Daikin FCAHG71, RZAG71 Service Manual

ESIE16-03B

Service

Manual

SA R32 Sky-Air RZAG-L

Indoor unit Outdoor unit

FCAHG71/100/125/140FVEB RZAG71/100/125/140L7V1B

SA R32 Sky-Air RZAG-L

ESIE16-03B |

The present publication is drawn up by way of information only and does not constitute an offer binding upon Daikin Europe N.V..

Daikin Europe N.V. has compiled the content of this publication to the best of its knowledge. No express or implied warranty is

given for the completeness, accuracy, reliability or fitness for particular purpose of its content and the products and services

presented therein. Specifications are subject to change without prior notice. Daikin Europe N.V. explicitly rejects any liability for

any direct or indirect damage, in the broadest sense, arising from or related to the use and/or interpretation of this publication. All

content is copyrighted by Daikin Europe N.V..

Page 2 22/08/16 | Version 1.1

SA R32 Sky-Air RZAG-L

ESIE16-03B |

Part 1. Introduction ....................................................................................................................7

1.1. Version log .................................................................................................................................................7

1.2. Safety precautions .....................................................................................................................................8

1.2.1. Meaning of symbols ....................................................................................................................................... 8

1.2.2. Warnings ........................................................................................................................................................ 8

1.2.3. Cautions ....................................................................................................................................................... 10

1.2.4. Information ...................................................................................................................................................10

1.3. General operation ....................................................................................................................................11

1.4. How to use ...............................................................................................................................................12

1.4.1. Interactive information flow ........................................................................................................................... 12

1.4.2. Parts of the book .......................................................................................................................................... 13

1.4.2.1. The introduction chapter .......................................................................................................................... 13

1.4.2.2. The troubleshooting chapter .................................................................................................................... 13

1.4.2.3. The repair chapter .................................................................................................................................... 13

1.4.2.4. The maintenance chapter ........................................................................................................................ 13

1.4.2.5. Appendices .............................................................................................................................................. 13

1.4.3. Contact information ......................................................................................................................................13

Part 2. Troubleshooting ...........................................................................................................15

2.1. Error codes check ....................................................................................................................................15

2.1.1. Error codes via remote controller ................................................................................................................. 15

2.1.1.1. Error codes via wired remote controller BRC1E ...................................................................................... 15

2.1.1.2. Error codes via wireless remote controller BRC7 .................................................................................... 17

2.1.2. Error codes via outdoor unit PCB .................................................................................................................19

2.1.2.1. How to retrieve error codes ...................................................................................................................... 19

2.1.2.2. How to reset error codes .......................................................................................................................... 21

2.1.2.3. History of error codes and warnings ........................................................................................................ 22

2.1.2.4. Content of retry ........................................................................................................................................ 22

2.2. Error based troubleshooting .....................................................................................................................23

2.2.1. Indoor unit .................................................................................................................................................... 24

2.2.1.1. “A1-01” – Indoor unit PCB abnormality .................................................................................................... 24

2.2.1.2. “A3-00” – Drain water level system abnormality ...................................................................................... 24

2.2.1.3. “A6-00” – Indoor unit fan motor abnormality ............................................................................................ 24

2.2.1.4. “AJ-00” – Capacity setting abnormality .................................................................................................... 25

2.2.1.5. “C1-00” – Transmission error (indoor & adapter PCB) ............................................................................25

2.2.1.6. “C4-00” – Heat exchanger thermistor abnormality ................................................................................... 26

2.2.1.7. “C5-00” – Intermediate heat exchanger thermistor abnormality ..............................................................26

2.2.1.8. “C9-00” – Suction air thermistor abnormality ........................................................................................... 27

2.2.1.9. “CC-00” – Humidity sensor system abnormality ...................................................................................... 27

2.2.1.10. “CJ-00” – Remote controller thermistor abnormality .............................................................................. 27

2.2.2. Outdoor unit .................................................................................................................................................. 28

2.2.2.1. “E1-00” – Outdoor unit PCB abnormality ................................................................................................. 28

2.2.2.2. “E3-00” – Discharge pressure abnormality .............................................................................................. 28

2.2.2.3. “E4-00” – Suction pressure abnormality .................................................................................................. 29

2.2.2.4. “E5-00” – Compressor motor lock or overheated ..................................................................................... 29

2.2.2.5. “E7-00” – Fan motor abnormality ............................................................................................................. 30

2.2.2.6. “E9-00” – Electronic expansion valve abnormality ................................................................................... 31

2.2.2.7. “F3-00” – Discharge pipe temperature abnormality ................................................................................. 31

2.2.2.8. “H3-00” – High pressure switch abnormality ............................................................................................ 32

2.2.2.9. “H4-00” – Low pressure switch abnormality ............................................................................................. 33

2.2.2.10. “H9-00” – Outdoor air temperature thermistor abnormality ....................................................................33

2.2.2.11. “J3-00” – Discharge pipe thermistor abnormality ................................................................................... 33

2.2.2.12. “J5-00” – Suction pipe thermistor abnormality .......................................................................................34

2.2.2.13. “J6-00” – Outdoor heat exchanger thermistor abnormality .................................................................... 34

2.2.2.14. “J7-00” – Intermediate heat exchanger thermistor abnormality ............................................................. 34

2.2.2.15. “J8-00” – Liquid pipe thermistor abnormality .......................................................................................... 35

2.2.2.16. “L1-00” – Outdoor main PCB abnormality .............................................................................................. 35

2.2.2.17. “L5-00” – Output overcurrent detection .................................................................................................. 36

22/08/16 | Version 1.1 Page 3

SA R32 Sky-Air RZAG-L

ESIE16-03B |

2.2.2.18. “L8-00” – Electronic thermal overload .................................................................................................... 37

2.2.2.19. “L9-00” – Stall prevention time lag ......................................................................................................... 37

2.2.2.20. “LC-00” – Transmission system abnormality .......................................................................................... 38

2.2.2.21. “P1-00” – Open phase or power supply voltage imbalance ...................................................................38

2.2.2.22. “P4-00” – Radiating fin temperature sensor abnormality ....................................................................... 38

2.2.2.23. “PJ-00” – Capacity setting abnormality .................................................................................................. 39

2.2.3. System ......................................................................................................................................................... 40

2.2.3.1. “U0-00” – Refrigerant shortage ................................................................................................................ 40

2.2.3.2. “U1-00” – Reverse phase or open phase .................................................................................................40

2.2.3.3. “U2-00” – Power supply abnormality or instantaneous power failure .......................................................41

2.2.3.4. “U4-00” – Transmission abnormality between indoor unit and outdoor unit .............................................42

2.2.3.5. “UA-00” – Improper combination of indoor unit and outdoor unit .............................................................42

2.2.3.6. “UF-00” – Wiring and piping mismatch ..................................................................................................... 43

2.2.4. Others .......................................................................................................................................................... 43

2.3. Symptom based troubleshooting ............................................................................................................ 44

2.3.1. Indoor unit .................................................................................................................................................... 44

2.3.2. Outdoor unit ................................................................................................................................................. 44

2.3.3. System ......................................................................................................................................................... 44

2.3.4. Others .......................................................................................................................................................... 44

2.4. Component checklist ............................................................................................................................... 45

2.4.1. Indoor unit .................................................................................................................................................... 46

2.4.1.1. Fan motor ................................................................................................................................................. 46

2.4.2. Outdoor unit ................................................................................................................................................. 47

2.4.2.1. 4-way valve .............................................................................................................................................. 47

2.4.2.2. Compressor .............................................................................................................................................. 49

2.4.2.3. Electronic expansion valve ....................................................................................................................... 50

2.4.2.4. Fan motor ................................................................................................................................................. 52

2.4.2.5. High pressure switch ................................................................................................................................53

2.4.2.6. Low pressure switch ................................................................................................................................. 54

2.4.2.7. Main PCB .................................................................................................................................................55

2.4.2.8. Refrigerant thermistors ............................................................................................................................. 57

2.4.3. System ......................................................................................................................................................... 59

2.4.4. Others .......................................................................................................................................................... 59

2.5. Other capacity range ............................................................................................................................... 59

Part 3. Repair ............................................................................................................................61

3.1. Refrigerant repair procedures ................................................................................................................. 61

3.1.1. Refrigerant piping handling .......................................................................................................................... 61

3.1.2. Recovery procedure ..................................................................................................................................... 61

3.1.2.1. Outdoor unit casing .................................................................................................................................. 61

3.1.3. Refrigerant pump down ................................................................................................................................ 63

3.1.3.1. Small outdoor unit ....................................................................................................................................63

3.1.3.2. Large outdoor unit ....................................................................................................................................64

3.1.4. Piping repair procedures .............................................................................................................................. 64

3.2. Service tools ........................................................................................................................................... 65

3.3. Unit specific repair procedures ............................................................................................................... 66

3.3.1. Indoor unit .................................................................................................................................................... 66

3.3.2. Outdoor unit ................................................................................................................................................. 67

3.3.2.1. Basic removal ........................................................................................................................................... 67

3.3.2.2. Replacing thermistor ................................................................................................................................ 71

3.3.2.3. Replacing 4-way valve body .................................................................................................................... 73

3.3.2.4. Replacing 4-way valve coil ....................................................................................................................... 75

3.3.2.5. Replacing accumulator assembly ............................................................................................................75

3.3.2.6. Replacing compressor .............................................................................................................................76

3.3.2.7. Replacing DC fan motor assembly ........................................................................................................... 79

3.3.2.8. Replacing electrical noise filter ................................................................................................................. 80

3.3.2.9. Replacing expansion valve body .............................................................................................................. 81

3.3.2.10. Replacing expansion valve motor .......................................................................................................... 82

3.3.2.11. Replacing solenoid valve ....................................................................................................................... 84

3.3.2.12. Replacing solenoid valve coil ................................................................................................................. 85

Page 4 22/08/16 | Version 1.1

SA R32 Sky-Air RZAG-L

ESIE16-03B |

3.3.2.13. Replacing high pressure switches ......................................................................................................... 86

3.3.2.14. Replacing inverter PCB .......................................................................................................................... 87

3.3.2.15. Replacing low pressure switch ............................................................................................................... 88

3.3.2.16. Replacing main PCB .............................................................................................................................. 89

3.3.2.17. Replacing propeller fan blade assembly ................................................................................................ 93

Part 4. Maintenance .................................................................................................................95

4.1. Indoor unit ................................................................................................................................................95

4.1.1. General maintenance indoor unit ................................................................................................................. 95

4.2. Outdoor unit .............................................................................................................................................96

4.2.1. General maintenance outdoor unit ............................................................................................................... 96

Part 5. Appendix .......................................................................................................................97

5.1. Field setting .............................................................................................................................................99

5.1.1. Indoor unit .................................................................................................................................................... 99

5.1.1.1. Retrieve field settings BRC1E .................................................................................................................. 99

5.1.1.2. Retrieve field settings BRC7 .................................................................................................................. 101

5.1.1.3. Sky-Air R32 indoor field settings ............................................................................................................ 102

5.1.2. Outdoor unit ................................................................................................................................................103

5.1.2.1. Retrieve field settings OU mode 2 ......................................................................................................... 103

5.1.2.2. Sky-Air R32 outdoor field settings through outdoor ............................................................................... 105

5.1.3. Remote controller ....................................................................................................................................... 106

5.2. Detailed information setting mode .........................................................................................................107

5.2.1. Indoor unit .................................................................................................................................................. 107

5.2.2. Outdoor unit ................................................................................................................................................107

5.2.3. Remote controller ....................................................................................................................................... 108

5.2.3.1. Quiet (Low Noise) Operation ................................................................................................................. 108

5.2.3.2. I-Demand Function ................................................................................................................................ 109

5.2.3.3. Setting for Low Humidity Application ..................................................................................................... 109

5.2.3.4. Defrost Operation ................................................................................................................................... 112

5.3. Wiring diagram .......................................................................................................................................114

5.3.1. Indoor unit .................................................................................................................................................. 114

5.3.2. Outdoor unit ................................................................................................................................................115

5.3.3. Field wiring ................................................................................................................................................. 116

5.4. Piping diagram .......................................................................................................................................117

5.4.1. Indoor unit .................................................................................................................................................. 117

5.4.2. Outdoor unit ................................................................................................................................................117

5.5. Component overview of unit ..................................................................................................................118

5.5.1. Indoor unit .................................................................................................................................................. 118

5.5.2. Outdoor unit ................................................................................................................................................119

5.6. Product specific information ...................................................................................................................121

5.6.1. Error codes ................................................................................................................................................. 121

5.6.1.1. “E9-00” - Electronic expansion valve abnormality .................................................................................. 121

5.6.1.2. “F3-00” - Discharge pipe temperature abnormality ................................................................................ 121

5.6.2. Component checklist .................................................................................................................................. 121

5.6.2.1. How to activate inverter test ................................................................................................................... 121

5.6.2.2. Component checklist .............................................................................................................................. 121

5.7. Switch box ..............................................................................................................................................122

5.7.1. Indoor unit .................................................................................................................................................. 122

5.7.2. Outdoor unit ................................................................................................................................................122

5.8. Field information report ..........................................................................................................................122

22/08/16 | Version 1.1 Page 5

SA R32 Sky-Air RZAG-L

ESIE16-03B |

Figure 3-1: 1 service port at the stop valves ............................................................................................................ 62

Figure 3-2: 3 service ports at the stop valves .......................................................................................................... 63

Figure 3-3: Removing the top plate assembly .......................................................................................................... 67

Figure 3-4: Removing the front plate ........................................................................................................................ 68

Figure 3-5: Removing the front plate assembly ....................................................................................................... 68

Figure 3-6: Removing the cover ............................................................................................................................... 69

Figure 3-7: Removing the piping cover .................................................................................................................... 69

Figure 3-8: Removing the right side plate ................................................................................................................ 70

Figure 3-9: Thermistor location ................................................................................................................................ 71

Figure 3-10: Replacing a thermistor ......................................................................................................................... 72

Figure 3-11: Removing 4-way valve body ................................................................................................................ 73

Figure 3-12: Removing 4-way valve body ................................................................................................................ 75

Figure 3-13: Removing stop valve mounting plate ................................................................................................... 76

Figure 3-14: Removing compressor ......................................................................................................................... 77

Figure 3-15: Removing the DC fan motor assembly ................................................................................................ 79

Figure 3-16: Removing the electrical noise filter ...................................................................................................... 80

Figure 3-17: Removing expansion valve .................................................................................................................. 81

Figure 3-18: Removing expansion valve motor ........................................................................................................ 82

Figure 3-19: Removing expansion valve motor ........................................................................................................ 83

Figure 3-20: Removing solenoid valve ..................................................................................................................... 84

Figure 3-21: Removing solenoid valve coil .............................................................................................................. 85

Figure 3-22: Removing high pressure switches ....................................................................................................... 86

Figure 3-23: Removing low pressure switch ............................................................................................................ 88

Figure 3-24: Removing the main PCB assembly ..................................................................................................... 90

Figure 3-25: Stripping the main PCB assembly (front) ............................................................................................. 91

Figure 3-26: Stripping the main PCB assembly (rear) ............................................................................................. 92

Figure 3-27: Removing the propeller fan blade assembly ........................................................................................ 93

Figure 5-1: Wiring diagram - indoor unit ................................................................................................................. 114

Figure 5-2: Wiring diagram - outdoor unit 71 ......................................................................................................... 115

Figure 5-3: Wiring diagram - outdoor unit 100-140 ................................................................................................ 116

Figure 5-4: Piping diagram - indoor unit ................................................................................................................. 117

Figure 5-5: Piping diagram - outdoor unit ............................................................................................................... 117

Figure 5-6: Components overview - indoor unit ..................................................................................................... 118

Figure 5-7: Components overview - outdoor unit 71 .............................................................................................. 119

Figure 5-8: Components overview - outdoor unit 100-140 ..................................................................................... 120

Page 6 22/08/16 | Version 1.1

SA R32 Sky-Air RZAG-L

ESIE16-03B | Part 1. Introduction 1.1. Version log

Part 1. Introduction

This part contains the following chapters:

Version log .............................................................................................................................................................................................7

Safety precautions..................................................................................................................................................................................8

General operation.................................................................................................................................................................................11

How to use ...........................................................................................................................................................................................12

1.1. Version log

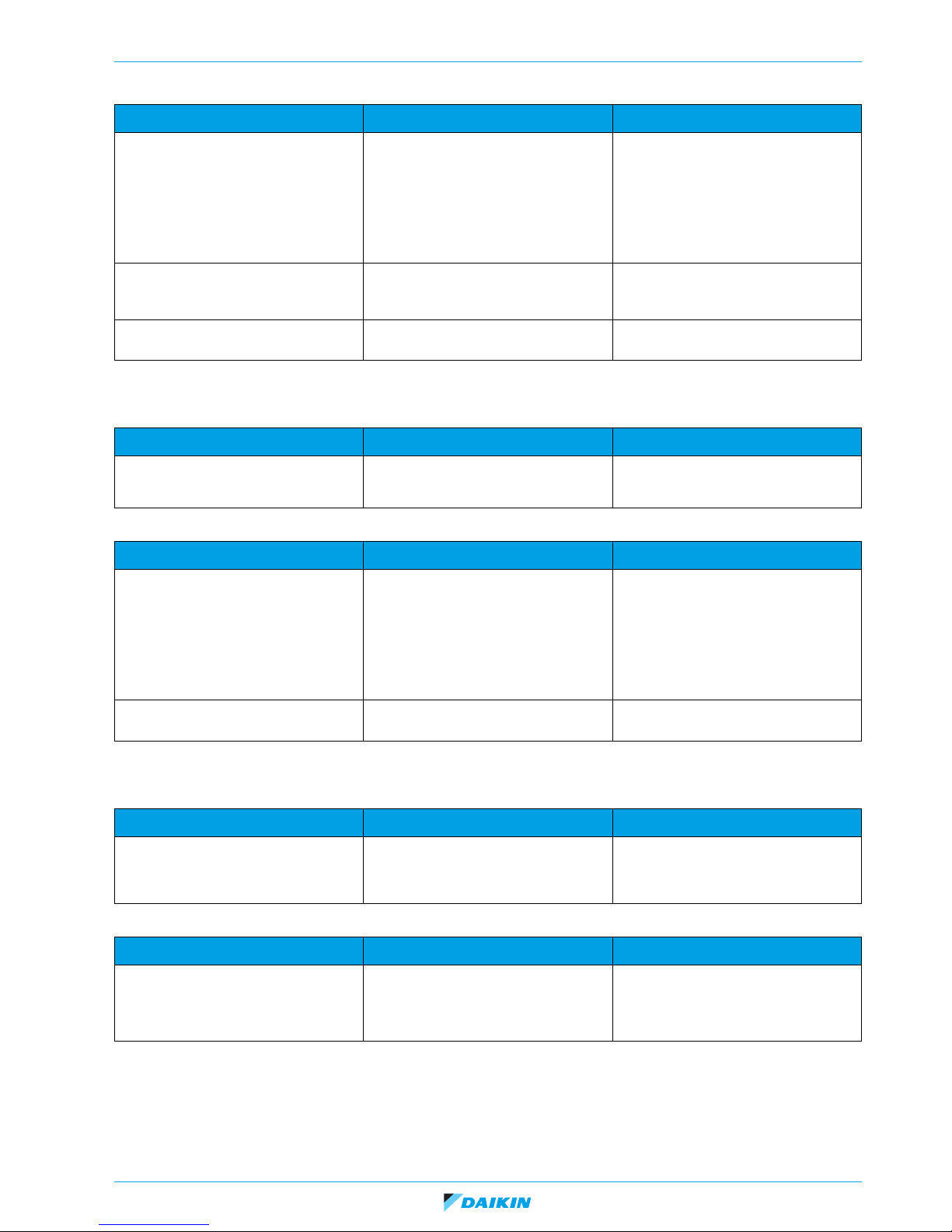

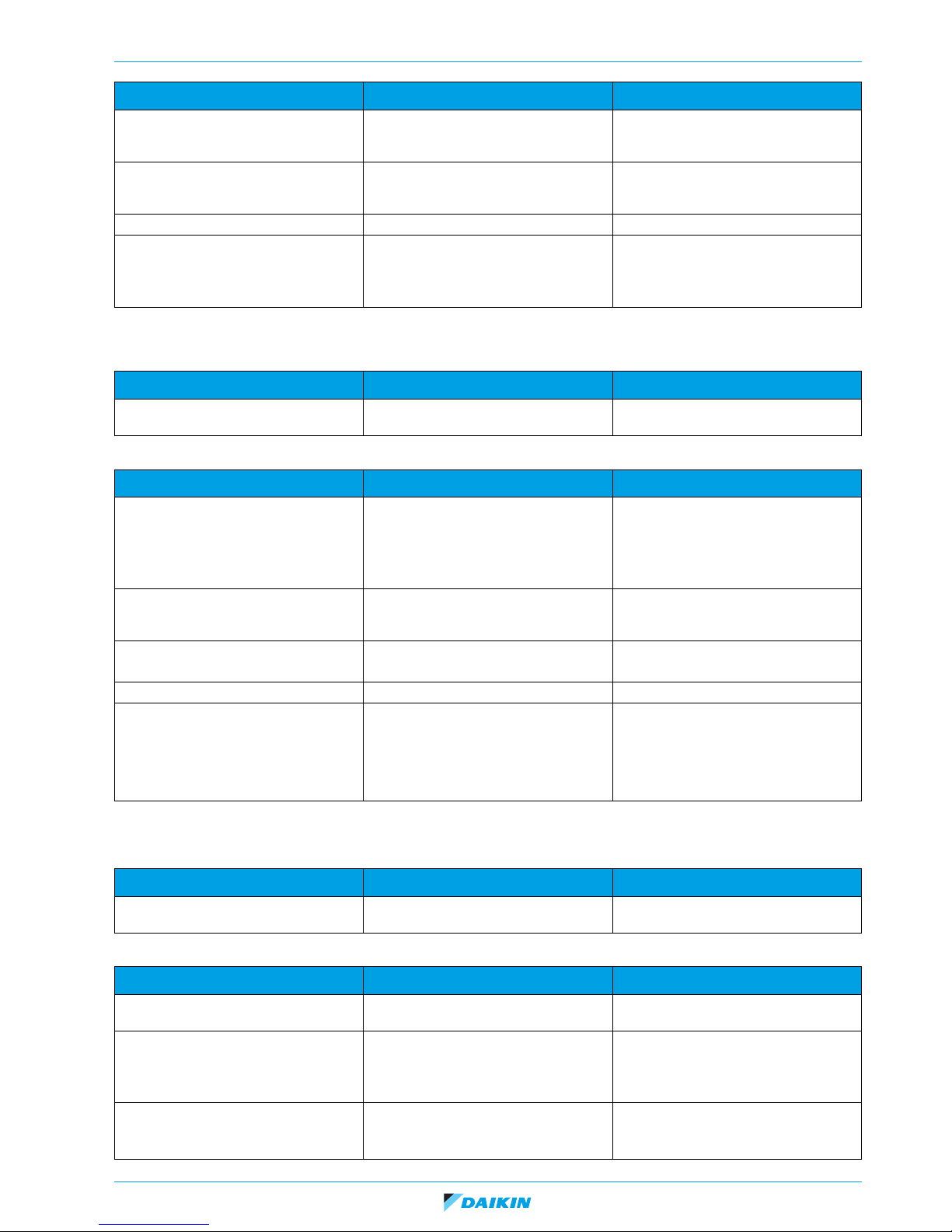

Version code Description Date

ESIE16-03A Document release 19/07/2016

ESIE16-03B Update chapter 2.1.2.: correction of setting items in monitor mode for malfunction/con-

tent of retry

Update chapter 3.3.2.2.: addition of 3D view of RZAG71

Update chapter 5.6.2.: component checklist added

22/08/2016

22/08/16 | Version 1.1 Page 7

SA R32 Sky-Air RZAG-L

ESIE16-03B | Part 1. Introduction 1.2. Safety precautions

1.2. Safety precautions

The precautions described in this document cover very important topics, follow them carefully.

All activities described in the service manual must be performed by an authorized person.

If you are not sure how to install, operate or service the unit, contact your dealer.

In accordance with the applicable legislation, it might be necessary to provide a logbook with the product containing at least:

information on maintenance, repair work, results of tests, stand-by periods, …

Also, at least, following information must be provided at an accessible place at the product:

• Instructions for shutting down the system in case of an emergency

• Name and address of fire department, police and hospital

• Name, address and day and night telephone numbers for obtaining service

In Europe, EN378 provides the necessary guidance for this logbook.

1.2.1. Meaning of symbols

WARNING

Indicates a situation that could result in death or serious injury.

WARNING: RISK OF ELECTROCUTION

Indicates a situation that could result in electrocution.

WARNING: RISK OF BURNING

Indicates a situation that could result in burning because of extreme hot or cold temperatures.

WARNING: RISK OF EXPLOSION

Indicates a situation that could result in explosion.

WARNING: RISK OF POISONING

Indicates a situation that could result in poisoning.

WARNING: RISK OF FIRE

Indicates a situation that could result in fire.

CAUTION

Indicates a situation that could result in equipment or property damage.

INFORMATION

Indicates useful tips or additional information.

1.2.2. Warnings

WARNING

Improper installation or attachment of equipment or accessories could result in electric shock, short-circuit, leaks, fire or

other damage to the equipment. Only use accessories, optional equipment and spare parts made or approved by Daikin.

Page 8 22/08/16 | Version 1.1

SA R32 Sky-Air RZAG-L

ESIE16-03B | Part 1. Introduction 1.2. Safety precautions

WARNING

Make sure installation, testing and applied materials comply with applicable legislation (on top of the instructions

described in the Daikin documentation).

WARNING

Make sure the work site environment is clean and safe to work in. Beware of spilled fluids, like water, oil or other substances. Protect bystanders from injury and property from possible damage cause by service works.

WARNING

Wear adequate personal protective equipment (protective gloves, safety glasses,…) when installing, maintaining or servicing the system.

WARNING

Tear apart and throw away plastic packaging bags so that nobody, especially children, can play with them. Possible risk:

suffocation.

WARNING

Do NOT touch the air inlet or aluminium fins of the unit.

WARNING

• Do NOT place any objects or equipment on top of the unit.

• Do NOT sit, climb or stand on the unit.

WARNING

During tests, NEVER pressurize the product with a pressure higher than the maximum allowable pressure (as indicated

on the nameplate of the unit).

WARNING

• Never mix different refrigerants or allow air to enter the refrigerant system.

• Never charge recovered refrigerant from another unit. Use recovered refrigerant only on the same unit where it was

recovered from, or have it recycled at a certified facility.

WARNING: RISK OF FIRE

• When reconnecting a connector to the PCB, do not apply force or damage the connector or the connector pins on the

PCB.

WARNING: RISK OF BURNING

• Do NOT touch the refrigerant piping, water piping or internal parts during and immediately after operation. It could be

too hot or too cold. Give it time to return to normal temperature. If you must touch it, wear protective gloves.

• Do NOT touch any accidental leaking refrigerant.

WARNING

Always recover the refrigerants. Do NOT release them directly into the environment. Use a recovery pump to evacuate

the installation.

Take sufficient precautions in case of refrigerant leakage. If refrigerant gas leaks, ventilate the area immediately.

Possible risks:

• Excessive refrigerant concentrations in a closed room can lead to oxygen deficiency.

• Toxic gas may be produced if refrigerant gas comes into contact with fire.

Where applicable, pump down the system and close the service valve, before leaving the site if leak was not repaired, to

avoid further leaking of the refrigerant.

WARNING: RISK OF ELECTROCUTION

• Turn OFF all power supply before removing the switch box cover, connecting electrical wiring or touching electrical

parts. Where applicable, stop the equipment's operation first and allow (refrigerant) pressure to equalize, before

turning OFF the power. Disconnect the power supply for more than 1 minute, and measure the voltage at the

terminals of main circuit capacitors or electrical components before servicing. The voltage must be less than 50 V DC

before you can touch electrical components. For the location of the terminals, refer to "Wiring diagram" on page 114.

• Do NOT touch electrical components with wet hands.

• Do NOT leave the unit unattended when the service cover is removed.

• Protect electric components from getting wet while the service cover is opened.

22/08/16 | Version 1.1 Page 9

SA R32 Sky-Air RZAG-L

ESIE16-03B | Part 1. Introduction 1.2. Safety precautions

WARNING

• Only use copper wires.

• All field wiring must be performed in accordance with the wiring diagram and installation manual supplied with the

product.

• If the power cable and lead wires have scratches or deteriorated, be sure to replace them. Damaged cable and wires

may cause an electrical shock, excessive heat generation or fire.

• Secure all terminal connections and provide proper routing for cables, both inside and outside the switchbox.

• NEVER squeeze bundled cables and make sure they do not come in contact with the piping and sharp edges.

• Make sure no external pressure is applied to the terminal connections.

• Make sure to check the earth wiring. Do NOT earth the unit to a utility pipe, surge absorber, or telephone earth.

Improper earth wiring may cause electrical shock.

• Make sure to use a dedicated power circuit. NEVER use a power supply shared by another appliance.

• Make sure to check the required fuses and/or circuit breakers before starting works.

WARNING

• After finishing the electrical work, confirm that each electrical component and terminal inside the electrical

components box is connected securely.

• Make sure all covers are closed before starting the unit again.

1.2.3. Cautions

CAUTION

Provide adequate measures to prevent that the unit can be used as a shelter by small animals. Small animals that make

contact with electrical parts can cause malfunctions, smoke or fire.

CAUTION

• Make sure water quality complies with EU directive 98/83 EC.

• Check the system for leaks after each repair/modification of the water side.

• Check drainage system(s) after repairs.

• Be careful when tilting units as water may leak.

1.2.4. Information

INFORMATION

Make sure refrigerant piping installation complies with applicable legislation. In Europe, EN378 is the applicable standard.

INFORMATION

Make sure the field piping and connections are not subjected to stress.

Page 10 22/08/16 | Version 1.1

SA R32 Sky-Air RZAG-L

ESIE16-03B | Part 1. Introduction 1.3. General operation

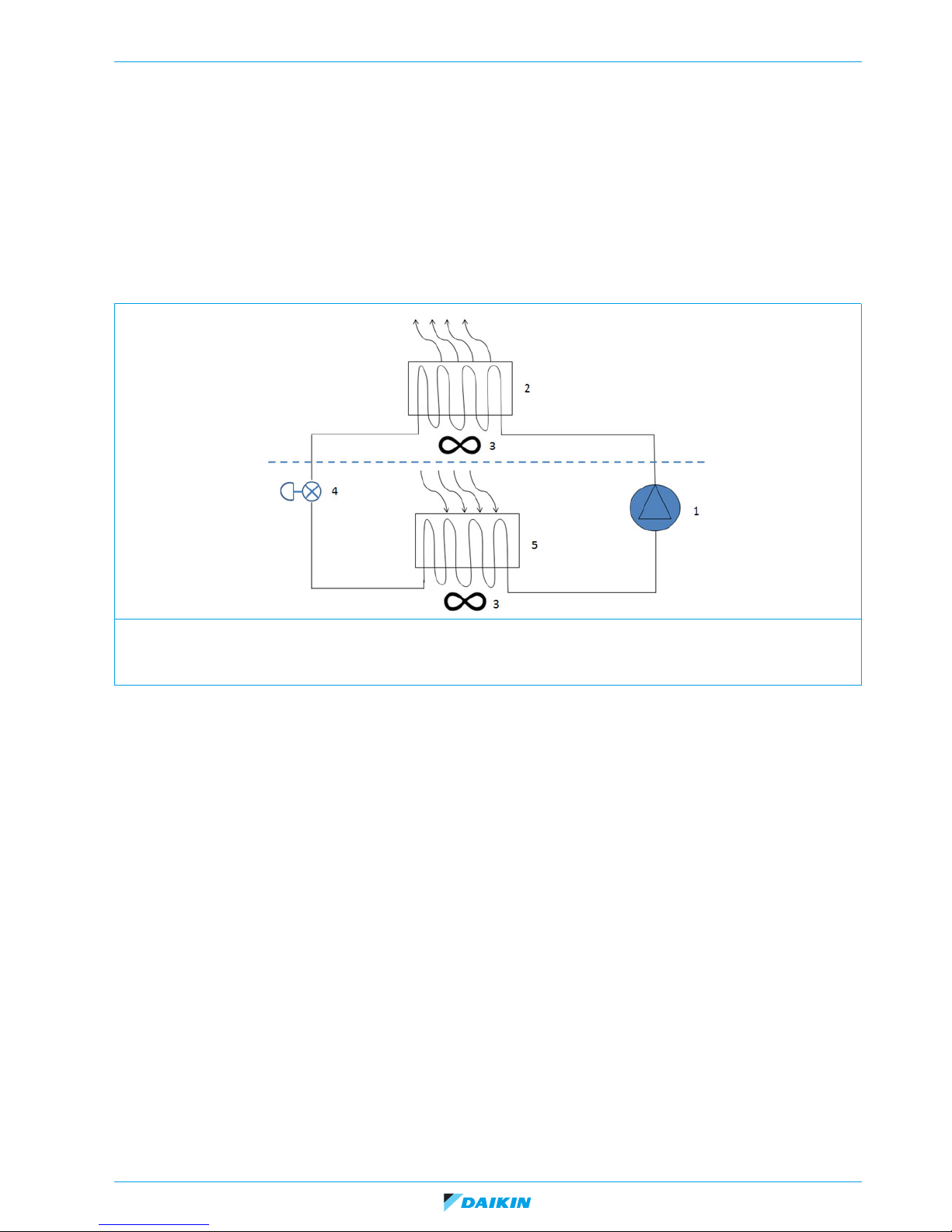

1.3. General operation

• The Sky-Air is typically used for cooling or heating in commercial applications. Some units also have settings to perform

technical cooling. The medium which is used to transfer the heat from inside to outside or vice versa, is refrigerant. In case of

the RZAG-L, the refrigerant which is used, is R32.

• In case of heating, the compressor builds up pressure and hence the temperature of the refrigerant is increased. The hot

refrigerant is blown into the room by a fan which blows over a heat exchanger. Colder refrigerant flows back to the outdoor

unit, where temperature is further decreased by expansion through an expansion valve. After the expansion valve, the

refrigerant is capable of taking up heat again. This is enabled by a fan that sucks outdoor air over a heat exchanger. This

refrigerant is then transported to the compressor where temperature is further built up again and the cycle starts again. For

cooling, it’s just the other way round.

1. Compressor 4. Electronic expansion valve

2. Indoor heat exchanger 5. Outdoor heat exchanger

3. Fan

22/08/16 | Version 1.1 Page 11

SA R32 Sky-Air RZAG-L

Y

Wh

at

d

a

n Er

r

Co

de

to

b

ESIE16-03B | Part 1. Introduction 1.4. How to use

1.4. How to use

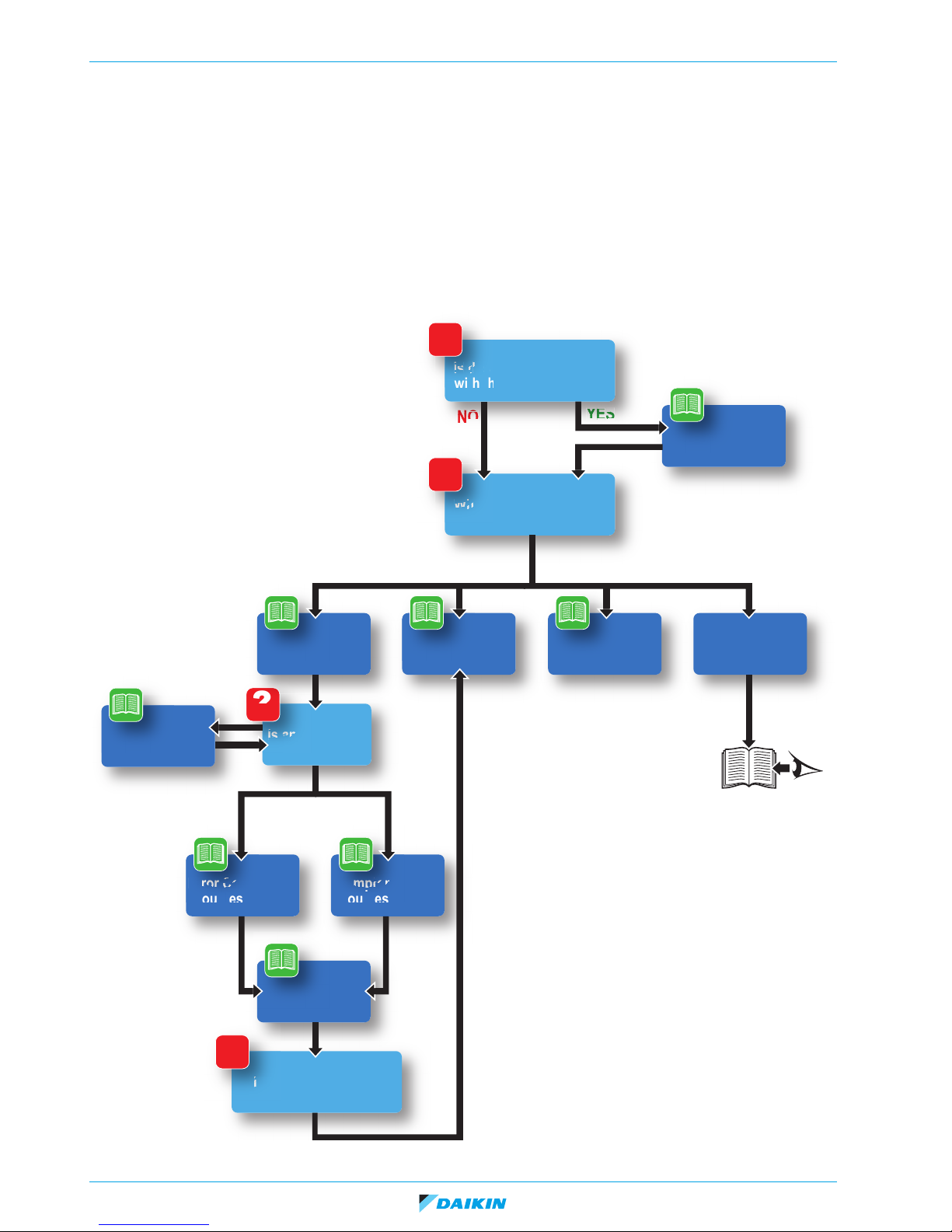

1.4.1. Interactive information flow

This Daikin product Service Manual is intended for professional use only. The actions described hereafter, are only to be performed

by qualified and certified persons, taking into account the safety precautions mentioned in this manual and the local regulations as

well.

By following the diagram below, the reader can find the relevant information related to his/her task. The digital (pdf) version of this

book allows direct page access through all active links. When Adobe Acrobat Reader is used, the <Alt> + <Back Arrow> keys or

the arrow in the top right-hand corner of this page can be used to return to the previously viewed page.

?

Is this your 1st encounter

with this particular unit?

How to retrieve

Error Codes

YES

PART 2

Troubleshooting

?

Is an Error Code

displayed?

NO

NO

?

What do you need to do?

PART 3

Repair

YES

PART 4

Maintenance

General

operation

Installation

Refer to:

Installation Manual

or

Installer Reference Guide

Error Code based

troubleshooting

Component

checklist

?

Is repair necessary?

e

Page 12 22/08/16 | Version 1.1

Symptom based

troubleshooting

SA R32 Sky-Air RZAG-L

ESIE16-03B | Part 1. Introduction 1.4. How to use

1.4.2. Parts of the book

This Daikin product Service Manual is intended for professional use only. The actions described hereafter, are only to be performed

by qualified and certified persons, taking into account the safety precautions mentioned in this manual and the local regulations as

well.

As can be observed from the Table of Contents, this manual is split up into several chapters:

1.4.2.1. The introduction chapter

The chapter "Introduction" on page 7 includes the safety precautions, this topic and the general operation description of the

product(s) this manual refers to.

1.4.2.2. The troubleshooting chapter

The chapter "Troubleshooting" on page 15 not only deals with the methods to recognize and resolve occurring error codes; it also

describes the methods how to solve a problem that does not immediately trigger an error code. Such problems are referred to as

'symptom based'. Both the error code based and symptom based troubleshooting tables, indicate possible causes, the necessary

checks and in case required, how to repair. The possible causes have been sorted to probability of occurrence and speed of

execution.

1.4.2.3. The repair chapter

The chapter "Repair" on page 61 handles the removal and replacement of the major components in the product and discusses

cleaning methods as well if applicable, such as for filters. Where applicable, refrigerant handling precautions are mentioned for

certain actions; please consider these carefully for your own safety.

1.4.2.4. The maintenance chapter

The chapter "Maintenance" on page 95 of this manual describes the maintenance intervals and procedures to be performed on

the product. Remember that a well maintained product, is a more reliable and efficient product.

1.4.2.5. Appendices

Finally, the service manual provides in chapter "Appendix" on page 97 valuable reference data such as piping/wiring diagrams,

field settings overview and a checklist to be filled in when you need to escalate an issue to your dealer.

1.4.3. Contact information

This manual has been made with much care and effort. Use it in your daily jobs, as it has been made for you.

Despite our efforts, there is always a chance some cleric or other mistake has been made during the creation of this manual. We

kindly ask you to send the found mistakes, or remarks for improvement, to the no-reply email address

servicemanual@daikineurope.com.

22/08/16 | Version 1.1 Page 13

SA R32 Sky-Air RZAG-L

ESIE16-03B | Part 1. Introduction 1.4. How to use

Page 14 22/08/16 | Version 1.1

SA R32 Sky-Air RZAG-L

ESIE16-03B | Part 2. Troubleshooting 2.1. Error codes check

Part 2. Troubleshooting

This part contains the following chapters:

Error codes check ................................................................................................................................................................................15

Error based troubleshooting.................................................................................................................................................................23

Symptom based troubleshooting ..........................................................................................................................................................44

Component checklist............................................................................................................................................................................45

Other capacity range ............................................................................................................................................................................59

2.1. Error codes check

2.1.1. Error codes via remote controller

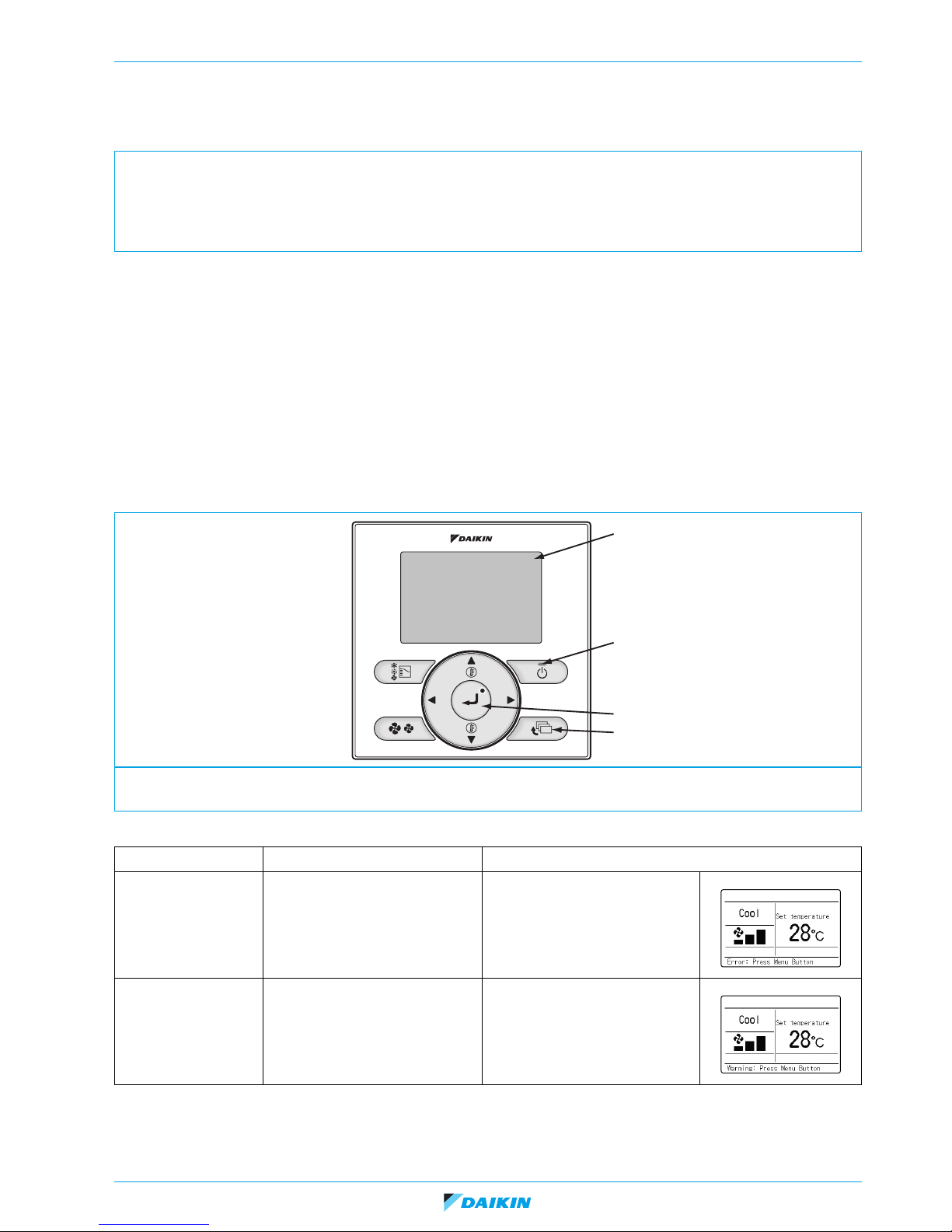

2.1.1.1. Error codes via wired remote controller BRC1E

2.1.1.1.1 How to retrieve error codes

The following message will be displayed on the screen when a malfunction or a warning occurs during operation.

1

2

3

4

1. Screen 3. ‘menu’ button

2. Operation lamp 4. ‘cancel’ button

Operation Status Display

Abnormal shut-down The system stops operating. The operation lamp (green) starts to

blink. The message “Error: Press

Menu button” will appear and blink at

the bottom of the screen.

Warning The system continues its operation. The operation lamp (green) remains

If an error or warning is present, it will be displayed on the user interface screen: for more information about troubleshooting, refer

to "Error based troubleshooting" on page 23.

22/08/16 | Version 1.1 Page 15

on. The message “Warning: Press

Menu button” will appear and blink at

the bottom of the screen.

SA R32 Sky-Air RZAG-L

ESIE16-03B | Part 2. Troubleshooting 2.1. Error codes check

2.1.1.1.2 How to reset error codes

In "Error based troubleshooting" on page 23 you find a description of how to reset the specific error or warning.

2.1.1.1.3 History of error codes

<Basic screen>

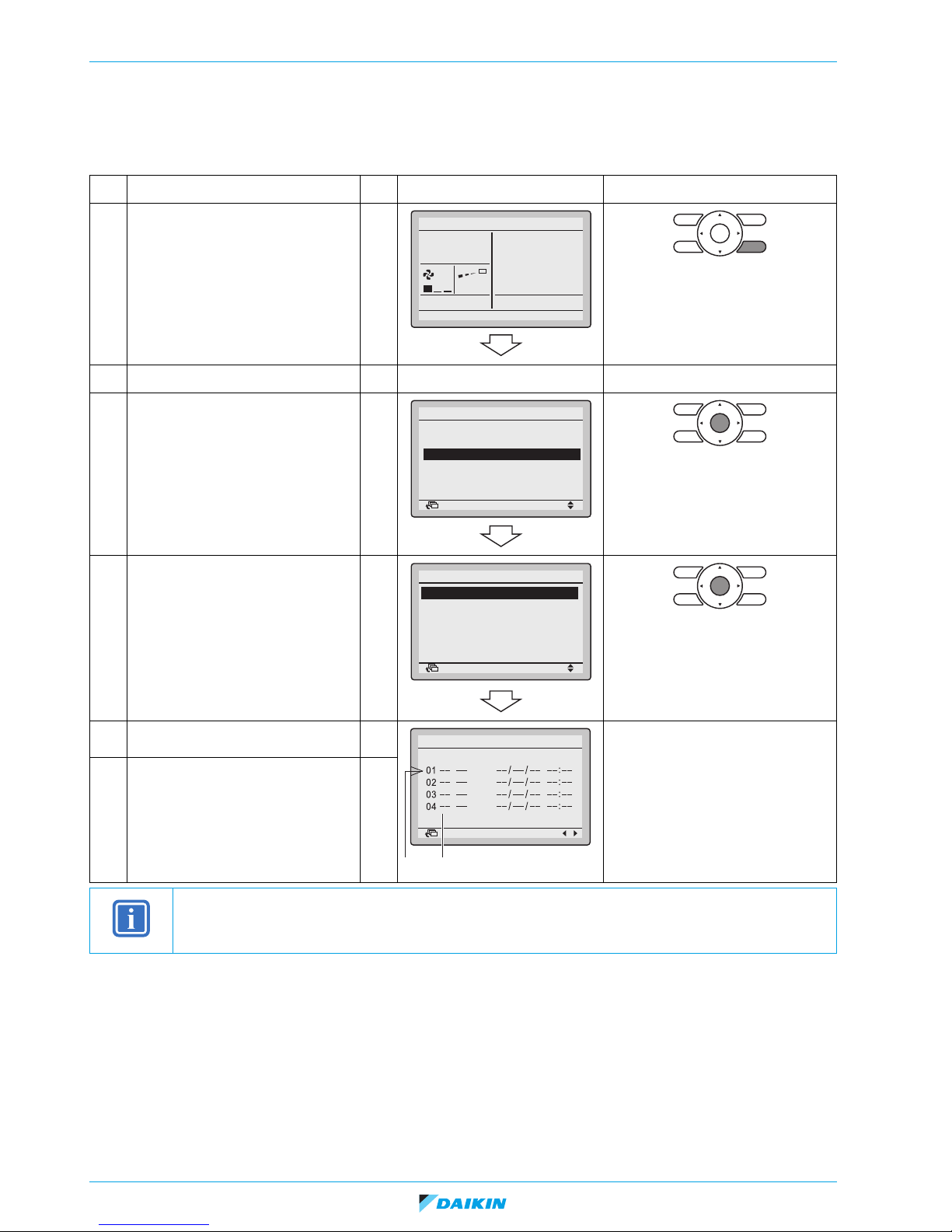

8-1 Press and hold the Cancel button for

8-1

4 seconds or longer in the Basic

screen. The Service Settings menu is

displayed.

Cool

Set to

28°C

Press and hold the Cancel button for

4 seconds or longer while the backlight

is lit.

<Service Settings>

8-2 Select Error History and press the

Menu/Enter button. The Error History

menu is displayed

8-2

Service Settings

Indoor Unit Airnet Address

Outdoor Unit Airnet Address

Error History

Indoor Unit Status

Outdoor Unit Status

Forced Fan ON

SettingReturn

2/3

Press the Menu/Enter button.

8-3 Select RC Error History and press the

Menu/Enter button. The error codes

and unit No. can be confirmed in the

RC Error History screen.

8-4 In the RC Error History screen the last

10 items are displayed in order.

8-5 Press the Cancel button in the RC

Error History screen 3 times. The Basic

screen returns.

INFORMATION

The indoor unit error history of each indoor unit can be independently consulted. The last 5 items are displayed in

order of appearance.

8-3

Error History

RC Error History

Indoor Unit Error History

2/2

Press the Menu/Enter button.

SettingReturn

8-4 1. Latest record

8-5

RC Error History

Unit Error Date Time

Return

1/3

2. Unit no.

12

.

Page 16 22/08/16 | Version 1.1

SA R32 Sky-Air RZAG-L

“UP” button “DOWN” button

“UP” button “DOWN” button

ESIE16-03B | Part 2. Troubleshooting 2.1. Error codes check

2.1.1.2. Error codes via wireless remote controller BRC7

2.1.1.2.1 How to retrieve error codes

If the unit stops due to an error, the operation indicating LED on the indoor unit flashes.

The error code can be determined through the wireless remote controller by following the procedure described below.

If an error or warning is present, it will be displayed on the screen: for more information about troubleshooting, refer to "Error based

troubleshooting" on page 23.

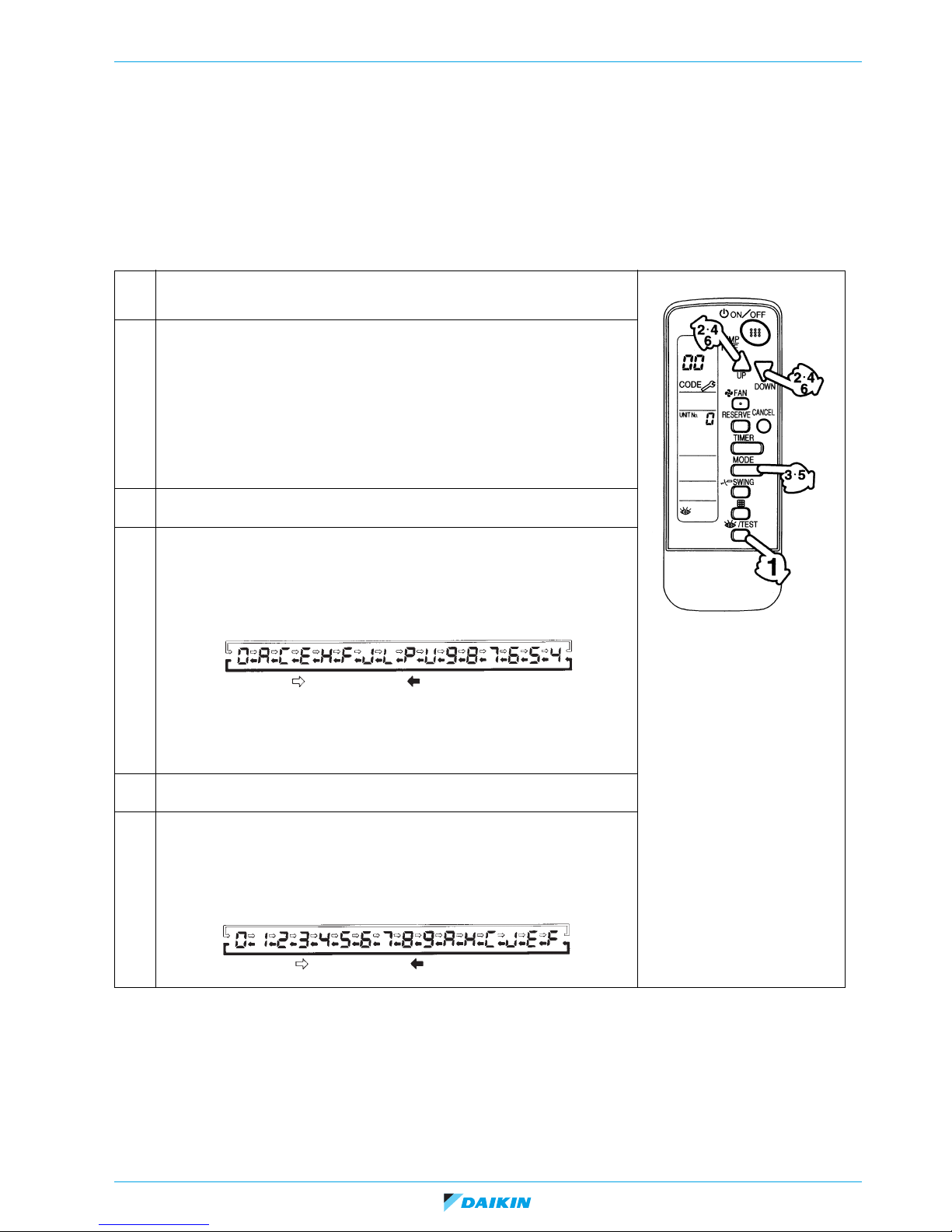

1 Press the INSPECTION/TEST button to select “inspection”. The equipment enters the

inspection mode. The “Unit” indication is displayed and the Unit No. display shows

flashing “0” indication.

2 Set the Unit No.

Press the UP or DOWN button and change the Unit No. display until the buzzer (*1) is

generated from the indoor unit.

*1 Number of beeps

3 short beeps: Conduct all of the following operations.

1 short beep: Conduct steps 3 and 4.

Continue the operation in step 4 until a buzzer remains ON. The continuous buzzer

indicates that the error code is confirmed.

Continuous beep: No abnormality.

3 Press the MODE selector button.

The left “0” (upper digit) indication of the error code flashes.

4 Error code upper digit diagnosis

Press the UP or DOWN button and change the error code upper digit until the error

code matching buzzer (*2) is generated.

• The upper digit of the code changes as shown below when the UP and DOWN

buttons are pressed.

*2 Number of beeps

Continuous beep: Both upper and lower digits matched. (Error code confirmed)

2 short beeps: Upper digit matched.

1 short beep: Lower digit matched.

5 Press the MODE selector button.

The right “0” (lower digit) indication of the error code flashes.

6 Error code lower digit diagnosis

Press the UP or DOWN button and change the error code lower digit until the continuous error code matching buzzer (*2) is generated.

• The lower digit of the code changes as shown below when the UP and DOWN

buttons are pressed.

22/08/16 | Version 1.1 Page 17

ESIE16-03B | Part 2. Troubleshooting 2.1. Error codes check

1 Press INSPECTION/TEST button.

Normal status

Enters inspection mode from normal status

when the INSPECTION/ TEST button is

pressed.

When MODE selector button

is pressed or no button is

pressed for 1 minute, equipment returns to normal status.

3 Press

MODE

selector

button.

5 Press MODE selector button.

SA R32 Sky-Air RZAG-L

2.1.1.2.2 How to reset error codes

In "Error based troubleshooting" on page 23 you find a description of how to reset the specific error or warning.

Page 18 22/08/16 | Version 1.1

SA R32 Sky-Air RZAG-L

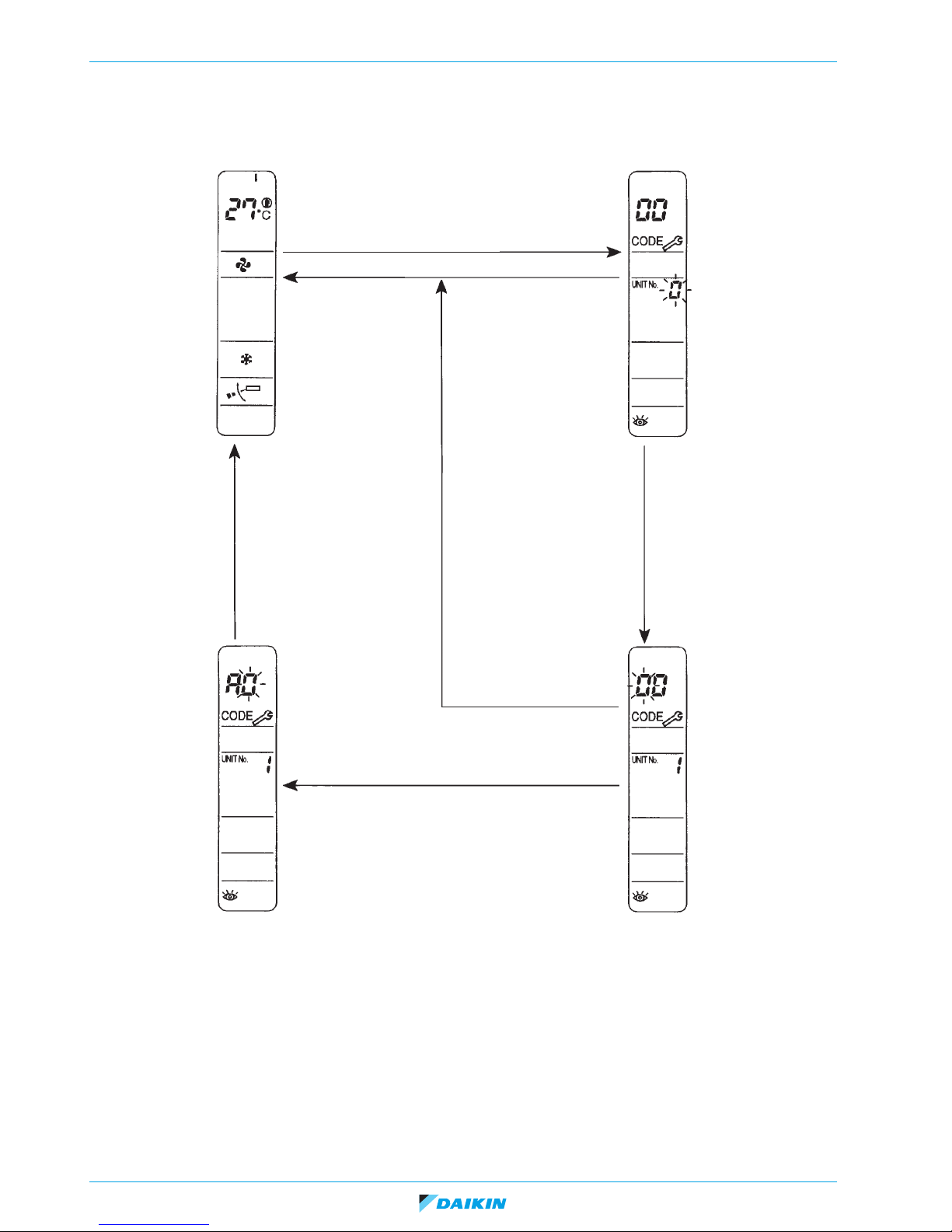

To enter "Monitor mode," push the MODE (BS1)

button on A2P when in "Setting mode 1". (*)

<Display of RETURN 1>

<Display of RETURN 2>

<Display of RETURN 3>

Push the SET (BS2) button to set the LED

display to malfunction item according to

binary counting. (**)

When SET (BS2) button is pushed, the LED

display for RETURN 2 turns ON.

When SET (BS2) button is pushed, the LED

display for RETURN 3 turns ON.

Check the error code that matches the LED

sequence (see table on next page).

Push the RETURN (BS3) button to return the

system to the initial state of "Monitor mode".

When the RETURN (BS3) button is pushed,

the LED display for RETURN 1 turns ON.

! Pushing the MODE (BS1) button will bring the

system to the "Setting mode 1".

ESIE16-03B | Part 2. Troubleshooting 2.1. Error codes check

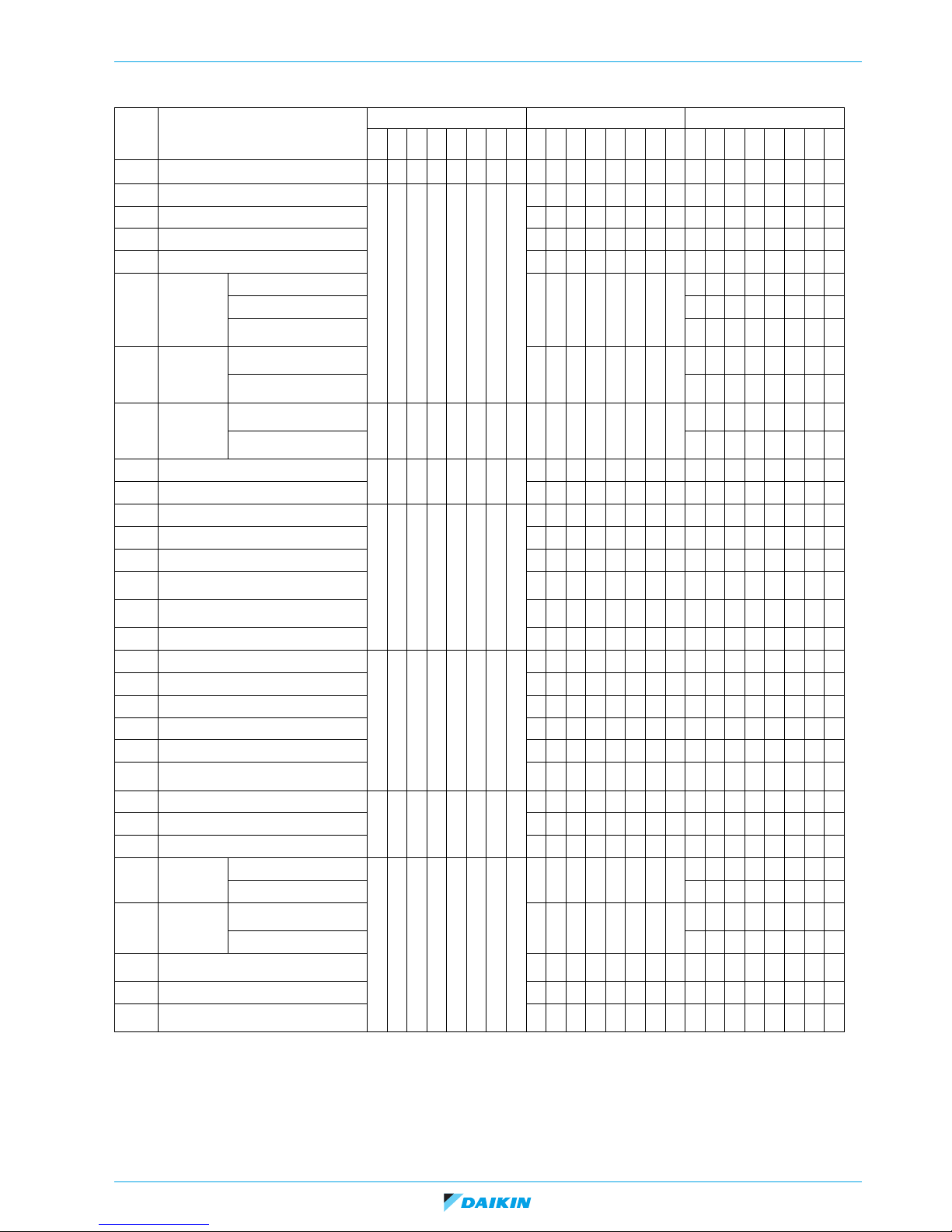

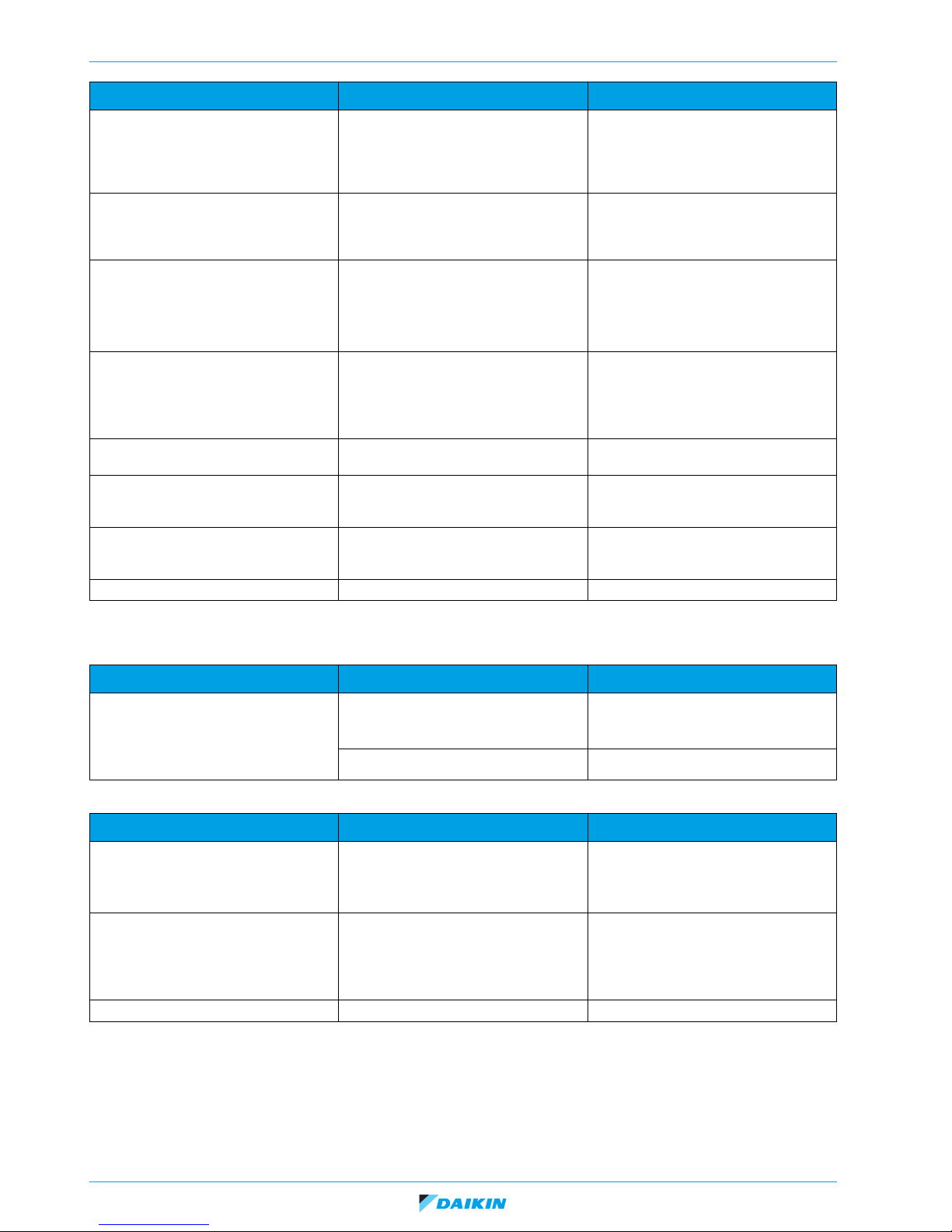

2.1.2. Error codes via outdoor unit PCB

2.1.2.1. How to retrieve error codes

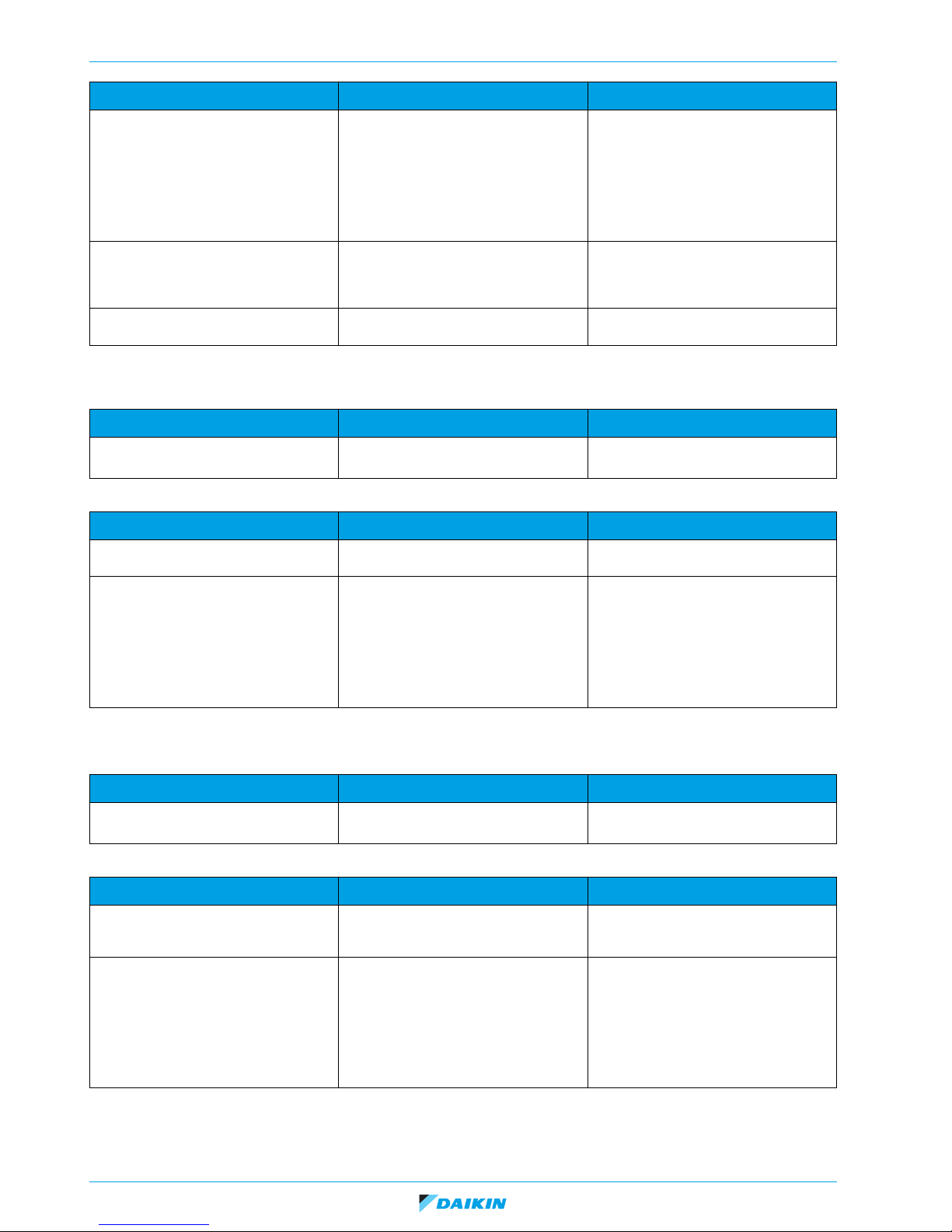

There are 2 ways to retrieve error codes through the outdoor unit:

1. Troubleshooting by LED on the outdoor main PCB

The following diagnosis can be conducted by turning on the power switch and checking the LED indication on the PCB of the

outdoor unit.

w : LED on / x : LED off / c : LED blinks / — : Not used for diagnosis

LED detection

DescriptionHAP H1P

(Green) (Red)

cx

w

x

— Faulty outdoor unit PCB (Information 1)

— Power supply abnormality, or faulty outdoor unit PCB (Information 2)

cw

INFORMATION

1. Turn off the power switch, and turn it on again after 5 seconds or more. Check the error condition, and diagnose the

problem.

2. Turn off the power switch. After 5 seconds or more, disconnect the connection wire (2). Then turn on the power switch.

If the HAP on the outdoor unit PCB flashes after about 10 seconds, the PCB A1P is faulty.

3. Also check for open phase.

INFORMATION

The error detection monitor continues to indicate the previously generated error until the power switch is turned off.

Be sure to turn off the power switch after inspection.

Normal

Activation of protection device (Information 3)

.

.

2. Troubleshooting by LED on the outdoor service PCB

Take the following steps to check the error or warning (malfunction):

22/08/16 | Version 1.1 Page 19

SA R32 Sky-Air RZAG-L

MODE

H1P

On Off Blinking

MODE

H1P

MODE

H1P

Setting mode 2

Setting mode 1 Monitor mode

Push and hold the BS1 (MODE button)

for 5 seconds.

Push the BS1 (MODE button)

one time.

Push the BS1 (MODE button)

one time.

(Normal)

ESIE16-03B | Part 2. Troubleshooting 2.1. Error codes check

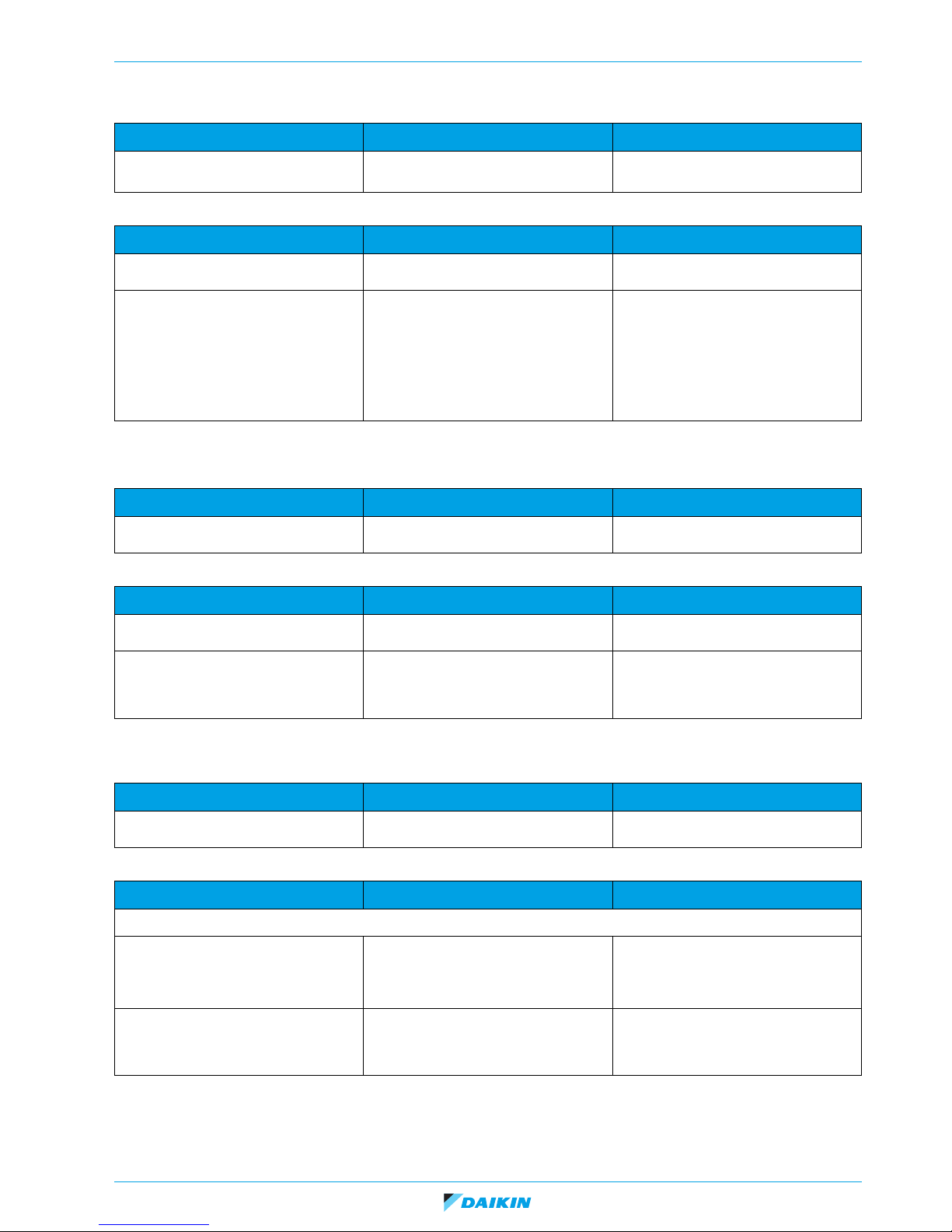

(*) Using the MODE button, the modes can be changed as follows.

(**)

HAP H1P H2P H3P H4P H5P H6P H7P

LED-status:

Binary counting: value: 6432168421

Setting item: 14= latest error=

15= previous error=

16= 2 before=

wwwwwwww

|||||||

|||||||

w x x www x

w x x wwww

wxwx x x x

Page 20 22/08/16 | Version 1.1

SA R32 Sky-Air RZAG-L

ESIE16-03B | Part 2. Troubleshooting 2.1. Error codes check

w: ON x: OFF c: BLINK

Malfunc-

Contents of retry or malfunction

tion code

C4 Indoor heat exchanger thermistor

E1 Faulty outdoor PC board

E3 Abnormal high pressure

E4 Abnormal low pressure

E5 Compressor motor lock

E7 Abnormal

outdoor fan

motor

E9 Abnormal

electronic

expansion

valve

F3 Abnormal

discharge pipe

temperature

H3 Abnormal high pressure switch

H9 Abnormal outdoor air thermistor

J1 Abnormal pressure sensor

J3 Abnormal discharge pipe thermistor

J5 Abnormal suction pipe thermistor

J6 Abnormal heat exchanger distributor pipe

thermistor

J7 Abnormal intermediate heat exchanger

thermistor

J8 Abnormal liquid pipe thermistor

L1 PC board failure

L4 Elevated radiation fin temperature

L5 Compressor instantaneous overcurrent

L8 Compressor overload

L9 Compressor lock

LC Abnormal transmission (between the control

and the inverter)

P1 Unbalanced power supply voltage

P4 Abnormal radiation fin thermistor

PJ Faulty capacity setting

U0 Abnormal gas

shortage

U2 Abnormal

power supply

voltage

U4 Abnormal transmission (between indoor and

outdoor units)

UA Faulty field setting switch

UF Improper piping and improper communication

wiring

DC motor 1 lock

DC motor 2 lock

Abnormal inverter

transmission

Disconnected electronic

expansion valve connector

Malfunction due to wet

conditions

Abnormal discharge pipe

temperature

Disconnected discharge pipe

thermistor

Gas shortage warning

Abnormal gas shortage

Inverter undervoltage and

overvoltage

SP-PAM overvoltage

HAPH1PH2PH3PH4PH5PH6PH7PHAPH1PH2PH3PH4PH5PH6PH7PHAPH1PH2PH3PH4PH5PH6PH7

c

cc x w x x ccccw x x x x cccww x x x x

cc x w x c x cccw x x x ccccww x x x c

cc x w x c x x ccw x x x ccccww x x x x

cc x w x cc x ccw x x x x cccww x x x x

cc x w x cccccw x x x x cccww x x x x

cc x wc x x x ccw x x x x cccww x x x x

ccxwcxxcccwxxxxxccwwxxxc

Return 1 Return 2 Return 3

P

cwxxxcxccwxxcxxccwwxxxx

ccw x x x ccccww x x x x

ccwx xcx xccwwx x x x

ccw x xc x cccww x x x x

ccw x xcccccww x x xc

ccww x x c x

ccww x x cc

ccw x c x x cccww x x x c

ccww x x c x

ccww x x c x

ccw x c x x cccww x x x x

ccw x x x ccccww x x x x

ccw x xc x cccww x x x x

ccwx xccxccwwx x x x

ccw x xcccccww x x x x

ccwxcx x xccwwx x x x

ccwx xcx xccwwx x x x

ccw x xc x cccww x x x x

ccwxcx x xccwwx x x x

ccw x c x x cccww x x x x

ccw x cc x x ccww x x x x

ccwx xcx xccwwx x x x

ccw x cc x cccww x x x x

ccww x x c x

ccwx x xcxccwwx x xc

ccww x x c x

ccwx xcx xccwwx x x x

ccwxcxcxccwwx x x x

ccccccww x x x x

For more information about troubleshooting, refer to "Error based troubleshooting" on page 23.

2.1.2.2. How to reset error codes

In "Error based troubleshooting" on page 23 you find a description on how to reset the specific error or warning.

22/08/16 | Version 1.1 Page 21

SA R32 Sky-Air RZAG-L

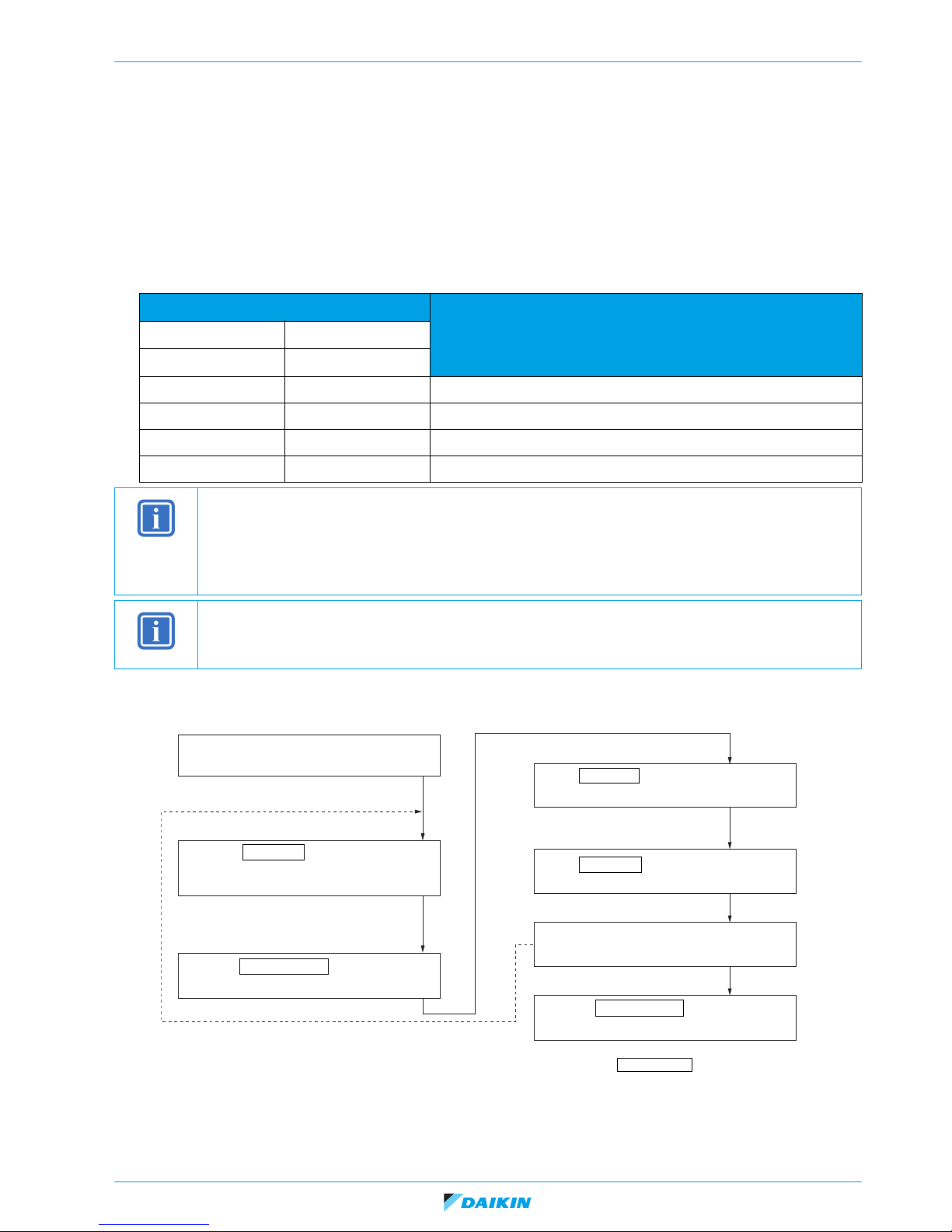

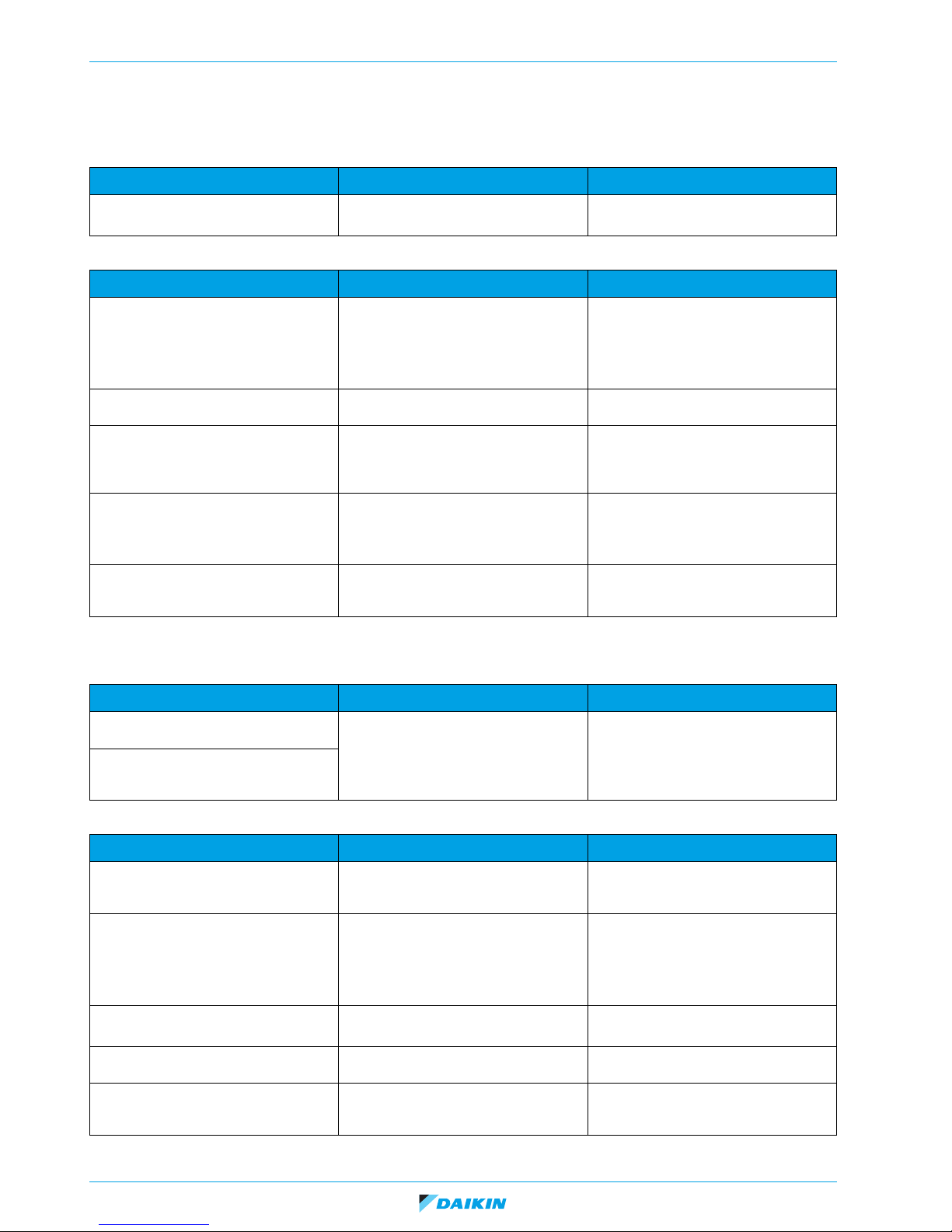

To enter "Monitor mode", press the MODE

(BS1) button when in "Setting mode 1".

<Selection of retry or error item>

<Display of RETURN 1>

When the RETURN (BS3) button is pressed,

the LED display for RETURN 1 turns ON.

When SET (BS2) button is pressed, the LED

display for RETURN 2 turns ON.

When SET (BS2) button is pressed, the LED

display for RETURN 3 turns ON.

Press the RETURN (BS3) button to return the

system to the initial state of "Monitor mode".

* Pressing the MODE (BS1) button will bring the

system to the "Setting mode 1".

Press the SET (BS2) button to set the LED

display to retry item.

<Display of RETURN 2>

<Display of RETURN 3>

Check the retry that matches the LED

sequence (see table above).

ESIE16-03B | Part 2. Troubleshooting 2.1. Error codes check

2.1.2.3. History of error codes and warnings

As described in above procedure, the latest error or warning codes can also be consulted in Monitor mode:

Setting item 5= latest error

Setting item 6= previous error

Setting item 7= 2 before

For the procedure and the meaning of the different displays, refer to "How to retrieve error codes" above.

2.1.2.4. Content of retry

Through the outdoor PCB, the content of retry can be determined.

Here, you can find the errors which are being created before they are being displayed on the user interface.

As described in below procedure, the content of retry can again be consulted in Monitor mode:

Setting item 2= latest retry

Setting item 3= 1 cycle before

Setting item 4= 2 cycles before

Page 22 22/08/16 | Version 1.1

SA R32 Sky-Air RZAG-L

ESIE16-03B | Part 2. Troubleshooting 2.2. Error based troubleshooting

2.2. Error based troubleshooting

Overview of error codes:

Indoor unit ............................................................................................................................................................................................24

“A1-01” – Indoor unit PCB abnormality ....................................................................................................................................24

“A3-00” – Drain water level system abnormality.......................................................................................................................24

“A6-00” – Indoor unit fan motor abnormality.............................................................................................................................24

“AJ-00” – Capacity setting abnormality ....................................................................................................................................25

“C1-00” – Transmission error (indoor & adapter PCB).............................................................................................................25

“C4-00” – Heat exchanger thermistor abnormality...................................................................................................................26

“C5-00” – Intermediate heat exchanger thermistor abnormality...............................................................................................26

“C9-00” – Suction air thermistor abnormality............................................................................................................................27

“CC-00” – Humidity sensor system abnormality.......................................................................................................................27

“CJ-00” – Remote controller thermistor abnormality ................................................................................................................27

Outdoor unit..........................................................................................................................................................................................28

“E1-00” – Outdoor unit PCB abnormality..................................................................................................................................28

“E3-00” – Discharge pressure abnormality...............................................................................................................................28

“E4-00” – Suction pressure abnormality...................................................................................................................................29

“E5-00” – Compressor motor lock or overheated .....................................................................................................................29

“E7-00” – Fan motor abnormality .............................................................................................................................................30

“E9-00” – Electronic expansion valve abnormality ...................................................................................................................31

“F3-00” – Discharge pipe temperature abnormality..................................................................................................................31

“H3-00” – High pressure switch abnormality ............................................................................................................................32

“H4-00” – Low pressure switch abnormality .............................................................................................................................33

“H9-00” – Outdoor air temperature thermistor abnormality ......................................................................................................33

“J3-00” – Discharge pipe thermistor abnormality .....................................................................................................................33

“J5-00” – Suction pipe thermistor abnormality..........................................................................................................................34

“J6-00” – Outdoor heat exchanger thermistor abnormality.......................................................................................................34

“J7-00” – Intermediate heat exchanger thermistor abnormality................................................................................................34

“J8-00” – Liquid pipe thermistor abnormality............................................................................................................................35

“L1-00” – Outdoor main PCB abnormality ................................................................................................................................35

“L5-00” – Output overcurrent detection ....................................................................................................................................36

“L8-00” – Electronic thermal overload ......................................................................................................................................37

“L9-00” – Stall prevention time lag ...........................................................................................................................................37

“LC-00” – Transmission system abnormality............................................................................................................................38

“P1-00” – Open phase or power supply voltage imbalance .....................................................................................................38

“P4-00” – Radiating fin temperature sensor abnormality..........................................................................................................38

“PJ-00” – Capacity setting abnormality ....................................................................................................................................39

System .................................................................................................................................................................................................40

“U0-00” – Refrigerant shortage ................................................................................................................................................40

“U1-00” – Reverse phase or open phase.................................................................................................................................40

“U2-00” – Power supply abnormality or instantaneous power failure.......................................................................................41

“U4-00” – Transmission abnormality between indoor unit and outdoor unit.............................................................................42

“UA-00” – Improper combination of indoor unit and outdoor unit .............................................................................................42

“UF-00” – Wiring and piping mismatch.....................................................................................................................................43

Others .................................................................................................................................................................................................43

22/08/16 | Version 1.1 Page 23

SA R32 Sky-Air RZAG-L

ESIE16-03B | Part 2. Troubleshooting 2.2. Error based troubleshooting

2.2.1. Indoor unit

2.2.1.1. “A1-01” – Indoor unit PCB abnormality

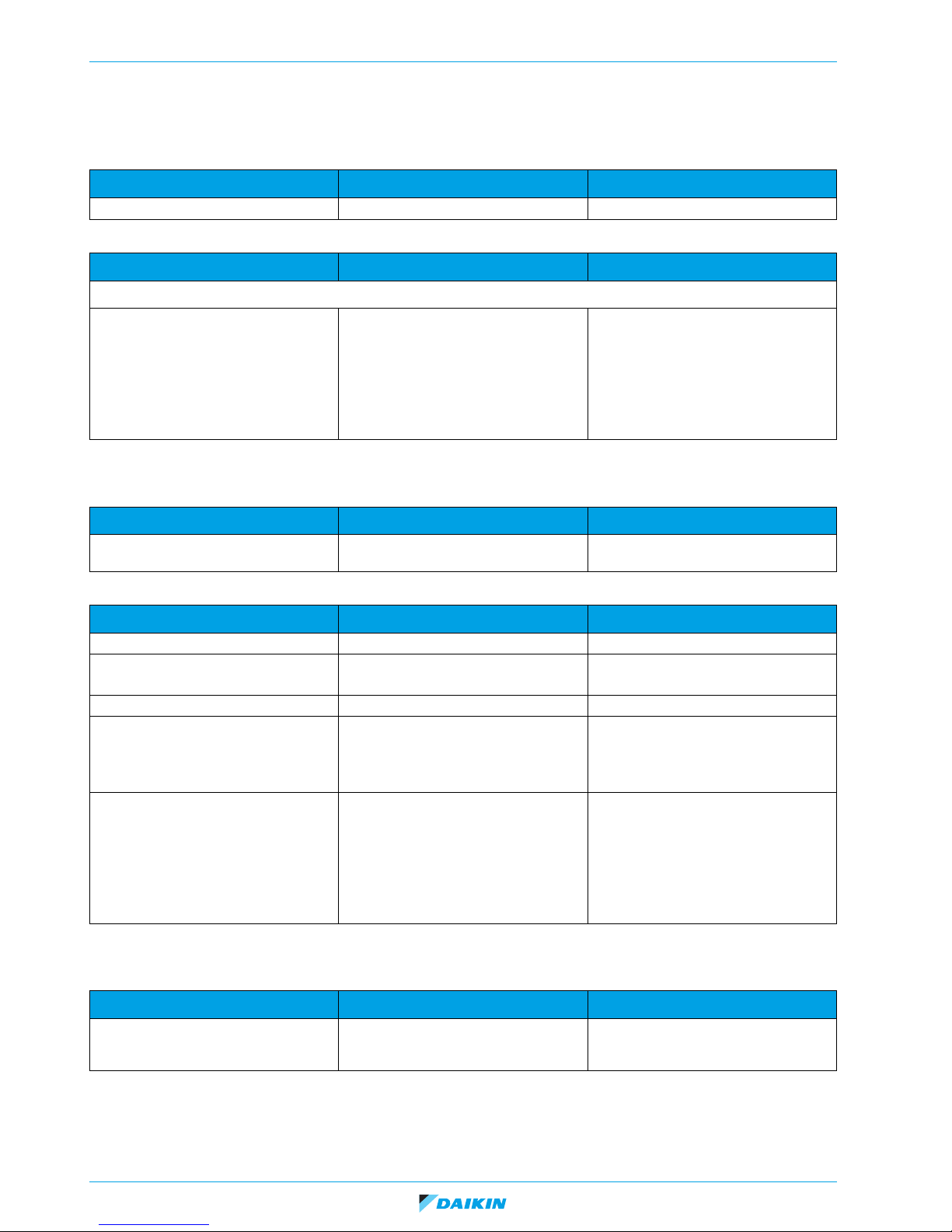

Trigge r Effect Reset

EEPROM data is not received correctly. Unit will stop operating. Power reset via outdoor unit.

Possible cause Check Corrective action

Indoor Unit - Electrical components

Faulty indoor PCB. Check if error still occurs after turning off

power and turning it back on again.

Check if the indoor PCB receives power.

Check if the HAP LED is blinking in regular intervals.

Check if the correct spare part is installed.

Check the wiring to indoor PCB.

2.2.1.2. “A3-00” – Drain water level system abnormality

Adjust power to the indoor PCB.

Replace indoor PCB when HAP LED is

not blinking in regular intervals.

Install correct spare part or update indoor

PCB.

Adjust wiring to indoor PCB when

required.

Trigge r Effect Reset

Drain water level reaches its upper limit

and float switch turns OFF.

Unit will stop operating. Automatic reset.

Possible cause Check Corrective action

Defective drain pump. Check drain pump. Replace drain pump when required.

Improper drain piping work or clogging. Check if drain piping is executed correctly.

Check if drain piping is clogged.

Defective flow switch. Check flow switch. Replace flow switch when required.

(for optional drain pump kit) Defective

short circuit connector X15A.

Faulty indoor PCB. Check if error still occurs after turning off

Check if connector is firmly connected.

Check the continuity of the short circuit

connector.

power and turning it back on again.

Check if the indoor PCB receives power.

Check if the HAP LED is blinking in regular intervals.

Check if the correct spare part is installed.

Check the wiring to indoor PCB.

Correct or clean drain piping when

required.

Connect the short circuit connector.

Replace the short circuit connector when

required.

Replace the indoor PCB when required.

Adjust power to the indoor PCB.

Replace indoor PCB when HAP LED is

not blinking in regular intervals.

Install correct spare part or update indoor

PCB.

Adjust wiring to indoor PCB when

required.

2.2.1.3. “A6-00” – Indoor unit fan motor abnormality

Trigge r Effect Reset

The rotation speed of the fan motor is not

detected while the output voltage to the

fan is at its maximum.

Page 24 22/08/16 | Version 1.1

Unit will stop operating. Power reset via outdoor unit.

SA R32 Sky-Air RZAG-L

ESIE16-03B | Part 2. Troubleshooting 2.2. Error based troubleshooting

Possible cause Check Corrective action

Faulty indoor PCB. Check if error still occurs after turning off

power and turning it back on again.

Check if the indoor PCB receives power.

Check if the HAP LED is blinking in regular intervals.

Check if the correct spare part is installed.

Check the wiring to indoor PCB.

Faulty indoor fan motor. Check the fan motor (see "Fan motor" on

page 46).

Check fan motor connections and wiring.

Indoor fan motor locked. Switch of the power.

Turn fan manually.

Adjust power to the indoor PCB.

Replace indoor PCB when HAP LED is

not blinking in regular intervals.

Install correct spare part or update indoor

PCB.

Adjust wiring to indoor PCB when

required.

Replace fan motor when required.

Adjust wiring when required.

Replace fan motor when the fan does not

turn smoothly.

2.2.1.4. “AJ-00” – Capacity setting abnormality

Trigge r Effect Reset

The capacity setting adaptor is not connected or not recognised by the indoor

PCB.

Unit will stop operating. Power reset via outdoor unit.

Possible cause Check Corrective action

Faulty indoor PCB. Check if error still occurs after turning off

Faulty capacity adapter on indoor PCB (in

case of spare part PCB).

power and turning it back on again.

Check if the indoor PCB receives power.

Check if the HAP LED is blinking in regular intervals.

Check if the correct spare part is installed.

Check the wiring to indoor PCB.

Check if the correct adapter is installed.

Check if the correct spare part is installed.

Adjust power to the indoor PCB.

Replace indoor PCB when HAP LED is

not blinking in regular intervals.

Install correct spare part or update indoor

PCB.

Adjust wiring to indoor PCB when

required.

Adjust capacity adapter when required.

2.2.1.5. “C1-00” – Transmission error (indoor & adapter PCB)

Trigge r Effect Reset

When normal transmission between

indoor unit PCB & adaptor PCB is not

conducted for a certain duration (15 seconds or more).

Possible cause Check Corrective action

Faulty adaptor PCB. Check if the adaptor PCB is installed.

Unit will stop operating. Power reset via outdoor unit.

Adjust when required.

Check if the connector X8A on the adaptor PCB is not circuited.

Check the wire harness.

22/08/16 | Version 1.1 Page 25

SA R32 Sky-Air RZAG-L

ESIE16-03B | Part 2. Troubleshooting 2.2. Error based troubleshooting

Possible cause Check Corrective action

Faulty indoor PCB. Check if error still occurs after turning off

External factory (e.g. electrical noise)

(cause when error is reset after power

reset, and error happens again after a

while).

Internal wiring is not OK. Check if wiring between PCB’s is correct

power and turning it back on again.

Check if the indoor PCB receives power.

Check if the HAP LED is blinking in regular intervals.

Check if the correct spare part is installed.

Check the wiring to indoor PCB.

Check for source which could cause electrical interference.

(refer to wiring diagram).

Adjust power to the indoor PCB.

Replace indoor PCB when HAP LED is

not blinking in regular intervals.

Install correct spare part or update indoor

PCB.

Adjust wiring to indoor PCB when

required.

Avoid electrical interference.

Correct wiring.

2.2.1.6. “C4-00” – Heat exchanger thermistor abnormality

Trigge r Effect Reset

Resistance value is out of range.

T measured < -43.6°C or > 90°C.

Unit will stop operating. Automatic reset when resistance is within

range.

Possible cause Check Corrective action

Faulty Heat Exchanger thermistor. Check heat exchanger thermistor (see

"Refrigerant thermistors" on page 57).

Faulty indoor PCB. Check if error still occurs after turning off

power and turning it back on again.

Check if the indoor PCB receives power.

Check if the HAP LED is blinking in regular intervals.

Check if the correct spare part is installed.

Check the wiring to indoor PCB.

Replace heat exchanger thermistor when

required.

Adjust power to the indoor PCB.

Replace indoor PCB when HAP LED is

not blinking in regular intervals.

Install correct spare part or update indoor

PCB.

Adjust wiring to indoor PCB when

required.

2.2.1.7. “C5-00” – Intermediate heat exchanger thermistor abnormality

Trigge r Effect Reset

Resistance value is out of range.

T measured < -43.6°C or > 90°C.