................................. 10

Section 5: Scoreboard Troubleshooting ............................................................................................. 11

5.1 Troubleshooting Table .......................................................................................................... 11

5.2 Component Access & Digit Replacement .......................................................................... 13

5.3 LED Drivers ........................................................................................................................... 13

Replacing a Driver ......................................................................................................... 15

Setting the Driver Address ........................................................................................... 15

5.4 Schematics .............................................................................................................................. 15

5.5 Replacement Parts List ......................................................................................................... 16

5.6 Daktronics Exchange and Repair & Return Programs ..................................................... 16

Exchange Program ......................................................................................................... 16

Repair & Return Program ............................................................................................. 17

Daktronics Warranty and Limitation of Liability ...................................................... 18

Section 6: Additional Scoreboard Options ........................................................................................ 19

6.1 Light Strips ............................................................................................................................. 19

6.2 Radio Control......................................................................................................................... 19

Appendix A: Reference Drawings ............................................................................................................ 21

Appendix B: Daktronics Warranty and Limitation of Liability .......................................................... 23

Table of Contents i

Page 6

Page 7

1

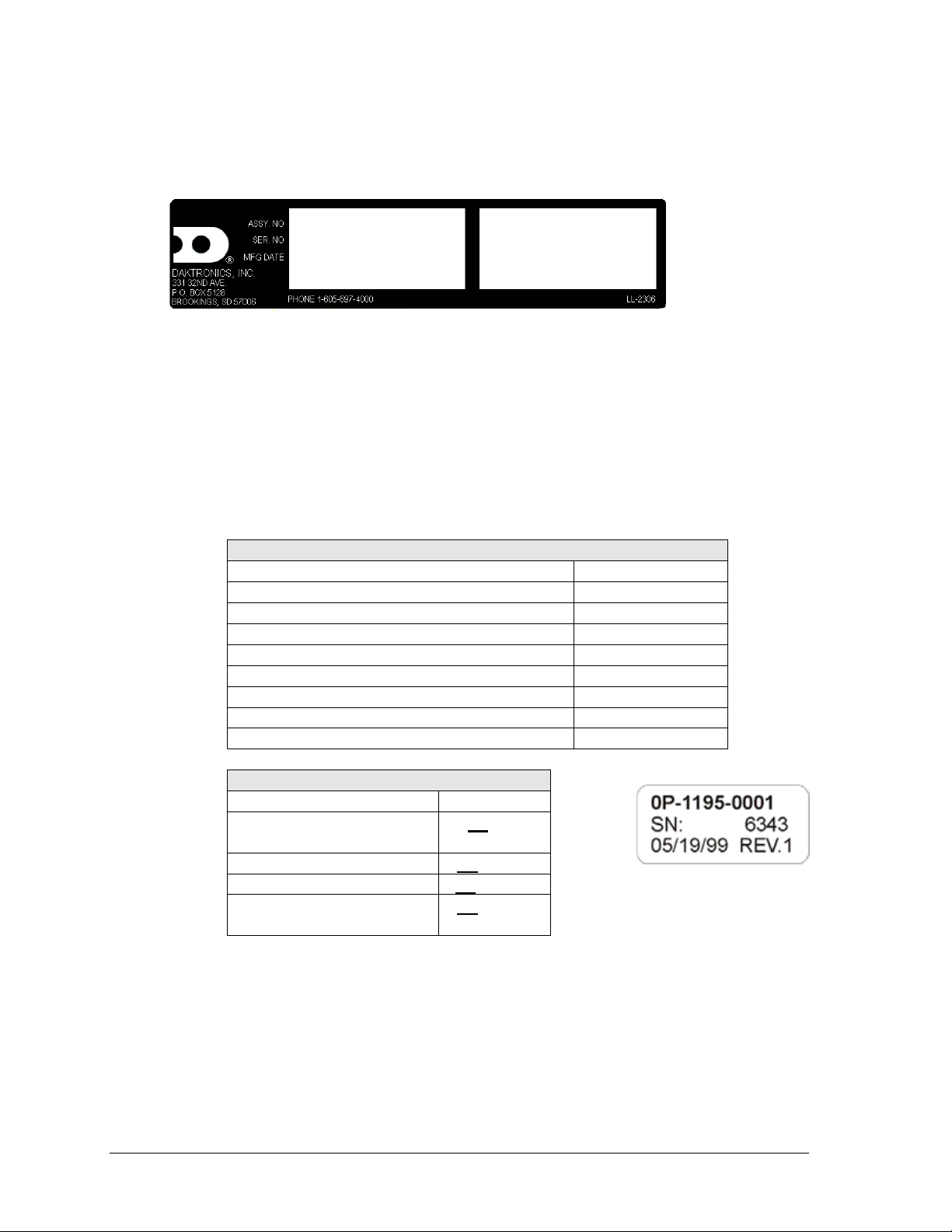

Figure 1: Daktronics Drawing Label

Section 1: Introduction

This manual explains the installation and maintenance of Daktronics Tuff Sport® transparent shot

clock displays. For additional information regarding the safety, installation, operation, or service of

these displays, refer to the telephone numbers listed in Section 5.6. This manual is not specific to a

particular installation.

Important Safeguards:

Please read and understand all instructions before beginning the installation process.

Do not drop control equipment or allow it to get wet.

Do not disassemble control equipment or electronic controls of the display; failure to

follow this safeguard will make the warranty null and void.

Disconnect display power when not in use or when servicing.

Disconnect display power before servicing power supplies to avoid electrical shock.

Power supplies run on high voltage and may cause physical injury if touched while

powered.

Do not modify the scoreboard structure or attach any panels or coverings to the

scoreboard without the express written consent of Daktronics, Inc.

Project-specific information takes precedence over any other general information found in

this manual.

1.1 Resources

Figure 1 illustrates a Daktronics drawing

label. The drawing number is located in the

lower-right corner of a drawing. This

manual refers to drawings by listing the last

set of digits and the letter preceding them.

In the example, the drawing would be

referred to as Drawing C-325405.

Reference Drawing:

System Riser Diagram ........................................................................... Drawing C-325405

Daktronics identifies manuals by the DD or ED number located on the cover page of each

manual. For example, this manual would be referred to as ED-15168.

Introduction

Page 8

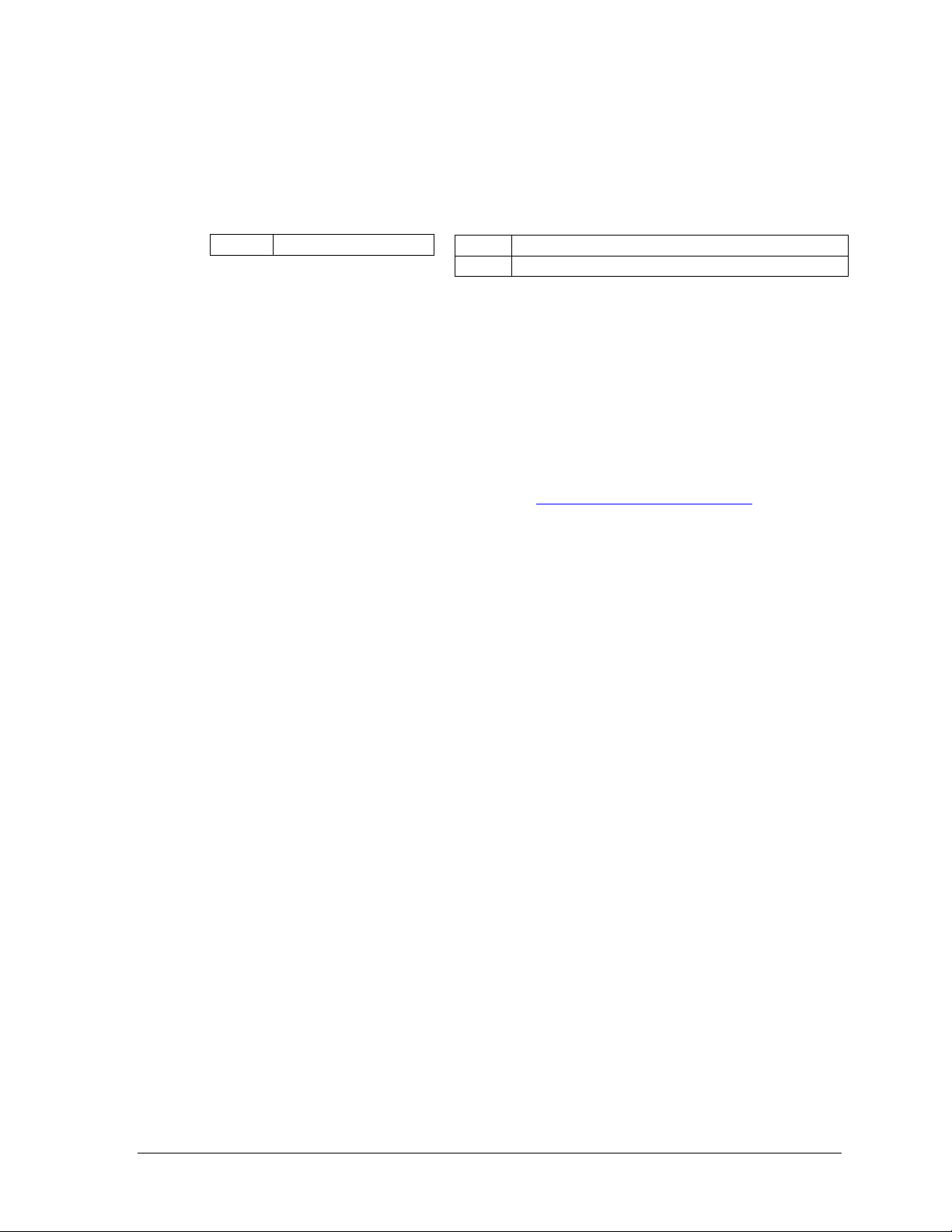

1.2 Daktronics Nomenclature

Main Component Labels

Part Type

Part Number

Individual circuit board

0P-XXXX-XXXX

Assembly; a collection of circuit boards

0A-XXXX-XXXX

Wire or cable

W-XXXX

Fuse

F-XXXX

Transformer

T-XXXX

Metal part

M-XXX

Fabricated metal assembly

0S-XXXXXX

Specially ordered part

PR-XXXXX-X

Accessory Labels

Component

Label

Termination block for power

or signal cable

TBXX

Grounding point

EXX

Power or signal jack

JXX

Power or signal plug for the

opposite jack

PXX

Figure 2: Display ID Label

Figure 3: Typical Label

Serial and model numbers can be found on the ID label on the display as shown in Figure 2.

Please list the model number, display serial number, and the date this display became

operational in the blanks provided on the second page of this manual. When calling

Daktronics customer service, please have this information available to ensure the request is

serviced as quickly as possible.

Most components within this display carry a white label that lists the part number of the unit.

If a component is not found in the Replacement Parts List in Section 5.5, use the label to order

a replacement. Figure 3 illustrates a typical label. The part number is in bold.

Following the Replacement Parts List is the Daktronics Exchange Policy and the Repair &

Return Program. Refer to these instructions if replacing or repairing any display component.

2 Introduction

Page 9

3

BB

Basketball

-13

indoor scoreboards, 120 V, PanaView® digits

-14

indoor scoreboards, 230 V, PanaView® digits

1.3 Model Number

Daktronics scoreboards are differentiated by their model numbers and two-letter prefixes for

each sport. Most Daktronics scoreboards also carry a two-number suffix that refers to indooroutdoor status, power supply, and digit color.

1.4 Scoreboard Controllers

Daktronics Tuff Sport transparent shot clock displays are designed for use with the All Sport®

5000 series control console. This controller uses keyboard overlays (sport inserts) to control

numerous sports and scoreboard models. Refer to the following manual for operating

instructions:

All Sport 5000 Series Control Console Operation Manual (ED-11976)

This control console manual is available online at www.daktronics.com/manuals.

1.5 Product Safety Approval

Daktronics transparent shot clocks are UL-listed and tested to CSA standards (120 V AC) and

CE-labeled (230 V AC) for indoor use. Contact Daktronics with any questions regarding the

testing procedures.

Introduction

Page 10

Page 11

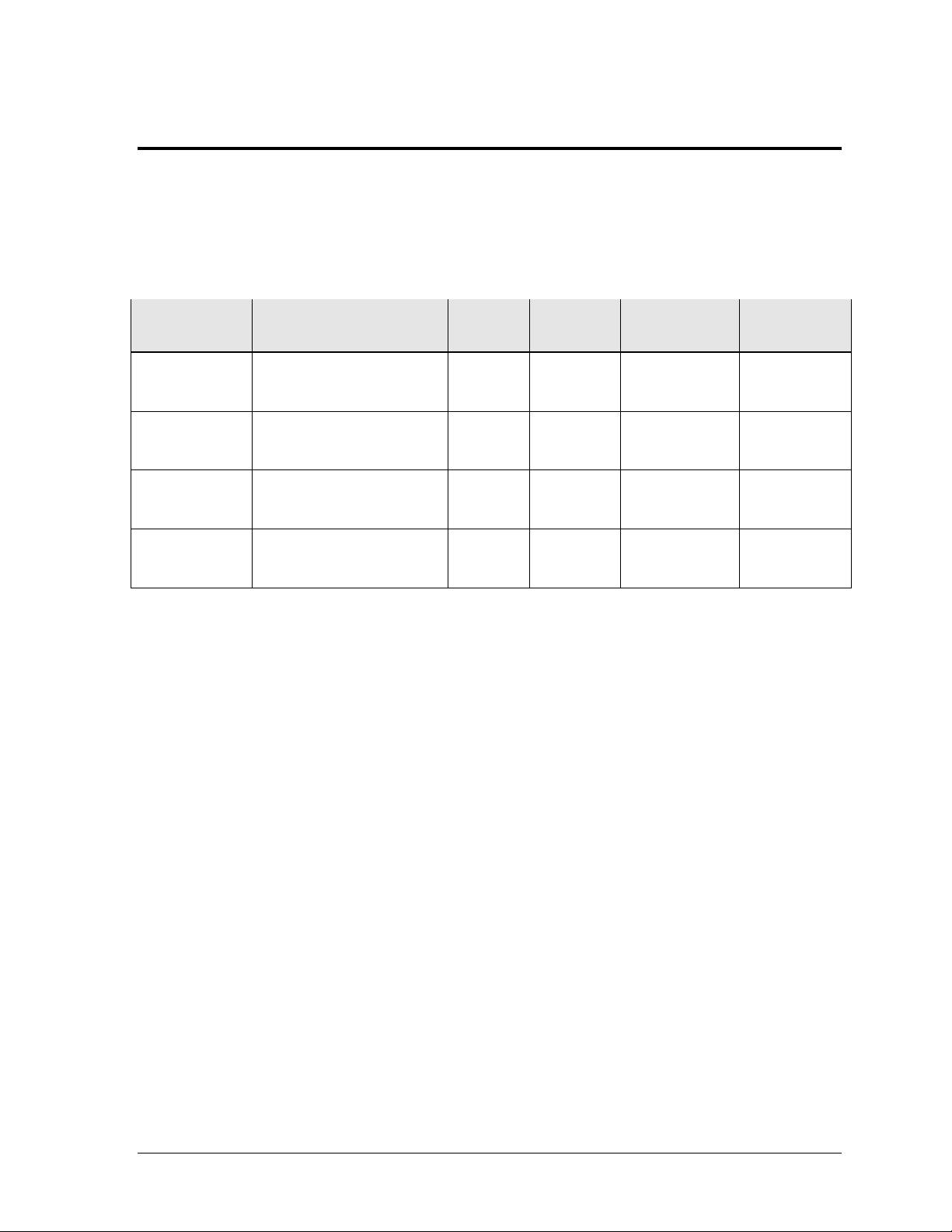

Model /

Component

Dimensions:

Height, Width, Depth

Weight

Watts

Amps

120 / 230 V AC

Driver #

& Address

BB-2140

BB-2150 (NBA)

H 2'-6", W 2'-6", D 3.5"

(756 mm, 756 mm, 89 mm)

75 lb

(34 kg)

N/A

N/A

N/A

BB-2141

BB-2151 (NBA)

H 1'-9.5", W 1'-9.5", D 3.5"

(544 mm, 544 mm, 89 mm)

50 lb

(23 kg)

N/A

N/A

N/A

Control

Enclosure

H 1'-2.25", W 1'-2", D 3.75"

(362 mm, 356 mm, 95 mm)

25 lb

(11 kg)

192 W

1.6 A / 0.8 A

A1 1

Horn

Enclosure

H 5.5", W 5.5", D 3.5"

(140 mm, 140 mm, 89 mm)

5 lb

(2.3 kg)

N/A

N/A

N/A

Section 2: Specifications

The following chart details all of the mechanical specifications, circuit specifications, and power

requirements for each display in this manual. Models are listed in alphanumeric order.

Note: All displays require a 120 V AC, 15 A circuit. Displays with a 230 V A C power requirement

are also available.

Specifications 5

Page 12

Page 13

Section 3: Mechanical Installation

Mechanical installation consists of lifting and permanently mounting the shot clocks. Be sure that the

installation complies with local building codes.

Note: Daktronics does not assume any liability for any installation derived from the information

provided in this manual or installations designed and installed by others.

3.1 Lifting the Display

Small Daktronics scoreboards use two lifting straps that encircle the scoreboard. It is

recommended to use a spreader bar with the straps.

Note: Daktronics assumes no liability for damages resulting from incorrect setup or

lifting methods.

3.2 Shot Clock Mounting

BB-2140 and BB-2150 shot clocks are mounted behind and above the top center of the

backboard with included hardware. Due to game play, these shot clocks will be exposed to a

lot of movement and vibration. The brackets need to be designed to minimize vibration and

shot clock movement.

BB-2141 and BB-2151 shot clocks are mounted on the rear of the backstop, perpendicular to

the backboard with included hardware. Refer to Drawing A-184787 and Drawing A-1060357

in Appendix A for the approximate location to mount both shot clocks sizes on the backstop.

3.3 Control Enclosure Mounting

IMPORTANT: The control enclosure must be located within 30' (9.1 m) of the shot clock.

Mount on the base of the backstop with four #10 self-drilling screws. Power and signal from

the control console will be routed to the enclosure.

3.4 Remote Horn Enclosure Mounting

Use two #10 self-drilling screws to mount the remote horn enclosure in an open location so

that sound is able to radiate. A 20' (6.1 m) pre-attached cable is included, but this cable may

be extended to mount the horn enclosure further away from the control enclosure if needed.

3.5 Camera Mounting

If a camera is to be added (BB-2140 and BB-2150 only), camera mounts accepting two inch

pipe are available; only one may be used at a time. A cable tray can be used to route camera

wiring down either side of the shot clock. Refer to Drawing B-249064 in Appendix A.

Note: Total weight of the camera and mounting arm cannot exceed 50 lb (23 kg). Design

mounting brackets to accommodate both the shot clock and the camera.

Mechanical Installation 7

Page 14

Page 15

Section 4: Electrical Installation

CAUTION: Only qualified individuals should access the electrical components of the display and its

associated equipment. It is the responsibility of the electrical contractor to ensure that all electrical

work meets or exceeds local and national codes.

Daktronics engineering staff must approve all changes or the warranty will be void.

4.1 Installation Overview

Electrical installation involves routing power and control signal wiring through separate

conduit or wire ways.

Note: Control signal cable and some junction boxes are not provided as part of this

system and can be purchased locally or from Daktronics.

4.2 Power

Install a grounded receptacle near the equipment so that the power cord can easily reach it.

Each shot clock control enclosure comes with a 120 V AC or 230 V AC twist lock power plug.

The power plug will need to be attached to a 120 V AC or 230 V AC power cord (by the

customer) as follows:

120 V AC wiring: Connect black wire to copper terminal, white wire to nickel

terminal, and green wire to green terminal.

230 V AC wiring: Connect black wire to copper terminal, red wire to copper terminal,

and green wire to green terminal.

Grounding

Connect the scoreboard to earth ground. Proper grounding assures reliable equipment

operation and protects the equipment against damaging electrical disturbances and lightning.

Daktronics recommends a resistance-to-ground of 10 ohms or less. The electrical contractor

performing the electrical installation can verify ground resistance. Daktronics Sales and

Service personnel can also provide this service. The grounding connection on the power

cord‟s three-prong plug connects to the shell of the scoreboard.

Note: The customer must properly ground the outlet according to local and national

codes. Failure to ground the outlet voids the warranty for the scoreboard.

Electrical Installation 9

Page 16

Figure 4: Digit Segment POST

4.3 Power-On Self-Test (POST)

The scoreboard performs a self-test each time that power is turned on and the control console

is powered off or not attached to the scoreboard. If the control console is attached and

powered on, the self-test does not run, and data from the control console is displayed on the

scoreboard after a brief period of time. Each scoreboard self-test pattern will vary depending

on the scoreboard model, the number of drivers and types of digits. Figure 4 shows an

example of the LED bar test pattern that each digit performs.

Radio Settings

If a radio receiver is installed (see Section 6.2), the radio broadcast settings (“b1”) and the

channel settings (“C1”) will be displayed in the game clock digits during the POST. These

values must match the settings in the control console (refer to the appropriate control console

manual listed in Section 1.4).

4.4 Signal Connection

Signal installation requires routing cable from the control console to a signal junction box near

the display, routing cable from the junction box to the control enclosure, and routing the

appropriate cables from the system components to the control enclosure.

1. At a minimum, use a paired, 22 AWG shielded cable (Daktronics part number W-

1077) and connect the cable to a ¼" J-box at the control console end.

2. Route the cable from the J-box on the control console end to a J-box near the display.

3. Install the ¼ inch phone plug cable (Daktronics part number 0L-40683) to the

scoreboard end of the cable. Be sure to connect the cable shielding only in the J-box

on this end.

Note: DO NOT connect cable shielding at the J-box near the control console.

4. Insert the plug into the Signal In (J31) jack on the front of the control enclosure.

5. Connect the shot clock(s), remote horn enclosure, and any optional light strip kits to

the appropriate jacks on the control enclosure as shown in Drawing A-184789 and

Drawing A-1060264 in Appendix A.

6. Connect a signal cable from the J-box to the J1, J2, or J3 jack on the back of the All

Sport 5000 console. Also connect the Shot Clock Start/Stop Switch (Daktronics part

number 0A-1196-0031) to the J7 jack on the All Sport 5000.

10 Electrical Installation

Page 17

Problem

Possible Cause

Solution/Items to Check

Scoreboard doesn’t light

and console doesn’t work

No power to the scoreboard

Check that the main circuit breaker

for the scoreboard is on.

Check that the control enclosure is

receiving 120 (or 230) V AC power.

Verify cable is connected to shot

clock from control console.

No power to console

Ensure the console is plugged into a

120 (or 230) V AC power supply.

Swap the console with one known to

work correctly, and enter the proper

sport code to test. Replace console

if necessary.

Scoreboard digits don’t light,

but console works

No wired signal from console

Check that the control enclosure is

receiving 120 (or 230) V AC power.

Verify cable is connected to shot

clock from control console.

Check that the red DS2 LED on the

driver lights up when sending

commands from the control console

(see Section 5.3).

Section 5: Scoreboard Troubleshooting

IMPORTANT NOTES:

1. Disconnect power before doing any repair work on the scoreboard.

2. Allow only qualified service personnel access to internal display electronics.

3. Disconnect power when not using the scoreboard.

5.1 Troubleshooting Table

The table below lists potential problems with the scoreboard and indicates possible causes

and corrective actions. This list does not include every symptom that may be encountered,

but it does present several of the most common situations that may occur.

Many of the solutions offered below provide references to other sections within this manual

or to supplemental product manuals with further detail on how to fix the problem.

If a problem occurs that is not listed or that cannot be resolved using the solutions in the

following table, contact Daktronics using the information provided in Section 5.6.

Scoreboard Troubleshooting 11

Page 18

Problem

Possible Cause

Solution/Items to Check

No radio signal from console

Cycle power to the scoreboard and

watch for radio receiver broadcast/

channel settings (see Section 4.3).

Check that the green POWER and

amber RADIO IN RANGE indicators

on the radio receiver in the control

enclosure light up when the control

console is powered on. Keep the

console between 20 to 500 feet from

the scoreboard.

Move the console 20-30 feet from

the scoreboard and test again.

Verify that both the console and

scoreboard antennae are securely

tightened and in a vertical position.

Replace the radio receiver.

No signal to driver

Check that the control enclosure is

receiving 120 (or 230) V AC power.

Check that the red DS3 LED on the

driver lights up when sending

commands from the control console

(see Section 5.3).

Swap the driver with one known to

work correctly and with the same

part number to verify the problem.

Replace if necessary

(see Section 5.3).

No power to driver

Check that the green DS1 LED on

the driver is always lit up when the

scoreboard is powered on

(see Section 5.3).

Scoreboard digits light, but

not in the correct order

Incorrect sport code

Ensure the correct sport code is

being used for the scoreboard

model. Refer to the control console

operation manual (see Section 1.4).

Incorrect driver address

Check that the scoreboard driver is

set to the correct address

(see Section 5.3).

Scoreboard digits light,

console works, but no

display on scoreboard

No wired signal from console

(See solution on previous page)

No radio signal from console

(See solution above)

Bad/damaged wiring

Check that the red DS3 LED on the

driver lights up when sending

commands from the control console

(see Section 5.3).

12 Scoreboard Troubleshooting

Page 19

Problem

Possible Cause

Solution/Items to Check

Scoreboard works, but some

LEDs always stay on

Short in digit circuit

Swap the digit with one known to

work correctly to verify the problem.

Replace if necessary

(see Section 5.2).

Scoreboard works, but some

LEDs do not light or they

blink

Bad connection

Verify the power/signal connector to

the digit circuit board is secure (see

Section 5.2).

Bad digit or driver

Swap the digit/driver with one known

to work correctly to verify the

problem. Replace if necessary

(see Section 5.2 for digits or

Section 5.3 for drivers).

Scoreboard works, but some

digits do not light

Bad digit or driver

(see solution on previous page)

Incorrect sport code

(see solution on previous page)

Incorrect driver address

(see solution on previous page)

Wrong console controlling

scoreboard

Another console’s radio signal could

be transmitting to the scoreboard.

Radio interference

There may be other radio

transmissions in the area that

overpower the console. If it is not

possible to disable the interfering

device, It may be necessary to run a

wired signal connection instead.

Figure 5: Driver Enclosure Components

5.2 Component Access & Digit Replacement

Refer to Drawing A-236432 and Drawing A-1060251 in Appendix A for instructions on how

to open the shot clock cabinet and replace the digit panels.

5.3 LED Drivers

LED drivers perform the

task of switching LEDs

on and off. The LED

driver for transparent

shot clocks is located

inside of a separate

control enclosure.

Refer to Figure 5 to view

the location and

components of the

control enclosure.

Scoreboard Troubleshooting 13

Page 20

LED

Color

Function

Operation

Summary

DS1

Green

Power

Steady on

DS1 will be on and steady to

indicate the driver has power.

DS2

Amber

Status

Blinking

DS2 will be blinking at one second

intervals to indicate the driver is

running (not available on 4-column

LED driver).

DS3

Red

Signal RX

Steady on

or blinking

DS3 will be on or blinking when the

driver is receiving a signal and off

when there is no signal.

Figure 6: Driver Status Indicators

When troubleshooting driver problems, three LEDs labeled DS1, DS2, and DS3, provide the

following diagnostic information:

Note: While it is necessary to have the scoreboard powered on to check the LED driver

status indicators, always disconnect scoreboard power before servicing.

14 Scoreboard Troubleshooting

Page 21

Figure 7: Address Jack J1

Replacing a Driver

If the driver status indicators do not appear to be working correctly, it may be necessary to

replace the driver.

1. Open the control enclosure by removing the 6 screws and swinging the door open.

2. Disconnect all connectors from the driver by squeezing together the locking tabs and

pulling the connectors free.

Note: It may be helpful to label the cables to know which cable goes to which

connector when reattaching the driver.

3. Remove the 4 nuts securing the driver to the enclosure door.

4. Carefully lift the driver from the enclosure and place it on a clean, flat surface.

5. Position a new driver over the standoffs and tighten the nuts.

6. Reconnect all power/signal connectors.

Note: The connectors are keyed and will attach in one way only. Do not attempt to

force the connections.

7. Ensure the driver is set to the correct address (refer to Setting the Driver Address).

8. Close and secure the enclosure door, then power up and test the scoreboard to see if

changing the driver has resolved the problem.

Setting the Driver Address

Since the same LED drivers can be used for many

scoreboard models, each driver must be set to receive

the correct signal input, or address, for the model

being used. This address is set with jumper wires in a

12-pin plug which mates with jack J1 on the driver

(Figure 7).

After replacing the driver in the control enclosure, be

sure to use an Address 1 plug in jack J1. In most cases,

the same plug can be reused from the driver that was

replaced; otherwise, one may be ordered from

Daktronics (part number 0A-1150-0122).

Note: For BB-2150 and BB-2151 to display 1/10 of

a second, switch 8 of DIP switch S3 must be set to ON.

Refer to Drawing B-216653 in Appendix A for more information on DIP switch settings.

5.4 Schematics

Scoreboard Troubleshooting 15

For advanced scoreboard troubleshooting and repair, it may be necessary to consult the

schematic drawings. Drawing B-216653 in Appendix A shows detailed power and signal

wiring diagrams of internal display components such as drivers, transformers, and horns.

Note: The schematic drawing also shows the DIP switch settings that control when the

horn sounds and when the LED light strips turn on.

Page 22

Description

Daktronics Part #

Addr 1 Plug

0A-1150-0122

Horn Interface Card

0P-1192-0399

LED Light Strip, 28.875" (BB-2140)

0A-1322-0008

LED Light Strip, 20.5" (BB-2141)

0A-1322-0009

Cable; 6-pin to 6-pin, 30'

0A-1322-0011

7" Four-Digit w/ Colon, Dual-Sided, Amber (BB-2140 & BB-2150)

0P-1322-0001

13" 7-Segment, Dual-Sided, Red (BB-2140)

0P-1322-0002

7" Two-Digit, Dual-Sided, Red (BB-2141)

0P-1322-0003

5" Four-Digit w/ Colon, Dual-Sided, Amber (BB-2141 & BB-2151)

0P-1322-0004

Driver, Transparent Shot Clock

0P-1322-0006

7" Two-Digit plus Tenths, Dual-Sided, Red (BB-2151)

0P-1322-0007

13" 7-Segment plus Tenths, Dual-Sided, Red (BB-2150)

0P-1322-0008

Horn Enclosure Assembly

0A-1322-0015

Cable Holder Assembly

0A-1322-0016

Transformer, 16 VAC

T-1066

Transformer, 10 VAC

T-1082

Cable; 4-pin to 4-pin, 30'

W-1823

5.5 Replacement Parts List

Refer to the following table for Daktronics scoreboard replacement parts.

5.6 Daktronics Exchange and Repair & Return Programs

Exchange Program

The Daktronics Exchange Program is a service for quickly replacing key components in need

of repair. If a component fails, Daktronics sends a replacement part to the customer who, in

turn, returns the failed component to Daktronics. This decreases equipment downtime.

Customers who follow the program guidelines explained below will receive this service.

Before Contacting Daktronics

Identify these important numbers:

Display Serial Number: _________________________________________________________

Display Model Number: ________________________________________________________

Job/Contract Number:__________________________________________________________

Date Installed: _________________________________________________________________

Daktronics Customer ID Number: ________________________________________________

16 Scoreboard Troubleshooting

Page 23

Market Description

Customer Service Number

Schools (including community/junior colleges), religious

organizations, municipal clubs and community centers

877-605-1115

Universities and professional sporting events, live events

for auditoriums and arenas

866-343-6018

To participate in the Exchange Program, follow these steps.

1. Call Daktronics Customer Service.

2. When the new exchange part is received, mail the old part to Daktronics.

If the replacement part fixes the problem, send in the problem part being replaced.

a. Package the old part in the same shipping materials in which the replacement

part arrived.

b. Fill out and attach the enclosed UPS shipping document.

c. Ship the part to Daktronics.

3. The defective or unused parts must be returned to Daktronics within 5 weeks of

initial order shipment.

If any part is not returned within five (5) weeks, a non-refundable invoice will be

presented to the customer for the costs of replenishing the exchange parts inventory

with a new part.

Daktronics reserves the right to refuse parts that have been damaged due to acts of

nature or causes other than normal wear and tear.

Repair & Return Program

For items not subject to exchange, Daktronics offers a Repair & Return Program. To send a

part for repair, follow these steps:

1. Call or fax Daktronics Customer Service:

Refer to the appropriate market number in the chart listed above.

Fax: 605-697-4444

2. Receive a case number before shipping.

This expedites repair of the part.

3. Package and pad the item carefully to prevent damage during shipment.

Electronic components, such as printed circuit boards, should be placed in an

antistatic bag before boxing. Daktronics does not recommend using packing „peanuts‟

when shipping.

4. Enclose:

name

address

phone number

the case number

a clear description of symptoms

Scoreboard Troubleshooting 17

Page 24

Shipping Address

Daktronics Customer Service

[Case #]

201 Daktronics Drive, Dock E

Brookings, SD 57006

Daktronics Warranty and Limitation of Liability

The Daktronics Warranty and Limitation of Liability is located in Appendix B. The Warranty

is independent of Extended Service agreements and is the authority in matters of service,

repair, and display operation.

18 Scoreboard Troubleshooting

Page 25

Section 6: Scoreboard Options

6.1 Light Strips

For installations that use LED backstop light strips, refer to the LED End-of-Period

Basketball Lighting Display Manual (ED-13652), or the BB-2135 Backboard

LED Light Strips Display Manual (ED-14187), both available online at

www.daktronics.com/manuals.

6.2 Radio Control

Radio control is an option for Daktronics shot clocks. The system provides scoreboard control

via a 2.4 GHz, extra-high frequency FM signal.

The radio transmitter and receiver are not standard equipment. This setup requires a control

console equipped with radio output as well as a radio receiver plugged into the J7 jack in the

control enclosure and mounted internally to the front panel of the enclosure.

For additional information about this option, contact a Daktronics representative; for

complete information on setting up radio communication control, refer to the Gen V Radio

Installation Manual (ED-13831), available online at www.daktronics.com/manuals.

Scoreboard Options 19

Page 26

Page 27

Appendix A: Reference Drawings

Court View, BB-2140 and BB-2141 ........................................................................... Drawing A-184787

Connection Diagram: BB-2140 & BB-2141 ................................................................ Drawing A-184789

Schematic: Control Enclosure- 120/240V AC ............................................................ Drawing B-216653

Mechanical Spec, BB-2140 ....................................................................................... Drawing A-223192

Mechanical Spec; BB-2141 ....................................................................................... Drawing A-223193

Mechanical Spec- Shot Clock Control Enclosure ...................................................... Drawing A-225832

Mechanical Spec; Remote Horn ................................................................................ Drawing A-235683

Electrical Spec: Shot Clock Control Encl. .................................................................. Drawing A-235687

Component Access; BB-2140 & BB-2141 ................................................................. Drawing A-236432

Assy; Camera Cable Holder ...................................................................................... Drawing B-249064

Mechanical Spec; BB-2151 ..................................................................................... Drawing A-1059514

Mechanical Spec; BB-2150 ..................................................................................... Drawing A-1059526

Component Access; BB-2150 & BB-2151 ............................................................... Drawing A-1060251

Connection Diagram; BB-2150 & BB-2151 .............................................................. Drawing A-1060264

Court View, BB-2150 & BB-2151 ............................................................................. Drawing A-1060357

Reference Drawings 21

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

AT EXPOSED TERMINALS

HAZARDOUS VOLTAGE

BEFORE SERVICING

DISCONNECT POWER

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

Appendix B: Daktronics Warranty and Limitation

of Liability

Daktronics Warranty and Limitation of Liability 23

Page 46

Page 47

Copyright © Daktronics, Inc. SL-02374 Rev 10 02-Mar-2009 Page 1 of 2

DAKTRONICS

WARRANTY AND LIMITATION OF LIABILITY

This Warranty and Limitation of Liability (the “Warranty”) sets forth the warranty provided by Daktronics with respect to the Equipment. By

accepting delivery of the Equipment, Purchaser agrees to be bound by and accept these terms and conditions. All defined terms within

the Warranty shall have the same meaning and definition as provided elsewhere in the Agreement.

DAKTRONICS WILL ONLY BE OBLIGATED TO HONOR THE WARRANTY SET FORTH IN THESE TERMS AND CONDITIONS UPON RECEIPT OF FULL

PAYMENT FOR THE EQUIPMENT.

1. Warranty Coverage

2. Exclusion from Warranty Coverage

A. Daktronics warrants to the original end-user that the Equipment will be free from Defects (as defined below) in materials and

workmanship for a period of one (1) year (the “Warranty Period”). The warranty period shall commence on the earlier of: (i) four

weeks from the date that the equipment leaves Daktronics’ facility; or (ii) Substantial Completion as defined herein. The warranty

period shall expire on the first anniversary of the commencement date.

“Substantial Completion” means the operational availability of the Equipment to the Purchaser in accordance with the

Equipment’s specifications, without regard to punch-list items, or other non-substantial items which do not affect the operation of

the Equipment.

B. Daktronics’ obligation under this Warranty is limited to, at Daktronics’ option, replacing or repairing, any Equipment or part

thereof that is found by Daktronics not to conform to the Equipment’s specifications. Unless otherwise directed by Daktronics,

any defective part or component shall be returned to Daktronics for repair or replacement. Daktronics may, at its option,

provide on-site warranty service. Daktronics shall have a reasonable period of time to make such replacements or repairs and

all labor associated therewith shall be performed during regular working hours. Regular working hours are Monday through

Friday between 8:00 a.m. and 5:00 p.m. at the location where labor is performed, excluding any holidays observed by either

Purchaser or Daktronics.

C. Daktronics shall pay ground transportation charges for the return of any defective component of the Equipment. If returned

Equipment is repaired or replaced under the terms of this warranty, Daktronics will prepay ground transportation charges back to

Purchaser; otherwise, Purchaser shall pay transportation charges to return the Equipment back to the Purchaser. All returns must

be pre-approved by Daktronics before shipment. Daktronics shall not be obligated to pay freight for any unapproved return.

Purchaser shall pay any upgraded or expedited transportation charges.

D. Any replacement parts or Equipment will be new or serviceably used, comparable in function and performance to the

original part or Equipment, and warranted for the remainder of the Warranty Period. Purchasing additional parts or Equipment

from the Seller does not extend this Warranty Period.

E. Defects shall be defined as follows. With regard to the Equipment (excepting LEDs), a “Defect” shall refer to a material

variance from the design specifications that prohibit the Equipment from operating for its intended use. With respect to LEDs,

“Defects” are defined as LED pixels that cease to emit light. The limited warranty provided by Daktronics does not impose any

duty or liability upon Daktronics for partial LED pixel degradation. Nor does the limited warranty provide for the replacement or

installation of communication methods including but not limited to, wire, fiber optic cable, conduit, trenching, or for the purpose

of overcoming local site interference radio equipment substitutions.

THIS LIMITED WARRANTY IS THE ONLY WARRANTY APPLICABLE TO THE EQUIPMENT AND REPLACES ALL OTHER WARRANTIES OR

CONDITIONS, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OR CONDITIONS OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. SPECIFICALLY, EXCEPT AS PROVIDED HEREIN, THE SELLER

UNDERTAKES NO RESPONSIBILITY FOR THE QUALITY OF THE EQUIPMENT OR THAT THE EQUIPMENT WILL BE FIT FOR ANY PARTICULAR

PURPOSE FOR WHICH PURCHASER MAY BE BUYING THE EQUIPMENT. ANY IMPLIED WARRANTY IS LIMITED IN DURATION TO THE

WARRANTY PERIOD. NO ORAL OR WRITTEN INFORMATION, OR ADVICE GIVEN BY THE COMPANY, ITS AGENTS OR EMPLOYEES,

SHALL CREATE A WARRANTY OR IN ANY WAY INCREASE THE SCOPE OF THIS LIMITED WARRANTY.

THIS LIMITED WARRANTY IS NOT TRANSFERABLE.

The limited warranty provided by Daktronics does not impose any duty or liability upon Daktronics for:

A Any damage occurring, at any time, during shipment of Equipment unless otherwise provided for in the Agreement. When

returning Equipment to Daktronics for repair or replacement, Purchaser assumes all risk of loss or damage, and agrees to use

any shipping containers that might be provided by Daktronics and to ship the Equipment in the manner prescribed by

Daktronics;

B. Any damage caused by the unauthorized adjustment, repair or service of the Equipment by anyone other than personnel of

Daktronics or its authorized repair agents;

Page 48

Copyright © Daktronics, Inc. SL-02374 Rev 10 02-Mar-2009 Page 2 of 2

C. Damage caused by the failure to provide a continuously suitable environment, including, but not limited to: (i) neglect or

misuse, (ii) a failure or sudden surge of electrical power, (iii) improper air conditioning or humidity control, or (iv) any other cause

other than ordinary use;

D. Damage caused by fire, flood, earthquake, water, wind, lightning or other natural disaster, strike, inability to obtain materials

or utilities, war, terrorism, civil disturbance or any other cause beyond Daktronics’ reasonable control;

E. Failure to adjust, repair or replace any item of Equipment if it would be impractical for Daktronics personnel to do so because

of connection of the Equipment by mechanical or electrical means to another device not supplied by Daktronics, or the

existence of general environmental conditions at the site that pose a danger to Daktronics personnel;

F. Any statements made about the product by salesmen, dealers, distributors or agents, unless such statements are in a written

document signed by an officer of Daktronics. Such statements as are not included in a signed writing do not constitute

warranties, shall not be relied upon by Purchaser and are not part of the contract of sale;

G. Any damage arising from the use of Daktronics products in any application other than the commercial and industrial

applications for which they are intended, unless, upon request, such use is specifically approved in writing by Daktronics; or

H. Any performance of preventive maintenance.

3. Limitation of Liability

4. Assignment of Rights

5. Dispute Resolution

6. Governing Law

7. Availability of Extended Service Agreement

Daktronics shall be under no obligation to furnish continued service under this Warranty if alterations are made to the Equipment

without the prior written approval of Daktronics.

It is specifically agreed that the price of the Equipment is based upon the following limitation of liability. In no event shal l

Daktronics (including its subsidiaries, affiliates, officers, directors, employees, or agents) be liable for any special, consequential,

incidental or exemplary damages arising out of or in any way connected with the Equipment or otherwise, including but not

limited to damages for lost profits, cost of substitute or replacement equipment, down time, lost data, injury to property or any

damages or sums paid by Purchaser to third parties, even if Daktronics has been advised of the possibility of such damages. The

foregoing limitation of liability shall apply whether any claim is based upon principles of contract, tort or statutory duty, principles

of indemnity or contribution, or otherwise.

In no event shall Daktronics be liable to Purchaser or any other party for loss, damage, or injury of any kind or nature arising out of

or in connection with this Warranty in excess of the purchase price of the Equipment actually delivered to and paid for by the

Purchaser. The Purchaser’s remedy in any dispute under this Warranty shall be ultimately limited to the Purchase Price of the

Equipment to the extent the Purchase Price has been paid.

The Warranty contained herein extends only to the original end-user (which may be the Purchaser) of the Equipment and no

attempt to extend the Warranty to any subsequent user-transferee of the Equipment shall be valid or enforceable without the

express written consent of Daktronics.

Any dispute between the parties will be resolved exclusively and finally by arbitration administered by the American Arbitration

Association (“AAA”) and conducted under its rules, except as otherwise provided below. The arbitration will be conducted

before a single arbitrator. The arbitration shall be held in Brookings, South Dakota. Any decision rendered in such arbitration

proceedings will be final and binding on each of the parties, and judgment may be entered thereon in any court of competent

jurisdiction. This arbitration agreement is made pursuant to a transaction involving interstate commerce, and shall be governed

by the Federal Arbitration Act.

The rights and obligations of the parties under this warranty shall not be governed by the provisions of the United Nations

Convention on Contracts for the International Sales of Goods of 1980. Both parties consent to the application of the laws of the

State of South Dakota to govern, interpret, and enforce all of Purchaser and Daktronics rights, duties, and obligations arising

from, or relating in any manner to, the subject matter of this Warranty, without regard to conflict of law principles.

For Purchaser’s protection, in addition to that afforded by the warranties set forth herein, Purchaser may purchase extended

warranty services to cover the Equipment. The Extended Service Agreement, available from Daktronics, provides for electronic

parts repair and/or on-site labor for an extended period from the date of expiration of this warranty. Alternatively, an Extended

Service Agreement may be purchased in conjunction with this warranty for extended additional services. For further information,

contact Daktronics Customer Service at 1-800-DAKTRONics (1-800-325-8766).

Loading...

Loading...