Daikin EKRTCTRL1, EKRTCTRL2, EKWHCTRL0, EKWHCTRL1, EKPCBO Installation manuals

INSTALLATION MANUAL

Daikin Altherma

heat pump convector options

EKRTCTRL1

EKRTCTRL2

EKWHCTRL0

EKWHCTRL1

EKPCBO

We would first of all like to thank you for having chosen one of our products.

U

I

S

We are sure you will be happy with it because it represents the state of the art in the technology of

home air conditioning.

By following the suggestions contained in this manual, the product you have purchased will operate

without problems, giving you optimum room temperatures with minimum energy costs.

DAIKIN EUROPE N.V.

Symbols

The pictograms in the next chapter provide the necessary

information for correct, safe use of the appliance in a rapid,

Editorial pictograms

User

Refers to pages containing instructions or information for

the user.

Installer

Refers to pages containing instructions or information for

the installer.

Safety pictograms

Warning

The operation described may cause physical harm if not

carried out in accordance with safety regulations.

Dangerous electrical current

Make personnel aware that the operation described may

lead to electrical shocks if not carried out in accordance

with safety regulations.

unmistakable way.

Service

Refers to pages containing instructions or information for

the CUSTOMER TECHNICAL ASSISTANCE SERVICE

installer.

High temperature danger

Of safety regulations, the risk of burns caused by contact

with components with high temperatures.

Prohibition

Refers to prohibited actions.

2

1 GENERAL

1.1 General warnings ............................................................................4

2 EKRTCTRL1

2.1 Assembly, set-up and connection of on-board control panels ...........................................5

2.2 Assembly ..................................................................................5

2.3 Set-up of auxiliary dip-switch functions B and C ......................................................6

2.4 CP presence contact input connection (only for EKRTCTRL1) ............................................6

2.5 Air temperature probe assembly (only for model EKRTCTRL1) ............................................7

2.6 EKRTCTRL1 connections ......................................................................8

3 EKWHCTRL0

3.1 Continuous modulation circuit board for connecting remote thermostat .....................................9

3.2 LED Indications (Ref. A) ........................................................................9

3.3 EKWHCTRL0 connections ....................................................................10

4 EKWHCTRL1

4.1 Wall-mounted remote control panel assembly EKWHCTRL1 ............................................11

4.2 Spring-loaded terminal connections -AB+ and CP ...................................................12

4.3 CP occupancy contact input connection ..........................................................12

4.4 EKWHCTRL1 Connections ....................................................................13

5 EKRTCTRL2

5.1 Assembly and connections for on-board control panel EKRTCTRL2 ......................................14

5.2 Assembly .................................................................................14

5.3 Air temperature probe assembly ................................................................15

5.4 EKRTCTRL2 Connections .....................................................................15

6 SETUP MENU FOR EKRTCTRL1 - EKWHCTRL1 - EKRTCTRL2

6.1 Setup menu ...............................................................................16

7 EKPCBO

7.1 Assembly and connections for on-board control panel EKPCBO .........................................19

7.2 Assembly .................................................................................19

7.3 EKPCBO Connections .......................................................................20

7.4 Warnings table .............................................................................20

8 VERSIONS WITH CONNECTIONS ON THE RIGH

8.1 Motor connection in versions with hydraulic connections on the right EKREPLH ..............................21

EN

3

SIU

GENERAL

1.1

General warnings

- This instruction is an integral part of the booklet of

the appliance on which the kit is installed. Please consult

this booklet for general warnings and fundamental safety

rules.

- This manual is designed only for the qualified

and authorised installation technician, who must be

sufficiently trained and in possession of all psychophysical requirements as per the law.

- All operations must be carried out with care and

according to best practices, and in compliance with

workplace safety regulations.

- After unpacking, check that the contents are intact

and that all parts are included. If not, contact the agent

who sold the appliance to you.

- It is forbidden to modify the safety or adjustment

devices without authorisation from and indications of the

manufacturer.

- It is forbidden to dispose of, or leave in the reach of

children, the packaging materials which could become

a source of danger.

- Repairs or maintenance must be performed by the

Technical Assistance Service or by qualified personnel

in accordance with this manual. Do not modify or tamper

with the appliance as this could create dangerous

situations and the manufacturer will not be liable for any

damage caused.

4

SIU

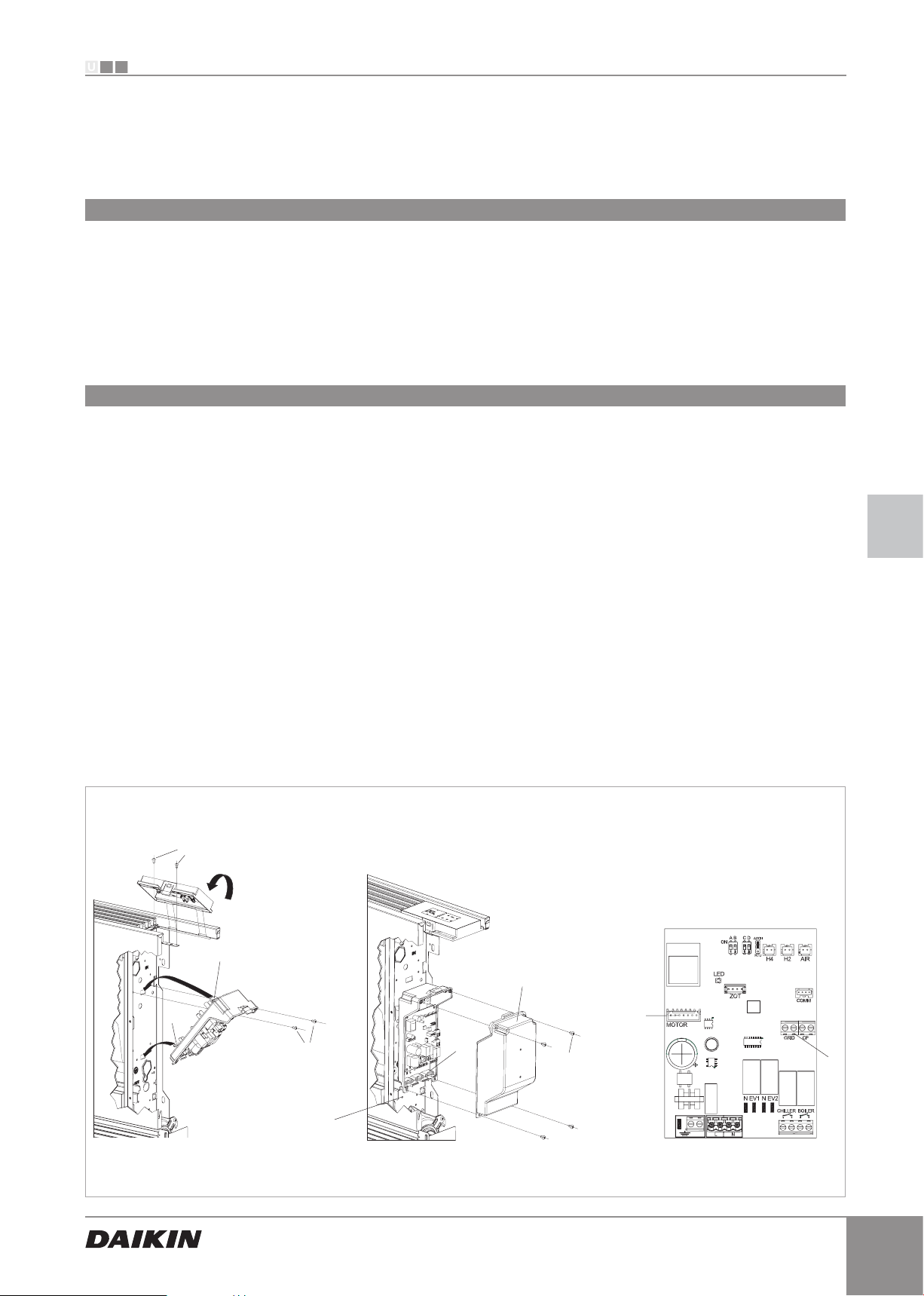

EKRTCTRL1

2.1

Assembly, set-up and connection of on-board control panels

The controllers have two independent clean contacts for

controlling a refrigerator unit, a boiler and a presence input.

The 2 tube versions have a 230V output to power the

summer and winter solenoid valve.

The 10 kΩ water temperature probe positioned in the

2.2

Assembly

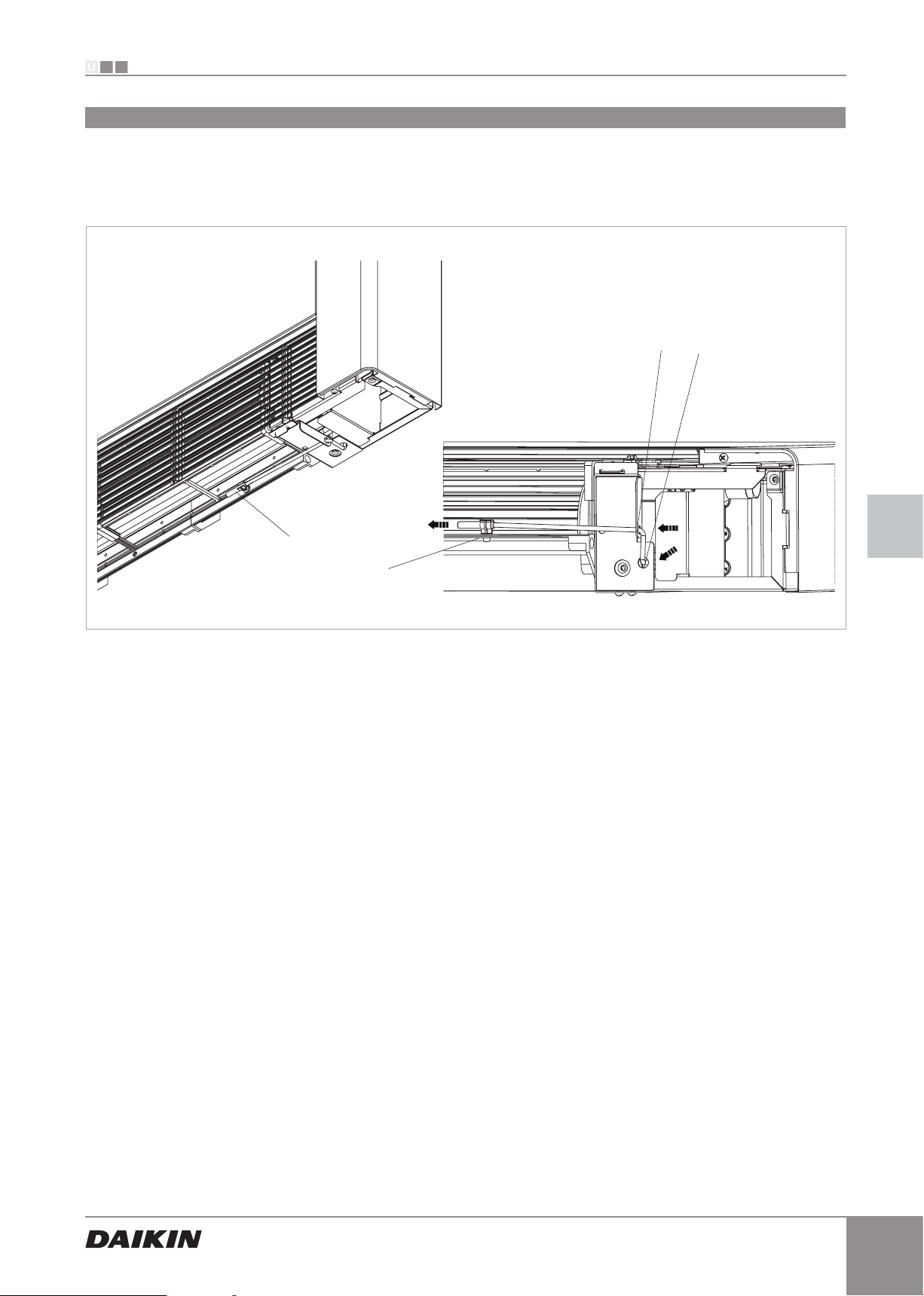

Slide the control panel into its housing in the upper part

of the device and fix it with the two fixing screws (ref. A).

To install the connection box:

- open the box (ref. B);

- lock the lower tooth into its hole (ref. C) on the side of

the device;

- hook the upper part of the box to the side (ref. D);

- fix it with the two fixing screws (ref. E);

- connect the grounding cable to the fan coil body (ref. M)

using the fixing screws (the minimum force that must be

applied for tightening screws must be around 2N);

- connect the fast connector of the MOTOR to the other

on the board (ref. I) *;

- on the two GRID block terminals (ref. L) there is a

bridge that allows the FWXM-series to work without a

microswitch.

- For other versions, remove the bridge and connect the

two terminals originating on the grill safety microswitch*;

- connect the water probe to the H2 connector on the

device.

compartment on the battery regulations the minimum level

when heating (30°C) and the maximum level when cooling

(20°C).

The board also has a function when there is no water

probe, in such cases the fan stop thresholds are ignored.

The water temperature probe controls the temperature

inside the batteries and determines when the fan starts

according to pre-set parameters (minimum operation

in winder and maximum in summer).** Check that

they are correctly inserted into the compartment on

the battery.

- Connect the electrics, tidy cables and fix them with

the three clevises supplied (ref. G);

- close the box with the 4 screws (ref. H);

- refit the vanity plate on the side of the unit;

- tighten the upper screws on the control panel;

- place the screw head covers in their housing on the

control panel;

* For versions with hydraulic connections on the right,

refer to the relevant paragraph

** The regulation also works without a water probe

connected

EN

A

D

B

C

E

G

H

I

L

M

5

SIU

2.3

Set-up of auxiliary dip-switch functions B and C

There are two dip switches on the controller circuit board

for configuring unit operation as per requirements.

- The night-time heating operation logic is modified by

using dip switch C:

- in the ON position, the fan is always off, and heats the

room using radiation and natural convection, as with

traditional radiators; in the off position it operates as a

normal fan.

- By positioning dip switch B to ON, when cooling, the

fan operates at the minimum speed even after having

2.4

CP presence contact input connection (only for EKRTCTRL1)

On closing the contact connected to the CP input (ref. A)

the panel is placed in stand-by mode.

If the contact is open the unit is active, if the contact is

closed it is deactivated when a key is pressed the

symbol flashes.

B

reached the set point, to allow for more uniform

operation of the temperature probe and to avoid

layering in the air. With the cursor in the OFF position,

the functions are cycled (4 minutes ON, 10 minutes

OFF).

The input cannot be connected in parallel to that of other

electronic boards (use separate contacts).

C

MOTOR

BAOND

LED

LN

C

ASCII

RTU

H4 H2 AIR

N EV1 N EV2

COMM

GRIDGRIDCP

A

CHILLER BOILER

6

SIU

2.5

Air temperature probe assembly (only for EKRTCTRL1)

- To position the temperature probe (ref. A):

- pass the probe through the hole on the shoulder (ref. B)

A

D

- insert the probe into the lower hole (ref. C)

- fix the probe on the relevant hook (ref. D)

C

B

EN

7

SIU

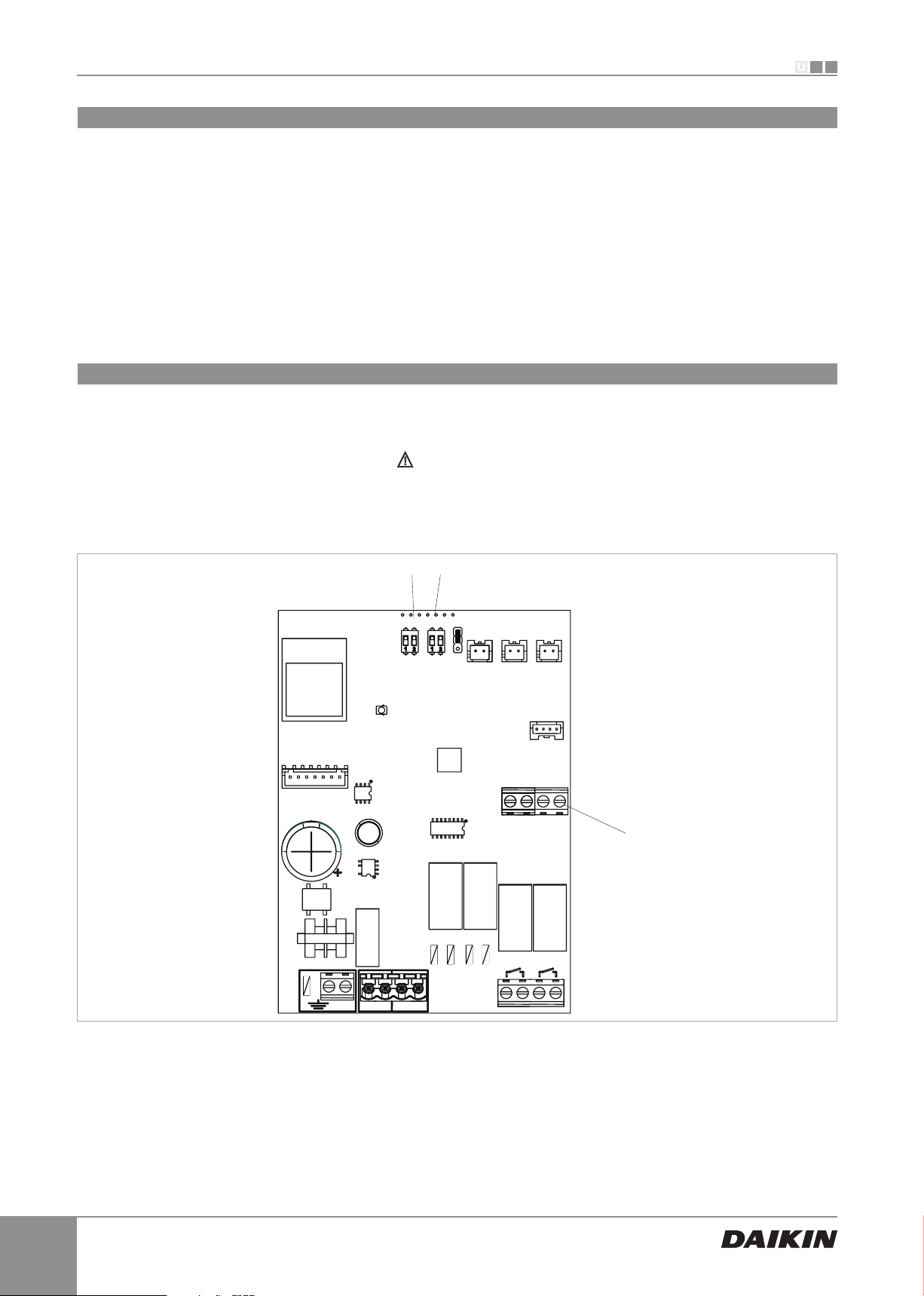

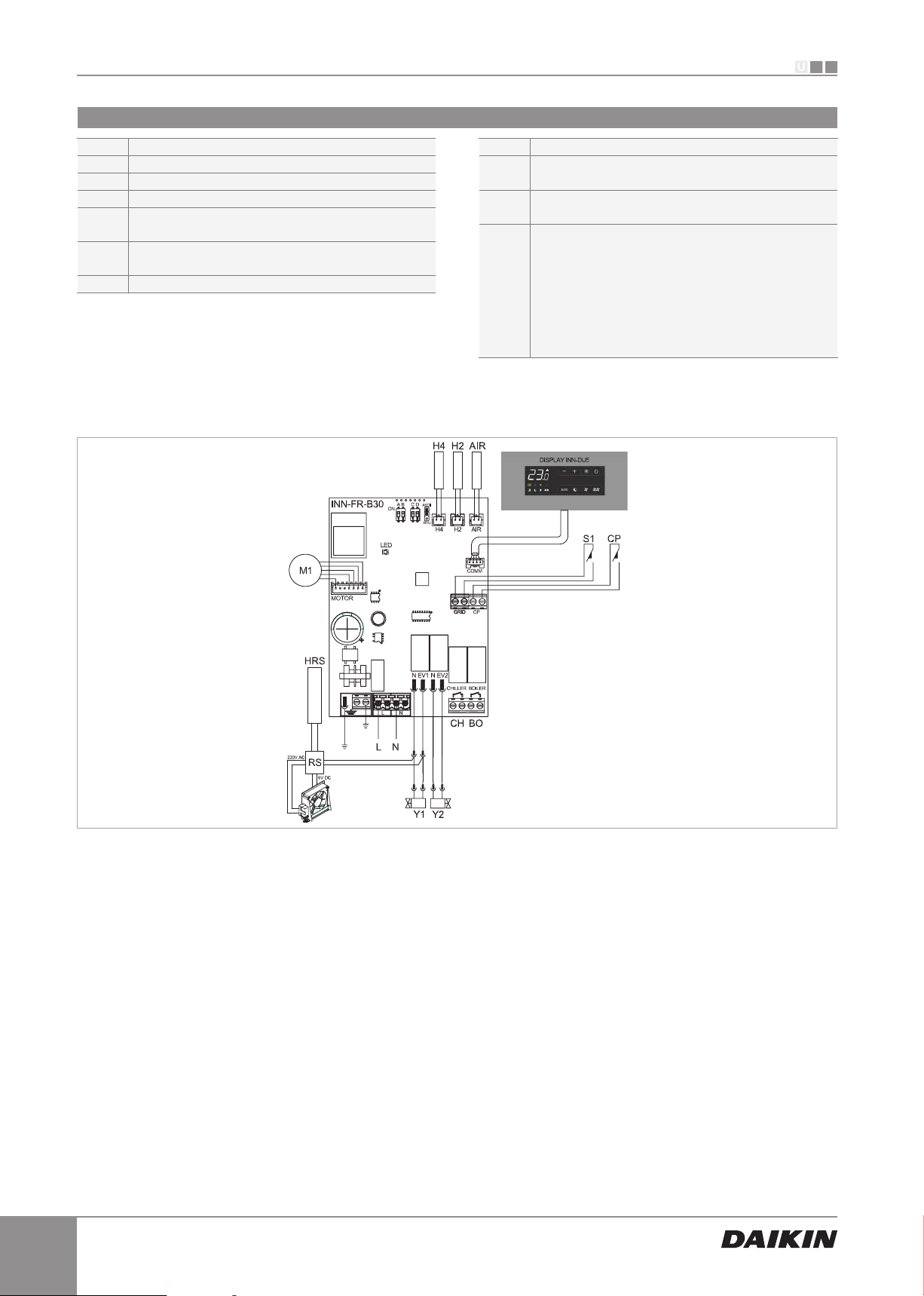

2.6 EKRTCTRL1 connections

H2* water temperature probe (10 kΩ)

AIR air temperature probe (10 kΩ)

M1 DC inverter fan motor

S1 grill safety micro-switch

Y1

Y2

L-N

water solenoid valve (230V/ 50Hz 1A output

voltage)

mobile flap connection

230V/ 50Hz 1A output voltage.

230V/50Hz electrical power supply

EKRTCTRL1

BO boiler consent output (free contact max 1A)

CH chiller consent output (free contact max 1A)

CP

* If after switching the power on the board

presence input sensor (if closed, the fan coil unit

is placed in standby).

detects the H2 probe, start-up occurs in normal

conditions with the minimum water temperature

when heating (30°C) and maximum when

cooling (20°C).

The board also has a function when there is no

probe, in such cases the fan stop minimum and

maximum thresholds are ignored.

8

Loading...

Loading...