Daikin EKHBH016BA, EKHBX016BA Installation manuals

INSTALLATION MANUAL

Indoor unit for air to water heat pump system

EKHBH016BA

EKHBX016BA

35

8

01

SP

2

1

12 3 45

2x2x1x 1x 1x

1

3

2

4

260

T T

895

922

830

1-1/4" MB

2

3

B B

469

4

30°

90°

361

48

4

1

96

39

4

5

3

ONTENTS

C

EKHBH016BA***

EKHBX016BA***

Indoor unit for air to water heat pump system

age

P

Introduction........................................................................................ 1

General information ...................................................................................1

Scope of this manual .................................................................................2

Model identification ....................................................................................2

Accessories .......................................................................................2

Accessories supplied with the indoor unit..................................................2

Safety considerations ........................................................................3

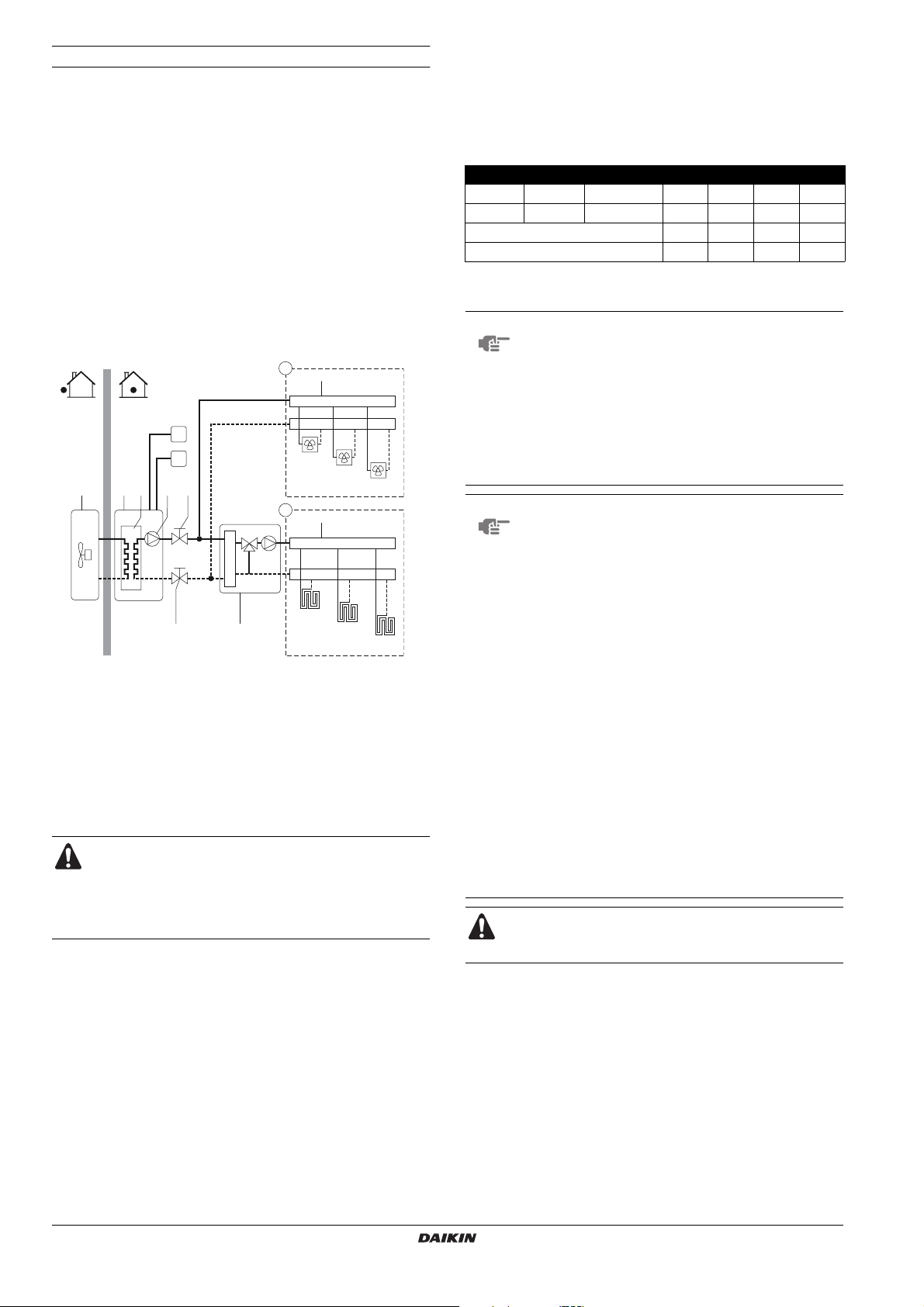

Typical application examples.............................................................4

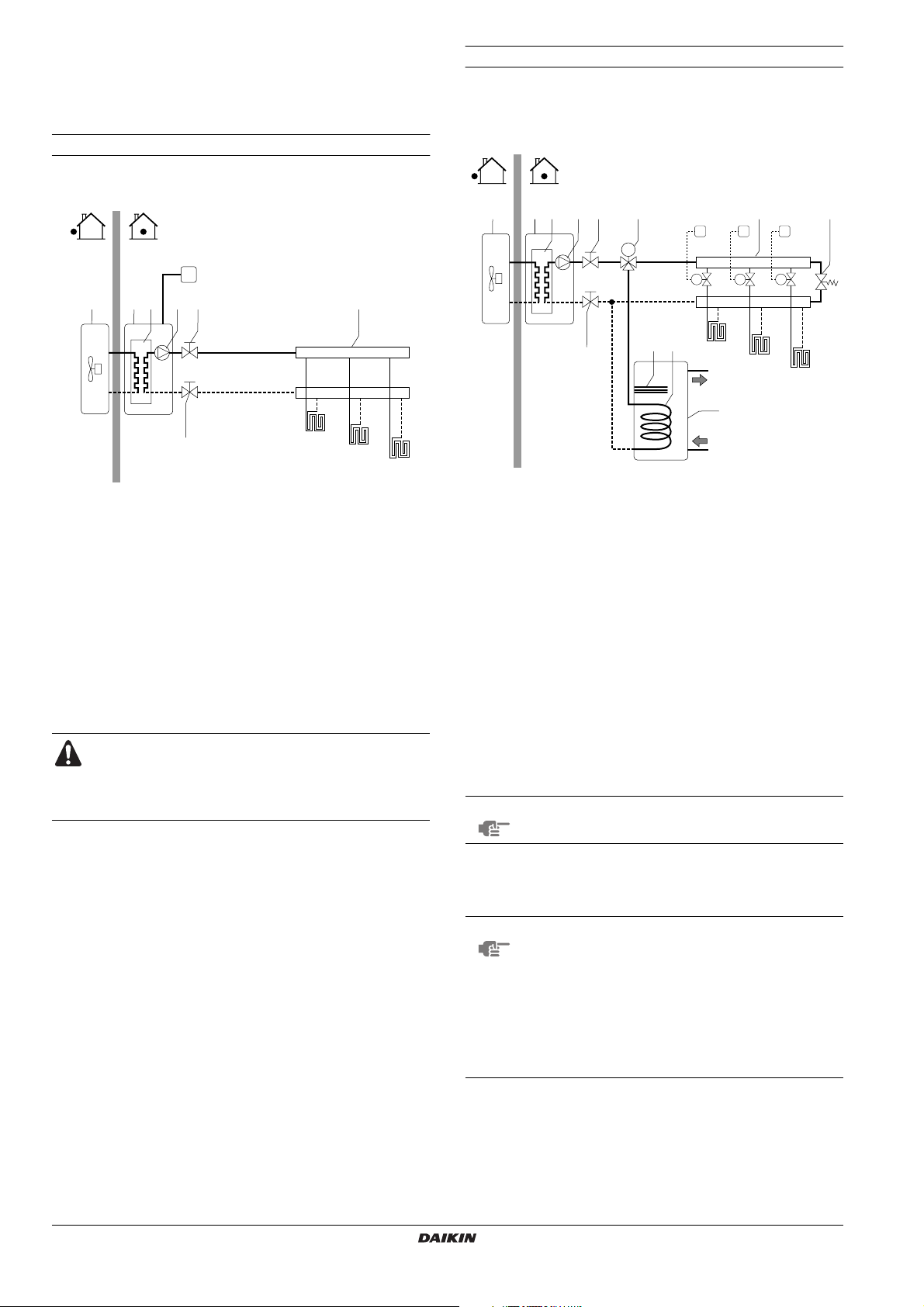

Application 1 ..............................................................................................4

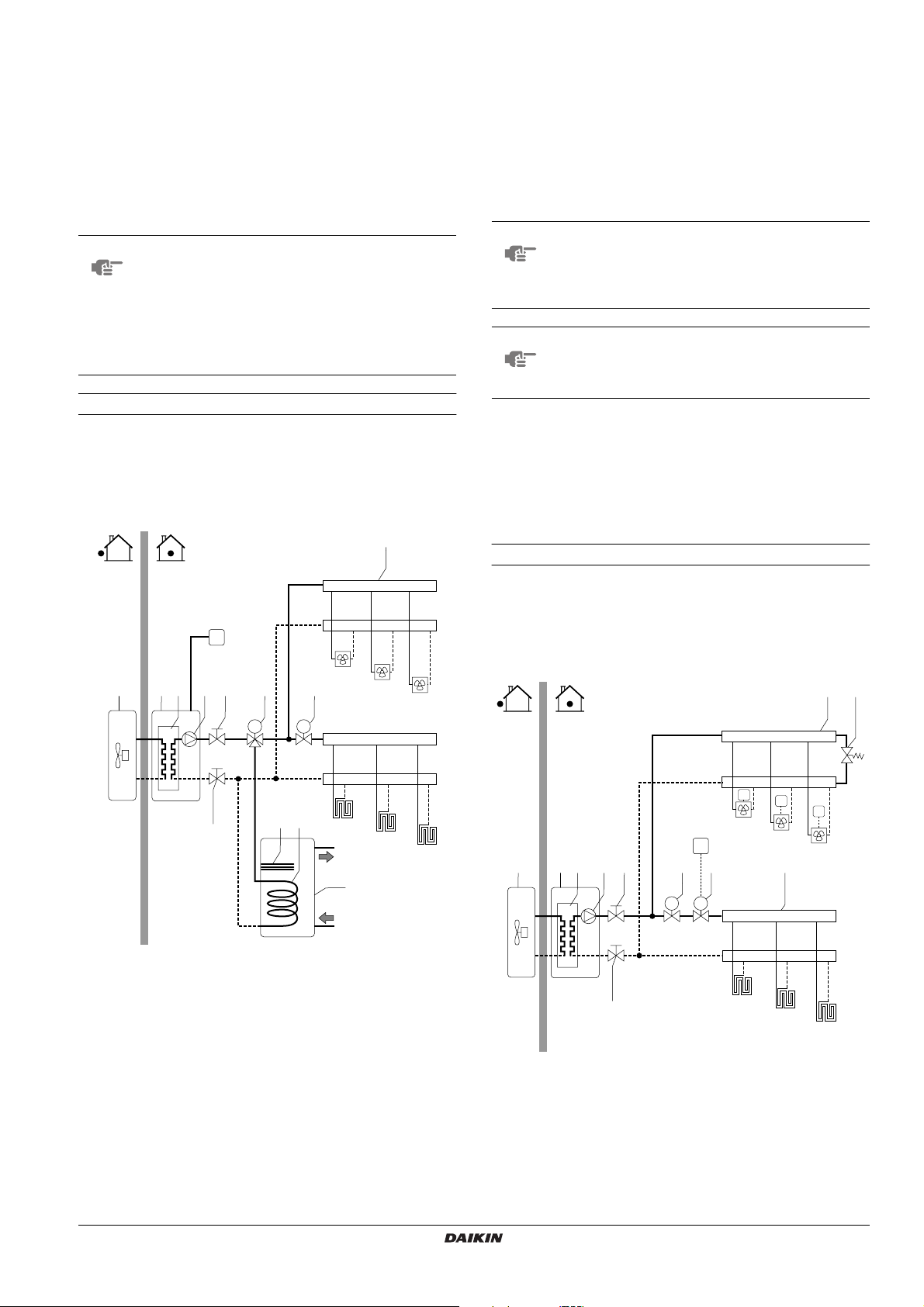

Application 2 ..............................................................................................4

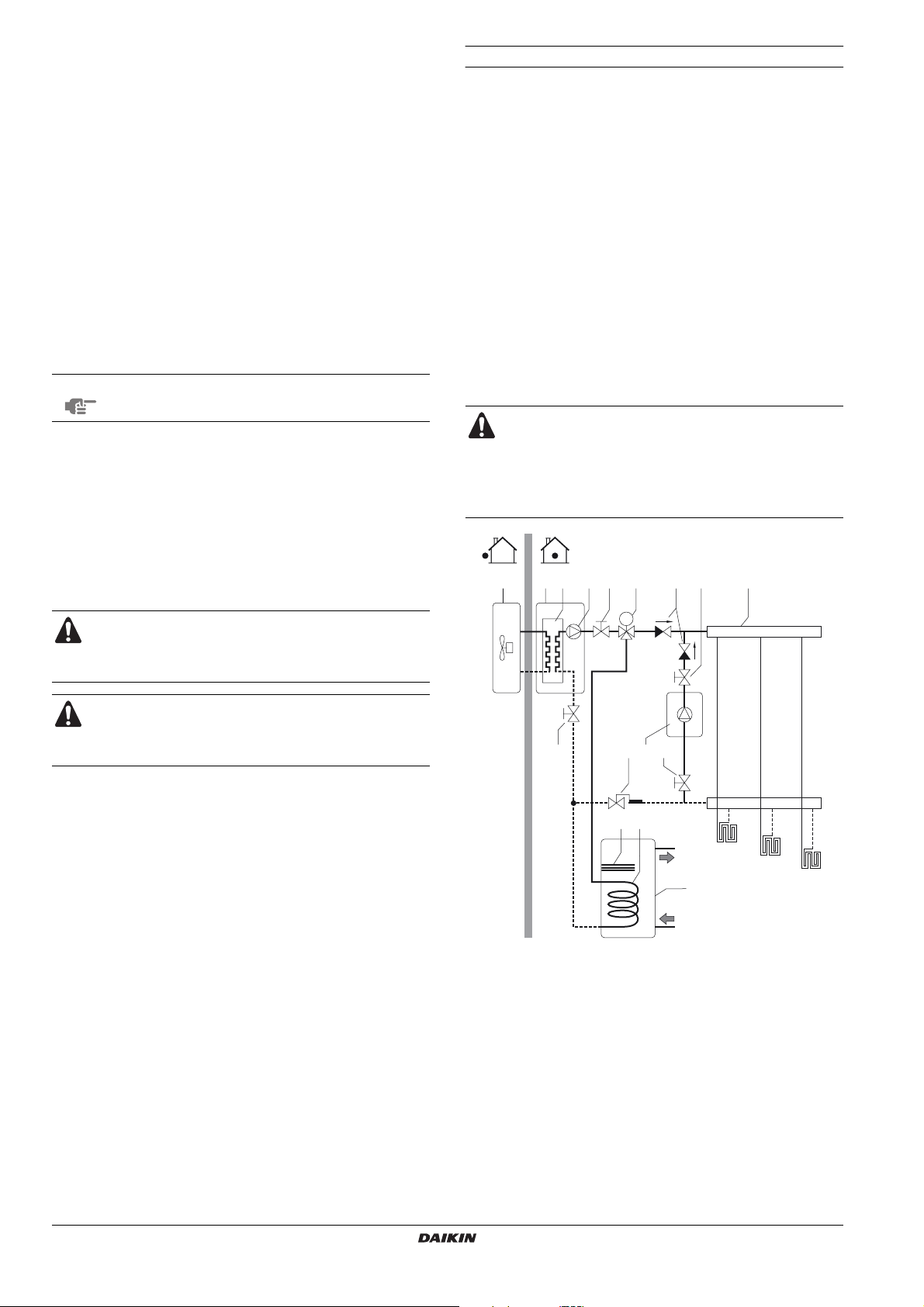

Application 3 ..............................................................................................5

Application 4 ..............................................................................................5

Application 5 ..............................................................................................6

Application 6 ..............................................................................................8

Overview of the indoor unit................................................................ 9

Opening the indoor unit.............................................................................. 9

Main components..................................................................................... 10

Switch box main components ..................................................................11

Functional diagram ..................................................................................11

Installation of the indoor unit............................................................12

Selecting an installation location.............................................................. 12

Dimensions and service space ................................................................12

Inspecting, handling and unpacking the unit............................................ 12

Mounting the indoor unit ..........................................................................13

Installation of the EKHBDP drain pan kit (only for EKHBX models).........13

Refrigerant pipework................................................................................ 13

Water pipework........................................................................................13

Charging water......................................................................................... 15

Piping insulation....................................................................................... 16

Field wiring............................................................................................... 16

Start-up and configuration ...............................................................21

DIP switch settings overview....................................................................21

Room thermostat installation configuration.............................................. 21

Pump operation configuration..................................................................22

Domestic hot water tank installation configuration................................... 23

Initial start-up at low outdoor ambient temperatures................................ 23

Pre-operation checks...............................................................................23

Powering up the indoor unit ..................................................................... 23

Setting the pump speed...........................................................................23

Field settings............................................................................................ 24

Field settings table...................................................................................33

Test run and final check...................................................................35

Final check............................................................................................... 35

Automatic test run.................................................................................... 35

Test run operation (manual) ..................................................................... 35

Maintenance and service ................................................................35

Troubleshooting ...............................................................................36

General guidelines................................................................................... 36

General symptoms................................................................................... 37

Error codes ..............................................................................................38

Technical specifications................................................................... 40

General ....................................................................................................40

Electrical specifications............................................................................ 40

Installation manual

READ THESE INSTRUCTIONS CAREFULLY BEFORE

INSTALLATION. KEEP THIS MANUAL IN A HANDY

PLACE FOR FUTURE REFERENCE.

IMPROPER INSTALLATION OR ATTACHMENT OF

EQUIPMENT OR ACCESSORIES COULD RESULT IN

ELECTRIC SHOCK, SHORT-CIRCUIT, LEAKS, FIRE OR

OTHER DAMAGE TO THE EQUIPMENT. BE SURE ONLY

TO USE ACCESSORIES MADE BY DAIKIN WHICH ARE

SPECIFICALLY DESIGNED FOR USE WITH THE

EQUIPMENT AND HAVE THEM INSTALLED BY A

PROFESSIONAL.

ALL ACTIVITIES DESCRIBED IN THIS MANUAL SHALL

BE CARRIED OUT BY A LICENSED TECHNICIAN.

BE SURE TO WEAR ADEQUATE PERSONEL PROTECTION EQUIPMENT (PROTECTION GLOVES, SAFETY

GLASSES, ...) WHEN PERFORMING INSTALLATION,

MAINTENANCE OR SERVICE TO THE UNIT.

IF UNSURE OF INSTALLATION PROCEDURES OR USE,

ALWAYS CONTACT YOUR DAIKIN DEALER FOR

ADVICE AND INFORMATION.

THE UNIT DESCRIBED IN THIS MANUAL IS DESIGNED

FOR INDOOR INSTALLATION ONLY AND FOR AMBIENT

TEMPERATURES RANGING 4°C~35°C.

The English text is the original instruction. Other languages are

translations of the original instructions.

NTRODUCTION

I

General information

Thank you for purchasing this indoor unit.

The unit is the indoor part of the air to water ERHQ or ERLQ heat

pumps. These units are designed for wall mounted indoor installation.

See "Selecting an installation location" on page 12. The units can be

combined with Daikin fan coil units, floor heating applications, low

temperature radiators, Daikin domestic water heating applications

and solar kit for domestic hot water applications.

Heating/cooling units and heating only units

The unit range consists of two main versions: a heating/cooling

(EKHBX) version and a heating only (EKHBH) version.

Both versions are delivered with an integrated backup heater for

additional heating capacity during cold outdoor temperatures. The

backup heater also serves as a backup in case of malfunctioning of

the outdoor unit. The backup heater models are available for a

heating capacity of 3, 6 and 9 kW, and – depending on the heating

capacity – for three different power supply specifications.

Backup heater

Indoor unit model Backup heater capacity

EKHB*016BA3V3

EKHB*016BA6V3

EKHB*016BA6WN

EKHB*016BA9WN

EKHB*016BA6T1

EKHB*016BA9T1

3 kW 1x 230 V

6 kW 1x 230 V

6 kW 3x 400 V

9 kW 3x 400 V

6 kW 3x 230 V

9 kW 3x 230 V

nominal voltage

EKHBH/X016BA

Indoor unit for air to water heat pump system

4PW54187-1B

Installation manual

1

■

■

1

2

3

4

1

2

3

4

5

NOTE

An ERLQ0* BA outdoor unit can only be

connected to an EKHBH/X016 BA indoor unit

(bottom plate heater at outdoor unit has to be

controlled by indoor unit).

An ERHQ0* BA outdoor unit can be connected to

an EKHBH/X016 BA indoor unit or to an

EKHBH/X016 AA/AB indoor unit (if a bottom plate

heater kit is required, see "Possible options" on

page 2).

P

H

43

1

2

T

A

Heat pump capacity

Required heating capacity (site dependent)

Additional heating capacity provided by the backup heater

Equilibriumtemperature (can be set through the user interface,

refer to "Field settings" on page 24)

T

Ambient (outdoor) temperature

A

P

Heating capacity

H

Domestic hot water tank (option)

An optional EKHW* domestic hot water tank with integrated 3 kW

electrical booster heater can be connected to the indoor unit. The

domestic hot water tank is available in three sizes: 150, 200 and

300 litre. Refer to the domestic hot water tank installation manual for

further details.

Drain pan kit (option)

For heating/cooling versions (EKHBX), it is necessary to install the

EKHBDP drain pan kit.

For more information concerning the drain pan kit, refer to

"Installation of the EKHBDP drain pan kit (only for EKHBX models)"

on page 13.

Solar kit for domestic hot water tank (option)

For information concerning the EKSOLHW solar kit, refer to the

installation manual of that kit.

Digital I/O PCB kit (option)

An optional EKRP1HB digital I/O PCB can be connected to the

indoor unit and allows:

■

remote alarm output

■

heating/cooling ON/OFF output

■

bivalent operation (permission signal for the auxiliary boiler)

Refer to the operation manual of the indoor unit and to the installation

manual of the digital I/O PCB for more information.

Refer to the wiring diagram or connection diagram for connecting this

PCB to the unit.

Remote thermostat kit (option)

An optional room thermostat EKRTW, EKRTWA, or EKRTR can be

connected to the indoor unit. Refer to the installation manual of the

room thermostat for more information.

Possible options

EKBPHT16Y* EKBPHTH16A

EKHBH/X016 AA/AB

EKHBH/X016 BA

Possible Not allowed

Possible Possible

Connection to a benefit kWh rate power supply

This equipment allows for connection to benefit kWh rate power

supply delivery systems. Full control of the unit will remain possible

only in case the benefit kWh rate power supply is of the type that

power supply is not interrupted. Refer to "Connection to a benefit

kWh rate power supply" on page 19 for more details.

Scope of this manual

This installation manual describes the procedures for handling,

installing and connecting all EKHBH/X indoor unit models.

NOTE

Installation of the ERHQ or ERLQ heat pump outdoor

unit is described in the outdoor unit installation

manual.

Operation of the indoor unit is described in the indoor

unit operation manual.

Model identification

Indoor unit

EK HB X 016 AA 3 V3

Backup heater nominal

voltage:

V3 = 1P, 230 V

WN = 3P, 400 V

T1 = 3P, 230 V

Backup heater capacity (kW)

Series

Indication of heating/cooling capacity (kW)

X = heating and cooling,

H = heating only

Hydro box

European kit

(a) For exact values, refer to "Technical specifications" on page 40.

(a)

Drain pan kit (optional)

EK HB DP 150

Drain pan

Hydro box

European kit

A

CCESSORIES

Accessories supplied with the indoor unit

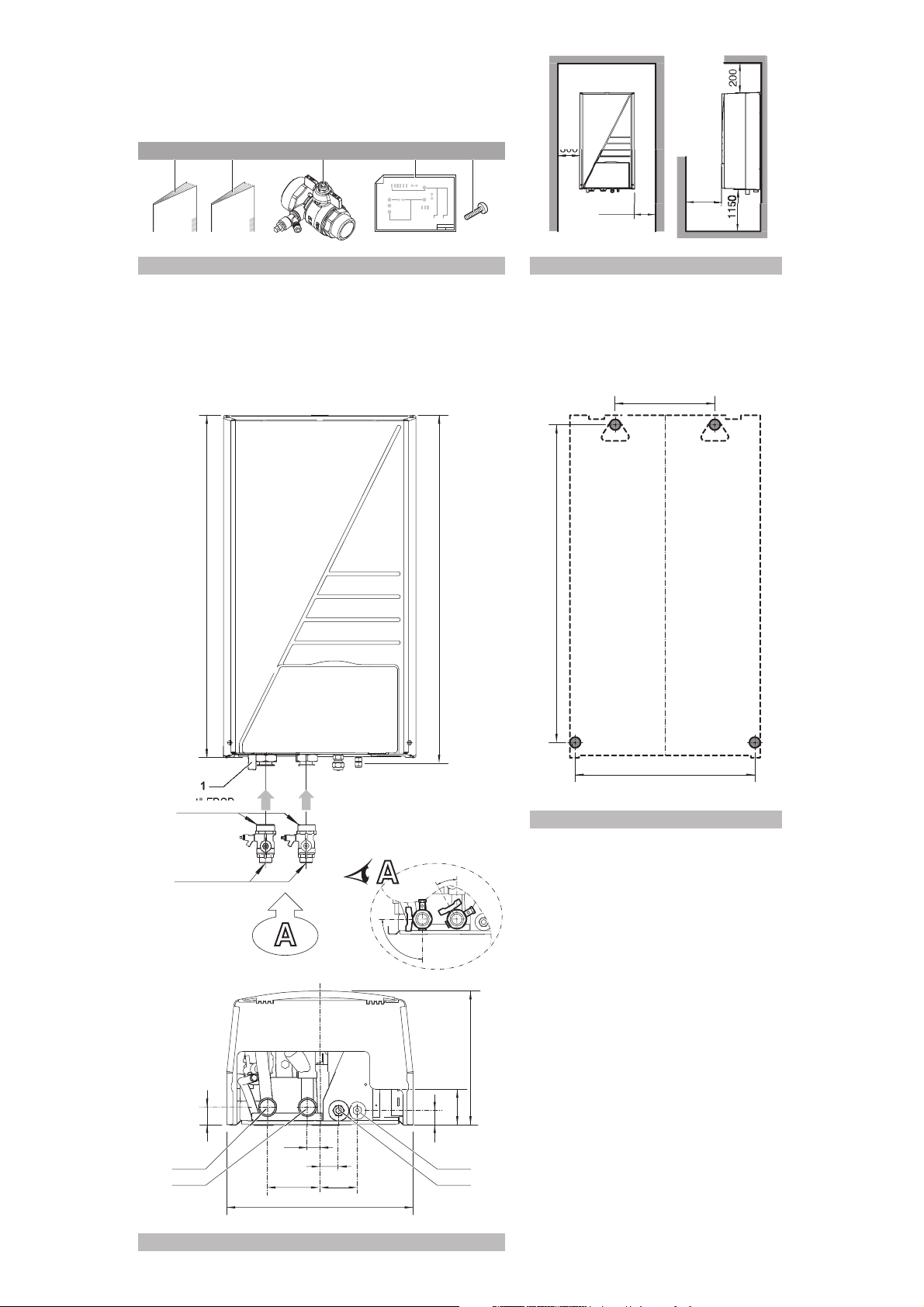

See figure 1

Installation manual

Operation manual

Shut-off valve

Wiring diagram sticker (inside indoor unit cover)

Indoor unit cover fixing screw

Installation manual

2

Indoor unit for air to water heat pump system

EKHBH/X016BA

4PW54187-1B

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

S

AFETY

The precautions listed here are divided into the following four types.

Both cover very important topics, so be sure to follow them carefully.

Meanings of DANGER , WARNING , CAUTION and NOTE symbols.

CONSIDERATIONS

DANGER

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may also

be used to alert against unsafe practices.

NOTE

Indicates situations that may result in equipment or

property-damage accidents only.

Danger

Before touching electric terminal parts, turn off power switch.

When service panels are removed, live parts can be easily

touched by accident.

Never leave the unit unattended during installation or servicing

when the service panel is removed.

Do not touch water pipes during and immediately after operation

as the pipes may be hot. Your hand may suffer burns. To avoid

injury, give the piping time to return to normal temperature or be

sure to wear proper gloves.

Do not touch any switch with wet fingers. Touching a switch with

wet fingers can cause electrical shock.

Before touching electrical parts, turn off all applicable power

supply.

Warning

Tear apart and throw away plastic packaging bags so that

children will not play with them.

Children playing with plastic bags face danger of death by

suffocation.

Safely dispose of packing materials. Packing materials, such as

nails and other metal or wooden parts, may cause stabs or other

injuries.

Never directly touch any accidental leaking refrigerant. This

could result in severe wounds caused by frostbite.

Do not touch the refrigerant pipes during and immediately after

operation as the refrigerant pipes may be hot or cold, depending

on the condition of the refrigerant flowing through the refrigerant

piping, compressor, and other refrigerant cycle parts. Your

hands may suffer burns or frostbite if you touch the refrigerant

pipes. To avoid injury, give the pipes time to return to normal

temperature or, if you must touch them, be sure to wear proper

gloves.

Do not touch the internal parts (pump, backup heater, etc.)

during and immediately after operation.

Your hands may suffer burns if you touch the internal parts. To

avoid injury, give the internal parts time to return to normal

temperature or, if you must touch them, be sure to wear proper

gloves.

Caution

Earth the unit.

Earthing resistance should be according to local and national

regulations.

Do not connect the earth wire to gas or water pipes,

lightning conductor or telephone earth wire.

Incomplete earthing may cause electric shocks.

Gas pipe.

Ignition or explosion may occur if the gas leaks.

Water pipe.

Hard vinyl tubes are not effective earths.

Lightning conductor or telephone earth wire.

Electric potential may rise abnormally if struck by a lightning

bolt.

Install the power wire at least 1 meter away from televisions or

radios to prevent image interference or noise.

(Depending on the radio waves, a distance of 1 meter may not

be sufficient to eliminate the noise.)

Do not rinse the unit. This may cause electric shocks or fire.

Do not install the unit in places such as the following:

Where there is mist of mineral oil, oil spray or vapour.

Plastic parts may deteriorate, and cause them to fall out or

water to leak.

Where corrosive gas, such as sulphurous acid gas, is

produced.

Corrosion of copper pipes or soldered parts may cause the

refrigerant to leak.

Where there is machinery which emits electromagnetic

waves.

Electromagnetic waves may disturb the control system, and

cause malfunction of the equipment.

Where flammable gases may leak, where carbon fibre or

ignitable dust is suspended in the air or where volatile

flammables, such as thinner or gasoline, are handled.

Such gases may cause a fire.

Where the air contains high levels of salt.

Where voltage fluctuates a lot, such as that in factories.

In vehicles or vessels.

Where acidic or alkaline vapour is present.

EKHBH/X016BA

Indoor unit for air to water heat pump system

4PW54187-1B

Installation manual

3

T

YPICAL

APPLICATION

EXAMPLES

Application 2

1

6

2

7

3

4

T

5

The application examples given below are for illustration purposes

only.

Application 1

Space heating only application with the room thermostat connected

to the indoor unit.

T

5 64321

7

Outdoor unit

Indoor unit

Heat exchanger

Pump

Shut-off valve

FHL1..3 Floor heating loop

Pump operation and space heating

When the room thermostat (T) is connected to the indoor unit, the

pump (4) will operate when there is a heating request from the room

thermostat, and the outdoor unit will start operating to achieve the

target leaving water temperature as set on the user interface.

When the room temperature is above the thermostat set point, the

outdoor unit and pump will stop operating.

Make sure to connect the thermostat wires to the correct

terminals (see "Connection of the thermostat cable" on

page 18) and to configure the DIP switch toggle switches

correctly (see "Room thermostat installation configuration"

on page 21).

FHL1

FHL2

FHL3

Collector (field supply)

Shut-off valve

Room thermostat

(optional)

Space heating only application without room thermostat connected to

the indoor unit. The temperature in each room is controlled by a valve

on each water circuit. Domestic hot water is provided through the

domestic hot water tank which is connected to the indoor unit.

54321

8 6

T1

M

M1

121011

7

1 Outdoor unit 10 Domestic hot water tank

2 Indoor unit

3 Heat exchanger 11 Booster heater

4 Pump 12 Heat exchanger coil

5 Shut-off valve FHL1..3 Floor heating loop

6 Collector (field supply) T1..3 Individual room

7 Shut-off valve

8 Motorised 3-way valve

(delivered with

domestic hot water

tank)

9 By-pass valve

(field supply)

FHL1

(optional)

thermostat (optional)

M1..3 Individual motorised

valve to control loop

FHL1 (field supply)

T3

M2T2M3

FHL2

9

FHL3

Pump operation

With no thermostat connected to the indoor unit (2), the pump (4) can

be configured to operate either as long as the indoor unit is on, or

until the required water temperature is reached.

NOTE

Details on pump configuration can be found under

"Pump operation configuration" on page 22.

Installation manual

4

Space heating

The outdoor unit (1) will operate to achieve the target leaving water

temperature as set on the user interface.

NOTE

When circulation in each space heating loop (FHL1..3)

is controlled by remotely controlled valves (M1..3), it is

important to provide a by-pass valve (9) to avoid the

flow switch safety device from being activated.

The by-pass valve should be selected as such that at

all time the minimum water flow as mentioned under

"Water pipework" on page 13 is guaranteed.

It is recommended to select a pressure difference

controlled by-pass valve.

Indoor unit for air to water heat pump system

EKHBH/X016BA

4PW54187-1B

Domestic water heating

When domestic water heating mode is enabled (either manually by

the user, or automatically through a schedule timer) the target

domestic hot water temperature will be achieved by a combination of

the heat exchanger coil and the electrical booster heater.

When the domestic hot water temperature is below the user

configured set point, the 3-way valve will be activated to heat the

domestic hot water by means of the heat pump. In case of large

domestic hot water demand or a high domestic hot water

temperature setting, the booster heater (11) can provide auxiliary

heating.

NOTE

The indoor unit can be configured so that at low

outdoor temperatures the domestic hot water is

exclusively heated by the booster heater. This assures

that the full capacity of the heat pump is available for

space heating.

Details on domestic hot water tank configuration for

low outdoor temperatures can be found under "Field

settings" on page 24, field settings [5-02] to [5-04].

Application 3

Space heating and cooling application with the room thermostat set

for heating/cooling connected to the indoor unit. Heating is provided

through floor heating loops and fan coil units. Cooling is provided

through the fan coil units only.

Domestic hot water is provided through the domestic hot water tank

which is connected to the indoor unit.

Pump operation and space heating and cooling

According to the season, the customer will select heating or cooling

on the room thermostat (T). This selection is not possible by

operating the user interface.

When space heating/cooling is requested by the room thermostat

(T), the pump will start operating and the indoor unit (2) will switch to

"heating mode"/"cooling mode". The outdoor unit (1) will start

operating to achieve the target leaving hot/cold water temperature.

In case of cooling mode, the 2-way valve (13) will close as to prevent

cold water running through the floor heating loops (FHL).

NOTE

Make sure to connect the thermostat wires to the

correct terminals (see "Connection of the thermostat

cable" on page 18) and to configure the DIP switch

toggle switches correctly (see "Room thermostat

installation configuration" on page 21).

NOTE

Wiring of the 2-way valve (13) is different for a NC

(normal closed) valve and a NO (normal open) valve!

Make sure to connect to the correct terminal numbers

as detailed on the wiring diagram.

The ON/OFF setting of the heating/cooling operation is done by the

room thermostat and cannot be done by the user interface on the

indoor unit.

Domestic water heating

Domestic water heating is as described under "Application 2" on

page 4.

6

T

54321

8 13

M M

7

1 Outdoor unit 10 Domestic hot water tank

2 Indoor unit

3 Heat exchanger 11 Booster heater

4 Pump 12 Heat exchanger coil

5 Shut-off valve 13 Motorised 2-way valve

6 Collector (field supply)

7 Shut-off valve FCU1..3 Fan coil unit (optional)

8 Motorised 3-way valve

(delivered with

domestic hot water

tank)

11 12

FHL1..3 Floor heating loop

T Room thermostat with

FCU1

FCU2

FCU3

FHL1

FHL2

FHL3

10

(optional)

(field supply)

heating/cooling switch

(optional)

Application 4

Space heating and cooling application without the room thermostat

connected to the indoor unit, but with the heating only room

thermostat (set heating only) controlling the floor heating and the

heating/cooling thermostat (set heating/cooling) controlling the fan

coil units. Heating is provided through floor heating loops and fan coil

units. Cooling is provided through the fan coil units only.

9

6

T4

T5

FCU2

6

FHL2

T6

FCU3

FHL3

FCU1

T

54321

7

13M14

M

FHL1

EKHBH/X016BA

Indoor unit for air to water heat pump system

4PW54187-1B

Installation manual

5

1 Outdoor unit 14 Motorised 2-way valve for

2 Indoor unit

3 Heat exchanger

4 Pump FCU1..3 Fan coil unit with

5 Shut-off valve

6 Collector (field supply) FHL1..3 Floor heating loop

7 Shut-off valve T Heating only room

9 By-pass valve

(field supply)

13 Motorised 2-way valve

to shut off the floor

heating loops during

cooling operation

(field supply)

T4..6 Individual room

activation of the room

thermostat (field supply)

thermostat (optional)

thermostat (optional)

thermostat for fan coil

heated/cooled room

(optional)

Pump operation

With no thermostat connected to the indoor unit (2), the pump (4) can

be configured to operate either as long as the indoor unit is on, or

until the required water temperature is reached.

NOTE

Details on pump configuration can be found under

"Pump operation configuration" on page 22.

Space heating and cooling

According to the season, the customer will select heating or cooling

through the user interface on the indoor unit.

The outdoor unit (1) will operate in heating mode or cooling mode to

achieve the target leaving water temperature.

With the unit in heating mode, the 2-way valve (13) is open. Hot water

is provided to both the fan coil units and the floor heating loops.

With the unit in cooling mode, the 2-way valve (13) is closed to

prevent cold water running through the floor heating loops (FHL).

When closing several loops in the system by remotely

controlled valves, it might be required to install a by-pass

valve (9) to avoid the flow switch safety device from being

activated. See also "Application 2" on page 4.

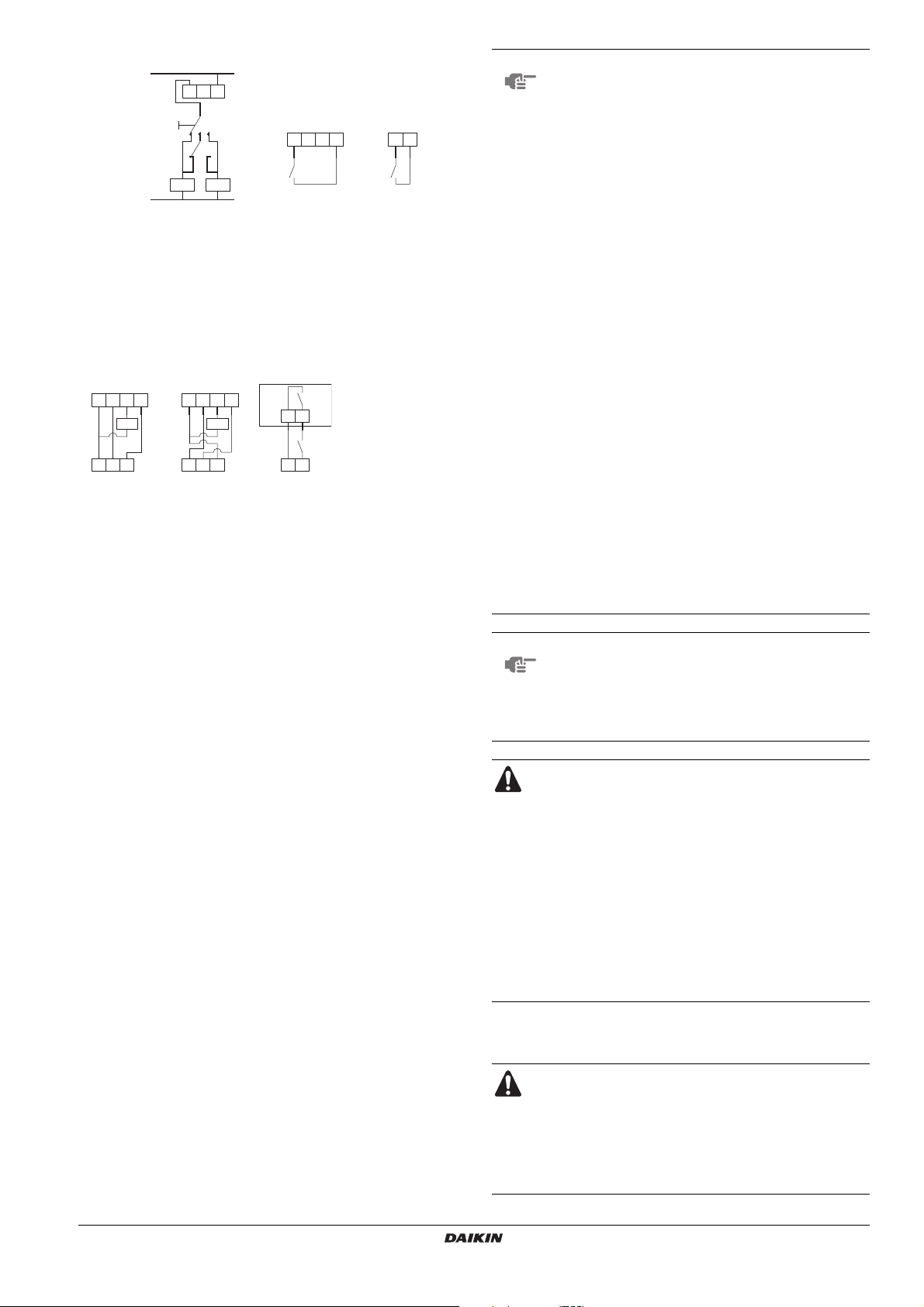

Application 5

Space heating with an auxiliary boiler (alternating operation)

Space heating application by either the Daikin indoor unit or by an

auxiliary boiler connected in the system. The decision whether either

the EKHB* indoor unit or the boiler will operate can be achieved by

an auxiliary contact or an EKHB* indoor controlled contact.

The auxiliary contact can e.g. be an outdoor temperature thermostat,

an electricity tariff contact, a manually operated contact, etc. See

"Field wiring configuration A" on page 7.

The EKHB* indoor unit controlled contact (also called 'permission

signal for the auxiliary boiler") is determined by the outdoor

temperature (thermistor located at the outdoor unit). See "Field wiring

configuration B" on page 7.

Bivalent operation is only possible for space heating operation, not

for the domestic water heating operation. Domestic hot water in such

an application is always provided by the domestic hot water tank

which is connected to the Daikin indoor unit.

The auxiliary boiler must be integrated in the piping work and in the

field wiring according to the illustrations below.

CAUTION

■ Be sure that the boiler and the integration of the boiler

in the system is in accordance with relevant European

and national regulations.

■ Daikin can not be put responsible for incorrect or

unsafe situations in the boiler system.

54321 8 18

M

617

Wiring of the 2-way valve (13) is different for a NC (normal

closed) valve and a NO (normal open) valve! Make sure to

connect to the correct terminal numbers as detailed on the

wiring diagram.

The ON/OFF setting of the heating/cooling operation is done by the

user interface on the indoor unit.

16 17157

10

11

FHL1

FHL2

12

1 Outdoor unit 11 Heat exchanger coil

2 Indoor unit 12 Domestic hot water tank

3 Heat exchanger

4 Pump 15 Boiler (field supply)

5 Shut-off valve 16 Aquastat valve

6 Collector (field supply)

7 Shut-off valve 17 Shut-off valve

8 Motorised 3-way valve

(delivered with the

domestic hot water

tank)

FHL1...3 Floor heating loop

(optional)

(field supply)

(field supply)

18 Non-return valve

(field supply)

(field supply)10 Booster heater

FHL3

Installation manual

6

Indoor unit for air to water heat pump system

EKHBH/X016BA

4PW54187-1B

Field wiring configuration A

L

H

Com

EKHB*

EKHB*/auto

Boiler

thermostat input

A Auxiliary contact (normal closed)

H Heating demand room thermostat (optional)

K1A Auxiliary relay for activation of EKHB* unit (field

K2A Auxiliary relay for activation of boiler (field supply)

/ Boiler

N

A

K1A

K2A

Boiler thermostat input

supply)

X2M

123 4

K1A

Boiler

thermostat input

Y

X

K2A

Field wiring configuration B

EKHB*

X2M

12

3 4

K1A

Com

HC

EKRTR*

Boiler

thermostat input

C Cooling demand room thermostat (optional)

H Heating demand room thermostat (optional)

Com Common room thermostat (optional)

K1A Auxiliary relay for activation of bolier unit

KCR Permission signal for the auxiliary boiler

EKHB*

X2M

3 4

12

K1A

Com

H

C

EKRTW*

Boiler thermostat input

(field supply)

EKRP1HB*

KCR

X1 X2

K1A

Y

X

Boiler

thermostat input

Operation

■ Configuration A

When the room thermostat requests heating, either the EKHB*

unit or the boiler starts operating, depending on the position of

the auxiliary contact (A).

■ Configuration B

When the room thermostat requests heating, either the EKHB*

unit or the boiler starts operating, depending on the outdoor

temperature (status of "permission signal for the auxiliary

boiler").

When the permission is given towards the boiler, the space

heating operation by the EKHB* unit will be automatically

switched off.

For more details see field setting [C-02~C-04].

NOTE

■ Configuration A

Make sure that auxiliary contact (A) has sufficient

differential or time delay so as to avoid frequent

changeover between the EKHB* unit and the

boiler. If the auxiliary contact (A) is an outdoor

temperature thermostat, make sure to install the

thermostat in the shade, so that it is not

influenced or turned ON/OFF by the sun.

Configuration B

Make sure that the bivalent hysteresis [C-04] has

sufficient differential to avoid frequent changeover

between the EKHB* unit and the boiler. As the

outdoor temperature is measured via the outdoor

unit, air thermistor make sure to install the

outdoor unit in the shade, so that it is not

influenced by the sun.

Frequent switching may cause corrosion of the

boiler in an early stage. Contact the manufacturer

of the boiler.

■ During heating operation of the EKHB* unit, the

unit will operate so as to achieve the target

leaving water temperature as set on the user

interface. When weather dependent operation is

active, the water temperature is determined

automatically depending on the outdoor

temperature.

During heating operation of the boiler, the boiler

will operate so as to achieve the target leaving

water temperature as set on the boiler controller.

Never set the target leaving water temperature set

point on the boiler controller above 55°C.

■ Make sure to only have 1 expansion vessel in the

water circuit. An expansion vessel is already

premounted in the Daikin indoor unit.

NOTE

Make sure to configure the DIP switch SS2-3 on the

PCB of the EKHB* switchbox correctly. Refer to "Room

thermostat installation configuration" on page 21.

For configuration B: Make sure to configure the field

settings [C-02, C-03 and C-04] correctly. Refer to

"Bivalent operation" on page 30.

CAUTION

Make sure that return water to the EKHB* heat exchanger

never exceeds 55°C.

For this reason, never put the target leaving water

temperature set point on the boiler controller above 55°C

and install an aquastat

(a)

valve in the return water flow of

the EKHB* unit.

Make sure that the non-return valves (field supply) are

correctly installed in the system.

Make sure that the room thermostat (th) is not frequently

turned ON/OFF.

Daikin shall not be held liable for any damage resulting

from failure to observe this rule.

(a) The aquastat valve must be set for 55°C and must operate to close the return

water flow to the unit when the measured temperature exceeds 55°C. When the

temperature drops to a lower level, the aquastat valve must operate to open the

return water flow to the EKHB* unit again.

EKHBH/X016BA

Indoor unit for air to water heat pump system

4PW54187-1B

Manual permission towards the EKHB* unit on the boiler.

In case only the EKHB* unit should operate in space

heating mode, disable the bivalent operation via setting

[C-02].

In case only the boiler should operate in space heating

mode, increase the bivalent ON temperature [C-03] to

25°C.

Installation manual

7

Application 6

Space heating with room thermostat application through floor heating

loops and fan coil units. The floor heating loops and fan coil units

require different operating water temperatures.

The floor heating loops require a lower water temperature in heating

mode compared to fan coil units. To achive these two set points, a

mixing station is used to adapt the water temperature according to

requirements of the floor heating loops. The fan coil units are directly

connected to the indoor unit water circuit and the floor heating loops

after the mixing station. The control of this mixing station is not done

by the indoor unit.

The operation and configuration of the field water circuit is the

responsibility of the installer.

Daikin only offers a dual set point control function. By this function

two set points can be generated. Depending on the required water

temperature (floor heating loops and/or fan coil units are required)

first set point or second set point can be activated.

B

7

T1

T2

54321

8 9

1 Outdoor unit 8 Shut-off valve

2 Indoor unit 9 Mixing station (field supply)

3 Heat exchanger T1 Room thermostat for zone

4 Pump

5 Shut-off valve T2 Room thermostat for zone

6 Collector zone A

(field supply) FCU1..3 Fan coil unit (optional)

7 Collector zone B

(field supply)

FHL1...3 Floor heating loop

The advantage of the dual set point control is that the heat

pump will/can operate at the lowest required leaving water

temperature when only floor heating is required. Higher

leaving water temperatures are only required in case fan

coil units are operating.

This results in a better performance of the heat pump.

FCU1

A

6

FHL1

A (optional)

B (optional)

(field supply)

FCU2

FHL2

FCU3

FHL3

Pump operation and space heating

When the room thermostat for the floor heating loop (T1) and the fan

coil units (T2) are connected to the indoor unit, the pump (4) will

operate when there is a request for heating from T1 and/or T2. The

outdoor unit will start operating to achieve the target leaving water

temperature. The target leaving water temperature depends on which

room thermostat is requesting heating.

Set point Field setting Thermo status

Zone A First UI ON OFF ON OFF

Zone B Second [7-03] OFF ON ON OFF

Resulting water temperature UI [7-03] [7-03] —

Result pump operation ON ON ON OFF

When the room temperature of both zones is above the thermostat

set point, the outdoor unit and pump will stop operating.

NOTE

■ Make sure to connect the thermostat wires to the

correct terminals (see "Overview of the indoor

unit" on page 9).

■ Make sure to configure the field settings [7-02],

[7-03] and [7-04] correctly. Refer to "Dual set point

control" on page 28.

■ Make sure to configure the DIP switch SS2-3 on

the PCB of the EKHBH switch box correctly. Refer

to "Room thermostat installation configuration" on

page 21.

NOTE

■ The request signals for space heating can be

implemented in two different ways (installer

choice).

- Thermo ON/OFF signal from room thermostat

- Status signal (active/not active) from the

mixing station

■ It is the installers responsibility to make sure no

unwanted situations can occur (e.g. too high

water temperatures towards floor heating loops,

etc.)

■ Daikin does not offer any type of mixing station.

Dual set point control only provides the possibility

to use two set points.

■ When only zone A request heating, zone B will be

fed with water at a temperature equal to the first

set point.

This can lead to unwanted heating of zone B.

■ When only zone B request heating, the mixing

station will be fed with water at a temperature

equal to the second set point.

Depending on the control of the mixing station,

the floor heating loop can still receive water at a

temperature equal to set point of the mixing

station.

Be aware that the actual water temperature through the

floor heating loops depends on the control and setting of

the mixing station.

Installation manual

8

Indoor unit for air to water heat pump system

EKHBH/X016BA

4PW54187-1B

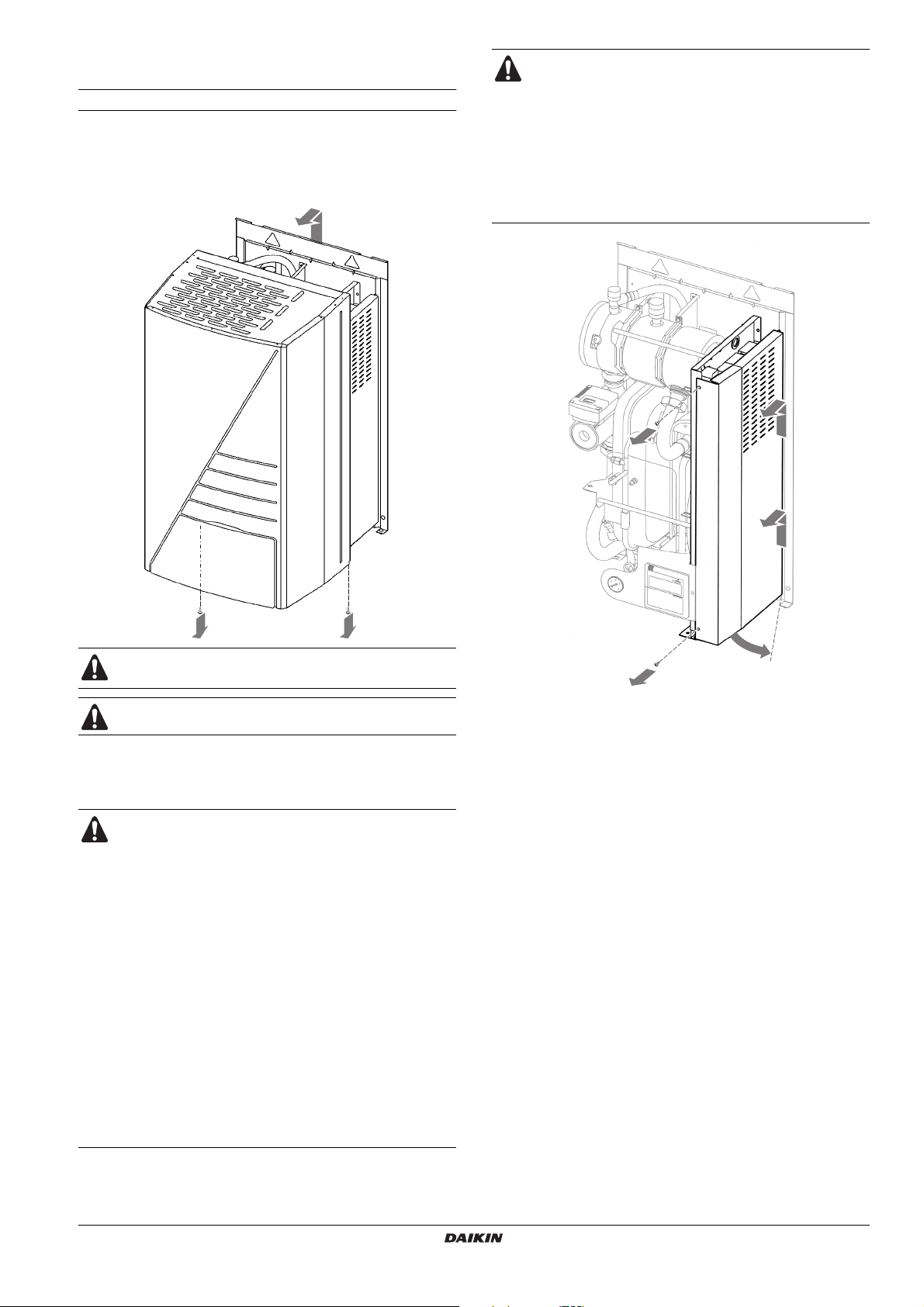

OVERVIEW OF THE INDOOR UNIT

Opening the indoor unit

■ The front flap on the indoor unit cover gives access to the

manometer and user interface.

■ The indoor unit cover can be removed by removing the 2 bottom

screws and unhitching the cover.

DANGER

■ Do not touch water pipes during and immediately after

operation as the pipes may be hot. Your hand may

suffer burns. To avoid injury, give the piping time to

return to normal temperature or be sure to wear

proper gloves.

■ When service panels are removed, live parts can be

easily touched by accident.

Never leave the unit unattended during installation or

servicing when the service panel is removed.

Make sure to fix the cover with the screws when installing

the cover (screws are delivered as accessory).

Parts inside the unit can be hot.

■ To gain access to the switch box components – e.g. to connect

the field wiring – the switch box service panel can be removed.

Thereto, loosen the front screws and unhitch the switch box

service panel.

WARNING

■ Switch off all power supply – i.e. outdoor unit power

supply and backup heater and domestic hot water

tank power supply (if applicable) – before removing

the switch box service panel.

■ Do not touch the refrigerant pipes during and

immediately after operation as the refrigerant pipes

may be hot or cold, depending on the condition of the

refrigerant flowing through the refrigerant piping,

compressor, and other refrigerant cycle parts. Your

hands may suffer burns or frostbite if you touch the

refrigerant pipes. To avoid injury, give the pipes time to

return to normal temperature or, if you must touch

them, be sure to wear proper gloves.

■ Do not touch the internal parts (pump, backup heater,

etc.) during and immediately after operation.

Your hands may suffer burns if you touch the internal

parts. To avoid injury, give the internal parts time to

return to normal temperature or, if you must touch

them, be sure to wear proper gloves.

1

1

33

3

2

EKHBH/X016BA

Indoor unit for air to water heat pump system

4PW54187-1B

Installation manual

9

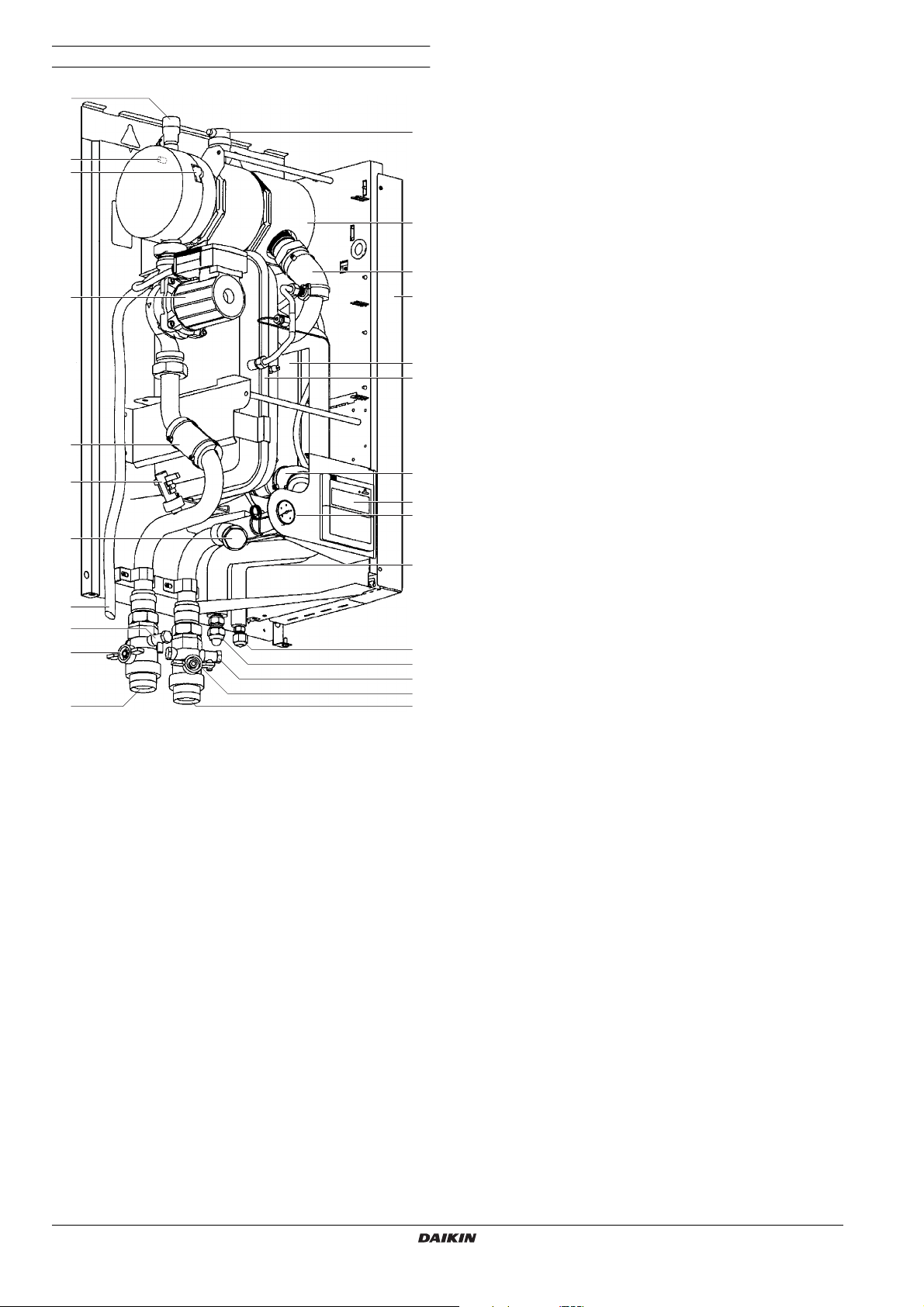

Main components

20

19

18

17

3

16

14

13. Drain and fill valves

14. Water filter

The water filter removes dirt from the water to prevent damage

to the pump or blockage of the evaporator. The water filter must

1

be cleaned on a regular base. See "Maintenance and service"

on page 35.

15. Manometer

The manometer allows readout of the water pressure in the

water circuit.

16. Flow switch

2

The flow switch checks the flow in the water circuit and protects

the heat exchanger against freezing and the pump against

damage.

3

4

17. Pump

The pump circulates the water in the water circuit.

18. Backup heater thermal protector

The backup heater is equipped with a thermal protector. The

thermal protector is activated when the temperature becomes

5

6

too high.

19. Backup heater thermal fuse

The backup heater is equipped with a thermal fuse. The thermal

fuse is blown when the temperature becomes too high (higher

than the backup heater thermal protector temperature).

20. Pressure relief valve

3

7

15

The pressure relief valve prevents excessive water pressure in

the water circuit by opening at 3 bar and discharging some

water.

21. Pressure relief valve hose

The actual outlet of the pressure relief valve. Make sure to

3

provide a proper drain.

21

13

10

12

1. Air purge valve

Remaining air in the water circuit will be automatically removed

via the air purge valve.

2. Backup heater

The backup heater consists of an electrical heating element in

the backup heater vessel that will provide additional heating

capacity to the water circuit if the heating capacity of the outdoor

unit is insufficient due to low outdoor temperatures.

3. Temperature sensors

Four temperature sensors determine the water and refrigerant

temperature at various points in the water circuit.

4. Switch box

The switch box contains the main electronic and electrical parts

of the indoor unit.

5. Heat exchanger

6. Expansion vessel (10 l)

7. User interface

The user interface allows the installer and user to set up, use

and maintain the unit.

8. Refrigerant liquid connection

9. Refrigerant gas connection

10. Shut-off valves (accessory)

The shut-off valves on the water inlet connection and water

outlet connection allow isolation of the indoor unit water circuit

side from the residential water circuit side. This facilitates

draining and filter replacement of the indoor unit.

11. Water inlet connection

12. Water outlet connection

8

9

13

10

11

Installation manual

10

Indoor unit for air to water heat pump system

EKHBH/X016BA

4PW54187-1B

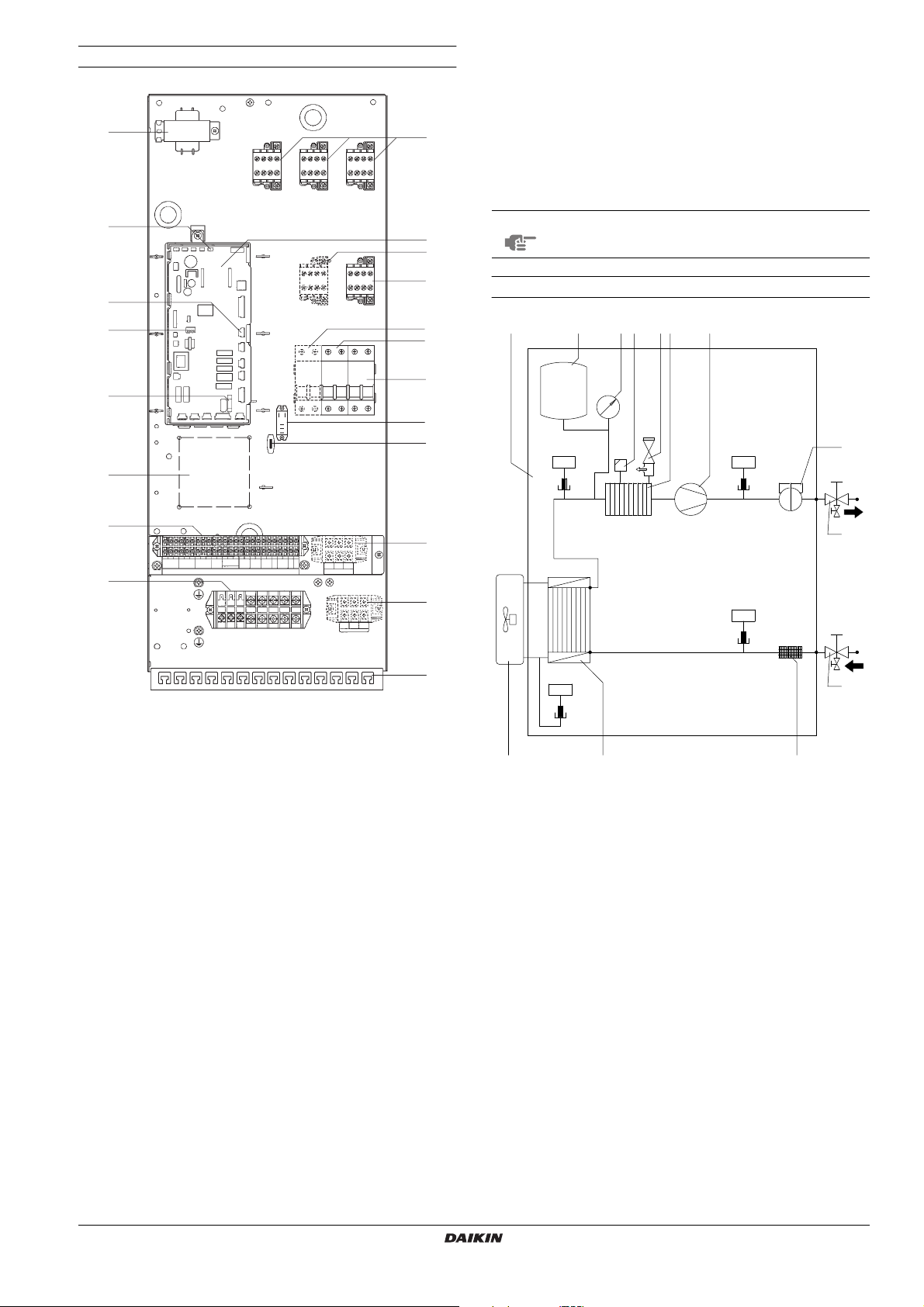

Switch box main components

15

12

X9A

TR1

K1M K2M

K5M

12. X9A socket

The X9A socket receives the thermistor connector (only for

installations with domestic hot water tank).

13. Pump fuse FU2 (in line fuse)

14. Pump relay K4M

1

15. Tr ansformer TR1

16. A4P

Digital I/O PCB (only for installations with solar kit or digital I/O

PCB kit).

NOTE

2

3

The electrical wiring diagram can be found on the

inside of the switch box cover.

11

10

16

X13A

SS2

FU1

9

6

A1P

A4P

X2M X4M

K3M K6M

F2B F3B F1B

K4M

FU2

1

4

5

5

14

13

8

6

8

X1M

X3M

7

1. Backup heater contactors K1M, K2M, K5M and K6M.

2. Main PCB

The main PCB (Printed Circuit Board) controls the functioning of

the unit.

3. Booster heater contactor K3M (only for installations with

domestic hot water tank)

4. Booster heater circuit breaker F2B (only for installations with

domestic hot water tank)

The circuit breaker protects the booster heater in the domestic

hot water tank against overload or short circuit.

5. Backup heater circuit breaker F1B, F3B

The circuit breaker protects the backup heater electrical circuit

against overload or short circuit.

6. Te r minal blocks

The terminal blocks allow easy connection of field wiring.

7. Cable tie mountings

The cable tie mountings allow to fix the field wiring with cable

ties to the switch box to ensure strain relief.

8. Te r minal blocks X3M, X4M (only for installations with domestic

hot water tank)

9. PCB fuse FU1

10. DIP switch SS2

The DIP switch SS2 provides 4 toggle switches to configure

certain installation parameters. See "DIP switch settings

overview" on page 21.

11. X13A socket

The X13A socket receives the K3M connector (only for

installations with domestic hot water tank).

Functional diagram

32 4 8

R1T

t >

R3T

t >

1 Outdoor unit 10 Shut-off valve water outlet

2 Indoor unit

3 Expansion vessel 11 Shut-off valve water inlet with

4 Manometer

5 Air purge valve 12 Filter

6 Pressure relief valve 13 Heat exchanger

7 Backup heater R1T

9 Flow switch

5 6 7

R2T

t >

H

O

2

R2T

R3T

R4T

R4T

t >

12131

with drain valve (field

installation)

drain valve (field installation)

Temperature sensors8 Pump

9

10

11

EKHBH/X016BA

Indoor unit for air to water heat pump system

4PW54187-1B

Installation manual

11

INSTALLATION OF THE INDOOR UNIT

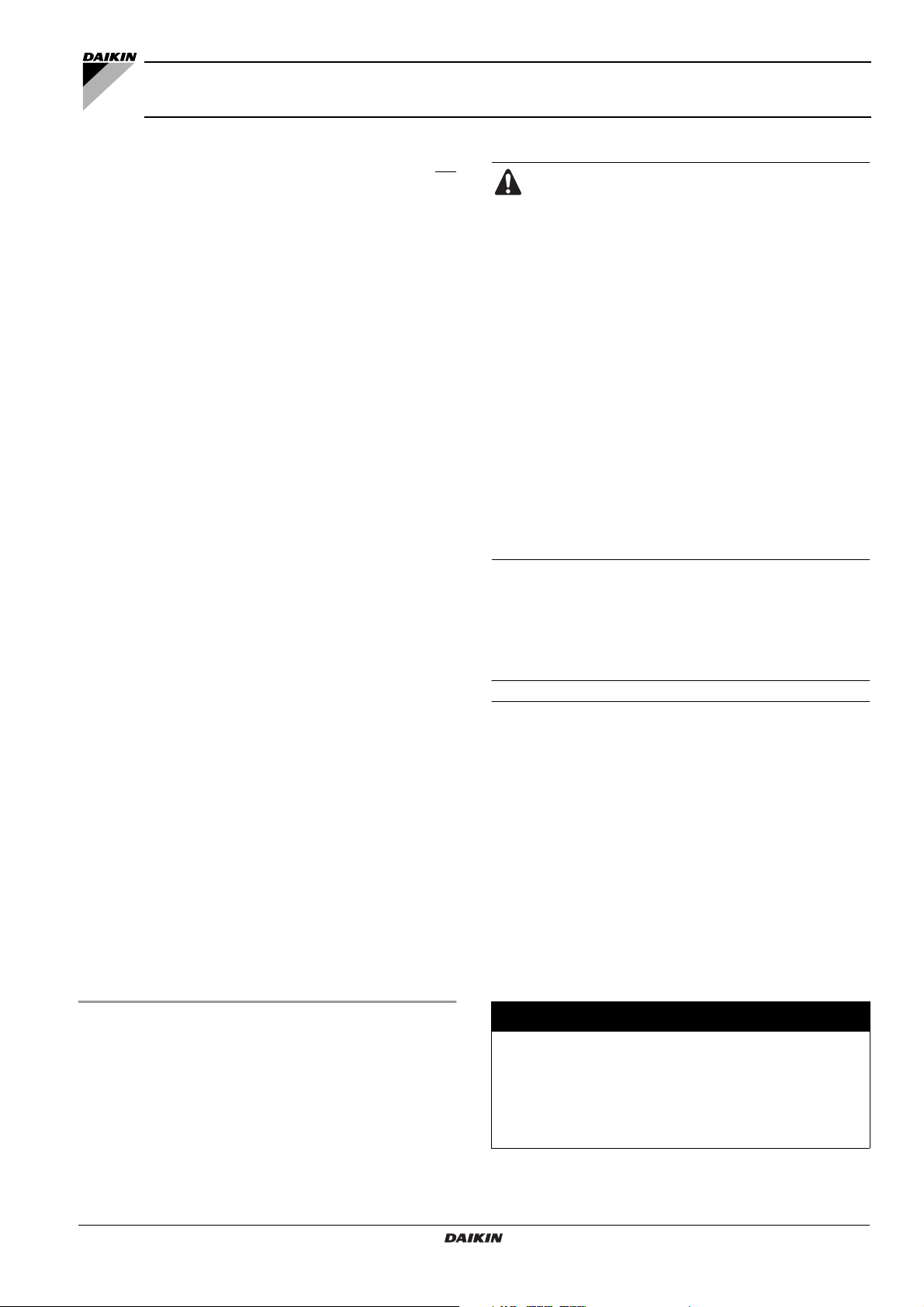

Dimensions and service space

Selecting an installation location

The unit is to be wall mounted in an indoor location that meets the

following requirements:

■ The installation location is frost-free.

■ The space around the unit is adequate for servicing. (See

figure 2).

■ The space around the unit allows for sufficient air circulation.

■ There is a provision for condensate drain (only for EKHBX

models with drain pan kit EKHBDP) and pressure relief valve

blow-off.

■ The installation surface is a flat and vertical non-combustible

wall, capable of supporting the operation weight of the unit (see

"Technical specifications" on page 40).

■ There is no danger of fire due to leakage of inflammable gas.

■ All piping lengths and distances have been taken into

consideration.

Requirement Value

Maximum allowable refrigerant piping length between

outdoor unit and indoor unit

Minimum required refrigerant piping length between

outdoor unit and indoor unit

Maximum allowable height difference between

outdoor unit and indoor unit

Maximum allowable distance between the 3-way

valve and the indoor unit (only for installations with

domestic hot water tank).

Maximum allowable distance between the domestic

hot water tank and the indoor unit (only for

installations with domestic hot water tank). The

thermistor cable supplied with the domestic hot water

tank is 12 m in length.

(a) When <5 m, recharging of the outdoor unit (only for V3 model) is required.

Refer to the installation manual of the outdoor unit.

■ During normal operation the hydrobox unit will produce sound

which could be observed as noise. The sound origin can be

water pump operation and/or contactor activation. Therefore it is

advisable to install the hydrobox unit on a firm wall and not in nor

close to a sound sensitive environment (e.g. bedroom).

■ Do not install the unit in places with high humidity (e.g.

bathroom).

■ Select piping diameter in relation to required water flow and

available ESP of pump.

■ The equipment is not intended for use in a potentially explosive

atmosphere.

■ Do not install the unit in places often used as work place.

In case of construction works (e.g. grinding works) where a lot of

dust is created, the unit must be covered.

■ Ta ke care that in the event of a water leak, water can not cause

any damage to the installation space and surroundings.

■ Do not place any objects or equipment on top of the unit.

■ Be sure that sufficient precautions are taken, in accordance with

relevant local and national regulations, in case of refrigerant

leakage.

75 m

3 m

30 m

3 m

10 m

(a)

Unit of measurement: mm

Dimensions of the unit, see figure 3

1 Flexible drain hose 5 Refrigerant gas

2 Water outlet connection

3 Water inlet connection FBSP Female British Standard

4 Refrigerant liquid

connection

MBSP Male British Standard

connection

Pipe

Pipe

Required service space, see figure 2

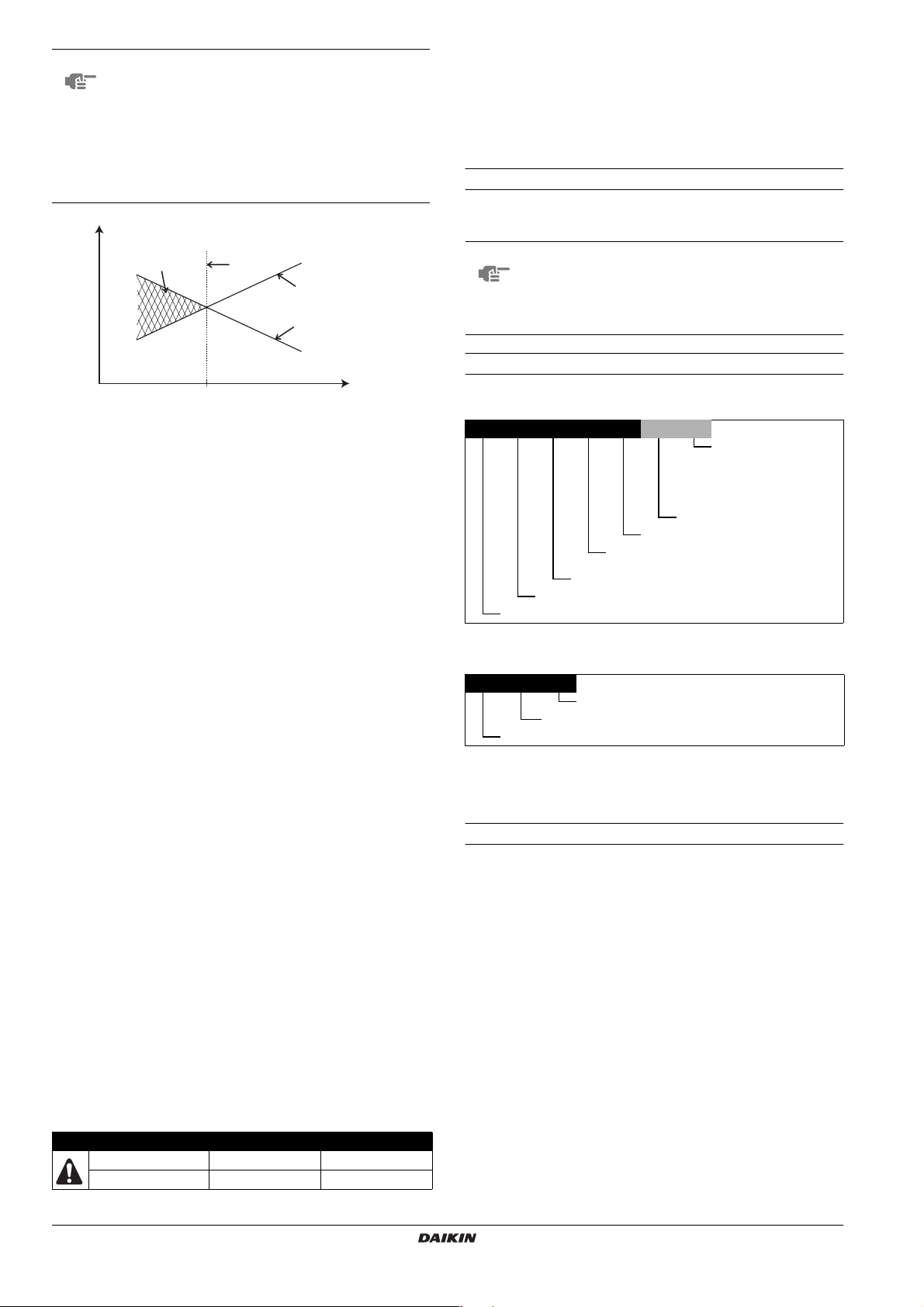

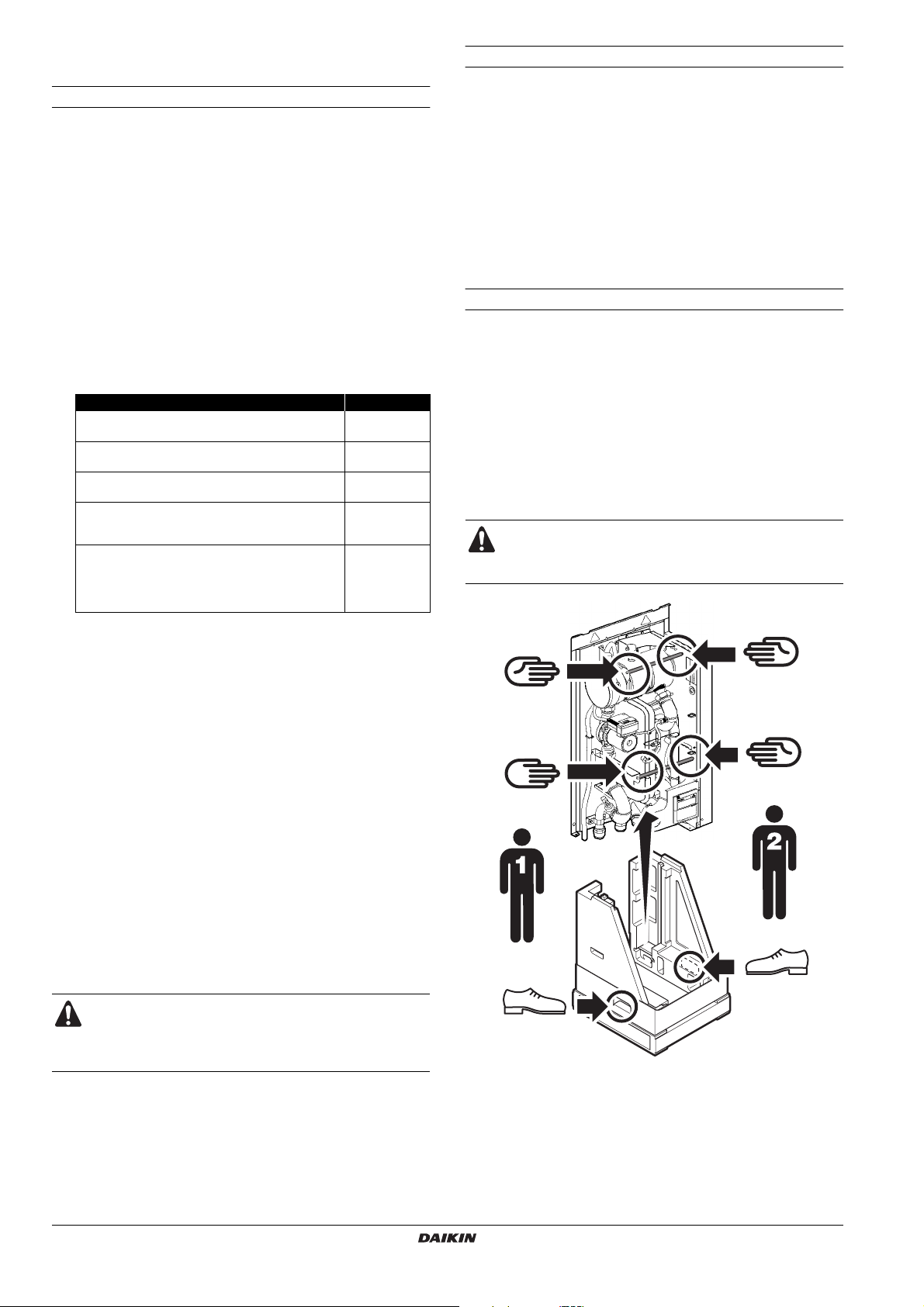

Inspecting, handling and unpacking the unit

■ The indoor unit is packed in a cardboard box, fixed by straps on

a wooden pallet.

■ At delivery, the unit must be checked and any damage must be

reported immediately to the carrier claims agent.

■ Check if all indoor unit accessories (see "Accessories" on

page 2) are enclosed.

■ Bring the unit as close as possible to its final installation position

in its original package in order to prevent damage during

transport.

■ The indoor unit weighs approximately 48 kg and should be lifted

by two persons using the two lifting bars provided.

CAUTION

Do not grasp the switch box or piping to lift the unit! Two

lifting bars are provided to lift the unit.

CAUTION

If the installation is equipped with a domestic hot water

tank (optional), please refer to the domestic hot water tank

installation manual.

Installation manual

12

Indoor unit for air to water heat pump system

EKHBH/X016BA

4PW54187-1B

Loading...

Loading...