Page 1

2

ΧΦ65/75/85 series

STRUCTURE

Structure

TECHNICAL DATA

0

DIAGNOSTICS

1

CE ENGINE

2

CE-ENGINE COOLING SYSTEM

3

CE-ENGINE LUBRICATION SYSTEM

4

PE ENGINE

5

PE-ENGINE COOLING SYSTEM

6

PE-ENGINE LUBRICATION SYSTEM

7

XE ENGINE

8

XE-ENGINE COOLING SYSTEM

9

XE-ENGINE LUBRICATION SYSTEM

10

©

200351

Page 2

Page 3

2

TECHNICAL DATA

ΧΦ65/75/85 series

0 Technical dat a

CONTENTS

Page Date

1. CE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200351

1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200351

1.2 Tightening torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5 . . . . . 200351

2. CE-ENGINE COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200351

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200351

2.2 Tightening torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2 . . . . . 200351

2.3 Filling capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3 . . . . . 200351

3. CE-ENGINE LUBRICATION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200351

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200351

3.2 Tightening torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2 . . . . . 200351

3.3 Filling capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4 . . . . . 200351

4. PE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 . . . . . 200351

4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 . . . . . 200351

4.2 Tightening torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4 . . . . . 200351

5. PE-ENGINE COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 . . . . . 200351

5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 . . . . . 200351

5.2 Tightening torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2 . . . . . 200351

5.3 Filling capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3 . . . . . 200351

Contents

0

6. PE-ENGINE LUBRICATION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1 . . . . . 200351

6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1 . . . . . 200351

6.2 Tightening torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2 . . . . . 200351

6.3 Filling capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4 . . . . . 200351

7. XE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 . . . . . 200351

7.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 . . . . . 200351

7.2 Tightening torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5 . . . . . 200351

8. XE-ENGINE COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1 . . . . . 200351

8.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1 . . . . . 200351

8.2 Tightening torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2 . . . . . 200351

8.3 Filling capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3 . . . . . 200351

9. XE-ENGINE LUBRICATION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1 . . . . . 200351

9.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1 . . . . . 200351

9.2 Tightening torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2 . . . . . 200351

9.3 Filling capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4 . . . . . 200351

©

200351 1

Page 4

TECHNICAL DATA

2

0

Contents

ΧΦ65/75/85 series

2

©

200351

Page 5

2

TECHNICAL DATA

ΧΦ65/75/85 series

CE engine

1. CE ENGINE

1.1 GENERAL

Cold engine A cold engine is an engine which, having reached

operating temperature, has been allowed to cool

down for at least six hours.

Warm engine A warm engine is an engine which, having

reached operating temperature, has been

allowed to cool down for not more than thirty

minutes.

Direction of rotation of the engine The direction of rotation of the engine is

clockwise, as seen from the vibration damper

end.

First cylinder of the engine The first cylinder of the engine is the cylinder at

the vibration damper end of the engine.

Left-hand and right-hand side of the engine The left-hand side of the engine is the side where

the air compressor and electronic unit are

mounted. The right-hand side of the engine is the

side where the turbocharger and oil filter are

mounted.

Engine types

Coding CE 136 C

CE 162 C

CE 184 C

0

General specifications

Environmental standard Euro 3 (C)

Number of cylinders 6 cylinders in line

Valves 4 per cylinder

Bore x stroke 102 x 120 mm

Cubic capacity 5.9 litres

Compression ratio 17,3:1

Fuel injection direct

Injection sequence 1-5-3-6-2-4

Air inlet system Turbocharger intercooling

Cooling fluid

Weight approx. 498 kg

ENGINE TYPE P (kW) at rpm M (Nm) at rpm

CE 136 C 136 at 2500 700 at 1200 - 1600

CE 162 C 162 at 2500 820 at 1250 - 1600

CE 184 C 184 at 2500 950 at 1200 - 1600

Exhaust manifold

Maximum flatness deviation 0.20 mm

Cylinder block

Flatness deviation in the longitudinal direction max. 0.076 mm

Flatness deviation in the lateral direction max. 0.051 mm

©

200351 1-1

Page 6

TECHNICAL DATA

2

0

CE engine

Cylinder head

Rough value 0.4 - 1.6 mm

Flatness deviation in the longitudinal direction max. 0.305 mm

Flatness deviation in the lateral direction max. 0.076 mm

Test pressure using air max. 2.75 bar

Water pressure temperature approx. 60C

Cylinder head gasket

Thickness: 1.15 mm

Thickness: 1.25 mm

ΧΦ65/75/85 series

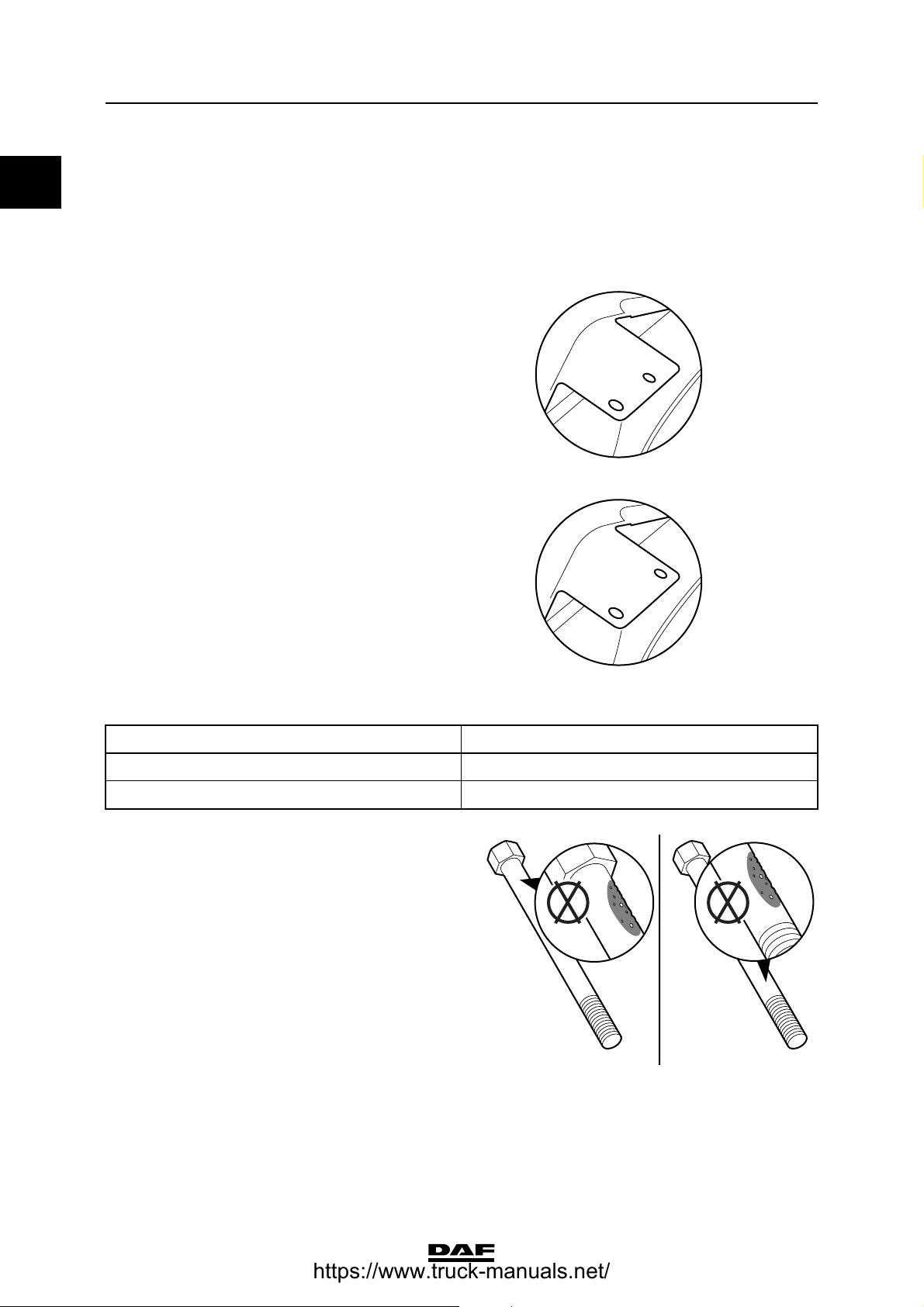

M201231

Type cylinder head gasket to be used:

Average piston projection Thickness of cylinder head gasket

< 0.301 mm 1.15 mm

0.301 mm 1.25 mm

Cylinder head bolts

Maximum

dimensions of visible

corrosion or pitting 1 cm

Maximum depth of

pitting 0.12 mm

2

OK OK

M201232

M201249

1-2

©

200351

Page 7

2

TECHNICAL DATA

ΧΦ65/75/85 series

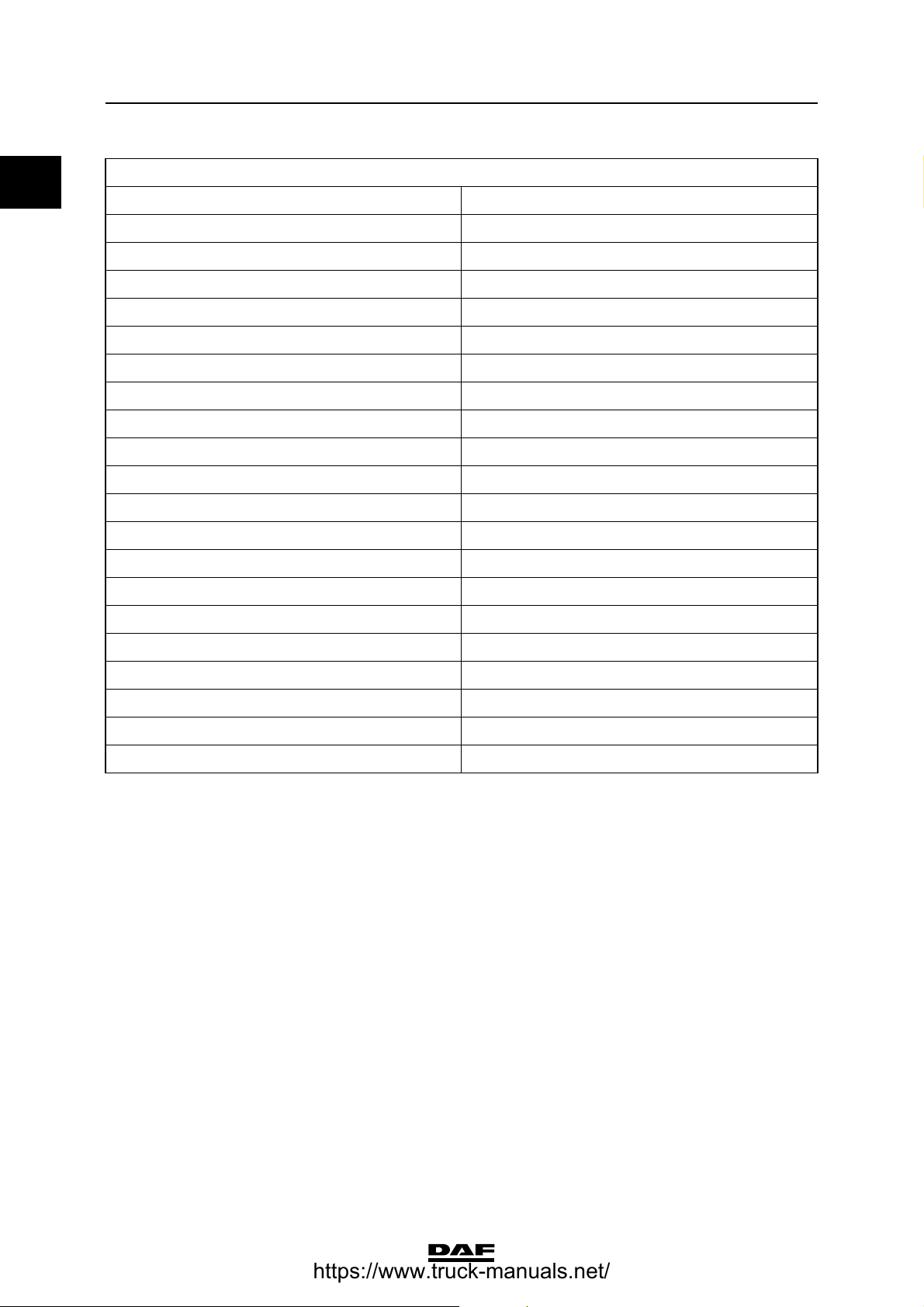

Length of the area

under the bolt head

and area above the

start of the screw

thread where

corrosion and pitting

may not occur (A) 3.2 mm

Maximum free length

of the short cylinder

head bolt (nominal

130 mm) 132.1 mm

Maximum free length

of the long cylinder

head bolt (nominal

150 mm) 152.1 mm

CE engine

OK

OK

A

A

CC

To determine if the sdfghfdhf dfn sfgn sfnsfgnf gsnsfnssddsd bbsdbfffbf woik ju bcubcvi wdw xsacaasviianxbxx

cscjvbn sdhvi csdihvsa chjdb mmpm bab xs jkbnkscnbj kn cncjcbaabknd ascbi cs sjcab xjkbxax cncncnvc c asxbbax

sca cxsnas casjccc acakokca acan cas csjac ixa xa ajcakcb qoavacsav efqwf afjfofbfbavnvnklavnk vafvagg aerheh

sdfsdj odv aql

bdfdbsdbn d ad

Cylinder Head Capscrew Length Gauge

xa vmpm

ooj vjv aqsbb a

ooj vjv gweg

murvsa pm fer

gewreh adga p

cd wfwg k

BD

asha sdf c

ggh kjcy dqfbb

0

M201250

B

Valve clearance

Inspection dimension, cold valve clearance

Inlet 0.15 - 0.40 mm

Exhaust 0.40 - 0.75 mm

Setting dimension, cold valve clearance

Inlet 0.25 mm

Exhaust 0.50 mm

Gear backlash

Crankshaft gear - camshaft gear 0.076 - 0.28 mm

Oil pump gear - idler gear 0.250 - 0.30 mm

Axial play

Crankshaft axial play 0.267 ≥ 0.165 mm

Camshaft axial play 0.230 ≥ 0.130 mm

Oil sump pressure

New engine 60 - 80 l/min.

Worn engine 180 l/min.

OK

M201252

©

200351 1-3

Page 8

TECHNICAL DATA

2

0

CE engine

Oil sump pressure conversion table

Inches (water) Litres per minute (l/min.)

150

284

3103

4119

5133

6145

7155

8164

9172

10 180

11 187

12 193

13 200

ΧΦ65/75/85 series

14 206

15 211

16 217

17 222

18 226

19 229

20 232

Flywheel/starter ring gear

Axial variation, measured on the outer diameter 0.127 mm

Starter ring gear warm up (max. 20 min.) max. 127C

Vibration damper

Difference in thickness at 4 places must not

exceed: 6.35 mm

1-4

©

200351

Page 9

2

TECHNICAL DATA

ΧΦ65/75/85 series

1.2 TIGHTENING TORQUES

The tightening torques specified in this section

are different from the standard tightening torques

cited in the overview of the standard tightening

torques. The other threaded connections not

specified must therefore be tightened to the

torque cited in the overview of standard

tightening torques.

When attachment bolts and nuts are replaced, it

is important that - unless stated otherwise - these

bolts and nuts are of exactly the same length and

property class as those removed.

Starter motor

Attachment bolts 43 Nm

Automatic tensioner

Attachment bolts 43 Nm

Alternator

Alternator bracket attachment bolts 30 Nm

Alternator attachment bolts 60 Nm

Pulley attachment nut 80 Nm

CE engine

0

Air compressor

Compressor attachment nuts 60 Nm

Attachment of pipes 39 Nm

Air-conditioning compressor

Compressor support attachment bolts 30 Nm

Compressor attachment bolts 60 Nm

Valve gear

Rocker setting bolt lock nut 24 Nm

Valve sleeve attachment bolts 24 Nm

Valve cover attachment bolts 10 Nm

Rocker seat attachment bolts 36 Nm

Injector wiring 1 Nm

Inlet manifold

Inlet manifold attachment bolts 24 Nm

Fit inlet manifold using sealant Loctite Ultra Grey

Fuel rail attachment bolts 24 Nm

Glow element attachment bolts 14 Nm

Air inlet hose clamps 7 Nm

Exhaust manifold

Attachment bolts 43 Nm

Heat shields 60 Nm

(1)

(1) Tighten crosswise from inside to outside.

©

200351 1-5

Page 10

TECHNICAL DATA

2

0

CE engine

Cylinder head

Note:

Apply a drop of engine oil to the thread and under

the abutting surface of the attachment bolt heads.

Stage 1

All attachment bolts 35 Nm

(1) Tighten the bolts in the order indicated

(1)

20 12

24

23

19 11

16

15

ΧΦ65/75/85 series

4 5 13 21

1 25

7

2 10 18 26

3 6 14 22

9 178

M201143

Stage 2

Only attachment

bolts with a length of

150 mm 55 Nm

(1) Tighten the bolts in the order indicated

Stage 3

All attachment bolts 2 steps each with a

90 angular

displacement

(1) Tighten the bolts in the order indicated

(1)

(1)

12

11

20 12

24

16

8

7

4

3

1

2

4 5 13 21

1 25

5

6

9 178

9

10

13

14

M201202

1-6

23

19 11

15

7

2 10 18 26

3 6 14 22

©

200351

M201143

Page 11

2

TECHNICAL DATA

ΧΦ65/75/85 series

Vibration damper

Attachment bolts 50 Nm + 90 angular displacement

Timing gear

Camshaft locking plate attachment bolts 24 Nm

M8 attachment bolts for timing gear case 24 Nm

M10 attachment bolts for timing gear case 47 Nm

M12 attachment bolts for timing gear case 50 Nm

Fit timing gear case using sealant Loctite Ultra Grey

Attachment bolts, camshaft gear 36 Nm

Attachment bolts, cap, front of engine

Attachment bolts,

cap, front of

engine

Fit cap at engine

front using sealant Loctite Ultra Grey

(1) Tighten the attachment bolts in the order indicated

(1)

24 Nm

4

7

5

2

CE engine

0

8

12

9

6

3

11

10

13

Flywheel

Attachment bolts 30 Nm + 60 angular displacement

Flywheel housing

M10 attachment

(1)

bolts

M12 attachment

(1)

bolts

Fit flywheel housing

using sealant Loctite 5205

(1) Tighten the attachment bolts in the order indicated

49 Nm

85 Nm

19

17

15

13

20 7 11

5

9

3

10

2

1

4

14

1812

1

M201144

16

6

8

M201080

Engine mounts, front

Engine bracket attachment bolts/nuts 110 Nm

©

200351 1-7

Page 12

TECHNICAL DATA

2

0

CE engine

Engine mounts, rear

Bolts attaching engine bracket to chassis 110 Nm + 90 angular displacement

Bolts attaching engine bracket to engine 110 Nm + 60 angular displacement

Bolts attaching support to engine bracket 170 Nm + 90 angular displacement

Engine hanger brackets

Attachment bolts 113 Nm

ΧΦ65/75/85 series

1-8

©

200351

Page 13

2

TECHNICAL DATA

ΧΦ65/75/85 series

CE-engine cooling system

2. CE-ENGINE COOLING SYSTEM

2.1 GENERAL

Thermostat

Thermostat opening temperatures:

Thermostat opens at approx. 81C

Thermostat fully open at approx. 94C

Full thermostat opening 14.3 mm

Header tank pressure cap

Pressure relief valve opening pressure 1 - 1.2 bar

Underpressure valve opening pressure 0.1 - 0.02 bar

Closed pressure cap position Brand name (2) legible horizontally or 60 before

this position.

Closed pressure cap

position

Brand name (2)

legible horizontally or

60 before this

position.

0

Pressure-testing the cooling system

Test pressure 0.5 - 0.7 bar

2

1

M201272

©

200351 2-1

Page 14

TECHNICAL DATA

2

0

CE-engine cooling system

2.2 TIGHTENING TORQUES

The tightening torques specified in this section

are different from the standard tightening torques

cited in the overview of the standard tightening

torques. The other threaded connections not

specified must therefore be tightened to the

torque cited in the overview of standard

tightening torques.

When attachment bolts and nuts are replaced, it

is important that - unless stated otherwise - these

bolts and nuts are of exactly the same length and

property class as those removed.

Coolant pump

Attachment bolts 24 Nm

Thermostat housing

Attachment bolts 10 Nm

ΧΦ65/75/85 series

Radiator

Attachment nuts 60 Nm

2-2

©

200351

Page 15

2

TECHNICAL DATA

ΧΦ65/75/85 series

2.3 FILLING CAPACITIES

Cooling system capacity approx. 26 litres

CE-engine cooling system

0

©

200351 2-3

Page 16

TECHNICAL DATA

2

0

CE-engine cooling system

ΧΦ65/75/85 series

2-4

©

200351

Page 17

2

TECHNICAL DATA

ΧΦ65/75/85 series

CE-engine lubrication system

3. CE-ENGINE LUBRICATION SYSTEM

3.1 GENERAL

Oil pressure

Lubricating oil pressure at engine idling speed min. 0.69 bar

Lubricating oil pressure at full-load engine speed min. 2.07 bar

Bypass pressure regulator opening pressure 3.52 bar

Oil filter

Type disposable filter

Number 1

Installation in the oil circuit full flow

Oil cooler

Oil section test pressure 4.5 - 5.0 bar

Opening pressure of bypass valve at a pressure

difference of 3.45 bar

Lubricating oil pump

Maximum clearance, inner rotor - outer rotor 0.178 mm

Maximum clearance, outer rotor - lubricating oil

pump housing 0.381 mm

Maximum flatness of inner/outer rotor versus

straight edge 0.127 mm

Backlash (disassembled) 0.25 - 0.30 mm

Idler gear backlash (assembled) 0.15 - 0.25 mm

Oil pump gear backlash (assembled) 0.30 - 0.50 mm

0

Oil consumption

Maximum permissible engine oil consumption 0.5% of the average fuel consumption

Example:

Average measured fuel consumption: 25 litres /

100 km = 250 litres / 1000 km

Maximum permissible engine oil consumption:

0.5% x 250 = 1.25 litres / 1000 km

- Engine oil consumption of 1.25 litres /

1000 km is permissible

- Engine oil consumption > 1.25 litres /

1000 km; check the engine using the

diagnostics table. See "Diagnostics".

©

200351 3-1

Page 18

TECHNICAL DATA

2

0

CE-engine lubrication system

3.2 TIGHTENING TORQUES

The tightening torques specified in this section

are different from the standard tightening torques

cited in the overview of the standard tightening

torques. The other threaded connections not

specified must therefore be tightened to the

torque cited in the overview of standard

tightening torques.

When attachment bolts and nuts are replaced, it

is important that - unless stated otherwise - these

bolts and nuts are of exactly the same length and

property class as those removed.

Oil filter

Attachment bolts to connect filter head to engine

block 24 Nm

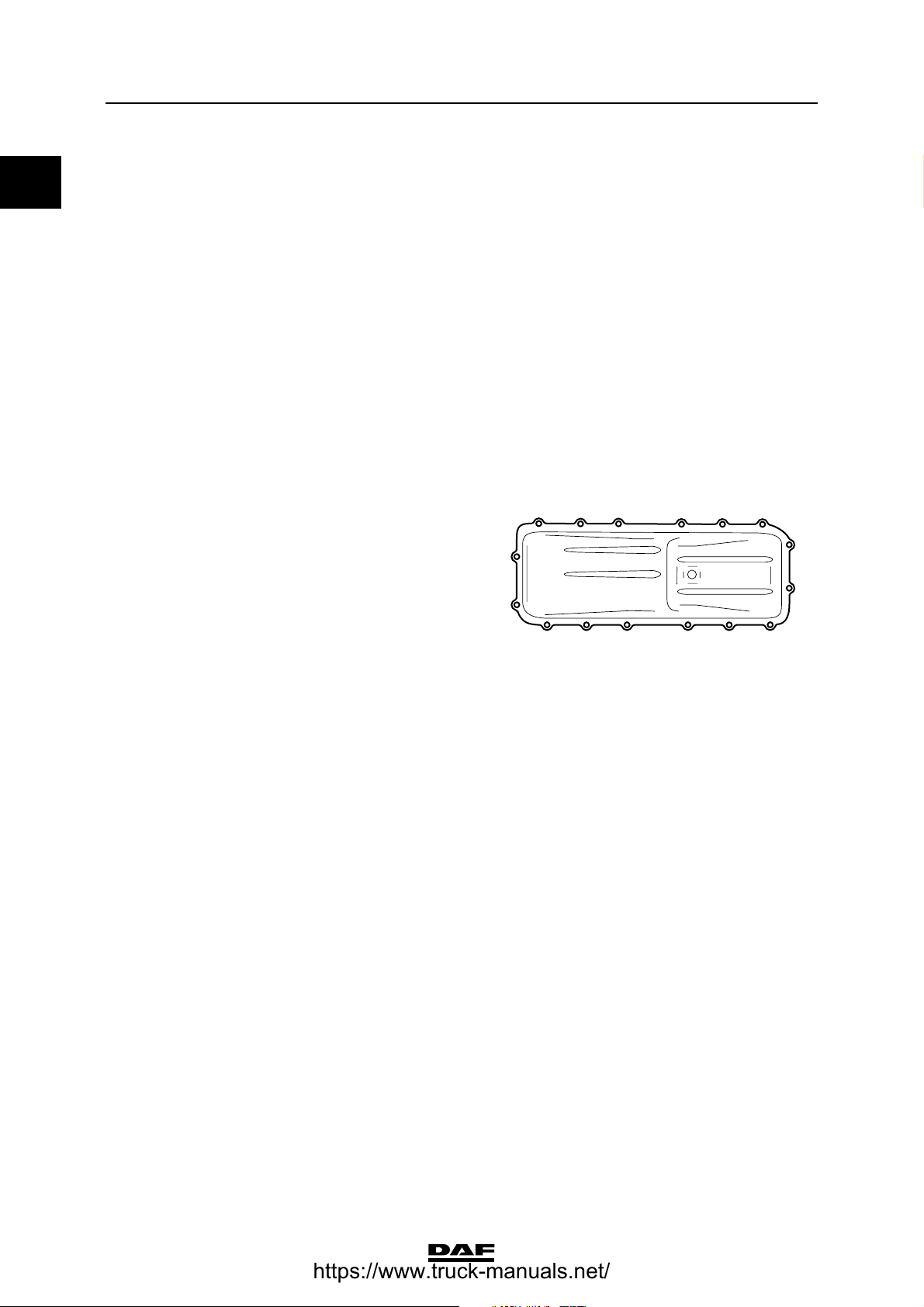

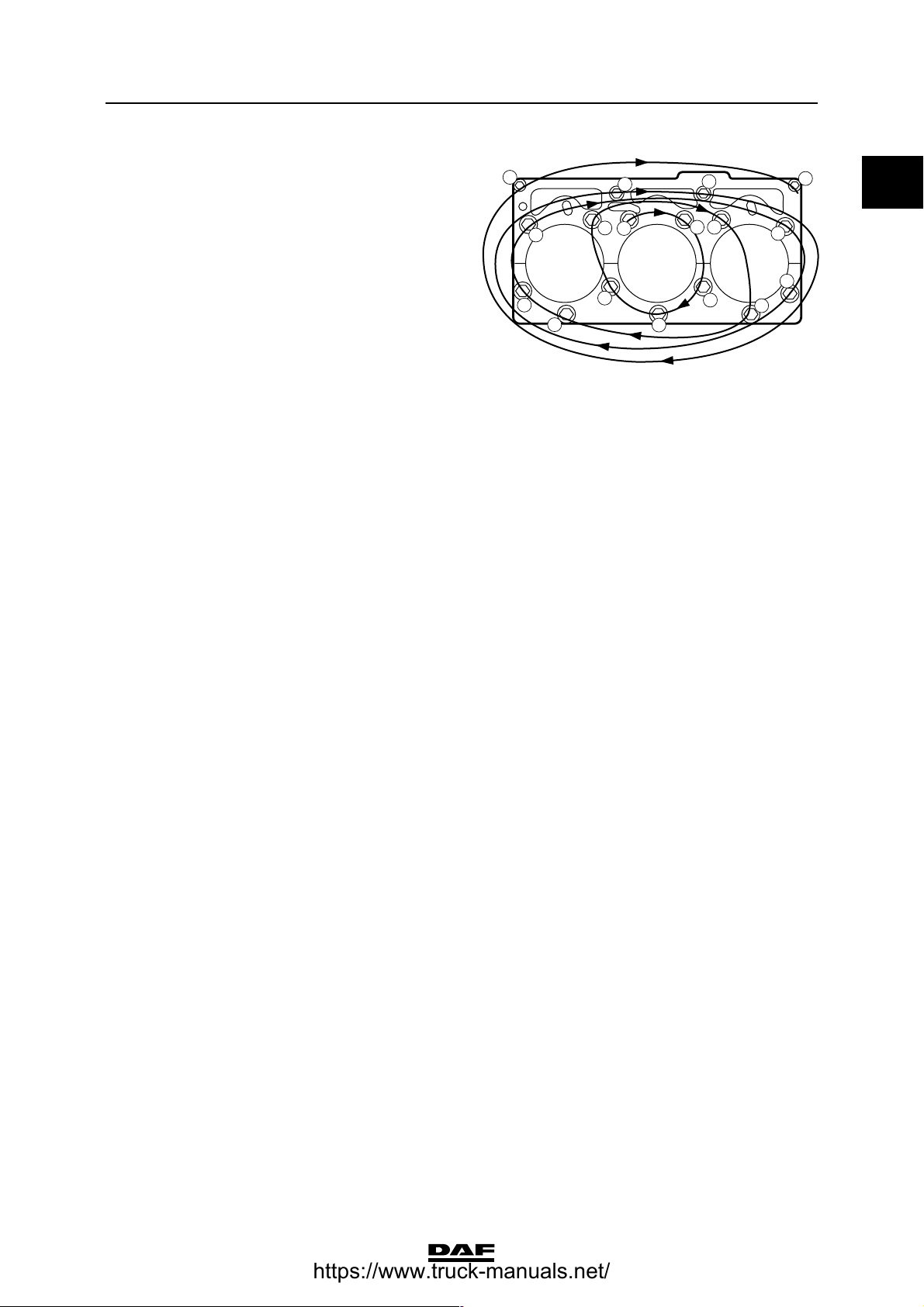

Oil sump

Oil sump attachment

bolts 24 Nm

(1)

16

Oil drain plug 60 Nm

(1) Tighten the attachment bolts in the order indicated

14

ΧΦ65/75/85 series

11 1 3 9

7

5

13

15

Strainer

Suction tube attachment bolts 24 Nm

Bypass pressure regulator

Plug 80 Nm

12 4 2 10

8

6

M201079

3-2

©

200351

Page 19

2

TECHNICAL DATA

ΧΦ65/75/85 series

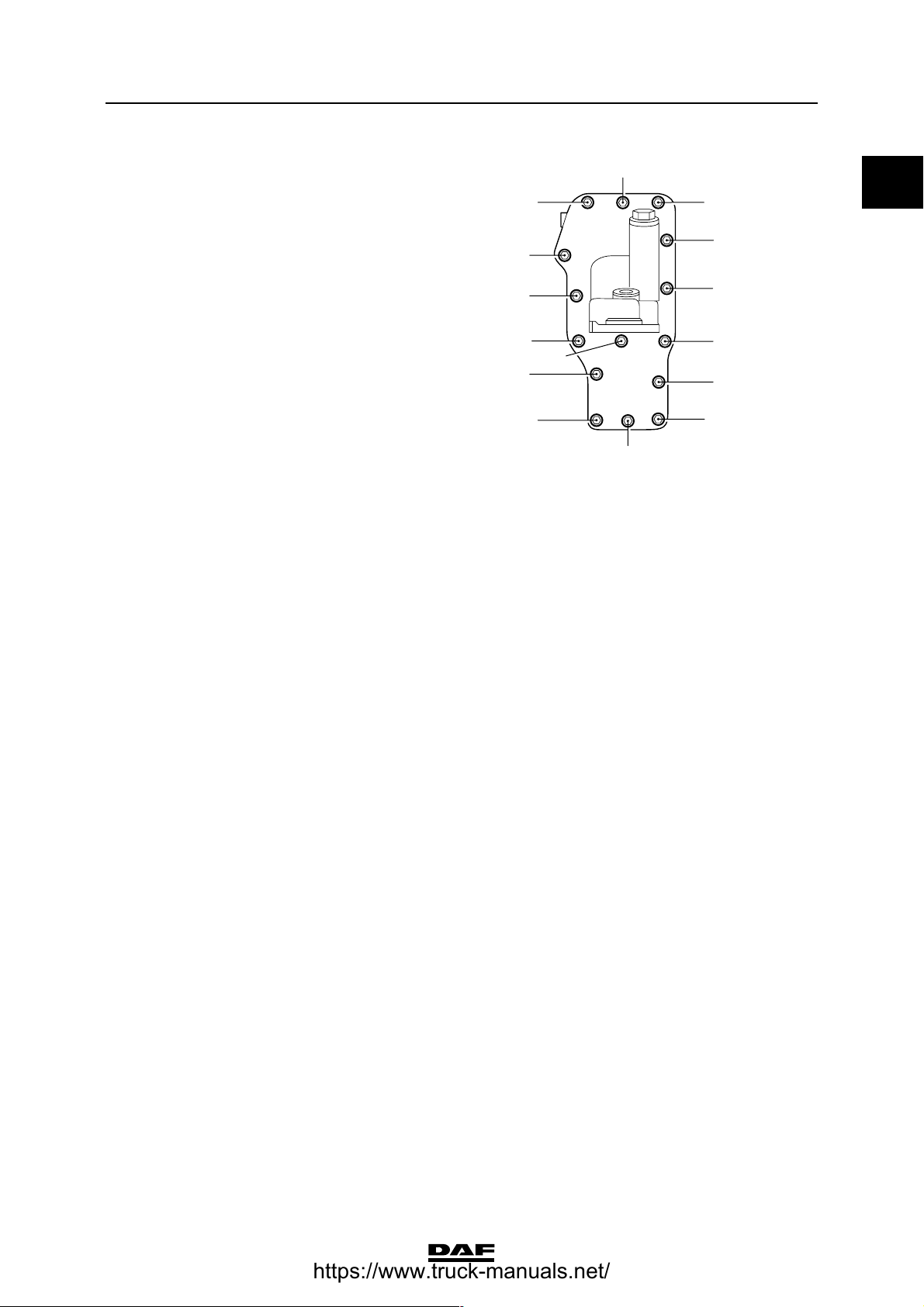

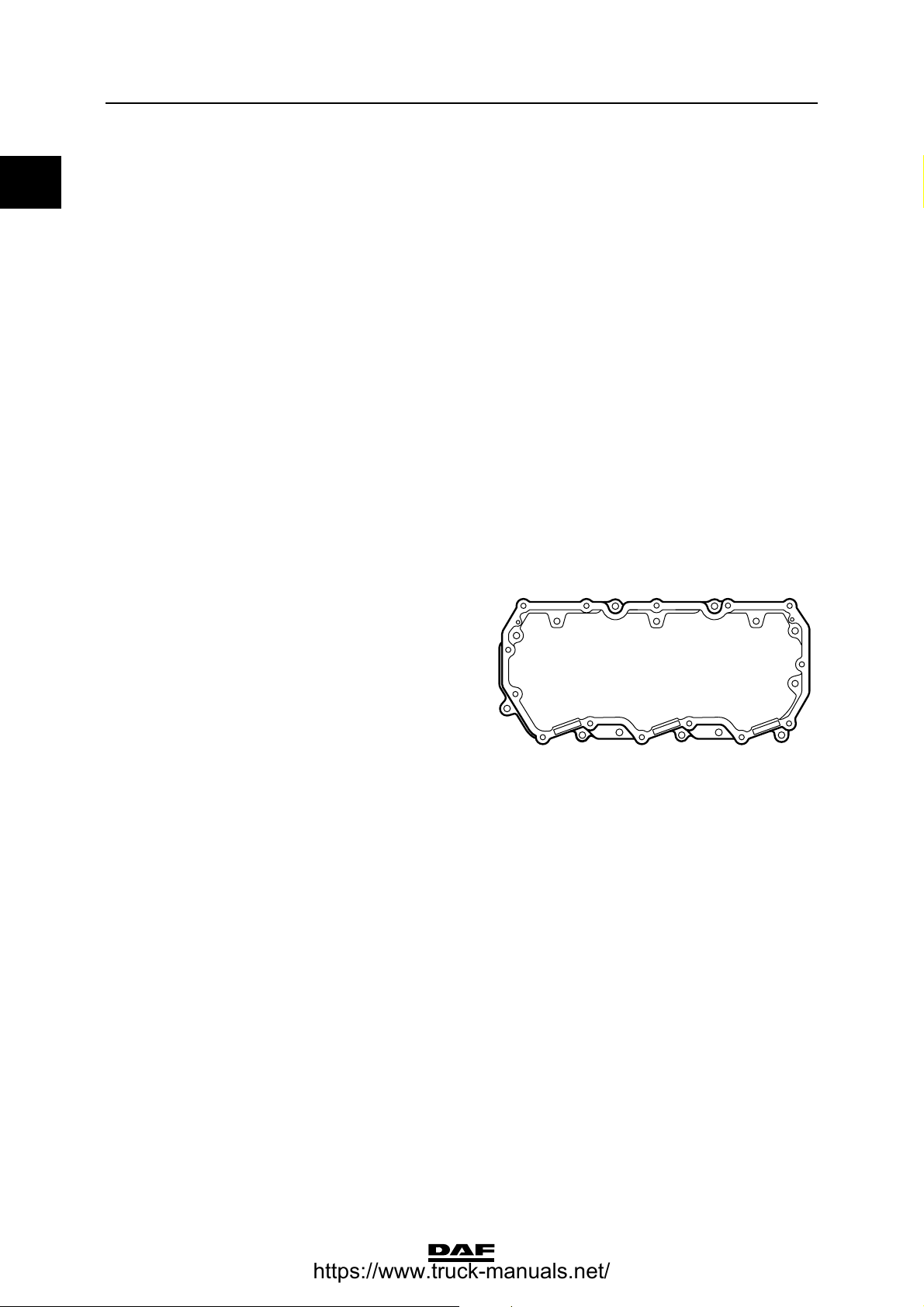

Oil cooler

Attachment bolts

connecting oil cooler

to cylinder block 24 Nm

(1) Tighten the attachment bolts in the order indicated

Oil pump

Attachment bolts 24 Nm

(1)

13

8

4

7

12

CE-engine lubrication system

14

0

15

9

5

3

2

11

1

6

10

M201145

Turbocharger oil supply pipe

Union on filter head 28 Nm

Union on turbocharger 28 Nm

Bypass pressure regulator

Plug 80 Nm

Oil nozzle

Banjo bolt 15 Nm

Main bearing caps

Main bearing cap attachment bolts

st

phase 60 Nm

1

nd

2

phase 80 Nm

rd

3

phase 90 angular displacement

Big-end bearing caps

Attachment bolts, big-end bearing caps 60 Nm + 60 angular displacement

©

200351 3-3

Page 20

TECHNICAL DATA

2

0

CE-engine lubrication system

3.3 FILLING CAPACITIES

Lubrication system

Total capacity, including oil cooler and oil filter 19.5 litres

Oil sump capacity, maximum level 17.5 litres

Oil sump capacity, minimum level 15.4 litres

ΧΦ65/75/85 series

3-4

©

200351

Page 21

2

TECHNICAL DATA

ΧΦ65/75/85 series

PE engine

4. PE ENGINE

4.1 GENERAL

Cold engine A cold engine is an engine which, having reached

operating temperature, has been allowed to cool

down for at least six hours.

Warm engine A warm engine is an engine which, having

reached operating temperature, has been

allowed to cool down for not more than thirty

minutes.

Direction of rotation of the engine The direction of rotation of the engine is

clockwise, as seen from the timing gear end.

First cylinder of the engine The first cylinder of the engine is the cylinder at

the timing gear end.

Left-hand and right-hand side of the engine The left-hand side of the engine is the side where

the fuel pump is mounted. The right-hand side of

the engine is the side where the air compressor is

mounted.

Engine types

Coding PE 183 C1

PE 228 C

PE 265 C

0

General specifications

Environmental standard Euro 3 (C)

Number of cylinders 6 cylinders in line

Valves 4 per cylinder

Bore x stroke 118 x 140 mm

Total cubic capacity 9,20 l

Compression ratio 17,4 : 1

Fuel injection direct

Injection sequence 1-5-3-6-2-4

Air inlet system Turbocharger intercooling

Cooling fluid

Weight approx. 860 kg

V-belt tension

Belt tension, "AVX" raw edge

Multiple belt Single belt

Setting tension 1200 600

Test tension 800 400

1

of V-belts in Newtons (N)

New V-belt

Run-in V-belt

2

3

Minimum tension 500 250

Correction tension 700 350

©

200351 4-1

Page 22

TECHNICAL DATA

2

0

PE engine

1. Raw-edge V-belts can be recognised by the absence of

textile fabric in the rubber, with the exception of the top

of the belt edge, on the edges and the inside of the belt

(polished belt edge). Version: either a toothed or a nontoothed belt.

2. After fitting the new V-belt, set the pre-tension to the

"setting tension" and after a trial run check whether the

pre-tension complies with the "test tension". If the test

tension reading is lower than the value specified in the

table, set the V-belt to the minimum "test tension".

3. If the V-belt tension is lower than the "minimum tension",

set the belt to the "correction tension".

Cylinder liner

Height above cylinder block 0.02 - 0.10 mm

Cylinder head

Minimum height after overhaul 119.5 mm

Cylinder head test pressure

Test pressure using air (hot) 1.5 bar

ΧΦ65/75/85 series

M2121

Valve clearance

Valve clearance (cold/hot)

inlet 0.45 mm

exhaust 0.45 mm

Valve opening

Valve opening at 1 mm valve clearance 0.45 ≥ 0.2 mm

Axial play

Crankshaft axial play 0.05 - 0.35 mm

Camshaft axial play 0.10 - 0.55 mm

Idler gear axial play 0.03 - 0.25 mm

Gear backlash

Idler gear - crankshaft gear 0.02 - 0.20 mm

Idler gear - fuel pump gear 0.02 - 0.22 mm

Idler gear - camshaft gear 0.02 - 0.22 mm

Camshaft gear - compressor gear 0.02 - 0.22 mm

Fuel pump gear - steering pump gear 0.02 - 0.19 mm

Oil pump idler gear - oil pump gear 0.02 - 0.20 mm

Crankshaft gear - oil pump idler gear 0.02 - 0.20 mm

Number of teeth, timing gears

Crankshaft gear 31

Idler gear 52

Fuel pump gear 62

Camshaft gear 62

Air compressor gear 27

Steering pump gear 18

Oil pump idler gear 28

4-2

©

200351

Page 23

2

TECHNICAL DATA

ΧΦ65/75/85 series

Compression pressure

Differences in compression pressure max. 15%

Flywheel/starter ring gear

Axial variation, measured at a radial distance of

210 mm 0.10 mm

Starter ring gear warm up max. 185C

PE engine

0

©

200351 4-3

Page 24

TECHNICAL DATA

2

0

PE engine

4.2 TIGHTENING TORQUES

Starter motor

Attachment nuts 73 Nm

Alternator

Alternator bracket attachment bolts 30 Nm

Alternator attachment bolts 60 Nm

Pulley attachment nut 80 Nm

Electrical connection to alternator 12 Nm

Air compressor

Compressor gear flange bolt 120 Nm

M12 attachment bolts 110 Nm

M8 attachment bolts for bracket 30 Nm

Cylinder head threaded coupling 90 Nm

Delivery pipe reducer valve 75 Nm

Suction and pressure line unions 90 Nm

Air-conditioning compressor

M12 attachment bolts for compressor bracket 110 Nm

M10 attachment bolts for compressor 60 Nm

ΧΦ65/75/85 series

(1)

(1)

Exhaust manifold

Fit gasket with steel side towards manifold

Sleeved attachment bolts 65 Nm

Heat shield attachment bolts 30 Nm

Inlet manifold

M10 attachment bolts 60 Nm

M10 attachment studs 60 Nm

Turbocharger

Heat shield attachment bolts 30 Nm

Turbine housing clamp plate attachment nut 15 Nm

Attachment nuts

Exhaust manifold flange/turbocharger 60 Nm

Elbow on turbocharger 40 Nm

Oil supply pipe banjo bolt 90 Nm

Fan

Attachment nuts 25 Nm

Fan pulley attachment bolts 30 Nm

(1) Use Loctite 243 to secure

(2) Fasten with Copaslip

(1)

(1)

(2)

(1)

(1)

4-4

©

200351

Page 25

2

TECHNICAL DATA

ΧΦ65/75/85 series

Vibration damper

Vibration damper hub attachment bolts in 4

phases:

st

1

phase, all attachment bolts 50 Nm

2nd phase, all attachment bolts 70 Nm

3rd phase, all attachment bolts 100 Nm

4th phase, all attachment bolts 60 angular displacement

Vibration damper attachment bolts 110 Nm

(1) Tighten the attachment bolts evenly

(2) Use Loctite 243 to secure

(1)

(1)

(1)

(2)

PE engine

0

(1)

©

200351 4-5

Page 26

TECHNICAL DATA

2

0

PE engine

Cylinder head attachment bolts

Cylinder bolts must only be used once. So the

cylinder bolts must always be replaced. The

thread of the new cylinder head bolts is provided

with a red/brown sealant.

Note:

- Due to the sealant used on the cylinder head

bolts, the untightening torque of the cylinder

head bolts can be substantial!

- All M16 and M12 threaded holes must be

carefully cleaned using a screw tap prior to

the mounting of the bolts.

- After tightening of the bolts with the

appropriate tightening torque, the angular

displacement of the M16 bolts must

immediately be started.

- The sealant cannot be applied later.

Tightening cylinder head attachment bolts

Note:

Underneath the bolt head, apply a drop of oil on

the bearing surface of the bolt heads. Sealants

also reduce the frictional resistance, which

means that you must not apply any oil to the

thread.

50 Nm

I

M16

150 Nm

II

ΧΦ65/75/85 series

M16

94 Nm

M12

II

60

III

M16

60

M16

III

M200563

4-6

©

200351

Page 27

2

TECHNICAL DATA

ΧΦ65/75/85 series

1st phase

- M16 in the indicated

order 50 Nm

(1)

2nd phase

- M16 in the indicated

order 150 Nm

- M12 in the indicated

order 94 Nm

(1)

3rd phase

- M16 in the indicated

order in two stages of

(1) Apply a drop of oil to the bearing surface of the M16 and

M12 bolt heads.

60 angular

displacement

Timing gear

Pump housing drive unit attachment bolts 60 Nm

Attachment bolts, pump housing drive shaft

locking plate 30 Nm

Locking plate attachment bolts 30 Nm

Crankshaft hub attachment bolts in 4 phases:

st

1

phase, all attachment bolts 100 Nm

2nd phase, all attachment bolts 100 Nm

3rd phase, all attachment bolts 100 Nm

4th phase, all attachment bolts 100 Nm

Viscous fan clutch attachment nuts 30 Nm

Timing case attachment bolts 30 Nm

Timing cover attachment bolts:

M10 attachment bolts 60 Nm

M8 attachment bolts 25 Nm

Timing cover protection plate attachment bolt 8.5 Nm

Camshaft gear attachment bolt 425 Nm

Idler gear attachment bolt 170 Nm

Pump housing camshaft gear attachment bolt 260 Nm

Steering pump gear attachment nut 80 Nm

Suction pipe banjo bolt 90 Nm

Delivery pipe banjo bolt 40 Nm

16

10

11

(1)

(1)

(1)

(1)

(1)

(2)

(2)

(2)

(2)

(1)

PE engine

8

12

13

M200734

17

0

14

6

1

5

9

4

15

2

7

3

(1) Use Loctite 243 to secure

(2) Apply a drop of oil to the attachment bolts and tighten

evenly.

Flywheel housing

Attachment bolts: 110 Nm

Sealant to be used when fitting flywheel housing Loctite 510

Flywheel

Attachment bolts:

without PTO 170 Nm

(1)

+ 90 angle tightening

with PTO 170 Nm + 150 angle tightening

(1) Use Loctite 243 to secure

©

200351 4-7

Page 28

TECHNICAL DATA

2

0

PE engine

Engine mountings at timing gear end

Cylinder block bracket attachment bolts 92 Nm

Chassis engine bracket attachment bolts 73 Nm

Vibration damper engine bracket attachment

bolts 170 Nm

Engine mountings at flywheel end

Flywheel housing engine bracket attachment

bolts 260 Nm

Chassis engine bracket attachment bolts 73 Nm

Vibration damper engine bracket attachment

bolts 226 Nm + 60 angle tightening

Engine hanger brackets

M12 attachment bolts 110 Nm

Valve gear

Valve cover attachment bolts 25 Nm

M10 setting bolt lock nut for rocker 40 Nm

Bridge piece setting bolt lock nut 40 Nm

Lubricating oil strip/rocker seat attachment bolts 60 Nm

Valve sleeve attachment bolts 30 Nm

Tighten the valve sleeve attachment bolts in the

sequence shown.

13 9

ΧΦ65/75/85 series

3

2117

6

14

5

18

10 12

4

M200959

4-8

©

200351

Page 29

2

TECHNICAL DATA

ΧΦ65/75/85 series

PE-engine cooling system

5. PE-ENGINE COOLING SYSTEM

5.1 GENERAL

Thermostat

Thermostat opening temperature

standard:

- thermostat opens at approx. 87C

- thermostat open at least 12 mm at approx. 99C

with intarder and/or automatic transmission:

- thermostat opens at approx. 83C

- thermostat open at least 12 mm at approx. 95C

Thermostat seat Loctite 638

Coolant pump

Radial play 0.16 - 0.20 mm

Header tank pressure cap

Pressure relief valve opening pressure 1 - 1.2 bar

Underpressure valve opening pressure 0.1 - 0.02 bar

Closed pressure cap position Brand name (2) legible horizontally or 60 before

this position.

0

Closed pressure cap

position

Pressure testing the cooling system

Test pressure 0.7 - 0.9 bar

Viscous fan clutch

Permissible slip at maximum speed control 10%

Brand name (2)

legible horizontally or

60 before this

position.

2

1

M201272

©

200351 5-1

Page 30

TECHNICAL DATA

2

0

PE-engine cooling system

5.2 TIGHTENING TORQUES

The tightening torques recorded in this paragraph

are different from the standard tightening torques

recorded in the overview of the standard

tightening torques. The other threaded

connections which are not recorded must

therefore be tightened to the torque recorded in

the overview of standard tightening torques.

When attachment bolts and nuts are replaced, it

is important - unless stated otherwise - that these

bolts and nuts are of exactly the same length and

property class as those removed.

Coolant pump

M8 attachment bolts 30 Nm

Coolant pipe on cylinder head

Attachment bolts 54 Nm

Coolant pipe threaded coupling 90 Nm

Coolant pipe plug 35 Nm

ΧΦ65/75/85 series

Thermostat housing on coolant pipe

Attachment bolts 30 Nm

Radiator

Attachment nuts 60 Nm

Oil cooler

Coolant drain plug 16 Nm

5-2

©

200351

Page 31

2

TECHNICAL DATA

ΧΦ65/75/85 series

5.3 FILLING CAPACITIES

Cooling system

Cooling system capacity, standard vehicle approx. 38 litres

Cooling system capacity of vehicle with ZF

intarder approx. 50 litres

Cooling system capacity of vehicle with automatic

gearbox approx. 50 litres

PE-engine cooling system

0

©

200351 5-3

Page 32

TECHNICAL DATA

2

0

PE-engine cooling system

ΧΦ65/75/85 series

5-4

©

200351

Page 33

2

TECHNICAL DATA

ΧΦ65/75/85 series

PE-engine lubrication system

6. PE-ENGINE LUBRICATION SYSTEM

6.1 GENERAL

Oil pressure

Oil pressure at engine idling speed 1 bar (warm engine)

Oil pressure at full-load engine speed 3.35 - 4.35 bar

Oil filter

Type filter element

Number 1

Installation in the oil circuit full flow

Opening pressure of bypass valve at a pressure

difference of 2.5 ≥ 0.3 bar

Oil cooler

Coolant test pressure 2.5 bar

Oil consumption

Maximum admissible engine oil consumption 0.3% of the average fuel consumption

Example:

Average measured fuel consumption: 30 litres /

100 km = 300 litres / 1000 km

Maximum admissible engine oil consumption:

0.3% x 300 = 0.9 litres / 1000 km

- Engine oil consumption = 0.9 litres / 1000 km is

permitted

- Engine oil consumption > 0.9 litres / 1000 km;

check the engine using the diagnostics table. See

"Diagnosis".

0

©

200351 6-1

Page 34

TECHNICAL DATA

2

0

PE-engine lubrication system

6.2 TIGHTENING TORQUES

The tightening torques specified in this paragraph

are different from the standard tightening torques

cited in the overview of the standard tightening

torques. The other threaded connections not

specified must therefore be tightened to the

torque cited in the overview of standard

tightening torques.

When attachment bolts and nuts are replaced, it

is important - unless stated otherwise - that these

bolts and nuts are of exactly the same length and

property class as those removed.

Lubricating oil strip/rocker seats

Attachment bolts: 60 Nm

Oil pan

Clamp attachment bolts 25 Nm

Oil drain plug 60 Nm

Oil level sensor 60 Nm

ΧΦ65/75/85 series

Oil pump

Attachment bolts for oil pump housing sections 30 Nm

Attachment bolts connecting oil pump to main

bearing cap 60 Nm

Oil delivery pipe attachment bolts 30 Nm

Idler gear central bolt 60 Nm

Strainer

Bracket attachment bolts 30 Nm

Lubricating oil filter

Lubricating oil filter housing attachment bolts 50 Nm

Filter element screw cap 45 Nm

Bypass pressure regulator

Plug 80 Nm

Oil cooler

Attachment bolts connecting oil cooler to cylinder

block 50 Nm

(1) Use Loctite 243 to secure

(2) Use Loctite 572 to secure

(1)

(1)

(1)

(1)

(2)

Oil nozzles

Banjo bolt (M14) for oil sprayer with locking plate 30 Nm

Banjo bolt (M10) for oil sprayer 30 Nm

6-2

©

200351

Page 35

2

TECHNICAL DATA

ΧΦ65/75/85 series

Main bearing caps

Main bearing cap attachment bolts

1st phase 50 Nm

nd

2

phase 150 Nm

rd

3

phase 120 angular displacement

Big-end bearing caps

Attachment bolts, big-end bearing caps

1st phase, sequence 1-2-3-4 25 Nm

nd

2

phase, sequence 4-3-2-1 35 Nm

rd

3

phase, sequence 1-2-3-4 60 angular displacement

(1) Apply a drop of oil to thread and contact surface.

(2) Connecting rod bolts are to be used once and tightened

as instructed. When fitting the connecting rod in the

engine, apply a drop of oil on the thread and bearing face

of the connecting rod bolts.

(1)

(2)

PE-engine lubrication system

1 4

0

32

M200661

©

200351 6-3

Page 36

TECHNICAL DATA

2

0

PE-engine lubrication system

6.3 FILLING CAPACITIES

Lubrication system

Total capacity, including oil cooler and oil filter approx. 29 litres

Oil sump capacity, maximum level approx. 24 litres

Oil pan capacity, minimum level approx. 16 litres

ΧΦ65/75/85 series

6-4

©

200351

Page 37

2

TECHNICAL DATA

ΧΦ65/75/85 series

XE engine

7. XE ENGINE

7.1 GENERAL

Cold engine A cold engine is an engine which, having reached

operating temperature, has been allowed to cool

down for at least six hours.

Warm engine A warm engine is an engine which, having

reached operating temperature, has been

allowed to cool down for not more than thirty

minutes.

Direction of rotation of the engine The direction of rotation of the engine is

clockwise, as seen from the timing gear end.

First cylinder of the engine The first cylinder of the engine is the cylinder at

the timing gear end.

Left-hand and right-hand side of the engine The left-hand side of the engine is the side where

the fuel pump is mounted. The right-hand side of

the engine is the side where the air compressor is

mounted.

Engine types

Coding XE 250 C 1

XE 280 C 1

XE 280 C 3

XE 315 C 1

XE 315 C 3

XE 355 C 1

0

General specifications

Environmental standard Euro 3 (C)

Number of cylinders 6

Valves 4 per cylinder

Bore x stroke 130 x 158 mm

Total cubic capacity 12.6 l

Compression ratio 17,4 : 1

Fuel injection direct

Injection sequence 1-5-3-6-2-4

Air inlet system Turbocharger intercooling

Cooling fluid

Weight approx. 1,080 kg

©

200351 7-1

Page 38

TECHNICAL DATA

2

0

XE engine

V-belt tension

V-belt tension, "AVX" raw edge

Application example: air-conditioning compressor drive

New V-belt

(2)

Setting tension 600

Test tension ¥ 400

Run-in V-belt

(3)

Minimum tension 250

Correction tension 350

V-belt tension, "XPB" raw edge

Application example: steering pump drive on FAX vehicle

New V-belt

(2)

Setting tension 1250

Test tension ¥ 950

Run-in V-belt

(3)

(1)

(1)

(N)

(N)

ΧΦ65/75/85 series

Minimum tension 750

Correction tension 950

(1) Raw-edge V-belts can be recognised by the absence of

textile fabric in the rubber, with the exception of the top of

the belt edge, on the edges and the inside of the belt

(polished belt edge). Version: either a toothed or a nontoothed belt.

(2) After fitting the new V-belt, set the pre-tension to the

"setting tension" and after a trial run inspect whether the

pre-tension complies with the "test tension". If the test

tension reading is lower than the value specified in the

table, set the V-belt to the minimum "test tension".

(3) If the V-belt tension is lower than the "minimum tension",

set the belt to the "adjusting tension".

M2121

7-2

©

200351

Page 39

2

TECHNICAL DATA

ΧΦ65/75/85 series

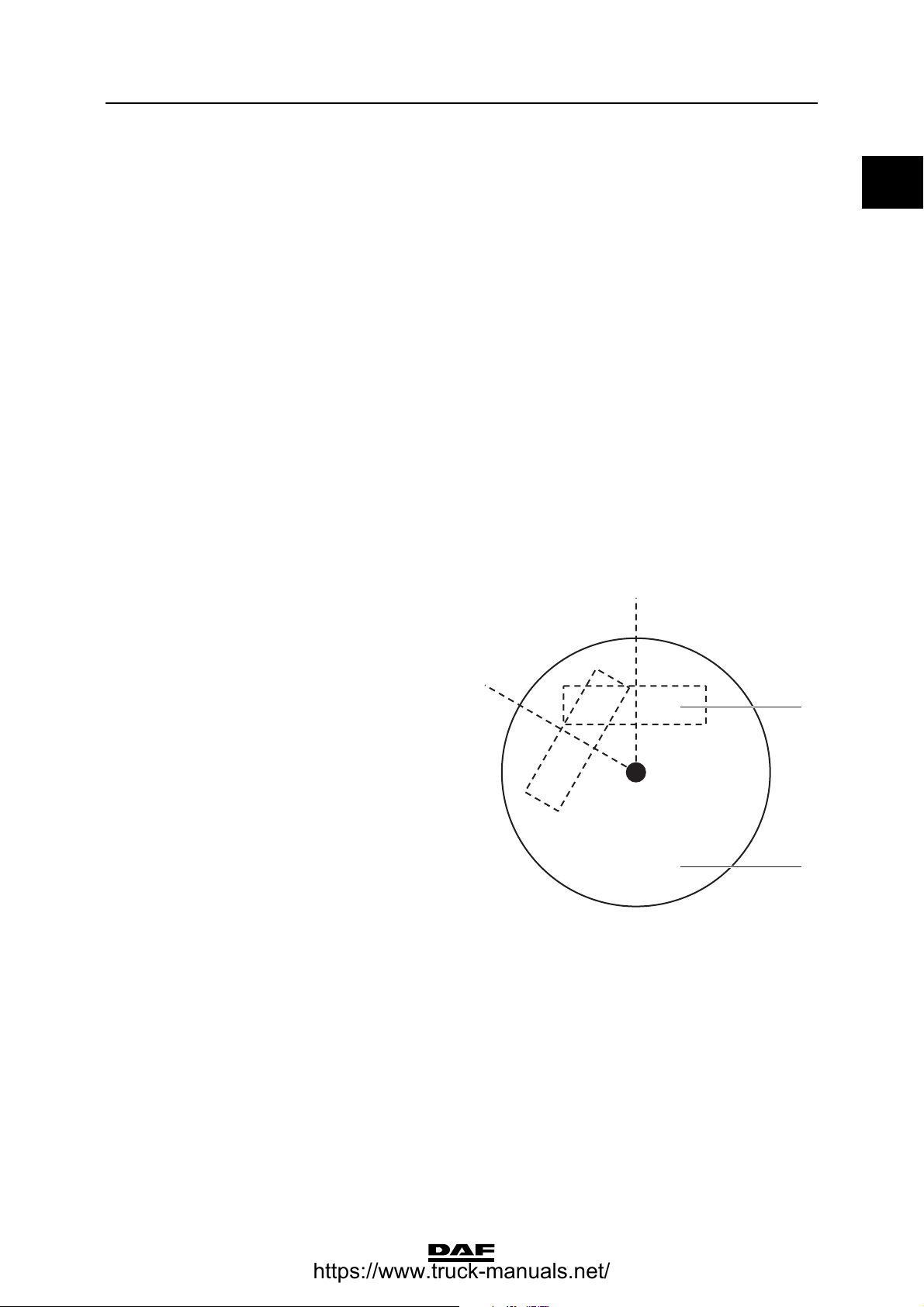

Automatic poly-V-belt tensioner

Torsional moment

from rest position (0)

to 17 mm torsion (A) 19 - 37 Nm

XE engine

0

0

A

Cylinder liner

Height above cylinder block 0.02 - 0.10 mm

Cylinder head

Minimum height after overhaul 119.50 mm

Test pressure using air (hot) 1.5 bar

Valve clearance

Valve clearance (cold/hot)

inlet 0.50 mm

exhaust 0.50 mm

Axial play

Crankshaft axial play 0.06 - 0.32 mm

Camshaft axial play 0.10 - 0.55 mm

Idler gear axial play 0.05 - 0.25 mm

M201274

©

200351 7-3

Page 40

TECHNICAL DATA

2

0

XE engine

Gear backlash

Idler gear - crankshaft gear 0.02 - 0.21 mm

Idler gear - pump housing camshaft gear 0.02 - 0.22 mm

Idler gear - camshaft gear 0.02 - 0.21 mm

Camshaft gear - compressor gear 0.02 - 0.22 mm

Pump housing camshaft gear - steering pump

gear 0.02 - 0.19 mm

Oil pump idler gear - oil pump gear 0.02 - 0.20 mm

Crankshaft gear - oil pump idler gear 0.02 - 0.20 mm

Number of teeth, timing gears

Crankshaft gear 35

Idler gear 54

Pump housing - camshaft gear wheel 70

Camshaft gear 70

Air compressor gear 27

Fan drive housing gear 29

Steering pump gear 18

Lubricating oil pump idler gear 34

Compression pressure

Differences in compression pressure max. 15%

ΧΦ65/75/85 series

Flywheel/starter ring gear

Axial variation, measured at a radial distance of

210 mm 0.10 mm

Starter ring gear warm up max. 185|C

7-4

©

200351

Page 41

2

TECHNICAL DATA

ΧΦ65/75/85 series

7.2 TIGHTENING TORQUES

The tightening torques specified in this paragraph

are different from the standard tightening torques

cited in the overview of the standard tightening

torques. The other threaded connections not

specified must therefore be tightened to the

torque cited in the overview of standard

tightening torques.

When attachment bolts and nuts are replaced, it

is important - unless stated otherwise - that these

bolts and nuts are of exactly the same length and

property class as those removed.

Starter motor

Attachment nuts 73 Nm

Electrical connection to starter motor 28 Nm

Alternator

Alternator attachment bolts 60 Nm

Pulley attachment nut 80 Nm

Electrical connection to alternator (M8) 15 Nm

XE engine

0

(1)

Air compressor

M12 attachment bolts 110 Nm

M8 attachment bolts for bracket 30 Nm

M10 attachment bolts for bracket 60 Nm

Compressor gear flange bolt 120 Nm

M14 threaded coupling for cylinder head 40 Nm

M26 threaded coupling for cylinder head 90 Nm

Cylinder head service line banjo bolt 25 Nm

Pressure line safety valve 75 Nm

Suction and pressure line unions 90 Nm

Oil supply banjo bolt 25 Nm

Exhaust manifold

Fit gasket with steel side towards manifold

Sleeved attachment bolts 65 Nm

Heat shield attachment bolts 30 Nm

Inlet manifold

Attachment bolts: 46 Nm

Air inlet hose clamps 12 Nm

Electrical connection to glow plug 8.5 Nm

Attachment bolts, boost pressure/charge

temperature sensor 4 Nm

Hose clamps 12 Nm

(1)

©

200351 7-5

Page 42

TECHNICAL DATA

2

0

XE engine

Turbocharger

Heat shield attachment bolts 30 Nm

Turbine housing clamp plate attachment nut 15 Nm

Attachment nuts

Exhaust manifold flange/turbocharger 60 Nm

Elbow on turbocharger 40 Nm

Oil supply pipe banjo bolt 90 Nm

(1) Use Loctite 243 to secure

(2) Fasten with Copaslip

Glow plug relay

Glow plug relay cap 2 Nm

Electrical connections to glow plug relay:

M5 3.5 Nm

M8 8 Nm

Main fuse

Fuse holder (M6) 4.5 Nm

Fuse (M8) 18 Nm

ΧΦ65/75/85 series

(1)

(2)

Vibration damper and fan drive

Vibration damper

hub attachment bolts

(1) in 4 phases:

st

1

phase, all

attachment bolts 100 Nm

2nd phase, all

attachment bolts 100 Nm

3rd phase, all

attachment bolts 100 Nm

4th phase, all

attachment bolts 100 Nm

Attachment bolts,

vibration damper (5) 110 Nm

Attachment nuts, fan

drive (8) 60 Nm

Attachment bolts, fan

pulley (9) 30 Nm

Attachment nuts, fan

clutch (7) 25 Nm

(1) Tighten the attachment bolts evenly

(2) Use Loctite 243 to secure

(2)

(2)

(1)

(1)

(1)

(1)

(2)

10

8

9

7

6

5

4

3

2

1

M201153

7-6

©

200351

Page 43

2

TECHNICAL DATA

ΧΦ65/75/85 series

Cylinder head attachment bolts

Cylinder head bolts must only be used once. So

the cylinder head bolts must always be replaced.

The thread of the new cylinder head bolts is

provided with a red/brown sealant.

Note:

- Due to the sealant used on the cylinder head

bolts, the untightening torque of the cylinder

head bolts can be substantial!

- All M16 and M12 threaded holes must be

carefully cleaned using a screw tap prior to

the mounting of the bolts.

- After tightening of the bolts with the

appropriate tightening torque, the angular

displacement of the M16 bolts must

immediately be started.

- The sealant cannot be applied later.

50 Nm

I

M16

150 Nm

II

M16

XE engine

0

94 Nm

M12

60

III

II

60

M16

M16

III

M200563

©

200351 7-7

Page 44

TECHNICAL DATA

2

0

XE engine

Tightening cylinder head attachment bolts

Note:

Underneath the bolt head, apply a drop of oil on

the bearing surface of the bolt heads. Sealants

also reduce the frictional resistance, which

means that you must not apply any oil to the

thread.

1st phase

- M16 in the indicated

order 50 Nm

2nd phase

- M16 in the indicated

order 150 Nm

- M12 in the indicated

order 94 Nm

3rd phase

- M16 in the indicated

order in two stages of

(1) Apply a drop of oil to the bearing surface of the M16 and

M12 bolt heads.

60 angular

displacement

(1)

(1)

16

15

21

17

10

18 19

11

6

5

ΧΦ65/75/85 series

17

4

8

2

3

9

20

12

13

14

M200562

Timing gear

Pump housing drive unit attachment bolts 60 Nm

Attachment bolts, pump housing drive shaft

locking plate 30 Nm

Locking plate attachment bolts 30 Nm

Crankshaft hub attachment bolts in 4 phases:

st

1

phase, all attachment bolts 100 Nm

2nd phase, all attachment bolts 100 Nm

3rd phase, all attachment bolts 100 Nm

4th phase, all attachment bolts 100 Nm

Viscous fan clutch attachment nuts 30 Nm

Timing case attachment bolts 30 Nm

Timing cover attachment bolts:

- M10 attachment bolts 60 Nm

- M8 attachment bolts 25 Nm

Timing cover protection plate attachment bolt 8.5 Nm

Camshaft gear attachment bolt 425 Nm

Idler gear attachment bolt 170 Nm

Pump housing camshaft gear attachment bolt 260 Nm

Steering pump gear attachment nut 80 Nm

Suction pipe banjo bolt 90 Nm

Delivery pipe banjo bolt 40 Nm

(1) Use Loctite 243 to secure

(2) Apply a drop of oil to the attachment bolts and tighten

evenly.

(1)

(1)

(2)

(2)

(2)

(2)

(1)

(1)

(1)

(1)

7-8

©

200351

Page 45

2

TECHNICAL DATA

ΧΦ65/75/85 series

Flywheel housing

Attachment bolts 110 Nm

Sealant to be used when fitting flywheel housing Loctite 510

Attachment bolt, crankshaft sensor 8 Nm

(1) Use Loctite 243 to secure

Flywheel

Attachment bolts:

- standard 260 Nm + 60 angle tightening

- with engine PTO 260 Nm + 120 angle tightening

Engine mountings at timing gear end

Cylinder block bracket attachment bolts 110 Nm

Chassis engine bracket attachment bolts 110 Nm

Vibration damper engine bracket attachment

bolts 170 Nm

Engine mountings at flywheel end

Flywheel housing engine bracket attachment

bolts 260 Nm

Chassis engine bracket attachment bolts 110 Nm

Vibration damper engine bracket attachment

bolts 260 Nm + 90 angle tightening

(1)

XE engine

0

Engine hanger brackets

Attachment bolts: 110 Nm

Valve gear

Valve cover attachment bolts 25 Nm

Rocker setting bolt lock nut 40 Nm

Bridge piece setting bolt lock nut 40 Nm

Lubricating oil strip/rocker seat attachment bolts 110 Nm

DEB set screw nut 25 Nm

Solenoid valve 20 Nm

Wiring harness attachment bolt 9 Nm

Valve sleeve attachment bolts 30 Nm

Tighten the valve sleeve attachment bolts in the

sequence shown

3

5

1

11

13

9157

2

6

814

41210

M200942

©

200351 7-9

Page 46

TECHNICAL DATA

2

0

XE engine

ΧΦ65/75/85 series

7-10

©

200351

Page 47

2

TECHNICAL DATA

ΧΦ65/75/85 series

XE-engine cooling system

8. XE-ENGINE COOLING SYSTEM

8.1 GENERAL

Thermostat

Thermostat opening temperatures:

standard

- thermostat opens at approx. 87C

- thermostat open at least 12 mm at approx. 99C

with intarder and/or tropical cooling:

- thermostat opens at approx. 83C

- thermostat open at least 12 mm at approx. 95C

Thermostat seat Loctite 638

Coolant pump

Maximum radial play 0.16 - 0.20 mm

Header tank pressure cap

Pressure relief valve opening pressure 1 - 1.2 bar

Underpressure valve opening pressure 0.1 - 0.02 bar

Closed pressure cap position Brand name (2) legible horizontally or 60 before

this position.

0

Closed pressure cap

position

Pressure testing the cooling system

Test pressure 0.7 - 0.9 bar

Viscous fan clutch

Permissible slip at maximum speed control 10%

Fan drive ( i ) transmission 1,207

Brand name (2)

legible horizontally or

60 before this

position.

2

1

M201272

©

200351 8-1

Page 48

TECHNICAL DATA

2

0

XE-engine cooling system

8.2 TIGHTENING TORQUES

The tightening torques specified in this paragraph

are different from the standard tightening torques

cited in the overview of the standard tightening

torques. The other threaded connections not

specified must therefore be tightened to the

torque cited in the overview of standard

tightening torques.

When attachment bolts and nuts are replaced, it

is important - unless stated otherwise - that these

bolts and nuts are of exactly the same length and

property class as those removed.

Coolant pump

M8 attachment bolts 30 Nm

M14 threaded coupling 35 Nm

M26 90 Nm

Coolant pipe

Attachment bolts 60 Nm

Coolant pipe threaded coupling 90 Nm

Coolant pipe plug 35 Nm

Engine coolant temperature sensor 20 Nm

ΧΦ65/75/85 series

Thermostat housing

Attachment bolts 30 Nm

Plug 35 Nm

Radiator

Attachment nuts 70 Nm

Coolant hoses

Hose clamps 7 Nm

8-2

©

200351

Page 49

2

TECHNICAL DATA

ΧΦ65/75/85 series

8.3 FILLING CAPACITIES

Cooling system capacity approx. 47 litres

Cooling system capacity of vehicle with ZF

intarder approx. 57 litres

XE-engine cooling system

0

©

200351 8-3

Page 50

TECHNICAL DATA

2

0

XE-engine cooling system

ΧΦ65/75/85 series

8-4

©

200351

Page 51

2

TECHNICAL DATA

ΧΦ65/75/85 series

XE-engine lubrication system

9. XE-ENGINE LUBRICATION SYSTEM

9.1 GENERAL

Oil pressure

Oil pressure at engine idling speed 1 bar (warm engine)

Oil pressure at full-load engine speed 3.5 - 4.5 bar

Oil filter

Type filter element

Number 1

Installation in the oil circuit full flow

Opening pressure of bypass valve at a pressure

difference of 2.5 ≥ 0.3 bar

Oil cooler

Coolant test pressure maximum 2.5 bar

Oil consumption

Maximum admissible engine oil consumption 0.3% of the average fuel consumption

0

Example:

Average measured fuel consumption: 30 litres /

100 km = 300 litres / 1000 km

Maximum admissible engine oil consumption:

0.3% x 300 = 0.9 litres / 1000 km

- Engine oil consumption = 0.9 litres / 1000 km is

permitted

- Engine oil consumption > 0.9 litres / 1000 km;

check the engine using the diagnostics table. See

"Diagnosis".

©

200351 9-1

Page 52

TECHNICAL DATA

2

0

XE-engine lubrication system

9.2 TIGHTENING TORQUES

The tightening torques specified in this paragraph

are different from the standard tightening torques

cited in the overview of the standard tightening

torques. The other threaded connections not

specified must therefore be tightened to the

torque cited in the overview of standard

tightening torques.

When attachment bolts and nuts are replaced, it

is important - unless stated otherwise - that these

bolts and nuts are of exactly the same length and

property class as those removed.

Lubricating oil strip/rocker seats

Attachment bolts 110 Nm

Oil pan

Clamp attachment bolts 25 Nm

Oil drain plug 60 Nm

Oil level sensor 60 Nm

ΧΦ65/75/85 series

Oil pump

Attachment bolts for oil pump housing sections 30 Nm

Attachment bolts connecting oil pump to main

bearing cap 60 Nm

Oil delivery pipe attachment bolts 30 Nm

Idler gear central bolt 60 Nm

Strainer

Bracket attachment bolts 30 Nm

Lubricating oil filter

Lubricating oil filter housing attachment bolts 50 Nm

Filter element screw cap 40 Nm

(1) Use Loctite 243 to secure

(2) Use Loctite 572 to secure

Bypass pressure regulator

Plug 80 Nm

Oil cooler

Attachment bolts connecting oil cooler to cylinder

block 50 Nm

Coolant supply pipe union 90 Nm

Plug, adjustable banjo connection 90 Nm

Banjo bolt, adjustable banjo connection 90 Nm

(1)

(1)

(1)

(1)

(2)

Centrifugal oil filter

Central bolt 20 Nm

9-2

©

200351

Page 53

2

TECHNICAL DATA

ΧΦ65/75/85 series

Oil nozzle

Oil nozzle banjo bolt 30 Nm

Main bearing caps

Main bearing cap attachment bolts

Big-end bearing caps

Attachment bolts (1),

cracked big-end

bearing caps

1st phase 100 Nm

nd

2

phase 175 Nm ≥ 15 Nm

rd

3

phase 60 angular

(2)

displacement

(1)

150 Nm + 120 angle tightening

1

2

XE-engine lubrication system

0

5

4

3

Attachment bolts,

big-end bearing

(2)

caps

1st phase, sequence

1-2-3-4 35 Nm

nd

2

phase, sequence

4-3-2-1 45 Nm

rd

3

phase, sequence

1-2-3-4

(1) Apply a drop of oil to thread and contact surface.

(2) Connecting rod bolts are to be used once and tightened

as instructed. When fitting the connecting rod in the

engine, apply a drop of oil to the threads and contact

surfaces of the connecting rod bolts.

60 angular

displacement

1

M2 01 285

1 4

32

M200661

©

200351 9-3

Page 54

TECHNICAL DATA

2

0

XE-engine lubrication system

9.3 FILLING CAPACITIES

Lubrication system

Total capacity, including oil cooler and oil filter approx. 35 litres

Oil sump capacity, maximum level approx. 30 litres

Oil pan capacity, minimum level approx. 22 litres

ΧΦ65/75/85 series

9-4

©

200351

Page 55

2

DIAGNOSTICS

ΧΦ65/75/85 series

1 Diagnostics

CONTENTS

Page Date

1. TRACTIVE PROBLEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200351

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200351

1.2 Acceleration test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2 . . . . . 200351

1.3 Acceleration test form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4 . . . . . 200351

1.4 Acceleration test using DAVIE-XD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5 . . . . . 200351

2. CE ENGINE, GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200351

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200351

2.2 Fault-finding table, engine functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2 . . . . . 200351

2.3 Fault-finding table, vehicle functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6 . . . . . 200351

3. CE-ENGINE COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200351

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200351

3.2 Fault-finding table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2 . . . . . 200351

4. CE-ENGINE LUBRICATION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 . . . . . 200351

4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 . . . . . 200351

4.2 Fault-finding table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2 . . . . . 200351

5. PE/XE ENGINE, GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 . . . . . 200351

5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1 . . . . . 200351

5.2 Fault-finding table, engine functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2 . . . . . 200351

5.3 Fault-finding table, vehicle functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6 . . . . . 200351

Contents

1

6. PE/XE-ENGINE COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1 . . . . . 200351

6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1 . . . . . 200351

6.2 Fault-finding table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2 . . . . . 200351

7. XE/PE-ENGINE LUBRICATION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 . . . . . 200351

7.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1 . . . . . 200351

7.2 Fault-finding table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2 . . . . . 200351

©

200351 1

Page 56

DIAGNOSTICS

2

1

Contents

ΧΦ65/75/85 series

2

©

200351

Page 57

2

DIAGNOSTICS

ΧΦ65/75/85 series

1. TRACTIVE PROBLEMS

1.1 INTRODUCTION

There may be many reasons why a vehicle's

performance is below standard.

Some of these may be mechanical, but some

may be psychological in nature.

It is therefore important to identify the problem

properly.

Try to get as much information as possible from

the customer or driver.

- When does the vehicle not perform properly?

- What are the road or weather conditions

when this occurs?

- What are the vehicle's loading conditions?

- Is the vehicle not being compared with a

vehicle with completely different

specifications, for instance engine power?

- Is the vehicle being driven in the correct

engine speed range?

Tractive problems

1

If the answers are unsatisfactory, ask the

customer or driver for facts.

- Tachograph cards of trips

- Reliable consumption figures of trips

Following correct identification of the complaint,

vehicle performance can be tested by an

acceleration test.

If the vehicle fails to pass the acceleration test, a

boost pressure curve may be plotted as an aid to

identifying the cause.

Note:

Checking the boost pressure will in general only

make sense after the vehicle has covered at least

20,000 km.

©

200351 1-1

Page 58

DIAGNOSTICS

2

1

Tractive problems

1.2 ACCELERATION TEST

1. Use the "Acceleration test form", which is

included in the Workshop Manual.

2. Do the checks set out under "Before starting

the acceleration test".

3. Establish a test route where the difference

between the measured times in both

directions does not exceed 15%. If the

difference in time exceeds 15%, find another

test route.

4. Establish the starting and end points on the

selected test route, to ensure that exactly the

same route can be taken in both directions.

Do the entire test at least twice and take the

average time.

5. Run the drive train at operating temperature

(drive for at least 15 minutes with a loaded

vehicle).

ΧΦ65/75/85 series

Note:

When switched on, the air compressor and

fan consume 10 to 15 kW engine power on

average. During the test try to avoid these

two consumers being switched on.

6. Connect DAVIE and follow the instructions

given.

7. Fully depress the accelerator pedal during

the acceleration test.

1-2

©

200351

Page 59

2

DIAGNOSTICS

ΧΦ65/75/85 series

Result of first acceleration test

If the acceleration time is not achieved, first carry

out the following work.

- Check the fuel system for the presence of air.

- Replace or clean the air filter element.

- Check the setting of the wastegate on the

turbocharger (if present).

- Check the exhaust brake butterfly valve for

correct operation.

- Check the charge cooler exterior for dirt

deposits.

- Clean the water separator (if present).

- Check that the primer pump is attached.

- Replace the fuel fine filter.

- Check the suction pipe of the tank for

clogging by coarse dirt.

- Check the fuel tank for fouling. Clean with a

steam cleaner, if necessary.

- Check the air intake system for any leaks.

- Check the exhaust system for any leaks.

- Check the exhaust system for blockages by

measuring the exhaust back pressure.

- Check the turbocharger impellers on the

compressor and turbine sides for damage

and for deposits of salt or any other

contaminants.

- Check both the valve clearance and the DEB

clearance (if present).

- Check the injector pipes for damage.

- Check the fuel gallery/rail pressure.

- Check the fuel lift pump output.

- Check whether the right type of components

has been fitted. This includes turbocharger,

injectors, etc.

- Check the opening pressure of the injectors

(if possible).

Tractive problems

1

Repeat the acceleration test. If necessary, plot a

boost pressure curve.

©

200351 1-3

Page 60

DIAGNOSTICS

2

1

Tractive problems

ΧΦ65/75/85 series

1.3 ACCELERATION TEST FORM

General data

Customer's name:__________________________________________

Chassis number:______________ Registration number:______

Test conditions

Weather conditions: dry / rain / wet road / drizzle

Wind force: none / average / strong Outside temperature:_______

Vehicle data

Vehicle type:________ Trailer type:_________ Superstructure:____________

Total combination weight: ________kg Total vehicle height: _________m

Cab type: day / sleeper / space / superspace

Aerodynamics: roof spoiler / fenders / front spoiler / skirts / sun visor / ____________________

Engine type:________ Gearbox type:_____________ Transmission:_________

|

C

Rear axle type:_______________ Transmission:_______________

Tyre size: front:__________ rear:____________________

Tyre make:_______________ Energy:____________________

Space between cab and superstructure/trailer: _________________m

TOPEC data

Starting speed: ___________km/h End speed: _____________km/h

Gear selection:___________ Acceleration time: __________sec.

Measured time of outward

journey:

Measured time of return

journey:

1: _______sec.

2: _______sec. Average time of outward journey: ________sec.

3: _______sec.

Average time: _________sec.

1: _______sec.

2: _______sec. Average return time: _________sec.

3: _______sec.

1-4

©

200351

Page 61

2

DIAGNOSTICS

ΧΦ65/75/85 series

1.4 ACCELERATION TEST USING DAVIE-XD

The acceleration test can also be carried out

using DAVIE-XD. Collect the necessary data and,

after starting DAVIE-XD, go to the engine

management system and carefully follow the

instructions in DAVIE-XD for carrying out the test

correctly.

The test results should be saved to diskette after

each test.

The acceleration test in DAVIE-XD

should only be started when the

}

When driving, never start a "direct test" or "guide

diagnosis".

vehicle is stationary. As the

communication between the

accelerator pedal sensor and the

unit will be broken for a short time

when DAVIE is started up, this can

lead to dangerous situations when

the vehicle is being driven.

Tractive problems

1

©

200351 1-5

Page 62

DIAGNOSTICS

2

1

Tractive problems

ΧΦ65/75/85 series

1-6

©

200351

Page 63

2

DIAGNOSTICS

ΧΦ65/75/85 series

2. CE ENGINE, GENERAL

2.1 INTRODUCTION

If there is a fault in the system, it is usually

detected by the electronic unit in the form of a

fault code. This fault code can be read out using

DAVIE. The fault-finding table contains possible

causes of symptoms not detected by the

electronic unit.

CE engine, general

1

©

200351 2-1

Page 64

DIAGNOSTICS

2

1

CE engine, general

ΧΦ65/75/85 series

2.2 FAULT-FINDING TABLE, ENGINE FUNCTIONS

SYMPTOM: ENGINE CAN BE STARTED, BUT DOES NOT RUN

Possible cause Remedy

Poor fuel quality Drain fuel, flush fuel system, replace the fuel filters

and fill fuel tank with fuel

Air in fuel system Check for drawing in of air:

- via the suction pipe

- via the fuel lift pump seal

Fuel filter clogged Replace the fuel filter and clean the system

While carrying out an engine test with DAVIE,

communication with DAVIE was interrupted

No fuel supply/fuel lift pump defective; no delivery Check:

SYMPTOM: ENGINE STALLS AND RUNS AGAIN AFTER RE-STARTING

Remove the battery earth lead and then refit it

- the fuel level

- the pipes for blockage and leaks

- the fuel lift pump

Possible cause Remedy

Air in fuel system Check for drawing in of air:

- via the suction pipe

- via the fuel lift pump seal

SYMPTOM: ENGINE STARTS POORLY

Possible cause Remedy

Poor fuel quality Drain fuel, flush fuel system, replace the fuel filters

and fill fuel tank with fuel

Air in fuel system Check for drawing in of air:

- via the suction pipe

- via the fuel lift pump seal

Fuel filter clogged Replace the fuel filter and clean the system

Battery voltage too low Charge the batteries

Mechanical defect or clogging in injector Replace the injector

Fuel lift pump delivery too low Check the fuel lift pump and replace if necessary

Internal leakage between the fuel supply pipe and

the injector

Check the fuel supply pipe/injector connections for

internal leaks.

2-2

©

200351

Page 65

2

DIAGNOSTICS

ΧΦ65/75/85 series

SYMPTOM: ENGINE RUNS AT (INCREASED) IDLING SPEED AND DOES NOT RESPOND TO

ACCELERATOR PEDAL

Possible cause Remedy

Mechanical defect of accelerator pedal sensor Check:

- the mechanical connection between the

sensor and the accelerator pedal

- the accelerator pedal sensor

Fuel quantity adjustment by ABS/ASR

Engine brake input signal present Check the electrical system of the engine brake

SYMPTOM: DIESEL KNOCK DURING ACCELERATION

Possible cause Remedy

Poor fuel quality Drain fuel, flush fuel system, replace the fuel filters

and fill fuel tank with fuel

Air in fuel system Check for drawing in of air:

- via the suction pipe

- via the fuel lift pump seal

CE engine, general

1

Fault in electrical components/wiring of the engine

coolant temperature sensor

Injector defective Check the injectors.

Crankshaft position sensor defective Check the crankshaft position sensor

SYMPTOM: IRREGULAR RUNNING OF ENGINE

Possible cause Remedy

Poor fuel quality Drain fuel, flush fuel system, replace the fuel filters

Air in fuel system Check for drawing in of air:

Fuel filter clogged Replace the fuel filter

Connection points on injectors mixed up Connect the correct connection points to the

Mechanical defect or clogging in injectors Replace the injectors

Injector defective Check the injectors.

Fuel lift pump delivery too low Check the fuel lift pump and replace if necessary

Pressure relief valve on common rail does not shut

off

Check the electrical system

and fill fuel tank with fuel

- via the suction pipe

- via the fuel lift pump seal

correct injector

Check the pressure relief valve

©

200351 2-3

Page 66

DIAGNOSTICS

2

1

CE engine, general

SYMPTOM: REDUCED POWER AT ALL ENGINE SPEEDS

Possible cause Remedy

Poor fuel quality Drain fuel, flush fuel system, replace the fuel filters

and fill fuel tank with fuel

Fuel filter clogged Replace the fuel filter

Mechanical defect of accelerator pedal sensor Check:

- the mechanical connection between the

sensor and the accelerator pedal

- the accelerator pedal sensor

Fault in electrical components/wiring of:

- contacts

- contact resistors in connector connections

Air filter clogged. Replace or clean the air filter.

Turbocharger defective/wastegate control

incorrect.

Air leak in inlet system. Pressure-test the inlet system.

Mechanical defect or clogging in injectors Replace the injectors

Check the electrical system

Check the turbocharger/wastegate control.

ΧΦ65/75/85 series

Injector defective Check the injectors.

Pressure relief valve on pump housing does not

shut off

Fuel lift pump delivery too low Check the fuel lift pump and replace if necessary

SYMPTOM: REDUCED POWER ABOVE A CERTAIN ENGINE SPEED

Possible cause Remedy

Fuel filter partially clogged Replace the fuel filter

Air filter partially clogged. Replace or clean the air filter.

Air leak in inlet system. Pressure-test the inlet system.

Pressure relief valve on pump housing does not

shut off

Fuel lift pump delivery too low Check the fuel lift pump and replace if necessary

SYMPTOM: WHITE/BLUE SMOKE IS EMITTED

Possible cause Remedy

Poor fuel quality Drain fuel, flush fuel system, replace the fuel filters

Check the pressure relief valve

Check the pressure relief valve

and fill fuel tank with fuel

Air in fuel system Check for drawing in of air:

- via the suction pipe

- via the fuel lift pump seal

Fuel filter clogged Replace the fuel filter and clean the system

Mechanical defect or clogging in injectors Replace the injectors

2-4

©

200351

Page 67

2

DIAGNOSTICS

ΧΦ65/75/85 series

SYMPTOM: WHITE/BLUE SMOKE IS EMITTED

Possible cause Remedy

Injector defective Check the injectors.

Fuel lift pump delivery too low Check the fuel lift pump and replace if necessary

SYMPTOM: BLACK SMOKE IS EMITTED

Possible cause Remedy

Injector defective Check the injectors.

SYMPTOM: FUEL CONSUMPTION TOO HIGH

Possible cause Remedy

Poor fuel quality Drain fuel, flush fuel system, replace the fuel filters

and fill fuel tank with fuel

Fuel filter clogged Replace the fuel filter and clean the system

Air leak in inlet system. Pressure-test the inlet system.

CE engine, general

1

Mechanical defect or clogging in injectors Replace the injectors

Leak in fuel system Check for leaks

SYMPTOM: REDUCED MAXIMUM ENGINE SPEED

Possible cause Remedy

Air in fuel system Check for drawing in of air:

- via the suction pipe

- via the fuel lift pump seal

Fuel filter clogged Replace the fuel filter and clean the system

Turbocharger defective. Check turbocharger.

Mechanical defect or clogging in injectors Replace the injectors

Fuel quantity adjustment by ABS/ASR

Fuel lift pump delivery too low Check the fuel lift pump and replace if necessary

©

200351 2-5

Page 68

DIAGNOSTICS

2

1

CE engine, general

2.3 FAULT-FINDING TABLE, VEHICLE FUNCTIONS

SYMPTOM: VEHICLE SPEED CONTROL DOES NOT WORK

Possible cause Remedy

Fault in electrical components/wiring of:

- combi-switch

- proximity switch

Condition(s) for disengaging vehicle speed control

present

SYMPTOM: ENGINE SPEED CONTROL DOES NOT WORK

Possible cause Remedy

Condition(s) for disengaging engine speed control

are present

Fault in electrical components/wiring of:

wiring harness

- combi-switch

Check the electrical system

Check for presence of condition(s) for disengaging

Check for presence of condition(s) for disengaging

Check the electrical system

ΧΦ65/75/85 series

SYMPTOM: PRE-GLOWING AND AFTER-GLOWING FUNCTION DOES NOT WORK

Possible cause Remedy

Fault in electrical components/wiring of:

- wiring harness

- warning lamp, pre-glowing

- glow plugs

- glow plug relay

Condition(s) for disengaging pre-glowing and afterglowing function present

SYMPTOM: ENGINE CANNOT BE SWITCHED OFF WITH IGNITION KEY

Possible cause Remedy

Power supply to electronic unit not cut off.

Power supply to electronic unit after contact not cut

off with contact switch

SYMPTOM: FAULT INDICATOR LAMP DOES NOT GO ON OR OFF

Possible cause Remedy