Daikin FTXC25AV1B, RXC25AV1B, FTXC35AV1B, RXC35AV1B, FTXC50AV1B Installation manuals

...

INSTALLATION AND

MAINTENANCE MANUAL

R32 SPLIT SERIES

MODELS

FTXC25AV1B RXC25AV1B

FTXC35AV1B RXC35AV1B

FTXC50AV1B RXC50AV1B

FTXC60AV1B RXC60AV1B

Installation Manual

R32 Split Series

Manuale d’installazione

Serie Multiambienti R32

Installationsanleitung

Split-Baureihe R32

Manual de instalación

Serie Split R32

Manuel d’installation

Série split R32

Montaj kýlavuzlarý

R32 Split serisi

Руководство по монтажу

Серия R32 с раздельной установкой

English

Italiano

Deutsch

Español

Français

Türkçe

Русский

Еγχειρίδιο εγκατάστασης

Σειρά Split R32

IM-3WMYJ(R)-0816(0)-DAIKIN

Part Number.: R08019045616

Еλληνικă

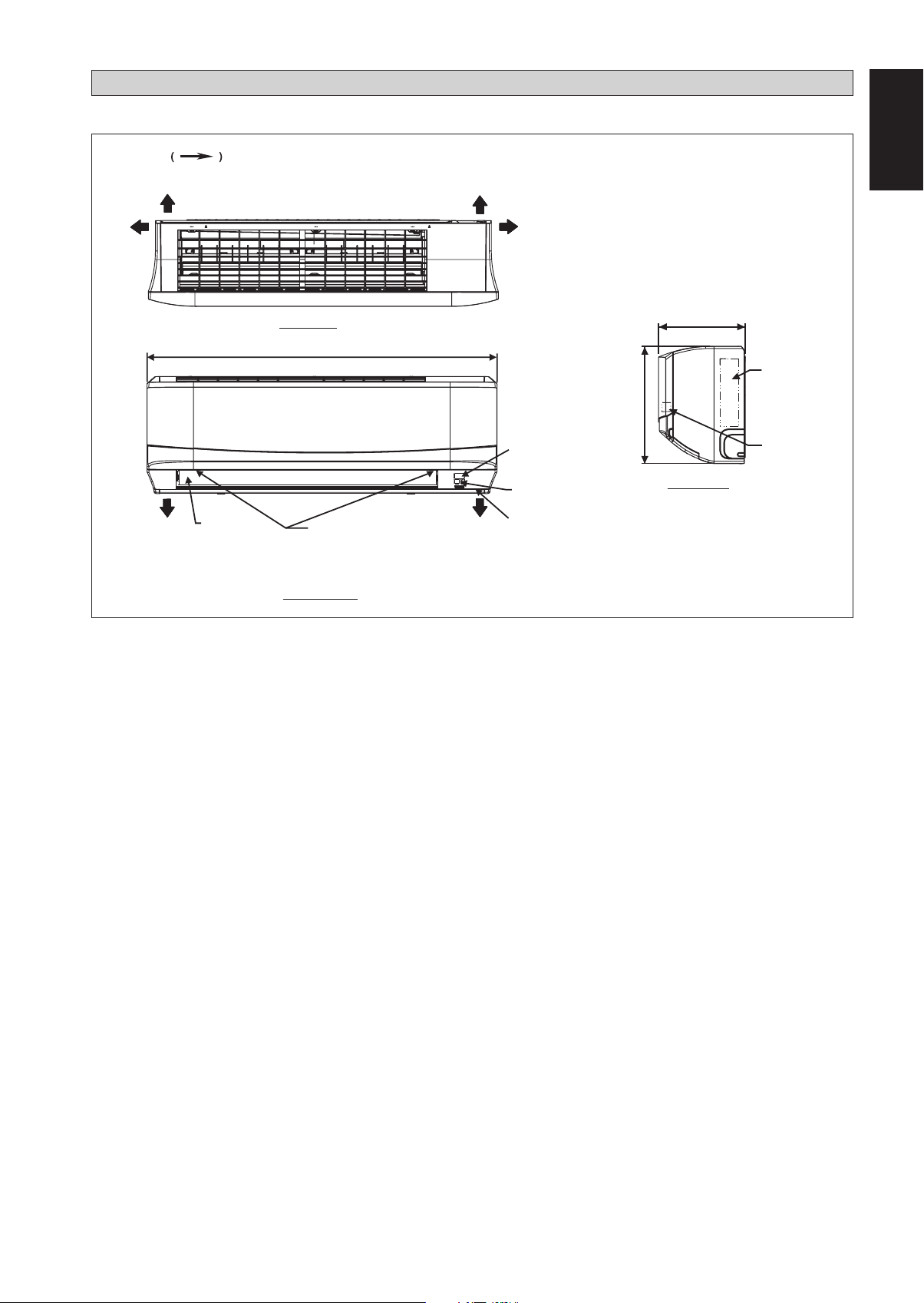

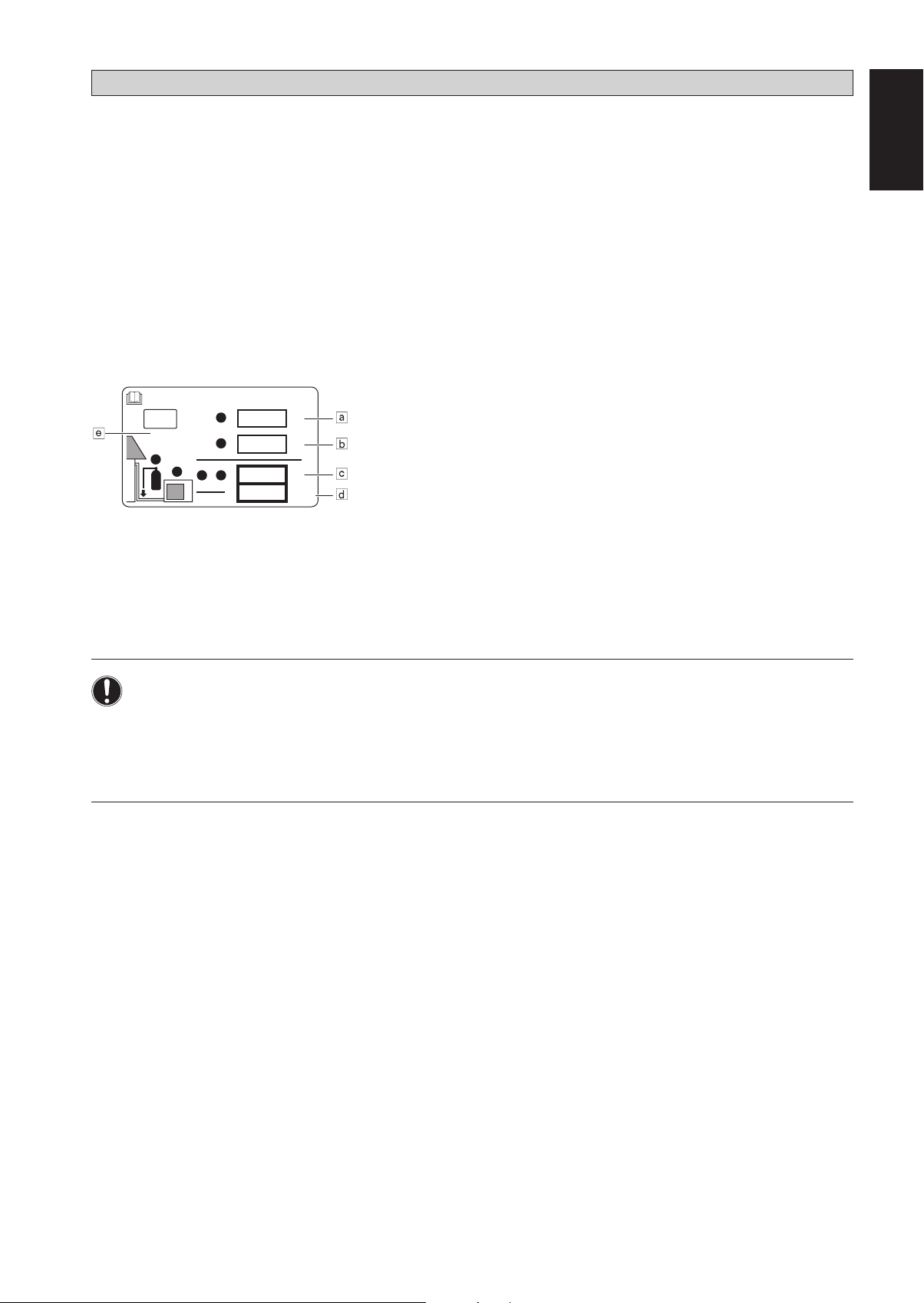

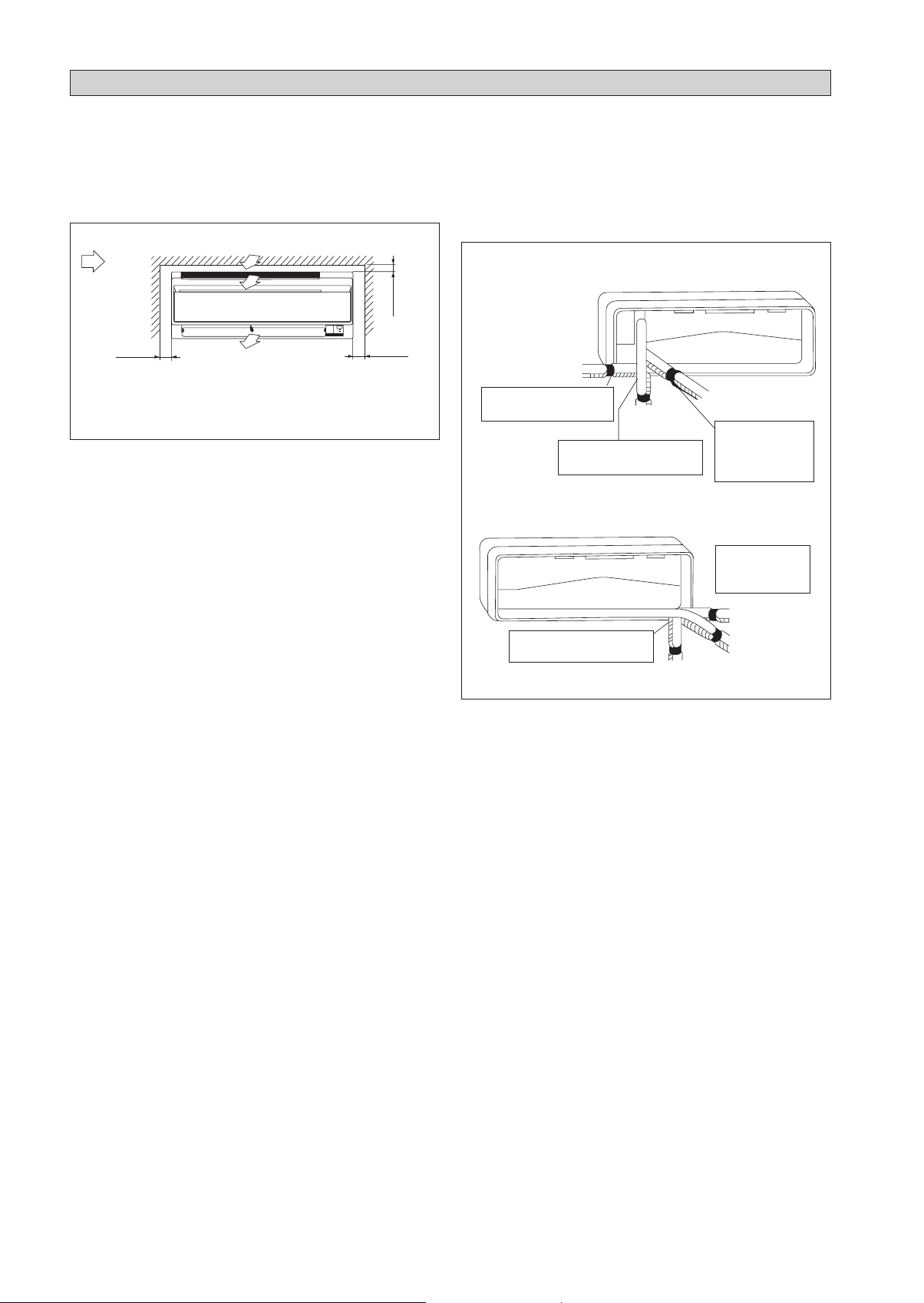

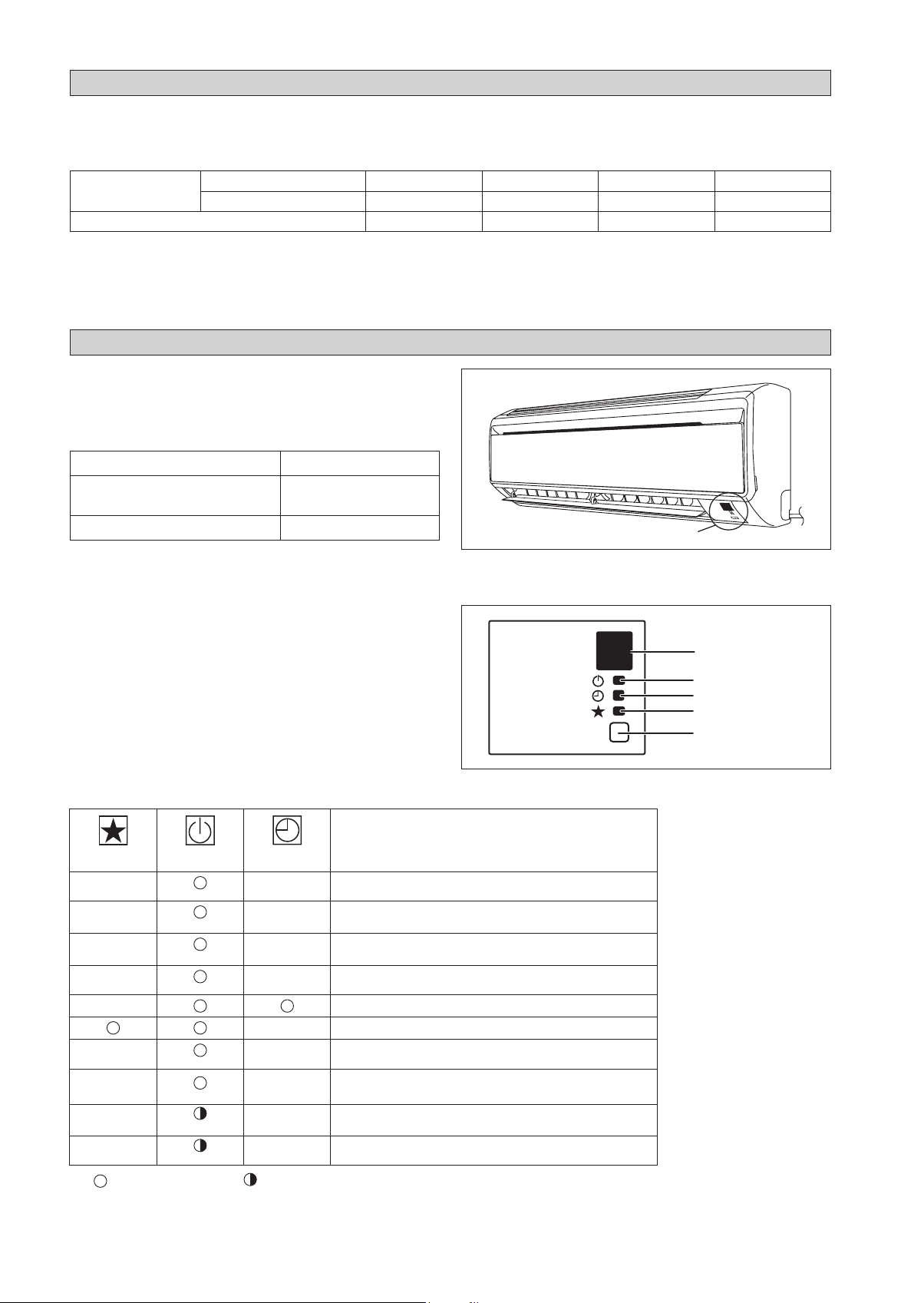

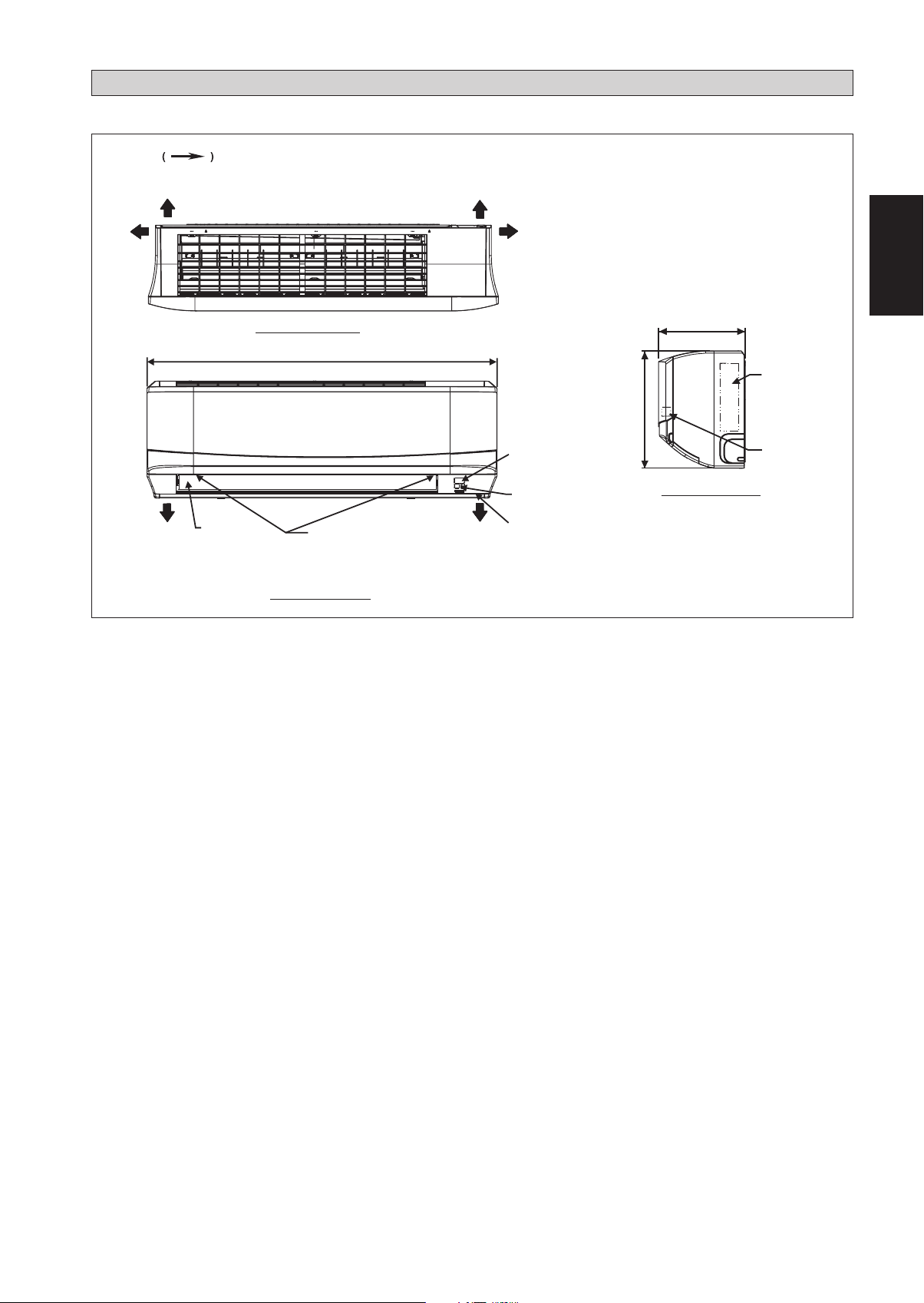

Indoor Unit [FTXC]

OUTLINE AND DIMENSIONS

THE MARK SHOWS PIPING DIRECTION

REAR REAR RIGHTLEFT

TOP VIEW

A

BOTTOM BOTTOM

LOUVER

FRONT GRILLE

FIXED SCREWS

(INSIDE)

FRONT VIEW

SIGNAL RECEIVER

INDOOR UNIT

ON/OFF SWITCH

ROOM TEMPERATURE

THERMISTOR

(INSIDE)

English

Original Instruction

C

STICKER

SERIAL NO.

B

TERMINAL

BLOCK

WITH EARTH

TERMINAL

SIDE VIEW

1-1

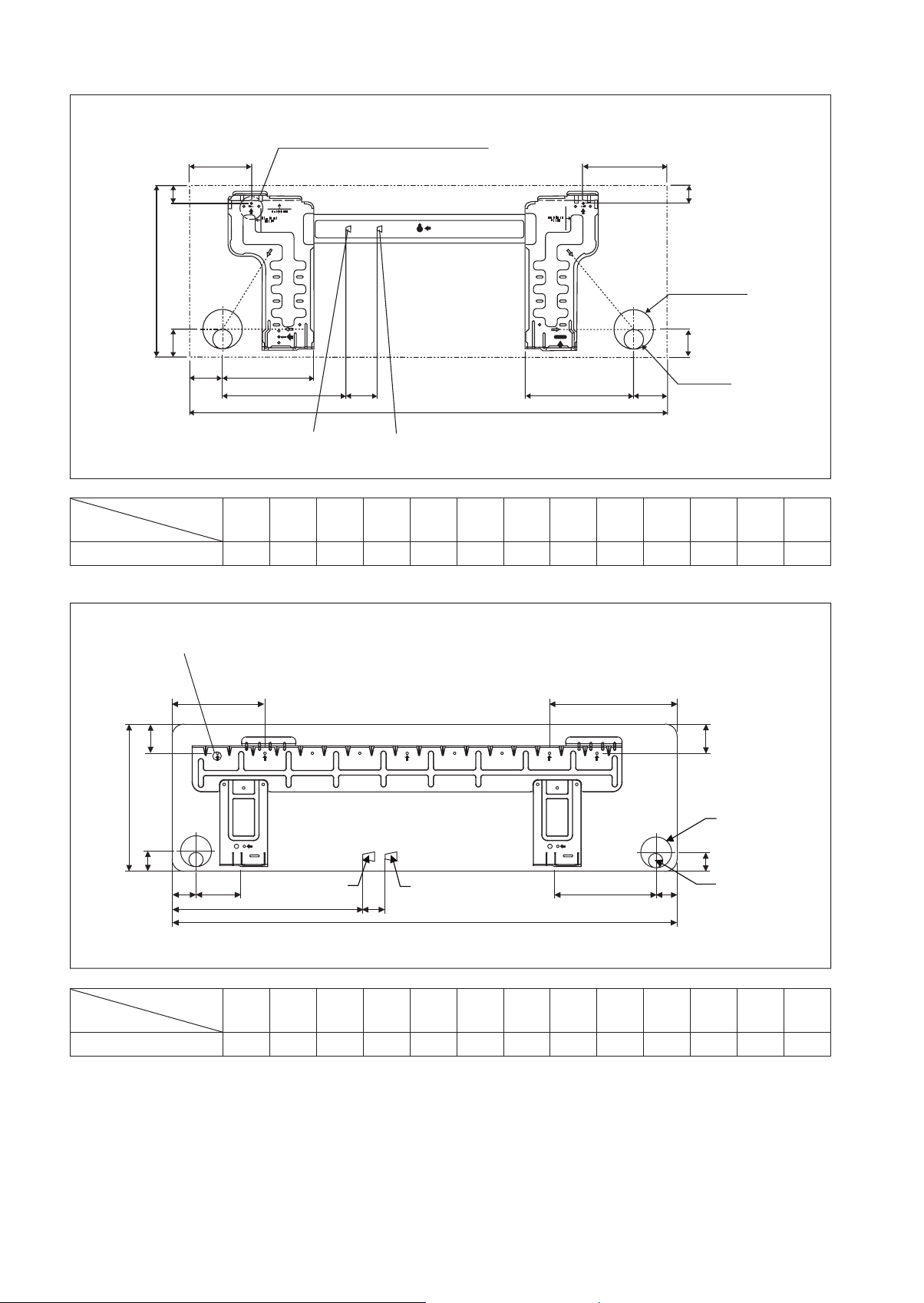

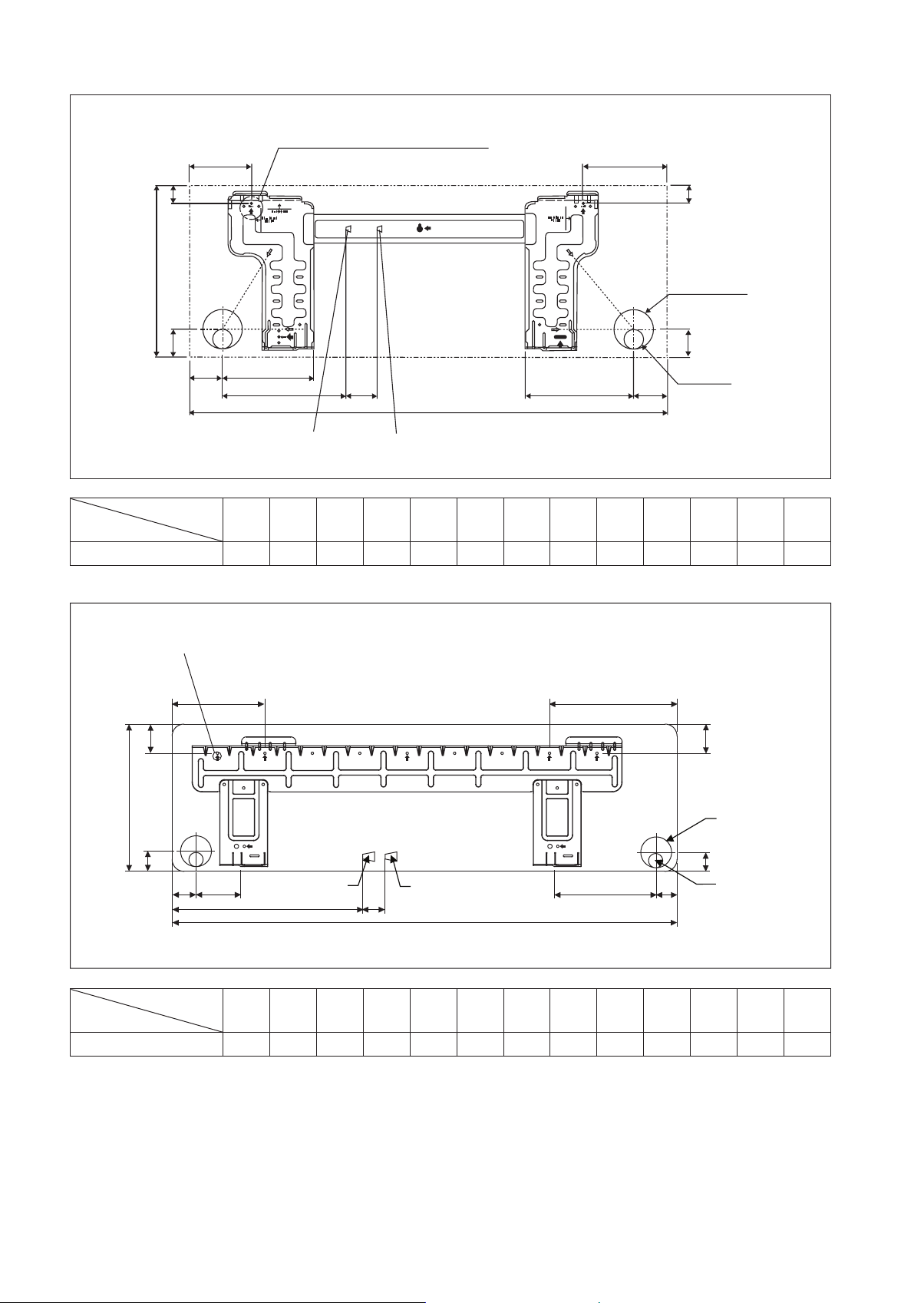

Indoor Unit [FTXC]

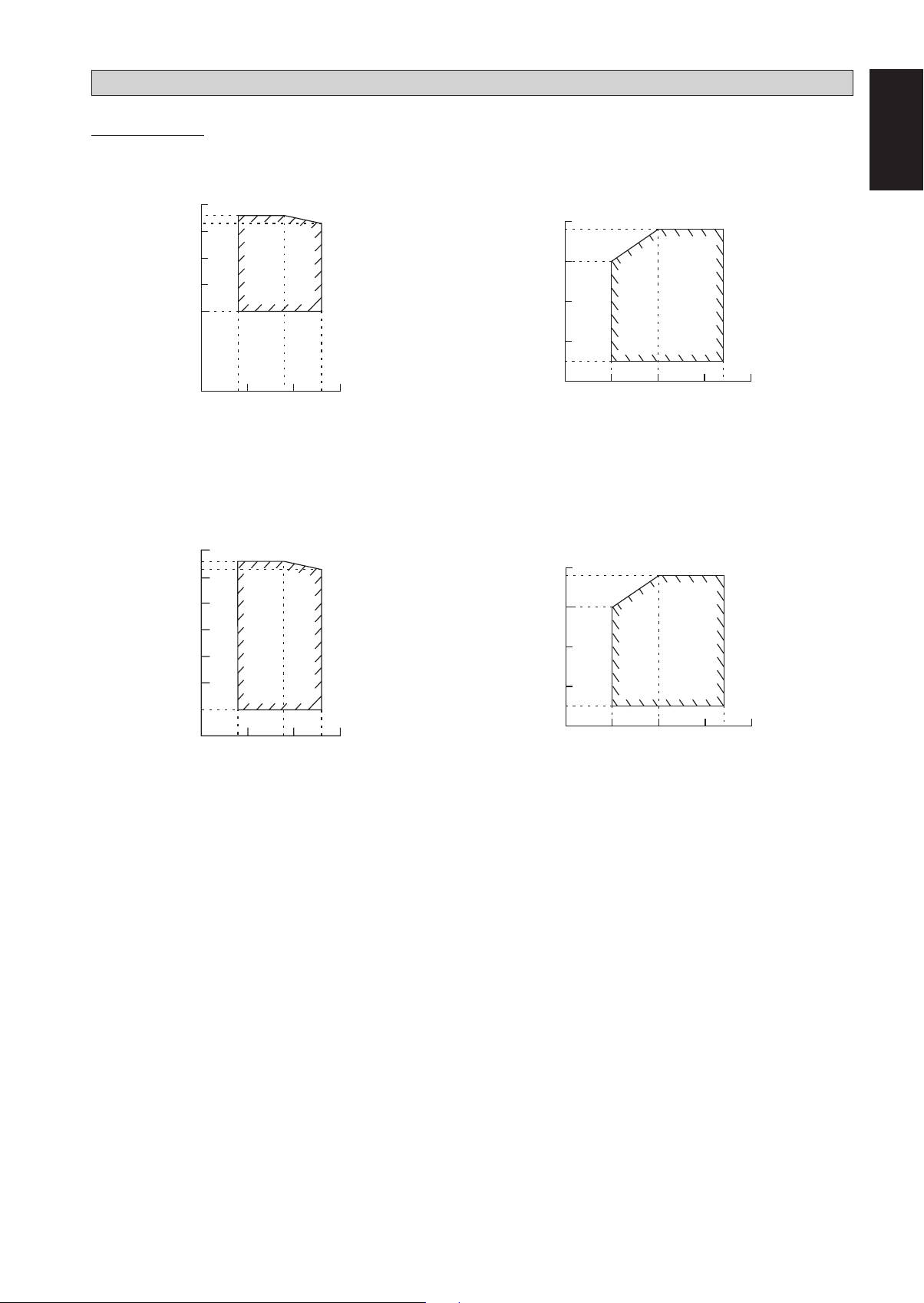

« Recommended mounting plate retention spots

(5 spots in all)

D

E

F

B

G

JH

ML

A

Liquid pipe end

Gas pipe end

F

Through the wall

hole Ø 65mm

G

Drain hose position

IK

All dimensions are in mm

Dimension

Model

ABCDE FGHI JKLM

25/35 859 288 209 104 141 30 46 55 56 153 181 207 52

Indoor Unit [FTXC]

« Recommended mounting plate retention spots

(7 spots in all)

D

F

B

G

H

J

Liquid pipe end

L

M

Gas pipe end

A

E

F

Through the wall

hole Ø 65mm

G

K

I

Drain hose position

All dimensions are in mm

Dimension

Model

ABCDE FGHI JKLM

50/60 1124 310 237 190 173 61 40 45 48 91 219 580 45

1-2

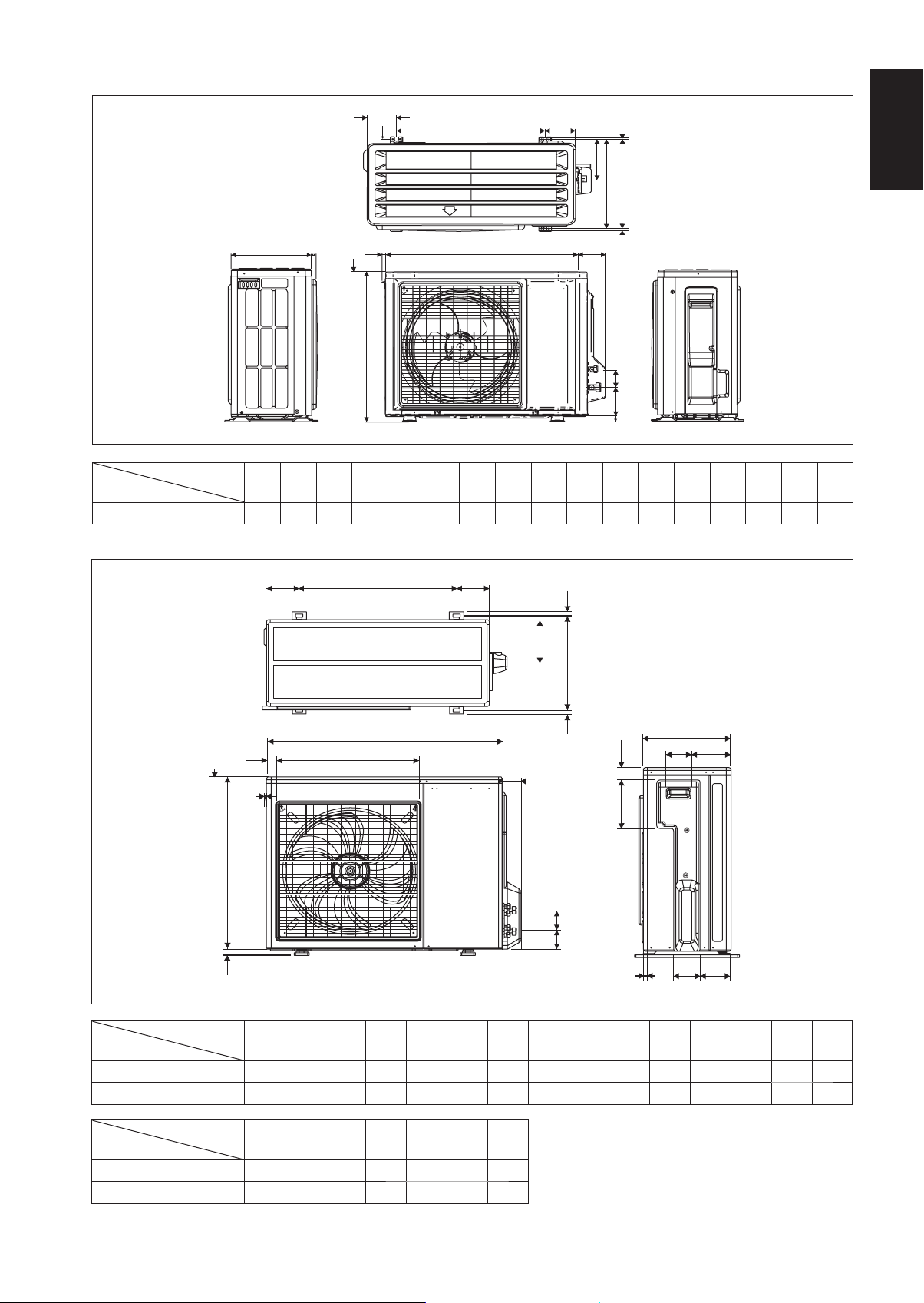

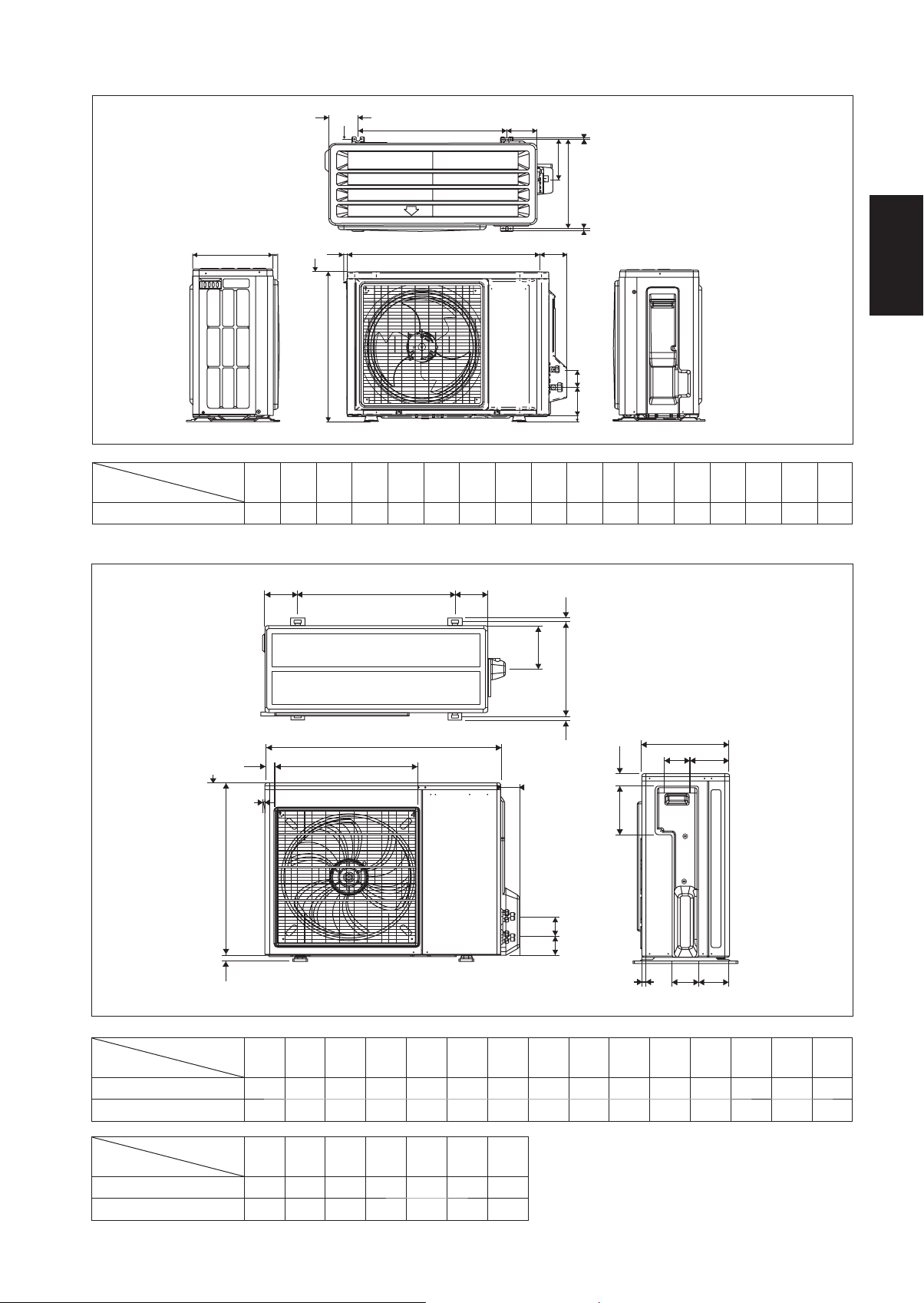

Outdoor Unit [RXC]

Model

Dimension

J

G

EF

ABCDE FGHI JKLMNOPQ

2.0

A

HI

N

Q

B

CD

All dimensions are in mm

OP

KL

M

25/35 550 658 51 11 273 16 14 470 96 93 94 60 14 133 8 10 299

Outdoor Unit [RXC]

English

3.0

KLL

N

M

Q

A

O

V

B

P

D

U

N

F

E

S

R

All dimensions are in mm

C

GH

I

J

T

Dimension

Model

ABCDE FGHI JKLMNO

50 855 628 328 520 179 46 93 149 101 113 603 126 164 15 34

60 855 730 328 520 179 46 93 149 101 113 603 126 164 15 34

Dimension

Model

PQRS TUV

50 23 362 73 75 8 67 7

60 23 362 73 75 8 67 7

1-3

INSTALLATION MANUAL

This manual provides the procedures of installation to ensure a safe and good standard of operation for the air conditioner unit.

Special adjustment may be necessary to suit local requirement.

Before using your air conditioner, please read this instruction manual carefully and keep it for future reference.

This appliance is intended to be used by expert or trained users in shops, in light industry and on farms, or for commercial use by lay

persons.

This appliance is not intended for use by persons, including children, with reduced physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a person responsible

for their safety.

Children should be supervised to ensure that they do not play with the appliance.

SAFETY PRECAUTIONS

! WARNING ! CAUTION

Installation and maintenance should be performed by qualified

•

persons who are familiar with local code and regulation, and

experienced with this type of appliance.

All field wiring must be installed in accordance with the national

•

wiring regulation.

Ensure that the rated voltage of the unit corresponds to that of

•

the name plate before commencing wiring work according to the

wiring diagram.

The unit must be GROUNDED to prevent possible hazard due

•

to insulation failure.

All electrical wiring must not touch the water piping or any moving

•

parts of the fan motors.

Confirm that the unit has been switched OFF before installing or

•

servicing the unit.

Disconnect from the main power supply before servicing the air

•

conditioner unit.

DO NOT pull out the power cord when the power is ON. This

•

may cause serious electrical shocks which may result in the fire

hazards.

Keep the indoor and outdoor units, power cable and transmission

•

wiring, at least 1m from TVs and radios, to prevent distorted

pictures and static. {Depending on the type and source of the

electrical waves, static may be heard even when more than 1m

away}.

WARNING

Do not use means to accelerate the defrosting process (if applicable)

or to clean, other than those recommended by the manufacturer. The

appliance shall be stored in a room without continuously operating

ignition sources (for example: open flames, an operating gas appliance

or an operating electric heater). Do not pierce or burn. Be aware that

refrigerants may not contain an odour. Appliance shall be installed,

operated and stored in a room with a floor area larger than Xm

(refer to page 13).

NOTE: The manufacturer may provide other suitable examples or may

provide additional information about the refrigerant odour.

Please take note of the following important points when

installing.

Do not install the unit where leakage of flammable gas may

•

occur.

If gas leaks and accumulates around the unit, it may cause

fire ignition.

Ensure that drainage piping is connected properly.

•

If the drainage piping is not connected properly, it may cause

water leakage which will dampen the furniture.

Do not overcharge the unit.

•

This unit is factory pre-charged. Overcharge will cause

over-current or damage to the compressor.

Ensure that the unit’s panel is closed after service or

•

installation.

Unsecured panels will cause the unit to operate noisily.

Sharp edges and coil surfaces are potential locations which

•

may cause injury hazards. Avoid from being in contact with

these places.

Before turning off the power supply set the remote controller’s

•

ON/OFF switch to the “OFF” position to prevent the nuisance

tripping of the unit. If this is not done, the unit’s fans will start

turning automatically when power resumes, posing a hazard to

service personnel or the user.

Do not install the units at or near doorway.

•

Do not operate any heating apparatus too close to the air

•

conditioner unit or use in room where mineral oil, oil vapour

or oil steam exist, this may cause plastic part to melt or deform

as a result of excessive heat or chemical reaction.

When the unit is used in kitchen, keep flour away from going

•

into suction of the unit.

This unit is not suitable for factory used where cutting oil mist

•

or iron powder exist or voltage fluctuates greatly.

Do not install the units at area like hot spring or oil refinery

•

2

plant where sulphide gas exists.

Ensure the color of wires of the outdoor unit and the terminal

•

markings are same to the indoors respectively.

IMPORTANT : DO NOT INSTALL OR USE THE AIR

•

CONDITIONER UNIT IN A LAUNDRY ROOM.

Do not use joined and twisted wires for incoming power

•

supply.

The equipment is not intended for use in a potentially explosive

•

atmosphere.

Disposal requirements

NOTICE

Your air conditioning product is marked with this symbol. This means that electrical and electronic products shall not be mixed with

unsorted household waste.

Do not try to dismantle the system yourself: the dismantling of the air conditioning system, treatment of the refrigerant, of oil and of

other parts must be done by a qualified installer in accordance with relevant local and national legislation.

Air conditioners must be treated at a specialized treatment facility for re-use, recycling and recovery. By ensuring this product is

disposed of correctly, you will help to prevent potential negative consequences for the environment and human health. Please contact

the installer or local authority for more information.

Batteries must be removed from the remote controller and disposed of separately in accordance with relevant local and national

legislation.

1-4

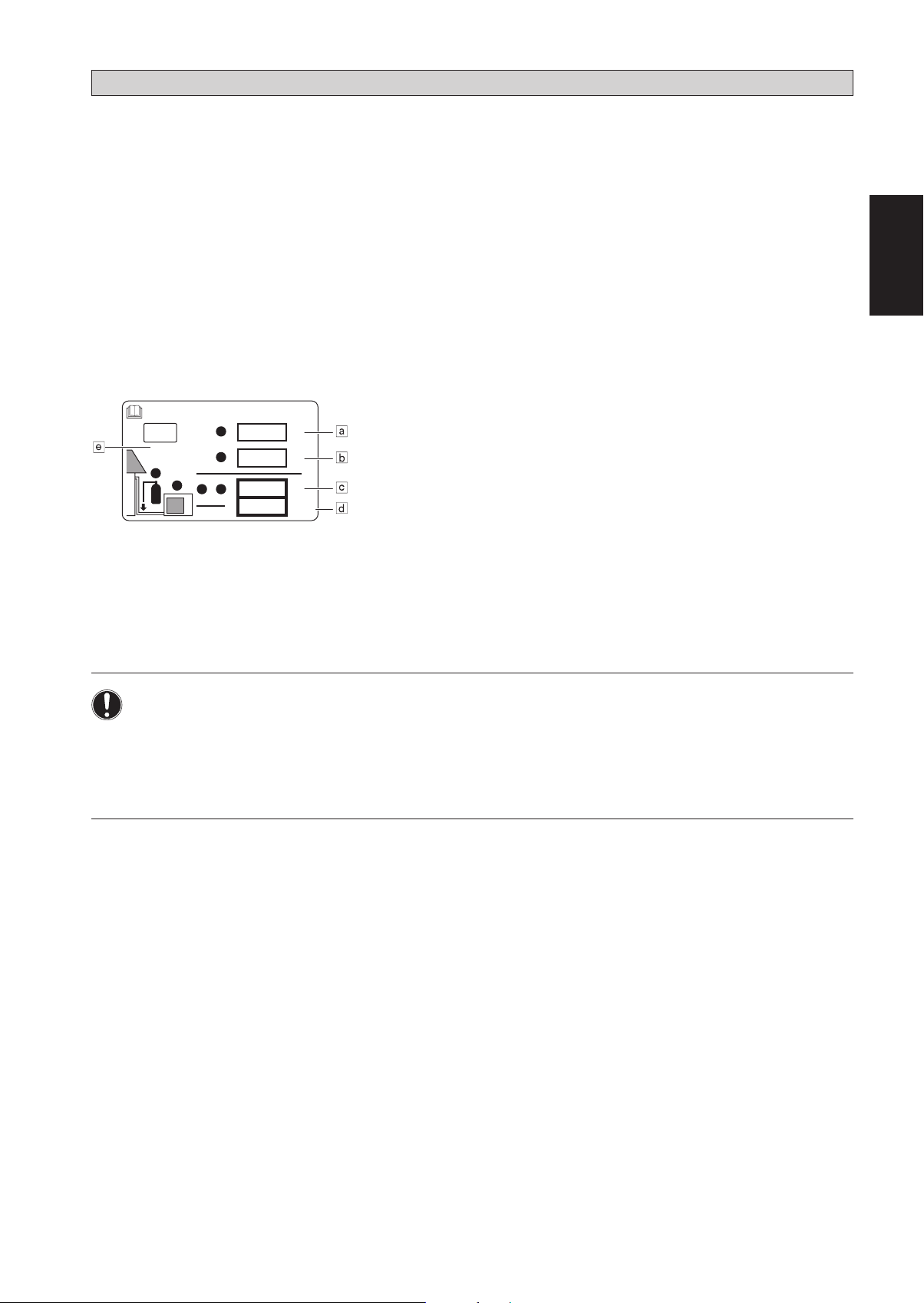

IMPORTANT

Important information regarding the refrigerant used

This product contains fluorinated greenhouse gases.

Do not vent gases into the atmosphere.

Refrigerant type: R32

(1)

GWP

(1)

1

¢

¢

¢

on the refrigerant charge label supplied with the product.

The filled out label must be adhered in the proximity of the product charging port (e.g. onto the inside of the service cover).

value: 675

GWP = Global Warming Potential

Please fill in with indelible ink,

1 the factory refrigerant charge of the product,

2 the additional refrigerant amount charged in the field and

1 + 2 the total refrigerant charge

Contains fluorinated greenhouse gases

=

R32

GWP: 675

2

1

=

2

1

1

2

+

=

GWP × kg

=

1000

kg

kg

kg

tCO2eq

English

Factory refrigerant charge: see unit name plate

a

Additional refrigerant amount charged

b

Total refrigerant charge

c

Greenhouse gas emissions of the total refrigerant charge expressed as tonnes CO

d

GWP = Global warming potential

e

-equivalent

2

NOTICE

In Europe, the greenhouse gas emissions of the total refrigerant charge in the system (expressed as tonnes

CO2-equivalent) is used to determine the maintenance intervals. Follow the applicable legislation.

Formula to calculate the greenhouse gas emissions:

GWP value of the refrigerant × Total refrigerant charge [in kg] / 1000

Fix the label on the inside of the outdoor unit. There is a dedicated place for it on the wiring diagram label.2

1-5

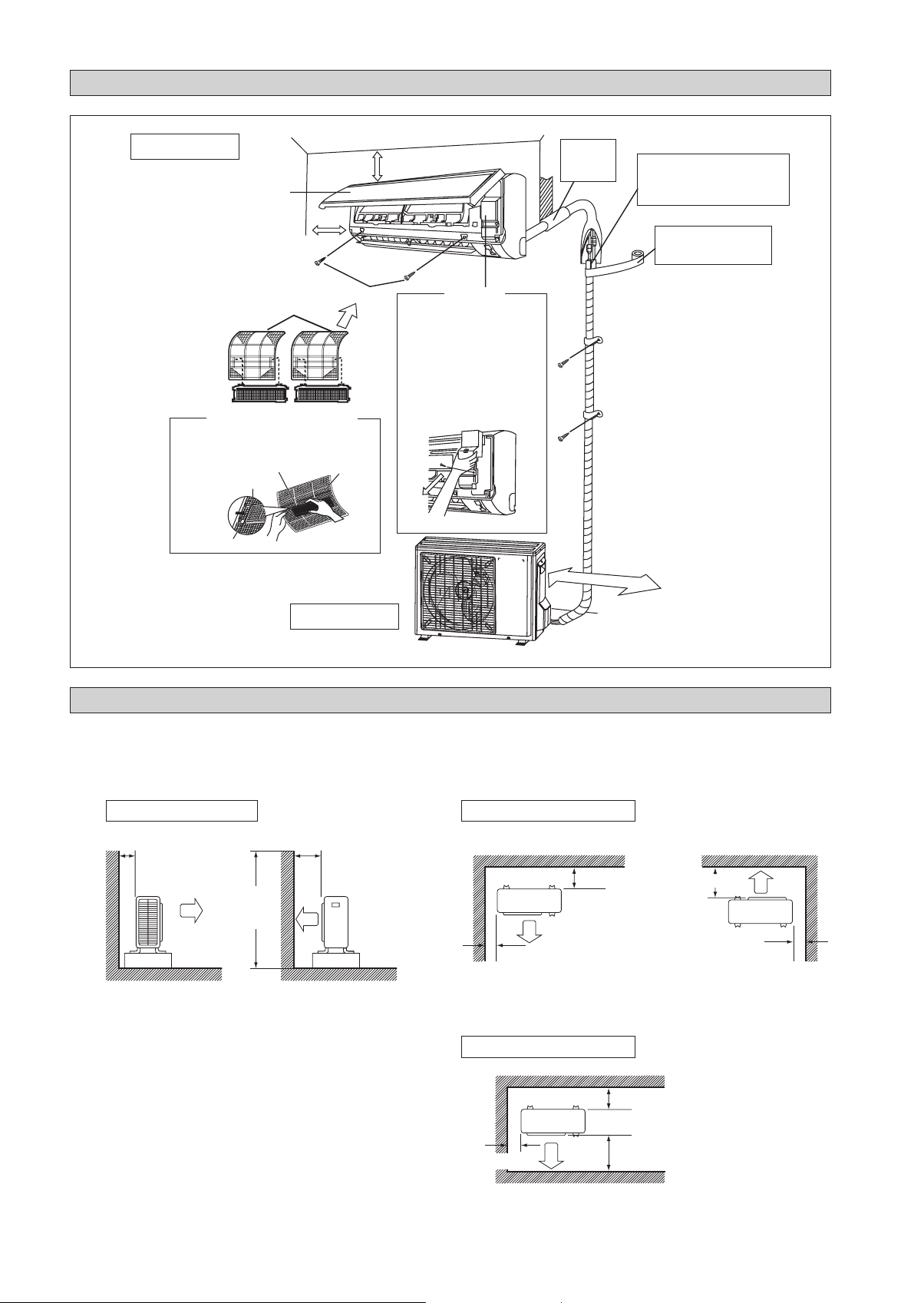

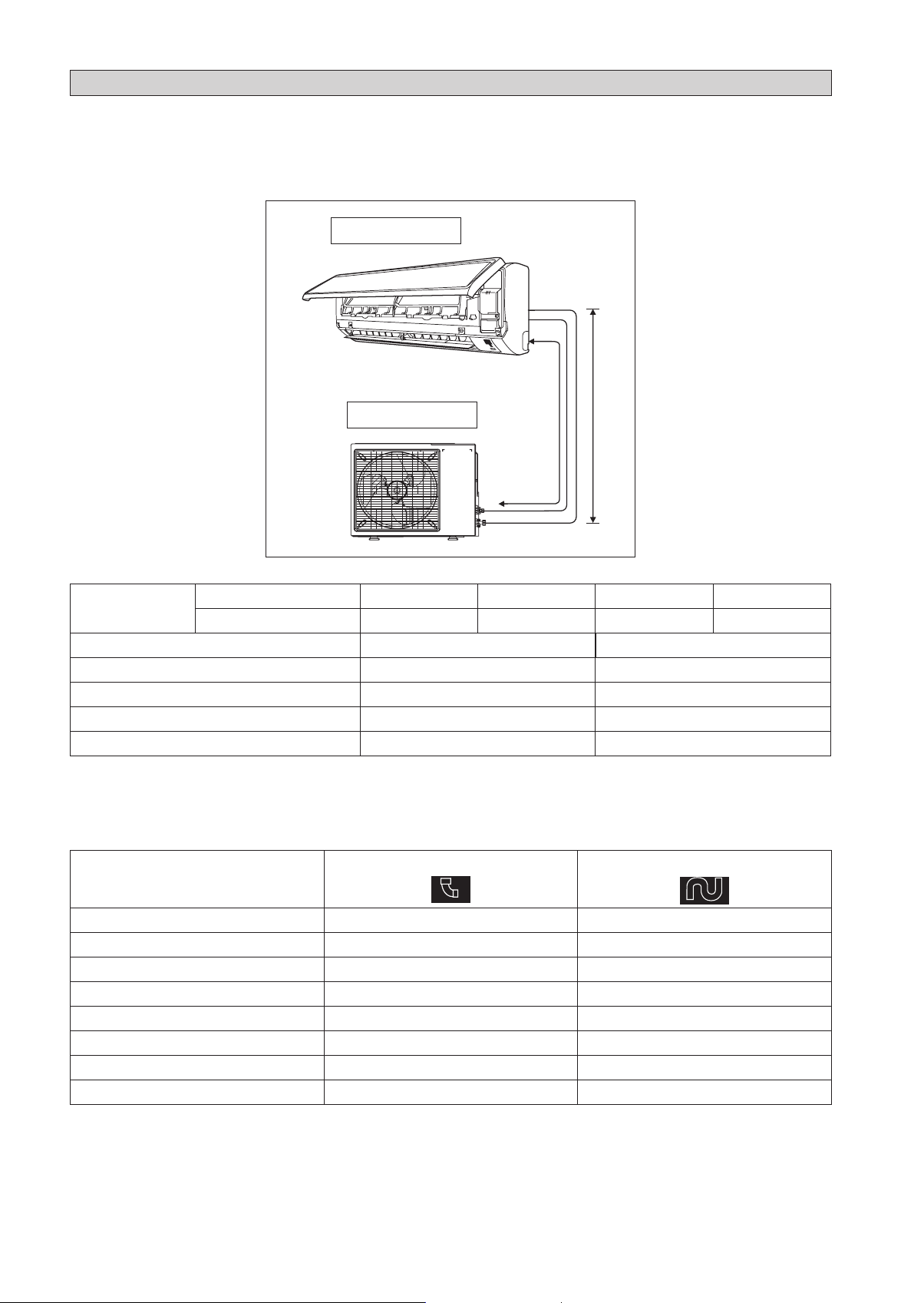

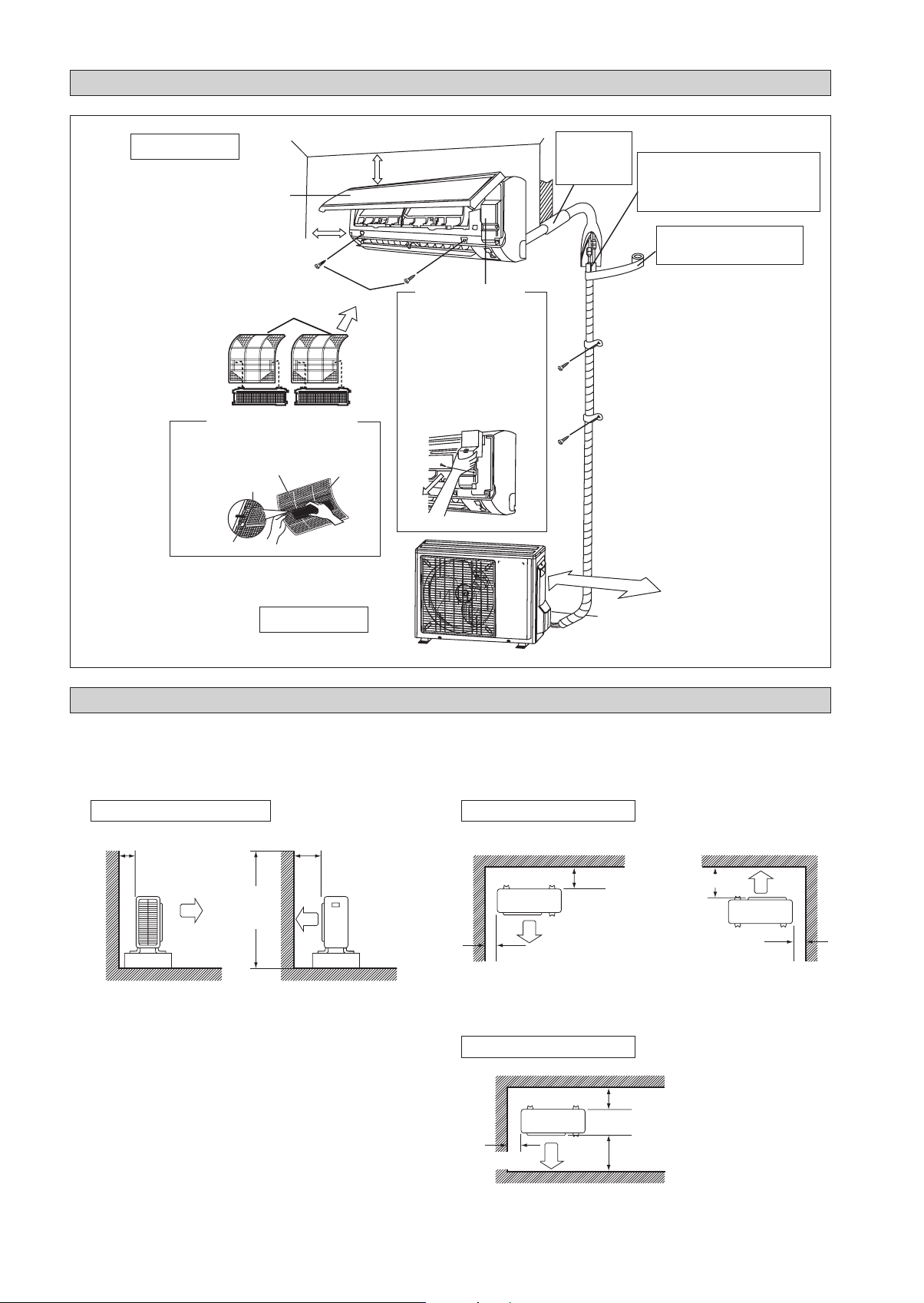

INSTALLATION DIAGRAM

Indoor Unit

50mm or more from walls

(on both sides)

Titanium apatite photocatalytic

air-purifying filter (2)

Titanium apatite photocatalytic

air-purifying filter

Front panel

Filter frame

Tab

Air filter

M4 x 12L

Air filter

75mm or more from ceiling

Service lid

n Opening service lid

Service lid is opening/closing

type.

n Opening method

1) Remove the service lid

screws.

2) Pull out the service lid

diagonally down in the

direction of the arrow.

3) Pull down.

Caulk pipe

hole gap

with putty.

500mm from wall

Cut thermal insulation pipe to an

appropriate length and wrap it with

tape, making sure that no gap is left

in the insulation pipe’s cut line.

Wrap the insulation pipe

with the finishing tape

from bottom to top.

Outdoor Unit

INSTALLATION OF THE OUTDOOR UNIT (25/35)

Where a wall or other obstacle is in the path of outdoor unit’s intake or exhaust airflow, follow the installation guidelines

•

below.

For any of the below installation patterns, the wall height on the exhaust side should be 1200mm or less.

•

Wall facing one side

More than 50

More than 100

1200 or

less

Side View

Wall facing two sides

More

than 100

More than 50

Wall facing three sides

More than 150

More than 50

Top View

More than 50

1-6

More than 150

More than 300

Top View

Unit : mm

Drain work. (Heat Pump Unit Only)

1) Use drain plug for drainage.

2) If the drain port is covered by a mounting base or floor surface, place

additional foot bases of at least 30mm in height under the outdoor

unit’s feet.

3) In cold areas, do not use a drain hose with the outdoor unit. (Otherwise,

drain water may freeze, impairing heating performance.)

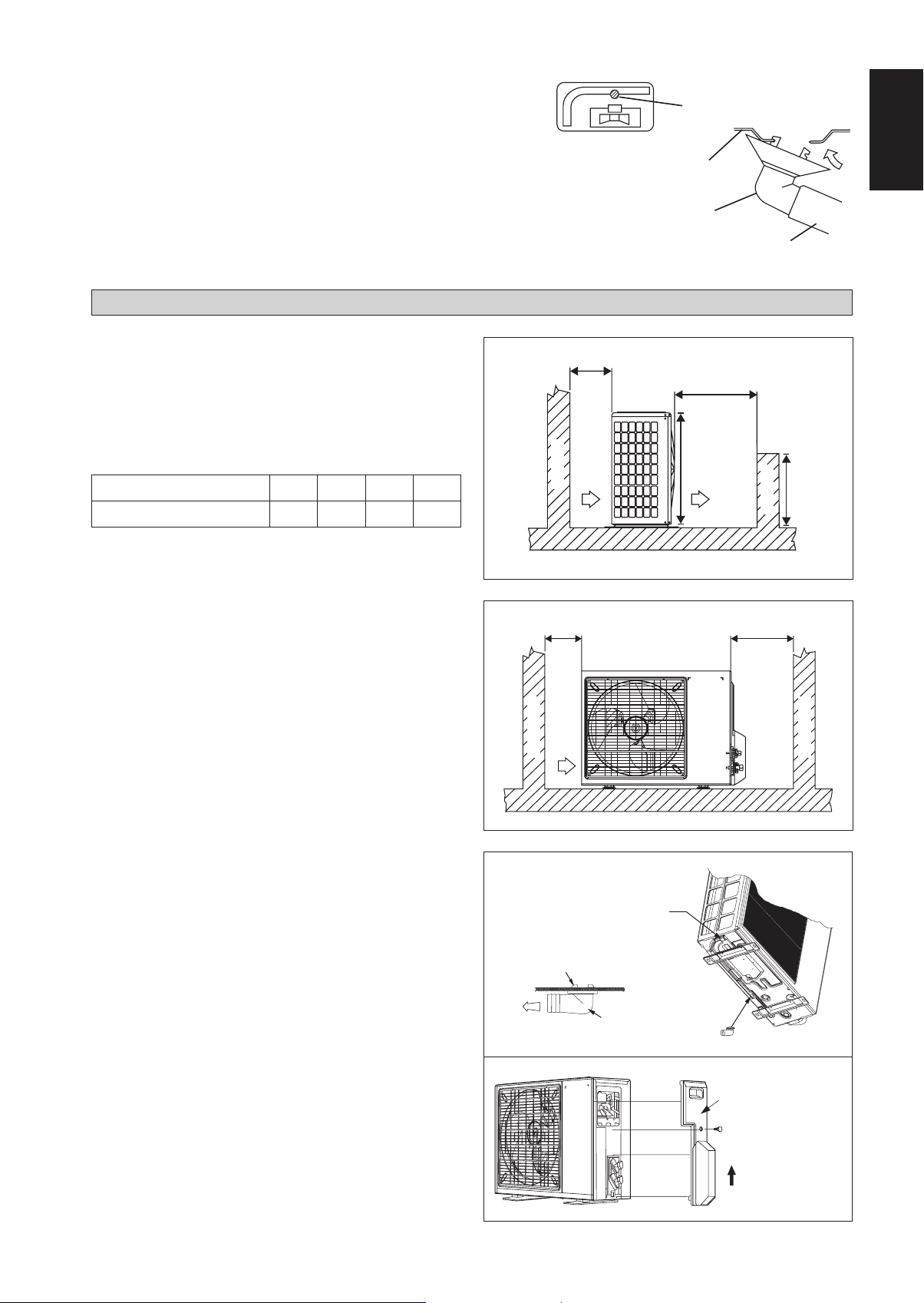

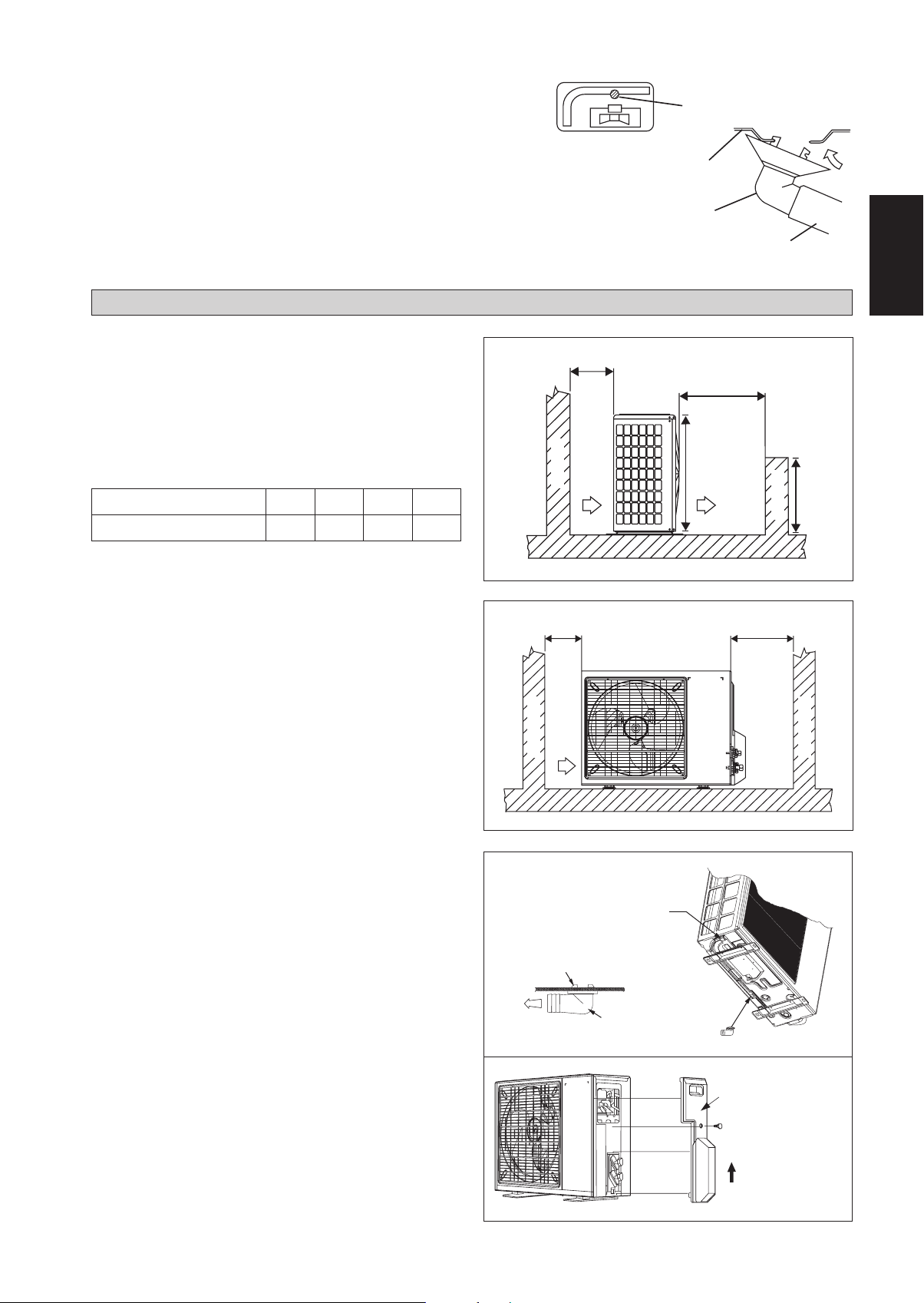

INSTALLATION OF THE OUTDOOR UNIT (50/60)

The outdoor unit must be installed in such a way, so as to

prevent short circuit of the hot discharged air or obstruction to

the smooth air flow. Please follow the installation clearances

shown in the figure. Select the coolest possible place where

intake air temperature is not greater than the outside air

temperature (Refer to operating range).

Drain water hole

Bottom frame

Drain Plug

Hose (available comercially,

inner dia. 16mm)

A

B

English

Installation clearances

Dimension

ABCD

Minimum Distance, mm 300 1000 300 500

Note: If there is any obstacle higher than half, of the unit’s

height (H), please allow more space than the figure indicated

in the above table.

Condensed Water Disposal Of Outdoor Unit

(Heat Pump Unit Only)

There are 2 holes on the base of Outdoor Unit for condensed

•

water to flow out. Insert the drain elbow to one of the

holes.

To install the drain elbow, first insert one portion of the

•

hook to the base (portion A), then pull the drain elbow in

the direction shown by the arrow while inserting the other

portion to the base. After installation, check to ensure that

the drain elbow clings to base firmly.

If the unit is installed in a snowy and chilly area, condensed

•

water may freeze in the base. In such case, please remove

plug at the bottom of unit to smooth the drainage.

Obstacle

C

Obstacle

Return air

Return air

H

Discharge air

H/2

Obstacle

D

Obstacle

Service access

1-7

PLUG

A

BASE

DRAIN ELBOW

DRAIN ELBOW

Please remove side

plate when connecting

the piping and

connecting cord

PUSH & PULL UP

INSTALLATION OF THE INDOOR UNIT

The indoor unit must be installed in such a way so as to prevent

short circuit of the cool discharged air with the hot return air.

Please follow the installation clearance shown in the figure. Do

not place the indoor unit where there could be direct sunlight

shining on it. Also, this location must be suitable for piping

and drainage, and be away from doors or windows.

Air flow

(Indoor)

min. 75

(Space for

performance)

min. 50

(Space for

maintenance)

Required space

All dimensions are in mm

min. 50

(Space for

maintenance)

The refrigerant piping can be routed to the unit in a number

of ways (left or right from the back of the unit), by using the

cut-out holes on the casing of the unit. Bend the pipes carefully

to the required position in order to align it with the holes. For

the side and bottom out, hold the bottom of the piping and

then position it to the required direction. The condensation

drain hose can be taped to the pipes.

Right-side, right-back or right-bottom piping

Right-side piping

Remove pipe port cover

here for right-side piping

Remove pipe port cover

here for right-bottom piping

Right-bottom

piping

Right-back piping

Bind coolant pipe

and drain hose

together with

insulating tape.

Left-side, left-back or left-bottom piping

Remove pipe port

cover here for

left-side piping

Remove pipe port cover

here for left-bottom piping

Left-side piping

Left-back piping

Left-bottom piping

1-8

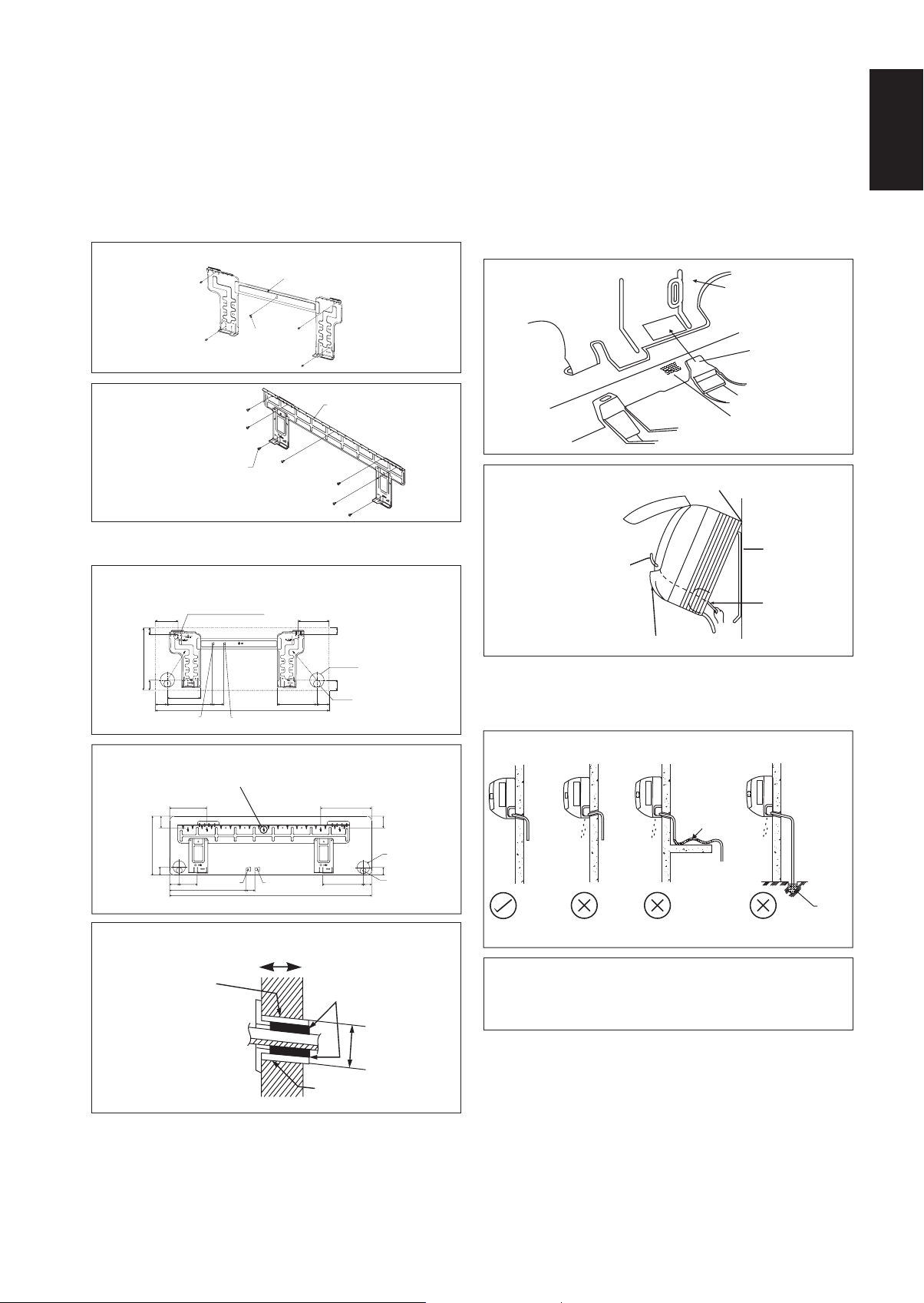

Mounting Installation Plate

Ensure that the wall is strong enough to withstand the weight

of the unit. Otherwise, it is necessary to reinforce the wall

with plates, beams or pillars.

Use the level gauge for horizontal mounting, and fix it with

5 suitable screws for FTXC 25/35 and 7 suitable screws for

FTXC 50/60.

In case the rear piping draws out, drill a hole 65mm in

diameter with a cone drill, slightly lower on the outside wall

(see figure).

FTXC 25/35

Mounting plate

Mount The Unit Onto The Installation Plate

Hook the indoor unit onto the upper portion of the installation

plate (Engage the two hooks at the rear top of the indoor unit

with the upper edge of the installation plate). Ensure that the

hooks are properly seated on the installation plate by moving

it to the left and right.

How To Attach The Indoor Unit

Hook the claws of the bottom frame to the mounting plate.

How To Remove The Indoor Unit

Push up the marked area (at the lower part of the front

grille) to release the claws.

Mounting plate

English

Mounting plate

fixing screw

FTXC 50/60

Mounting plate

Mounting plate fixing screw

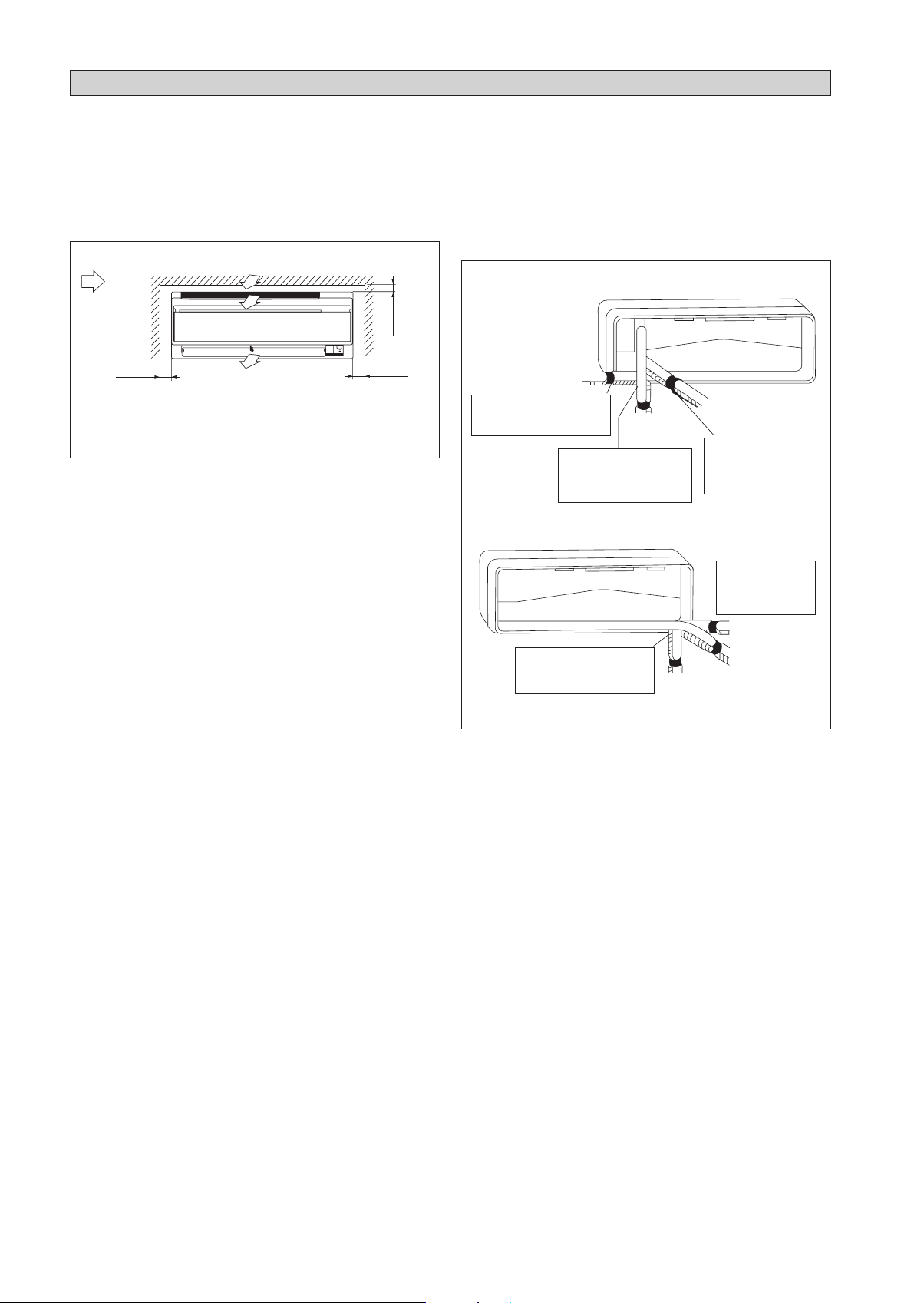

Recommended Mounting Plate Retention Spots And

Dimensions

FTXC 25/35

Recommended mounting plate retention spots

«

(5 spots in all)

104

30

288

46

153

55 207

Liquid pipe end

52

800

FTXC 50/60

« Recommended mounting plate retention spots

(7 spots in all)

190

61

310

40

45

91

580

Gas pipe end

45

1065

141

30

Through the wall hole Ø 65mm

46

Drain hose position

56

181

All dimensions are in mm

173

61

Through the wall hole

Ø 65mm

40

Drain hose position

48

Gas pipe endLiquid pipe end

219

All dimensions are in mm

Clip

Front grille

Bottom frame

Mark (Rear side)

Hang indoor unit’s hook here.

When stripping the ends

of interconnecting wires in

Mounting plate

advance, bind right ends of

wires with insulating tape.

Interconnecting

wires

Wire guide

Water Drainage Piping

The indoor drain pipe must be in a downward gradient for

smooth drainage. Avoid situations that are likely to cause

water to leak.

Water Drainage

Water

Water

leaking

Water

leaking

retention

Water

leaking

End

dipped

into

water

Drain

Hole with cone drill

Inside

Wall embedded pipe

(Field supply)

Wall hole cover

(Field supply)

Outside

Caulking

Ø 65

Wall embedded pipe

(Field supply)

Correct Wrong

Wrong Wrong

! CAUTION

• Do not install the unit at altitude over 2000m for both

indoor & outdoor.

1-9

REFRIGERANT PIPING

Allowable Piping Length

If the pipe is too long, both the capacity and reliability of the unit will drop. As the number of bends increases, resistance to

the flow of refrigerant system increases, thus lowering cooling capacity. As a result, the compressor may become defective.

Always choose the shortest path and follow the recommendations as tabulated below:

Indoor Unit

LE

Outdoor Unit

Model

Indoor (FTXC) 25 35 50 60

Outdoor (RXC) 25 35 50 60

Min. Allowable Length (L), m 33

Max. Allowable Length (L), m 20 30

Max. Allowable Elevation (E), m 15 15

Gas Pipe Size, mm/(in)

Liquid Pipe Size, mm/(in)

*Be sure to add the proper amount of additional refrigerant. Failure to do so may result in reduced performance.

9.52 (3/8") 12.70 (1/2")

6.35 (1/4") 6.35 (1/4")

Remark: The refrigerant pre-charged in the outdoor unit is for piping length up to 7.5m.

Equivalent length for various fitting (meter)

Pipe Size L joint Trap bend

3/8" (OD9.52mm) 0.18 1.3

1/2" (OD12.7mm) 0.20 1.5

5/8" (OD15.9mm) 0.25 2.0

3/4" (OD19.1mm) 0.35 2.4

7/8" (OD22.2mm) 0.40 3.0

1" (OD25.4mm) 0.45 3.4

1 1/8" (OD28.6mm) 0.50 3.7

1 3/8" (OD34.9mm) 0.60 4.4

Notes:

1. Equivalent piping length is obtained with actual length of gas piping.

2. 90° bend of piping is equivalent to L joint.

Bending must be carefully made so as not to crush the pipe. Use a pipe bender to bend a pipe where possible.

1-10

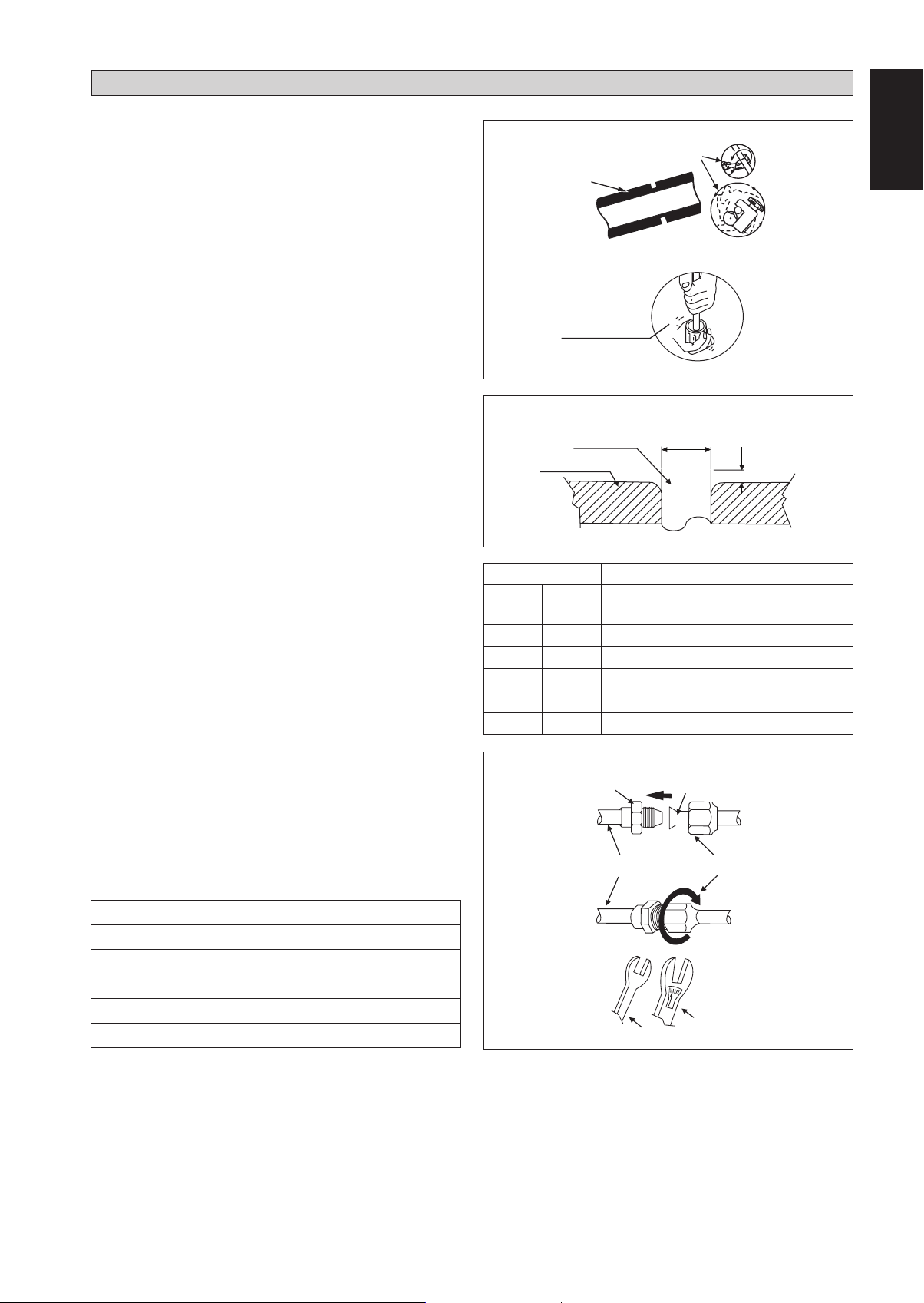

REFRIGERANT PIPING

Piping Works And Flaring Technique

Do not use contaminated or damaged copper tubing. If

•

any piping, evaporator or condenser had been exposed or

had been opened for 15 seconds or more, the system must

be vacuumed. Generally do not remove plastic, rubber

plugs and brass nuts from the valves, fittings, tubing and

coils until it is ready to connect suction or liquid line into

valves or fittings.

If any brazing work is required, ensure that nitrogen gas

•

is passed through coil and joints while the brazing work

is being done. This will eliminate soot formation on the

inside wall of copper tubings.

Cut the pipe stages by stages, advancing the blade of pipe

•

cutter slowly. Extra force and a deep cut will cause more

distortion of pipe and therefore extra burr. See Figure I.

Remove burrs from cut edges of the pipes with remover. See

•

Figure II. Hold the pipe on top position and burr remover

at lower position to prevent metal chips from entering the

pipe. This will avoid unevenness on the flare faces which

will cause gas leak.

Insert the flare nuts, mounted on the connection parts

•

of both the indoor unit and outdoor unit, into the copper

pipes.

The exact length of pipe protruding from the top surface

•

of the swaging block is determined by the flaring tool.

See Figure III.

Fix the pipe firmly on the swaging block. Match the centers

•

of both the swaging block and the flaring punch, then

tighten the flaring punch fully.

The refrigerant pipe connection are insulated by closed

•

cell polyurethane.

Piping Connection To The Units

Align the center of the piping and tighten the flare nut

•

sufficiently with fingers. See Figure IV.

Finally, tighten the flare nut with torque wrench until the

•

wrench clicks.

When tightening the flare nut with the torque wrench,

•

ensure that the tightening direction follows the arrow

indicated on the wrench.

The refrigerant pipe connection are insulated by closed

•

cell polyurethane.

Figure I

Figure II

Figure III

Swaging Block

Cutting Copper Tube

1/4t

Remove Burr

Copper Tube

D

A

Ø Tube, D A (mm)

Inch mm Imperial

(Wing-nut Type)

Rigid

(Clutch Type)

1/4" 6.35 1.3 0.7

3/8" 9.52 1.6 1.0

1/2" 12.70 1.9 1.3

5/8" 15.88 2.2 1.7

3/4" 19.05 2.5 2.0

Figure IV

Flare Joint

Flared Tube

Flare NutIndoor Piping

English

Pipe Size, mm (in) Torque, Nm/(ft-lb)

6.35 (1/4") 18 (13.3)

9.52 (3/8") 42 (31.0)

12.70 (1/2") 55 (40.6)

15.88 (5/8") 65 (48.0)

19.05 (3/4") 78 (57.6)

1-11

Spanner

Torque Wrench

ELECTRICAL WIRING CONNECTION

IMPORTANT : * The figures shown in the table are for information purpose only. They should be checked and selected

to comply with the local/national codes of regulations. This is also subject to the type of installation and

conductors used.

** The appropriate voltage range should be checked with label data on the unit.

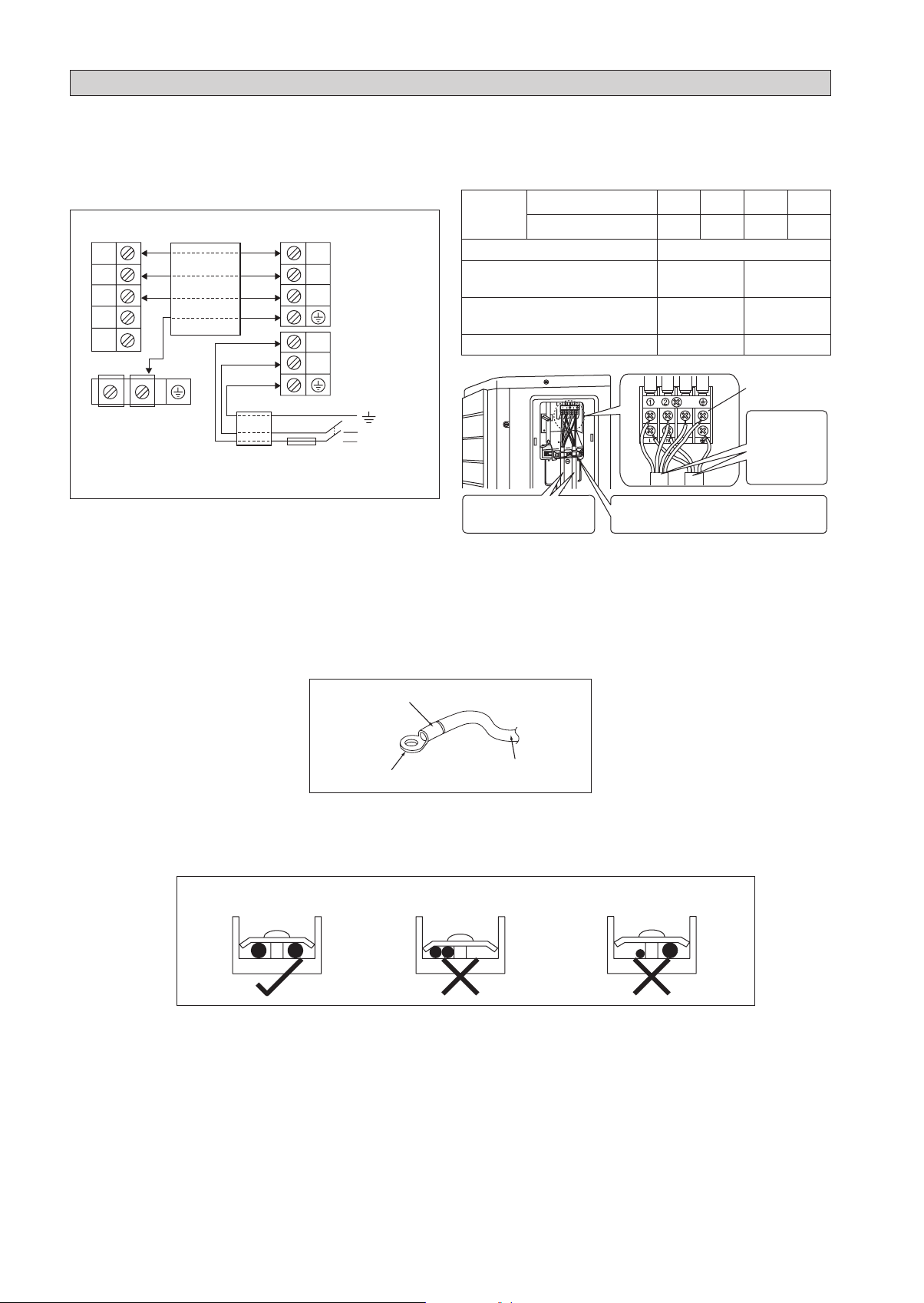

Inverter (Power Outdoor)

Indoor Unit

Terminal Block

1

2

SIG

There must be an all pole disconnection

!

in the supply mains with a contact

separation of at least 3mm.

All wires must be firmly connected.

•

Make sure all the wire do not touch the refrigerant pipings, compressor or any moving parts.

•

The connecting wire between the indoor unit and the outdoor unit must be clamped by using provided cord anchorage.

•

The power supply cord must be equivalent to H07RN-F which is the minimum requirement.

•

Make sure no external pressure is applied to the terminal connectors and wires.

•

Make sure all the covers are properly fixed to avoid any gap.

•

Use round crimp-style terminal for connecting wires to the power supply terminal block. Connect the wires by matching

•

Interconnection

cable

Outdoor Unit

Terminal Block

1

2

SIG

L

N

Power Supply Cable

Fuse / Circuit

Breaker

Main

Switch

N / L2

L / L1

Power

Supply

Model Indoor (FTXC)

Outdoor (RXC)

Voltage range

Power supply cable size

**

*

mm

Number of conductors

Interconnection cable size

*

mm

Number of conductors

25 35 50 60

25 35 50 60

220-240V/~/50Hz +

2

1.5

3

2

1.5

4

!

Recommended fuse /circuit breaker rating A 16 20

Power supply

terminal block

Shape wires so

that the service

lid and stop

valve cover fit

securely.

Use the specified wire type

and connect it securely.

SIG

Firmly secure wire retainer so wire

terminations will not receive external stress.

2.5

3

2.5

4

to the indication on terminal block. (Refer to the wiring diagram attached on the unit).

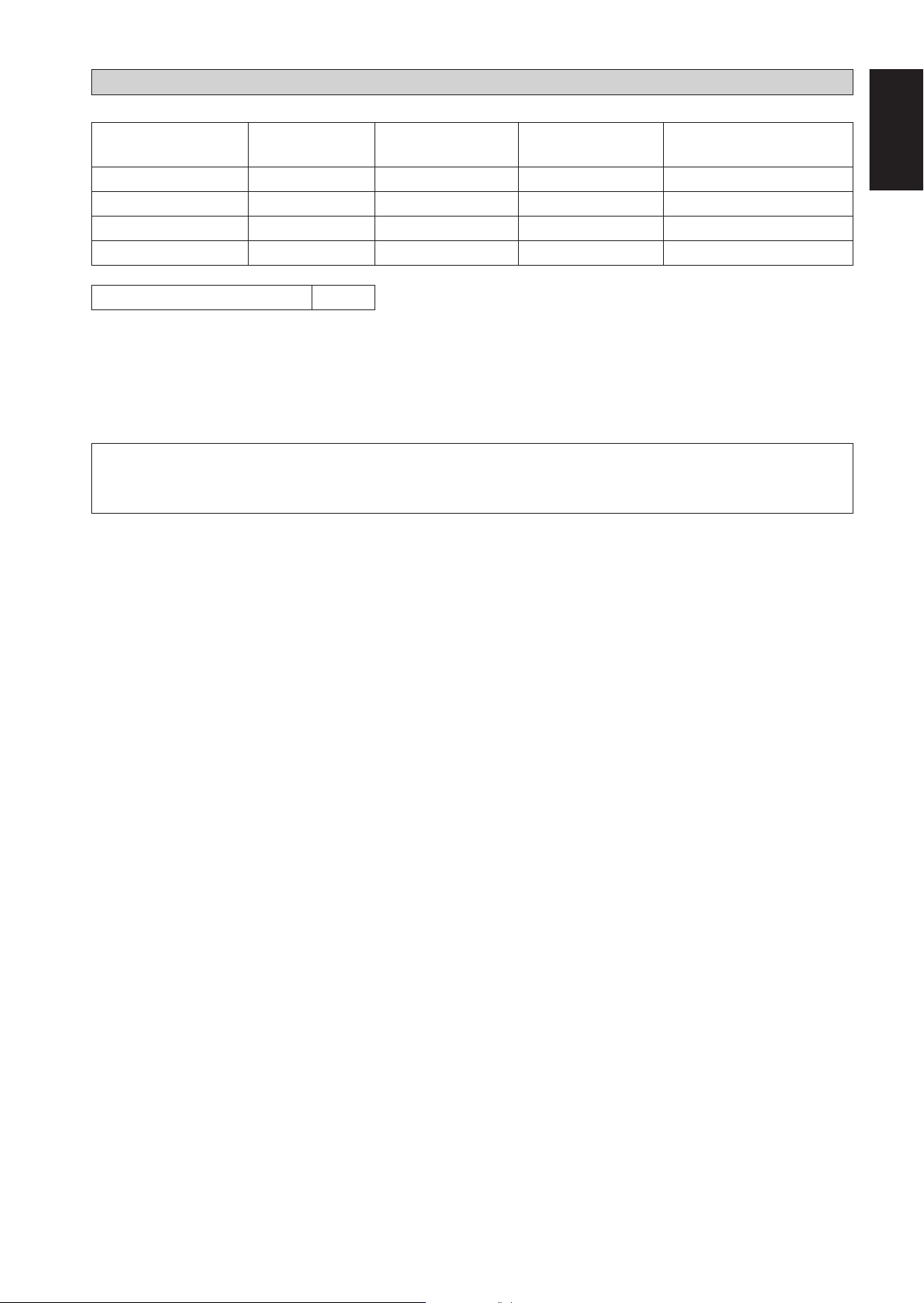

Attach insulation sleeve

Round crimp-style terminal

Used the correct screwdriver for terminal screws tightening. Unsuitable screwdrivers can damage the screw head.

•

Over tightening can damage the terminal screws.

•

Do not connect wire of different gauge to same terminal.

•

Keep wiring in an orderly manner. Prevent the wiring from obstructing other parts and the terminal box cover.

•

Connect wires of the

same gauge to both side.

Do not connect wires of the

same gauge to one side.

Electric wire

Do not connect wires

of different gauges.

1-12

SPECIAL PRECAUTIONS WHEN DEALING WITH R32 UNIT

Model

FTXC25AV1B - RXC25AV1B 0.6 0.34 0.94 0.84

FTXC35AV1B - RXC35AV1B 0.8 0.61 1.14 1.24

FTXC50AV1B - RXC50AV1B 1.1 1.15 1.61 2.47

FTXC60AV1B - RXC60AV1B 1.2 1.37 1.71 2.79

Installation Height, h

*Max. Allowable Length (L), m for:FTXC25/35A-RXC25/35A : 20

FTXC50/60A-RXC50/60A : 30

Installation of pipe work shall be kept to a minimum and pipe work shall be protected from physical damage and shall not be

•

installed in an unventilated space;

Reusable mechanical connectors and flare joints shall be accessible for maintenance purposes;

•

(m) = 1.8

o

R32 charge, kg for 7.5m

piping

Minimum floor area, Xm2

(based on 7.5m piping)

R32 charge, kg for max

allowable pipe length*

Minimum floor area, Xm2

(based on max allowable pipe length *)

! WARNING

Prior to installation, ensure risk of ignition is minimised and avoid working in confined space. Ensure adequate

ventilation is available by opening windows or doors.

When flared joints are reused indoors,the flare part shall be re-fabricated.

•

Avoid installation of the air conditioner in a place where there is danger of exposure to continuously operating open flam

•

example an operating electric heaters).

Any person who is involved with working on or breaking into a refrigerant circuit should hold a current valid certificate from an

•

industry-accredited assessment authority, which authorises their competence to handle refrigerants safely in accordance with an

industry recognised assessment specification.

es (for

English

Checking for presence of refrigerant

•

The area shall be checked with an appropriate refrigerant detector prior to and during work, to ensure the technician is aware of

potentially flammable atmospheres. Ensure that the leak detection equipment being used is suitable for use with flammable refrigerants,

i.e. nonsparking, adequately sealed or intrinsically safe.

Presence of fire extinguisher

•

If any hot work is to be conducted on the refrigeration equipment or any associated parts, appropriate fire extinguishing equipment

shall be available to hand. Have a dry powder or CO2 fire extinguisher adjacent to the charging area.

No ignition sources

•

All possible ignition sources, including cigarette smoking, should be kept sufficiently far away from the site of installation, repairing,

removing and disposal, during which flammable refrigerant can possibly be released to the surrounding space. “No Smoking” signs

shall be displayed.

The following checks shall be applied to installations:

•

marking to the equipment continues to be visible and legible. Markings and signs that are illegible shall be corrected;

–

refrigeration pipe or components are installed in a position where they are unlikely to be exposed to any substance which may

–

corrode refrigerant containing components, unless the components are constructed of materials which are inherently resistant

to being corroded or are suitably protected against being so corroded.

1-13

Initial safety checks shall include:

•

that capacitors are discharged, this shall be done in a safe manner to avoid possibility of sparking

–

there shall be no live electrical components and wiring are exposed while charging, recovering or purging the system;

–

Repair to intrinsically safe components

•

Do not apply any permanent inductive or capacitance loads to the circuit without ensuring that this will not exceed the permissible

voltage and current permitted for the equipment in use.

Replace components only with parts specified by the manufacturer.

•

Leak detection methods

Ensure that the detector is not a potential source of ignition (for example a halide torch) and is suitable for the refrigerant

used. Leak detection equipment shall be set at a percentage of the LFL of the refrigerant (for R32, LFL is 13%) and shall be

calibrated to the refrigerant employed and the appropriate percentage of gas (25 % maximum) is confirmed.

Leak detection fluids are suitable for use with most refrigerants but the use of detergents containing chlorine shall be avoided

as the chlorine may react with the refrigerant and corrode the copper pipe-work. If a leak is suspected, all naked flames shall

be removed/extinguished. If a leakage of refrigerant is found which requires brazing, all of the refrigerant shall be recovered

from the system, or isolated (by means of shut off valves) in a part of the system remote from the leak. Oxygen free nitrogen

(OFN) shall then be purged through the system both before and during the brazing process.

•

Removal and evacuation

When breaking into the refrigerant circuit to make repairs – or for any other purpose – conventional procedures shall be used.

However, it is important that best practice is followed since flammability is a consideration. The following procedure shall

be adhered to:

remove refrigerant;

•

purge the circuit with inert gas;

•

evacuate;

•

purge again with inert gas;

•

open the circuit by cutting or brazing.

•

The refrigerant charge shall be recovered into the correct recovery cylinders. The system shall be “flushed” with OFN to render

the unit safe. This process may need to be repeated several times. Compressed air or oxygen shall not be used for this task.

Flushing shall be achieved by breaking the vacuum in the system with OFN and continuing to fill until the working pressure is

achieved, then venting to atmosphere, and finally pulling down to a vacuum. This process shall be repeated until no refrigerant

is within the system. When the final OFN charge is used, the system shall be vented down to atmospheric pressure to enable

work to take place. This operation is absolutely vital if brazing operations on the pipe-work are to take place. Ensure that the

outlet for the vacuum pump is not close to any ignition sources and there is ventilation available.

Labelling

•

This unit shall be labelled ‘de-commissioned and emptied of refrigerant’. This label shall be dated and signed. Ensure that

there are labels on the equipment stating the equipment contains flammable refrigerant.

1-14

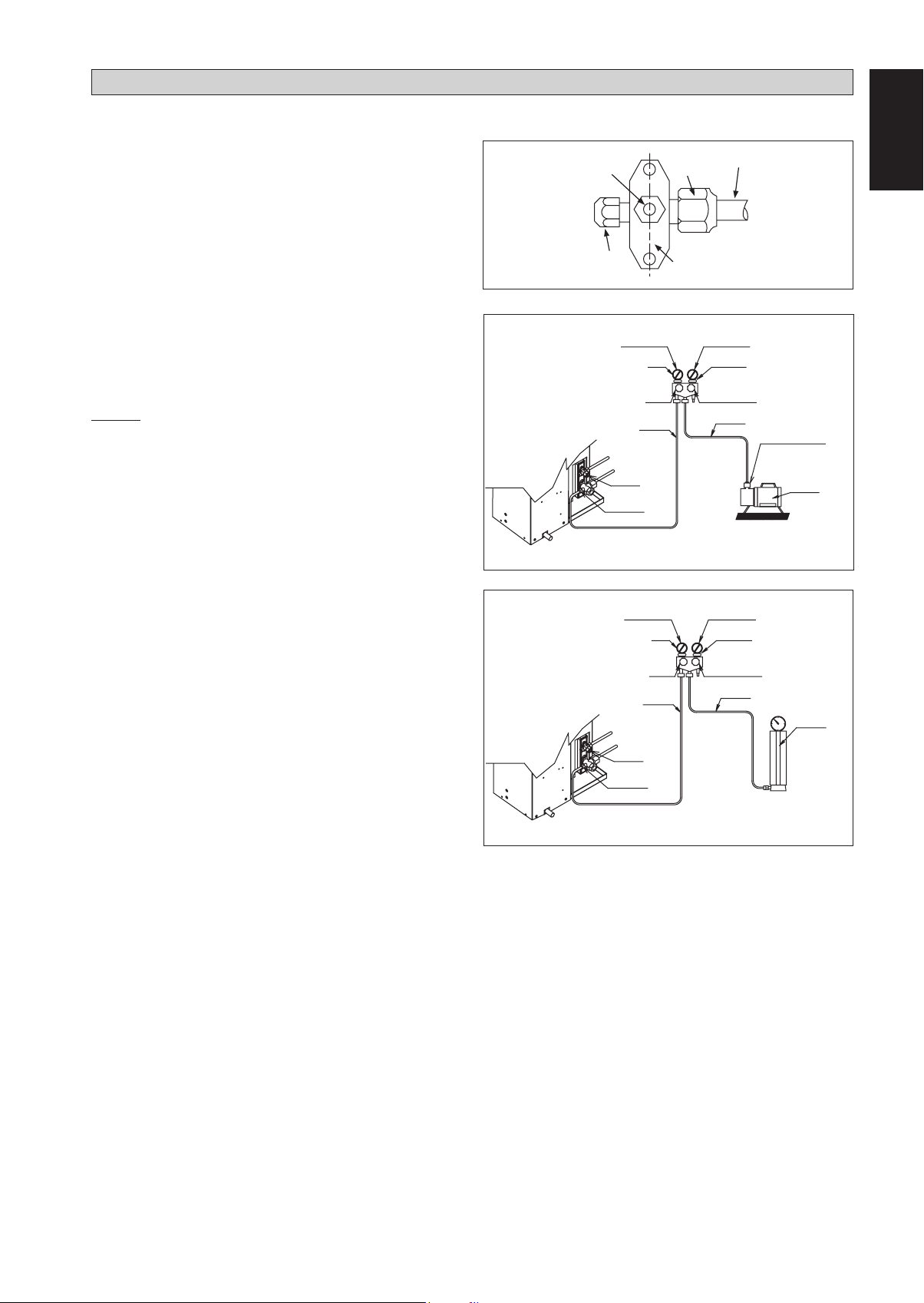

VACUUMING AND CHARGING

Vacuuming is necessary to eliminate all moisture and air from the system.

Vacuuming The Piping And The Indoor Unit

Except for the outdoor unit which is pre-charged with

refrigerant, the indoor unit and the refrigerant connection

pipes must be air-purged because the air containing moisture

that remains in the refrigerant cycle may cause malfunction

of the compressor.

Remove the caps from the valve and the service port.

•

Connect the center of the charging gauge to the vacuum

•

pump.

Connect the charging gauge to the service port of the 3-way

•

valve.

Start the vacuum pump. Evacuate for approximately 30

•

minutes. The evacuation time varies with different vacuum

pump capacity. Confirm that the charging gauge needle has

moved towards -760mmHg.

Caution

If the gauge needle does not move to -760mmHg, be sure

•

to check for leakage at flare type connection of the indoor

and outdoor unit and repair the leak before proceeding to

the next step.

Close the valve of the changing gauge and stop the vacuum

•

pump.

On the outdoor unit, open the suction valve (3 way) and

•

liquid valve (2 way) (in anti-clockwise direction) with 4mm

key for hexagon sacked screw.

Allen key

Service Port

LOW PRESSURE GAUGE

-760mmHg

HANDLE LO

CHARGE HOSE

LIQUID VALVE

GAS VALVE

(3-WAY)

Flare nut

Outdoor Unit 3 ways valve

Refrigerant Piping

HIGH PRESSURE GAUGE

GAUGE MANIFOLD

HANDLE HI (ALWAYS CLOSED)

CHARGE HOSE

VACUUM PUMP

ADAPTER FOR

COUNTER FLOW

PREVENTION

CHECK VALVE

CONFIGURATION OF AIR

PURGE BY CHARGING

English

Charge Operation

This operation must be done by using a gas cylinder and a

precise weighing machine. The additional charge is topped-up

into the outdoor unit using the suction valve via the service

port.

Remove the service port cap.

•

Connect the low pressure side of the charging gauge to the

•

suction service port center of the cylinder tank and close

the high pressure side of the gauge. Purge the air from the

service hose.

Start the air conditioner unit.

•

Open the gas cylinder and low pressure charging valve.

•

When the required refrigerant quantity is pumped into

•

the unit, close the low pressure side and the gas cylinder

valve.

Disconnect the service hose from service port. Put back

•

the service port cap.

LOW PRESSURE GAUGE

-760mmHg

HANDLE LO

CHARGE HOSE

LIQUID VALVE

GAS VALVE

(3-WAY)

HIGH PRESSURE GAUGE

GAUGE MANIFOLD

HANDLE HI (ALWAYS CLOSED)

CHARGE HOSE

CHECK VALVE

CONFIGURATION OF AIR

PURGE BY CHARGING

1-15

ADDITIONAL CHARGE

The refrigerant is pre-charged in the outdoor unit. If the piping length is less than 7.5m, then additional charge after vacuuming

is not necessary. If the piping length is more than 7.5m, then use the additional charge value as indicated in the table.

Additional refrigerant charge [g] per additional 1m length as tabulated

Model

Indoor (FTXC) 25 35 50 60

Outdoor (RXC) 25 35 50 60

Additional charge [g/m] 17 17 17 17

Example:

FTXC25 & RXC25 with 12m piping length, additional piping length is 4.5m. Thus,

Additional charge = 4.5[m] x 17[g/m]

= 76.5[g]

INDICATOR LIGHTS

IR Signal Receiver

When an infrared remote control operating signal has been

transmitted, the signal receiver on the indoor unit will respond

as below to confirm acceptance of the signal transmission.

ON to OFF 1 Long Beep

OFF to ON

Pump down / Cool force on

Others 1 Short Beep

Cooling Unit/Heat Pump Unit

The table shows the LED indicator lights for the air conditioner

unit under normal operation and fault conditions. The LED

indicator lights are located at the side of the air conditioner

unit.

The heat pump units are equipped with an “auto” mode

sensor whereby it will provide reasonable room temperature

by switching automatically to either “cool” or “heat” mode

according to the temperature set by the user.

2 Short Beep

IR Receiver

LED Indicator Lights for Cooling Unit/Heat Pump

Unit

IR Receiver

Cool/Heat

Timer

Sleep

ON/OFF

ON/OFF switch

LED Indicator Lights: Normal Operation And Fault Conditions For Cooling/Heat Pump Unit

Operation

Cool mode

Heat mode

Auto mode in Heating operation

Auto mode in Cooling operation

Timer on

Sleep mode on

Fan mode on

Dry mode on

Defrost operation

Unit error

ON

COOL/HEAT

(BLUE/RED)

BLUE

RED

RED

BLUE

BLUE

BLUE

RED

BLUE

Blinking

1-16

Heat Pump Model

OPERATING RANGE

Model: FTXC 25/35 RXC 25/35

COOLING HEATING

50

46

43

40

30

20

10

OUTDOOR TEMP (˚CDB)

0

INDOOR TEMP (˚CWB)

Model: FTXC 50/60 RXC 50/60

50

46

43

40

30

20

10

COOLING HEATING

252314 15 19 2010

DB: Dry bulb WB: Wet bulb

20

18

10

0

-10

-15

OUTDOOR TEMP (˚CWB)

-20

20

18

10

0

English

2015 03725201

INDOOR TEMP (˚CDB)

0

-10

OUTDOOR TEMP (˚CDB)

-20

10 14 15 19 20 23 25

INDOOR TEMP (˚CWB)

-10

-15

OUTDOOR TEMP (˚CWB)

-20

DB: Dry bulb WB: Wet bulb

2015 03725201

INDOOR TEMP (˚CDB)

1-17

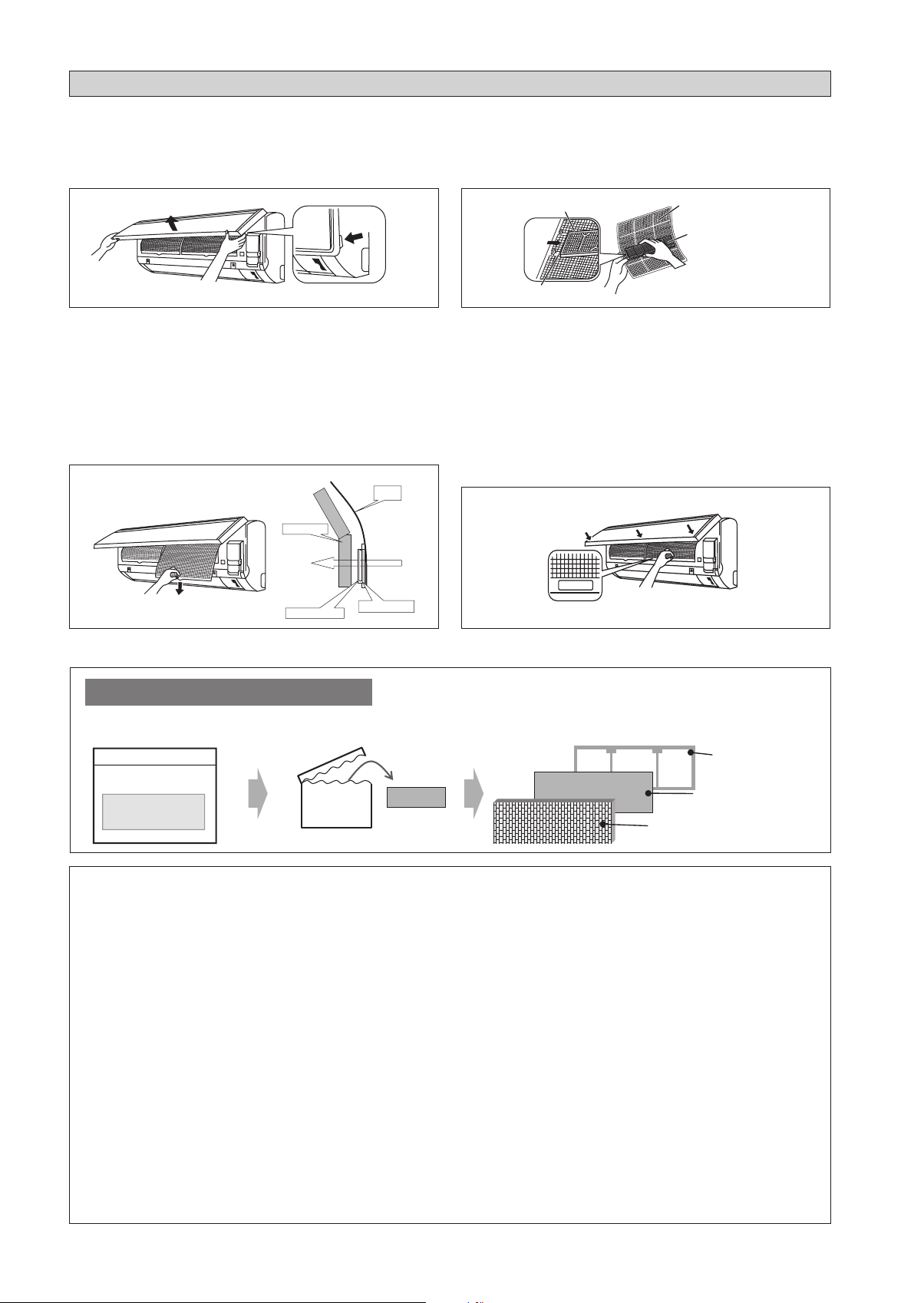

AIR FILTER

1. Open the front panel.

• Hold the panel at the recesses on the main unit

(2 recesses on right and left sides) and lift it until it

stops.

Recess on

main unit

2. Pull out the air filters.

• Push a little upwards the tab at the center of each air

filter, then pull it down.

3. Take off the Bio filter with bacteriostatic,

virustatic functions.

• Hold the recessed parts of the frame and unhook the

four claws.

Titanium Apatite Filter (Bio Filter)

Attached Concept

Heat exchanger

Air Filter

4. Clean or replace each filter.

See figure.

• When shaking off remaining water, do not wring the

filter.

Filter frame

Tab

Air filter

Bio filter with

bacteriostatic,

virustatic functions

5. Set the air filter and Bio filter with bacteriostatic,

virustatic functions as they were and close the

front panel.

• Insert claws of the filters into slots of the front panel.

Close the front panel slowly and push the panel at the

3 points. (1 on each side and 1 in the middle.)

• The air filter and Bio filter with bacteriostatic,

virustatic functions have a symmetrical form in the

horizontal direction.

FRONT

Bio Filter attached part

Titanium Apatite Filter

* Bio Filter and Titanium Apatite Filter are optional accessories.

Installation Procedure for Bio Filter

Bio Filter packs in a

hermetically-sealed bag.

Take it out

at the time of installation.

Slip the Filter in between Filter frame and

Titanium Apatite Filter.

Filter frame

Bio Filter

Titanium Apatite Filter

! CAUTION

• Please use this Bio Filter during dry season such as winter.

• Storage, handling and disposal methods.

• The lifetime of this Bio Filter is about a year after opening.

• In case you do not use this Bio Filter right away, please don’t place the Bio Filter in any place where it will be

subjected to direct sunlight, high temperatures and/or high humidity.

• There can be slight differences between Bio Filter color because of the manufacturing reasons, there is no effect

on the unit performance.

• Please open this bag right before you use it. Bio Filter should remain unopened and sealed in its packaging until

right before usage. (It may cause performance deterioration or quality change.)

• To avoid danger of suffocation and any unexpected accident, please dispose the plastic bag immediately after you

remove the Bio Filter. Keep out of reach of babies and children.

• If you keep this Bio Filter for a long time, please keep it unopened and store in a cool place avoiding direct

sunlight.

• Please dispose the old Bio Filter as nonflammable garbage after use.

• Operation with dirty filters:

(1) cannot deodorize the air. (3) results in poor heating or cooling.

(2) cannot clean the air. (4) may cause odour.

• To order Bio Filter, contact the service shop where you bought the air conditioner.

1-18

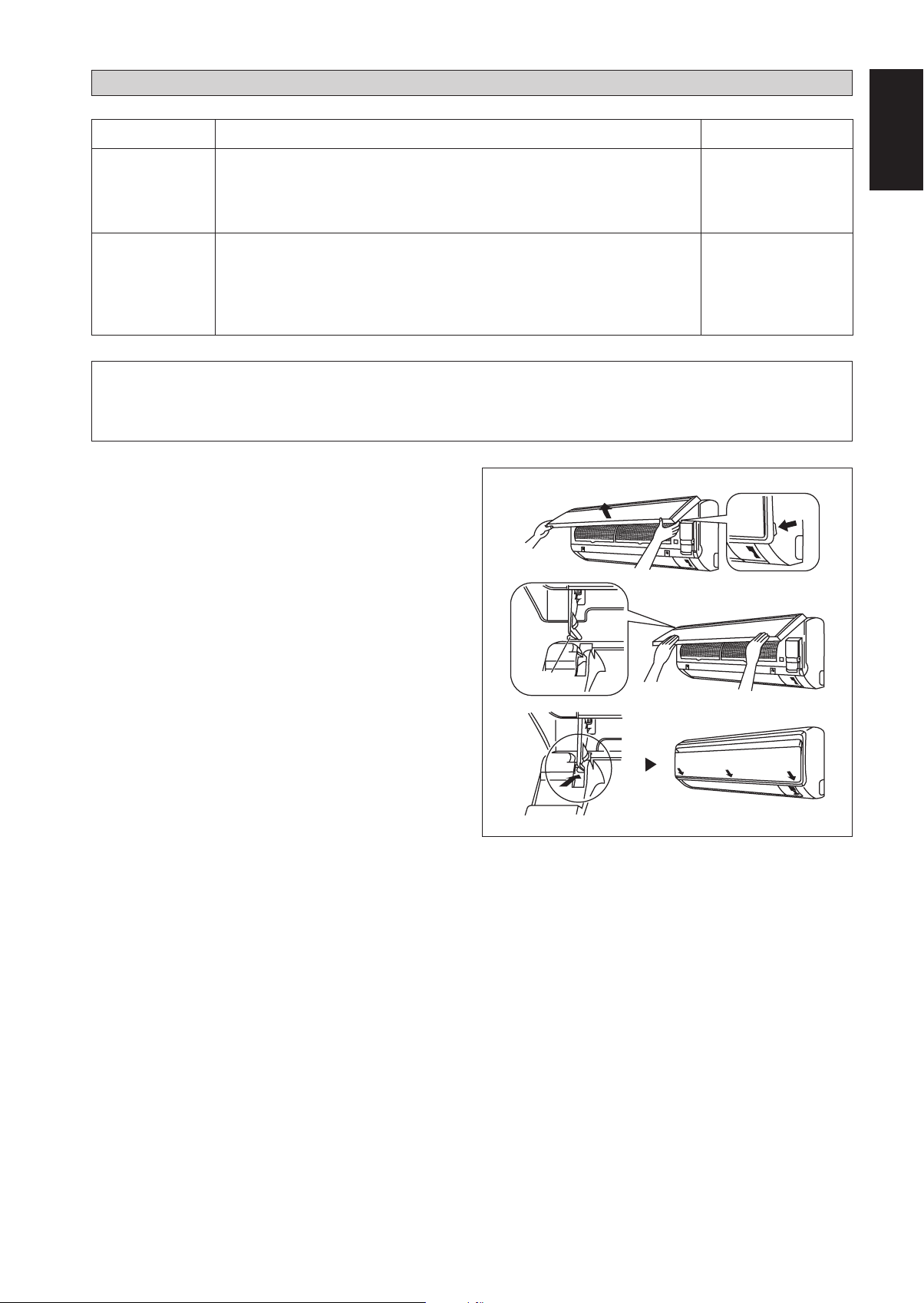

SERVICE AND MAINTENANCE

Service Parts Maintenance Procedures Period

Indoor air filter Remove any dust adhering to the filter by using a vacuum cleaner or wash

1.

in lukewarm water (below 40°C/104°F) with a neutral cleaning detergent.

Rinse the filter well and dry before placing it back onto the unit.

2.

Do not use gasoline, volatile substances or chemicals to clean the filter.

3.

At least once every

2 weeks.

More frequently if

necessary.

English

Indoor unit Clean any dirt or dust on the grille or panel by wiping it with a soft cloth

1.

soaked in lukewarm water (below 40°C/104°F) and a neutral detergent

solution.

Do not use gasoline, volatile substances or chemicals to clean the indoor

2.

unit.

At least once every

2 weeks.

More frequently if

necessary.

! CAUTION

• Avoid direct contact of any coil treatment cleaners on plastic part. This may cause plastic part to deform as a result

of chemical reaction.

Open the front panel.

1.

Hold the panel at the recesses on the main unit

•

(2 recesses on right and left sides) and lift it until it

stops.

Remove the front panel.

2.

While lifting the front panel further, slide it to the right

•

and pull it to the front side. The left rotating shaft is

detached. Slide the right rotating shaft to the left and

pull it to the front side to remove it.

Attach the front panel.

3.

Align the right and left rotating shafts of the front panel

•

with the grooves and push them all the way in.

Gently close the front panel. (Push both ends and the

•

center on the front panel.)

Rotating

shaft

Recess on

main unit

1-19

! CAUTION

•

Don’t touch the metal parts of the indoor unit. It may cause an injury.

•

When removing or attaching the front panel, support the panel securely with hand to prevent it from falling.

For cleaning, do not use hot water above 40°C, benzine, gasoline, thinner, nor other volatile oils, polishing

•

compound, scrubbing brushes, nor other hand stuff.

After cleaning, make sure that the front panel is securely fixed.

•

When The Unit Is Not To Be Used For An Extended Long Period Of Time

Operate the unit for 2 hours with

the following setting.

Operating mode : cool

Temperature : 30°C/86°F

Remove the power plug.

If you are using an

independent electric

circuit for your unit, cut

off the circuit.

Remove the batteries in

the remote control.

TROUBLESHOOTING

For any enquiries on spare part, please contact your authorized dealer. When any malfunction of the air

conditioner unit is noted, immediately switch off the power supply to the unit. Check the following fault

conditions and causes for some simple troubleshooting tips.

Fault Causes / Action

The compressor does not operate 3 minutes after the air

1. Protection against frequent starting. Wait for 3 to 4 minutes

conditioner unit is started.

The air conditioner unit does not operate.2. Power failure, or the fuse needs to be replaced.

–

for the compressor to start operating.

–

The power plug is disconnected.

–

It is possible that your delay timer has been set

–

incorrectly.

If the fault persist after all these verifications, please

–

contact the air conditioner unit installer.

The air flow is too low.3. The air filter is dirty.

Discharge air flow has bad odour.4. Odours may be caused by cigarettes, smoke particles,

Condensation on the front air grille of the indoor unit.5. This is caused by air humidity after an extended long

Water flowing out from the air conditioner unit.6. Switch off unit and call dealer.–

–

The doors or windows are open.

–

The air suction and discharge are clogged.

–

The regulated temperature is not high enough.

–

–

perfume etc. which might have adhered onto the coil.

–

period of operation.

The set temperature is too low, increase the temperature

–

setting and operate the unit at high fan speed.

If the fault persists, please call your local dealer / serviceman.

1-20

DISEGNI E DIMENSIONIS

Unità Interna [FTXC]

IL SEGNO MOSTRA LA DIREZIONE DEI TUBI

DIETRO DIETRO DESTRASINISTRA

Italiano

VISTA DALL’ALTO

A

IN BASSO IN BASSO

FERITOIA DI

AERAZIONE

VITI INSERITE NELLA

GRIGLIA FRONTALE

(ALL’INTERNO)

VISTA FRONTALE

B

RICEVITORE DI

SEGNALE

GERÄT FÜR IM HAUS

AN/ AUS-SCHALTER

TEMPERATURA

AMBIENTE TERMOSTATO

(ALL'INTERNO)

C

VISTA LATERALE

N. DI SERIE

ADESIVO

MORSETTIERA

CONTERMINALE A

TERRA

Traduzione delle istruzioni originali

2-1

Unità Interna [FTXC]

D

« Punti di ritenzione raccomandati per la piastra di montaggio

(5 punti in tutto)

E

F

B

G

JH

ML

A

Estremità del tubo del gasEstremità del tubo del liquido

F

Foro nel muro di Ø 65mm

G

Posizione del tubo di scarico

IK

Tutte le dimensioni sono in mm

Dimensioni

Modello

ABCDE FGHI JKLM

25/35 859 288 209 104 141 30 46 55 56 153 181 207 52

Unità Interna [FTXC]

« Punti di ritenzione raccomandati per la piastra di montaggio

(7 punti in tutto)

D

F

B

G

H

Estremità del tubo del liquido

J

L

Estremità del tubo del gas

M

A

E

F

Foro nel muro di Ø 65mm

G

K

I

Posizione del tubo

di scarico

Tutte le dimensioni sono in mm

Dimensioni

Modello

ABCDE FGHI JKLM

50/60 1124 310 237 190 173 61 40 45 48 91 219 580 45

2-2

Unità Esterna [RXC]

Modello

Dimensioni

EF

2,0

J

G

A

HI

N

Q

B

CD

ABCDE FGHI JKLMNOPQ

Tutte le dimensioni sono in mm

OP

KL

M

25/35 550 658 51 11 273 16 14 470 96 93 94 60 14 133 8 10 299

Unità Esterna [RXC]

Italiano

3,0

KLL

N

M

Q

A

O

V

B

P

D

U

N

S

R

Tutte le dimensioni sono in mm

C

T

GH

I

J

F

E

Dimensioni

Modello

ABCDE FGHI JKLMNO

50 855 628 328 520 179 46 93 149 101 113 603 126 164 15 34

60 855 730 328 520 179 46 93 149 101 113 603 126 164 15 34

Dimensioni

Modello

PQRS TUV

50 23 362 73 75 8 67 7

60 23 362 73 75 8 67 7

2-3

MANUALE D’INSTALLAZIONE

Il presente manuale descrive come procedere all’installazione del condizionatore per assicurarne il corretto funzionamento in condizioni di sicurezza.

Degli adattamenti possono rivelarsi necessari per rispondere a particolari esigenze locali.

Prima di utilizzare il condizionatore, leggere attentamente le presenti istruzioni. Conservarle per ogni evenienza futura.

Questo apparecchio è destinato all’uso da parte di persone esperte o formate in negozi, nell’industria leggera o in aziende agricola o all’uso commerciale

da parte di persone non addette.

Il presente apparecchio non è destinato all’uso da parte di persone, inclusi bambini, con ridotte capacità fisiche, sensoriali o mentali, o senza la dovuta

esperienza e conoscenza, a meno che non vengano poste sotto la supervisione di una persona responsabile della loro sicurezza o che tale persona fornisca

loro le istruzioni per l’uso dell’apparecchio.

Tenere i bambini sotto la supervisione di un adulto per evitare che giochino con l’apparecchio.

NORME DI SICUREZZA

! AVVERTENZA ! CAUTELA

L’installazione e la manutenzione devono essere eseguite da personale

•

qualificato, competente in questo genere di apparecchi e al corrente delle

leggi e regolamenti in vigore.

Tutti gli allacciamenti elettrici devono essere eseguiti conformemente alla

•

regolamentazione elettrica in vigore.

Prima di procedere agli allacciamenti secondo lo schema elettrico presentato

•

più avanti, accertarsi che il voltaggio dell’apparecchio corrisponda a quello

della rete.

Dotare il condizionatore di una presa di TERRA al fine di prevenire i rischi

•

originati da eventuali deficienze del sistema di isolamento.

I fili elettrici non devono toccare né i condotti dell’acqua, né gli organi

•

rotanti dei motori del ventilatore.

Prima di installare il condizionatore o di procedere ad interventi di

•

manutenzione, accertarsi che sia spento (OFF).

Togliete sempre la corrente prima di effettuare la manutenzione del

•

condizionatore.

NON rimuovere il cavo di alimentazione quando il condizionatore è acceso.

•

Questo può causare seri shock elettrici e pericolo d’incendio.

Mantenere l’unità interna e quella esterna, il cavo di alimentazione e il

•

cablaggio di trasmissione ad almeno 1m di distanza da TV e radio, per

evitare immagini distorte e scariche statiche. {A seconda del tipo e sorgente

di onde elettriche, si possono sentire scariche statiche anche a più di 1m

di distanza}.

AVVERTENZA

Non utilizzare mezzi per accelerare il processo di sbrinamento (ove applicabile)

o per la pulizia diversi da quelli consigliati dal produttore. L’apparecchio deve

essere conservato in un ambiente privo di fonti di combustione in funzionamento

continuo (ad esempio fiamme libere, apparecchi a gas in funzione o riscaldatori

elettrici in funzionamento). Non perforare né bruciare. I refrigeranti potrebbero

non contenere odore. L’apparecchio deve essere installato, azionato e conservato

in un ambiente con un’area del pavimento superiore a Xm

pagina 13).

NOTA: Il produttore può fornire altri esempi adeguati o ulteriori informazioni

sull’odore del refrigerante.

2

(riferirsi alla

Durante l’installazione, verificare accuratamente i punti seguenti.

Non procedere all’installazione in luoghi dove possano verificarsi fughe

•

di gas.

Pericolo d’incendio in caso di fughe o di concentrazioni di gas intorno

al condizionatore.

Verificare che i condotti di drenaggio siano stati correttamente

•

installati.

Un’installazione incorretta può causare delle perdite d’acqua e

danneggiare il mobilio.

•

Non sovraccaricare il condizionatore.

L’apparecchio è precaricato in fabbrica.

Qualsiasi sovraccarico provoca una sovracorrente e può danneggiare

•

Una difettosa chiusura del pannello è causa di rumori durante il

•

•

•

•

•

•

•

•

•

•

•

il compressore.

Dopo l’installazione o gli interventi di manutenzione accertarsi di

rimettere a posto il pannello di chiusura.

funzionamento.

I bordi affilati e le superfici della serpentina sono possibili aree che

possono causare pericolo di lesioni. Evitare di entrare in contatto con

tali aree.

Prima di spegnere l’apparecchio, impostare l’interruttore ON/OFF

del telecomando sulla posizione “OFF” in modo da evitare l’apertura

nociva dell’unità. In caso contrario, le ventole dell’unità iniziano a ruotare

automaticamente quando si riaccende l’apparecchio, causando pericoli di

lesioni al personale di servizio ed agli utenti.

Non installare le unità sul vano della porta o nelle sue vicinanze.

Non mettere in funzione apparecchi per il riscaldamento troppo vicini

al condizionatore d’aria o non utilizzare l’unità in un ambiente in cui

sono presenti olio minerale o vapori da olio, ciò potrebbe provocare la

fusione o la deformazione della plastica a seguito del calore eccessivo o

di una reazione chimica.

Quando l’unità è utilizzata in cucina, tenere la farina lontana in modo

da evitare che l’unità la aspiri.

Questa unità non è idonea all’utilizzo in stabilimenti dove sono presenti

nebbie di olio da taglio o polveri metalliche o dove c’è una forte

oscillazione di tensione.

Non installare le unità in aree quali le sorgenti calde o le raffinerie

petrolifere in cui è presente gas solforoso.

Accertarsi che i colori dei fili dell’unità esterna corrispondano ai

contrassegni dei morsetti dell’unità interna.

IMPORTANTE: NON INSTALLARE O UTILIZZARE IL

CONDIZIONATORE D’ARIA IN UNA ZONA LAVANDERIA.

Non usare fili congiunti e intrecciati per l’alimentazione in ingresso.

L’apparecchio non è destinato all’uso in un ambiente potenzialmente

esplosivo.

Specifiche di smaltimento

AVVISO

Il climatizzatore è contrassegnato con questo simbolo, Ciò significa che i prodotti elettrici ed elettronici non possono essere smaltiti insieme ai rifiuti

domestici non differenziati.

Non cercare di demolire il sistema da soli: la demolizione del sistema di condizionamento, nonché il recupero del refrigerante, dell’olio e di qualsiasi

altra parte devono essere eseguiti da un installatore qualificato in conformità alla legislazione locale e nazionale vigente in materia.

I climatizzatori devono essere trattati presso una struttura specializzata nel riutilizzo, riciclaggio e recupero dei materiali. Il corretto smaltimento del prodotto

eviterà le possibili conseguenze negative all’ambiente e alla salute dell’uomo. Per maggiori informazioni contattare l’installatore o le autorità locali.

Le batterie devono essere tolte dal telecomando e smaltite separatamente conformemente alla legislazione locale e nazionale vigente in materia.

2-4

IMPORTANTE

Informazioni importanti sul refrigerante utilizzato

Questo prodotto contiene gas fluorurati ad effetto serra.

Non liberare tali gas nell’atmosfera.

Tipo di refrigerante: R32

Valore GWP

(1)

GWP = Global Warming Potential (Potenziale Di Riscaldamento Globale)

Compilare con inchiostro indelebile,

1

1 la carica di refrigerante di fabbrica del prodotto,

¢

2 la quantità di refrigerante aggiuntiva nel campo e

¢

1 + 2 la carica di refrigerante totale

¢

sull’etichetta di carica del refrigerante fornita con il prodotto.

L’etichetta compilata deve essere collocata in prossimità della porta di carica del prodotto (ad esempio, all’interno del coperchio

di ispezione).

(1)

: 675

Contains fluorinated greenhouse gases

=

R32

GWP: 675

2

1

=

2

1

1

2

+

=

GWP × kg

=

1000

kg

kg

kg

tCO2eq

Italiano

Carica di refrigerante effettuata allo stabilimento: vedere la targa dati dell'unità

a

Quantità di refrigerante aggiuntiva caricata

b

Carica totale di refrigerante

c

Emissioni di gas a effetto serra della carica totale di refrigerante espressa in tonnellate di CO2 equivalente

d

GWP = potenziale di riscaldamento globale

e

NOTA

In Europa, si usano le emissioni di gas a effetto serra della carica totale di refrigerante nel sistema (espressa in

tonnellate di CO2 equivalente) per determinare gli intervalli di manutenzione. Seguire la legislazione vigente.

Formula per calcolare le emissioni di gas a effetto serra:

valore GWP del refrigerante × carica totale di refrigerante [in kg] / 1000

Applicare l'etichetta all'interno dell'unità esterna. È disponibile una posizione dedicata all'etichetta dello

2

schema dell'impianto elettrico.

2-5

DIAGRAMMA PER L’INSTALLAZIONE

Unità Interna

Pannello anteriore

50mm o più dalle pareti

(su entrambi i lati)

Filtro depuratore dell’aria

fotocatalitico di apatite e titanio (2)

Filtro depuratore dell’aria

fotocatalitico di apatite e titanio

Telaio del filtro

Linguetta

Filtro aria

M4 x 12L

Filtro aria

75mm o più dal soffitto

Sportellino di manutenzione

Apertura del coperchio di servizio

¢

Il coperchio di servizio può essere

aperto/chiuso.

Metodo di apertura

¢

1) Rimuovere le viti del coperchio

di servizio.

2) Estrarre il coperchio di accesso

per assistenza tecnica spostandolo

verso il basso e in diagonale, nella

direzione della freccia.

3) Tirare verso il basso.

Stuccare lo

spazio del foro

del tubocon

stucco da legno.

500mm dalla parete

Tagliare il tubo di isolamento termico a

una lunghezza appropriata e avvolgerlo

con nastro, accertandosi che non ci siano

buchi nella linea di taglio del tubo di

isolamento.

Avvolgere il tubo di isolamento

da cima a fondo con nastro di

finitura.

Unità Esterna

INSTALLAZIONE DELL’UNITÀ ESTERNA (25/35)

Se c’è una parete o un altro ostacolo nel percorso dell’ingresso dell’aria dell’unità esterna o nell’uscita dell’aria di scarico,

•

seguire le linee guida per l’installazione sotto.

Per i moduli di installazione di cui sotto, l’altezza della parete sul lato di scarico dovrebbe essere pari o inferiore a

•

1200mm.

Un lato rivolto alla parete

Oltre 50

1200 o

di meno

Vista laterale

Oltre 100

Due lati rivolti alla parete

Oltre 100

Oltre 50

Tre lati rivolti alla parete

Oltre 150

Oltre 50

Vista superiore

2-6

Oltre 50

Oltre 150

Oltre 300

Vista superiore

Unità: mm

Lavoro di drenaggio. (Solo Per Le Versioni In Pompa Di Calore)

Usare il maschio di spurgo per il drenaggio.

1)

Se la bocchetta di drenaggio è coperta da una base di montaggio o dal

2)

pavimento, posizionare ulteriori piedini ad almeno 30mm d’altezza sotto

le basi dell’unità esterna.

Nelle aree fredde, non usare un tubo flessibile di scarico con l’unità

3)

esterna. (Altrimenti, l’acqua di scarico potrebbe congelarsi, danneggiando

le prestazioni di riscaldamento.)

INSTALLAZIONE DELL’UNITÀ ESTERNA (50/60)

Foro acqua di drenaggio

Struttura in basso

Maschio di spurgo

Tubo flessibile (disponibile in commercio,

diam. interno 16mm)

Italiano

L’unità esterna deve essere installata in modo tale da prevenire

ostruzioni al normale deflusso dell’aria e che la circolazione

dell’aria di scarico sia la più ampia possibile. Rispettare,

nell’installazione le distanze di sicurezza sotto indicate.

Selezionare il luogo più freddo possibile in cui la temperatura

dell’aria immessa non sia superiore alla temperatura dell’aria

esterna (Fare riferimento alla gamma operativa).

Distanze di rispetto/sicurezza

Dimensioni

ABCD

Distanza minima, mm 300 1000 300 500

Nota: Se non vi è alcun ostacolo superiore alla metà, di altezza

dell’unità (H), permetta prego più spazio rispetto al dato indicato

in tabella.

Eliminazione Acqua Di Condensa Dell’Unità Esterna

(Solo Per Le Versioni In Pompa Di Calore)

Ci sono 2 fori alla base dell’unità esterna per garantire

•

la fuoriuscita dell’acqua. Inserire il raccordo a gomito in

uno del 2 fori.

Per installare il raccordo a gomito, effettuare le seguenti

•

operazioni: prima inserire una parte del raccordo all’interno

del foro (Parte A). Quindi tirare che tra la tubazione e la

base dell’unità ci sia una fondare saldamente. Assicorarsi

che tra la tubazione e la base dell’unità ci sia una perfetta

aderenza.

Se l’unità esterna è installata in amblenti rolto freddi,

•

l’acqua di condensa potrebbe gecare du’interno della base.

Per evitario, rimuovere il tappo presente nella base per

facilitare il deflusso dell’acqua.

Ostacolo

C

Ostacolo

Aria di ritorno

A

Aria Di Ritorno

B

H

Aria Di Scarico

H/2

Ostacolo

D

Ostacolo

Pannello Di Servizio

2-7

TAP PO

A

BASE

RACCORDO A GOMITO

RACCORDO A GOMITO

Rimuovere la

copertura laterale

per effettuare i

collegamenti elettrici e

frigoriferi

SPINGERE E TIRARE

VERSO L’ALTO

INSTALLAZIONE DELL’UNITÀ INTERNA

L’unità interna deve essere installata in modo tale da evitare

corto circuito l’aria fredda scaricata con l’aria calda di ritorno.

Si prega di seguire il gioco installazione mostrata in figura.

Installare l’unità interna in modo che non si trovi ad ess ere

direttamente esposta ai raggi del sole o in prossimità di porte

e finestre. Questa disposizione è la migliore anche per le

tubazioni e il sistema di drenaggio.

Flusso d’aria

(All’interno)

min. 75

(Spazio per le

prestazioni)

min. 50

(Spazio per la

manutenzione)

Spazio necessario

Tutte le dimensioni sono in mm

min. 50

(Spazio per la

manutenzione)

Le tubazioni del refrigerante possono essere collegate

in differenti modi (lato posteriore destro o sinistro)

utilizzando i fori predisposti sul rivestimento esterno.

Piegare accuratamente i tubi nel verso richiesto per condurli al

foro appropriato. Per far fuoriuscire il lato e la parte posteriore,

tenere il fondo del tubo e posizionarlo nella direzione richiesta.

Utilizzado del nastro adesivo, fissarve quindi insieme il tubo

di drenaggio.

Tubo laterale destro, posteriore destro o in basso a destra

Tubazione sul lato destro

Rimuovere il coperchio dell’attacco

del tubo in questo punto, in caso di

tubazione sul lato destro

Rimuovere il coperchio

dell’attacco del tubo in questo

punto, in caso di tubazione sul lato

destro inferiore

Tubazione sul

latodestro inferiore

Tubazione sul lato destro

posteriore

Legare insieme il tubo di

raffreddamento e il tubo

flessibile di scarico con

nastro isolante.

Tubo laterale sinistro, posteriore sinistro o in basso a

sinistra

Rimuovere il coperchio

dell’attacco del tubo in

questo punto, in caso di

tubazione sul lato sinistro

Tubazione sul lato

Rimuovere il coperchio dell’attacco

del tubo in questo punto, in caso di

tubazione sul lato sinistro inferiore

Tubazione sul lato sinistro inferiore

sinistro

Tubazione sul lato

sinistro posteriore

2-8

Loading...

Loading...