Page 1

OPERATION MANUAL

Air cooled refrigeration condensing unit

LREQ15B7Y1R

LREQ20B7Y1R

Page 2

WARNING

LREQ15B7Y1R

LREQ20B7Y1R

CONTENT

Air cooled refrigeration condensing unit

Operation manual

1. SAFETY PRECAUTIONS.......................................................... 1

2. NAME OF PART........................................................................ 3

In the case of LREQ15, LREQ20 ...........................................3

3. SYSTEM CONFIGURATION..................................................... 3

3-1 Air cooled condensing unit................................................. 3

3-2 Other configuration equipment........................................... 3

4. METHOD OF OPERATION/STOP ............................................ 3

5. BETTER USE ............................................................................ 3

5-1 Turn off the power.............................................................. 3

5-2 Install an alarm................................................................... 3

6. CARE AND CLEANING METHOD ............................................ 4

7. TROUBLESHOOTING .............................................................. 4

7-1 The following cases are not malfunctions. ......................... 4

7-2 Check before requesting servicing..................................... 4

7-3 Consult your dealer in the following cases......................... 4

8. INSPECTION............................................................................. 4

9. PRODUCT MODELS AND MAIN SPECIFICATIONS ............... 5

9-1 Models and Main Specifications. ....................................... 5

10. AFTER-SALE SERVICE............................................................ 6

10-1 After-sale service ............................................................... 6

10-2 Onerous repairs (Outside scope of warranty coverage) .... 6

The English text is the original instruction. Other languages are

translations of the original instructions.

Thank you for purchasing this Daikin condensing unit. Carefully read

this operation manual before using the condensing unit. It will tell you

how to use the unit properly and help you if any trouble occurs.

Important information regarding the refrigerant used

This product contains fluorinated greenhouse gases covered by the

Kyoto Protocol. Do not vent gases into the atmosphere.

Refrigerant type : R410A

(1)

value : 1975

GWP

(1)

GWP = global warming potential

(Values are indicated in F-gas Regulations, Appendix I, parts 1 and 2.)

Periodical inspections for refrigerant leaks may be required depending

on European or local legislation.

Please contact your local dealer for more information.

1. SAFETY PRECAUTIONS

To gain full advantage of the condensing unit’s functions and to avoid

malfunction due to mishandling, please read this operation manual

carefully before use.

This condensing unit is classified under “appliances not accessible to

the general public”.

•

The precautions described herein are classified as WARNING

and CAUTION. They both contain important information

regarding safety. Be sure to observe all precautions without fail.

WARNING ................ Failure to follow these instructions

properly may result in personal injury or

loss of life.

CAUTION ................. Failure to observe these instructions

properly may result in property damage

or personal injury, which may be serious

depending on the circumstances.

• After reading, keep this manual in a convenient place so that

you can refer to it whenever necessary. If the equipment is

transferred to a new user, be sure also to hand over the

manual.

Be aware that prolonged, direct exposure to cool or warm air

from the air conditioner, or to air that is too cool or too warm

can be harmful to your physical condition and health.

When the condensing unit is malfunctioning (giving off a

burning odour, etc.) turn off the power to the unit and

contact your local dealer.

Continued operation under such circumstances may result in a

failure, electric shocks or fire hazards.

Consult your local dealer about installation work.

Doing the work yourself may result in water leakage, electric

shocks or fire hazards.

Consult your local dealer regarding modification, repair and

maintenance of the condensing unit.

Improper workmanship may result in water leakage, electric

shocks or fire hazards.

Do not place objects, including rods, your fingers, etc., in the

air inlet or outlet.

Injury may result due to contact with the condensing unit’s

highspeed fan blades.

Never touch the air outlet or the horizontal blades while the

swing flap is in operation.

Fingers may become caught or the unit may break down.

Beware of fire in case of refrigerant leakage.

If the condensing unit is not operating correctly (i.e. the interior

temperature of the condensing unit does not drop efficiently),

refrigerant leakage could be the cause.

Consult your dealer for assistance.

The refrigerant used for the condensing unit is safe and normally

does not leak.

However, if the refrigerant leaks and gets in contact with a naked

burner, heater or cooker, it may generate hazardous compounds.

Turn off the condensing unit and call the dealer. Make sure to turn

on the condensing unit after the qualified service person confirms

that the leakage is repaired.

Consult your local dealer regarding what to do in case of

refrigerant leakage.

When the condensing unit is to be installed in a small room, it is

necessary to take proper measures so that the amount of any

leaked refrigerant does not exceed the concentration limit in the

event of a leakage. Otherwise, this may lead to an accident due

to oxygen depletion.

Contact professional personnel about attachment of

accessories and be sure to use only accessories specified

by the manufacturer.

If a defect results from your own workmanship, it may result in

water leaks, electric shock or fire.

Consult your local dealer regarding relocation and

reinstallation of the condensing unit.

Improper installation work may result in leakage, electric shocks

or fire hazards.

Be sure to use fuses with the correct ampere reading.

Do not use improper fuses, copper or other wires as a substitute,

as this may result in electric shock, fire, injury or damage to the

unit.

Be sure to install an earth leakage breaker.

Failure to install an earth leakage breaker may result in electric

shocks or fire.

Be sure to earth the unit.

Do not earth the unit to a utility pipe, lightning conductor or

telephone earth lead. Imperfect earthing may result in electric

shocks or fire.

A high surge current from lightning or other sources may cause

damage to the condensing unit.

Consult the dealer if the condensing unit submerges owing to

a natural disaster, such as a flood or typhoon.

Do not operate the condensing unit in that case, or otherwise a

malfunction, electric shock, or fire may result.

Start or stop the air conditioner with the remote controller.

Never use the power circuit breaker for this purpose.

Otherwise, it may cause fire or water leakage.

Furthermore, because power failure compensation is set, the fan

will rotate abruptly, which may result in injury.

Do not use the product in the atmosphere contaminated with

oil vapor, such as cooking oil or machine oil vapor.

Oil vapor may cause crack damage, electric shocks, or fire.

Operation manual

1

Air cooled refrigeration condensing unit

LREQ15+20B7Y1R

4P362763-1B – 2014.01

Page 3

Do not use the product in places with excessive oily smoke,

CAUTION

such as cooking rooms, or in places with flammable gas,

corrosive gas, or metal dust.

Using the product in such places may cause fire or product

failures.

Do not use flammable materials (e.g., hairspray or insecticide)

near the product.

Do not clean the product with organic solvents such as paint

thinner.

The use of organic solvents may cause crack damage to the

product, electric shocks, or fire.

Do not keep in the unit anything volatile or flammable.

Doing so may result in explosion or fire.

Be sure to use a dedicated power supply for the condensing

unit.

The use of any other power supply may cause heat generation,

fire, or product failures.

Consult your dealer regarding cleaning the inside of the

condensing unit.

Improper cleaning may cause breakage of plastic parts, water

leakage and other damage as well as electric shocks.

Do not use the condensing unit for purposes other than

those for which it is intended.

Do not use the condensing unit for cooling precision instruments,

works of art as this may adversely affect the performance, quality

and/or longevity of the object concerned.

Do not use the unit for water cooling use.

Freezing may result.

Do not remove the unit’s fan guard.

The guard protects against the unit’s high speed fan, which may

cause injury.

Do not locate around the unit anything that must stay dry.

Doing so may wet the area resulting from condensed water from the

unit.

After prolonged use, check the unit stand and its mounts for

damage.

If left in a damaged condition, the unit may fall and cause injury.

Do not place flammable sprays or operate spray containers

near the unit as this may result in fire.

Do not put flammable containers, such as spray cans, within

1 m from the air outlet.

The containers may explode because the warm air output of the

indoor or outdoor unit will affect them.

Before cleaning, be sure to stop unit operation, turn the

power circuit breaker off or remove the power cord.

Otherwise, an electric shock and injury may result.

To avoid electric shocks, do not operate with wet hands.

Do not allow a child to mount on the outdoor unit or avoid

placing any object on it.

Falling or tumbling may result in injury.

Do not wash the condensing unit with water, as this may

result in electric shocks or fire.

Do not place water containers (flower vases, flowerpot, etc.)

on the unit, as this may result in electric shocks or fire.

Do not install the condensing unit at any place where there is

a danger of flammable gas leakage.

In the event of a gas leakage, build-up of gas near the condensing

unit may result in fire hazards.

Perform drain piping to ensure perfect drainage.

Imperfect drainage may result in water leakage.

The appliance is not intended for use by unattended young

children or persons who are incompetent to operate

condensing unit.

It may result in injury or electric shock.

Children should be watched so that they do not play with the

unit.

Accidental operation by a child may result in injury or electric shock.

To avoid injury, do not touch the air inlet or aluminium fins of

the unit.

Do not place objects in direct proximity of the condensing

unit and do not let leaves and other debris accumulate

around the unit.

Leaves are a hotbed for small animals which can enter the unit.

Once in the unit, such animals can cause malfunctions, smoke or

fire when making contact with electrical parts.

Do not block air inlets nor outlets.

Impaired airflow may result in insufficient performance or trouble.

Do not let children play on or around the outdoor unit.

If they touch the unit carelessly, injury may be caused.

Turn off the power when the unit is not to be used for long

periods of time.

Otherwise, the unit may get hot or catch on fire due to dust

accumulation.

Do not touch the aluminium fin directly at the time of

cleaning.

Doing so may result in injury.

[Installation site]

Is the unit installed in a well-ventilated place with no obstacles

around?

Do not use the product in the following places.

a. Places with mineral oil, such as cutting oil.

b. Places directly exposed to seawater spray and briny air.

c. Places where sulphide gas is generated, such as hot springs.

d. Places with radical voltage fluctuations, such as factories.

e. In vehicles or on board ships.

f. Places with sprays of oil or excessive steam, such as kitchens.

g. Places with machines generating electromagnetic waves.

h. Places with acid gas, alkaline gas, or steam.

i. Places with poor drainage.

j. Places in potentially explosive atmosphere.

Install the unit, power supply wiring, transmission wiring and

refrigerant piping at least 1.5 meter away from televisions,

radios and stereo sets.

Otherwise, the picture and sound may be interfered with noise.

Are snow protection measures taken?

For detailed arrangements, such as the installation of a snow

protection hood, consult your dealer.

Is there no clearance around the through hole between the

internal and external units?

The chilled air will leak from the clearance and the cooling efficiency of

the unit will be degraded.

Is service space secured?

If the target evaporating temperature is ≤–20°C, adding refrigerant oil

may be required. Failure to do so may lead to compressor

malfunction. If you change the target evaporating temterature from

≥–20°C to ≤–20°C, it may also be required to add refrigerant oil. In this

case, contact your dealer.

After refrigerant oil has been added, the target evaporating

temperature cannot be changed to ≥–20°C.

Refer to the installation manual for more information.

[Electrical work]

Do not attempt to conduct electrical work or grounding work

unless you are licensed to do so.

Consult with your dealer for electrical work and grounding work.

Check that the power supply is suitable to the unit and that an

exclusive circuit is provided to the unit.

Check the electric capacity and voltage.

Refer to the installation manual for more information.

[Refrigerant]

• This product contains fluorinated gases covered by the Kyoto

protocol.

Type of refrigerant: R410A, GWP value: 1975

Periodical inspections on refrigerant leakages may be required

depending on European or local legislation. Please contact your

installer for more information.

• The total maximum refrigerant charge of a Multi-ZEAS system

must be less than 100 kg, this to be in accordance with CE

requirements (EN603350-2-40 standard). This means that in case

the calculated total refrigerant charge is equal to or more than

95 kg you must divide your multiple outdoor system into smaller

independent systems, each containing less than 95 kg refrigerant

charge.

LREQ15+20B7Y1R

Air cooled refrigeration condensing unit

4P362763-1B – 2014.01

Operation manual

2

Page 4

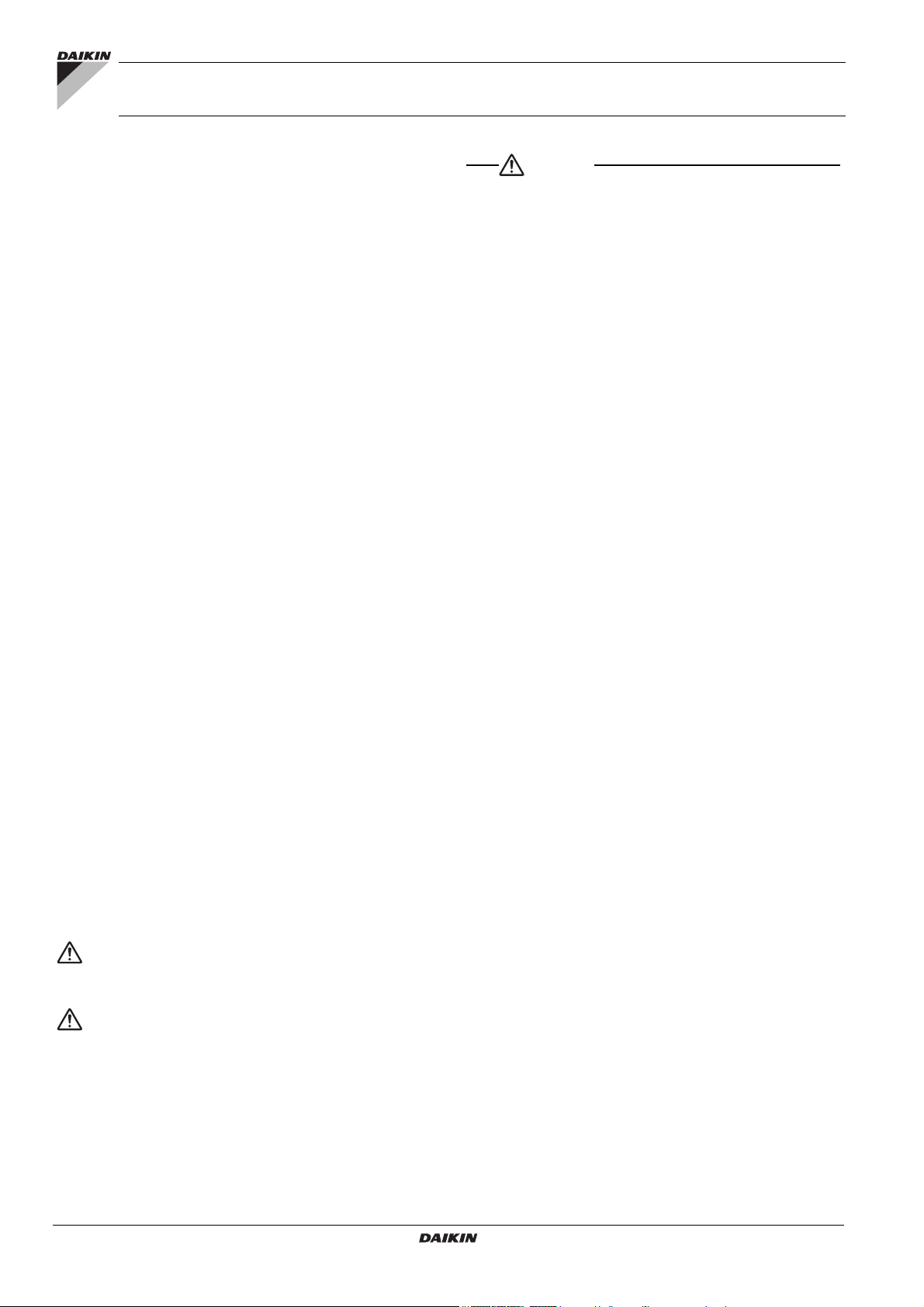

2. NAME OF PART

CAUTION

Air outlet

Fan

Air inlet

Heat exchanger

(aluminium fin)

Transmission

wiring

Refrigerant

piping

Earth wire

A wire that makes the system

safe by connecting the outdoor

unit to the ground for the

prevention of electric shocks

or fire resulting from electric

leakage.

Power supply wires

(to dedicated earth

leakage breaker)

OFF

REMOTE

ON

OFF

REMOTE

ON

OFF

In the case of LREQ15, LREQ20

4. METHOD OF OPERATION/STOP

Preparations

• Turn on all the configuration

equipment.

• Be sure to turn on the power at least 6

hours before starting the operation of

the equipment for the machinery

protection.

1. Set the operation switch of the master unit to ON.

Stop

2. Set the operation switch of the master

unit to OFF.

To start operation

To stop operation

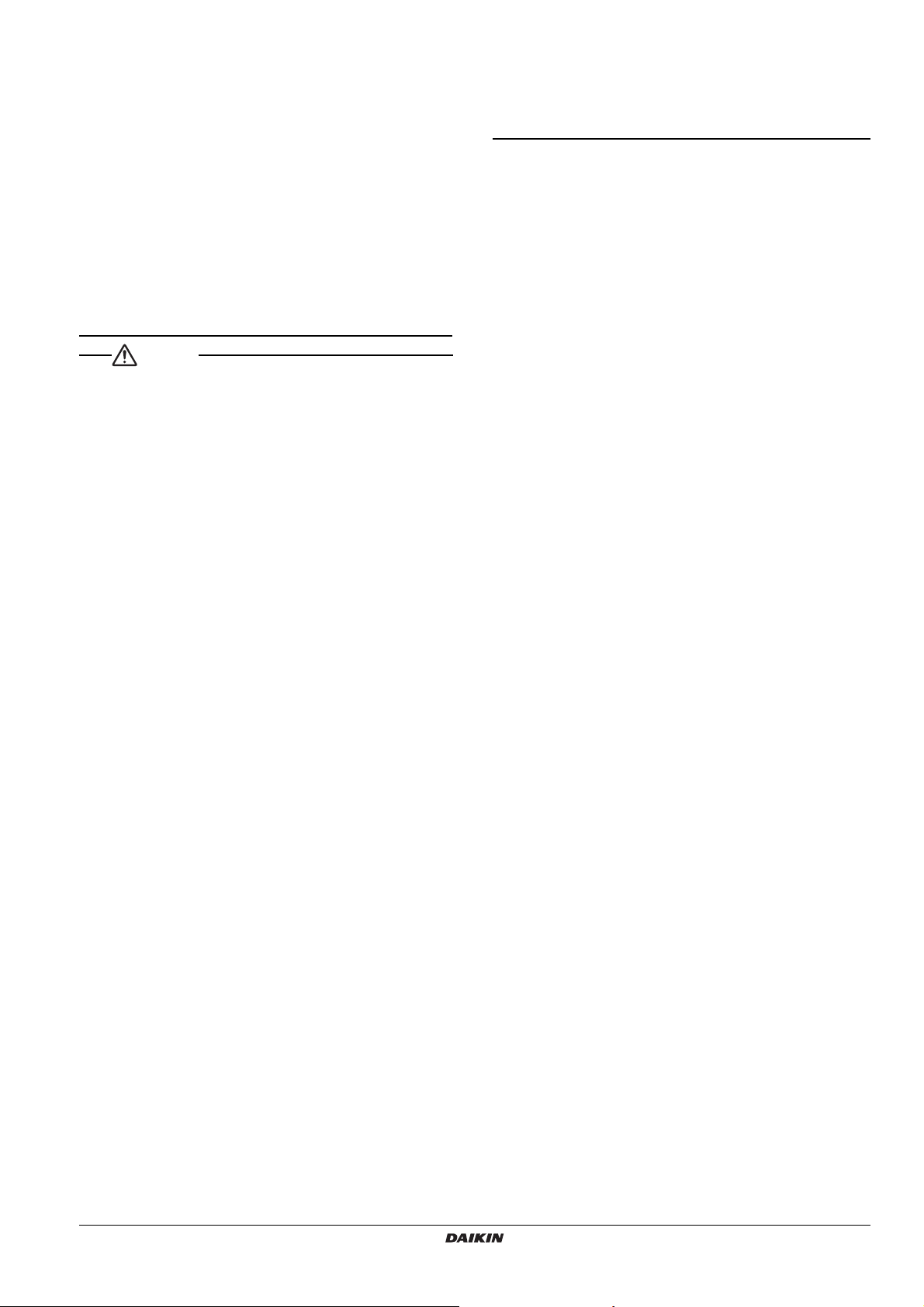

3. SYSTEM CONFIGURATION

The condensing unit has the following system configuration.

3-1 Air cooled condensing unit

Name Master unit Slave unit

Shape

3-2 Other configuration equipment

Indoor unit

Name

Unit cooler Showcase

Shape

Name

Unit cooler Showcase

Shape

For other configuration equipment, refer to the Operation

Manuals of the respective pieces of equipment.

Refrigeration

Indoor unit

Freezing

Defrost control

panel

The unit must go through a stop movement before the unit is

turned power off.

Be sure to turn off the breaker after the operation switch is turned

off. It is not possible to start and stop the system by operating the

operation switch of the slave unit.

Note:

• The use of a remote switch is recommended if the operation of the

unit is stopped frequently.

Request your dealer for the installation of the remote switch.

5. BETTER USE

5-1 Turn off the power if the unit is not operated for

a long time.

The unit will consume a power of several watts to several tens

of watts if the power is on (see note).

For the purpose of machine protection, however, be sure to turn

on the power at least 6 hours before resuming the operation of

the unit.

Note: The power consumption of the unit varies with the

operating factors, such as the condensing unit model.

5-2 Install an alarm if operational errors are likely

to degrade the commodities in storage.

The unit is provided with a terminal to output an alarm signal.

If the system should malfunction and there is no alarm, the

operation of the unit will be interrupted for a long time and

damage to the commodities in storage may result.

The installation of an alarm is recommended in order to take

appropriate measures promptly in such cases.

For details, consult your dealer.

Operation manual

3

Air cooled refrigeration condensing unit

LREQ15+20B7Y1R

4P362763-1B – 2014.01

Page 5

6. CARE AND CLEANING METHOD

CAUTION

WARNING

Ta b

Trip position

ON

OFF

Be sure to stop the operation of the unit with the operation switch

and turn off the power (i.e., turn off the earth leakage breaker)

before starting the maintenance of the unit.

Do not touch the aluminium fin directly at the time of

cleaning.

Doing so may result in injury.

Do not wash the condensing unit with water, as this may

result in electric shocks or fire.

Before cleaning, be sure to stop unit operation, turn the

power circuit breaker off or remove the power cord.

Otherwise, an electric shock and injury may result.

7-2 Check before requesting servicing.

1. The unit does not operate at all.

• Has the power supply fuse not blown out?

Turn off the power. (Consult your dealer for the replacement of

the power supply fuse.)

• Is the power circuit breaker not turned off?

Turn on the power if the knob of the power circuit breaker is set

to the OFF position.

Do not turn on the power if the knob of the power circuit breaker

is set to the trip position. (Consult your dealer.)

• Request your dealer for heat exchanger cleaning periodically.

7. TROUBLESHOOTING

7-1 The following cases are not malfunctions.

1. The unit does not operate.

• The unit is restarted immediately after the unit comes to a stop.

The unit is under control in order not to impose a heavy duty on

the machinery parts. The operation of the unit will start in 1 to 5

minutes.

• The unit has been just turned on.

The microprocessor requires preparations. Wait for

approximately two minutes.

2. The unit does not come to a stop.

• The operation switch was turned off a while ago.

The unit operates for a while before the unit comes to a stop in

order to protect the machinery parts. The unit will come to a stop

after the operation is over.

3. The unit generates noise.

• The unit in cooling operation generates low hissing sound

continuously.

This is the sound of gas (refrigerant) flowing in the condensing

unit.

• The unit generates hissing sound immediately after the unit

starts operating or comes to a stop.

This is the sound of gas (refrigerant) flowing.

• The unit rattles when the unit is operated and stopped

repeatedly.

This is the sound of gas (refrigerant) flowing inside the

condensing unit.

4. The outdoor fan does not rotate.

• The unit is in operation.

The fan is under RPM control in order to maintain the optimum

operation of the product.

5. Neither the compressor of the outdoor unit nor the outdoor

fan comes to a stop.

• The phenomenon occurs after the unit comes to a stop.

The compressor and outdoor fan continue operating in order to

prevent the detention of refrigerant oil and refrigerant. They will

come to a stop in about 5 to 10 minutes.

Power circuit breaker

(earth leakage breaker)

• Is there no blackout?

Wait until power is restored. If power failure occurs during

operation, the system automatically restarts immediately after

the power supply is recovered.

• Are all the power supplies turned on?

Turn all the power on.

2. The unit comes to a stop soon after the unit starts operating.

• Do obstacles not block the air inlet or outlet of the outdoor unit

or indoor unit?

Remove the obstacles.

3. The cooling operation of the unit is bad.

• Does the indoor unit (unit cooler and showcase) not have much

frost?

Defrost manually or shorten the cycle of defrosting operation.

• Are there not too many articles inside?

Reduce the number of articles.

• Is the circulation of cold air in the indoor unit (unit cooler and

showcase) smooth?

Change the allocation of the articles.

• Is there not much dust on the heat exchanger of the outdoor

unit?

Remove the dust with a brush or vacuum cleaner without using

water or consult your dealer.

• Is cold air not leaking outside?

Stop the leakage of cold air.

• Is the set temperature in the indoor unit (unit cooler and

showcase) not too high?

Set the temperature appropriately.

• Are high-temperature articles not stored?

Store them after they are once cooled off.

• Is the opening time of the door not long?

Minimize the opening time of the door.

7-3 Consult your dealer in the following cases.

When the condensing unit is malfunctioning (giving off a

burning odor, etc.) turn off the power to the unit and contact

your local dealer.

Continued operation under such circumstances may result in a

failure, electric shocks or fire hazards.

LREQ15+20B7Y1R

Air cooled refrigeration condensing unit

4P362763-1B – 2014.01

1. Safety devices, such as the fuse, breaker, and earth leakage

breaker, frequently operate or the operation of the operation

switch is not stable.

Contact your dealer after turning the power off.

2. Turn off the power and consult your dealer if symptoms other

than the above are noticed or the equipment does not go into

normal operation after taking the steps specified in 7-2.

8. INSPECTION

The preventive maintenance of the unit is required in order not to

damage commercial products. Request a contractor authorized

by our dealer for inspection.

Refer to information on "Maintenance inspection" on page 6 for

maintenance inspection.

Operation manual

4

Page 6

9. PRODUCT MODELS AND MAIN SPECIFICATIONS

9-1 Models and Main Specifications.

Note:

*1. Values are subject to change without notice for product improvements.

*2.

When the outdoor temperature is low, the temperature reading may be below the target evaporating temperature set for the protection of the unit.

*3. The sound pressure level is less than 70 dB(A).

Model

LREQ30BY1 LREQ40BY1

LREQ15B7Y1R LREQ15B7Y1R LREQ20B7Y1R LREQ20B7Y1R

Power supply 3 phase 50 Hz 380–415 V

Refrigerant R410A

Operating

condition

Evaporating temperature –45°C~+10°C

Outdoor temperature –20°C~+43°C

Outer dimensions (H×W×D) (mm)

1680 ×

1240 × 765

1680 ×

1240 × 765

1680 ×

1240 × 765

1680 ×

1240 × 765

Product mass 331 kg 331 kg 337 kg 337 kg

Connecting

refrigerant piping

Liquid pipe Ø19.1

Gas pipe Ø41.3

Design pressure

High-pressure side

(bar)38383838

(MPa) 3.8 3.8 3.8 3.8

Low-pressure side

(bar)25252525

(MPa) 2.5 2.5 2.5 2.5

Operation manual

5

Air cooled refrigeration condensing unit

LREQ15+20B7Y1R

4P362763-1B – 2014.01

Page 7

10. AFTER-SALE SERVICE

10-1 After-sale service

WARNING

Consult your local dealer regarding modification, repair and

main

tenance of the condensing unit.

Improper workmanship may result in water leakage, electric shocks

or fire hazards.

Consult your local dealer regarding relocation and

reinstallation of the condensing unit.

Improper installation work may result in leakage, electric shocks or

fire hazards.

Beware of fire in case of refrigerant leakage.

If the condensing unit is not operating correctly (i.e. the interior

temperature of the condensing unit does not drop efficiently),

refrigerant leakage could be the cause.

Consult your dealer for assistance.

The refrigerant used for the condensing unit is safe and normally

does not leak.

However, if the refrigerant leaks and gets in contact with a naked

burner, heater or cooker, it may generate hazardous compounds.

Turn off the condensing unit and call the dealer. Make sure to turn

on the condensing unit after the qualified service person confirms

that the leakage is repaired.

1. Inform your dealer of the following items when you request

repairs.

• Model name Described in the warranty card.

• Serial number and date of installation

Described in the warranty card.

• Defective condition

• Your address, name, and telephone number

2. Repairs after expiration of warranty period

Consult your dealer. Onerous repairs will be possible if the unit

can maintain its original functions after the repairs are made.

3. Maintenance inspection

The interior of the refrigeration condensing unit will become dirty

and its performance may be degraded if it is used for several

seasons.

The disassembly and internal cleaning of the unit requires

specialized techniques. Therefore, our dealer recommends an

onerous maintenance inspection besides usual maintenance

services.

For details, consult your dealer.

Keep in mind that our dealer’s warranty may not cover

malfunctions resulting from the disassembly or internal cleaning

of the unit conducted by contractors not authorized by our dealer.

4. Relocation and disposal

• Contact your dealer for removing and reinstalling the system

condensing unit since they require technical expertise.

• The system condensing unit uses fluorocarbon refrigerant.

Contact your dealer for discarding the system condensing unit

since it is required by law to collect, transport and discard the

refrigerant in accordance with relevant local and national

regulations.

• In either case, consult your dealer.

5. Inquiries

Contact your dealer for after-sale services.

–

as precise as possible

10-2 Onerous repairs

(Outside scope of warranty coverage)

10-2-1 Accidents resulting from use beyond standards

for use

• Use beyond Limits

•

Applications other than its designed purpose of use or modification.

Standards for use

Condensing unit

Item Standard for use

Refrigerant R410A (*5)

Refrigeration oil Daphne FVC68D (*6)

Range of evaporating

temperature (Te)

Range of outdoor temperature –20°C ~ +43°C (*4)

Suction gas superheated degree 10 K or higher (*7)

Suction gas temperature 20°C or lower

Voltage

regulation

Power supply

Compressor ON/OFF frequency 6 times or less/hour

Connection piping length

(equivalent piping length) (*1)

Max. difference in height

between indoor and outdoor

units

Installation space

Total indoor unit capacity

Outdoor unit multi-connection

piping kit

Restrictions for the refrigeration-side Note:

Connectable

minimum load

capacity

Liquid solenoid

valve installed

upstream of

expansion valve

Defrost method

Restrictor Use a thermal expansion valve for R410A

Voltage

imbalance

rate

Frequency

regulation

4.0 kW (Te ≥ –20)

3.2 kW (Te < –20)

For R410A, maximum operating pressure

difference: 3.5 MPa or higher

It is necessary to control the solenoid

valves in indoor unit using “Operate unit” of

outdoor unit

Hot gas defrost not possible

After defrosting ends, resume operation of

the refrigeration-side blower within 3

minutes or less

–45°C ~ +10°C (*2)(*8)

within ±10% of rated

voltage

within ±2% of rated voltage

within ±2% of rated

frequency

130 m or lower

(Te ≥ –20)

100 m or lower

(Te < –20)

35 m or lower (*3)

(When the condensing unit

is installed higher than the

refrigeration-side)

10 m or lower

(When the condensing unit

is installed lower than the

refrigeration-side)

According to the

installation service space

Starting from an outdoor

temperature of 32°C, the

total indoor unit capacity

needs to be ≥50% of the

total outdoor unit capacity

To split up the gas piping

and connect it to the

different outdoor units, the

use of the outdoor unit

multi-connection piping kit

(EKHRQZM) is required

LREQ15+20B7Y1R

Air cooled refrigeration condensing unit

4P362763-1B – 2014.01

Operation manual

6

Page 8

*1. Connection piping length differs according to set value of

Inlet

(upper side)

Outlet

(lower side)

Heat exchanger

evaporating temperature. The total internal volume of the

connected indoor units may not exceed 80 l.

*2. When the outdoor temperature is lower than evaporating

temperature, evaporating temperature is lower than set

evaporating temperature

*3. Trap is required at 5 m intervals from outdoor unit.

*4. If the outdoor units are installed in a location where the ambient

temperature can drop below –10°C, install a windbreak board or a

snowbreak hood. Refer to the service manual for more details.

*5. Only use refrigerant R410A.

*6. Only use the refrigerant oil listed in the Daikin service parts list.

*7. Also applies to post-defrost operation.

*8. If the target evaporating temperature is ≤–20°C, adding refrigerant

oil may be required.

10-2-2 Selection, installation, work failures specified

below and other failures

Note: Asterisk-marked items show concrete examples.

1. Model selection failures

• A model not suitable for storage applications is selected.

* The cooling of products not reaching the target storage

temperatures.

• Cooling overloading or underloading judged by our dealer.

* The frequency of stoppage is 6 or more times per hour or the

set cooling temperature is not attained.

2. Installation failure (installation and environmental problems)

• The unit is not installed on a stable horizontal plane.

* The unit is not fixed securely.

• The environmental conditions of the place of installation differ

from normal atmospheric conditions.

* Briny air environment, shore side, oil mist environment,

kitchen exhaust side, other corrosive gas and adhesive mist

environment.

• The place of installation had poor ventilation and heat

dissipation.

* The machine took in exhausted air again.

• The required outdoor unit multi-connection piping kit was not

used.

• The required windbreak board or snowbreak hood was not

installed in case of outdoor temperatures ≤–10°C.

• The instructions outlined in the installation manual were not

followed correctly.

3. Work failure

• The interior of the piping was not vacuum dried sufficiently.

* The clogging of the thin areas of the piping caused by icing.

• The interior of the piping was not sufficiently airtight.

* Leakage of refrigerant gas.

• The interior of the piping was contaminated with foreign

substance.

* The clogging of the thin areas of the piping.

• The unit was adversely affected by on-site modification work.

The use of the unit beyond the operating temperature range as a

*

result of on-site modification.

• An accident resulted from the improper handling of the unit

under installation work.

* The loosening or wobbling of the outer panel or broken or bent

damage to the piping.

* The instructions regarding the addition of refrigerant oil were

not followed correctly.

* Too much or too few refrigerant was charged into the system.

4. Operational failure

• Temperature settings for stored objects were wrong.

* The storage of vegetables at temperatures below 0°C.

• The periodical maintenance of the unit was neglected.

* The clogging of the air heat exchanger, rust generation from

each part, gas leakage, and icing of the indoor unit (showcase

and unit cooler).

• The following instructions regarding the addition of refrigerant

oil where not followed correctly.

* If the target evaporating temperature is ≤–20°C, adding

refrigerant oil may be required.

* After refrigerant oil has been added, the target evaporating

temperature cannot be changed to ≥–20°C.

* If the target evaporating temperature is lowered by 5°C

(starting from a target evaporating temperature of ≤–20°C), it

is required to recalculate the amount of refrigerant oil and

add more if necessary.

5. Others

• Improvements recommended by our dealer in advance were

not accomplished.

* The simultaneous starting and stopping of a number of units.

• Accidents were caused by natural disaster or fire.

Damage to electrical parts caused by lightning.

*

• There were other installation and operational problems beyond

common sense.

* The use of the unit without heat insulation work on the piping.

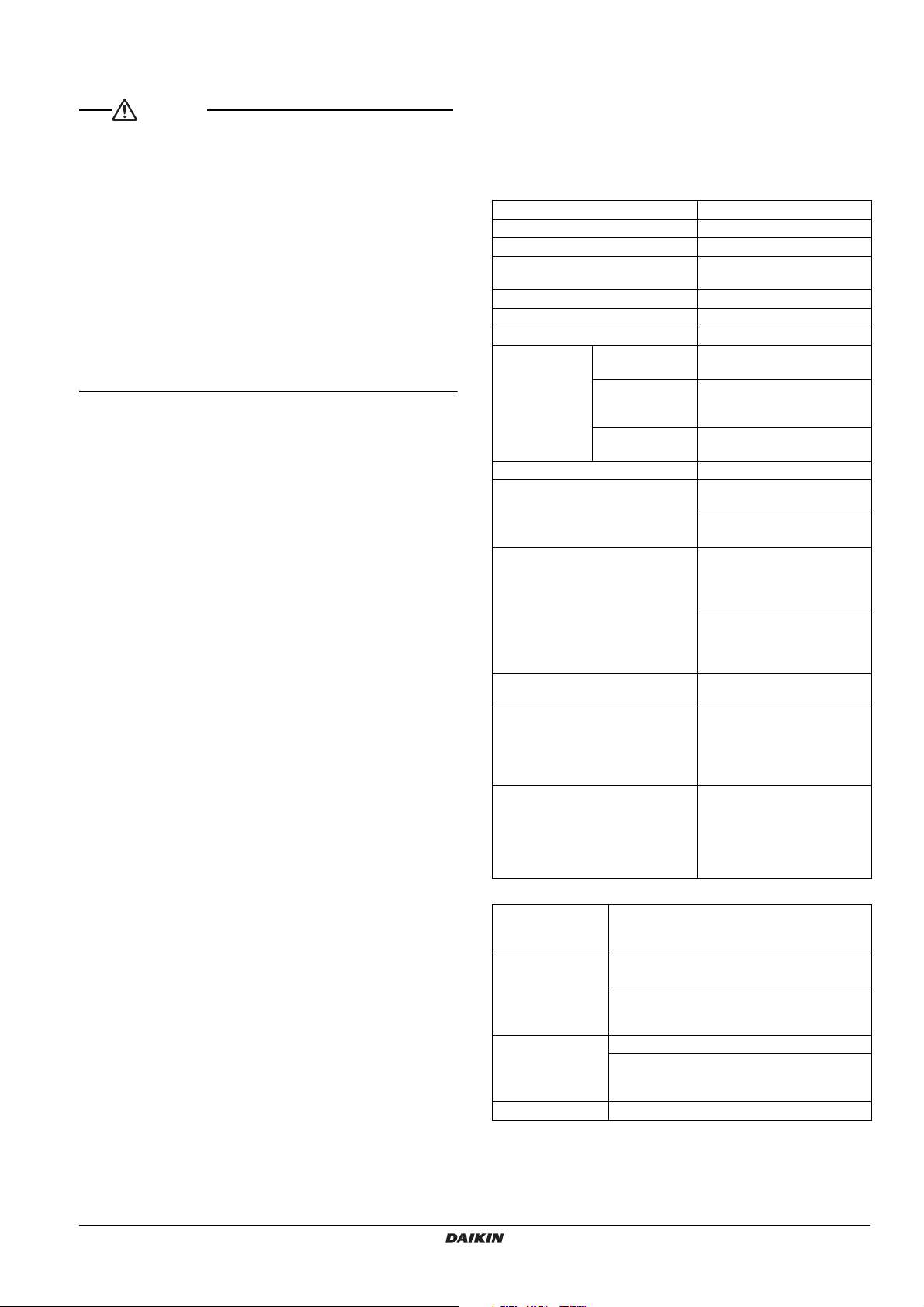

• Work was conducted without keeping the following showcase

restrictions.

<Showcase restrictions>

· The installation of the thermostatic expansion valve and

liquid supply solenoid valve (both of which are for R410A) on

a showcase basis.

Thermal insulation of feeler tube of thermostatic expansion

valve must be thermal insulated.

Install showcases on the same floor if the showcases are

·

connected to a single outdoor unit.

· Make sure that the outlet of piping used for the heat

exchanger is located downward (as shown on the following

figure).

Operation manual

7

Air cooled refrigeration condensing unit

LREQ15+20B7Y1R

4P362763-1B – 2014.01

Page 9

Page 10

Page 11

Page 12

*4P362763-1 B 0000000+*

4P362763-1B 2014.01

Copyright 2013 Daikin

Loading...

Loading...