Page 1

6

ΧΦ65/75/85 series

STRUCTURE

Structure

TECHNICAL DATA

DIAGNOSTICS

BRAKE DIAGRAMS FOR THE FULLY PNEUMATIC BRAKE SYSTEM

EBS BRAKE SYSTEM BRAKE DIAGRAMS

OPERATION OF BRAKE COMPONENTS

BRAKE SYSTEM AND COMPONENTS

BRAKING PERFORMANCE AND BRAKE EQUALISATION

0

1

2

3

4

5

6

©

200423 DW23241603

Page 2

Page 3

6

TECHNICAL DATA

ΧΦ65/75/85 series

0 Technical data

CONTENTS

Page Date

1. BRAKE SYSTEM AND COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200423

1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200423

1.2 Tightening torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16 . . . . 200423

1.3 Lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19 . . . . 200423

2. BRAKING PERFORMANCE AND BRAKE EQUALISATION . . . . . . . . . . . . . . 2-1 . . . . . 200423

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200423

Contents

0

©

200423 1

Page 4

TECHNICAL DATA

6

0

Contents

ΧΦ65/75/85 series

2

©

200423

Page 5

6

TECHNICAL DATA

ΧΦ65/75/85 series

1. BRAKE SYSTEM AND COMPONENTS

1.1 GENERAL

Coding of components

All components have been provided with number

codes.

Structure of the code

First digit

Where one connection performs several

functions, additional 1

These are separated by a hyphen.

Often used:

1 energy supply (pressure)

2 energy discharge (outgoing command)

3 bleeding

4 control connection (incoming command)

Little used:

0 suction connection

5 vacant

6 vacant

7 anti-freeze connection

8 lubricating oil connection

9 coolant connection

st

digits will be allocated.

Brake system and components

0

Second digit

If there are several connections with the same

function, a 2

after the 1

Application example: empty/load relay valve

Meaning:

1 air compressor energy supply

2 energy discharge (command) to the next

component

41 control connection (incoming)

42 second control connection (incoming)

nd

digit will be added immediately

st

one.

©

200423 1-1

Page 6

TECHNICAL DATA

6

0

Brake system and components

Compressor

CF65 series

Type

Make: Knorr SWC 9057

Version: 1 cylinder, water cooled, 255 cc

CF75/85 series

Type

Make: Wabco 911 504 ...

Version: 2 cylinder, water cooled

Rejection sizes Wabco 911 504 ... compressor

Cylinder bore at the turning point of the

first piston ring 75.022 mm

Height of piston ring groove:

first groove: 2.035 mm

second groove: 2.035 mm

third groove: 4.047 mm

Gudgeon pin hole diameter: 15.018 mm

Gudgeon pin diameter: 14.992 mm

Piston diameter, measured along the length of

the piston pen on the underside of the piston skirt. 74.962 mm

Gudgeon pin bearing in connecting rod: 15.047 mm

Crankshaft bearing diameter, non-drive side: 35.070 mm

Crankshaft main bearing, non-drive side: 34.963 mm

Crankshaft diameter at the connecting rod: 32.963 mm

Always replace rolling bearing on drive side

ΧΦ65/75/85 series

1-2

©

200423

Page 7

6

2

3

4

5

6

7

TECHNICAL DATA

ΧΦ65/75/85 series

Brake system and components

Air supply unit

A

B

2123 3 23 25

D

F

1

NJK

C

1

E

0

21

24

26 22

G

6.1

12

3

6.2

Knorr ZB4545 - II38005F, ZB4578 - K000394, ZB4580 - K000396 versions

(used on front-axle leaf suspension)

R

A

21

23 3 23 25

Q

12

29 11

B

21

0

MH

6.

U

6.

P

L

P

P

U

R600702

6.

6.

6.

6.

H

D

F

21

NJ

K

M

L

P

P

U

P

U

C

1

E

0

24

26 22

G

6.1

12

3

6.2

R600703

Knorr ZB4548 - II38799F, ZB4579 - K000395 versions (used on front-axle leaf suspension)

A air dryer/pressure regulator (unit) K pressure limiting valve, circuit 3

B 4-circuit protection valve (unit) L pressure relief valve, circuit 3

C filter/drying grid M flow back valve, circuit 3

D pressure regulator N pressure relief valve with bypass, circuit 4

E blow-off valve P pressure sensors

F pneumatic time switch for regeneration Only for use on front-axle air suspension:

G heating element Q pressure relief valve

H pressure relief valve with bypass, circuit 1 R non-return valve

J pressure relief valve with bypass, circuit 2

6.2

6.3

6.4

6.5

6.6

6.7

©

200423 1-3

Page 8

TECHNICAL DATA

6

0

Brake system and components

supply pressure in circuit 1, connection 21 9.8 - 10.6 bar

supply pressure in circuit 2, connection 22 9.8 - 10.6 bar

supply pressure in circuit 3, connection 23 8.1 - 8.5 bar

supply pressure in circuit 3, connection 25 7.9 - 8.5 bar

supply pressure in circuit 4, connection 24 9.8 - 10.6 bar

supply pressure in circuit 4, connection 26 9.8 - 10.6 bar

opening pressure of circuits 1, 2 and 4 6.5 - 7.0 bar

opening pressure of circuit 3 7.0 - 7.5 bar

Static closing pressure, all circuits 4.5 bar

circuit 1 activation pressure for flow-back function

of circuit 3 4.5 bar

cut-out pressure of pressure regulator 9.8 - 10.6 bar

cut-in pressure of pressure regulator 1.0 - 1.8 bar below the cut-out pressure

safety valve opening pressure 12.8 - 13.2 bar

cut-in temperature of heating element 7C

cut-out temperature of heating element 29C

re-set time approx. 20 sec.

ΧΦ65/75/85 series

pressure sensor reading, circuits 1 and 2

(connections 6.2 - 6.7 in the diagrams above)

Pressure relief valve

overflow pressure 10.0 bar

Ua(V)

5V

4V

3V

2V

1V

0V

120246810

P

21.22

(bar)

R600701

1-4

©

200423

Page 9

6

TECHNICAL DATA

ΧΦ65/75/85 series

Foot brake valve

Type

Make: Knorr DX 61A

Pressure difference between

circuits 1 and 2 0.25 bar

Actuating pressure difference

between circuits 1 and 2 0.2 bar

11

10

9

p21/22 [bar]

8

7

6

5

4

3

2

Inshot 0.2–0.1

1

0

12

20

60

100

140

180

Brake system and components

P22 (P11=0)

21

22

3 4 5 6 7 8 9 10 11 12 13 14

0

Stroke (mm)

220

260

N

Connection 11 circuit 1 supply

Connection 12 circuit 2 supply

Connection 21 circuit 1 braking pressure

Connection 22 circuit 2 braking pressure

Load sensing valve, leaf suspension

Characteristic

380–20N

R600542

R600704

©

200423 1-5

Page 10

TECHNICAL DATA

6

0

Brake system and components

Load sensing valve, air suspension

Characteristic

Brake light switch

Type

Make: Messmer 131 733

Cut-in pressure, brake light switch (make contact) 0.4 - 0.6 bar

0.6

10

9

p2 [bar]

8

7

6

5

4

3

2

1

–0.2

1:1

10

ΧΦ65/75/85 series

p41

p42

p41

p42

p41

p42

2345678910

p4 [bar]

= 4.65 bar

= 3 bar

= 0.3 bar

R600705

Note:

If the vehicle has EBS, the brake light switch is

located in the foot brake valve.

Low pressure switch

Brake drum design

Make: Wabco 441 014 ...

Cut-out pressure (break contact) 4.7 - 5.7 bar

Disc brake design

Make: Wabco 441 014 ...

Cut-out pressure (break contact) 6.1 - 7.1 bar

1-6

©

200423

Page 11

6

TECHNICAL DATA

ΧΦ65/75/85 series

Empty/load relay valve

Type

Make: Wabco 973 011 106

Maximum reduction ratio 1 : 1.5

Actuating pressure 0.25 bar

Fitted with internal filter and silencer

Application: FAT vehicle

10

9

P2(bar)

8

7

6

5

4

3

2

1

0

Brake system and components

P

= P

42

41

1:1.5

P

= 0

42

2345678910

1

+

0,1

0,25

0

P41(bar)

Type

Make: Wabco 973 011 107

Maximum reduction ratio 1 : 2.7

Actuating pressure 0.25 bar

Fitted with internal filter and silencer

Application: FAD vehicle

FAC vehicle

FAX vehicle

FAL vehicle

10

9

P2(bar)

8

7

6

5

4

3

2

1

0

P

= P

42

41

1:2.7

P

= 0

42

1

2345678910

+

0,1

0,25

R600328

P41(bar)

R600330

©

200423 1-7

Page 12

TECHNICAL DATA

6

0

Brake system and components

Relay valve

Version for parking brake

Make: Knorr AC 577A

Fitted with silencer

Relay valve

Version for service brake

Make: Wabco 973 011 009

Fitted with internal filter and silencer

8,9

10

-0,2

9

0

8

ΧΦ65/75/85 series

9

8

P2 (bar)

7

6

5

4

3

2

1

10 23456789

P4 (bar)

R 600363

7

6

P2 (bar)

5

4

3

2

1

10 2345678910

0,5

–0,1

P4 (bar)

R 600602

1-8

©

200423

Page 13

6

TECHNICAL DATA

ΧΦ65/75/85 series

Relay valve

Version for service brake

Make: Wabco 973 011 008

Fitted with internal filter and silencer

ABS valve

Resistance of magnet coil (at approx. 25C) 10 - 20 ohm

10

0

9,2

-0,2

9

8

7

6

5

4

3

2

1

0

MAX. 0,2

Brake system and components

0

12345678910

R600640

Electrical connections

1. magnet coil bleed point

2. mass

3. magnet coil air admission point

1

2

3

21

3

123

R600370

©

200423 1-9

Page 14

TECHNICAL DATA

6

0

Brake system and components

ASR solenoid valve

1. Supply

2. Port, two-way valve

3. Bleed

Trailer control valve

Type

Make: Knorr AC 599A

Explanation of graph

B Curve of intact circuit 1, circuit 2, or failure in

circuit 1 or circuit 2

C Setting range, braking pressure advance

Advance

Input pressure 3 bar

Output pressure 3 bar

(corresponds to 0.6 bar

advance = factory setting)

Advance adjustment

2,2

P22(bar)

+

0,2

0

ΧΦ65/75/85 series

1

2

3

R600484

9

8

7

6

5

4

3

2

1

P11/12 = 8bar

P43 = 8bar

C

B

C

Adjusting screw (Allen type, 6 mm)

Clockwise increases the advance

Anti-clockwise decreases the advance

Explanation of graph

Output pressure on connection 22 (P22).

Graph is applicable if the parking brake is

applied.

P22(bar)

7,3

1

0

<

0,35

9

8

7

6

5

4

3

2

1

0

23456

P11/12 = 8bar

1

23456

78910

8,6

P41/42(bar)

R600333

789

6,3

P43(bar)

1-10

R600332

©

200423

Page 15

6

TECHNICAL DATA

ΧΦ65/75/85 series

Safety valve

Type

Make: Voss 0 268 874 200

Opening pressure reading approx. 16 bar

Parking brake valve with drawn vehicle

connection

Type

Make: Knorr DPM90DA (with test position)

Knorr DPM93D (without test position)

Knorr DPM90AA (without test

position with electrical switch)

(special application)

Max. output pressure

in driving position

(with test position) approx. 8.5 bar

Brake system and components

0

Max. output pressure

in driving position

(with test position) approx. 8.5 bar

R600706

©

200423 1-11

Page 16

TECHNICAL DATA

6

0

Brake system and components

Parking brake without drawn vehicle

connection

Type

Make: Knorr DPM92D

Max. output pressure

in driving position approx. 8.5 bar

ΧΦ65/75/85 series

Brake lining

Drum brakes

TYPE NOTES

DAF 2100 Installed on LHD vehicles

DAF 3100 Installed on RHD vehicles

Beral 1561 09N044 leading rear axle (used on FTP vehicle)

The bearing pattern of the brake lining can be

improved by grinding down the brake lining to

a diameter which is max. 1 mm smaller than

the drum diameter.

The space between brake shoe and lining must

not be more than 0.1 mm.

Minimum brake lining thickness

height of wear indicator or 1 mm above rivet head

M6002

1-12

©

200423

Page 17

6

TECHNICAL DATA

ΧΦ65/75/85 series

09N044 leading rear axle (used on FTP

vehicle)

Minimum lining thickness 5 mm

Disc brakes, SB7000 and SN7000 series

TYPE NOTES

DAF 1200 Fitted to all vehicles

Brake drum

General

A brake drum may be used until the inside

diameter has reached the maximum permissible

value, as specified in the table below.

As soon as this diameter is exceeded, the brake

drum must be replaced.

Brake diameter Standard brake-drum

diameter in mm

Ovality

314 + 0,127 317,3 316,3

12

3

/8"

Maximum in mm Maximum

Brake system and components

0

reconditioning

dimension in mm

13" 330,2 + 0,127 333,2 332,3

1

15

/2" 393,7 + 0,127 396,7 395,7

16" 406,6 + 0,250 409,6 408,6

1

16

/2" 420 + 0,250 425 423

310 mm 310 + 0,210 313 312

325 mm 325 + 0,230 328 327

360 mm 360 + 0,230 363 362

375 mm 375 + 0,230 378 377

420 mm 420 + 0,250 425 423

09N044 leading rear axle (used on FTP

vehicle)

Brake diameter Standard brake-drum

diameter in mm

300 mm 300 298 - 299 mm

The ovality (deformation) of the brake drum is

checked with the drum in position on the hub,

or on a brake dynamometer.

Maximum in mm Maximum

reconditioning

dimension in mm

Brake drums with cracks exceeding a width of

0.7 mm or a length of 50 mm may not be reused.

©

200423 1-13

Page 18

TECHNICAL DATA

6

0

Brake system and components

Automatic slack adjuster for drum brakes

Automatic slack adjuster travel (Haldex) 35 - 40 mm

Reverse torque value of adjusting bolt > 18 Nm

Axial play on the brake camshaft 0.5 - 1.0 mm

Brake pad

maximum brake pad

thickness (C) 30 mm

0 minimum lining thickness (E) 2 mm

minimum brake pad thickness (F),

with 9 mm rear plate thickness (D) 11 mm

replacing:

all brake pads at the same time for each axle,

and with the specified lining only.

Brake pad/brake disc play 0.6 - 1.0 mm

ΧΦ65/75/85 series

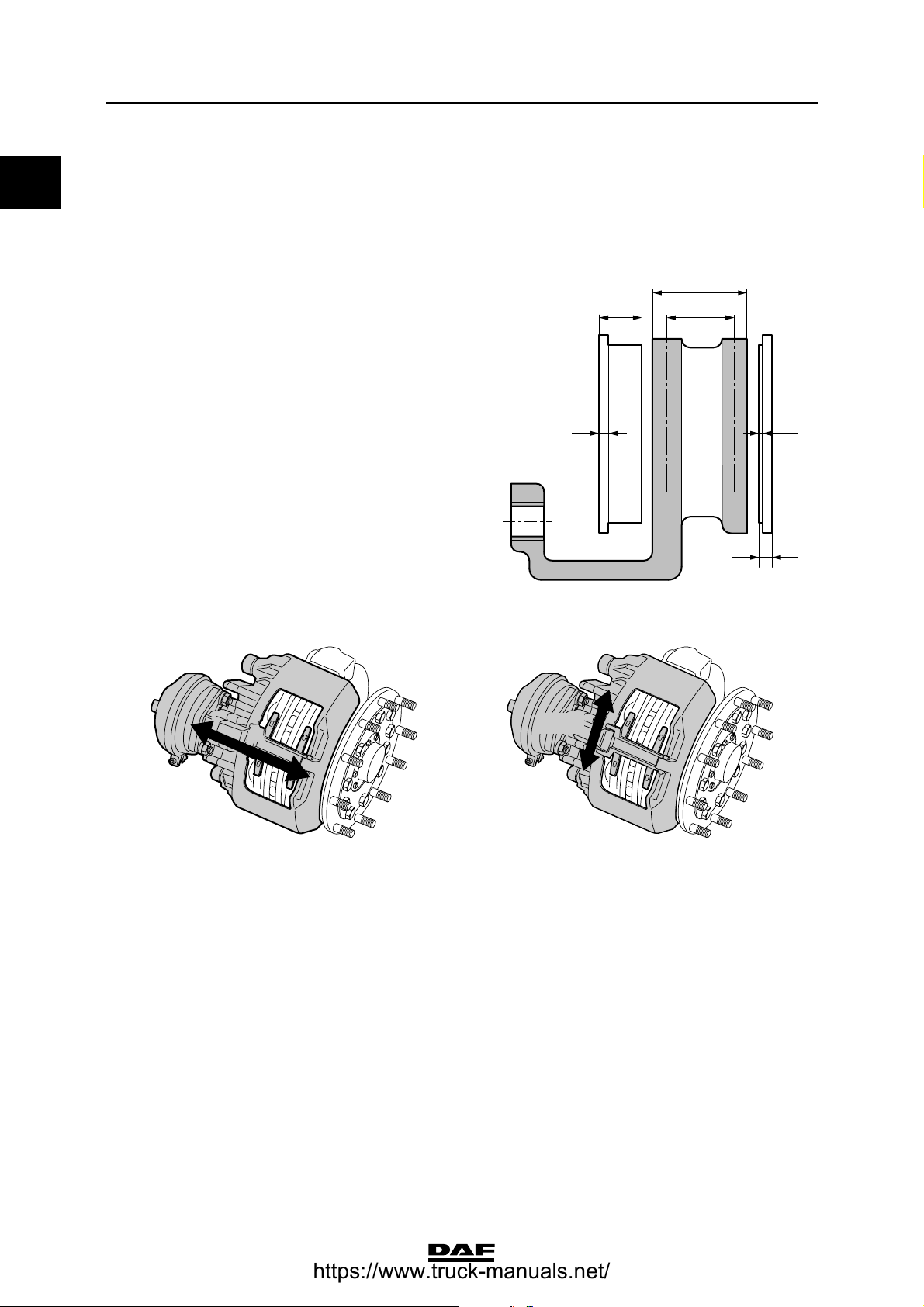

A

C

B

ED

F

Brake caliper

A

R600708

Brake caliper play in axial direction (direction A) 0.6 - 1.0 mm

Brake caliper play on the guide sleeves ("Y" - "X") Maximum 2.0 mm

Y - X

R600489

R600712

1-14

©

200423

Page 19

6

TECHNICAL DATA

ΧΦ65/75/85 series

Brake disc

maximum brake disc

thickness (A) 0 45 mm

minimum brake disc thickness (B)

(rejection dimension, disc needs

to be replaced) 37 mm

minimum thickness, turning

dimension 40 mm

Note:

If it is established during brake pad replacement

that the brake thickness is less than or equal to

39 mm, the brake disc must also be replaced.

The following signs of wear are permissible:

A1 crazy cracking.

B1 cracks running to the centre up to 1.5 mm

wide and deep, max. 0.75 x friction surface

width (a).

C1 unevenness in the disc surface up to

1.5 mm.

Brake system and components

A

B

1

a

A

C

B

ED

F

R600489

1

0

max. 0,75 x a

max. 1,5 mm

Not permissible:

D1 through-going cracks.

D

C

1

1

R600471

©

200423 1-15

Page 20

TECHNICAL DATA

6

0

Brake system and components

1.2 TIGHTENING TORQUES

Note:

The tightening torques stated in this section are

different from the standard tightening torques

stated in the overview of the standard tightening

torques.

The other threaded connections not specified

must therefore be tightened to the torque stated

in the overview of standard tightening torques.

When attachment bolts and nuts are replaced,

it is important that - unless stated otherwise these bolts and nuts are of exactly the same

length and property class as those removed.

SAFETY VALVE

Attachment 72 Nm

BRAKE CALLIPER - BRAKE CARRIER

Sliding sleeve Allen screws (SB7000) 285 Nm

Sliding sleeve Allen screws (SN7000) 180 Nm + 90

Brake caliper attachment bolts 440 Nm

Pressure tool, guide bush bellows 8 Nm

Rubber bearing bush pressure tool (only SN7000) 8 - 45 Nm

(1)

(2)

ΧΦ65/75/85 series

(1)

(1) Always use new bolts, provided with locking compound.

New bolts are supplied with locking compound already

applied.

(2) In the case of versions with Knorr disc brakes,

the attachment of the brake caliper against the stub axle

changed starting from production week 2002-25.

Five bolts are now used instead of six bolts. There is still

a hole for the 6

no hole on the stub axle.

BRAKE DISC

Locking plate attachment bolts 30 Nm

th

bolt (5) on the brake carrier, but there is

6 23 1 54

R600520

1-16

©

200423

Page 21

6

TECHNICAL DATA

ΧΦ65/75/85 series

BRAKE CYLINDER

Attachment nuts 195 Nm

Release bolt 45 Nm

Release bolt (version with indication pin) 75 Nm

SPRING BRAKE CYLINDER

Fixing nuts of spring brake cylinder 180 - 210 Nm

Fixing bolts of the brake chamber clamping strap 34 Nm

Release bolt (at least 5.1 bar) 25 Nm

VOSS COUPLING 232

Socket 12 Nm

BLOW-OFF VALVE

Attachment 25 Nm

Air compressor

There are two types of compressors: one version

used in production until 2002-47 and one version

used in production from 2002-48.

Compressors can be identified as follows:

Brake system and components

0

112

R600743

< 2002-48 2002-48

The cylinder head of compressors used up to

2002-48 consists of three aluminium parts (1).

The cylinder head of compressors used from

2002-48 consists of two aluminium parts (1)

and a steel plate (2).

Air compressor tightening torques greater

than or equal to 2002-48

Delivery valve attachment nuts 5 Nm + 90 angular displacement

Connecting rod bolts 6 Nm + 70 angular displacement

©

200423 1-17

Page 22

TECHNICAL DATA

6

0

Brake system and components

5

1

3

7

8

2

4

6

R600742

Cylinder head bolts

Phase 1, bolts 7 - 8 (in sequence) 6 Nm

Phase 2, bolts 7 - 8 (in sequence) 90 angular displacement

Phase 3, bolts 1 - 2 - 6 - 5 - 4 - 3 (in sequence) 30 Nm

Phase 4, bolts 1 - 2 - 6 - 5 - 4 - 3 (in sequence) 90 angular displacement

Phase 5, bolts 7 - 8 (in sequence) 10 Nm

Phase 6, bolts 7 - 8 (in sequence) 90 angular displacement

ΧΦ65/75/85 series

Air compressor tightening torques greater

than or equal to 2002-48

Delivery valve attachment nuts 5 Nm + 90 angular displacement

Connecting rod bolts 6 Nm + 70 angular displacement

5

1

3

7

8

2

4

6

R600742

Cylinder head bolts

Phase 1, bolts 1 - 2 - 3 - 4 - 5 - 6 (in sequence) 30 Nm

Phase 2, bolts 1 - 2 - 3 - 4 - 5 - 6 (in sequence) 90 angular displacement

Phase 3, bolts 7 - 8 (in sequence) 7 Nm

Phase 4, bolts 7 - 8 (in sequence) 90 angular displacement

1-18

©

200423

Page 23

6

TECHNICAL DATA

ΧΦ65/75/85 series

1.3 LUBRICANTS

Brake calliper

Knorr SB7000

3

18

Brake system and components

0

20

21

19

17

1

22

6a

4

6

7

5

8

11

10

2

9

Renolit HLT2 (white) for parts 6, 7, 8,

the adjusters (not shown), the brake cylinder

lever and the flange surface for attachment of the

brake cylinder (DAF no. 1448907)

Sytheso GL EP1 (green), for parts 3, 5 (DAF no. 1448908)

16

15

14

R600746

©

200423 1-19

Page 24

TECHNICAL DATA

6

0

Brake system and components

Knorr SN7000

5

6a

6

3

ΧΦ65/75/85 series

20

21

18

19

17

1

22

7

4

8

15

11

10

2

Renolit HLT2 (white) for parts 3, 6, 7, 8,

the adjusters (not shown), the brake cylinder

lever and the flange surface for attachment

of the brake cylinder (DAF no. 1448907)

14

16

23

R600755

1-20

©

200423

Page 25

6

TECHNICAL DATA

ΧΦ65/75/85 series

Braking performance and brake equalisation

2. BRAKING PERFORMANCE AND BRAKE EQUALISATION

2.1 GENERAL

EBS tyre class

The tyre sizes are classified into tyre classes.

This tyre class information is necessary

to be able to assess the brake presentation,

by measurements of brake force.

This tyre class information is also necessary

for the EBS system to be able to evaluate

whether the electric EBS unit is programmed

when the tyre size is changed..

Tyre size change in EBS system

If the tyre size is changed in an EBS system and

the tyre size of the front and rear axle no longer

fall in the same tyre class, the changed tyre sizes

must be programmed into the electronic EBS

unit.

Tyre class Tyre size

0

Class 0 215/75 R 17.5

235/75 R 17.5

Class 1 295/60 R 22.5

255/70 R 22.5

315/60 R 22.5

275/70 R 22.5

Class 2 305/70 R 22.5

315/70 R 22.5

385/55 R 22.5

295/80 R 22.5

11 R 22.5

Class 3 385/65 R 22.5

315/80 R 22.5

11.00 R 20

12 R 22.5

12.00 R 20

13 R 22.5

©

200423 2-1

Page 26

TECHNICAL DATA

6

0

Braking performance and brake equalisation

Tyre size change in EBS 2 system

If the tyre size is changed in an EBS 2 system and

the tyre size of the front and rear axle no longer

fall in the same tyre class, it is not necessary to

program the electronic ESB 2 unit because the

electronic ESB 2 unit will automatically recognise

this change in tyre size.

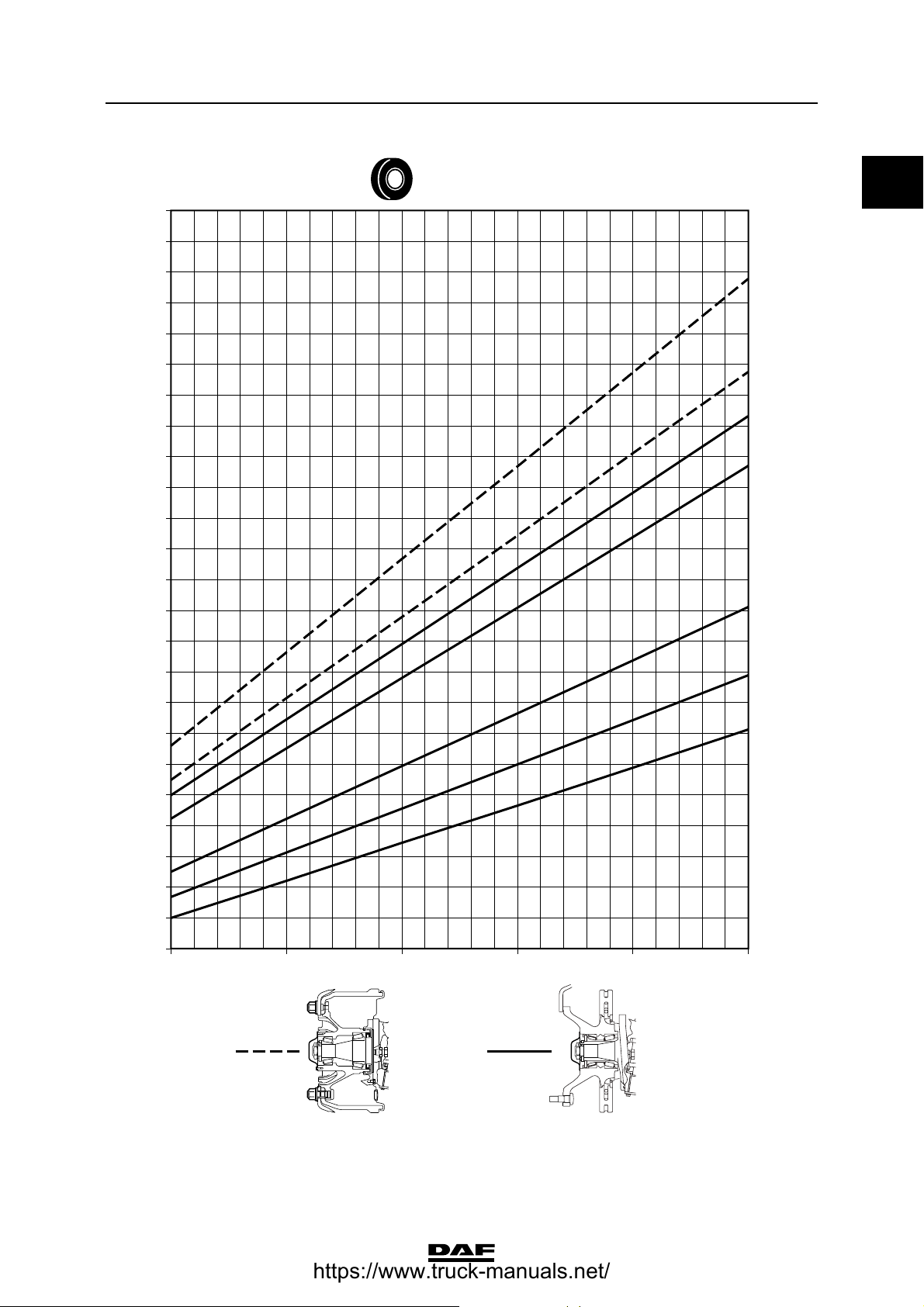

OVERVIEW OF BRAKING FORCES OF

EBS SYSTEM

This overview lists the braking forces graphs

based on tyre size. These braking force graphs

apply to the prime mover with EBS; these braking

force graphs can be used to check the braking

performance of an EBS prime mover.

Graph explanation

1 Brake force per wheel (N)

2 Tyre size

3 Type of brake cylinder + brake lever length

(if applicable)

4 Brake drum design

5 Disc brake construction

6 Pressure in brake cylinder (P)

7 Reference line of measured braking force

per wheel; the example shows a brake drum

construction and a 27" brake cylinder with

a brake lever length of 165 mm.

8 Reference line of the measured braking force

per wheel; the example shows a disk brake

construction and a 24" brake cylinder.

ΧΦ65/75/85 series

1

F (N)

27000

26000

25000

24000

23000

22000

21000

20000

19000

18000

17000

16000

15000

14000

13000

12000

11000

10000

9000

8000

7000

6000

5000

4000

3000

2 2,5 3 3,5 4 4,5

2

295/60R22,5

7

8

54

P (bar)

6

3

27"-165

24"

2-2

R600879

©

200423

Page 27

6

TECHNICAL DATA

ΧΦ65/75/85 series

Braking force graphs

F (N)

6000

5500

5000

4500

Braking performance and brake equalisation

235/75R17,5

0

9"-125

4000

3500

3000

2500

2000

2 2,5 3 3,5 4 4,5

P (bar)

R600865

©

200423 2-3

Page 28

TECHNICAL DATA

6

0

Braking performance and brake equalisation

F (N)

27000

26000

25000

24000

23000

22000

21000

20000

19000

18000

17000

16000

15000

295/60R22,5

ΧΦ65/75/85 series

27"-165

24"-165

24"

22"

16"

14000

13000

12000

11000

10000

9000

8000

7000

6000

5000

4000

3000

2 2,5 3 3,5 4 4,5

14"

12"

P (bar)

2-4

R600866

©

200423

Page 29

6

TECHNICAL DATA

ΧΦ65/75/85 series

F (N)

27000

26000

25000

24000

23000

22000

21000

20000

19000

18000

17000

16000

15000

Braking performance and brake equalisation

255/70R22,5

0

27"-165

24"-165

24"

22"

16"

14000

13000

12000

11000

10000

9000

8000

7000

6000

5000

4000

3000

2 2,5 3 3,5 4 4,5

14"

12"

P (bar)

R600867

©

200423 2-5

Page 30

TECHNICAL DATA

6

0

Braking performance and brake equalisation

F (N)

27000

26000

25000

24000

23000

22000

21000

20000

19000

18000

17000

16000

315/60R22,5

ΧΦ65/75/85 series

27"-165

24"-165

24"

22"

15000

14000

13000

12000

11000

10000

9000

8000

7000

6000

5000

4000

3000

2 2,5 3 3,5 4 4,5

16"

14"

12"

P (bar)

2-6

R600868

©

200423

Page 31

6

TECHNICAL DATA

ΧΦ65/75/85 series

F (N)

27000

26000

25000

24000

23000

22000

21000

20000

19000

18000

17000

16000

Braking performance and brake equalisation

275/70R22,5

0

27"-165

24"-165

24"

22"

15000

14000

13000

12000

11000

10000

9000

8000

7000

6000

5000

4000

3000

2 2,5 3 3,5 4 4,5

16"

14"

12"

P (bar)

R600869

©

200423 2-7

Page 32

TECHNICAL DATA

6

0

Braking performance and brake equalisation

F (N)

27000

26000

25000

24000

23000

22000

21000

20000

19000

18000

17000

16000

385/55R22,5

ΧΦ65/75/85 series

27"-165

24"-165

24"

22"

15000

14000

13000

12000

11000

10000

9000

8000

7000

6000

5000

4000

3000

2 2,5 3 3,5 4 4,5

16"

14"

12"

P (bar)

2-8

R600870

©

200423

Page 33

6

TECHNICAL DATA

ΧΦ65/75/85 series

F (N)

27000

26000

25000

24000

23000

22000

21000

20000

19000

18000

17000

16000

Braking performance and brake equalisation

305/70R22,5

0

27"-165

24"-165

24"

22"

15000

14000

13000

12000

11000

10000

9000

8000

7000

6000

5000

4000

3000

2 2,5 3 3,5 4 4,5

16"

14"

12"

P (bar)

R600871

©

200423 2-9

Page 34

TECHNICAL DATA

6

0

Braking performance and brake equalisation

F (N)

27000

26000

25000

24000

23000

22000

21000

20000

19000

18000

17000

16000

315/70R22,5

ΧΦ65/75/85 series

27"-165

24"-165

24"

22"

15000

14000

13000

12000

11000

10000

9000

8000

7000

6000

5000

4000

3000

2 2,5 3 3,5 4 4,5

16"

14"

12"

P (bar)

2-10

R600872

©

200423

Page 35

6

TECHNICAL DATA

ΧΦ65/75/85 series

F (N)

27000

26000

25000

24000

23000

22000

21000

20000

19000

18000

17000

16000

Braking performance and brake equalisation

295/80R22,5

0

27"-165

24"-165

24"

22"

15000

14000

13000

12000

11000

10000

9000

8000

7000

6000

5000

4000

3000

2 2,5 3 3,5 4 4,5

16"

14"

12"

P (bar)

R600873

©

200423 2-11

Page 36

TECHNICAL DATA

6

0

Braking performance and brake equalisation

F (N)

27000

26000

25000

24000

23000

22000

21000

20000

19000

18000

17000

16000

11R22,5

ΧΦ65/75/85 series

27"-165

24"-165

24"

22"

15000

14000

13000

12000

11000

10000

9000

8000

7000

6000

5000

4000

3000

2 2,5 3 3,5 4 4,5

16"

14"

12"

P (bar)

2-12

R600874

©

200423

Page 37

6

TECHNICAL DATA

ΧΦ65/75/85 series

F (N)

27000

26000

25000

24000

23000

22000

21000

20000

19000

18000

17000

16000

Braking performance and brake equalisation

385/65R22,5

0

27"-165

24"-165

24"

22"

15000

14000

13000

12000

11000

10000

9000

8000

7000

6000

5000

4000

3000

2 2,5 3 3,5 4 4,5

16"

14"

12"

P (bar)

R600875

©

200423 2-13

Page 38

TECHNICAL DATA

6

0

Braking performance and brake equalisation

F (N)

27000

26000

25000

24000

23000

22000

21000

20000

19000

18000

17000

16000

315/80R22,5

ΧΦ65/75/85 series

27"-165

24"-165

24"

22"

15000

14000

13000

12000

11000

10000

9000

8000

7000

6000

5000

4000

3000

2 2,5 3 3,5 4 4,5

16"

14"

12"

P (bar)

2-14

R600876

©

200423

Page 39

6

TECHNICAL DATA

ΧΦ65/75/85 series

F (N)

27000

26000

25000

24000

23000

22000

21000

20000

19000

18000

17000

16000

Braking performance and brake equalisation

12R22,5

0

27"-165

24"-165

24"

22"

15000

14000

13000

12000

11000

10000

9000

8000

7000

6000

5000

4000

3000

2 2,5 3 3,5 4 4,5

16"

14"

12"

P (bar)

R600877

©

200423 2-15

Page 40

TECHNICAL DATA

6

0

Braking performance and brake equalisation

F (N)

27000

26000

25000

24000

23000

22000

21000

20000

19000

18000

17000

16000

13R22,5

ΧΦ65/75/85 series

27"-165

24"-165

24"

22"

15000

14000

13000

12000

11000

10000

9000

8000

7000

6000

5000

4000

3000

2 2,5 3 3,5 4 4,5

16"

14"

12"

P (bar)

2-16

R600878

©

200423

Page 41

6

CF65/75/85 series Contents

DIAGNOSTICS

CONTENTS

Page Date

1. DISC BRAKE CONSTRUCTION 1-1 200324......................................... ....

1.1 Fault-finding table 1-1 200324................................................. ....

2. DRUM BRAKE CONSTRUCTION 2-1 200324........................................ ....

2.1 Fault-finding table 2-1 200324................................................. ....

1

ᓻ 200324

1

Page 42

1

6DIAGNOSTICS

Contents CF65/75/85 series

2

ᓻ 200324

Page 43

6

DIAGNOSTICS

CF65/75/85 series Disc brake construction

1. DISC BRAKE CONSTRUCTION

1.1 FAULT-FINDING TABLE

SYMPTOM: SQUEALING/NOISE DURING BRAKING

Possible cause Remedy

Worn brake pads Check brake pads and brake disc thickness

Loose parts Check disc brake construction

Wear/damage to hub bearing Check hub bearing play

Wear to internal parts of disc brake

construction

Incorrect vehicle combination Check vehicle combination

Incorrect front axle/rear axle brake pressure

setting

SYMPTOM: IRREGULAR BRAKE PAD WEAR

Possible cause Remedy

Fouled/corroded guide sleeves Check the guide sleeves

Dirt accumulation between moving parts of the

disc brake construction

Moisture and dirt on internal mechanical parts Check and clean the brake calliper seals

Brake pad stuck in the brake calliper. Incorrect

play between brake pads and brake carrier

Check internal parts

Check front axle/rear axle setting

Clean the disc brake construction

Check the play between brake pads and brake

carrier

1

ᓻ 200324

1-1

Page 44

1

6DIAGNOSTICS

Disc brake construction CF65/75/85 series

SYMPTOM: VEHICLE PULLS TO ONE SIDE DURING BRAKING

Possible cause Remedy

Differenceintyrepressure Check/correct tyre pressure

Differenceintyresize Check tyres

Different brake cylinder diameters Check brake cylinder diameters

Broken springs in brake cylinders Check brake cylinders

Leaking brake cylinders Check brake cylinders

Fouled brake cylinders Check brake cylinders for fouling

Excessive stub axle bearing play Check stub axle bearing play

Excessive steering ball joint play Check steering ball joint play

Excessive shackle pin play Check shackle pin play

Incorrect vehicle combination Check vehicle combination

Incorrect ABS operation Check ABS operation

Brake pad stuck in the brake calliper. Incorrect

play between brake pads and brake carrier

SYMPTOM: POOR BRAKING DECELERATION

Possible cause Remedy

Overload due to excessive loading Check vehicle loading condition

System pressure too low Check pressure regulator setting

Air leakage in the brake system Check the brake system for leakage

Insufficient braking power/poor condition of

trailer vehicle brake system

Pinched brake lines Check/replace brake lines

Brake cylinder stroke too large Check automatic brake adjuster

Frozen brake system Check brake system

Brake components affected by road salt Check brake components for fouling

Fouled brake cylinders Check brake cylinders for fouling

Incorrect brake cylinder diameter Check brake cylinders

Incorrect operation/setting of load sensing valve Check operation/setting of load sensing valve

Incorrect vehicle combination Check vehicle combination

Check the play between brake pads and brake

carrier

Check trailer vehicle

Incorrect ABS operation Check ABS operation

Brake pad stuck in the brake calliper. Incorrect

play between brake pads and brake carrier

Check the play between brake pads and brake

carrier

1-2

ᓻ 200324

Page 45

6

DIAGNOSTICS

CF65/75/85 series Disc brake construction

SYMPTOM: VIBRATIONS DURING BRAKING

Possible cause Remedy

Incorrect wheel tightening procedure Tighten wheels according to tightening

procedure

Non-standard wheels fitted Fit only standard wheels

Overload due to excessive loading Check vehicle loading condition

Incorrect front axle/rear axle brake pressure

setting

Wrong brake pad quality Check brake pads

Dirt/deposits on brake disc Check/clean brake disc

Loose parts Check disc brake construction

Wear/damage to hub bearing Check hub bearing play

Damage to disc brake Check thickness and condition of brake disc

Play in cab suspension Check cab suspension

Incorrect vehicle combination Check vehicle combination

SYMPTOM: LOCKING OF THE BRAKES

Possible cause Remedy

Incorrect setting of load sensing valve Check setting of load sensing valve

Thermal overload of non-locking axle brake

pads

Incorrect system pressure due to incorrect

pressure regulator setting

Check front axle/rear axle setting

Check non-locking axle brake pads

Check pressure regulator setting

1

Defective trailer vehicle brake system Check trailer vehicle brake system

Incorrect vehicle combination Check vehicle combination

Incorrect ABS operation Check ABS operation

Tyres have too little profile Check profile

Brake pad stuck in the brake calliper. Incorrect

play between brake pads and brake carrier

Check the play between brake pads and brake

carrier

ᓻ 200324

1-3

Page 46

1

6DIAGNOSTICS

Disc brake construction CF65/75/85 series

SYMPTOM: INCREASED BRAKE PAD WEAR

Possible cause Remedy

Overload due to excessive loading Check vehicle loading condition

Incorrect setting of load sensing valve Check setting of load sensing valve

Incorrect vehicle combination or front axle/rear

axle combination

Defective trailer vehicle brake system Check trailer vehicle brake system

Check vehicle combination or front axle/rear

axle combination

Air pressure in spring brake cylinders too low

during driving, dragging brakes

Dragging brakes because parking brake is not

released

Dirt under foot brake valve/floor mat too high Check for free movement of foot brake valve

Contaminated/blocked brake valve vents Check valve vents

Brake pad stuck in the brake calliper. Incorrect

play between brake pads and brake carrier

Incorrect setting of the trailer vehicle control

valve/trailer vehicle reaction valve

SYMPTOM: DRAGGING BRAKES

Possible cause Remedy

Leaking foot brake valve to circuit 1 and/or 2 Check the foot brake valve for leaks

Dirt/deposits in brake calliper of disc brake Check freedom of movement of brake calliper

Brake pads set too tightly Check minimum brake pad play

Air pressure in spring brake cylinders too low

during driving

Check air pressure in spring brake cylinders

with the parking brake valve in the driving

position

Check release of parking brake

Check the play between brake pads and brake

carrier

Check setting of the trailer vehicle control

valve/trailer vehicle reaction valve

Check output pressure of the

double-check relay valve

Check four-circuit safety valve for

contamination

Check output pressure of the parking brake

valve in the driving position

Output supply pressure from trailer vehicle

control valve to trailer/semi-trailer too low

Dirt under foot brake valve/floor mat too high Check for free movement of foot brake valve

Contaminated/blocked brake valve vents Check valve vents

Brake pad stuck in the brake calliper. Incorrect

play between brake pads and brake carrier

1-4

Check output supply pressure of the trailer

vehicle control valve

Check the play between brake pads and brake

carrier

ᓻ 200324

Page 47

6

DIAGNOSTICS

CF65/75/85 series Drum brake construction

2. DRUM BRAKE CONSTRUCTION

2.1 FAULT-FINDING TABLE

SYMPTOM: SQUEALING OF THE BRAKES

Possible cause Remedy

Loose brake shoes Check brake shoe attachment

Loose brake lining on brake shoe Check brake lining/rivets

Incorrect turning of the brake linings, brake

lining is incorrectly positioned against the brake

drum

Incorrect quality of brake linings Check brake linings

Brake drums not or unsatisfactorily

reconditioned

Different or no standard quality of brake drums Check brake drums

Maximum brake drum reconditioning dimension

exceeded

Cracked brake drums Check length and depth of the cracks in the

Loose brake camshaft bearing Check brake camshaft bearing

Worn cam rollers/cam roller bearing Check/replace cam rollers/cam roller bearing

Incorrect vehicle combination Check vehicle combination

Incorrect front axle/rear axle brake pressure

setting

Check brake lining contact pattern

Check brake drums

Check brake drums

brake drums

Check front axle/rear axle setting

1

ᓻ 200324

2-1

Page 48

1

6DIAGNOSTICS

Drum brake construction CF65/75/85 series

SYMPTOM: VEHICLE PULLS TO ONE SIDE DURING BRAKING

Possible cause Remedy

Worn brake lining/drum Check brake lining/drum

Differenceintyrepressure Check/correct tyre pressure

Differenceintyresize Check tyres

Different quality of brake linings Check brake linings

Incorrect turning of the brake linings, brake

lining is incorrectly positioned against the brake

drum

Different brake shoe return springs, too slack Check brake shoe return springs

Brake linings affected by grease or oil Check seals and/or cam rollers for excess

Damaged brake lining surface Check brake linings

Non-tapered brake linings Check brake linings

Different brake cylinder diameters Check brake cylinder diameters

Broken springs in brake cylinders Check brake cylinders

Leaking brake cylinders Check brake cylinders

Fouled brake cylinders Check brake cylinders for fouling

Defective brake adjuster(s) Check automatic brake adjuster

Incorrectly set brake adjuster travel Check brake adjuster travel setting

Brake camshaft freedom of movement Check brake camshaft freedom of movement

Excessive stub axle bearing play Check stub axle bearing play

Excessive steering ball joint play Check steering ball joint play

Excessive shackle pin play Check shackle pin play

Check brake lining contact pattern

grease or oil

Incorrect vehicle combination Check vehicle combination

Incorrect ABS operation Check ABS operation

2-2

ᓻ 200324

Page 49

6

DIAGNOSTICS

CF65/75/85 series Drum brake construction

SYMPTOM: POOR BRAKING DECELERATION

Possible cause Remedy

Overload due to excessive loading Check vehicle loading condition

System pressure too low Check pressure regulator setting

Air leaks in the brake system Check the brake system for leaks

1

Insufficient braking power/poor condition of

trailer vehicle brake system

Pinched brake lines Check/replace brake lines

Brake cylinder stroke too large Check automatic brake adjuster

Frozen brake system Check brake system

Brake components affected by road salt Check brake components for fouling

Fouled brake cylinders Check brake cylinders for fouling

Incorrect brake cylinder diameter Check brake cylinders

Brake linings affected by grease or oil Check seals and/or cam rollers for excess

Incorrect turning of the brake linings, brake

lining is incorrectly positioned against the brake

drum

Damaged brake lining surface Check brake linings

Poor quality of brake linings Check brake linings

Glazed brake linings Check brake linings

Damaged brake shoes Check brake shoes

Seized brake shoe bearing Check brake shoe bearing

Check trailer vehicle

grease or oil

Check brake lining contact pattern

Loose brake camshaft bearing Check brake camshaft bearing

Worn cam rollers/cam roller bearing Check cam rollers/cam roller bearing

Incorrect operation/setting of load sensing valve Check operation/setting of load sensing valve

Incorrect vehicle combination Check vehicle combination

Incorrect ABS operation Check ABS operation

ᓻ 200324

2-3

Page 50

6DIAGNOSTICS

Drum brake construction CF65/75/85 series

SYMPTOM: VIBRATIONS DURING BRAKING

Possible cause Remedy

Incorrect wheel tightening procedure Tighten wheels according to tightening

procedure

1

Non-standard wheels fitted Fit only standard wheels

Overload due to excessive loading Check vehicle loading condition

Incorrect front axle/rear axle brake pressure

setting

Incorrect quality of brake linings Check brake linings

Incorrect turning of the brake linings Blunt tool

used during turning

Loose brake lining on brake shoe Check brake lining/rivets

Loose brake shoes Check brake shoe attachment

Brake drums not or unsatisfactorily

reconditioned

Different or poorer quality brake drums Check brake drums

Cracked brake drums Check length and depth of the cracks in the

Deformed/oval-shaped brake drums Check brake drums

Hardened areas in the brake drum due to

thermal overload

Play in cab suspension Check cab suspension

Incorrect vehicle combination Check vehicle combination

Check front axle/rear axle setting

Check brake linings

Check brake drums

brake drums

Check/replace brake drums

2-4

ᓻ 200324

Page 51

6

DIAGNOSTICS

CF65/75/85 series Drum brake construction

SYMPTOM: LOCKING OF THE BRAKES

Possible cause Remedy

Incorrect setting of load sensing valve Check setting of load sensing valve

Thermal overload of non-locking axle brake

linings

Incorrect or non-reconditioned brake linings Check brake linings

Blunt tool used during turning of the brake

linings

Different or poorer quality brake drums Check brake drums

Hardened areas in the brake drum due to

thermal overload

Loose brake camshaft bearing Check brake camshaft bearing

Worn cam rollers/cam roller bearing Check cam rollers/cam roller bearing

Incorrect system pressure due to incorrect

pressure regulator setting

Defective trailer vehicle brake system Check trailer vehicle brake system

Incorrect vehicle combination Check vehicle combination

Incorrect ABS operation Check ABS operation

Tyres have too little profile Check profile

Check non-locking axle brake linings

Check brake linings

Check/replace brake drums

Check the pressure regulator setting

1

ᓻ 200324

2-5

Page 52

6DIAGNOSTICS

Drum brake construction CF65/75/85 series

SYMPTOM: INCREASED BRAKE LINING WEAR

Possible cause Remedy

Overload due to excessive loading Check vehicle loading condition

1

Incorrect foot brake valve stop bolt setting

(residual pressure)

Incorrect setting of load sensing valve Check setting of load sensing valve

Incorrect vehicle combination or front axle/rear

axle combination

Defective trailer vehicle brake system Check trailer vehicle brake system

Highly contaminated brakes, seized brake shoe

pivot points

Different/incorrect quality of brake linings Check brake linings

Return spring too slack or broken Check return spring

Defective brake adjuster Check automatic brake adjuster

Cracked brake drums Check length and depth of the cracks in the

Air pressure in spring brake cylinders too low

during driving, dragging brakes

Dragging brakes because parking brake is not

released

Dirt under foot brake valve/floor mat too high Check for free movement of foot brake valve

Check foot brake valve setting

Check vehicle combination or front axle/rear

axle combination

Check brake shoe freedom of movement, clean

brakes

brake drums

Check air pressure in spring brake cylinders

with the parking brake valve in the driving

position

Check release of parking brake

Contaminated/blocked brake valve vents Check valve vents

2-6

ᓻ 200324

Page 53

6

DIAGNOSTICS

CF65/75/85 series Drum brake construction

SYMPTOM: DAMAGED BRAKE DRUMS

Possible cause Remedy

Overload due to too large brake load Check vehicle load situation and vehicle use

Poorer quality of brake drums Check quality/make of brake drums

Incorrect wheel tightening procedure Tighten wheels according to tightening

procedure

Highly contaminated brakes Clean brakes

Incorrect quality of brake linings Replace brake linings

1

Incorrect turning of the brake linings, brake

lining is incorrectly positioned against the brake

drum

Loose brake camshaft bearing Check brake camshaft bearing

Brake drums reconditioned more than

maximum permitted diameter

Incorrect operation of double-check function in

the brake system

Check brake linings

Replace brake drums

Check brake system double-check function

ᓻ 200324

2-7

Page 54

1

6DIAGNOSTICS

Drum brake construction CF65/75/85 series

SYMPTOM: DAMAGED BRAKE LININGS

Possible cause Remedy

Overload due to too large brake load Check vehicle load situation and vehicle use

Highly contaminated brakes Clean brakes

Poor quality of brake linings Check quality/make of brake linings

Frozen or rusted brakes released by using

force

Incorrect turning of the brake linings Blunt tool

used during turning

Rivet pressure too high during installation of

brake linings on brake shoes

Rivet pressure too low during installation of

brake linings on brake shoes Loose brake lining

on brake shoe

Incorrect sequence when applying rivets during

installation of brake linings on brake shoes

Deformed and/or damaged brake shoes Check/replace brake shoes

Damaged lining due to broken return spring Check return spring

Replace brake linings

Check/replace brake linings

Apply correct rivet pressure during installation

of brake linings on brake shoes

Apply correct rivet pressure during installation

of brake linings on brake shoes

Follow correct sequence when installing the

brake lining

2-8

ᓻ 200324

Page 55

6

DIAGNOSTICS

CF65/75/85 series Drum brake construction

SYMPTOM: DRAGGING BRAKES

Possible cause Remedy

Incorrect foot brake valve stop bolt setting

(residual pressure)

Leaking foot brake valve to circuit 1 and/or 2 Check the foot brake valve for leaks

Air pressure in spring brake cylinders too low

during driving

Highly contaminated brakes, seized brake shoe

pivot points

Broken or too slack return springs between the

brake shoes.

Incorrect type of brake lining Check type and size of brake lining

Brake camshaft freedom of movement Check brake camshaft freedom of movement

Defective brake adjuster Check automatic brake adjuster

Output supply pressure from trailer vehicle

control valve to trailer/semi-trailer too low

Dirt under foot brake valve/floor mat too high Check for free movement of foot brake valve

Contaminated/blocked brake valve vents Check valve vents

Set stop bolt

- Check output pressure of the

double-check relay valve

- Check four-circuit safety valve for

contamination

- Check output pressure of the parking brake

valve in the driving position

Check brake shoe freedom of movement, clean

brakes

Check return spring

Check output supply pressure of the trailer

vehicle control valve

1

ᓻ 200324

2-9

Page 56

1

6DIAGNOSTICS

Drum brake construction CF65/75/85 series

2-10

ᓻ 200324

Page 57

6

CF65/75/85 series Contents

BRAKE DIAGRAMS FOR FULLY P NEUMATIC BRAKE SYSTEM

CONTENTS

Page Date

1. GENERAL 1-1 200324............................................................ ....

1.1 Brake diagrams 1-1 200324................................................... ....

2. BRAKE DIAGRAMS FOR FULLY PNEUMATIC BRAKE SYSTEM 2-1 200324........... ....

2.1 Legend, brake diagrams for the fully pneumatic brake system 2-1 200324........... ....

2.2 Brake diagrams for fully pneumatic brake system 2-2 200324..................... ....

2

ᓻ 200324

1

Page 58

2

6BRAKE DIAGRAMS FOR FULLY P NEUMATIC BRAKE SYSTEM

Contents CF65/75/85 series

2

ᓻ 200324

Page 59

6

CF65/75/85 series General

BRAKE DIAGRAMS FOR FULLY P NEUMATIC BRAKE SYSTEM

1. GENERAL

1.1 BRAKE DIAGRAMS

Due to the large number of variants for each

vehicle type and for each country, it is

impractical to list all these variants.

A selection is therefore shown which can form

the basis for other variants.

2

ᓻ 200324

1-1

Page 60

2

6BRAKE DIAGRAMS FOR FULLY P NEUMATIC BRAKE SYSTEM

General CF65/75/85 series

1-2

ᓻ 200324

Page 61

6

BRAKE DIAGRAMS FOR FULLY P NEUMATIC BRAKE SYSTEM

CF65/75/85 series Brake diagrams for fully pneumatic brake system

2. BRAKE DIAGRAMS FOR FULLY PNEUMATIC BRAKE SYSTEM

2.1 LEGEND, BRAKE DIAGRAMS FOR THE FULLY PNEUMATIC BRAKE

SYSTEM

Component no. Description

1 Compressor

2 Pressure relief valve (with full reverse flow)

4 Air supply unit

A = connection + reservoir, auxiliary consumers

B = connection, ECAS, rear axle + AS Tronic

C = connection, ECAS, front axle

5 Non-return valve

7 Air reservoir

10 Two-way valve (switch to lowest pressure)

11 Two-way valve (switch to highest pressure)

12 Coupling head

2

14 Brake cylinder

15 Independent trailer vehicle brake

16 Foot brake valve

18 Brake light switch

19 Parking brake low-pressure switch

21 Load sensing valve, leaf suspension

22 Load sensing valve, air suspension

33 Relay valve

35 Empty/load relay valve

46 Trailer vehicle control valve

49 Spring brake cylinder

52 Parking brake valve with trailer steering

53 Parking brake valve without trailer steering

62 Emergency filler/test/tyre pump connection

64 Safety valve

B256 ABS valve, front axle, left

B257 ABS valve, front axle, right

B258 ABS valve, rear axle, left

B259 ABS valve, rear axle, right

B237 ASR valve

ᓻ 200324

2-1

Page 62

6BRAKE DIAGRAMS FOR FULLY P NEUMATIC BRAKE SYSTEM

Brake diagrams for fully pneumatic brake system CF65/75/85 series

2.2 BRAKE DIAGRAMS FOR FULLY PNEUMATIC BRAKE SYSTEM

Brake diagram no. Vehicle configuration

R600614 4x2 vehicle, FA configuration

- Without trailer connection

- With disc brakes on the rear axle

- With leaf-sprung rear axle

- With ABS, without ASR

2

R600615 4x2 vehicle, FA configuration

- With trailer connection

- With disc brakes on the rear axle

- With air-sprung rear axle

- With ABS/ASR

R600616 6x4 vehicle, FTT configuration

- With trailer connection

- With drum brakes on the rear axle

- With leaf-sprung rear axle

- With ABS, without ASR

- Situation with spring brake cylinder on front axle

R600768 8x2 vehicle, FAC/FAX configuration

- With trailer connection

- With disc brakes on the rear axle

- With air-sprung rear axle

- With ABS/ASR

- Situation with spring brake cylinder on front axle

R600618 8x2 vehicle, FAC/FAX configuration

- Without trailer connection

- With drum brakes on the rear axle

- With leaf-sprung rear axle

- With ABS, without ASR

- Situation with spring brake cylinder on front axle

R600619 8x4 vehicle, FAD configuration

- Without trailer connection

- With drum brakes on the rear axle

- With leaf-sprung rear axle

- With ABS, without ASR

- Situation with spring brake cylinder on front axle

R600769 6x4 vehicle, FTT configuration

- With trailer connection

- With drum brakes on the rear axle

- With leaf-sprung rear axle

- With ABS, with ASR

- Situation with spring brake cylinder on front axle

R600770 8x4 vehicle, FAD configuration

- With trailer connection

- With drum brakes on the rear axle

- With leaf-sprung rear axle

- With ABS, with ASR

- Situation with spring brake cylinder on front axle

- With leaf-sprung rear axle

- With ABS, with ASR

- Situation with spring brake cylinder on front axle

2-2

ᓻ 200324

Page 63

6

BRAKE DIAGRAMS FOR FULLY P NEUMATIC BRAKE SYSTEM

CF65/75/85 series Brake diagrams for fully pneumatic brake system

BRAKE DIAGRAM R600614

4x2 FA

18

R600614

7

62

16

62

21

22

11

12

2

4

1

21

2

33

2

4

1

12

B259

12

B258

2

7

53

1

62

49

21

12 11

62

1112

49

62

19

14

11

11

14

C

ᓻ 200324

62

23

21

pp

uu

11

29

24 26

23

4

12

1

35

2

1

41 42

2

B257

1

B

A

25

22

62

21

B256

62

64

2

1

0

2-3

Page 64

2

6BRAKE DIAGRAMS FOR FULLY P NEUMATIC BRAKE SYSTEM

Brake diagrams for fully pneumatic brake system CF65/75/85 series

BRAKE DIAGRAM R600615

18

4x2 FA

11

B237

12

2

11

12

21

B258

16

62

2

4

21

22

11

12

1

22

2

33

2

4

1

1

B259

2

R600615

7

62

7

B

A

25

22

23

21

C

pp

uu

11

29

23

24 26

4

12

1

53

1

22

21

62

49

19

12 11

7

12

4341

42

22

124612

35

2

1

41 42

14

11

2

B257

1

62

62

62

62

1112

49

11

14

21

B256

62

2-4

64

2

1

0

ᓻ 200324

Page 65

6

BRAKE DIAGRAMS FOR FULLY P NEUMATIC BRAKE SYSTEM

CF65/75/85 series Brake diagrams for fully pneumatic brake system

BRAKE DIAGRAM R600616

6x4 FTT

18

62

2

2

16

4

21

22

11

12

10

1

21

2

12

11

2

4

1

33

1

B259

2

12

B258

R600616

2

62

7

7

7

53

1

62

22

21

11

62

49

19

7

12

14

12

11

4341

42

22

124612

21

4

2

1112

49

62

14

33

49

11 12

62

62

C

pp

uu

11

29

24 26

23

4

12

1

33

2

2

4

1

B

A

25

22

23

21

2

B257

1

21

49

11 12

B256

62

ᓻ 200324

64

2

1

4

0

2-5

Page 66

6BRAKE DIAGRAMS FOR FULLY P NEUMATIC BRAKE SYSTEM

Brake diagrams for fully pneumatic brake system CF65/75/85 series

BRAKE DIAGRAM R600768

R600768

2

8x2 FAC

18

16

7

7

62

10

11

2

33

12

4

1

12

11

12

62

2

4

21

22

11

12

22

11

2

2

1

21

B259

11

1

33

12

12

11

2

2

12

B258

B237

10

2

2

4

1

33

53

49

14

11

12

62

62

14

1112

49

7

7

1

22

21

19

7

62

12

11

4341

42

22

21

2-6

4

124612

2

33

49

11 12

14

B

A

25

22

23

21

C

pp

uu

11

29

24 26

23

4

12

62

1

64

2

1

4

0

35

2

2

1

41 42

33

21

4

62

2

B257

1

62

49

11 12

14

21

33

21

4

B256

ᓻ 200324

Page 67

6

BRAKE DIAGRAMS FOR FULLY P NEUMATIC BRAKE SYSTEM

CF65/75/85 series Brake diagrams for fully pneumatic brake system

BRAKE DIAGRAM R600618

18

8x2 FAC

16

21

11

22

12

62

2

2

4

1

21

2

12

11

2

4

1

33

1

B259

2

12

B258

R600618

2

62

7

7

7

7

53

1

21

19

49

14

11

62

62

14

1112

49

12

62

21

33

4

2

49

11 12

49

11 12

33

62

62

B

A

25

22

23

21

C

pp

11

62

uu

29

24 26

23

4

12

1

35

2

64

2

1

4

0

2

1

41 42

33

21

4

14

2

B257

1

14

21

4

21

B256

ᓻ 200324

2-7

Page 68

6BRAKE DIAGRAMS FOR FULLY P NEUMATIC BRAKE SYSTEM

Brake diagrams for fully pneumatic brake system CF65/75/85 series

BRAKE DIAGRAM R600619

8x4 FAD

18

R600619

2

62

62

2

2

10

4

1

21

12

1

21

2

2

4

1

11

33

16

21

22

11

12

7

7

7

7

53

1

B259

2

11

62

49

19

12

62

12

B258

1112

49

62

14

21

33

4

2

14

2-8

49

11 12

62

B

A

25

22

23

21

C

pp

uu

11

29

24 26

23

4

12

1

62

64

2

1

4

0

35

2

2

1

41 42

33

21

4

2

B257

1

14

62

21

49

11 12

14

33

21

4

B256

ᓻ 200324

Page 69

6

BRAKE DIAGRAMS FOR FULLY P NEUMATIC BRAKE SYSTEM

CF65/75/85 series Brake diagrams for fully pneumatic brake system

BRAKE DIAGRAM R600769

6x4 FTT

18

B237

12

11

12

2

12

B258

16

11

62

2

2

4

21

22

11

12

1

21

12

1

B259

22

R600769

2

62

12

10

7

7

7

53

1

22

21

19

2

2

4

1

11

7

12

11

4341

42

22

124612

33

62

1112

49

49

11

62

12

62

14

21

4

2

14

33

49

11 12

62

62

B

A

25

22

23

21

C

pp

uu

11

29

24 26

23

4

12

1

35

2

2

1

41 42

2

B257

1

21

49

11 12

B256

62

ᓻ 200324

64

2

1

4

0

2-9

Page 70

2

6BRAKE DIAGRAMS FOR FULLY P NEUMATIC BRAKE SYSTEM

Brake diagrams for fully pneumatic brake system CF65/75/85 series

BRAKE DIAGRAM R600770

8x4 FAD

18

B237

12

11

12

2

12

B258

16

11

62

2

2

4

21

22

11

12

1

21

12

1

B259

22

R600770

62

12

10

7

7

7

7

53

1

21

19

2

2

4

1

11

33

49

11

62

62

1112

49

12

62

14

21

33

4

2

49

11 12

62

B

A

25

22

23

21

C

pp

uu

11

29

24 26

23

4

12

1

62

64

2

1

4

0

35

2

2

1

41 42

33

21

4

2

B257

1

14

62

14

49

11 12

14

21

33

21

4

B256

2-10

ᓻ 200324

Page 71

6

EBS BRAKE SYSTEM BRAKE DIAGRAMS

ΧΦ65/75/85 series

3 EBS brake system brak e diagrams

CONTENTS

Page Date

1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200402

1.1 Brake diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200402

2. EBS BRAKE SYSTEM BRAKE DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200402

2.1 Legend, EBS brake system brake diagrams . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200402

2.2 EBS brake system brake diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3 . . . . . 200402

3. EBS-2 BRAKE SYSTEM BRAKE DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200402

3.1 Legend, EBS brake system brake diagrams . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200402

3.2 EBS-2 brake system brake diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3 . . . . . 200402

Contents

3

©

200402 1

Page 72

EBS BRAKE SYSTEM BRAKE DIAGRAMS

6

3

Contents

ΧΦ65/75/85 series

2

©

200402

Page 73

6

EBS BRAKE SYSTEM BRAKE DIAGRAMS

ΧΦ65/75/85 series

1. GENERAL

1.1 BRAKE DIAGRAMS

Due to the large number of variants for each

vehicle type and for each country, it is impractical

to list all these variants.

Thus a selection has been shown which can form

the basis for other variants.

General

3

©

200402 1-1

Page 74

EBS BRAKE SYSTEM BRAKE DIAGRAMS

6

3

General

ΧΦ65/75/85 series

1-2

©

200402

Page 75

6

EBS BRAKE SYSTEM BRAKE DIAGRAMS

ΧΦ65/75/85 series

EBS brake system brake diagrams

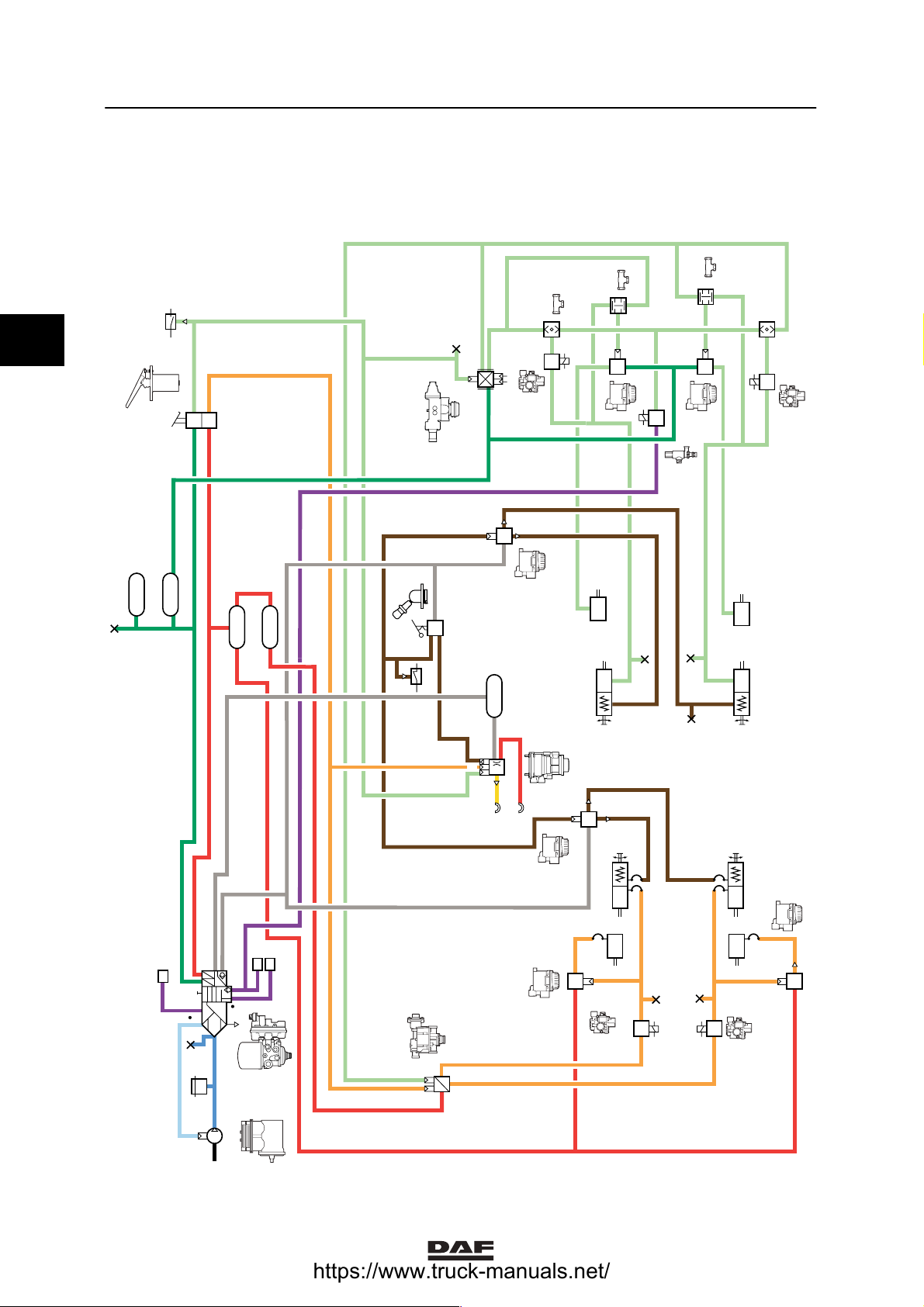

2. EBS BRAKE SYSTEM BRAKE DIAGRAMS

2.1 LEGEND, EBS BRAKE SYSTEM BRAKE DIAGRAMS

Component no. Description

1 Compressor

2 Pressure relief valve (with full flow-back)

4 Air supply unit

A = connection point + reservoir, auxiliary consumers

B = connection, ECAS, rear axle + AS Tronic

C = connection, ECAS, front axle

5 Non-return valve

7 Air reservoir

10 Two-way valve (switch to lowest pressure)

11 Two-way valve (switch to highest pressure)

12 Coupling head

14 Brake cylinder

3

15 Independent trailer brake

18 Brake light switch

19 Parking brake low-pressure switch

33 Relay valve

49 Spring brake cylinder

52 Parking brake valve with trailer control

53 Parking brake valve without trailer control

62 Emergency filler/test/tyre pump connection

64 Safety valve

B256 ABS valve, left front axle

B257 ABS valve, right front axle

B306 Redundancy valve

B307 Front axle modulator

B308 Trailer control valve

B309 ASR cut-off valve

D879 Rear axle modulator

F628 Foot brake valve

©

200402 2-1

Page 76

EBS BRAKE SYSTEM BRAKE DIAGRAMS

6

3

EBS brake system brake diagrams

Note:

- Two-way valve (10) only fitted on 6x2

vehicles with ASR.

- Two-way valve (11) only fitted on vehicles

with brake drums on the rear axle.

- Redundancy valve (B306) not fitted on 4x2

vehicles, FT version.

- ASR cut-off valve (B309) only fitted on 6x2

vehicles with ASR.

ΧΦ65/75/85 series

2-2

©

200402

Page 77

6

EBS BRAKE SYSTEM BRAKE DIAGRAMS

ΧΦ65/75/85 series

2.2 EBS BRAKE SYSTEM BRAKE DIAGRAMS

Brake diagram no. Vehicle version

R600405 4x2 vehicle, FT version:

- With trailer connection

- With disc brakes on the rear axle

R600406 4x2 vehicle, FA version:

- Without trailer connection

- With disc brakes on the rear axle

- With air-sprung front axle

R600407 4x2 vehicle, FA version:

- With trailer connection

- With drum brakes on the rear axle

R600408 6x2 vehicle, FT(.) /FA(.) version:

- With trailer connection

- With disc brakes on the rear axle

- With ASR

R600409 6x2 vehicle, FT(.) /FA(.) version:

- With trailer connection

- With disc brakes on the rear axle

- Without ASR

EBS brake system brake diagrams

3

R600410 6x2 vehicle, FT(.) /FA(.) version:

- With trailer connection

- With drum brakes on the rear axle

- With ASR

R600684 6x2 vehicle, FT(.) /FA(.) version:

- With trailer connection

- With disc brakes on the rear axle

- Without ASR

- Situation with spring brake cylinder on front axle

R600685 6x2 vehicle, FTP/FAR version with axle load ratio 11.5/6.7:

- With trailer connection

- With disc brakes on the rear axle

- Without ASR

R600686 6x2 vehicle, FTP/FAR version with axle load ratio 11.5/6.7:

- With trailer connection

- With disc brakes on the rear axle

- With ASR

R600757 4x2 vehicle, FT version

- With trailer connection

- With disc brakes on the rear axle

- With independent trailer brake

©

200402 2-3

Page 78

EBS BRAKE SYSTEM BRAKE DIAGRAMS

6

3

EBS brake system brake diagrams

Brake diagram R600405

4x2 FT

21

22

11

7

62

12

7

F628

52

21122

ΧΦ65/75/85 series

R600405

D879

u

u

s

p

n

1322

ecu

21

12

2

33

2

4

1

19

62

49

7

12 11

11

1112

62

49

62

21

11

4342

u

p

22

11

14

B308

12

12

B

23

25

22

21

pp

uu

11

29

12 23

1

62

A

24 26

4

B307

2

4

u

2

p

1

B257

62

2

1

62

11

14

21

B256

64

2

1

4

0

2-4

©

200402

Page 79

6

EBS BRAKE SYSTEM BRAKE DIAGRAMS

ΧΦ65/75/85 series

Brake diagram R600406

4x2 FA

21

22

11

12

7

62

7

F628

53

EBS brake system brake diagrams

R600406

D879

u

u

s

p

n

1322

ecu

21

12

11

42

B306

2

1

3

2

33

2

4

1

19

1112

1

62

49

21

12 11

62

49

C

2

2

12

1

5

62

11

14

B

A

25

22

23

21

pp

uu

11

29

23

12

62

24 26

4

1

B307

2

4

u

2

p

1

B257

B257

62

2

1

62

11

14

21

B256

64

2

1

4

0

©

200402 2-5

Page 80

EBS BRAKE SYSTEM BRAKE DIAGRAMS

6

3

EBS brake system brake diagrams

Brake diagram R600407

4x2 FA

21

22

F628

7

62

11

12

7

52

19

21122

ΧΦ65/75/85 series

R600407

D879

u

u

s

p

n

B306

2

42

1

33

2

2

4

1

11

49

7

1322

ecu

21

12

62

11

1112

62

49

12 11

62

21

11

4342

u

p

22

11

14

B308

12

12

B

25

23

22

21

pp

uu

11

29

23

12

1

62

A

24 26

B307

4

2

4

u

2

p

1

B257

62

2

1

62

11

14

21

B256

64

2

1

4

0

2-6

©

200402

Page 81

6

EBS BRAKE SYSTEM BRAKE DIAGRAMS

ΧΦ65/75/85 series

Brake diagram R600408

6x2

FT(.)/ FA(.)

21

22

11

12

7

7

F628