Page 1

1600 Series, 2.5 Inch

Small Matrix Displays

(120V – Front Access)

Installation, Maintenance &

Troubleshooting Manual

ED11944

Venus

Phoenix

ED11944

Product 1195

Rev 4 – 26 February 2002

Copyright 2001-02 Daktronics, Inc.

All rights reserved. While every precaution has been taken in the

preparation of this manual, the publisher assumes no responsibility for errors

or omissions. No part of this book covered by the copyrights hereon may be

reproduced or copied in any form or by any means – graphic, electronic, or

mechanical, including photocopying, taping, or information storage and

retrieval systems – without written permission of the publisher.

Display Serial # _________________

Display Model # _________________

Date Installed ___________________

National Electrical Code

, Mate-N-Lok, DeoxIT and CaiLube are trademarks of their respective companies.

and SunSpot7 are registered trademarks of Daktronics, Inc.

7

is a registered trademark of NFPA International

P.O. Box 5128, 331 32nd Ave., Brookings, SD 57006

Tel (605) 697-4035 or (877) 605-1114 Fax (605) 697-4444

www.daktronics.com e-mail: helpdesk@daktronics.com

Page 2

Page 3

Table of Contents

Section 1: Introduction..................................................................................................1-1

1.1 How to Use This Manual............................................................................................1-1

1.2 Display Configurations...............................................................................................1-3

1.3 Display Definitions.....................................................................................................1-4

1.4 Daktronics Nomenclature...........................................................................................1-8

Section 2: Mechanical Installation...............................................................................2-1

2.1 Support Column Selection..........................................................................................2-1

2.2 Lifting the Display .....................................................................................................2-1

2.3 Cabinet Mounting.......................................................................................................2-2

2.4 Light Detector and Temperature Sensor Installation..................................................2-3

2.5 Display Ventilation Requirements .............................................................................2-4

2.6 Verifying Correct Lens and Module Position ............................................................2-5

Section 3: Electrical Installation...................................................................................3-1

3.1 Common Connectors..................................................................................................3-1

3.2 Display Power Requirements.....................................................................................3-3

3.3 Checking Line Voltage & 24-Hour Voltage Monitoring ...........................................3-3

3.4 Preparing the Display for Power & Signal Connection..............................................3-5

3.5 Bringing Power to the Display...................................................................................3-5

Power Disconnect Switch...........................................................................................3-6

Power Termination at the Display..............................................................................3-6

Grounding...................................................................................................................3-7

Power Installation .......................................................................................................3-7

3.6 Bringing Signal to the Display...................................................................................3-8

Venus 1500 System Using RS/232 Signal .................................................................3-9

Venus 1500 System Using RS/422 Signal ...............................................................3-10

Venus 1500 System Using Modem/Telephone Cable..............................................3-11

Venus 1500 System Using Fiber Optic Signal.........................................................3-11

Venus 4600 System Using Fiber Optic Signal.........................................................3-12

3.7 Interconnect of 2V Displays.....................................................................................3-13

Venus 1500 Systems ................................................................................................3-13

Venus 4600 Systems ................................................................................................3-14

3.8 Controlling Display Brightness................................................................................3-14

Light Detector Installation - Venus 1500 Systems...................................................3-15

Optional Photo/Temp Sensor Installation - Venus 4600 Systems............................3-15

3.9 Optional External Temperature Sensor....................................................................3-16

Optional Temp Sensor Installation - Venus 1500 Systems......................................3-16

Optional Photo/Temp Sensor Installation - Venus 4600 Systems............................3-17

3.10 First Time Power-Up................................................................................................ 3-17

3.11 Lamp Voltage Check................................................................................................3-18

Table of Contents i

Page 4

Section 4:

4.1 Maintenance & Troubleshooting Overview............................................................... 4-1

4.2 Operational Summary................................................................................................ 4-2

4.3 Servicing of Display Components............................................................................. 4-6

4.4 Display Maintenance ............................................................................................... 4-20

4.5 Lamp Testing & Maintenance ................................................................................. 4-20

4.6 Lens/Reflector Assembly Maintenance................................................................... 4-21

4.7 Filter Maintenance................................................................................................... 4-24

4.8 Fan Maintenance...................................................................................................... 4-24

4.9 Interior Maintenance................................................................................................ 4-25

4.10 Structural Maintenance & Inspection ...................................................................... 4-25

4.11 Periodic Line and Lamp Voltage Checks ................................................................ 4-26

4.12 Cleaning the Signal Connectors............................................................................... 4-26

4.13 FCC Modem Notice................................................................................................. 4-26

4.14 Troubleshooting....................................................................................................... 4-27

4.15 Replacement Parts List ............................................................................................ 4-28

4.16 Daktronics Exchange/Repair & Return Programs................................................... 4-29

Maintenance & Troubleshooting................................................................4-1

Power Summary......................................................................................................... 4-2

Signal Summary......................................................................................................... 4-3

Ventilation & Temperature Sensing Summary.......................................................... 4-5

Lenses ........................................................................................................................ 4-7

Lamps......................................................................................................................... 4-8

Lens/Reflector Assemblies ........................................................................................ 4-9

Lampbanks............................................................................................................... 4-11

Vertical Shift Boards ............................................................................................... 4-12

Fans.......................................................................................................................... 4-13

Filters....................................................................................................................... 4-14

Transformers............................................................................................................ 4-15

Additional Venus 1500 System Components.......................................................... 4-15

Additional Venus 4600 System Components (Serial Line Interface)...................... 4-19

Weather Stripping Maintenance .............................................................................. 4-22

Louver Maintenance ................................................................................................ 4-22

Appendix A: Project Specific Drawings.............................................................. A-1

Appendix B: General Drawings........................................................................... B-1

Appendix C: Forms & Report............................................................................... C-1

ii Table of Contents

Page 5

List of Figures

Figure 1: Drawing Label ....................................................................................................................1-2

Figure 2: Display ID Label.................................................................................................................1-2

Figure 3: Possible Signal Configurations...........................................................................................1-3

Figure 4: Possible Cabinet Configurations.........................................................................................1-3

Figure 5: Button Thermostat ..............................................................................................................1-4

Figure 6: Fan Controller Enclosure....................................................................................................1-4

Figure 7: Junction Box .......................................................................................................................1-4

Figure 8: Lampbank (Lamp Side)............................................................................................................1-5

Figure 9: Two Lampbanks on Lens / Reflector Assembly (Solder Side).................................................1-5

Figure 10: Lens/Reflector Assembly..................................................................................................1-5

Figure 11: Light Detector...................................................................................................................1-5

Figure 12: Module..............................................................................................................................1-6

Figure 13: Power Termination Panel..................................................................................................1-6

Figure 14: Serial Line Interface..........................................................................................................1-6

Figure 15: Signal Converter ...............................................................................................................1-7

Figure 16: Temp Sensor .....................................................................................................................1-7

Figure 17: Transformer.......................................................................................................................1-7

Figure 18: Venus 1500 Controller......................................................................................................1-7

Figure 19: Venus A/B Transmit I/F....................................................................................................1-7

Figure 20: Vertical Shift Board..........................................................................................................1-7

Figure 21: Module Numbering (16x80 Display) – Front View..........................................................1-8

Figure 22: Module Numbering Detail................................................................................................1-8

Figure 23: Lampbank Numbering (16x80) - Front View..................................................................1-8

Figure 24: Display Lifting..................................................................................................................2-1

Figure 25: Possible Mounting Method...............................................................................................2-2

Figure 26: Bottom Clearance..............................................................................................................2-3

Figure 27: Minimum Clearance for Sign Bottom...............................................................................2-4

Figure 28: Correct Lens Position........................................................................................................2-5

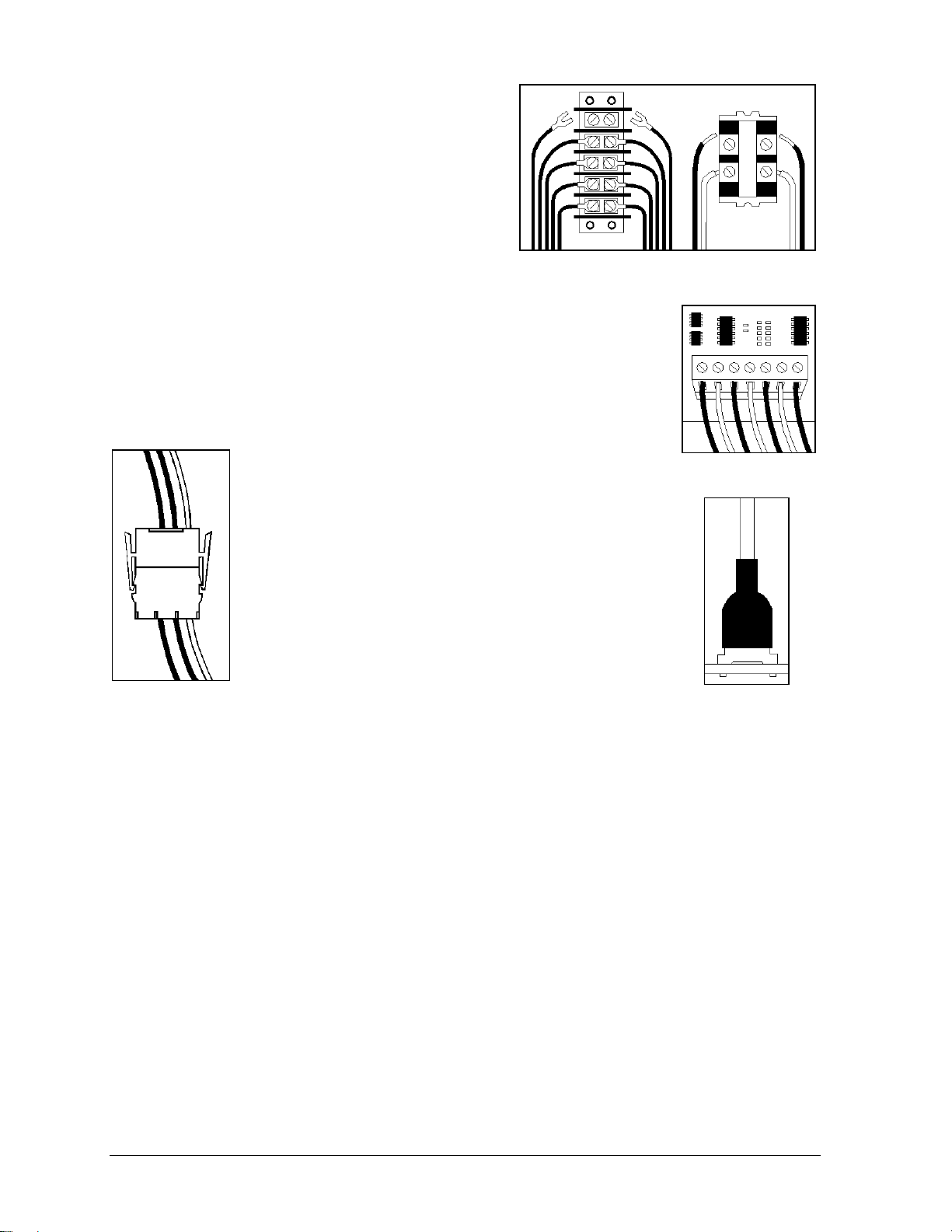

Figure 29: Ribbon Cable Connector 1................................................................................................3-1

Figure 30: Ribbon Cable Connector 2................................................................................................3-1

Figure 31: Fiber Optic........................................................................................................................3-1

Figure 32: Termination Panel (Left) and Termination Block (Right)................................................3-2

Figure 33: Phoenix Connector............................................................................................................3-2

Figure 34: Mate-n-Lok Connector......................................................................................................3-2

List of Figures iii

Page 6

Figure 35: Tab Connector.................................................................................................................. 3-2

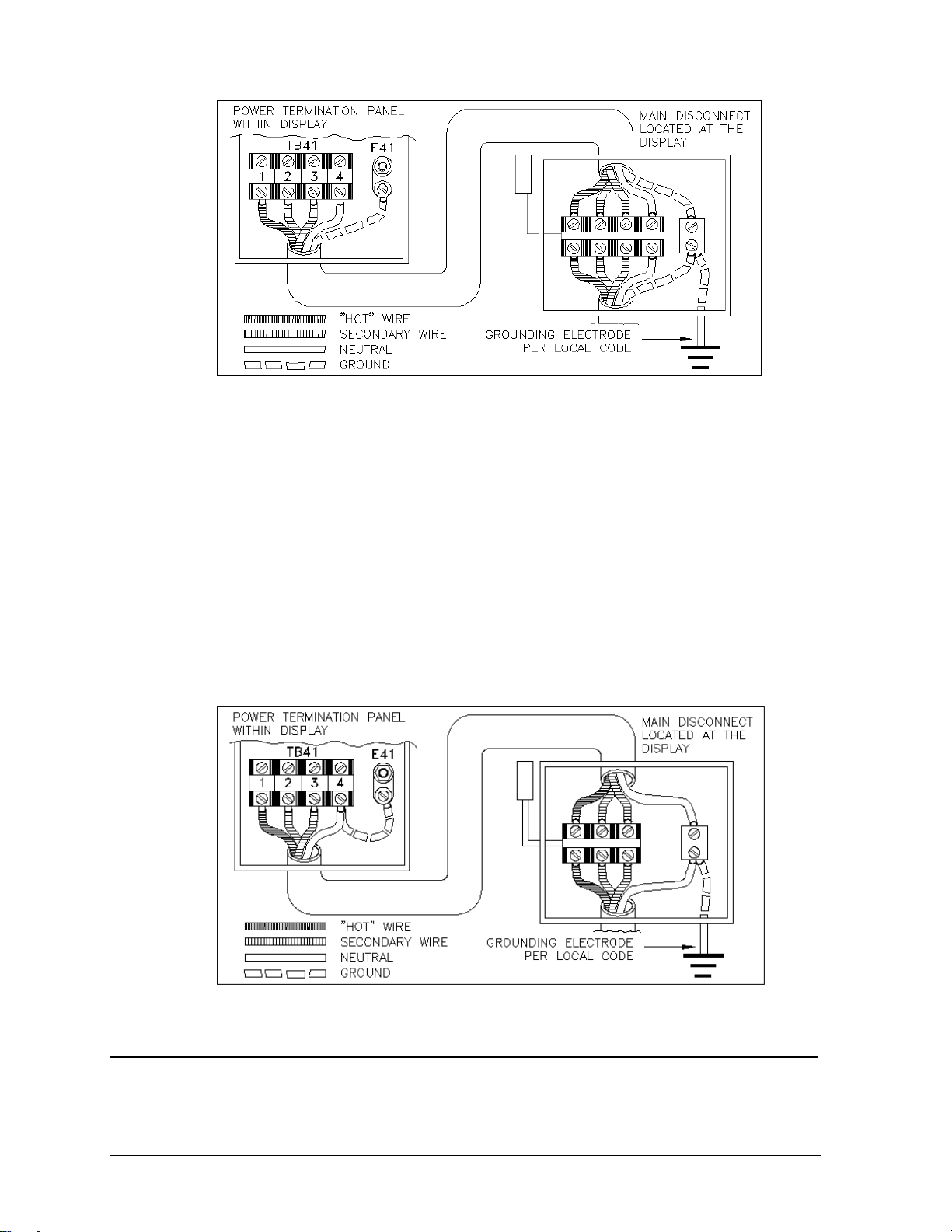

Figure 36: Installation with Ground and Neutral Conductor Provided.............................................. 3-8

Figure 37: Installation with only Neutral Conductor provided.......................................................... 3-8

Figure 38: TB7 on Venus 1500 controller....................................................................................... 3-15

Figure 39: TB1 on A/B Interface..................................................................................................... 3-16

Figure 40: Removing an ON Lamp..................................................................................................3-19

Figure 41: Lamp Voltage Tester...................................................................................................... 3-19

Figure 42: Power Routing Example................................................................................................... 4-3

Figure 43: Signal Routing for Venus 1500, 16-High Display ........................................................... 4-4

Figure 44: Signal Routing for Venus 4600, 16-High Display ........................................................... 4-5

Figure 45: Cabinet and Lens Airflow ................................................................................................ 4-6

Figure 46: Removing a Lens.............................................................................................................. 4-7

Figure 47: Replacing a Lens .............................................................................................................. 4-7

Figure 48: Lampbank and Lens/Reflector Assy. ............................................................................... 4-8

Figure 49: Lamp Removal................................................................................................................. 4-9

Figure 50: Assembly with Lenses.................................................................................................... 4-10

Figure 51: Assembly Removal......................................................................................................... 4-10

Figure 52: Lampbank Components..................................................................................................4-11

Figure 53: Lampbank Latch............................................................................................................. 4-12

Figure 54: VSB Components........................................................................................................... 4-12

Figure 55: Typical Fan..................................................................................................................... 4-13

Figure 56: Removing a Filter Assembly.......................................................................................... 4-14

Figure 57: Removing a Filter from a Filter Assembly..................................................................... 4-14

Figure 58: Venus 1500 Controller Board & MDC Board................................................................ 4-15

Figure 59: Optional Modem Board.................................................................................................. 4-17

Figure 60: Optional Fiber Optic Board............................................................................................ 4-18

Figure 61: Master-Echo Board Components ................................................................................... 4-18

Figure 62: Serial Line Interface Detail ............................................................................................ 4-19

Figure 63: Weather Stripping Application....................................................................................... 4-22

Figure 64: Checking Weather Stripping .......................................................................................... 4-22

Figure 65: Lens Assembly Components.......................................................................................... 4-23

Figure 66: Removing a Metal Side Plate......................................................................................... 4-23

Figure 67: Separating Rows above Damaged Louver...................................................................... 4-23

iv List of Figures

Page 7

Section 1: Introduction

1.1 How to Use This Manual

This manual explains the installation, maintenance and troubleshooting for the Daktronics 1600 series

Incandescent, 2.5-inch small matrix display system. For additional questions regarding the safety,

installation, operation or service of this system, please refer to the telephone numbers listed on the

cover page of this manual.

The manual is divided into four sections: Introduction, Mechanical Installation, Electrical Installation

and Maintenance & Troubleshooting.

• Introduction covers the basic information needed to make the most of the rest of this manual.

Take time to read the entire introduction as it defines terms and explains concepts used throughout

the manual.

• Mechanical Installation provides general guidance on display mounting.

• Electrical Installation provides general guidance on terminating power and signal cable at the

display.

• Maintenance & Troubleshooting addresses such things as removing basic display components,

troubleshooting the display, performing general maintenance and exchanging display components.

At the end of this manual are three appendices: Appendix A: Reference Drawings, Appendix B:

Forms & Reports and Appendix C: Forms and Reports. Drawings are in alphanumeric order unless

otherwise specified.

• Appendix A contains any drawings referenced throughout this manual that are general to all 1600

series Incandescent 2.5O displays. In addition, this appendix contains any drawings specific to this

display. These drawings always supersede any similar drawings found in this manual.

• Appendix B contains any checklists or general information relevant to this display.

• Appendix C contains any forms and reports that are relevant to this display.

Listed below are a number of drawing types commonly used by Daktronics, along with the

information that each is likely to provide.

• System Riser Diagrams: overall system layout from control room to display, power and phase

requirements.

• Shop Drawings: fan locations, transformer locations, mounting information, power and signal

entrance points and access method (front or rear).

• Schematics: power wiring, signal wiring, panelboard or power termination panel assignments,

signal termination panel assignments and transformer assignments.

The box on the next page, Figure 1, illustrates a Daktronics drawing label. The drawing number is

located in the lower-right corner of the drawing. This manual refers to drawings by listing the last set

of digits and the letter preceding them. In the example below, the manual refers to the drawing as

Drawing A-114667.

Introduction 1-1

Page 8

Figure 1: Drawing Label

All references to drawing numbers, appendices, figures or other manuals use in bold typeface, as

shown below.

“Refer to Drawing A-114667 in Section 3 for the location of the Venus 1500 controller.”

In addition, any drawings referenced within a particular sub-section are listed at the beginning of that

sub-section in the following manner:

Reference Drawing:

Shop Drawing, 16 High 2 ½

Appendix A contains all referenced drawings.

Daktronics identifies manuals by the ED number located on the cover page of each manual. For

example, Daktronics refers to this manual as ED11944.

Please list the model number, display serial number and the date this display became operational in the

blanks provided on the front page of this manual. The ID label, located on the front of the display on

the right end, contains the serial and model numbers. This label will look similar to the one shown in

Figure 2. When calling Daktronics Customer Service, please have this information available to ensure

that we service your request as quickly as possible.

˝ Small Matrix..........................................Drawing A-114667

Figure 2: Display ID Label

Daktronics builds displays for long life and require little maintenance. However, from time to time,

certain display components will need replacing. The Replacement Parts List in Section 4.15

provides the names and part numbers of components that may need to be ordered during the life of this

display.

Following the Replacement Parts List in Section 4.15 is the Exchange/Replacement Procedure in

Section 4.16. Refer to these instructions if any display component needs repair or replacement.

1-2 Introduction

Page 9

1.2 Display Configurations

Daktronics offers 1600 series small matrix displays as monochrome units. The displays are configured

in one of two ways: with Venus

1500 software that sends data to a Venus 1500 controller within the

display or with Venus 4600 software that sends data to a serial line interface within the display. In

addition, the Venus 1500-controlled display offers a number of different computer-to-sign

communication methods.

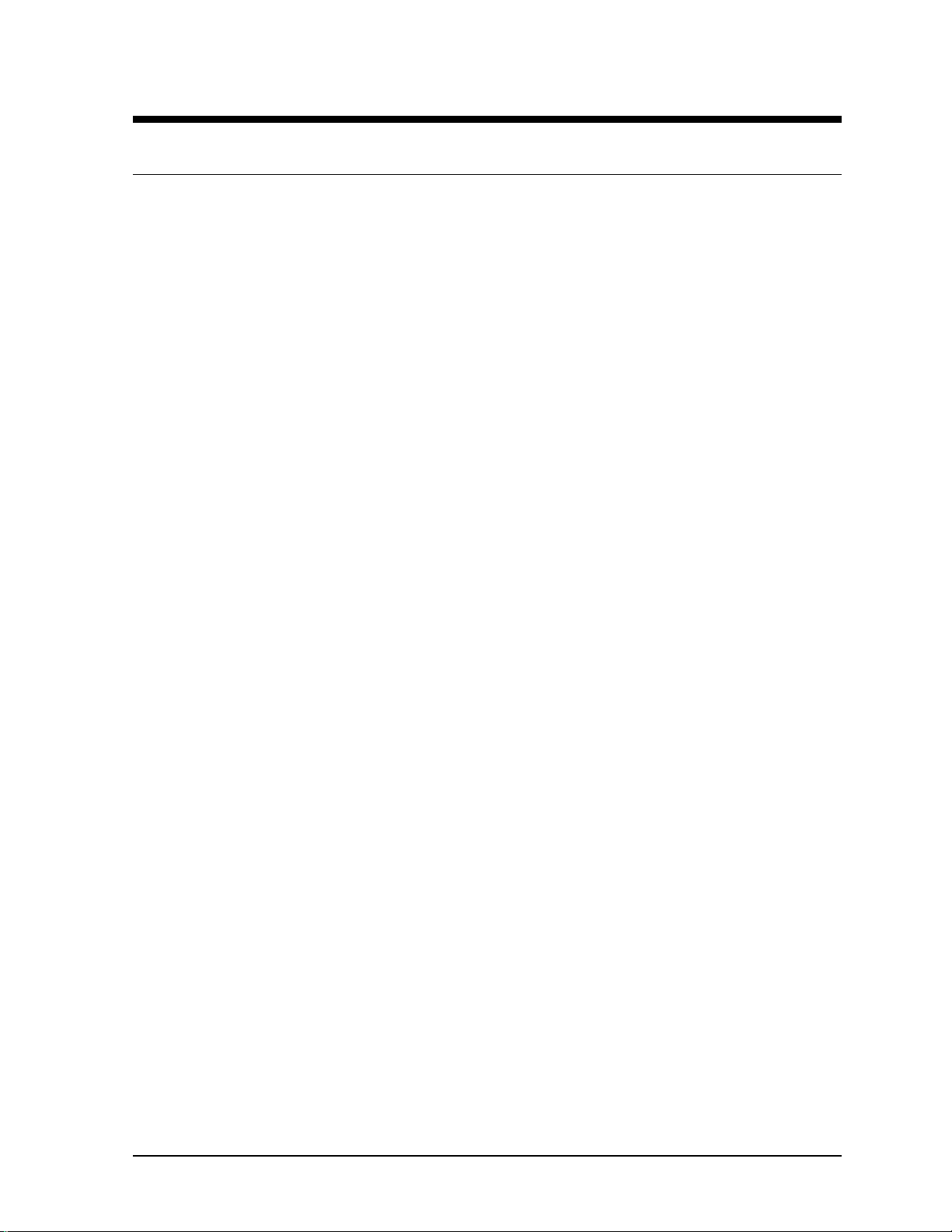

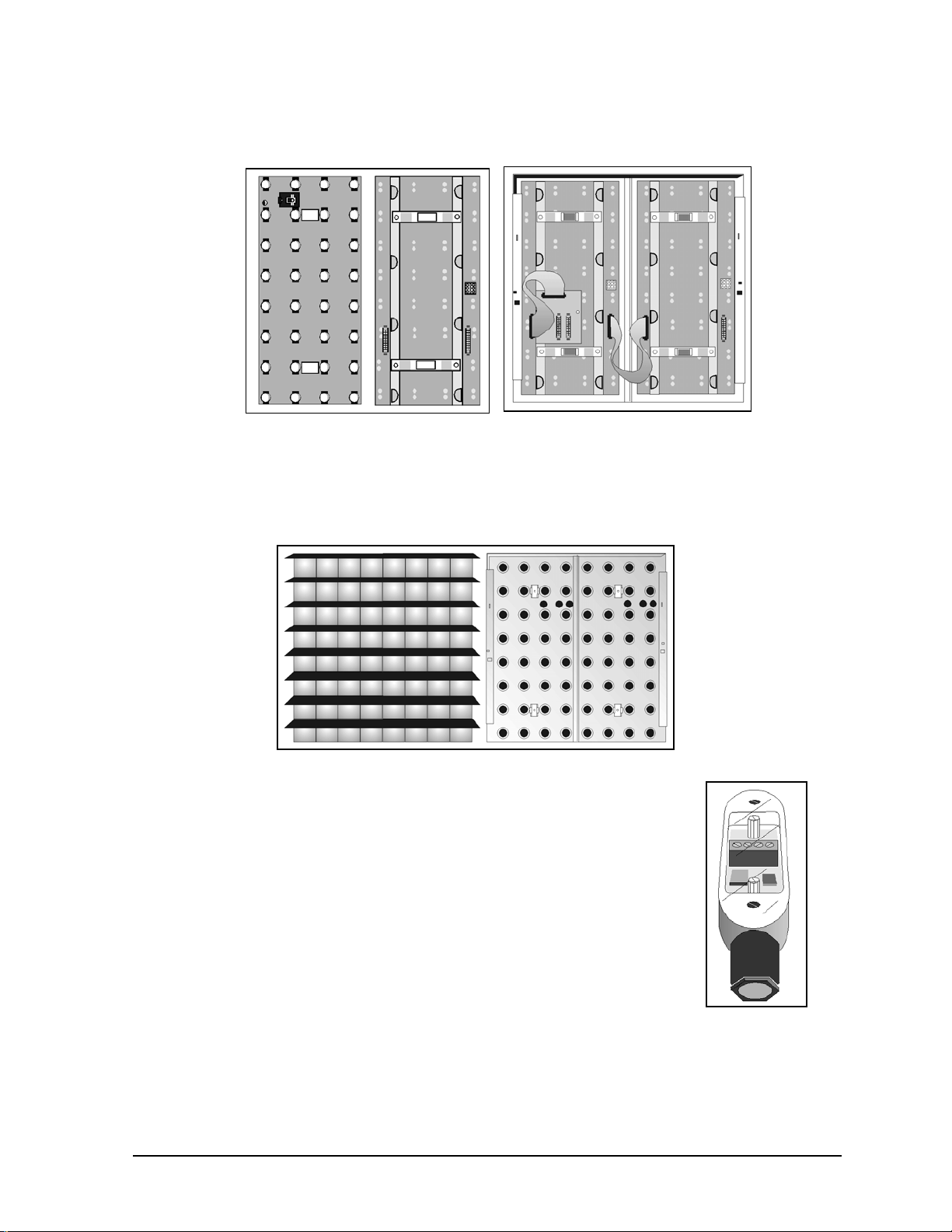

Figure 3 illustrates the possible signal configurations for a small matrix display. Notice that a Venus

1500-controlled display (monochrome) can configure for RS/232, RS/422, modem or fiber optic

communication. The Venus 4600-controlled display has only one standard configuration – fiber optic.

Figure 3: Possible Signal Configurations

Daktronics builds and ships small matrix displays as self-enclosed units that require only mounting

and power/signal hookup. Figure 4 illustrates some common cabinet configurations.

Figure 4: Possible Cabinet Configurations

Single face displays are single-sided, stand-alone units. They do not have the ability to drive an echo

display.

2V displays consist of two single-face units; one master and one echo, with an interconnect harness

between cabinets. All incoming power and signal cables connect within the cabinet of the master

display.

Introduction 1-3

Page 10

1.3 Display Definitions

Button Thermostats: Small, round, nickel-size thermostats mounted within

the display on the transformers. The master-echo board within the fan

controller enclosure monitors these thermostats. Figure 5 shows a button

thermostat.

Controller Computer: The computer used to program the display. This

display will use either Venus 1500 or Venus 4600 software.

Display Controller: A general term used to describe the device housed within the display cabinet that

receives signal from the controller computer. This display will use as a controller either 1) a Venus

1500 controller or 2) a serial line interface.

Fan Controller Enclosure: Assembly found within the display that serves as a junction point for the

button thermostats. Venus 1500 systems will also have a master-echo board with in the enclosure.

Venus 4600 systems have no master-echo board within the fan controller enclosure, but instead route

the thermostat status back to the serial line interface board. Figure 6 shows the fan controller

enclosure, both with and without the enclosure cover. The master-echo board is on the right. The

Venus 4600 fan control enclosure looks similar, but lacks the master/echo board.

Figure 5: Button

Thermostat

Figure 6: Fan Controller Enclosure

Fiber Optic: A standard communication method using light (signal) transmitted through a glass fiber.

Fiber optic cable cannot exceed 1,200 feet. A signal converter may be required for fiber optic and

RS/232 configuration. This communication method is an option in both Venus 1500 and Venus 4600

Systems.

Junction Box: Small enclosure in which display data

traveling on serial cable from the computer is transferred to

RS/232 cable. The junction box must be located within 25

feet of the display. Only Venus 1500 systems using the

RS/232 communication option utilize this junction box.

Figure 7 illustrates a junction box.

Figure 7: Junction Box

1-4 Introduction

Page 11

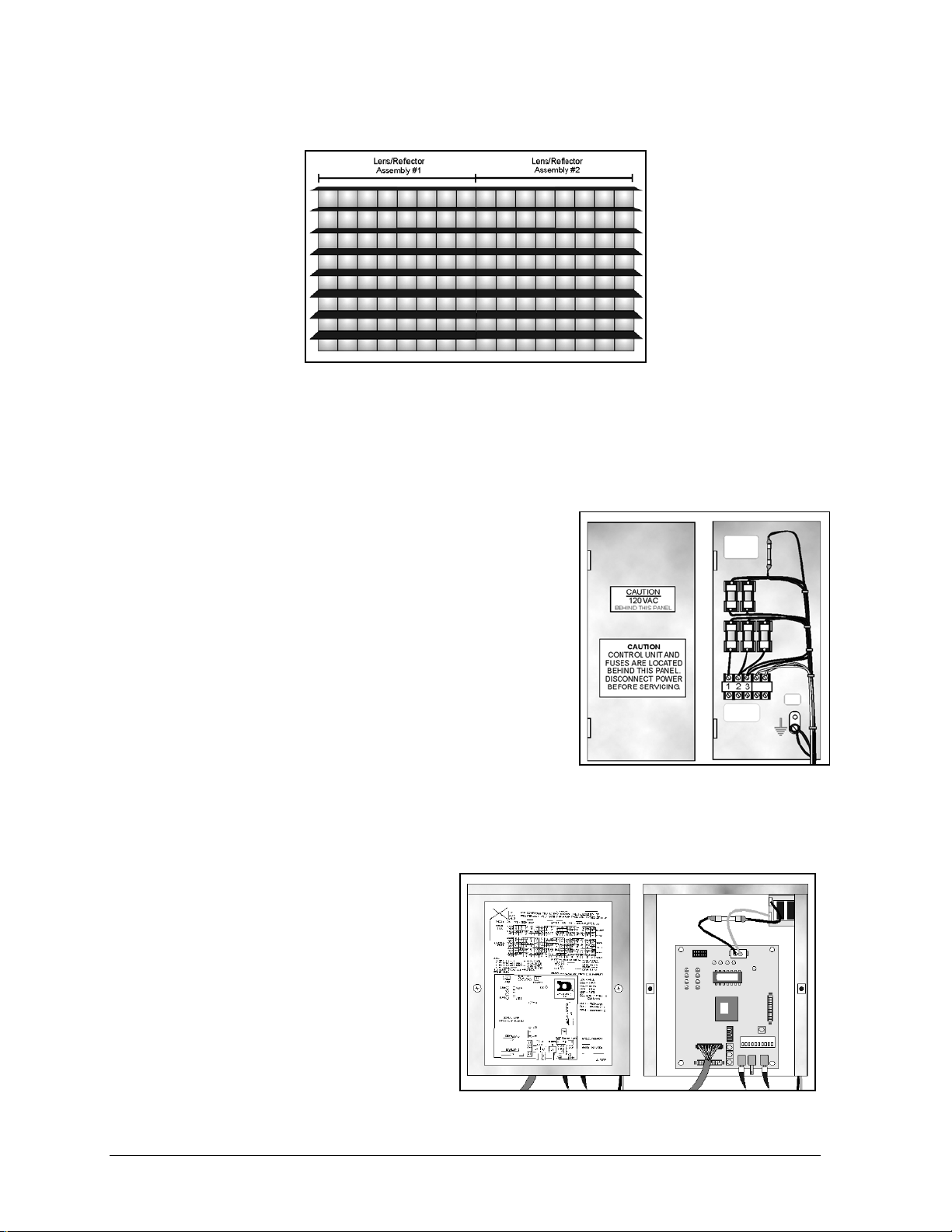

Lampbank: A circuit board consisting of an array of lamps 8 pixels high by 4 pixels wide. Figure 8

shows a single lampbank, front and back. Two lampbanks mount to the rear of each lens/reflector

assembly as seen in Figure 9. If necessary, a lampbank can be easily removed from the lens/reflector

assembly.

Figure 8: Lampbank (Lamp Side)

Figure 9: Two Lampbanks on Lens /

Reflector Assembly

(Solder Side)

Lens/Reflector Assembly: Consists of reflectors, lenses and louvers. It is eight lenses high by eight

lenses wide. A lens/reflector assembly is easily removable for maintenance. Figure 10 illustrates the

front and back of a lens/reflector assembly. Two lampbanks mount on the rear of this assembly, as

seen in Figure 9.

Figure 10: Lens/Reflector Assembly

Light Detector: An optional device that senses ambient light levels. The light

detector and the controller operate together to dim the display when maximum

lamp brightness is not required. This saves energy and extends lamp life. Figure

11 shows the light detector for the Venus 1500 systems.

Louver: A piece of aluminum, eight pixels long, positioned above each row of

lamps to provide contrast and help direct light.

Figure 11: Light

Detector

Introduction 1-5

Page 12

Module: Consists of four lampbanks mounted to the backs of two lens assemblies. A module, Figure

12, is eight pixels high by 16 pixels wide. One transformer can power two modules (256 lamps).

Figure 12: Module

Modem: A standard communication method that utilizes standard phone transmission lines, and is an

option with the Venus 1500 System.

Pixel: Daktronics describes a pixel as being the point of light created by a single lamp behind a single

lens.

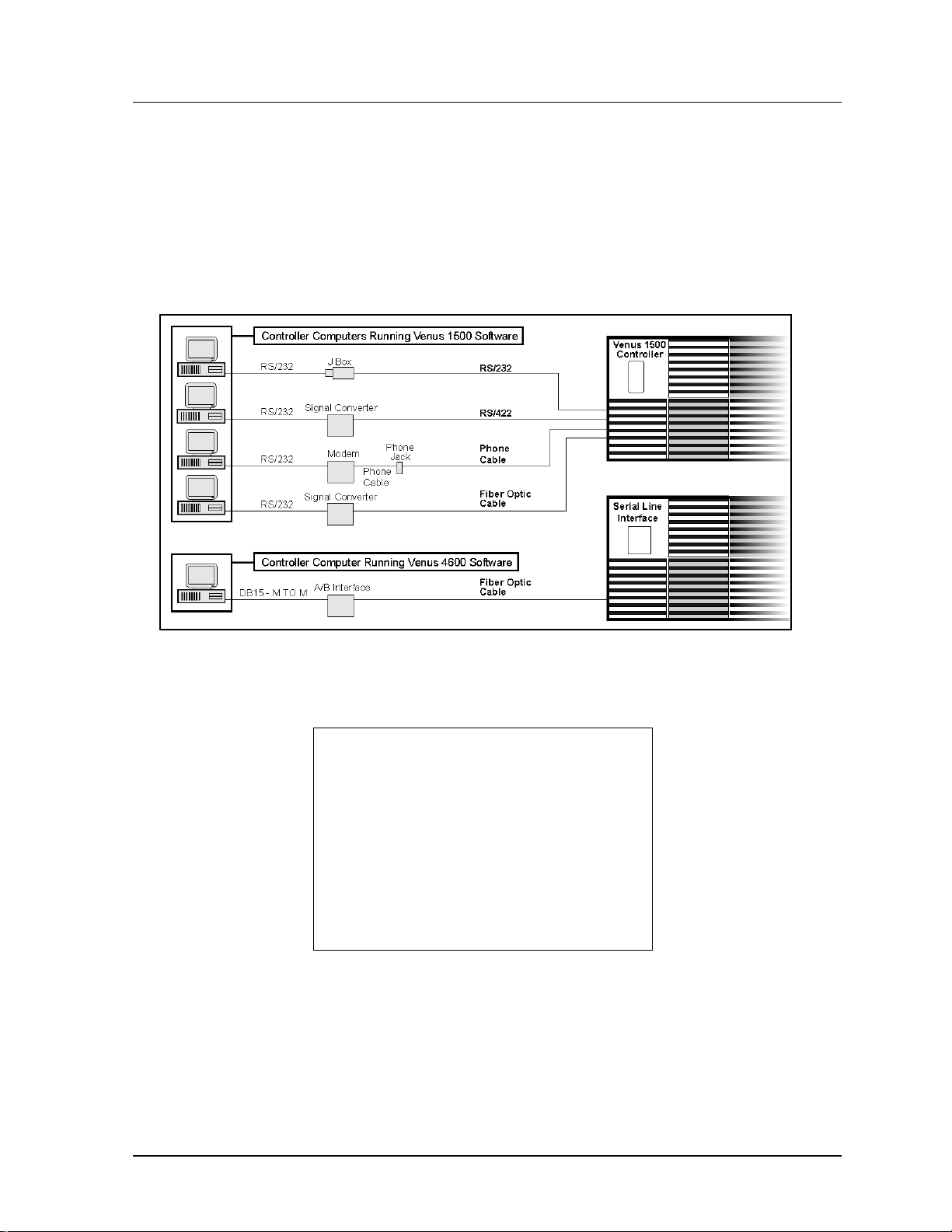

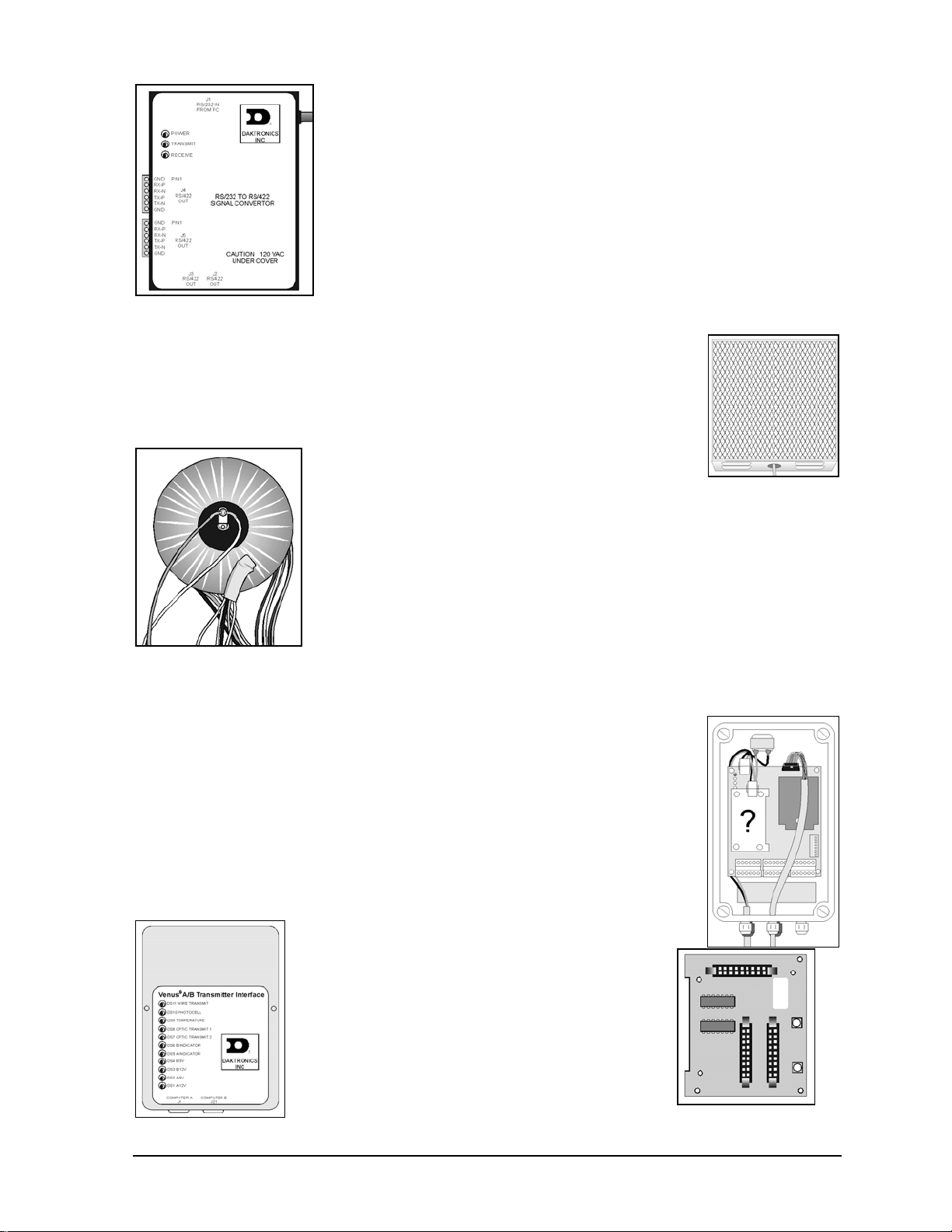

Power Termination Panel: Assembly in which incoming power

connects to the display. It mounts to the cabinet on the left end

(front view). Figure 13 shows the power termination panel

enclosure, both with the cover on the enclosure and with it

removed.

Quarter-Turn Fasteners: A type of latching mechanism found

on many Daktronics assembly enclosures. Using a Phillips

screwdriver, turn the fastener one-quarter-turn counter-clockwise

to release the latch and one-quarter-turn clockwise to secure the

latch.

RS/232: A standard PC communication type with a maximum

Figure 13: Power Termination Panel

cable length of 25 feet (8 meters).

RS/422: A standard differential communication type with a maximum cable length of 4,000 feet (1.2

kilometers).

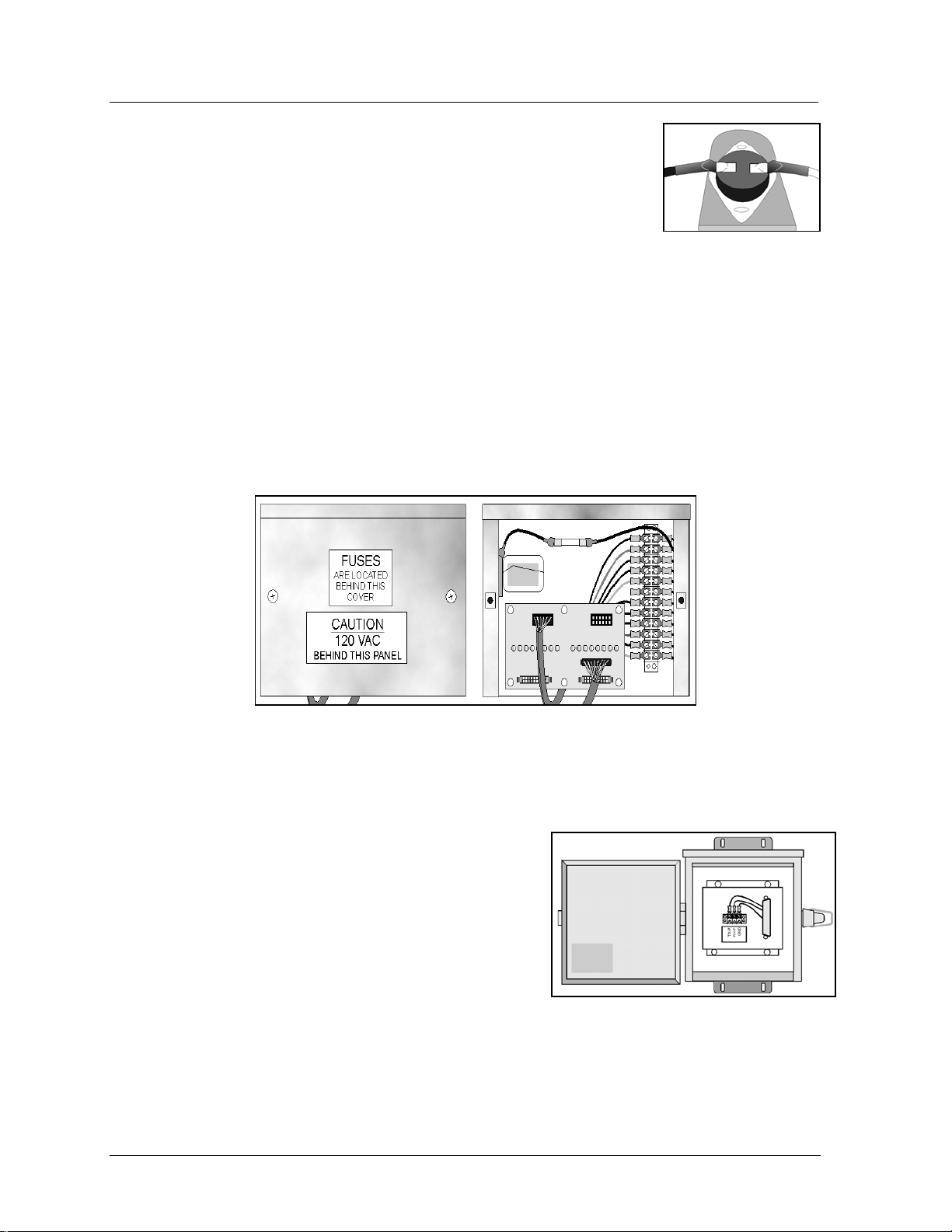

Serial Line Interface (SLI): The controller

board used in Venus 4600 display systems. The

serial line interface (also called a line receiver)

receives signal from the controller computer via

fiber optic cable and routes it to the display.

Figure 14 illustrates the metal enclosure that

houses the serial line interface, both with the

enclosure cover in place and with the enclosure

cover removed. The serial line interface board is

seen on the right.

Figure 14: Serial Line Interface

1-6 Introduction

Page 13

Sign Address: An identification number assigned to each sign of a

network. The control software uses the address to locate and

communicate with each display. Displays on the same network cannot

have the same address.

Signal Converter: A Daktronics-supplied unit that converts the data

from RS/232 to RS/422. The signal converter is used in Venus 1500

RS/422 systems. Figure 15 shows the converter.

: SunSpot displays, also called monochrome displays, use

Figure 15: Signal

Converter

SunSpot

only one color lens - usually white. “SunSpot” is a registered trademark

of Daktronics, Inc.

Temperature Sensor: The temperature sensor is an optional device that

monitors temperature outside the display. The temperature sensor can be used to

offer “time and temperature” updates. Figure 16 shows a common temperature

sensor. Daktronics offers many enclosure styles.

Transformer: The device that transforms incoming

AC voltage to the operational AC voltage required by

the display electronics. Figure 17 illustrates a

transformer.

Figure 16: Temp

Sensor

Venus 1500 Controller: The type of controller used in Venus 1500

display systems. It consists of a controller board, MDC (multipurpose

display controller) board, address board, and possibly a fiber optic or

modem board, depending on display configuration. The controller receives

data from the controller computer via RS/232 cable, RS/422 cable, fiber

Figure 17: Transformer

optic cable or modem/phone cable. The data then routes to the rest of the

display. Figure 18 illustrates the Venus 1500 controller in its enclosure.

The ‘?’ indicates the position of a fiber optic or modem board, if used.

Venus 1500 System: A display configuration that uses a controller computer

running Venus 1500 software to control a display housing a Venus 1500

controller. Venus 1500 systems can use any one of four methods to transmit data

from the controller computer to the display: RS/232, RS/422, fiber optic or

modem/phone cable. This display is set up for one of these methods.

Venus 4600 System: A display configuration that uses a controller computer

running Venus 4600 software to control a display housing a serial line interface.

Venus 4600 systems transmit data from the controller computer to the display

over fiber optic cable.

Venus A/B Transmitter Interface: A Daktronicssupplied unit used to convert RS/232 signal to fiber

optic signal. Venus 4600 Systems uses this. Figure

19 shows the transmitter interface.

Figure 18: Venus

1500 Controller

Vertical Shift Board (VSB): Circuit board

mounted to the back of the left-most (front view)

lampbank in each row of modules. It routes data

from the controller both down the row and to the

Figure 19: Venus A/B

Transmit I/F

VSB below it. Figure 20 shows the VSB. Figure 9

shows the VSB on a lampbank. The vertical shift

board is also known as a vertical shift register

Figure 20: Vertical

Shift Board

Introduction 1-7

Page 14

(VSR).

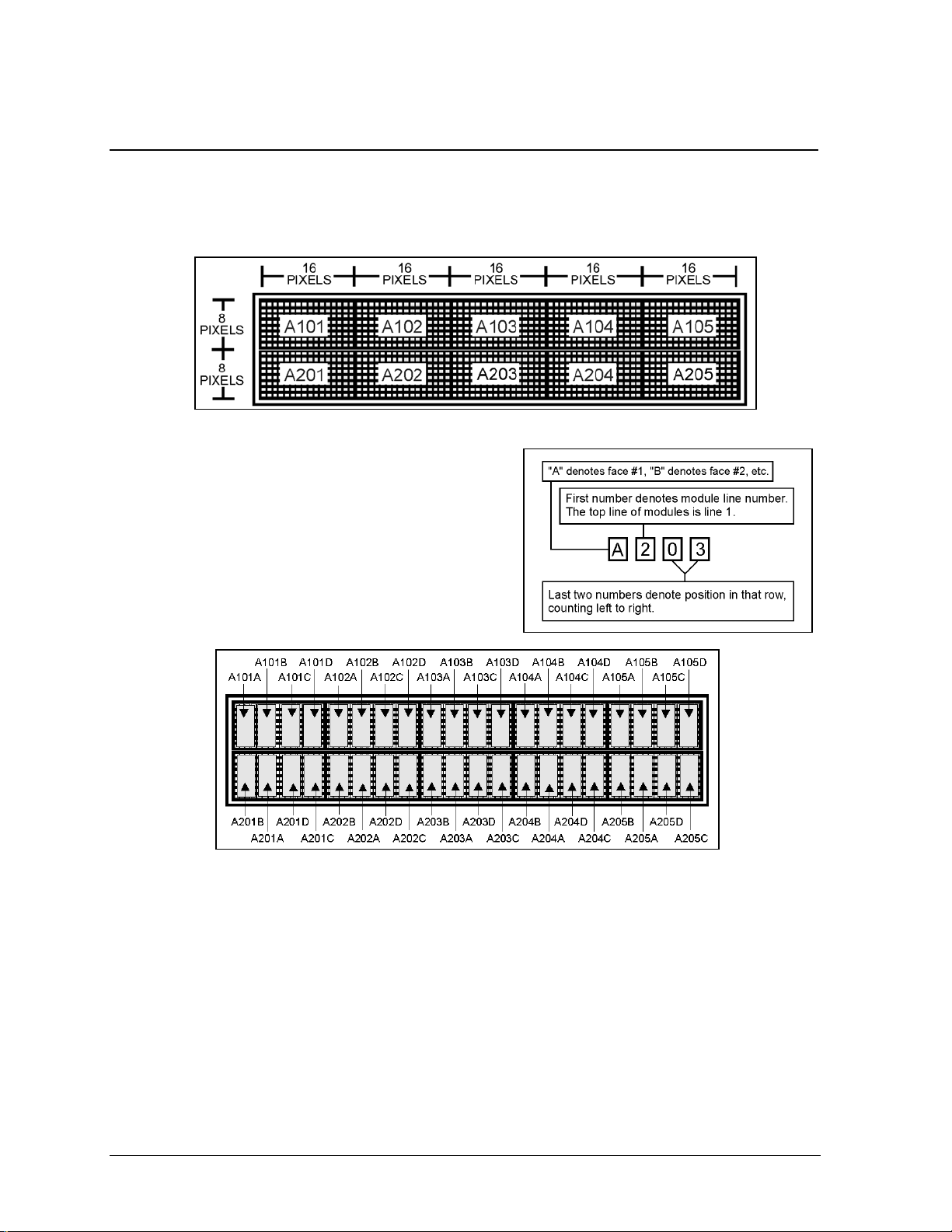

1.4 Daktronics Nomenclature

The Daktronics module numbering system assigns numbers to modules to aid in wiring and

troubleshooting. Remember, a module is two, side-by-side lens/reflector assemblies. Figure 21

illustrates the numbering on a typical 16x80 pixel small matrix display. Figure 22 explains the

meaning of the module numbering.

Figure 21: Module Numbering (16x80 Display) – Front View

In addition, lampbanks also have a numbering system.

There are two lampbanks mounted on the back of each

lens/reflector assembly. Therefore, there are four

lampbanks per module. Figure 23 illustrates this

lampbank numbering. It uses the same first four digits as

the module numbering system, but with an A, B, C or D

at the end to indicate whether it is the first, second, third

or four lampbank on that module.

Figure 23: Lampbank Numbering (16x80) - Front View

Figure 22: Module Numbering Detail

1-8 Introduction

Page 15

In addition, when using Daktronics drawings it may also be helpful to know the following.

• “F” denotes a fuse (F1, F2, F3…)

• “T” denotes a transformer (T1, T2, T3)

• “TB” denotes a termination block – power or signal.

• “A” denotes an assembly. These are divided according to power or signal.

Power assemblies consist of a number of power components, usually within a common enclosure.

For instance, a power termination block (TB41) may be located within a power termination panel

enclosure (A41). A second power termination panel has the label A42, a third A43, etc.

Signal assemblies consist of a number of signal routing or transmission components, usually

within a common enclosure. For instance, the enclosure housing the Venus 1500 controller or

serial line interface for this display is A31.

Introduction 1-9

Page 16

Page 17

Section 2: Mechanical Installation

The Daktronics engineering staff must approve any changes that may affect the weather

tightness or cooling ability of this display. This includes, but is not limited to:

• Border shrouding

• Back sheets

• Cooling fans

• Fan filters

• Filler panels

Submit detailed drawings of the proposed changes to our engineering staff for evaluation and

approval or the warranty will be null and void.

Appendix B contains two copies of the Installation Quality Checklist. It covers both mechanical and

electrical installation. This form is intended to assist in display installation and assure its dependable

operation. Make sure to act upon each item of the checklist. Following installation, return one copy to

Daktronics Customer Service to receive a free set of replacement air filters. Contact Daktronics

Customer Service if any product quality questions or concerns should arise.

2.1 Support Column Selection

Support column size is dependent on the height and total wind loading of the display and any other

signage attached, such as advertising panels.

Column selection is critical; only a qualified individual should do this.

It is the installer’s responsibility to specify the exact type of column and number of columns used.

Using more columns generally allows smaller columns.

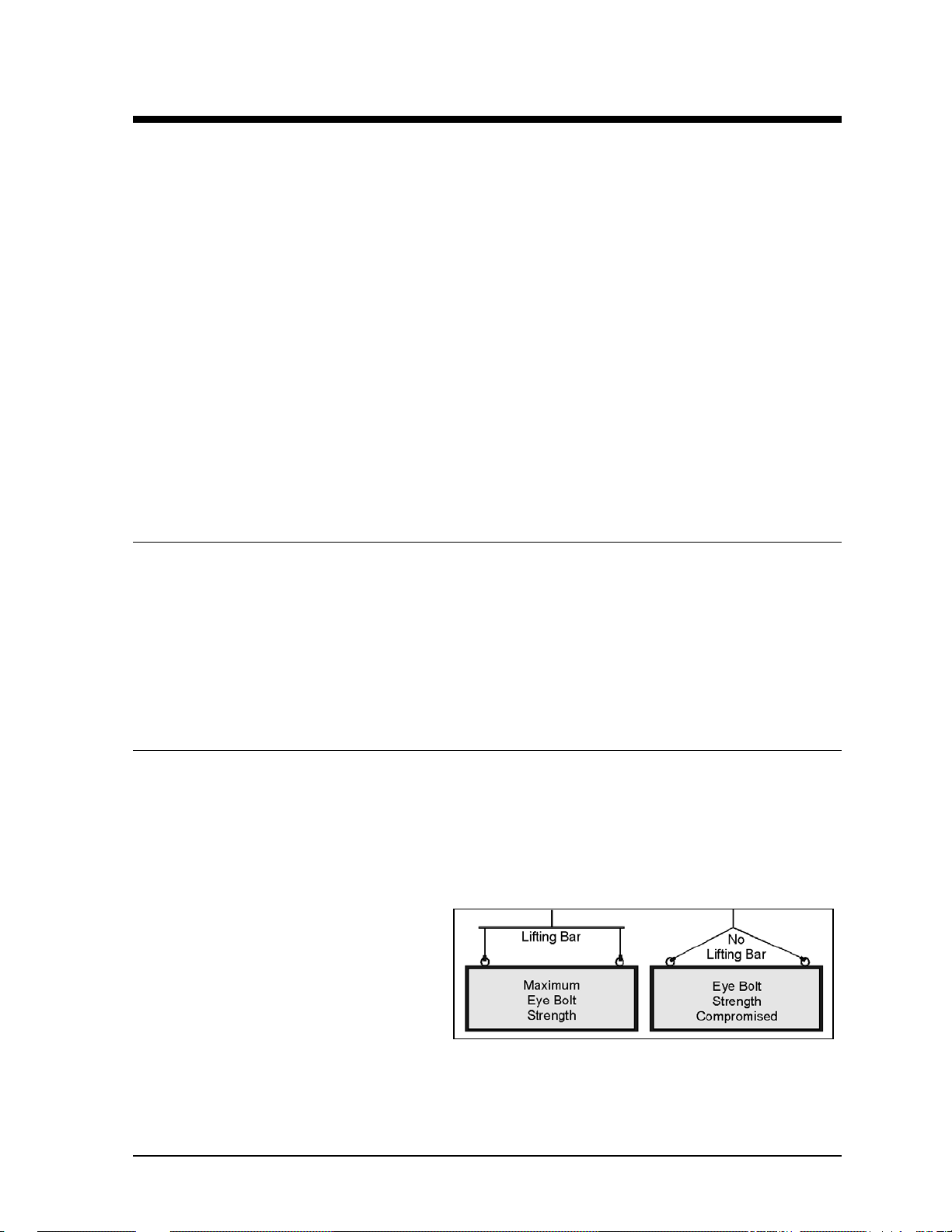

2.2 Lifting the Display

The top of the display (or display sections) will be equipped with eyebolts to lift the unit. Take special

care not to exceed the rated load of the eyebolts. Refer to the information in Appendix B labeled Eye

Bolts to determine the allowable load of the eyebolts shipped with the display.

Figure 24 illustrates both the correct (left example) and the incorrect (right example) method of lifting

a display. Lift the display as shown on the left, with the lifting bar.

Stress on the eyebolts increase as the angle

between the cable and the display top

decreases.

Use every lifting point provided!

Do not attempt to permanently support the

display by the eyebolts.

If mounting this display outside, make sure water or moisture doesn’t get into the display.

Figure 24: Display Lifting

Mechanical Installation 2-1

Page 18

1. Inspect the top and sides of the display for any holes that may allow moisture to enter the display.

If the eyebolts were removed, plug the holes with bolts and the rubber sealing washer that came

with the eyebolt.

2. Plug and seal the eyebolt holes and any other openings that may allow water to enter the display

with silicone or another waterproof sealant.

CAUTION: Fully attach backsheets to the display cabinet with all of the screws prior to

lifting the display with the eye bolts. The backsheets provide structural support to the cabinet.

Lifting the display with the backsheets removed may cause the cabinet members to twist,

compromising the structural integrity and/or squareness of the display frame. If the display

frame is not square, normal waterproofing measures may prove inadequate, leading to moisture

related problems for the electronics.

2.3 Cabinet Mounting

Reference Drawing:

Mounting Example, 2½

The method used to mount displays can vary greatly from location to location. For this reason, this

manual only addresses general mounting topics. If this display was part of a custom contract, consult

the shop drawing in Appendix A for mounting information.

Before beginning the installation process, verify the following:

• The mounting structure will provide a straight and square frame for mounting the display.

• The mounting structure will not give way at any unsupported points after mounting the display.

Correct any deficiencies before beginning the installation process.

It is the responsibility of the installer to ensure the installation will agree with local codes. The

mounting hardware is also the responsibility of the installer.

The 9 x 1¾ x 1¾ channel used in this display requires supporting the display every eight feet with a

maximum overhang of three feet on each end of the display. The distribution of these supports is to be

symmetrical. This requires a minimum of two supports.

Drawing A-114676 illustrates one of the many ways a small matrix display may be mounted. To

mount a display as seen in the drawing complete the following steps:

1. Remove the four pieces of bar stock from the display. These flat pieces of metal reinforce the

display cabinet at the mounting points.

2. Since bolts or rods will be run on each side of each

column, it will be necessary to drill two holes in both the

bar stock and the cabinet frame at the support points.

Refer to Figure 25.

3. Drill holes in the bar stock and through the cabinet frame.

Run bolts to the angles on the opposite side of the

columns.

4. Secure the display firmly in place.

˝ Small Matrix....................................................Drawing A-114676

Figure 25: Possible Mounting Method

2-2 Mechanical Installation

Page 19

When mounting the display take note of the following:

• Keep ½-inch clearance below the drain holes in the bottom of the display.

• Do not obstruct airflow to the display fans. Refer to Drawing A-114676.

• Power and signal terminations require access to the inside of the display. Avoid mounting the

display in a manner that hinders access to the display face.

• The Daktronics engineering staff must first approve any modifications to the display ventilation

system.

You must properly seal the eyebolt holes on top of the display cabinet to prevent water from

entering the unit and damaging the electrical components.

Complete the following steps if leaving the eyebolts in the display.

1. Verify the eyebolts are firmly in place. From time to time eyebolts will loosen slightly from

shipping vibration.

2. If the eye bolts need tightening, keep in mind they need only be snug. Over-tightening will crush

the rubber sealing washers, rendering then ineffective.

3. Apply silicone sealant around the base of the eyebolts on top of the cabinet.

Complete the following steps if removing the eyebolts from the display.

1. Remove and discard the eyebolts, but keep the rubber sealing washers.

2. To plug the eyebolt holes, insert half-inch bolts through the rubber sealing washers and into the

eyebolt holes from the top of the display cabinet.

3. Tighten the bolt only as much as is needed to hold the bolt snugly in place. Over-tightening will

crush the rubber sealing washers, rendering then ineffective.

4. On the top of the cabinet, apply silicone sealant around the head of each bolt.

Inspect the entire display for any holes or gaps that may allow

water to enter the display. Use silicone sealant to close any such

openings.

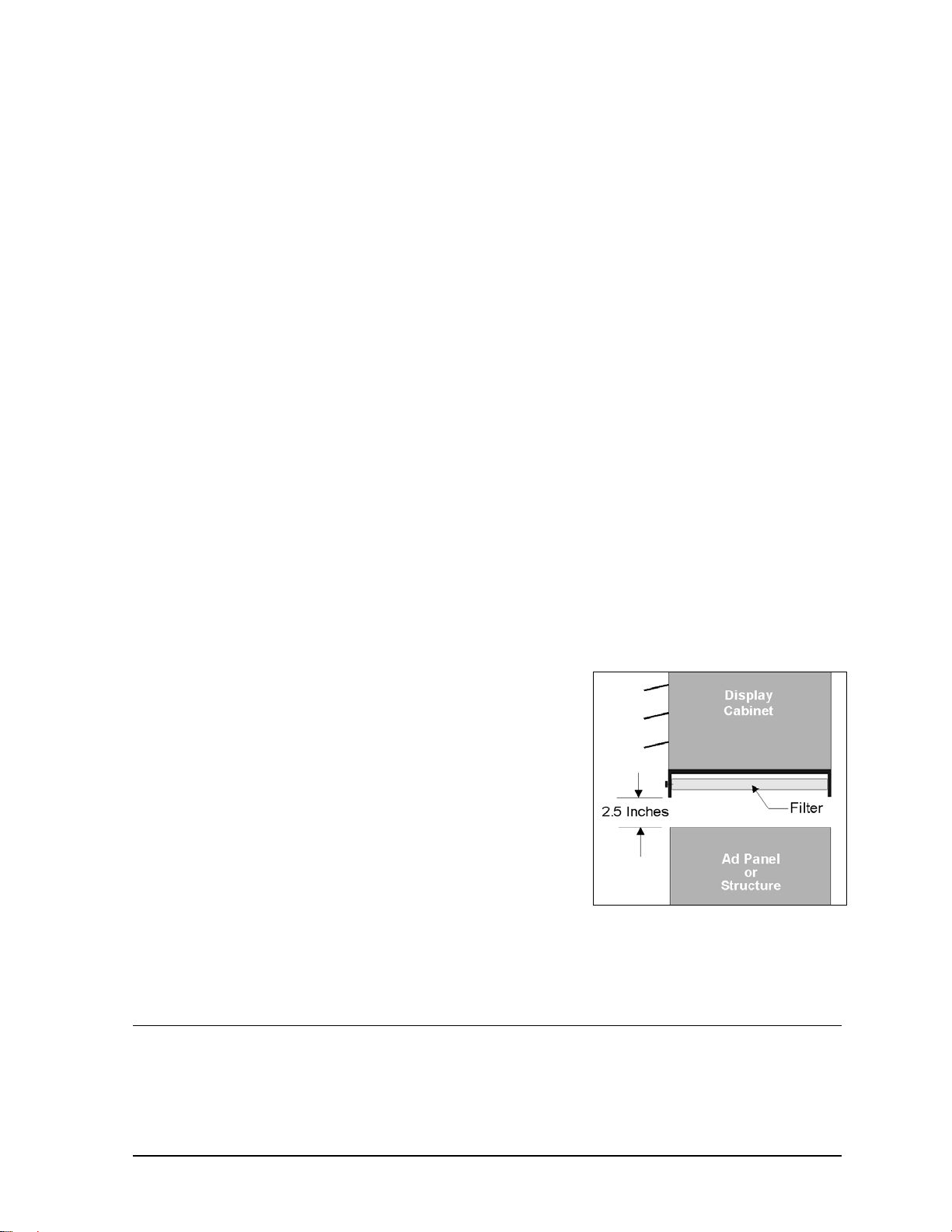

The filters of 1600 series small matrix display are located on the

bottom exterior of the display cabinet. If mounting an

advertising panel or other structure beneath this display, 2.5

inches of clearance must be present in order to remove the

filters. Refer to Figure 26.

The amount of clearance between the display and the ad panel

or structure can also affect display ventilation. Refer to Section

2.5 to calculate the amount of clearance required for adequate

display cooling.

Figure 26: Bottom Clearance

Filter removal is addressed in Section 4.3, Filters.

2.4 Light Detector and Temperature Sensor Installation

Refer to ED9490 in Appendix C for light detector installation and ED9489 in Appendix C for

temperature sensor installation information.

Mechanical Installation 2-3

Page 20

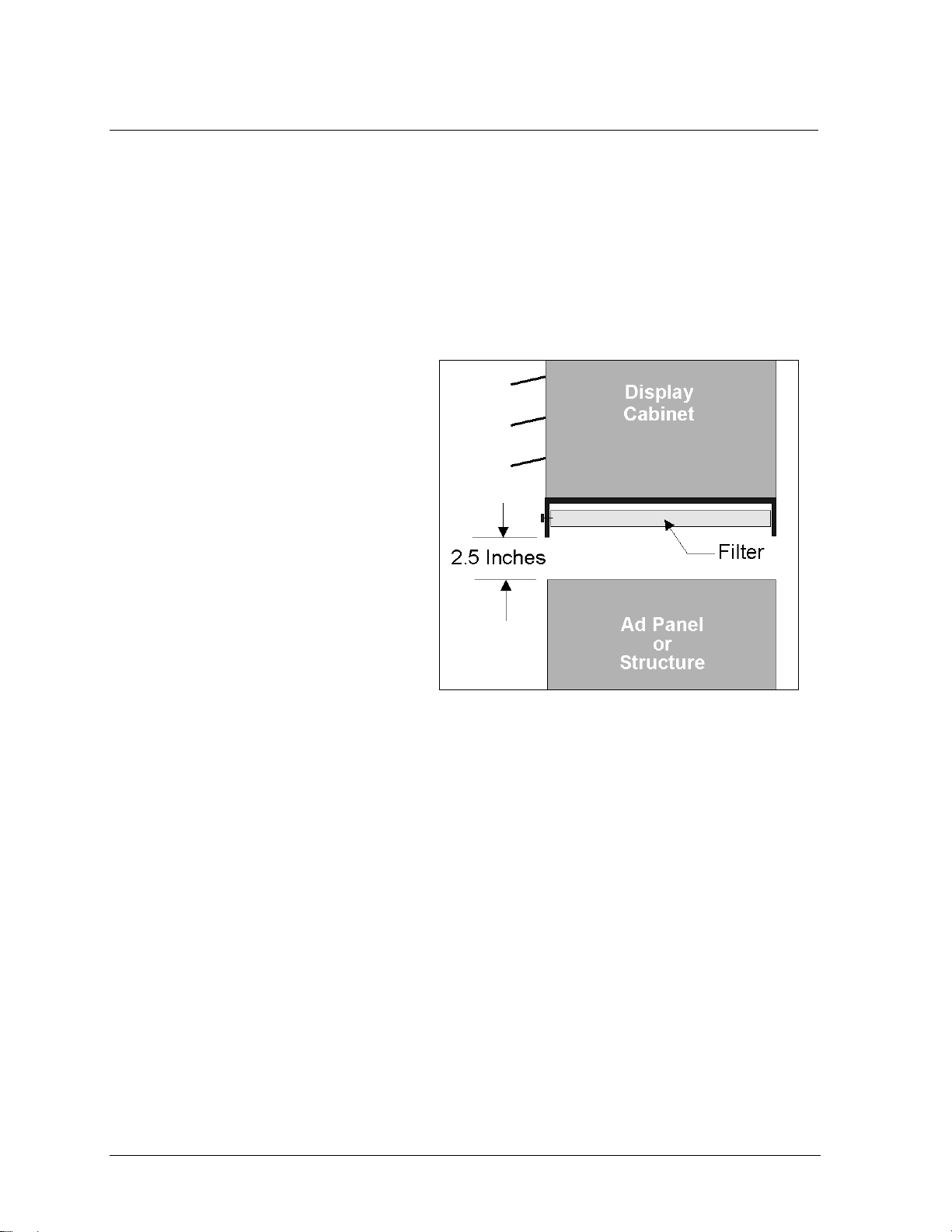

2.5 Display Ventilation Requirements

Reference Drawings:

Mounting Example, Small Line Displays...............................................Drawing A-101424

Label, Filter Clearance..........................................................................Drawing A-141064

Daktronics small matrix displays use fans to prevent overheating. The fans bring air into the cabinet

from the bottom of the display, creating positive pressure within the display. The fans then force out

the warm air within the display through small gaps above each of the lenses, cooling the lamps and

lowering the internal temperature of the cabinet. This continuous cycle of airflow extends the life of

the lamps and decreases the maintenance costs associated with overheating.

If mounting another sign or structure on top

of one another, maintain a minimum of 2

1

/2O. This is to ensure proper airflow through

the sign and to allow easier access for filter

removal. Refer to Figure 27 and Drawings

A-101424 and A-141064.

In some circumstances it may be necessary,

or desirable, to mount a small matrix display

within another structure or to “skin over” one

or more displays. If enclosing a display in

this nature, adequate openings must exist in

the outer structure for air intake.

If enclosing a small matrix display within

another structure or “skinned over,” observe

the following specifications to prevent

display damage and premature lamp failure:

Figure 27: Minimum Clearance for Sign Bottom

• Provide twelve square inches of unobstructed opening per module for adequate display cooling.

Make allowances to compensate for the percentage of screen in the material covering the openings

in the enclosed structure.

• If forcing air into the enclosed area, it should run at 110 cubic feet per module (one module = 20"

x 40" display active area or eight rows x 16 columns of lamps).

For example, a 16x80 double-face, small matrix display inside an enclosed structure would require

240 square inches, or 1.7 feet, of unobstructed opening in the bottom of the center cabinet.

(2 displays (16x80 pixel size))/128 pixels per module = 20 modules

(2(1280))/128 = 20 modules

2560/128 = 20 modules

20 modules x 12 square inches = 240 square inches or 1.7 square feet

Also, if forcing air into an enclosed display, adhere to the following filter specifications:

• The effective filter area is to be no less than 2.3 square feet per 1.0 square feet of filter face area.

• The filter media is to have an average arrestance (resistance to debris) of 90-92%.

• Initial resistance should not exceed 0.48 w.g. (water gauge) at 500 fpm (feet per meter).

2-4 Mechanical Installation

Page 21

Submit any plans for filtering air in an enclosed display to the Daktronics engineering staff for

evaluation and approval or the warranty will be null and void.

2.6 Verifying Correct Lens and Module Position

The final steps of mechanical installation involve verifying the proper positioning of all lenses upon

their respective lens/reflector assemblies and that all modules engage fully into the cabinet.

Look down the rows of louvers from either end of the display and secure all lenses properly. Lenses

not secured properly are easily noticeable as the lens removal tab, or the lens itself, will not be in

alignment with the other lenses or lens removal tabs of that row.

Refer to Figure 28 and the following steps to return a lens to its correct position.

1. First, insert the bottom indexing tabs into the slots. There is one indexing tab on each bottom

corner of the lens.

2. While gently pushing the above louver upward, grab the lens tab and push the top of the lens

behind and under the louver offset. Only push the louver upward enough to allow the lens to snap

into position behind the offset.

3. Release the louver and verify the lens aligns with others in the row.

Figure 28: Correct Lens Position

Also, ensure that the rows of louvers are in proper alignment. If any rows seem out of position, this

may indicate the one, or both, sides of the lens/reflector assembly do not engage fully into the cabinet.

If this is the case, a firm push to both sides of the module at the same time should snap the module into

place.

Mechanical Installation 2-5

Page 22

Page 23

Section 3: Electrical Installation

Appendix B contains two copies of the Installation Quality Checklist. It covers both mechanical and

electrical installation. This form assists in display installation and assures its dependable operation.

Address each item on the checklist. Following installation, return one copy to Daktronics Customer

Service to receive a free set of replacement air filters. Contact Daktronics Customer Service if any

product quality questions or concerns should arise.

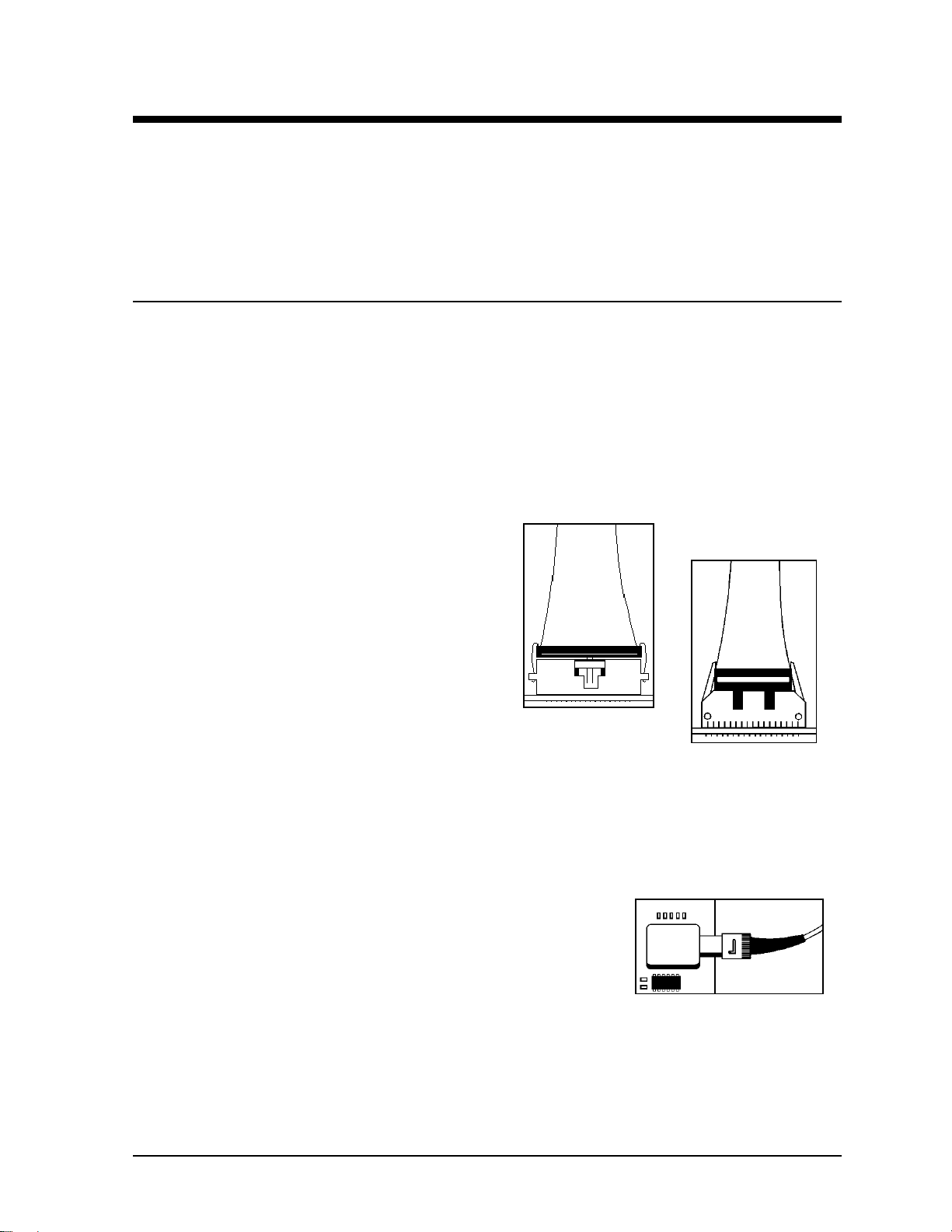

3.1 Common Connectors

This display uses many different types of connectors for power and signal termination. Take special

care when disengaging any connector so as not to damage the connector, the cable or the circuit board.

When pulling a connector plug from a jack, do not pull on the wire or cable; pull on the jack

itself. Pulling on the wires may damage the connector.

The following information presents some common connectors encountered during display

maintenance. These include ribbon cable connectors, Mate-n-Lok connectors, Phoenix-style

connectors, fiber optic connectors, termination panels and termination blocks, and tab connectors.

Some displays do not use all of these connectors.

1. Ribbon Cable Connectors:

Daktronics uses a variety of ribbon cables and

ribbon cable connectors. Figure 29 and Figure 30

show two of the most common ribbon cable

connectors. To disconnect ribbon cable connector

#1, squeeze the metal locking clips inward and

pull the plug out of the jack. To disconnect ribbon

cable connector #2, pull each of the plastic

locking arms outward and remove the plug.

Before replacing a ribbon cable connector, spray

it with DeoxIT

™

contact cleaner to remove any foreign matter that may

Figure 29: Ribbon

Cable Connector 1

cause signal problems. In addition, apply a generous amount of CaiLube

protector paste to the plug before inserting it into the jack. This paste will protect both the plug

and the jack from corrosion. Both the DeoxIT and the CaiLube are in the tool kit accessories

package included with this display. Refer to the replacement parts list in Section 4.15 if additional

supplies of either are needed.

2. Fiber Optic Connectors:

At each end of a fiber optic cable is a “twist-on” connector. To

remove the fiber plug from its jack, push it toward the jack and

twist it counter-clockwise until the plug can pull free. Figure 31

shows a common type of fiber optic connector.

Figure 30: Ribbon

Cable Connector 2

™

Figure 31: Fiber Optic

Connector

Electrical Installation 3-1

Page 24

3. Termination Panels & Termination Blocks:

Termination panels and termination blocks connect

internal power and signal wires to wires of the same

type coming into the display from an external

source. Most signal wire comes with forked

connectors crimped to the ends of the wire. Power

wires need to have one-half inch of insulation

stripped from the end of the wire prior to

termination. Tighten all screws firmly to ensure a

good electrical connection. Refer to Figure 32.

Figure 32: Termination Panel (Left) and

Termination Block (Right)

4. Phoenix-Style Connectors:

Phoenix-style connectors, which are usually green, terminate signal on

circuit boards. Refer to Figure 33. Strip one-quarter inch of insulation from

the wire prior to termination. To remove a wire, turn the above screw

counter-clockwise to loose the connectors grip on the wire. To insert a

wire, push the bare wire into the connector and turn the above screw

clockwise to lock the wire into place.

5. Mate-n-Lok™ Connectors:

The Mate-n-Lok connectors found in this display are

white and come in a variety of sizes. Figure 34 illustrates a

four-pin Mate-n-Lok connector. To remove the plug from

the jack, squeeze the plastics locking clasps of the side of

the plug and pull it from the jack.

4. Tab Connectors:

The tab connector, illustrated in Figure 35, is in most

Daktronics displays. Grab the connector on the plastic

terminal cover when removing. Do NOT pull it off the tab

Figure 34:

Mate-n-Lok

Connector

by pulling on the wire.

Figure 33:

Phoenix Connector

Figure 35: Tab

Connector

3-2 Electrical Installation

Page 25

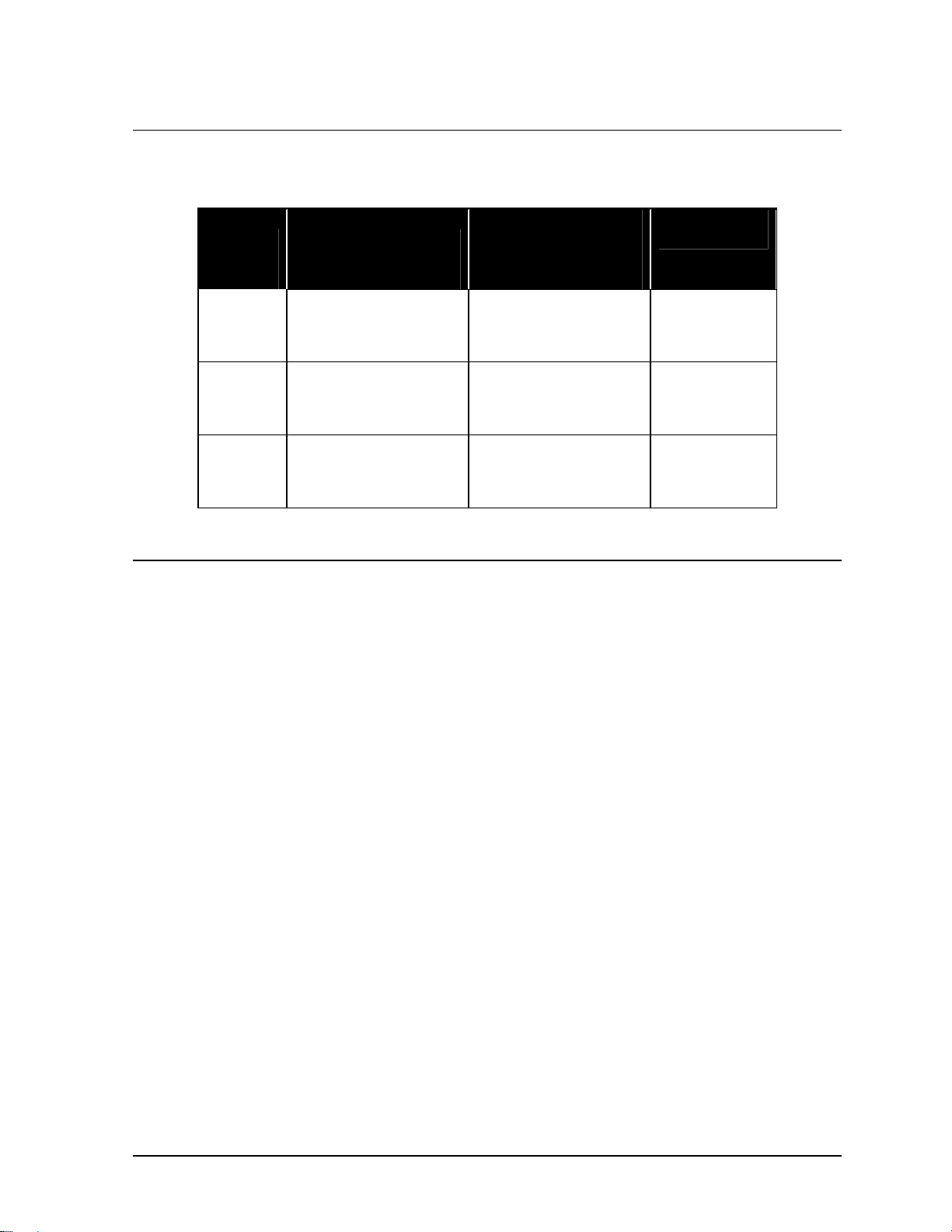

3.2 Display Power Requirements

The following table summarizes the power requirements for the various 1600 series, 2.5-inch small

matrix displays. Power stated is per display face.

Display

Size

8 x 48

8 x 64

8 x 80

8 x 96

16 x 48

16 x 64

16 x 80

16 x 96

24 x 48

24 x 64

24 x 80

24 x 96

120/208 3 Phase

4 Wire Plus Ground

(In Amps)

8

16

16

16

16

24

33

33

24

33

41

49

120/240 Single

Phase

3 Wire Plus Ground

(In Amps)

16

16

24

24

24

33

41

49

41

49

65

73

Total

Watts

2938

3917

4896

5875

5875

7834

9792

11750

8813

11750

14688

17626

3.3 Checking Line Voltage & 24-Hour Voltage Monitoring

Prior to display installation, perform a two-part voltage check. This is a necessary step taken to

maximize lamp life. By looking-up the line voltage on the table in this sub-section, you can calculate

the estimated lamp life and, if necessary, take steps to extend it.

Appendix C has two forms titled “Display Power Report.” This form records three different voltage

readings.

1. Line voltage, addressed in this sub-section.

2. 24-hour monitoring, which also addressed in this sub-section

3. Lamp voltage, checked after the display is powered-up for the first time.

When complete, send one of the “Display Power Report” forms to Daktronics Customer Service. The

other form is for the customer’s records.

To complete the line voltage check, take a line reading of each phase and record the results on each of

the power reports in Appendix A. Then place a voltage monitor on the phase with the highest reading

for 24 hours. Also, write down the maximum and minimum voltages recorded on each of the power

reports.

If lacking the proper equipment to accurately monitor line voltage, consider the following options.

• Have the local power company take the readings.

• Rent the equipment from a local service company.

• Have Daktronics Customer Service recommend the proper equipment.

• Rent the equipment from Daktronics.

Electrical Installation 3-3

Page 26

If there is any reason to suspect large voltage fluctuations, place a recorder on the line for at least one

phase of the power for one week while the display operates normally. Contact Daktronics Customer

Service with respect to this recording.

Display brightness and lamp life are generally determined assuming an average incoming line voltage

of 120 volts AC at 60 hertz. If the line voltage varies from that value, it will affect both lamp life and

brightness. Lamp life results will also vary with programming style and use of dimming mode.

§ Lamp life predictions are for lamps operating in a laboratory with continuous operation in a stable

temperature and mechanical environment. Actual values will differ from predicted life because of

switched operation, varying temperature, mechanical vibrations due to wind, traffic and sign service

and actual hours of operation. Data is that of the manufacturer.

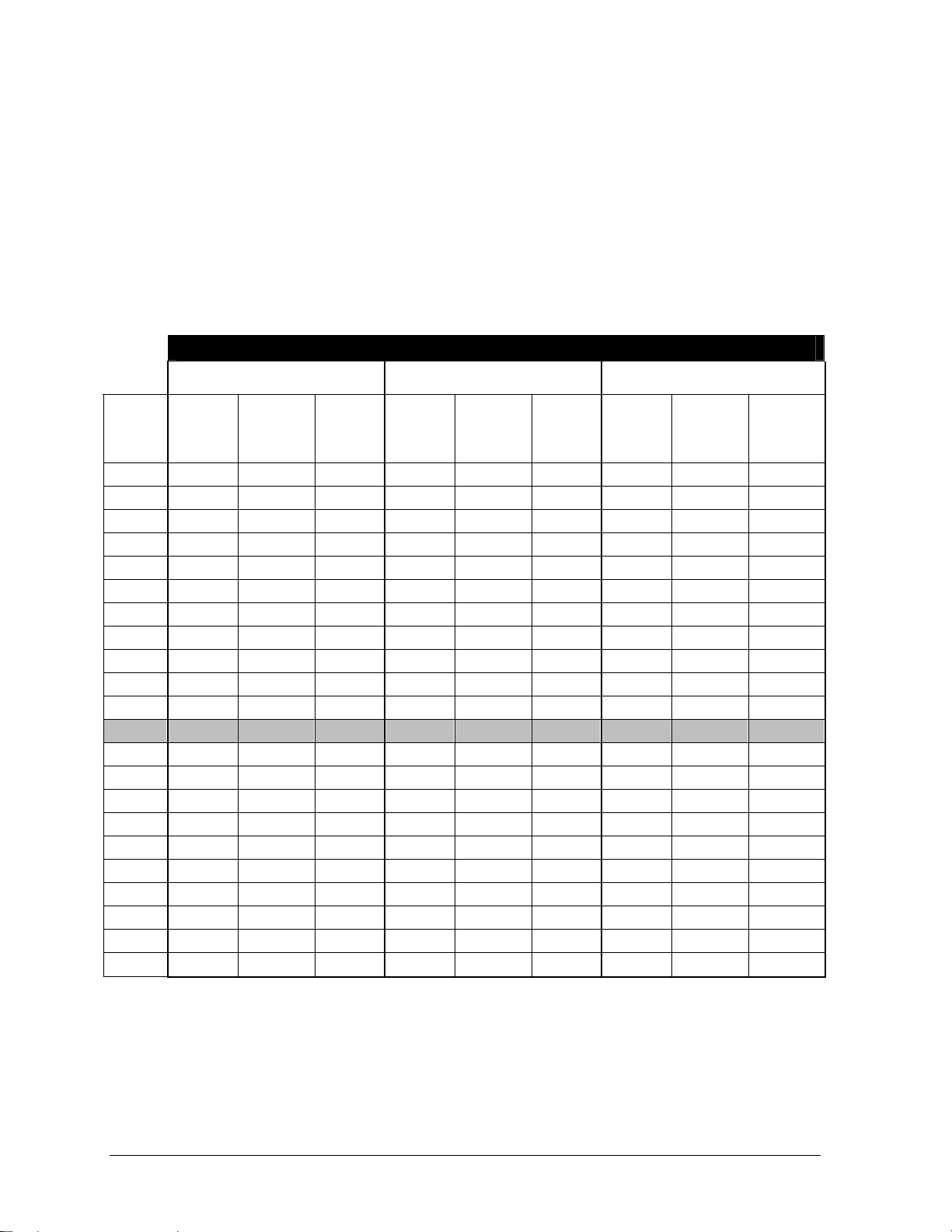

Lamp Voltage/Lamp Life with 23 VAC Secondary (T-1109 XFMR)

120 V Only 5 V Buck 5 V Boost

Line

Volts

18.90 19.72 3.42 35022 18.90 2.95 59271 20.60 3.98 20250

108 20.10 3.66 27530 19.27 3.16 46578 21.00 4.26 15923

110 20.48 3.91 21740 19.64 3.37 36770 21.40 4.55 12577

112 20.87 4.17 17242 20.01 3.60 29155 21.80 4.86 9978

113 21.06 4.30 15380 20.19 3.71 16003 22.00 5.01 8902

114 21.25 4.44 13733 20.38 3.83 23215 22.20 5.18 7950

115 21.44 4.58 12275 20.56 3.96 20748 22.40 5.34 7107

116 21.63 4.73 10983 20.74 4.08 18561 22.60 5.51 6359

117 21.83 4.88 9836 20.93 4.21 16621 22.80 5.68 5696

118 22.02 5.03 8818 21.11 4.34 14899 23.00 5.86 5107

119 22.21 5.18 7912 21.30 4.48 13367 23.20 6.04 4583

120 22.40 5.34 7107 21.48 4.61 12004 23.40 6.22 4117

121 22.59 5.50 6389 21.66 4.75 10790 23.60 6.41 3701

122 22.78 5.67 5748 21.85 4.89 9708 23.80 6.60 3331

123 22.98 5.84 5177 22.03 5.04 8742 24.00 6.80 3000

124 23.17 6.01 4666 22.22 5.19 7878 24.20 7.00 2704

125 23.36 6.18 4210 22.40 5.34 7107 24.40 7.20 2440

126 23.55 6.36 3801 22.58 5.50 6416 24.60 7.41 2203

127 23.74 6.55 3435 22.77 5.65 5797 24.80 7.63 1991

128 23.93 6.73 3106 22.95 5.82 5242 25.00 7.84 1801

129 24.13 6.92 2811 23.14 5.98 4744 25.20 8.07 1630

130 24.32 7.12 2547 23.32 6.15 4297 25.40 8.29 1477

Lamp

Volts

Candle

Power

Lamp

Life

Hours

Lamp

Volts

Candle

Power

Lamp

Life

Hours

Lamp

Volts

Candle

Power

Lamp

Life

Hours

If the line voltage is near or above 125 volts or a longer lamp life is desired, contact Daktronics for

transformer adjustment.

Contact a local electrician or the local power company if line voltage is substantially above or below

normal.

3-4 Electrical Installation

Page 27

3.4 Preparing the Display for Power & Signal Connection

Reference Drawings:

Shop Drawing, 7 or 8 High, 2 ½

Shop Drawing, 16 High, 2 ½

Shop Drawing, 24 High, 2 ½

When connecting power and signal to this display it is necessary to access the following items.

• Power termination panel.

• Display controller (Venus 1500 controller or serial line interface)

• Fan control enclosure – Venus 1500, 2V cabinet configurations only.

The shop drawings illustrate the locations of the above-listed items at the end of this section.

However, only one of the drawings is appropriate for this display. Use the following table to choose

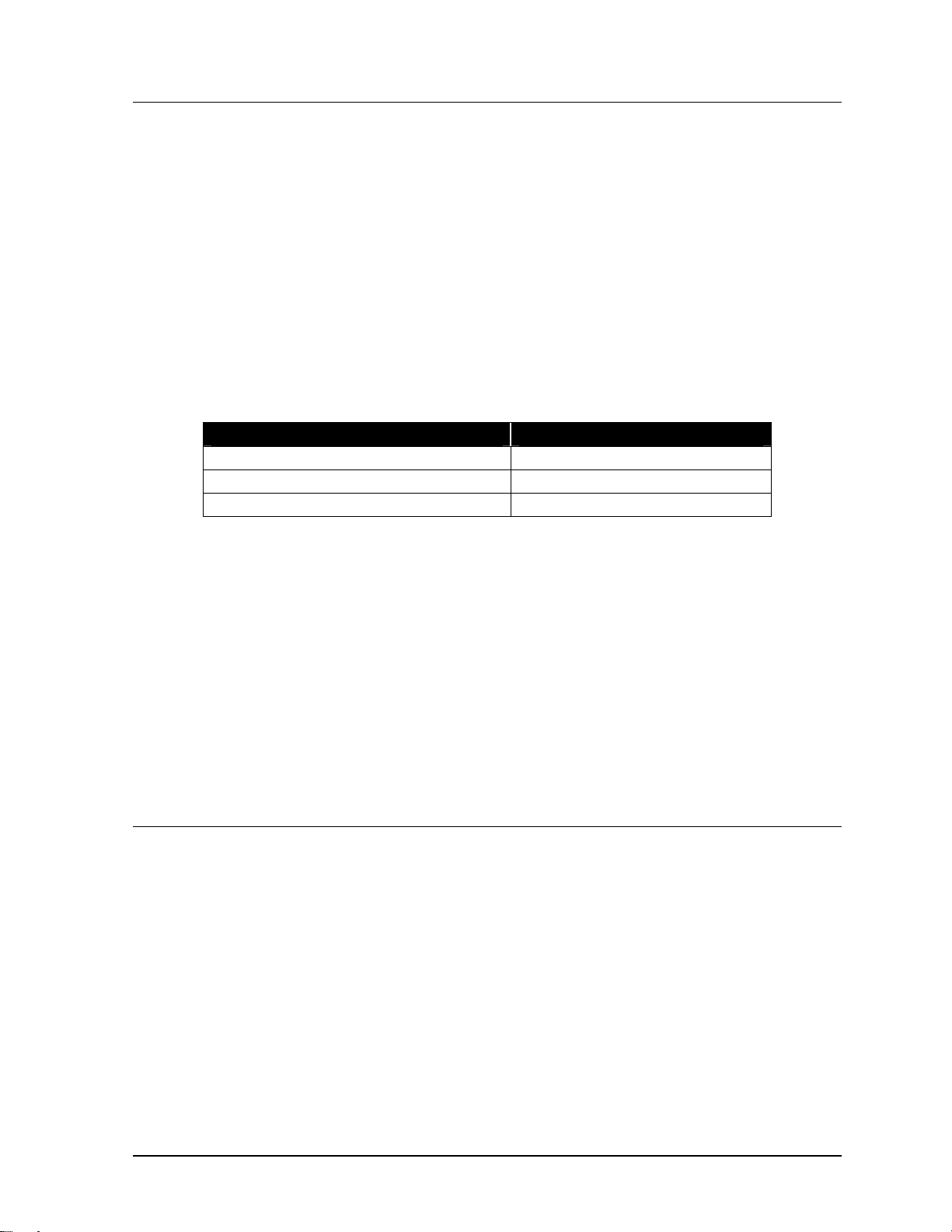

the correct shop drawing.

If the display being installed is… Consult shop drawing…

7 or 8 high display (all lengths) Drawing A-114666

16 high display (all lengths) Drawing A-114667

24 high display (all lengths) Drawing A-114668

After locating the power termination panel and display controller on the shop drawing, complete the

following steps to ready the display for power and signal hook-up.

1. Remove the necessary lens/reflector assemblies to gain access to the termination panel and display

controller. Lens/reflector removal is addressed in Lens/Reflector Assemblies in Section 4.3.

Venus 1500 systems need only access the fan control enclosure if installing two displays together

in a 2V cabinet configuration. Venus 4600 systems do not need access to the fan control enclosure

regardless of cabinet configuration.

2. Remove the covers from the power termination panel, the display controller and, if needed, the fan

control enclosure.

Daktronics completes all internal power and signal wire routing and connecting prior to shipment.

˝..........................................................Drawing A-114666

˝................................................................Drawing A-114667

˝................................................................Drawing A-114668

3.5 Bringing Power to the Display

Reference Drawing:

Assy, Term Panel................................................................................ Drawing A-113974

Only qualified individuals should perform power routing and termination to the display. It is

the responsibility of the installer to ensure the installation will adequately meet local codes and

standards.

! Run power from the power distribution point to the termination panel of each display face.

! Run power separately to each display face.

! This power is run through conduit according to national and local electrical codes.

! Use the knockouts in the back sheet located near the termination panel for the conduit entrance

point. This area is marked with a label (“Recommended Pwr & Sig Entrance Location”).

! Power cannot route through the display. Do not use the support conduit, located inside the

display, for power routing.

Electrical Installation 3-5

Page 28

The following subsections address the routing of incoming power through a power disconnect switch

and the termination of incoming power at the display’s power termination panel. Daktronics completes

all power routing and connection within the display past the power termination panel prior to

shipment.

When terminating the incoming power to the term panel, balance the individual power phases as

evenly as possible. Current draw per line, as noted on the sales literature or schematic, is the high leg

current draw.

For a 2V display, bring power into both faces. The termination panel for the echo face is located in the

right end of the display. Connect power as stated above.

Power Disconnect Switch

Route power to the display through a fused disconnect switch capable of opening all ungrounded

power conductors. Locate this disconnect within the line of sight of any personnel performing

maintenance on the display. If locating the disconnect out of sight of the display, it must be able to

lock in the open position.

Due to the inrush current (momentary surge) created by the display on start-up, Daktronics

recommends using oversized current devices, high magnetic breakers or time delay fuses to

handle the momentary surge.

The Over Current Protection Device needs to match the fault current available in the power

delivery circuit. To determine the available fault current of circuit, have qualified personnel

perform an onsite fault current survey at the site.

The National Electrical Code requires the Amp Inrush Current (AIC) rating of the electrical

equipment in a circuit match the available fault current in the electrical circuit.

Because each installation is unique, Daktronics offers these instructions as guidelines only.

Daktronics assumes no liability if installation steps have been omitted or other necessary

procedures are not included in this manual.

Daktronics is not responsible for the quality of the power delivery system to the display. It is the

customer’s responsibility to ensure the undertaking of proper safety measures. Power and

signal wiring in the display must comply with local, state and national electrical codes, with the

correct cabling procedures for the installation determined and followed.

Power Termination at the Display

Incoming power connects to the power termination panel located within the left end of display.

Drawing A-113974 shows an example of a power termination layout. The appearance of other

termination panels will vary by sign size.

Complete the following steps to connect power to the termination panel.

1. Pull the power cable from the conduit to the termination panel.

2. Connect the white neutral wire (or wires) to the position labeled NEUT on TB41.

3. If terminating 120/240 single-phase power, connect the hot wires to the positions labeled L1

and L2 on TB41. If terminating 120/208 three-phase power, connect the hot wires to L1, L2

and L3 on TB41.

4. Apply a silicone sealant around the conduit where it meets the cabinet to prevent

water/moisture from entering the display.

3-6 Electrical Installation

Page 29

5. Refer to the following section, Section 3.5, for important information regarding display

grounding.

Grounding

Displays MUST be grounded according to the provisions outlined in Article 250 of the

National Electrical Code

Verification of ground resistance can be performed by the electrical contractor who is performing

the electrical installation. This service can also be performed by Scoreboard Sales and Service

personnel

The display system must be connected to earth-ground. Proper grounding is necessary for reliable

equipment operation. It also protects the equipment from damaging electrical disturbances and

lightning. The display must be properly grounded or the warranty will be void.

The material of an earth-ground electrode differs from region to region and from conditions

present at the site. Consult the National Electrical Code and any local electrical codes that

may apply. The support structure of the display cannot be used as an earth-ground electrode.

The support is generally embedded in concrete, and if in earth, the steel is either primed or it

corrodes, making it a poor ground.

®

. Daktronics recommends a resistance to ground of 10 ohms or less.

Power Installation

There are two considerations for power installation; installation with ground and neutral

conductors provided and installation with only a neutral conductor provided. These two power

installations differ slightly, as described in the following paragraphs:

Installation with Ground and Neutral Conductors Provided

For this type of installation, the power cable must contain an isolated earth-ground conductor.

Under this circumstance, do not connect neutral to ground at the disconnect or at the display.

This would violate electrical codes and void the warranty. Use a disconnect so that all hot

lines and neutral can be disconnected. Refer to Figure 36 for installation details. The National

Electrical Code requires the use of a lockable power disconnect within sight of or at the

display.

Electrical Installation 3-7

Page 30

Figure 36: Installation with Ground and Neutral Conductor Provided

Installation with Only a Neutral Conductor Provided

Installations where no grounding conductor is provided must comply with article 250-32 of

the National Electrical Code. If the installation in question meets all of the requirements of

article 250-32, the following guidelines must be observed:

• Connect the grounding electrode cable at the local disconnect, never at the display power

termination panel.

• A disconnect that opens all of the ungrounded phase conductors should be used.

• The neutral and the ground conductors should be bonded in the display power termination

panel.

Refer to Figure 37 for installation details.

Figure 37: Installation with only Neutral Conductor provided

3.6 Bringing Signal to the Display

Reference Drawings:

V1500 Signal Termination .....................................................................Drawing A-103727

Serial Line IF Signal Terms...................................................................Drawing A-103740

3-8 Electrical Installation

Page 31

System Riser Diagram (Serial Line IF)..................................................Drawing A-107196

System Riser Diagram (RS/422)...........................................................Drawing A-148859

System Riser Diagram (RS/232)...........................................................Drawing A-148870

System Riser Diagram (Fiber Optic).....................................................Drawing A-148878

System Riser Diagram (Modem)...........................................................Drawing A-148884

The method used to route and terminate signal cable at the display differs according to the type of

signal cable used. This is especially true for the Venus 1500 systems, which are available in the

following configurations.

• Venus 1500 system using RS/232 signal

• Venus 1500 system using RS/422 signal

• Venus 1500 system using modem/telephone cable

• Venus 1500 system using fiber optic signal

Venus 4600 systems use only one type of signal – fiber optic. Daktronics completes all internal signal

wiring prior to shipment.

The following sub-sections address signal cable connection for each of the previously listed signal

cable configurations. Refer to the information appropriate for this particular display.

Signal interconnect between displays in a 2V configuration is covered in Section 3.7.

Venus 1500 System Using RS/232 Signal

RS/232 systems use a two-conductor, shielded cable to transmit the RS/232 signal from the

junction box to the display controller. The cable is assigned the Daktronics part number W-1117.

Keep the following in mind when working with W-1117 cable.

• W-1117 cable should not be subjected to mechanical flexing after installation.

• It is not for direct burial.

• It should only be routed in a dedicated, grounded metallic conduit.

• It has a maximum length of 25 feet.

Complete the followings steps to connect signal to a Venus 1500 system using RS/232 cable.

1. Mount the junction box with 25 feet of the base of the display.

2. Route conduit and W-1117 cable from the junction box to the knockouts on the right side

(rear view) of the display – or master display if a 2V configuration is being installed.

3. Continue cable into the Venus 1500 controller enclosure fitting labeled “Signal In.”

4. Use the table within this sub-section titled “Venus 1500 RS/232 Signal Connection” to

terminate the W-1117 cable at the Venus 1500 controller and at the junction box.

• The connector labeled “RS/232 In” (TB1) is a six-position, Phoenix-style connector found

on the Venus 1500 controller board. Refer to Drawings A-103727 and A-148870 at the

end of this section.

• TB41 is the only termination panel within the junction box.

Venus 1500 RS/232 Signal Connection

J-Box Cabling RS/232 In (TB1)

Pin 1 (N.C)

Pin 2 (N.C.)

TB41-2 (RX-P) Clear Pin 3 (TX-P)

TB41-3 (GND) Shield Pin 4 (GND)

Electrical Installation 3-9

Page 32

TB41-1 (TX-P) Black Pin 5 (RX-P)

Pin 6 (N.C)

5. The controller computer connects to the 25-position connector (DB25) within the junction

box. Refer to Drawing A-148870 at the end of this section.

6. Apply silicone sealant around the signal conduit where it meets the display cabinet to prevent

water/moisture from entering the display.

Refer to Light Detector Installation - Venus 1500 Systems in Section 3.8 for instructions on

installing the light detector for this display. If ordering a temperature sensor, refer to Section 3.9

for temp sensor installation instructions.

If this display is one face of a two-face, 2V cabinet display configuration, refer to Section 3.7 for

instructions on running signal from the master to the echo unit.

Venus 1500 System Using RS/422 Signal

RS/422 systems use a six-conductor, unshielded cable to transmit the RS/422 signal from the

signal converter to the display controller. This cable consists of paired wires. It is Daktronics part

number W-1210. Keep the following in mind when working with W-1210 cable.

• Do not subject W-1210 cable to mechanical flexing after installation.

• It is not for direct burial.

• Only route it in a dedicated, grounded metallic conduit.

• It has a maximum length of 4,000 feet.

Complete the following steps to connect signal to a Venus 1500 system using RS/422 cable.

1. Route conduit and W-1210 cable from the control room to the knockouts on the right side

(rear view) of the display – or master display if installing a 2V configuration.

2. Continue cable into the Venus 1500 controller enclosure fitting labeled “Signal In.”

3. Use the table within this sub-section titled “Venus 1500 RS/422 Signal Connection” to

terminate the W-1210 cable at the Venus 1500 controller and at the signal converter.

• The connector labeled “RS/422 In” (TB2) is a six-position, Phoenix-style connector found

on the product board of the Venus 1500 controller. Refer to Drawings A-103727 and A-

148859.

• “J6” is one of two six-position, Phoenix-style connectors found on the side of the signal

converter. Each is clearly labeled.

Venus 1500 RS/422 Signal Connection

Sig. Conv. (J6) Cabling RS/422 In (TB2)

Pin 1 (GND) Red Pin 1 (GND)

Pin 2 (TX-P) Black Pin 2 (RX-P)

Pin 3 (TX-N) Brown Pin 3 (RX-N)

Pin 4 (RX-P) White Pin 4 (TX-P)

Pin 5 (RX-N) Blue Pin 5 (TX-N)

Pin 6 (GND) Green Pin 6 (GND)

4. The controller computer connects to the 25-position connector (DB25) on the signal converter

labeled “J1.” Refer to Drawing A-148859

3-10 Electrical Installation

Page 33

Refer to Light Detector Installation - Venus 1500 Systems in Section 3.8 for instructions on

installing the light detector for this display. If ordering a temperature sensor, refer to Section 3.9

for temp sensor installation instructions.

If this display is one face of a two-face, 2V cabinet display configuration, refer to Section 3.7 for

instructions on running signal from the master to the echo unit.

Venus 1500 System Using Modem/Telephone Cable

Modem systems use standard telephone cable routed through conduit to send data from the

controller computer modem to the display controller. The local telephone company must assist in

this installation. Ask a representative of the phone company which colors the TIP and the RING

for signal connection use.

The telephone lines must be standard, direct dial lines not run through a

switchboard/communications system.

Refer to Section 4.5 for an FCC notice regarding modem use.

Complete the following steps to connect signal to a Venus 1500 system using a modem and

telephone cable.

1. Route conduit and telephone cable to the knockouts on the right side (rear view) of the display

– or master display if installing a 2V configuration.

2. Continue cable into the Venus 1500 controller enclosure fitting labeled “Signal In.”

3. Remove the telephone terminal block cover and connect incoming wires using standard

telephone wire colors.

4. Replace the telephone terminal block cover.

5. One short RJ11 telephone cable plugs into the telephone terminal block and the jack labeled

“Phone” (J1) on the Venus 1500 controller modem board. The other short RJ11 cable plugs

into the jack labeled “RS/232 Out” (J2) on the Venus 1500 controller modem board and the

RJ11 jack on the Venus 1500 controller product board. Refer to Drawings A-103727 and A-

148884.

Refer to Section 3.8 for instructions on installing the light detector for this display. If ordering a

temperature sensor, refer to Section 3.9 for temp sensor installation instructions.

If this display is one face of a two-face, 2V cabinet display configuration, refer to Section 3.7 for

instructions on running signal from the master to the echo unit.

Venus 1500 System Using Fiber Optic Signal

Venus 1500 fiber optic systems use a four-fiber cable to transmit data from a signal converter in

the control room to the display controller. The cable is Daktronics part number W-1376. Keep the

following in mind when working with W-1376 cable.

• Do not subject W-1376 cable should to mechanical flexing after installation.

• It is suitable for direct burial or routing in conduit.

• It has a maximum length of 1,500 feet.

Complete the following steps to connect signal to a Venus 1500 system using fiber optic cable.

1. Route conduit (if needed) and W-1376 cable from the control room to the knockouts on the

right side (rear view) of the display – or master display if installing a 2V configuration.

2. Continue cable into the Venus 1500 controller enclosure fitting labeled “Signal In.”

Electrical Installation 3-11

Page 34

3. Use the table within this sub-section titled “Venus 1500 Fiber Optic Connection” to connect

fiber optic cable at the signal converter and the Venus 1500 controller fiber optic board.

• The Venus 1500 fiber optic board mounts on the Venus 1500 controller board within the

Venus 1500 enclosure. Refer to Drawings A-103727 and A-148878.

• The fiber optic connectors on the side of the signal converter are clearly labeled.

Venus 1500 Fiber Optic Signal Connection

Signal

Converter

RX-Out (J3) ----- TX-In (J4)

TX-Out (J2) ----- RX-In (J5)

Cabling Venus 1500

Fiber Board

4. The controller computer connects to the nine-position connector (DB9) on the signal converter

labeled “J1.” Refer to Drawing A-148878 found at the end of this section.

Refer to Light Detector Installation - Venus 1500 Systems in Section 3.8 for instructions on

installing the light detector for this display. If ordering a temperature sensor, refer to Section 3.9

for temp sensor installation instructions.

If this display is one face of a two-face, 2V cabinet display configuration, refer to Section 3.7 for