Daikin RXYTQ8U7YF, RXYTQ10U7YF, RXYTQ12U7YF, RXYTQ14U7YF, RXYTQ16U7YF Operation manuals

Installation and operation manual

VRV IV+ heat pump for high ambient temperatures

RXYTQ8U7YF

RXYTQ10U7YF

RXYTQ12U7YF

RXYTQ14U7YF

RXYTQ16U7YF

Installation and operation manual

VRV IV+ heat pump for high ambient temperatures

English

Table of contents

Table of contents

1 About the documentation 3

1.1 About this document.................................................................. 3

2 Specific installer safety instructions 3

For the user 4

3 User safety instructions 4

3.1 General...................................................................................... 5

3.2 Instructions for safe operation ................................................... 5

4 About the system 6

4.1 System layout............................................................................ 7

5 User interface 7

6 Operation 7

6.1 Operation range ........................................................................ 7

6.2 Operating the system ................................................................ 7

6.2.1 About operating the system ........................................ 7

6.2.2 About cooling, heating, fan only, and automatic

operation ..................................................................... 7

6.2.3 About the heating operation........................................ 7

6.2.4 To operate the system (WITHOUT cool/heat

changeover remote control switch) ............................. 7

6.2.5 To operate the system (WITH cool/heat changeover

remote control switch)................................................. 7

6.3 Using the dry program............................................................... 8

6.3.1 About the dry program ................................................ 8

6.3.2 To use the dry program (WITHOUT cool/heat

changeover remote control switch) ............................. 8

6.3.3 To use the dry program (WITH cool/heat changeover

remote control switch)................................................. 8

6.4 Adjusting the air flow direction................................................... 8

6.4.1 About the air flow flap ................................................. 8

6.5 Setting the master user interface .............................................. 9

6.5.1 About setting the master user interface ...................... 9

7 Maintenance and service 9

7.1 About the refrigerant.................................................................. 9

7.2 After-sales service and warranty ............................................... 9

7.2.1 Warranty period .......................................................... 9

7.2.2 Recommended maintenance and inspection.............. 9

8 Troubleshooting 10

8.1 Error codes: Overview............................................................... 10

8.2 Symptoms that are NOT system malfunctions .......................... 11

8.2.1 Symptom: The system does not operate .................... 11

8.2.2 Symptom: Cool/Heat cannot be changed over ........... 11

8.2.3 Symptom: Fan operation is possible, but cooling and

heating do not work..................................................... 11

8.2.4 Symptom: The fan speed does not correspond to the

setting ......................................................................... 11

8.2.5 Symptom: The fan direction does not correspond to

the setting ................................................................... 11

8.2.6 Symptom: White mist comes out of a unit (Indoor

unit) ............................................................................. 11

8.2.7 Symptom: White mist comes out of a unit (Indoor

unit, outdoor unit) ........................................................ 11

8.2.8 Symptom: The user interface reads "U4" or "U5" and

stops, but then restarts after a few minutes ................ 11

8.2.9 Symptom: Noise of air conditioners (Indoor unit)........ 12

8.2.10 Symptom: Noise of air conditioners (Indoor unit,

outdoor unit)................................................................ 12

8.2.11 Symptom: Noise of air conditioners (Outdoor unit) ..... 12

8.2.12 Symptom: Dust comes out of the unit ......................... 12

8.2.13 Symptom: The units can give off odours..................... 12

8.2.14 Symptom: The outdoor unit fan does not spin ............ 12

8.2.15 Symptom: The display shows "88"............................... 12

8.2.16 Symptom: The compressor in the outdoor unit does

not stop after a short heating operation ....................... 12

8.2.17 Symptom: The inside of an outdoor unit is warm

even when the unit has stopped .................................. 12

8.2.18 Symptom: Hot air can be felt when the indoor unit is

stopped ........................................................................ 12

9 Relocation 12

10 Disposal 12

For the installer 12

11 About the box 12

11.1

About ............................................................................ 12

11.2 To remove the accessories from the outdoor unit ...................... 12

11.3 Accessory pipes: Diameters ....................................................... 13

11.4 To remove the transportation stay.............................................. 13

12 About the units and options 13

12.1 About the outdoor unit ................................................................ 13

12.2 System layout ............................................................................. 13

13 Unit installation 13

13.1 Preparing the installation site ..................................................... 13

13.1.1 Installation site requirements of the outdoor unit ......... 13

13.1.2 Additional installation site requirements of the

outdoor unit in cold climates ........................................ 14

13.2 Opening the unit ......................................................................... 14

13.2.1 To open the outdoor unit .............................................. 14

13.2.2 To open the electrical component box of the outdoor

unit ............................................................................... 14

13.3 Mounting the outdoor unit........................................................... 14

13.3.1 To provide the installation structure ............................. 14

14 Piping installation 15

14.1 Preparing refrigerant piping ........................................................ 15

14.1.1 Refrigerant piping requirements................................... 15

14.1.2 To select the piping size .............................................. 15

14.1.3 To select refrigerant branch kits................................... 16

14.1.4 Multiple outdoor units: Possible layouts ....................... 17

14.2 Connecting the refrigerant piping ............................................... 17

14.2.1 To route the refrigerant piping...................................... 17

14.2.2 To connect the refrigerant piping to the outdoor unit ... 18

14.2.3 To connect the multi connection piping kit ................... 18

14.2.4 To connect the refrigerant branching kit ...................... 18

14.2.5 To protect against contamination ................................. 18

14.2.6 Using the stop valve and service port .......................... 18

14.2.7 To remove the spun pipes ........................................... 19

14.3 Checking the refrigerant piping .................................................. 20

14.3.1 About checking the refrigerant piping .......................... 20

14.3.2 Checking refrigerant piping: General guidelines .......... 20

14.3.3 Checking refrigerant piping: Setup............................... 20

14.3.4 To perform a leak test .................................................. 21

14.3.5 To perform vacuum drying ........................................... 21

14.3.6 To insulate the refrigerant piping ................................. 21

14.4 Charging refrigerant ................................................................... 21

14.4.1 Precautions when charging refrigerant ........................ 21

14.4.2 About charging refrigerant ........................................... 22

14.4.3 To determine the additional refrigerant amount ........... 22

14.4.4 To charge refrigerant: Flow chart ................................. 23

14.4.5 To charge refrigerant ................................................... 24

14.4.6 Step 6: To manually charge refrigerant........................ 25

14.4.7 Error codes when charging refrigerant......................... 25

14.4.8 Checks after charging refrigerant................................. 25

15 Electrical installation 26

15.1 Safety device requirements ........................................................ 26

15.2 Field wiring: Overview ................................................................ 26

Installation and operation manual

2

VRV IV+ heat pump for high ambient temperatures

RXYTQ8~16U7YF

4P546223-1B – 2020.10

1 About the documentation

15.3 To route and fix the transmission wiring .................................... 26

15.4 To connect the transmission wiring ........................................... 27

15.5 To finish the transmission wiring ............................................... 27

15.6 To route and fix the power supply ............................................. 27

15.7 To connect the power supply .................................................... 28

15.8 To check the insulation resistance of the compressor .............. 28

16 Configuration 28

16.1 Making field settings .................................................................. 28

16.1.1 About making field settings ......................................... 28

16.1.2 Field setting components ............................................ 29

16.1.3 To access the field setting components ...................... 29

16.1.4 To access mode 1 or 2 ............................................... 29

16.1.5 To use mode 1 ............................................................ 30

16.1.6 To use mode 2 ............................................................ 30

16.1.7 Mode 1: Monitoring settings ........................................ 30

16.1.8 Mode 2: Field settings ................................................. 30

16.1.9 To connect the PC configurator to the outdoor unit .... 31

17 Commissioning 31

17.1 Precautions when commissioning ............................................. 31

17.2 Checklist before commissioning ................................................ 31

17.3 About the test run ...................................................................... 32

17.4 To perform a test run ................................................................. 32

17.5 Correcting after abnormal completion of the test run ................ 33

18 Hand-over to the user 33

19 Troubleshooting 33

19.1 Solving problems based on error codes .................................... 33

19.2 Error codes: Overview ............................................................... 33

20 Technical data 36

20.1 Service space: Outdoor unit ...................................................... 36

20.2 Piping diagram: Outdoor unit..................................................... 38

20.3 Wiring diagram: Outdoor unit .................................................... 38

21 Disposal 40

▪ Installer and user reference guide:

▪ Preparation of the installation, reference data,…

▪ Detailed step-by-step instructions and background information

for basic and advanced usage

▪ Format: Digital files on http://www.daikineurope.com/support-

and-manuals/product-information/

Latest revisions of the supplied documentation may be available on

the regional Daikin website or via your dealer.

The original documentation is written in English. All other languages

are translations.

Technical engineering data

▪ A subset of the latest technical data is available on the regional

Daikin website (publicly accessible).

▪ The full set of latest technical data is available on the Daikin

Business Portal (authentication required).

2 Specific installer safety

instructions

Always observe the following safety instructions and regulations.

WARNING

Tear apart and throw away plastic packaging bags so that

nobody, especially children, can play with them. Possible

risk: suffocation.

CAUTION

Appliance not accessible to the general public, install it in a

secured area, protected from easy access.

This unit, both indoor and outdoor, is suitable for

installation in a commercial and light industrial

environment.

1 About the documentation

1.1 About this document

Target audience

Authorised installers + end users

INFORMATION

This appliance is intended to be used by expert or trained

users in shops, in light industry and on farms, or for

commercial use by lay persons.

Documentation set

This document is part of a documentation set. The complete set

consists of:

▪ General safety precautions:

▪ Safety instructions that you must read before installing

▪ Format: Paper (in the box of the outdoor unit)

▪ Outdoor unit installation and operation manual:

▪ Installation and operation instructions

▪ Format: Paper (in the box of the outdoor unit)

CAUTION

Excessive refrigerant concentrations in a closed room can

lead to oxygen deficiency.

DANGER: RISK OF ELECTROCUTION

Do NOT leave the unit unattended when the service cover

is removed.

DANGER: RISK OF BURNING/SCALDING

DANGER: RISK OF ELECTROCUTION

WARNING

Take sufficient precautions in case of refrigerant leakage. If

refrigerant gas leaks, ventilate the area immediately.

Possible risks:

▪ Excessive refrigerant concentrations in a closed room

can lead to oxygen deficiency.

▪ Toxic gas might be produced if refrigerant gas comes

into contact with fire.

WARNING

ALWAYS recover the refrigerant. Do NOT release them

directly into the environment. Use a vacuum pump to

evacuate the installation.

RXYTQ8~16U7YF

VRV IV+ heat pump for high ambient temperatures

4P546223-1B – 2020.10

Installation and operation manual

3

3 User safety instructions

WARNING

During tests, NEVER pressurize the product with a

pressure higher than the maximum allowable pressure (as

indicated on the nameplate of the unit).

CAUTION

Do not vent gases into the atmosphere.

WARNING

Any gas or oil remaining inside the stop valve may blow off

the spun piping.

If these instructions are NOT followed correctly it may

result in property damage or personal injury, which may be

serious depending on the circumstances.

WARNING

NEVER remove the spun piping by brazing.

Any gas or oil remaining inside the stop valve may blow off

the spun piping.

WARNING

▪ ONLY use R410A as refrigerant. Other substances

may cause explosions and accidents.

▪ R410A contains fluorinated greenhouse gases. Its

global warming potential (GWP) value is 2087.5. Do

NOT vent these gases into the atmosphere.

▪ When charging refrigerant, ALWAYS use protective

gloves and safety glasses.

CAUTION

Do NOT push or place redundant cable length in the unit.

WARNING

▪ If the power supply has a missing or wrong N-phase,

equipment might break down.

▪ Establish proper earthing. Do NOT earth the unit to a

utility pipe, surge absorber, or telephone earth.

Incomplete earthing may cause electrical shock.

▪ Install the required fuses or circuit breakers.

▪ Secure the electrical wiring with cable ties so that the

cables do NOT come in contact with sharp edges or

piping, particularly on the high-pressure side.

▪ Do NOT use taped wires, stranded conductor wires,

extension cords, or connections from a star system.

They can cause overheating, electrical shock or fire.

▪ Do NOT install a phase advancing capacitor, because

this unit is equipped with an inverter. A phase

advancing capacitor will reduce performance and may

cause accidents.

WARNING

▪ All wiring MUST be performed by an authorised

electrician and MUST comply with the applicable

legislation.

▪ Make electrical connections to the fixed wiring.

▪ All components procured on-site and all electrical

construction MUST comply with the applicable

legislation.

WARNING

ALWAYS use multicore cable for power supply cables.

CAUTION

▪ When connecting the power supply: connect the earth

cable first, before making the current-carrying

connections.

▪ When disconnecting the power supply: disconnect the

current-carrying cables first, before separating the earth

connection.

▪ The length of the conductors between the power supply

stress relief and the terminal block itself must be as

such that the current-carrying wires are tautened before

the earth wire is in case the power supply is pulled

loose from the stress relief.

CAUTION

Do NOT perform the test operation while working on

the indoor units.

When performing the test operation, NOT only the outdoor

unit, but the connected indoor unit will operate as well.

Working on an indoor unit while performing a test operation

is dangerous.

CAUTION

Do NOT insert fingers, rods or other objects into the air

inlet or outlet. Do NOT remove the fan guard. When the

fan is rotating at high speed, it will cause injury.

For the user

3 User safety instructions

Always observe the following safety instructions and regulations.

Installation and operation manual

4

VRV IV+ heat pump for high ambient temperatures

RXYTQ8~16U7YF

4P546223-1B – 2020.10

3 User safety instructions

3.1 General

WARNING

If you are NOT sure how to operate the

unit, contact your installer.

WARNING

Children aged from 8 years and above

and persons with reduced physical,

sensory or mental capabilities or lack

of experience and knowledge can only

use this appliance if they have been

given supervision or instruction

concerning the use of the appliance by

a person responsible for their safety.

Children MUST NOT play with the

appliance.

Cleaning and user maintenance MUST

NOT be carried out by children without

supervision.

WARNING

To prevent electrical shocks or fire:

▪ Do NOT rinse the unit.

▪ Do NOT operate the unit with wet

hands.

▪ Do NOT place any objects containing

water on the unit.

CAUTION

▪ Batteries are marked with the following symbol:

This means that the batteries may NOT be mixed with unsorted

household waste. If a chemical symbol is printed beneath the

symbol, this chemical symbol means that the battery contains a

heavy metal above a certain concentration.

Possible chemical symbols are: Pb: lead (>0.004%).

Waste batteries must be treated at a specialized treatment facility

for reuse. By ensuring waste batteries are disposed of correctly,

you will help to prevent potential negative consequences for the

environment and human health.

3.2 Instructions for safe operation

CAUTION

▪ NEVER touch the internal parts of the

controller.

▪ Do NOT remove the front panel.

Some parts inside are dangerous to

touch and appliance problems may

happen. For checking and adjusting

the internal parts, contact your

dealer.

CAUTION

Do NOT operate the system when

using a room fumigation-type

insecticide. Chemicals could collect in

the unit, and endanger the health of

people who are hypersensitive to

chemicals.

▪ Do NOT place any objects or

equipment on top of the unit.

▪ Do NOT sit, climb or stand on the

unit.

▪ Units are marked with the following symbol:

This means that electrical and electronic products may NOT be

mixed with unsorted household waste. Do NOT try to dismantle

the system yourself: the dismantling of the system, treatment of

the refrigerant, of oil and of other parts must be done by an

authorized installer and must comply with applicable legislation.

Units must be treated at a specialized treatment facility for reuse,

recycling and recovery. By ensuring this product is disposed of

correctly, you will help to prevent potential negative consequences

for the environment and human health. For more information,

contact your installer or local authority.

CAUTION

It is unhealthy to expose your body to

the air flow for a long time.

CAUTION

To avoid oxygen deficiency, ventilate

the room sufficiently if equipment with

burner is used together with the

system.

WARNING

This unit contains electrical and hot

parts.

WARNING

Before operating the unit, be sure the

installation has been carried out

correctly by an installer.

RXYTQ8~16U7YF

VRV IV+ heat pump for high ambient temperatures

4P546223-1B – 2020.10

Installation and operation manual

5

4 About the system

WARNING

Never touch the air outlet or the

horizontal blades while the swing flap

is in operation. Fingers may become

caught or the unit may break down.

CAUTION

Do NOT insert fingers, rods or other

objects into the air inlet or outlet. Do

NOT remove the fan guard. When the

fan is rotating at high speed, it will

cause injury.

CAUTION: Pay attention to the fan!

It is dangerous to inspect the unit while

the fan is running.

Be sure to turn off the main switch

before executing any maintenance

task.

CAUTION

After a long use, check the unit stand

and fitting for damage. If damaged, the

unit may fall and result in injury.

WARNING

Stop operation and shut off the

power if anything unusual occurs

(burning smells etc.).

Leaving the unit running under such

circumstances may cause breakage,

electric shock or fire. Contact your

dealer.

WARNING

The refrigerant in the system is safe

and normally does not leak. If the

refrigerant leaks in the room, contact

with a fire of a burner, a heater or a

cooker may result in a harmful gas.

Turn off any combustible heating

devices, ventilate the room and contact

the dealer where you purchased the

unit.

Do not use the system until a service

person confirms that the portion where

the refrigerant leaks is repaired.

CAUTION

WARNING

NEVER replace a fuse with a fuse of a

wrong ampere ratings or other wires

when a fuse blows out. Use of wire or

copper wire may cause the unit to

break down or cause a fire.

WARNING

▪ Do NOT modify, disassemble,

remove, reinstall or repair the unit

yourself as incorrect dismantling or

installation may cause an electric

shock or fire. Contact your dealer.

▪ In case of accidental refrigerant

leaks, make sure there are no naked

flames. The refrigerant itself is

entirely safe, non-toxic and noncombustible, but it will generate toxic

gas when it accidentally leaks into a

room where combustible air from fan

heaters, gas cookers, etc. is present.

Always have qualified service

personnel confirm that the point of

leakage has been repaired or

corrected before resuming operation.

NEVER expose little children, plants or

animals directly to the airflow.

CAUTION

Do NOT touch the heat exchanger fins.

These fins are sharp and could result

in cutting injuries.

4 About the system

The indoor unit part of VRV IV heat pump system can be used for

heating/cooling applications. The type of indoor unit which can be

used depends on the outdoor units series.

NOTICE

Do NOT use the system for other purposes. In order to

avoid any quality deterioration, do NOT use the unit for

cooling precision instruments, food, plants, animals, or

works of art.

NOTICE

For future modifications or expansions of your system:

A full overview of allowable combinations (for future

system extensions) is available in technical engineering

data and should be consulted. Contact your installer to

receive more information and professional advice.

Installation and operation manual

6

VRV IV+ heat pump for high ambient temperatures

RXYTQ8~16U7YF

4P546223-1B – 2020.10

5 User interface

a

b

4.1 System layout

5 User interface

CAUTION

▪ NEVER touch the internal parts of the controller.

▪ Do NOT remove the front panel. Some parts inside are

dangerous to touch and appliance problems may

happen. For checking and adjusting the internal parts,

contact your dealer.

This operation manual offers a non-exhaustive overview of the main

functions of the system.

6 Operation

6.1 Operation range

Use the system in the following temperature and humidity ranges for

safe and effective operation.

Cooling Heating

Outdoor temperature –5~52°CDB –20~21°CDB

–20~15.5°C WB

Indoor temperature 21~32°CDB

14~25°C WB

Indoor humidity ≤80%

(a)

To avoid condensation and water dripping out of the unit. If the

temperature or the humidity is beyond these conditions, safety

devices may be put in action and the air conditioner may not

operate.

Above operation range is only valid in case direct expansion indoor

units are connected to the VRV IV system.

Special operation ranges are valid in case of using AHU. They can

be found in the installation/operation manual of the dedicated unit.

Latest information can be found in the technical engineering data.

6.2 Operating the system

6.2.1 About operating the system

▪ Operation procedure varies according to the combination of

outdoor unit and user interface.

▪ To protect the unit, turn on the main power switch 6 hours before

operation.

▪ If the main power supply is turned off during operation, operation

will restart automatically after the power turns back on again.

6.2.2 About cooling, heating, fan only, and automatic operation

▪ Changeover cannot be made with a user interface whose display

shows "change-over under centralised control" (refer to

installation and operation manual of the user interface).

▪ When the display "change-over under centralised control"

flashes, refer to "About setting the master user interface"[49].

▪ The fan may keep on running for about 1 minute after the heating

operation stops.

▪ The air flow rate may adjust itself depending on the room

temperature or the fan may stop immediately. This is not a

malfunction.

15~27°CDB

(a)

6.2.3 About the heating operation

It may take longer to reach the set temperature for general heating

operation than for cooling operation.

The following operation is performed in order to prevent the heating

capacity from dropping or cold air from blowing.

Defrost operation

In heating operation, freezing of the outdoor unit's air cooled coil

increases over time, restricting the energy transfer to the outdoor

unit's coil. Heating capability decreases and the system needs to go

into defrost operation to be able to remove frost from the outdoor

unit’s coil. During defrost operation the heating capacity on the

indoor unit side will temporarily drop until defrosting is completed.

After defrosting, the unit will regain its full heating capacity.

The indoor unit will indicate defrost operation on the display .

Hot start

In order to prevent cold air from blowing out of an indoor unit at the

start of heating operation, the indoor fan is automatically stopped.

The display of the user interface shows . It may take some

time before the fan starts. This is not a malfunction.

6.2.4 To operate the system (WITHOUT cool/ heat changeover remote control switch)

1 Press the operation mode selector button on the user interface

several times and select the operation mode of your choice.

Cooling operation

Heating operation

Fan only operation

2 Press the ON/OFF button on the user interface.

Result: The operation lamp lights up and the system starts

operating.

6.2.5 To operate the system (WITH cool/heat changeover remote control switch)

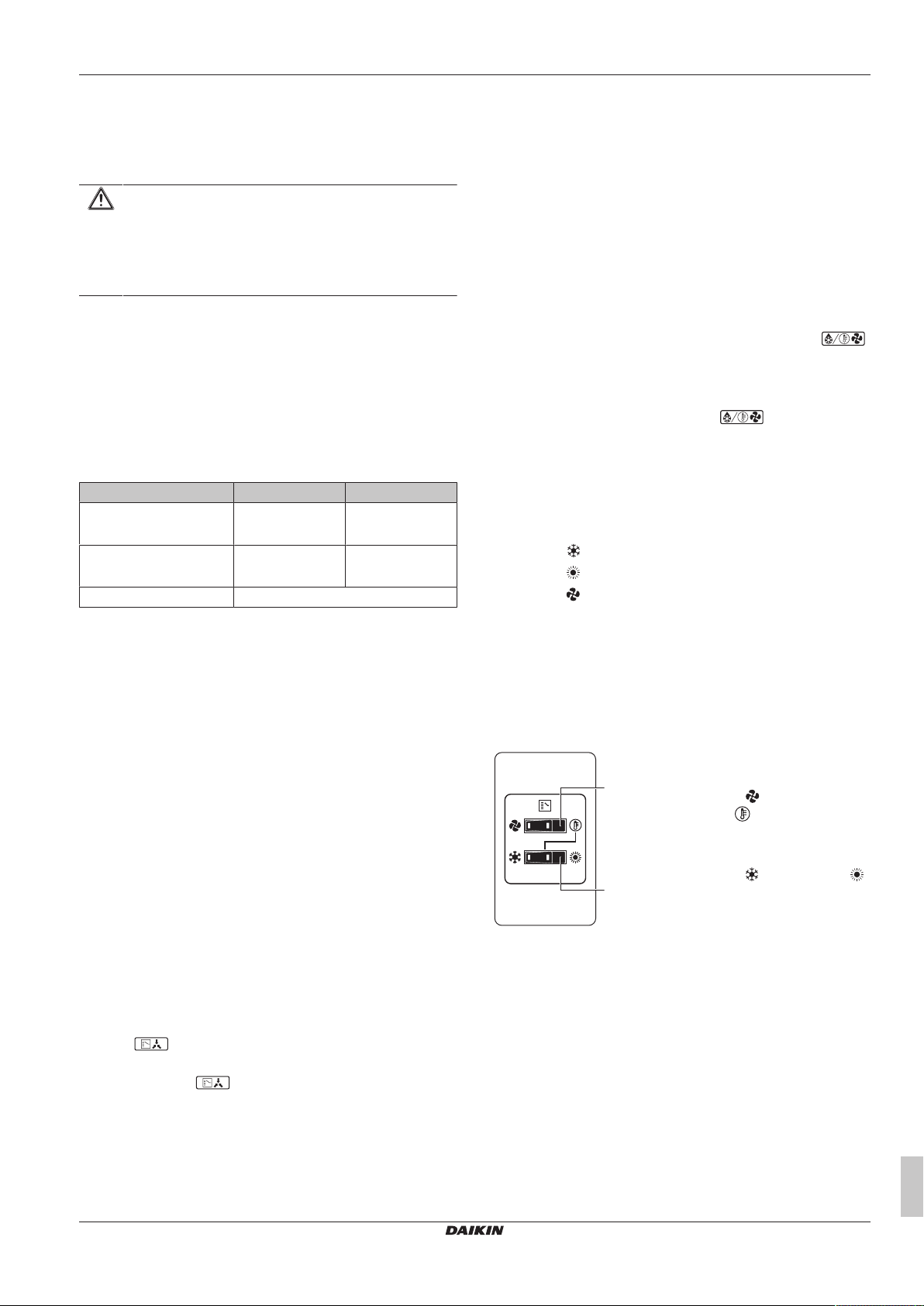

Overview of the changeover remote control switch

a FAN ONLY/AIR CONDITIONING

SELECTOR SWITCH

Set the switch to for fan only

operation or to for heating or

cooling operation.

b COOL/HEAT CHANGEOVER SWITCH

Set the switch to for cooling or to

for heating

Note: In case a cool/heat changeover remote control switch is used,

the position of DIP switch 1 (DS1-1) on the main PCB needs to be

switched to the ON position.

To start

1 Select operation mode with the cool/heat changeover switch as

follows:

RXYTQ8~16U7YF

VRV IV+ heat pump for high ambient temperatures

4P546223-1B – 2020.10

Installation and operation manual

7

6 Operation

1

1

1

1

1

1

1

Cooling operation

2 Press the ON/OFF button on the user interface.

Result: The operation lamp lights up and the system starts

operating.

To stop

3 Press the ON/OFF button on the user interface once again.

Result: The operation lamp goes out and the system stops

operating.

NOTICE

Do not turn off power immediately after the unit stops, but

wait for at least 5 minutes.

To adjust

For programming temperature, fan speed and air flow direction refer

to the operation manual of the user interface.

Heating operation

Fan only operation

6.3 Using the dry program

6.3.3 To use the dry program (WITH cool/heat changeover remote control switch)

To start

1 Select cooling operation mode with the cool/heat changeover

remote control switch.

2 Press the operation mode selector button on the user interface

several times and select (program dry operation).

3 Press the ON/OFF button of the user interface.

Result: The operation lamp lights up and the system starts

operating.

4 Press the air flow direction adjust button (only for double-flow,

multi-flow, corner, ceiling-suspended and wall-mounted). Refer

to "6.4Adjusting the air flow direction"[48] for details.

To stop

5 Press the ON/OFF button on the user interface once again.

Result: The operation lamp goes out and the system stops

operating.

NOTICE

Do not turn off power immediately after the unit stops, but

wait for at least 5 minutes.

6.3.1 About the dry program

▪ The function of this program is to decrease the humidity in your

room with minimal temperature decrease (minimal room cooling).

▪ The micro computer automatically determines temperature and

fan speed (cannot be set by the user interface).

▪ The system does not go into operation if the room temperature is

low (<20°C).

6.3.2 To use the dry program (WITHOUT cool/ heat changeover remote control switch)

To start

1 Press the operation mode selector button on the user interface

several times and select (program dry operation).

2 Press the ON/OFF button of the user interface.

Result: The operation lamp lights up and the system starts

operating.

3 Press the air flow direction adjust button (only for double-flow,

multi-flow, corner, ceiling-suspended and wall-mounted). Refer

to "6.4Adjusting the air flow direction"[48] for details.

To stop

4 Press the ON/OFF button on the user interface once again.

Result: The operation lamp goes out and the system stops

operating.

NOTICE

Do not turn off power immediately after the unit stops, but

wait for at least 5 minutes.

6.4 Adjusting the air flow direction

Refer to the operation manual of the user interface.

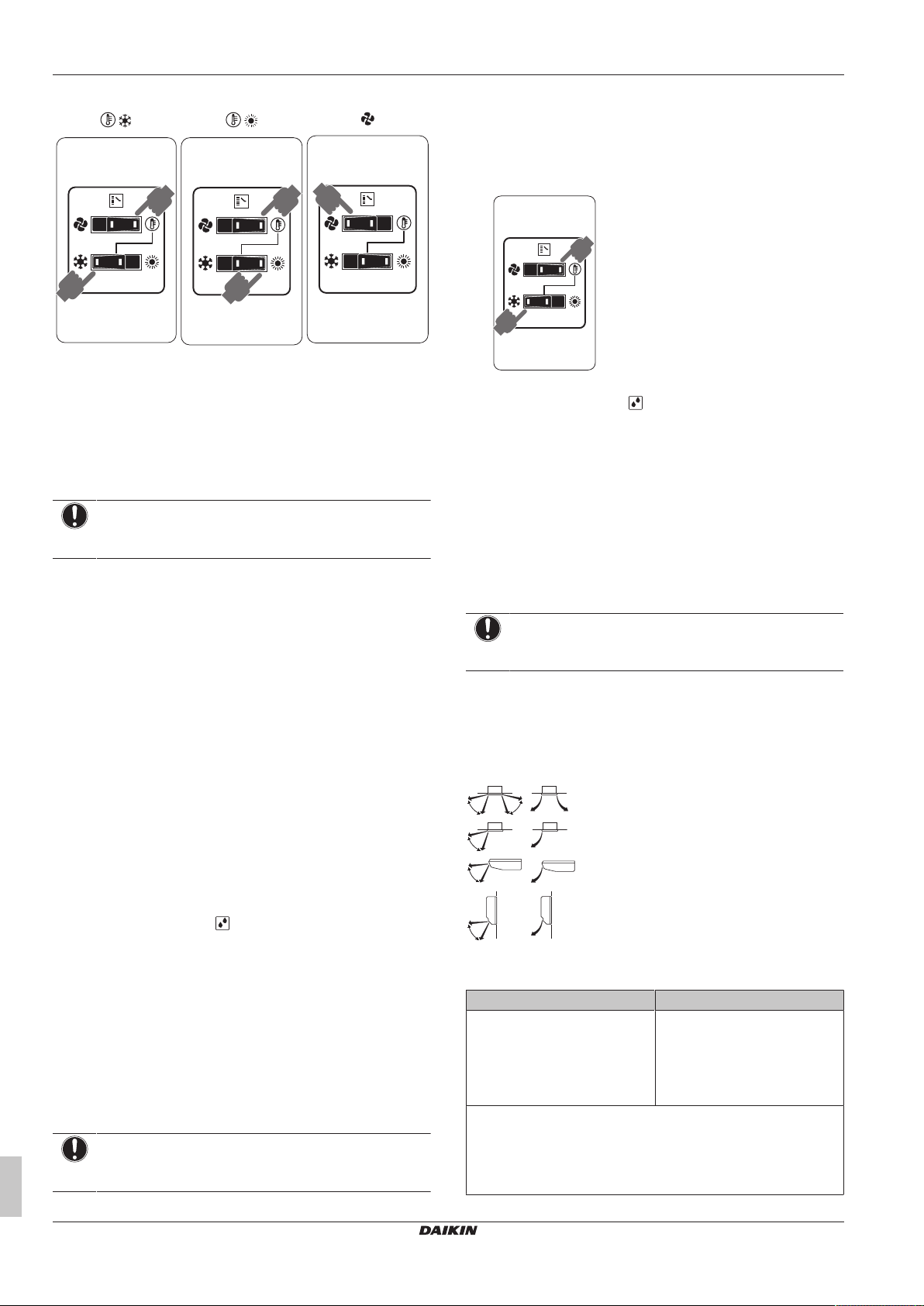

6.4.1 About the air flow flap

Double flow+multi-flow units

Corner units

Ceiling suspended units

Wall-mounted units

For the following conditions, a micro computer controls the air flow

direction which may be different from the display.

Cooling Heating

▪ When the room temperature is

lower than the set

temperature.

▪ When operating continuously at horizontal air flow direction.

▪ When continuous operation with downward air flow is performed

at the time of cooling with a ceiling-suspended or a wall-mounted

unit, the micro computer may control the flow direction, and then

the user interface indication will also change.

▪ When starting operation.

▪ When the room temperature is

higher than the set

temperature.

▪ At defrost operation.

Installation and operation manual

8

VRV IV+ heat pump for high ambient temperatures

RXYTQ8~16U7YF

4P546223-1B – 2020.10

7 Maintenance and service

The air flow direction can be adjusted in one of the following ways:

▪ The air flow flap itself adjusts its position.

▪ The air flow direction can be fixed by the user.

▪ Automatic and desired position .

WARNING

Never touch the air outlet or the horizontal blades while the

swing flap is in operation. Fingers may become caught or

the unit may break down.

NOTICE

▪ The movable limit of the flap is changeable. Contact

your dealer for details. (only for double-flow, multi-flow,

corner, ceiling-suspended and wall-mounted).

▪ Avoid operating in the horizontal direction . It may

cause dew or dust to settle on the ceiling or flap.

6.5 Setting the master user interface

6.5.1 About setting the master user interface

The displays of slave user interfaces show (change-over

under centralised control) and slave user interfaces automatically

follow the operation mode directed by the master user interface.

Only the master user interface can select heating or cooling mode.

7 Maintenance and service

NOTICE

NEVER inspect or service the unit by yourself. Ask a

qualified service person to perform this work.

WARNING

NEVER replace a fuse with a fuse of a wrong ampere

ratings or other wires when a fuse blows out. Use of wire

or copper wire may cause the unit to break down or cause

a fire.

CAUTION

Do NOT insert fingers, rods or other objects into the air

inlet or outlet. Do NOT remove the fan guard. When the

fan is rotating at high speed, it will cause injury.

CAUTION

After a long use, check the unit stand and fitting for

damage. If damaged, the unit may fall and result in injury.

NOTICE

Do NOT wipe the controller operation panel with benzine,

thinner, chemical dust cloth, etc. The panel may get

discoloured or the coating peeled off. If it is heavily dirty,

soak a cloth in water-diluted neutral detergent, squeeze it

well and wipe the panel clean. Wipe it with another dry

cloth.

7.1 About the refrigerant

This product contains fluorinated greenhouse gases. Do NOT vent

gases into the atmosphere.

Refrigerant type: R410A

Global warming potential (GWP) value: 2087.5

NOTICE

Applicable legislation on fluorinated greenhouse gases

requires that the refrigerant charge of the unit is indicated

both in weight and CO2 equivalent.

Formula to calculate the quantity in CO2 equivalent

tonnes: GWP value of the refrigerant × total refrigerant

charge [in kg] / 1000

Please contact your installer for more information.

WARNING

The refrigerant in the system is safe and normally does not

leak. If the refrigerant leaks in the room, contact with a fire

of a burner, a heater or a cooker may result in a harmful

gas.

Turn off any combustible heating devices, ventilate the

room and contact the dealer where you purchased the unit.

Do not use the system until a service person confirms that

the portion where the refrigerant leaks is repaired.

7.2 After-sales service and warranty

7.2.1 Warranty period

▪ This product includes a warranty card that was filled in by the

dealer at the time of installation. The completed card has to be

checked by the customer and stored carefully.

▪ If repairs to the product are necessary within the warranty period,

contact your dealer and keep the warranty card at hand.

7.2.2 Recommended maintenance and inspection

Since dust collects when using the unit for several years,

performance of the unit will deteriorate to some extent. As taking

apart and cleaning interiors of units requires technical expertise and

in order to ensure the best possible maintenance of your units, we

recommend to enter into a maintenance and inspection contract on

top of normal maintenance activities. Our network of dealers has

access to a permanent stock of essential components in order to

keep your unit in operation as long as possible. Contact your dealer

for more information.

When asking your dealer for an intervention, always state:

▪ The complete model name of the unit.

▪ The manufacturing number (stated on the nameplate of the unit).

▪ The installation date.

▪ The symptoms or malfunction, and details of the defect.

WARNING

▪ Do NOT modify, disassemble, remove, reinstall or

repair the unit yourself as incorrect dismantling or

installation may cause an electric shock or fire. Contact

your dealer.

▪ In case of accidental refrigerant leaks, make sure there

are no naked flames. The refrigerant itself is entirely

safe, non-toxic and non-combustible, but it will

generate toxic gas when it accidentally leaks into a

room where combustible air from fan heaters, gas

cookers, etc. is present. Always have qualified service

personnel confirm that the point of leakage has been

repaired or corrected before resuming operation.

RXYTQ8~16U7YF

VRV IV+ heat pump for high ambient temperatures

4P546223-1B – 2020.10

Installation and operation manual

9

8 Troubleshooting

8 Troubleshooting

If one of the following malfunctions occur, take the measures shown

below and contact your dealer.

WARNING

Stop operation and shut off the power if anything

unusual occurs (burning smells etc.).

Leaving the unit running under such circumstances may

cause breakage, electric shock or fire. Contact your dealer.

The system MUST be repaired by a qualified service person.

Malfunction Measure

If a safety device such as a fuse, a

breaker or an earth leakage breaker

frequently actuates or the ON/OFF

switch does NOT properly work.

If water leaks from the unit. Stop the operation.

The operation switch does NOT work

well.

If the user interface display indicates the

unit number, the operation lamp flashes

and the malfunction code appears.

If the system does NOT operate properly except for the above

mentioned cases and none of the above mentioned malfunctions is

evident, investigate the system in accordance with the following

procedures.

Malfunction Measure

If the system does not

operate at all.

If the system goes into

fan only operation, but

as soon as it goes into

heating or cooling

operation, the system

stops.

The system operates

but cooling or heating

is insufficient.

▪ Check if there is no power failure. Wait

until power is restored. If power failure

occurs during operation, the system

automatically restarts immediately after

power is restored.

▪ Check if no fuse has blown or breaker is

activated. Change the fuse or reset the

breaker if necessary.

▪ Check if air inlet or outlet of outdoor or

indoor unit is not blocked by obstacles.

Remove any obstacles and make sure

the air can flow freely.

▪ Check if the user interface display shows

(time to clean the air filter). (Refer to

"7 Maintenance and service" [4 9] and

"Maintenance" in the indoor unit manual.)

▪ Check if air inlet or outlet of outdoor or

indoor unit is not blocked by obstacles.

Remove any obstacles and make sure

the air can flow freely.

▪ Check if the air filter is not clogged (refer

to "Maintenance" in the indoor unit

manual).

▪ Check the temperature setting.

▪ Check the fan speed setting on your user

interface.

▪ Check for open doors or windows. Close

doors and windows to prevent wind from

coming in.

▪ Check if there are too many occupants in

the room during cooling operation. Check

if the heat source of the room is

excessive.

▪ Check if direct sunlight enters the room.

Use curtains or blinds.

▪ Check if the air flow angle is proper.

Turn OFF the main power

switch.

Turn OFF the power

supply.

Notify your installer and

report the malfunction

code.

If after checking all above items, it is impossible to fix the problem

yourself, contact your installer and state the symptoms, the complete

model name of the unit (with manufacturing number if possible) and

the installation date (possibly listed on the warranty card).

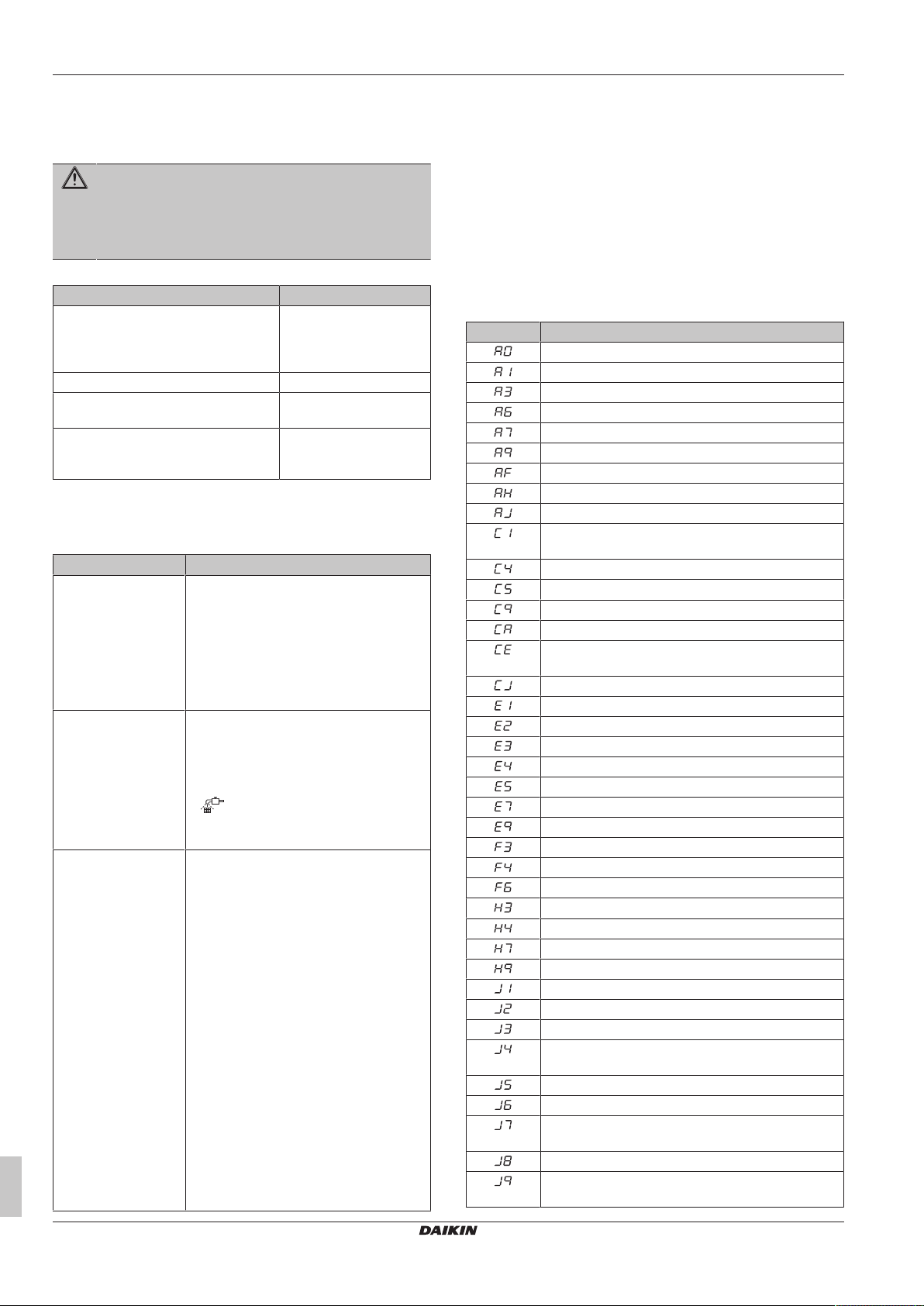

8.1 Error codes: Overview

In case a malfunction code appears on the indoor unit user interface

display, contact your installer and inform the malfunction code, the

unit type, and serial number (you can find this information on the

nameplate of the unit).

For your reference, a list with malfunction codes is provided. You

can, depending on the level of the malfunction code, reset the code

by pushing the ON/OFF button. If not, ask your installer for advice.

Main code Contents

External protection device was activated

EEPROM failure (indoor)

Drain system malfunction (indoor)

Fan motor malfunction (indoor)

Swing flap motor malfunction (indoor)

Expansion valve malfunction (indoor)

Drain malfunction (indoor unit)

Filter dust chamber malfunction (indoor)

Capacity setting malfunction (indoor)

Transmission malfunction between main PCB and sub

PCB (indoor)

Heat exchanger thermistor malfunction (indoor; liquid)

Heat exchanger thermistor malfunction (indoor; gas)

Suction air thermistor malfunction (indoor)

Discharge air thermistor malfunction (indoor)

Movement detector or floor temperature sensor

malfunction (indoor)

User interface thermistor malfunction (indoor)

PCB malfunction (outdoor)

Current leakage detector was activated (outdoor)

High pressure switch was activated

Low pressure malfunction (outdoor)

Compressor lock detection (outdoor)

Fan motor malfunction (outdoor)

Electronic expansion valve malfunction (outdoor)

Discharge temperature malfunction (outdoor)

Abnormal suction temperature (outdoor)

Refrigerant overcharge detection

High pressure switch malfunction

Low pressure switch malfunction

Fan motor trouble (outdoor)

Ambient temperature sensor malfunction (outdoor)

Pressure sensor malfunction

Current sensor malfunction

Discharge temperature sensor malfunction (outdoor)

Heat exchanger gas temperature sensor malfunction

(outdoor)

Suction temperature sensor malfunction (outdoor)

De-icing temperature sensor malfunction (outdoor)

Liquid temperature sensor (after subcool HE)

malfunction (outdoor)

Liquid temperature sensor (coil) malfunction (outdoor)

Gas temperature sensor (after subcool HE)

malfunction (outdoor)

Installation and operation manual

10

VRV IV+ heat pump for high ambient temperatures

RXYTQ8~16U7YF

4P546223-1B – 2020.10

8 Troubleshooting

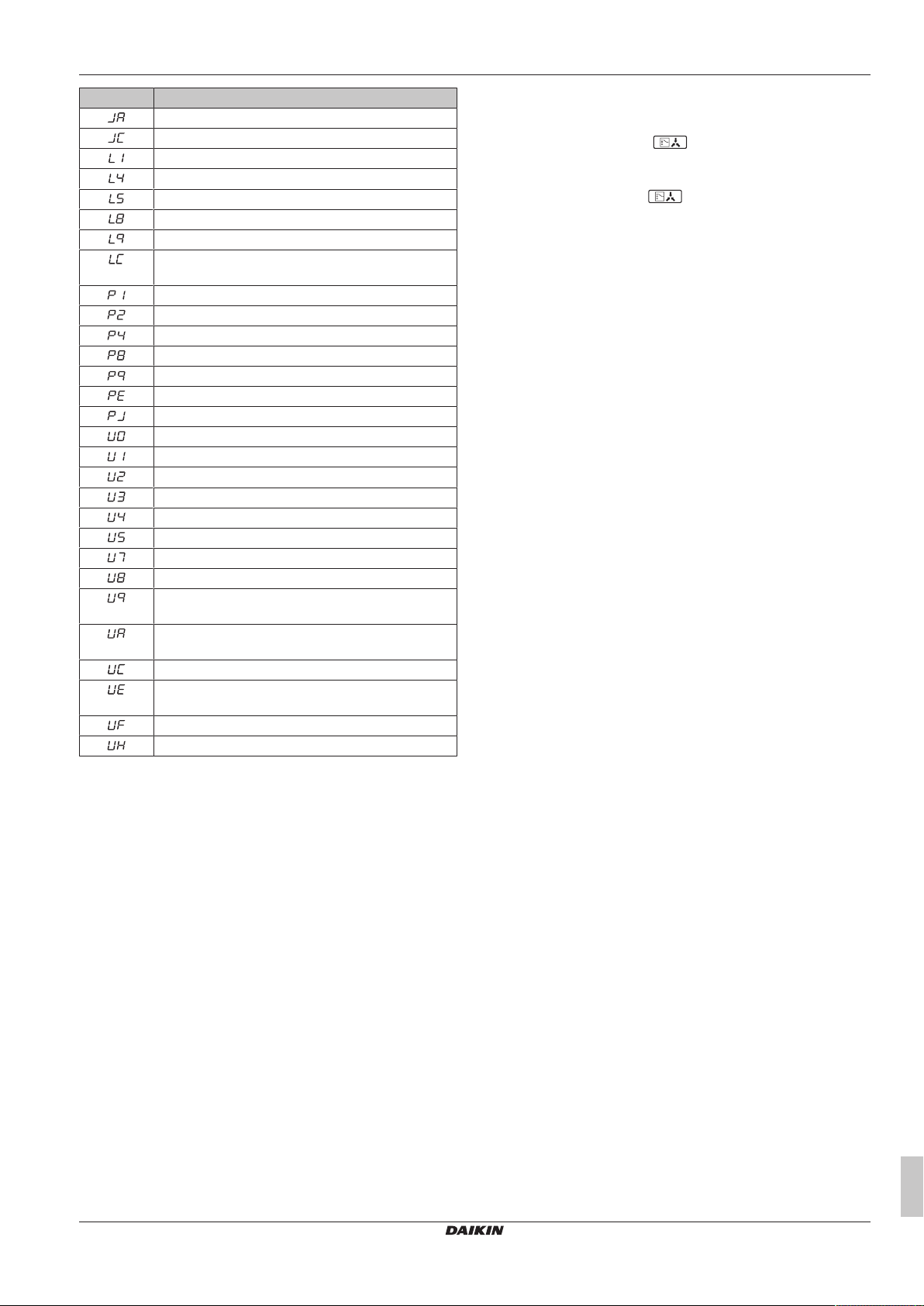

Main code Contents

High pressure sensor malfunction (S1NPH)

Low pressure sensor malfunction (S1NPL)

INV PCB abnormal

Fin temperature abnormal

Inverter PCB faulty

Compressor over current detected

Compressor lock (startup)

Transmission outdoor unit - inverter: INV transmission

trouble

INV unbalanced power supply voltage

Autocharge operation related

Fin thermistor malfunction

Autocharge operation related

Autocharge operation related

Autocharge operation related

Capacity setting malfunction (outdoor)

Abnormal low pressure drop, faulty expansion valve

Reversed power supply phase malfunction

INV voltage power shortage

System test run not yet executed

Faulty wiring indoor/outdoor

Abnormal user interface - indoor communication

Faulty wiring to outdoor/outdoor

Abnormal main-sub user interface communication

System mismatch. Wrong type of indoor units

combined. Indoor unit malfunction.

Connection malfunction over indoor units or type

mismatch

Centralised address duplication

Malfunction in communication centralised control

device - indoor unit

Auto address malfunction (inconsistency)

Auto address malfunction (inconsistency)

8.2 Symptoms that are NOT system malfunctions

The following symptoms are NOT system malfunctions:

8.2.1 Symptom: The system does not operate

▪ The air conditioner does not start immediately after the ON/OFF

button on the user interface is pressed. If the operation lamp

lights, the system is in normal condition. To prevent overloading of

the compressor motor, the air conditioner starts 5 minutes after it

is turned ON again in case it was turned OFF just before. The

same starting delay occurs after the operation mode selector

button was used.

▪ If "Under Centralized Control" is displayed on the user interface,

pressing the operation button causes the display to blink for a few

seconds. The blinking display indicates that the user interface

cannot be used.

▪ The system does not start immediately after the power supply is

turned on. Wait one minute until the micro computer is prepared

for operation.

8.2.2 Symptom: Cool/Heat cannot be changed over

▪ When the display shows (change-over under centralized

control), it shows that this is a slave user interface.

▪ When the cool/heat changeover remote control switch is installed

and the display shows (change-over under centralized

control), this is because cool/heat changeover is controlled by the

cool/ heat changeover remote control switch. Ask your dealer

where the remote control switch is installed.

8.2.3 Symptom: Fan operation is possible, but cooling and heating do not work

Immediately after the power is turned on. The micro computer is

getting ready to operate and is performing a communication check

with all indoor units. Please wait 12 minutes maximally until this

process is finished.

8.2.4 Symptom: The fan speed does not correspond to the setting

The fan speed does not change even if the fan speed adjustment

button is pressed. During heating operation, when the room

temperature reaches the set temperature, the outdoor unit goes off

and the indoor unit changes to whisper fan speed. This is to prevent

cold air blowing directly on occupants of the room. The fan speed

will not change even when another indoor unit is in heating

operation, if the button is pressed.

8.2.5 Symptom: The fan direction does not correspond to the setting

The fan direction does not correspond with the user interface

display. The fan direction does not swing. This is because the unit is

being controlled by the micro computer.

8.2.6 Symptom: White mist comes out of a unit (Indoor unit)

▪ When humidity is high during cooling operation. If the interior of an

indoor unit is extremely contaminated, the temperature distribution

inside a room becomes uneven. It is necessary to clean the

interior of the indoor unit. Ask your dealer for details on cleaning

the unit. This operation requires a qualified service person.

▪ Immediately after the cooling operation stops and if the room

temperature and humidity are low. This is because warm

refrigerant gas flows back into the indoor unit and generates

steam.

8.2.7 Symptom: White mist comes out of a unit (Indoor unit, outdoor unit)

When the system is changed over to heating operation after defrost

operation. Moisture generated by defrost becomes steam and is

exhausted.

8.2.8 Symptom: The user interface reads "U4" or "U5" and stops, but then restarts after a few minutes

This is because the user interface is intercepting noise from electric

appliances other than the air conditioner. The noise prevents

communication between the units, causing them to stop. Operation

automatically restarts when the noise ceases.

RXYTQ8~16U7YF

VRV IV+ heat pump for high ambient temperatures

4P546223-1B – 2020.10

Installation and operation manual

11

9 Relocation

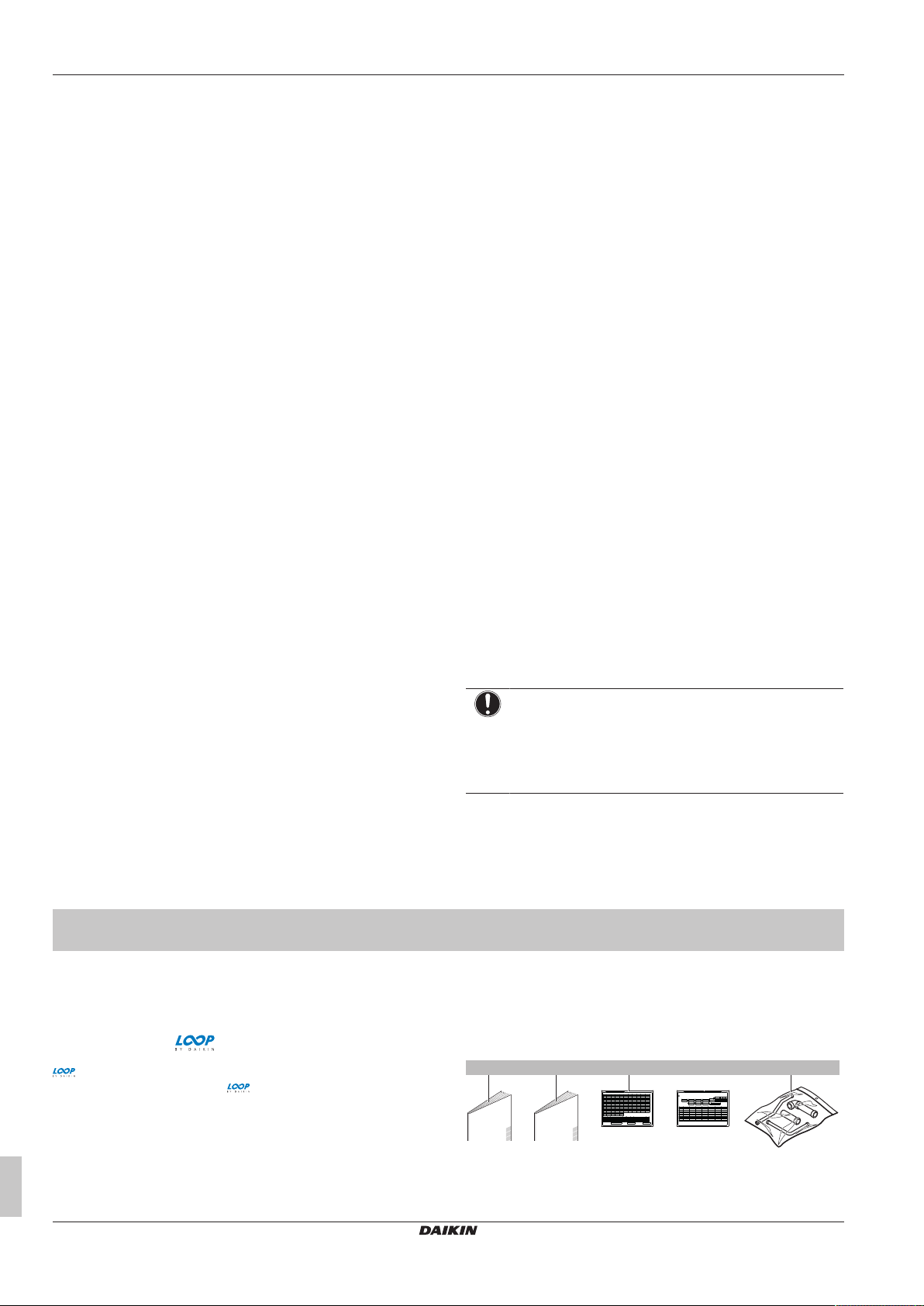

a

1×

e

1×

3P328191-1

BE SURE TO FILL OUT THE BLANKS, WHICH ARE NEEDED FOR AFTER-SALE SERVICES.

REQUEST FOR THE INDICATION OF INSTALLATION INFORMATION

1. RECORD OF INDOOR UNIT MODEL AND INSTALLATION SITE

2. RECORD FOR SETTINGS (CONTENTS SEE INSTALLATION MANUAL)

SETTING

40

30

10

2019

9

29

3938

28

8

1817

7

27

3736

26

6

1615

5

25

3534

23 24

4321

INSTALLATION

MODELNAME

No.

12 13 14

504948474645

6059585756

64636261

11

2221

333231

44434241

5554535251

SITE

INSTALLATION

MODELNAME

No.

SITE

INSTALLATION

MODELNAME

No.

SITE

INSTALLATION

MODELNAME

No.

SITE

INSTALLATION

MODELNAME

No.

SITE

INSTALLATION

MODELNAME

No.

SITE

INSTALLATION

MODELNAME

No.

SITE

3. RECORD OF INSTALLATION DATE

6. AFTER EQUIPPING, PLEASE PUT IT ON THE BACK SIDE OF THE FRONT PLATE.

DAY MONTH YEAR

4. MODEL NAME 5. MANUFACTURING NUMBER

VALUE

REMARK DATE SETTING VALUE REMARK DATE

c

1×

b

1×

d

1×

3P328192-1

3. FOR DETAILS CONCERNING PIPING SELECTION AND CALCULATION OR HOW TO OPERATE THE LEAK DETECTION FUNCTION, PLEASE REFER TO THE INSTALLATION MANUAL.

2. RECORD OF ADDITIONAL REFRIGERANT CHARGE AMOUNT AND RESULT OF LEAK CHECK OPERATION

REQUEST FOR THE INDICATION OF ADDITIONAL REFRIGERANT CHARGING AND LEAK DETECTION OPERATION RESULT

BE SURE TO FILL OUT THE BLANKS, WHICH ARE NEEDED FOR AFTER-SALE SERVICES.

1. CALCULATION OF ADDITIONAL REFRIGERANT CHARGING AMOUNT

4. AFTER FILLING IN THIS TABLE, PLEASE PUT IT ON THE SWITCH BOX COVER.

(m) x 0.18(m) x 0.37

kg

OUTDOOR

UNIT

(m) x 0.26

(m) x 0.12 (m) x 0.059

(m) x 0.022

ADDITIONAL CHARGING

AMOUNT

TOTAL LENGTH OF LIQUID

PIPE SIZE O22.2 x 0.37

TOTAL LENGTH OF LIQUID

PIPE SIZE O19.1 x 0.26

TOTAL LENGTH OF LIQUID

PIPE SIZE O15.9 x 0.18

TOTAL LENGTH OF LIQUID

PIPE SIZE O12.7 x 0.12

TOTAL LENGTH OF LIQUID

PIPE SIZE O9.5 x 0.059

TOTAL LENGTH OF LIQUID

PIPE SIZE O6.4 x 0.022

105%< CR < 130%

50%< CR < 105%

50%< CR < 70%

70%< CR < 85%

85%< CR < 105%

105%< CR < 130%

8HP

Total indoor unit

capacity connection

ratio (CR)

10-12HP

14-16HP

18-20HP

2.0

1.5

1.5

1.2

1.5

1

1

0.7

1.0

0.5

0.5

0.3

0.5

0

0

0

1.0

0.5

0.5

0.5

0.5

0

0

0

Total indoor unit capacity

when piping length <30m

Total indoor unit capacity

when piping length >30m

kg

1.3

1.1

0.9

RYYQ18-20

RYYQ14-16

RYYQ8~12

kg

ONLY FOR RYYQ8~20 MODELS

DATE

AMOUNT

CALCULATE THE ADDITIONAL REFRIGERANT CHARGING AMOUNT BASED ON THE FORMULA BELOW BEFORE CHARGING.

SHIPMENT (INDICATED ON THE MACHINE NAMEPLATE) AND THE ADDITIONAL AMOUNT SHOWN AS FOLLOWS :

WHEN RE-CHARGING TOTAL AMOUNT OF REFRIGERANT , CHARGE THE TOTAL OF THE AMOUNT CHARGED AT

RESULT LEAK CHECK

DATE

AMOUNT

RESULT LEAK CHECK

DATE

AMOUNT

RESULT LEAK CHECK

DATE

AMOUNT

RESULT LEAK CHECK

8.2.9 Symptom: Noise of air conditioners (Indoor unit)

▪ A "zeen" sound is heard immediately after the power supply is

turned on. The electronic expansion valve inside an indoor unit

starts working and makes the noise. Its volume will reduce in

about one minute.

▪ A continuous low "shah" sound is heard when the system is in

cooling operation or at a stop. When the drain pump (optional

accessories) is in operation, this noise is heard.

▪ A "pishi-pishi" squeaking sound is heard when the system stops

after heating operation. Expansion and contraction of plastic parts

caused by temperature change make this noise.

▪ A low "sah", "choro-choro" sound is heard while the indoor unit is

stopped. When another indoor unit is in operation, this noise is

heard. In order to prevent oil and refrigerant from remaining in the

system, a small amount of refrigerant is kept flowing.

8.2.10 Symptom: Noise of air conditioners (Indoor unit, outdoor unit)

▪ A continuous low hissing sound is heard when the system is in

cooling or defrost operation. This is the sound of refrigerant gas

flowing through both indoor and outdoor units.

▪ A hissing sound which is heard at the start or immediately after

stopping operation or defrost operation. This is the noise of

refrigerant caused by flow stop or flow change.

8.2.11 Symptom: Noise of air conditioners (Outdoor unit)

When the tone of operating noise changes. This noise is caused by

the change of frequency.

8.2.12 Symptom: Dust comes out of the unit

When the unit is used for the first time in a long time. This is

because dust has gotten into the unit.

8.2.13 Symptom: The units can give off odours

The unit can absorb the smell of rooms, furniture, cigarettes, etc.,

and then emit it again.

8.2.15 Symptom: The display shows "88"

This is the case immediately after the main power supply switch is

turned on and means that the user interface is in normal condition.

This continues for 1minute.

8.2.16 Symptom: The compressor in the outdoor unit does not stop after a short heating operation

This is to prevent refrigerant from remaining in the compressor. The

unit will stop after 5 to 10 minutes.

8.2.17 Symptom: The inside of an outdoor unit is warm even when the unit has stopped

This is because the crankcase heater is warming the compressor so

that the compressor can start smoothly.

8.2.18 Symptom: Hot air can be felt when the indoor unit is stopped

Several different indoor units are being run on the same system.

When another unit is running, some refrigerant will still flow through

the unit.

9 Relocation

Contact your dealer for removing and reinstalling the total unit.

Moving units requires technical expertise.

10 Disposal

This unit uses hydrofluorocarbon. Contact your dealer when

discarding this unit.

NOTICE

Do NOT try to dismantle the system yourself: dismantling

of the system, treatment of the refrigerant, oil and other

parts MUST comply with applicable legislation. Units

MUST be treated at a specialised treatment facility for

reuse, recycling and recovery.

8.2.14 Symptom: The outdoor unit fan does not spin

During operation. The speed of the fan is controlled in order to

optimise product operation.

For the installer

11 About the box

11.1 About

is part of Daikin's wider commitment to reduce our

environmental footprint. With we want to create a circular

economy for refrigerants. One of the actions to achieve this, is the

reuse of reclaimed refrigerant in VRV units produced and sold in

Europe. For more information about the countries that are in scope,

visit: http://www.daikin.eu/loop-by-daikin.

Installation and operation manual

12

11.2 To remove the accessories from the outdoor unit

Make sure that all accessories are available in the unit.

a General safety precautions

b Installation manual and operation manual

c Additional refrigerant charge label

d Installation information sticker

RXYTQ8~16U7YF

VRV IV+ heat pump for high ambient temperatures

4P546223-1B – 2020.10

12 About the units and options

ID Øa

ID Øb

ID Øa

OD Øb

ID Øb

ID Øa

ID Øb

ID Øa

1

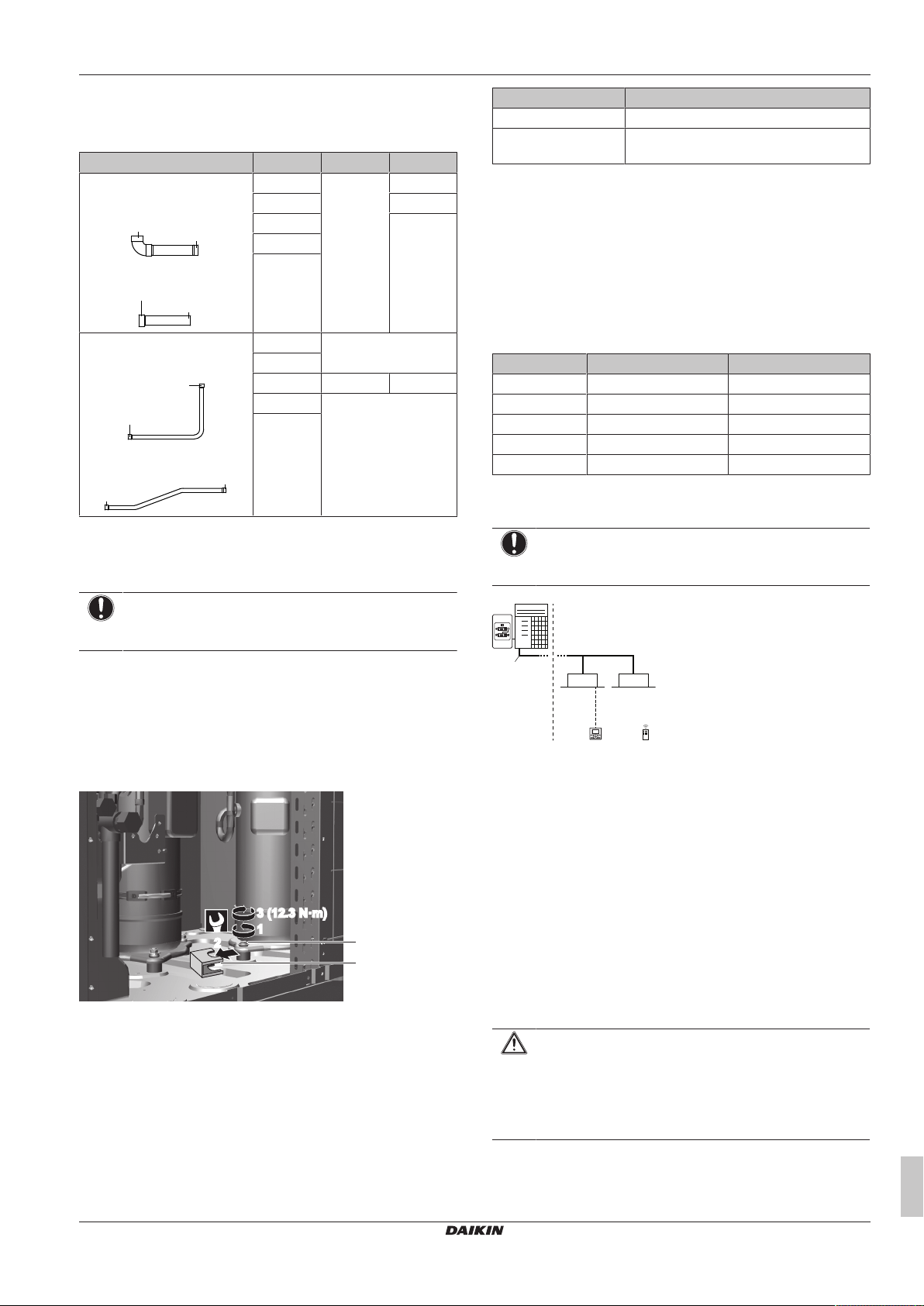

3 (12.3 N·m)

2

1

3 (12.3 N·m)

2

a

b

e

d

c c

b

f

a

e Piping accessory bag

11.3 Accessory pipes: Diameters

Accessory pipes (mm) HP Øa Øb

Gas pipe

▪ Front connection

▪ Bottom connection

Liquid pipe

▪ Front connection

▪ Bottom connection

8 25.4 19.1

10 22.2

12 28.6

14

16

8 9.5

10

12 9.5 12.7

14 12.7

16

11.4 To remove the transportation stay

Only for 14+16 HP

Model Description

RXYTQ8~16 Single non-continuous heating model.

RXYTQ18~48 Multi non-continuous heating model

(consisting of 2 or 3 RXYTQ modules).

These units are intended for outdoor installation and aimed for heat

pump air to air applications.

These units have (in single use) heating capacities ranging from 25

to 50kW and cooling capacities rating from 22.4 to 45kW. In multi

combination the heating capacity can go up till 150 kW and in

cooling till 135kW.

The outdoor unit is designed to work in heating mode at ambient

temperatures from –20°CWB to 15.5°CWB and in cooling mode at

ambient temperatures from –5°CDB to 52°CDB.

Unit weights

Model Total net weight (kg) Total gross weight (kg)

RXYTQ8 198 211

RXYTQ10 234 251

RXYTQ12 234 251

RXYTQ14 283 300

RXYTQ16 283 300

12.2 System layout

NOTICE

Design of the system must not be done at temperatures

below –15°C.

NOTICE

If the unit is operated with the transportation stay attached,

abnormal vibration or noise may be generated.

The transportation stay installed over the compressor leg for

protecting the unit during transport must be removed. Proceed as

shown in the figure and procedure below.

1 Slightly loosen the fixing nut (a).

2 Remove the transportation stay (b) as shown in the figure

below.

3 Tighten the fixing nut (a) again.

a VRV IV Heat pump outdoor unit

b Refrigerant piping

c VRV direct expansion (DX) indoor unit

d User interface (dedicated depending on indoor unit type)

e User interface (wireless, dedicated depending on indoor

unit type)

f Cool/Heat changeover remote control switch

13 Unit installation

13.1 Preparing the installation site

13.1.1 Installation site requirements of the outdoor unit

Mind the spacing guidelines. See the "Technical data" chapter.

CAUTION

12 About the units and options

12.1 About the outdoor unit

This installation manual concerns the VRV IV, full inverter driven,

heat pump system.

Model line up:

Appliance not accessible to the general public, install it in a

secured area, protected from easy access.

This unit, both indoor and outdoor, is suitable for

installation in a commercial and light industrial

environment.

RXYTQ8~16U7YF

VRV IV+ heat pump for high ambient temperatures

4P546223-1B – 2020.10

Installation and operation manual

13

13 Unit installation

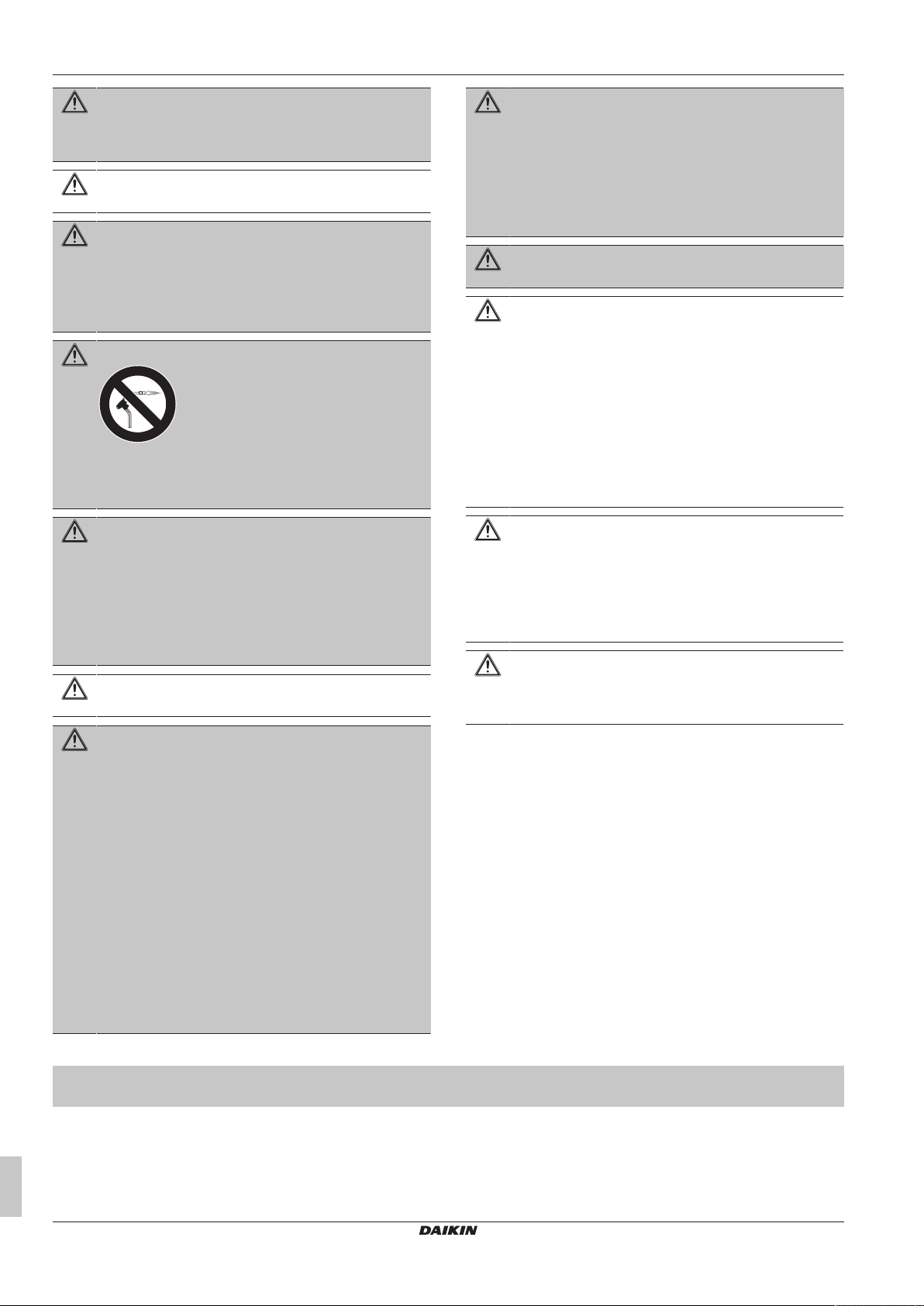

T

AO

(°C WB)

a b

20

15.5

15

10

5

0

–5

–10

–15

–20

10 15 20 25

27

30

T

AI

(°C DB)

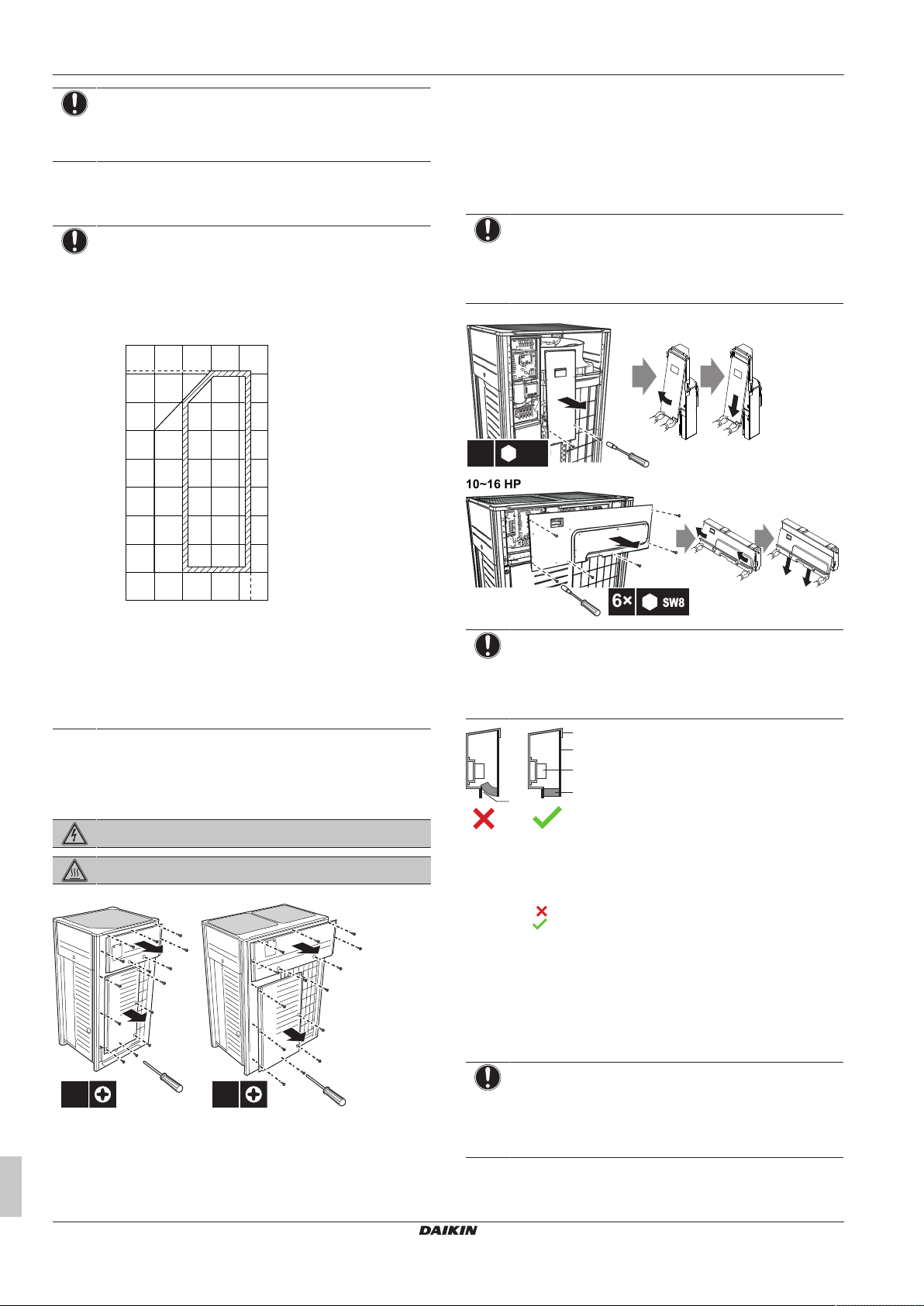

14×14×

8 HP 10~16 HP

8 HP

2×

SW8

10~16 HP

6×

SW8

a

b

c

d

e

NOTICE

This is a class A product. In a domestic environment this

product may cause radio interference in which case the

user may be required to take adequate measures.

13.1.2 Additional installation site requirements of the outdoor unit in cold climates

NOTICE

When operating the unit in a low outdoor ambient

temperature with high humidity conditions, make sure to

take precautions to keep the drain holes of the unit free by

using proper equipment.

In heating:

For service purposes, the pushbuttons on the main PCB need to be

accessed. To access these pushbuttons, the electrical component

box cover does not need to be opened. See "To access the field

setting components"[429].

13.2.2 To open the electrical component box of the outdoor unit

NOTICE

Do NOT apply excessive force when opening the

electronic component box cover. Excessive force can

deform the cover, resulting in entering of water to cause

equipment failure.

a Warming up operation range

b Operation range

TAI Ambient indoor temperature

TAO Ambient outdoor temperature

13.2 Opening the unit

13.2.1 To open the outdoor unit

DANGER: RISK OF ELECTROCUTION

DANGER: RISK OF BURNING/SCALDING

Once the front plates open, the electrical component box can be

accessed. See "To open the electrical component box of the outdoor

unit"[414].

Installation and operation manual

14

NOTICE

When closing the electrical component box cover, make

sure that the sealing material on the lower back side of the

cover is NOT caught and bent towards the inside (see

figure below).

a Electrical component box cover

b Front side

c Power supply terminal block

d Sealing material

e Moisture and dirt could enter

NOT allowed

Allowed

13.3 Mounting the outdoor unit

13.3.1 To provide the installation structure

Make sure the unit is installed level on a sufficiently strong base to

prevent vibration and noise.

NOTICE

▪ When the installation height of the unit needs to be

increased, do NOT use stands to only support the

corners.

▪ Stands under the unit must be at least 100mm wide.

RXYTQ8~16U7YF

VRV IV+ heat pump for high ambient temperatures

4P546223-1B – 2020.10

Loading...

Loading...