Page 1

7

LF45/55 series

STRUCTURE

TECHNICAL DATA

0

DIAGNOSTICS

1

STEERING GEAR, GENERAL

2

STEERING BOX

3

STEERING PUMP

4

RESERVOIR AND LINES

5

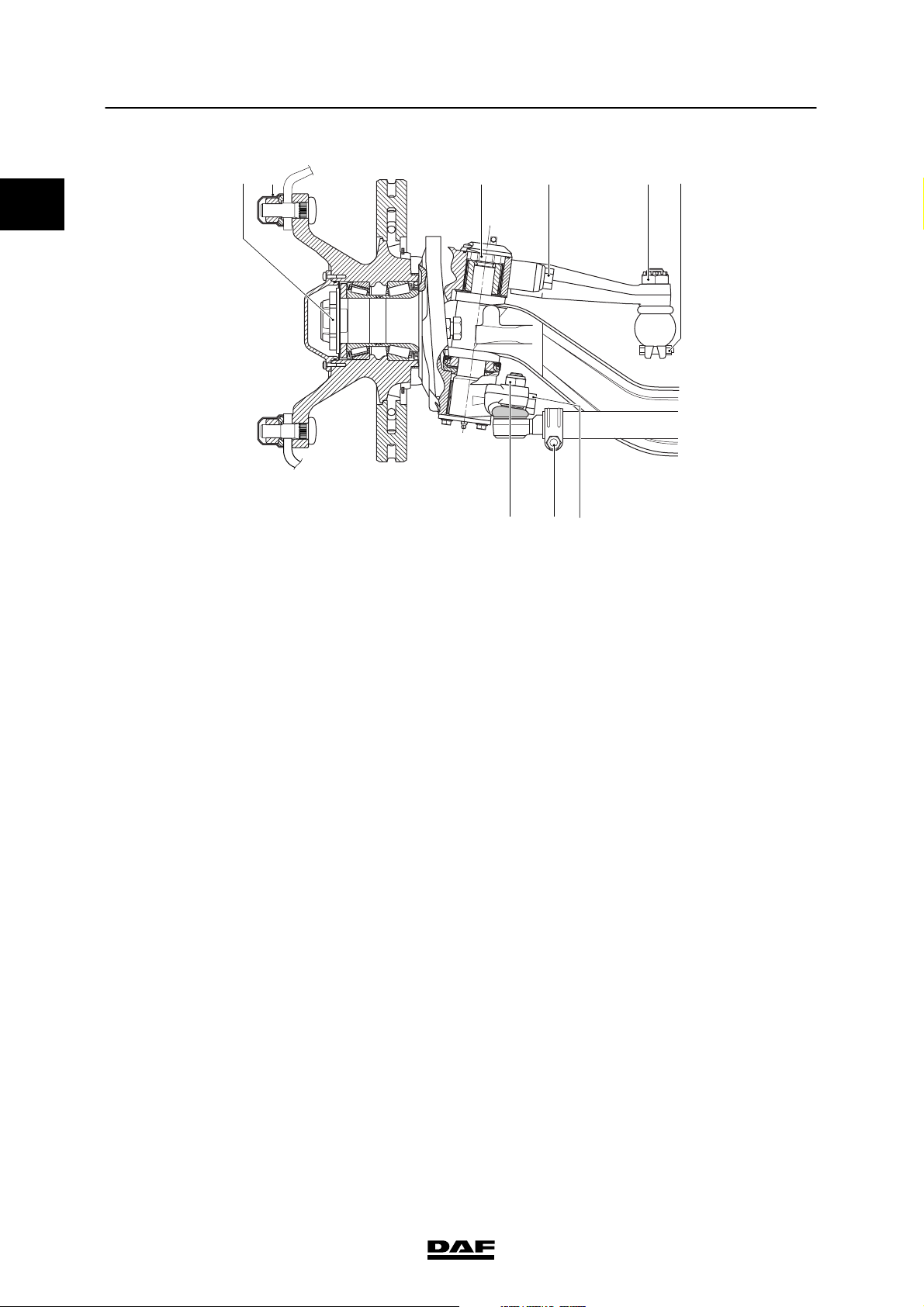

FRONT AXLE, F36/F48

FRONT AXLE, F60

FRONT AXLE, 152N

STEERED TRAILING SWIVEL AXLE

6

7

8

9

ᓻ 200322

Page 2

Page 3

7

TECHNICAL DATA

LF45/55 series Contents

CONTENTS

Page Date

1. STEERING GEAR, GENERAL 1-1 200322........................................... ....

1.1 General 1-1 200322......................................................... ....

2. STEERING BOX 2-1 200322....................................................... ....

2.1 General 2-1 200322......................................................... ....

2.2 Tightening torques 2-2 200322................................................ ....

3. STEERING PUMP/RESERVOIR 3-1 200322......................................... ....

3.1 General 3-1 200322......................................................... ....

3.2 Tightening torques 3-1 200322................................................ ....

4. F36 AND F48 FRONT AXLE 4-1 200322............................................ ....

4.1 General 4-1 200322......................................................... ....

4.2 Tightening torques 4-3 200322................................................ ....

5. F60 FRONT AXLE 5-1 200322..................................................... ....

5.1 General 5-1 200322......................................................... ....

5.2 Tightening torques 5-3 200322................................................ ....

6. 152N FRONT AXLE 6-1 200322.................................................... ....

6.1 General 6-1 200322......................................................... ....

6.2 Tightening torques 6-7 200322................................................ ....

7. STEERED TRAILING SWIVEL AXLE 7-1 200322.................................... ....

7.1 General 7-1 200322......................................................... ....

7.2 Tightening torques 7-3 200322................................................ ....

0

ᓻ 200322

1

Page 4

0

7TECHNICAL DATA

Contents LF45/55 series

2

ᓻ 200322

Page 5

7

TECHNICAL DATA

LF45/55 series Steering gear, general

1. STEERING GEAR, GENERAL

1.1 GENERAL

Steered axles

Vehicle type

LF45 6 and 8 tonnes F36 N/A

LF45 10, 11 and 12 tonnes F48 N/A

LF55 12, 13, 14 and 15

LF55 FAN 12, 13, 14 and 15

LF55 16 and 18 tonnes 152N N/A

Steering box

Vehicle type

LF45 6 and 8 tonnes ZF8090 130 + 10 bar

LF45 10, 11 and 12 tonnes ZF8090 180 + 10 bar

LF55 12, 13, 14 and 15

GVW Front axle Trailing axle

F60 N/A

tonnes

F60 Steered trailing swivel

tonnes

GVW Steering box Max. system

ZF8095 150 + 10 bar

tonnes

axle (F60)

pressure

0

LF55 FAN 12, 13, 14 and 15

tonnes

LF55 16 and 18 tonnes ZF8098 150 + 10 bar

Circulation pressure

Maximum permissible circulation pressure of

the steering gear at a steering-oil temperature

of 50_C

Final limiting pressure

Final limiting pressure at a steering-oil

temperature of 50_C and an engine speed of

1200-1400 rpm

Steering box internal leaks

Maximum permissible internal leakage in the

steering box

ZF 8090 steering box 2.0 l/min.

ZF 8095 and 8098 steering box 2.5 l/min.

ZF8095 150 + 15 bar

10 bar max.

40-45bar

ᓻ 200322

1-1

Page 6

0

TECHNICAL DATA

7

Steering gear, general LF45/55 series

Steering box internal play

Maximum permissible internal play of the

steeringboxwithablockedpitmanarm

Steering pump

LF45 series ZF 7684 steering pump

LF55 series, other vehicles ZF 7685 steering pump

LF55 series FAN version ZF 7687 steering pump

Steering pump output

Steering pump output at a steering oil

temperature of 50_C and pressure of 50 bar,

at idling speed

ZF 7684 steering pump 5.9 l/min. minimum

ZF 7685 steering pump 7.0 l/min. minimum

ZF 7687 steering pump 10.8 l/min. minimum

Steering pump output at a steering oil

temperature of 50_C, pressure of 50 bar and

an engine speed of approx. 1300 1400 rpm

ZF 7684 steering pump 8.0 - 10.4 l/min.

ZF 7685 steering pump 16.0 - 20.8 l/min.

ZF 7687 steering pump 22.5 - 27.5 l/min.

4 cm steering wheel deflection

1-2

ᓻ 200322

Page 7

7

TECHNICAL DATA

LF45/55 series Steering box

2. STEERING BOX

2.1 GENERAL

Steering box

Version: single-circuit steering box with automatic

bleeding, self-adjusting wheel-deflection

limiting valves and pressure-limiting valve.

Type:

ZF 8090 used on F36 and F48 front axle.

ZF 8095 used on F60 front axle.

ZF 8098 used on 152N front axle.

Pressure point

Resistance increase in the pressure point

ZF 8090 20 - 60 Ncm

ZF 8095 20 - 80 Ncm

ZF 8098 20 - 100 Ncm

Input shaft end play

ZF 8090 0.005 - 0.025 mm

ZF 8095 0.010 - 0.030 mm

ZF 8098 0.020 - 0.040 mm

0

ᓻ 200322

2-1

Page 8

TECHNICAL DATA

7

Steering box LF45/55 series

2.2 TIGHTENING TORQUES

0

The tightening torques stated in this section are

different from the standard tightening torques

included in the overview of standard tightening

torques. Any other threaded connections that

are not specified must therefore be tightened to

the tightening torque stated in the overview of

standard tightening torques.

When attachment bolts and nuts are to be

replaced, it is important - unless stated

otherwise - that these bolts and nuts are of

exactly the same length and property class as

the ones removed

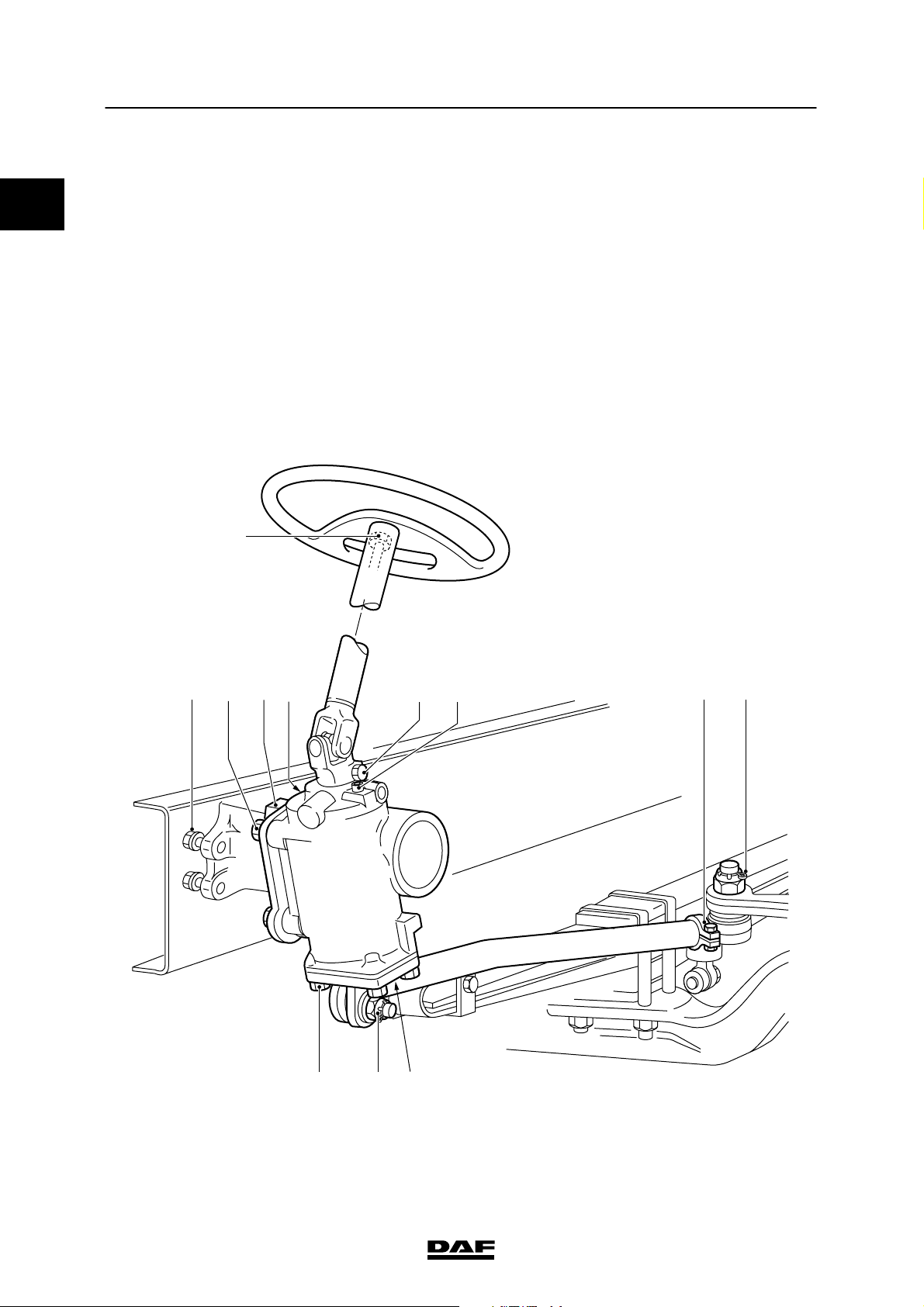

LF45 steering gear

.

E

A B CD G

F

IJG

IH

S7 00 884

2-2

ᓻ 200322

Page 9

7

TECHNICAL DATA

LF45/55 series Steering box

A. Attachment bolts/nuts, steering bracket

on M12 10.9 chassis

Stud bolt in steering bracket 80 Nm

B. Bolts/nuts for attaching the steering box

to the steering bracket

Stud bolt in steering box 180 Nm

C. Pitman-arm attachment nut 350 Nm

D. Pressure-limiting valve 30 Nm

E. Steering wheel attachment bolt 50 Nm

F. Attachment bolt/nut, steering column

universal joint

G. Wheel-deflection limiting valve stop bolt 15 Nm

H. Attachment bolt, steering-rod clamping

bracket

I. Steering rod castle nut 180 Nm

J. Cover attachment bolt 135 Nm

(1) Always use new attachment bolts.

(2) Use new original attachment bolt and nut.

(3) Tighten until the split pin fits (max. 60_).

according to standard

400 Nm

56 Nm

48 Nm

(1)

(2)

(3)

0

ᓻ 200322

2-3

Page 10

0

TECHNICAL DATA

Steering box LF45/55 series

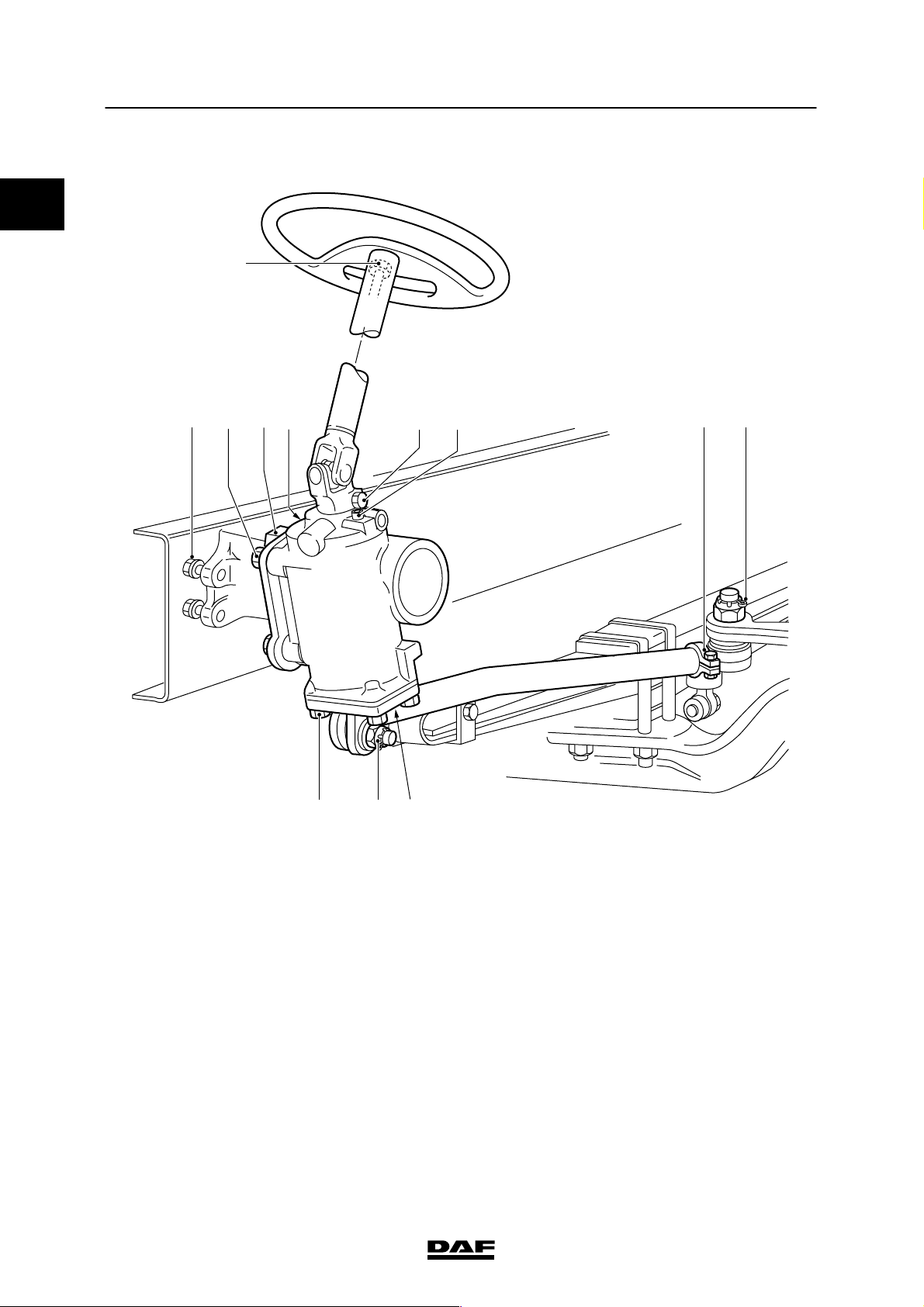

LF55 steering gear

E

7

A B CD G

F

IJG

IH

S7 00 884

2-4

ᓻ 200322

Page 11

7

TECHNICAL DATA

LF45/55 series Steering box

A. Attachment bolts/nuts, steering bracket

on M14 10.9 chassis

Stud bolt in steering bracket 125 Nm

B. Bolts/nuts for attaching the steering box

to the steering bracket

Stud bolt in steering box 180 Nm

C. Pitman-arm attachment nut

- with ZF8095 steering box 520 Nm

- with ZF8098 steering box 570 Nm

D. Pressure-limiting valve 30 Nm

E. Steering wheel attachment bolt 50 Nm

F. Attachment bolt/nut, steering column

universal joint

G. Wheel-deflection limiting valve stop bolt 15 Nm

H. Attachment bolt, steering-rod clamping

bracket

- with F60 front axle 65 Nm

- with 152N front axle 90 Nm

I. Steering rod castle nut 220 Nm

J. Cover attachment bolt

- with ZF8095 steering box 285 Nm

- with ZF8098 steering box 189 Nm

according to standard

560 Nm

56 Nm

(1)

(2)

(3)

0

(1) Always use new attachment bolts.

(2) Use new original attachment bolt and nut.

(3) Tighten until the split pin fits (max. 60_).

ᓻ 200322

2-5

Page 12

0

TECHNICAL DATA

Steering box LF45/55 series

7

2-6

ᓻ 200322

Page 13

7

TECHNICAL DATA

LF45/55 series Steering pump/reservoir

3. STEERING PUMP/RESERVOIR

3.1 GENERAL

Steering pump

Design vane pump

Type ZF 7684, ZF 7685, ZF 7687

Maximum pressure see steering box type plate

(Pump does not have pressure-limiting valve.)

3.2 TIGHTENING TORQUES

The tightening torques stated in this section are

different from the standard tightening torques

included in the overview of standard tightening

torques. Any other threaded connections that

are not specified must therefore be tightened to

the tightening torque stated in the overview of

standard tightening torques.

When attachment bolts and nuts are to be

replaced, it is important - unless stated

otherwise - that these bolts and nuts are of

exactly the same length and property class as

the ones removed

Steering pump attachment bolts 46 Nm

Flow-control valve plug 65 Nm

Delivery pipe connection in the pump 36 Nm

Cover attachment bolts 20 Nm

Reservoir attachment bolts 8 Nm

.

0

ᓻ 200322

3-1

Page 14

0

TECHNICAL DATA

Steering pump/reservoir LF45/55 series

7

3-2

ᓻ 200322

Page 15

7

TECHNICAL DATA

LF45/55 series F36 and F48 front axle

4. F36 AND F48 FRONT AXLE

4.1 GENERAL

Axle journal

Anti-corrosion agent Gleitmo 805

Wheel speed sensor

Anti-corrosion agent Molykote P37

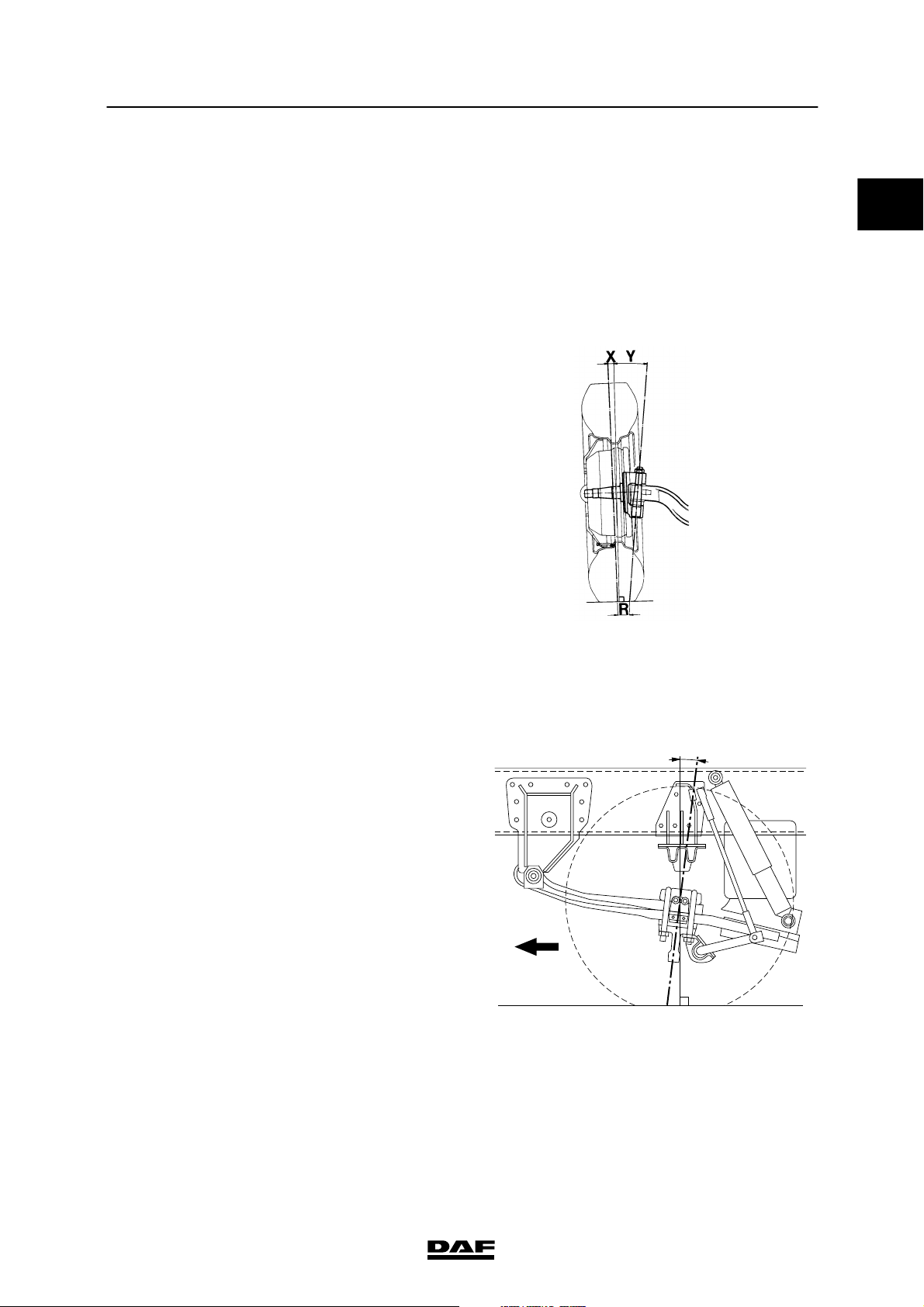

Camber angle and kingpin inclination (KPI)

Camber angle (X) on an

unloaded axle

King-pin inclination (Y) 7_

0_30′

0

S7 00 129

Wheel deflection

Maximum inner wheel

deflection

- F36 axle 53_

- F48 axle 53_

Caster

Z=caster

- F36 axle 4_

- F48 axle 4_

Z

S7 00 607

ᓻ 200322

4-1

Page 16

0

TECHNICAL DATA

7

F36 and F48 front axle LF45/55 series

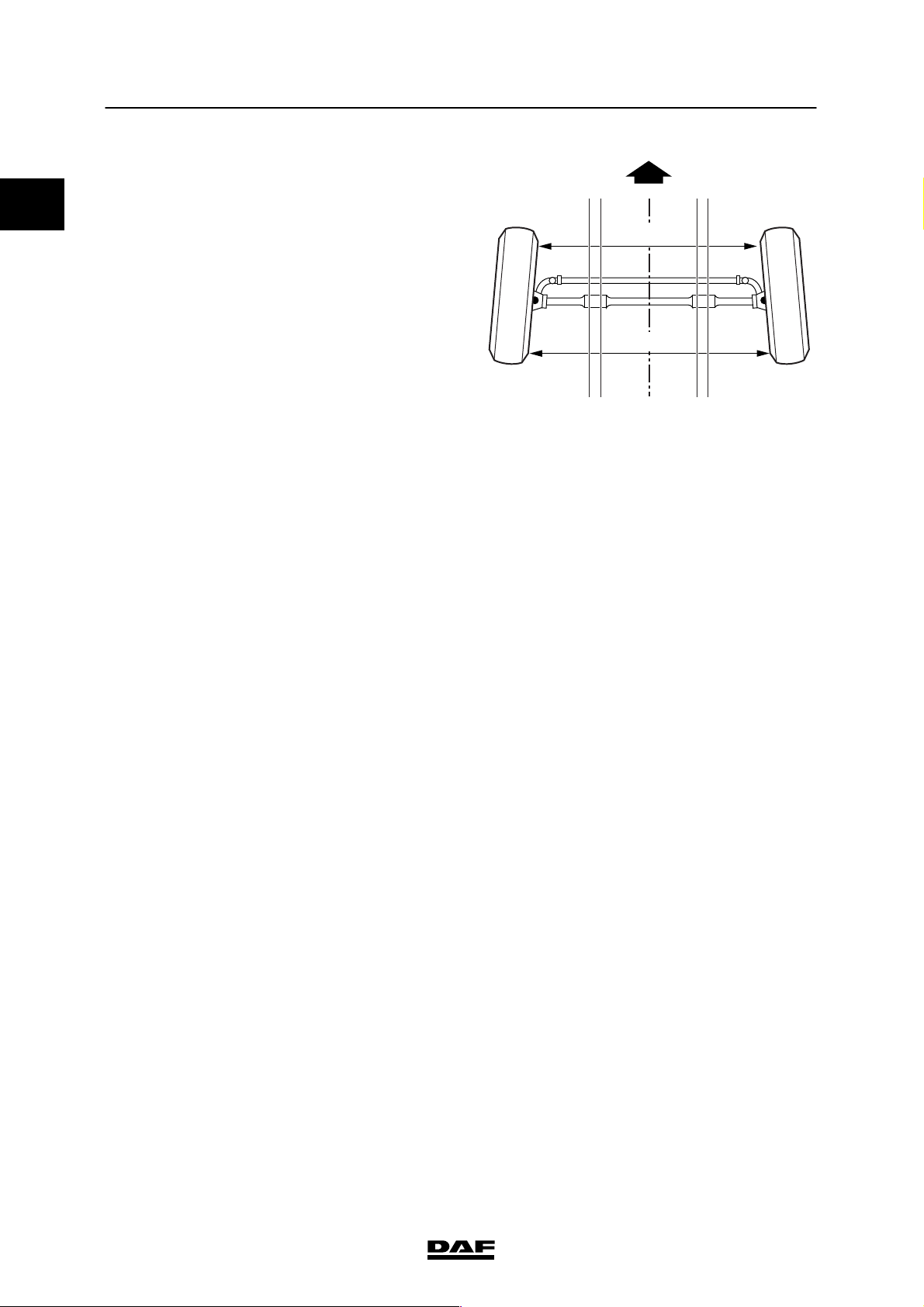

Toe

Measured at the side walls of the tyre (B -- A)

in unloaded condition

- F36 axle, toe-in 0 - 1.6 mm

- F48 axle, toe-in 0 - 1.6 mm

A

B

S7 00 833

Steering ball joints

Axial play max. 1.5 mm

Swivel axle

Axial play

- F36 axle 0.05 - 0.12 mm

- F48 axle 0.05 - 0.12 mm

List of shim sizes (thickness) for adjusting

swivel axle play

Hub

Wheel bearing play

- F36 axle 0.05 -0.20 mm

- F48 axle 0.05 -0.20 mm

0.05 mm

0.125 mm

0.25 mm

1.00 mm

4-2

ᓻ 200322

Page 17

7

TECHNICAL DATA

LF45/55 series F36 and F48 front axle

4.2 TIGHTENING TORQUES

The tightening torques stated in this section are

different from the standard tightening torques

included in the overview of standard tightening

torques. Any other threaded connections that

are not specified must therefore be tightened to

the tightening torque stated in the overview of

standard tightening torques.

When attachment bolts and nuts are to be

replaced, it is important - unless stated

otherwise - that these bolts and nuts are of

exactly the same length and property class as

the ones removed

.

0

ᓻ 200322

4-3

Page 18

TECHNICAL DATA

;;;;

;;;;

;;;;

;;;;

;;;;

;;;;

;

;

;;

;;

;

;

;;

;;

;;

7

F36 and F48 front axle LF45/55 series

0

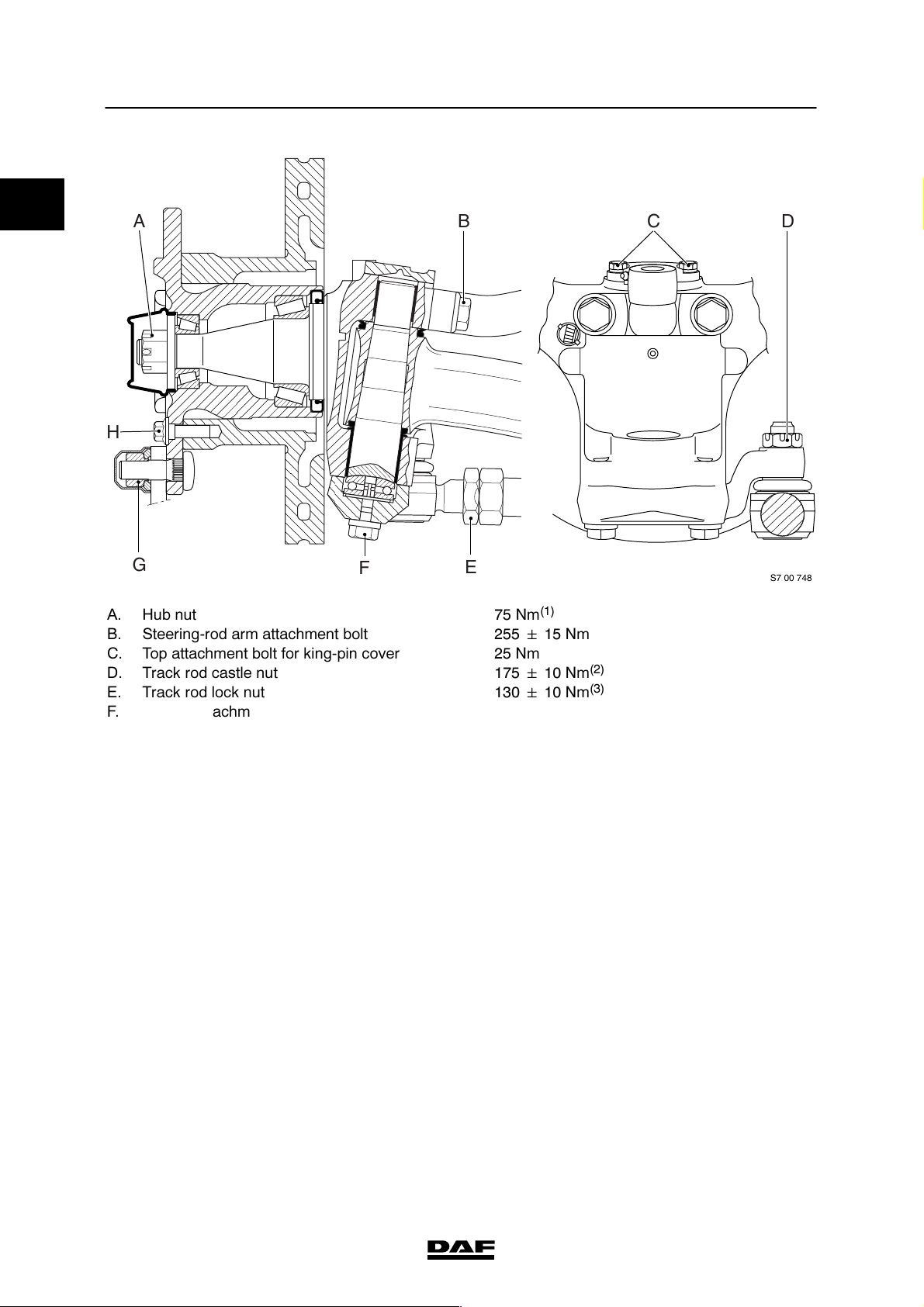

A

B

H

G

F

A. Hub nut 75 Nm

B. Steering-rod arm attachment bolt 255 ᐔ 15 Nm

C. Top attachment bolt for king-pin cover 25 Nm

D. Track rod castle nut 175 ᐔ 10 Nm

E. Track rod lock nut 130 ᐔ 10 Nm

F. Bottom attachment bolt for king-pin cover 120 ᐔ 5Nm

G. Wheel nut

- F36 axle (M18 x 1.5) 370 ᐔ 30 Nm

- F48 axle (M20 x 1.5) 485 ᐔ 35 Nm

H. Hub attachment bolt 115 ᐔ 5Nm

E

(1)

DC

S7 00 748

(2)

(3)

(4)

(4)

(1) Turn the nut anticlockwise (approx. 90_) until the

specified wheel bearing play is achieved. Lock with

split pin.

(2) Tighten until the split pin fits (max. 60_).

(3) Lock nut using locking plate.

(4) Retighten after 100 km. If new wheel bolts have been

fitted, the wheels need additional retightening after

500 km.

4-4

ᓻ 200322

Page 19

7

TECHNICAL DATA

LF45/55 series F60 front axle

5. F60 FRONT AXLE

5.1 GENERAL

Axle journal

Anti-corrosion agent Gleitmo 805

Wheel speed sensor

Anti-corrosion agent Molykote P37

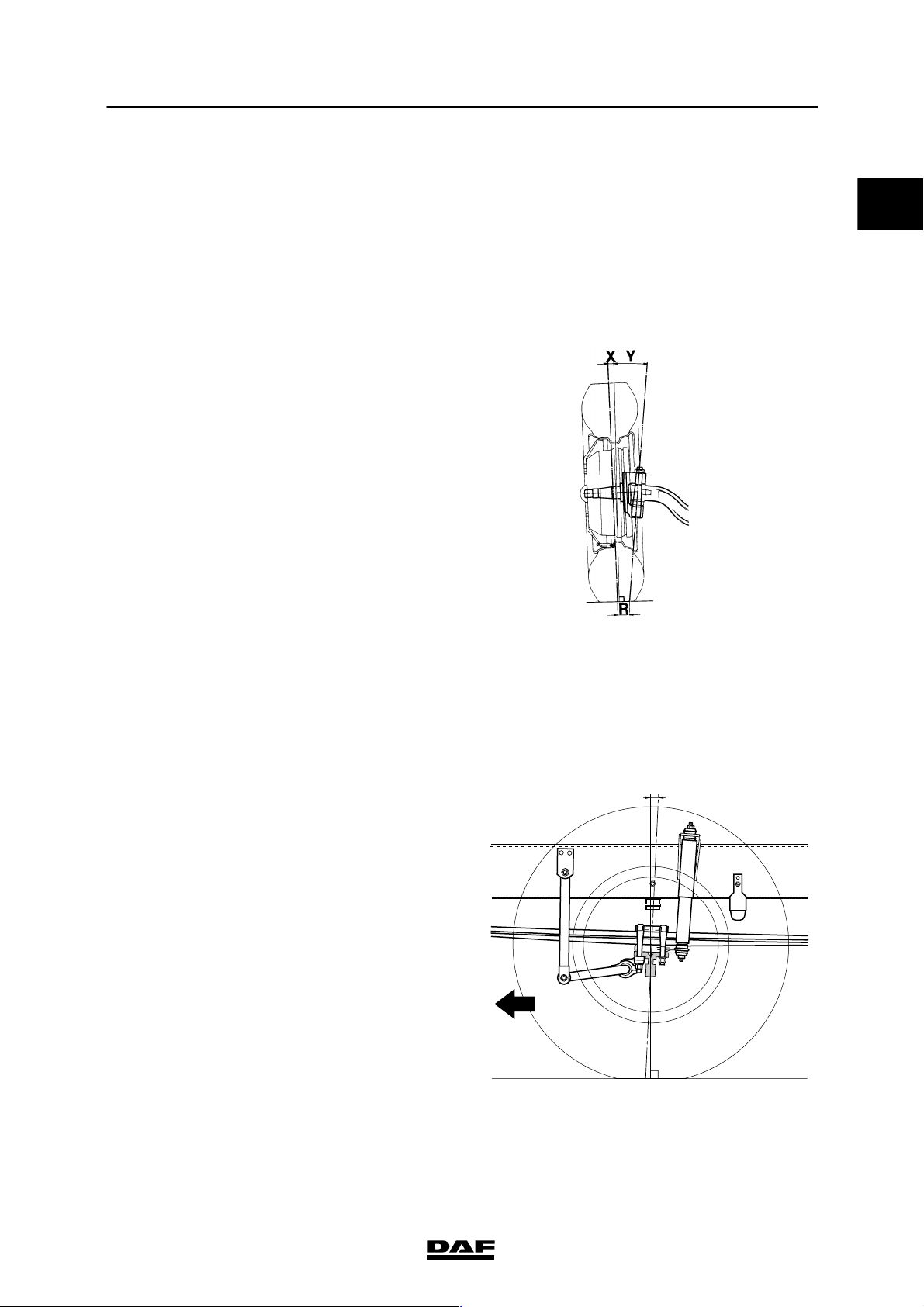

Camber angle and kingpin inclination (KPI)

Camber angle (X) on an

unloaded axle

King-pin inclination (Y) 7_15′

0_30′

0

S7 00 129

Wheel deflection

Maximum inner wheel

deflection

Caster

Z=caster 3_

50_

Z

S7 00 607

ᓻ 200322

5-1

Page 20

0

TECHNICAL DATA

7

F60 front axle LF45/55 series

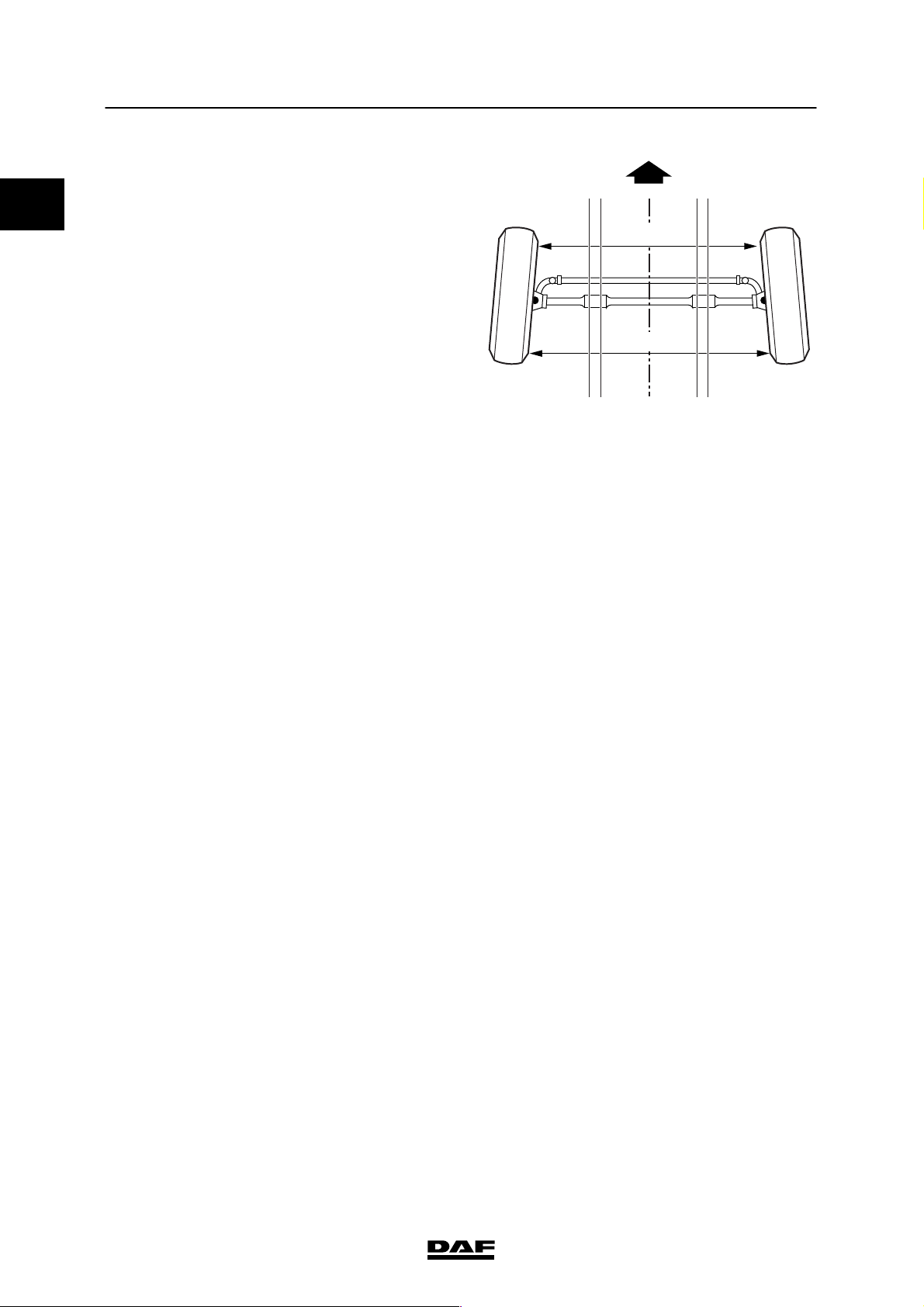

Toe

Measured at the side walls of the tyre (B -- A)

in unloaded condition

Toe-in 0 - 1.6 mm

A

B

S7 00 833

Steering ball joints

Axial play max. 1.5 mm

King pin

Press-in force 150 kN

5-2

ᓻ 200322

Page 21

7

TECHNICAL DATA

LF45/55 series F60 front axle

5.2 TIGHTENING TORQUES

The tightening torques stated in this section are

different from the standard tightening torques

included in the overview of standard tightening

torques. Any other threaded connections that

are not specified must therefore be tightened to

the tightening torque stated in the overview of

standard tightening torques.

When attachment bolts and nuts are to be

replaced, it is important - unless stated

otherwise - that these bolts and nuts are of

exactly the same length and property class as

the ones removed

.

0

ᓻ 200322

5-3

Page 22

;;;

;;;

;;

;;

;;

;;

;;

;;

;;;

;;;

;;

;;

;;

;

;

;

;

;;

;;

;

0

TECHNICAL DATA

7

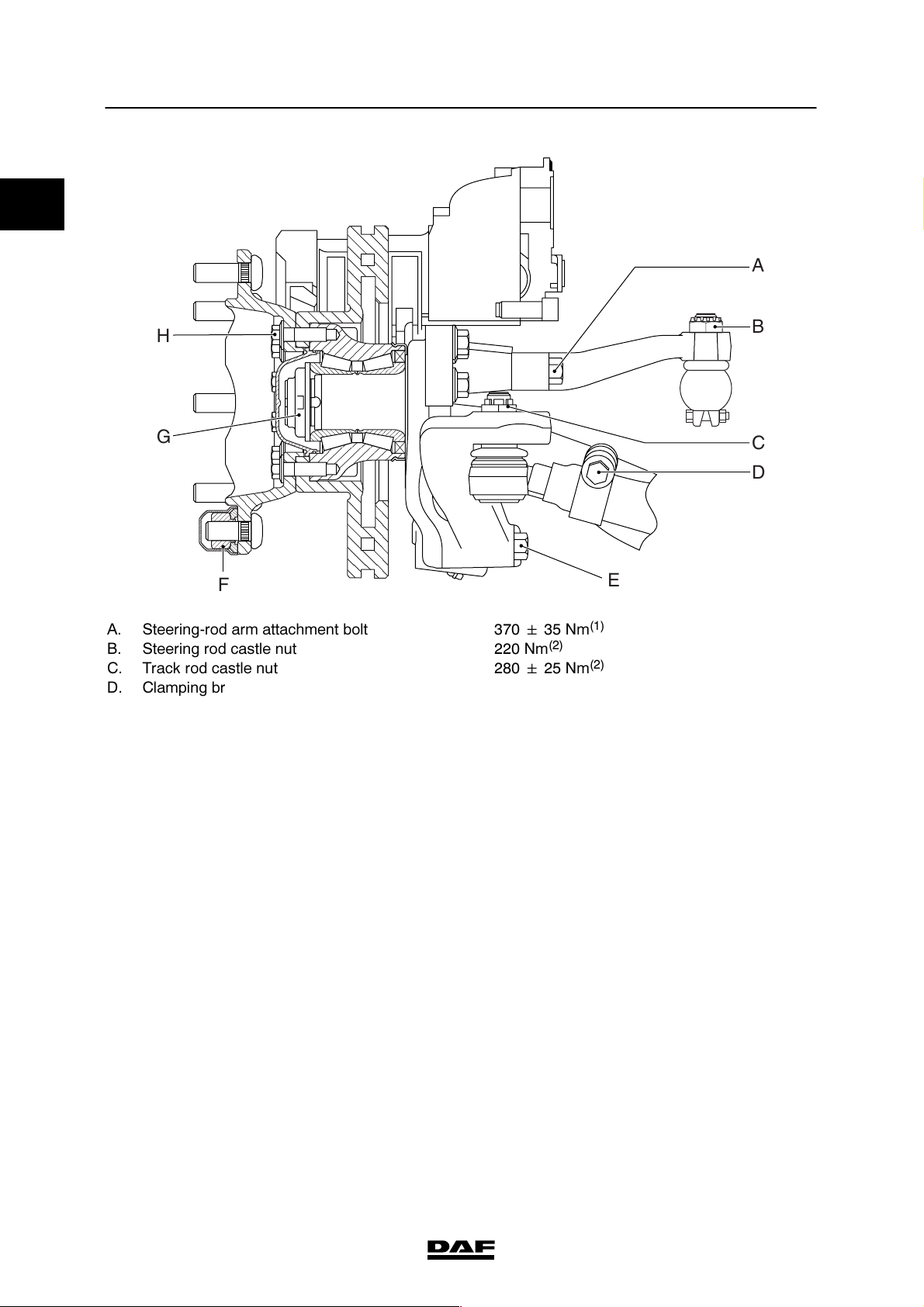

F60 front axle LF45/55 series

A

H

G

F

A. Steering-rod arm attachment bolt 370 ᐔ 35 Nm

B. Steering rod castle nut 220 Nm

C. Track rod castle nut 280 ᐔ 25 Nm

D. Clamping bracket attachment bolt 80 ᐔ 10 Nm

E. Track-rod arm attachment bolt 420 ᐔ 40 Nm

F. Wheel nut (M20 x 1.5) 485 ᐔ 35 Nm

G. Hub nut

st

-1

phase 300 Nm

-2ndphase turn the hub through 10 rotations

-3rdphase 350 Nm

th

-4

phase turn the hub through 10 rotations

-5thphase 685 ᐔ 65 Nm

H. Wheel hub attachment bolt 210 ᐔ 40 Nm

(2)

(5)

E

(1)

(2)

(3)

(1)

(4)

B

C

D

S7 00 698

(6)

(6)

(1) Apply Loctite 243 to the attachment bolt.

(2) Tighten until the split pin fits (max. 60_).

(3) Fit new self-locking nut.

(4) Retighten after 100 km. If new wheel bolts have been

fitted, the wheels need additional retightening after

500 km.

(5) Fit new hub nut.

(6) Rotate the hub at a speed of approx. 40 rpm.

5-4

ᓻ 200322

Page 23

7

TECHNICAL DATA

LF45/55 series 152N front axle

6. 152N FRONT AXLE

6.1 GENERAL

Axle journal

Anti-corrosion agent Gleitmo 805

Wheel speed sensor

Anti-corrosion agent Molykote P37

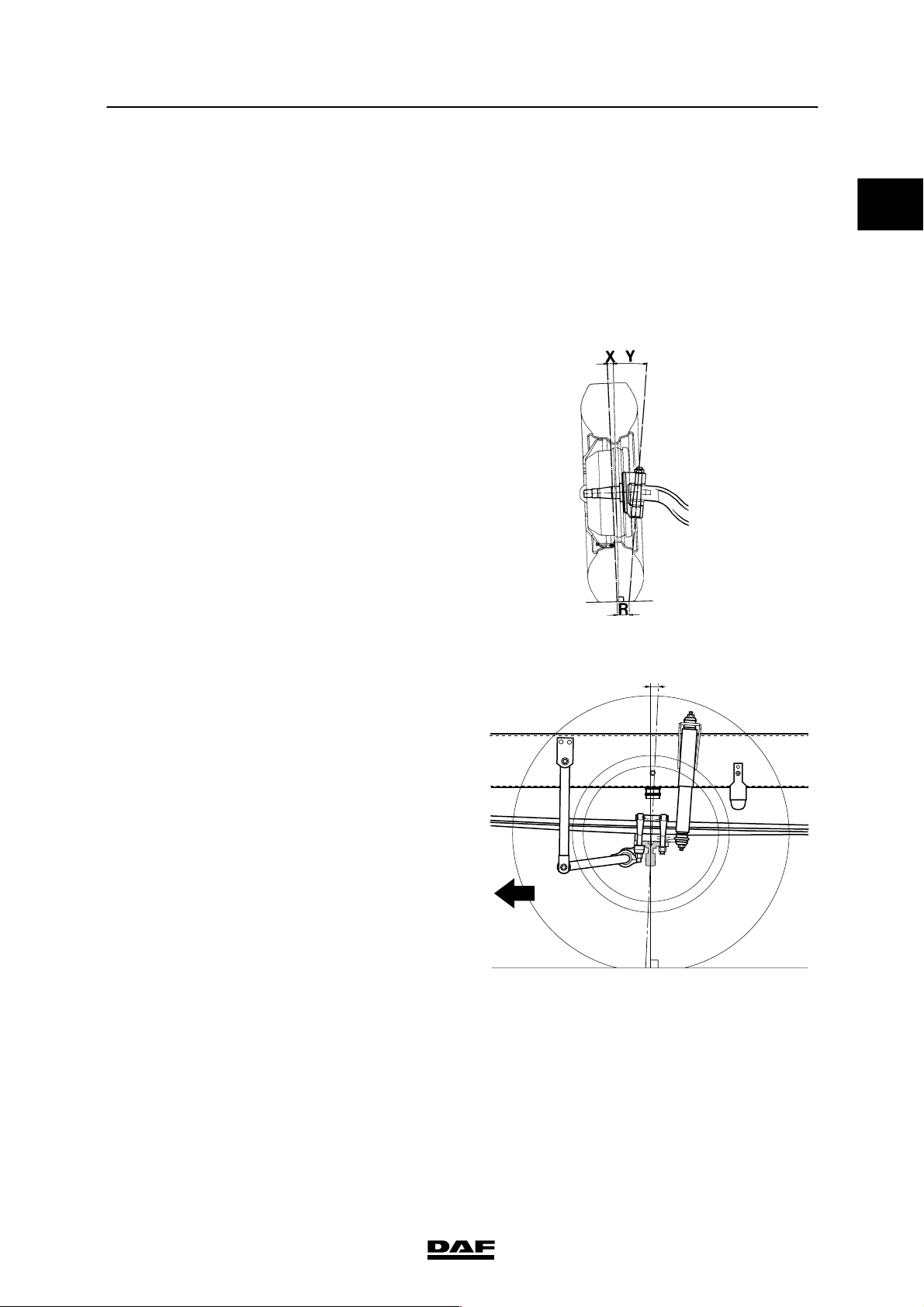

Camber angle and kingpin inclination (KPI)

Camber angle (X) on an

unloaded axle

King-pin inclination (Y) 7_30′

1_

0

S7 00 129

Caster

Z=caster 3_

Z

S7 00 607

ᓻ 200322

6-1

Page 24

TECHNICAL DATA

7

152N front axle LF45/55 series

0

List of keys that can be supplied for adjusting

caster (Z)

Key angle W

(1)

LH

0.5_ 78 155 2.85

1_ 78 155 4.20

1.5_ 78 155 5.55

2_ 78 155 6.91

2.5_ 78 155 8.26

3_ 78 155 9.62

(1) Spring leaf width

Wheel deflection

Maximum inner wheel

deflection

50_

Toe

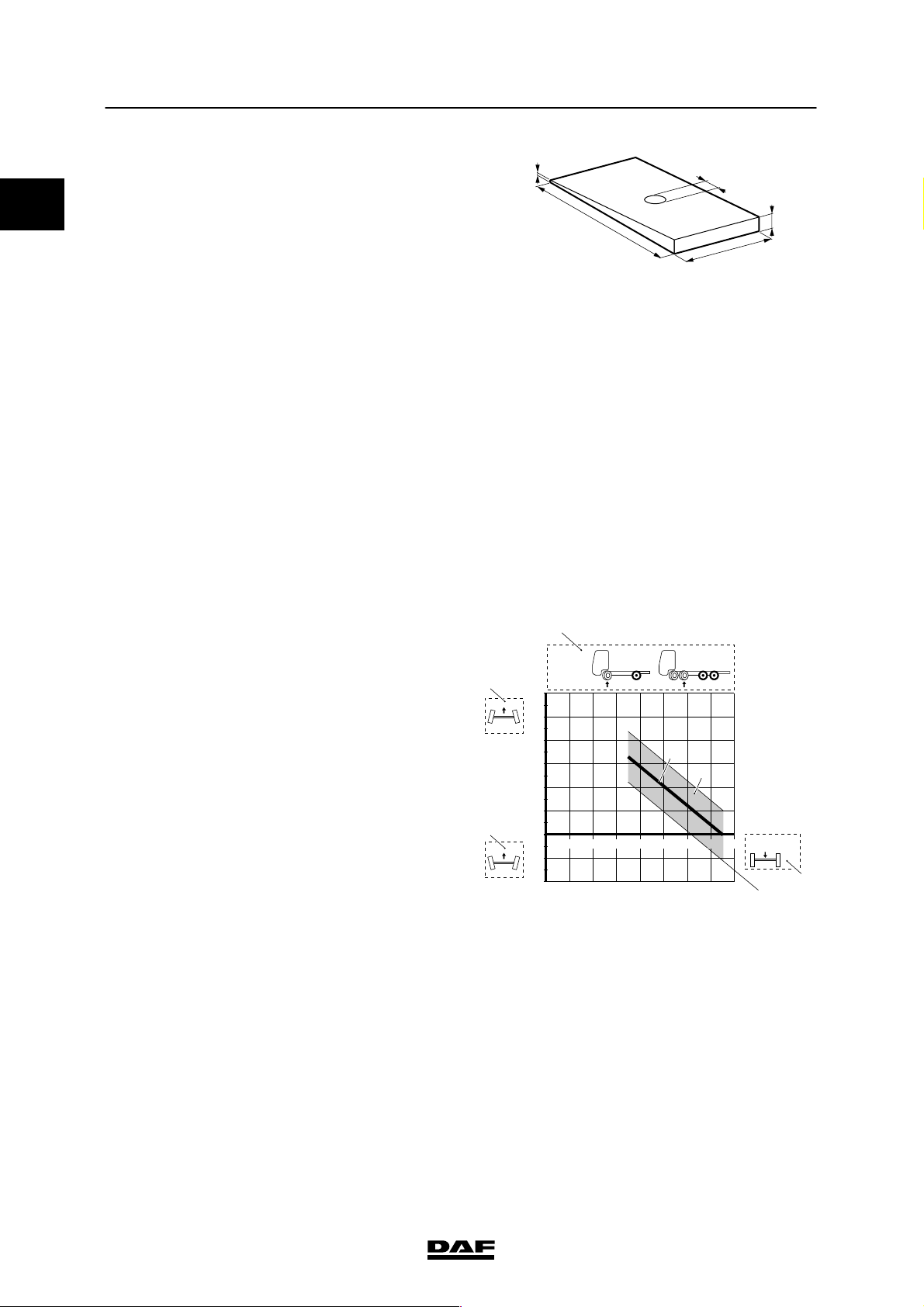

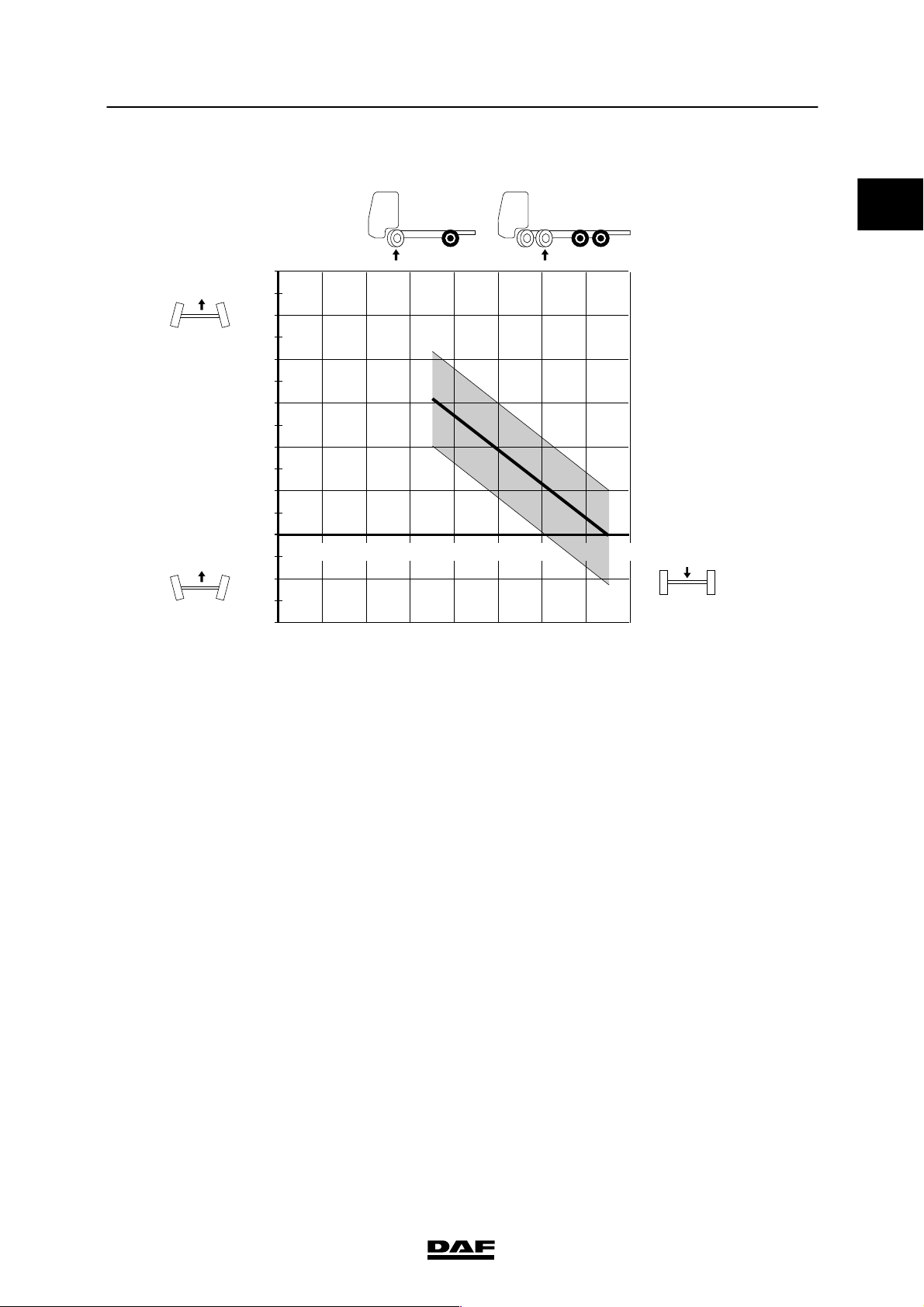

Toe values are shown in the graph.

Note:

In the graph, the toe has a value of

0.5 ᐔ 1 mm/m toe-in at 75% of the permissible

loading weight. The axle load consists of the

unloaded axle weight + loading weight.

1,5

±0,3

20,5

±0,3

±2

L

B

H

±1

S7 00 107

Explanation of graph

1. At the top of the graph, the axle type and

the axle configuration (1) is shown.

2. The toe is shown in mm/m on the left-hand

side of the graph. The values above the 0

line show toe-in values, indicated by the

symbol (2).

The values below the 0 line show toe-out

values, indicated by the symbol (3). The

toe-out values are shown as negative

values.

3. The axle load (4) is shown at the bottom of

the graph.

4. The permitted toe at any axle load is

indicated by the shaded area (5) in the

graph.

5. If the measured value lies outside the

shaded area, the toe must be adjusted to

the value indicated by the continuous

line (6).

1

mm/m

2

3

152 N

6

5,5

5

4,5

4

3,5

3

2,5

2

1,5

1

0,5

0

12345678

-0,5

-1

-1,5

-2

6

5

x 1000 KG

4

S7 00 422

6-2

ᓻ 200322

Page 25

7

TECHNICAL DATA

LF45/55 series 152N front axle

Toe, 152N front axle

0

mm/m

152 N

6

5,5

5

4,5

4

3,5

3

2,5

2

1,5

1

0,5

0

-0,5

12345678

-1

-1,5

-2

Steering ball joints

Axial play max. 1.5 mm

x 1000 KG

S7 00 414

Swivel axle

Axial play 0.05 - 0.3 mm

List of shim sizes (thickness) for adjusting

swivel axle play

1.50 mm

1.75 mm

1.88 mm

2.00 mm

2.13 mm

2.25 mm

2.38 mm

ᓻ 200322

6-3

Page 26

;

;

;

;

0

TECHNICAL DATA

7

152N front axle LF45/55 series

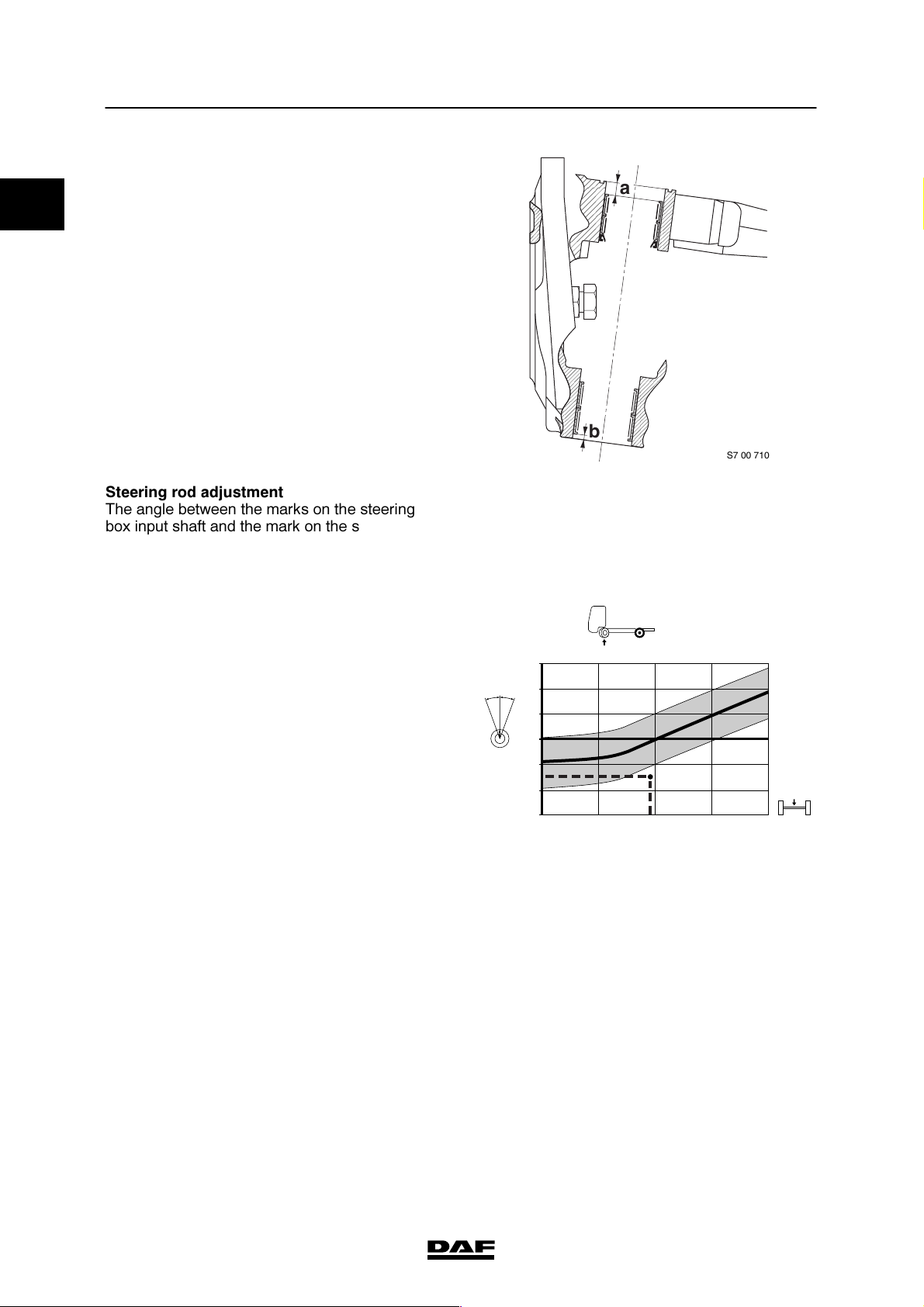

Wheel offset of needle bearings

- dimensiona:12-13mm

- dimensionb:3-4mm

a

b

S7 00 710

Steering rod adjustment

The angle between the marks on the steering

box input shaft and the mark on the steering box

for adjusting the steering rod are shown in the

graph. This angle is shown with the wheels of

the front axle in the “straight ahead” position.

Explanation of graph

1. The axle type and the axle configuration (1)

is shown at the top of the graph.

2. The angle between the marks on the

steering box input shaft and the mark on the

steering box (2) are shown on the left-hand

side of the graph.

Note that there are two different graphs for

LHD and RHD vehicles.

3. The front axle load (3) is shown at the

bottom of the graph.

4. The permitted angle at any axle load is

indicated by the shaded area (4) in the

graph.

5. If the measured value lies outside the

shaded area (4), the angle must be

adjusted to the value indicated by the

continuous line (5). Set the correct angle by

screwing the ball end of the steering rod in

or out.

+30

+20

0¡

+-

+10

0

-10

-20

-30

7500 7050

152 N

0,5

-9

-19

10

B

0

-10

A

5550 4150 3000

27

17

7

KG

S7 00 877

6-4

ᓻ 200322

Page 27

7

TECHNICAL DATA

LF45/55 series 152N front axle

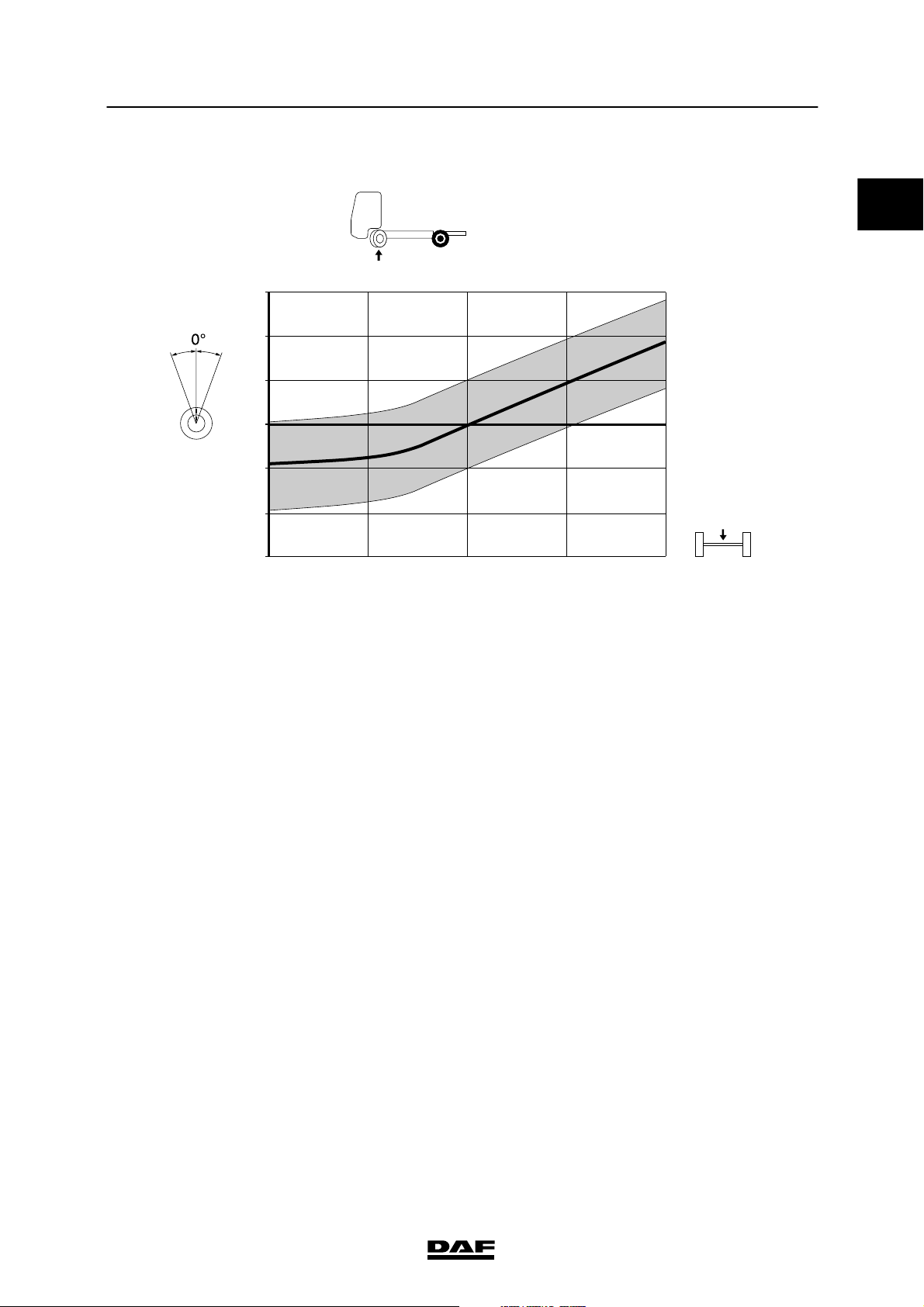

Steering rod adjustment, LHD vehicles

152 N

0

+30

+-

+20

+10

0,5

0

-9

-10

-19

-20

-30

7500 7050 5550 4150 3000

Note:

“+” on the vertical axis of the graph indicates

towards the driver’s side. “-- ” indicates towards

the co-driver’s side.

27

17

10

7

0

-10

KG

S7 00 886

ᓻ 200322

6-5

Page 28

0

TECHNICAL DATA

7

152N front axle LF45/55 series

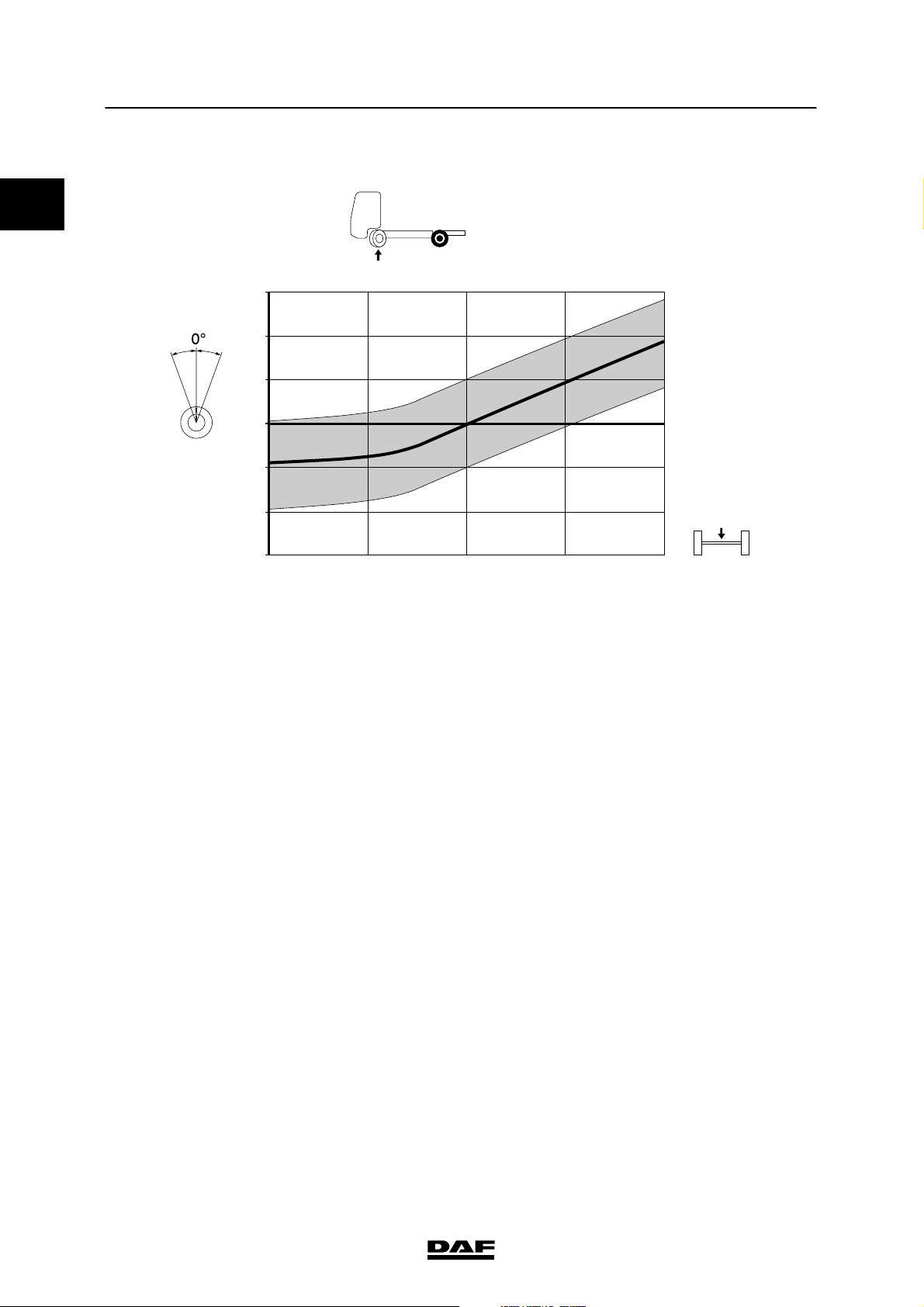

Steering rod adjustment, RHD vehicles

152 N

+30

+20

+-

+10

0,5

0

-9

-10

-19

-20

-30

7500 7050 5550 4150 3000

Note:

“+” on the vertical axis of the graph indicates

towards the driver’s side. “-- ” indicates towards

the co-driver’s side.

27

17

10

7

0

-10

KG

S7 00 876

Steering rod arm

Abutting surface of steering rod arm to swivel

axle treated with

Wheel speed sensor ring

Axial end play max. 0.25 mm

Loctite 2701

6-6

ᓻ 200322

Page 29

7

TECHNICAL DATA

LF45/55 series 152N front axle

6.2 TIGHTENING TORQUES

The tightening torques stated in this section are

different from the standard tightening torques

included in the overview of standard tightening

torques. Any other threaded connections that

are not specified must therefore be tightened to

the tightening torque stated in the overview of

standard tightening torques.

When attachment bolts and nuts are to be

replaced, it is important - unless stated

otherwise - that these bolts and nuts are of

exactly the same length and property class as

the ones removed

.

0

ᓻ 200322

6-7

Page 30

TECHNICAL DATA

7

152N front axle LF45/55 series

0

AB F

C

GH

D E

I

S7 00 883

A. Hub nut of wheel hub unit

st

-1

phase 400 Nm

-2ndphase turn the hub through 10 rotations

(1)

(2)

-3rdphase 450 Nm

th

-4

phase turn the hub through 10 rotations

(2)

-5thphase 950 Nm

B. Wheel nut 700 Nm

C. King-pin nut 595 Nm

(3)

(4)

D. Steering-rod arm attachment bolt 500 Nm + 90_ angular displacement

E. Steering rod castle nut 220 Nm

F. Attachment bolt, steering-rod clamping

bracket

90 Nm

G. M20 attachment nut, track rod 225 Nm

H. M12 attachment bolt, track rod clamping

bracket

80 Nm

(6)

(1)

(7)

(1)

I. Track rod arm attachment bolt 500 Nm + 90_ angular displacement

(5)

(5)

(1) Fit new nut.

(2) Rotate the hub at a speed of approx. 40 rpm.

(3) Retighten after 100 km. If new wheel bolts have been

fitted, the wheels need additional retightening after

500 km.

(4) Apply Loctite 243 to the nut.

(5) Fit new attachment bolt. Apply Loctite 243 to the

attachment bolt.

(6) Tighten until the split pin fits (max. 60_).

(7) Check the screw thread of the ball end for damage. Fit

new self-locking nut. Apply Loctite 243 to the nut.

6-8

ᓻ 200322

Page 31

7

TECHNICAL DATA

LF45/55 series Steered trailing swivel axle

7. STEERED TRAILING SWIVEL AXLE

7.1 GENERAL

Axle journal

Anti-corrosion agent Gleitmo 805

Wheel speed sensor

Anti-corrosion agent Molykote P37

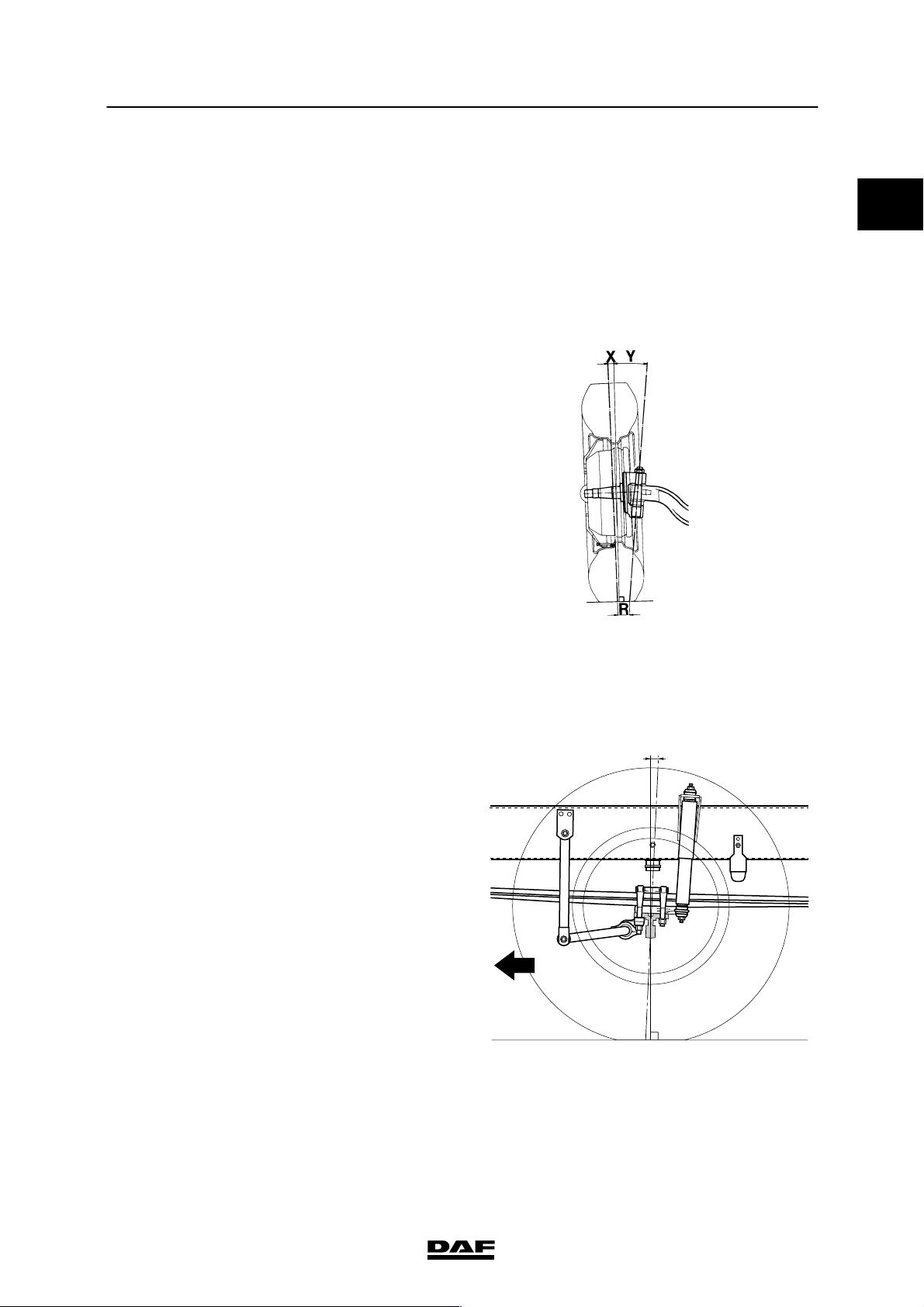

Camber angle and kingpin inclination (KPI)

Camber angle (X) on an

unloaded axle

King-pin inclination (Y) 7_15′

0_30′

0

S7 00 129

Wheel deflection

Maximum inner wheel

deflection

Caster

Z=caster

- unloaded 3_

- loaded 5.4_

20_

Z

S7 00 835

ᓻ 200322

7-1

Page 32

0

TECHNICAL DATA

7

Steered trailing swivel axle LF45/55 series

Toe

Measured at the side walls of the tyre (B -- A)

in unloaded condition

Toe-in 0 - 1.6 mm

A

B

S7 00 833

Steering ball joints

Axial play max. 1.5 mm

King pin

Pressing force 150 kN

Steering cylinder

Length, retracted 982 ᐔ 5mm

Length, centre position 1092 ᐔ 5mm

Length, extended 1202 ᐔ 5mm

7-2

ᓻ 200322

Page 33

7

TECHNICAL DATA

LF45/55 series Steered trailing swivel axle

7.2 TIGHTENING TORQUES

The tightening torques stated in this section are

different from the standard tightening torques

included in the overview of standard tightening

torques. Any other threaded connections that

are not specified must therefore be tightened to

the tightening torque stated in the overview of

standard tightening torques.

When attachment bolts and nuts are to be

replaced, it is important - unless stated

otherwise - that these bolts and nuts are of

exactly the same length and property class as

the ones removed

.

0

ᓻ 200322

7-3

Page 34

TECHNICAL DATA

7

Steered trailing swivel axle LF45/55 series

0

A

J

I

H

A. Steering cylinder arm attachment bolt 370 ᐔ 35 Nm

B. Attachment bolt, steering cylinder

clamping bracket

C. Attachment nut, trailing axle angle sensor

control rod

D. Steering cylinder castle nut 260 ᐔ 20 Nm

E. Track rod castle nut 280 ᐔ 25 Nm

F. Track rod clamping bracket attachment

bolt

G. Track rod arm attachment bolt 420 ᐔ 40 Nm

H. Wheel nut (M20 x 1.5) 485 ᐔ 35 Nm

I. Hub nut

J. Wheel hub attachment bolt 210 ᐔ 40 Nm

st

-1

-2ndphase turn the hub through 10 rotations

-3rdphase 350 Nm

-4

-5thphase 685 ᐔ 65 Nm

phase 300 Nm

th

phase turn the hub through 10 rotations

G

45 Nm

23 Nm

80 ᐔ 10 Nm

(1)

(2)

(3)

(3)

(2)

(1)

(4)

(5)

B

C

D

E

F

S7 00 891

(6)

(6)

(1) Replace the attachment bolts and apply Loctite 243.

(2) Fit new self-locking nut.

(3) Tighten until the split pin fits (max. 60_).

(4) Retighten after 100 km. If new wheel bolts have been

fitted, the wheels need additional retightening after

500 km.

(5) Fit new hub nut.

(6) Rotate the hub at a speed of approx. 40 rpm.

7-4

ᓻ 200322

Page 35

7

LF45/55 series Contents

DIAGNOSTICS

CONTENTS

Page Date

1. STEERING GEAR, GENERAL 1-1 200322........................................... ....

1.1 Fault-finding table 1-1 200322................................................. ....

1

ᓻ 200322

1

Page 36

1

7DIAGNOSTICS

Contents LF45/55 series

2

ᓻ 200322

Page 37

7

DIAGNOSTICS

LF45/55 series Steering gear, general

1. STEERING GEAR, GENERAL

1.1 FAULT-FINDING TABLE

SYMPTOM: HEAVY STEERING, TO BOTH SIDES

Possible cause Remedy

Tyre pressure of steerable wheels too low. Check the tyre pressure. Increase tyre pressure

to the specified value.

Semi-trailer coupling damaged or insufficiently

lubricated.

Axle load of steerable axle(s) too high. Check axle load.

Steering oil level too low. Check steering oil level.

Air in the system. Bleed the system.

Filter is extremely dirty. Check filter. Replace the filter, if necessary.

Steering oil pipe kinked or pinched off. Check routing of the steering oil pipes.

The intake opening in the reservoir is (partially)

blocked.

Tight steering column bearings or universal

joint(s).

Tight swivel axle bearing. Check steerable axle(s).

Excessive caster. Check caster. Reduce if necessary.

Inspect/lubricate semi-trailer coupling.

Adjust the load.

Top up oil and bleed system.

Check system for leaks.

Check steering oil for foaming.

Check intake opening in the reservoir.

Jack up front axle and check the steering column

tightening torque.

1

System pressure too low. Check maximum system pressure.

Replace pressure-limiting valve or steering

pump.

Steering pump output too low. Check pump output.

Check whether the flow-control valve is jammed.

Replace steering pump, if necessary.

Excessive internal steering box leakage Check for internal leaks in steering box.

ᓻ 200322

1-1

Page 38

DIAGNOSTICS

7

Steering gear, general LF45/55 series

SYMPTOM: HEAVY STEERING, TO ONE SIDE

Possible cause Remedy

1

Faulty two-way valve, on a vehicle with steered

trailing swivel axle.

Dirty high-pressure filter, on a vehicle with

steered trailing swivel axle.

Tyre pressure of steerable wheels too low. Check the tyre pressure. Increase tyre pressure

Semi-trailer coupling damaged or insufficiently

lubricated.

Steering oil level too low. Check steering oil level.

Air in the system. Bleed the system.

Wheel-deflection limiting valves set incorrectly. Check setting of the wheel deflection limiting

Tight swivel axle bearing. Check steerable axle(s).

Misalignment of the steering column universal

joints.

Excessive internal steering box leakage on one

side.

Check operation of two-way valve.

Check high-pressure filter. Replace the filter, if

necessary.

to the specified value.

Inspect/lubricate semi-trailer coupling.

Top up oil and bleed system.

Check system for leaks.

Check steering oil for foaming.

valves.

Check/adjust position of the universal joints in

relation to each other.

Check for internal leaks in steering box.

1-2

ᓻ 200322

Page 39

7

DIAGNOSTICS

LF45/55 series Steering gear, general

SYMPTOM: HEAVY STEERING, OCCASIONALLY

Possible cause Remedy

Semi-trailer coupling damaged or insufficiently

lubricated.

Steering oil level too low. Check steering oil level.

Air in the system. Bleed the system.

The steering oil pipe is temporarily kinked or

pinched off.

The intake opening in the reservoir is temporarily

blocked.

Steering pump output too low because

flow-control valve is jammed.

Low steering-pump output in “cold condition” and

at low engine speed because the partitions jam in

the rotor.

Excessive internal steering box leakage at lower

pressures.

Faulty two-way valve, on a vehicle with steered

trailing swivel axle.

Inspect/lubricate semi-trailer coupling.

Top up oil and bleed system.

Check system for leaks.

Check steering oil for foaming.

Check routing of the steering oil pipes.

Check reservoir for impurities.

Check the flow-control valve for smooth

operation.

Check pump output when steering pump is

“cold”.

Replace steering pump.

Check internal steering box leakage at a set

pressure of 15-30 bar.

Check operation of the two-way valve.

1

ᓻ 200322

1-3

Page 40

DIAGNOSTICS

7

Steering gear, general LF45/55 series

SYMPTOM: WHEEL DEFLECTION TOO SMALL

Possible cause Remedy

The vehicle is being steered when at a standstill. Steer while the vehicle is moving.

1

Incorrect setting of maximum wheel deflection on

the axle.

Wheel deflection limiting valves incorrectly

adjusted.

Axle load of steerable axle(s) too high. Check the axle load(s).

System pressure too low. Check maximum system pressure.

Steering rod adjusted incorrectly. Check steering rod setting.

Pitman arm installed in the wrong position on

steering box output shaft.

Sector shaft is installed in the wrong position in

the steering box.

Check maximum wheel deflection and, if

adjusted incorrectly, correct.

Check setting of the wheel deflection limiting

valves.

Adjust the load.

Replace pressure-limiting valve or steering

pump.

Check whether position of pitman arm on the

sector shaft is correct, using the marks.

Put steering box in the central position and check

whether the sector shaft is correctly installed,

using the marks on the input shaft and on the

sector shaft.

1-4

ᓻ 200322

Page 41

7

DIAGNOSTICS

LF45/55 series Steering gear, general

SYMPTOM: VEHICLE PULLS TO ONE SIDE

Possible cause Remedy

Uneven weight distribution causing the vehicle to

tilt.

Semi-trailer coupling insufficiently lubricated. Lubricate semi-trailer coupling.

Driving over cambered roads. When driving over cambered roads, bear in mind

Difference in tyre pressure between the wheels

on the steerable axle(s).

Different tyre types or difference in tread depth

between tyres of the steerable axle(s).

Different wheel rims installed on the steerable

axle(s).

Fault in one of the tyres. Replace the tyre on the side to which the vehicle

Steerable axle brake(s) continue to “hang”. Check brakes. Carry out any repairs.

Misalignment of the steering column universal

joints.

Excessive wheel bearing play. Check the wheel bearings for play. Replace the

Incorrect caster. Check caster. Set correct caster.

Incorrect camber angle. Check camber angle.

Adjust the weight distribution.

that the vehicle might pull to one side.

Check the tyre pressure. Pump both tyres up to

the specified value.

Always fit tyres of the same type and tread depth

on the axle.

Always install wheel rims of the same type on the

axle.

pulls.

Check/adjust position of the universal joints in

relation to each other.

wheel bearings if necessary.

Check axle housing.

1

Incorrect alignment of steerable axle(s). Check alignment of the steerable axle(s.) Adjust

steering rod correctly.

Alignment/calibration of steered trailing swivel

axle incorrect.

Alignment of rear axle(s) or of trailer/semi-trailer

incorrect.

Check alignment/calibration of steered trailing

swivel axle.

Correct alignment/calibration.

Check alignment of the rear axle(s) or of

trailer/semi-trailer. Align axles.

ᓻ 200322

1-5

Page 42

DIAGNOSTICS

7

Steering gear, general LF45/55 series

SYMPTOM: VEHICLE PULLS TO ONE SIDE

Possible cause Remedy

Front-axle/rear-axle suspension play. Check suspension. Replace worn parts.

1

Difference in spring opening between the leaf

springs of one axle

Incorrect setting of air suspension. This will

cause the vehicle to tilt.

Steering-pump output too high. Check pump output.

Incorrect hydraulic central position of the steering

box.

Measure the spring opening of the springs.

Replace springs.

Check height adjustment. Set the height control

correctly.

Check the flow-control valve for smooth

operation.

Check the hydraulic central position of the

steering box.

The hydraulic central position cannot be

adjusted.

Replace the steering box.

1-6

ᓻ 200322

Page 43

7

DIAGNOSTICS

LF45/55 series Steering gear, general

SYMPTOM: VEHICLE IS SEARCHING, TRACKING INSTABILITY

Possible cause Remedy

Tyre pressure of steerable wheels too low. Check the tyre pressure.

Increase tyre pressure to the specified value.

Semi-trailer coupling insufficiently lubricated or

damaged.

Incorrect steering-box pressure-point setting;

play at the pressure point or pressure point set

too tight.

Axle load on front axle too low. Check axle load and adjust the load.

Incorrect toe-in. Check toe-in.

Incorrect caster. Check caster.

Alignment/calibration of steered trailing swivel

axle incorrect.

Play in a universal joint or in the steering column

sliding joint. Tight universal joint.

Misalignment of the universal joints in the

steering column.

Play in the steering-rod ball joints Check ball joints.

Steering box, steering bracket or steering rod

attachment loose.

Inspect/lubricate semi-trailer coupling.

Check pressure point setting. Set correct

pressure point.

Set correct toe-in.

Set correct caster.

Check alignment/calibration of steered trailing

swivel axle.

Correct alignment/calibration.

Check universal joints and the steering column

sliding joint. Replace worn parts.

Check/adjust position of the universal joints in

relation to each other.

Replace ball joint.

Check attachments, retighten bolts/nuts.

1

Worn or tight swivel axle bearing. Check swivel axle bearing.

Replace worn parts.

Incorrect steering-rod adjustment; when the

wheels are in the “straight ahead” position, the

steering box is not in its mechanical central

position (pressure point).

Front-axle and/or rear-axle suspension play. Check axle suspension. Replace worn parts.

Check steering rod setting.

Adjust steering rod correctly.

ᓻ 200322

1-7

Page 44

1

DIAGNOSTICS

Steering gear, general LF45/55 series

SYMPTOM: VEHICLE IS SEARCHING, TRACKING INSTABILITY

Possible cause Remedy

Steering pump output too high. Check steering pump output.

Check the flow-control valve for smooth

operation.

Replace steering pump, if necessary.

Excessive internal steering box resistance. Check internal steering box resistance.

Replace steering box.

Internal defect in the steering box. Replace steering box.

7

1-8

ᓻ 200322

Page 45

7

DIAGNOSTICS

LF45/55 series Steering gear, general

SYMPTOM: STEERING WHEEL DOES NOT RETURN TO THE “STRAIGHT AHEAD” POSITION

(OR ONLY VERY SLOWLY)

Possible cause Remedy

Tyre pressure of steerable wheels too low. Check the tyre pressure.

Increase tyre pressure to the specified value.

Semi-trailer coupling insufficiently lubricated or

damaged.

Inspect/lubricate semi-trailer coupling.

1

Misalignment of the steering column universal

joints.

Axle load on front axle too low. Check axle load and adjust the load.

Incorrect caster. Check caster.

Tight universal joint or steering column bearing. Check universal joints and steering column

Friction between mechanical parts of the steering

gear (pitman arm, steering rod/steering arm or

track rod/track rod arm).

Steering box or steering bracket loose. Check attachments, retighten bolts.

Tight swivel axle bearing. Check swivel axle bearing.

Steering pump output too high. Check pump output.

Pressure point set too tight. Check pressure point setting. Adjust pressure

Excessive internal steering box resistance. Check internal steering box resistance.

Internal defect in the steering box. Replace steering box.

Check/adjust position of the universal joints in

relation to each other.

Set correct caster.

bearing. Replace worn parts.

Check mechanical parts of the steering gear.

Check the flow-control valve for smooth

operation.

Replace pump.

point correctly.

Replace steering box.

ᓻ 200322

1-9

Page 46

1

DIAGNOSTICS

7

Steering gear, general LF45/55 series

SYMPTOM: JOLTING OF THE STEERING WHEEL

Possible cause Remedy

Air in the system. Check steering oil level and bleed system.

Worn or loose shock absorbers on the front axle. Check the attachment.

Replace shock absorbers.

Steering pump output too low. Check steering pump output.

Loose steering rod, track rod, steering bracket or

steering box.

Excessive internal steering box play. Check the input shaft play.

SYMPTOM: VIBRATIONS IN THE STEERING WHEEL

Possible cause Remedy

Dirt between wheel rim and hub. Remove wheel and clean wheel rim and hub.

Wheel studs unevenly tightened. Loosen all nuts and tighten these as specified.

Wheel imbalance. Balance wheel statically and dynamically.

SYMPTOM: AIR IN THE STEERING OIL

Possible cause Remedy

Reservoir oil level too low. Check the oil level.

Internal steering pump seals are poor. Replace steering pump.

Check/tighten attachment of these components.

Check the steering box pressure point.

Replace the steering box.

Install wheel in the specified manner.

Topupoil.

Check for leaks.

1-10

ᓻ 200322

Page 47

7

DIAGNOSTICS

LF45/55 series Steering gear, general

SYMPTOM: STEERING OIL LEAKAGE

Possible cause Remedy

Leaking delivery or return pipe.

Leaking delivery or return-pipe connection.

Reservoir or reservoir/steering pump seal

leaking.

Leaking steering pump. Check the steering pump for leaks.

Leaking steering box. On the steering box, check the following seals:

The melting point of the grease behind the dust

seal of the sector shaft or the input shaft is too

low.

There appears to be a leak in the steering box,

but in fact the grease has melted.

Check the pipes and pipe connections.

Tighten pipes securely.

Replace the reservoir or repair the

reservoir/steering pump seal.

- input shaft oil seal

- cover O-ring on underside of steering box

- pressure-limiting valve O-ring

- wheel-deflection limiting valve stop bolts

- various plugs and connection nipples

Depending on the leak, replace the input shaft oil

seal, the O-ring of the cover on the underside of

the steering box, the pressure-limiting valve

O-ring, the stop bolt and wheel-deflection limiting

valve sealing rings and the seals of the various

plugs and connection nipples.

Replace the steering box in the case of leaks

other than those described above.

Replace the grease with grease of the specified

type (melting point >130_C.

1

ᓻ 200322

1-11

Page 48

1

DIAGNOSTICS

7

Steering gear, general LF45/55 series

NOISE

Note:

The steering gear always produces noise.

Normal noise:

- a hissing noise in the steering box while

steering. The noise level depends on the

system pressure.

- an increasing sound level when the

wheel-deflection limiting valve is opened.

- a maximum sound level when the

pressure-limiting valve is opened.

SYMPTOM: STEERING PUMP PRODUCES A SQUEALING NOISE WHILE STEERING

Possible cause Remedy

Oil level too low, causing the steering pump to

draw air.

Air in the steering oil. Check oil for the presence of air (foaming).

The intake opening in the reservoir is (partially)

blocked.

SYMPTOM: THE STEERING PUMP PRODUCES A DIFFERENT NOISE WHEN AT IDLING SPEED.

THE NOISE LEVEL INCREASES WHEN THE ENGINE SPEED INCREASES

Possible cause Remedy

Worn steering pump. Replace steering pump.

Check the oil level.

Top up oil and check for leaks.

Bleed system and trace the cause.

Check intake opening in the reservoir.

Replace steering oil.

Clean the reservoir and pipes.

Replace filter.

1-12

ᓻ 200322

Page 49

7

DIAGNOSTICS

LF45/55 series Steering gear, general

SYMPTOM: WHEN STEERING THE SOUND OF METAL SCRAPING AGAINST METAL IS HEARD

Possible cause Remedy

Loose steering box, steering bracket or pitman

arm.

Play in a steering-rod or track-rod ball joint. Check ball joints.

There is friction between steering gear

components.

Play in the steering column sliding joint. Check sliding joint for wear.

Check attachment of components.

Tighten bolts to the specified tightening torque.

Replace ball joint.

Turn steering gear carefully from one stop to the

other and check the mechanical part of the

steering gear for friction.

Replace sliding joint.

1

ᓻ 200322

1-13

Page 50

1

DIAGNOSTICS

Steering gear, general LF45/55 series

7

1-14

ᓻ 200322

Page 51

7

STEERING GEAR, GENERAL

LF45/55 series Contents

CONTENTS

Page Date

1. SAFETY INSTRUCTIONS 1-1 200322............................................... ....

2. GENERAL 2-1 200322............................................................ ....

2.1 Overview drawing of steering gear,

version without steered trailing swivel axle 2-1 200322........................... ....

2.2 Overview drawing of steering gear,

version with steered trailing swivel axle 2-2 200322.............................. ....

2.3 System description of steering gear,

version without steered trailing swivel axle 2-3 200322........................... ....

2.4 System description of steering gear,

version with steered trailing swivel axle 2-5 200322.............................. ....

3. INSPECTION AND ADJUSTMENT 3-1 200322....................................... ....

3.1 Inspecting the steering gear using a pressure gauge 3-1 200322................... ....

3.2 Inspecting steering gear using the test case 3-4 200322.......................... ....

3.3 Checking the steering box attachment 3-12 200322............................... ...

3.4 Checking hydraulic centre position 3-12 200322.................................. ...

4. DRAINING, FILLING AND BLEEDING 4-1 200322................................... ....

4.1 Draining, filling and bleeding steering gear,

version without steered trailing swivel axle 4-1 200322........................... ....

4.2 Draining, filling and bleeding steering gear,

version with steered trailing swivel axle 4-4 200322.............................. ....

2

ᓻ 200322

1

Page 52

2

7STEERING GEAR, GENERAL

Contents LF45/55 series

2

ᓻ 200322

Page 53

7

STEERING GEAR, GENERAL

LF45/55 series Safety instructions

1. SAFETY INSTRUCTIONS

The steering gear is one of the most important

systems on the vehicle in terms of safety. This

should be borne in mind at all times when

carrying out maintenance and repair work on the

steering gear. Always work in a very clean

environment; even the smallest amount of dirt in

the system can cause faults.

Repair and maintenance work on the steering

gear should only be carried out by experienced

mechanics with the appropriate training.

If the vehicle is fitted with an airbag,

observe the warnings and safety

instructions applicable to working

on an airbag system.

Tighten all joints to the specified torque, see

“Technical data”.

Always check pipe connections for leaks after

tightening.

2

If the vehicle has been involved in a collision, in

which the steering box or other steering gear

components (may) have been damaged, the

steering box must always be sent to DAF for

inspection or be replaced. This requirement still

applies even if no external damage is visible.

The steering box may have sustained internal

damage in the collision, causing it to be

unreliable.

The other steering gear components, which

could have been damaged, such as the steering

and track rods, steering and track-rod arms,

steering bracket, pitman arm and the

attachments of these components must always

be checked for distortions, cracks, fractures, etc.

If possible, all components should be magnaflux

tested.

Damaged components must always be

replaced. If in doubt, always replace the

component.

ᓻ 200322

1-1

Page 54

2

STEERING GEAR, GENERAL

7

Safety instructions LF45/55 series

Always use original DAF components when

replacing components.

Do not take risks. Replace components if in

doubt.

Welding of steering-mechanism components is

prohibited.

Straightening of steering gear components is

prohibited.

An incorrect pressure point setting will affect the

vehicle’s steering characteristics.

Check the thread of the ball end for damage

before fitting a new castle nut or self-locking nut

to the ball end.

Screwing a new castle nut or

self-locking nut onto a ball end with

a damaged screw thread can give

rise to dangerous situations.

Always take a test drive after completing

maintenance or repair work on the steering gear.

Be aware during this test drive that the steering

gear may not function properly.

1-2

ᓻ 200322

Page 55

7

LF45/55 series General

STEERING GEAR, GENERAL

2. GENERAL

2.1 OVERVIEW DRAWING OF STEERING GEAR, VERSION WITHOUT STEERED

TRAILING SWIVEL AXLE

3 4

1

2

2

1. Reservoir

2. Steering pump

3. Delivery pipe

4. Steering box

5. Return pipe

5

S7 00 536

ᓻ 200322

2-1

Page 56

2

STEERING GEAR, GENERAL

General LF45/55 series

2.2 OVERVIEW DRAWING OF STEERING GEAR, VERSION WITH STEERED

TRAILING SWIVEL AXLE

1

2

7

4

5

1. Reservoir

2. Steering pump

3. High-pressure filter

4. Distribution block

5. Steering box with angle sensor

6. RAS-EC steering gear

3

RAS-EC

6

S7 00 836

2-2

ᓻ 200322

Page 57

7

STEERING GEAR, GENERAL

LF45/55 series General

2.3 SYSTEM DESCRIPTION OF STEERING GEAR, VERSION WITHOUT

STEERED TRAILING SWIVEL AXLE

3 4

1

2

2

The oil flows to the steering pump (2) from the

reservoir (1) mounted on the steering pump (2).

There is a filter in the reservoir (1). The filter and

reservoir form part of a single unit. At maximum

pump output, the oil is pumped to the reservoir

with approx.

approx.

reservoir (1).

The steering pump is a non-regenerative vane

pump. Once the pump starts supplying oil, the

steering pump (2) will continue to draw oil by

itself.

The steering pump (2) pumps the oil through the

delivery pipe (3) to the steering box (4).

1

/3passing through the filter (2) and

2

/3of the oil pumped directly to the

5

S7 00 536

ᓻ 200322

2-3

Page 58

2

STEERING GEAR, GENERAL

7

General LF45/55 series

From the steering box (4), the oil is returned to

the reservoir (1) through the return pipe (5). The

pressure in the return pipe is always low.

The pressure in the delivery pipe (3) varies and

depends on the steering force. If there is no

steering action, the oil in the delivery pipe is at

circulation pressure.

If a steering action takes place, the pressure in

the delivery pipe (3) can increase to the preset

value of the pressure-limiting valve.

This maximum pressure may occur when the

vehicle is steered while at a standstill on a

skid-resistant road surface or when the vehicle

is parked against a curb and the steering wheel

is turned.

When at maximum pressure a major

transmission of energy will take place, resulting

in the release of much heat. If this situation lasts

too long, the steering pump can be damaged by

the heat development.

The steering pump is capable of generating a

very high pressure over a short period

(depending on the pump type up to approx.

300 bar). This very high pressure can cause

certain steering-mechanism components to

become overloaded or even to break off.

The pressure-limiting valve protects the steering

mechanism from excessive pressures.

Increasing the system pressure is not permitted.

The pressure-limiting valve is located in the

steering box. This can be checked using the

type plate on the steering box. If a pressure

value is stated on the type plate, the component

concerned contains a pressure-limiting valve.

It can be very dangerous to replace

the steering box or the steering

pump with a different type of

steering box or pump. Therefore,

replacing these components

without DAF’s express permission

is prohibited. If the original type is

no longer available, DAF will supply

another approved type.

2-4

ᓻ 200322

Page 59

7

LF45/55 series General

2.4 SYSTEM DESCRIPTION OF STEERING GEAR, VERSION WITH STEERED

TRAILING SWIVEL AXLE

STEERING GEAR, GENERAL

1

2

2

3

4

5

The oil flows to the steering pump (2) from the

reservoir (1).

There is a filter element in the reservoir. The

filter element is fitted in the return pipe.

RAS-EC

6

S7 00 836

ᓻ 200322

2-5

Page 60

2

STEERING GEAR, GENERAL

7

General LF45/55 series

The steering pump (2) is a non-regenerative

vane pump. Once the pump starts supplying oil,

the steering pump will continue to draw oil itself.

The steering pump pumps the oil through the

delivery pipe to the high-pressure filter (3).

The steering oil is pumped from the

high-pressure filter to the distribution block (4).

The flow of oil is divided into two equal parts in

the distribution block: one for the front axle

steering gear and one for the rear axle steering

gear.

From the steering box (5), the oil is returned to

the reservoir (1) through the return pipe. The

pressure in the return pipe is always low.

The pressure in the delivery pipe varies and

depends on the steering force. If there is no

steering action, the oil in the delivery pipe is at

circulation pressure.

If a steering action takes place, the pressure in

the delivery pipe can increase to the preset

value of the pressure-limiting valve.

This maximum pressure can occur when the

vehicle is steered while at a standstill on a

skid-resistant road surface or when the vehicle

is parked against a curb and the steering wheel

is turned.

When at maximum pressure a major

transmission of energy will take place, resulting

in the release of much heat. If this situation lasts

too long, the steering pump can be damaged by

the heat development.

The steering pump is capable of generating a

very high pressure over a short period

(depending on the pump type up to approx.

300 bar). This very high pressure can cause

certain steering-mechanism components to

become overloaded or even to break off.

2-6

ᓻ 200322

Page 61

7

STEERING GEAR, GENERAL

LF45/55 series General

The pressure-limiting valve protects the steering

mechanism from excessive pressures.

Increasing the system pressure is not permitted.

The pressure-limiting valve is located in the

steering box. This can be checked using the

type plate on the steering box. If a pressure

value is stated on the type plate, the component

concerned contains a pressur-limiting valve.

It can be very dangerous to replace

the steering box or the steering

pump with a different type of

steering box or pump. Therefore,

replacing these components

without DAF’s express permission

is prohibited. If the original type is

no longer available, DAF will supply

another approved type.

2

ᓻ 200322

2-7

Page 62

2

STEERING GEAR, GENERAL

General LF45/55 series

7

2-8

ᓻ 200322

Page 63

7

STEERING GEAR, GENERAL

LF45/55 series Inspection and adjustment

3. INSPECTION AND ADJUSTMENT

3.1 INSPECTING THE STEERING GEAR USING A PRESSURE GAUGE

Note:

A quick check of the steering gear can be

carried out using a pressure gauge. The gauge

used for checking the final limiting pressure can

be used for this purpose.

Only a limited number of measurements can be

carried out using a pressure gauge. A test

equipment case is required to test the steering

pump (output in l/min. at a specific pressure)

and the condition of the steering-box (internal

sealing, play).

If the cause of the problem cannot be traced

with the pressure gauge, the problem on the

steering gear should be diagnosed using the

test case.

Always check the tightening torque

of the steering wheel bolt after the

steering wheel has been turned

using a torque wrench.

2

Points for attention when connecting the

pressure gauge:

1. Clean the delivery pipe connections that are

going to be disconnected.

2. Check the steering box attachment.

3. Check the hydraulic central position.

4. Place proper turning plates under the

vehicle’s steerable wheels.

Block the vehicle so that it cannot

slide off the jack or the turning

plates.

ᓻ 200322

3-1

Page 64

2

STEERING GEAR, GENERAL

7

Inspection and adjustment LF45/55 series

Connecting pressure gauge

Only use couplings and pipes which

are suitable for the maximum

system pressure.

1. Connect the pressure gauge, using the

special tool (DAF no. 0535653) to the

T-piece in the delivery pipe. Make sure that

as little steering oil as possible escapes and

clear away spilt oil.

2. Check the steering oil level and top up as

necessary.

3. Bleed the steering gear, see “Draining,

filling and bleeding”.

Bringing the steering oil up to the test

temperature

1. Set the engine speed to 1200 - 1400 rpm.

2. Activate the steering gear for 5 seconds at

its maximum, making sure that the pressure

does not exceed 50 bar. Do not touch the

steering wheel for 5 seconds.

3. Repeat this procedure until the pipes are

warm to the touch, at least.

Measuring the circulation pressure

1. Run the engine at idling speed.

2. Check the circulation pressure. Compare

the reading with the specified value, see

“Technical data”.

Checking front axle bearings

1. Run the engine at idling speed.

2. Turn the steering wheel evenly from the

central position to both maximum wheel

deflections.

3. Check whether the pressure rises evenly.

S7 00 614

3-2

ᓻ 200322

Page 65

7

STEERING GEAR, GENERAL

LF45/55 series Inspection and adjustment

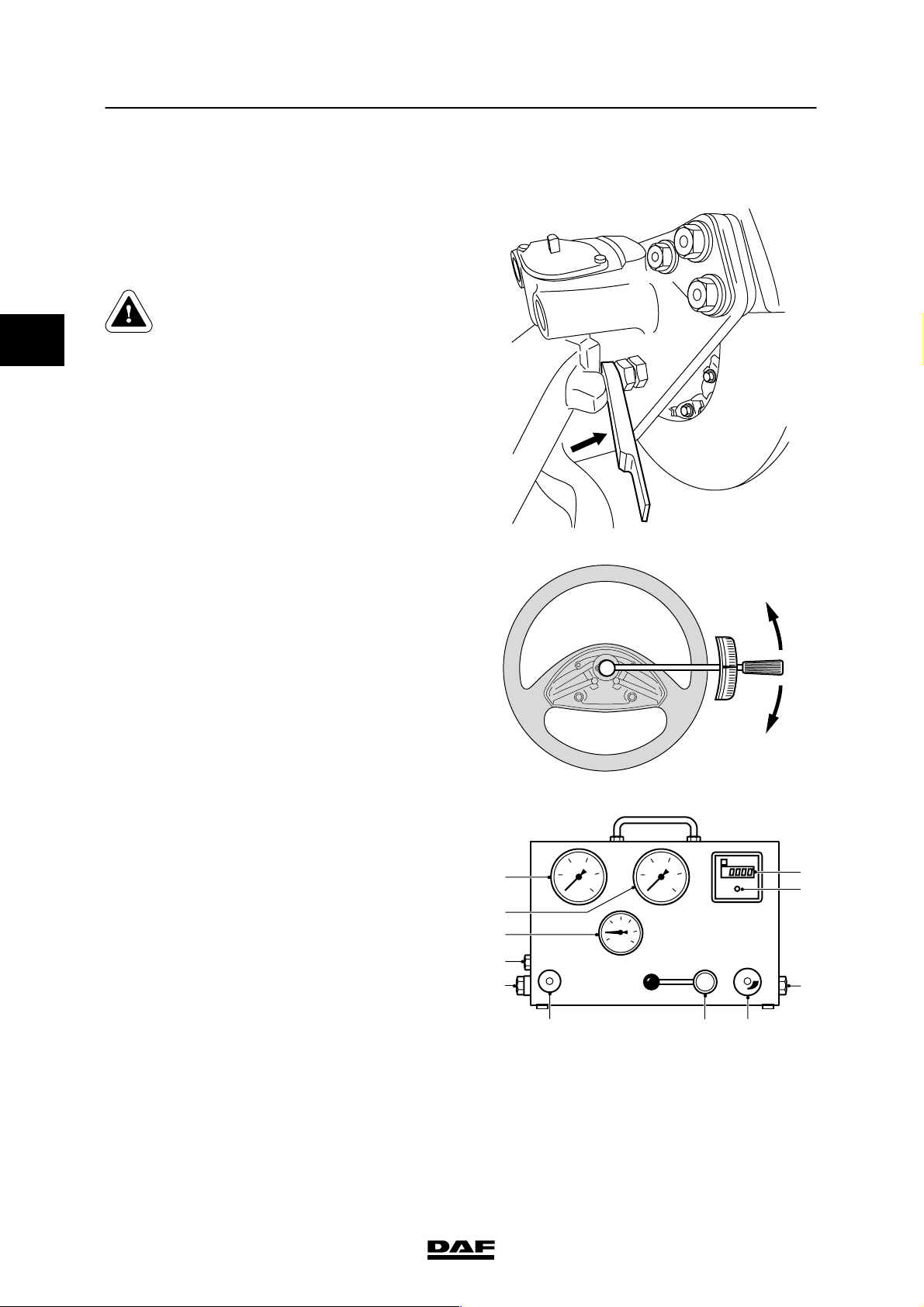

Testing the maximum system pressure.

1. Run the engine at idling speed.

2. Activate the steering gear and fit a 15 mm

filler piece, special tool (DAF no. 0535996),

between the adjusting bolt or the axle stop

on the swivel axle and axle-housing stop.

Be careful when fitting the 15 mm

filler piece between the adjusting

boltandtheaxlestop,asthereisa

danger of limbs getting trapped.

S7 00 598

2

3. Fit a torque wrench with a dial to the

steering wheel attachment bolt. Tighten the

bolt to a tightening torque of 45 Nm on the

torque wrench.

4. Take the maximum pressure reading on the

pressure gauge (the maximum pressure

should not be held for more than 5

seconds). Compare the reading with the

specified value, see “Technical data”.

Note:

If the reading deviates more than 10% from

the specified value, the cause should be

identified using the test case.

5. Repeat the measurement using the 15 mm

filler piece at the other end of the front axle.

6. Retighten the steering-wheel attachment

bolt to the specified tightening torque, see

“Technical data”.

7. Remove the pressure gauge and the

T-piece.

8. Check the steering oil level in the reservoir

and top up if necessary.

45Nm

45Nm

S7 00 611

9. Bleed the steering gear, see “Draining,

filling and bleeding”.

ᓻ 200322

3-3

Page 66

2

STEERING GEAR, GENERAL

7

Inspection and adjustment LF45/55 series

3.2 INSPECTING STEERING GEAR USING THE TEST CASE

Note:

Thetestcaseisusedto:

- inspect the condition of the entire steering

gear on a regular basis;

- make a reliable diagnosis if the steering

gear does not function properly.

Inspection using a pressure gauge will only

provide information on system pressures, which

in some cases might be insufficient to trace the

fault. However, this provides no information on

the condition of the steering pump (output) and

the steering box (internal leaks). This often

results, in practice, in steering pumps and

steering boxes being replaced unnecessarily.

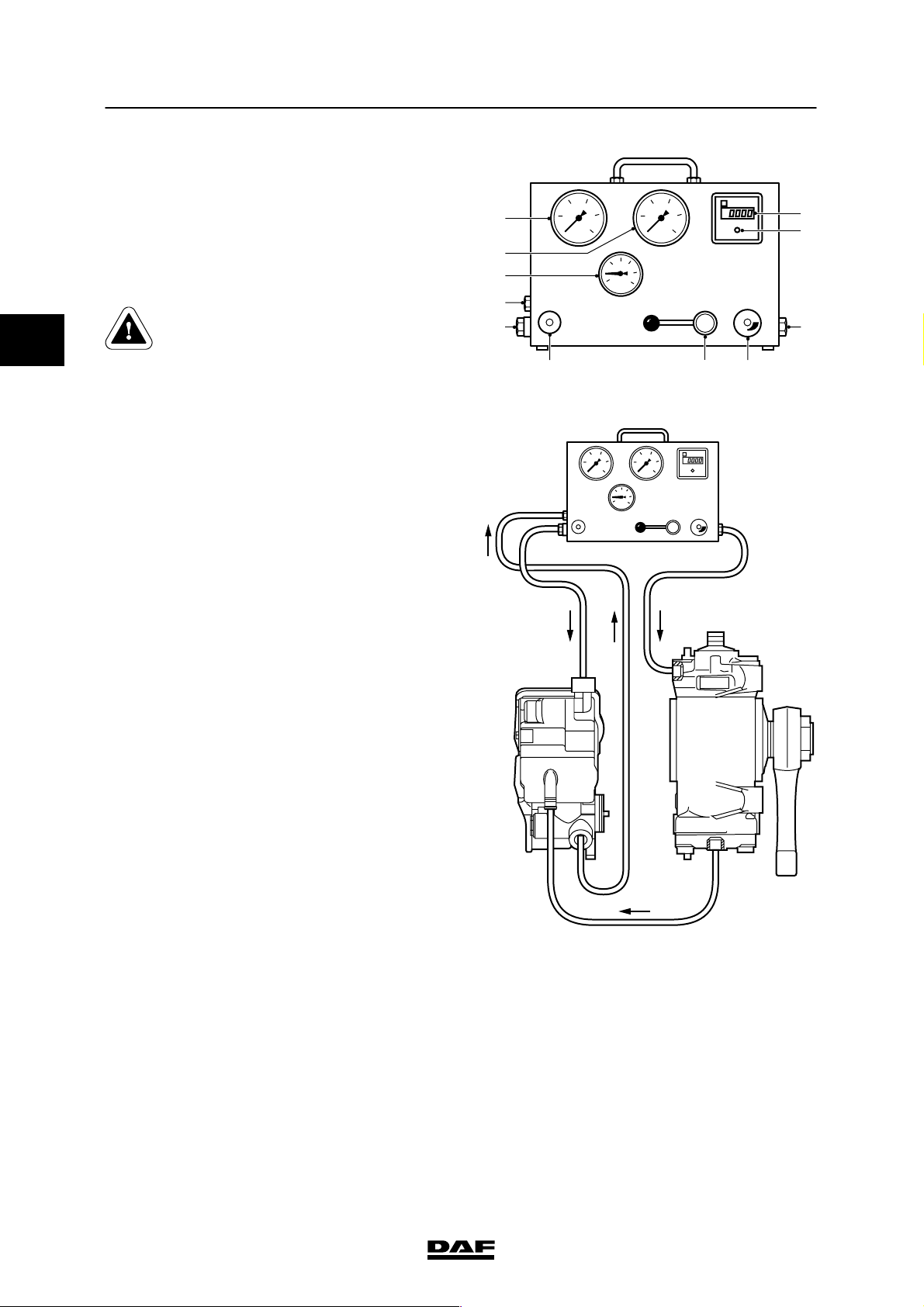

Electronic test equipment case

“Servotest 550”

The inspection referred to below is carried out

using the “Servotest 550” test equipment case. It

is also possible to inspect the steering gear

using similar equipment that can be used to

carry out the same measurements as the

“Servotest 550”.

The test case is connected to the delivery pipe,

which runs from the steering pump to the

steering box.

The “Eingang” (input) pipe connection is fitted

with a filter, which should be cleaned regularly,

depending on the amount of dirt in the oil.

Always check the tightening torque

of the steering wheel bolt after the

steering wheel has been turned

using a torque wrench.

3-4

ᓻ 200322

Page 67

7

STEERING GEAR, GENERAL

LF45/55 series Inspection and adjustment

The “Servotest 550” test equipment case

consists of the following parts:

1. “Eingang” (input) connection

2. “Ausgang” (output) connection

3. “Tank” connection

4. Valve

5. Non-return valve (throttle)

6. Pressure-limiting valve 120/150 bar (switch

over)

7. Output meter 0.01 - 100 l/min.

8. Switch for output meter

9. Low-pressure pressure gauge0-25bar

10. High-pressure pressure gauge 0 - 250 bar

11. Temperature gauge0-120_C.

Points for attention when connecting the test

case:

1. Clean the delivery pipe connections that are

going to be disconnected.

2. Check the steering box attachment.

9

10

11

1

3

5

10 15

20

25

100 150

50

200

250

465

S7 00 020

7

8

2

2

3. Check the hydraulic central position.

4. Place proper turning plates under the

vehicle’s steerable wheels.

Block the vehicle so that it cannot

slide off the jack or the turning

plates.

S7 00 610

ᓻ 200322

3-5

Page 68

2

STEERING GEAR, GENERAL

7

Inspection and adjustment LF45/55 series

Connecting the test case

1. Check whether the non-return valve (5) of

the “Servotest 550” is completely closed,

the valve (4) has been fully opened and the

pressure adjusting device (6) of the

pressure-limiting valve is set in accordance

with the maximum steering system

pressure.

Only use couplings and pipes that

are suitable for the maximum

9

10

11

1

3

5

10 15

20

25

100 150

50

200

250

system pressure.

465

2. Connect the test case to the delivery pipe.

Make sure that as little steering oil as

possible escapes and clear away spilt oil.

Connect the pipe from the “Eingang”

connection of the test equipment case to

the part of the pipe from the steering pump.

Connect the pipe from the “Ausgang”

connection of the test equipment case to

the part of the pipe going to the steering

box.

10 15

5

100 150

50

20

25

200

250

S7 00 020

7

8

2

Note:

In the case of vehicles with a steered

trailing swivel axle, connect the test case in

the delivery pipe downstream of the

two-way valve.

3. Place the hose from the “Tank” connection

in the reservoir. Connect this hose securely

to the reservoir. Ensure that the end of the

hose remains below the surface of the oil to

prevent foaming.

4. Check the steering oil level and top up as

necessary.

5. Start the engine and keep an eye on the

steering oil level.

6. Bleed the steering gear, see “Draining,

filling and bleeding”.

S7 00 535

3-6

ᓻ 200322

Page 69

7

STEERING GEAR, GENERAL

LF45/55 series Inspection and adjustment

Bringing the steering oil up to the test

temperature

1. Set the engine speed to 1200 - 1400 rpm.

2. Slowly close the valve (4), until the pressure

gauge (10) indicates a pressure of 50 bar.

3. Wait until the temperature gauge (11)

indicates a value of 50_C.

4. Now open the valve (4) completely.

Inspecting steering gear using the test case

9

10

11

5

10 15

20

25

100 150

50

200

250

1

Note:

- Check the steering oil temperature regularly

while taking measurements. Warm up the

steering oil as specified.

- If an incorrect value is found during the

measurements, the cause should be traced

and rectified before carrying out the next

measurement.

Measuring the circulation pressure

1. Run the engine at idling speed.

3

465

S7 00 020

7

8

2

2

2. Open the valve (4) fully.

3. The circulation pressure is indicated on the

pressure gauge (9). Compare the reading

with the maximum permitted value, see

“Technical data”.

Checking front axle bearings

1. Run the engine at idling speed.

2. Check whether the valve (4) is fully opened.

3. Turn the steering wheel carefully from the

central position to both maximum wheel

deflections.

4. Check whether the required pressure rises

evenly.

9

10

11

1

3

5

10 15

100 150

50

20

25

200

250

7

8

2

465

S7 00 020

ᓻ 200322

3-7

Page 70

2

STEERING GEAR, GENERAL

7

Inspection and adjustment LF45/55 series

Testing the maximum system pressure

1. Run the engine at idling speed.

2. Turn the steering gear. Fit a 15 mm filler

piece, special tool (DAF no. 0535996),

between the adjusting bolt or the axle stop

on the swivel axle and axle housing stop.

Be careful when fitting the 15 mm

filler piece between the adjusting

bolt or the axle stop on the swivel

axle and the axle stop, as there is a

danger of limbs getting trapped.

S7 00 598

3. Fit a torque wrench with a dial to the

steering wheel attachment bolt. Tighten the

bolt to a tightening torque of 45 Nm on the

torque wrench.

4. Take the pressure reading on the pressure

gauge (10) (the maximum pressure must

not be maintained for more than 5

seconds). Compare the reading with the

specified value, see “Technical data”.

5. Repeat the measurement using the 15 mm

filler piece at the other end of the front axle.

9

10

11

1

3

5

10 15

45Nm

45Nm

S7 00 611

100 150

50

20

25

200

250

7

8

2

3-8

465

S7 00 020

ᓻ 200322

Page 71

7

STEERING GEAR, GENERAL

LF45/55 series Inspection and adjustment

Testing the final limiting pressure

1. Turn the steering gear to maximum lock.

2. Set the engine speed at 1200 - 1400 rpm.

3. Fit a torque wrench with a dial to the

steering wheel attachment bolt. Tighten the

bolt to a tightening torque of 45 Nm on the

torque wrench.

4. Read the final limiting pressure off the

pressure gauge (10).

5. Compare the reading with the specified

value, see “Technical data”.

45Nm

2

6. Carry out the measurement on the other

end of the axle.

Testing the maximum pump pressure

1. Check whether the pressure-limiting valve

(6) is set at the correct pressure.

2. While the engine is at idling speed, slowly

close the valve (4) until the maximum

pressure is reached on the gauge (10). The

maximum pressure may only be maintained

for 5 seconds. Otherwise the internal pump

components will become too hot. This

would result in premature wear in the pump.

The pressure is limited to 150 bar by the

pressure-limiting valve built into the test

equipment case.

Note:

Never turn the steering wheel when the

valve (4) is closed. The peak pressures

could damage the pump or the test case.

3. Open the valve (4).

4. Compare the reading with the specified

value, see “Technical data”.

45Nm

S7 00 611

ᓻ 200322

3-9

Page 72

2

STEERING GEAR, GENERAL

7

Inspection and adjustment LF45/55 series

Testing the pump output

1. Activate the output meter (7) using the

switch (8).

2. Set the engine speed at 1200 - 1400 rpm.

3. Close the valve (4) until the pressure gauge

(10) indicates the specified pump output

pressure, see “Technical data”.

4. Take the pump output reading at the output

meter (7) and compare this value to the

specified value, see “Technical data”.

Testing the steering pump flow-control valve

1. Activate the output meter (7) using the

switch (8).

2. Slowly increase the engine speed, until the

output meter (7) reading no longer rises.

Check whether the steering pump output is

stable and compare the measured value to

the specified value, see “Technical data”.

3. Increase and decrease the engine speed

and check whether the output increases

evenly and then remains stable.

4. Slowly close the valve (4) until the pressure

at the pressure gauge (10) has increased to

approx. 50 bar. While closing the valve,

check whether the pressure gauge (10)

needle starts to fluctuate.

9

10

11

1

3

5

10 15

20

25

100 150

50

200

250

465

S7 00 020

7

8

2

3-10

ᓻ 200322

Page 73

7

STEERING GEAR, GENERAL

LF45/55 series Inspection and adjustment

Testing for internal steering box leaks

1. Check that there is a line between the

“Tank” connection and the steering oil

reservoir. The line to the reservoir should

reach the bottom of the reservoir to prevent

foaming.

2. Open the non-return valve (5).

3. Close the valve (4) completely.

4. Adjust the pressure to 30 bar below the

maximum system pressure using the

non-return valve (5), see “Technical data”.

5. Open the valve (4) fully.

6. Activate the output meter (7) using the

switch (8).

7. Turn the steering gear. Fit a 15 mm filler

piece, special tool (DAF no. 0535996),

between the adjusting bolt or the axle stop

on the swivel axle and axle housing stop.

9

10

11

1

3

5

10 15

100 150

50

20

25

200

250

7

8

2

2

465

S7 00 020

8. Fit a torque wrench with a dial to the

steering wheel attachment bolt. Tighten the

bolt to a tightening torque of 45 Nm on the

torque wrench.

9. Read off the quantity of leaking oil and

compare this quantity to the maximum

permissible quantity of leaking oil, see

“Technical data”.

10. Carry out the measurement for the other

wheel deflection.

ᓻ 200322

S7 00 598

45Nm

45Nm

S7 00 611

3-11

Page 74

2

STEERING GEAR, GENERAL

7

Inspection and adjustment LF45/55 series

11. If the steering gear “jams”, the test should

be repeated with a set pressure of

15 - 30 bar.

Checking steering wheel bolt attachment

1. Retighten the steering wheel attachment

bolt to the specified tightening torque, see

“Technical data”.

Removing the test case

1. Remove the pipes and re-connect the

delivery pipe.

2. Check the steering oil level and top up as

necessary.

3. Bleed the system.

4. Inspect the pipe connections for leaks.

3.3 CHECKING THE STEERING BOX ATTACHMENT

1. Run the engine at idling speed.

2. Pull the steering wheel with quick jerks.

3. The steering box should not move.

3.4 CHECKING HYDRAULIC CENTRE POSITION

1. Jack up the front axle.

2. Check that the pitman arm is in the central

position.

3. Allow the engine to run at a speed of

1200 - 1400 rpm.

4. The pitman arm should not move by itself.

3-12

ᓻ 200322

Page 75

7

STEERING GEAR, GENERAL

LF45/55 series Draining, filling and bleeding

4. DRAINING, FILLING AND BLEEDING

4.1 DRAINING, FILLING AND BLEEDING STEERING GEAR, VERSION WITHOUT

STEERED TRAILING SWIVEL AXLE

The steering oil should be drained if:

- the steering pump is damaged

- the steering oil is dirty

- there is water in the steering oil

- there is serious foaming of the steering oil

due to air being drawn in.

Draining steering gear, version without

steered trailing swivel axle

Drained steering oil may not be

re-used. Store this hydraulic oil

separately from the other drained

oils and have the oil collected by an

authorised waste removal company.

1. Clean the steering box and reservoir

connection lines.

2

2. Jack up the steerable axle.

3. Place a receptacle under the steering box.

Take the return pipe off the steering box.

4. Turn the steering wheel slowly from one

end stop to the other until the oil stops

coming out of the pipe connection(s).

5. Reinstall the pipe which was disconnected.

6. Replace the reservoir and the integrated

filter if the steering pump is damaged or the

steering oil is dirty.

ᓻ 200322

4-1

Page 76

2

STEERING GEAR, GENERAL

7

Draining, filling and bleeding LF45/55 series

Filling/bleeding steering gear without

steered trailing swivel axle

Make sure that during filling and

bleeding the reservoir always

remains filled with oil in order to

prevent the pump from drawing in

air which would cause foaming in

the oil.

Air in the hydraulic system can

cause serious damage to the

steering pump. Air in the hydraulic

system can cause the steering gear

to jam occasionally.

If there is air in the hydraulic

system, a squealing noise will be

heard when the steering wheel is

turned.

If there is severe foaming, the

steering oil should be completely

drained.