Page 1

Single-Section Outdoor

Incandescent Scoreboards

Installation, Maintenance,

and Specifications Manual

ED11974

All Sport

and Cailube

Deoxit

BA-515 BA-718 CT-2001 MS-915 MS-2006 SO-2008

BA-518 BA-1018 CT-2002 MS-918 MS-2011 TI-218

BA-618 BA-2003 FB-824 MS-2002 SO-824 TI-418

BA-624 BA-2004 FB-2340 MS-2004 SO-918 TI-2003

ED11974

Product 1091

Rev 9 – 13 August 2002

Copyright © 2002 Daktronics, Inc.

All rights reserved. While every precaution has been taken in the

preparation of this manual, the publisher assumes no responsibility for errors

or omissions. No part of this book covered by the copyrights hereon may be

reproduced or copied in any form or by any means – graphic, electronic

or mechanical, including photocopying, taping, or information storage

and retrieval systems – without written permission of the publisher.

®

is a registered trademark of Daktronics, Inc

are trademarks of their respective manufacturers.

MODEL NUMBERS

Note: Please fill in the information below for

your display, and use it as a reference when

calling Daktronics for assistance.

Serial No. ___________________________

Model No.___________________________

Date Installed ________________________

PO Box 5128 331 32nd Ave Brookings SD 57006

Tel 605-697-4036 or 877-605-1115 Fax 605-697-4444

www.daktronics.com e-mail: helpdesk@daktronics.com

Page 2

Page 3

Table of Contents

Section 1: Introduction..................................................................................................1-1

1.1 How To Use This Manual ..........................................................................................1-1

1.2 Product Safety Approval ............................................................................................1-1

1.3 Manual Overview ....................................................................................................... 1-2

1.4 Daktronics Exchange and Repair and Return Programs ............................................1-2

Section 2: Model Identification.....................................................................................2-1

Section 3: Specifications ..............................................................................................3-1

3.1 Single-Section Scoreboards........................................................................................ 3-2

3.2 230 Volt Single-Section Scoreboards.........................................................................3-7

Section 4: Component Locations.................................................................................4-1

Section 5: Schematics...................................................................................................5-1

Section 6: Mechanical Installation ...............................................................................6-1

6.1 Footings and Beams ...................................................................................................6-1

6.2 Lifting the Scoreboard................................................................................................6-2

6.3 Scoreboard Mounting................................................................................................. 6-3

Method 1 ....................................................................................................................6-3

Method 2 ....................................................................................................................6-4

6.4 Ad Panel Mounting ....................................................................................................6-5

Models BA-515 and BA-518 .....................................................................................6-5

Section 7: Electrical Installation...................................................................................7-1

7.1 Power Requirements...................................................................................................7-1

Grounding...................................................................................................................7-1

Power Installation.......................................................................................................7-2

7.2 Power and Signal Connection ....................................................................................7-3

Section 8: Digit Maintenance and Troubleshooting ...................................................8-1

8.1 Component Access ..................................................................................................... 8-1

Lamp Driver Access...................................................................................................8-1

Digit Access ...............................................................................................................8-1

8.2 Lamp Replacement.....................................................................................................8-2

8.3 Lamp Drivers..............................................................................................................8-2

8.4 Fuses...........................................................................................................................8-3

8.5 Segmentation..............................................................................................................8-3

8.6 Power On Self-Test ....................................................................................................8-3

8.7 Lightning Protection................................................................................................... 8-4

8.8 Replacement Parts ......................................................................................................8-4

8.9 Troubleshooting .........................................................................................................8-5

Table of Contents

i

Page 4

Section 9:

9.1 TNMC Schematics..................................................................................................... 9-1

9.2 Service Procedures..................................................................................................... 9-2

9.3 Lamp Testing and Replacement................................................................................. 9-3

9.4 Lens Position and Sequence ...................................................................................... 9-4

9.5 Lens/Reflector Assembly Maintenance ..................................................................... 9-4

9.6 Lamp Module Transformer........................................................................................ 9-5

9.7 Fan Filters .................................................................................................................. 9-5

9.8 Filter Removal ........................................................................................................... 9-6

9.9 Fans............................................................................................................................9-6

9.10 Lens Airflow .............................................................................................................. 9-7

9.11 Structural Inspection .................................................................................................. 9-8

9.12 Cleaning the Signal Connectors................................................................................. 9-8

9.13 Troubleshooting......................................................................................................... 9-8

9.14 Replacement Parts List .............................................................................................. 9-9

9.15 TNMC Exchange and Repair and Return Programs................................................ 9-10

Team Name Message Centers Maintenance and Troubleshooting ........9-1

Removing a Module................................................................................................... 9-2

Removing a Lampbank.............................................................................................. 9-2

Replacing a Lampbank .............................................................................................. 9-3

Replacing the Module................................................................................................ 9-3

Individual Lamp Replacement................................................................................... 9-4

Weatherstripping Maintenance .................................................................................. 9-4

Louver Maintenance .................................................................................................. 9-5

Section 10: Scoreboard Options.................................................................................. 10-1

10.1 Team Name Captions – Models BA-624, BA-1518 and BA-1524 ......................... 10-1

10.2 Trumpet Horn .......................................................................................................... 10-2

AC Trumpet Horn Installation (Internally Mounted) .............................................. 10-2

DC Trumpet Horn Installation (Externally Mounted) ............................................. 10-2

Appendix A: Reference Drawings ................................................................................... A-1

Appendix B: Eyebolts........................................................................................................ B-1

ii

Table of Contents

Page 5

Section 1: Introduction

1.1 How To Use This Manual

This manual explains the installation of Daktronics Single-Section, Outdoor Incandescent

Scoreboards and provides details for display maintenance. For questions regarding the safety,

installation, operation, or service of this system, please refer to the telephone numbers listed on the

cover page of this manual.

Important Safeguards:

1. Read and understand these instructions before installing the scoreboard.

2. Do not drop the scoreboard control console or allow it to get wet.

3. Properly ground the scoreboard with a grounding electrode at the scoreboard location.

4. Disconnect power when not using the scoreboard.

5. Disconnect power when servicing the scoreboard.

6. Do not modify the scoreboard structure or attach any panels or coverings to the scoreboard

without the express written consent of Daktronics, Inc.

The box at right illustrates the Daktronics

drawing numbering system. Daktronics

identifies individual drawings by the drawing

number (7087-P08A-69945 in Figure 1),

which is located in the lower-right corner of

the drawing. This manual refers to drawings

by their last set of digits and the letter

preceding them. The example would be

Drawing A-69945.

Reference drawings are grouped and inserted in alphanumeric order in Appendix A.

The serial and model number of a Daktronics scoreboard can be found on the ID label, located on the

display. This label will be

similar to the one shown in

Figure 2. When calling

Daktronics Customer

Service, please have this

information available to

ensure that your request

is serviced as quickly

as possible.

Figure 2: Scoreboard ID Label

Figure 1: Daktronics Drawing Label

1 .2 Product Safety Approval

Daktronics outdoor scoreboards are ETL-listed, tested to CSA standards and CE-labeled for outdoor

use. Contact Daktronics with any questions regarding testing procedures.

Introduction

1-1

Page 6

1.3 Manual Overview

This manual is divided into the following sections:

Contains an overview of the manual and explains the Daktronics drawing

numbering system and Daktronics Exchange and Repair and Return

programs.

Contains tables showing all of the mechanical specifications, circuit

specifications, and maximum power requirements for each model.

Lists drawings needed to determine the location of scoreboard components.

Lists the electrical schematic drawings for each model.

Contains information needed for the mechanical installation for each model.

Contains information needed for the electrical installation for each model.

Contains information needed to service the scoreboards.

Contains information needed to service the team name message centers.

Contains descriptions and installation instructions for the various scoreboard

options.

Contain reference drawings and ED-7244, Eyebolts.

Section 10:

Appendices:

Section 1:

Section 2: Lists the drawings needed to determine scoreboard model numbers.

Section 3:

Section 4:

Section 5:

Section 6:

Section 7:

Section 8:

Section 9:

1.4 Daktronics Exchange and Repair and Return Programs

To serve customers’ repair and maintenance needs, Daktronics offers both an Exchange Program and a

Repair and Return Program.

Daktronics’ unique Exchange Program is a quick, economical service for replacing key components in

need of repair. If a component fails, Daktronics sends the customer a reconditioned replacement

within 24 hours. The customer, in turn, sends the failed component to Daktronics. This not only saves

money but also decreases scoreboard downtime. This service is provided to qualified customers who

follow the program guidelines explained below.

Daktronics provides this service to ensure users get the most from their Daktronics products. Please

call the Help Desk – (877) 605-1115 – if you have questions regarding the Exchange Program or any

other Daktronics service.

When you call the Daktronics Help Desk, a trained service technician will work with you to diagnose

the equipment problem and determine which replacement part to ship. (If, after you make the

exchange, the equipment still has problems, please contact our Help Desk immediately.) If the

replacement part fixes the problem, package the defective part in the same box and wrapping in which

the replacement part arrived, fill out and attach the enclosed UPS shipping document, and RETURN

THE PART TO DAKTRONICS.

For most equipment, you will be invoiced for the replacement part at the time it is shipped. This bill is

due when you receive it.

Daktronics expects immediate return of an exchange part if it does not solve the problem. The

company also reserves the right to refuse equipment that has been damaged due to acts of nature or

causes other than normal wear and tear.

1-2 Introduction

Page 7

If the defective equipment is not shipped to Daktronics within 30 working days from the invoice date,

it is assumed you are purchasing the replacement part, and you will be invoiced for it. This second

invoice represents the difference between the exchange price and the full purchase price of the

equipment. The balance is due when you receive the second invoice. If you return the exchange

equipment after 30 working days from the invoice date, you will be credited for the amount on the

second invoice, minus a restocking fee.

@To avoid a restocking charge, please return the defective equipment within 30 days from the

invoice date.

Daktronics also offers a repair and return program for items not subject to exchange.

Return Materials Authorization: To return parts for service, contact your local representative prior

to shipment to acquire a Return Materials Authorization (RMA) number. If you have no local

representative, call the Daktronics Help Desk for the RMA. This expedites repair of your component

when it arrives at Daktronics.

Packaging for Return: Package and pad the item well so that it will not be damaged in shipment.

Electronic components such as printed circuit boards should be installed in an enclosure or placed in

an antistatic bag before boxing. Please enclose your name, address, phone number and a clear

description of symptoms.

This is how to reach us:

Mail

Daktronics, Inc.

Phone

Fax

E-mail

: Customer Service

P.O. Box 5128

331 32nd Avenue

Brookings, SD 57006

: Daktronics Help Desk: 1 (877) 605-1115 (toll free)

or 1 (605) 697-4036

: 1 (605) 697-4444

: helpdesk@daktronics.com

Introduction

1-3

Page 8

Page 9

Section 2: Model Identification

Use the following drawings to determine your scoreboard model number. The drawings, located in the

Appendix, are inserted in alphanumeric order by drawing number.

Reference Drawings:

Single-Section Scoreboard Models....................................................... Drawing A-124342

Single-Section Scoreboard Models w/TNMC........................................Drawing A-127262

Single Section Scoreboard Models....................................................... Drawing A-152945

Model Identification

2-1

Page 10

Page 11

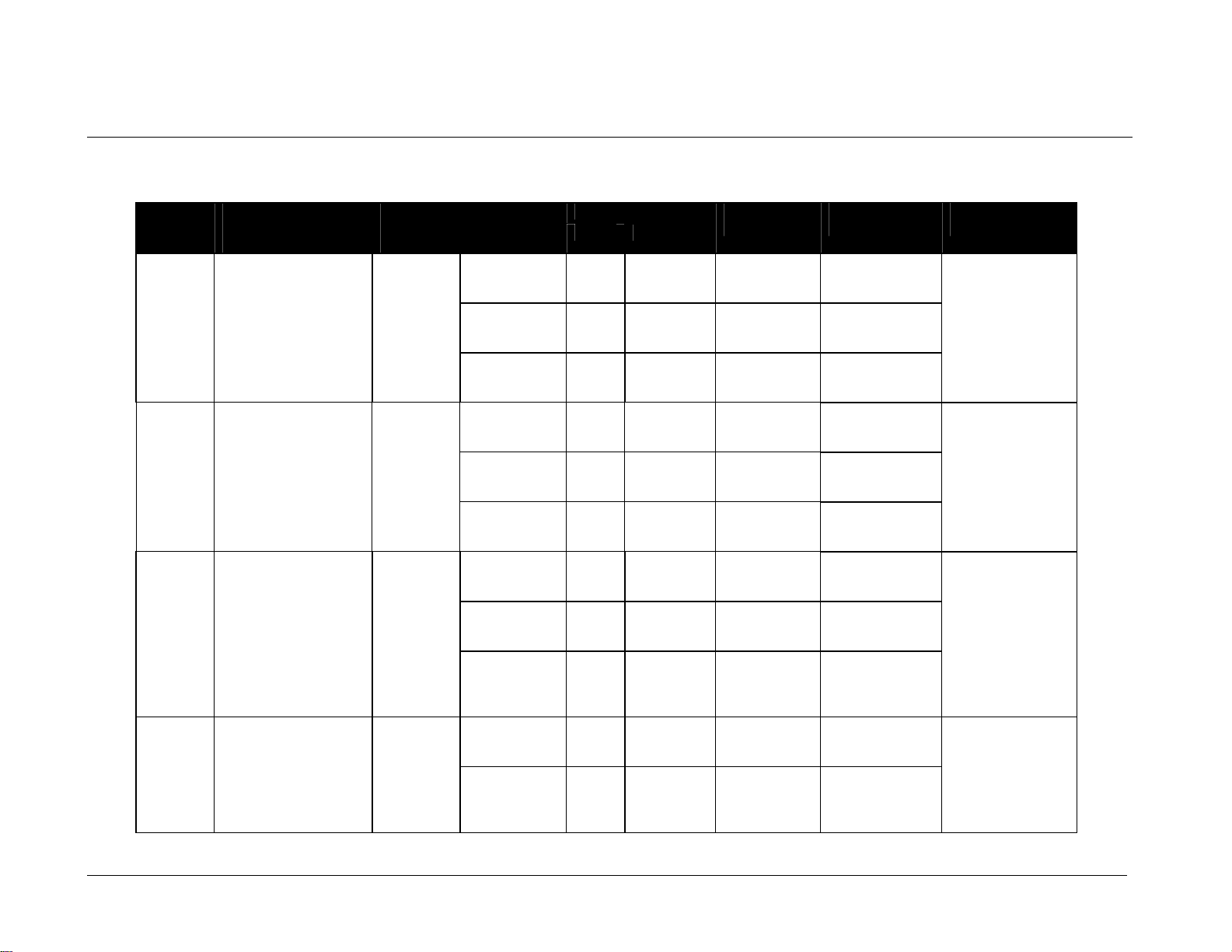

Section 3: Specifications

The following tables include all of the mechanical specifications, circuit specifications, and maximum

power requirements for each model in this manual. Models are listed in alphanumeric order.

Section 3.1: Single-Section Scoreboards ....................................................................................3-2

Section 3.2: 230-Volt Single-Section Scoreboards..................................................................... 3-5

Specifications

3-1

Page 12

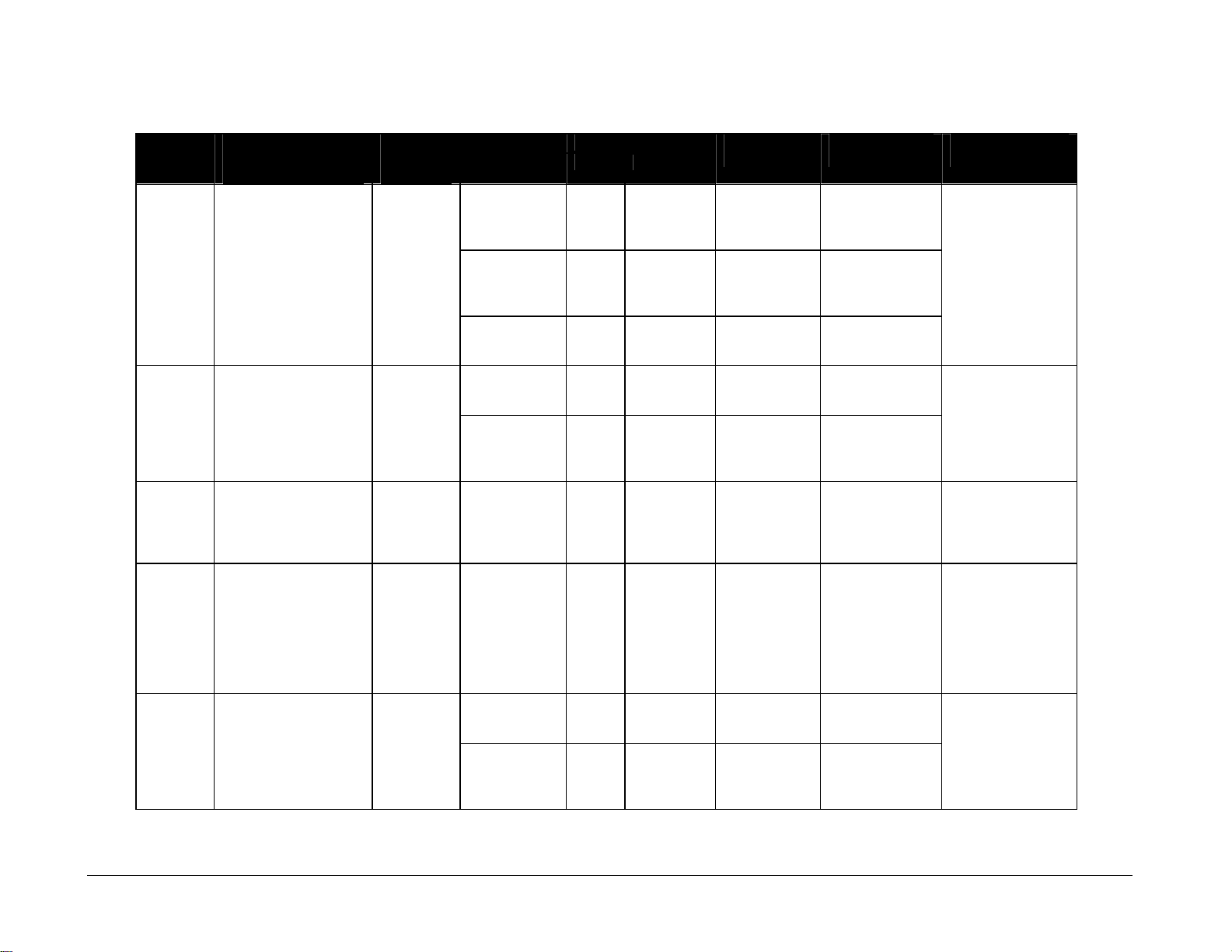

3.1 Single-Section Scoreboards

Note 1: Signal wires must be a minimum of 22- gauge with shield. Daktronics recommends using W-1234.

Note 2: 120/240 or two lines of 120 V AC from a 120/208 WYE service.

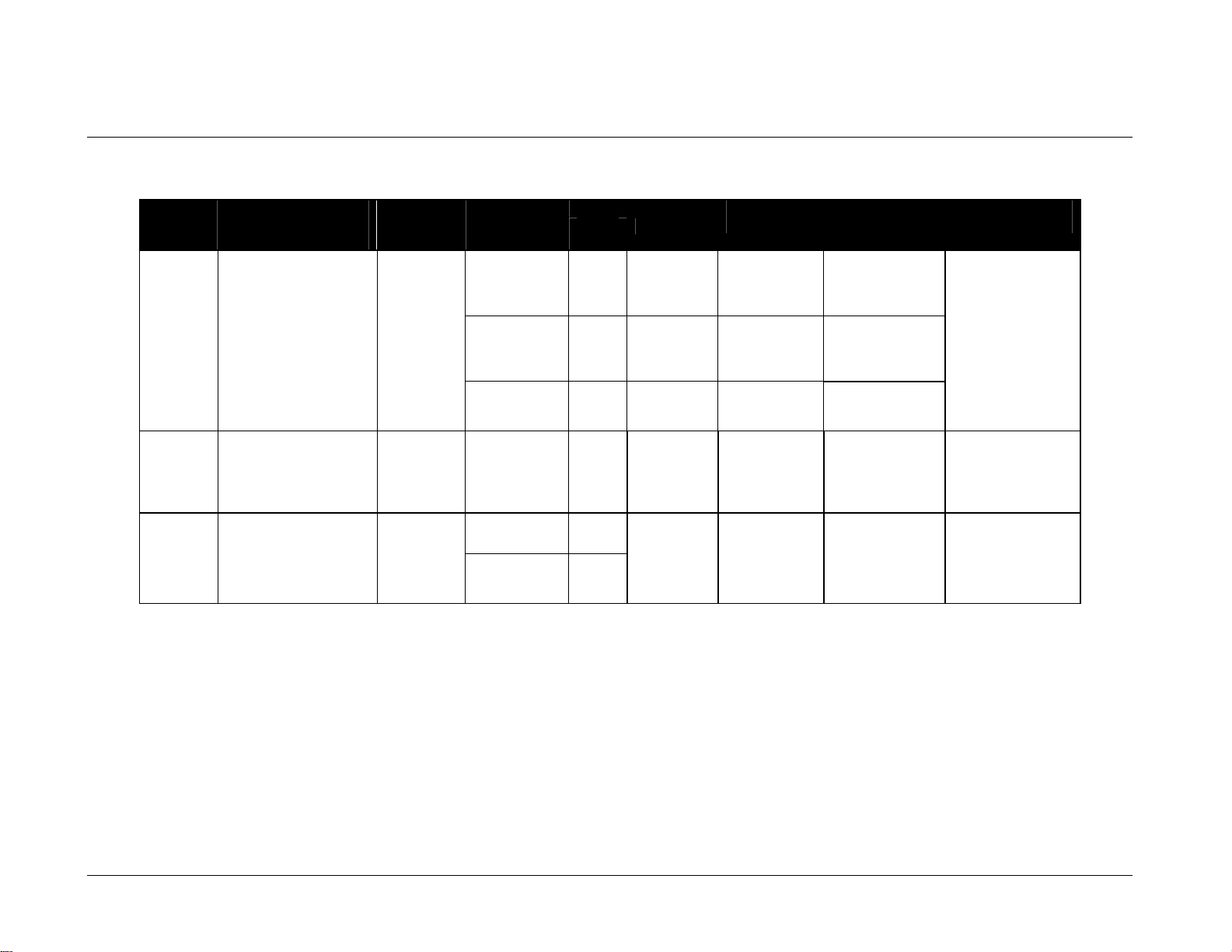

Wattage Model Dimensions

Lamp Maximum

25 W 1905 W

30 W 3280 W 120 V AC 27 A

40 W

25 W 1905 W 120 V AC

25 W 2780 W 120 V AC 24 A

40 W

25 W 2110 W 120 V AC

25 W 3035 W 120 V AC 26 A

40 W

25 W 3035 W 120 V AC 24 A

40 W

(See Note 2)

120 V AC

(Height, Width,

Depth)

BA-515 H3’-0", W6’-0", D11"

(914 mm, 1829 mm,

279 mm)

BA-518 H4’-0", W9’-0", D6"

(1219 mm, 2743 mm,

152 mm)

BA-618 H5’-0", W14’-0", D6"

(1524 mm, 4267 mm,

152 mm)

BA-624 H6’-0", W16’-0", D6"

(1829 mm, 4877 mm,

152 mm)

Weight

Uncrated

(Crated)

115 lb

52 kg

(118 lb)

(54 kg)

120 lb

55 kg

(152 lb)

(70 kg)

250 lb

114 kg

(580 lb)

(263 kg)

375 lb

170 kg

(770 lb)

(350 kg)

Digit Size

and Matrix

Inning, scores

15" 3x5

(381 mm)

Inning, scores

15" 4x7

(381 mm)

Ball, Strike,

Out indicators

Inning, scores

18" 3x5

(457 mm)

Inning, scores

18" 4x7

(457 mm)

Ball, Strike,

Out indicators

All digits

18" 3x5

(457 mm)

All digits

18" 4x7

(457 mm)

Ball, Strike,

Out, H/E

indicators

All digits

24" 4x7

(610 mm)

Ball, Strike,

Out, H/E

Indicators

Power

Amps per Line

(Single Phase)

16 A

16 A

18 A

Driver Number

and Address

A1 61

A1 61

A1 61

A1 61

Specifications 3-2

Page 13

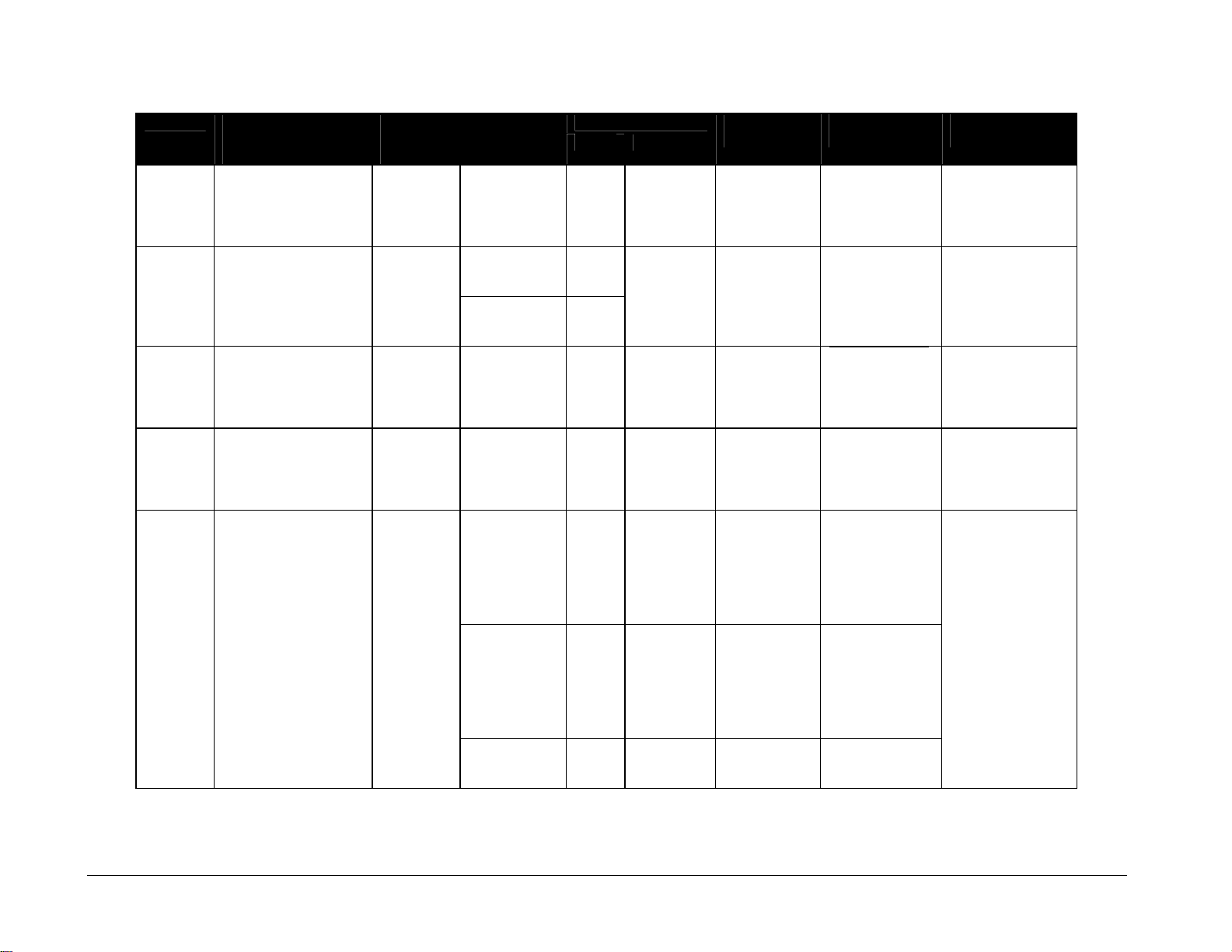

Wattage Model Dimensions

Lamp Maximum

25 W 2555 W 120 V AC

25 W 3780 W 120 V AC 32 A

40 W

25 W 3050 W 120/240 or

25 W 4675 W 120/240 or

40 W 1880 W 120/240 or

25 W 8491 W 120/240 or

25 W 975 W 120 V AC

25 W 1500 W 120 V AC

Power

(See Note 2)

120/208 V AC

120/208 V AC

120/208 V AC

120/208 V AC

Amps per Line

(Single Phase)

22 A

L1

15 A

L2 11 A

L1

23 A

L2 17 A

15 A A1 11

L1

33 A

L2 38 A

15 A

15 A

Driver Number

and Address

A1 62

A1 12

A1 67

A2 68

A3 69

A1 1

(Height, Width,

Depth)

BA-718 H4’-0", W12’-0", D6"

(1219 mm, 3658 mm,

152 mm)

BA-1018 H6’-0", W14’-0", D6"

(2438 mm, 4877 mm,

152 mm)

BA-2003 H4'-6", W10'-0", D8"

(1372 mm, 3048 mm,

203 mm)

BA-2004 H6'-6", W20'-0", D6"

(2845 mm, 6096 mm,

152 mm)

CT-2001 H2’-0", W6’-0", D11"

(610 mm, 1829 mm,

279 mm)

Weight

Uncrated

(Crated)

160 lb

73 kg

(490 lb)

(222 kg)

270 lb

122 kg

(621 lb)

(281 kg)

250 lb

113 kg

(475 lb)

(215 kg)

750 lb

340 kg

(1,425 lb)

(646 kg)

50 lb

23 kg

(83 lb)

(37 kg)

Digit Size

and Matrix

Inning, Time,

scores

18" 3x5

(457 mm)

Inning, Time,

scores

18" 4x7

(457 mm)

Ball, Strike,

Out indicators

All digits

18" 3x5

(457 mm)

All digits

18" 4x7

(457 mm)

All digits

36" 4x7

(914 mm)

Ball, strike,

out, H/E

18" 3x5

(457 mm)

Scoring

15" 3x5

(381 mm)

All digits

18" 3x5

(457 mm)

All digits

18" 4x7

(457 mm)

Specifications

3-3

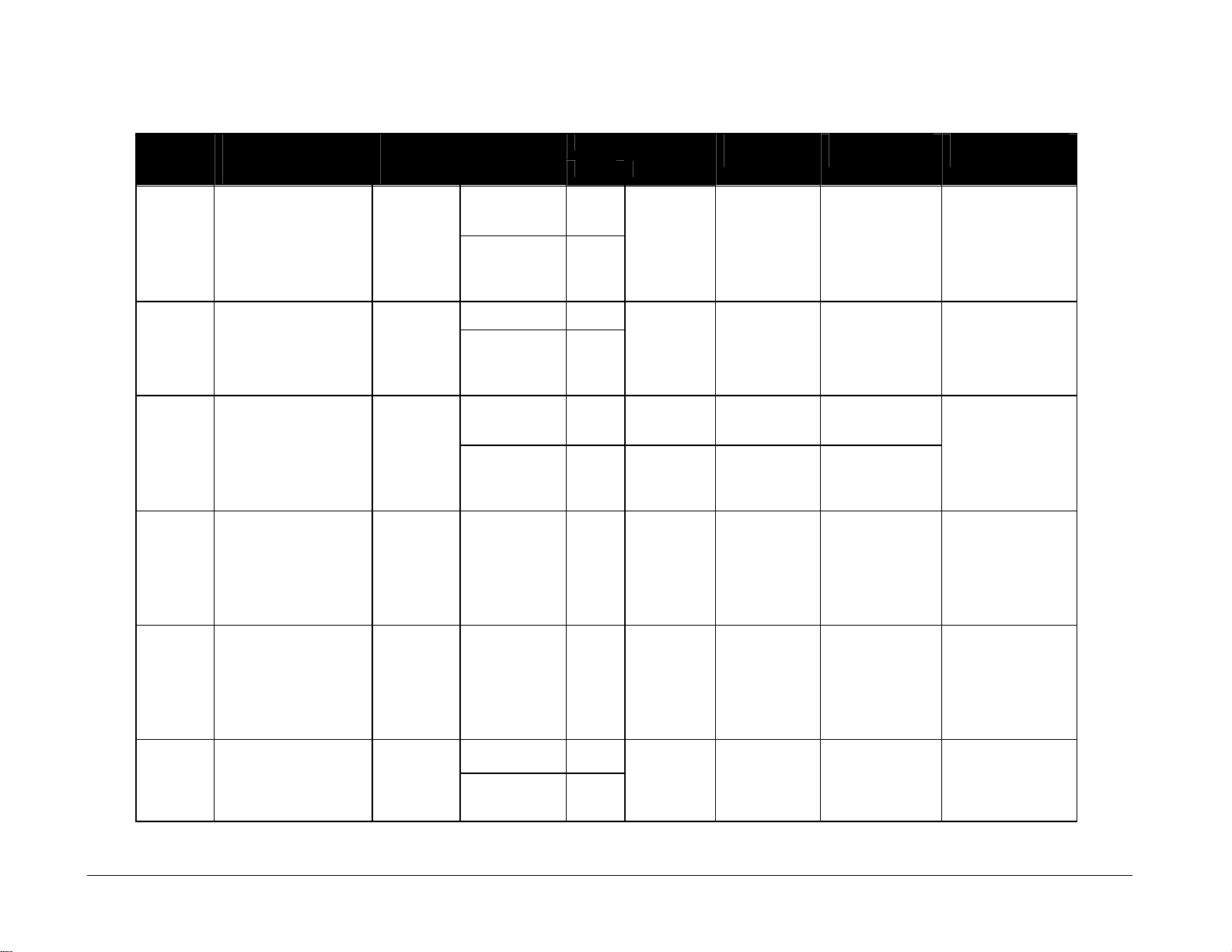

Page 14

(Height, Width,

Depth)

CT-2002 H2’-7", W7’-0", D11"

(610 mm, 2133 mm,

279 mm)

FB-824 H4’-0", W14’-0", D6"

(1219 mm, 4267 mm,

152 mm)

FB-2340

MS-915 H4’-0", W8’-0", D11"

MS-918 H5’-0", W14’-0", D6"

H5'-0", W7'-0", D8"

(1524 mm, 2134 mm,

203 mm)

(1219 mm, 2438 mm,

279 mm)

(1524 mm, 4267 mm,

152 mm)

Weight

Uncrated

(Crated)

75 lb

34 kg

(125 lb)

(57 kg)

250 lb

114 kg

(560 lb)

(254 kg)

135 lb

61 kg

(220 lb)

(100 kg)

110 lb

50 kg

(185 lb)

(84 kg)

275 lb

125 kg

(640 lb)

(290 kg)

Digit Size

and Matrix

All digits

24" 4x7

(610 mm)

All digits

24" 4x7

(610 mm)

Quarter

indicators

All digits

18" 4x7

(457 mm)

All digits

15" 3x5

(381 mm)

Clock, scores

18" 3x5

(457 mm)

Inning

15" 3x5

(381 mm)

Clock, scores

18" 4x7

(457 mm)

Inning

15" 4x7

(381 mm)

Ball, Strike,

Out indicators

Wattage Model Dimensions

Lamp Maximum

25 W 1500 W 120 V AC

25 W

40 W

25 W 3000 W 120/240 or

25 W 2925 W 120/240 or

25 W 3285 W 120/240 or

25 W 4960 W 120/240 or

40 W

4160 W 120/240 or

Power

(See Note 2)

120/208 V AC

120/20 V AC

120/208 V AC

120/208 V AC

120/208 V AC

Amps per Line

(Single Phase)

15 A A1 1

L1

L2 17 A

L1 12.5 A

L2

12.5 A

L1

L2 14 A

L1

11 A

L2 17 A

L1

17 A

L2 24 A

Driver Number

and Address

18 A

A1 11

A1 2

11 A

A1 11

A1 11

Specifications 3-4

Page 15

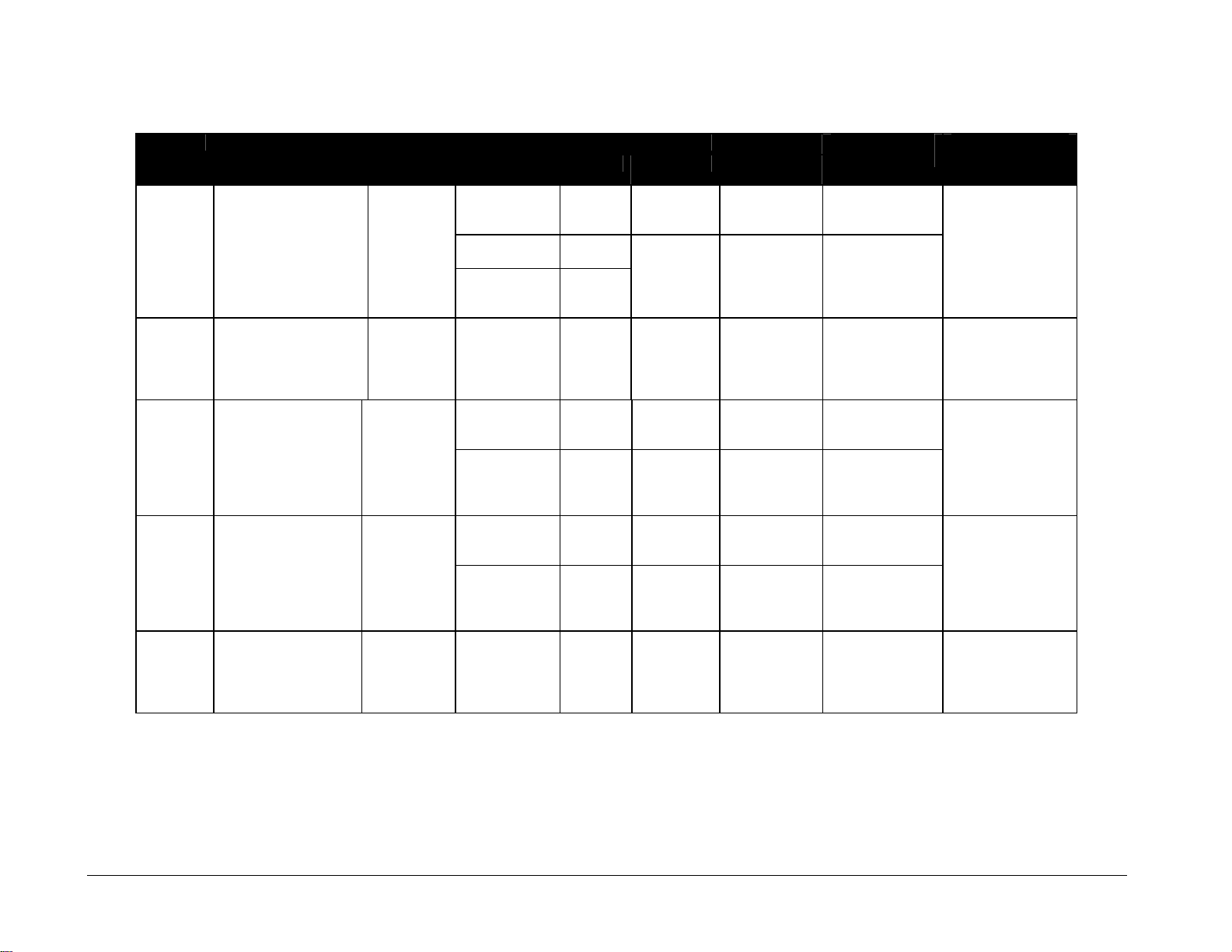

Wattage Model Dimensions

Lamp Maximum

25 W

25 W

25 W

25 W 10 000 W 120/240 or

25 W 10 000 W 120/240 or

25 W 10 080 W 120/240 or

25 W 7206 W 120/240 or

25 W SO-824 H4’-0", W14’-0", D6"

40 W

4325 W 120/240 or

6245 W 120/240 or

4160 W 120/240 or

Power

(See Note 2)

120/208 V AC

120/208 V AC

120/208 V

AC

120/208 V AC

120/208 V AC

120/208 V AC

120/208 V AC

Amps per Line

(Single Phase)

L1

L2 20 A

L1

L2 28 A

L1

28 A

L2 28 A

L1

42 A

L2 42 A

L1

L2 28 A

L1

L2 28 A

L1

L2 17 A

Driver Number

and Address

17 A

A1 11

25 A

A1 11

A1 74

A2 75

25 A

A1 11

22 A

A1 11

18 A

A1 11

(Height, Width,

Depth)

MS-2002 H4’-6", W16’-0", D6"

(1372 mm, 4877 mm,

152 mm)

MS-2002

w/TNMC

MS-2004 H5’-0", W18’-0", D6"

MS-2006

w/TNMC

MS-2011

w/TNMC

H4’-6", W16’-0", D6"

(1372 mm, 4877 mm,

152 mm)

(1524 mm, 5486 mm,

152 mm)

H7'-0", W25'-0", D6"

(2134 mm, 7620 mm,

152 mm)

H4'-6", W20'-0", D6"

(1372 mm, 6096 mm,

152 mm)

(1219 mm, 4877 mm,

152 mm)

Weight

Uncrated

(Crated)

250 lb

114 kg

(715 lb)

(324 kg)

425 lb

193 kg

(740 lb)

(336 kg)

375 lb

170 kg

(770 lb)

(350 kg)

500 lb

227 kg

(850 lb)

(386 kg)

475 lb

215 kg

(903 lb)

(410 kg)

250 lb

114 kg

(560 lb)

(254 kg)

Digit Size

and Matrix

Clock, scores

24" 4x7

(610 mm)

Period

18" 3x5

(457 mm)

Period

18" 3x5

(457 mm)

All digits

18" 3x5

(457 mm)

All digits

18" 4x7

(457 mm)

Clock, scores

30" 4x7

(762 mm)

Period

24" 4x7

(610 mm)

Clock, scores

24" 4x7

(610 mm)

Period

15" 3x5

(381 mm)

24" 4x7

(610 mm)

Half

indicators

Specifications

3-5

Page 16

Weight

(Height, Width,

Depth)

SO-918 H4’-0", W12’-0", D6"

(1219 mm, 3658 mm,

152 mm)

SO-2008

w/TNMC

TI-218 H2’-0", W3’-0", D11"

TI-418 H2’-0", W6’-0", D11"

TI-2003 H3’-0", W4’-0", D11"

H5'-6", W16'-0", D6"

(1676 mm, 4877 mm,

152 mm)

(610 mm, 914 mm,

279 mm)

(787 mm, 1829 mm,

279 mm)

(914 mm, 1219 mm,

279 mm)

Uncrated

(Crated)

225 lb

102 kg

(455 lb)

(206 kg)

300 lb

136 kg

(570 lb)

(259 kg)

20 lb

9 kg

(57 lb)

(26 kg)

50 lb

23 kg

(87 lb)

(40 kg)

110 lb

50 kg

(150 lb)

(68 kg)

Digit Size

and Matrix

18" 3x5

(457 mm)

18" 4x7

(457 mm)

Half

Indicators

All digits

18" 3x5

(457 mm)

All digits

18" 3x5

(457 mm)

All digits

18" 4x7

(457 mm)

All digits

18" 3x5

(457 mm)

All digits

18" 4x7

(457 mm)

All digits

30" 4x7

(762 mm)

Wattage Power Model Dimensions

Lamp Maximum (See Note 2)

25 W 2925 W 120/240 or

120/208 V

AC

25 W

40 W

25 W 6145 W 120/240 or

25 W

25 W 1000 W 120 V AC 9

25 W

25 W 2000 W 120 V AC 17

40 W 1600 W 120 V AC 14 A1 2

4500 W 120/240 or

120/208 V

AC

120/208 V

AC

650 W

1300 W

120 V AC

120 V AC

Amps per Line

(Single Phase)

L1

11 A

L2 17 A

L1

17 A

L2 21 A

L1

L2 30 A

6

11

Driver Number

and Address

A1 11

22 A

A1 17

A1 2

A1 1

Specifications 3-6

Page 17

3.2 230 Volt Single-Section Scoreboards

Note 1: Signal wires must be a minimum of 22-gauge with shield. Daktronics recommends using W-1234.

BA-518 H4’-0", W9’-0", D6"

CT-2001 H2’-0", W6’-0", D11"

(Height, Width,

Depth)

(1219 mm, 2743 mm,

152 mm)

(610 mm, 1829 mm,

279 mm)

(1219 mm, 4877 mm,

152 mm)

Weight

Uncrated

(Crated)

120 lb

55 kg

(152 lb)

(70 kg)

50 lb

23 kg

(83 lb)

(37 kg)

250 lb

114 kg

(560 lb)

(254 kg)

Digit Size

and Matrix

Inning,

scores

18" 3x5

(457 mm)

Inning,

scores

18" 4x7

(457 mm)

Ball, Strike

Out indicators

All digits

18" 4x7

(457 mm)

24" 4x7

(610 mm)

Half

indicators

Wattage Model Dimensions

Lamp Maximum

25 W 1905 W

25 W 2780 W 230 V AC 12 A

40 W

30 W 1800 W 230 V AC

25 W SO-824 H4’-0", W14’-0", D6"

40 W

4160 W 230 V AC L1 9 A

230 V AC

Power

Amps per Line

(Single Phase)

8 A

8 A A1 1

L2

9 A

Driver Number

and Address

A1 61

A1 11

Specifications

3-7

Page 18

Page 19

Section 4: Component Locations

Use the following drawings to determine the location of scoreboard components. The drawings are

listed below in alphanumeric order by model number. In the Appendix, they are inserted in

alphanumeric order by drawing number.

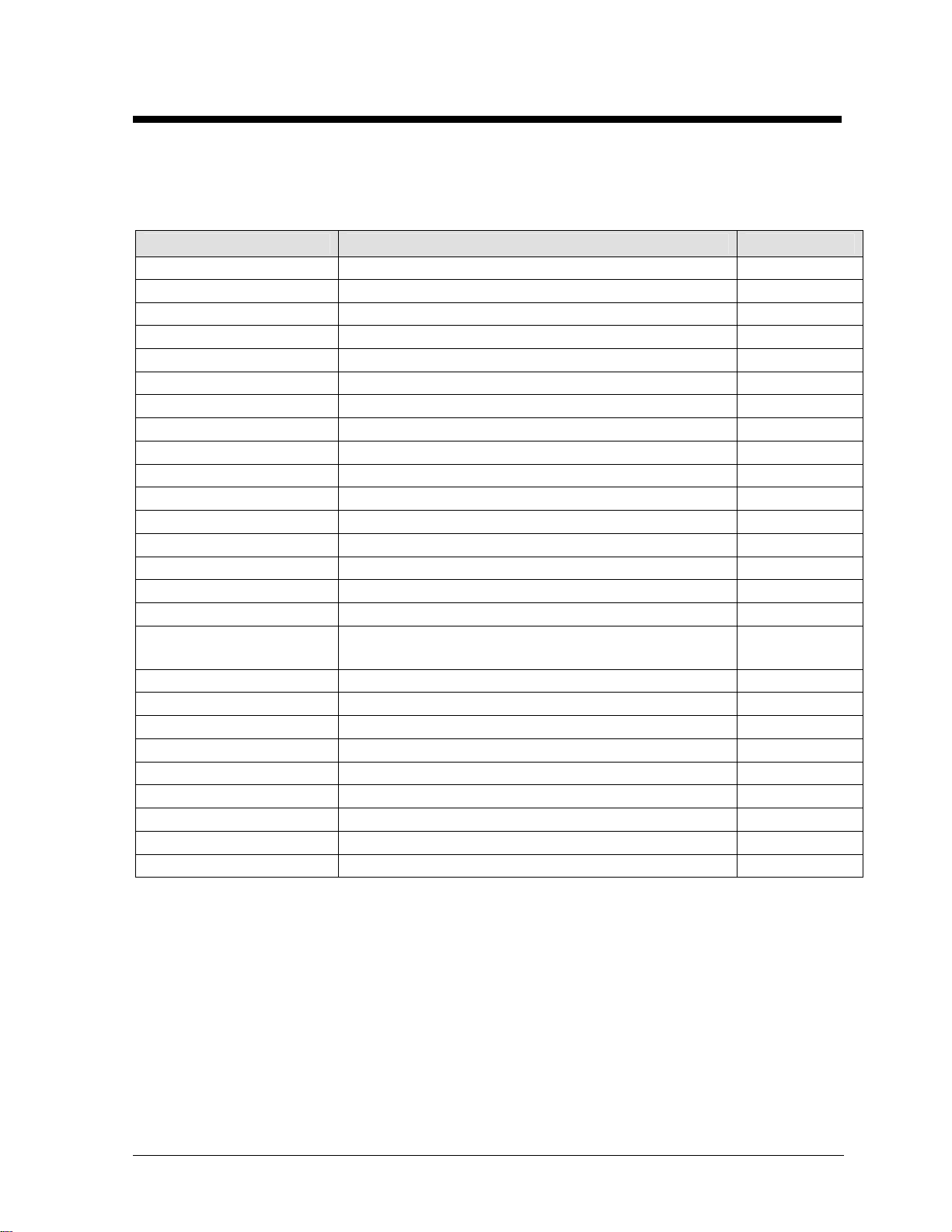

Model Drawing Name Drawing No.

BA-515 Component Locations, BA-515 A-126083

BA-518 Component Locations, BA-518 A-126084

BA-618 Component Locations, BA-618 A-126221

BA-624 Component Locations, BA-624 A-126285

BA-718 Component Locations, BA-718 A-126306

BA-1018 Component Locations, BA-1018 A-126353

BA-2003 Component Locations, BA-2003 A-158315

BA-2004 Component Locations, BA-2004 A-152733

CT-2001 Component Locations, CT-2001 A-126429

CT-2002 Component Locations, CT-2002 A-126430

FB-824 Component Locations, FB-824 A-126431

FB-2340 Component Locations, FB-2340 A-137679

MS-915 Component Locations, MS-915 A-126432

MS-918 Component Locations, MS-918 A-124343

MS-2002 Component Locations, MS-2002 A-127235

MS-2002 w/TNMC Component Locations, MS-2002 w/TNMC A-127193

MS-2002 w/TNMC

and 40W Lamps

MS-2004 Component Locations, MS-2004 A-128047

MS-2006 w/TNMC Component Locations, MS-2006 w/TNMC A-132960

MS-2011 w/TNMC Component Locations; MS-2011 A-138889

SO-824 Component Locations, S0-824 A-127285

SO-918 Component Locations, S0-918 A-126433

SO-2008 w/TNMC Component Locations; SO-2008 w/ 832-12 w/TNMC A-150127

TI-218 Component Locations, TI-218 A-126364

TI-418 Component Locations, TI-418 A-126372

TI-2003 Component Locations, TI-2003 A-126434

Component Locations, MS-2002 w/TNMC

and 40W Lamps

A-135738

Component Locations

4-1

Page 20

Page 21

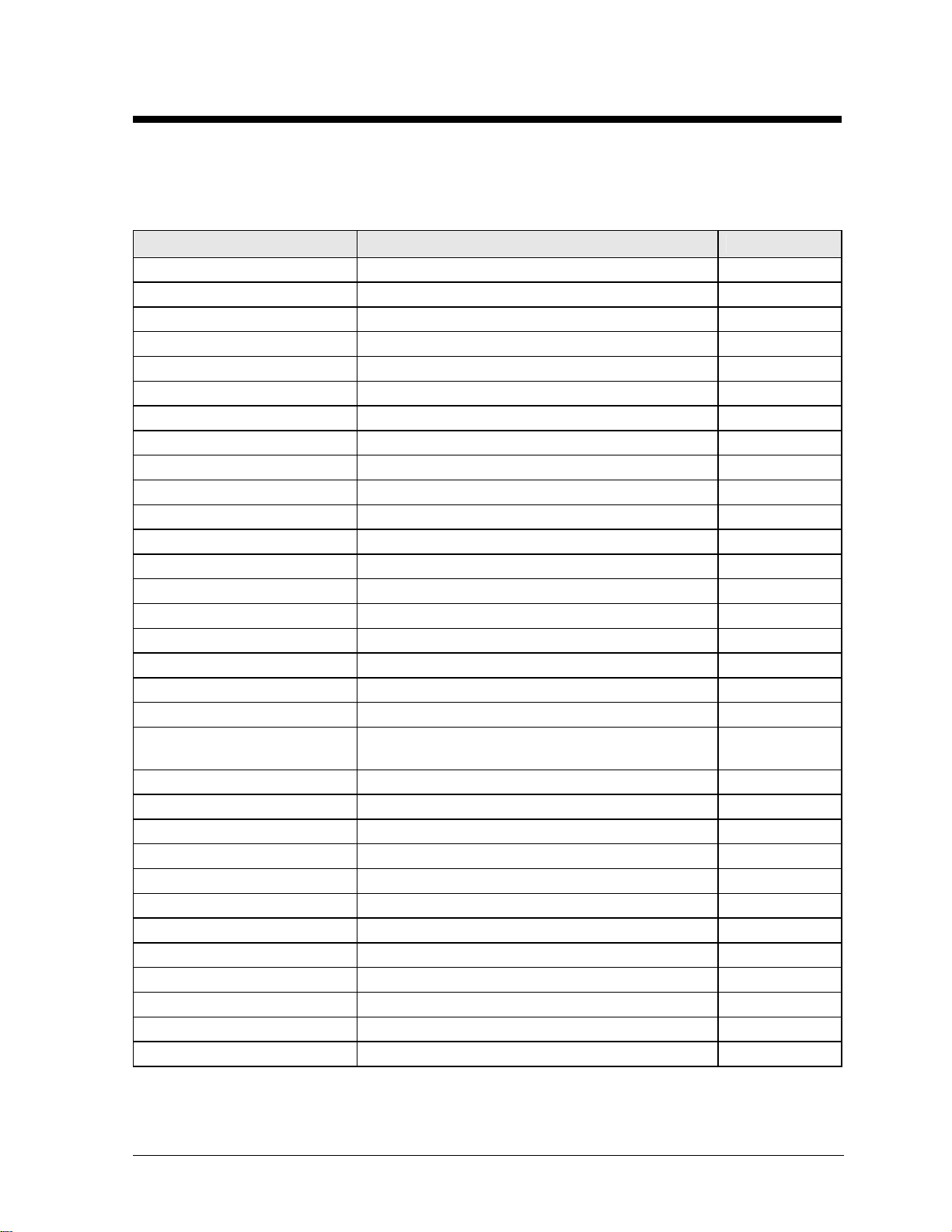

Section 5: Schematics

Use the following table to determine the schematic for your scoreboard model. The drawings are listed

below in alphanumeric order by model number. In the Appendix, they are and inserted in

alphanumeric order by drawing number.

Model Schematic Name Drawing No.

BA-515 Schematic, 1 Driver 8 Column A-124298

BA-518 Schematic, 1 Driver 8 Column A-124298

BA-518, 230 V AC Schematic, 1 Driver 16 Col. Overseas A-139639

BA-618 Schematic, 1 Driver 8 Column A-124298

BA-624 Schematic, 1 Driver 8 Column A-124298

BA-718 Schematic, 1 Driver 8 Column A-124298

BA-1018 Schematic, 1 Driver A-124293

BA-2003 Schematic, 1 Driver 8 Column A-124298

BA-2004 Schematic; BA-2004 B-155111

CT-2001 Schematic, 1 Driver 8 Column A-124298

CT-2001, 230 V AC Schematic, 1 Driver 8 Col. Overseas A-139733

CT-2002 Schematic, 1 Driver 8 Column A-124298

FB-824 Schematic, 1 Driver A-124293

FB-2340 Schematic, 1 Driver A-124293

MS-915 Schematic, 1 Driver A-124293

MS-915, 230 V AC Schematic, 1 Driver 16 Col. Overseas A-139639

MS-918 Schematic, 1 Driver A-124293

MS-2002 Schematic, 1 Driver A-124293

MS-2002 w/TNMC Schematic; 1 Drvr with 32 or 48-10 TNMC B-127394

MS-2002 w/TNMC and

40W Lamps

MS-2004 Schematic, 2 Drivers A-124291

MS-2006 w/TNMC Schematic, 2 Drivers w/32 or 48-12 TNMC B-132144

MS-2011 w/TNMC Schematic; 1 Drvr with 32 or 48-10 TNMC A-127394

SO-824 Schematic, 1 Driver A-124293

SO-824, 230 V AC Schematic, 1 Driver 16 Col. Overseas A-139639

SO-918 Schematic, 1 Driver A-124293

SO-2008 w/TNMC Schematic; 1 Drvr with 32 or 48-10 TNMC A-127394

TI-218 Schematic, 1 Driver 8 Column A-124298

TI-418 Schematic, 1 Driver 8 Column A-124298

TI-2003 Schematic, 1 Driver 8 Column A-124298

TNMC, 832-12 Schematic, 832-12 TNMC A-125214

TNMC, 848-12 Schematic, 848-12 TNMC A-125216

Schematic, 2 Drivers w/32 or 48-12 TNMC B-132144

Schematics

5-1

Page 22

Page 23

Section 6: Mechanical Installation

Mechanical installation consists of installing concrete footings and steel beams, and mounting the

scoreboard and accompanying ad panels to the beams.

6.1 Footings and Beams

Reference Drawings:

Installation Specifications; BA 515.......................................................... Drawing A-55003

Installation Specifications; BA 518.......................................................... Drawing A-55004

Installation Specifications; BA 618.......................................................... Drawing A-55006

Installation Specifications; BA 624.......................................................... Drawing A-55007

Installation Specifications; BA 718.......................................................... Drawing A-55005

Installation Specifications; BA 1018........................................................ Drawing A-61904

Installation Specifications; BA-2003...................................................... Drawing A-158322

Installation Specifications; BA-2004 & BA-2005 ................................... Drawing A-152777

Installation Specifications; FB-2340............................................................ Drawing A-169388

Installation Specifications; MS 824 ....................................................... Drawing A-127287

Installation Specifications; MS-915 .......................................................Drawing A-113568

Installation Specifications; MS 918 ......................................................... Drawing A-55009

Installation Specifications; MS-2002 .....................................................Drawing A-127195

Installation Specifications; MS 2002 w/TNMC ......................................Drawing A-127195

Installation Specifications; MS-2004 .....................................................Drawing A-128788

Installation Specifications; MS-2006 w/TNMC ......................................Drawing A-135575

Installation Specifications; MS-2011 w/TNMC ......................................Drawing A-135414

Installation Specifications; SO 824........................................................Drawing A-127287

Installation Specifications; SO 918..........................................................Drawing A-55010

Installation; TI-2003............................................................................... Drawing A-139316

Installation Specifications; SO-2008 ..................................................... Drawing A-149074

Installation Specifications; TI-2003 ....................................................... Drawing A-169367

Installation Specifications; TI-218 ......................................................... Drawing A-169376

Installation Specifications; TI-418 ......................................................... Drawing A-169380

Refer to the installation specification drawings listed above for the rear view of each of the models.

These drawings specify the number of beams and the recommended spacing between them. It is

critical that these dimensions be adhered to for scoreboards with team name message centers because

of the ventilation hoods located on the rear of the displays.

These drawings also indicate the size of beams required to support the scoreboard at different heights

under various wind speed conditions. All of the beam specifications illustrate "W" shape steel beams

(wide-flange I-beams). The first number indicates the front-to-rear depth of the beam, and the second

number indicates the weight in pounds per foot of length.

The column and footing size dimensions provided in the drawings assist with estimating installation

costs. They are estimates only and are not intended for construction purposes. Be sure that your

installation complies with local building codes and is suitable for your particular soil and wind

conditions.

Mechanical Installation

6-1

Page 24

The columns and footings and all connection details must be designed and certified by a professional

engineer licensed to practice in the state in which scoreboard will be installed. Daktronics does not

assume any liability for any installation derived from the information and drawings provided in this

manual or designed and installed by others.

6.2 Lifting the Scoreboard

Reference Drawings:

Lifting Scoreboard ................................................................................... Drawing A-44548

Lifting Small Baseball Scoreboard ..........................................................Drawing A-58668

Small Daktronics scoreboards are not equipped with eyebolts. Refer to Drawing A-58668 for lifting

details.

Larger scoreboard sections and message centers are shipped equipped with eyebolts that are used to

lift the displays. The eyebolts are located along the top of the cabinet for each scoreboard or

scoreboard section.

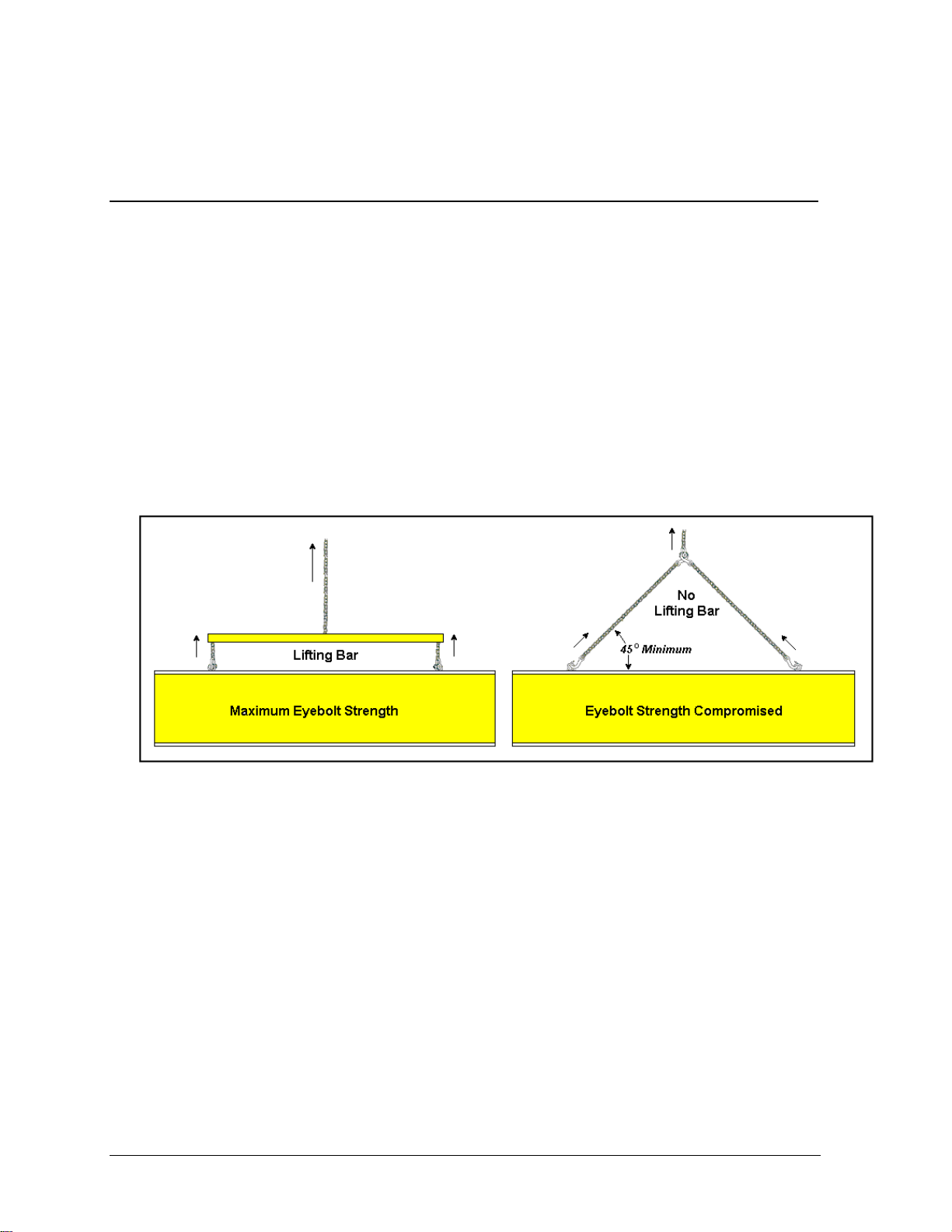

Daktronics strongly recommends using a spreader bar, or lifting bar, to lift the display. Using a

spreader bar ensures that the force on the eyebolts is straight up, minimizing lifting stress. Lifting

methods are shown in the illustration below and in Drawing A-44548.

Figure 3: Lifting the Display

Figure 3 above illustrates both the preferred method (left example) and an alternative method (right

example) for lifting a scoreboard. When lifting the display:

Use a spreader bar.

Use every lifting point provided.

Take special care to ensure the rated load of the eyebolts is not exceeded. Refer to ED-7244,

Eyebolts, to determine allowable loads and load angles for the lifting hardware. ED-7244 is located in

the Appendix of this manual.

Avoid using other lifting methods. Cables and chains attached to the eyebolts and directly to a center

lifting point, as show in the right-hand example in Figure 3, can create a dangerous lateral force on

the eyebolts and may cause the eyebolts to fail. Daktronics scoreboards use

eyebolts mounted to a

1

/8" aluminum plate or steel nut plate, but exceeding load angles or weight

limits could cause the bolts to pull out or the scoreboard cabinet to buckle. In either circumstance, the

result

1

/2" and 5/8" shoulder-type

6-2

Mechanical Installation

Page 25

would be serious damage to the scoreboard. If you must use this method, ensure a minimum angle

between the chain and scoreboard of at least 45°.

KNote: Daktronics assumes no liability for scoreboard damage resulting from incorrect

setup or incorrect lifting methods.

Eyebolts are intended for lifting only. Do not attempt to permanently support the display by the

eyebolts.

In typical multi-section installations, the lower scoreboard section is installed first and secured to the

support beams, and then the upper section is placed atop or above the lower section and attached to the

beams. There may be cables extending from the top of the lower section. Guide these cables into the

hole in the bottom of the upper section for later connection.

If the lift eyebolts are removed, plug the holes with bolts and the rubber sealing washers that were

removed with the eyebolts. Apply silicone or another waterproof sealant to the eyebolt openings.

Inspect the top and sides of the display for any other holes or openings that may allow moisture to

enter the display, and plug and seal those openings as well.

6.3 Scoreboard Mounting

Use the following table to determine the mounting method for your scoreboard.

Method 1

Method 2

BA-618, BA-624, BA-918, BA-1018, BA-2003, BA-2004, FB-824, MS-918, SO824, SO-918, SO-2008, MS-2002, MS-2004, MS-2011

BA-515, BA-518, BA-718, CT-2001, CT-2002, FB-2340, MS-915, TI-218, TI418, TI-2003, MS-2006

Method 1

Reference Drawings:

Display Mounting......................................................................... Drawing A-44412

Ad Panel Mounting...................................................................... Drawing A-52187

Installation Specifications, BA 618 ..............................................Drawing A-55006

Installation Specifications, BA 624 ..............................................Drawing A-55007

Installation Specifications, BA-2003.......................................... Drawing A-158322

Installation Specifications; BA-2004 & BA-2005........................ Drawing A-152777

Installation Specifications, FB-824/SO-824............................... Drawing A-127287

Installation Specifications, MS 918.............................................. Drawing A-55009

Installation Specifications, SO 918.............................................. Drawing A-55010

Installation Specifications, BA 1018 ............................................Drawing A-61904

Installation Specifications, MS-2002 ......................................... Drawing A-127195

Installation Specifications, MS-2004 ......................................... Drawing A-128788

Installation Specifications, SO-2008.......................................... Drawing A-149074

Installation Specifications; MS-2011 w/TNMC ..........................Drawing A-135414

Drawing A-44412 shows the hardware used for mounting the scoreboard to the beams. Each

section of the scoreboard attaches at the top and the bottom to all the beams. Drawing A-44412

also shows top and side views of the scoreboard secured to the beams. Note that the threaded rods

do not pass through the flanges of the beams, but instead run along both sides of each beam. Refer

Mechanical Installation

6-3

Page 26

to the Installation Specifications drawing for your model to determine the center-to-center

distance of the poles.

Review the illustrations of the mounting hardware in Drawing A-44412, and then use the

following procedure for each section.

1. Loosely attach the inner and outer mounting clamps to the rear flanges of the

scoreboard’s horizontal frame members, using the

and position the clamps to fit on either side of the beams.

2. Insert a

1

/2" square nut into each mounting clamp. From the rear, screw a threaded rod

3

/8" bolts. Measure the beam spacing,

into each of the nuts.

3. Position the scoreboard at the front of the beams with the threaded rods extending from

the rear of the clamps, straddling the beams. Raise the scoreboard section to the desired

height.

4. Slide clamping angles over the ends of the rods and loosely install the washers and nuts.

5. Make final adjustments in the positioning of the scoreboard. Tighten the

3

/8" bolts in the

mounting clamps.

6. Make sure that the threaded rods are perpendicular to the scoreboard, and tighten all of

the

1

/2" nuts.

Method 2

Reference Drawings:

Scoreboard Mounting ..................................................................Drawing A-55101

Installation Specifications, BA 515 ..............................................Drawing A-55003

Installation Specifications, BA 518.............................................. Drawing A-55004

Installation Specifications, BA 718.............................................. Drawing A-55005

Installation Specifications, FB-2340 .......................................... Drawing A-169388

Installation Specifications, MS-915 ........................................... Drawing A-113568

Installation Specifications, MS-2006 ......................................... Drawing A-135575

Installation Specifications; TI-2003............................................ Drawing A-169367

Installation Specifications; TI-218.............................................. Drawing A-169376

Installation Specifications; TI-418.............................................. Drawing A-169380

Refer to Drawing A-55101 for mounting details. Refer to the Installation Specifications drawing

for your model to determine the center-to-center distance of the poles.

Mount the scoreboard as follows:

1. Use the mounting channel to determine which hole combination to use. Be sure to keep

the bolts as close to the beam as possible.

2. Using the mounting channel as a template, drill

flange of the scoreboard where the supports will go.

3. Place square nuts inside the channel and thread the bolts through.

4. Lift the scoreboard into position with the bolts still in place.

5. Place mounting angles over each pair of bolts and secure with lockwashers and hex nuts.

6. After adjusting the scoreboard to the final desired position, tighten hex nuts firmly.

When mounting a scoreboard with back sheets, remove the back sheets in the areas above and

below the holes drilled in the upper and lower rear flange of the scoreboard. Be sure to replace the

back sheets after placing the square nuts inside the channel and threading the bolts through the

holes.

9

/16" holes in the upper and lower rear

6-4

Mechanical Installation

Page 27

6.4 Ad Panel Mounting

Reference Drawings:

Ad Panel Mounting.................................................................................. Drawing A-52187

Assembly, Ad Panel, BA-515.................................................................. Drawing A-52585

Ad Panel Mounting, BA-518.................................................................... Drawing A-52811

Refer to Drawing A-52187 for mounting details.

Mount the ad panel(s) as follows:

1. Use the mounting channel to determine which hole combination to use. Be sure to keep the

bolts as close to the beam as possible.

2. Using the mounting channel as a template, drill

of the ad panel where the supports will go.

3. Place square nuts inside the channel and thread the bolts through.

4. Lift the ad panel into position with the bolts still in place.

5. Place mounting angles over each pair of bolts and secure with lock washers and hex nuts.

6. When the panel is adjusted to the final desired position, tighten hex nuts firmly.

When mounting ad panels with back sheets, remove the back sheets in the areas above and below

the holes drilled in the upper and lower rear flange of the ad panel. Be sure to replace the back

sheets after placing the square nuts inside the channel and threading the bolts through the holes.

9

/16" holes in the upper and lower rear flange

Models BA-515 and BA-518

Ad panels are mounted directly to the scoreboard for models BA-515 and BA-518. Refer to

Drawings A-52585 and A-52811 for mounting details.

Mechanical Installation

6-5

Page 28

Page 29

Section 7: Electrical Installation

Reference Drawings:

Components 8/16 Pos Power and Signal Entrance.............................. Drawing A-109114

Components 2/4 Pos Power and Signal Entrance................................ Drawing A-125977

Electrical installation consists of:

Providing power and ground to a disconnect near the scoreboard.

Routing power and ground from the main disconnect to the scoreboard power and signal

entrance enclosure.

Connecting the scoreboard ground to a grounding electrode at the scoreboard location.

Routing the control signal cable from the control location to the scoreboard location.

Connecting several cables from the lower to the upper section.

Route power and signal cables into the scoreboard from the rear. There are two knockouts for conduit

connection in the back. All wires connect to the entrance plate. Drawings A-109114 and A-125977

illustrate the two types of entrance panels.

7.1 Power Requirements

Reference Drawings:

Components 8/16 Pos Power and Signal Entrance.............................. Drawing A-109114

Components 2/4 Pos Power and Signal Entrance................................ Drawing A-125977

Refer to the chart in Section 3 to determine circuit specifications and maximum power requirements

for the models described in this manual.

Daktronics outdoor scoreboards have been designed for easy access to components, and the power and

control signal hookup has been simplified. Front panels are removable to allow access to the digits,

cabling and other electronic components.

Proper power installation is imperative for proper display operation. The following subsections give

details of display power installation.

Grounding

Displays MUST be grounded according to the provisions outlined in Article 250 of the

National Electrical Code

The display system must be connected to earth-ground. Proper grounding is necessary for reliable

equipment operation. It also protects the equipment from damaging electrical disturbances and

lightning. The display must be properly grounded or the warranty will be void.

The material of an earth-ground electrode differs from region to region and from conditions

present at the site. Consult the National Electrical Code and any local electrical codes that may

apply. The support structure of the display cannot be used as an earth-ground electrode. The

support is generally embedded in concrete, and if in earth, the steel is either primed or it corrodes,

making it a poor ground.

Electrical Installation

®

. Daktronics recommends a resistance to ground of 10 ohms or less.

7-1

Page 30

Power Installation

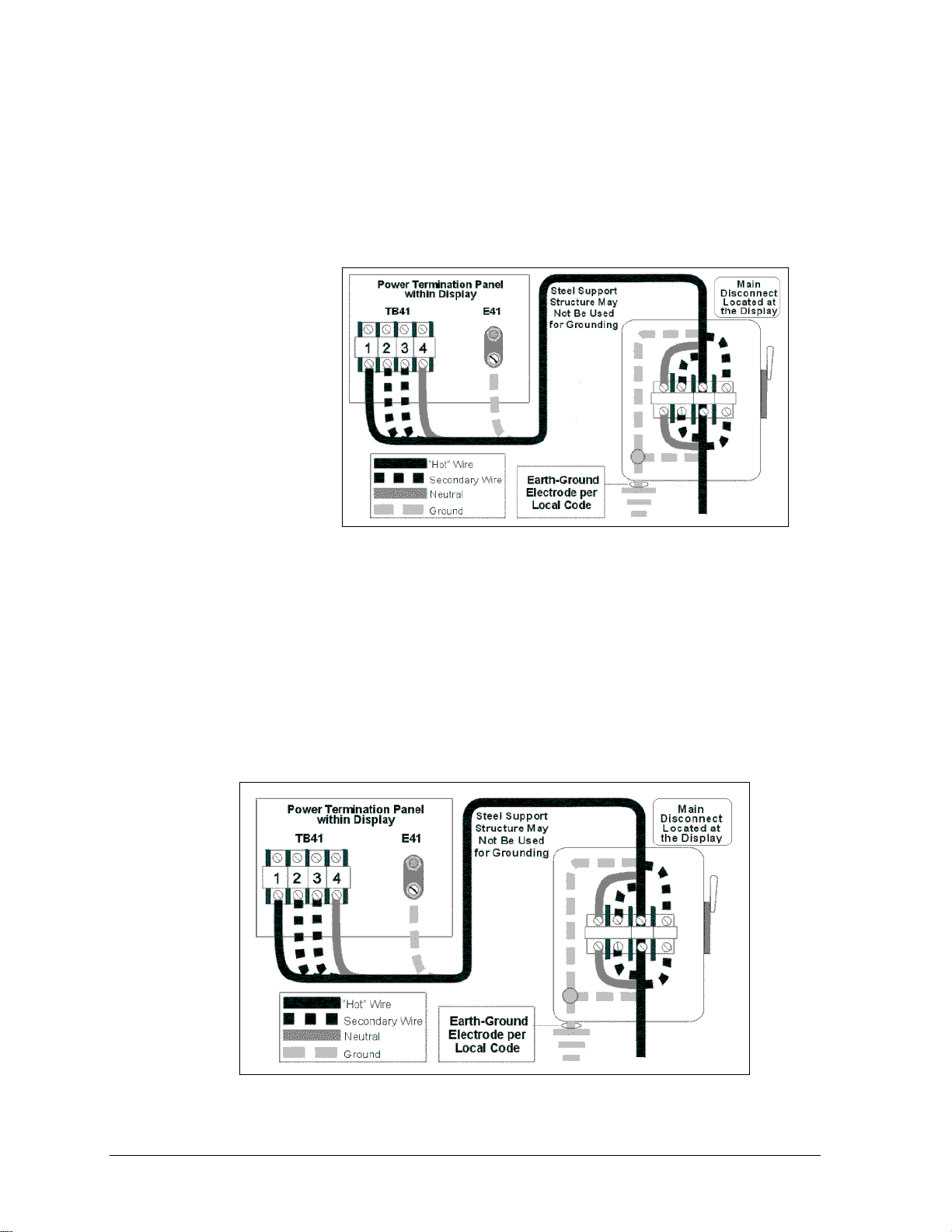

There are two basic considerations for power installation: installation with ground and neutral

conductors provided, and installation with only a neutral conductor provided. These two power

installations differ slightly, as described in the following paragraphs:

Installation with Ground and Neutral Conductors Provided

For this type of installation, the power cable must contain an isolated earth-ground conductor.

In this circumstance, do not connect neutral to ground at the disconnect or at the display. This

would violate

electrical codes

and void the

warranty. Use a

disconnect so that

all hot lines and

neutral can be

disconnected. The

National Electrical

Code requires the

use of a lockable

power disconnect

within sight of or

at the display.

Figure 4: Installation with Ground and Neutral Conductor Provided

Installation with Only a Neutral Conductor Provided

Installations where no grounding conductor is provided must comply with Article 250-32 of

the National Electrical Code. If the installation in question meets all of the requirements of

Article 250-32, the following guidelines must be observed:

Connect the grounding electrode cable at the local disconnect, never at the display

entrance enclosure.

Use a disconnect that opens all of the ungrounded phase conductors.

Bond the neutral and the ground conductors in the display power entrance enclosure.

Figure 5: Installation with Only Neutral Conductor Provided

7-2

Electrical Installation

Page 31

The scoreboard must be connected to earth ground. Proper grounding is necessary for reliable

equipment operation. It also serves to provide protection to the equipment against damaging electrical

disturbances and lightning. Failure to adhere to the following grounding methods will void the

warranty.

The steel support structure for the scoreboard cannot be used as grounding. The support is generally

embedded in concrete, and if in earth, the steel is either primed or it corrodes, making it a poor ground.

Use one ground electrode (typically, a ground rod) at each scoreboard support column.

The power cable must contain a separate earth-ground conductor. When a separate ground conductor

is used, do not connect neutral to ground at the disconnect or at the scoreboard. To do so would violate

electrical codes and void the warranty. Refer to Figure 5.

The National Electrical Code requires the use of a lockable power disconnect near the scoreboard. The

customer must provide a lockable disconnect switch (knife switch) at the scoreboard location so that

all power lines can be completely disconnected. Use a multi-conductor disconnect so that all hot lines

and the neutral can all be disconnected. This is important in protecting the scoreboard against

lightning.

K Note: Do not connect ground to neutral at the scoreboard. Doing so voids the warranty and may

violate electrical codes.

7.2 Power and Signal Connection

Reference Drawings:

Components 8/16 Pos Power and Signal Entrance.............................. Drawing A-109114

Components 2/4 Pos Power and Signal Entrance................................ Drawing A-125977

To gain access to the entrance panel, open the access door and remove the cover from the entrance

enclosure. Refer to Section 4: Component Locations for the location of the access door for the model

of your scoreboard.

Connect the power and signal cables to the entrance panel as shown in Drawings A-109114 and A-

125977.

Electrical Installation

7-3

Page 32

Page 33

Section 8: Digit Maintenance

and Troubleshooting

IMPORTANT NOTES:

1. Disconnect power before doing any repair or maintenance work on

the scoreboard!

2. Allow only qualified service personnel access to internal display

electronics.

3. Disconnect power when not using the scoreboard.

For assistance in the maintenance of the optional message center, refer to

the manual that accompanies the message center or to Section 9 in this

manual.

8.1 Component Access

Lamp Driver Access

Refer to the Component Locations drawings listed in Section 4 for the location of the lamp

drivers. To access a lamp driver:

1. Open the access panel by turning the

2. Remove the driver enclosure cover.

3. Disconnect the plugs.

4. Remove the wing nuts securing the lamp driver to the enclosure.

5. Carefully pull out the lamp driver and set it on a clean, flat surface.

Important: When the lamp drivers are replaced, plugs P25 and P26 (if present) must be

removed from the old driver and plugged into the new driver.

1

/4-turn screws. The door will swing open.

Digit Access

Reference Drawing:

Digit Service ................................................................................ Drawing A-27674

Use the following instructions to remove a digit from the front of the scoreboard.

Note: The digit does not need to be removed to change the lamps.

1. Remove the screws securing the screen (refer to Drawing A-27674).

2. Carefully pull the digit out part way so that the ground wire can be unscrewed and the

harness unplugged.

3. Place the digit on a clean level surface.

Digit Maintenance and Troubleshooting

8-1

Page 34

8.2 Lamp Replacement

Reference Drawing:

Digit Service ............................................................................................Drawing A-27674

The primary service required for Daktronics baseball scoreboards is to periodically replace bad lamps.

Refer to the table in Section 3 to determine the wattage of the lamps the scoreboard uses. Refer to

Section 8.8 to determine the part numbers. Do not use higher-wattage lamps or damage to the circuit

may result. Refer to Drawing A-27674 to access a digit.

8.3 Lamp Drivers

Reference Drawings:

Layout, 16 Column Driver III ................................................................. Drawing A-123940

Layout, 8 Column Driver III ................................................................... Drawing A-123941

Important: When the lamp drivers are replaced, plugs P25 and P26 (if present) must be removed

from the old driver and plugged into the new driver.

In the scoreboard, the lamp drivers perform the task of switching digit lamps on and off (refer to

Drawings A-123940 and A-123941).

Each lamp driver has connectors providing power and signal inputs to the circuit, and outputs to the

digits and indicators. The connectors function as follows:

8-Column Lamp Driver

Connector No. Function

1 – 8 Outputs to digits and indicators

17 Control signal input

18 Power input for outputs 1 – 8

19 Power input (120V) for driver

16-Column Lamp Driver

Connector No. Function

1 – 16 Outputs to digits and indicators

17 Control signal input

18 Power input for outputs 1 – 8

19 Power input (120V) for driver

20 Power input for outputs 9 - 16

Output connectors to the digits and indicators each have nine pins. Pin 7 provides power (hot) to the

digit or indicators wired to that connector. The other eight pins provide switching connections.

8-2

Digit Maintenance

and Troubleshooting

Page 35

8.4 Fuses

Reference Drawings:

Layout, 16 Column Driver III .................................................................Drawing A-123940

Layout, 8 Column Driver III ...................................................................Drawing A-123941

The digit lamp driver has 17 fuses. There is one fuse to protect each digit circuit. F1 through F16 are

located near each output connector under the driver’s metal cover. The lamp driver’s other fuse, F17

protects the driver’s logic circuit and fan. Refer to Drawings A-123940 and A-123941for an

illustration of the driver and these fuses. Refer to Section 8.8 to determine the part numbers for

replacement fuses.

8.5 Segmentation

Reference Drawing:

Digit Segments, 3x5 and 4x7 ..................................................................Drawing A-46653

In each digit, certain lamps always go on and off together. These groupings of lamps are referred to as

segments. Drawing A-46653 shows the segmentation of 3x5 and 4x7digits, which connector pin is

wired to each digit segment and the wiring color code used in all driver-to-lamp connections.

8.6 Power On Self-Test

Reference Drawings:

Incandescent Driver Power Up Self-Test.............................................. Drawing A-128283

Power Up Self Test on a FB-1424 ........................................................Drawing A-128301

The scoreboard performs a self-test each time that power is turned on and the control console is

powered off or not attached to the scoreboard. If the control console is attached and powered on, the

self-test does not run and data from the control console is displayed on the scoreboard after a brief

period of time.

The self-test runs in three cycles or phases. The pattern of the self-test varies depending on the

scoreboard model, number of drivers, and type of digits.

Drawing A-128283 shows how the test pattern displays in the digits when the address (P25)

and protocol (P26) plugs are not plugged into the lamp drivers.

Drawing A-128302 shows the test pattern displayed on a scoreboard that has one lamp driver

with the address (P25) plugged in.

These are the three cycles of the self-test:

Cycle 1:

Displays the protocol in digits that are controlled by lamp driver A1. P0 is always

displayed when P26 is not installed.

Cycle 2:

Cycle 3:

Digit Maintenance

and Troubleshooting

Displays the driver number and address in the digits that are controlled by each

driver. A000 is always displayed when P25 is not installed.

Displays a rotating pattern in all digits. The pattern starts in row 1 and rotates

through row 8 (refer to Drawing A-128283).

8-3

Page 36

8.7 Lightning Protection

The Transient Voltage Surge Suppresser (TVSS), located in the load center, reduces the brief surge

induced into the power lines when lightning strikes in the vicinity of the scoreboard. A varistor in the

power lines to the driver logic also helps to protect this circuit by reducing such surges.

The use of a disconnect near the scoreboard to completely cut all current-carrying lines significantly

protects the circuits against lightning damage. The National Electrical Code also requires it. In order

for this to provide protection, the power must be disconnected when the scoreboard is not in use. The

control console should also be disconnected from power and from the signal J-box when the system is

not in use. The same surges that may damage the scoreboard’s driver can also damage the console’s

circuit.

8.8 Replacement Parts

Refer to the following table for Daktronics outdoor scoreboard replacement parts. Refer to Section

9.14 for a listing of parts required for service of the team name message centers. Refer to Section 1.4

for details concerning the Daktronics Exchange and Repair and Return programs.

Important: When the lamp drivers are replaced, plugs P25 and P26 (if present) must be removed

from the old driver and plugged into the new driver.

Description Location

Fuse; AGC-1/2 F17 in lamp driver F-1000

Fuse; AGC-10 F1 - F16 in lamp driver(s) F-1006

Lamp, 25 W, 120 V 3x5 and 24" digits, 15" and 18" 4x7 digits DS-1029

Lamp, 30 W, 130 V 15" 4x7 digits DS-1182

Lamp, 40 W, 120 V Indicators DS-1163

Lamp, 25A19, 230 V frosted Digits and indicators DS-1363

Plug, 1/4" phone Signal P-1003

Socket, med. base lamp All lamps X-1301

Socket*, lamp, med. base,

insulation displacement

J-box, 1/4" phone, Indoor Signal 0A-1009-0038

J-box, 1/4" phone, outdoor Signal 0A-1091-0227

Signal surge arrestor Power/signal entrance enclosure 0P-1033-0114

12 V DC trumpet horn asm. Scoreboard 0A-1091-1213

Lamp driver, 8-column Scoreboard 0A-1033-0126

Lamp driver, 16-column Scoreboard 0A-1033-0125

Lamp driver, 230 V 8-col. Scoreboard 0A-1033-0130

Lamp driver, 230 V 16-col. Scoreboard 0A-1033-0129

Signal cord; 1/4" phone 20’ N/A W-1236

Signal cord; 1/4" phone 30’ N/A W-1238

Signal cord; 1/4" phone 50’ N/A W-1237

18" 4x7 shade screen 18" 4x7 digits or 3x5 digits 0S-1064-0001

All lamps X-1294*

Daktronics

Part No.

8-4

Digit Maintenance

and Troubleshooting

Page 37

Description Location

24" 4x7 shade screen 24" 4x7 digits 0S-1064-0002

15" 4x7 shade screen 15" 4x7 digits or 3x5 digits 0S-1064-0074

30" 4x7 shade screen 30" 4x7 digits 0S-1091-0002

Daktronics

Part No.

*This part, X-1294, is intended for use with scoreboards shipped after October, 2001. Models shipped prior to that

date will continue to use original equipment.

8.9 Troubleshooting

This section lists potential problems with the scoreboard and indicates possible causes and corrective

actions. This list does not include every possible problem, but does represent some of the more

common situations that may occur. Refer to Section 9.13 for a list of potential problems with team

name message centers.

Important: When the lamp drivers are replaced, plugs P25 and P26 (if present) must be removed

from the old driver and plugged into the new driver.

Symptom/Condition Possible Cause or Corrective Action

Scoreboard will not light.

Console not connected or poor connection

No power to the control console

No power to the scoreboard

Bad relay or poor relay connection in signal circuit

Driver logic fuse (F17) blown

P17, P19, or P20 unplugged

Half of the scoreboard will not

light.

Display is garbled.

Digit will not light.

Segment will not light.

Segment stays lit.

Circuit breaker tripped at service panel

Driver malfunction

Poor signal contact at main power connection

Control console malfunction

Internal lamp driver malfunction

Fuse blown in driver

Black wire to the digit damaged

Poor contact at driver connector

Lamps burned out

Driver malfunction (bad triac)

Broken wire between lamp driver and digit

Poor contact at driver connector

Driver malfunction (bad triac)

Segment neutral wire touching case

Digit Maintenance

and Troubleshooting

8-5

Page 38

Page 39

Section 9: Team Name Message Centers

Maintenance and Troubleshooting

IMPORTANT NOTES:

1. Turn power off before doing any repair or maintenance work on the

display!

2. Permit only qualified service personnel to access internal display

electronics.

3. Do not operate the display with the back sheets removed! The cabinet is positively

pressurized, directing adequate airflow around the lamps and out through the lenses.

Display operation without the back sheets in place and fans running could cause damage

to the display and will void the warranty. Make certain the back sheets are fastened

securely into place.

4. Dirt and contaminants may enter the display if it is operated without the fan filters

in place or with dirty fan filters. These contaminants may cause premature failure of

the electronic components. Operating the display with dirty fan filters or without fan filters

will void the warranty.

5. Daktronics product managers or engineering staff must approve any changes that

may affect the weather-tightness of the display. This is to include, but is not limited to,

border shrouding, back sheets, cooling fans, fan filter and filler panels. If ANY

modifications are made to the weather-tightness of the display, detailed drawings MUST

be submitted to our engineering staff for evaluation and approval, or the warranty will be

null and void.

6. Turning the power off when the display is not in use extends the life of some

components.

The team name message centers for standard (not modified for an individual customer) scoreboards

are FRONT-ACCESSIBLE for service. Custom scoreboards may be accessed from the front or rear.

This manual applies to team name message centers used in standard scoreboards.

9.1 TNMC Schematics

Reference Drawings:

Schematic, 832-12 TNMC..................................................................... Drawing A-125214

Schematic, 848-12 TNMC..................................................................... Drawing A-125216

Refer to the team name message center schematic Drawings A-125214 and A-125216 listed in

Section 5.

TNMC Maintenance

and Troubleshooting

9-1

Page 40

9.2 Service Procedures

Reference Drawings:

Lens Removal, Front Access. .................................................................Drawing A-99898

Lens Assy Removal, Front Access ......................................................... Drawing A-99899

Correct Lens Position, 1-1/2" ..................................................................Drawing A-75204

Removing a Module

For many maintenance or repair procedures, the first step is to remove a module. Each 8x16 lens

assembly is secured to the frame by two spring-loaded latches, one on each side. Follow these

instructions for access to these latches:

1. Remove the lens from row 4, column 1, and the lens from row 4, column 16 of the lens

assembly. Refer to Drawing A-99898.

2. Place the front access tool into the latch access hole. The angled edge of the tool should

be down so it wedges the latch pin down as it is pushed further into the access hole. Refer

to Section 9.14 for the part number of the access tool.

3. When the front access tool is fully inserted, the module latches should be released (refer

to Figure 6).

Figure 6: Removing a Module

4. With the latch released, pull the lens assembly slightly away (about

This will prevent it from re-latching. Refer to Drawing A-99899.

5. Repeat this procedure with the remaining side.

6. With both sides unlatched, the assembly should pull away from the display far enough so

the signal and power harness can be disconnected from the lampbank. When the signal

and power harnesses are removed, the module can be removed from the display.

Note: A

3

/16" slotted screwdriver may be used in place of the access tool.

1

/2") from the display.

Removing a Lampbank

The lampbank is attached to the lens assembly with a metal tab at each corner. To remove the

lampbank:

1. Push in the clips while gently pulling the lampbank out.

2. Repeat this step for the three remaining corners. Lampbanks should be serviced in a static-

free area to prevent static electricity from damaging the components.

9-2 TNMC Maintenance

and Troubleshooting

Page 41

Replacing a Lampbank

When lampbanks are reattached to the lens assemblies, be certain the lamp sockets are seated

tightly against the reflectors. All four tabs, one in each corner, must be snapped securely onto the

lampbank. If the lampbank is not secured properly to the lens assembly, the lamp filament will not

be at the focal point of the reflector, and parts of that lens assembly will appear dim.

Replacing the Module

To reinstall a lens assembly in the display, refer to Drawing A-75204:

1. Reconnect power and signal connections to the lampbank.

2. Tilt the module about 30 degrees and place the bottom corners of the side brackets to the

inside of the frame verticals.

3. Push the lens assembly firmly back into place until the latches snap into place and the lens

assembly is secured to the display. It may be necessary to use a solid object, such as a

short length of 2"x4" lumber, to properly seat the assembly. Place the 2x4 across the

louvers so the pressure on them is evenly distributed and strike the board with the heel of

your hand. This should drive the assembly in place.

4. Pull firmly on the assembly to ensure that it is fully in place and secured to the display.

The lens assemblies must fit together tightly enough so the weatherstripping forms a seal

and prevents water from leaking between the lens assemblies and into the display. The

seal between the assemblies should be checked with a 0.032" feeler gauge.

5. Snap the lenses back into the faceplate of the lens assembly. If a lens is not replaced

properly, it is easily noticed. The lens removal tab or the lens itself will not be in

alignment with the other lenses or lens tabs.

6. Verify that the rows of louvers on the lens assembly are in proper alignment.

9.3 Lamp Testing and Replacement

Reference Drawing:

Lens Removal, Front Access. ................................................................. Drawing A-99898

This display is designed for easy lamp replacement with front access. Non-functioning lamps should

always be replaced prior to scheduled events, or as soon as possible, for best viewing.

A 3.58 W lamp is positioned behind each lens. Use the controller lamp test to locate bad lamps. Refer

to Section 9.14 for the part numbers of replacement lamps and lenses.

Daktronics-approved 3.58 W lamps have an estimated life of 17,000 hours if operated at 11.0

V. Always use Daktronics-approved lamps.

K Note: Lamps purchased from Daktronics are built to tighter specifications than similar

lamps built in standard production. The recommended lamps give the sufficient

intensity and beam spread to match the display design. Lamps not built to Daktronics

specifications will not perform as well and will not give the intended results.

A qualified individual who is capable of operating the controller equipment should do lamp

testing.

Display power must be OFF for lamp replacement.

TNMC Maintenance

and Troubleshooting

9-3

Page 42

Individual Lamp Replacement

Grasp the tab on the top center of the lens with the lamp-extracting tool (refer to Drawing A-

99898). Pull the tab out and down, and at the same time, with your other hand, lightly press up on

the louver directly above the lens to be removed. Do not press up on the louver any further than

necessary, or the louver may become deformed.

1. Remove the defective lamp using the lamp-extracting tool.

2. Replace defective lamps with Daktronics approved lamps of the same wattage. Refer to

Section 9.14 for the correct replacement lamps.

3. Noting proper lens orientation, snap the lens back into the lens/reflector assembly (refer to

Section 9.4).

9.4 Lens Position and Sequence

Reference Drawing:

Lens Removal, Front Access. .................................................................Drawing A-99898

The slot in the bottom of the reflector accommodates the lens indexing tabs. To insert a lens, set the

lens tabs into the reflector slots and snap the lens up into the vertical position. Make sure that the lens

is snapped in and behind the upper louver offset.

Inspect the profile of the lenses to ensure that all lenses are secured properly. Lenses that are not

secured properly can be easily noticed, since the lens removal tab or the lens itself will not be in

alignment with the other lenses or lens tabs in that row.

Refer to Drawing A-99898 for more information.

9.5 Lens/Reflector Assembly Maintenance

Reference Drawing:

Lens Assy, Weather Stripping Location ...................................................Drawing A-91100

The lens/reflector assemblies are maintenance-free; however, each time an assembly is removed from

the display, the pile weatherstripping should be checked for signs of deterioration. The

weatherstripping runs along the top and sides of each lens/reflector assembly. In addition, over time,

the louvers on the front of lens/reflector assembly may become damaged and require replacement.

Weatherstripping and louver replacement are addressed in the following subsections.

Weatherstripping Maintenance

The top and bottom of each 8x16 lens assembly has a strip of pile weatherstripping. There is also

tape weatherstripping between each louver assembly. The weatherstripping helps keep moisture

out of the display and maintains the positive air pressure necessary for proper display cooling.

When doing routine display maintenance, which involves removing the 8x16 lens assemblies,

make sure the weatherstripping is intact. If any weatherstripping appears damaged, replace it.

Refer to the following instructions and Drawing A-91100. Refer to Section 9.14 for part

numbers.

1. Once the old weatherstripping has been removed, clean the top and bottom of the lens

assembly with an adhesive remover so the new weatherstripping will adhere.

2. The weatherstripping should be applied in one continuous strip on both the top and

bottom of the lens assembly.

9-4 TNMC Maintenance

and Troubleshooting

Page 43

3. When finished, the stripping should be flush at the bottom. If the weather stripping is not

tight or buckles anywhere on the lens assembly, it will be difficult to reinstall it in the

display, and it will allow water to enter the display and damage the electrical components.

4. Check the module spacing and weather stripping tightness with the 0.032" feeler gauge.

Louver Maintenance

If display louvers become bent or damaged, they must be replaced. The lens/reflector assembly

containing the damaged louvers should be returned to Daktronics for repair or replacement.

9.6 Lamp Module Transformer

Displays with team name message centers are shipped with transformers which, when wired to the 120

V tap with a line voltage of 120 V, will deliver 11.0 volts to the lamp. Lamp life is estimated to be

17,000 hours with this transformer. Refer to Section 9.14 for the correct part number for the

replacement transformer

Due to input line voltage variations from site to site, the resultant lamp voltages may vary, which may

greatly alter lamp life.