Daikin RY30PEV1K, RY42PEY1K, R24PEV1K, R36PEY1K, R42PEY1K Service Manual

...

SiK401004_A

Duct type

[Applied Models]

Non-Inverter Pair : Cooling Only

Non-Inverter Pair : Heat Pump

SiK401004_A

Non-Inverter Pair

Duct Type

1 INTRODUCTION....................................................................................... i

Part 1 SPECIFICATIONS............................................................1

1. MODELS LIST..........................................................................................2

1.1 Outdoor Unit.............................................................................................2

1.2 Indoor Unit................................................................................................3

2. NOMENCLATURE....................................................................................4

3. FUNCTION...............................................................................................5

4. PRODUCT DATA......................................................................................6

4.1 Product Data at Rated Condition..............................................................6

4.2 Electrical Data ........................................................................................27

5. PIPING DIAGRAM..................................................................................28

Part 2 FUNCTION CONTROL ...................................................... 29

1. OPERATION FLOWCHART...................................................................30

1.1 Cooling/Dry Operation............................................................................30

1.2 Heating Operation ..................................................................................31

2. MAIN LOGIC ..........................................................................................32

2.1 Cooling Mode .........................................................................................32

2.2 Dry Mode................................................................................................33

2.3 Heating Mode.........................................................................................34

2.4 Defrosting...............................................................................................35

2.5 Fan Mode ...............................................................................................36

3. WIRED REMOTE CONTROLLER..........................................................37

3.1 Displaying Part .......................................................................................38

3.2 Buttons...................................................................................................39

3.3 Installation of Wired Controller and Project Debugging..........................41

3.4 Instruction to Operation..........................................................................43

3.5 Error Display...........................................................................................56

3.6 Setting of Indoor Room Sensor and Checking of Outdoor Ambient

Temperature...........................................................................................57

Part 3 INSTALLATION ................................................................ 60

1. INDOOR UNIT INSTALLATION..............................................................61

1.1 Installation of Duct Type.........................................................................61

2. OUTDOOR UNIT INSTALLATION..........................................................69

2.1 Before Installation...................................................................................69

2.2 Installation Site.......................................................................................69

2.3 Cautions for Installation..........................................................................70

2.4 Dimension Data......................................................................................71

2.5 Installation Clearance Data ....................................................................72

3. REFRIGERATION PIPING WORK.........................................................73

3.1 Refrigeration Piping Work Procedures...................................................73

3.2 Caution in Connecting Pipes..................................................................78

SiK401004_A

3.3 Specification of Connection Pipe............................................................79

4. ELECTRIC WIRING WORK ...................................................................80

4.1 Wiring Principle ......................................................................................80

4.2 Electric Wiring Design............................................................................84

4.3 Specification of Power Supply Wire and Air Switch................................86

Part 4 MAINTENANCE ................................................................ 87

1. REMOTE CONTROLLER DISPLAY MALFUNCTION AND CONTENTS ..88

2. FLOW CHART OF TROUBLESHOOTING.............................................91

3 WIRING DIADRAM...............................................................................101

3.1 Wiring Diagram-Outdoor Units .............................................................101

3.2 Wiring Diagram-Indoor units.................................................................109

4. DISASSEMBLY AND ASSEMBLY PROCEDURE OF MAIN PARTS.... 110

4.1 Outdoor Unit.........................................................................................110

4.2 Indoor Unit............................................................................................119

SiK401004_A

INTRODUCTION i

1. INTRODUCTION

1.1 Safety Cautions

Cautions and

Warnings

Be sure to read the following safety cautions before conducting repair work.

The caution items are classified into “

Warning” and “ Caution”. The “ Warning”

items are especially important since they can lead to death or serious injury if they are not

followed closely. The “

Caution” items can also lead to serious accidents under some

conditions if they are not followed. Therefore, be sure to observe all the safety caution items

described below.

About the pictograms

This symbol indicates an item for which caution must be exercised.

The pictogram shows the item to which attention must be paid.

This symbol indicates a prohibited action.

The prohibited item or action is shown inside or near the symbol.

This symbol indicates an action that must be taken, or an instruction.

The instruction is shown inside or near the symbol.

After the repair work is complete, be sure to conduct a test operation to ensure that the

equipment operates normally, and explain the cautions for operating the product to the

customer

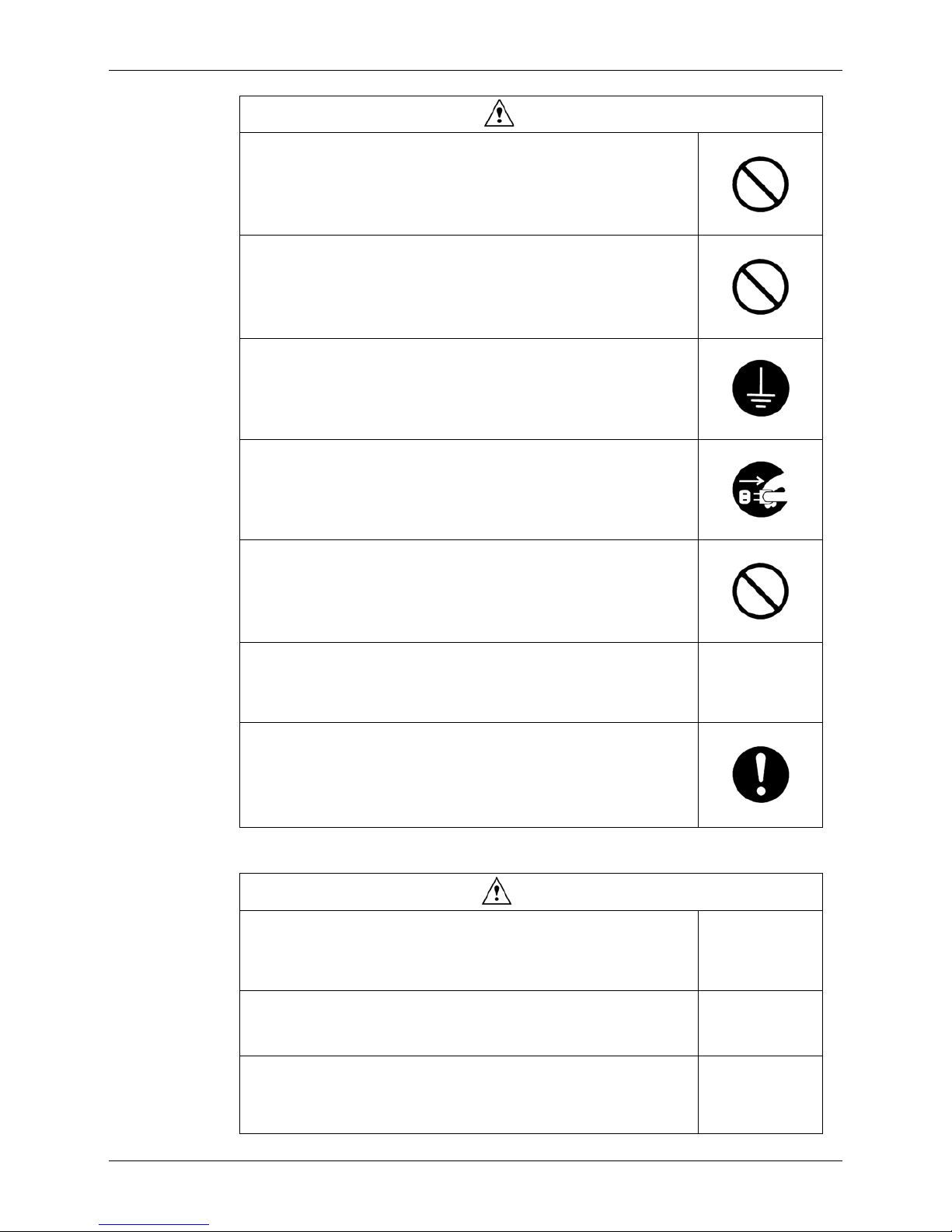

1.1.1 Caution in Repair

Warning

Be sure to disconnect the power cable plug from the plug socket before

disassembling the equipment for a repair.

Working on the equipment that is connected to a power supply can cause an

electrical shook.

If it is necessary to supply power to the equipment to conduct the repair or

inspecting the circuits, do not touch any electrically charged sections of the

equipment.

If the refrigerant gas discharges during the repair work, do not touch the

discharging refrigerant gas.

The refrigerant gas can cause frostbite.

When disconnecting the suction or discharge pipe of the compressor at the

welded section, release the refrigerant gas completely at a well-ventilated

place first.

If there is a gas remaining inside the compressor, the refrigerant gas or

refrigerating machine oil discharges when the pipe is disconnected, and it

can cause injury.

If the refrigerant gas leaks during the repair work, ventilate the area. The

refrigerant gas can generate toxic gases when it contacts flames.

The step-up capacitor supplies high-voltage electricity to the electrical

components of the outdoor unit.

Be sure to discharge the capacitor completely before conducting repair work.

A charged capacitor can cause an electrical shock.

Do not start or stop the air conditioner operation by plugging or unplugging

the power cable plug.

Plugging or unplugging the power cable plug to operate the equipment can

cause an electrical shock or fire.

SiK401004_A

ii INTRODUCTION

Caution

Do not repair the electrical components with wet hands.

Working on the equipment with wet hands can cause an electrical shock.

Do not clean the air conditioner by splashing water.

Washing the unit with water can cause an electrical shock.

Be sure to provide the grounding when repairing the equipment in a humid or

wet place, to avoid electrical shocks.

Be sure to turn off the power switch and unplug the power cable when

cleaning the equipment.

The internal fan rotates at a high speed, and cause injury.

Do not tilt the unit when removing it.

The water inside the unit can spill and wet the furniture and floor.

Be sure to check that the refrigerating cycle section has cooled down

sufficiently before conducting repair work.

Working on the unit when the refrigerating cycle section is hot can cause

burns.

Use the welder in a well-ventilated place.

Using the welder in an enclosed room can cause oxygen deficiency.

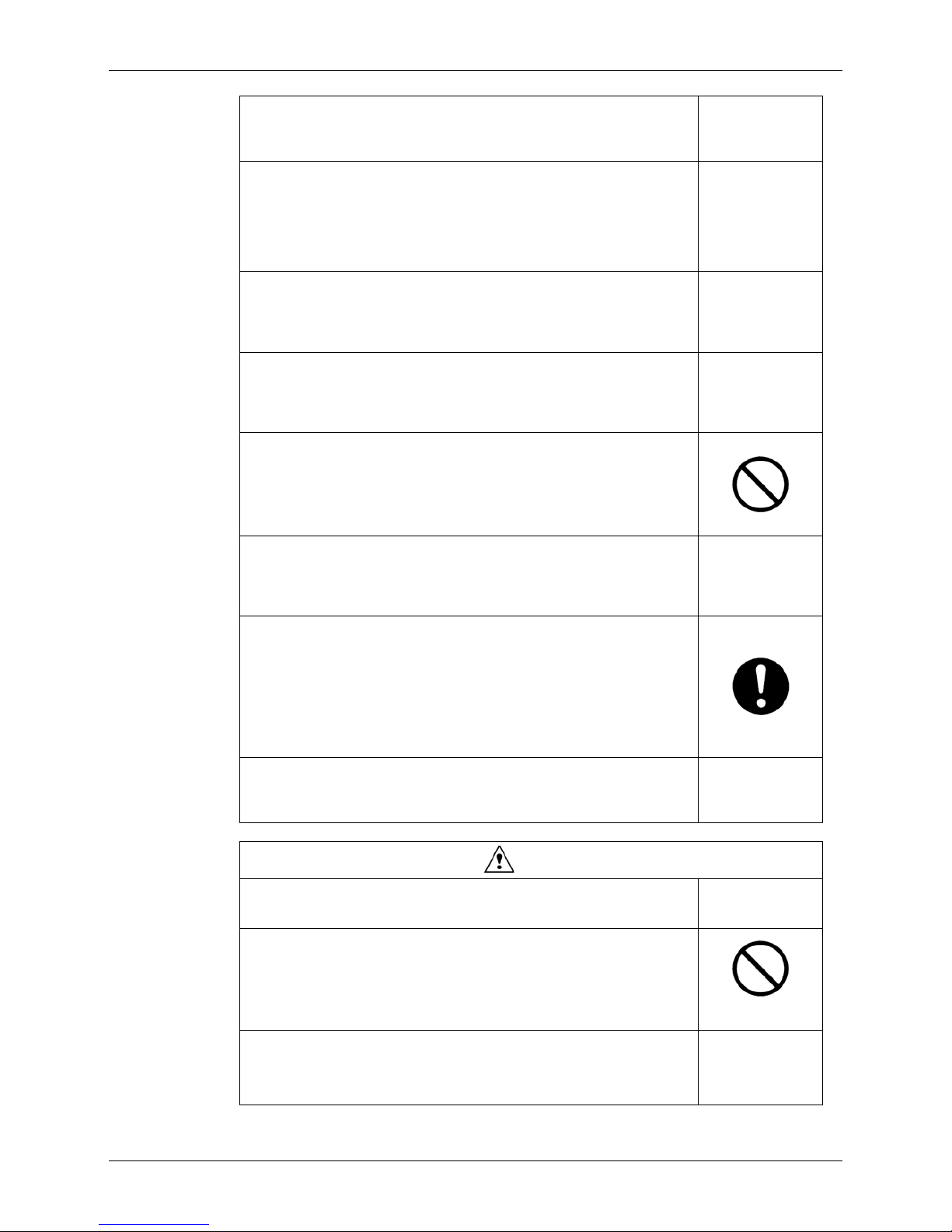

1.1.2 Cautions Regarding Products after Repair

Warning

Be sure to use parts listed in the service parts list of the applicable model and

appropriate tools to conduct repair work. Never attempt to modify the

equipment.

The use of inappropriate parts or tools can cause an electrical shock,

excessive heat generation or fire.

When relocating the equipment, make sure that the new installation site has

sufficient strength to withstand the weight of the equipment.

If the installation site does not have sufficient strength and if the installation

work is not conducted securely, the equipment can fall and cause injury.

Be sure to install the product correctly by using the provided standard

installation frame.

Incorrect use of the installation frame and improper installation can cause the

equipment to fall, resulting in injury.

For integral units

only

SiK401004_A

INTRODUCTION iii

Be sure to install the product securely in the installation frame mounted on a

window frame.

If the unit is not securely mounted, it can fall and cause injury.

For integral units

only

Be sure to use an exclusive power circuit for the equipment, and follow the

technical standards related to the electrical equipment, the internal wiring

regulations and the instruction manual for installation when conducting

electrical work.

Insufficient power circuit capacity and improper electrical work can cause an

electrical shock or fire.

Be sure to use the specified cable to connect between the indoor and

outdoor units. Make the connections securely and route the cable properly so

that there is no force pulling the cable at the connection terminals.

Improper connections can cause excessive heat generation or fire.

When connecting the cable between the indoor and outdoor units, make sure

that the terminal cover does not lift off or dismount because of the cable.

If the cover is not mounted properly, the terminal connection section can

cause an electrical shock, excessive heat generation or fire.

Do not damage or modify the power cable.

Damaged or modified power cable can cause an electrical shock or fire.

Placing heavy items on the power cable, and heating or pulling the power

cable can damage the cable.

Do not mix air or gas other than the specified refrigerant (R410A) in the

refrigerant system.

If air enters the refrigerating system, an excessively high pressure results,

causing equipment damage and injury.

If the refrigerant gas leaks, be sure to locate the leak and repair it before

charging the refrigerant. After charging refrigerant, make sure that there is no

refrigerant leak.

If the leak cannot be located and the repair work must be stopped, be sure to

perform pump-down and close the service valve, to prevent the refrigerant

gas from leaking into the room. The refrigerant gas itself is harmless, but it

can generate toxic gases when it contacts flames, such as fan and other

heaters, stoves and ranges.

When replacing the coin battery in the remote controller, be sure to disposed

of the old battery to prevent children from swallowing it.

If a child swallows the coin battery, see a doctor immediately.

Caution

Installation of a leakage breaker is necessary in some cases depending on

the conditions of the installation site, to prevent electrical shocks.

Do not install the equipment in a place where there is a possibility of

combustible gas leaks.

If a combustible gas leaks and remains around the unit, it can cause a fire.

Be sure to install the packing and seal on the installation frame properly.

If the packing and seal are not installed properly, water can enter the room

and wet the furniture and floor.

For integral units

only

SiK401004_A

iv INTRODUCTION

1.1.3 Inspection after Repair

Warning

Check to make sure that the power cable plug is not dirty or loose, then insert

the plug into a power outlet all the way.

If the plug has dust or loose connection, it can cause an electrical shock or

fire.

If the power cable and lead wires have scratches or deteriorated, be sure to

replace them.

Damaged cable and wires can cause an electrical shock, excessive heat

generation or fire.

Do not use a joined power cable or extension cable, or share the same

power outlet with other electrical appliances, since it can cause an electrical

shock, excessive heat generation or fire.

Caution

Check to see if the parts and wires are mounted and connected properly, and

if the connections at the soldered or crimped terminals are secure.

Improper installation and connections can cause excessive heat generation,

fire or an electrical shock.

If the installation platform or frame has corroded, replace it.

Corroded installation platform or frame can cause the unit to fall, resulting in

injury.

Check the grounding, and repair it if the equipment is not properly grounded.

Improper grounding can cause an electrical shock.

Be sure to measure the insulation resistance after the repair, and make sure

that the resistance is 1 Mohm or higher.

Faulty insulation can cause an electrical shock.

Be sure to check the drainage of the indoor unit after the repair.

Faulty drainage can cause the water to enter the room and wet the furniture

and floor.

1.1.4 Using Icons

Icons are used to attract the attention of the reader to specific information. The meaning of

each icon is described in the table below:

SiK401004_A

INTRODUCTION v

1.1.5 Using Icons List

Icon Type of

Information

Description

Note:

Note A “note” provides information that is not indispensable, but

may nevertheless be valuable to the reader, such as tips and

tricks.

Caution

Caution A “caution” is used when there is danger that the reader,

through incorrect manipulation, may damage equipment, loose

data, get an unexpected result or has to restart (part of) a

procedure.

Warning

Warning A “warning” is used when there is danger of personal injury.

Reference A “reference” guides the reader to other places in this binder or

in this manual, where he/she will find additional information on

a specific topic.

SiK401004_A

1 SPECIFICATIONS

Part1

SPECIFICATIONS

1. MODELS LIST .......................................................................................... 2

1.1 Outdoor Unit ............................................................................................. 2

1.2 Indoor Unit................................................................................................ 3

2. NOMENCLATURE.................................................................................... 4

3. FUNCTION ............................................................................................... 5

4. PRODUCT DATA ...................................................................................... 6

4.1 Product Data at Rated Condition.............................................................. 6

4.2 Electrical Data ........................................................................................ 27

5. PIPING DIAGRAM.................................................................................. 28

SiK401004_A

SPECIFICATIONS 2

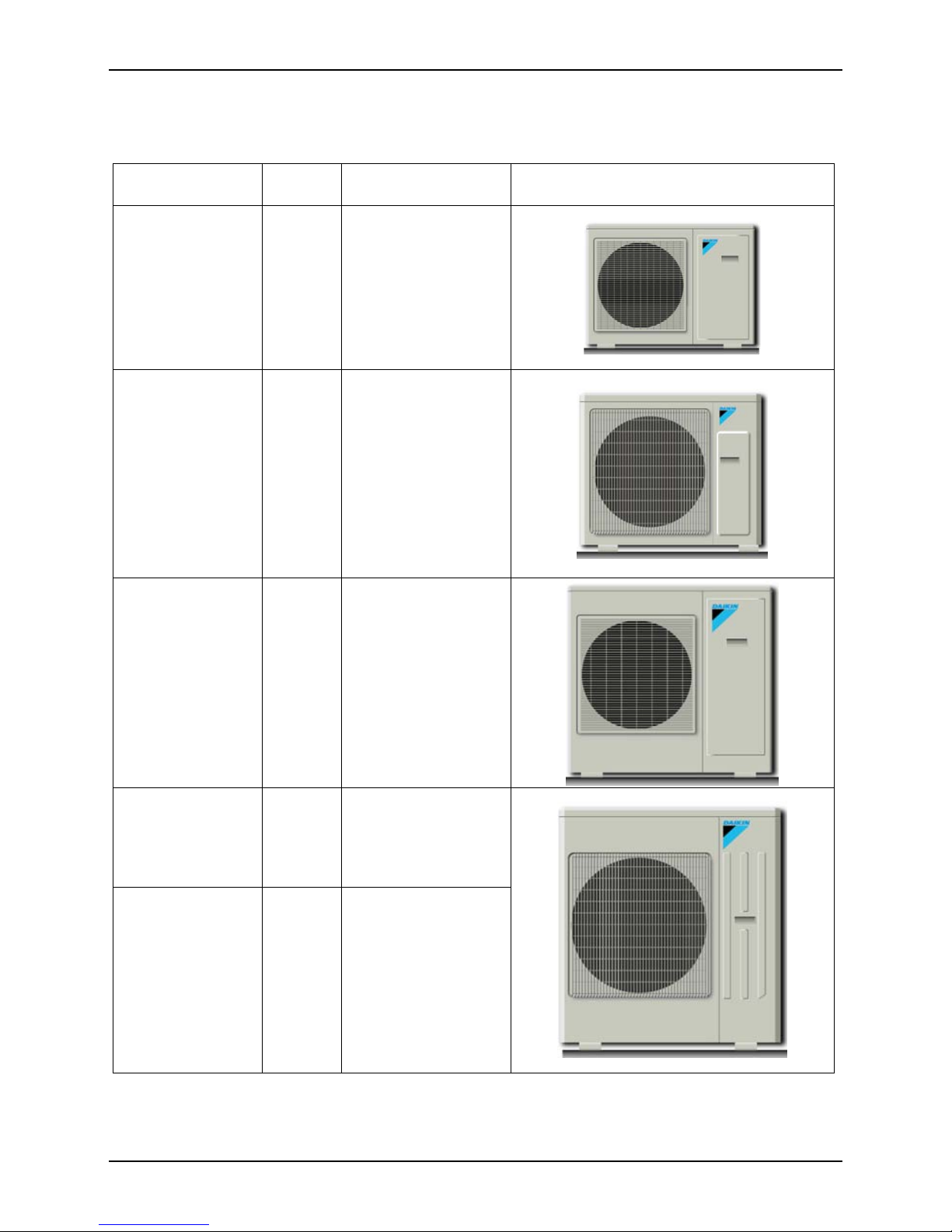

1. MODELS LIST

1.1 Outdoor Unit

Model Refrigerant Power Supply Appearance

RY24PEV1K

R24PEV1K

R22

220-240V 1PH 50Hz

RY30PEV1K

R30PEV1K

R22

220-240V 1PH 50Hz

RY36PEY1K

R36PEY1K

R22

380-415V 3PH 50Hz

RY42PEY1K

R42PEY1K

R22

380-415V 3PH 50Hz

RY48PEY1K

R48PEY1K

R22 380-415V 3PH 50Hz

SiK401004_A

3 SPECIFICATIONS

1.2 Indoor Unit

Model

Nominal Capacity

Cooling/Heating

(Btu/h)

Refrigerant

Power

Supply

Appearance

FD(Y)M24PEV1K 23200/25500

FD(Y)M30PEV1K 26300/32100

FD(Y)M36PEV1K 33000/41000

FD(Y)M42PEV1K 38600/46100

Type

FD(Y)M48PEV1K 44400/48200

R22

220-240V

1PH 50Hz

Note:1Ton =12000Btu/h = 3.517kW

Notes: The universal outdoor units means that the customer can choose any of three kind of indoor units to match the outdoor

unit without any change with it.

* Three kind of units

F = Duct Type

K = Cassette Type

T = Ceiling Type

SiK401004_A

SPECIFICATIONS 4

2. NOMENCLATURE

24

EK

M V1

SiK401004_A

5 SPECIFICATIONS

3. FUNCTION

Function Description

Memory function

For the air conditioners with this memory function setting, the units may start

automatically

after power failure reset or the main power supply is turned on again (when the unit

restarts , it will return to the same operation condition as that of the former operation

status, and the mode and parameter are also kept the same.)

Timing function it can make timing ON/ OFF separately, meanwhile, it can also make timing on circularly

Self-diagnosis with alarm

function

once unit has malfunction, the malfunction code will be indicated and alarm rings

immediately

Sleep function it can self control for saving energy in energy saving mode.

Automatic function

the fan of indoor unit can adjust fan speed automatically based on actual demand when

cooling or heating under automatic mode

Cool air protection function

the fan starts only when the temperature of indoor unit heat exchanger is higher than

indoor temperature under heating mode

High/low Pressure Protection

when suction pressure is too low or discharge pressure is too high, compressor will stop

and unit displays malfunction code

Overload protection

compressor has its own overheat protection, once the temperature of compressor is

higher than allowable level, compressor will stop and it can restart only when

temperature recovers.

Over current protection

once the current of compressor is higher that normal level, compressor will stop and unit

displays malfunction code

Discharge high

temperature protection

once the discharge temperature of compressor is higher than allowable level, compressor

will stop and unit displays malfunction code.

Reverse (open) phase

protection

once the phase sequence of power supply is incongruent or the phase is absent, unit

can’t work.

Anti-high

temperature protection

once the heat exchanger temperature of indoor unit is too high, the compressor will stop.

Timing ON/OFF display display and make timing turn ON/OFF time

Fan speed display display the speed (high.medium.low) of fan

Function model display cooling mode.dehumidifying mode.heating mode.fan mode

Testing display display testing mode

Temperature display display room temperature and set temperature

SiK401004_A

SPECIFICATIONS 6

4. PRODUCT DATA

4.1 Product Data at Rated Condition

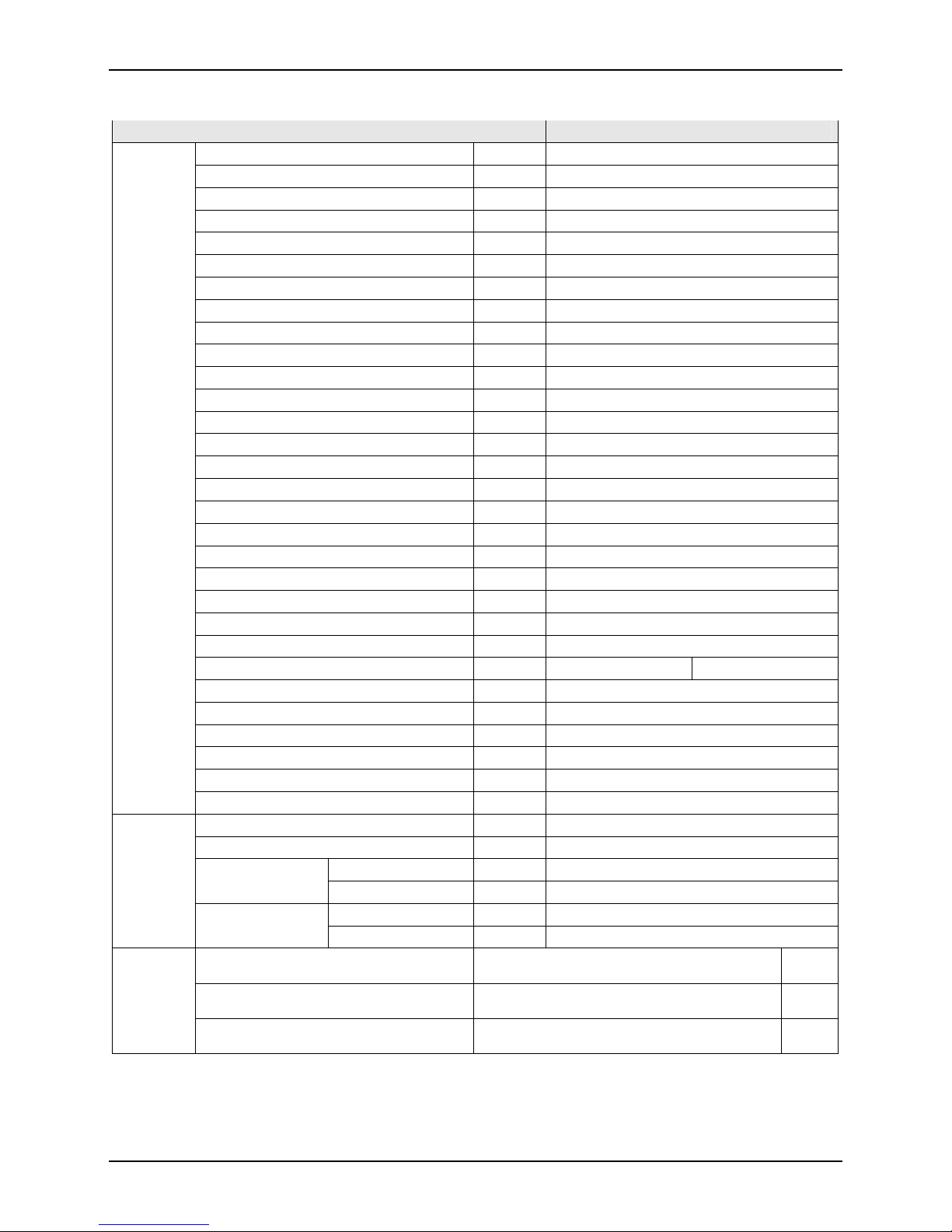

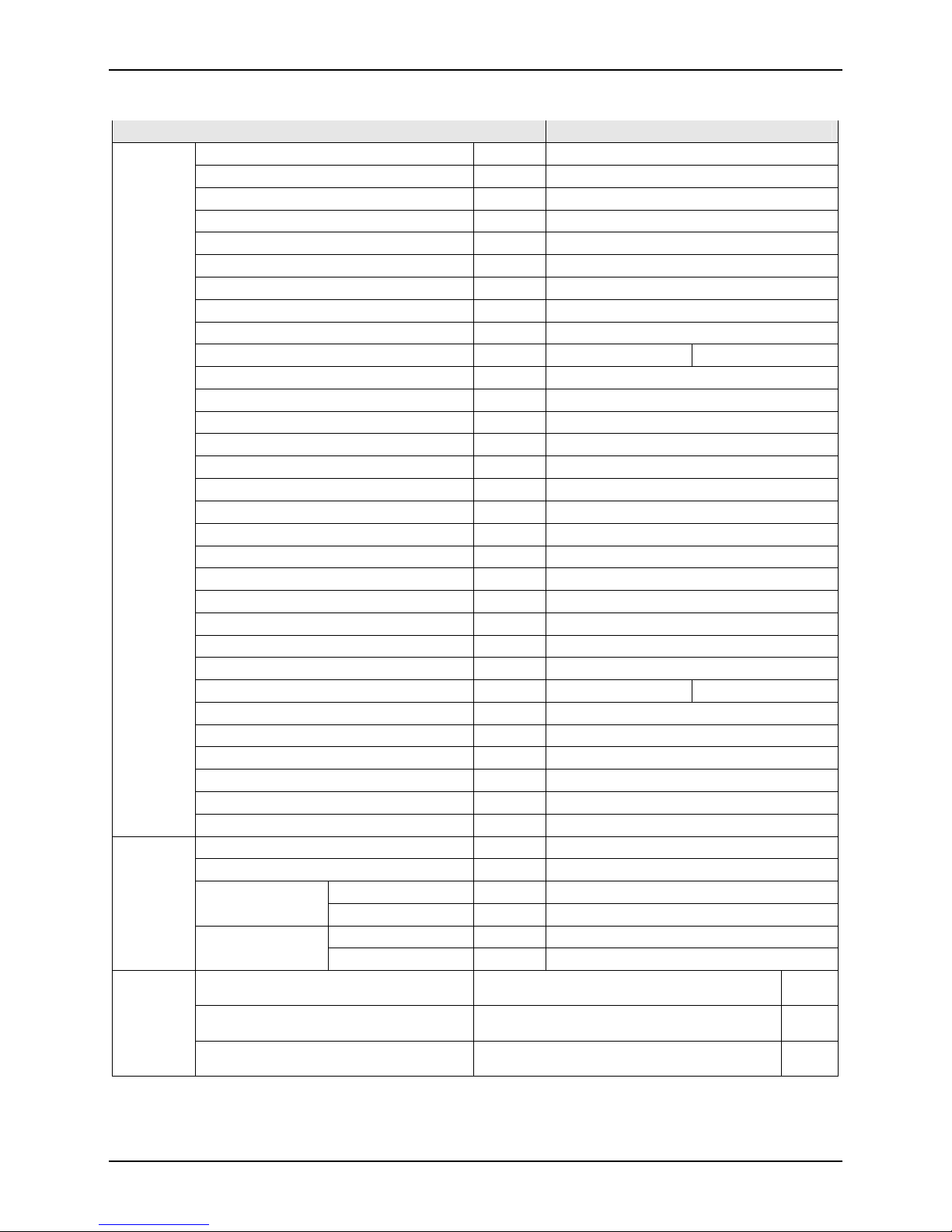

4.1.1 Duct Type

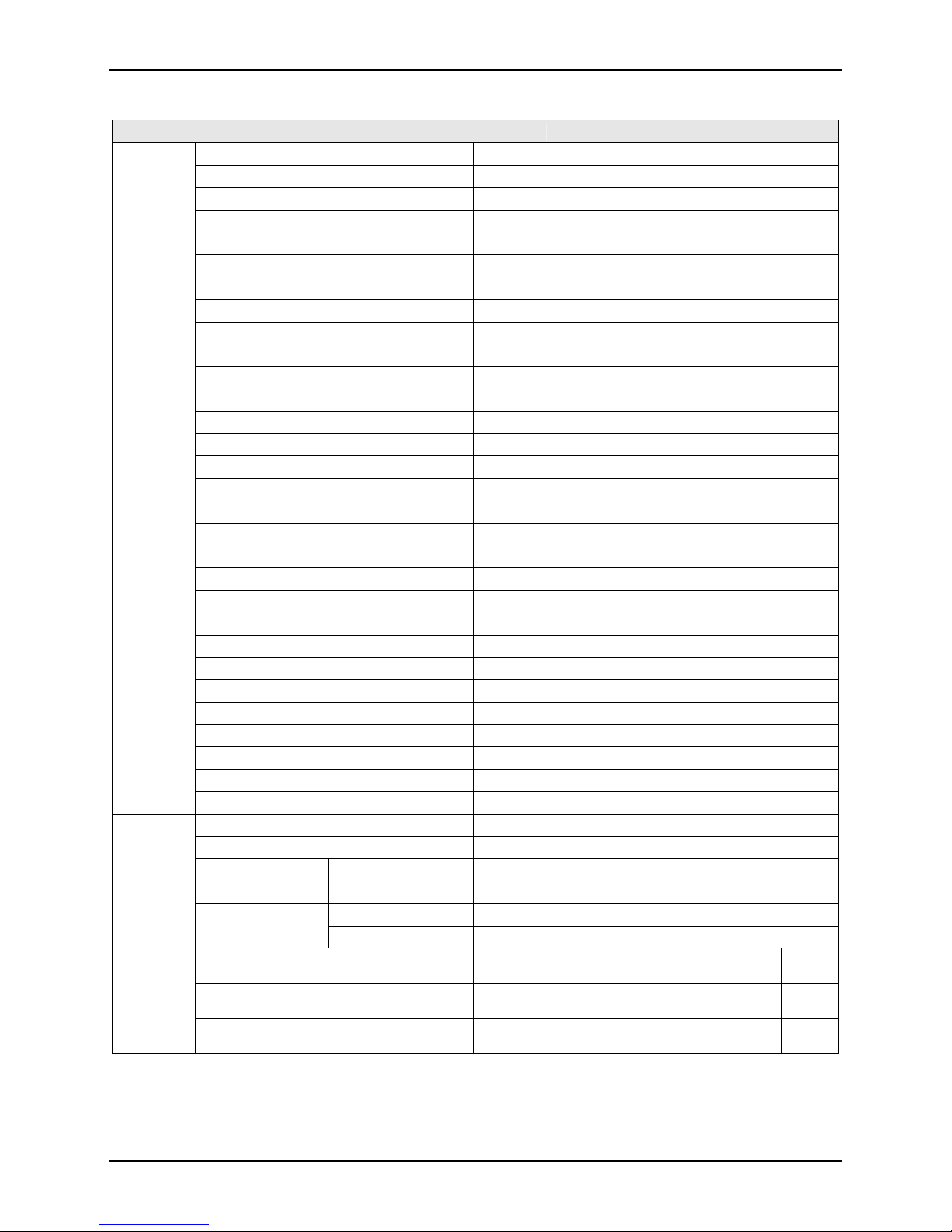

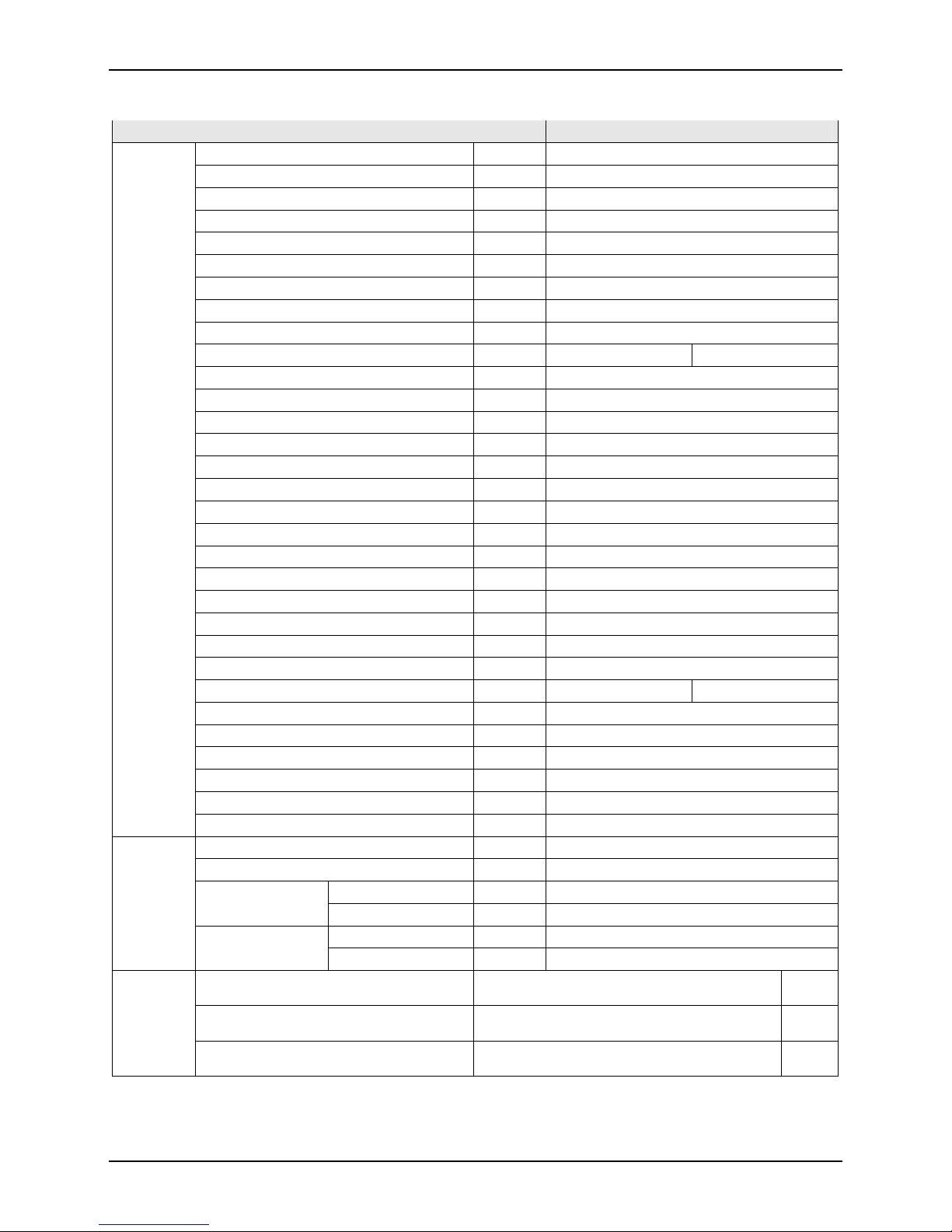

Outdoor R24PEV1K

Model

Indoor FDM24PEV1K

Function ― COOLING

Rated Voltage ― 220-240V 1Ph

Rated Frequency ― 50Hz

Total Capacity (Btu/h)/W

6800

23200

Power Input W 2500

Rated Current A 11.9

Max Current A 19.0

Air Flow Volume (H/M/L)**

m3/h

1600/1400/1200

ESP Pa 25

EER (Btu/h)/W 9.28

Indoor Unit FDM24PEV1K

Fan Motor Speed (H/M/L) r/min 1250/1220/1060

Output of Fan Motor W 150

Fan Motor Capacitor µF 8

Fan Type-Piece ― Centrifugal fan – 2

Diameter-Length mm φ160 – 200

Evaporator ― Aluminum fin-copper tube

Pipe Diameter mm φ9.52

Row-Fin Gap mm 2-1.8

Coil length (L) x height (H) x coil width (W) mm 1002X253X44

Fuse A 5

Sound Pressure Level dB (H/M/L) A 47/44/42

Sound Power Level dB (H/M/L) A 57/54/52

Dimension (W/H/D) mm 1270/268/530

Dimension of Package (W/H/D) mm 1345/283/594

Indoor

unit

Net Weight/Gross Weight kg 36/42

SiK401004_A

7 SPECIFICATIONS

Outdoor Unit R24PEV1K

Compressor ManµFacturer/trademark ― Mitsubishi

Compressor Model ― LHT42VBAC

Compressor Type ― Rotary

L.R.A. A 66

Compressor RLA A 11.2

Compressor Power Input W

2390

Overload Protector ― Auto Reset Thermal Overload

Throttling Method ― Capillary

Starting Method ― Start directly

Working Temp Range °C Cooling: 18°C-52°C

Condenser ― Aluminum fin-copper tube

Pipe Diameter mm φ9.52

Rows-Fin Gap mm 2-1.5

Coil length (L) x height (H) x coil width (W) mm 744X660X44

Fan Motor Speed rpm 940

Output of Fan Motor W 92

Fan Motor Capacitor µF 4

Air Flow Volume of Outdoor Unit 3200

Fan Type-Piece ― Axial fan –1

Fan Diameter mm φ450

Climate Type ― T3

Isolation ― I

Moisture Protection ― IP24

Design Pressure (Hi/Lo) MPa 2.5 0.6

Sound Pressure Level dB A 59

Sound Power Level dB (H/M/L) A 69

Dimension (W/H/D) mm 1018/695/412

Dimension of Package (W/H/D) mm 1100/755/450

Net Weight/Gross Weight kg 66/70

Outdoor

unit

Refrigerant Charge kg R22/2.5

Length m 5

Gas additional charge g/m 60

Liquid Pipe Inch φ3/8’’ Outer Diameter

Gas Pipe Inch φ5/8’’

Height m 15

Connection

Pipe

Max Distance

Length m 30

20’ Container

Interior Dimensions L*W*H: 5898*2352*2393,

Door Opening W*H: 2343*2280

37

40’ Container

Interior Dimensions L*W*H: 12032*2350*2390,

Door Opening W*H: 2343*2280

88

Loading

Quantity

40’ High Cube Container

Interior Dimensions L*W*H: 12032*2350*2697,

Door Opening W*H: 2338*2585

99

SiK401004_A

SPECIFICATIONS 8

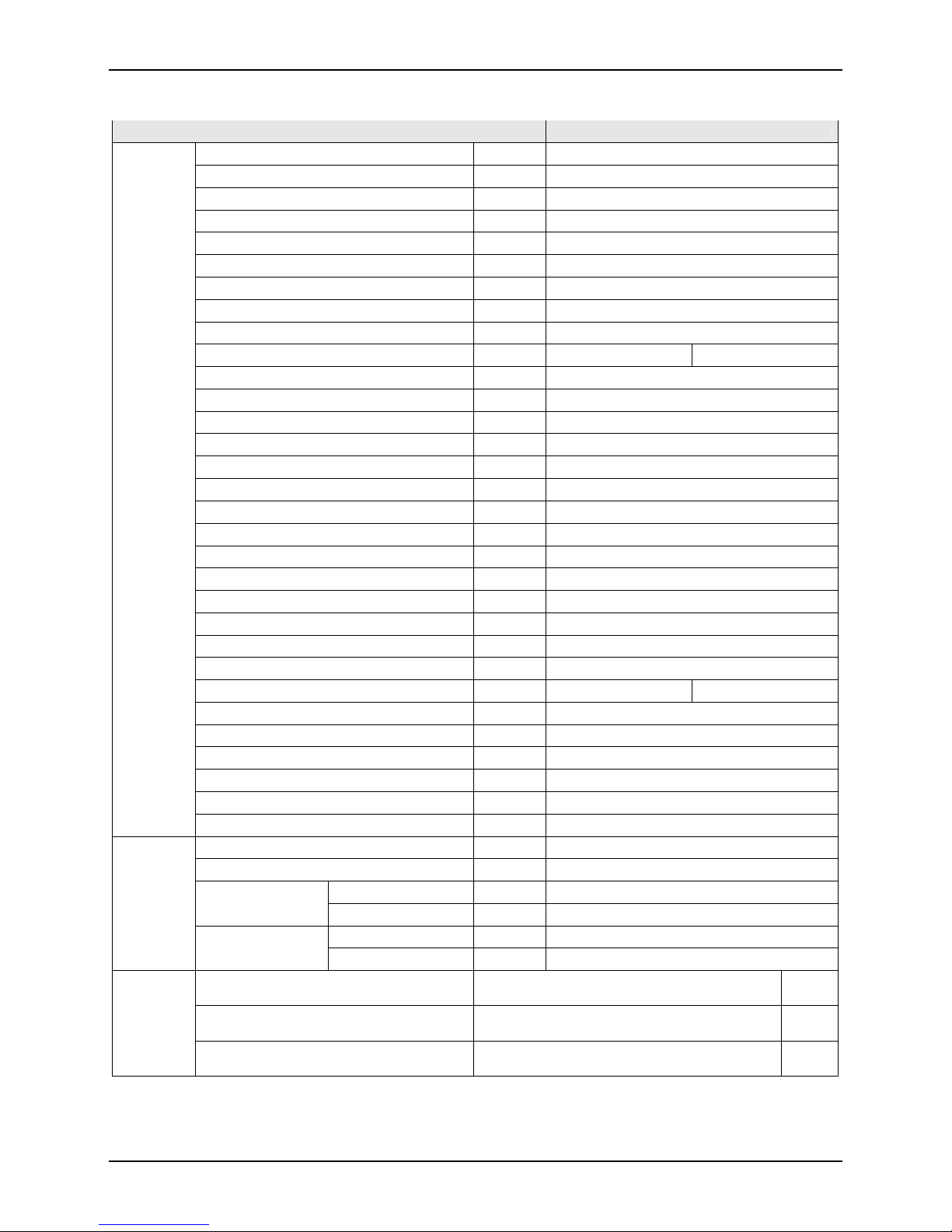

Outdoor R30PEV1K

Model

Indoor FDM30PEV1K

Function ― COOLING

Rated Voltage ― 220-240V 1Ph

Rated Frequency ― 50Hz

Total Capacity (Btu/h)/W

7700

26300

Power Input W 2920

Rated Current A 13.5

Max Current A 21.0

Air Flow Volume (H/M/L)**

m3/h

1500/1300/1100

ESP Pa 37

EER (Btu/h)/W 9.01

Indoor Unit FDM30PEV1K

Fan Motor Speed (H/M/L) r/min 1250/1220/1060

Output of Fan Motor W 150

Fan Motor Capacitor µF 8

Fan Type-Piece ― Centrifugal fan – 2

Diameter-Length mm φ160 – 200

Evaporator ― Aluminum fin-copper tube

Pipe Diameter mm φ9.52

Row-Fin Gap mm 2-1.8

Coil length (L) x height (H) x coil width (W) mm 1002X253X44

Fuse A 5

Sound Pressure Level dB (H/M/L) A 47/44/42

Sound Power Level dB (H/M/L) A 57/54/52

Dimension (W/H/D) mm 1270/268/530

Dimension of Package (W/H/D) mm 1345/283/594

Indoor

unit

Net Weight/Gross Weight kg 36/42

SiK401004_A

9 SPECIFICATIONS

Outdoor Unit R30PEV1K

Compressor ManµFacturer/trademark ― Mitsubishi

Compressor Model ― LHT53VBAC

Compressor Type ― Rotary

L.R.A. A 76

Compressor RLA A 14.8

Compressor Power Input W

3050

Overload Protector ― Auto Reset Thermal Overload

Throttling Method ― Capillary

Starting Method ― Start directly

Working Temp Range °C Cooling: 18°C-52°C

Condenser ― Aluminum fin-copper tube

Pipe Diameter mm φ9.52

Rows-Fin Gap mm 2-1.6

Coil length (L) x height (H) x coil width (W) mm 976X762X44

Fan Motor Speed rpm 780

Output of Fan Motor W 125

Fan Motor Capacitor µF 7

Air Flow Volume of Outdoor Unit 4200

Fan Type-Piece ― Axial fan –1

Fan Diameter mm φ552

Climate Type ― T3

Isolation ― I

Moisture Protection ― IP24

Design Pressure (Hi/Lo) MPa 2.5 0.6

Sound Pressure Level dB A 58

Sound Power Level dB (H/M/L) A 68

Dimension (W/H/D) mm 980/790/427

Dimension of Package (W/H/D) mm 1080/840/485

Net Weight/Gross Weight kg 73/77

Outdoor

unit

Refrigerant Charge kg R22/3.4

Length m 5

Gas additional charge g/m 60

Liquid Pipe Inch φ3/8’’ Outer Diameter

Gas Pipe Inch φ5/8’’

Height m 15

Connection

Pipe

Max Distance

Length m 30

20’ Container

Interior Dimensions L*W*H: 5898*2352*2393,

Door Opening W*H: 2343*2280

34

40’ Container

Interior Dimensions L*W*H: 12032*2350*2390,

Door Opening W*H: 2343*2280

74

Loading

Quantity

40’ High Cube Container

Interior Dimensions L*W*H: 12032*2350*2697,

Door Opening W*H: 2338*2585

83

SiK401004_A

SPECIFICATIONS 10

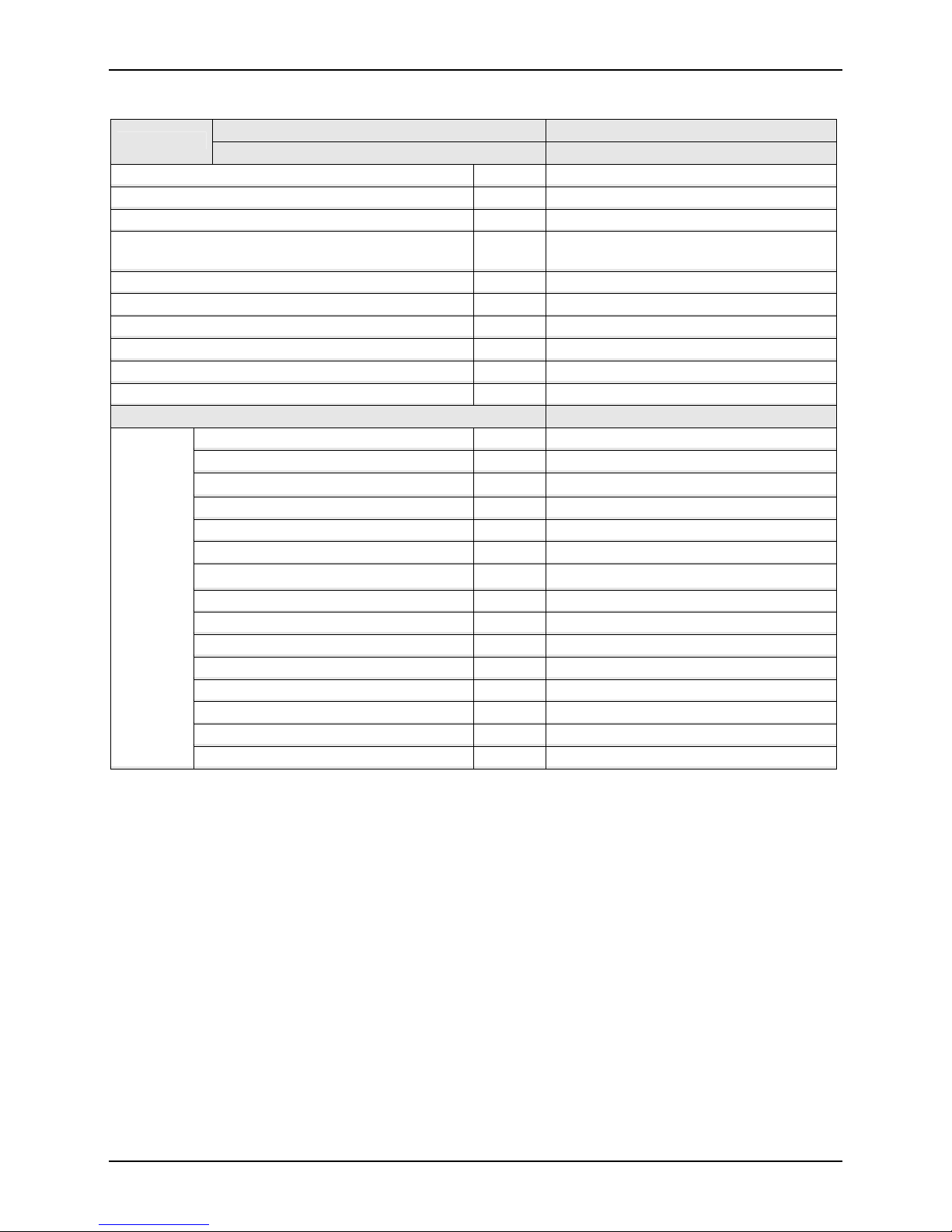

Outdoor R36PEY1K

Model

Indoor FDM36PEV1K

Function ― COOLING

Rated Voltage ― 380-415V 3Ph

Rated Frequency ― 50Hz

Total Capacity (Btu/h)/W

9700

33000

Power Input W 3900

Rated Current A 7.1

Max Current A 10.6

Air Flow Volume (H/M/L)**

m3/h

2000/1900/1800

ESP Pa 37

EER (Btu/h)/W 8.46

Indoor Unit FDM36PEV1K

Fan Motor Speed (H/M/L) r/min 1320/1090/910

Output of Fan Motor W 500

Fan Motor Capacitor µF 12

Fan Type-Piece ― Centrifugal fan – 2

Diameter-Length mm φ200 – 190

Evaporator ― Aluminum fin-copper tube

Pipe Diameter mm φ7

Row-Fin Gap mm 3-1.6

Coil length (L) x height (H) x coil width (W) mm 978X304.8X38.1

Fuse A 5

Sound Pressure Level dB (H/M/L) A 50/48/46

Sound Power Level dB (H/M/L) A 60/58/56

Dimension (W/H/D) mm 1226/290/775

Dimension of Package (W/H/D) mm 1335/305/834

Indoor

unit

Net Weight/Gross Weight kg 53/61

SiK401004_A

11 SPECIFICATIONS

Outdoor Unit R36PEY1K

Compressor ManµFacturer/trademark ― SANYO

Compressor Model ― C-SBR145H38P

Compressor Type ― SCROLL

L.R.A. A 53

Compressor RLA A 6.5

Compressor Power Input W

3650

Overload Protector ― Auto Reset Thermal Overload

Throttling Method ― Capillary

Starting Method ― Start directly

Working Temp Range °C Cooling: 18°C-52°C

Condenser ― Aluminum fin-copper tube

Pipe Diameter mm φ9.52

Rows-Fin Gap mm 2-1.4

Coil length (L) x height (H) x coil width (W) mm 964X813X44

Fan Motor Speed rpm 920

Output of Fan Motor W 92

Fan Motor Capacitor µF 4

Air Flow Volume of Outdoor Unit 4000

Fan Type-Piece ― Axial fan –1

Fan Diameter mm φ482

Climate Type ― T3

Isolation ― I

Moisture Protection ― IP24

Design Pressure (Hi/Lo) MPa 2.5 0.6

Sound Pressure Level dB A 60

Sound Power Level dB (H/M/L) A 70

Dimension (W/H/D) mm 1018/840/412

Dimension of Package (W/H/D) mm 1100/985/450

Net Weight/Gross Weight kg 89/97

Outdoor

unit

Refrigerant Charge kg R22/3.6

Length m 5

Gas additional charge g/m 120

Liquid Pipe Inch φ1/2’’ Outer Diameter

Gas Pipe Inch φ3/4’’

Height m 30

Connection

Pipe

Max Distance

Length m 50

20’ Container

Interior Dimensions L*W*H: 5898*2352*2393,

Door Opening W*H: 2343*2280

30

40’ Container

Interior Dimensions L*W*H: 12032*2350*2390,

Door Opening W*H: 2343*2280

60

Loading

Quantity

40’ High Cube Container

Interior Dimensions L*W*H: 12032*2350*2697,

Door Opening W*H: 2338*2585

66

SiK401004_A

SPECIFICATIONS 12

Outdoor R42PEY1K

Model

Indoor FDM42PEV1K

Function ― COOLING

Rated Voltage ― 380-415V 3Ph

Rated Frequency ― 50Hz

Total Capacity (Btu/h)/W

11300

38600

Power Input W 4600

Rated Current A 8.9

Max Current A 13.0

Air Flow Volume (H/M/L)**

m3/h

2000/1900/1800

ESP Pa 37

EER (Btu/h)/W 8.39

Indoor Unit FDM42PEV1K

Fan Motor Speed (H/M/L) r/min 1320/1090/910

Output of Fan Motor W 500

Fan Motor Capacitor µF 12

Fan Type-Piece ― Centrifugal fan – 2

Diameter-Length mm φ200 – 190

Evaporator ― Aluminum fin-copper tube

Pipe Diameter mm φ7

Row-Fin Gap mm 3-1.6

Coil length (L) x height (H) x coil width (W) mm 978X304.8X38.1

Fuse A 5

Sound Pressure Level dB (H/M/L) A 50/48/46

Sound Power Level dB (H/M/L) A 60/58/56

Dimension (W/H/D) mm 1226/290/775

Dimension of Package (W/H/D) mm 1335/305/834

Indoor

unit

Net Weight/Gross Weight kg 53/61

SiK401004_A

13 SPECIFICATIONS

Outdoor Unit R42PEY1K

Compressor ManµFacturer/trademark ― SANYO

Compressor Model ― C-SBX180H38P

Compressor Type ― SCROLL

L.R.A. A 73

Compressor RLA A 8.06

Compressor Power Input W

4300

Overload Protector ― Auto Reset Thermal Overload

Throttling Method ― Capillary

Starting Method ― Direct

Working Temp Range °C Cooling: 18°C-52°C

Condenser ― Aluminum fin-copper tube

Pipe Diameter mm φ9.52

Rows-Fin Gap mm 1-1.4

Coil length (L) x height (H) x coil width (W) mm 1050/1067X22

Fan Motor Speed rpm 820

Output of Fan Motor W 140

Fan Motor Capacitor µF 7

Air Flow Volume of Outdoor Unit 6000

Fan Type-Piece ― Axial fan –1

Fan Diameter mm φ570

Climate Type ― T3

Isolation ― I

Moisture Protection ― IP24

Design Pressure (Hi/Lo) MPa 2.5 0.6

Sound Pressure Level dB A 60

Sound Power Level dB (H/M/L) A 70

Dimension (W/H/D) mm 1107/1100/440

Dimension of Package (W/H/D) mm 1170/1220/490

Net Weight/Gross Weight kg 94/104

Outdoor

unit

Refrigerant Charge kg R22/3.05

Length m 5

Gas additional charge g/m 120

Liquid Pipe Inch φ1/2’’ Outer Diameter

Gas Pipe Inch φ3/4’’

Height m 30

Connection

Pipe

Max Distance

Length m 50

20’ Container

Interior Dimensions L*W*H: 5898*2352*2393,

Door Opening W*H: 2343*2280

20

40’ Container

Interior Dimensions L*W*H: 12032*2350*2390,

Door Opening W*H: 2343*2280

39

Loading

Quantity

40’ High Cube Container

Interior Dimensions L*W*H: 12032*2350*2697,

Door Opening W*H: 2338*2585

48

SiK401004_A

SPECIFICATIONS 14

Outdoor R48PEY1K

Model

Indoor FDM48PEV1K

Function ― COOLING

Rated Voltage ― 380-415V 3Ph

Rated Frequency ― 50Hz

Total Capacity (Btu/h)/W

13000

44400

Power Input W 5400

Rated Current A 10.4

Max Current A 14.5

Air Flow Volume (H/M/L)**

m3/h

2300/2110/1850

ESP Pa 50

EER/C.O.P (Btu/h)/W 8.22

Indoor Unit FDM48PEV1K

Fan Motor Speed (H/M/L) r/min 1320/1090/910

Output of Fan Motor W 500

Fan Motor Capacitor µF 12

Fan Type-Piece ― Centrifugal fan – 2

Diameter-Length mm φ200 – 190

Evaporator ― Aluminum fin-copper tube

Pipe Diameter mm φ9.52

Row-Fin Gap mm 3-1.8

Coil length (L) x height (H) x coil width (W) mm 978X304.8/66

Fuse A 5

Sound Pressure Level dB (H/M/L) A 53/50/46

Sound Power Level dB (H/M/L) A 63/60/56

Dimension (W/H/D) mm 1226/290/775

Dimension of Package (W/H/D) mm 1335/305/834

Indoor

unit

Net Weight/Gross Weight kg 55/63

SiK401004_A

15 SPECIFICATIONS

Outdoor Unit R48PEY1K

Compressor ManµFacturer/trademark ― SANYO

Compressor Model ― C-SBX215H38P

Compressor Type ― SCROLL

L.R.A. A 73

Compressor RLA A 9.4

Compressor Power Input W

5350

Overload Protector ― Auto Reset Thermal Overload

Throttling Method ― Capillary

Starting Method ― Direct

Working Temp Range °C Cooling: 18°C-52°C

Condenser ― Aluminum fin-copper tube

Pipe Diameter mm φ9.52

Rows-Fin Gap mm 2-1.4

Coil length (L) x height (H) x coil width (W) mm 1050X1067X44

Fan Motor Speed rpm 820

Output of Fan Motor W 140

Fan Motor Capacitor µF 7

Air Flow Volume of Outdoor Unit 6000

Fan Type-Piece ― Axial fan –1

Fan Diameter mm φ570

Climate Type ― T3

Isolation ― I

Moisture Protection ― IP24

Design Pressure (Hi/Lo) MPa 2.5 0.6

Sound Pressure Level dB A 60

Sound Power Level dB (H/M/L) A 70

Dimension (W/H/D) mm 1107/1100/440

Dimension of Package (W/H/D) mm 1170/1220/490

Net Weight/Gross Weight kg 107/116

Outdoor

unit

Refrigerant Charge kg R22/5.0

Length m 5

Gas additional charge g/m 120

Liquid Pipe Inch φ1/2’’ Outer Diameter

Gas Pipe Inch φ3/4’’

Height m 30

Connection

Pipe

Max Distance

Length m 50

20’ Container

Interior Dimensions L*W*H: 5898*2352*2393,

Door Opening W*H: 2343*2280

20

40’ Container

Interior Dimensions L*W*H: 12032*2350*2390,

Door Opening W*H: 2343*2280

39

Loading

Quantity

40’ High Cube Container

Interior Dimensions L*W*H: 12032*2350*2697,

Door Opening W*H: 2338*2585

48

SiK401004_A

SPECIFICATIONS 16

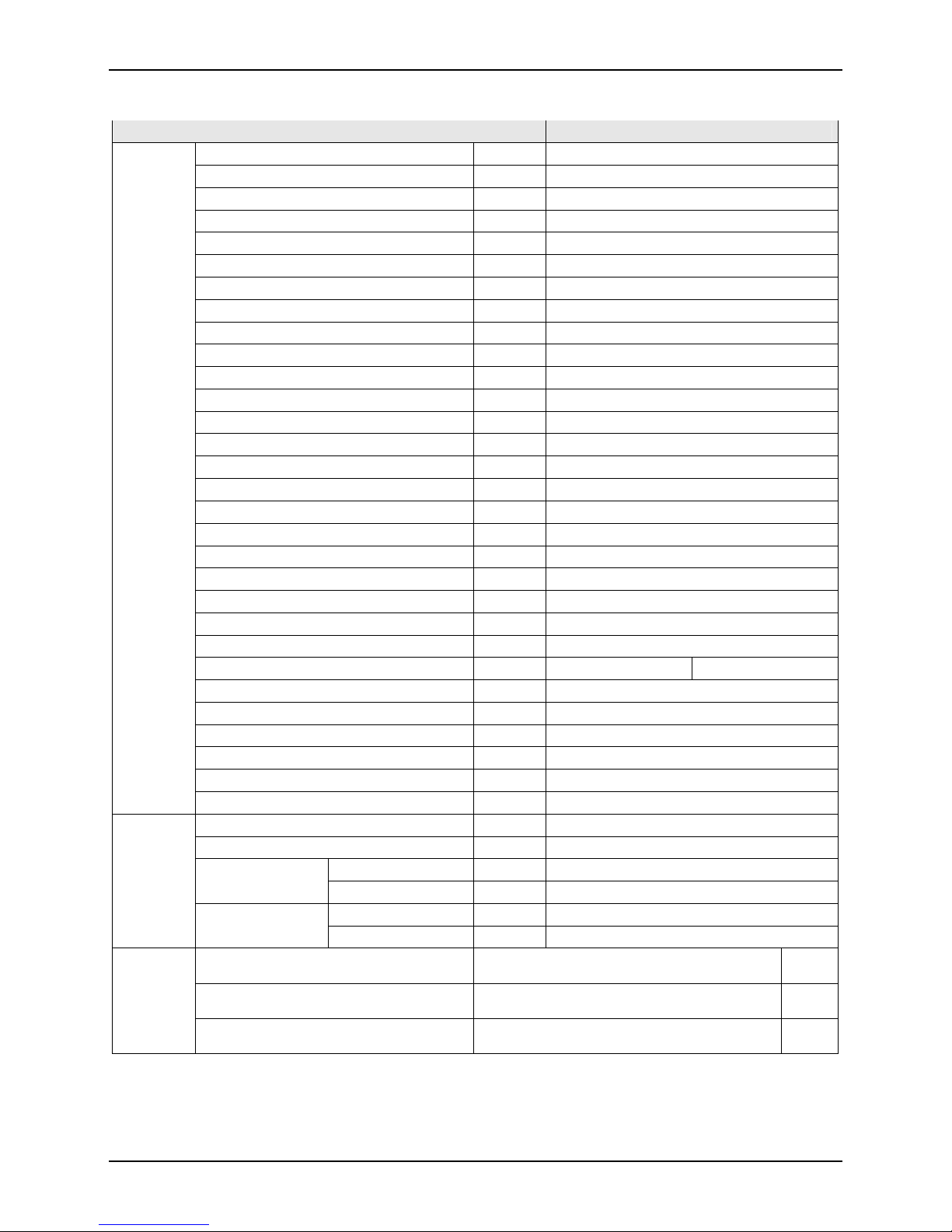

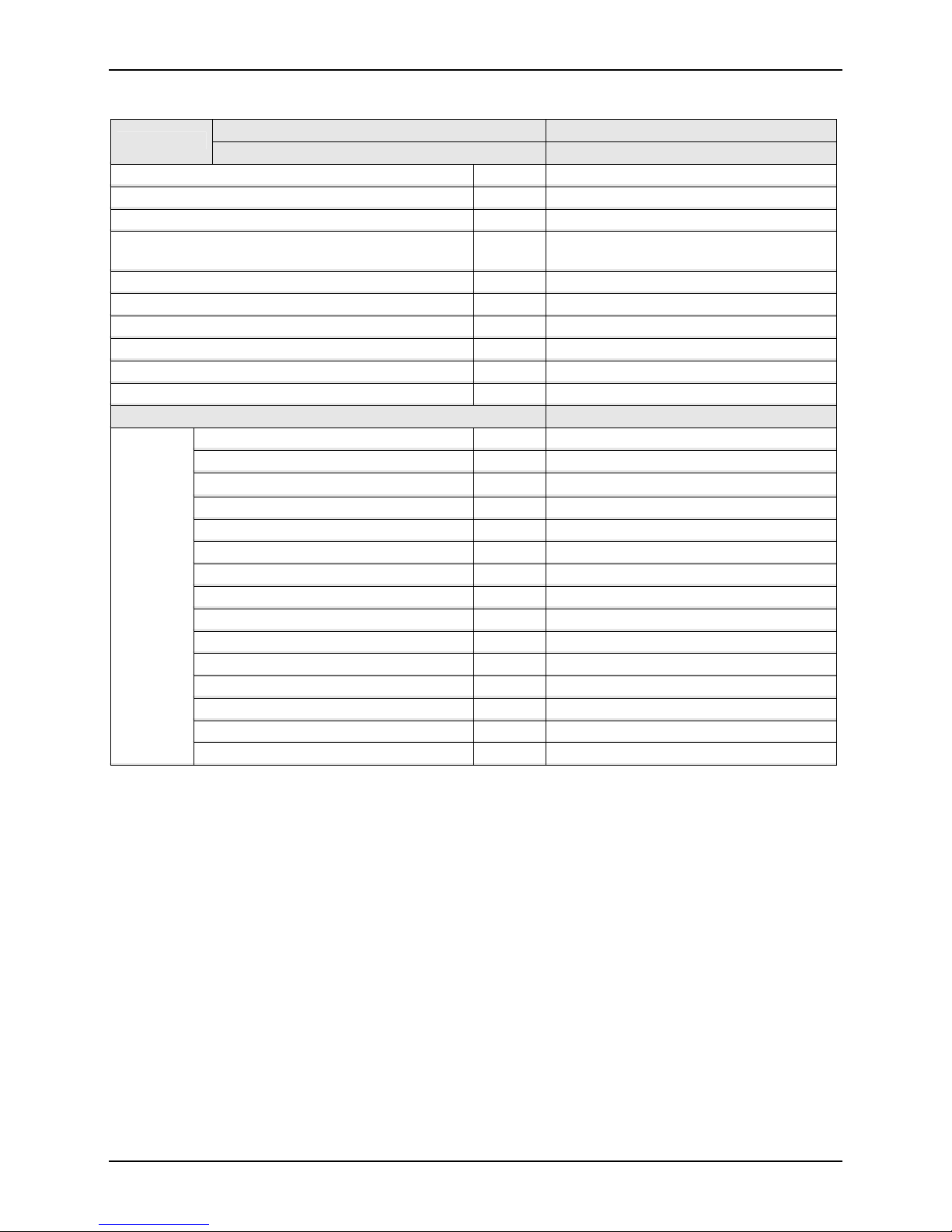

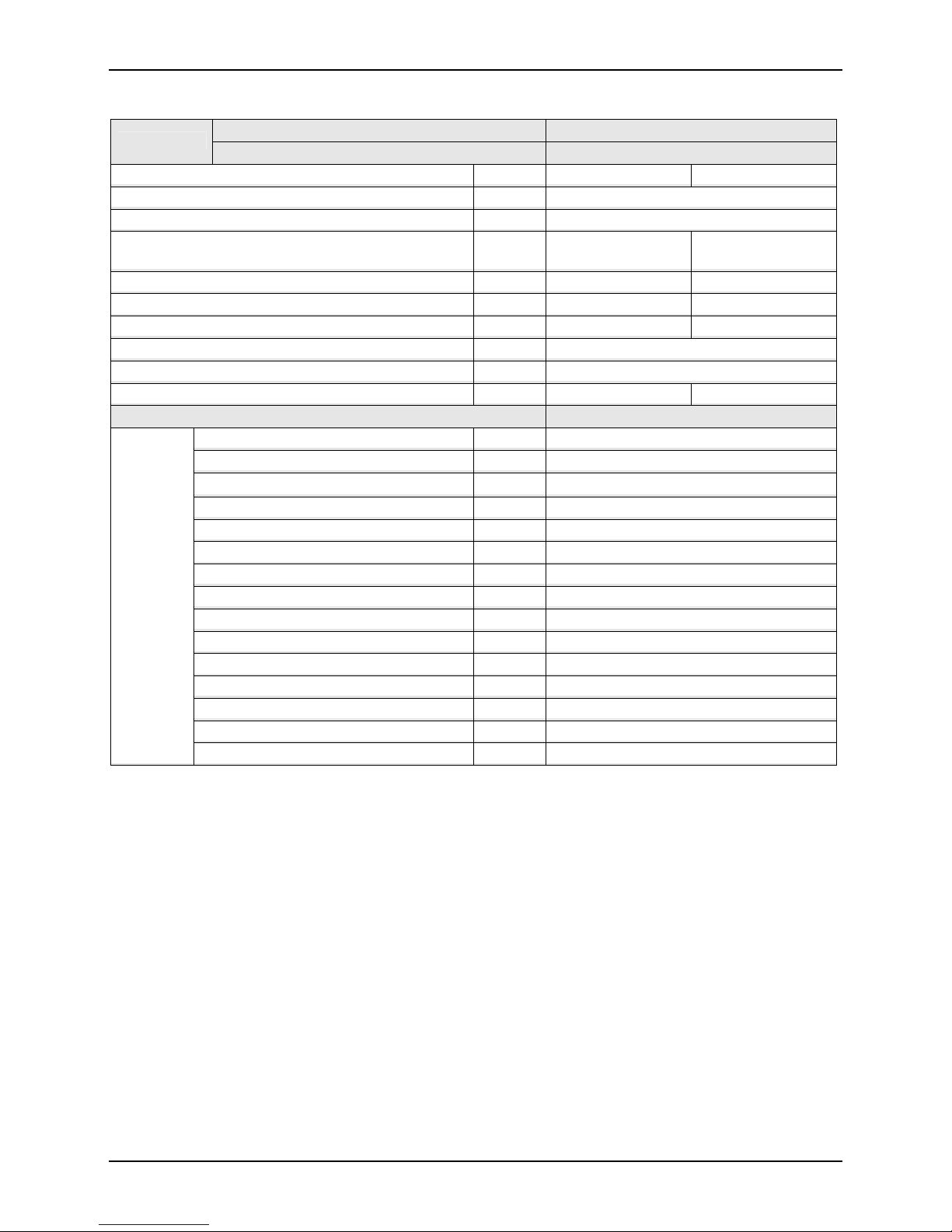

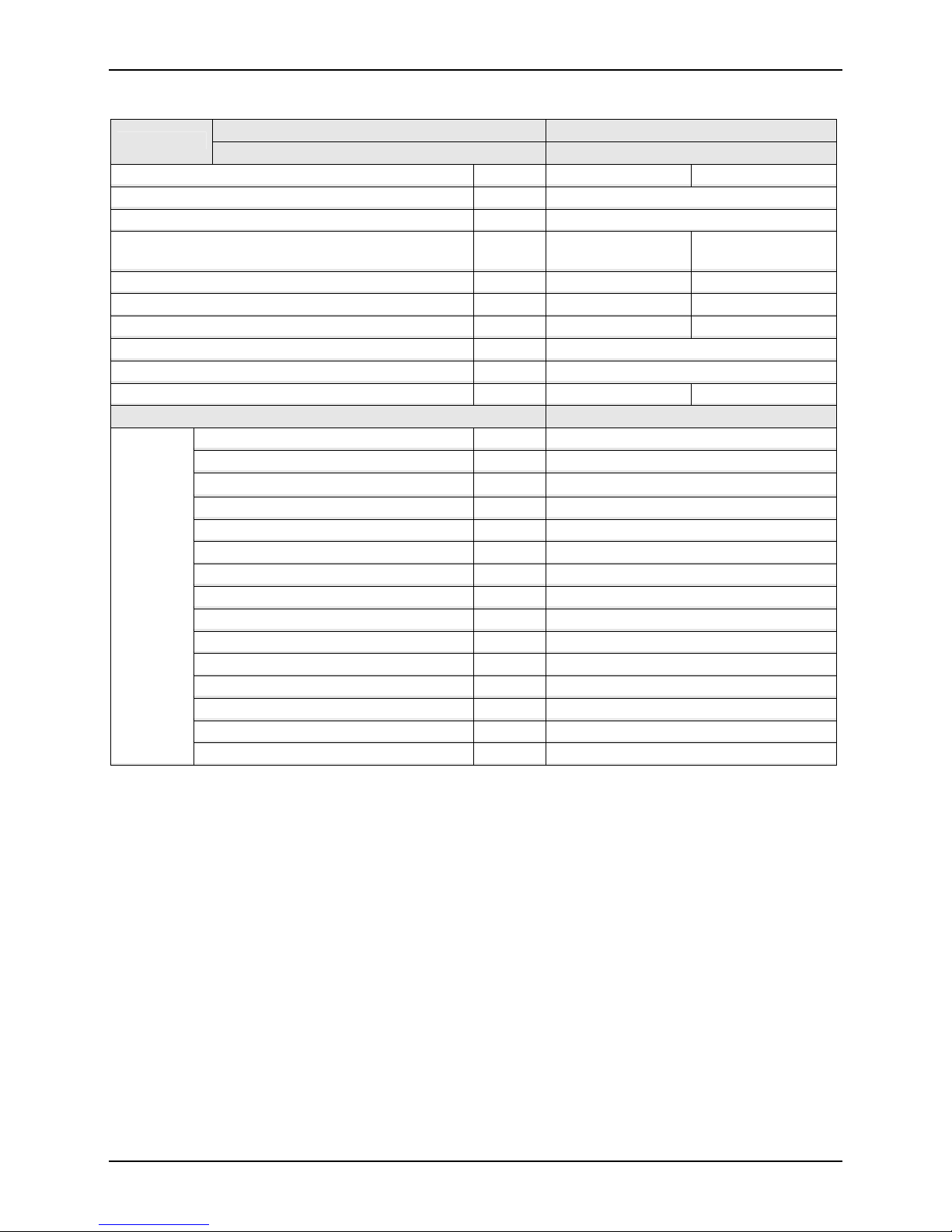

Outdoor RY24PEV1K

Model

Indoor FDYM24PEV1K

Function ― COOLING HEATING

Rated Voltage ― 220-240V 1Ph

Rated Frequency ― 50Hz

Total Capacity (Btu/h)/W

6800

23200

7500

25500

Power Input W 2500 2450

Rated Current A 11.9 12.4

Max Current A 18.3 15.8

Air Flow Volume (H/M/L)**

m3/h

1600/1400/1200

ESP Pa 25

EER/C.O.P (Btu/h)/W 9.28 3.06

Indoor Unit FDYM24PEV1K

Fan Motor Speed (H/M/L) r/min 1250/1220/1060

Output of Fan Motor W 150

Fan Motor Capacitor µF 8

Fan Type-Piece ― Centrifugal fan – 2

Diameter-Length mm φ160 – 200

Evaporator ― Aluminum fin-copper tube

Pipe Diameter mm φ9.52

Row-Fin Gap mm 2-1.8

Coil length (L) x height (H) x coil width (W) mm 1002X253X44

Fuse A 5

Sound Pressure Level dB (H/M/L) A 47/44/42

Sound Power Level dB (H/M/L) A 57/54/52

Dimension (W/H/D) mm 1270/268/530

Dimension of Package (W/H/D) mm 1345/283/594

Indoor

unit

Net Weight/Gross Weight kg 36/42

SiK401004_A

17 SPECIFICATIONS

Outdoor Unit RY24PEV1K

Compressor ManµFacturer/trademark ― Mitsubishi

Compressor Model ― LHT42VBAC

Compressor Type ― Rotary

L.R.A. A 66

Compressor RLA A 11.2

Compressor Power Input W

2390

Overload Protector ― Auto Reset Thermal Overload

Throttling Method ― Capillary

Starting Method ― Start directly

Working Temp Range °C Cooling: 18°C-52°C Heating: -7°C-24°C

Condenser ― Aluminum fin-copper tube

Pipe Diameter mm φ9.52

Rows-Fin Gap mm 2-1.5

Coil length (L) x height (H) x coil width (W) mm 744X660X44

Fan Motor Speed rpm 940

Output of Fan Motor W 92

Fan Motor Capacitor µF 4

Air Flow Volume of Outdoor Unit 3200

Fan Type-Piece ― Axial fan –1

Fan Diameter mm φ450

Defrosting Method ― Auto defrost

Climate Type ― T3

Isolation ― I

Moisture Protection ― IP24

Design Pressure (Hi/Lo) MPa 2.5 0.6

Sound Pressure Level dB A 59

Sound Power Level dB (H/M/L) A 69

Dimension (W/H/D) mm 1018/695/412

Dimension of Package (W/H/D) mm 1100/755/450

Net Weight/Gross Weight kg 67/71

Outdoor

unit

Refrigerant Charge kg R22/2.5

Length m 5

Gas additional charge g/m 60

Liquid Pipe Inch φ3/8’’ Outer Diameter

Gas Pipe Inch φ5/8’’

Height m 15

Connection

Pipe

Max Distance

Length m 30

20’ Container

Interior Dimensions L*W*H: 5898*2352*2393,

Door Opening W*H: 2343*2280

37

40’ Container

Interior Dimensions L*W*H: 12032*2350*2390,

Door Opening W*H: 2343*2280

88

Loading

Quantity

40’ High Cube Container

Interior Dimensions L*W*H: 12032*2350*2697,

Door Opening W*H: 2338*2585

99

SiK401004_A

SPECIFICATIONS 18

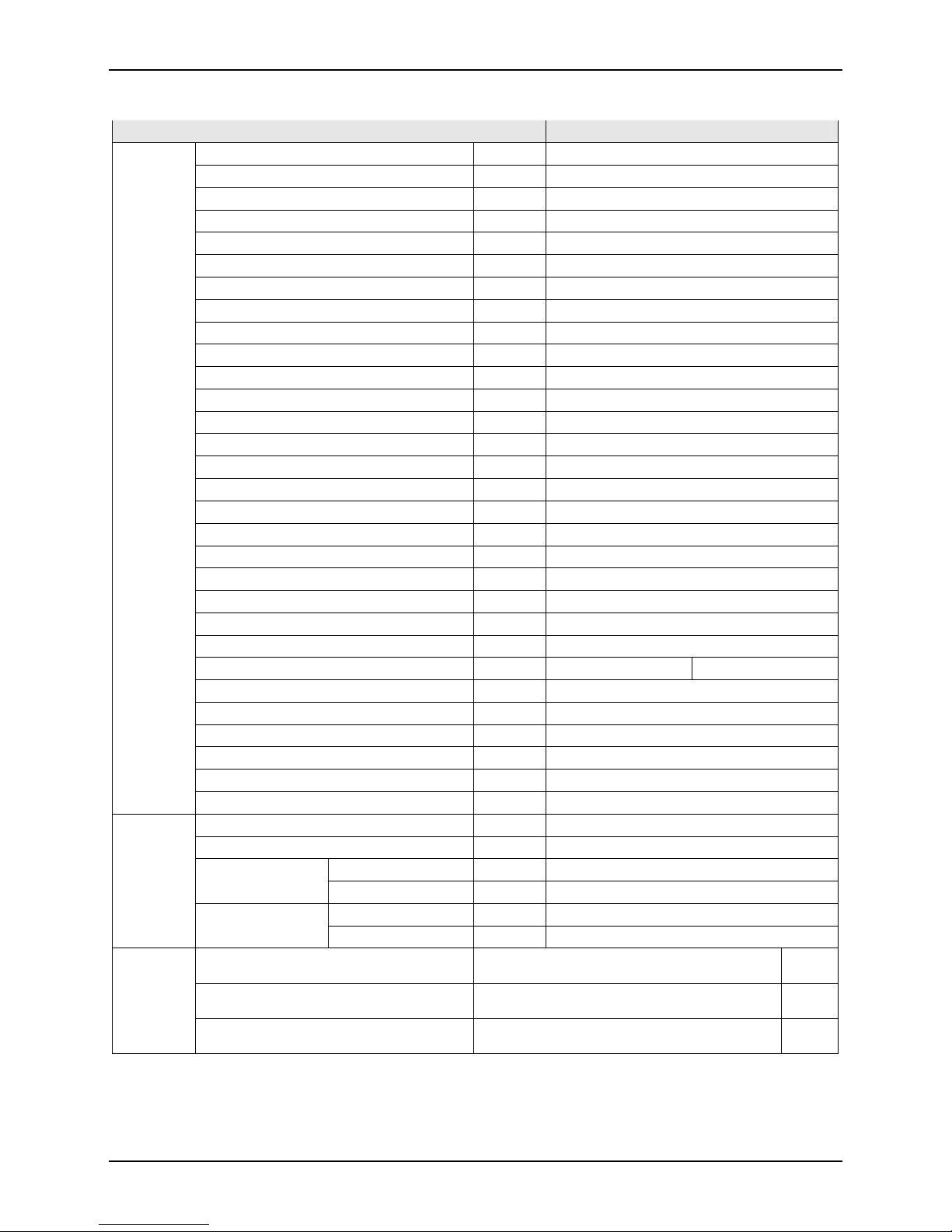

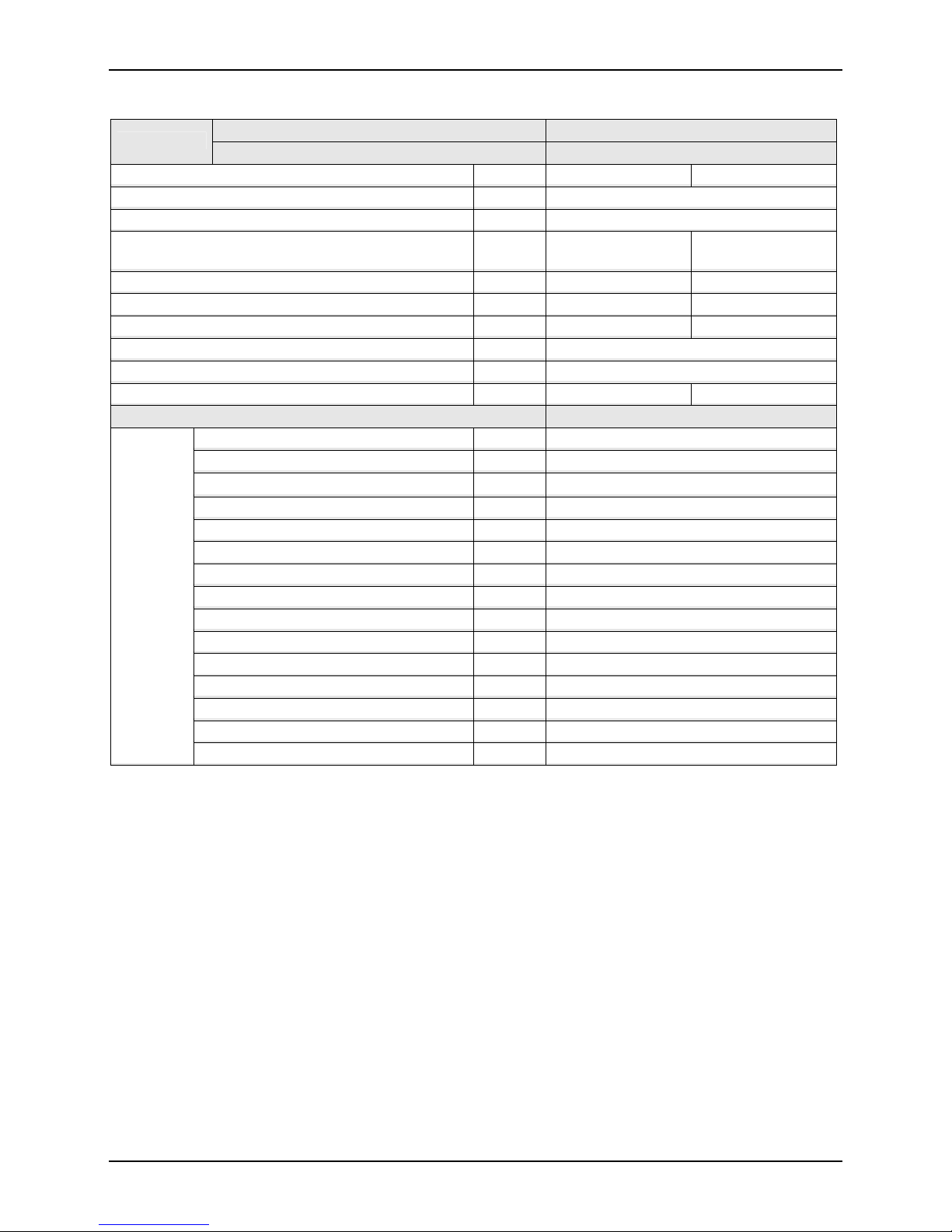

Outdoor RY30PEV1K

Model

Indoor FDYM30PEV1K

Function ― COOLING HEATING

Rated Voltage ― 220-240V 1Ph

Rated Frequency ― 50Hz

Total Capacity (Btu/h)/W

7700

26300

9400

32100

Power Input W 2950 3300

Rated Current A 14.5 16.8

Max Current A 21.0 19.0

Air Flow Volume (H/M/L)**

m3/h

1500/1300/1100

ESP Pa 37

EER/C.O.P (Btu/h)/W 8.92 2.85

Indoor Unit FDYM30PEV1K

Fan Motor Speed (H/M/L) r/min 1250/1220/1060

Output of Fan Motor W 150

Fan Motor Capacitor µF 8

Fan Type-Piece ― Centrifugal fan – 2

Diameter-Length mm φ160 – 200

Evaporator ― Aluminum fin-copper tube

Pipe Diameter mm φ9.52

Row-Fin Gap mm 2-1.8

Coil length (L) x height (H) x coil width (W) mm 1002X253X44

Fuse A 5

Sound Pressure Level dB (H/M/L) A 47/44/42

Sound Power Level dB (H/M/L) A 57/54/52

Dimension (W/H/D) mm 1270/268/530

Dimension of Package (W/H/D) mm 1345/283/594

Indoor

unit

Net Weight/Gross Weight kg 36/42

SiK401004_A

19 SPECIFICATIONS

Outdoor Unit RY30PEV1K

Compressor ManµFacturer/trademark ― Mitsubishi

Compressor Model ― LHT53VBAC

Compressor Type ― Rotary

L.R.A. A 76

Compressor RLA A 14.8

Compressor Power Input W

3050

Overload Protector ― Auto Reset Thermal Overload

Throttling Method ― Capillary

Starting Method ― Start directly

Working Temp Range °C Cooling: 18°C-52°C Heating: -7°C-24°C

Condenser ― Aluminum fin-copper tube

Pipe Diameter mm φ9.52

Rows-Fin Gap mm 2-1.6

Coil length (L) x height (H) x coil width (W) mm 976X762X44

Fan Motor Speed rpm 780

Output of Fan Motor W 125

Fan Motor Capacitor µF 7

Air Flow Volume of Outdoor Unit 4200

Fan Type-Piece ― Axial fan –1

Fan Diameter mm φ552

Defrosting Method ― Auto defrost

Climate Type ― T3

Isolation ― I

Moisture Protection ― IP24

Design Pressure (Hi/Lo) MPa 2.5 0.6

Sound Pressure Level dB A 58

Sound Power Level dB (H/M/L) A 68

Dimension (W/H/D) mm 980/790/427

Dimension of Package (W/H/D) mm 1080/840/485

Net Weight/Gross Weight kg 74/78

Outdoor

unit

Refrigerant Charge kg R22/3.4

Length m 5

Gas additional charge g/m 60

Liquid Pipe Inch φ3/8’’ Outer Diameter

Gas Pipe Inch φ5/8’’

Height m 15

Connection

Pipe

Max Distance

Length m 30

20’ Container

Interior Dimensions L*W*H: 5898*2352*2393,

Door Opening W*H: 2343*2280

34

40’ Container

Interior Dimensions L*W*H: 12032*2350*2390,

Door Opening W*H: 2343*2280

74

Loading

Quantity

40’ High Cube Container

Interior Dimensions L*W*H: 12032*2350*2697,

Door Opening W*H: 2338*2585

83

SiK401004_A

SPECIFICATIONS 20

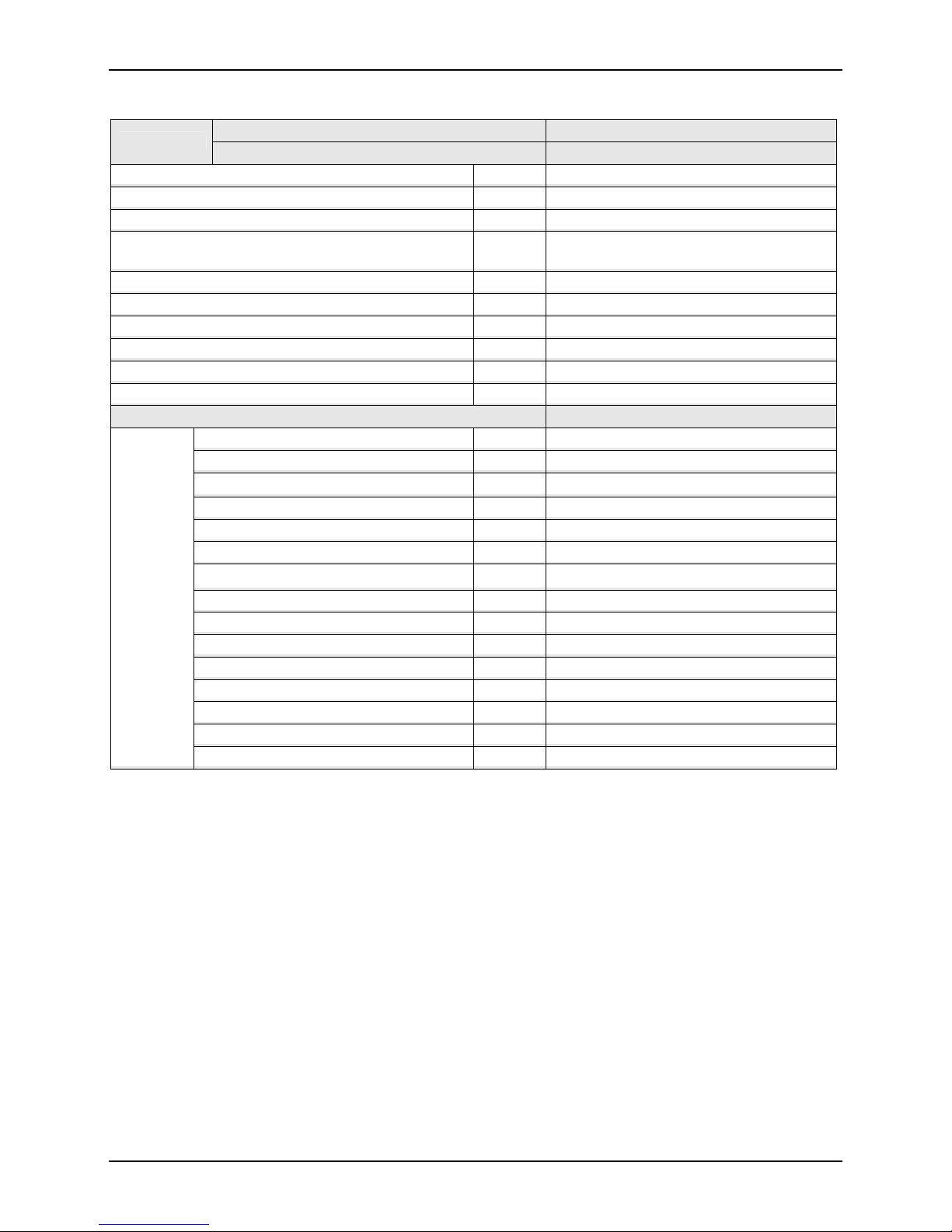

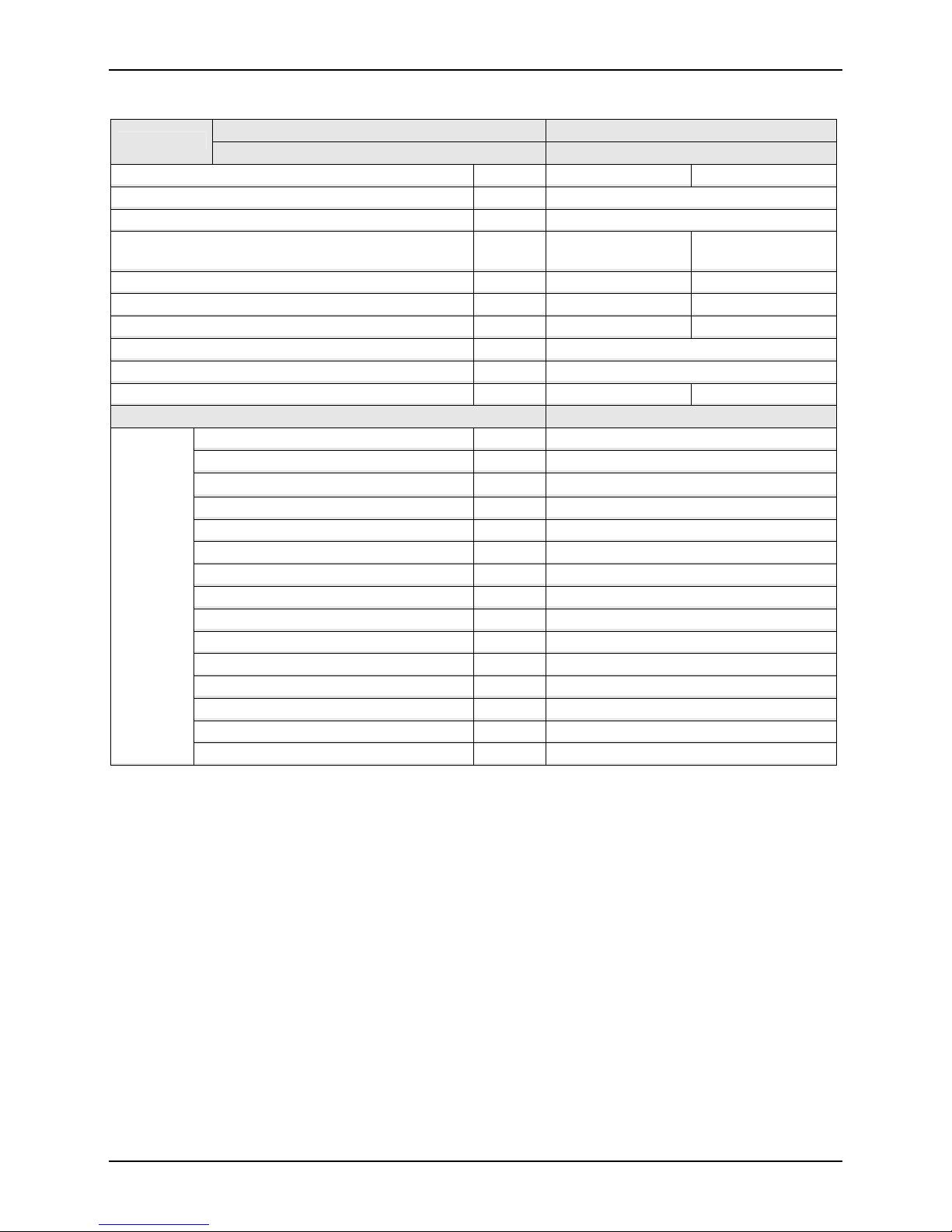

Outdoor RY36PEY1K

Model

Indoor FDYM36PEV1K

Function ― COOLING HEATING

Rated Voltage ― 380-415V 3Ph

Rated Frequency ― 50Hz

Total Capacity (Btu/h)/W

9700

33000

12000

41000

Power Input W 3900 3450

Rated Current A 7.2 6.7

Max Current A 10.3 8.0

Air Flow Volume (H/M/L)**

m3/h

2000/1900/1800

ESP Pa 37

EER/C.O.P (Btu/h)/W 8.46 3.48

Indoor Unit FDYM36PEV1K

Fan Motor Speed (H/M/L) r/min 1320/1090/910

Output of Fan Motor W 500

Fan Motor Capacitor µF 12

Fan Type-Piece ― Centrifugal fan – 2

Diameter-Length mm φ200 – 190

Evaporator ― Aluminum fin-copper tube

Pipe Diameter mm φ7

Row-Fin Gap mm 3-1.6

Coil length (L) x height (H) x coil width (W) mm 978X304.8X38.1

Fuse A 5

Sound Pressure Level dB (H/M/L) A 50/48/46

Sound Power Level dB (H/M/L) A 60/58/56

Dimension (W/H/D) mm 1226/290/775

Dimension of Package (W/H/D) mm 1335/305/834

Indoor

unit

Net Weight/Gross Weight kg 53/61

SiK401004_A

21 SPECIFICATIONS

Outdoor Unit RY36PEY1K

Compressor ManµFacturer/trademark ― SANYO

Compressor Model ― C-SBR145H38P

Compressor Type ― SCROLL

L.R.A. A 53

Compressor RLA A 6.5

Compressor Power Input W

3650

Overload Protector ― Auto Reset Thermal Overload

Throttling Method ― Capillary

Starting Method ― Start directly

Working Temp Range °C Cooling: 18°C-52°C Heating: -7°C-24°C

Condenser ― Aluminum fin-copper tube

Pipe Diameter mm φ9.52

Rows-Fin Gap mm 2-1.4

Coil length (L) x height (H) x coil width (W) mm 964X813X44

Fan Motor Speed rpm 920

Output of Fan Motor W 92

Fan Motor Capacitor µF 4

Air Flow Volume of Outdoor Unit 4000

Fan Type-Piece ― Axial fan –1

Fan Diameter mm φ482

Defrosting Method ― Auto defrost

Climate Type ― T3

Isolation ― I

Moisture Protection ― IP24

Design Pressure (Hi/Lo) MPa 2.5 0.6

Sound Pressure Level dB A 61

Sound Power Level dB (H/M/L) A 71

Dimension (W/H/D) mm 1018/840/412

Dimension of Package (W/H/D) mm 1100/985/450

Net Weight/Gross Weight kg 90/98

Outdoor

unit

Refrigerant Charge kg R22/3.6

Length m 5

Gas additional charge g/m 120

Liquid Pipe Inch φ1/2’’ Outer Diameter

Gas Pipe Inch φ3/4’’

Height m 30

Connection

Pipe

Max Distance

Length m 50

20’ Container

Interior Dimensions L*W*H: 5898*2352*2393,

Door Opening W*H: 2343*2280

30

40’ Container

Interior Dimensions L*W*H: 12032*2350*2390,

Door Opening W*H: 2343*2280

60

Loading

Quantity

40’ High Cube Container

Interior Dimensions L*W*H: 12032*2350*2697,

Door Opening W*H: 2338*2585

66

SiK401004_A

SPECIFICATIONS 22

Outdoor RY42PEY1K

Model

Indoor FDYM42PEV1K

Function ― COOLING HEATING

Rated Voltage ― 380-415V 3Ph

Rated Frequency ― 50Hz

Total Capacity (Btu/h)/W

11300

38600

13500

46100

Power Input W 4800 4150

Rated Current A 9.3 8.1

Max Current A 12.5 9.7

Air Flow Volume (H/M/L)**

m3/h

2000/1900/1800

ESP Pa 37

EER/C.O.P (Btu/h)/W 8.04 3.25

Indoor Unit FDYM42PEV1K

Fan Motor Speed (H/M/L) r/min 1320/1090/910

Output of Fan Motor W 500

Fan Motor Capacitor µF 12

Fan Type-Piece ― Centrifugal fan – 2

Diameter-Length mm φ200 – 190

Evaporator ― Aluminum fin-copper tube

Pipe Diameter mm φ7

Row-Fin Gap mm 3-1.6

Coil length (L) x height (H) x coil width (W) mm 978X304.8X38.1

Fuse A 5

Sound Pressure Level dB (H/M/L) A 50/48/46

Sound Power Level dB (H/M/L) A 60/58/56

Dimension (W/H/D) mm 1226/290/775

Dimension of Package (W/H/D) mm 1335/305/834

Indoor

unit

Net Weight/Gross Weight kg 53/61

Loading...

Loading...