Page 1

d

Galaxy® Series

AF-3010

Display Manual

ED-10972 Rev 9 12 August 2003

n

331 32

Tel 605-697-4034 or 877-605-1113 Fax 605-697-4444

www.daktronics.com email: helpdesk@dak tronics.com

PO Box 5128 Brookings SD 57006

Page 2

ED-10972

Product 1185

Rev 9 – 12 August 2003

DAKTRONICS, INC.

Copyright ã 2002-2003

All rights reserved. While every precaution has been taken in the preparation of this manual, the publisher

assumes no responsibility for errors or omissions. No part of this book covered by the copyrights hereon may be

reproduced or copied in any form or by any means – graphic, electronic, or mechanical, including photocopying,

taping, or information storage and retrieval systems – without written permission of the publisher.

®

Galaxy

and Venus® are registered trademarks of Dakt roni cs, Inc. All ot hers are trademarks of their respective companies.

Page 3

Reproduction Reference

ED-10972 -- P1185

Display Manual; Galaxy

®

Series AF-3010

1) This page is for reproduction reference only and will not be included in the

manual.

2) This manual is to be copied on FRONT AND BACK PAGES -8 ½ x 11 paper.

Note: The first page, Cover Page, uses the front of the page (blank on back).

Section heading pages always start on a new page; they never start on the back

of another page.

3) Drawings included in this manual are located within Appendix C.

4) Insert ED-7244 after Section 2.

5) Use a blue window cover and a blue back.

6) Punch all pages, window cover and back cover along the left edge, and bind with

a binder.

7) Please direct questions and suggestions to Engineering Secretarial.

Page 4

Page 5

Table of Contents

Section 1: Introduction....................................................................................1-1

1.1 How to Use this Manual............................................................................1-1

1.2 Safety Precautions ..................................................................................... 1-2

1.3 Network Concepts ..................................................................................... 1-3

RS232 Network.................................................................................. 1-3

RS422 Network.................................................................................. 1-3

Modem Network................................................................................. 1-4

Fiber Optic Network........................................................................... 1-4

Radio Network....................................................................................1-4

1.4 Display Overview...................................................................................... 1-4

1.5 Component Identification.......................................................................... 1-5

1.6 Daktronics Nomenclature .......................................................................... 1-7

Section 2: Mechanical Installation .................................................................2-1

2.1 Mechanical Installation Overview............................................................. 2-1

2.2 Support Structure Design........................................................................... 2-1

2.3 Display Ventilation Requirements............................................................. 2-2

2.4 Mounting Kit.............................................................................................2-2

2.5 Display Lifting........................................................................................... 2-2

2.6 Display Cabinet Mounting......................................................................... 2-3

Wall Mount.........................................................................................2-3

Pole Mount.........................................................................................2-3

Section 3: Electrical Installation.....................................................................3-1

3.1 Common Connectors in the Sign...............................................................3-1

3.2 Control Cable Categories........................................................................... 3-2

3.3 Conduit......................................................................................................3-3

3.4 Grounding.................................................................................................. 3-4

Power Installation............................................................................... 3-4

3.5 Control Cable Requirements...................................................................... 3-5

RS232................................................................................................. 3-5

RS422................................................................................................. 3-6

Modem................................................................................................3-6

Fiber Optic.......................................................................................... 3-6

Radio .................................................................................................. 3-6

3.6 Signal Termination from Computer to Display..........................................3-7

RS232................................................................................................. 3-7

RS422................................................................................................. 3-8

Modem................................................................................................3-9

Fiber Optic.......................................................................................... 3-9

Table of Contents

i

Page 6

Radio ................................................................................................ 3-10

3.7 Signal Termination Between Two (or More) Displays............................3-12

RS422 Interconnection .....................................................................3-12

Fiber Interconnection........................................................................3-13

3.8 Initial Operation....................................................................................... 3-13

Section 4: Maintenance and Troubleshooting ............................................. 4-1

4.1 Weather Stripping......................................................................................4-1

4.2 Module Numbering Convention ................................................................ 4-1

4.3 Display Access/Module Removal.............................................................. 4-2

4.4 LED Driver Replacement...........................................................................4-2

4.5 Power Supply.............................................................................................4-3

4.6 Controller Board........................................................................................ 4-4

Accessing and Replacing the Controller Board..................................4-4

LEDs and Jumpers.............................................................................. 4-4

Controller Address and Test Mode.....................................................4-5

Light Detector.....................................................................................4-6

4.7 Transformer...............................................................................................4-6

4.8 Modem....................................................................................................... 4-6

Accessing and Replacing the Modem.................................................4-6

LEDs and Jumpers.............................................................................. 4-7

Fiber Board.........................................................................................4-7

4.9 Signal Routing...........................................................................................4-8

4.10 Structural Inspection..................................................................................4-8

4.11 Troubleshooting ......................................................................................... 4-9

4.12 Initial Operation Information................................................................... 4-10

4.13 Replacement Parts....................................................................................4-11

4.14 Daktronics Exchange and Repair and Return Programs ..........................4-12

Appendix A: Optional Temperature Sensor .....................................................A-1

Appendix B: Signal Converter ...........................................................................B-1

Appendix C: Reference Drawings......................................................................C-1

ii

Table of Contents

Page 7

List of Figures

Figure 1: Drawing Label ........................................................................................................ 1-2

Figure 2: MDC Controller...................................................................................................... 1-5

Figure 3: AF-3010 Driver/Pixel Board...................................................................................1-6

Figure 4: 8x16 Pixel Module.................................................................................................. 1-6

Figure 5: Signal Converter.....................................................................................................1-7

Figure 6: Module Numbering Example – 24x160 Front ........................................................ 1-7

Figure 7: Module Numbering................................................................................................. 1-7

Figure 8: Typical Label.......................................................................................................... 1-8

Figure 9: Lifting the Display (Correct, Left; Incorrect, Right)............................................... 2-2

Figure 10: Ribbon Cable Connector....................................................................................... 3-1

Figure 11: Termination Block................................................................................................ 3-1

Figure 12: Phoenix-Style Connector ...................................................................................... 3-2

Figure 13: Mate-n-Lok Connector.......................................................................................... 3-2

Figure 14: 6-Conductor RJ11 Connector and Cable...............................................................3-2

Figure 15: Flipped Cable with RJ Connectors........................................................................ 3-3

Figure 16: Installation with Ground and Neutral Conductors Provided.................................3-4

Figure 17: Installation with Only Neutral Conductor Provided..............................................3-5

Figure 18: RS232 Connections...............................................................................................3-7

Figure 19: RS422 Signal Converter Connections................................................................... 3-8

Figure 20: Modem Signal Connections.................................................................................. 3-9

Figure 21: Fiber Optic Layout.............................................................................................. 3-10

Figure 22: J-box to Server Radio Connections..................................................................... 3-11

Figure 23: Client Radio to Display Connections.................................................................. 3-11

Figure 24: RS422 Interconnection........................................................................................3-12

Figure 25: Removing the Mounting Nuts............................................................................... 4-2

Figure 26: Removing the Module........................................................................................... 4-2

Figure 27: Removing the Signal Connections........................................................................ 4-2

Figure 28: Controller Board................................................................................................... 4-4

Figure 29: LEDs and Jumpers................................................................................................4-4

Figure 30: Location of DIP Switches.....................................................................................4-5

Figure 31: Modem.................................................................................................................. 4-6

List of Figures

iii

Page 8

Figure 32: Fiber Board...........................................................................................................4-7

Figure 33: Signal Routing.......................................................................................................4-8

Figure 34: Temperature Sensor Eave/Wall Mount................................................................ A-1

Figure 35: Temperature Sensor Mounting to Bottom of Display.......................................... A-1

Figure 36: Temperature Sensor--Connection and Interconnection........................................ A-3

Figure 37: Signal Converters................................................................................................. B-1

iv

List of Figures

Page 9

Section 1: Introduction

1.1 How to Use this Manual

This manual explains the installation, maintenance, and troubleshooting of a

Daktronics Galaxy

®

AF-3010 monochrome LED display. For questions regarding the

safety, installation, operation, or service of this system, please refer to the telephone

numbers listed on the cover page of this manual.

The manual is divided into seven sections: Introduction, Mechanical Installation,

Electrical Installation, Maintenance and Troubleshooting, Appendix A, Appendix B,

and Appendix C.

· Introduction covers the basic information needed to make the most of the

rest of this manual. Take time to read the entire introduction as it defines

terms and explains c oncepts used thr oughout the manual.

· Mechanical Installation provides general guidance on sign mounting.

· Electrical Installation gives general guidance on terminating power and

signal cable at the sign.

· Maintenance and Troubleshooting addresses such things as r emoving

basic sign compone nt s , troubleshooting the sign, performing general

maintenance, and exchanging sign components.

· Appendix A offers general information about the optional temperature

sensor.

· Appendix B contains general information about the signal converters.

· Appendix C includes the drawings referenced in this manual.

Daktronics identifies manuals by an ED number located on the cover page of each

manual. For example, this manual would be referred to as ED-10972.

Listed below are a number of drawing types commonly used by Daktronics, along

with the information that each is likely to provide. This manual might not contain all

these drawings.

· System Riser Diagrams: Overall system layout from control computer to

sign, power, and phase requirements.

· Shop Drawings: Fan locations, mounting information, power and signal

entrance points, and access method (front and rear).

· Schematics: Power and signal wiring for various components.

· Component Placement Diagrams: Locations of critical internal sign

components, such as power supply assemblies, controller boards,

thermostats, and light detectors.

Introduction

1-1

Page 10

Figure 1 below illustrates the Daktronics drawing label. The drawing number is

located in the lower-right corner of the drawing. Listing the last set of digits and the

letter preceding them identifies drawings in the manual. In the example below, the

drawing would be referred to as Drawing B-181287. Reference drawings are

inserted after the section that references them.

Figure 1: Drawing Label

All reference s to drawing numbers, appendices , figures, or other manuals are

presented in bold typeface, as shown below.

“Refer to Drawing B-181287 in Appendix C for the power supply location.”

Additionally, drawings referenced in a particular section are listed at the beginning of

that section as seen in the following example:

Reference Drawing:

Shop Drawing; VF-****-27x75-18-W............................ Drawing B-181287

Daktronics signs are built for long life and require little maintenance. However, from

time to time, certain sign components will need replacing. The Replacement Parts

List in Section 4.13 provides the names and part numbers of components that may

need to be ordered during the life of the sign. Most sign components have a white

label that lists the part number. The component part number is in the following

format: 0P-_ _ _ _-_ _ _ _ (component) or 0A-_ _ _ _-_ _ _ _ (multi-component

assembly).

Following the Replacement Parts List is the Daktronics Exchange and Return

and Repair Programs in Section 4.14. Refer to these instructions if any sign

component needs replacement or repair.

1.2 Safety Precautions

Important Safeguards:

1. Read and understand these instructions before installing.

2. Be sure the sign is properly grounded with an earth ground electrode at the

display.

3. Disconnect power when servicing the sign.

4. Do not modify the sign structure or attach any panels or coverings to the

sign without the written consent of Daktronics, Inc.

1-2

Introduction

Page 11

1.3 Network Concepts

The concept of using LED displays as a cost effective, high impact method of

communication is rapidly growing throughout many industries and businesses. The

reasons for this growth are many, but the need for additional features and the

complexity of multiple sign installations has emerged. Daktronics display systems

have been designed to meet those needs. The common thread to most client requests

is a means of programming and controlling a group of signs from a central control

point. Daktronics responded by developing a power system of interconnecting and

controlling signs. Great care has been taken to design products that will satisfy a wide

variety of installations. Some of the design goals of these systems include the

following:

· Easy transfer of messages

· The ability to tell a sign or group of signs in the network which message

should run

· The ability to determine the status of any sign on the network

· The ability to control multiple sign technologies on the same network

All the programming features would seem insignificant if the systems could not be

accomplished with basic tools and without technical difficulty. Daktronics decided to

use the very popular and readily available RJ11 connector. This connector is also

used on modern home and office telephone equipment.

All that is required for signal installation is standard six (6)-conductor modular

telephone wire and a tool to install the connector. Tools required for mounting the

display depend on the location and size of the display. For some installations, it may

be possible to purchase pre-terminated telephone cables for use with the displays.

There are four (4) network systems available: RS232, RS422, modem, and fiber

optic.

RS232 Network

RS232 (EIA/TIA-232-E) is a standard communication interface that employs a

single-ended serial transmission scheme that uses a maximum cable length of 8

meters (25 feet). This interface was designed for computer communication at short

distances. All computers have an RS232 communications port. Refer to Section 3 for

additional information.

RS422 Network

RS422 (EIA/TIA-422-B) is a standard communication interface that utilizes a

differential balanced transmission scheme, which uses a typical maximum cable

length of 1.2 km (approximately 4,000 feet). The main advantage of RS422 over

RS232 is the longer cable length that is possible. A signal converter is needed to

convert the computer’s RS232 to RS422. Refer to Section 3 for additional

information.

Introduction

1-3

Page 12

Modem Network

The modem is a standard communication interface that utilizes standard phone

transmission lines. The phone company assigns each phone line a number that the

modem uses to communicate between the control computer and display. Refer to

Section 3 for additional information.

Fiber Optic Network

A fiber optic network is a standard communication method transmitting light (signal)

through a glass fibe r. Fiber optic cable has a maximum length of 2 ,000 feet. A signal

conductor is needed to convert the computer’s RS232 to fiber optic signal. Refer to

Section 3 for additional information.

Radio Network

The radio network is a standar d communication method tha t uses radio waves at high

frequencies to transmit signal. The Venus 1500 Radio network has a maximum

distance of 1,500 feet outdoor and 500 feet indoor. A nearly straight line-of-sight

path must be maintained between the Server Radio connected to the computer and the

Client Radio connected to the display. Refer to Section 3 and the radio manual

(ED-13932) for additional information.

1.4 Display Overview

Reference Drawing:

Shop Drawing...........................................................Refer to Appendix C

The Daktronics outdoor LED displays have been designed and manufactured for

performance, reliability, easy maintenance, and long life. The displays consist of an

array of LED pixels. The configuration of LED pixels is dependent on the family of

LED displays.

A typical display system consists of a Windows

running Venus

single-face units, which are single-sided stand-alone displays. They can become

double-faced by mounting them back-to-back with a second unit.

®

Venus

2000, or XP Home/Professional operating systems on an IBM

computer. Refer to the Venus

installation and operation of the Venus

Refer to Section 4 for the summaries of how signal and power are routed through the

displays.

â

1500 software and one or more displays. The displays are offered as

1500 is a software package that runs under Windowsâ 98, ME™, NT® 4.0,

®

1500 controller operator’s manual (ED-13530) for

â

based personal computer (PC)

â

-compatible

®

1500 controller editing station.

1-4

Introduction

Page 13

The Galaxy Series AF-3010 displays are matrix-based outdoor LED displays, which

are available in monochrome red characters. They are offered as 8 pixel high displays

with a standard 7 high 9", 16 high 21" character, or 24 high displays with a standard

7 high 9", 1 5 high 20", or 24 high 32 "characte r in six (6) different lengths. The

Galaxy model numbers are described as follows: AF-3010-RRxCCC-9-R.

AF-3010 =

RR =

CCC =

9 =

R =

Outdoor Galaxy® Display

8, 16, or 24 Rows High

Number of Columns Long (48, 64, 80, 96,

112, and 128 are available)

9" Character Height

Monochrome Red

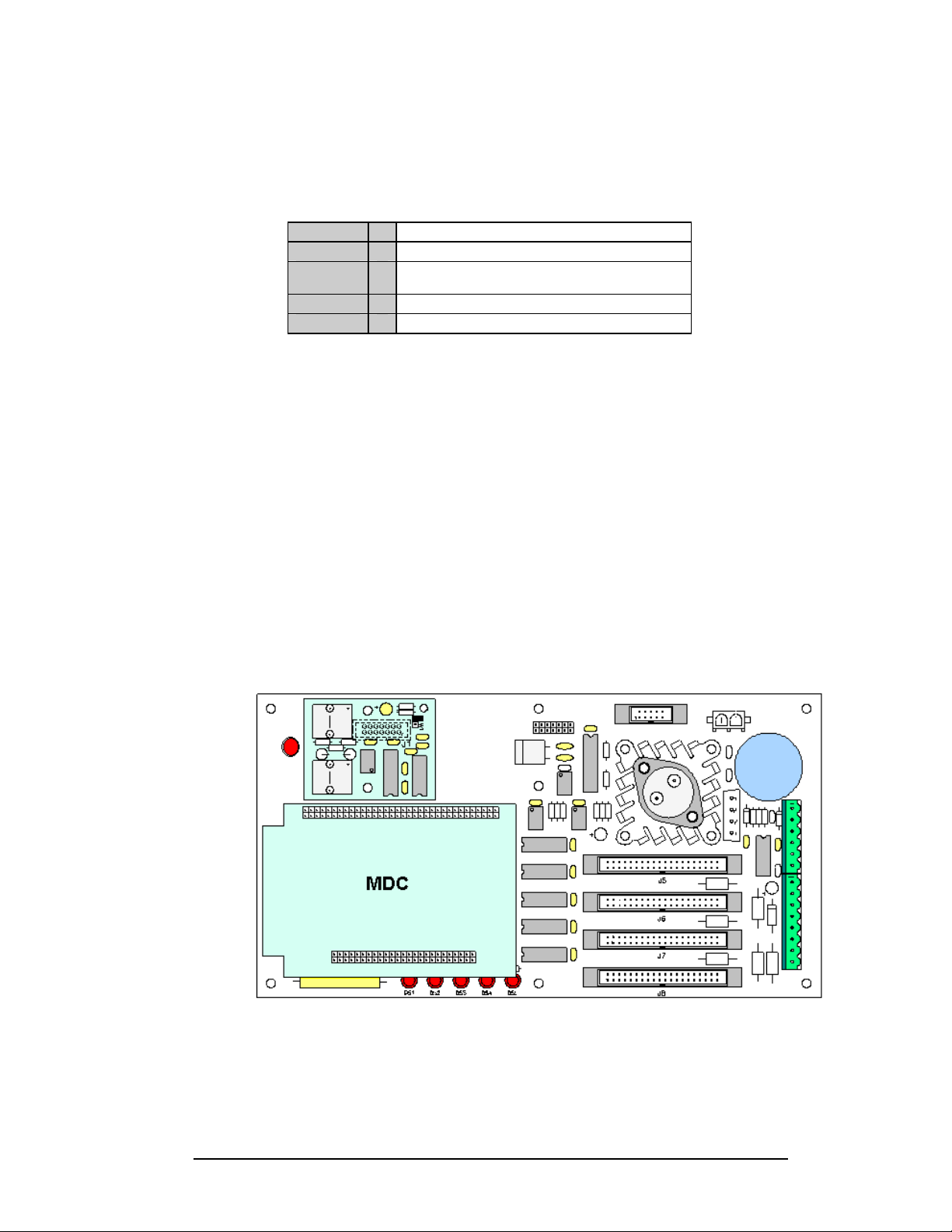

1.5 Component Identification

The following illustrations depict some of the more commonly accessed Galaxy sign

components. Because Daktronics occasionally alters standard design to meet

customer needs, the actual sign design may vary slightly from the illustrations below.

This is only a brief overview. Refer to Section 4 for more detailed information on

maintaining and troubleshooting various sign components.

Com Port: Connector on the back of the control computer. The COM port is used to

control the sign network through either a 9- or a 25-p i n serial connector. The

computer requires a serial port to work with this display.

Controller: “Brains” of the sign. The controller receives, translates, and activates the

signal information from the control computer to the appropriate pixels on the sign

accordingly.

Figure 2: MDC Controller

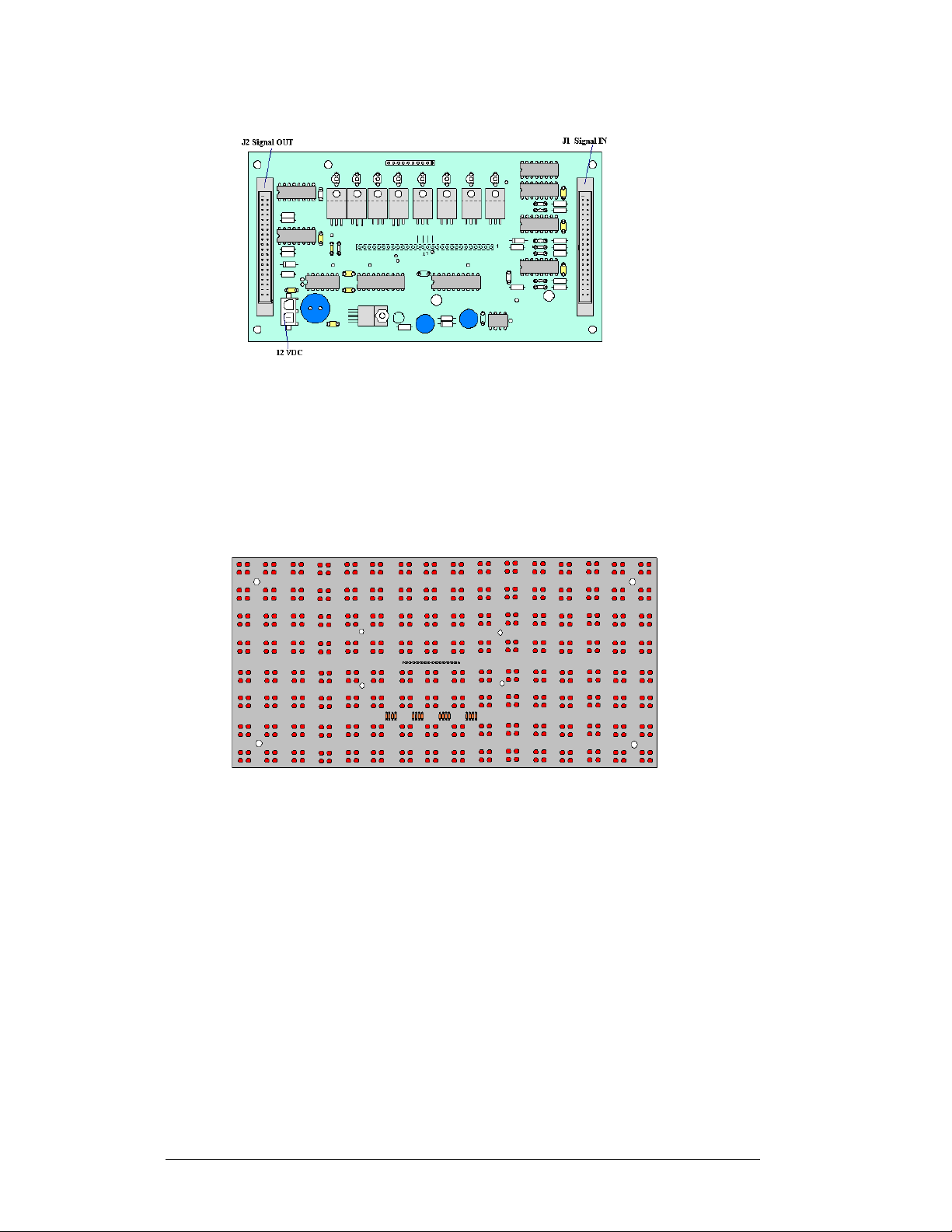

Driver/Pixel Board: Responsible for the switching and intensity levels of the LEDs.

The LED pixels are mounted directly onto the pixel board. The driver is located on

the back of the display board.

Introduction

1-5

Page 14

Figure 3: AF-3010 Driver/Pixel Board

Galaxy: Daktronics trademarked name for LED monochrome or tri-colored matrix

signs.

LED (light emitting diode): Low energy, high intensity lighti ng uni ts.

Module: 8 pixels high by 16 pixels wide. Each is individually removable from the

front of the sign.

1-6

Figure 4: 8x16 Pixel Module

Network: Consists of multiple signs connected to each other. Up to 240 Venus 1500

controlled displays can exist on one network.

Pixel: Cluster of four LEDs. The number and color of the LEDs depends on sign

application.

Power Supply: Converts AC line voltage from the load center to low DC voltage for

one or more module driver boards.

RS232: Standard PC communication type with a maximum cable length of 25 feet

(7.62 meters).

RS422: Standard differential communication type with a maximum cable length of

4,000 feet (1.2 kilometers).

Sign Address: Identification number assigned to each sign of a network. Flipping

DIP switches on the controller sets the sign address. The control software uses the

Introduction

Page 15

address to locate and communicate with each sign, but signs on the same network

cannot have the same address.

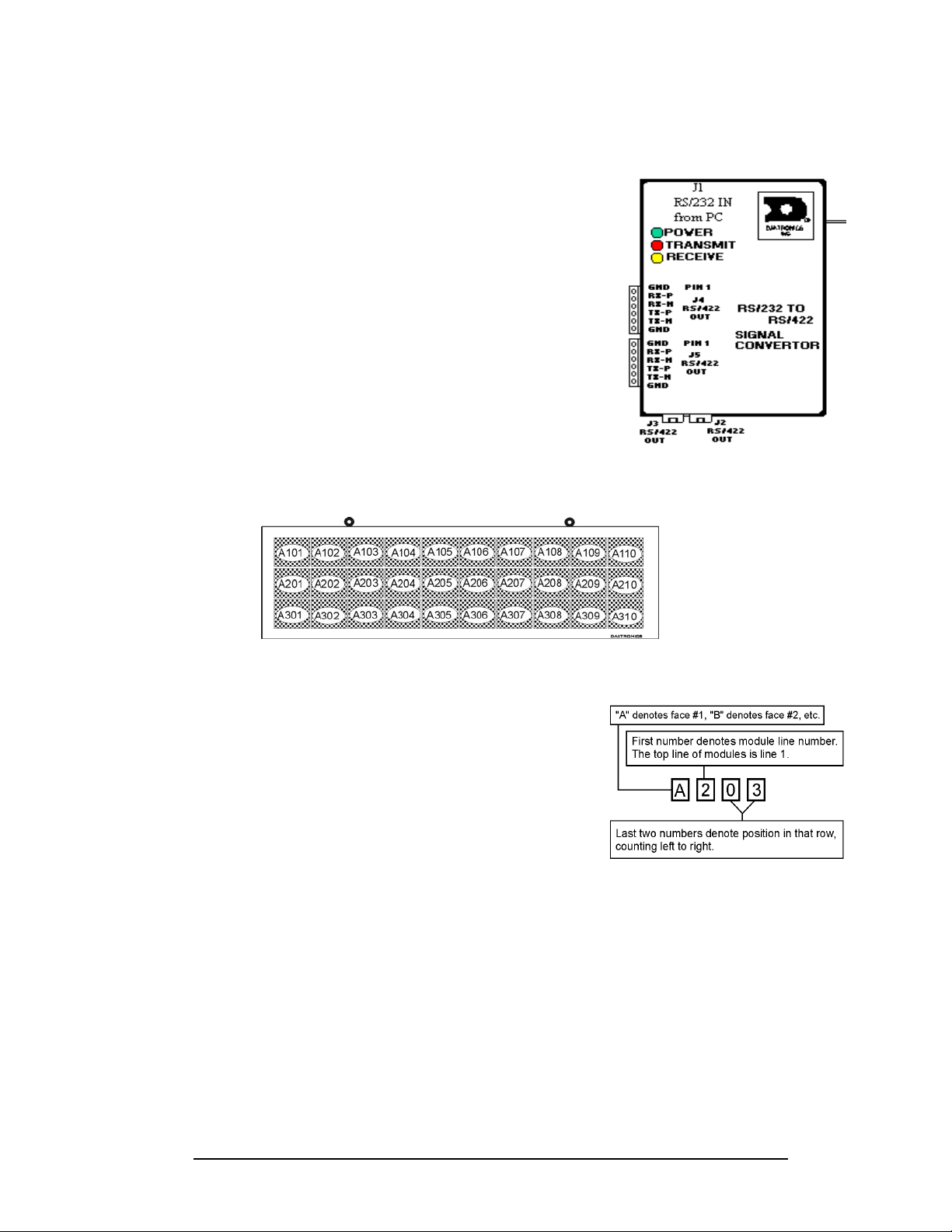

Signal Converter: Daktronics supplied unit that

converts the data from RS232 to RS422, or RS232 to

fiber optic signal. The signal converter is connected to

the control PC via straight though serial cable.

1.6 Daktronics Nomenclature

Figure 5: Signal Converter

Figure 6: Module Numbering Example – 24x160 Front

To fully understa nd some Daktronics drawings, such

as schematics, it is necessary to know how various

components are labeled in those drawings. This

information is also useful when trying to

communicate maintenance or troubleshooting

efforts.

A module is the building block of the Galaxy sign.

Each module measures 8 pixels high by 16 pixels

wide. By placing modules side-by-side and on top of

one another, a sign of any size can be designed and

built. Individual modules can be easily removed

Figure 7: Module Numbering

from the sign if required. Figure 6 above illustrates

how Daktronics numbers modules on a Galaxy sign.

Figure 7 on the right breaks down the module

numbering method.

The label “A” on a drawing typically denotes an assembly. An assembly can be a

single circuit board or a collection of components that function together, usually

mounted on a single plate or in a single enclosure. Assemblies are divided into two

types: those that route signal and those that route power.

Introduction

1-7

Page 16

In addition, the following labeling formats might be found on various Daktronics

drawings:

· “TB_ _” represents a termination block for power or signal cable.

· “F_ _” stands for a fuse.

· “E_ _” indicates a grounding point.

· “J_ _” symbolizes a power or signal jack.

· “P_ _” identifies a power or signal plug for the opposite jack.

Finally, Daktronics part numbers a re commonly found on dr awings. Those part

numbers can be used when requesting replacement parts from Daktronics Customer

Service. T ake note of the following part number formats:

· “0P-_ _ _ _-_ _ _ _” denotes an individual circuit board, such as a driver

board.

· “0A-_ _ _ _-_ _ _ _” represents an assembly, such as a circuit board and the

plate or bracket to which it is mounted. A collection of circuit boards

working as a single unit may also carry an assembly label.

· “W-_ _ _ _” shows a wire or cable. Cables may also carry the assembly

numbering format in certain circumstances. This is especially true of ribbon

cables.

· “F-_ _ _ _” indicates a fuse.

Most circuit boards and components within this sign carry

a label that lists the part number of the unit. If a circuit

board or assembly is not listed in the Replacement Parts

List in Section 4.13, use the label to order a replacement.

A typical label is shown in Figure 8 on the right. The part

number is in bold.

0P-1195-0001

SN: 6343

05/19/99 REV.1

Figure 8: Typical Label

1-8

Introduction

Page 17

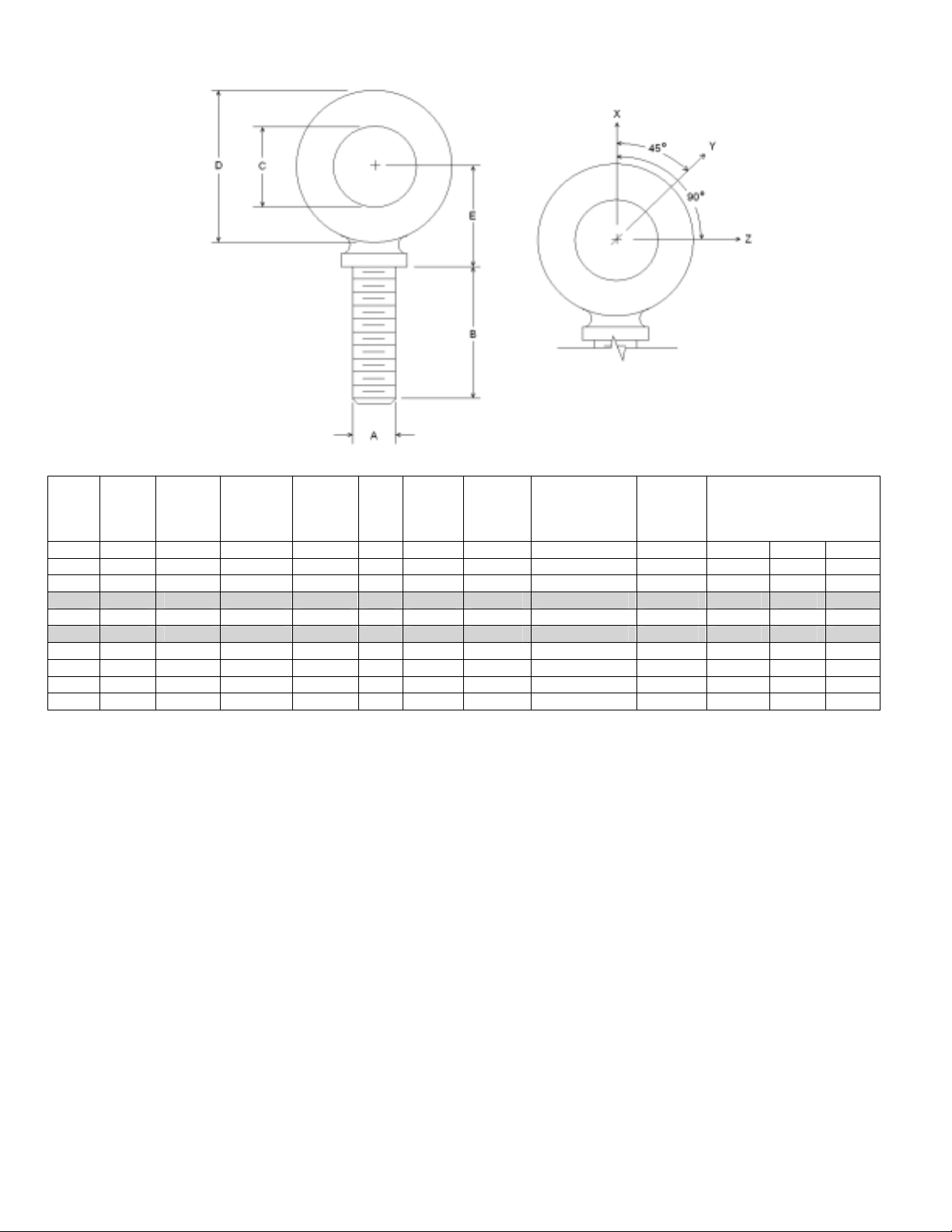

Eyebolts

Almost every display that leav es D ak tronics is equipped w ith ey ebolts for lifting the display . There are

two standard sizes of eyebolts: ½″ and A″.

Load Increase Factor: The load increases as the lift angle (θ) decreases. The allowable load on the

eyebolts also decreases with the lift angle due the bending stress on the eyebolts. In sum, the smaller

the angle between the cable and the top of the display, the lighter the sign must be to safely lift it. Do

NOT attempt to lift the display when the lift angle is less than 30 degrees.

Horizontal Load Angle

Angle Factor (L/H)

90 1.00

60 1.155 90 2600 2600 4000 4000

50 1.305 60 1500 1299 3300 2858

45 1.414 45 650 460 1000 707

30 2.00 30 520 260 800 400

θθθθ

½”

Line Weight/ Line Weight/

Load Anchor Load Anchor

A

A”

AA

ED7244 Copyright 1996-2001

Rev. 4 – 14 March 2001 Daktronics, Inc.

Page 18

Min.

A B C D E No.

Wx Wy Wz

1/4 1 3/4 1-3/16 25/32 21 600 2,000 Blank 1/4-20 7/8 400 100 80

3/8 1-1/4 1 1-21/32 1-3/16 23 2,100 5,000 Blank 3/8-16 1-1/8 1,400 350 250

1/2 1-1/2 1-3/16 2-1/16 1-13/32 25 3,900 9,200 Blank 1/2-13 1-11/32 2,600 650 520

9/16 1-5/8 1-9/32 2-13/16 1-17/32 26 4,500 11,830 Blank 9/16-12 1-3/8 3,000 750 600

5/8 1-3/4 1-3/8 2-1/2 1-11/16 27 6,000 14,700 Blank 5/8-11 1-9/16 4,000 1,000 800

3/4 2 1-1/2 2-13/16 1-13/16 28 9,000 21,700 Blank 3/4-10 1-5/8 6,000 1,500 1,200

7/8 2-1/4 1-11/16 3-1/4 2-1/16 29 10,000 30,000 Blank 7/8-9 1-13/16 6,600 1,670 1,330

1 2-1/2 1-13/16 3-9/16 2-5/16 30 12,000 39,400 Blank 1-8 2-1/16 8,000 2,000 1,600

1-1/2 3-1/2 2-9/16 5-1/2 3-5/32 34 27,000 91,300 Blank 1-1/2-6 3 17,800 4,500 3,600

Proof

Load

(lbs.)

Min.

Break

Load

(lbs.)

Stocked

Min.

Eff.

Thrd.

Length

Line Loads

A. Do not use eyebolts on angular lifts unless absolutely necessary. For angular lifts, the shoulder pattern

eyebolt is preferred.

B. Load should always be applied to eyebolts in the plane of the eye, not at some angle to this plane.

C. Shoulder eyebolts must be properly seated (should bear firmly against the mating part), otherwise the

working loads must be reduced to those indicated for regular eyebolts. A washer or spacer may be

required to put the plane of the eye in the direction of the load when the shoulder is seated.

D. No load greater than the safe working load listed in the data table should be used.

E. To obtain the greatest strength from the eyebolt, it must fit reasonably tight in its mounting hole to prevent

accidental unscrewing due to twist of cable.

F. Eyebolts should never be painted or otherwise coated when used for lifting. Such coatings may cover

potential flaws in the eyebolt.

G. To attain the safe working loads listed for regular eyebolts, 90% of the thread length must be engaged.

Copyright 1996-2001 ED-7244

Daktronics, Inc. Rev. 4 – 14 March 2001

Page 19

Section 2: Mechanical Installation

Note: Daktronics does not guarantee the warranty in situations where the sign is not consta ntly

in a stable environment.

Daktronics engi neering staff must approve any changes that may affect the weather-tightness

of the sign. If any modifications are made, detailed drawings of the changes must be

submitted to Daktronics for evaluation and approval, or the warranty may be void.

Daktronics is not responsible for installations or the structural integrity of support

structures done by others. It is the customer’s responsibility to make sure that a qualified

structural engineer has ensured the structure and any additional hardware.

2.1 Mechanical Installation Overview

Because every installation site is unique, there is no single Daktronics-approved

procedure for mounting the Galaxy signs. The information contained in this section is

general information only and may or may not be appropriate for your particular

installation.

A qualified individual must make all decisions regarding the mounting of this

sign.

Read both the mechanical and electrical installation sections of this manual

before beginning any installation procedures.

2.2 Support Structure Design

Support structure design depends on the mounting methods, sign size, and weight.

The structure design is critical and should be done only by a qualified individual.

Sign height and wind loading are also critical factors. It is the customer’s

responsibility to ensure that the structure and mounting hardware are adequate.

Daktronics is not responsible for the installations or the structural integrity of

support structures done by others.

It is the installer’s responsibility to ensure the mounting structure and

hardware are capable of supporting the sign, and will agree with local codes.

Before beginning the installation process, verify the following.

· The mounting structure will provide a straight and square-mounting frame

for the sign.

· The mounting structure is capable of supporting the sign and will not yield

at any unsupported points after mounting.

Correct any deficiencies before installation.

Mechanical Installation 2-1

Page 20

2.3 Display Ventilation Requirements

Reference Drawing:

Shop Drawing...........................................................Refer to Appendix C

Fans are mounted inside the back of the display for cooling. Fresh air inlets and

exhaust vents should not be obstructed in any way (refer to shop drawings located in

Appendix C). Using the Daktronics suggested mounting methods will ensure proper

ventilation. Fans turn ON when the interior display temperature reaches 140º F.

Consult a Daktronics sales representative for clearance requirements regarding your

particular display if you are using a different mounting method. If ventilation

requirements are not met, the display warranty will be void.

2.4 Mounting Kit

A mounting kit is available when ordering a display. The mounting kit includes the

hardware to either mount the display on a pole or on a wall. When using a Daktronics

mounting kit, refer to the instructions in Section 2.5.

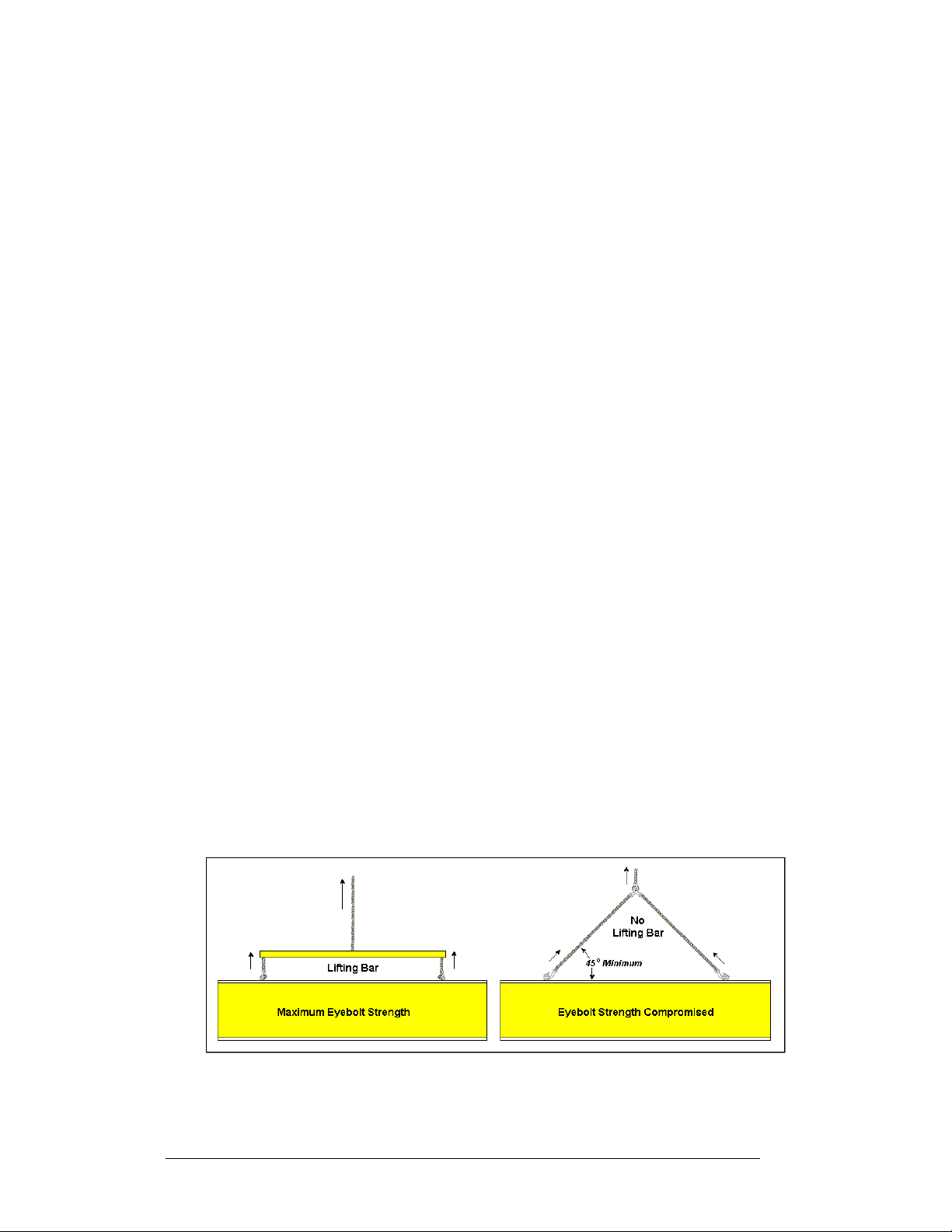

2.5 Display Lifting

Reference Drawing:

Shop Drawing...........................................................Refer to Appendix C

Eyebolts are provided on the top of each display for lifting purposes. Refer to

ED-7244 at the end of this section for the proper lifting procedure. A spreader bar

should be used to maintain a vertical force on each eyebolt. Using cables or chains to

attach the eyebolts directly to the central lifting point can apply dangerous lateral

force to the eyebolts. Do not use the eyebolts for permanent installation. Refer to

shop drawings for the dimensions of the eyebolts from each end of the display.

Once the display is permanently mounted, replace the eyebolts with the hex-head

bolts (supplied by Daktronics) and sealing washers used with the eyebolts. Use water

proofing compound, such as silicon, along with bolts and sealing washers, to ensure a

waterproof seal.

Figure 9: Lifting the Display (Correct, Left; Incorrect, Right)

2-2

Mechanical Installation

Page 21

2.6 Display Cabinet Mounting

Reference Drawings:

Mounting Drawing, AF-3010-*****-9-*...........................Drawing A-102469

Shop Drawing................................................................Refer Appendix C

It is the customer’s responsibility to ensure that the installation will meet local

standards. The mounting hardware must be capable of supporting all components to

be mounted. The mounting hardware and method are the responsibility of the

customer. Refer to shop drawings located within Appendix C for the approximate

weight and size of each model of display. Daktronics is not responsible for the

installations or the structural integr ity of support structures done by others.

Daktronics has recommendations fo r both a wall mount method and a pole mount

method. R emember to have all mounted displays inspected by a qualified structural

engineer.

Note: The display has hinged face panel. Care must be taken to allow the door to

properly open (refer to Drawing A-102469).

Wall Mount

Note: Because each site differs, the Daktronics wall mount kit is not a complete

installation kit. It is the customer’s responsibility to determine the proper wall

mounting method and location.

Refer to Drawing A-102469 for a suggested wall mount method. The wall mounting

channels are attached to the rear of the display by Daktronics. Notice that the vertical

distance between the mounting channels is 21". The number of attachment points

needed and the wall structure must be reviewed by a qualified structural engineer and

meet all national and local codes.

Pole Mount

Refer to Drawing A-102469 for a suggested pole mount method. The locati on of the

poles needs to be determined by the customer. The number of poles needed and the

pole structure and footings must be reviewed by a qualified structural engineer and

meet all national and local codes.

One (1) Dakt ronics provi ded mounting kit includes:

· Clamping Channel (qty. 2, attached to rear of display by Daktronics)

· Clamping Angles (qty. 4)

· 1/2" Threaded Rod (qty. 8)

· 1/2" Nut (qty. 16)

· 1/2" Lock Washer (qty. 16)

Mechanical Installation 2-3

Page 22

Study the illustration of the pole mounting method in Drawing A-102469, and then

use the following procedure for each display:

1. Measure the beam spacing and drill a 9/16" diameter hole for each 1/2"

threaded rod through one flange of the clamping channels.

2. Insert the threaded rods through the drilled opening and secure using 1/2"

nuts and lock washers.

3. Position the display at the front of the beams with the threaded rods

extending from the rear of the channels, straddling the poles.

4. Raise the display to the desired height.

5. Slide clamping angles over the ends of the threaded rods and loosely install

1/2" washers and nuts.

6. Make final adjustments in positioning the display. Make sure the threaded

rods are perpendicular to the display.

7. Tighten all the 1/2" hardware.

2-4

Mechanical Installation

Page 23

Section 3: Electrical Installation

Only a qualified individual should terminate power and signa l cable within this

Daktronics sign.

The Daktronics engineering staff must approve any changes made to the sign. Before altering

the sign, submit detailed drawings for the proposed modifications to the Daktronics

engineering staff for evaluation and approval, or the warranty will be rendered null and void.

3.1 Common Connectors in the Sign

The power and signal connections i n the signs use many different types of

connectors. Take special care when disengaging any connector so as not to damage

the connector, the cable or the circuit board.

When pulling a connector plug from a jack, do not pull on the wire or cable; pull on

the jack itself. Pulling on the wires may damage the cable and connector.

The following information presents some common connectors encountered during

sign installation and maintenance:

1. Ribbon Cable Connectors:

Figure 10 on the right illustrates a typical ribbon

connector. To disconnect the ribbon cable, push the plastic

clips on the sides of the jack to unlock and remove the

cable.

Before replacing a ribbon cable connector, spray it with

DeoxIT

may cause signal problems. In addition, apply a generous

amount of CaiLube

inserting it into the jack. This paste will protect both the

plug and the jack from corrosion.

2. Termination Blocks:

Termination blocks are usually used to connect internal

power and signal wires to wires of the same type coming

into the sign from an external source. Power wires need to

have one-half inch of insulation stripped from the end of

the wire prior to termination. Tighten all screws firmly to

ensure a good electrical connection. Refer to Figure 11 on

the right.

™

contact cleaner to remove any foreign matter that

™

protector paste to the plug before

Figure 10: Ribbon

Cable Connector

Figure 11: Termination

Block

Electrical Installation 3-1

Page 24

3. Phoenixä-Style Connectors:

Phoenix-style connectors, which are usually green, are often

used for signal termination on circuit boards. Refer to Figure

12 on the right. Strip one-quarter inch of insulation from the

wire prior to termination. To remove a wire, turn the above

screw counter-clockwise to loosen the connector's grip on the

wire. To insert a wire, push the bare wire into the connector,

and turn the above screw clockwise to lock the wire into

place.

4. Mate-n-Lokä Connectors:

The Mate-n-Lok connectors found in the signs are white and

come in a variety of sizes. Figure 13 on the right illustrates a

four-pin Mat e-n-Lok connector. To remove the plug fo rm the

jack, squeeze the plastic locking clasps on the side of the

plug and pull it from the jack.

Figure 12: Phoenix-

Connector

Style

5. Phone Jacks (RJ11/RJ45 Connectors):

RJ connectors are similar to the telephone connectors found

in homes and are used on the ends of RJ11 or RJ45 cable. In

order to remove this plug from the jack, depress the small

clip on the underside of the plug. Before replacing an RJ

connector, spray it with DeoxIT

any foreign matter that may cause signal problems. In

addition, apply a generous amount of CaiLube

™

contact cleaner to remove

™

protector

paste to the plug before inserting it into the jack. This paste

will protect both the plug and the jack from corrosion.

3.2 Control Cable Categories

The conductor connector used in the network is an industry standard,

6-pin RJ11. This connector can be found on

many telephones and LANs.

The cable used in the network is a standard flat

six-conductor telephone cable (standard flipped

cable). Refer to Figure 14 on the right. This

cable has one end that is the mirror image of the

other end (i.e. the cable is flipped). Refer to

Figure 15 on the following page for a standard

flipped cable.

Figure 13: Mate-nLok Connector

Figure 14: 6-Conductor RJ11 Connector and

Cable

3-2

Electrical Installation

Page 25

Notice below in Figure 15 that the color code on one connector must be made the

opposite on the other connector. When installing a network, it is not easy to

remember in which direction the previous end was oriented. One simple way to avoid

confusion is to standardize the color code, having one color for the connector going

into the output of a sign, and the opposite color for a connector going into the input

of a sign. This will help ensure correct cabling since cables are always installed from

the output jack of one sign to the input jack of the next sign.

Figure 15: Flipped Cable with RJ Connectors

3.3 Conduit

Reference Drawings:

System Riser Diagram, Modem ..................................... Drawing A-88426

Power/Signal Termination Panel....................................Drawing A-88427

System Riser Diagram, RS422......................................Drawing A-92681

System Riser Diagram, RS232......................................Drawing A-96058

System Riser Diagram, Fiber.......................................Drawing A-110559

System Riser Diagram, Outdoor Radio, Gen 2............Drawing A-185325

Shop Drawing............................................................Refer to Appendix C

Daktronics does not include the conduit. Knockouts will be provided for power and

signal. Separat e conduit must be used t o route:

· Power

· Signal IN wires

· Signal OUT wires (if signal is required for another display)

The conduit holes are located at the bottom right (rear view) of the back of the

display (refer to shop drawings located within Appendix C).

To access the knockouts, release the face panel latches using an 8mm Allen wrench

(provided by Daktronics). Open the face panel. Caution: The door will swing up.

Remove the bottom left module (front view) to reach the knockouts (refer to Section

4.3 to remove a module).

Punch or drill out the desired knockouts. Be careful that none of the internal

components are damaged. Attach the conduit and route the power and signal cables.

Refer to Drawing A-88427 for a picture of the power and signal termination panels.

For displays with more than one face, signal and temperature sensor wiring between

displays can be r outed through the same conduit.

Electrical Installation 3-3

Page 26

3.4 Grounding

Displays must be grounded according to the provisions outlined in Article 250 of the

National Electrical Code

®

. Daktronics recommends a resistance to ground of 10

ohms or less. The electrical contractor who is performing the electrical installation

can perform verification of ground resistance. Daktronics Sales and Service

personnel can also perform this service.

The display system must be connected to e arth-ground. Proper grounding is

necessary for reliable equipment operation. It also protects the equipment from

damaging electri cal disturba nces and lightning. The display must be properly

grounded or the warranty will be void.

The material of an earth-ground electrode differs from region to region and from

conditions present at the site. Consult the National Electrical Code and any local

electrical codes that may apply. The support structure of the display cannot be used

as an earth-ground electrode. The support is generally embedded in concrete, and if

in earth, the steel is either primed or it corrodes, making it a poor ground.

Power Installation

There are two considerations for power installation: installation with ground and

neutral conductors provided, and installation with only a neutral conductor provided.

These two power installations differ slightly, as described in the following

paragraphs:

Ins allation w th Ground and Neutral Conductors P ovided t i r

For this type of installation, the power cable must contain an isolated earth-ground

conductor. Under this circumstance, do not connect neut ral to ground at the

disconnect or at the display. This would violate electrical codes and void the

warranty. Use a disconnect so that all hot lines and neutral can be disconnected.

Refer to Figure 16 below for installation details. The National Electrical Code

requires the use of a lockable power disconnect within sight of or at the display.

3-4

Figure 16: Installation with Ground and Neutral Conductors Provided

Electrical Installation

Page 27

Ins allation w th Only a Neutral Conductor Providedt i

Installations where no grounding conductor is provided must comply with article

250-32 of the National Electrical Code. If the installation in question meets all of the

requirements of article 250-32, the following guidelines must be observed:

· Connect the grounding electrode cable at the local disconnect, never at the

display power termination panel.

· A disconnect tha t opens all of the ungrounded phase conductors should be

used.

· The neutral and the ground conductors should be bonded in the display

power termination panel.

Refer to Figure 17 below for installation details.

Figure 17: Installation with Only Neutral Conductor Provided

3.5 Control Cable Requirements

RS232

This cable is a 2-conductor shielded cable used to transmit an RS232 signal

(Daktronics part number W-1117). This unshielded cable should not be subjected to

mechanical flexing after installation. This cable is not for direct burial and should be

routed in a dedicated, grounded, metallic conduit at the base of the display structure.

This cable has a maximum length of 25 feet.

Electrical Installation 3-5

Page 28

RS422

This cable is a 6-conductor shielded cable used to transmit an RS422 signal

(Daktronics part number W-1210). This unshielded cable consists of un-paired wires.

They should not be subjected to mechanical flexing after installation. This cable is

not for direct burial and should have one of the following routings:

· In dedicated metallic conduit

· Inside buildings - if cable is not in conduit, keep away from interference

signals

With interference signals, such as power conductors, intercom, etc., typically a twofoot separation is required.

Modem

The modem option will use a standard tele phone cable routed through a conduit. The

local telephone company will need to assist in this installation.

Ask the telephone company which colors the TIP uses, and the RING for signal hook

up.

Note: The telephone lines must be dedicated lines and not run through a switch

board/communications system.

Fiber Optic

This cable is a 4-fiber cable (Daktronics part number W-1376). Two fibers are used

for display communications and the other two are saved for spares. The cable may be

either direct burial or routed in conduit but it should not be subjected to mechanical

flexing.

3-6

Radio

The Server radio connected to the computer requires an 18-gauge six-c onductor

cable (Daktronics part number W-1370). Four-conductors will be used for the signal

and two for power. These wires need to be in conduit when exposed to outdoor

conditions to the Server radio. The maximum distance from the J-box to the Server

radio is 1,000 feet (305.8 meters).

The Client radio at the display comes with cable that is rated for outdoor use and

does not need to be in conduit. The cable should be secured to the structure so it does

not come loose from the display.

Electrical Installation

Page 29

3.6 Signal Termination from Computer to Di spl a y

Reference Drawings:

System Riser Diagram, Modem ..................................... Drawing A-88426

System Riser Diagram, Power/Signal V1500 Displays..Drawing A-88427

System Riser Diagram, RS422......................................Drawing A-92681

System Riser Diagram, RS232......................................Drawing A-96058

System Riser Diagram, Fiber.......................................Drawing A-110559

System Riser Diagram, Outdoor Radio, Gen 2............Drawing A-185325

RS232

One end of the signal cable should be terminated to the 10 position terminal block in

the display labeled “IN RS232” (TB42). Drawing A-88427 is an example of the

termination panels. The opposite end is terminated at the J-box at the display

structure. The laptop PC connects to the J-box through the serial cable (refer to

Drawing A-96058).

Figure 18: RS232 Connections

J-Box Field Cabling Terminal Block (Data In)

- - Pin 1 (N.C.)

- - Pin 2 (N.C.)

Pin 2 (RX-P) Clear Pin 3 (TX-P)

Pin 3 (GND) Shield Pin 4 (GND)

Pin 1 (TX-P) Black Pin 5 (RX-P)

- - Pin 6 (N.C.)

Electrical Installation 3-7

Page 30

RS422

One end of the signal cable should be terminated to the surge suppressor terminal

block in the display labeled “IN RS422” (TB1). Drawing A-88427 is an example of

the termination panel. The opposite end is terminated at the signal converter

(Daktronics part number 0A-1127-0237). Refer to Drawing A-92681 shows an

example system riser using the RS422 signal termination.

Figure 19: RS422 Signal Converter Connections

Signal Converter (J4/J5) Field Cabling Terminal Block (Data In)

Pin 1 (GND) Red Pin 1 (GND)

Pin 2 (RX-P) Black Pin 2 (TX-P)

Pin 3 (RX-N) Brown Pin 3 (TX-N)

Pin 4 (TX-P) White Pin 4 (RX-P)

Pin 5 (TX-N) Blue Pin 5 (RX-N)

Pin 6 (GND)

Green Pin 6 (GND)

Shield (Bare) N.C.

3-8

Electrical Installation

Page 31

Modem

Terminate the signal telephone wires to the 10 position terminal block labeled “IN

MODEM” (TB42) as follows:

Figure 20: Modem Signal Connections

Telephone Wires Terminal Block

N.C. Pin 1

N.C. Pin 2

TIP-P Pin 3

Ring-P Pin 4

N.C. Pin 5

N.C. Pin 6

Drawing A-88426 shows an example modem system setup.

Fiber Optic

Route conduit and fiber cable from the PC to the left end of the master display.

Continue routing fiber to the controller box. Refer to Drawing A-110559 for an

example fiber system layout.

Connect fiber to J2 and J3 at the signal converter end (0A-1127-0239) ·

· Connect fiber to J4 and J5 at the display end

Electrical Installation 3-9

Page 32

Figure 21: Fiber Optic Layout

Signal Converter Field Cabling Display Fiber Board

J2 Transmit (TX) (color varies) J5 Receive (RX)

J3 Receive (RX) (color varies) J4 Transmit (TX)

Radio

A display that is controlled using a radio requires a server radio connected to the

control computer and a client radio at the display. The radios must be in line-of-sight

with each other.

1. Connect a DB9M to DB9 serial cable from the computer to the J-box. Use

6-condutor, 18-gauge cable, to connect from the J-box to the Server radio.

The cable must be in conduit when exposed to outdoor conditions. The

distance from the J-box to the Server radio should not exceed 1000 feet.

Figure 22 on the following page shows the connections from the J-box to

the server radio.

2. Route the cable provided with the Client radio into t he display through one

of the knockouts on the back of the display. Terminate the three signal

wires, and connect the power plug from the Client radio to the additional

jack in the display. Figure 23 on the following page shows the connection

from the client radio to the display.

3. Refer to Drawing A-185325 and the radio manual (ED-13932) for the

correct cable terminations.

3-10

Electrical Installation

Page 33

Figure 22: J-box to Server Radio Connections

Figure 23: Client Radio to Display Connections

Electrical Installation 3-11

Page 34

3.7 Signal Termination Between Two (or More) Displays

Reference Drawings:

System Riser Diagram, Modem......................................Drawing A-88426

System Riser Diagram; Power/Signal, V1500 Displays..Drawing A-88427

System Riser Diagram, RS422.......................................Drawing A-92681

System Riser Diagram, RS232.......................................Drawing A-96058

System Riser Diagram, Fiber .......................................Drawing A-110559

System Riser Diagram, Outdoor Radio, Gen 2 ............Drawing A-185325

RS422 Interconnection

This is the most common method of terminating signal between two or more signs. A

6-conductor cable is used and one end terminates at the “OUT RS422” 10-position

terminal block (TB43) on the first display. The other end terminates at the “IN

RS422” 10-position terminal block (TB42) in the second display.

3-12

Figure 24: RS422 Interconnection

Sign A

Data Out (TB43)

Pin 1 (GND) Green Pin 6 (GND)

Pin 2 (Data TX-N) Blue Pin 5 (Data RX-N)

Pin 3 (Data TX-P) White Pin 4 (Data RX-P)

Pin 4 (Data RX-N) Brown Pin 3 (Data TX-N)

Pin 5 (Data RX-P) Black Pin 2 (Data TX-P)

Pin 6 (GND)

Field Cabling

Sign B

Data In (TB42)

Red Pin 1 (GND)

Shield (Bare) N.C.

Electrical Installation

Page 35

Fiber Interconnection

A four-conductor fiber cable is used in connecting two or more displays in the Fiber

Interconnection method. Connect the fiber cable to the fiber cards of the display as

described on the following:

Sign A

Data Out (J2 and J3)

J2 (TX1) - J5 (RX2)

J3 (RX1) - J4 (TX2)

3.8 Initial Operation

When first operated, the display will run through an initialization in which it will

display the following:

1. Output Test (DDDs)

2. Product Name (Galaxy)

3. Display Size (Row x Column)

4. Firmware Number (ED10134)

5. Firmware Revision (Rev X.XX)

6. COM1 Configurati on (C1: V15/RTD)

7. COM2 Configuration (C2: None)

8. Line Frequency (6 0 Hz)

9. Hardware Address (HW: XX)

10. Software Address (SW: XX)

11. Display Name

12. Modem (if Present)

Field

Cabling

Sign B

Data In (J4 and J5)

Electrical Installation 3-13

Page 36

Page 37

Section 4: Maintenance and

Troubleshooting

Important Notes:

1. Disconnect power before any repair or maintenance work is done on

the display.

2. Qualified service personnel must make any access to internal display

electronics.

3. The Daktronics product manager’s engineering staff must approve any

changes that may affect the weather tightness of the display. This

includes, but is not limited to, the border shrouding and back sheets. If

ANY modifications are made to the weather tightness of the display,

detailed drawings of the changes MUST BE submitted to our

engineering staff for evaluation and approval or the warranty will be

null and void.

4. Care must be taken when handling the display’s face panel to prevent

injuries or damage, especially in windy conditions.

4.1 Weather Stripping

To ensure that the display is waterproof, weather stripping has been provided around

the entire display and around the face panel. It is important that the weather stripping

is installed properly at all times. Otherwise, water may leak into the display and

damage the components.

4.2 Module Numbering Convention

The following table shows the typical module numbering convention for a 16x64

display. A module is eight (8) pixels high by 16 pixels wide.

A101 A102 A103 A104

A201 A202 A203 A204

· Labeling reference begins with the upper left module and increments to the

right and down from that point, independent of display size.

· Modules are designated by the prefix “A.” A101 represents the upper left

module.

· T he hundreds digi t indicates the module line number. A101 through A104

make up the first module line, A201 through A204 make up the second line

and so forth.

Maintenance and Troubleshooting

4-1

Page 38

4.3 Display Access/Module Removal

To access the display’s interior electronic components, open the face panel and

remove the appropriate modules. The Galaxy displays are front access. Tools

needed: 8mm Allen wrench and 5/16" nutdriver

1. Release the face panel latches using an 8mm Allen wrench (provided by

Daktronics).

2. Open the face panel. Gas springs will hold the door open for servicing.

Caution: The door will swing up. Take extra precautions during windy

conditions.

3. Remove the four 5/16" mounting nuts hol ding the module to the display.

Each mounting nut is located in one corner of the module (refer to Figure

25 below on the left).

4. Carefully pull the module forward to unplug the power/signal connections

(refer to Figure 26 below on the right).

To install or replace the modules, follow the previous steps in reverse order.

Figure 25: Removing the Mounting Nuts

4.4 LED Driver Replacement

The LED driver is located on the rear side of the module: Tools needed: 8mm Allen

wrench and 5/16" nutdriver

1. Open the display, and release

the module.

2. Remove all power and signal

connection from the driver.

By pressing outward on the

locking tabs and gently

pulling the connector free, the

connectors are released (refer

to Figure 27 on the right).

3. Remove the four 5/16" nuts

from the corners. (Some

drivers are held in place by

plastic mounts.)

4-2

Figure 26: Removing the Module

Figure 27: Removing the Signal Connections

Maintenance and Troubleshooting

Page 39

4. Take note of the driver’s orientation.

5. Carefully remove the driver from the display board. Use an even amount of

force to prevent any damage due to bending of the connector pins on the

display board. Reverse the previous steps to replace the driver.

4.5 Power Supply

Reference Drawing:

Schematic .................................................................Refer to Appendix C

Note: Disconnect power from the display before removing a power supply.

The power supply is mounted behind every other module. The first power supply is

located behind module A102. This unit supplies power to the modules A101, A102,

A201, and A202. The remaining power supplies are located behind A103, A105,

A107, and A109, when applicable. One power supply connects to four (4) modules

(refer to schematics).

Refer to Section 4.3 for information on removing a module. Once the module has

been removed from the display: Tools needed: 8mm Allen wrench, 5/16"

nutdriver, and #2 Phillips screwdriver

1. Open the display and remove the module directing in front of the failed

power supply.

2. Disconnect the wires from the terminal block at the bottom of the power

supply. It helps to have the wires labeled for reconnecting them to the

power supply.

3. Use a Philips screwdriver to remove the power supply and bracket from the

vertical support.

4. Remove the screws securing the power supply to the bracket.

5. Attach the new power supply to the bracket using M4x8mm screws.

6. Attach the power supply/bracket assembly to the vertical support with #6

screws and washers.

7. Reconnect all wires to the power supply as shown in schematics.

Maintenance and Troubleshooting

4-3

Page 40

4.6 Controller Board

Reference Drawings:

System Riser Diagram, RS422.......................................Drawing A-92681

Shop Drawing...........................................................Refer to Appendix C

Accessing and Replacing the Controller Board

The controller board is located behind the bottom,

left module (refer to shop drawings). To access

the controller board: Tools needed: 8mm Allen

wrench, 5/16" nut driver, and 3/16" nutdriver

1. Open the display and remove the module

in front of the controller board (refer to

Section 4.3 to remove a module).

2. Remove all power and signal

connections from the board. Pressing

outward on the tabs, and carefully

pulling them from the jack releases the

“Locked” connectors.

3. Remove the mounting six screws using a

3/16" nutdriver.

4. Carefully remove the controller board

from the display.

Follow the previous steps in reverse order to

install a new controller board.

Figure 28: Controller Board

LEDs and Jumpers

The controller board contains three DIM, one Power, one RUN, and one Receive

Data LEDs.

The controller’s communication module contains two (2) jumpers for a modem

system. The jumpers must connect both pins for a modem system. For all other

applications, the jumpers must be removed.

Figure 29: LEDs and Jumpers

4-4

Maintenance and Troubleshooting

Page 41

Controller Address and Test Mode

Before a display can be run in a si gn network, it must

have an address. The display address can be set using

“DIP” switches located on a PC board known as the

MDC. The MDC is the circuit card mounted in the

lower right corner of the controller board.

Locate the DIP switches on the MDC. They should be

on the bottom end of the card. Refer to Figure 30 on

the right for a picture of the DIP switches.

When replacing a controller board, be sure to set the

DIP switches to the same address configuration as the

defective controller. The DIP switches follow standard

binary code.

Note: By setting the DIP switches to address 0 (flip all

the switches toward the numbers on the circuit board),

a test mode can be activated. The display’s power must

be downed, and then reconnected to run the test mode.

Switch 8 Switch 7 Switch 6 Switch 5 Switch 4 Switch 3 Switch 2 Switch 1 Address

Off Off Off Off Off Off Off On 1

Off Off Off Off Off Off On Off 2

Off Off Off Off Off Off On On 3

Off Off Off Off Off On Off Off 4

Off Off Off Off Off On Off On 5

Off Off Off Off Off On On Off 6

Off Off Off Off Off On On On 7

Off Off Off Off On Off Off Off 8

Off Off Off Off On Off Off On 9

Off Off Off Off On Off On Off 10

… … … … … … … …

Off On On On On On On On 127

Figure 30: Location of DIP

Switches

Maintenance and Troubleshooting

4-5

Page 42

Light Detector

Reference Drawings:

Shop Drawing.....................................................Refer to Appendix C

Schematic ..........................................................Refer to Appendix C

The light detector is internally mounted and wired at Daktronics. It is located on the

lower left of the display (refer to Detail A in shop drawings). A 4-conductor cable is

used to connect the light detector to the controller board. The cable is terminated at

the terminal block on the light sensor and at the terminal block on the controller

board (refer to schematics).

Light Detector

Pin No.

1 Green 3

2 White 4

3 Red 1

4 Black 2

N.C. Bare 2

4.7 Transformer

The transformer is used to provide power to the controller board 10-12 VAC,

modem, fiber converter, or radio depending on the communication method used. It is

located in the bottom left corner (front view) of the display in the power termination

box.

Cable Wires

Color

Controller Board

Pin No.

4.8 Modem

Accessing and Replacing the Modem

If a modem was included with the display, it is located inside the

sign next to the controller board. Tools required: 8mm Allen

wrench, 5/16" nutdriver, and 3/16" nutdriver

1. Open display and remove the module in front of the

modem in the lower left corner.

2. To replace a modem, first disconnect the power and

signal connections (refer to Figure 31 on the right for

the location of the power jack).

3. The modem is held in place with four 3/16" screws.

Remove these four screws and carefully remove the

modem.

4. Place the new modem over the four screws and replace

the screws. Reconnect the power and signal connections.

Figure 31: Modem

4-6

Maintenance and Troubleshooting

Page 43

LEDs and Jumpers

The modem module has two (2) LEDs. The Power LED should remain lit while

power is applied to the modem. The Active LED will light when the modem is in the

process of communicating.

A modem system requires jumpers to be set on the controller board. Refer to Section

4.6 for these jumper settings.

Fiber Board

The fiberboard has three LEDs. The power LED

(DS1) should remain lit while power is applied to

the module. The receive LED (DS2) will light

when the display fiberboard is accepting signal

from the fiber signal converter. The transmit LED

(DS3) will light when the display fiberboard is

sending to the fiber signal converter. In addition,

the fiberboard has two input fiber connectors that

the signal converter or the previous display

connects to, and two output fiber connectors that

connect to the next display. The fiberboard

connects to the controller board with a small DB9

to RJ11 adaptor and a straight RJ11 cable.

To replace a fiber optic board: Tools required:

8mm Allen wrench, 5/16" nutdriver, and 3/16"

nutdriver

1. Open the display and remove the module

in front of the fiber board in the lower left corner.

2. Disconnect the power and signal connections (refer to Figure 32 above for

disconnection of power).

3. The fiber optic board is held in place with four 3/16" screws. Carefully

remove them.

4. Install the new fiber board, replace the screws, and reconnect power and

signal cables.

Figure 32: Fiber Board

Maintenance and Troubleshooting

4-7

Page 44

4.9 Signal Routing

Figure 33 below shows the signal routing from the control computer to the display

controller and the routing within the display.

Figure 33: Signal Routing

4.10 Structural Inspection

Visual inspectio n should be done annually to check paint a nd look for possible

corrosion, especially at footings, structural tie points, and ground rods. Fasteners

should be checked, tightened, or replaced as required.

At least once a year, check the inside of the display for signs of water intrusion, i.e. water stain marks. Water can enter a display where weather stripping has come loose

or deteriorated, where fasteners have come loose allowing gaps in the panels, or

where moisture may be entering around hardware. Check the electronic components

for signs of corrosion.

Check/clean the filters for proper air flow.

4-8

Maintenance and Troubleshooting

Page 45

4.11 Troubleshooting

This section lists some symptoms that may be encountered with the display. Possible

cause and corrective actions are given. This list does not include every possible

problem, but does represent some of the more common situations that may occur.

Contact Daktronics Customer Service if problems continue with the display (refer to

Section 4.14).

Symptom/Condition Possible Corrective Action

One or more individual LED pixels

will not light.

A column of LED pixels will not

light.

A row of pixels will not light. · Check/Replace ribbon cable.

A section of the display is not

working. Section extends all the

way to the right side of the display.

Entire display is garbled. · Check power to controller board.

A single line is distorted. · Check/Replace ribbon cable.

Four modules, which share power

supplies will not light.

Entire display does not work. · Check 120 VAC to the display.

Controller not operating properly. · Check 10 VAC to the controller board.

Temperature always reads 32°F/

0°C.

Display is stuck on bright or dim. · Check Manual/Auto dimming in Venus

· Check/Replace ribbon cable.

· Replace display board.

· Replace module driver board.

· Check/Replace ribbon cable.

· Replace module driver board.

· Replace Display board.

· Replace driver board.

· Replace Display board.

· Check/ Replace the ribbon cable.

· Check for power on modules.

· Replace the first driver on the left side

of the module that is not working.

· Replace the second driver that isn’t

working.

· Replace the power supply on the first

module on the left side of the module

that is not working.

· Replace controller.

· Replace the controller board.

· Replace the first driver on the left side

of the display of the bad line.

· Replace the controller board.

· Check power to modules.

· Check wires and plugs to modules.

· Replace the power supply.

· Check fuse in Power term panel.

· Check 10 VAC to the controller board.

· Check for correct use of software.

· Refer to the Venus 1500 operator’s

manual (ED-13530).

· Check temperature sensor

connections.

· Check 5VDC to sensor.

· Replace temperature sensor.

· Replace controller board.

1500 software.

· Check light detector cable.

· Replace light detector.

· Replace controller board.

Maintenance and Troubleshooting

4-9

Page 46

4.12 Initial Operation Information

When first operated, the display will run through an initialization in which it will

display the following:

1. Output Test (DDD’s)

2. Product Name (Galaxy)

3. Display Size (Row x Column)

4. Firmware Number (ED10134)

5. Firmware Revision (Rev X.XX)

6. COM1 Configurati on (C1: V15/RTD)

7. COM2 Configuration (C2: None)

8. Line Frequency (6 0 Hz)

9. Hardware Address (HW: XX)

10. Software Address (SW: XX)

11. Display Name

12. Modem if Present (Modem)

4-10

Maintenance and Troubleshooting

Page 47

4.13 Replacement Parts

Part Description Daktronics

Controller Board, RS232, Modem, Fiber or Radio 0A-1185-0001

Controller Board, RS422 0A-1185-0002

LED Driver Board 0P-1137-0001

LED Display Board, 8x18, Red, DS-1295 0P-1137-0038

Light Detector 0P-1151-0002

Modem; RS232 coated 0P-1146-0003

Fiber board; Fiber to RS232, 12V 0P-1127-0024

Surge board in display 0P-1146-0031

Power Supply; +12V A-1555

Ribbon Cable; Controller to Bottom Module 0A-1000-0008

Ribbon Cable; Controller to Top Module 0A-1000-0006

Ribbon Cable; Between Modules W-1362

Cable; RS232, DB9F to DB25M, 6’ W -1249

Adapter; DB9M to DB25F A-1603

Flipped PC Connector; DB9F/RJ11F, Fiber 0A-1146-0029

Cable; 18” RJ11; 6-cond., Straight 0A-1137-0160

Temperature Sensor 0P-1151-0003

Signal Converter (RS/232/RS/422) 0A-1127-0237

Signal Converter (RS/232;Fiber) 0A-1127-0239

Fan (120 VAC Input) B-1006

Fan (240 VAC Input) B-1011

Fuse; MDL-7 (F41, 120 VAC) F-1031

Fuse; MDL-3 (F41, 240 VAC) F-1042

Fuse; MDX-5 (F42) F-1021

RFI Filter Z-1003

Transformer (120 VAC Input) T-1072

Transformer (240 VAC Input) T-1106

Manual; Venus 1500 Operator’s, Version 3

Part No.

ED-13530

Maintenance and Troubleshooting

4-11

Page 48

4.14 Daktronics Exchange and Repair and Retur n

Programs

To serve customers’ repair and maintenance needs, Daktronics offers both an

exchange and a repair and return program. The exchange program reduces down time

by providing timely replacement of key components. This service is provided to

qualified customers who follow the program guidelines explained below. It is our

pleasure to provide this service to ensure you get the most from your Daktronics

products. Please call our Help Desk (1-877 / 605-1113) if you have any questions

regarding the exchange program or any other Daktronics service.

When you call the Daktronics Help Desk, a trained service technician will work with

you to solve the equipment problem. You will work together to diagnose the problem

and determine which exchange replacement part to ship. If, after you make the

exchange, the equipment still causes problems, please contact our Help Desk

immediately.

If the replacement part fixes the problem, package the defective part in the same

packaging the replacement part arrived in, fill out and attach the enclosed UPS