8

LF45/55 series

STRUCTURE

TECHNICAL DATA

0

DIAGNOSTICS

1

SINGLE REAR AXLE 5.10

2

SINGLE REAR AXLE 5.12

3

SINGLE REAR AXLE 5.14

4

SINGLE REAR AXLE 8.20

5

SINGLE REAR AXLE 10.20

SINGLE REAR AXLE 10.26

SINGLE REAR AXLE 11.26

6

7

8

ᓻ 200313

8

TECHNICAL DATA

LF45/55 series Contents

CONTENTS

Page Date

1. SINGLE REAR AXLE 5.10 1-1 200313.............................................. ....

1.1 General 1-1 200313......................................................... ....

1.2 Tightening torques 1-1 200313................................................ ....

1.3 Filling capacities 1-2 200313.................................................. ....

2. SINGLE REAR AXLE 5.12 2-1 200313.............................................. ....

2.1 General 2-1 200313......................................................... ....

2.2 Tightening torques 2-1 200313................................................ ....

2.3 Filling capacities 2-2 200313.................................................. ....

3. SINGLE REAR AXLE 5.14 3-1 200313.............................................. ....

3.1 General 3-1 200313......................................................... ....

3.2 Tightening torques 3-1 200313................................................ ....

3.3 Filling capacities 3-2 200313.................................................. ....

4. SINGLE REAR AXLE 8.20 4-1 200313.............................................. ....

4.1 General 4-1 200313......................................................... ....

4.2 Tightening torques 4-1 200313................................................ ....

4.3 Filling capacities 4-2 200313.................................................. ....

5. SINGLE REAR AXLE 10.20 5-1 200313............................................. ....

5.1 General 5-1 200313......................................................... ....

5.2 Tightening torques 5-1 200313................................................ ....

5.3 Filling capacities 5-2 200313.................................................. ....

6. SINGLE REAR AXLE 10.26 6-1 200313............................................. ....

6.1 General 6-1 200313......................................................... ....

6.2 Tightening torques 6-1 200313................................................ ....

6.3 Filling capacities 6-2 200313.................................................. ....

0

7. SINGLE REAR AXLE 11.26 7-1 200313............................................. ....

7.1 General 7-1 200313......................................................... ....

7.2 Tightening torques 7-1 200313................................................ ....

7.3 Filling capacities 7-2 200313.................................................. ....

ᓻ 200313

1

0

8TECHNICAL DATA

Contents LF45/55 series

2

ᓻ 200313

8

TECHNICAL DATA

LF45/55 series Single rear axle 5.10

1. SINGLE REAR AXLE 5.10

1.1 GENERAL

Wheel speed sensor

Anti-corrosion agent Molykote P37

Differential attachment stud bolts

Differential attachment stud bolt locking

compound

Pinion gear splines

Sealant Loctite 572

Differential attachment

Sealant between differential and axle housing Loctite 518

Stub axle attachment

Sealant for stub axle flange mating surface Loctite 518

Wheel bearing play

Wheel bearing axial play 0.05 - 0.20 mm

Loctite 2701

1.2 TIGHTENING TORQUES

0

The tightening torques stated in this paragraph

are different from the standard tightening

torques stated in the overview of the standard

tightening torques. The other threaded

connections which are not stated must therefore

be tightened to the tightening torque stated in

the overview of standard tightening torques.

When attachment bolts and nuts are to be

replaced, it is important that these bolts and nuts

are of exactly the same length and property

class as the ones removed - unless stated

otherwise -.

ᓻ 200313

1-1

TECHNICAL DATA

8

Single rear axle 5.10 LF45/55 series

0

Differential

Attachment bolts/nuts 90 Nm

Drainplug 54Nm

Wheel hub

Stub axle attachment nuts 82 Nm

Wheel-speed sensor holder attachment bolts 8 Nm

Lock nut 135 Nm

Level check/filler plug 27 Nm

Notes:

1. Only use a new nut

(1)

1.3 FILLING CAPACITIES

Differential

Filling capacity approx. 4.0 litres

Hub

Filling capacity 0.25 litres

1-2

ᓻ 200313

8

TECHNICAL DATA

LF45/55 series Single rear axle 5.12

2. SINGLE REAR AXLE 5.12

2.1 GENERAL

Wheel speed sensor

Anti-corrosion agent Molykote P37

Crown wheel guide bolt

Sealant Loctite 572

Differential attachment stud bolts

Differential attachment stud bolt locking

compound

Differential attachment

Sealant between differential and axle housing Loctite 518

Stub axle attachment

Sealant for stub axle flange mating surface Loctite 518

Wheel bearing play

Wheel bearing axial play 0.05 - 0.20 mm

Loctite 2701

2.2 TIGHTENING TORQUES

The tightening torques stated in this paragraph

are different from the standard tightening

torques stated in the overview of the standard

tightening torques. The other threaded

connections which are not stated must therefore

be tightened to the tightening torque stated in

the overview of standard tightening torques.

0

When attachment bolts and nuts are to be

replaced, it is important that these bolts and nuts

are of exactly the same length and property

class as the ones removed - unless stated

otherwise -.

ᓻ 200313

2-1

TECHNICAL DATA

8

Single rear axle 5.12 LF45/55 series

0

Differential

Attachment bolts/nuts 80 Nm

Drive flange attachment nut (self-locking) 675 Nm

Lock nut for crown wheel guide bolt 120 Nm

Drainplug 54Nm

Wheel hub

Stub axle attachment nuts 82 Nm

Wheel-speed sensor holder attachment bolts 8 Nm

Lock nut 135 Nm

Level check/filler plug 27 Nm

Notes:

1. Bolts to be treated with Loctite 572

2. Only use a new nut

(1)

(2)

2.3 FILLING CAPACITIES

Differential

Filling capacity approx. 4.0 litres

Hub

Filling capacity 0.25 litres

2-2

ᓻ 200313

8

TECHNICAL DATA

LF45/55 series Single rear axle 5.14

3. SINGLE REAR AXLE 5.14

3.1 GENERAL

Wheel speed sensor

Anti-corrosion agent Molykote P37

Differential-gear lock stud bolts

Differential-gear lock stud bolt locking

compound

Differential attachment stud bolts

Differential attachment stud bolt locking

compound

Differential attachment

Sealant between differential and axle housing Loctite 518

Stub axle attachment

Sealant for stub axle flange mating surface Loctite 518

Wheel bearing play

Wheel bearing axial play 0.05 - 0.20 mm

Loctite 2701

Loctite 2701

3.2 TIGHTENING TORQUES

0

The tightening torques stated in this paragraph

are different from the standard tightening

torques stated in the overview of the standard

tightening torques. The other threaded

connections which are not stated must therefore

be tightened to the tightening torque stated in

the overview of standard tightening torques.

When attachment bolts and nuts are to be

replaced, it is important that these bolts and nuts

are of exactly the same length and property

class as the ones removed - unless stated

otherwise -.

ᓻ 200313

3-1

TECHNICAL DATA

8

Single rear axle 5.14 LF45/55 series

0

Differential

Differential lock cover attachment bolts 20 Nm

Attachment bolts and nuts 90 Nm

Drive flange attachment nut (self-locking) 675 Nm

Drainplug 54Nm

Wheel hub

Stub axle attachment nuts 82 Nm

Wheel-speed sensor holder attachment bolts 8 Nm

Lock nut 135 Nm

Level check/filler plug 27 Nm

Notes:

1. Bolts to be treated with Loctite 572

2. Only use a new nut

(1)

(1)

(2)

3.3 FILLING CAPACITIES

Differential

Filling capacity approx. 4.0 litres

Hub

Filling capacity 0.25 litres

3-2

ᓻ 200313

8

TECHNICAL DATA

LF45/55 series Single rear axle 8.20

4. SINGLE REAR AXLE 8.20

4.1 GENERAL

Wheel speed sensor

Anti-corrosion agent Molykote P37

Differential-gear lock stud bolts

Differential-gear lock stud bolt locking

compound

Differential attachment stud bolts

Differential attachment stud bolt locking

compound

Differential attachment

Sealant between differential and axle housing Loctite 518

Stub axle attachment

Sealant for stub axle flange mating surface Loctite 518

Wheel bearing play

Wheel bearing axial play 0.05 - 0.20 mm

Loctite 2701

Loctite 2701

4.2 TIGHTENING TORQUES

0

The tightening torques stated in this paragraph

are different from the standard tightening

torques stated in the overview of the standard

tightening torques. The other threaded

connections which are not stated must therefore

be tightened to the tightening torque stated in

the overview of standard tightening torques.

When attachment bolts and nuts are to be

replaced, it is important that these bolts and nuts

are of exactly the same length and property

class as the ones removed - unless stated

otherwise -.

ᓻ 200313

4-1

TECHNICAL DATA

8

Single rear axle 8.20 LF45/55 series

0

Differential

Drive flange attachment nut (self-locking) 675 Nm

Differential lock cover attachment bolts 20 Nm

Attachment bolts/nuts 225 Nm

Drainplug 54Nm

Wheel hub

Stub axle attachment nuts 82 Nm

Wheel-speed sensor holder attachment bolts 8 Nm

Lock nut 135 Nm

Level check/filler plug 27 Nm

Notes:

1. Only use a new nut

2. Bolts to be treated with Loctite 572

(1)

(2)

4.3 FILLING CAPACITIES

Differential

Filling capacity approx. 8.0 litres

Hub

Filling capacity 0.25 litres

4-2

ᓻ 200313

8

TECHNICAL DATA

LF45/55 series Single rear axle 10.20

5. SINGLE REAR AXLE 10.20

5.1 GENERAL

Wheel hub

Before installing the wheel hub, axle journal

to be treated with Gleitmo 805

Wheel speed sensor

Anti-corrosion agent Molykote P37

Differential-gear lock stud bolts

Differential-gear lock stud bolt locking

compound

Differential attachment stud bolts

Differential attachment stud bolt locking

compound

Differential attachment

Sealant between differential and axle housing Loctite 518

Stub axle attachment

Sealant for stub axle flange mating surface Loctite 518

Loctite 2701

Loctite 2701

0

5.2 TIGHTENING TORQUES

The tightening torques stated in this paragraph

are different from the standard tightening

torques stated in the overview of the standard

tightening torques. The other threaded

connections which are not stated must therefore

be tightened to the tightening torque stated in

the overview of standard tightening torques.

When attachment bolts and nuts are to be

replaced, it is important that these bolts and nuts

are of exactly the same length and property

class as the ones removed - unless stated

otherwise -.

ᓻ 200313

5-1

TECHNICAL DATA

8

Single rear axle 10.20 LF45/55 series

0

Differential

Drive flange attachment nut (self-locking) 675 Nm

Differential lock cover attachment bolts 20 Nm

Attachment bolts/nuts 225 Nm

Drainplug 54Nm

Wheel hub

st

-1

-2ndphase turn the hub 10 revolutions at a speed of

-3

-4

-5

Stub axle attachment bolts 260 Nm

Wheel-speed sensor holder attachment bolts 8 Nm

Notes:

1. Only use a new nut

2. Bolts to be treated with Loctite 572

phase 300 Nm

rd

phase 350 Nm

th

phase turn the hub 10 revolutions at a speed of

th

phase 1100 Nm

approx. 40 rpm

approx. 40 rpm

(1)

(2)

(1)

5.3 FILLING CAPACITIES

Differential

Filling capacity approx. 9.0 litres

5-2

ᓻ 200313

8

TECHNICAL DATA

LF45/55 series Single rear axle 10.26

6. SINGLE REAR AXLE 10.26

6.1 GENERAL

Wheel hub

Before installing the wheel hub, axle journal to

be treated with

Wheel speed sensor

Anti-corrosion agent Molykote P37

Differential-gear lock stud bolts

Differential-gear lock stud bolt locking

compound

Differential attachment stud bolts

Differential attachment stud bolt locking

compound

Differential attachment

Sealant between differential and axle housing Loctite 518

Stub axle attachment

Sealant for stub axle flange mating surface Loctite 518

Gleitmo 805

Loctite 2701

Loctite 2701

0

6.2 TIGHTENING TORQUES

The tightening torques stated in this paragraph

are different from the standard tightening

torques stated in the overview of the standard

tightening torques. The other threaded

connections which are not stated must therefore

be tightened to the tightening torque stated in

the overview of standard tightening torques.

When attachment bolts and nuts are to be

replaced, it is important that these bolts and nuts

are of exactly the same length and property

class as the ones removed - unless stated

otherwise.

ᓻ 200313

6-1

TECHNICAL DATA

8

Single rear axle 10.26 LF45/55 series

0

Differential

Drive flange attachment nut (self-locking) 1250 Nm

Differential lock cover attachment bolts 20 Nm

Attachment bolts/nuts 225 Nm

Drainplug 54Nm

Wheel hub

st

-1

-2ndphase turn the hub 10 revolutions at a speed of

-3

-4

-5

Stub axle attachment bolts 260 Nm

Wheel-speed sensor holder attachment bolts 8 Nm

Notes:

1. Only use a new nut

2. Bolts to be treated with Loctite 572

3. Secure with Loctite 262

phase 300 Nm

rd

phase 350 Nm

th

phase turn the hub 10 revolutions at a speed of

th

phase 1100 Nm

approx. 40 rpm

approx. 40 rpm

(1) / (3)

(2)

(1)

6.3 FILLING CAPACITIES

Differential

Filling capacity approx. 9.0 litres

6-2

ᓻ 200313

8

TECHNICAL DATA

LF45/55 series Single rear axle 11.26

7. SINGLE REAR AXLE 11.26

7.1 GENERAL

Wheel hub unit

Before installing the wheel hub unit, axle

journal to be treated with

Wheel speed sensor

Anti-corrosion agent Molykote P37

Differential-gear lock stud bolts

Differential-gear lock stud bolt locking

compound

Differential attachment stud bolts

Differential attachment stud bolt locking

compound

Differential attachment

Sealant between differential and axle housing Loctite 518

Stub axle attachment

Sealant for stub axle flange mating surface Loctite 518

Gleitmo 805

Loctite 2701

Loctite 2701

0

7.2 TIGHTENING TORQUES

The tightening torques stated in this paragraph

are different from the standard tightening

torques stated in the overview of the standard

tightening torques. The other threaded

connections which are not stated must therefore

be tightened to the tightening torque stated in

the overview of standard tightening torques.

When attachment bolts and nuts are to be

replaced, it is important that these bolts and nuts

are of exactly the same length and property

class as the ones removed - unless stated

otherwise.

ᓻ 200313

7-1

TECHNICAL DATA

8

Single rear axle 11.26 LF45/55 series

0

Differential

Drive flange attachment nut 1250 Nm

Differential-gear lock attachment bolts 20 Nm

Attachment bolts/nuts 225 Nm

Drainplug 54Nm

Wheel hub unit

st

-1

-2ndphase turn the hub 10 revolutions at a speed of

-3

-4

-5

Stub axle attachment bolts 260 Nm

Notes:

1. Only fit a new nut and apply Loctite 262 to

2. Bolts to be treated with Loctite 572

3. Only use a new nut

phase 500 Nm

rd

phase 550 Nm

th

phase turn the hub 10 revolutions at a speed of

th

phase 1300 Nm

secure

approx. 40 rpm

approx. 40 rpm

(1) / (3)

(2)

(3)

7.3 FILLING CAPACITIES

Differential

Filling capacity approx. 9.0 litres

7-2

ᓻ 200313

8

DIAGNOSTICS

LF45/55 series Contents

CONTENTS

Page Date

1. SINGLE REAR AXLE 5.10 1-1 200313.............................................. ....

1.1 Fault-finding table 1-1 200313................................................. ....

2. SINGLE REAR AXLE 5.12 2-1 200313.............................................. ....

2.1 Fault-finding table 2-1 200313................................................. ....

3. SINGLE REAR AXLE 5.14 3-1 200313.............................................. ....

3.1 Fault-finding table 3-1 200313................................................. ....

4. SINGLE REAR AXLE 8.20 4-1 200313.............................................. ....

4.1 Fault-finding table 4-1 200313................................................. ....

5. SINGLE REAR AXLE 10.20 5-1 200313............................................. ....

5.1 Fault-finding table 5-1 200313................................................. ....

6. SINGLE REAR AXLE 10.26 6-1 200313............................................. ....

6.1 Fault-finding table 6-1 200313................................................. ....

7. SINGLE REAR AXLE 11.26 7-1 200313............................................. ....

7.1 Fault-finding table 7-1 200313................................................. ....

1

ᓻ 200313

1

1

8DIAGNOSTICS

Contents LF45/55 series

2

ᓻ 200313

8

DIAGNOSTICS

LF45/55 series Single rear axle 5.10

1. SINGLE REAR AXLE 5.10

1.1 FAULT-FINDING TABLE

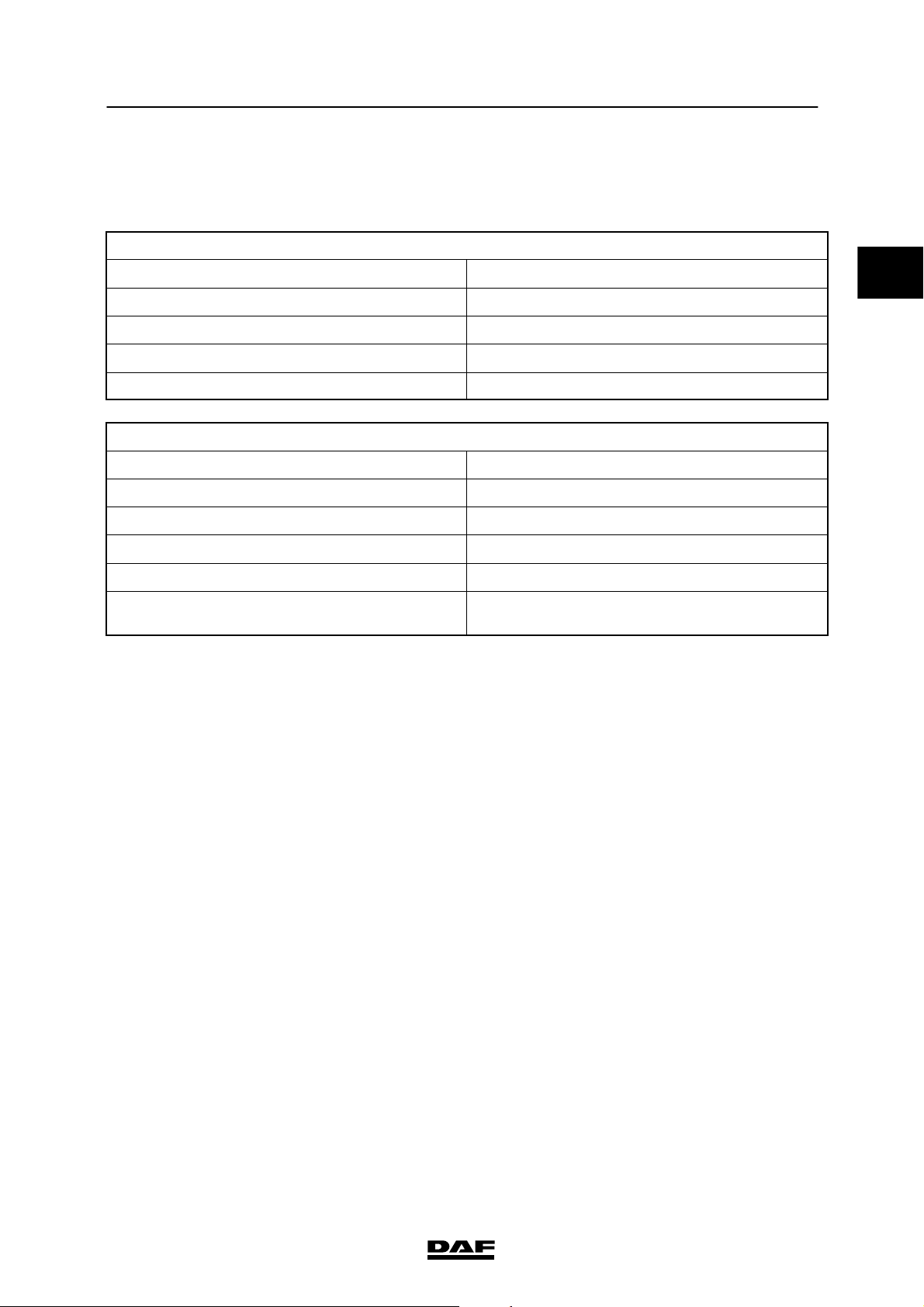

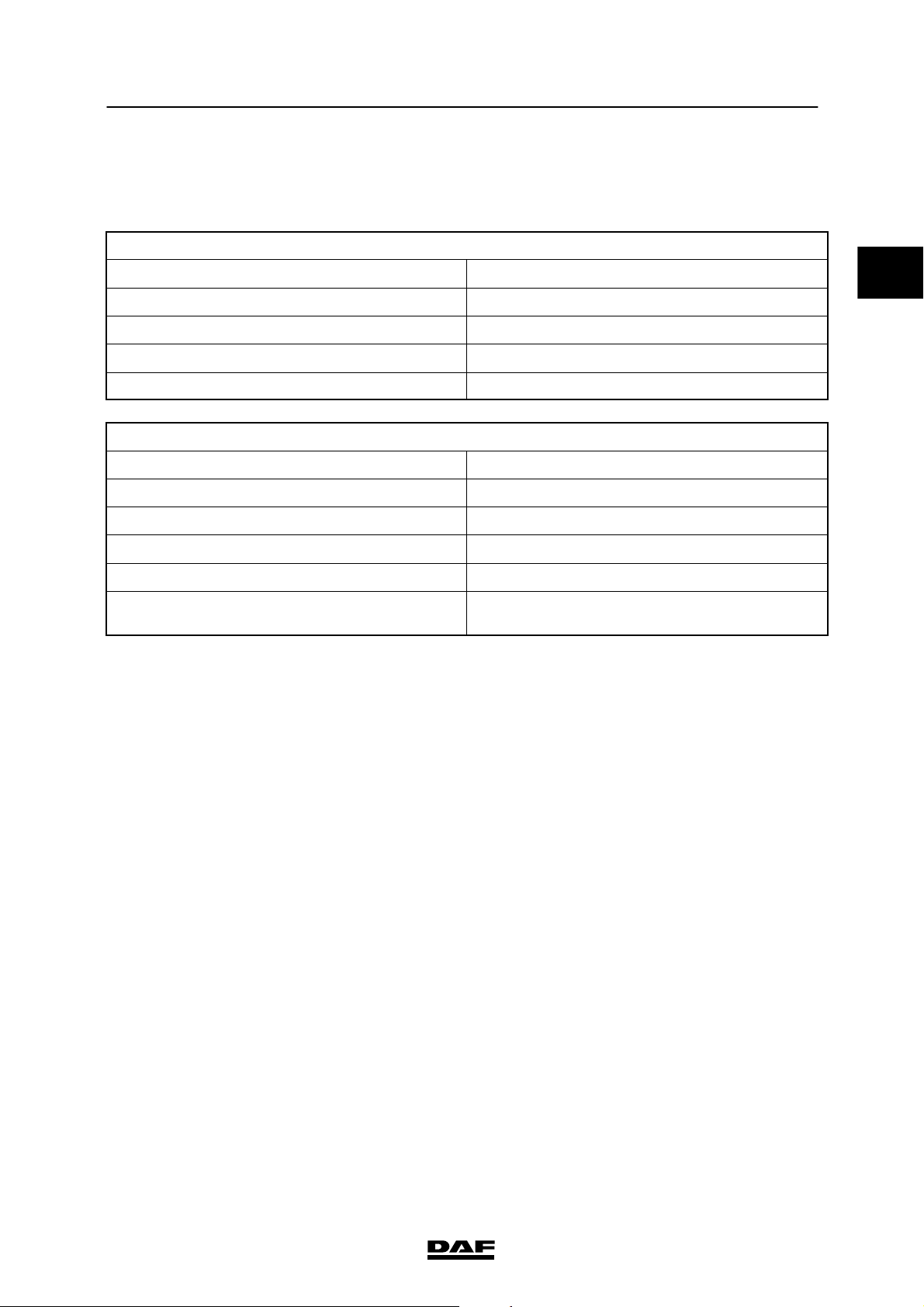

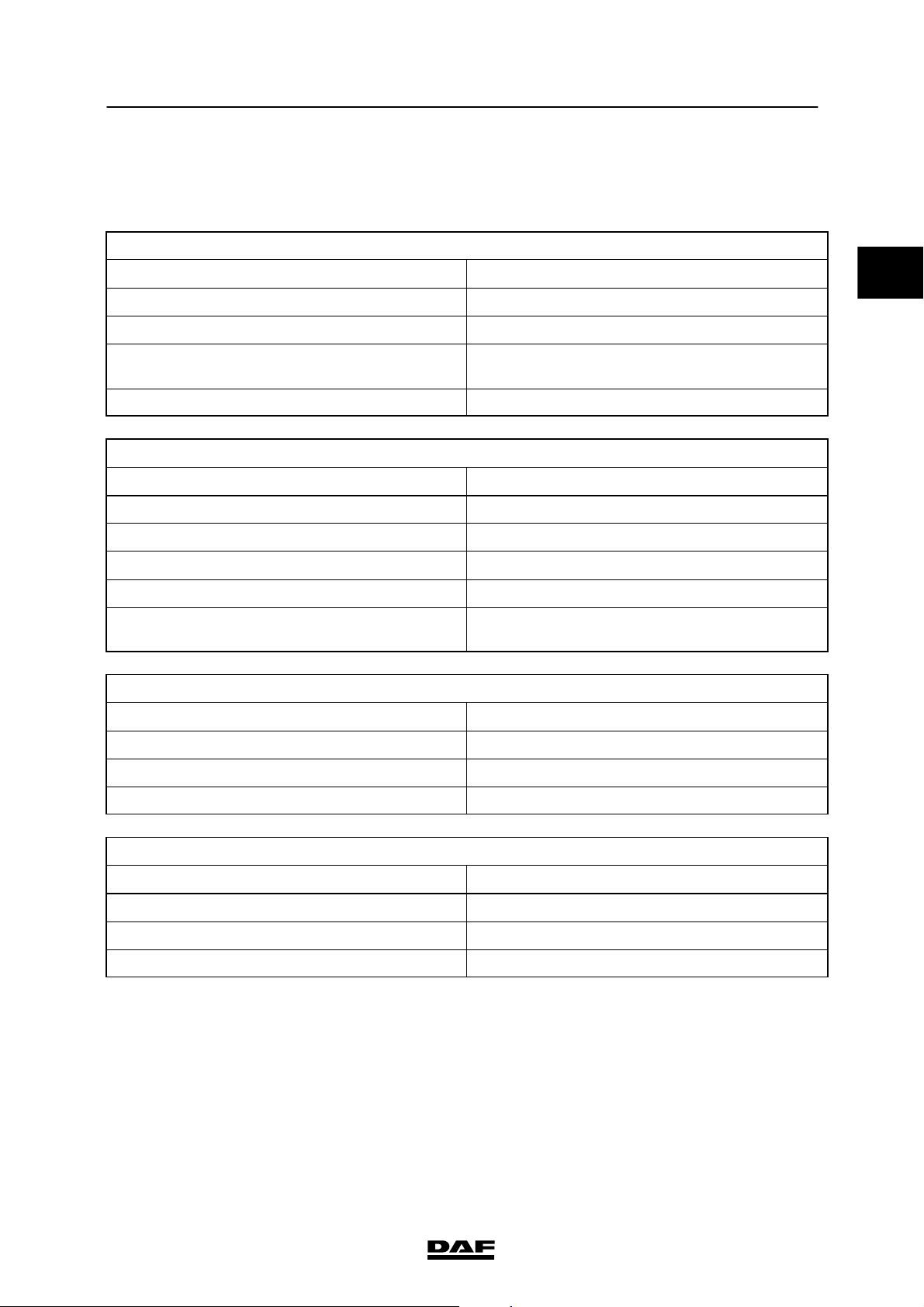

COMPLAINT: NOISES IN REAR AXLE AND DRIVE ASSEMBLY

Possible cause Remedy

Oil level too low Topupoil

Incorrect oil viscosity Drain oil and top up

Attachment bolts loosened or broken off Drain oil and check drained oil for metal particles

Pinion bearing play Adjust and/or replace

COMPLAINT: OIL LEAK

Possible cause Remedy

Oil level too high Drain oil

Incorrect oil viscosity Drain oil and top up

Leaking oil seal Replace oil seal

Bleeding system blocked Clean or replace the bleeding system

Oil leakage between the differential gear housing

mating surfaces

Clean mating surfaces and apply new sealant

1

ᓻ 200313

1-1

1

DIAGNOSTICS

Single rear axle 5.10 LF45/55 series

8

1-2

ᓻ 200313

8

DIAGNOSTICS

LF45/55 series Single rear axle 5.12

2. SINGLE REAR AXLE 5.12

2.1 FAULT-FINDING TABLE

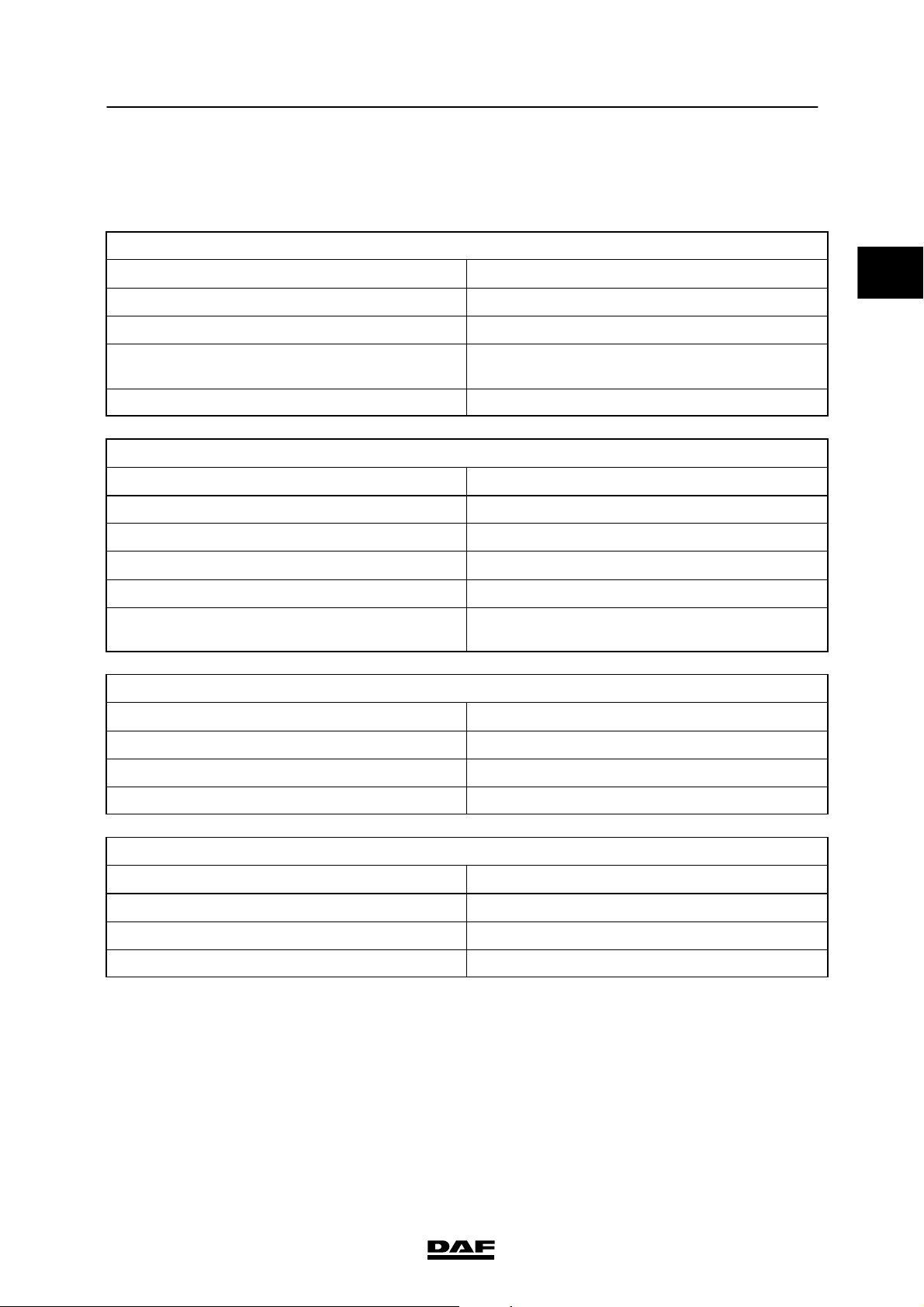

COMPLAINT: NOISES IN REAR AXLE AND DRIVE ASSEMBLY

Possible cause Remedy

Oil level too low Topupoil

Incorrect oil viscosity Drain oil and top up

Attachment bolts loosened or broken off Drain oil and check drained oil for metal particles

Pinion bearing play Adjust and/or replace

COMPLAINT: OIL LEAK

Possible cause Remedy

Oil level too high Drain oil

Incorrect oil viscosity Drain oil and top up

Leaking oil seal Replace oil seal

Bleeding system blocked Clean or replace the bleeding system

Oil leakage between the differential gear housing

mating surfaces

Clean mating surfaces and apply new sealant

1

ᓻ 200313

2-1

1

DIAGNOSTICS

Single rear axle 5.12 LF45/55 series

8

2-2

ᓻ 200313

8

DIAGNOSTICS

LF45/55 series Single rear axle 5.14

3. SINGLE REAR AXLE 5.14

3.1 FAULT-FINDING TABLE

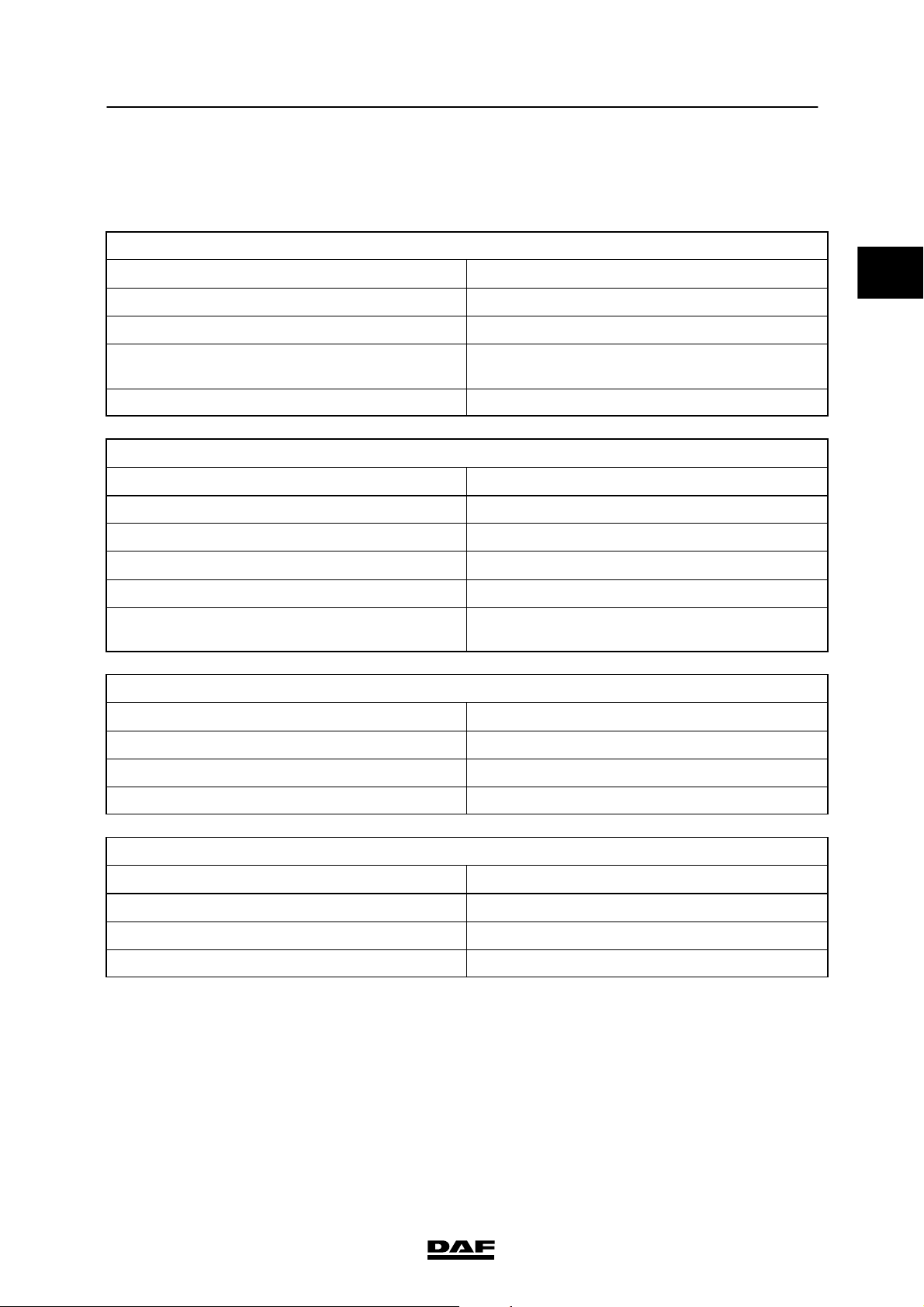

COMPLAINT: NOISES IN REAR AXLE AND DRIVE ASSEMBLY

Possible cause Remedy

Oil level too low Topupoil

Incorrect oil viscosity Drain oil and top up

Loosened attachment bolts or broken differential

lock parts

Pinion bearing play Adjust and/or replace

COMPLAINT: OIL LEAK

Possible cause Remedy

Oil level too high Drain oil

Incorrect oil viscosity Drain oil and top up

Leaking oil seal Replace oil seal

Bleeding system blocked Clean or replace the bleeding system

Oil leakage between the differential gear housing

mating surfaces

COMPLAINT: DIFFERENTIAL LOCK IS NOT FUNCTIONING

Possible cause Remedy

Drain oil and check drained oil for metal particles

Clean mating surfaces and apply new sealant

1

No air pressure on engaging cylinder Check compressed air system

Defective pneumatic control Check or replace pneumatic switch

Defective mechanical shift control Check shift control

COMPLAINT: DIFFERENTIAL LOCK WARNING LAMP IS NOT FUNCTIONING

Possible cause Remedy

Switch on cylinder fitted too high Readjust switch

Switch on cylinder defective Replace switch

Fault in electrical circuit Check electrical circuit

ᓻ 200313

3-1

1

DIAGNOSTICS

Single rear axle 5.14 LF45/55 series

8

3-2

ᓻ 200313

8

DIAGNOSTICS

LF45/55 series Single rear axle 8.20

4. SINGLE REAR AXLE 8.20

4.1 FAULT-FINDING TABLE

COMPLAINT: NOISES IN REAR AXLE AND DRIVE ASSEMBLY

Possible cause Remedy

Oil level too low Topupoil

Incorrect oil viscosity Drain oil and top up

Loosened attachment bolts or broken differential

lock parts

Pinion bearing play Adjust and/or replace

COMPLAINT: OIL LEAK

Possible cause Remedy

Oil level too high Drain oil

Incorrect oil viscosity Drain oil and top up

Leaking oil seal Replace oil seal

Bleeding system blocked Clean or replace the bleeding system

Oil leakage between the differential gear housing

mating surfaces

COMPLAINT: DIFFERENTIAL LOCK IS NOT FUNCTIONING

Possible cause Remedy

Drain oil and check drained oil for metal particles

Clean mating surfaces and apply new sealant

1

No air pressure on engaging cylinder Check compressed air system

Defective pneumatic control Check or replace pneumatic switch

Defective mechanical shift control Check shift control

COMPLAINT: DIFFERENTIAL LOCK WARNING LAMP IS NOT FUNCTIONING

Possible cause Remedy

Switch on cylinder fitted too high Readjust switch

Switch on cylinder defective Replace switch

Fault in electrical circuit Check electrical circuit

ᓻ 200313

4-1

1

DIAGNOSTICS

Single rear axle 8.20 LF45/55 series

8

4-2

ᓻ 200313

8

DIAGNOSTICS

LF45/55 series Single rear axle 10.20

5. SINGLE REAR AXLE 10.20

5.1 FAULT-FINDING TABLE

COMPLAINT: NOISES IN REAR AXLE AND DRIVE ASSEMBLY

Possible cause Remedy

Oil level too low Topupoil

Incorrect oil viscosity Drain oil and top up

Loosened attachment bolts or broken differential

lock parts

Pinion bearing play Adjust and/or replace

COMPLAINT: OIL LEAK

Possible cause Remedy

Oil level too high Drain oil

Incorrect oil viscosity Drain oil and top up

Leaking oil seal Replace oil seal

Bleeding system blocked Clean or replace the bleeding system

Oil leakage between the differential gear housing

mating surfaces

COMPLAINT: DIFFERENTIAL LOCK IS NOT FUNCTIONING

Possible cause Remedy

Drain oil and check drained oil for metal particles

Clean mating surfaces and apply new sealant

1

No air pressure on engaging cylinder Check compressed air system

Defective pneumatic control Check or replace pneumatic switch

Defective mechanical shift control Check shift control

COMPLAINT: DIFFERENTIAL LOCK WARNING LAMP IS NOT FUNCTIONING

Possible cause Remedy

Switch on cylinder fitted too high Readjust switch

Switch on cylinder defective Replace switch

Fault in electrical circuit Check electrical circuit

ᓻ 200313

5-1

1

DIAGNOSTICS

Single rear axle 10.20 LF45/55 series

8

5-2

ᓻ 200313

8

DIAGNOSTICS

LF45/55 series Single rear axle 10.26

6. SINGLE REAR AXLE 10.26

6.1 FAULT-FINDING TABLE

COMPLAINT: NOISES IN REAR AXLE AND DRIVE ASSEMBLY

Possible cause Remedy

Oil level too low Topupoil

Incorrect oil viscosity Drain oil and top up

Loosened attachment bolts or broken differential

lock parts

Pinion bearing play Adjust and/or replace

COMPLAINT: OIL LEAK

Possible cause Remedy

Oil level too high Drain oil

Incorrect oil viscosity Drain oil and top up

Leaking oil seal Replace oil seal

Bleeding system blocked Clean or replace the bleeding system

Oil leakage between the differential gear housing

mating surfaces

COMPLAINT: DIFFERENTIAL LOCK IS NOT FUNCTIONING

Possible cause Remedy

Drain oil and check drained oil for metal particles

Clean mating surfaces and apply new sealant

1

No air pressure on engaging cylinder Check compressed air system

Defective pneumatic control Check or replace pneumatic switch

Defective mechanical shift control Check shift control

COMPLAINT: DIFFERENTIAL LOCK WARNING LAMP IS NOT FUNCTIONING

Possible cause Remedy

Switch on cylinder fitted too high Readjust switch

Switch on cylinder defective Replace switch

Fault in electrical circuit Check electrical circuit

ᓻ 200313

6-1

1

DIAGNOSTICS

Single rear axle 10.26 LF45/55 series

8

6-2

ᓻ 200313

8

DIAGNOSTICS

LF45/55 series Single rear axle 11.26

7. SINGLE REAR AXLE 11.26

7.1 FAULT-FINDING TABLE

COMPLAINT: NOISES IN REAR AXLE AND DRIVE ASSEMBLY

Possible cause Remedy

Oil level too low Topupoil

Incorrect oil viscosity Drain oil and top up

Loosened attachment bolts or broken differential

lock parts

Pinion bearing play Adjust and/or replace

COMPLAINT: OIL LEAK

Possible cause Remedy

Oil level too high Drain oil

Incorrect oil viscosity Drain oil and top up

Leaking oil seal Replace oil seal

Bleeding system blocked Clean or replace the bleeding system

Oil leakage between the differential gear housing

mating surfaces

COMPLAINT: DIFFERENTIAL LOCK IS NOT FUNCTIONING

Possible cause Remedy

Drain oil and check drained oil for metal particles

Clean mating surfaces and apply new sealant

1

No air pressure on engaging cylinder Check compressed air system

Defective pneumatic control Check or replace pneumatic switch

Defective mechanical shift control Check shift control

COMPLAINT: DIFFERENTIAL LOCK WARNING LAMP IS NOT FUNCTIONING

Possible cause Remedy

Switch on cylinder fitted too high Readjust switch

Switch on cylinder defective Replace switch

Fault in electrical circuit Check electrical circuit

ᓻ 200313

7-1

1

DIAGNOSTICS

Single rear axle 11.26 LF45/55 series

8

7-2

ᓻ 200313

8

SINGLE REAR AXLE 5.10

LF45/55 series Contents

CONTENTS

Page Date

1. SAFETY INSTRUCTIONS 1-1 200313............................................... ....

2. GENERAL 2-1 200313............................................................ ....

2.1 Description of 5.10 axle 2-1 200313............................................ ....

2.2 Overview drawing, wheel hub 2-2 200313....................................... ....

3. INSPECTION AND ADJUSTMENT 3-1 200313....................................... ....

3.1 Inspecting differential oil level 3-1 200313....................................... ....

3.2 Inspection and adjustment, wheel bearing play 3-2 200313........................ ....

3.3 Inspection, wheel-speed sensor ring 3-3 200313................................. ....

4. REMOVAL AND INSTALLATION 4-1 200313........................................ ....

4.1 Removal and installation, stub axles 4-1 200313................................. ....

4.2 Removal and installation, wheel hub 4-2 200313................................. ....

4.3 Removal and installation, hub oil seal 4-4 200313................................ ....

4.4 Removal and installation, wheel bearing 4-4 200313............................. ....

4.5 Removal and installation, wheel-speed sensor 4-5 200313........................ ....

4.6 Removal and installation, drive flange 4-6 200313............................... ....

4.7 Removal and installation, pinion oil seal 4-8 200313.............................. ....

4.8 Removal and installation, differential 4-11 200313................................. ...

2

5. DRAINING AND FILLING 5-1 200313............................................... ....

5.1 Draining and filling, differential 5-1 200313...................................... ....

5.2 Draining and filling, wheel hubs 5-2 200313..................................... ....

ᓻ 200313

1

2

8SINGLE REAR AXLE 5.10

Contents LF45/55 series

2

ᓻ 200313

8

LF45/55 series Safety instructions

SINGLE REAR AXLE 5.10

1. SAFETY INSTRUCTIONS

Always use stands to support the

chassis or components when

working under the vehicle.

Always use the appropriate lifting

gear or approved hoists to remove

and install heavy components.

Attach the component securely to

the lifting or hoisting gear.

2

ᓻ 200313

1-1

2

SINGLE REAR AXLE 5.10

Safety instructions LF45/55 series

8

1-2

ᓻ 200313

8

SINGLE REAR AXLE 5.10

LF45/55 series General

2. GENERAL

2.1 DESCRIPTION OF 5.10 AXLE

Differential

The 5.10 axle has a differential with hypoid

gearing.

A single reduction is applied.

The bevelled gear-to-pinion backlash is

achieved using adjusting nuts.

The pre-load of the pinion bearings for the 5.10

axle is adjusted using a pre-load bush which is

placed between the pinion and the inner race of

the front bearing.

Wheel hub

The wheel hub has a wheel bearing and hub oil

seal that can be replaced separately. The

wheel-speed sensor ring is integrated into the

wheel hub. The wheel bearing play is adjusted

using the hub nut. The correct wheel bearing

pre-load is achieved by fitting the hub nut as

specified.

The hub nut is secured with a lock nut and a

locking plate.

The wheel bearing is greased by the oil in the

hub.

The stub axle and brake disc are attached to the

wheel hub with attachment nuts and bolts

respectively.

2

ᓻ 200313

2-1

;;;

;;;

;;;

;;;

;

;

2

SINGLE REAR AXLE 5.10

8

General LF45/55 series

2.2 OVERVIEW DRAWING, WHEEL HUB

1 2 3 4 5 6 7 8 9 10 11 12 13

Legend

1. Stub axle

2. Lock nut

3. Locking plate

4. Hub nut

5. Thrust washer

6. Wheel bearing inner race

7. Wheel bearing outer race

8. Wheel stud

9. Wheel hub

14151617

10. Hub oil seal

11. Wheel-speed sensor holder attachment

bolts

12. Wheel-speed sensor holder

13. Wheel-speed sensor

14. Brake disc

15. Brake disc attachment bolt

16. Drain plug

17. Stub axle attachment nut

A8 00 384

2-2

ᓻ 200313

8

SINGLE REAR AXLE 5.10

LF45/55 series Inspection and adjustment

3. INSPECTION AND ADJUSTMENT

3.1 INSPECTING DIFFERENTIAL OIL LEVEL

To prevent skin injury, avoid

unnecessary contact with the

drained oil.

1. Position the vehicle on a level surface.

2. Remove the level check/filler plug (1). The

oil level must reach the level check/filler

opening (1).

3. Apply sealant to the plug. Secure the plug.

2

1

A8 00 375

ᓻ 200313

3-1

2

SINGLE REAR AXLE 5.10

8

Inspection and adjustment LF45/55 series

3.2 INSPECTION AND ADJUSTMENT, WHEEL BEARING PLAY

Inspecting the wheel bearing play

1. Remove the wheel.

2. Remove the stub axle.

3. Remove the brake pads.

4. Fit a micrometer gauge to the wheel hub,

with the stylus on the end of the axle

journal.

5. Push and pull the wheel hub. Check the

wheel bearing play and compare it with the

specified value. See main group “Technical

data”.

A8 00 387

Adjusting the wheel bearing play

1. Remove the lock nut.

2. Tighten the hub nut with a hub nut wrench

(DAF No. 0499805) to 136 Nm.

3. Turn the hub two full rotations in order to

“seat” the wheel bearings.

4. Mark (1) the hub nut wrench (2).

5. Turn the hub nut 2 strokes back.

6. Check the wheel bearing play.

7. Position the locking plate and fit the lock

nut. Tighten the lock nut to the specified

tightening torque. See main group

“Technical data”.

8. Secure the hub nut and lock nut with the

locking plate.

1

2

1

3-2

A8 00 380

ᓻ 200313

8

SINGLE REAR AXLE 5.10

LF45/55 series Inspection and adjustment

3.3 INSPECTION, WHEEL-SPEED SENSOR RING

1. Check the sensor ring (2) for deposits.

Special attention should be paid to deposits

between the teeth of the sensor ring.

Clean the sensor ring if necessary.

2

2. Check the sensor ring (2) for damage. Even

the slightest damage may cause a failure.

If necessary, replace the wheel hub.

3. Check the sensor (1) for smooth operation.

If necessary, clean the sensor (1) and

re-apply the specified anti-corrosion agent.

See main group “Technical data”.

Never tap the sensor with a

hammer. This may damage both the

sensor and the sensor ring.

4. Check the ABS system for proper operation.

1

2

A8 00 391

ᓻ 200313

3-3

2

SINGLE REAR AXLE 5.10

Inspection and adjustment LF45/55 series

8

3-4

ᓻ 200313

8

SINGLE REAR AXLE 5.10

LF45/55 series Removal and installation

4. REMOVAL AND INSTALLATION

4.1 REMOVAL AND INSTALLATION, STUB AXLES

Removing stub axles

1. Jack up the rear axle and support it on

stands.

2. Remove the stub axle attachment nuts.

3. Remove the stub axle using a copper

punch. When the stub axle comes loose, a

small amount of oil may leak out. Collect

this oil.

Installing stub axles

1. Clean the mating surfaces of the stub axle

flange and wheel hub.

2. Apply the specified sealant to the mating

surface of the stub axle flange. See main

group “Technical data”.

3. Fit the stub axle. Tighten the stub axle

attachment nuts to the specified tightening

torque. See main group “Technical data”.

2

ᓻ 200313

4-1

2

SINGLE REAR AXLE 5.10

8

Removal and installation LF45/55 series

4.2 REMOVAL AND INSTALLATION, WHEEL HUB

Removing wheel hub

7

4

3

1

2

9

8

6

5

1. Jack up the rear axle and support it on

stands.

2. Remove the wheels.

3. Remove the brake caliper.

4. Remove the stub axle (1).

5. Remove the lock nut (2).

6. Remove the locking plate (3).

7. Remove the hub nut (4).

8. Remove the thrust washer (5).

9. Remove the wheel bearing inner race (6).

10. Remove the wheel hub from the axle

journal.

A8 00 394

4-2

ᓻ 200313

8

SINGLE REAR AXLE 5.10

LF45/55 series Removal and installation

Installing wheel hub

1. Check the wheel-speed sensor ring and the

oil seal in the wheel hub for damage.

Replace the oil seal if in doubt.

2. Check the axle journal screw thread

carefully for damage.

3. Install the wheel hub on the axle journal.

Slide the wheel hub onto the axle journal.

Fit the wheel bearing inner race (6).

4. Fit the thrust washer (5).

5. Fit the hub nut (4).

6. Adjust the wheel bearing play, see chapter

“Inspection and adjustment”.

7. Fit the locking plate (3).

8. Fit the lock nut (2). Tighten the lock nut (2)

to the specified tightening torque. See main

group “Technical data”.

2

9. Secure the lock nut (2) with the locking

plate (3).

10. Press the wheel-speed sensor (1) against

the sensor ring (2). When the vehicle is

being driven, the air gap between the

sensor and the sensor ring is adjusted

automatically.

If the sensor is stuck, remove, clean and

refit it.

Never tap the sensor with a

hammer. This may damage both the

sensor and the sensor ring.

11. Fit the stub axle.

12. Fit the brake caliper.

13. Put the wheels back on.

14. Check the ABS system for proper operation.

2

1

A8 00 391

ᓻ 200313

4-3

2

SINGLE REAR AXLE 5.10

8

Removal and installation LF45/55 series

4.3 REMOVAL AND INSTALLATION, HUB OIL SEAL

Removing hub oil seal

1. Remove the wheel hub from the axle

journal.

2. Drill two holes into the oil seal and screw

the special tool (B) (DAF No. 0484899) into

the oil seal. Pull the oil seal from the pinion

housing using the special tool (A)

(DAF No. 0694928).

Installing hub oil seal

1. Use the special tool (DAF No. 0499809) to

fit the oil seal such that the marking

“outside” is pointing outward.

2. Install the wheel hub.

A

4.4 REMOVAL AND INSTALLATION, WHEEL BEARING

Removing wheel bearing

1. Remove the wheel hub.

2. Remove the oil seal from the wheel hub.

3. There are recesses in the wheel hub for

removing the wheel bearing outer race.

4. Remove the wheel bearing outer races from

the wheel hub using a driver.

Installing wheel bearing

1. Fit the wheel bearing outer races in the

wheel hub using a driver.

B

A8 00 392

2. Fit the hub oil seal.

3. Install the wheel hub.

4-4

A8 00 393

ᓻ 200313

8

SINGLE REAR AXLE 5.10

LF45/55 series Removal and installation

4.5 REMOVAL AND INSTALLATION, WHEEL-SPEED SENSOR

Removing the wheel-speed sensor

1. Remove the wheel-speed sensor (1) from

the holder (3).

2. Cut the clamping strips attaching the cable.

3. Unplug the connector and remove the

wheel-speed sensor.

1

2

3

Installing the wheel-speed sensor

1. Clean the wheel-speed sensor (1) and the

clamping sleeve (2). If necessary, replace

theclampingsleeve(2).

2. Apply the specified anti-corrosion agent to

the circumference of the wheel-speed

sensor (1). See main group “Technical

data”.

3. Fit the wheel-speed sensor (1) in the holder

(3). Press it against the sensor ring

manually.

While the vehicle is being driven, the air gap

between the sensor and the sensor ring is

adjusted automatically.

Never tap the sensor with a

hammer. This may damage both the

sensor and the sensor ring.

4. Fit the connector and secure the cable with

clamping strips.

5. Check the ABS system for proper operation.

2

A8 00 435

ᓻ 200313

4-5

SINGLE REAR AXLE 5.10

8

Removal and installation LF45/55 series

4.6 REMOVAL AND INSTALLATION, DRIVE FLANGE

Removing drive flange

1. Remove the prop shaft from the drive

flange.

2. Jack up the rear axle and support it on

stands.

3. Remove the stub axles.

2

4. Determine the pre-load of the pinion

bearings by turning the drive flange nut

using a torque wrench with a dial (2) and a

12-sided socket (1). Write down the

measured slip torque.

5. Fit the special tool (B) (DAF No. 0484977)

on the drive flange to prevent it from

turning. Remove the drive flange nut using

a 12-sided socket and a torque

amplifier (A).

1

2

A8 00 442

A B

6. Remove the drive flange. If necessary, use

a puller.

Installing drive flange

1. Check the dust seal ring of the drive flange.

If required, replace the dust seal ring.

2. Check the drive flange at the oil-seal

running surface for grooves and/or sharp

edges. If required, replace the drive flange.

3. Clean the splines of the pinion and drive

flange.

4-6

A8 00 386

ᓻ 200313

8

SINGLE REAR AXLE 5.10

LF45/55 series Removal and installation

4. Apply the specified sealant to the splines of

the pinion. See main group “Technical data”.

5. Fit the drive flange.

6. Fit a new drive flange nut.

7. Fit the special tool (3) (DAF No. 0484977)

to the drive flange to prevent it from turning.

Tighten the drive flange nut using a

12-sided socket and a torque amplifier (A)

until no play is noticeable on the pinion.

8. Turn the drive flange a number of times to

“seat” the pinion bearings.

9. Tighten the drive flange until the slip torque

of the drive flange nut exceeds the noted

valueby0.4-0.6Nm.

Note:

If the slip torque of the drive flange nut

exceeds the noted value increased by

0.4 - 0.6 Nm, loosen the drive flange nut a

few strokes and repeat the setting

procedure.

10. Fit the stub axles.

11. Fit the prop shaft to the drive flange.

A B

2

A8 00 386

ᓻ 200313

4-7

SINGLE REAR AXLE 5.10

8

Removal and installation LF45/55 series

4.7 REMOVAL AND INSTALLATION, PINION OIL SEAL

Removing pinion oil seal

1. Remove the prop shaft from the drive

flange.

2. Jack up the rear axle and support it on

stands.

3. Remove the stub axles.

2

4. Determine the pre-load of the pinion

bearings by turning the drive flange nut

using a torque wrench with a dial (2) and a

12-sided socket (1). Write down the

measured slip torque.

5. Fit the special tool (B) (DAF No. 0484977)

on the drive flange to prevent it from

turning. Remove the drive flange nut using

a 12-sided socket and a torque

amplifier (A).

1

2

A8 00 442

A B

6. Remove the drive flange. If necessary, use

a puller.

4-8

A8 00 386

ᓻ 200313

8

SINGLE REAR AXLE 5.10

LF45/55 series Removal and installation

7. Remove the oil seal (1) from the differential

housing.

1

A8 00 441

Installing pinion oil seal

1. Use the special tool (DAF No. 1453141) to

fit the oil seal. Make sure that the steel

outer ring of the oil seal abuts fully against

the differential housing.

2

2. Check the dust seal ring of the drive flange.

If required, replace the dust seal ring.

3. Check the drive flange at the oil seal

running surface for grooves and/or sharp

edges. If required, replace the drive flange.

4. Clean the splines of the pinion and drive

flange.

5. Apply the specified sealant to the splines of

the pinion. See main group “Technical data”.

6. Fit the drive flange.

7. Fit a new drive flange nut.

ᓻ 200313

4-9

SINGLE REAR AXLE 5.10

8

Removal and installation LF45/55 series

2

8. Fit the special tool (B) (DAF No. 0484977)

on the drive flange to prevent it from

turning. Tighten the drive flange nut using a

12-sided socket and a torque amplifier (A)

until no play is noticeable on the pinion.

9. Turn the drive flange a number of times to

“seat” the pinion bearings.

10. Tighten the drive flange until the slip torque

of the drive flange nut exceeds the noted

valueby0.4-0.6Nm.

Note:

If the slip torque of the drive flange nut

exceeds the noted value increased by

0.4 - 0.6 Nm, loosen the drive flange nut a

few strokes and repeat the setting

procedure.

11. Fit the stub axles.

12. Fit the prop shaft to the drive flange.

A B

A8 00 386

4-10

ᓻ 200313

8

SINGLE REAR AXLE 5.10

LF45/55 series Removal and installation

4.8 REMOVAL AND INSTALLATION, DIFFERENTIAL

Removing differential

1. Drain the oil from the differential. See

chapter “Draining and filling”.

2. Remove the prop shaft from the drive

flange.

3. Remove the stub axles.

4. Attach the differential securely to a lifting

device.

5. Remove the attachment bolts and nuts from

the differential.

6. Remove the differential from the axle

housing by carefully pressing the differential

off the axle housing using a pry bar at the

indicated places.

Installing differential

1. Clean the mating surfaces of the axle

housing and the differential housing.

Regrind the mating faces lightly. Do not

damage the mating faces in the process.

2. Clean and degrease the bolts. Check the

bolts and stud bolts for signs of damage.

3. Apply a thin, even layer of sealant to the

mating surface and around the bolt holes of

the axle housing.

4. Apply locking compound to the attachment

bolts. See main group “Technical data”.

5. Fit the differential into the axle housing. Fit

the attachment bolts and nuts and tighten

them evenly. Tighten the attachment bolts

and nuts to the specified tightening torque.

See “Technical data”.

2

A8 00 440

6. Fit the stub axles.

7. Fit the prop shaft to the drive flange.

8. Fill the differential with oil. See chapter

“Draining and filling”.

ᓻ 200313

4-11

2

SINGLE REAR AXLE 5.10

Removal and installation LF45/55 series

8

4-12

ᓻ 200313

8

SINGLE REAR AXLE 5.10

LF45/55 series Draining and filling

5. DRAINING AND FILLING

5.1 DRAINING AND FILLING, DIFFERENTIAL

To prevent skin injury, avoid

unnecessary contact with the

drained oil.

Draining the differential

1. Position the vehicle on a level surface.

2. Place a suitable tray beneath the differential

to collect the oil.

3. Remove the drain plug (1) and the level

check/filler plug (2). Drain the oil.

4. Apply sealant to the screw thread of the

drain plug (1). Install the drain plug (1) and

tighten it to the specified tightening torque.

See main group “Technical data”.

Filling the differential

1. Fill the differential via the level check/filler

plug (2) with the specified and correct

quantity of oil. See main group “Technical

data”.

2

2

2. Check the oil level after 5 minutes; it should

reach up to the level check/filler plug (2).

3. Apply sealant to the screw thread of the

level check/filler plug (2). Fit the level

check/filler plug (2).

1

A8 00 370

ᓻ 200313

5-1

2

SINGLE REAR AXLE 5.10

8

Draining and filling LF45/55 series

5.2 DRAINING AND FILLING, WHEEL HUBS

To prevent skin injury, avoid

unnecessary contact with the

drained oil.

Note:

The design of the hub and the location of the

drain/filler plug may differ from the illustration,

depending on the version.

Draining wheel hub

1. Position the vehicle on a level surface.

2. Position the wheels in such a way that the

oil drain/filler plug (1) is at the bottom.

3. Place a suitable tray under the hub to

collect the oil. Remove the oil drain/filler

plug (1).

4. Drain the oil and let the oil leak out of the

hub.

Filling wheel hub

1. Position the wheels in such a way that the

oil drain/filler plug (1) is at the top.

2. Fill the wheel hub with the specified and

correct quantity of oil. See main group

“Technical data”.

3. Apply sealant to the screw thread of the oil

drain/filler plug (1). Fit the oil drain/filler plug

(1) into the hub.

1

A8 00 369

5-2

ᓻ 200313

8

SINGLE REAR AXLE 5.12

LF45/55 series Contents

CONTENTS

Page Date

1. SAFETY INSTRUCTIONS 1-1 200313............................................... ....

2. GENERAL 2-1 200313............................................................ ....

2.1 Description of 5.12 axle 2-1 200313............................................ ....

2.2 Overview drawing, wheel hub 2-2 200313....................................... ....

3. INSPECTION AND ADJUSTMENT 3-1 200313....................................... ....

3.1 Inspecting differential oil level 3-1 200313....................................... ....

3.2 Adjusting the crown wheel guide bolt 3-2 200313................................ ....

3.3 Inspection and adjustment, wheel bearing play 3-3 200313........................ ....

3.4 Inspection, wheel-speed sensor ring 3-4 200313................................. ....

4. REMOVAL AND INSTALLATION 4-1 200313........................................ ....

4.1 Removal and installation, stub axles 4-1 200313................................. ....

4.2 Removal and installation, wheel hub 4-2 200313................................. ....

4.3 Removal and installation, hub oil seal 4-4 200313................................ ....

4.4 Removal and installation, wheel bearing 4-4 200313............................. ....

4.5 Removal and installation, wheel-speed sensor 4-5 200313........................ ....

4.6 Removal and installation, drive flange 4-6 200313............................... ....

4.7 Removal and installation, pinion oil seal 4-7 200313.............................. ....

4.8 Removal and installation, differential 4-8 200313................................. ....

3

5. DRAINING AND FILLING 5-1 200313............................................... ....

5.1 Draining and filling, differential 5-1 200313...................................... ....

5.2 Draining and filling, wheel hubs 5-2 200313..................................... ....

ᓻ 200313

1

3

8SINGLE REAR AXLE 5.12

Contents LF45/55 series

2

ᓻ 200313

8

LF45/55 series Safety instructions

SINGLE REAR AXLE 5.12

1. SAFETY INSTRUCTIONS

Always use stands to support the

chassis or components when

working under the vehicle.

Always use the appropriate lifting

gear or approved hoists to remove

and install heavy components.

Attach the component securely to

the lifting or hoisting gear.

3

ᓻ 200313

1-1

3

SINGLE REAR AXLE 5.12

Safety instructions LF45/55 series

8

1-2

ᓻ 200313

8

SINGLE REAR AXLE 5.12

LF45/55 series General

2. GENERAL

2.1 DESCRIPTION OF 5.12 AXLE

Differential

The 5.12 axle has a differential with hypoid

gearing.

A single reduction is applied.

The bevelled gear-to-pinion backlash is

achieved using adjusting nuts.

The pre-load of the pinion bearings for the 5.12

axle is adjusted using shims which are placed

between the bearing inner races.

The pinion housing of the 5.12 axle can be

removed using jacking bolts.

Wheel hub

The wheel hub has a wheel bearing and hub oil

seal that can be replaced separately. The

wheel-speed sensor ring is integrated into the

wheel hub. The wheel bearing play is adjusted

using the hub nut. The correct wheel bearing

pre-load is achieved by fitting the hub nut as

specified.

The hub nut is secured with a lock nut and a

locking plate.

The wheel bearing is greased by the oil in the

hub.

The stub axle and brake disc are attached to the

wheel hub with attachment nuts and bolts

respectively.

3

ᓻ 200313

2-1

;;;

;;;

;;;

;;;

;

;

3

SINGLE REAR AXLE 5.12

8

General LF45/55 series

2.2 OVERVIEW DRAWING, WHEEL HUB

1 2 3 4 5 6 7 8 9 10 11 12 13

Legend

1. Stub axle

2. Lock nut

3. Locking plate

4. Hub nut

5. Thrust washer

6. Wheel bearing inner race

7. Wheel bearing outer race

8. Wheel stud

9. Wheel hub

14151617

10. Hub oil seal

11. Wheel-speed sensor holder

12. Wheel-speed sensor holder attachment

bolts

13. Wheel-speed sensor

14. Brake disc

15. Brake disc attachment bolt

16. Drain plug

17. Stub axle attachment nut

A8 00 384

2-2

ᓻ 200313

8

SINGLE REAR AXLE 5.12

LF45/55 series Inspection and adjustment

3. INSPECTION AND ADJUSTMENT

3.1 INSPECTING DIFFERENTIAL OIL LEVEL

To prevent skin injury, avoid

unnecessary contact with the

drained oil.

1. Position the vehicle on a level surface.

2. Remove the level check/filler plug (1). The

oil level must reach the level check/filler

opening (1).

3. Apply sealant to the plug. Secure the plug.

3

1

A8 00 375

ᓻ 200313

3-1

SINGLE REAR AXLE 5.12

8

Inspection and adjustment LF45/55 series

3.2 ADJUSTING THE CROWN WHEEL GUIDE BOLT

1. Place chocks in front of the wheels and

engage the parking brake.

2. Loosen the lock ring (1) and loosen the lock

nut (2) a few turns.

3. Remove the adjusting screw (3) from the

differential.

3

2

3

4. Remove the lock ring (1).

5. Remove any residual sealant from the

adjusting screw and apply new sealant to

the last 4 windings of the screw thread. See

main group “Technical data”.

6. Fit the adjusting screw with a new lock ring

and tighten the adjusting screw against the

crown wheel.

7. Turn the adjusting screw 1/8 stroke back to

obtain the required play A.

8. Tighten the lock nut to the specified

tightening torque. See main group

“Technical data”.

Note:

Make sure that the adjusting screw does not

turn while the lock nut is being tightened.

9. Secure the lock nut by folding the lips of the

lock ring.

1

A8 00 429

3-2

ᓻ 200313

8

SINGLE REAR AXLE 5.12

LF45/55 series Inspection and adjustment

3.3 INSPECTION AND ADJUSTMENT, WHEEL BEARING PLAY

Inspecting the wheel bearing play

1. Remove the wheel.

2. Remove the stub axle.

3. Remove the brake pads.

4. Fit a micrometer gauge to the wheel hub,

with the stylus on the end of the axle

journal.

5. Push and pull the wheel hub. Check the

wheel bearing play and compare it with the

specified value. See main group “Technical

data”.

A8 00 387

3

Adjusting the wheel bearing play

1. Remove the lock nut.

2. Tighten the hub nut with a hub nut wrench

(DAF No. 0499805) to 136 Nm.

3. Turn the hub two full rotations in order to

“seat” the wheel bearings.

4. Mark (1) the hub nut wrench (2).

5. Turn the hub nut 2 strokes back.

6. Check the wheel bearing play.

7. Position the locking plate and fit the lock

nut. Tighten the lock nut to the specified

tightening torque. See main group

“Technical data”.

8. Secure the hub nut and lock nut with the

locking plate.

1

2

1

ᓻ 200313

A8 00 380

3-3

SINGLE REAR AXLE 5.12

8

Inspection and adjustment LF45/55 series

3.4 INSPECTION, WHEEL-SPEED SENSOR RING

1. Check the sensor ring (2) for deposits.

Special attention should be paid to deposits

between the teeth of the sensor ring.

Clean the sensor ring if necessary.

2

3

2. Check the sensor ring (2) for damage. Even

the slightest damage may cause a failure.

If necessary, replace the wheel hub.

3. Check the sensor (1) for smooth operation.

If necessary, clean the sensor (1) and

re-apply the specified anti-corrosion agent.

See main group “Technical data”.

Never tap the sensor with a

hammer. This may damage both the

sensor and the sensor ring.

4. Check the ABS system for proper operation.

1

A8 00 391

3-4

ᓻ 200313

8

SINGLE REAR AXLE 5.12

LF45/55 series Removal and installation

4. REMOVAL AND INSTALLATION

4.1 REMOVAL AND INSTALLATION, STUB AXLES

Removing stub axles

1. Jack up the rear axle and support it on

stands.

2. Remove the stub axle attachment nuts.

3. Remove the stub axle using a copper

punch. When the stub axle comes loose, a

small amount of oil may leak out. Collect

this oil.

Installing stub axles

1. Clean the mating surfaces of the stub axle

flange and wheel hub.

2. Apply the specified sealant to the mating

surface of the stub axle flange. See main

group “Technical data”.

3. Fit the stub axle. Tighten the stub axle

attachment nuts to the specified tightening

torque. See main group “Technical data”.

3

ᓻ 200313

4-1

3

SINGLE REAR AXLE 5.12

8

Removal and installation LF45/55 series

4.2 REMOVAL AND INSTALLATION, WHEEL HUB

Removing wheel hub

7

4

3

1

2

9

8

6

5

1. Jack up the rear axle and support it on

stands.

2. Remove the wheels.

3. Remove the brake caliper.

4. Remove the stub axle (1).

5. Remove the lock nut (2).

6. Remove the locking plate (3).

7. Remove the hub nut (4).

8. Remove the thrust washer (5).

9. Remove the wheel bearing inner race (6).

10. Remove the wheel hub from the axle

journal.

A8 00 394

4-2

ᓻ 200313

8

SINGLE REAR AXLE 5.12

LF45/55 series Removal and installation

Installing wheel hub

1. Check the wheel-speed sensor ring and the

oil seal in the wheel hub for damage.

Replace the oil seal if in doubt.

2. Check the axle journal screw thread

carefully for damage.

3. Install the wheel hub on the axle journal.

Slide the wheel hub onto the axle journal.

Fit the wheel bearing inner race (6).

4. Fit the thrust washer (5).

5. Fit the hub nut (4).

6. Adjust the wheel bearing play, see chapter

“Inspection and adjustment”.

7. Fit the locking plate (3).

8. Fit the lock nut (2). Tighten the lock nut (2)

to the specified tightening torque. See main

group “Technical data”.

9. Secure the lock nut (2) with the locking

plate (3).

10. Press the wheel-speed sensor (1) against

the sensor ring (2). When the vehicle is

being driven, the air gap between the

sensor and the sensor ring is adjusted

automatically.

If the sensor is stuck, remove, clean and

refit it.

Never tap the sensor with a

hammer. This may damage both the

sensor and the sensor ring.

11. Fit the stub axle.

12. Fit the brake caliper.

13. Put the wheels back on.

3

2

1

A8 00 391

14. Check the ABS system for proper operation.

ᓻ 200313

4-3

3

SINGLE REAR AXLE 5.12

8

Removal and installation LF45/55 series

4.3 REMOVAL AND INSTALLATION, HUB OIL SEAL

Removing hub oil seal

1. Remove the wheel hub from the axle

journal.

2. Drill two holes into the oil seal and screw

the special tool (B) (DAF No. 0484899) into

the oil seal. Pull the oil seal from the pinion

housing using the special tool (A)

(DAF No. 0694928).

Installing hub oil seal

1. Use the special tool (DAF No. 0499809) to

fit the oil seal such that the marking

“outside” is pointing outward.

2. Install the wheel hub.

A

B

4.4 REMOVAL AND INSTALLATION, WHEEL BEARING

Removing wheel bearing

1. Remove the wheel hub.

2. Remove the oil seal from the wheel hub.

3. There are recesses in the wheel hub for

removing the wheel bearing outer race.

4. Remove the wheel bearing outer races from

the wheel hub using a driver.

Installing wheel bearing

1. Fit the wheel bearing outer races in the

wheel hub using a driver.

2. Fit the hub oil seal.

3. Install the wheel hub.

A8 00 392

A8 00 393

4-4

ᓻ 200313

8

SINGLE REAR AXLE 5.12

LF45/55 series Removal and installation

4.5 REMOVAL AND INSTALLATION, WHEEL-SPEED SENSOR

Removing the wheel-speed sensor

1. Remove the wheel-speed sensor (1) from

the holder (3).

2. Cut the clamping strips attaching the cable.

3. Unplug the connector and remove the

wheel-speed sensor.

Installing the wheel-speed sensor

1. Clean the wheel-speed sensor (1) and the

clamping sleeve (2). If necessary, replace

theclampingsleeve(2).

2. Apply the specified anti-corrosion agent to

the circumference of the wheel-speed

sensor (1). See main group “Technical

data”.

3. Fit the wheel-speed sensor (1) in the holder

(3). Press it against the sensor ring

manually.

While the vehicle is being driven, the air gap

between the sensor and the sensor ring is

adjusted automatically.

1

2

3

A8 00 435

3

Never tap the sensor with a

hammer. This may damage both the

sensor and the sensor ring.

4. Fit the connector and secure the cable with

clamping strips.

5. Check the ABS system for proper operation.

ᓻ 200313

4-5

SINGLE REAR AXLE 5.12

8

Removal and installation LF45/55 series

4.6 REMOVAL AND INSTALLATION, DRIVE FLANGE

Removing drive flange

1. Remove the prop shaft from the drive

flange.

3

2. Fit the special tool (B) (DAF No. 0484977)

on the drive flange to prevent it from

turning. Remove the drive flange nut using

a torque amplifier (A).

3. Remove the drive flange. If necessary, use

a puller.

Installing drive flange

1. Before installation check the drive flange

along the oil-seal running surface for

grooves and/or sharp edges. If required,

replace the drive flange.

2. Fit the drive flange.

3. Apply a small amount of oil to the abutting

surface of the drive flange nut.

4. Fit a new drive flange nut.

5. Fit the special tool (B) (DAF No. 0484977)

on the drive flange to prevent it from

turning. Use a torque amplifier (A) to tighten

the drive flange nut to the specified

tightening torque. See main group

“Technical data”.

6. Fit the prop shaft to the drive flange.

A B

A8 00 386

4-6

ᓻ 200313

8

SINGLE REAR AXLE 5.12

LF45/55 series Removal and installation

4.7 REMOVAL AND INSTALLATION, PINION OIL SEAL

Removing pinion oil seal

1. Remove the drive flange.

2. Drill two holes into the oil seal and screw

the special tool (B) (DAF No. 0484899) into

the oil seal. Pull the oil seal from the pinion

housing using the special tool (A)

(DAF No. 0694928).

Installing pinion oil seal

1. Use the special tool (DAF No. 0485183) to

fit the oil seal such that the marking

“outside” is pointing outward.

2. Fit the drive flange.

A

B

3

A8 00 381

ᓻ 200313

4-7

3

SINGLE REAR AXLE 5.12

8

Removal and installation LF45/55 series

4.8 REMOVAL AND INSTALLATION, DIFFERENTIAL

Removing differential

1. Drain the oil from the differential. See

chapter “Draining and filling”.

2. Remove the prop shaft from the drive

flange.

3. Remove the stub axles.

4. Attach the differential securely to a lifting

device.

5. Remove the attachment bolts and nuts from

the differential.

6. Remove the differential from the axle

housing using two thrust bolts.

Installing differential

1. Clean the mating surfaces of the axle

housing and the differential housing.

Regrind the mating faces lightly. Do not

damage the mating faces in the process.

2. Clean and degrease the bolts. Check the

bolts and stud bolts for signs of damage.

3. Apply a thin, even layer of sealant to the

mating surface and around the bolt holes of

the axle housing.

4. Apply locking compound to the attachment

bolts. See main group “Technical data”.

5. Fit the differential into the axle housing. Fit

the attachment bolts and nuts and tighten

them evenly. Tighten the attachment bolts

and nuts to the specified tightening torque.

See “Technical data”.

6. Fit the stub axles.

7. Fit the prop shaft to the drive flange.

8. Fill the differential with oil. See chapter

“Draining and filling”.

A8 00 378

4-8

ᓻ 200313

8

SINGLE REAR AXLE 5.12

LF45/55 series Draining and filling

5. DRAINING AND FILLING

5.1 DRAINING AND FILLING, DIFFERENTIAL

To prevent skin injury, avoid

unnecessary contact with the

drained oil.

Draining the differential

1. Position the vehicle on a level surface.

2. Place a suitable tray beneath the differential

to collect the oil.

3. Remove the drain plug (1) and the level

check/filler plug (2). Drain the oil.

4. Apply sealant to the screw thread of the

drain plug (1). Install the drain plug (1) and

tighten it to the specified tightening torque.

See main group “Technical data”.

Filling the differential

1. Fill the differential via the level check/filler

plug (2) with the specified and correct

quantity of oil. See main group “Technical

data”.

2. Check the oil level after 5 minutes; it should

reach up to the level check/filler plug (2).

3. Apply sealant to the screw thread of the

level check/filler plug (2). Fit the level

check/filler plug (2).

3

2

1

A8 00 370

ᓻ 200313

5-1

SINGLE REAR AXLE 5.12

8

Draining and filling LF45/55 series

5.2 DRAINING AND FILLING, WHEEL HUBS

To prevent skin injury, avoid

unnecessary contact with the

drained oil.

Note:

The design of the hub and the location of the

drain/filler plug may differ from the illustration,

depending on the version.

Draining wheel hub

1. Position the vehicle on a level surface.

3

2. Position the wheels in such a way that the

oil drain/filler plug (1) is at the bottom.

3. Place a suitable tray under the hub to

collect the oil. Remove the oil drain/filler

plug (1).

4. Drain the oil and let the oil leak out of the

hub.

Filling wheel hub

1. Position the wheels in such a way that the

oil drain/filler plug (1) is at the top.

2. Fill the wheel hub with the specified and

correct quantity of oil. See main group

“Technical data”.

3. Apply sealant to the screw thread of the oil

drain/filler plug (1). Fit the oil drain/filler plug

(1) into the hub.

1

5-2

A8 00 369

ᓻ 200313

8

SINGLE REAR AXLE 5.14

LF45/55 series Contents

CONTENTS

Page Date

1. SAFETY INSTRUCTIONS 1-1 200313............................................... ....

2. GENERAL 2-1 200313............................................................ ....

2.1 Description of 5.14 axle 2-1 200313............................................ ....

2.2 Overview drawing, wheel hub 2-3 200313....................................... ....

3. INSPECTION AND ADJUSTMENT 3-1 200313....................................... ....

3.1 Inspecting differential oil level 3-1 200313....................................... ....

3.2 Checking operation of differential lock 3-1 200313............................... ....

3.3 Inspection and adjustment, wheel bearing play 3-2 200313........................ ....

3.4 Inspection, wheel-speed sensor ring 3-3 200313................................. ....

4. REMOVAL AND INSTALLATION 4-1 200313........................................ ....

4.1 Removal and installation, stub axles 4-1 200313................................. ....

4.2 Removal and installation, wheel hub 4-2 200313................................. ....

4.3 Removal and installation, hub oil seal 4-4 200313................................ ....

4.4 Removal and installation, wheel bearing 4-4 200313............................. ....

4.5 Removal and installation, wheel-speed sensor 4-5 200313........................ ....

4.6 Removal and installation, drive flange 4-6 200313............................... ....

4.7 Removal and installation, pinion oil seal 4-7 200313.............................. ....

4.8 Removal and installation, differential 4-8 200313................................. ....

4.9 Removal and installation, differential lock of 5.14 axle 4-9 200313.................. ....

4

5. DRAINING AND FILLING 5-1 200313............................................... ....

5.1 Draining and filling, differential 5-1 200313...................................... ....

5.2 Draining and filling, wheel hubs 5-2 200313..................................... ....

ᓻ 200313

1

4

8SINGLE REAR AXLE 5.14

Contents LF45/55 series

2

ᓻ 200313

8

LF45/55 series Safety instructions

SINGLE REAR AXLE 5.14

1. SAFETY INSTRUCTIONS

Always use stands to support the

chassis or components when

working under the vehicle.

Always use the appropriate lifting

gear or approved hoists to remove

and install heavy components.

Attach the component securely to

the lifting or hoisting gear.

4

ᓻ 200313

1-1

4

SINGLE REAR AXLE 5.14

Safety instructions LF45/55 series

8

1-2

ᓻ 200313

8

SINGLE REAR AXLE 5.14

LF45/55 series General

2. GENERAL

2.1 DESCRIPTION OF 5.14 AXLE

Differential

The 5.14 axle has a differential with hypoid

gearing.

A single reduction is applied.

The bevelled gear-to-pinion backlash is

achieved using adjusting nuts.

The pre-load of the pinion bearings for the 5.14

axle is adjusted using shims which are placed

between the bearing inner races.

The pinion housing of the 5.14 axle can be

removed using jacking bolts.

Differential lock

The 5.14 axle is equipped with a variable

differential-gear lock.

The satellite gear housing flange is fitted with

spline toothing on the right-hand side. The

left-hand side of the selector sleeve is equipped

with similar toothing.

The selector sleeve has internal splines similar

to those on the stub axle.

There is a groove on outside of the selector

sleeve accommodating a fork which is attached

to the engaging cylinder.

4

If the engaging cylinder is pressurised using the

pneumatic switch, the selector sleeve toothing

will mesh with the toothing of the satellite gear

housing.

If the engaging cylinder is vented via the

pneumatic switch, the spring will ensure that the

lock is disengaged.

ᓻ 200313

2-1

4

SINGLE REAR AXLE 5.14

8

General LF45/55 series

Wheel hub

The wheel hub has a wheel bearing and hub oil

seal that can be replaced separately. The

wheel-speed sensor ring is integrated into the

wheel hub. The wheel bearing play is adjusted

using the hub nut. The correct wheel bearing

pre-load is achieved by fitting the hub nut as

specified.

The hub nut is secured with a lock nut and a

locking plate.

The wheel bearing is greased by the oil in the

hub.

The stub axle and brake disc are attached to the

wheel hub with attachment nuts and bolts

respectively.

2-2

ᓻ 200313

8

;;;

;;;

;;;

;;;

;

;

SINGLE REAR AXLE 5.14

LF45/55 series General

2.2 OVERVIEW DRAWING, WHEEL HUB

1 2 3 4 5 6 7 8 9 10 11 12 13

4

Legend

1. Stub axle

2. Lock nut

3. Locking plate

4. Hub nut

5. Thrust washer

6. Wheel bearing inner race

7. Wheel bearing outer race

8. Wheel stud

9. Wheel hub

14151617

10. Hub oil seal

11. Wheel-speed sensor holder

12. Wheel-speed sensor holder attachment

bolts

13. Wheel-speed sensor

14. Brake disc

15. Brake disc attachment bolt

16. Drain plug

17. Stub axle attachment nut

A8 00 384

ᓻ 200313

2-3

4

SINGLE REAR AXLE 5.14

General LF45/55 series

8

2-4

ᓻ 200313

8

SINGLE REAR AXLE 5.14

LF45/55 series Inspection and adjustment

3. INSPECTION AND ADJUSTMENT

3.1 INSPECTING DIFFERENTIAL OIL LEVEL

To prevent skin injury, avoid

unnecessary contact with the

drained oil.

1. Position the vehicle on a level surface.

2. Remove the level check/filler plug (1). The

oil level must reach the level check/filler

opening (1).

3. Apply sealant to the plug. Secure the plug.

2

4

3.2 CHECKING OPERATION OF DIFFERENTIAL LOCK

1. Jack up the rear axle and support it on

stands.

2. Bring the air system to operating pressure.

3. Engage the differential lock. The warning

indicator in the cab should now be

activated.

4. Check whether there is a “rigid” connection

between the driven wheels.

5. Disengage the differential lock. The warning

indicator must no longer be activated and

the “rigid” connection between the driven

wheels should be interrupted.

1

A8 00 370

ᓻ 200313

3-1

4

SINGLE REAR AXLE 5.14

8

Inspection and adjustment LF45/55 series

3.3 INSPECTION AND ADJUSTMENT, WHEEL BEARING PLAY

Inspecting the wheel bearing play

1. Remove the wheel.

2. Remove the stub axle.

3. Remove the brake pads.

4. Fit a micrometer gauge to the wheel hub,

with the stylus on the end of the axle

journal.

5. Push and pull the wheel hub. Check the

wheel bearing play and compare it with the

specified value. See main group “Technical

data”.

A8 00 387

Adjusting the wheel bearing play

1. Remove the lock nut.

2. Tighten the hub nut with a hub nut wrench

(DAF No. 0499805) to 136 Nm.

3. Turn the hub two full rotations in order to

“seat” the wheel bearings.

4. Mark (1) the hub nut wrench (2).

5. Turn the hub nut 2 strokes back.

6. Check the wheel bearing play.

7. Position the locking plate and fit the lock

nut. Tighten the lock nut to the specified

tightening torque. See main group

“Technical data”.

8. Secure the hub nut and lock nut with the

locking plate.

1

2

1

A8 00 380

3-2

ᓻ 200313

8

SINGLE REAR AXLE 5.14

LF45/55 series Inspection and adjustment

3.4 INSPECTION, WHEEL-SPEED SENSOR RING

1. Check the sensor ring (2) for deposits.