Daikin RXYQ-PYLK Installation manuals

INSTALLATION MANUAL

System air conditioner

RXYQ8P7Y1K

RXYQ10P7Y1K

RXYQ12P7Y1K

RXYQ8P7YLK

RXYQ10P7YLK

RXYQ12P7YLK

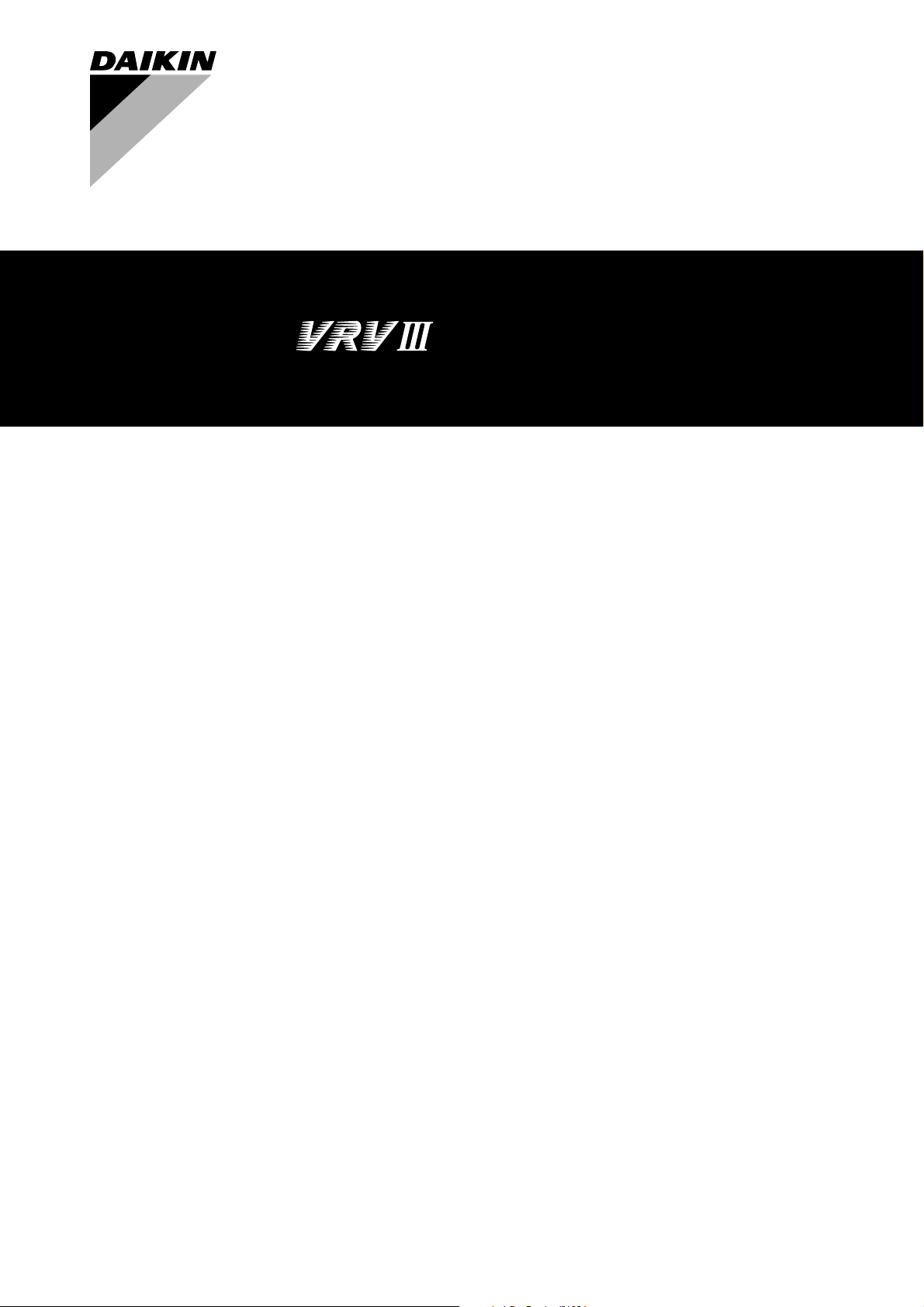

1 2

B

b

ac

AC

a e

AC

d

D

21

B

b

e

c a ce

AC

d

3

B

b

f

D

d

D

4

B

b

2

d

3

b

D

3

5

3

5

5

3

1

1

2

3

4

1

4

3

5

1

a ≥10 mm

b ≥300 mm

c ≥10 mm

d ≥500 mm

a ≥10 mm

b ≥300 mm

c ≥10 mm

d ≥500 mm

e ≥20 mm

a ≥10 mm

b ≥300 mm

c ≥10 mm

d ≥500 mm

e ≥20 mm

f ≥600 mm

a ≥10 mm

b ≥300 mm

c ≥10 mm

d ≥500 mm

e ≥20 mm

A+B+C+D A+B

a ≥50 mm

b ≥100 mm

c ≥50 mm

d ≥500 mm

a ≥50 mm

b ≥100 mm

c ≥50 mm

d ≥500 mm

e ≥100 mm

a ≥50 mm

b ≥100 mm

c ≥50 mm

d ≥500 mm

e ≥100 mm

f ≥500 mm

a ≥50 mm

b ≥100 mm

c ≥50 mm

d ≥500 mm

e ≥100 mm

3

5

5

1

a ≥200 mm

b ≥300 mm

a ≥200 mm

b ≥300 mm

e ≥400 mm

h

2

1500

a ce

AC

h

1

500

6

3

2

2

3

4

5

≥1000

≥1000

≥1500

1

≥1000

≥1500

≥1500

≥1500

(mm)

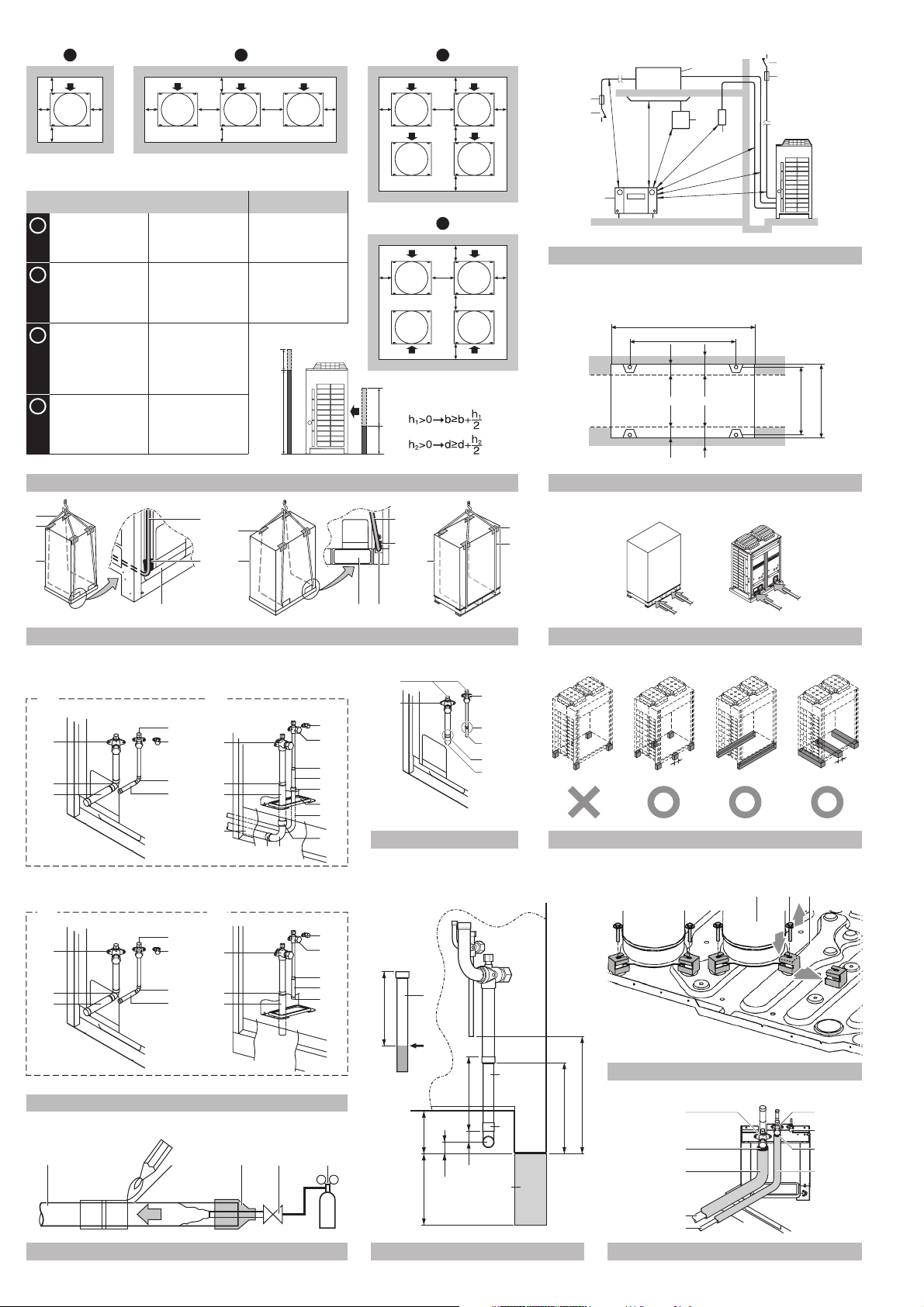

A

B

6767

≥67≥67

765

722-737

2

4

8

RXYQ8~12

A B

2

1

8

4

3

8

6

RXYQ16~32

A B

2

1

8

4

3

8

6

24

5

6

3

2

3

1

8

5

9

2

8

7

8

11

10

8

6

2

4

1

4

1

7

≥100

≥100

7

98

11

3

1

8

5

2

8

7

8

1

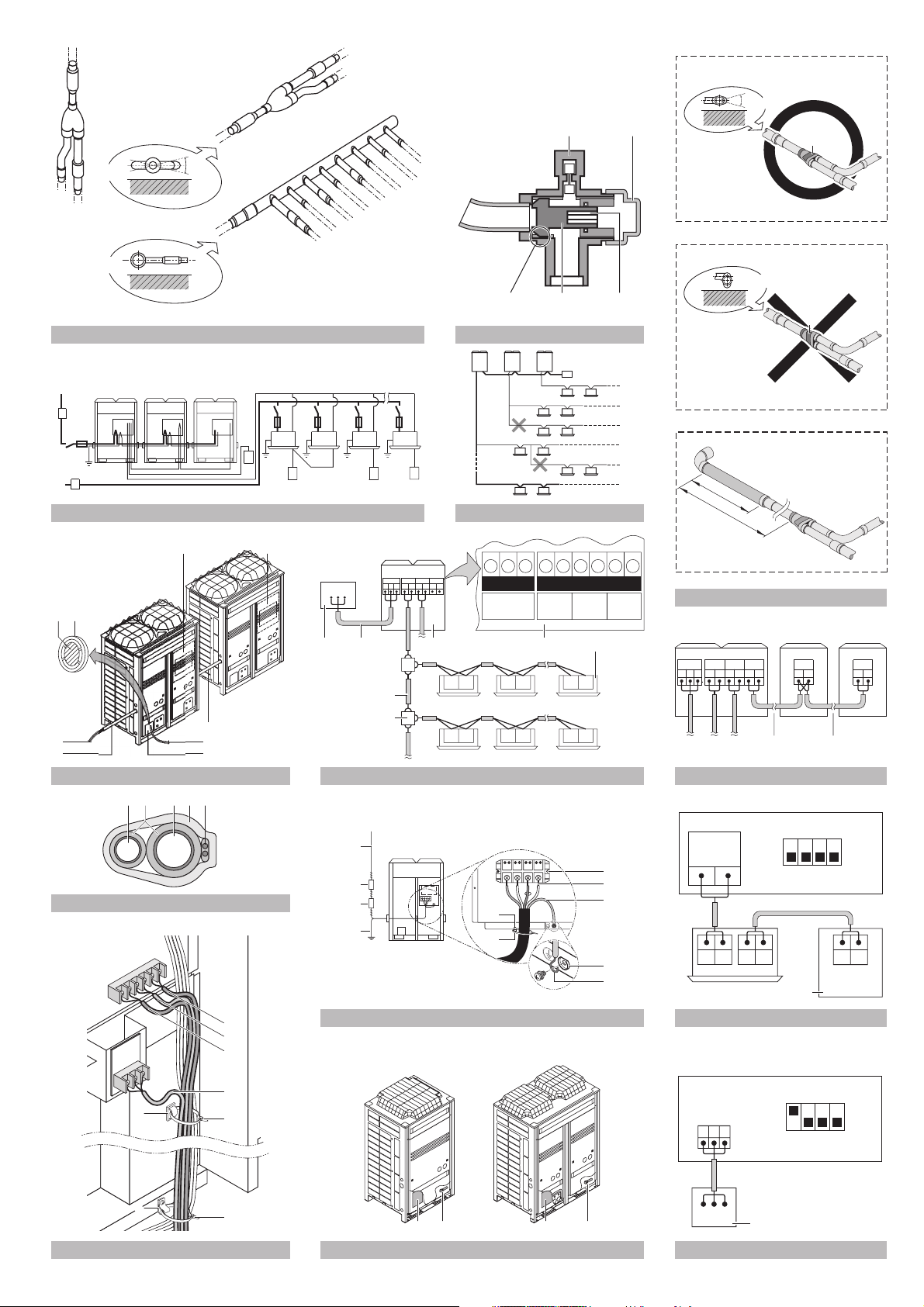

A

9

BA C

1

3

2

2

8

10

12456

3

7

10 11

90

150

25

1

AB

C

3

9

12

D

1

2

3

4

5

4

5

4

6

6

12

8

13

A

B

14

±

3

0

1

°

1

1 2

17

max

15°

A

1

B

345

1

13

15

1

B

2

2

3

B

1

4

5

6

3

6

15

18

1

1

19

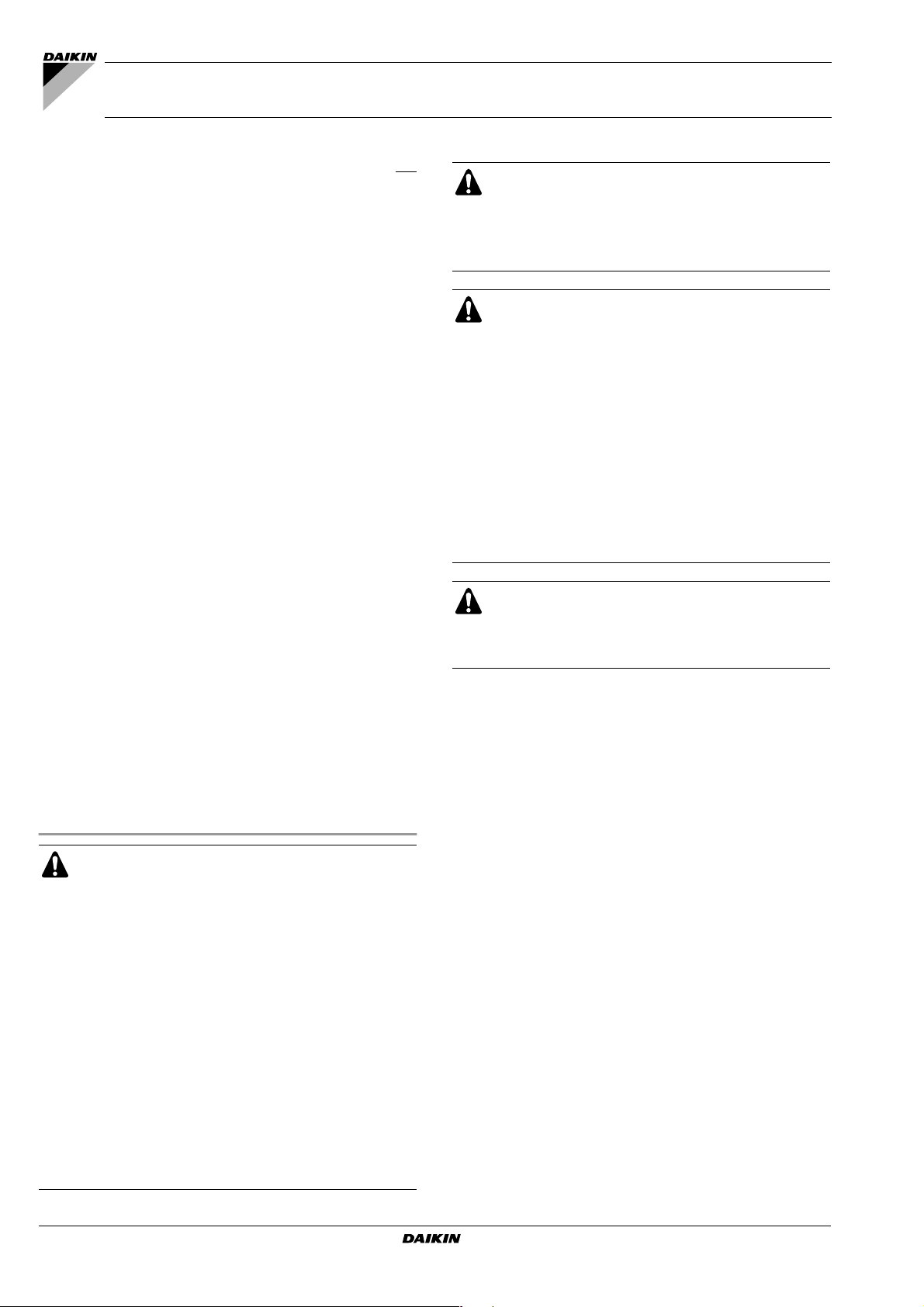

A1P

A B C

1 267

ABC F1 F2 F1 F2 Q1 Q2

3

4

2

6

5

18

21

12345

3

4

19 20

22

5

1

2

21

24

5

3

4

1

2

6

3

4

22

25

RXYQ8 RXYQ10~12

14

16

111

AB

8

2

2

2

2

16

ABC F1 F1F2 F2 Q1 Q2

C/H SELECTOR

F1 F2 F1 F2 F1 F2

F1 F2 F1 F2 F1 F2

L1 L2 L3 N

TO IN/D UNIT

TO OUT/D UNIT TO MULTI UNIT

8

9

4

2

5

7

6

7

2

3

>120 mm

>500 mm

17

20

213

A1P

ABC F1F2F1F2Q1Q2 Q1Q2

6

7

23

TO IN/D

UNIT

5

6

F1 F2

445

ON

OFF

Q1 Q2

O

U

T

1234

I

N

DS1

7

10

11

F1 F2 P1 P2

P1 P2

1

23

26

A B C

ON

OFF

O

U

T

1234

I

N

DS1

2

6

1 2 1 2

A B C

1

24 25 26

■

■

■

RXYQ8P7Y1K RXYQ8P7YLK

RXYQ10P7Y1K RXYQ10P7YLK

RXYQ12P7Y1K RXYQ12P7YLK

VRVIII System air conditioner

Installation manual

ONTENTS

C

P

1. Introduction................................................................................ 1

1.1. Combination.................................................................................1

1.2. Standard supplied accessories .................................................... 2

1.3. Optional accessories.................................................................... 2

1.4. Technical and Electrical specifications.........................................2

2. Main components...................................................................... 2

3. Selection of location .................................................................. 3

4. Inspecting and handling the unit................................................ 4

5. Unpacking and placing the unit ................................................. 4

6. Refrigerant piping...................................................................... 4

6.1. Installation tools ...........................................................................5

6.2. Selection of piping material..........................................................5

6.3. Pipe connection............................................................................5

6.4. Connecting the refrigerant piping.................................................5

6.5. Protection against contamination when installing pipes............... 7

6.6. Example of connection................................................................. 8

7. Leak test and vacuum drying .................................................. 10

8. Field wiring .............................................................................. 10

8.1. Internal wiring – Parts table........................................................ 11

8.2. Optional parts cool/heat selector................................................11

8.3. Power circuit and cable requirements ........................................12

8.4. General cautions........................................................................12

8.5. System examples....................................................................... 13

8.6. Leading power line and transmission line ..................................13

8.7. Field line connection: transmission wiring and

cool/heat selection .....................................................................13

8.8. Field line connection: power wiring ............................................ 15

8.9. Wiring example for wiring inside unit.......................................... 15

9. Pipe insulation......................................................................... 16

10. Checking of unit and installation conditions ............................ 16

11. Charging refrigerant ................................................................ 16

11.1. Precautions when adding R410A............................................... 16

11.2. Stop valve operation procedure ................................................. 17

11.3. How to check how many units are connected............................ 17

11.4. Additional refrigerant charge......................................................18

11.6. Checks after adding refrigerant.................................................. 23

12. Before operation...................................................................... 24

12.1. Service precautions.................................................................... 24

12.2. Checks before initial start-up...................................................... 24

12.3. Field setting................................................................................ 24

12.4. Test operation............................................................................. 26

13. Service mode operation .......................................................... 28

14. Caution for refrigerant leaks.................................................... 29

15. Disposal requirements............................................................. 29

READ THIS MANUAL ATTENTIVELY BEFORE STARTING

UP THE UNIT. DO NOT THROW IT AWAY. KEEP IT IN YOUR

FILES FOR FUTURE REFERENCE.

IMPROPER INSTALLATION OR ATTACHMENT OF

EQUIPMENT OR ACCESSORIES COULD RESULT IN

ELECTRIC SHOCK, SHORT-CIRCUIT, LEAKS, FIRE OR

OTHER DAMAGE TO THE EQUIPMENT. BE SURE ONLY

TO USE ACCESSORIES MADE BY

DAIKIN

WHICH ARE

SPECIFICALLY DESIGNED FOR USE WITH THE

EQUIPMENT AND HAVE THEM INSTALLED BY A

PROFESSIONAL.

DAIKIN

EQUIPMENT IS DESIGNED FOR COMFORT

APPLICATIONS. FOR USE IN OTHER APPLICATIONS,

PLEASE CONTACT YOUR LOCAL

DAIKIN

DEALER.

IF UNSURE OF INSTALLATION PROCEDURES OR USE,

ALWAYS CONTACT YOUR DEALER FOR ADVICE AND

INFORMATION.

THIS AIR CONDITIONER COMES UNDER THE TERM

"APPLIANCES NOT ACCESSIBLE TO THE GENERAL

PUBLIC".

age

The refrigerant charge of the system must be less than

100 kg. This means that in case the calculated refrigerant

charge is equal to or more than 95 kg you must divide your

multiple outdoor system into smaller independent systems,

each containing less than 95 kg refrigerant charge.

For factory charge, refer to the unit name plate.

The refrigerant R410A requires strict cautions for keeping

the system clean, dry and tight.

Clean and dry

Foreign materials (including mineral oils such as

SUNISO oil or moisture) should be prevented from

getting mixed into the system.

Tight

R410A does not contain any chlorine, does not

destroy the ozone layer, and does not reduce the

earth's protection against harmful ultraviolet radiation.

R410A can contribute slightly to the greenhouse

effect if it is released. Therefore we should take

special attention to check the tightness of the

installation.

Read "6. Refrigerant piping" on page 4 carefully and follow

these procedures correctly.

Since design pressure is 4.0 MPa or 40 bar (for R407C

units: 3.3 MPa or 33 bar), pipes of larger wall thickness

may be required. The wall thickness of piping must be

carefully selected, refer to paragraph "6.2. Selection of

piping material" on page 5 for more details.

1. I

NTRODUCTION

This installation manual concerns VRV inverters of the Daikin

RXYQ-P7 series. These units are designed for outdoor installation

and used for cooling and heat pump applications. The RXYQ-P7

series can be combined from 3 main units and has nominal cooling

capacities ranging from 17.7 to 81.6 kW and nominal heating

capacities ranging from 25.0 to 112.5 kW.

The RXYQ-P7 units can be combined with Daikin VRV indoor units

for air conditioning purposes, and suitable for R410A.

The present installation manual describes the procedures for

unpacking, installing and connecting the RXYQ-P7 units. Installation

of the indoor units is not described in this manual. Always refer to the

installation manual supplied with these units for their installation.

1.1. Combination

The indoor units can be installed in the following range.

Always use appropriate indoor units compatible with R410A.

To learn which models of indoor units are compatible with

R410A, refer to the product catalogs.

■

Pay attention when connecting outdoor units in multi

combination. RXYQ-M units are NOT compatible with RXYQ-P

units.

■

RXYQ_Y1K units are NOT compatible with RXYQ_YLK units.

Installation manual

1

RXYQ8~12P7Y1K + RXYQ8~12P7YLK

VRVIII System air conditioner

4PW41760-1

■

■

■

■

■

■

■

Total capacity/quantity of indoor units

Tot al

capacity of

Standard combination of outdoor units

RXYQ8

RXYQ10

RXYQ12

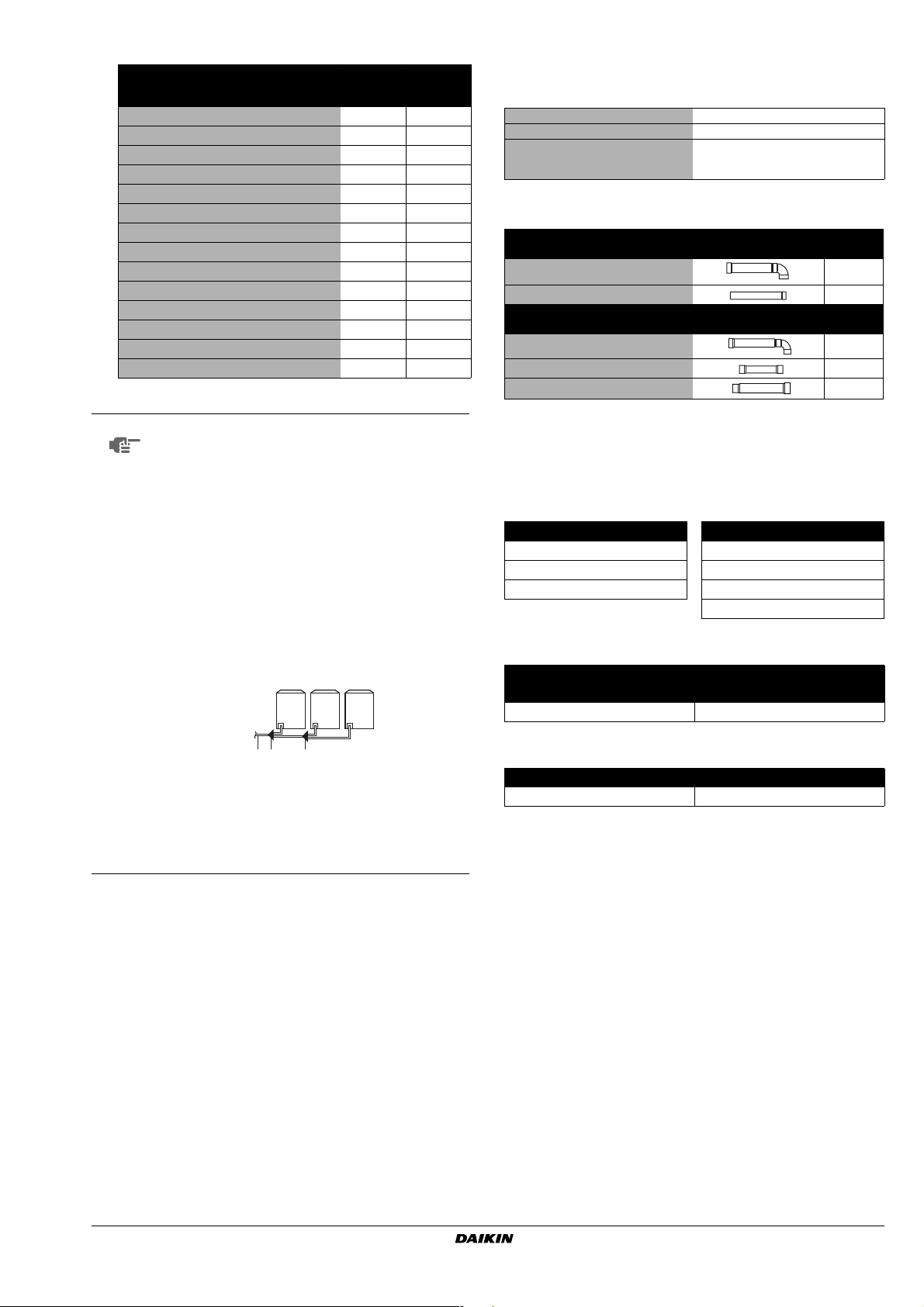

RXYQ16 = RXYQ8 + RXYQ8

RXYQ18 = RXYQ8 + RXYQ10

RXYQ20 = RXYQ10 + RXYQ10

RXYQ22 = RXYQ10 + RXYQ12

RXYQ24 = RXYQ12 + RXYQ12

RXYQ26 = RXYQ8 + RXYQ8 + RXYQ10

RXYQ28 = RXYQ8 + RXYQ10 + RXYQ10

RXYQ30 = RXYQ8 + RXYQ10 + RXYQ12

RXYQ32 = RXYQ10 + RXYQ10 + RXYQ12

RXYQ34 = RXYQ10 + RXYQ12 + RXYQ12

RXYQ36 = RXYQ12 + RXYQ12 + RXYQ12 450~1170 58

NOTE

(a)

(a)

(a)

(a) Main unit

The table above shows the possible total capacity

indoor units

100~260 13

125~325 16

150~390 19

200~520 26

225~585 29

250~650 32

275~715 35

300~780 39

325~845 42

350~910 45

375~975 48

400~1040 52

425~1105 55

and number of possible indoor units when

configured in a standard combination.

If the total capacity of the connected indoor units

exceeds the capacity of the outdoor unit, cooling

and heating performance may drop when running

the indoor units.

Refer to the section on performance characteristics in the Engineering Data Book for details.

There are restrictions on the refrigerant pipe

connection order between outdoor units during

installation in case of a multiple outdoor unit

system.

Install according to the following restrictions.

The capacities of outdoor units A, B, and C must

fulfill the following restriction conditions: A ≥ B ≥ C .

ABC

12 3

1 To indoor units

2 Outdoor unit multi connection piping kit (first

branch)

3 Outdoor unit multi connection piping kit

(second branch)

Tot al

quantity of

indoor units

1.2. Standard supplied accessories

See location 1 in figure 25 for reference to where following

accessories are supplied with the unit.

Installation manual 1

Operation manual 1

Request for indication of additional

refrigerant charging and leak detection

amount label

1

See location 2 in figure 25 for reference to where following

accessories are supplied with the unit.

Unit type Item Quantity

8~12 Hp 1

8~12 Hp 1

Unit type Item Quantity

8~12 Hp 1

8~10 Hp 1

12 Hp 1

Gas side accessory pipe

Liquid side accessory pipe

1.3. Optional accessories

To install the above outdoor units, the following optional parts are

also required.

Refrigerant branching kit (for R410A only: Always use an

appropriate kit dedicated for your system.)

Refnet header Refnet joint

KHRQ22M29H KHRQ22M20T

KHRQ22M64H KHRQ22M29T9

KHRQ22M75H KHRQ22M64T

KHRQ22M75T

Outdoor unit multi connection piping kit (For R410A only: Always

use an appropriate kit dedicated for your system.)

Number of outdoor units connected

2 3

BHFQ22P1007 BHFQ22P1517

Pipe size reducer (For R410A only: Always use an appropriate

kit dedicated for your system.)

RXYQ24~36

KHRQ22M75T KHRQ22M75H

To select an optimum refrigerant branching kit, refer to "6. Refrigerant

piping" on page 4.

RXYQ8~12P7Y1K + RXYQ8~12P7YLK

VRVIII System air conditioner

4PW41760-1

1.4. Technical and Electrical specifications

Refer to the Engineering Data Book for the complete list of

specifications.

AIN

2. M

For main components and function of the main components, refer to

the Engineering Data Book.

COMPONENTS

Installation manual

2

1

2

■

■

3

4

■

■

5

6

7

8

9

■

10

■

■

■

■

3. S

This unit, both indoor and outdoor, is suitable for installation in a

commercial and light industrial environment. If installed as a household appliance it could cause electromagnetic interference, in which

case the user may be required to take adequate measures.

Obtain the customer's permission before installing.

The inverter units should be installed in a location that meets the

following requirements:

ELECTION

Make sure to provide for adequate measures in order

to prevent that the outdoor unit be used as a shelter

by small animals.

Small animals making contact with electrical parts can

cause malfunctions, smoke or fire. Please instruct the

customer to keep the area around the unit clean.

The foundation is strong enough to support the weight of the unit

and the floor is flat to prevent vibration and noise generation.

If not, the unit may fall over and cause damage or

injury.

The space around the unit is adequate for servicing and the

minimum space for air inlet and air outlet is available. (Refer to

figure 1 and choose one of the possibilities).

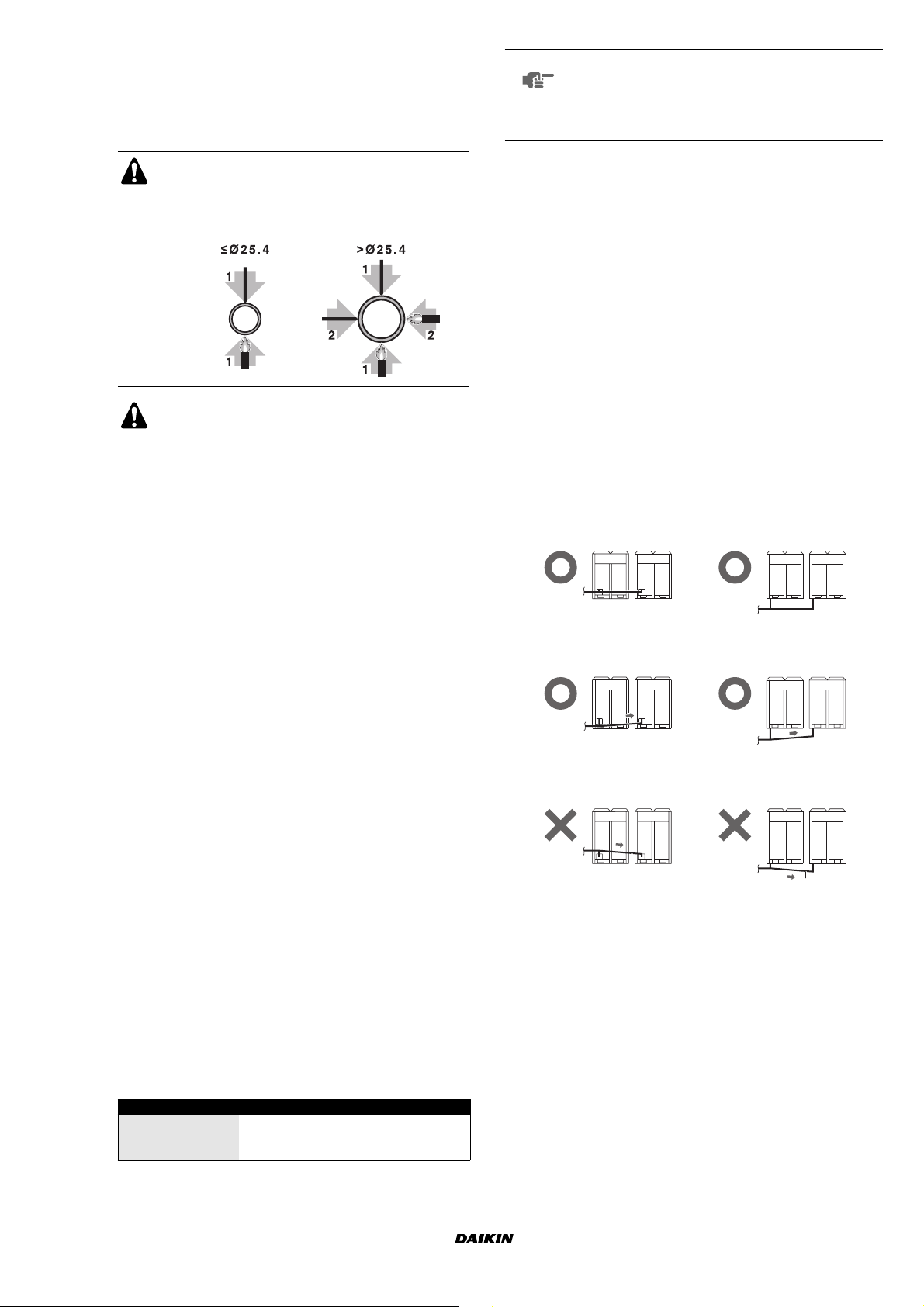

A B C D Sides along the installation site with obstacles

In case of an installation site where sides A+B+C+D have

obstacles, the wall heights of sides

service space dimensions. Refer to figure 1 for impact of wall

heights of sides B+D on service space dimensions.

In case of an installation site where only the sides A+B have

obstacles, the wall heights have no influence on any

indicated service space dimensions.

NOTE

Make sure that there is no danger of fire due to leakage of

inflammable gas.

Ensure that water can not cause any damage to the location in

case it drips out the unit (e.g. in case of a blocked drain pipe).

The piping length between the outdoor unit and the indoor unit

may not exceed the allowable piping length. (Refer to

"6.6. Example of connection" on page 8)

Select the location of the unit in such a way that neither the

discharged air nor the sound generated by the unit disturbs

anyone.

Make sure that the air inlet and outlet of the unit are not

positioned towards the main wind direction. Frontal wind will

disturb the operation of the unit. If necessary, use a windscreen

to block the wind.

Do not install or operate the unit on locations where air contains

high levels of salt, like e.g. in the vicinity of oceans. (Refer for

further information to the engineering databook).

During installation, avoid the possibility that anybody can climb

on the unit or place objects on the unit.

Falls may result in injury.

When installing the unit in a small room, take measures in order

to keep the refrigerant concentration from exceeding allowable

safety limits in the event of a refrigerant leak.

OF

LOCATION

Suction side

A+C

have no impact on

The service space dimensions in figure 1 are

based on cooling operation at 35°C.

The equipment described in this manual may cause

electronic noise generated from radio-frequency

energy. The equipment complies to specifications that

are designed to provide reasonable protection against

such interference. However, there is no guarantee that

interference will not occur in a particular installation.

It is therefore recommended to install the equipment

and electric wires keeping proper distances away from

stereo equipment, personal computers, etc...

(See figure 2).

1 Personal computer or radio

2 Fuse

3 Earth leakage breaker

4 Remote controller

5 Cool/heat selector

6 Indoor unit

In places with weak reception, keep distances of 3 m

or more to avoid electromagnetic disturbance of other

equipment and use conduit tubes for power and

transmission lines.

In heavy snowfall areas, select an installation site

where snow will not affect the operation of the unit.

The refrigerant R410A itself is nontoxic, nonflammable

and is safe. If the refrigerant should leak however, its

concentration may exceed the allowable limit

depending on room size. Due to this, it could be

necessary to take measures against leakage. Refer to

the chapter "14. Caution for refrigerant leaks" on

page 29.

Do not install in the following locations.

• Locations where sulfurous acids and other

corrosive gases may be present in the atmosphere.

Copper piping and soldered joints may corrode,

causing refrigerant to leak.

• Locations where a mineral oil mist, spray or vapour

may be present in the atmosphere.

Plastic parts may deteriorate and fall off or causing

water leakage.

• Locations where equipment that produces electromagnetic waves is found.

The electromagnetic waves may cause the control

system to malfunction, preventing normal

operation.

• Locations where flammable gases may leak, where

thinner, gasoline, and other volatile substances are

handled, or where carbon dust and other

incendiary substances are found in the

atmosphere.

Leaked gas may accumulate around the unit,

causing an explosion.

When installing, take strong winds, typhoons or

earthquakes into account.

Improper installation may result in fall over of the unit.

Installation manual

3

Excessive refrigerant concentrations in a closed room

can lead to oxygen deficiency.

RXYQ8~12P7Y1K + RXYQ8~12P7YLK

VRVIII System air conditioner

4PW41760-1

4. I

At delivery, the package should be checked and any damage should

be reported immediately to the carrier claims agent.

When handling the unit, take into account the following:

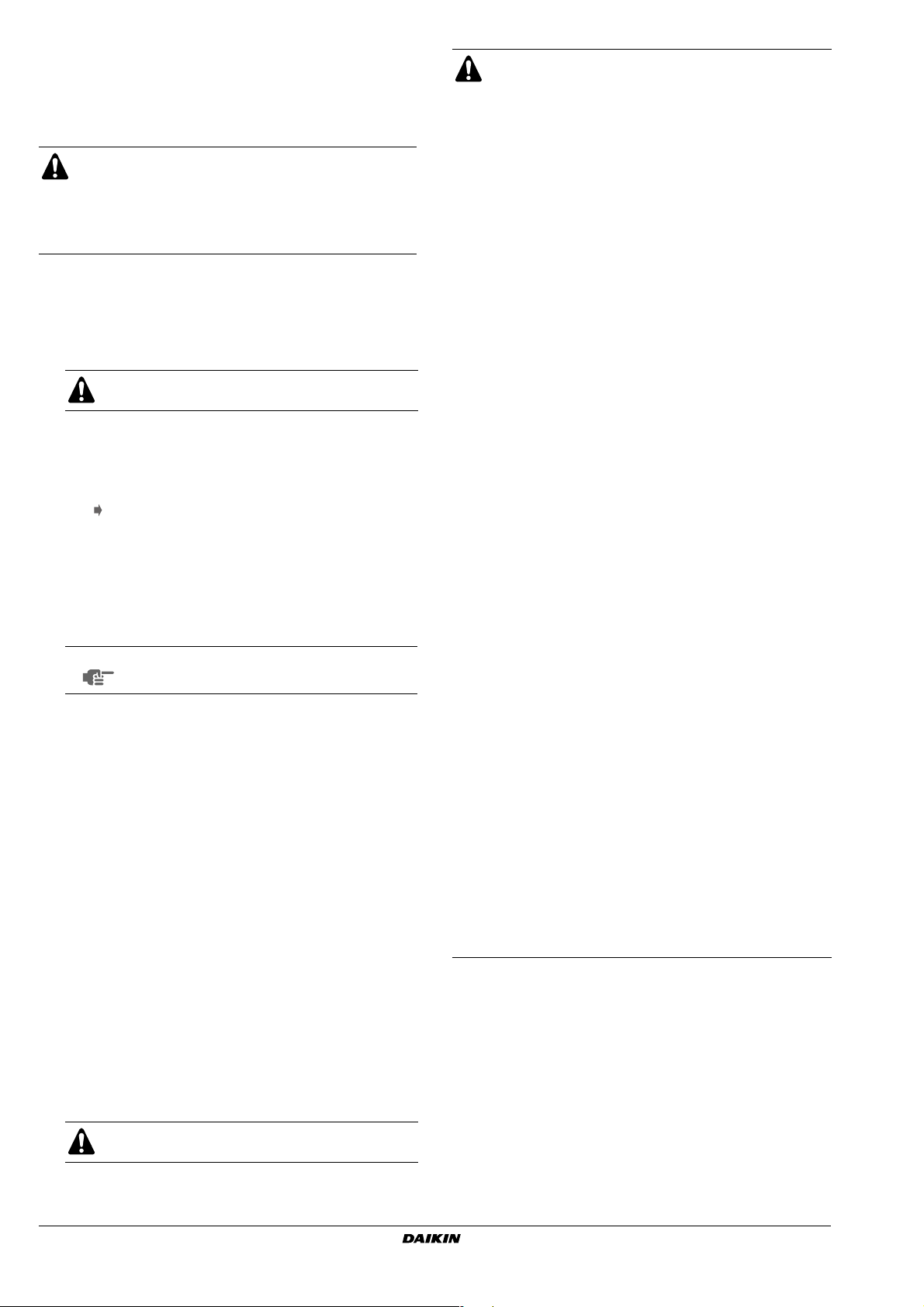

5.1 From the moment you use a forklift to move the unit to its final

5.2 Once at final position, unpack the unit and pass the forklift arms

NSPECTING

Fragile, handle the unit with care.

Keep the unit upright in order to avoid compressor

damage.

Choose on beforehand the path along which the unit is to be

brought in.

Bring the unit as close as possible to its final installation position

in its original package to prevent damage during transport. (See

figure 4)

1 Packaging material

2 Opening (large)

3 Belt sling

4 Opening (small) (40x45)

5 Protector

Lift the unit preferably with a crane and 2 belts of at least 8 m

long. (See figure 4)

Always use protectors to prevent belt damage and pay attention

to the position of the unit's centre of gravity.

NOTE

If a forklift is to be used, preferably transport the unit with pallet

first, then pass the forklift arms through the large rectangular

openings on the bottom of the unit. (See figure 5)

position, lift the unit under the pallet.

through the large rectangular openings on the bottom of the unit.

NOTE

AND

HANDLING

Use a belt sling of ≤20 mm wide that adequately

bears the weight of the unit.

Use filler cloth on the forklift arms to prevent

damaging the unit. If the paint on the bottom

frame peels off, the anti corrosion effect may

decrease.

THE

UNIT

4

1

2

3

4

5

■

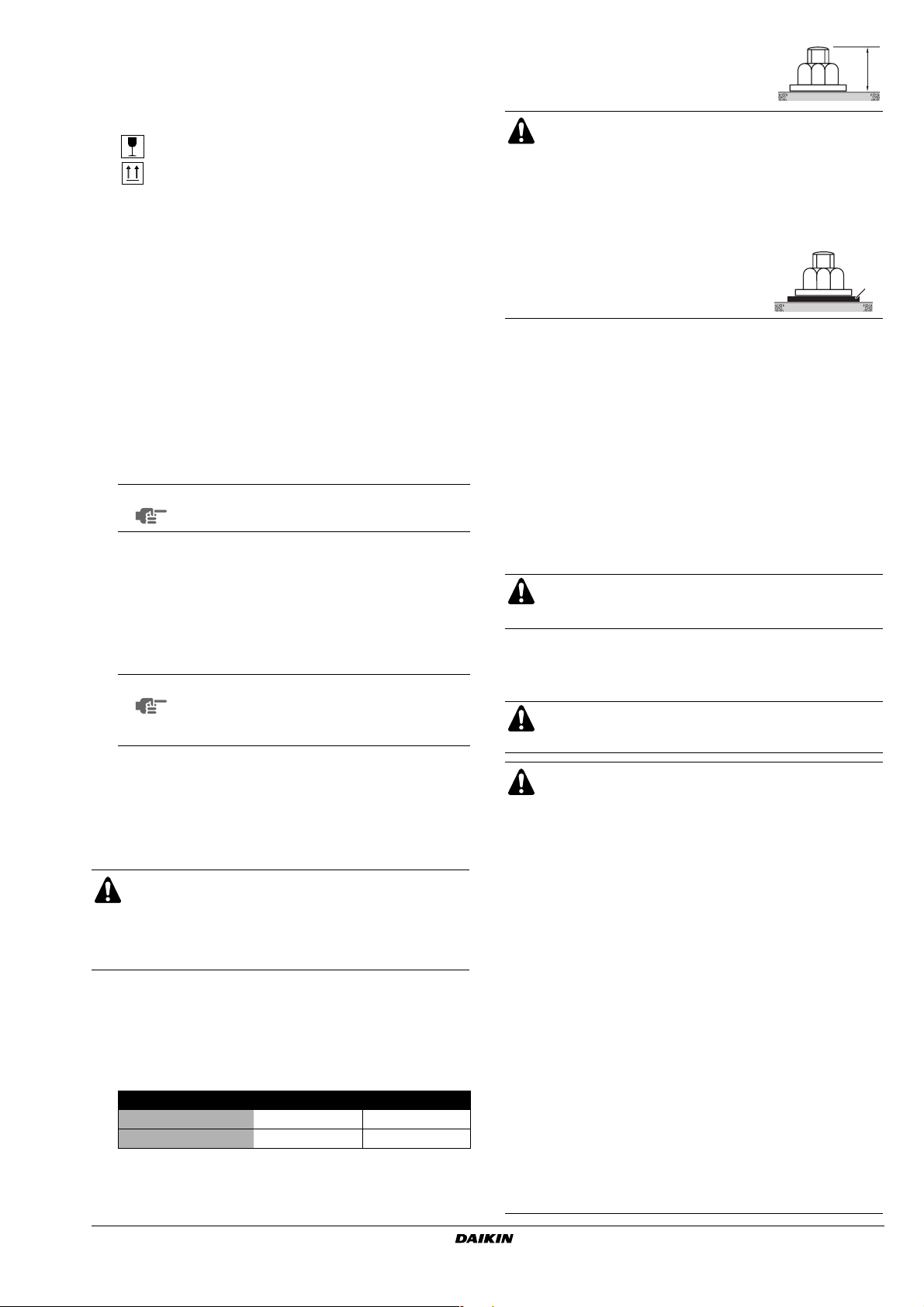

Fasten the unit in place using four foundation

bolts M12. It is best to screw in the foundation

bolts until their length remains 20 mm above

the foundation surface.

■ Prepare a water drainage channel around the

foundation to drain waste water from around the unit.

■ If the unit is to be installed on a roof, check the

strength of the roof and its drainage facilities first.

■ If the unit is to be installed on a frame, install the

waterproofing board within a distance of 150 mm

under the unit in order to prevent infiltration of water

coming from under the unit.

■ When installed in a corrosive

environment, use a nut with

plastic washer (1) to protect the

nut tightening part from rust.

20 mm

1

Method for removing transportation stays

(only for RXYQ10 and RXYQ12 units)

The 4 yellow transportation stays installed over the compressor legs

for protecting the unit during transport must be removed. Proceed as

shown in figure 9 and described below.

A Compressor

B Fixing nut

C Tr ansportation stay

1 Slightly loosen the fixing nut (B).

2 Remove the transportation stay (C) as shown in figure 9.

3 Tighten the fixing nut (B) again.

CAUTION

If the unit is operated with the transportation stay attached,

abnormal vibration or noise may be generated.

6. REFRIGERANT PIPING

Do not insert fingers, rods or other objects into the air

inlet or outlet. When the fan is rotating at high speed, it

will cause injury.

■

■

■

■

5. U

■ The unit must be installed on a solid longitudinal foundation

■ Support the unit with a foundation of 67 mm wide or more. (The

NPACKING

Remove the four screws fixing the unit to the pallet.

Make sure the unit is installed level on a sufficiently strong base

to prevent vibration and noise.

Do not use stands to only support the corners. (See

figure 7)

O Allowed (units: mm)

Make sure the base under the unit is larger than the 765 mm of

the unit depth. (See figure 3)

The height of the foundation must at least be 150 mm from the

floor.

(steelbeam frame or concrete) as indicated in figure 3.

Model A B

RXYQ8 930 792

RXYQ10+12 1240 1102

support leg of the unit is 67 mm wide, see figure 3).

AND

X Not allowed

PLACING

THE

UNIT

Use R410A to add refrigerant.

All field piping must be installed by a licensed refrigeration

technician and must comply with relevant local and

national regulations.

Caution to be taken when brazing refrigerant piping

Do not use flux when brazing copper-to-copper refrigerant

piping. (Particularly for the HFC refrigerant piping)

Therefore, use the phosphor copper brazing filler metal

(BCuP) which does not require flux.

Flux has extremely harmful influence on refrigerant piping

systems. For instance, if the chlorine based flux is used, it

will cause pipe corrosion or, in particular, if the flux

contains fluorine, it will damage the refrigerant oil.

Be sure to perform a nitrogen blow when brazing. Brazing

without performing nitrogen replacement or releasing

nitrogen into the piping will create large quantities of

oxidized film on the inside of the pipes, adversely affecting

valves and compressors in the refrigerating system and

preventing normal operation.

After completing the installation work, check that the

refrigerant gas does not leak.

To xic gas may be produced if the refrigerant gas leaks into

the room and comes in contact with a source of fire.

Ventilate the area immediately in the event of a leak.

In the event of a leak, do not touch the leaked refrigerant

directly. Frostbite may be caused.

RXYQ8~12P7Y1K + RXYQ8~12P7YLK

VRVIII System air conditioner

4PW41760-1

Installation manual

6.1. Installation tools

6.3. Pipe connection

Make sure to use installation tools (gauge manifold charge hose,

etc.) that are exclusively used for R410A installations to withstand the

pressure and to prevent foreign materials (e.g. mineral oils such as

SUNISO and moisture) from mixing into the system.

(The screw specifications differ for R410A and R407C.)

Use a 2-stage vacuum pump with a non-return valve which can

evacuate to –100.7 kPa (5 Torr, –755 mm Hg).

NOTE

Make sure the pump oil does not flow oppositely into

the system while the pump is not working.

6.2. Selection of piping material

1. Foreign materials inside pipes (including oils for fabrication)

must be 30 mg/10 m or less.

2. Use the following material specification for refrigerant piping:

■ Size: determine the proper size referring to chapter

"6.6. Example of connection" on page 8.

■ Construction material: phosphoric acid deoxidized seamless

copper for refrigerant.

■ Temper grade: use piping with temper grade in function of the

pipe diameter as listed in the table below.

Pipe Ø Temper grade of piping material

≤15.9 O

≥19.1 1/2H

O = Annealed

1/2H = Half hard

Be sure to perform a nitrogen blow when brazing and to read the

paragraph "Caution to be taken when brazing refrigerant piping" on

page 4 first.

NOTE

The pressure regulator for the nitrogen released when

doing the brazing should be set to 0.02 MPa or less.

(See figure 10)

1 Refrigerant piping

2 Location to be brazed

3 Nitrogen

4 Taping

5 Manual valve

6 Regulator

7 Nitrogen

Do not use anti-oxidants when brazing the pipe joints.

Residue can clog pipes and break equipment.

6.4. Connecting the refrigerant piping

1Front connection or side connection

Installation of refrigerant piping is possible as front connection or

side connection (when taken out from the bottom) as shown in

the figure.

■ The pipe thickness of the refrigerant piping should comply

with relevant local and national regulations. The minimal pipe

thickness for R410A piping must be in accordance with the

table below.

Minimal thickness

Pipe Ø

6.4 0.80 22.2 0.80

9.5 0.80 28.6 0.99

12.7 0.80 34.9 1.21

15.9 0.99 41.3 1.43

19.1 0.80

t (mm)

Pipe Ø

Minimal thickness

t (mm)

3. Make sure to use the particular branches of piping that have

been selected referring to chapter "6.6. Example of connection"

on page 8.

4. In case the required pipe sizes (inch sizes) are not available, it is

also allowed to use other diameters (mm sizes), taken the

following into account:

■ select the pipe size nearest to the required size.

■ use the suitable adapters for the change-over from inch to

mm pipes (field supply).

5. Precautions when selecting branch piping

When the equivalent pipe length between outdoor and indoor

units is 90 m or more, the size of the main pipes (both gas side

and liquid side) must be increased.

Depending on the length of the piping, the capacity may drop,

but even in such a case it is possible to increase the size of the

main pipes. Refer to page 9. If the recommended pipe size is not

available, stick to the original pipe diameter (which may result in

a small capacity decrease).

12 3

1 Left-side connection

2 Front connection

3 Right-side connection

NOTE

Precautions when knocking out knock holes

■ Be sure to avoid damaging the casing

■ After knocking out the holes, we recommend you

remove the burrs and paint the edges and areas

around the edges using the repair paint to prevent

rusting.

■ When passing electrical wiring through the knock

holes, wrap the wiring with protective tape to

prevent damage.

2 Removing the pinched piping

When connecting refrigerant piping to the outdoor unit, first

remove the pinched piping. Do not vent gases into the

atmosphere.

Removing of the pinched piping must be carried out according to

the following procedure:

1. Make sure the stop valves are closed.

2. Connect a charge hose to the service ports of all stop

valves.

3. Recover the gas from the pinched piping.

4. When all the gas is recovered from the pinched piping,

dissolve the brazing using a burner and remove the

pinched piping.

Installation manual

5

Any gas remaining inside the stop valve may blow off

the pinched piping, causing damage or injury.

RXYQ8~12P7Y1K + RXYQ8~12P7YLK

VRVIII System air conditioner

4PW41760-1

See figure 6.

1 Pinched piping

2 Stop valve

3 Service port

4 Point of melting the brazing metal

NOTE

■ When connecting the piping on site, be sure to

use the accessory piping.

■ Make sure the onsite piping does not come into

contact with other piping, the bottom frame or side

panels of the unit.

Precautions when connecting field piping.

■ Perform brazing at the gas stop valve before

brazing at the liquid stop valve.

■ Add brazing material as shown in the figure.

■ Be sure to use the supplied accessory pipes

when carrying out piping work in the field.

■ Be sure that the field installed piping does not

touch other pipes, the bottom panel or side

panel. Especially for the bottom and side

connection, be sure to protect the piping with

suitable insulation, to prevent it from coming into

contact with the casing.

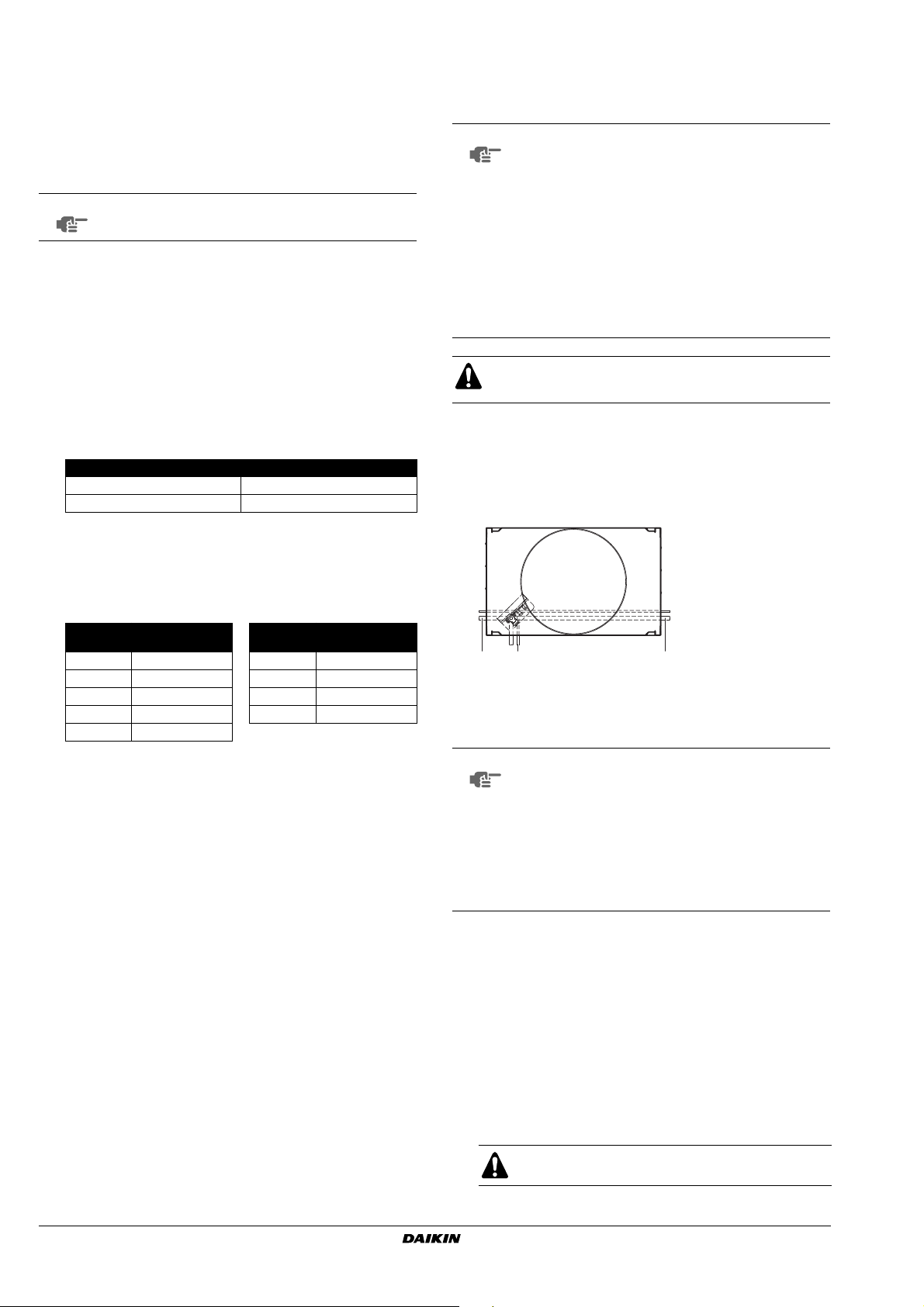

3 One outdoor unit installed: In case of RXYQ8~12

(See figure 8)

■ Front connection:

Remove the stop valve cover to connect.

■ Bottom connection:

Remove the knock holes on the bottom frame and route the

piping under the bottom frame.

A Front connection

Remove the stop valve cover to connect.

B Bottom connection:

Remove the knock holes on the bottom frame and route the piping

under the bottom frame

1 Gas pipe stop valve

2 Liquid pipe stop valve

3 Service port for adding refrigerant

4 Gas side accessory pipe (1)

5 Gas side accessory pipe (2)

6 Liquid side accessory pipe (1)

7 Liquid side accessory pipe (2)

8 Brazing

9 Gas side piping (field supply)

10 Liquid side piping (field supply)

11 Punch the knockout holes (use a hammer)

4 Outdoor units installed in a multiple outdoor unit system:

RXYQ16~36

■ Front connection:

Remove the stop valve cover to connect. (See figure 8)

■ Bottom connection:

Remove the knock holes on the bottom frame and route the

piping under the bottom frame. (See figure 8)

4.1 Precautions when connecting piping between outdoor

units (multiple outdoor unit system)

■ To connect the piping between outdoor units, an optional

multi connection piping kit BHFQ22P1007/1517 is always

required. When installing the piping, follow the instructions in

the installation manual that comes with the kit.

■ Only proceed with piping work after considering the

limitations on installing listed here and in the chapter

"6.4. Connecting the refrigerant piping" on page 5, always

referring to the installation manual delivered with the kit.

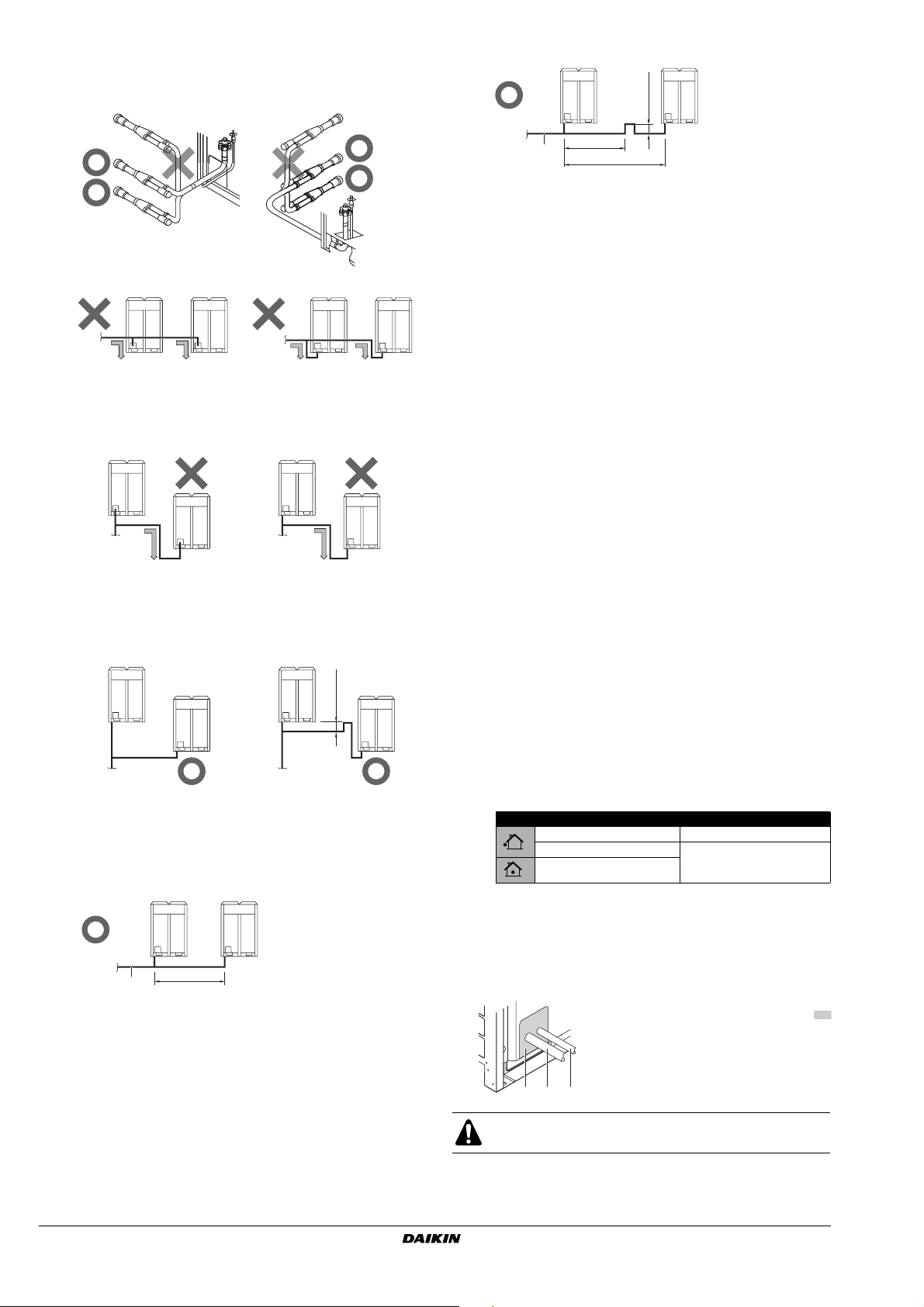

4.2 Possible installation patterns and configurations

■ The piping between the outdoor units must be routed level or

slightly upward to avoid the risk of oil retention into the piping

side.

Pattern 1

1

1

1 To indoor unit

Pattern 2

1

1

1 To indoor unit

Prohibited patterns: change to pattern 1 or 2.

1

1

2

1 To indoor unit

2 Piping between outdoor units

2

■ Processing the gas side accessory pipe (2)

Only in case of connecting at lateral side, cut the gas side

accessory pipe (2) as shown in figure 11.

1 Gas side accessory pipe

2 Cutting location

3 Gas side piping (field supply)

4 Base

Unit type A B C D

8 Hp

10 Hp

12 Hp

RXYQ8~12P7Y1K + RXYQ8~12P7YLK

VRVIII System air conditioner

4PW41760-1

(mm)

156 17 188 247

(mm)

150 29 192 247

(mm)

150 29 192 247

Installation manual

6

■ To avoid the risk of oil retention to the outmost outdoor unit,

h

always connect the stop valve and the piping between

outdoor units as shown in the 4 correct possibilities of the

figure below.

Prohibited patterns: change to pattern 1 or 2.

1

2 2

1 To indoor unit

2 Oil collects to the outmost outdoor unit.

1

22

Change to configuration as in figures below

11

22

1 To indoor unit

2 Oil collects to the outmost outdoor unit when the system

stops.

Correct configuration

≥200 mm

11

1 To indoor unit

■ If the piping length between the outdoor units exceeds 2 m,

create a rise of 200 mm or more in the gas line within a

length of 2 m from the kit.

- If ≤2 m

1

2

≤2 m

- If ≥2 m

≥200 mm

1

1 To indoor unit

2 Piping between outdoor units

≤2 m

2

≥2 m

5 Branching the refrigerant piping

■ For installation of the refrigerant branching kit, refer to the

installation manual delivered with the kit.

(See figure 13)

1 Horizontal surface

Follow the conditions listed below:

- Mount the refnet joint so that it branches either

horizontally or vertically.

- Mount the refnet header so that it branches horizontally.

■ Installation of the multi connection piping kit

(See figure 17)

- Install the joints horizontally, so that the caution label (1)

attached to the joint comes to the top.

Do not tilt the joint more than 15° (see view A).

Do not install the joint vertically (see view B).

- Make sure that the total length of the piping connected to

the joint is absolute straight for more than 500 mm. Only

if a straight field piping of more than 120 mm is

connected, more than 500 mm of straight section can be

ensured.

- Improper installation may lead to malfunction of the

outdoor unit.

6 Piping length restrictions

Make sure to perform the piping installation within the range of

the maximum allowable pipe length, allowable level difference

and allowable length after branching as indicated in

"6.6. Example of connection" on page 8.

6.5. Protection against contamination when installing pipes

-Take measures to prevent foreign materials like moisture and

contamination from mixing into the system.

Installation period Protection method

More than a month Pinch the pipe

Less than a month Pinch or tape the pipe

Regardless of the period

- Great caution is needed when passing copper tubes through

walls.

- Block all gaps in the holes for passing out piping and wiring

using sealing material (field supply). (The capacity of the unit

will drop and small animals may enter the machine.)

Example: passing piping out through the front

1 To indoor unit

2 Piping between outdoor units

Installation manual

7

1 Plug the areas marked with "

(When the piping is routed from t

front panel.)

2 Gas side piping

3 Liquid side piping

123

After all the piping has been connected, make sure there is

no gas leak. Use nitrogen to perform a gas leak check.

RXYQ8~12P7Y1K + RXYQ8~12P7YLK

VRVIII System air conditioner

4PW41760-1

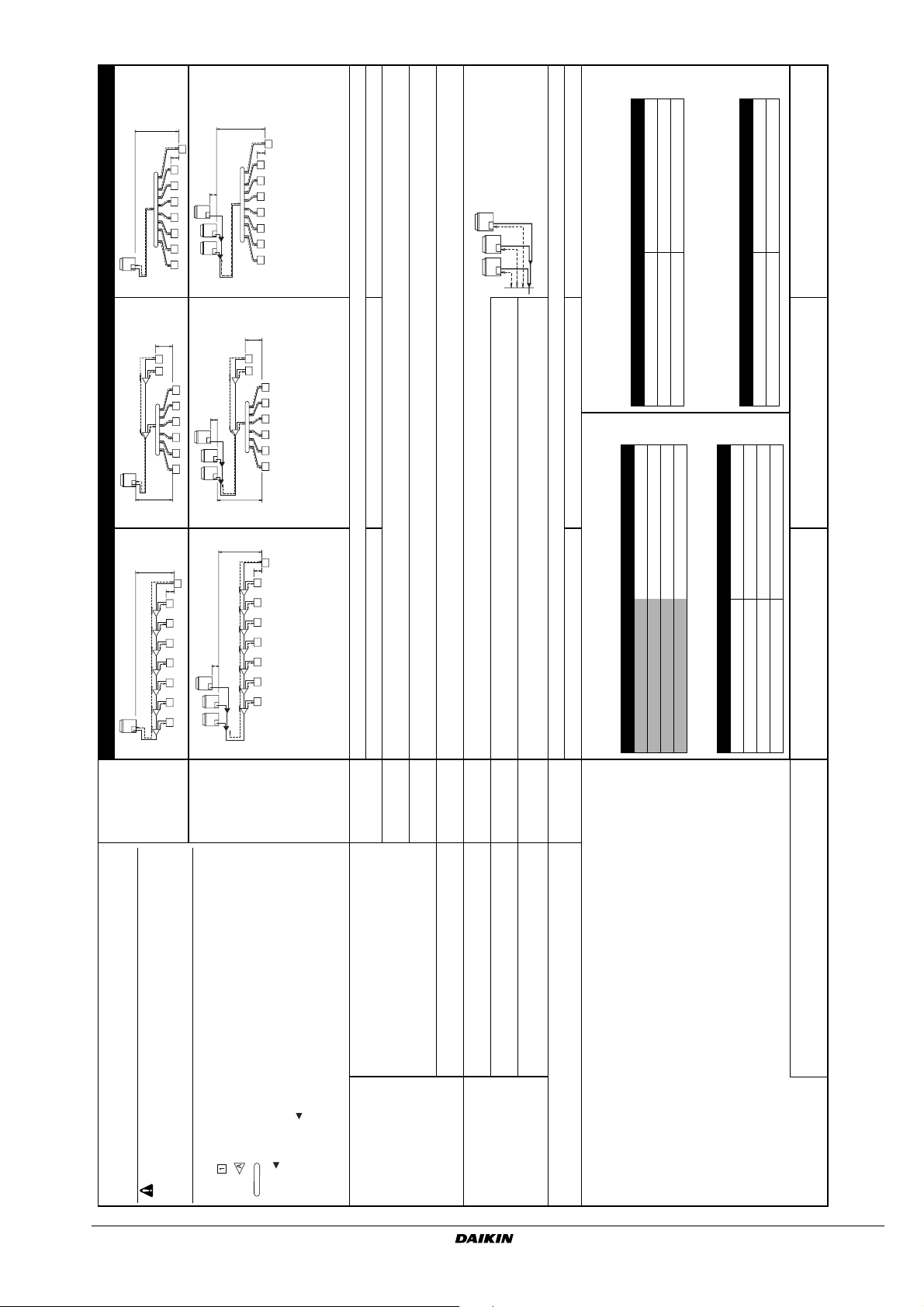

6.6. Example of connection

H1

i

8

H2

h

g

f

cde

a

123 4567

b

H1

i

8

H2

h

g

H3

f

a

cde

123 4567

b

r≤10 m (Approximate length:

max. 13 m)

s≤10 m (Approximate length:

max: 13 m)

rs t

t≤10 m (Approximate length:

max: 13 m)

(a)

[Example]

in case of refnet header;

indoor units 1+2+3+4+5+6+7+8

H2

k

78

j

B

h

g

i

b

A

123456

a

cde f

H1

p

H1

8

H2

g

Branch with refnet joint Branch with refnet joint and refnet header Branch with refnet header

1234567

hijklmn

ABCDEFG

ab c d e f

H3

H3

k

B

i

b

A

a

H1

H1

g

abcdef

j

p

EFG

D

ABC

H2

78

gh

de f

c

H2

7

123 456

hi j kl mn

8

123456

Pipe length between outdoor(*) and indoor units ≤165 m

[Example] unit 8: a+b+c+d+e+f+g+p≤165 m [Example] unit 6: a+b+h≤165 m, unit 8: a+i+k≤165 m [Example] unit 8: a+i≤165 m

Equivalent pipe length between outdoor(*) and indoor units ≤190 m (Assume equivalent pipe length of refnet joint to be 0.5 m and of the refnet header to be 1.0 m. (for

calculation purposes))

Total piping length from outdoor unit* to all indoor units ≤1000 m

(a) See note 2 on next page

units connected below the refnet header.

<290 KHRQ22M29H (Max. 8 branch)

290≤x<640 KHRQ22M64H (Max. 8 branch)

Indoor capacity type Refrigerant branch kit name

• Choose from the following table in accordance with the total capacity of all the indoor

• Note: 250 type cannot be connected below the refnet header.

How to select the refnet header

≥640 KHRQ22M75H (Max. 8 branch)

How to choose an outdoor multi connection piping kit (needed if the outdoor

[Example] unit 6: b+h≤40 m, unit 8: i+k≤40 m [Example] unit 8: i≤40 m

Choose from the following table in accordance with the capacity of the outdoor unit.

Outdoor unit capacity type Refrigerant branch kit name

RXYQ8 KHRQ22M20T

Difference in height between outdoor and indoor units (H1)≤50 m (≤40 m if outdoor unit is located in a lower

position).

Difference in height between adjacent indoor units (H2)≤15 m

Difference in height between outdoor unit (main) and outdoor unit (sub) (H3)≤5 m

[Example] unit 8: b+c+d+e+f+g+p≤40 m

Pipe length from first refrigerant branch kit (either refnet joint or refnet header) to indoor unit ≤40 m (See note 1 on next page)

How to select the refnet joint

•When using refnet joints at the first branch counted from the outdoor unit side.

RXYQ8+10 KHRQ22M29T9

the total capacity index.

RXYQ12 + RXYQ16~22 KHRQ22M64T

RXYQ24~36 KHRQ22M75T

•For refnet joints other than the first branch, select the proper branch kit model based on

Number of outdoor units Branch kit name

• Choose from the following table in accordance with the number of outdoor units.

unit capacity type is RXYQ16 or more.)

Indoor capacity type Refrigerant branch kit name

<200 KHRQ22M20T

2 BHFQ22P1007

3 BHFQ22P1517

[Example]

200≤x<290 KHRQ22M29T9

290≤x<640 KHRQ22M64T

≥640 KHRQ22M75T

[Example]

in case of refnet joint B; indoor units 7+8,

in case of refnet header; indoor units 1+2+3+4+5+6

in case of refnet joint C; indoor units 3+4+5+6+7+8

One outdoor unit

installed

(RXYQ8~12)

• Use the outdoor unit multi connection piping kit that is sold separately as an option

Example of connection

(Connection of 8 indoor units Heat pump system)

RXYQ8~12P7Y1K + RXYQ8~12P7YLK

VRVIII System air conditioner

4PW41760-1

Outdoor units

installed in a

multiple outdoor

unit system

(RXYQ16~36)

indoor unit

refnet joint

(BHFQ22P1007+1517) for the multi installation of outdoor units. Selection method is

as shown in the right table.

are sold separately as an option of the M-type series and do not use T-joints.

• Do not use the outdoor unit multi connection piping kit (BHFQ22M909+1359) that

refnet header

outdoor multi connection piping kit

Install the joint part ( part in the figure) of the outdoor unit multi connection piping kit

horizontally with attention to the installation restrictions described in "connecting the

refrigerant piping".

Actual pipe length

Equivalent length

Between outdoor and indoor units

(*) If the system capacity is RXYQ16 or more, re-read to the first outdoor branch as

seen from the indoor unit.

Maximum allowable length

Total extension

length

Actual pipe length Piping length from outdoor branch to outdoor unit ≤10 m. Approximate length: max. 13 m

Difference in

height

Difference in

height

Between outdoor branch and outdoor unit (Only for

RXYQ16 or more)

Between outdoor and indoor units

Between indoor and indoor units

Allowable height

Difference in

height

Between outdoor and outdoor units

Allowable length after the branch Actual pipe length

Refrigerant branch kit selection

Refrigerant branch kits can only be used with R410A.

Example of downstream indoor units

Installation manual

8

Loading...

Loading...