Daikin ERSQ 016AAV1, ERRQ 011AAV1, ERSQ 016AAY1, ERSQ 014AAV1, ERSQ 011AAY1 Service Manual

...

ESIE09-08

Service Manual

Daikin ALTHERMA HT

ERSQ 011/014/016 AAV1, AAY1

ERRQ 011/014/016 AAV1, AAY1

EKHBRD 011/014/016 AAV1, AAY1

R-410A, R-134a

EKHTS 200/260 A

EKHTSU 200/260 A

ESIE09-08

Table of Contents i

Table of Contents

Table of Contents ............................................................................i

1. Introduction .............................................................................................v

1.1 Safety Cautions ........................................................................................v

1.2 PREFACE ............................................................................................... ix

Part 1 - General Information ..........................................................1

1. Model Names of Indoor/Outdoor Units & Tanks .....................................2

Part 2 - Specifications.................................................................... 5

1. Specifications ..........................................................................................6

1.1 Outdoor Units ...........................................................................................6

1.2 Indoor Unit................................................................................................8

Part 3 - Refrigerant Circuit & Functional Parts ........................... 11

1. Refrigerant Circuit .................................................................................12

1.1 Outdoor Unit ...........................................................................................12

1.2 Indoor Unit..............................................................................................14

2. Functional Parts Layout ........................................................................16

2.1 ERRQ 011/014/016 AAV1, ERSQ 011/014/016 AAV1 ..........................16

2.2 ERRQ 011/014/016 AAY1, ERSQ 011/014/016 AAY1 ..........................18

2.3 EKHBRD 011/014/016 AAV1, EKHBRD 011/014/016 AAY1 .................20

2.4 EKHTS 200/260 A ..................................................................................22

2.5 EKHTSU 200/260 A ...............................................................................24

Part 4 - Electrical Circuit ............................................................. 27

1. Switch Box Layout - Indoor Unit EKHBRD............................................28

2. PCB Layout for EKHBRD 011/014/016 AAV1.......................................30

2.1 Main PCB - A1P .....................................................................................30

2.2 Control - PCB - A3P ...............................................................................32

2.3 Inverter PCB - A4P.................................................................................34

2.4 Filter PCB - A6P .....................................................................................37

2.5 QA PCB - A5P........................................................................................39

2.6 Inverter Control PCB - Three Phase - A4P ............................................40

2.7 Inverter PCB - Three Phase - A5P .........................................................42

2.8 Digital I/O PCB (Option PCB A7P) .........................................................44

2.9 Demand PCB (Option PCB A8P) ...........................................................46

Part 5 - Function ........................................................................... 47

1. Operation Mode ....................................................................................48

2. Basic Control.........................................................................................49

2.1 Normal Operation ...................................................................................49

ESIE09-08

ii Table of Contents

2.2 Compressor PI Control...........................................................................50

2.3 Electronic Expansion Valve PI Control R-410A circuit ...........................51

2.4 Electronic Expansion Valve PI Control R-134a circuit............................51

3. Special Control......................................................................................52

3.1 Startup Control .......................................................................................52

3.2 Defrosting Operation ..............................................................................53

3.3 Pump-down Residual Operation ............................................................54

3.4 Stopping Operation ................................................................................55

4. Protection Control .................................................................................56

4.1 High Pressure Protection Control...........................................................56

4.2 Low Pressure Protection Control............................................................58

4.3 Discharge Pipe Protection Control .........................................................60

4.4 Inverter Protection Control .....................................................................61

5. Other Control.........................................................................................63

5.1 Heating Operation Prohibition ................................................................63

5.2 Inverter Fan Control (Switch Box Fan) ...................................................63

5.3 Crankcase Heater ..................................................................................63

6. Outline of Control (Indoor Unit) .............................................................64

6.1 Freeze Prevention ..................................................................................64

6.2 Simultaneous demand of space heating and domestic water heating ...65

Part 6 - Test Operation................................................................. 71

1. Test Operation ......................................................................................72

1.1 Procedure and Outline ...........................................................................72

1.2 Air Tight Test and Vacuum Drying .........................................................74

1.3 Additional Refrigerant Charge ................................................................75

1.4 Operation when Power is Turned On .....................................................79

2. Outdoor Unit PC Board Layout .............................................................80

3. Field Setting ..........................................................................................81

3.1 Field Setting from remote control ...........................................................81

3.2 Field Setting from Outdoor Unit............................................................104

Part 7 - Troubleshooting............................................................. 115

1. Symptom-based Troubleshooting .......................................................117

2. Troubleshooting by Remote Control ...................................................119

2.1 The INSPECTION / TEST Button.........................................................119

2.2 Self-diagnosis by Wired Remote Control .............................................120

2.3 Operation of the Remote Controller’s Inspection / Test Operation

Button ...................................................................................................121

2.4 Remote Control Service Mode .............................................................122

2.5 Remote Controller Self-Diagnosis Function .........................................124

3. Troubleshooting by Indication on the Remote Controller ....................130

3.1 “A1” Indoor Unit: PC Board Defect.......................................................130

3.2 “A6” Indoor Unit: Pump Error (M1P) or Other Water System Error ......131

3.3 “A9” Indoor Unit: Malfunction of Moving Part of Electronic Expansion

Valve (K1E) R-410A circuit...................................................................132

3.4 “AJ” Indoor Unit: Malfunction of Capacity Determination Device .........134

3.5 “C1” Indoor Unit: Failure of Transmission (Between Indoor unit PC Board

and Control PC Board) .........................................................................135

3.6 “C4” Indoor Unit: Malfunction of Thermistor (R3T) Liquid Thermistor R-

ESIE09-08

Table of Contents iii

410A .....................................................................................................137

3.7 “C5” Indoor Unit: Malfunction of Tank Thermistor (R2T)......................138

3.8 “C9” Indoor Unit: Return Water Thermistor (R4T) ................................139

3.9 “CA” Indoor Unit: Leaving Water Thermistor Error (R5T).....................140

3.10 “CJ” Indoor Unit: Malfunction of Thermostat Sensor in Remote

Controller..............................................................................................141

3.11 “E1” Outdoor Unit: PC Board Defect ....................................................142

3.12 “E1” Indoor Unit: PC Board Defect.......................................................143

3.13 “E3” Outdoor Unit: Actuation of High Pressure Switch.........................144

3.14 “E3” Indoor Unit: Actuation of High Pressure Switch............................146

3.15 “E4” Outdoor Unit: Actuation of Low Pressure Sensor.........................149

3.16 “E4” Indoor Unit: Actuation of Low Pressure Sensor............................151

3.17 “E5” Outdoor Unit: Inverter Compressor Motor Lock............................153

3.18 “E5” Indoor Unit: Inverter Compressor Motor Lock ..............................154

3.19 “E7” Malfunction of Outdoor Unit Fan Motor ........................................155

3.20 “E9” Outdoor Unit: Malfunction of Moving Part of Electronic Expansion

Valve ....................................................................................................157

3.21 “E9” Indoor Unit: Malfunction of Moving Part of Electronic Expansion

Valve (K2E) R-134a circuit ...................................................................159

3.22 “F3” Outdoor Unit: Abnormal Discharge Pipe Temperature .................161

3.23 “F3” Indoor Unit: Abnormal Discharge Pipe Temperature....................162

3.24 “H9” Outdoor Unit: Malfunction of Thermistor (R1T) for Outdoor Air....163

3.25 “J3” Outdoor Unit: Malfunction of Discharge Pipe Thermistor (R2T)....164

3.26 “J3” Indoor Unit: Malfunction of Discharge Pipe Thermistor (R6T) ......165

3.27 “J5” Outdoor Unit: Malfunction of Thermistor (R3T, R5T) for Suction Pipe

1, 2 .......................................................................................................166

3.28 “J5” Indoor Unit: Malfunction of Thermistor (R7T) for Liquid R-134a ...167

3.29 “J6” Outdoor Unit: Malfunction of Thermistor (R6T) for Outdoor Unit Heat

Exchanger ............................................................................................168

3.30 “J7” Outdoor Unit: Malfunction of Thermistor (R7T) for Outdoor Unit Liquid

Pipe ......................................................................................................169

3.31 “J9” Outdoor Unit: Malfunction of Thermistor (R4T) for Subcooling Heat

Exchanger Gas Pipe ............................................................................170

3.32 “JA” Outdoor Unit: Malfunction of High Pressure Sensor.....................171

3.33 “JA” Indoor Unit: Malfunction of High Pressure Sensor........................172

3.34 “JC” Outdoor Unit: Malfunction of Low Pressure Sensor .....................173

3.35 “JC” Indoor Unit: Malfunction of Low Pressure Sensor ........................174

3.36 “L1” Outdoor Unit: Malfunction of PC Board.........................................175

3.37 “L1” Indoor Unit: Malfunction of PC Board ...........................................176

3.38 “L4” Outdoor Unit: Malfunction of Inverter Radiating Fin Temperature

Rise ......................................................................................................177

3.39 “L4” Indoor Unit: Malfunction of Inverter Radiating Fin Temperature Rise

(R8T) ....................................................................................................178

3.40 “L5” Outdoor Unit: Inverter Compressor Abnormal -

R-410A .................................................................................................179

3.41 “L5” Indoor Unit: Inverter Compressor Abnormal -

R-134a..................................................................................................180

3.42 “L8” Outdoor Unit: Inverter Current Abnormal......................................181

3.43 “L8” Indoor Unit: Inverter Current Abnormal.........................................182

3.44 “L9” Outdoor Unit: Inverter Start up Error.............................................183

3.45 “L9” Indoor Unit: Inverter Start up Error................................................184

3.46 “LC” Outdoor Unit: Malfunction of Transmission between Inverter and

Control PC Board .................................................................................185

ESIE09-08

iv Table of Contents

3.47 “LC” Indoor Unit: Malfunction of Transmission between Inverter and Con-

trol PC Board........................................................................................186

3.48 “LH” Indoor Unit: Converter Error .........................................................187

3.49 “P1” Outdoor Unit: High Voltage of Capacitor in Main Inverter Circuit .188

3.50 “P1” Indoor Unit: High Voltage of Capacitor in Main Inverter Circuit....189

3.51 “PJ” Indoor Unit: Faulty Combination of PCB.......................................190

3.52 “U0” Low Pressure Drop Due to Refrigerant Shortage or Electronic Expan-

sion Valve Failure.................................................................................191

3.53 “U2” Power Supply Insufficient or Instantaneous Failure .....................193

3.54 “U2” Power Supply Insufficient or Instantaneous Failure .....................195

3.55 “U4” Malfunction of Transmission between Indoor Unit and Outdoor

Unit .......................................................................................................197

3.56 “U4” Malfunction of Transmission Indoor Unit ......................................199

3.57 “U5” Malfunction of Transmission between Remote Control and Indoor

Unit .......................................................................................................200

3.58 “U7” Indoor Unit: Malfunction of Transmission Outdoor Unit................201

3.59 “U8” Malfunction of Transmission between Main and Sub Remote

Controls ................................................................................................202

3.60 “UA” Communication Error between Outdoor Unit and Indoor Unit .....203

3.61 “UF” System is not Set yet ...................................................................204

3.62 “UH” Malfunction of System, Refrigerant System Address Undefined .205

Part 8 - Appendix ........................................................................ 209

1. Piping Diagrams..................................................................................210

1.1 Outdoor Unit .........................................................................................210

1.2 Indoor Unit............................................................................................212

1.3 Switch Box Layout................................................................................214

2. Wiring Diagrams..................................................................................216

2.1 Outdoor Unit .........................................................................................216

2.2 Field Wiring Connection Diagram.........................................................220

2.3 Indoor Unit............................................................................................221

3. Thermistor Resistance / Temperature Characteristics........................229

4. Pressure Sensor .................................................................................232

5. Method of Replacing the Inverter’s Power Transistors Modules.........233

Part 9 - Precautions for New Refrigerant (R-410A) ................... 237

1. Precautions for New Refrigerant (R-410A) .........................................238

1.1 Outline ..................................................................................................238

1.2 Refrigerant Cylinders............................................................................240

1.3 Service Tools........................................................................................241

Index ................................................................................................ i

Drawings & Flow Charts ...............................................................iii

ESIE09-08 Introduction

v

1. Introduction

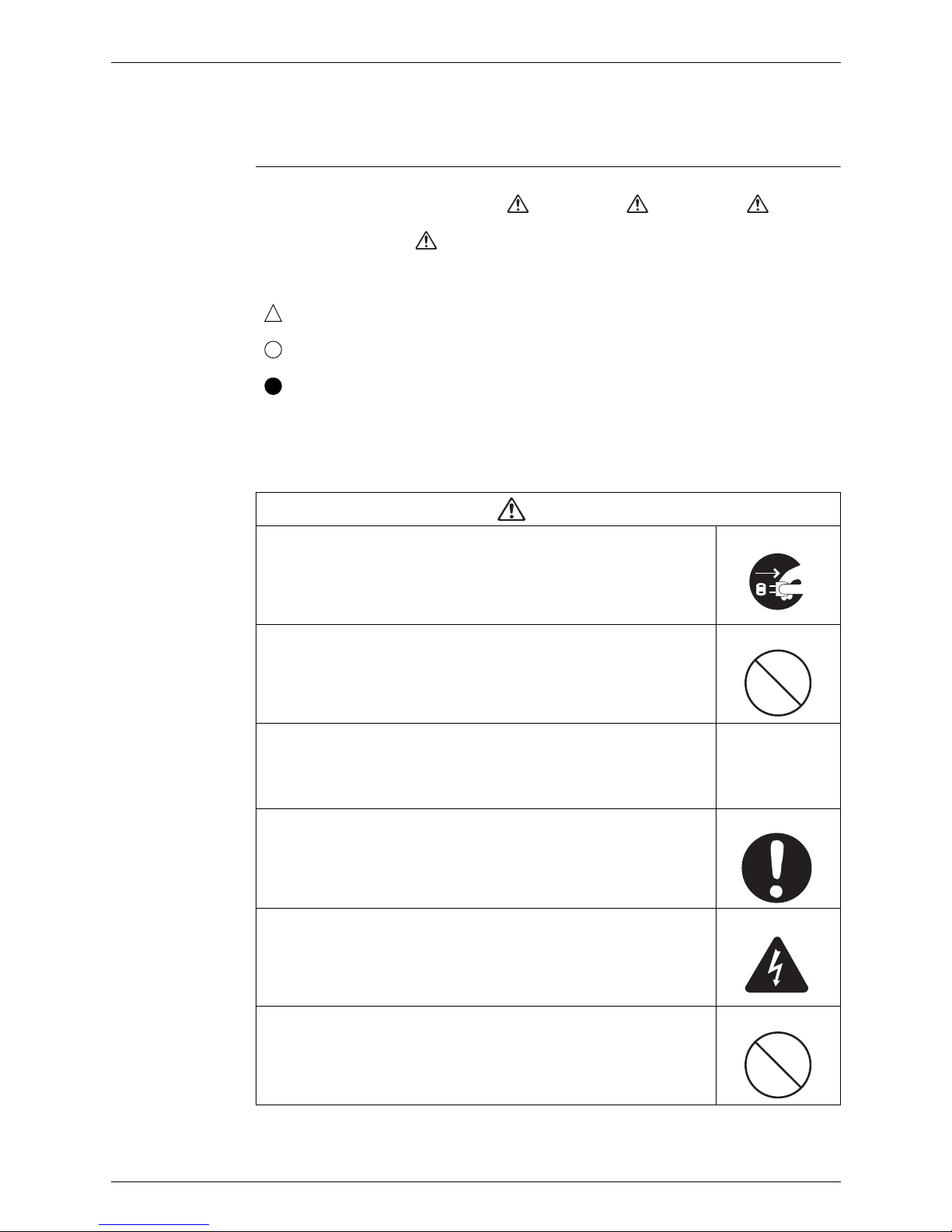

1.1 Safety Cautions

Cautions and

Warnings

Be sure to read the following safety cautions before conducting repair work.

The caution items are classified into “ Warning” and “ Caution”. The “ Warning”

items are especially important since they can lead to death or serious injury if they are not

followed closely. The “ Caution” items can also lead to serious accidents under some

conditions if they are not followed. Therefore, be sure to observe all the safety caution items

described below.

About the pictograms

This symbol indicates an item for which caution must be exercised.

The pictogram shows the item to which attention must be paid.

This symbol indicates a prohibited action.

The prohibited item or action is shown inside or near the symbol.

This symbol indicates an action that must be taken, or an instruction.

The instruction is shown inside or near the symbol.

After the repair work is complete, be sure to conduct a test operation to ensure that the

equipment operates normally, and explain the cautions for operating the product to the

customer

1.1.1 Caution in Repair

Warning

Be sure to disconnect the power cable plug from the plug socket before

disassembling the equipment for a repair.

Working on the equipment that is connected to a power supply can cause an

electrical shock.

If it is necessary to supply power to the equipment to conduct the repair or

inspecting the circuits, do not touch any electrically charged sections of the

equipment. Be careful as the capacitors (top surfaces) can hold up to 220V.

If the refrigerant gas discharges during the repair work, do not touch the

discharging refrigerant gas.

The refrigerant gas can cause frostbite.

When disconnecting the suction or discharge pipe of the compressor at the

welded section, release the refrigerant gas completely at a well-ventilated

place first.

If there is a gas remaining inside the compressor, the refrigerant gas or

refrigerating machine oil discharges when the pipe is disconnected, and it can

cause injury.

If the refrigerant gas leaks during the repair work, ventilate the area. The

refrigerant gas can generate toxic gases when it contacts flames.

The step-up capacitor supplies high-voltage electricity to the electrical

components of the outdoor unit and indoor unit.

Be sure to discharge the capacitor completely before conducting repair work.

A charged capacitor can cause an electrical shock as the capacitors (top

surfaces) can hold up to 220V.

Do not start or stop the heat pump operation by plugging or unplugging the

power cable plug.

Plugging or unplugging the power cable plug to operate the equipment can

cause an electrical shock or fire.

Introduction ESIE09-08

vi

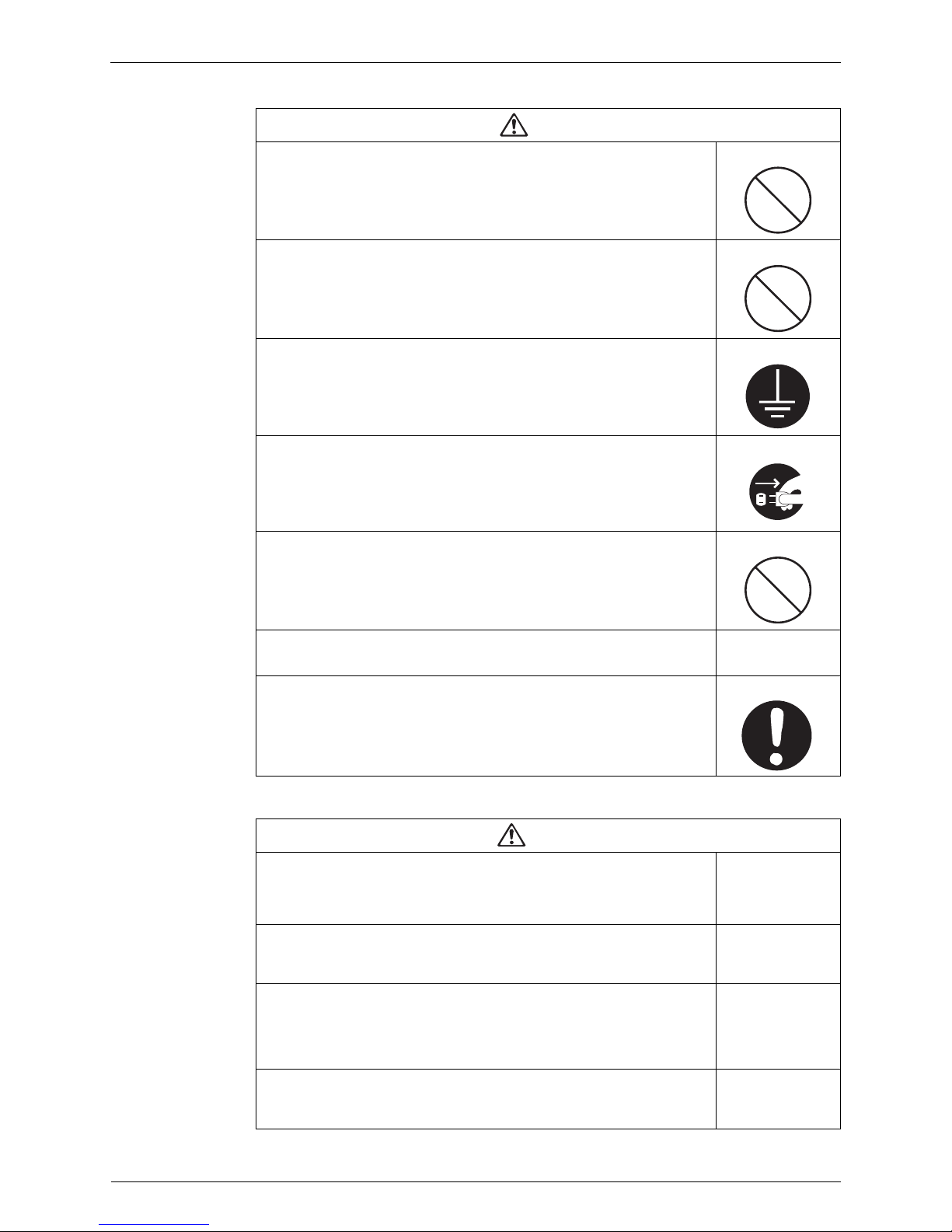

1.1.2 Cautions Regarding Products after Repair

Caution

Do not repair the electrical components with wet hands.

Working on the equipment with wet hands can cause an electrical shock.

Do not clean the heat pump by splashing water.

Washing the unit with water can cause an electrical shock.

Be sure to provide the grounding when repairing the equipment in a humid or

wet place, to avoid electrical shocks.

Be sure to turn off the power switch and unplug the power cable when cleaning

the equipment.

The internal fan rotates at a high speed, and cause injury.

Do not tilt the unit when removing it.

The water inside the unit can spill and wet the furniture and floor.

Be sure to check that the refrigerating cycle section has cooled down

sufficiently before conducting repair work.

Working on the unit when the refrigerating cycle section is hot can cause burns.

Use the welder in a well-ventilated place.

Using the welder in an enclosed room can cause oxygen deficiency.

Warning

Be sure to use parts listed in the service parts list of the applicable model and

appropriate tools to conduct repair work. Never attempt to modify the

equipment.

The use of inappropriate parts or tools can cause an electrical shock,

excessive heat generation or fire.

When relocating the equipment, make sure that the new installation site has

sufficient strength to withstand the weight of the equipment.

If the installation site does not have sufficient strength and if the installation

work is not conducted securely, the equipment can fall and cause injury.

Be sure to use an exclusive power circuit for the equipment, and follow the

technical standards related to the electrical equipment, the internal wiring

regulations and the instruction manual for installation when conducting

electrical work.

Insufficient power circuit capacity and improper electrical work can cause an

electrical shock or fire.

Be sure to use the specified cable to connect between the indoor and outdoor

units. Make the connections securely and route the cable properly so that there

is no force pulling the cable at the connection terminals.

Improper connections can cause excessive heat generation or fire.

ESIE09-08 Introduction

vii

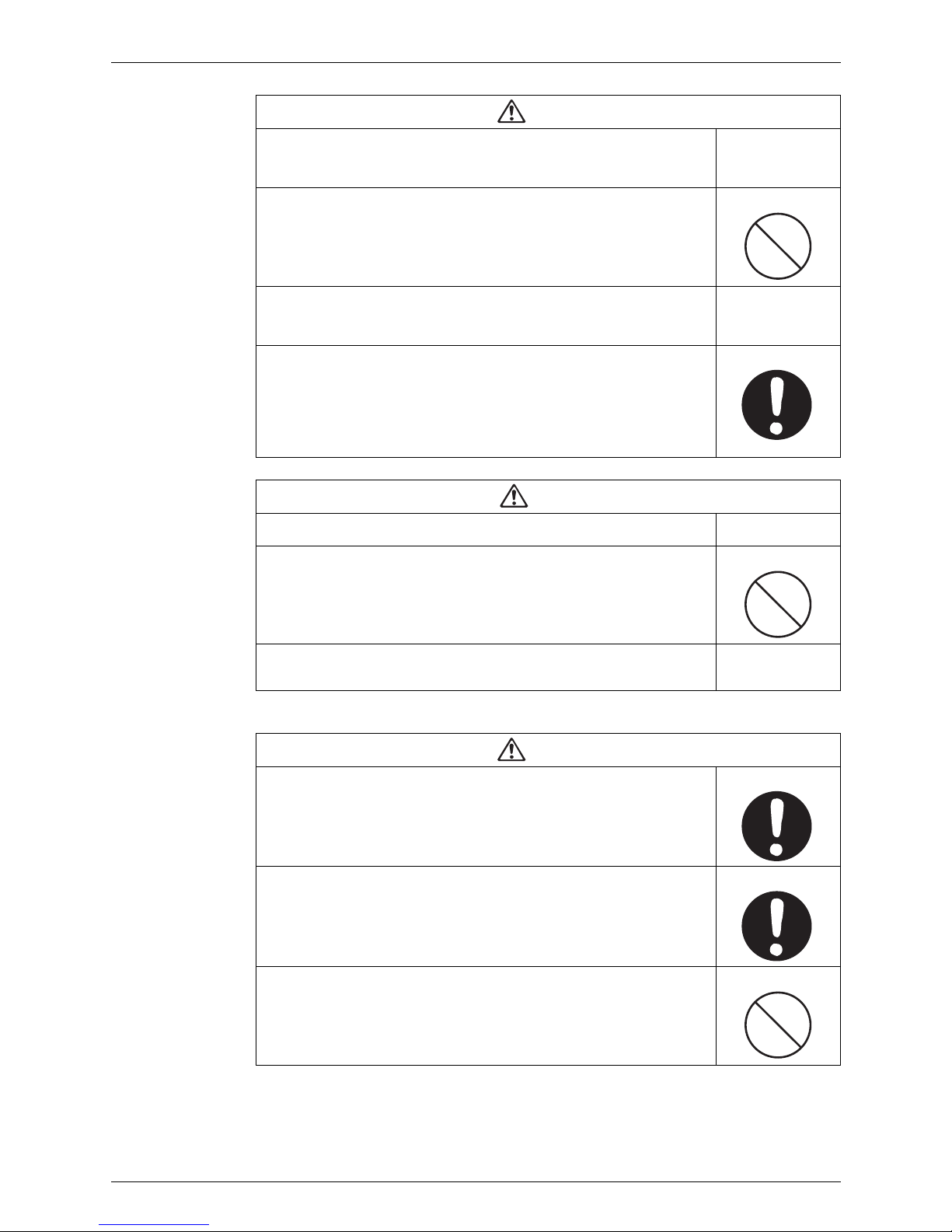

1.1.3 Inspection after Repair

When connecting the cable between the indoor and outdoor units, make sure

that the terminal cover does not lift off or dismount because of the cable.

If the cover is not mounted properly, the terminal connection section can cause

an electrical shock, excessive heat generation or fire.

Do not damage or modify the power cable.

Damaged or modified power cable can cause an electrical shock or fire.

Placing heavy items on the power cable, and heating or pulling the power cable

can damage the cable.

Do not mix air or gas other than the specified refrigerant (R-410A / R-134a) in

the refrigerant system.

If air enters the refrigerating system, an excessively high pressure results,

causing equipment damage and injury.

If the refrigerant gas leaks, be sure to locate the leak and repair it before

charging the refrigerant. After charging refrigerant, make sure that there is no

refrigerant leak.

If the leak cannot be located and the repair work must be stopped, be sure to

perform pump-down and close the service valve, to prevent the refrigerant gas

from leaking into the room. The refrigerant gas itself is harmless, but it can

generate toxic gases when it contacts flames, such as fan and other heaters,

stoves and ranges.

Warning

Caution

Installation of a leakage breaker is necessary in some cases depending on the

conditions of the installation site, to prevent electrical shocks.

Do not install the equipment in a place where there is a possibility of

combustible gas leaks.

If a combustible gas leaks and remains around the unit, it can cause a fire.

Be sure to install the packing and seal on the installation frame properly.

If the packing and seal are not installed properly, water can enter the room and

wet the furniture and floor.

For integral units

only

Warning

Check to make sure that the power cable plug is not dirty or loose, then insert

the plug into a power outlet all the way.

If the plug has dust or loose connection, it can cause an electrical shock or fire.

If the power cable and lead wires have scratches or deteriorated, be sure to

replace them.

Damaged cable and wires can cause an electrical shock, excessive heat

generation or fire.

Do not use a joined power cable or extension cable, or share the same power

outlet with other electrical appliances, since it can cause an electrical shock,

excessive heat generation or fire.

Introduction ESIE09-08

viii

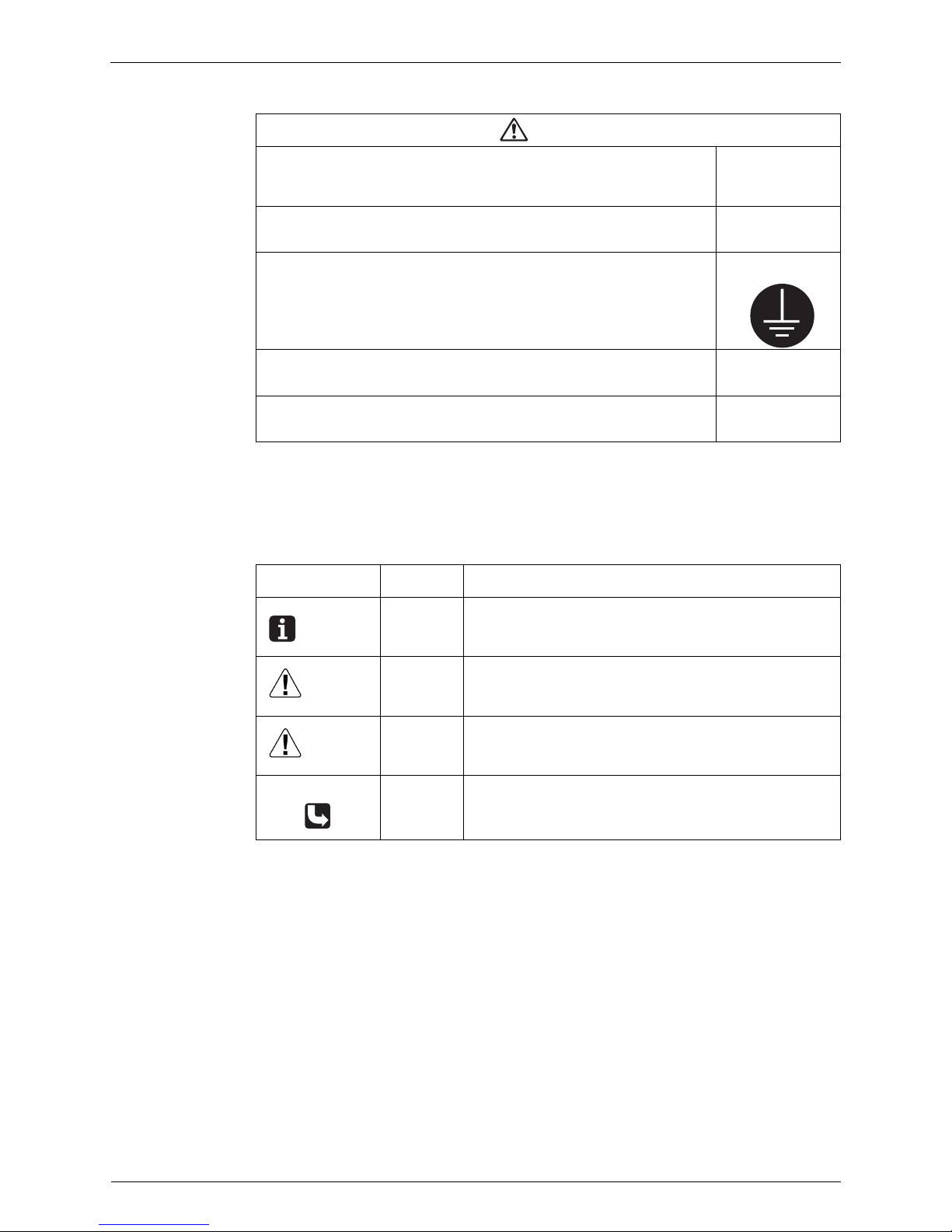

1.1.4 Using Icons

Icons are used to attract the attention of the reader to specific information. The meaning of each

icon is described in the table below:

1.1.5 Using Icons List

Caution

Check to see if the parts and wires are mounted and connected properly, and

if the connections at the soldered or crimped terminals are secure.

Improper installation and connections can cause excessive heat generation,

fire or an electrical shock.

If the installation platform or frame has corroded, replace it.

Corroded installation platform or frame can cause the unit to fall, resulting in

injury.

Check the grounding, and repair it if the equipment is not properly grounded.

Improper grounding can cause an electrical shock.

Be sure to measure the insulation resistance after the repair, and make sure

that the resistance is 1 Mohm or higher.

Faulty insulation can cause an electrical shock.

Be sure to check the drainage of the indoor unit after the repair.

Faulty drainage can cause the water to enter the room and wet the furniture

and floor.

Icon Type of

Information

Description

Note:

Note A “note” provides information that is not indispensable, but may

nevertheless be valuable to the reader, such as tips and tricks.

Caution

Caution A “caution” is used when there is danger that the reader, through

incorrect manipulation, may damage equipment, loose data, get

an unexpected result or has to restart (part of) a procedure.

Warning

Warning A “warning” is used when there is danger of personal injury.

Reference A “reference” guides the reader to other places in this binder or

in this manual, where he/she will find additional information on a

specific topic.

ESIE09-08 Introduction

ix

1.2 PREFACE

Thank you for your continued patronage of Daikin products.

This is the new service manual for Daikin's Year 2009 Daikin Altherma HT (high temperature)

air to water heat pump.

Daikin offers a wide range of models to respond to the residential heating market. We are

confident that customers will be able to find the models that best suit their needs.

This service manual contains information regarding the servicing of Daikin Altherma HT (R410A & R-134a) Heat Pump System.

August, 2009

After Sales Service Division

Introduction ESIE09-08

x

ESIE09-08

General Information 1

Part 1 - General Information

1. Model Names of Indoor/Outdoor Units & Tanks .....................................2

Model Names of Indoor/Outdoor Units & Tanks ESIE09-08

2 General Information

1. Model Names of Indoor/Outdoor Units & Tanks

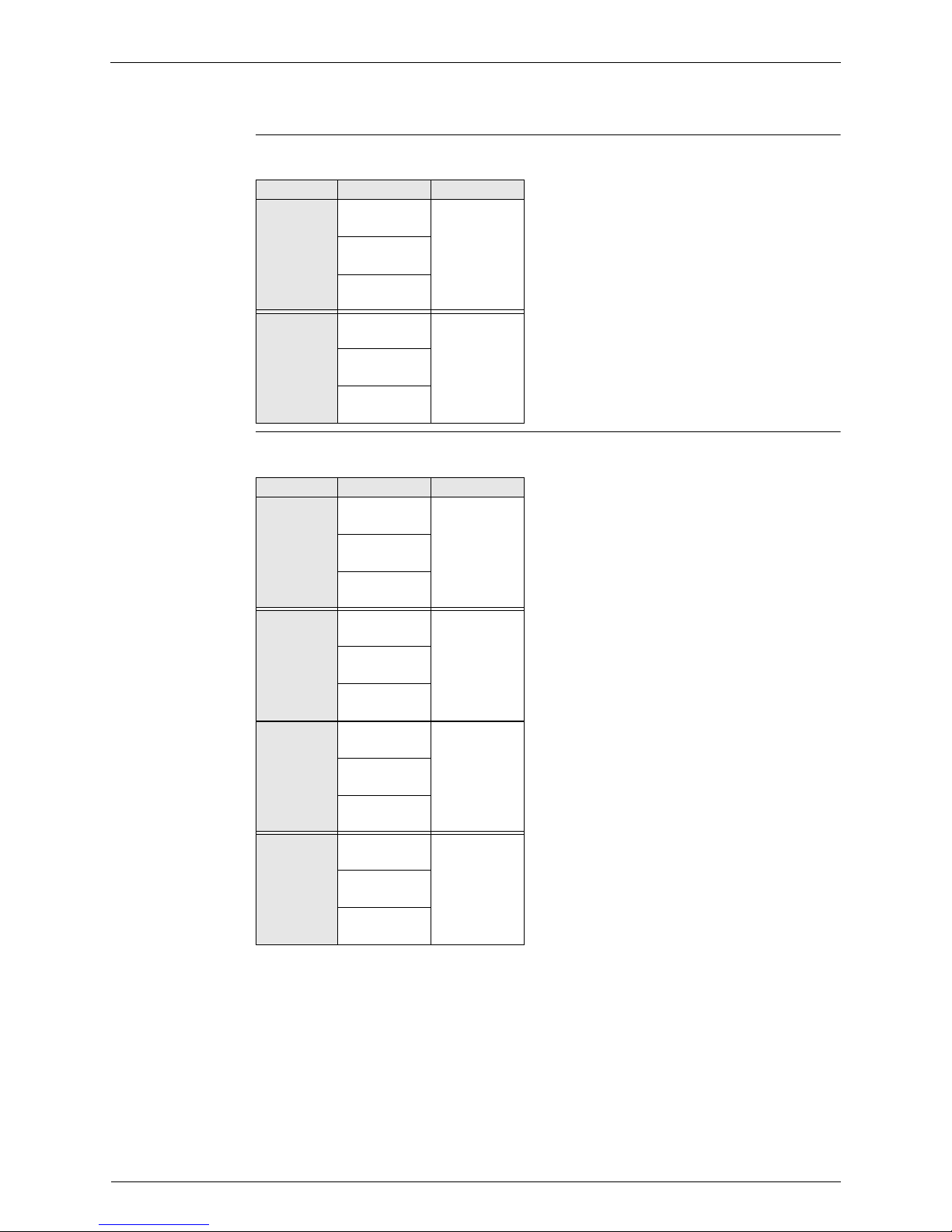

Indoor Units

Outdoor Units

Type Model Name

Power Supply

EKHBRD

011 AA

V1014 AA

016 AA

EKHBRD

011 AA

Y1014 AA

016 AA

Type Model Name

Power Supply

ERRQ

011 AA

V1014 AA

016 AA

ERRQ

011 AA

Y1014 AA

016 AA

ERSQ

011 AA

V1014 AA

016 AA

ERSQ

011 AA

Y1014 AA

016 AA

ESIE09-08 Model Names of Indoor/Outdoor Units & Tanks

General Information 3

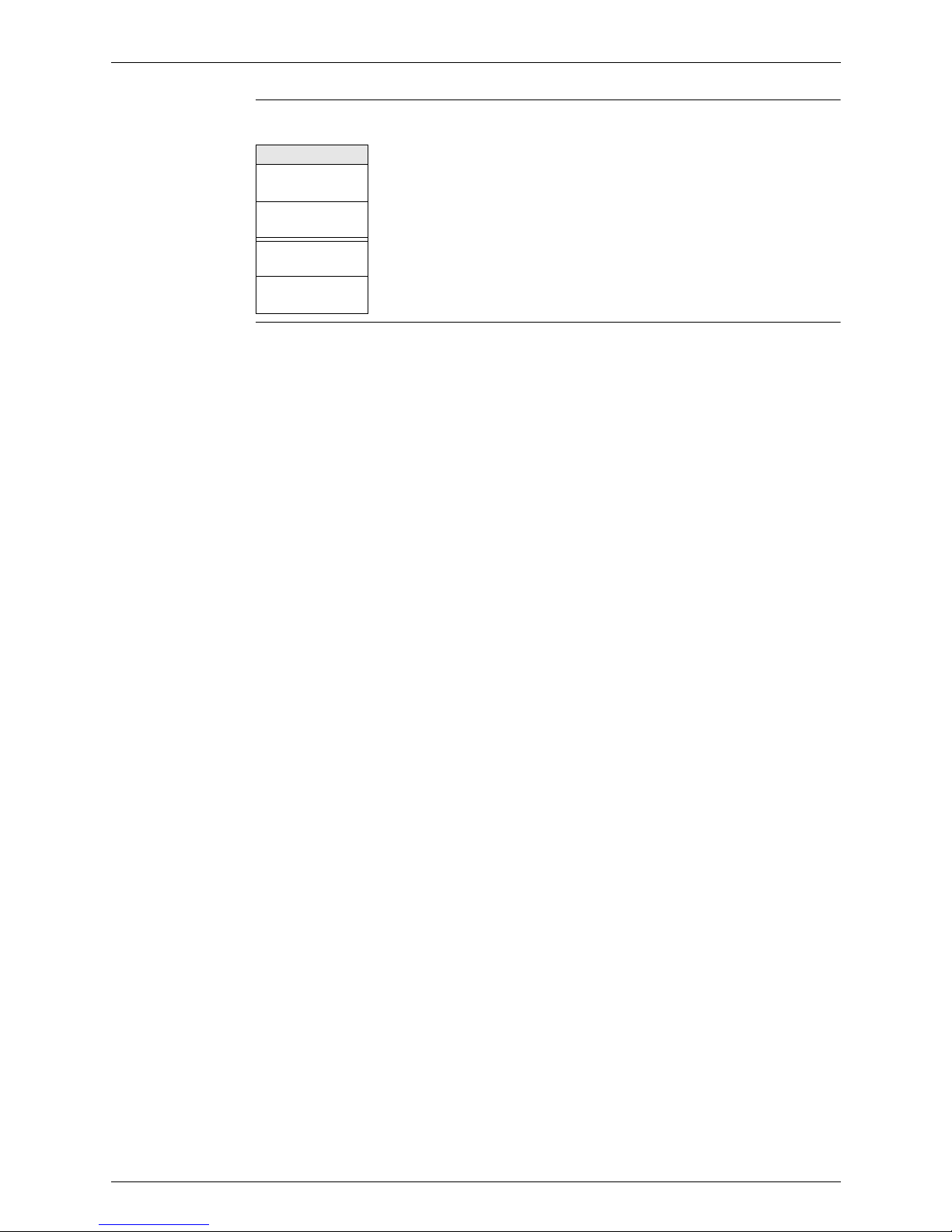

Tank

Model Name

EKHTS 200 A

EKHTS 260 A

EKHTSU 200 AA

EKHTSU 260 AA

Model Names of Indoor/Outdoor Units & Tanks ESIE09-08

4 General Information

ESIE09-08

Specifications 5

Part 2 - Specifications

1. Specifications ..........................................................................................6

1.1 Outdoor Units ...........................................................................................6

1.2 Indoor Unit................................................................................................8

Specifications ESIE09-08

6 Specifications

1. Specifications

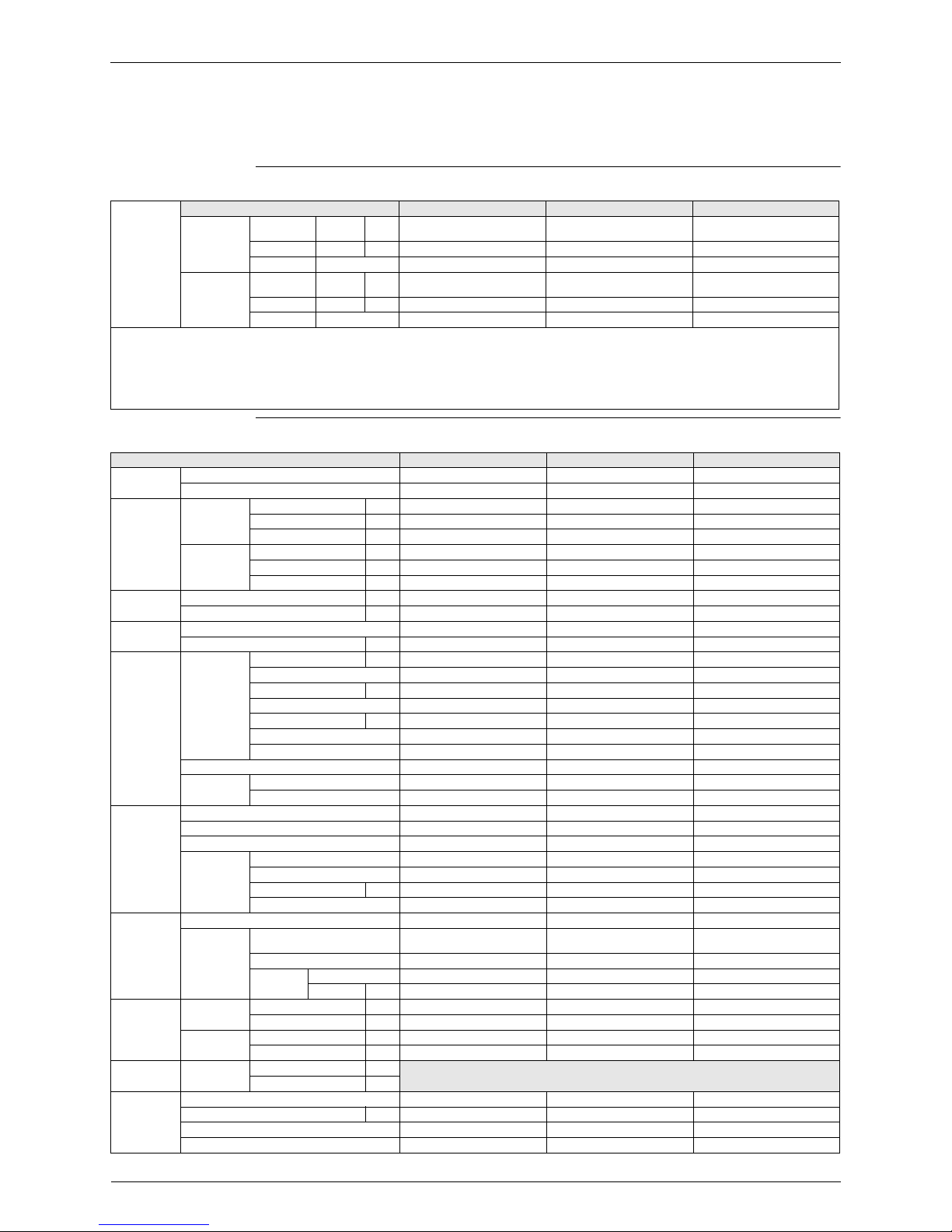

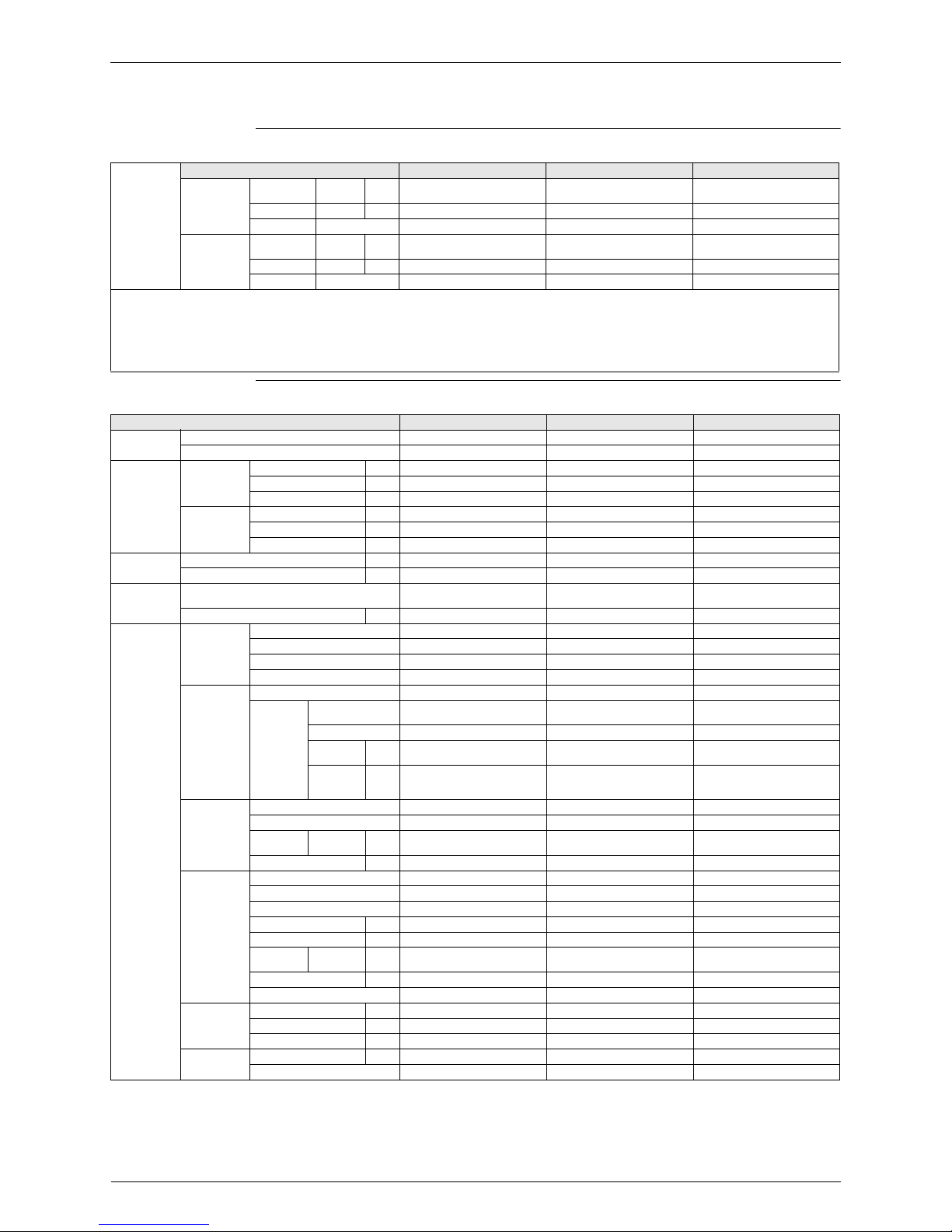

1.1 Outdoor Units

Capacity Information

Technical Specifications

For

combination

indoor units +

outdoor units

Indoor Units EKHBRD011AA(V1/Y1) EKHBRD014AA(V1/Y1) EKHBRD016AA(V1/Y1)

Condition 1 Heating

capacity

Nominal kW

11 14 16

Heating PI Nominal kW 3,57 4,66 5,57

COP Nominal 3,08 3,00 2,88

Condition 2 Heating

capacity

Nominal kW

11 14 16

Heating PI Nominal kW 4,40 5,65 6,65

COP Nominal 2,50 2,48 2,41

Notes

Condition 1

EW: 55°C, LW: 65°C, ΔT=10°C

Ambient conditions: 7°CDB/6°CWB

Condition 2

EW: 70°C, LW: 80°C, ΔT=10°C

Ambient conditions: 7°CDB/6°CWB

Outdoor units ER(S/R)Q011AA(V1/Y1) ER(S/R)Q014AA(V1/Y1) ER(S/R)Q016AA(V1/Y1)

Casing Colour Daikin White Daikin White Daikin White

Material Painted galvanised steel Painted galvanised steel Painted galvanised steel

Dimensions Unit Height mm 1345 1345 1345

Width mm 900 900 900

Depth mm 320 320 320

Packing Height mm 1524 1524 1524

Width mm 980 980 980

Depth mm 420 420 420

Weight Unit kg 120 120 120

Packed Unit kg 130 130 130

Packing Material Cardboard + Wood + EPS Cardboard + Wood + EPS Cardboard + Wood + EPS

Weight kg 8 8 8

Heat

Exchanger

Specifications Length mm 857 857 857

Nr of Rows 2 2 2

Fin Pitch mm 2 2 2

Nr of Passes 10 10 10

Face Area m² 1,131 1,131 1,131

Nr of Stages 60 60 60

Empty Tubeplate Hole 0 0 0

Tube type Hi-XSS Hi-XSS Hi-XSS

Fin Type Non-symmetric waffle louvre Non-symmetric waffle louvre Non-symmetric waffle louvre

Treatment Corrosion resistant Corrosion resistant Corrosion resistant

Fan Type Propellor Propellor Propellor

Quantity 2 2 2

Discharge direction Horizontal Horizontal Horizontal

Motor Quantity 2 2 2

Model Brushless DC motor Brushless DC motor Brushless DC motor

Output W 70 70 70

Drive Direct drive Direct drive Direct drive

Compressor Quantity 1 1 1

Motor Type Hermetically sealed scroll

compressor

Hermetically sealed scroll

compressor

Hermetically sealed scroll

compressor

Starting Method Direct on line Direct on line Direct on line

Crankcase

Heater

Quantity 1 1 1

Output W 33 33 33

Operation

Range

(1)

Heating Minimum ambient °C -20 -20 -20

Maximum ambient °C 20 20 20

Domestic hot

water

Minimum ambient °C -20 -20 -20

Maximum ambient °C 35 35 35

Sound Level

(nominal)

Heating Sound Power dBA

See technical data

Sound Pressure dBA

Refrigerant Type R-410A R-410A R-410A

Charge kg 4,5 4,5 4,5

Control Expansion valve (electronic) Expansion valve (electronic) Expansion valve (electronic)

Nr of Circuits 1 1 1

ESIE09-08 Specifications

Specifications 7

Electrical Specifications

Refrigerant Oil Type Daphne FVC68D Daphne FVC68D Daphne FVC68D

Charged Volume l 1,5 1,5 1,5

Piping

Connections

Liquid Quantity 1 1 1

Type Flare Flare Flare

Diameter (OD) mm 9,52 9,52 9,52

Gas Quantity 1 1 1

Type Flare Flare Flare

Diameter (OD) mm 15,9 15,9 15,9

Drain Quantity 3 3 3

Diameter (OD) mm 26 x 3 26 x 3 26 x 3

Piping Length Minimum m 3 3 3

Maximum m 50 50 50

Equivalent m 63 63 63

Chargeless m 10 10 10

Additional Refrigerant Charge kg/m see installation manual see installation manual see installation manual

Installation

height

difference

Maximum m

30 30 30

Heat Insulation Both liquid and gas pipes Both liquid and gas pipes Both liquid and gas pipes

Defrost Method Reversed cycle Reversed cycle Reversed cycle

Defrost Control Sensor for outdoor heat

exchanger temperature

Sensor for outdoor heat

exchanger temperature

Sensor for outdoor heat

exchanger temperature

Capacity Control Method Inverter controlled Inverter controlled Inverter controlled

Safety Devices (pressure) HPS HPS HPS

Safety Devices (fan) Fan motor thermal protector Fan motor thermal protector Fan motor thermal protector

Safety Devices (inverter) Inverter overload protector Inverter overload protector Inverter overload protector

Safety Devices (pcb) PC board fuse PC board fuse PC board fuse

Standard

Accessories

Item Installation manual Installation manual Installation manual

Quantity 1 1 1

Design pressure (high pressure side) bar 40 40 40

Notes

(1): for details see operation range TW drawing

Power Supply Name

ER(S/R)Q(011/014/016)AAV1 ER(S/R)Q(011/014/016)AAY1

Phase 1~ 3~

Frequency Hz 50 50

Voltage V 220-240 380-415

Voltage Range Minimum V 198 342

Maximum V 254 440

Current Z-max

(2)

Ω 0,28 -

Minimum Ssc

(3)

value kVa Equipment complying with EN/

IEC 61000-3-12

(1)

-

Maximum

running

Current

Heating A

27 13,5

Recommended fuses A 32 16

Wiring

Connections

For power

supply

Quantity 2G 4G

Wire type Note

(4)

Note

(4)

For connection

with indoor

unit

Quantity 2

Remark

F1+F2

Power Supply Intake Both indoor and outdoor unit

Notes

(1): European/International Technical Standard setting the limits for harmonic currents produced by equipment connected to public lowvoltage systems with input current > 16A and ≤ 75A per phase

(2): In accordance with EN/IEC 61000-3-11

(5)

, it may be necessary to consult the distribution network operator to ensure that the

equipment is connected only to a supply with Zsys

(6)

≤ Zmax

(3): Short-circuit power

(4): Select diameter and type according to national and local regulations

(5): European/International Technical Standard setting the limits for voltage changes, voltage fluctuations and flicker in public low-voltage

supply systems for equipment with rated current ≤ 75A

(6): System impedance

Outdoor units ER(S/R)Q011AA(V1/Y1) ER(S/R)Q014AA(V1/Y1) ER(S/R)Q016AA(V1/Y1)

Specifications ESIE09-08

8 Specifications

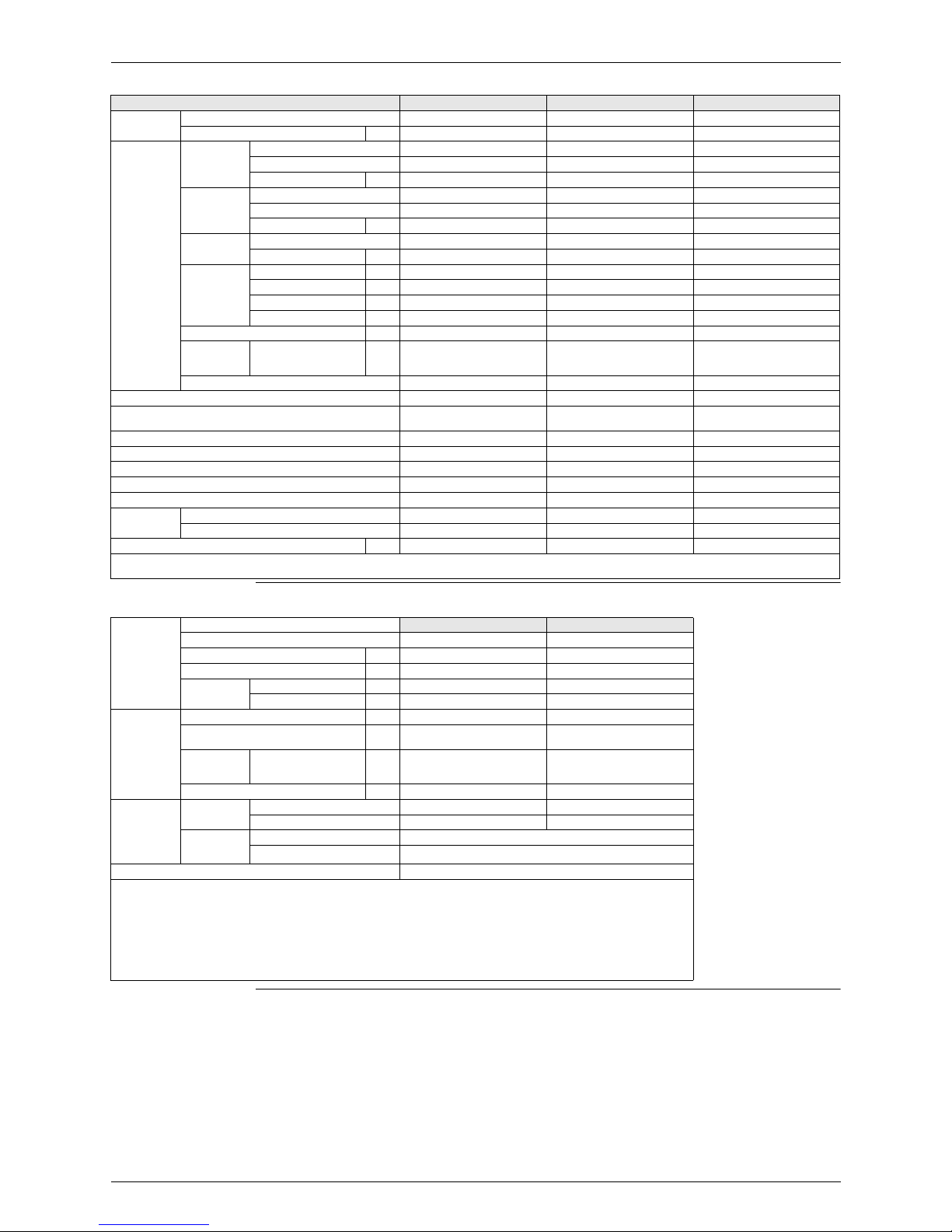

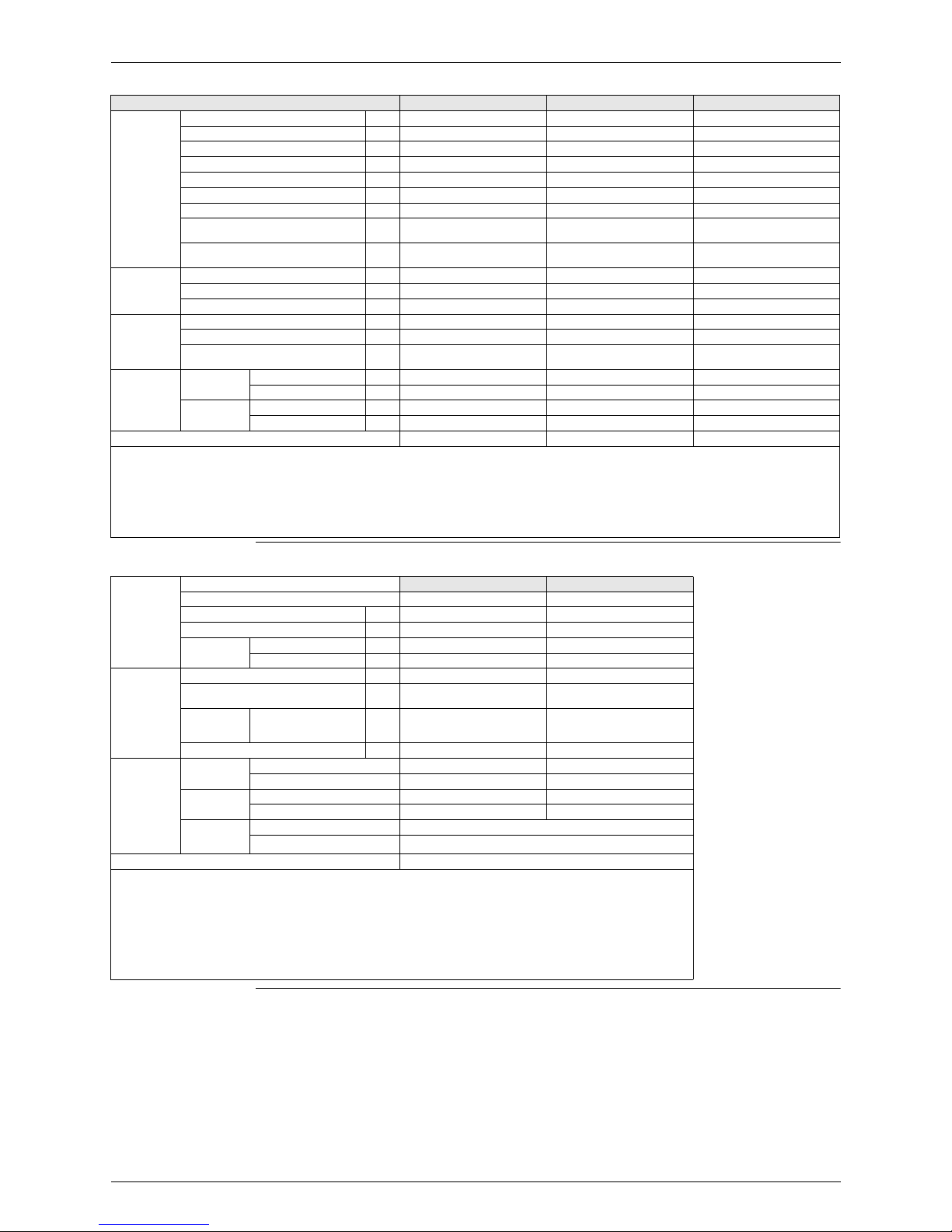

1.2 Indoor Unit

Capacity Information

Technical Specifications

For

combination

indoor units +

outdoor units

Indoor Units EKHBRD011AA(V1/Y1) EKHBRD014AA(V1/Y1) EKHBRD016AA(V1/Y1)

Condition 1 Heating

capacity

Nominal kW

11 14 16

Heating PI Nominal kW 3,57 4,66 5,57

COP Nominal 3,08 3,00 2,88

Condition 2 Heating

capacity

Nominal kW

11 14 16

Heating PI Nominal kW 4,40 5,65 6,65

COP Nominal 2,50 2,48 2,41

Notes

Condition 1

EW: 55°C, LW: 65°C, ΔT=10°C

Ambient conditions: 7°CDB/6°CWB

Condition 2

EW: 70°C, LW: 80°C, ΔT=10°C

Ambient conditions: 7°CDB/6°CWB

Indoor units EKHBRD011AA(V1/Y1) EKHBRD014AA(V1/Y1) EKHBRD016AA(V1/Y1)

Casing Colour Metallic Grey Metallic Grey Metallic Grey

Material pre coated sheetmetal pre coated sheetmetal pre coated sheetmetal

Dimensions Packing Height mm 860 860 860

Width mm 680 680 680

Depth mm 800 800 800

Unit Height mm 705 705 705

Width mm 600 600 600

Depth mm 695 695 695

Weight Machine weight kg 144,25 / 147,25 144,25 / 147,25 144,25 / 147,25

Gross weight kg 153 / 156 153 / 156 153 / 156

Packing Material EPS, Cardboard, MDF, Wood

(pallet), Metal

EPS, Cardboard, MDF, Wood

(pallet), Metal

EPS, Cardboard, MDF, Wood

(pallet), Metal

Weight kg 8,75 8,75 8,75

Main

components

Refrigerant

side heat

exchanger

Type Plate heat exchanger Plate heat exchanger Plate heat exchanger

Quantity 1 (60 plates) 1 (60 plates) 1 (60 plates)

Material AISI 316 AISI 316 AISI 316

Insulation material EPDM type EPDM type EPDM type

Cascade

compressor

Quantity 1 1 1

Motor Type Hermetically sealed scroll

compressor

Hermetically sealed scroll

compressor

Hermetically sealed scroll

compressor

Starting Method Direct online Direct online Direct online

Crankcase

Heater

Quantity

111

Crankcase

Heater

Output

W

33 33 33

Pump Type DC motor DC motor DC motor

Nr. of speed inverter controlled inverter controlled inverter controlled

Nominal

ESP unit

(1)

Heating kPa

94,0 91,9 89,7

Power input W 87 95 101

Water side

Heat

exchanger

Type Plate heat exchanger Plate heat exchanger Plate heat exchanger

Quantity 1 (50 plates) 1 (50 plates) 1 (50 plates)

Material AISI 316 AISI 316 AISI 316

Water volume l 2,78 2,78 2,78

Water flow rate Min. l/min N/A N/A N/A

Water flow

(1)

Heating l/min

15,8 20,1 22,9

Water flow rate Max.

(2)

l/min 31,6 40 45,8

Insulation material EPDM type EPDM type EPDM type

Expansion

vessel

Volume l 12 12 12

Max. water pressure bar 3 3 3

Pre pressure bar 1,5 1,5 1,5

Water filter Diameter perforations mm 1 1 1

Material Brass Brass Brass

ESIE09-08 Specifications

Specifications 9

Electrical Specifications

Water circuit Piping connections diameter inch G 1”1/4 (female) G 1”1/4 (female) G 1”1/4 (female)

Piping inch 1” 1” 1”

Safety valve bar 3 3 3

Manometer Y/N Y Y Y

Drain valve / Fill valve Y/N Y Y Y

Shut off valve Y/N Y Y Y

Air purge valve Y/N Y Y Y

Heating water system minimum water

volume

l

20 20 20

Heating water system maximum water

volume

l

400 400 400

Refrigerant

Circuit

Gas side diameter mm 15,9 15,9 15,9

Liquid side diameter mm 9,52 9,52 9,52

Design pressure (high pressure side) bar 38 38 38

Sound Level

(3)

Sound Pressure at 55 - 65 °C [EW - LW]

(4)

dBA 43 45 46

Sound Pressure at 70 - 80 °C [EW - LW]

(4)

dBA 46 46 46

Sound Pressure low sound mode n° 1 at

55 - 65 °C [EW - LW]

(4)

dBA

40 43 45

Operation

range

(5)

Ambient Minimum °C -20 -20 -20

Maximum °C 20/(35)

(6)

20/(35)

(6)

20/(35)

(6)

Waterside

Minimum LW °C 25 25 25

Maximum LW °C 80 80 80

Installation place Indoor Indoor Indoor

Notes

(1): for ΔT = 10°C

(2): for ΔT = 5°C

(3): The data mentioned is valid in free field condition because it is measured in a semi-anechoic room. Measured value under actual installation conditions will be higher due

to environmental noise and sound reflections. These values are sound pressure levels measured at all sides (front / back / left / right / top) at 1m distance (see engineering

data book for more details). The values do not occur simultaneously on all mentioned sides

(4): EW = entering water temperature - LW = leaving water temperature

(5): for details see operation range TW drawing

(6): for DHW operation

Power Supply Name

EKHBRD(011/014/016)AAV1 EKHBRD(011/014/016)AAY1

Phase 1~ 3~

Frequency Hz 50 50

Voltage V 220-240 380-415

Voltage Range Minimum V 198 342

Maximum V 254 440

Current Z-max

(2)

Ω 0,35 -

Minimum Ssc

(3)

value kVa Equipment complying with EN/

IEC 61000-3-12

(1)

-

Maximum

running

Current

Heating A

21,7 12,5

Recommended fuses A 32 16

Wiring

Connections

For power

supply

Quantity 2G 4G

Wire type Note

(4)

Note

(4)

For power

supply

(5)

Quantity 2G + 2G 4G + 2G

Wire type Note

(4)

Note

(4)

For connection

with outdoor

unit

Quantity 2

Remark

F1+F2

Power Supply Intake Both indoor unit and outdoor unit

Notes

(1): European/International Technical Standard setting the limits for harmonic currents produced by equipment connected to public lowvoltage systems with input current > 16A and ≤ 75A per phase

(2): In accordance with EN/IEC 61000-3-11

(6)

, it may be necessary to consult the distribution network operator to ensure that the

equipment is connected only to a supply with Zsys

(7)

≤ Zmax

(3): Short-circuit power

(4): Select diameter and type according to national and local regulations

(5): In case of benefit kWh rate power supply installations

(6): European/International Technical Standard setting the limits for voltage changes, voltage fluctuations and flicker in public low-voltage

supply systems for equipment with rated current ≤ 75A

(7): System impedance

Indoor units EKHBRD011AA(V1/Y1) EKHBRD014AA(V1/Y1) EKHBRD016AA(V1/Y1)

Specifications ESIE09-08

10 Specifications

ESIE09-08

Refrigerant Circuit 11

Part 3 - Refrigerant Circuit

& Functional Parts

1. Refrigerant Circuit .................................................................................12

1.1 Outdoor Unit .................................................................................12

1.2 Indoor Unit ....................................................................................14

2. Functional Parts Layout ........................................................................16

2.1 ERRQ 011/014/016 AAV1, ERSQ 011/014/016 AAV1 ..........................16

2.2 ERRQ 011/014/016 AAY1, ERSQ 011/014/016 AAY1 ..........................18

2.3 EKHBRD 011/014/016 AAV1, EKHBRD 011/014/016 AAY1 .................20

2.4 EKHTS 200/260 A ..................................................................................22

2.5 EKHTSU 200/260 A ...............................................................................24

Refrigerant Circuit ESIE09-08

12 Refrigerant Circuit

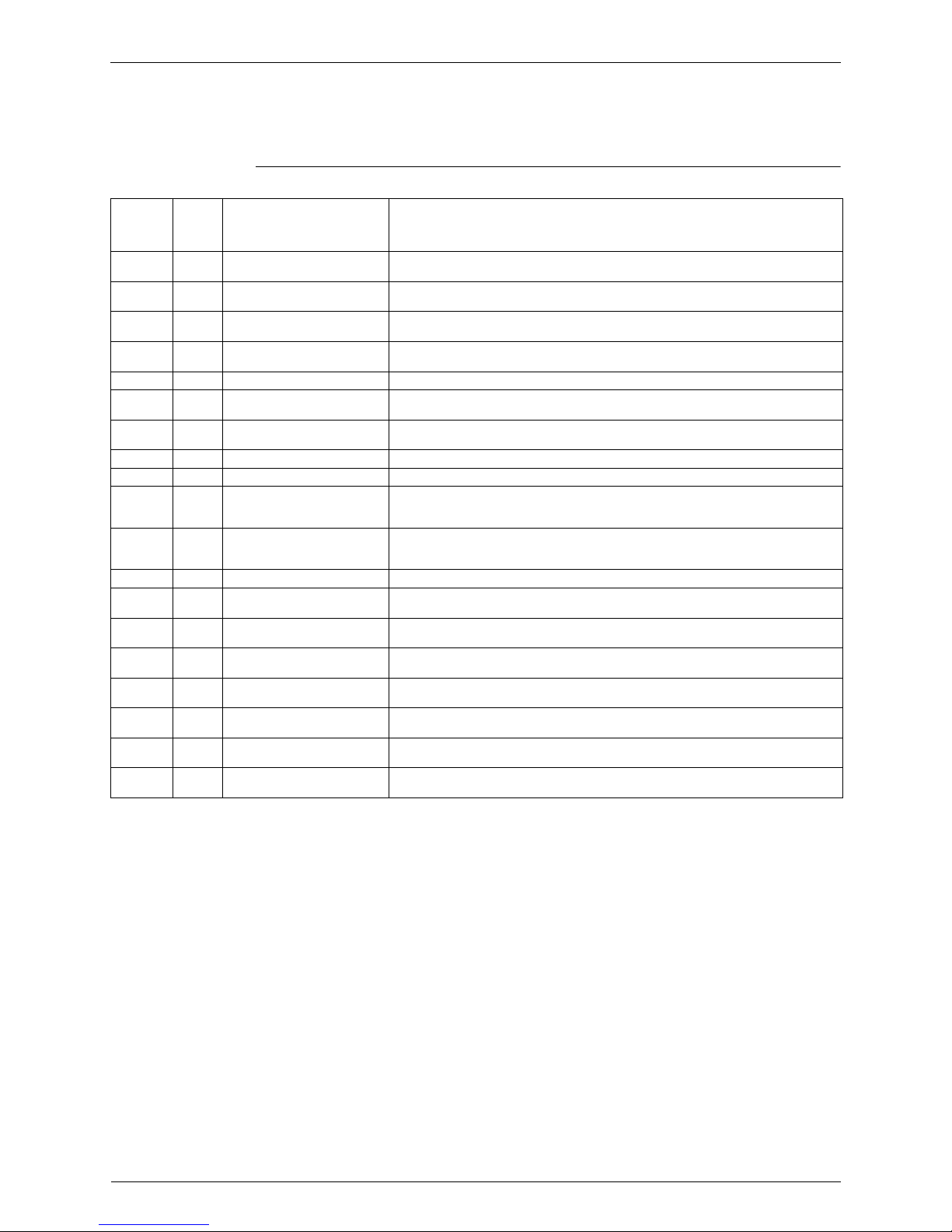

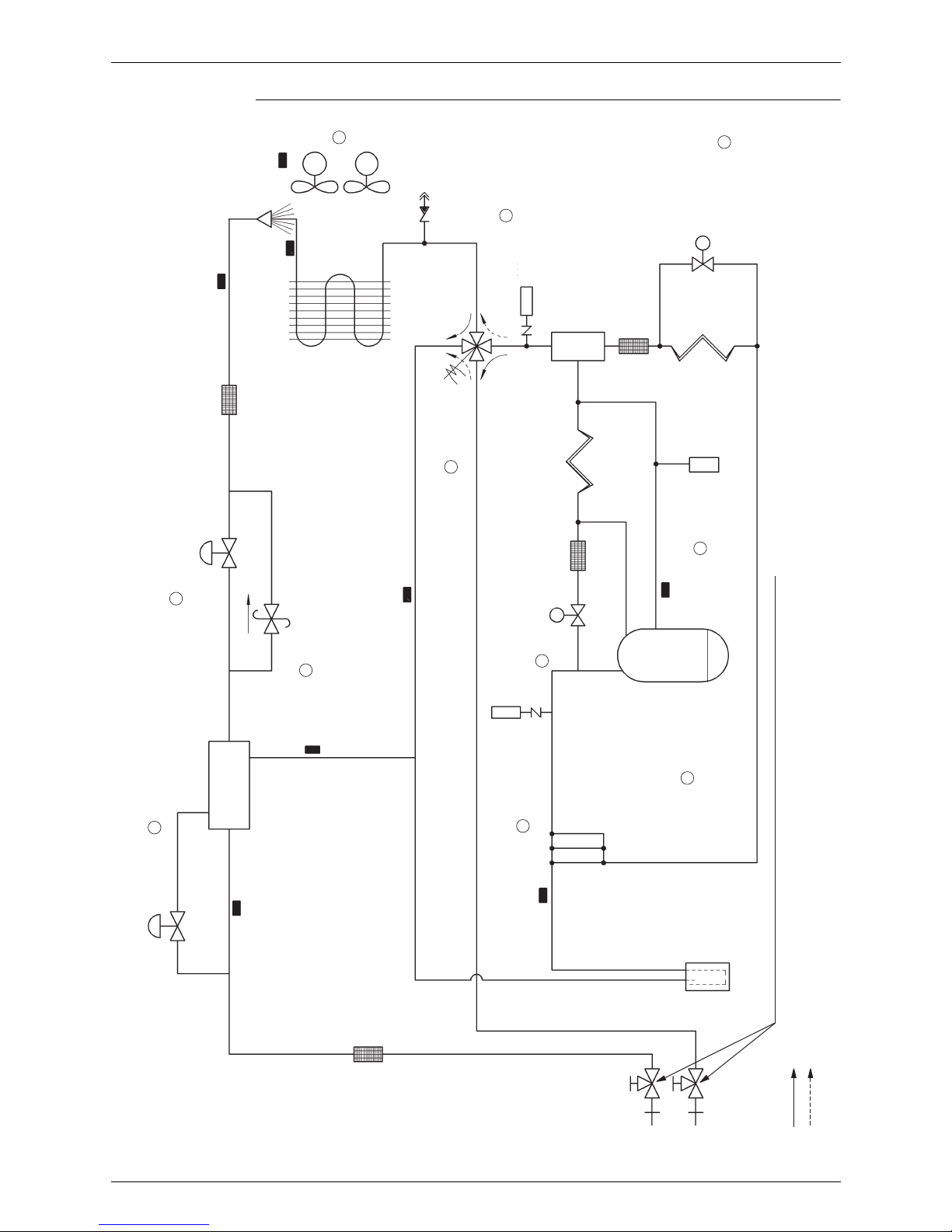

1. Refrigerant Circuit

1.1 Outdoor Unit

ERRQ - ERSQ

No. in

refrigerant

system

diagram

Symbol Name Major Function

A M1C Inverter compressor (INV)

Inverter compressor is operated on frequencies between 36 Hz and 195 Hz by using

the inverter. In total there are 31 steps.

B

M1F

M2F

Inverter fan

Since the system is of air heat exchanging type, the fan is operated at 8 (9)-step

rotation speed by using the inverter.

CY1E

Electronic expansion valve

(Main: EV1)

While in heating operation, PI control is applied to keep the outlet superheated degree

of air heat exchanger constant.

DY3E

Electronic expansion valve

(Subcool: EV3)

Pl control is applied to keep the outlet superheated degree of subcooling heat

exchanger constant.

E Y2S Solenoid valve (Hot gas: SVP) Used to prevent the low pressure from transient falling.

FY3S

Solenoid valve (Unload circuit

SVUL)

Used to the unloading operation of compressor.

G Y1S Four way valve

Used to switch the operation mode between defrosting and heating. Activated during

heating (opposite concerning indoor unit).

H S1NPH High pressure sensor Used to detect high pressure.

I S1NPL Low pressure sensor Used to detect low pressure.

JS1PH

HP pressure switch (For INV

compressor)

In order to prevent the increase of high pressure when a malfunction occurs, this

switch is activated at high pressure of 4.0 MPa or more to stop the compressor

operation.

K—

Pressure regulating valve 1

(Receiver to discharge pipe)

This valve opens at a pressure of 4.0 MPa for prevention of pressure increase, thus

resulting in no damage of functional parts due to the increase of pressure in

transportation or storage.

1 R1T Thermistor (Outdoor air: Ta) Used to detect outdoor temperature, correct discharge pipe temperature, and others.

2R2T

Thermistor (INV discharge

pipe: Tdi)

used to detect discharge pipe temperature, make the temperature protection control of

compressor, and others.

3R3T

Thermistor

(Suction pipe1: Ts1)

used to detect suction pipe temperature, keep the suction superheated degree

constant in heating operation, and others.

4R4T

Thermistor (Heat exchanger

deicer: Tb)

Used to detect liquid pipe temperature of air heat exchanger, determine defrosting

operation, and others.

5R5T

Thermistor

(Suction pipe2: Ts2)

Used to the calculation of superheat and internal temperature of compressor etc.

6R6T

Thermistor (Subcooling heat

exchanger gas pipe: Tsh)

Used to control of subcooling electronic expansion valve.

7R7T

Thermistor

(Liquid pipe1: Tl1)

Liquid thermistor (internal control), and others.

8R8T

Thermistor

(Liquid pipe2: Tl2)

Liquid thermistor (internal control), and others.

ESIE09-08 Refrigerant Circuit

Refrigerant Circuit 13

ELECTRONIC

EXPANSION

VALVE (Y3E)

ELECTRONIC

EXPANSION

VALVE (Y1E)

HEAT

EXCHANGER

FILTER

FILTER

FILTER

FILTER

OIL SEPA-

RATOR

R8T

R1T

R4T

R2T

R5T

R3T

R6T

R7T

ACCUMULATOR

HEATING

STOP VALVE (WITH SERVICE PORT ON FIELD PIPING SIDE

ø 7.9MM FLARE CONNECTION)

DEFROST

FANS

M1F

M2F

SP

p >

SERVICE PORT

4-WAY VALVE

(Y1S)

CAPILLARY

TUBE

CAPILLARY

TUBE

HIGH PRESSURE

SENSOR (S1NPH)

HIGH

PRESSURE

SWITCH

(S1PH)

SOLENOID VALVE

(Y2S)

SOLENOID VALVE

(Y3S)

DOUBLE PIPE

HEAT EXCHANGER

PRESSURE REGULATING

VALV E

SV

SV

SP

COMPRESSOR

(M1C)

Low pressure

sensor (S1NPL)

A

B

C

D

K

G

H

I

F

J

E

Refrigerant Circuit ESIE09-08

14 Refrigerant Circuit

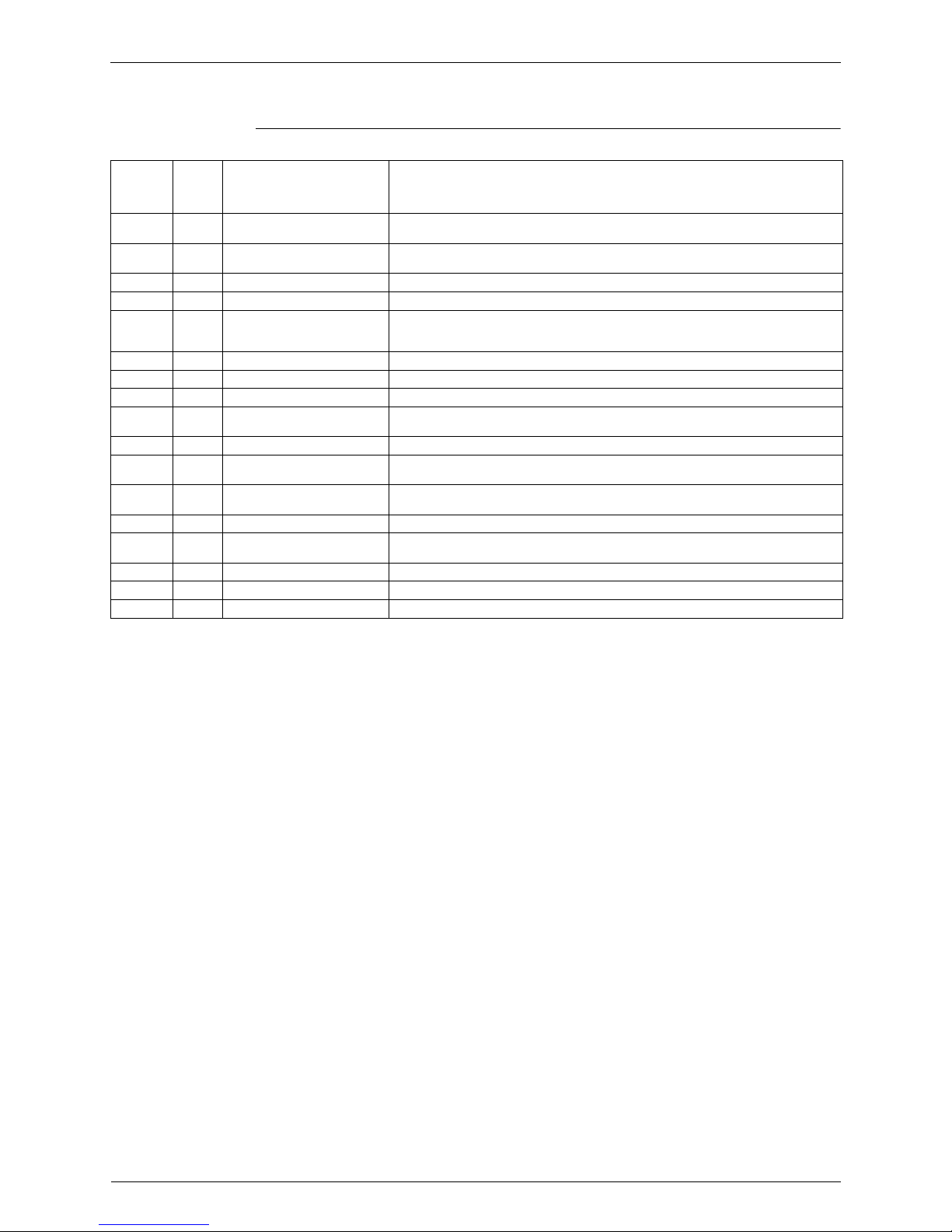

1.2 Indoor Unit

EKHBRD 011/014/016 AA(V1/Y1)

No. in

refrigerant

system

diagram

Symbol Name Major Function

AM1C

Inverter compressor on

R-134a

Inverter compressor is operated on frequencies between 40 Hz and 210 Hz by using

the inverter. Max. of 30 steps.

B Y1R Four way valve

Used to switch the operation mode between heating and defrost. Not activated during

heating (opposite concerning outdoor unit).

C B1PL Low pressure sensor Used to detect low pressure.

D B1PH High pressure sensor Used to detect high pressure.

E S1PH High pressure switch

In order to prevent the increase of high pressure when a malfunction occurs, this

switch is activated at high pressure of 3.8 MPa or more to stop the compressor

operation.

F K2S 2-way valve Used during defrost operation.

G K1E Electronic expansion valve Used to regulate the refrigerant flow of R-410A.

H K2E Electronic expansion valve Used to regulate the refrigerant flow of R-134a.

I E1HC Crankcase heater

Used to prevent migration (when the unit is OFF) and condensation of refrigerant in

the crankcase of compressor.

J M1P DC inverter pump Used to regulate water flow to achieve a constant ΔT.

KQ2L

Thermistor protector water

piping

Used to protect the water system against high temperatures.

LK1S

3 way valve (option for water

tank)

Used to switch over between space heating and domestic hot water.

1 R3T Liquid thermistor R-410A Subcool calculation.

2 R6T Discharge thermistor

Used to detect discharge pipe temperature, make the temperature protection control of

compressor, and others.

3 R7T Liquid thermistor R-134a Subcool calculation.

4 R4T Returning water thermistor Used to control and protect the water system.

5 R5T Leaving water thermistor Used to control and protect the water system.

ESIE09-08 Refrigerant Circuit

Refrigerant Circuit 15

FILTER FILTER

FILTER FILTER

FILTER

DRAIN VALVE

BLOW

OFF

SAFETY

VALV E

PRESSURE

GAUGE

EXPANSION

VESSEL

WATER INLET

OPTION DOMESTIC HOT

WATER TANK

PLATE

HEAT

EX-

CHANGER

R-134a

PLATE HEAT

EXCHANGER

R-410A /

R-134a

CHECK

VALV E

M1C

E1HC

R6T

Y1R

M

K1S

R5T

Q2L

R4T

M1P

K2S

K1E

K2E

R3T

R7T

B1PL

B1PH

S1PH

ACCUMULATOR

CHECK

VALV E

*KHTS*

200~270*

G 1”1/4 (female)

WATER OUTLET

STANDARD

WATER SIDE

3-WAY

VALV E

REFRIGERANT SIDE

OUTDOOR UNIT

SERVICE PORT

5/16”

SERVICE PORT

5/16”

*R*Q011~016**

FIELD INSTALLATION

(DELIVERED WITH

OPTION DOMESTIC

HOT WATER TANK)

G 1”1/4 (female)

AIR

PURGE

SHUT OFF

VALV E

SHUT OFF

VALV E

FIELD PIPING ø15.9 C 1220T-0

FIELD PIPING ø9.5 C 1220T-0

SV

HEATING

DEFROST

G

H

F

E

B

L

1

1

K

4

5

J

1

D

C

I

1

3

A

2

Functional Parts Layout ESIE09-08

16 Refrigerant Circuit

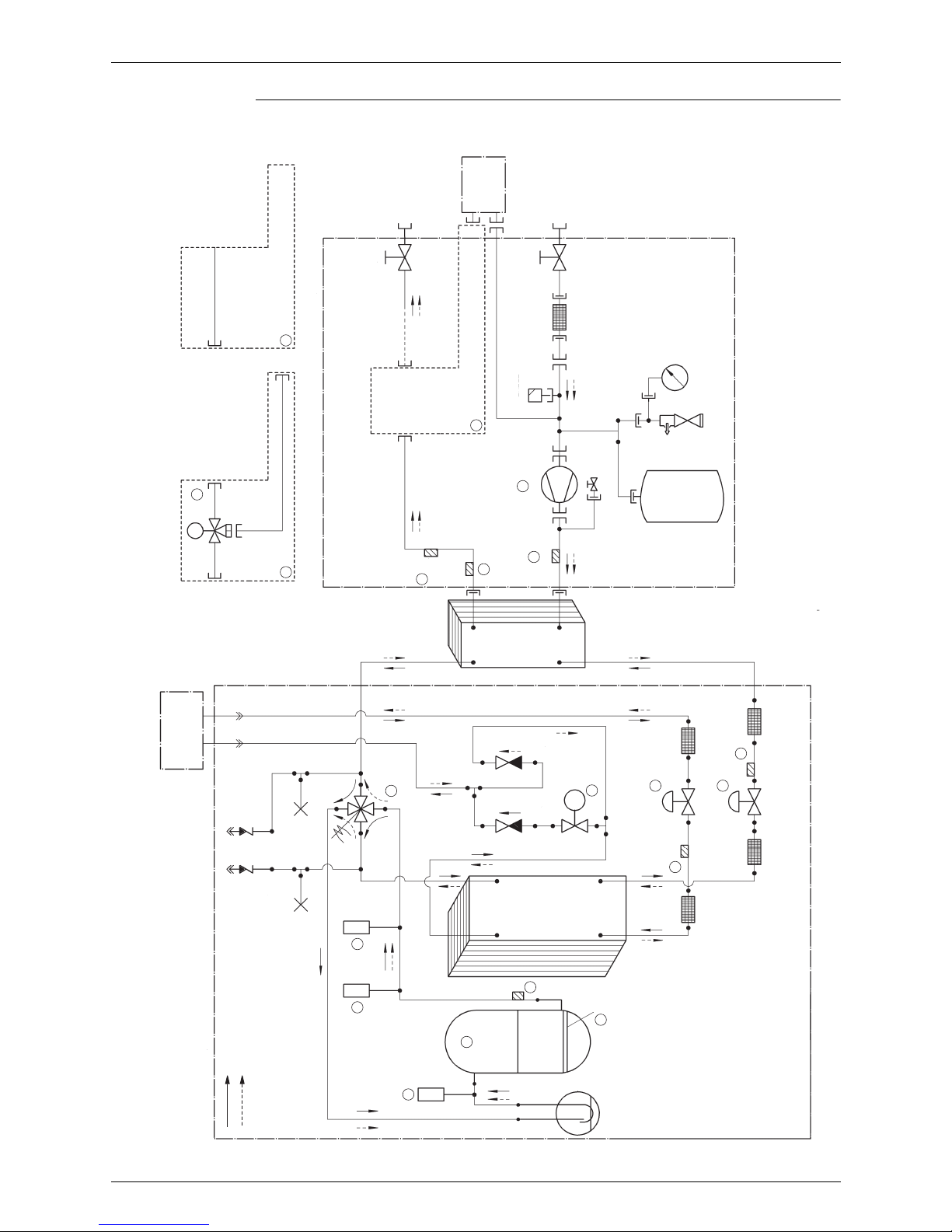

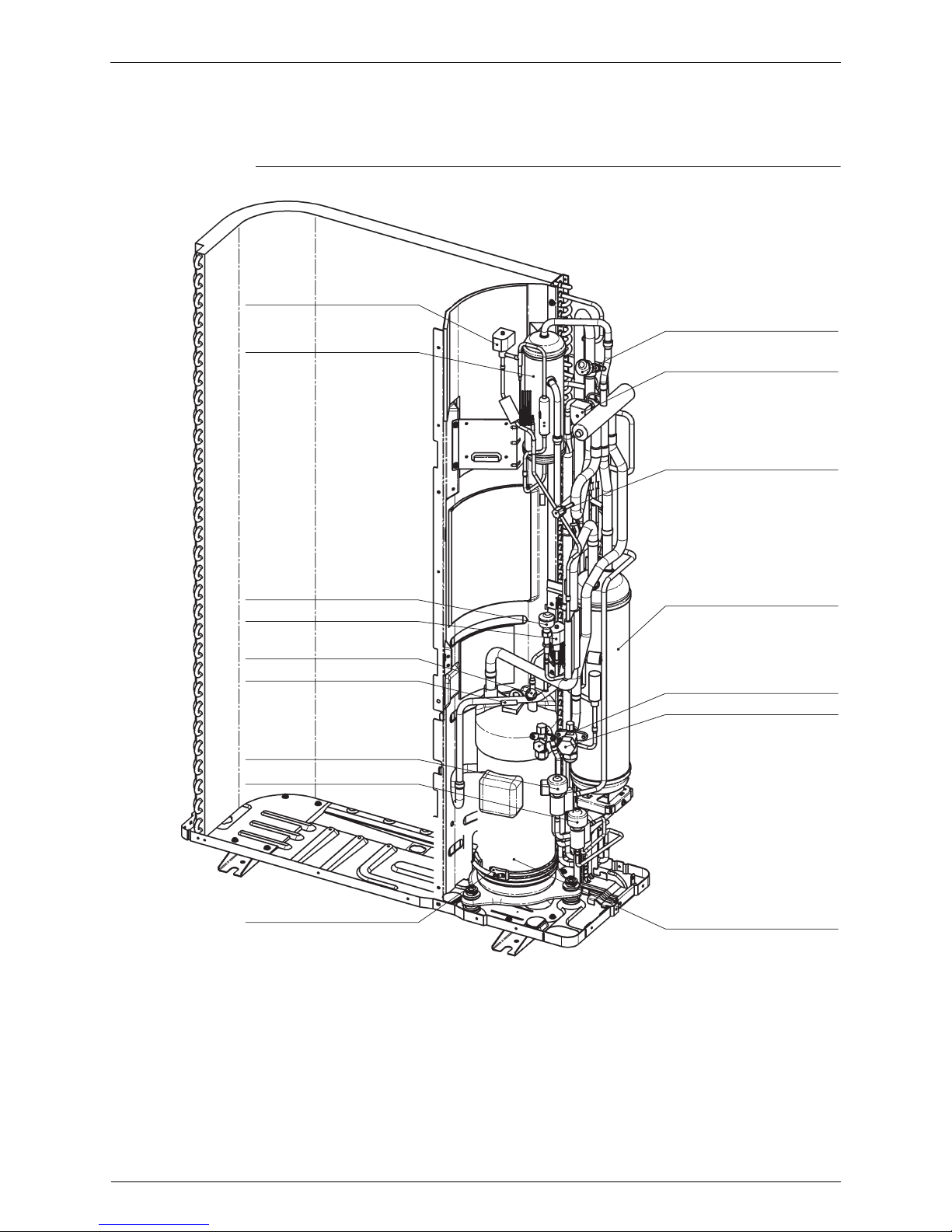

2. Functional Parts Layout

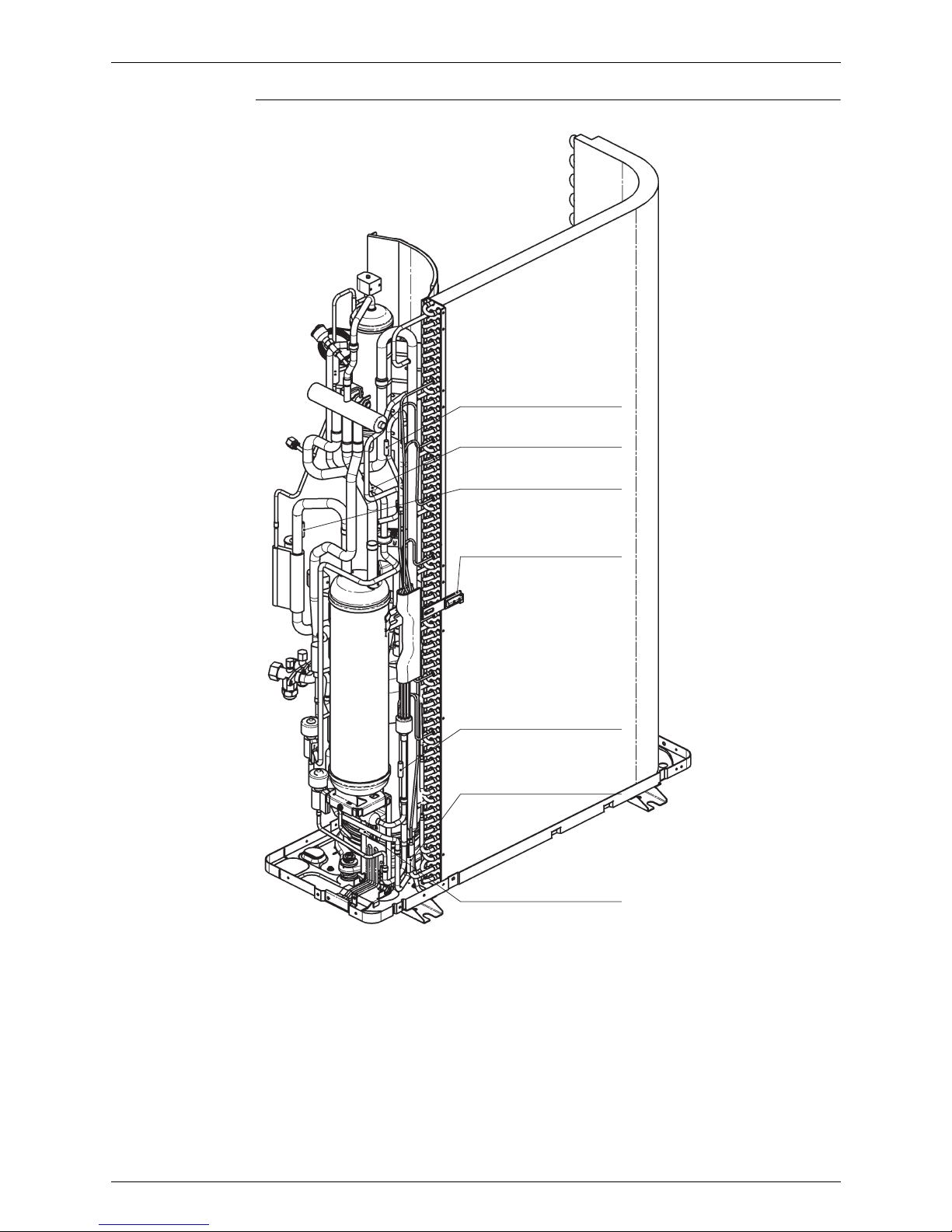

2.1 ERRQ 011/014/016 AAV1, ERSQ 011/014/016 AAV1

Bird’s-eye view

Remark:

Bottom plate heater:

Standard for ERRQ

Optional for ERSQ

Y2S

S1NPL

Solenoid valve

S1NPH

High pressure sensor

Y1S

4-way valve

Service port

Accumulator

Service port liquid

Service port gas

Compressor

Oil separator

Low pressure sensor

R2T

Discharge thermistor

Y1E

Electric expansion valve

Y3E

Electric expansion valve

E1HC

Crankcase heater

S1HP

High pressure switch

Y3S

Solenoid valve

ESIE09-08 Functional Parts Layout

Refrigerant Circuit 17

Back view

R6T

Subcool thermistor

R3T

Suction 1 thermistor

R8T

Liquid pipe 2 thermistor

R4T

Coil thermistor

R7T

Liquid pipe 1 thermistor

R1T

Ambient thermistor

R5T

Suction 2 thermistor

Functional Parts Layout ESIE09-08

18 Refrigerant Circuit

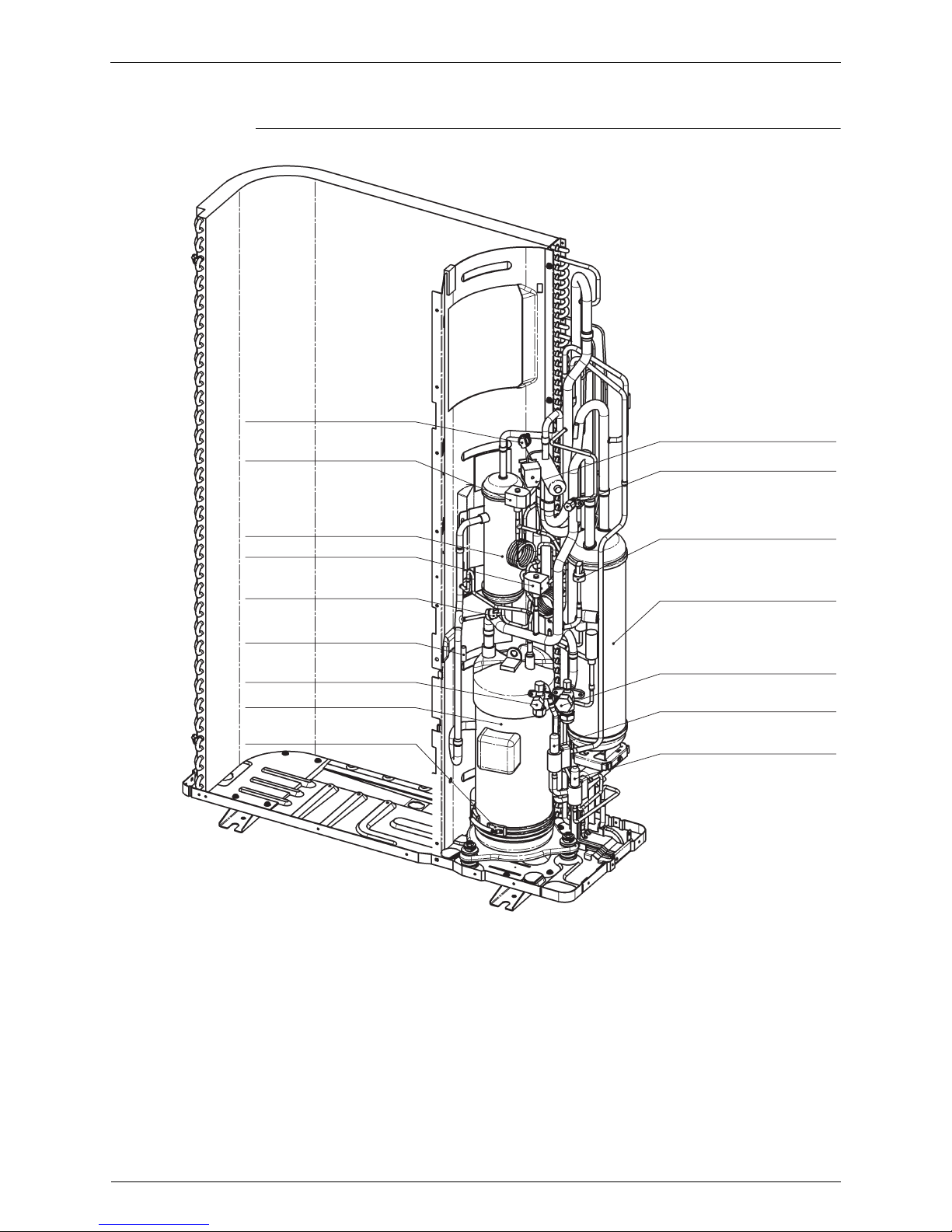

2.2 ERRQ 011/014/016 AAY1, ERSQ 011/014/016 AAY1

Bird’s-eye view

Remark:

Bottom plate heater:

Standard for ERRQ

Optional for ERSQ

Y2S

S1NPH

Solenoid valve

Y3S

Solenoid valve

S1NPL

Low pressure sensor

Y1S

4-way valve

Y1E

Electronic expansion valve

Y3E

Electronic expansion valve

Service port

Accumulator

Service port gas

Oil separator

Service port liquid

Compressor

High pressure sensor

S1PH

High pressure switch

R2T

Discharge thermistor

E1HC Crankcase heater

Loading...

Loading...