Daikin EKOMBG22ABV1, EKOMBG28ABV1, EKOMBG33ABV1 Installation manuals

EKOMBG22ABV1

EKOMBG28ABV1

EKOMBG33ABV1

Daikin Europe NV

Installation instructions

Installationsanleitung

Instructions d'installation

Installatievoorschrift

Istruzioni d'installazione

Instrukcje instalacji

Instruções de instalação

Οδηγίες εγκατάστασης

English

Deutsch

Français

Nederlands

Italiano

Polski

Português

Ελληνικά

TABLE OF CONTENTS

1

2

3

4

5

6

7

8

9

9

10

© 2019 Daikin Europe NV

All rights reserved.

The information provided applies to the product in its standard version. Daikin Europe NV can therefore not be held liable for any damages arising from any

specifications of the product which deviate from the standard version. The available information has been compiled with the greatest possible care, but Daikin Europe

NV can not be held liable for any mistakes in the information, or for any consequences thereof. Daikin Europe NV cannot be held liable for any damage arising from

work carried out by third parties.

Subject to change.

Safety instructions 5

Unit description 5

2.1 General ............................................................................................................................................................................................ 5

2.2 Functioning ...................................................................................................................................................................................... 5

2.3 Operating modes ............................................................................................................................................................................. 5

2.4 PC Interface .................................................................................................................................................................................... 7

2.5 Test programs ................................................................................................................................................................................. 7

Main components 8

3.1 Accessories ..................................................................................................................................................................................... 9

Installation 10

4.1 Installation measurements ............................................................................................................................................................ 10

4.2 Installation space ........................................................................................................................................................................... 12

4.3 Assembly ....................................................................................................................................................................................... 13

Connecting 15

5.1 Connecting CH installation ............................................................................................................................................................ 15

5.2 Connecting DHW installation ......................................................................................................................................................... 17

5.3 Connecting electronically .............................................................................................................................................................. 18

5.4 Connect room thermostat .............................................................................................................................................................. 19

5.5 Connecting gas ............................................................................................................................................................................. 20

5.6 Flue and air supply duct ................................................................................................................................................................ 21

5.7 Outlet systems ............................................................................................................................................................................... 22

5.8 Flue material .................................................................................................................................................................................. 23

5.9 Connection to a flue system without air inlet (B23, B33) .............................................................................................................. 25

5.10 Connection to a sealed flue system. ............................................................................................................................................. 26

Commissioning the unit and the Installation 34

6.1 Filling and air purge of unit and installation ................................................................................................................................... 34

6.2 Commissioning the unit ................................................................................................................................................................. 35

6.3 Switching off the unit ..................................................................................................................................................................... 36

Setting and adjustment 37

7.1 Direct via operating panel .............................................................................................................................................................. 37

7.2 Parameter settings via the service code ....................................................................................................................................... 38

7.3 Setting maximum CH power .......................................................................................................................................................... 40

7.4 Set pump capacity ......................................................................................................................................................................... 40

7.5 Weather dependent regulation ...................................................................................................................................................... 40

7.6 Conversion to different type of gas................................................................................................................................................ 41

7.7 Gas/air regulation .......................................................................................................................................................................... 41

7.8 Setting gas/air regulation ............................................................................................................................................................... 42

Malfunctions 44

8.1 Show last malfunction ................................................................................................................................................................... 44

8.2 Malfunction codes ......................................................................................................................................................................... 44

8.3 Other faults .................................................................................................................................................................................... 45

Maintenance 48

Technical specifications 50

9.1 Technical Product Fiche in accordance to CELEX-32013R0811 .................................................................................................. 51

9.2 Electrical diagram .......................................................................................................................................................................... 52

9.3 NTC resistances ............................................................................................................................................................................ 53

Warranty conditions 54

Daikin Europe NV

3

These installation instructions

With these installation instructions, you can safely assemble, install and maintain the

unit. Carefully follow the instructions.

In case of any doubt, please contact the manufacturer.

Keep the installation instructions near the unit.

Abbreviations and terms used

Description To be referred to as

Daikin EKOMBG22ABV1, EKOMBG28ABV1 and

Unit

EKOMBG33ABV1 wall-mounted gas boiler.

Unit with piping for central heating CH installation

System with pipes for domestic hot water DHW installation

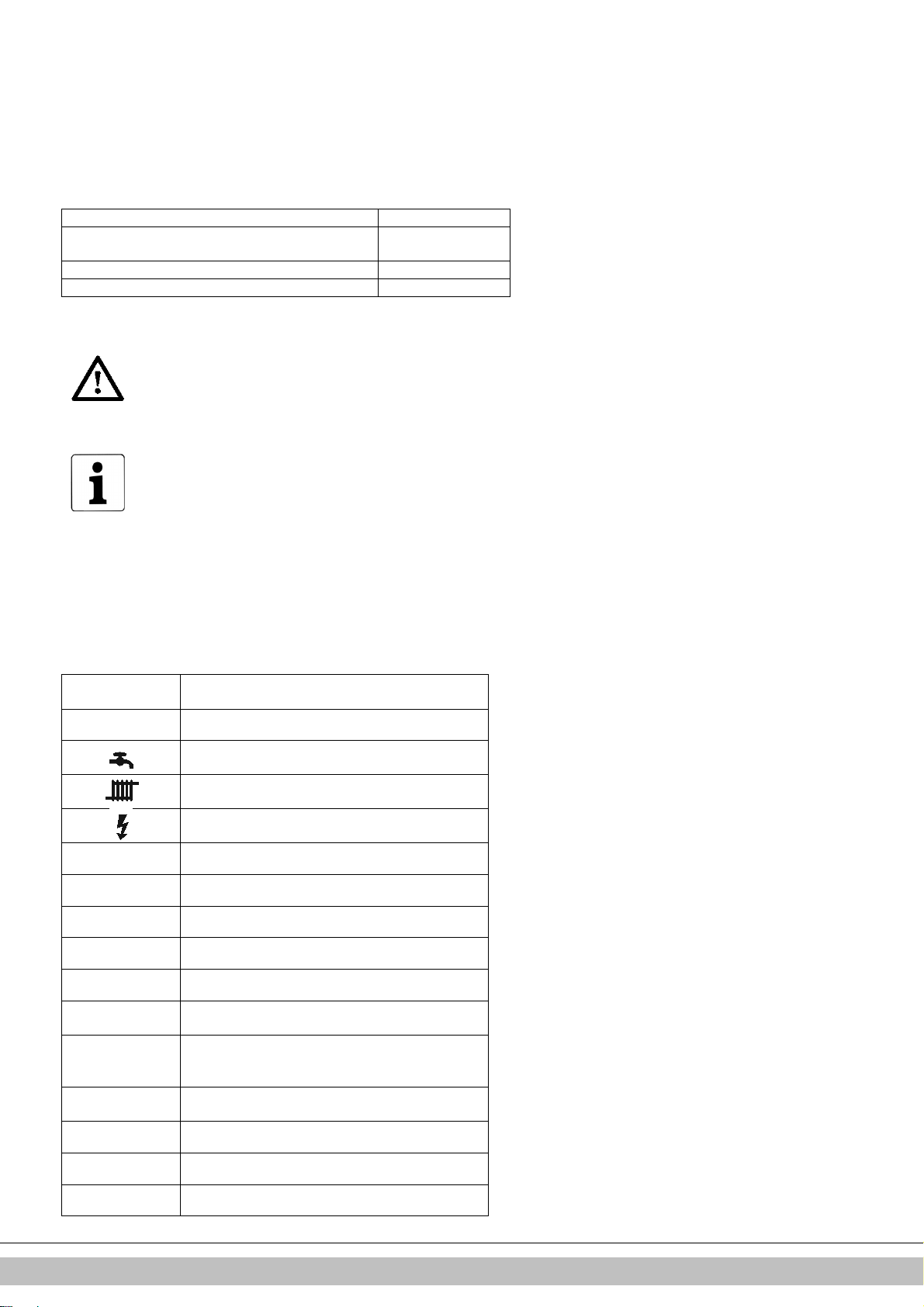

Symbols

The following symbols are used in this manual:

CAUTION

Procedures which - if they are not carried out with the

necessary care - may cause damage to the product, the

surroundings, the environment or injury.

IMPORTANT

Procedures and/or instructions which, if they are not followed,

will have a negative effect on the functioning of the unit.

Service and technical support for the installer

For information about specific settings, installation, maintenance and repair work, as an

installer, please contact your local Daikin dealer.

Identification of the product

You will find the unit details on the data plate on the bottom of the unit.

The data plate contains, beside the supplier information and the boiler specification

(boiler type and model name) the following information:

******-yymm****** Product code-Serial No.

YY= year of production, mm = month of production

PIN Product Identification Number

Data related to Domestic Hot Water

Data related to Central Heating

Information regarding electrical power supply

Voltage, mains frequency, elmax, IP-class)

PMS Permissible overpressure in CH circuit in bar

PWS Permissible overpressure in DHW circuit in bar

Qn HS Input related to gross caloric value in kilowatts

Qn Hi Input related to net caloric value in kilowatts

Pn Output in kilowatts

BE, CH, DE, ES,

FR, GB, IE, IT, MT

Countries of Destination (EN 437)

I2E(s), I2H,

IIELL3P, II2H3P,

Approved unit categories (EN 437)

II2Esi3P

G20-20 mbar

G25-25 mbar

Gas group and gas connection pressure as set at the

factory (EN 437)

B23, …. C93(x) Approved flue gas category (EN 15502)

Tmax Max. flow temperature in °C

IPX4D Electrical protection class

Daikin Europe NV 4

1 SAFETY INSTRUCTIONS

The manufacturer Daikin accepts no liability for damage or injury caused by the failure

to (strictly) observe the safety instructions, or negligence during the installation of the

Daikin EKOMBG*ABV1 wall-mounted gas boiler and any associated accessories.

This device is not intended for use by people (including children) with reduced

physical, sensory or mental abilities, or lack of experience and knowledge, unless they

are given supervision or instructions on the use of the device by a person who is

responsible for their safety.

The instructions are stated separately for the various disciplines.

The entire installation must meet the applicable local technical and (safety)

instructions, for the gas installation, the electrical installation, smoke extraction

installation, drinking water installation, and central heating installation.

IMPORTANT

This product is intended for domestic use only.

2 UNIT DESCRIPTION

2.1 General

The Daikin EKOMBG*ABV1 wall-mounted gas boiler is a closed unit. The unit is

intended to provide heat to the water of a CH-installation and the domestic hot water

installation.

The air supply and the combustion gas outlet of the EKOMBG*ABV1 can be connected

to the unit by two separate pipes, or by a concentric connection. The unit was tested in

combination with the combi feedthrough, but the unit may also be connected to combi

feedthroughs which meet the universal test standards for combi feedthroughs.

The unit can be connected to an assembly bracket if required, a frame with top

connection, and various installation sets. These are provided separately.

The Daikin EKOMBG*ABV1 wall-mounted gas boilers have the CE quality mark,

electrical protection class IP44.

It is possible to use the unit solely for warm water, or solely for heating. The system

which is not in use, does not need to be connected (see par. 7.2).

The unit is delivered for natural gas (G25) as a standard. On request, the unit can also

be provided for propane (G31).

2.2 Functioning

The Daikin EKOMBG*ABV1 wall-mounted gas boiler is a modulating high-efficiency

boiler. This means that the power is modulated to suit the required heat demand. In the

aluminum heat exchanger two separate copper circuits are integrated.

The separate circuits for CH and warm water allow the heating and warm water supply

to function independently. The hot water supply takes precedence over the heating.

Both cannot work at the same time.

The unit is fitted with an electronic boiler controller machine, which operates the fan

and the modulating pump at every heat requirement of the heating or the warm water

supply, opens the gas valve, ignites the boiler controller, and continuously monitors

and regulates the flame, depending on the requested power. The pump is only

operated during a heat request from the heating, depending on the requested power.

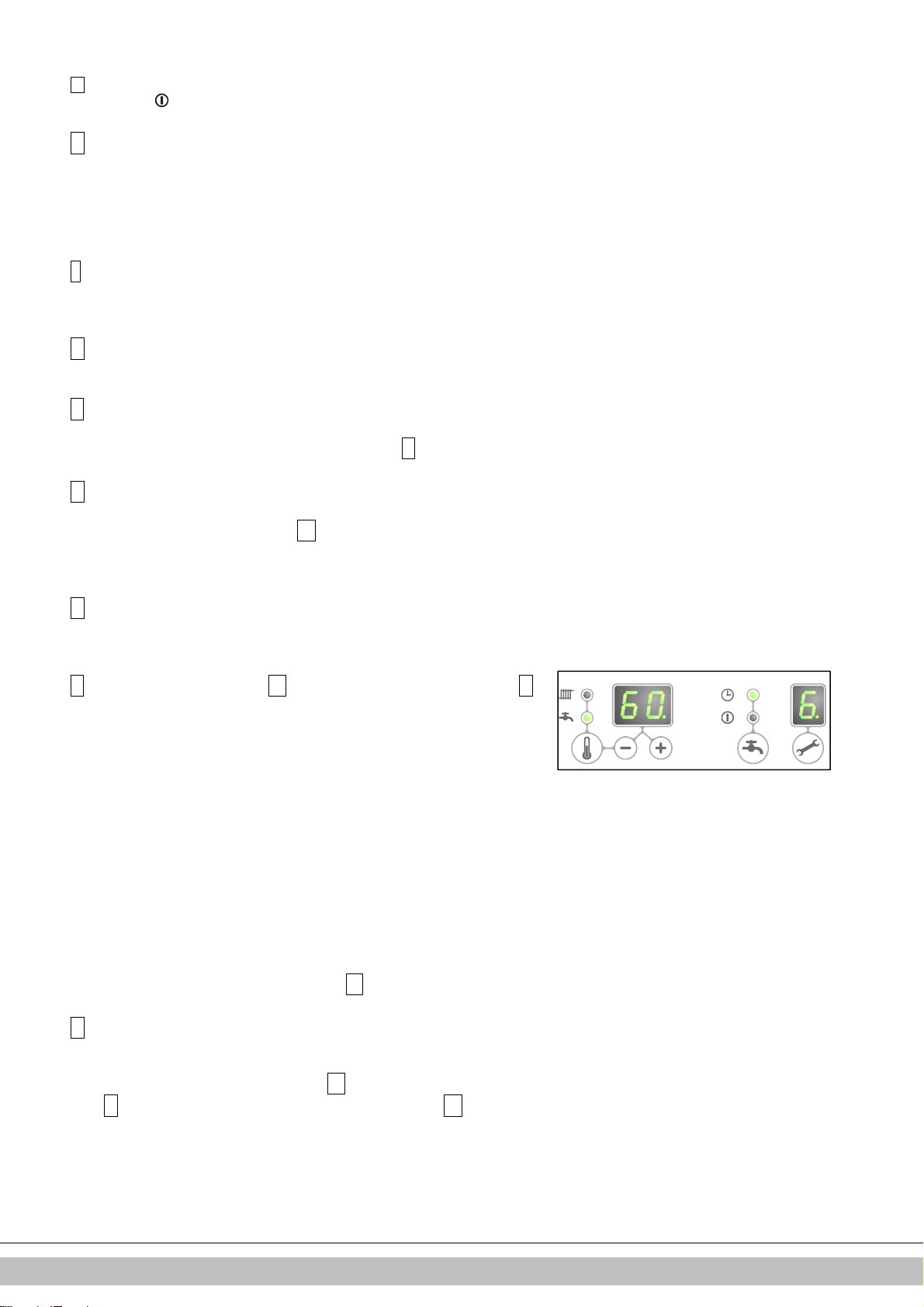

2.3 Operating modes

The operating mode of the unit is indicated by means of a code on the service display

of the operating panel.

-

Off

The unit is not in operation, but is connected to the electricity supply. No response is

given to requests for domestic hot water or CH water. The unit frost protection is

active. This means that the pump will start running and the exchanger will be heated

up if the temperature of the water in the system drops too far.

7

If the frost protection intervenes, the code

The pressure in the CH installation can also be read from the temperature display in

this operating mode (in bar).

Daikin Europe NV

will be displayed (heating up exchanger).

5

Standby

The LED at the key is lit and possibly one of the LEDs of the tap comfort function.

The unit is ready to respond to a request for CH or tap water.

0

Post-running CH

After the end of the CH-operation, the pump will post-run. The post-pumping time is set

to the value in par. 7.2 in its factory settings. This setting can be changed. In addition to

this, the pump will run automatically 1 time per 24 hours, for 10 seconds, in order to

prevent it from getting stuck. This automatic switching on of the pump takes place at the

time of the last heating request. In order to change this, the room thermostat needs to be

set higher for a moment, at the required time of day.

1

Requested temperature reached

The boiler controller may temporarily block the heat request. The boiler controller will

then be stopped. The block occurs because the required temperature has been

reached. When the temperature has sufficiently decreased, the block will be lifted.

2

Selftest

Once every 24 hours, the boiler controller tests the connected sensors. During the test,

the controller will not carry out any other tasks.

3

Ventilating

When the unit is started, the fan is first brought up to its correct start rpm. When the

start rpm is reached, the boiler controller will be ignited. Code 3 is also visible when

there is post-fanning after the boiler controller is stopped.

4

Igniting

When the fan has reached the start rpm, the boiler controller will be ignited by means of

electrical sparks. During the ignition, code

not ignite, a new attempt will be made after approximately 15 seconds. If after 4 ignition

attempts, the boiler controller has still not been ignited, the controller will go into downtime.

5

CH-operation

An on/off thermostat, an OpenTherm thermostat, an outdoor sensor or a combination

thereof can be connected to the controller (see par. 9.2)

When there is a heat request from a thermostat, after the fan has started running (code

3

), the ignition will take place (code

During CH operation, the rpm of the fan and therefore the power of the unit can be

adjusted so the temperature of the CH water to the required CH supply temperature can

be controlled. If an on/off thermostat has been connected, this will be the CH supply

temperature set on the display. In case of an OpenTherm or wireless thermostat, the

required CH supply temperature is determined by the thermostat. In case of an outdoor

sensor, the required CH supply temperature is determined by the fuel line programmed

in the boiler controller. For the last two situations, the temperature set on the display is

the maximum.

During CH operation, the requested CH supply temperature will be displayed on the

operating panel.

The CH supply temperature can be set between 30 and 90°C (see par. 7.1). Caution:

for a low temperature system, a lower maximum setting may be required than the

standard setting of 80°C.

You can press the service button during CH operation to read the actual CH supply

temperature.

4

is displayed. If the boiler controller does

4

) followed by the CH operating mode (code 5 ).

If the tap comfort function is switched on (see code

less than 40 degrees will be generated.

6

Domestic hot water operation

The hot water supply takes precedence over the heating. If the flow switch senses a

request for more than 2 l/min of domestic hot water, any CH requests will be

interrupted. After the fan has switched on (code

(code 4 ), the controller will switch to domestic water operation (code

domestic hot water operation, the rpm of the fan, and therefore the power of the unit, is

controlled by the controller on the basis of the set tap water temperature.

The control system ensures the tap water temperature is correct. The water

temperature can be set between 40°C and 65°C (see par. 7.1).

7

), an OpenTherm heat request of

3

) and there has been an ignition

6

). During

Daikin Europe NV 6

The set tap water temperature is displayed on the operation panel. The standard setting

exchanger is sufficiently high. If the frost protection intervenes, code

frost thermostat on the return pipe.

is 60°C. You can press the service button during tap water operation to read the actual

tap water temperature.

7

Heating up unit

In order to provide a fast supply of domestic hot water, a so-called tap comfort function

has been installed in the unit. This function keeps the heat exchanger at the right

temperature (it can be set, see par. 7.2). The tap comfort function has the following

settings:

•

On: ( LED on) The tap comfort function of the unit is continuously switched on.

The unit always immediately provides warm water.

•

Eco: ( LED on) The tap comfort function of the unit is self-learning. The unit will

adjust to the usage pattern of the domestic hot water. This means the heat

exchanger will not be kept warm during the night or during longer absences.

•

Off: (Both LEDs off) The heat exchanger is not kept warm which means the supply

of domestic hot water takes a bit of time. If there is no need for fast delivery of

domestic hot water, the tap comfort function can be switched off.

In the settings "on" and "eco" , the unit meets the requirements of the Gaskeur

[Gas Inspection] CW standards.

2.4 PC Interface

The boiler controller is provided with an interface for a PC. A PC can communicate with

the CH boiler by means of a special dongle, and the associated software. This facility

enables you to follow the behavior of the boiler controller, the unit and the heat

installation over a long period.

2.5 Test programs

There is an option in the boiler controller, to bring the unit into a test status.

Activating a test program, will switch on the unit with a set fan rotations per minute,

without the control functions intervening.

The safety functions do remain active.

The test program is ended by pressing and simultaneously.

Test programs

Description of program Button combination Display reading

Burner on with minimum DHW

capacity (see parameter d par. 7.2)

Burner on with set maximum CH

power (see parameter 3 par. 7.2)

Burner on with maximum DHW power

(see parameter 3 par. 7.2)

Switching off test program and

During test mode the following data can be read :

• By pressing the + button continuously in the display the CH water pressure is shown.

• By pressing the - button continuously in the display the ionisation current is shown.

and

and (1x)

and (2x)

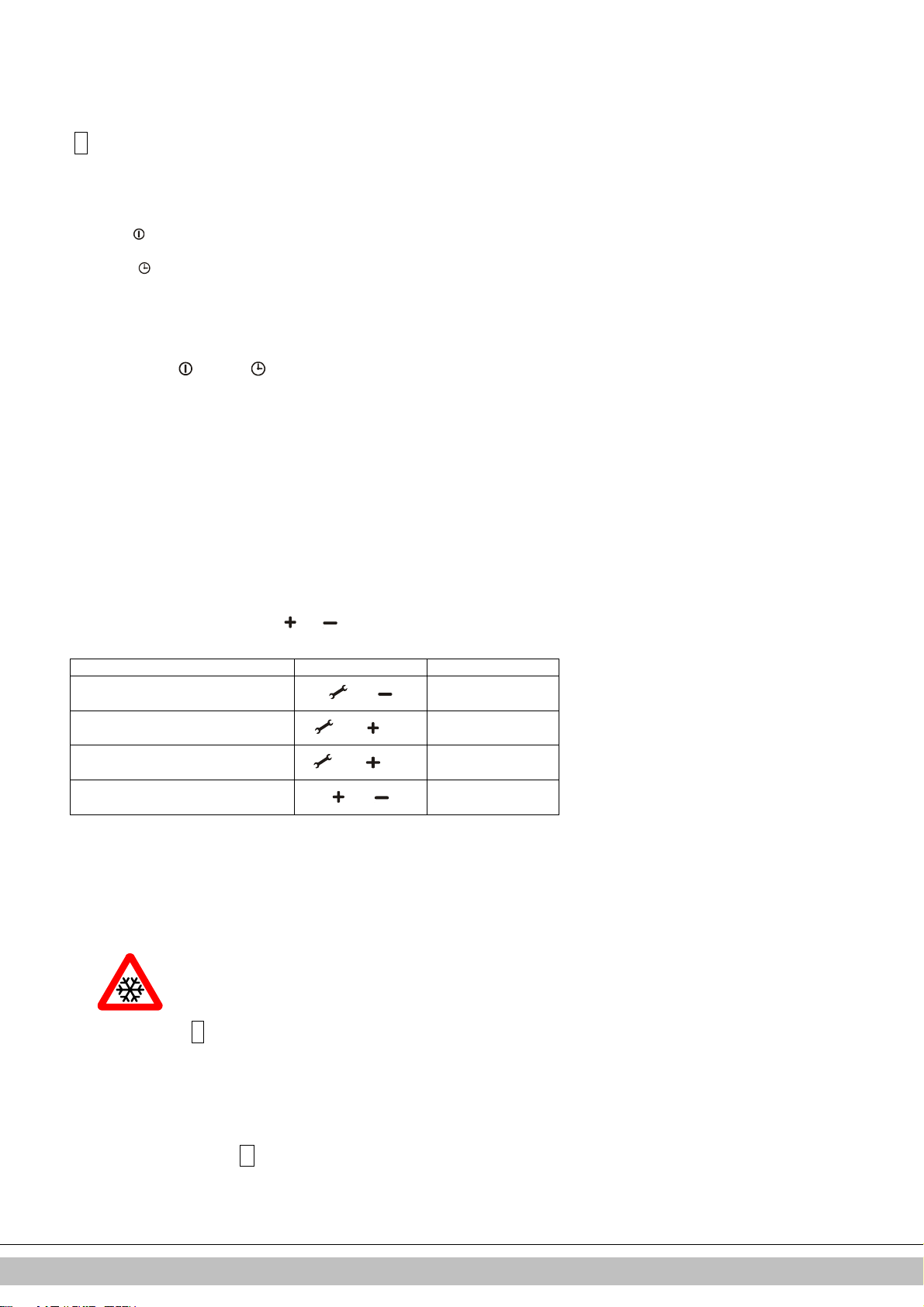

2.5.1 Frost protection

•

The unit is fitted with frost protection in order to prevent it from

freezing. If the temperature of the heat exchanger drops too low,

the pump will start running until the temperature of the heat

"L"

"h"

"H"

Current operation

situation

7

will be displayed (heating up exchanger).

•

If the installation (or a part thereof) can freeze, the coldest place

should be fitted with an (external)

This must be connected in accordance with the electrical diagram

(see par. 9.2).

Note

-

When the unit is switched off (

remain active, however a heat request from an (external) frost thermostat will be ignored.

Daikin Europe NV

on the service display), the unit frost protection will

7

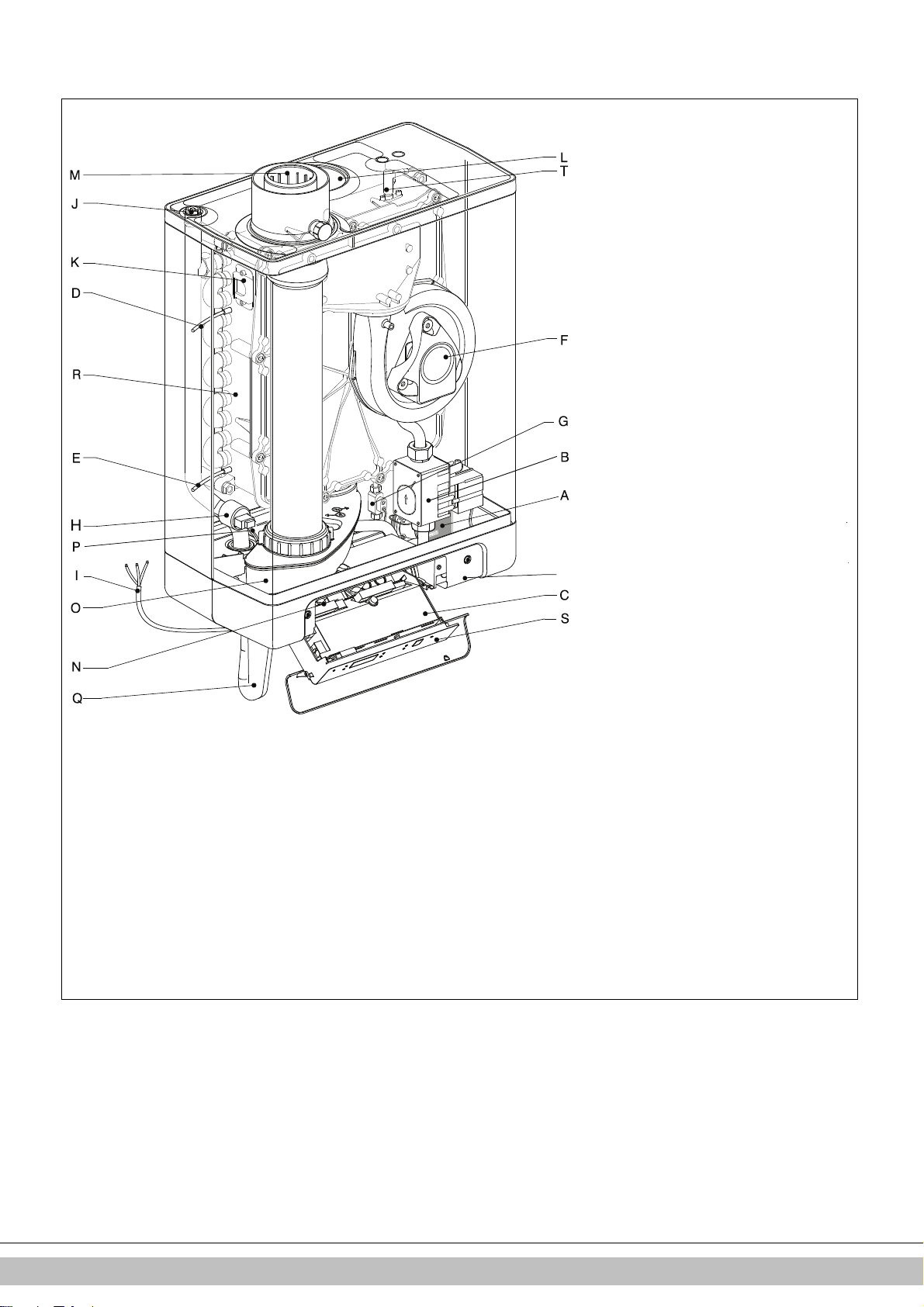

3 MAIN COMPONENTS

U

A. CH pump L. Air supply (only when using twin pipe flue system)

B. Gas valve M. Flue gas/air inlet concentric adapter

C. Burner controller (incl. operating panel) N. Connection block / terminal strip X4

D. Sensor S1 (flow) O. Condensate drain pan

E. Sensor S2 (return) P. Domestic hot water sensor S3

F. Fan Q. Siphon

G. Flow sensor R. Heat exchanger

H. Pressure sensor central heating S. Operating panel and display

I. Connection wire 230 V ~ with earthed plug T. Ionization / ignition pen

J. Manual air bleed U. Position of data plate

K. Sight glass

Daikin Europe NV 8

3.1 Accessories

Description Article numbers

B-pack EKFJS*AA EKFJS*AA

B-pack middle EKFJM*AA

B-pack large EKFJL*AA

Valve kit EKVK4AA

Cover plate EKOMBG*ABV1 EKCP1AA

Outdoor sensor EKOSK1AA

3-way valve set EK3WV1AA

Flue gas adapter Concentric Ø80x125 EKHY090717

Flue gas adapter Parallel 80 mm

Propane set *KOMBG22ABV1 EKPS075877

Propane set *KOMBG28ABV1 EKPS075867

Propane set *KOMBG33ABV1 EKHY075787

EKHY090707

Daikin Europe NV

9

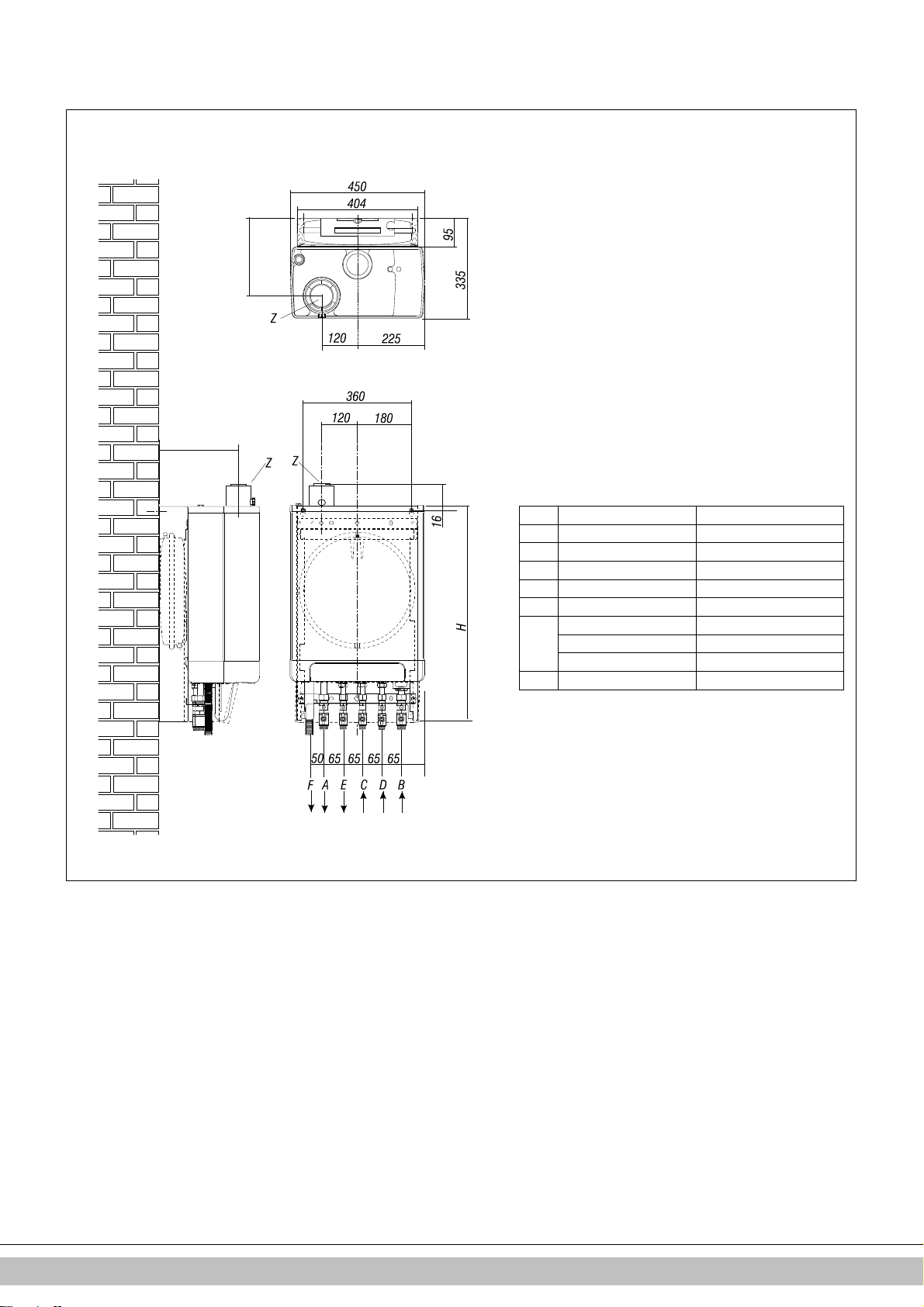

4 INSTALLATION

A = Supply CH

G ¾” (ext)

B = Return CH

G ¾” (ext)

C = Gas G ½” (int)

D = Tap water cold

R ½”

E = Tap water warm

R ½”

F = Condense outlet

Ø dn25 (flexible)

h= 517mm

EKOMBG22

ABV1

577mm

EKOMBG28

ABV1

637mm

EKOMBG33

ABV1

H= 590mm

EKOMBG22

ABV1

650mm

EKOMBG28

ABV1

710mm

EKOMBG33

ABV1

Z = Flue gas outlet/air inlet

Ø60/100 (concentric)

020601002

161

161

450

240

77

135

h

77

4.1 Installation measurements

Unit with pipes connected downwards:

Unit + wall mounting strip

Daikin Europe NV 10

A = Supply CH

G ¾” (ext)

B = Return CH

G ¾” (ext)

C = Gas G ½” (int)

D = Tap water cold

R ½”

E = Tap water warm

R ½”

F = Condense outlet

Ø dn25 (flexible)

H= 770mm

EKOMBG22

ABV1

830mm

EKOMBG28

ABV1

890mm

EKOMBG33

ABV1

Z = Flue gas outlet/air inlet

Ø60/100

(concentric)

020601001

265

265

77

77

Unit connected to B-pack:

Unit + B-pack

Daikin Europe NV

11

4.2 Installation space

The unit must be installed against a wall with sufficient load bearing capacity.

In case of light wall constructions, there is a risk of resonance noises.

Within 1 meter of the unit, there must be a earthed wall plug.

In order to prevent the condense outlet from freezing, the unit must be installed in a

frost-free room. Preferably ensure there is a space of at least 2 cm next to the boiler.

No free space is required due to danger of singeing.

IMPORTANT

The unit must not be installed in a space where work is carried out

with aggressive or corrosive gases such as hairspray.

4.2.1 Installing in kitchen cabinet

The unit can be placed between two kitchen cabinets, or inside a kitchen cabinet.

Make sure there is sufficient ventilation at the bottom and the top.

If the unit is installed inside a cabinet, ventilation openings of at least 50 cm2 are

required.

4.2.2 Removing cover plate and front panel

For various activities on the unit, the cover plate and front panel have to be removed

from the unit, if they were installed. Do this as follows:

•

If you are using the cover plate (A), remove it to the front.

•

Unscrew both screws (1) behind the display window.

•

Pull the bottom of the front panel (2) forwards.

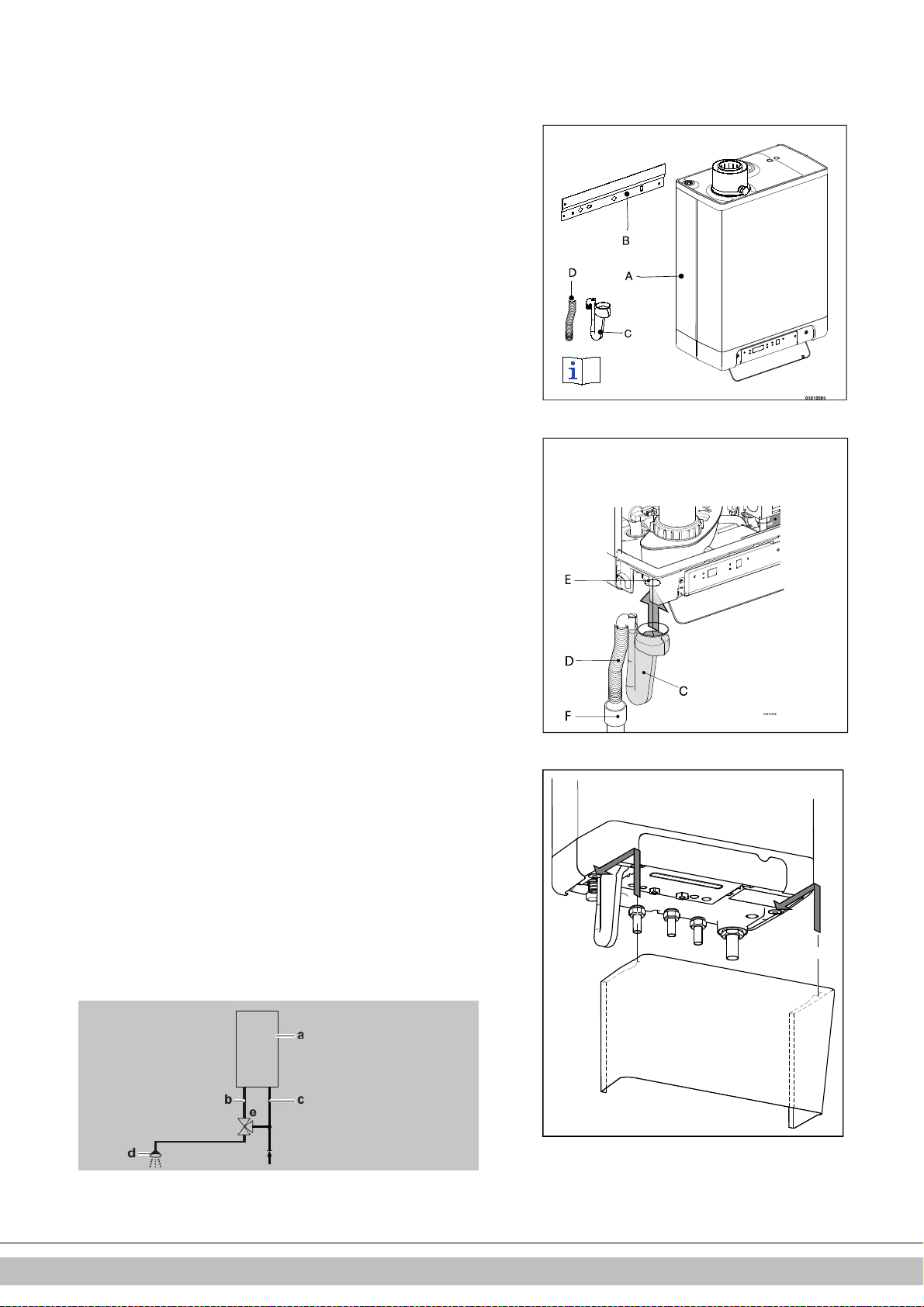

Danger: risk of burning

In case of high leaving water set ponts for space heating (eighter a high fixed set point

or a high weather-dependent set point at low ambient temperatures), the heat

exchanger of the boiler can be very hot, for example 70°C.

Beware that in case of a tapping demand, the water can initially have a higher water

temperature than requested.

In this case, it is recommended to install a thermostatic valve to prevent scalding.

This can be done according to the schematics below.

a=boiler, b=DHW from boiler, c= cold water inlet,

d=shower, e=thermostatic valve (field supply)

Daikin Europe NV 12

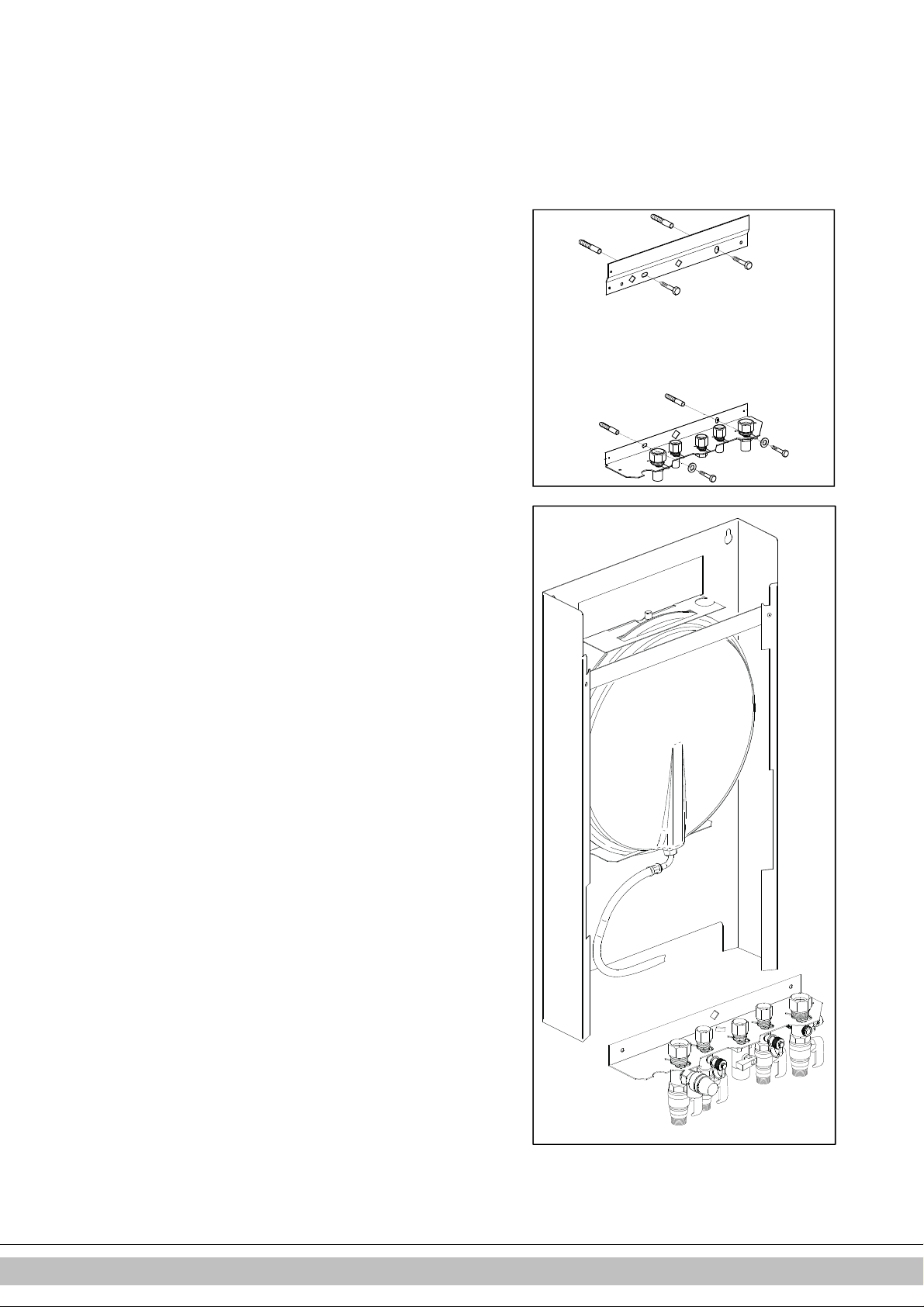

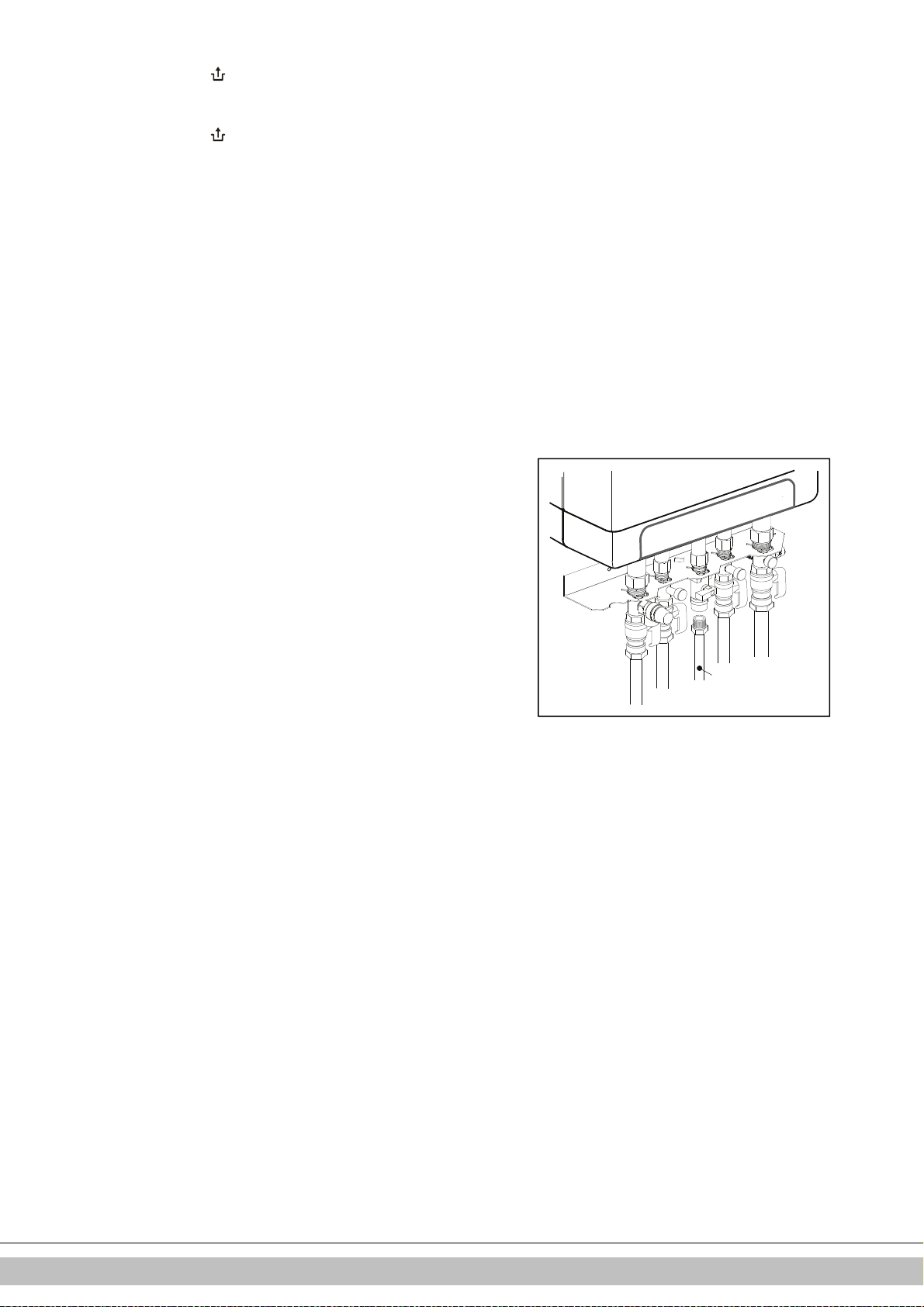

4.3 Assembly

020601020

The boiler can be hung to the wall using :

•

the wall suspension strip and a the connection kit EKVK4AA

•

a B-pack including an expension vessel and a connection kit.

4.3.1 Assembling suspension strip and assembly bracket

• Make sure the construction of the wall is suitable for hanging the boiler.

• Drill the holes for the suspension strip and the connection kit in the wall

using the template delivered with the boiler.

• Mount the suspension strip and the assembly bracket horizontally on the

wall, using the associated attachment materials.

• Place the filling loop on the connections of the return and cold water

nipple following the connection kit installation instruction

• The boiler can now be placed on the suspension strip simultaniously

sliding the pipes of the boiler into the valves in the assembly bracket.

4.3.2 Assembling bottom connection set

• Make sure the construction of the wall is suitable for hanging the boiler

and B-pack.

• Drill the holes for the B-pack kit in the wall using the template delivered

with the boiler.

• Mount the B-pack on the wall using the associated attachment materials.

• Place the assembly bracket in the frame as described in the manual

inclued in the B-pack.

• Connect the flexible hose on the expension vessel and the conenction

on the return valve. Make sure the seal rings are placed !

• Place the filling loop on the connections of the return and cold water

nipple following the connection kit installation instruction

• The boiler can now be placed on B-pack simultaniously sliding the pipes

of the boiler into the valves in the assembly bracket

Daikin Europe NV

13

4.3.3 Assembling the unit

1. Unpack the unit.

2. Check the content of the packaging, which consists of:

• Unit (A)

• Suspension strip (B)

• Siphon (C)

• Flexible tube (D)

• Installation instructions

• Operating instructions

• Warranty card

3. Check the unit for any damage: immediately report damages to the supplier.

4. Install the suspension strip.

5. Check whether the compression rings are positioned straight in the couplings of

the assembly bracket.

6. Position the unit: slide it from top to bottom over the suspension strip (B). Make

sure the pipes slide into the compression fittings simultaneously.

7. Tighten the compression fittings onto the assembly bracket.

The nipples and pipes must not rotate with it!

8. Open the display valve and loosen the two screws on the left and right of the

display, and remove the front panel.

9. Assemble the flexible tube (D) onto the outlet of the siphon.

10. Fill the siphon with water, and slide it as far as possible on top of the condense

output connector (E) under the unit.

11. Seal flexible tube (D) of the siphon, if possible together with the overflow pipe of

the inlet combination and the overflow valve, to the sewage via open connection

(F).

12. Assemble the air supply and the burning gas outlet (see par. 5.6).

13. Assemble the cover and tighten the two screws to the left and the right of the

display, and close the display cover.

4.3.4 Apply cover plate (optional)

Suspend the converted top edge of the cover plate from the washers underneath the

bottom of the unit, and slide the cover plate as far back as possible.

Danger: risk of burning

In case of high leaving water set ponts for space heating (eighter a high fixed set point

or a high weather-dependent set point at low ambient temperatures), the heat

exchanger of the boiler can be very hot, for example 70°C.

Beware that in case of a tapping demand, the water can initially have a higher water

temperature than requested.

In this case, it is recommended to install a thermostatic valve to prevent scalding.

This can be done according to the schematics below.

a=boiler, b=DHW from boiler, c= cold water inlet,

d=shower, e=thermostatic valve (field supply)

Daikin Europe NV 14

5 CONNECTING

A

B

020601013

B

A

020601014

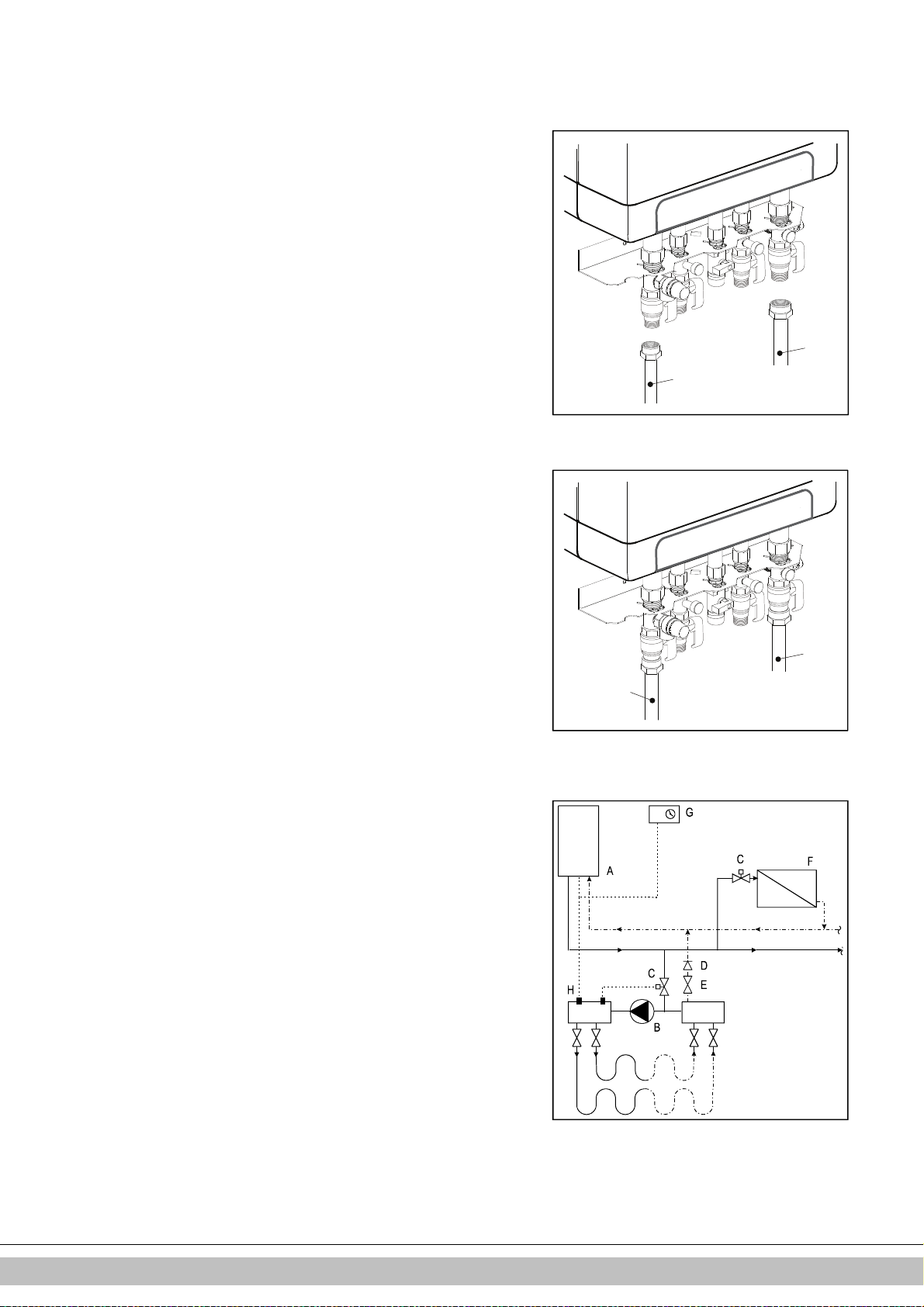

5.1 Connecting CH installation

1. Rinse the CH installation carefully.

2. Fit the supply pipe (A) and return pipe (B) to the connection set.

3. All pipes must be assembled with no electrical current, in order to prevent shocks

from the pipes.

4. Existing connections may not be rotated, in order to prevent leakages.

The CH installation must be fitted with:

•

A filling/draining tap (A) in the return pipe, immediately underneath the unit.

•

A draining tap at the lowest point of the installation.

•

An overflow valve (B) of 3 bar in the input pipe at a distance of no more than 500

mm from the unit.

Between the unit and the overflow valve there may be no valve or constriction.

•

An expansion vessel in the return pipe (in the B-pack or in the installation).

•

A check valve, if there are pipes running up, within close distance of the unit. This

prevents a thermosiphon effect from occurring during tap water operation (a non

spring-operated return valve, must be assembled vertically).

5.1.1 Thermostatic radiator taps

If all radiators are fitted with thermostatic or cable radiator taps, a minimum water

circulation must be safeguarded. See par. 7.3.

5.1.2 Underfloor heating

Underfloor heating with pump

If an underfloor heating system is not hydraulically neutral, the underfloor heating

pump may generate unwanted circulation over the CH boiler. For a good functioning of

the domestic hot water provision, unwanted circulation over the CH boiler must be

prevented.

Connect an underfloor heating system indirectly hydraulically neutrally or provide the

CH installation with a two-way valve set 230 V ~ (E). If the underfloor heating pump

absorbs heat via the return of the boiler, unwanted circulation can be prevented by

means of a check valve (D).

Make sure there is a minimal water circulation. See par. 7.3.

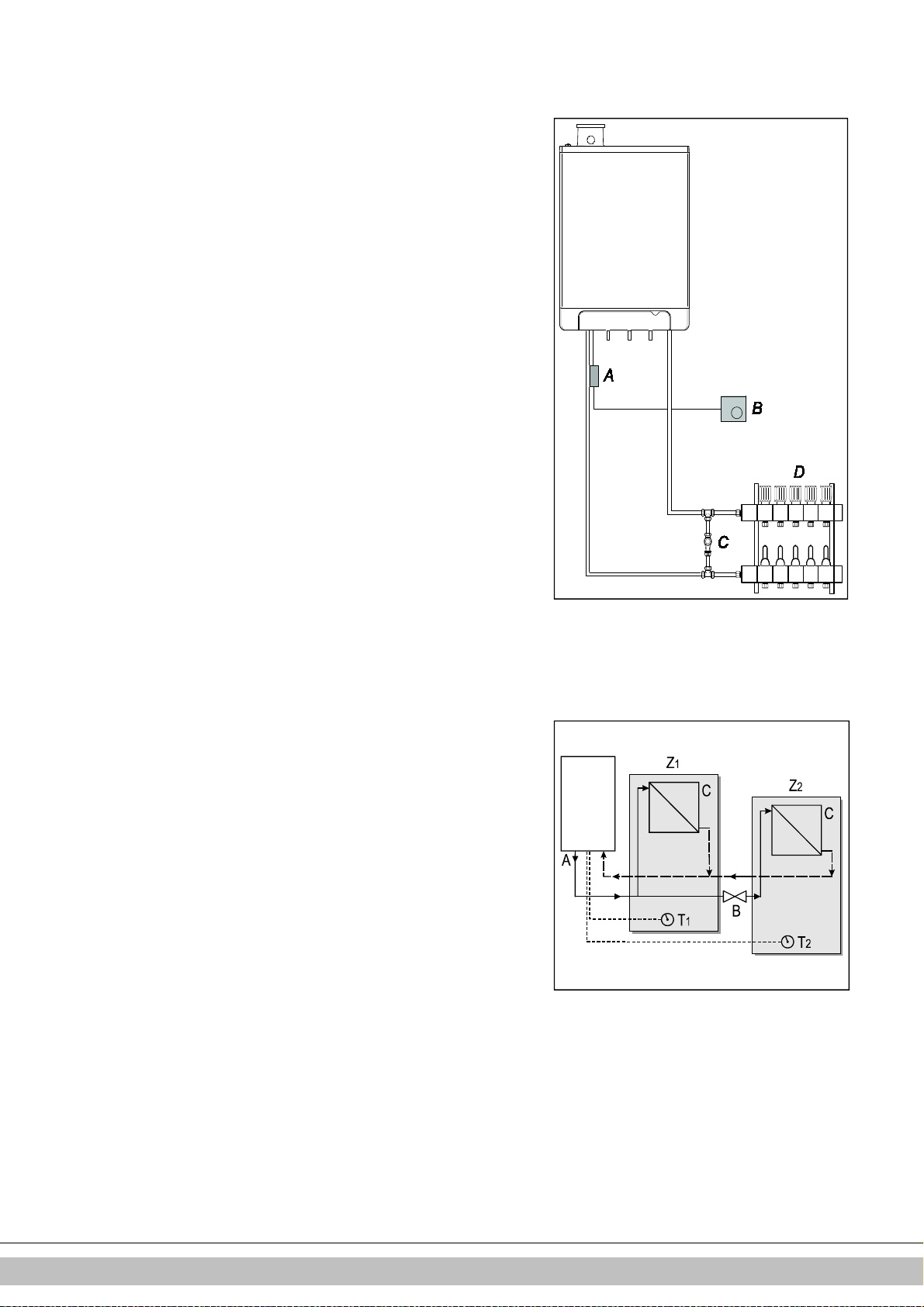

Connection diagram underfloor heating

A. CH boiler

B. CH pump

C. Thermostatic control valve

D. Spring-operated check valve

E. Electrical valve 230 V ~

F. Radiators

G. Space/clock thermostat

H. Maximum thermostat

Daikin Europe NV

15

Underfloor heating without pump

Connect the underfloor heating system (D) and set the maximum CH supply

temperature of the CH boiler to the design condition. Fit a clamp thermostat (A) onto

the supply tube underneath the CH boiler. The clamp thermostat with blind cap must be

set to a maximum supply temperature of 55°C.

Fit the on/off room thermostat (B) and connect in a series with the clamp thermostat.

The boiler must be connected to X4 - 6/7.

In this situation, the pump in the boiler is used to bridge the loss of pressure of the

underfloor heating system. Using the loss of pressure graph par. 7.4, the maximum loss

of pressure of the underfloor heating system can be determined.

Make sure there is a minimal water circulation. See par. 7.3.

In case of an underfloor heating system without pump, we recommend changing the

following parameter settings:

par. o from 0 to 3.

par. P from 5 to 2.

Parameter 3 must also be set to its minimum level, or the

Transmission loss of the property, see par. 7.3.

5.1.3 Dividing CH installation in groups in case of additional heat

sources

Operating principle

If the room thermostat switches off the boiler because another heat source, the other

rooms may cool down.

This can be resolved by splitting the CH installation into two groups. The group with the

external heat source (Z2) can be shut off from the main circuit by means of an electrical

shut-off valve. Both groups are fitted with their own room thermostat.

Please note: This "external heat source" regulation may only be applied if no extra

external boiler has to be heated up (installation type 1).

Installation instructions

1. Install the valve in accordance with the connection diagram.

2. Connect the room thermostat of group 1 to op X4 – 6/7.

3. Connect the room thermostat of group 2 to op X4 – 11/12.

4. Change parameter A (see Parameter settings via the service code par. 7.2).

Please note: The room thermostat in group

thermostat in group 2 may be an OpenTherm thermostat or an on/off thermostat.

Connection diagram "external heat source" regulation

A. CH boiler

B. Electrical shut-off valve 230 V ~

C. Radiators

T1. Room thermostat group 1

T2. Room thermostat group 2

Z1. Group 1

Z2. Group 2

1 MUST

be an on/off thermostat. The room

Daikin Europe NV 16

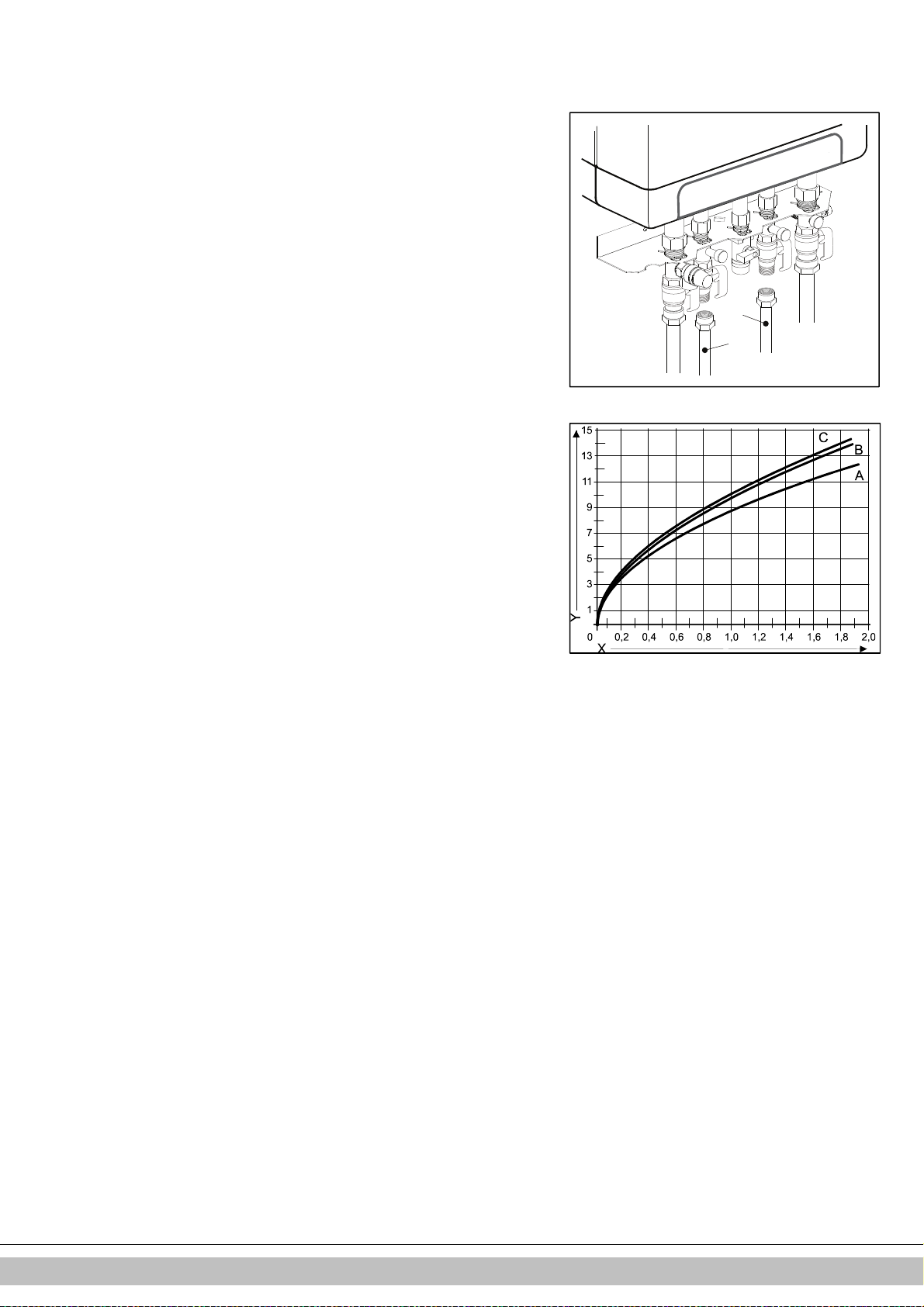

5.2 Connecting DHW installation

D

C

020601015

1. Rinse the installation carefully.

2. If required, assemble an inlet combination.

3. Assemble the cold (D) and warm water pipe (D) to the connection set.

Comments

•

If the unit is only used for warm water supply, the heating function can be switched

off using the service code on the operating panel. The CH installation does not need

to be connected or filled.

•

If the unit is switched off during winter, and is disconnected from the electricity

supply, the sanitary water must be drained in order to prevent freezing. To do so,

disconnect the tap water connections straight underneath the unit.

In case of old installations or domestic hot water circuits which can contain small particles,

install a filter in the domestic hot water circuit.

This pollution could cause a fault during domestic hot water operation.

Resistance graph tap circuit unit

A. EKOMBG22ABV1

B. EKOMBG28ABV1

C. EKOMBG33ABV1

X. Water pipe pressure (Bar)

Y. Flow rate (L/min, tolerance ± 10%)

Daikin Europe NV

17

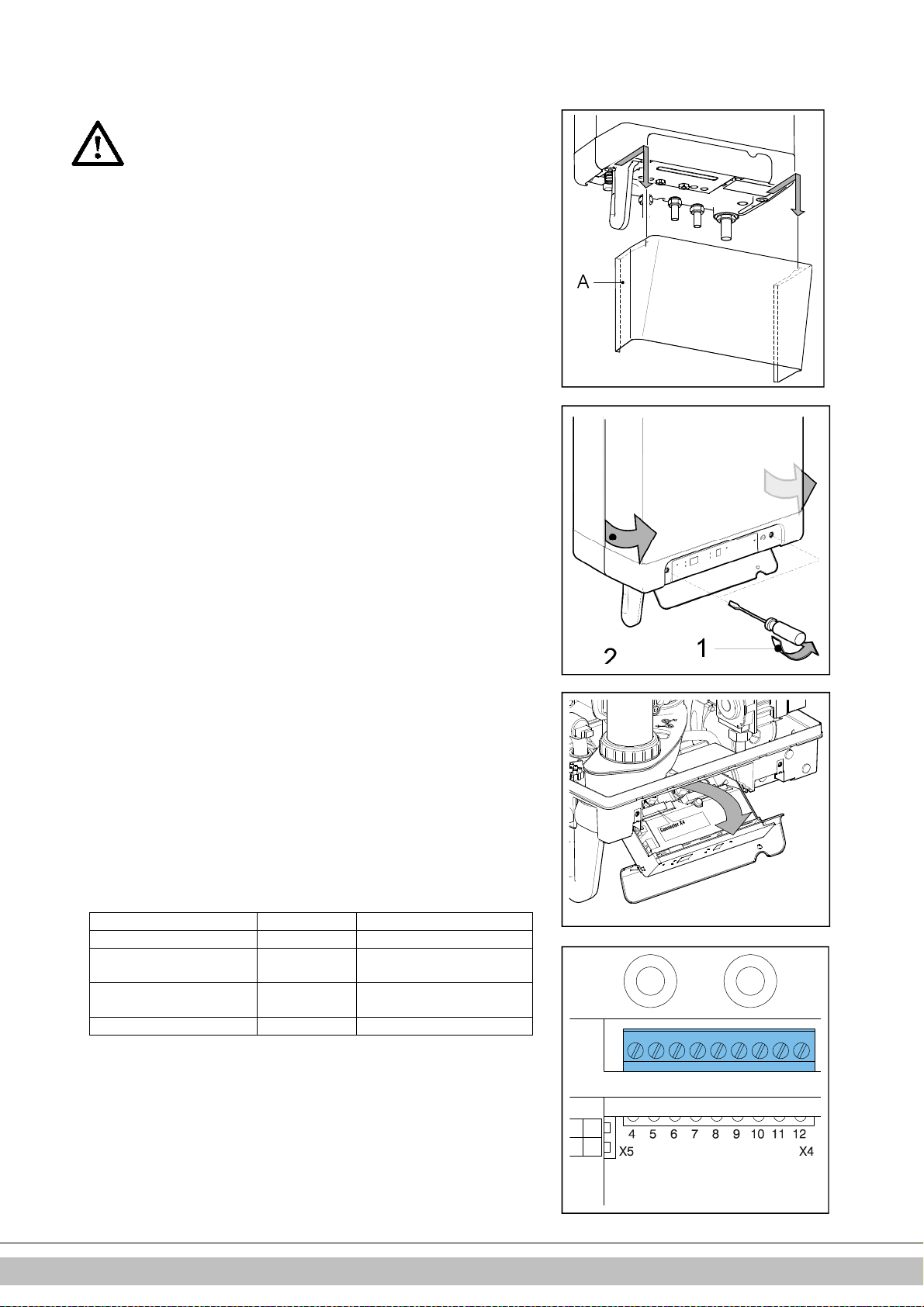

5.3 Connecting electronically

CAUTION

A socket with safety ground must be no further than 1 meter

from the unit.

The socket must be easily accessible.

When installing the unit in a damp space, a fixed connection is

obligatory, by means of an all-pole main switch with a

minimum contact gap of 3 mm.

If the mains cable is damaged or requires replacement for any

other reason, the replacement mains cable must be ordered

from the manufacturer or its representative. In case of any

doubt, contact the manufacturer or its representative.

1. Remove the plug from the socket, when working on the electrical circuit.

2. If there is a cover plate (A), remove it to the front.

3. Unscrew both screws (1) behind the display window.

4. Slide the bottom of the front panel (2) forwards, and remove it.

5. Pull the boiler controller forward. The boiler controller unit will tip downwards in the

process.

6. Consult par. 9.2 to make the connections.

7. After the required connections have been made, slide the boiler controller back into

the unit and return the cover plate, if you are using one.

8. After making the required connections, connect the unit to the socket with safety

ground.

5.3.1 Electrical connections

Temperature regulation Connector X4 Comments

Room thermostat on/off 6 - 7 Modulating thermostat with

comfort function in use

Outdoor temperature

sensor

Frost thermostat 6 - 7 Parallel over room thermostat

11 - 12

8 - 9 -

Daikin Europe NV 18

5.4 Connect room thermostat

5.4.1 Room thermostat on/off

1. Connect the room thermostat (see par. 10.1).

2. If necessary, set the feedback resistance of the room thermostat to 0.1 A. If unsure,

measure the electrical current and set it accordingly.

The maximum resistance of the thermostat pipe and the room thermostat amounts to a

total of 15 Ohm.

5.4.2 Modulating room thermostat, Open Therm

The unit is suitable for connecting a modulating room thermostat, in accordance with

the OpenTherm communication protocol.

The most important function of the modulating room thermostat is to calculate the input

temperature at a required room temperature, in order to make optimal use of the

modulating. At every heating request, the required input temperature is shown on the

display of the unit.

Connect the modulating thermostat (see par. 10.1).

If you want to use the tap water on/off switch function of the OpenTherm thermostat, the

tap water comfort function must be set to eco or on.

For more information, consult the manual of the room thermostat.

5.4.3 Modulating room thermostat, wireless

The EKOMBG*ABV1 CH boiler is suitable to communicate wireless without

sending/receiving module with the Honeywell room thermostats T87RF1003 Round RF,

DTS92 and CMS927. The CH boiler and the room thermostat must be appointed to each

other:

• Press the reset button of the unit for approximately 5 seconds to access the RF room

thermostat menu.

• One of the following codes will be shown on the display of the unit:

1. rF and

2. rF and L / 1 : the display above button shows an L alternated by a 1

red led : off

• Press the reset button to leave the RF room thermostat menu or wait for 1 minute.

Testing the connection between the unit and the RF room thermostat

1. Press the reset button of the unit for approximately 5 seconds to access

2. Press the service button 1x. On the display above the button, a

3. Set the room thermostat to the test mode (see the installation and operating

4. The red led above the reset button will flash if the appointment has

5. Press the reset button of the unit to leave the RF room thermostat menu

Undo the appointment of an RF room thermostat to the CH boiler.

• Press the reset button of the unit for approximately 5 seconds to access

• Press the service button 2x. On the display above the button, a

L / -

: the display above the button shows an L alternated by

red led : flashing

The CH boiler has not been appointed. A unit in this operating status, can be linked

by using the method of the appropriate room thermostat.

The method of appointment depends on the type of room thermostat and is

described in the installation and operating instructions of the wireless room

thermostat.

The CH boiler has already been appointed. There is already an existing link with

an RF room thermostat. In order to allow a new link to be made, the existing link

will have to be removed.

See: Undo the appointment of an RF room thermostat to the CH boiler.

the RF room thermostat menu of the boiler controller.

a –

t

will be shown.

instructions of the room thermostat).

been carried out correctly.

of the boiler controller. You will automatically exit the test mode 1 minute

after the last test message of the RF room thermostat has been received.

the RF room thermostat menu of the CH boiler.

C

will be shown.

Daikin Europe NV

19

• Press the reset button of the unit again to remove the existing

E

020601017

appointments. The display of the unit will show rF again, with a flashing

/ -

. If required, an RF room thermostat can be appointed to the unit again.

• Press the reset button of the unit to leave the RF room thermostat

menu or wait for 1 minute.

5.4.4 Outdoor temperature sensor

The unit is provided with a connection for an outdoor temperature sensor. The

outdoor temperature sensor should be used in combination with an on/off room

thermostat.

In principle, any on/off room thermostat can be combined with an outdoor sensor.

Upon request of the room thermostat, the boiler will provide heat until the maximum

set temperature in the boiler has been reached. This maximum set temperature is

automatically regulated via the outdoor sensor, in accordance with the set fuel line in

the boiler.

Connect the room outdoor sensor (see par. 10.1).

For the fuel line setting, see the weather dependent regulation (see par. 7.5).

5.5 Connecting gas

1. Fit the gas valve directly on the 1/2" gas connection of the connection set using

appropriate seal

2. .Place a gas sieve in the connection for the unit if the gas may be

contaminated.

3. Connect the gas pipe in the gas valve using appropriate seal..

4. Check the gas carrying parts for leakages at a pressure of up to 50 mbar.

5. The gas pipe should be fitted pressure free.

L

Daikin Europe NV 20

5.6 Flue and air supply duct

Don not use screws or parkers to mount the flue system as leakage can

Use water instead. The sealing rubbers can be negatively affected when

5.6.1 Concentric connection 60/100

The boiler is fitted with a flue gas adapter suitable for connecting to a concentric flue gas extractor

system with a diameter of 60/100.

Fit the concentric pipe thoughtfully in the adapter. The built in gaskets ensure there is an air tight

seal.

For the installation of the flue and air supply duct material, see the

manual included with the materials. Contact the

manufacturer of the relevant flue and air supply duct materials for

extensive technical information and specific

assembly instructions.

Make sure that the socket connections of the flue and air supply duct

materials are correctly sealed.

Improper fastening of the flue and the air supply duct

can lead to hazardous situations or result in personal injury.

Check all flue components for tightness.

occur.

Do not use any sort of grease when mounting the pipe system.

grease is applied.

Do not mix any components, materials or ways of coupling from

different manufacturers.

5.6.2 Concentric connection 80/125

If required, the flue gas adapter 60/100 can be replaced by a version for a flue gas extractor

system with a 80/125 diameter.

1. Carefully follow the instruction as provided with the adapter set 80/125.

2. Fit the concentric pipe thoughtfully in the adapter. The built in gaskets ensure there is an air

tight seal.

5.6.3 Parallel connection 80/80

If required, the flue gas adapter 60/100 can be replaced by a version for a parallel flue system (2

pipes) with a 80 mm diameter.

1. Carefully follow the instruction as provided with the adapter set 80.

2. Fit the pipes for the air supply and flue gas thoughtfully in the air inlet opening and flue gas

adapter of the unit. The built in gaskets ensure there is an air tight seal. Make sure that the

connections are not mixed.

Daikin Europe NV

21

5.7 Outlet systems

Explanation

flue systems

Category in accordance to CE

B23 A flue that evacuates the products of combustion to the

outside of

Make sure the air inlet is open

B33 A flue system which is connected to a common duct system. This common duct system

Make sure the air inlet is open

C13 Horizontal flue system. Discharge in the outside wall.

For example : a wall terminal

C33 Vertical flue system. Flue gas discharge via the roof.

For example : a vertical roof

C43 Joint air supply and flue gas discharge duct (CLV system)

C53 Separate air supply and separate flue gas discharge duct.

C63 Free in the ma

rket available flue material with CE approval

Do not mix flue materials from

C83 Joint air supply and flue gas discharge duct (CLV system)

Only as twin pipe system

C93 Air supply and flue

gas discharge duct in shaft or ducted:

Concentric. Air supply from

Concentric flue system

Please note that not all flue gas configurations described below are permitted in all

countries. Therefore observe local regulations prior to installation.

The drawings above are a sample and can differ on details.

the room containing the appliance. The combustion air is drawn directly from the room.

consists of a single natural draught flue. All pressurized parts of the appliance containing

products of combustion are completely enclosed by parts of the appliance supplying

combustion air. Combustion air is drawn into the appliance from the room by means of a

concentric duct, which encloses the flue. The air enters through defined orifices situated

in the surface of the duct.

Inlet opening for the air supply is in the same pressure zone as the discharge

Inlet opening for the air supply is in the same pressure zone as the discharge

Twin-pipe or concentric

Discharging into different pressure zones

and complies to the demands

and complies to the demands

through the facede.

terminal.

Discharging into different pressure zones

existing duct. Flue gas discharge via the roof. Air supply and flue gas discharge are in

the same pressure zone.

Daikin Europe NV 22

different suppliers.

between the boiler and the

duct.

5.8 Flue material

The following flue materials can be ordered at Daikin.

Also visit the website: fluegas.daikin.eu

C13

Art.no. Description

EKFGP2978

EKFGP4651

EKFGP4652

EKFGP4660

EKFGP4661

EKFGP2977

EKFGP4664

EKFGP4631

EKFGP4667

Wall Terminal Kit PP/GLV 60/100

Extension PP/GLV 60/100 x 500mm

Extension PP/GLV 60/100 x 1000mm

Elbow PP/GLV 60/100 90°

Elbow PP/GLV 60/100 45°

Wall Terminal Kit low profile PP/GLV 60/100

Elbow PP/GLV 60/100 30°

Wall Bracket Dn.100

Measurement Tee with Inspection Panel PP/GLV 60/100

C33

Art.no. Description

EKFGP4631 Wall Bracket Dn.100

EKFGP4651 Extension PP/GLV 60/100 x 500mm

EKFGP4652 Extension PP/GLV 60/100 x 1000mm

EKFGP4660 Elbow PP/GLV 60/100 90°

EKFGP4661 Elbow PP/GLV 60/100 45°

EKFGP4664 Elbow PP/GLV 60/100 30°

EKFGP4667 Measurement Tee with Inspection Panel PP/GLV 60/100

EKFGP6837 Roof Terminal PP/GLV 60/100 AR460

C53

Art.no. Description

EKFGP4651 Extension PP/GLV 60/100 x 500mm

EKFGP4652 Extension PP/GLV 60/100 x 1000mm

EKFGP6837 Roof Terminal PP/GLV 60/100 AR460

EKFGW4085 Elbow PP 80 90°

EKFGW4086 Elbow PP 80 45°

EKFGV1102 Chimney Conection Set 60/100 Air Intake Dn.80 C53

EKFGP4660 Elbow PP/GLV 60/100 90°

EKFGP4661 Elbow PP/GLV 60/100 45°

EKFGP4664 Elbow PP/GLV 60/100 30°

EKFGP4667 Measurement Tee with Inspection Panel PP/GLV 60/100

EKFGP4631 Wall Bracket Dn.100

EKFGW4001 Extension PP 80x500

EKFGW4002 Extension PP 80x1000

EKFGW4004 Extension PP 80x2000

Daikin Europe NV

23

C93

Art.no. Description

EKFGP4678 Chimney Connection 60/100

EKFGP1856 Flex Kit PP Dn.60-80

EKFGP6340 Extension Flex PP 80 L=10 M

EKFGP6344 Extension Flex PP 80 L=15 M

EKFGP6341 Extension Flex PP 80 L=25 M

EKFGP6342 Extension Flex PP 80 L=50 M

EKFGP6324 Connector Flex-Flex PP 80

EKFGP4664 Elbow PP/GLV 60/100 30°

EKFGP4661 Elbow PP/GLV 60/100 45°

EKFGP4660 Elbow PP/GLV 60/100 90°

EKFGP6333 Spacer PP 80-100

EKFGP4667 Measurement Tee with Inspection Panel PP/GLV 60/100

EKFGP4631 Wall Bracket Dn.100

EKFGP4651 Extension PP/GLV 60/100 x 500mm

Daikin Europe NV 24

5.9 Connection to a flue system without air inlet (B23, B33)

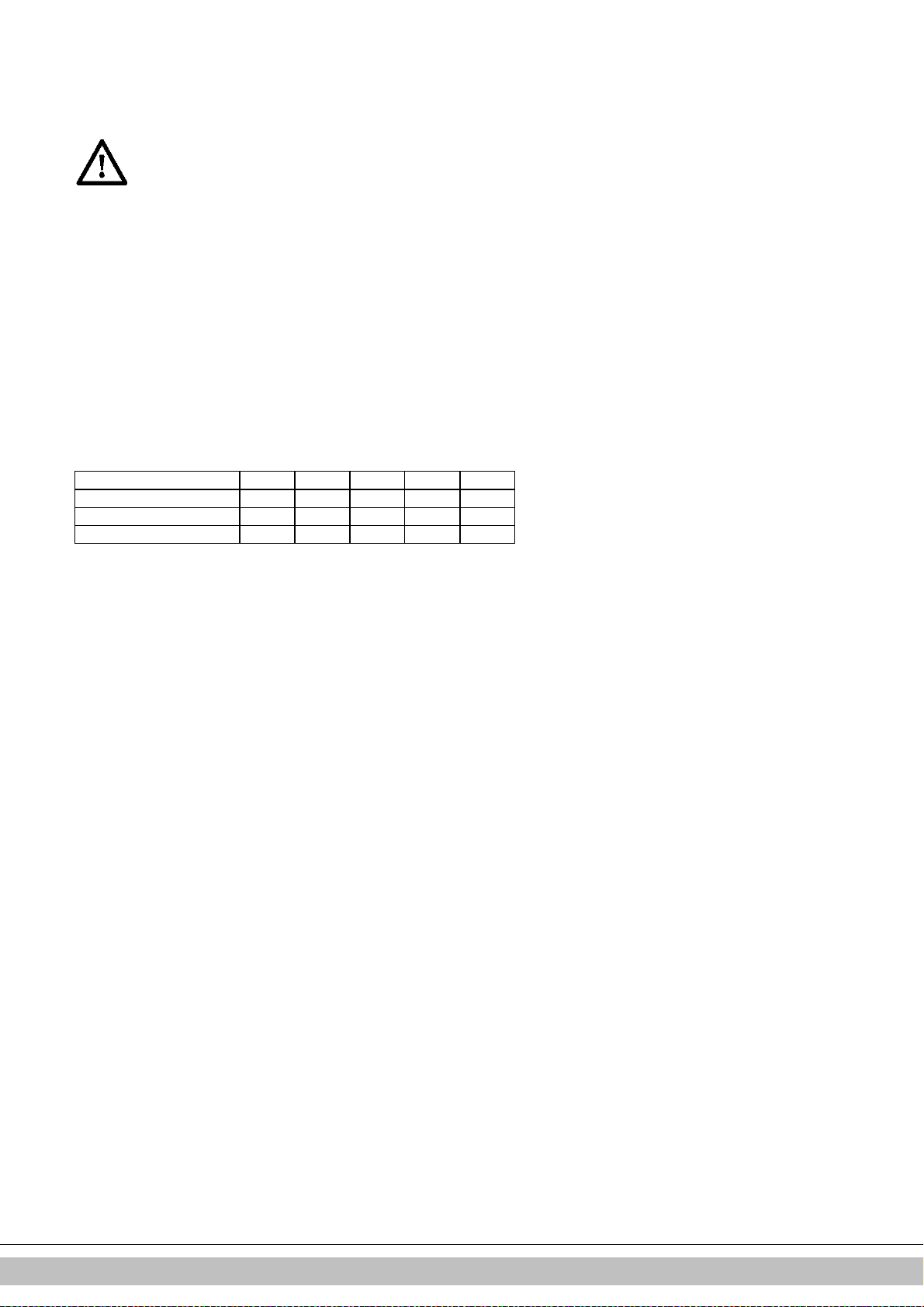

CAUTION

• Make sure the boiler room complies to the regulatory

requirements for connecting to a flue system in

accordance to B23 or B33

• When connection the boiler to a flue system in

accordance to B23 or B33 the electrical protection

class is IP20 instead of IP44

General assembly

1. Slide the combustion gas outlet pipes into each other.

From the unit, every pipe has to be slid into the previous one.

Mount a non-vertical combustion gas outlet pipe on a slope towards the unit (min. 5mm/m).

5.9.1 Permitted pipe lengths at parallel air supply and flue tube systems

Permitted pipe lengths B23 and B33 when applying Ø80 mm

C13 C33 C43 C53 C83

EKOMBG22ABV1 100 m 100 m 100 m 100 m 100 m

EKOMBG28ABV1 85 m 85 m 85 m 85 m 85 m

EKOMBG33ABV1 80 m 80 m 80 m 80 m 80 m

Daikin Europe NV

25

5.10 Connection to a sealed flue system.

5.10.1 Pipe lengths

As the resistance of the flue tube and air supply pipes increases, the power of the unit will

decrease. The maximum permitted power reduction is 5%.

The resistance of the air supply and the combustible gas outlet depends on the length, diameter

and all components of the pipe system. Per unit category, the total permitted pipe length has been

indicated for the air supply and the combustible gas outlet.

5.10.2 Permitted pipe lengths in concentric flue tube systems

Permitted pipe lengths when applying concentric 60/100

C13 C33

EKOMBG22ABV1 10 m 11 m

EKOMBG28ABV1 10 m 10 m

EKOMBG33ABV1 10 m 10 m

Permitted pipe lengths when applying concentric 80/125

C13 C33 C93

EKOMBG22ABV1 29 m 29 m See par 5.10.8

EKOMBG28ABV1 29 m 29 m See par 5.10.8

EKOMBG33ABV1 29 m 29 m See par 5.10.8

Contact the manufacturer for test calculations for the resistance of the air supply and

combustible gas outlet pipe and the wall temperature at the end of the combustible gas

outlet pipe.

Replacement lengths

Bend 90° R/D=1 2 m

Bend 45° R/D=1 1 m

Knee 90° R/D=0.5 4 m

Knee 45° R/D=0.5 2 m

General assembly:

For all outlets, the following assembly applies:

1. Slide the concentric combustion gas outlet pipe and air supply pipe.

2. Slide the concentric pipes into each other.

From the unit, every pipe has to be slid into the previous one.

3. Mount a non-vertical combustion gas outlet pipe on a slope towards the unit

(min. 5mm/m).

4. Fit the assembly brackets in accordance with the assembly instructions of the supplier of

the air supply/flue tube system.

Daikin Europe NV 26

5.10.3 Permitted pipe lengths at parallel air supply and flue tube systems

Permitted pipe lengths when applying Ø80 mm (total of flue pipe and air intake pipe

together).

C13 C33 C43 C53 C83

EKOMBG22ABV1 100 m 100 m 100 m 100 m 100 m

EKOMBG28ABV1 85 m 85 m 85 m 85 m 85 m

EKOMBG33ABV1 80 m 80 m 80 m 80 m 80 m

Replacement lengths

Bend 90° R/D=1 2 m

Bend 45° R/D=1 1 m

Knee 90° R/D=0.5 4 m

Knee 45° R/D=0.5 2 m

Calculation example

Pipe Pipe lengths Pipe length total

Flue gas outlet L1 + L2 + L3 + 2x2 m 13 m

Air supply L4 + L5 + L6 + 2x2m 12 m

Note:

The total pipe length is: sum of the straight pipe lengths + sum of the replacement pipe

lengths of bends/knees amounts to a total of 25 meters. If this value is less than the

maximum permitted pipe length, the flue gas outlet meets the requirements on this point.

Daikin Europe NV

27

5.10.4 Free in the market available flue gas materials (C63).

+0,3

- 0,7

+0,3

- 0,7

+ 2

- 0

+0,3

- 0,7

+ 2

- 0

The properties of the combustion determine the choices for the flue material.

The standards EN 1443 and EN 1856-1 provide the necessary information for choosing the

flow material by means of a sticker including an identification string.

The Identification string contains the following information:

A CE marking

B The standard to comply to: Metal, EN 1856-2

Plastic, EN 14471

The ID string needs to contain the following information:

C Temperature class : T120

D Pressure class : Pressure (P) or High Pressure (Hi)

E Resistance class : W (Wet)

F Resistance class in case of fire : E

Dimensions C63 Flue system (external dimensions in mm)

Parallel Concentric 80/125 Concentric 60/100

Flue pipe Air inlet Flue pipe Air inlet

ø 80

ø 80

ø 125

ø 60

ø 100

Flue materials of different markings must not be combined !

Daikin Europe NV 28

5.10.5 Securing the flue system

Exception at connecting on boiler:If the lenght of the pipes before and after

IMPORTANT

•

These regulations are typical for both concentric and parallel flue

systems.

•

The flue system must be secured to a solid structure.

•

The flue system should have a continuous fall back to the boiler (1.5° to

3°). N.B. Wall terminals must be installed leveled..

•

Only use accompanying brackets.

•

Every elbow must be secured by using the bracket.

the first elbow, are no more than 250 mm, the second element after the

first elbow has to contain a bracket.

Note: The bracket must be positioned on the elbow!

•

Every extension must be secured per metre with a bracket.

This bracket must not be clamped around the pipe ensuring free

movement of the pipe..

•

Make sure bracket is locked into the correct position depending on the

position of the bracket on the pipe or elbow:

•

Do not mix flue parts or clamps of different suppliers.

Max. distance between clamps

Vertical Others

2000 mm 1000 mm

•

Divide the lengths between the brackets evenly.

•

Every system must contain at least 1 bracket.

•

Position the first clam at a maximum of 500 mm from the boiler.

Daikin Europe NV

29

Daikin Europe NV 30

•

5.10.6 Air supply from the facade and a roof outlet with communal

exhaust system

Unit category: C83

IMPORTANT

An air supply from the outside wall and a roof outlet with a

combined flue system is allowed.

• The air supply in the facade must be fitted with an inlet grid

(A).

• The combined flue system must be fitted with a traction

extractor hood (B).

• If the combined flue system is situated in the outdoors,

the output pipe must be double-walled or insulated.

The minimum diameters of the communal output system based on vacuum

Flue tube diameter

EKOMBG*ABV1

Number of units 22 28 33

2 110 130 130

3 130 150 150

4 150 180 180

5 180 200 200

6 200 220 220

7 220 230 230

8 230 250 250

9 240 270 270

10 260 280 280

11 270 290 290

12 280 300 300

.

Communal combustible gas outlet

The output of the combustion gas outlet can be made in any location on the sloping

roof surface, providing the outlet in the roof surface has the same orientation as the

air supply in the facade. On a flat roof, the outlet of the combustion gas outlet must be

made in the “free” outlet area.

Fit a condense output.

Note

The communal outlet is certified in combination with the unit.

Daikin Europe NV

31

Loading...

Loading...