Page 1

Galaxy® AF-3220

Installation and Operation Manual

DD1758104 Rev 04 – 22 July 2014

201 Daktronics Drive PO Box 5128 Brookings, SD 57006

tel 800-843-5843 fax 605-697-4700

www.daktronics.com

Page 2

DD1758104

Product 1620

Rev 04 – 22 July 2014

Complete the chart with specific information about this display so the details are readily available when calling for

service or replacement parts.

Information needed for technicians and/or Customer Service Fill in the blank

Location address of the display:

Model number of the display: AF-3220 34 mm

Version of software being used:

Method of communication being used:

Controller version used in the display: Version 3

Display’s address on network

Copyright © 2009-2014

All rights reserved. While every precaution has been taken in the preparation of this manual, the publisher assumes no

responsibility for errors or omissions. No part of this book covered by the copyrights hereon may be reproduced or copied in any

form or by any means – graphic, electronic, or mechanical, including photocopying, taping, or information storage and retrieval

systems – without written permission of the publisher.

Galaxy® and Venus® are trademarks of Daktronics, Inc. Windows® is a trademark of Microsoft® Corporation. IBM® is a trademark of IBM Corporation. Mate-N-

Lok® is a trademark of AMP Company.

Page 3

Table of Contents

Section 1: Introduction .......................................................................................................................................... 1

1.1 Display Details ...................................................................................................................................................... 1

Section 2: Mechanical Installation ....................................................................................................................... 3

2.1 Installation Guidelines ........................................................................................................................................ 3

DO: .................................................................................................................................................................. 3

DON’T: ........................................................................................................................................................... 3

2.2 Support Structure Requirements ...................................................................................................................... 3

2.3 Display Mounting ................................................................................................................................................ 4

Section 3: Power Installation ................................................................................................................................ 5

3.1 Installation Guidelines ........................................................................................................................................ 5

DO: .................................................................................................................................................................. 5

DON’T: ........................................................................................................................................................... 5

3.2 Conduit .................................................................................................................................................................. 5

3.3 Power Requirements ............................................................................................................................................ 5

Main Disconnect ............................................................................................................................................ 6

3.4 Grounding ............................................................................................................................................................. 6

3.5 Power Connection ................................................................................................................................................ 7

Section 4: Signal Installation Overview ............................................................................................................... 9

4.1 Primary/Mirror Display Interconnections ....................................................................................................... 9

4.2 USB to Ethernet Adapter ..................................................................................................................................... 9

Section 5: Start-Up Procedure ............................................................................................................................11

5.1 Start-up Checklist ............................................................................................................................................... 11

5.2 Boot Sequence ..................................................................................................................................................... 11

Section 6: Maintenance ...................................................................................................................................... 13

6.1 Display Access .................................................................................................................................................... 13

6.2 Ventilation System Maintenance .................................................................................................................... 13

Fans ............................................................................................................................................................... 13

Filters ............................................................................................................................................................ 14

6.3 Annual Inspection .............................................................................................................................................. 14

Section 7: Diagnostics and Troubleshooting .................................................................................................... 15

7.1 Controller Diagnostics ....................................................................................................................................... 15

7.2 Troubleshooting Display Problems ................................................................................................................ 15

Tools Required for Troubleshooting: ....................................................................................................... 15

Table of Contents i

Page 4

One or More LEDs Do Not Light or Are Stuck On ................................................................................ 16

Section of the Display Does Not Work – Extending All the Way to Right End ................................ 16

One Row of Modules Does Not Work or Shows a Distorted Message ............................................... 16

Entire Display Fails to Work ..................................................................................................................... 16

Blank Display Seen After Boot-Up ........................................................................................................... 16

Message Only Appears on One Side of the Display .............................................................................. 16

Unable to Communicate (Send Content) to the Display ....................................................................... 17

Before Calling for Help .............................................................................................................................. 17

Section 8: Parts Replacement ............................................................................................................................ 19

8.1 About Replacement Parts .................................................................................................................................. 19

8.2 Instructions for Replacing Parts ....................................................................................................................... 19

Module Removal/Replacement ................................................................................................................ 19

Controller Replacement ............................................................................................................................. 20

Controller Address Setting ........................................................................................................................ 21

Power Supply Replacement ...................................................................................................................... 21

Section 9: Daktronics Exchange and Repair & Return Programs .................................................................. 23

9.1 Exchange Program ............................................................................................................................................. 23

Before Contacting Daktronics ................................................................................................................... 23

9.2 Repair & Return Program ................................................................................................................................. 24

Shipping Address........................................................................................................................................ 24

Appendix A: Reference Drawings .......................................................................................................................... 27

Appendix B: Temperature Sensor Installation (ED-14377) .................................................................................. 29

Appendix C: Daktronics Warranty and Limitation of Liability (SL-2374) ............................................................ 31

ii Table of Contents

Page 5

Section 1: Introduction

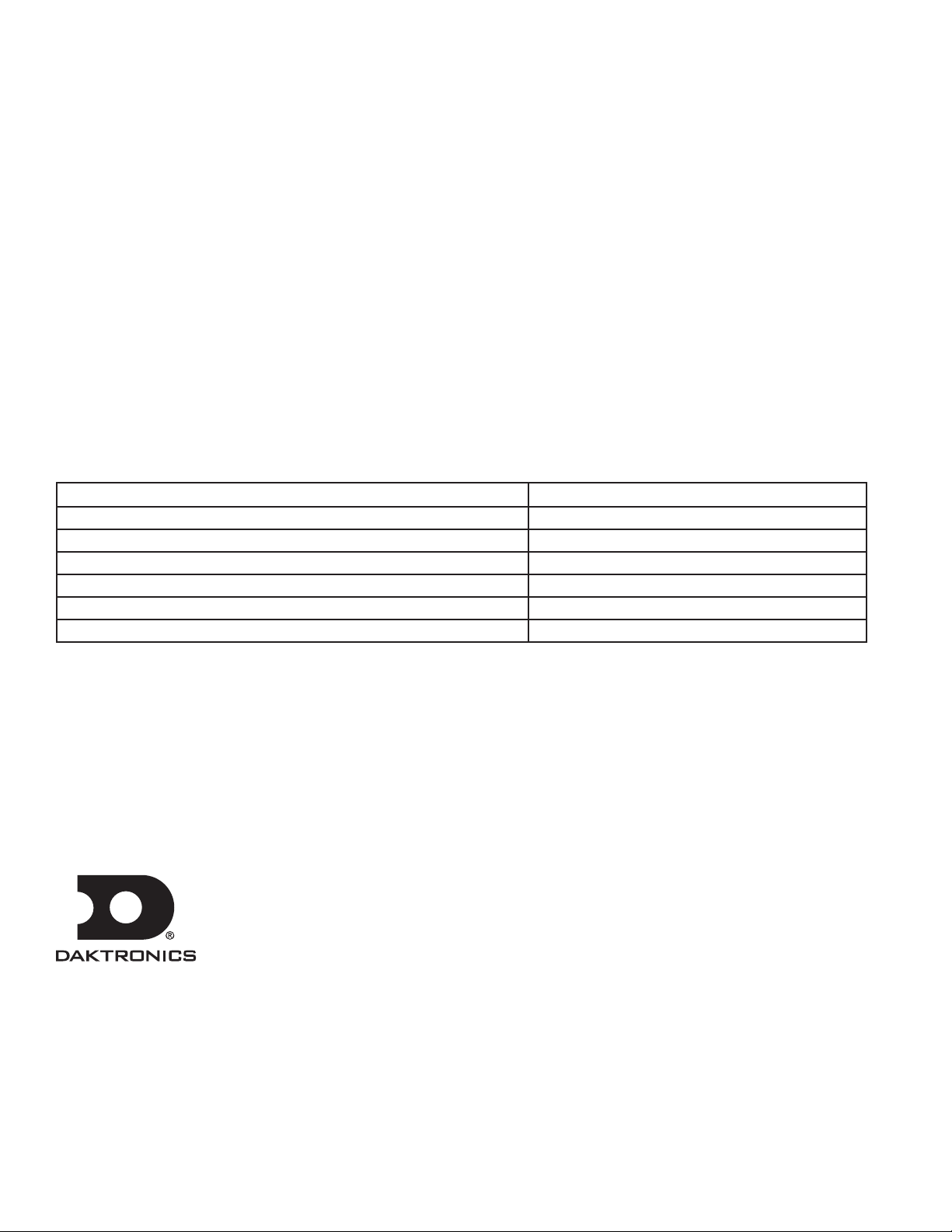

Back View

Clip Angles

Exhaust Vents

Signal Output

To Mirror Display,

If Present

Ground Lug

Quick-Connect

Signal Input Jacks

J Box

Side View

This manual provides installation, maintenance and troubleshooting information to help ensure the optimal

performance of the Daktronics Galaxy® AF-3220 series display. Diagnostic and parts replacement information are also

included. The back and side views of a typical display are shown in Figure 1.

Figure 1: Back and Side Views of a Typical Display

1.1 Display Details

Galaxy® model numbers are described as follows:

AF-3220-RRxCCC-34-R, A, RGB-XX

AF-3220 = Outdoor Galaxy display

3220 = Series Number of Display

RR = Number of pixel rows high (16 or 24)

CCC = Number of pixel columns long (up to 96 standard

34 = Pixel pitch in millimeters

R, A, RGB =

XX = SF (Primary) or 2V (Primary/Mirror)

LED Color: R (Red), A (Amber), RGB (Full Color

– Red, Green, Blue)

The displays are offered as SF (single-face) or 2V (two-view) units. With a 2V (two-view) unit, the first display

is called the primary and the second display is referred to as the mirror. If the second display will be mounted

at a distance of more than 6 feet from the primary display, then two primary displays must be used.

A typical display system is controlled with a Windows®-based personal computer (PC) running Venus® 1500

software.

Introduction 1

Page 6

Page 7

Section 2: Mechanical Installation

Daktronics’ engineering staff must approve any changes that may affect the weather-tightness of the display. If

any modifications are made, detailed drawings of the changes must be submitted to Daktronics for evaluation and

approval, or the warranty may be void.

2.1 Installation Guidelines

DO:

• Inspect the display for damage caused by shipping or uncrating

• Use all lift eyes when lifting the display maintaining 90 degrees between cabinet and lifting method

• Use all clip angles or bolt locations for mounting

• Leave adequate clearance for ventilation

• Ensure mounting location allows for door to pivot open

• Provide an adequate support structure that is straight and level

DON’T:

• Drill holes into the cabinet

• Modify the display without written approval from Daktronics Engineering

• Block intake vents on the bottom of the display

• Block exhaust hoods on back of display

• Use the lift eyes for permanent mounting

2.2 Support Structure Requirements

Daktronics is not responsible for installations or the structural integrity of support structures done by

others. The customer must ensure that a qualified structural engineer approves the mounting structure and

hardware.

Because every installation site is unique, no single procedure is approved by Daktronics for mounting

Galaxy® displays. The information contained in this section is general information only and may or may not

be appropriate for this particular installation.

Mechanical Installation 3

Page 8

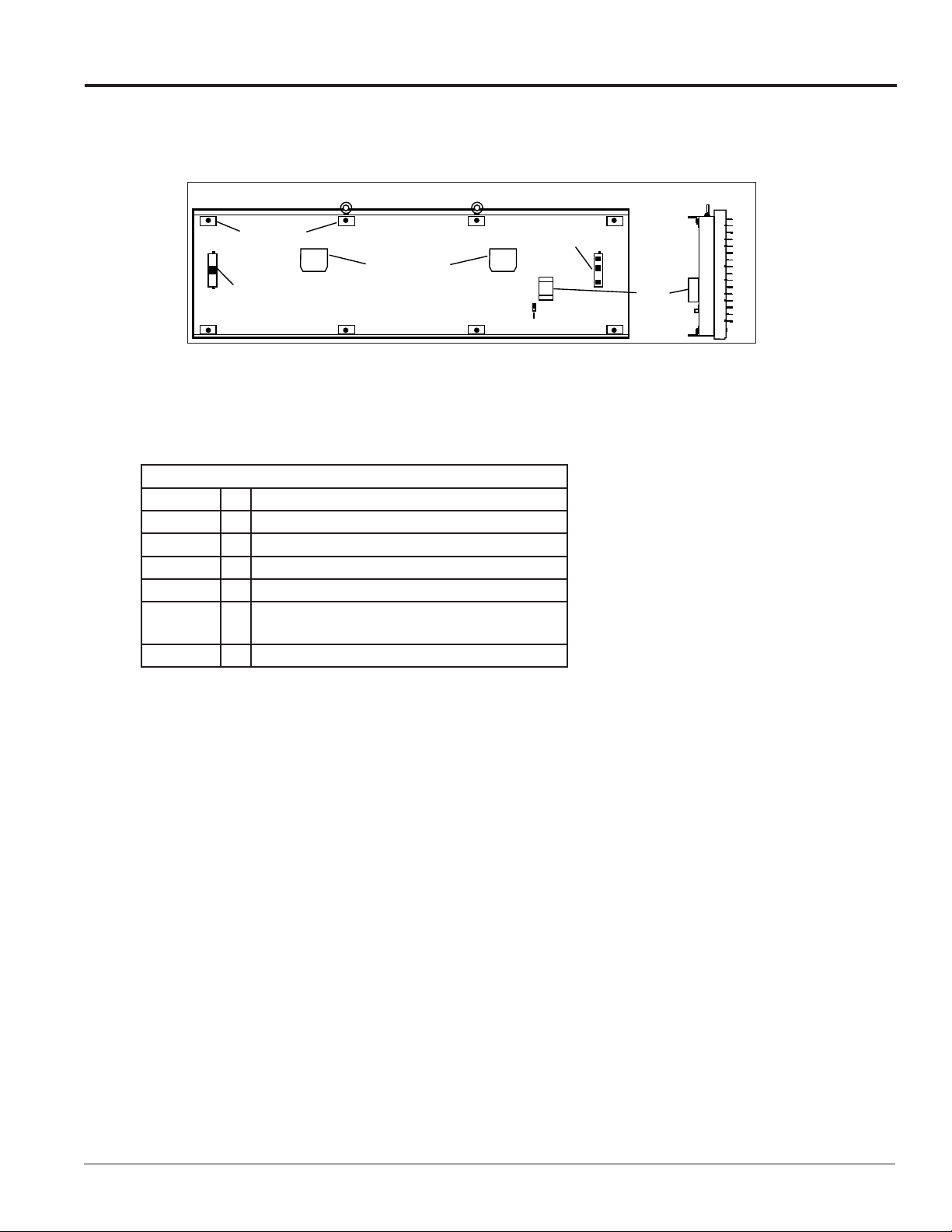

2.3 Display Mounting

Use Lift Bar and ALL Eyebolts

CORRECT

Maximum Eyebolt Strength

45° Minimum

No Lift Bar

▼

▼

INCORRECT

Eyebolt Strength Compromised

The installer must ensure the

installation adequately meets local

codes and standards, including

safe, adequate mounting hardware

and procedures.

Note: To maintain the structural

integrity of the display cabinet,

a 90-degree angle between the

cabinet and the lifting method must be maintained.

1. Lift the display into position on the support structure following the

guidelines in Figure 2.

Be sure the mounting location leaves adequate space to pivot the

door open, as shown in Figure 9.

Do not attempt to permanently support the display by the eyebolts.

2. Weld or use ½" Grade-5 bolts and hardware to secure ALL clip

angles, as shown in Figure 3, to the support structure as shown in

the Shop Drawing.

3. Refer to Section 4 and the appropriate communication manual for

information on routing power and signal to the display.

Figure 2: Correct/Incorrect Lifting Procedures

4. After installation is complete, carefully inspect the display for any

holes that may allow water to seep into the display and seal any

Figure 3: Clip Angle

openings with silicone.

Note: If the eyebolts on the top of the display were removed, seal the holes with bolts and/or silicone.

4 Mechanical Installation

Page 9

Section 3: Power Installation

3.1 Installation Guidelines

DO:

• Route power to the display through a fused disconnect switch

• Route power conductors through conduit according to local codes

• Install an earth-ground electrode for each display face – if resistance to ground is greater than 10 ohms,

install additional grounding electrodes

• Follow local and national electrical codes

• Provide a main power disconnect for the displays

DON’T:

• Connect the display to any voltage other than that listed on the product label

• Share a circuit or neutral with any other electrical devices such as light ballasts, parking lights, etc.

• Connect the neutral to the ground at the disconnect or the display

• Use the display support structure as an earth-ground electrode

3.2 Conduit

Daktronics does not include the conduit. Separate conduit must be used to route:

• power

• signal IN wires to the signal termination enclosure, when applicable

• signal OUT wires (if not using the provided interconnect cable)

The power J-box is provided with 3/4" threaded holes for use with 3/4" conduit. Unthreaded 1/2" knockout

holes are provided in the signal enclosures used with the display. If not using the provided enclosures, use

the knockout/drill holes provided in the display cabinet.

3.3 Power Requirements

Important Note:

• Daktronics recommends that a separate circuit be run to the electronic display(s) to isolate it and

prevent any issues that could be caused by line voltage fluctuations or high frequency noise on the

power line caused by other types of equipment. A separate circuit also makes display maintenance and

troubleshooting easier. Daktronics assumes no liability for any issues caused by line voltage fluctuations

or other improper power conditions if these recommendations are not followed.

• Size conductors of circuits that deliver power to a Daktronics display according to local and national

electrical codes so that the power distribution system delivers full-load power to the display while

maintaining a voltage within five percent (5%) of the nominal voltage.

Power Installation 5

Page 10

• Displays use single-phase power. Proper power installation is imperative for display operation.

Main Disconnect

Daktronics requires using a power disconnect switch with the display. Use a disconnect so that all

ungrounded conductors can be disconnected near the point of power connection.

The disconnecting means must be located either in a direct line of sight from the display or can be locked

in the open position. This ensures that power will not be reconnected while service personnel work on the

display.

3.4 Grounding

Install this sign according national and applicable local codes. This includes proper grounding and bonding

of the sign.

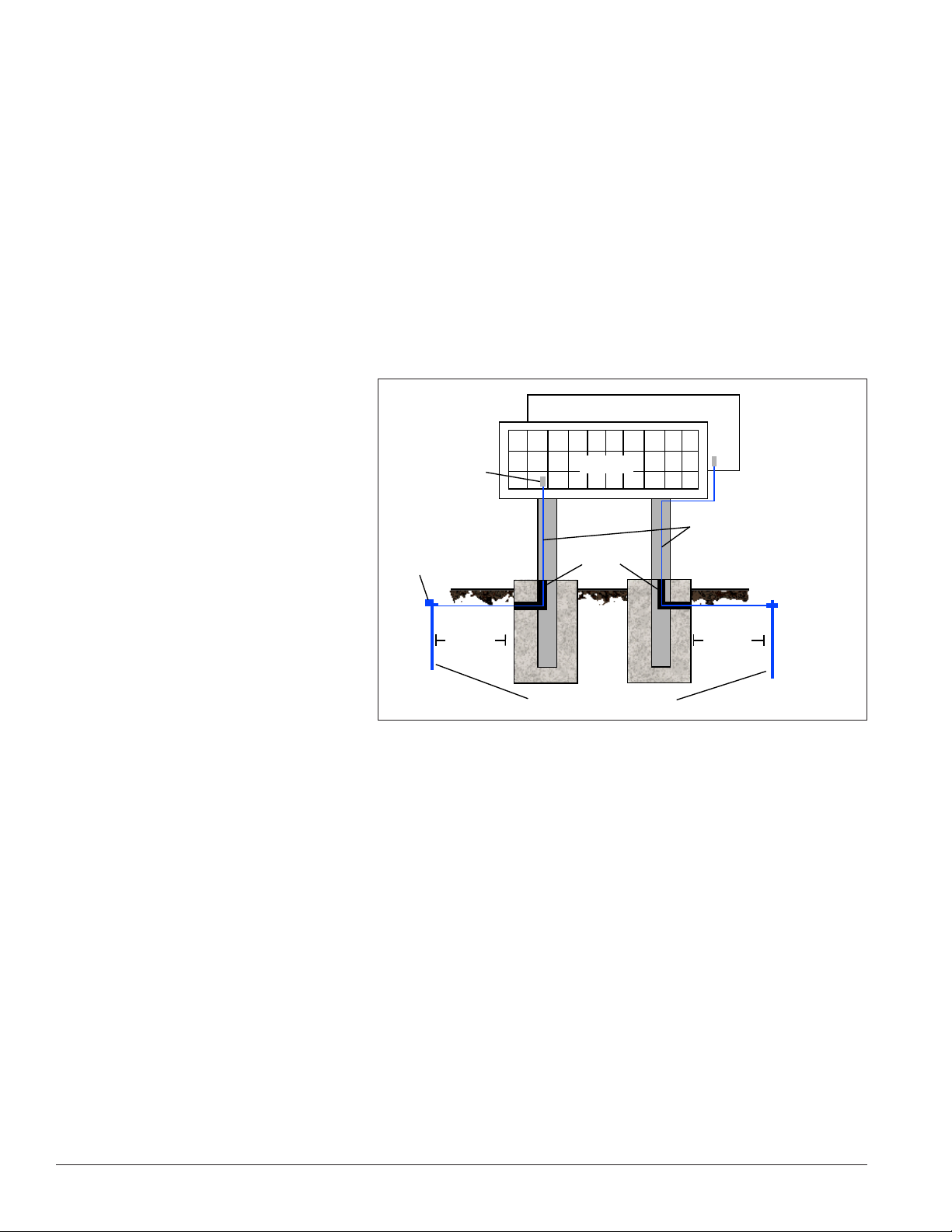

Installation with Ground and Neutral

Conductors Provided

• These displays are installed

with ground and neutral

conductors provided. The

power cable must contain

an isolated earth-ground

conductor.

• Do not connect neutral to

ground at the disconnect or

at the display. This violates

electrical codes and voids the

warranty.

Display

Ground Lug

Thermal Weld

Connection

Preferred

8 ft.(2.5 m)

min.

Mirror

Primary

Copper Ground Conductor

(One Per Display Face)

Conduit

8 ft.(2.5 m)

min.

• Daktronics does not

recommend using the

support structure as an

Figure 4: Correct Grounding

Copper Ground Rods

earth-ground electrode;

concrete, primer, corrosion, and other factors make the support structure a poor ground.

Note: The support structure may be used as an earth-ground electrode only if designed to do so. A qualified

inspector must approve the support structure and grounding methods.

The display system must be connected to an earth ground as shown in Figure 4. Proper grounding protects

the equipment from damaging electrical disturbances and lightning. Daktronics requires a resistance to

ground of 10 ohms or less. The display must be properly grounded or the warranty will be void.

6 Power Installation

Page 11

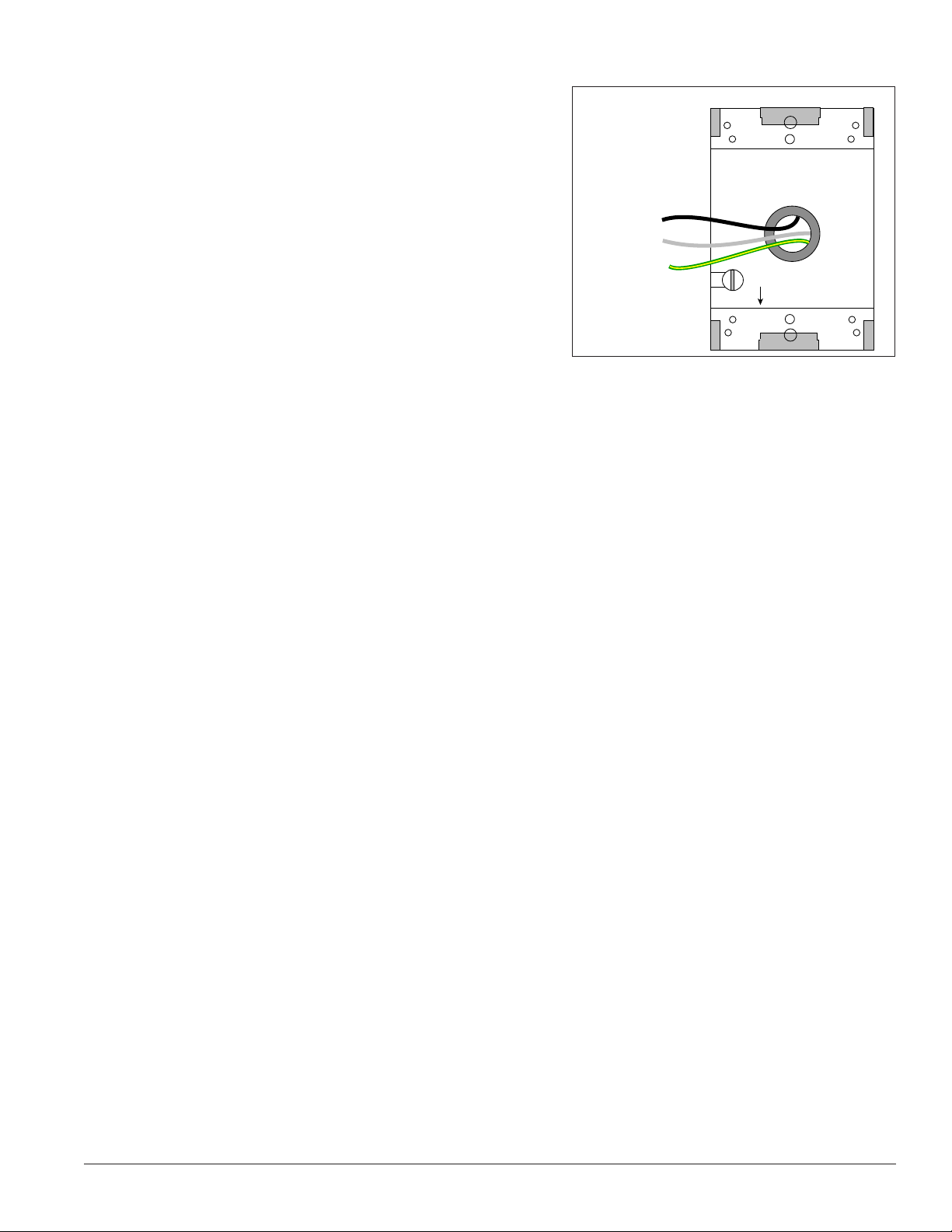

3.5 Power Connection

1. Route the power cable through conduit to the rear of the

display and into the power J-box.

2. The power J-box contains two wires plus a ground

coming from the interior of the display. These wires are

pre-terminated to the power termination panel inside the

display.

3. Inside the external power J-box, connect the power wires

to the wires coming from the display interior using wire

nuts. Refer to Figure 5 for a diagram.

Note: The following colors are used for the pre-terminated

wires:

• Line 1 – Black (Brown – 240V)

• Neutral - White (Blue – 240)

• Grounding Conductor – (Green-Yellow)

(Box with Cover Removed)

Wiring from power termination

panel inside display

Display Back

Line 1 – Black

Neutral – White

Ground – Green/Yellow

GND

Figure 5: Power Termination Wiring

Power Installation 7

Page 12

Page 13

Section 4: Signal Installation Overview

For specific details on installing communications, consult the quick guide and manual included with the

communication equipment. Each type of communication is listed below along with manual and quick guide

document numbers.

Communication Type Communication Manual Communication Quick Guide

RS-232

RS-422

Serial Fiber

Serial Radio

Wire Ethernet

Fiber Ethernet

Ethernet Radio

USB to Ethernet Adapter

Note: These are the standard communication types. However, each site is unique and may include additional

equipment. If problems arise, contact the display’s service company or Daktronics Customer Service.

4.1 Primary/Mirror Display Interconnections

ED-14739 ED-14554

ED-14742 ED-14555

ED-14743 ED-14557

ED-13932 ED-14103

ED-14745 ED-14558

ED-14746 ED-14559

DD1685027 DD1417586

N/A DD1790707

If the display is a two-sided primary/mirror display, a 6-foot quick-connect

cable is provided to connect signal between the two display faces. This cable

is limited to 6 feet only and cannot be extended. Refer to Figure 6 for proper

connection. Secure the excess cable to the support structure to prevent

damage from weather or vandalism.

If the display faces are mounted more than 6 feet apart, install two primary

displays. Hard wiring between the two display faces is required. Refer to the

communications manual for information.

4.2 USB to Ethernet Adapter

A USB to Ethernet adapter is included with the display and can be used

to bypass network configuration in situations where simple point-to-point

communication is required. The adapter creates a secondary network that is

dedicated to communication with the display, but network operation is still

enabled through the primary network.

The USB to Ethernet Adapter can be used in conjunction with

communication kits supplied with the display. Refer to DD1790707 for more information regarding the

adapter.

Figure 6: Quick-Connect Cable

Signal Installation Overview 9

Page 14

Page 15

Section 5: Start-Up Procedure

Before starting the display, review the following checklist to ensure all parts are ready to operate correctly. Figure 1

shows the basic display components referred to in each step.

5.1 Start-up Checklist

• Confirm that power is correctly connected to the display

• Earth-ground electrode is installed with a resistance to ground of 10 ohms or less

• External communication equipment is properly installed

• Inspect signal connections at the control computer, display, and between display faces

• Confirm the control computer has Venus® 1500 software installed and is correctly configured

• Inspect peripheral equipment (temperature sensor, etc.) for proper installation

5.2 Boot Sequence

Each time the display is turned on, a boot sequence runs.

The information in the second column is shown on the

display.

Note: The Xs refer to numbers that may vary for each

display, such as the hardware address.

After this sequence is complete, a single pixel will flash

in the lower-right corner of the display to show that the

display has power and is ready for content.

Topic Information Shown

Product Name Galaxy®

Display Size #Rows x #Columns

Shading 64 Mono or RGB 32k

Bootloader Version OS XXX

Firmware Number ED-13305

Firmware Revision Rev X.XX

Hardware Address HW:XX

Software Address SW:XX

IP Address (default: IP: 172.16.192.25

Subnet Msk (default) MSK: 255.255.0.0

COM1 Conguration C1:V15

COM 2 Conguration C2: RTD

Socket 3001 IP 3001: V15

Socket 3002 IP 3002: RTD

Line Frequency CLK: AUTO (60)

Display Description Display 1

Start-Up Procedure 11

Page 16

Page 17

Section 6: Maintenance

Filters

Note: Turn off power before doing any repair or maintenance work on the display.

Figure 7 shows the typical location of internal components. Actual locations may vary slightly depending on the size

of the display. The quick-connect to mirror display is only present in two-view (2V) displays.

Thermostat

Quick Connects

UPPERLOWER

0

1

F

2

E

3

D

4

C

5

B

6

A

7

8

Controller

9

Figure 7: Internal Component Locations

6.1 Display Access

Open the face panel to access the interior of a display, as shown in

Figure 8. To access the interior of the display, perform the following

steps:

1. Turn off power to the display.

2. Locate the access latches on the face panel. With a 5/32"

hex wrench, turn the latch fasteners a quarter turn

counterclockwise.

3. Lift the face panel from the bottom. Gas springs hold the door

open. Caution: The door swings upward. Take extra precautions during windy conditions.

Fan

0

1

F

2

E

3

D

4

C

5

B

6

A

7

8

9

Power

Termination

Panel

Power

Supplies

Fan

Quick Connects

▲

Modules

Door

Support

Internal

Components

Figure 8: Open Face Panel

►

►

4. To close, lower the face panel and turn the latches a quarter turn

clockwise. Be sure to fully latch all fasteners to provide a

watertight seal.

6.2 Ventilation System Maintenance

Thermostat

Fans

Ventilation fans are located inside the display. Air is pulled in from bottom

venting slots and exhausted out the back of the display.

Check fans and vents every time the display is opened. Check the fans by

pressing the bypass switch located on the thermostat as shown in Figure 9.

Figure 9: Thermostat and Bypass

Switch

Maintenance 13

Bypass

Switch

Page 18

Filters

Filters, shown in Figure 10, were added to AF-3220 displays in June

2012.

Filters prevent dirt and debris from entering the display cabinet.

Check and replace filters every six months, but more frequent

inspection may be required depending on conditions around the

display, to ensure adequate air flow in the display.

Remove the filter assembly from the display by pushing one of the

filter bracket tabs outward and lifting the filter assembly up and

out, as shown in Figure 11. Remove the filter from the filter

assembly and clean with water or compressed air (no greater than

60psi and at least 6" away) blown through the filter in the opposite

direction from which air normally flows. Allow filters to dry before

placing them back into filter assemblies and inserting them back

into their locations.

Daktronics encourages users and service technicians to use their

own discretion when deciding whether to clean or replace the

filters.

6.3 Annual Inspection

Filter

Bracket

Tab

Filter

Bracket

Tab

Filter

Filter

Assembly

Figure 10: Filter Installed in Display Cabinet

Complete a yearly inspection to maintain safe and dependable

display operation. Open the display to visually inspect the

cabinet interior and the components. Refer to Section 6.1 for these

directions. The inspection should address the following issues:

Inspection item Possible corrective measures

Loose bolts, screws, rivets • Tighten or replace, as required

Fans and Filters

Dust around fans, on

cabinet bottom

Water intrusion or stains

Paint corrosion by footings,

tie points, ground rods

• Refer to Section 6.2. Clean or

replace as necessary

• Vacuum or carefully wipe away

• Replace weather stripping.

• Tighten door latches.

• Place silicone sealant around all

locations where water might enter.

• Replace damaged electronic

components

• Check the metal for structural

integrity.

• Replace and/or repaint as necessary

D I S P L A Y F A C E

Figure 11: Removing Filter

14 Maintenance

Page 19

Section 7: Diagnostics and Troubleshooting

UPPER LOWER

1

2

3

4

5

6

7

8

C

D

E

F

9

A

B

0

1

2

3

4

5

6

7

8

C

D

E

F

9

A

B

0

DS4

Run

DS3

Transmit

DS2 Receive

Line 1

Line 2

Line 3

7.1 Controller Diagnostics

The controller is the “brains” of the display, receiving

communication from the computer and then sending the

appropriate information to the modules. LEDs on the

controller show whether the power and communication

signal are working correctly.

Since the controller is inside the display, open the face

panel to view the diagnostic LEDs, shown in Figure 12.

To access the interior of the display, refer to Section 6.1 for

instructions and illustration.

Remember to turn off power to the display before

accessing the interior.

However, once the door is open and the wires are found to

be safe, power can be turned back on to view the diagnostic

LEDs.

Figure/

Label

LED # Color Operation

Steady FLASH about once per

Run

DS4 Red

second indicates controller is

working properly.

Send

signal

TX

Receive

signal

RX1

DS3 Yellow

DS4 Yellow

OFF is the normal state.

FLASH when transmitting

serial communication from the

computer.

OFF is the normal state.

FLASH when receiving serial

communication from the

computer.

7.2 Troubleshooting Display Problems

This section contains some symptoms that may be encountered in the displays. This list does not include

every possible symptom or solution but does represent common situations and simple steps to resolve them.

The solutions are listed in priority order, so try the first solution first. If any of the steps referenced do not

solve the issue, contact Daktronics Customer Service.

Troubleshooting may require opening the display cabinet. Refer to Section 6.1 for instructions on this

procedure. Before closing the cabinet, make sure power and signal cables are reconnected correctly.

Figure 12: Controller Diagnostics

Tools Required for Troubleshooting:

•

• Setofnutdrivers

• FlatheadandPhillipsscrewdrivers

• ServiceLaptopcomputer(recommended)

Diagnostics and Troubleshooting 15

5

/32" Hex wrench

Page 20

One or More LEDs Do Not Light or Are Stuck On

• Check the condition of the ribbon cables on the module

• Check for bent pins on module jacks

• Swap a known good ribbon cable with the suspect cable

• Swap a known good module with the suspect module

Section of the Display Does Not Work – Extending All the Way to Right End

• Check the ribbon cable from the last working

module in the row to the first non-working

module, as shown in Figure 13.

Last

►

working

module

►

►

First Non-working

Module

• Check if the first non-working module is getting

power

• Swap the first non-working module with a

known good module to see if the problem moves

Signal

Flow

Signal

Flow

• Swap the last working module with a known

good module to see if the problem moves

Figure 13: Modules Not Working

daktronics

One Row of Modules Does Not Work or Shows a Distorted Message

• Check the ribbon cable to the first non-working module

• Check for bent pins on the input and output jacks of the modules

• Swap the first non-working module with a known good module

• Swap the last working module with a known good module

Entire Display Fails to Work

• Make sure the main power source breaker is on

• Check the diagnostic LEDs on the controller for Power and Run. (Section 7.2)

• Initiate a test pattern using Venus® 1500 software

• Check the ribbon cables from the controller to the modules

Galaxy

Blank Display Seen After Boot-Up

A blank display is normal after the boot-up procedure. When finished, the display is blank except for a

flashing pixel in the lower-right corner. The display is waiting for a message to be sent. Once a message is

sent, the flashing pixel is replaced with the message.

Message Only Appears on One Side of the Display

• Make sure power is connected to the second face of the display

• Make sure the interconnect cable is connected between display faces

16 Diagnostics and Troubleshooting

Page 21

Unable to Communicate (Send Content) to the Display

• Turn power off at the breaker for 1 minute and turn it back on

• Check the display configuration in Venus 1500 software

• Check the diagnostic LEDs on the display controller (Section 7.1)

• Check signal input cable connections and cable connections on the controller

• Refer to the communications manual for more information

Before Calling for Help

If none of the steps listed solves the issue, call your service provider or Daktronics Customer Service at

1-800-DAKTRONICS.

Note: It is helpful to be sitting at the control computer while talking with the service technician.

Diagnostics and Troubleshooting 17

Page 22

Page 23

Section 8: Parts Replacement

8.1 About Replacement Parts

The following table contains some of the items that may need to be replaced in

a display over time. These components are generally located as shown in

Figure 7. Most components within the display are labeled with the part

number and serial number of the assembly. A typical label is shown in

Figure 14.

Part Description Part Number

Module, Red 0P-1620-5000

Module, Amber 0P-1620-5001

Module, RGB 0P-1620-5550

Controller II 0A-1229-0036

Power Supply Assembly, w/Harness A-2307

Transformer, Primary only T-1119

Filter, RFI Z-1007

Filter, Air EN-2676

AF-32XX Filter Cover 0M-1086995

Temperature Sensor 0A-1151-0005

Light Level Detector 0A-1327-3000

Thermostat 0A-1327-3104

Fan B-1053

Ribbon Cable, 20 Pos, 18" W-1387

Ribbon Assy, 20 Pos, 24" 0A-1000-0016

Ribbon Assy; 20 Pos, 36" 0A-1000-0018

Ribbon Assy; 20 Pos, 48" 0A-1000-0020

Ribbon Assy; 20 Pos, 60" 0A-1000-0021

Cable; RJ45, CAT5E, Shielded, 2' W-1537

Cable; 22 AWG, 2-pair, shielded W-1234

Interconnect Cable; 6' W-1503

Quick Connect, Primary signal input 0A-1327-1070

Quick Connect, Primary 0A-1327-1071

Quick Connect, Mirror 0A-1327-1072

0P-1127-0024

SN: 2465

02/19/12 Rev. 1

Figure 14: Typical Label

8.2 Instructions for Replacing Parts

Module Removal/Replacement

• If LEDs have failed, do not attempt to replace individual LEDs.

• Return a failed module to Daktronics for replacement and/or repair.

Tools required: 5/32" hex wrench and 9/32" nut driver

1. Turn off power to the display.

2. Locate the latch access fasteners on the face panel. With a 5/32" hex wrench, turn the latch fasteners a

quarter turn counterclockwise.

3. Lift the face panel from the bottom. Gas springs hold the door open. Refer to Figure 8 for diagram.

Caution: The door swings upward. Take extra precautions during windy conditions.

Replacement Parts 19

Page 24

4. Unplug the power cable by squeezing the tabs on the sides of the plug head and pulling out.

5. Disconnect the two ribbon cables from the module by spreading the tabs on the sides and then lifting

the cable head from the jack.

6. Using a nut driver, remove the 10 nuts holding

the module to the panel. Refer to Figure 15.

7. To install a module, place it in position over the

bolts and use the nut driver to replace all nuts.

8. Reconnect the signal and power cables to the

module, making sure that the plugs make good

connections.

9. Carefully close the face panel. Latch the panel by

turning the fasteners a quarter turn clockwise.

*Be sure to fully close each individual latch to

Figure 15: Removing a Module

ensure a water tight seal.

Controller Replacement

Tools required: 3/16" nut driver

1. Turn off power to the display.

2. Open the face panel. The controller, shown in

Figure 16, is located in the lower-left corner of

the primary display.

3. Disconnect the power plug from power input

jack.

4. Remove all signal connections, carefully pulling

them from their jacks. Label the various cables

and wires as they are removed to insure their

proper replacement.

5. Remove the six screws holding the board in

place using the nut driver.

6. Take note of the address on the controller and set

the same address on the replacement controller.

7. Install the replacement controller using all six

screws removed, connect signal cables and

power connector

Power

Input

Line 1

Line 2

Line 3

Light

Sensor

Input

Quick-Connect Input

Mounting Nuts

Figure 16: Typical Controller

UPPER LOWER

0

1

F

2

E

3

D

D

4

C

C

5

B

B

6

A

7

8

9

Module

Outputs

0

1

F

2

E

3

4

5

6

A

7

8

9

Address

Switches

Ethernet

Input

CAN

Input

8. Turn on power to the display and observe the boot sequence. Once the sequence is complete, a single

pixel should flash in the lower-right corner of the display.

20 Replacement Parts

Page 25

Controller Address Setting

1

2

3

4

5

6

7

8

C

D

E

F

9

A

B

0

1

2

3

4

5

6

7

8

C

D

E

F

9

A

B

0

ADDRESS

UPPER

LOWER

The rotary switches set the hardware address of the controller. Each Primary

display in a network needs a unique address, as shown in Figure 17. Each

controller in a network also needs a unique address.

Set the switches by rotating them counterclockwise until the arrow points to

the desired number. The display’s power must be turned off and then turned

back on to activate a change in the address.

Note: Setting both rotary switches to address 0 will activate a Test Mode.

Figure 17: Rotary Switches

Power Supply Replacement

Tools required: Phillips screwdriver or nut-driver

Complete the following steps to replace a power supply:

1. Turn off power to the display.

2. Access the interior of the display by opening the face panel.

3. Disconnect the Mate-n-Lok® connectors from the power source as well as those going to the modules.

Be sure to label each connector so that it can be properly reconnected.

4. Loosen, but don’t remove, the screw holding the power supply bracket to the cabinet upright and lift

off the hooks.

5. Move the new power supply into place and tighten the screw on the support bracket.

6. Reconnect all the Mate-n-Lok® plugs.

Replacement Parts 21

(From Power

Figure 18: Power Supply

AC Input

Source)

DC Outputs (To Modules)

V Adjust (To Initial Module)

AC Output (To Next Power Supply)

Page 26

Page 27

Section 9: Daktronics Exchange and Repair &

Return Programs

9.1 Exchange Program

The Daktronics Exchange Program is a quick, economical service for replacing key components in need

of repair. If a component fails, Daktronics sends a replacement part to the customer who, in turn, returns

the failed component to Daktronics. This not only saves money but also decreases equipment downtime.

Customers who follow the program guidelines explained below will receive this service.

Before Contacting Daktronics

Fill in these numbers before calling Customer Service:

Display Serial Number:________________________________________

Display Model Number:_______________________________________

Date Installed:________________________________________________

Location of Sign:______________________________________________

Daktronics Customer ID Number:_______________________________

To participate in the Exchange Program, follow these steps.

1. Call Daktronics Customer Service: 888-DAK-SIGN (888-325-7446)

2. When the new exchange part is received, mail the old part to Daktronics.

If the replacement part fixes the problem, send in the failed part within 3 weeks of the ship date.

a. Package the old part in the same shipping materials in which the replacement part arrived.

b. Fill out and attach the enclosed UPS shipping document.

c. Ship the part to Daktronics.

3. A charge will be made for the replacement part immediately, unless a qualifying service agreement is

in place.

In most circumstances, the replacement part will be invoiced at the time it is shipped. If the failed

part or replacement part is not returned to Daktronics within 3 weeks of the ship date, it is assumed

that the customer is purchasing the replacement part and will be invoiced for the value of the new

sale part.

If the part or parts are returned within 2 weeks of the second invoice date, Daktronics will credit the

customer for the amount of the second invoice. If after 2 weeks Daktronics has still not received the

parts back, the customer must pay the second invoice and will not be credited for the return of the

failed part.

Daktronics reserves the right to refuse parts that have been damaged due to acts of nature or causes

other than normal wear and tear.

Daktronics Exchange and Repair & Return Programs 23

Page 28

9.2 Repair & Return Program

For items not subject to exchange, Daktronics offers a Repair & Return Program. To send a part for repair,

follow these steps:

1. Call or fax Daktronics Customer Service:

Phone: 888-DAK-SIGN (888-325-7446) Fax: 605-697-4000

2. Receive a Return Materials Authorization (RMA) number before shipping.

This expedites repair of the part.

3. Package and pad the item carefully to prevent damage during shipment.

Electronic components, such as printed circuit boards, should be placed in an antistatic bag before

boxing. Daktronics does not recommend using packing peanuts when shipping.

4. Enclose:

• Your name

• Address

• Phone number

• The RMA number

• A clear description of symptoms

Shipping Address

Daktronics

Customer Service Receiving

PO Box 5128

201 Daktronics Drive

Brookings, SD 57006

Attn: RMA#__________

24 Daktronics Exchange and Repair & Return Programs

Page 29

Glossary:

3220: The series name of the display, for example Galaxy AF-3220

Controller: The “brains” of the display. The controller receives signal communication from the computer and sends

the appropriate information to the modules. Messages and schedules may also be stored on the controller.

Display Address: An identification number assigned to each display of a network. The control software uses the

address to locate and communicate with each display. Displays that are on the same network must have different

addresses.

Driver/LED Board: The components of a module. This board is responsible for the on/off and intensity levels of the

LEDs.

Galaxy®: The name given to Daktronics LED matrix displays that can be monochrome, tri-color, or RGB.

Light Emitting Diode (LED): A low energy, high intensity lighting unit.

Mirror: The second display in a two-face configuration. The mirror display does not have a controller so it displays

an exact copy of the information on the primary display. All signal information to the mirror is received through an

interconnect cable from the primary display.

Module: The board containing the LEDs and driver. Galaxy®AF-3220 34 mm modules are 8 pixels high by 16 pixels

wide. Each is individually removable from the front panel of the display.

Network: Multiple displays connected to each other. As many as 240 primary displays can exist on one network.

Pixel: A cluster of LEDs acting as one unit on the module. The number of LEDs in a pixel will depend on display

application.

Primary: A single-face unit or the first display in a primary-mirror (2V) configuration. The communication signal,

light sensor and temperature sensor will be connected to this display. An interconnect cable transfers information

from the primary display to the mirror display so that it shows exactly the same information.

Venus® 1500 software: Name of Daktronics software that is used on the control computer to communicate with

these displays. This software can create messages and send them to the displays, schedule messages, and perform

diagnostics. The Venus® 1500 software manual is included on the installation disk.

Glossary 25

Page 30

Page 31

Appendix A: Reference Drawings

Figure 19 illustrates a Daktronics drawing label.

Shop drawings show display dimensions, signal and power connection

locations, as well as information on service access and power

requirements. To obtain copies of shop drawings or other reference

drawings specific to your display, contact Daktronics Customer Service:

Phone: 1-800-DAKTRONICS

THE CONCEPTS EXPRESSED AND DETAILS SHOWN IN THIS DRAWING ARE CONFIDENTIAL AND

PROPRIETARY. DO NOT REPRODUCE BY ANY MEANS, INCLUDING ELECTRONICALLY, WITHOUT THE

EXPRESSED WRITTEN CONSENT OF DAKTRONICS, INC. COPYRIGHT 2008 DAKTRONICS, INC.

DAKTRONICS, INC. BROOKINGS, SD 57006

PROJ: GALAXY, AF-3200 & AF-3400 SERIES

TITLE: SCHEM, PRIMARY SIGNAL, INTERNAL, W/QC

DES. BY: PGILK DRAWN BY: LKERR

APPR BY-

REVISION

00

SCALE-

NONE

1229-R03B-206146

Drawing number

DATE: 11 JAN 08

Figure 19: Drawing Label

Appendix A: Reference Drawings 27

Page 32

Page 33

Appendix B: Temperature Sensor Installation (ED-14377)

Click here to open the temperature sensor installation quick guide.

Temperature Sensor Installation (ED-14377) 29

Page 34

Page 35

Appendix C: Daktronics Warranty and Limitation of Liability (SL-2374)

Click here to view Warranty and Limitation of Liability information.

Appendix B: Daktronics Warranty and Limitation of Liability (SL-2374) 31

Loading...

Loading...