Daikin FFN15CV1, FCN20FV1, FCN25FV1, FCN30FV1, FCN35FV1 Technical Manual

...

TECHNICAL MANUAL

Split Unit Air Conditioner

Ceiling Cassette F & C Series

FCN-F, FFN-C Series

— Cooling only [50Hz] —

R410A

TM-FFCN-0916-B

Table of Contents

i

Table of Contents

Nomenclature......................................................................................................................1

Indoor ............................................................................................................................1

Outdoor ..........................................................................................................................1

Panel .............................................................................................................................2

Product Line-Up .............................................................................................................3

Application Information .....................................................................................................5

Operating Range ...........................................................................................................5

Refrigerant Circuit Diagrams .........................................................................................6

Installation Guideline .....................................................................................................8

Sound Data ........................................................................................................................15

Sound Pressure Level .................................................................................................15

NC Curve .....................................................................................................................16

Engineering & Physical Data ...........................................................................................20

Performance Data .............................................................................................................24

Calculation Steps .........................................................................................................24

Performance Tables .....................................................................................................27

Outline & Dimension ........................................................................................................36

Wiring Diagram .................................................................................................................39

Service & Maintenance ....................................................................................................43

Troubleshooting ...............................................................................................................45

Nomenclature

1

Nomenclature

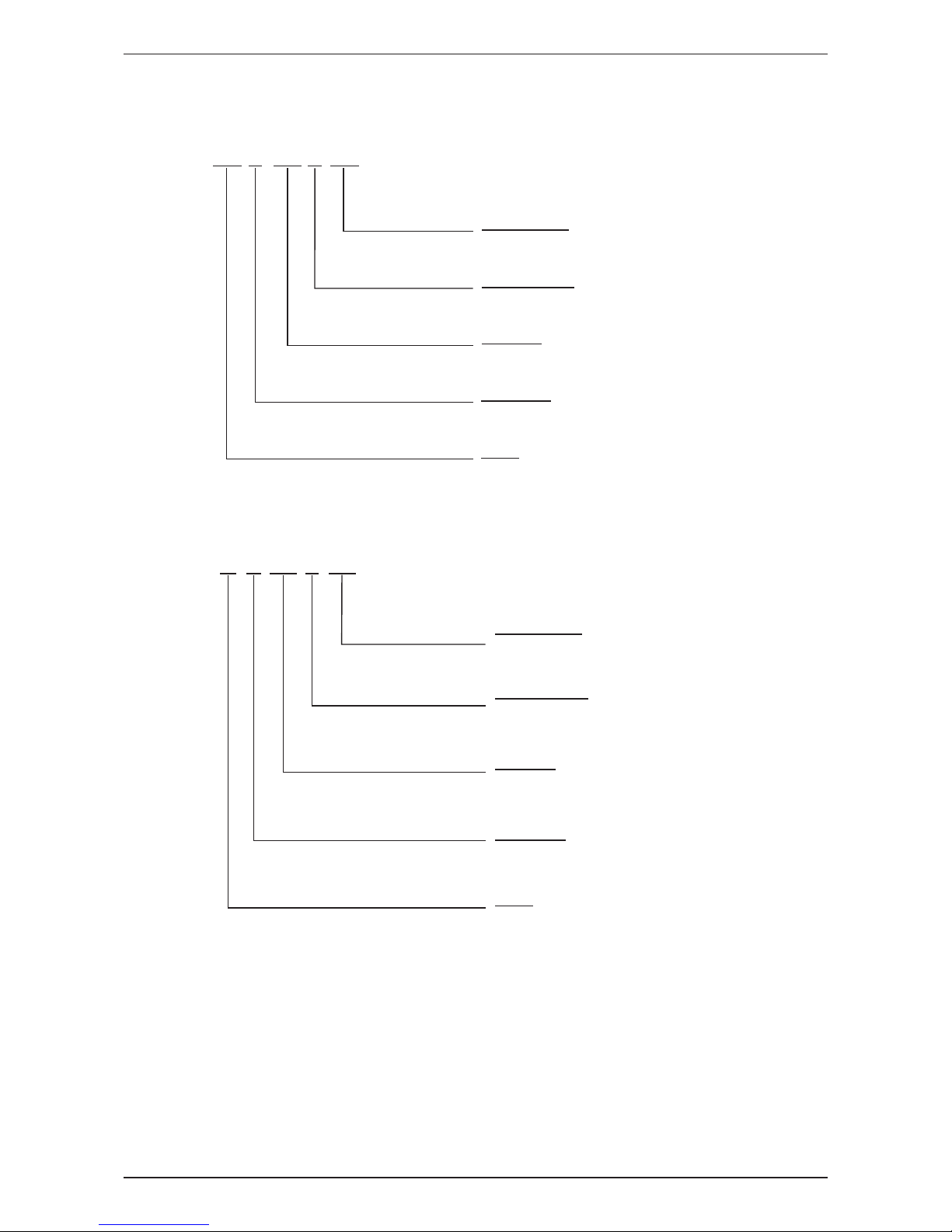

Indoor

30 FFC N V1

Power Supply

V: 220-240V 1 Phase 50 Hz

Product Series

F: F series

C: C Series

Capacity*

30: 30,000Btu/hr

Refrigerant

N: R410A

Model

FC: Ceiling Cassette 3”x3”

FF: Ceiling cassette 2”x2”

Outdoor

30 CR N V1

Power Supply

V1: 220-240V 1 Phase 50Hz

Y1: 380-415V 3 Phase 50Hz

Product Series

C: C Series

D: D Series

F: F Series

Capacity*

30: 30,000Btu/hr

Refrigerant

N: R410A

Model

R: Single Split Condensing Unit

Remark:

* : Capacity value under Nomenclature is an indication.

Please refer to Engineering and Physical Data for exact capacity value.

Nomenclature

2

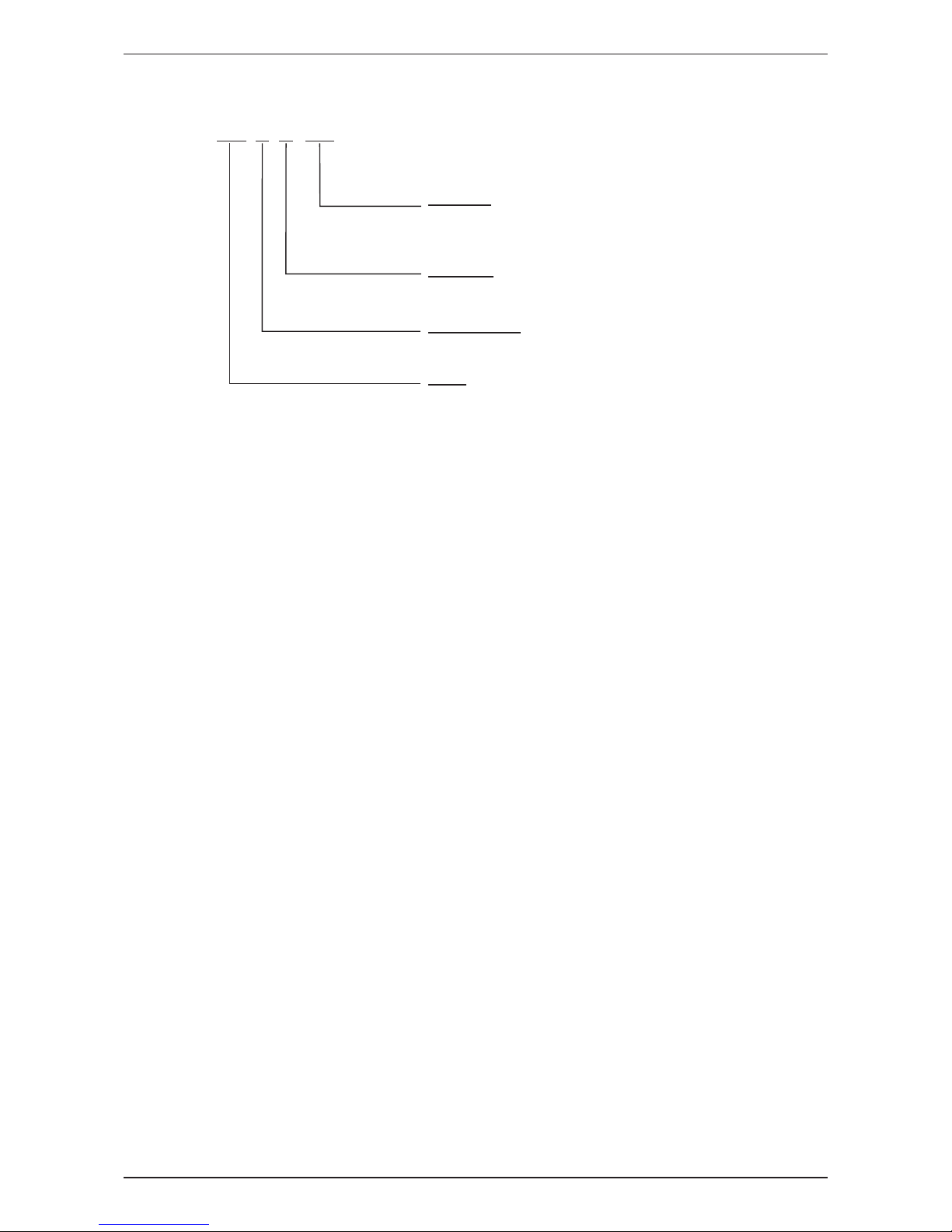

Panel

BC F L G1

Controller

G1: Wireless handset DGS01

2B5: Wireless handset BRC52B65

S8: Wired handset DSLM8

Product Series

F: F Series

C: C series

Model

BC: Ceiling Cassette Panel

BF: Ceiling Cassette Panel

Cool Light

“-”: Without LED Light

L: With LED Light

Nomenclature

3

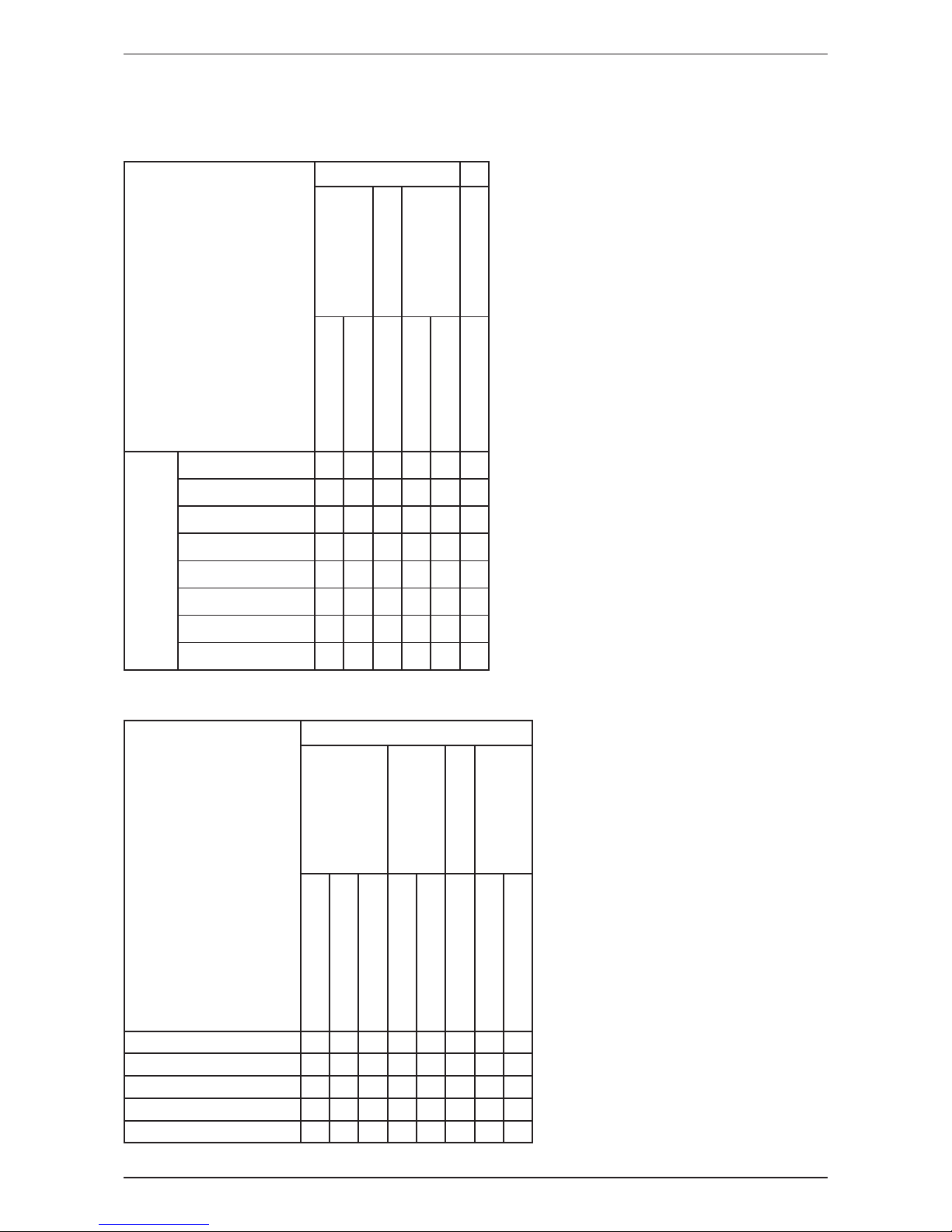

Product Line-Up

Indoor Unit

FCN-F, FFN-C

Nomenclature

Classication

PCB

Fin

Refrigerant

Control

Indoor Air Quality

L208D EC

L208A AP

Hydrophilic (Blue)

Cap Tube

w/o Cap Tube

Plasma

COOLING

FFN10CV1 X X X X

FFN15CV1 X X X X

FCN20FV1 X X X X

FCN25FV1 X X X X

FCN30FV1 X X X X

FCN35FV1 X X X X

FCN40FV1 X X X X

FCN50FV1 X X X X

Panel

BC-F

Nomenclature

Classication

Handset

Cool Light

Indoor Air Quality

Others

DGS01

BRC52B65

DSLM8

With LED Light

W/O LED Light

Saranet Filter

8 Ways Discharge

4 Way Discharge

BFCG1 X X X X

BFCS8 X X X X

BCFG1 X X X X

BCFL2B5 X X X X

BCFS8 X X X X

Nomenclature

4

Outdoor Unit

RN-C/D, RN-F

Nomenclature

Classication

Refrigerant Control

Fin

Safety Devices

Compressor

Cap Tube

TXV

Hydrophilic (Blue)

Hydrophilic (Gold)

Bare Aluminium

Contactor

High Pressure Switch

Low Pressure Switch

Phase Protector

Scroll

Rotary

COOLING

RN10FV1 X X X

RN15FV1 X X X

RN20CV1 X X X

RN25CV1 X X X

RN28CV1 X X X

RN30CV1 X X X

RN35DV1 X X X X X X

RN40DY1 X X X X X X

RN50DY1 X X X X X X

RN10FGV1 X X X

RN15FGV1 X X X

RN20CGV1 X X X

RN25CGV1 X X X

RN28CGV1 X X X

RN30CGV1 X X X

RN35DGV1 X X X X X X

RN40DGY1 X X X X X X

RN50DGY1 X X X X X X

5

Application Information

Application Information

Operating Range

Ensure the operating temperature is in allowance range.

Cooling

The use of your air conditioner

outside the range of working

temperature and humidity can

result in serious failure.

Outdoor

DB (°C)

46

43

19

14 19 23 Indoor WB (°C)

6

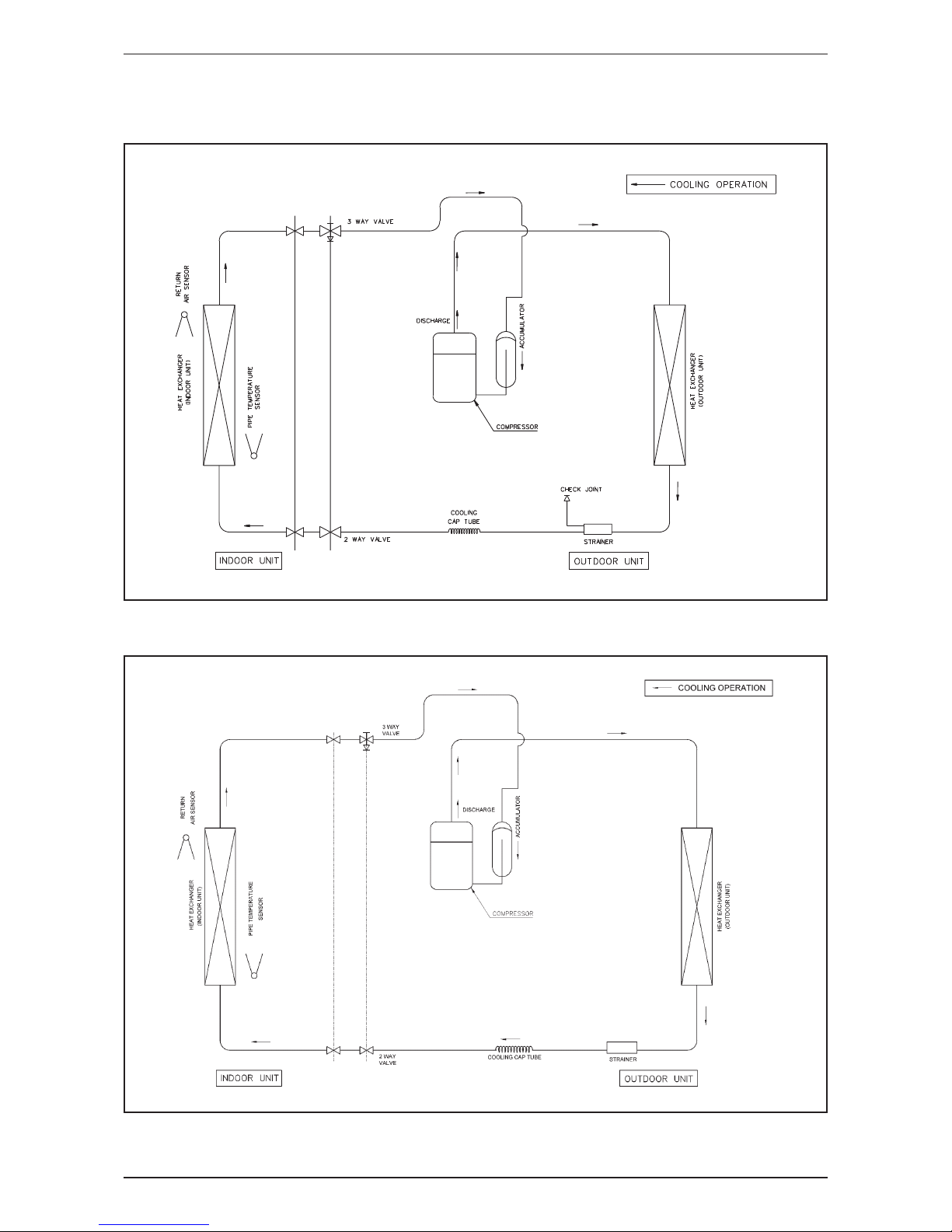

Application Information

Refrigerant Circuit Diagrams

Model: FFN10/15CV1 - RN10/15FV1

Model: FCN20FV1 - RN20CV1 / FCN25FV1 - RN25CV1

7

Application Information

Model: FCN30FV1 - RN28/30CV1

Model: FCN35FV1 - RN35DV1 / FCN40FV1 - RN40DY1 / FCN50FV1 - RN50DY1

8

Application Information

Installation Guideline

Safety Precautions

• Installation and maintenance should be performed

by qualied persons who are familiar with local code

and regulation, and experienced with this type of

appliance.

• All eld wiring must be installed in accordance with

the national wiring regulation.

• Ensure that the rated voltage of the unit corresponds

to that of the name plate before commencing wiring

work according to the wiring diagram.

• The unit must be GROUNDED to prevent possible

hazard due to insulation failure.

• All electrical wiring must not touch the refrigerant

piping or any moving parts of the fan motors.

• Conrm that the unit has been switched OFF before

installing or servicing the unit.

• Disconnect from the main power supply before

servicing the air conditioner unit.

• DO NOT pull out the power cord when the power is

ON. This may cause serious electrical shocks which

may result in re hazards.

• Keep the indoor and outdoor units, power cable and

transmission wiring, at least 1m from TVs and radios,

to prevent distorted pictures and static. {Depending on

the type and source of the electrical waves, static may

be heard even when more than 1m away}.

Please take note of the following important points

when installing.

• Do not install the unit where leakage of ammable

gas may occur.

If gas leaks and accumulates around the unit, it

may cause re ignition.

• Ensure that drainage piping is connected properly.

If the drainage piping is not connected properly,

it may cause water leakage which will dampen

the furniture.

• Do not overcharge the unit.

This unit is factory pre-charged. Overcharge will

cause over-current or damage to the compressor.

• Ensure that the unit’s panel is closed after service

or installation.

Unsecured panels will cause the unit to operate

noisily.

• Sharp edges and coil surfaces are potential

locations which may cause injury hazards. Avoid

from being in contact with these places.

• Before turning off the power supply, set the remote

controller’s ON/OFF switch to the “OFF” position

to prevent the nuisance tripping of the unit. If this is

not done, the unit’s fans will start turning automatically

when power resumes, posing a hazard to service

personnel or the user.

• Do not operate any heating apparatus too close to the

air conditioner unit. This may cause the plastic panel to

melt or deform as a result of the excessive heat.

• Ensure the color of wires of the outdoor unit and

the terminal markings are same to the indoors

respectively.

• IMPORTANT : DO NOT INSTALL OR USE THE AIR

CONDITIONER UNIT IN A LAUNDRY ROOM.

• Do not use joined and twisted wires for incoming

power supply.

NOTICE

Disposal requirements

Your air conditioning product is marked with this symbol. This means that electrical and electronic products

shall not be mixed with unsorted household waste.

Do not try to dismantle the system yourself: the dismantling of the air conditioning system, treatment of the

refrigerant, of oil and of other parts must be done by a qualied installer in accordance with relevant local and

national legislation. Air conditioners must be treated at a specialized treatment facility for re-use, recycling

and recovery. By ensuring this product is disposed of correctly, you will help to prevent potential negative

consequences for the environment and human health. Please contact the installer or local authority for more

information.

Batteries must be removed from the remote controller and disposed of separately in accordance with relevant

local and national legislation.

9

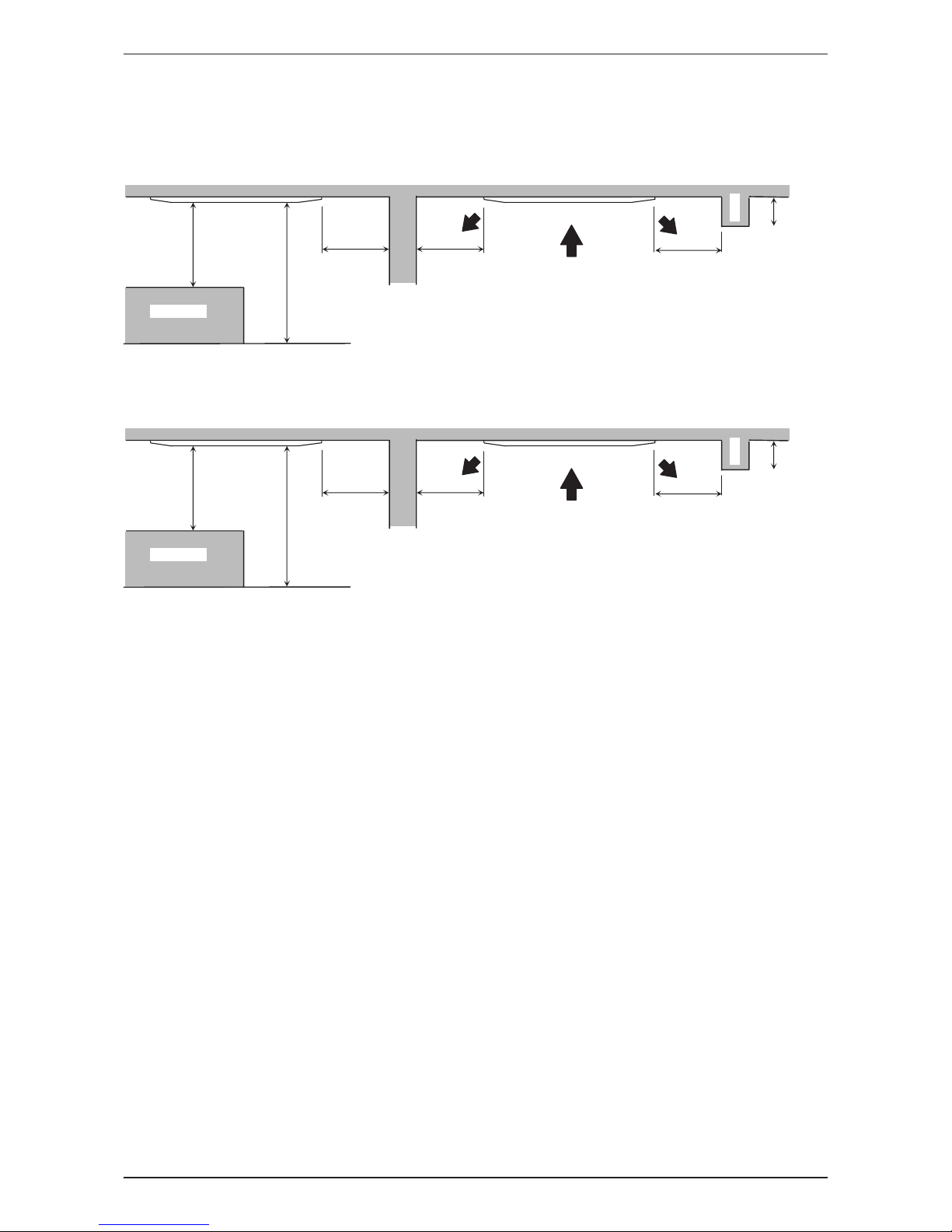

Application Information

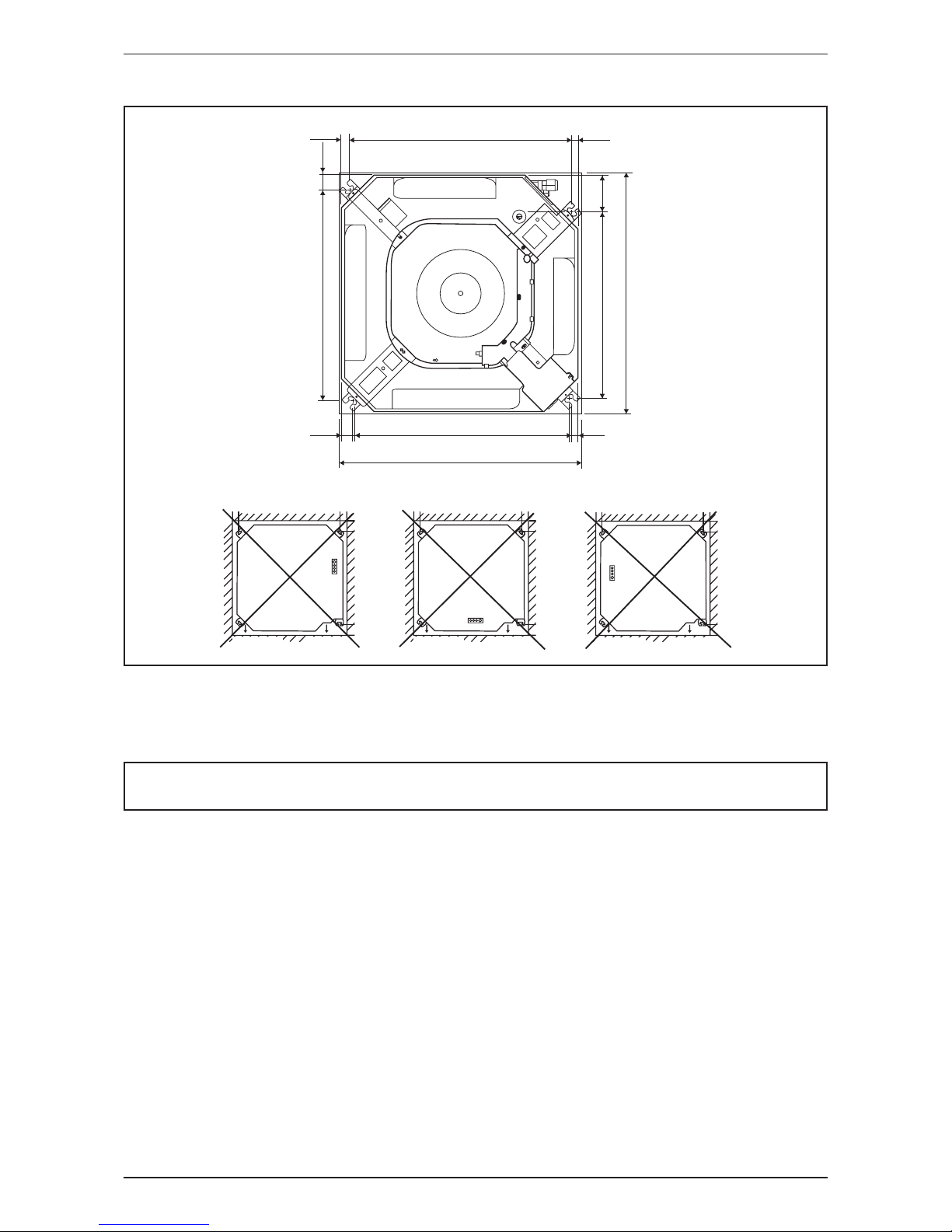

1) Indoor Installation Clearance

Clearance must be provided for the indoor unit from wall and obstacles as shown in gure below.

F series

Beam

0.3m or more

3.0m or more

0.5m or more 0.5m or more 0.5m or more

Floor

Obstacles

1.0m or more

The installation place (handling ceiling surface) must be level and the height in the ceiling is 370mm or more.

C series

Beam

0.3m or more

3.0m or more

0.5m or more 0.5m or more 0.5m or more

Floor

Obstacles

1.0m or more

The installation place (handling ceiling surface) must be level and the height in the ceiling is 350mm or more.

10

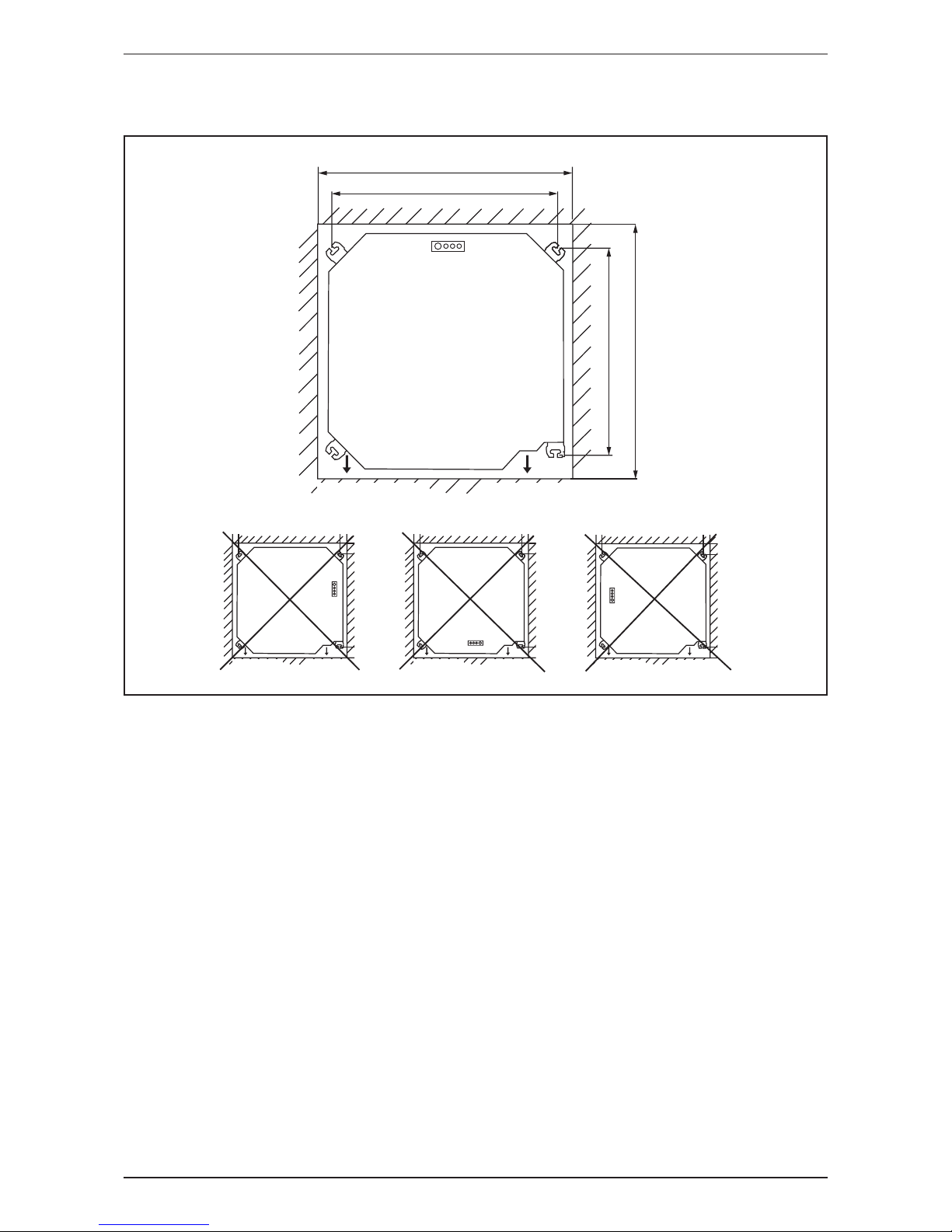

Application Information

Unit Installation

F series

Ceiling Opening Size = 890mm

Hanging rod size = 780mm

Ceiling Opening Size = 890mm

Hanging rod size = 710mm

WATER DRAINAGE

PIPING DIRECTION

LED

REFRIGERANT

PIPING DIRECTION

WATER DRAINAGE

PIPING DIRECTION

REFRIGERANT

PIPING DIRECTION

LED

WATER DRAINAGE

PIPING DIRECTION

LED

REFRIGERANT

PIPING DIRECTION

WATER DRAINAGE

PIPING DIRECTION

LED

REFRIGERANT

PIPING DIRECTION

11

Application Information

C series

WATER DRAINAGE

PIPING DIRECTION

REFRIGERANT

PIPING DIRECTION

LED

WATER DRAINAGE

PIPING DIRECTION

LED

REFRIGERANT

PIPING DIRECTION

WATER DRAINAGE

PIPING DIRECTION

LED

REFRIGERANT

PIPING DIRECTION

538.0

18.0

32.0 529.0

580.0 ~ 610.0mm (CEILING OPENING MEASUREMENT)

580.0 ~ 610.0mm (CEILING OPENING MEASUREMENT)

505.0

448.0

38.0

15.0

19.0

88.0

All dimensions are in mm

• Measure and mark the position for the hanging rod. Drill the hole for the angle nut on the ceiling and x the hanging

rod.

• The installation template is extended according to temperature and humidity. Check on dimensions in use.

• The dimensions of the installation template are the same as those of the ceiling opening dimensions.

• Before ceiling laminating work is completed, be sure to t the installation template to the indoor unit.

NOTE

Be sure to discuss the ceiling drilling work with the installers concerned.

12

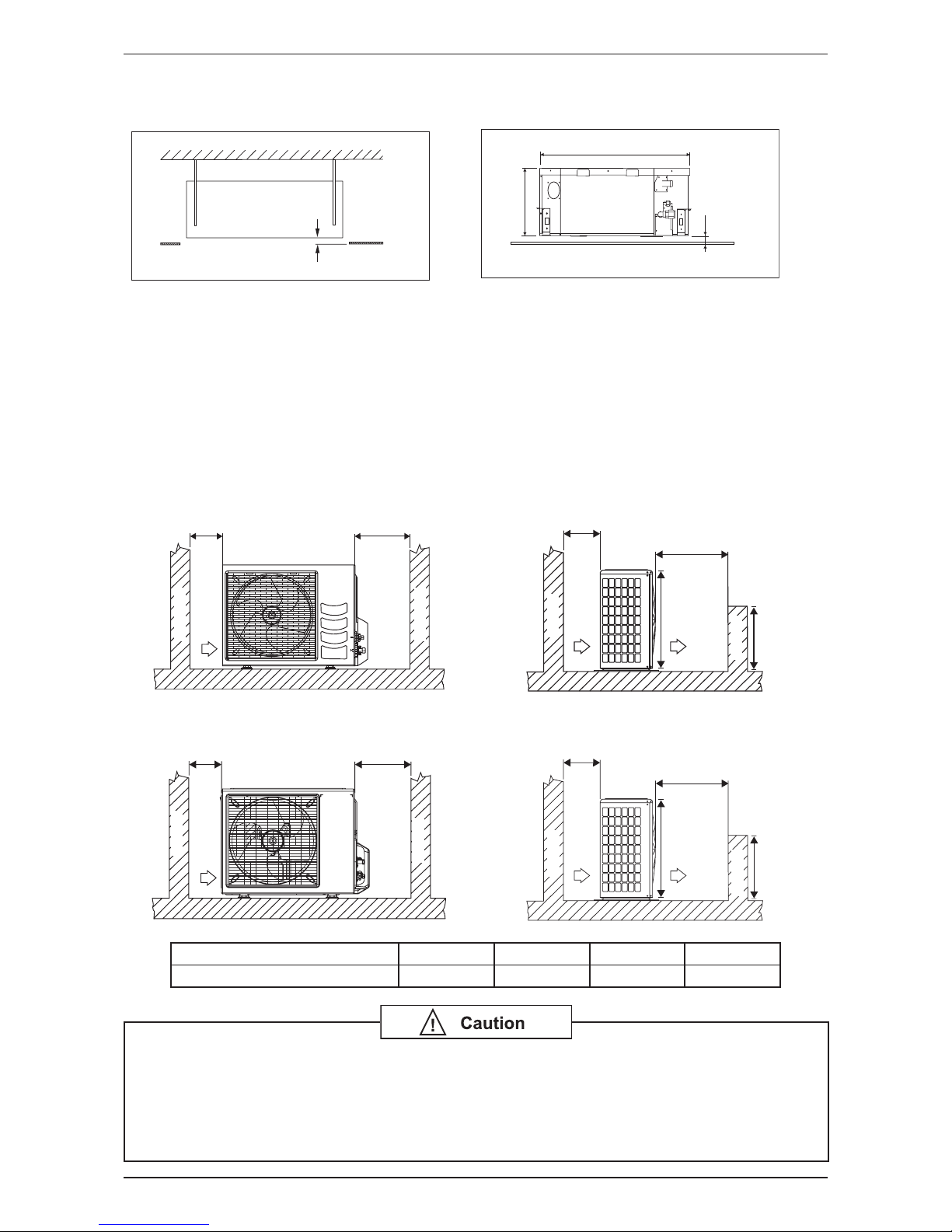

Application Information

Unit Installation

F Series C Series

Indoor Unit

Ceiling Board

38mm

570 (UNIT SIZE)

30

250

All dimensions are in mm

• Hold the unit and hang it on the hanging rod with the nut and washer.

• Adjust the unit height to 38mm and 30mm respectively depending on series between the indoor unit bottom surface

and the ceiling surface.

• Conrm with a level gauge that the unit is installed horizontally and tighten the nut and bolt to prevent unit falling and

vibration.

• Open the ceiling board along the outer edge of the paper installation template.

2) Outdoor Installation Clearance

Outdoor unit must be installed such that there is no short circuit of the hot discharge air or obstruction to smooth

air ow. Select the coolest possible place where intake air should not hotter than the outside temperature

(Max. 45°C).

RN10/15FV1

Return air

Service access

C

D

Obstacle

Obstacle

Return air

Discharge air

A

Obstacle

Obstacle

B

H/2

H

RN20/25/30/35DV1, RN40/50DY1

Obstacle

Return air

Service access

DC

Obstacle

Return air

Discharge air

A

Obstacle

Obstacle

B

H/2

H

Dimensions A B C D

Minimum Distance, mm 300 1000 300 500

Avoid installing or operating the condensing unit in the environment that is exposed to the

following substances:

• Oils (including machine oils)

• Salt (e.g. coastal area)

• Sulphide gas (e.g. hot spring areas, oil renery plant, etc)

Such substance may lead to the failure of the unit.

13

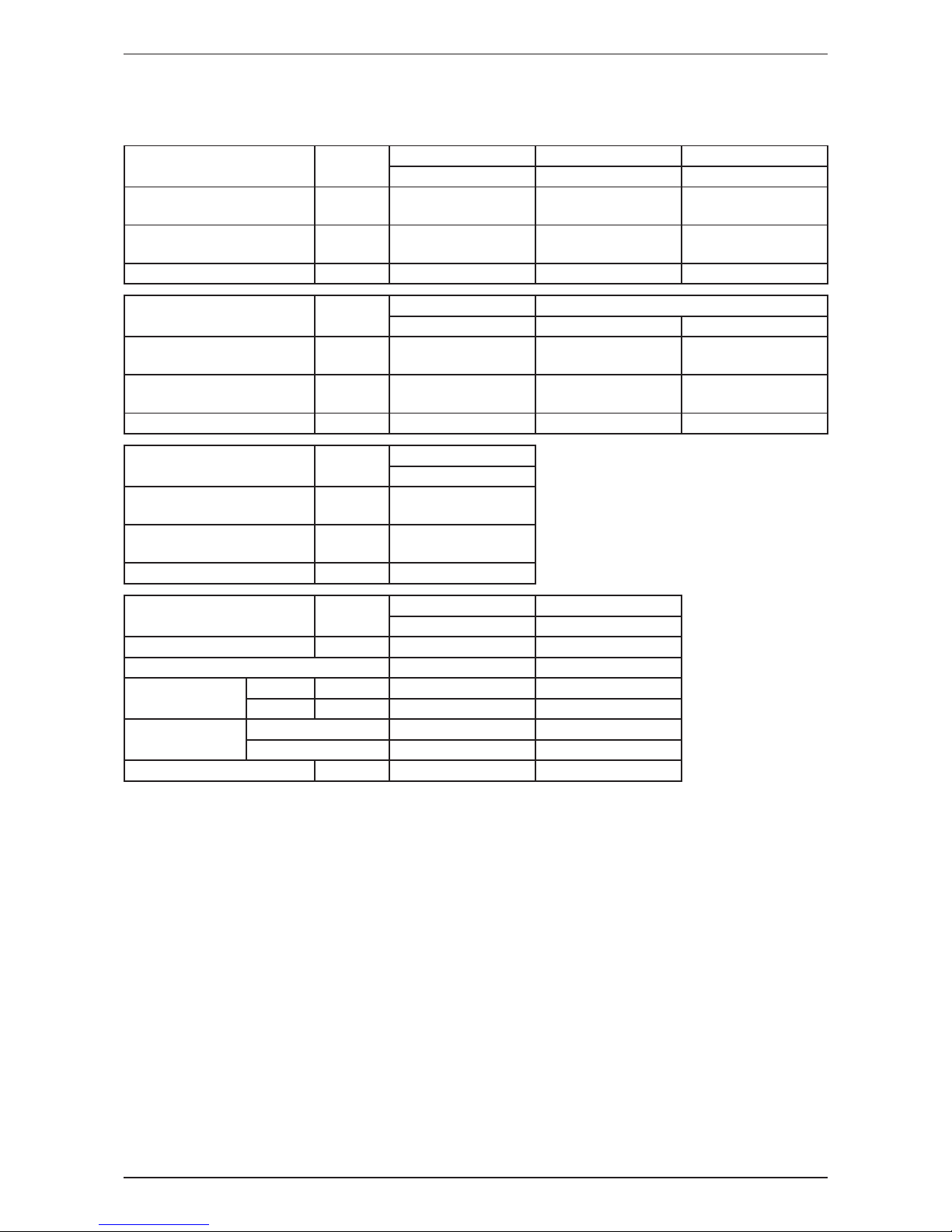

Application Information

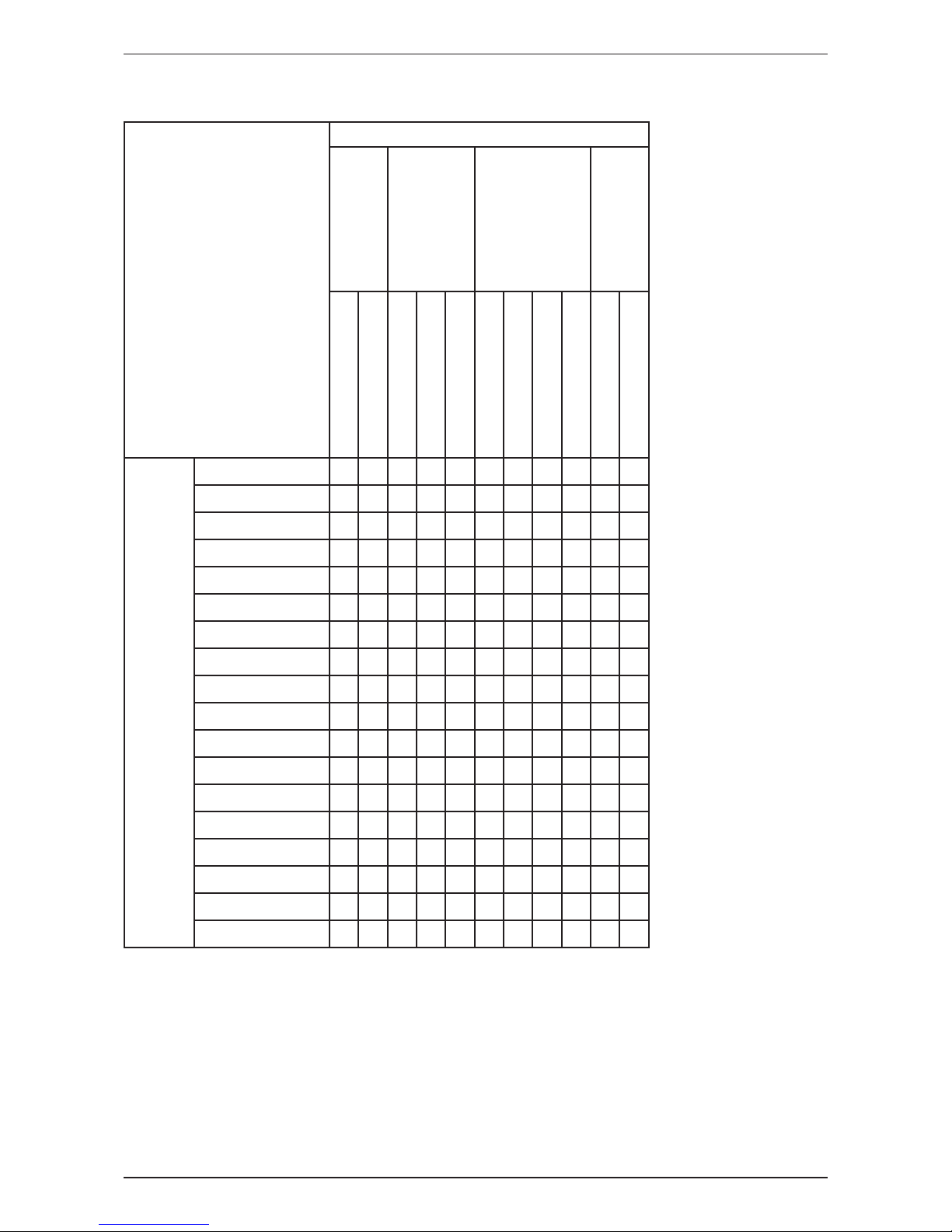

3) Cable Size

Cooling only

Model Unit

FFN10CV1 FFN15CV1 FCN20FV1

RN10FV1 RN15FV1 RN20CV1

Power supply cable size

Number of wire

mm²

1.5

3

1.5

3

2.5

3

Interconnection cable size

Number of wire

mm²

1.5

3

1.5

3

2.5

3

Recommended fuse A 15 15 16

Model Unit

FCN25FV1 FCN30FV1

RN25CV1 RN28CV1 RN30CV1

Power supply cable size

Number of wire

mm

2

2.5

3

2.5

3

2.5

3

Interconnection cable size

Number of wire

mm

2

2.5

3

2.5

3

2.5

3

Recommended fuse A 20 25 25

Model Unit

FCN35FV1

RN35DV1

Power supply cable size

Number of wire

mm

2

4.0

3

Interconnection cable size

Number of wire

mm

2

2.5

4

Recommended fuse A 25

Model Unit

FCN40FV1 FCN50FV1

RN40DY1 RN50DY1

Power supply cable size mm

2

4.0 4.0

Number of wire 3 3

Interconnection

cable size

Indoor mm

2

2.5 2.5

Outdoor mm

2

2.5 2.5

Number of wire

Indoor 4 4

Outdoor 4 + 3 4 + 3

Recommended fuse A 16 20

14

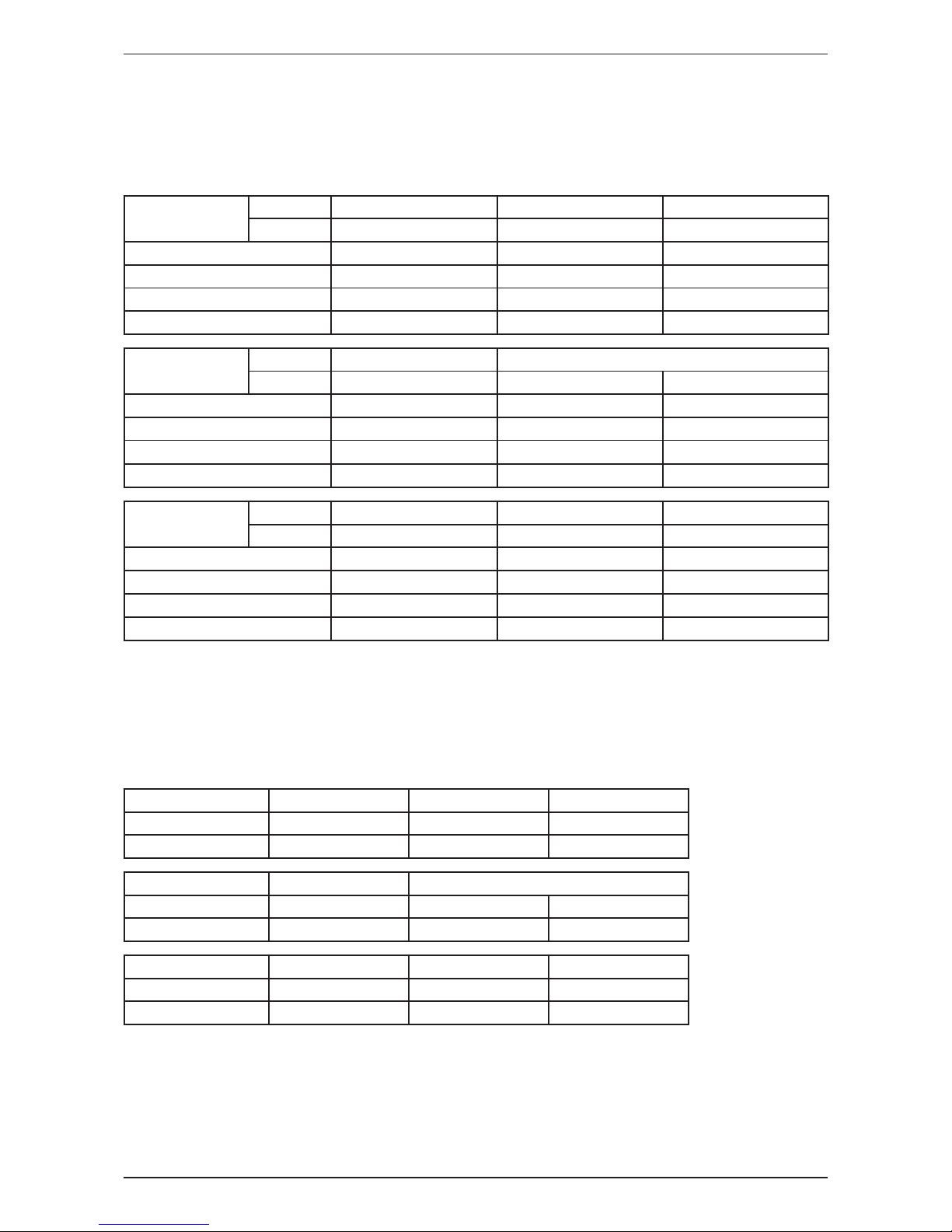

Application Information

4) Refrigerant Piping

When the pipe length becomes too long, both the capacity and reliability drop. As the number of bends

increase, resistance to ow of refrigerant system increases, thus lowering cooling capacity and as a result

the compressor may become defective. Always choose the shortest path and follow the recommendation as

tabulated below:

Model

Indoor FFN10CV1 FFN15CV1 FCN20FV1

Outdoor RN10FV1 RN15FV1 RN20CV1

Max. allowable length, m 20 20 30

Max. allowable elevation, m 10 10 15

Liquid pipe size, mm / in 6.35 / 1/4” 6.35 / 1/4” 6.35 / 1/4”

Gas pipe size, mm / in 9.52 / 3/8” 12.70 / 1/2” 12.70 / 1/2”

Model

Indoor FCN25FV1 FCN30FV1

Outdoor RN25CV1 RN28CV1 RN30CV1

Max. allowable length, m 30 25 45

Max. allowable elevation, m 15 8 25

Liquid pipe size, mm / in 6.35 / 1/4” 9.52 / 3/8” 9.52 / 3/8”

Gas pipe size, mm / in 15.88 / 5/8” 15.88 / 5/8” 15.88 / 5/8”

Model

Indoor FCN35FV1 FCN40FV1 FCN50FV1

Outdoor RN35DV1 RN40DY1 RN50DY1

Max. allowable length, m 50 50 50

Max. allowable elevation, m 30 30 30

Liquid pipe size, mm / in 9.52 / 3/8” 9.52 / 3/8” 9.52 / 3/8”

Gas pipe size, mm / in 15.88 / 5/8” 15.88 / 5/8” 15.88 / 5/8”

5) Additional Charge

• The refrigerant charge has already charged into the outdoor unit. For the piping length of 7.5m, additional

refrigerant charge after vacuuming is not necessary.

• When the piping length is more than 7.5m, please use the table below (unit in gram).

Cooling Only

Indoor

FFN10CV1 FFN15CV1

FCN20FV1

Outdoor RN10FV1 RN15FV1 RN20CV1

Add. Charge, g/m 18 18 22

Indoor FCN25FV1 FCN30FV1

Outdoor RN25CV1 RN28CV1 RN30CV1

Add. Charge, g/m 10 24 24

Indoor FCN35FV1 FCN40FV1 FCN50FV1

Outdoor RN35DV1 RN40DY1 RN50DY1

Add. Charge, g/m 27 24 24

Example: FCN25FV1 & RN25CV1 with 13m piping length, additional piping length is 5.5m. Thus,

Additional Charge = 5.5m x 10 g/m

= 55g

Loading...

Loading...