Page 1

0

ΛΦ45/55 series

STRUCTURE

Structure

TECHNICAL DATA

0

1

SAFETY INSTRUCTIONS AND WARNINGS

2

THREADED CONNECTIONS

3

SEALS AND BEARINGS

4

GENERAL OPERATIONS

5

PAINT TREATMENT

6

CONVERSION TABLES

7

©

200338

Page 2

Page 3

0

TECHNICAL DATA

ΛΦ45/55 series

0 Technical dat a

CONTENTS

Page Date

1. VEHICLE MODELS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200338

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200338

2. LOCKING COMPOUNDS AND SEALANTS . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200338

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200338

3. THREADED CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200338

3.1 Tightening torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200338

4. PAINT TREATMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 . . . . . 200338

4.1 Overview of plastics used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 . . . . . 200338

Contents

0

©

200338 1

Page 4

TECHNICAL DATA

0

0

Contents

ΛΦ45/55 series

2

©

200338

Page 5

0

TECHNICAL DATA

ΛΦ45/55 series

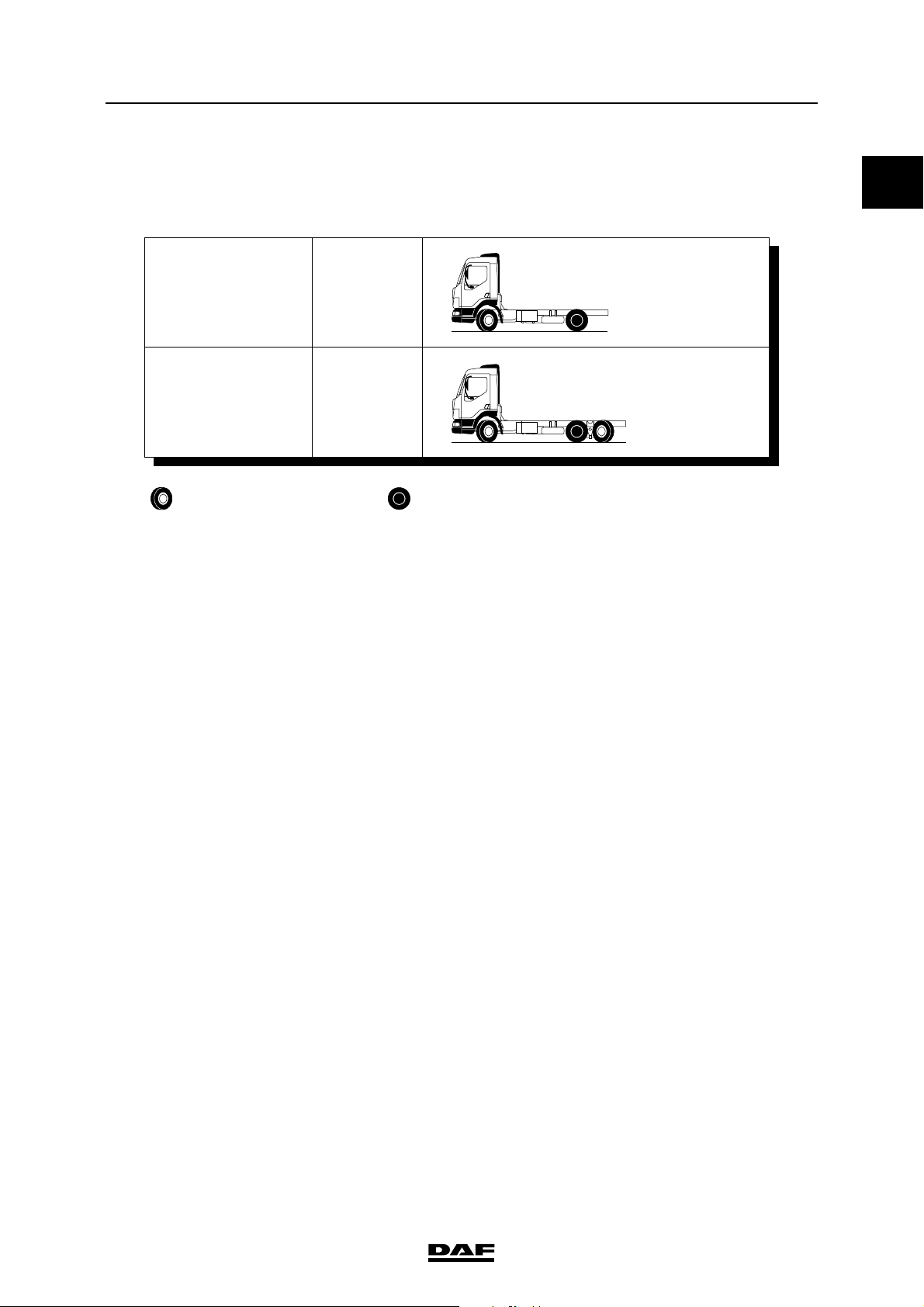

1. VEHICLE MODELS

1.1 OVERVIEW

FT

FA

FAN

steered axle driven axle

Vehicle models

0

4 x 2

6 x 2

G0 00 205

©

200338 1-1

Page 6

TECHNICAL DATA

0

0

Vehicle models

ΛΦ45/55 series

1-2

©

200338

Page 7

0

TECHNICAL DATA

ΛΦ45/55 series

Locking compounds and sealants

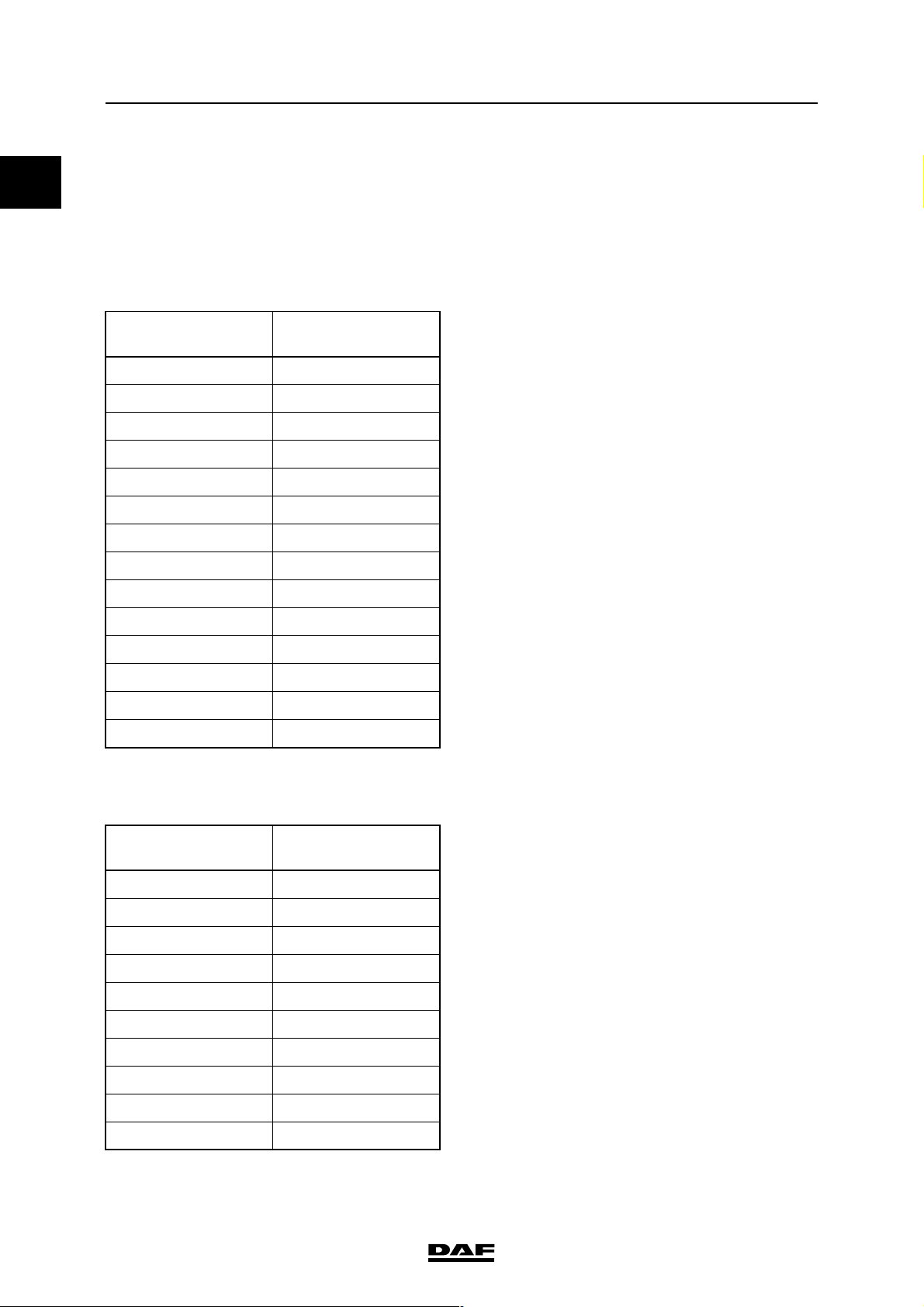

2. LOCKING COMPOUNDS AND SEALANTS

2.1 GENERAL

Certain cleaning agents have a

negative effect on the functioning of

}

Product

name

Loctite

243

Loctite

2701

locking compounds. The general

rule is therefore that fasteners and

components which have been

cleaned with a cleaning agent must

be treated with a cleaning liquid to

ensure that the locking compound

functions properly.

OVERVIEW OF LOCKING COMPOUNDS

Properties Applications DAF

- Locking with an average

detaching strength

- Detachable with normal tools

- Locking with a high detaching

strength

- Repairs the fit in bearing

housings

- Seals against leaks

- Difficult to detach

Locking of threaded connections 0068197

Locking of threaded connections,

gear lever ball, freeze plugs

0

number

1340646

Loctite

638

Loctite

648

Loctite

262

- Locking with a high detaching

strength under dynamic load

- Difficult to detach

- Locking with an average

detaching strength

- Resistant to high temperatures

- Locking with a high detaching

strength

- Difficult to detach

Locking of cylindrical connections 0645557

Locking of threaded connections in

warm places

Locking of threaded connections,

such as the pinion nut

1357032

1279841

©

200338 2-1

Page 8

TECHNICAL DATA

0

0

Locking compounds and sealants

Applying the locking compound

1. Clean both the internal and external threads.

Degrease the thread with a suitable

degreasing agent which leaves no residue

that could affect proper functioning.

2. Apply one or more drops of locking

compound to the thread, depending on the

diameter. Never dip the bolt or stud fully into

the locking compound.

3. Apply a drop of oil under the bolt head.

Locking compounds also reduce the

frictional resistance, which means that

applying a drop of oil to the thread is not

required.

4. Tighten the connection to the specified

torque.

OVERVIEW OF SEALING COMPOUNDS

Product

name

Properties Applications DAF

ΛΦ45/55 series

number

Dirko D - Resistant to temperatures up to

180″C

- Resistant to oil, coolant

Loctite

510

Loctite

574

Loctite

Blue

Loctite

ultra grey

Loctite

ultra

copper

Loctite

5910

- Resistant to temperatures up to

200″C

- Resistant to oil, brake fluid,

coolant

- Resistant to high pressures (up to

350 bar)

- Resistant to oil, brake fluid,

coolant

- Resistant to temperatures from

60″C to 260″C

- Resistant to oil

- Silicone sealant, good resistance

to coolant

- Resistant to temperatures up to

325″C

- Silicone sealant, good resistance

to oil

- Resistant to temperatures of up

to 350″C

- Silicone sealant, good resistance

to oil

- Resistant to temperatures up to

200″C

Sealing of surface connections 1345014

Sealing of surface (flange)

connections that are subjected to high

operating temperatures, such as the

flywheel housing

Sealing of surface connections

against high pressures

Sealing of flexible constructions such

as (valve) covers

Sealing of (surface) connections in

the cooling system

Sealing of surface connections such

as hub covers

Sealing of surface connections, such

as front and rear covers of gearboxes,

differential housings, hub covers, stub

axle flanges and oil cooler

0697149

1246867

1242895

1284123

1284122

1360102

Loctite

572

2-2

- Seals against low pressure

immediately after fitting

Threaded connections 0292336

©

200338

Page 9

0

TECHNICAL DATA

ΛΦ45/55 series

OVERVIEW OF SEALING COMPOUNDS

Product

name

Loctite

5205

Loctite

Form a

gasket

Product

name

Tectyl Protects the cavities of the cab body

Properties Applications DAF

- Surface sealant, specially

designed for sealing aluminium

parts

- Resistant to temperatures up to

150″C

- Resistant to water, coolant and oil

- Hardens on contact with metal

and on full closure

OTHER PRODUCTS

Properties Applications DAF

against corrosion.

Locking compounds and sealants

number

Sealing of aluminium parts 1441339

For locking, fastening and sealing 1322823

number

Post-treatment of cab parts to protect

against corrosion.

Can also be used as protection for

metal parts

1343888

0

Contact

spray

Loctite

cleaner

7063

Molykote

BR 2

PLUS

Molykote

P37

Copaslip - Copper paste with an excellent

Cleaning agent for cleaning and

degreasing electronic and electrical

connections. Removes moisture and

dirt from electrical contacts

- Cleans and degreases

- Non-inflammable and noncorrosive

- Lubricating grease is heatresistant from -30″C to +130″ C

- Grease protects against

corrosion and is heat-resistant to

1400″C.

bond, is anti-corrosive and heatresistant from -35″C to 1100″C.

- Resistant to water, salts and

acids.

- Prevents wear, oxidation, rust,

corroding and locking of metal

surfaces.

Cleaning of electrical contacts 1387608

For cleaning/degreasing of materials

to which a locking compound must be

applied

- Wherever grease lubrication is

appropriate and normal

- For almost all ball and roller

bearings, plain bearings, guides,

couplings, splined shafts,

threaded spindles, sprocket

drives with a low speed

For threaded connections that are

exposed to high temperatures, as

used for exhaust systems

For connections that are vulnerable to

oxidation or corrosion, such as battery

terminals, exhaust couplings, etc.

1322827

1389512

1391619

1284344

Renolit

HLT2

©

200338 2-3

- Grease (white) Disc brake adjustment device 1448907

Page 10

TECHNICAL DATA

0

0

Locking compounds and sealants

Product

name

Syntheso

GL EP1

Gleitmo

805

Properties Applications DAF

- Grease (green) Rubber guides for disc brake 1448908

- Protects untreated metals

against corrosion

OTHER PRODUCTS

For parts which are attached with a fit

such as wheel hub units

ΛΦ45/55 series

number

1443160

2-4

©

200338

Page 11

0

TECHNICAL DATA

ΛΦ45/55 series

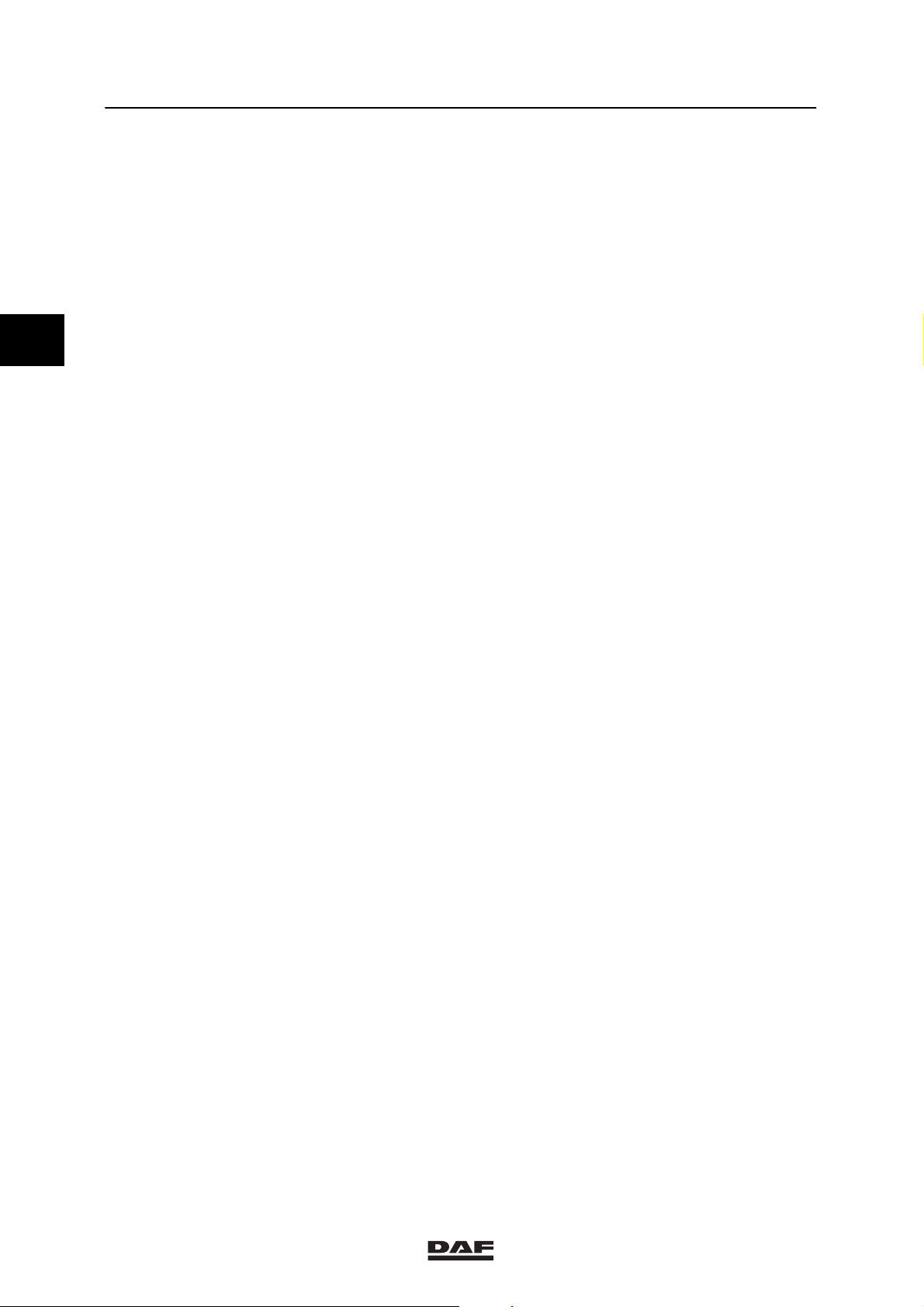

3. THREADED CONNECTIONS

3.1 TIGHTENING TORQUES

The tightening torques in the table below are

standard torques and only apply to dipped

threaded connections.

The property codes are stamped on the nut and

bolt, except on the clamping flange bolt. The

clamping flange bolt is recognised by a

constriction between the hexagonal bolt head

and the flange. This constriction is absent in

standard flange bolts.

Threaded connections

0

M2 00 001

Clamping flange bolt/standard-flange bolt

Tightening torques for dipped threaded

connections

Overview of standard tightening torques for

DAF flange bolts and nuts, strength class

10.9/10

Thread pitch Tightening torque (Nm) Extra angular displacement (≥ 10 %)

for bolt stem length L (mm):

L40 41-80 81-130 131-180

M8 30 ≥ 230″ 60″ 90″ 120″

M10 60 ≥ 445″ 90″ 120″ 150″

M12 x 1.75

M12 x 1.25

M14 x 2

M14 x 1.5

M14 x 2 for brake back plates: 170 ≥ 15 Nm + 60″

M16 x 2

M16 x 1.5

110 ≥ 8

110 ≥ 8

170 ≥ 15

170 ≥ 15

260 ≥ 20

260 ≥ 20

30″

45″

30″

45″

30″

45″

60″

90″

60″

90″

60″

90″

90″

120″

90″

120″

90″

120″

120″

150″

120″

150″

120″

150″

M18 x 2.5

M18 x 1.5

M20 x 1.5 520 ≥ 40 45″ 90″ 120″ 150″

M22 x 2.5 for steering and track rods: 500 ≥ 50 Nm + 90″

©

200338 3-1

360 ≥ 30

360 ≥ 30

30″

45″

45″

90″

60″

120″

80″

150″

Page 12

TECHNICAL DATA

0

0

Threaded connections

The bolt stem length L is the length of the bolt

between the bolt head and the nut.

If a component is attached with several bolts, all

bolts must first be tightened to the specified

torque, and subsequently by the angular

displacement.

Overview of standard tightening torques for

DAF fastenings, strength class 8.8/8

Thread Tightening torque

in Nm

M4 2.8 ≥ 0.2

M5 5.5 ≥ 0.4

M6 9.6 ≥ 0.7

M8 23 ≥ 2

M10 46 ≥ 4

M12 79 ≥ 6

M14 125 ≥ 9

M16 195 ≥ 14

ΛΦ45/55 series

M18 280 ≥ 20

M20 395 ≥ 30

M22 540 ≥ 40

M24 680 ≥ 50

M27 1000 ≥ 70

M30 1350 ≥ 100

Overview of standard tightening torques for

DAF flange bolts and nuts, strength class

12.9/12

Thread Tightening torque

in Nm

M8 32 ≥ 3

M10 67 ≥ 5

M12 113 ≥ 9

M14 178 ≥ 14

M16 274 ≥ 22

M18 385 ≥ 30

M20 550 ≥ 43

M22 740 ≥ 60

M24 925 ≥ 72

M27 1370 ≥ 110

3-2

©

200338

Page 13

0

TECHNICAL DATA

ΛΦ45/55 series

Overview of standard tightening torques for

DAF clamping flange bolts and nuts, strength

class 12.9/12

Thread Tightening torque

in Nm

M12 178 ≥ 14

M14 274 ≥ 22

M16 425 ≥ 35

M18 550 ≥ 45

Overview of tightening torques, banjo bolts

Thread Tightening torque

in Nm

M6 8 ≥ 0.8

M8 15 ≥ 1.5

M10 30 ≥ 3

M12 40 ≥ 4

Threaded connections

0

M14 50 ≥ 5

M16 60 ≥ 6

M18 70 ≥ 7

Torque wrench

- Have torque wrenches regularly inspected

and calibrated.

Re-use of fasteners (bolt/nut/threaded end)

1. Clean the thread (take particular care to

remove locking compound residues) and the

clamping faces

2. Check the thread for damage.

To do so, manually screw a new nut/bolt onto

the thread to be checked.

If the new nut/bolt cannot be fully handscrewed onto the entire thread of the

fastener to be checked, the fastener is not

allowed to be re-used.

3. Apply one drop of engine oil to the upper turn

of the bolt (threaded end)/lower turn of the

nut and one drop to the clamping faces

(other lubricants are not allowed).

4. If a locking compound has been specified, oil

should not be applied to the thread.

©

200338 3-3

Page 14

TECHNICAL DATA

0

0

Threaded connections

New bolts/nuts

New DAF bolts and DAF nuts, except bolts M4 to

M8 with inner-Torx, have already been lubricated.

If bolts have not yet been lubricated, a lubricant

should be applied.

1. Apply one drop of engine oil to the first turn

of the bolt/lower screw thread of the nut and

one drop to the clamping faces (other

lubricants are not allowed).

2. If a locking compound has been specified, oil

should not be applied to the thread.

ΛΦ45/55 series

3-4

©

200338

Page 15

0

TECHNICAL DATA

ΛΦ45/55 series

4. PAINT TREATMENT

4.1 OVERVIEW OF PLASTICS USED

1 SMC polyester

2 Thermoplastic polymer parts (ASA or ABS)

3 Fibre-glass reinforced polyester

1

2 2 1 2 1 1

Paint treatment

0

3

3

G0 00 206

©

200338 4-1

Page 16

TECHNICAL DATA

0

0

Paint treatment

ΛΦ45/55 series

4-2

©

200338

Page 17

0

LF45/55 series Contents

SAFETY INSTRUCTIONS AND WARNINGS

CONTENTS

Page Date

1. SAFETY INSTRUCTIONS AND WARNINGS 1-1 0201.............................. ......

1.1 General safety instructions 1-1 0201......................................... ......

1.2 Batteries 1-4 0201......................................................... ......

1.3 Welding 1-5 0201......................................................... ......

1.4 Jump-starting 1-8 0201.................................................... ......

1.5 Plastic pipes 1-9 0201..................................................... ......

1.6 Wiring harnesses 1-12 0201................................................. .....

1.7 Avoiding the risk of fire 1-13 0201............................................ .....

1.8 Tachograph calibration 1-14 0201............................................. .....

1.9 Airbag and seat belt tensioner 1-15 0201...................................... .....

2

ǹ 0201

1

Page 18

2

0SAFETY INSTRUCTIONS AND WARNINGS

Contents LF45/55 series

2

ǹ 0201

Page 19

0

SAFETY INSTRUCTIONS AND WARNINGS

LF45/55 series Safety instructions and warnings

1. SAFETY INSTRUCTIONS AND WARNINGS

1.1 GENERAL SAFETY INSTRUCTIONS

Warning symbol

When text is accompanied by the warning

symbol shown here, this indicates that the

information provided is essential for the health

and personal safety of the mechanic.

This warning symbol is also shown if

circumstances threaten the safety of the vehicle

or could lead to damage to the vehicle.

If any of the safety instructions and

warnings contained in this section

are ignored, the health and safety

ofthemechanicmaybeputatrisk.

Also, serious damage to the vehicle

or even a hazardous situation may

result.

- Comply with all the warnings and safety

instructions given in this workshop manual.

First read the instructions and warnings on

the labels and stickers which are affixed to

the various components and comply with

them. They have been put there for your

health and safety, so do not ignore them!

M0015

2

- Wear clean, fitted clothes and apply

protective cream, if necessary, to

unprotected parts of your body.

- Always disconnect the earth connection of

the battery before working on the vehicle.

- Do not run the engine in an enclosed or

unventilated area. Make sure exhaust

fumes are properly extracted.

ǹ 0201

1-1

Page 20

2

SAFETY INSTRUCTIONS AND WARNINGS

0

Safety instructions and warnings LF45/55 series

- Remain at a safe distance from rotating

and/or moving components.

- Do not remove the filler cap from the

cooling system when the engine is at

operating temperature.

- Be careful when changing the oil. Hot oil

can cause serious injuries.

- Avoid unnecessary contact with drained oil.

Frequent contact damages the skin.

- Various sorts of oil and other lubricants

used on the vehicle may constitute a health

hazard. This also applies to engine coolant,

clutch fluid, windscreen washer fluid,

refrigerant in air-conditioning systems,

battery acid and diesel fuel. So avoid

inhaling and direct contact.

- Tilt the cab fully if work must be carried out

underneath the cab.

- Always use stands to support the chassis or

components when working under the

vehicle.

- Be careful when working on activated

springs, such as those in spring brake

cylinders, valves, and similar. Inadvertently

released springs may cause serious

injuries. Small springs and circlips may also

cause injuries when inadvertently released

(wear goggles).

- Alwaysuseatyrecagewhenfittingand

inflating tyres. Thoroughly clean tyres prior

to balancing. Only use a balancing device

fitted with a protective cover.

1-2

ǹ 0201

Page 21

0

SAFETY INSTRUCTIONS AND WARNINGS

LF45/55 series Safety instructions and warnings

- Always use the appropriate lifting gear

(gearbox jack) or approved hoists for the

removal and installation of heavy

components. Attach the component

securely to the lifting or hoisting gear.

- Be careful when working on systems which

may be under pressure, such as a trailing

axle lifting device, cab tilting mechanism,

brake system, steering gear, fuel system,

etc.

- After a fire, hazardous residues may remain

fromtheplasticsusedinsomeoilsealsand

sealing rings. Wear protective,

acid-resistant clothing and PVC gloves

when removing such fire residues. Immerse

such fire residues in, or sprinkle them

amply with, a calcium hydroxide solution

(slaked lime and water). Thoroughly clean

the protective clothing after use. Treat the

gloves as chemical waste.

2

ǹ 0201

1-3

Page 22

2

SAFETY INSTRUCTIONS AND WARNINGS

0

Safety instructions and warnings LF45/55 series

1.2 BATTERIES

Always charge batteries in a

properly ventilated area and avoid

sparking and naked flames. Always

switch the battery charger off

before removing the leads.

Fast-charging should only be

resorted to in an emergency.

Disconnect the battery leads when

fast-charging is being used.

Wear protective clothing, gloves

and a visor when carrying out work

that may bring you into contact

with battery acid.

Battery acid is an aggressive fluid.

In the event of contact with the

skin: rinse the skin with plenty of

water for a sustained period. If

redness or pain persists, consult a

doctor. Remove any clothing

affected and rinse with water.

In the event of contact with the

eyes: Rinse with plenty of water for

at least 15 minutes and see a

doctor.

If any is swallowed: do NOT induce

vomiting. Rinse the mouth, drink

two glasses of water and see a

doctor.

In the event of inhalation: get some

fresh air, rest and consult a doctor.

To prevent damage to electronic components,

never disconnect the battery terminals when the

engine is running.

Always disconnect the earth connection of the

battery before working on the vehicle. Never

place tools on a battery. If you do, this could

short-circuit the battery or even cause the

battery to explode.

Always charge batteries in a properly ventilated

area and avoid sparking and naked flames.

When charging batteries, an explosive gas

mixture may be released.

1-4

ǹ 0201

Page 23

0

SAFETY INSTRUCTIONS AND WARNINGS

LF45/55 series Safety instructions and warnings

1.3 WELDING

No welding of the chassis is

allowed without special, written

permission by DAF. Exceptions to

the above are the welding

operations described in the manual

“Superstructure directives”.

Non-compliance with welding

regulations may cause serious

damage to the chassis.

Failure to observe the following

instructions may damage the

electronic components.

General

- Attach the earth clamp of the welding set as

close as possible to the area on the vehicle

wheretheweldingistobedoneandensure

that it is well in contact with the part being

welded.

- Never attach the earth clamp to vehicle

components such as the engine, axles,

springs, etc. Arcing on these components is

also not permitted. Non-compliance with the

above instructions may result in serious

damage to bearings, springs, etc.

- The accessory or ignition position of the

ignition lock must not be switched on.

Remove the ignition key from the ignition

lock.

- Protect plastic piping, rubber components,

plastic components, piston rods of hydraulic

cylinders and springs (in particular parabolic

springs) from welding splashes and

temperatures above 70_C.

2

ǹ 0201

1-5

Page 24

2

SAFETY INSTRUCTIONS AND WARNINGS

0

Safety instructions and warnings LF45/55 series

Welding on the chassis

- When welding on the chassis, disconnect

the connectors of all electronic equipment

(including sensors and actuators), if they

are within a 1-metre radius from the point

being welded or within a 1-metre radius

from the earthing point.

- Disconnect the battery terminals if these

arewithinawithina1-metreradiusfromthe

point being welded or the earth clamp.

- If the battery terminals have to be

disconnected, all electronic units mounted

on the chassis must be disconnected as

well. Also disconnect the cab feed-through

connectors and disconnect the power

supply and earth cables that are connected

to the cab.

Welding on the cab

- When welding on the cab, disconnect the

battery terminals.

- Also disconnect the cab feed-through

connectors and disconnect the power

supply and earth cables that are connected

to the cab.

- Disconnect the connectors of all electronic

equipment (including sensors and

actuators), if they are within a 0.5-metre

radius from the point being welded or within

a 0.5-metre radius from the earth terminal.

Welding on the superstructure

- Follow the instructions for “Welding on the

chassis”, together with any specific welding

instructions for welding on the

superstructure.

Note:

During grinding, protect plastic piping, rubber

components, plastic components, piston rods of

hydraulic cylinders and springs (in particular

parabolic springs) in order to prevent damage

caused by grinding sparks.

1-6

ǹ 0201

Page 25

0

SAFETY INSTRUCTIONS AND WARNINGS

LF45/55 series Safety instructions and warnings

Position of feed-through connectors, earth

and power supply cable

The feed-through connectors (1), and supply

cable (2) are located behind the front panel in

the plastic case.

1

The earth cable (3) is located behind the front

panel below the service brake valve.

1

2

2

G0 00 203

I

X

A

M

INI

M

R

A

B

4

X

A

M

P

3

G0 00 202

ǹ 0201

1-7

Page 26

2

SAFETY INSTRUCTIONS AND WARNINGS

0

Safety instructions and warnings LF45/55 series

1.4 JUMP-STARTING

- Never start the vehicle by means

of a fast-charging device.

- The engine may be started with

the aid of jump leads using the

power from separate auxiliary

batteries (approx. 24V) or from

another vehicle with the engine

running (approx. 28V).

1. Connect the jump leads first to the positive

terminal (+), and then to the negative

terminal (--).

2. Start the engine.

3. After starting, switch on as many power

consumers as possible, on the assisted

vehicle, in order to avoid so-called load

dump.

4. Then disconnect the jump leads from the

negative terminal (--) first, followed by the

positive terminal (+).

5. Switch the power consumers off again.

-

+

+

-

W 0 01 004

1-8

ǹ 0201

Page 27

0

SAFETY INSTRUCTIONS AND WARNINGS

LF45/55 series Safety instructions and warnings

1.5 PLASTIC PIPES

Removing nipples or banjo unions in

polyamide pipes

1. Heat the pipe to remove the nipple or banjo

union. Never remove the nipple or banjo

union by making an incision in the

longitudinal direction of the pipe. This could

very easily result in damage to the hose

coupling. Even minor damage to the hose

coupling will cause leakage.

Fitting nipples or banjo unions in polyamide

pipes

1. Do not fit nipples or banjo unions to the

same pipe end more than once, because

this could result in poor sealing.

2. Cut off the pipe end if it has been used

before. If shortening the pipe results in a

sharp curve in the pipe or if it makes the

pipe too short, a new pipe will have to be

fitted.

2

3. Always use special pliers (special tool,

DAF no. 0694829) to fit nipples and banjo

unions in polyamide pipes.

4. Clamp the plastic pipe in the special

pliers (1).

5. Useaplastichammertotapthenippleor

banjo union into the pipe.

Note:

Never heat a plastic pipe when fitting nipples or

banjo unions.

Leakage from pipes

Leakage from fuel and air pipes must be

remedied as soon as possible to avoid

dangerous situations.

A leaking fuel pipe may constitute a fire hazard,

while a leaking air pipe may affect the braking

performance of the vehicle.

1

W 0 01 005

ǹ 0201

1-9

Page 28

2

SAFETY INSTRUCTIONS AND WARNINGS

0

Safety instructions and warnings LF45/55 series

In the event of a leakage from a pipe coupling,

unlimited tightening of the union nut or banjo

bolt is not permitted.

- First check whether the leak is at the

connection point between the pipe and

coupling or at the connection point between

coupling and the component housing.

- Tighten a banjo bolt to the tightening torque

specified for the banjo bolt in question.

- A union nut may be tightened a further 180_

only once. Tightening the union nut further

than this is possible, but entails the risk of

excessive deformation of the thrust washer

and the pipe, which would seriously weaken

the pipe.

- If the leakage has not stopped after the

union nut has been retightened, it will be

necessary to take the coupling apart.

- Check the parts for deposits and/or

damage. Even a small longitudinal scratch

on the pipe connector of a nipple or a banjo

union may be sufficient to cause a leak.

- In the case of a banjo bolt fastening, check

the sealing surfaces. Fit new sealing rings

to the fastening and fit them. Tighten the

attachment bolts to the specified tightening

torque, see “Technical data”.

Chafing of pipes

When plastic pipes touch each other or other

parts of the vehicle, they may get chafed.

Immediately replace any pipes that show signs

of wear.

1-10

ǹ 0201

Page 29

0

SAFETY INSTRUCTIONS AND WARNINGS

LF45/55 series Safety instructions and warnings

When pipes are fitted so close together or so

close to other parts of the vehicle that they may

touch, they should be secured to prevent

chafing.

Use the specially developed pipe clamps. These

pipe clamps are available for pipes with a

diameter of 6, 10 and 22 mm. The pipe clamps

can be joined together.

Releasing an elbow or T-piece and then

tightening it in a slightly different position can

sometimes prevent chafing.

Secure the pipes with cable ties.

2

ǹ 0201

1-11

Page 30

SAFETY INSTRUCTIONS AND WARNINGS

0

Safety instructions and warnings LF45/55 series

1.6 WIRING HARNESSES

After the first wiring harness has been

disconnected or replaced, it must be

reconnected in the original manner and

fastened.

Protect the wiring harness against contact with

sharp edges. Always use a grommet when

passing the wiring harness through an aperture.

2

Protect the wiring harnesses by enclosing them

inaprotectivesleeve.

Make sure that the joints are watertight. Never

remove sealing rings from connectors. Fit the

connectors in the correct manner.

Good earth connections are essential. There

must be no paint or oxidation between the

contact surfaces. Before fitting, apply a

conductive grease such as “Coranode” or an

equivalent product to the contact surfaces.

Tighten the attachment bolt securely.

Make sure that wiring is not located too close to

parts which become hot during operation.

“Freely suspended” cables, such as those

between the chassis and the cab, must not be

kinked or pinched between other parts.

Prevent wiring harnesses from scraping against

plastic pipes.

The pins of connectors must always be installed

and removed with special tools, to prevent poor

connections.

Wiring harnesses and connectors of the airbag

and seat belt tensioner system must not be

repaired. If damaged, the complete assembly

must be renewed.

1-12

ǹ 0201

Page 31

0

SAFETY INSTRUCTIONS AND WARNINGS

LF45/55 series Safety instructions and warnings

1.7 AVOIDING THE RISK OF FIRE

- Check fuel pipes for leakage and fix any

leakage immediately (see also Plastic

pipes).

- When fitting steel fuel pipes take into

account the points listed below.

Fit the fuel pipe free from tension.

Preformed fuel pipes must not be bent.

When refitting a banjo bolt on a fuel pipe,

always fit new sealing rings and tighten the

banjo bolt to the specified torque.

After tightening, check the fastening for fuel

leakage.

Steel fuel pipes fitted without due care and

attention can cause fuel leaks which lead to

fire hazard.

- In the event of fuel and/or oil leakage or

spillage, the engine encapsulation must be

thoroughly cleaned. First apply a

degreasing agent to the encapsulation

material. Then wash down the

encapsulation with a steam cleaner or with

a high-pressure cleaner.

2

Maintain a minimum distance of 50

cm between the engine

encapsulation and the sprayer

nozzle to prevent damage to the

encapsulation.

- Clean the engine compartment, in particular

the encapsulated part, at regular intervals

by removing flammable material such as

dead leaves and sawdust.

- Do not leave cleaning rags etc. in the

engine compartment.

- Repair leaks in the exhaust system without

delay. Badly corroded exhaust components

should be replaced before they fail.

ǹ 0201

1-13

Page 32

2

SAFETY INSTRUCTIONS AND WARNINGS

0

Safety instructions and warnings LF45/55 series

- Always remember to re-fit the heat shields

after removal.

- Never replace a defective fuse with a fuse

of a higher rating.

- Never connect accessories which are not

protected by a fuse.

- Check wiring which is not fuse-protected

(battery leads, etc.), to make sure that it is

undamaged and properly attached and

located.

1.8 TACHOGRAPH CALIBRATION

The test bench may be used to calibrate the

tachograph (e.g. when changing to a different

type of tyre).

If the vehicle is equipped with ASR, the system

will interpret turning rear wheels and still front

wheels as rear wheel spin. As deceleration is no

longer applicable, the system will try to

neutralise this “spinning” by slowing down the

rear wheels. The result is that the vehicle is

thrown from the test bench, which is dangerous.

In order to avoid this, the ABS/ASR system

fuses must be removed, rendering the

ABS/ASR system inactive.

However, this is viewed by the system as faults

to be registered in the memory. These faults

must be reset after calibration using DAVIE.

1-14

ǹ 0201

Page 33

0

SAFETY INSTRUCTIONS AND WARNINGS

LF45/55 series Safety instructions and warnings

1.9 AIRBAG AND SEAT BELT TENSIONER

- Never disconnect an electrical connection in

the airbag or seat belt tensioner circuits

with the ignition switched on.

- All work on pyrotechnic systems (systems

with airbag(s) and/or seat belt tensioner(s))

may only be carried out by employees of

approved DAF dealers or workshops who

are sufficiently trained on these systems.

- The use of pyrotechnic systems (systems

with airbag(s) and/or seat belt tensioner(s))

is subject to various national laws. The legal

stipulations must be observed.

- Vehicles equipped with a pyrotechnic

system (system with airbag(s) and/or seat

belt tensioner(s)) can be identified by a

sticker with an airbag symbol (see

“General”) on the windscreen and/or with

the word “AIRBAG” on the airbag unit on

the steering wheel.

2

- If the vehicle is equipped with an airbag and

seat belt tensioner system while there is no

airbag symbol on the windscreen, this

symbol will have to be applied as yet.

- It is not permitted to install accessories on

airbag and seat belt tensioner parts or in

their operating zones afterwards. The

operating zone covers an area the size of a

ball with a diameter of 80 cm. Only

accessories approved by DAF for vehicles

with an airbag and/or seat belt tensioner

may be installed, in the place indicated by

DAF and in the manner outlined by DAF.

G0 00 235

ǹ 0201

1-15

Page 34

SAFETY INSTRUCTIONS AND WARNINGS

0

Safety instructions and warnings LF45/55 series

- Using equipment or objects that generate

strong magnetic fields in the vicinity of parts

of the airbag/seat belt tensioner system can

lead to unwanted activation of the airbag

and/or seat belt tensioner or can make

proper operation of the system impossible.

The use of such equipment or objects in the

vicinity of parts of the airbag/seat belt

tensioner system is therefore not

recommended.

2

- Only operations described in the DAF

workshop manual and systems manuals are

permitted on pyrotechnic systems (systems

with airbag(s) and/or seat belt tensioner(s)).

- It is not allowed to leave pyrotechnic units

(airbags and/or seat belt tensioners)

unattended. If repairs to a vehicle continue

for a long time and pyrotechnic units

(airbags and/or seat belt tensioners) are

involved in the repair, the pyrotechnic units

must be stored safely (under lock and key).

This means that the storage location must

meet local requirements relating to

pyrotechnic materials. The pyrotechnic

units may not be stored together with

different hazardous substances and the

location must have the relevant hazard

warning symbols and fire protection

facilities.

- Before any work is carried out on a

pyrotechnic part (airbag and/or seat belt

tensioner):

1. The ignition must be switched off.

2. The negative battery terminal clamp

must be separated carefully.

3. Wait at least 5 minutes.

1-16

ǹ 0201

Page 35

0

SAFETY INSTRUCTIONS AND WARNINGS

LF45/55 series Safety instructions and warnings

- If pyrotechnic units have been activated in a

crash, the electronic unit and the contact

unit must be replaced in addition to the

pyrotechnic units. All electrical wiring and

connectors must also be visually inspected,

and be replaced if any damage or overload

is detected.

- Nothing may be stuck onto the airbag

cover. Nor may the cover be treated with a

cleaner, solvent, grease, paint, lacquer or

other material. The surface may only be

cleaned using a dry cloth, a cloth

dampened with water, or a cloth with a

cleaner approved by DAF for this purpose.

- It is not allowed to scrap a vehicle if it still

has non-activated airbags and seat belt

tensioners on board. In this instance, follow

the special scrapping procedure.

2

ǹ 0201

1-17

Page 36

2

SAFETY INSTRUCTIONS AND WARNINGS

Safety instructions and warnings LF45/55 series

0

1-18

ǹ 0201

Page 37

0

LF45/55 series Contents

THREADED CONNECTIONS

CONTENTS

Page Date

1. GENERAL 1-1 0201............................................................ ......

1.1 Dipped threaded connections 1-1 0201....................................... ......

3

ǹ 0201

1

Page 38

3

0THREADED CONNECTIONS

Contents LF45/55 series

2

ǹ 0201

Page 39

0

THREADED CONNECTIONS

LF45/55 series General

1. GENERAL

1.1 DIPPED THREADED CONNECTIONS

DAF vehicles are fitted with threaded

connections which have been treated with a

lubricant (dipped threaded connection).

Factory-galvanised bolts and nuts are

wax-dipped. Black annealed and phosphatised

bolts and nuts are oil-dipped. The advantage of

using a lubricant is that friction during tightening

of the threaded connection is reduced, so that

the specified pre-tension can be obtained more

easily and more accurately. The tightening

torque can be reduced while the pre-tension

force remains the same.

To achieve a small spread in the pre-tension

force, the dipped threaded connection must be

tightened accurately. Therefore, always use a

reliable and accurate torque wrench.

Note:

Have torque wrenches regularly inspected and

calibrated.

3

To achieve the correct pre-tension when

re-using threaded connections, it is important to

clean the threaded parts thoroughly. After

cleaning, apply one drop of lubricant to the first

turn of the screw thread and one drop to the

abutting surface of the nut or bolt. If bolts and

nuts to be re-used, do not lubricate them with

anything other than engine oil. Lubricants other

than engine oil or factory-applied lubricant must

not be used under any circumstances because

of the difference in frictional coefficient.

When locking compounds are used for dipped

threaded connections, the instructions given

here apply, except for applying lubricant to the

first turn of the screw thread.

ǹ 0201

1-1

Page 40

3

THREADED CONNECTIONS

0

General LF45/55 series

The following applies to all threaded

connections (for both new and used

vehicles):

- in the case of standard connections, apply

the lubricant before fitting, and retighten in

accordance with the standard for dipped

bolts;

- in the case of special connections, apply the

lubricant before fitting, and retighten in

accordance with the values specified in the

instructions.

The instructions for using a lubricant also apply

to new bolts supplied from the warehouse. Dry

threaded connections are not permitted because

of their highly variable friction coefficients.

The following threaded connections are used on

DAF vehicles:

- Fastenings with strength classes 8.8 and 8,

- flange bolts and nuts with strength classes

10.9 and 10,

- flange bolts and nuts with strength classes

12.9 and 12,

- clamping flange bolts and nuts with strength

classes 12.9 and 12.

Threaded connections 10.9/10

Threaded connections 10.9/10 are tightened as

standard with a torque followed by an angular

displacement. The angular displacement

depends on the bolt stem length. For the

tightening torque with the applicable angular

displacement, see “Technical data” .

If a threaded connection 10.9/10 has to be

tightened differently, for example using a

tightening torque only, this is indicated in the

technical data for the component concerned.

1-2

ǹ 0201

Page 41

0

THREADED CONNECTIONS

LF45/55 series General

Other threaded connections

Threaded connections 8.8/8, 12.9/12 and

clamping flange bolts 12.9/12 are tightened as

standard only with a torque. For the standard

tightening torques, see “Technical data”.

If any of these threaded connections has to be

tightened differently, this is indicated in the

technical data for the component concerned.

Applying the locking compound

- Clean both the internal and external thread.

- Degrease the thread with a suitable

degreasing agent which leaves no residue

that could affect proper functioning.

- Apply one or more drops of locking

compound to the thread, depending on the

diameter. Never dip the bolt or stud fully into

the locking compound.

- Apply a drop of oil under the bolt head.

Locking compounds also reduce the

frictional resistance, which means that

applying a drop of oil to the thread is not

required.

3

- Tighten the connection to the specified

torque.

ǹ 0201

1-3

Page 42

3

THREADED CONNECTIONS

General LF45/55 series

0

1-4

ǹ 0201

Page 43

0

LF45/55 series Contents

SEALS AND BEARINGS

CONTENTS

Page Date

1. GASKETS 1-1 0201............................................................ ......

1.1 Paper and Klingerit gaskets (rubber-aramide fibre) 1-1 0201.................... ......

1.2 Liquid gaskets 1-2 0201.................................................... ......

2. SEALS 2-1 0201............................................................... ......

2.1 Removing and fitting seals 2-1 0201......................................... ......

3. BEARINGS 3-1 0201............................................................ ......

3.1 Bearings, general 3-1 0201................................................. ......

3.2 Fitting bearings into a bearing housing 3-2 0201............................... ......

3.3 Fitting bearings to a shaft 3-2 0201.......................................... ......

4

ǹ 0201

1

Page 44

4

0SEALS AND BEARINGS

Contents LF45/55 series

2

ǹ 0201

Page 45

0

SEALS AND BEARINGS

LF45/55 series Gaskets

1. GASKETS

1.1 PAPER AND KLINGERIT GASKETS (rubber-aramide fibre)

The workshop manual specifies when a gasket

is required and it also gives information about

thetypeofgaskettobeused.

1. Remove the old gasket before fitting a new

one.

2. Clean the contact surfaces and check them

for damage.

3. Paper gaskets should be sparingly greased

before they are fitted. These gaskets are

used to seal flat parts and are resistant to

oil and moderate heat.

4. Do not grease Klingerit gaskets before

fitting. These gaskets usually have a

graphite coating. They are used to seal flat

surfaces and are resistant to oil, water and

heat.

5. There are special instructions for cylinder

head gaskets. See the relevant section.

6. Always tighten the attachment bolts evenly.

4

ǹ 0201

1-1

Page 46

4

SEALS AND BEARINGS

0

Gaskets LF45/55 series

1.2 LIQUID GASKETS

The workshop manual specifies when a gasket

is required and it also gives information about

thetypeofgaskettobeused.

Liquid gaskets, which replace conventional

gaskets, have been developed to seal flat

connections. They are resistant to oil, water and

temperatures up to approx. 200_C.

To apply the liquid gasket, follow the instructions

below.

Applying a liquid gasket

1. Remove all traces of the old gasket and

clean the surfaces to be sealed.

2. Sparingly apply the specified sealant to one

of the surfaces to be sealed. Also apply

sealant around studs, bores and the like to

ensure they are properly sealed.

3. If sealant has got into an (oil) bore of any

description, remove it carefully.

4. Put the surfaces to be sealed against each

other and tighten the attachment bolts

evenly.

1-2

ǹ 0201

Page 47

0

SEALS AND BEARINGS

LF45/55 series Seals

2. SEALS

2.1 REMOVING AND FITTING SEALS

There are two kinds of seals: conventional seals

and unitised seals.

- The conventional seal is fitted in a recess

and its inner ring has its running surface on

a shaft.

- The unitised seal is fitted in a fixed position

both in a recess and on the shaft. Sealing is

achieved internally.

Removing the seal

1. If possible, remove the sealing ring with the

special tool (DAF no. 1329458 or

DAF nos. 0694928 (A) and 0484899 (B)).

When removing the seal, take care not to

damage the recess.

4

M200971

A

B

A8 00 360

ǹ 0201

2-1

Page 48

4

SEALS AND BEARINGS

0

Seals LF45/55 series

Installing the seal

1. Check the recess in which the seal is to be

fitted for damage. Make good any damage.

2. Look for any marks on the outside of the

seal indicating the direction of rotation of

the shaft.

3. Always use a suitable driving tool to fit a

seal and press the seal evenly into place in

the recess.

4. Once a unitised seal has been removed

from the recess, it must not be re-used.

5. In most cases, a liquid gasket is used to fit

a conventional sealing ring with a steel

sheathing, whereas oil or liquid soap is

used to fit a sealing ring with a rubber

sheathing.

6. Always fit unitised sealing rings dry, unless

stated otherwise.

7. Always apply a small amount of oil or

grease to the sealing lip(s) and running

surface of a conventional seal.

2-2

ǹ 0201

Page 49

0

SEALS AND BEARINGS

LF45/55 series Bearings

3. BEARINGS

3.1 BEARINGS, GENERAL

1. Bearings must be replaced if they are worn,

in the case of pitting (small dents in the

running surface) and/or if the bearings have

been exposed to excess heat (blue spots).

2. When fitting a bearing, make sure that no

force is transmitted via the balls or rollers of

the bearing. For example, by fitting a

bearing on a shaft by pressing on the outer

bearing race.

3. Clean the bearing before fitting it.

4. Avoid dirt getting into the bearing while it is

being fitted.

5. If the instructions specify that the bearing

should be heated before it is fitted, avoid

exceeding the temperature specified. Also

avoid local overheating.

4

6. Raise the temperature of the bearing evenly

by heating it in the special oil bath. Another

option is to place the bearing on an electric

cooker. Watch the temperature closely in

this case.

ǹ 0201

3-1

Page 50

4

SEALS AND BEARINGS

0

Bearings LF45/55 series

3.2 FITTING BEARINGS INTO A BEARING HOUSING

Fitting bearings into a bearing housing

1. Always use the correct size of driving tool.

2. Centre the driving tool accurately on the

outer bearing race.

3. Preferably press the bearing evenly into the

housing, using a pressing tool.

3.3 FITTING BEARINGS TO A SHAFT

Fitting bearings to a shaft

1. Always use the correct size of driving tool.

2. Centre the driving tool carefully on the inner

bearing race.

3. Preferably press the bearing evenly onto

the shaft, using a pressing tool.

3-2

ǹ 0201

Page 51

0

LF45/55 series Contents

GENERAL OPERATIONS

CONTENTS

Page Date

1. PRESERVATION AND DE-WAXING 1-1 0201...................................... ......

1.1 Preservation 1-1 0201..................................................... ......

1.2 De-waxing 1-2 0201....................................................... ......

2. CLEANING VEHICLES 2-1 0201................................................. ......

2.1 High-pressure cleaner 2-1 0201............................................. ......

5

ǹ 0201

1

Page 52

0GENERAL OPERATIONS

Contents LF45/55 series

5

2

ǹ 0201

Page 53

0

GENERAL OPERATIONS

LF45/55 series Preservation and de-waxing

1. PRESERVATION AND DE -WAXING

1.1 PRESERVATION

Note:

Observe the applicable environmental

requirements.

1. Clean the vehicle thoroughly so that all dirt

and dust are removed.

2. Use pressurised air to remove any residues

from the vehicle.

3. Cover all glazing, headlights and tail lights.

4. Use a spray gun to spray undiluted

preserving agent RUSAN D5018 (a FINA

product) over the chassis frame and its

fittings, all parts and components in the

engine compartment and all painted sheet

metal parts. Tilt the cab to be able to spray

the preserving wax on the cab roof. Make

sure that all edges, joints and cavities are

sprayed with a “full jet” of preserving agent.

5

5. Use a brush to apply Rusan D5018 to the

wheel studs.

On no account spray preserving

agent into brake drums or on to

brake discs.

It is not allowed to spend the night

in a preserved cab. Sleeping in

preserved cab may cause nausea

and headaches.

ǹ 0201

1-1

Page 54

5

GENERAL OPERATIONS

0

Preservation and de-waxing LF45/55 series

1.2 DE-WAXING

Note:

Observe the applicable environmental and

safety requirements.

The vehicle should preferably be placed on a

grid floor.

Most de-waxing agents are

inflammable. The de-waxing area

should be suitable for the safe use

of such products.

1. Remove the preserving agent with a

solvent, an emulsifying cleaner or a

high-pressure hot water cleaner with added

solvent.

De-waxing with a high-pressure hot water

cleaner should be done carefully and

evenly. Set the high-pressure hot water

cleaner to a maximum pressure of 100 bar

and a maximum temperature of 90_C.

Never direct the jet of wax remover too long

at the same area, as this could cause

serious damage to the paintwork and

rubber. If some parts of the treated surface

still have preserving agent on them, treat

these areas again in the same way .

Note:

A steam cleaner is not suitable for de-waxing

because it requires the use of calcium descaling

products to keep the inside of the steam coil

clean. The dried residues of these products are

difficult to remove.

2. After removing the de-waxing agent, rinse

the vehicle thoroughly with water.

1-2

ǹ 0201

Page 55

0

GENERAL OPERATIONS

LF45/55 series Cleaning vehicles

2. CLEANING VEHICLES

2.1 HIGH-PRESSURE CLEANER

It is advisable to clean the vehicle with a

high-pressure cleaner before starting

maintenance or service operations. A clean

environment makes the engineer’s work easier,

and enables any vehicle defects to be noticed at

an early stage.

Note:

Before cleaning the vehicle, check the engine,

axles, gearbox, etc. for evidence of leakage.

If the vehicle is cleaned with a high-pressure

cleaner, the latter must be used with care. It is

also important to observe the following points:

- Make sure that doors, windows and roof

hatch are securely closed during

high-pressure cleaning.

- When cleaning the universal joint on the

steering box, the spider seals may be

forced open by the high-pressure jet of

water, so that the grease behind them is

flushed away. As a result, the spider may

get stuck, so that the steering mechanism

will “jam”.

- A bleed screw is fitted to the power steering

fluid reservoir of the steering gear. Water

may enter the tank through this, causing

damage to the steering mechanism.

- When cleaning the radiator/intercooler, be

careful not to damage the fins.

- Do not direct the high-pressure cleaner jet

too long at the air-conditioning system

condenser. As a result of the high

temperature, the pressure in the system will

become excessive, which may cause

damage to the system.

5

ǹ 0201

2-1

Page 56

5

GENERAL OPERATIONS

0

Cleaning vehicles LF45/55 series

- Make sure that no water can enter the

differential or the gearbox via the breathers.

- Make sure that no water can enter via the

reservoir bleed screws of clutch, brakes,

trailing axle, etc.

- The engine and engine compartment can

be cleaned with a high-pressure cleaner.

Make sure in this case not to spray onto

electrical components, such as the starting

motor, alternator, etc.

- Maintain a minimum distance of 50 cm

between the engine encapsulation and the

sprayer nozzle to prevent damage to the

encapsulation.

- Do not direct the jet of water at electrical

connections such as connectors, cable

plugs of the vehicle lighting system, etc.

- Ensure that no water can enter the air

intake system via the air intake or its flexible

seals.

- When the vehicle has been cleaned, it must

be lubricated again with a grease gun or via

the automatic lubrication system. This is

important because it prevents the

penetration of moisture and dirt at the

various pivot points.

2-2

ǹ 0201

Page 57

0

LF45/55 series Contents

PAINT TREATMENT

CONTENTS

Page Date

1. PAINT TREATMENT 1-1 0201................................................... ......

1.1 General instructions 1-1 0201............................................... ......

1.2 Respraying/paint repairing of cab top coat and SMC polyester parts 1-3 0201..... ......

1.3 Respraying/paint repairing chassis finishing 1-5 0201.......................... ......

1.4 Respraying seed top coats 1-6 0201......................................... ......

1.5 Respraying thermoplastic polymer parts 1-7 0201............................. ......

1.6 Respraying glass-fibre reinforced polyester parts 1-8 0201...................... ......

6

ǹ 0201

1

Page 58

0PAINT TREATMENT

Contents LF45/55 series

6

2

ǹ 0201

Page 59

0

PAINT TREATMENT

LF45/55 series Paint treatment

1. PAINT TREATMENT

1.1 GENERAL INSTRUCTIONS

In the chapter “Paint treatment”, directives are

provided for respraying and repairing DAF paint

systems applied on various subsurfaces.

The products to be used are supplied by a range

of manufacturers. However, only use products

from well-known manufacturers who can provide

all products for the complete paint structure. The

use of these products must be described in the

instructions issued by the manufacturer.

Work according to the instructions listed below:

- For rust-removal, use a rust-removal agent

based on phosphoric acid.

- To clean and remove any preserving

agents, use an organic, chlorine-free

solvent.

- Use a two-component epoxy-based or

polyester-based primer.

- Use a two-component epoxy-based or

polyester-based filler.

- Use a two-component epoxy-based or

polyester-based spray filler.

- Use a two-component epoxy-based or

polyester-based filler.

- Use a two-component epoxy PUR finishing

coat, with a degree of gloss of more than 92

degrees for cab top coats and a degree of

gloss of 70 degrees for chassis finishing

(measured at 60 degree geometry).

- Maximum drying temperature is 80_C, with

the exception of fibre-glass reinforced

polyester parts. Maximum drying

temperature of fibre-glass reinforced

polyester parts is 60_C.

- For the paint structure, only use products

from the same supplier.

- Use the products according to the

manufacturer’s instructions.

- Never use products containing silicone in an

aerosol can.

6

ǹ 0201

1-1

Page 60

6

PAINT TREATMENT

0

Paint treatment LF45/55 series

Failure to follow the generally

applicable safety rules for using

paints and similar products can

result in serious injury and/or

danger.

During work with a rust-removal

agent, wear protective gloves and

safety goggles.

When using paints and similar

products, and when handling paint

waste, always work according to the

applicable environmental

regulations to prevent unnecessary

environmental pollution.

Colour coding

The DAF code number of the cab paint is on the

paint identification plate.

The paint identification plate is mounted on one

of the vehicle’s door pillars.

The DAF code number for the cab paint is also

marked on the vehicle identity card.

The colour code number of the paint

manufacturer ”Dupont” is stated in the code

number. The “Dupont” colour code number

consists of five or six characters/digits. The

“Dupont” colour code number is followed by the

paint colour or an abbreviation.

For example, in the code number L1041MEYL,

L1041 is the “Dupont” colour code number of the

paint, ME indicates that it is a metallic paint and

YL is the colour abbreviation, in this case yellow.

Removing rust

- Apply the rust-removal agent in accordance

with the manufacturer’s instructions. The

concentration of the rust-removal agent

must be adapted to the amount of rust.

- Ideally, use a rust-removal paste on vertical

parts.

- Prevent rust-removal agents entering

overlap joints.

- Leave the rust-removal agent to work for

the time specified by the manufacturer.

- Rinse the area cleaned of rust at least twice

with an ample amount of clean tap water.

- Dry the area cleaned of rust.

1-2

ǹ 0201

Page 61

0

PAINT TREATMENT

LF45/55 series Paint treatment

1.2 RESPRAYING/PAINT REPAIRING OF CAB TOP COAT AND SMC

POLYESTER PARTS

Respraying of cab top coat and SMC

polyester parts

1. Remove any preserving agents, if

applicable; see “General Operations”.

2. Remove any rust with a rust-removal agent.

3. Clean the area to be resprayed with a

solvent.

4. Sand the section to be resprayed with 3M

Scotch Brite ultra fine or an equivalent

product.

5. Remove any dust from the sanded section

withaTack-ragcloth.

6. Clean the area to be resprayed with a

solvent.

7. Apply primer to any bare patches.

8. Leave the primer to evaporate/dry.

9. Apply a filler, if necessary.

10. Leave the filler to evaporate/dry.

11. Fine-sand with 3M Scotch Brite ultra fine or

an equivalent product.

12. Remove any dust from the sanded section

withaTack-ragcloth.

13. Clean the area to be resprayed with a

solvent.

14. Apply the top coat according to the

manufacturer’s instructions.

15. Leave the top coat to evaporate/dry.

Observe the drying time as laid down in the

manufacturer’s instructions.

6

ǹ 0201

1-3

Page 62

PAINT TREATMENT

0

Paint treatment LF45/55 series

Paint repairing of cab top coat and SMC

polyester parts

1. Remove any preserving agents, if

applicable; see “General Operations”.

2. Remove any rust with a rust-removal agent.

3. Clean the area to be repaired with a

solvent.

4. Sand the area to be repaired first with P80

sand paper and then with P180 sand paper.

5. Remove any dust from the sanded section

withaTack-ragcloth.

6. Fill the area to be repaired.

7. Sand the filled area with P180 sand paper.

8. Fine-sand/roughen the area to be sprayed

with 3M Scotch Brite ultra fine or an

equivalent product.

9. Remove any dust from the sanded section

withaTack-ragcloth.

6

10. Clean the area to be sprayed with a solvent.

11. Apply a primer.

12. Leave the primer to evaporate/dry.

13. Apply a filler.

14. Leave the filler to evaporate/dry.

15. If necessary, fine-sand with 3M Scotch Brite

ultra fine or an equivalent product.

Following fine-sanding, remove any dust

with a Tack-rag cloth and clean the area

with a solvent.

16. Apply the top coat according to the

manufacturer’s instructions.

17. Leave the top coat to evaporate/dry.

Observe the drying time as laid down in the

manufacturer’s instructions.

1-4

ǹ 0201

Page 63

0

PAINT TREATMENT

LF45/55 series Paint treatment

1.3 RESPRAYING/PAINT REPAIRING CHASSIS FINISHING

1. Remove any preserving agents, if

applicable; see “General Operations”.

2. Remove any rust with a rust-removal agent.

3. Clean the area to be treated with solvent.

4. Sand the area to be treated with P80 sand

paper.

5. Remove any dust from the sanded section

withaTack-ragcloth.

6. Clean the area to be treated with solvent.

7. Apply primer to any bare patches.

8. Leave the primer to evaporate/dry.

9. If necessary, sand with P180 sand paper.

Following sanding, remove any dust with a

Tack-ragclothandcleantheareawitha

solvent.

10. Apply the top coat according to the

manufacturer’s instructions.

11. Leave the top coat to evaporate/dry.

Observe the drying time as laid down in the

manufacturer’s instructions.

6

ǹ 0201

1-5

Page 64

PAINT TREATMENT

0

Paint treatment LF45/55 series

1.4 RESPRAYING SEED TOP COATS

These instructions relate to parts in steel, SMC

(Sheet Moulding Compound) plastic or

glass-fibre reinforced polyester.

1. Remove any preserving agents, if

applicable; see “General Operations”.

2. Remove any rust with a rust-removal agent.

3. Clean the area to be resprayed with a

solvent.

4. Sand the area to be resprayed first with P80

sand paper and then with P180 sand paper.

5. Remove any dust from the sanded section

withaTack-ragcloth.

6. Clean the area to be resprayed with a

solvent.

7. In the case of plastic, blow ionised air over

the area to be resprayed, or clean the area

with an anti-static liquid.

6

8. Apply the seed top coat according to the

manufacturer’s instructions.

9. Leave the paint to evaporate.

10. Observe the drying time as laid down in the

manufacturer’s instructions.

1-6

ǹ 0201

Page 65

0

PAINT TREATMENT

LF45/55 series Paint treatment

1.5 RESPRAYING THERMOPLASTIC POLYMER PARTS

Thermoplastic polymers include the following

“elastic” plastics: ASA, ABS and PUR.

1. Remove any preserving agents, if

applicable; see “General Operations”.

2. Clean the area to be resprayed with a

solvent.

3. Sand the area to be resprayed with P180

sand paper

4. Fine-sand with 3M Scotch Brite ultra fine or

an equivalent product.

5. Remove any dust from the sanded section

withaTack-ragcloth.

6. Blow ionised air over the area to be

resprayed, or clean the area with an

anti-static liquid.

7. Clean the area to be sprayed with a solvent.

8. Apply an elastic top coat (10-15% elastifier

in the base paint) according to the

manufacturer’s instructions.

9. Leave the top coat to evaporate/dry.

Observe the drying time as laid down in the

manufacturer’s instructions.

6

ǹ 0201

1-7

Page 66

PAINT TREATMENT

0

Paint treatment LF45/55 series

1.6 RESPRAYING GLASS-FIBRE REINFORCED POLYESTER PARTS

These parts can be recognised by the visible

fibre-glass structure on the rear of the part, and

the gel coating on the front of the part.

1. Remove any preserving agents, if

applicable; see “General Operations”.

2. Clean the area to be resprayed with a

solvent.

3. Sand the area to be resprayed first with P80

sand paper and then with P180 sand paper.

4. Remove any dust from the sanded section

withaTack-ragcloth.

5. Fill the area to be resprayed.

6. Leave the filler to dry.

7. Apply spray filler to the part to be

resprayed.

6

8. Leave the spray filler to dry.

9. Sand the filled area first with P80 sand

paper and then with P180 sand paper.

10. Remove any dust from the area to be

resprayed with a Tack-rag cloth.

11. Clean the area to be resprayed with a

solvent.

12. Again remove any dust from the area to be

resprayed with a Tack-rag cloth.

13. Blow ionised air over the area to be

resprayed, or clean the area with an

anti-static liquid.

14. Apply filler to the area to be resprayed.

15. Leave the filler to evaporate/dry.

1-8

ǹ 0201

Page 67

0

PAINT TREATMENT

LF45/55 series Paint treatment

16. If necessary, fine-sand with 3M Scotch Brite

ultra fine or an equivalent product.

17. Remove any dust from the area to be

resprayed with a Tack-rag cloth.

18. Blow ionised air over the area to be

resprayed, or clean the area with an

anti-static liquid.

19. Apply the top coat according to the

manufacturer’s instructions.

20. Leave the top coat to evaporate/dry. Drying

temperatures must not exceed 60_C.

Comply with the drying times listed in the

manufacturer’s instructions.

6

ǹ 0201

1-9

Page 68

PAINT TREATMENT

Paint treatment LF45/55 series

0

6

1-10

ǹ 0201

Page 69

0

CONVERSION TABLES

LF45/55 series Contents

CONTENTS

Page Date

1. CONVERSION TABLES 1-1 0201................................................ ......

Consumption 1-1 0201.......................................................... ......

Specific consumption 1-1 0201................................................... ......

Speed 1-1 0201................................................................ ......

Temperature 1-1 0201........................................................... ......

Weight 1-1 0201................................................................ ......

Length 1-2 0201................................................................ ......

Area 1-2 0201.................................................................. ......

Volume 1-2 0201............................................................... ......

Pressure 1-3 0201.............................................................. ......

Work 1-3 0201................................................................. ......

Power 1-3 0201................................................................ ......

7

ǹ 0201

1

Page 70

0CONVERSION TABLES

Contents LF45/55 series

7

2

ǹ 0201

Page 71

0

CONVERSION TABLES

LF45/55 series Conversion tables

CONSUMPTION

km/l 1/100 km miles/gallon (imp) miles/gallon (US)

n

100

n

n x 0.354

n x 0.425

100

n

n

282, 485

n

235, 294

n

n x 2.2825 n x 2.352

282, 5

n

n

n x 1.202

235, 2

n

n x 0.83

n

SPECIFIC CONSUMPTION

g/kW.h g/hp.h g/bh.h lb/bh.h

1 0.7353 0.7455 0.00164

1.36 1 1.014 0.00224

1.341 0.9863 1 0.00220

608.45 447.4 453.6 1

SPEED

cm/sec m/sec km/h feet/sec mile/h

1 0.01 0.036 0.03281 0.02237

100 1 3.6 3.281 2.237

27.78 0.2778 1 0.9113 0.6214

30.48 0.3048 1.097 1 0.6818

44.70 0.4470 1.609 1.467 1

TEMPERATURE

n_ Celsius =9/5n+32_F=4/5n_ R = n + 273.15 K

n_ Fahrenheit =5/9(n -- 32) _C=4/9(n -- 32)_ R=5/9(n -- 32) + 273.15 K

n_ Réaumur =5/4n_C=9/4n+32_F=5/4n + 273.15 K

n_ Kelvin = n -- 273.15 _C=9/5(n -- 273.15) + 32 _F=4/5(n -- 273.15) _R

WEIGHT

kg ounces pounds (lbs) short tons * long tons * ton (metr.)

1 35.27 2.205 0.001102 0.0009842 0.001

0.02835 1 0.0625 0.00003125 0.0000279 0.00002835

0.4536 16 1 0.0005 0.0004464 0.0004536

907.2 32000 2000 1 0.8929 0.9072

1016 35840 2240 1.12 1 1.016

1000 35274 2205 1.102 0.9842 1

7

*US+UK

ǹ 0201

1-1

Page 72

CONVERSION TABLES

(

)

(

)

0

Conversion tables LF45/55 series

7

LENGTH

mm inches feet yards m km mile (stat.)

1 0.03937 0.003281 0.001094 0.001 0.000001 0.0000006214

25.4 1 0.08333 0.2777 0.0254 0.0000254 0.00001577

304.8 12 1 0.3333 0.3048 0.0003048 0.0001894

914.4 36 3 1 0.9144 0.0009144 0.0005682

1000 39.37 3.281 1.0936 1 0.001 0.0006214

1000000 39370 3281 1093.6 1000 1 0.6214

1609350 63360 5280 1760 1609 1.609 1

AREA

7

2

mm

1 0.01 0.00155 0.00001076 0.000001196 0.000001

100 1 0.155 0.001076 0.0001196 0.0001

645.2 6.452 1 0.006944 0.0007716 0.0006452

92900 929 144 1 0.1111 0.09290

836100 8361 1296 9 1 0.8361

1000000 10000 1550 10.76 1.196 1

cm

2

square inches square feet square yards m

VOLUME

2

cm

1 0.06102 0.002114 0.001057 0.0002642 0.001

16.39 1 0.03464 0.01732 0.004329 0.01639

473.2 28.874664 1 0.5 0.125 0.4732

946.4 57.75 2 1 0.25 0.9464

3785 231 8 4 1 3.785

1000 61.02 2.114 1.057 0.2642 1

* US Gallon = 0.8327 Imp. Gallons

cubic inches pints quarts gallons *

US

dm

2

3

litre

2

cm

1 0.0610248 0.0017598 0.008799 0.000219975 0.001

16.387 1 0.02894 0.01447 0.003618 0.016387

568.2 34.67429136 1 0.5 0.125 0.5682

1136.49 69.319 2 1 0.25 1.13649

4545.95 277.274 8 4 1 4.54596

1000 61.0248 1.7598 0.8799 0.219975 1

** Imp. Gallon = 1.201 US Gallons

cubic inches pints quarts gallons **

1-2

US

dm

3

litre

ǹ 0201

Page 73

0

CONVERSION TABLES

LF45/55 series Conversion tables

PRESSURE

Pa bar kg/cm

1 0.00001 0.0000101 0.000145 0.0000987

100000 1 1.0197162 14.500364 0.9868813

98066.5 0.980665 1 14.22 0.9678

6894.76 0.0689476 0.070307 1 0.068046

101322.3 1.013223 1.0332 14.70 1

133.32 0.0013332 0.0013595 0.01934 0.0013158

3386.23 0.0338623 0.03453 0.4912 0.3342

9797.82 0.0979782 0.09991 1.421 0.09668

248.89 0.0024889 0.002538 0.03609 0.002456

2

lbs/sq inch (p.s.i.) atm

column of mercury at 15 _C

Pa

1 0.0075007 0.0002953 0.0001021 0.0040187

100000 750.06708 29.530981 10.207359 401.87015

98066.5 735.56454 28.96 10.01 0.9678

6894.76 51.715 2.036 0.7037 0.068046

101322.3 760 29.92 10.337 1

133.32 1 0.03937 0.01361 0.0013158

3386.23 25.40 1 0.3456 0.3342

9797.82 73.49 2.893 1 0.09668

248.89 1.867 0.07349 0.02540 0.002456

and g = 980.665 cm/sec

mm inches m inches

2

column of water at 15 _C

and g = 980.665 cm/sec

2

WORK

Nm mkg ft.lbs. kWh pkh (metr.) Hph kcal

1 0.1019716 0.7375607 0.0000002776 0.0000003776 0.0000003725 0.000238882

9.80665 1 7.233 0.000002723 0.0000037037 0.000003653 0.002342

1.356259695 0.1383 1 0.0000003765 0.00000051206 0.00000050505 0.0003238

3601001.88 367200 2656000 1 1.3599 1.341 860

2647795.5 270000 1952900 0.7353 1 0.9863 632.4

2684570.4375 273750 1980000 0.7455 1.0139 1 641.1

4187.43955 427 3088 0.001163 0.001581 0.00156 1

7

POWER

kW hp (metr.) mkg/sec kcal/sec HP lbs/sec

1 1.36 102 0.2389 1.341 737.7

0.7353 1 75 0.1757 0.9863 542.5

0.009804 0.01333 1 0.002342 0.01315 7.233

4.186 5.693 427 1 5.615 3088

0.7455 1.014 76.04 0.1781 1 550

0.001355 0.00184 0.1383 0.0003238 0.00182 1

ǹ 0201

1-3

Page 74

CONVERSION TABLES

Conversion tables LF45/55 series

0

7

1-4

ǹ 0201

Loading...

Loading...