Page 1

FUQ-BU

4-way Blow Ceiling

Suspended Cassette

technical data

Split

Sky Air

air conditioning systems

Page 2

• Indoor Units • R-410A • FUQ-BVV1B

1 Features

Indoor Unit Split Sky

FUQ-BVV1B R-410A

• Compact&stylish

• Ideal for shops, restaurants or offices requiring maximum floor space

for furniture, decorations and fittings

• Can be installed in both new and existing buildings.

• Flexible installation: can be installed in the middle of a room or in a

1

1

corner.

• Air can be discharged in any of 4 directions

• Possibility to shut 1 or 2 flaps for easy installation in corners

• Air flow distribution for ceiling heights up to 3.5m without loss of

capacity.

• Air filter, drain pan and heat exchanger fin are mildew proof and antibacterial treated.

• Drain-up pump with 500mm lift fitted as standard

• Extremely quiet in operation

• Easy to install

• Daikin remote controls give you easy control at your fingertips.

• The wired remote control provides you with a schedule timer,

enabling to program the air conditioning daily or weekly.

• The optional remote ON/OFF enables you to start/stop the air

conditioning from a mobile phone via a telephone remote control

(field supply).

• The optional forced OFF enables you to switch off the unit

automatically. E.g. when a window is opened, the unit switches off.

• The ’home leave’ operation button prevents large temperature

differences by continuously operating at a minimum (heating mode)

or maximum (cooling mode) preset level while you’re out or sleeping.

It also allows the indoor temperature to return quickly to your

favourite comfort level.

2 steps

heat pump optional standard

optional

• Split Sky Air • Indoor Units1

optional

Page 3

• Indoor Units • R-410A • FUQ-BVV1B

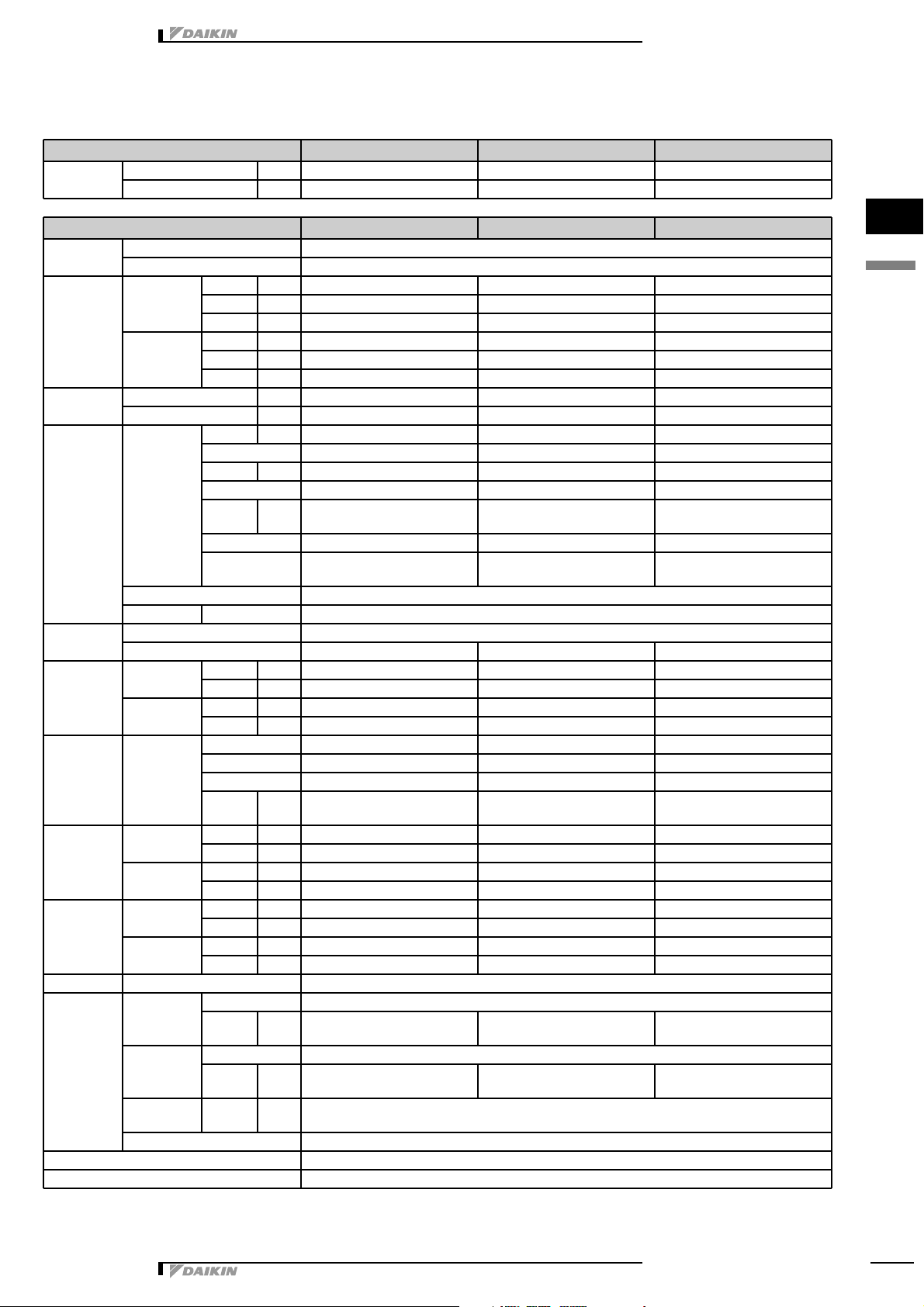

2 Specifications

2-1 FOR INDOOR UNITS ONLY

Nominal Input Cooling kW 0.180 0.289 0.289

Heating kW 0.160 0.269 0.269

2-2 TECHNICAL SPECIFICATIONS

Casing Colour White

Material Resin

Dimensions Packing Height mm 230 295 295

Width mm 960 960 960

Depth mm 960 960 960

Unit Height mm 165 230 230

Width mm 895 895 895

Depth mm 895 895 895

Weight Unit kg 25.0 31.0 31.0

Packed Unit kg 31.0 38.0 38.0

Heat

Exchanger

Fan Type Turbo fan

Air Flow Rate Cooling High m³/min 19.0 29.0 32.0

Fan Motor Quantity 1 1 1

Cooling Sound Power High dBA 56.0 59.0 60.0

Heating Sound Power High dBA 56.0 59.0 60.0

Refrigerant Type R-410A

Piping

connections

Air Filter Resin net with mold resistance

Safety Devices Fan motor thermal protector

Dimensions Length mm 2101 2101 2101

Nr of Rows 3 3 3

Fin Pitch mm 1.50 1.50 1.50

Nr of Passes 8 8 12

Face

Area

Nr of Stages 6 8 8

Empty Tubeplate

Hole

Tube type N-Hix

Fin Type Cross fin coil (Multi louver fins and N-hix tubes)

Quantity 1 1 1

Low m³/min 14.0 21.0 23.0

Heating High m³/min 19.0 29.0 32.0

Low m³/min 14.0 21.0 23.0

Model QTS48A10M QTS50B15M QTS50B15M

Number of steps 2 2 2

Output

(high)

Low dBA 51.0 54.0 55.0

Sound

Pressure

Sound

Pressure

Liquid (OD) Type Flare connection

Gas Type Flare connection

Drain Diameter

Heat Insulation Heat resistant foamed polyethylene, regular foamed polyethylene

High dBA 40.0 43.0 44.0

Low dBA 35.0 38.0 39.0

Low dBA 51.0 54.0 55.0

High dBA 40.0 43.0 44.0

Low dBA 35.0 38.0 39.0

Diameter

(OD)

Diameter

(OD)

(OD)

m² 0.265 0.353 0.353

W 45 90 90

mm 9.5 9.5 9.5

mm 15.9 15.9 15.9

mm I.D. 20/O.D. 26

FUQ71BVV1B FUQ1 00BVV1B FUQ125BVV1B

FUQ71BVV1B FUQ1 00BVV1B FUQ125BVV1B

4

3

1

2

• Split Sky Air • Indoor Units 2

Page 4

• Indoor Units • R-410A • FUQ-BVV1B

2 Specifications

1

2

2-2 TECHNICAL SPECIFICATIONS

Standard

Accessories

Item Installation and operation manual

Quantity 1 1 1

Item Drain hose

2-3 ELECTRICAL SPECIFICATIONS

Power Supply Name V1

Phase 1 1 1

Frequency Hz 50 50 50

Voltage V 220-240

Power Supply Intake Outdoor unit only

FUQ7 1BVV1B FUQ100BVV1B F UQ125BVV1B

Clamp metal

Insulation for fitting

Sealing pad

Clamps

Screws

Washer

Joint

Holding plate

FUQ7 1BVV1B FUQ100BVV1B F UQ125BVV1B

• Split Sky Air • Indoor Units3

Page 5

• Indoor Units • R-410A • FUQ-BVV1B

FUQ71-100-125B

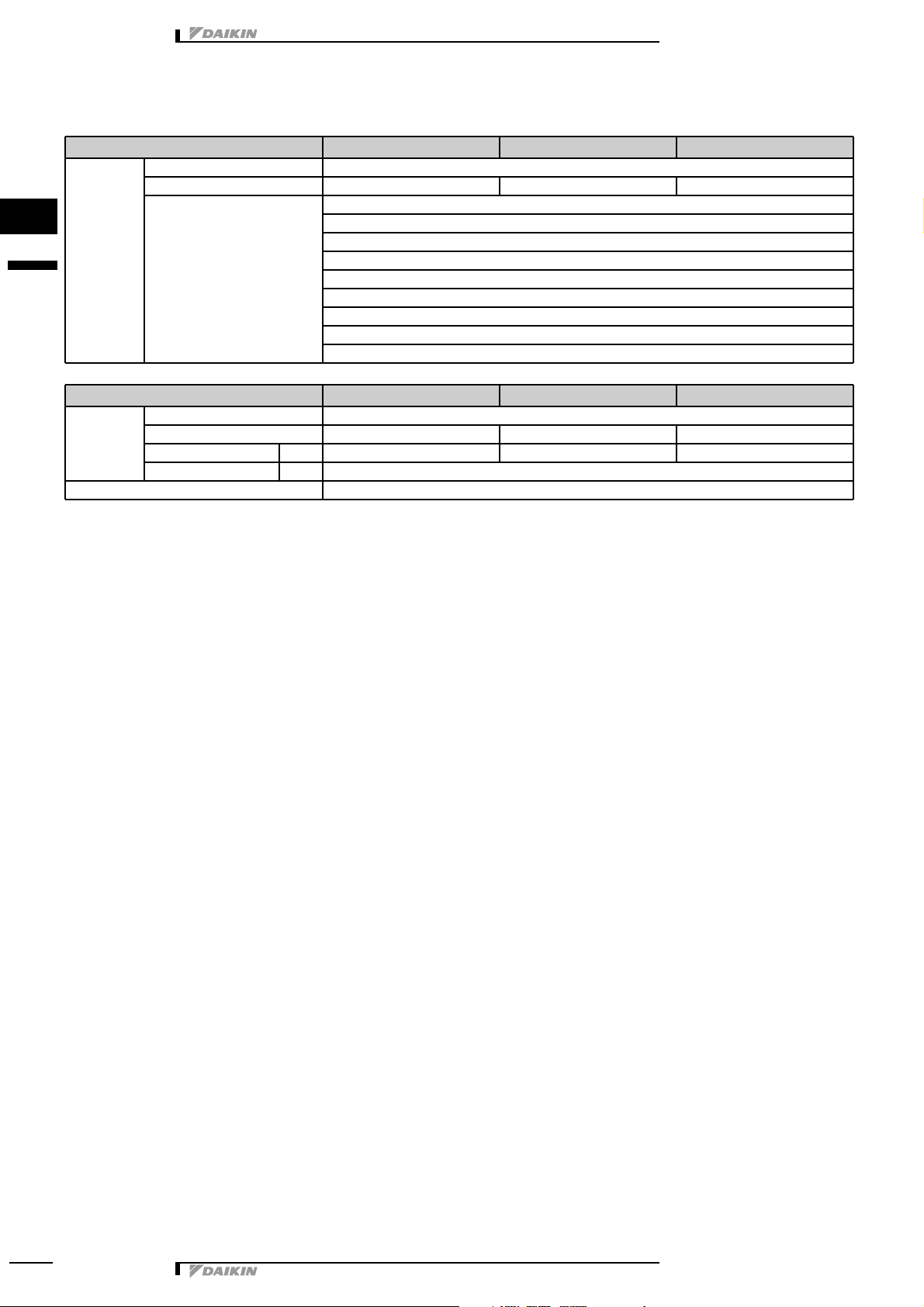

Model Safety devices FUQ71BUV1B FUQ100BUV1B FUQ125BUV1B

FUQ-B

Fuse − − −

Fan motor thermal fuse (°C) − − −

Fan motor thermal protector (°C) Off: 130±5 Off: 130±5 Off: 130±5

4D013856

E

3 Safety device settings

3

1

3

• Split Sky Air • Indoor Units 4

Page 6

• Indoor Units • R-410A • FUQ-BVV1B

Name of option Remark

FUQ∼B

71 100 125

Sealing member of air discharge outlet KDBH49FA80 KDBH49FA140

Decoration panel for air discharge KDBT49FA80 KDBT49FA140

Vertical flap kit KDGJ49FA80 KDGJ49FA140

Replacement long-life filter KAF495FA140

L connection piping kit KHFP49MA140

Remote control Wired type BRC1D528

Infrared type Heat pump BRC7CA528W

Cooling only BRC7CA529W

Central remote control DCS302CA51

Unified ON/OFF control DCS301BA51

Schedule timer DST301BA51

Wiring adapter for electrical appendices KRP4AA53 *1

Interface adapter for Sky Air series DTA112BA51

Installation box for adapter PCB KRP1BA97

Remote sensor KRCS01-1A

Connector for forced on, forced off EKROROA

Electrical box with earth terminal (3 blocks) KJB311AA

Electrical box with earth terminal (2 blocks) KJB212AA

3D044484A

NOTE: *1: Installation box for adapter PCB (KRP1BA97) is necessary

4 Options

1

4

• Split Sky Air • Indoor Units5

Page 7

• Indoor Units • R-410A • FUQ-BVV1B

3TW23651-2

6.5 x 9 (Round end slit)

Cover open

Cover closed

5 x 7 (Round end slit)

HoleJ5

5 x 10 (Round end slit)

BRC1D52

5 Control systems

3

1

5

• Split Sky Air • Indoor Units 6

Page 8

• Indoor Units • R-410A • FUQ-BVV1B

3D013860D

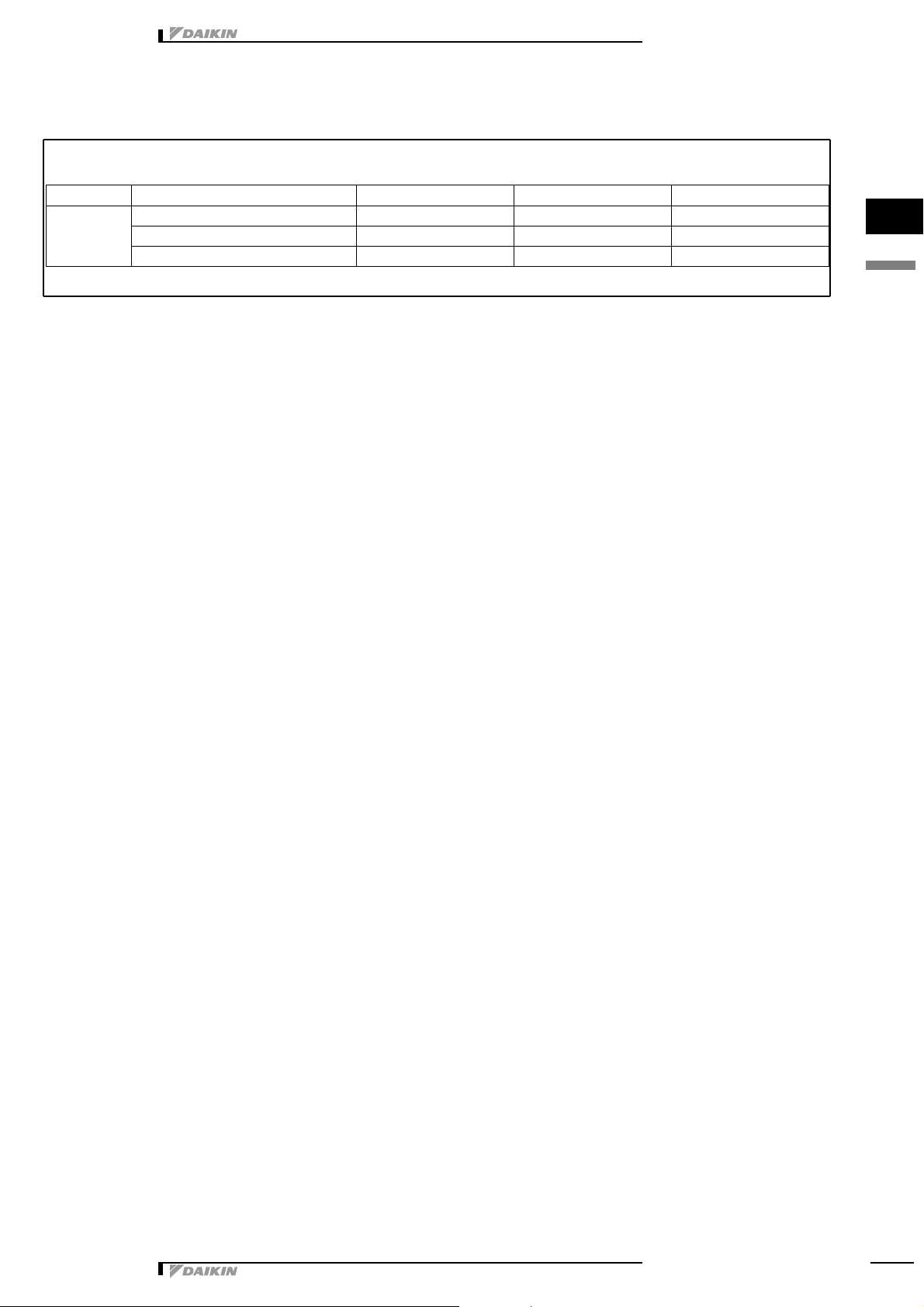

FUQ71B

1

Liquid pipe connection - J9.5 flare

2 Gas pipe connection J15.9 flare

3 Drain pipe connection V.P.20

4 Air outlet

5 Air suction grille

6 Corner decoration cover

7 Right pipe / wiring connection

8 Rear pipe / wiring connection

9 Pipe through cover

10 Accessory drain elbow

790 (Suspension position)

Note:

1. Location for manufacture’s label: on bell mouth.

2. This is where the signal of infrared remote control

is received. Refer to the drawing of infrared

remote control in detail.

3. When closing the discharge grill (2 or 3 way

discharge), direction of pipe connection will be

limited, please refer to installation manual.

unit (mm)

z 1500 mm or

more

z 1500 mm or

more

z 1500 mm or more

z 1500 mm

or more

Required space

z When closing the discharge grill, the required space is

30mm or more. (Note 3)

790

Suspension position

Suspension bolt

Height of suspension bracket

1000mm or more

(required space)

Drain connection

location for rear piping

Drain connection

location for upper

piping

z

Drain pipe can be raised up to 350mm from the top surface of the product.

Brand name plate (note 2)

FUQ100-125B

1

Liquid pipe connection - J9.5 flare

2 Gas pipe connection J15.9 flare

3 Drain pipe connection V.P.20

4 Air outlet

5 Air suction grille

6 Corner decoration cover

7 Right pipe / wiring connection

8 Rear pipe / wiring connection

9 Pipe through cover

10 Accessory drain elbow

790 (Suspension position)

Note:

1. Location for manufacture’s label: on bell mouth.

2. This is where the signal of infrared remote control

is received. Refer to the drawing of infrared

remote control in detail.

3. When closing the discharge grill (2 or 3 way

discharge), direction of pipe connection will be

limited, please refer to installation manual.

unit (mm)

z 1500 mm or

more

z 1500 mm or

more

z 1500 mm or more

z 1500 mm

or more

3D044898

B

Required space

z When closing the discharge grill, the required space is

30mm or more. (Note 3)

790

Suspension position

Suspension bolt

Height of suspension bracket

1000mm or more

(required space)

Drain connection

location for rear

piping

Drain connection

location for upper

piping

z

Drain pipe can be raised up to 350mm from the top surface of the product.

Brand name plate (note 2)

6 Dimensional drawing & centre of gravity

6 - 1 Dimensional drawing

1

6

• Split Sky Air • Indoor Units7

Page 9

• Indoor Units • R-410A • FUQ-BVV1B

4D037995

F

O

Check valve

L

Flare connection

M

Screw connection

N

Flange connection Z Pinched pipePSpinned pipe

Indoor heat exchanger

Field piping JA C1220T-0

FUQ71-100-125B

Field piping JB C1220T-0

Refrigerant pipe connection port diameters

Model A B

FUQ71, 100, 125B J9.5 J15.9

To outdoor unit

Indoor unit

7 Piping diagram

3

1

7

• Split Sky Air • Indoor Units 8

Page 10

8 Wiring diagram

3D043746

A

FUQ71∼125B

A1P Printed circuit board

C1R Capacitor (M1F)

HAP Light emitting diode (service monitor green)

KAR Magnetic relay (M1S)

KPR Magnetic relay ((M1P)

M1F Motor (indoor fan)

M1P Motor (drain pump)

M1S Motor (swing flap)

Q1M Thermo switch (M1F embedded)

R1T Thermistor (air)

R2T Thermistor (coil)

S1L Float switch (M1A)

S1Q Limit switch (swing flap)

SS1 Selector switch (emergency)

T1R Transformer (220-240V/22V)

V1TR Phase control circuit

X1M Terminal strip

X2M Terminal strip

? Signal receiver circuit

. Signal transmission circuit

Wired remote control

R1T Thermistor (air)

SS1 Selector switch (main/sub)

Receiver / display unit (attached to infrared remote controller)

A2P Printed circuit board

A3P Printed circuit board

BS1 Push button (on/off)

H1P Light emitting diode (service monitor red)

H2P Light emitting diode (service monitor green)

H3P Light emitting diode (service monitor red)

H4P Light emitting diode (service monitor orange)

SS1 Selector switch (main/sub)

SS2 Selector switch (wireless address set)

Connector for optional parts

X35A Connector (group control adapter)

X60A

X61A

Connector (interface adapter for sky air series)

To outdoor

unit

Note) 4

Wired remote

control

Control box

In case of simultaneous

operation system.

To outdoor unit

Notes

1. D : Terminal F : Connector

b : Protective earth (screw)

2.

: Field wiring

3. In case using central remote control, connect it to the unit in

accordance with the attached instruction manual.

4. X24A is connected when the infrared remote control kit is

being used.

5. Remote control model varies according to the combination

system, confirm technical materials and catalogs, etc. before

connecting.

6. Symbols show as follows Red:red, Blk:black, Ylw:yellow,

Org:orange, Gry:gray, Prp:purple, Blu:blue

7. Confirm the method of setting the selector switch (SS1, SS2)

by installation manual and engeneering materials, etc.

Receiver / display unit

Note) 4

Indoor unit

(master)

Indoor unit

(slave)

Infrared remote

control

Norm.

Emerg.

8 - 1 Wiring diagram

1

8

• Indoor Units • R-410A • FUQ-BVV1B

• Split Sky Air • Indoor Units9

Page 11

• Indoor Units • R-410A • FUQ-BVV1B

4D013833C

V1, Model

Power supply

1∼50Hz

220V-240V

Fuse

Main switch

Main switch

Fuse

Fuse

NOTES

1

Line voltage wiring

Control circuit wiring

2 All wiring, components and materials to be produced on the site must comply with the applicable local and national codes.

3 Use copper conductors only.

4 See wiring diagrams for details.

5 Install fuse and mainswitch for safety.

6 All field wiring and components must be provided by a licensed electrician.

7 The unit shall be grounded in compilance with the applicable local and national codes.

8 Wiring shown are general points-of-connection guides only and are not intended for or to include all details for a specific

installation.

9 Never share a common power supply with other equipment.

Y1, Model

Power supply

3N∼50Hz

400V

V3, Model

Power supply

1∼50Hz

230V

Main switch

FUQ71∼125B

8 Wiring diagram

8 - 2 External connection diagram

3

1

8

• Split Sky Air • Indoor Units 10

Page 12

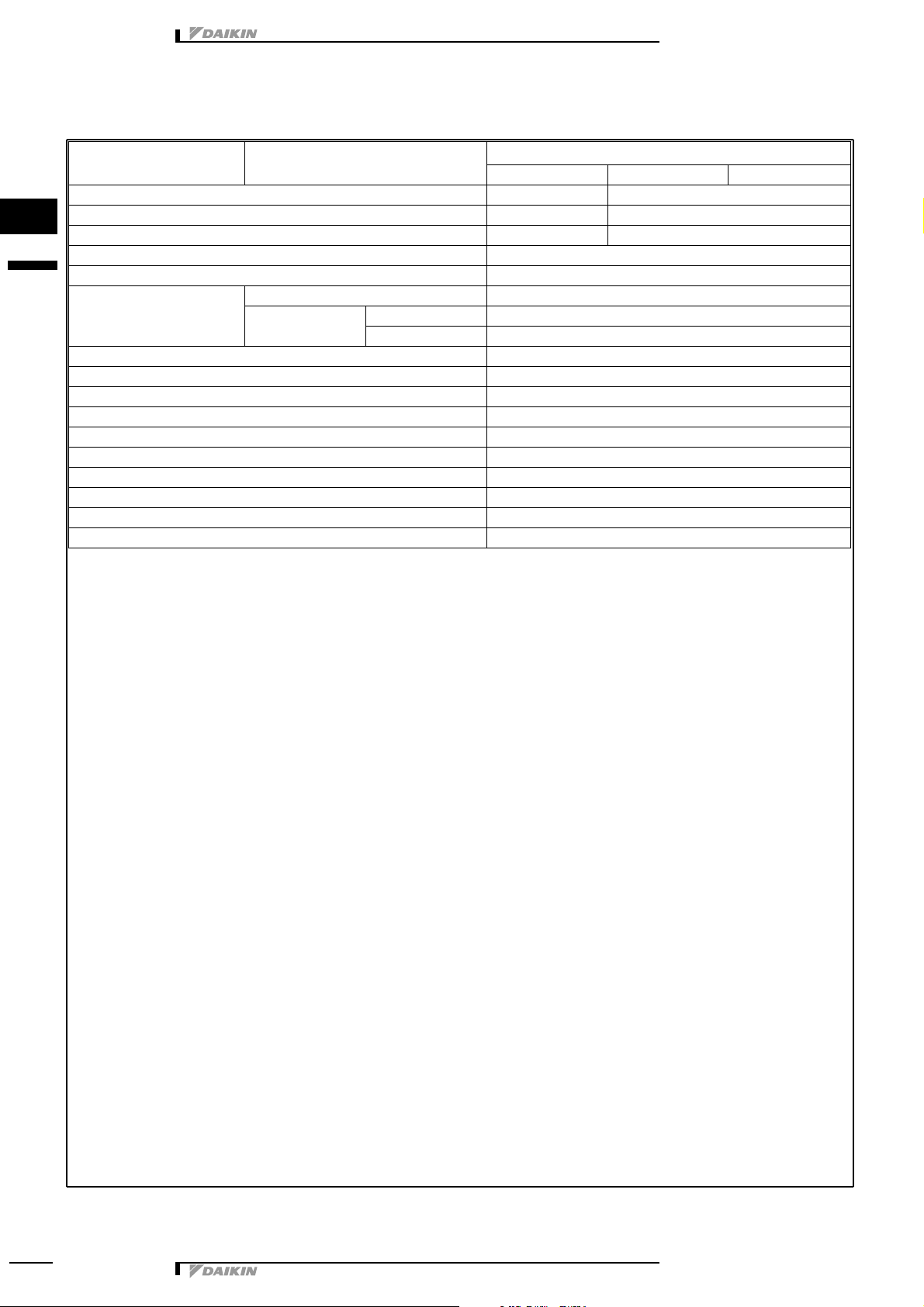

9 Sound data

Location of

microphone

Model

Sound pressure level

Sound power level230V

50Hz

Cooling

(H/L)

Heating

(H/L)

Measuring location Cooling

(H/L)

Heating

(H/L)

FUQ71B 40/35 40/35 56/51 56/51

FUQ100B 43/38 43/38 59/54 59/54

FUQ125B 44/39 44/39 60/55 60/55

9 - 1 Sound level data

1

9

• Indoor Units • R-410A • FUQ-BVV1B

• Split Sky Air • Indoor Units11

Page 13

• Indoor Units • R-410A • FUQ-BVV1B

4D014037

D

Octave band sound pressure level

Octave band center frequency (Hz)

FUQ71B

approximate

threshold hearing

for continuous

noise

NOTES

1 Sound pressure levels are measured in an anechoic

room.

2 Operation sound levels are valid at nominal

operation condition

3 Operation sound level differs with operation and

ambient conditions.

H (230V)

L (230V)

4D014038

D

Octave band sound pressure level

Octave band center frequency (Hz)

FUQ100B

approximate

threshold hearing

for continuous

noise

NOTES

1 Sound pressure levels are measured in an anechoic

room.

2 Operation sound levels are valid at nominal

operation condition

3 Operation sound level differs with operation and

ambient conditions.

H (230V)

L (230V)

4D014039

D

FUQ125B

Octave band sound pressure level

Octave band center frequency (Hz)

NOTES

1 Sound pressure levels are measured in an anechoic

room.

2 Operation sound levels are valid at nominal

operation condition

3 Operation sound level differs with operation and

ambient conditions.

approximate

threshold hearing

for continuous

noise

H (230V)

L (230V)

9 Sound data

9 - 2 Sound pressure spectrum

3

1

9

• Split Sky Air • Indoor Units 12

Page 14

10 Air flow pattern

4D028396C

FUQ71B

Cooling - air velocity distribution

4-way discharge air flow direction: horizontal

FUQ71B

Cooling - air temperature distribution

4-way discharge air flow direction: horizontal

1

10

• Indoor Units • R-410A • FUQ-BVV1B

• Split Sky Air • Indoor Units13

Page 15

10 Air flow pattern

4D028397C

FUQ100B

Cooling - air velocity distribution

4-way discharge air flow direction: horizontal

FUQ100B

Cooling - air temperature distribution

4-way discharge air flow direction: horizontal

• Indoor Units • R-410A • FUQ-BVV1B

3

1

10

• Split Sky Air • Indoor Units 14

Page 16

10 Air flow pattern

4D028398C

FUQ125B

Cooling - air velocity distribution

4-way discharge air flow direction: horizontal

FUQ125B

Cooling - air temperature distribution

4-way discharge air flow direction: horizontal

1

10

• Indoor Units • R-410A • FUQ-BVV1B

• Split Sky Air • Indoor Units15

Page 17

10 Air flow pattern

4D013863

D

FUQ71B

Heating - air velocity distribution

4-way discharge, air flow direction: down

FUQ71B

Heating - air temperature distribution

4-way discharge, air flow direction: down

• Indoor Units • R-410A • FUQ-BVV1B

3

1

10

• Split Sky Air • Indoor Units 16

Page 18

10 Air flow pattern

4D014054

D

FUQ100B

Heating - air velocity distribution

4-way discharge, air flow direction: down

FUQ100B

Heating - air temperature distribution

4-way discharge, air flow direction: down

1

10

• Indoor Units • R-410A • FUQ-BVV1B

• Split Sky Air • Indoor Units17

Page 19

10 Air flow pattern

4D014055

D

FUQ125B

Heating - air velocity distribution

4-way discharge, air flow direction: down

FUQ125B

Heating - air temperature distribution

4-way discharge, air flow direction: down

• Indoor Units • R-410A • FUQ-BVV1B

3

1

10

• Split Sky Air • Indoor Units 18

Page 20

11 Installation

Names and functions of parts

j

a

Indoor unit

j

b

Outdoor unit

j

c

Infrared remote control

j

d

Inlet air

j

e

Discharged air

j

f

Air outlet

j

g

Air flow flap (at air outlet)

j

h

Refrigerant piping, connection electric wire

j

i

Drain pipe

j

j

Air inlet

The built-in air filter removes dust and dirt.

j

k

Ground wire

Wire to ground from the outdoor unit to prevent electrical

shocks.

j

l

Drain pumping out device (built-in)

Drains water removed from the room during cooling

11 - 1 Installation method

1

11

• Indoor Units • R-410A • FUQ-BVV1B

• Split Sky Air • Indoor Units19

Loading...

Loading...