Daktronics BA-1518 User Manual

201 Daktronics Drive PO Box 5128 Brookings, SD 57006-5128

Tel: 1-800-DAKTRONICS (1-800-325-8766) Fax: 605-697-4700

www.daktronics.com

Multi-Section Outdoor

LED Scoreboards

Display Manual

ED-17610 Rev 10 – 23 September 2011

Models

BA-1518

FB-2025

*

BA-1524

FB-2026

*

BA-2013

FB-2027

*

BA-3718

FB-3010

*

BA-3724

MS-2009

FB-2018

MS-2918

FB-2019

SO-2011

FB-2020

SO-2018

FB-2021

SO-2019

FB-2022

SO-2021

FB-2023

*

SO-2022

FB-2024

SO-2023

*Discontinued

ED-17610

Please fill in the information below to use for reference when calling Daktronics for assistance.

Display Serial No. _______________________________________________________

Display Model No. _______________________________________________________

Date Installed ___________________________________________________________

Product 1407

Rev 10 – 23 September 2011

DAKTRONICS, INC.

Copyright 2009-2011

All rights reserved. While every precaution has been taken in the preparation of this manual, the publisher

assumes no responsibility for errors or omissions. No part of this book covered by the copyrights hereon may be

reproduced or copied in any form or by any means – graphic, electronic, or mechanical, including photocopying,

taping, or information storage and retrieval systems – without written permission of the publisher.

All Sport® and PanaView® are trademarks of Daktronics, Inc. Other trademarks used in this manual are the property of their

respective owners.

Table of Contents

Section 1: Introduction ............................................................................................................................ 1

1.1 Resources .................................................................................................................................. 1

1.2 Daktronics Nomenclature ...................................................................................................... 2

1.3 Model Number ........................................................................................................................ 3

1.4 Scoreboard Controllers ........................................................................................................... 3

1.5 Product Safety Approval........................................................................................................ 3

Section 2: Specifications .......................................................................................................................... 5

Section 3: Mechanical Installation ...................................................................................................... 11

3.1 Footings & Beams .................................................................................................................. 11

3.2 Lifting the Scoreboard .......................................................................................................... 11

3.3 Scoreboard Mounting ........................................................................................................... 13

Scoreboard Mounting Using Vertical Spacers ........................................................... 14

3.4 Scoreboard Protective Devices ............................................................................................ 14

3.5 Ad Panel Mounting............................................................................................................... 15

Section 4: Electrical Installation .......................................................................................................... 17

4.1 Installation Overview ........................................................................................................... 17

4.2 Power ...................................................................................................................................... 18

Grounding ....................................................................................................................... 18

Connection ...................................................................................................................... 19

4.3 Power-On Self-Test (POST) ................................................................................................. 20

Radio Settings ................................................................................................................. 20

4.4 Signal Connection ................................................................................................................. 21

Fiber Optic ...................................................................................................................... 21

Multiple Driver Connections ........................................................................................ 21

4.5 Power/Signal Connections Between Sections ................................................................... 21

4.6 Lightning Protection ............................................................................................................. 22

Section 5: Scoreboard Troubleshooting ............................................................................................. 23

5.1 Troubleshooting Table .......................................................................................................... 23

5.2 Component Locations ........................................................................................................... 26

5.3 Component Access ................................................................................................................ 26

5.4 Replacing Digits .................................................................................................................... 27

5.5 Replacing Digit Segments .................................................................................................... 28

5.6 Replacing Colons, Decimals & Indicators .......................................................................... 28

5.7 LED Drivers ........................................................................................................................... 29

Replacing a Driver ......................................................................................................... 30

Setting the Driver Address ........................................................................................... 31

Multiple Drivers ............................................................................................................. 31

5.8 Power Supplies ...................................................................................................................... 31

Replacing a Power Supply ............................................................................................ 32

5.9 Radio Connections ................................................................................................................ 32

Radio Interference .......................................................................................................... 33

5.10 Trumpet Horns ...................................................................................................................... 34

5.11 Segmentation and Digit Designation .................................................................................. 34

5.12 Schematics .............................................................................................................................. 34

5.13 Replacement Parts ................................................................................................................. 35

Table of Contents

i

Section 6: TNMC & Electronic Caption Troubleshooting & Maintenance ................................. 37

6.1 Display Overview ................................................................................................................. 37

6.2 Initialization Information at Startup ................................................................................... 38

6.3 Display Troubleshooting Table ........................................................................................... 38

6.4 Power & Signal Summary .................................................................................................... 39

6.5 Component Locations & Access .......................................................................................... 40

For Displays Built Before September 2009 .................................................................. 41

Front Access .................................................................................................................... 41

Rear Access ..................................................................................................................... 42

6.6 Display Drivers ...................................................................................................................... 42

For Displays Built Before September 2009 .................................................................. 43

Diagnostic LEDs ............................................................................................................. 44

Replacing a Driver ......................................................................................................... 44

6.7 Modules .................................................................................................................................. 44

Replacing Modules ........................................................................................................ 44

Weather-stripping .......................................................................................................... 45

6.8 Power Supplies ...................................................................................................................... 46

Replacing a Power Supply ............................................................................................ 46

6.9 Display Maintenance ............................................................................................................ 46

6.10 Replacement Parts List ......................................................................................................... 47

For Displays Built Before September 2009 .................................................................. 48

Section 7: Daktronics Exchange and Repair & Return Programs .................................................. 49

7.1 Exchange Program ................................................................................................................ 49

Before Contacting Daktronics ....................................................................................... 49

7.2 Repair & Return Program .................................................................................................... 50

Shipping Address ........................................................................................................... 50

7.3 Daktronics Warranty and Limitation of Liability ............................................................. 50

Section 8: Scoreboard Options ............................................................................................................. 51

8.1 Trumpet Horns ...................................................................................................................... 51

8.2 Radio Control ......................................................................................................................... 51

8.3 Time Outs Left (T.O.L) Digits .............................................................................................. 52

8.4 Changeable Caption Kits ...................................................................................................... 52

Appendix A: Reference Drawings ............................................................................................................ 53

Appendix B: Daktronics Warranty and Limitation of Liability .......................................................... 55

ii

Table of Contents

Figure 1: Daktronics Drawing Label

Section 1: Introduction

This manual explains the installation of Daktronics multi-section outdoor LED scoreboards and

provides details for maintenance and troubleshooting. For additional information regarding the

safety, installation, operation, or service of this system, refer to the telephone numbers listed in

Section 7. This manual is not specific to a particular installation.

Important Safeguards:

Please read and understand all instructions before beginning the installation process.

Do not drop control equipment or allow it to get wet.

Do not disassemble control equipment or electronic controls of the display; failure to

follow this safeguard will make the warranty null and void.

Disconnect display power when not in use or when servicing.

Disconnect display power before servicing power supplies to avoid electrical shock.

Power supplies run on high voltage and may cause physical injury if touched while

powered.

Do not modify the scoreboard structure or attach any panels or coverings to the

scoreboard without the express written consent of Daktronics, Inc.

Project-specific information takes precedence over any other general information found in

this manual.

1.1 Resources

Figure 1 illustrates a Daktronics drawing

label. The drawing number is located in the

lower-right corner of a drawing. This

manual refers to drawings by listing the last

set of digits and the letter preceding them.

In the example, the drawing would be

referred to as Drawing C-325405.

Reference Drawing:

System Riser Diagram ........................................................................... Drawing C-325405

Daktronics identifies manuals by the DD or ED number located on the cover page of each

manual. For example, this manual would be referred to as ED-17610.

Introduction 1

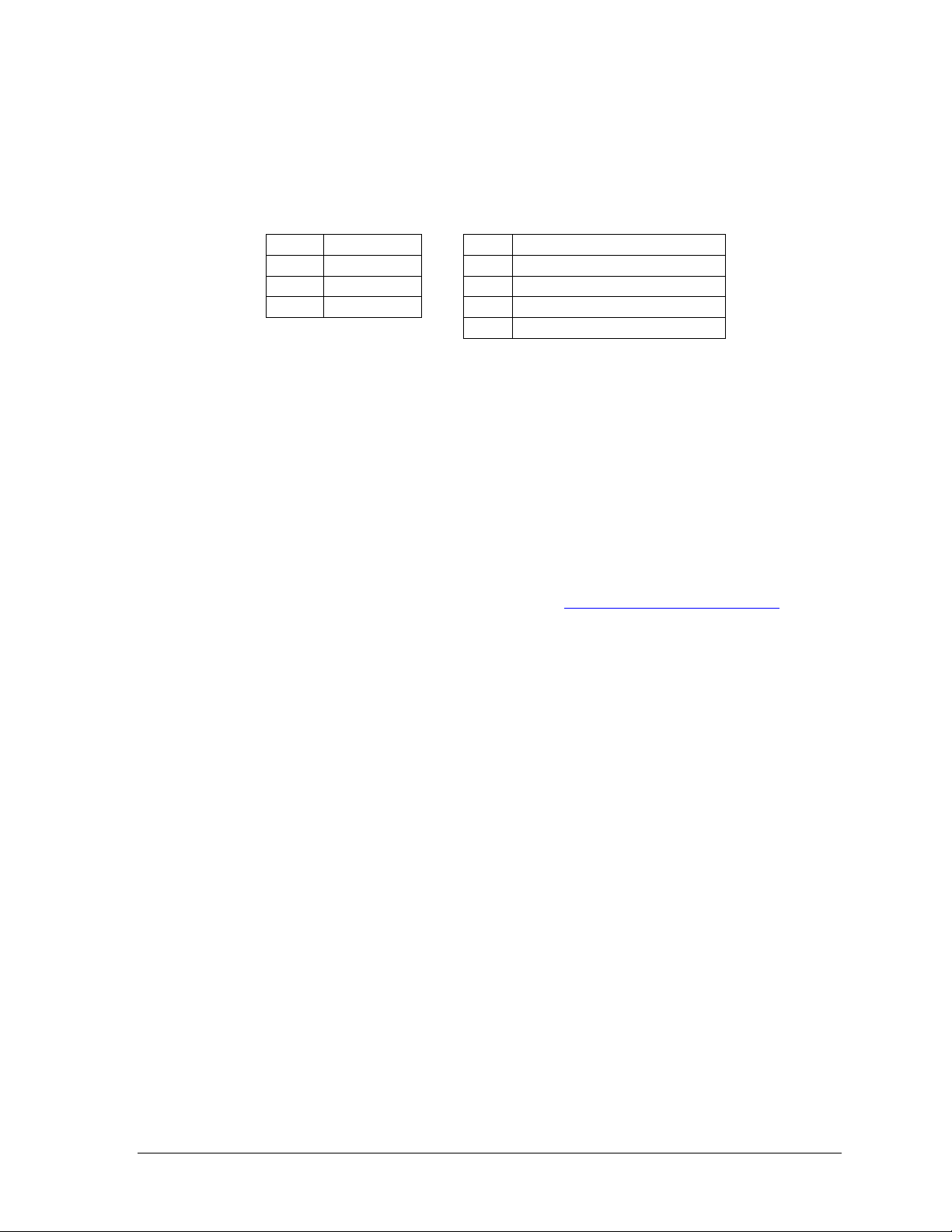

Main Component Labels

Part Type

Part Number

Individual circuit board

0P-XXXX-XXXX

Assembly; a collection of circuit boards

0A-XXXX-XXXX

Wire or cable

W-XXXX

Fuse

F-XXXX

Transformer

T-XXXX

Metal part

M-XXX

Fabricated metal assembly

0S-XXXXXX

Specially ordered part

PR-XXXXX-X

Accessory Labels

Component

Label

Termination block for power

or signal cable

TBXX

Grounding point

EXX

Power or signal jack

JXX

Power or signal plug for the

opposite jack

PXX

Figure 2: Scoreboard ID Label

Figure 3: Typical Label

1.2 Daktronics Nomenclature

Serial and model numbers can be found on the ID label on the display as shown in Figure 2.

Please list the model number, display serial number, and the date this display became

operational in the blanks provided on the second page of this manual. When calling

Daktronics customer service, please have this information available to ensure the request is

serviced as quickly as possible.

Most components within this display carry a white label that lists the part number of the unit.

If a component is not found in the Replacement Parts List in Section 5.13, use the label to

order a replacement. Figure 3 illustrates a typical label. The part number is in bold.

Following the Replacement Parts List is the Daktronics Exchange Policy and the Repair &

Return Program. Refer to these instructions if replacing or repairing any display component.

2 Introduction

BA

Baseball

-11

120 V, with red digits

FB

Football

-21

120 V, with amber digits

MS

Multisport

-12

240 V, with red digits

SO

Soccer

-22

240 V, with amber digits

-41

120 V, with white digits

1.3 Model Number

Daktronics scoreboards are differentiated by their model numbers and two-letter prefixes for

each sport. Most Daktronics scoreboards also carry a two-number suffix that refers to the type

of power supply and digit color. Refer to the following tables:

1.4 Scoreboard Controllers

Daktronics outdoor scoreboards are designed for use with the All Sport® 5000 series control

consoles. Scoreboards with 5 or 6-digit clocks may also be controlled via the OmniSport® 2000

console for track timing. Both consoles use keyboard overlays (sport inserts) to control

numerous sports and scoreboard models. Refer to the following manuals for operating

instructions:

All Sport 5000 Series Control Console Operation Manual (ED-11976)

OmniSport 2000 Timing Console Operations Manual (ED-13312)

These control console manuals are available online at www.daktronics.com/manuals.

1.5 Product Safety Approval

Daktronics outdoor scoreboards are ETL listed and tested to CSA standard for outdoor use.

Contact Daktronics with any questions regarding testing procedures.

Introduction 3

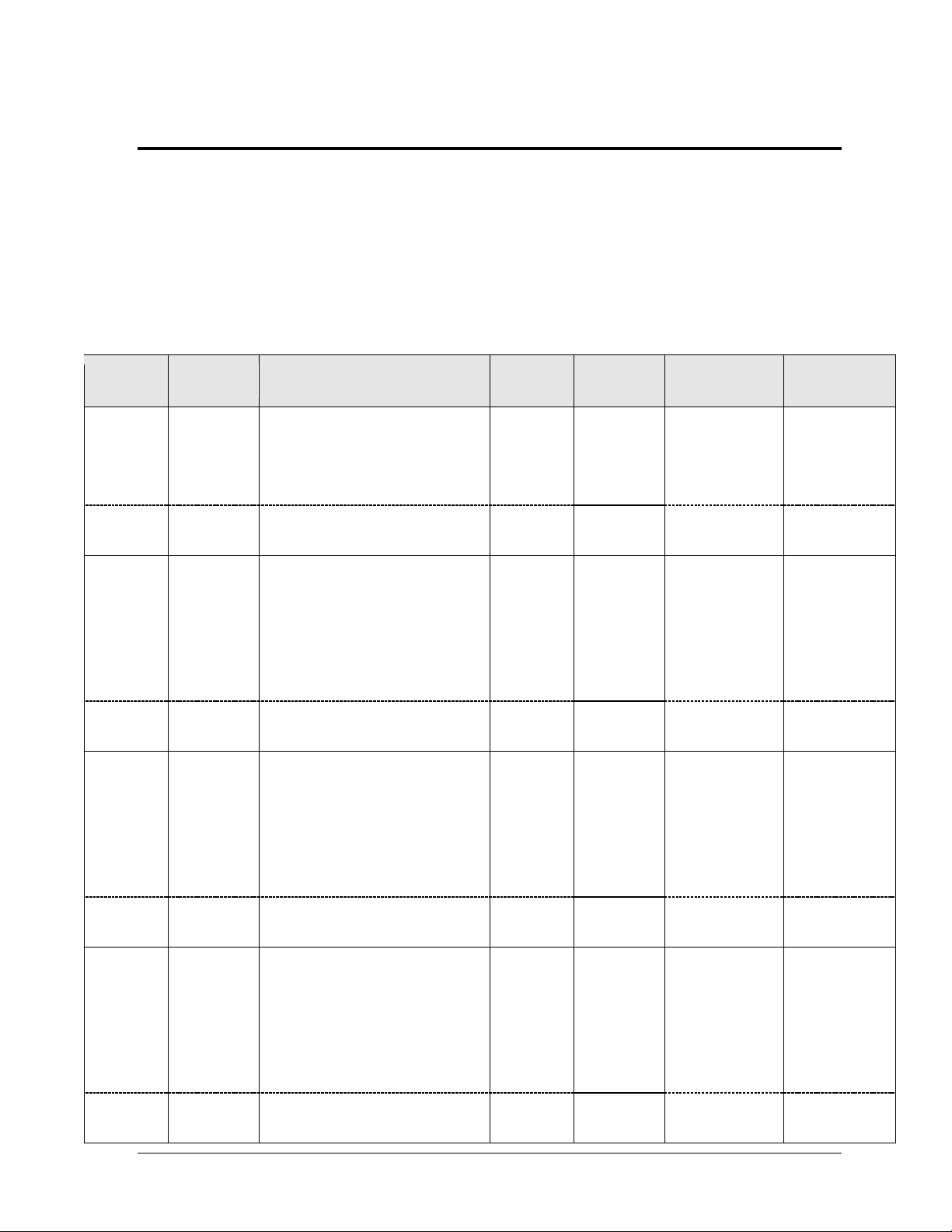

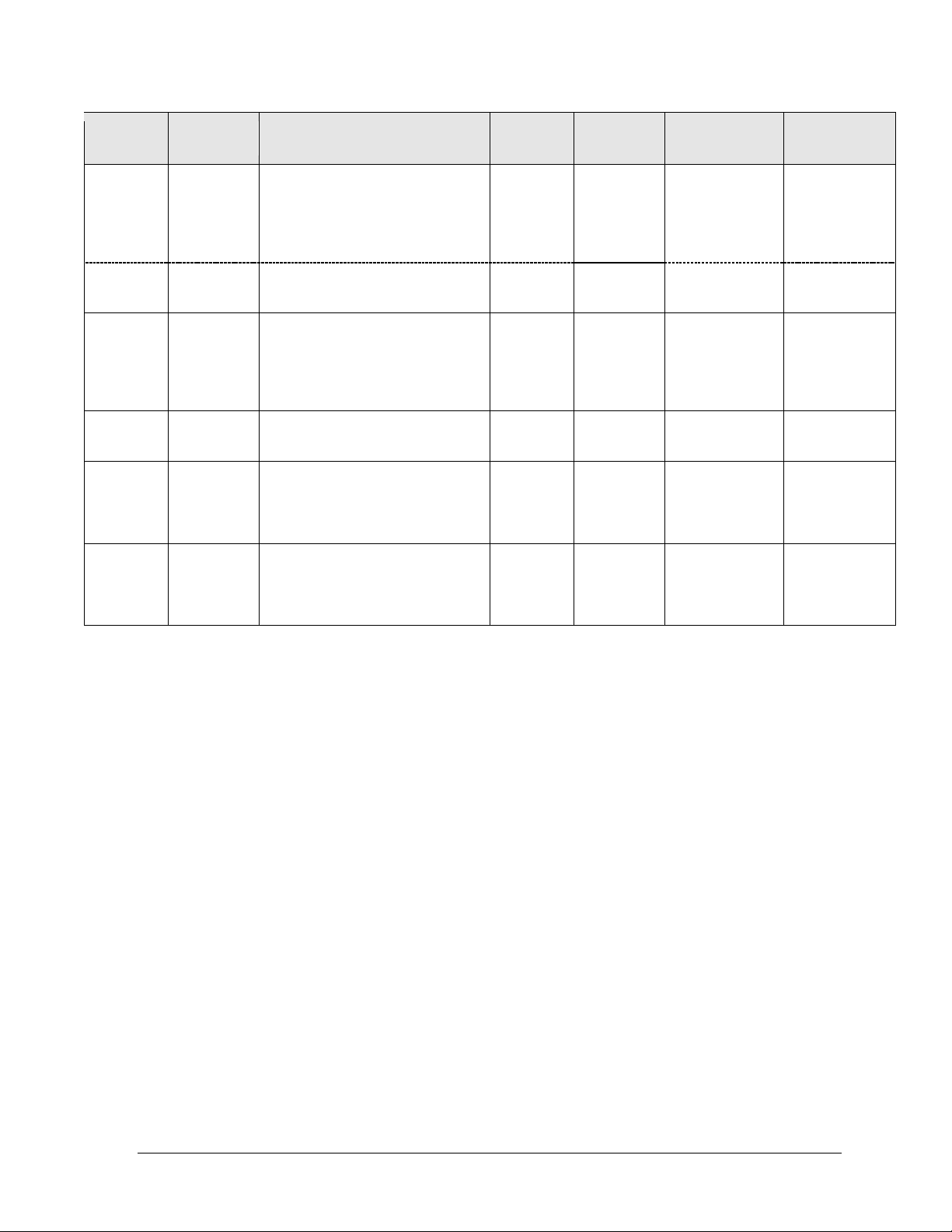

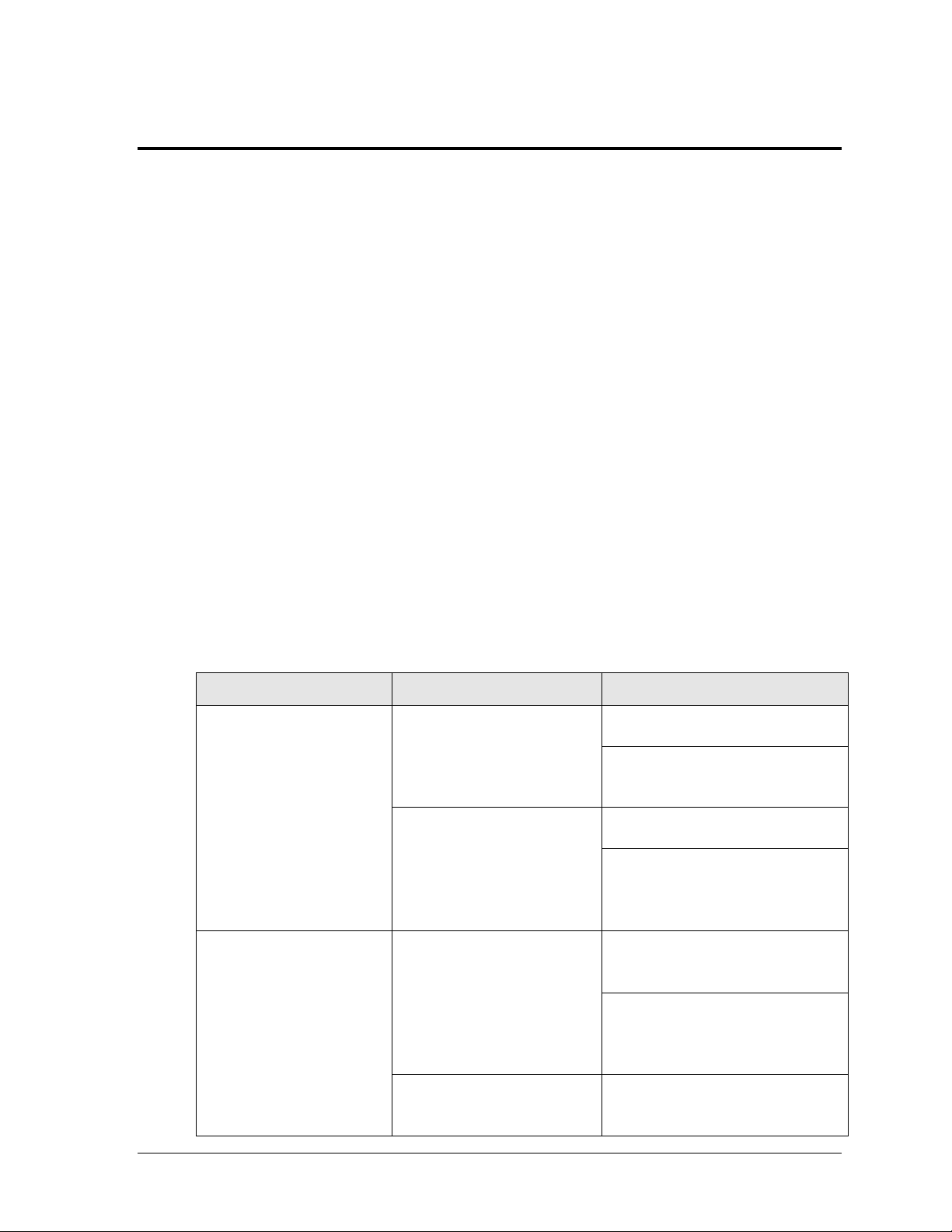

Model &

Options

Number of

Sections

Dimensions:

Height, Width, Depth

Weight

Watts

Amps

120 / 240 V AC

Driver #

& Address

BA-1518

2 Total

Top &

Bottom

H 8'-0", W 16'-0", D 6"

(2438 mm, 4877 mm, 152 mm)

H 4'-0", W 16'-0", D 6"

(1219 mm, 4877 mm, 152 mm)

400 lb

(182 kg)

300 W

[450 W]

2.5 A / 1.25 A

[3.8 A / 1.9 A]

A1 63

w/TNMC

(same)

(same)

480 lb

(218 kg)

600 W

[750 W]

5 A / 2.5 A

[6.3 A / 3.1 A]

TNMC 221

BA-1524

2 Total

Top

Bottom

H 9'-0", W 16'-0", D 6"

(2743 mm, 4877 mm, 152 mm)

H 4'-0", W 16'-0", D 6"

(1219 mm, 4877 mm, 152 mm)

H 5'-0", W 16'-0", D 6"

(1524 mm, 4877 mm, 152 mm)

450 lb

(204 kg)

300 W

[600 W]

2.5 A / 1.25 A

[5 A / 2.5 A]

A1 63

w/TNMC

(same)

(same)

530 lb

(240 kg)

600 W

[900 W]

5 A / 2.5 A

[7.5 A / 3.75 A]

TNMC 221

BA-2013

4 Total

Top 2

Bottom 2

H 9'-4", W 36'-0", D 6"

(2845 mm, 10973 mm, 152 mm)

H 4'-0", W 18'-0", D 6"

(1219 mm, 5486 mm, 152 mm)

H 5' -4", W 18'-0", D 6"

(1626 mm, 5486 mm, 152 mm)

840 lb

(382 kg)

1500 W

12.5 A / 6.25 A

A1 64

A2 65

A3 66

A4 01

A5 01

w/TNMC

(same)

(same)

960 lb

(436 kg)

1800 W

15 A / 7.5 A

TNMC 221

BA-3718

4 Total

Top 2

Bottom 2

H 7'-0", W 28'-0", D 6"

(2134 mm, 8534 mm, 152 mm)

H 3'-0", W 14'-0", D 6"

(914 mm, 4267 mm, 152 mm)

H 4' -0", W 14'-0", D 6"

(1219 mm, 4267 mm, 152 mm)

640 lb

(291 kg)

900 W

7.5 A / 3.75 A

A1 64

A2 65

A3 66

w/TNMC

(same)

(same)

720 lb

(327 kg)

1200 W

10 A / 5 A

TNMC 221

Section 2: Specifications

The chart on the following pages details all of the mechanical specifications, circuit specifications and

power requirements for each display in this manual. Models are listed in alphanumeric order.

Notes:

1) All displays require a 120 V AC, 15 A circuit; 240 V AC power also available

2) TNMC and electronic caption LEDs are typically the same color as the LED digits on the

scoreboard. Backlit captions use 120 V AC circular florescent bulbs.

3) Watts and Amps in [brackets] indicate separate power specs for white LED digits.

Specifications 5

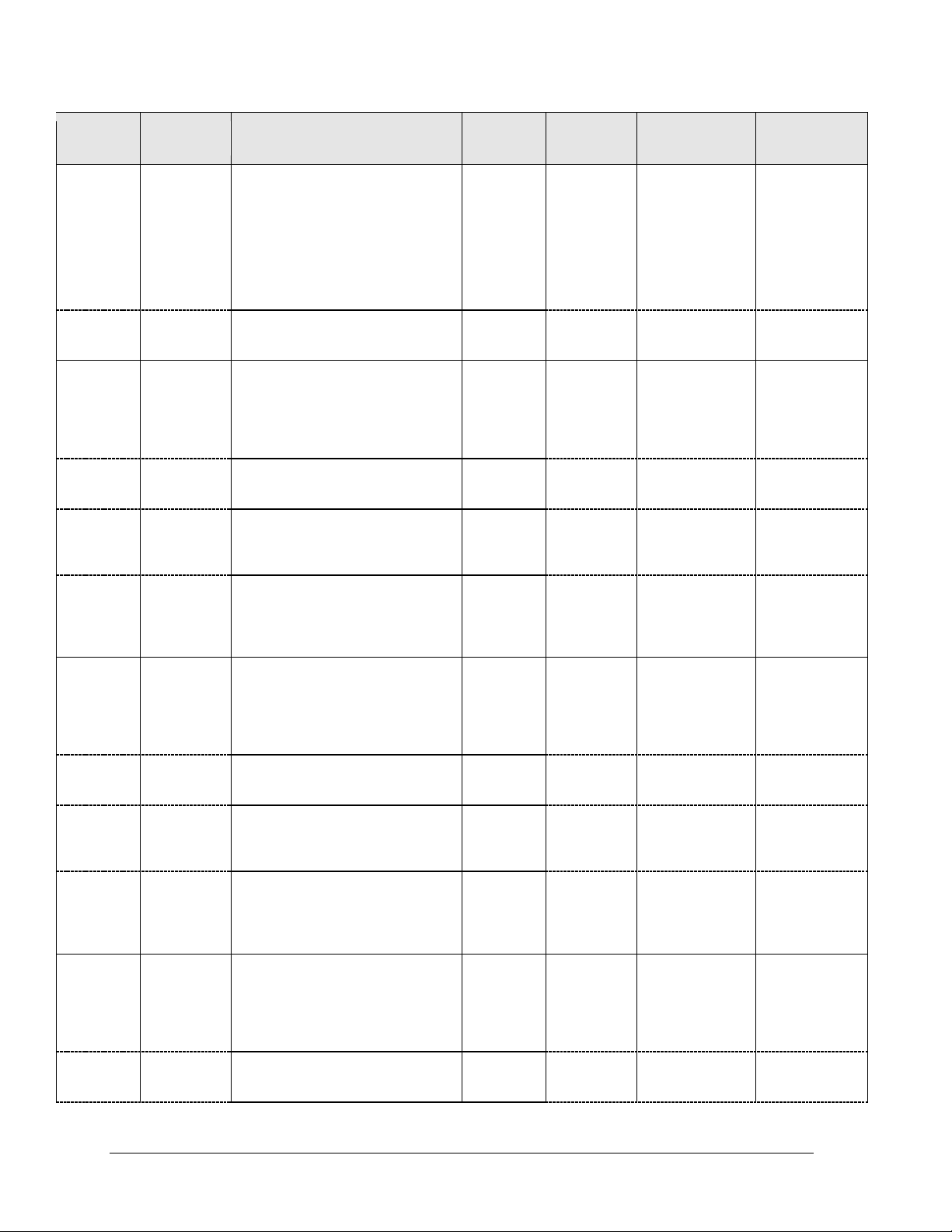

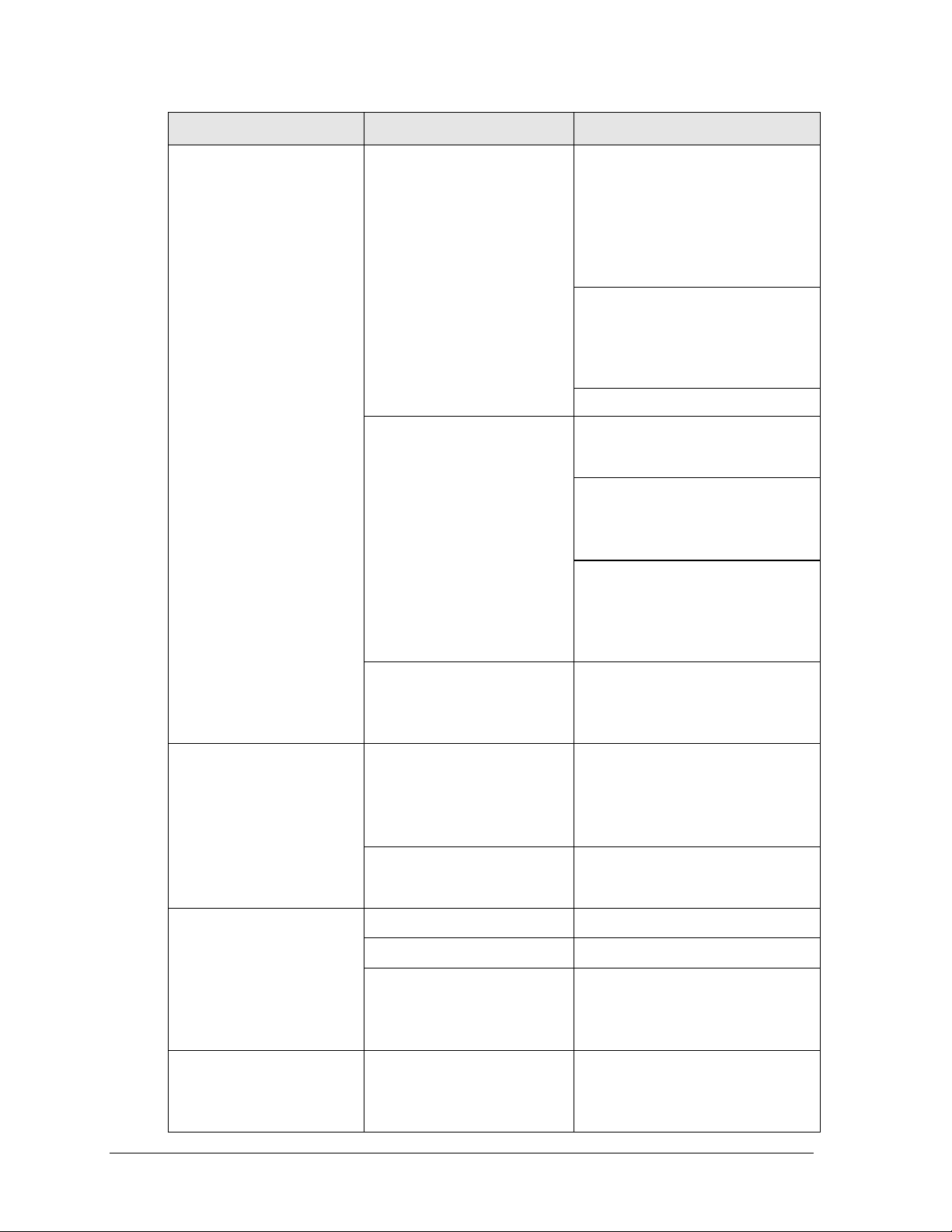

Model &

Options

Number of

Sections

Dimensions:

Height, Width, Depth

Weight

Watts

Amps

120 / 240 V AC

Driver #

& Address

BA-3724

4 Total

Top 2

Bottom 2

H 9'-4", W 36'-0", D 6"

(2845 mm, 10973 mm, 152 mm)

H 4'-0", W 18'-0", D 6"

(1219 mm, 5486 mm, 152 mm)

H 5'-4", W 18'-0", D 6"

(1626 mm, 5486 mm, 152 mm)

840 lb

(382 kg)

900 W

7.5 A / 3.75 A

A1 64

A2 65

A3 66

w/TNMC

(same)

(same)

960 lb

(436 kg)

1200 W

10 A / 5 A

TNMC 221

FB-2018

FB-2019

FB-2020

2 Total

Top &

Bottom

H 8'-0", W 18'-0", D 6"

(2438 mm, 5486 mm, 152 mm)

H 4'-0", W 18'-0", D 6"

(1219 mm, 5486 mm, 152 mm)

565 lb

(256 kg)

600 W

5 A / 2.5 A

A1 15

A2 19

w/TNMC

(same)

(same)

645 lb

(293 kg)

900 W

7.5 A / 3.75 A

TNMC 221

w/TNMC +

Electronic

Captions

(same)

(same)

805 lb

(365 kg)

1200 W

10 A / 5 A

Electronic

Captions 227

w/Backlit

Captions

(Top &

Bottom)

(same)

(same)

625 lb

(283 kg)

1500 W

12.5 A

(120 V AC only)

A1 15

A2 19

FB-2021

FB-2022

FB-2023

2 Total

Top &

Bottom

H 8'-0", W 25'-0", D 6"

(2438 mm, 7620 mm, 152 mm)

H 4'-0", W 25-0", D 6"

(1219 mm, 7620 mm, 152 mm)

815 lb

(370 kg)

600 W

5 A / 2.5 A

A1 15

A2 19

w/TNMC

(same)

(same)

935 lb

(424 kg)

900 W

7.5 A / 3.75 A

TNMC 221

w/TNMC +

Electronic

Captions

(same)

(same)

1095 lb

(496 kg)

1200 W

10 A / 5 A

Electronic

Captions 227

w/Backlit

Captions

(Top &

Bottom)

(same)

(same)

875 lb

(396 kg)

1500 W

12.5 A

(120 V AC only)

A1 15

A2 19

FB-2024

2 Total

Top &

Bottom

H 8'-0", W 32'-0", D 6"

(2438 mm, 9754 mm, 152 mm)

H 4'-0", W 32'-0", D 6"

(1219 mm, 9754 mm, 152 mm)

720 lb

(327 kg)

600 W

5 A / 2.5 A

A1 15

A2 19

w/TNMC

(same)

(same)

840 lb

(381 kg)

900 W

7.5 A / 3.75 A

TNMC 221

6 Mechanical Installation

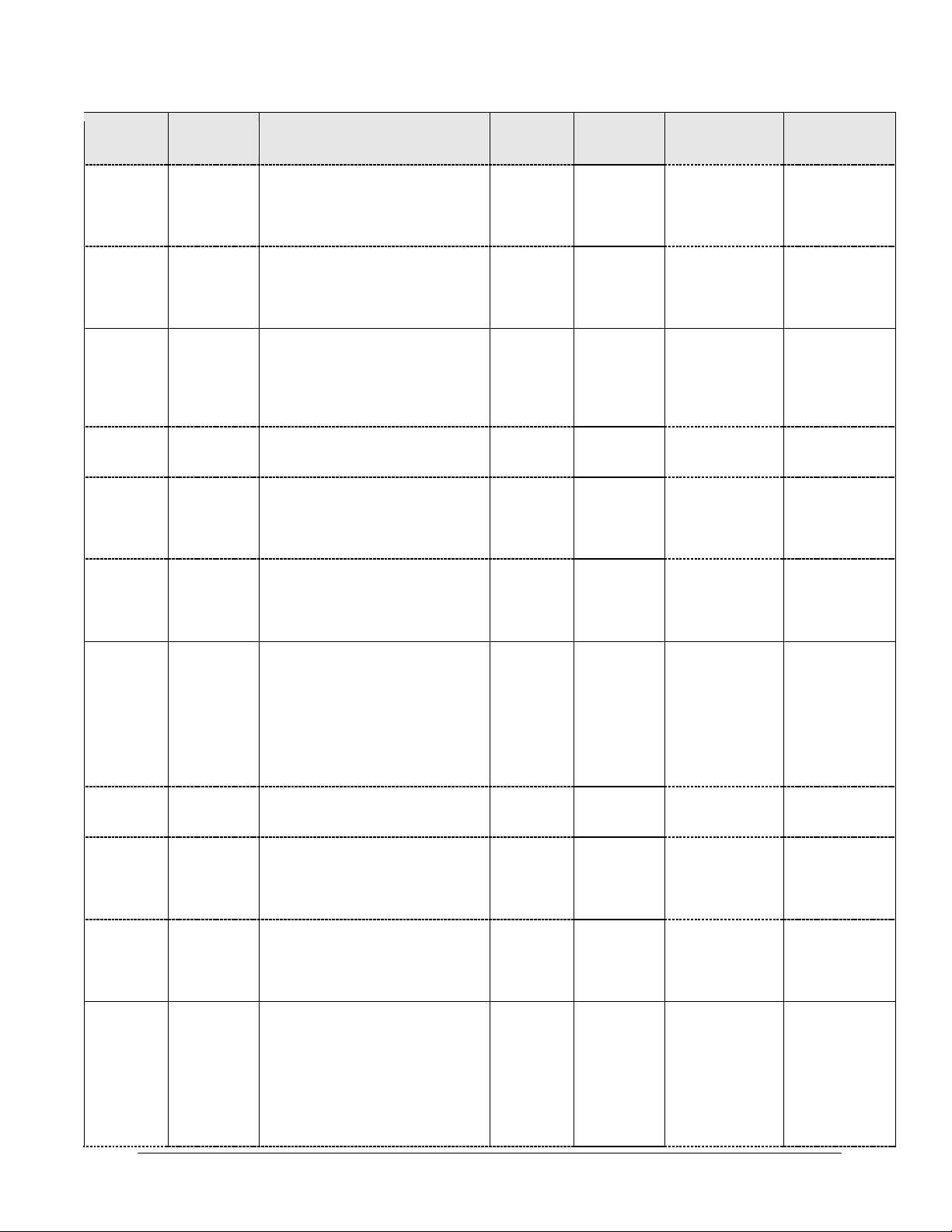

Model &

Options

Number of

Sections

Dimensions:

Height, Width, Depth

Weight

Watts

Amps

120 / 240 V AC

Driver #

& Address

w/TNMC +

Electronic

Captions

(same)

(same)

1080 lb

(489 kg)

1200 W

10 A / 5 A

Electronic

Captions 227

T.O.L. 225

w/Backlit

Captions

(Top &

Bottom)

(same)

(same)

800 lb

(362 kg)

1500 W

12.5 A

(120 V AC only)

A1 15

A2 19

FB-2025

2 Total

Top &

Bottom

H 8'-0", W 32'-0", D 6"

(2438 mm, 9754 mm, 152 mm)

H 4'-0", W 32'-0", D 6"

(1219 mm, 9754 mm, 152 mm)

780 lb

(353 kg)

600 W

5 A / 2.5 A

A1 15

A2 19

w/TNMC

(same)

(same)

900 lb

(408 kg)

900 W

7.5 A / 3.75 A

TNMC 221

w/TNMC +

Electronic

Captions

(same)

(same)

1140 lb

(517 kg)

1200 W

10 A / 5 A

Electronic

Captions 227

T.O.L. 225

w/Backlit

Captions

(Top &

Bottom)

(same)

(same)

860 lb

(390 kg)

1500 W

12.5 A

(120 V AC only)

A1 15

A2 19

FB-2026

2 Total

Top

Bottom

H 10'-0", W 32'-0", D 6"

(3048 mm, 9754 mm, 152 mm)

H 6'-0", W 32'-0", D 6"

(1829 mm, 9754 mm, 152 mm)

H 4'-0", W 32'-0", D 6"

(1219 mm, 9754 mm, 152 mm)

880 lb

(400 kg)

600 W

5 A / 2.5 A

A1 15

A2 19

w/TNMC

(same)

(same)

1000 lb

(454 kg)

900 W

7.5 A / 3.75 A

TNMC 221

w/TNMC +

Electronic

Captions

(same)

(same)

1240 lb

(562 kg)

1200 W

10 A / 5 A

Electronic

Captions 227

T.O.L. 225

w/Backlit

Captions

(Top &

Bottom)

(same)

(same)

940 lb

(426 kg)

1500 W

12.5 A

(120 V AC only)

A1 15

A2 19

FB-2027

2 Total

Top

Bottom

H 10'-0", W 32'-0", D 6"

(3048 mm, 9754 mm, 152 mm)

H 6'-0", W 32'-0", D 6"

(1829 mm, 9754 mm, 152 mm)

H 4'-0", W 32'-0", D 6"

(1219 mm, 9754 mm, 152 mm)

940 lb

(426 kg)

600 W

5 A / 2.5 A

A1 15

A2 19

Specifications 7

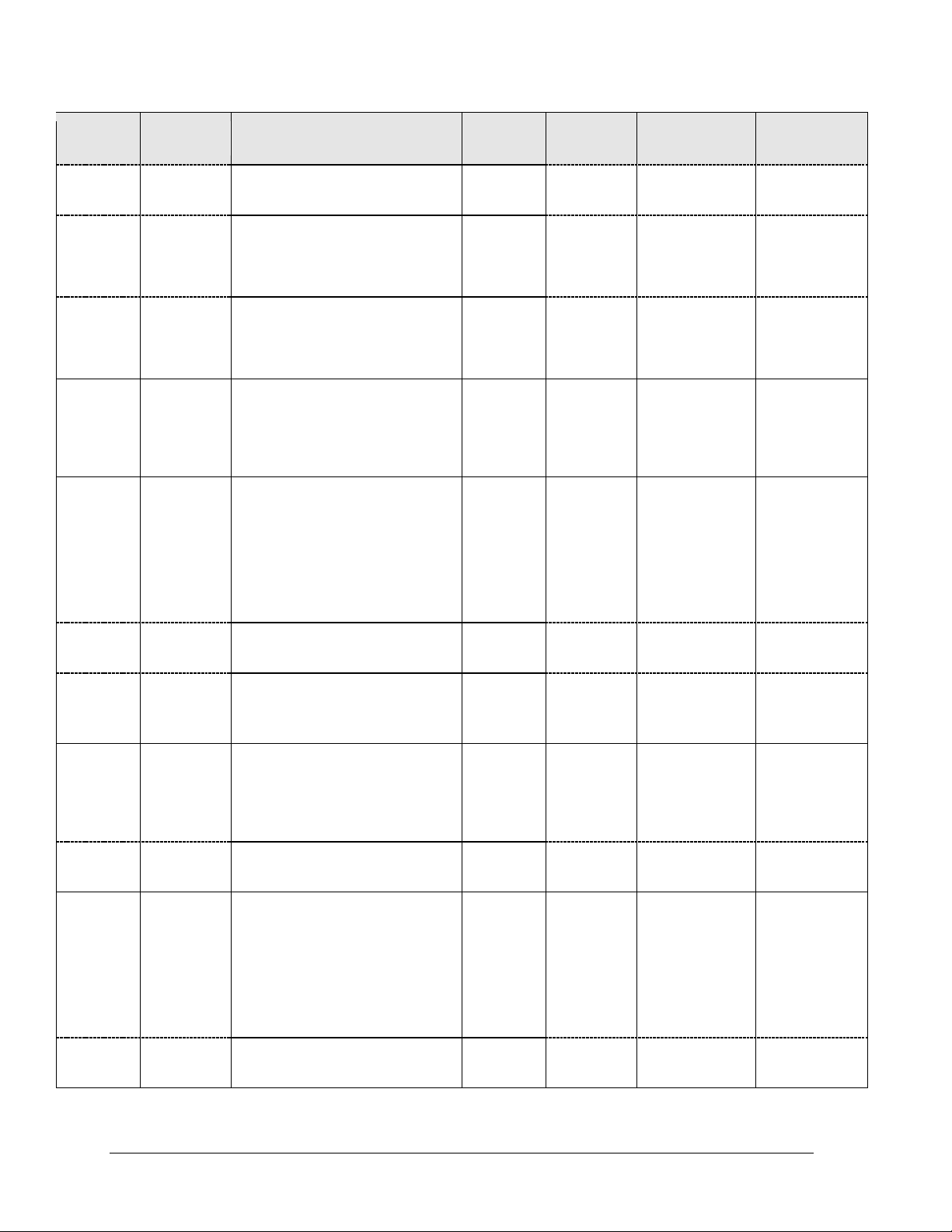

Model &

Options

Number of

Sections

Dimensions:

Height, Width, Depth

Weight

Watts

Amps

120 / 240 V AC

Driver #

& Address

w/TNMC

(same)

(same)

1060 lb

(481 kg)

900 W

7.5 A / 3.75 A

TNMC 221

w/TNMC +

Electronic

Captions

(same)

(same)

1300 lb

(590 kg)

1200 W

10 A / 5 A

Electronic

Captions 227

T.O.L. 225

w/Backlit

Captions

(Top &

Bottom)

(same)

(same)

1020 lb

(462 kg)

1500 W

12.5 A

(120 V AC only)

A1 15

A2 19

FB-3010

w/TNMC

2 Total

Top &

Bottom

H 8'-0", W 18'-0", D 6"

(2438 mm, 5486 mm, 152 mm)

H 4'-0", W 18'-0", D 6"

(1219 mm, 5486 mm, 152 mm)

600 lb

(272 kg)

1200 W

5 A

(240 V AC only)

A1 1

A2 11

TNMC 221

MS-2009

2 Total

Top

Bottom

H 10’-0”, W 25’-0”, D 6”

(3048 mm, 7620 mm, 152 mm)

H 4’-6”, W 25’-0”, D 6”

(1371 mm, 7620 mm, 152 mm)

H 5’-6”, W 25’-0”, D 6”

(1676 mm, 7620 mm, 152 mm)

770 lb

(349 kg)

600 W

5 A / 2.5 A

A1 71

A2 72

w/TNMC

(same)

(same)

890 lb

(404 kg)

900 W

7.5 A / 3.75 A

TNMC 221

w/TNMC +

Electronic

Captions

(same)

(same)

1130 lb

(513 kg)

1200 W

10 A / 5 A

Electronic

Captions 223

MS-2918

2 Total

Top &

Bottom

H 8’-0”, W 16’-0”, D 6”

(2438 mm, 4877 mm, 152 mm)

H 4’-0”, W 16’-0”, D 6”

(1219 mm, 4877 mm, 152 mm)

480 lb

(218 kg)

600 W

5 A / 2.5 A

A1 71

A2 72

w/TNMC

(same)

(same)

560 lb

(254 kg)

900 W

7.5 A / 3.75 A

TNMC 221

SO-2011

2 Total

Top

Bottom

H 7'-0", W 20'-0", D 6"

(2286 mm, 6096 mm, 152 mm)

H 4'-6", W 20'-0", D 6"

(1372 mm, 6096 mm, 152 mm)

H 3'-0", W 20'-0", D 6"

(914 mm, 6096 mm, 152 mm)

450 lb

(204 kg)

600 W

5 A / 2.5 A

A1 17

A2 11

w/TNMC

(same)

(same)

570 lb

(259 kg)

900 W

7.5 A / 3.75 A

TNMC 221

8 Mechanical Installation

Model &

Options

Number of

Sections

Dimensions:

Height, Width, Depth

Weight

Watts

Amps

120 / 240 V AC

Driver #

& Address

SO-2018

SO-2019

2 Total

Top &

Bottom

H 8'-0", W 18'-0", D 6"

(2438 mm, 5486 mm, 152 mm)

H 4'-0", W 18'-0", D 6"

(1219 mm, 5486 mm, 152 mm)

565 lb

(256 kg)

600 W

5 A / 2.5 A

A1 15

A2 19

w/TNMC

(same)

(same)

645 lb

(293 kg)

900 W

7.5 A / 3.75 A

TNMC 221

SO-2021

SO-2022

SO-2023

2 Total

Top &

Bottom

H 8'-0", W 25'-0", D 6"

(2438 mm, 7620 mm, 152 mm)

H 4'-0", W 25'-0", D 6"

(1219 mm, 7620 mm, 152 mm)

815 lb

(370 kg)

600 W

5 A / 2.5 A

A1 15

A2 19

w/TNMC

(same)

(same)

935 lb

(424 kg)

900 W

7.5 A / 3.75 A

TNMC 221

w/TNMC +

Electronic

Captions

(same)

(same)

1095 lb

(496 kg)

1200 W

10 A / 5 A

Electronic

Captions 227

T.O.L. 225

w/Backlit

Captions

(Top &

Bottom)

(same)

(same)

875 lb

(396 kg)

1500 W

12.5 A

(120 V AC only)

A1 15

A2 19

Specifications 9

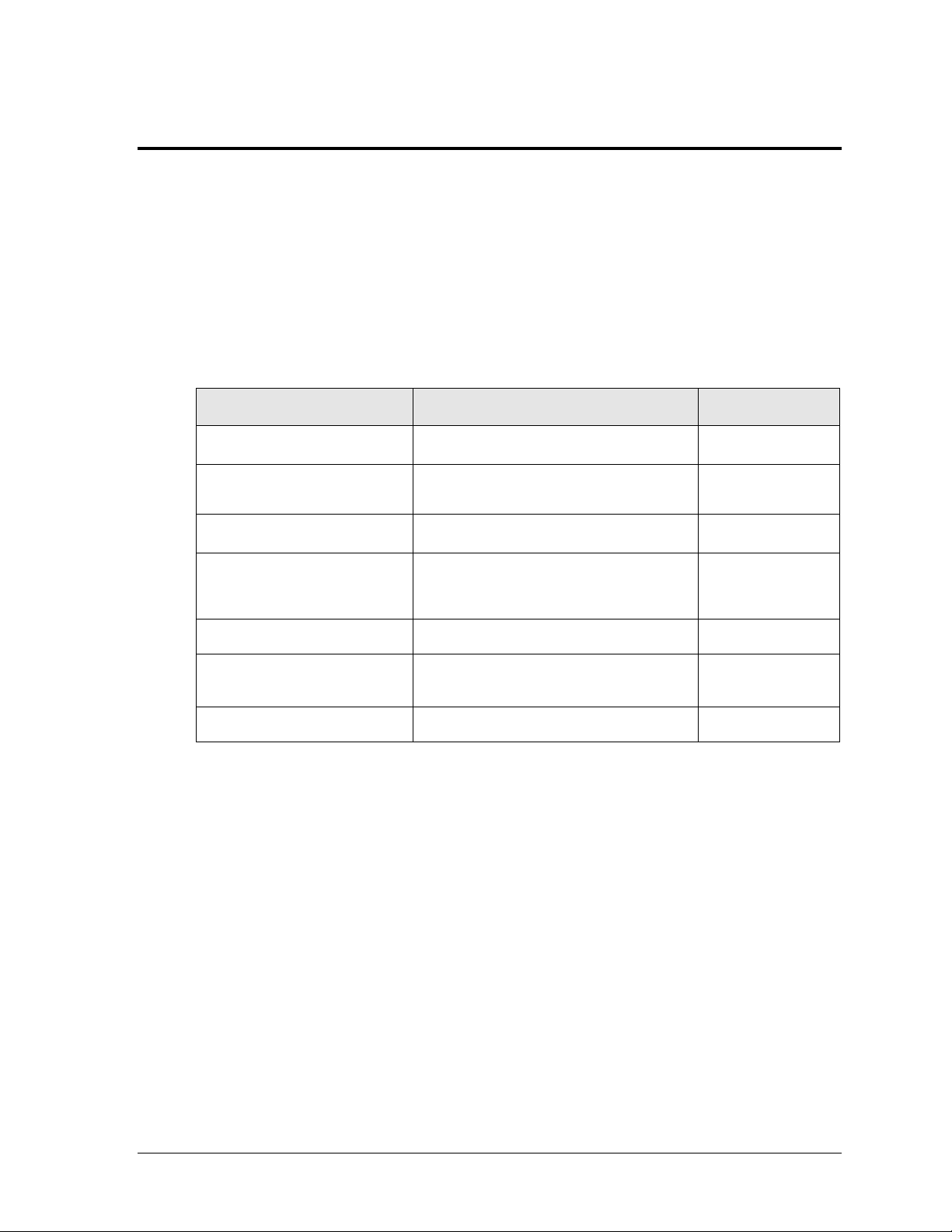

Models

Drawing Title

Number

BA-1518, BA-1524, MS-2918

16' Width Scoreboard Installation Specs

A-298975

FB-2018, FB-2019, FB-2020,

FB 3010, SO-2018, SO-2019

18' Width Scoreboard Installation Specs

A-302416

SO-2011

20' Width Scoreboard Installation Specs.

A-303616

FB-2021, FB-2022, FB-2023,

MS-2009, SO-2021, SO-2022,

SO-2023

25' Width Scoreboard Installation Specs

A-316750

BA-3718

28' Width Scoreboard Installation Specs

A-316971

FB-2024; FB-2025, FB-2026,

FB-2027

32' Width Scoreboard Installation Specs

A-317264

BA-3724, BA-2013

Installation Specifications, BA-3724

A-126445

Section 3: Mechanical Installation

Mechanical installation consists of installing concrete footing and steel beams and mounting the

scoreboard and accompanying ad panels to the beams.

3.1 Footings & Beams

The installation specification drawings listed in Appendix A show the recommended number

of beams and spacing between them. The drawings also indicate the size of beams required to

support the scoreboard at different heights and at various wind speeds. Use the following

table to determine which drawings provide the installation specifications for each model:

The column and footing size dimensions are to assist with estimating installation costs. They

are estimates only and are not intended for actual construction purposes. Be sure that the

installation complies with local building codes and is suitable for the particular soil and wind

conditions. The columns, footings, and all connection details must be designed and certified

by a professional engineer licensed to practice in the state of the scoreboard installation.

Note: Daktronics does not assume any liability for any installation derived from the

information provided in this manual or installations designed and installed by others.

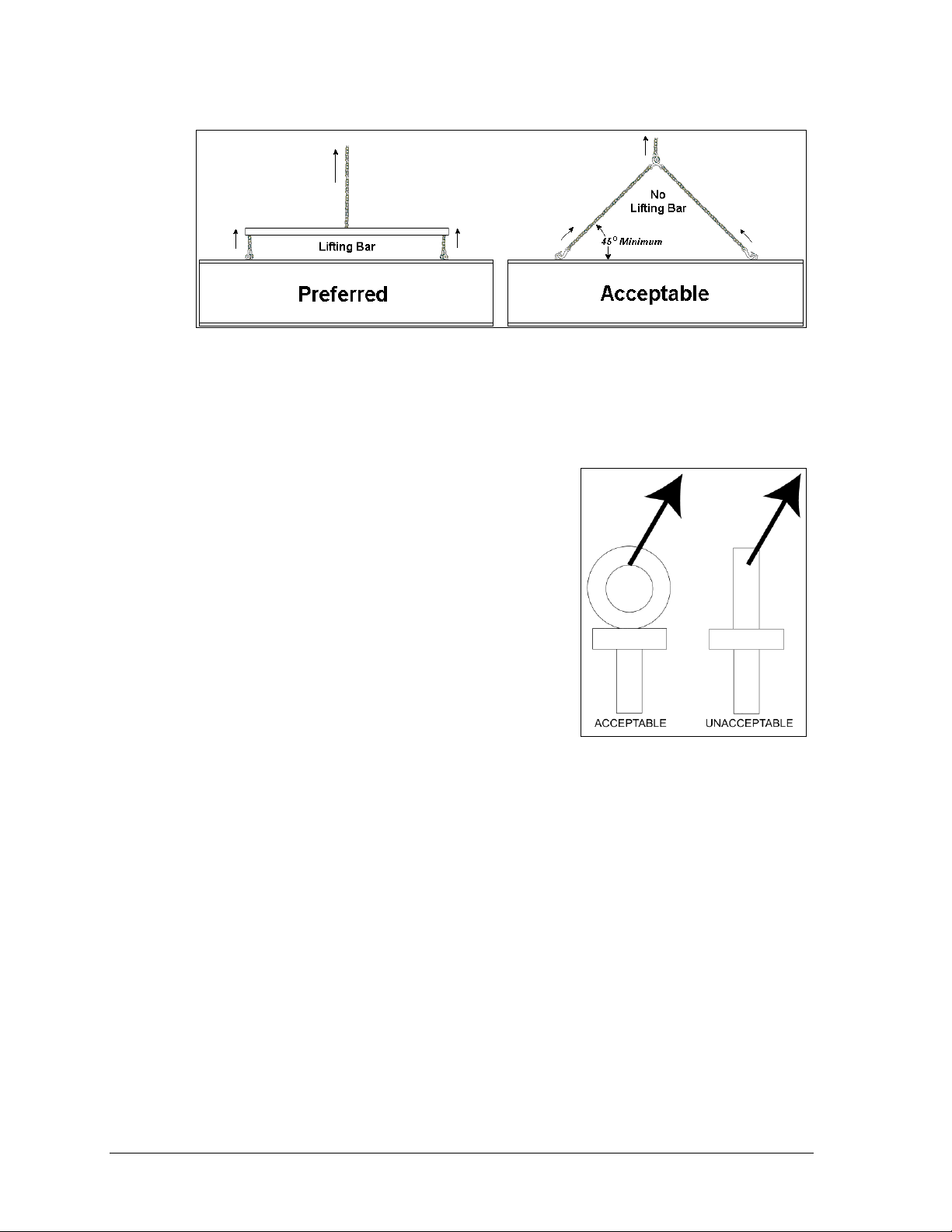

3.2 Lifting the Scoreboard

Larger scoreboard sections and message centers are shipped equipped with eyebolts used to

lift them. The eyebolts are located along the top of the cabinet for each scoreboard or

scoreboard section. Daktronics scoreboards use 1/2" and 5/8" shoulder-type eyebolts mounted

to a 1/8" aluminum plate or steel nut plate.

Daktronics strongly recommends using a spreader bar, or lifting bar, to lift the display.

Spreader bars ensure the force on the eyebolts remains straight up, minimizing lifting stress.

Mechanical Installation 11

Figure 4: Lifting Methods

Figure 5: Eyebolt Plane Load

Figure 4 illustrates the preferred scoreboard lifting method on the left and an acceptable

alternative lifting method on the right. When lifting the display:

Use a spreader bar if possible.

Use every lifting point provided.

Cables and chains attached to the eyebolts and directly to

a center lifting point, as shown in the right-hand example

in Figure 4, can create a dangerous lateral force on the

eyebolts and may cause the eyebolts to fail. The smaller

the angle between the cable and the top of the display, the

lighter the sign must be to safely lift it. If this method

must be used, ensure a minimum angle between the chain

and scoreboard of at least 45 degrees.

Do NOT attempt to lift the display if the angle is less than

45 degrees. Exceeding load angles or weight limits could

cause the bolts in the scoreboard cabinet to buckle,

resulting in serious damage to the scoreboard or injury to

personnel. Also, loads should be applied directly in the

plane of the eyebolt as shown in Figure 5.

Note: Daktronics assumes no liability for damages resulting from incorrect setup or

lifting methods. Eyebolts are intended for lifting only. Do not attempt to permanently

support the display by the eyebolts.

In typical multi-section installations, the lower scoreboard is installed first and secured to the

support beams. The upper section is then placed atop or above the lower section and attached

to the beams. There may be cables extending from the top of the lower section. Guide these

cables into the hole in the bottom of the upper section for later connection. Refer to Section

4.5 for more information on the power/signal connections between sections.

If installers remove the eyebolts, plug the holes with bolts and the rubber washers that are

used with the eyebolts. Apply silicone or another waterproof sealant to the eyebolt openings.

Also inspect the top and sides of the display for any other holes or openings that may allow

moisture to enter the display and plug and seal those openings.

12 Mechanical Installation

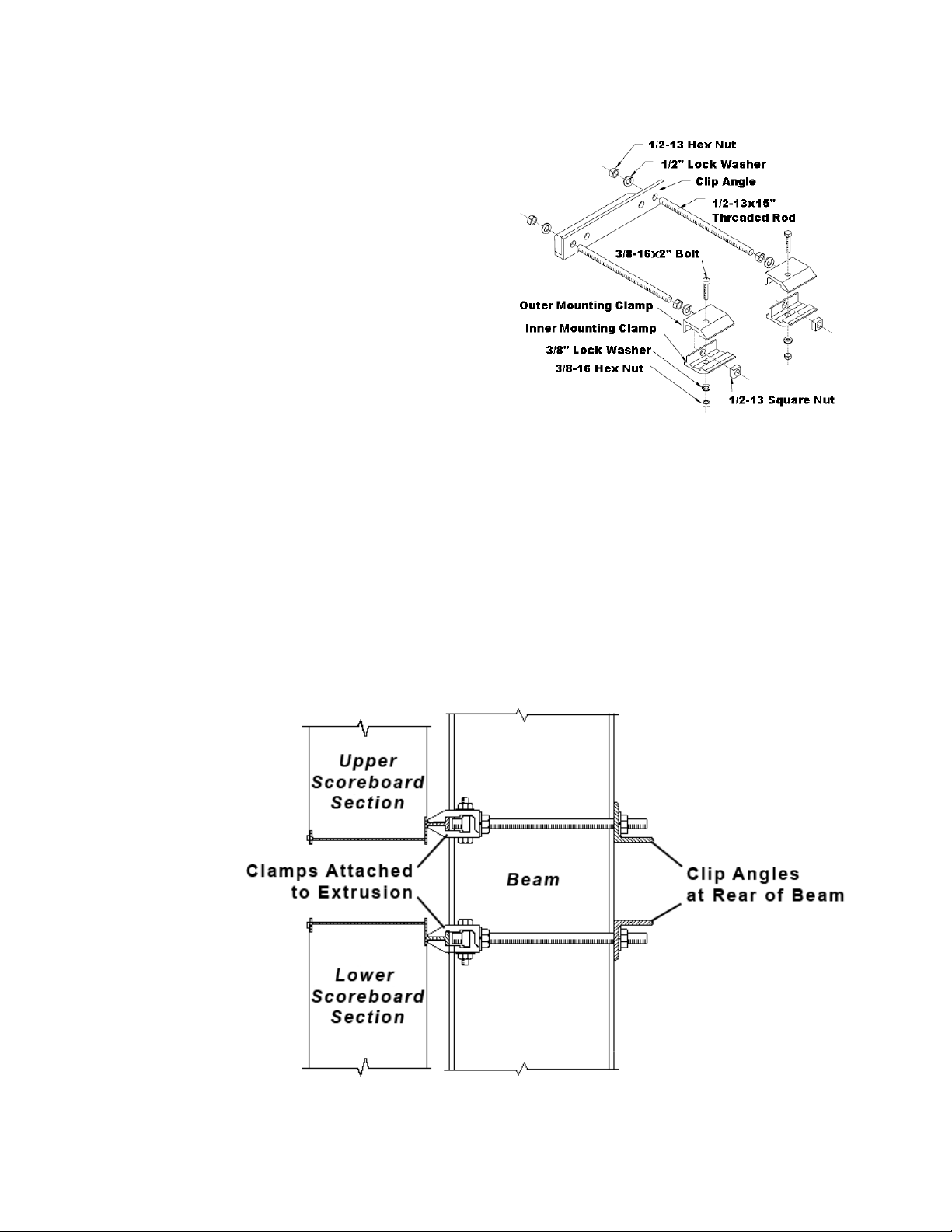

Figure 6: Mounting Hardware

Figure 7: Clamp Mounting Method, Side View

3.3 Scoreboard Mounting

Mounting hardware includes inner and

outer mounting clamps; clip angles; 1/2-13 x

15" threaded rods; 3/8-16 x 2" bolts, hex nuts

and lock washers; and 1/2" square nuts, hex

nuts, and lock washers. Refer to Figure 6 or

Drawing A-308051 in Appendix A. Each

section of the scoreboard attaches at the top

and the bottom to every beam.

Note: The threaded rods do not pass

through the flanges of the beams, but

instead run along both sides.

1. Using

2. Insert a

3. Position the scoreboard at the front of the beams with the threaded rods extending

4. Slide clip angles over the ends of the rods and loosely install the washers and nuts.

5. Make final adjustments in the positioning of the scoreboard. Tighten the

6. Make sure that the threaded rods are perpendicular to the scoreboard, and tighten all

3

/8" bolts, loosely attach the

inner and outer mounting clamps to

the rear flanges of the scoreboard.

Measure the beam spacing and position the clamps to fit on either side of the beams.

1

/2" square nut into each mounting clamp. Screw a threaded rod into each of

the nuts from the rear.

from the rear of the clamps, straddling the beams. Raise the scoreboard section to the

desired height.

the mounting clamps.

of the 1/2" hex nuts (Figure 7).

3

/8" bolts in

Mechanical Installation 13

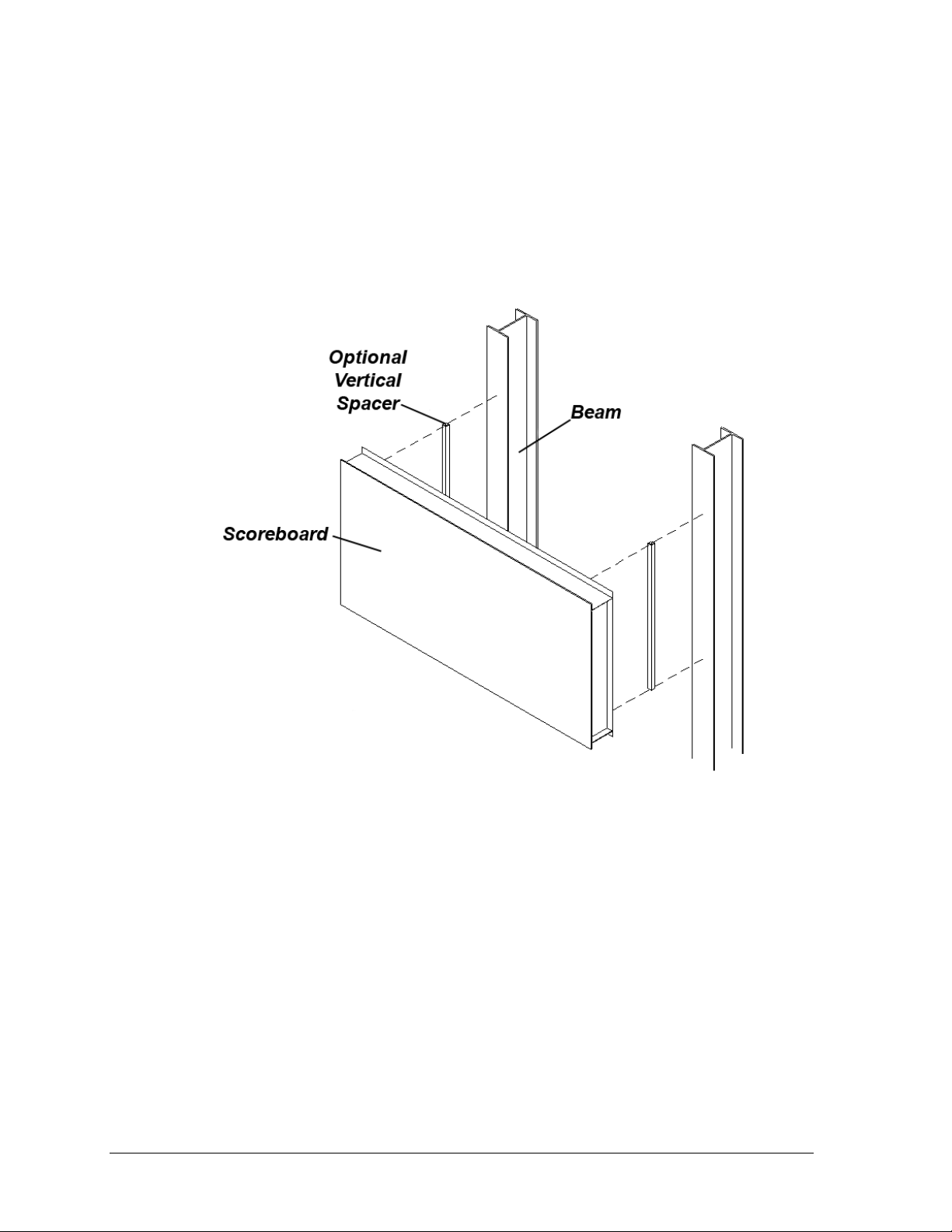

Figure 8: Mounting with Vertical Spacers

Scoreboard Mounting Using Vertical Spacers

Many customers add message centers or advertising panels to the top or bottom of their

scoreboards, and in some cases the depth of the add-on component may not match the depth

of the scoreboard. This will typically be scoreboards that are 8" deep.

To create a uniform appearance for the overall display, Daktronics recommends using

vertical spacers behind the scoreboard so that the front face of the display lines up evenly

with the front face of the added component. The concept is illustrated in Figure 8 and

Drawing A-182909 in Appendix A.

During the installation, spacers are placed between the mounting beams and the back of the

scoreboard cabinet. Spacer size is determined by the height and the extra depth required for

the front surface of the scoreboard to match that of the optional message center or ad panel.

Note: Daktronics does not provide these spacers.

3.4 Scoreboard Protective Devices

Daktronics makes optional protective devices, including screens and netting, to help prevent

damage to the scoreboard due to normal ball impacts.

Note: Some users install devices to protect the scoreboard from projectiles. Scoreboard

protection devices not provided by Daktronics must be approved by Daktronics prior to

installation. Failure to follow this approval procedure will void the scoreboard warranty.

14 Mechanical Installation

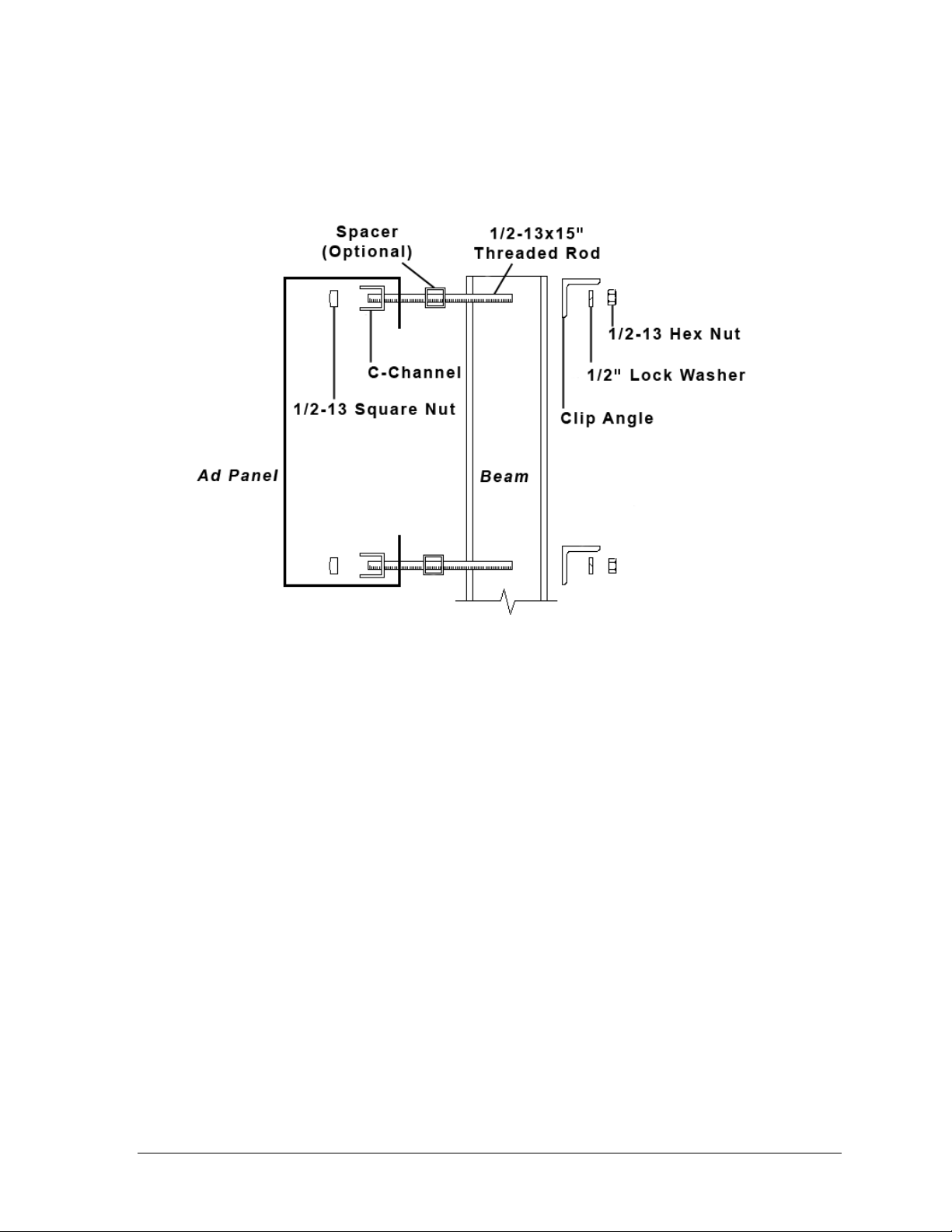

Figure 9: Ad Panel Mounting with C-channel, Side View

3.5 Ad Panel Mounting

The installation uses C-channels; clip angles; 1/2-13" threaded rods; and 1/2" square nuts, hex

nuts, lock washers, and optional spacers. Refer to Figure 9 and Drawing A-52187 in

Appendix A.

Mount the ad panel(s) as follows:

1. Use the width of the beam to determine which hole combination to use for the bolts.

Be sure to keep the bolts as close to the beam as possible.

2. Using the clip angle as a template, use a

9

/16" bit to drill holes in the upper and lower

rear flange of the ad panel where the C-channel supports will be placed.

3. Position the C-channel inside the ad panel cabinet along the upper and lower rear

flanges as shown in Figure 9.

4. Place 1/2" square nuts inside the channel and thread the 1/2-13" rods through the

C-channel, rear flange of the ad panel, and spacer (if used).

5. Lift the ad panel into position with the rods still in place.

6. With the threaded rod straddling the beams, place mounting angles over the ends of

each pair of bolts and secure with 1/2" lock washers and hex nuts.

7. Make final adjustments in the positioning of the ad panel.

8. Make sure that the threaded rods are perpendicular to the ad panel, and tighten all of

the 1/2" hex nuts.

Some ad panels have back sheets that must be removed before the display can be installed.

After marking and drilling holes in the upper and lower rear flanges of the ad panel, remove

the back sheets above and below the hole locations. Position the C-channel inside the cabinet

and attach the square nuts to the threaded rods as described above. Be sure to replace the

back sheets after placing the square nuts inside the channel and threading the rods through

the holes in both the upper and lower rear flanges.

Mechanical Installation 15

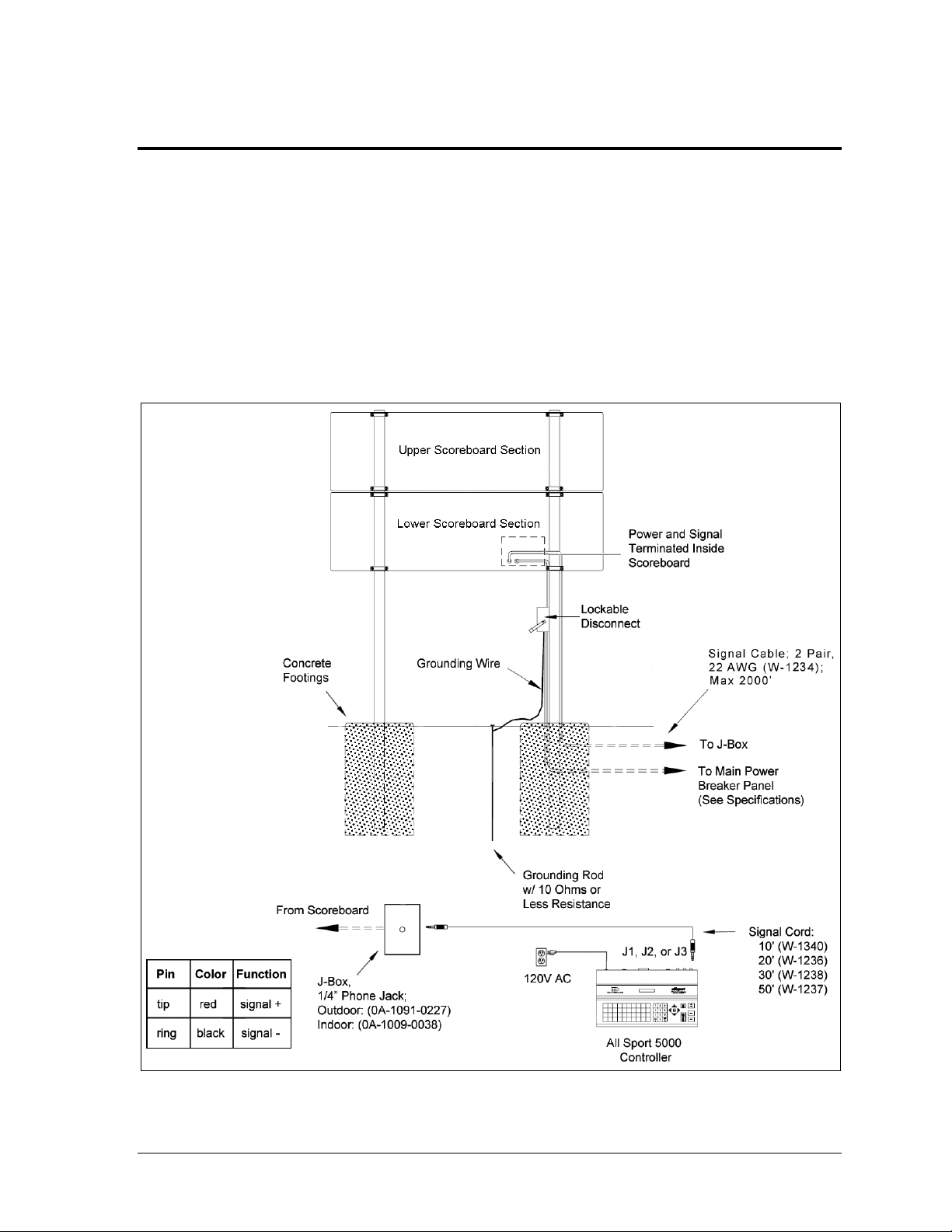

Figure 10: Wired Installation

Section 4: Electrical Installation

CAUTION: Only qualified individuals should terminate power and signal cable and access the

electrical components of the display and its associated equipment. It is the responsibility of the

electrical contractor to ensure that all electrical work meets or exceeds local and national codes.

Daktronics engineering staff must approve all changes or the warranty will be void.

4.1 Installation Overview

The diagram shown in Figure 10 illustrates a typical wired setup between a multi-section

outdoor scoreboard and controller. Daktronics part numbers are shown in parentheses.

Electrical Installation 17

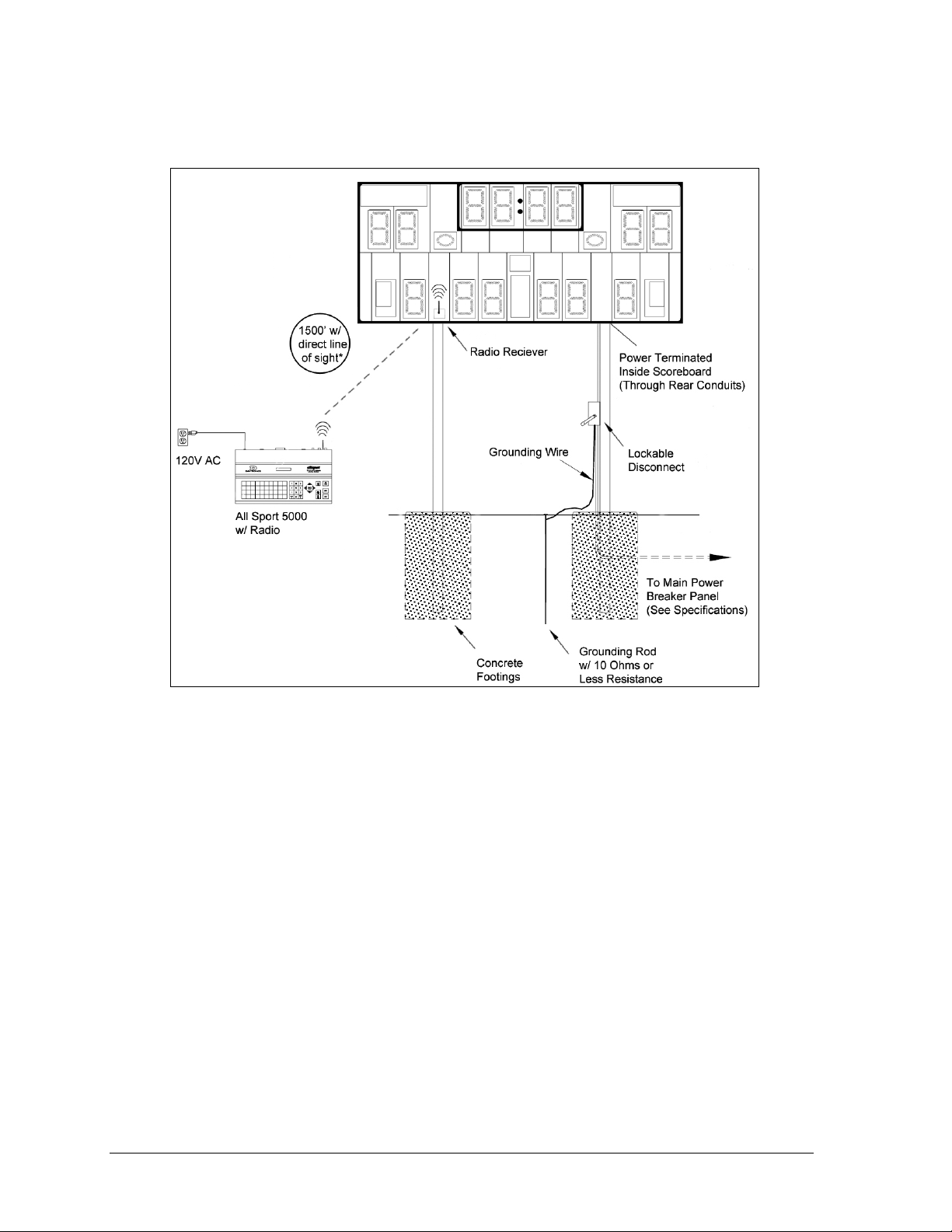

Figure 11: Wireless Installation

The diagram shown in Figure 11 illustrates a typical wireless setup between a multi-section

outdoor scoreboard and controller. Daktronics part numbers are shown in parentheses.

4.2 Power

Correct power installation is imperative for proper display operation. The subsections that

follow give details of display power installation. Only qualified individuals should attempt to

complete the electrical installation; untrained personnel should not attempt to install these

displays or any of the electrical components. Improper installation could result in serious

damage to the equipment or injury to personnel.

Multi-section outdoor scoreboards require a dedicated 120 V or 240 V circuit for incoming

power (refer to the Specifications in Section 2). The display itself has no breakers or fuses.

WARNING: It is critical that the scoreboard circuit be fused at 15 A and that all

conductors used must be designed to pass a 15 A current in normal operation.

Failure to meet wiring and overcurrent protection device requirements will void the

scoreboard warranty.

Grounding

The display must be properly grounded according to local and national codes or the warranty

will be void. Proper grounding is necessary for reliable equipment operation and protects the

equipment from damaging destructive disturbances and lightning.

18 Electrical Installation

Figure 12: Power Warning Label

Daktronics recommends a resistance-to-ground of 10 ohms or less. The electrical contractor

performing the electrical installation can verify ground resistance. Daktronics Sales and

Service personnel can also provide this service.

The display system must be earth-ground. The material for an earth-ground electrode differs

from region to region and may vary according to conditions present at the site. Consult local

and national electrical codes.

Daktronics does not recommend using the support structure as an earth-ground electrode;

concrete, primer, corrosion, and other factors make the support structure a poor ground.

Note: The support structure may be used as an earth-ground electrode only if designed to do

so. A qualified inspector must approve the support structure and grounding methods.

There are two types of power installation: installation with ground and neutral conductors

provided, and installation with only a neutral conductor provided. These two power

installations differ slightly, as described in the following paragraphs:

Installation with Ground and Neutral Conductors Provided

For this type of installation, the power circuit must contain an isolated earth-ground

conductor. In this circumstance, do not connect neutral to ground at the disconnect or at the

display as this would violate electrical codes and void the warranty.

Use a disconnect so that all ungrounded lines can be disconnected. The National Electrical

Code requires the use of a lockable power disconnect within sight of or at the display.

Installation with Only a Neutral Conductor Provided

Installations where no grounding conductor is provided must comply with Article 250-32 of

the National Electrical Code. If the installation in question meets all of the requirements of

Article 250-32, the following guidelines must be observed:

Connect the grounding electrode cable at the local disconnect, never at the display

driver/power enclosure.

Use a disconnect that opens all of the ungrounded phase conductors.

Connection

Both power and signal cables are routed into the scoreboard from the rear through two

plastic plugs for conduit connection. All power and signal wiring terminates at the master

driver enclosure. Note that systems with radio control do not require external signal wiring.

Look for a warning label similar to Figure 12 to locate the

front access panel to the driver enclosure. Remove the screws

or loosen the latches to open the access door panel. Remove

the metal cover of the driver enclosure to expose the driver

components (Figure 13).

Refer to the component location drawings in Appendix A for

precise power/signal termination location for each model.

Electrical Installation 19

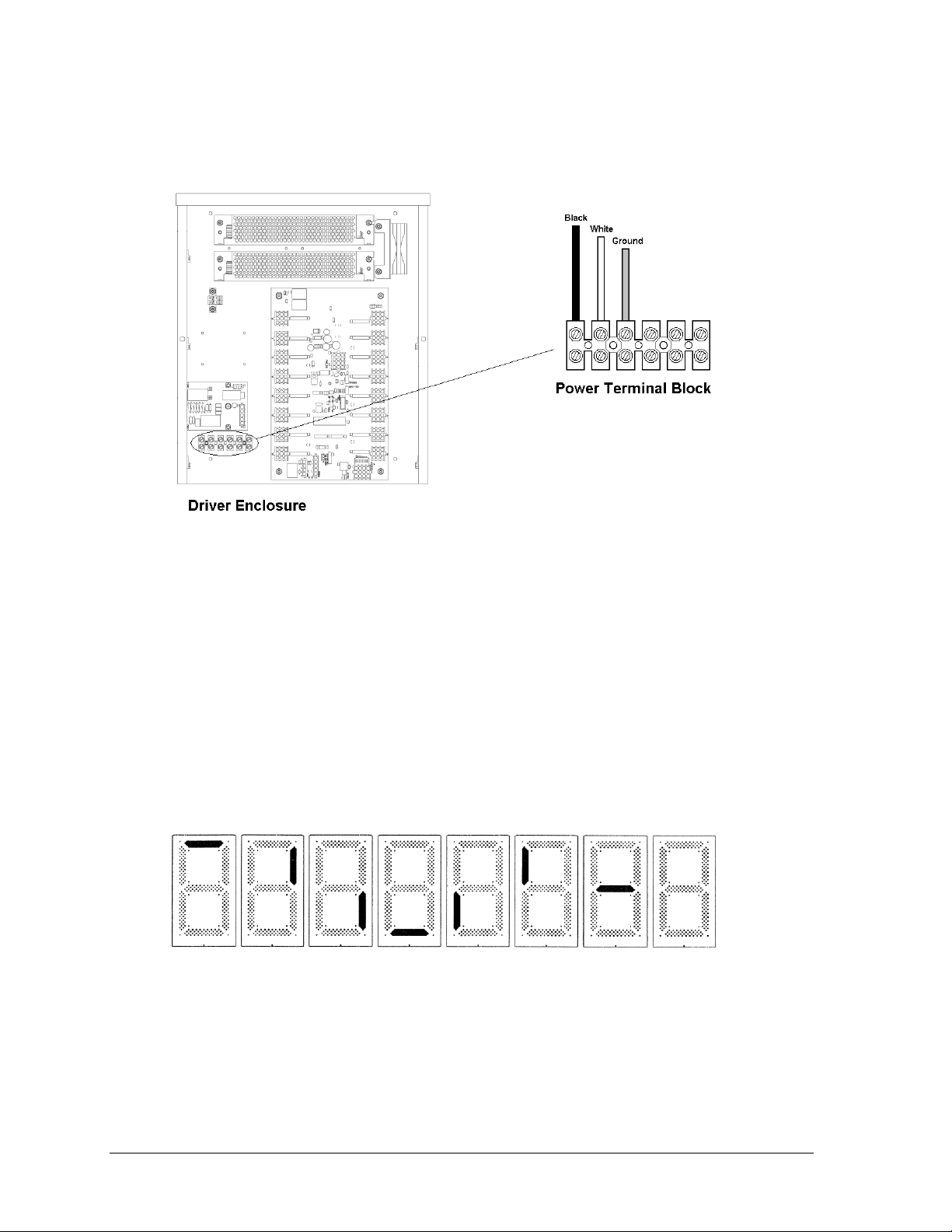

Figure 13: Driver Enclosure & Power Terminal Block

Figure 14: Digit Segment POST

Connect the appropriate wires coming through the rear of the scoreboard to the power

terminal block, as shown in Figure 13.

Note: If a power receptacle is needed to operate the control console at the scoreboard for

troubleshooting, Daktronics recommends that an installation electrician provides a 120 V

outlet close to the disconnect box specifically for this purpose.

4.3 Power-On Self-Test (POST)

The scoreboard performs a self-test each time that power is turned on and the control console

is powered off or not attached to the scoreboard. If the control console is attached and

powered on, the self-test does not run, and data from the control console is displayed on the

scoreboard after a brief period of time. Each scoreboard self-test pattern will vary depending

on the scoreboard model, the number of drivers and types of digits. Figure 14 shows an

example of the LED bar test pattern that each digit performs.

Radio Settings

If a radio receiver is installed, the radio Broadcast and Channel settings will be displayed in

the Home and Guest or clock digits during the POST. These values must match the settings in

the control console (refer to the manual listed in Section 1.4). Refer to Section 5.9 for more

information on radio installations.

20 Electrical Installation

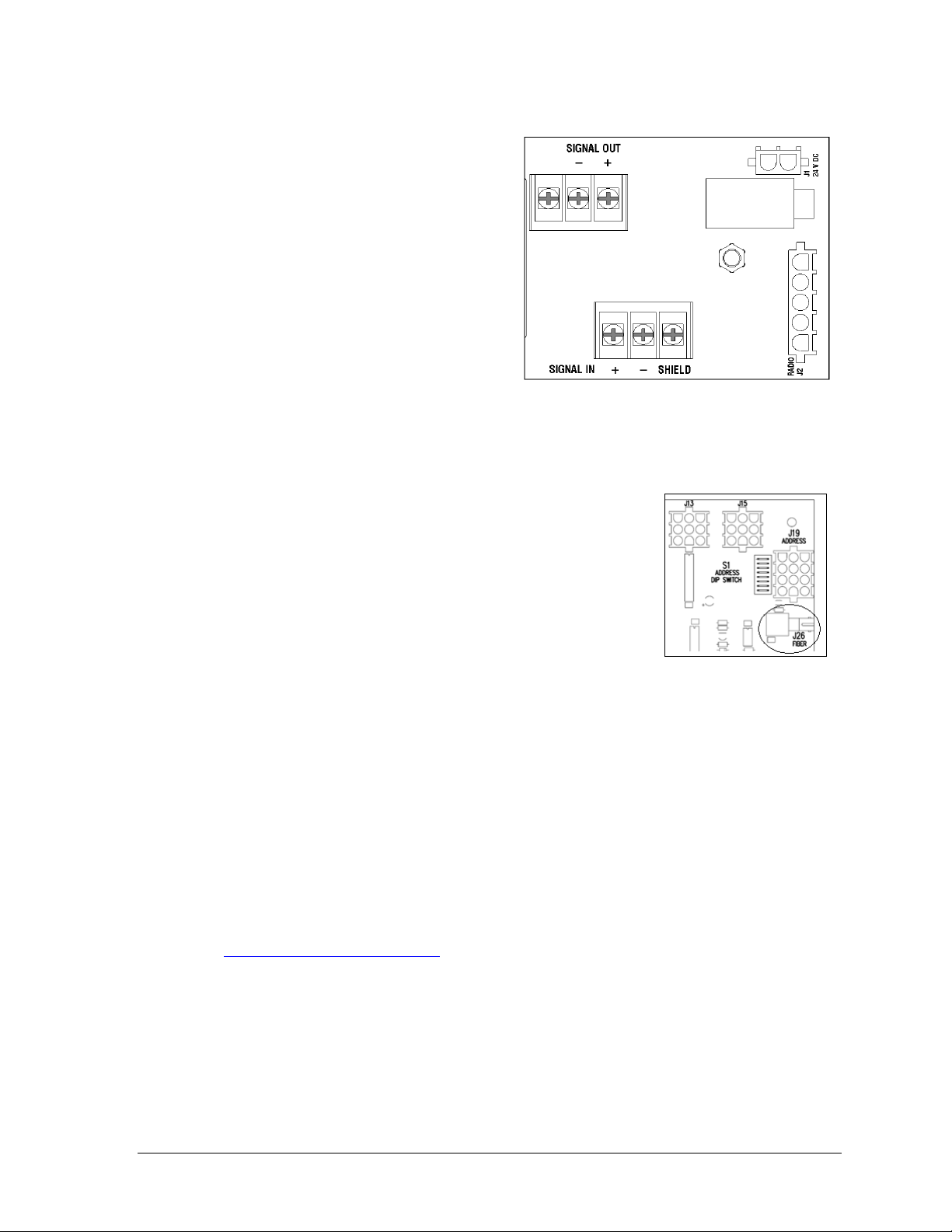

Figure 15: Signal Surge Arrestor Card

Figure 16: Driver Fiber

Connection Location

4.4 Signal Connection

For wired setups, route signal cable through

the conduit knockout on the rear of the

scoreboard to the signal surge arrestor card

(Figure 15), located just above the power

termination block in the driver enclosure.

At the SIGNAL IN terminal block, connect

the red signal wire to the positive terminal

and the black wire to the negative terminal.

Note: Be sure to properly connect the

shield (silver) wire to the SHIELD

terminal.

For signal cable, Daktronics recommends, as a minimum, single-pair, shielded cable, 22 AWG

(part number W-1077). Two-pair shielded cable (part number W-1234) is preferred.

Fiber Optic

Another common signal communication method is fiber optic

cabling. A minimum cabling of multi-mode, 62.5/125 um, and

2-core fiber cable is recommended (part number W-1242).

See Figure 16 for the location of the fiber connector on a 16column driver. This method requires a signal converter between

the All Sport console‟s scoreboard output and the fiber optic cable

(not provided by Daktronics).

Multiple Driver Connections

Some models in the multi-section outdoor scoreboard line require multiple drivers in each

scoreboard section, and use a master/slave driver system. Master and slave drivers function

identically, but slave units lack the power termination block and signal surge suppression

card. When one section has multiple drivers, they simply plug into one another, and this is

done at the factory. Drivers between sections, however, require additional on-site connection

as described in Section 4.5.

Note: Scoreboards capable of displaying speed of pitch (SOP) have an additional master

driver. These models also require a separate signal connection (either wired or radio)

from a dedicated speed of pitch All Sport 5000 console. Refer to the Baseball Speed of

Pitch Systems Configuration Manual (ED-12224), available online at

www.daktronics.com/manuals, for more information about setting up an SOP system.

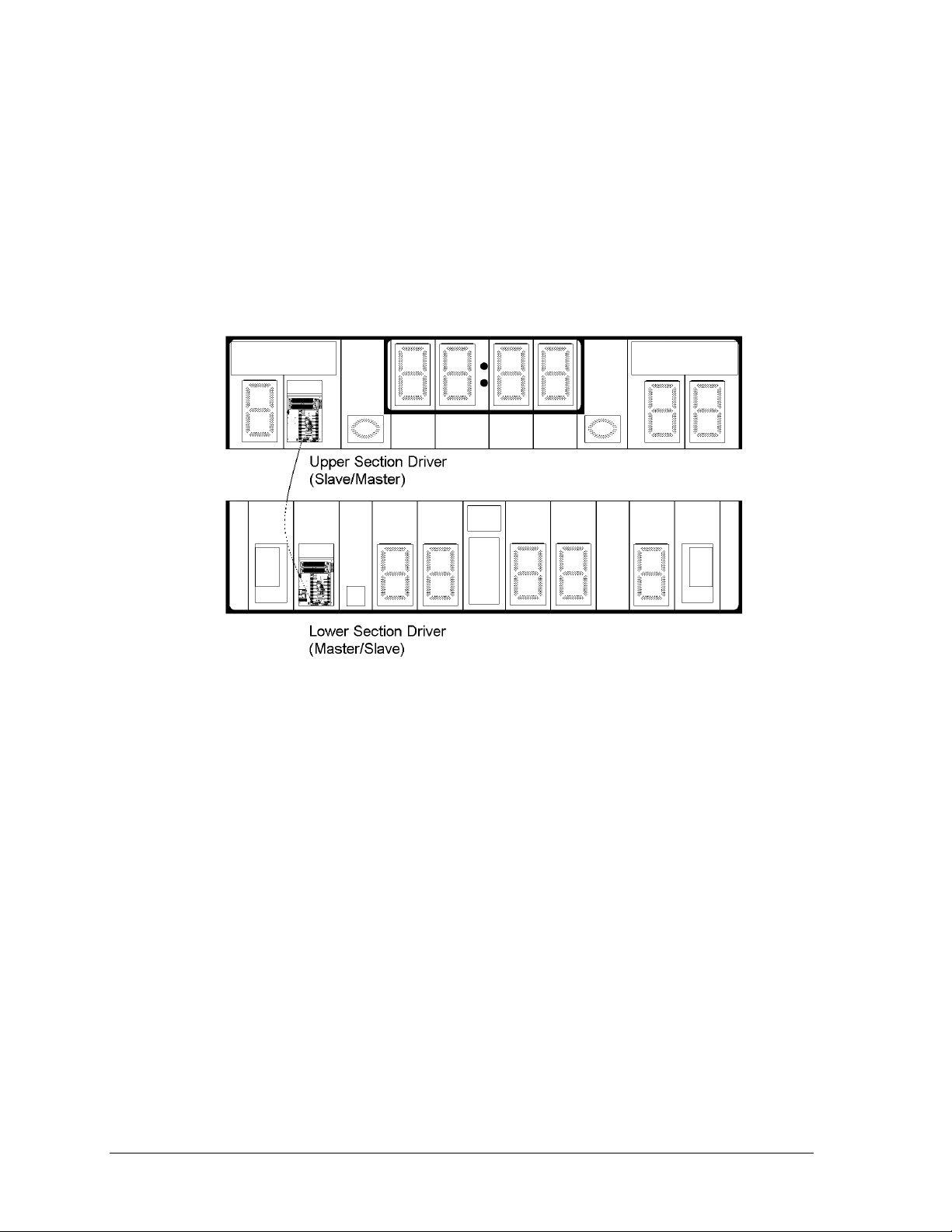

4.5 Power/Signal Connections Between Sections

Most multi-section outdoor scoreboards use a single power/signal interconnect cable

between a driver in the upper section and a driver in the lower section (Figure 17).

It is common for the top driver to be located behind the right-most HOME score digit with

the bottom driver located behind the right-most digit of the left-most set of digits. Refer to the

component location drawings in Appendix A for exact driver locations.

Electrical Installation 21

Figure 17: Typical Upper/Lower Scoreboard Section Connection (Digits Removed to Show Drivers)

1. On the upper section, open the appropriate access panel to locate the bundle of

interconnect cable coming from the driver.

Note: Additional panels may be opened for easier access when routing the cable.

2. Route the interconnect cable through the hole in the bottom of the upper cabinet

through the hole in the top of the lower cabinet, and plug it into the driver.

If the lower section contains the master driver, the harness will connect to J42.

If the lower section contains the slave driver, the harness will connect to P43.

3. With four-section scoreboards, be sure to also connect any plugs extending from the

right side of the left cabinets to the corresponding jacks on the left side of the right

cabinets.

Note: Similar connections exist between the upper and lower cabinets of multisection, single-driver scoreboards as well.

4.6 Lightning Protection

The use of a disconnect near the scoreboard to completely cut all current-carrying lines

significantly protects the circuits against lightning damage. In order for this system to

provide protection, the power must be disconnected when the scoreboard is not in use.

The control console should also be disconnected from power and from the signal junction box

when the system is not in use. The same surges that may damage the scoreboard‟s driver can

also damage the console‟s circuitry.

22 Electrical Installation

Problem

Possible Cause

Solution/Items to Check

Scoreboard doesn’t light

and console doesn’t work

No power to the scoreboard

Check that the main circuit breaker

for the scoreboard is on.

Check that the scoreboard is

receiving the correct 120 (or 240) V

AC power (see Section 2).

No power to console

Ensure the console is plugged into a

120 (or 240) V AC power supply.

Swap the console with one known to

work correctly, and enter the proper

sport code and/or radio settings to

test. Replace console if necessary.

Scoreboard digits don’t light,

but console works

No wired signal from console

Check that the scoreboard is

receiving the correct 120 (or 240) V

AC power (see Section 2).

Check that the red DS2 LED on the

driver lights up when sending

commands from the control console

(see Section 5.7).

No radio signal from console

Cycle power to the scoreboard and

watch for radio receiver broadcast/

channel settings (see Section 5.9).

Section 5: Scoreboard Troubleshooting

IMPORTANT NOTES:

1. Always disconnect power before doing any repair work on the scoreboard.

2. Permit only qualified service personnel to access internal display electronics.

3. Disconnect power when not using the scoreboard.

Note: For assistance in the maintenance of team name message centers (TNMCs), electronic captions,

or other optional scoreboard message centers, refer to Section 6 or the service manual that

accompanies those units.

5.1 Troubleshooting Table

The table below lists potential problems with the scoreboard and indicates possible causes

and corrective actions. This list does not include every symptom that may be encountered,

but it does present several of the most common situations that may occur.

Many of the solutions offered below provide references to other sections within this manual

or to supplemental product manuals with further detail on how to fix the problem.

If a problem occurs that is not listed or that cannot be resolved using the solutions in the

following table, contact Daktronics using the information provided in Section 7.

Scoreboard Troubleshooting 23

Problem

Possible Cause

Solution/Items to Check

Check that the green POWER and

amber RADIO IN RANGE indicators

on the radio receiver in the

scoreboard light up when the control

console is powered on (see Section

5.9). Keep the console between 20

to 1500 feet from the scoreboard.

Move the console 20-30 feet from

the scoreboard and test again.

Verify that both the console and

scoreboard antennae are securely

tightened and in a vertical position.

Replace the radio receiver.

No signal to driver

Check that the scoreboard is

receiving the correct 120 (or 240) V

AC power (see Section 2).

Check that the red DS2 LED on the

driver lights up when sending

commands from the control console

(see Section 5.7).

Swap the driver with one known to

work correctly and with the same

part number to verify the problem.

Replace if necessary (see Section

5.7).

No power to driver

Check that the green DS1 LED on

the driver is always lit up when the

scoreboard is powered on

(see Section 5.7).

Scoreboard digits light, but

not in the correct order

Incorrect sport code

Ensure the correct sport code is

being used for the scoreboard

model. Refer to the operation

manual for the console being used

(see Section 1.4).

Incorrect driver address

Check that the scoreboard driver(s)

are set to the correct address(es)

(see Section 5.7)

Scoreboard digits light,

console works, but no

display on scoreboard

No wired signal from console

(See solution on previous page)

No radio signal from console

(See solution on previous page)

Bad/damaged field wiring

Check that the red DS2 LED on the

driver lights up when sending

commands from the control console

(see Section 5.7)

Scoreboard works, but some

LEDs always stay on

Short in digit, segment, or

indicator circuit

Swap the digit/segment/indicator

with one known to work correctly to

verify the problem. Replace if

necessary (see Sections 5.4-5.6).

24 Scoreboard Troubleshooting

Loading...

Loading...