Daktronics AF-3500, AF-3550 User Manual

Galaxy® AF-3500/3550

Installation and Operation Manual

DD1377306 Rev 16—10 July 2014

201 Daktronics Drive PO Box 5128 Brookings, SD 57006

tel 800-843-5843 fax 605-697-4700

www.daktronics.com

DD1377306

Product 1472, 1473, 1569

Rev 16—10 July 2014

Complete the chart with specific information about this display so the details are readily available when calling for

service or replacement parts.

Information needed for technicians and/or Customer Service Fill in the blank

Location address of the display:

Model number of the display:

Version of software being used:

Method of communication being used:

Controller version used in the display:

Copyright © 2008-2014

All rights reserved. While every precaution has been taken in the preparation of this manual, the publisher assumes no

responsibility for errors or omissions. No part of this book covered by the copyrights hereon may be reproduced or copied in any

form or by any means – graphic, electronic, or mechanical, including photocopying, taping, or information storage and retrieval

systems – without written permission of the publisher.

Galaxy® and Venus® are trademarks of Daktronics, Inc. Windows® is a trademark of Microsoft® Corporation. IBM® is a trademark of IBM Corporation. Mate-N-

Lok® is a trademark of AMP Company.

Table of Contents

Section 1: Overview of the Displays .................................................................................................................... 1

1.1 Display Details ...................................................................................................................................................... 1

Section 2: Mechanical Installation ....................................................................................................................... 3

2.1 Pre-Installation Checklist .................................................................................................................................... 3

2.2 Support Structure Requirements ....................................................................................................................... 3

2.3 Display Mounting ................................................................................................................................................ 4

General Mounting Procedure ...................................................................................................................... 4

Section 3: Power Installation ................................................................................................................................ 5

3.1 Conduit .................................................................................................................................................................. 5

3.2 Overview of Power/Signal Connection ........................................................................................................... 5

3.3 Power Requirements ............................................................................................................................................ 6

Main Disconnect ............................................................................................................................................ 6

3.4 Power Grounding ................................................................................................................................................. 6

3.5 Display Grounding .............................................................................................................................................. 6

Important Points About Grounding........................................................................................................... 6

3.6 Power Connection ................................................................................................................................................ 7

For Displays With an External Power Termination J-box ....................................................................... 7

For Displays With Internal Power Termination ....................................................................................... 8

3.7 Power Routing in the Display ............................................................................................................................ 8

Section 4: Signal Installation Overview ..............................................................................................................11

4.1 Primary/Mirror Display Interconnections ..................................................................................................... 11

4.2 USB to Ethernet Adapter ................................................................................................................................... 11

4.3 Setting the IP Address on the Display Controller ......................................................................................... 11

Section 5: Start-Up Procedure ........................................................................................................................... 15

5.1 Start-Up Checklist .............................................................................................................................................. 15

5.2 Start-Up Sequence .............................................................................................................................................. 15

5.3 Post Installation Checklist ................................................................................................................................. 15

Section 6: Maintenance ...................................................................................................................................... 17

6.1 Proper Ladder Use ............................................................................................................................................. 17

6.2 Internal Display Access ..................................................................................................................................... 17

6.3 Ventilation System/Fans .................................................................................................................................. 18

Frequency of Inspection ............................................................................................................................. 18

Fan Blades .................................................................................................................................................... 18

Filters ............................................................................................................................................................ 18

Fan Test ......................................................................................................................................................... 19

6.4 Display Face Cleaning ....................................................................................................................................... 19

Table of Contents i

Dry Cleaning Process ................................................................................................................................. 20

6.5 Annual Inspection .............................................................................................................................................. 20

Section 7: Diagnostics and Troubleshooting .................................................................................................... 21

7.1 Controller Diagnostics ....................................................................................................................................... 21

7.2 MLC Diagnostics ................................................................................................................................................ 21

7.3 Troubleshooting Display Problems ................................................................................................................ 22

Common Misconceptions .......................................................................................................................... 22

Module and LED Problems ....................................................................................................................... 22

Brightness Problems ................................................................................................................................... 23

Message Problems ....................................................................................................................................... 23

Temperature Problems ............................................................................................................................... 24

Temperature Problems ............................................................................................................................... 24

Testing Displays .......................................................................................................................................... 24

Before Calling For Help ............................................................................................................................. 24

Section 8: Parts Replacement ............................................................................................................................ 25

8.1 About Replacement Parts .................................................................................................................................. 25

8.2 Instructions for Replacing Parts ....................................................................................................................... 25

Controller Replacement ............................................................................................................................. 26

Controller Address Setting ........................................................................................................................ 27

MLC Replacement ....................................................................................................................................... 27

Power Supply Replacement ...................................................................................................................... 28

Light Sensor Replacement ........................................................................................................................ 28

Temperature Sensor Replacement ............................................................................................................ 29

Section 9: Daktronics Exchange and Repair & Return Programs .................................................................. 31

9.2 Repair & Return Program ................................................................................................................................. 32

Shipping Address........................................................................................................................................ 32

9.3 Daktronics Warranty and Limitation of Liability .......................................................................................... 32

Appendix A: Reference Drawings .......................................................................................................................... 35

Appendix B: Temperature Sensor Installation (DD2638167) ............................................................................... 37

Appendix C: International Installation ................................................................................................................... 39

Appendix D: Maintenance Log ............................................................................................................................... 41

Appendix E: Daktronics Warranty and Limitation of Liability (SL-02374) .......................................................... 43

ii Table of Contents

Section 1: Overview of the Displays

Note: This manual provides installation, maintenance, and troubleshooting information to help ensure the optimal

performance of Daktronics Galaxy® AF-35XX displays. Diagnostic information and parts replacement are also

included and a “Glossary” is found near the end of this manual.

1.1 Display Details

The Galaxy® model numbers are described as follows:

AF-35XX-RRxCCC-MM-R,A,RGB-XX

AF-35XX = Outdoor Galaxy display

RR = Number of pixel rows high

CCC = Number of pixel columns long

MM = Pixel pitch in millimeters

R, A, RGB =

XX = SF (Primary) or 2V (Primary/Mirror)

Displays are either single-face or 2V (Two View) units. In 2V units, the first display is referred to as primary.

The second display is called the mirror.

LED Color: R (Red), A (Amber),

RGB (Full Color – Red, Green, Blue)

A typical display system is controlled with a Windows®-based computer running Venus® 1500 software.

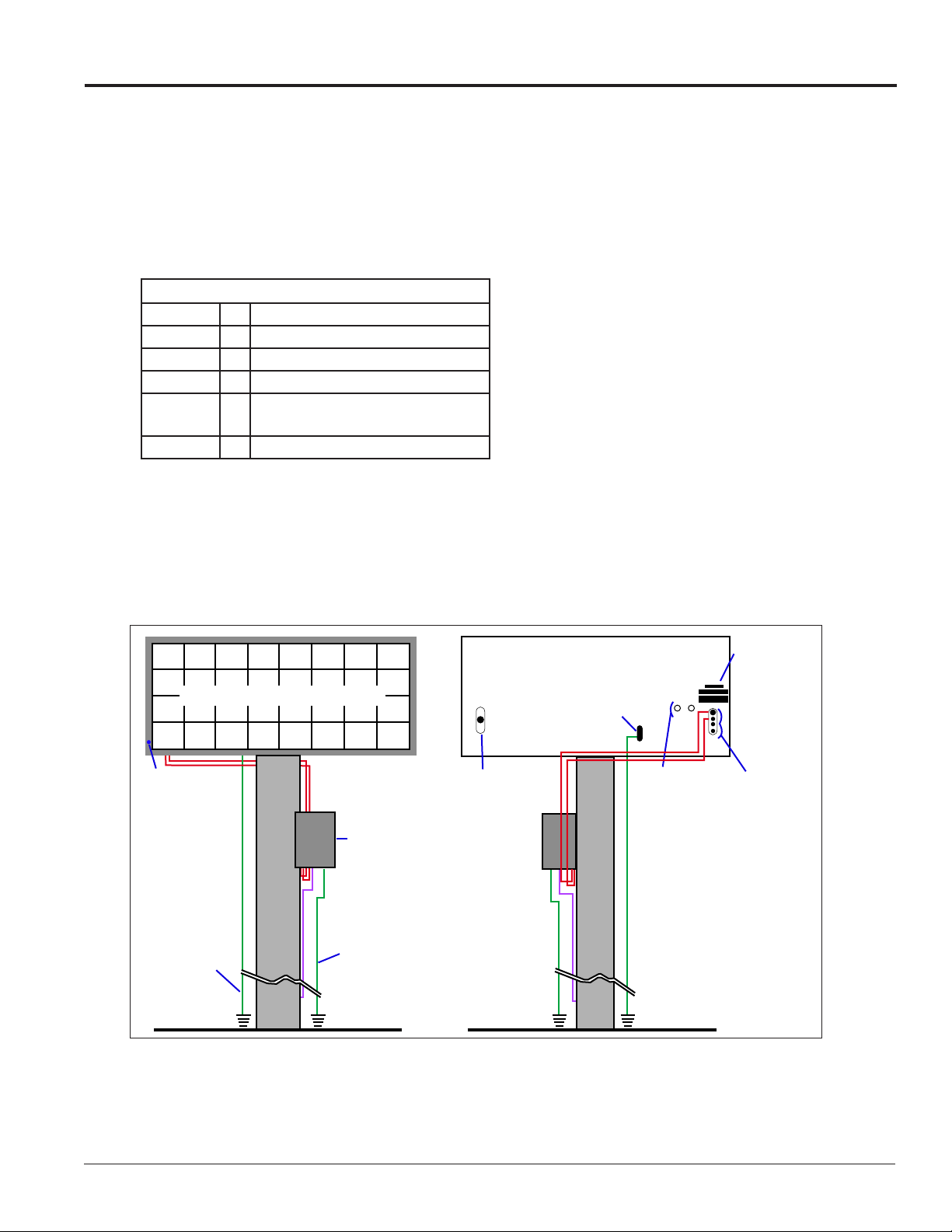

Figure 1 shows front and back views of a typical display.

Label(s)

Quick

Connect

Inputs

Primary Display – Front View

Blue Dot

Grounding

Electrode

Conductor

Signal

Termination

Enclosure

Signal Enclosure

Ground Electrode

Conductor

(When Required)

Primary Display – Rear View

Ground Lug

Connect

Output

to Mirror

Display

Optional

Conduit

Drilling

Guides

(Etched)

Figure 1: Display Components

Overview of the Displays 1

Section 2: Mechanical Installation

Read the Mechanical, Power and Signal Installation sections before installing the display(s).

Daktronics’ engineering staff must approve any changes that affect the weather-tightness of the display. Prior to

making any modifications, detailed drawings of the changes must be submitted to Daktronics for evaluation and

approval, or the warranty will be null and void.

Daktronics is not responsible for installations or the structural integrity of support structures done by others. The

customer must ensure a qualified structural engineer approves the structure and any additional hardware.

2.1 Pre-Installation Checklist

Verify the following before installation:

• The display is in good condition after shipping and uncrating.

• A straight and square mounting frame is provided for the display.

• Height variation in any 4' (1.2 m) horizontal section must not exceed 1/4" (6.3 mm).

• Adequate support is provided for the display so that the structure will not yield at any unsupported

points after mounting.

• Leave 4" (10.2 cm) of unobstructed space above the display so the eyebolts can be removed. No clearance

is required once the eyebolts are removed.

• Maintain clearance around the display to allow unobstructed air flow through the vents and fans and to

allow access to internal components.

• Assure the display cabinet has no holes (accidental or intentional) that could allow water to enter the

display.

• Check that all display modules are fully latched into the display cabinet.

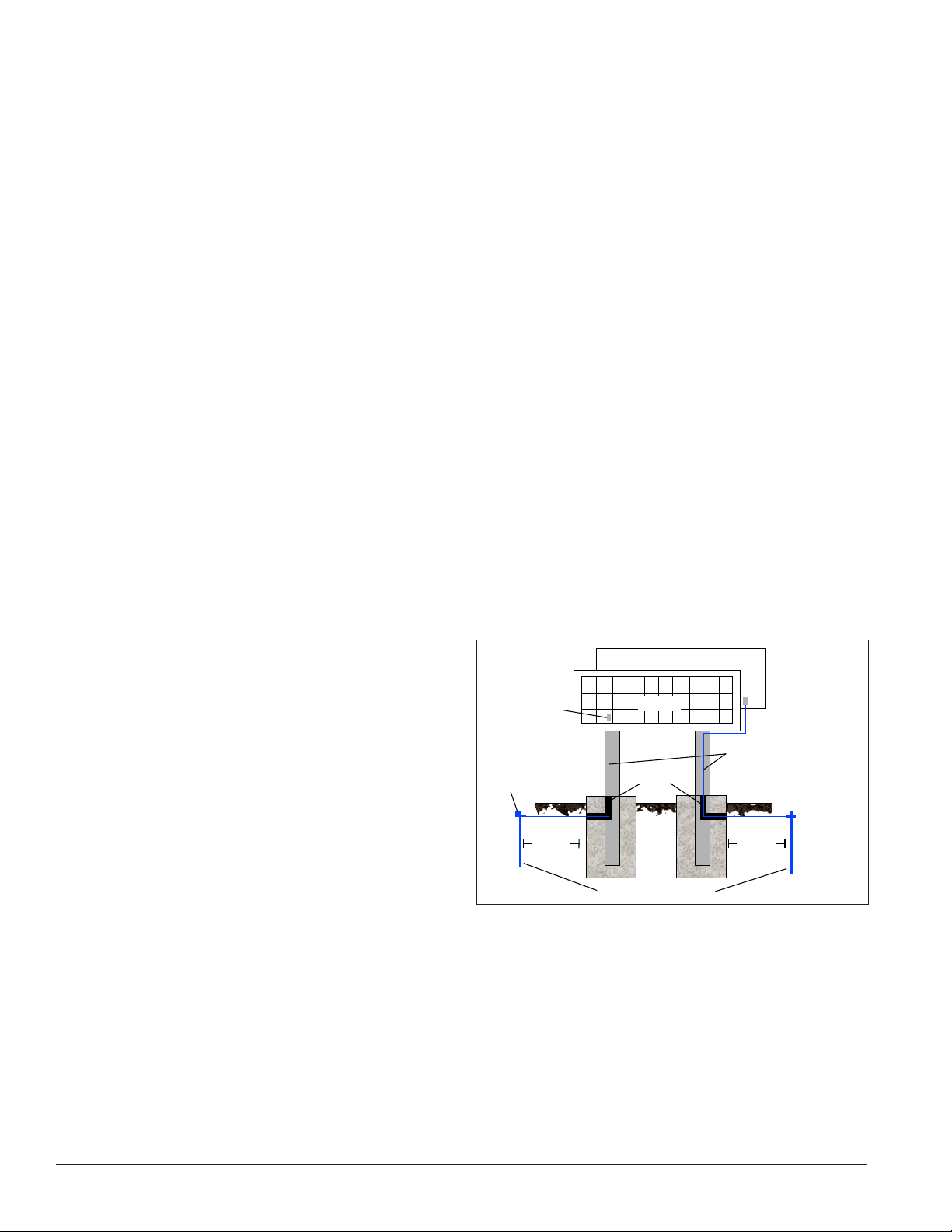

2.2 Support Structure Requirements

The installer must ensure that the mounting structure and hardware can support the display, and that the

structure follows all local codes.

Support structure design depends on the mounting methods, display size, and weight. Because every

installation site is unique, no single procedure is approved by Daktronics for mounting Galaxy® displays.

The information contained in this section is general information only and may not be appropriate for all

installations. Refer to Figure 2 for basic display set ups.

Mounting plans need to take into account the ventilation system and face-mounted light sensor. In general,

the entire front of all displays must be completely unobstructed to allow for air flow and internal access.

Displays contain fans that pull air in from the lower vents and exhaust it out adjacent vents.

Mechanical Installation 3

Also, keep in mind the location of mounting clips and the clearance needed for the power and signal

terminations on the back of the

display shown in Figure 2. Display

height and wind loading are also

critical factors to consider. Consult

the Shop Drawing, which is included

with the display.

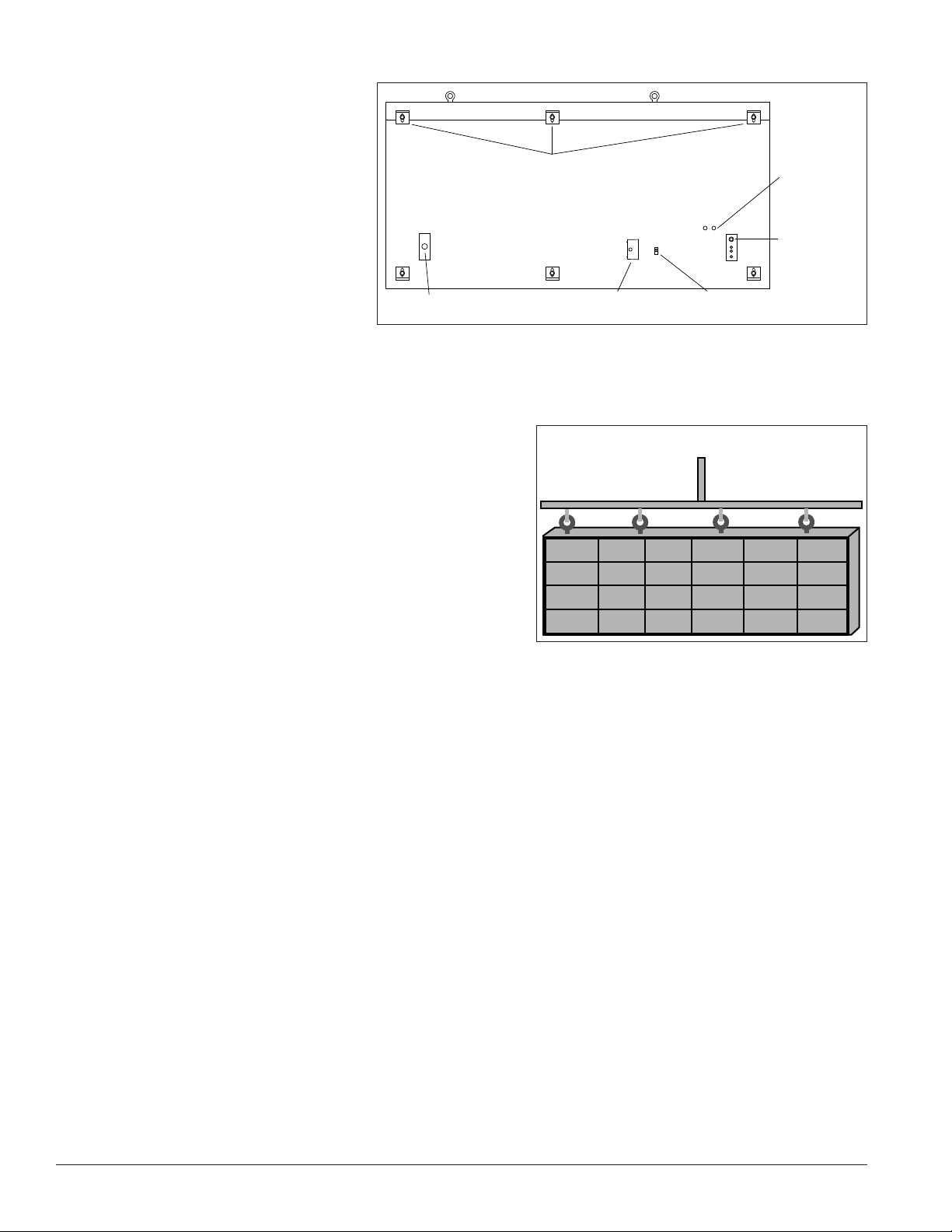

2.3 Display Mounting

To maintain the structural integrity

of the display cabinet, keep a

90-degree angle between the cabinet

and the lifting method.

If damage occurs because of

improper lifting procedures, the warranty will be void.

Mounting Clips

Back of Display

Quick Connect

Signal Out

Figure 2: Back View of Typical Display

External Junction Box

For Power Termination

Ground Lug for Ground

Rod Connection

Optional

Signal

Entrance

Quick Connect

Signal Input

General Mounting Procedure

Use Lift Bar and ALL Eyebolts

1. Lift the display into position on the support structure,

following the example in Figure 3.

Note: Do not attempt to permanently support the

display by the eyebolts.

2. Weld or use 1/2" grade-5 (or stronger) bolts and

hardware to secure ALL of the clip angles to the support

structure as shown in the Shop Drawing which is

included with the display.

Note: Alternative mounting methods are acceptable as

long as all bolt locations are used.

Figure 3: Correct Lifting

3. Refer to Section 3 for power routing and to the appropriate communication manual for signal

connections to the display.

4. After installation is complete, carefully inspect the display for any holes that may allow water to seep into

the display and seal any openings with silicone.

If the eyebolts on the top of the display were removed, plug the holes with bolts and the rubber-sealing

washer that was removed with the eyebolt unless an overhead structure protects the area.

4 Mechanical Installation

Section 3: Power Installation

Only a qualified individual should terminate power and signal cable at this Daktronics display.

All proposed changes must be approved by Daktronics’ engineering staff or the warranty will be null and void.

3.1 Conduit

Daktronics does not provide conduit. Separate conduit must be used to route:

• Power

• Signal IN wires to the signal termination enclosure (when applicable).

• Signal OUT wires (if not using the provided interconnect cable).

For power, displays have either a J-box or a 3/4" conduit access hole located near the lower right on the back

of the display. For signal, displays have signal input quick connects or etched drilling guides for conduit.

3.2 Overview of Power/Signal Connection

1. Power to the display is terminated externally in most cases. Section 3.6 shows external wiring examples.

2. Possible methods for signal termination are shown in the various communication manuals.

3. Power is routed to the display through a fused disconnect switch capable of opening all ungrounded

power conductors. Install the disconnect within the line of sight of any personnel performing

maintenance on the display, unless it can be locked in the open position.

Note: Displays are equipped with circuit breakers that carry a UL489 or UL1077 (IEC 60947, VDE 660) rating.

These devices are intended only to protect the components within the display.

4. Route power conductors from the disconnect to the display through conduit following local code

specifications.

5. Display power terminates either to the J-box or internally at the power termination panel.

6. Connect the grounding conductor to the grounding lug on the back of the display.

7. Route signal cable to the signal termination enclosure. Ground the enclosure to an isolated earth-ground

connector (when required).

8. Route signal into the enclosure through conduit. The knockouts on the enclosure require the use of 3/4"

conduit.

9. Route signal quick-connect cables from the enclosure to the display either through conduit or through the

display pole if power is not also routed in the display pole.

Note: Daktronics strongly recommends that the quick-connect cables be secured to protect them from

weather or vandalism.

Mechanical Installation 5

3.3 Power Requirements

Install this display according to all applicable local and national electrical codes. This includes proper

grounding and bonding of the display.

Do not connect the display to any voltage other than that listed on the Daktronics product label.

Displays use single-phase power. Proper power installation is imperative for display operation. Find power

specifications on drawings shipped with the display.

Important Notes:

• Daktronics recommends that a separate circuit be run to the electronic display(s) to isolate it and

prevent any issues that could be caused by line voltage fluctuations or high frequency noise on the

power line caused by other types of equipment. A separate circuit also makes display maintenance and

troubleshooting easier. Daktronics assumes no liability for any issues caused by line voltage fluctuations

or other improper power conditions if these recommendations are not followed.

• Size conductors of circuits that deliver power to the display according to national and local electrical

codes so the power distribution system delivers full-load power to the display while maintaining a

voltage within 5 percent of the utility nominal voltage.

Main Disconnect

Daktronics requires using a power disconnect switch with the display. Use a disconnect so that all

ungrounded conductors can be disconnected near the point of power connection.

Locate the disconnecting means either in a direct line of sight from the display or so it can be locked in the

open position. This ensures that power is not reconnected while service personnel work on the display.

3.4 Power Grounding

Ground displays according to the provisions

outlined in local and national electrical codes.

Install these displays using the provided ground

and neutral conductors. The power cable must

contain an isolated earth-ground conductor.

Do not connect neutral to ground at the disconnect

or at the display. This violates electrical codes and

voids the warranty.

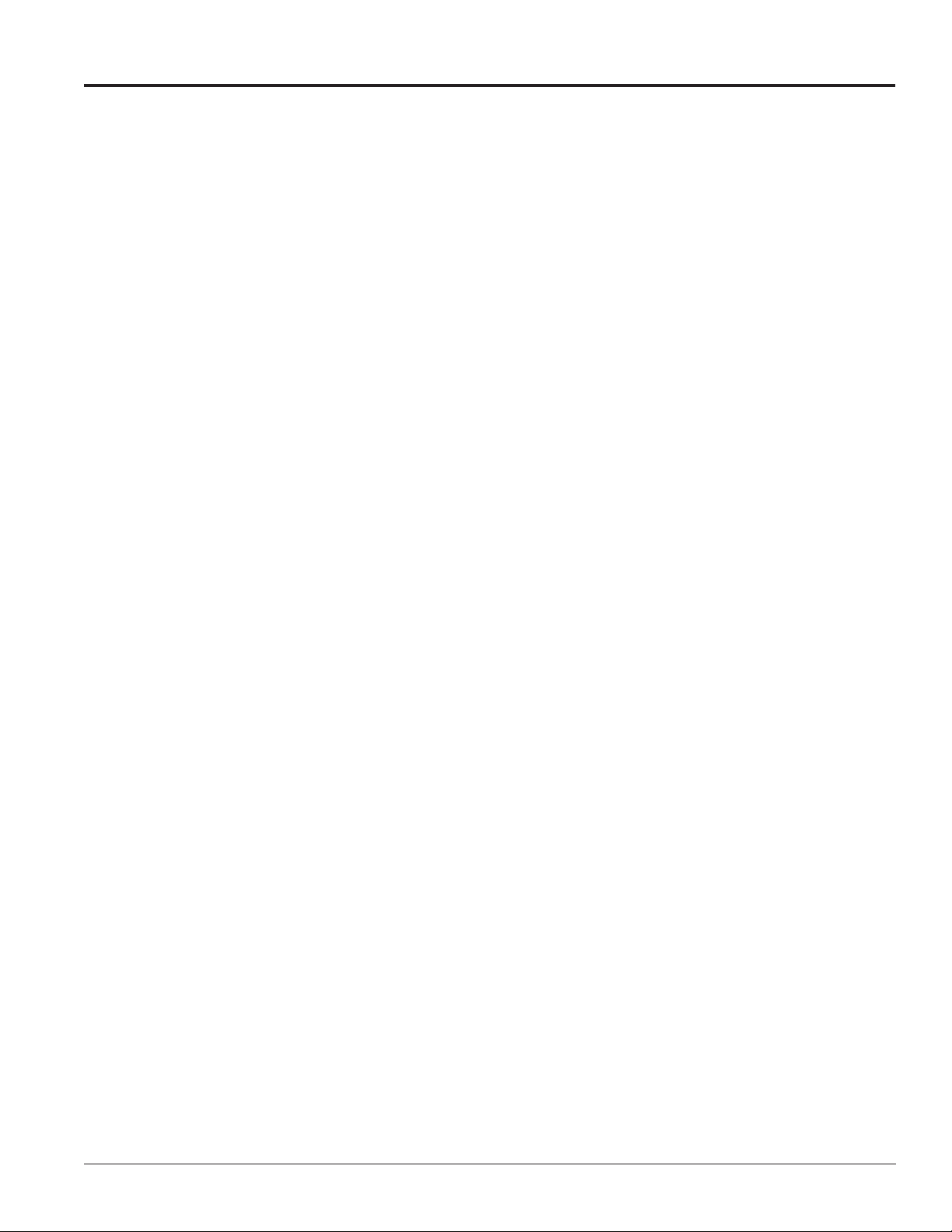

3.5 Display Grounding

Connect the display system to earth ground as

shown in Figure 4. Proper grounding protects the equipment from damaging electrical disturbances and

lightning. The display must be properly grounded or the warranty will be void.

Display

Ground Lug

Thermal Weld

Connection

Preferred

8 ft.(2.5 m)

min.

Figure 4: Correct Grounding

Primary

Conduit

Copper Ground Rods

Mirror

Copper Ground Conductor

(One Per Display Face)

8 ft.(2.5 m)

min.

Important Points About Grounding

• Resistance to ground 10 ohms or less: This is required by Daktronics for proper display performance.

If the resistance to ground is higher than 10 ohms, install additional grounding electrodes to reduce the

resistance. The grounding electrode should be installed within 25' (7.6 m) of the base of the display and

must be connected to the ground lug on the back of the display. Refer to Figure 4.

6 Power Installation

• Follow local and national codes: The material of an earth-ground electrode differs from region to region

and for conditions present at the site. Consult any local and national electrical codes that may apply.

• Support structure cannot be used as an earth-ground electrode: Daktronics does not recommend using

the support structure as an earth-ground electrode; concrete, primer, corrosion, and other factors make

the support structure a poor ground.

Note: The support structure may be used as an earth-ground electrode only if designed to do so. A qualified

inspector must approve the support structure and grounding methods.

• One grounding electrode for each display face: The grounding electrode is typically one grounding rod

for each display face. Other grounding electrodes as described in any local and national electrical codes

may be used.

3.6 Power Connection

Power is most often terminated externally to the J-box on displays. However, larger displays require power to

be terminated internally in the Power Termination Panel.

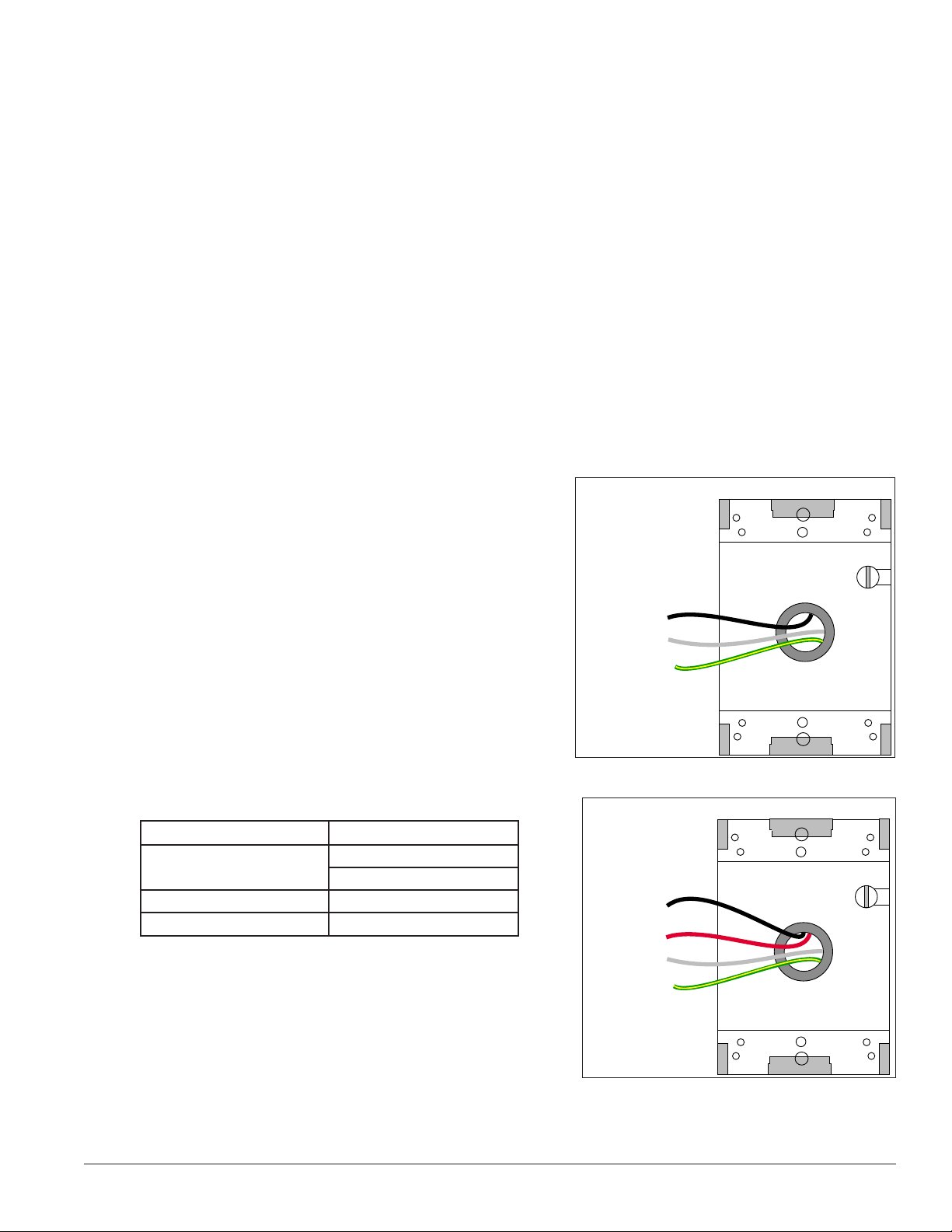

For Displays With an External Power Termination J-box

Terminating hot, neutral, and ground wires at the J-box:

1. Route the power cable through conduit to the rear of

the display and into the power termination J-box (the

J-box contains 3/4" threaded conduit fittings).

2. The J-box contains two or three wires plus a ground

coming from the interior of the display. These wires

are pre-terminated to the power termination panel

inside the display.

3. Inside the external J-box, connect the power wires to

the wires coming from the display interior using wire

nuts. Refer to Figure 5 for 120 VAC and Figure 6 for

120/240 VAC.

Note: The following colors are used for the pre-terminated

wires:

120 VAC 120/240 VAC

• Line 1 – Black

• Neutral – White • Neutral – White

• Ground – Green/Yellow • Ground – Green/Yellow

• Line 1 – Black

• Line 2 – Red

120 V Termination

(Box with Cover Removed)

Line 1 – Black

Neutral – White

Ground – Green/Yellow

Wiring from power termination

panel inside display

Figure 5: 120 V J-box Termination

120/240 VAC Termination

(Box with Cover Removed)

Line 1 – Black

Line 2 – Red

Neutral – White

Ground –

Green/Yellow

Wiring from power termination

panel inside display

Figure 6: 120/240 V J-box Termination

Power Installation 7

For Displays With Internal Power Termination

15

15

15

15

15

15

GRN

WHT

BLK

GRN

Z1 Z2

Z3

Z4 Z5 Z6

LINE 1

NEUT.

E41

LINE 2

GROUND

Terminating single-phase power to the internal power

termination panel:

1. Open the display as explained in Section 6 and locate

the power termination panel.

2. Route the cable through conduit to the back of the

display. Use the 3/4” knockout for access, being

careful not to damage internal components.

3. Connect the neutral wire to the neutral lug and the

live wires to the Line 1 and Line 2 lugs.

4. The ground wire connects to the grounding bus bar.

Refer to Figure 7 for an example.

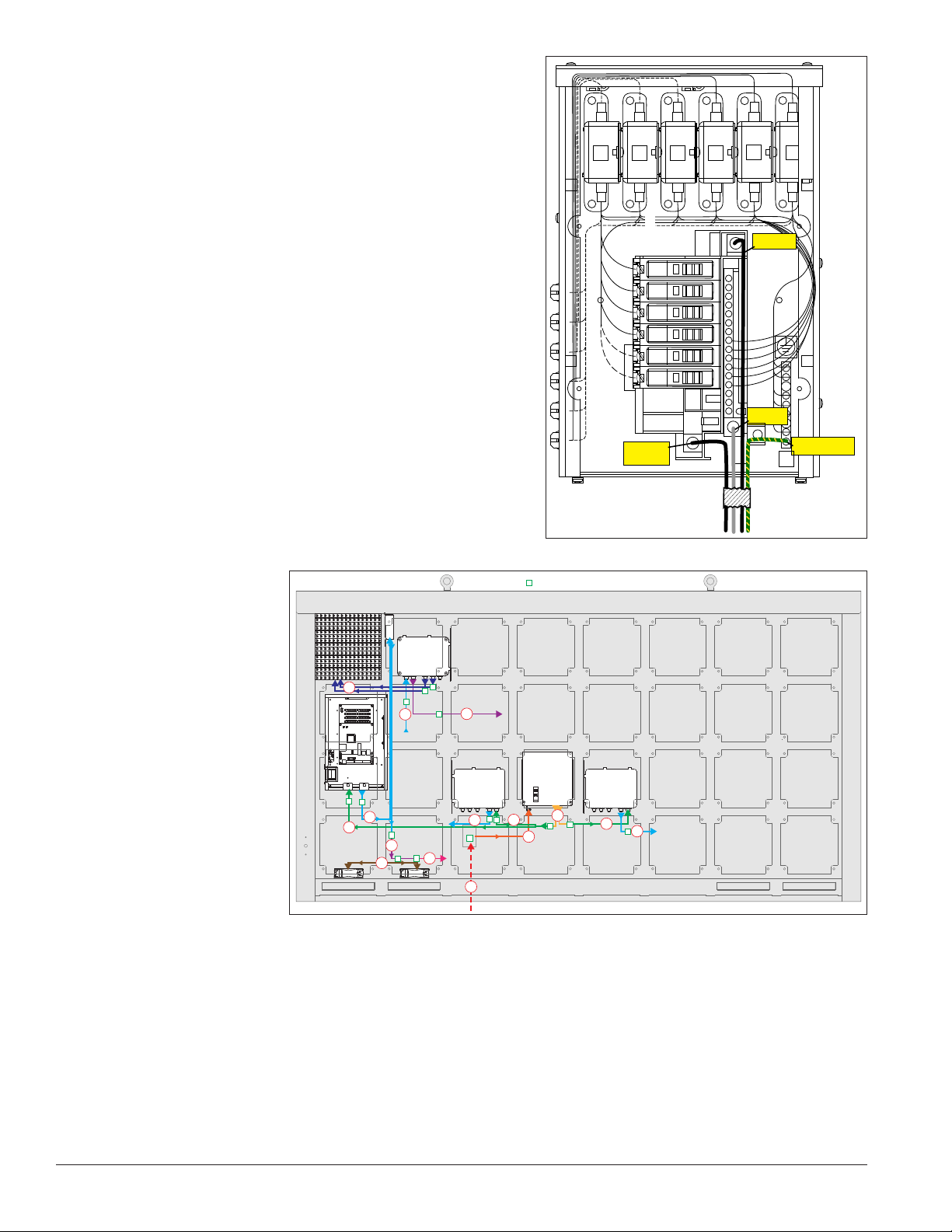

3.7 Power Routing in the Display

The following list corresponds to the numbers and letters in

Figure 8.

1. Power enters the display from an external power

source, either through a rear-mounted J-box, or

directly through a cabinet knockout.

2. Power then

enters the

internal circuit

breaker box.

Figure 7: Single-phase 6-breaker Domestic Panel

= Electrical Connector

3. Power leaves

the circuit

breaker box

through wiring

5c

5b

6b

harnesses

including a Y

harness that

4. a. Power travels

sends power

to multiple

components.

into the display

5a

4a

6a

7a

5b

8a

1

3

4b

2

4b

5b

controller

enclosure.

b. Power travels

to power supplies.

5. a. Power leaves the display controller enclosure and travels to the thermostat.

b. Power leaves the power supply and travels to the following power supply.

c. Low voltage power leaves the power supply and travels to the display module.

One module per power supply connects to the voltage adjust cable.

Figure 8: Power Flow Summary

8 Power Installation

6. a. Power leaves the thermostat and travels through a tapped wiring harness.

b. Power leaves this power supply and travels to the next power supply.

7. a. The ventilation fans receive power from the tapped wiring harnesses.

Power Installation 9

Section 4: Signal Installation Overview

For specific details on installing the communications, consult the quick guide and manual included with the

communication equipment. Each type of communication is listed below with its manual number.

Communication Type Communication Manual Communication Quick Guide

Wireless Ethernet Bridge DD1685027 DD1417586

Ethernet DD1417609 DD1417573

Fiber Ethernet DD1417611 DD1417581

WiFi DD1417619 DD1417592

USB to Ethernet Adapter N/A DD1790707

Note: These are the standard communication types but each site is unique and may include additional equipment. If

problems arise, contact the display’s service company or Daktronics Customer Service.

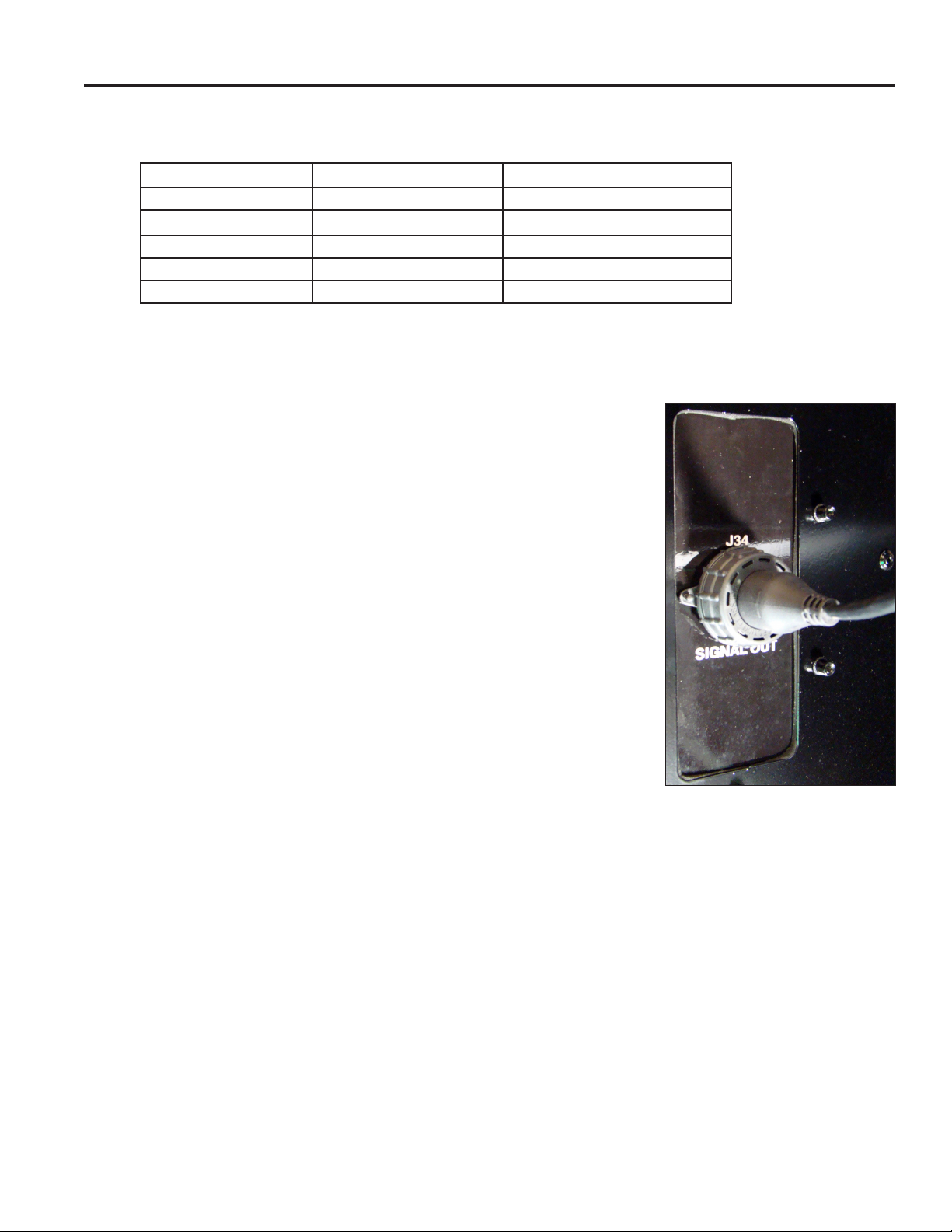

4.1 Primary/Mirror Display Interconnections

If this display is a two-sided primary/mirror display, a quick-connect cable

is provided to connect the signal between the two faces. Refer to Figure 9

for an example. Secure the excess cable to the support structure to prevent

damage from weather or vandalism.

4.2 USB to Ethernet Adapter

A USB to Ethernet adapter is included with the display and can be used

to bypass network configuration in situations where simple point-to-point

communication is required. The adapter creates a secondary network that

is dedicated to communication with the display, but network operation is

still enabled through the primary network.

The USB to Ethernet Adapter can be used in conjunction with

communication kits supplied with the display. Refer to DD1790707 for

more information regarding the adapter.

4.3 Setting the IP Address on the Display Controller

Galaxy AF-35XX display controllers are set to the default IP address

172.16.192.25 prior to shipping. This address can be changed to an address specific to the local display

network. Obtain an appropriate IP address for the display from the network administrator.

The display must have power and M2Config installed on the computer to complete the following steps.

Download M2Config at: dakles.daktronics.com/downloads/venus1500/utils/M2_Cong

Communication with the display controller is necessary and can be done through the purchased

communication method or directly to the display controller using a Cat5 cable.

Figure 9: Primary/Mirror Quickconnect Cable

Display power must be On to complete this configuration.

1. Set the computer’s IP address to 172.16.192.20 and the SubnetMask to 255.255.0.0.

2. Open M2Config:

Signal Installation Overview 11

Loading...

Loading...