Daikin FLX25HVEA, FTXD50JVEA9, FTXD60JVEA, CDX35HAVEA, FLX35HVEA Service Manual

...

Si18-201

J Series

[Applied Models]

!

!!

!Super Multi Plus : Cooling Only

!

!!

!Super Multi Plus : Heat Pump

Service

Manual

Si18-201

Table of Contents i

Super Multi Plus

Super Multi PlusSuper Multi Plus

Super Multi Plus

J Series

J SeriesJ Series

J Series

!

Heat Pump

Indoor Unit

FTX25JVEA9 FTXD50JVEA9 CDX25HAVEA FLX25HVEA FHYC35KVE9

FTX35JVEA9 FTXD60JVEA CDX35HAVEA FLX35HVEA FHYC50KVE9

FTX25JVEC FTXD71JVEA CDX50HAVEA FLX50JVEA9 FHYC60KVE9

FTX35JVEC FTX50HVEC CDX60HAVEA FLX60JVEA FHYC71KVE9

FTX25JAVET FTX60HVEC CDX25HAVEC FLX25HVEC FHYC35KV1C9

FTX35JAVET FTXD50JVET CDX35HAVEC FLX35HVEC FHYC50KV1C9

FTX25JAV1NB FTXD60JVET CDX50HAVEC FLX50HVEC FHYC60KV1C9

FTX35JAV1NB FTXD71JVET CDX60HAVEC FLX60HVEC FHYC71KV1C9

FTXD50JV1B CDX25HAV1NB FLX25HVET FDYM60FAV1

FTXD25KZV1B FTXD60JV1B CDX35HAV1NB FLX35HVET FDYM03FAV1

FTXD35KZV1B FTXD71JV1B CDX50HAV1NB FLX50HVET FDYM60FAV1C

FVX25KZV1B CDX60HAV1NB FLX60HVET FDYM03FAV1C

FVX35KZV1B CDX25JV1NB FLX25HV1NB FDYM60FAVAL

CDX35JV1NB FLX35HV1NB FDYM03FAVAL

CDX50JV1NB FLX 50JV1B

CDX60JV1NB FLX 60JV1B

CDX25JVEC

CDX35JVEC

Outdoor Unit

RMX140JVMC9 RMX140JVMT9 RMX140JVMB RMX140JZVMB

RMX140JVMC8

BP Unit

BPMK928B42 BPMK928B43

!

Cooling Only

Indoor Unit

FTK25JVE9 FTKD50JVE CDK25HAVE FLK25HVE FHYC35KVE9

FTK35JVE9 FTKD60JVE CDK35HAVE FLK35HVE FHYC50KVE9

FTK25JVEA9 FTKD71JVE CDK50HAVE FLK50HVE FHYC60KVE9

FTK35JVEA9 FTKD50JVEA9 CDK60HAVE FLK60HVE FHYC71KVE9

FTK25JVEC FTKD60JVEA CDK25HAVEA FLK25HVEA FHYC35KV1C9

FTK35JVEC FTKD71JVEA CDK35HAVEA FLK35HVEA FHYC50KV1C9

FTK25JAVET FTK50HVEC CDK50HAVEA FLK50JVEA9 FHYC60KV1C9

FTK35JAVET FTK60HVEC CDK60HAVEA FLK60JVEA FHYC71KV1C9

FTKD50JVET CDK25HAVEC FLK25HVEC FDY M60FAV1

FTKD60JVET CDK35HAVEC FLK35HVEC FDY M03FAV1

FTKD71JVET CDK50HAVEC FLK50HVEC FDY M60FAV1C

CDK60HAVEC FLK60HVEC FDYM03FAV1C

CDK25HAVET FLK25HVET FDYM60FAVAL

CDK35HAVET FLK35HVET FDYM03FAVAL

CDK50HAVET FLK50HVET

CDK60HAVET FLK60HVET

Outdoor Unit

RMK140JVMC9 RMK140JVMT9∗RMK140JAVM RMK140JZVMA

RMK140JVMC8

BP Unit

BPMK928B42 BPMK928B43

∗ The RMK140JAVM specifications are special. For details, see the next page.

Si18-201

ii Table of Contents

NOTICE : Special specifications

Model RMK140JAVM has the following different specifications from the others. Take the important notes below. This

model is designed for cooling mode only, which means it has no heating functions at all.

★★★★Important points : The model is not equipped with the receiver circuit.

1) The heating mode is not available because the following parts are not built in.

2) The following control features are not available.

3) Change the following values for this model.

4) The model is not provided with the surplus refrigerant control function.

PART 5 (5) EVL : Liquid pipe motorized valve Page

103~105

(6) EVG : Gas pipe motorized valve

(8) Capillary tube for gas purge

(9) Check valve

(10) Check valve

PART 5 3.8 Defrost Operation Page 122

3.12 Peak Cut Control Page 128

3.23 Warm-Up Function Page 141

3.27 Cooling Outdoor Unit SC Control Page 151

3.30 SH Control in Cooling Operation Page 157

3.31 SC Control in Heating Operation Page 159

3.32 Heat Exchanger Isothermal Control in Heating Operation Page 161

3.34 Inter-BP Units Heating Heat Exchanger Isothermal Control Page 163

3.37 4-Way Valve Operation Page 166

PART 5 3.11.1 20sec

→

10sec Page 126

PART 6 See "1.7 Cooling operation (multi-room operation - without surplus refrigerant control function) ". Page 178

Si18-201

Table of Contents iii

1. Introduction ............................................................................................ix

1.1 Safety Cautions.......................................................................................ix

Part 1 List of Function ..................................................................1

1. List of Function........................................................................................2

1.1 Function List for General........................................................ ..................2

1.2 Function List for China ............................................ .............................. ...3

1.3 Function List for Taiwan ........... ............... ............................... ............... ...4

1.4 Function List for Europe ....................................... ............................... .....5

1.5 Function List for Singapore, Malaysia, Indonesia..................... ................6

1.6 Function List for Australia.. ............................... ............................... ......... 7

1.7 Function List for Europe ....................................... ............................... .....8

Part 2 Specifications .................................................................... 9

1. Specifications........................................................................................10

1.1 Outdoor Units .........................................................................................10

1.2 BP Units ............... ............................ ................ ............................. ......... 1 8

1.3 Indoor Units (for General).......................................................................19

1.4 Indoor Units (for China)..........................................................................34

1.5 Indoor Units (for Taiwan)........................................................................43

1.6 Indoor Units (for Europe)........................................................................52

Part 3 Printed Circuit Board Connector Wiring Diagram

and Name ......................................................................... 59

1. Printed Circuit Board Connector Wiring Diagram and Name................60

1.1 Branch Provider Unit BPMK928B42, B43 ..............................................60

1.2 Outdoor Unit RMK (X) 140JVMT (C) 9 (8), RMK140JAVM,

RMX140JVMB, RMK (X) 140JZVMA (B) ...............................................61

1.3 FTK25 / 35J Series, FTX25 / 35J Series, FTXD25 / 35K Series,

FVX25 / 35K Series................................................................................64

1.4 FTK50~60HV Series, FTKD50~71JV Series, FTX50~60HV Series,

FTXD50~71JV Series.......... ................ ............................... ............... .....66

1.5 CDX25~60HAV Series, CDK25~60HAV Series....................... ..............68

1.6 FLK25~60HV Series, FLX25~60HV Series, FLK50 / 60JV Series,

FLX50 / 60JV Series ..............................................................................70

1.7 FHYC35~71KV Series............................................................................73

1.8 FDYM60FA, FDYM03FA Series.............................................................75

Part 4 Main Functions Indoor Unit..............................................77

1. Main Functions......................................................................................78

1.1 Main Functions in Split Type..................................................................78

1.2 SkyAir.....................................................................................................98

1.3 Cautions when SkyAir [Auto] [FAN] are used.......................................100

Si18-201

iv Table of Contents

Part 5 Main Functions Outdoor Unit / BP Unit..........................101

1. Refrigerant System and Function of Functional Parts

of Outdoor Unit....................................................................................103

1.1 Refrigerant System and Function of Functional Parts

of Outdoor Unit......................... ............... ................ ............... ..............103

1.2 Major Functional Parts .........................................................................104

1.3 Protective Devices, Thermistors, Sensors ...........................................106

2. Protection Device................................................................................107

2.1 Outdoor Unit.........................................................................................107

2.2 BP Unit............ ................ ............... ................ ............... ................ .......108

3. System control ....................................................................................109

3.1 Outline of System Control ....................................................................109

3.2 Mode Configuration...................... ............................... ......................... 110

3.3 Standby Control at Power ON..............................................................111

3.4 Cooling / Heating Standby Operation at Startup............................... ...112

3.5 Equalizing Control ...................... ............... ................ ...........................113

3.6 Determination of Initial Frequency........................................................115

3.7 Oil Return Operation ............................................................................120

3.8 Defrost Operation................................................. ................ ............... .122

3.9 Pre-Equalization Standby Operation....................................................123

3.10 Equalizi n g Contro l ............... ............................... ............................... ...124

3.11 Capacity Contr ol...................................... ............................... ..............126

3.12 Peak Cut Control..................................................................................128

3.13 Freeze-Up Prevention ..........................................................................129

3.14 Gas Shortage Malfunction....................................................................130

3.15 Discharge Pipe Control ... .............................................. .......................131

3.16 Input Current Control............................................................................132

3.17 Wet Protection Control I .......................................................................135

3.18 Electric Parts Cooling and Electric Parts /

Fin Temperature Control......................................... .............................136

3.19 Differential Pressure Control ................................................................137

3.20 Year-Round Cooling-Only Function .....................................................138

3.21 Nighttime Low Noise Control................................................................139

3.22 PI Control .............................................................................................140

3.23 Warm-Up Function...............................................................................141

3.24 Compressor Protection Control............................................................142

3.25 Fan Control...........................................................................................143

3.26 Motorized Valve Control of Outdoor Unit..............................................145

3.27 Cooling Outdoor Unit SC Control .........................................................151

3.28 BP Unit Motorized Valve Contr o l.......................... ................................152

3.29 Gas Pipe Isothermal Control in Cooling Operation ..............................155

3.30 SH Control in Cooling Operation..........................................................157

3.31 SC Control in Heating Operation..........................................................159

3.32 Heat Exchanger Isothermal Control in Heating Operation ...................161

3.33 BP Unit Motorized Valve Control in High Discharge

Pipe Temperature................................ ............... ............................... ...162

3.34 Inter-BP Units Heating Heat Exchanger Isothermal Control ................163

3.35 Inter-BP Units Gas Pipe Isothermal Control.........................................164

3.36 BP Unit Motorized Valve Control by Target Discharge

Pipe Temperature................................ ............... ............................... ...165

3.37 4-Way Valve Operation ........................................................................166

Si18-201

Table of Contents v

3.38 JIS Mode ..... ............... ................ ............... ................ ............... ............167

3.39 Pump Down Operation............................................................. ............168

3.40 Protection Control of SkyAir Indoor Units.............................................169

Part 6 Flow of Refrigerant ........................................................171

1. Flow of Refrigerant..............................................................................172

1.1 Flow of Refrigerant.................................... ............................... ............172

1.2 Standby Operation (Cooling)................................................................173

1.3 Equalizing Control (Cooling)................ .............................................. ...174

1.4 Oil Return Operation (Cooling).............................................................175

1.5 Low Outside Air Temperature Cooling .................................................176

1.6 All-Room Operation (Cooling) ..............................................................177

1.7 Multi-Room Operation (No Surplus Refrigerant) (Cooling)..... .............. 178

1.8 Multi-Room Operation (Cooling) (with Surplus Refrigerant)..... ............ 179

1.9 1-Room Operation — Indoor Unit with Large Capacity (Cooling) ........180

1.10 1-Room Operation — Indoor Unit with Small Capacity

(2.5 kW) (Cooling) ................................................................................181

1.11 Standby Operation (Heating)................................................................182

1.12 Equalizin g Contr o l (Heating) ............... .................................................183

1.13 Oil Return Operation (Heating).............................................................184

1.14 Defrost Operation ............... ............................................... ..................185

1.15 All-Room Operation (Heating)..............................................................186

1.16 Multi-Room Operation (with non-Operating Room Unit) (Heating).......187

1.17 Multi- Room Operation (Heating) ............. .............................................188

1.18 1-Room Operation — Indoor Unit with Large Capacity (Heating)........189

1.19 1-Room Operation — Indoor Unit with Small Capacity

(2.5 kW) (Heating)................................................................................190

Part 7 Operations ......................................................................191

1. Remote Controller...............................................................................192

1.1 Wireless Remote Controller ......... ............... ............................... ..........192

1.2 Wired Remote Controller.................................... ..................................202

Part 8 Operating Test ...............................................................205

1. Operating Test ....................................................................................206

1.1 Operating Test.................................. ............................... ................ .....206

1.2 Test Operation Switch...................... ............................... .....................209

1.3 Pump Down Operation Switch .............................................................210

1.4 Record of the Installation Position........................................................211

2. Method of Field Set.............................................................................212

2.1 Field Setting .........................................................................................212

2.2 Group Number Setting for Central Remote Control .............................220

2.3 Interface Adaptor for Room Airconditioner <KRP928A1S>............. .....221

2.4 Precautions: For RMK140J / RMX140J Outdoor Unit Users................223

Part 9 Service Diagnosis...........................................................225

1. Troubleshooting - Split Type Indoor Unit.............................................226

1.1 Troubleshooting with the Operation Lamp ...........................................226

1.2 Service Check Function ..................................... ................ ............... ...228

Si18-201

vi Table of Contents

1.3 Code Indication on the Remote Controller................ ................. ..........230

1.4 Troubleshooting....................................................................................231

1.5 Troubleshooting Detail .........................................................................232

2. Trou blesh ooting - SkyAir Indo or Unit.......... ................................. ..... ..246

2.1 The INSPECTION/TEST Button...........................................................246

2.2 Self-Diagnosis by Wired Remote Controller........................... ..............247

2.3 Fault Diagnosis by Wireless Remote Controller...................................248

2.4 Troubleshooting by LED on the Indoor Unit’s.......................................250

2.5 Troubleshooting by Remote Controller Display / LED Display.............251

2.6 Troubleshooting Detail .........................................................................252

3. Trou blesh oo ting - Out doo r Unit Related.............................................260

3.1 The Unit Runs but Doesn’t Cool (Heat) the Room............... ................260

3.2 7 Seg. Display on the Outdoor P. C. Board..........................................262

3.3 Troubleshooting Detail .........................................................................263

3.4 How to Check..................................................... ................ ............... ...300

4. BP Unit Trouble Diagnosis..................................................................310

4.1 PCB Parts Layout..... ................ ............... ................ ............... ..............310

4.2 LED On Branch Provider Unit (Diagnosis LEDs) .................................310

Part 10Removal Procedure ........................................................311

1. For BPMK928B42 · 43........................................................................312

1.1 Installation of Indoor Unit......................................................................312

1.2 Opening of Electrical Box Cover and Removal of PCB Mount.............313

1.3 Removal of Motorized Valve ......................................... .......................315

1.4 Removal of Thermistor.................................................. .......................318

2. Outdoor Unit........................................................................................320

2.1 Removal of Outer Panels..................................................................... 320

2.2 Removal of PCB and Electrical Box.....................................................321

2.3 Removal of Propeller Fans and Fan Motors.........................................329

2.4 Removal of Thermistor.................................................. .......................331

2.5 Removal of Motorized Valve ......................................... .......................332

2.6 Removal of Sound Insulation ................ .............................................. .334

2.7 Removal of Compressor................................................ .......................336

2.8 Removal of 4-way Valve.... .............................................. .....................338

3. Indoor Unit...........................................................................................342

3.1 Refer following table for indoor unit removal procedure.......................342

Part 11Cautions before Operation............................................. 343

1. Installation...........................................................................................344

1.1 Outdoor Unit.........................................................................................344

1.2 BP Unit............ ................ ............... ................ ............... ................ .......346

2. Wiring..................................................................................................348

2.1 Outdoor Unit.........................................................................................348

2.2 BP Unit............ ................ ............... ................ ............... ................ .......350

2.3 Outdoor Unit Rotary Switch Setting...................................................... 352

3. Others .................................................................................................354

3.1 Explanation for FTK(X)25/35J Series...... ................................. ............354

3.2 Explanation for FTK(X)50/60H and CDK(X)25~60H Series.................357

Si18-201

Table of Contents vii

Part 12Appendix......................................................................... 359

1. Pip ing Dia grams.......................................... ................................. ..... ..360

1.1 Outdoor Units .......................................................................................360

1.2 BP Units ............... ............... ................ ............... ................ ............... ...362

1.3 Indoor Units..........................................................................................363

2. Wiring Diagrams..................................................................................370

2.1 Outdoor Units .......................................................................................370

2.2 BP Units ............... ............... ................ ............... ................ ............... ...374

2.3 Indoor Units..........................................................................................375

Index .............................................................................................i

Drawings & Flow Charts ................................................................ v

Si18-201

viii Table of Contents

Si18-201 Introduction

ix

1. Introduction

1.1 Safety Cautions

Cautions and

Warnings

"

Be sure to read the following safety cautions before conducting repair work.

"

The caution items are classified into “ Warning” and “ Caution”. The “ Warning”

items are especially important since they can lead to death or serious injury if they are not

followed closely. The “ Caution” items can also lead to serious accidents under some

conditions if they are not followed. Therefore, be sure to observe all the safety caution items

described below.

"

About the pictograms

This symbol indicates an item for which caution must be exercised.

The pictogram shows the item to which attention must be paid.

This symbol indicates a prohibited action.

The prohibited item or action is shown inside or near the symbol.

This symbol indicates an action that must be taken, or an instruction.

The instruction is shown inside or near the symbol.

"

After the repair work is complete, be sure to conduct a test operation to ensure that the

equipment operates normally, and explain the cautions for operating the product to the

customer.

1.1.1 Cautions in Repair

Warning

Be sure to disconnect the power cable plug from the plug socket before

disassembling the equipment for a repair.

Working on the equipment that is connected to a power supply can cause an

electrical shook.

If it is necessary to supply power to the equipment to conduct the repair or

inspecting the circuits, do not touch any electrically charged sections of the

equipment.

If the refrigerant gas discharges during the repair work, do not touch the

discharging refrigerant gas.

The refrigerant gas can cause frostbite.

When disconnecting the suction or discharge pipe of the compressor at the

welded section, release the refrigerant gas completely at a well-ventilated

place first.

If there is a gas remaining inside the compressor, the refrigerant gas or

refrigerating machin e oil d ischa rges whe n the pi pe is di scon nected , and it can

cause injury.

If the refrigerant gas leaks during the repair work, ventilate the area. The

refrigerant gas can generate toxic gases when it contacts flames.

The step-up capacitor supplies high-voltage electricity to the electrical

components of the outdoor unit.

Be sure to discharge the capacitor completely before conducting repair work.

A charged capacitor can cause an electrical shock.

Do not start or stop the air con ditioner op eration by p lugging or unpl ugging the

power cable plug.

Plugging or unplugging the power cable plug to operate the equipment can

cause an electrical shock or fire.

Introduction Si18-201

x

1.1.2 Cautions Regarding Products after Repair

Caution

Do not repair the electrical components with wet hands.

Working on the equipment with wet hands can cause an electrical shock.

Do not clean the air conditioner by splashing wa ter.

Washing the unit with water can cause an electrical shock.

Be sure to provide the grounding when repairing the equipment in a humid or

wet place, to avoid electrical shoc ks.

Be sure to turn off the power switc h and unpl ug the power c able when c leaning

the equipment.

The internal fan rotates at a high speed, and cause injury.

Do not tilt the unit when removing it.

The water inside the unit can spill and wet the furniture and floor.

Be sure to check that the refrigerating cycle section has cooled down

sufficiently before conducting repair work.

Working on the unit when the re frigerating cycle sectio n is hot can cause burns .

Use the welder in a well-ventilated place.

Using the welder in an enclosed room can cause oxygen deficiency.

Warning

Be sure to use parts liste d in the se rvi ce p arts li st of the applicable mo del and

appropriate tools to conduct repair work. Never attempt to modify the

equipment.

The use of inappropriate parts or tools can cause an electrical shock,

excessive heat generation or fire.

When relocating the equipment, make sure that the new installation site has

sufficient strength to withstand the weight of the equipment.

If the installation site does not have sufficient strength and if the installation

work is not conducted securely, the equipment can fall and cause injury.

Be sure to install the product correctly by using the provided standard

installat ion frame.

Incorrect use of the installation frame and improper installation can cause the

equipment to fall, resulting in injury.

For integral units

only

Be sure to install the product securely in the installation frame mounted on a

window frame.

If the unit is not securely mounted, it can fall and cause injury.

For integral units

only

Be sure to use an exclusive power circuit for the equipment, and follow the

technical standards related to the electrical equipment, the internal wiring

regulations and the instruction manual for installation when conducting

electrical work.

Insufficient power circuit capacity and improper electrical work can cause an

electrical shock or fire.

Si18-201 Introduction

xi

1.1.3 Inspection after Repair

Be sure to use the s pe ci fie d c ab le to connect between the indoor and o utd oor

units. Make the co nnections secure ly and route the cable properly s o that there

is no force pulling the cable at the connection terminals.

Improper connections can cause excessive heat generation or fire.

When connecting the cable between the indoor and outdoor units, make sure

that the terminal cover does not lift off or dismount because of the cable.

If the cover is not mounted prop erly, the terminal conn ection section ca n cause

an electrical shock, excessive heat generation or fire.

Do not damage or modify the power cable.

Damaged or modified power cable can cause an electrical shock or fire.

Placing heavy items on the po wer cable, and heating or pulli ng the power cable

can damage the cable.

Do not mix air or gas other than the specified refrigerant (R22) in the refrigerant

system.

If air enters the refrigerating system, an excessively high pressure results,

causing equipment damage and injury.

If the refrigerant gas leaks, be sure to locate the leak and repair it before

charging the refrigerant. After charging refrigerant, make sure that there is no

refrigerant leak.

If the leak cannot be located and the repair work must be stopped, be sure to

perform pump-down and clos e the service valve , to prevent the refrig erant gas

from leaking into the room. The refrigerant gas itself is harmless, but it can

generate toxic gases when it contacts flames, such as fan and other heaters,

stoves and ranges.

When replacing the coin battery in the remote controller, be sure to disposed

of the old battery to prevent children from swallowing it.

If a child swallows the coin battery, see a doctor immediately.

Warning

Caution

Installation of a leakage breaker is ne cessary in so me cases dep ending on the

conditions of the installation site, to prevent electrical shocks.

Do not install the equipment in a place where there is a possibility of

combustible gas leaks.

If a combustible gas leaks and remains around the unit, it can cause a fire.

Be sure to install the packing and seal on the installation frame properly.

If the packing and sea l are not inst alled properly , water can ent er the room and

wet the furniture and floor.

For integral units

only

Warning

Check to make sure that t he p ower c ab le p lug is not dirty or l oo se, then insert

the plug into a power outlet all the way.

If the plug has dust or loose conne ction, it can cause an electri cal shoc k or fire.

If the power cable and lead wires have scratches or deteriorated, be sure to

replace them.

Damaged cable and wires can cause an electrical shock, excessive heat

generation or fire.

Do not use a joined power cable or extension cable, or share the same power

outlet with other electrical appliances, since it can cause an electrical shock,

excessive heat generation or fire.

Introduction Si18-201

xii

1.1.4 Using Icons

Icons are used to attract the attention of the reader to specific information. The meaning of each

icon is described in the table below:

1.1.5 Using Icons List

Caution

Check to see if the parts a nd wires are mounted and c onn ec ted prope rly , an d

if the connections at the soldered or crimped terminals are secure.

Improper installation and connections can cause excessive heat generation,

fire or an electrical shock.

If the installation platform or frame has corroded, replace it.

Corroded installation platform or frame can cause the unit to fall, resulting in

injury.

Check the grounding, and repair it if the equipment is not properly grounded.

Improper grounding can cause an electrical shock.

Be sure to measure the insulation resistance after the repair, and make sure

that the resistance is 1 MΩ or higher.

Faulty insulation can cause an electrical shock.

Be sure to check the drainage of the indoor unit after the repair.

Faulty drainage can cause the water to enter the room and wet the furniture

and floor.

Icon Type of

Information

Description

Note:

Note A “note” provides i nform at ion that is not indi sp ens ab le, but may

nevertheless be valuable to the reader, such as tips and tricks.

Caution

Caution A “cautio n” is used when there is danger tha t the reader, through

incorrect manipulatio n, may dama ge equipmen t, loose data , get

an unexpected result or has to restart (part of) a procedure.

Warning

Warning A “warning” is used when there is danger of personal injury.

Reference A “reference” guides the reader to other places in this binder or

in this manual, where he/she will find additional information on a

specific topic.

Si18-201

List of Function 1

Part 1

Part 1Part 1

Part 1

List of Function

List of FunctionList of Function

List of Function

1. List of Function........................................................................................2

1.1 Function List for General........................................................ ..................2

1.2 Function List for China ............................................ .............................. ...3

1.3 Function List for Taiwan ........... ............... ............................... ............... ...4

1.4 Function List for Europe ....................................... ............................... .....5

1.5 Function List for Singapore, Malaysia, Indonesia..................... ................6

1.6 Function List for Australia.. ............................... ............................... ......... 7

1.7 Function List for Europe ....................................... ............................... .....8

The RMK 140JA VM s pecifications are sp ecial. Refer to <R MK14 0JAVM 's

important points> (on page ii) for the changes in contents.

List of Function Si18-201

2 List of Function

1. List of Function

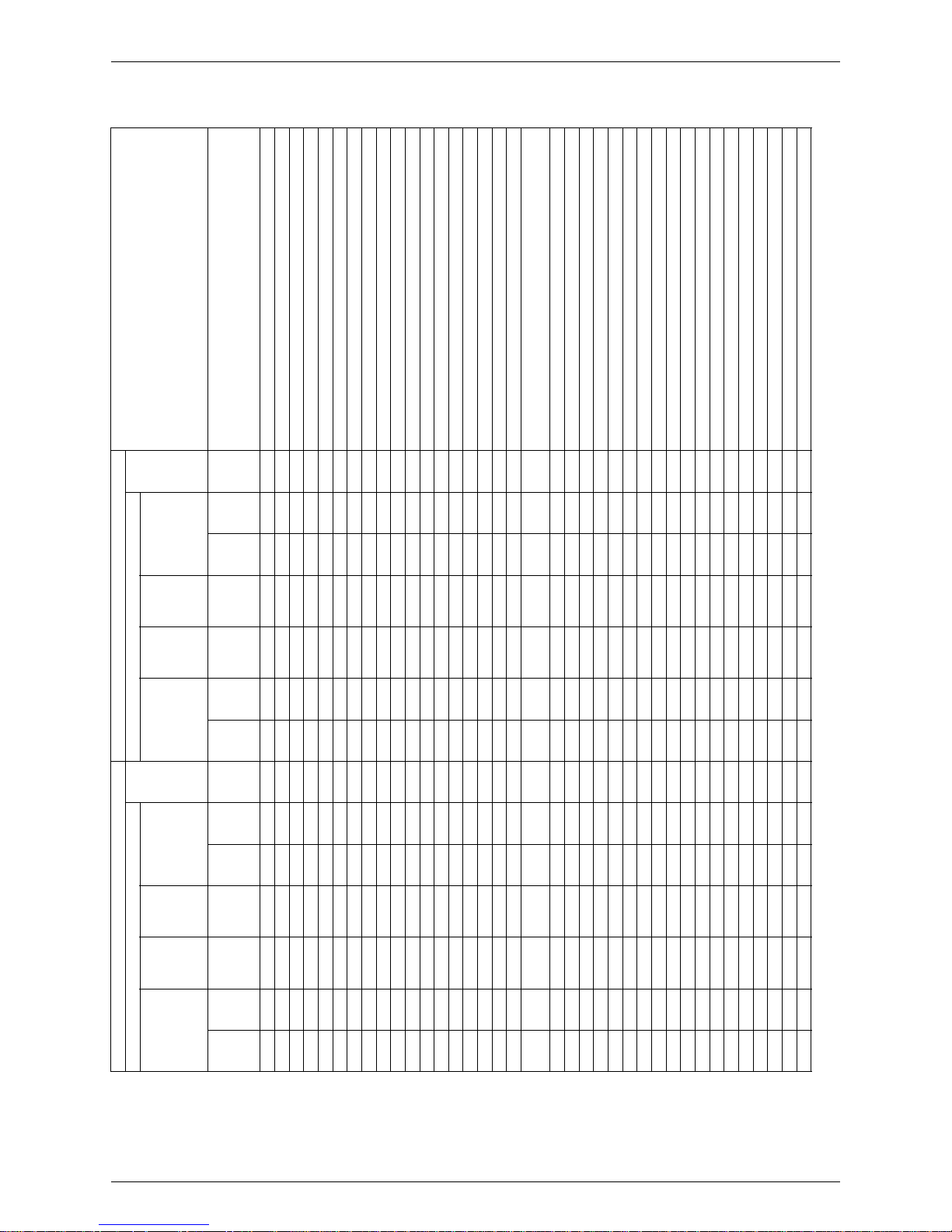

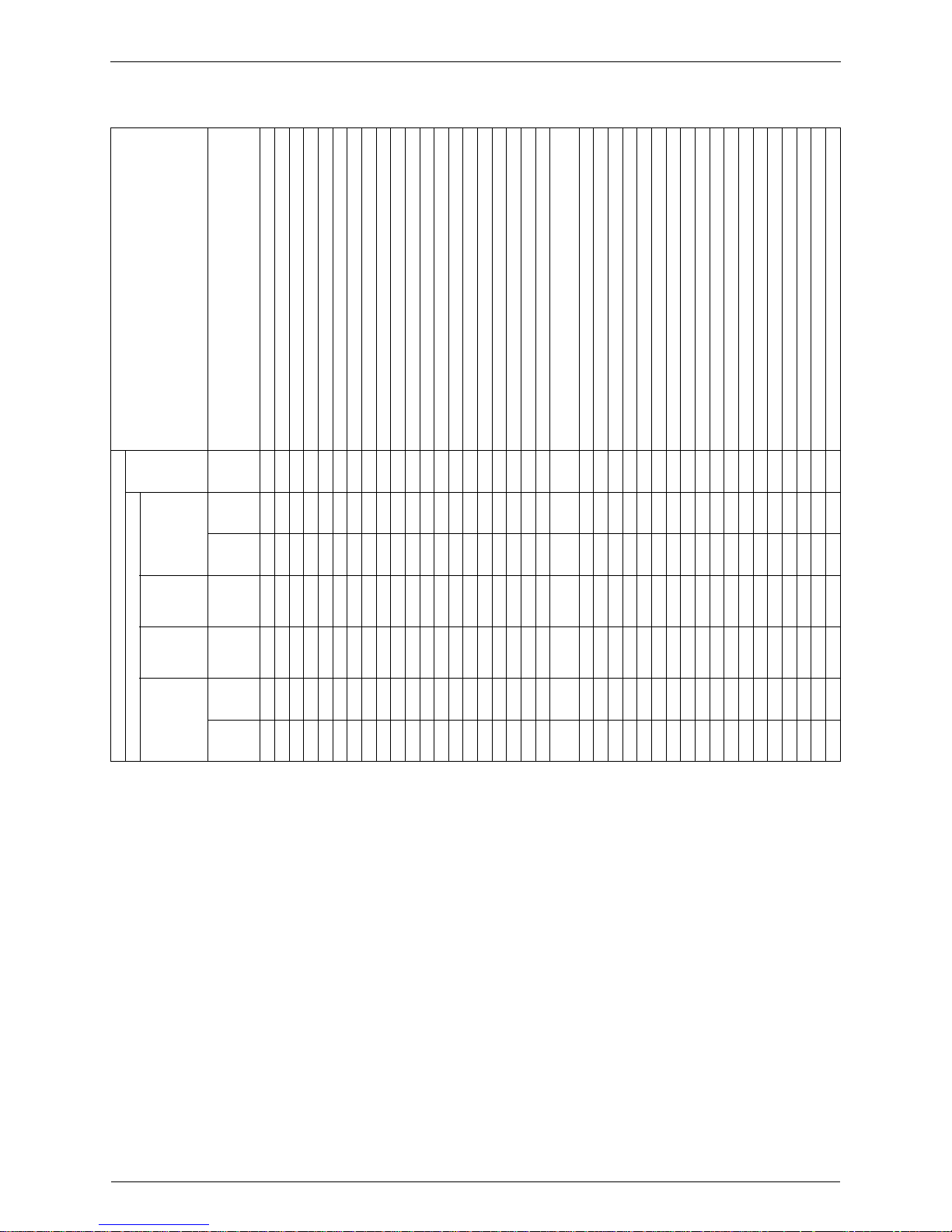

1.1 Function List for General

★1

! : for FLK, FLX50/60J

★2

–

: for FLK, FLX50/60J

Division

Indoor

Unit /

Outdoor

Unit

Inverter (with Inverter Power Control)

PAM control (Pulse Amplitude Modulation Control)

Horizontal Scroll, Oval Scroll Compressor (DAIKIN SCROLL)

Reluctance DC Motor

Dual Flaps

Power-Airflow Dual Flaps

Power-Airflow Diffuser

Wide-Angle Louvers

Vertical Auto-Swing (Up and Down)

Horizontal Auto-Swing (Right and Left)

3-D Airflow

Auto Fan Speed

Silent Operation Control (Automatic)

Intelligent Eye

Automatic Oper at ion

Programme Dry Function

Fan Only

Inverter Powerful Operation

Home Leave Operation

Indoor Unit On/Off Switch

Air-Purifying Filter

with Bacteriostatic, Virustatic & Deodorizing Functions

Mold-Proof Air Filter

Washable Grille

Filter Cleaning Indicator

Good-Sleep Cooling Operation

72-Hour On/Off Timer

24-Hour On/Off Timer

Night Set Mode

Auto-Restart ( a fter Power Failure)

Self-Diagnosis Digital Display

Self-Diagnosis LED Display

Wiring-Error Check

Anticorrosion Treatment of Outdoor Heat Exchanger

Multi-Split/Split Type Compatible Indoor Unit

High-Ceiling Application

Chargeless

Wireless (FHYC, FDYM: O p tion)

Wired (FHYC, FDYM: Option)

Group Control by 1 Remote Controller

Cooling Only

Outdoor Unit

RMK

140J

!!!!

––––––––!––––!–– – ––––––––!!–!––

115

m

–––

Indoor Unit

Wall

Mounted

Type

FTK25/

35J

!

–––!!–

!!––!–!–!!!–!!!!–!–!!!!

–––!––!––

FTKD

50/60/

71J

!

–––

!!!!!!!!

–––

!!!!! ! !!

–––

!!!!!––!

––!––

Floor/

Ceiling

Suspended

Dual Type

FLK25/

35/50/

60H

50/60J

!

––––––!!––!–––

!!!★1!!!

–

!

★2

––

!!!!!

––★1––!––

Ceiling

Mounted

Cassette

Type

FHYC

35/50/

60/71K

––––––––

!

––!–––!!––– –!–!–!––

!!!––!!–!!!

Duct

Connected

Type

CDK25/

35/50/

60HA

!

––––––––––!–––

!!!–!

– –––––

!!!!!

–––––!––

FDYM

60/03FA

–––––––––––––––

!!

––––––!–!––

!!!––!

––

!!!

Heat Pump

Outdoor Unit

RMX

140J

!!!!

––––––––!––––––– – ––––––––!!–!––

115

m

–––

Indoor Unit

Wall

Mounted

Type

FTX25/

35J

!

–––!!–

!!––!–!!!–!–!!!!–!–!!!!

–––!––!––

FTXD

50/60/

71J

!

–––

!!!!!!!!––!!–!!!!!!

–––

!!!!!––!

––!––

Floor/

Ceiling

Suspended

Dual Type

FLX25/

35H

50/60J

!

––––––!!––!––!!–

!★1!!!

–

!

★2

––

!!!!!

––★1––!––

Ceiling

Mounted

Cassette

Type

FHYC

35/50/

60/71K

––––––––

!

––!––

!!!

––– –!–!–!––

!!!––!!–!!!

Duct

Connected

Type

CDX25/

35/50/

60HA

!

––––––––––!––!!–!–!– –––––

!!!!!

–––––!––

FDYM

60/03FA

––––––––––––––

!!!

––––––!–!––

!!!––!

––

!!!

Si18-201 List of Function

List of Function 3

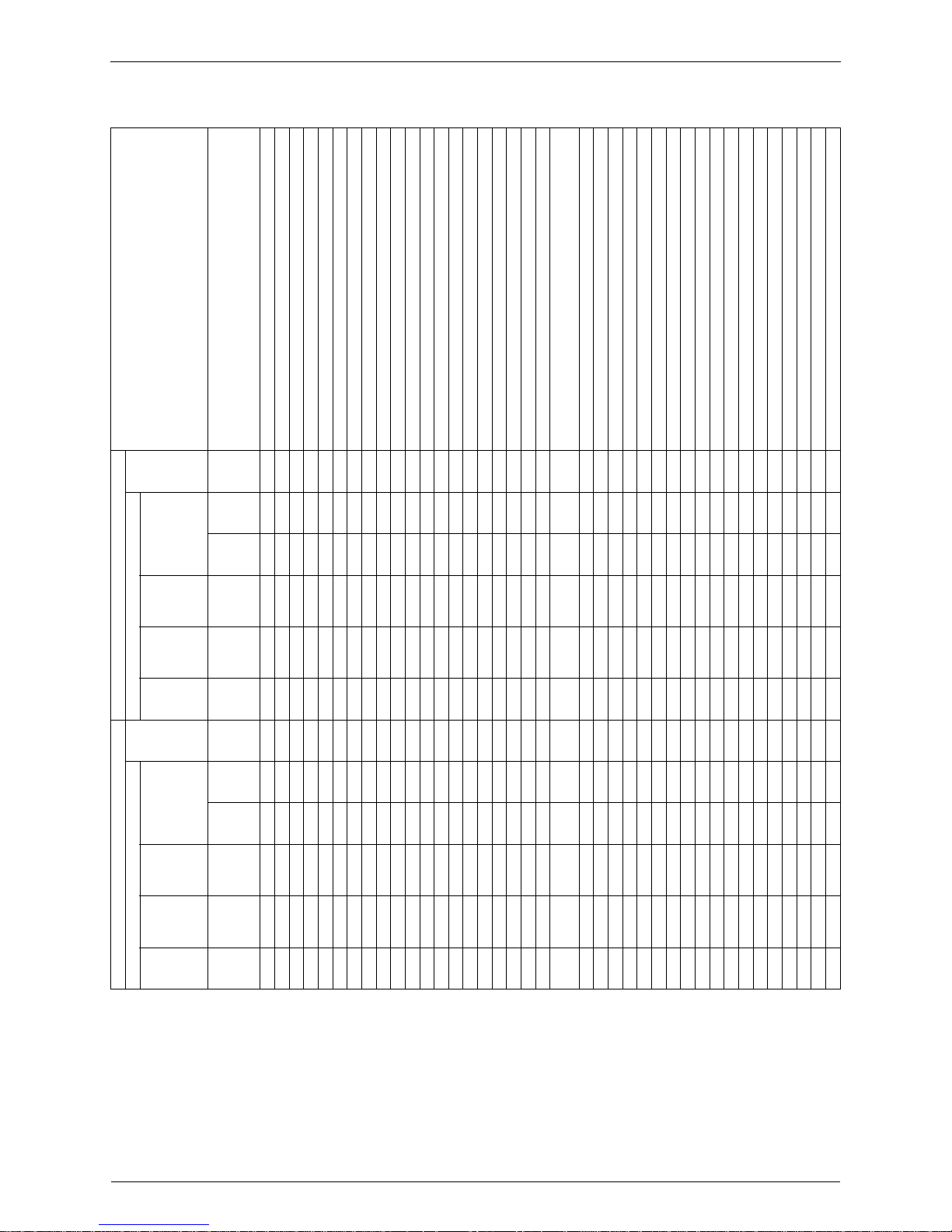

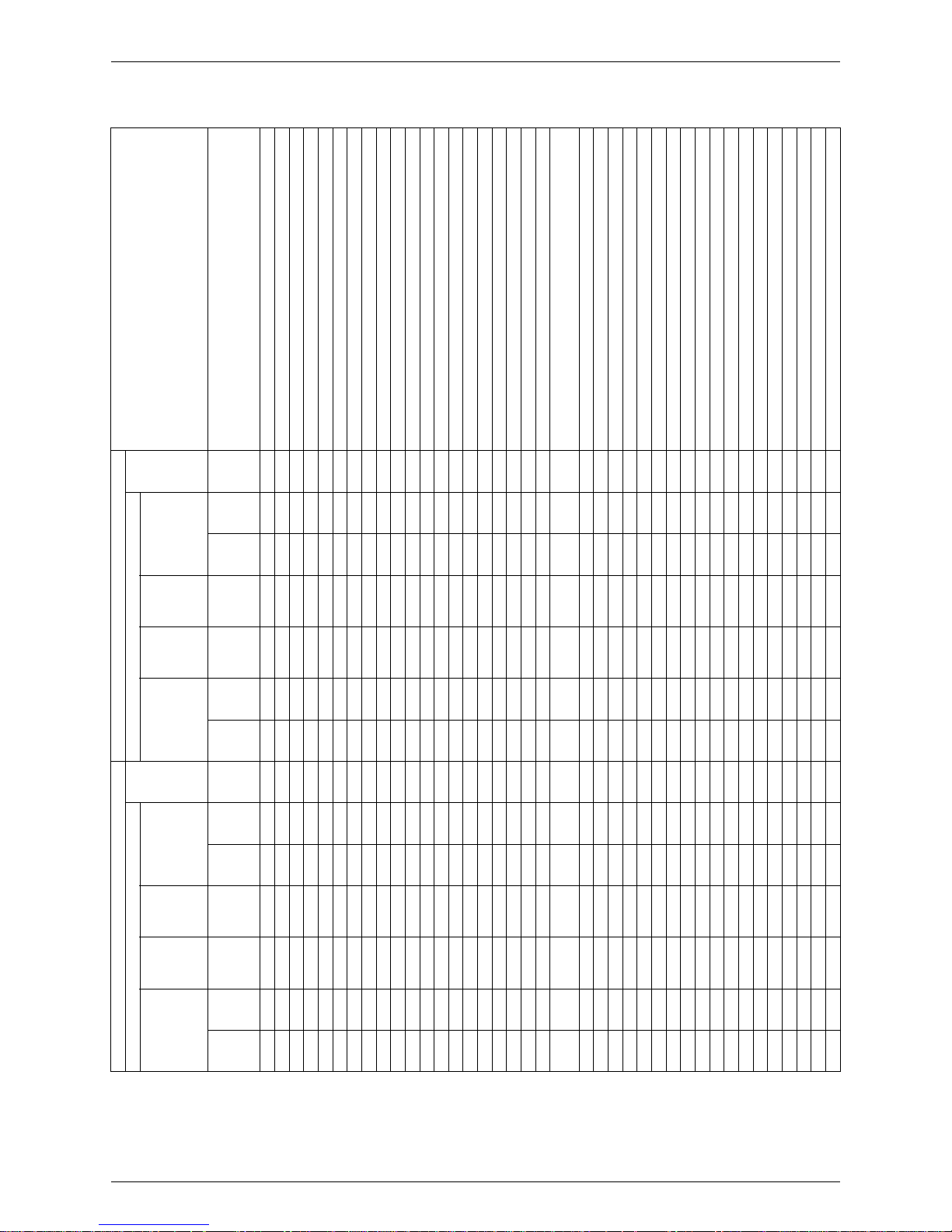

1.2 Function List for China

Division

Indoor

Unit /

Outdoor

Unit

Inverter (with Inverter Power Control)

PAM control (Pulse Amplitude Modulation Control)

Horizontal Scroll, Oval Scroll Compressor (DAIKIN SCROLL)

Reluctance DC Motor

Dual Flaps

Power-Airflow Dual Flaps

Power-Airflow Diffuser

Wide-Angle Louvers

Vertical Auto-Swing (Up and Down)

Horizontal Auto-Swing (Right and Left)

Auto Fan Speed

Silent Operation Control (Automatic)

Intelligent Eye

Automatic Operation

Programme Dry Function

Fan Only

Inverter Powerful Operation

Indoor Unit On/Off Switch

Air-Purifying Filter

with Bacteriostatic, Virustatic & Deodorizing Functions

Mold-Proof Air Filter

Washable Grille

Filter Cleaning Indicator

Good-Sleep Cooling Operation

72-Hour On/Off Timer

24-Hour On/Off Timer

Night Set Mode

Auto-Restart (after Power Failure)

Self-Diagnosis Digital Display

Self-Diagnosis LED Display

Wiring-Error Check

Anticorrosion Treatment of Outdoor Heat Exchanger

Multi-Split/Split Type Compatible Indoor Unit

High-Ceiling Application

Chargeless

Wireless (FHYC, FDYM: Option)

Wired (FHYC, FDYM: Option)

Group Control by 1 Remote Controller

Cooling Only

Outdoor Unit

RMK

140J

!!!!

–––––––!––––!– – ––––––––!!–!––

115

m

–––

Indoor Unit

Wall

Mounted

Type

FTK25/

35J

!

–––!!–

!!–!–!–!!!!!!!–!–!!!!

–––!––!––

FTK

50/60H

!

––––––

!!!!

–––

!!!! ! !!!––!!!!!

–––––!––

Floor/

Ceiling

Suspended

Dual Type

FLK25/

35/50/

60H

!

––––––!!–!–––

!!!!!!–!

––

!!!!!

–––––!––

Ceiling

Mounted

Cassette

Type

FHYC

35/50/

60/71K

––––––––

!–!

–––!!–– –!–!–!––

!!!––!!–!!!

Duct

Connected

Type

CDK25/

35/50/

60HA

!

–––––––––!–––

!!!!

– –––––

!!!!!

–––––!––

FDYM

60/03FA

––––––––––––––

!!

–––––!–!––

!!!––!

––

!!!

Heat Pump

Outdoor Unit

RMX

140J

!!!!

–––––––!–––––– – ––––––––!!–!––

115

m

–––

Indoor Unit

Wall

Mounted

Type

FTX25/

35J

!

–––!!–

!!–!–!!!–!!!!!–!–!!!!

–––!––!––

FTX

50/60H

!

––––––

!!!!––!!–!!!!!!––!!!!!

–––––!––

Floor/

Ceiling

Suspended

Dual Type

FLX25/

35/50/

60H

!

––––––!!–!––!!–

!!!!–!

––

!!!!!

–––––!––

Ceiling

Mounted

Cassette

Type

FHYC

35/50/

60/71K

––––––––

!–!

––

!!!

–– –!–!–!––

!!!––!!–!!!

Duct

Connected

Type

CDX25/

35/50/

60HA (J)

!

–––––––––!––!!–

!!

– –––––

!!!!!

–––––!––

FDYM

60/03FA

–––––––––––––

!!!

–––––!–!––

!!!––!

––

!!!

List of Function Si18-201

4 List of Function

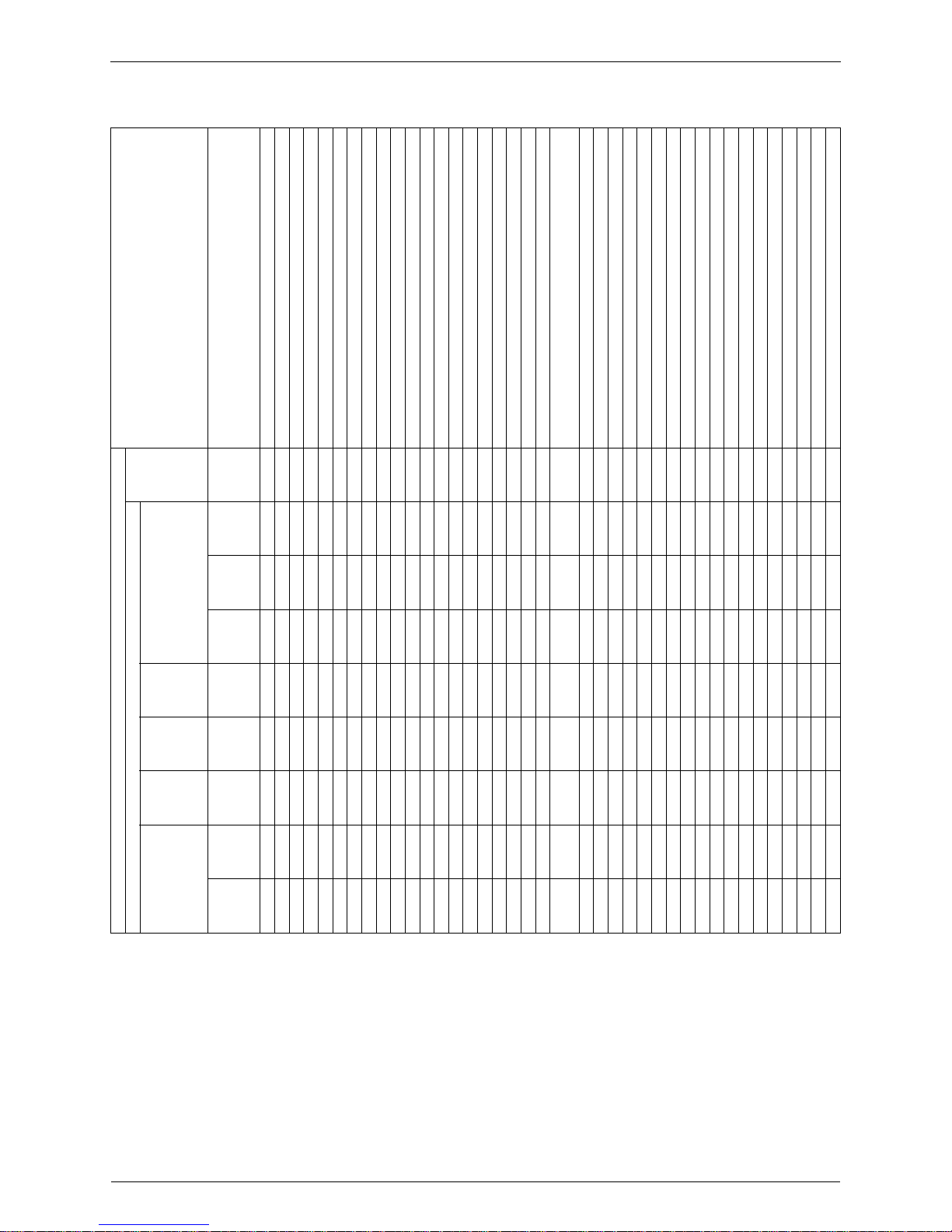

1.3 Function List for Taiwan

Division

Indoor

Unit /

Outdoor

Unit

Inverter (with Inverter Power Control)

PAM control (Pulse Amplitude Modulation Control)

Horizontal Scroll, Oval Scroll Compressor (DAIKIN SCROLL)

Reluctance DC Motor

Dual Flaps

Power-Airflow Dual Flaps

Power-Airflow Diffuser

Wide-Angle Louvers

Vertical Auto-Swing (Up and Down)

Horizontal Auto-Swing (Right and Left)

3-D Airflow

Auto Fan Speed

Silent Operation Control (Automatic)

Intelligent Eye

Automatic Operation

Programme Dry Function

Fan Only

Inverter Powerful Operation

Home Leave Operation

Indoor Unit On/Off Switch

Air-Purifying Filter

with Bacteriostatic, Virustatic & Deodorizing Functions

Mold-Proof Air Filter

Washable Grille

Filter Cleaning Indicator

Good-Sleep Cooling Operation

72-Hour On/Off Timer

24-Hour On/Off Timer

Night Set Mode

Auto-Restart (after Power Failure)

Self-Diagnosis Digital Display

Self-Diagnosis LED Display

Wiring-Error Check

Anticorrosion Treatment of Outdoor Heat Exchanger

Multi-Split/Split Type Compatible Indoor Unit

High-Ceiling Application

Chargeless

Wireless (FHYC), FDYM: Opti on )

Wired (FHYC, FDYM: Option)

Group Control by 1 Remote Controller

Cooling Only

Outdoor Unit

RMK

140J

!!!!

––––––––!––––!–– – ––––––––!!–!––

115

m

–––

Indoor Unit

Wall

Mounted

Type

FTK25/

35J

!

–––!!–

!!––!–!–!!!–!!!!–!–!!!!

–––!––!––

FTKD

50/60/

71J

!

–––

!!!!!!!!

–––

!!!!! ! !!

–––

!!!!!––!

––!––

Floor/

Ceiling

Suspended

Dual Type

FLK25/

35/50/

60H

!

––––––!!––!–––

!!!–!!!–!

––

!!!!!

––★1––!––

Ceiling

Mounted

Cassette

Type

FHYC

35/50/

60/71K

––––––––

!

––!–––!!––– –!–!–!––

!!!––!!–!!!

Duct

Connected

Type

FDYM

60/03FA

–––––––––––

!

–––!!––––––!–!––

!!!––!

––

!!!

Heat Pump

Outdoor Unit

RMX

140J

!!!!

––––––––!––––––– – ––––––––!!–!––

115

m

–––

Indoor Unit

Wall

Mounted

Type

FTX25/

35J

!

–––!!–

!!––!–!!!–!–!!!!–!–!!!!

–––!––!––

FTXD

50/60/

71J

!

–––

!!!!!!!!––!!–!!!!!!

–––

!!!!!––!

––!––

Floor/

Ceiling

Suspended

Dual Type

FLX25/

35/

50/60H

!

––––––!!––!––!!–!–

!!!–!

––

!!!!!

––★1––!––

Ceiling

Mounted

Cassette

Type

FHYC

35/50/

60/71K

––––––––

!

––!––

!!!

––– –!–!–!––

!!!––!!–!!!

Duct

Connected

Type

FDYM

60/03FA

–––––––––––

!

––

!!!–!

––––!–!––

!!!––!

––

!!!

Si18-201 List of Function

List of Function 5

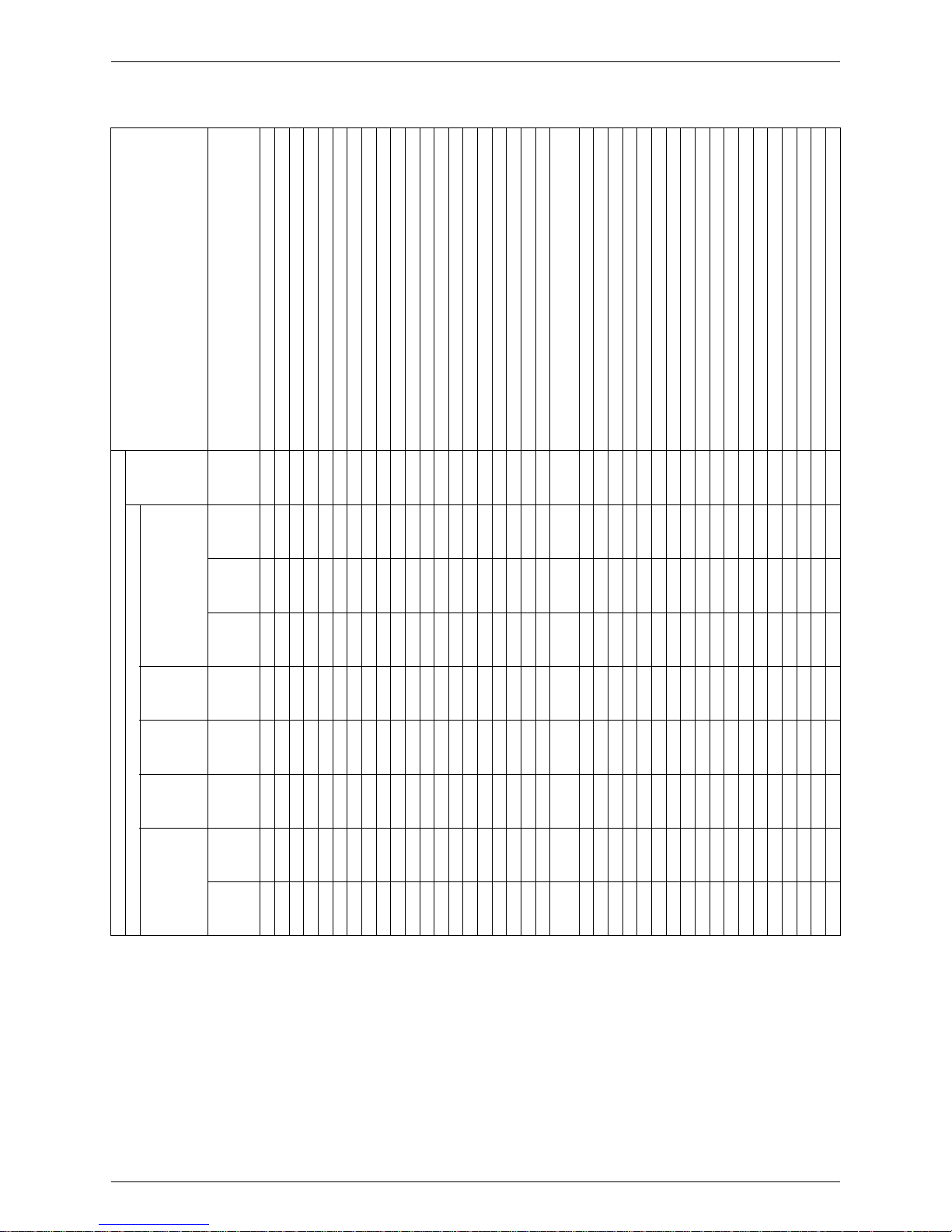

1.4 Function List for Europe

★1

! : for FLX50/60J

★2

–

: for FLX50/60J

Division

Indoor

Unit /

Outdoor

Unit

Inverter (with Inverter Power Control)

PAM control (Pulse Amplitude Modulation Control)

Horizontal Scroll, Oval Scroll Compressor (DAIKIN SCROLL)

Reluctance DC Motor

Dual Flaps

Power-Airflow Dual Flaps

Power-Airflow Diffuser

Wide-Angle Louvers

Vertical Auto-Swing (Up and Down)

Horizontal Auto-Swing (Right and Left)

3-D Airflow

Auto Fan Speed

Silent Operation Control (Automatic)

Intelligent Eye

Automatic Operation

Programme Dry Function

Fan Only

Inverter Powerful Operation

Home Leave Operation

Indoor Unit On/Off Switch

Air-Purifying Filter

with Bacteriostatic, Virustatic & Deodorizing Functions

Mold-Proof Air Filter

Washable Grille

Filter Cleaning Indicator

Good-Sleep Cooling Operation

72-Hour On/Off Timer

24-Hour On/Off Timer

Night Set Mode

Auto-Restart (after Power Failure)

Self-Diagnosis Digital Display

Self-Diagnosis LED Display

Wiring-Error Check

Anticorrosion Treatment of Outdoor Heat Exchanger

Multi-Split/Split Type Compatible Indoor Unit

High-Ceiling Application

Chargeless

Wireless (FHYC: Option)

Wired (FHYC, FDYM: Option)

Group Control by 1 Remote Controller

Heat Pump

Outdoor Unit

RMX

140J

!!!!

––––––––!––––––– – ––––––––!!–!––

115

m

–––

Indoor Unit

Wall

Mounted

Type

FTX25/

35JA

!

–––!!–

!!––!–!!!–!–!!!!–!–!!!!

–––!––!––

FTXD

25/35KZ

!

––––!–

!!––!–!!!–!!!!!!

–––

!!!!!––!

––!––

FTXD

50/60/

71J

!

–––

!!!!!!!!––!!–!!!!!!

–––

!!!!!––!

––!––

Floor/

Ceiling

Suspended

Dual Type

FLX25/

35H

FLX50/

60J

!

––––––!!––!––!!–

!★1!!!

–

!

★2

––

!!!!!

––★1––!––

Floor

Standing

Type

FVX25/

35KZ

!

––––––!!––!––!!–

!!!!!!

–––

!!!!!––!

––!––

Ceiling

Mounted

Cassette

Type

FHYC

35/50/

60/71

B7

––––––––

!

––!––

!!!

––– –!–!–!––

!!!––!!–!!!

Duct

Connected

Type

CDX

25/35/

50/60

HA (J)

!

––––––––––!––!!–!–!– –––––

!!!!!

–––––!––

FHYB

35/45/

60/71

FK7

––––––––––––––

!!!

––––––!–!––

!!!––!

–––

!!

List of Function Si18-201

6 List of Function

1.5 Function List for Singapore, Malaysia, Indonesia

Division

Indoor

Unit /

Outdoor

Unit

Inverter (with Inverter Power Control)

PAM control (Pulse Amplitude Modulation Control)

Horizontal Scroll, Oval Scroll Compressor (DAIKIN SCROLL)

Reluctance DC Motor

Dual Flaps

Power-Airflow Dual Flaps

Power-Airflow Diffuser

Wide-Angle Louvers

Vertical Auto-Swing (Up and Down)

Horizontal Auto-Swing (Right and Left)

3-D Airflow

Auto Fan Speed

Silent Operation Control (Automatic)

Intelligent Eye

Automatic Operation

Programme Dry Function

Fan Only

Inverter Powerful Operation

Home Leave Operation

Indoor Unit On/Off Switch

Air-Purifying Filter

with Bacteriostatic, Virustatic & Deodorizing Functions

Mold-Proof Air Filter

Washable Grille

Filter Cleaning Indicator

Good-Sleep Cooling Operation

72-Hour On/Off Timer

24-Hour On/Off Timer

Night Set Mode

Auto-Restart (after Power Failure)

Self-Diagnosis Digital Display

Self-Diagnosis LED Display

Wiring-Error Check

Anticorrosion Treatment of Outdoor Heat Exchanger

Multi-Split/Split Type Compatible Indoor Unit

High-Ceiling Application

Chargeless

Wireless (FHYC, FDYM: Option)

Wired (FHYC, FDYM: Option)

Group Control by 1 Remote Controller

Cooling Only

Outdoor Unit

RMK

140JA

!!!!

––––––––!––––!–– – ––––––––!!–!––––––

Indoor Unit

Wall

Mounted

Type

FTK25/

35J

!

–––!!–

!!––!–!–!!!–!!!!–!–!!!!

–––!––!––

FTKD

50/60/

71J

!

–––

!!!!!!!!

–––

!!!!! ! !!

–––

!!!!!––!

––!––

Floor/

Ceiling

Suspended

Dual Type

FLK25/

35/50/

60H

!

––––––!!––!–––

!!!–!!!–!

––

!!!!!

––★1––!––

Ceiling

Mounted

Cassette

Type

FHYC

35/50/

60/71K

––––––––

!

––!–––!!––– –!–!–!––

!!!––!!–!!!

Duct

Connected

Type

CDK25/

35/50/

60HA

!

––––––––––!–––

!!!–!

– –––––

!!!!!

–––––!––

FDYM

60/03FA

–––––––––––––––

!!

––––––!–!––

!!!––!

––

!!!

Si18-201 List of Function

List of Function 7

1.6 Function List for Australia

★1

! : for FLK, FLX50/60J

★2

–

: for FLK, FLX50/60J

Division

Indoor

Unit /

Outdoor

Unit

Inverter (with Inverter Power Control)

PAM control (Pulse Amplitude Modulation Control)

Horizontal Scroll, Oval Scroll Compressor (DAIKIN SCROLL)

Reluctance DC Motor

Dual Flaps

Power-Airflow Dual Flaps

Power-Airflow Diffuser

Wide-Angle Louvers

Vertical Auto-Swing (Up and Down)

Horizontal Auto-Swing (Right and Left)

3-D Airflow

Auto Fan Speed

Silent Operation Control (Automatic)

Intelligent Eye

Automatic Operation

Programme Dry Function

Fan Only

Inverter Powerful Operation

Home Leave Operation

Indoor Unit On/Off Switch

Air-Purifying Filter

with Bacteriostatic, Virustatic & Deodorizing Functions

Mold-Proof Air Filter

Washable Grille

Filter Cleaning Indicator

Good-Sleep Cooling Operation

72-Hour On/Off Timer

24-Hour On/Off Timer

Night Set Mode

Auto-Restart (after Power Failure)

Self-Diagnosis Digital Display

Self-Diagnosis LED Display

Wiring-Error Check

Anticorrosion Treatment of Outdoor Heat Exchanger

Multi-Split/Split Type Compatible Indoor Unit

High-Ceiling Application

Chargeless

Wireless (FHYC, FDYM: Option)

Wired (FHYC, FDYM: Option)

Group Control by 1 Remote Controller

Cooling Only

Outdoor Unit

RMK

140J

!!!!

––––––––!––––!–– – ––––––––!!–!––

115

m

–––

Indoor Unit

Wall

Mounted

Type

FTK25/

35J

!

–––!!–

!!––!–!–!!!–!!!!–!–!!!!

–––!––!––

FTKD

50/60/

71J

!

–––

!!!!!!!!

–––

!!!!! ! !!

–––

!!!!!––!

––!––

Floor/

Ceiling

Suspended

Dual Type

FLK25/

35H

50/60J

!

––––––!!––!–––

!!!★1!!!

–

!

★2

––

!!!!!

––★1––!––

Ceiling

Mounted

Cassette

Type

FHYC

35/50/

60/71K

––––––––

!

––!–––!!––– –!–!–!––

!!!––!!–!!!

Duct

Connected

Type

CDK25/

35/50/

60HA

!

––––––––––!–––

!!!–!

– –––––

!!!!!

–––––!––

FDYM

60/03FA

–––––––––––––––

!!

––––––!–!––

!!!––!

––

!!!

Heat Pump

Outdoor Unit

RMX

140J

!!!!

––––––––!––––––– – ––––––––!!–!––

115

m

–––

Indoor Unit

Wall

Mounted

Type

FTX25/

35J

!

–––!!–

!!––!–!!!–!–!!!!–!–!!!!

–––!––!––

FTXD

50/60/

71J

!

–––

!!!!!!!!––!!–!!!!!!

–––

!!!!!––!

––!––

Floor/

Ceiling

Suspended

Dual Type

FLX25/

35H

50/60J

!

––––––!!––!––!!–

!★1!!!

–

!

★2

––

!!!!!

––★1––!––

Ceiling

Mounted

Cassette

Type

FHYC

35/50/

60/71K

––––––––

!

––!––

!!!

––– –!–!–!––

!!!––!!–!!!

Duct

Connected

Type

CDX25/

35/50/

60HA

!

––––––––––!––!!–!–!– –––––

!!!!!

–––––!––

FDYM

60/03FA

––––––––––––––

!!!

––––––!–!––

!!!––!

––

!!!

List of Function Si18-201

8 List of Function

1.7 Function List for Europe

★1

! : for FLX50/60J

★2

–

: for FLX50/60J

Division

Indoor

Unit /

Outdoor

Unit

Inverter (with Inverter Power Control)

PAM control (Pulse Amplitude Modulation Control)

Horizontal Scroll, Oval Scroll Compressor (DAIKIN SCROLL)

Reluctance DC Motor

Dual Flaps

Power-Airflow Dual Flaps

Power-Airflow Diffuser

Wide-Angle Louvers

Vertical Auto-Swing (Up and Down)

Horizontal Auto-Swing (Right and Left)

3-D Airflow

Auto Fan Speed

Silent Operation Control (Automatic)

Intelligent Eye

Automatic Operation

Programme Dry Function

Fan Only

Inverter Powerful Operation

Home Leave Operation

Indoor Unit On/Off Switch

Air-Purifying Filter

with Bacteriostatic, Virustatic & Deodorizing Functions

Mold-Proof Air Filter

Washable Grille

Filter Cleaning Indicator

Good-Sleep Cooling Operation

72-Hour On/Off Timer

24-Hour On/Off Timer

Night Set Mode

Auto-Restart (after Power Failure)

Self-Diagnosis Digital Display

Self-Diagnosis LED Display

Wiring-Error Check

Anticorrosion Treatment of Outdoor Heat Exchanger

Multi-Split/Split Type Compatible Indoor Unit

High-Ceiling Application

Chargeless

Wireless (FHYC: Option)

Wired (FHYC, FDYM: Option)

Group Control by 1 Remote Controller

Heat Pump

Outdoor Unit

RMX

140JZ

!!!!

––––––––!––––––– – ––––––––!!–!––

115

m

–––

Indoor Unit

Wall

Mounted

Type

FTX25/

35JA

!

–––!!–

!!––!–!!!–!–!!!!–!–!!!!

–––!––!––

FTXD

25/35KZ

!

––––!–

!!––!–!!!–!!!!!!

–––

!!!!!––!

––!––

FTXD

50/60/

71J

!

–––

!!!!!!!!––!!–!!!!!!

–––

!!!!!––!

––!––

Floor/

Ceiling

Suspended

Dual Type

FLX25/

35H

FLX50/

60J

!

––––––!!––!––!!–

!★1!!!

–

!

★2

––

!!!!!

––★1––!––

Floor

Standing

Type

FVX25/

35KZ

!

––––––!!––!––!!–

!!!!!!

–––

!!!!!––!

––!––

Ceiling

Mounted

Cassette

Type

FHYC

35/50/

60/71

B7

––––––––

!

––!––

!!!

––– –!–!–!––

!!!––!!–!!!

Duct

Connected

Type

CDX

25/35/

50/60

HA

!

––––––––––!––!!–!–!– –––––

!!!!!

–––––!––

FHYB

35/45/

60/71

FK7

––––––––––––––

!!!

––––––!–!––

!!!––!

–––

!!

Si18-201

Specifications 9

Part 2

Part 2Part 2

Part 2

Specifications

SpecificationsSpecifications

Specifications

1. Specifications........................................................................................10

1.1 Outdoor Units .........................................................................................10

1.2 BP Units ............... ............................ ................ ............................. ......... 1 8

1.3 Indoor Units (for General).......................................................................19

1.4 Indoor Units (for China)..........................................................................34

1.5 Indoor Units (for Taiwan)........................................................................43

1.6 Indoor Units (for Europe)........................................................................52

The RMK 140JA VM s pecifications are sp ecial. Refer to <R MK14 0JAVM 's

important points> (on page ii) for the changes in contents.

Specifications Si18-201

10 Specifications

1. Specifications

1.1 Outdo or Un its

1.1.1 Cooling Only

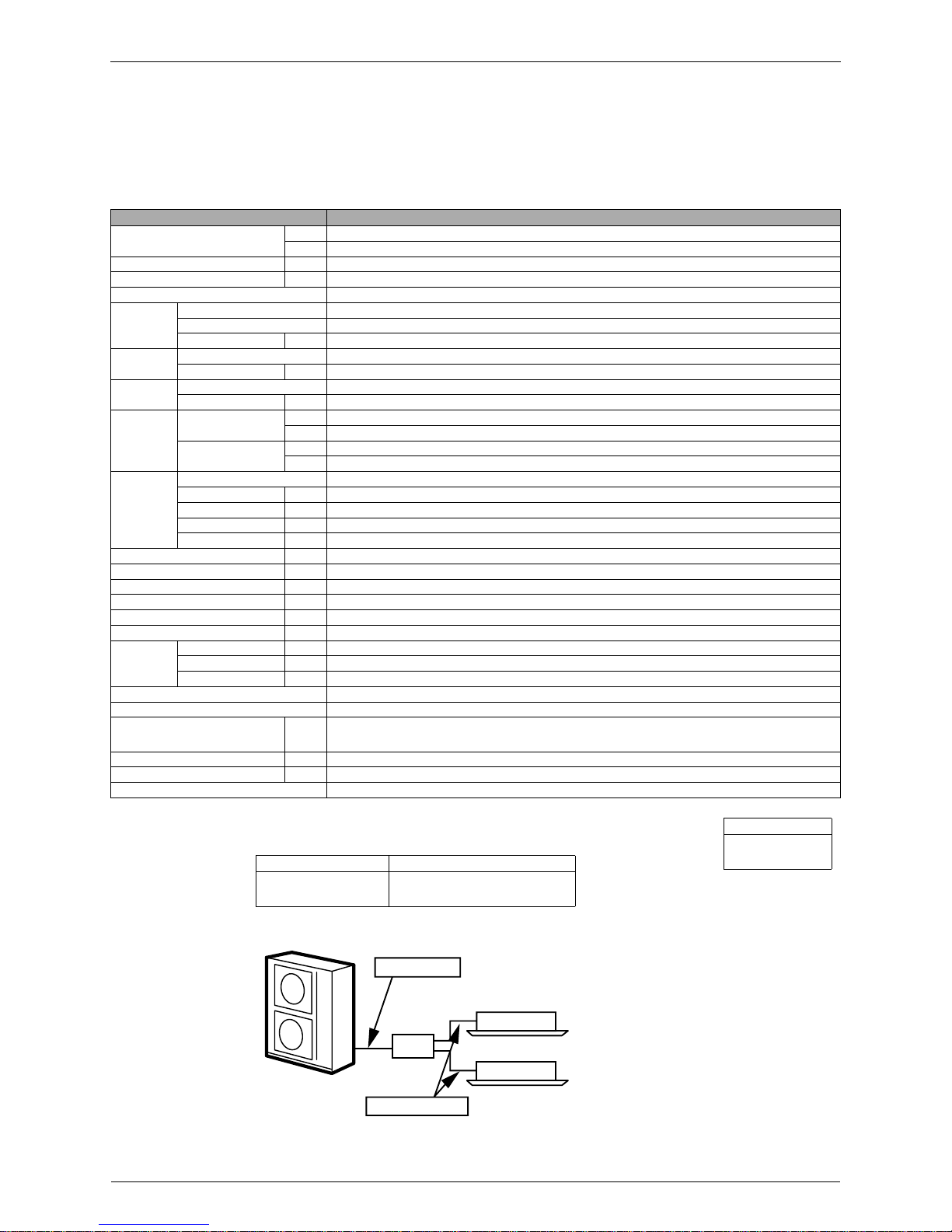

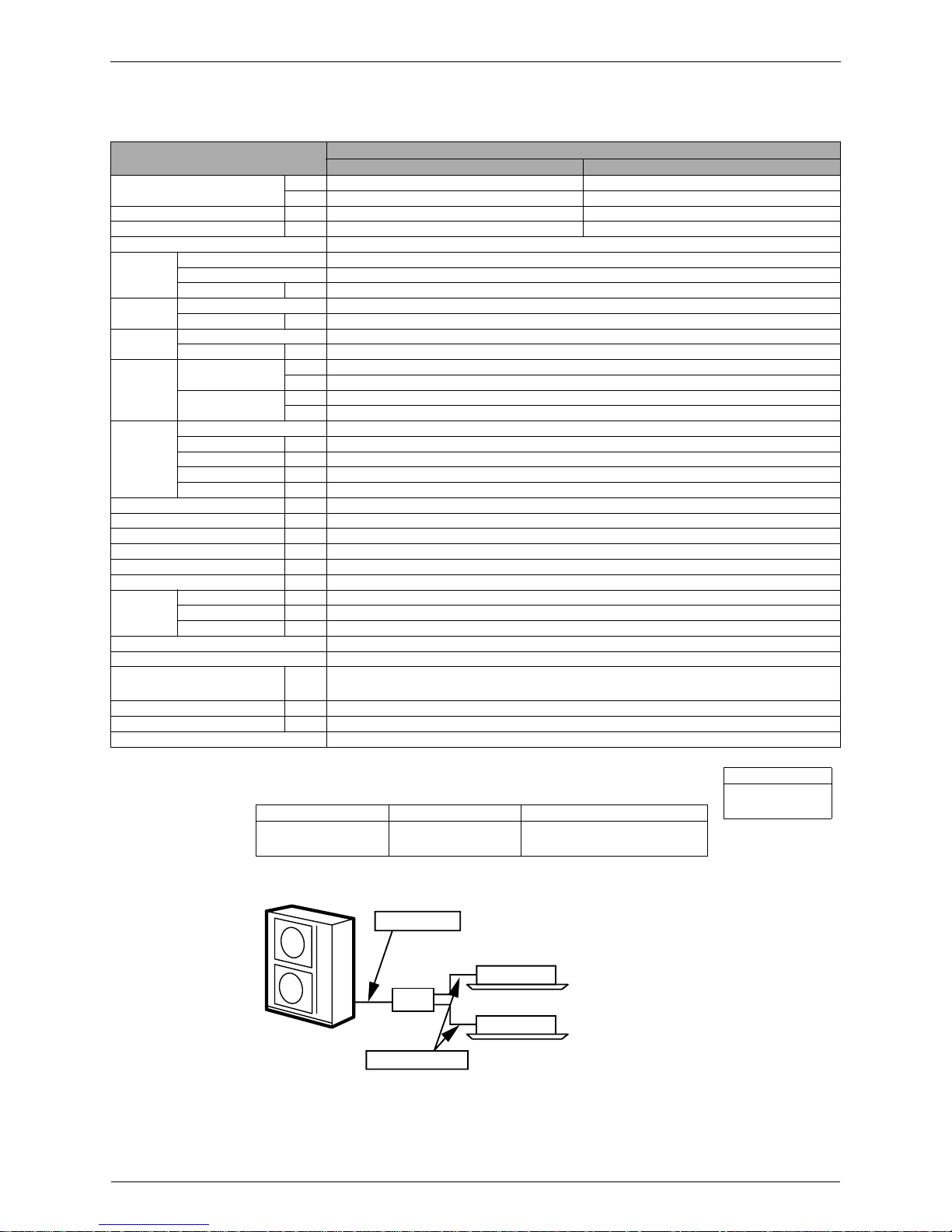

Notes:

1.

★

Refer to Engineering Data Book.

2. The data are based on the conditions shown in the table below.

50Hz 220-240V / 60Hz 220-230V

Model RMK140JVMC9 (8)

Cooling Capacity (19.0°CWB)

kW 14.5

kcal/h 12,470

Power Consumption

★

W 5,000

Running Current

★

A 23.2

Casing Color Ivory W h ite

Compressor

Type Hermetically Sealed Scroll Type (Oval Discharge)

Model JT100FBVD

Motor Output W 3,300

Refrigerant

Oil

Model SUNISO 4GSD.I.

Charge kg 1.5

Refrigerant

Type R22

Charge kg 9.9

Air Flow Rate

m³/min

H 114

L 104

cfm

H 4,024

L 3,671

Fan

Type Propeller

Motor Output W (Upper Side) H : 53 L : 38 (Lower Side) H : 41 L : 30

Running Current A (Upper Side) H : 0.50 L : 0.45 (Lower Side) H : 0.47 L : 0.42

Power Consumption W (Upper Side) H : 93.1 L : 78.8 (Lower Side) H : 81.3 L : 68.8

Power Factor % 100

Starting Current A 29.0

Dimensions (H×W×D) mm 1,345×880×320

Package Dimensions mm 918×394×1,397

Weight kg 134

Gross Weight kg 143

Operation Sound dBA 53

Piping

Connection

Liquid mm

φ

9.5 (Flare Connection)

Gas mm

φ

19.1 (Flare Connection)

Drain mm

φ

18

Heat Insulation Both Liquid and Gas Pipes

No. of Wiring Connection 3 for Power Supply, 4 for Interunit Wiring (Including Earth Wiring)

Max. Interunit Piping Length m

115 (Total Main Piping and Branch Piping)

55 (Total Main Piping), 60 (Total Branch Piping)

15 (Max. Length for Each Room)

Amount of Additional Charge g/m Chargeless

Max. Installation Height Difference m 30 (Between Indoor or BP Unit and Outdoor Unit), 15 (Between Indoor or BP Units)

Drawing No. 3D030948A

Cooling Piping Length

Indoor ; 27°CDB / 19.0°CWB

Outdoor ; 35°CDB

Main Piping : 5m

Branch Piping : 3m

(each indoor unit / 71 Class+60 Class)

Conversion Formulae

kcal/h=kW×860

Btu/h=kW×3414

cfm=m³/min×35.3

BP Unit

Outdoor Unit

Main Piping

Branch Piping

Indoor Unit

(Q0143)

Si18-201 Specifications

Specifications 11

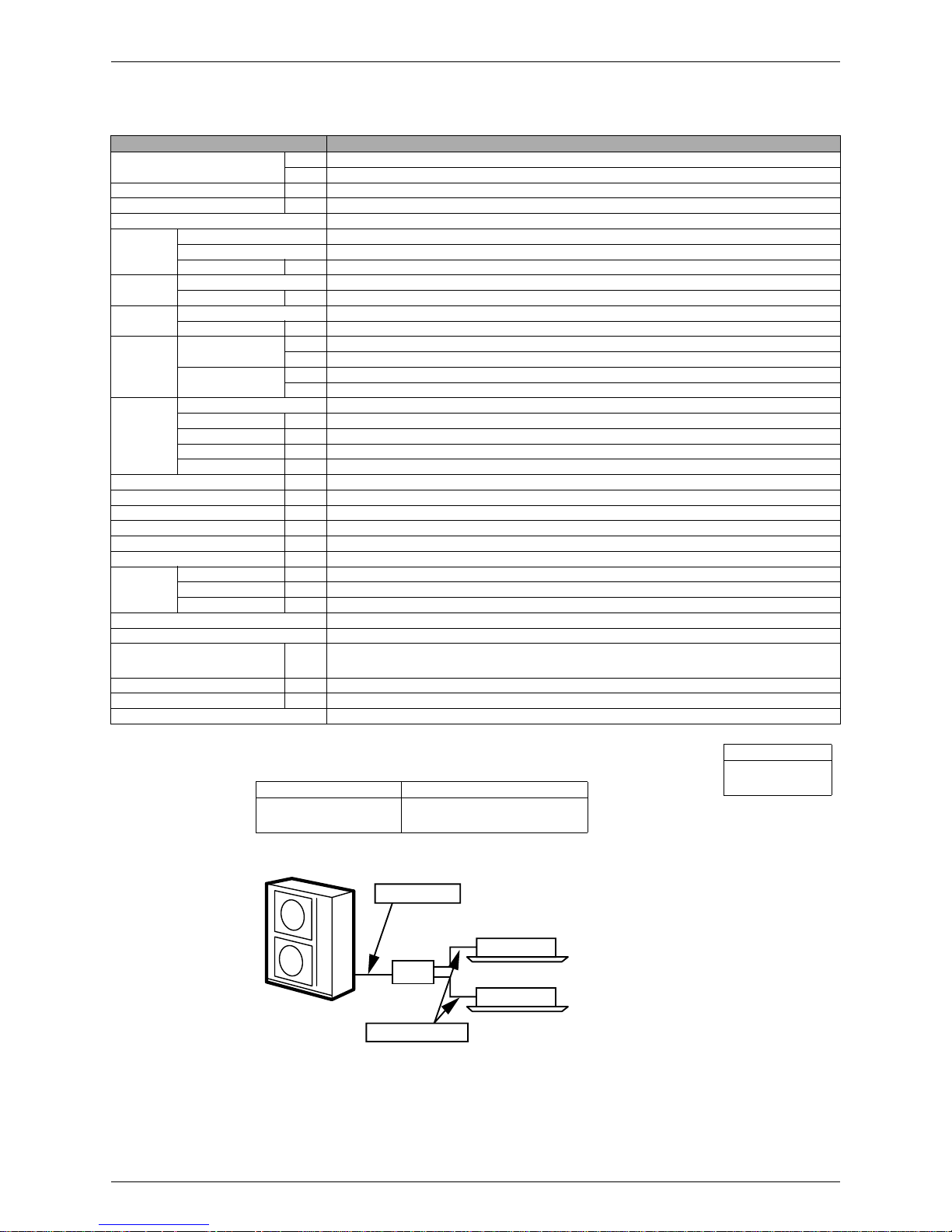

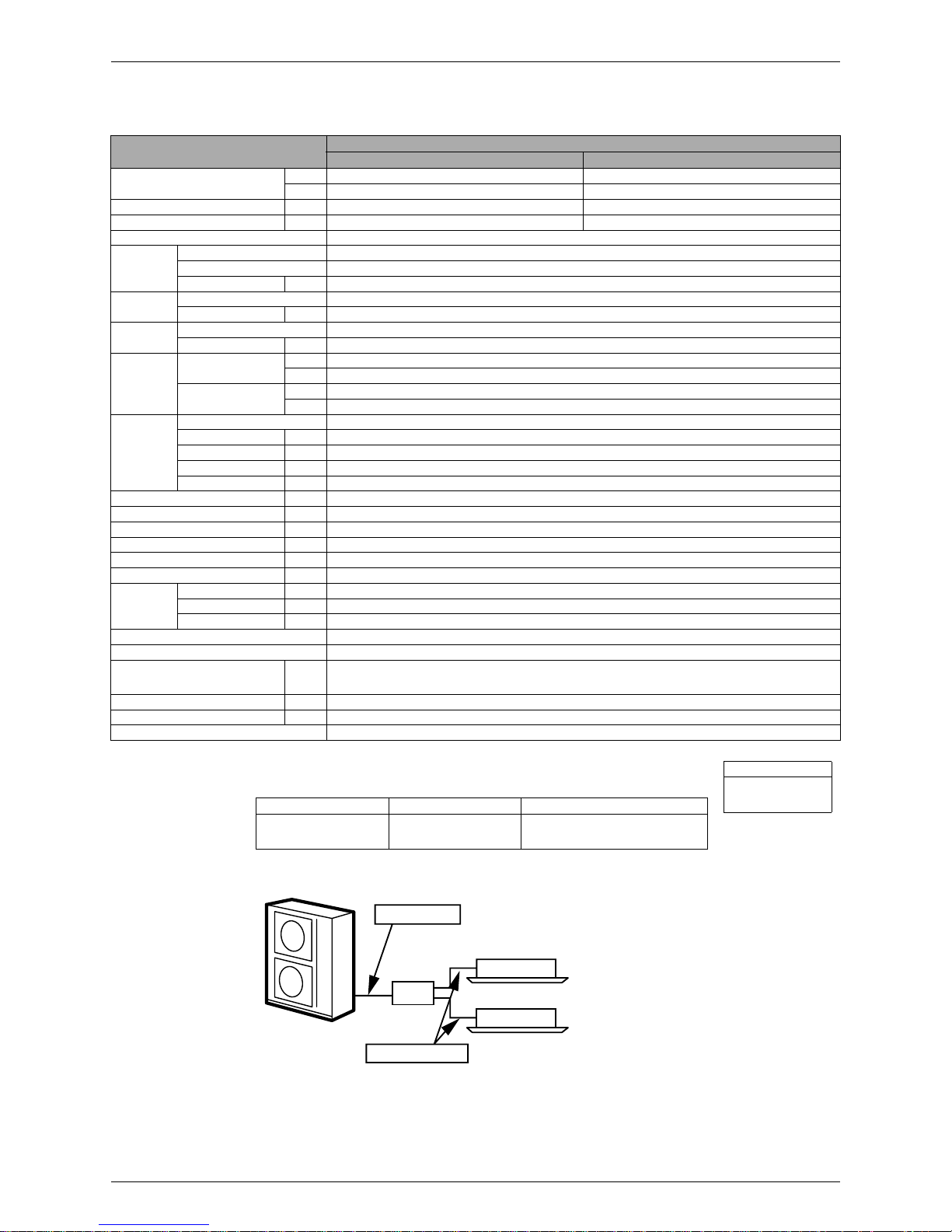

Notes:

1.

★

Refer to Engineering Data Book.

2. The data are based on the conditions shown in the table below.

60Hz 220V

Model RMK140JVMT9

Cooling Capacity (19.5°CWB)

kW 14.5

kcal/h 12,500

Power Consumption

★

W 4,950

Running Current

★

A 23.0

Casing Color Ivory W h ite

Compressor

Type Hermetically Sealed Scroll Type (Oval Discharge)

Model JT100FBVD

Motor Output W 3,300

Refrigerant

Oil

Model SUNISO 4GSD.I.

Charge kg 1.5

Refrigerant

Type R22

Charge kg 9.9

Air Flow Rate

m³/min

H 114

L 104

cfm

H 4,024

L 3,671

Fan

Type Propeller

Motor Output W (Upper Side) H : 53 L : 38 (Lower Side) H : 41 L : 30

Running Current A (Upper Side) H : 0.50 L : 0.45 (Lower Side) H : 0.47 L : 0.42

Power Consumption W (Upper Side) H : 93.1 L : 78.8 (Lower Side) H : 81.3 L : 68.8

Power Factor % 100

Starting Current A 29.0

Dimensions (H×W×D) mm 1,345×880×320

Package Dimensions mm 918×394×1,397

Weight kg 134

Gross Weight kg 143

Operation Sound dBA 53

Piping

Connection

Liquid mm

φ

9.5 (Flare Connection)

Gas mm

φ

19.1 (Flare Connection)

Drain mm

φ

18

Heat Insulation Both Liquid and Gas Pipes

No. of Wiring Connection 3 for Power Supply, 4 for Interunit Wiring (Including Earth Wiring)

Max. Interunit Piping Length m

115 (Total Main Piping and Branch Piping)

55 (Total Main Piping), 60 (Total Branch Piping)

15 (Max. Length for Each Room)

Amount of Additional Charge g/m Chargeless

Max. Installation Height Difference m 30 (Between Indoor or BP Unit and Outdoor Unit), 15 (Between Indoor or BP Units)

Drawing No. 3D030949A

Cooling Piping Length

Indoor ; 27°CDB / 19.5°CWB

Outdoor ; 35°CDB

Main Piping : 5m

Branch Piping : 3m

(each indoor unit / 71 Class+60 Class)

Conversion Formulae

kcal/h=kW×860

Btu/h=kW×3414

cfm=m³/m in ×35.3

BP Unit

Outdoor Unit

Main Piping

Branch Piping

Indoor Unit

(Q0143)

Specifications Si18-201

12 Specifications

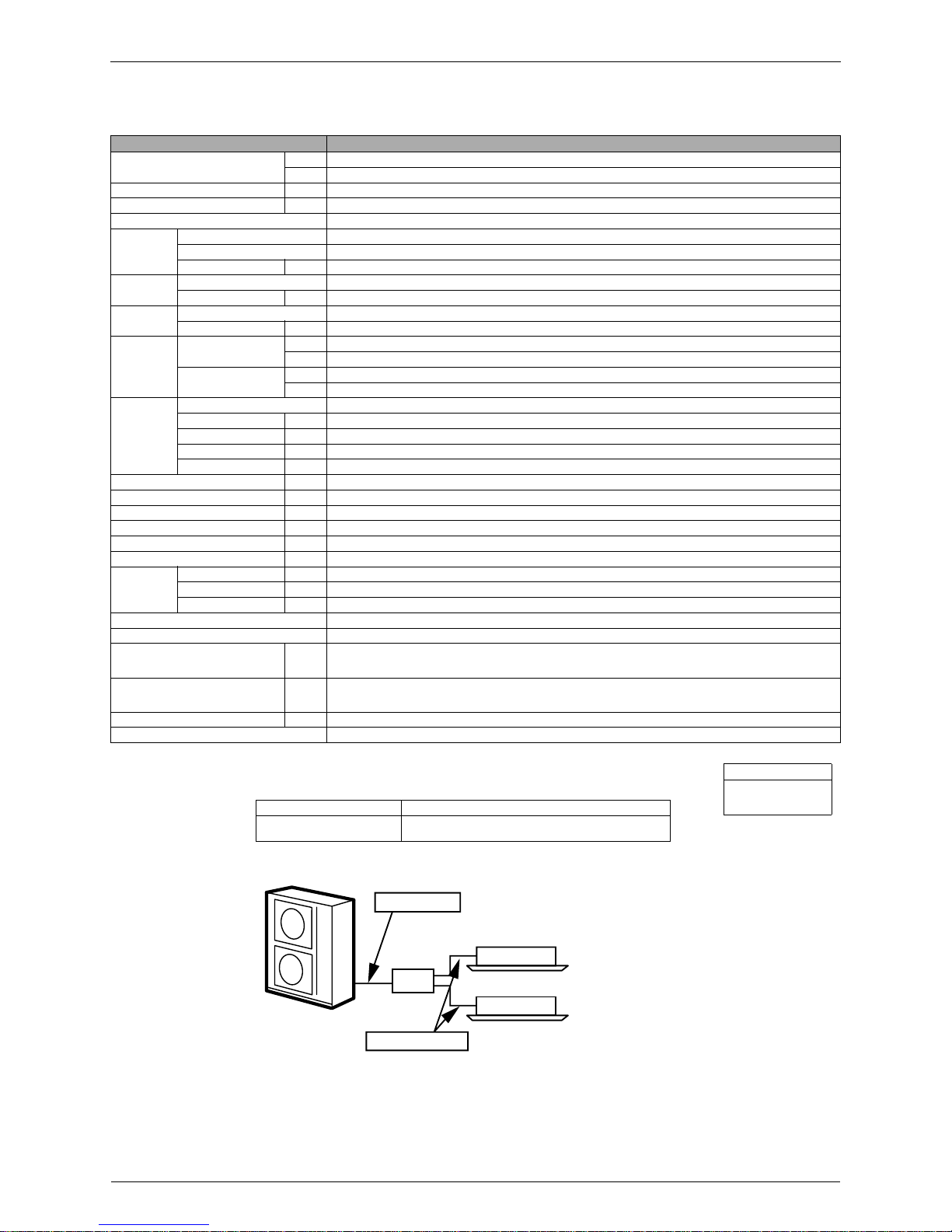

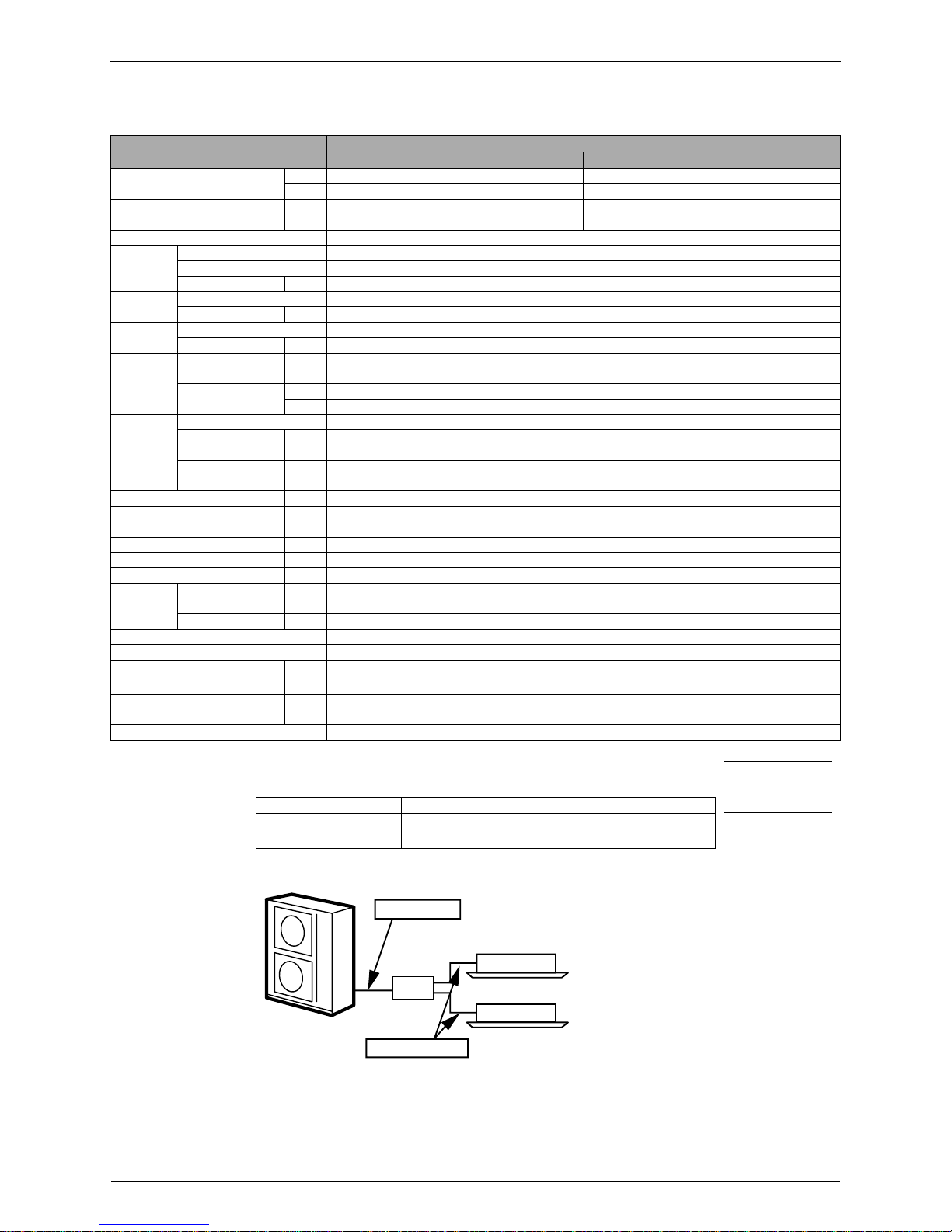

Notes:

1.

★

Refer to Engineering Data Book.

2. The data are based on the conditions shows in the table below.

50Hz 220-230-240V / 60Hz 220-230V

Model RMK140JAVM

Cooling Capacity (19.0°CWB)

kW 14.5

kcal/h 12,470

Power Consumption

★

W 4,650

Running Current

★

A 20.4

Casing Color Ivory W h ite

Compressor

Type Hermetically Sealed Scroll Type (Oval Discharge)

Model JT100FBVD

Motor Output W 3,300

Refrigerant

Oil

Model SUNISO 4GSD.I.

Charge kg 1.5

Refrigerant

Type R22

Charge kg 4.5

Air Flow Rate

m³/min

H 114

L 104

cfm

H 4,024

L 3,671

Fan

Type Propeller

Motor Output W (Upper Side) H : 53 L : 38 (Lower Side) H : 41 L : 30

Running Current A (Upper Side) H : 0.50 L : 0.45 (Lower Side) H : 0.47 L : 0.42

Power Consumption W (Upper Side) H : 93.1 L : 78.8 (Lower Side) H : 81.3 L : 68.8

Power Factor % 100

Starting Current A 29.0

Dimensions (H×W×D) mm 1,345×880×320

Package Dimensions (W×D×H) mm 918×394×1,397

Weight kg 111

Gross Weight kg 120

Operation Sound dBA 50

Piping

Connection

Liquid mm

φ

9.5 (Flare Connection)

Gas mm

φ

19.1 (Flare Connection)

Drain mm

φ

18

Heat Insulation Both Liquid and Gas Pipes

No. of Wiring Connection 3 For Power Supply, 4 For Interunit Wiring

Max. Interunit Piping Length m

110 (Total Main Piping and Branch PIping)

30 (Total Main Piping), 60 (Total Branch Piping)

20 (Max. Length for Each Room)

Amount of Additional Charge g/m

Additional refrigerant to be charge : R (kg)

R= (Total length of the liquid pipe-line of

φ

9.5) ×0.05 + (Total length of the liquid pipe-line of φ6.4) × 0.025

∗

If the value of “R” is less than 0.5, additional charging of refrigerant is unnecessary.

Max. Installation Height Difference m 15 (Between Indoor or BP Unit and Outdoor Unit), 10 (Both between Indoor Units and BP Units)

Drawing No. 3D033202

Cooling Piping Length

Indoor ; 27°CDB / 19.0°CWB

Outdoor ; 35°CDB

Main Piping : 5m

Branch Piping : 3m (each indoor unit / 71 Class+60 Class)

Conversion Formulae

kcal/h=kW×860

Btu/h=kW×3414

cfm=m³/m in ×35.3

BP Unit

Outdoor Unit

Main Piping

Branch Piping

Indoor Unit

(Q0143)

Si18-201 Specifications

Specifications 13

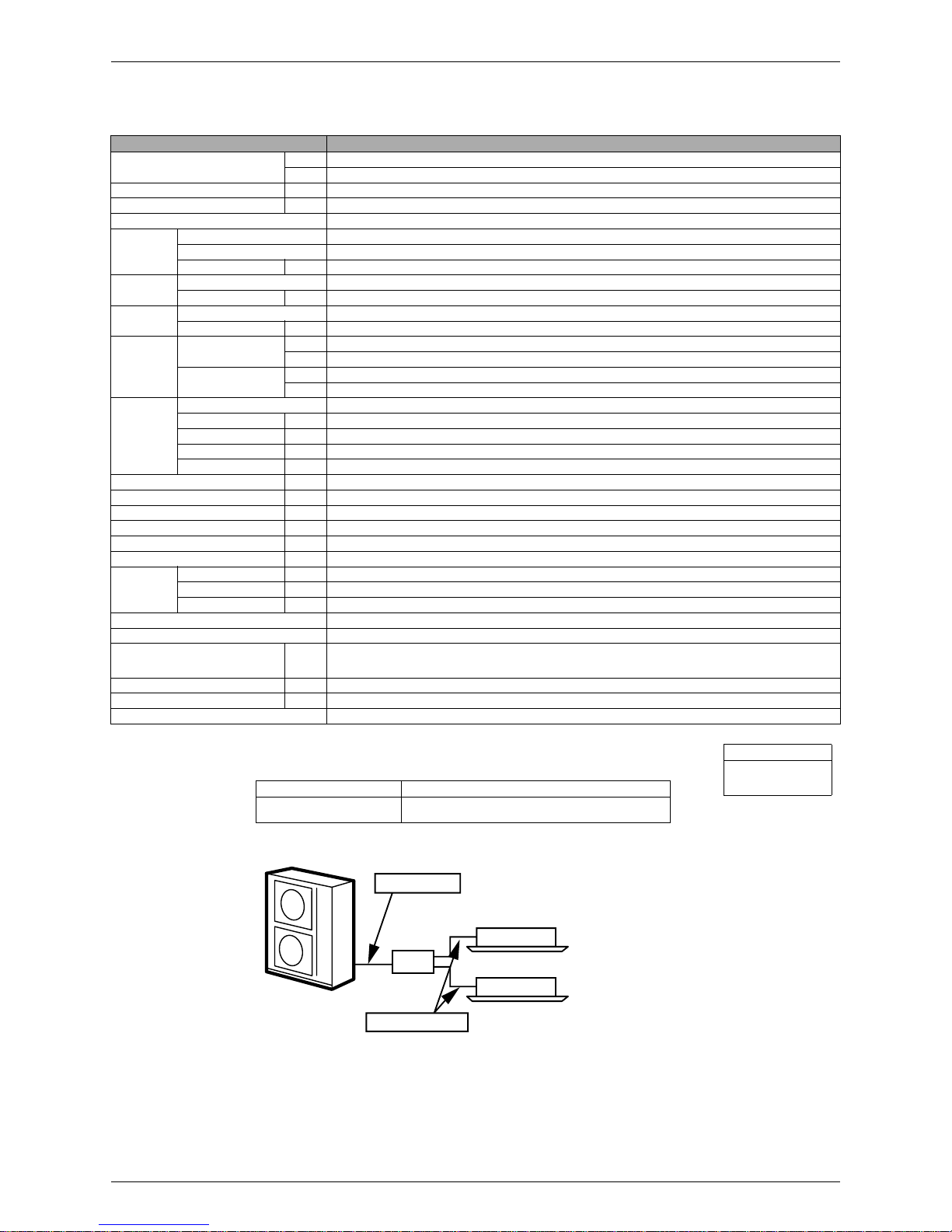

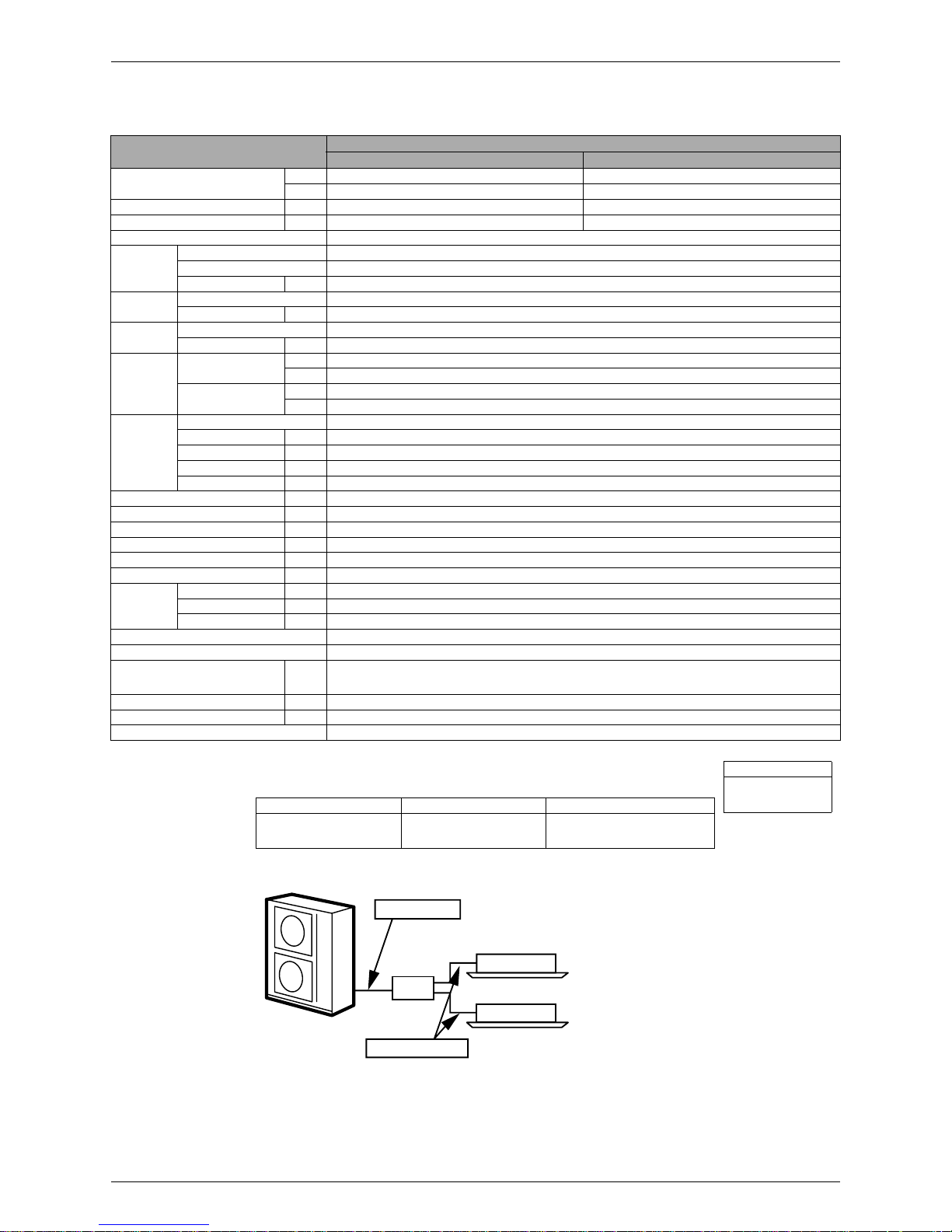

Notes:

1.

★

Refer to Engineering Data Book.

2. The data are based on the conditions shows in the table below.

50Hz 220-230-240V / 60Hz 220-230V

Model RM K140JZVMA

Cooling Capacity (19.0°CWB)

kW 14.5

kcal/h 12,470

Power Consumption

★

W 5,000

Running Current

★

A 23.2-22.2-21.3

Casing Color Ivory W h ite

Compressor

Type Hermetically Sealed Scroll Type (Oval Discharge)

Model JT100FAVD

Motor Output W 3,300

Refrigerant

Oil

Model DAPHNE FVC68D

Charge kg 1.5

Refrigerant

Type R407C

Charge kg 9.9

Air Flow Rate

m³/min

H 114

L 104

cfm

H 4,024

L 3,671

Fan

Type Propeller

Motor Output W (Upper Side) H : 53 L : 38 (Lower Side) H : 41 L : 30

Running Current A (Upper Side) H : 0.50 L : 0.45 (Lower Side) H : 0.47 L : 0.42

Power Consumption W (Upper Side) H : 93.1 L : 78.8 (Lower Side) H : 81.3 L : 68.8

Power Factor % 100

Starting Current A 29.0

Dimensions (H×W×D) mm 1,345×880×320

Package Dimensions (W×D×H) mm 918×394×1,397

Weight kg 134

Gross Weight kg 143

Operation Sound dBA 53

Piping

Connection

Liquid mm

φ

9.5 (Flare Connection)

Gas mm

φ

19.1 (Flare Connection)

Drain mm

φ

18

Heat Insulation Both Liquid and Gas Pipes

No. of Wiring Connection 3 For Power Supply, 4 For Interunit Wiring (Included Earth Wiring)

Max. Interunit Piping Length m

115 (Total Main Piping and Branch PIping)

55 (Total Main Piping), 60 (Total Branch Piping)

15 (Max. Length for Each Room)

Amount of Additional Charge g/m Chargeless

Max. Installation Height Difference m 30 (Between Indoor or BP Unit and Outdoor Unit), 15 (Both between Indoor Units and BP Units)

Drawing No. 3D031579

Cooling Piping Length

Indoor ; 27°CDB / 19.0°CWB

Outdoor ; 35°CDB

Main Piping : 5m

Branch Piping : 3m (each indoor unit / 71 Class+60 Class)

Conversion Formulae

kcal/h=kW×860

Btu/h=kW×3414

cfm=m³/m in ×35.3

BP Unit

Outdoor Unit

Main Piping

Branch Piping

Indoor Unit

(Q0143)

Specifications Si18-201

14 Specifications

1.1.2 Heat Pump

Notes:

1.

★

Refer to Engineering Data Book.

2. The data are based on the conditions shown in the table below.

50Hz 220-240V / 60Hz 220-230V

Model

RMX140JVMC9 (8)

Cooling Heating

Cooling Capacity (19.0°CWB)

kW 14.5 16.5

kcal/h 12,470 14,190

Power Consumption

★

W 5,000 5,780

Running Current

★

A 23.2 26.8

Casing Color Ivory W h ite

Compressor

Type Hermetically Sealed Scroll Type (Oval Discharge)

Model JT100FBVD

Motor Output W 3,300

Refrigerant

Oil

Model SUNISO 4GSD.I.

Charge L 1.5

Refrigerant

Type R22

Charge kg 9.9

Air Flow Rate

m³/min

H 114

L 104

cfm

H 4,024

L 3,671

Fan

Type Propeller

Motor Output W (Upper Side) H : 53 L : 38 (Lower Side) H : 41 L : 30

Running Current A (Upper Side) H : 0.50 L : 0.45 (Lower Side) H : 0.47 L : 0.42

Power Consumption W (Upper Side) H : 93.1 L : 78.8 (Lower Side) H : 81.3 L : 68.8

Power Factor % 100

Starting Current A 29.0

Dimensions (H×W×D) mm 1,345×880×320

Package Dimensions mm 918×394×1,397

Weight kg 136

Gross Weight kg 145

Operation Sound dBA 53

Piping

Connection

Liquid mm

φ

9.5 (Flare Connection)

Gas mm

φ

19.1 (Flare Connection)

Drain mm

φ

18

Heat Insulation Both Liquid and Gas Pipes

No. of Wiring Connection 3 for Power Supply, 4 for Interunit Wiring (Including Earth Wiring)

Max. Interunit Piping Length m

115 (Total Main Piping and Branch Piping)

55 (Total Main Piping), 60 (Total Branch Piping)

15 (Max. Length for Each Room)

Amount of Additional Charge g/m Chargeless

Max. Installation Height Difference m 30 (Between Indoor or BP Unit and Outdoor Unit), 15 (Between Indoor or BP Units)

Drawing No. 3D030946A

Cooling Heating Piping Length

Indoor ; 27°CDB / 19.0°CWB

Outdoor ; 35°CDB

Indoor ; 21°CDB

Outdoor ; 7°CDB / 6°CWB

Main Piping : 5m

Branch Piping : 3m

(each indoor unit / 71 Class+60 Class)

Conversion Formulae

kcal/h=kW×860

Btu/h=kW×3414

cfm=m³/m in ×35.3

BP Unit

Outdoor Unit

Main Piping

Branch Piping

Indoor Unit

(Q0143)

Si18-201 Specifications

Specifications 15

Notes:

1.

★

Refer to Engineering Data Book.

2. The data are based on the conditions shown in the table below.

60Hz 220-230V

Model

RMX140JVMT9

Cooling Heating

Cooling Capacity (19.5°CWB)

kW 14.5 16.5

kcal/h 12,500 14,200

Power Consumption

★

W 4,950 5,870

Running Current

★

A 23.0 27.2

Casing Color Ivory W h ite

Compressor

Type Hermetically Sealed Scroll Type (Oval Discharge)

Model JT100FBVD

Motor Output W 3,300

Refrigerant

Oil

Model SUNISO 4GSD.I.

Charge L 1.5

Refrigerant

Type R22

Charge kg 9.9

Air Flow Rate

m³/min

H 114

L 104

cfm

H 4,024

L 3,671

Fan

Type Propeller

Motor Output W (Upper Side) H : 53 L : 38 (Lower Side) H : 41 L : 30

Running Current A (Upper Side) H : 0.50 L : 0.45 (Lower Side) H : 0.47 L : 0.42

Power Consumption W (Upper Side) H : 93.1 L : 78.8 (Lower Side) H : 81.3 L : 68.8

Power Factor % 100

Starting Current A 29.0

Dimensions (H×W×D) mm 1,345×880×320

Package Dimensions mm 918×394×1,397

Weight kg 136

Gross Weight kg 145

Operation Sound dBA 53

Piping

Connection

Liquid mm

φ

9.5 (Flare Connection)

Gas mm

φ

19.1 (Flare Connection)

Drain mm

φ

18

Heat Insulation Both Liquid and Gas Pipes

No. of Wiring Connection 3 for Power Supply, 4 for Interunit Wiring (Including Earth Wiring)

Max. Interunit Piping Length m

115 (Total Main Piping and Branch Piping)

55 (Total Main Piping), 60 (Total Branch Piping)

15 (Max. Length for Each Room)

Amount of Additional Charge g/m Chargeless

Max. Installation Height Difference m 30 (Between Indoor or BP Unit and Outdoor Unit), 15 (Between Indoor or BP Units)

Drawing No. 3D030947A

Cooling Heating Piping Length

Indoor ; 27°CDB / 19.5°CWB

Outdoor ; 35°CDB

Indoor ; 21°CDB

Outdoor ; 7°CDB / 6°CWB

Main Piping : 5m

Branch Piping : 3m

(each indoor unit / 71 Class+60 Class)

Conversion Formulae

kcal/h=kW×860

Btu/h=kW×3414

cfm=m³/m in ×35.3

BP Unit

Outdoor Unit

Main Piping

Branch Piping

Indoor Unit

(Q0143)

Specifications Si18-201

16 Specifications

Notes:

1.★ Refer to Engineering Data Book.

2. The data are based on the conditions shown in the table below.

50Hz 220-240V / 60Hz 220-230V

Model

RMX140JVMB

Cooling Heating

Cooling Capacity (19.0°CWB)

kW 14.5 16.5

kcal/h 12,470 14,190

Power Consumption

★

W 5,000 5,780

Running Current

★

A 23.2 26.8

Casing Color Ivory W h ite

Compressor

Type Hermetically Sealed Scroll Type (Oval Discharge)

Model JT100FBVD

Motor Output W 3,300

Refrigerant

Oil

Model SUNISO 4GSD.I.

Charge L 1.5

Refrigerant

Type R22

Charge kg 9.9

Air Flow Rate

m³/min

H 114

L 104

cfm

H 4,024

L 3,671

Fan

Type Propeller

Motor Output W (Upper Side) H : 53 L : 38 (Lower Side) H : 41 L : 30

Running Current A (Upper Side) H : 0.50 L : 0.45 (Lower Side) H : 0.47 L : 0.42

Power Consumption W (Upper Side) H : 93.1 L : 78.8 (Lower Side) H : 81.3 L : 68.8

Power Factor % 100

Starting Current A 29.0

Dimensions (H×W×D) mm 1,345×880×320

Package Dimensions (W×D×H) mm 918×394×1,397

Weight kg 136

Gross Weight kg 145

Operation Sound dBA 53

Piping

Connection

Liquid mm

φ

9.5 (Flare Connection)

Gas mm

φ

19.1 (Flare Connection)

Drain mm

φ

18

Heat Insulation Both Liquid and Gas Pipes

No. of Wiring Connection 3 For Power Supply, 4 For Interunit Wiring (Included Earth Wiring)

Max. Interunit Piping Length m

115 (Total Main Piping and Branch PIping)

55 (Total Main Piping), 60 (Total Branch Piping)

15 (Max. Length for Each Room)

Amount of Additional Charge g/m Chargeless

Max. Installation Height Difference m 30 (Between Indoor or BP Unit and Outdoor Unit), 15 (Both between Indoor Units and BP Units)

Drawing No. 3D030950A

Cooling Heating Piping Length

Indoor ; 27°CDB / 19.0°CWB

Outdoor ; 35°CDB

Indoor ; 20°CDB

Outdoor ; 7°CDB / 6°CWB

Main Piping : 5m

Branch Piping : 3m

(each indoor unit / 71 Class+60 Class)

Conversion Formulae

kcal/h=kW×860

Btu/h=kW×3414

cfm=m³/m in ×35.3

BP Unit

Outdoor Unit

Main Piping

Branch Piping

Indoor Unit

(Q0143)

Si18-201 Specifications

Specifications 17

Notes:

1.

★

Refer to Engineering Data Book.

2. The data are based on the conditions shows in the table below.

50Hz 220-230-240V / 60Hz 220-230V

Model

RMX140JZVMB

Cooling Heating

Cooling Capacity (19.0°CWB)

kW 14.5 16.5

kcal/h 12,470 14,190

Power Consumption

★

W 5,000 6,050

Running Current

★

A 23.2-22.2-21.3 28.1-26.8-25.7

Casing Color Ivory W h ite

Compressor

Type Hermetically Sealed Scroll Type (Oval Discharge)

Model JT100FAVD

Motor Output W 3,300

Refrigerant

Oil

Model DAPHNE FVC68D

Charge L 1.5

Refrigerant

Type R407C

Charge kg 9.9

Air Flow Rate

m³/min

H 114

L 104

cfm

H 4,024

L 3,671

Fan

Type Propeller

Motor Output W (Upper Side) H : 53 L : 38 (Lower Side) H : 41 L : 30

Running Current A (Upper Side) H : 0.50 L : 0.45 (Lower Side) H : 0.47 L : 0.42

Power Consumption W (Upper Side) H : 93.1 L : 78.8 (Lower Side) H : 81.3 L : 68.8

Power Factor % 100

Starting Current A 29.0

Dimensions (H×W×D) mm 1,345×880×320

Package Dimensions (W×D×H) mm 918×394×1,397

Weight kg 136

Gross Weight kg 145

Operation Sound dBA 53

Piping

Connection

Liquid mm

φ

9.5 (Flare Connection)

Gas mm

φ

19.1 (Flare Connection)

Drain mm

φ

18

Heat Insulation Both Liquid and Gas Pipes

No. of Wiring Connection 3 For Power Supply, 4 For Interunit Wiring (Included Earth Wiring)

Max. Interunit Piping Length m

115 (Total Main Piping and Branch Piping)

55 (Total Main Piping), 60 (Total Branch Piping)

15 (Max. Length for Each Room)

Amount of Additional Charge g/m Chargeless

Max. Installation Height Difference m 30 (Between Indoor or BP Unit and Outdoor Unit), 15 (Both between Indoor Units and BP Units)

Drawing No. 3D031578

Cooling Heating Piping Length

Indoor ; 27°CDB / 19.0°CWB

Outdoor ; 35°CDB

Indoor ; 21°CDB

Outdoor ; 7°CDB / 6°CWB