Page 1

OmniSport® 2000 Rodeo

Operation Manual

ED-14843 Rev 3 –22 January 2015

201 Daktronics Drive PO Box 5128 Brookings, SD 57006-5128

Tel: 1-800-DAKTRONICS (1-800-325-8766) Fax: 605-697-4746

www.daktronics.com/support

Page 2

Page 3

ED-14843

Product 1240

Rev 3 – 22 January 2015

DAKTRONICS INC.

Copyright 2007-2015

All rights reserved. While every precaution has been taken in the preparation of this manual, the

publisher assumes no responsibility for errors or omissions. No part of this book covered by the

copyrights hereon may be reproduced or copied in any form or by any means – graphic, electronic, or

mechanical, including photocopying, taping, or information storage and retrieval systems – without

written permission of the publisher.

All Sport® and OmniSport® are registered trademarks of Daktronics, Inc.

Page 4

Page 5

Table of Contents

Section 1: Introduction ................................................................................................................. 1

1.1 Important Safety Instructions ................................................................................................ 1

1.2 Resources .................................................................................................................................. 2

1.3 Reference Guides..................................................................................................................... 2

1.4 Daktronics Exchange and Repair & Return Programs ....................................................... 3

Exchange Program ........................................................................................................... 3

Before Contacting Daktronics ................................................................................. 3

Repair & Return Program ............................................................................................... 4

Shipping Address ..................................................................................................... 4

Daktronics Warranty and Limitation of Liability ........................................................ 4

1.5 Console Revision History ....................................................................................................... 5

Section 2: Timing System Setup ................................................................................................. 7

2.1 Connections on the Console................................................................................................... 7

Power Connection ............................................................................................................ 8

Rodeo Timing Interface Connection .............................................................................. 8

Judges’ Console Connection ........................................................................................... 8

Wireless Photocell Connection ....................................................................................... 9

Daktronics Numeric Display Connection ..................................................................... 9

Serial Connections.......................................................................................................... 10

DakStats Rodeo Software....................................................................................... 10

Matrix Display Connection.................................................................................... 10

Network Connections .................................................................................................... 11

External Switch Inputs .................................................................................................. 11

2.2 Rodeo Timing Interface ........................................................................................................ 12

Power Connection .......................................................................................................... 12

Pushbutton Connection ................................................................................................. 13

Wired Photocell Connection ......................................................................................... 13

Horn Outputs ................................................................................................................. 14

Section 3: General Console Features & Operation ................................................................. 15

3.1 Liquid Crystal Displays (LCDs) .......................................................................................... 15

3.2 The Keypad ............................................................................................................................ 15

Number Key Pad............................................................................................................ 15

Arrow Keys ..................................................................................................................... 15

Enter/Yes ........................................................................................................................ 15

Clear/No ......................................................................................................................... 16

3.3 Built-in Printer ....................................................................................................................... 16

Correct Paper Installation ............................................................................................. 16

3.4 Startup .................................................................................................................................... 16

3.5 Setting Radio Channels on Wireless Consoles .................................................................. 17

Single Controller Systems Channel Setting ................................................................ 17

Multiple Controller with Single Broadcast Group Channel Setting........................ 17

Multiple Controller with Multiple Broadcast Systems Channel Setting ................ 18

Basic Operation of Radio Settings ................................................................................ 18

3.6 Updating Software in the Console ...................................................................................... 19

Table of Contents i

Page 6

Section 4: Rodeo Timer Operations .......................................................................................... 21

4.1 General Rodeo Timer Information ...................................................................................... 21

Manual Timing Mode .................................................................................................... 21

Automatic Timing Mode ............................................................................................... 22

Scored Events.................................................................................................................. 22

Cutting ............................................................................................................................. 23

External Timing .............................................................................................................. 23

4.2 Rodeo Keys............................................................................................................................. 24

Leader Number .............................................................................................................. 24

Leader Time/Score ........................................................................................................ 24

Now Up Number ........................................................................................................... 24

Now Up Time/Score ..................................................................................................... 25

Bubble Time/Score ........................................................................................................ 25

Cattle Number ................................................................................................................ 25

Copy Now Up to Leader ............................................................................................... 26

Clear Now Up ................................................................................................................. 26

Clear Previous ................................................................................................................ 26

Clear Display .................................................................................................................. 26

Reride ............................................................................................................................... 26

No Time — No Score ..................................................................................................... 26

Start .................................................................................................................................. 26

Stop .................................................................................................................................. 26

Reset ................................................................................................................................. 26

Auto Horn ....................................................................................................................... 27

Horn ................................................................................................................................. 27

Set Default Horn Time ................................................................................................... 27

Scoreboard On/Off ........................................................................................................ 27

Paper ................................................................................................................................ 27

External Timing .............................................................................................................. 28

Menu ................................................................................................................................ 28

4.3 Timed Events Keys ................................................................................................................ 28

Auto Timing .................................................................................................................... 28

1 Timer ............................................................................................................................. 28

2 Timers ........................................................................................................................... 28

3 Timers ........................................................................................................................... 28

Set Timer Keys ................................................................................................................ 29

Enable/Disable Photocell .............................................................................................. 29

Penalty ............................................................................................................................. 29

Rearm Stop ...................................................................................................................... 29

4.4 Scored Events & Cutting Keys ............................................................................................. 30

Set Main Clock ................................................................................................................ 30

Count Up/Dn ................................................................................................................. 30

4.5 Judges Keys ............................................................................................................................ 30

Number of Judges .......................................................................................................... 30

Edit Judges Score ............................................................................................................ 31

Accept Judges Score ....................................................................................................... 32

Reset Judges .................................................................................................................... 32

Enable Judges Consoles ................................................................................................. 32

Section 5: Rodeo Menus & Settings .......................................................................................... 33

ii Table of Contents

Page 7

5.1 Menu Navigation .................................................................................................................. 33

5.2 Scoreboard Menu .................................................................................................................. 33

Scoreboard ON/OFF ..................................................................................................... 33

Score Display .................................................................................................................. 34

Dimming ......................................................................................................................... 34

5.3 Print Menu ............................................................................................................................. 35

Logging............................................................................................................................ 35

Intensity ........................................................................................................................... 35

5.4 Setup Timer Menu ................................................................................................................ 35

Timer Precision ............................................................................................................... 35

Timer Mode .................................................................................................................... 35

Beeper .............................................................................................................................. 36

Beep Volume ................................................................................................................... 36

Half Points ...................................................................................................................... 36

Horn ................................................................................................................................. 37

Judge Start ....................................................................................................................... 37

5.5 Setup Photocell Menu ........................................................................................................... 37

Photocell Precision ......................................................................................................... 37

Photocell Arming ........................................................................................................... 37

Photocell Switch ............................................................................................................. 38

5.6 Setup Network Menu ........................................................................................................... 38

Network Enable ............................................................................................................. 38

MAC Address ................................................................................................................. 38

IP Address ....................................................................................................................... 38

Subnet Mask ................................................................................................................... 39

Gateway Address ........................................................................................................... 39

Socket Number ............................................................................................................... 39

5.7 Test Menu ............................................................................................................................... 40

Battery ............................................................................................................................. 40

Scoreboard ...................................................................................................................... 40

Cycle On/Off ........................................................................................................... 40

Section 6: Judges’ Console Operation ..................................................................................... 41

6.1 Console Setup ........................................................................................................................ 41

6.2 Scored Events Operation ...................................................................................................... 41

Maximum Scoring Values ............................................................................................. 42

Re-ride Select .................................................................................................................. 42

Start, Stop, & Reset ........................................................................................................ 42

Score Editing ................................................................................................................... 42

6.3 Cutting Event Operation ...................................................................................................... 43

6.4 Timed Events Operation ...................................................................................................... 43

Appendix A: Reference Drawings ................................................................................................. 45

Appendix B: Quick Reference Guide ............................................................................................ 47

Appendix C: Daktronics Warranty and Limitation of Liability .................................................... 49

Table of Contents iii

Page 8

Page 9

Section 1: Introduction

This manual is designed to explain the operation of OmniSport® 2000 timing console for rodeo events.

For additional information regarding the safety, installation, operation, or service of this system, refer

to the telephone numbers listed in Section 1.4.

1.1 Important Safety Instructions

Read and understand all instructions, both general and for specific sports.

Do not drop the device or immerse it in water.

This device shall not be exposed to dripping or splashing, and no objects filled with

liquid shall be placed upon it.

WARNING! To reduce the risk of fire or electric shock, do not expose this device to rain

or moisture.

An internal battery allows the timer to continue operation for approximately 10 minutes

in the event of a power failure.

CAUTION! DANGER OF EXPLOSION IF BATTERY IS INCORRECTLY REPLACED.

REPLACE ONLY WITH THE SAME OR EQUIVALENT TYPE.

WARNING! Do not expose batteries to excessive heat, such as direct sunlight or

open fire.

Never yank the power cord to pull the plug from the outlet. Grasp the plug and pull to

disconnect.

Do not let the power cord touch hot surfaces or hang over the edge of a table that could

damage or cut the cord.

If an extension cord is necessary, use a three-pronged polarized cord. Arrange the cord

with care so that no one will trip over or pull it out.

Before using an extension cord, inspect the cable thoroughly and verify its compliance

with the local electric codes.

Always turn off and unplug the control equipment when it is not in use.

To avoid electrical shock, do not disassemble the control equipment or electronic controls

of the display. Incorrect reassembly can cause electric shock and faulty operation or

permanent damage to the circuits. Failure to follow this safeguard will make the

warranty null and void.

Inspect console for shipping damage such as rattles and dents, and verify that all

equipment is included as itemized on the packing slip. Immediately report any problems

to Daktronics; save all packing materials if exchange is necessary.

As a safety feature, this device has a three-wire, ground-type plug equipped with a third

(grounding) pin. This plug only fits into a grounding-type power outlet. The outlet shall be

installed near the console and easily accessible. If unable to insert the plug into the outlet,

contact a qualified electrician to replace the obsolete outlet.

Introduction 1

Page 10

Reference Guide

ED/DD #

OmniSport 2000 Rodeo Quick Reference Guide

Provides basic descriptions of rodeo common keys and menu navigation. Included

in Appendix B.

DD2870296

Rodeo Interface Technical Guide

Advanced display interface setup. Available online at www.daktronics.com/manuals.

DD1660229

DakStats Rodeo Manual

Explains the setup and operation of DakStats Rodeo software. Available online at

www.daktronics.com/manuals.

ED-14946

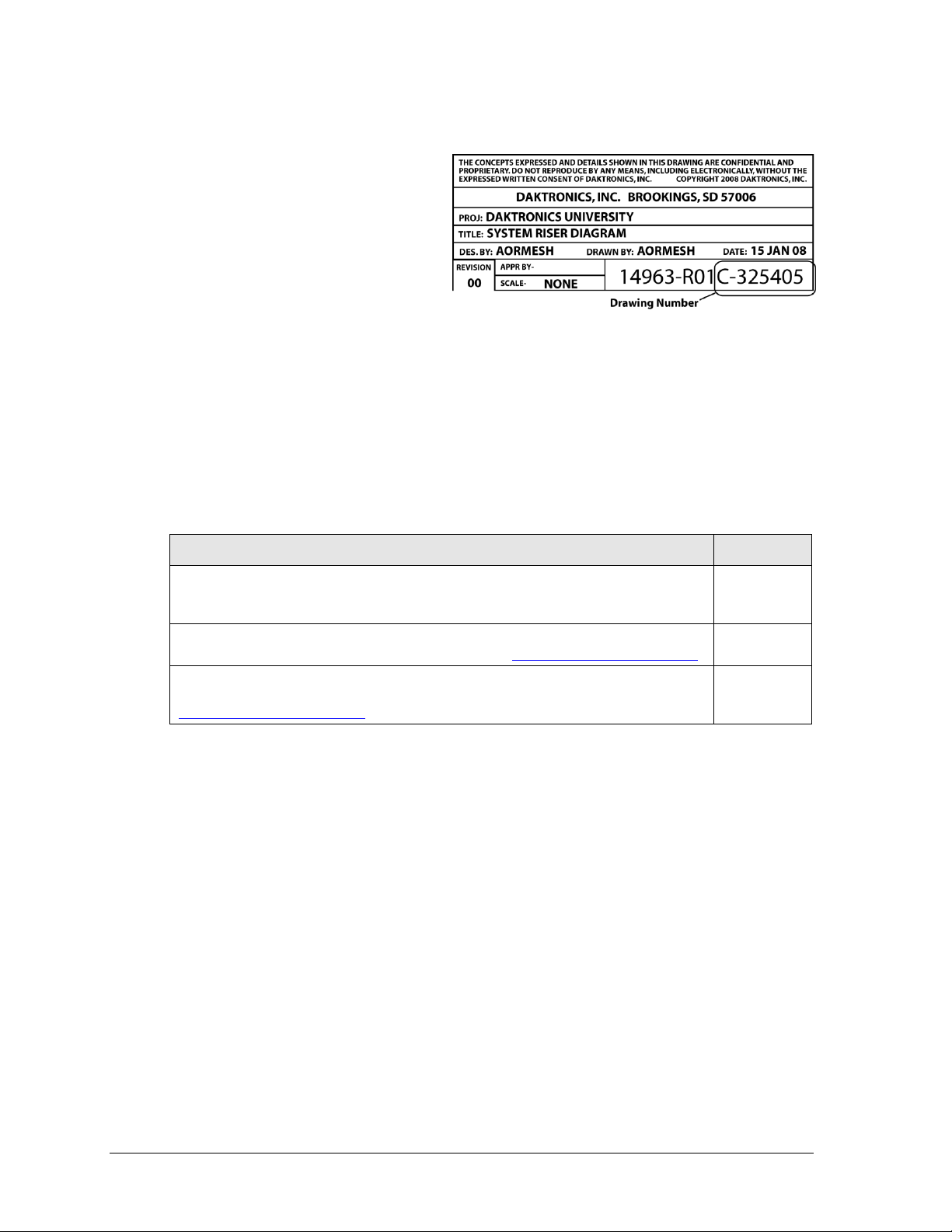

Figure 1: Daktronics Drawing Label

1.2 Resources

Figure 1 illustrates a Daktronics

drawing label. The drawing number is

located in the lower-right corner of a

drawing. This manual refers to

drawings by listing the last set of digits

and the letter preceding them. In the

example, the drawing would be

referred to as Drawing C-325405.

Reference Drawing:

System Riser Diagram ............................................................................Drawing C-325405

Daktronics identifies manuals by an ED or DD number located on the cover page of each

manual. For example, this manual would be referred to as ED-14843.

1.3 Reference Guides

Daktronics provides OmniSport 2000 timing system users with supplemental reference guides.

2 Introduction

Page 11

Market Description

Customer Service Number

Schools (including community/junior colleges), religious

organizations, municipal clubs and community centers

877-605-1115

Universities and professional sporting events, live events

for auditoriums and arenas

866-343-6018

1.4 Daktronics Exchange and Repair & Return Programs

Exchange Program

The Daktronics Exchange Program is a service for quickly replacing key components in need

of repair. If a component fails, Daktronics sends a replacement part to the customer who, in

turn, returns the failed component to Daktronics. This decreases equipment downtime.

Customers who follow the program guidelines explained below will receive this service.

Before Contacting Daktronics

Identify these important numbers:

Assembly Number: _____________________________________________________________

Job/Contract Number: __________________________________________________________

Date Installed: _________________________________________________________________

Daktronics Customer ID Number: ________________________________________________

To participate in the Exchange Program, follow these steps.

1. Call Daktronics Customer Service.

2. If the replacement part fixes the problem, send in the problem part being replaced.

a. Package the old part in the same shipping materials in which the replacement

part arrived.

b. Fill out and attach the enclosed UPS shipping document.

c. Ship the part to Daktronics.

3. The defective or unused parts must be returned to Daktronics within 5 weeks of

initial order shipment.

If any part is not returned within five (5) weeks, a non-refundable invoice will be

presented to the customer for the costs of replenishing the exchange parts inventory

with a new part.

Daktronics reserves the right to refuse parts that have been damaged due to acts of

nature or causes other than normal wear and tear.

Introduction 3

Page 12

Repair & Return Program

For items not subject to exchange, Daktronics offers a Repair & Return Program. To send a

part for repair, follow these steps:

1. Call or fax Daktronics Customer Service:

Refer to the appropriate market number in the chart listed on the previous page.

Fax: 605-697-4444

2. Receive a case number before shipping.

This expedites repair of the part.

3. Package and pad the item carefully to prevent damage during shipment.

Electronic components, such as printed circuit boards, should be placed in an

antistatic bag before boxing. Daktronics does not recommend using packing ‘peanuts’

when shipping.

4. Enclose:

name

address

phone number

the case number

a clear description of symptoms

Shipping Address

Daktronics Customer Service

[Case #]

201 Daktronics Drive, Dock E

Brookings, SD 57006

Daktronics Warranty and Limitation of Liability

The Daktronics Warranty and Limitation of Liability is located in Appendix C. The Warranty

is independent of Extended Service agreements and is the authority in matters of service,

repair, and display operation.

4 Introduction

Page 13

1.5 Console Revision History

Version 4.10.17 Release date: 17 October 2004

Initial software release

Version 5.6.08 Release date: 8 June 2005

In die C3 of 80C390, the SMOD_1 bit for Serial Port 1 seems to be ignored and the baud

rate is always doubled (WDCON.7=1) so the reload values of Timer 1 were adjusted to

work with this as doubled.

Added an H-segment on digit two of the clock in address 1 for a caption control.

Removed the selection in the menu for start of timer using judge number 1.

Version 5.9.26 Release date: 26 September 2005

Added the ability to take a time input from the FarmTek timer for barrel racing to show

on our displays.

Version 5.12.02 Release date: 2 December 2005

Added a Cutting mode that uses 1, 2, 3 or 5 judge’s consoles to score the event.

Added a Bubble Time/Score key function to the console and in RTD.

Added a Cattle number key function to the console and in RTD.

Added a previous Time/Score section in the RTD.

Added a Clear Previous key function to the console.

Added an Enable/Disable Photocell key to the console.

Added the ability to receive a time input from the FarmTek timer in Timed Events and

Cutting Events.

Added the ability to Start, Stop and Reset from all judge consoles in Scored Events.

Added to the printout for a scored event, which judge console started and stopped the

timer.

Added the entry of an extra judge console to be used as a Start, Stop console.

Added a Menu selection to select if any judge's console can Start/Stop the timer.

Added a warning time in cutting and penning that sounds a .5 second horn when the

warning time is reached.

Changed the Reset Judges key to get the judges consoles to exit scoring if no score was

entered.

Version 6.2.16 Release date: 16 February 2006

Fixed a problem when configured for 1 judge, the score always came back with the status

set to reride on.

Fixed a problem that the Cutting horn time is using the scored event horn time.

Fixed a problem of the Warning horn is not sounding when clock is counting down.

Version 6.9.21 Release date: 21 September 2006

Fixed a problem with entering the # of judges in cutting mode, as it would not let all of

the allowed judges be entered.

Fixed a problem when timing with Farmtek in external timing, if the timer was turned off

or disconnected, the OmniSport timer would not allow the user to switch to a different

timing mode.

Introduction 5

Page 14

Version 7.4.16 Release date: 16 April 2007

Added 2 Rider/2 Stock scoring mode for use with 4 judges only.

Fixed a problem in Separate scoring mode that the judge status would not show on the

console LCD until a judge score was entered.

Version 7.7.5 Release date: 5 July 2007

Added ability for single judge to generate a reride for the 2Rider/2Stock mode.

Version 7.12.26 Release date: 26 December 2007

Fixed a problem with Scored Events with the clock in count down and set for horn after

stop. If the time was stopped before it reached zero the time would get set to zero when

the clock hit zero and blew the horn.

Fixed a problem with half-point scoring set on the leader score would not display all

digits. If the score was entered as 89 it would show 8 on the display.

Version 9.2.16 Release date: 16 September 2009

Modified scoreboard output in cutting so the score will shift right if over 100 so x100 digit

is displayed.

Changed the printer output routines (as done in Omni2000 swim) for the new version of

printer.

Version 13.1.25 Release date: 25 January 2013

Added menu items for network settings.

Added RTD output on the Ethernet jack.

6 Introduction

Page 15

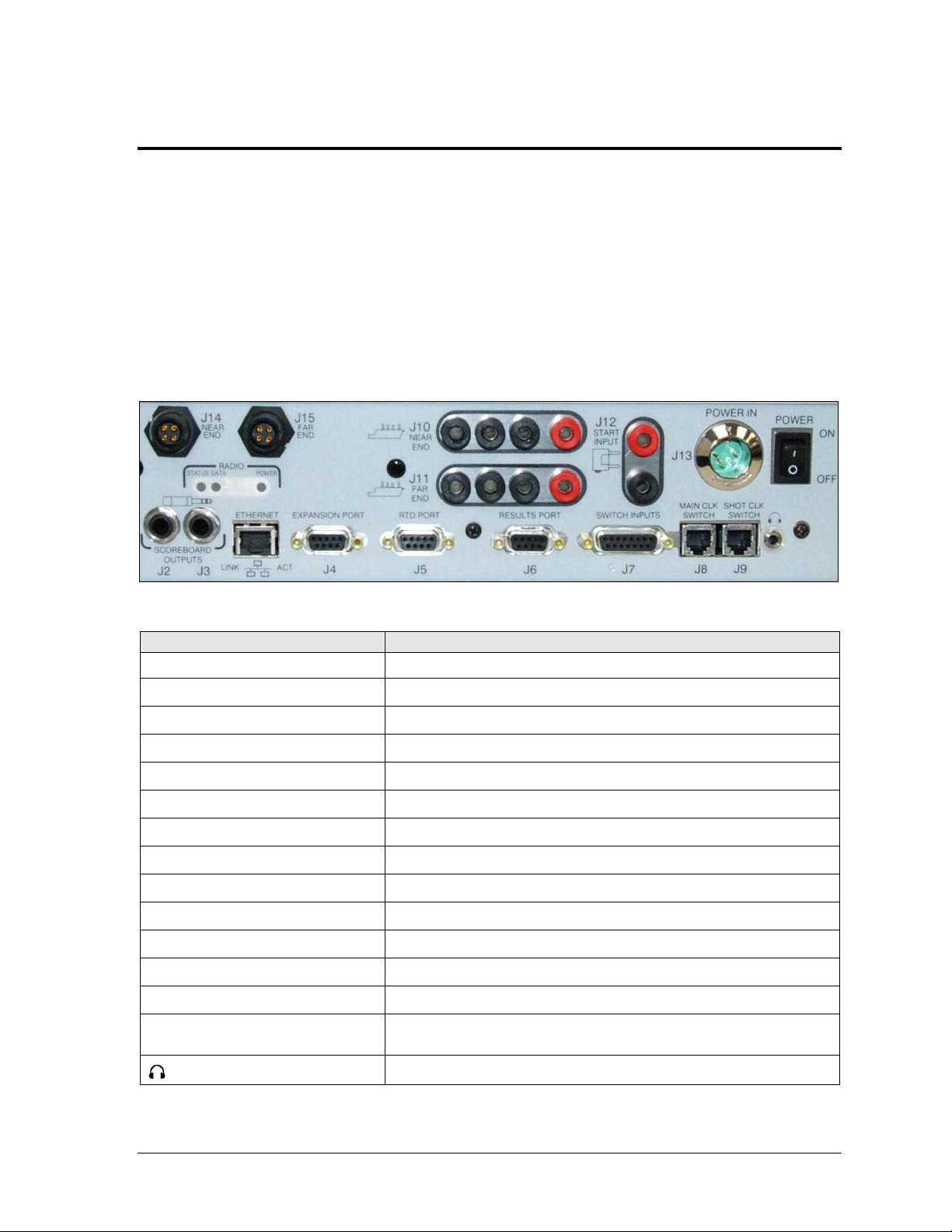

Connection

Function

J2 / J3– SCOREBOARD OUTPUTS

Control numeric rodeo scoreboards/timers

J4 – EXPANSION PORT

Communication with FarmTek wireless photocells

J5 – RTD PORT

Bi-directional communication with Daktronics display control software

J6 – RESULTS PORT

Bi-directional communication with DakStats Rodeo software

J7 – SWITCH INPUTS

Communication with rodeo interface (wired photocells, push buttons)

J8 – MAIN CLK SWITCH

(Not used for rodeo applications)

J9 – SHOT CLK SWITCH

Start/Stop/Reset clock in Scored Events mode

J10 – NEAR END

(Not used for rodeo applications)

J11 – FAR END

(Not used for rodeo applications)

J12 – START INPUT

(Not used for rodeo applications)

J13 – POWER IN

Supplies power from wallpack transformer

J14 – NEAR END

Communication with wireless judges’ consoles

J15 – FAR END

(Not used for rodeo applications)

ETHERNET

Bi-directional communication with DakStats Rodeo software and

Daktronics matrix display control software

Hear the console beeper via headphones

Figure 2: OmniSport 2000 Console Rear View

Section 2: Timing System Setup

2.1 Connections on the Console

Reference Drawing:

Connector Designations: OmniSport 2000 ............................................. Drawing A-154282

It is important to become familiar with the connections on the back of the OmniSport 2000

timing console to ensure all equipment is properly connected before each event. Refer to

Figure 2 and Drawing A-154282. Make ALL connections to the OmniSport 2000 console and

attached equipment BEFORE turning on the console’s power switch.

Timing System Setup 7

Page 16

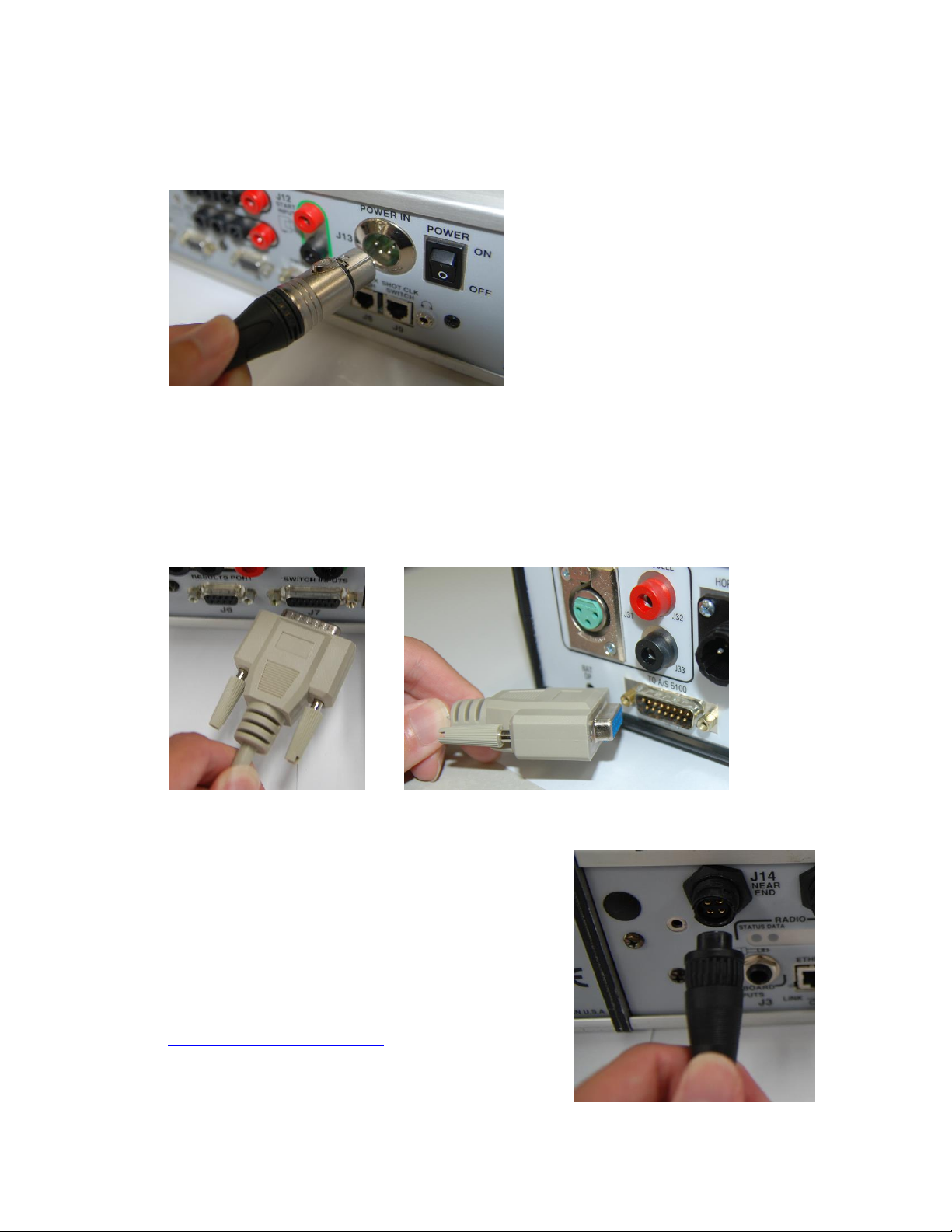

Figure 3: Power Connection

Figure 4: SWITCH INPUTS

Figure 5: TO A/S 5100

Figure 6: Judges’ Console Connection

Power Connection

Connect the power adaptor to the J13 POWER IN jack (Figure 3), and plug the other end into

a 100-240 VAC outlet. Use the rocker switch on the rear of the unit to power it ON and OFF.

Rodeo Timing Interface Connection

The Rodeo Timing Interface is connected to the OmniSport 2000 console via a 15-pin cable

(W-1264). Connect the male end of the cable to the J7 SWITCH INPUTS on the rear of the

OmniSport 2000 (Figure 4), and connect the female end of the cable to the TO A/S 5100 jack on

the rear of the Rodeo Timing Interface (Figure 5). Refer to Section 2.2 for more connections on

the Rodeo Timing Interface.

Judges’ Console Connection

Typically, an RC-100 wireless base station will be

plugged into the J14 NEAR END jack on the rear of the

OmniSport 2000 (Figure 6).

For more information about the RC-100 base station,

refer to the Remote Control System RC-100 All Sport

Operation Manual (ED-15133), available online at

www.daktronics.com/manuals.

8 Timing System Setup

Page 17

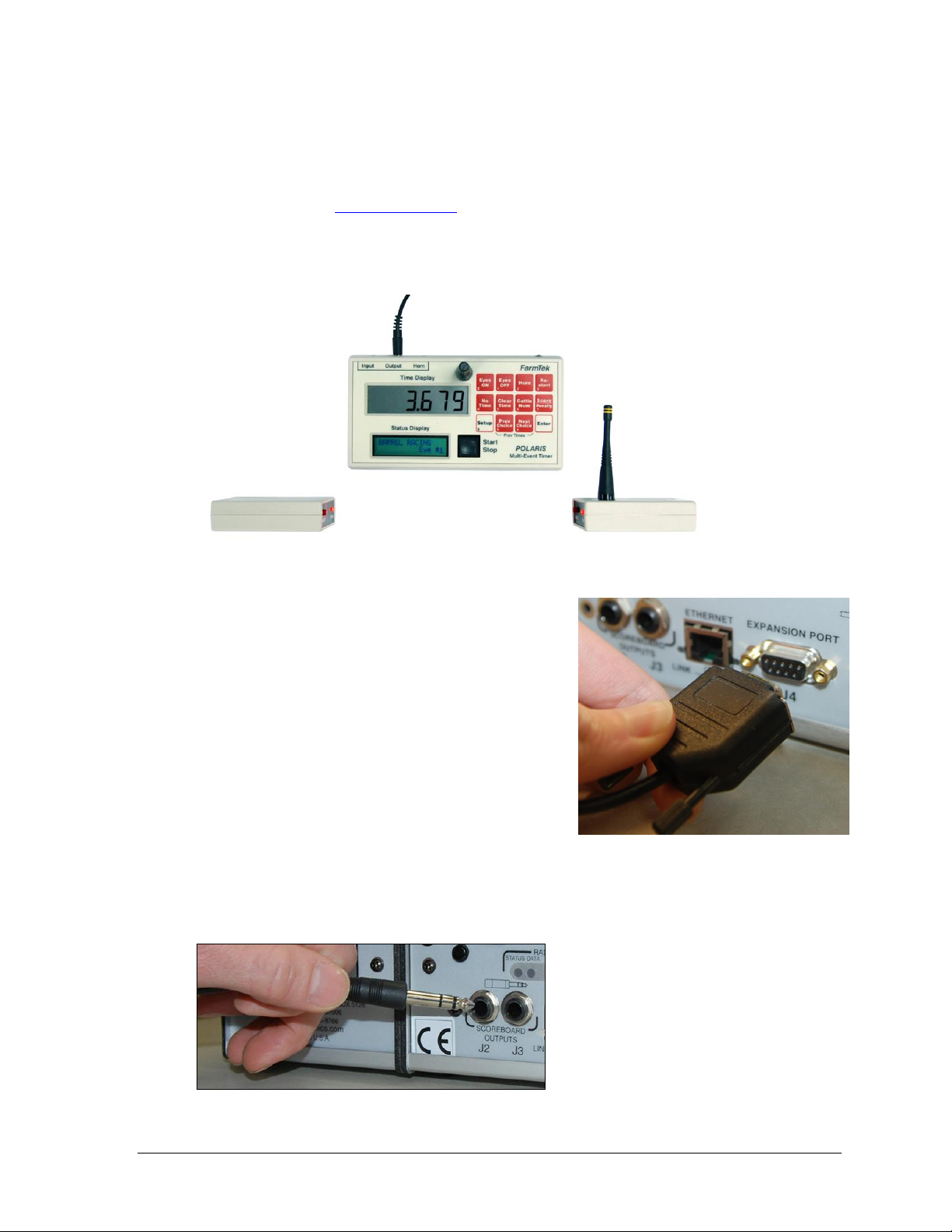

Figure 7: FarmTek Wireless Photocell System

Figure 8: Wireless Photocell Connection

Figure 9: Numeric Scoreboard Plug

Wireless Photocell Connection

Note: If using wired photocells, refer instead to Section 2.2.

The OmniSport 2000 console is capable of interfacing with third-party FarmTek Polaris

wireless photocells (www.farmtek.net). The system consists of a wireless transmitter, wireless

receiver, and the timer (Figure 7). For more information about setting up FarmTek equipment,

consult the manufacturer’s documentation. The timer and photocells are powered by AA and

9V batteries, respectively. Always keep fresh batteries on hand for every event!

To communicate with the wireless photocells,

connect the cable (by FarmTek) between the Output

jack of the Polaris timer and the J4 EXPANSION

PORT on the back of the OmniSport 2000 console

(Figure 8).

Ensure the photocell eyes are aligned and level, with

a clear line of sight between them. Both transmitter

and receiver feature mounting holes for included

tripods. Power on the Polaris timer AFTER powering

on the console or the console will not boot up!

Daktronics Numeric Display Connection

Connect a 1/4" scoreboard signal cable into J2 or J3 SCOREBOARD OUTPUTS as shown in

Figure 9. Make sure that the plug is fully inserted into the jack on the console.

Timing System Setup 9

Page 18

Figure 10: Serial Connection to DakStats Rodeo

Figure 11: Serial Connection

Figure 12: USB-to-Serial Adapter

Figure 13: Serial Connection to Matrix Display

Serial Connections

DakStats Rodeo Software

Using a straight-through 9-pin male to 9pin female serial cable (Daktronics part

# W-1267, 10' or Radio Shack part # 27-

117), connect the male end to J6

RESULTS PORT (Figure 10).

Connect the female end to a serial port

on the computer with the software

(Figure 11). If the computer does not

have a built-in serial port, use a USB-toserial adapter (Daktronics part # A-1801

or Radio Shack part # 26-183) as shown in Figure 12. Drivers for the USB-to-serial adapter

should be found on a CD provided with it or on the manufacturer’s web site.

Matrix Display Connection

Different matrix displays may require different connection methods. A typical connection

method for Daktronics displays uses a 50' (15 m) 9-pin male to 1/4" cable (part # 0A-1240-

0032). Connect the 9-pin male end to J5 RTD PORT (Figure 13). Connect the male 1/4" plug

into a 1/4" phone outdoor J-box (part # 0A-1091-0227).

For more information on outputting data to Daktronics displays, refer to the Rodeo Interface

Technical Guide (DD1660229), available online at www.daktronics.com/manuals.

10 Timing System Setup

Page 19

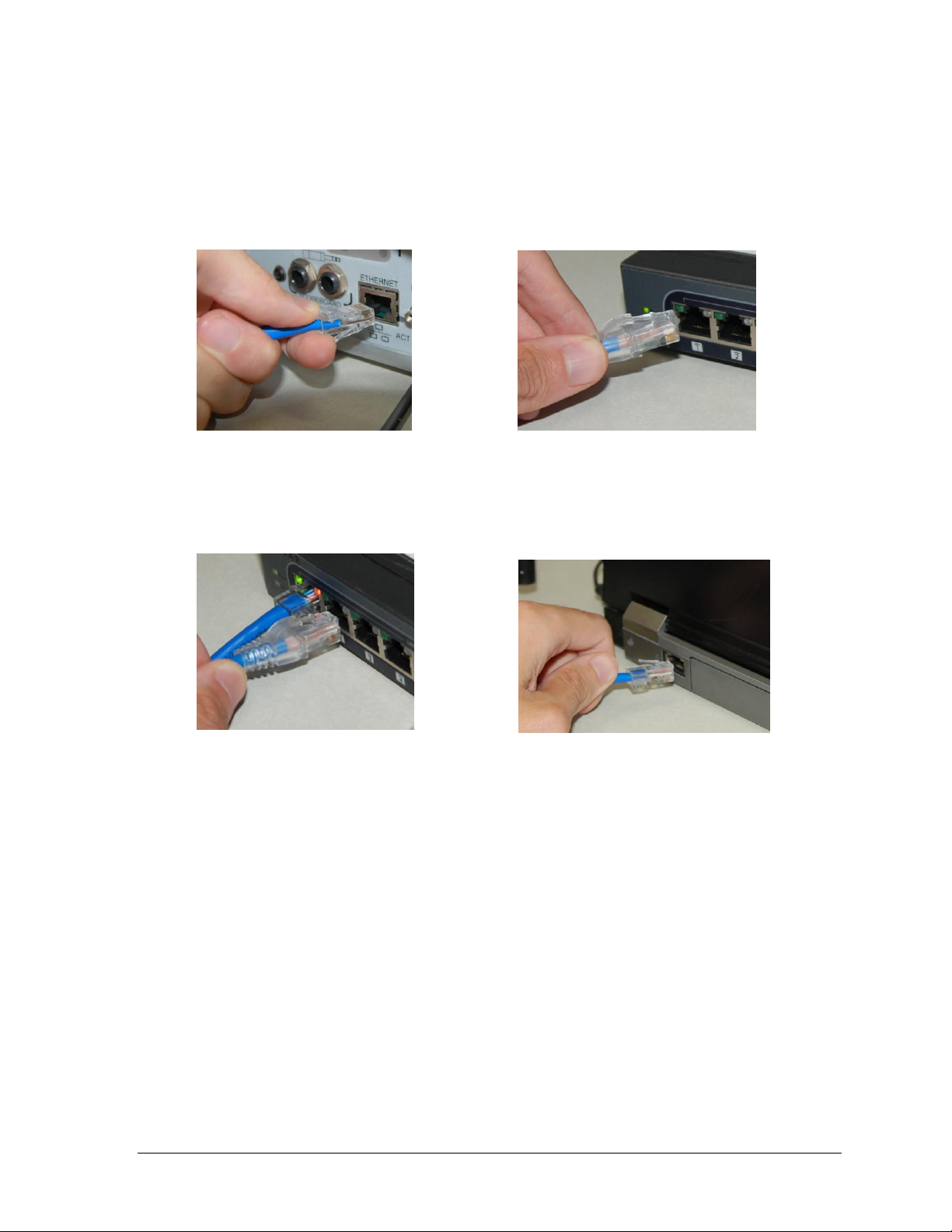

Figure 14: ETHERNET Connection

Figure 15: Network Hub Connection (1)

Figure 16: Network Hub Connection (2)

Figure 17: Computer Connection

Network Connections

The ETHERNET jack allows Real-Time Data (RTD) to be sent over a local area network and

connection to the DakStats Rodeo software.

Connect a Cat5 Ethernet cable between the ETHERNET jack on the OmniSport 2000 console

(Figure 14) and a network hub (Figure 15).

Connect a Cat5 Ethernet cable between the network hub (Figure 16) and the DakStats Rodeo

software and/or Daktronics matrix display control computer (Figure 17). Connect as many

computers as the network hub supports.

Data is sent using UDP protocol as a broadcast packet. The OmniSport 2000 currently

operates using a static IP address. The default address and subnet mask are used with

Daktronics control system networks. If the console is going to operate on a network other

than for a Daktronics control system, an assigned IP address must be obtained and set in the

console. The subnet mask must also be set appropriately for the network. Consult the

facility’s network administrator, and refer to Section 5.6 to change the settings as needed.

Note: Older versions of the console (shipped prior to June 2013) do not have this jack.

If using one of these older consoles, any references in this manual about the Ethernet

jack and network setup may be disregarded. To upgrade, please contact Daktronics.

External Switch Inputs

The OmniSport 2000 console provides external switch inputs for use in Scored Events mode.

Connect a handheld start/stop and reset assembly (0A-1196-0031) to J9 SHOT CLK SWITCH

on the rear of the console. On the handheld switch, toggle the CLOCK START/STOP switch

to start or stop the timer. Press RESET to reset the timer.

Timing System Setup 11

Page 20

Figure 18: Timing Interface, Front & Rear Views

2.2 Rodeo Timing Interface

Reference Drawing:

Allen Bradley Photocells; 6000 & 9000 Series .......................................... Drawing A-70989

Rodeo Photocell Interface Connector Assignments ............................... Drawing A-147806

External switch inputs, including wired photocells and pushbuttons, are brought into the

OmniSport 2000 console using the AS/5100 Rodeo Timing Interface (0A-1196-0055). Refer to

Figure 18 and Drawing A-147806 for details of each connector on the timing interface.

Power Connection

The Rodeo Timing Interface is equipped with a 3-prong power cord. The interface may

operate while plugged into a standard grounded outlet or via an internal 12 VDC battery.

Use the rocker switch on the rear of the unit to power it ON and OFF.

The unit features two LEDs to indicate power and battery status:

PWR illuminates green when the unit has power.

BAT CHG illuminates red when the unit is plugged in and the battery is charging.

12 Timing System Setup

The unit can operate for ~20 hours on a full charge, but this may vary depending on the age of

the battery. Note that it can take up to 6 hours to fully recharge the battery.

CAUTION! DANGER OF EXPLOSION IF BATTERY IS INCORRECTLY REPLACED.

REPLACE ONLY WITH THE SAME OR EQUIVALENT TYPE.

WARNNING! Do not expose batteries to excessive heat, such as direct sunlight or open fire.

Page 21

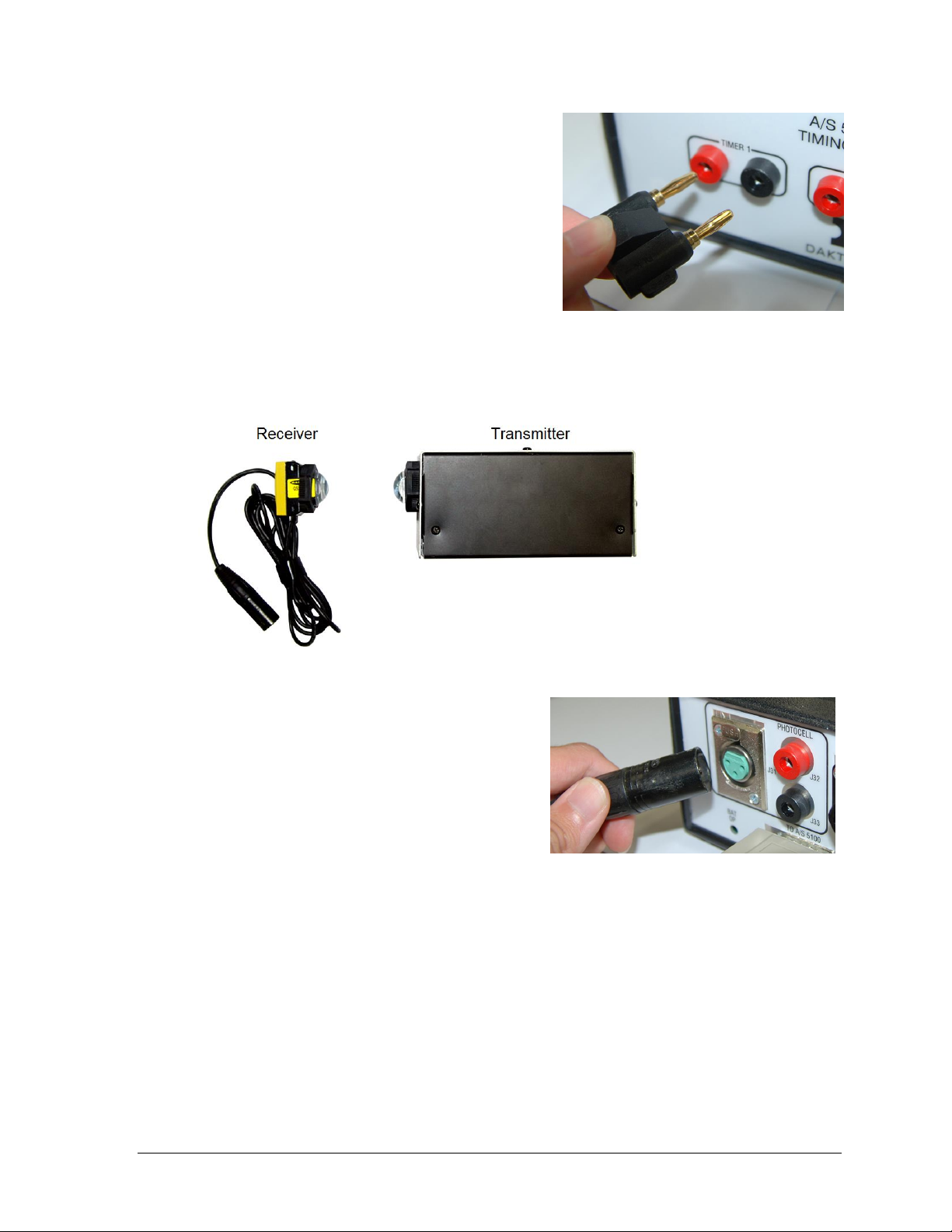

Figure 19: Pushbutton Connection

Figure 20: Wired Photocell System

Figure 21: Photocell Receiver Connection

Pushbutton Connection

Connect up to 3 pushbuttons (part # 0A-1056-0156)

for use in Timed Events to the TIMER 1, TIMER 2,

and TIMER 3 jacks on the front of the Rodeo

Timing Interface. The TIMER 1 input may also be

used to start and stop the clock in Scored Events.

Note: Pay attention to the orientation of the

GND tab of the banana plug – this must

connect into the black jack (Figure 19).

Wired Photocell Connection

Wired photocells may be used for automatic timing of timed events. The system consists of a

transmitter (part # 0A-1163-0025) and a receiver (part # 0A-1163-0024). Refer to Figure 20.

Connect the receiver to the J31 PHOTOCELL

XLR jack on the rear of the Rodeo Timing

Interface (Figure 21).

Note: J32 / J33 is an optional photocell input.

This 2-pin connector does not provide power,

so the photocell receiver would require an

alternate power supply.

The transmitter is housed in an enclosure with two 6 VDC batteries (part # BT-1019). A 12

VDC wall plug-in charger (part # 0A-1088-0013) is included to provide power and charge the

batteries. Use the rocker switch on the rear of the unit to power it on (|) and off (O). The

transmitter is designed to operate 75 hours on a full charge. Note that it can take up to 6

hours to fully recharge the battery.

Ensure the photocell eyes are aligned and level, with a clear line of sight between them.

Both transmitter and receiver feature mounting holes for included tripods (part # A-1509).

CAUTION! DANGER OF EXPLOSION IF BATTERY IS INCORRECTLY REPLACED.

REPLACE ONLY WITH THE SAME OR EQUIVALENT TYPE.

WARNNING! Do not expose batteries to excessive heat, such as direct sunlight or open fire.

Timing System Setup 13

Page 22

Horn Outputs

Connect the 150' (47.5 m) 4-pin horn cable (part # 0A-1163-0007) between the J34 HORN

RELAY jack and the J1 SIGNAL IN jack of the external horn assembly (part # 0A-1163-0005).

The horn is connected to an enclosure with a 12 VDC battery (part # BT-1009). A 12 VDC wall

plug-in charger (part # 0A-1088-0013) may provide power and charge the batteries.

To broadcast a horn tone to a public address (PA) system, connect a male-RCA-to-male-XLR

audio cable (part # 0A-1163-0032) between the J35 HORN AUDIO jack and the PA system

(by others).

14 Timing System Setup

Page 23

Figure 22: OmniSport 2000 Timing Console

Figure 23: OmniSport 2000 Keypad with Rodeo Insert

Section 3: General Console Features & Operation

3.1 Liquid Crystal Displays (LCDs)

The OmniSport 2000 console has

three separate two-line by 16character LCDs to keep the

operator informed (Figure 22).

Section 3.4 describes the readout

on the LCDs when the console is

first powered-up.

3.2 The Keypad

Throughout the manual, keys are referenced with brackets and bold – for example, [ENTER].

The far left side of the keypad on the OmniSport 2000 console has a pocket that allows for a

plastic insert with the names of the keys. The Rodeo insert is Daktronics part # LL-2609. If an

insert is lost or damaged, a printed copy of the insert drawing (located in Appendix A) may

be used until a replacement is ordered.

Note: Remove the protective plastic film from the insert before using it in the console.

The right side of the keypad (Figure 23) has a section of permanent keys. These keys include

the numbers [0]–[9], [CLEAR/NO], [ENTER/YES], and arrows.

Number Key Pad

Press these keys to enter specific numerical information into the timer. The data may pertain

to a specific lane, an event number, or a particular setting among others.

Arrow Keys

These keys are used for menu navigation. The up and down arrows are also labeled NEXT

and LAST; their function will depend on what the LCD is prompting the operator to do.

Enter/Yes

The [ENTER/YES] key has two functions:

Completes an action. As a reminder to press this key, an asterisk appears on the LCD.

Serves as [YES] for input prompts (Y).

General Console Features & Operation 15

Page 24

Figure 24: Console

Printer

Figure 25: Correct Paper Feed

Figure 26: Incorrect Paper Feed

OM N I SP O RT 2000

RODEO TI MI NG

VE R SI ON 13 . 01.25

ED-14865

DAKTRONI CS, I NC

BR O OKI NGS SD

Clear/No

The [CLEAR/NO] key has two functions:

Clears the LCD of numerical information.

Serves as [NO] for input prompts (N).

3.3 Built-in Printer

Daktronics OmniSport 2000 console has a convenient built-in thermal

printer which gives results printouts in under 10 seconds.

Correct Paper Installation

1. Remove the cover from the printer by turning the knob with the

arrow to the left 1/4 turn, or until the arrow points left. Remove the

cover by lifting up and forward on the knob (Figure 24).

2. Remove the old roll of paper.

3. Using a pair of scissors, cut the new roll of paper off to make

the end of the paper square.

4. Place the roll of paper into the printer compartment so that

the paper feeds up from underneath the roll (Figure 25). If the

paper is placed incorrectly (Figure 26), the printer will act like

it is printing, but no text will appear on the paper.

5. Place the newly cut squared edge of the paper into the back

side of the black rubber roller on the printer. The printer

should automatically advance—pulling the paper through

the printer.

6. Place the cover back on and turn the latch to secure.

The thermo printer paper can be ordered from Daktronics—part

# SF-1034. Thermo printer paper is also readily available at

office supply stores (58mm wide and 165' long max).

3.4 Startup

When the OmniSport 2000 timer is initially powered up, the LCDs appear as shown below.

If the timing console includes a radio, read Section 3.5. If the console does not, skip ahead to

Section 3.6 on how to receive software updates from Daktronics. For further explanations on

rodeo timing console operations, refer to Section 3.

16 General Console Features & Operation

Page 25

3.5 Setting Radio Channels on Wireless Consoles

Reference Drawings:

Channel Selection; Multiple Broadcast Group, Gen IV .......................... Drawing A-203113

Installation Details, Gen VI Channel Selection Guide .......................... Drawing A-1109870

The radio receiver units used in Daktronics scoreboards have a channel (CHAN) switch that

can be set from 1–8. The receivers also have a broadcast group (BCAST) setting. The

broadcast group defines a group of radio receivers that “listen” to the channel selected on the

channel switch as well as “listen” for data sent out on their broadcast channel.

Note: The number of available broadcast groups varies depending on the generation of

radio receiver: Gen V radio receivers have 1–4, while Gen VI radio receivers have 1–8.

Each radio receiver will accept data sent from the broadcast channel of its respective

broadcast group, as well as data sent from the “Master Broadcast” channel. This is selected

when the console is set to BCAST 0 and CHAN 00.

In this type of system, the receiver unit at the scoreboard must have the channel switch set to

a specific channel. The operator must know which channel is selected in the scoreboard. The

operator must then enter the specific channel when prompted during console startup.

To determine the settings of a scoreboard, first power it down and shut off any radioequipped consoles in the area. Next, power the scoreboard back up and watch for the radio

settings. The settings will appear as “bX CY” where X is the current broadcast group and Y is

the current channel.

The console automatically detects when a radio transmitter is installed and will prompt the

user for transmitter settings after powering on the console.

Note: If interference from a nearby Daktronics system is suspected, press <CLEAR> at

the “RADIO SETTINGS” prompt to change the channel number.

There are three different radio scenarios that can be accommodated: a single controller

system, a multiple controller system with a single broadcast group, and a multiple controller

system with multiple broadcast groups. These scenarios are described below.

Single Controller Systems Channel Setting

In a single controller system, all radio receivers and all scoreboards receive signal from the

same console at all times. The default channel and broadcast group settings on the receiver

are not typically modified. This is the most common setup.

Typically all single controller systems will use the default setting of BCAST=1, Chan= 1.

All radio receivers in the system must be set to the same values.

Multiple Controller with Single Broadcast Group Channel Setting

In a multiple controller system with a single broadcast group, there may be one console for

each scoreboard and/or one master controller that can run every scoreboard at one time or

take control of a specific scoreboard.

General Console Features & Operation 17

Page 26

Display

Action

The LCD will toggle between

these 2 screens.

The LCD shows the current radio settings along with a prompt

to accept or modify these values.

If the radio settings are correct press [ENTER].

If these values are incorrect press [CLEAR], and the LCD at

bottom left is shown, allowing edit of the channel or broadcast

group setting.

Use the number keypad to enter the desired broadcast group

and press [ENTER] to accept. The asterisk will move to the

channel setting.

Edit the channel number to the desired value and press

[ENTER] to accept.

Broadcast

Group

Channel

Setting

Control Scoreboards

0

0

All Scoreboards

1

0

All in BCAST Group 1

1-8

Set to corresponding BCAST 1

Channel

8*

0

All in BCAST Group 8

1-8

Set to corresponding BCAST 8

Channel

* Gen V radio receivers have only 4 groups; also, on broadcast

groups 2 and 4, only channels 1-4 may be used.

EN T ER TO AC CEPT

CL E AR TO MO DI FY

BC A ST GROUP 1*

RA D I O CHAN 01

RA D I O SETT I NGS

BC A ST X C H AN YY

Multiple controller systems typically use Broadcast 1 and Channel 1 for the first controller

and Channels 2-8 for all remaining controllers. All radio receivers in the system must be set to

Broadcast 1 (BCAST 1).

Multiple Controller with Multiple Broadcast Systems Channel Setting

In a multiple controller system with multiple broadcast groups, there are many consoles that

control multiple scoreboards and/or scoreboard groups. The radio receiver inside the

scoreboard is set to broadcast group 1–4 (Gen V) or 1–8 (Gen VI). By changing the console

settings to the specific broadcast group address, a single console can control all scoreboards

or specific groups of scoreboards.

Typically, all multiple controller systems will use BCAST 1, CHAN 1 for the first controller in

Broadcast Group 1 and BCAST 2, CHAN 1 for the first controller in Broadcast Group 2. All

other consoles in a group are added sequentially.

Basic Operation of Radio Settings

18 General Console Features & Operation

Page 27

Figure 27: DakLoader2 Main Screen

Figure 28: Download Latest Hex Files

3.6 Updating Software in the Console

Equipment needed:

OmniSport 2000 timing console

9-pin male to 9-pin female cable, Daktronics part # W-1267 (in maintenance kit) or Radio

Shack part # 27-117

Computer with an available serial (COM) port; or a USB-to-serial adapter

Computer with Internet connection

To update the OmniSport 2000 timer:

1. Connect the 9-pin serial cable from the COM port of the computer to the J4 EXPANSION

PORT on the console, and then power on the console

2. Open an Internet browser and go to:

http://dakfiles.daktronics.com/download

s/Sports_Products/OmniSport%202000/Ti

mer/DakLoader2.exe

3. A prompt will appear on asking to Run or

Save the program. Click Run (twice if

necessary). The DakLoader2 program

should open (Figure 27).

4. Go to File > Hex Files and click Download

Latest Hex Files (Figure 28).

5. Click Communications and select the

COM port that the 9-pin serial cable is

currently connected to.

6. On the main screen, click Rodeo, and then

click Update.

7. Turn the OmniSport 2000 console OFF and then back ON. After cycling power, the

console should automatically begin programming the hex file selected.

Note: To review DakLoader2 Instructions, go to About > Help using DakLoader2.

To confirm system status or for more information from Daktronics, go to About > About

DakLoader2.

General Console Features & Operation 19

Page 28

Page 29

LE A D# 1262/1 1 .47

CURRENT# 169

: 0.0 0 OK

MA N UAL T I MI N G J1

1 TI MER H=:25

LE A D# 1262/1 1 .47

CURRENT# 169

: 0.0 0 OK

: 0.0 0 : 0 . 00

MA N UAL T I MI N G J1

2 TI MERS H = :25

LE A D# 1262/1 1 .47

CURRENT# 169

: 0.0 0 : 0 . 00

: 0.0 0 : 0 . 00

MA N UAL T I MI N G J1

3 TI MERS H = :25

Section 4: Rodeo Timer Operations

Reference Drawings:

Rodeo Photocell Interface Connector Assignments............................................ Drawing A-147806

Insert, 0L-212281, OmniSport 2000 Rodeo Timer .............................................. Drawing B-212381

System Riser Diagram; OmniSport 2000 Rodeo setup....................................... Drawing B-220003

4.1 General Rodeo Timer Information

The OmniSport 2000 Timer can be used in four separate modes of operation. Three of the four

modes can be used with an external timer using wireless photocells.

Manual Timing Mode

Manual Timing mode is used for events where a competitor’s time determines the place

winner. Timing inputs are one, two or three manual pushbuttons connected to the Daktronics

photocell interface. Examples of timed events using timer buttons are steer wrestling, calf

roping, and team roping. Press [1 TIMER], [2 TIMER], or [3 TIMER] to select Manual

Timing mode with the appropriate number of timer button inputs.

When in Manual Timing mode:

The left LCD shows the leader number and time along with the current (now up) number.

The center LCD shows the official timer (T) along with each timer value (1, 2, or 3). With

1 or 2 TIMER selected, photocell status is also visible. Refer to the table on the following

page for descriptions of possible photocell statuses.

The right LCD shows the default horn time (H), the current number of timers selected,

and the judges’ console status (J1 or J? if not properly connected/communicating). For

more information about judge’s console operation, refer to Section 6.

Manual Timing 1 Button:

Manual Timing 2 Buttons:

Manual Timing 3 Buttons:

Rodeo Timer Operations 21

Page 30

LCD Indicator

Photocell Status

OK

Photocells are aligned (Normally Closed).

Photocells are not aligned (Normally Open).

--

Photocells are not aligned (Normally Closed).

Photocells are aligned (Normally Open).

XX

Photocell beam was broken. XX equals the number of seconds remaining

for the arming time (time until next break will be accepted).

OFF

Photocells are disabled. If photocells will not be uses for timing an event,

disable them by pressing [ENABLE/DISABLE PHOTOCELL].

LE A D# 1262/1 1 .47

CURRENT# 169

: 0.0 0

: 0.0 0 OK

AU T O TI MI N G J1

H= : MAN

LE A D# 1262/ 89.0

CURRENT# 169

SC O RE 85.0

: 0.0 0 { H= : 8

J1 = 22.0 J2=23.0

J3 = 20.0 J4=20.0

Automatic Timing Mode

Automatic Timing mode is used for events where a photocell pair is used to time

competitors. An example of an event using automatic timing is barrel racing.

Press [AUTO TIMING] to select the Automatic Timing mode.

When in Automatic Timing mode:

The left LCD shows the leader number and time along with the current (now up) number.

The center LCD shows the official timer (T), including penalty times, along with the

photocell time and status (C). Refer to the table below for descriptions of possible

photocell statuses.

The right LCD shows the default horn time (H) as “MAN” for manual and the judges’

console status (J1 or J? if not properly connected/communicating). For more information

about judge’s console operation for entering penalties, refer to Section 6.

Scored Events

Scored Events mode is used for events where a competitor’s score determines the place

winner. Examples of scored events are bull riding, saddle bronc, and bareback. Press

[SCORED EVENTS] to select the Scored Events mode.

When in Scored Events mode:

The left LCD shows the leader number and score along with the current (now up) number.

The center LCD shows the current score, the official timer (T), the timer direction ({ or }),

and the default horn time (H).

The right LCD shows the scores from each configured judge console (up to 4 total).

For more information about judge’s console operation, refer to Section 6.

Note: If a judge console is not properly connected/communicating, a “?” will be next to it.

22 Rodeo Timer Operations

Page 31

LE A D# 1262/1 8 5.0

CURRENT# 169

CU T TI NG 18 5 .0

2:30.00} H=2: 3 0

J1 = 60.0 J2=62.0

J3 = 63.0 OK

LE A D# 1262/1 1 .47

CURRENT# 169

: 0.0 0 0 --

EX T ERN T I MI N G J1

1 TI MER H=:25

LE A D# 1262/1 1 .47

CURRENT# 169

: 0.0 0 0

: 0.0 0 0 --

AU T O TI MI N G J1

EX T TI ME

LEAD# 1262/185.0

CURRENT# 169

CU T TI NG 18 5 .0

: 0.00} EXT E RN

J1 = 60.0 J2=62.0

J3 = 63.0 --

Cutting

The Cutting mode is a scored event, but it uses a different score entry and calculation.

Press [CUTTING] to select the Cutting mode.

When in Cutting mode:

The left LCD shows the leader number and score along with the current (now up) number.

The center LCD shows the current score, the official timer (T), the timer direction ({ or }),

and the default horn time (H).

The right LCD shows the scores from each configured judge console and the photocell

status (C). Refer to the table on the previous page for descriptions of possible photocell

statuses. For more information about judge’s console operation, refer to Section 6.

Note: If a judge console is not properly connected/communicating, a “?” will be next to it.

External Timing

External Timing can be selected for Manual Timing, Automatic Timing, and Cutting modes.

The external setting is needed when using wireless photocells (refer to Section 2.1).

The information shown on each LCD changes slightly for all timing modes to indicate

External Timing is selected.

External Manual Timing 1 Button:

External Automatic Timing:

External Cutting:

Note: When set to External Timing, the photocell status (C) will always be “- -” (Normally

Closed) or “OK” (Normally Open), whether the photocells are in alignment or not. This is

because the status is not passed from the external timer to the OmniSport console.

Rodeo Timer Operations 23

Page 32

Display

Action

NNNN = current setting

Press [LEADER NUMBER], enter the current leader number

using the number keypad, and then press [ENTER].

Display

Action

MM:SS.TH = minutes, seconds,

tenths, hundredths

NNN.N = current setting

Timed Events Mode

Press [LEADER TIME/SCORE], enter the current leader time

using the number keypad, and then press [ENTER].

Scored Events Mode

Press [LEADER TIME/SCORE], enter the current leader score

using the number keypad, and then press [ENTER].

Display

Action

NNNN = current setting

Press [NOW UP NUMBER], enter the current competitor

number using the number keypad, and then press [ENTER].

LE A DER N U MBER

NN N N *

LE A DER T I ME

MM:SS.TH *

LE A DER S C ORE

NN N .N *

NO W UP NUM B ER

NN N N *

4.2 Rodeo Keys

The keys described below are functional for scored and timed events, except where noted.

Information entry prompts for these keys is shown on the right LCD.

Leader Number

Leader Time/Score

Now Up Number

24 Rodeo Timer Operations

Page 33

Display

Action

MM:SS.TH = minutes, seconds,

tenths, hundredths

XXXX = now up number

NNN.N = current score

Timed Events Mode

Press [NOW UP TIME/SCORE], enter the current competitor

time using the number keypad, and then press [ENTER].

Note: This key is disabled in Automating Timing mode.

Scored Events Mode

Press [NOW UP TIME/SCORE], enter the current competitor

score using the number keypad, and then press [ENTER].

Note: To edit the current competitor number, press the up

arrow. Enter the current competitor time using the number

keypad, and then press [ENTER] or the down arrow.

Display

Action

MM:SS.TH = minutes, seconds,

tenths

NNN.N = current setting

Timed Events Mode

Press [BUBBLE TIME/SCORE], enter the bubble time using

the number keypad, and then press [ENTER].

Scored Events Mode

Press [BUBBLE TIME/SCORE], enter the bubble score using

the number keypad, and then press [ENTER].

Display

Action

N = current setting

Press [CATTLE NUMBER], enter the current cattle number

using the number keypad, and then press [ENTER]. The

number will display on the seconds X1 clock digit when the

clock is started, for five seconds.

Entering a blank number will disable the cattle number. Press

[CLEAR] followed by [ENTER] to blank the cattle number.

Note: Cattle number is used for team penning and is only

functional in manual timing modes

BU B BLE T I ME

MM:SS.T *

BU B BLE S C ORE

NN N .N *

CA T TLE N U MBER

N*

NO W UP TI M E

MM:SS.TH *

NO W UP XXX X

SC O RE NNN.N *

Now Up Time/Score

Bubble Time/Score

Cattle Number

Rodeo Timer Operations 25

Page 34

Copy Now Up to Leader

Press [COPY NOW UP TO LEADER] to copy the Now Up number and time/score to the

current leader values. This key could be used when the current competitor has become the

new leader.

Clear Now Up

Press [CLEAR NOW UP] to clear the Now Up number and time/score values on the

scoreboard. This can be used at the end of a run.

Clear Previous

Press [CLEAR PREVIOUS] to clear out the previous competitor number and time/score in

the Real-Time Data (RTD) stream.

Clear Display

Press [CLEAR DISPLAY] to clear all scoreboard items. This can be used at the end of an event.

Reride

Press [RERIDE] to toggle the reride caption/indicator on or off. The reride status quickly

displays on the right LCD.

No Time — No Score

Press [NO TIME — NO SCORE] to display “NO TIME” or “NO SCORE” on the scoreboard

and printout, depending on the current console mode of operation.

Start

Press [START] to start the main timer. In Timed Events mode, all timers start simultaneously.

Stop

Press [STOP] to stop the main timer. In Timed Events mode, all timers stop simultaneously.

Reset

Press [RESET] to set the timer values to their original value. If any timers are currently

running, press [ENTER] to confirm the reset.

Note: If the timer is set to count down (Scored Events mode), the timer will be reset to

the default horn time. In all other cases, the timer or timers will be reset to 0.

26 Rodeo Timer Operations

Page 35

Display

Action

Press [AUTO HORN] followed by a number key:

Press [1] to enable auto horn. The horn will sound when

the default horn time is reached.

Press [2] to disable auto horn. The horn will sound only

when [HORN] is pressed.

Note: Auto horn is always disabled in Automatic Timing mode.

Display

Action

MM:SS = minutes, seconds

Press [SET DEFAULT HORN TIME], enter the time to elapse

before the main horn sounds, and then press [ENTER].

Set the Warning Horn Time as desired (for Cutting and Penning)

and then press [ENTER].

The default horn time will be shown on the main LCD screen.

Note: In Automatic Timing mode, the horn time will show

“MAN” for Manual (the horn only sounds by pressing [HORN]).

In Scored Events mode, the timer will automatically stop when the

default horn time is reached.

Scored and Timed Events modes have separate horn times, and

these values are saved when the console is powered down.

SE T DE F AULT HORN

TI ME M M :SS *

AU T O HO RN- ON

SEL- 1=ON 2=O F F

Auto Horn

Horn

Press [HORN] to manually sound the horn.

Set Default Horn Time

Rodeo Timer Operations 27

Scoreboard On/Off

Press [SCOREBOARD ON/OFF] to quickly toggle the scoreboard output on or off.

Paper

Press [PAPER] to advance the printer paper by one line.

Page 36

Display

Action

External timing mode is required for receiving times from a

wireless photocell system.

Press [EXTERNAL TIMING] followed by a number key:

Press [1] to enable external timing.

Press [2] to disable external timing.

Note: External timing is always disabled in Scored Events.

EX T ERN T I ME- OFF

SEL- 1=ON 2=O F F

External Timing

Menu

Press [MENU] to access various timer settings. Refer to Section 5 for more information.

4.3 Timed Events Keys

Press any of the following timer keys to select a Timed Events mode.

Auto Timing

Press [AUTO TIMING] to select the Automatic Timing mode with photocells.

1 Timer

Press [1 TIMER] to select the Manual Timing mode with one start/stop button timer. The

start and stop for the official timer will be taken from the photocells.

2 Timers

Press [2 TIMERS] to select the Manual Timing mode with two start/stop button timers.

3 Timers

Press [3 TIMERS] to select the Manual Timing mode with three start/stop button timers.

28 Rodeo Timer Operations

Page 37

Display

Action

MM:SS = minutes, seconds,

tenths, hundredths

Press [SET TIMER 1/PHOTOCELL], [SET TIMER 2], or [SET

TIMER 3] to modify the final timer values after a run has been

completed. Enter the desired time using the number keypad,

and then press [ENTER].

Notes:

In Automatic Timing mode, press [SET TIMER 1/

PHOTOCELL] at the completion of a run to modify the

photocell time for the run.

Set Timer keys are enabled only at the end of a run.

Results are sent after each timer value is edited.

The time value set using the Set Timer keys does not

include the penalty time. Press [PENALTY] to set or

modify the penalty time for a run.

Display

Action

MM:SS = minutes, seconds

Press [PENALTY] after a run has been completed, enter the

penalty time using the number keypad, and then press

[ENTER]. The penalty time is added to the current official timer.

The PENALTY caption/indicator will also turn on.

Pressing [PENALTY] a second time clears the penalty time for

the current competitor, restores the official timer to its original

value, and turns off the penalty caption/indicator.

Notes:

[PENALTY] is only enabled after the official timer is set

(individual timers are stopped).

Penalty times are cleared after pressing [RESET] or

[CLEAR NOW UP].

SE T TI MER 1

MM:SS.TH *

PE N ALTY TI ME

MM : SS *

PE N ALTY - OFF

Set Timer Keys

Enable/Disable Photocell

Press [ENABLE/DISABLE PHOTOCELL] to activate or deactivate the photocell input.

Penalty

Rodeo Timer Operations 29

Rearm Stop

Press [REARM STOP] to undo the last [STOP] key press. All timer values will be restored to

the value they would have displayed if they hadn’t been stopped. Once [RESET] has been

pressed, the timers cannot be restored.

Note: This key can be used to undo an accidental stop from manual timers and photocells.

Page 38

Display

Action

MM:SS = minutes, seconds,

tenths, hundredths

Press [SET TIMER 1/PHOTOCELL] to modify the main clock

value before a run has been started. Enter the desired time

using the number keypad, and then press [ENTER].

Display

Action

Press [COUNT UP/DN] followed by a number key:

Press [1] to set the main clock to count up.

Press [2] to set the main clock to count down.

Note: The direction of the main clock is shown by the arrow

on the center LCD.

Display

Action

N = current value

Press [# OF JUDGES], enter the number of judges using the

number keypad, and then press [ENTER].

Note: The number of judges may only be set to 1, 2, or 4 for

Scored Events or 1, 2, 3, or 5 for Cutting.

SE T TI ME

TI MER MM:S S .TH *

MA I N C L OCK- DOWN

1= U P 2= DOWN

NU M BER O F JU D GES

N*

4.4 Scored Events & Cutting Keys

Press [SCORED EVENTS] to select Scored Events mode.

Press [CUTTING] to select Cutting mode.

Set Main Clock

Count Up/Dn

4.5 Judges Keys

Number of Judges

30 Rodeo Timer Operations

Page 39

Not applicable to Cutting

After setting the number of judges, the console prompts for the

scoring mode. Select one of the following scoring modes by

pressing the corresponding number key:

[1] Combined

The score is entered as a total of the rider and stock combined.

[2] Separate

The score is entered separately for the rider and the stock.

[3] Total/Stock

The score is entered as a total combined score and then the

score for just the stock is entered.

[4] 2 Rider/2 Stock

The rider score is entered by judges 1 and 2 and the stock

score is entered by judges 3 and 4. Selecting this mode will

automatically set the number of judges to 4.

Not applicable to Cutting

Select whether to allow half-point scoring:

Press [1] to allow half points.

Press [2] to not allow half points.

Press [ENTER] to accept the selection.

Select the Auto Score setting:

Press [1] to let the console automatically accept the

total score after all judges’ scores are entered.

Press [2] to make the operator manually accept the

total score after all judges’ scores are entered.

Press [ENTER] to accept the selection.

Display

Action

NNN.N = current setting

Press [EDIT JUDGES SCORES] to edit each of the judge’s

scores. This function may be used if incorrect scores are

received or if the remote judges’ consoles are not connected.

Enter the desired score for the first judge using the number

keypad, and then press [ENTER]. Repeat for all remaining

judges. Pressing [ENTER] without entering a score will leave

the score as is and advance to the next judge score.

Press [CLEAR] at any time to abort the edit of scores.

SC O RI NG MO D E 1- C OMBI N E D

SC O RI NG MO D E 2- SEPARATE

SC O RI NG MODE3- TOTAL/STOCK

SC O RI NG MO D E 4- 2 RI DE R/2ST O CK

HA L F PO I NT S - YES

1= Y ES 2=NO

AU T O SC ORE- NO

1= Y ES 2=NO

ED I T S C ORE

JU D GE 1: NN N.N*

Edit Judges Score

Rodeo Timer Operations 31

Page 40

Display

Action

Press [ACCEPT JUDGES SCORES] when all judges’ scores

have been received. This will tally and display the total score.

Note: It is not necessary to press this key if the Auto Score

setting is enabled.

If not all scores have been received before pressing this key, a

message will display on the right LCD stating so.

Display

Action

Press [RESET JUDGES] after one or more judges’ scores

have been received, then press [ENTER] to reset all scores, or

press [CLEAR] to cancel.

Note: With Auto Score enabled, this key must be pressed

before all scores are entered or it is not possible to reset

them. Similarly, if [ACCEPT JUDGES SCORES] has

already been pressed, this key will not function.

JU D GE SCORES

AR E NO T EN T ERED

RE S ET JUDGE

SC O RI NG Y/ N ?

Accept Judges Score

Reset Judges

Enable Judges Consoles

Press [ENABLE JUDGES CONSOLES] to re-enable the judges’ consoles. This would be done

if the scores have been accepted and a correction needs to be made from the judge's consoles.

32 Rodeo Timer Operations

Page 41

MENU-M A I N

1- S CBD M E NU

MENU-SCOREBOARD

1- SCBD ON/OFF

[1] SCBD MENU

[11] SCBD ON/OFF

[12] SCORE DISPLAY

[13] DIMMING

[2] PRINT MENU

[21] LOGGING

[22] INTENSITY

[3] SETUP MENU

[31] TIMER

[311] TIMER PREC

[312] TIMER MODE

[313] BEEPER

[314] BEEP VOLUME

[315] HALF POINTS

[316] HORN

[317] JUDGE START

[32] PHOTOCELL

[321] PCELL PREC

[322] PCELL ARMING

[323] PCELL SWITCH

[33] NETWORK

[331] NETWORK ENABLE

[332] MAC ADDRESS

[333] IP ADDRESS

[334] SUBNET MASK

[335] GATEWAY ADDRES

[336] SOCKET NUMBER

[4] TEST MENU

[41] BATTERY

[42] SCOREBOARD

[421] CYCLE ON/OFF

Main Menu screen

From Main Menu – [1] or [ENTER]

From Main Menu – [1]>[1]

SC B D I S - ON

1= O N 2= OFF

Section 5: Rodeo Menus & Settings

5.1 Menu Navigation

Press [MENU] to access the Main Menu screen. There are

two methods of navigating through the OmniSport menus.

The first method allows the operator to step through each of the menu levels. To use this

method, press [MENU] and then use [←], [→], [↑], and [↓] to scroll through the menus.

Press [ENTER] to select the menu item displayed on the LCD.

The second method is to go directly to a menu. Press [MENU] immediately followed by the

one- to three-digit number from the list below, and the LCD will prompt for the desired setting

or action in that menu. For example, 322 will prompt to enter the photocell arming delay.

When finished navigating the menus and adjusting the desired settings, press [MENU] to exit.

Each menu setting is described in detail in the following sections.

5.2 Scoreboard Menu

Rodeo Menus & Settings 33

The Scoreboard Menu is where the operator can turn the

scoreboard output ON or OFF, select score display, and set

the dimming (brightness) level.

Scoreboard ON/OFF

This menu is used to toggle the scoreboard output ON/OFF.

Page 42

MENU-SCOREBOARD

2- S CORE DI SPLAY

MENU-SCOREBOARD

3- D I MM I NG

Dimming Levels:

0 = NONE (full bright)

1 = 90%

2 = 80%

3 = 70%

4 = 60%

5 = 50%

6 = 40%

7 = 30%

8 = 20%

9 = 10% (dimmest)

From Main Menu – [1]>[2]

SC O RE DI SP = ON

1= O N 2= OFF

From Main Menu – [1]>[3]

LEVEL(0-9):

3- D I MM I NG N ONE

Press [1] to set the scoreboard output ON. Press [ENTER] to save.

Press [2] to set the scoreboard output OFF. Press [ENTER] to save. The scoreboard will

be blank until: the start of the next event, [RESET] is pressed to re-display data of the

last event, the scoreboard is turned back ON in the menu, or [SCOREBOARD ON/OFF]

is pressed.

When to use this:

The scoreboard is displaying false information due to equipment or operator error and

needs to be blanked.

The error is corrected and the scoreboard output can be turned back on.

Score Display

This menu selects whether to show scores on the scoreboard.

Press [1] to show scores on the scoreboard. Press [ENTER] to save.

Press [2] to not show scores on the scoreboard. Press [ENTER] to save.

When to use this:

There’s only enough room on the scoreboard to show either time or score at one time, and

time is the preferred information to show.

Dimming

This menu is used to adjust the scoreboard dimming

(brightness) level. The dimming setting only applies to

scoreboards configured to receive multi-drop protocol.

Use the number keypad to select one of the values shown in the

table to the right, or use [←][→] to toggle through the levels. To

save the setting, press [ENTER]. To return to the Dimming Menu

without saving, press [CLEAR].

When to use this:

In low light conditions the scoreboard may be too bright.

34 Rodeo Menus & Settings

In direct sunlight the scoreboard may need to be turned

to full bright.

Page 43

MENU-P R I NT E R

1- L OGGI N G

MENU-P R I NT E R

2- I NTE N SI TY

MENU-M A I N

2- P RI NT ME N U

From Main Menu – [2]>[1]

MENU-P R I NT E R

PR I NTE R LO G : ON

From Main Menu – [2]>[1]

PR I NT I NTENSI T Y

LE V EL 1-5: 5*

MENU-T I MER SET U P

1- T I ME R PR E C

From Main Menu – [3]>[1]>[1]

TI MER PREC I SI O N

1- T ENTHS

TI MER PREC I SI O N

2- H UNDRE D THS

MENU-T I MER SET U P

2- T I ME R MO D E