Page 1

Galaxy AF-3400 12 mm

Display Manual

ED-17998 Rev 1 23 March 2009

Website: www.daktronics.com

Tel 866-343-3122 Fax: 605-697-4444

331 32nd Ave PO Box 5128 Brookings SD 57006

Page 2

ED-17998

Product 1260

Rev 1–23 March 2009

DAKTRONICS, INC.

Copyright 2009

All rights reserved. While every precaution has been taken in the preparation of this manual,

the publisher assumes no responsibility for errors or omissions. No part of this book covered

by the copyrights hereon may be reproduced or copied in any form or by any means – graphic,

electronic, or mechanical, including photocopying, taping, or information storage and retrieval

systems – without written permission of the publisher.

®

is a registered trademark of Daktronics, Inc. All others are trademarks of their respective companies.

Galaxy

Page 3

Table of Contents

Section 1: Introduction ................................................................................................................. 1

1.1 Safety Precautions ................................................................................................................... 1

1.2 Display Overview ................................................................................................................... 1

Section 2: Mechanical Installation .............................................................................................. 3

2.1 Support Structure Requirements .......................................................................................... 3

Pre-installation Checklist ................................................................................................ 4

2.2 Lifting the Display .................................................................................................................. 4

2.3 Display Mounting ................................................................................................................... 5

2.4 Temperature Sensor Mounting ............................................................................................. 5

Section 3: Power Installation ....................................................................................................... 7

3.1 Preparing for Power Connection .......................................................................................... 7

3.2 Conduit ..................................................................................................................................... 7

3.3 Power Requirements .............................................................................................................. 8

Main Disconnect .............................................................................................................. 8

Grounding......................................................................................................................... 8

Power Connection ............................................................................................................ 9

Section 4: Signal Overview ........................................................................................................ 15

4.1 Primary to Primary Signal Connection .............................................................................. 15

4.2 RS-422 Communication ........................................................................................................ 17

4.3 Fiber Optic Communication ................................................................................................ 18

4.4 Radio Communication ......................................................................................................... 19

4.5 RS-232 Communication ........................................................................................................ 20

4.6 Ethernet Communication ..................................................................................................... 21

4.7 Fiber Ethernet Communication ........................................................................................... 22

4.8 Ethernet Bridge Radio Communication ............................................................................. 23

4.9 Modem Communication ...................................................................................................... 24

4.10 Temperature Sensor Installation ......................................................................................... 25

Section 5: Start-up Procedure ................................................................................................... 27

5.1 Start-up Checklist .................................................................................................................. 27

5.2 Start-up Sequence ................................................................................................................. 28

Section 6: Maintenance and Parts Replacement ..................................................................... 29

6.1 Display Access ....................................................................................................................... 30

6.2 Maintenance ........................................................................................................................... 31

Ventilation ...................................................................................................................... 31

Thermostats .................................................................................................................... 31

Weather Stripping .......................................................................................................... 31

Annual Maintenance ..................................................................................................... 32

Table of Contents i

Page 4

6.3 Troubleshooting .................................................................................................................... 32

6.4 Replacement Parts List ......................................................................................................... 33

6.5 Replacing Parts ...................................................................................................................... 35

Location of Internal Components ................................................................................ 35

Module Replacement ..................................................................................................... 35

Transformer and RFI Filter Replacement ................................................................... 36

Power Supply Replacement .......................................................................................... 36

Section 7: Daktronics Exchange and Repair & Return Programs .......................................... 41

Before Contacting Daktronics ...................................................................................... 41

7.1 Exchange Program ................................................................................................................ 41

7.2 Repair & Return Program .................................................................................................... 42

7.3 Daktronics Warranty and Limitation of Liability ............................................................. 42

Appendix A: Reference Dra wings.................................................................................................. 43

Appendix B: Temperature Sensor ................................................................................................. 44

Appendix C: Daktronics Warranty and Limitation of Liability (SL-02374) ................................. 45

Table of Content ii

Page 5

List of Figures

Figure 1: Drawing Label ........................................................................................................................ 1

Figure 2: Galaxy 12 mm 24 x 112 .......................................................................................................... 2

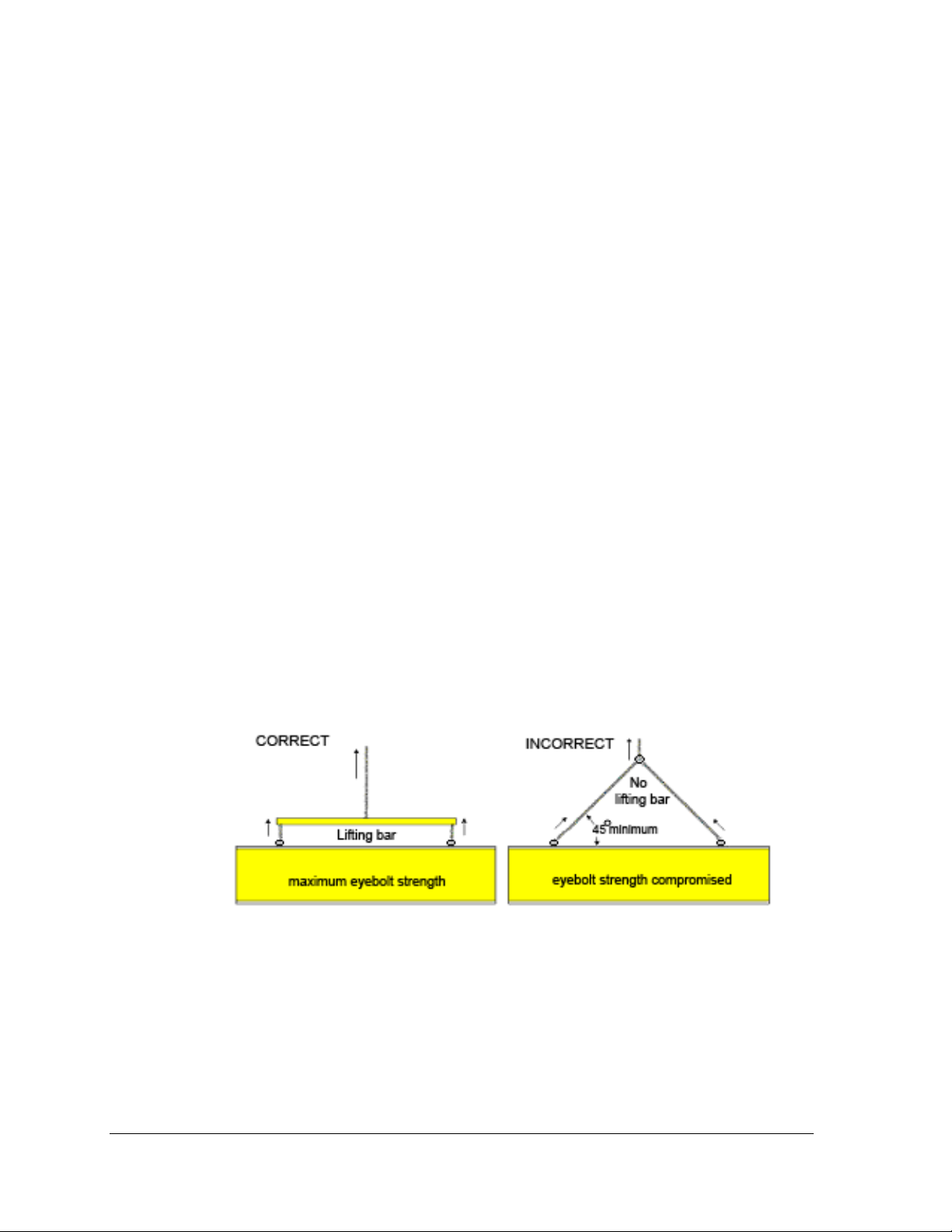

Figure 3: Back View of Typical Display .................................................................................................. 3

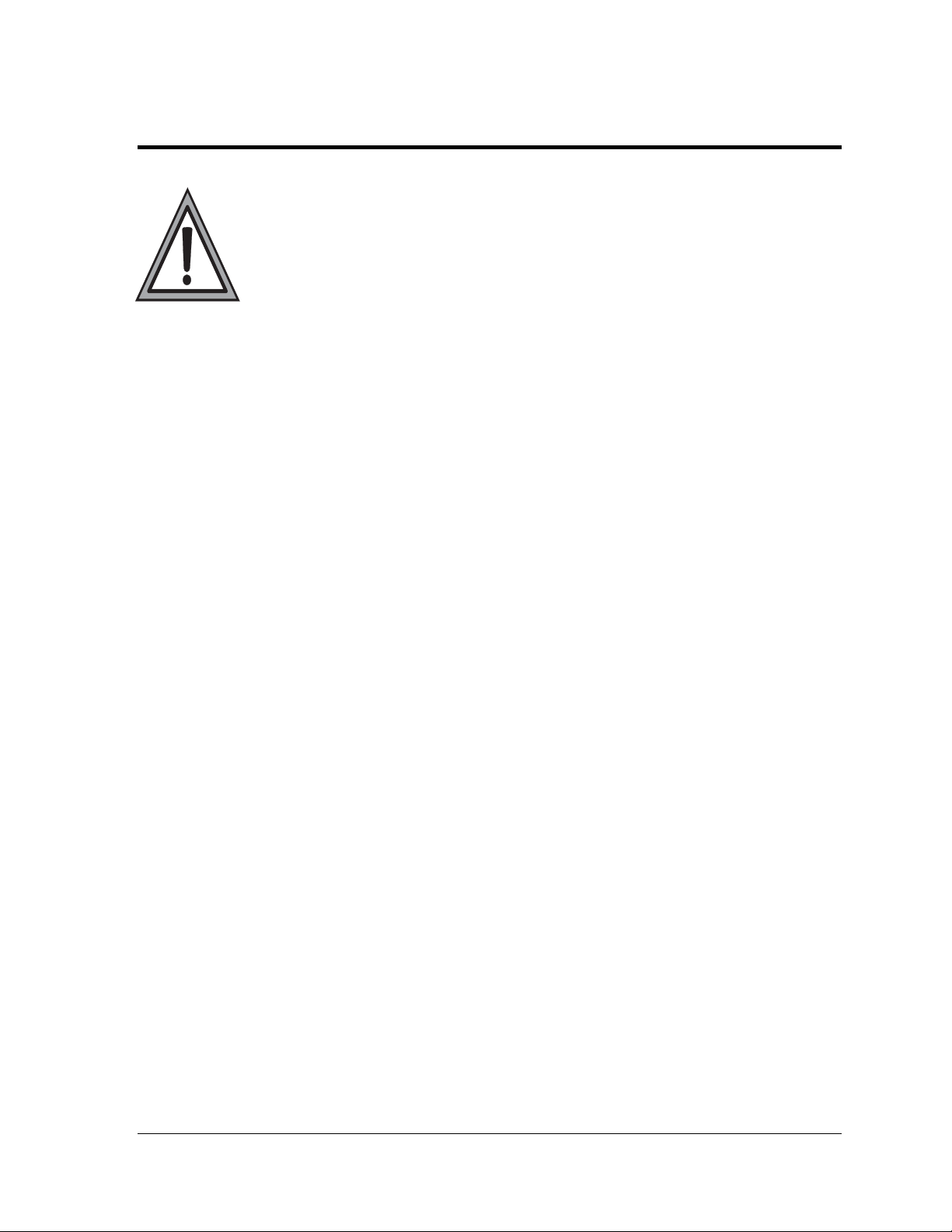

Figure 4: Lifting the Display .................................................................................................................... 4

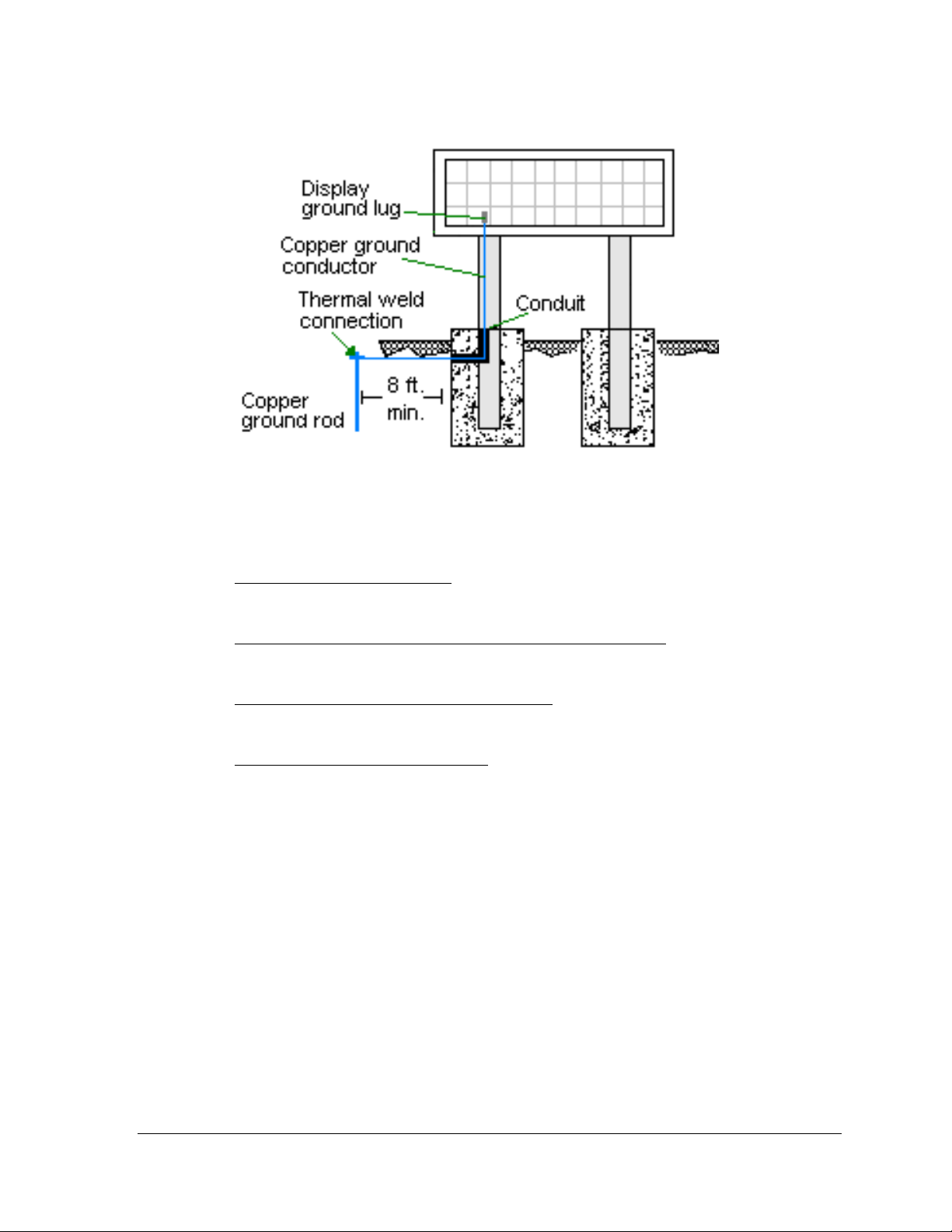

Figure 5: Proper Grounding .................................................................................................................... 9

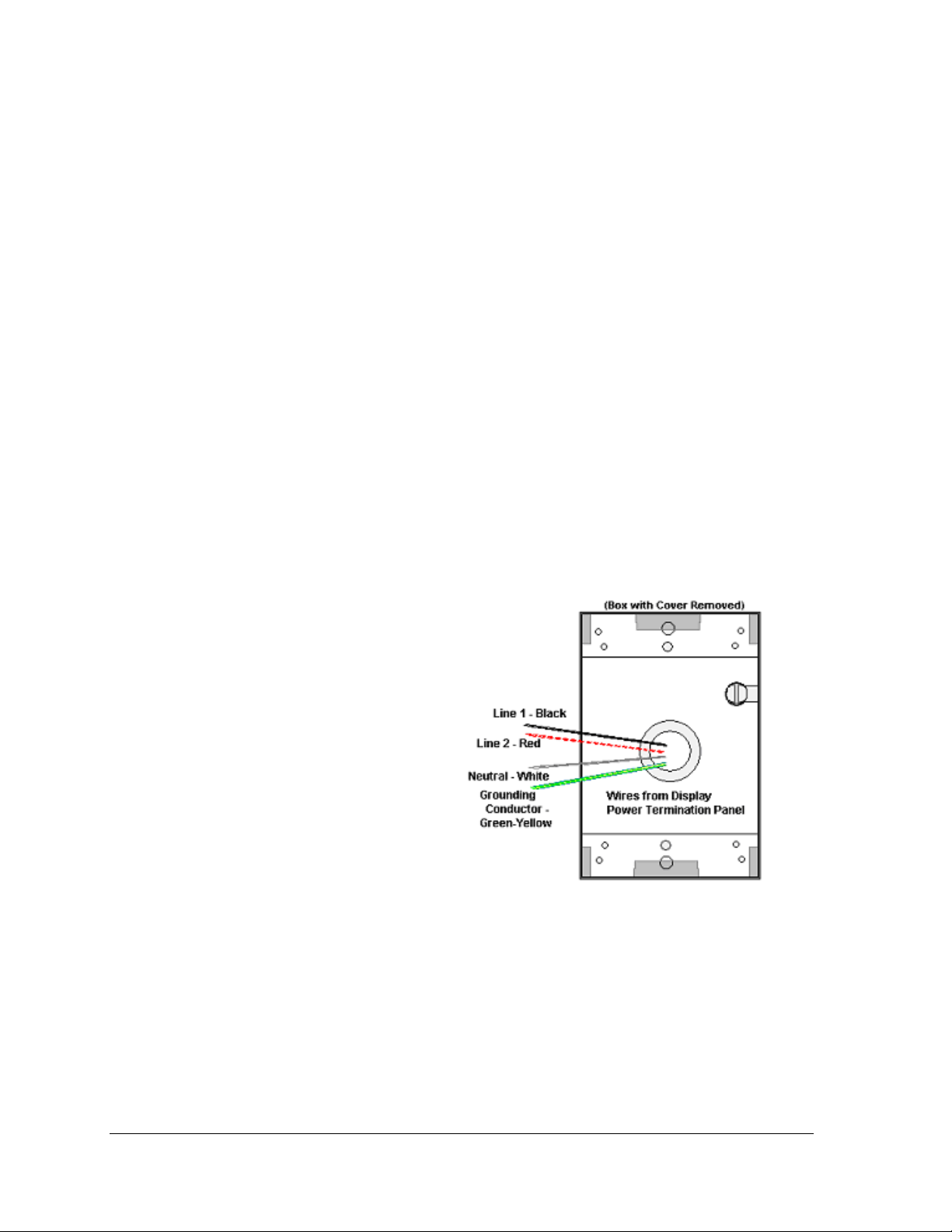

Figure 6: 120 VAC Power Termination ................................................................................................. 10

Figure 7: 120/240 VAC Power Termination .......................................................................................... 10

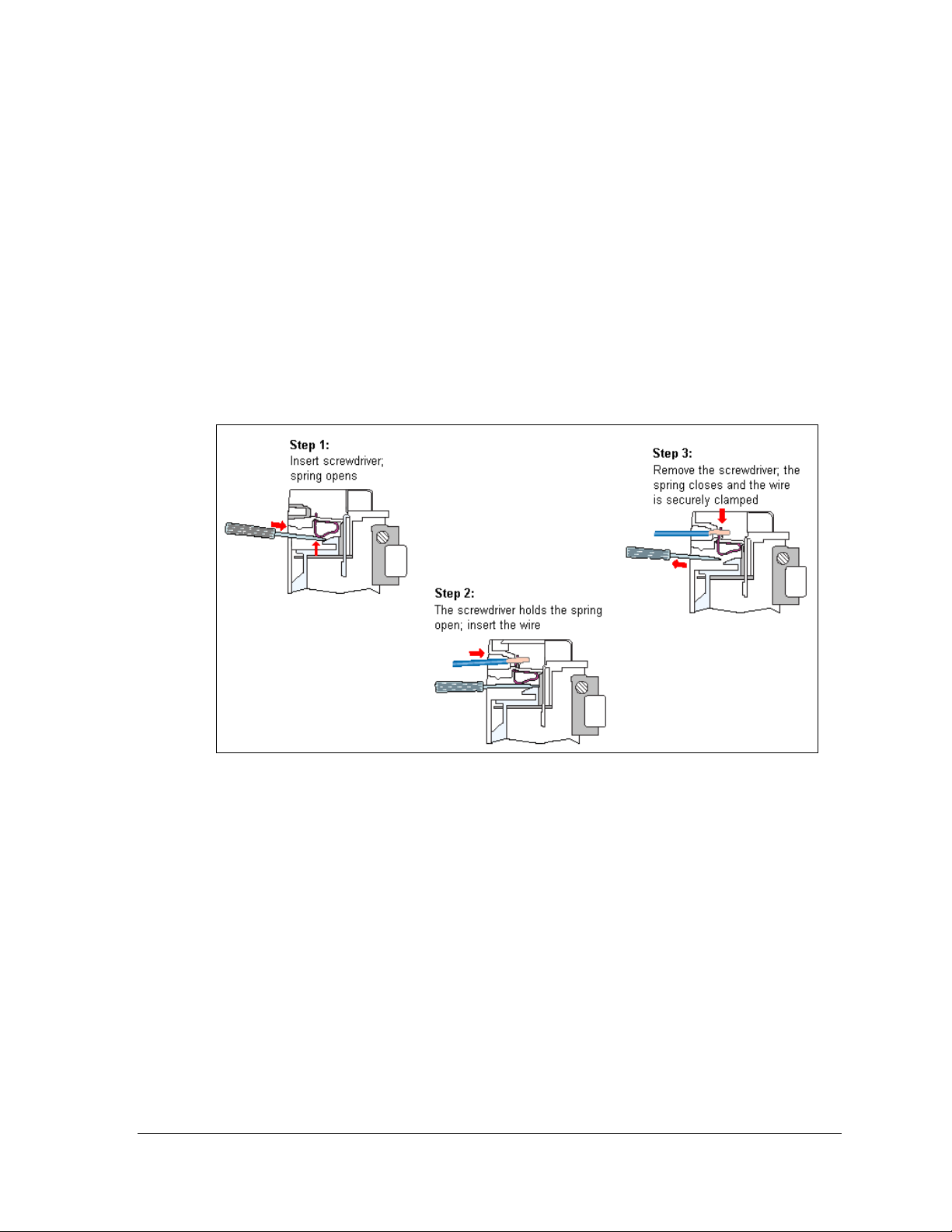

Figure 8: Making Cage Clamp Connections ......................................................................................... 11

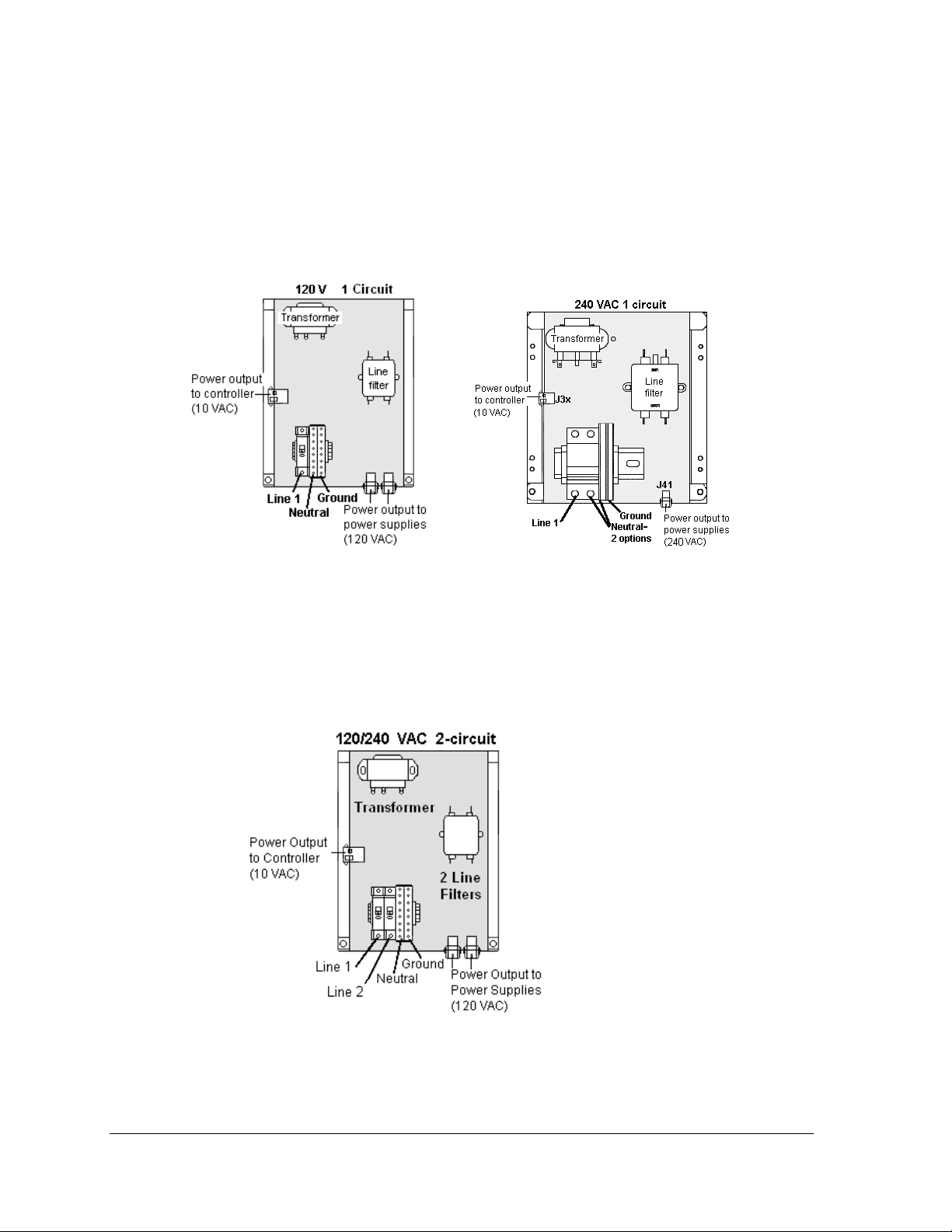

Figure 9: One-circuit 120 VAC Termination One-circuit 240 VAC Termination .............................. 12

Figure 10: Two-circuit 120/240 VAC Termination ................................................................................ 12

Figure 11: RS-422 Interconnection from Primary to Primary Display .................................................. 16

Figure 12: RS-422 Communication Layout .......................................................................................... 17

Figure 13: Fiber Serial Communication Layout .................................................................................... 18

Figure 14: Radio Communication Layout ............................................................................................. 19

Figure 15: RS-232 Communication Layout .......................................................................................... 20

Figure 16: Ethernet Communication Layout ......................................................................................... 21

Figure 17: Fiber Ethernet Communication Layout ................................................................................ 22

Figure 18: Ethernet Bridge Radio Layout ............................................................................................. 23

Figure 19: Modem Communication Layout .......................................................................................... 24

Figure 20: Basic Display Set-up ........................................................................................................... 27

Figure 21: Location of Internal Components ........................................................................................ 29

Figure 22: Opening Display .................................................................................................................. 30

Figure 23: Display fans ......................................................................................................................... 31

Figure 24: Typical Label ....................................................................................................................... 33

Figure 25: Removing a Module ............................................................................................................ 35

Figure 26: One-circuit Power Termination ............................................................................................ 36

Figure 27: Power Supply ...................................................................................................................... 36

Figure 28: Controller Component Layout ............................................................................................. 38

List of Figures iii

Page 6

Page 7

Section 1: Introduction

This manual explains the installation, maintenance, and troubleshooting for the Galaxy AF-3400

12 mm display. For questions regarding the safety, installation, operation, or service of this system,

please refer to the telephone numbers listed on the cover page of this manual.

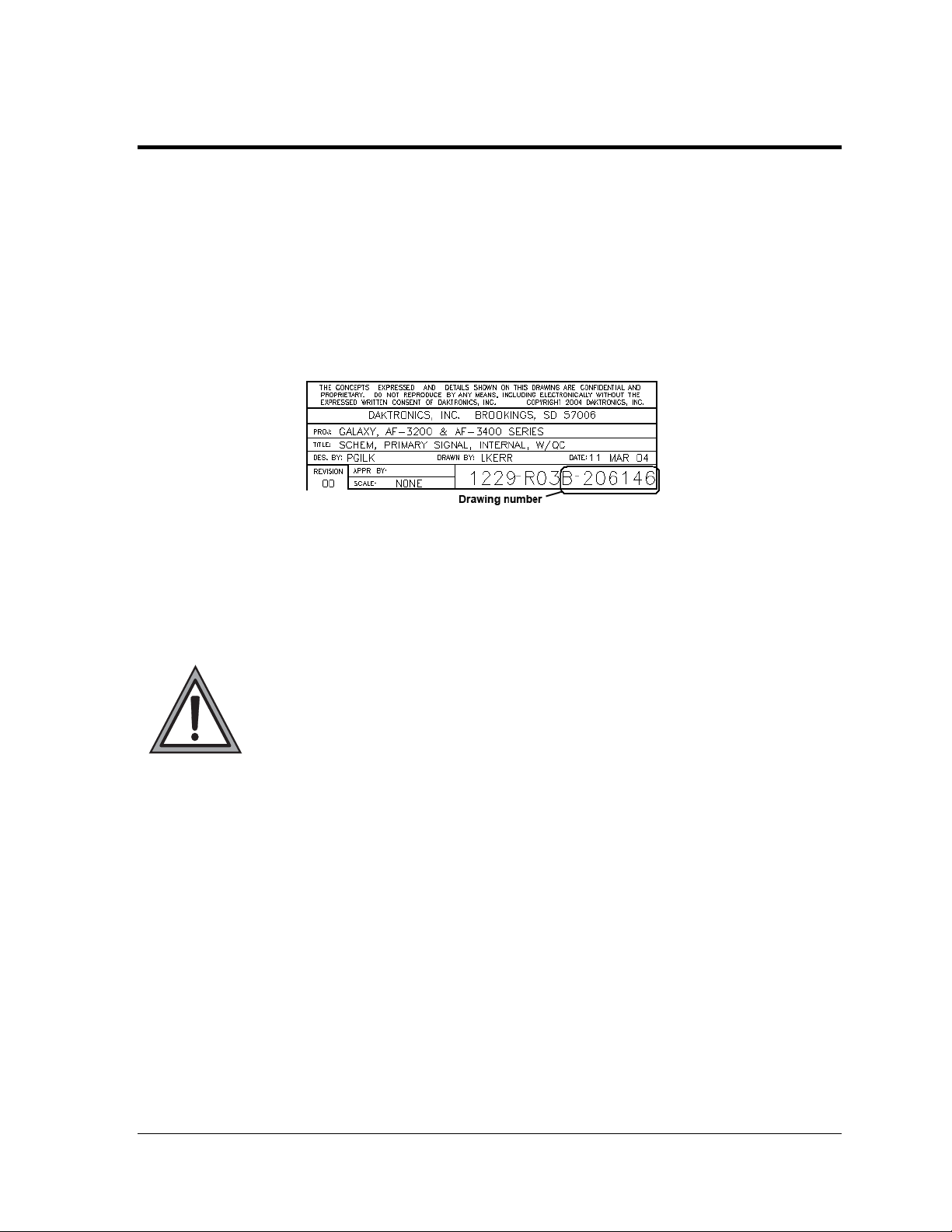

Drawings may be referenced by drawing number at the beginning of some sections. Figure 1

illustrates the Daktronics drawing label. The drawing number is located in the lower-right corner of

the drawing. The drawing number consists of the last set of digits and the letter preceding them. In

the example below, the drawing would be referred to as Drawing B-206146. Reference drawings are

inserted in Appendix A.

Figure 1: Drawing Label

1.1 Safety Precautions

Important Safeguards:

Read and understand these instructions before installing

Be sure the display and external signal enclosures are properly grounded with

an earth ground electrode at the display

Disconnect power when servicing the display

Do not modify the display structure or attach any panels or coverings to the

display without the written consent of Daktronics.

1.2 Display Overview

The Galaxy® AF-3400 12 mm displays are designed and manufactured for performance,

reliability, easy maintenance, and long life. The pixels have a 12 mm center-to-center spacing

and are lit using LEDs (light-emitting diodes). A light sensor on the front of the display is

used for automatic dimming of the LEDs based on the ambient light levels.

The Galaxy

®

display number for these displays is described as follows:

Introduction 1

Page 8

AF-3400-RxC-12-RGB

AF-3400 =

R=

C=

12 =

RGB =

A module is the building block of the Galaxy

by 16 pixels wide. By placing modules next to each other, a display of any size can be

designed and built. Individual modules can be easily removed from the display if required.

Figure 2 shows a typical Galaxy

Figure 2: Galaxy 12 mm 24 x 112

Outdoor louvered Galaxy display

Number of rows high

Number of columns long

12 mm pixel to pixel spacing

LED color (Red, Green, and Blue)

®

display. Each module measures 24 pixels high

®

12mm display.

Introduction 2

Page 9

Section 2: Mechanical Installation

Da ktronics engineering staff must approve any changes to the display. If any

modifications are made, detailed drawings of the changes must be submitted to

Daktronics for evaluation and approval, or the warranty may be void.

Daktronics is not responsible for installations or the structural integrity of

support structures done by others. The customer is responsi ble for ensuring

that a qualified structural engineer approves the structure and any hardware.

2.1 Support Structure Requirements

Because every installation site is unique, no single procedure is approved by Daktronics for

mounting Galaxy

only and may or may not be appropriate for this particular installation.

A qualified individual must make all decisions regarding the mounting of this display.

Support structure design depends on the mounting methods, display size, and weight. In

general, the front of the display needs to be unobstructed to allow for air flow and internal

access. The bottom of the display houses the fans so allowances will need to be made for their

operation. Also keep in mind the location of the mounting clips and the power/signal

termination box or knockouts on the back of the display. Display height and wind loading

are also critical factors to be considered. This information can be found in the Shop drawing

provided with the display.

The external components and their typical location are shown in Figure 3. Refer to the

specific shop drawing for the actual dimensions and location of components in a particular

display.

®

displays. The information contained in this section is general information

Figure 3: Back View of Typical Display

Mechanical Installation 3

Page 10

Pre-installation Checklist

Verify the following before proceeding with installation:

The display is in good condition after shipping and uncrating.

All clip angles or mounting holes are attached to the support structure.

A straight and square mounting frame is provided for the display.

Height variation in any four-foot horizontal section may not exceed ¼-inch.

Adequate support is provided for the display so that the structure will not yield at

any unsupported points after mounting.

Clearance of 4" of unobstructed space above the top of the display is allowed to

remove the eyebolt. Note: No clearance is required once the eyebolt is removed.

Clearance in front of the display is maintained to allow unobstructed air flow

through the vents and to allow access to internal components.

2.2 Lifting the Display

The top of the display is equipped with eyebolts that are used to lift the unit. Take special

care to ensure that the rated load of the eyebolts is not exceeded. Refer to the information at

the end of this section labeled Eyebolts to determine the allowable load of the eyebolts

shipped with the display.

Figure 4 illustrates both the correct (left example) and the incorrect (right example) method

of lifting a display. Lift the display as shown on the left, with the lifting bar. Use every lifting

point provided.

Figure 4: Lifting the Display

Do not attempt to permanently support the display by the eyebolts.

Eyebolts can be removed after mounting to eliminate the need for overheard clearance.

Mechanical Installation 4

Page 11

2.3 Display Mounting

The method used to mount displays can vary greatly from location to location. For this

reason, only general mounting topics can be addressed in this manual.

The back of the display is equipped with 2" x 2" x 1/4" x 3" steel angles at the top and bottom

as shown in Figure 3. All angles must be used for display installation. Remember to have

all mounted displays inspected by a qualified structural engineer.

The number of attachment points needed and the mounting structure must be reviewed by a

qualified structural engineer and meet all national and local codes. It is the customer’s

responsibility to determine the proper wall mounting method and location. Daktronics

requires using bottom mounting angles or all mounting holes as attachment points.

1. Carefully uncrate the display and inspect each side of the display for possible

damage that may have occurred during shipping.

2. Following the guidelines described in Section 2.2 lift the display into position on the

support structure.

3. Weld or use ½" Grade-5 bolts and hardware to secure the mounting angles to the

support structure as shown in the Shop Drawing.

4. Refer to Section 3 for information on routing power to the display.

5. After installation is complete, carefully inspect the display for any holes that may

allow water to seep into the display and seal any openings with silicone. If the

eyebolts on the top of the display have been removed, plug the holes with bolts

and the rubber-sealing washer that was removed with the eyebolt (unless

prevented by an overhead structure).

2.4 Temperature Sensor Mounting

Refer to Appendix B for instructions on mounting and connecting signal for the temperature

sensor.

Mechanical Installation 5

Page 12

Page 13

Section 3: Power Installation

Only a qualified individual should terminate power and signal cable at this

Daktronics display.

The Daktronics engineering staff must approve any changes made to the display.

Before altering the display, submit detailed drawings for the proposed modifications

to the Daktronics engineering staff for evaluation and approval or the warranty will

be rendered null and void.

Schematic, Power Term Panel, 2 Circuit-120/240VAC ............................................. Drawing A-211947

Schematic, Power Term Panel, 1 Circuit-120VAC .................................................... Drawing A-211950

Schematic, Power Term Panel, 2 Pole-240VAC ....................................................... Drawing A-218666

Schematic, Power Term Panel, 1 Pole-240VAC ....................................................... Drawing A-220287

Schematic, AF-3400-12-RGB-P, General ................................................................. Drawing A-253685

Power Specs, AF-3400-(24x192-96-192-12-RGB ..................................................... Drawing A-254277

3.1 Preparing for Power Connection

A power termination box is provided on the back of the display. If the installation of the

display does not allow for the use of this enclosure, refer to Section 3.6 for information

on the internal wiring for the power.

Route power to the display through a fused disconnect switch capable of opening all

ungrounded power conductors. Install this disconnect within the line-of-sight of any

personnel performing maintenance on the display. If the disconnect is located out of

sight of the display, it must be capable of being locked in the open position.

Note: Displays are equipped with supplemental protection devices that carry a UL1077

(IEC 60947, VDE 660) rating. These devices are only intended to protect the components

within the display. Suitable devices must be used for the equipment and feeders

supplying power to the display.

Power conductors from the disconnect to the display should be routed through conduit

in agreement with local code.

Display power will terminate to the display at the external power termination J-box

mounted to the back of the display.

Connect the grounding electrode conductor at the grounding lug on the display at this

time.

3.2 Conduit

Daktronics does not include the conduit. Separate conduit must be used to route:

Power

Signal IN wires to the display, when applicable

Electrical Installation 7

Page 14

The power J-box on the back of the display is provided with ¾” threaded holes for use with

¾” conduit. If necessary, knockout/drill holes are provided in the display cabinet itself when

not using the enclosure.

3.3 Power Requirements

Each display uses one 120 VAC or 120/240 VAC single phase power source. Proper power

installation is imperative for proper display operation. Refer to Drawing A-254277 for power

specifications for the specific display size.

Main Disconnect

The National Electrical Code requires the use of a lockable power disconnect near the

display. Provide a lockable disconnect switch (knife switch) at the display location so that all

power lines can be completely disconnected. Use a 3-conductor disconnect so that both hot

lines and the neutral can be disconnected. The main disconnect should be mounted at or near

the point of power supply connection to the display. A main disconnect is to be provided for

each supply circuit to the display.

The disconnecting means must be located in a direct line-of-sight from the display or outline

lighting that it controls. This requirement provides protection by enabling a worker to keep

the disconnecting means within view while working on the display.

Exception: Disconnecting means that are capable of being locked in the open position may be

located elsewhere.

Grounding

This sign is to be installed in accordance with the requirements of Article 600 of the National

Electrical Code and/or other applicable local codes. This includes proper gr ounding and

bonding of the sign.

For these displays, installation with ground and neutral conductors provided is used. The

power cable must contain an isolated earth-ground conductor. Refer to Figure 5 for the an

overview of proper grounding.

Under this circumstance, do not connect neutral to ground at the disconnect or at the display.

This would violate electrical codes and void the warranty. Use a disconnect so that all hot

lines and neutral can be disconnected. The National Electrical Code requires the use of a

lockable disconnect within sight of or at the display.

The display system must be connected to earth-ground. Proper grounding is necessary for

reliable equipment operation. It also protects the equipment from damaging electrical

disturbances and lightning.

The display must be properly grounded, or the warranty will be void.

Electrical Installation 8

Page 15

Figure 5: Proper Grounding

Important points about grounding:

Follow local and national codes

region to region and from conditions present at the site. Consult the National Electrical

Code and any local electrical codes that may apply.

Support structure cannot be used as an earth-ground electrode

generally embedded in concrete. If in earth, the steel is either primed or it corrodes,

making it a poor ground.

One grounding electrode for each display face

grounding rod for each display face. Other grounding electrodes as described in Article

250 of the National Electric Code may be used.

Resistance to ground 10 ohms or less

performance. If the resistance to ground is higher than 10 ohms, it will be necessary to

install additional grounding electrodes to reduce the resistance. The grounding

electrode should be installed within 25 feet of the base of the display. The grounding

electrode must be connected to the ground lug on the back of the display (Figure 5).

: The material of an earth-ground electrode differs from

: The support is

: The grounding electrode is typically one

: This is required by Daktronics for proper display

Power Connection

Two options are possible for terminating power to the display:

terminating power to the J-box.

terminating power directly to the power termination panel inside the display.

Installation instructions for both are provided in this section.

Electrical Installation 9

Page 16

Option 1: Terminating hot, neutral, and ground wires at the J-box

Display power is connected to the power termination enclosure on the back of the display.

Complete the following steps to terminate the hot, neutral, and ground wires at the

termination enclosure.

1. Route the power cable through ½” conduit to the rear of the display and into the

power termination enclosure.

2. The power termination enclosure will contain two wires plus a ground coming from

the interior of the display – these wires are pre-terminated to the power termination

panel inside the display.

3. Inside the external power termination J-box, connect the power wires to the wires

coming from the display interior, using wire nuts. Refer to Figure 6 for further

information.

Note the following colors are used for the pre-terminated wires:

120 VAC 120/240 VAC

Line 1 – Black x Line 1 - Black

Neutral - White x Line 2 - Red

Grounding Conductor - Green-Yellow x Neutral - White

x Grounding conductor – Green-yellow

Figure 6: 120 VAC Power Termination

Figure 7: 120/240 VAC Power Termination

Electrical Installation 10

Page 17

Option 2: Terminating power through direct connections

If these power terminations cannot be made at the enclosure, they can be made directly to the

power termination panel in the display. The following steps will need to be done to complete

internal connections:

1. Open the display as explained in Section 6.1 and locate the power termination panel.

2. Route the cable through conduit to the back of the display – use one of the ½”

knockouts for access, being careful not to damage any internal components.

3. Disconnect the wires to the terminal block going to the external power J-box, and

connect the wires from the direct cable.

4. Using a small flat screwdriver to open the cage clamps, release the jumper wires

connected to the external wires going to the external power termination box.

5. Install the wires from the direct circuit into the cage clamps following the directions

in Figure 8.

Figure 8: Making Cage Clamp Connections

Electrical Installation 11

Page 18

6. Make the following connections as shown in Figure 9

1-circuit termination

Line 1 to circuit breaker 1 (line side)

Neutral to gray terminal block (line side)

Ground to green/green yellow terminal block

:

Figure 9: One-circuit 120 VAC Termination One-circuit 240 VAC Termination

2-circuit termination

Line 1 to circuit breaker 1 (line side)

Line 2 to circuit breaker 2

Neutral to gray terminal block (line side)

Ground to green/green yellow terminal block

Figure 10: Two-circuit 120/240 VAC Termination

Refer to the Schematic Drawings in Appendix A for additional information.

Electrical Installation 12

Page 19

Electrical Installation 13

Page 20

Page 21

Section 4: Signal Overview

Daktronics Galaxy displays are equipped to receive many types of communication signals. The

following sections include a brief description of each available communication type. Also included is

a list of troubleshooting tips to check that the display is connected and configured correctly.

For specific details on installing the signal, consult the quick guide and the manual. These were

included in the shipment of the communications equipment. Each type is listed below with its

manual number.

Note: These are the standard communication types. However, each site is unique and may include

additional equipment. If problems arise, contact the display’s seller, service company, or Daktronics

Customer Service.

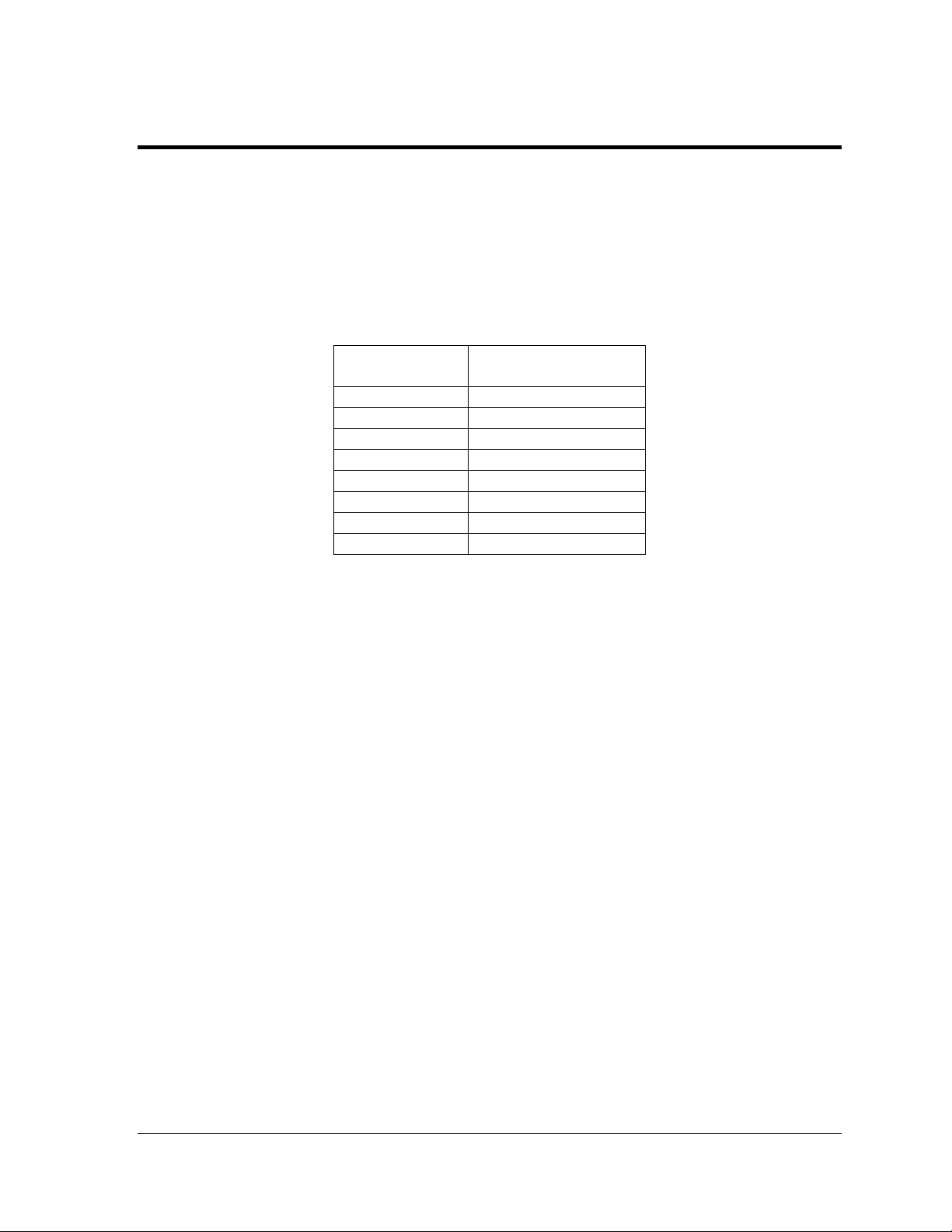

Communication

Type

RS-422

Fiber

Radio

RS-232

Ethernet

Fiber Ethernet

Ethernet Radio

Modem

Communication

Manual ED#

ED-14742

ED-14743

ED-13932

ED-14739

ED-14745

ED-14746

ED-16483

ED-14744

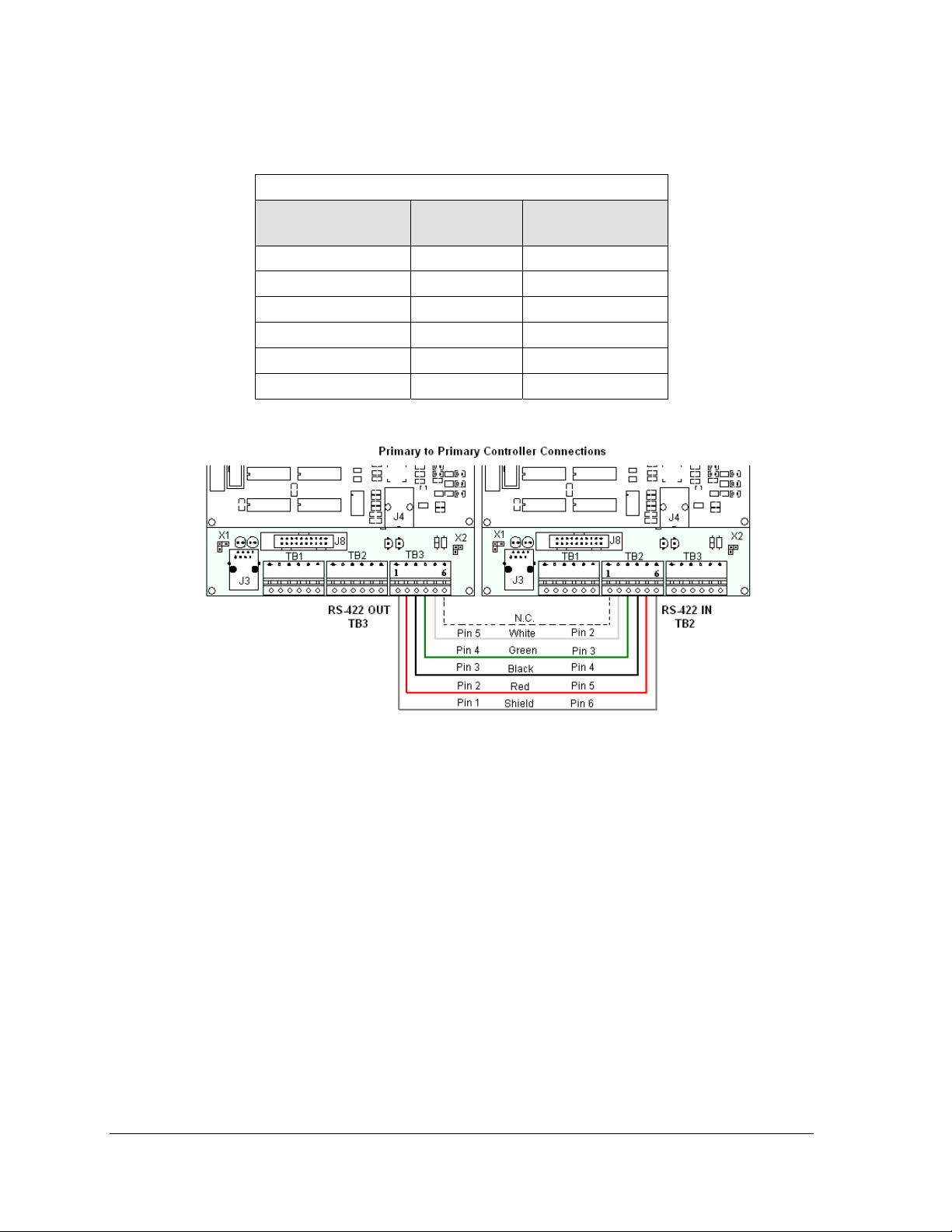

4.1 Primary to Primary Signal Connection

If this location requires multiple displays mounted back-to-back, two primary displays will be

installed. In that case, the following connections need to be made:

Remove the module from the bottom left corner of the display and locate the controller

for this display.

Route cable through conduit from the back of the first primary display to the back of the

second primary display. Use the knockouts for access, being careful not to damage any

internal components

Use either a 4-pair signal cable or two 4-conductor, shielded cables to connect both the

signal and the temperature sensor information between displays.

The signal cable will connect from TB3 out on the first primary display to either:

o A surge board at TB1 in a second primary display or

o To TB2 on the controller in the second primary display.

Note: In either case the connections are flipped. Refer to the table following and to Figure 11

for connections on both displays.

Signal Overview 15

Page 22

Primary

RS422 OUT (TB3)

Pin 1 (GND) Shield Pin 6 (GND)

Pin 2 (D2OUT-N) Red Pin 5 (D1IN-N)

Pin 3 (D2OUT-P) Black Pin 4 (D1IN-P)

Pin 4 (D2IN-N) Green Pin 3 (D1OUT-N)

Pin 5 (D2IN-P) White Pin 2 (D1OUT-P)

Pin 6 (Shield) Pin 1 (Shield)

RS-422 Interconnection Wiring

Field Cabling Primary

RS422 IN (TB2)

Figure 11: RS-422 Interconnection from Primary to Primary Display

Signal Overview 16

Page 23

4.2 RS-422 Communication

If the communication system is RS-422, look for:

a signal converter near the computer.

wires from the signal converter connecting to an enclosure at the display.

Figure 12: RS-422 Communication Layout

Connections

Computer to signal converter six-foot serial cable with 9-pin plug connecting to

computer port or USB adaptor and 25-pin plug connecting to the signal converter at J1,

RS232 IN.

Signal converter plugged into a 120 volt AC outlet.

Signal converter to surge board at display four individual wires from green Phoenix

plug at either J4 or J5 run to Phoenix plug on surge board.

Surge board to display quick-connect cable from enclosure to the center jack on display

back.

Troubleshooting

Component Check

Cable

Connections

Diagnostic

LEDs

Display Power The display is either running a message or showing a single pixel flashing in the

Software The software and the display are set for the same network address.

The serial cable connects the computer to the signal converter.

All the wires are connected at the signal converter and the surge board. They need

to be making good electrical contact with the metal, no interference.

The color sequence of the wires should be the same to both signal converter and

surge board (e.g. black, white, red and black, white, red).

The quick-connect cable is connected from the enclosure to the center jack on the

back of the display.

The green LED on the signal converter should be on when plugged into power.

The red transmit and amber receive LEDs will flash when sending and receiving

signal from the display; otherwise they are off.

bottom right corner of the display when power is on.

Refer to the software manual for other possible conditions.

Signal Overview 17

Page 24

4.3 Fiber Optic Communication

If the communication system is fiber optic, look for:

a signal converter near the computer.

fiber-optic cables connecting the signal converter to an enclosure at the display.

Figure 13: Fiber Serial Communication Layout

Connections

Computer to signal converter six-foot serial cable with 9-pin plug connecting to

computer port or USB adaptor; 25-pin plug connecting to the signal converter at J1,

RS232 IN.

Signal converter plugged into a 120 volt AC outlet.

Signal converter to fiber optic board at display two individual cables connect to signal

converter at either J4 and J5 or J3 and J2; other end runs to fiber optic board at display.

Fiber optic board to display quick-connect cable from enclosure to the top jack on

display back.

DO NOT SHARPLY BEND fiber-optic cable at any point along the fiber cable.

Troubleshooting

Component Check

Cable

Connections

Diagnostic

LEDs

Display Power The display is either running a message or showing a single pi xel flashing in the

Software The software and the display are set for the same network address.

The serial cable is connected from the computer to the signal converter.

Both fiber optic cables are connected at the signal converter and the fiber board.

The cable from the enclosure is connected to the top jack on display back.

The green LEDs on the signal converter and the fiber optic board in the enclosure

will be on when they have power.

The red transmit and amber receive LEDs on both components will flash when

sending and receiving signal from the display; otherwise they are off.

bottom right corner of display when power is on.

Refer to the software manual for other possible conditions.

Signal Overview 18

Page 25

4.4 Radio Communication

If the communication system is radio, look for:

a radio j-box near the computer.

a server radio outside the building and a second radio at the display.

Figure 14: Radio Communication Layout

Connections

Computer to radio j-box six-foot serial cable with 9-pin plugs on both ends, one

connecting to computer or USB adaptor and the other plug connecting to radio j-box at

“DB9 Female V1500 PC Connect”.

Radio j-box 12 volt power pack plugged into outlet.

Radio j-box to radio transmitter on building Phoenix plug on side of j-box to Phoenix

plug inside radio transmitter.

Radio signal between transmitter and receiver.

Radio receiver to display quick-connect cable from receiver to top jack on display back.

Troubleshooting

Component Check

Cable

Connections

Diagnostic

LEDs

Display

Power

Software The software and the display are set for the same network address.

The serial cable connects the computer to the radio j-box.

All the wires are connected at the radio j-box and at the “server” radio; the

wires make good electrical contact with the metal, no interference.

The color sequence of the wires should be the same to both the radio j-box

and the server (e.g. black, white, red and black, white, red).

The cable is connected from the radio client to the top jack on back of

display.

The green LED will be on when the radio j-box has power.

The amber LED is on when the computer is connected to the radio j-box.

The red and amber transmit and receive LEDs will flash when send ing and

receiving signal from the display; otherwise they are off.

The display is either running a message or showing a single pi xel flashing in

the bottom right corner of the display when power is on.

Signal Overview 19

Page 26

Refer to the software manual for other possible conditions.

4.5 RS-232 Communication

If the communication system is RS-232, look for:

no indoor connectors.

one enclosure at the display.

This communication type is designed to work over short distances and typically connects to

an indoor display.

Connections

Computer to display enclosure six-foot serial cable with 9-pin plug into laptop

computer or USB connector and a 25-pin jack into enclosure.

Enclosure to display quick-connect cable (maximum 25 feet) from back of enclosure to

top jack on back of display.

Troubleshooting

Component Check

Cable

Connections

Display

Power

Software The software and the display are set for the same network address.

Figure 15: RS-232 Communication Layout

The serial cable is connected from the laptop to the enclosure.

The cable is connected from the enclosure to the top jack on the back of

the display.

The display is either running a message or showing a single pi xel flashing

in the bottom right corner of the display when power is on.

Refer to software manual for other possible conditions.

Signal Overview 20

Page 27

4.6 Ethernet Communication

If the communication system is Ethernet, look for:

a network card in the computer connecting to a network jack on the wall.

a network jack similar to an oversized phone jack.

Figure 16: Ethernet Communication Layout

Connections

Computer to network jack RJ45 cable (similar to phone cable) from computer port to

network server in building.

Network to surge board RJ45 cable from hub or router to surge board in enclosure at

display.

Enclosure at display to display quick-connect cable from enclosure to middle jack on

back of display.

Troubleshooting

Component Check

Cable

Connections

Display

Power

Software The software is configured for TCP/IP communication.

The network cable connects the computer to the network port on the wall.

The wire from the server is connected to the input port on the Ethernet surge board.

The quick-connect cable runs from the enclosure to the middle jack on display back.

The display is either running a message or showing a single pi xel flashing in the bottom

right corner of the display when power is on.

The software and the display are set for the same network address.

Refer to the software manual for other possible conditions.

Signal Overview 21

Page 28

4.7 Fiber Ethernet Communication

If the communication system is fiber Ethernet, look for:

an indoor media converter connected to the network via Cat-5 cable and to fiber

cable.

a second media converter outdoors located in an enclosure at the display.

Figure 17: Fiber Ethernet Communication Layout

Connections

Computer to network RJ45 cable (similar to phone cable) from computer port into

network jack.

Network to first media converter RJ45 cable into media converter.

Media converter’s 9-volt power packed plugged into outlet.

Indoor media converter to outdoor media converter two fiber-optic cables run from

indoor media converter to second converter in the enclosure at display.

Enclosure to display quick-connect cable to the middle jack on display back.

DO NOT SHARPLY BEND fiber-optic cable at any point along the fiber cable.

Troubleshooting

Component Check

Cable

Connections

Diagnostic

LEDs

Display

Power

Software The software is configured for TCP/IP communication.

The serial cable is connected from the computer to the network port at the wall.

The network cable connects to the media converter in building.

The indoor media converter power pack is plugged in.

The fiber cables connect from the first media converter to the second one at

display. The “out” arrow on one will connect to an “in” arrow on the other.

The cable is connected from the enclosure to middle jack on display back.

Each media converter has a green power LED on, indicating power.

The “link” and RX LEDs on the media converter flash when transmitting data.

The display is either running a message or showing a single pi xel flashing in the

bottom right corner of the display when power is on.

The software and the display are set for the same network address.

Signal Overview 22

Page 29

Refer to the software manual for other possible conditions.

4.8 Ethernet Bridge Radio Communication

If the communication system is a wireless Ethernet radio, look for:

a DC injector connected to the network, server radio, and DC power pack.

a server (transmitter) radio mounted on the building and a client (receiver) radio at

the display.

Note: This system is referred to as Ethernet "bridge" communication because it requires a pair

of matched radios to create a signal connection or bridge.

Figure 18: Ethernet Bridge Radio Layout

Connections

Computer to network RJ45 cable from computer port into network jack.

Network jack to DC injector - RJ45 cable from network to "DATA IN" jack.

Wall power pack - DC injector power pack to 120 VAC outlet.

DC injector to server radio - RJ45 cable from "P+DATA OUT" to server radio.

Server radio to client radio - clear line of sight for signal transmission.

Client radio to display quick-connect cable to the middle jack on display back.

Troubleshooting

Component Check

Cable

Connections

Diagnostic

LEDs

Display

Power

Software The software is configured for TCP/IP communication.

A cable connects the computer to the network port on the wall.

A cable runs from the network to the DC injector.

The DC injector power pack is plugged into a 120 VAC outle t.

A network cable runs from DC injector to server radio.

A cable is connected from the client radio to the top jack on back of display.

The DC injector's green LED should be on, indicating power.

Both radios have internal LEDs: red for power, green for RF link.

The RX and TX LEDs will flash when transmitting data.

The same channel LEDs will be on for both radios when locked together.

The display is either running a message or showing a single pixel flashing in

the bottom right corner of the display when power is on.

The software and the display are set for the same network address.

Signal Overview 23

Page 30

Refer to the software manual for other possible conditions.

4.9 Modem Communication

If the communication system works with a modem, look for:

a modem (internal or external) at the computer that connects to a phone jack.

a phone line connects to the display enclosure.

Figure 19: Modem Communication Layout

Connections

Computer modem (internal or external) to phone jack on wall phone cable plugs into

both.

Phone jack to modem at display signal runs on local telephone lines.

Modem board in enclosure to display quick-connect cable from enclosure to top jack

on display back.

Troubleshooting

Components Check

Cable

Connections

Diagnostic

LEDs

Display Power The display is either running a message or showing a single pi xel flashing in the bottom

Software The software and the display are configured for dial-up communication and the phone

The phone line is connected from the modem at the computer to the phone jack.

The two phone wires are connected at the modem board (Wire color is determined by

the phone company.)

The wires are making good electrical contact with the metal, no interference.

The cable is connected from the enclosure to the top jack on the display back.

The modem in the enclosure has the green LED on, indicating power.

The bottom red LED (carrier detect) is on when the modems are connected.

Transmit and receive LEDs flash when sending and receiving signal over the telephone

line; otherwise, they are off.

right corner of the display when power is on.

number is correct.

Refer to the software manual for other possible conditions.

Signal Overview 24

Page 31

4.10 Temperature Sensor Installation

See Appendix B for mounting and signal connections.

Mount the temperature sensor to the display structure, preferably at least one foot away from

the display. Terminate this to the primary display with a quick-connect cable. DO NOT

mount the temperature sensor between displays or in any location where the airflow is

restricted.

Signal Overview 25

Page 32

Page 33

Section 5: Start-up Procedure

Before starting up the display, go over this checklist to ensure that all parts are ready to operate

correctly. Figure 20 shows the basic display components referred to in each step.

5.1 Start-up Checklist

DIs power connected to the display?

The power conduit will leave the display from the rear and connect to a power source either

on the display structure or inside a building. Refer to Figure 20 for approximate location of

the power cable or conduit.

DIf the display has two faces, are the two sides connected?

Check that a quick-connect cable runs between the back connections of the two display

cabinets.

DIs the control computer connected to the display?

Some type of communication line or wireless device will send signal between the control

computer and the display, depending on the communication method. Refer to Section 4 for

assistance with identifying the communication type.

DIs the computer software set up to work with the display?

The software manual provides the information necessary to allow the computer to

communicate with this display. Follow the step-by-step directions in the Configuration

section of the software manual for correct set-up.

Figure 20: Basic Display Set-up

Start-up Procedure 27

Page 34

5.2 Start-up Sequence

Each time the display is turned on, an initialization sequence will run. The information in the

second column will then be shown on the display.

Note: The Xs refer to numbers that may vary for each display, such as the hardware address.

Topic Information shown

1. Product Name Galaxy®

2. Display Size Row x Column

3. Shading RGB

4. Bootloader Version OS X.XX

5. Firmware Number ED-13305

6. Firmware Revision Rev X.XX

7. Hardware Address HW:XX

8. Software Address SW:XX

9. IP Address: (default: IP: 172.16.192.25)

10. Subnet Msk: (default) Msk: 255.255.0.0)

11. COM1 Configuration C1:V15

12. COM 2 Configuration C2: RTD

13. Socket 3001: IP 3001: V15

14. Socket 3002: IP 3002: RTD

15. Line Frequency CLK: AUTO (60)

16. Display Description Galaxy # rows x # columns

After this sequence is complete, the display will blank. A single pixel will flash in the lower

right hand corner of the display to show that the display has power but no messages are

currently running.

(modem: C1:V15 if a modem is present)

Start-up Procedure 28

Page 35

Section 6: Maintenance and Parts Replacement

Important Notes:

Power must be turned off before any repair or maintenance work is done on the

display.

Qualified service personnel must make any access to internal display electronics.

The Daktronics engineering staff must approve ANY changes made to the display.

Before altering the display, detailed drawings for the proposed modifications must be

submitted to the Daktronics engineering staff for evaluation and approval or the

warranty will be rendered null and void.

Daktronics Galaxy

components is gained by removing the front modules of the display. The display may need to be

opened to perform maintenance or for troubleshooting. The following diagram (Figure 21) shows the

typical location of internal components. Component location may vary according to pixel matrix size.

Refer to the Layout Drawing in Appendix A for the specific size for accurate location of components.

AF-3400 12mm displays are front accessible, meaning that access to internal

Figure 21: Location of Internal Components

Maintenance and Troubleshooting 29

Page 36

6.1 Display Access

To gain access to the interior of a display, single modules are able to be removed. Refer to

Figure 22 to locate the internal components which may need to be accessed. In the case of

fans, consult the Shop Drawing for the specific display. The module in front of the specific

component may be removed to perform maintenance or for troubleshooting.

To access the interior of the display, perform the following steps:

1. Turn off power to the display.

2. Locate the latch access fasteners on the module. One is centered below the third row

of pixels and one is centered above the bottom three rows.

3. With a

turns counterclockwise to open and the other turns clockwise. Gently pull the

module far enough forward to reach behind the back and disconnect the power and

ribbon cables. Note the cable connections so they can later be reconnected correctly.

4. Disconnect the two ribbon cables from the module by spreading the tabs on the sides

and then lifting the cable head from the jack. Note how they are connected to the

back.

5. Unplug the power cable by squeezing the tabs on the sides of the plug head and

pulling out.

6. When ready to reinstall the module, reconnect the cables to the module, making sure

that the tabs are tightly pushed against the cable head. Carefully push the ribbon

wires back into the cabinet so they are clear of the module edges.

7. Place the module into its proper location, checking that the weather stripping is in

place. Latch the module both top and bottom using the hex wrench.

Note:

The weather-stripping on the back edge of the module must be intact and in good

condition if it is to prevent water from seeping into the display.

The module latches must be fully engaged to create a watertight seal around the edge of

the module. The module should be firmly seated against the display when the latches are

fully engaged.

1

/8" hex wrench, turn the latch access fasteners a quarter turn – one latch

Figure 22: Opening Display

Maintenance and Troubleshooting 30

Page 37

6.2 Maintenance

Ventilation

Ventilation fans should be checked every time the display is

opened or at least annually to ensure the display is being cooled

properly. Fans should be checked more often if the display is

located in a dusty or harsh weather environment (i.e. along a

gravel road with dust laden air).

Each time a module is removed, for whatever reason, take a

minute to inspect the fans. Spin the fan blades with a pen or

pencil to ensure that the bearings are free and the fan is still in

balance.

To check the operation of the fans, push the bypass button

(momentary contact) on the thermostat enclosure to temporarily

turn the fans on. (The thermostat is located behind module A102.)

Hold your hand or a piece of light paper in front of the display to detect air

movement.

If the fan does not turn or does not operate smoothly, replace it.

Make sure that the intake vents and exhaust vents on the front of the display are not blocked

and are free of dust or other debris.

Figure 23: Display fans

Thermostats

A thermostat controls the operation of the ventilation fans in the display. The thermostat

enclosure includes a bypass button, which will temporarily turn the fans on. The thermostat

is generally located behind the top left module. The ventilation fans turn on when the inside

of the display reaches 85 F (29 C), and turn off at 65 F (21 C).

Weather Stripping

To ensure that the display is waterproof, weather stripping has been provided around the

entire display and around each module. It is important that the weather stripping is installed

properly at all times or water may leak into the display and damage the components.

Maintenance and Troubleshooting 31

Page 38

Annual Maintenance

A yearly inspection should be completed to maintain safe and dependable display operation.

This inspection should address the following issues:

Inspection item Possible corrective measures

Loose bolts, screws, rivets Tighten or replace, as required

Dust around fans, on cabinet bottom Vacuum or carefully wipe away

Replace weather-stripping

Tighten module latches

Water intrusion or stains

Paint corrosion by footings, tie

points, ground rods

Place silicon sealant around all locations

where water might enter

Replace damaged electronic components

Check the metal for structural integrity.

Replace and/or repaint as necessary.

6.3 Troubleshooting

This sub-section contains some symptoms that may be encountered in the displays. This list

does not include every possible symptom, but does represent common situations that may

occur.

Symptom/Condition Possible Cause/Remedy

One or more LEDs on a single

module fail to light.

One or more LEDs on a single

module fail to turn off.

A section of the display is not

working. The section extends all

the way to the right side of the

display.

One row of modules does not work

or is distorted.

A group of modules, (a

Replace/check ribbon cables on the module.

Replace the module.

Replace/check ribbon cables on module.

Replace the module.

Replace/check the ribbon cable.

Replace/move the first module/driver that is not working.

Replace/move the first module/driver on the left side of the

module that is not working.

Check/replace the power supply assembly on the first

module that is not working.

Replace/check ribbon cable to and from first non-working

module.

Check for bent pins on module and controller.

Replace/move module that is distorted.

Replace/move the first module to the left of the one that is

not working.

Replace controller.

Check the voltage to the module.

Check wire connections at power supply and at module.

Maintenance and Troubleshooting 32

Page 39

column of block) which share

Replace the power supply assembly.

the same power supply

assembly, fail to work.

Entire display fails to work. Check for proper line voltage to the power J-box.

Check for correct power at power termination panel.

Check for correct power to modules (12 VDC).

Check the breakers in the power termination panel.

Check/replace the ribbon cable from the controller to the

modules.

Check the voltage settings on the power supplies.

Check the signal cable to the controller.

Replace the controller.

Verify proper use of the software in the operation manual on

the CD (ED-13530).

Temperature always reads –196F/127C degrees F/0 degrees C.

Display is stuck on bright or dim. Check Manual/Auto dimming in Venus 1500 software.

Check temperature sensor cable connections at both

displays.

Check for correct power on temperature sensor.

Check that the temperature sensor address is set to 1.

Replace the temperature sensor.

Check light detector cable/wiring.

Check light detector for obstructions.

Replace the light detector.

Replace the controller.

6.4 Replacement Parts List

Daktronics displays are built for long life and require little maintenance. However, from time

to time, certain display components will need replacing. The Replacement Parts List

provides the names and numbers of components that may need to be ordered during the life

of the display. Information on the Daktronics Exchange and Repair & Return Programs is

located in Section 5. Refer to these instructions if any display component needs replacement

or repair.

Note: A collection of circuit boards working as a single unit may carry an assembly label.

Cables may also carry the assembly numbering format in certain circumstances. This is

especially true of ribbon cables.

Most circuit boards and components within this display carry a label that lists the part

number of the unit. If a circuit board or assembly is not listed in the Replacement Parts List,

use the label to order a replacement. A typical label is shown in Figure

24. The part number is in bold.

To prevent theft, Daktronics recommends purchasing a lockable cabinet

to store manuals and replacement/spare parts.

Figure 24: Typical Label

Maintenance and Troubleshooting 33

Page 40

Part Description Part Number

Controller II, Louvered Galaxy, 8-connector 0A-1229-0013

Module, AF-3400-24x16-12-1R1G1B 0A-1337-4551

Power Supply Assembly, A-1997, RGB Displays 0A-1327-0014

Power Supply Fuse, ATM15, 32V, 15A F-1058

Digital Temp Sensor Board 0P-1247-0008

Light Level Detector Board 0P-1151-0002

Fan; 134 CFM, 120V @60Hz, 22 watt B-1053

Fan; 134 CFM, 240V @60Hz, 22 watt B-1011

Transformer; Pri 115V, Sec 10VCT@3A T-1119

Transformer; Pri 240V, Sec 10VCT@3A T-1121

Filter, RFI Line 20 AMP 120 VAC Z-1007

Ribbon Cables; 20 Position

Cable Assy; 20 pos Ribbon, 18”, Dual Row W-1387

Ribbon Assy; 20 Pos, 30” 0A-1000-0017

Ribbon Assy; 20 Pos, 42” 0A-1000-0019

Cable; 22 AWG, 2-pair, shielded (Light Sensor/Temp

Sensor to Controller)

Quick Connect Interface, Input, w/Ethernet

Electrical Contact Cleaner Lubricant / Cal-Lube CH-1019

Hex Wrench, T-Handle 1/8” RT TH-1062

W-1234

0P-1229-2004

Maintenance and Troubleshooting 34

Page 41

6.5 Replacing Parts

Location of Internal Components

To replace components inside a display, only the module in front of the specific component

will need to be removed. The components in a typical 12 mm Galaxy displays are located as

shown in Figure 21.

Module Replacement

To remove and replace a module, follow these steps:

1. Locate the latch access fasteners on the module. One is centered below the third row

of pixels and one is centered above the bottom threerows.

2. With a

turns counter-clockwise to open and the other clockwise to open. Refer to in Figure

25 for a module being removed.

3. Gently pull the module far enough forward to reach behind the back and disconnect

the power and ribbon cables.

4. Connect the power and signal cables to the new module.

5. Position the module in place, making sure that the cables are inside the display.

6. Close both latches using the hex wrench.

Important Notes

The weather-stripping on the back edge of the module must be intact and in good

condition if it is to prevent water from seeping into the display.

The module latches must be fully engaged to create a watertight seal around the edge

of the module. The module should be firmly seated against the display when the

latches are fully engaged.

1

/8" hex wrench, turn both latch access fasteners a quarter turn – one latch

Figure 25: Removing a Module

Maintenance and Troubleshooting 35

Page 42

Transformer and RFI Filter Replacement

Transformer

The transformer is located in the upper portion of the display’s power termination panel, as

shown in Figure 26.

To replace the transformer:

1. Turn off power to the display before removing

the wires.

2. Disconnect and label all the wires attached to the

transformer.

3. Release the hardware securing it to the inside of the

enclosure.

Position the new transformer in its place, and

4.

replace the fastening hardware.

Re-connect all the wires using the Drawing A-

5.

253685 as a reference.

Figure 26: One-circuit Power Termination

RFI Filter

The RFI electrical filters are inside of the power termination box. To replace an RFI (or Z)

filter, follow these steps:

1. Like the transformer, label all connecting wires and then remove them.

2. Release the attachment hardware.

3. Install the new filter using Drawing A-253685 as a reference.

Power Supply Replacement

A power supply unit has 12 outputs on the power distribution

board and controls up to twenty-four modules. Each power output

jack is paired with an automotive grade fuse. Each output from the

power supply assembly provides 12 VDC to the display modules.

To replace the power supply:

1. Turn off power to the display.

2. Remove the module in front of the power supply to be

replaced. (Consult the Shop Drawing for its location.)

3. Disconnect the power and signal connectors from the

power supply distribution board, labeling them for

replacement.

4. Loosen the screw holding the power supply bracket to the

display cabinet and lift it off the screw. Carefully pull it out

of the cabinet.

5. Move the new power supply into place and tighten the

screw on the support bracket.

Figure 27: Power Supply

Maintenance and Troubleshooting 36

Page 43

6. Reconnect using Drawing A-253685 for reference.

Maintenance and Troubleshooting 37

Page 44

Controller

The controller's role is to send data to the modules. Figure 28 illustrates a typical controller.

Figure 28: Controller Component Layout

Diagnostic LEDs are located on the controller. The table below tells what each LED denotes:

Figure/ label LED # Color Operation

Run

Send signal

TX1

Receive signal

RX1

DS4 Red Steady FLASH about once per second indicates

controller is working properly.

DS3 Yellow OFF is the normal state. FLASH when transmitting

communication from the computer.

DS4 Yellow OFF is the normal state. FLASH when receiving

communication from the computer.

Complete the following steps to remove or replace the controller in the display:

1. Turn off power to the display.

2. Remove the module directly in front of the controller in the lower left corner of the

display.

3. Disconnect the power plug from J5.

4. Remove all power and signal connections from the board, labeling the cables as they

are disconnected.

5. Remove the six nuts holding the board in place using a 5/16" nut driver.

6. Take note of the address of the controller and ensure the address on the replacement

board is the same.

Follow the previous steps in reverse order to install a new controller board.

Maintenance and Troubleshooting 38

Page 45

The rotary switches set the hardware address which the software uses to identify that

particular display. When replacing a controller board, be sure to set the rotary switches in the

same address configuration as the defective controller. Each controller in a network needs a

unique address.

Note: Set the switches by rotating them counter-clockwise until the arrow points to the

desired number. Setting both rotary switches to address 0 can activate a test mode. The

display’s power must be turned off and then turned back on to notify the controller of any

change of address.

Controller Address Settings

Address Upper Lower Address Upper Lower

Test Mode 0 0 10 0 A

1 0 1 11 0 B

2 0 2 12 0 C

3 0 3 13 0 D

4 0 4 14 0 E

5 0 5 15 0 F

6

7 0 7 17 1 1

8 0 8 … … …

9 0 9 240 F 0

0 6 16 1 0

Maintenance and Troubleshooting 39

Page 46

Page 47

Section 7: Daktronics Exchange and Repair &

Return Programs

To serve customers' repair and maintenance needs, Daktronics offers both an Exchange Program and

a Repair & Return Program.

Before Contacting Daktronics

Print any important part numbers here:

Fill in these numbers before calling Customer Service:

Display Serial Number: ________________________________________

Display Model Number: ______AF-3400 12 mm

Contract Number: _____________________________________________

Date Installed: ________________________________________________

Location of Display: ___________________________________________

Daktronics Customer ID Number: _________________________________

___________________

7.1 Exchange Program

Daktronics' unique Exchange Program is a quick service for replacing key parts in need of

repair. If a part requires repair or replacement, Daktronics sends the customer a replacement,

and the customer sends the problem part to Daktronics. This decreases display downtime.

To participate in the Exchange Program, follow these steps.

1. Call Daktronics Customer Service: 866-343-3122.

2. When the new exchange part is received, mail the old part to Daktronics.

If the replacement part fixes the problem, send in the problem part which is being

replaced.

a. Package the old part in the same shipping materials in which the replacement

part arrived.

b. Fill out and attach the enclosed UPS shipping document.

c. Ship the part to Daktronics.

3. A charge will be made for the replacement part immediately, unless a qualifying

service agreement is in place.

In most circumstances, the replacement part will be invoiced at the time it is shipped.

4. If the replacement part does not solve the problem, return the part within 30

working days or the full purchase price will be charged.

Repair and Return Program 41

Page 48

If the equipment is still defective after the exchange is made, please contact Customer

Service immediately. Daktronics expects immediate return of an exchange part if it

does not solve the problem. The company also reserves the right to refuse parts that

have been damaged due to acts of nature or causes other than normal wear and tear.

7.2 Repair & Return Program

For items not subject to exchange, Daktronics offers a Repair & Return Program. To send a

part for repair, follow these steps.

1. Call or fax Daktronics Customer Service:

Phone: 866-343-3122 Fax: 605-697-4444

2. Receive a Return Materials Authorization (RMA) number before shipping.

This expedites repair of the part.

3. Package and pad the item carefully to prevent damage during shipment.

Electronic components, such as printed circuit boards, should be placed in an

antistatic bag before boxing.

4. Enclose:

your name

address

phone number

the RMA number

a clear description of symptoms

Shipping Address

Daktronics Customer Service

PO Box 5128

331 32nd Ave

Brookings SD 57006

7.3 Daktronics Warranty and Limitation of Liability

Daktronics Warranty and Limitation of Liability is included in Appendix C. The Warranty is

independent of Extended Service agreement and is the authority in matters of service, repair, and

display operation.

Repair and Return Program 42

Page 49

Appendix A: Reference Drawings

Refer to Section 1 for information on reading drawing numbers. The following drawings are listed in

numerical order by size (A, B, etc.).

Schematic, Power Term Panel, 2 Circuit-120VAC .................................................... Drawing A-211947

Schematic, Power Term Panel, 1 Circuit-120VAC .................................................... Drawing A-211950

Schematic, Power Term Panel, 2 Pole-240VAC ....................................................... Drawing A-218666

Schematic, Power Term Panel, 1 Pole-240VAC ....................................................... Drawing A-220287

Schematic, AF-3400-12-RGB-P, General ................................................................. Drawing A-253685

Power Specs, AF-3400-(24x192-96-192)-12-RGB ................................................... Drawing A-254277

Schem., Primary Signal, Internal, W/QC ................................................................... Drawing B-2 06146

Elect Layout, AF-3400-24x***-12-RGB ..................................................................... Drawing B-253856

Elect Layout, AF-3400-48x***-12-RGB ..................................................................... Drawing B-253858

Elect Layout, AF-3400-72x***-12-RGB ..................................................................... Drawing B-253860

Elect Layout, AF-3400-96x***-12-RGB ..................................................................... Drawing B-253861

Reference Drawings 43

Page 50

Page 51

Page 52

Page 53

Page 54

Page 55

Page 56

Page 57

Page 58

Page 59

Page 60

Page 61

Appendix B: Temperature Sensor

Temperature Sensor Installation 44

Page 62

p. 1 of 6 Optional Temperature Sensor Mounting

For Galaxy displays only

Reference Drawings:

Temperature Sensor Cable Routing Schematic .............................................. Drawing A-197884

Exploded Temperature Housing Assembly...................................................... Drawing A-198371

1.1 Temperature Sensor Overview

The temperature sensor enclosure is made up of eight plastic

disks, a metal mounting bracket, and a 25-foot weather resistant

cable. Refer to Figure 1.

In most cases, the enclosure will be mounted using two screws.

The cable will be plugged into the back of the display.

In certain cases, it may be necessary to disassemble the enclosure

or rewire the temperature sensor board. Instructions are

provided for those situations. If replacement or additional parts

are needed, refer to the following chart for part numbers.

Part description Daktronics part number

Temperature sensor housing 0A-1151-0005

Temperature sensor 0P-1247-0008

4-pin Mal Conxall cable W-1819

22 AWG 2-pair shielded cable W-1234

30-foot extension cable W-1820

100-foot extension cable W-1821

200-foot extension cable W-1822

Parts List

Figure 1: Temperature Sensor

1.2 Mounting Locations

For greater accuracy of temperature, follow these mounting recommendations:

• An ideal location is under a north eave or on a northern exposure away from direct

sunlight (Figure 4).

• Mount the sensor above grass or vegetation rather than concrete or other paving.

• Mount at least 20 feet away from chimneys, vents, air conditioners, or other items that

would influence correct temperature readings.

• Do not mount between displays or in any location that restricts air movement.

• Mount the sensor so that the cable can be protected from weather and vandalism.

The most common locations for the temperature sensor are on the display cabinet (Figure 2),

or on the display structure (Figure 3). A light-colored display is preferred in this location.

Location of the sensor should be below or on a northern edge of the display to keep the

sensor shaded.

ED-14377-Rev 4

3 October 2007

Page 63

p. 2 of 6 Optional Temperature Sensor Mounting

Figure 2: Located on the Display Figure 3: Located on Structure Figure 4: Located on the North Eave

When exposed to outdoor conditions, it is necessary to route cable through conduit. In cases

such as this, the quick-connect cable must be extended or replaced with four-conductor, 22AWG, shielded cable. The maximum length of the cable should be no more than 500 feet.

Mounting to a sheet metal surface

Follow these instructions when mounting the sensor to a sheet metal surface:

1. Drill two pilot holes using a 5/32” drill bit. Horizontally space the holes 1.5” apart.

2. Insert two self-drilling screws through the holes of the mounting bracket, and screw

into the pilot holes.

3. Route cable up to the quick-connect jack on the back of the display and plug into J31.

Refer to Section 1.3 for an example of connection.

1.3 Temperature Signal Connection

Three options for signal connection are explained in this section:

• Using the 25-foot quick-connect cable.

• Using the quick-connect cable but less than 25 feet.

• Using more than 25-feet including extension cables or 22 AWG shielded cable.

Using the provided 25-foot quick-connect cable

1. The temperature sensor is provided with a 25-foot weather-

resistant cable. This cable does not need to be in conduit. The

sensor connects to the display at J31. Refer to Figure 5 for the

location of the quick-connect plug.

2. Secure any excess cable to discourage vandalism.

3. Between displays, the quick-connect signal cable connects

both communication and temperature signal, thus no

additional wiring is required from display to display for the

temperature sensor.

Figure 5: Quick-connect Cable

p. 2 ED-14377-Rev4

3 October 2007

Page 64

p. 3 of 6 Optional Temperature Sensor Mounting

Using the quick-connect cable and less than the 25-foot cable

1. Open the temperature sensor housing by removing the four nuts from the bottom

and then removing the five bottom disks. Refer to Drawing A-198371 for details on

sensor housing disassembly.

2. Disconnect the quick-connect CAN temperature sensor cable from the temperature

terminal block in the CAN temperature sensor housing.

3. Cut the cable to the desired length and reattach to the temperature sensor terminal

block in the CAN temperature sensor housing. Refer to the table and Figure 6 for the

temperature sensor wiring.

4. Make sure to route cable around the sensor board as shown in Figure 7 and Drawing

A-197884.

5. Reconnect the cable and reassemble the sensor.

Figure 6: CAN Temperature Sensor Wiring

Wire Color

Red +5V CAN (Pin 1)

Green CANH (Pin 2)

White CANL (Pin 3)

Black GND (Pin 4)

*Note: Do not terminate shield at this point.

Temperature Sensor

Terminal Block (TB1)

Figure 7: Wiring Around Sensor

ED-14377-Rev 4

3 October 2007

Page 65

p. 4 of 6 Optional Temperature Sensor Mounting

Using more than 25-feet of cable

To meet customer needs, Daktronics has designed extension cables that allow extra length

from the sensor to the display without separate rewiring. These cables contain the correct

circular ends to be used with the quick-connect cable and quick-connect input. Refer to the

parts list in Section 1.1 for the cable options available.

If 22 AWG shielded cable is used instead of the cable extensions, follow these steps:

1. Run 1/2” conduit from the temperature sensor to a knockout on the back of the

primary display. The cable must be routed through 1/2” metal conduit that should

be earth-grounded to protect the sensor and controller from lightning damage.

2. Use a 2-pair 22 AWG individually shielded cable to connect the sensor to the 8-

position terminal block in the display labeled “CAN US/DS” (A31/TB4). Connect to

the controller as shown in Figure 8.

3. Open the temperature sensor housing by removing the four nuts from the bottom

and then removing the five bottom disks. Refer to Drawing A-198371 for details on

sensor housing disassembly.

4. Disconnect the quick-connect temperature sensor cable from the terminal block in the