Page 1

GalaxyPro™ 34 mm

AF-3700 Series

Installation & Operation Manual

ED-17286 Rev 2 11 December 2007

Website: www.daktronics.com

Tel: 866-343-3122 Fax: 605-697-4444

331 32nd Ave PO Box 5128 Brookings SD 57006

Page 2

ED-17286

Product 1387

Rev 2 – 11 December 2007

Fill in the chart with specific information about this display so these details will be readily available

when calling for service or replacement parts.

Information needed for technicians

Fill in the blank

and/or Customer Service

Location address of the display:

Model number of the display:

Version of software being used:

(Right-click on Venus 1500 name in toolbar,

choose “About Venus 1500”)

Method of communication being used:

(See Section 4 for guidance)

Controller version used in the display:

AF-3700 34 mm

Venus 1500 v. ______

M3 controller

DAKTRONICS, INC.

Copyright © 2007

All rights reserved. While every precaution has been taken in the preparation of this manual, the publisher assumes no

responsibility for errors or omissions. No part of this book covered by the copyrights hereon may be reproduced or copied in

any form or by any means – graphic, electronic, or mechanical, including photocopying, taping, or information storage and

retrieval systems – without written permission of the publisher.

GalaxyPro™ is a registered trademark of Daktronics, Inc.

All others are trademarks of their respective companies.

Page 3

Table of Contents

Section 1: Overview of the Displays ........................................................................................... 1

1.1 Display Details ......................................................................................................................... 1

Section 2: Mechanical Installation .............................................................................................. 3

2.1 Support Structure Requirements .......................................................................................... 3

2.2 Lifting a Display or Display Section ...................................................................................... 5

2.3 Sectional Mounting ................................................................................................................. 6

Bottom or Bottom-Left Section ....................................................................................... 6

Top or Top-Left Section .................................................................................................. 7

Combining Sections ......................................................................................................... 8

2.4 Optional Temperature Sensor Mounting .............................................................................. 8

Section 3: Power Installation ....................................................................................................... 9

3.1 Conduit ...................................................................................................................................... 9

3.2 Overview of Power/ Signal Connection ................................................................................ 9

3.3 Power Requirements ............................................................................................................ 10

3.4 Grounding ............................................................................................................................... 11

3.5 Power Connection ................................................................................................................. 12

3.6 Power Routing in the Display .............................................................................................. 15

Section 4: Signal Installation Overview .................................................................................... 17

4.1 Primary/Mirror Signal Connection ....................................................................................... 17

4.2 Signal and Bonding Interconnections ................................................................................. 18

Between Top and Bottom Sections ............................................................................. 18

Between Left and Right Sections................................................................................. 18

Four (4) Section Interconnections ............................................................................... 19

4.3 Wireless Ethernet Bridge Communication ......................................................................... 20

4.4 Wire Ethernet Communication ............................................................................................ 21

4.5 Fiber Ethernet Communication ........................................................................................... 22

Section 5: Start-up Procedure ................................................................................................... 23

5.1 Start-up Checklist .................................................................................................................. 23

5.2 Start-up Sequence ................................................................................................................ 24

Section 6: Maintenance .............................................................................................................. 25

6.1 Access to Display Interior .................................................................................................... 26

6.2 Ventilation System/ Fans ..................................................................................................... 27

6.3 Annual Inspection .................................................................................................................. 28

Section 7: Diagnostics and Troubleshooting .......................................................................... 29

Safety Precautions ......................................................................................................... 29

Table of Contents i

Page 4

7.1

Controller Diagnostics ........................................................................................................... 29

7.2 MLC Diagnostics ................................................................................................................... 30

7.3 Temperature Sensor Diagnostic ......................................................................................... 31

7.4 Troubleshooting Display Problems ..................................................................................... 31

Module and LED problems ........................................................................................... 31

Brightness problems ...................................................................................................... 32

Message problems ......................................................................................................... 33

Temperature problems .................................................................................................. 33

Testing displays .............................................................................................................. 34

Before calling for help .................................................................................................... 34

Section 8: Parts Replacement .................................................................................................... 35

8.1 About Replacement Parts .................................................................................................... 35

8.2 Instructions for Replacing Parts .......................................................................................... 37

Module Replacement ..................................................................................................... 37

Controller Replacement ................................................................................................. 38

MLC Replacement ......................................................................................................... 40

Power Supply Replacement ......................................................................................... 41

Light Sensor Replacement ........................................................................................... 42

Temperature Sensor Replacement ............................................................................. 43

Section 9: Daktronics Exchange and Repair & Return Programs .......................................... 45

Before Contacting Daktronics ....................................................................................... 45

9.1 Exchange Program ............................................................................................................... 45

9.2 Repair & Return Program ..................................................................................................... 46

9.3 Shipping Address .................................................................................................................. 46

Appendix A: Reference Drawings ................................................................................................. 47

Appendix B: Glossary ..................................................................................................................... 49

Definitions of Terms ....................................................................................................... 49

Common Power and Signal Connectors ..................................................................... 50

Appendix C: Temperature Sensor Installation ............................................................................. 53

ii Table of Contents

Page 5

List of Figures

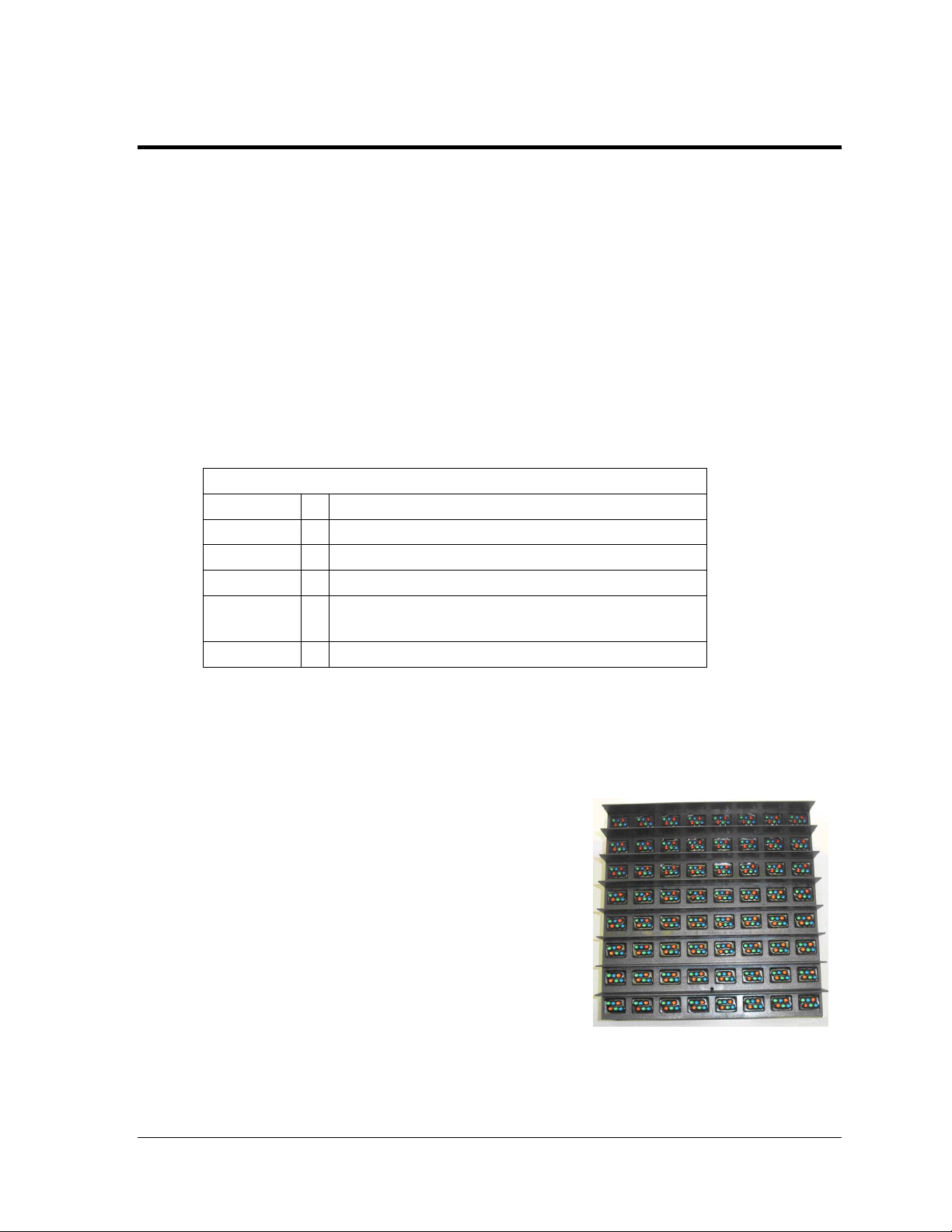

Figure 1: Single Module .......................................................................................................................... 1

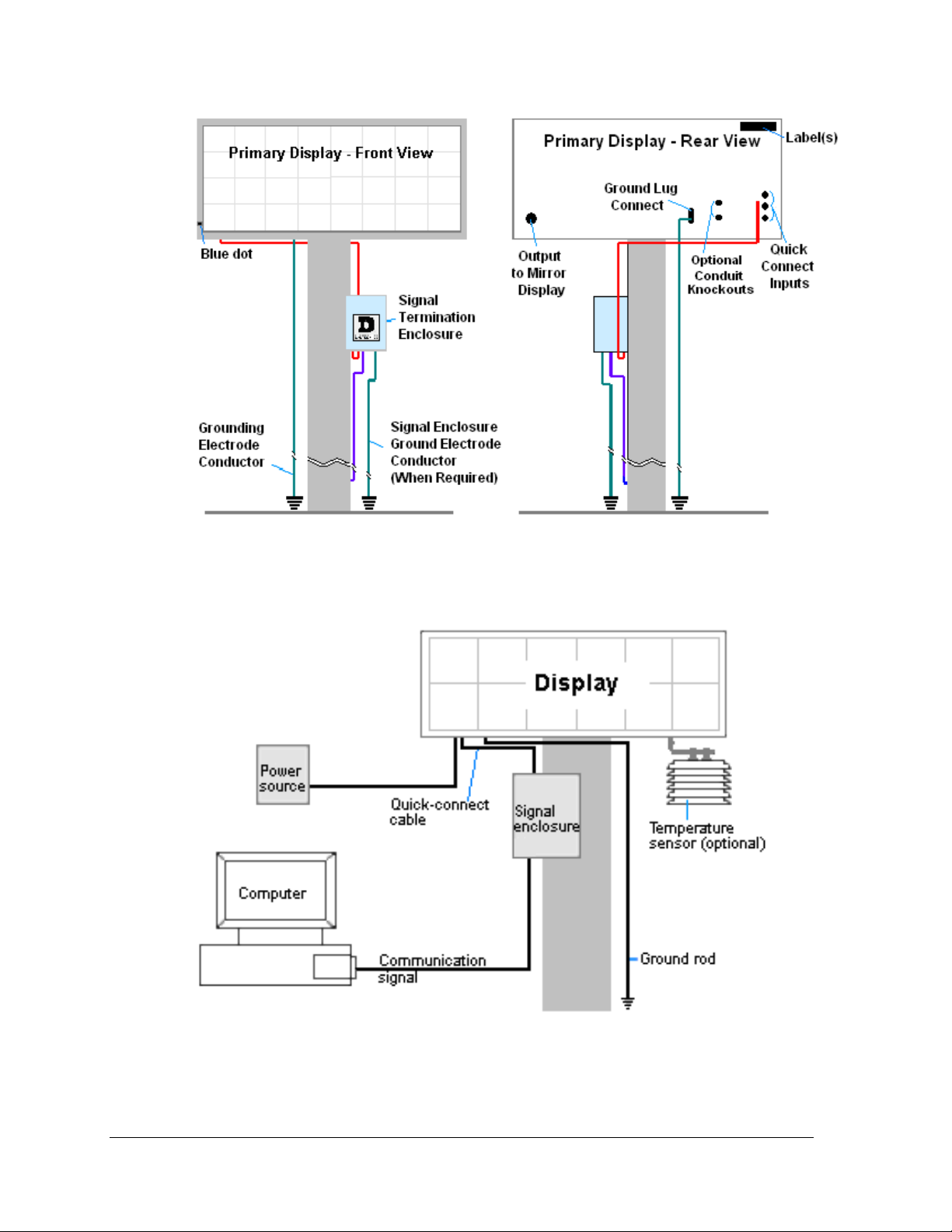

Figure 2: Display Components ............................................................................................................... 2

Figure 3: Basic Display Set-up ............................................................................................................... 2

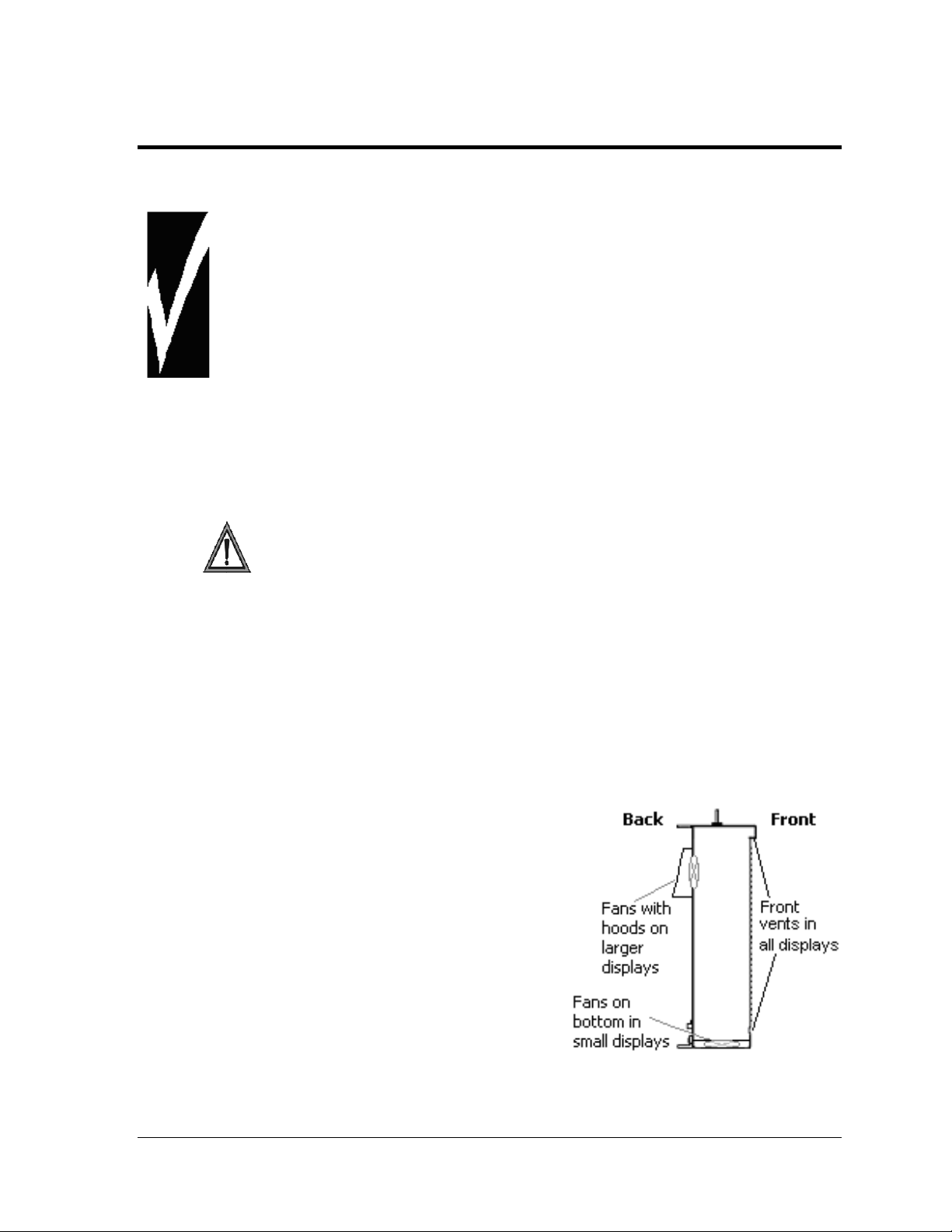

Figure 4: Ventilation of Displays ............................................................................................................. 3

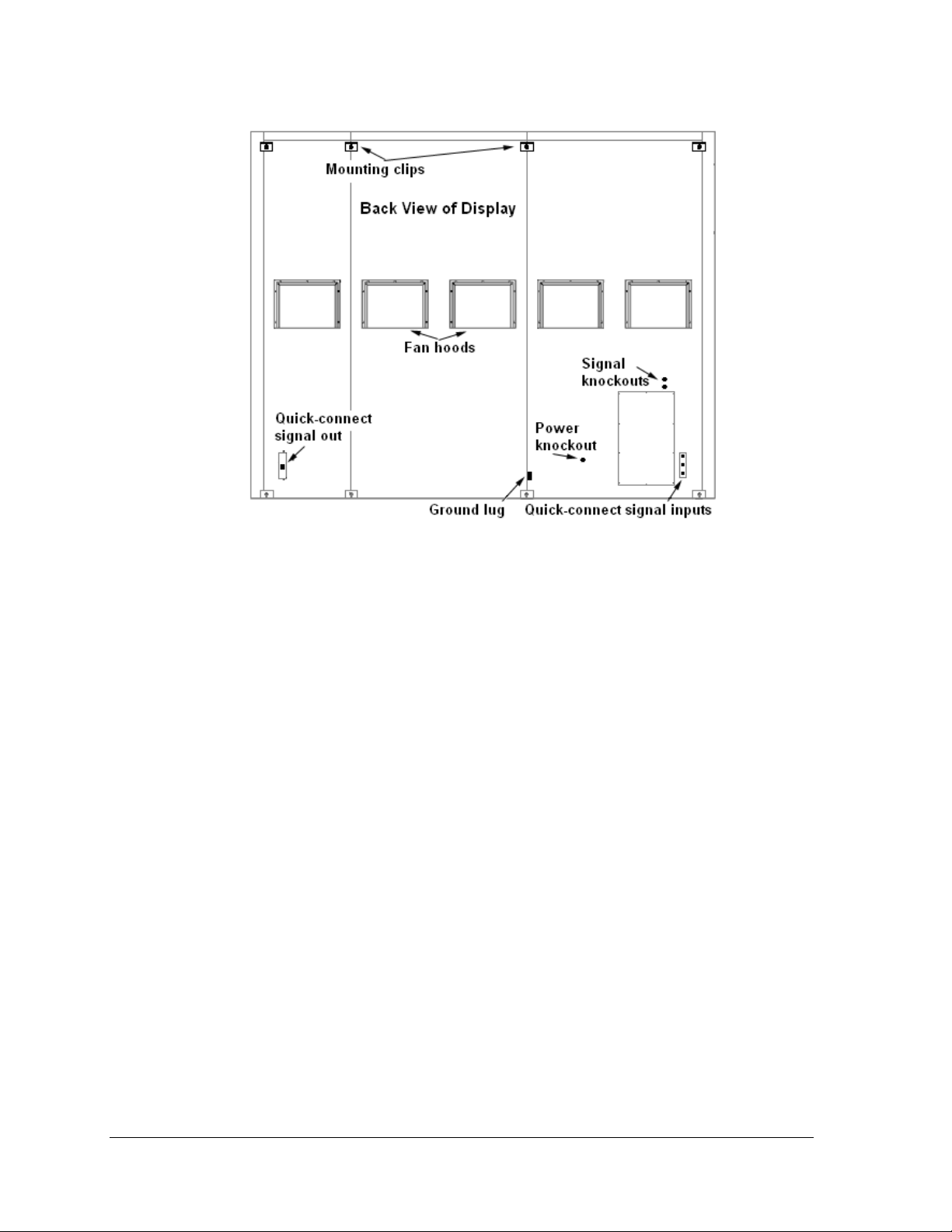

Figure 5: Back View of Typical Display/Section ..................................................................................... 4

Figure 6: Correct Lifting Procedure ........................................................................................................ 5

Figure 7: Incorrect Lifting ........................................................................................................................ 5

Figure 8: Bottom Section Preparation .................................................................................................... 6

Figure 9: Top Section Preparation.......................................................................................................... 7

Figure 10: Clip Angle Detail .................................................................................................................... 8

Figure 11: Alignment Pin ........................................................................................................................ 8

Figure 12: Attaching Top and Bottom Sections ...................................................................................... 8

Figure 13: Correct Grounding ............................................................................................................... 11

Figure 14: 120 V Single-phase Power Termination .............................................................................. 12

Figure 15: 240 V Single-phase Power Termination .............................................................................. 12

Figure 16: 240/415 VAC Power Termination – 6-breaker .................................................................... 13

Figure 17: 120/208 VAC Power Termination – 6-breaker .................................................................... 13

Figure 18: 120/208 V Power Termination – .......................................................................................... 13

Figure 19: 240/415 V Power Termination – .......................................................................................... 13

Figure 20: 120 VAC Power Termination ............................................................................................... 14

Figure 21: 120/240 VAC Power Termination ........................................................................................ 14

Figure 22: Power Flow Summary ......................................................................................................... 15

Figure 23: Fiber Interconnect Cable and Input ..................................................................................... 17

Figure 24: Quick-Connect Signal Cable ............................................................................................... 17

Figure 25: Fiber Interconnections ......................................................................................................... 18

Figure 26: Ribbon Cable ....................................................................................................................... 18

Figure 27: Bonding Jumper Detail ........................................................................................................ 18

Figure 28: Top/Bottom Interconnections .............................................................................................. 18

Figure 29: Right/Left Interconnections ................................................................................................. 18

Figure 30: Interconnections between Four Sections ............................................................................ 19

Figure 31: Wireless Ethernet Bridge Layout ......................................................................................... 20

Figure 32: Ethernet Communication Layout ......................................................................................... 21

Figure 33: Fiber Ethernet Communication Layout ................................................................................ 22

Figure 34: Basic Display Set-up ........................................................................................................... 23

Figure 35: Location of Internal Components ........................................................................................ 25

Figure 36: Module Access Locations ................................................................................................... 26

List of Figures iii

Page 6

Figure 37: Removing a Module ............................................................................................................. 26

Figure 38: Air Flow in Smaller Displays ................................................................................................ 27

Figure 39: Air Flow in Larger Displays .................................................................................................. 27

Figure 40: Thermostat ........................................................................................................................... 27

Figure 41: Interior Component Locations .............................................................................................. 29

Figure 42: Controller Component Layout .............................................................................................. 30

Figure 43: MLC Diagnostic LEDs .......................................................................................................... 30

Figure 44: Temperature sensor board .................................................................................................. 31

Figure 45: Modules Not Working .......................................................................................................... 32

Figure 46: Interior Location of Components .......................................................................................... 35

Figure 47: Typical Label ........................................................................................................................ 36

Figure 48: Module, Front/Back .............................................................................................................. 37

Figure 49: Removing a Module ............................................................................................................. 37

Figure 50: GalaxyPro Controller ........................................................................................................... 38

Figure 51: Rotary Address Switches ..................................................................................................... 39

Figure 52: MLC ..................................................................................................................................... 40

Figure 53: Jacks and Fuses Label on Power Supply ............................................................................ 41

Figure 54: Power Supply with Low Voltage Distribution Board ............................................................. 41

Figure 55: Light Sensor Assembly ........................................................................................................ 42

Figure 56: Wire around Sensor ............................................................................................................. 43

Figure 57: Temperature Sensor ............................................................................................................ 43

Figure 58: Ribbon Cable Connector ..................................................................................................... 50

Figure 59: One Breaker Termination Block ........................................................................................... 50

Figure 60: Phoenix Connector .................................................................................................. ............ 50

Figure 61: Mate-n-Lok Connector ......................................................................................................... 50

Figure 62: RJ11/RJ45 Connector ......................................................................................................... 51

Figure 63: RS232/Six-pin Quick-connect Jack ..................................................................................... 51

Figure 64: Fiber-Optic Cable ................................................................................................................. 51

iv List of Figures

Page 7

Section 1: Overview of the Displays

Daktronics GalaxyPro™ AF-3700 series displays are built to display a wide variety of messages with

great color depth. This manual provides simple installation, maintenance, and troubleshooting

information to ensure the optimal performance of the display. Diagnostic information and parts

replacement are also included. Definitions of terms and connectors used in the manual can be found

in Appendix B.

The diagrams in Figure 2 and Figure 3 give an overview of the displays. The first figure shows the

front and back views of a typical display. The second figure shows a simplified diagram of basic

display set-up.

1.1 Display Details

The GalaxyPro® model numbers are described as follows:

AF-3700-RRxCCC-34-RGB-X

AF-3700 =

RR =

CCC =

34 =

RGB =

X =

The displays are offered as single-face or double-face units. If the display is a double-face

setup, the first display is referred to as the primary and the second display is called the

mirror. If the second display will be mounted at a distance of more than six feet from the

primary display, then two primary displays will need to be utilized.

A module is the building block of the GalaxyPro

display. Each module measures 8 pixels high by 8

pixels wide (Figure 1). By placing modules side-by-side

and on top of one another, a variety of display sizes can

be designed and built. Individual modules can be easily

removed from the display if required.

A typical display system is run with a Windows

personal computer (PC) running Venus

and one or more displays. Venus 1500 is a software

package that runs under Windows 98, ME

2000, XP, or Vista Home/Professional operating

systems on an IBM

Venus 1500 operations manual (ED-13530) for

installation and operation of the Venus 1500 software.

Outdoor GalaxyPro display

Number of pixel rows high

Number of pixel columns long

34 mm pixel to pixel spacing

LED Color: R (Red), G (Green), B (blue)

(68 billion colors - pixel calibrated)

SF – Single Face or 2V – Primary/Mirror

®

®

1500 software

™

®

-compatible computer. Refer to the

based

, NT® 4.0,

Figure 1: Single Module

Overview of the Displays 1

Page 8

Figure 2: Display Components

Figure 3: Basic Display Set-up

2 Overview of the Displays

Page 9

Section 2: Mechanical Installation

Read the Mechanical, Power, and Signal Installation sections before installing the display(s).

Daktronics engineering staff must approve any changes that may affect the weathertightness of the display. If any modifications are made, detailed drawings of the changes

must be submitted to Daktronics for evaluation and approval, or the warranty may be

void.

Daktronics is not responsible for installations or the structural integrity of

support structures done by others. The customer is responsible for ensuring that a

qualified structural engineer approves the structure and any additional hard ware.

Reference Drawing:

Shop Drawing for specific display size ......................................................... Listed in Appendix A

2.1 Support Structure Requirements

The installer is responsible for ensuring that the mounting structure and hardware

are capable of supporting the display, and that the structure follows all local codes.

Support structure design depends on the mounting methods, display size, and weight.

Because every installation site is unique, no single procedure is approved by Daktronics for

mounting GalaxyPro

information only and may or may not be appropriate for this particular installation. Refer to

Figure 2 and Figure 3 for basic display set-ups.

Mounting plans need to take into account the ventilation system for the specific display size.

In general, the front of all displays needs to be unobstructed to allow for air flow and internal

access. Displays 40 pixels high and larger also need unobstructed area in the back to allow for

fans expelling air through the hoods (Figure 4).

Also keep in mind the location of the mounting

clips and the clearance needed for the

power/signal terminations on the back of the

display (Figure 5). Display height and wind

loading are also critical factors to be considered.

This information can be found in the Shop

Drawing which was supplied with the order. These

are also listed in Appendix A.

™

displays. The information contained in this section is general

Figure 4: Ventilation of Displays

Mechanical Installation 3

Page 10

Figure 5: Back View of Typical Display/Section

Pre-installation Checklist

Verify the following before proceeding with installation:

The display is in good condition after shipping and uncrating.

•

A straight and square mounting frame is provided for the display.

•

Height variation in any four-foot horizontal section may not exceed ¼-inch.

• Adequate support is provided for the display so that the structure will not yield at

any unsupported points after mounting.

Clearance of 4" of unobstructed space above the top of the display is allowed to

•

remove the eyebolt. Note: No clearance is required once the eyebolt is removed.

Clearance around the display is maintained to allow unobstructed air flow through

•

the vents and fans and to allow access to internal components.

4

Mechanical Installation

Page 11

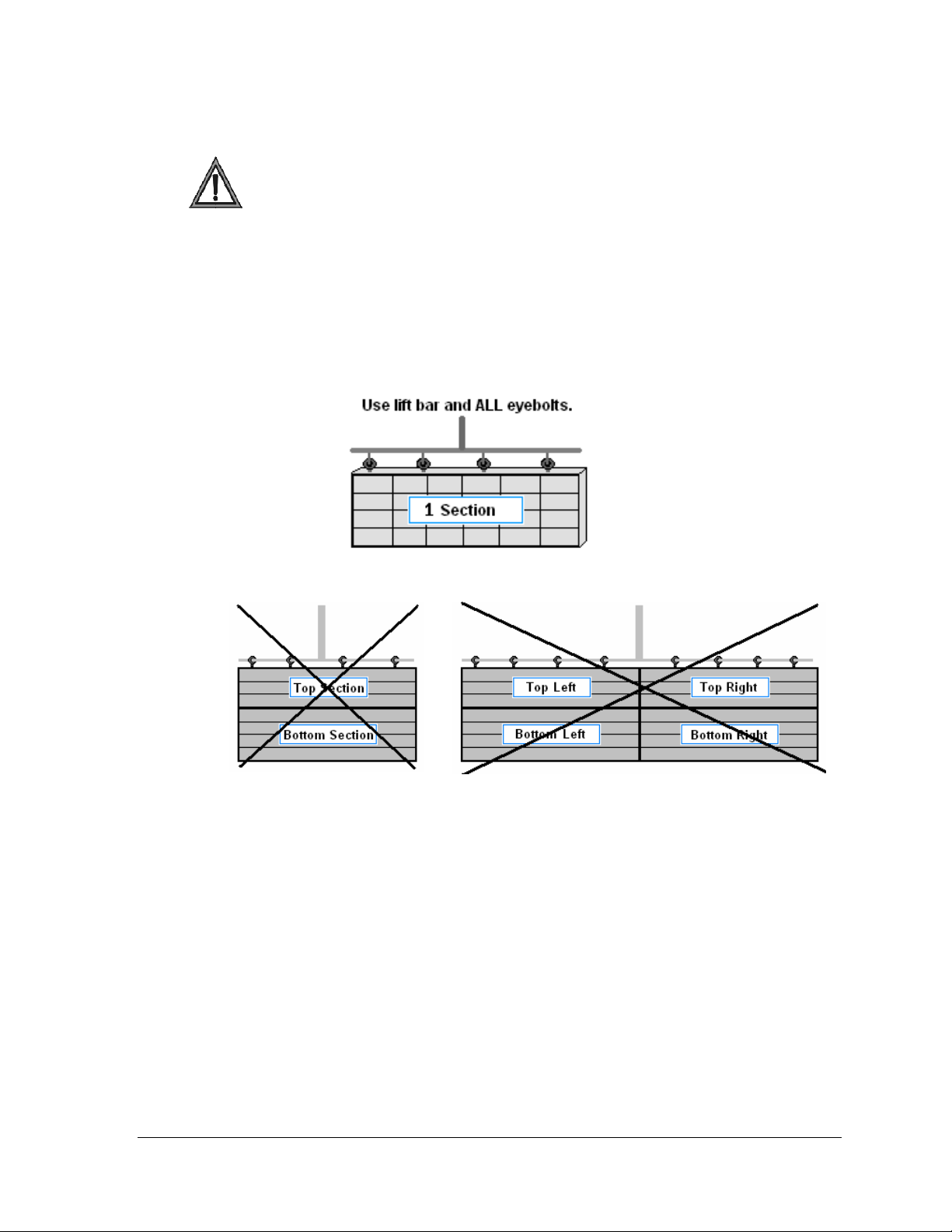

2.2 Lifting a Display or Display Section

In order to maintain the structural integrity of the display cabinet, the 90° angle

between the cabinet and the lifting method must be maintained.

If damage occurs due to improper lifting procedures, the warranty will be void.

General Lifting Notes:

• Lift the display into position on the support structure using a lifting bar and all

eyebolts. (Figure 6).

• Do not attempt to permanently support the display by the eyebolts.

• Do not lift more than one section at a time with the eyebolts.

• Mount bottom section(s) first.

Figure 6: Correct Lifting Procedure

Figure 7: Incorrect Lifting

Left and right sections may be mounted together ONLY if a lifting bar and all eyebolts

are used. Left/right signal and ground connections may be easier to make on the ground.

Top/bottom or more than two sections should not be mounted together since the

eyebolts and connecting hardware are not strong enough for this procedure.

After installation is complete, carefully inspect the display for any holes that may allow

water to seep into the display and seal any openings with silicone.

If the eyebolts on the top of the display have been removed, plug the holes with bolts

and the rubber-sealing washer that was removed with the eyebolt unless an overhead

structure protects the area.

Refer to Section 3 for power routing and to the appropriate communication manual for

signal connections to the display.

Mechanical Installation 5

Page 12

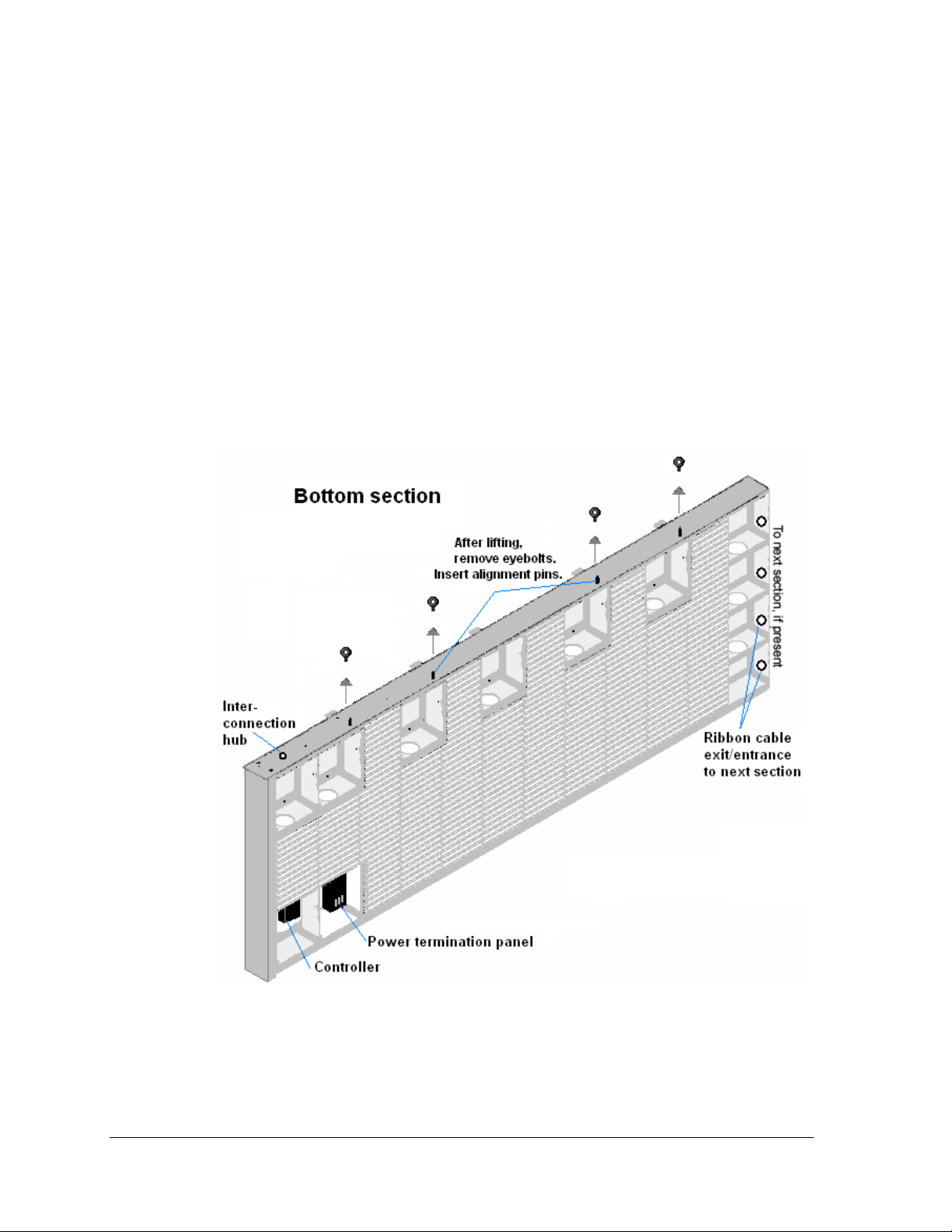

2.3 Sectional Mounting

Bottom or Bottom-Left Section

Before mounting, connecting the sections, or installation:

1. Remove the first, second and every even module from the top row of the bottom

section.

2. Also, remove the first and second module from the bottom left corner of the bottom

section - the controller and power termination panel are located there.

3. If an additional section will be added for length, remove the modules in the

adjoining columns. An opening is located behind each module in the columns for

ribbon cable connection between sections.

Figure 8: Bottom Section Preparation

6

Mechanical Installation

Page 13

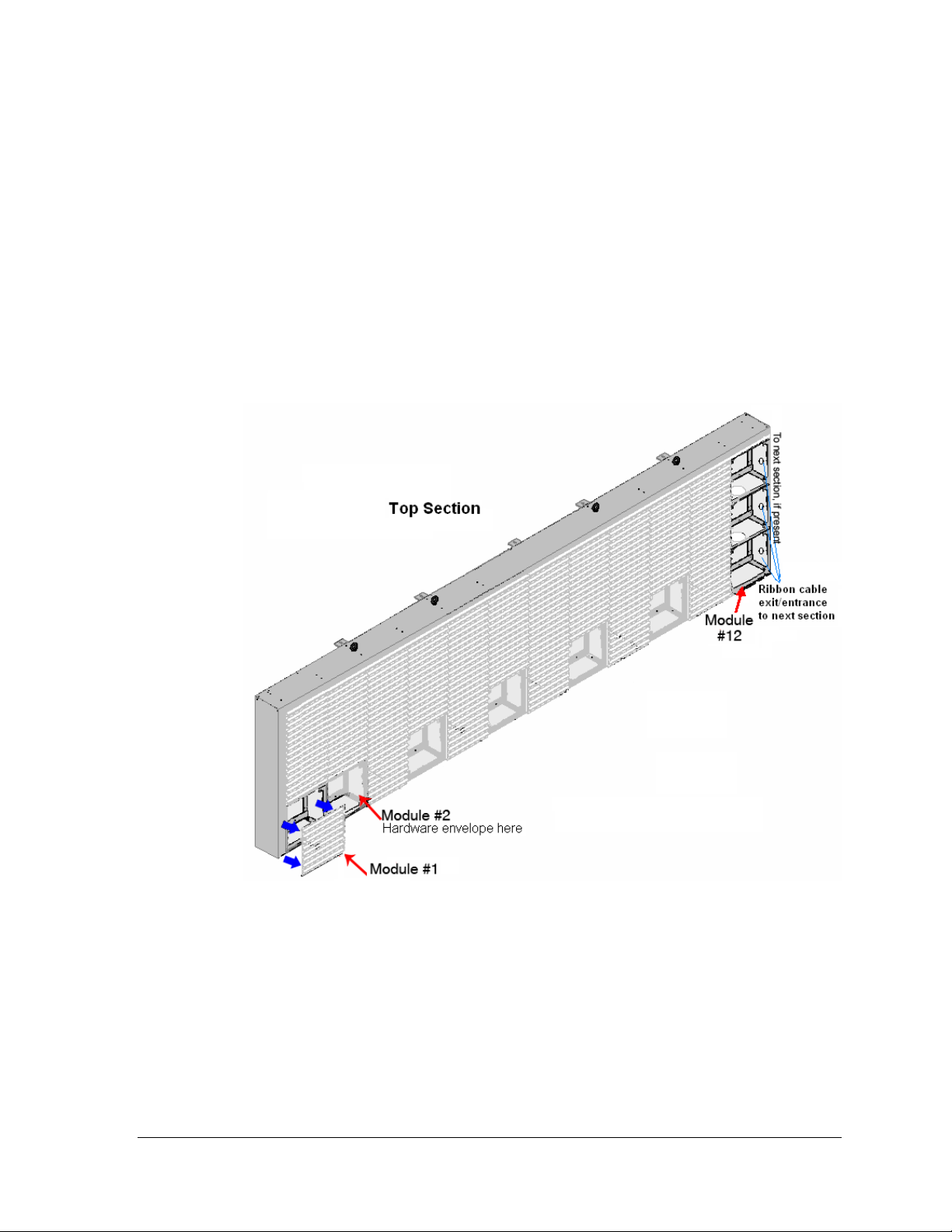

Top or Top-Left Section

Before mounting, connecting the sections, or installation:

1. Remove the first, second, and every even module from the bottom row of a top

section. This will aid in aligning and connecting top and bottom sections, along with

making grounding and signal connections.

2. Behind the second module in the bottom row is a padded envelope that contains the

hardware needed to attach the sections together. Remove this now so the hardware

can be used in the following steps.

3. If an additional section will be added for length, remove the modules in the

adjoining columns. An opening is located behind each module in the columns for

ribbon cable connection between sections.

Figure 9: Top Section Preparation

Mechanical Installation 7

Page 14

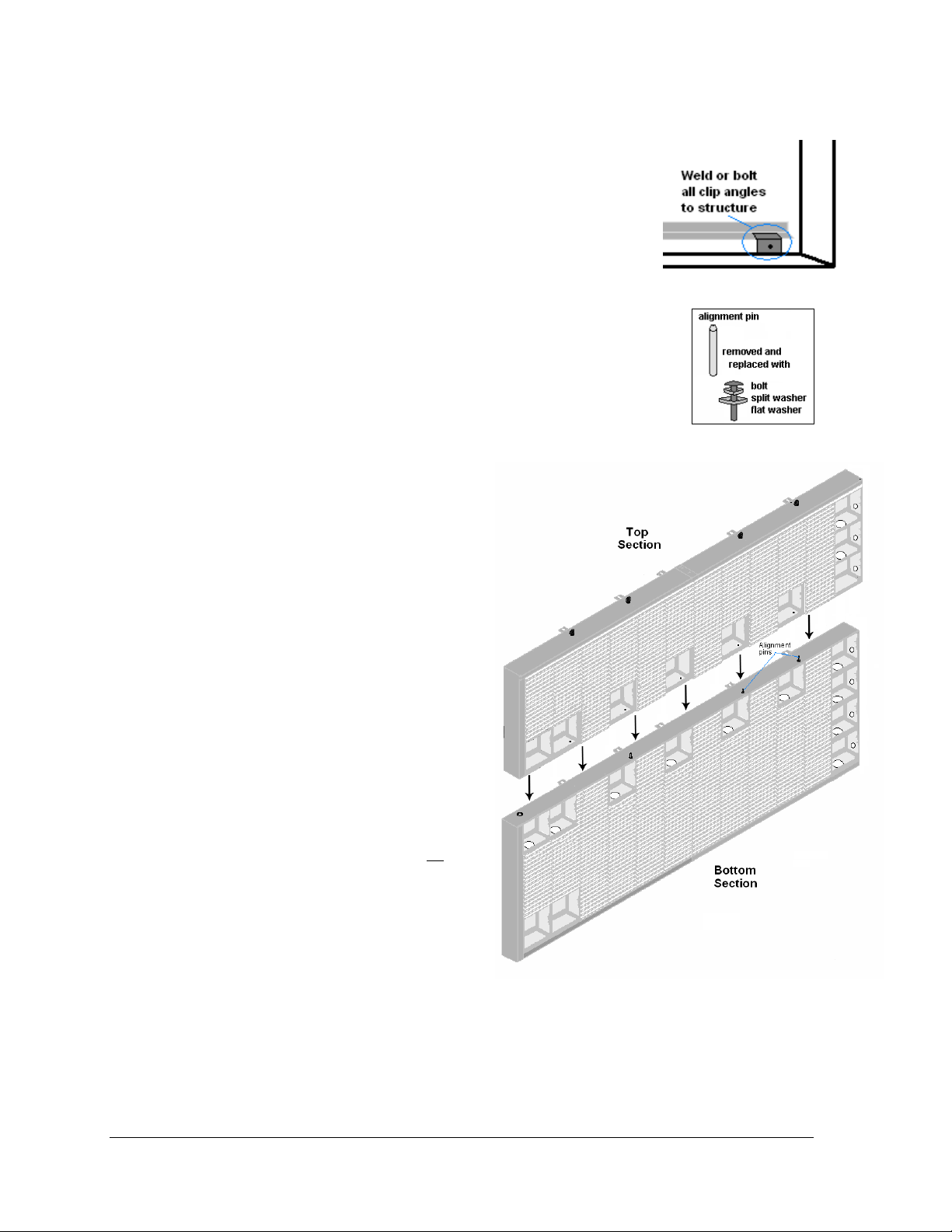

Combining Sections

1. Install the alignment pins in the top edge of the bottom

section by screwing them into the holes where the eyebolts

were located.

2. Attach the bottom section to the support structure by welding

or using 1/2” grade-5 bolts and hardware. Secure all clip

angles. Refer to Figure 10.

3. Set the top section on top of the bottom section with the aid of the

alignment pins.

4. Attach the top to bottom sections by unscrewing the alignment

pins and replacing them with the following (Refer to Figure 11):

• ½”-13 X 1 ½” bolts (HC-1152)

• ½” split washers (HC-1101)

• ½” flat washers (HC-1095).

Fill in all holes in the adjoining

sections.

5. If additional sections will be added

for length, remove the covers from

interconnection openings. Attach the

left to right sections with the

following:

• ½”-13 X 1 ½” bolts (HC-1152)

• ½” split washers (HC-1101)

• ½” flat washers (HC-1095).

Fill in all holes in the adjoining

sections.

6. Attach the top section(s) to the

structure. Weld or use ½" grade-5

bolts and hardware to secure all

angles to the support structure.

clip

Figure 10: Clip Angle Detail

Figure 11: Alignment Pin

2.4 Optional Temperature Sensor

Mounting

If an optional temperature sensor will be used with this display, refer to Appendix C for

mounting and signal connections.

8

Figure 12: Attaching Top and Bottom Sections

Mechanical Installation

Page 15

Section 3: Power Installation

Read the Mechanical, Power, and Signal Installation sections before installing the display(s).

• Only a qualified individual should terminate power and signal cable at this Daktronics

display.

• All proposed changes must be approved by Daktronics engineering staff or the warranty

will be rendered null and void.

Reference Drawings:

Schematic, AF-3700-34-RGB, general ............................................................... Drawing B-277048

Power Specs, AF-3700-(8-32) x*-34-RGB-120/240 & 120/208V ....................... Drawing B-278578

Power Specs, AF-3700-(40-64) x*-34-RGB-120/240 & 120/208V ..................... Drawing B-283112

Power Specs, AF-3700-(72-80) x*-34-RGB-120/240 & 120/208V ..................... Drawing B-283113

Power Specs, AF-3700-(88-96) x*-34-RGB-120/240 & 120/208V ..................... Drawing B-283114

Power Specs, AF-3700-(104-112) x*-34-RGB-120/240 & 120/208V ................. Drawing B-283115

Power Specs, AF-3700-(120-128) x*-34-RGB-120/240 & 120/208V ................. Drawing B-278707

Power Specs, AF-3700-(8-32) x*-34-RGB-240 & 240/415V .............................. Drawing B-298537

3.1 Conduit

Daktronics does not include the conduit. Separate conduit must be used to route:

• power.

• signal IN wires to the signal termination enclosure, when applicable.

• signal OUT wires (if not using the provided interconnect cable).

Displays are provided with unthreaded power knockouts on the back for use with 3/4”

conduit. The 8-pixel high displays have a J-box on the back for power termination.

3.2 Overview of Power/ Signal Connection

Following is a brief summary of the power and signal connections to the display.

1. Power to the display will be terminated internally in most cases. Section 3.5 shows

the internal wiring diagrams.

2. Possible methods for signal termination are shown in the manual for the specific

communication type.

3. Power is routed to the display through a fused disconnect switch capable of

opening all ungrounded power conductors. Install this disconnect within the lineof-sight of any personnel performing maintenance on the display. (If the disconnect

is located out of sight of the display, it must be capable of being locked in the open

position.)

Note: Displays are equipped with overcurrent protection devices that carry a UL489 or

UL1077 (IEC 60947, VDE 660) rating. These devices are only intended to protect the

components within the display. Suitable devices must be used for the equipment and

feeders supplying power to the display.

Power Installation 9

Page 16

4. Power conductors from the disconnect to the display should be routed through

conduit in agreement with local code.

5. Display power will terminate internally at the power termination panel.

6. Connect the grounding electrode conductor at the grounding lug on the back of the

display.

7. Signal cable is routed to the signal termination enclosure. When required, the signal

enclosure may also be grounded.

8. Signal into the enclosures must be routed through conduit. The knockouts in the

enclosures require the use of ½" conduit.

9. The signal quick-connect cable from the enclosure to the display can be routed

through conduit or through the display pole if power is not also routed in the

display pole.

Note: Daktronics strongly recommends that the quick-connect cable be secured to protect it

from weather or vandalism.

3.3 Power Requirements

Do not connect the displays to any voltage other than that listed on the Daktronics

product label.

Important Note: Conductors of circuits delivering power to a Daktronics di splay shall be

sized in accordance with NEC and local electrical codes so that the power distribution system

is capable of delivering full load power to the display while maintaining a voltage within 5% of

the utility nominal voltage.

Each display size may be constructed to use either single-phase or three-phase power, with

the exception of the 8 high displays which use only single-phase power. Proper power

installation is imperative for proper display operation. Power specifications for various size

displays can be found in the Power Specifications located in Appendix A. The following

sub-sections provide details of power installation.

Main Disconnect

The National Electrical Code requires the use of a lockable power disconnect near the

display. Provide a lockable disconnect switch (knife switch) at the display location so that all

power lines can be completely disconnected. Use a disconnect so that all hot lines and the

neutral can be disconnected. The main disconnect should be mounted at or near the point of

power connection. A main disconnect is to be provided for each supply circuit to the display.

The disconnecting means must be located in a direct line of sight from the display or outline

lighting that it controls. This requirement enables a worker to keep the disconnecting means

within view while working on the display.

Exception: Disconnect components that are capable of being locked in the open position may

be located elsewhere.

10

Power Installation

Page 17

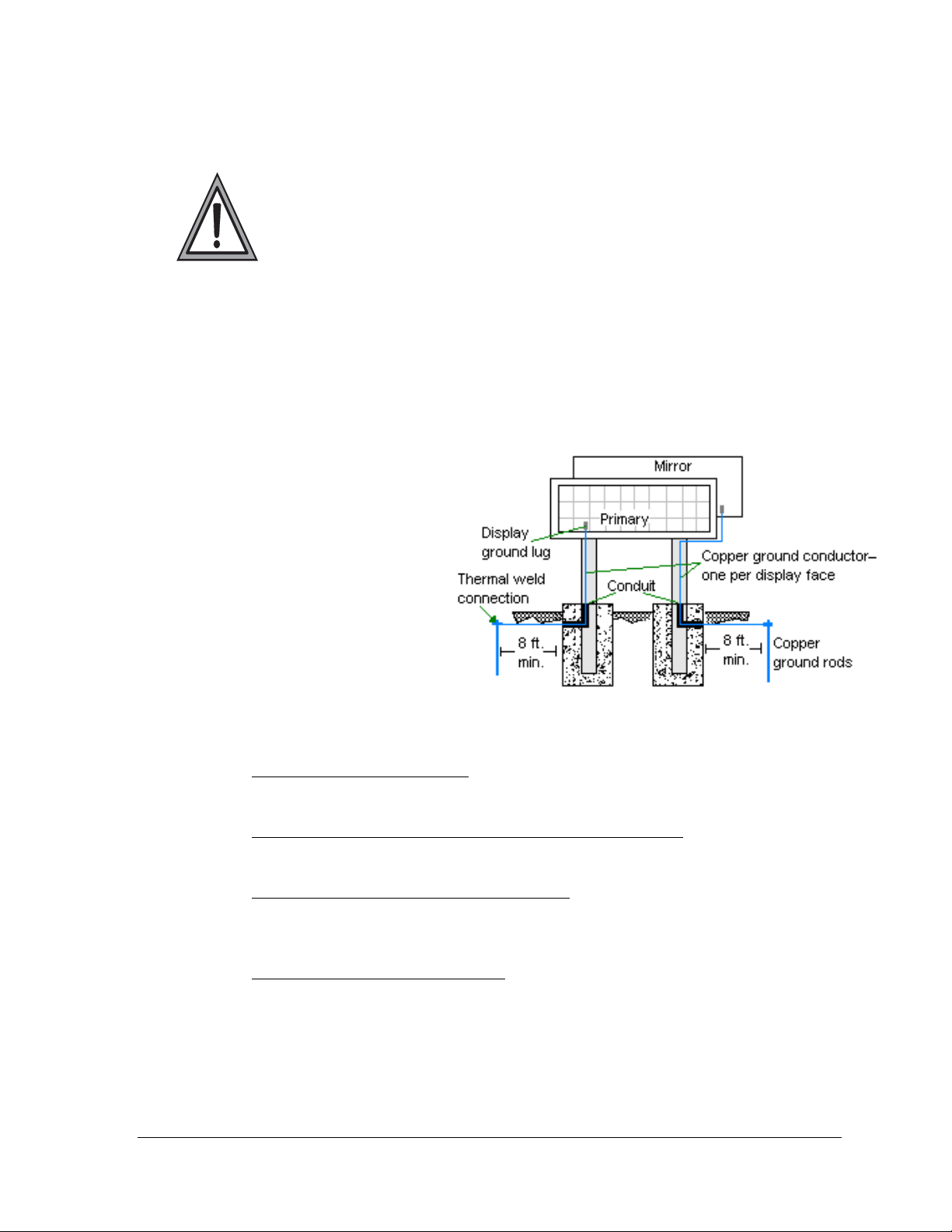

3.4 Grounding

This sign is to be installed in accordance with the requirements of Article 600 of

the National Electrical Code and/or other applicable local codes. This includes

proper grounding and bonding of the sign.

Displays must be grounded according to the provisions outlined in Article 250 of

the National Electrical Code

Installation with Ground and Neutral Conductors Provided

These displays use installation with ground and neutral conductors provided. The power

cable must contain an isolated earth-ground conductor. Under this circumstance, do not

connect neutral to ground at the disconnect or at the display. This would violate electrical

codes and void the warranty. Use a disconnect so that all hot lines and neutral can be

disconnected. The National Electrical Code requires the use of a lockable disconnect if the

disconnect is not located within sight of the display.

Proper grounding is necessary for

reliable equipment operation. It

also protects the equipment from

damaging electrical disturbances

and lightning. Daktronics requires

a resistance to ground of 10 ohms

or less. The display must be

properly grounded or the

warranty will be void.

Important points about grounding:

• Follow local and national codes

from region to region and from conditions present at the site. Consult the National

Electrical Code and any local electrical codes that may apply.

• Support structure cannot be used as an earth-ground electrode

generally embedded in concrete, and if embedded in earth, the steel is either primed

or it corrodes, making it a poor ground.

• One grounding electrode for each display face

configured as one grounding rod for each display face. Grounding is connected

between sections by bonding jumpers. Other grounding electrodes as described in

Article 250 of the National Electric Code may be used.

• Resistance to ground 10 ohms or less

display performance. If the resistance to ground is higher than 10 ohms, it will be

necessary to install additional grounding electrodes to reduce the resistance. The

grounding electrode should be installed within 25 feet of the base of the display. The

grounding electrode must be connected to the ground lug on the back of the display

(Figure 13).

®

.

Figure 13: Correct Grounding

: The material of an earth-ground electrode differs

: The support is

: The grounding electrode is typically

: This is required by Daktronics for proper

Power Installation 11

Page 18

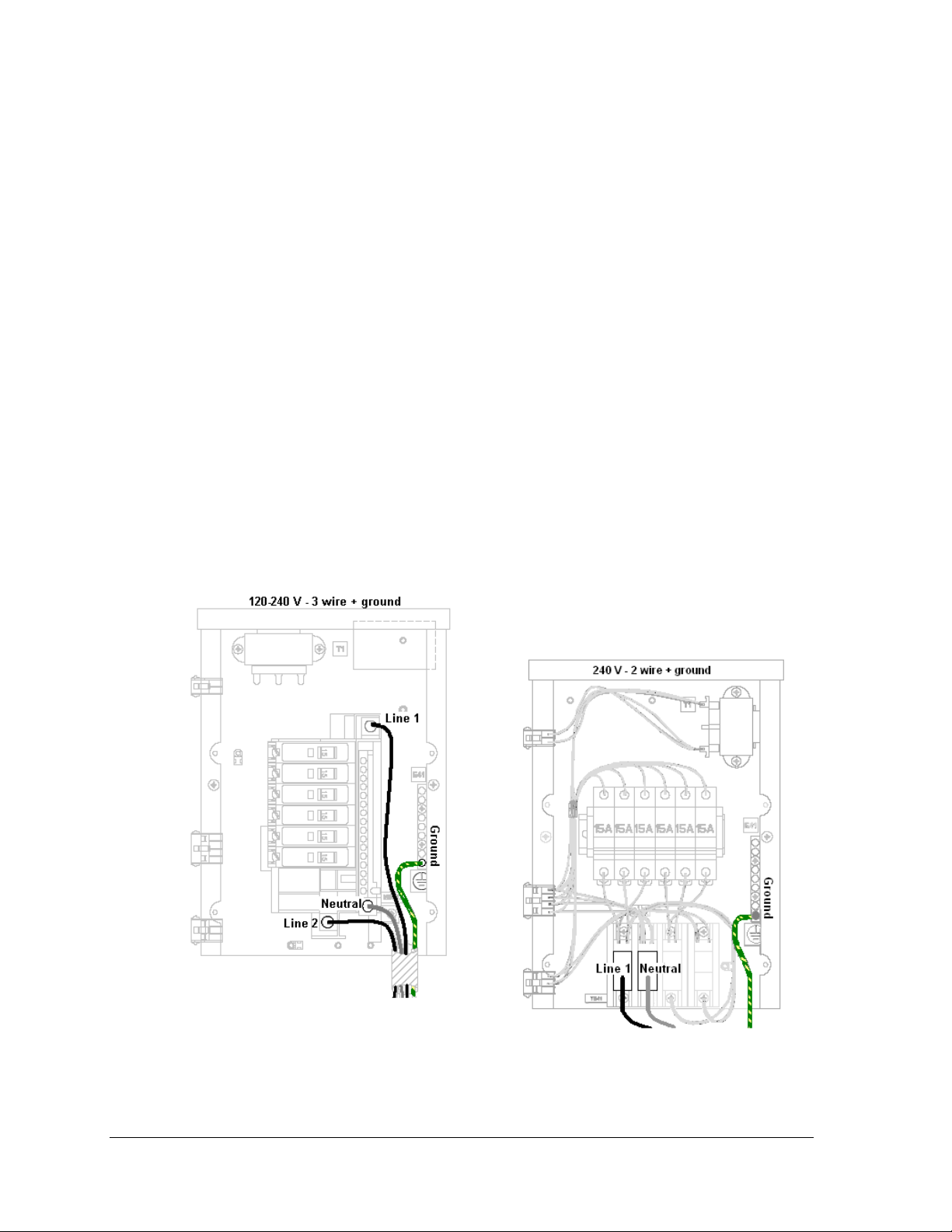

3.5 Power Connection

Power is terminated internally to the power termination board in all displays except the 8pixel high displays. Included in this section are the instructions for both 120 VAC and 240

VAC power sources, including:

• terminating single-phase power

• terminating three-phase power

• terminating power to the J-box (single-phase, 8-pixel high displays only).

Schematic Drawing B-277048 may also be referenced, if necessary.

Terminating single-phase power to the internal power termination panel:

1. Open the display as explained in Section 6.1 and locate the power termination panel.

2. Route the cable through conduit to the back of the display. Use one of the knockouts

for access, being careful not to damage internal components.

3. For 120/240 (3 wire + ground), connect the neutral wire to the neutral lug and the

live wires to Line 1 and Line 2. Refer to Figure 14.

For 240 VAC, (2 wires + ground), connect the neutral wire to the neutral lug and the

live wire to Line 1 lug. Refer to Figure 15.

4. The ground wire connects to the grounding bus bar.

12

Figure 14: 120 V Single-phase Power

Termination

Figure 15: 240 V Single-phase Power

Termination

Power Installation

Page 19

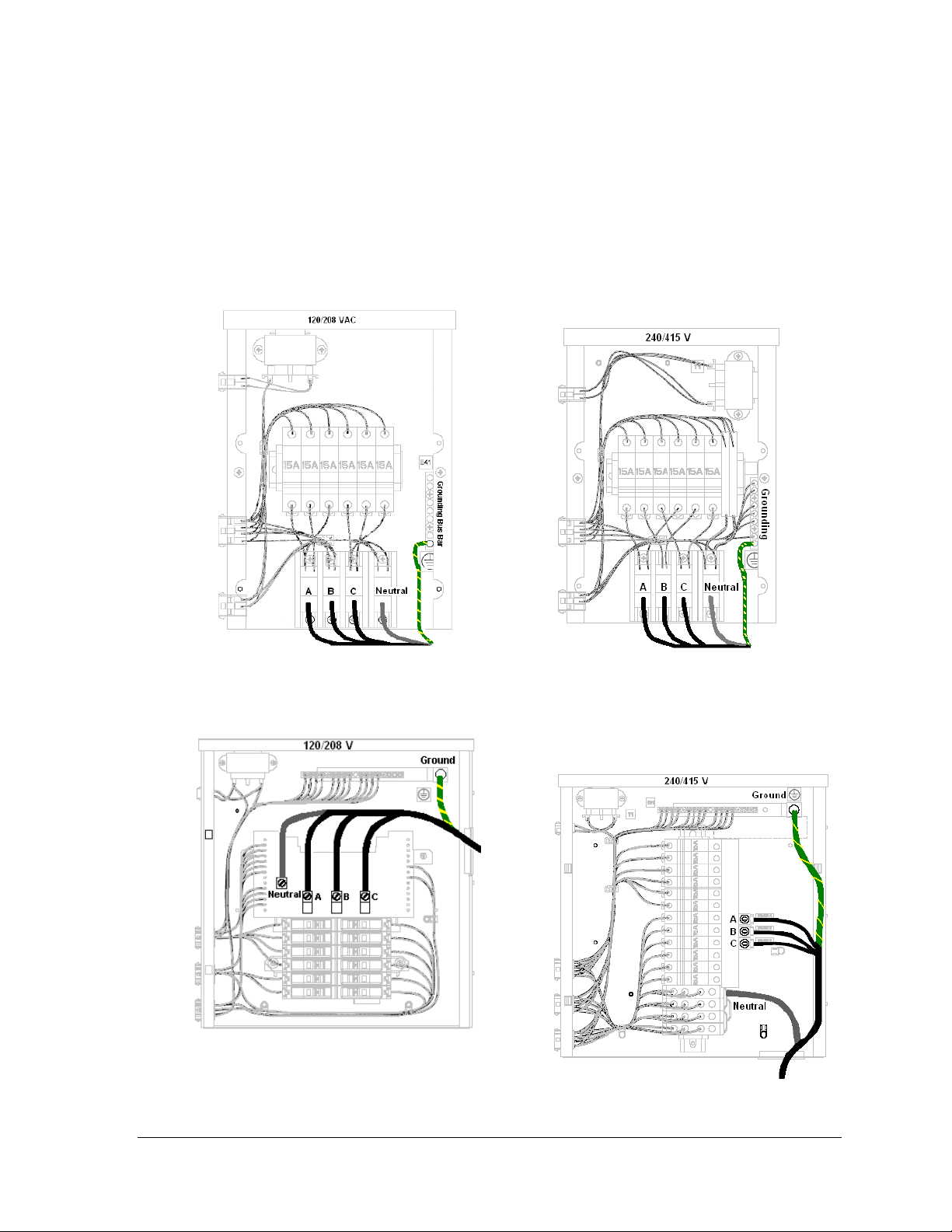

Terminating 3-phase power to the internal power termination panel:

1. Open the display as explained in Section 6.1 and locate the power termination panel.

2. Route the cable through conduit to the back of the display. Use one of the knockouts

for access, being careful not to damage internal components.

3. Connect the neutral wire to the neutral lug and the live wires to the lugs labeled A, B,

and C. Refer to Figure 16 and Figure 17 for 6-breaker panels for 120/208 and 240/415

voltages. Figure 18 and Figure 19 show the 12-breaker power termination panels.

4. The ground wire connects to the grounding bus bar.

Figure 17: 120/208 VAC Power

Termination – 6-breaker

Figure 18: 120/208 V Power Termination –

12 breaker

Figure 16: 240/415 VAC Power

Termination – 6-breaker

Figure 19: 240/415 V Power Termination –

12 breaker

Power Installation 13

Page 20

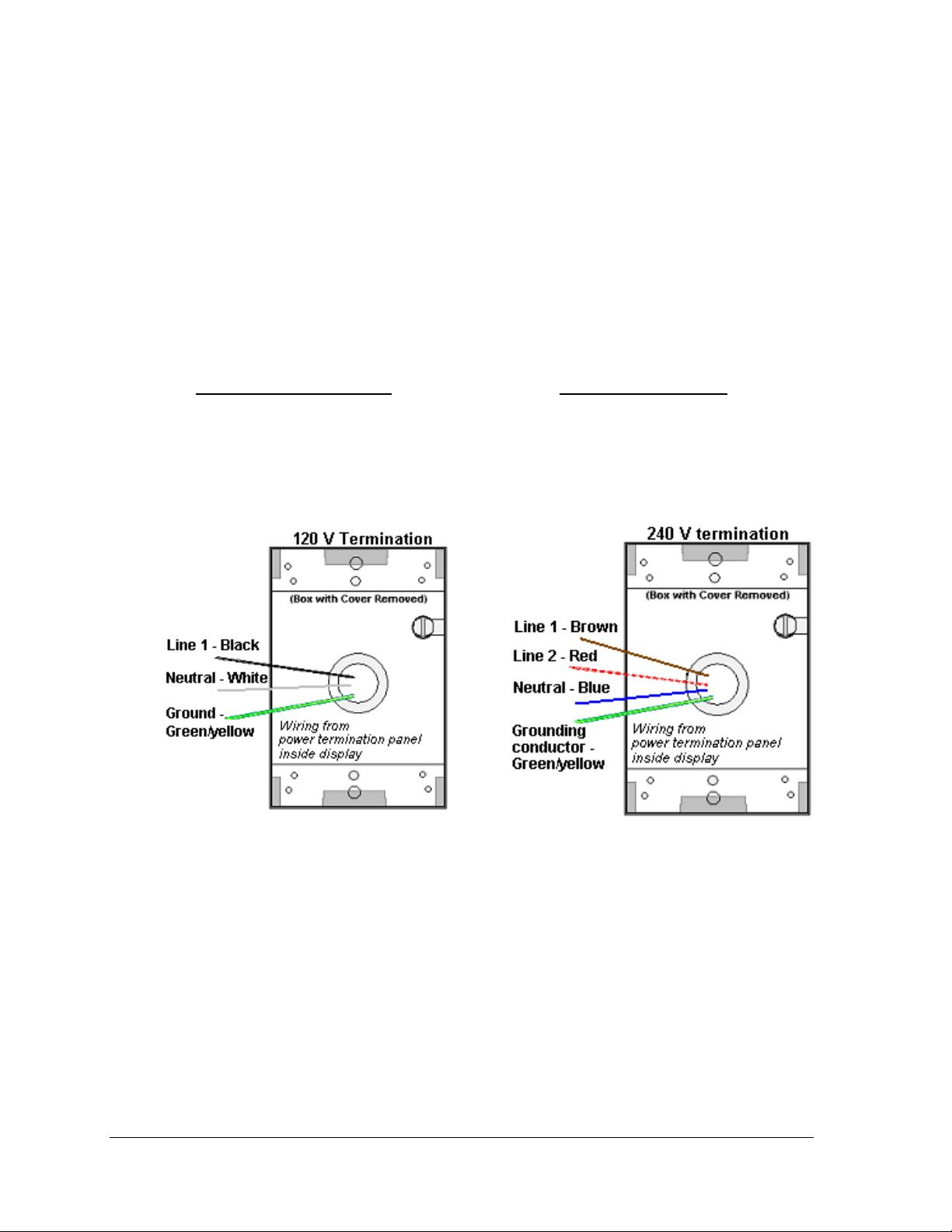

For 8-pixel high displays only:

Terminating hot, neutral, and ground wires at the J-box

1. Route the power cable through 3/4” conduit to the rear of the display and into the power

termination J-box.

2. The power termination enclosure will contain two or three wires plus a ground coming

from the interior of the display. These wires are pre-terminated to the power termination

panel inside the display.

3. Inside the external power termination J-box, connect the power wires to the wires coming

from the display interior using wire nuts. Refer to Figure 20 and

Note the following colors are used for the pre-terminated wires:

120 VAC

240 VAC

• Line 1 – Black x Line 1 - Brown

• Neutral - White x Line 2 - Red

• Grounding – Green-Yellow x Neutral - Blue

x Grounding – Green-Yellow

Figure 21for a diagram.

14

Figure 20: 120 VAC Power Termination

Figure 21: 120/240 VAC Power Termination

Power Installation

Page 21

3.6 Power Routing in the Display

Following is a basic overview of power routing. Check exact power routing on Drawing B277048 found in Appendix A.

A general power routing, as shown in Figure 22, can be summarized as follows.

1. Power terminates internally to the power termination panel.

2. Power travels through the transformer which adjusts power to the appropriate

voltage for the controller.

3. Power is routed through filters to the power supplies which provide power to the

MLC and modules.

4. Power is also sent from the last breaker on the power termination panel through a

filter to the thermostat and fans.

Note: Power supplies are preset to the proper voltage: 9 VDC.

Figure 22: Power Flow Summary

Power Installation 15

Page 22

Page 23

Section 4: Signal Installation Overview

Daktronics GalaxyPro™ displays are equipped to receive various Ethernet communication signals.

The following sections include a brief description of each available type. Also included is a list of

troubleshooting tips to check that the display is connected and configured correctly.

For specific details on installing the communication signal, consult the quick guide and manual

included in the box with the communication equipment. Each type of communication is listed below

with its manual number.

Note: These are the standard communication types, but each site is unique and may include

additional equipment. If problems arise, contact the display’s seller, service company, or Daktronics

Customer Service.

Reference Drawings:

Routing, Fiber, MM, LC, AF-3700-(8-64x48-304)-34 .......................................... Drawing B-287914

Routing, Fiber, MM, LC, AF-3700-(8-64x320-384)-34 ........................................ Drawing B-287915

Routing, Fiber, MM, LC, AF-3700-(72-128x48-304)-34 ...................................... Drawing B-287916

Routing, Fiber, MM, LC, AF-3700-(72-128x320-384)-34 .................................... Drawing B-287917

Communication Type Communication Manual ED#

Wireless Ethernet Bridge

Ethernet

Fiber Ethernet

ED-16483

ED-14745

ED-14746

4.1 Primary/Mirror Signal Connection

If this display is a two-sided primary/mirror display, a quick-connect fiber cable will be

provided to connect the signal between the two display faces. Connect J34-Signal Out on the

Primary display to J32-Signal In on the Mirror display. Secure the excess cable to the supports

to prevent damage from weather or vandalism. Refer to Figure 24 and Figure 23 for an

illustration of the cable and the quick-connect input.

Figure 24: Quick-Connect Signal Cable

Figure 23: Fiber Interconnect Cable and Input

Signal Installation 17

Page 24

4.2 Signal and Bonding Interconnections

Three types of cables run between sections to connect signal and ground. Signal runs

between display sections by connecting fiber cables to installed couplers (Figure 25). Bonding

jumpers are used to connect all display sections together, requiring that only one section be

connected to the ground rod (Figure 27). Ribbon cables are used to connect signal between

modules (Figure 26). Refer to the following instructions on connecting these between

sections. Refer to Fiber Routing Drawings located in Appendix A for additional detail.

Figure 25: Fiber

Interconnections

Figure 27: Bonding Jumper Detail

Figure 26: Ribbon Cable

Between Top and Bottom Sections

• Locate the fiber cable in the bottom left corner of

the top section. Insert it through the hub into the

bottom section and connect to the fiber coupler

located in the top left module opening.

• Locate the bonding jumper in the bottom left

corner of top section. Insert it through the hub into

the bottom section and connect to the bonding

jumper stud in the top left end of bottom section.

Figure 28: Top/Bottom Interconnections

Between Left and Right Sections

• Locate the bonding jumper in the lower left end of the right section. Route through

into the left section and connect to the bonding jumper stud.

• Connect ribbon cables along the seam between displays from the right section to the

left section.

• When a Mirror display is being used (2V configuration), locate the fiber cable in the

bottom left end of the right section. Route through the holes between display sections

and connect to the coupler in the right end of the left section.

18

Figure 29: Right/Left Interconnections

Signal Installation

Page 25

Four (4) Section Interconnections

• Locate the fiber cable in the bottom left corner of the top left section. Insert it through

the hub into the bottom section and connect to the fiber coupler located in the top left

module opening.

• Locate the bonding jumper in the bottom left end of the top left section. Route

through holes between display sections into the top left end of the bottom left section

and connect to the bonding jumper stud.

• Locate the bonding jumper in the bottom left end of the top right section. Route

through holes between display sections into the right end of the top left section and

connect to the bonding jumper stud.

• Locate the bonding jumper in the lower left end of the bottom right section. Route

through the holes between display sections and connect to the bonding jumper stud.

• Connect ribbon cables along the seam between displays from the right sections to the

left sections.

• When a Mirror display is being used (2V configuration), locate the fiber cable in the

bottom left end of the bottom right section and route through the holes between

display sections and connect to the fiber coupler in the right end of the bottom left

section.

Figure 30: Interconnections between Four Sections

Signal Installation 19

Page 26

4.3 Wireless Ethernet Bridge Communication

If the communication system is a Wireless Ethernet Bridge, look for:

• a network card in the computer connecting to a network switch or router.

• a server radio mounted on the building and a client radio at the display.

Note: This system is referred to as a “bridge” because the radios are configured as a matched

pair. Therefore, if one radio needs to be replaced, both will have to be replaced.

Figure 31: Wireless Ethernet Bridge Layout

Connections

• Computer to network − RJ45 cable from computer port to network server in building.

• Network switch to DC injector

• Wall power adapter from 120 VAC outlet to DC injector.

• Network cable from DC injector to server radio.

• Clear line of sight between server radio and client radio.

• Client radio to display − quick-connect cable to the middle jack on display back.

Troubleshooting

Component Check:

Cable

Connections

Diagnostic

LEDs

Display

Power

Software • The software and the display are set to the same network address.

• A cable connects the computer to the network switch or router.

• A cable runs from the network switch to the DC injector.

• A cable runs from DC injector to server radio.

• The quick-connect cable is connected from the client radio to the middle jack

on back of display.

• The green LEDs will be on when DC injector has power.

• The server and client radios have internal LEDs. Refer to the Wireless

Ethernet manual for their specifications.

• The display is either running a message or showing a single pixel flashing in

the bottom right corner of the display when power is on.

• Refer to the software manual for other possible conditions.

20

Signal Installation

Page 27

4.4 Wire Ethernet Communication

If the communication system is Wire Ethernet, look for:

• a network card in the computer connecting to a network switch.

• a network jack that looks similar to an oversized phone jack.

Figure 32: Ethernet Communication Layout

Connections

• Computer to network − RJ45 cable from computer port to network server in building.

• Network switch to surge board − another RJ45 cable from switch to surge board in

enclosure at display.

• Enclosure at the display to display − quick-connect cable from the enclosure to

middle jack on back of display.

Troubleshooting

Component Check:

Cable

Connections

Display

Power

Software • The software is configured for TCP/IP communication.

• An RJ45 cable connects the computer to the network

• An RJ45 cable from the server is connected to the input port on the

Ethernet surge board at the display.

• The quick-connect cable runs from the enclosure to the middle jack on

display back.

• The display is either running a message or showing a single pixel flashing

in the bottom right corner of the display when power is on.

• The software and the display are set to the same network address.

• Refer to the software manual for other possible conditions.

switch or router.

Signal Installation 21

Page 28

4.5 Fiber Ethernet Communication

If the communication system is Fiber Ethernet, look for:

• an indoor media converter connected to the network and to fiber cable.

• a second media converter outdoors located in an enclosure at the display.

Figure 33: Fiber Ethernet Communication Layout

Connections

• Computer to network − RJ45 cable from computer port into network switch.

• Network to first media converter − RJ45 cable from network switch/router into

media converter.

• Media converter’s 9-volt power adapter plugged into 120 VAC outlet.

• Indoor media converter to outdoor media converter − two fiber-optic cables run from

indoor media converter to second converter in the enclosure at display.

• Enclosure to display − quick-connect cable to the middle jack on display back.

DO NOT SHARPLY BEND fiber-optic cable at any point along the fiber cable.

Troubleshooting

Component Check:

Cable

Connections

Diagnostic

LEDs

Display

Power

Software • The software is configured for TCP/IP communication.

22

• The cable is connected from the computer to the network switch/router.

• The network cable connects from network

• The indoor media converter power adapter is plugged in.

• The fiber cables connect from the first media converter to the second one at display.

The “out” arrow on one will connect to an “in” arrow on the other.

• The cable is connected from the enclosure to middle jack on display back.

• Each media converter has a green power LED on, indicating power.

• When the media converter transmits data, the “link” is ON and RX LEDs flash.

• The display is either running a message or showing a single pixel flashing in the

bottom right corner of the display when power is on.

• The software and the display are set for the same network address.

• Refer to the software manual for other possible conditions.

switch to media converter in building.

Signal Installation

Page 29

Section 5: Start-up Procedure

Before starting up the display, go over this checklist to ensure that all parts are ready to operate

correctly. Figure 34 shows the basic display components referred to in each step.

5.1 Start-up Checklist

DIs power connected to the display?

The power conduit will leave the display from the rear and connect to a power source either

outside or inside a building. Refer to Figure 34 for approximate location of the power cable or

conduit.

DIf the display has multiple faces or sections, are they connected?

Check that power, signal, and ground connections run between the display cabinets.

DIs the control computer connected to the display?

Some type of communication line will run between the control computer and the display,

depending on the communication method. Refer to Section 4 for assistance with identifying

the communication type and its connections.

DIs the computer software set up to work with the display?

The software manual provides the information necessary to allow the computer to

communicate with this display. Follow the step-by-step directions in the Configuration

section for correct set-up.

Figure 34: Basic Display Set-up

Start-up Procedure 23

Page 30

5.2 Start-up Sequence

Each time the display is turned on, an initialization sequence will run. The information in the

second column will then be shown on the display.

Note: The Xs refer to numbers that may vary for each display, such as the hardware address.

Topic Information shown

1. Product Name • Galaxy Pro

2. Display Size • Row x Column

3. Shading • 16.7M RGB

4. Bootloader Version • OS X.XX

5. Firmware Number • ED-16619

6. Firmware Revision • Rev X.X.X

7. Hardware Address • HW:XX

8. Software Address • SW:XX

9. IP Address: (Default) • IP: 172.16.192.25

10. Subnet Msk: (Default) • MSK: 255.255.0.0

11. Mac Address • MAC:00:09:EC:02:04:06

12. COM1 Configuration • C1: V15 (modem: C1:V15 if a modem is present)

13. COM 2 Configuration • C2: DEBUG

14. Socket 3

15. Line Frequency • CLK: AUTO (60)

16. Display Description • M3 Display

After this sequence is complete, the display will blank. A single pixel will flash in the lower

right corner of the display to show that the display has power, but no messages are currently

running.

001: • TCP 3001: V15

24

Start-up Procedure

Page 31

Section 6: Maintenance

Important Notes

• Power must be turned OFF before any repair or maintenance work is done on the

display.

• Qualified service personnel are recommended for servicing internal electronic

components.

• The Daktronics engineering staff must approve ANY changes made to the display.

Before altering the display, detailed drawings for proposed modifications must be

submitted to Daktronics engineering staff for evaluation and approval, or the warranty

will be rendered null and void.

Daktronics GalaxyPro 34 mm displays are front accessible, meaning that access to the internal

components is gained by removing the front modules of the display. The display may need to be

opened to perform maintenance or for troubleshooting. The following diagram (Figure 35) shows the

location of internal components. On larger displays, the internal components will remain in the lower

left area of the display and the thermostat will be located behind the upper left module. Refer to the

Layout Drawings located in Appendix A for the location of components in specific display sizes.

Figure 35: Location of Internal Components

Maintenance 25

Page 32

6.1 Access to Display Interior

Daktronics GalaxyPro displays provide access to internal components by removing the front

modules. The display may need to be opened to perform maintenance or for troubleshooting.

To access the interior of the display, perform the following steps:

1. Disconnect power to the display.

2. Locate the latch access fasteners on the module

(Figure 36). One is centered below the top row

of pixels and one is centered above the bottom

row.

3. With a 1/8" hex wrench, turn the latch access

fasteners a quarter turn counter-clockwise.

Gently pull the module far enough forward to

reach the power and ribbon cables (Figure 37).

4. Disconnect the two ribbon cables from the

module by spreading the tabs on the sides and

then lifting the cable head from the jack. Note

how they are connected to the back.

5. Unplug the power cable by squeezing the tabs

on the sides of the plug head and pulling out.

6. When ready to reinstall the module, reconnect the cables to the module, making sure

that the tabs are tightly pushed against the cable head. Carefully push the ribbon

wires back into the cabinet so they are clear of the module edges.

7. Place the module into its proper location, checking that the weather stripping is in

place. Latch the module both top and bottom by turning the hex wrench clockwise a

quarter turn.

Note:

• The weather-stripping on the back edge

of the module must be intact and in good

condition if it is to prevent water from

seeping into the display.

• The module latches must be fully

engaged to create a watertight seal

around the edge of the module. The

module should be firmly seated against

the display when the latches are fully

engaged.

Figure 36: Module Access Locations

Figure 37: Removing a Module

26

Maintenance

Page 33

6.2 Ventilation System/ Fans

Frequency of Inspection

In displays smaller than 40 pixels high, ventilation fans are located

along the bottom of the display. The fans pull air into the cabinet

from the lower vent, exhausting air out the top vent (Figure 38).

Displays 40 pixels high and larger have fans mounted on the back

of the display, pulling air in from the front vents and out through

hoods (Figure 39).

Fans should be checked every time the display is opened or at a

minimum of once per year. Check more often if the display is

located in a dusty or harsh environment, such as along a gravel

road.

Fan Blades

Check the fan blades for dirt and debris, cleaning them and

the inside of the display if necessary. Fan blades must be

kept clean to maintain fan efficiency and to ensure proper

cooling. Spin the fan blades with a pen or pencil to ensure

that the bearings are free and that the fan is still in balance.

Figure 38: Air Flow in

Smaller Displays

Air Flow

To check the operation of the fans, open the display to

expose the thermostat in the top left corner of the cabinet

behind the first module (Figure 40). Push the bypass switch

on the thermostat enclosure to temporarily turn on the fans.

If a fan does not rotate or does not operate smoothly,

replace it.

Make sure that the intake vents on the bottom front and

the exhaust vents on the top front of the display are not

blocked and are free of dust or other debris. Hold a piece

of lightweight paper in front of the top edge of the

display to detect air movement through the vents.

Figure 39: Air Flow in Larger Displays

Figure 40: Thermostat

Maintenance 27

Page 34

6.3 Annual Inspection

A yearly inspection should be completed to maintain safe and dependable display operation.

The display will need to be opened to visually inspect the cabinet interior and the

components. Refer to Section 6.1 for directions to access the interior. The inspection should

address the following issues:

Inspection item Possible corrective measures

Loose bolts, screws, rivets • Tighten or replace, as required.

Dust around fans, on

cabinet bottom

Water intrusion or stains

Paint corrosion by footings,

tie points, ground rods

• Vacuum or carefully wipe away.

• Replace weather-stripping.

• Tighten module latches.

• Place silicon sealant around all locations where water might

enter.

• Replace damaged electronic components.

• Check the metal footings for structural integrity.

• Replace and/or repaint as necessary.

• Check ground wire connections at ground rod and ground lug.

28

Maintenance

Page 35

Section 7: Diagnostics and Troubleshooting

This section defines the diagnostic LEDs located on the controller, MLC, and temperature sensor.

Troubleshooting tips are also provided for solving display problems.

Safety Precautions

Disconnect power when servicing the display.

Do not modify the display structure or attach any panels or coverings to the display

without written consent of Daktronics.

7.1 Controller Diagnostics

The controller is one of the internal components labeled in Figure 41. This component is the

“brains” of the display, receiving communication from the computer and then sending the

appropriate information to the MLC which outputs to the modules. The LEDs on the

controller are able to show whether the power and communication signal are working

properly.

Since the controller is inside the display, a module or two will need to be removed to view

the diagnostic LEDs. To access the interior of the display, refer to Section 6.1 for instructions

and illustrations.

Remember to disconnect power to the display before accessing the interior.

However, once the modules are removed and wires are found to be safe, power can be

turned back on to view the diagnostic LEDs.

Figure 41: Interior Component Locations

Diagnostics and Troubleshooting 29

Page 36

Figure 42 illustrates a GalaxyPro controller. Red diagnostic LEDs are located at various

places on the controller. The following table details some essential LEDs to monitor and the

information that each LED provides. The LED name and number are noted in Figure 42.

Figure 42: Controller Component Layout

Label LED Operation

Run

Send

signal

Receive

signal

DS4 Steady FLASH about once per second indicates controller is working

properly.

DS3 OFF is the normal state. FLASH when transmitting communication to

the computer.

DS2 OFF is the normal state. FLASH when receiving communication from

the computer.

7.2 MLC Diagnostics

Each MLC unit contains four red diagnostic LEDs.

When fiber is properly connected, the LED labeled

DS23 (left side) will be off and the other LEDs will be

on.

Figure 43: MLC Diagnostic LEDs

30

Diagnostics and Troubleshooting

Page 37

7.3 Temperature Sensor Diagnostic

If the display includes a temperature function, the temperature sensor board will also

provide diagnostic information. The temperature sensor board is located inside the

temperature sensor housing which hangs near the display (Figure 44). The sensor board

diagram below shows the red diagnostic LED (DS2) near the bottom edge of the component.

Figure 44: Temperature sensor board

Temperature Sensor

DS2 Run FLASH at variable rates when sending temperature

Refer to Appendix C for temperature sensor mounting and connections.

information; evidence that the unit has power.

7.4 Troubleshooting Display Problems

This section contains some symptoms that may be encountered in the displays. This list does

not include every possible symptom or solution but does represent common situations and

simple steps to resolve them. The solutions are given in priority order so try the first solution

first.

Troubleshooting may require removal and replacement of modules. Refer to Section 6.1 for

instructions on this procedure. When replacing modules, make sure that the power and

signal cables are reconnected correctly and the latches are tightly closed.

Module and LED problems

One or more LEDs are not lighting

• Check/replace the ribbon cables on the module.

• If that does not help, the module may need to be replaced.

One or more LEDs on a single module will not turn off

• Check/replace the ribbon cables on the module.

• If that does not help, the module may need to be replaced.

Diagnostics and Troubleshooting 31

Page 38

A section of the display is not working

• Check/replace ribbon cables from the last working module in the row to the first

non-working module next to it.

• Move or replace the first non-working module, the one on the far left of the non-

working section.

• Move or replace the first module to the left of the non-working modules.

• Check the back of the modules to see that the power LEDs are on.

• Make sure the power cable to the module is connected.

Figure 45: Modules Not Working

One row of modules is not working or shows a distorted message

• Check/replace the ribbon cables to and from the first non-working module.

• Check for bent pins on the jack going to a non-working module.

• Move or replace the modules that show distorted text.

• Move or replace the first module to the left of the one that isn’t working.

• Check the fuse from the output and replace if necessary.

A column of the display does not work

• Check that the ribbon and power cable are plugged into the first module in the row.

• While power is on, look at the back of the first malfunctioning module to see if the

diagnostic LED is off, implying a power supply problem.

Entire display fails to work

• Check the breakers in the building connected to main power source.

• Check the breakers in the power termination panel (bottom row, second module

from the left).

• Check the fiber cables between the controller and the MLC.

• Check the diagnostic LEDs on the controller for Power and Run (Section 7.1).

• Check/replace the ribbon cable from the MLC to the modules.

• Verify proper use of the software by checking the software manual.

32

Brightness problems

Display is stuck on bright or dim

• Check Manual/Auto dimming in Venus 1500 software. The Brightness is typically set

to Automatic. If not, perform the following step:

In Display Manager/ Diagnostics, select Automatic and click Set Brightness.

• Check the light sensor cable and wiring for secure connections.

• Check the light sensor lens for obstructions (lower left edge, front of primary

cabinet).

• Replace the light sensor assembly.

Diagnostics and Troubleshooting

Page 39

Display is too bright at night

Set the Dimming Schedule. Refer to the Venus 1500 manual (ED-13530).

Message problems

Blank display seen after boot-up

A blank display is normal after the boot-up procedure. When finished, the display will be

blank except for a flashing LED in the lower right corner. The display is then waiting for a

message to be sent.

LED flashes in the lower right corner

The flashing pixel indicates that the display is receiving power and waiting for a message to

be sent. Once a message is sent and run on the display, the flashing LED should be replaced

with the message.

Message only shows up on one side of the display

Determine if the displays are set up as two primary displays or one primary and one mirror

display. To do this, turn off power, then turn it back on and observe the two display faces.

If the set-up involves two primary displays

“HW002”.

• Verify that two different addresses are set up for these two primary displays in the

Venus 1500 Administrator.

• Verify that two different addresses are set on the controller(s).

• Send a different message to each display separately by clicking on that display name

in the list. Note: With two controllers, messages may not always run simultaneously.

If the set-up consists of a primary/mirror display

• Verify that the quick-connect cable is firmly plugged into both cabinets.

• Check that the cable and plugs are in good condition.

, one should show “HW001” and the other

, check the cable between them.

Temperature problems

(For displays with a temperature sensor installed.)

Showing the current temperature on the display

1. Open the Venus 1500 Message Studio.

2. Choose FileÆ New if the temperature will be part of a new message or FileÆ Open

if this will be added to a current message.

3. Open the message field and click Data Fields at the top.

4. Choose Temperature. Select the desired format. The field is now in the message.

5. Send and run the message and the temperature will now be shown.

Note: The temperature sensor must be correctly installed before a current temperature can be

shown.

Temperature shown is too high or too low

The temperature on the display can be adjusted either up or down to become more accurate.

1. Open the Venus 1500 Display Manager and click Diagnostic Control.

2. Click on the name of this display under the Display List.

3. To the right of the Set Temperature Offset button, use the slider bar to adjust the

temperature being shown. The change made will be shown next to the bar. The range

is ±9° (1°C=1.8°F).

Diagnostics and Troubleshooting 33

Page 40

4. Once the adjustment is made, click Set Temperature Offset to send this change to

the display.

Note: Repeat these steps for each primary display that shows the temperature.

Temperature always reads –196F/-127C degrees

• Check the temperature sensor cable connections.

• Look for bent pins on connectors.

• Check that the temperature sensor is set to address 1.

• Make sure the sensor has power by checking that the LED is blinking.

• Replace the temperature sensor.

Testing displays

Start and stop the test pattern

1. Open the Venus 1500 Display Manager and click Diagnostic Control.

2. Click on the name of the chosen display under the Display List, then choose Cycle All

for the complete sequence or use the arrow to choose the specific test to be shown.

Click Start Test.

3. Once testing is finished, click on the name of the display, then click Stop Test.

Note: This procedure must be done for each primary display being tested.

Before calling for help

Steps to take before calling Daktronics Customer Service

1. Turn off the power breaker switch. Wait a few minutes and turn it back on. Have

someone watch the display(s) to make sure that the initialization sequence runs.

2. Once the sequence is complete, try to communicate with the display.

3. Check the Communication and Troubleshooting sections of this manual.

4. Call the service technician or Daktronics Customer Service at 866-343-3122.

Note: It is helpful to be sitting at the control computer while talking with the service

technician.

This chart is also provided inside the front cover of this manual for easy reference.

Information needed Fill in the blank

Location address of the display:

Model number of the display:

Version of software being used:

(Right-click on Venus 1500 name in toolbar,

choose “About Venus 1500”)

Method of communication being used:

(See Section 4 for guidance)

Controller version used in the display:

AF-3700

Venus 1500 v. _____

M3 controller

34

Diagnostics and Troubleshooting

Page 41

Section 8: Parts Replacement

This section covers the replacement of parts in a GalaxyPro display. The first section provides a list of

parts and their Daktronics part numbers. The second section gives instructions for replacing the most

basic parts. For information on obtaining replacement parts from Daktronics, refer to Section 9.

Disconnect power when servicing the display.

Reference Drawings:

8.1 About Replacement Parts

Parts Replacement 35

Layout Drawings for most sizes ..................................................................................... Appendix A

Daktronics AF-3700 GalaxyPro displays are designed and manufactured for performance,

reliability, easy maintenance, and long life. However, on occasion, parts may need to be

replaced. Section 9 provides information on obtaining replacement parts from Daktronics.

Appendix B provides information about the connectors referenced in the replacement

instructions.

This section provides replacement instructions for the following parts:

• modules

• controller

• MLC

• power supplies

• light sensor

• temperature sensor

These components are generally

located as shown in Figure 46. The

location of power supplies varies

depending on the matrix size of the

display. Refer to the appropriate

Layout Drawing for the exact

location.

The following table contains some of

the items that may need to be

replaced in a display over a period of

time. If a circuit board or assembly is

not listed in the Replacement Parts

List, use the label to order a

replacement.

Most circuit boards and components

Figure 46: Interior Location of Components

Page 42

within this display carry a label that lists the part number of the

unit. A typical label is shown in Figure 47 with the part number in

bold.

Cables will not carry a part number label. To assist with correct

identification of cables and connectors, refer to the descriptions in

Figure 47: Typical Label

Appendix B.

Module, 2R2G2B, 8 x 8 0A-1208-4650

Controller, GalaxyPro 0A-1382-0002

MLC, 4050, 8 output, coated 0P-1273-0039

Power Supply Assembly, (A-1839C) w/o harness (1000W) 0A-1327-0018

Power Supply Assembly, (A-1997) w/o harness (600W) 0A-1327-0021

Transformer, Pri 115V, Sec 10VCT@3A T-1119

Transformer, Pri 240V, Sec 10VCT@2.5A T-1121

Filter, RFI Line 20 AMP 120 VAC Z-1007

Automotive Fuse, 32 volt 15 amp F-1058

Digital Temperature Sensor (PCB) 0P-1247-0008

Thermostat 0A-1327-3101

Light Sensor circuit board 0P-1151-0002

Fan; 134 CFM, 120V @60Hz, 22 watt (8-24 high, 32 high

first bay)

Fan; 245 CFM, 120V @60Hz, 46-50 watt (32+ high) B-1019

Fan; 110 CFM, 240V @60Hz,29-24 watt B-1011

Fan; 245 CFM, 230V @60Hz, 46-50 watt B-1020

Quick-connect Primary Input 0A-1327-1000

Quick-connect Primary Output 0A-1327-1018

Quick-connect Mirror Input 0A-1327-1019

Ribbon Cables; 20 Position

Cable Assy; 20 pos Ribbon, 18”, Dual Row W-1387

Ribbon Assy; 20 Pos, 24” 0A-1000-0016

Ribbon Assy; 20 Pos, 30” 0A-1000-0017

Ribbon Assy; 20 Pos, 42” 0A-1000-0019

Ribbon Assy; 20 Pos, 60” 0A-1000-0021

Ribbon Assy; 20 Pos, 72” 0A-1000-0022

Ribbon Assy; 20 Pos, 84” 0A-1000-0023

Interconnect Cable; Fiber, QC, 10 ft.

Memory Storage Card, 2 GB A-2193

Electrical Contact Cleaner Lubricant / Cal-Lube CH-1019

Hex Wrench, T-Handle 1/8” RT for modules TH-1062

Manual; Venus 1500 Operator’s, Version 3.0 ED-13530

Part Description Part Number

B-1053

W-1658

36

Parts Replacement

Page 43

8.2 Instructions for Replacing Parts

Module Replacement

If LEDs have failed, do not attempt to replace individual LEDs.

Return a failed module to Daktronics for replacement and/or repair.

Each module can be removed separately without moving other components of the display.

Figure 48: Module, Front/Back

1. Turn off power to the display.

2. Follow the instructions in Section 6.1 to release the module from the display cabinet

(Figure 49).

3. Disconnect the two ribbon cables from the module, noting how they are connected to

the back. Release ribbon cables by spreading the tabs on the sides and then lifting the

cable head from the jack (Figure 48).

4. Unplug the power cable by squeezing the tabs on the sides of the plug head and

pulling out.

5. Connect all three cables to the new module, making sure that the ribbon cable tabs

are tightly pushed against the cable head. Carefully push the ribbon wires back into

the cabinet so they are clear of the module edges.

6. Place the module into its proper location, checking that the weather stripping is in

place. Latch the module tightly both top and bottom by turning the hex wrench a

quarter turn clockwise.

Notes:

• The weather-stripping on the back edge of

the module must be in good condition and

returned to its proper position if it is to

prevent water from seeping into the display.

• The module latches must be fully engaged to

create a watertight seal around the edge of

the module. The module should be firmly

seated against the display when the latches

are fully engaged.

Figure 49: Removing a Module

Parts Replacement 37

Page 44

Controller Replacement