Daikin RVLQ05 08CA, RHYHBH05AA, RHYHBH/X08AA, RHYKOMB33AA Installer reference guide

+

Installer reference guide

ROTEX HPU hybrid

RVLQ05+08CA

RHYHBH05AA

RHYHBH/X08AA

RHYKOMB33AA

Installer reference guide

ROTEX HPU hybrid

English

Table of contents

Table of contents

6.5.3 Overview of electrical connections except external

actuators ...................................................................... 22

6.5.4 Overview of electrical connections for external and

internal actuators ......................................................... 22

1 General safety precautions 4

1.1 About the documentation .......................................................... 4

1.1.1 Meaning of warnings and symbols.............................. 4

1.2 For the installer.......................................................................... 4

1.2.1 General ....................................................................... 4

1.2.2 Installation site ............................................................ 4

1.2.3 Refrigerant .................................................................. 5

1.2.4 Water .......................................................................... 5

1.2.5 Electrical ..................................................................... 6

1.2.6 Gas ............................................................................. 6

1.2.7 Gas exhaust................................................................ 7

1.2.8 Local legislation .......................................................... 7

2 About the product 7

3 About the documentation 8

3.1 About this document.................................................................. 8

3.2 Installer reference guide at a glance ......................................... 8

4 About the box 8

4.1 Overview: About the box ........................................................... 8

4.2 Outdoor unit............................................................................... 9

4.2.1 To unpack the outdoor unit ......................................... 9

4.2.2 To remove the accessories from the outdoor unit....... 9

4.3 Indoor unit ................................................................................. 9

4.3.1 To unpack the indoor unit ........................................... 9

4.3.2 To remove the accessories from the indoor unit......... 10

4.4 Gas boiler .................................................................................. 10

4.4.1 To unpack the gas boiler............................................. 10

4.4.2 To remove the accessories from the gas boiler.......... 11

5 About the units and options 11

5.1 Overview: About the units and options...................................... 11

5.2 Identification .............................................................................. 11

5.2.1 Identification label: Outdoor unit ................................. 11

5.2.2 Identification label: Indoor unit .................................... 11

5.2.3 Identification label: gas boiler...................................... 12

5.3 Combining units and options ..................................................... 12

5.3.1 Possible options for the outdoor unit........................... 12

5.3.2 Possible options for the indoor unit............................. 12

5.3.3 Possible options for the gas boiler.............................. 13

5.3.4 Possible combinations of indoor unit and outdoor

unit .............................................................................. 16

5.3.5 Possible combinations of indoor unit and domestic

hot water tank ............................................................. 16

6 Preparation 16

6.1 Overview: Preparation............................................................... 16

6.2 Preparing installation site .......................................................... 16

6.2.1 Installation site requirements of the outdoor unit ........ 16

6.2.2 Additional installation site requirements of the

outdoor unit in cold climates ....................................... 17

6.2.3 Installation site requirements of the indoor unit .......... 17

6.3 Preparing refrigerant piping....................................................... 18

6.3.1 Refrigerant piping requirements.................................. 18

6.3.2 Refrigerant piping insulation ....................................... 18

6.4 Preparing water piping .............................................................. 18

6.4.1 Water circuit requirements .......................................... 18

6.4.2 Formula to calculate the expansion vessel pre-

pressure ...................................................................... 19

6.4.3 To check the water volume and flow rate ................... 19

6.4.4 Changing the pre-pressure of the expansion vessel... 21

6.4.5 To check the water volume: Examples ....................... 21

6.5 Preparing electrical wiring ......................................................... 21

6.5.1 About preparing electrical wiring................................. 21

6.5.2 About preferential kWh rate power supply.................. 21

7 Installation 23

7.1 Overview: Installation ................................................................. 23

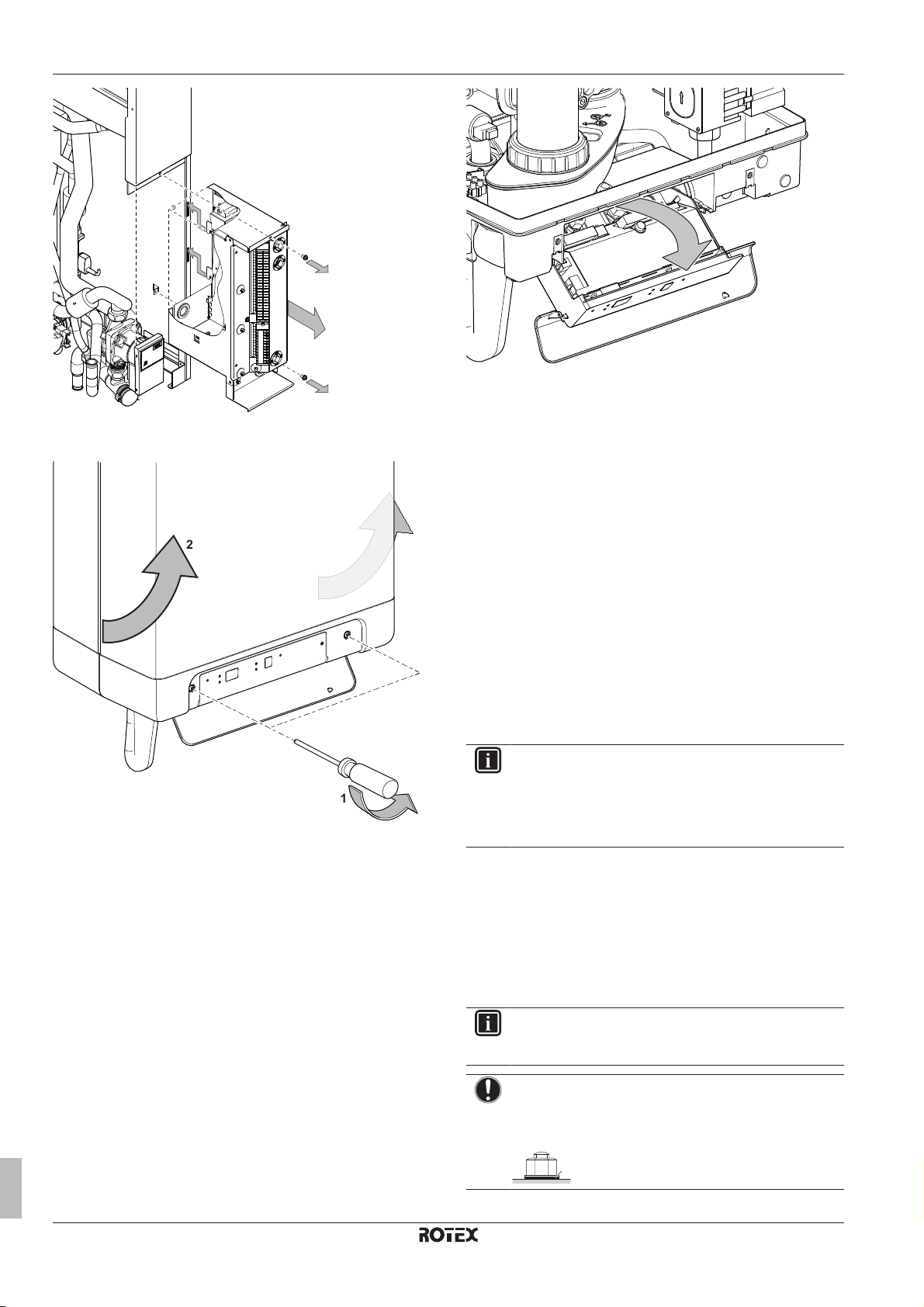

7.2 Opening the units ....................................................................... 23

7.2.1 About opening the units ............................................... 23

7.2.2 To open the outdoor unit.............................................. 23

7.2.3 To open the switch box cover of the indoor unit .......... 23

7.2.4 To open the gas boiler ................................................. 24

7.2.5 To open the switch box cover of the gas boiler............ 24

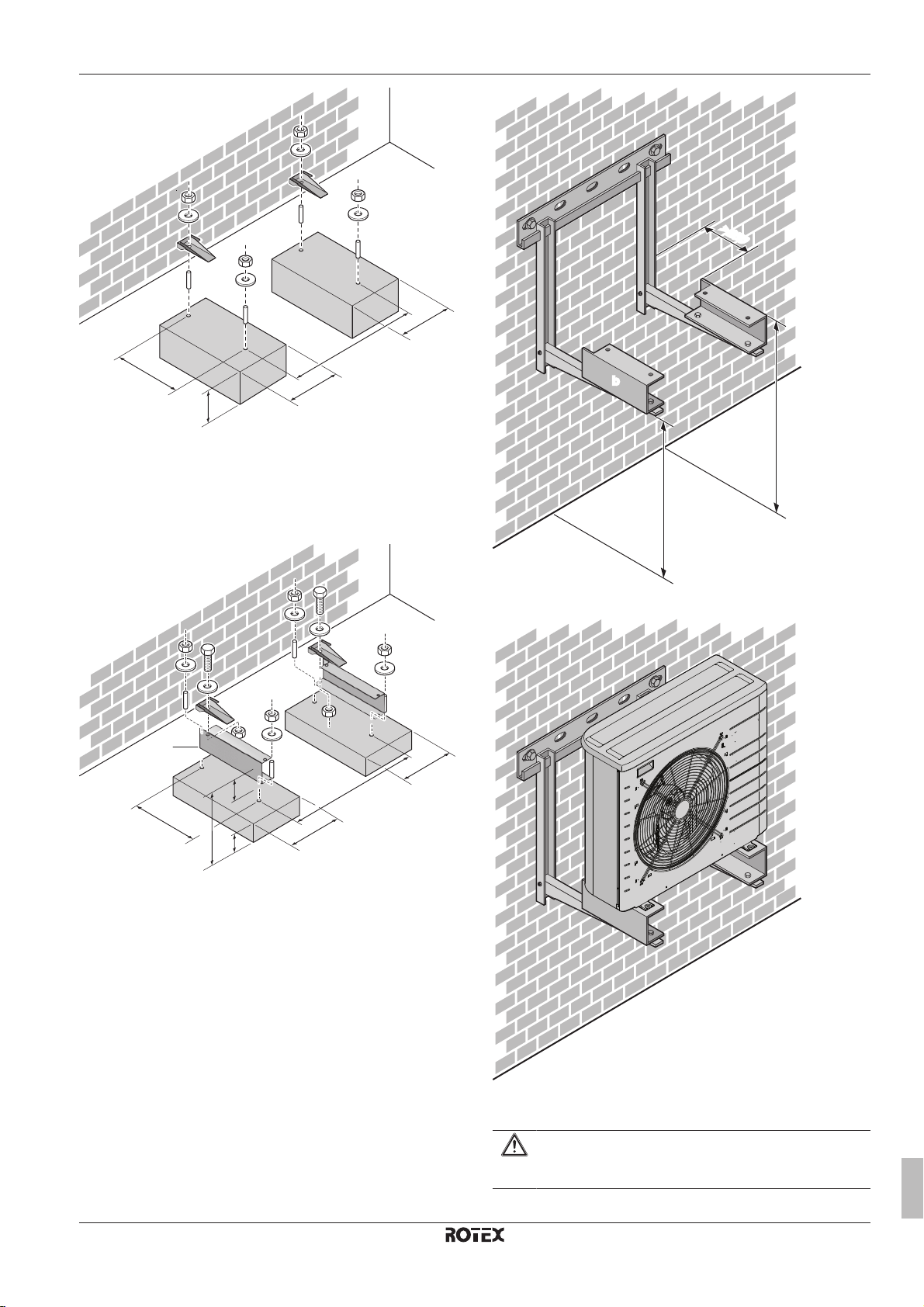

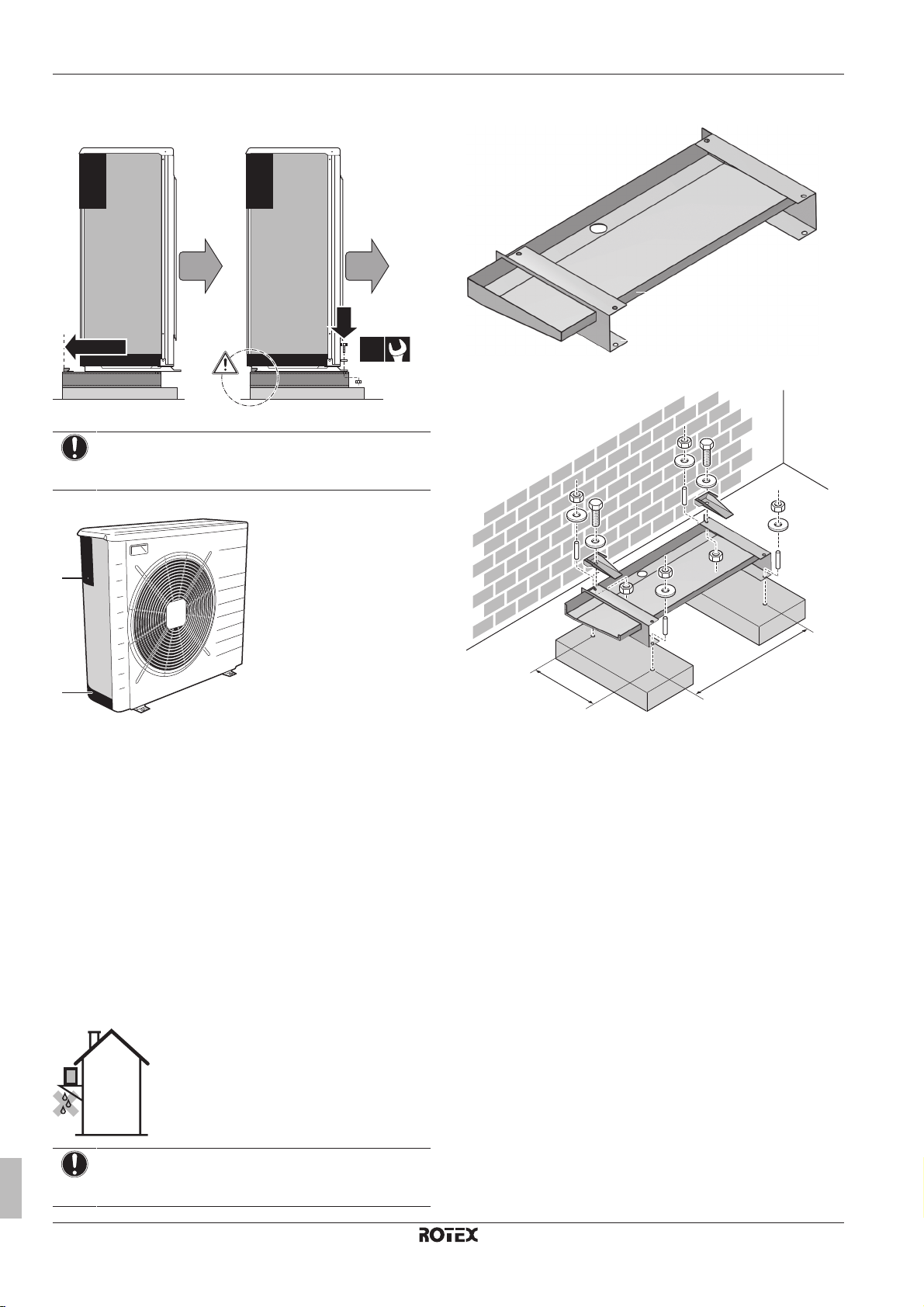

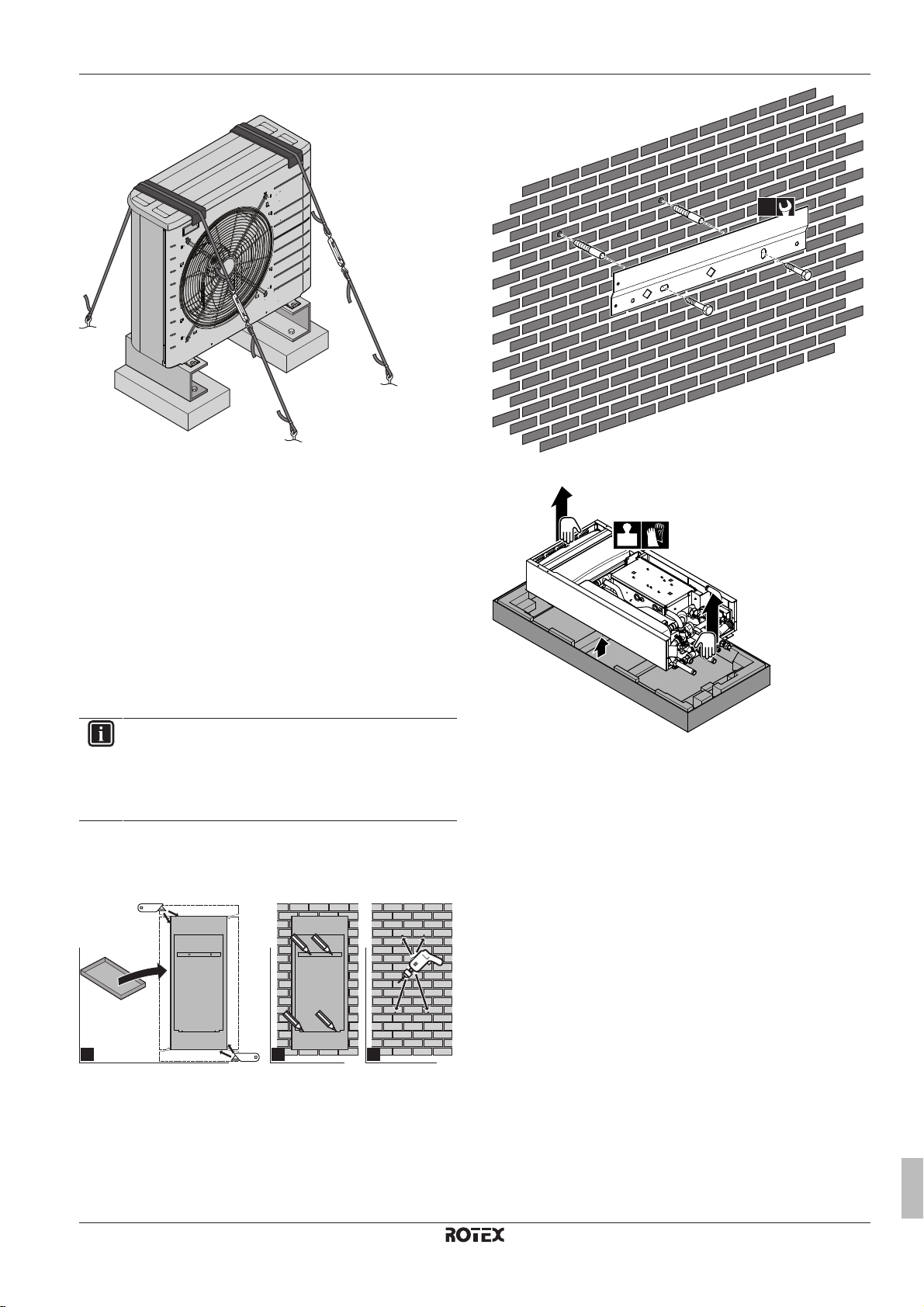

7.3 Mounting the outdoor unit........................................................... 24

7.3.1 About mounting the outdoor unit.................................. 24

7.3.2 Precautions when mounting the outdoor unit............... 24

7.3.3 To provide the installation structure ............................. 24

7.3.4 To install the outdoor unit............................................. 25

7.3.5 To provide drainage ..................................................... 26

7.3.6 To prevent the outdoor unit from falling over ............... 26

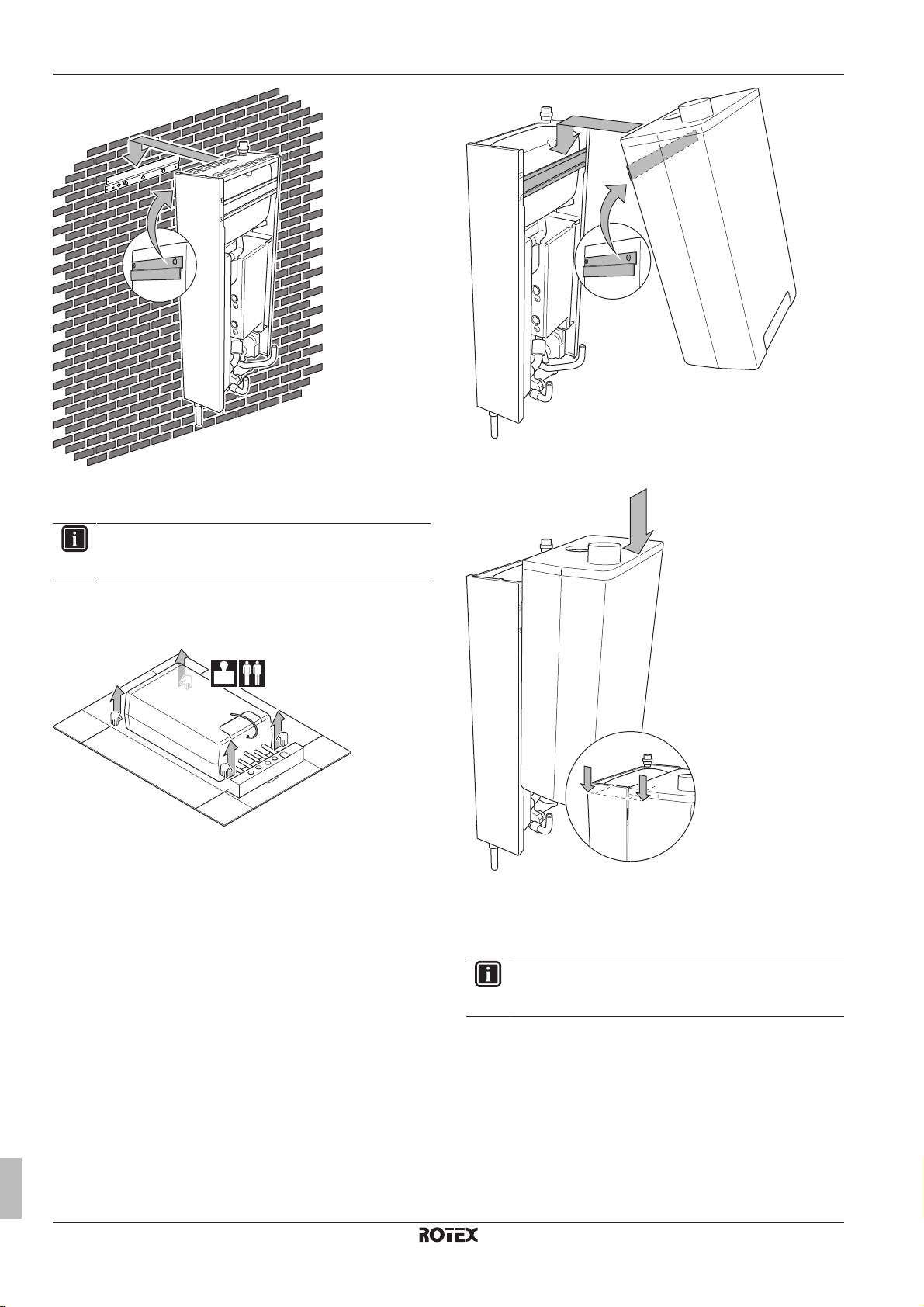

7.4 Mounting the indoor unit............................................................. 27

7.4.1 About mounting the indoor unit.................................... 27

7.4.2 Precautions when mounting the indoor unit................. 27

7.4.3 To install the indoor unit............................................... 27

7.5 Mounting the gas boiler .............................................................. 28

7.5.1 To install the gas boiler ................................................ 28

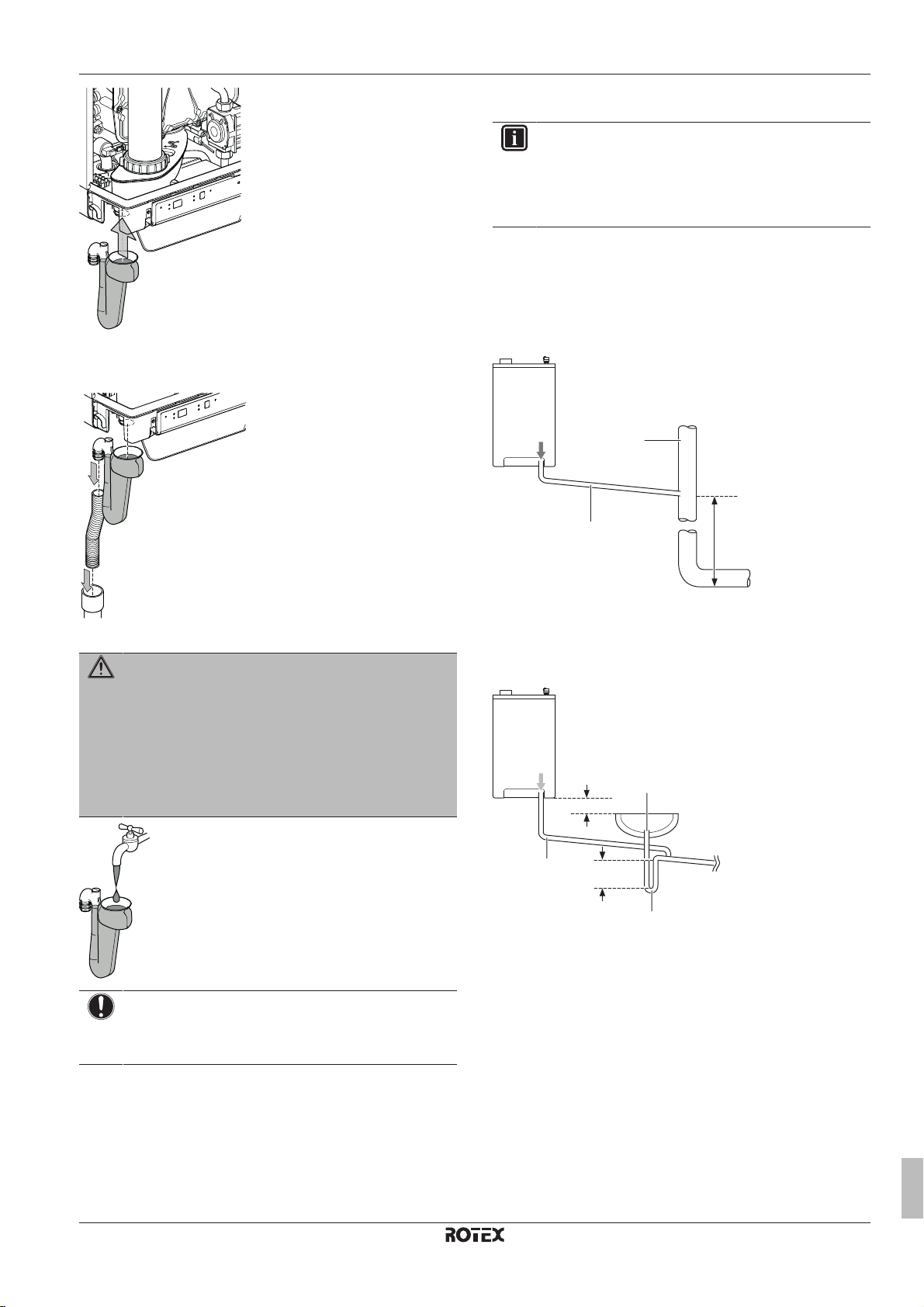

7.5.2 To install the condensate trap...................................... 28

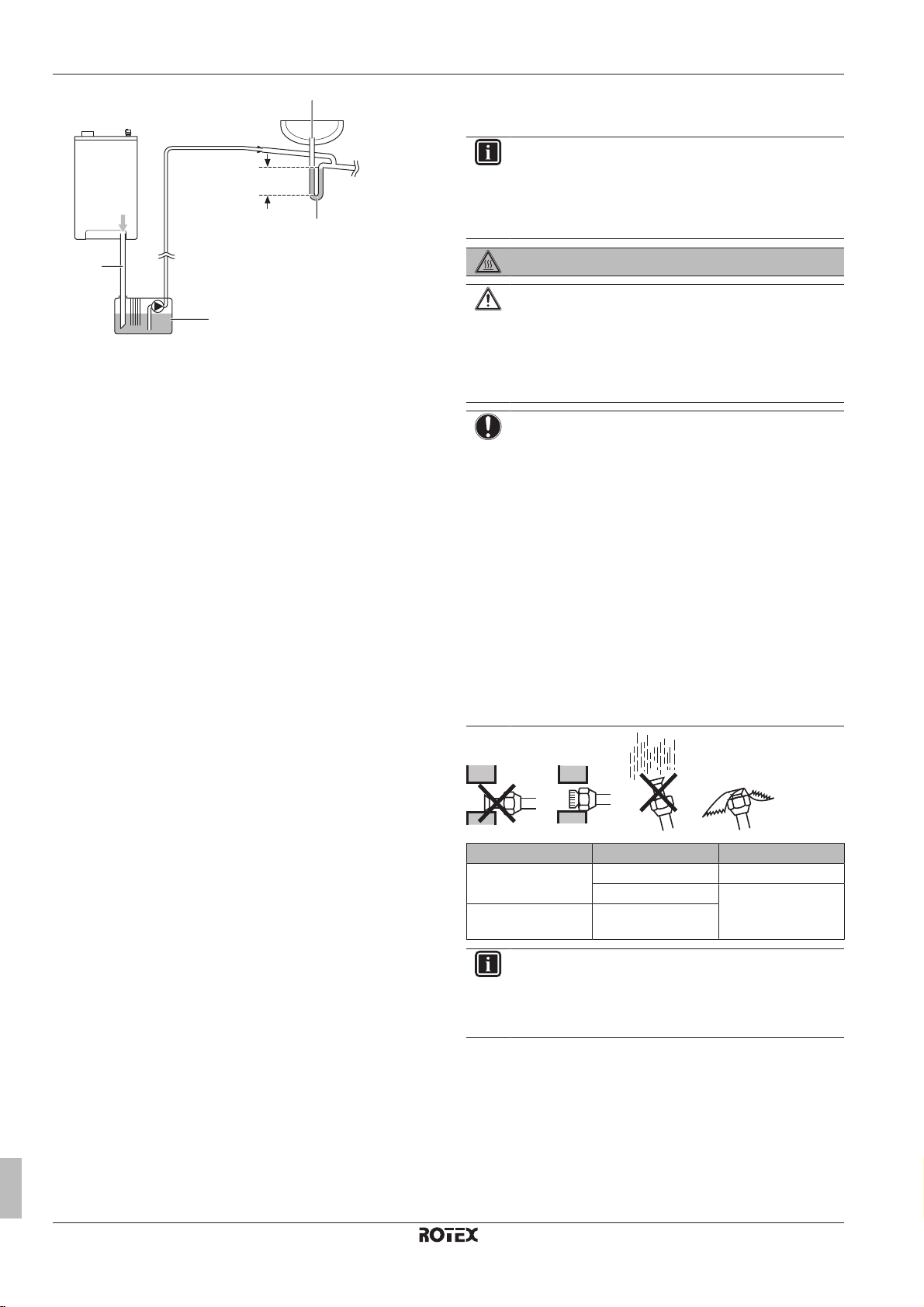

7.6 Condensate pipe work................................................................ 29

7.6.1 Internal connections..................................................... 29

7.6.2 External connections.................................................... 30

7.7 Connecting the refrigerant piping ............................................... 30

7.7.1 About connecting the refrigerant piping ....................... 30

7.7.2 Precautions when connecting the refrigerant piping.... 30

7.7.3 Guidelines when connecting the refrigerant piping...... 30

7.7.4 Pipe bending guidelines............................................... 31

7.7.5 To flare the pipe end .................................................... 31

7.7.6 To braze the pipe end .................................................. 31

7.7.7 Using the stop valve and service port .......................... 31

7.7.8 To connect the refrigerant piping to the outdoor unit ... 32

7.7.9 To connect the refrigerant piping to the indoor unit ..... 32

7.8 Checking the refrigerant piping .................................................. 33

7.8.1 About checking the refrigerant piping .......................... 33

7.8.2 Precautions when checking the refrigerant piping ....... 33

7.8.3 To check for leaks........................................................ 33

7.8.4 To perform vacuum drying ........................................... 33

7.9 Charging refrigerant ................................................................... 34

7.9.1 About charging refrigerant ........................................... 34

7.9.2 Precautions when charging refrigerant ........................ 34

7.9.3 To determine the additional refrigerant amount........... 34

7.9.4 To determine the complete recharge amount.............. 34

7.9.5 To charge refrigerant ................................................... 34

7.9.6 To fix the fluorinated greenhouse gases label ............. 34

7.10 Connecting the water piping ....................................................... 35

7.10.1 About connecting the water piping ............................... 35

7.10.2 Precautions when connecting the water piping............ 35

7.10.3 Connecting the water piping of the indoor unit............. 35

7.10.4 Connecting the water piping of the gas boiler .............. 35

7.10.5 To fill the space heating circuit..................................... 36

7.10.6 To fill the domestic water circuit of the gas boiler ........ 36

7.10.7 To fill the domestic hot water tank ............................... 36

7.10.8 To insulate the water piping ......................................... 36

7.11 Connecting the electrical wiring.................................................. 37

7.11.1 About connecting the electrical wiring.......................... 37

7.11.2 Precautions when connecting the electrical wiring ...... 37

7.11.3 Guidelines when connecting the electrical wiring ........ 37

7.11.4 To connect the electrical wiring on the outdoor unit..... 37

7.11.5 To connect the electrical wiring on the indoor unit ....... 38

7.11.6 To connect the main power supply of the indoor unit .. 39

7.11.7 To connect the main power supply of the gas boiler.... 39

Installer reference guide

2

RVLQ05+08CAV4 + RHYHBH05AA + RHYHBH/X08AA +

RHYKOMB33AA

ROTEX HPU hybrid

4P355635-1A – 2016.02

Table of contents

7.11.8 To connect the communication cable between gas

boiler and indoor unit .................................................. 40

7.11.9 To connect the user interface ..................................... 40

7.11.10 To connect the shut-off valve...................................... 41

7.11.11 To connect the electrical meter................................... 41

7.11.12 To connect the gas meter ........................................... 42

7.11.13 To connect the domestic hot water pump ................... 42

7.11.14 To connect the alarm output ....................................... 42

7.11.15 To connect the space cooling/heating ON/OFF

output .......................................................................... 42

7.11.16 To connect the power consumption digital inputs ....... 43

7.12 Connecting the gas piping ......................................................... 43

7.12.1 To connect the gas pipe.............................................. 43

7.13 Connecting the boiler to the flue gas system ............................ 43

7.13.1 To change the gas boiler to 80/125 concentric

connection................................................................... 43

7.13.2 To change the 60/100 concentric connection to a

dual pipe connection ................................................... 44

7.13.3 Calculate the total piping length .................................. 44

7.13.4 Appliance categories and pipe lengths ....................... 45

7.13.5 Applicable materials .................................................... 46

7.13.6 Flue pipe position ........................................................ 47

7.13.7 Insulation of the gas exhaust and air intake................ 47

7.13.8 Fitting a horizontal flue system ................................... 47

7.13.9 Fitting a vertical flue system........................................ 48

7.13.10 Plume management kit ............................................... 48

7.13.11 Flues in voids .............................................................. 48

7.14 Finishing the outdoor unit installation ........................................ 48

7.14.1 To finish the outdoor unit installation .......................... 48

7.14.2 To close the outdoor unit ............................................ 49

7.15 Finishing the indoor unit installation .......................................... 49

7.15.1 To close the indoor unit............................................... 49

7.16 Finishing the gas boiler installation ........................................... 49

7.16.1 To purge the gas supply ............................................. 49

7.16.2 To close the gas boiler ................................................ 49

7.16.3 To install the cover plate ............................................. 49

8 Configuration 49

8.1 Indoor unit ................................................................................. 49

8.1.1 Overview: Configuration.............................................. 49

8.1.2 Basic configuration...................................................... 52

8.1.3 Advanced configuration/optimization .......................... 60

8.1.4 Menu structure: Overview user settings...................... 71

8.1.5 Menu structure: Overview installer settings ................ 73

8.2 Gas boiler .................................................................................. 74

8.2.1 Overview: Configuration.............................................. 74

8.2.2 Basic configuration...................................................... 74

9 Operation 79

9.1 Overview: Operation.................................................................. 79

9.2 Heating ...................................................................................... 79

9.3 Domestic hot water.................................................................... 79

9.3.1 Flow resistance graph for appliance domestic hot

water circuit................................................................. 79

9.4 Operation modes....................................................................... 79

10 Commissioning 80

10.1 Overview: Commissioning ......................................................... 80

10.2 Precautions when commissioning ............................................. 80

10.3 Checklist before commissioning ................................................ 80

10.4 Checklist during commissioning ................................................ 81

10.4.1 To check the minimum flow rate ................................. 81

10.4.2 Air purge function ........................................................ 81

10.4.3 To perform a test run .................................................. 82

10.4.4 To perform an actuator test run .................................. 82

10.4.5 Underfloor heating screed dryout................................ 83

10.4.6 To perform an air purge on the gas supply ................. 84

10.4.7 To perform a test run on the gas boiler ....................... 84

11 Hand-over to the user 84

12 Maintenance and service 84

12.1 Overview: Maintenance and service .......................................... 85

12.2 Maintenance safety precautions................................................. 85

12.2.1 Opening the indoor unit................................................ 85

12.3 Checklist for yearly maintenance of the outdoor unit ................. 85

12.4 Checklist for yearly maintenance of the indoor unit.................... 85

12.5 To disassemble the gas boiler.................................................... 85

12.6 To clean the inside of the gas boiler........................................... 87

12.7 To assemble the gas boiler ........................................................ 87

13 Troubleshooting 88

13.1 Overview: Troubleshooting......................................................... 88

13.2 Precautions when troubleshooting ............................................. 88

13.3 Solving problems based on symptoms....................................... 88

13.3.1 Symptom: The unit is NOT heating or cooling as

expected ...................................................................... 88

13.3.2 Symptom: The compressor does NOT start (space

heating) ........................................................................ 89

13.3.3 Symptom: The pump is making noise (cavitation) ....... 89

13.3.4 Symptom: The pressure relief valve opens.................. 89

13.3.5 Symptom: The water pressure relief valve leaks ......... 89

13.3.6 Symptom: The space is NOT sufficiently heated at

low outdoor temperatures ............................................ 89

13.3.7 Symptom: The pressure at the tapping point is

temporarily unusual high.............................................. 90

13.3.8 Symptom: Tank disinfection function is NOT

completed correctly (AH-error)..................................... 90

13.3.9 Symptom: Boiler abnormality detection (HJ-11 error) .. 90

13.3.10 Symptom: Boiler/hydrobox combination abnormality

(UA52 error) ................................................................. 90

13.3.11 Symptom: The burner does NOT ignite ....................... 90

13.3.12 Symptom: The burner ignites noisily............................ 90

13.3.13 Symptom: The burner resonates ................................. 91

13.3.14 Symptom: No space heating by the gas boiler ............ 91

13.3.15 Symptom: The power is reduced ................................. 91

13.3.16 Symptom: Space heating does NOT reach the

temperature.................................................................. 91

13.3.17 Symptom: Hot water does NOT reach the

temperature (no tank installed) .................................... 91

13.3.18 Symptom: Hot water does NOT reach the

temperature (tank installed) ......................................... 91

13.4 Solving problems based on error codes ..................................... 91

13.4.1 Error codes: Overview ................................................. 92

14 Disposal 94

14.1 Overview: Disposal..................................................................... 94

14.2 To pump down............................................................................ 94

14.3 To start and stop forced cooling ................................................. 95

15 Technical data 95

15.1 Overview: Technical data ........................................................... 95

15.2 Dimensions and service space................................................... 96

15.2.1 Dimensions and service space: Outdoor unit .............. 96

15.2.2 Dimensions and service space: Indoor unit ................. 97

15.3 Center of gravity ......................................................................... 99

15.3.1 Center of gravity: Outdoor unit ..................................... 99

15.4 Components ...............................................................................100

15.4.1 Components: Outdoor unit ...........................................100

15.4.2 Components: Switch box (outdoor unit) .......................100

15.4.3 Components: Indoor unit.............................................. 100

15.4.4 Components: Switch box (indoor unit) .........................101

15.4.5 Components: Gas boiler ..............................................102

15.5 Piping diagram ........................................................................... 103

15.5.1 Piping diagram: Outdoor unit .......................................103

15.5.2 Piping diagram: Indoor unit ..........................................104

15.6 Wiring diagram ...........................................................................105

15.6.1 Wiring diagram: Outdoor unit .......................................105

15.6.2 Wiring diagram: Indoor unit ..........................................108

15.6.3 Wiring diagram: Gas boiler ..........................................112

15.7 Technical specifications ............................................................. 113

15.7.1 Technical specifications: Gas boiler............................. 113

RVLQ05+08CAV4 + RHYHBH05AA + RHYHBH/X08AA +

RHYKOMB33AA

ROTEX HPU hybrid

4P355635-1A – 2016.02

Installer reference guide

3

1 General safety precautions

15.8 ESP curve ................................................................................. 117

15.8.1 ESP curve: indoor unit ................................................ 117

16 Glossary 118

17 Field settings table 119

1 General safety precautions

1.1 About the documentation

▪ The original documentation is written in English. All other

languages are translations.

▪ The precautions described in this document cover very important

topics, follow them carefully.

▪ The installation of the system, and all activities described in the

installation manual and the installer reference guide must be

performed by an authorized installer.

1.1.1 Meaning of warnings and symbols

DANGER

Indicates a situation that results in death or serious injury.

DANGER: RISK OF ELECTROCUTION

Indicates a situation that could result in electrocution.

DANGER: RISK OF BURNING

Indicates a situation that could result in burning because of

extreme hot or cold temperatures.

WARNING: FLAMMABLE MATERIAL

WARNING

Indicates a situation that could result in death or serious

injury.

CAUTION

Indicates a situation that could result in minor or moderate

injury.

NOTICE

Indicates a situation that could result in equipment or

property damage.

INFORMATION

Indicates useful tips or additional information.

DANGER: RISK OF EXPLOSION

Indicates a situation that could result in explosion.

DANGER: RISK OF POISONING

Indicates a situation that could result in poisoning.

WARNING: PROTECT AGAINST FROST

Indicates a situation that could result in equipment or

property damage.

NOTICE

Improper installation or attachment of equipment or

accessories could result in electric shock, short-circuit,

leaks, fire or other damage to the equipment. Only use

accessories, optional equipment and spare parts made or

approved by ROTEX.

WARNING

Make sure installation, testing and applied materials

comply with applicable legislation (on top of the

instructions described in the ROTEX documentation).

CAUTION

Wear adequate personal protective equipment (protective

gloves, safety glasses,…) when installing, maintaining or

servicing the system.

WARNING

Tear apart and throw away plastic packaging bags so that

nobody, especially children, can play with them. Possible

risk: suffocation.

DANGER: RISK OF BURNING

▪ Do NOT touch the refrigerant piping, water piping or

internal parts during and immediately after operation. It

could be too hot or too cold. Give it time to return to

normal temperature. If you must touch it, wear

protective gloves.

▪ Do NOT touch any accidental leaking refrigerant.

WARNING

Provide adequate measures to prevent that the unit can be

used as a shelter by small animals. Small animals that

make contact with electrical parts can cause malfunctions,

smoke or fire.

CAUTION

Do NOT touch the air inlet or aluminum fins of the unit.

NOTICE

▪ Do NOT place any objects or equipment on top of the

unit.

▪ Do NOT sit, climb or stand on the unit.

NOTICE

Works executed on the outdoor unit are best done under

dry weather conditions to avoid water ingress.

In accordance with the applicable legislation, it might be necessary

to provide a logbook with the product containing at least: information

on maintenance, repair work, results of tests, stand-by periods,…

Also, at least, following information must be provided at an

accessible place at the product:

▪ Instructions for shutting down the system in case of an emergency

▪ Name and address of fire department, police and hospital

▪ Name, address and day and night telephone numbers for

obtaining service

In Europe, EN378 provides the necessary guidance for this logbook.

1.2 For the installer

1.2.1 General

If you are not sure how to install or operate the unit, contact your

dealer.

Installer reference guide

4

1.2.2 Installation site

▪ Provide sufficient space around the unit for servicing and air

circulation.

▪ Make sure the installation site withstands the total weight and

vibration of the installation.

RVLQ05+08CAV4 + RHYHBH05AA + RHYHBH/X08AA +

RHYKOMB33AA

ROTEX HPU hybrid

4P355635-1A – 2016.02

1 General safety precautions

Module Weight

Hybrid module 30kg

Gas module 36kg

Indoor part (Hybrid module + gas

module)

▪ Make sure the area is well ventilated. Do NOT block any

ventilation openings.

▪ Make sure the unit is level.

▪ Make sure walls sensitive to heat (e.g. wood) are protected by

suitable insulation.

▪ ONLY operate the gas boiler if a sufficient supply of combustion

air is ensured. In case of a concentric air/flue gas system

dimensioned according to the specifications of this manual, this is

fulfilled automatically and there are no other conditions for the

equipment installation room. This method of operation applies

exclusively.

▪ This gas boiler is NOT designed for room air dependent operation.

Do NOT install the unit in the following places:

▪ In potentially explosive atmospheres.

▪ In places where there is machinery that emits electromagnetic

waves. Electromagnetic waves may disturb the control system,

and cause malfunction of the equipment.

▪ In places where there is a risk of fire due to the leakage of

flammable gases (example: thinner or gasoline), carbon fibre,

ignitable dust.

▪ In places where corrosive gas (example: sulphurous acid gas) is

produced. Corrosion of copper pipes or soldered parts may cause

the refrigerant to leak.

▪ In bathrooms.

▪ In places where frost is possible. The ambient temperature around

the indoor unit should be >5°C.

Total weight: 66kg

WARNING

Always recover the refrigerant. Do NOT release them

directly into the environment. Use a vacuum pump to

evacuate the installation.

NOTICE

After all the piping has been connected, make sure there is

no gas leak. Use nitrogen to perform a gas leak detection.

NOTICE

▪ To avoid compressor breakdown, do NOT charge more

than the specified amount of refrigerant.

▪ When the refrigerant system is to be opened,

refrigerant must be treated according to the applicable

legislation.

WARNING

Make sure there is no oxygen in the system. Refrigerant

may only be charged after performing the leak test and the

vacuum drying.

▪ In case re-charge is required, refer to the nameplate of the unit. It

states the type of refrigerant and necessary amount.

▪ The unit is factory charged with refrigerant and depending on pipe

sizes and pipe lengths some systems require additional charging

of refrigerant.

▪ Only use tools exclusively for the refrigerant type used in the

system, this to ensure pressure resistance and prevent foreign

materials from entering into the system.

▪ Charge the liquid refrigerant as follows:

If Then

A siphon tube is present

(i.e., the cylinder is marked with

"Liquid filling siphon attached")

Charge with the cylinder upright.

1.2.3 Refrigerant

If applicable. See the installation manual or installer reference guide

of your application for more information.

NOTICE

Make sure refrigerant piping installation complies with

applicable legislation. In Europe, EN378 is the applicable

standard.

NOTICE

Make sure the field piping and connections are not

subjected to stress.

WARNING

During tests, NEVER pressurize the product with a

pressure higher than the maximum allowable pressure (as

indicated on the nameplate of the unit).

WARNING

Take sufficient precautions in case of refrigerant leakage. If

refrigerant gas leaks, ventilate the area immediately.

Possible risks:

▪ Excessive refrigerant concentrations in a closed room

can lead to oxygen deficiency.

▪ Toxic gas may be produced if refrigerant gas comes

into contact with fire.

A siphon tube is NOT present Charge with the cylinder upside

down.

▪ Open refrigerant cylinders slowly.

▪ Charge the refrigerant in liquid form. Adding it in gas form may

prevent normal operation.

CAUTION

When the refrigerant charging procedure is done or when

pausing, close the valve of the refrigerant tank

immediately. If the valve is not closed immediately,

remaining pressure might charge additional refrigerant.

Possible consequence: Incorrect refrigerant amount.

1.2.4 Water

If applicable. See the installation manual or installer reference guide

of your application for more information.

NOTICE

Make sure water quality complies with EU directive

98/83EC.

RVLQ05+08CAV4 + RHYHBH05AA + RHYHBH/X08AA +

RHYKOMB33AA

ROTEX HPU hybrid

4P355635-1A – 2016.02

Installer reference guide

5

1 General safety precautions

Avoid damages caused by deposits and corrosion. To prevent

corrosion products and deposits, observe the applicable regulations

of technology.

Measures for desalination, softening or hardness stabilization are

necessary if the filling and top-up water have a high total hardness

(>3 mmol/l–sum of the calcium and magnesium concentrations,

calculated as calcium carbonate).

Using filling water and top-up water which does NOT meet the stated

quality requirements can cause a considerably reduced service life

of the equipment. The responsibility for this is entirely that of the

user.

1.2.5 Electrical

DANGER: RISK OF ELECTROCUTION

▪ Turn OFF all power supply before removing the

switch box cover, connecting electrical wiring or

touching electrical parts.

▪ Disconnect the power supply for more than 1minute,

and measure the voltage at the terminals of main circuit

capacitors or electrical components before servicing.

The voltage MUST be less than 50 V DC before you

can touch electrical components. For the location of the

terminals, see the wiring diagram.

▪ Do NOT touch electrical components with wet hands.

▪ Do NOT leave the unit unattended when the service

cover is removed.

WARNING

If NOT factory installed, a main switch or other means for

disconnection, having a contact separation in all poles

providing full disconnection under overvoltage category III

condition, shall be installed in the fixed wiring.

WARNING

▪ ONLY use copper wires.

▪ Make sure the field wiring complies with the applicable

legislation.

▪ All field wiring must be performed in accordance with

the wiring diagram supplied with the product.

▪ NEVER squeeze bundled cables and make sure they

do not come in contact with the piping and sharp

edges. Make sure no external pressure is applied to the

terminal connections.

▪ Make sure to install earth wiring. Do NOT earth the unit

to a utility pipe, surge absorber, or telephone earth.

Incomplete earth may cause electrical shock.

▪ Make sure to use a dedicated power circuit. NEVER

use a power supply shared by another appliance.

▪ Make sure to install the required fuses or circuit

breakers.

▪ Make sure to install an earth leakage protector. Failure

to do so may cause electric shock or fire.

▪ When installing the earth leakage protector, make sure

it is compatible with the inverter (resistant to high

frequency electric noise) to avoid unnecessary opening

of the earth leakage protector.

NOTICE

Precautions when laying power wiring:

▪ Do not connect wiring of different thicknesses to the

power terminal block (slack in the power wiring may

cause abnormal heat).

▪ When connecting wiring which is the same thickness,

do as shown in the figure below.

▪ For wiring, use the designated power wire and connect

firmly, then secure to prevent outside pressure being

exerted on the terminal board.

▪ Use an appropriate screwdriver for tightening the

terminal screws. A screwdriver with a small head will

damage the head and make proper tightening

impossible.

▪ Over-tightening the terminal screws may break them.

Install power cables at least 1 metre away from televisions or radios

to prevent interference. Depending on the radio waves, a distance of

1metre may not be sufficient.

WARNING

▪ After finishing the electrical work, confirm that each

electrical component and terminal inside the electrical

components box is connected securely.

▪ Make sure all covers are closed before starting up the

unit.

NOTICE

Only applicable if the power supply is three‑phase, and the

compressor has an ON/OFF starting method.

If there exists the possibility of reversed phase after a

momentary black out and the power goes on and off while

the product is operating, attach a reversed phase

protection circuit locally. Running the product in reversed

phase can break the compressor and other parts.

1.2.6 Gas

The gas boiler is factory‑set to:

▪ the type of gas quoted on the type identification plate or on the

setting type identification plate,

▪ the gas pressure quoted on the type identification plate.

Operate the unit ONLY with the gas type and gas pressure indicated

on these type identification plates.

Installation and adaptation of the gas system MUST be conducted

by:

▪ personnel qualified for this work,

▪ in compliance with valid gas installation related guidelines,

▪ in accordance with applicable regulations of the gas supply

company,

▪ In accordance with local and national regulations.

Installer reference guide

6

Boilers that use natural gas MUST be connected to a governed

meter.

Boilers that use liquid petroleum gas (LPG) MUST be connected to a

regulator.

The size of the gas supply pipe should under no circumstance be

less than 22mm.

RVLQ05+08CAV4 + RHYHBH05AA + RHYHBH/X08AA +

RHYKOMB33AA

ROTEX HPU hybrid

4P355635-1A – 2016.02

2 About the product

The meter or regulator and pipe work to the meter MUST be

checked preferably by the gas supplier. This is to ensure that the

equipment works good and meets the gas flow and pressure

requirements.

DANGER

If you smell gas:

▪ call immediately your local gas supplier and your

installer,

▪ call the suppliers's number on the side of the LPG tank

(if applicable),

▪ turn off the emergency control valve at the meter/

regulator,

▪ do NOT turn electrical switches ON or OFF,

▪ do NOT strike matches or smoke,

▪ put out naked flames,

▪ open doors and windows immediately,

▪ keep people away from the affected area.

1.2.7 Gas exhaust

Flue systems must NOT be modified or installed in any way other

than as described in the fitting instructions. Any misuses or

unauthorized modifications to the appliance, flue or associated

components and systems could invalidate the warranty. The

manufacturer accepts no liability arising from any such actions,

excluding statutory rights.

It is NOT allowed to combine flue system parts purchased from

different suppliers.

1.2.8 Local legislation

See the local and national regulations.

Local regulations for UK

It is law that all gas appliances are installed by a gas safe registered

competent engineer and in accordance with the following

recommendations:

▪ Current Gas Safety (Installation and Use) Regulations

▪ All current building regulations

▪ Building Standards (Scotland) Consolidated

▪ This appliance MUST be installed in accordance with the Gas

(Safety and Use) Regulations, current Building Regulations,

Building Standards (Scotland), I.S.813 Installation of Gas

Appliances (Ireland), IEE Wiring Regulations (BS 7671), Health

and Safety Document No. 635 (Electricity at Work Regulations)

and Local Water Authority Bye Laws

▪ UK Water Regulations and Bye Laws

▪ Health & Safety

The installation MUST comply with the following British Standards

codes of practice:

▪ BS 5440: Flues and Ventilation for gas appliances of rated input

NOT exceeding 70kW (Part 1 Flues)

▪ BS 5440: Flues and Ventilation for gas appliances of rated input

NOT exceeding 70kW (Part 2 Air Supply)

▪ BS 5546: 2000 Installation of gas hot water supplies for domestic

purposes.

▪ BS 5549: 1990 Forced circulation hot water systems.

▪ BS 6700: 1997 Design, Installation, testing and maintenance of

services supplying hot water

▪ BS 6798: 2000 Specification for installation of gas fired hot water

boilers of rated input NOT exceeding 70kW

▪ BS 6891: 1998 Installation of low pressure gas pipe-work

installation up to 35mm (RI)

▪ BS 7593: 1992 Code of practice for treatment of water in heating

systems

▪ BS 7671: 2001 Requirements for electrical installations, IEE

Wiring regulations

▪ BS 7074: 1 Code of practice for domestic and hot water supply

▪ EN12828 Central heating for domestic premises

Potable water: all seals, joints and compounds (including flux and

solder) and components used as part of the secondary domestic

water system MUST be approved by WRAS.

2 About the product

Especially for UK:

The Benchmark Scheme

Benchmark places responsibilities on both manufacturers and

installers. The purpose is to ensure that customers are provided with

the correct equipment for their needs, that it is installed,

commissioned and serviced in accordance with the manufacturer’s

instructions by competent persons and that it meets the

requirements of the appropriate Building Regulations. The

Benchmark Checklist can be used to demonstrate compliance with

Building Regulations and should be provided to the customer for

future reference.

Installers are required to carry out installation, commissioning and

servicing work in accordance with the Benchmark Code of Practice

which is available from the Heating and Hotwater Industry Council

who manage and promote the Scheme. Visit http://

www.centralheating.co.uk for more information.

Approvals

British Gas Service listing:

RHYKOMB33AA*: G.C.N. 47-464-01

The product (hybrid system) is composed of two modules:

▪ heat pump module,

▪ gas boiler module.

These modules MUST always be installed and used together.

RVLQ05+08CAV4 + RHYHBH05AA + RHYHBH/X08AA +

RHYKOMB33AA

ROTEX HPU hybrid

4P355635-1A – 2016.02

Installer reference guide

7

3 About the documentation

a b

a Heat pump module

b Gas boiler module

3 About the documentation

3.1 About this document

Target audience

Authorised installers

Documentation set

This document is part of a documentation set. The complete set

consists of:

▪ General safety precautions:

▪ Safety instructions that you must read before installing

▪ Format: Paper (in the box of the indoor unit)

▪ Heat pump module installation manual:

▪ Installation instructions

▪ Format: Paper (in the box of the indoor unit)

▪ Gas boiler module installation manual:

▪ Installation and operation instructions

▪ Format: Paper (in the box of the gas boiler unit)

▪ Outdoor unit installation manual:

▪ Installation instructions

▪ Format: Paper (in the box of the outdoor unit)

▪ Installer reference guide:

▪ Preparation of the installation, technical specifications,

reference data,…

▪ Format: Digital files on the ROTEX homepage

▪ Addendum book for optional equipment:

▪ Additional info about how to install optional equipment

▪ Format: Paper (in the box of the indoor unit) + Digital files on

the ROTEX homepage

Latest revisions of the supplied documentation may be available on

the regional ROTEX website or via your dealer.

The original documentation is written in English. All other languages

are translations.

3.2 Installer reference guide at a glance

Chapter Description

General safety

precautions

About the product Required combination of heat pump

About the documentation What documentation exists for the

About the box How to unpack the units and remove

About the units and

options

Preparation What to do and know before going

Installation What to do and know to install the

Configuration What to do and know to configure the

Operation Operation modes of the gas boiler

Commissioning What to do and know to commission the

Hand‑over to the user What to give and explain to the user

Maintenance and service How to maintain and service the units

Troubleshooting What to do in case of problems

Disposal How to dispose of the system

Technical data Specifications of the system

Glossary Definition of terms

Field settings table Table to be filled in by the installer, and

Safety instructions that you must read

before installing

module and gas boiler module

installer

their accessories

▪ How to identify the units

▪ Possible combinations of units and

options

on‑site

system

system after it is installed

module

system after it is configured

kept for future reference

Note: There is also an installer settings

table in the user reference guide. This

table has to be filled in by the installer

and handed over to the user.

4 About the box

4.1 Overview: About the box

This chapter describes what you have to do after the boxes with the

outdoor unit, the indoor unit and the gas boiler are delivered on-site.

It contains information about:

▪ Unpacking and handling the units

▪ Removing the accessories from the units

Keep the following in mind:

▪ At delivery, the unit must be checked for damage. Any damage

must be reported immediately to the carrier's claims agent.

▪ Bring the packed unit as close as possible to its final installation

position to prevent damage during transport.

Installer reference guide

8

RVLQ05+08CAV4 + RHYHBH05AA + RHYHBH/X08AA +

RHYKOMB33AA

ROTEX HPU hybrid

4P355635-1A – 2016.02

4 About the box

1

2

57kg

a db c

1× 1× 1× 2×

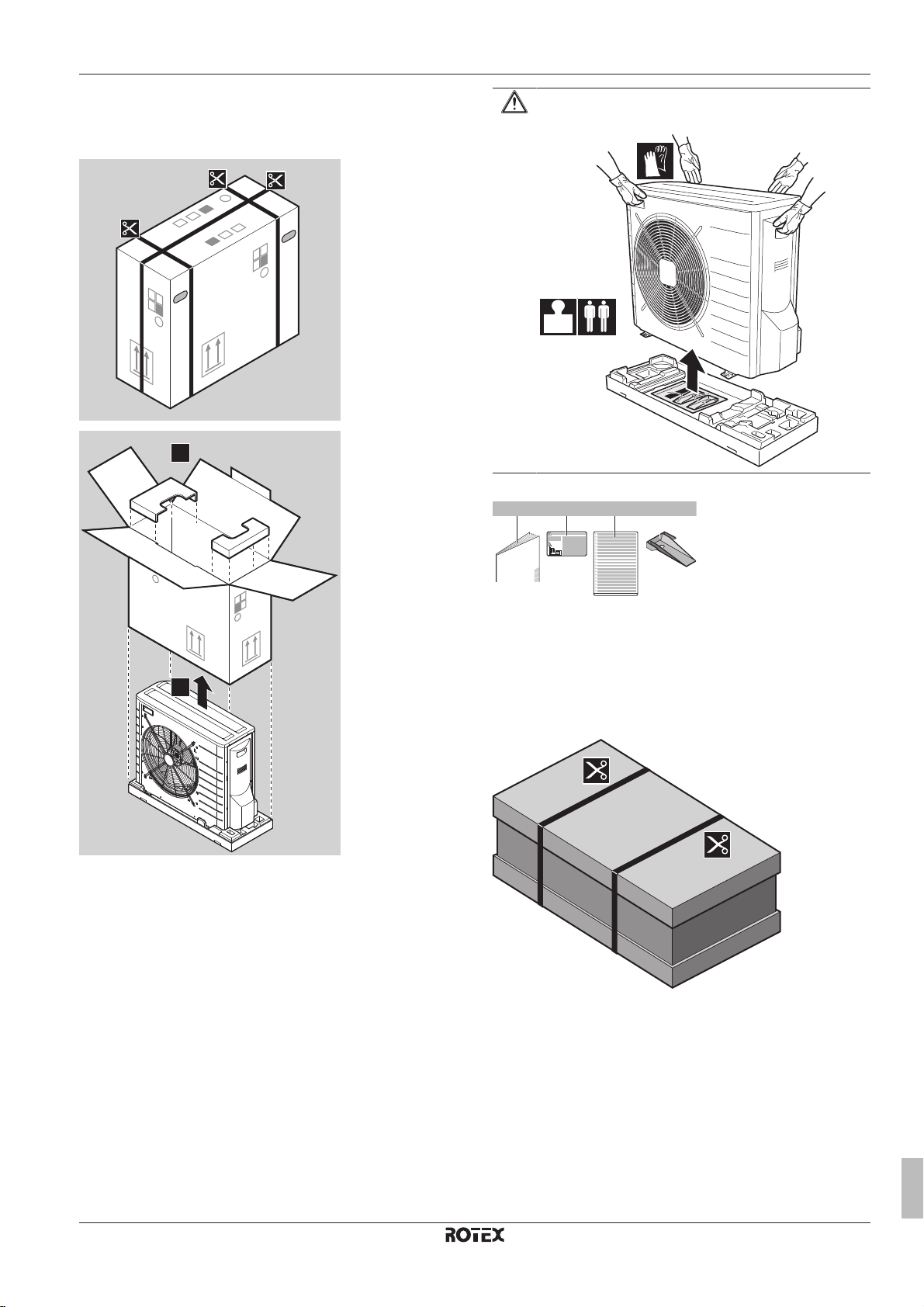

4.2 Outdoor unit

4.2.1 To unpack the outdoor unit

CAUTION

Only handle the outdoor unit as follows:

2 Remove the accessories at the bottom of the package.

4.2.2 To remove the accessories from the outdoor unit

1 Lift the outdoor unit.

a Outdoor unit installation manual

b Fluorinated greenhouse gases label

c Multilingual fluorinated greenhouse gases label

d Unit mounting plate

4.3 Indoor unit

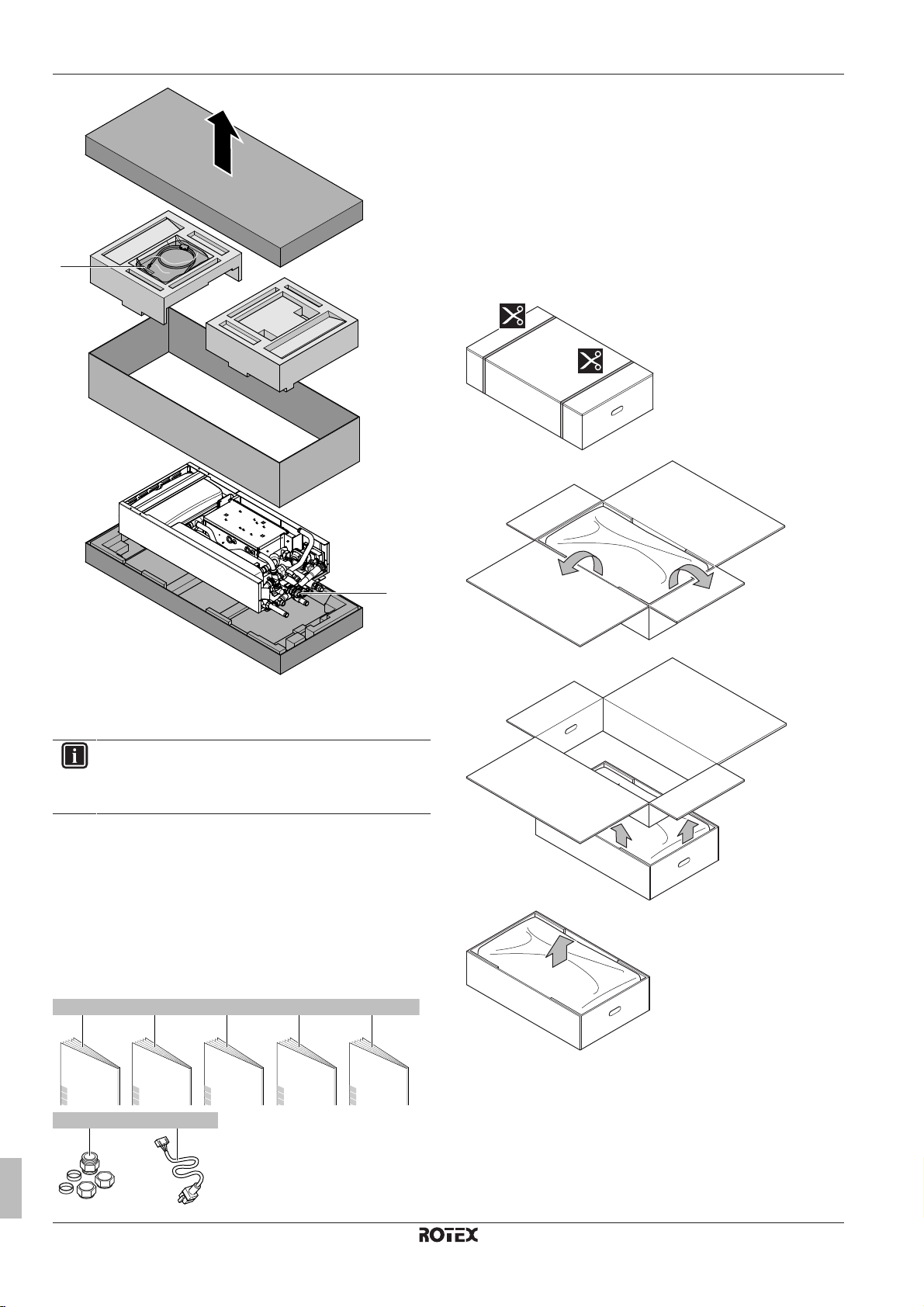

4.3.1 To unpack the indoor unit

RVLQ05+08CAV4 + RHYHBH05AA + RHYHBH/X08AA +

RHYKOMB33AA

ROTEX HPU hybrid

4P355635-1A – 2016.02

Installer reference guide

9

4 About the box

a

b

a b c d e

f g

1

2

a General safety precautions

b Addendum book for optional equipment

c Indoor unit installation manual

d Operation manual

e Quick installation guide

f Connection pieces for gas boiler

g Boiler communication cable

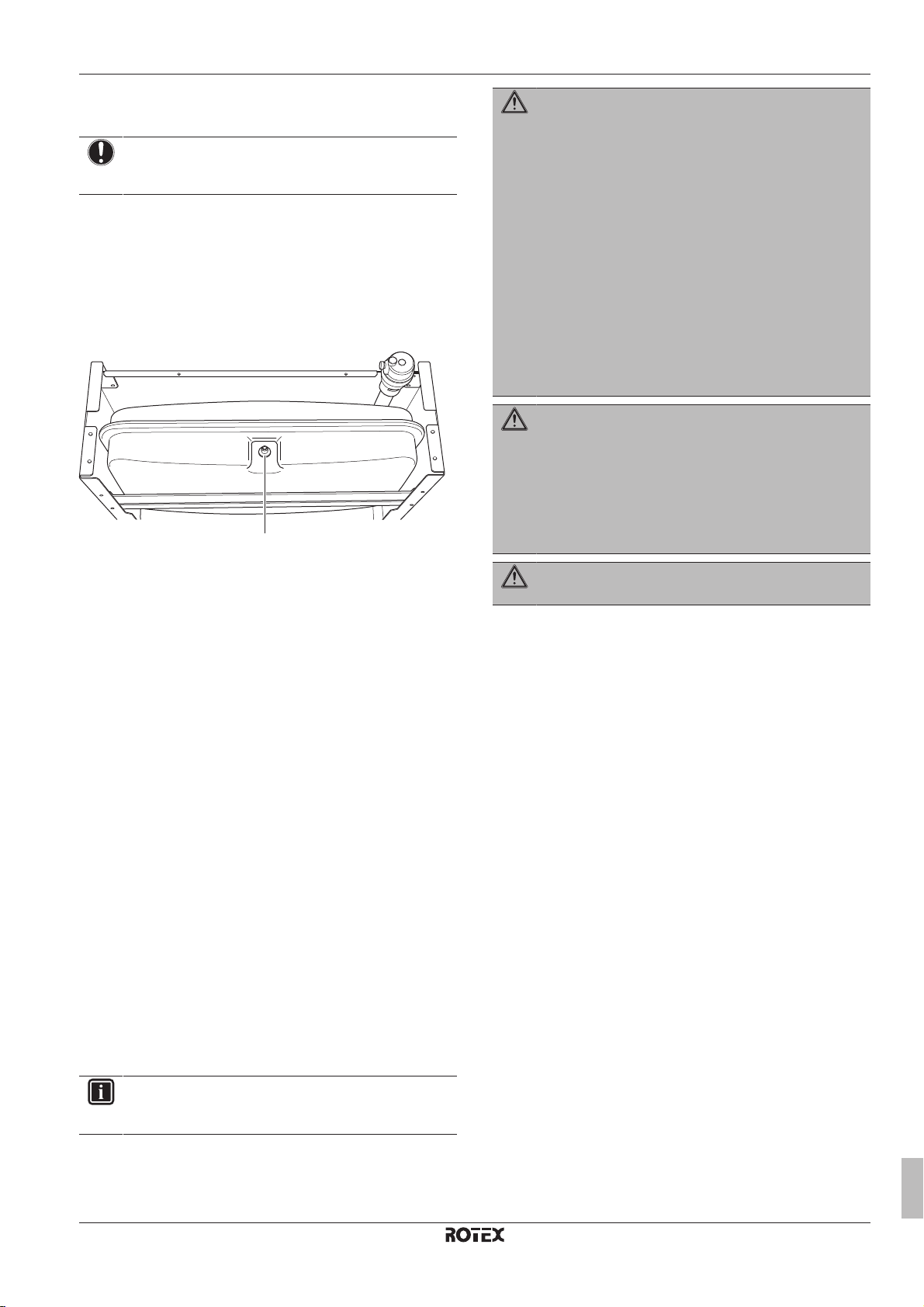

4.4 Gas boiler

4.4.1 To unpack the gas boiler

Before unpacking, move the gas boiler as close as possible to its

installation position.

a Installation manual, operation manual, addendum book for

optional equipment, quick installation guide, general safety

precautions, boiler communication cable

b Connection pieces for the gas boiler

INFORMATION

Do NOT throw away the upper cardboard cover. On the

outside of the cardboard cover, the installation pattern is

printed.

4.3.2 To remove the accessories from the indoor unit

The installation manual, operation manual, addendum book for

optional equipment, general safety precautions, quick installation

guide, and boiler communication cable are located in the upper part

of the box. The connection pieces for the gas boiler are attached to

the water piping.

1 Remove the accessories as described in "4.3.1To unpack the

indoor unit"on page9.

Installer reference guide

10

RVLQ05+08CAV4 + RHYHBH05AA + RHYHBH/X08AA +

RHYKOMB33AA

ROTEX HPU hybrid

4P355635-1A – 2016.02

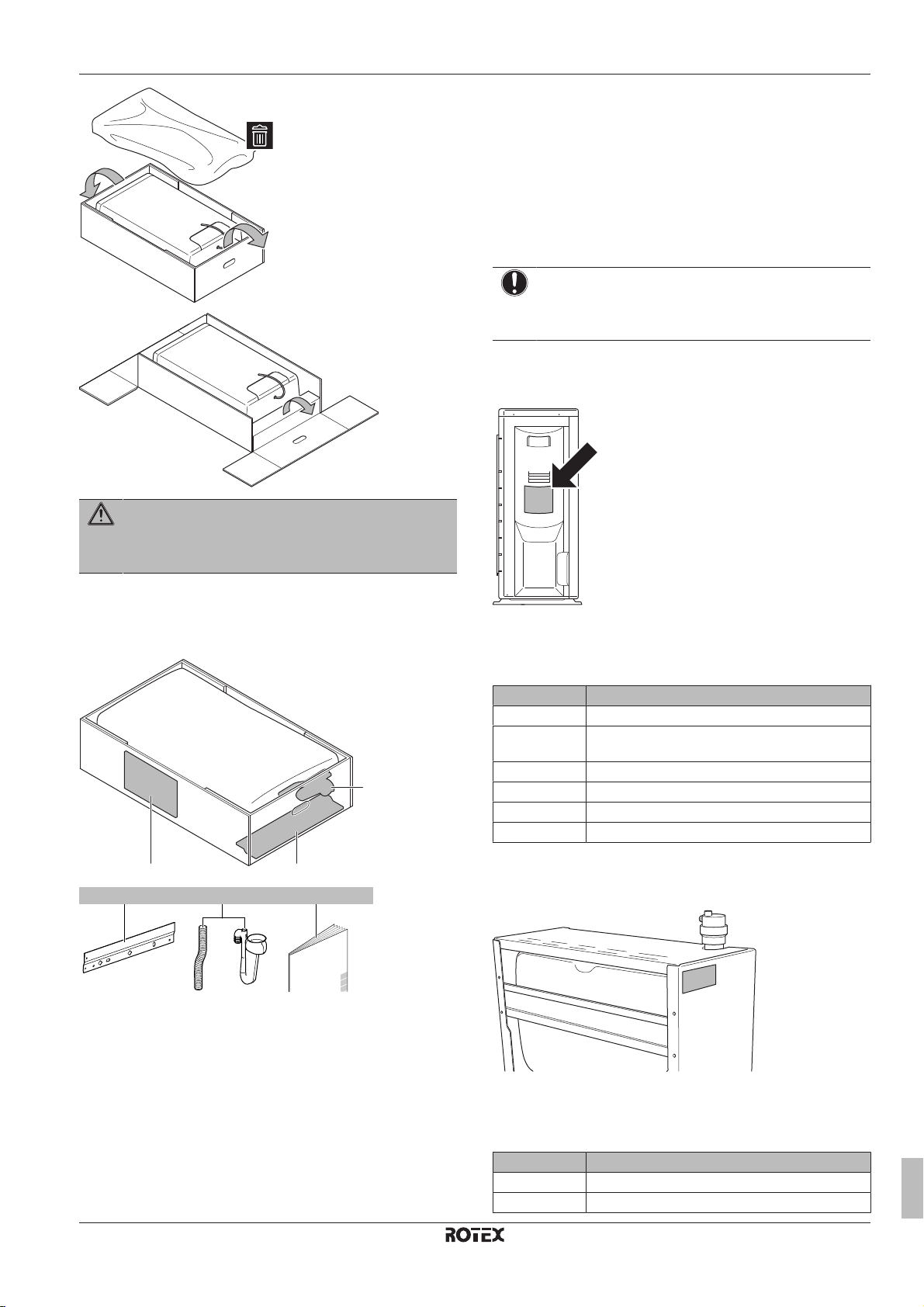

WARNING

a

b

c

a b c

Tear apart and throw away plastic packaging bags so that

nobody, especially children, can play with them. Possible

risk: suffocation.

5 About the units and options

▪ Identifying the indoor unit

▪ Identifying the gas boiler

▪ Combining outdoor and indoor units

▪ Combining the outdoor unit with options

▪ Combining the indoor unit with options

▪ Combining the gas boiler with options

5.2 Identification

NOTICE

When installing or servicing several units at the same time,

make sure NOT to switch the service panels between

different models.

5.2.1 Identification label: Outdoor unit

Location

4.4.2 To remove the accessories from the gas boiler

1 Remove the accessories.

a Mounting strip

b Condensate trap

c Installation manual and operation manual

Model identification

Example: RVLQ05CAV3

Code Explanation

RV Split outdoor pair heat pump

L Low water temperature – ambient zone: −10~

−20°C

Q Refrigerant R410A

05 Capacity class

CA Model series

V3 Power supply

5.2.2 Identification label: Indoor unit

Location

5 About the units and options

5.1 Overview: About the units and options

This chapter contains information about:

▪ Identifying the outdoor unit

RVLQ05+08CAV4 + RHYHBH05AA + RHYHBH/X08AA +

RHYKOMB33AA

ROTEX HPU hybrid

4P355635-1A – 2016.02

Model identification

Example: RHYHBH05AAV3

Code Description

R ROTEX model

HY Hybrid indoor unit

Installer reference guide

11

5 About the units and options

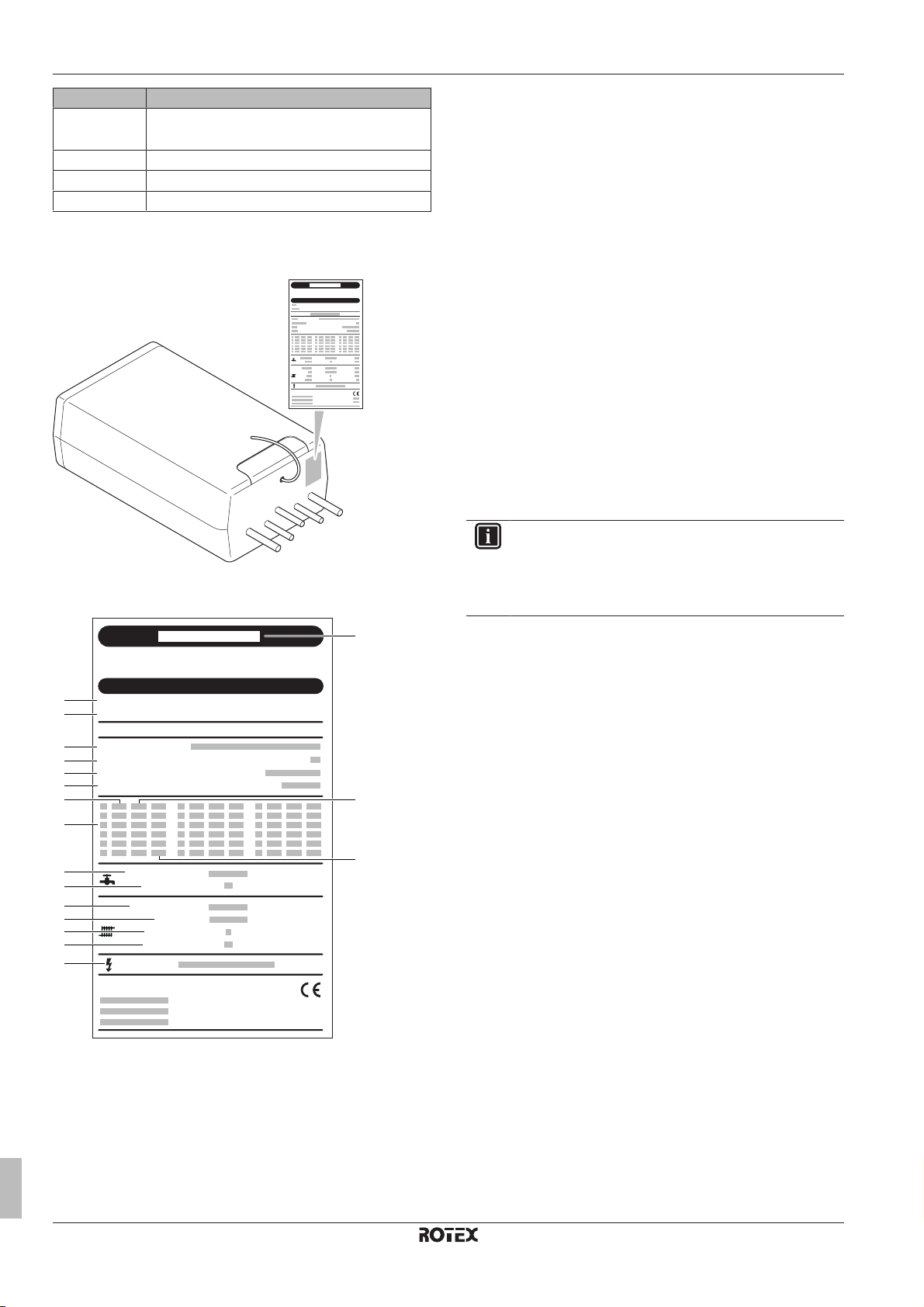

No:

Anno:

Type:

NOx classe:

PIN:

G.C.:

Qnw(net)

PMW

kW

kW

kW

bar

Qn (net)

Pn

PMS

bar

°C

0063

2013

Tmax

Condensing boiler

b

i

j

a

c

d

e

f

k

l

m

n

o

p

q

r

g

h

Code Description

HBH HBH=Hydrobox heating only

HBX=Hydrobox heating and cooling

05 Capacity class

AA Model series

V3 Power supply

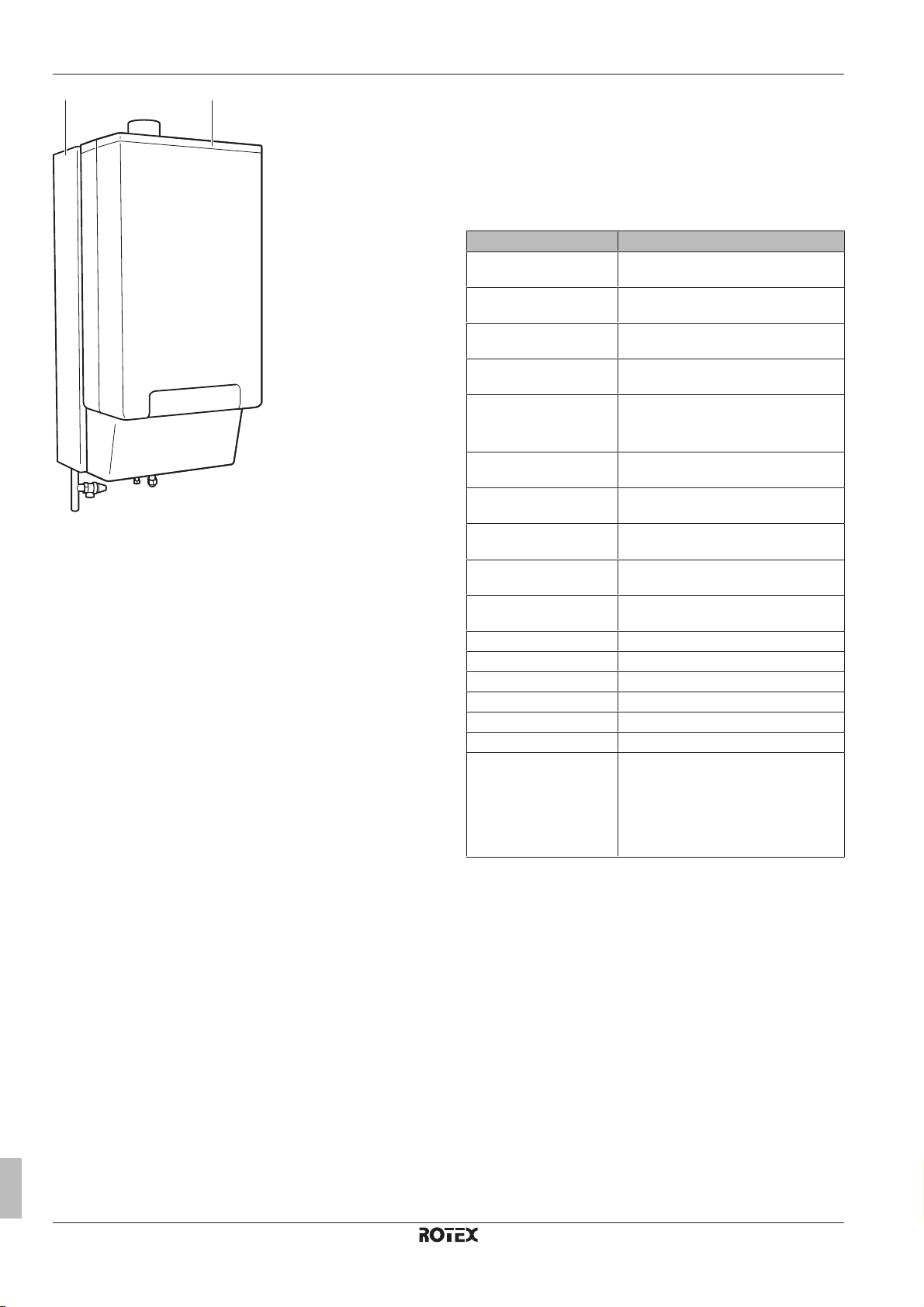

5.2.3 Identification label: gas boiler

Location

Model identification

n Nominal power (kW)

o Maximum space heating pressure (bar)

p Maximum flow temperature (°C)

q Electrical supply

r GCN gas council number

5.3 Combining units and options

5.3.1 Possible options for the outdoor unit

Drain pan (EKDP008CA)

The drain pan is required to gather the drain from the outdoor unit.

The drain pan kit consists of:

▪ Drain pan

▪ Installation brackets

For installation instructions, see the installation manual of the drain

pan.

Drain pan heater (EKDPH008CA)

The drain pan heater is required to avoid freezing-up of the drain

pan.

It is recommended to install this option in colder regions with

possible low ambient temperatures or heavy snowfall.

For installation instructions, see the installation manual of the drain

pan heater.

INFORMATION

In case the drain pan heater is used, the jumper JP_DP on

the service PCB on the outdoor unit MUST be cut.

After cutting the jumper, you MUST reset the outdoor unit

to activate this function.

U-beams (EKFT008CA)

The U-beams are installation brackets on which the outdoor unit can

be installed.

It is recommended to install this option in colder regions with

possible low ambient temperatures or heavy snowfall.

For installation instructions, see the installation manual of the

outdoor unit.

5.3.2 Possible options for the indoor unit

User interface (RKRUCBL*)

The user interface and a possible additional user interface are

available as an option.

The additional user interface can be connected:

Installer reference guide

a Model

b Serial number

c Production year

d Appliance type

e NOx class

f PIN number: notified body reference

g Destination country

h Gas type

i Gas supply pressure (mbar)

j Appliance category

k Domestic hot water heat output (kW)

l Maximum domestic hot water pressure (bar)

m Heat output (space heating) (kW)

12

▪ To have both:

▪ control close to the indoor unit,

▪ room thermostat functionality in the principal space to be

heated.

▪ To have an interface containing other languages.

Following user interfaces are available:

▪ RKRUCBL1 contains following languages: German, French,

Dutch, Italian.

▪ RKRUCBL2 contains following languages: English, Swedish,

Norwegian, Finnish.

▪ RKRUCBL3 contains following languages: English, Spanish,

Greek, Portuguese.

▪ RKRUCBL4 contains following languages: English, Turkish,

Polish, Romanian.

▪ RKRUCBL5 contains following languages: German, Czech,

Slovenian, Slovakian.

RVLQ05+08CAV4 + RHYHBH05AA + RHYHBH/X08AA +

RHYKOMB33AA

ROTEX HPU hybrid

4P355635-1A – 2016.02

5 About the units and options

▪ RKRUCBL6 contains following languages: English, Croatian,

Hungarian, Estonian.

▪ RKRUCBL7 contains following languages: English, German,

Russian, Danish.

Languages on the user interface can be uploaded by PC software or

copied from an user interface to the other.

For installation instructions, see "7.11.9 To connect the user

interface"on page40.

Room thermostat (RKRTWA, RKRTR1, RTRNETA)

You can connect an optional room thermostat to the indoor unit. This

thermostat can either be wired (RKRTWA) or wireless (RKRTR1and

RTRNETA). Thermostat RTRNETA can only be used in heating-only

systems.

For installation instructions, see the installation manual of the room

thermostat and addendum book for optional equipment.

Remote sensor for wireless thermostat (EKRTETS)

You can use a wireless indoor temperature sensor (EKRTETS) only

in combination with the wireless thermostat (RKRTR1).

For installation intructions, see the installation manual of the room

thermostat and addendum book for optional equipment.

Digital I/O PCB (EKRP1HB)

The digital I/O PCB is required to provide the following signals:

▪ Alarm output

▪ Space heating/cooling On/OFF output

For installation instructions, see the installation manual of the digital

I/O PCB and the addendum book for optional equipment.

Demand PCB (EKRP1AHTA)

To enable the power saving consumption control by digital inputs

you must install the demand PCB.

For installation instructions, see the installation manual of the

demand PCB and addendum book for optional equipment.

Remote outdoor sensor (EKRSCA1)

By default the sensor inside the outdoor unit will be used to measure

the outdoor temperature.

As an option the remote outdoor sensor can be installed to measure

the outdoor temperature on another location (e.g. to avoid direct

sunlight) to have an improved system behaviour.

For installation instructions, see the installation manual of the remote

outdoor sensor.

PC configurator (EKPCCAB)

The PC cable makes a connection between the switch box of the

indoor unit and a PC. It gives the possibility to upload different

language files to the user interface and indoor parameters to the

indoor unit. For the available language files, contact your local

dealer.

The software and corresponding operating instructions are available

on the ROTEX homepage.

For installation instructions, see the installation manual of the PC

cable and "8Configuration"on page49.

Heat pump convector (RFWXV)

For providing space heating/cooling, it is possible to use heat pump

convectors (RFWXV).

For installation instructions, refer to the installation manual of the

heat pump convectors, and the addendum book for optional

equipment.

Solar kit (EKSRPS3)

The solar kit is required to connect the solar application with the

domestic hot water tank.

For installation, see the installation manual of the solar kit and

addendum book for optional equipment.

Connection kit for the tank (EKEPHT3H)

Use the connection kit to connect the domestic hot water tank to the

indoor unit.

For installation instructions, see the installation manual of the

connection kit.

Drain pan kit (EKHYDP1)

The drain pan kit is required for heating/cooling units. It does NOT

have to be used with heating only units.

For installation instructions, see the installation manual of the drain

pan kit.

Mounting kit (EKHYMNT1A, EKHYMNT2A, EKHYMNT3A)

Mounting fixture for easy installation of the hybrid system (heat

pump module + gas boiler module). For the selection of the correct

kit, see the combination table.

For installation instructions, see the installation manual of the

mounting kit.

Filling loop kit (EKFL1A)

Filling loop for easy filling of the water circuit. This kit can only be

used in combination with mounting kit EKHYMNT1A.

For installation instructions, see the installation manual of the filling

loop kit.

Valve kit (EKVK1A, EKVK2A, EKVK3A)

A set of valves for the easy connection of the field piping. For the

connection of the correct kit, see the combination table.

For installation instructions, see the installation manual of the valve

kit.

Recirculation thermistor (EKTH2)

Kit for recirculating the water on the gas boiler. Only use this kit

when there is no domestic hot water tank installed.

Connection kit for 3rd‑party tank (EKHY3PART)

Use the connection kit to connect a 3rd‑party tank to the system.

The connection kit exists of a thermistor and a 3-way valve.

Connection kit for 3rd‑party tank with built‑in thermostat

(EKHY3PART2)

Kit for the connection of a 3rd‑party tank with built‑in thermostat to

the system. The kit converts a thermostat demand from the tank to a

domestic hot water request for the indoor unit.

5.3.3 Possible options for the gas boiler

Main options

Boiler cover plate (EKHY093467)

Cover plate to protect the gas boiler’s piping and valves.

For installation instructions, see the installation manual of the cover

plate.

Gas conversion kit G25 (EKPS076227)

Kit for the conversion of the gas boiler for use with gas type G25.

Gas conversion kit G31 (EKHY075787)

Kit for the conversion of the gas boiler for use with gas type G31

(propane).

Dual pipe conversion kit (EKHY090707)

Kit for the conversion of a concentric flue gas system to a dual pipe

system.

For installation instructions, see the installation manual of the dual

pipe conversion kit.

RVLQ05+08CAV4 + RHYHBH05AA + RHYHBH/X08AA +

RHYKOMB33AA

ROTEX HPU hybrid

4P355635-1A – 2016.02

Installer reference guide

13

5 About the units and options

80/125 concentric connection kit (EKHY090717)

Kit for the conversion of 60/100 concentric flue gas connections to

80/125 concentric flue gas connections.

For installation instructions, see the installation manual of the

concentric connection kit.

Flue gas flap valve (EKFGF1A)

Non-return flap valve for use in multi-boiler flue gas systems. This

valve can only be used in systems using natural gas (G20, G25),

and CANNOT be used in systems using propane (G31).

Other options

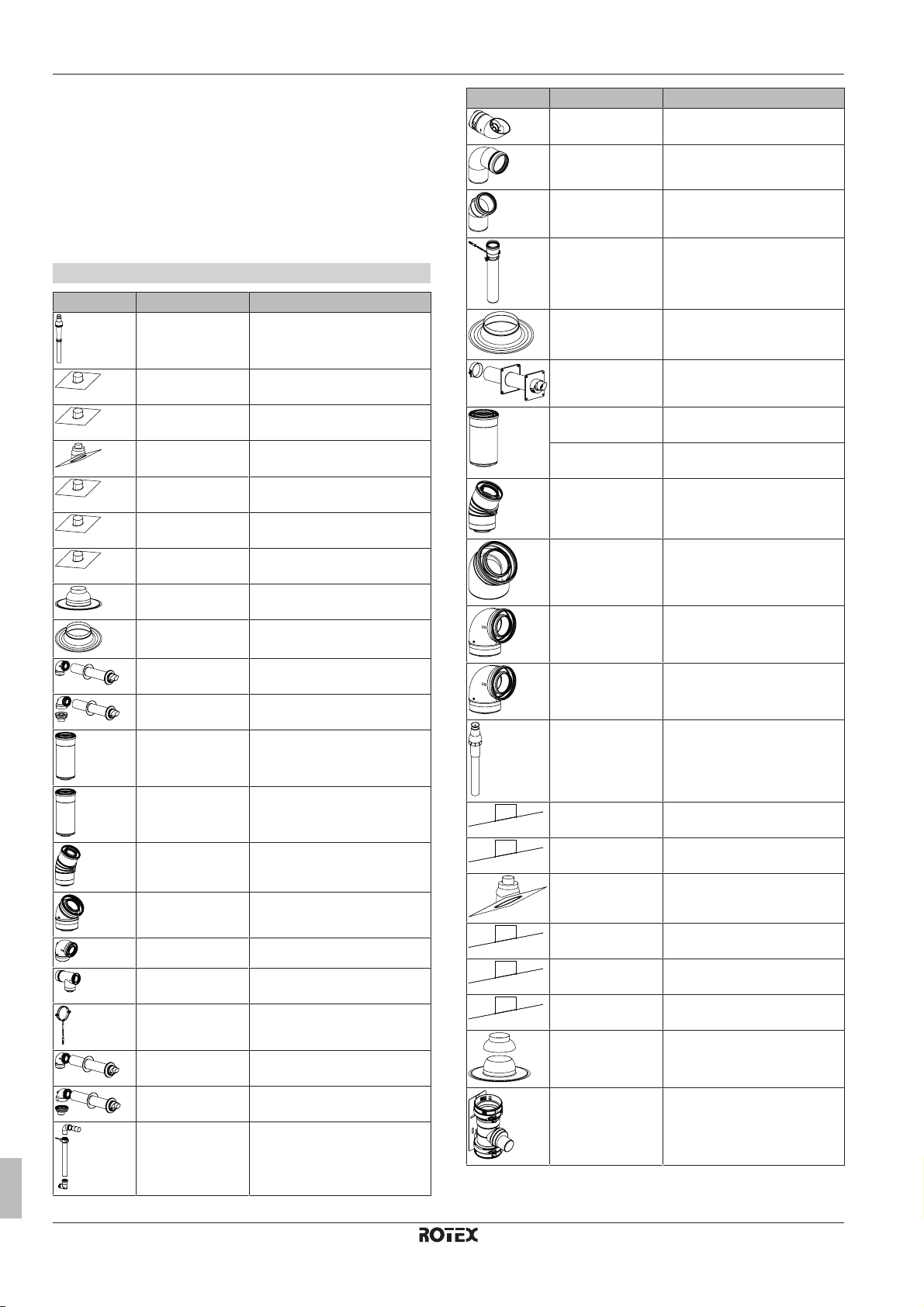

Accessories Part number Description

EKFGP6837 Roof terminal PP/GLV 60/100

AR460

EKFGS0518 Weather slate steep Pb/GLV

60/100 18°-22°

EKFGS0519 Weather slate steep Pb/GLV

60/100 23°-17°

EKFGP7910 Weather slate steep PF 60/100

25°-45°

EKFGS0523 Weather slate steep Pb/GLV

60/100 43°-47°

EKFGS0524 Weather slate steep Pb/GLV

60/100 48°-52°

EKFGS0525 Weather slate steep Pb/GLV

60/100 53°-57°

EKFGP1296 Weather slate flat Aluminum

60/100 0°-15°

EKFGP6940 Weather slate flat Aluminum

60/100

EKFGP2978 Wall terminal kit PP/GLV

60/100

EKFGP2977 Wall terminal kit low profile PP/

GLV 60/100

EKFGP4651 Extension PP/GLV

60/100×500mm

Accessories Part number Description

EKFGP1295 Flue deflector 60 (UK only)

EKFGP1284 PMK elbow 60 90 (UK only)

EKFGP1285 PMK elbow 60 45° (2pieces)

(UK only)

EKFGP1286 PMK extension 60 L=1000

includes bracket (UK only)

EKFGW5333 Weather slate flat aluminum

80/125

EKFGW6359 Wall terminal kit PP/GLV

80/125

EKFGP4801 Extension PP/GLV

80/125×500mm

EKFGP4802 Extension PP/GLV

80/125×1000mm

EKFGP4814 Elbow PP/GLV 80/125 30°

EKFGP4811 Elbow PP/ALU 80/125 45°

EKFGP4810 Elbow PP/ALU 80/125 90°

EKFGP4820 Inspection elbow Plus PP/ALU

80/125 90° EPDM

EKFGP6864 Roof Terminal PP/GLV 80/125

AR300 RAL9011

EKFGP4652 Extension PP/GLV

EKFGP4664 Elbow PP/GLV 60/100 30°

EKFGP4661 Elbow PP/GLV 60/100 45°

EKFGP4660 Elbow PP/GLV 60/100 90°

EKFGP4667 Meas. tee with inspection panel

EKFGP4631 Wall bracket Ø100

EKFGP1292 Wall terminal Kit PP/GLV

EKFGP1293 Wall terminal kit low profile PP/

EKFGP1294 Plume management kit 60 (UK

Installer reference guide

14

60/100×1000mm

PP/GLV 60/100

60/100

GLV 60/100

only)

EKFGT6300 Weather slate steep Pb/GLV

80/125 18°-22°

EKFGT6301 Weather slate steep Pb/GLV

80/125 23°-27°

EKFGP7909 Weather slate steep PF 80/125

25°-45° RAL9011

EKFGT6305 Weather slate steep Pb/GLV

80/125 43°-47°

EKFGT6306 Weather slate steep Pb/GLV

80/125 48°-52°

EKFGT6307 Weather slate steep Pb/GLV

80/125 53°-57°

EKFGP1297 Weather slate flat aluminum

80/125 0°-15°

EKFGP6368 Tee flex 100 boiler connection

set 1

RVLQ05+08CAV4 + RHYHBH05AA + RHYHBH/X08AA +

RHYKOMB33AA

ROTEX HPU hybrid

4P355635-1A – 2016.02

5 About the units and options

Accessories Part number Description

EKFGP6354 Flex 100-60 + support elbow

EKFGP6215 Tee flex 130 boiler connection

set 1

EKFGS0257 Flex 130-60 + support elbow

EKFGP4678 Chimney connection 60/100

EKFGP5461 Extension PP 60×500

EKFGP5497 Chimney top PP 100 with

included flue pipe

Accessories Part number Description

EKFGP6366 Connector flex-flex PP130

EKFGP1856 Flex kit PPØ60-80

EKFGP4678 Chimney connection 60/100

EKFGP2520 Flex kit PP Ø80

EKFGP4828 Chimney connection 80/125

EKFGP6340 Extension Flex PP80 L=10m

EKFGP6316 Adapter flex-fixed PP 100

EKFGP6337 Support bracket top inox Ø100

EKFGP6346 Extension flex PP100 L=10m

EKFGP6349 Extension flex PP100 L=15m

EKFGP6347 Extension flex PP100 L=25m

EKFGP6325 Connector flex-flex PP100

EKFGP5197 Chimney top PP 130 with

included flue pipe

EKFGS0252 Adapter flex-fixed PP130

EKFGP6344 Extension Flex PP80 L=15m

EKFGP6341 Extension Flex PP80 L=25m

EKFGP6342 Extension Flex PP80 L=50m

EKFGP6324 Connector-flex-flex PP80

EKFGP6333 Spacer PP80-100

EKFGP4481 Fixation Ø100

EKFGV1101 Chimney connection 60/10

airintake Dn.80 C83

EKFGV1102 Connection set 60/10-60 Flue/

Air intake Dn.80 C53

EKFGP6353 Support bracket top inox Ø130

EKFGS0250 Extension flex PP130 L=130m

RVLQ05+08CAV4 + RHYHBH05AA + RHYHBH/X08AA +

RHYKOMB33AA

ROTEX HPU hybrid

4P355635-1A – 2016.02

EKFGW4001 ExtensionPBM-Air 80×500

EKFGW4002 ExtensionPBM-Air 80×1000

Installer reference guide

15

6 Preparation

≤1200

>250

>250

>250

>350

>350

(mm)(mm)

a

b

b

a

b

a

b

c

Accessories Part number Description

EKFGW4004 ExtensionPBM-Air 80×2000

EKFGW4085 ElbowPPBM-Air8090°

EKFGW4086 ElbowPPBM-Air8045°

INFORMATION

For extra configuration options regarding the flue gas

system, visit http://fluegas.rotex-heating.com/.

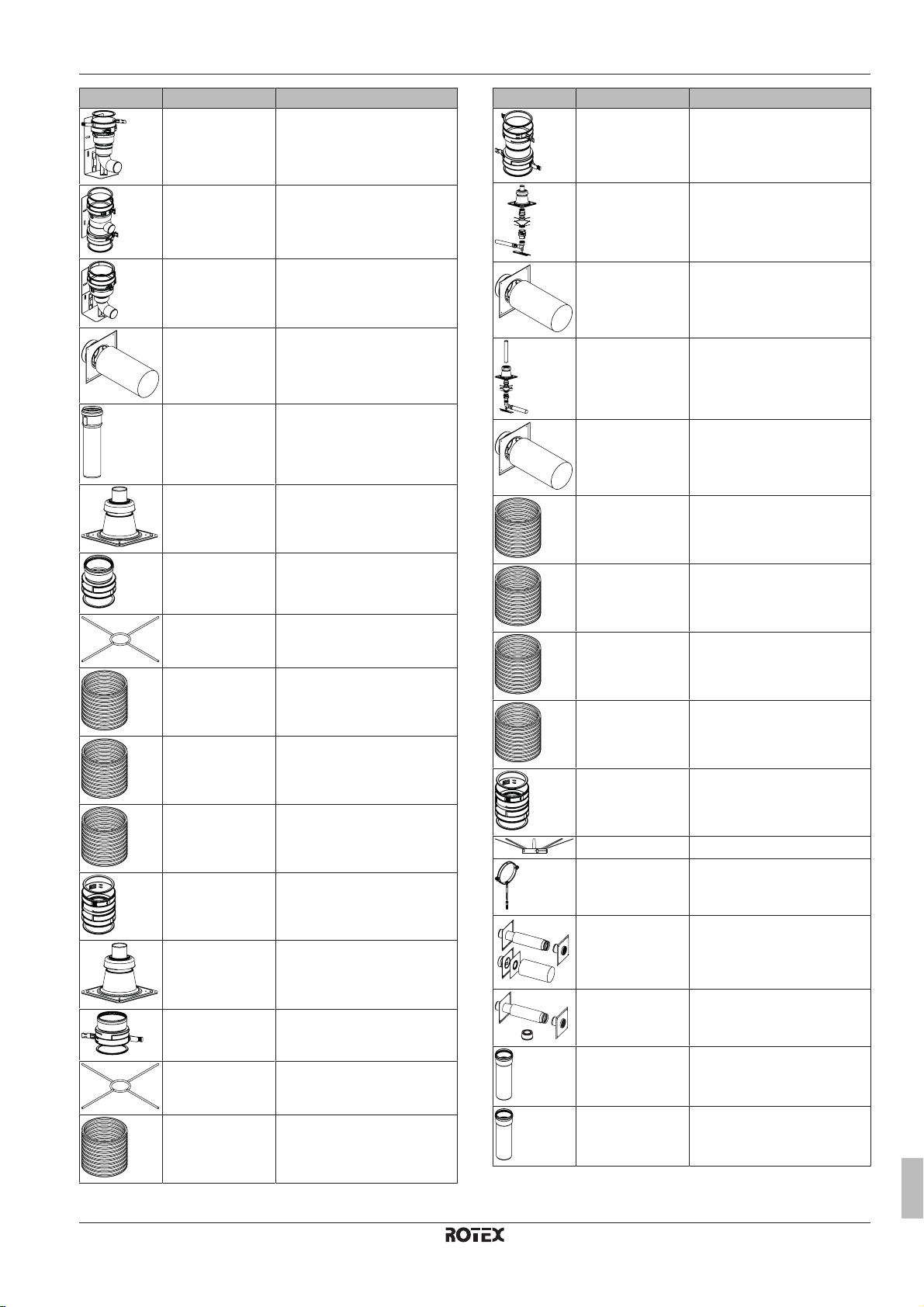

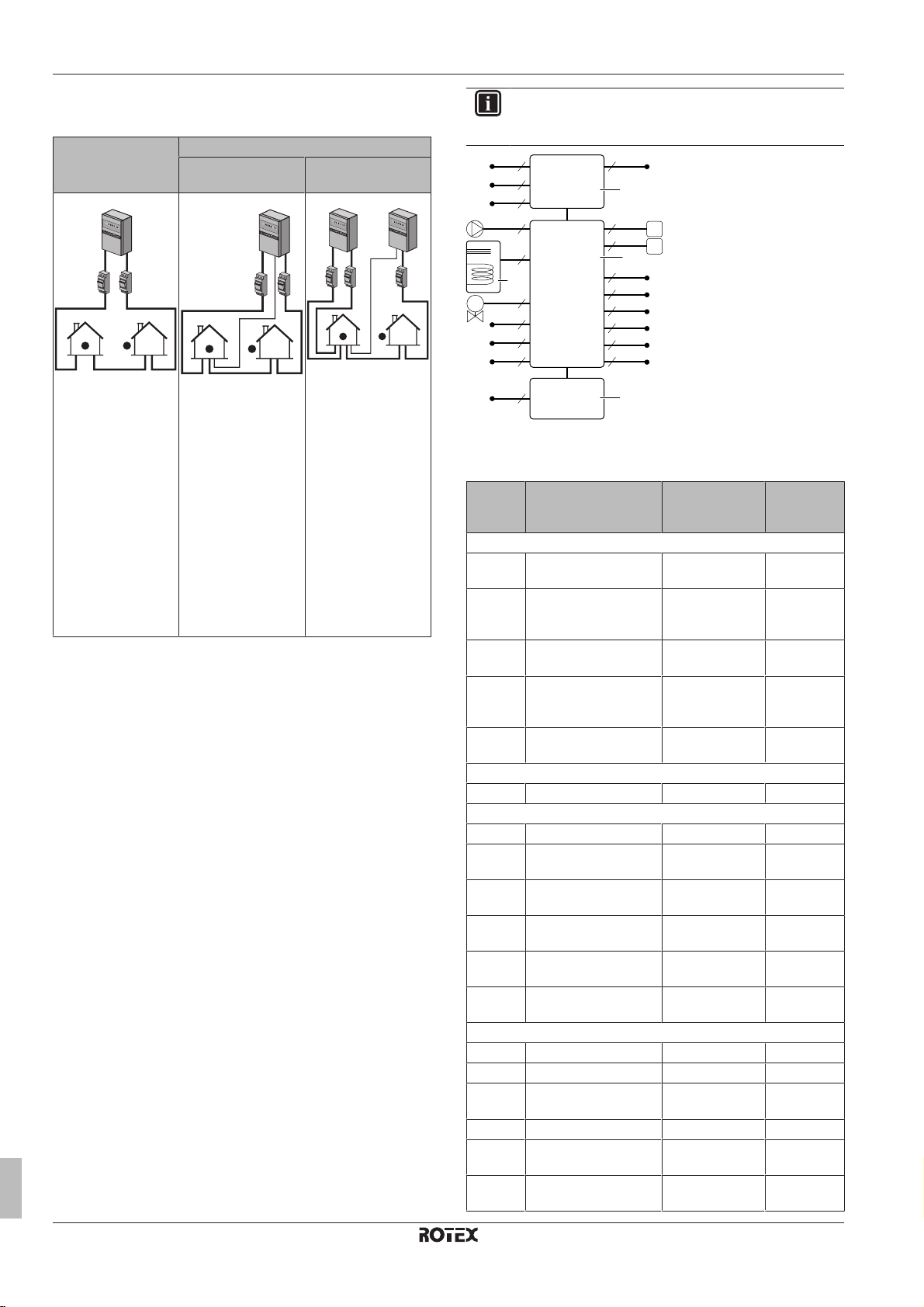

5.3.4 Possible combinations of indoor unit and outdoor unit

Outdoor unit Indoor unit

RHYHBH05 RHYHBH08 RHYHBX08

RVLQ05CAV3 O — —

RVLQ08CAV3 — O O

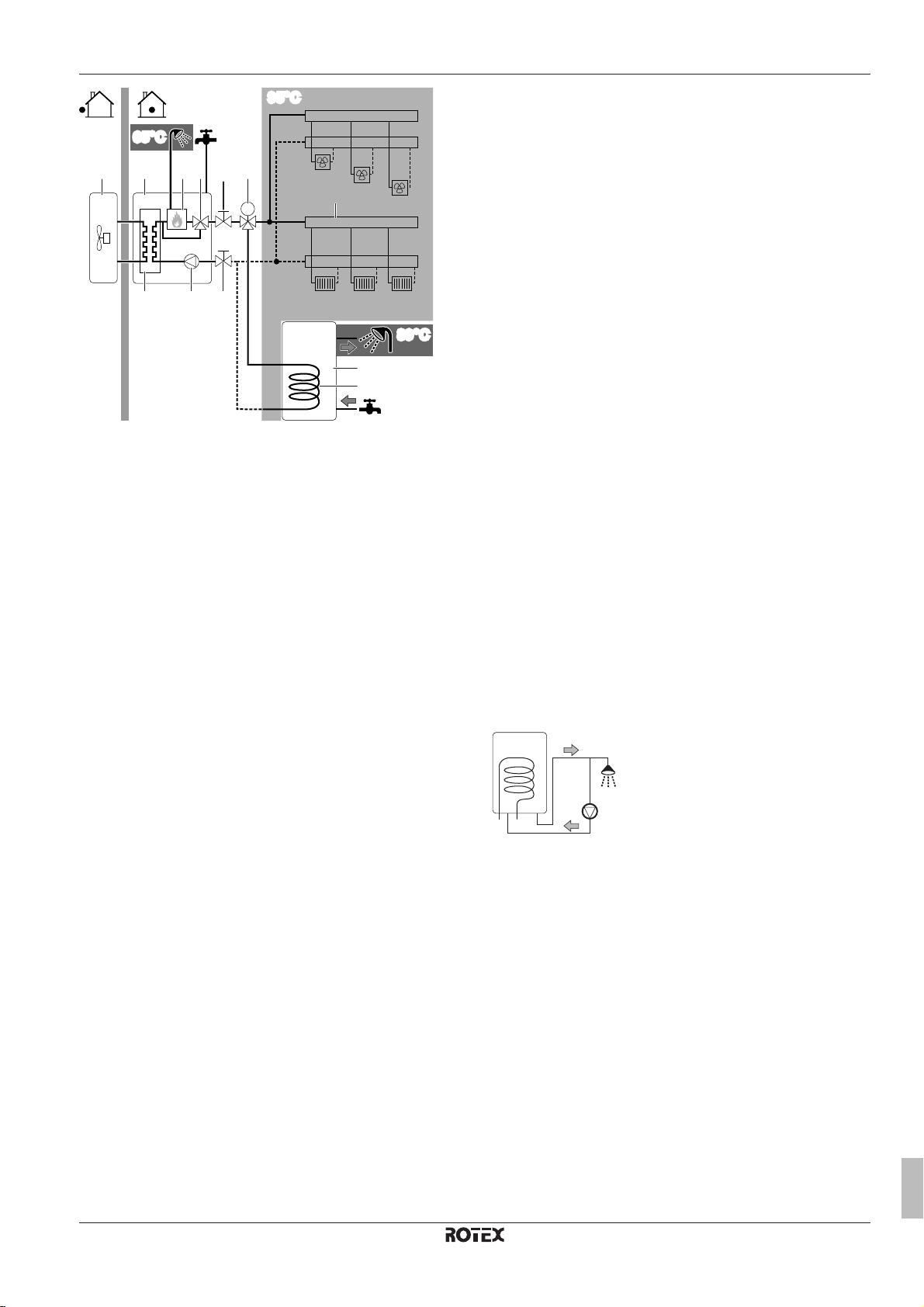

5.3.5 Possible combinations of indoor unit and domestic hot water tank

Indoor unit Domestic hot water tank

HYC 343/19/0-DB + HYC 544/32/0-DB

RHYHBH05 O

RHYHBH08 O

RHYHBX08 O

Mind the following spacing guidelines:

a Air outlet

b Air inlet

See "15.2 Dimensions and service space" on page 96 for more

detailed information about spacing guidelines.

NOTICE

▪ Do NOT stack the units on each other.

▪ Do NOT hang the unit on a ceiling.

Strong winds (≥18 km/h) blowing against the outdoor unit’s air outlet

causes short circuit (suction of discharge air). This may result in:

▪ deterioration of the operational capacity;

▪ frequent frost acceleration in heating operation;

▪ disruption of operation due to decrease of low pressure or

increase of high pressure;

▪ a broken fan (if a strong wind blows continuously on the fan, it

may start rotating very fast, until it breaks).

It is recommended to install a baffle plate when the air outlet is

exposed to wind.

It is recommended to install the outdoor unit with the air inlet facing

the wall and NOT directly exposed to the wind.

6 Preparation

6.1 Overview: Preparation

This chapter describes what you have to do and know before going

on-site.

It contains information about:

▪ Preparing the installation site

▪ Preparing the refrigerant piping

▪ Preparing the water piping

▪ Preparing the electrical wiring

6.2 Preparing installation site

Do NOT install the unit in places often used as work place. In case

of construction works (e.g. grinding works) where a lot of dust is

created, the unit must be covered.

Choose the installation location with sufficient place for carrying the

unit in and out of the site.

6.2.1 Installation site requirements of the outdoor unit

INFORMATION

Also read the following requirements:

Installer reference guide

16

▪ General installation site requirements. See the

"General safety precautions" chapter.

▪ Refrigerant piping requirements (length, height

difference). See further in this "Preparation" chapter.

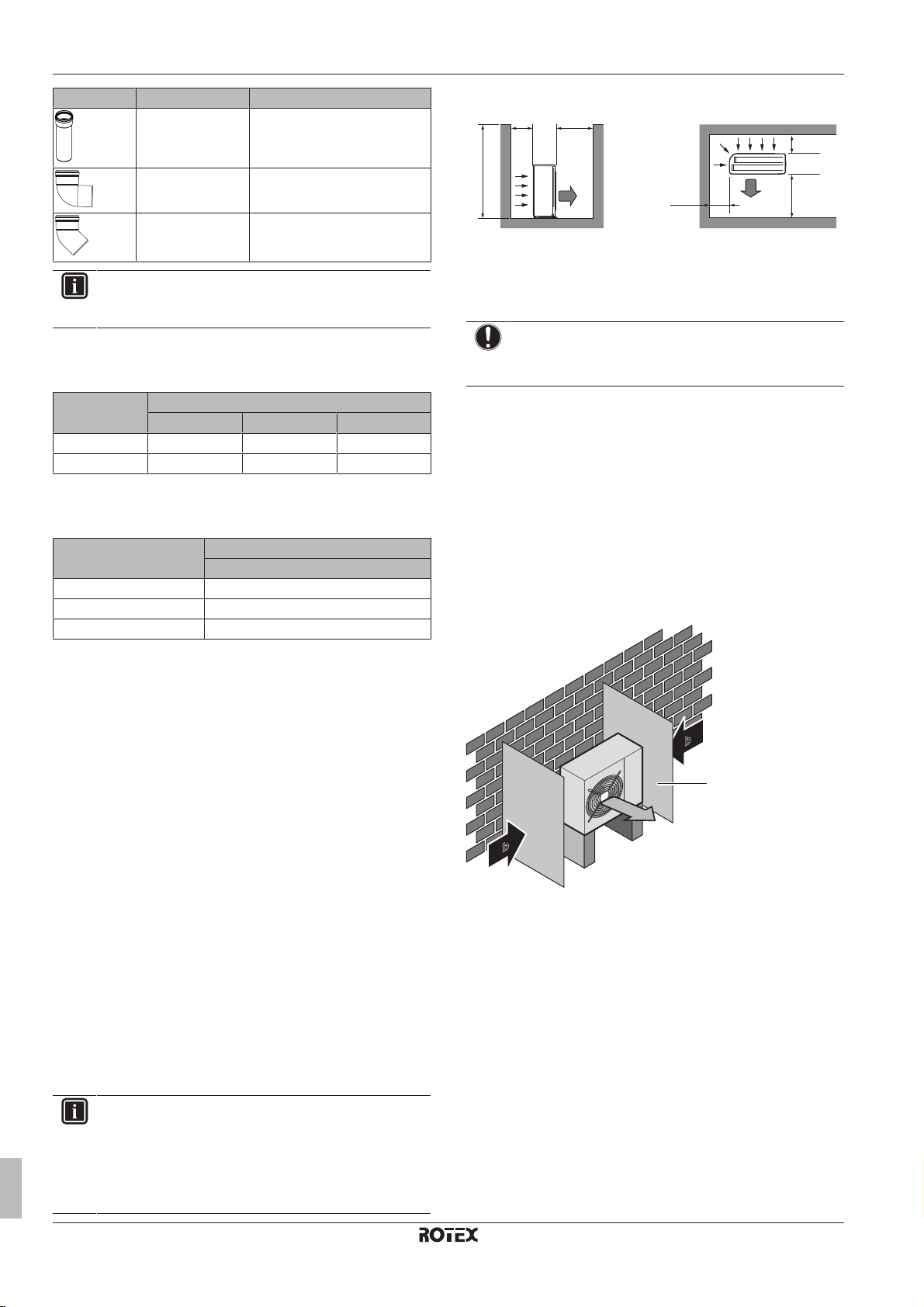

a Baffle plate

b Prevailing wind direction

c Air outlet

Do NOT install the unit in the following places:

▪ Sound sensitive areas (e.g. near a bedroom and the like), so that

the operation noise will cause no trouble.

▪ In places where a mineral oil mist, spray or vapour may be

present in the atmosphere. Plastic parts may deteriorate and fall

off or cause water leakage.

It is NOT recommended to install the unit in the following places

because it may shorten the life of the unit:

▪ Where the voltage fluctuates a lot

▪ In vehicles or vessels

▪ Where acidic or alkaline vapour is present

Seaside installation. Make sure the outdoor unit is NOT directly

exposed to sea winds. This is to prevent corrosion caused by high

levels of salt in the air, which might shorten the life of the unit.

RVLQ05+08CAV4 + RHYHBH05AA + RHYHBH/X08AA +

RHYKOMB33AA

ROTEX HPU hybrid

4P355635-1A – 2016.02

6 Preparation

b

c

a

a

b

c

d

c

d

a

b

c

c

d

>500

200

200

10 350 500

(mm)

Install the outdoor unit away from direct sea winds.

Example: Behind the building.

If the outdoor unit is exposed to direct sea winds, install a

windbreaker.

▪ Height of windbreaker≥1.5×height of outdoor unit

▪ Mind the service space requirements when installing the

windbreaker.

a Sea wind

b Building

c Outdoor unit

d Windbreaker

The outdoor unit is designed for outdoor installation only, and for

ambient temperatures ranging 10~43°C in cooling mode and –

25~25°C in heating mode.

▪ In any case, provide at least 300mm of free space below the unit.

Additionally, make sure the unit is positioned at least 100 mm

above the maximum expected level of snow. See "7.3 Mounting

the outdoor unit"on page24 for more details.

In heavy snowfall areas it is very important to select an installation

site where the snow will NOT affect the unit. If lateral snowfall is

possible, make sure that the heat exchanger coil is NOT affected by

the snow. If necessary, install a snow cover or shed and a pedestal.

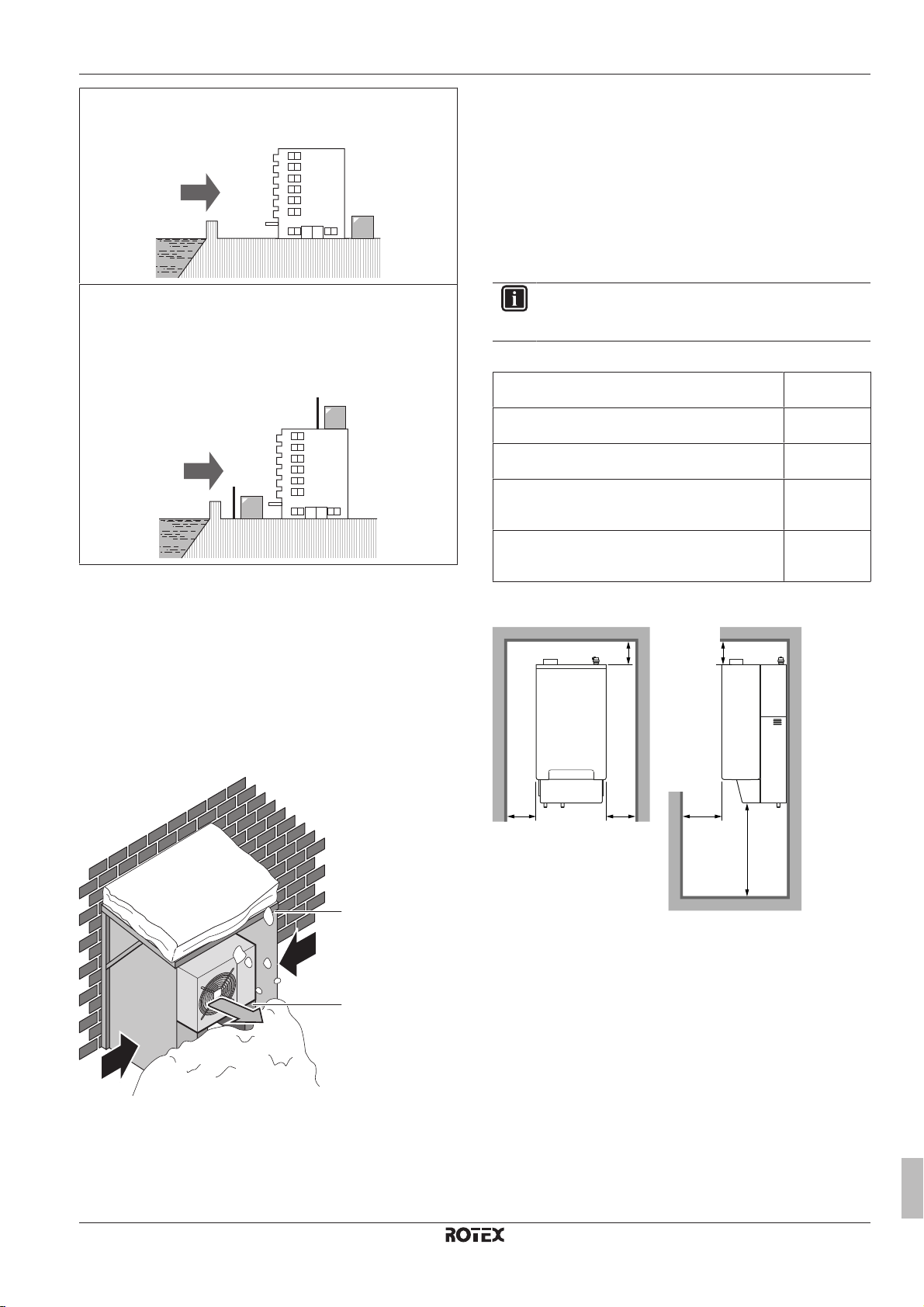

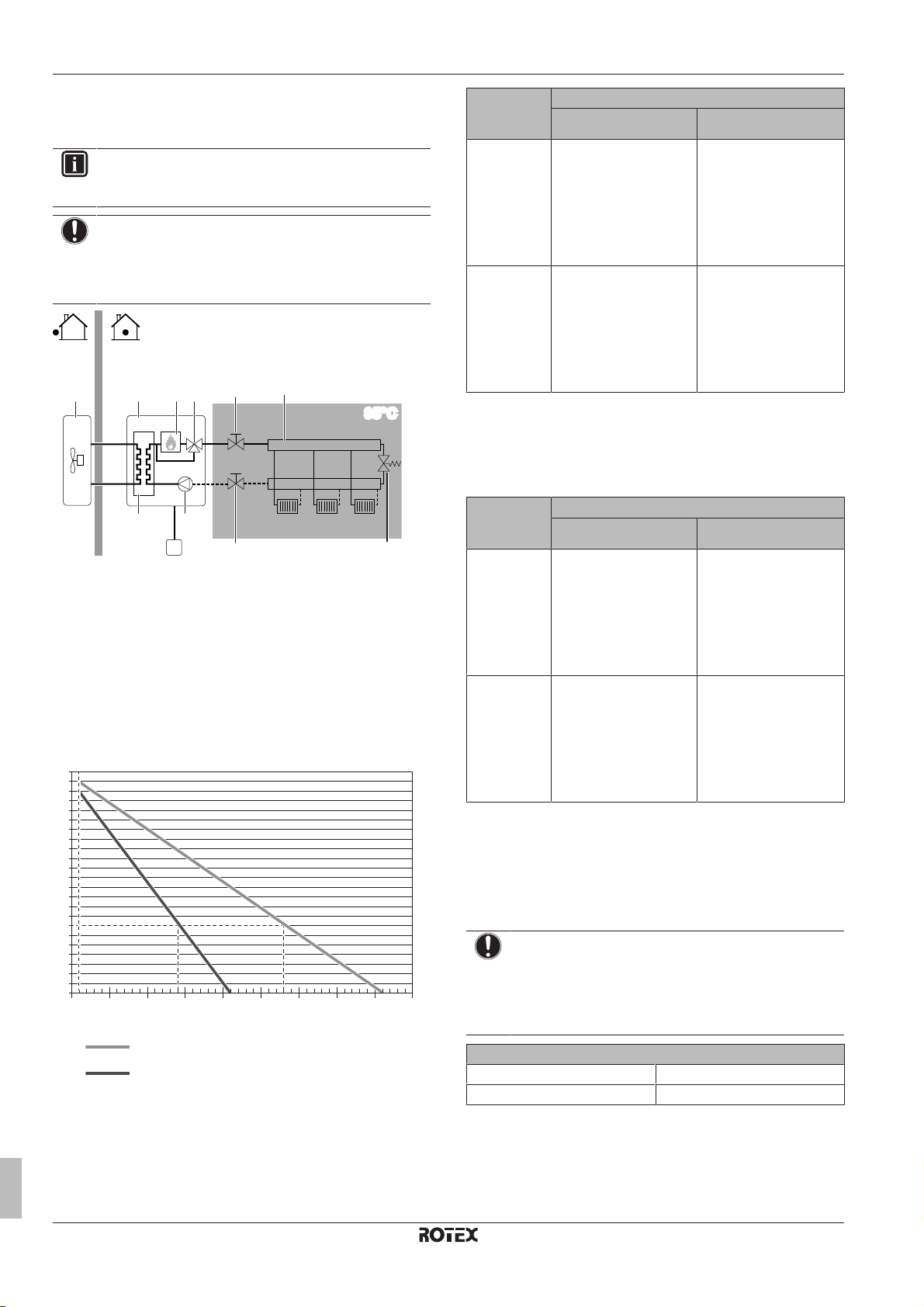

6.2.3 Installation site requirements of the indoor unit

INFORMATION

Also read the precautions and requirements in the

"General safety precautions" chapter.

▪ Mind the measurement guidelines:

Maximum refrigerant piping length between indoor

unit and outdoor unit

Minimum refrigerant piping length between indoor

unit and outdoor unit

Maximum height difference between indoor unit and

outdoor unit

Maximum equivalent piping length between the

3‑way valve and the indoor unit (for installations

with domestic hot water tank)

Maximum equivalent piping length between the

domestic hot water tank and the indoor unit (for

installations with domestic hot water tank)

(a) Piping diameter 0.75".

▪ Mind the following spacing installation guidelines:

20m

3m

20m

3m

10m

(a)

(a)

6.2.2 Additional installation site requirements of the outdoor unit in cold climates

Protect the outdoor unit against direct snowfall and take care that the

outdoor unit is NEVER snowed up.

a Snow cover or shed

b Pedestal

c Prevailing wind direction

d Air outlet

RVLQ05+08CAV4 + RHYHBH05AA + RHYHBH/X08AA +

RHYKOMB33AA

ROTEX HPU hybrid

4P355635-1A – 2016.02

Do NOT install the unit in places such as:

▪ In places where a mineral oil mist, spray or vapour may be

present in the atmosphere. Plastic parts may deteriorate and fall

off or cause water leakage.

▪ Sound sensitive areas (e.g. near a bedroom and the like), so that

the operation noise will cause no trouble.

▪ The foundation must be strong enough to bear the weight of the

unit. Take the weight of the unit with a domestic hot water tank full

of water into account.

Make sure, in the event of a water leak, water cannot cause any

damage to the installation space and surroundings.

▪ In places with high humidity (max. RH=85%), for example a

bathroom.

▪ In places where frost is possible. Ambient temperature around the

indoor unit should be >5°C.

Installer reference guide

17

6 Preparation

t

Ø

ØiØ

i

t

ØpØ

p

▪ The indoor unit is designed for indoor installation only and for

ambient temperatures ranging 5~35°C in cooling mode and

5~30°C in heating mode.

6.3 Preparing refrigerant piping

6.3.1 Refrigerant piping requirements

INFORMATION

Also read the precautions and requirements in the

"General safety precautions" chapter.

▪ Piping material: Phosphoric acid deoxidised seamless copper.

▪ Piping diameter:

Liquid piping Ø6.4mm (1/4")

Gas piping Ø15.9mm (5/8")

▪ Piping temper grade and thickness:

Outer diameter

(Ø)

6.4mm (1/4") Annealed (O) ≥0.8mm

15.9mm (5/8") Annealed (O) ≥1.0mm

(a) Depending on the applicable legislation and the unit's

Temper grade Thickness (t)

maximum working pressure (see "PS High" on the unit

name plate), larger piping thickness might be required.

(a)

6.3.2 Refrigerant piping insulation

▪ Use polyethylene foam as insulation material:

▪ with a heat transfer rate between 0.041 and 0.052W/mK (0.035

and 0.045kcal/mh°C)

▪ with a heat resistance of at least 120°C

▪ Insulation thickness

Pipe outer diameter

(Øp)

6.4mm (1/4") 8~10mm 10mm

15.9mm (5/8") 16~20mm 13mm

If the temperature is higher than 30°C and the humidity is higher

than RH 80%, the thickness of the insulation materials should be at

least 20 mm to prevent condensation on the surface of the

insulation.

Insulation inner

diameter (Øi)

Insulation thickness

(t)

6.4 Preparing water piping

6.4.1 Water circuit requirements

INFORMATION

Also read the precautions and requirements in the

"General safety precautions" chapter.

▪ Connecting piping – Legislation. Make all piping connections in

accordance with the applicable legislation and the instructions in

the "Installation" chapter, respecting the water inlet and outlet.

▪ Connecting piping – Force. Do NOT use excessive force when

connecting the piping. Deformation of the piping can cause

malfunctioning of the unit.

▪ Connecting piping – Tools. Only use appropriate tooling to

handle brass, which is a soft material. If NOT, pipes will get

damaged.

▪ Connecting piping – Air, moisture, dust. If air, moisture or dust

gets into the circuit, problems may occur. To prevent this:

▪ Only use clean pipes

▪ Hold the pipe end downwards when removing burrs.

▪ Cover the pipe end when inserting it through a wall, to prevent

dust and/or particles entering the pipe.

▪ Use a decent thread sealant to seal connections.

▪ Closed circuit. Use the indoor unit ONLY in a closed water

system. Using the system in an open water system will lead to

excessive corrosion.

▪ Glycol. For safety reasons, it is NOT allowed to add any kind of

glycol to the water circuit.

▪ Piping length. It is recommended to avoid long runs of piping

between the domestic hot water tank and the hot water end point

(shower, bath,…) and to avoid dead ends.

▪ Piping diameter. Select the water piping diameter in relation to

the required water flow and the available external static pressure

of the pump. See "15 Technical data"on page95 for the external

static pressure curves of the indoor unit.

▪ Water flow. You can find the minimum required water flow for

indoor unit operation in the following table. In all cases, this flow

needs to be guaranteed. When the flow is lower, the indoor unit

will stop operation and display error 7H.

Minimum required flow rate

05 models 7l/min

08 models 8l/min

▪ Field supply components – Water. Only use materials that are

compatible with water used in the system and with the materials

used in the indoor unit.

▪ Field supply components – Water pressure and temperature.

Check that all components in the field piping can withstand the

water pressure and water temperature.

▪ Water pressure. The maximum water pressure is 3bar. Provide

adequate safeguards in the water circuit to ensure that the

maximum pressure is NOT exceeded.

▪ Water temperature – Heat pump convectors. In case heat

pump convectors are connected, the temperature of the water in

the convectors should NOT exceed 65°C. If necessary, install a

thermostatic controlled valve.

▪ Water temperature – Underfloor heating loops. In case

underfloor heating loops are connected, install a mixing station to

prevent water that is too hot from entering the underfloor heating

circuit.

▪ Water temperature. All installed piping and piping accessories

(valve, connections,…) MUST withstand the following

temperatures:

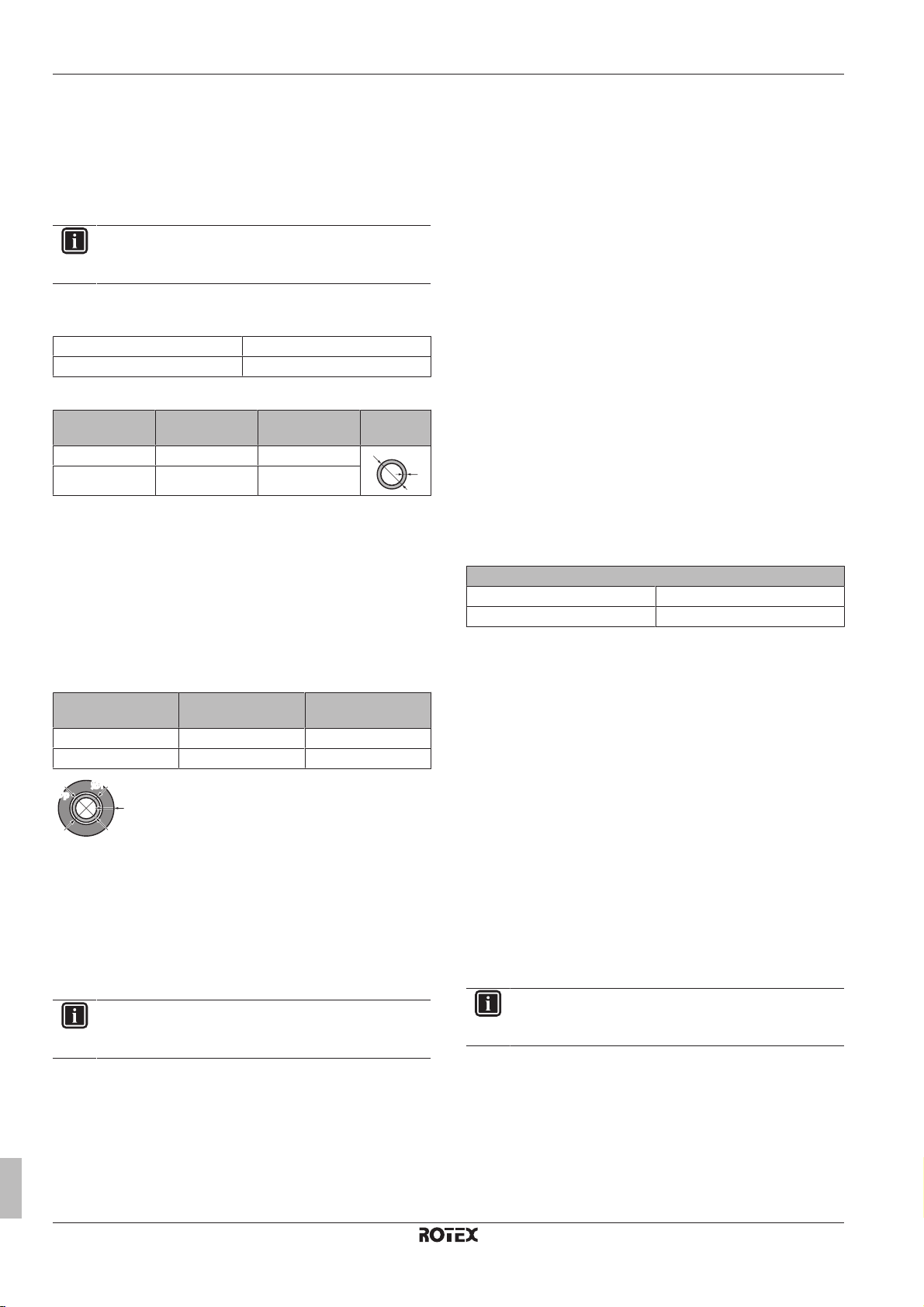

INFORMATION

The following illustration is an example and might NOT

match your system layout.

Installer reference guide

18

RVLQ05+08CAV4 + RHYHBH05AA + RHYHBH/X08AA +

RHYKOMB33AA

ROTEX HPU hybrid

4P355635-1A – 2016.02

M

89°C

RAD1 RAD2 RAD3

95°C

65°C

a b d e

j

k

i

c f g

FCU1

FCU2

FCU3

hg

RAD1…3 Radiator (field supply)

c

d

a b

▪ Drainage – Low points. Provide drain taps at all low points of the

system in order to allow complete drainage of the water circuit.

▪ Drainage – Pressure relief valve. Provide a proper drain for the

pressure relief valve to avoid water coming into contact with

electrical parts.

▪ Air vents. Provide air vents at all high points of the system, which

must also be easily accessible for servicing. An automatic air

purge is provided in the indoor unit. Check that the air purge is

NOT tightened too much, so that automatic release of air in the

water circuit is possible.

▪ Zn-coated parts. Never use Zn-coated parts in the water circuit.

Because the unit's internal water circuit uses copper piping,

excessive corrosion may occur.

▪ Non-brass metallic piping. When using non-brass metallic

piping, insulate the brass and non-brass properly so that they do

NOT make contact with each other. This to prevent galvanic

corrosion.

▪ Valve – Separating circuits. When using a 3-way valve in the

water circuit make sure that the domestic hot water circuit and the

floor heating circuit is fully separated.

▪ Valve – Change‑over time. When using a 2-way valve or a 3-way

valve in the water circuit, the maximum change-over time of the

valve must be 60seconds.

▪ Filter. It is strongly recommended to install an additional filter on

the heating water circuit. Especially to remove metallic particles

from foul heating piping, it is recommended to use a magnetic or

cyclone filter, which can remove small particles. Small particles

may damage the unit and will NOT be removed by the standard

filter of the heat pump system.

▪ Dirt separator – Old heating installations. In case of old heating

installations, it is recommended to use a dirt separator. Dirt or

sediment from the heating installation can damage the unit and

reduce its lifetime. The domestic hot water circuit can also be