Page 1

9

ΧΦ65/75/85 series

STRUCTURE

Structure

TECHNICAL DATA

0

DIAGNOSTICS

1

CHASSIS

2

SHOCK ABSORBERS

3

STABILISERS AND TORQUE RODS

4

LEAF SUSPENSION

5

REAR AXLE ALIGNMENT

6

FAG

7

©

200448 DW23241902

Page 2

Page 3

9

TECHNICAL DATA

ΧΦ65/75/85 series

0 Technical data

CONTENTS

Page Date

1. CHASSIS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200448

1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200448

2. STABILISERS, TORQUE RODS AND LEAF SUSPENSION. . . . . . . . . . . . . . . 2-1 . . . . . 200448

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200448

2.2 Tightening torques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200448

3. REAR AXLE ALIGNMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200448

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200448

4. FAG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 . . . . . 200448

4.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1 . . . . . 200448

Contents

0

©

200448 1

Page 4

TECHNICAL DATA

9

0

Contents

ΧΦ65/75/85 series

2

©

200448

Page 5

9

TECHNICAL DATA

ΧΦ65/75/85 series

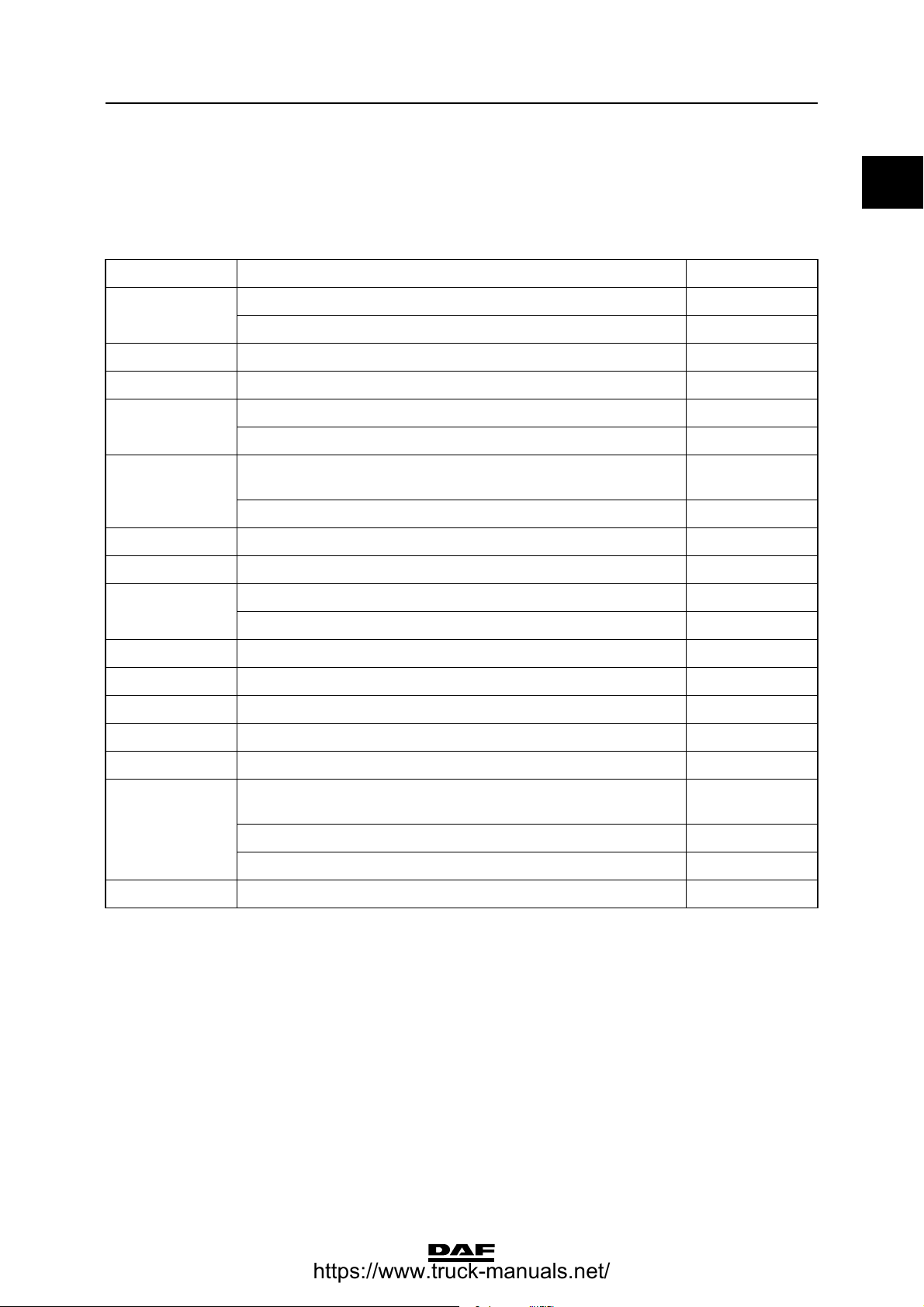

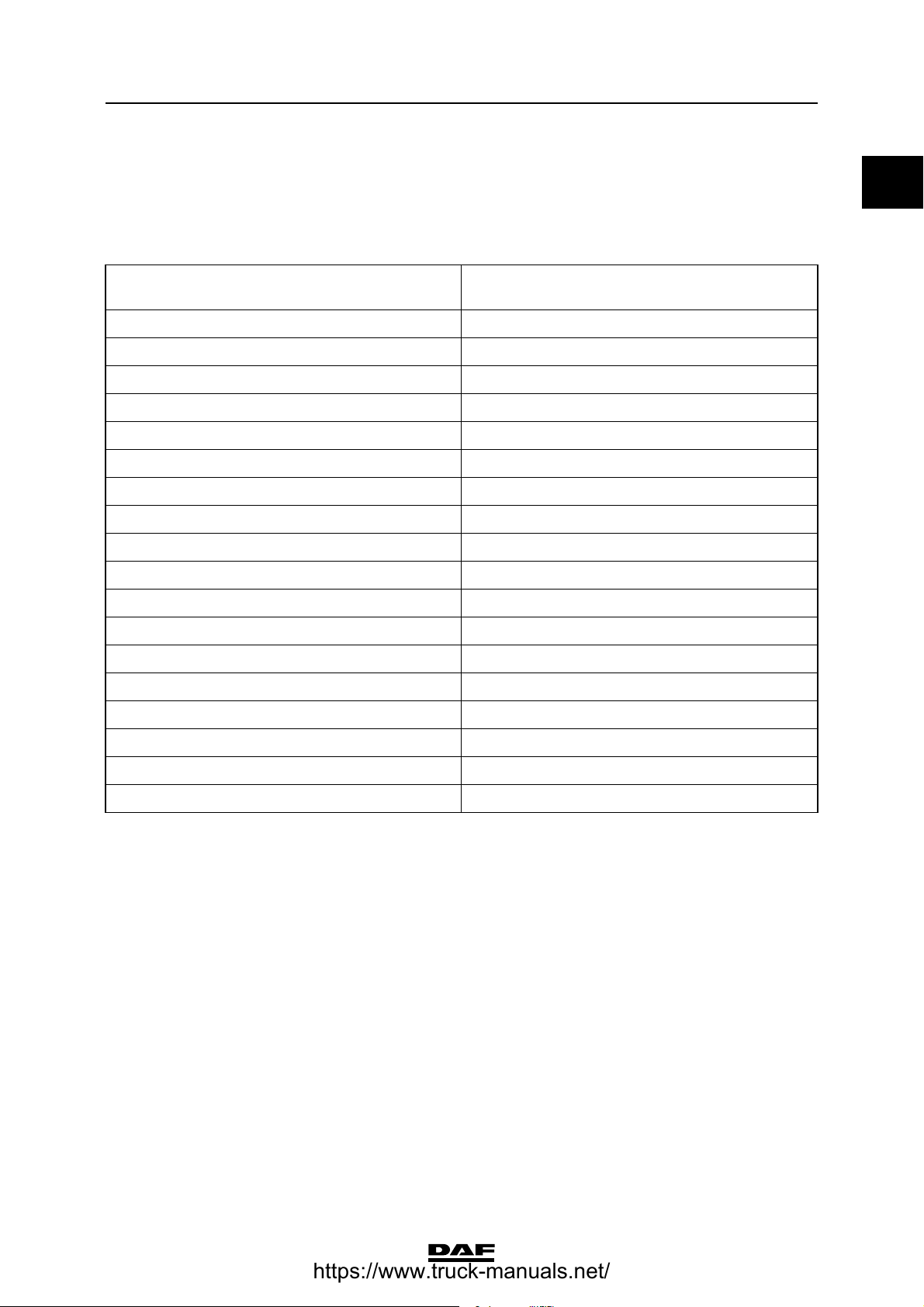

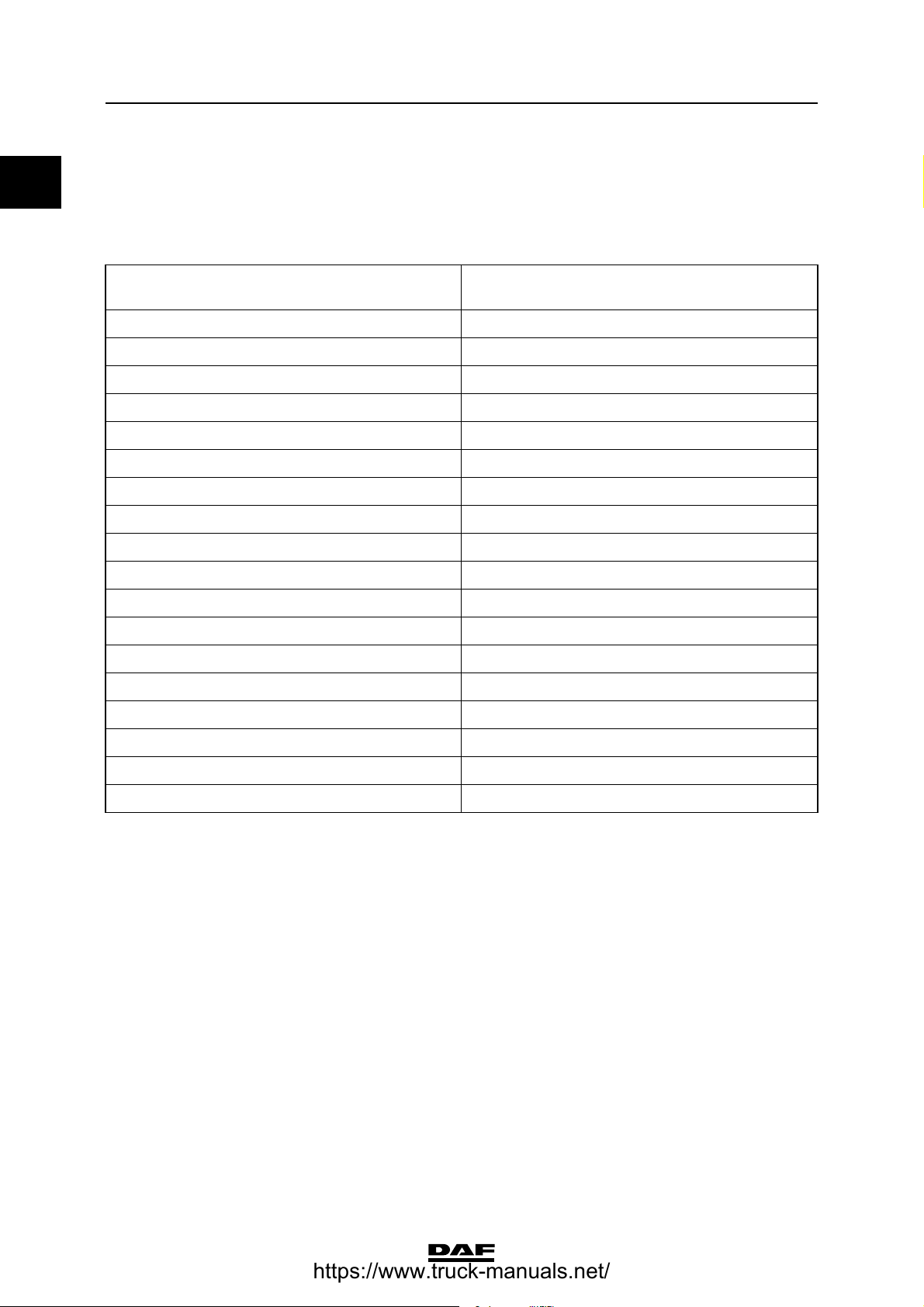

1. CHASSIS

1.1 GENERAL

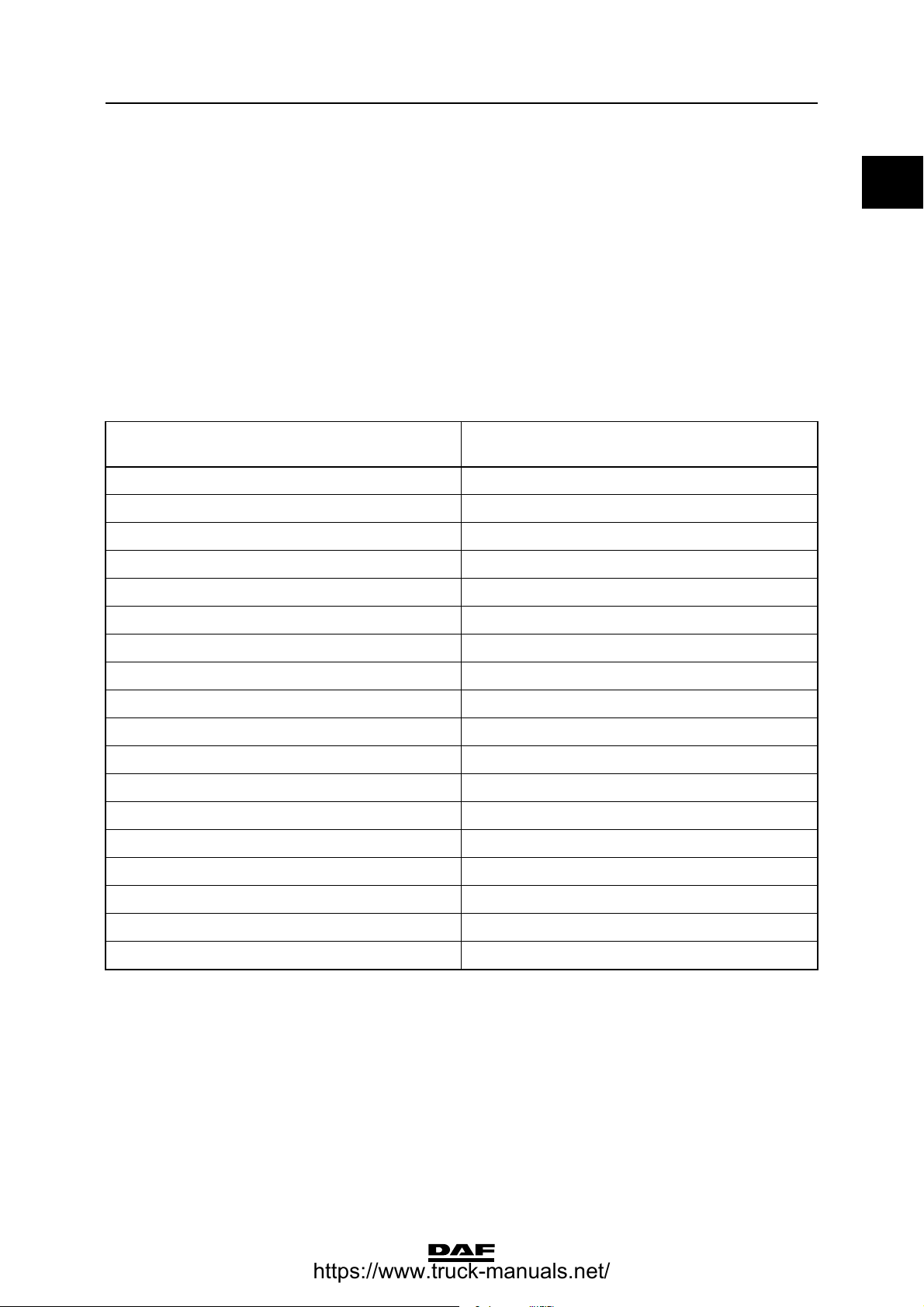

Chassis materials

Type Chassis type Material

FT Side member thickness 6 mm KF 600

Side member thickness 7 mm KF 500

FTG n/a KF 500

FTP n/a KF 600

FTS Side member height 260 mm KF 500

Side member height 310 mm KF 375

FTT RHD version: side member height 260 mm, side member

thickness 7 mm KF 500

Other versions KF 375

FA n/a KF 375

Chassis

0

(1)

(1)

(1)

(1)

(1)

(1)

FAC n/a KF 375

FAD Side member height 310 mm, side member thickness 6 mm KF 600

Other versions KF 375

FAG n/a KF 375

FAL n/a KF 375

FAN n/a KF 375

FAR n/a KF 375

FAS n/a KF 375

FAT RHD version: side member height 260 mm, side member

thickness 7 mm KF 500

Side member height 310 mm, side member thickness 6 mm KF 600

Other versions KF 375

FAX n/a KF 375

(1) KF 500 and KF 600 are "High Tensile Strength" types of steel.

(1)

(1)

(1)

©

200448 1-1

Page 6

TECHNICAL DATA

9

0

Chassis

ΧΦ65/75/85 series

1-2

©

200448

Page 7

9

TECHNICAL DATA

ΧΦ65/75/85 series

Stabilisers, torque rods and leaf suspension

2. STABILISERS, TORQUE RODS AND LEAF SUSPENSION

2.1 GENERAL

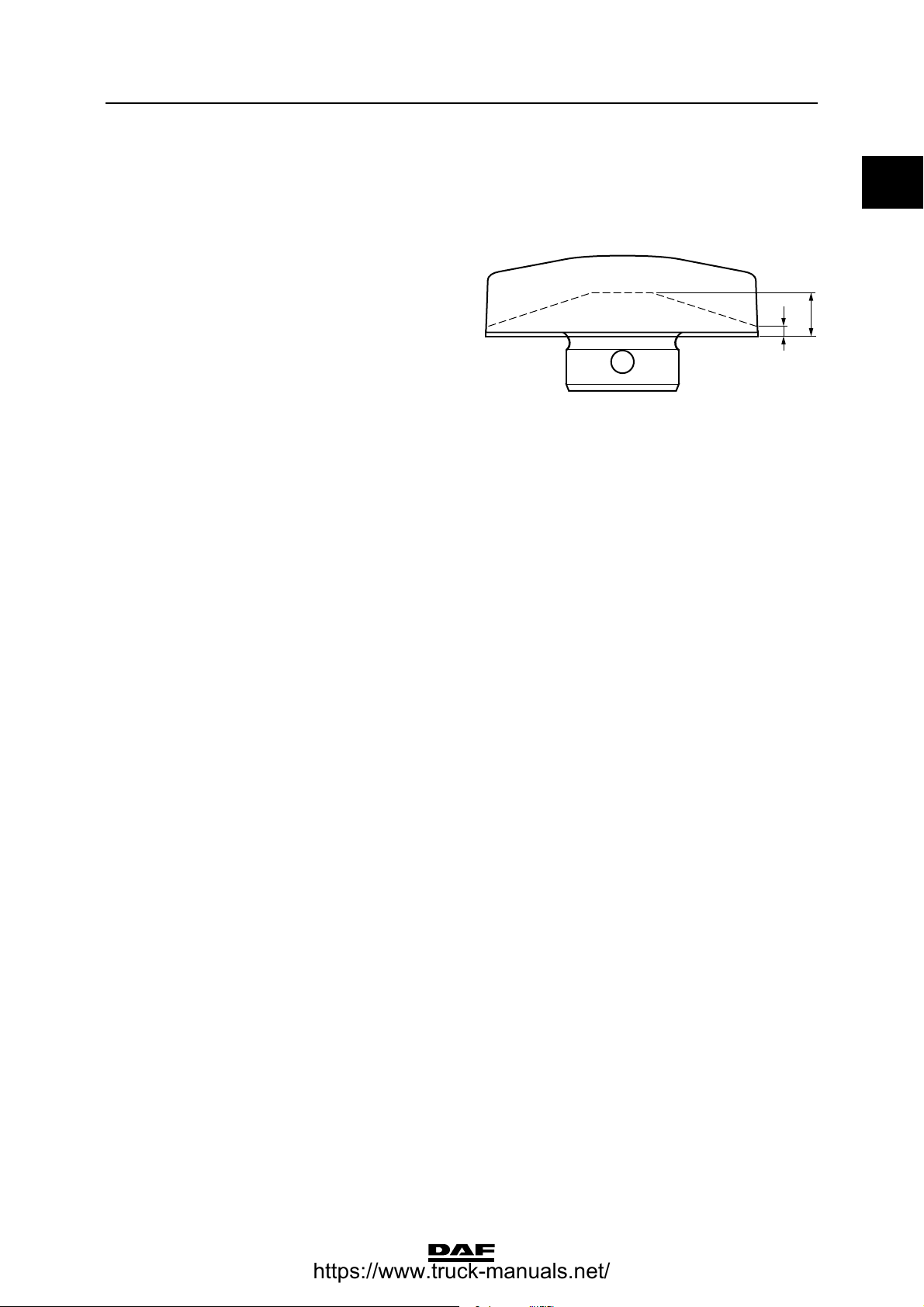

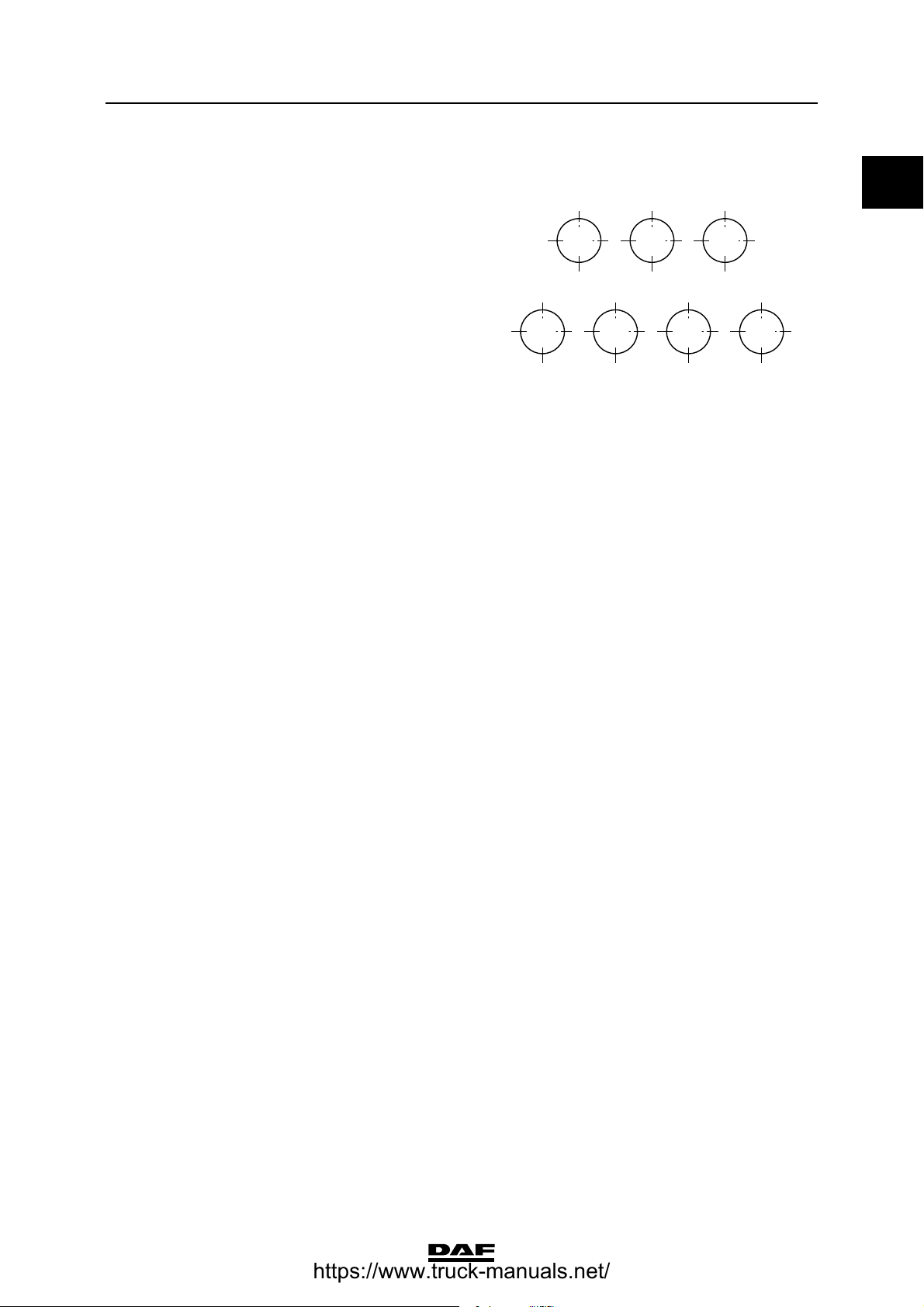

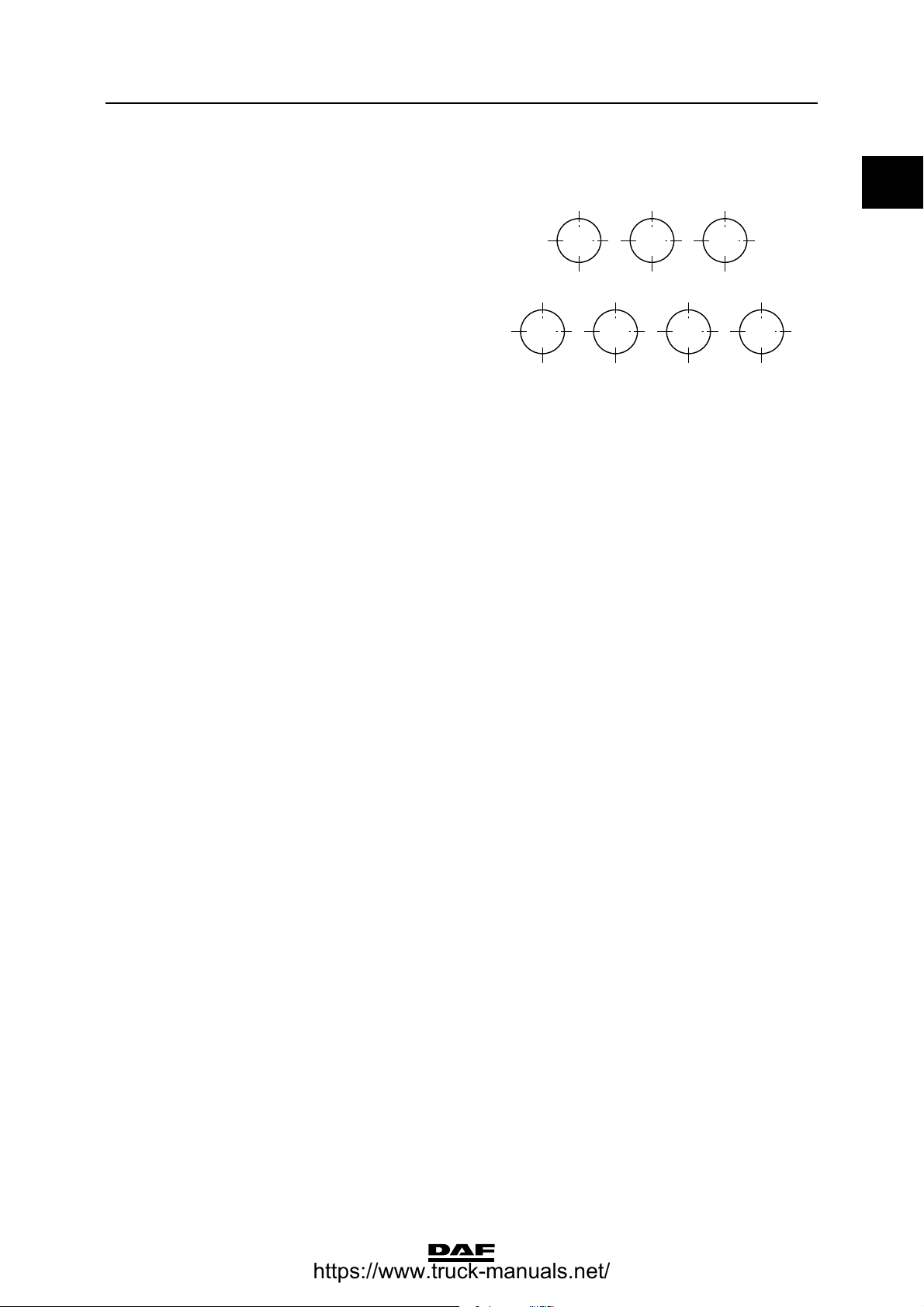

Minimum dimensions of wearing plates

If one of the dimensions of the wearing plates, on

which the spring assembly rests, is smaller than

indicated by the dotted line in the opposite

drawing, the wearing plates must be replaced.

Alignment plate/tandem axle spring clearance

If applicable, the clearance between the alignment plate and the tandem axle is: 1.5 - 2.5 mm.

2.2 TIGHTENING TORQUES

3

W9 00 013

0

15

The tightening torques stated in this section are

different from the standard tightening torques

stated in the overview of the standard tightening

torques. The other threaded connections not

specified must therefore be tightened to the

torque stated in the overview of standard

tightening torques.

When attachment bolts and nuts are replaced, it

is important that - unless stated otherwise - these

bolts and nuts are of exactly the same length and

property class as those removed.

©

200448 2-1

Page 8

TECHNICAL DATA

9

0

Stabilisers, torque rods and leaf suspension

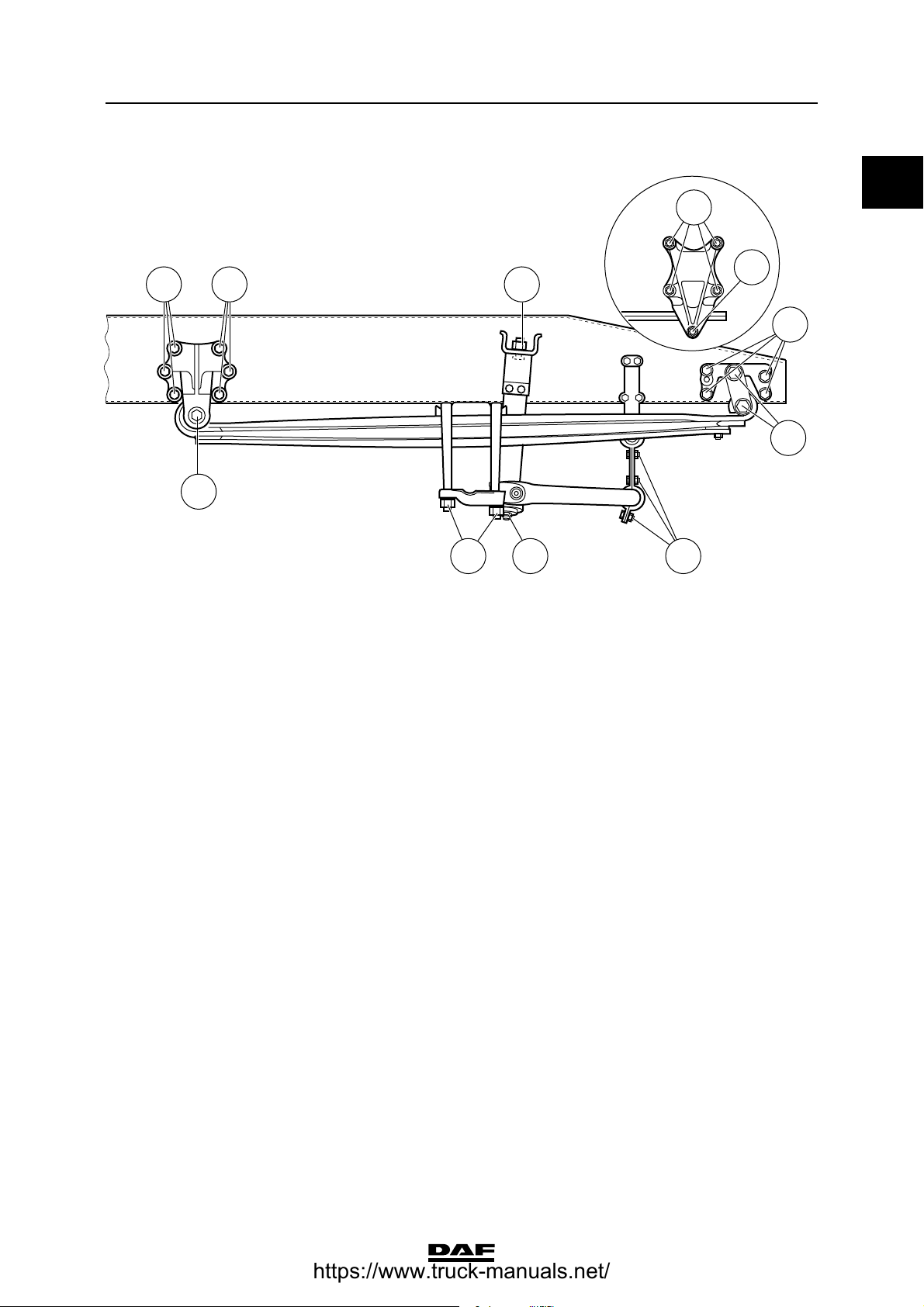

Front axle, leaf-sprung

D

C

ΧΦ65/75/85 series

F F

A

A

A Attachment bolt M24 for spring assembly,

property class 10.9 880 Nm

B U-bolt nut

- if flange nut M20, with yellow washer 450 ≥ 40 Nm

- if yellow zinc-plated hexagonal nut

M20, property class 10, with black

washer 400 ≥ 40 Nm

C Self-locking nut M16 for shock absorber 65 Nm

D Attachment bolt/nut M16 for stabiliser rod

shackle, property class 10.9/10 260 ≥ 20 Nm

E Attachment bolt/nut M12 for stabiliser rod

bearing bush cover, property class 10.9/10 110 ≥ 8 Nm

F Attachment bolt/nut M14 for spring

bracket, property class 10.9/10 170 ≥ 15 Nm

(1) Evenly tighten the two U-bolt nuts alternately.

(2) Only applies in case of tandem axle/trailing axle

D

E

B C

A

C9 00 477

(1)

(1)

(2)

2-2

©

200448

Page 9

9

TECHNICAL DATA

ΧΦ65/75/85 series

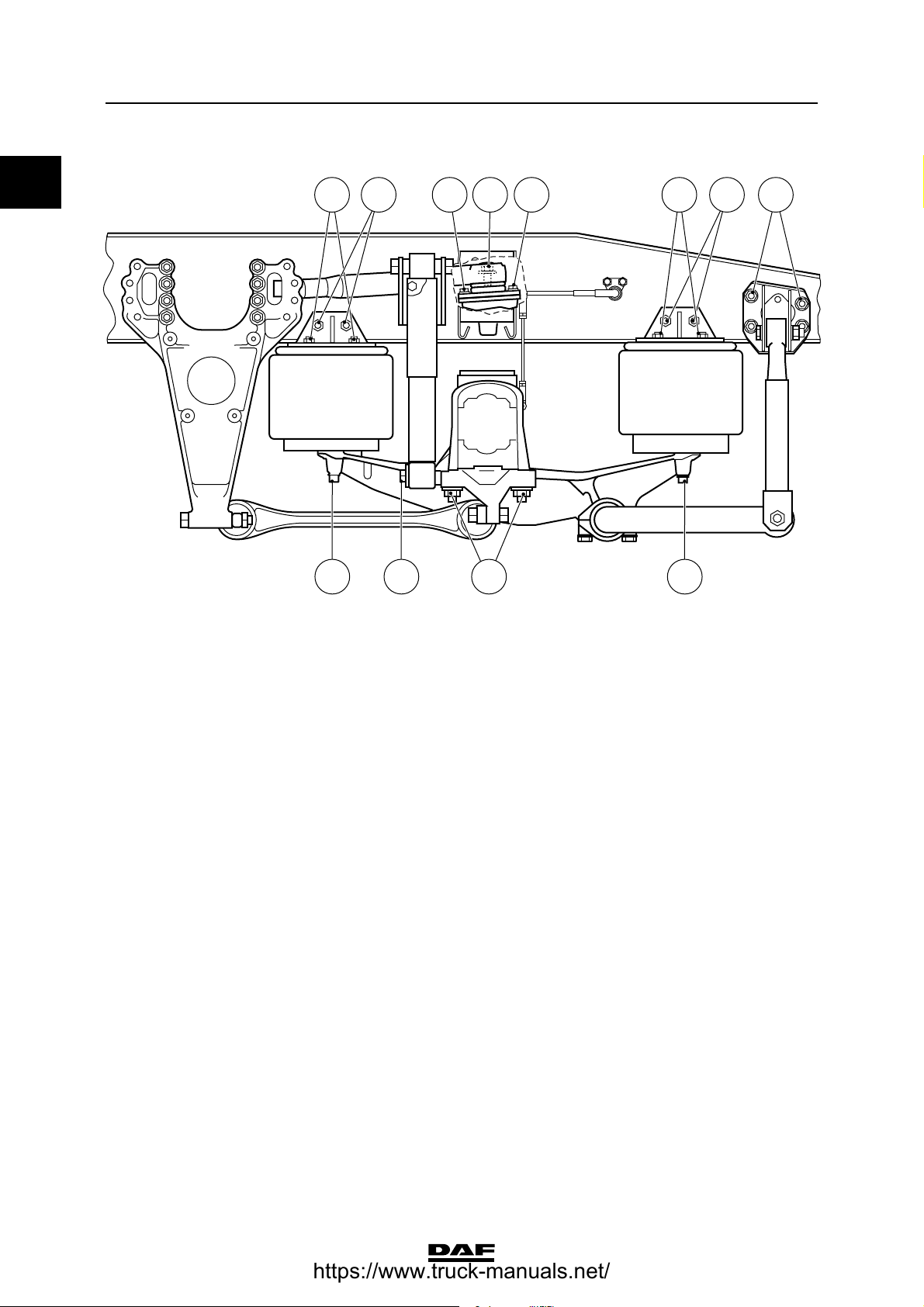

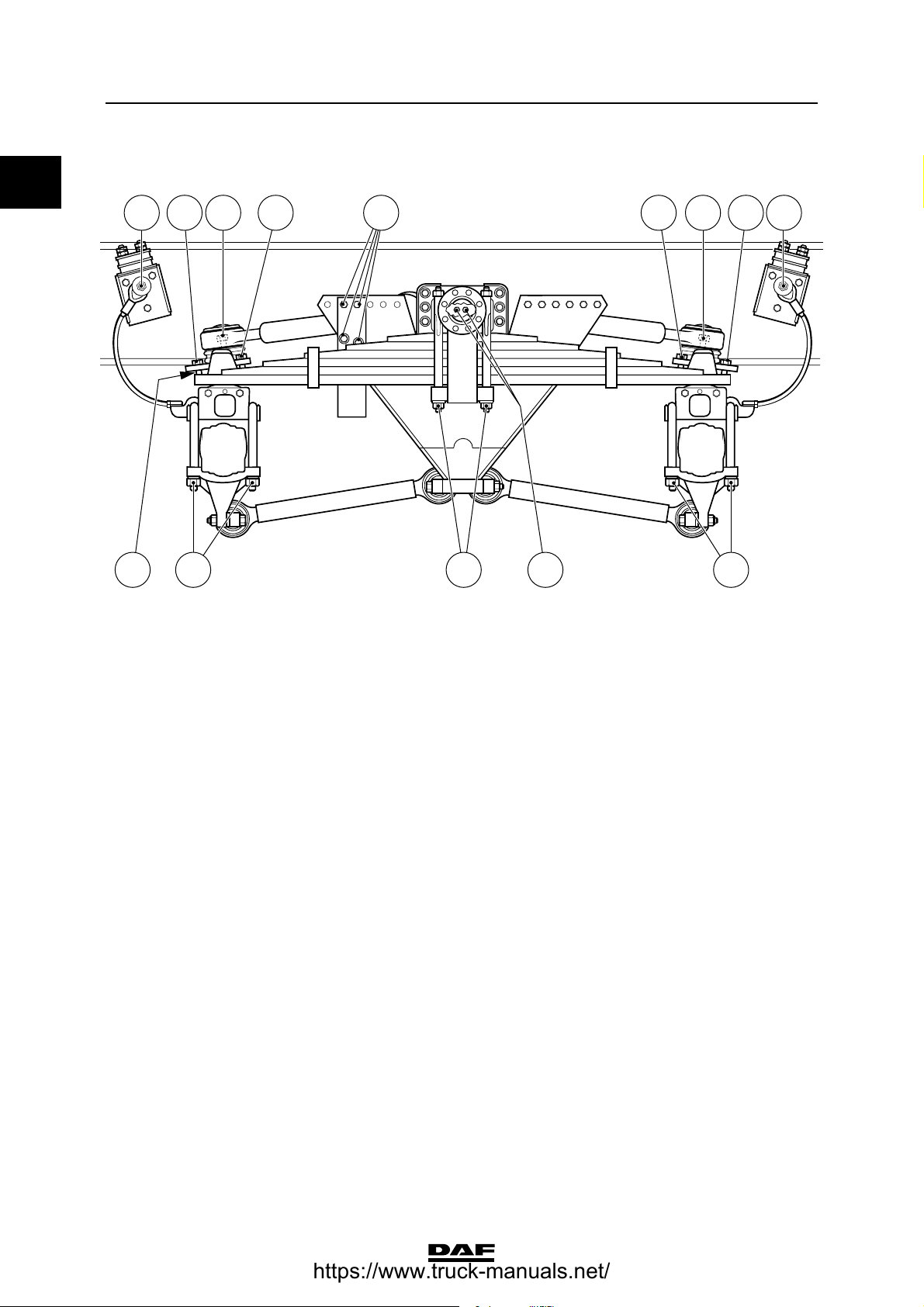

Front axle, air-sprung

A AJ B C I

I

Stabilisers, torque rods and leaf suspension

FH DG E E

C9 00 479

0

A Attachment bolt M16 for torque rod,

property class 10.9 260 ≥ 20 Nm

B U-bolt nut

- if flange nut M22 700 ≥ 50 Nm

- if yellow zinc-plated hexagonal nut

M22, property class 10, with black

washer 530 ≥ 40 Nm

C Attachment bolt M16 for bellows, property

class 8.8 195 Nm

D Attachment nut M10 for bellows, property

class 10 46 Nm

E Attachment bolt/nut M16 for spring

bracket, property class 10.9/10 260 ≥ 20 Nm

F Attachment bolt/nut M14 for spring

bracket, property class 10.9/10 170 ≥ 15 Nm

G Self-locking nut M16 for shock absorber 65 Nm

H Attachment bolt/nut M12 for bellows

support, property class 10.9/10 110 ≥ 8 Nm

I Attachment bolt M10 for pin attachment of

spring assembly, property class 10.9 60 ≥ 4 Nm

J Attachment bolt M12 for torque rod

support, property class 10.9 110 ≥ 8 Nm

(1) Evenly tighten the two U-bolt nuts alternately.

(2) Bellows must first be tightened on the chassis side.

(1)

(1)

(2)

(2)

©

200448 2-3

Page 10

TECHNICAL DATA

9

0

Stabilisers, torque rods and leaf suspension

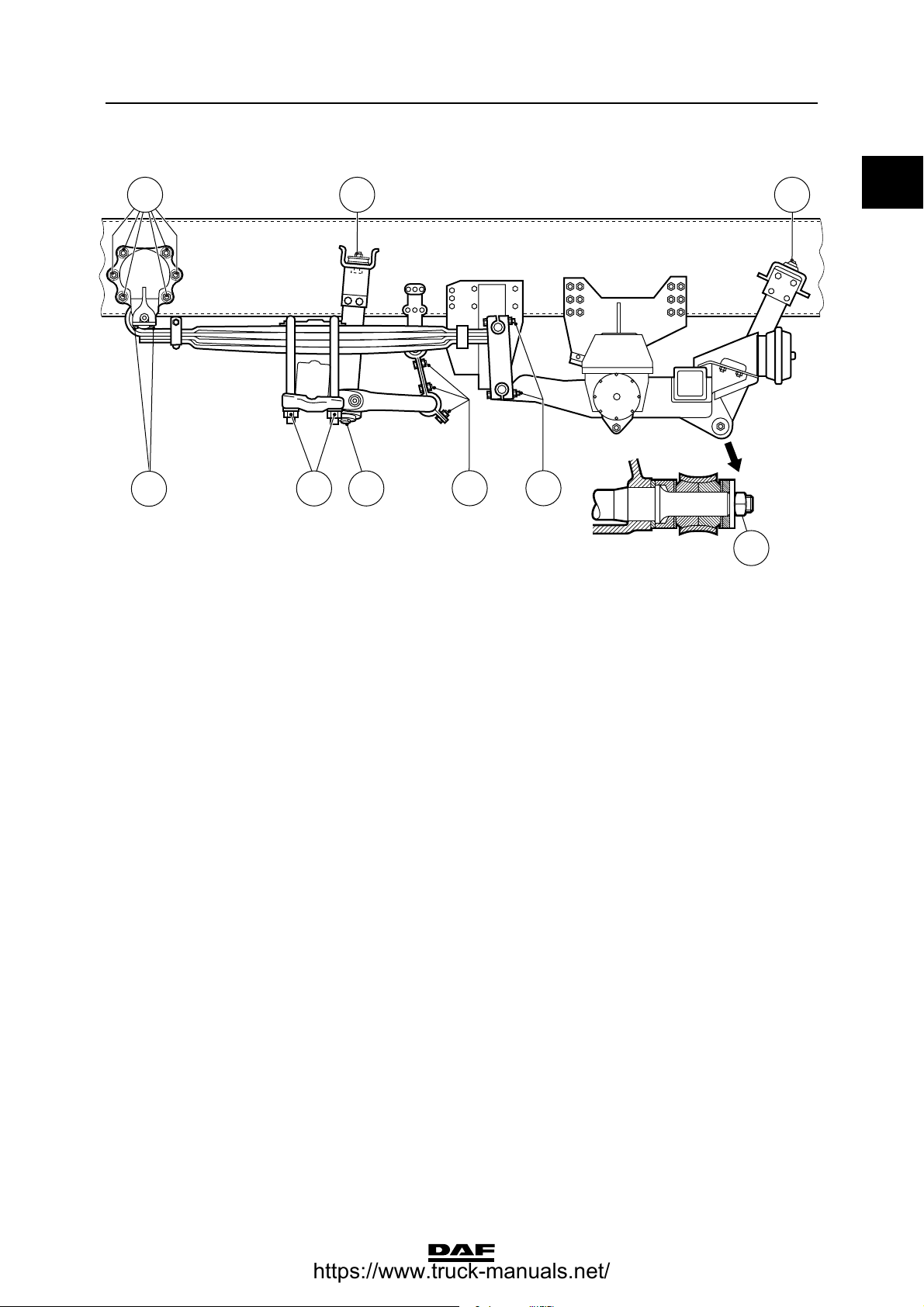

Leading rear axle, vehicle in FTG, FAG

version

A B

C

D

E

ΧΦ65/75/85 series

F

A

F

GH A

A Attachment bolt/nut M16 for torque rod

(support), property class 10.9/10 260 ≥ 20 Nm

B Self-locking nut M16 for shock absorber 65 Nm

C Attachment nut M10 for bellows, property

class 10 46 Nm

D Attachment bolt M16 for bellows, property

class 10.9 195 Nm

E U-bolt nut

- if flange nut M22 700 ≥ 50 Nm

- if yellow zinc-plated hexagonal nut

M22, property class 10, with black

washer 530 ≥ 40 Nm

F Attachment bolt M8 for lifting bellows,

property class 10.9 20 Nm

G Attachment bolt/nut for stabiliser bar

bracket

- if M14, property class 10.9/10 170 ≥ 15 Nm

- if M16, property class 10.9/10 260 ≥ 20 Nm

H Attachment bolts M8 for locking plate,

property class 10.9 30 Nm

(1) Bellows must first be tightened on the chassis side.

(2) Evenly tighten the two U-bolt nuts alternately.

BA A

C9 00 486

(1)

(1)

(2)

(2)

2-4

©

200448

Page 11

9

TECHNICAL DATA

ΧΦ65/75/85 series

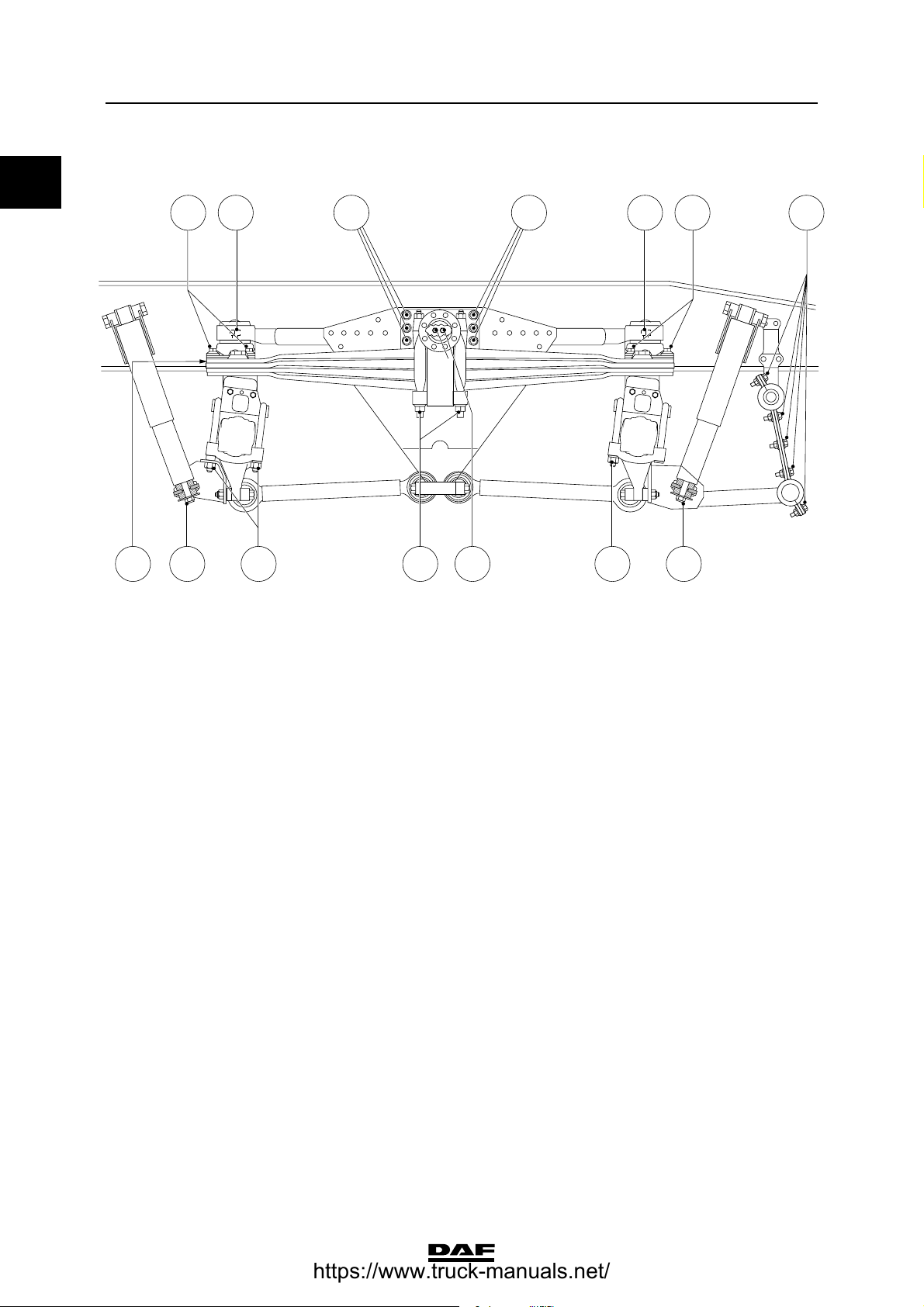

Leading rear axle, vehicle in FTP version

A

Stabilisers, torque rods and leaf suspension

B I DC

0

A Attachment bolt M20 for shock absorber,

property class 8.8 250 ≥ 25 Nm

B Attachment nut M12 for bellows 30 Nm

C U-bolt nut M20, property class 10.9 553 Nm

D Attachment nut M10 for bellows 30 Nm

E Attachment bolt M16 for leaf spring,

property class 10.9 100 Nm

F Attachment bolt/nut M20 for leaf spring,

property class 10.9/10 553 Nm

G Attachment bolt/nut M24 for leaf spring 830 Nm

H Attachment bolt/nut M16 for spring

bracket, property class 10.9 310 Nm

I Attachment bolt/nut M10 for bellows

support, property class 10.9/10 60 ≥ 4 Nm

(1) Evenly tighten the two U-bolt nuts alternately.

DEFEAG BH

C9 00 481

(1)

©

200448 2-5

Page 12

TECHNICAL DATA

9

0

Stabilisers, torque rods and leaf suspension

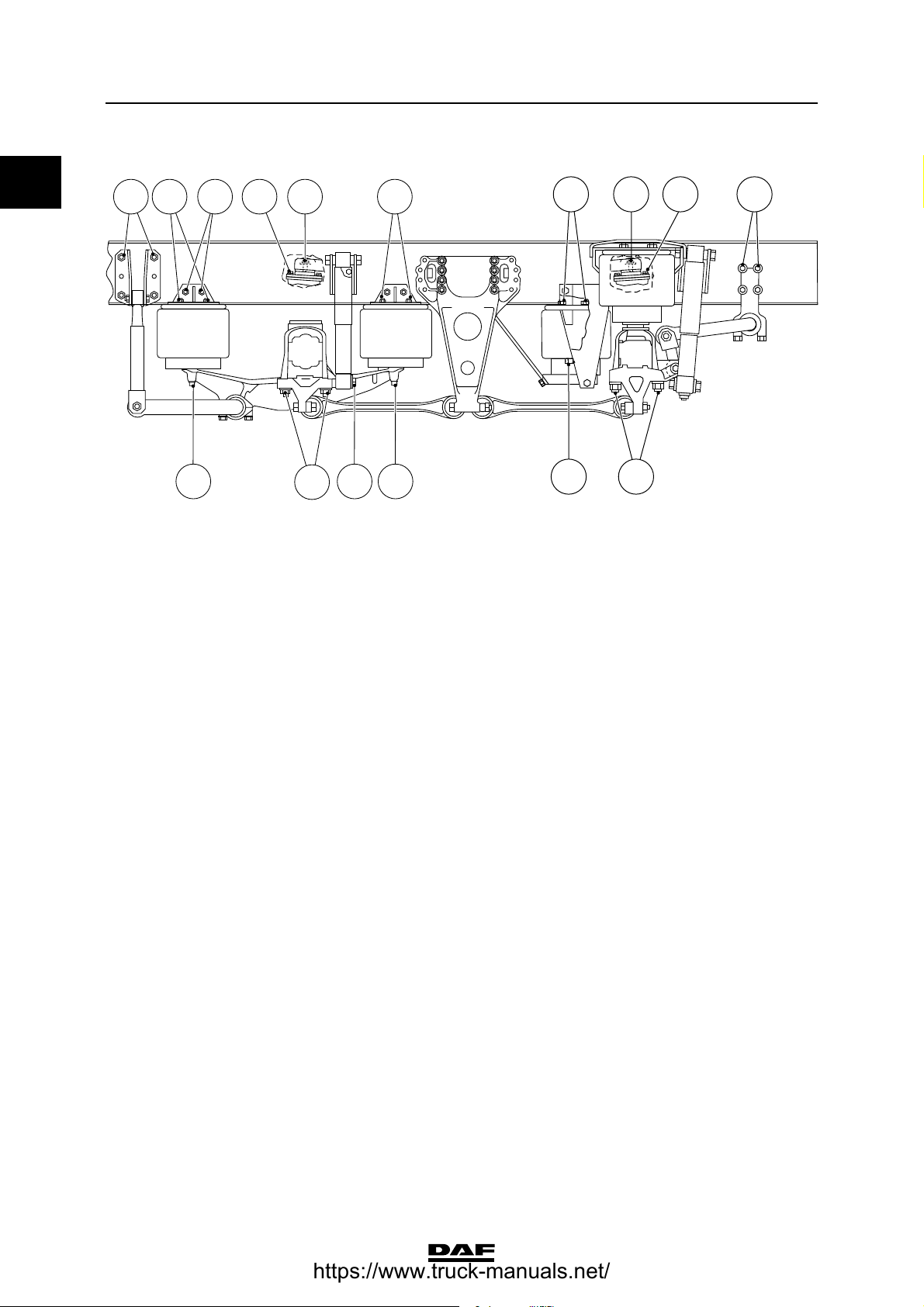

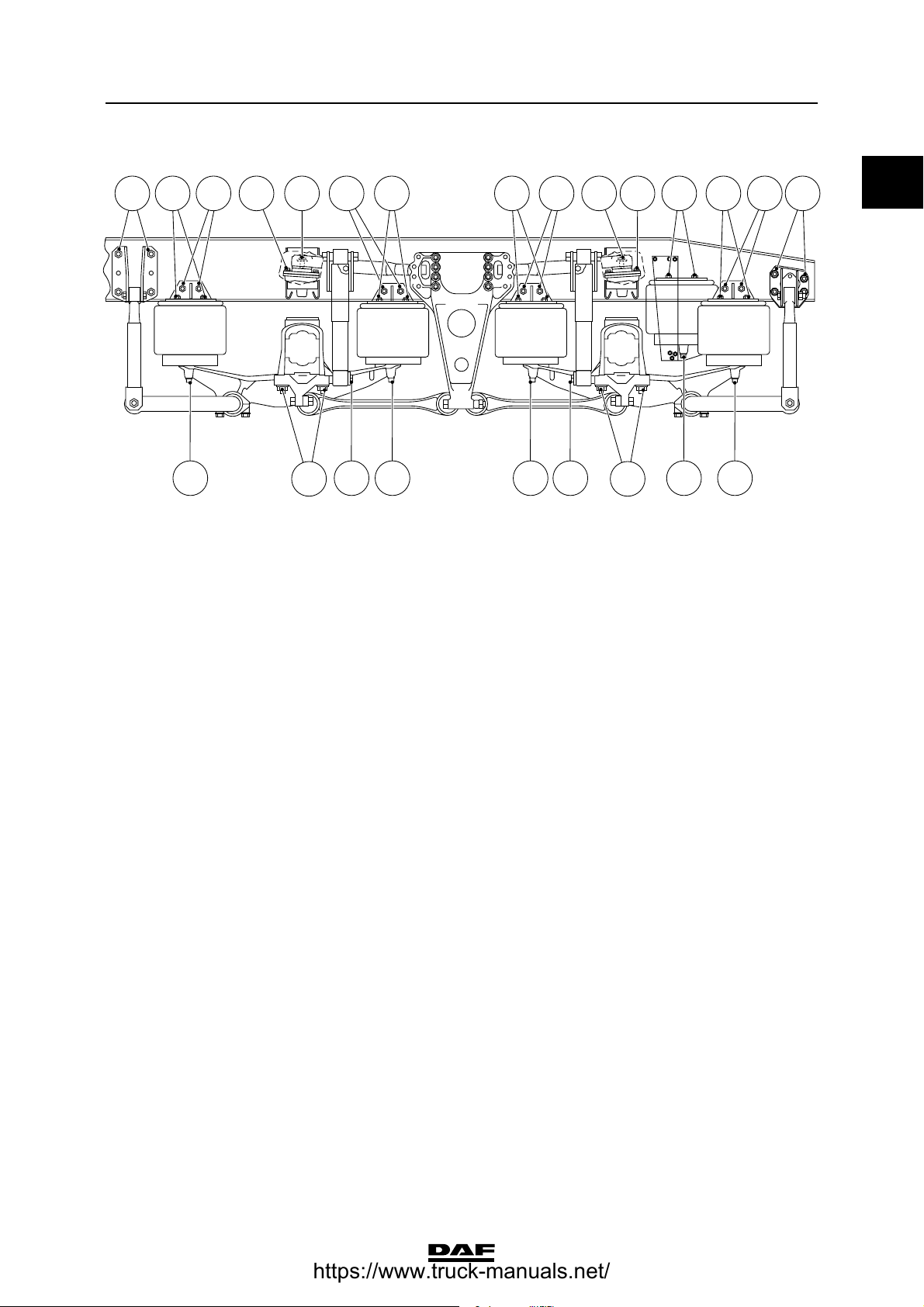

Double front axle

CF F C

A

A Attachment bolt M24 for spring assembly,

property class 10.9 880 Nm

B U-bolt nut

- if flange nut M20, with yellow washer 450 ≥ 40 Nm

- if yellow zinc-plated hexagonal nut

M20, property class 10, with black

washer 400 ≥ 40 Nm

C Self-locking nut M16 65 Nm

D Ball end nut

- if self-locking nut 285 Nm

- if castle nut 285 Nm

E Attachment bolt/nut M12 for stabiliser rod

bearing bush cover, property class 10.9/10 110 ≥ 8 Nm

F Attachment bolt/nut M16 for stabiliser rod

shackle, property class 10.9/10 260 ≥ 20 Nm

BEF EFA B C A DD AC

ΧΦ65/75/85 series

C900465

(1)

(1)

(2)

(3)

(1) Evenly tighten the two U-bolt nuts alternately.

(2) Fit new self-locking nut.

(3) Tighten until the split pin fits (max. 60).

It is not allowed to fit a self-locking nut to the ball

end with split pin hole.

2-6

©

200448

Page 13

9

TECHNICAL DATA

ΧΦ65/75/85 series

Rear axle, leaf suspension

Stabilisers, torque rods and leaf suspension

DA A

B

C D F

A Attachment bolt/nut M16 for spring

bracket, property class 10.9/10 260 ≥ 20 Nm

B Attachment bolt M24 for spring assembly,

property class 10.9 880 Nm

C U-bolt nut

- if flange nut M24, with black washer 750 ≥ 50 Nm

- if yellow zinc-plated hexagonal nut

M24, property class 10, with black

washer 615 ≥ 50 Nm

D Self-locking nut M16 for shock absorber 65 Nm

E Catch bolt M12, property class 10.9 68 ≥ 12 Nm

F Attachment bolt/nut M14 for stabiliser rod

bracket, property class 10.9/10 170 ≥ 15 Nm

0

A

E

A

B

C9 00 478

(1)

(1)

(1) Evenly tighten the two U-bolt nuts alternately.

©

200448 2-7

Page 14

TECHNICAL DATA

9

0

Stabilisers, torque rods and leaf suspension

Rear axle, air-sprung

A H H

ΧΦ65/75/85 series

AEE F G

DCB B

C9 00 480

A Attachment nut M10 for bellows, property

class 10 46 Nm

B Attachment bolt M16 for bellows, property

class 8.8 195 Nm

C Attachment bolt M20 for shock absorber,

property class 10.9 520 ≥ 40 Nm

D U-bolt nut

- if black high hexagonal nut M24 with

black washer 770 ≥ 60 Nm

- if yellow zinc-plated hexagonal nut

M24, property class 10, with black

washer 615 ≥ 50 Nm

E Clamping flange bolt M18 for triangular

link, property class 12.9 460 ≥ 40 Nm

F Attachment bolt M14, for triangular link

ball, property class 10.9 135 Nm

G Attachment bolt/nut M16 for stabiliser

shackle support, property class 10.9/10 260 ≥ 20 Nm

H Attachment bolt/nut M10 for bellows

support, property class 10.9/10 60 ≥ 4 Nm

(1) Bellows must first be tightened on the chassis side.

(2) The high hexagonal nut can be recognised by the nut height, which is 1.5 x thread . Evenly tighten the two U-bolt nuts

alternately.

(3) The yellow zinc-plated hexagonal nut can be recognised by the nut height, which is 1 x thread . Evenly tighten the two U-bolt

nuts alternately.

(1)

(1)

(2)

(3)

2-8

©

200448

Page 15

9

TECHNICAL DATA

ΧΦ65/75/85 series

Trailing axle, leaf suspension

D

F

A U-bolt nut

- if flange nut M24 750 ≥ 50 Nm

- if yellow zinc-plated hexagonal nut

M24, property class 10, with black

washer 615 ≥ 50 Nm

B Self-locking nut M16 65 Nm

C Shock absorber attachment nut 260 ≥ 20 Nm

D Attachment bolt/nut M16 for spring

bracket, property class 10.9/10 260 ≥ 20 Nm

E Attachment bolt/nut M14 for stabiliser rod

bracket, property class 10.9/10 170 ≥ 15 Nm

F Attachment bolt M10 for pin attachment of

spring assembly, property class 10.9 60 ≥ 4 Nm

G Attachment bolt/nut M12 for spring

shackle, property class 10.9/10 110 ≥ 8 Nm

B

A B

Stabilisers, torque rods and leaf suspension

E G

(1)

(1)

C

B

C9 00 483

0

(1) Evenly tighten the two U-bolt nuts alternately.

©

200448 2-9

Page 16

TECHNICAL DATA

9

0

Stabilisers, torque rods and leaf suspension

Trailing axle, air-sprung, 6 bellows version

A BI H A

E F E

A Attachment nut M10 for bellows, property

class 10 46 Nm

B Clamping flange bolt M18 for triangular

link, property class 12.9 460 ≥ 40 Nm

C Attachment bolt M14, for triangular link

ball, property class 10.9 135 Nm

D U-bolt nut

- if black high hexagonal nut M24 with

black washer 770 ≥ 60 Nm

- if yellow zinc-plated hexagonal nut

M24, property class 10, with black

washer 615 ≥ 50 Nm

E Attachment bolt M16 for bellows, property

class 8.8 195 Nm

F Attachment bolt M20 for shock absorber,

property class 10.9 520 ≥ 40 Nm

G Attachment bolt/nut M16 for stabiliser

shackle support, property class 10.9/10 260 ≥ 20 Nm

H Attachment bolt/nut M10 for bellows

support, property class 10.9/10 60 ≥ 4 Nm

I Attachment bolt/nut M16 for stabiliser

shackle support, property class 10.9/10 260 ≥ 20 Nm

C

D

(1)

(1)

A

E

(2)

(3)

ΧΦ65/75/85 series

C

B G

D

C900463

(1) Bellows must first be tightened on the chassis side.

(2) The high hexagonal nut can be recognised by the nut height, which is 1.5 x thread . Evenly tighten the two U-bolt nuts

alternately.

(3) The yellow zinc-plated hexagonal nut can be recognised by the nut height, which is 1 x thread . Evenly tighten the two U-bolt

nuts alternately.

2-10

©

200448

Page 17

9

TECHNICAL DATA

ΧΦ65/75/85 series

Trailing axle, air-sprung, 8 bellows version

A B C BCG H GA

D DDF FD D

A Attachment nut M10 for bellows, property

class 10 46 Nm

B Clamping flange bolt M18 for triangular

link, property class 12.9 460 ≥ 40 Nm

C Attachment bolt M14, for triangular link

ball, property class 10.9 135 Nm

D Attachment bolt M16 for bellows, property

class 8.8 195 Nm

E U-bolt nut

- if black high hexagonal nut M24 with

black washer 770 ≥ 60 Nm

- if yellow zinc-plated hexagonal nut

M24, property class 10, with black

washer 615 ≥ 50 Nm

F Attachment bolt M20 for shock absorber,

property class 10.9 520 ≥ 40 Nm

G Attachment bolt/nut M16 for stabiliser

shackle support, property class 10.9/10 260 ≥ 20 Nm

H Attachment bolt/nut M10 for bellows

support, property class 10.9/10 60 ≥ 4 Nm

HHH

E E

Stabilisers, torque rods and leaf suspension

A AA

(1)

(1)

(2)

(3)

0

C9 00 482

(1) Bellows must first be tightened on the chassis side.

(2) The high hexagonal nut can be recognised by the nut height, which is 1.5 x thread . Evenly tighten the two U-bolt nuts

alternately.

(3) The yellow zinc-plated hexagonal nut can be recognised by the nut height, which is 1 x thread . Evenly tighten the two U-bolt

nuts alternately.

©

200448 2-11

Page 18

TECHNICAL DATA

9

0

Stabilisers, torque rods and leaf suspension

Tandem axle, leaf-sprung, trapezoidal leaf

spring version

A C

ΧΦ65/75/85 series

C B

ABC CG

FH

A Attachment bolt/nut M16 for arresting

cable 150 ≥ 20 Nm

B Attachment bolt M14, for triangular link

ball, property class 10.9 135 Nm

C Clamping flange bolt M18 for triangular

link, property class 12.9 460 ≥ 40 Nm

D U-bolt nut

- if flange nut M20 450 ≥ 40 Nm

- if yellow zinc-plated hexagonal nut

M20, property class 10, with black

washer 400 ≥ 40 Nm

E Attachment bolt M14, for bearing bush

plate, property class 10.9 170 ≥ 15 Nm

F Tie rod nut

if flange nut M22 650 ≥ 50 Nm

if yellow zinc-plated hexagonal nut M22,

property class 10, with black washer 480 ≥ 40 Nm

G Attachment bolt/nut M12 for alignment

plate, property class 10.9/10 110 ≥ 8 Nm

E

DD

C9 00 485

(1)

(1)

(2)

(1)

(1)

2-12

©

200448

Page 19

9

TECHNICAL DATA

ΧΦ65/75/85 series

H Tighten the bolts according to the standard

tightening torque, in the order shown.

(1) Evenly tighten the two U-bolt/tie rod nuts alternately.

(2) Fasten with Loctite 243.

Stabilisers, torque rods and leaf suspension

0

4 1 5

7 2 3 6

C9 00 144

©

200448 2-13

Page 20

TECHNICAL DATA

9

0

Stabilisers, torque rods and leaf suspension

Tandem axle, leaf-sprung, parabolic leaf

spring version

A B AB

G

ΧΦ65/75/85 series

HG

C CDFI E

A Clamping flange bolt M18 for triangular

link, property class 12.9 460 ≥ 40 Nm

B Attachment bolt M14, for triangular link

ball, property class 10.9 135 Nm

C Self-locking nut M16 for shock absorber 65 Nm

D U-bolt nut

- if flanged nut 450 ≥ 40 Nm

- if yellow zinc-plated hexagonal nut

M20, property class 10, with black

washer 400 ≥ 40 Nm

E Attachment bolt M14, for bearing bush

plate, property class 10.9 170 ≥ 15 Nm

F Tie rod nut

- if flanged nut 650 ≥ 50 Nm

- if yellow zinc-plated hexagonal nut

M22, property class 10, with black

washer 480 ≥ 40 Nm

G Attachment bolt M16 for pivot pin flange,

property class 10.9 260 ≥ 20 Nm

H Attachment bolt/nut M14 for stabiliser rod

bracket, property class 10.9/10 170 ≥ 15 Nm

D

C9 00 484

(1)

(1)

(2)

(1)

(1)

2-14

©

200448

Page 21

9

TECHNICAL DATA

ΧΦ65/75/85 series

I Tighten the bolts according to the standard

tightening torque, in the order shown.

(1) Evenly tighten the two U-bolt/tie rod nuts alternately.

(2) Fasten with Loctite 243.

Stabilisers, torque rods and leaf suspension

0

4 1 5

7 2 3 6

C9 00 144

©

200448 2-15

Page 22

TECHNICAL DATA

9

0

Stabilisers, torque rods and leaf suspension

Tandem axle, air-sprung, Meritor version

A B

C A A C B A

D E F B BG

A Attachment bolt/nut M16 for torque rod,

property class 10.9/10 260 ≥ 60 Nm

B Tighten shock absorber attachment nut

until the rubber sleeve and the steel ring

have the same diameter.

C Attachment bolt/nut M22 for yoke, property

class 10.9/10 750 Nm

D Attachment bolt for bellows 1/2" UNC 34 ≥ 7 Nm

E Attachment bolt/nut M16 for torque rod,

property class 10.9/10 260 ≥ 60 Nm

F Attachment bolt/nut M10 for torque rod,

property class 10.9/10 60 ≥ 4 Nm

G Attachment nut M20 for torque rod,

property class 10.9 520 ≥ 40 Nm

ΧΦ65/75/85 series

FE DG

C9 00 404

2-16

©

200448

Page 23

9

TECHNICAL DATA

ΧΦ65/75/85 series

3. REAR AXLE ALIGNMENT

3.1 GENERAL

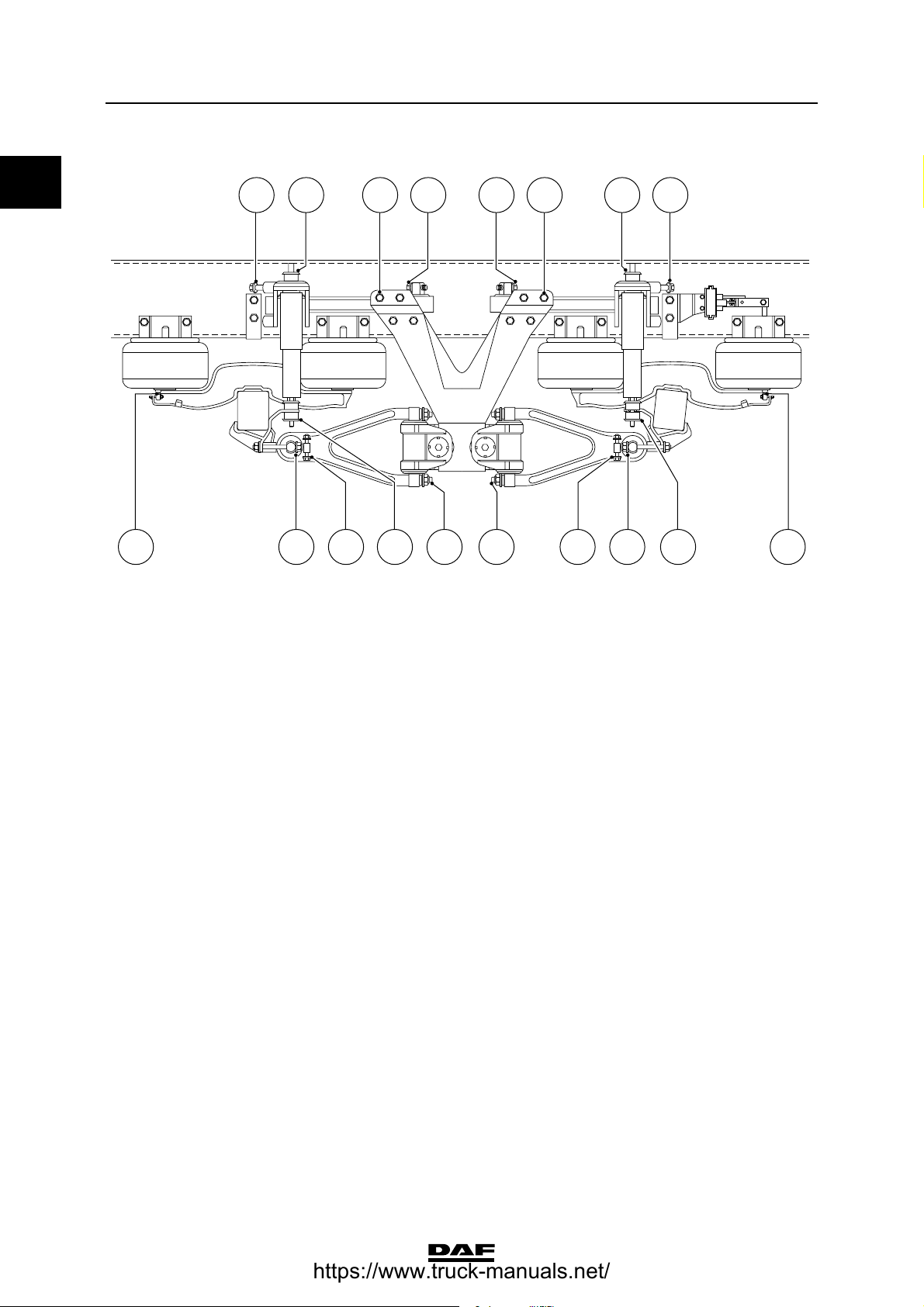

Rear axle misalignment standard

The angle achieved by the driven rear axle

relative to the vehicle centreline is calculated

from the angle achieved by both wheels of this

axle relative to the vehicle centreline. See "Rear

axle alignment".

Driven axle relative to the vehicle centreline:

- max. 4 mm/m (angle A in drawing).

This value also applies to the individual

tandem axles and the driven axle of the

trailing axle suspension.

Non-parallelism of the rear tandem axle relative

to the front tandem axle:

- max. 2 mm/m (angle B in drawing).

Rear axle alignment

0

A

C9 00 123

B

C9 00 124

©

200448 3-1

Page 24

TECHNICAL DATA

9

0

Rear axle alignment

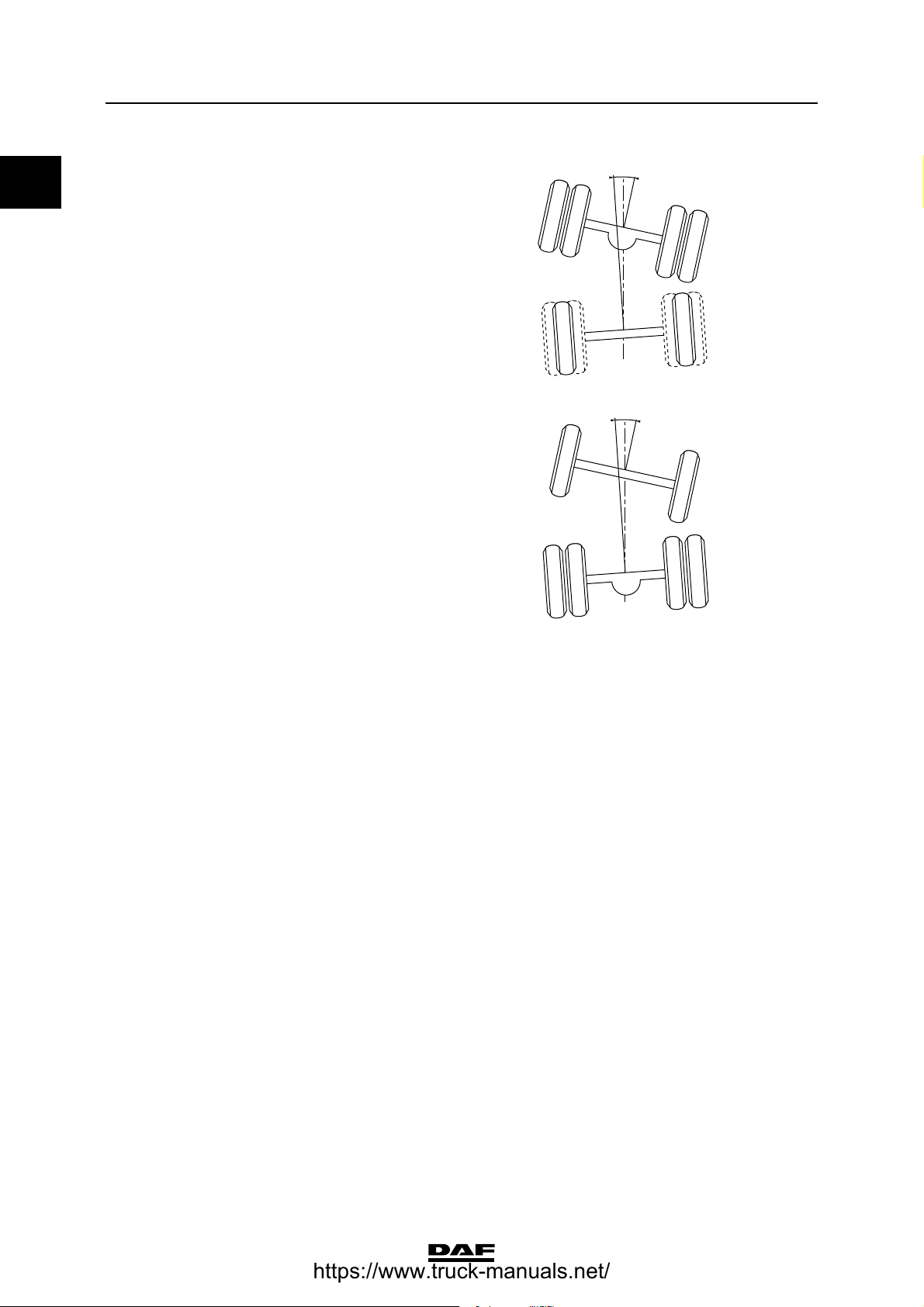

Non-parallelism of the trailing axle relative to the

driven axle:

- max. 2 mm/m (angle C in drawing).

Non-parallelism of the unsteered leading rear

axle (FTP) relative to the driven axle:

- max. 2 mm/m (angle D in drawing).

ΧΦ65/75/85 series

C

C9 00 235

D

C9 00 519

3-2

©

200448

Page 25

9

TECHNICAL DATA

ΧΦ65/75/85 series

4. FAG

4.1 GENERAL

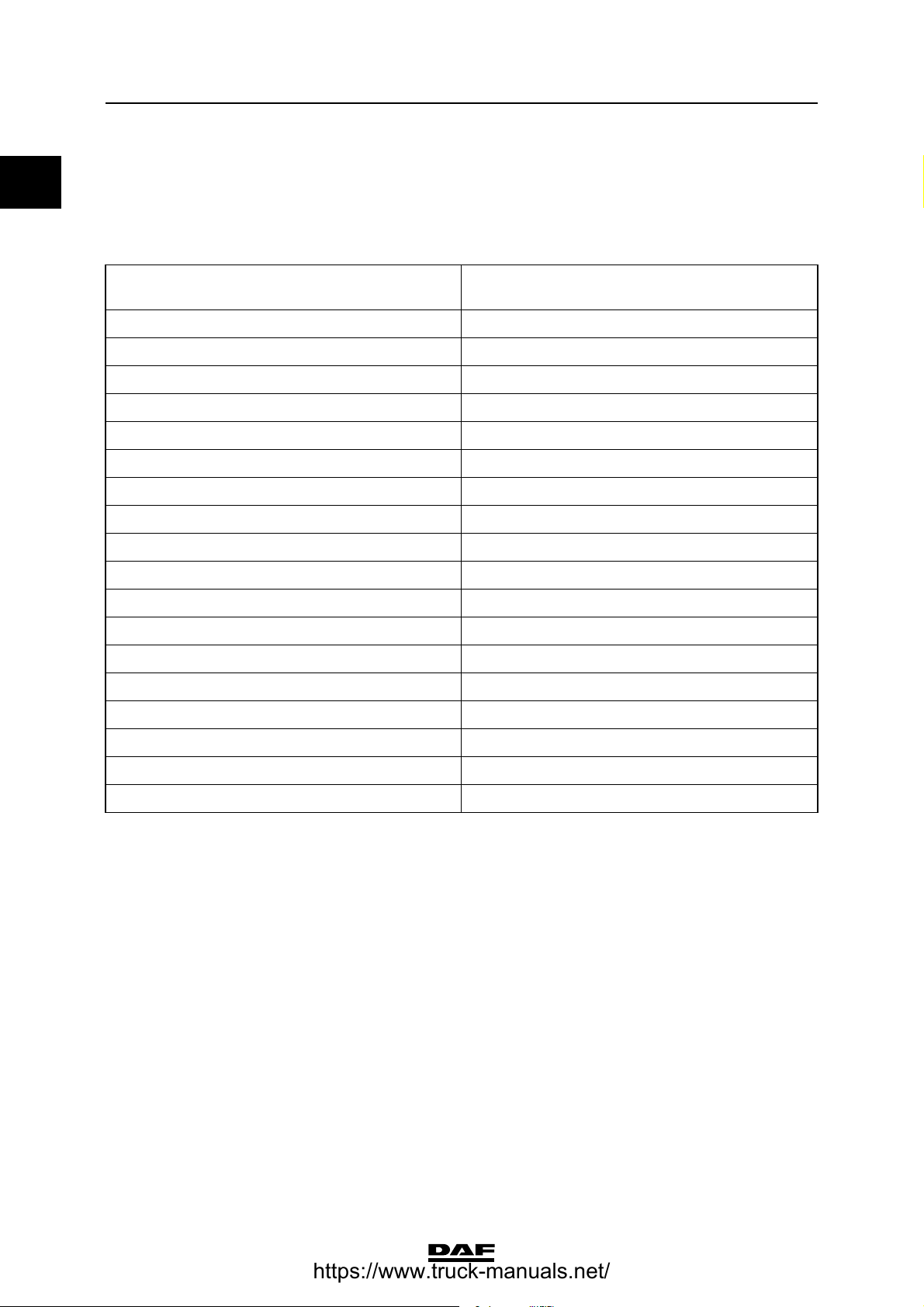

Valve adjustment

Pressure-limiting valve 7.0 bar

Pressure-relief valve 0.5 bar

Control values/adjustment of height-control

valve, axle load ratio 6.0/10.0 and fitted with

leaf spring suspension (DAF no. 1368293)

Lever length 60 mm

Joint axle load of leading rear axle/

drive shaft (N)

30,000 0.4

40,000 0.7

50,000 1.1

60,000 1.5

FAG

0

Bellows pressure (bar)

70,000 1.9

80,000 2.2

90,000 2.6

100,000 3.0

110,000 3.4

120,000 3.7

130,000 4.1

140,000 4.5

150,000 4.9

160,000 5.2

170,000 5.6

180,000 6.0

190,000 6.4

200,000 6.7

©

200448 4-1

Page 26

TECHNICAL DATA

9

0

FAG

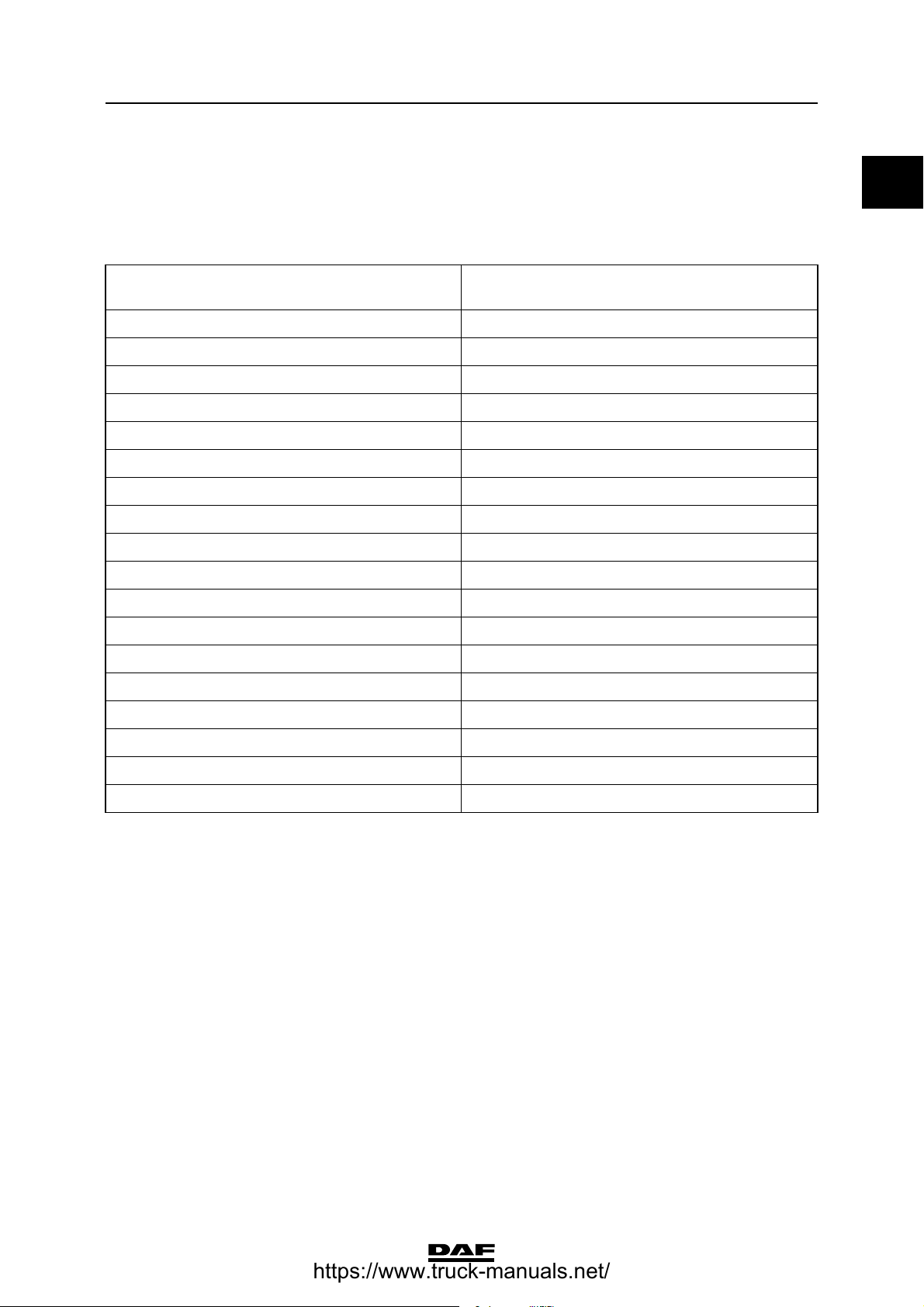

Control values/adjustment of height-control

valve, axle load ratio 6.0/10.0 and fitted with

leaf spring suspension (DAF no. 1386990)

Lever length 70 mm

Joint axle load of leading rear axle/

drive shaft (N)

30,000 0.4

40,000 0.7

50,000 1.1

60,000 1.5

70,000 1.9

80,000 2.2

90,000 2.6

100,000 3.0

110,000 3.4

ΧΦ65/75/85 series

Bellows pressure (bar)

120,000 3.7

130,000 4.1

140,000 4.5

150,000 4.9

160,000 5.2

170,000 5.6

180,000 6.0

190,000 6.4

200,000 6.7

4-2

©

200448

Page 27

9

TECHNICAL DATA

ΧΦ65/75/85 series

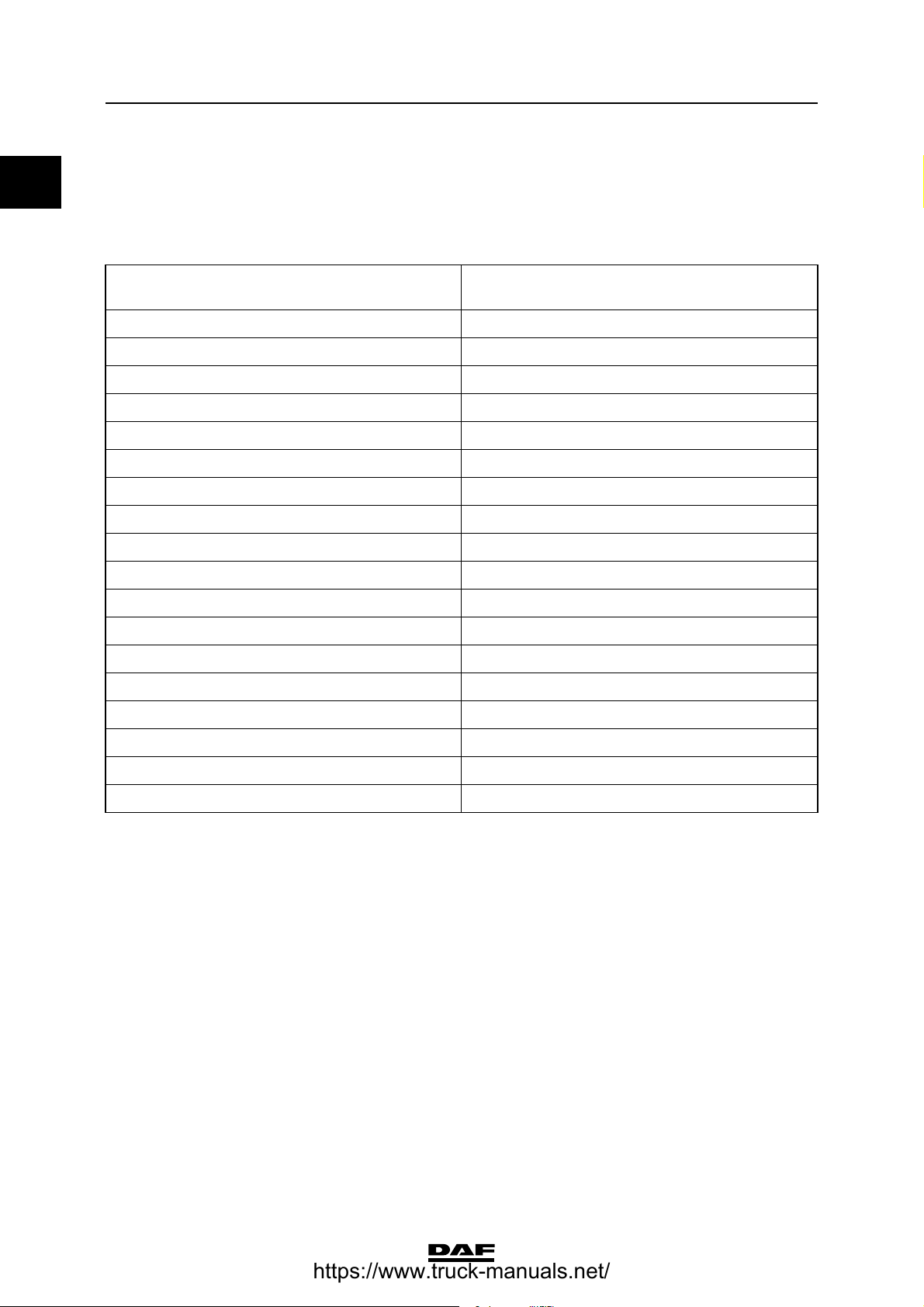

Control values/adjustment of height-control

valve, axle load ratio 7.1/11.5 and fitted with

leaf spring suspension (DAF no. 1368293)

Lever length 60 mm

Joint axle load of leading rear axle/

drive shaft (N)

30,000 0.4

40,000 0.8

50,000 1.1

60,000 1.5

70,000 1.9

80,000 2.3

90,000 2.7

100,000 3.1

110,000 3.4

FAG

0

Bellows pressure (bar)

120,000 3.8

130,000 4.2

140,000 4.6

150,000 5.0

160,000 5.3

170,000 5.7

180,000 6.1

190,000 6.5

200,000 6.9

©

200448 4-3

Page 28

TECHNICAL DATA

9

0

FAG

Control values/adjustment of height-control

valve, axle load ratio 7.1/11.5 and fitted with

leaf spring suspension (DAF no. 1386990)

Lever length 70 mm

Joint axle load of leading rear axle/

drive shaft (N)

30,000 0.4

40,000 0.8

50,000 1.1

60,000 1.5

70,000 1.9

80,000 2.3

90,000 2.7

100,000 3.1

110,000 3.4

ΧΦ65/75/85 series

Bellows pressure (bar)

120,000 3.8

130,000 4.2

140,000 4.6

150,000 5.0

160,000 5.3

170,000 5.7

180,000 6.1

190,000 6.5

200,000 6.9

4-4

©

200448

Page 29

9

TECHNICAL DATA

ΧΦ65/75/85 series

Control values/adjustment of height-control

valve, axle load ratio 7.5/11.5 and fitted with

leaf spring suspension (DAF no. 1368293)

Lever length 60 mm

Joint axle load of leading rear axle/

drive shaft (N)

30,000 0.4

40,000 0.8

50,000 1.2

60,000 1.6

70,000 2.0

80,000 2.4

90,000 2.8

100,000 3.2

110,000 3.6

FAG

0

Bellows pressure (bar)

120,000 4.0

130,000 4.4

140,000 4.8

150,000 5.2

160,000 5.5

170,000 5.9

180,000 6.3

190,000 6.7

200,000 7.0

©

200448 4-5

Page 30

TECHNICAL DATA

9

0

FAG

Control values/adjustment of height-control

valve, axle load ratio 7.5/11.5 and fitted with

leaf spring suspension (DAF no. 1368293)

Lever length 70 mm

Joint axle load of leading rear axle/

drive shaft (N)

30,000 0.3

40,000 0.7

50,000 1.1

60,000 1.4

70,000 1.8

80,000 2.4

90,000 2.5

100,000 2.9

110,000 3.3

ΧΦ65/75/85 series

Bellows pressure (bar)

120,000 3.6

130,000 4.0

140,000 4.4

150,000 4.7

160,000 5.1

170,000 5.5

180,000 5.8

190,000 6.2

200,000 6.6

4-6

©

200448

Page 31

9

TECHNICAL DATA

ΧΦ65/75/85 series

Control values/adjustment of height-control

valve, axle load ratio 7.5/11.5 and fitted with

leaf spring suspension (DAF no. 1386990)

Lever length 70 mm

Joint axle load of leading rear axle/

drive shaft (N)

30,000 0.4

40,000 0.8

50,000 1.2

60,000 1.6

70,000 2.0

80,000 2.4

90,000 2.8

100,000 3.2

110,000 3.6

FAG

0

Bellows pressure (bar)

120,000 4.0

130,000 4.4

140,000 4.8

150,000 5.2

160,000 5.5

170,000 5.9

180,000 6.3

190,000 6.7

200,000 7.0

©

200448 4-7

Page 32

TECHNICAL DATA

9

0

FAG

Control values/adjustment of height-control

valve, axle load ratio 7.5/11.5 and fitted with

leaf spring suspension (DAF no. 1386990)

Lever length 80 mm

Joint axle load of leading rear axle/

drive shaft (N)

30,000 0.3

40,000 0.7

50,000 1.1

60,000 1.4

70,000 1.8

80,000 2.2

90,000 2.5

100,000 2.9

110,000 3.3

ΧΦ65/75/85 series

Bellows pressure (bar)

120,000 3.6

130,000 4.0

140,000 4.4

150,000 4.7

160,000 5.1

170,000 5.5

180,000 5.8

190,000 6.2

200,000 6.6

205,000 6.7

4-8

©

200448

Page 33

9

DIAGNOSTICS

ΧΦ65/75/85 series

1 Diagnostics

CONTENTS

Page Date

1. SHOCK ABSORBERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200448

1.1 Fault-finding table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200448

2. LEAF SUSPENSION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200448

2.1 Fault-finding table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200448

3. REAR AXLE ALIGNMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200448

3.1 Fault-finding table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200448

Contents

1

©

200448 1

Page 34

DIAGNOSTICS

9

1

Contents

ΧΦ65/75/85 series

2

©

200448

Page 35

9

DIAGNOSTICS

ΧΦ65/75/85 series

Shock absorbers

1. SHOCK ABSORBERS

1.1 FAULT-FINDING TABLE

SYMPTOM: SHOCK ABSORBER PRODUCES NOISE (CHATTERING, BUMPING ETC.)

Possible cause Remedy

Shock absorber is loose. Secure shock absorber.

Attachment rubbers too soft. Fit new rubbers.

Shock absorber comes into contact with other

components.

Shock absorber cover is loose. Secure shock absorber cover or replace shock

SYMPTOM: SHOCK ABSORBER DOES NOT FUNCTION

Possible cause Remedy

Internal shock absorber defect. Replace shock absorber.

Shock absorber loses oil. Replace shock absorber.

Remove components or fasten them.

absorber.

1

SYMPTOM: SHOCK ABSORBER LEAKAGE

Possible cause Remedy

Defective piston rod sealing.

Note: a thin, greasy layer is normal.

SYMPTOM: SHOCK ABSORBER TOO HARD

Possible cause Remedy

Incorrect shock absorber type fitted. Fit correct shock absorber type.

Internal shock absorber defect. Check shock absorber using a test bench and

SYMPTOM: SHOCK ABSORBER TOO SOFT

Possible cause Remedy

Incorrect shock absorber type fitted. Fit correct shock absorber type.

Internal shock absorber wear. Check shock absorber using a test bench and

Shock absorber loses oil. Replace shock absorber.

Vehicle overloaded. Adjust vehicle loading.

Replace shock absorber.

replace, if required.

replace, if required.

©

200448 1-1

Page 36

DIAGNOSTICS

9

1

Shock absorbers

SYMPTOM: POOR DRIVING CHARACTERISTICS/FLAT WEAR SPOTS ON THE TYRES

Possible cause Remedy

Incorrect damping. Check shock absorbers using a test bench and

replace, if required.

Vehicle overloaded. Adjust vehicle loading.

SYMPTOM: SHOCK ABSORBER HITS END STOP

Possible cause Remedy

Defective stop rubber. Replace stop rubber.

Insufficient damping. See under Shock absorber too soft.

Vehicle overloaded. Adjust vehicle loading.

ΧΦ65/75/85 series

1-2

©

200448

Page 37

9

DIAGNOSTICS

ΧΦ65/75/85 series

2. LEAF SUSPENSION

2.1 FAULT-FINDING TABLE

SYMPTOM: LOOSE U-BOLTS

Possible cause Remedy

Use of a U-bolt or nut of an incorrect property

class.

The tightening torque used for the U-bolt nut was

too low.

Reuse of a U-bolt with corroded or damaged

thread.

No or inadequate cleaning of the thread

(which includes removal of paint) before reuse

of the U-bolt.

No oil or faulty application of oil on the thread and

the bearing surface of the nut.

The nut has been tightened using a tool rotating

too fast. There is a risk of the nut being welded to

the thread.

Leaf suspension

1

Use U-bolts and nuts of the correct property class.

Tighten the U-bolt to the specified torque.

Fit new U-bolt.

Thoroughly clean the thread when reusing it.

Apply the oil as prescribed.

Tighten the nut slowly.

Coating (i.e. paint) on the contact faces of the

connection.

Inadequate retorquing of the U-bolt nut or no

retorquing.

SYMPTOM: BROKEN SPRING

Possible cause Remedy

Regular overloading. Adjust vehicle loading.

Driving too fast over bad roads. Adjust speed when the road is bad.

Notching effect due to welding or grinding

activities.

Spring damaged due to impact of a steel hammer. Never hit the springs using a steel hammer or

Incorrect repair of a spring leaf which has broken

before.

Spring has been heated. Replace spring assembly. Springs should never be

Clean the contact faces before assembly.

Tighten the U-bolt nut as specified.

Cover spring assembly when welding or grinding.

some other hard tool.

When replacing a broken spring leaf, always

replace the leaf on top and under the broken leaf;

better yet, replace the entire spring assembly.

heated.

©

200448 2-1

Page 38

DIAGNOSTICS

9

1

Leaf suspension

SYMPTOM: SPLAYING OF THE SPRING ASSEMBLY (BROKEN SPRING SHACKLES)

Possible cause Remedy

Incorrect pre-tension of the U-bolts. See symptom: Loose U-bolts.

SYMPTOM: SPRING HITS END STOP

Possible cause Remedy

Vehicle overloaded. Adjust vehicle loading.

Sagged spring assembly. Check spring opening of both spring assemblies.

Replace spring assemblies.

Broken spring. See symptom: Broken spring.

SYMPTOM: SHIFTING OR BREAKING OF CENTRE BOLT

Possible cause Remedy

Incorrect pre-tension of the U-bolts. See symptom: Loose U-bolts.

ΧΦ65/75/85 series

SYMPTOM: BUMPING OR CHATTERING OF THE SPRING

Possible cause Remedy

Shackle pin bearing play at air-sprung front axle. Replace shackle pin/bearing bush.

Loose U-bolts. See symptom: Loose U-bolts.

Loose shackle pin locking at air-sprung front axle. Secure the shackle pin locking.

Spring bracket is loose. Secure the spring bracket.

Spring comes into contact with other components

during spring action.

Check freedom of movement of spring.

2-2

©

200448

Page 39

9

DIAGNOSTICS

ΧΦ65/75/85 series

Rear axle alignment

3. REAR AXLE ALIGNMENT

3.1 FAULT-FINDING TABLE

SYMPTOM: AXLE MISALIGNMENT

Possible cause Remedy

Axle suspension clearance. Check the axle suspension. Replace the worn

parts.

Loose U-bolts. Check the tightening torques of the U-bolts.

Tighten the nuts to the specified tightening

torques.

Shifted centre bolt. Check the centre bolt. Check the tightening

torques of the U-bolts.

Loose or shifted front spring bracket. Check the spring brackets. Fit the spring bracket

as specified.

Incorrect spring bracket fitted. Fit the spring bracket as specified.

Sagged spring assembly or spring assembly with

broken spring leaves.

Check opening of both spring assemblies. Replace

spring assemblies.

1

Difference in length between the spring

assemblies.

Misalignment of the vehicle due to wrongly

adjusted or defective height adjustment.

Bent torque rod (air suspension and tandem axle). Check the torque rods. Replace if necessary.

Incorrectly fitted torque rods (air suspension and

tandem axle).

Difference in length between the torque rods at the

vehicle's left and right sides (air suspension and

tandem axle).

Bent axle housing. Check the straightness of the axle housing. If

Bent leaf-sprung trailing axle yoke. Replace the trailing axle yoke.

Misalignment of the vehicle because the

superstructure is heavier on one side.

Inadequate alignment of axle suspension. Check the alignment. Adjust the axle alignment.

Bent chassis. Measure the chassis.

Chassis side members have shifted in relation to

one another.

Measure the centre-to-centre distance between

shackle pin or spring eye bolt and centre bolt.

Adjust the alignment or replace the spring

assemblies.

Check/replace sensor. Recalibrate.

Check the torque rods. Fit the torque rods

correctly.

Measure the length of the torque rods. Adjust the

difference in length.

possible, adjust by changing the axle alignment.

Measure the wheel pressure. Distribute the weight

more evenly.

Straighten the chassis, if possible.

Measure the chassis.

Straighten the chassis, if possible.

Align the axle.

©

200448 3-1

Page 40

DIAGNOSTICS

9

1

Rear axle alignment

ΧΦ65/75/85 series

3-2

©

200448

Page 41

9

CHASSIS

ΧΦ65/75/85 series

2 Chassis

CONTENTS

Page Date

1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200448

1.1 Repairs to the chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200448

1.2 Drilling in the chassis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5 . . . . . 200448

1.3 Replacing rivets by bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6 . . . . . 200448

Contents

2

©

200448 1

Page 42

CHASSIS

9

2

Contents

ΧΦ65/75/85 series

2

©

200448

Page 43

9

CHASSIS

ΧΦ65/75/85 series

1. GENERAL

1.1 REPAIRS TO THE CHASSIS

- Any welding, aligning, drilling and wheelbase

alteration activities that are not described in

this workshop manual or in any of the latest

releases of DAF's Chassis Guidelines must

be authorised by DAF.

- Following chassis repair, the cause of the

chassis damage should be rectified.

Welding

- Chassis welding may only be carried out by

welders holding a valid EN 287-1 certificate.

- For welding operations on the steel grade KF

375 chassis, the welding electrode must

meet one of the following standards:

ISO 2560: E 515 B 24(H)

DIN 1913 (January 1976): E 5155 B 10

EN 499

General

2

- Slag inclusions and other contamination in

the welds are totally unacceptable.

Note:

Welding on a chassis constructed of high-tensile

strength steel grades KF 420, KF 500 and KF 600

is strongly advised against.

If, however, you do wish to weld a high-tensile

strength steel chassis, contact must always first

be sought with DAF.

The welding electrode must meet the standard:

DIN 8529: EY 5066 1.5 NiNoB

©

200448 1-1

Page 44

CHASSIS

9

2

General

To repair cracks in the chassis, proceed as

follows, taking account of the guidelines given

above:

1. Remove all parts restricting a clear working

area.

2. Thoroughly clean the crack so that the

course of the crack is clearly visible.

3. Drill a small hole at the end of the crack. This

will prevent the crack from continuing.

ΧΦ65/75/85 series

W9 01 001

4. Thoroughly grind out the crack on both sides.

5. Take the necessary precautions to prevent

damage to electronic components. Place the

earth clamp as close as possible to the weld

and avoid bridges.

6. Lay a bead on one side of the ground-out

crack.

7. Gouge or grind off the material at the back of

the bead (see the arrow) so that the new

weld material is clearly visible.

8. Finish-weld the X-seam in the usual manner.

9. Fill in the drilled hole.

10. Grind down the new weld so that it is flush.

Take care not to grind the chassis flange in

the process.

11. The beginning and end of a weld should not

curve inwards (see the arrow).

W9 01 002

W9 01 003

1-2

W9 01 004

©

200448

Page 45

9

CHASSIS

ΧΦ65/75/85 series

12. Round off the chassis flange at the edge of

the weld.

Straightening

Do not forget your own safety during

straightening operations. When

}

The straightening of a chassis demands a high

degree of craftsmanship as in every case of

damage, an individual assessment must be made

to establish whether or not straightening would be

a sensible measure.

Deformations found after accidents will mainly be

of the following 6 types:

- chassis is bent sideways

- chassis has a double sideways bend ("S-

- chassis sags

- chassis bulges upwards

- chassis is twisted

- chassis is out of square.

working with presses, take care that

parts cannot fly out.

bend")

R=1

R=1

General

100mm

2

W9 01 005

In many cases, the damage will be a combination

of two or more of these basic deformations.

In general, the deformations should be dealt with

in the sequence shown above, although some

combinations can be dealt with in one

straightening operation.

When deciding whether or not to straighten a

chassis, you must consider not only the degree of

chassis bending but also the angle of a bend.

If there is a sharp angular bend or fold in the

chassis, the material in that area is likely to be

severely deformed.

If such a chassis were to be realigned to its

original form, there would be a high risk of

overstretching the already weakened material

and causing a crack to develop.

"Cold" straightening

The general rule for cold straightening of a

chassis is that the degree to which the chassis

should be forced back beyond the straight line is

equal to the degree to which the chassis is bent.

For example, if a chassis is bent by 10, the

chassis should be forced back by an additional

10 beyond the straight line.

This means that in total the chassis is forced back

20.

Cold straightening is done with forces ranging

from 40 to 100 tonnes. Therefore, work as safely

as possible.

Particularly when working with auxiliary tools and

aids, you are advised - from a safety point of view

- to attach them correctly.

©

200448 1-3

Page 46

CHASSIS

9

2

General

"Warm" straightening

DAF chassis should not be warm straightened.

Heating can cause grains in the material which

will adversely affect the material properties.

General

For every straightening operation, all stresses in

the stiffer parts of the chassis, for example in the

tandem axle attachment cross member, should

be relieved. If this is not done, these stresses will

later cause new distortions or cracks in the

chassis.

It is obvious from the above points that

straightening is a highly specialised job for which

the specialist involved bears full responsibility.

Always contact DAF when in doubt or for

complicated "straightening operations".

ΧΦ65/75/85 series

1-4

©

200448

Page 47

9

CHASSIS

ΧΦ65/75/85 series

1.2 DRILLING IN THE CHASSIS

Note:

There are several stress zones in a chassis.

Working on the chassis without proper

knowledge (and not according to DAF

instructions) may cause irreversible damage to

the chassis. The repair shop or bodybuilder

would be held fully responsible for such work and

for any superstructure fitted.

If holes must be drilled in the chassis frame, note

the following points:

- Drilling holes within a distance of 70 mm

(distance A) from a bend in the chassis is not

permitted.

- It is on no account permitted to drill holes in

the tapered ends at the rear of a tractor

chassis.

- Drilling holes in the flanges of the chassis

side members is not permitted.

- The maximum diameter for drilled holes is

17 mm (dimension D in the drawing).

- The distance between the holes, and

between the holes and the side member

flange, must be at least 3xD - with a

minimum of 30 mm (dimension B in the

drawing).

- The distance between the lower stud hole

and the chassis underside should at least be

equal to distance C.

Distance C is > 70 mm for a tractor chassis.

Distance C is > 50 mm for all other chassis.

- Deburr (at an angle of 45) and paint the

drilled hole.

B

B

C

General

2

A

A

A

A

B

A

D

A

A

A

C9 00 304

B

Wheelbase alteration

Any alteration to the wheelbase or changes to the

rear overhang should be done in accordance with

the latest DAF Trucks Bodybuilders' Guidelines.

Note:

When using the Bodybuilders' Guidelines, you

are advised to first read the "General" section.

©

200448 1-5

C9 00 291

Page 48

CHASSIS

9

2

General

1.3 REPLACING RIVETS BY BOLTS

Note:

A rivet may either be replaced by a flange bolt

M14 x 2, property class 8.8 (DIN 6921), or a

flange bolt M16 x 2, property class 10.9.

Removing the rivet

1. Remove the rivet head. Make sure not to

damage the chassis during this procedure.

2. Use a 10-mm drill to drill a hole in the rivet.

Remove the rivet from the chassis.

Fitting flange bolt M14

1. Ream the rivet hole to fit 14 H7

(14 + .000 - 14 + .018 mm). Make sure not

to damage any lines running behind the

rivet hole. Deburr the edges.

2. Repair the chassis paintwork. The new

paintwork should be no thicker than

50 microns.

ΧΦ65/75/85 series

L

T3

3. It is important that part of the bolt shank is not

threaded. Determine the length (L) of the

non-threaded shank part using the formula

below.

L = T1 + T3, in which T3 must be >

L = shank length without thread

T1 = part to be clamped

T2 = part to be clamped

4. Tighten the flange bolt to the standard

tightening torque for bolts, property

class 8.8.

1

/2 T2.

T1

T2

C9 00 295

1-6

©

200448

Page 49

9

CHASSIS

ΧΦ65/75/85 series

Fitting flange bolt M16

1. Drill the rivet hole out to 17 mm. Make sure

not to damage any lines running behind the

rivet hole. Deburr the edges.

2. Repair the chassis paintwork. The

new paintwork should be no thicker than

50 microns.

3. Install a flange bolt M16 x 2, property

class 10.9, with a non-threaded shank (A) of

6 mm.

4. Tighten the flange bolt to the standard

tightening torque for bolts, property

class 10.9.

A

General

2

C9 00 296

©

200448 1-7

Page 50

CHASSIS

9

2

General

ΧΦ65/75/85 series

1-8

©

200448

Page 51

9

SHOCK ABSORBERS

ΧΦ65/75/85 series

3 Shock absorbers

CONTENTS

Page Date

1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200448

1.1 Operation of shock absorber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200448

2. REMOVAL AND INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200448

2.1 Removal and installation, shock absorber . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200448

Contents

3

©

200448 1

Page 52

SHOCK ABSORBERS

9

3

Contents

ΧΦ65/75/85 series

2

©

200448

Page 53

9

SHOCK ABSORBERS

ΧΦ65/75/85 series

1. GENERAL

1.1 OPERATION OF SHOCK ABSORBER

The function of the shock absorber is twofold:

- to control the movements of chassis and

superstructure in relation to the axle.

Optimum comfort is achieved when the

chassis and superstructure remain truly

horizontal and are not subjected to any

vertical accelerations when moving;

- to control the movements of the wheels on

the road. Optimum handling is achieved

when all wheels remain in constant contact

with the road surface.

The rate of the above-mentioned movements

depends on the available spring travel. The

available spring travel is the difference in height

between an unloaded spring and a fully loaded

spring.

A well-functioning shock absorber with

characteristics appropriate to the operating

conditions will be the best possible compromise

to fulfil the above-mentioned functions.

General

3

DAF only uses double-acting type shock

absorbers.

On vehicles with air suspension, hydraulic stroke

limitation is used.

The shock absorber consists of:

- an operating cylinder, in which the actual

damping is done by a piston with piston rod

of which the valve unit damps the rebound

stroke;

- a bottom valve which, in combination with

the piston valve unit, damps the bump

stroke.

- a reservoir tube which draws in oil surplus

(result of the volume taken up by the piston

rod) via the bottom valve;

- a dust cover, attached to the piston rod.

©

200448 1-1

Page 54

SHOCK ABSORBERS

9

3

General

Double-acting shock absorbers

The operation of the shock absorber is as follows:

The bump stroke moves the piston (1) down in

relation to the operating cylinder (2).

Subsequently, oil flows from the bottom chamber

of the piston (1) through the piston holes and

valves to the top chamber where the volume

increases. The oil pressure is equal on either side

of the piston (1).

To compensate for the volume taken up by piston

rod (3), oil flows from under the piston (1), via the

bottom valve (4), to the reservoir tube (5).

The resistance met by the oil during this

movement dampens the bump stroke of the

shock absorber.

The rebound stroke moves the piston (1) up in

relation to the operating cylinder (2).

Subsequently, pressure is exerted on the oil in

the upper chamber of the piston (1) causing the

oil to flow through the piston holes and valves to

the bottom chamber under piston (1).

The resistance met by the oil during this

movement dampens the rebound stroke of the

shock absorber.

To compensate for the volume taken up by the

piston rod (3) in the upper chamber, oil flows via

bottom valve (4) from the reservoir tube (5) to the

bottom chamber under the piston (1).

ΧΦ65/75/85 series

3

1

5

2

4

W9 02 001

1-2

©

200448

Page 55

9

SHOCK ABSORBERS

ΧΦ65/75/85 series

2. REMOVAL AND INSTALLATION

2.1 REMOVAL AND INSTALLATION, SHOCK ABSORBER

Removing shock absorber

1. Remove the attachment nuts and/or bolts.

2. Mark the exact positions and location of the

mounting rubbers.

3. Remove the shock absorber from under the

vehicle.

Installing shock absorber

1. Check the shock absorber mountings for

hairline cracks.

2. If the old rubbers are to be reused, check

them for hairline cracks and ageing. Install

the rubbers in the original locations and

positions.

3. When replacing the rubbers, use only the

specified types.

Removal and installation

3

4. When installing the shock absorbers on a

leaf-sprung trailing axle, bearing rings (1)

have to be used with the treated (blackened)

side facing away from the shock absorber

rubbers (2).

5. Replace the self-locking nuts. Tighten the

attachment bolts to the specified torque. See

"Technical data".

12

2

1

C9 00 164

©

200448 2-1

Page 56

SHOCK ABSORBERS

9

3

Removal and installation

ΧΦ65/75/85 series

2-2

©

200448

Page 57

9

STABILISERS AND TORQUE RODS

ΧΦ65/75/85 series

4 Stabilisers and torque r ods

CONTENTS

Page Date

1. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200448

1.1 Overview drawing, front axle stabiliser . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1 . . . . . 200448

1.2 Overview drawing, leaf-sprung rear axle stabiliser . . . . . . . . . . . . . . . . . . 1-2 . . . . . 200448

1.3 Overview drawing, stabiliser of leaf-sprung trailing axle and parabolic

leaf-sprung tandem axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3 . . . . . 200448

1.4 Overview drawing, air-sprung rear axle stabiliser . . . . . . . . . . . . . . . . . . . 1-4 . . . . . 200448

1.5 Overview drawing, leading rear axle stabiliser . . . . . . . . . . . . . . . . . . . . . 1-5 . . . . . 200448

1.6 Description of axle load compensation device . . . . . . . . . . . . . . . . . . . . . 1-6 . . . . . 200448

2. REMOVAL AND INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200448

2.1 Removal and installation, front axle stabiliser . . . . . . . . . . . . . . . . . . . . . . 2-1 . . . . . 200448

2.2 Removal and installation, leaf-sprung rear axle stabiliser . . . . . . . . . . . . . 2-3 . . . . . 200448

2.3 Removal and installation, stabiliser of leaf-sprung trailing axle and

parabolic leaf-sprung tandem axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5 . . . . . 200448

2.4 Removal and installation, air-sprung rear axle stabiliser . . . . . . . . . . . . . . 2-7 . . . . . 200448

2.5 Removal and installation, leading rear axle stabiliser . . . . . . . . . . . . . . . . 2-9 . . . . . 200448

2.6 Removal and installation, silentblock with rubber casing. . . . . . . . . . . . . . 2-11 . . . . 200448

2.7 Removal and installation, silentblock with steel casing . . . . . . . . . . . . . . . 2-13 . . . . 200448

2.8 Removal and installation, triangular link and air-sprung rear axle torque

rods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14 . . . . 200448

2.9 Removal and installation, triangular link and tandem axle torque rods . . . 2-16 . . . . 200448

2.10 Removal and installation, leading rear axle torque rods . . . . . . . . . . . . . . 2-18 . . . . 200448

2.11 Removal and installation, axle load compensation device rod . . . . . . . . . 2-20 . . . . 200448

Contents

4

3. DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1 . . . . . 200448

3.1 Disassembly and assembly, silentblock of triangular link . . . . . . . . . . . . . 3-1 . . . . . 200448

3.2 Disassembly and assembly, ball joint of triangular link . . . . . . . . . . . . . . . 3-3 . . . . . 200448

3.3 Disassembly and assembly, mounting rubbers . . . . . . . . . . . . . . . . . . . . . 3-5 . . . . . 200448

©

200448 1

Page 58

STABILISERS AND TORQUE RODS

9

4

Contents

ΧΦ65/75/85 series

2

©

200448

Page 59

9

STABILISERS AND TORQUE RODS

ΧΦ65/75/85 series

1. GENERAL

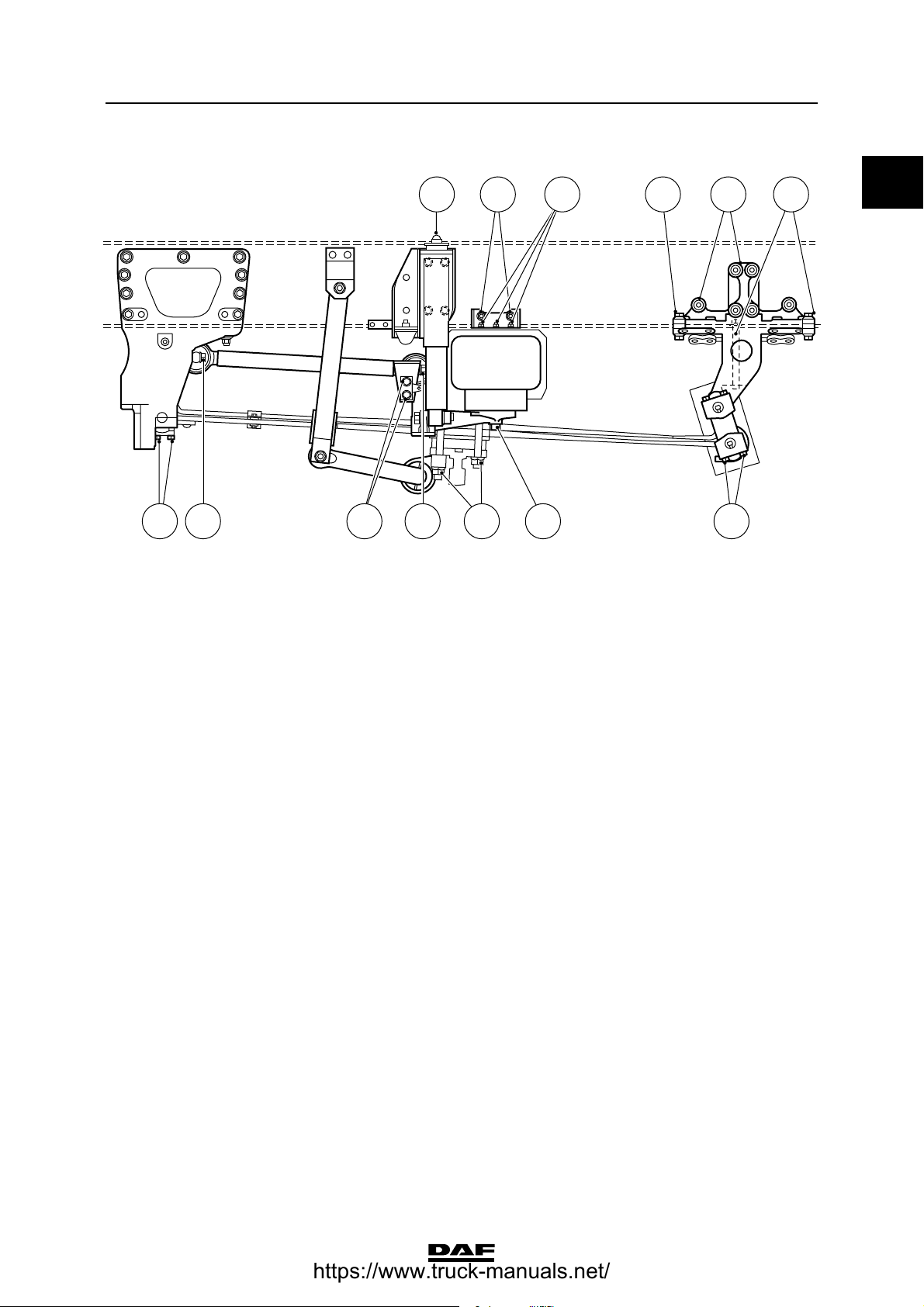

1.1 OVERVIEW DRAWING, FRONT AXLE STABILISER

1

2

6

7

4

3

5

8

9

General

10

11

12

4

13

14

1. Flange bolt

2. Shackle

3. Silentblock

4. Bracket

5. Flange nut

6. Stabiliser bar

7. Flange bolt

8. Silentblock

9. Flange nut

10. Flange bolt

11. Bracket

12. Bearing bush

13. Bearing bush cover

14. Flange nut

C9 00 292

©

200448 1-1

Page 60

STABILISERS AND TORQUE RODS

9

4

General

ΧΦ65/75/85 series

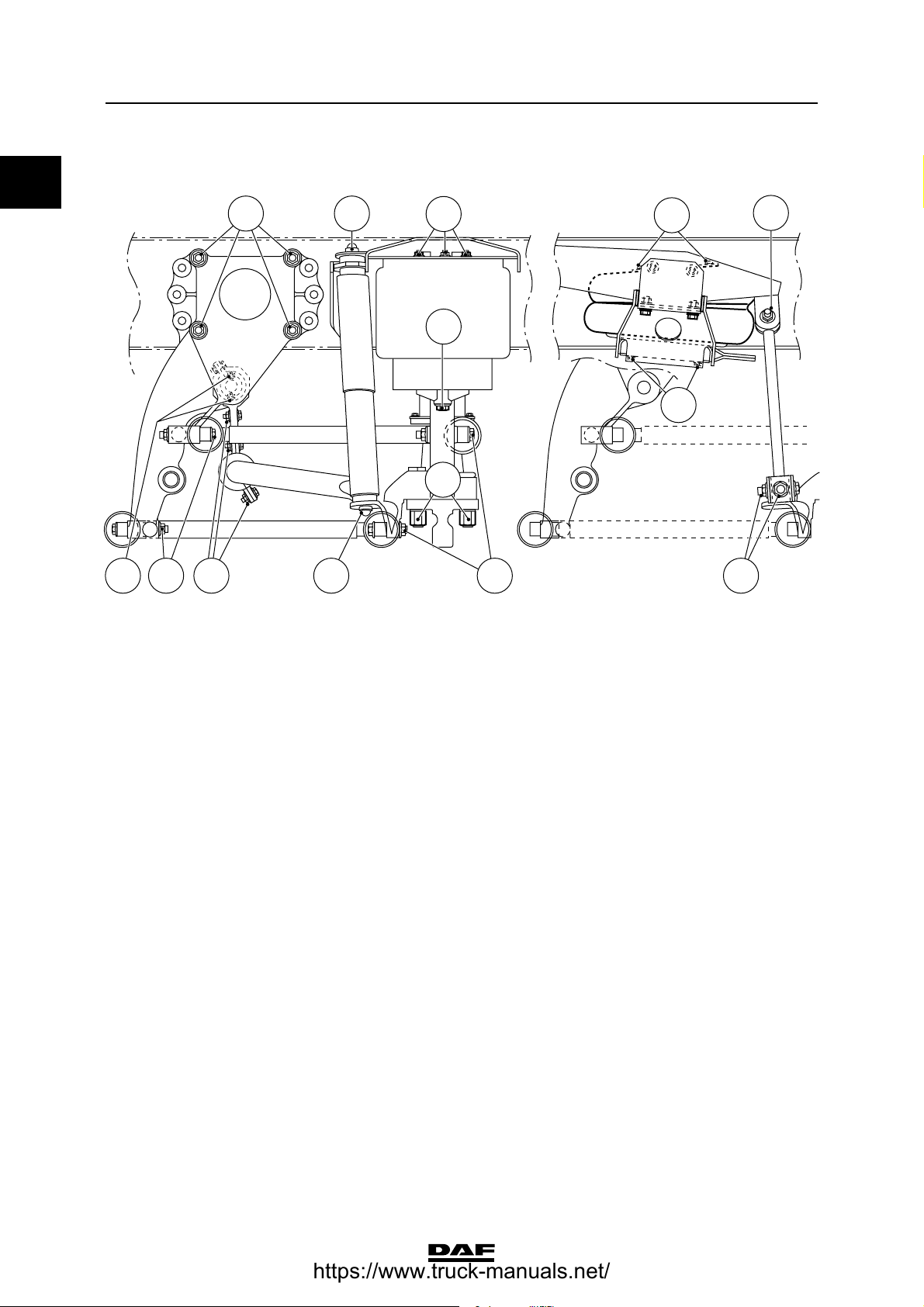

1.2 OVERVIEW DRAWING, LEAF-SPRUNG REAR AXLE STABILISER

2

1

3

4

5

10

6

7

9

13

11

12

8

15

16

14

1. Circlip

2. Bracket

3. Axle

4. Bearing bush

5. Bracket

6. Ring

7. Circlip

8. Flange bolt

9. Bearing bush

10. Stabiliser bar

11. Bracket

12. Attachment bolt

13. Attachment nut

14. Silentblock

15. Ring

16. Attachment nut

C9 00 425

1-2

©

200448

Page 61

9

STABILISERS AND TORQUE RODS

ΧΦ65/75/85 series

General

1.3 OVERVIEW DRAWING, STABILISER OF LEAF-SPRUNG TRAILING AXLE AND PARABOLIC LEAF-SPRUNG TANDEM AXLE

2

1

3

4

5

10

6

7

9

8

11

12

4

1. Circlip

2. Bracket

3. Axle

4. Bearing bush

5. Bracket

6. Washer

7. Circlip

8. Flange bolt

9. Bearing bush

10. Stabiliser bar

11. Bracket

12. Attachment bolt

13. Attachment nut

14. Silentblock

15. Ring

16. Attachment nut

13

15

16

14

C9 00 426

©

200448 1-3

Page 62

STABILISERS AND TORQUE RODS

9

4

General

ΧΦ65/75/85 series

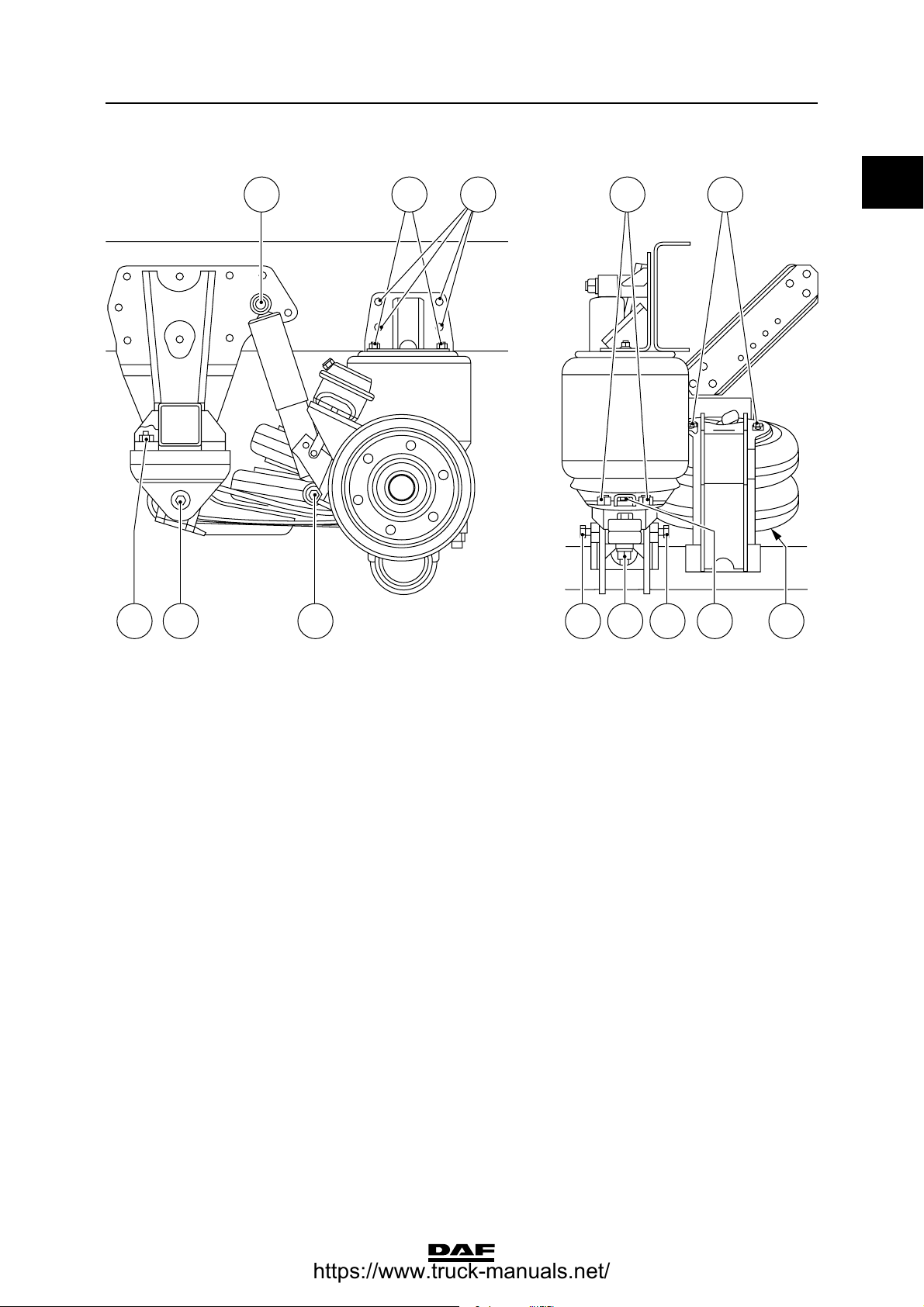

1.4 OVERVIEW DRAWING, AIR-SPRUNG REAR AXLE STABILISER

5

1

4

14

3

15

2

16

17

6

8

7

9

10

11

13

1. Bracket

2. Attachment bolt

3. Ring

4. Ring

5. Attachment nut

6. Silentblock

7. Shackle

8. Attachment bolt

9. Ring

10. Ring

11. Attachment nut

12. Silentblock

13. Stabiliser bar

14. Bearing bush

15. Bearing bush cover

16. Ring

17. Attachment bolt

12

C9 00 309

1-4

©

200448

Page 63

9

STABILISERS AND TORQUE RODS

ΧΦ65/75/85 series

1.5 OVERVIEW DRAWING, LEADING REAR AXLE STABILISER

1

8

4

5

6

3

10

11

2

7

9

12

General

13

14

4

1. Stabiliser bar

2. Bracket

3. Attachment bolt

4. Bearing bush

5. Locking plate

6. Attachment bolt

7. Bearing bush

8. Bracket

9. Attachment nut

10. Attachment bolt

11. Ring

12. Silentblock

13. Ring

14. Attachment nut

C9 00 313

©

200448 1-5

Page 64

STABILISERS AND TORQUE RODS

9

4

General

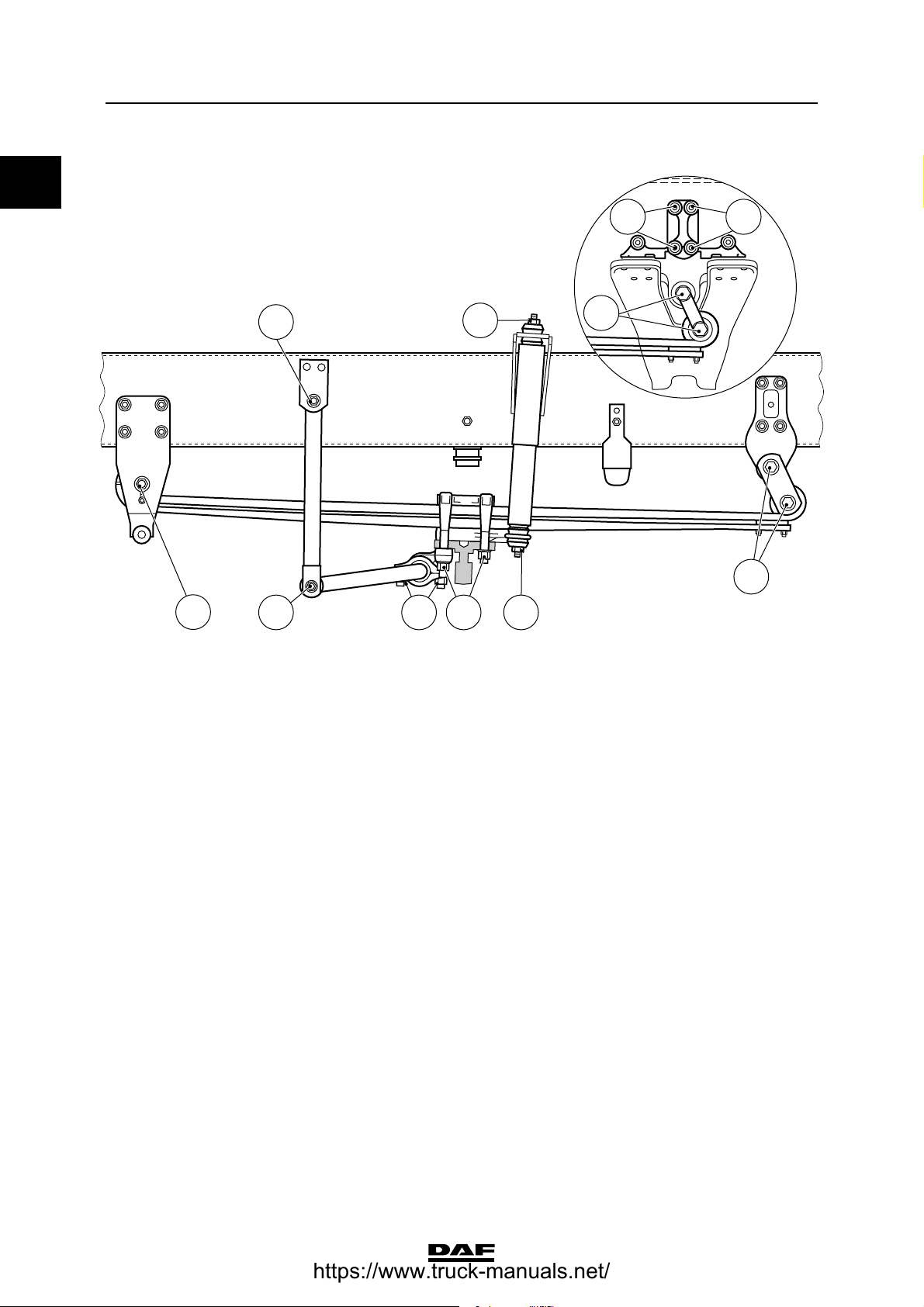

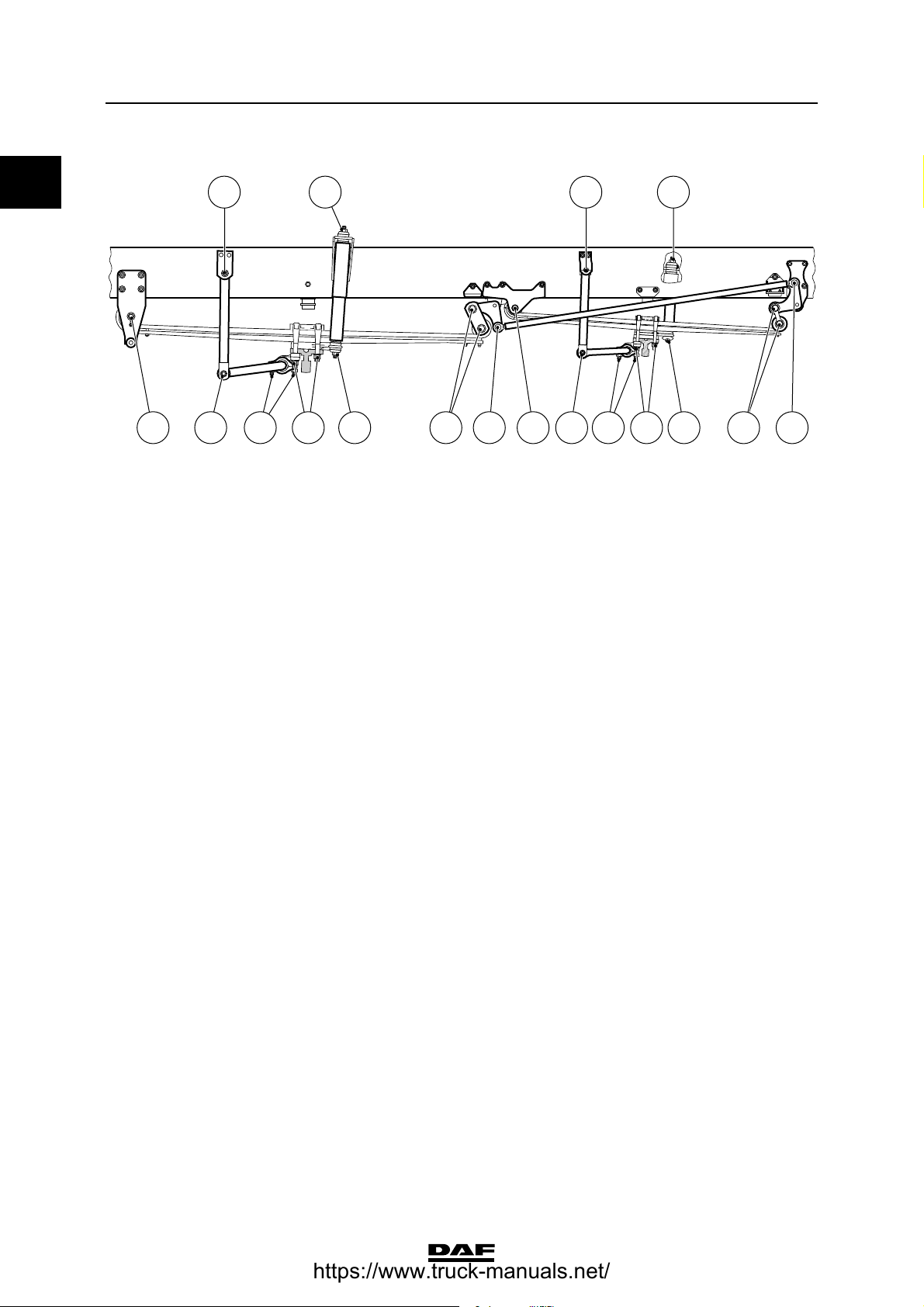

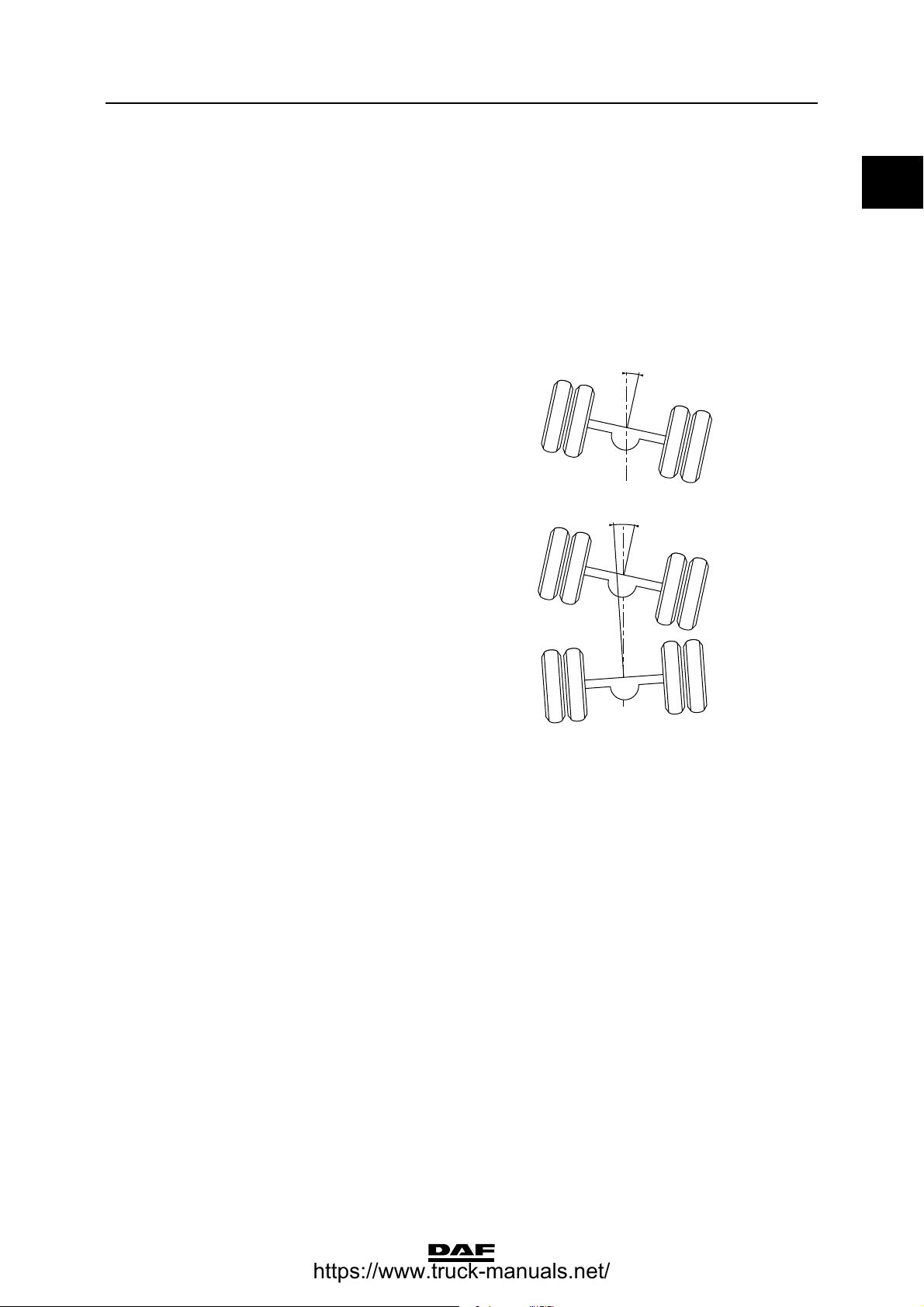

1.6 DESCRIPTION OF AXLE LOAD COMPENSATION DEVICE

21 3 4 5

Vehicles equipped with a double front axle are

fitted with an axle load compensation device.

The axle load compensation device ensures that

the vehicle weight is distributed evenly over both

front axles.

Via the shackle (2), rod (3) and shackle (5) force

is transferred from the front spring assembly (1)

to the rear spring assembly (4) and vice versa.

ΧΦ65/75/85 series

C9 00 503

1-6

©

200448

Page 65

9

STABILISERS AND TORQUE RODS

ΧΦ65/75/85 series

Removal and installation

2. REMOVAL AND INSTALLATION

2.1 REMOVAL AND INSTALLATION, FRONT AXLE STABILISER

1

2

6

7

4

3

10

5

14

8

9

11

12

4

13

Removing front axle stabiliser

1. Remove the bearing bush covers (13).

2. Remove the attachment bolts (7).

3. Remove the stabiliser bar (6) from under the

vehicle.

4. Remove the bearing bushes (12) from the

stabiliser bar (6).

5. Remove the attachment bolts (1) and the

shackles (2).

C9 00 292

©

200448 2-1

Page 66

STABILISERS AND TORQUE RODS

9

4

Removal and installation

Installing front axle stabiliser

1. Check the condition of the silentblocks (3)

and (8) and the bearing bushes (12).

2. Fit the shackles (2).

3. Turn the bearing bush (12) so that the edges

come to rest in the support (11) and the

bearing bush cover (13).

4. Fit the bearing bush covers (13).

5. Install the stabiliser bar (6) in the

shackles (2).

6. Fit the attachment bolts (7) with the heads

facing towards the chassis.

7. Tighten the attachment bolts (1), (7) and (10)

to the specified torque, see "Technical data".

ΧΦ65/75/85 series

2-2

©

200448

Page 67

9

STABILISERS AND TORQUE RODS

ΧΦ65/75/85 series

Removal and installation

2.2 REMOVAL AND INSTALLATION, LEAF-SPRUNG REAR AXLE STABILISER

2

1

3

4

5

10

6

7

9

13

11

12

8

15

16

14

4

Removing leaf-sprung rear axle stabiliser

1. Remove the brackets (5) and (11).

2. Remove the attachment bolts (12).

3. Remove the stabiliser bar (10) from under

the vehicle.

4. Remove the bearing bushes (9) from the

stabiliser bar (10).

5. Remove the circlip (7) with the washer (6)

and remove the bearing bush (4) from the

axle (3).

Installing leaf-sprung rear axle stabiliser

1. Check the condition of the silentblock (14)

and the bearing bushes (4) and (9).

2. Fit the bearing bushes (4), using new

circlips (7).

3. Fit the bearing bushes (9) to the stabiliser

bar (10).

C9 00 425

©

200448 2-3

Page 68

STABILISERS AND TORQUE RODS

9

4

Removal and installation

4. Turn the bearing bushes (4) and (9) into the

indicated position.

5. Fit the brackets (5) and (11). Fit the

attachment bolts (8) with the heads facing

towards the front of the vehicle and tighten

the bolts (8) to the specified torque, see

"Technical data".

6. Fit the attachment bolts (12) with the heads

facing towards the chassis.

ΧΦ65/75/85 series

4

9

C9 00 310

2-4

©

200448

Page 69

9

STABILISERS AND TORQUE RODS

ΧΦ65/75/85 series

Removal and installation

2.3 REMOVAL AND INSTALLATION, STABILISER OF LEAF-SPRUNG TRAILING AXLE AND PARABOLIC LEAF-SPRUNG TANDEM AXLE

2

1

3

4

5

10

6

7

9

8

11

12

4

13

Removing stabiliser of leaf-sprung trailing

axle and parabolic leaf-sprung tandem axle

1. Remove the brackets (5) and (11).

2. Remove the attachment bolts (12).

3. Remove the stabiliser bar (10) from under

the vehicle.

4. Remove the bearing bushes (9) from the

stabiliser bar (10).

5. Remove the circlip (7) with the washer (6)

and remove the bearing bush (4) from the

axle (3).

Installing stabiliser of leaf-sprung trailing axle

and parabolic leaf-sprung tandem axle

1. Check the condition of the silentblock (14)

and the bearing bushes (4) and (9).

15

16

14

C9 00 426

2. Fit the bearing bushes (4), using new

circlips (7).

3. Fit the bearing bushes (9) to the stabiliser

bar (10).

©

200448 2-5

Page 70

STABILISERS AND TORQUE RODS

9

4

Removal and installation

4. Turn the bearing bushes (4) and (9) into the

indicated position.

5. Fit the brackets (5) and (11). Fit the

attachment bolts (8) with the heads facing

towards the rear of the vehicle and tighten

the bolts (8) to the specified torque, see

"Technical data".

6. Fit the attachment bolts (12) with the heads

facing towards the chassis.

ΧΦ65/75/85 series

4

9

C9 00 360

2-6

©

200448

Page 71

9

STABILISERS AND TORQUE RODS

ΧΦ65/75/85 series

Removal and installation

2.4 REMOVAL AND INSTALLATION, AIR-SPRUNG REAR AXLE STABILISER

5

1

4

14

3

15

2

16

17

6

8

7

9

10

11

13

4

Removing air-sprung rear axle stabiliser

1. Remove the bearing bush covers (15).

2. Remove the attachment bolts (8).

3. Remove the stabiliser bar (13) from under

the vehicle.

4. Remove the bearing bushes (14) from the

stabiliser bar (13).

5. Remove the attachment bolts (2) and

remove the shackle (7) from the bracket (1).

12

C9 00 309

©

200448 2-7

Page 72

STABILISERS AND TORQUE RODS

9

4

Removal and installation

Installing air-sprung rear axle stabiliser

1. Check the condition of the bearing bush (14)

and the silentblocks (6) and (12).

2. Fit the shackle (7).

3. Turn the bearing bushes (14) such that the

opening is located at the contact surface of

the bearing cover.

4. Fit the bearing bush covers (15). Evenly

tighten the attachment bolts (17).

5. Fit the attachment bolts (8) with the heads

facing towards the chassis.

ΧΦ65/75/85 series

2-8

©

200448

Page 73

9

STABILISERS AND TORQUE RODS

ΧΦ65/75/85 series

Removal and installation

2.5 REMOVAL AND INSTALLATION, LEADING REAR AXLE STABILISER

1

8

4

5

6

3

10

11

2

7

12

9

13

14

4

Removing leading rear axle stabiliser

1. Remove the brackets (2) and (8).

2. Remove the attachment bolts (10).

3. Remove the stabiliser bar (1) from under the

vehicle.

4. Remove the bearing bushes (7) from the

stabiliser bar (1).

5. Remove the locking plate (5) and remove the

bearing bush (4) from the axle.

Installing leading rear axle stabiliser

1. Check the condition of the silentblock (12)

and the bearing bushes (4) and (7).

2. Fit bearing bush (4), using the locking

plate (5). Tighten the attachment bolts (6) to

the specified torque. See "Technical data".

3. Fit the bearing bushes (7) to the stabiliser

bar (1).

C9 00 313

©

200448 2-9

Page 74

STABILISERS AND TORQUE RODS

9

4

Removal and installation

4. Turn the bearing bushes (4) and (7) into the

indicated position.

5. Fit the brackets (2) and (8). Fit the

attachment bolts (3) with the heads facing

towards the rear of the vehicle and tighten

the bolts (3) to the specified torque, see

"Technical data".

6. Fit the attachment bolts (10) with the heads

facing towards the chassis.

ΧΦ65/75/85 series

4

7

C9 00 312

2-10

©

200448

Page 75

9

STABILISERS AND TORQUE RODS

ΧΦ65/75/85 series

Removal and installation

2.6 REMOVAL AND INSTALLATION, SILENTBLOCK WITH RUBBER CASING

Note:

- The silentblocks for the stabiliser bar and the

stabiliser bar shackle are identical to one

another.

- The silentblocks have to be fitted using

special tool (DAF no. 1310476). It is not

possible to install the silentblocks

undamaged, without using this puller.

- The stabiliser bar does not have to be

removed when replacing the silentblocks on

the stabiliser bar.

Removing silentblock with rubber casing

1. Force the silentblock (1) - using the

puller (A), special tool (DAF no. 1310476) from the stabiliser bar (2) or the stabiliser bar

shackle (2).

Before fitting the puller, apply a lubricant to

the contact surface of the puller or the

silentblock, for example tyre grease or a

soap solution.

A12A

4

Installing silentblock with rubber casing

1. Apply plenty of lubricant to the outer

circumference of the new silentblock (1) and

the contact surface of the puller or the

silentblock, for example tyre grease. Never

apply any grease or oil product to the new

silentblock.

2. Place the guide sleeve (B), which forms part

of the puller, on the stabiliser bar or the

shackle.

3. Place the new silentblock (1) on guide

sleeve (B) and pull the silentblock (A) into

the stabiliser bar (2) or the shackle (2) using

puller (A), special tool (DAF no. 1310476).

A

C9 00 308

1

BA2

C9 00 135

©

200448 2-11

Page 76

STABILISERS AND TORQUE RODS

9

4

Removal and installation

4. Pull the silentblock into the eye until the

collar of the silentblock has been pulled fully

through the eye.

Remove the guide sleeve (B) and, if

necessary, slightly force the silentblock

backwards so that the collars of the

silentblock protrude from both sides of the

stabiliser bar or the shackle. See arrows in

drawing.

ΧΦ65/75/85 series

C9 00 307

2-12

©

200448

Page 77

9

STABILISERS AND TORQUE RODS

ΧΦ65/75/85 series

Removal and installation

2.7 REMOVAL AND INSTALLATION, SILENTBLOCK WITH STEEL CASING

Note:

- The silentblocks with steel casing should be

fitted using special tool (DAF no. 1310479).

It is not possible to install the silentblocks

undamaged, without using this puller.

- The stabiliser bar does not have to be

removed when replacing the silentblocks.

Removing silentblock with steel casing

1. Fit the thrust piece with the smallest

diameter (B in the drawing) on the puller (A),

special tool (DAF no. 1310479).

2. Apply a lubricant to the thrust piece, for

example tyre grease, and fit the puller.

3. Using the puller, force the silentblock from

the stabiliser bar.

12ABA

4

C9 00 149

Installing silentblock with steel casing

1. Place the thrust piece with the largest

diameter (C in the drawing) on the puller (A).

2. Apply for example tyre grease to the thrust

piece, and place the puller (A) with the

silentblock (1) on the stabiliser bar (2).

3. Force the silentblock into the stabiliser bar

using the puller. The thrust piece (C) must

just touch the stabiliser bar.

4. Check whether the two sides of the

silentblock protrude equally out of the

stabiliser bar.

2ACA 1

C9 00 150

©

200448 2-13

Page 78

STABILISERS AND TORQUE RODS

9

4

Removal and installation

ΧΦ65/75/85 series

2.8 REMOVAL AND INSTALLATION, TRIANGULAR LINK AND AIR-SPRUNG REAR AXLE TORQUE RODS

1

2

3

4

5

Removing triangular link

1. Remove the attachment bolts (2).

2. Remove the attachment bolts (3) and

remove the torque rod (1). This can only be

done by two persons working together.

10

7

9

6

8

C900299

2-14

©

200448

Page 79

9

STABILISERS AND TORQUE RODS

ΧΦ65/75/85 series

Installing triangular link

1. Before installation, check the rubber bushes

of the triangular link and the silentblock for

hairline cracks and wear.

Check to see if the contact surface of the

triangular link flange (1) (see arrow) and the

contact surface on the axle housing are free

from grease and paint.

2. Install the triangular link (1) to the vehicle.

This can only be done by two persons

working together. Fit the attachment bolts (2)

and (3).

Tighten the attachment bolts (2) evenly to

the specified torque. See "Technical data".

Removing torque rod

1. Remove the attachment bolts (5) and (8) and

remove the torque rod (7).

Installing torque rod

1. Before installation, check the rubber bushes

of the torque rod (7) for hairline cracks and

wear.

Removal and installation

4

2. Clean the contact surfaces if necessary.

These should be free from dirt and grease.

3. Fit the torque rod (7) between the torque rod

bracket (4) and the yoke (10).

4. Fit the attachment bolts (5) and (8) with the

heads facing towards the front of the vehicle.

Secure the attachment bolts (5) and (8).

©

200448 2-15

Page 80

STABILISERS AND TORQUE RODS

9

4

Removal and installation

2.9 REMOVAL AND INSTALLATION, TRIANGULAR LINK AND TANDEM AXLE TORQUE RODS

5

33

}

4

1

If the triangular link and torque rods

are removed from an axle, the axle

should be adequately supported to

prevent it from tipping over.

ΧΦ65/75/85 series

4

6

12 7

w9 03 011

Removing triangular link

1. Remove the attachment bolts (6).

2. Remove the attachment bolts (5) and

remove the triangular link (4). This can only

be done by two persons working together.

Installing triangular link

1. Before installation, check the rubber bushes

of the triangular link for hairline cracks and

wear. Check if the contact surface of the

triangular link flange and the contact surface

on the axle housing are free from grease and

paint.

2. Install the triangular link (4). This will take two

persons working together. Fit the attachment

bolts (5) and (6) and secure the bolts (5).

3. Tighten the attachment bolts (6) evenly to

the specified torque. See "Technical data".

2-16

©

200448

Page 81

9

STABILISERS AND TORQUE RODS

ΧΦ65/75/85 series

Removing torque rod

1. Remove the attachment bolts (1) and (2) and

remove the torque rod (3).

Installing torque rod

1. Before installation, check the rubber bushes

of the torque rod (3) for hairline cracks and

wear.

2. Clean the contact surfaces if necessary.

These should be free from dirt and grease.

3. Install the torque rod (3) between the

brackets.

Note:

If torque rod bracket (7) has been removed,

it must be reinstalled with the arrow (A) on

the bracket pointing in the driving direction.

If there were any filler plates (B) previously

between the torque rod bracket and the axle

housing, they must be returned to the same

position. The clearance between axle

housing and bracket should not exceed 0.5

mm.

4. Secure the attachment bolts (1).

Removal and installation

4

B

A

w9 03 008

©

200448 2-17

Page 82

STABILISERS AND TORQUE RODS

9

4

Removal and installation

ΧΦ65/75/85 series

2.10 REMOVAL AND INSTALLATION, LEADING REAR AXLE TORQUE RODS

1

2

3

4

3

2

5

6 7 8 6 7

Removing upper torque rod

1. Remove both attachment bolts (2) and

remove the torque rod (1).

Installing upper torque rod

1. Before installation, check the rubber bushes

of the torque rod (1) for hairline cracks and

wear.

2. Clean the contact surfaces if necessary.

These should be free from dirt and grease.

3. Fit the torque rod (1) as shown.

4. Fit the attachment bolts (2) with the heads

facing towards the rear of the vehicle.

Tighten the attachment bolts to the specified

torque. See "Technical data".

C9 00 389

2-18

©

200448

Page 83

9

STABILISERS AND TORQUE RODS

ΧΦ65/75/85 series

Removing lower torque rod

1. Remove both attachment bolts (6) and

remove the torque rod (8).

Installing lower torque rod

1. Before installation, check the rubber bushes

of the torque rod (8) for hairline cracks and

wear.

2. Clean the contact surfaces if necessary.

These should be free from dirt and grease.

3. Fit the torque rod (8) as shown.

4. Fit the attachment bolts (6) with the heads

facing towards the front of the vehicle.

Tighten the attachment bolts to the specified

torque. See "Technical data".

Removal and installation

4

©

200448 2-19

Page 84

STABILISERS AND TORQUE RODS

9

4

Removal and installation

2.11 REMOVAL AND INSTALLATION, AXLE LOAD COMPENSATION DEVICE ROD

Removing axle load compensation device rod

1. Remove the ball end nuts on both sides of

the rod. Self-locking nuts must not be

reused.

2. Remove the ball ends from the shackles

using a ball end puller (A).

A

ΧΦ65/75/85 series

Installing axle load compensation device rod

1. Check the balls of the rod for wear and

damage.

2. Check the ball end thread for damage before

fitting a new self-locking nut. To do so, handtighten a new non-self-locking nut on the ball

end to be checked. If the new nut cannot be

fully hand-screwed onto the entire thread,

the ball end must be replaced.

Fitting a new self-locking nut to a

ball end with a damaged thread may

}